Page 1

BASIC BRAKE

SYSTEM

CONTENTS

35A-1

SERVICE SPECIFICATIONS 2. . . . . . . . . . . . . .

LUBRICANTS 2. . . . . . . . . . . . . . . . . . . . . . . . . . .

SEALANT 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 3. . . . . . . . . . . . . . . . . . . . . . . .

ON-VEHICLE SERVICE 3. . . . . . . . . . . . . . . . . .

1. Brake Booster Operation Check 3. . . . . . . .

2. Proportioning Valve Function Test 3. . . . . . .

3. Bleeding <EVOLUTION-V> 4. . . . . . . . . . . . .

4. Disc Brake Pad Check and Replacement

<EVOLUTION-IV> 4. . . . . . . . . . . . . . . . . . . . .

5. Disc Brake Pad Check and Replacement

<EVOLUTION-V> 4. . . . . . . . . . . . . . . . . . . . .

6. Brake Disc Thickness Check 6. . . . . . . . . . .

7. Brake Drum I.D. Check 6. . . . . . . . . . . . . . . .

8. Lining to Brake Drum Contact Check 6. . .

FRONT BRAKE 7. . . . . . . . . . . . . . . . . . . . . . . . . .

REAR BRAKE 8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

35A-2

action test generated fluid pres

test generated fluid pressure kPa

BASIC BRAKE SYSTEM – Service Specifications / Lubricants

SERVICE SPECIFICATIONS

<EVOLUTION-IV>

Items

Brake booster nonboosting

f

sure kPa {kgf/cm2}

Brake booster boosting actionfPedal force 98 N {10 kgf} 2,354 – 3,334 {24 – 34} –

{kgf/cm2}

Proportioning valve Split point kPa {kgf/cm2} 2,697 – 3,187 {27.5 – 32.5} –

Output fluid pressure kPa {kgf/cm2}

(input fluid pressure kPa {kgf/cm2})

Front disc brake drag force N {kgf} 51 {5.2} –

Rear disc brake Brake pad thickness mm 10.0 2.0

Brake disc thickness mm 20.0 18.4

Brake drag force N {kgf} 69 {7.0} –

Brake drum I.D. mm 168.0 169.0

Pedal force 98 N {10 kgf} 49 {0.5} or more –

-

Pedal force 294 N {30 kgf} 1,177 {12} or more –

Pedal force 294 N {30 kgf} 6,963 – 9,414 {71 – 96} –

Standard value Limit

4,658 {47.5} (9,807 {100}) –

<EVOLUTION-V>

Same as EVOLUTION-IV except for followings.

Items

Front disc brake Brake pad thickness mm 10.0 2.0

Brake drag force N {kgf} 69 {7.0} –

Rear disc brake Brake pad thickness mm 10.0 2.0

Brake drag force N {kgf} 69 {7.0} –

Standard value Limit

LUBRICANTS

Items

Brake fluid MITSUBISHI GENUINE DIA QUEEN BRAKE

Piston boot, piston seal Repair kit grease

Guide pin, lock pin

Pin boot, guide pin sleeve

Piston, wheel cylinder body

Packing plate CHUO YUKA AKB100

Specified lubricant Quantity

FLUID SUPER

As required

Shoe & lining assembly

Auto adjuster assembly

Page 3

BASIC BRAKE SYSTEM – Sealant / Special Tools / On-vehicle Service

HELMESEAL 101Y [MZ100022 (containing 100 g)], [MZ100023 (containing 500 g)]

SEALANT

35A-3

Items

Fitting Semi-drying sealant: THREEBOND 1104 [0110207]

Vacuum switch

NOTE

Given in [ ] are the genuine part numbers.

Specified sealant

HELMESEAL 201-52B [0110511 (containing 100 g)], [0110512 (containing 500 g)]

SPECIAL TOOLS

Tool

1

Number Name Use

MB990964

1: MB991008

(F)

Brake tool set Installation of rear drum brake piston cup

ON-VEHICLE SERVICE

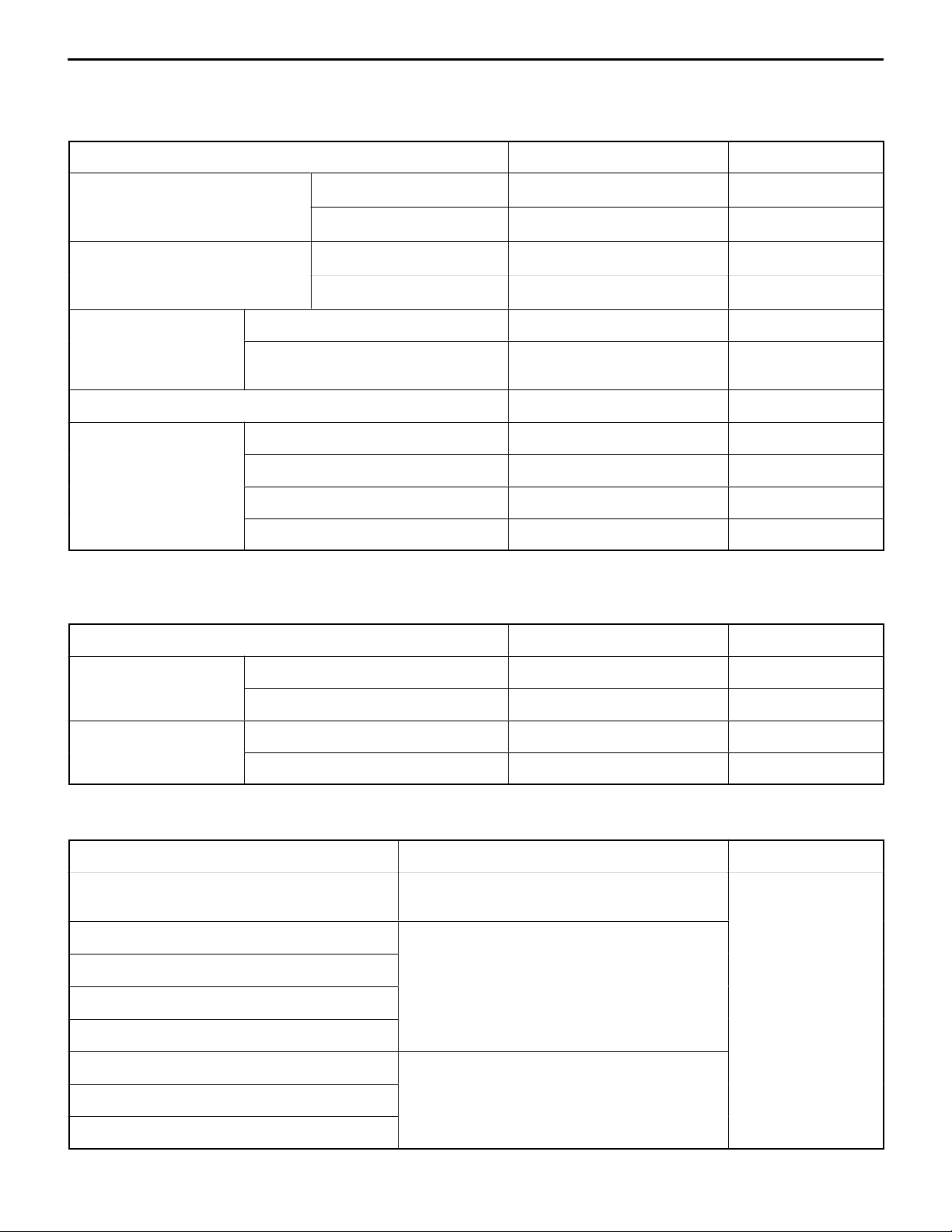

1. BRAKE BOOSTER OPERATION CHECK

Pressure

gauges

Vacuum gauge

The conventional procedures apply except for the following

standard value.

Nonboosting action test

Output

fluid

pressure

Split point

Vacuum hose

Check

valve

Pedal

pressure

gauge

Standard value:

2

Fluid pressure generated kPa {kgf/cm

}

Pedal force 98 N {10 kgf}: 49 {0.5} or more

Pedal force 294 N {30 kgf}: 1,177 {12} or more

Boosting action test

Standard value:

2

Fluid pressure generated kPa {kgf/cm

}

Pedal force 98 N {10 kgf}: 2,354 – 3,334 {24 – 34}

Pedal force 294 N {30 kgf}: 6,963 – 9,414 {71 – 96}

2. PROPORTIONING VALVE FUNCTION TEST

The conventional procedures apply except for the following

standard value.

Standard value:

Input fluid pressure

kPa {kgf/cm2}

Output fluid pressure

kPa {kgf/cm2}

Input fluid pressure

Split point 2,697 – 3,187 {27.5 – 32.5}

9,807 {100} 4,658 {47.5}

Page 4

35A-4

BASIC BRAKE SYSTEM – On-vehicle Service

Air bleeder screws

<Front> <Rear>

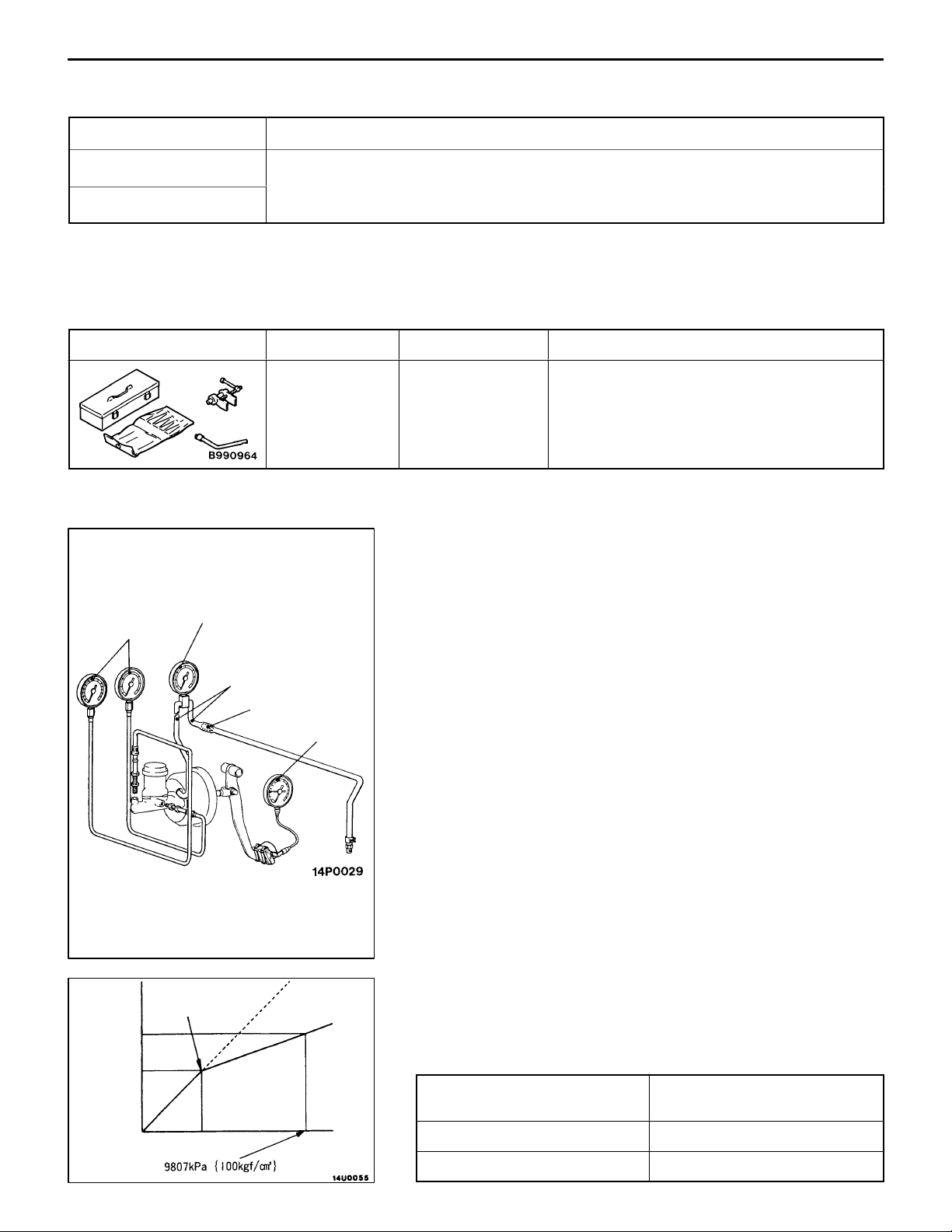

3. BLEEDING <EVOLUTION-V>

Connect a vinyl tube to the outer end of the air bleeder screw

to bleed the circuit of air. Then, connect the vinyl tube to

the inner end and bleed the circuit of air. Except for these,

the conventional procedures shall be followed. After the circuit

has been bled of air, tighten both air bleeder screws to the

specified torque.

4. DISC BRAKE PAD CHECK AND

REPLACEMENT <EVOLUTION-IV>

4-1 FRONT BRAKE

Use the same procedure as that for the 2-pot type disc brake.

4-2 REAR BRAKE

The conventional procedures apply except for the following

standard value for the brake pad thickness.

Standard value (brake pad thickness): 10.0 mm

Limit: 2.0 mm

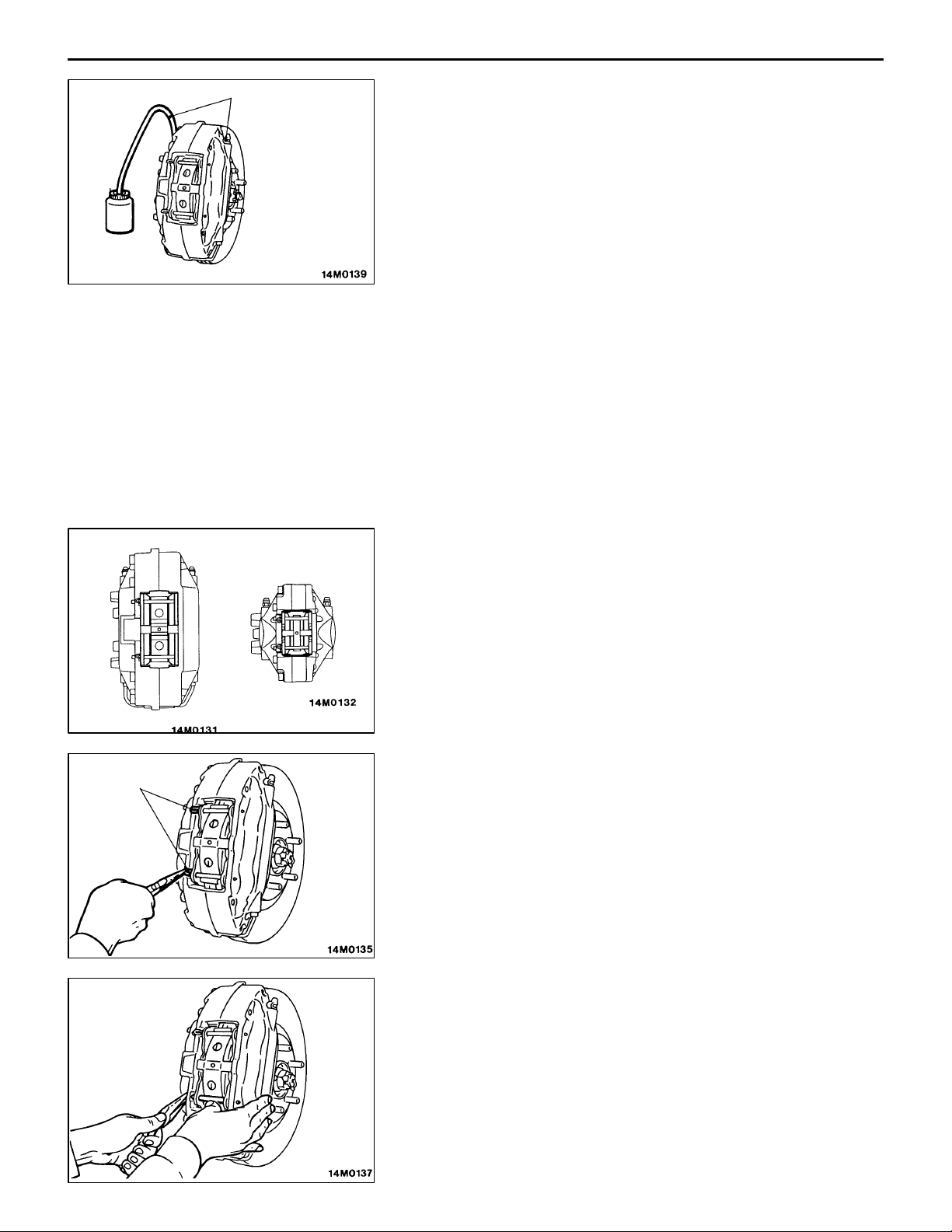

5. DISC BRAKE PAD CHECK AND

REPLACEMENT <EVOLUTION-V>

NOTE

The wear indicator contacts the brake disc to squeak when

the pad thickness becomes about 2 mm, warning the driver

that the pad needs replacement.

(1) Visually check for the brake pad thickness through the

inspection hole in the caliper body.

Clips

Standard value: 10.0 mm

Limit: 2.0 mm

(2) If the brake pad thickness is less than the limit, follow

steps (3) and onward to replace the brake pads on both

sides with new ones as a set.

(3) Remove clips from the pins.

(4) Holding the cross spring with one hand, pull the pin out

of the caliper.

Page 5

BASIC BRAKE SYSTEM – On-vehicle Service

(5) Remove the pad from the caliper.

(6) To measure brake drag force after new pads have been

installed, use a spring balance to measure the turning

sliding resistance of the hub with the pads removed.

(7) Clean the piston and, using the special tool, push the

piston into the cylinder.

35A-5

<Front> <Rear>

Pins

Cross

spring

(8) Apply repair kit grease to the portions of the pads indicated

on the left. At this time, make sure that the grease will

not be applied to any other surfaces.

(9) Mount the pad to the caliper so that its side with the

wear indicator is on the outside of the vehicle. With the

rear pad, ensure that the arrow on the pad faces in the

same direction as the brake disc turns when the vehicle

moves forward.

(10)Holding the cross spring with one hand, fit pins in the

caliper.

(11)Mount clips to the pins.

(12)Using a spring balance, measure the turning sliding

resistance of the hub in the forward direction.

(13)Find the brake disc drag force [the difference in

measurements taken in step (6) and in step (12)].

Standard value: 69 N {7.0 kgf}

Page 6

35A-6

BASIC BRAKE SYSTEM – On-vehicle Service

6. BRAKE DISC THICKNESS CHECK

(1) Remove dirt and rust from the surface of the brake disc.

(2) Measure the thickness of the disc, over which the pad

slides, at 4 places or more.

Standard value: <Front> 24.0 mm

<Rear> 20.0 mm

Limit: <Front> 22.4 mm

<Rear> 18.4 mm

(3) If any of the brake disc thickness measurements exceeds

the limit, replace the brake discs and brake pads on both

sides as a set.

7. BRAKE DRUM I.D. CHECK

(1) Remove the rear brake assembly and support it with a

wire.

(2) Remove the brake disc.

(3) Measure the I.D. of the brake drum at 2 places or more.

Standard value: 168.0 mm

Limit: 169.0 mm

(4) If the brake drum I.D. has worn to exceed the limit, or

if an excessive eccentric wear is evident, replace the

brake disc with a new one.

8. LINING TO BRAKE DRUM CONTACT

CHECK

(1) Remove the rear brake assembly and support it with a

wire.

(2) Remove the brake disc.

(3) Remove the shoe & lining assembly. (Refer to GROUP

36.)

(4) Apply chalk to the brake disc inner surface (brake drum)

and rub the shoe & lining assembly against it.

(5) If any irregular contact is evident, replace the shoe &

lining assembly or brake disc.

NOTE

Wipe the surfaces clean of chalk after the check has

been completed.

Page 7

BASIC BRAKE SYSTEM – Front Brake

FRONT BRAKE

REMOVAL AND INSTALLATION

Except for the followings, use the same procedure as that

for conventional disc brake.

INSTALLATION SERVICE POINT

"AA DISC BRAKE ASSEMBLY INSTALLATION

Follow the conventional procedures except the standard value

for the disc brake drag force.

Standard value (disc brake drag force):

51 N {5.2 kgf} <EVOLUTION-IV>

69 N {7.0 kgf} <EVOLUTION-V>

DISASSEMBLY AND REASSEMBLY

NOTE

On EVOLUTION-IV, follow the same procedure as conventional.

On EVOLUTION-V, disassemble in the order shown.

35A-7

7

6

7

2

1

5

3

1

8

6

5

4

Grease: Repair kit grease

4

Disassembly steps

1. Clip

2. Pin

3. Cross spring

4. Pad & wear indicator assembly

5. Pad assembly

6. Air bleeder screw

7. Cap

8. Disc brake caliper assembly

Page 8

35A-8

BASIC BRAKE SYSTEM – Rear Brake

REAR BRAKE

REMOVAL AND INSTALLATION

Pre-removal Operation

D Brake Fluid Draining

49 – 59 {5.0 – 6.0}

Removal steps

1. Brake hose connection

2. Gasket

"AA 3. Rear brake assembly

4. Brake disc

Post-installation Operation

D Brake Fluid Refilling and Bleeding

29 {3.0}

1

2

3

4

Unit: Nm {kgf@m}

NOTE

Shown here is the illustration of rear brake for

EVOLUTION-IV.

INSTALLATION SERVICE POINT

"AA DISC BRAKE ASSEMBLY INSTALLATION

Follow the conventional procedures except the standard value

for the disc brake drag force.

Standard value (disc brake drag force): 69 N {7.0 kgf}

Page 9

BASIC BRAKE SYSTEM – Rear Brake

DISASSEMBLY AND REASSEMBLY

<EVOLUTION-IV>

35A-9

13

43 {4.4}

14 14

11

11

2

14

7.8 {0.8}

12

5

11

13

9

8

1

3

10

7

6

4

14

5

12

13

3

9

5

7

12

14

14

Pad kit

2

1

3

5

Brake caliper kit

Disassembly steps

"AA 1. Lock pin

"AA 2. Guide pin

3. Bushing

4. Caliper support (pad, clip, shim)

5. Pin boot

6. Boot ring

AA" 7. Piston boot

Unit: Nm {kgf@m}

6

Grease

Seal & boot kit

5

5

9

4

8

7

6

AA" 8. Piston

AB" 9. Piston seal

10. Caliper body

11. Pad & wear indicator assembly

12. Pad assembly

13. Outer shim

14. Clip

Page 10

35A-10

BASIC BRAKE SYSTEM – Rear Brake

LUBRICANT APPLICATION POINTS

Caution

Do not wipe the piston seal in the

seal & boot kit clean of the special

grease applied to it.

Brake fluid:

MITSUBISHI GENUINE

DIA QUEEN BRAKE

FLUID SUPER 4

Grease: Repair kit grease

Grease: Repair kit grease

Grease: Repair kit grease

Page 11

BASIC BRAKE SYSTEM – Rear Brake

DISASSEMBLY SERVICE POINTS

AA" PISTON BOOT / PISTON REMOVAL

Cover the outer end of the caliper body with a cloth. Blow

compressed air through the brake hose connection to remove

the piston and piston boot.

Caution

Do not send a sudden blast of air, as it causes the piston

to rush out. Send a gentle, gradual blow of compressed

air.

AB" PISTON SEAL REMOVAL

(1) Remove the piston seal with a finger tip.

Caution

Do not use a flat-blade screwdriver or similar tool

to prevent the cylinder inner surface from being

damaged.

(2) Clean the piston surface and cylinder inner surface with

trichloroethylene, alcohol, or the specified brake fluid.

Brake fluid:

MITSUBISHI GENUINE DIA QUEEN BRAKE FLUID

SUPER 4

35A-11

ID mark “L”

ID mark “G”

Front

INSTALLATION SERVICE POINT

"AA LOCK PIN / GUIDE PIN INSTALLATION

Install the guide pin and lock pin so that each head mark

matches the ID mark indicated on the caliper body as illustrated

on the left.

INSPECTION

PAD WEAR CHECK

Measure the thickness at a location that wears most of the

pad. If the thickness is less than the limit, replace the pad

assembly.

Standard value: 10.0 mm

Limit: 2.0 mm

Caution

(1) Whenever a pad is to be replaced with a new one,

be sure to replace both right and left sides as a set.

(2) If there is an excessive difference in pad thickness

noted between the right and left ones, check the

sliding mechanism.

Page 12

35A-12

BASIC BRAKE SYSTEM – Rear Brake

DISASSEMBLY AND REASSEMBLY

<EVOLUTION-V>

5

7

6

8

Disassembly steps

1. Clip

2. Pin

3. Cross spring

4. Pad & wear indicator assembly

3

5

4

1

Grease: Repair kit grease

2

5. Pad assembly

6. Air bleeder screw

7. Cap

8. Disc brake caliper assembly

4

Loading...

Loading...