Page 1

GROUP INDEX

LANCER

WORKSHOP MANUAL

SUPPLEMENT

FOREWORD

This Workshop manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and installation.

Use the following manuals in combination with this

manual as required.

General . . . . . . . . . . . . . . . . . . . . . . . .

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .

00

13

TECHNICAL INFORMATION MANUAL

PYME0302

PYME0302-A

PYME0302-B

WORKSHOP MANUAL

CHASSIS GROUP PWME0302

PWME0302-A

PWME0302-B

BODY REPAIR MANUAL

PBME0302

PBME0302-A

PBME0302-B

PARTS CATALOGUE

B606K006A_

All information, illustrations and product descriptions

contained in this manual are current as at the time of

publication. We, however, reserve the right to make

changes at any time without prior notice or obligation.

©Mitsubishi Motors Corporation Oct. 2005

Page 2

GROUP 00

GENERAL

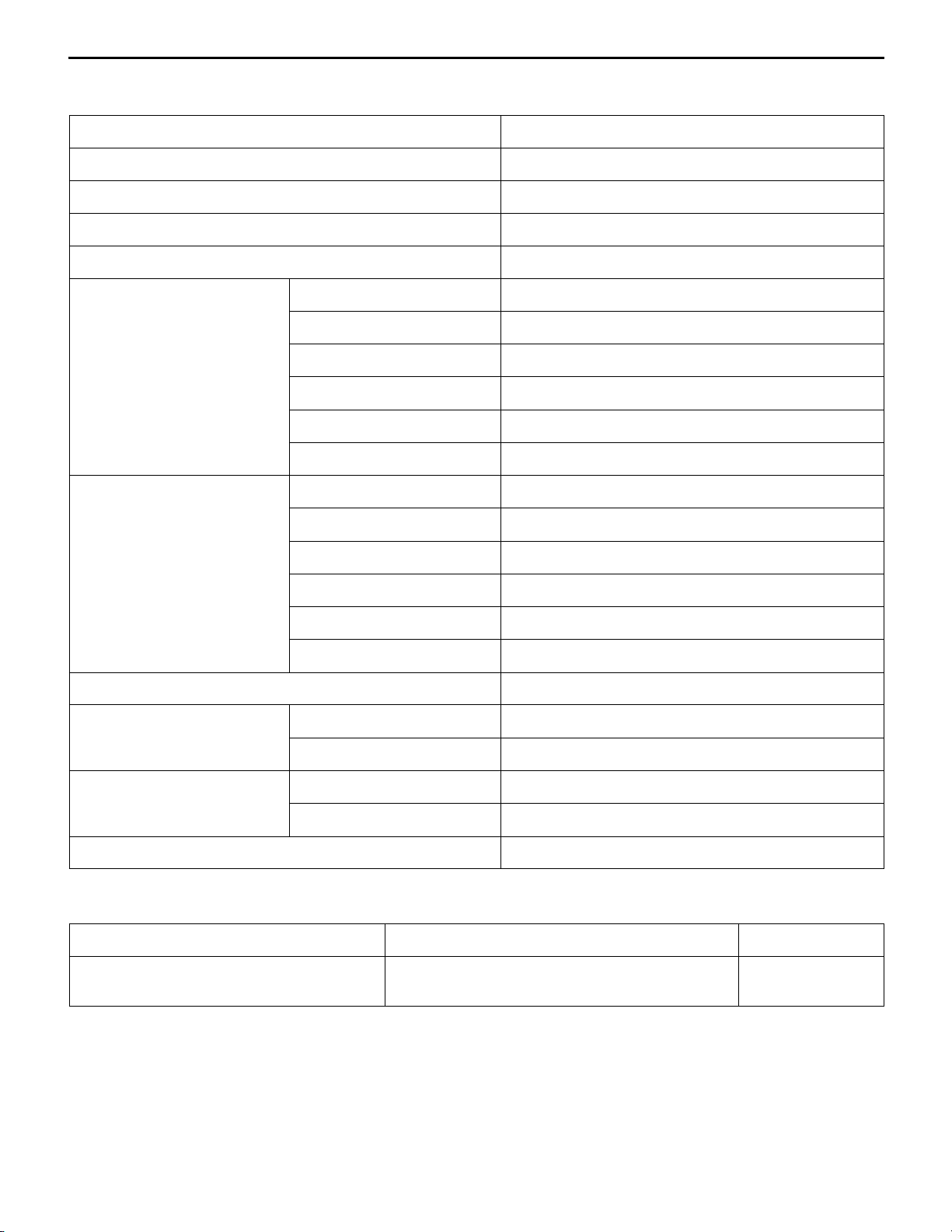

CONTENTS

VEHICLE IDENTIFICATION . . . . . . . 00-2 GENERAL DATA AND

SPECIFICATIONS . . . . . . . . . . . . . . . 00-3

00-1

Page 3

00-2

VEHICLE IDENTIFICATION

GENERAL

VEHICLE IDENTIFICATION

M1001000401448

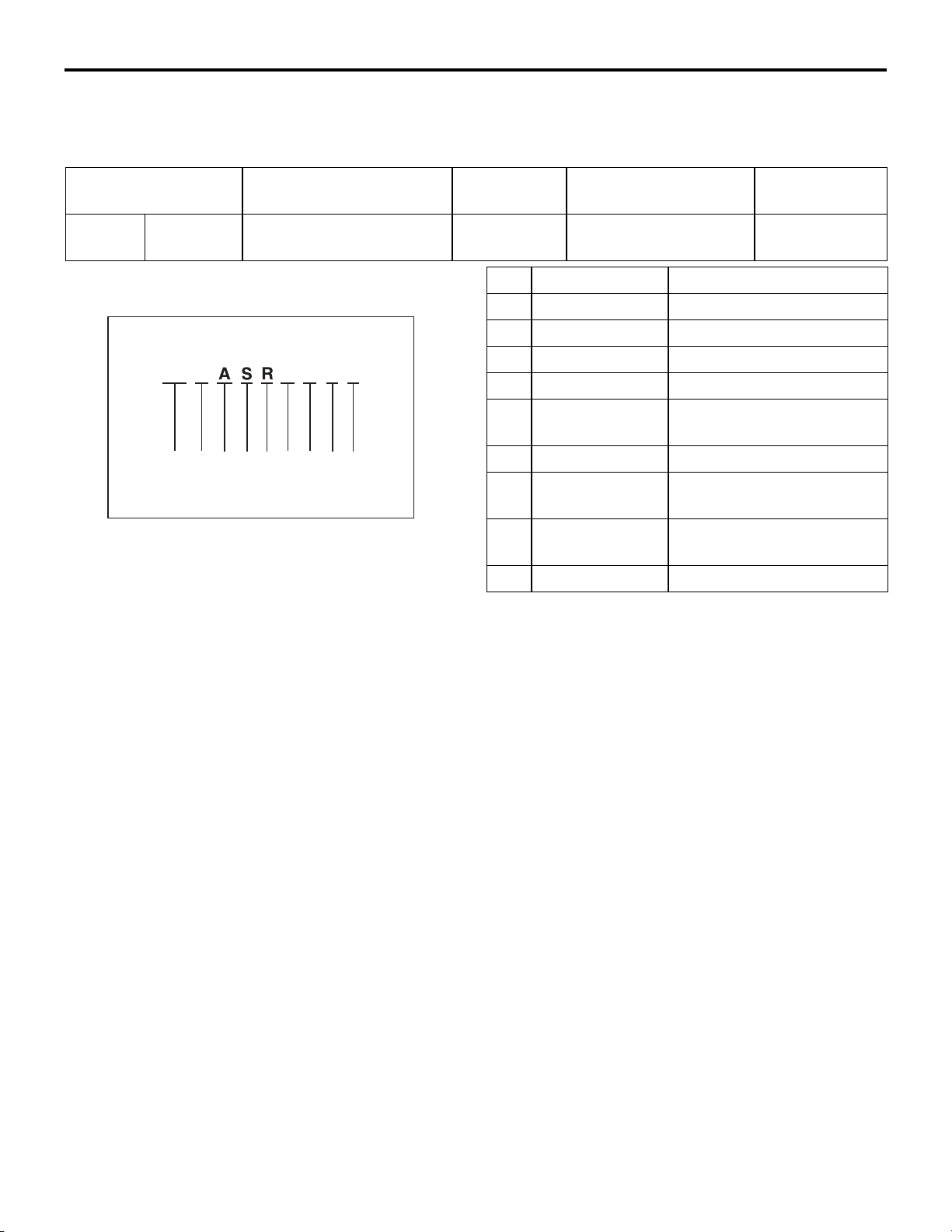

MODELS

Model code Engine model Price class Transmission model Fuel supply

system

CS9A SRHML6 4G63-DOHC (1,997 mL) Intense F4A4B

<2WD, 4A/T>

No. Item Content

MODEL CODE

CS 9 W L

123

LNHM 6

456789

AC303950

AC

1 Development CS: MITSUBISHI LANCER

2 Engine type 9: 1,997mL

3 Sort A: Passenger car

4 Body style S: 4-door sedan

5 Transmission

type

6 Trim level H: Intense

7 Specification

engine feature

8 Steering wheel

location

R: 4-speed automatic

transmission

M: MPI-DOHC

L: Left hand

MPI

9 Destination 6: For Europe

Page 4

GENERAL

GENERAL DATA AND SPECIFICATIONS

GENERAL DATA AND SPECIFICATIONS

8

7

1

2

3465

00-3

M1001000901197

9

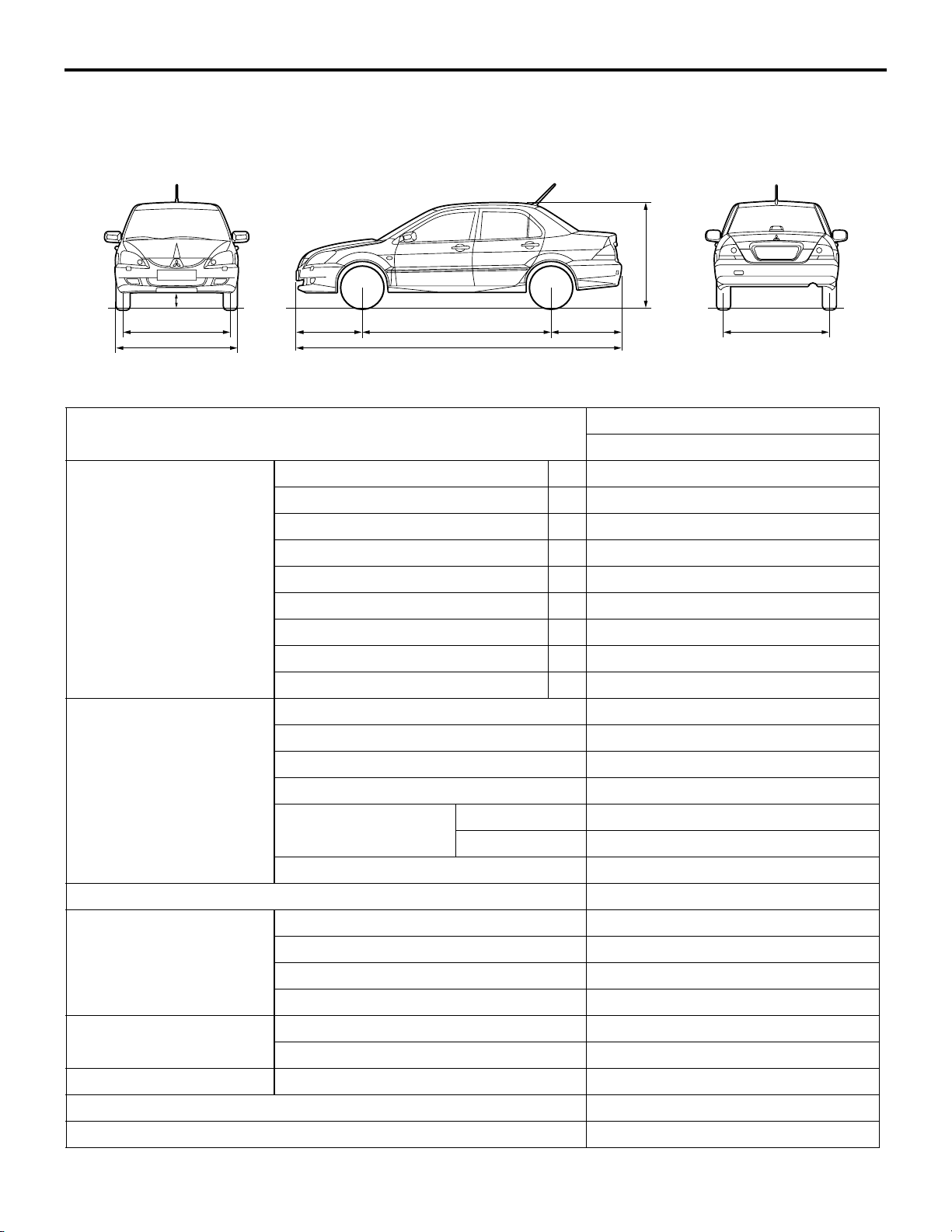

Items CS9A

SRHML6

Vehicle dimensions mm Front track 1 1,470

Overall width 2 1,715

Front overhang 3 965

Wheel base 4 2,600

Rear overhang 5 970

Overall length 6 4,535

Ground clearance (unladen) 7 135

Overall height (unladen) 8 1,415

Rear track 9 1,470

Vehicle weight kg Kerb weight 1,295

Max. gross vehicle weight 1,770

Max. axle weight rating-front 930

Max. axle weight rating-rear 840

Max. trailer weight With brake 1,000

Without brake 400

Max. trailer-nose weight 60

AC303990

AB

Seating capacity 5

Engine Model code 4G63

To ta l d i spl ac em en t mL 1,997

Maximum output kW/r/min 99/5,750

Maximum torque N⋅m/r/min 176/4,500

Transmission Model code F4A4B

Type 4-speed automatic

Fuel system Fuel supply system MPI

Maximum speed km/h 187

Minimum turning radius m 5.7

Page 5

NOTES

Page 6

13D-1

MULTIPOINT FUEL

INJECTION (MPI)

<4G63>

CONTENTS

GENERAL 2.................................

Outline of Change 2............................

GENERAL INFORMATION 3...................

SERVICE SPECIFICATIONS 6.................

SEALANT 6..................................

SPECIAL TOOLS 7...........................

TROUBLESHOOTING 10......................

ON-VEHICLE SERVICE 90....................

Throttle Body (Throttle Valve Area)

Cleaning 90...................................

Throttle Position Sensor Adjustment 90............

Basic Idle Speed Adjustment 91..................

Fuel Pressure Test 92...........................

Component Location 95.........................

Engine Control Relay Continuity Check 96.........

Fuel Pump Relay Continuity Check 96.............

Intake Air Temperature Sensor Check 97..........

Engine Coolant Temperature Sensor Check 98.....

Throttle Position Sensor Check 98................

Oxygen Sensor Check 99.......................

Injector Check 101..............................

Idle Speed Control (ISC) Servo (Stepper Motor)

Check 102.....................................

Purge Control Solenoid Valve Check 104..........

EGR Control Solenoid Valve Check 104...........

Page 7

13D-2

MPI <4G63> ï General

GENERAL

OUTLINE OF CHANGE

Following service procedures have been established due to the addition of vehicles with 4G63-MPI engine

for Russia.

Page 8

MPI <4G63> ï General Information

GENERAL INFORMATION

13D-3

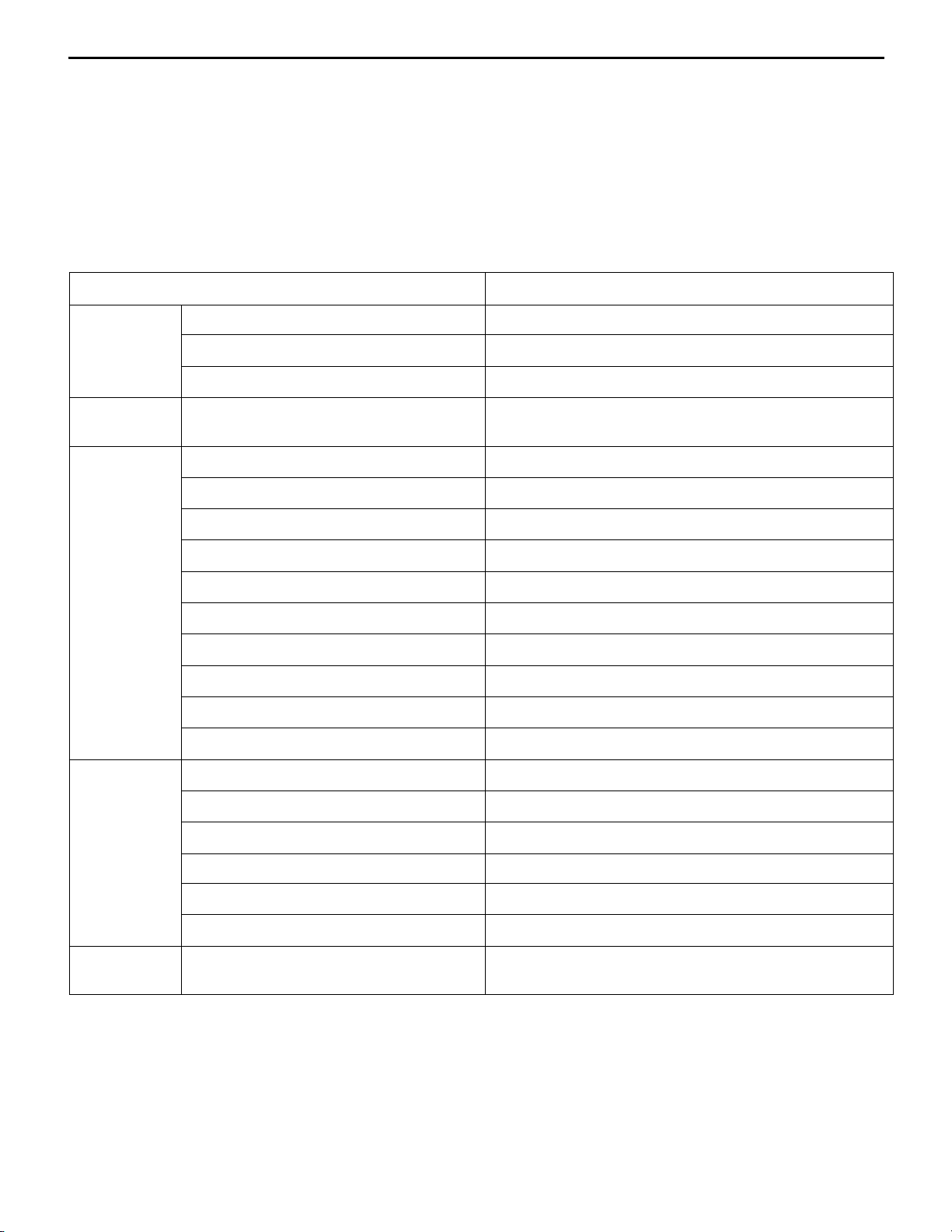

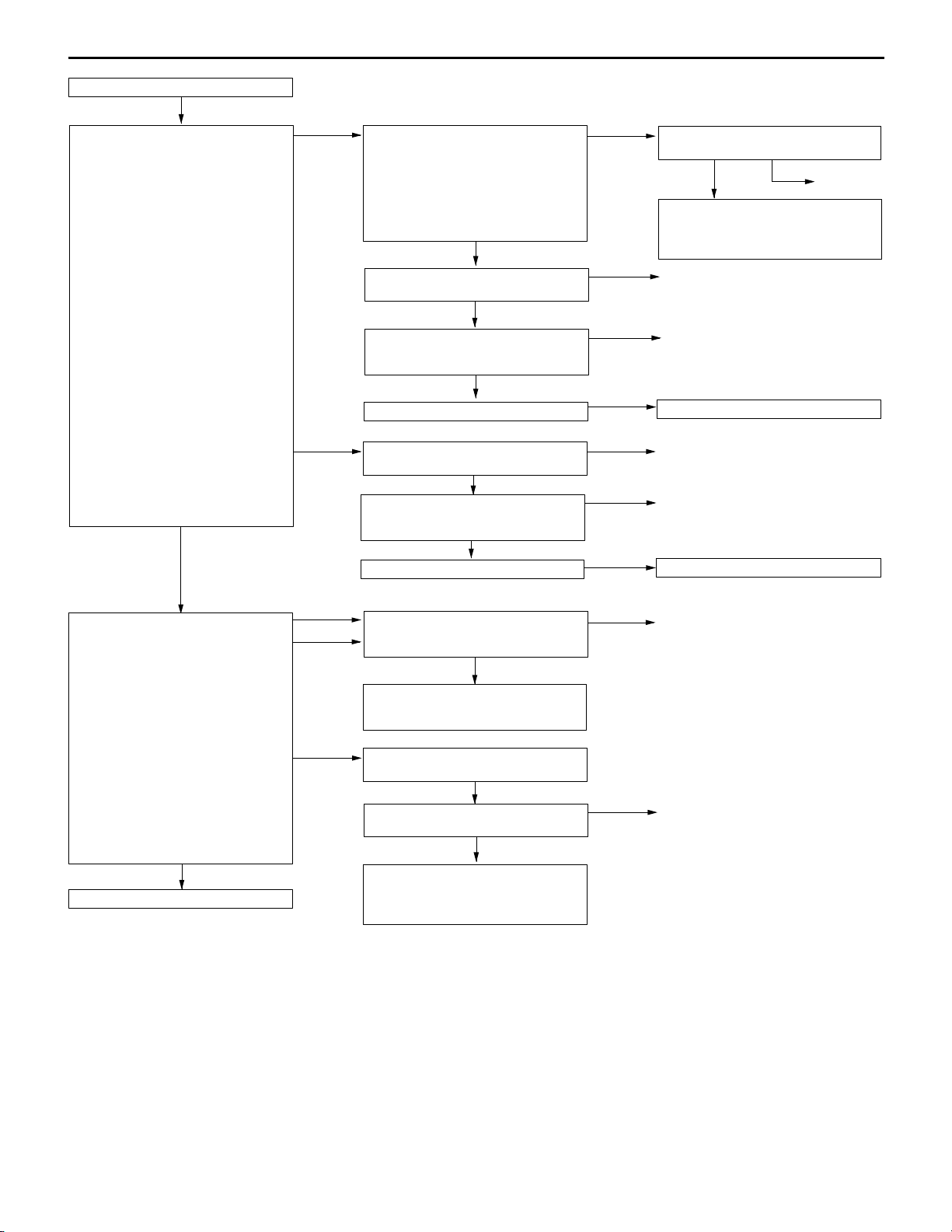

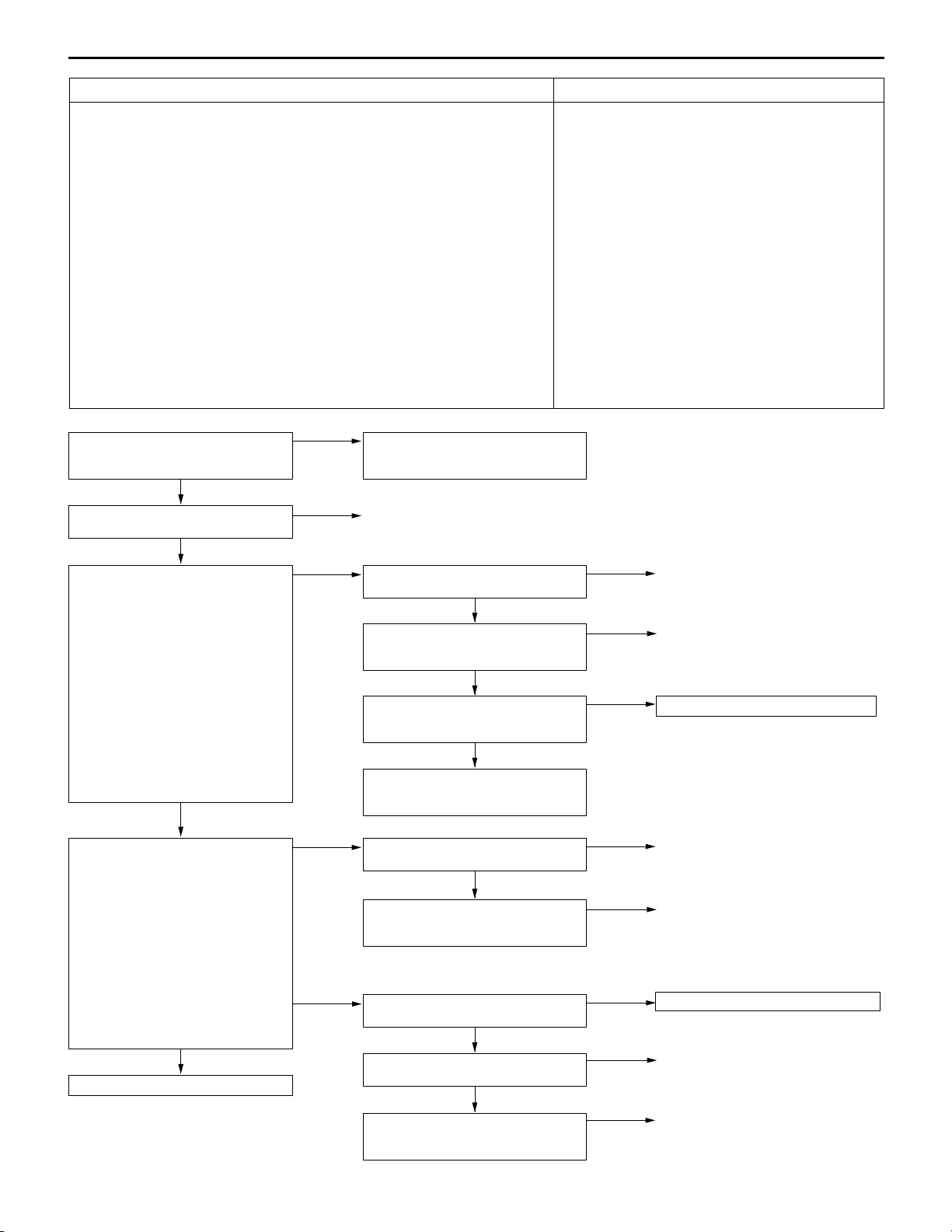

The Multipoint Fuel Injection System consists

of sensors which detect the engine conditions,

the engine-A/T-ECU which controls the system

based on signals from these sensors, and

actuators which operate under the control of

the engine-A/T-ECU. The engine-A/T-ECU

FUEL INJECTION CONTROL

The injector drive times and injection timing

are controlled so that the optimum air/fuel

mixture is supplied to the engine to correspond

to the continually-changing engine operation

conditions.

A single injector is mounted at the intake port

of each cylinder. Fuel is sent under pressure

from the fuel tank by the fuel pump, with the

pressure being regulated by the fuel pressure

regulator. The fuel thus regulated is distributed

to each of the injectors.

Fuel injection is normally carried out once for

each cylinder for every two rotations of the

crankshaft. The firing order is 1ï3ï4ï2. This

is called sequential fuel injection. The

carries out activities such as fuel injection

control, idle speed control and ignition timing

control. In addition, the engine-A/T-ECU is

equipped with several diagnosis modes which

simplify troubleshooting when a problem

develops.

engine-A/T-ECU provides a richer air/fuel

mixture by carrying out “open-loop” control

when the engine is cold or operating under

high load conditions in order to maintain engine

performance. In addition, when the engine is

warm or operating under normal conditions,

the engine-A/T-ECU controls the air/fuel mixture

by using the oxygen sensor signal to carry out

“closed-loop” control in order to obtain the

theoretical air/fuel mixture ratio that provides

the maximum cleaning performance from the

three way catalyst.

IDLE AIR CONTROL

The idle speed is kept at the optimum speed

by controlling the amount of air that bypasses

the throttle valve in accordance with changes

in idling conditions and engine load during

idling. The engine-A/T-ECU drives the idle

speed control motor to keep the engine running

at the pre-set idle target speed in accordance

with the engine coolant temperature and air

IGNITION TIMING CONTROL

The power transistor located in the ignition

primary circuit turns ON and OFF to control

the primary current flow to the ignition coil. This

controls the ignition timing in order to provide

the optimum ignition timing with respect to the

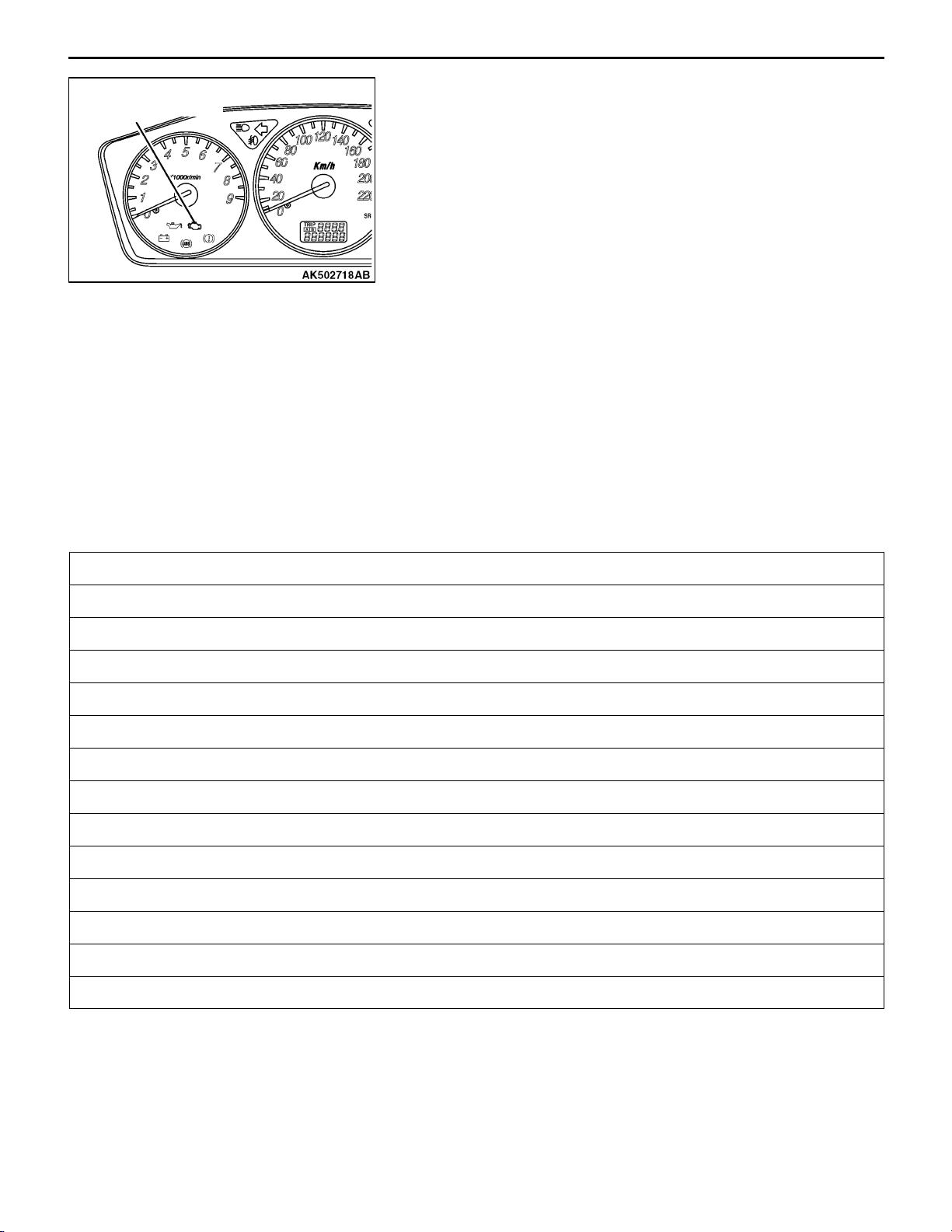

SELF-DIAGNOSIS FUNCTION

D When an abnormality is detected in one

of the sensors or actuators related to

emission control, the engine warning lamp

(check engine lamp) illuminates as a

warning to the driver.

D When an abnormality is detected in one

of the sensors or actuators, a diagnosis

conditioner load. In addition, when the air

conditioner switch is turned off and on while

the engine is idling, the idle speed control motor

operates to adjust the throttle valve bypass

air amount in accordance with the engine load

conditions in order to avoid fluctuations in the

engine speed.

engine operating conditions. The ignition timing

is determined by the engine-A/T-ECU from the

engine speed, intake air volume, engine coolant

temperature and atmospheric pressure.

code corresponding to the abnormality is

output.

D The RAM data inside the engine-A/T-ECU

that is related to the sensors and actuators

can be read by means of the M.U.T.-II/III.

In addition, the actuators can be

force-driven under certain circumstances.

Page 9

13D-4

Throttl

Throttl

60

Inject

tificati

k

HDA250E

MPI <4G63> ï General InformationMPI <4G63> ï General Information

OTHER CONTROL FUNCTIONS

1. Fuel Pump Control

3. Fan Motor Control

Turns the fuel pump relay ON so that current

is supplied to the fuel pump while the engine

is cranking or running.

2. A/C Relay Control

Turns the compressor clutch of the A/C

ON and OFF.

4. Purge Control Solenoid Valve Control

5. EGR Control Solenoid Valve Control

GENERAL SPECIFICATIONS

Item Specification

The revolutions of the radiator fan and

condenser fan are controlled in response to

the engine coolant temperature and vehicle

speed.

ebody

Engine-A/TECU

Sensors

ebore mm

Throttle position sensor Variable resistor type

Idle speed control servo Stepper motor type

Identification No. E6T37983

Air flow sensor Karman vortex type

Barometric pressure sensor Semiconductor type

Intake air temperature sensor Thermistor type

Engine coolant temperature sensor Thermistor type

Oxygen sensor Zirconia type

Inhibitor switch Contact switch type

Camshaft position sensor Hall element type

Crank angle sensor Hall element type

Detonation sensor Piezoelectric type

Power steering fluid pressure switch Contact switch type

Actuators

Fuel pressure

regulator

Engine control relay Contact switch type

Fuel pump relay Contact switch type

Injector type and number Electromagnetic type, 4

oriden

EGR control solenoid valve Duty cycle type solenoid valve

Purge control solenoid valve Duty cycle type solenoid valve

Regulator pressure kPa 328

on mar

Page 10

MPI <4G63> ï General Information

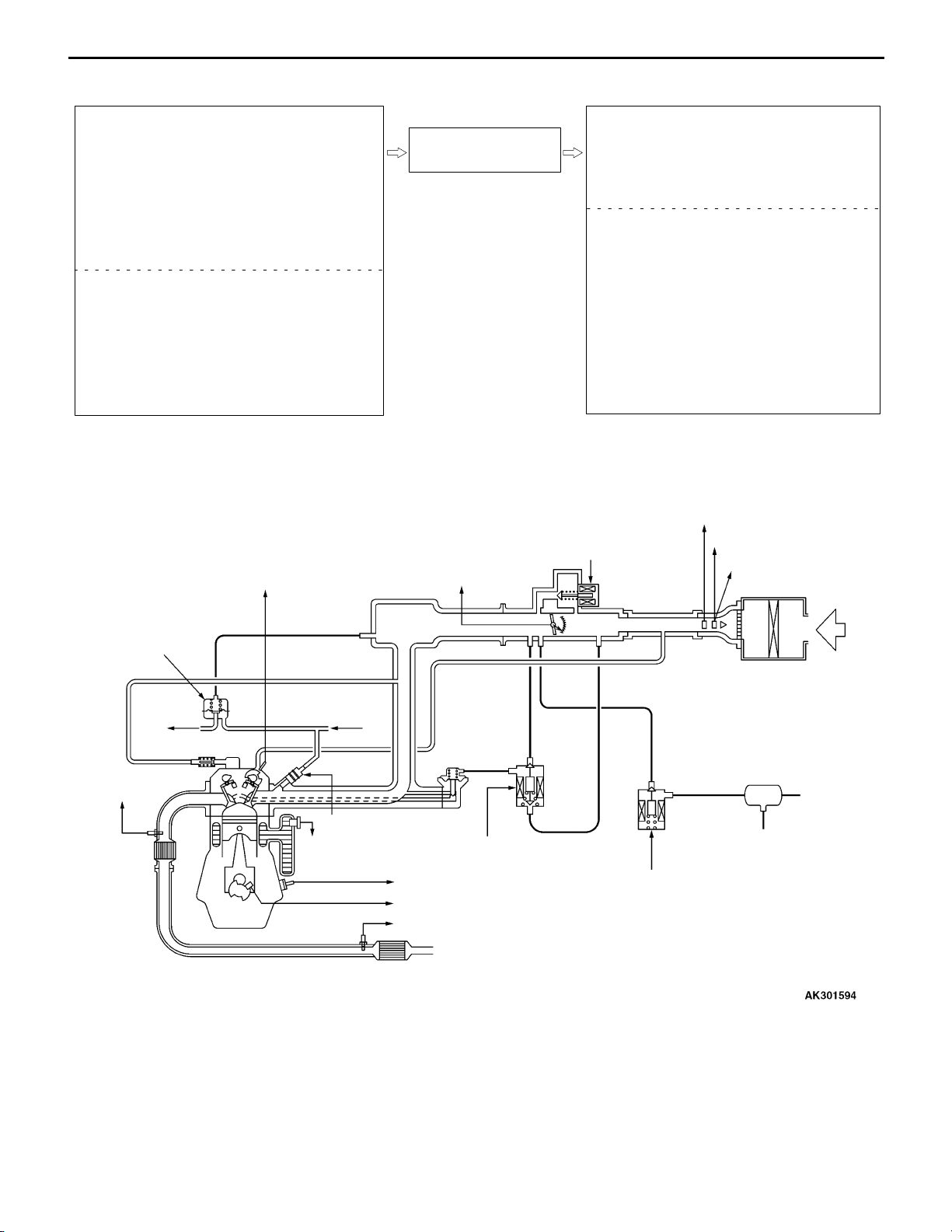

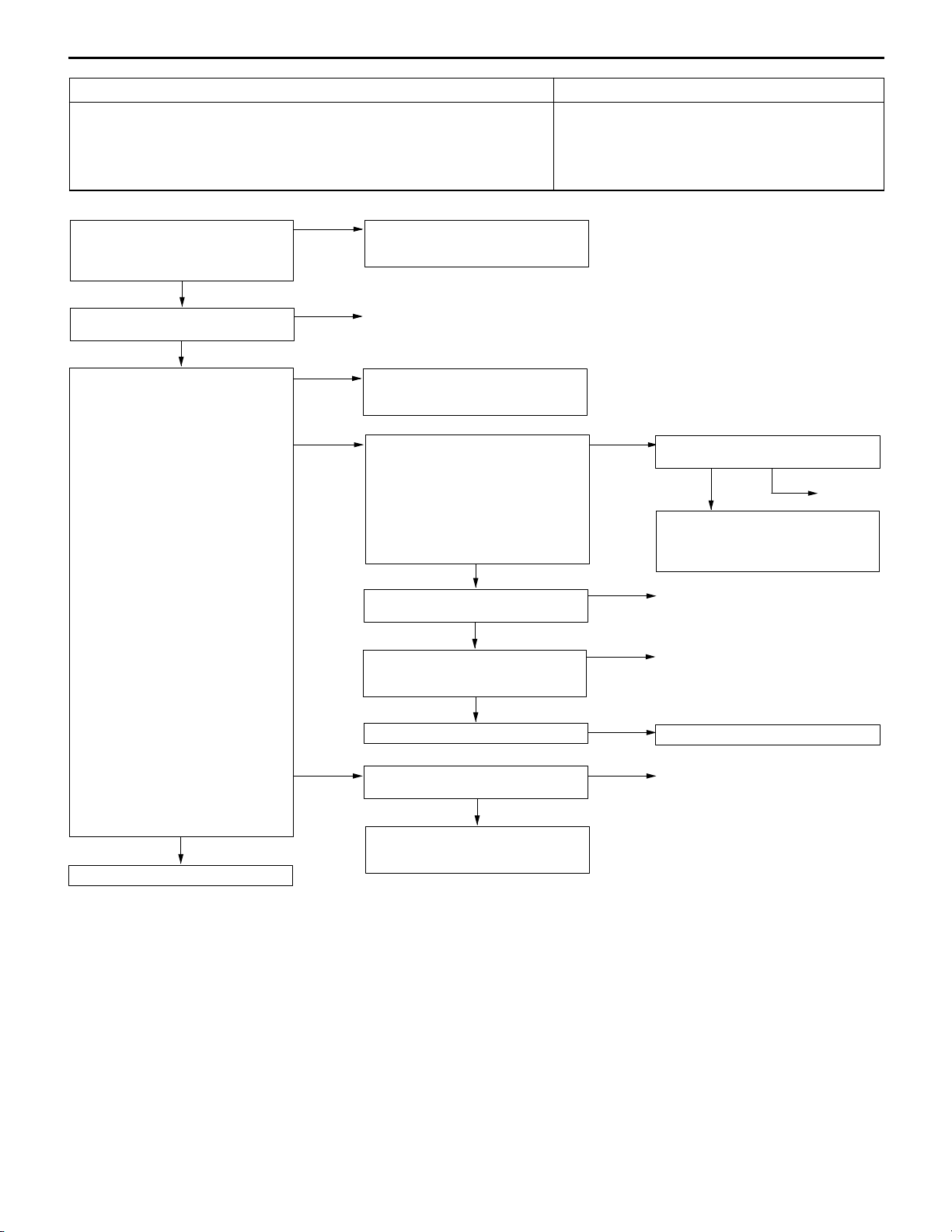

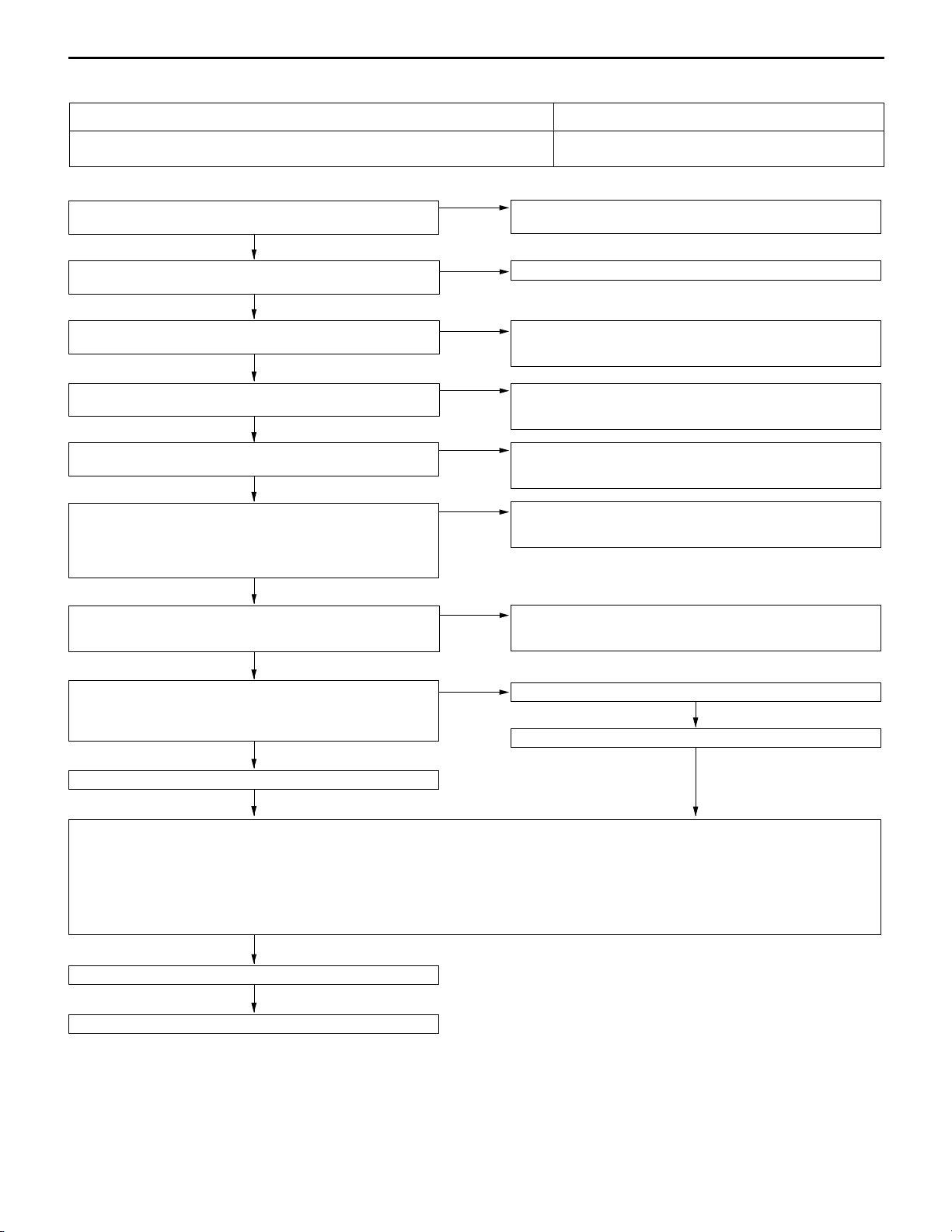

MULTI-POINT FUEL INJECTION SYSTEM DIAGRAM

13D-5

L1 Oxygen sensor (front)

L2 Oxygen sensor (rear)

L3 Air flow sensor

L4 Intake air temperature sensor

L5 Throttle position sensor

L6 Camshaft position sensor

L7 Crank angle sensor

L8 Barometric pressure sensor

L9 Engine coolant temperature sensor

L10 Detonation sensor

D Power supply

D Ignition switch-IG

D Ignition switch-ST

D A/C switch

D A/C load signal

D Power steering fluid pressure switch

D Alternator FR terminal

D Vehicle speed sensor

L6 Camshaft position sensor

Engine-A/T-ECU

L5 Throttle position

sensor

l1 Injector

l2 Idle speed control servo

(Stepper motor)

l3 EGR control solenoid valve

l4 Purge control solenoid valve

D Engine control relay

D Fuel pump relay

D A/C compressor relay

D Ignition coil

D Fan controller

D Air flow sensor filter reset signal

D Engine warning lamp

D Diagnosis output

D Alternator G terminal

D Oxygen sensor (front) heater

D Oxygen sensor (rear) heater

D Tachometer

L4 Intake air temperature sensor

l2 Idle speed control servo

(Stepper motor)

L3 Air flow sensor

L8 Barometric

pressure sensor

Fuel pressure

regulator

To

fuel tank

L1 Oxygen sensor

(front)

Catalytic

converter

From

fuel pump

l1 Injector

L9 Engine coolant

temperature sensor

L10 Detonation sensor

L7 Crank angle sensor

L2 Oxygen sensor (rear)

Catalytic converter

EGR valve

l3 EGR control

solenoid valve

Air

M

AM

Canister

l4 Purge control

solenoid valve

Page 11

13D-6

k

:

k

:

t

20_C)

:

MPI <4G63> ï Service Specifications/Sealant

SERVICE SPECIFICATIONS

Items Specifications

Basic idle speed r/min 750 r 50

Throttle position sensor adjusting voltage mV 535 ï 735

Throttle position sensor resistance k: 3.5 ï 6.5

Idle speed control servo coil resistance (at 20_C) : 28 ï 33

Intake air temperature sensor

resistance

Engine coolant temperature

sensor resistance

Oxygen sensor output voltage (at racing) V 0.6 ï 1.0

Oxygen sensor heater

resistance(a

_

ï20_C 13 ï 17

0_C 5.3 ï 6.7

20_C 2.3 ï 3.0

40_C 1.0 ï 1.5

60_C 0.56 ï0.76

80_C 0.30 ï 0.42

ï20_C 14 ï 17

0_C 5.1 ï 6.5

20_C 2.1 ï 2.7

40_C 0.9 ï 1.3

60_C 0.48 ï 0.68

80_C 0.26 ï 0.36

front 4.5 ï 8.0

rear 11 ï 18

Fuel pressure kPa Vacuum hose disconnection 324 ï 343 at kerb idle

Vacuum hose connection Approximately 265 at kerb idle

Injector coil resistance (at 20_C) : 10.5 ï 13.5

SEALANT

Item Specified sealant Remark

Engine coolant temperature sensor

threaded portion

3M Nut Locking Part No. 4171 or equivalent Drying sealant

Page 12

MPI <4G63> ï Special Tools

SPECIAL TOOLS

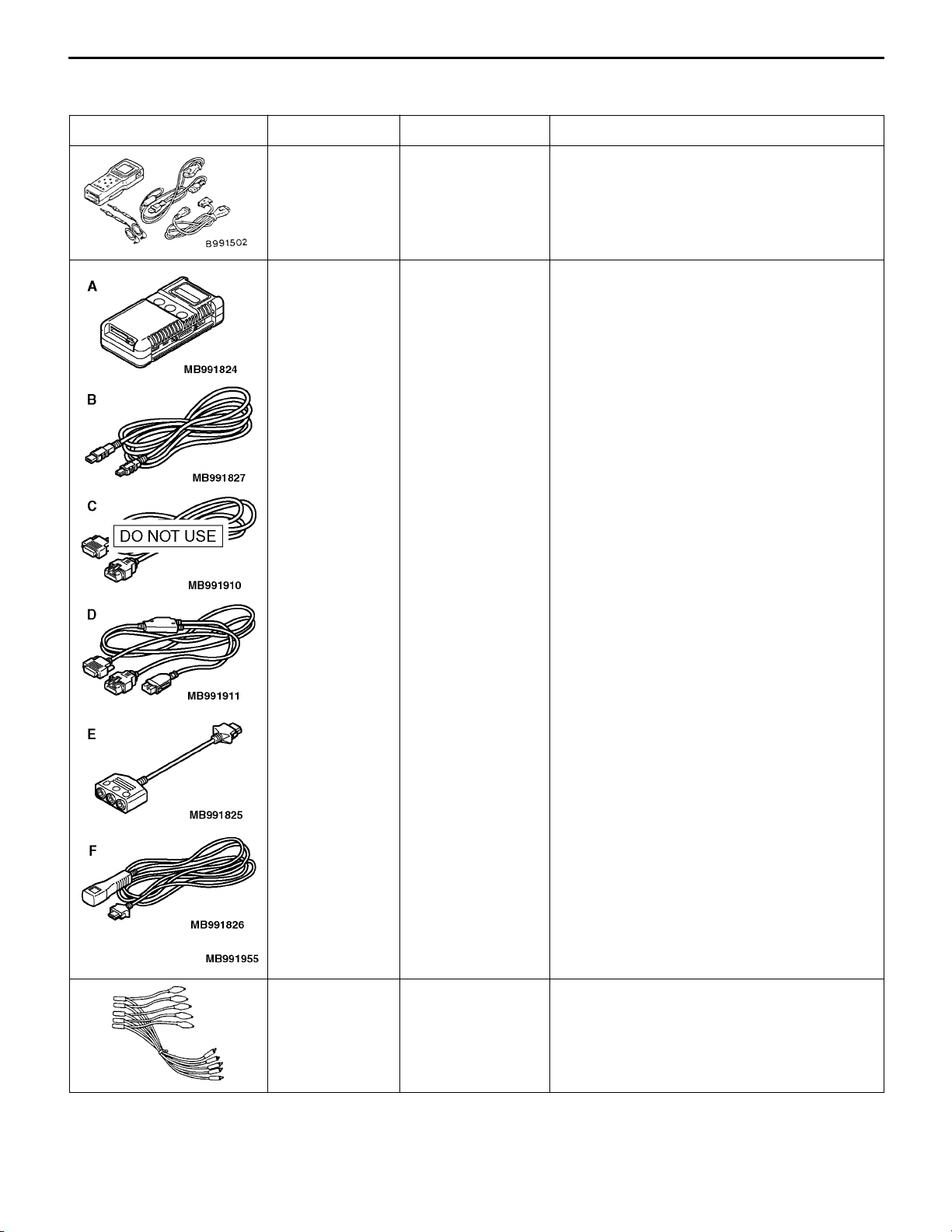

Too l Number Name Use

13D-7

MB991502 M.U.T.-II sub

assembly

MB991955

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991825

F: MB991826

M.U.T.-III sub

assembly

A: Vehicle com-

munication interface (V.C.I.)

B: M.U.T.-III

USB cable

C: M.U.T.-III

main harness A

(Vehicles with

CAN communication system)

D: M.U.T.-III

main harness B

(Vehicles without CAN communication system)

E: M.U.T.-III

measurement

adapter

F: M.U.T.-III

trigger harness

M.U.T.-III sub

assembly

D Reading diagnosis code

D MPI system inspection

D Measurement of fuel pressure

D Reading diagnosis code

D MPI system inspection

D Measurement of fuel pressure

MB991348 Test harness set D Inspection using an oscilloscope

Page 13

13D-8

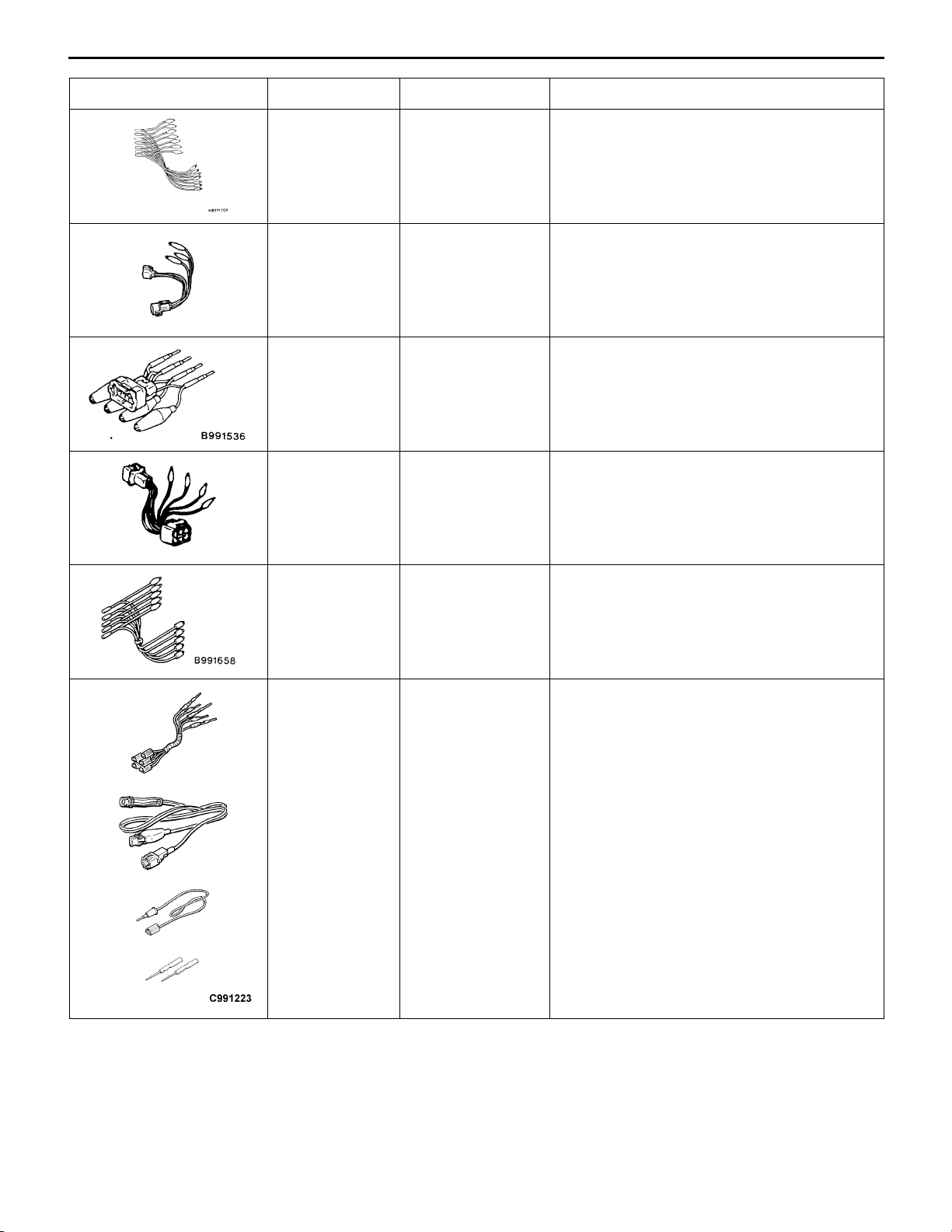

Too l Us eNameNumber

MB991709 Test harness D Measurement of voltage during

MPI <4G63> ï Special Tools

troubleshooting

D Inspection using an oscilloscope

D Check of idle speed control servo

MD998478 Test harness

(3-pin, triangle)

MB991536 Check harness for

throttle position

sensor adjustment

MD998464 Test harness

(4-pin, square)

MB991658 Test harness D Measurement of voltage during

D Measurement of voltage during

Troubleshooting

D Inspection using an oscilloscope

D Measurement of voltage during

Troubleshooting

D Adjusting of throttle position sensor

D Measurement of voltage during

Troubleshooting

D Inspection of oxygen sensor (front)

Troubleshooting

D Inspection of oxygen sensor (rear)

A

B

C

D

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222

Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: Probe

D Check at the ECU terminals

A: Connector pin contact pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester connection

Page 14

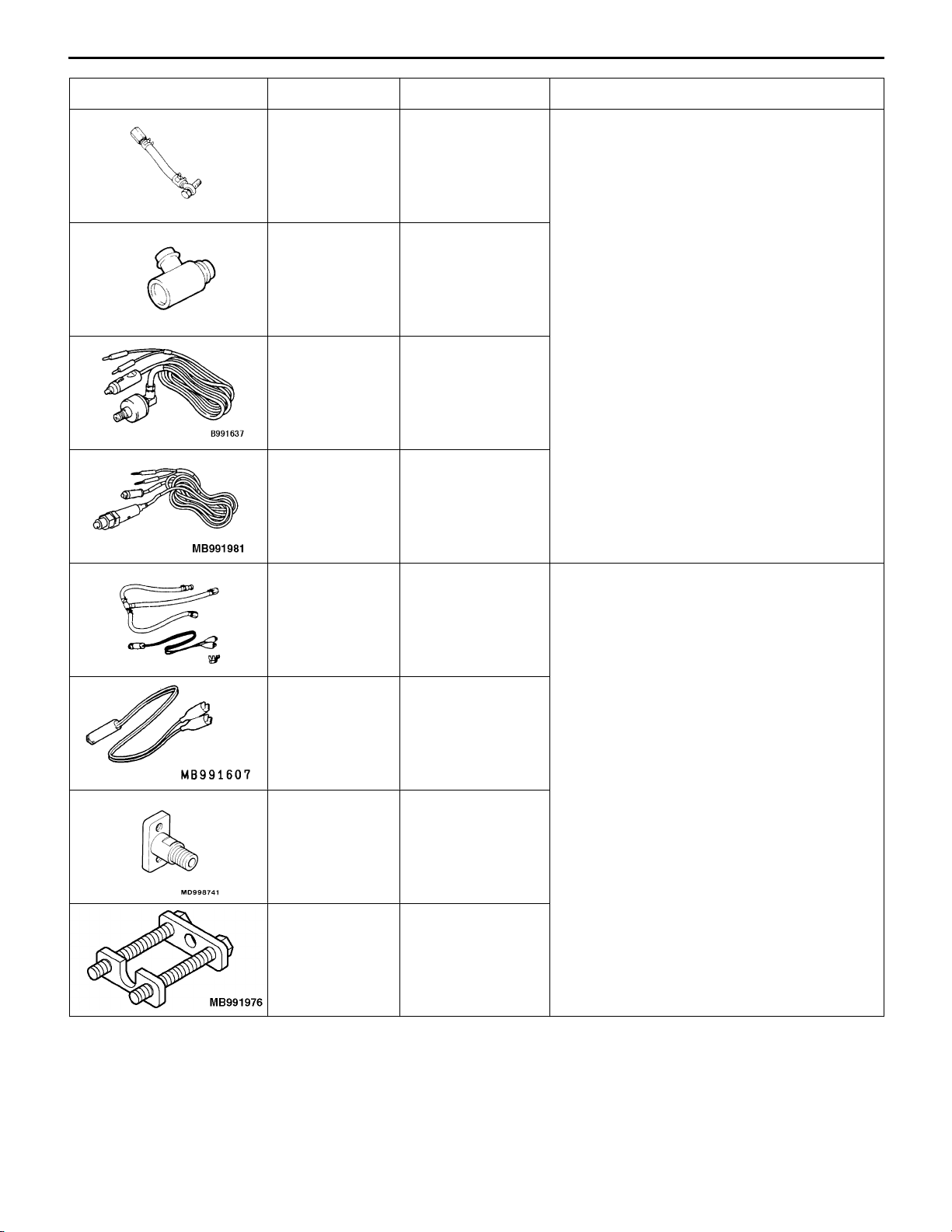

Too l Us eNameNumber

MD998709 Adaptor hose Measurement of fuel pressure

MD998742 Hose adaptor

MB991637 Fuel pressure

MB991981 Fuel pressure

MPI <4G63> ï Special Tools

gauge set

gauge set

13D-9

MB992076 Injector test set Checking the spray condition of injectors

MB991607 Injector test

harness

MD998741 Injector test

adaptor

MB991976 Injector test holder

assembly

Page 15

13D-10

MPI <4G63> ï Troubleshooting

Engine warning lamp

(check engine lamp)

Engine warning lamp inspection items

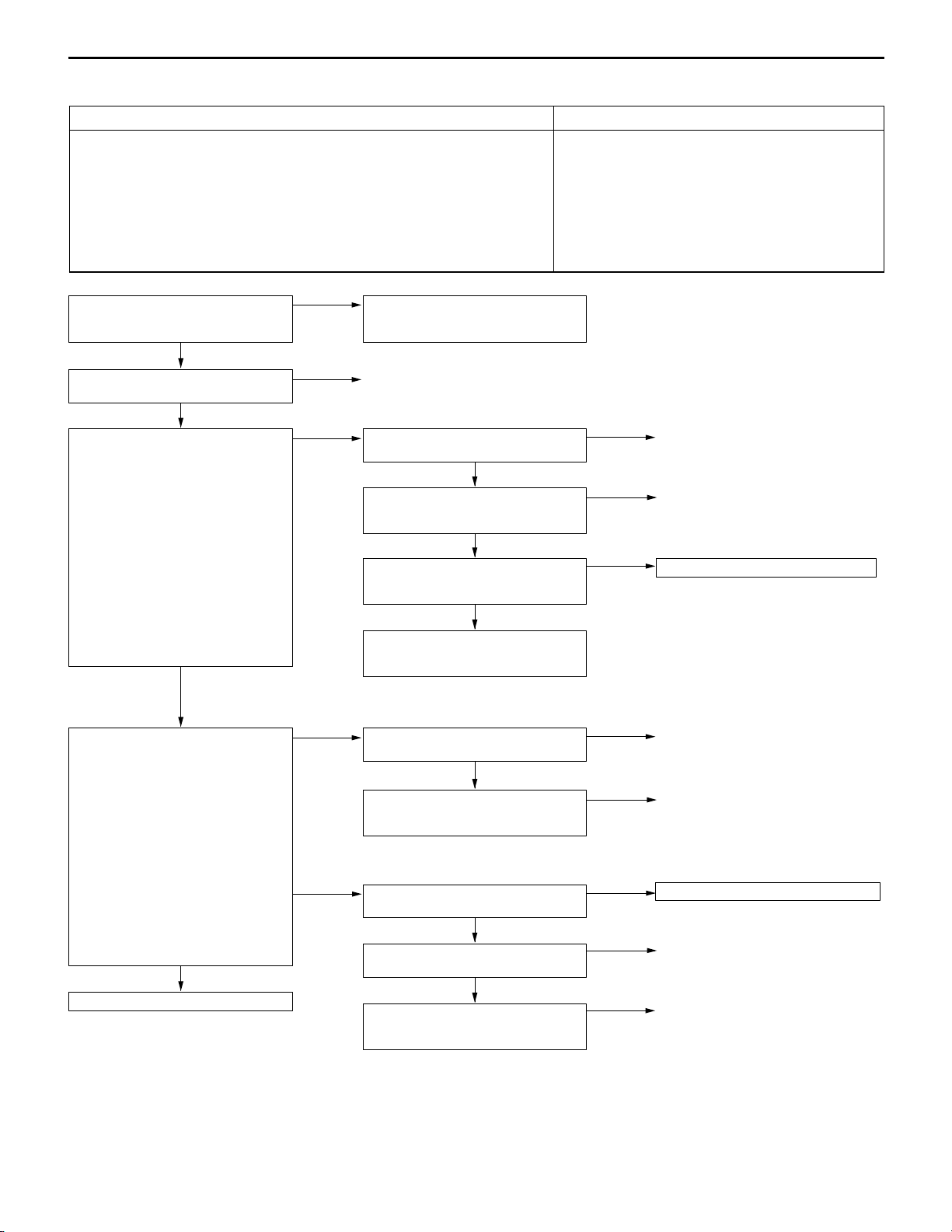

TROUBLESHOOTING

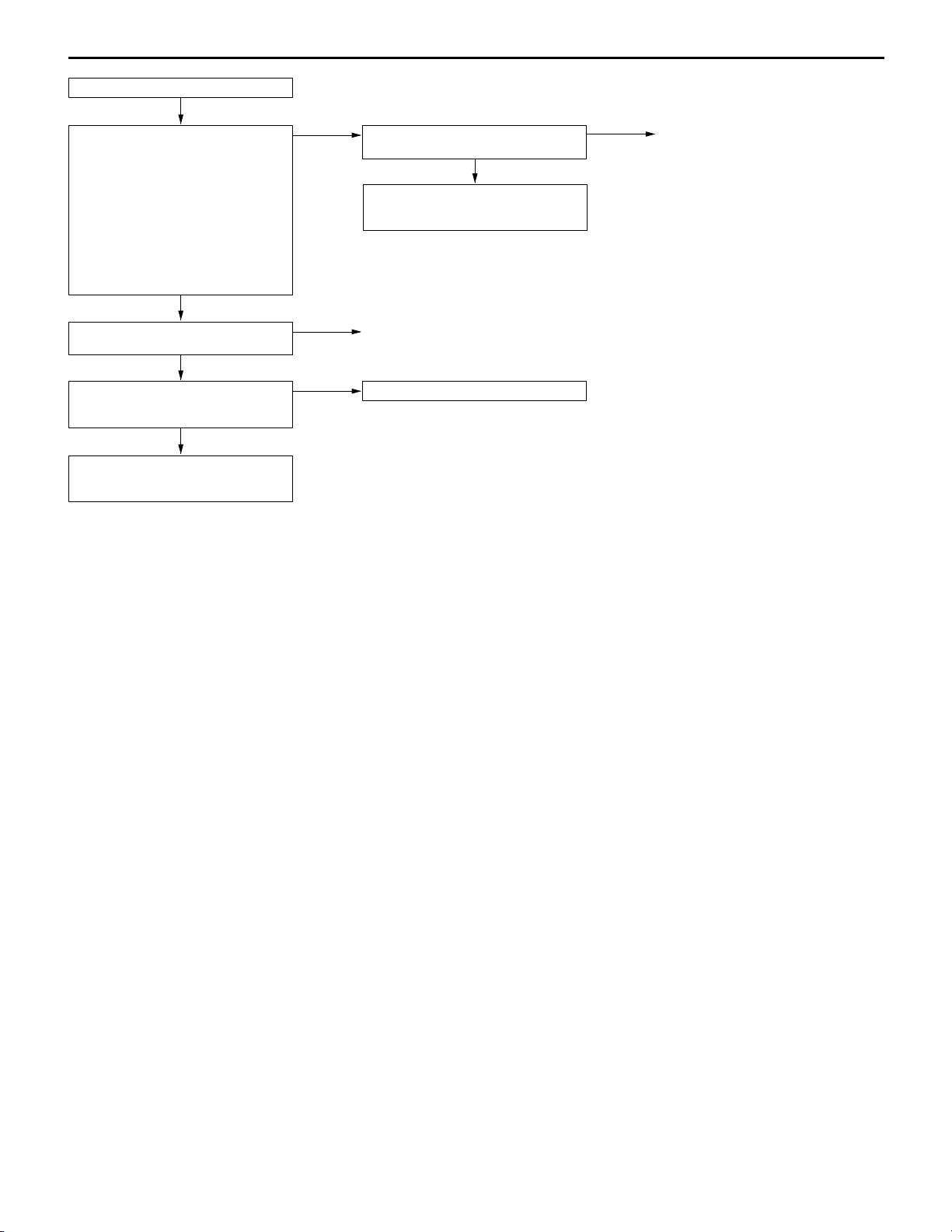

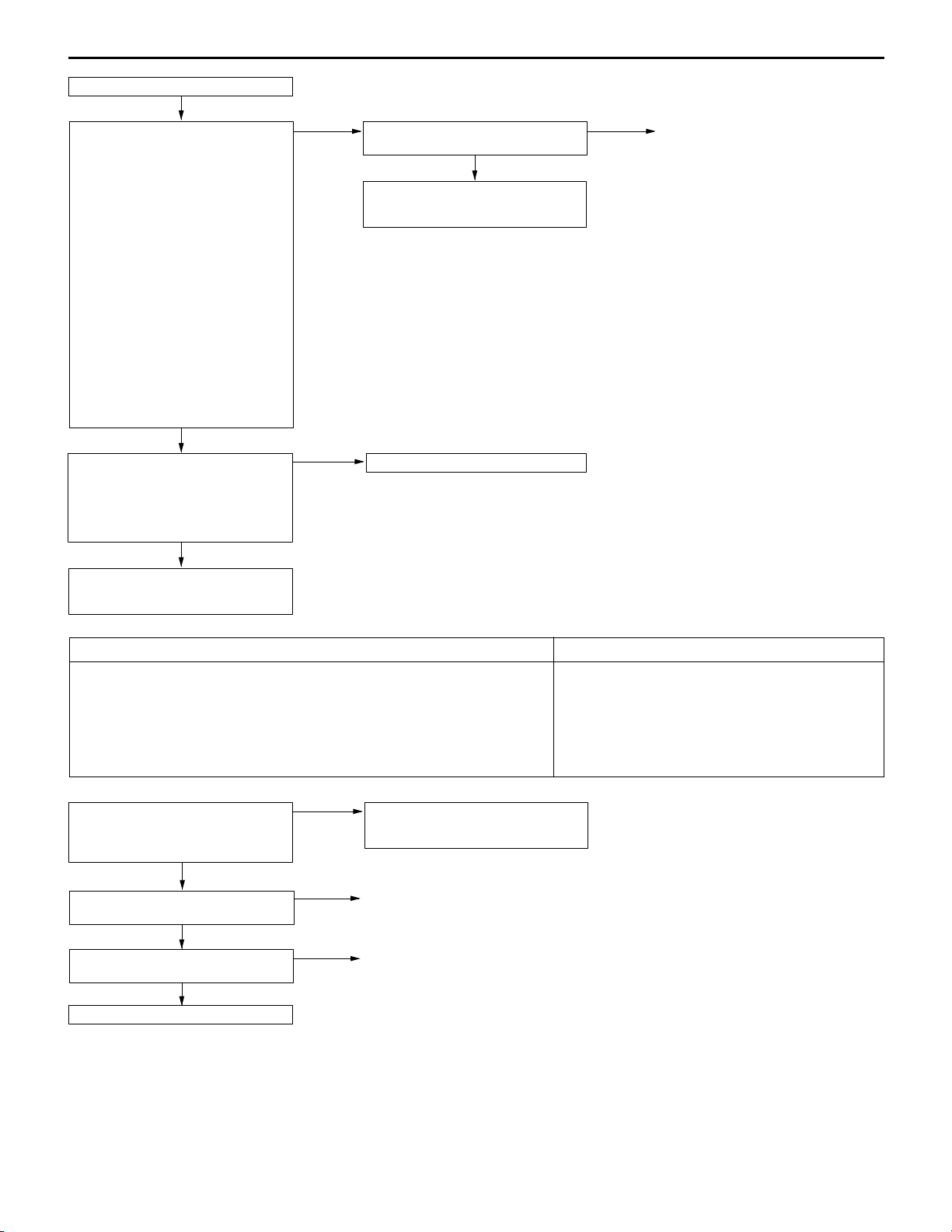

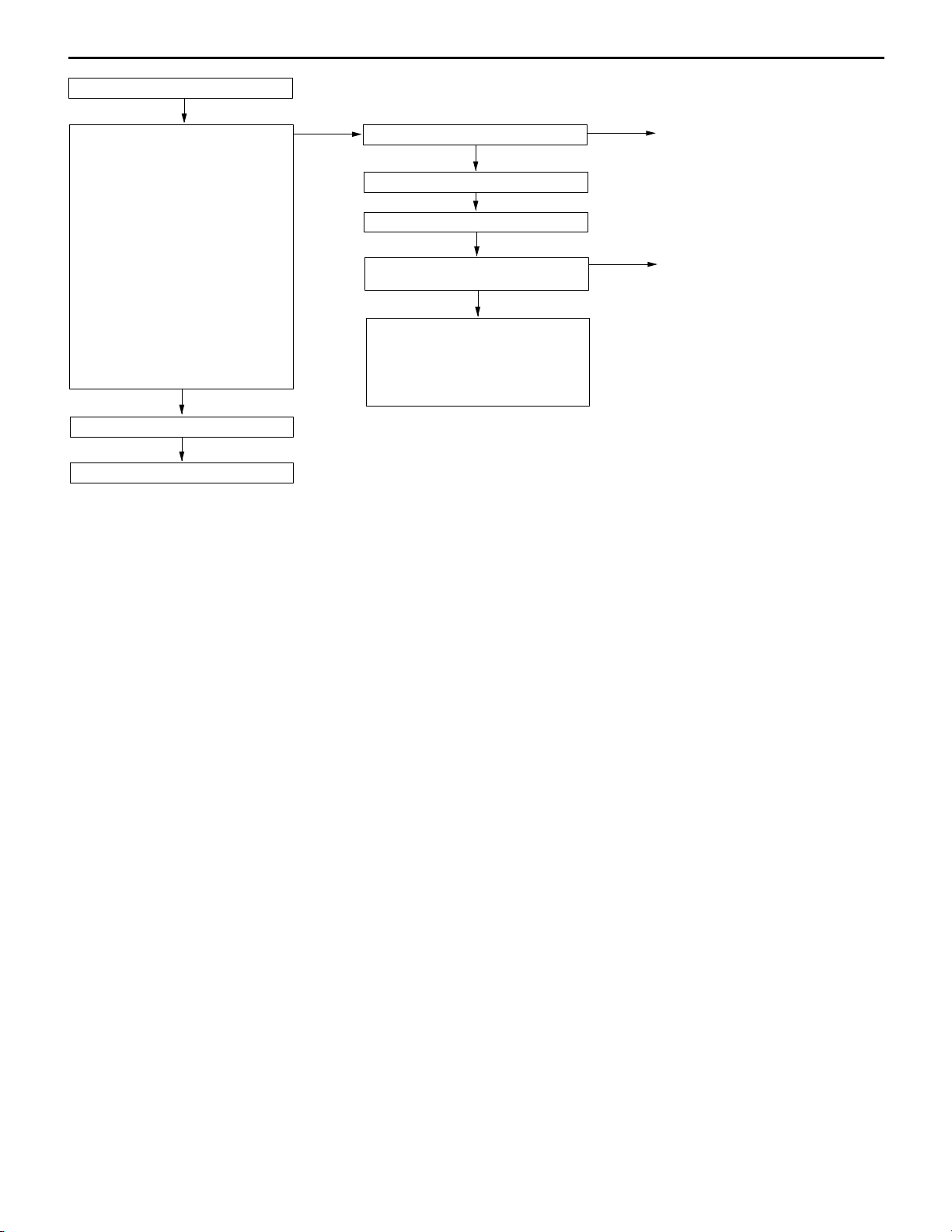

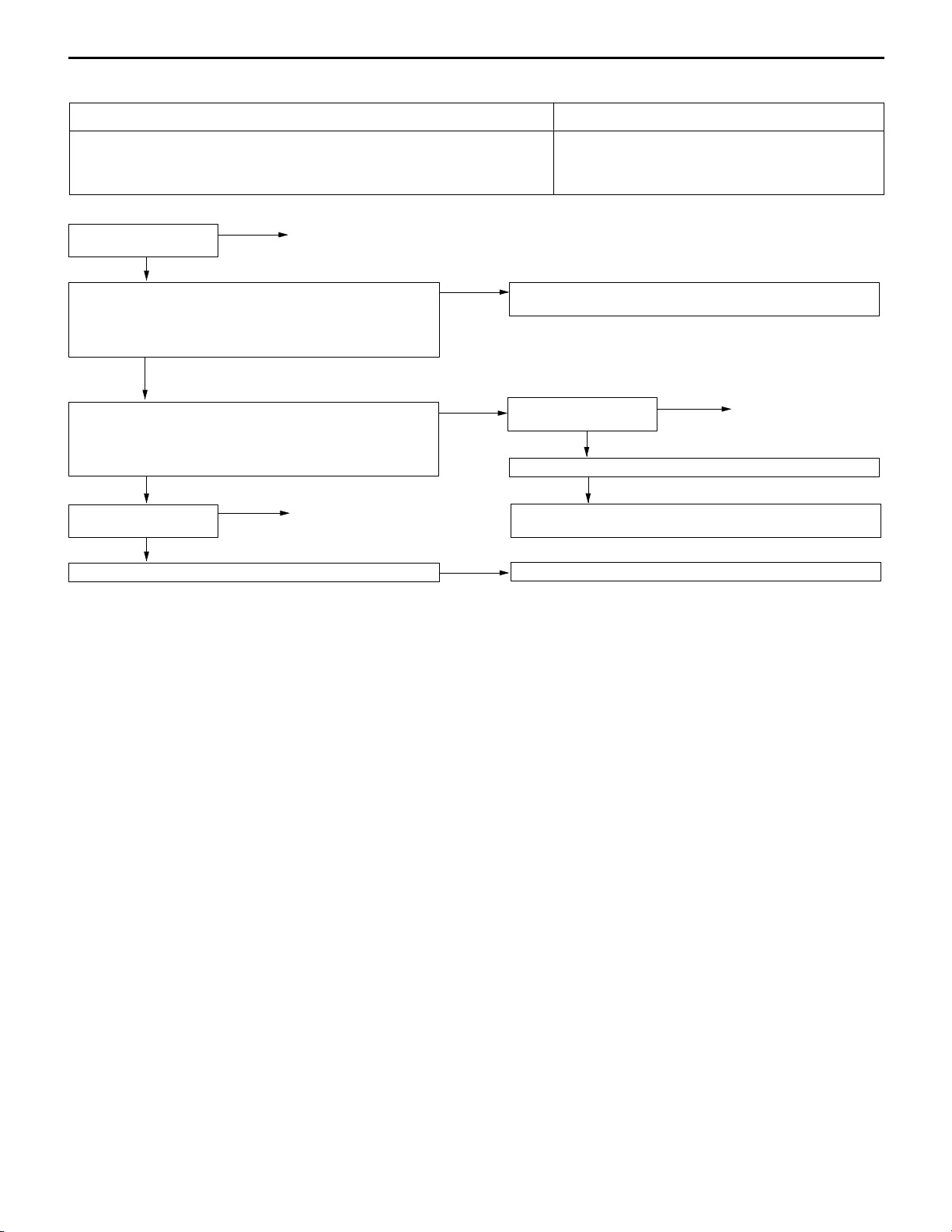

DIAGNOSIS TROUBLESHOOTING FLOW

Refer to GROUP 00 ï How to Use Troubleshooting/Inspection

Service Point.

NOTE

If the engine-A/T-ECU is replaced, ring antenna with built

in immobilizer-ECU should be replaced, ignition key can be

kept, but must be registered.

DIAGNOSIS FUNCTION

ENGINE WARNING LAMP (CHECK ENGINE LAMP)

If an abnormality occurs in any of the following items related

to the MPI system, the engine warning lamp will illuminate

or flash. If the lamp remains illuminated or if the lamp

illuminates while the engine is running, check the diagnosis

code output.

However, the warning lamp will illuminate as bulb check for

five seconds whenever the ignition switch is turned to the

ON position.

Engine-A/T-ECU

Oxygen sensor (front)

Air flow sensor

Intake air temperature sensor

Throttle position sensor

Engine coolant temperature sensor

Crank angle sensor

Camshaft position sensor

Barometric pressure sensor

Detonation sensor

Ignition coil, power transistor unit

Injector

Immobilizer system

Oxygen sensor (rear)

NOTE

If the engine warning lamp illuminates because of a malfunction of the engine-A/T-ECU, communication

between M.U.T.-II/III and the engine-A/T-ECU is impossible. In this case, the diagnosis code cannot

be read.

Page 16

MPI <4G63> ï Troubleshooting

METHOD OF READING AND ERASING DIAGNOSIS

CODES

Refer to GROUP 00 ï How to Use Troubleshooting/Inspection

Service Points.

INSPECTION USING M.U.T.-II/III DATA LIST AND

ACTUATOR TESTING

1. Carry out inspection by means of the data list and the

actuator test function. If there is an abnormality, check

and repair the chassis harnesses and components.

2. After repairing, re-check using the M.U.T.-II/III and check

that the abnormal input and output have returned to normal

as a result of the repairs.

3. Erase the diagnosis code memory.

4. Remove the M.U.T.-II/III, and then start the engine again

and carry out a road test to confirm that the problem

has disappeared.

13D-11

FAIL-SAFE FUNCTION REFERENCE TABLE

When the main sensor malfunctions are detected by the diagnosis function, the vehicle is controlled

by means of the pre-set control logic to maintain safe conditions for driving.

Malfunctioning item Control contents during malfunction

Air flow sensor 1. Uses the throttle position sensor signal and engine speed signal (crank angle sensor

signal) to take reading of the basic injector drive time and basic ignition timing from

the pre-set mapping.

2. Fixes the ISC servo in the appointed position so idle control is not performed.

Intake air temperature

sensor

Throttle position

sensor (TPS)

Engine coolant

temperature sensor

Camshaft position

sensor

Barometric pressure

sensor

Controls as if the intake air temperature is 25_C.

No increase in fuel injection amount during acceleration due to the throttle position sensor

signal.

Controls as if the engine coolant temperature is 80_C.

Injects fuel into the cylinders in the order 1-3-4-2 with irregular timing.

(However, after the ignition switch is turned to ON, the No. 1 cylinder top dead centre is not

detected at all.)

Controls as if the barometric pressure is 101 kPa.

Detonation sensor Switches the ignition timing from ignition timing for super petrol to ignition timing for standard

petrol.

Ignition coil, power

transistor

Alternator FR terminal Does not control the output of the alternator according to an electrical load. (works as a

Cuts off the fuel supply to cylinders with an abnormal ignition.

normal alternator)

Page 17

13D-12

MPI <4G63> ï Troubleshooting

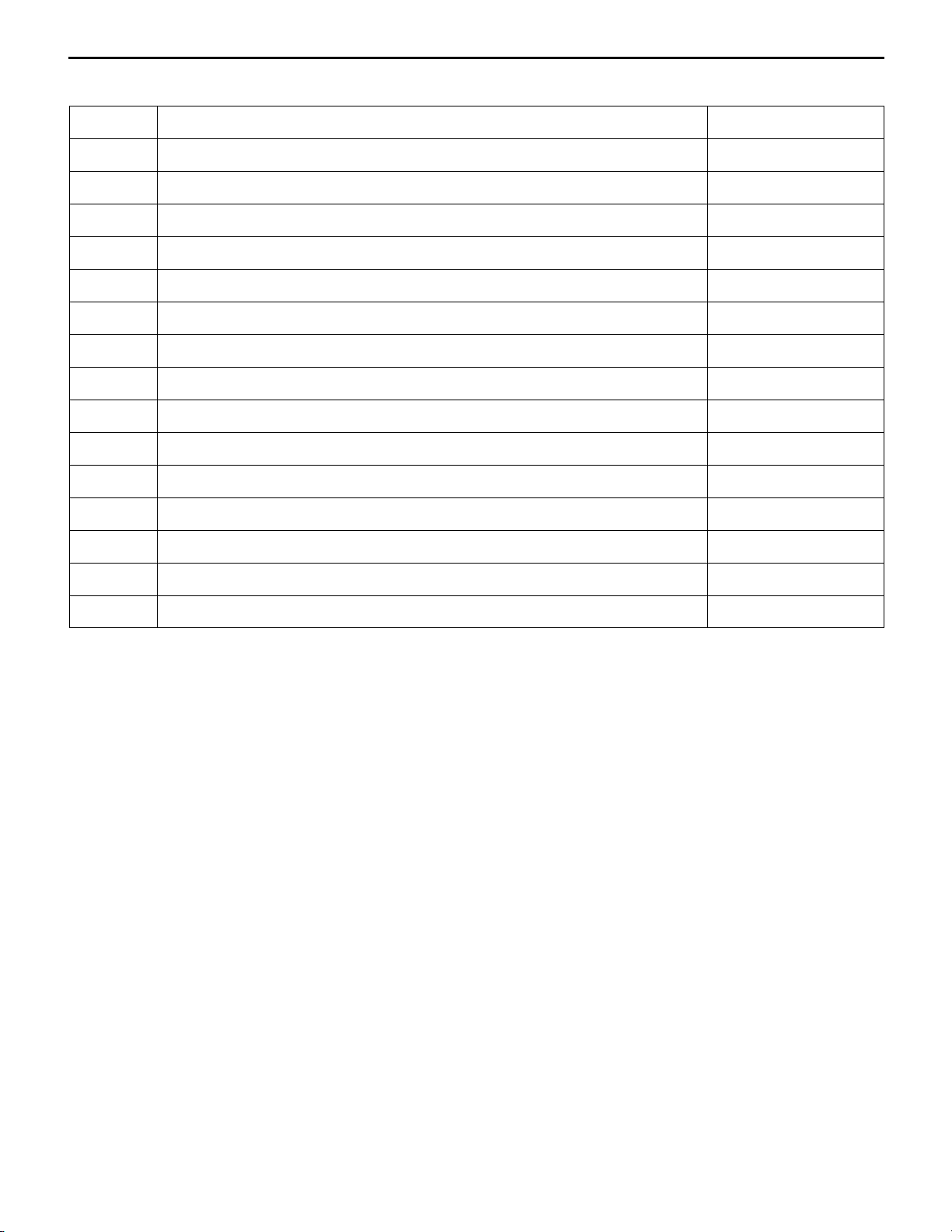

INSPECTION CHART FOR DIAGNOSIS CODES

Code No. Diagnosis item Reference page

11 Oxygen sensor (front) system 13D-13

12 Air flow sensor system 13D-15

13 Intake air temperature sensor system 13D-16

14 Throttle position sensor system 13D-18

21 Engine coolant temperature sensor system 13D-20

22 Crank angle sensor system 13D-22

23 Camshaft position sensor system 13D-23

24 Vehicle speed signal system 13D-25

25 Barometric pressure sensor system 13D-26

31 Detonation sensor system 13D-28

41 Injector system 13D-29

44 Ignition coil (power transistor) system 13D-30

54 Immobilizer system 13D-31

59 Oxygen sensor (rear) system 13D-32

64 Alternator FR terminal system 13D-34

NOTE

1. Do not replace the engine-A/T-ECU until a through terminal check reveals there are no short/open

circuit.

2. Check that the engine-A/T-ECU earth circuit is normal before checking for the cause of the problem.

Page 18

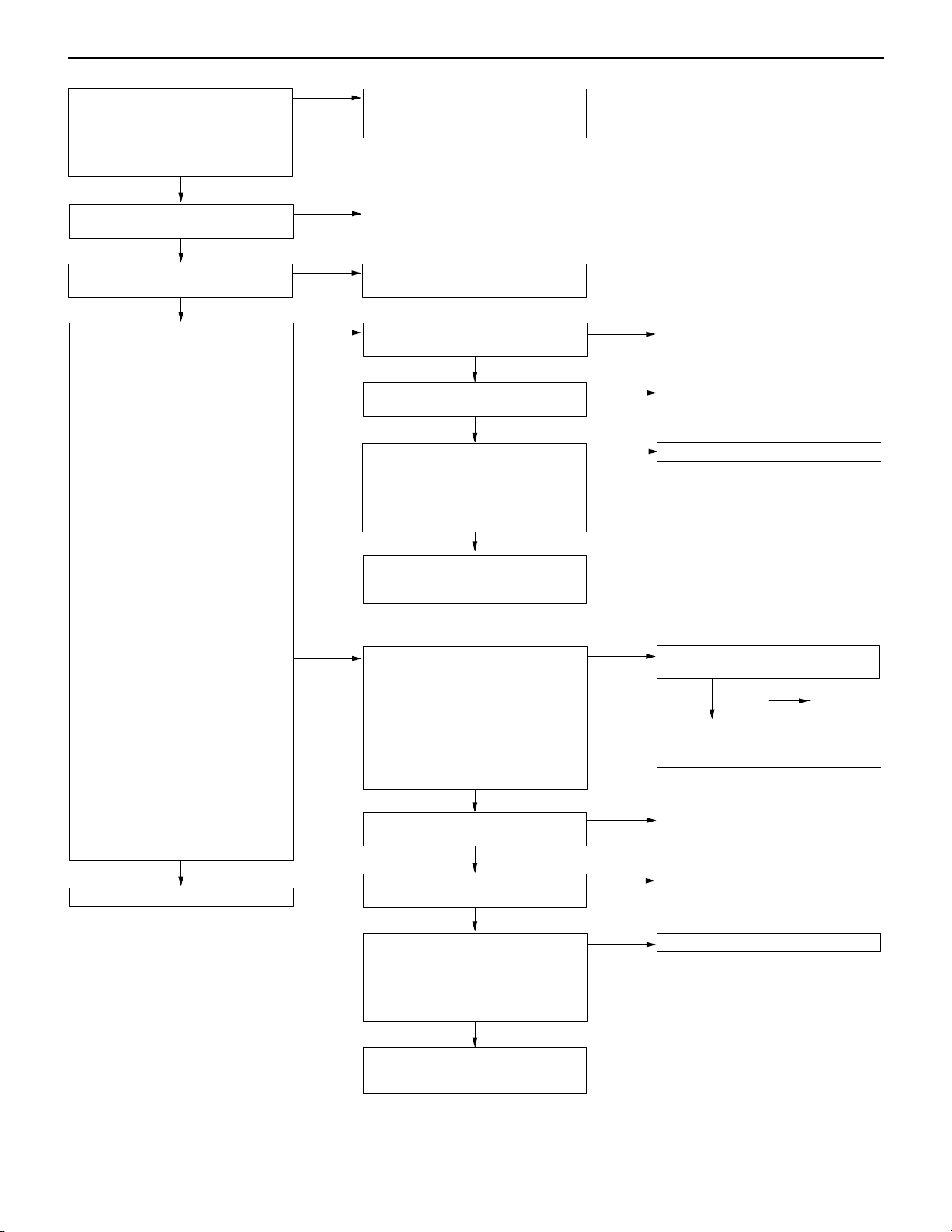

MPI <4G63> ï Troubleshooting

INSPECTION PROCEDURE FOR DIAGNOSIS CODE

Code No. 11 Oxygen sensor (front) system Probable cause

Range of Check

D More than 3 minutes passed after completion of start of engine

D The engine coolant temperature is approximately more than 80_C.

D Intake air temperature 0 ï 55_C.

D The engine speed is more than 1,800 ï 3,500 r/min.

D The volumetric efficiency is 16 ï 60% or more.

Set Conditions

D For 30 seconds, the oxygen sensor output voltage continues to be 0.5 V or

lower, or 0.5 V or higher.

D The Engine-A/T-ECU monitors for this condition once during the drive cycle.

D Malfunction of the oxygen sensor (front)

D Oxygen sensor (front) circuit disconnection,

short-circuit, or connector contact defect.

D Malfunction of the engine-A/T-ECU

13D-13

M.U.T.-II/III Data list

D No. 11 Oxygen sensor (front)

(Refer to P.13D-66.)

NG

Check the following connector:

B-17

OK

Measure at the B-17 oxygen sensor

(front) connector.

D Disconnect connector to measure

at the harness side

D Resistance between terminal No.

2 and earth.

OK: Less than 2 :

OK

Measure at the B-17 oxygen sensor

(front) connector.

D Using the test harness

(MD998464), connect the

connector, and measure at the

pickup harness.

D Engine: After warm-up

(1) Voltage between terminal No. 2

and earth

OK: Less than 0.5 V

(2) Voltage between terminal No. 4

and the earth

D At rapid deceleration from 4,000

r/min

OK: 200 mV or less

D During rapid racing

OK: 600 ï 1,000 mV

OK

To the next page

OK

NG

NG

(1) NG

(2) NG

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

Repair

Check the following connector:

C-124

OK

Check the harness between the

oxygen sensor (front) and

engine-A/T-ECU.

OK

M.U.T.-II/III Data list

D No. 11 Oxygen sensor (front)

(Refer to P.13D-66.)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

Check the following connector:

C-124

OK

Check the harness between the

oxygen sensor (front) and

engine-A/T-ECU.

Check the oxygen sensor (front).

(Refer to P.13D-99.)

OK

Check the following connector:

C-126

OK

Check the harness between the

oxygen sensor (front) and

engine-A/T-ECU.

NG

NG

NG

NG

NG

NG

NG

NG

Repair

Repair

Replace the engine-A/T-ECU.

Repair

Repair

Replace the oxygen sensor (front).

Repair

Repair

Page 19

13D-14

From the previous page

OK

Measure at the C-126 engine-A/T-ECU

connector.

D Measure the engine-A/T-ECU

terminal voltage.

D Engine: After warm-up

D Voltage between terminal No. 71

and earth.

D At rapid deceleration from 4,000

r/min

OK: 200 mV or less

D During rapid racing

OK: 600 ï 1,000 mV

OK

Check the following connectors:

C-124, C-126

OK

M.U.T.-II/III Data list

D No. 11 Oxygen sensor (front)

(Refer to P.13D-66.)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

MPI <4G63> ï Troubleshooting

NG

NG

NG

Check the following connector:

C-126

OK

Check and repair the harness between

the oxygen sensor (front) and

engine-A/T-ECU.

Repair

Replace the engine-A/T-ECU.

NG

Repair

Page 20

MPI <4G63> ï Troubleshooting

Code No. 12 Air flow sensor system Probable cause

Range of Check

D The engine speed is more than 500 r/min

Set Condition

D The sensor output frequency is less than 3.3 Hz for 4 seconds.

D Malfunction of the air flow sensor

D Air flow sensor circuit disconnection, short-circuit,

or connector contact defect

D Malfunction of the engine-A/T-ECU

13D-15

M.U.T.-II/III Data list

D No. 12 Air flow sensor

(Refer to P.13D-66.)

NG

Check the following connector:

B-08

OK

Measure at the B-08 air flow sensor

connector.

D Disconnect the connector to

measure at the harness side

(1) Voltage between terminal No. 3

and earth

(Ignition switch: ON)

OK: 4.9 ï 5.1 V

(2) Voltage between terminal No. 4

and earth

(Ignition switch: ON)

OK: System voltage

(3) Resistance between terminal No.

5 and earth

OK: Less than 2 :

OK

NG

(1) NG

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

Repair

Measure at the C-124 engine-A/T-ECU

connector.

D Measure the voltage of the

engine-A/T-ECU terminal.

D Ignition switch: ON

D Voltage between terminal No. 65

and earth.

OK: 4.9 ï 5.1 V

NG

Check the following connector:

C-124

OK

Check the harness between the air

flow sensor and engine-A/T-ECU.

OK

M.U.T.-II/III Data list

D No. 12 Air flow sensor

(Refer to P.13D-66.)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

OK

NG

NG

NG

Check the following connector:

C-124

OK

Check and repair the harness between

the air flow sensor and engine-A/TECU.

Repair

Repair

Replace the engine-A/T-ECU.

NG

Repair

To the next page

OK

(2) NG

(3) NG

Check the following connector:

B-16X

OK

Check the harness between the air

flow sensor and engine control relay.

Check the following connector:

C-122

OK

Check the harness between the air

flow sensor and engine-A/T-ECU.

OK

M.U.T.-II/III Data list

D No. 12 Air flow sensor

(Refer to P.13D-66.)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

NG

NG

NG

NG

Repair

Repair

Repair

Replace the engine-A/T-ECU.

Page 21

13D-16

From the previous page

OK

Measure at the B-08 air flow sensor

connector.

D Using the test harness

(MB991709), connect the

connector, and measure at the

pickup.

D Ignition switch: ON

D Voltage between terminal No. 7

and earth.

OK: 7 ï 8V

OK

MPI <4G63> ï Troubleshooting

NG

Check the following connector:

C-122

OK

Check the harness between the air

flow sensor and engine-A/T-ECU.

OK

Replace the air flow sensor.

NG

NG

Repair

Repair

Measure at the B-08 air flow sensor

connector.

D Using the test harness

(MB991709), connect the

connector, and measure at the

pickup harness.

D Voltage between terminal No. 7

and earth.

OK: Engine: idle

0 ï 1V

Engine: 3,000 r/min

6 ï 9V

OK

Measure the output waveform at the

B-08 air flow sensor connector (using

an analyzer).

D Using the test harness

(MB991709), connect the

connector, and measure at the

pickup harness.

D Engine: Idle

D Voltage between terminal No. 3

and earth.

OK: Output the waveform as

shown on P.13D-79 (inspection procedure by analyzer), and check that there

is noise in the output waveform.

OK

NG

NG

Check the following connector:

C-122

OK

Check the harness between air flow

sensor and engine-A/T-ECU.

OK

M.U.T.-II/III Data list

D No. 12 Air flow sensor

(Refer to P.13D-66.)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

Replace the air flow sensor.

Check the trouble symptom.

NG

Check the following connectors:

B-16X, C-122, C-124

OK

Check the harness between the air

flow sensor and engine control relay.

OK

Check the harness between the air

flow sensor and engine-A/T-ECU.

NG

NG

NG

OK

NG

NG

Repair

Repair

Replace the engine-A/T-ECU.

End

Repair

Repair

M.U.T.-II/III Data list

D No. 12 Air flow sensor

(Refer to P.13D-66.)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

NG

Replace the engine-A/T-ECU.

Code No. 13 Intake air temperature sensor system Probable cause

Range of Check

D 60 seconds after the ignition switch is set to the “ON” position, or after the

completion of the start of engine.

Set Conditions

D The sensor output voltage is more than 4.6 V for 4 seconds (Equivalent to intake

air temperature less than ï40_C)

or

D The sensor output voltage is less than 0.2 V for 4 seconds (Equivalent to intake

air temperature of more than 120_C)

D Malfunction of the intake air temperature sensor

D Intake air temperature sensor circuit disconnection,

short-circuit, or connector contact defect

D Malfunction of the engine-A/T-ECU

Page 22

MPI <4G63> ï Troubleshooting

13D-17

M.U.T.-II/III Data list

D No. 13 Intake air temperature

sensor

OK: Ambient temperature (More

or less the same as the air

temperature)

NG

Check the following connector:

B-08

OK

Check the intake air temperature

sensor alone. (Refer to P.13D-97.)

OK

Measure at the B-08 air flow sensor

connector.

D Disconnect the connector to

measure at the harness side

(1) Resistance between terminal No.

5 and earth

OK: Less than 2 :

(2) Voltage between terminal No. 6

and earth

(Ignition switch: ON)

OK: 4.5 ï 4.9 V

OK

NG

NG

(1) NG

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

Repair

Replace the intake air temperature

sensor.

Check the following connector:

C-122

OK

Check the harness between the air

flow sensor and engine-A/T-ECU.

OK

M.U.T.-II/III Data list

D No. 13 Intake air temperature

sensor

OK: Ambient temperature (More

or less the same as the air

temperature)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

NG

NG

NG

Repair

Repair

Replace the engine-A/T-ECU.

To the next page

OK

(2) NG

Measure at the C-124 engine-A/T-ECU

connector.

D Measure the engine-A/T-ECU

terminal voltage.

D Disconnect the B-08 air flow

sensor connector.

D Ignition switch: ON

D Voltage between terminal No. 64

and earth.

OK: 4.5 ï 4.9 V

NG

Check the following connector:

C-124

OK

Check the harness between the air

flow sensor and engine-A/T-ECU.

OK

M.U.T.-II/III Data list

D No. 13 intake air temperature

sensor

OK: Ambient temperature (More

or less the same as air

temperature)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

OK

NG

NG

NG

Check the following connector:

C-124

OK

Check and repair the harness between

the air flow sensor and engine-A/TECU.

Repair

Repair

Replace the engine-A/T-ECU.

NG

Repair

Page 23

13D-18

From the previous page

OK

Measure at the B-08 air flow sensor

connector.

D Using the test harness

(MB991709), connecting only

connector terminals No. 5 and

No. 6, and measure at the

pickup harness.

D Ignition switch: ON

D Voltage between terminal No. 6

and earth.

OK: Ambient temperature ï20_C

3.8 ï 4.4 V

Ambient temperature 0_C

3.2 ï 3.8 V

Ambient temperature 20_C

2.3 ï 2.9 V

Ambient temperature 40_C

1.5 ï 2.1 V

Ambient temperature 60_C

0.8 ï 1.4 V

Ambient temperature 80_C

0.4 ï 1.0 V

OK

M.U.T.-II/III Data list

D No. 13 intake air temperature

sensor

OK: Ambient temperature (More

or less the same as the air

temperature)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

MPI <4G63> ï Troubleshooting

NG

NG

Check the following connectors:

C-122, C-124

OK

Check and repair the harness between

the air flow sensor and engine-A/TECU.

Replace the engine-A/T-ECU.

NG

Repair

Code No. 14 Throttle position sensor system Probable cause

Range of Check

D 60 seconds after the ignition switch is set to the “ON” position, or after the

completion of start of engine.

Set Conditions

D The sensor output voltage is 4.3 V or more for 4 seconds and volumetric

efficiency 40 % or less.

or

D The sensor output voltage is 0.2 V or less for 2 seconds

M.U.T.-II/III Data list

14 Throttle position sensor

(Refer to P.13D-66, DATA LIST

REFERENCE TABLE.)

NG

Check the throttle position sensor.

(Refer to P.13D-98.)

OK

Check the following connector:

B-06

OK

To the next page

OK

NG

NG

Intermittent malfunction

(Refer to GROUP 00 ï Points to

Note for Intermittent Malfunctions.)

Replace

Repair

D Malfunction of the throttle position sensor

D Improper connector contact, open circuit or

short-circuited harness wire

D Malfunction of the engine-A/T-ECU

Page 24

From the previous page

OK

Measure at throttle position sensor

connector B-06.

D Disconnect the connector and

measure at the harness side.

(1) Voltage between terminal 1 and

earth

(Ignition switch: ON)

OK: 4.9 ï 5.1 V

(2) Resistance between terminal 4

and earth

OK: 2 : or less

MPI <4G63> ï Troubleshooting

(1) NG

Measure at engine-A/T-ECU

connector C-124.

D Measure the voltage at the

engine-A/T-ECU terminals.

D Ignition switch: ON

D Voltage between terminal 46 and

earth

OK: 4.9 ï 5.1 V

NG

Check the following connector:

C-124

OK

Check the harness wire between the

throttle position sensor and the

engine-A/T-ECU.

OK

Check the trouble symptoms.

OK

NG

NG

NG

13D-19

Check the following connector:

C-124

OK

Check the harness wire between the

throttle position sensor and the

engine-A/T-ECU, and repair if

necessary.

Repair

Repair

Replace the engine-A/T-ECU.

NG

Repair

OK

Measure at throttle position sensor

connector B-06.

D Use test harness (MB991536) to

connect the connector, and

measure at the pick-up harness.

D Ignition switch: ON

(1) Voltage between terminal 1 and

earth

OK: 4.9 ï 5.1 V

(2) Voltage between terminal 4 and

earth

OK: 0.5 V or less

(3) Voltage between terminal 2 and

earth

OK: Accelerator pedal fully re-

leased: 0.335 ï 0.935 V

Accelerator pedal fully depressed: 4.4 ï 5.3 V

OK

To the next page

(2) NG

(1) NG

(2) NG

(3) NG

Check the following connector:

C-124

OK

Check the harness wire between the

throttle position sensor and the

engine-A/T-ECU.

OK

Check the trouble symptoms.

Check the following connector:

C-124

OK

Check the harness wire between the

throttle position sensor and the

engine-A/T-ECU.

Adjust the throttle position sensor.

(Refer to P.13D-98.)

Check the following connector:

C-126

OK

Check the harness wire between the

throttle position sensor and the

engine-A/T-ECU, and repair if

necessary.

NG

NG

NG

NG

NG

Repair

Repair

Replace the engine-A/T-ECU.

Repair

Repair

Page 25

13D-20

From the previous page

OK

Measure at the engine-A/T-ECU

connector C-126

D Measure voltage at the

engine-A/T-ECU terminal.

D Ignition switch: ON

D Voltage between terminal 78 and

earth

OK: Accelerator pedal fully re-

leased: 0.335 ï 0.935 V

Accelerator pedal fully depressed: 4.4 ï 5.3 V

MPI <4G63> ï Troubleshooting

NG

OK

Check the following connector:

C-126

OK

Check the harness wire between the

throttle position sensor and the

engine-A/T-ECU, and repair if

necessary.

Check the following connectors:

C-124, C-126

OK

Check the trouble symptoms.

NG

Replace the engine-A/T-ECU.

NG

NG

Code No. 21 Engine coolant temperature sensor system Probable cause

Range of Check

D 60 seconds after the ignition switch is set to the “ON” position, or after the

completion of start of engine.

Set Conditions

D The sensor output voltage is 4.6 V or more for 4 seconds (equivalent to

ï45_C or lower of engine coolant temperature)

or

D The sensor output voltage is 0.1 V or less for 4 seconds (equivalent to

140_C or higher of engine coolant temperature)

Range of Check

D Engine: After starting

Set Condition

D The engine coolant temperature has reduced from over 40_C to less than

40_C, and that condition has lasted for five minutes or more.

D Malfunction of the engine coolant temperature

sensor

D Open or short circuit in the engine coolant

temperature sensor circuit or loose connector

contact

D Malfunction of the engine-A/T-ECU

Repair

Repair

M.U.T.-II/III Data list

21 Engine coolant temperature

sensor

OK: When the engine is cold,

the temperature is roughly

the same as ambient temperature. If warm, it is 80 ï

120_C.

NG

Measure at engine coolant

temperature sensor connector

B-111.

D Disconnect the connector and

measure at the sensor side.

D Resistance between terminals 1

and 2

OK: At 20_C of engine coolant

temperature: 2.1 ï 2.7 k:

At 80_C of engine coolant

temperature:

0.26 ï 0.36 k:

OK

Check the following connector:

B-111

OK

To the next page

OK

NG

NG

Intermittent malfunction

(Refer to GROUP 00 ï Points to

Note for Intermittent Malfunctions.)

Replace

Repair

Page 26

From the previous page

OK

Measure at engine coolant

temperature sensor connector B-111.

D Disconnect the connector and

measure at the harness side.

(1) Voltage between terminal 1 and

earth

(Ignition switch: ON)

OK: 4.5 ï 4.9 V

(2) Resistance between terminal 2

and earth

OK: 2 : or less

OK

MPI <4G63> ï Troubleshooting

(1) NG

(2) NG

Measure at engine-A/T-ECU

connector C-124.

D Measure the voltage at the

engine-A/T-ECU terminal.

D Disconnect connector B-111.

D Ignition switch: ON

D Voltage between terminal 44 and

earth

OK: 4.5 ï 4.9 V

NG

Check the following connector:

C-124

OK

Check the harness wire between the

engine coolant temperature sensor

and the engine-A/T-ECU.

OK

Check the trouble symptoms.

Check the following connector:

C-124

OK

Check the harness wire between the

engine coolant temperature sensor

and the engine-A/T-ECU.

OK

Check the trouble symptoms.

OK

NG

NG

NG

NG

NG

NG

13D-21

Check the following connector:

C-124

OK

Check the harness wire between the

engine coolant temperature sensor

and the engine-A/T-ECU, and repair

if necessary.

Repair

Repair

Replace the engine-A/T-ECU.

Repair

Repair

Replace the engine-A/T-ECU.

NG

Repair

Measure at engine coolant

temperature sensor connector B-111.

D Use test harness (MB991658) to

connect the connector, and

measure at the pick-up harness.

D Ignition switch: ON

D Voltage between terminal 1 and

earth

OK: At 0_C of engine coolant

temperature: 3.2 ï 3.8 V

At 20_C of engine coolant

temperature: 2.3 ï 2.9 V

At 40_C of engine coolant

temperature: 1.3 ï 1.9 V

At 80_C of engine coolant

temperature: 0.3 ï 0.9 V

OK

Check the trouble symptoms.

NG

NG

Check the engine coolant

temperature sensor.

(Refer to P.13D-98.)

OK

Check the following connector:

C-124

OK

Check the harness wire between the

engine coolant temperature sensor

and the engine-A/T-ECU, and repair

if necessary.

Replace the engine-A/T-ECU.

NG

NG

Repair

Repair

Page 27

13D-22

MPI <4G63> ï Troubleshooting

Code No. 22 Crank angle sensor system Probable cause

Range of Check

D Engine is cranking

Set Condition

D Sensor output voltage does not change for 4 seconds (no pulse signal input).

D Malfunction of the crank angle sensor.

D Open or short circuit in the crank angle sensor

circuit or loose connector contact.

D Malfunction of the engine-A/T-ECU

M.U.T.-II/III Data list

22 Crank angle sensor

OK: Refer to P.13D-66, DATA

LIST REFERENCE TABLE.

NG

Check the following connector:

B-116

OK

Measure at the crank angle sensor

connector B-116.

D Disconnect the connector and

measure at the harness side.

(1) The resistance between terminal

1 and earth

OK: 2 : or less

(2) The voltage between terminal 2

and earth

(Ignition switch: ON)

OK: 4.9 ï 5.1 V

(3) The voltage between terminal 3

and earth

(Ignition switch: ON)

OK: System voltage

OK

NG

(1) NG

(2) NG

Intermittent malfunction

(Refer to GROUP 00 ï Points to

Note for Intermittent Malfunctions.)

Repair

Check the harness between the

crank angle sensor and earth, and

repair if necessary.

Measure at the engine-A/T-ECU

connector C-124.

D Measure the voltage at the

engine-A/T-ECU terminal.

D Disconnect the connector B-116

D Ignition switch: ON

D The voltage between terminal 45

and earth

OK: 4.9 ï 5.1 V

NG

Check the following connector:

C-124

OK

Check the harness wire between the

crank angle sensor and the

engine-A/T-ECU.

OK

Check the trouble symptoms.

OK

NG

NG

NG

Check the following connector:

C-124

OK

Check the harness wire between the

crank angle sensor and the

engine-A/T-ECU, and repair if

necessary.

Repair

Repair

Replace the engine-A/T-ECU.

NG

Repair

To the next page

OK

(3) NG

Check the following connector:

B-16X

OK

Check the harness wire between the

crank angle sensor and the engine

control relay, and repair if necessary.

NG

Repair

Page 28

From the previous page

OK

Use an analyzer to measure the

output waveform at the crank angle

sensor connector B-116.

D Use the test harness

(MD998478) to connect the

connector, and measure at the

pick-up harness side.

D Engine: Idling

D The voltage between terminal 2

and earth

OK: A normal waveform should

be displayed as described

on P.13D-81 (Inspection

Procedure Using an Analyzer). Its maximum value

should be 4.8 V or more,

and its minimum value

should be 0.6 V or less

with no noise in waveform.

OK

Check the trouble symptoms.

NG

Replace the engine-A/T-ECU.

MPI <4G63> ï Troubleshooting

NG

Check the crank angle sensor vane.

OK

Replace the crank angle sensor.

Check the trouble symptoms.

NG

Check the following connectors:

B-16X, C-124

OK

Check the harness wires between

the crank angle sensor and the

engine-A/T-ECU, crank angle sensor

and the engine control relay, and the

crank angle sensor and earth. Then,

repair if necessary.

NG

NG

13D-23

Replace

Repair

Page 29

13D-24

MPI <4G63> ï Troubleshooting

Code No. 23 Camshaft position sensor system Probable cause

Range of Check

D During engine cranking and driving

Set Condition

D The sensor output voltage does not change for 4 seconds (no pulse signal

input).

D Malfunction of the camshaft position sensor

D Open or short circuit in the camshaft position

sensor circuit or loose connector contact.

D Malfunction of the engine-A/T-ECU

Check the following connector:

B-107

OK

Measure at camshaft position sensor

connector B-107.

D Disconnect the connector and

measure at the harness side.

(1) The voltage between terminal 3

and earth

(Ignition switch: ON)

OK: System voltage

(2) The voltage between terminal 2

and earth

(Ignition switch: ON)

OK: 4.9 ï 5.1 V

(3) The resistance between terminal

1 and earth

OK: 2 : or less

OK

NG

(1) NG

(2) NG

Repair

Check the following connector:

B-16X

OK

Check the harness wire between the

camshaft position sensor connector

and the engine control relay, and

repair if necessary.

Measure at the engine-A/T-ECU

connector C-124.

D Measure the voltage at the

engine-A/T-ECU terminal.

D Disconnect connector B-107.

D Ignition switch: ON

D The voltage between terminal 56

and earth

OK: 4.9 ï 5.1 V

NG

Check the following connector:

C-124

OK

Check the harness wire between the

intermediate connector and the

engine-A/T-ECU.

OK

Check the trouble symptoms.

NG

OK

NG

NG

NG

Repair

Check the following connector:

C-124

OK

Check the harness wire between the

camshaft position sensor connector

and the engine-A/T-ECU, and repair if

necessary.

Repair

Repair

Replace the engine-A/T-ECU.

NG

Repair

Use an analyzer to measure the

output waveform at camshaft position

sensor connector B-107.

D Use test harness (MB991709) to

connect the connector, and

measure at the pick-up harness.

D Engine: Idling

D The voltage between terminal 2

and earth

OK: A normal waveform should

be displayed as described

on P.13D-81 (Inspection

Procedure Using an Analyzer), its maximum value

should be 4.8 V or more,

and its minimum value

should be 0.6 V or less

with no noise in waveform.

OK

Check the trouble symptoms.

NG

Replace the engine-A/T-ECU.

(3) NG

NG

OK

Check the harness wire between the

camshaft position sensor connector

and earth, and repair if necessary.

Check the camshaft position sensing

cylinder.

OK

Replace the camshaft position

sensor.

Check the trouble symptoms.

NG

Check the following connectors:

B-16X, C-124

OK

Check the harness wires between the camshaft position sensor connector and the

engine-A/T-ECU, the camshaft position sensor connector and the engine control relay,

and the camshaft position sensor connector and earth. Then, repair if necessary.

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note for Intermittent Malfunctions.)

NG

NG

Replace

Repair

Page 30

MPI <4G63> ï Troubleshooting

Code No. 24 Vehicle speed signal system Probable cause

Range of Check

D 60 seconds after the ignition switch is set to the “ON” position, or after the

completion of start of engine.

D The engine speed is more than 2,300 r/min.

D Volumetric efficiency 50 % or more

Set Condition

D The vehicle speed signal does not change for 4 seconds (no pulse signal

input.)

D Malfunction of the output shaft speed sensor

D Open or short circuit in the output shaft speed

sensor circuit or loose connector contact

D Malfunction of the engine-A/T-ECU

13D-25

M.U.T.-II/III Self-Diag code

D Is diagnosis code of automatic transmission system output?

NO

Check the trouble symptoms.

NG

Replace the engine-A/T-ECU.

YES

OK

D Automatic transmission system check

(Refer to GROUP 23B ï Troubleshooting ï Inspection

chart for diagnosis codes)

Intermittent malfunction. (Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

Page 31

13D-26

MPI <4G63> ï Troubleshooting

Code No. 25 Barometric pressure sensor system Probable cause

Range of Check

D 60 seconds after the ignition switch is set to the “ON” position, or after the

completion of start of engine.

D Battery voltage 8 V or more.

Set Conditions

D The sensor output voltage is more than 4.5 V for 4 seconds (Equivalent to

air pressure of more than 114 kPa)

or

D The sensor output voltage is less than 0.2 V for 4 seconds (Equivalent to air

pressure of less than 5 kPa)

D Malfunction of the barometric pressure sensor

D Barometric pressure sensor circuit disconnection,

short-circuit, or connector contact defect

D Malfunction of the engine-A/T-ECU

M.U.T.-II/III Data list

D No. 25 Barometric pressure

sensor (Refer to P.13D-66.)

NG

Check the following connector:

B-08

OK

Measure at the B-08 air flow sensor

connector.

D Disconnect the connector to

measure at the harness side

(1) Voltage between terminal No. 1

and earth

(Ignition switch: ON)

OK: 4.9 ï 5.1 V

(2) Resistance between terminal No.

5 and earth.

OK: Less than 2 :

OK

NG

(1) NG

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

Repair

Measure at the C-124 engine-A/T-ECU

connector.

D Measure the engine-A/T-ECU

terminal voltage.

D Ignition switch: ON

D Voltage between terminal No. 46

and earth

OK: 4.9 ï 5.1 V

NG

Check the following connector:

C-124

OK

Check the harness between the air

flow sensor and engine-A/T-ECU.

OK

M.U.T.-II/III Data list

D No. 25 Barometric pressure

sensor (Refer to P.13D-66.)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

OK

NG

NG

NG

Check the following connector:

C-124

OK

Check and repair the harness between

the air flow sensor and engine-A/TECU.

Repair

Repair

Replace the engine-A/T-ECU.

NG

Repair

To the next page

OK

(2) NG

Check the following connector:

C-122

OK

Check the harness between the air

flow sensor and engine-A/T-ECU.

OK

M.U.T.-II/III Data list

D No. 25 Barometric pressure

sensor (Refer to P.13D-66.)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

NG

NG

NG

Repair

Repair

Replace the engine-A/T-ECU.

Page 32

From the previous page

OK

Measure at the B-08 air flow sensor

connector.

D Using the test harness

(MB991709), connect only

connector terminals No. 1, No. 2,

and No. 5, and measure at the

pickup harness.

D Ignition switch: ON

(1) Voltage between terminal No. 1

and earth

OK: 4.9 ï 5.1 V

(2) Voltage between terminal No. 5

and earth

OK: Less than 0.5 V

(3) Voltage between terminal No. 2

and earth

OK: High 0 m 3.8 ï 4.2 V

High 600 m 3.5 ï 3.9 V

High 1,200 m 3.3 ï 3.7 V

High 1,800 m 3.0 ï 3.4 V

OK

MPI <4G63> ï Troubleshooting

(1) NG

(2) NG

(3) NG

Check the following connector:

C-124

OK

Check and repair the harness between

the air flow sensor and engine-A/TECU.

Check the following connector:

C-122

OK

Check and repair the harness between

the air flow sensor and engine-A/TECU.

Check the following connector:

C-124

OK

Check the harness between the air

flow sensor and engine-A/T-ECU.

OK

Replace the air flow sensor.

NG

NG

NG

NG

13D-27

Repair

Repair

Repair

Repair

Measure at the C-124 engine-A/T-ECU

connector.

D Measure the engine-A/T-ECU

terminal voltage.

D Ignition switch: ON

D Voltage between terminal No. 55

and earth.

OK: High 0 m 3.8 ï 4.2 V

High 600 m 3.5 ï 3.9 V

High 1,200 m 3.3 ï 3.7 V

High 1,800 m 3.0 ï 3.4 V

OK

Check the following connectors:

C-122, C-124

OK

M.U.T.-II/III Data list

D No. 25 Barometric pressure

sensor (Refer to P.13D-66.)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

NG

NG

NG

Check the following connector:

C-124

OK

Check and repair the harness between

the air flow sensor and engine-A/TECU.

Repair

Replace the engine-A/T-ECU.

NG

Repair

Page 33

13D-28

MPI <4G63> ï Troubleshooting

Code No. 31 Detonation sensor system Probable cause

Range of Check

D 60 seconds after the ignition switch is set to the “ON” position, or after the

completion of start of engine.

D The engine speed is more than 2,500 r/min.

D Volumetric efficiency 30 % or more

Set Condition

D Changes in sensor output voltage (detonation sensor peak voltage per 1/2

crankshaft rotation) in 200 consecutive cycles are 0.078 V or less.

D Malfunction of the detonation sensor

D Open or short circuit in the detonation sensor

circuit or loose connector contact

D Malfunction of the engine-A/T-ECU

Check the following connector: B-117

OK

Measure at the detonation sensor connector B-117.

D Disconnect the connector and measure at the harness

side.

D The resistance between terminal 2 and earth

OK: 2 : or less

OK

Check the following connector: C-126

OK

Check the harness wire between the detonation sensor and

the engine-A/T-ECU.

OK

Check the trouble symptoms.

NG

Replace the detonation sensor.

Check the trouble symptoms.

NG

Replace the engine-A/T-ECU.

NG

NG

NG

NG

OK

Repair

Check the harness wire between the detonation sensor and

earth, and repair if necessary.

Repair

Repair

Intermittent malfunction (Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

Page 34

MPI <4G63> ï Troubleshooting

Code No. 41 Injector system Probable cause

Range of Check

D Fuel cut and injector not in forced drive (actuator test) mode.

D The engine speed is 50 ï 1,000 r/min

D The throttle position sensor output voltage is 1.15 V or less.

Set Condition

D Surge voltage of injector coil is not detected for 4 seconds.

D Malfunction of the injector

D Improper connector contact, open circuit or short-cir-

cuited harness wire of the injector circuit

D Malfunction of the engine-A/T-ECU

13D-29

M.U.T.-II/III Actuator Test

01 No. 1 injector

02 No. 2 injector

03 No. 3 injector

04 No. 4 injector

OK: The idling condition should change

NG

Check the following connectors:

B-02, B-03, B-04, B-05

OK

Check the injector. (Refer to P.13D-101.)

OK

Measure at the injector connector B-02, B-03, B-04, B-05.

D Disconnect the connector, and measure at the harness side.

D Voltage between 1 and earth (Ignition switch: ON)

OK: System voltage

OK

Check the following connector: C-122

OK

Measure at the engine-A/T-ECU connector C-122.

D Disconnect the connector, and measure at the harness side.

D Voltage between 1, 2, 9, 24 and earth (Ignition switch: ON)

OK: System voltage

OK

Check the trouble symptoms.

NG

Use an analyzer to measure the signal waveform at injector

connector B-02, B-03, B-04, B-05.

D Use a test harness (MB991348) to connect the connector, and

measure at the pick-up harness side.

D Engine: Idling

D The voltage between terminal 2 and earth

OK: A normal waveform should be displayed as described

on P.13D-83 (INSPECTION PROCEDURE USING

AN ANALYZER).

NG

Replace the engine-A/T-ECU.

OK

NG

NG

NG

NG

NG

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note for Intermittent Malfunctions.)

Repair

Replace

Check the harness wire between the engine control relay and the

injector connector, and repair if necessary.

Repair

Check the harness wire between the engine-A/T-ECU and the

injector connector, and repair if necessary.

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note for Intermittent Malfunctions.)

Page 35

13D-30

MPI <4G63> ï Troubleshooting

Code No. 44 Ignition coil system Probable cause

Range of Check

D The engine speed is 1,500 ï 4,500 r/min

D Volumetric efficiency 30 ï 55 %

D Fuel cut and injector not in forced drive (actuator test) mode.

D The throttle deviation is within the range of ï0.06 V/25 ms to 0.06 V/10 ms.

D The coolant temperature is 80_C or higher, and the intake air temperature is ï10_C

or higher.

Set condition

D After driven for 250 rotations or more in the above check range, crank angle

sensor detects abnormal rotation caused by misfire (one failed coil of the two

coils).

D Malfunction of the ignition coil

D Improper connector contact, open circuit or

short-circuited harness wire of the ignition primary

circuit

D Malfunction of the spark plug and spark plug cable.

D Faulty compression

D Malfunction of the engine-A/T-ECU

Check the ignition coil.

(Refer to GROUP 16 ï Ignition System.)

OK

Measure at the ignition coil connectors

B-104, B-113.

D Disconnect the connector, and

measure at the harness side.

(1) Voltage between 1 and earth

(Ignition switch: ON)

OK: System voltage

(2) Voltage between 3 and earth

(Engine: Cranking)

OK: 0.5 ï 4.0 V

(3) Continuity between 2 and earth

OK: 2 : or less

OK

Check the following connectors:

B-104, B-113

OK

Check the trouble symptom.

NG

Check the following items in order.

D Check the spark plug cables, spark

plugs.

D Check the compression pressure.

OK

Replace the ignition coil.

NG

Repair

NG

(1) NG

(2) NG

(3) NG

NG

Replace

Check the following connectors:

A-13, C-27, C-210, C-212

OK

Check the trouble symptom.

Checkthefollowing connector:C-122

OK

Check the trouble symptom.

NG

Check the harness wire between the

engine-A/T-ECU and ignition coil connector.

OK

Replace the engine-A/T-ECU.

Check the harness between the ignition

coil connector and the earth and repair

if necessary.

Repair or Replace

NG

NG

NG

NG

Repair

D Check the harness wire between

the ignition coil and ignition

switch connector, and repair if

necessary.

Repair

Repair

Check the trouble symptom.

NG

Replace the engine-A/T-ECU.

Page 36

MPI <4G63> ï Troubleshooting

13D-31

Cord No. 54 Immobilizer system Probable cause

Range of Check

D Ignition switch: ON

Set Condition

D Improper communication between the engine-A/T-ECU and the

immobilizer-ECU

D Open or short circuit, or loose connector contact

D Malfunction of the immobilizer-ECU

D Malfunction of the engine-A/T-ECU

NOTE

(1) If the registered ignition keys are close each other when starting the engine, radio interference may

cause this code to be displayed.

(2) This code may be displayed when registering the key encrypted code.

Check the following connectors:

C-13, C-128, C-202

OK

Check the harness wire between the

immobilizer-ECU and the

engine-A/T-ECU.

OK

Check the trouble symptoms.

NG

Replace the immobilizer-ECU.

Check the trouble symptoms.

NG

Replace the engine-A/T-ECU.

NG

NG

Repair

Replace

Page 37

13D-32

MPI <4G63> ï Troubleshooting

Code No. 59 Oxygen sensor (rear) system Probable cause

Range of Check

D More than 3 minutes passed after completion of start of engine

D The engine coolant temperature is approximately more than 80_C.

D Intake air temperature 0 ï 55_C

D The engine speed is more than 1,800 ï 3,500 r/min.

D The volumetric efficiency is 16 ï 60% or more.

D Other than the fuel cut mode

D When 0.2 seconds or more of the fuel cut passed, 30 seconds elapsed after

return.

D The air flow sensor output frequency is 81 Hz or more.

Set Conditions

D When the throttle position sensor is 4.4 V or higher, other than the engine is

idling, and other than in feedback mode, all the following states continue to

be true for 5 seconds or more: the oxygen sensor (front) output voltage is

0.5 V or higher; the oxygen sensor (rear) output voltage is less than 0.1 V;

and the oxygen sensor (rear) output voltage variation is less than 0.078 V.

D When the air/fuel ratio is forcibly turned to a rich state for 10 seconds, all

the following states continue to be true for 5 seconds or more: the oxygen

sensor (front) output voltage is 0.5 V or more; the oxygen sensor (rear)

output voltage is less than 0.1 V; and the oxygen sensor (rear) output

voltage variation is less than 0.078 V.

D The engine-A/T-ECU monitors for this condition once during the drive cycle.

D Malfunction of the oxygen sensor (rear)

D Oxygen sensor (rear) circuit disconnection,

short-circuit, or connector contact defect

D Malfunction of the engine-A/T-ECU

M.U.T.-II/III Data list

D No. 59 Oxygen sensor (rear)

(Refer to P.13D-66.)

NG

Check the following connector:

C-130

OK

Measure at the C-130 oxygen sensor

(rear) connector.

D Disconnect connector to measure

at the harness side

D Resistance between terminal No.

2 and earth.

OK: Less than 2 :

OK

Measure at the C-130 oxygen sensor

(rear) connector.

D Using the test harness

(MB991658), connect the

connector, and measure at the

pickup harness.

D Engine: After warm-up

(1) Voltage between terminal No. 2

and earth

OK: Less than 0.5 V

(2) Voltage between terminal No. 1

and the earth

D During rapid racing

OK: 0 and 600 ï 1,000 mV

alternate.

OK

To the next page

OK

NG

NG

(1) NG

(2) NG

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

Repair

Check the following connector:

C-124

OK

Check the harness between the

oxygen sensor (rear) and

engine-A/T-ECU.

OK

M.U.T.-II/III Data list

D No. 59 Oxygen sensor (rear)

(Refer to P.13D-66.)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

Check the following connector:

C-124

OK

Check the harness between the

oxygen sensor (rear) and

engine-A/T-ECU.

Check the oxygen sensor (rear).

(Refer to P.13D-100.)

OK

Check the following connector:

C-126

OK

Check the harness between the

oxygen sensor (rear) and

engine-A/T-ECU.

NG

NG

NG

NG

NG

NG

NG

NG

Repair

Repair

Replace the engine-A/T-ECU.

Repair

Repair

Replace the oxygen sensor (rear).

Repair

Repair

Page 38

From the previous page

OK

Measure at the C-126 engine-A/T-ECU

connector.

D Measure the engine-A/T-ECU

terminal voltage.

D Engine: After warm-up

D Voltage between terminal No. 73

and earth.

D During rapid racing

OK: 0 and 600 ï 1,000 mV

alternate.

OK

Check the following connectors:

C-122, C-124, C-126

OK

M.U.T.-II/III Data list

D No. 59 Oxygen sensor (rear)

(Refer to P.13D-66.)

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to Note

for Intermittent Malfunctions.)

MPI <4G63> ï Troubleshooting

NG

NG

NG

Check the following connector:

C-126

OK

Check and repair the harness between

the oxygen sensor (rear) and

engine-A/T-ECU.

Repair

Replace the engine-A/T-ECU.

NG

13D-33

Repair

Page 39

13D-34

MPI <4G63> ï Troubleshooting

Code No. 64 Alternator FR terminal system Probable cause

Range of Check

D During the engine running.

Set Condition

D Input voltage from the alternator FR terminal is system voltage for 20

seconds.

D Open circuit in alternator FR terminal circuit

D Malfunction of the engine-A/T-ECU

Check the following connector:

B-26

OK

Measure at the alternator connector

B-26.

D Use test harness (MB991519) to

connect the connector, and

measure at the pick-up harness.

D Ignition switch: ON

D The voltage between terminal 4

and earth

OK: 9 ï 10 V

OK

Measure at the alternator connector

B-26.

D Use test harness (MB991519) to

connect the connector, and

measure at the pick-up harness.

D Engine: Idling (After warming up)

D Radiator fan: Not operating

D The voltage between terminal 4

and earth

OK: The voltage drops when

the headlamps are turned

on.

OK

NG

NG

NG

Repair

Measure at the engine-A/T-ECU

connector C-124.

D Measure the voltage at the

engine-A/T-ECU terminal.

D Ignition switch: ON

D The voltage between terminal 54

and earth

OK: 9 ï 10 V

NG

Check the following connector:

C-124

OK

Check the harness wire between the

alternator connector and the

engine-A/T-ECU.

OK

Check the trouble symptoms.

Check the following connectors:

B-18, C-124

OK

Check the harness wire between the

alternator connector and the

engine-A/T-ECU.

OK

Check the trouble symptoms.

NG

Replace the alternator.

OK

NG

NG

NG

NG

NG

Check the following connectors:

B-18, C-124

OK

Check the harness wire between the

alternator connector and the

engine-A/T-ECU, and repair if

necessary.

Repair

Repair

Replace the engine-A/T-ECU.

Replace

Repair

NG

Repair

Check the trouble symptoms.

NG

Replace the engine-A/T-ECU.

OK

Intermittent malfunction

(Refer to GROUP 00 ï Points to

Note for Intermittent Malfunctions.)

Page 40

MPI <4G63> ï Troubleshooting

with

M.U.T

.

II/

(I

idling)

(Engi

)

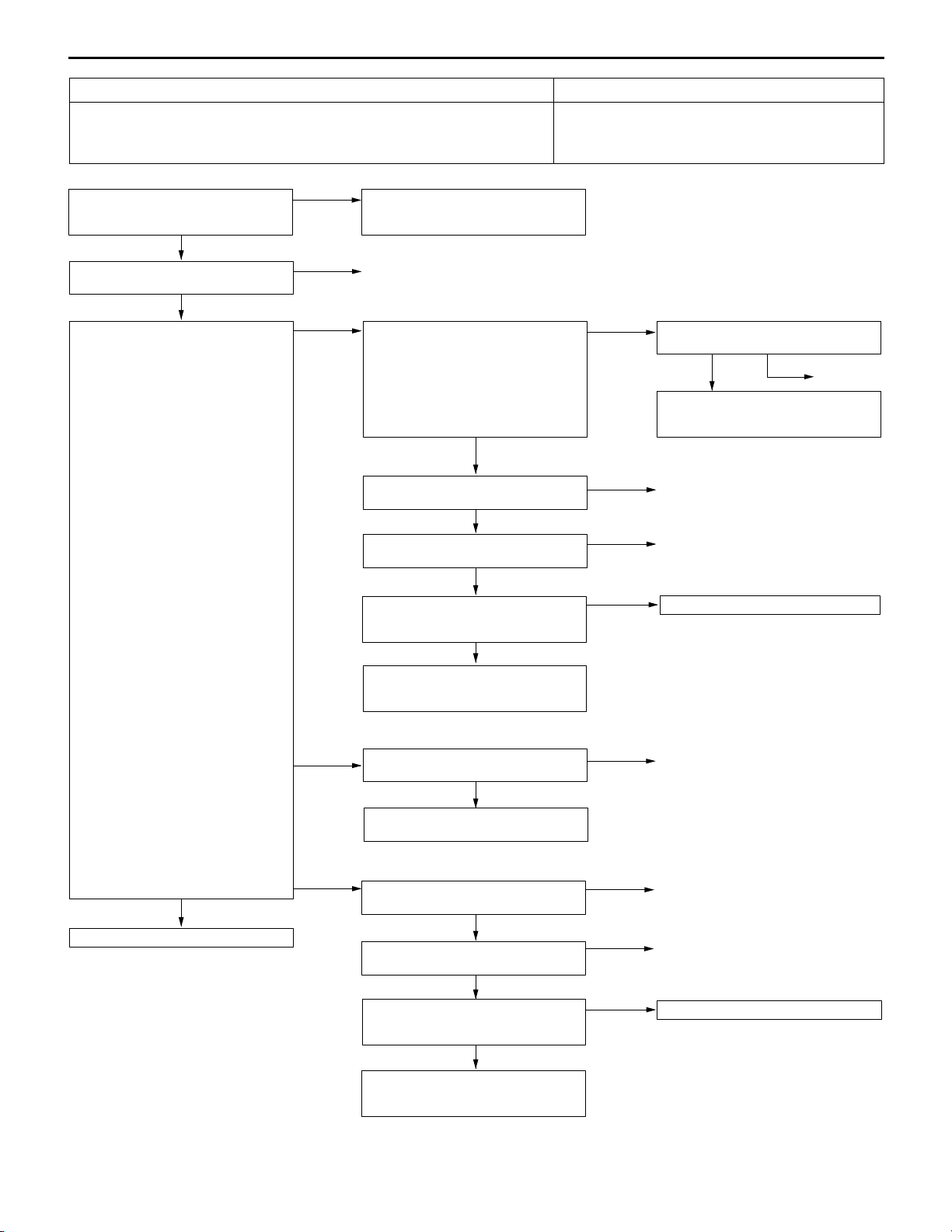

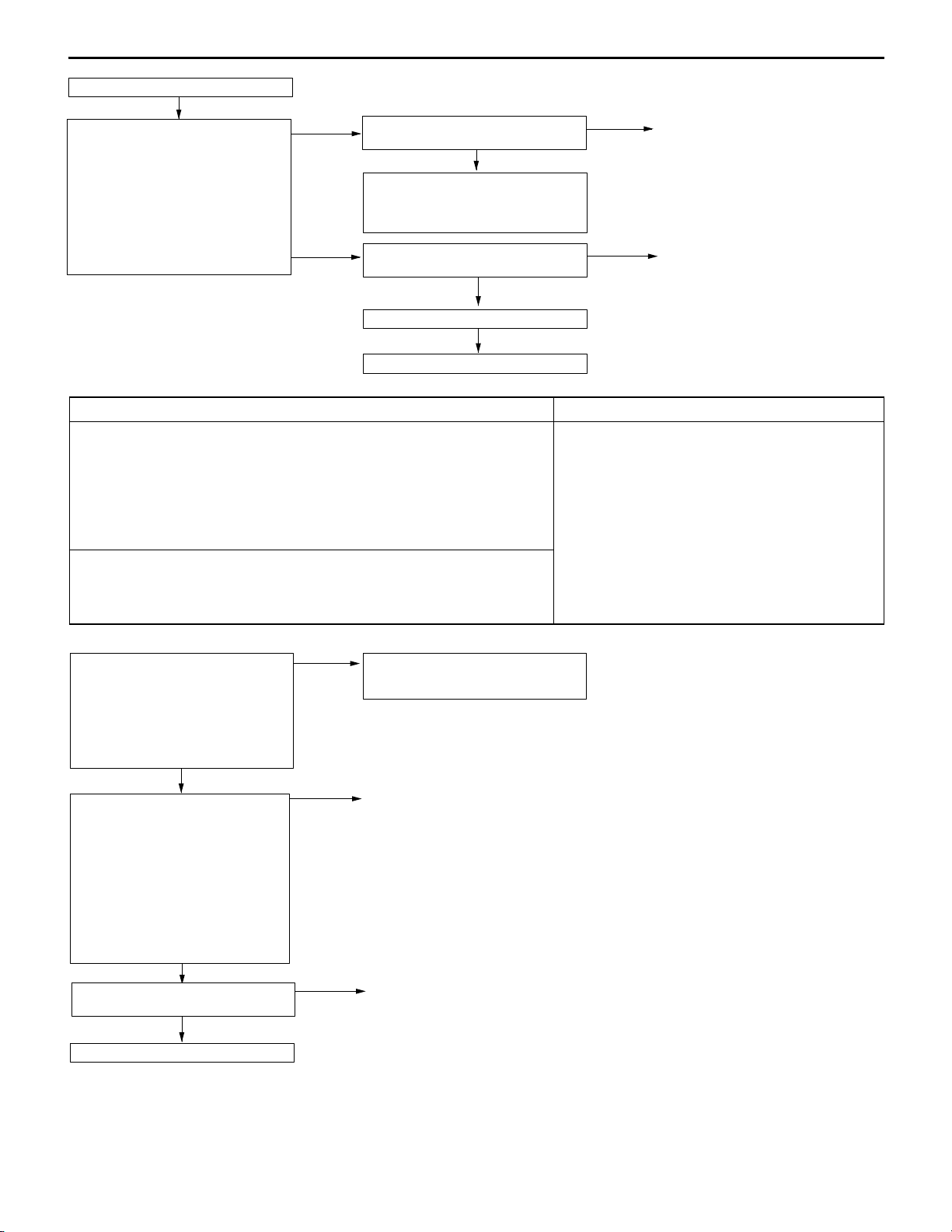

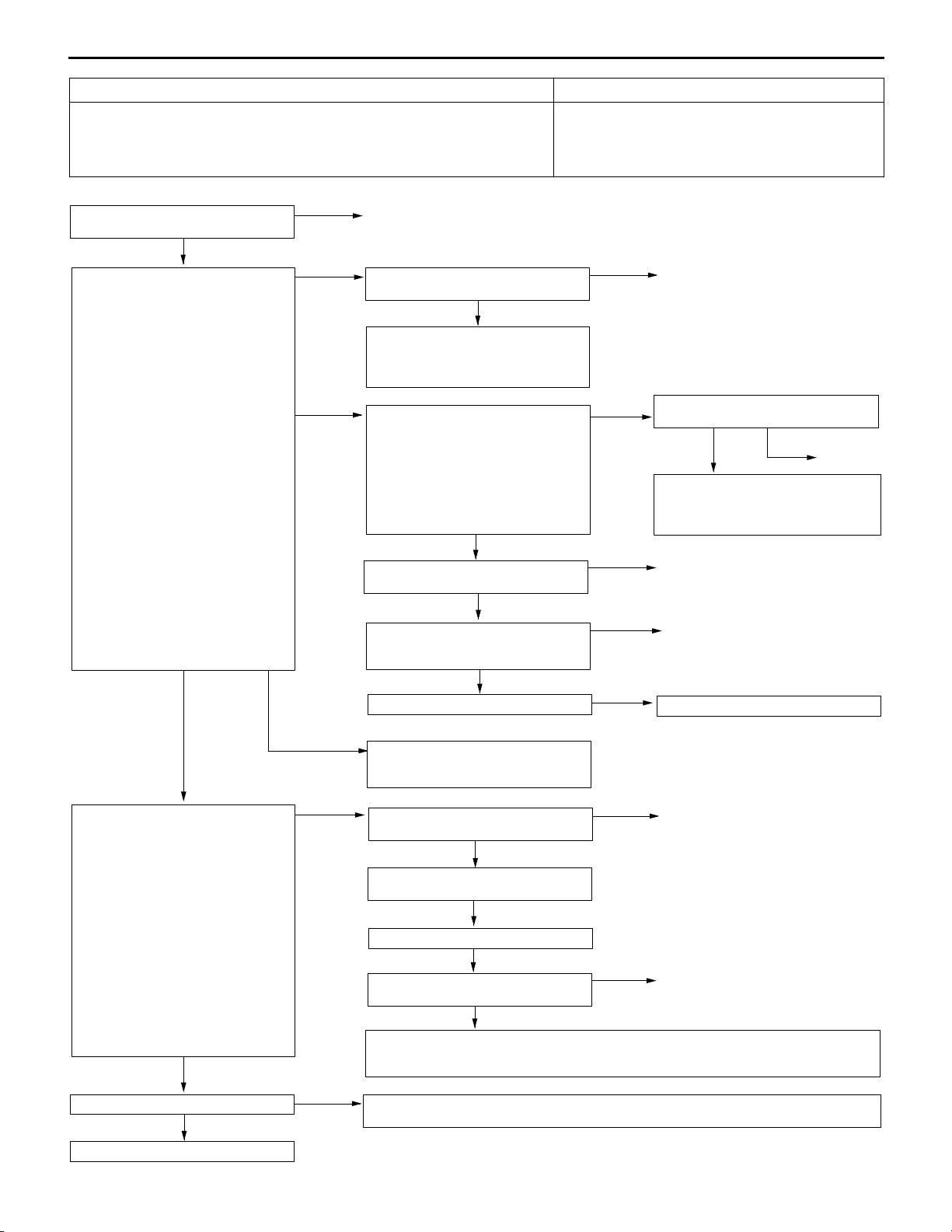

INSPECTION CHART FOR TROUBLE SYMPTOMS

13D-35

Trouble symptom Inspection

procedure

No.

Communication

with M.U.T.-II/

III is impossible.

Engine warning

lamp and

relatedparts

Starting No initial combustion (starting impossible) 5 13D-41

Idling stability

mproper

Communication with all systems is not possible. 1 13D-39

Communication with engine-A/T-ECU only is not possible. 2 13D-39

The engine warning lamp does not illuminate right after the

ignition switch is turned to the ON position.

The engine warning lamp remains illuminating and never goes

out.

Initial combustion but no complete combustion

(starting impossible)

Long time to start (improper starting) 7 13D-43

Unstable idling (Rough idling, hunting) 8 13D-44

Idling speed is high. (Improper idling speed) 9 13D-46

Idling speed is low. (Improper idling speed) 10 13D-46

3 13D-40

4 13D-40

6 13D-42

Reference page

Idling stability

ne stalls

Driving Hesitation, sag or stumble 15 13D-51

Dieseling 21 13D-55

Too high CO and HC concentration when idling 22 13D-56

Low alternator output voltage (approx. 12.3 V) 23 13D-57

Idling speed is improper when A/C is operating 24 13D-57

When the engine is cold, it stalls at idling. (Die out) 11 13D-47

When the engine is hot, it stalls at idling. (Die out) 12 13D-48

The engine stalls when starting the car. (Pass out) 13 13D-50

The engine stalls when decelerating. 14 13D-50

The feeling of impact or vibration when accelerating 16 13D-52

The feeling of impact or vibration when decelerating 17 13D-52

Poor acceleration 18 13D-53

Surge 19 13D-54

Knocking 20 13D-55

Fans (radiator fan, A/C condenser fan) are inoperative 25 13D-58

Page 41

13D-36

bilit

MPI <4G63> ï Troubleshooting

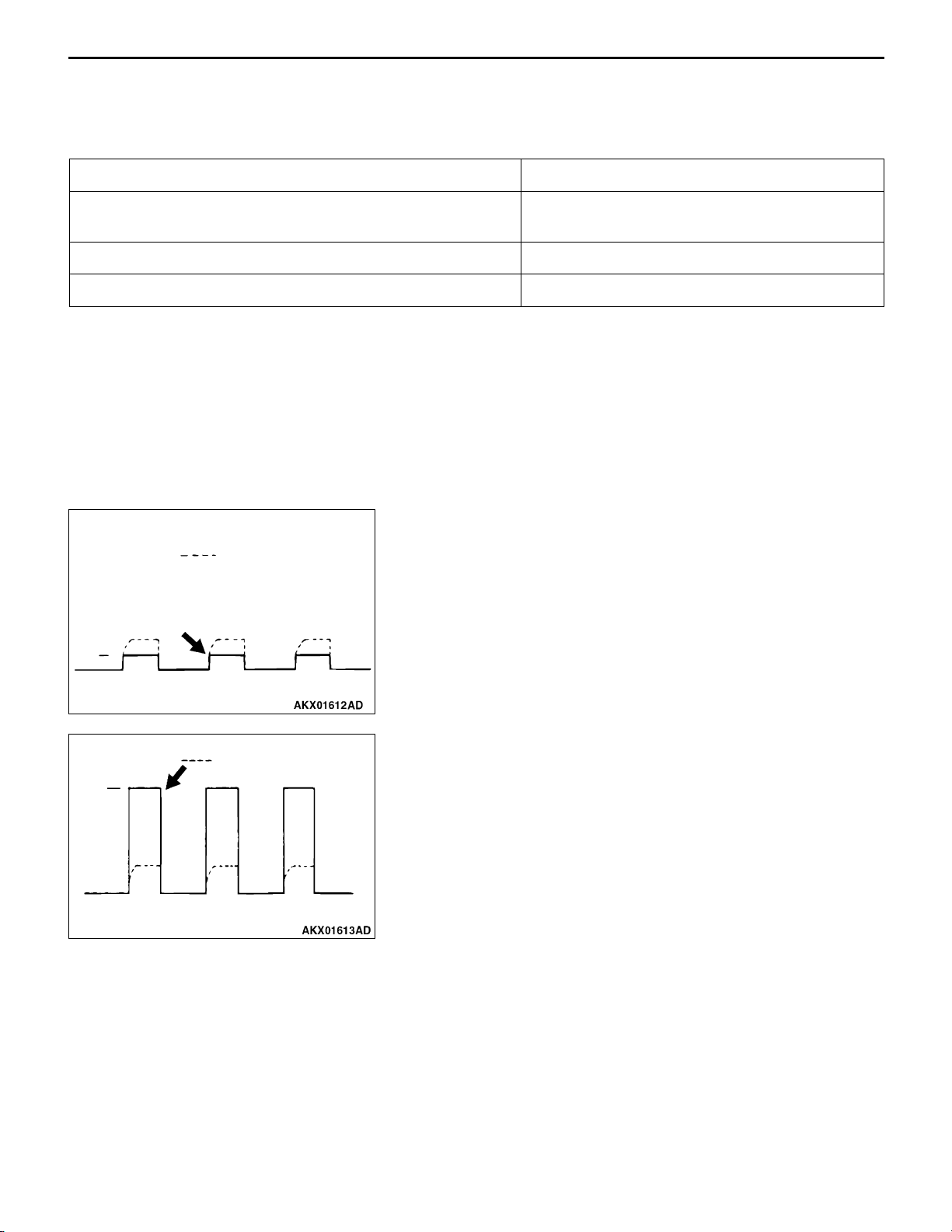

PROBLEM SYMPTOMS TABLE (FOR YOUR INFORMATION)

Items Symptom

Starting Won’t start The starter is used to crank the engine, but there is no combustion within the

cylinders, and the engine won’t start.

Fires up and dies There is combustion within the cylinders, but then the engine soon stalls.

Hard starting Engine starts after cranking a while.

Idling

sta

y

Hunting Engine speed doesn’t remain constant; changes at idle.

Rough idle Usually, a judgement can be based upon the movement of the tachometer

pointer, and the vibration transmitted to the steering wheel, shift lever, body,

etc. This is called rough idle.

Incorrect idle

The engine doesn’t idle at the usual correct speed.

speed

Engine stall

(Die out)

Engine stall

(Pass out)

The engine stalls when the foot is taken from the accelerator pedal,

regardless of whether the vehicles is moving or not.

The engine stalls when the accelerator pedal is depressed or while it is being

used.

Driving Hesitation Sag “Hesitation” is the delay in response of the vehicle speed (engine speed) that

occurs when the accelerator is depressed in order to accelerate from the

speed at which the vehicle is now traveling, or a temporary drop in vehicle

speed (engine speed) during such acceleration.

Serious hesitation is called “sag”. (Refer to Fig. 1)

Poor acceleration Poor acceleration is inability to obtain an acceleration corresponding to the

degree of throttle opening, even though acceleration is smooth, or the inability

to reach maximum speed.

Stumble Engine speed increase is delayed when the accelerator pedal is initially

depressed for acceleration. (Refer to Fig. 2)

Shock The feeling of a comparatively large impact or vibration when the engine is

Surge This is repeated surging ahead during constant speed travel or during

Knocking A sharp sound like a hammer striking the cylinder walls during driving and

Stopping Run on

(“Dieseling”)

Fig. 1

Normal

Vehicle

speed

Initial accelerator

pedal depression

Time

Hesitation

Sag

accelerated or decelerated.

variable speed travel.

which adversely affects driving.

The condition in which the engine continues to run after the ignition switch is

turned to LOCK (OFF) position. Also called “Dieseling”.

Fig. 2

Vehicle

speed

Normal

Initial accelerator

pedal depression

Idling

Stumble

Time

Page 42

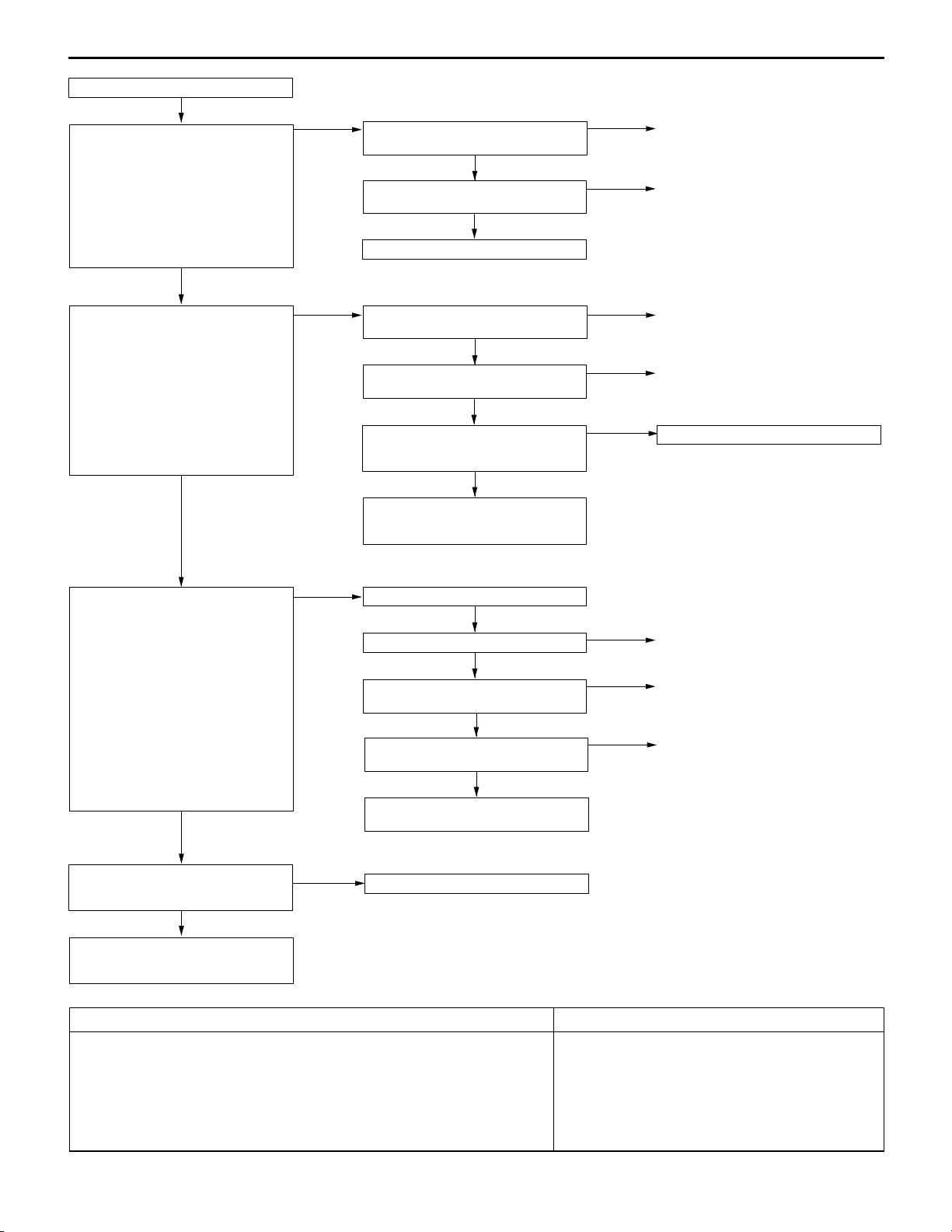

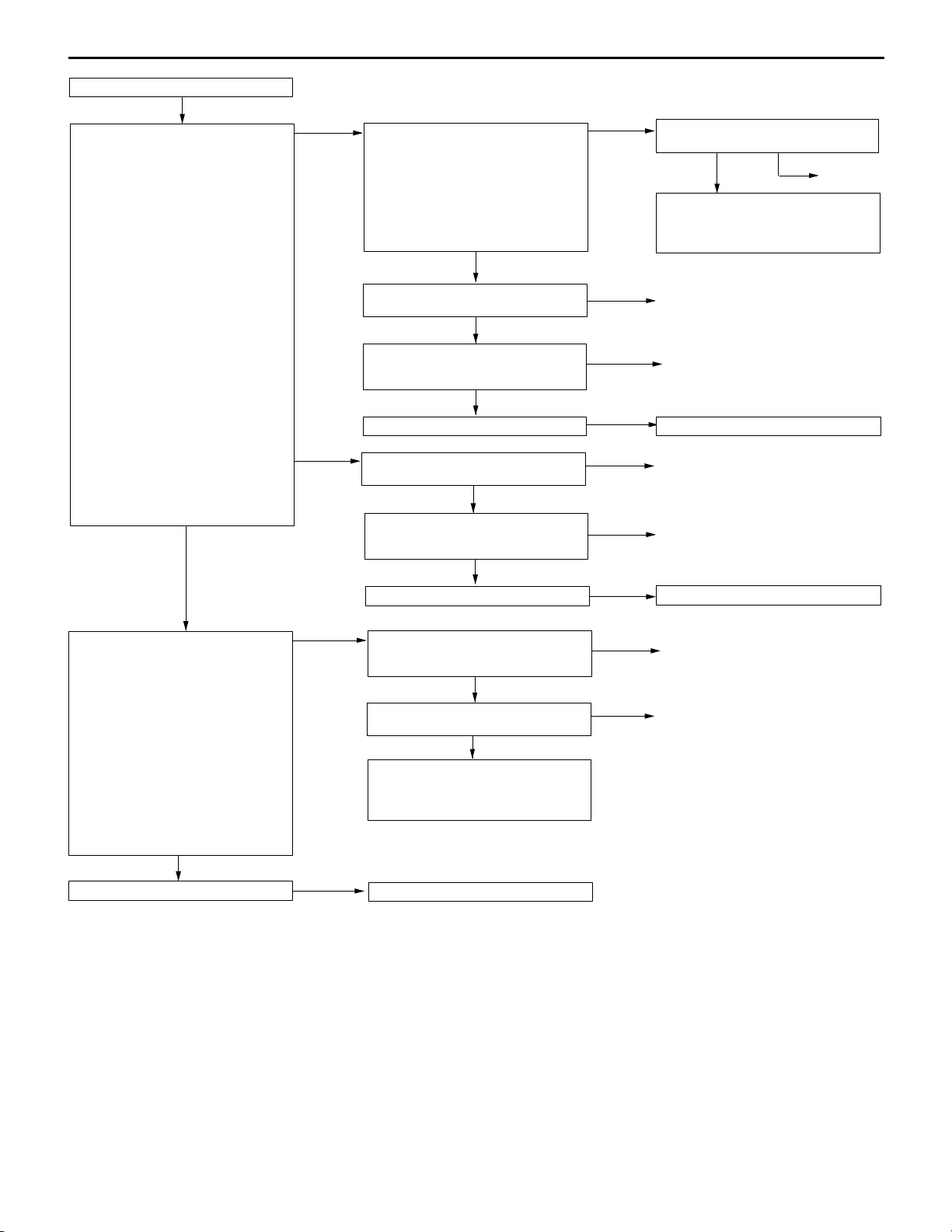

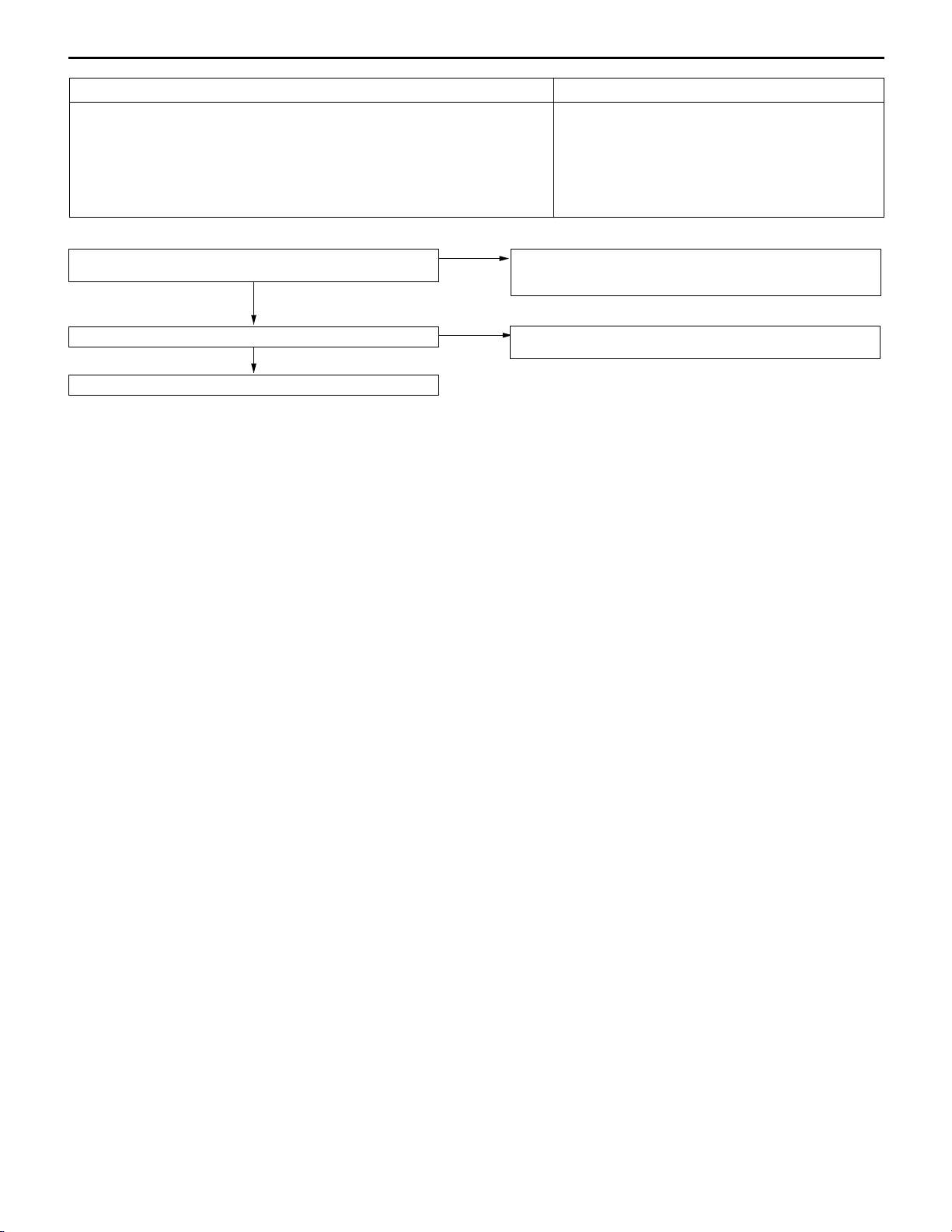

MPI <4G63> ï Troubleshooting

PROBLEM SYMPTOMS TABLE

13D-37

Inspection

procedure

No.

1 Communication with all system is not possible 13D-39

2 Communication with engine-A/T-ECU only is not possible 13D-39

3 The engine warning lamp does not illuminate right after the ignition switch is turned

4 The engine warning lamp remains illuminating and never goes out 13D-40

5 No initial combustion (Starting impossible) 13D-41

6 Initial combustion but no complete combustion (Starting impossible) 13D-42

7 It takes too long time to start (Incorrect starting) 13D-43

8 Unstable idling (Rough idling, hunting) 13D-44

9 Idling speed is high (Improper idling speed) 13D-46

10 Idling speed is low (Improper idling speed) 13D-46

11 When the engine is cold, it stalls at idling (Die out) 13D-47

12 When the engine is hot, it stalls at idling (Die out) 13D-48

Trouble symptom Reference

page

13D-40

to the “ON” position

13 The engine stalls when starting the car (Pass out) 13D-50

14 The engine stalls when decelerating 13D-50

15 Hesitation, sag or stumble 13D-51

16 The feeling of impact or vibration when accelerating 13D-52

17 The feeling of impact or vibration when decelerating 13D-52

18 Poor acceleration 13D-53

19 Surge 13D-54

20 Knocking 13D-55

21 Dieseling 13D-55

22 Too high CO and HC concentration when idling 13D-56

23 Low alternator output voltage (approx. 12.3 V) 13D-57

24 Idling speed is improper when A/C is operating 13D-57

25 Fans (radiator fan, A/C condenser fan) are inoperative 13D-58