Page 1

ENGINE

CONTENTS

1-1

ENGINE <4G6> 2. . . . . . . . . . . . . . . . . . . . . . . . . .

OVERVIEW 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Major Specifications <EVOLUTION-IV> 2. . . . .

Major Specifications <EVOLUTION-V> 3. . . . .

ENGINE PERFORMANCE CURVES 4. . . . .

MAIN UNIT 5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pistons 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Rods 5. . . . . . . . . . . . . . . . . . . . . . . . .

Flywheel 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION SYSTEM 6. . . . . . . . . . . . . . . .

Engine Oil Cooler 6. . . . . . . . . . . . . . . . . . . . . . . .

COOLING SYSTEM 7. . . . . . . . . . . . . . . . . . . .

Radiator Fan Assembly 7. . . . . . . . . . . . . . . . . . .

Intercooler and

Intercooler Water Spray System 8. . . . . . . . . . .

Intercooler and

Radiator Water Spray System 9. . . . . . . . . . . . .

Water Pump 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INTAKE AND EXHAUST SYSTEMS 10. . . .

Turbocharger 10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Pipe 11. . . . . . . . . . . . . . . . . . . . . . . . . . .

MOUNTING 12. . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Roll Stoppers <EVOLUTION-V> 12. . . .

Center Member <EVOLUTION-V> 12. . . . . . .

FUEL SYSTEM 13. . . . . . . . . . . . . . . . . . . . . . .

CONTROL SYSTEM 13. . . . . . . . . . . . . . . . . .

Sensors 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Actuators 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Injection Control 17. . . . . . . . . . . . . . . . . . .

Idle Speed Control 17. . . . . . . . . . . . . . . . . . . . .

Ignition Timing and

Energization Time Control 18. . . . . . . . . . . . . . .

Power Supply and Fuel Pump Control 19. . .

Air Conditioner Relay Control; Air Flow

Sensor Filter Reset Control; Fuel Pressure

Control; Boost Pressure Control; Exhaust

Temperature Warning Lamp Control 19. . . . . .

Alternator Control 20. . . . . . . . . . . . . . . . . . . . . . .

Engine Speed Output 20. . . . . . . . . . . . . . . . . . .

Fan Motor Relay (Radiator Fan;

Air Conditioner Condenser Fan) Control 21. .

Scondary Air Control 22. . . . . . . . . . . . . . . . . . .

Fuel Pump Delivery Rate Control 23. . . . . . . .

Self-diagnosis System 24. . . . . . . . . . . . . . . . . .

EXHAUST EMISSION

CONTROL SYSTEM 26. . . . . . . . . . . . . . . . . .

Page 2

1-2

ENGINE – Overview

ENGINE <4G6>

OVERVIEW

<EVOLUTION-IV>

The engine of the EVOLUTION-IV is based on the 4G63 DOHC turbocharged unit used in the EVOLUTION-III.

Its right/left alignment has been reversed and its structure simplified and optimized. In addition, it incorporates

the revisions shown below for increased output and durability.

Aim (f: Newly adopted item;

F: Item already adopted on other engines)

Revision

Revised engine mounting alignment F

Serpentine-belt-driven auxiliary devices F

Three-layer cylinder head metal gasket F F

High-strength forged pistons f

Higher

performance

Quieter

operation

Cleaner

exhaust

emissions

Higher

reliability

Lower

weight

High-strength connecting rods f

Steel flywheel f f

High-capacity water pump f

Straight-port intake manifold F

Twin-scroll turbocharger f

Throttle body with new type of ISC system F F F

New type of compact throttle position sensor F F

New type of air flow sensor f

Secondary air system f

Low-noise fan alternator F

Crankshaft mounted crank angle sensor F F F

Plug-top ignition coils F F

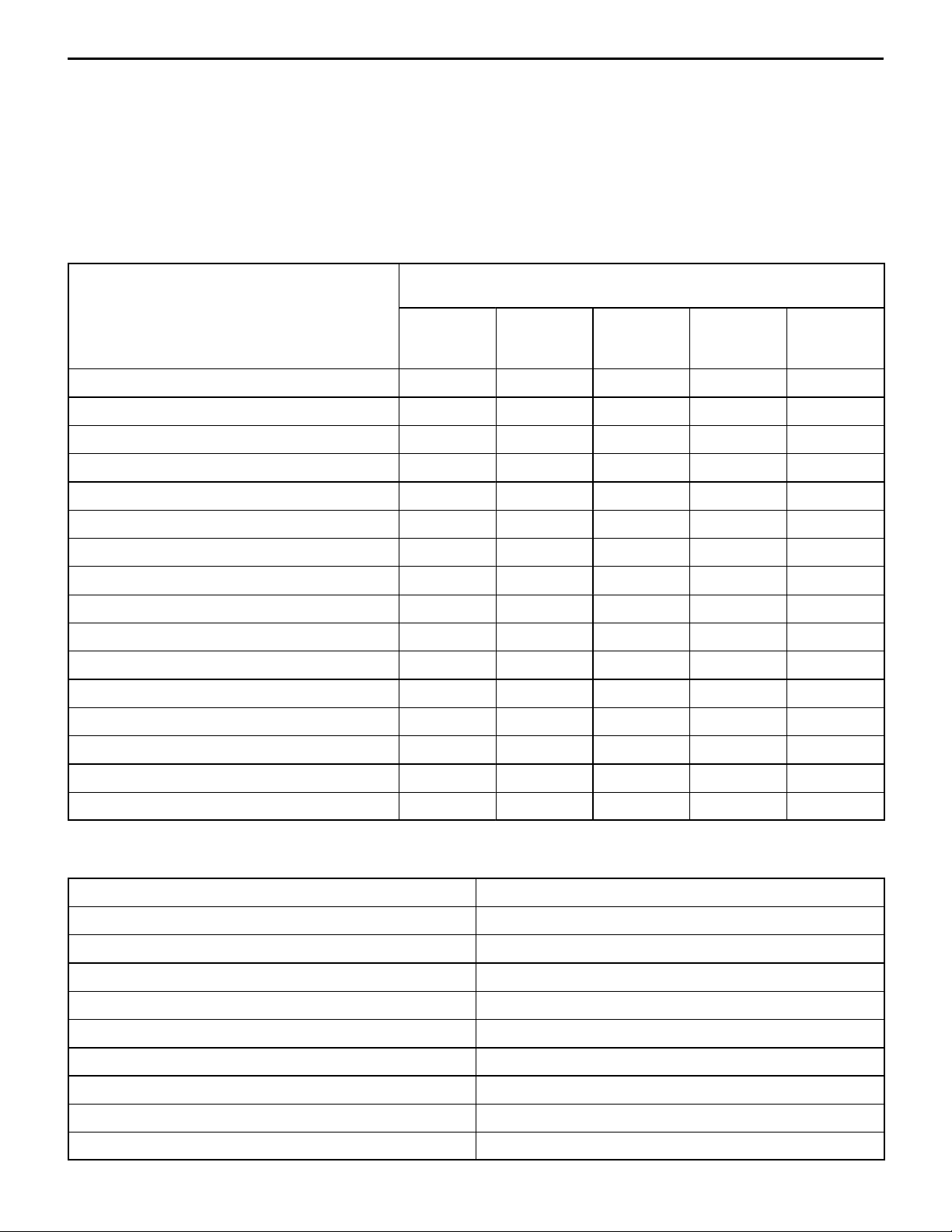

MAJOR SPECIFICATIONS <EVOLUTION-IV>

Items 4G63-DOHC-T/C

Displacement (cc) 1,997

Cylinder bore stroke (mm) 85.0 88.0

Compression ratio 8.8

Valve mechanism DOHC 16-valve

Fuel Unleaded premium gasoline

Max. output (PS/rpm) 280/6,500

Max. torque (kgf⋅m/rpm) 36.0/3,000

Fuel supply Electronically controlled MPI

Ignition timing Electronically controlled

Page 3

ENGINE – Overview

Revision

1-3

OVERVIEW

<EVOLUTION-V>

The engine of the EVOLUTION-V is based on the 4G63 DOHC turbocharged unit used in the EVOLUTION-IV .

It incorporates the revisions shown below for increased output and durability.

Aim (f: Newly adopted item;

F: Item already adopted on other engines)

Higher performance

Crankshaft pins induction hardened f

Three-piece crankshaft thrust bearings F

Lighter pistons f f

Increased turbocharger nozzle area f

Higher maximum injector flow rate (MDL510

→ MDL560)

Heater added to O2 sensor F

Divided connection of positive crankcase

ventilation (PCV) system to intake manifold

f

Reduced exhaust

emissions

Higher reliability

MAJOR SPECIFICATIONS <EVOLUTION-V>

Items 4G63-DOHC-T/C

Displacement (cc) 1,997

Cylinder bore stroke (mm) 85.0 88.0

Compression ratio 8.8

Valve mechanism DOHC 16-valve

F

Fuel Unleaded premium gasoline

Max. output (PS/rpm) 280/6,500

Max. torque (kgf⋅m/rpm) 38.0/3,000

Fuel supply Electronically controlled MPI

Ignition timing Electronically controlled

Page 4

1-4

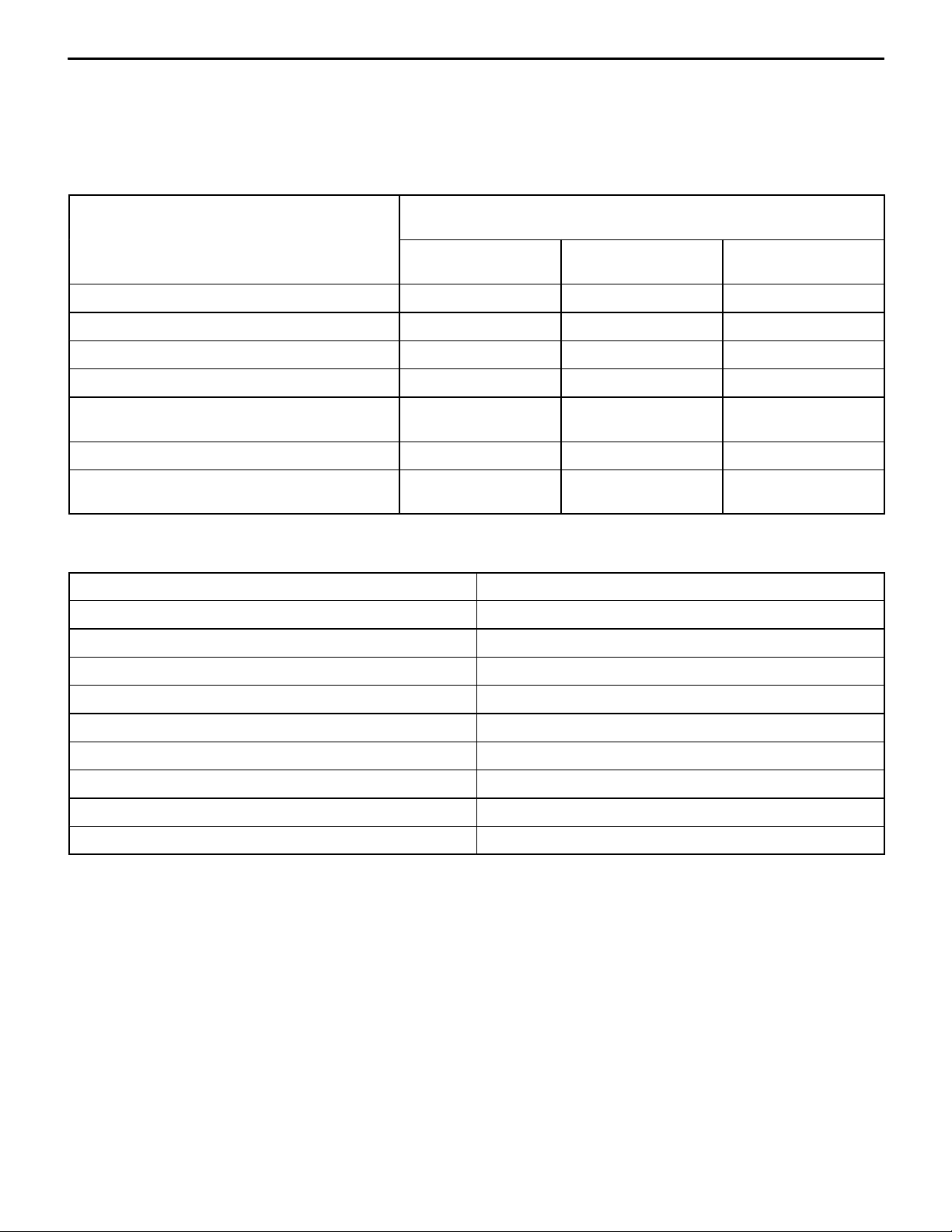

ENGINE – Engine Performance Curves

ENGINE PERFORMANCE CURVES

<EVOLUTION-IV>

4G63 DOHC with Turbocharger 4G63 DOHC with Turbocharger

Output (PS)

Output (PS)

Torque (kgf.m)

<EVOLUTION-V>

Torque (kgf.m)

Engine speed (rpm)

Fuel consumption rate (g/PS.h)

Engine speed (rpm)

Fuel consumption rate (g/PS.h)

Page 5

ENGINE – Main Unit

1-5

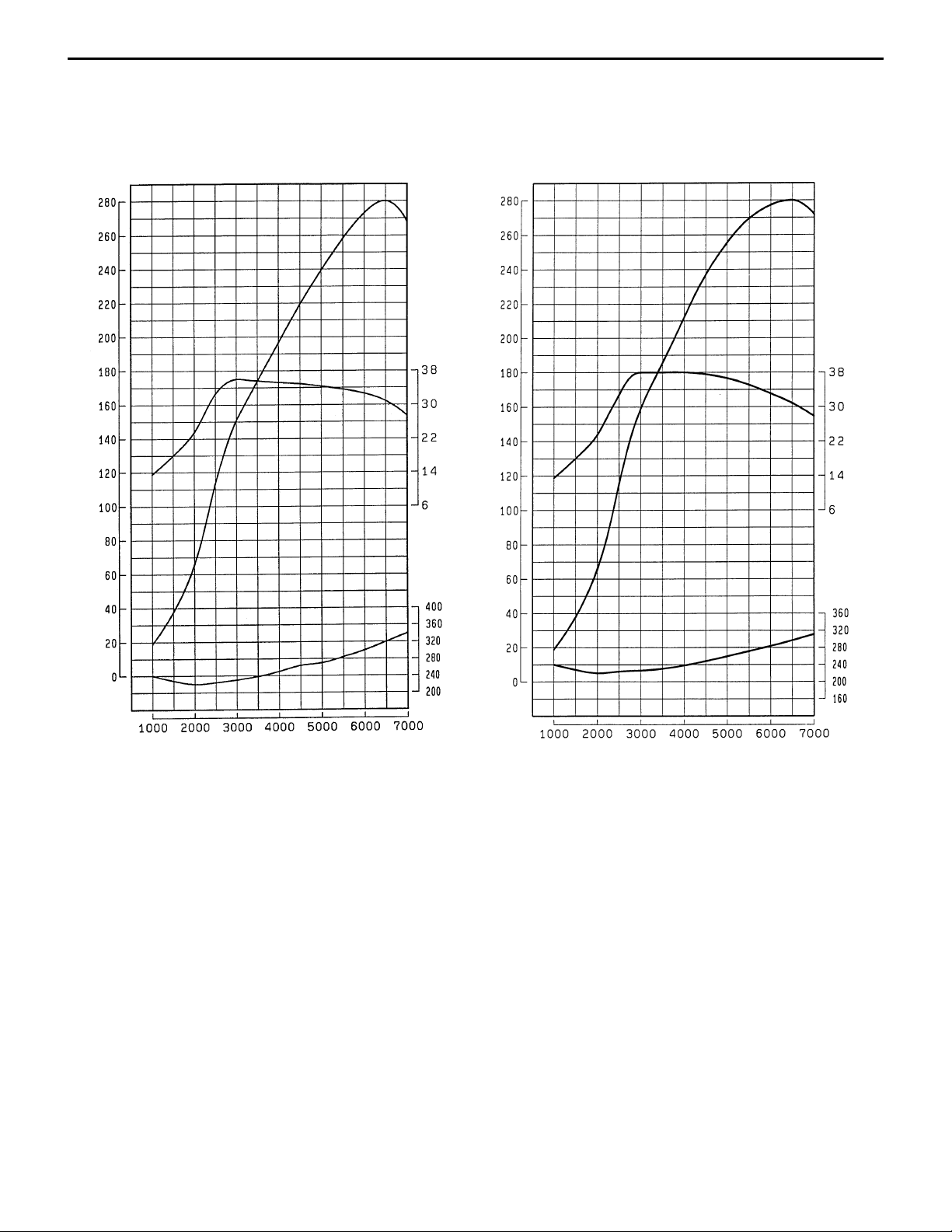

Alumite-treated

54.65 mm ← 61.65 mm

MAIN UNIT

PISTONS

(1) A revised production method enhances the pistons’ fatigue

strength.

(2) The No. 1 ring grooves are alumite-treated.

<EVOLUTION-V>

Reduced weight enhances engine responsiveness.

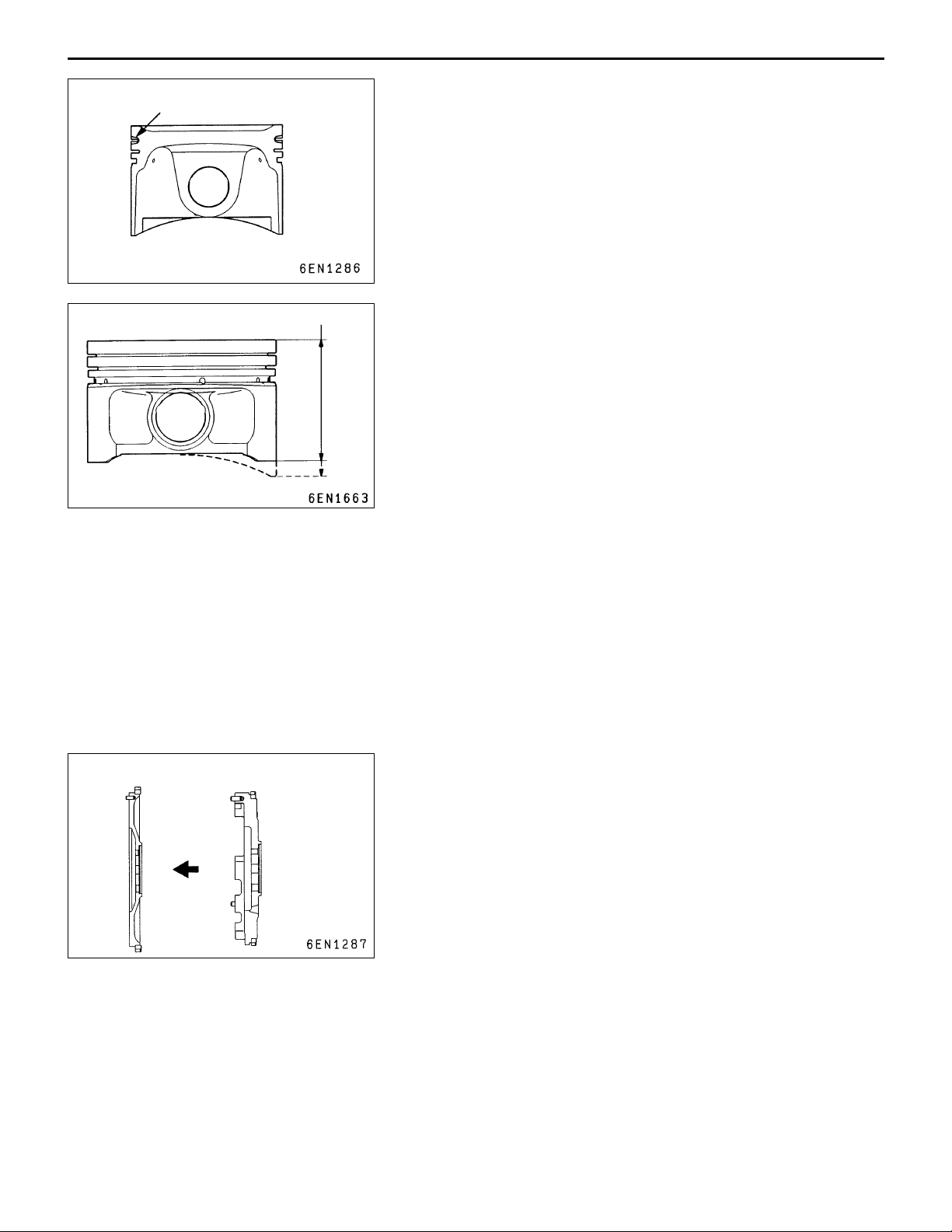

CONNECTING RODS

Shot blasting is performed again after coining, giving the connecting rods approximately 15% more fatigue strength than

the connecting rods used in the EVOLUTION-III.

Steel flywheel

Cast iron flywheel

FLYWHEEL

For lightness, the flywheel is made from steel instead of the

earlier cast iron.

Page 6

1-6

ENGINE – Lubrication System

LUBRICATION SYSTEM

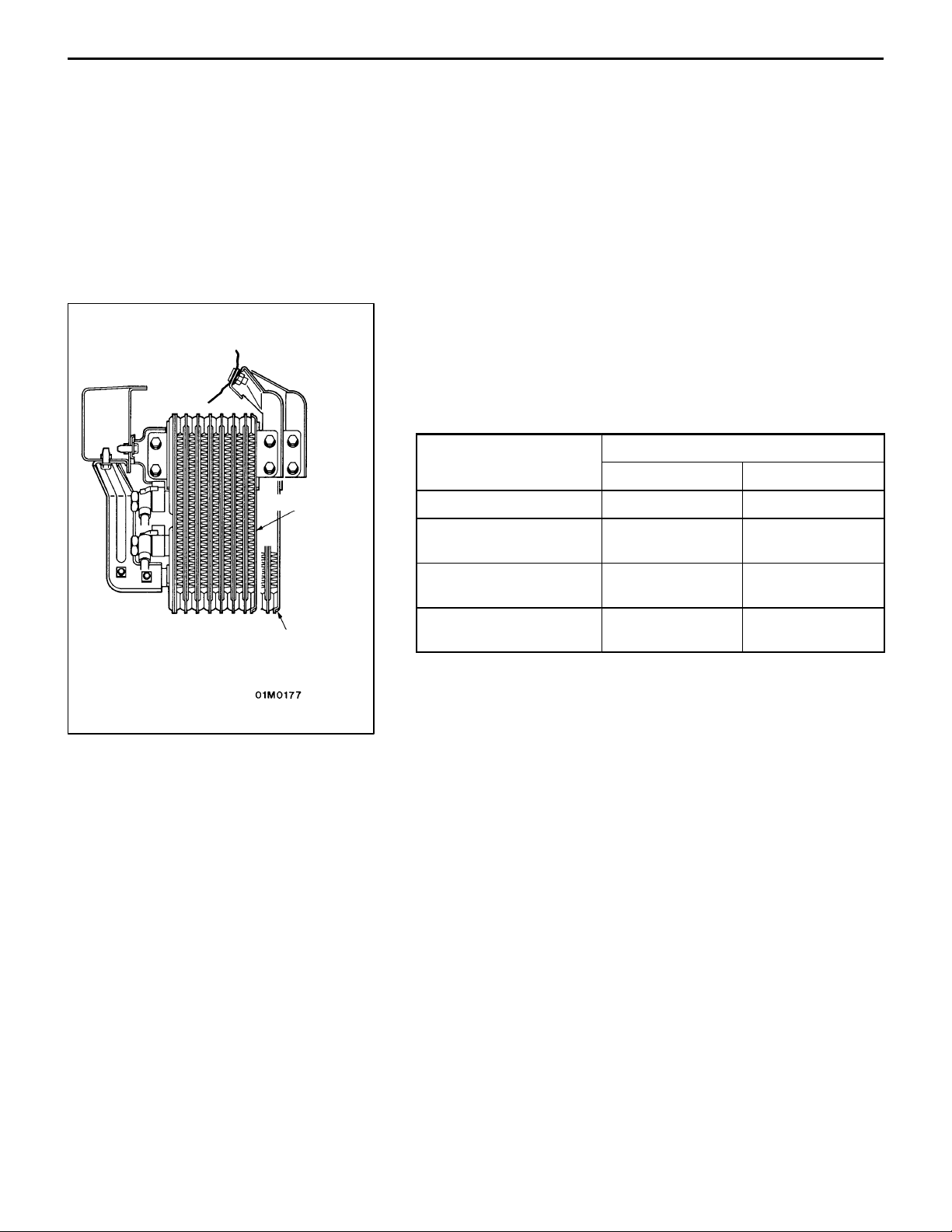

ENGINE OIL COOLER

<EVOLUTION-IV>

A corrugated-fin-type air-cooled engine oil cooler is utilized.

<EVOLUTION-V>

The oil cooler core has increased dimensions, and an air

duct has been added to the front bumper to improve the efficiency with which the engine oil is cooled.

Specifications

Item Specification

EVOLUTION-IV

Type Drawn-cup ←

EVOLUTION-IV EVOLUTION-V

EVOLUTION-V

Core dimensions (width

height depth) (mm)

Engine oil cooler oil

capacity (cc)

Heat release

(kW {kcal/h})

200 100 32 200 130 32

160 210

4.7 {4,080} 5.1 {4,380}

Page 7

ENGINE – Cooling System

{kgf⋅m})

1-7

COOLING SYSTEM

As compared with the EVOLUTION-IV’s cooling system, the EVOLUTION-V’ system incorporates the following

modifications for further enhancement of cooling performance:

2

D Revised radiator cap valve opening pressure (88 kPa {0.9 kgf/cm

D Modified radiator fan assembly

D Intercooler water spray system plus new radiator water spray system

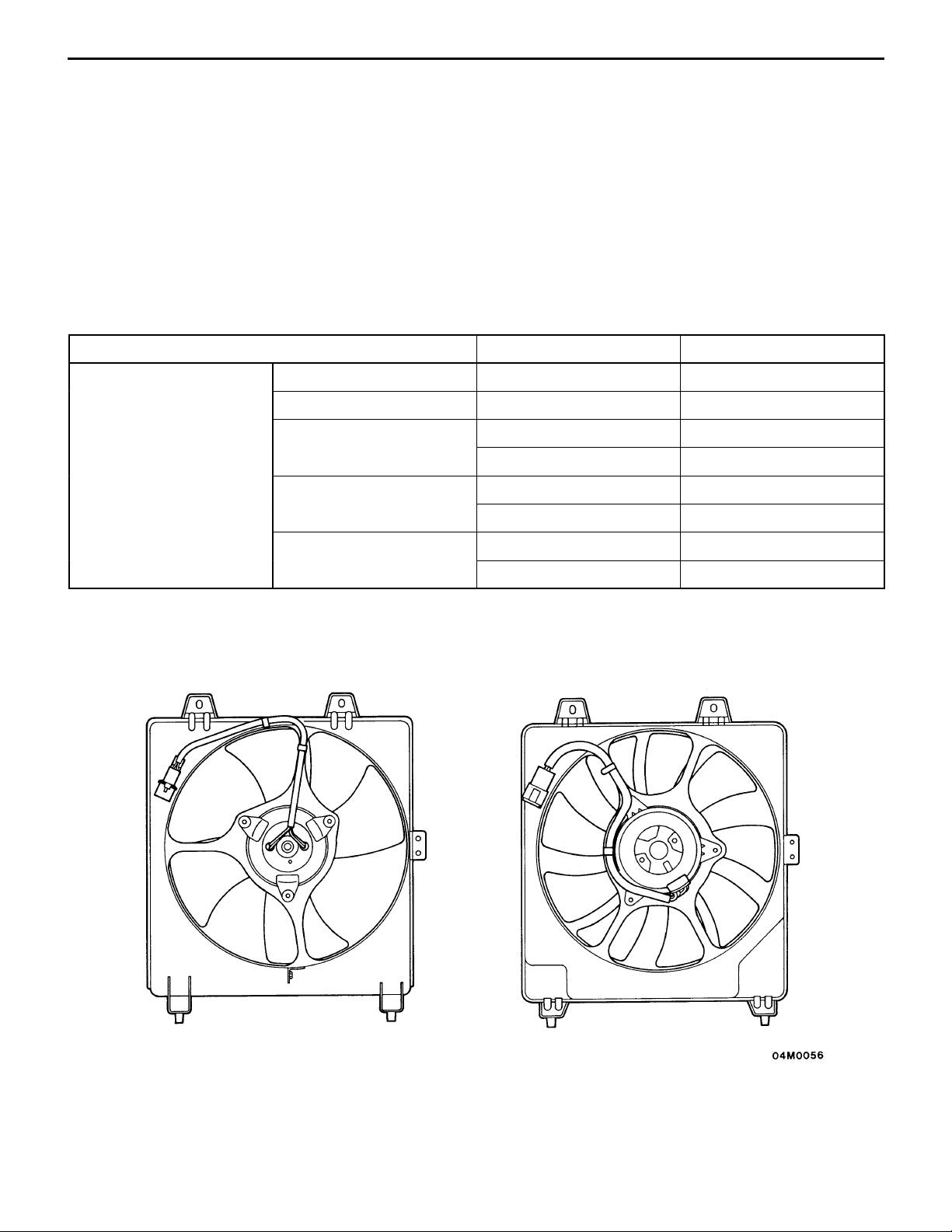

RADIATOR FAN ASSEMBLY

For improved cooling performance, the radiator fan’s shape has been modified and the motor specifications

have been revised.

Specifications

Item EVOLUTION-IV EVOLUTION-V

Radiator fan motor Manufacturer Calsonic ←

Type Direct-current ferrite ←

} → 108 kPa {1.1 kgf/cm2})

Rated load torque (Nm

Speed (r/min) LOW: 1,750 " 250 LOW: 1,900 " 250

Current (A) LOW: 12.0 (or lower) LOW: 13.3 (or lower)

LOW: 43.1 {4.4} LOW: 31.4 {3.2}

HI: 53.2 {5.4} HI: 53.9 {5.5}

HI: 2,100 " 250 HI: 2,200 " 250

HI: 15.5 (or lower) HI: 16.7 (or lower)

<EVOLUTION-V><EVOLUTION-IV>

Page 8

1-8

ENGINE – Cooling System

INTERCOOLER AND INTERCOOLER WATER SPRAY SYSTEM

A large intercooler is utilized to improve cooling performance. An intercooler water spray system sprays

water from the washer tank onto the intercooler’s front surface to lower the intercooler’s temperature.

The intercooler water spray system is basically the same as that used on the EVOLUTION-III.

Construction

Washer tank

Water spray nozzle

Intercooler

Bumper

Water

spray

Water

Intercooler

Floor console

Water spray

switch

Page 9

ENGINE – Cooling System

1-9

INTERCOOLER AND RADIATOR WATER SPRAY SYSTEM

<EVOLUTION-V>

The EVOLUTION-V is provided with a new radiator water spray system in addition to the intercooler water

spray system.

Radiator

Nozzle assembly

Nozzle assembly

(for radiator)

Air conditioner

condenser

Bumper face

for radiator

Nozzle assembly

(for intercooler)

WATER PUMP

The water pump’s inlet diameter and impeller diameter have

been increased to improve cooling performance.

Page 10

1-10

ENGINE – Intake and Exhaust Systems

INTAKE AND EXHAUST SYSTEMS

TURBOCHARGER

Low-speed performance and responsiveness are improved

by a twin-scroll turbocharger with a dual passage arrangement

from the exhaust manifold to the turbine.

Twin scroll

Dual exhaust

manifold

<EVOLUTION-V>

The nozzle cross-sectional area has been increased for improved performance at mid-range and high

speeds.

Section A-A

Nozzle cross-sectional area

Page 11

ENGINE – Intake and Exhaust Systems

1-11

EXHAUST PIPE

EVOLUTION-IV

The exhaust pipe is constructed in three parts. It has the following key features:

D Large, sound-absorbing pre-mufflers that reduce the high-frequency components of exhaust noise;

D A stainless steel main muffler that is highly resistant to corrosion;

D A heat-retaining cover on the front pipe that enhances the catalytic converter’s effectiveness.

Construction

Main muffler

Catalytic converter

Pre-muffler

EVOLUTION-V

D In accordance with revised safety regulations, the high temperature sensor and heat protectors have

been eliminated.

D In accordance with the addition of a front cross member bar (see “Suspension” in Group 3) the front

exhaust pipe has been provided with an indent to prevent interference <vehicles with 17-inch wheels>.

High temperature sensor (eliminated)

<Vehicles with 17-inch wheels>

Front exhaust pipe

Indent

Front cross

member bar

Heat protector (eliminated)

Page 12

1-12

ENGINE – Mounting

Rear roll

stopper

Insulator diameter reduced

from φ70 mm to φ60 mm

MOUNTING

REAR ROLL STOPPERS <EVOLUTION-V>

Front of

vehicle

Center member

The insulator diameter has been reduced from φ70 mm to

φ60 mm to reduce engine roll.

CENTER MEMBER <EVOLUTION-V>

D Rigid mounting of the center member (achieved using added spacers) decreases engine roll.

D In accordance with the addition of a front cross member bar (see “Suspension” in Group 3) a bracket

has been added to the lower reinforcement to protect the heads of the front cross member bar’s

mounting bolts and a front cross member bar mounting nut has been added <vehicles with 17-inch

wheels>.

Center Member Mounting

<EVOLUTION-V><EVOLUTION-IV>

Collar

Upper bushing

Lower bushing

Center member

Center member

NOTE:

This drawing shows the front mounting. The rear mounting is similar.

Rigid mounting spacer (added)

Front cross member bar

mounting nut (added)

Front of

vehicle

Bracket added to lower reinforcement to protect

heads of front cross member bar mounting bolts

<vehicles with 17-inch wheels>

Rigid mounting spacer (added)

Page 13

ENGINE – Fuel System / Control System

1-13

FUEL SYSTEM

The fuel system is basically the same as that of the 4G63 DOHC turbocharged engine used in the EVOLUTIONIII.

Fuel filter

Intake manifold

Delivery pipe

Injector

Injector

Engine

Injector

Injector

Fuel pressure control

solenoid valve

Fuel pressure

regulator

(regulated pressure:

294 kPa {3.00 kgf/cm

Fuel tank

2

})

Filter

Fuel pump

CONTROL SYSTEM

The control system is based on that of the 4G63 DOHC turbocharged engine used in the EVOLUTION-III.

For enhanced torque and output, it incorporates the following improvements:

(1) A new type of air flow sensor significantly reduces air intake resistance.

(2) A flow-limiter-type idle speed control system provides superior control over the engine’s idle speed

during warm-up.

(3) The crank angle sensor is attached directly to the crankshaft to enhance accuracy.

(4) A stick-type cam position sensor is used.

(5) The ignition system utilizes plug-top coils with built-in power transistors for enhanced ignition performance.

(6) An alternator control system enhances fuel efficiency while the engine is idling.

(7) A high/low two-speed fan control relay is utilized.

(8) The engine control relay and fuel pump control relay are located separately to enable simpler circuitry.

(9) A secondary air system has been added to enhance acceleration response.

(10)The ignition timing adjustment connector has been eliminated.

(11)The air conditioner refrigerant medium pressure switch has been eliminated.

Page 14

1-14

ENGINE – Control System

Air flow sensor (AFS)

Intake temperature sensor

Atmospheric pressure sensor

Coolant temperature sensor

Throttle position sensor (TPS)

Idle switch

Cam position sensor

Crank angle sensor

O2 sensor

Vehicle speed sensor

Air conditioner switch

Power steering fluid pressure switch

Engine ECU

[1] Fuel injection control

[2] Idle speed control (ISC)

[3] Ignition timing control

[4] Control relay control

(supply of power to sensors and actuators)

[5] Fuel pump control

[6] Air conditioner relay con-

trol

[7] Air flow sensor filter reset

control

[8] Alternator control

[9] Fan relay control (radiator; air

conditioner condenser)

[10] Fuel pressure control

[11] Boost pressure control

No. 1 injector

No. 2 injector

No. 3 injector

No. 4 injector

ISC servo (stepper motor)

Ignition coils (power transistors)

Control relay

Fuel pump relay

Air conditioner relay

Air flow sensor (AFS)

Alternator G terminal

Fan motor relay (radiator; air conditioner condenser)

Fuel pressure control valve

Wastegate solenoid valve

Alternator FR terminal

Ignition switch IG terminal

Ignition switch ST terminal

Knock sensor

Power supply

High temperature sensor

Diagnosis control terminal

[12] Secondary air control

[13] Fuel pump delivery rate

control

[14] Exhaust temperature warning

lamp control

[15] Engine warning lamp control

[16] Diagnosis output

[17] Engine speed output

[18] RAM data transmission

Secondary air control solenoid

valve

Fuel pump relay No. 2

Exhaust temperature warning

lamp

Engine warning lamp

Diagnosis output terminal

Tachometer

Diagnosis output terminal (MUT -II)

Page 15

<4G63 DOHC with Turbocharger>

Vehicle speed sensor

Air conditioner switch

Power steering fluid pressure switch

Alternator FR terminal

Ignition switch IG terminal

Ignition switch ST terminal

Power supply

Cam position sensor

Crank angle sensor

High temperature sensor

Coolant temperature sensor

Knock sensor

O

Atmospheric pressure sensor

Air flow sensor

Intake temperature sensor

Idle switch

Throttle position sensor

ENGINE – Control System

Engine ECU

Injectors

sensor

2

Fuel pressure control valve

ISC servo

Wastegate solenoid valve

Secondary air control solenoid valve

1-15

Ignition coils (power transistors)

Control relays

Fuel pump relay

Air conditioner relay

Alternator G terminal

Fan motor relay

Exhaust temperature warning lamp

Engine warning lamp

Diagnosis output terminal

Tachometer

Secondary

air valve

Page 16

1-16

ENGINE – Control System

Air flow sensing

element

Air

Air deflector

Bypass

passage

Air

Vortex-inducing

pillar

Air flow sensing circuitry

Vortex-inducing pillar

Bypass passage

Shape of

conventional

sensor

Air from

bypass

passage

Kármán

vortex

SENSORS

Air Flow Sensor (Incorporating Atmospheric Pressure

Sensor)

To reduce pressure losses and thus improve performance,

Mitsubishi Motors developed a new air flow sensor known

as MUKAS. In contrast with a conventional sensor, which

senses Kármán vortices downstream of a vortex-inducing pillar

using a pressure-sensitive element, the MUKAS sensor counts

Kármán vortices in a bypass passage using a hot-wire arrangement.

Pressure losses

reduced by 50%

Size and weight

reduced by 20%

Improved resistance

to contamination and

noise

Increased sensitivity at low air flow

rates enables the use of a larger air

inlet. Thus, pressure losses are reduced.

A more condensed circuit layout

and a new, compact connector enable a significant reduction in overall length.

Only a small amount of air flows

through the bypass passage, so

contamination is greatly reduced.

Also, Kármán vortices are mea-

sured digitally in accordance with

the difference in signals received

from left and right hot-wire arrangements, so the sensor is resistant to

noise and to changes in the components that occur over time.

From air

intake hose

ACTUATORS

Secondary Air Control Solenoid Valve

The secondary air control valve is an ON/OFF solenoid valve.

It switches the pressure applied to the secondary air valve

between the intake manifold vacuum pressure and the atmospheric pressure.

When the coil is not energized, continuity exists between the

X-nipple and ambient air. When the coil is energized, continuity

exists between the X-nipple and Y-nipple.

Secondary Air Valve

The secondary air valve turns ON and OFF the secondary

air supply by opening and closing in accordance with the vacuum pressure applied to the diaphragm chamber.

To exhaust

manifold

Page 17

FUEL INJECTION CONTROL

Fuel pressure

regulator

To fuel tank

To cam

rear side

From fuel

pump

ENGINE – Control System

Fuel pressure

control valve

Engine ECU

Injectors

Air flow sensor

Intake temperature sensor

Atmospheric pressure sensor

Throttle position sensor

Idle switch

Ignition switch ST terminal

sensor

O

2

Vehicle speed sensor

Crank angle sensor

Knock sensor

Coolant temperature sensor

Cam position sensor

1-17

IDLE SPEED CONTROL

Bimetallic limiter

To intake manifold

ISC servo

(stepper motor)

Speed adjusting

screw (SAS)

From air cleaner

Engine ECU

Ignition switch IG terminal

Ignition switch ST terminal

Power steering fluid pressure switch

Air conditioner switch

Vehicle speed sensor

Crank angle sensor

Coolant temperature sensor

Atmospheric pressure sensor

Air flow sensor

Intake temperature sensor

Throttle position sensor

Idle switch

Alternator FR terminal

Page 18

1-18

ENGINE – Control System

IGNITION TIMING AND ENERGIZATION TIME CONTROL

Air flow sensor

Intake temperature sensor

Atmospheric pressure sensor

Coolant temperature sensor

Idle switch

Cam position sensor

Crank angle sensor

Vehicle speed sensor

Ignition switch ST terminal

Knock sensor

Engine ECU

Tachometer

Ignition coil B

Cylinders

Ignition

switch

Ignition coil A

Battery

Page 19

ENGINE – Control System

POWER SUPPLY AND FUEL PUMP CONTROL

Battery

1-19

Ignition

switch

Fuel

pump

relay

Fuel pump control

Engine ECU

To fuel

pump

Ignition switch

IG signal

To injectors, ISC

servo, etc.

Control

relay

Power

supply

Backup

power

Power

control

AIR CONDITIONER RELAY CONTROL; AIR FLOW SENSOR FILTER RESET CONTROL;

FUEL PRESSURE CONTROL; BOOST PRESSURE CONTROL; EXHAUST TEMPERATURE WARNING LAMP CONTROL

The control arrangement is the same as that used with the 4G63 DOHC turbocharged engine of the EVOLUTION-III.

Page 20

1-20

ALTERNATOR CONTROL

ENGINE – Control System

Coolant temperature sensor

Crank angle sensor

Air conditioner switch

Power steering fluid pressure

switch

Ignition switch ST terminal

Engine ECU

Alternator G terminal

Alternator FR terminal

Alternator

ENGINE SPEED OUTPUT

Engine speed signals are issued in synchronization with crank angle sensor signals.

Engine ECU

Crank angle

sensor signals

To tachometer

Engine speed

signals

Page 21

ENGINE – Control System

1-21

F AN MOTOR RELA Y (RADIA TOR FAN; AIR CONDITIONER CONDENSER FAN) CONTROL

Battery

Ignition switch

Radiator fan

motor relay

(HI)

Radiator

fan motor

Radiator fan

motor relay (LO)

Condenser

fan motor

relay (HI)

Condenser

fan motor

Engine ECU

High-speed side

Condenser fan

motor relay (LO)

Coolant temperature

sensor

Throttle position sensor

Idle switch

Crank angle sensor

Air conditioner switch

Condenser fan

operation

Air conditioner

switch

Engine coolant

temperature (°C)

Power transistor

(low-speed side)

Low-speed side

Power transistor

(high-speed side)

Radiator fan

operation

OFF Below approx. 95 OFF OFF Stationary Stationary

Approx. 95 to 105 ON OFF Low speed Low speed

Above approx. 105 ON ON High speed Low speed

ON Below approx. 105 ON OFF Low speed Low speed

Above approx. 105 ON ON High speed High speed

Page 22

1-22

ENGINE – Control System

SECONDARY AIR CONTROL

During deceleration from a high speed, secondary air is introduced upstream of the turbocharger. This

operation prevents the turbine’s speed from dropping and thus enhances responsiveness when the driver

next wishes to accelerate. For maximum effectiveness, secondary air is introduced into the exhaust manifold

immediately downstream of each cylinder.

Engine ECU

Secondary air

control solenoid

valve

Secondary air

valve

Control relay

Battery

Vacuum

tank

Secondary air is introduced for approximately three minutes when both of the following conditions are

satisfied:

D The engine speed is 4,000 rpm or higher.

D The engine speed drops sharply after at least three seconds of full-throttle acceleration.

Page 23

Control

relay

Ignition

switch

Fuel pump

relay No. 2

Engine ECU

Battery

ENGINE – Control System

FUEL PUMP DELIVERY RATE CONTROL

1-23

Fuel

pump

Resistor

Page 24

1-24

ENGINE – Control System

SELF-DIAGNOSIS SYSTEM

Engine Warning Lamp (Check Engine Lamp) Control

The engine warning lamp illuminates in the event of an abnormality in any of the items shown in the

following table.

Air flow sensor Atmospheric pressure sensor

Intake temperature sensor Knock sensor

Throttle position sensor Injectors

Coolant temperature sensor Ignition coils; power transistor units

Crank angle sensor Engine ECU

Cam position sensor

Diagnosis Function

Diagnosis items are shown in the following table.

Code No. Diagnosis item Main fault(s) diagnosed

12 Air flow sensor Open/short circuit in sensor-related circuitry No

13 Intake temperature sensor Open/short circuit in sensor-related circuitry No

14 Throttle position sensor Abnormal sensor output No

21 Coolant temperature sensor D Open/short circuit in sensor-related circuitry

D Increased contact resistance in connector

22 Crank angle sensor Abnormal sensor output No

23 Cam position sensor Abnormal sensor output No

24 Vehicle speed sensor Open/short circuit in sensor circuitry No

25 Atmospheric pressure sensor Open/short circuit in sensor-related circuitry No

31 Knock sensor Abnormal sensor output No

41 Injectors Open/short circuit in injector-related circuitry No

44 Ignition coils; power transistor units Abnormality in ignition system (failure in one out

of two coils)

64 Alternator FR terminal Open circuit in sensor circuitry No

— Normal state — —

Dealer mode

diagnosis

No

No

Page 25

ENGINE – Control System

Service Data Output

Service data output items are shown in the following table.

Item No. Service data item Unit

11 O2 sensor mV

12 Air flow sensor output Hz

13 Intake temperature sensor output °C

14 Throttle position sensor output mV

16 Battery voltage V

18 Cranking signal (ignition switch ST terminal) ON-OFF

21 Coolant temperature sensor output °C

22 Crank angle sensor output RPM

25 Atmospheric pressure sensor output kPa

26 Idle switch ON-OFF

27 Power steering fluid pressure switch ON-OFF

28 Air conditioner switch ON-OFF

1-25

41 Injector energization time ms

44 Ignition advance angle °BTDC, °ATDC

45 ISC stepper motor position STEP

49 Air conditioner relay ON-OFF

Actuator Tests

Actuator test items are shown in the following table.

Item No. Actuator test item

01 No. 1 injector: OFF

02 No. 2 injector: OFF

03 No. 3 injector: OFF

04 No. 4 injector: OFF

07 Fuel pump: ON

09 Fuel pressure control valve: ON

12 Wastegate solenoid valve: ON

13 Fuel pump relay No. 2: ON (current supplied via resistor)

17* Ignition timing: 5°BTDC

20 Radiator fan (high), air conditioner condenser fan (high): high-speed operation

21 Radiator fan (low), air conditioner condenser fan (low): low-speed operation

30* ISC servo: locked in reference step during SAS adjustment

*: Continues for 27 minutes unless cancelled by depression of clear key.

Page 26

1-26

ENGINE – Exhaust Emission Control System

EXHAUST EMISSION CONTROL SYSTEM

System Diagram

Canister

Check valve

O

sensor

2

PCV valve

Fuel pressure

regulator

Injector

Intake air

High temperature sensor

Three-way catalytic converter

Loading...

Loading...