Page 1

GROUP INDEX

LANCER /

LANCER WAGON

WORKSHOP MANUAL

FOREWORD

This Workshop manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and installation.

Use the following manuals in combination with this

manual as required.

General . . . . . . . . . . . . . . . . . . . . . . . .

Engine. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Lubrication . . . . . . . . . . . . . .

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Cooling . . . . . . . . . . . . . . . . .

Intake and Exhaust . . . . . . . . . . . . . .

Engine Electrical . . . . . . . . . . . . . . . .

Engine and Emission Control . . . . .

Clutch . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Transmission . . . . . . . . . . . .

Automatic Transmission. . . . . . . . . .

Front Axle. . . . . . . . . . . . . . . . . . . . . .

00

11

12

13

14

15

16

17

21

22

23

26

TECHNICAL INFORMATION MANUAL

PYME0302

PYME0302-A

WORKSHOP MANUAL

CHASSIS GROUP PWME0302

BODY REPAIR MANUAL

PBME0302

PBME0302-A

PARTS CATALOGUE

B606K005A_

All information, illustrations and product descriptions

contained in this manual are current as at the time of

publication. We, however, reserve the right to make

changes at any time without prior notice or obligation.

Rear Axle . . . . . . . . . . . . . . . . . . . . . .

Wheel and Tyre . . . . . . . . . . . . . . . . .

Power Plant Mount . . . . . . . . . . . . . .

Front Suspension . . . . . . . . . . . . . . .

Rear Suspension . . . . . . . . . . . . . . . .

Service Brakes. . . . . . . . . . . . . . . . . .

Parking Brakes . . . . . . . . . . . . . . . . .

Power Steering . . . . . . . . . . . . . . . . .

Body . . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior . . . . . . . . . . . . . . . . . . . . . . . .

Interior and Supplemental

. . . . . . . . . .

Restraint System (SRS)

Chassis Electrical . . . . . . . . . . . . . . .

Heater, Air Conditioner and

. . . . . . .

Ventilation

Component Locations. . . . . . . . . . . .

27

31

32

33

34

35

36

37

42

51

52

54

55

70

Mitsubishi Motors Corporation May 2004

Configration Diagrams . . . . . . . . . . .

Circuit Diagrams . . . . . . . . . . . . . . . .

80

90

Page 2

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL

RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

(1) Improper service or maintenance of any component of the SRS or any SRS-related component,

can lead to personal injury or death to service personnel (from inadvertent firing of the air bag)

or to the driver and passenger (from rendering the SRS inoperative).

(2) The SRS components and seat belt with pretensioner should not be subjected to heat, so

remove the SRS-ECU, driverís and front passengerís air bag modules, clock spring, side air bag

modules, and seat belt -pre-tensioner before drying or baking the vehicle after painting.

ï SRS-ECU, air bag module and clock spring 93°C or more

ï Seat belt with pre-tensioner: 90°C or more

(3) Service or maintenance of any SRS component or SRS-related component must be performed

only at an authorized MITSUBISHI dealer.

(4) MITSUBISHI dealer personnel must thoroughly review this Manual, and especially its GROUP

52B - Supplemental Restraint System (SRS), before beginning any service or maintenance of

any component of the SRS or any SRS-related component.

NOTE

Section titles with asterisks (*) in the table of contents in each group indicate operations requiring warnings.

Page 3

GROUP 17

ENGINE AND

EMISSION

CONTROL

CONTENTS

17-1

ENGINE CONTROL. . . . . . . . . .

GENERAL INFORMATION . . . . . . 17-2

SERVICE SPECIFICATIONS. . . . . 17-2

ON-VEHICLE SERVICE. . . . . . . . . 17-2

ACCEL CABLE CHECK AND

ADJUSTMENT. . . . . . . . . . . . . . . . . . . . 17-2

ACCELERATOR CABLE AND

PEDAL . . . . . . . . . . . . . . . . . . . . . .

REMOVAL AND INSTALLATION . . . . . 17-3

17-2

17-3

EMISSION CONTROL MPI . . . . 17-5

GENERAL INFORMATION . . . . . .

EMISSION CONTROL DEVICE

REFERENCE TABLE . . . . . . . . . .

SERVICE SPECIFICATION(S) . . . 17-5

VACUUM HOSE. . . . . . . . . . . . . . . 17-6

VACUUM HOSE PIPING DIAGRAM . . . 17-6

VACUUM CIRCUIT DIAGRAM . . . . . . . 17-7

VACUUM HOSE CHECK. . . . . . . . . . . . 17-8

VACUUM HOSE INSTALLATION . . . . . 17-8

CRANKCASE EMISSION CONTROL

SYSTEM. . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-8

17-5

17-5

17-8

COMPONENT LOCATION (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-9

POSITIVE CRANKCASE VENTILATION

SYSTEM CHECK . . . . . . . . . . . . . . . . . . 17-9

POSITIVE CRANKCASE VENTILATION

(PCV) VALVE CHECK . . . . . . . . . . . . . . 17-9

EVAPORATIVE EMISSION CONTROL

SYSTEM . . . . . . . . . . . . . . . . . . . . . 17-9

GENERAL INFORMATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-9

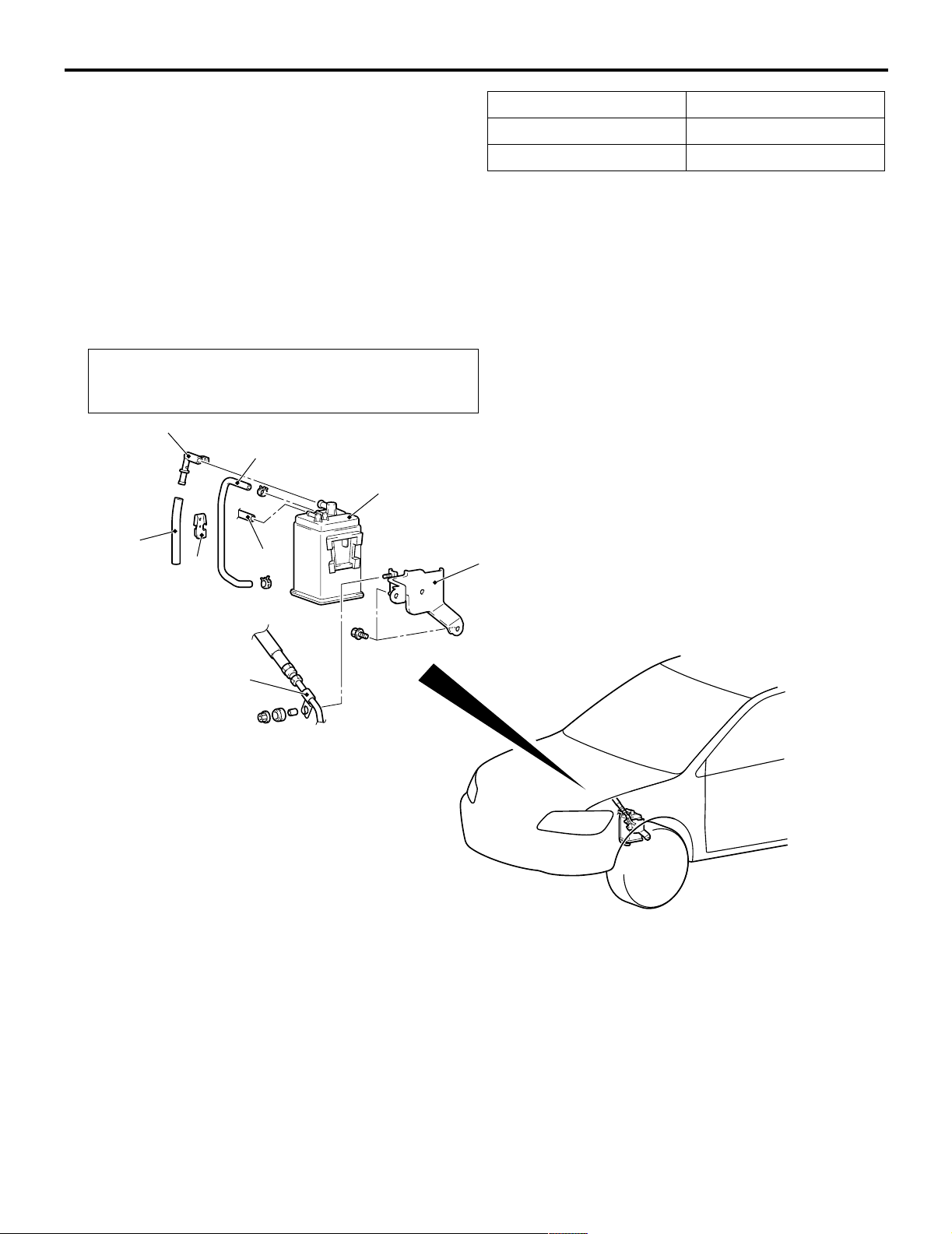

COMPONENT LOCATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-10

PURGE CONTROL SYSTEM CHECK. . 17-10

PURGE PORT VACUUM CHECK . . . . . 17-11

PURGE CONTROL SOLENOID VALVE

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 17-11

FUEL VAPOUR CANISTER REMOVAL

AND INSTALLATION . . . . . . . . . . . . . . . 17-12

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM . . . . . . . . . . . . . . .

GENERAL INFORMATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-13

COMPONENT LOCATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-14

EGR SYSTEM CHECK . . . . . . . . . . . . . 17-15

EGR VALVE CHECK . . . . . . . . . . . . . . . 17-15

EGR PORT VACUUM CHECK <4G1>. . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G1> . . . . . . . . . . . . . . . . . . . . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G6> . . . . . . . . . . . . . . . . . . . . 17-17

EXHAUST GAS RECIRCULATION (EGR)

VALVE REMOVAL AND

INSTALLATION . . . . . . . . . . . . . . . . . . . 17-18

CATALYTIC CONVERTER . . . . . . 17-18

REMOVAL AND INSTALLATION . . . . . . 17-18

17-13

Page 4

17-2

ENGINE AND EMISSION CONTROL

ENGINE CONTROL

ENGINE CONTROL

GENERAL INFORMATION

M1171000100277

A cable-type accelerator mechanical

suspended-type pedal has been adopted.

SERVICE SPECIFICATIONS

M1171000300088

Item Standard value

Accel cable play mm 1.0 − 2.0

Engine idle speed r/min 4G1 750 ± 50

4G6 750 ± 100

ON-VEHICLE SERVICE

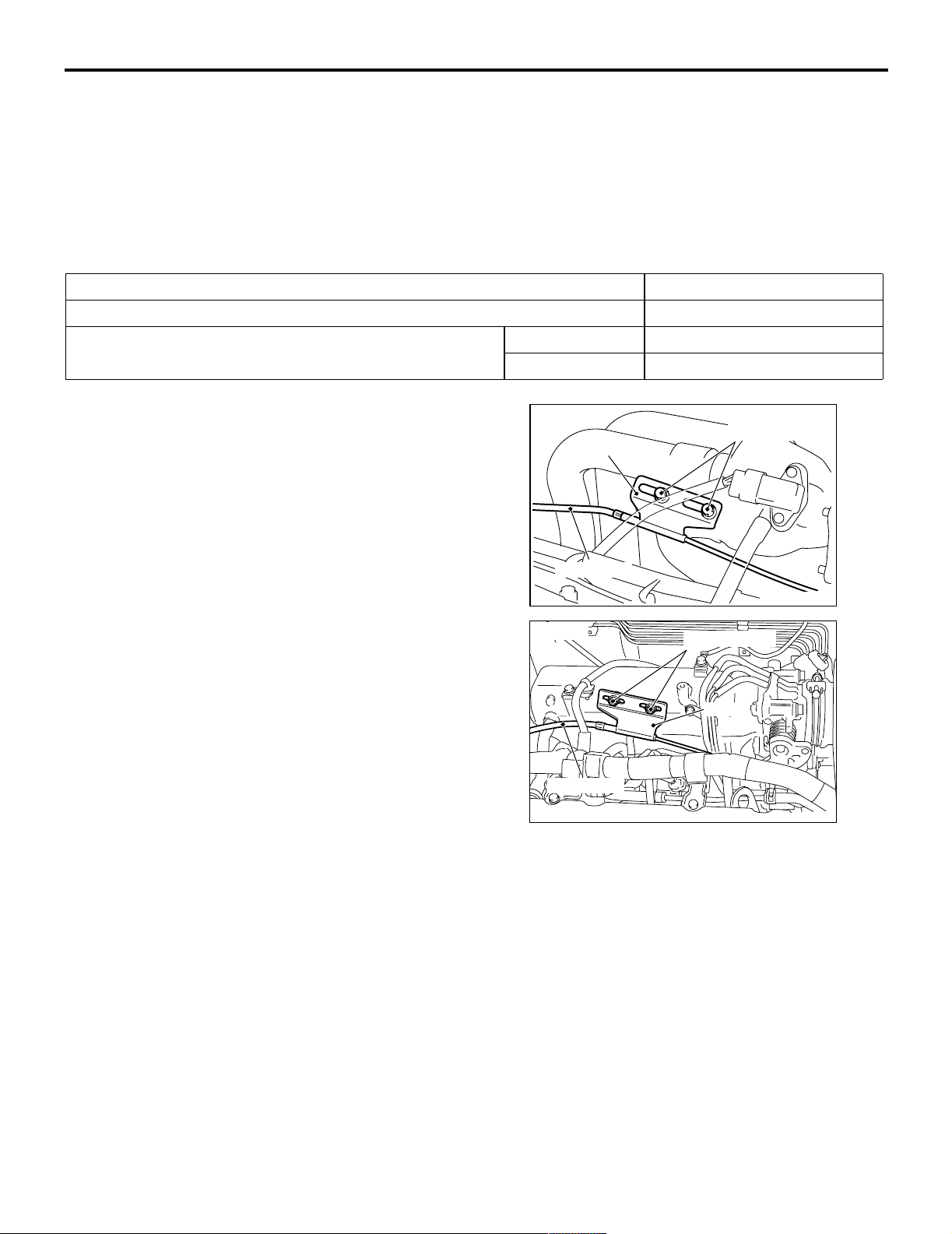

ACCEL CABLE CHECK AND

<4G1>

Adjusting bolts

Plate

ADJUSTMENT

M1171000900314

1. Turn A/C and lights OFF. Inspect and adjust at no

load.

2. Warm engine until stabilized at idle.

3. Confirm idle speed is at standard value.

Standard value:

750 ± 50 r/min <4G1>

750 ± 100 r/min <4G6>

Accel cable

<4G6>

Adjusting bolts

AC207966

AC

4. Stop engine. [ignition switch: LOCK (OFF)

position].

5. Confirm there are no sharp bends in the

accelerator cable.

6. Check the inner cable for correct slack.

Standard value: 1.0 − 2.0 mm

7. If there is too much slack or no slack, adjust play

by the following procedures.

Plate

Accel cable

AC301055

AC

(1) Loosen the adjusting bolts to release the

cable.

(2) Move the plate until the inner cable play is at

the standard value, and then tighten the

adjusting bolts.

(3) After adjusting, check that the throttle lever is

touching the stopper.

Page 5

ENGINE AND EMISSION CONTROL

ENGINE CONTROL

ACCELERATOR CABLE AND PEDAL

17-3

REMOVAL AND INSTALLATION

Post-installation Operation

Adjusting the Accelerator Cable (Refer to P.17-2).

<L.H. drive vehicles>

3

M1171001200341

2

5.0 ± 1.0 N·m

12 ± 2 N·m

10

1

7

9

7

N

5

4

<R.H. drive vehicles>

5.0 ± 1.0 N·m

2

Accelerator cable assembly

removal steps

1. Inner cable connection (Accelerator

pedal side)

2. Inner cable connection (Throttle body

side)

3. Accelerator cable assembly

8

13

N

12

6

Y1060AU

11

3

1

12 ± 2 N·m

9

7

13

11

12

6

N

Y1059AU

AC304070

AB

10

N

5

4

7

8

Accelerator pedal assembly

removal steps

1. Inner cable connection (Accelerator

pedal side)

4. Accelerator pedal assembly

5. Accelerator control equip nut

6. Accelerator pedal arm and

accelerator pedal pad assembly

Page 6

17-4

ENGINE AND EMISSION CONTROL

ENGINE CONTROL

Accelerator pedal assembly

removal steps (Continued)

7. Accelerator control equip bushing

8. Accelerator pedal arm return spring

9. Accelerator pedal arm stopper

INSTALLATION SERVICE POINT

>>A<< ACCEL PEDAL PAD

INSTALLATION

CAUTION

To p reve nt damag es to the ac c eler ator pe dal pad,

warm the thumb area of the accelerator pedal

pad with a dryer, etc. prior to assembling it.

NOTE: If it is difficult to assemble, apply soapy water

to the thumb area to enhance the assembling

process.

>>A<<

Accelerator pedal assembly

removal steps (Continued)

10. Accelerator pedal arm bracket

11. Ac c e l erator p edal a rm

12. Accelerator pedal pad

13. Accelerator pedal arm stopper

Page 7

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

EMISSION CONTROL <MPI>

17-5

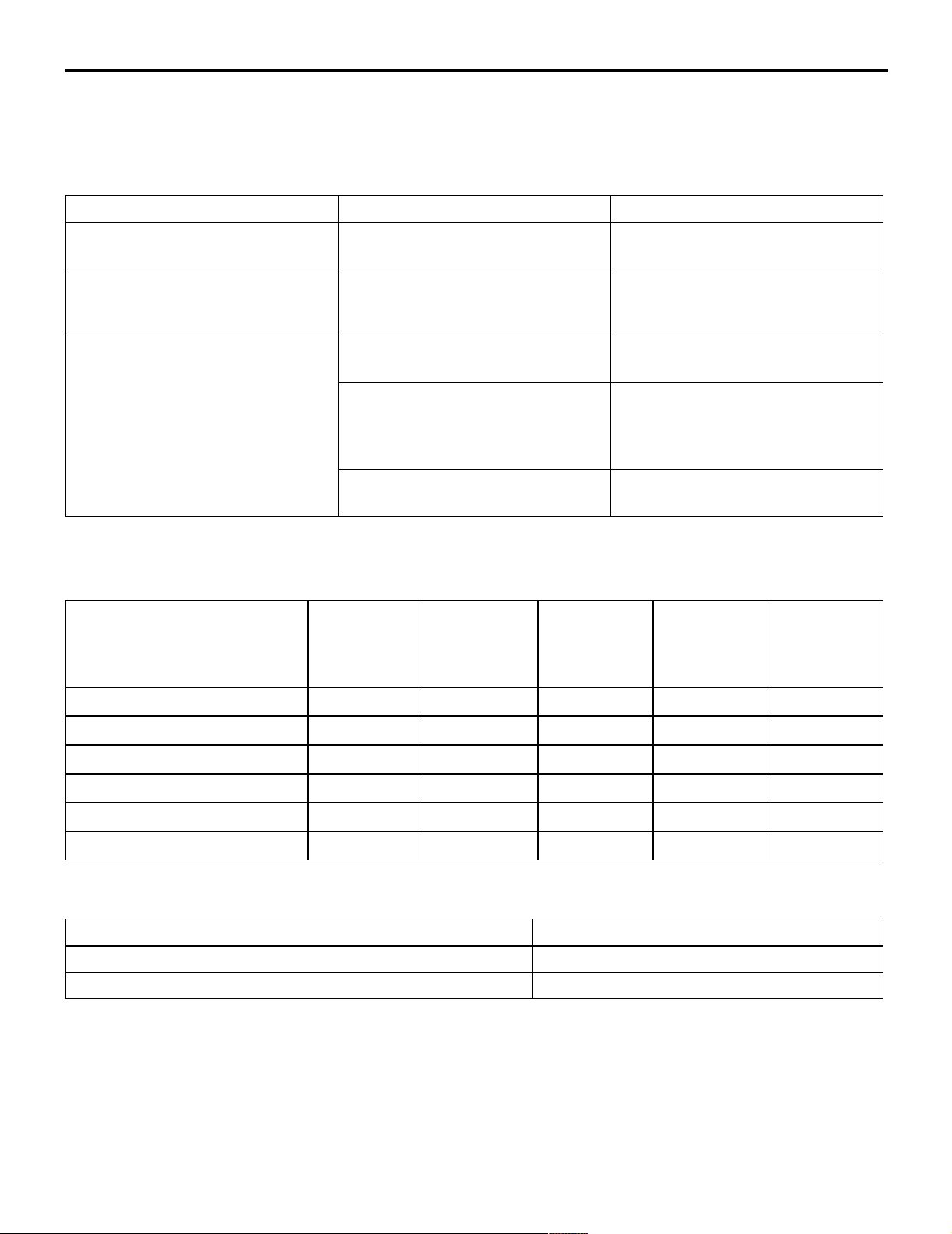

GENERAL INFORMATION

M1173000100370

The emission control system consists of the following

subsystems:

Items Name Specification

Crankcase emission control

system

Evaporative emission control

system

Exhaust emission control system Air-fuel ratio control device - MPI

Positive crankcase ventilation

(PCV) valve

Canister

Purge control solenoid valve

system

Exhaust gas recirculation system

• EGR valve

• EGR control solenoid valve

Catalytic converter Monolith type

• Crankcase emission control system

• Evaporative emission control system

• Exhaust emission control system

Varia b le flo w t yp e

(Purpose: HC reduction)

Equipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

Oxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Equipped

Single type

Duty cycle type solenoid valve

(Purpose: NOx reduction)

(Purpose: CO, HC, NOx reduction)

EMISSION CONTROL DEVICE

REFERENCE TABLE

M1173006600135

Related parts Crankcase

emission

control

system

Evaporative

emission

control

system

Air/fuel ratio

control

system

Catalytic

converter

Exhaust gas

recirculation

system

PCV valve

Purge control solenoid valve

MPI system component

Catalytic converter

EGR valve

EGR control solenoid valve

×

×

××

SERVICE SPECIFICATION(S)

M1173000300288

Items Standard value

Purge control solenoid valve coil resistance (at 20°C) Ω 30 − 34

EGR control solenoid valve coil resistance (at 20°C) Ω 29 − 35

×

×

×

Page 8

17-6

VACUUM HOSE

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

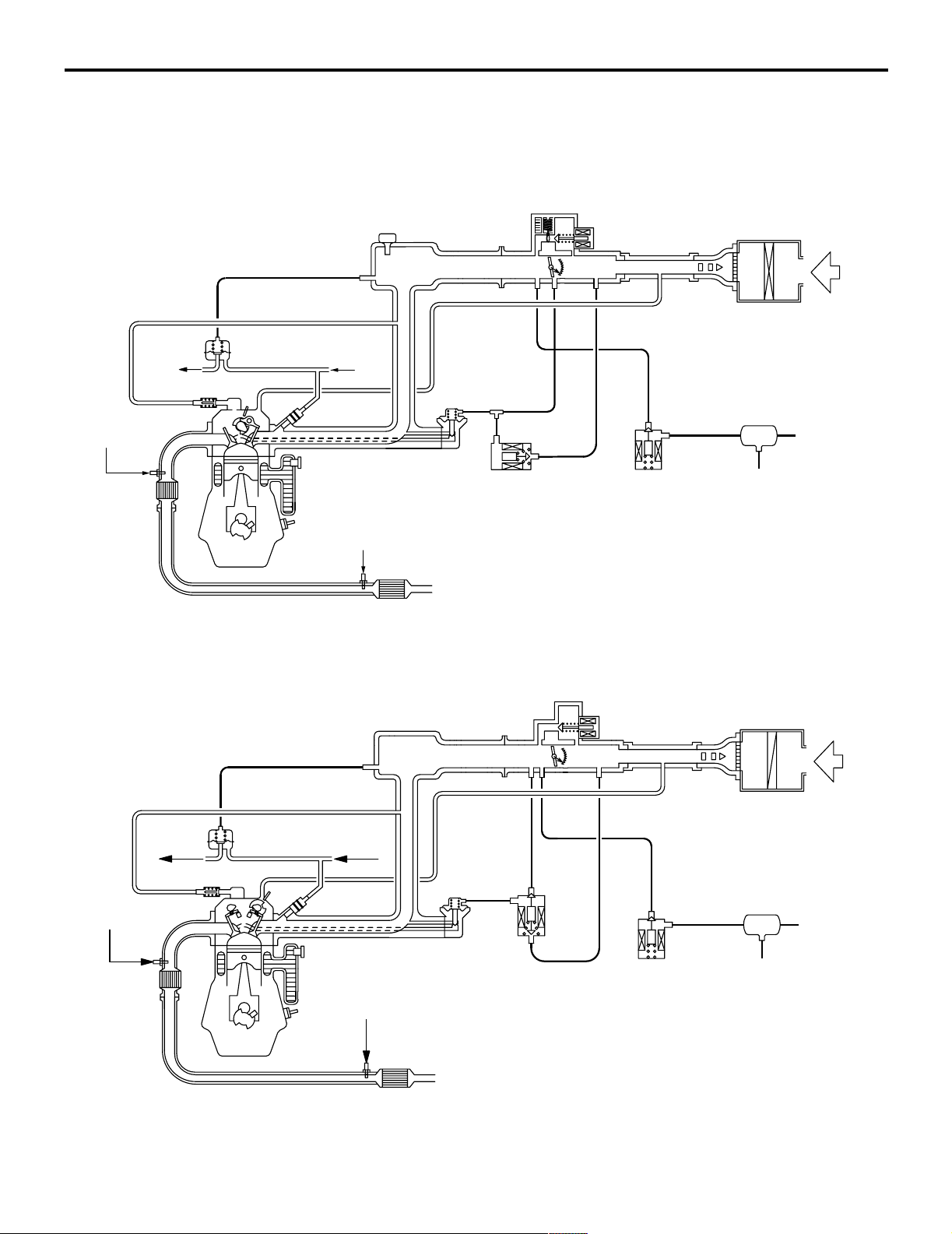

VACUUM HOSE PIPING DIAGRAM

M1173000900417

<4G1>

To

fuel tank

Oxygen sensor

(front)

Catalytic

converter

Fuel pressure

regulator

Oxygen sensor (rear)

From

fuel pump

EGR valve

EGR control

solenoid valve

Air cleaner

Air

Canister

Purge control

solenoid valve

<4G6>

To

fuel tank

Oxygen sensor

(front)

Catalytic

converter

PCV valve

Fuel pressure

regulator

Catalytic

converter

From

fuel pump

EGR valve

Oxygen sensor (rear)

Catalytic

converter

EGR control

solenoid valve

Purge control

solenoid valve

Air cleaner

Canister

AK300964

AB

Air

AK204364

AC

Page 9

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

17-7

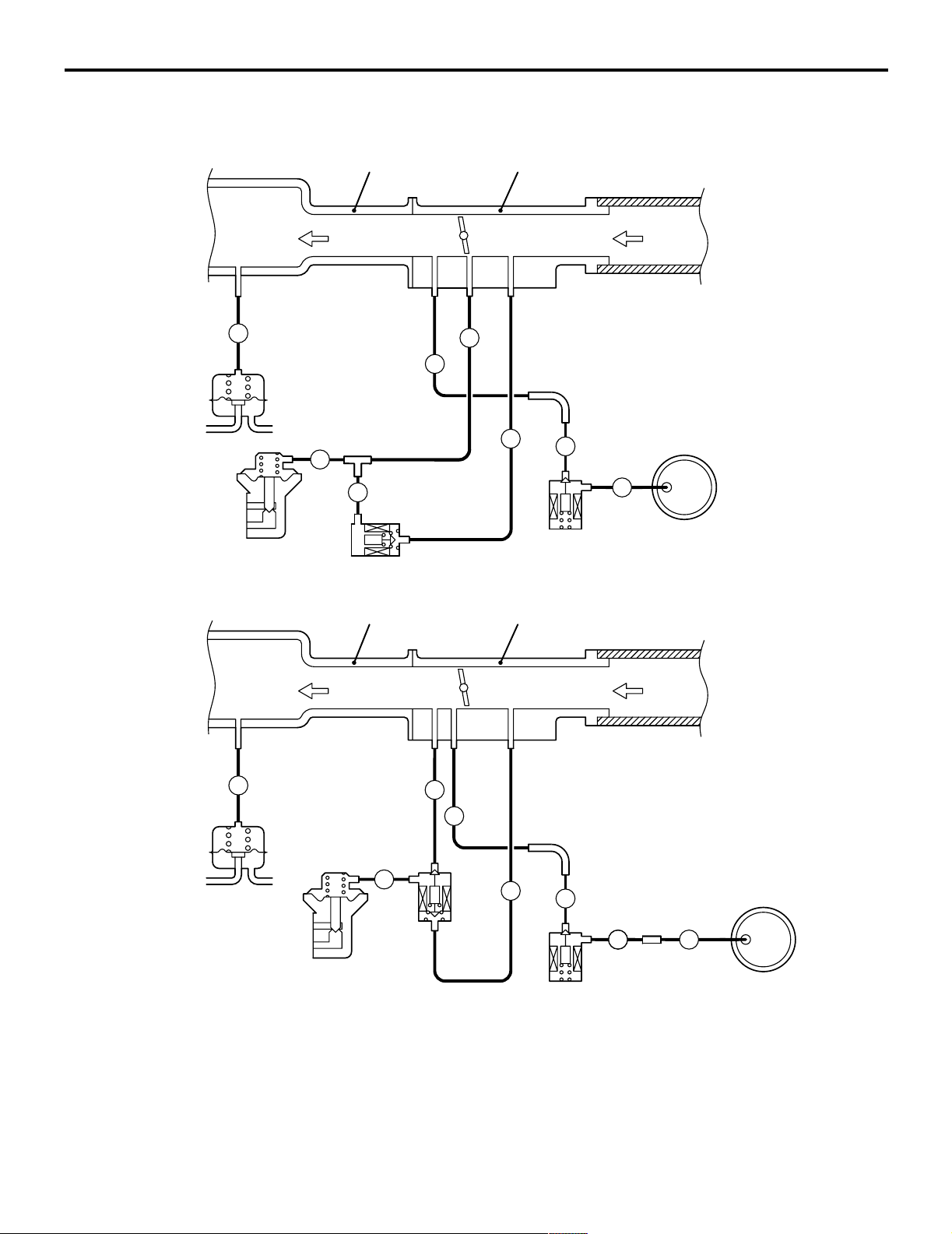

VACUUM CIRC UIT DIA GRAM

<4G1>

To

combustion

chamber

L

Fuel

pressure

regulator

Vacuum hose colour

B: Black

G: Green

R: Red

Y: Yellow

L: Blue

EGR

valve

G

M1173007100263

Intake manifold

G

EGR

control

solenoid

valve

Throttle body

From

air

cleaner

G

R

Y

R

Purge

control

solenoid

valve

Canister

B

AK300765

AB

<4G6>

To

combustion

chamber

Fuel

pressure

regulator

Vacuum hose colour

B: Black

G: Green

R: Red

W: White

Y: Yellow

L: Blue

Intake manifold

L

G

EGR

control

solenoid

EGR

valve

valve

W

R

Throttle body

Y

B

B

Purge

control

solenoid

valve

From

air

cleaner

Canister

B

AK300766

AB

Page 10

17-8

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

VACUUM HOSE CHECK

M1173007300159

1. Using the piping diagram as a guide, check to be

sure that the vacuum hoses are correctly

connected.

2. Check the connection condition of the vacuum

hoses, (removed, loose, etc.) and check to be

sure that there are no bends or damage.

VACUUM HOSE INSTALLATION

M1173007200107

1. When connecting the vacuum hoses, they should

be securely inserted onto the nipples.

2. Connect the hoses correctly, using the vacuum

hose piping diagram as a guide.

CRANKCASE EMISSION CONTROL

SYSTEM

GENERAL INFORMATION (CRANKCASE

EMISSION CONTROL SYSTEM)

M1173005000237

The crankcase emission control system prevents

blow-by gases from escaping inside the crankcase

into the atmosphere.

Fresh air is sent from the air cleaner into the

crankcase through the breather hose.

The air becomes mixed with the blow-by gases

inside the crankcase.

The blow-by gas inside the crankcase is drawn into

the intake manifold through the positive crankcase

ventilation (PCV) valve.

The PCV valve lifts the plunger according to the

intake manifold vacuum so as to regulate the flow of

blow-by gas properly.

In other words, the blow-by gas flow is regulated

during low load engine operation to maintain engine

stability, while the flow is increased during high load

operation to improve the ventilation performance.

SYSTEM DIAGRAM

Ventilation hose

PCV valve

Breather hose

Air cleaner

AK204365

Air

AB

Page 11

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

17-9

COMPONENT LOCATION (CRANKCASE

EMISSION CONTROL SYSTEM)

M1173007400208

<4G1>

PCV valve

AK300767

<4G6>

PCV valve

AK204366

AB

AC

POSITIVE CRANKCASE VENTILATION

(PCV) VALVE CHECK

M1173001200187

PCV valve

AK100010

AC

1. Insert a thin rod into the PCV valve from the side

shown in the illustration (rocker cover installation

side), and move the rod back and forth to check

that the plunger moves.

2. If the plunger does not move, there is a clogging

in the PCV valve. In this case, clean or replace

the PCV valve.

EVAPORATIVE EMISSION CONTROL

SYSTEM

POSITIVE CRANKCASE VENTILATION

SYSTEM CHECK

M1173001100179

1. Remove the ventilation hose from the PCV valve.

2. Remove the PCV valve from the rocker cover.

3. Reinstall the PCV valve at the ventilation hose.

4. Start the engine and run at idle.

PCV valve

AKX00336

5. Place a finger at the opening of the PCV valve

and check that vacuum of the intake manifold is

felt.

NOTE: At this moment, the plunger in the PCV

valve moves back and forth.

6. If vacuum is not felt, clean the PCV valve or

replace it.

AD

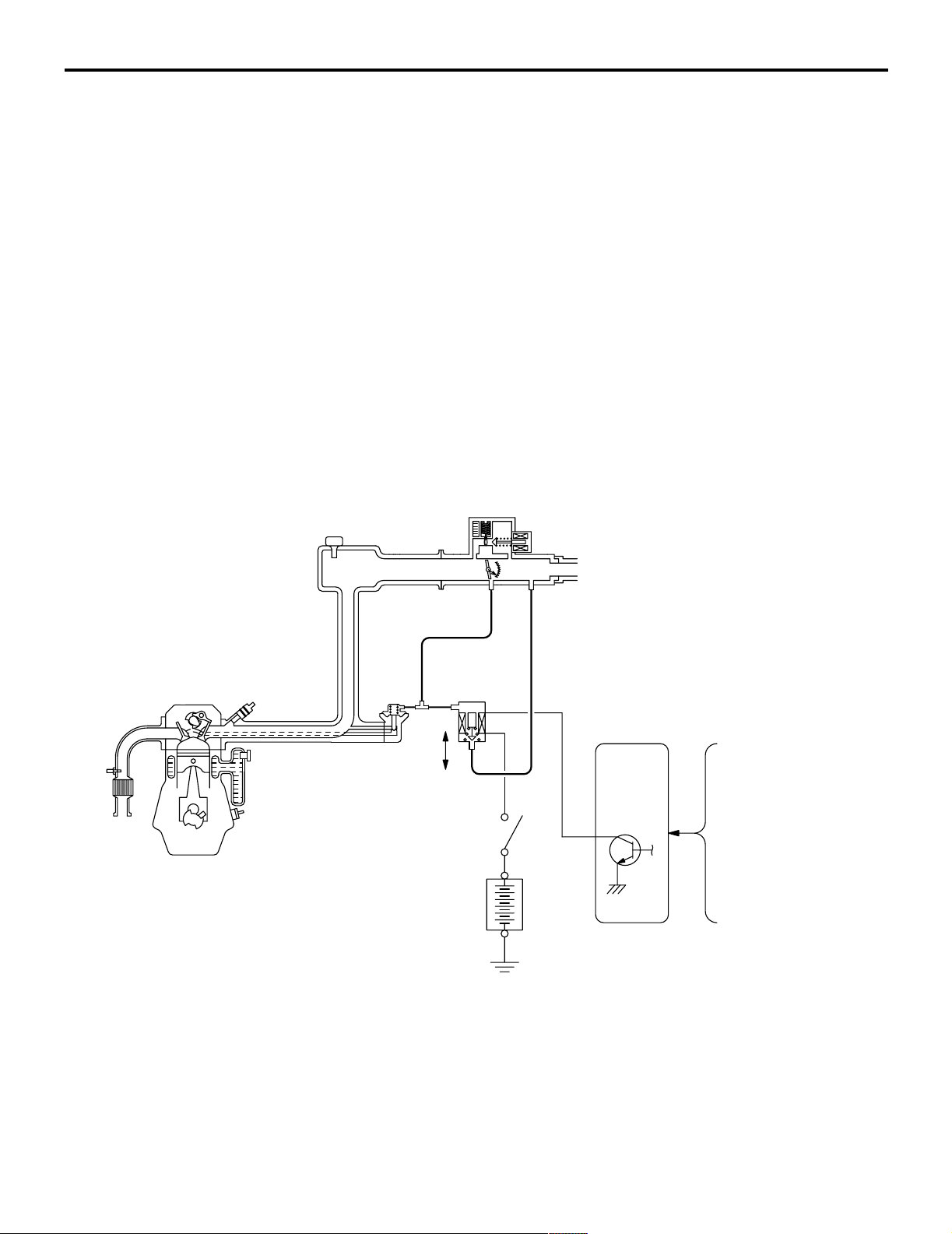

GENERAL INFORMATION (EVAPORATIVE

EMISSION CONTROL SYSTEM)

M1173005100405

The evaporative emission control system prevents

fuel vapours generated in the fuel tank from escaping

into the atmosphere.

Fuel vapours from the fuel tank flow through the fuel

tank pressure control valve and vapour pipe/hose to

be stored temporarily in the canister.

When driving the vehicle, fuel vapours stored in the

canister flow through the purge solenoid and purge

port and go into the intake manifold to be sent to the

combustion chamber.

When the engine coolant temperature is low or when

the intake air quantity is small (when the engine is at

idle, for example), the engine control unit turns the

purge solenoid off to shut off the fuel vapour flow to

the intake manifold.

This does not only insure the driveability when the

engine is cold or running under low load but also

stabilize the emission level.

Page 12

17-10

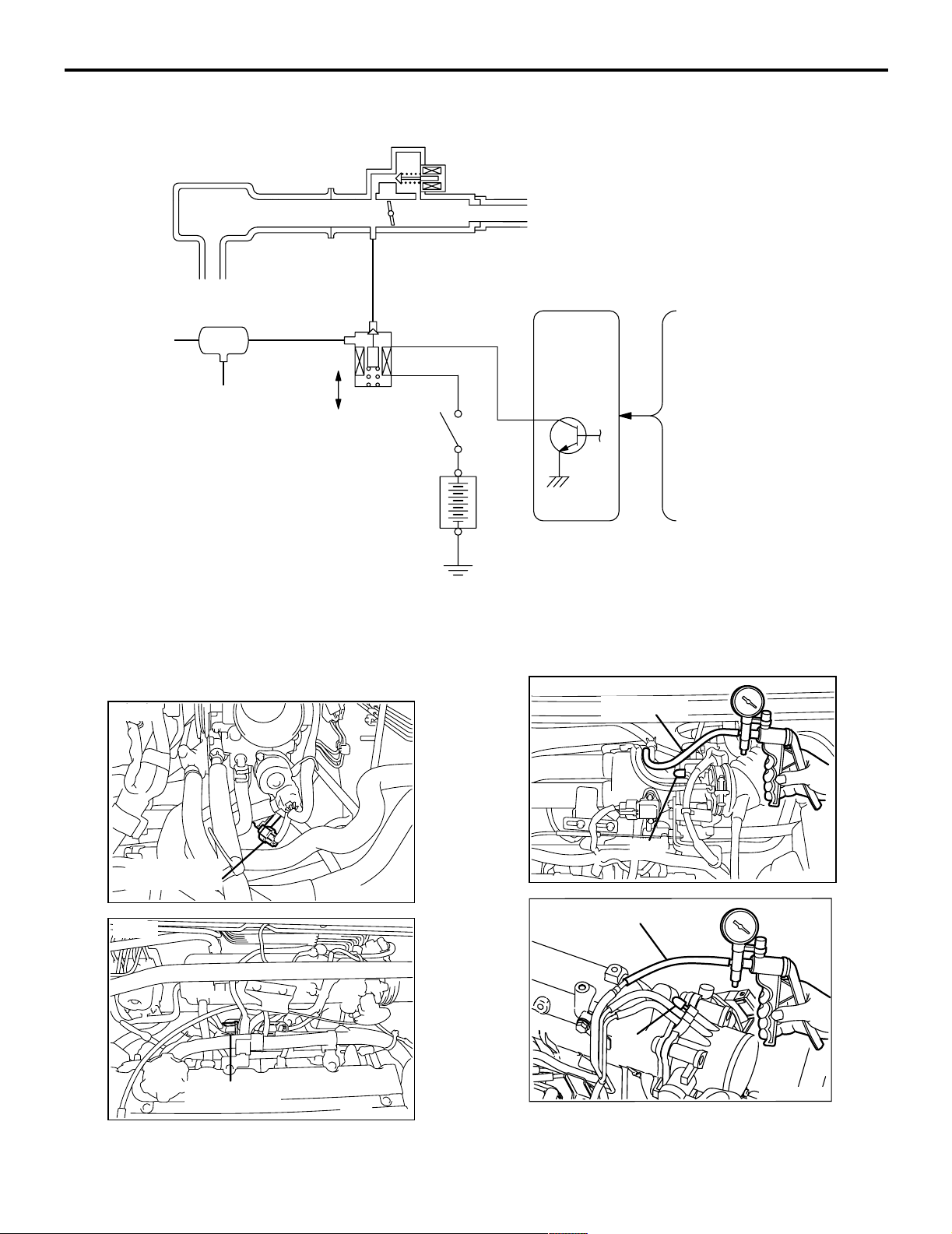

SYSTEM DIAGRAM

From

fuel

tank

Canister

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

Throttle body

Engine-ECU <4G1-M/T, 4G6>,

Engine-A/T-ECU <4G1-A/T>

OFF

Purge

control

ON

solenoid

valve

Battery

Control

relay

Manifold absolute pressure

(MAP) sensor <4G1>

Air flow sensor <4G6>

Engine coolant

temperature sensor

Intake air

temperature sensor

Barometric pressure

sensor <4G6>

COMPONENT LOCATION (EVAPORATIVE

EMISSION CONTROL SYSTEM)

M1173007500216

<4G1>

Purge control

solenoid valve

<4G6>

AK300769

AB

AK204367

PURGE CONTROL SYSTEM CHECK

M1173001400299

<4G1>

Vacuum hose

Plug

<4G6>

AK300771

Vacuum hose

Plug

AB

AC

Purge control

solenoid valve

AK300770

AB

AK300772

AB

Page 13

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

1. Disconnect the vacuum hose (red stripe) from

throttle body and connect it to a hand vacuum

pump.

2. Plug the nipple from which the vacuum hose was

removed.

3. When the engine is cold or hot, apply a vacuum of

53 kPa, and check the condition of the vacuum.

17-11

Vacuum

When engine is cold

(Engine coolant temperature: 40°C or less)

Engine condition Normal condition

At idle Vacuum is maintained.

3,000 r/min

When engine is hot

(Engine coolant temperature: 80°C or higher)

Engine condition Normal condition

At idle Vacuum is maintained.

3,000 r/min (within 3

Vacuum will leak.

minutes after engine

starts)

PURGE PORT VACUUM CHECK

M1173001500177

<4G1>

Vacuum hose

Plug

Engine speed (r/min)

AK100011

AC

3. Start the engine.

4. Check that a fairly constant negative pressure is

generated regardless of the engine speed.

5. If no negative pressure is generated, the port is

probably blocked and should be cleaned.

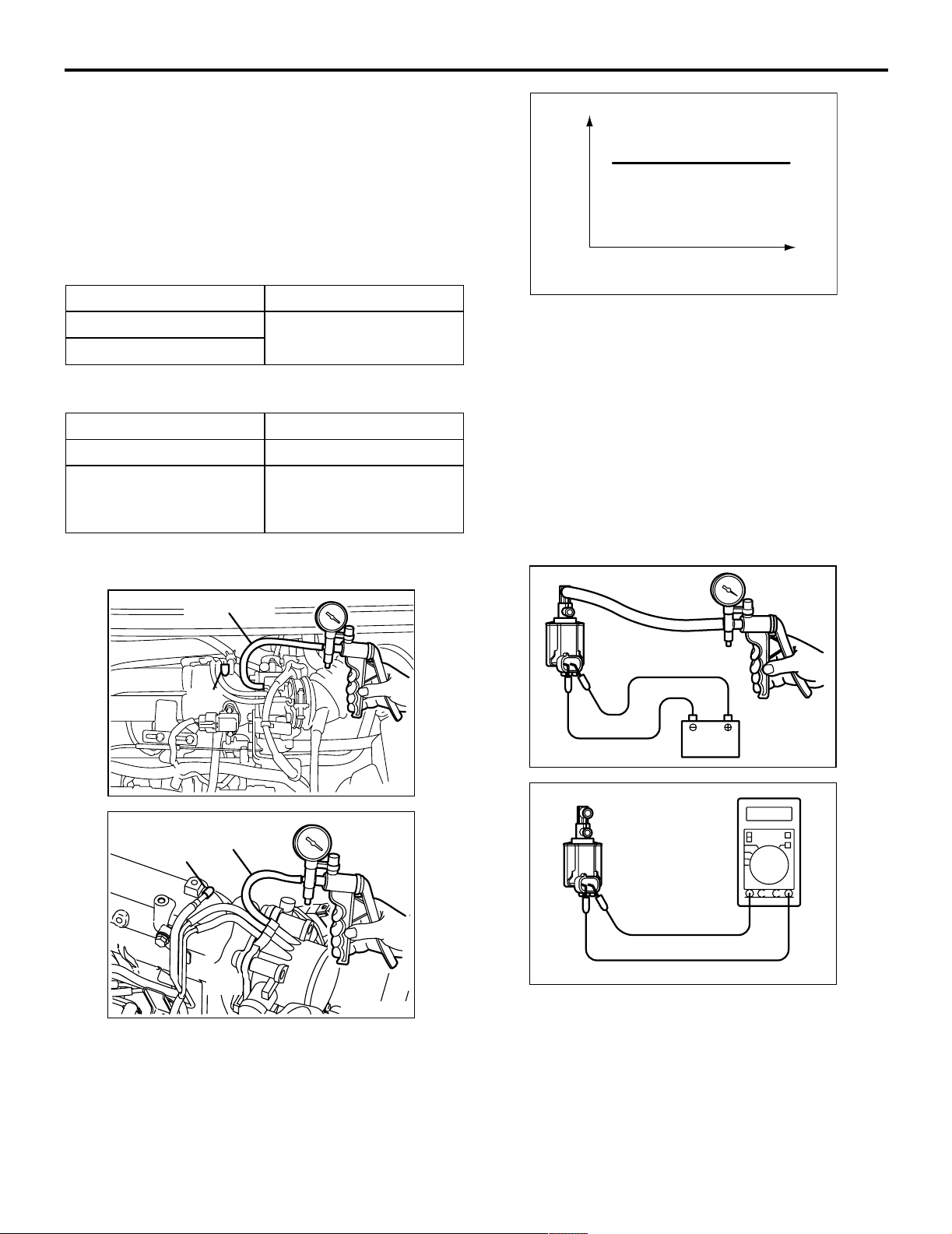

PURGE CONTROL SOLENOID VALVE

CHECK

M1173001700193

NOTE: When disconnecting the vacuum hose,

always make a mark so that it can be reconnected at

original position.

A

AK300773

<4G6>

Vacuum hose

Plug

AK300774

AB

AB

1. Disconnect the vacuum hose (red stripe) from the

throttle body and connect a hand vacuum pump to

the nipple.

2. Plug the vacuum hose (red stripe).

Battery

AK100012

AC

AK100013

1. Disconnect the vacuum hose from the solenoid

valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the

solenoid valve (refer to the illustration at left).

Page 14

17-12

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

4. Check airtightness by applying a vacuum with

voltage applied directly from the battery to the

purge control solenoid valve and without applying

voltage.

FUEL VAPOUR CANISTER REMOVAL

AND INSTALLATION

M1173004200153

Pre-removal and Post-installation Operation

Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

3

2

6

4

5

1

Battery voltage Normal condition

Applied Vacuum leaks

Not applied Vacuum maintained

5. Measure the resistance between the terminals of

the solenoid valve.

Standard value: 30 − 34 Ω (at 20°C)

8

7

Removal steps

1. Emission vacuum hose connection

2. Fuel vapour control line hose

3. Fuel vapour control check valve

4. Fuel vapour control line hose

AC208253

Removal steps (Continued)

5. Fuel vapour control line clamp

6. Fuel vapour canister

7. Fuel high-pressure hose clamp

8. Fuel vapour canister bracket

AD

Page 15

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

17-13

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM

GENERAL INFORMATION (EGR SYSTEM)

M1173005200327

The exhaust gas recirculation (EGR) system lowers

the nitrogen oxide (NOx) emission level.

When the air/fuel mixture combustion temperature is

high, a large quantity of nitrogen oxides (NOx) is

generated in the combustion chamber.

Therefore, this system recirculates part of emission

gas from the exhaust port of the cylinder head to the

combustion chamber through the intake manifold to

decrease the air/fuel mixture combustion

temperature, resulting in reduction of NOx.

SYSTEM DIAGRAM

<4G1>

The EGR flow rate is controlled by the EGR valve so

as not to decrease the driveability.

OPERATION

The EGR valve is being closed and does not

recirculate exhaust gases under one of the following

conditions.

Otherwise, the EGR valve is opened and recirculates

exhaust gases.

• The engine coolant temperature is low.

• The engine is at idle.

• The throttle valve is widely opened.

EGR valve

OFF

ON

Battery

EGR

control

solenoid

valve

Control

relay

Engine-ECU <M/T>,

Engine-A/T-ECU <A/T>

Manifold absolute

pressure (MAP) sensor

Engine coolant

temperature sensor

Crank angle sensor

AK300775

AB

Page 16

17-14

<4G6>

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

EGR

control

Solenoid

valve

OFF

EGR valve

ON

Battery

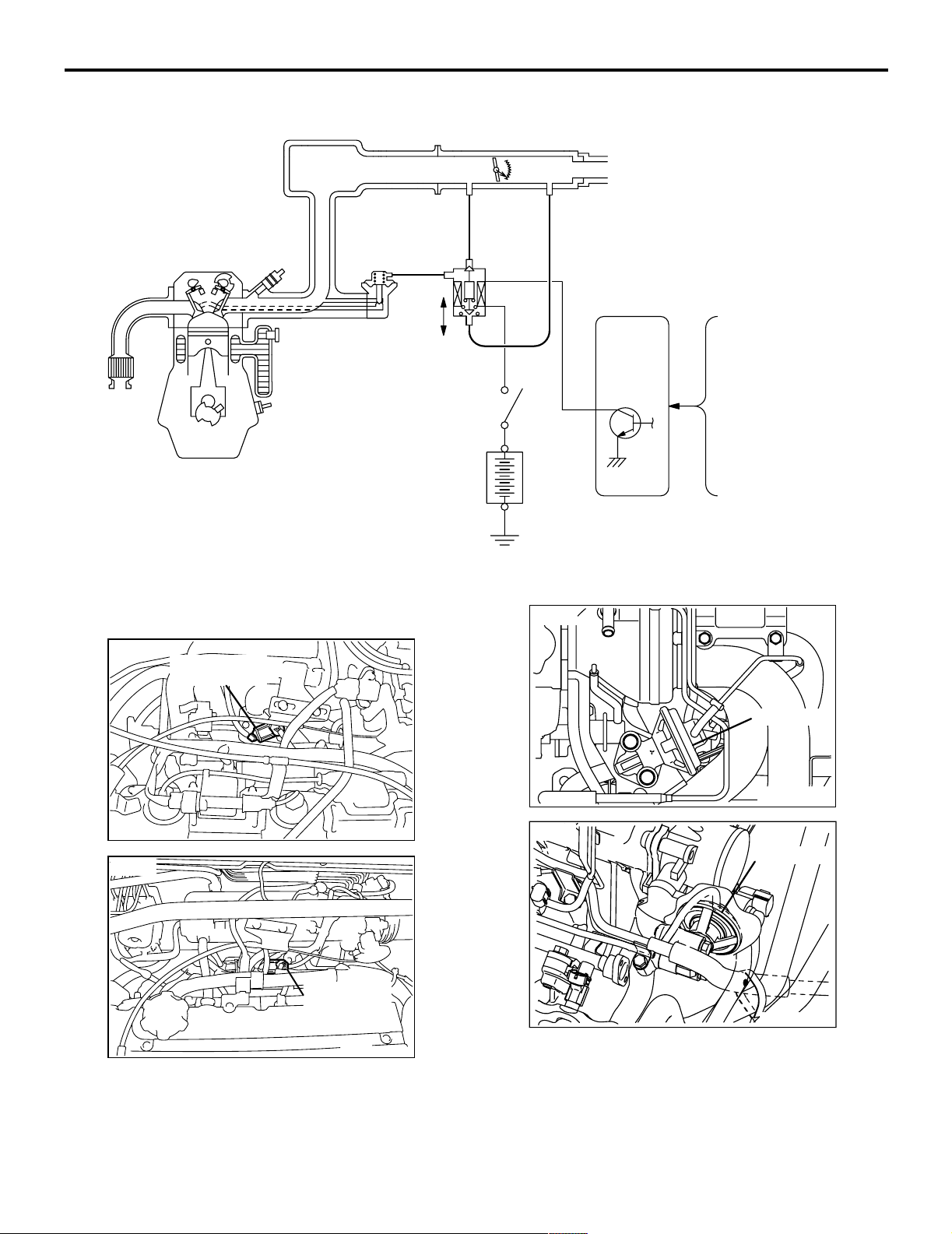

COMPONENT LOCATION (EGR SYSTEM)

M1173007600224

<4G1>

EGR control

solenoid valve

Control

relay

<4G1>

Engine-ECU

Barometric pressure

sensor

Air flow sensor

Engine coolant

temperature sensor

Crank angle sensor

AK302349

EGR valve

AB

<4G6>

AK300776

EGR control

solenoid valve

AK300778

AB

AB

<4G6>

AK300777

EGR valve

AK300779

AB

AB

Page 17

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

17-15

EGR SYSTEM CHECK

M1173002600348

<4G1>

Green stripe

Three-way

terminal

<4G6>

EGR valve

Three-way

terminal

Green stripe

AK300780

EGR valve

AK300781

1. Disconnect the vacuum hose (Green stripe) from

the EGR valve, and then connect a hand vacuum

pump via the three-way terminal.

2. When the engine is hot or cold, check the

condition of vacuum by racing the engine.

When engine is cold

(Engine coolant temperature: 20°C or less)

Throttle valve Normal vacuum condition

Open quickly No vacuum will generate (the

same as barometric pressure.)

When engine is hot

(Engine coolant temperature: 80°C or higher)

Throttle valve Normal vacuum condition

AB

AB

<4G1>

Green stripe

EGR valve

AK300782

<4G6>

Green stripe

EGR valve

AK300783

AB

AB

4. Connect the hand vacuum pump to the EGR

valve nipple.

5. Check whether the engine stalls or the idling is

unstable when a vacuum of 30 kPa or higher is

applied during idling.

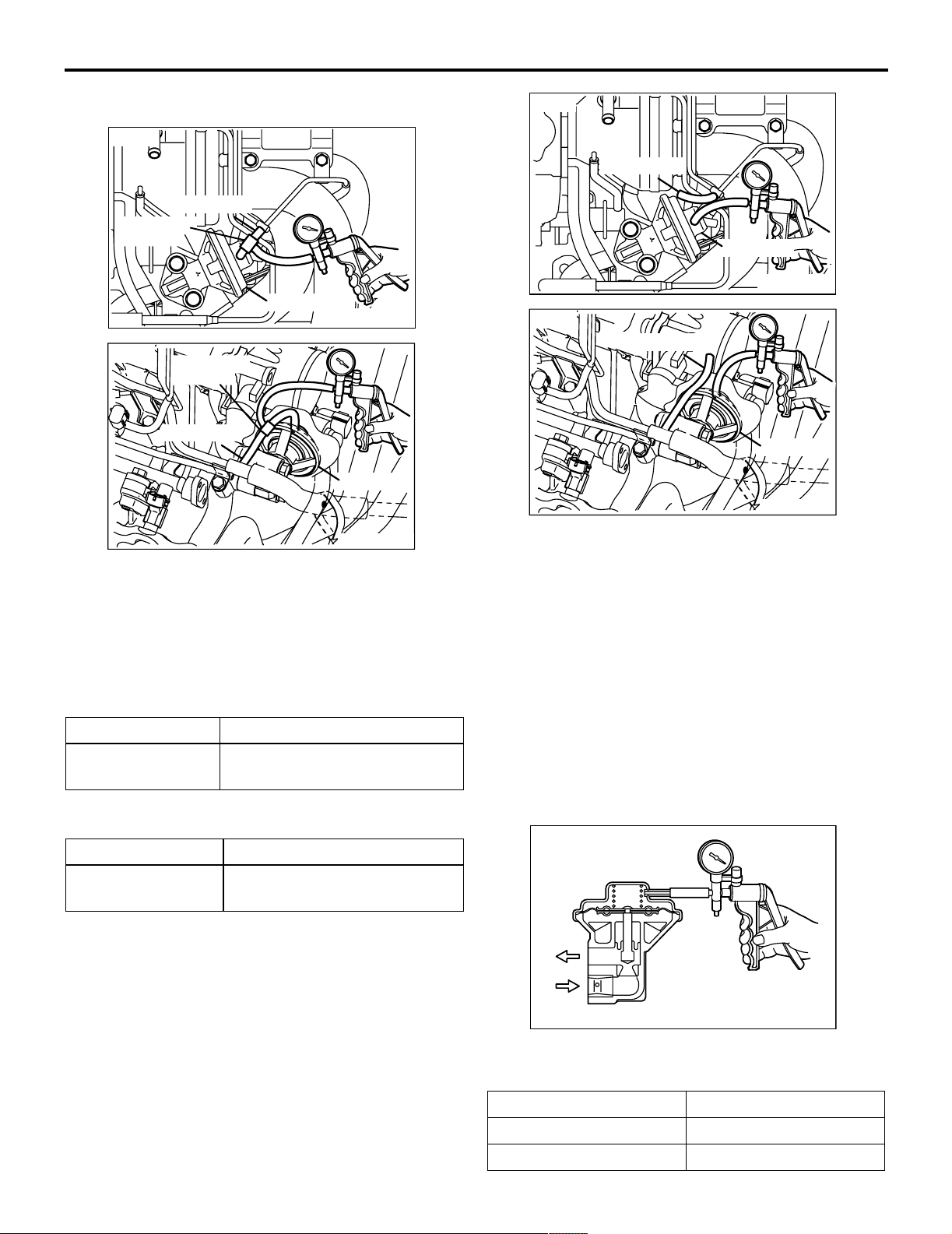

EGR VALVE CHECK

M1173002800223

1. Remove the EGR valve and inspect for sticking,

carbon deposits, etc. If found, clean with a

suitable solvent so that the valve seats correctly.

2. Connect a hand vacuum pump to the EGR valve.

3. Apply 67 kPa of vacuum, and check that the

vacuum is maintained.

Open quickly It will momentarily rise over 13

kPa

3. Disconnect the three-way terminal.

AKX00348

4. Apply a vacuum and check the passage of air by

blowing through one side of the EGR passage.

Vacuum Passage of air

5.3 kPa or less Air is not blown out

27 kPa or more Air is blown out

Page 18

17-16

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

5. Replace the gasket, and tighten to the specified

torque.

Tightening torque:

<4G1> 21 ± 4 N⋅m

<4G6> 20 ± 2 N⋅m

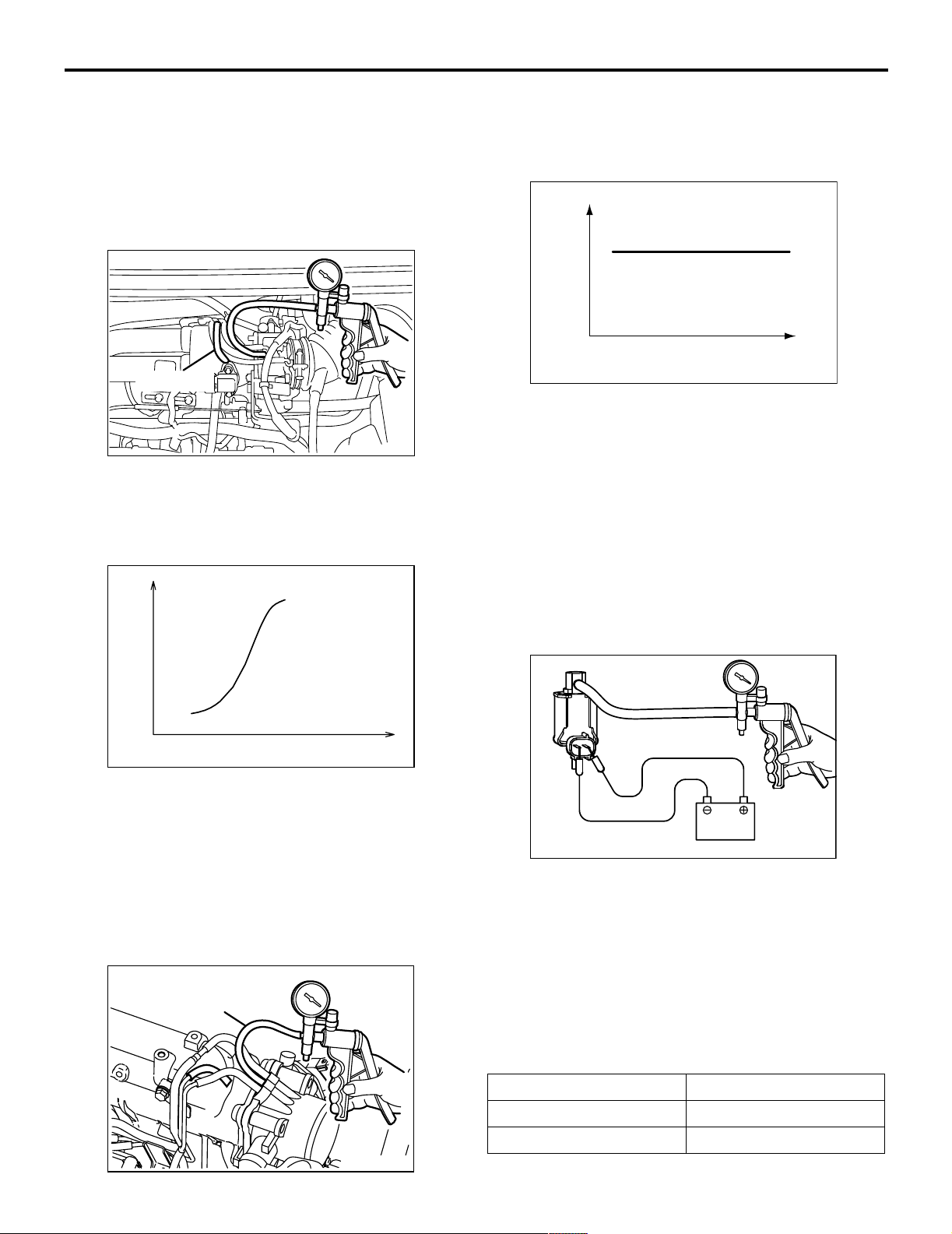

EGR PORT VACUUM CHECK <4G1>

M1173002900167

Green strip

AK300784

1. Disconnect the vacuum hose (Green stripe) from

the throttle body EGR vacuum nipple and connect

a hand vacuum pump to the nipple.

2. Plug the vacuum hose (Green stripe).

Vacuum

AB

1. Disconnect the vacuum hose (White stripe) from

the throttle body EGR vacuum nipple and connect

a hand vacuum pump to the nipple.

2. Plug the vacuum hose (White stripe).

Vacuum

Engine speed (r/min)

AK100011

AC

3. Start the engine.

4. Check that a fairly constant negative is generated

regardless of the engine speed.

5. If no negative pressure is generated, the port is

probably blocked and should be cleaned.

EGR CONTROL SOLENOID VALVE

CHECK <4G1>

M1173003100238

NOTE: When disconnecting the vacuum hose,

always make a mark so that it can be reconnected at

original position.

A

Engine speed (r/min)

AK201224AB

3. Start the engine and check that, after raising the

engine speed by racing the engine, purge vacuum

raises according to engine speed.

NOTE: If there is a problem with change in

vacuum, the throttle body purge port may be

clogged and require cleaning.

EGR PORT VACUUM CHECK <4G6>

M1173002900156

White stripe

AK300786

AB

B

Battery

AKX00351

AE

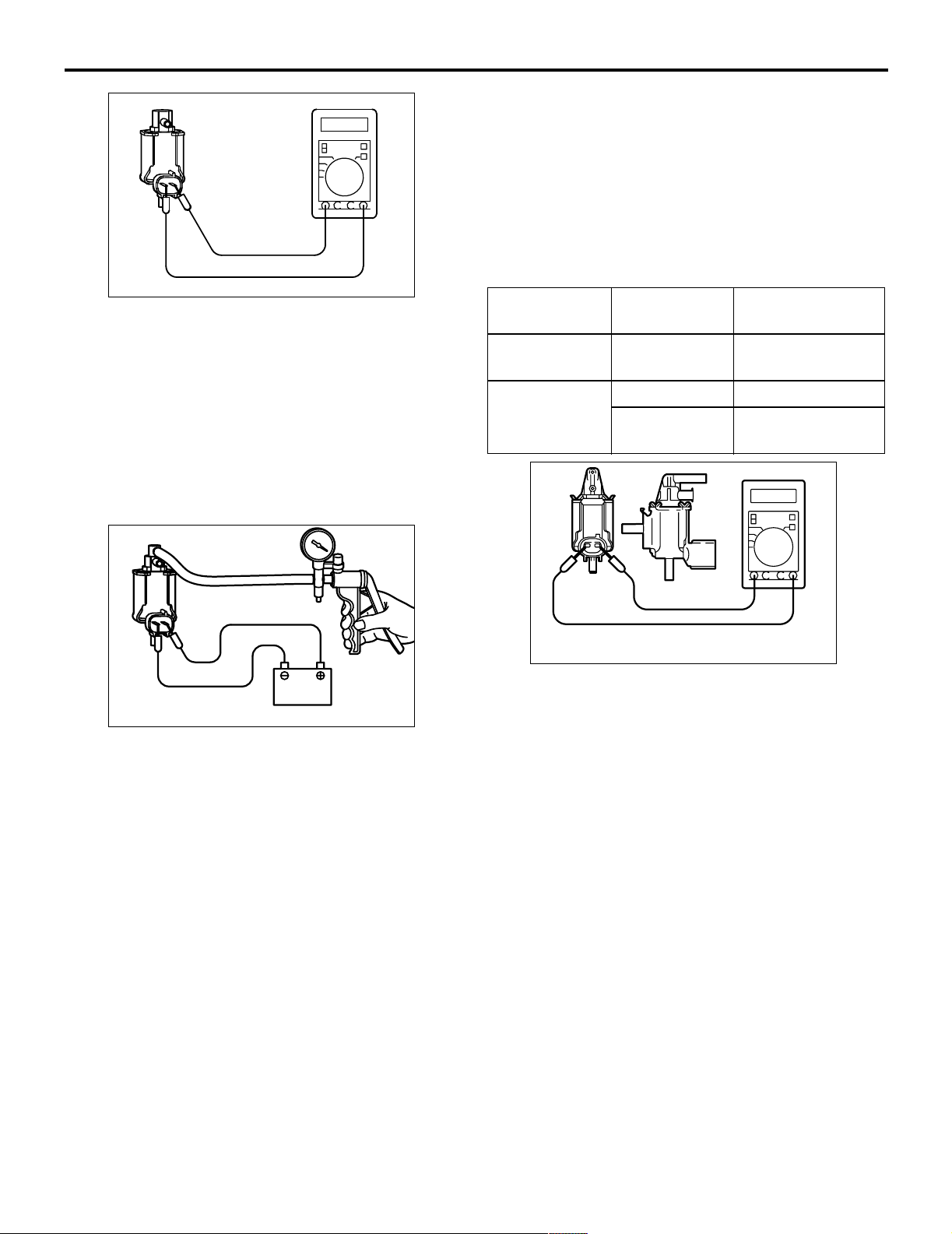

1. Disconnect the vacuum hose from the solenoid

valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the

solenoid valve (refer to the illustration at left).

4. Check air tightness by applying a vacuum with

voltage applied directly from the battery to the

EGR control solenoid valve and without applying

voltage.

Battery voltage Normal condition

Applied Vacuum leaks

Not applied Vacuum maintained

Page 19

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

AKX00352

5. Measure the resistance between the terminals of

the solenoid valve.

Standard value: 29 − 35 Ω (at 20°C)

EGR CONTROL SOLENOID VALVE

CHECK <4G6>

M1173003100249

NOTE: When disconnecting the vacuum hose,

always make a mark so that it can be reconnected at

original position.

17-17

1. Disconnect the vacuum hose from the solenoid

valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the

solenoid valve (refer to the illustration at left).

4. Check air tightness by applying a vacuum with

voltage applied directly from the battery to the

EGR control solenoid valve and without applying

voltage.

Battery

voltage

Not applied Open Vacuum

Applied Open Vacuum leaks

B nipple

Normal condition

condition

maintained

Closed Vacuum

maintained

A

B

C

Battery

AK201251AB

5. Measure the resistance between the terminals of

the solenoid valve.

AK100016

Standard value: 29 − 35 Ω (at 20°C)

Page 20

17-18

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

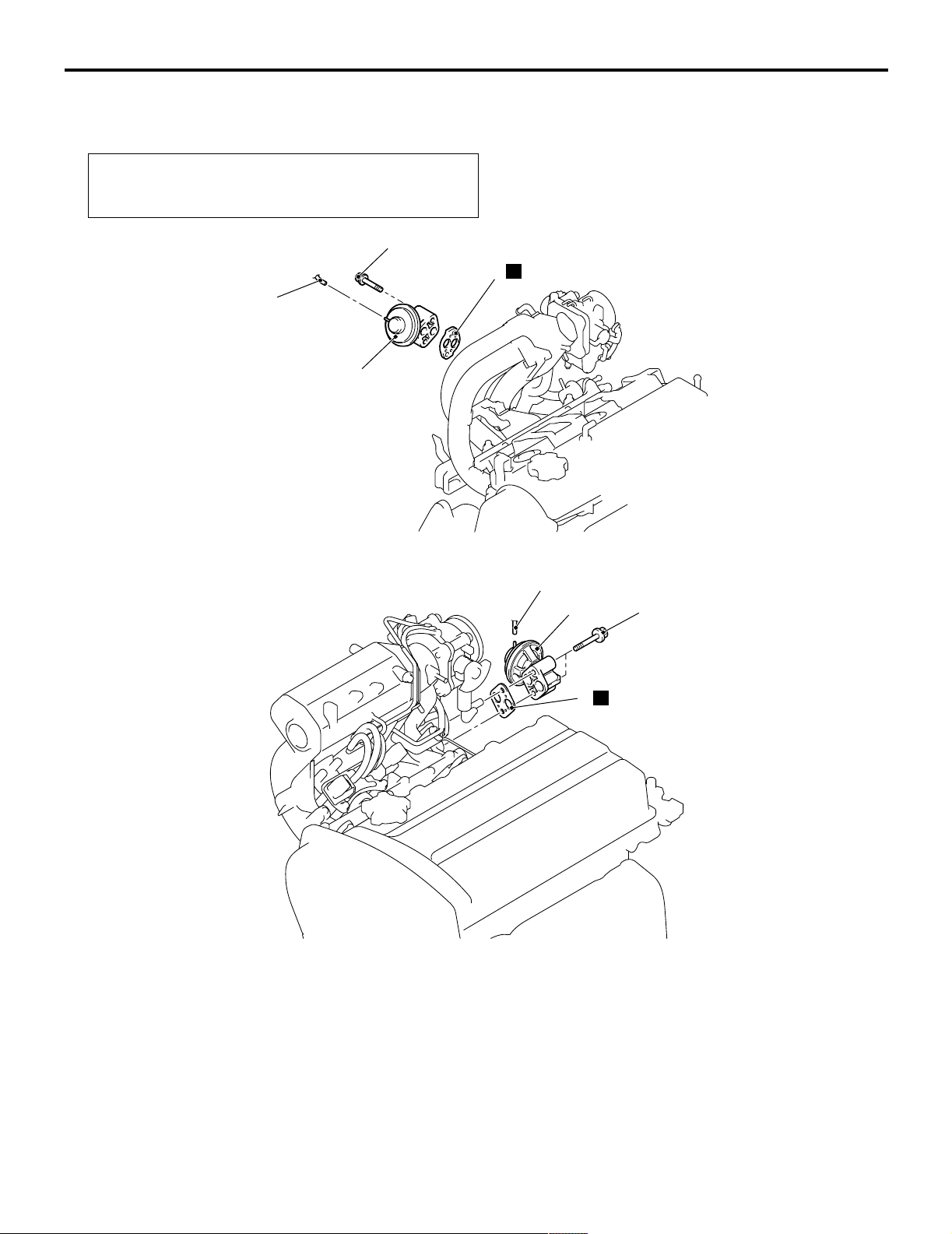

EXHAUST GAS RECIRCULATION (EGR)

VALVE REMOVAL AND INSTALLATION

M1173010500175

Pre-removal and Post-installation Operation

Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

<4G1>

<4G6>

21 ± 4 N·m

N

3

1

2

AC208130

AC

1

2

19 ± 3 N·m

Removal steps

1. Emission vacuum hose connection

CATALYTIC CONVERTER

REMOVAL AND INSTALLATION

M1173003900386

Refer to GROUP 15 - Exhaust Pipe and Main Muffler P.15-11.

N

3

Removal steps (Continued)

2. EGR valve

3. EGR valve gasket

AC301219

AC

Page 21

GROUP 13

FUEL

CONTENTS

MULTIPORT FUEL INJECTION (MPI) <4G1> . . . . . . . . . . . . . . 13A

MULTIPORT FUEL INJECTION (MPI) <4G6> . . . . . . . . . . . . . . 13B

13-1

FUEL SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13C

Page 22

NOTES

Page 23

GROUP 32

POWER PLANT

MOUNT

CONTENTS

32-1

GENERAL INFORMATION . . . . . . . . 32-2

SERVICE SPECIFICATION . . . . . . . . 32-3

SPECIAL TOOL . . . . . . . . . . . . . . . . . 32-3

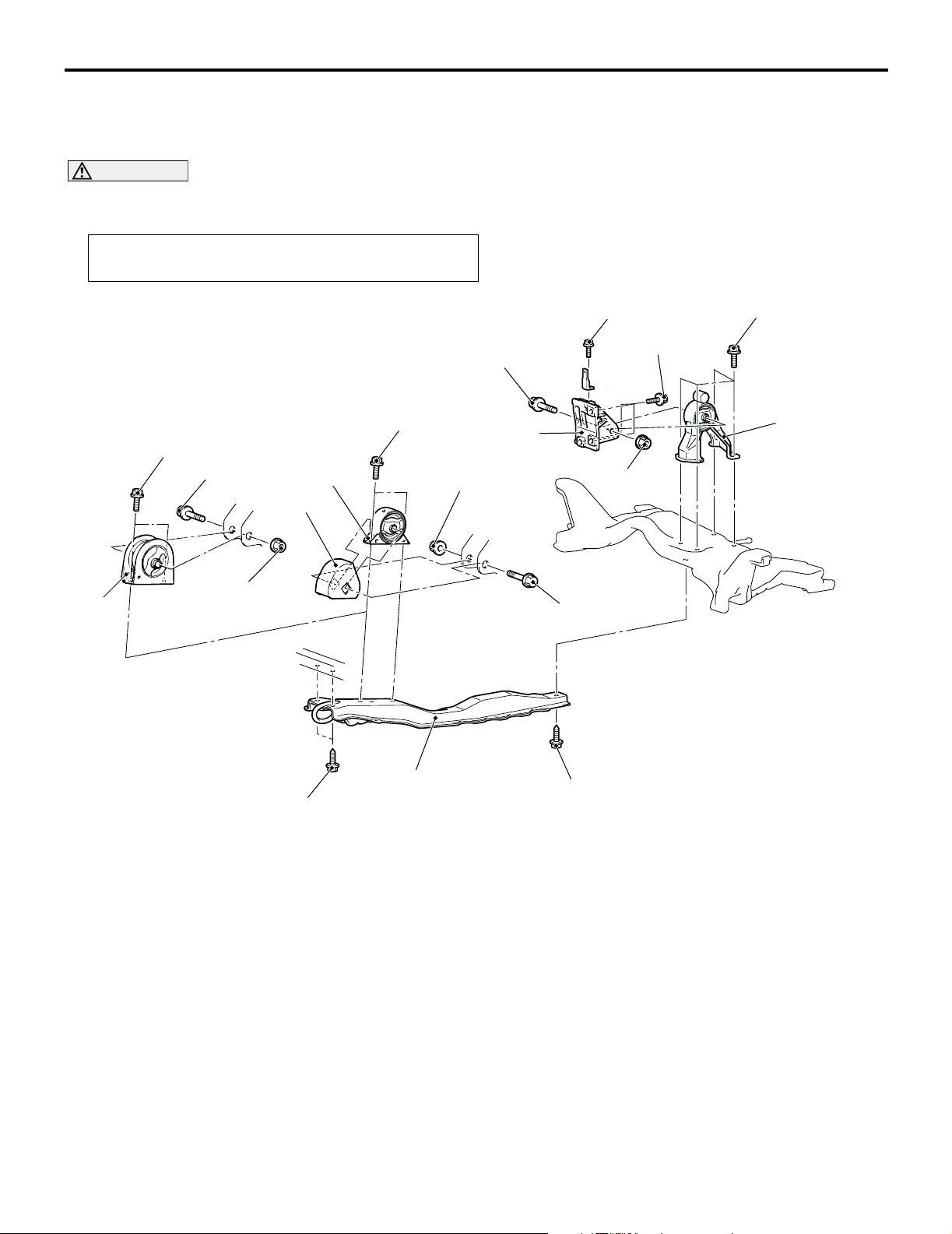

ENGINE MOUNTING . . . . . . . . . . . . . 32-4

REMOVAL AND INSTALLATION . . . . . . . . 32-4

TRANSMISSION MOUNTING . . . . . . 32-5

REMOVAL AND INSTALLATION . . . . . . . . 32-5

ENGINE ROLL STOPPER,

CENTERMEMBER . . . . . . . . . . . . . . . 32-7

REMOVAL AND INSTALLATION . . . . . . . . 32-7

CROSSMEMBER . . . . . . . . . . . . . . . . 32-8

REMOVAL AND INSTALLATION . . . . . . . . 32-8

Page 24

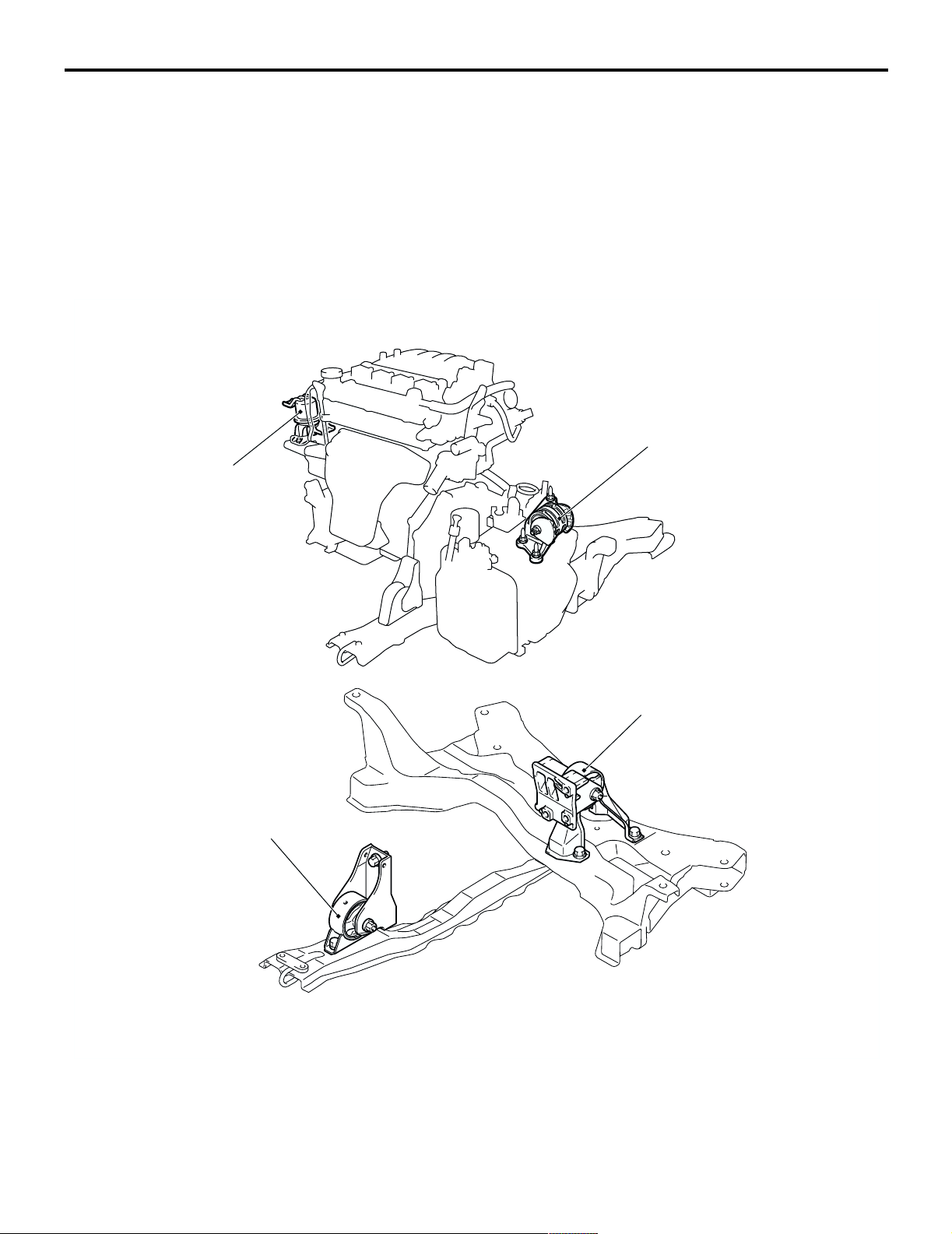

32-2

POWER PLANT MOUNT

GENERAL INFORMATION

GENERAL INFORMATION

The engine mounting system employs the inertial

axis four-point suspension method, which is field

proven.

• The optimised locations of the front and rear roll

mounts well distribute their loads thereby

reducing engine idling vibrations.

CONSTRUCTION DIAGRAM

Engine front

mounting bracket

• The fore-and-aft, liquid-filled engine mount of

M1321000100340

cylinder type is adopted to reduce engine shake

for improved riding comfort.

Transmission mounting

body side bracket

Engine front roll stopper bracket

Engine rear roll stopper bracket

Y0290AU

AC107318

AC303563

AB

Page 25

POWER PLANT MOUNT

SERVICE SPECIFICATION

SERVICE SPECIFICATION

Item Standard value

Protruding length of stabilizer link thread part mm 22 ± 1.5

SPECIAL TOOL

Tool Numb er Name Use

MB991897 Ball joint remover Knuckle and tie rod end ball joint

disconnection

NOTE: Steering linkage puller

(MB990635 or MB991113) is also

AC106827

available to disconnect knuckle and

tie rod end ball joint.

32-3

M1321000300333

M1321000600378

Page 26

32-4

POWER PLANT MOUNT

ENGINE MOUNTING

ENGINE MOUNTING

REMOVAL AND INSTALLATION

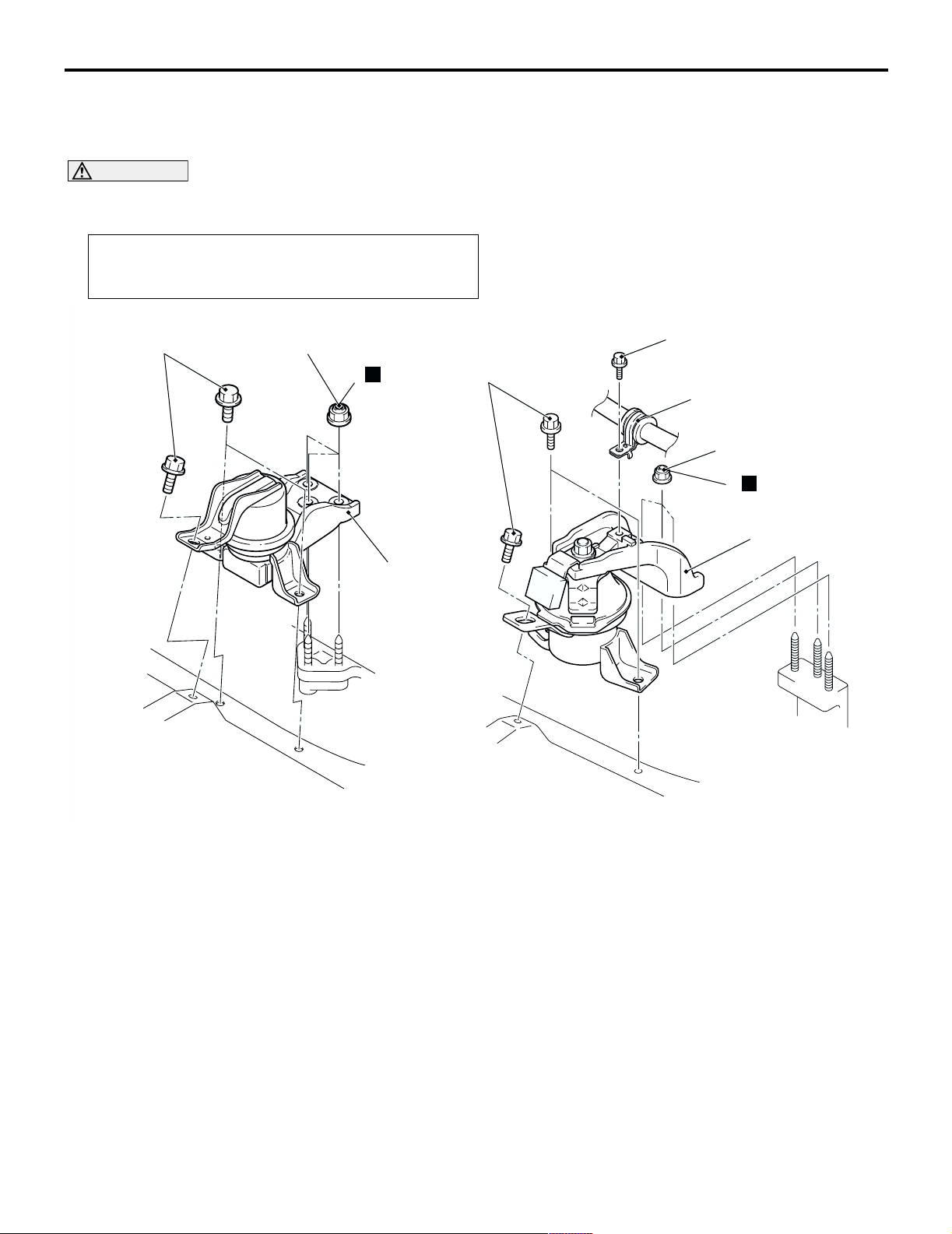

M1321001100440

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

Raise the engine and transmission assembly until its weight

is not applied to the insulator, and support it securely.

<4G1> <4G6>

44 ± 10 N·m*

67 ± 7 N·m*

N

2

44 ± 10 N·m*

3

12 ± 2 N·m

1

67 ± 7 N·m*

N

2

3

AC303999 AC303968

Removal steps

1. Pressure hose clamp <4G6>

AC304304

Removal steps (Continued)

2. Self-locking nuts

3. Engine front mounting bracket

AB

Page 27

POWER PLANT MOUNT

TRANSMISSION MOUNTING

TRANSMISSION MOUNTING

32-5

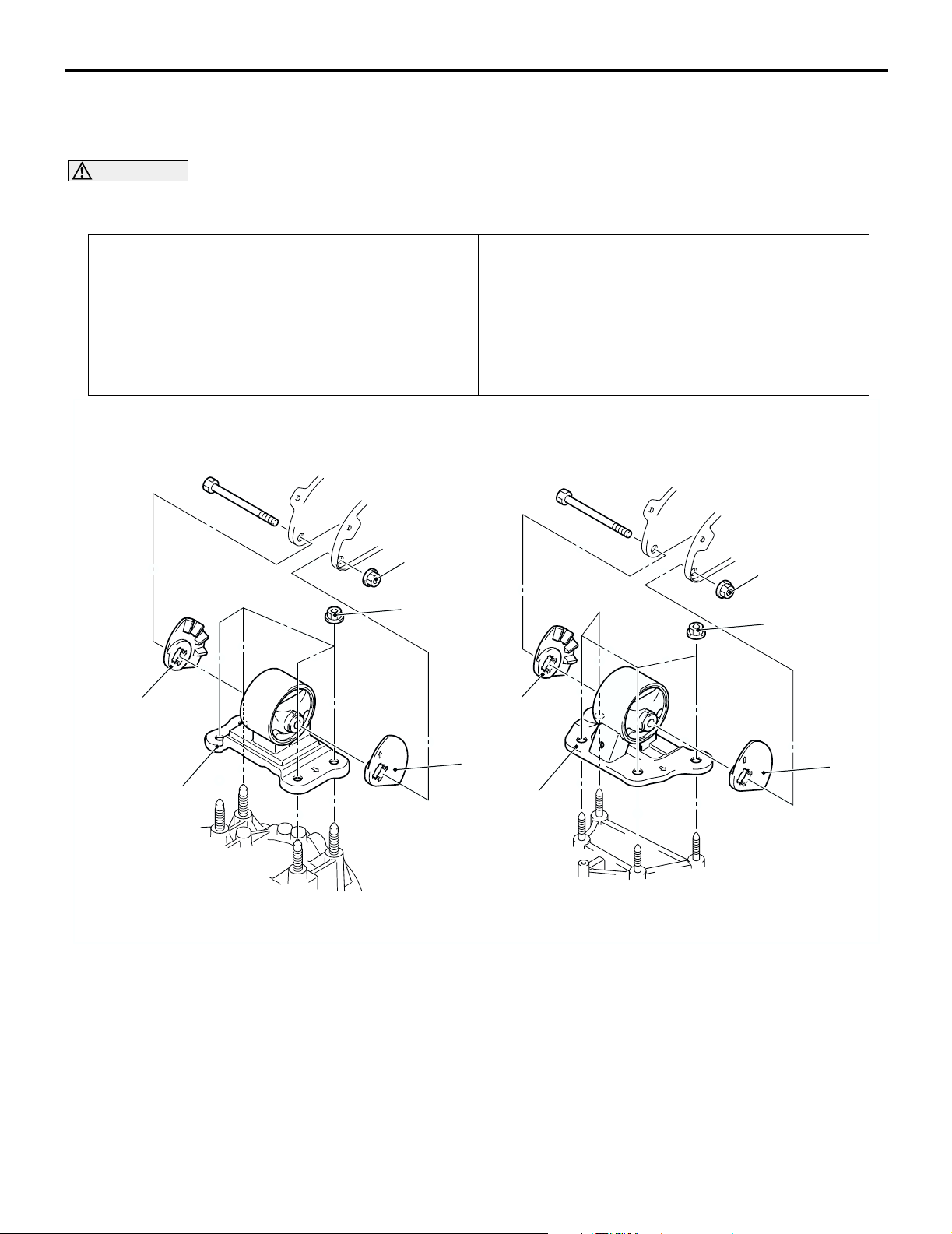

REMOVAL AND INSTALLATION

M1321001400430

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

• Raise the engine and transmission assembly until its

weight is not applied to the insulator, and support it

securely.

• Battery and Battery tray Removal

• Air Cleaner Removal (Refer to GROUP 15, Air Cleaner

P.15-3).

• Engine Rear Roll Stopper Bracket Removal (Refer to

P.32-7).

<M/T> <A/T>

80 ± 7 N·m*

Post-installation Operation

• Engine Rear Roll Stopper Bracket Installation (Refer to

P.32-7).

• Air Cleaner Installation (Refer to GROUP 15, Air Cleaner

P.15-3).

• Battery and Battery tray Installation

80 ± 7 N·m*

2

>>A<<

1

Removal steps

1. Transmission mounting body side

bracket

2. Transmission mounting stopper

47 ± 7 N·m*

2

AC303988

47 ± 7 N·m*

2

2

1

AC303989

AC304258

AB

Page 28

32-6

POWER PLANT MOUNT

TRANSMISSION MOUNTING

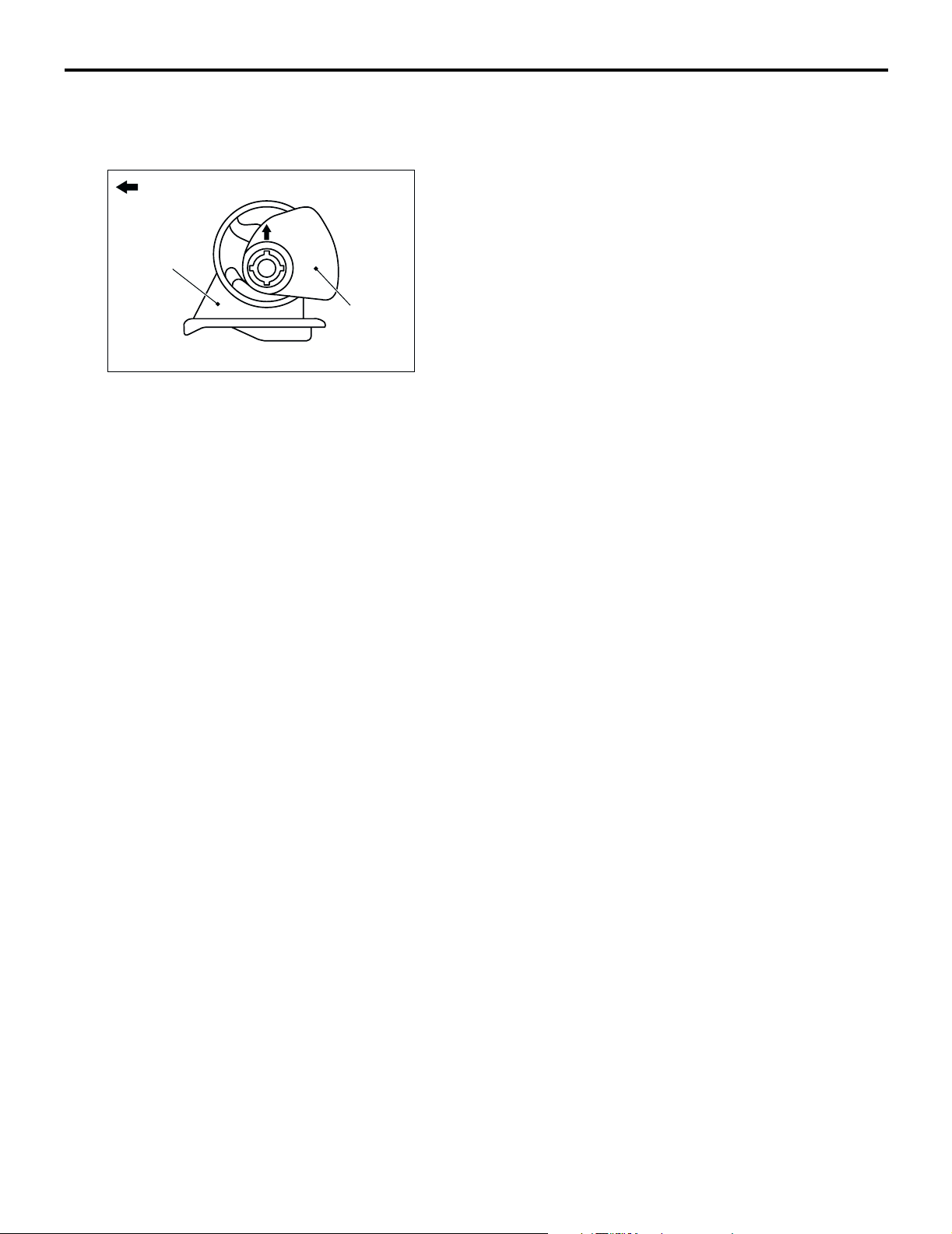

INSTALLATION SERVICE POINT

>>A<< TRANSMISSION MOUNTING

STOPPER INSTALLATION

Engine side

Transmission

mounting body

side bracket

Transmission

mounting

stopper

AC200645

AB

Install the transmission mounting stopper so that its

arrow points upward.

Page 29

POWER PLANT MOUNT

ENGINE ROLL STOPPER, CENTERMEMBER

ENGINE ROLL STOPPER, CENTERMEMBER

32-7

REMOVAL AND INSTALLATION

M1321002300287

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal and Post-installation Operation

Under Cover Removal and Installation

45 ± 5 N·m*

7

<4G1> <4G6>

45 ± 5 N·m*

1

3

2

45 ± 5 N·m*

5

52 ± 7 N·m*

11 ± 1 N·m

69 ± 10 N·m

6

52 ± 7 N·m*

3

>>B<<

>>A<<

52 ± 7 N·m*

4

69 ± 10 N·m

Engine front roll stopper bracket

and centermember removal

steps

1. Engine front roll stopper bracket

connecting bolt

Centermember and engine front roll

•

stopper bracket assembly

2. Engine mounting cushion stopper

<4G6>

3. Engine front roll stopper bracket

4. Centermember

1

69 ± 10 N·m

5. Engine rear roll stopper bracket

6. Transmission case rear roll stopper

7. Engine rear roll stopper bracket

AC303978

AC304309

Engine rear roll stopper bracket

removal steps

connecting bolt

bracket

AB

Page 30

32-8

POWER PLANT MOUNT

CROSSMEMBER

INSTALLATION SERVICE POINTS

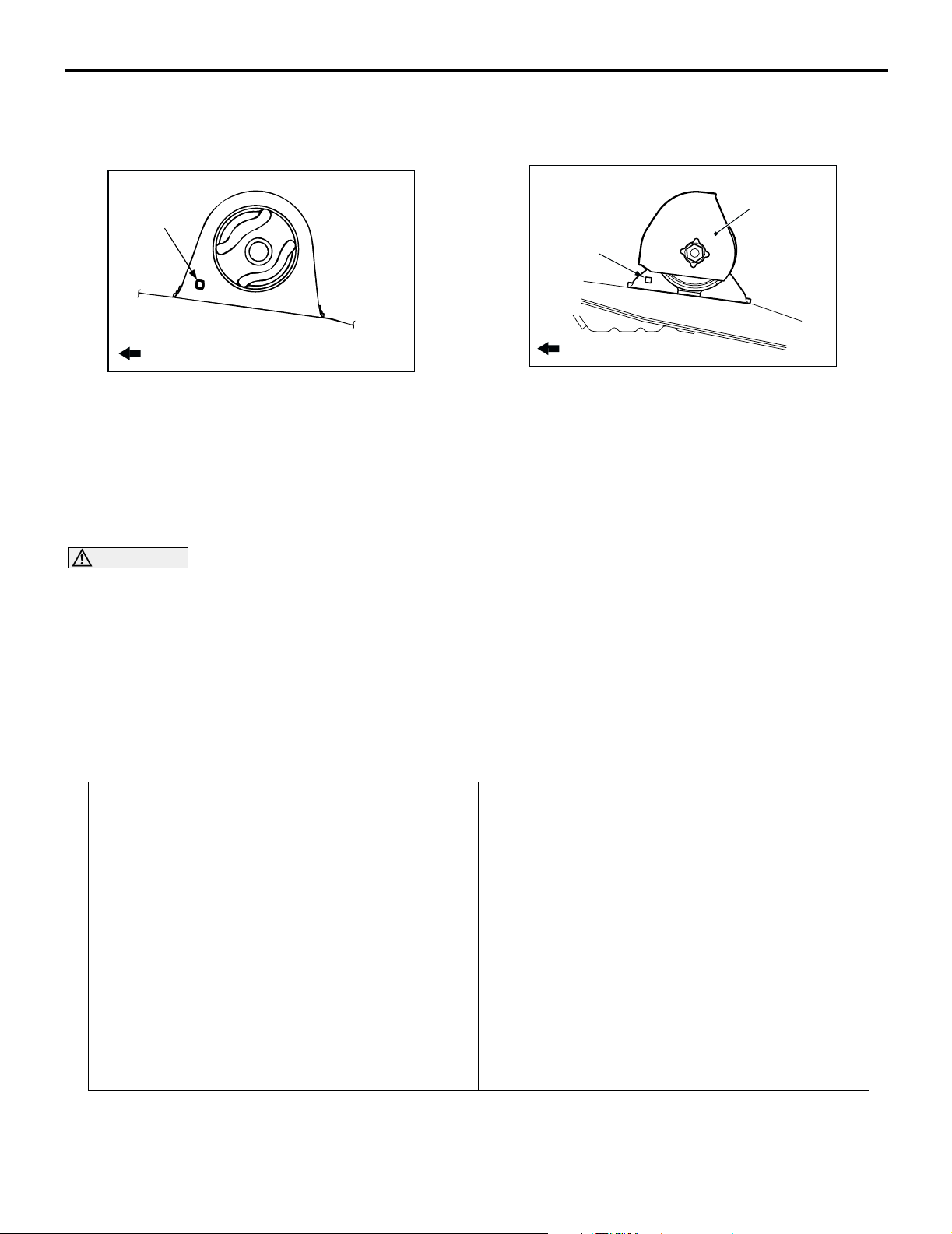

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

Hole

>>B<< ENGINE MOUNTING CUSHION

STOPPER INSTALLATION <4G6>

Engine mounting

cushion stopper

Hole

Front of vehicle

AC005918

AC

Install the engine front roll stopper bracket so that its

hole points towards the front side of the vehicle.

Install the engine mounting cushion stopper as

shown.

Front of vehicle

AC304315

AB

CROSSMEMBER

REMOVAL AND INSTALLATION

CAUTION

• Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B Service Precautions P.52B-5, Air bag Module and Clock Spring P.52B-210. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

1

: Indicates parts which should be initially tightened, and then fully tightened after placing the

• *

vehicle horizontally and loading the full weight of the engine on the vehicle body.

2

: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

• *

on the earth in the unladen condition.

Pre-removal Operation

• Centermember Removal (Refer to P.32-7).

• Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

• Stee ring Wheel Air Bag Module Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

• Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).

M1321003200368

Post-installation Operation

• Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

• Centermember Installation (Refer to P.32-7).

• Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

• Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

• Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

• Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-13).

• Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

• Checking Steering Wheel Position with Wheels Straight

Ahead.

• Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-5).

Page 31

<L.H. drive vehicles>

POWER PLANT MOUNT

CROSSMEMBER

32-9

6

52 ± 7 N·m*

45 ± 5 N·m*

7

1

12 ± 2 N·m

70 ± 10 N·m

12

1

8

16

21 ± 4 N·m

10

70 ± 10 N·m

14

11

4

N

57 ± 7 N·m

9

5

18 ± 2 N·m

N

13

25 ± 4 N·m

15

21 ± 4 N·m

N

2

108 ± 10 N·m

3

17

>>B<<

186 ± 10 N·m*

Removal steps

1. Lower arm and knuckle connection

2. Self-locking nut

3. Lower arm assembly

4. Shaft cover

5. Steering shaft assembly and gear

box connecting bolt

6. Engine rear roll stopper bracket

connection bolt

7. Engine rear roll stopper bracket

8. Return hose connection

2

167 ± 9 N·m

49 ± 10 N·m

<<A>>

<<B>>

>>A<<

1

AC304000

Removal steps (Continued)

9. Eye bolt

10. Pressure hose connection

11. Gasket

12. Clamp

13. Self-locking nut

14. Tie rod end and knuckle connection

Crossmember assembly

•

15. Stabilizer bar

16. Steering gear and linkage

17. Crossmember

AB

Page 32

32-10

<R.H. drive vehicles>

POWER PLANT MOUNT

CROSSMEMBER

12

52 ± 7 N·m*¹

45 ± 5 N·m*¹

13

16

8

57 ± 7 N·m

5

N

6

15

7

4

11

9

18 ± 2 N·m

5.0 ± 1.0 N·m

70 ± 10 N·m

N

10

25 ± 4 N·m

14

21 ± 4 N·m

N

2

3

108 ± 10 N·m

>>B<<

186 ± 10 N·m*²

167 ± 9 N·m

Removal steps

1. Lower arm and knuckle connection

2. Self-locking nut

3. Lower arm assembly

4. Eye bolt

5. Pressure hose connection

6. Gasket

7. Return hose connection

8. Shaft cover

9. Steering shaft assembly and gear

box connecting bolt

49 ± 10 N·m

<<A>>

<<B>>

>>A<<

1

AC101614

Removal steps (Continued)

10. Self-locking nut

11. Ti e r od end a nd knu c k le conn e c tion

12. Engine rear roll stopper bracket

connection bolt

Crossmember assembly

•

13. Engine rear roll stopper bracket

14. Stabilizer bar

15. Steering gear and linkage

16. Crossmember

AE

Page 33

POWER PLANT MOUNT

CROSSMEMBER

32-11

REMOVAL SERVICE POINTS

<<A>> TIE ROD END AND KNUCKLE

DISCONNECTION

CAUTION

• Do not remove the nut from ball joint. Loosen

it and use special tool to avoid possible

damage to ball joint threads.

• Hang special tool with a cord to prevent it

from falling.

Cord

Nut

Ball joint

1. Install the special tool ball joint remover

(MB991897) as shown in the figure.

MB991897

Bolt

AC208247

AD

<<B>> CROSSMEMBER ASSEMBLY

REMOVAL

Piece of wood

Transmission

jack

AC102600

AD

1. Use a transmission jack to hold the crossmember,

and then remove the crossmember mounting nuts

and bolts.

2. Lower the crossmember with the engine rear roll

stopper bracket, the stabilizer bar, the return tube,

and the steering gear.

INSTALLATION SERVICE POINTS

>>A<< STABILIZER

BAR/BUSHING/FIXTURE INSTALLATION

Bolt

Parallel

Knob

Good

Bad

AC106821

AB

2. Turn the bolt and knob as necessary to make the

jaws of the special tool parallel, tighten the bolt by

hand and confirm that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the

figure.

3. Tighten the bolt with a wrench to disconnect the

tie rod end.

Outside of

vehicle

Bushing (LH)

Approximately

10 mm

Identification

mark

Fixture (LH)

AC006141

AD

Align the stabilizer bar identification mark with the

right end of the bushing (LH).

>>B<< SELF-LOCKING NUT

INSTALLATION

A

AC101741

AC

Tighten the self-locking nut until the stabilizer link

thread part protruding length meets the standard

value.

Standard value (A): 22 ± 1.5 mm

Page 34

NOTES

Page 35

GROUP 15

INTAKE AND

EXHAUST

CONTENTS

15-1

GENERAL INFORMATION . . . . . . . . 15-2

SERVICE SPECIFICATION . . . . . . . . 15-2

SPECIAL TOOL . . . . . . . . . . . . . . . . . 15-2

AIR CLEANER . . . . . . . . . . . . . . . . . . 15-3

REMOVAL AND INSTALLATION . . . . . . . . 15-3

INLET MANIFOLD . . . . . . . . . . . . . . . 15-5

REMOVAL AND INSTALLATION <4G1> . . 15-5

REMOVAL AND INSTALLATION <4G6> . . 15-6

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 15-7

EXHAUST MANIFOLD . . . . . . . . . . . . 15-7

REMOVAL AND INSTALLATION <4G1> . . 15-7

REMOVAL AND INSTALLATION <4G6> . . 15-9

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 15-10

EXHAUST PIPE AND MAIN

MUFFLER . . . . . . . . . . . . . . . . . . . . . . 15-11

REMOVAL AND INSTALLATION . . . . . . . . 15-11

Page 36

15-2

INTAKE AND EXHAUST

GENERAL INFORMATION

GENERAL INFORMATION

The exhaust pipe is divided into three parts.

SERVICE SPECIFICATION

Item Standard value Limit

Manifold distortion of the installation surface mm 0.15 or less 0.20

SPECIAL TOOL

Tool Numb e r Name Use

MD998770 Oxygen sensor wrench Removal and installation of

engine control oxygen sensor

M1151000100402

M1151000300428

M1151000600399

Page 37

INTAKE AND EXHAUST

AIR CLEANER

AIR CLEANER

15-3

REMOVAL AND INSTALLATION

M1151002100486

CAUTION

Parts marked by * are made of recycled-paper mixed plastic material, so observe the following

precautions.

• Avoid any shock or load to these parts when removing and installing them.

• When installing, securely set the air cleaner cover clamp to the air cleaner body.

NOTE: Parts marked by * are made of recycled-paper mixed plastic material. Dispose of according to state

and local laws.

<4G1>

9.0 ± 1.0 N·m

10*

4.0 ± 1.0 N·m

3*

9*

8*

4.0 ± 1.0 N·m

4

5

1*

12 ± 1 N·m

11

9.0 ± 1.0 N·m

12 ± 1 N·m

Clamp

AC303618

AB

Page 38

15-4

INTAKE AND EXHAUST

AIR CLEANER

<4G6>

1*

10*

9.0 ± 1.0 N·m

12 ± 1 N·m

9*

11

Removal steps

1. Air cleaner intake duct

2. Air cleaner air flow sensor connector

<4G6>

3. Air cleaner assembly <4G1> or Air

cleaner and air cleaner air flow sensor

assembly <4G6>

4. Rocker cover breather hose

connection

5. Air cleaner to throttle body duct

3*

8*

4.0 ± 1.0 N·m

N

67

2

12 ± 1 N·m

6. Air cleaner air flow sensor <4G6>

7. Air cleaner air flow sensor gasket

8. Air cleaner cover

9. Air cleaner element

10. Air cleaner body assembly

11. Ai r clea n e r brack e t

4

4.0 ± 1.0 N·m

8.8 ± 1.0 N·m

Clamp

9.0 ± 1.0 N·m

AC303619

Removal steps (Continued)

<4G6>

5

AB

Page 39

INTAKE AND EXHAUST

INLET MANIFOLD

INLET MANIFOLD

15-5

REMOVAL AND INSTALLATION <4G1>

M1151003000749

Pre-removal Operation

• Fuel Line Pressure Reduction (Refer to GROUP 13A On-vehicle Service P.13A-389).

• Engine Coolant Draining (Refer to GROUP 14 On-vehicle Service P.14-22).

• Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

• Throttle Body Assembly Removal (Refer to GROUP 13A

P.13A-400).

• Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13A P.13A-398).

9.0 ± 1.0 N·m

15

21 ± 4 N·m

9

18 ± 2 N·m

13

9.0 ± 1.0 N·m

7

N

14

Post-installation Operation

• Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13A P.13A-398).

• Throttle Body Assembly Installation (Refer to GROUP

13A P.13A-400).

• Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

• Engine Coolant Supplying (Refer to GROUP 14 -

On-vehicle Service P.14-22).

• Accelerator Cable Adjustment (Refer to GROUP 17 On-vehicle Service P.17-2).

• Fuel Leak Check

1

N

11

2

8

18 ± 2 N·m

5.0 ± 1.0 N·m

10

N

12

3

6

5

18 ± 2 N·m

31 ± 3 N·m

49 ± 9 N·m

4

Removal steps

1. Inlet manifold absolute pressure

sensor

2. Engine control pressure sensor

O-ring

3. Engine control detonation sensor

connector

4. T/M housing front lower cover stay

(L.H.)

5. Battery wiring harness clamp

connection

6. Inlet manifold stay

7. Brake booster vacuum hose

connection

AC303642

AB

Removal steps (Continued)

8. Emission control equip hose

connection

9. Fuel vapour control hose

connection

10. Inlet manifold stay

11. Inlet m a n ifol d

12. Inlet manifold gasket

13. EGR valve

14. EGR valve gasket

15. Emission vacuum hose & pipe and

emission solenoid valve assembly

Page 40

15-6

INTAKE AND EXHAUST

INLET MANIFOLD

REMOVAL AND INSTALLATION <4G6>

M1151003001236

Pre-removal Operation

• Fuel Line Pressure Reduction (Refer to GROUP 13A On-vehicle Service P.13A-389).

• Engine Coolant Draining (Refer to GROUP 14 On-vehicle Service P.14-22).

• Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

• Throttle Body Assembly Removal (Refer to GROUP 13B

P.13B-336).

• Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13B P.13B-334).

5.0 ± 1.0 N·m

2

20 ± 2 N·m

3

Post-installation Operation

• Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13B P.13B-334).

• Throttle Body Assembly Installation (Refer to GROUP

13B P.13B-336).

• Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

• Engine Coolant Supplying (Refer to GROUP 14 -

On-vehicle Service P.14-22).

• Accelerator Cable Adjustment (Refer to GROUP 17 On-vehicle Service P.17-2).

• Fuel Leak Check

11 ± 1 N·m

12

7

9.0 ± 1.0 N·m

36 ± 6 N·m

5

13 ± 1 N·m

(Engine oil)

N

36 ± 6 N·m

6

11 ± 1 N·m

4

8

20 ± 2 N·m

10

20 ± 2 N·m

36 ± 6 N·m

13

N

14

11

N

1

9

31 ± 3 N·m

Removal steps

1. Emission control equip hose

connector

2. Brake booster vacuum hose

connection

3. Earth cable connection

AC303657

AB

Removal steps (Continued)

4. Engine control detonation sensor

connector

5. Engine oil level gauge and guide

assembly

6. Engine oil filler O-ring

7. Emission vacuum hose connection

Page 41

INTAKE AND EXHAUST

EXHAUST MANIFOLD

Removal steps (Continued)

8. Battery wiring harness clamp

9. Inlet manifold stay

10. Inlet manifold

11. Inlet m a n ifol d g asket

12. Emission vacuum hose & pipe and

emission solenoid valve assembly

13. EGR valve

14. EGR valve gasket

15-7

INSPECTION

M1151003100616

Check the following points; replace the part if a

problem is found.

Inlet Manifold Check

1. Check for damage or cracking of any part.

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION <4G1>

M1151003300568

29 ± 3 N·m

6

2. Clogging of the negative pressure (vacuum) outlet

port, or clogging of the exhaust gas recirculation

passages.

3. Using a straight edge and feeler gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

3

29 ± 3 N·m

44 ± 5 N·m

4

N

5

(Engine oil)

N

9

29 ± 3 N·m

24 ± 4 N·m

7

35 ± 6 N·m

50 ± 10 N·m

8

2

1

17 ± 2 N·m

N

29 ± 3 N·m

AC303662

AB

Page 42

15-8

INTAKE AND EXHAUST

EXHAUST MANIFOLD

Removal steps

1. Front exhaust pipe connection

2. Exhaust pipe gasket

<<A>> >>A<<

3. Engine control oxygen sensor (front)

4. Engine oil level gauge and guide

assembly

5. Engine oil filler O-ring

REMOVAL SERVICE POINT

<<A>> ENGINE CONTROL OXYGEN

SENSOR (FRONT) REMOVAL

MD998770

Engine control

oxygen sensor

(front)

AC212566

Use special tool oxygen sensor wrench (MD998770)

to remove the engine control oxygen sensor (front).

AC

Removal steps (Continued)

6. Exhaust manifold cover

7. Exhaust manifold bracket

8. Exhaust manifold

9. Exhaust manifold gasket

INSTALLATION SERVICE POINT

>>A<< ENGINE CONTROL OXYGEN

SENSOR (FRONT) INSTALLATION

MD998770

Engine control

oxygen sensor

(front)

AC212566

Use special tool oxygen sensor wrench (MD998770)

to install the engine control oxygen sensor (front).

AC

Page 43

INTAKE AND EXHAUST

EXHAUST MANIFOLD

15-9

REMOVAL AND INSTALLATION <4G6>

Pre-removal and Post-installation Operation

Under cover Removal and Installation

29 ± 3 N·m

49 ± 9 N·m

8

10

M1151003300579

N

9

49 ± 5 N·m

29 ± 3 N·m

14 ± 1 N·m

3

44 ± 5 N·m

<<A>> >>A<<

7

6

9.0 ± 2.0 N·m

Removal steps

1. Front exhaust pipe connection

2. Exhaust pipe gasket

3. Engine control oxygen sensor (front)

4. Exhaust manifold cover

5. Exhaust manifold bracket

49 ± 5 N·m

44 ± 5 N·m

50 ± 10 N·m

5

35 ± 6 N·m

14 ± 1 N·m

4

N

2

1

AC303680

Removal steps (Continued)

6. Starter cover

7. Starter cover bracket

8. Engine hanger

9. Exhaust manifold

10. Exhaust manifold gasket

AB

Page 44

15-10

INTAKE AND EXHAUST

EXHAUST MANIFOLD

REMOVAL SERVICE POINT

<<A>> ENGINE CONTROL OXYGEN

SENSOR (FRONT) REMOVAL

MD998770

Engine control

oxygen sensor

(front)

AC212566

AC

Use special tool oxygen sensor wrench (MD998770)

to remove the engine control oxygen sensor (front).

INSPECTION

M1151003400543

Check the following points; replace the part if a

problem is found.

Exhaust Manifold Check

1. Check for damage or cracking of any part.

INSTALLATION SERVICE POINT

>>A<< ENGINE CONTROL OXYGEN

SENSOR (FRONT) INSTALLATION

MD998770

Engine control

oxygen sensor

(front)

AC212566

Use special tool oxygen sensor wrench (MD998770)

to install the engine control oxygen sensor (front).

2. Using a straight edge and a feeler gauge, check

for distortion of the cylinder head installation

surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

AC

Page 45

INTAKE AND EXHAUST

EXHAUST PIPE AND MAIN MUFFLER

EXHAUST PIPE AND MAIN MUFFLER

15-11

REMOVAL AND INSTALLATION

<4G1>

45 ± 5 N·m

5

9

45 ± 5 N·m

5

N

8

50 ± 10 N·m

<4G6>

N

8

9

6

9

6

M1151008700301

N

7

13 ± 2 N·m

2

59 ± 10 N·m

13 ± 2 N·m

2

4

N

3

13 ± 2 N·m

1

4

45 ± 5 N·m

AC303694

4

N

3

13 ± 2 N·m

AB

1

4

45 ± 5 N·m

50 ± 10 N·m

9

Exhaust main muffler removal

steps

1. Exhaust main muffler

3. Exhaust pipe gasket

4. Exhaust muffler hanger

Centre exhaust pipe removal

steps

2. Centre exhaust pipe

3. Exhaust pipe gasket

7. Exhaust pipe gasket

59 ± 10 N·m

N

7

<<A>> >>A<<

AC30 3695

Front exhaust pipe removal

steps

5. Engine control oxygen sensor

(rear)

6. Front exhaust pipe

7. Exhaust pipe gasket

8. Exhaust pipe gasket

9. Exhaust muffler hanger

AB

Page 46

15-12

INTAKE AND EXHAUST

EXHAUST PIPE AND MAIN MUFFLER

REMOVAL SERVICE POINT

<<A>> ENGINE CONTROL OXYGEN

SENSOR (REAR) REMOVAL

MD998770

Engine control

oxygen sensor

(rear)

AC212566

Use special tool oxygen sensor wrench (MD998770)

to remove the engine control oxygen sensor (rear).

AD

INSTALLATION SERVICE POINT

>>A<< ENGINE CONTROL OXYGEN

SENSOR (REAR) INSTALLATION

MD998770

Engine control

oxygen sensor

(rear)

AC212566

Use special tool oxygen sensor wrench (MD998770)

to install the engine control oxygen sensor (rear).

AD

Page 47

GROUP 14

ENGINE COOLING

CONTENTS

14-1

GENERAL INFORMATION . . . . . . . . 14-2

SERVICE SPECIFICATIONS. . . . . . . 14-2

LUBRICANT. . . . . . . . . . . . . . . . . . . . 14-2

SEALANTS . . . . . . . . . . . . . . . . . . . . 14-3

SPECIAL TOOLS. . . . . . . . . . . . . . . . 14-3

TROUBLESHOOTING . . . . . . . . . . . . 14-5

INSPECTION CHART FOR TROUBLE

SYMPTOMS . . . . . . . . . . . . . . . . . . . . . . . . 14-5

INSPECTION PROCEDURE FOR

TROUBLE SYMPTOMS . . . . . . . . . . . . . . . 14-6

ON-VEHICLE SERVICE. . . . . . . . . . . 14-22

ENGINE COOLANT LEAK CHECK . . . . . . 14-22

RADIATOR CAP VALVE OPENING

PRESSURE CHECK. . . . . . . . . . . . . . . . . . 14-22

ENGINE COOLANT REPLACEMENT . . . . 14-22

CONCENTRATION MEASUREMENT . . . . 14-23

COOLING FAN MOTOR DRIVE CONTROL

UNIT CHECK. . . . . . . . . . . . . . . . . . . . . . . . 14-23

FAN CONTROL RELAY CONTINUITY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-24

COOLING FAN MOTOR CHECK . . . . . . . . 14-25

THERMOSTAT . . . . . . . . . . . . . . . . . . 14-26

REMOVAL AND INSTALLATION . . . . . . . . 14-26

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-27

WATER PUMP . . . . . . . . . . . . . . . . . . 14-29

REMOVAL AND INSTALLATION <4G1> . . 14-29

REMOVAL AND INSTALLATION <4G6> . . 14-30

WATER HOSE AND WATER PIPE . . 14-31

REMOVAL AND INSTALLATION <4G1> . . 14-31

REMOVAL AND INSTALLATION <4G6> . . 14-33

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-34

RADIATOR . . . . . . . . . . . . . . . . . . . . . 14-35

REMOVAL AND INSTALLATION . . . . . . . . 14-35

Page 48

14-2

ENGINE COOLING

GENERAL INFORMATION

GENERAL INFORMATION

The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced

circulation type in which the water pump pressurizes

coolant and circulates it throughout the engine. If the

coolant temperature exceeds the prescribed

Item Specification

Radiator Performance kJ/h 4G13 Standard vehicles 137,720

temperature, the thermostat opens to circulate the

coolant through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal type and is

driven by the alternator drive belt from the

crankshaft. The radiator is the corrugated fin, down

flow type.

M1141000100371

Vehicles with capacity up radiator

(option)

4G18 Standard vehicles 161,288

Vehicles with capacity up radiator

(option)

4G63 181,800

A/T oil cooler Performance kJ/h 5,651

161,288

181,800

SERVICE SPECIFICATIONS

M1141000300416

Item Standard value Limit

High-pressure valve opening pressure of radiator cap kPa 93 − 123 Minimum 83

Range of coolant antifreeze concentration of radiator % 30 − 60 -

Thermostat Valve opening temperature of

thermostat °C

Full-opening temperature of

thermostat °C

Valve lift mm 8.5 or m or e -

4G1 88 ± 1.5 -

4G6 82 ± 1.5 -

4G1 100 -

4G6 95 -

LUBRICANT

Item Specified coolant Quantity L

Engine coolant (including

condense tank)

DIAQUEEN SUPER LONG LIFE COOLANT

or an equivalent

4G1 5.0

4G6 7.0

M1141000400338

Page 49

ENGINE COOLING

SEALANTS

SEALANTS

Item Specified sealant

Cylinder block drain plug 3M Nut Locking Part No.4171 or equivalent

14-3

M1141000500324

Water pump <4G1>, Thermostat case

<4G6>, Cooling water outlet hose fitting

<4G6>

MITSUBISHI GENUINE Part No.MD970389 or equivalent

SPECIAL TOOLS

Tool Numb e r Name Use

MB991502 MUT-II sub assembly Reading diagnosis code

B991502

M1141000600246

Page 50

14-4

ENGINE COOLING

SPECIAL TOOLS

Tool Numb e r Name Use

A

B

C

DO NOT USE

D

MB991824

MB991827

MB991910

MB991911

MB991955

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991825

F: MB991826

MUT-III sub assembly

A: Vehicle

communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main

harness A (Vehicles

with CAN

communication

system)

D: MUT-III main

harness B (Vehicles

without CAN

communication

system)

E: MUT-III

measurement

adapter

F: MUT-III trigger

harness

Checking the A/T

(Diagnosis display using the

MUT-III)

E

MB991825

F

MB991826

MB991955

Page 51

ENGINE COOLING

TROUBLESHOOTING

Tool Numb e r Name Use

14-5

MB991223

A

A: MB991219

B: MB991220

C: MB991221

D: MB991222

B

Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: Probe

Making voltage and

resistance measurement

during troubleshooting

A: Connector pin contact

pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester

connection

C

D

MB991223

AC

MB991871 LLC changer Coolant refilling

MB991871

TROUBLESHOOTING

INSPECTION CHART FOR TROUBLE

SYMPTOMS

Trouble symptom Inspection

Cooling fan (L.H.) and Cooling fan (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan <4G6> do not operate

Cooling fan (L.H.) and Cooling fan (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan <4G6> do not change speed or stop

Cooling fan (L.H.) does not operate {When cooling fan (R.H.)

<4G1> or A/C condenser fan <4G6> operate} <Vehicles with A/C>

Cooling fan (R.H.) <4G1> or A/C condenser fan <4G6> does not

operate {When cooling fan (L.H.) operate} <Vehicles with A/C>

M1141005600360

procedure No.

1

2

3

4

Reference page

P.14-6

P.14-16

P.14-20

P.14-21

Page 52

14-6

ENGINE COOLING

TROUBLESHOOTING

INSPECTION PROCEDURE FOR

TROUBLE SYMPTOMS

INSPECTION PROCEDURE 1: Cooling Fan (L.H.) and Cooling Fan (R.H.) <4G1 (Vehicles with A/C)> or

A/C Condenser Fan <4G6> do not Operate

Cooling Fan (L.H.) and Cooling Fan (R.H.) or A/C Condenser Fan Drive Circut

ENGINE-ECU <M/T> OR

ENGINE-A/T-ECU <A/T>

C-123

(MU801824)

C-122

(MU803784)

A-13

(MU802611)

C-111

15

2 3 4

6

21 C-123 <M/T>

18 C-122 <A/T>

L

1 A-13 <LHD>

12 C-111 <RHD>

12

1179810

L

FAN CONTROL

RELAY

A-09X

FUSIBLE

LINK No.2

B-W

4

R-Y

28

J/C (6)

C-12 <LHD>

C-134 <RHD>

33

R-Y

8 A-13 <LHD>

11 C-111 <RHD>

R-Y

1

ENGINE CONTROL

RELAY

B-16X

A-13

(MU802611)

C-111

15

2 3 4

6

1179810

12

(MU802322)

COOLING FAN

MOTOR DRIVE

CONTROL UNIT

COOLING FAN

MOTOR (R.H.)

<4G1 (VEHICLES

WITH A/C>

OR

A/C CONDENSER

FAN MOTOR <4G6>

2

L

A-18-1

3

B

2

A-18

2211

A-18-2

COOLING FAN

MOTOR (L.H.)

3

B

Wire colour code

B : Black LG : Light green

1

G : Green L : Blue

W : White Y : Yellow

SB : Sky blue BR : Brown

O : Orange GR : Gray

R : Red P : Pink V : Violet

AC303577

AB

Page 53

ENGINE COOLING

TROUBLESHOOTING

14-7

CIRCUIT OPERATION

• The cooling fan motor drive control unit is

powered from fusible link (2).

• The engine-ECU <M/T> or engine-A/T-ECU

<A/T> uses input signals from the A/C switch, the

water temperature sensor unit and the vehicle

speed sensor <M/T> or the output shaft speed

sensor <A/T> to control the speed of the cooling

fan motor (L.H.) and the cooling fan motor (R.H.)

<4G1 (Vehicles with A/C)> or A/C condenser fan

motor <4G6>.

• The engine-ECU <M/T> or engine-A/T-ECU

<A/T> controls the cooling fan motor drive control

unit to activate the cooling fan motor (L.H.) and

the cooling fan motor (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan motor <4G6>.

TECHNICAL DESCRIPTION

• The cause could be a malfunction of the cooling

fan motor drive control unit power supply or earth

circuit.

• If the communication line wiring harness between

the cooling fan motor drive control unit and the

engine-ECU <M/T> or engine-A/T-ECU <A/T> is

short-circuited to earth, the cooling fan motor

(L.H.) and the cooling fan motor (R.H.) <4G1

(Vehicles with A/C)> or the A/C condenser fan

motor <4G6> will not rotate.

• The cause could also be a malfunction of the

cooling fan motor (L.H.). <Vehicles without A/C>

• The cause could also be a malfunction of imput

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor <M/T>

or the output shaft speed sensor <A/T> to the

engine-ECU <M/T> or engine-A/T-ECU <A/T>.

• The cause could also be a malfunction of the

cooling fan motor drive control unit or the

engine-ECU <M/T> or engine-A/T-ECU <A/T>.

TROUBLESHOOTING HINTS

• Malfunction of fusible link (2)

• Malfunction of fan control relay

• Malfunction of cooling fan motor (L.H.) <Vehicles

without A/C>

• Malfunction of cooling fan motor drive control unit

• Malfunction of engine-ECU <M/T> or

engine-A/T-ECU <A/T>

• Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the cooling fan motor (L.H.).

<Vehicles without A/C>

Refer to P.14-25.

Q: Is the cooling fan motor (L.H.) in good condition?

Go to Step 2 .

YES :

NO : Replace the cooling fan motor (L.H.) (Refer

to P.14-35). Then go to Step 24 .

STEP 2. Measure the power supply voltage at

cooling fan motor drive control unit connector

A-18.

Connector: A-18

A-18

3 2 1

AC100293

(1) Disconnect cooling fan motor drive control unit

connector A-18 and measure wiring harness side

connector.

(2) Turn the ignition switch to the "ON" position.

A-18 Connector

(Component side)

AC000246

(3) Measure the voltage between cooling fan motor

drive control unit connector A-18 terminal 3 and

body earth.

• The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF)

position.

(5) Connect cooling fan motor drive control unit

connector A-18.

Q: Is the measured voltage system voltage?

Go to Step 17 .

YES :

NO : Go to Step 3 .

AD

AF

Page 54

14-8

ENGINE COOLING

TROUBLESHOOTING

STEP 3. Check the cooling fan motor drive

control unit connector A-18.

Connector: A-18

A-18

3 2 1

AC100293

AD

Q: Is the connector in good condition?

YES : .

Go to Step 4 .

NO : . Repair or replace the connector. Then go to

Step 24 .

STEP 4. Check the fusible link No.2.

Relay box

(1) Disconnect fan control relay connector A-09X

(remove the fan control relay) and measure relay

box side connector.

(2) Turn the ignition switch to the "ON" position.

A-09X Connector

(Relay box side)

AC303511

AB

(3) Measure the voltage between fan control relay

connector A-09X terminal 4 and body earth.

• The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF)

position.

(5) Connect fan control relay connector A-09X

(install the fan control relay).

Q: Is the measured voltage system voltage?

Go to Step 8 .

YES :

NO : Go to Step 6 .

Fusible link

No.2

AC303509

AB

Q: Is the fusible link No.2 in good condition?

YES : .

Go to Step 5 .

NO : . Replace the fusible link No.2. Then go to

Step 24 .

STEP 5. Measure the power supply voltage at fan

control relay connector A-09X.

Connector: A-09X

A-09X

Relay box

Fan control relay

AC303510

AB

STEP 6. Check the fan control relay connector

A-09X.

Connector: A-09X

A-09X

Q: Is the connector in good condition?

YES :

Go to Step 7 .

NO : Repair the connector or replace the relay

Relay box

Fan control relay

AC303510

AB

box. Then go to Step 24 .

Page 55

ENGINE COOLING

TROUBLESHOOTING

14-9

STEP 7. Check the harness wire between fusible

link No.2 and fan control relay connector A-09X

terminal 4.

Relay box

Fusible link

No.2

Connector: A-09X

AC303509

Relay box

Fan control relay

A-09X

AB

Q: Is the connector in good condition?

Go to Step 10 .

YES :

NO : Repair the connector or replace the relay

box. Then go to Step 24 .

STEP 10. Check the harness wire between fan

control relay connector A-09X terminal 2 and

cooling fan motor drive control unit connector

A-18 terminal 3.

Connector: A-09X

A-09X

Connector: A-18

Relay box

Fan control relay

AC303510

AB

AC303510

AB

Q: Is the harness wire in good condition?

YES : .

An intermittent malfunction is suspected

(Refer to GROUP 00 - How to use

troubleshooting P.00-5).

NO : . Repair the damaged harness wire. Then go

to Step 24 .

STEP 8. Check the fan control relay.

Refer to P.14-24.

Q: Is the fan control relay in good condition?

Go to Step 9 .

YES :

NO : Replace the fan control relay. Then go to

Step 24 .

STEP 9. Check the fan control relay connector

A-09X.

Connector: A-09X

Relay box

Fan control relay

A-18

3 2 1

AC100293

AD

Q: Is the harness wire in good condition?

Go to Step 11 .

YES :

NO : Repair the damaged harness wire. Then go

to Step 24 .

STEP 11. Measure the terminal voltage at fan

control relay connector A-09X.

Connector: A-09X

A-09X

Relay box

Fan control relay

A-09X

AC303510

AB

AC303510

AB

(1) Disconnect fan control relay connector A-09X

(remove the fan control relay) and measure relay

box side connector.

(2) Turn the ignition switch to the "ON" position.

Page 56

14-10

A-09X Connector

(Relay box side)

ENGINE COOLING

TROUBLESHOOTING

STEP 12. Check the J/C No.6 C-12 <L.H. drive

vehicles> or C-134 <R.H. drive vehicles>,

intermediate connector A-13 <L.H. drive

vehicles> C-111 <R.H. drive vehicles> and fan

control relay connector A-09X.

Connector: C-12 <L.H. drive vehicles>

AC303517

AB

(3) Measure the voltage between fan control relay

connector A-09X terminal 1 and body earth.

• The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF)

position.

(5) Connect fan control relay connector A-09X

(install the fan control relay).

Q: Is the measured voltage system voltage?

YES : .

NO : . Go to Step 12 .

Go to Step 14 .

C-12

C-12

AC303524

Connector: C-134 <R.H. drive vehicles>

C-134

C-134

AC303525

Connector: A-13 <L.H. drive vehicles>

AB

AB

A-13

A-13

AC303526

Connector: C-111 <R.H. drive vehicles>

C-111

C-111

15

2 3 4

1179810

6

12

AC303527

AB

AB

Page 57

ENGINE COOLING

TROUBLESHOOTING

14-11

Connector: A-09X

A-09X

Relay box

Fan control relay

AC303510

AB

Q: Are there connectors in good condition?

YES : .

Go to Step 13 .

NO : . Repair or replace the connector. Then go to

Step 24 .

STEP 13. Check the harness wire between J/C

No.6 C-12 terminal 33 <L.H. drive vehicles> or

C-134 terminal 33 <R.H. drive vehicles> and fan

control relay connector A-09X terminal 1.

Connector: C-12 <L.H. drive vehicles>

Q: Are these harness wires in good condition?

An intermittent malfunction is suspected

YES :

(Refer to GROUP 00 - How to use

troubleshooting P.00-5).

NO : Repair the damaged harness wire. Then go

to Step 24 .

STEP 14. Check the continuity between fan

control relay connector A-09X and body earth.

Connector: A-09X

A-09X

Relay box

Fan control relay

AC303510

AB

(1) Disconnect fan control relay connector A-09X

(remove the fan control relay) and measure relay

box side connector.

C-12

C-12

AC303524

Connector: C-134 <R.H. drive vehicles>

C-134

C-134

AC303525

Connector: A-09X

Relay box

Fan control relay

AB

AB

A-09X Connector

(Relay box side)

AC303533

AB

(2) Measure the resistance between fan control relay

connector A-09X terminal 3 and body earth.

• Continuity exists.

(3) Connect fan control relay connector A-09X

(install the fan control relay).

Q: Does the continuity exists?

YES : An intermittent malfunction is suspected

(Refer to GROUP 00 - How to use

troubleshooting P.00-5).

NO : Go to Step 15 .

A-09X

AC303510

AB

Page 58

14-12

ENGINE COOLING

TROUBLESHOOTING

STEP 15. Check the fan control relay connector

A-09X.

Connector: A-09X

A-09X

Q: Is the connector in good condition?

Go to Step 16 .

YES :

NO : Repair the connector or replace the relay

Relay box

Fan control relay

AC303510

AB

box. Then go to Step 24 .

STEP 16. Check the harness wire between fan

control relay connector A-09X terminal 3 and

body earth.

Connector: A-09X

Relay box

STEP 17. Check the continuity between cooling

fan motor drive control unit connector A-18 and

body earth.

Connector: A-18

A-18

3 2 1

AC100293

AD

(1) Disconnect cooling fan motor drive control unit

connector A-18 and measure wiring harness side

connector.

A-18 Connector

(Wiring harness side)

Fan control relay

A-09X

AC303510

AB

Q: Is the harness wire in good condition?

An intermittent malfunction is suspected

YES :

(Refer to GROUP 00 - How to use

troubleshooting P.00-5).

NO : Repair the damaged harness wire. Then go

to Step 24 .

AC303534

AB

(2) Measure the resistance between cooling fan

motor drive control unit connector A-18 terminal 1

and body earth.

• Continuity exists.

(3) Connect cooling fan motor drive control unit

connector A-18.

Q: Dose the continuity exists?

YES : Go to Step 20 .

NO : Go to Step 18 .

Page 59

ENGINE COOLING

TROUBLESHOOTING

14-13

STEP 18. Check the cooling fan motor drive

control unit connector A-18.

Connector: A-18

A-18