Page 1

General ........................

00

WORKSHOP MANUAL

SUPPLEMENT

FOREWORD

This manual outlines changes in servicing

procedures related to th e chassis including vehicle

inspections, adjustments and improvements in the

newly equipped models.

Please read this manual carefully so that it will be of

assistance for your service activities.

Please note that the following service manuals are

also available and should be used in conjunction

with this manual.

TECHNICAL INFORMATION MANUAL

PYME9501

PYME9501-1

WORKSHOP MANUAL

CHASSIS GROUP PWME9511 (Basic)

PWME9511-A (Supplement)

PWME9511-B (Supplement)

ENGINE GROUP PWEE____

(Looseleaf edition)

ELECTRICAL WIRING PHME9511 (Basic)

PHME9511-A (Supplement)

PHME9511-B (Supplement)

PHME9511-C (Supplement)

BODY REPAIR MANUAL PBME9501 (Basic)

PBME9501-1 (Supplement)

PBME9501-2 (Supplement)

PARTS CATALOGUE B806F006A_

Engine .........................

Engine Lubrication .............

Fuel ...........................

Engine Cooling .................

Intake and Exhaust .............

Engine Electrical ...............

Engine and Emission Control ....

Automatic Transmission ........

11

12

13

14

15

16

17

23

All information, illustrations and product

descriptions contained in this manual are current

as at the time of publication. We, however, reserve

the right to make changes at any time without prior

notice or obligation.

Mitsubishi Motors Corporation Jun. 2000

E

Page 2

WARNING!

(1) Improper service or maintenance of any component of the SRS and any SRS-related component,

can lead to personal injury or death to service personnel (from inadvertent firing of the air

bag or to the driver and passenger (from rendering the SRS inoperative).

(2) SRS components should not be subjected to heat, so remove the SRS-ECU, air bag module

(driver’s side and front passenger’s side), clock spring, side impact sensor and front seat

assembly (side air bag module) before drying or baking the vehicle after painting.

SRS-ECU, air bag module, clock spring and side impact sensor: 93_C or more

(3) Service or maintenance of any SRS component and SRS-related component must be performed

only at an authorized MITSUBISHI dealer.

(4) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP

52B - Supplemental Restraint System (SRS), before beginning any service or maintenance

of any component of the SRS and any SRS-related component.

NOTE

Section titles with asterisks (*) in the table of contents in each group indicate operations requiring warnings.

Page 3

GENERAL

CONTENTS

00-1

VEHICLE IDENTIFICATION 2.................

Models 2......................................

Model Code 2.................................

Chassis Number 3.............................

MAJOR SPECIFICATIONS 4...................

Hatchback 4...................................

Page 4

00-2

GENERAL - Vehicle Identification

VEHICLE IDENTIFICATION

MODELS

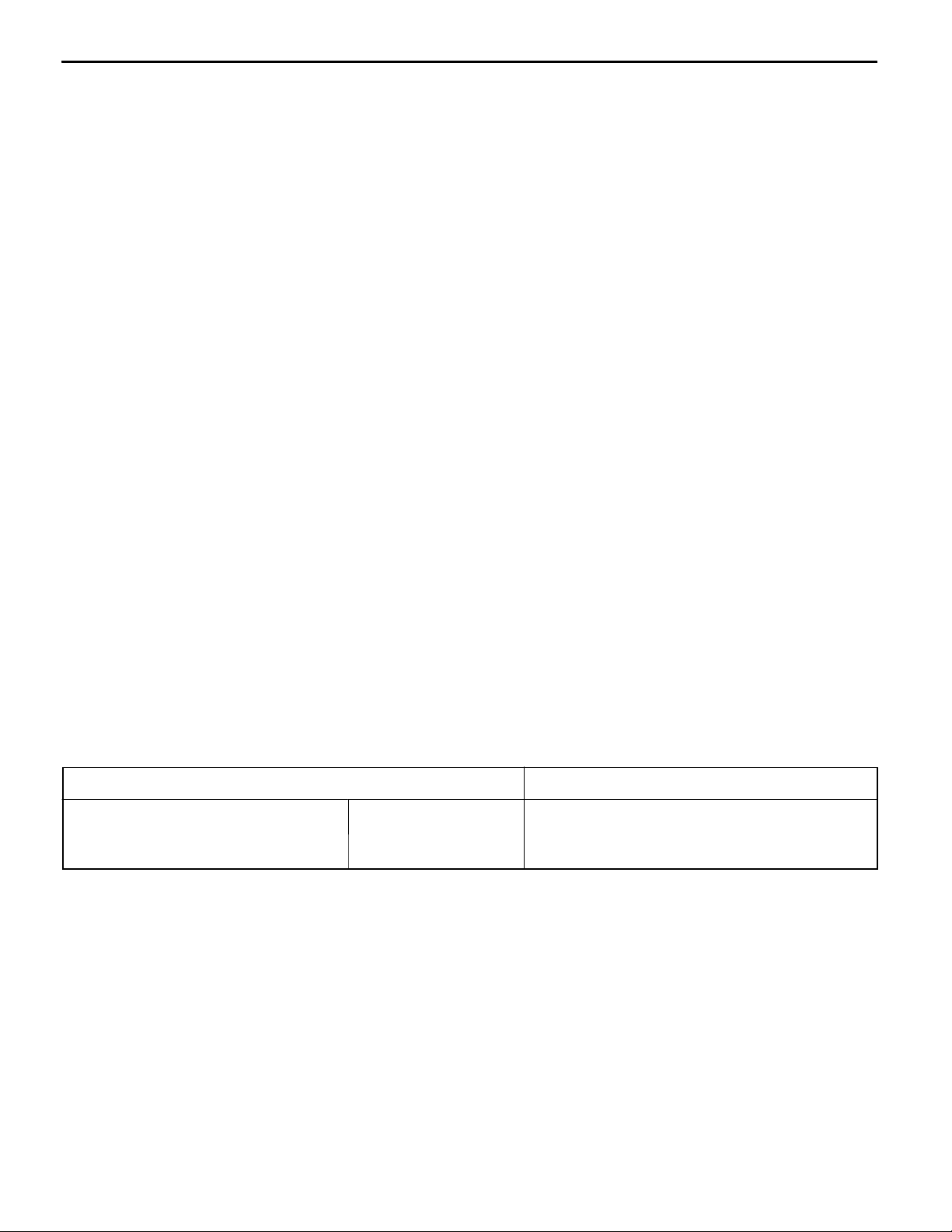

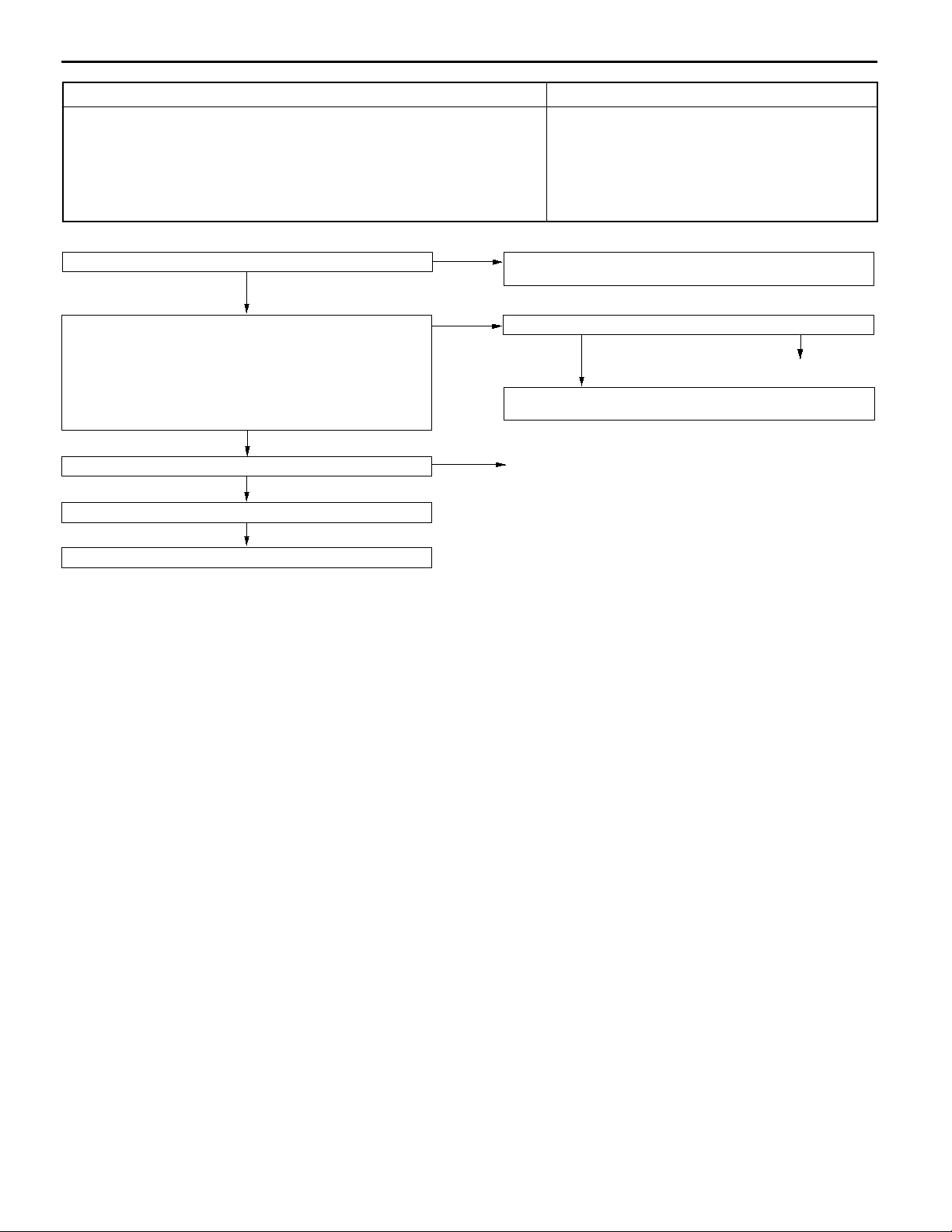

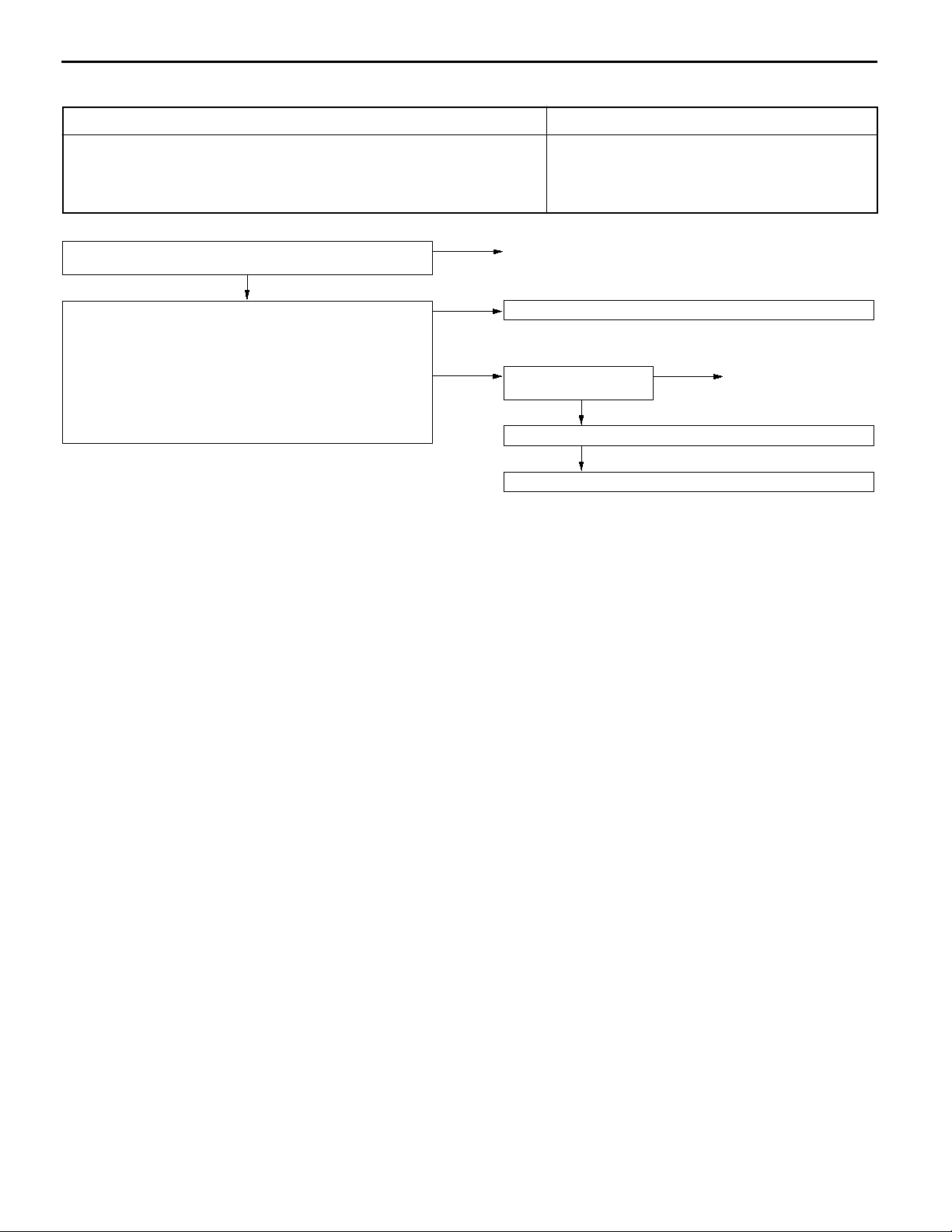

Model code Engine model Transmission model Fuel supply system

CJ1A MNDEL6/R6 4G13 (1,298 mL) F5M41 <5M/T> MPI

(Electronically Controlled

MNJEL6/R6

CJ4A MNJEL6/R6 4G92 MPI (1,597 mL)

MRJEL6/R6 F4A41

<INVECS-II 4A/T>

Multi Point Fuel Injection)

CJ

1

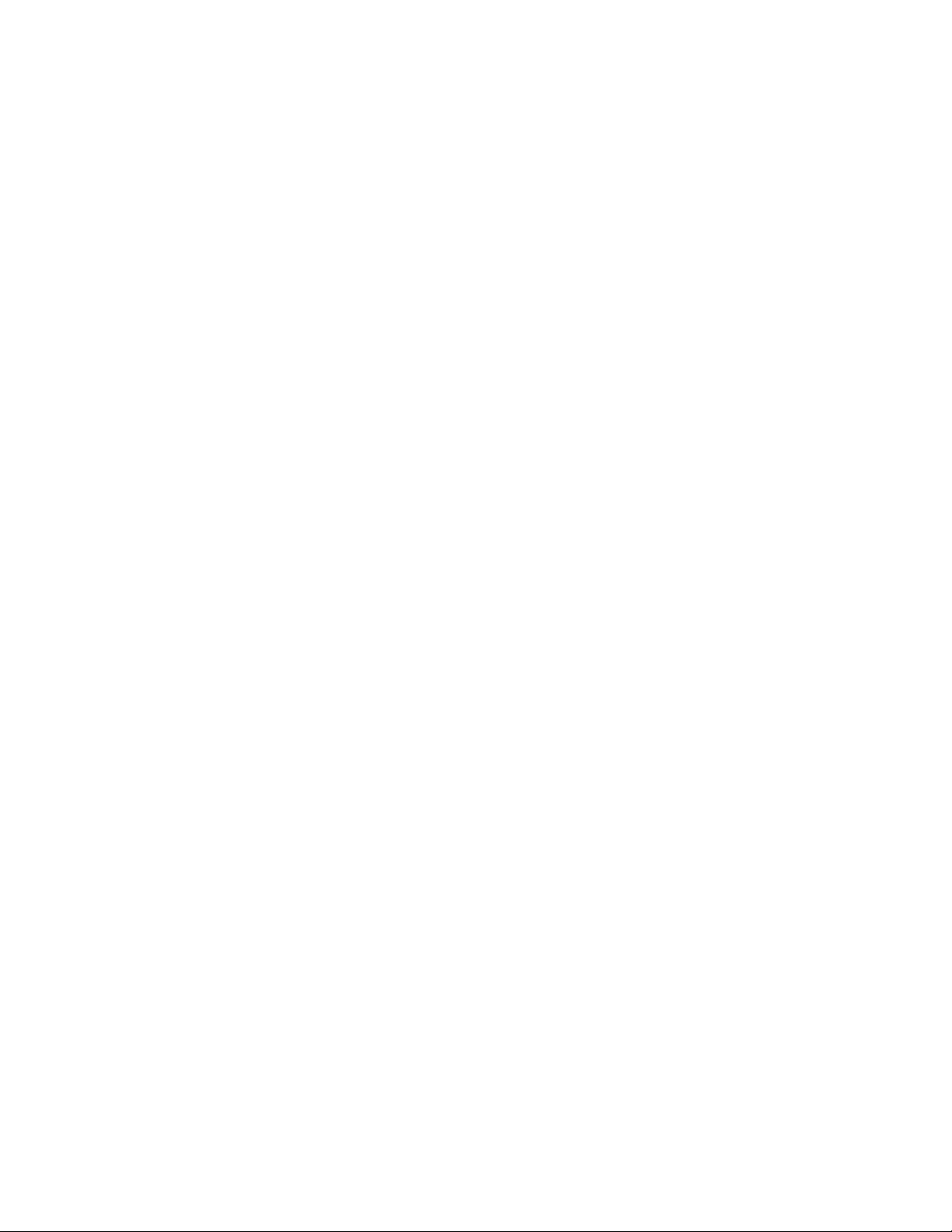

MODEL CODE

A

4

2

M

NJEL

3

5

4

67

6

9

8

No. Items Contents

1 Development CJ: MITSUBISHI (2-door)

2 Engine type 1: 1,298 mL petrol engine

4: 1,597 mL petrol engine

3 Sort A: Passenger car

4 Body style M: 2-door hatchback

5 Transmission type N: 5-speed manual

transmission

R: 4-speed automatic

transmission

6 Trim level D: GL

J: GLX or GLXi

7 Specification engine

feature

8 Steering wheel

location

E: SOHC-MPI

L: Left hand

R: Right hand

9 Destination 6: For Europe

Page 5

GENERAL - Vehicle Identification

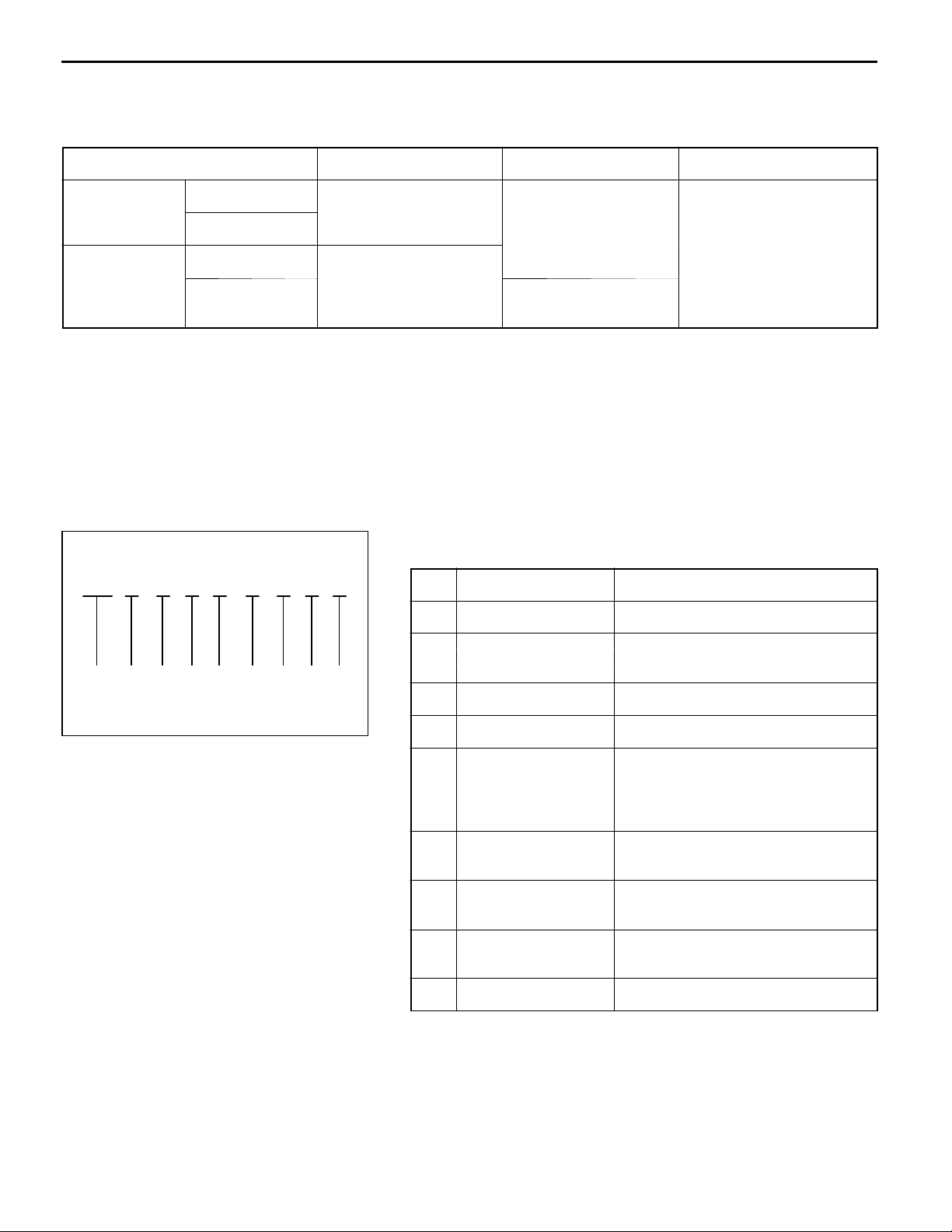

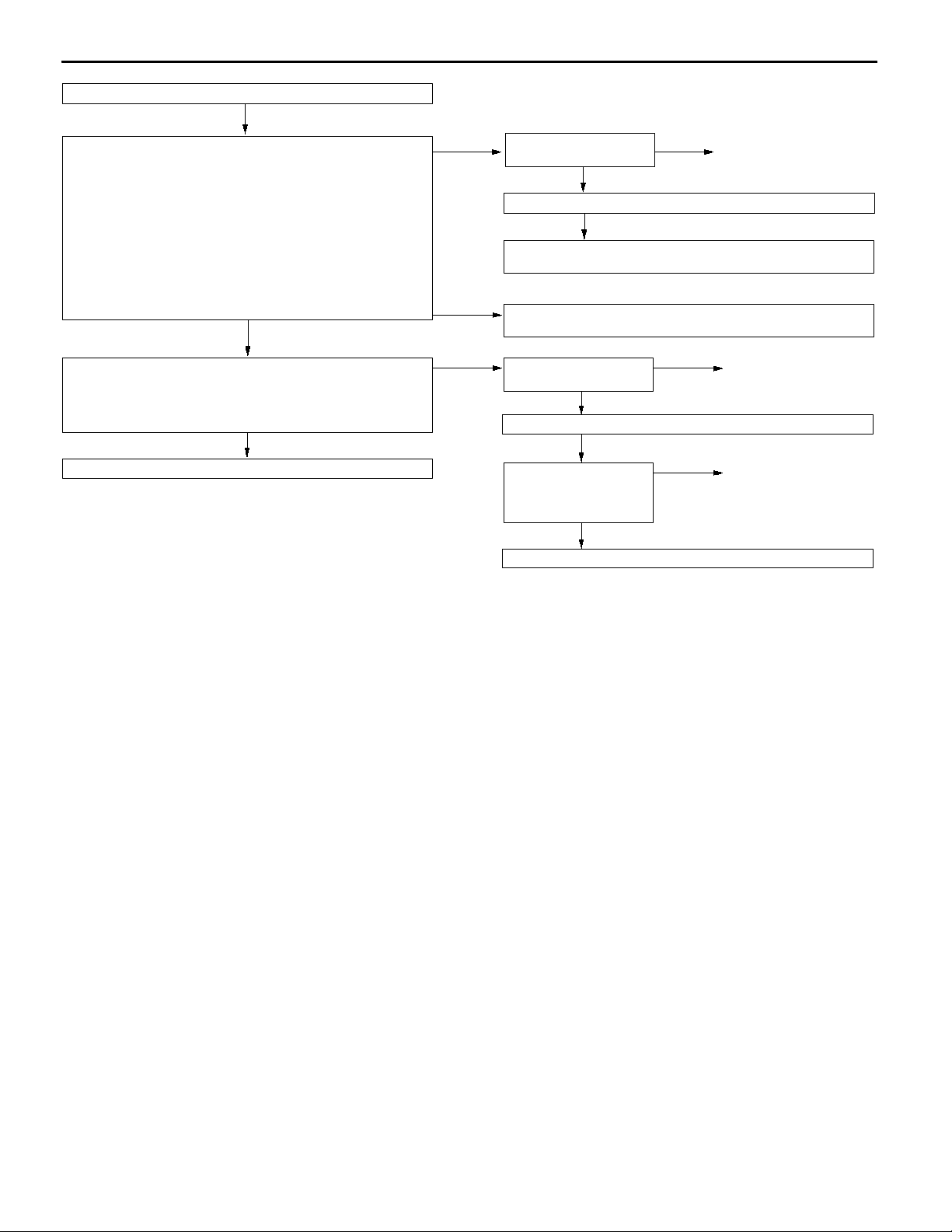

CHASSIS NUMBER

The chassis number is stamped on the toeboard inside the

engine compartment.

00-3

12 3

No. Items Contents

1 Fixed figure J Asia

2 Distribution channel M Japan channel

3 Destination A For Europe, right hand drive

4 Body style M 2-door hatchback

5 Transmission type N 5-speed manual transmission

6 Development order CJ COLT

7 Engine 1 4G13: 1,298 mL petrol engine

8 Sort A Passenger car

5

4

67891110

B For Europe, left hand drive

R 4-speed automatic transmission

4 4G92: 1,597 mL petrol engine

9 Model year 1 2001

10 Plant U Mizushima Motor Vehicle Works

11 Serial number - -

Page 6

00-4

GENERAL - Major Specifications

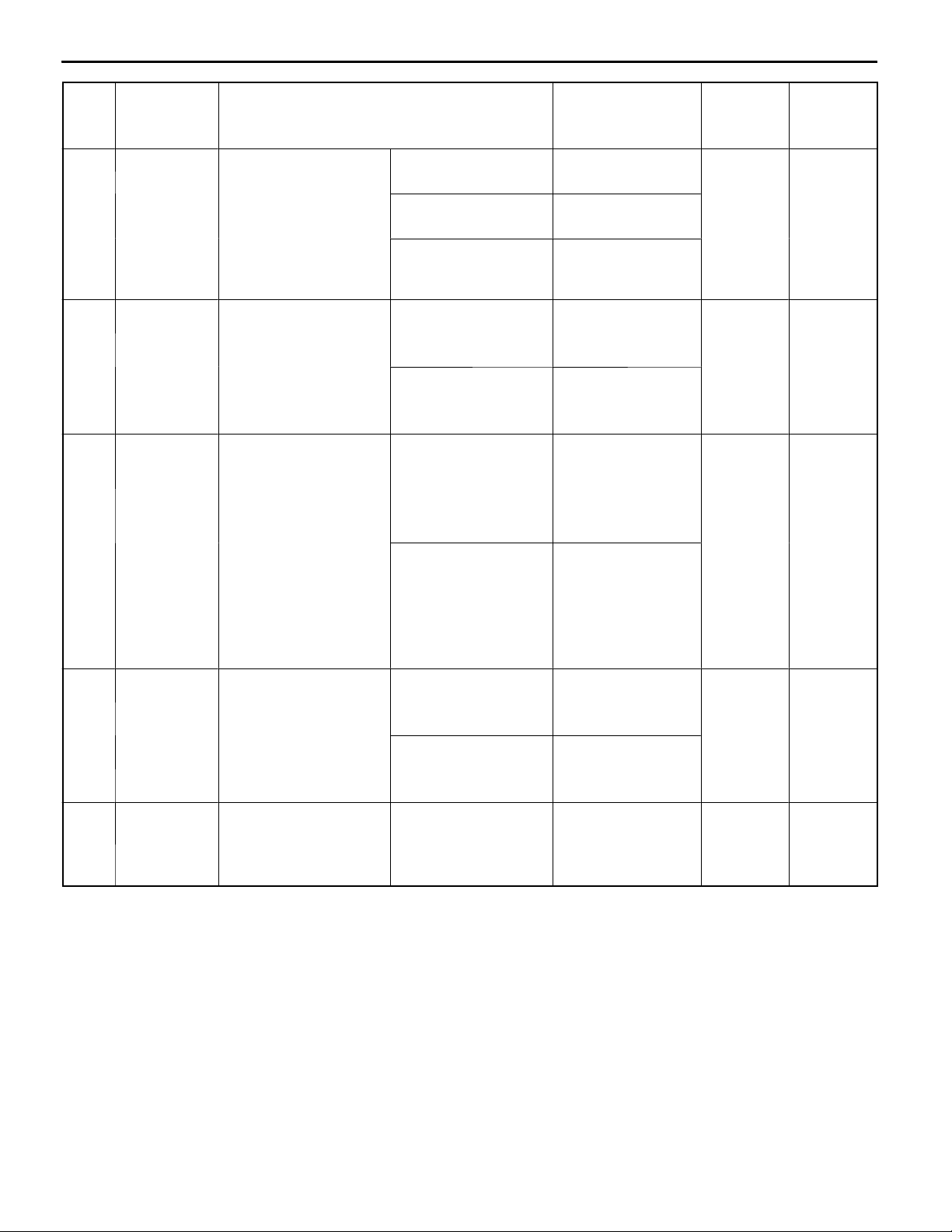

MAJOR SPECIFICATIONS

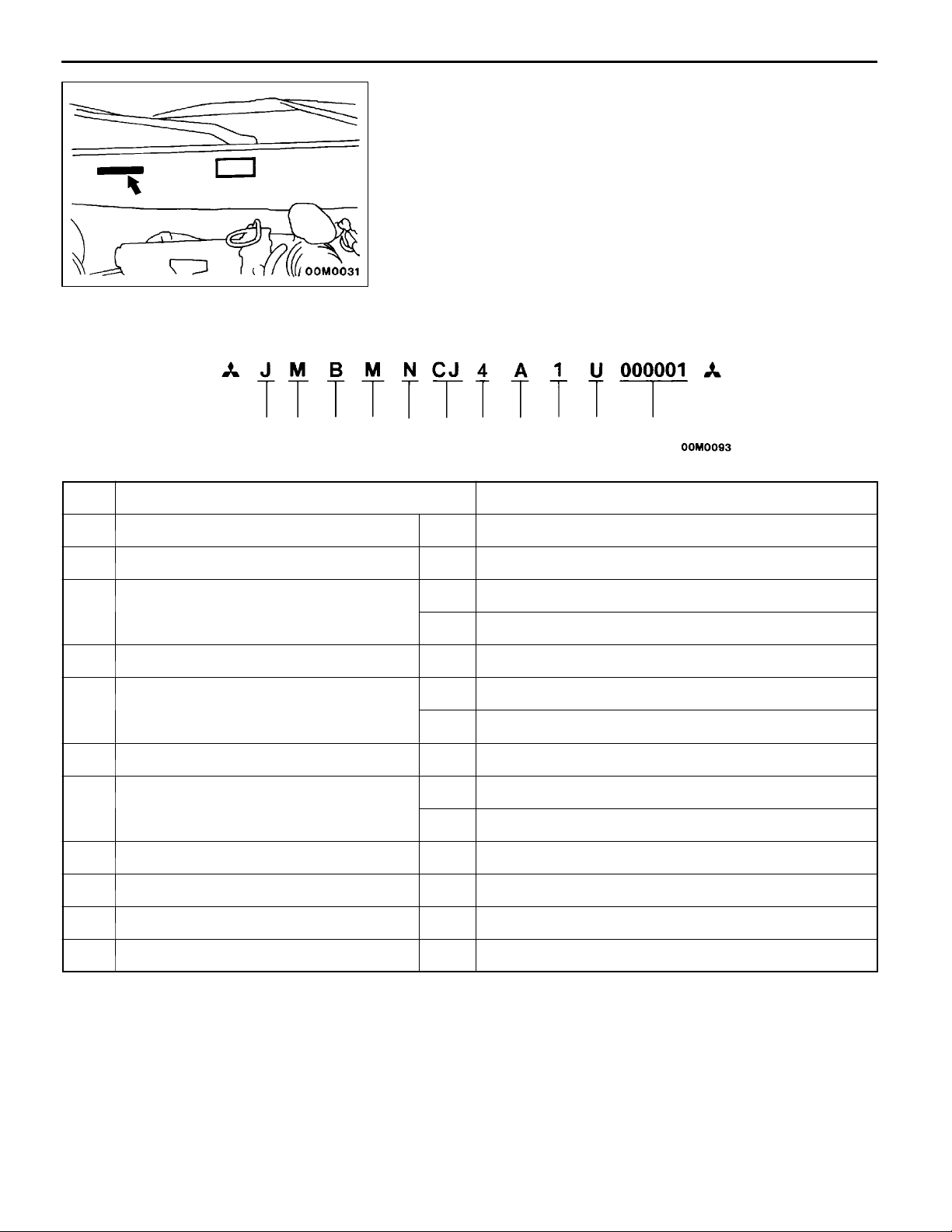

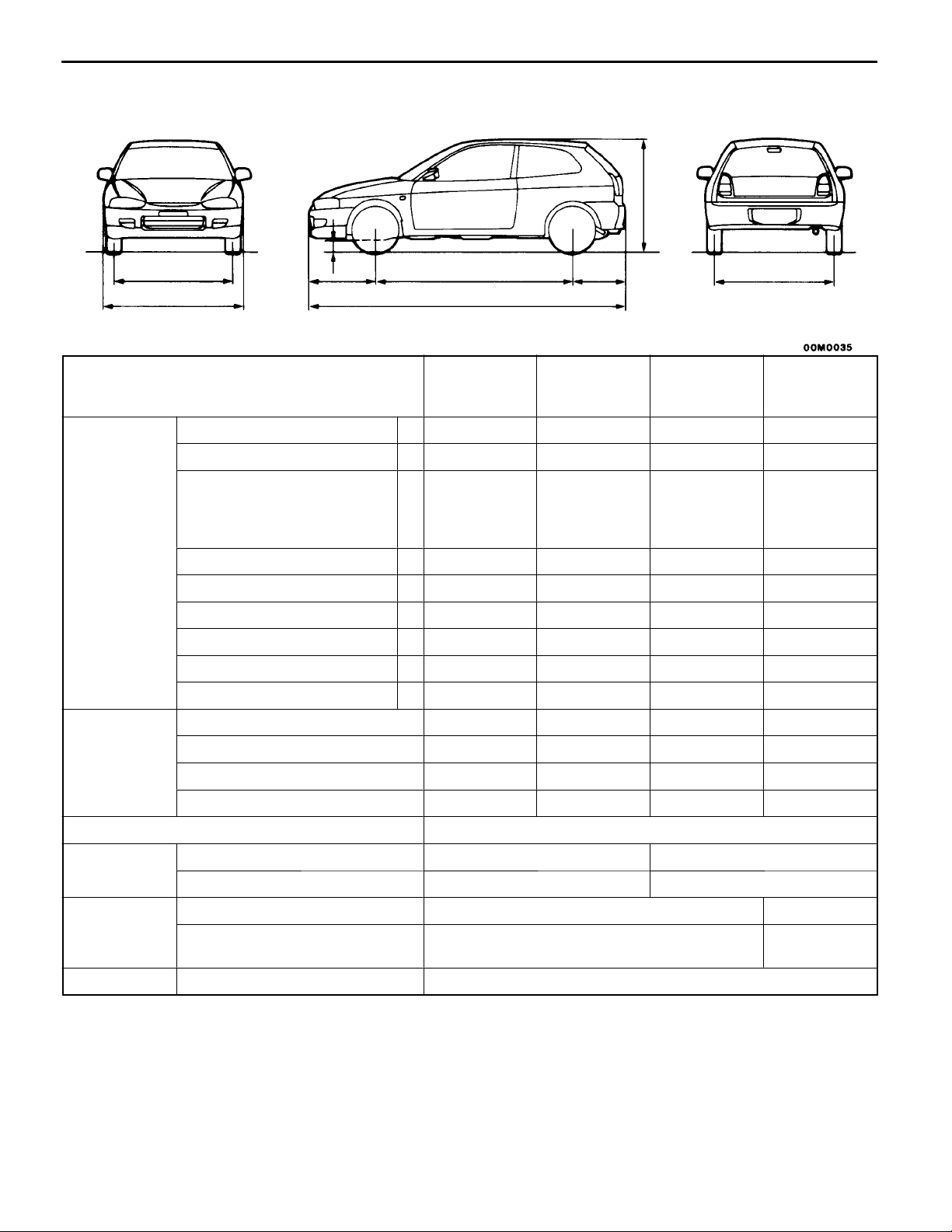

HATCHBACK

9

5

2

7

3

4

1

86

Items CJ1A

MNDEL6,

MNDER6

Vehicle

dimensions

mm

mm

Overall length 1 3,900 3,900 3,900 3,900

Overall width 2 1,680 1,680 1,680 1,680

Overall height (unladen) 3 1,365,

1,380*

1,385*

1,400*

Wheelbase 4 2,415 2,415 2,415 2,415

Track-front 5 1,450 1,450 1,450 1,450

Track-rear 6 1,460 1,460 1,460 1,460

Overhang-front 7 825 825 825 825

Overhang-rear 8 660 660 660 660

Ground clearance (unladen) 9 150, 165*1,*3150, 165*1,*3150, 165*1,*3150, 165*1,*

Vehicle

weight kg

Kerb weight 950 955 975 995

Max. gross vehicle weight rating 1,445 1,445 1,470 1,480

Max. axle weight rating-front 810 810 810 810

Max. axle weight rating-rear 705 705 705 705

CJ1A

MNJEL6,

MNJER6

1

,

2

,

3

1,365,

1,380*

1,385*

1,400*

1

,

2

,

3

CJ4A

MNJEL6,

MNJER6

1,365,

1

1,380*

1,385*

1,400*

,

2

,

3

CJ4A

MNJEL6,

MNJER6

1,365,

1

1,380*

1,385*

1,400*

,

2

,

3

3

Seating capacity 5

Engine

Model No. 4G13 4G92

Total displacement mL 1,298 1,597

Transmission

Model No. F5M41 F4A41

Type 5 speed-manual 4 speed-

automatic

Fuel system Fuel supply system MPI (Electronically Controlled Multi Point Fuel Injection)

NOTE

1

: indicates vehicles with high ground suspension.

1. *

2

: indicates vehicles with rear spoiler.

2. *

3

3. *

: indicates vehicles with high ground suspension and rear spoiler.

Page 7

ENGINE

CONTENTS

ENGINE <4G1> 11A......................................................

ENGINE <4G9> 11B......................................................

11A-1

Page 8

11A-2

ENGINE <4G1>

CONTENTS

GENERAL 3.................................

Outline of Changes 3..........................

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 3.................

SEALANT 3..................................

SPECIAL TOOLS 4..........................

ON-VEHICLE SERVICE 5.....................

Compression Pressure Check 5.................

Lash Adjuster Check 5.........................

CAMSHAFT AND CAMSHAFT OIL SEAL 8....

CRANKSHAFT FRONT OIL SEAL 11..........

CYLINDER HEAD GASKET 12...............

Page 9

General/General Information/

ENGINE <4G1> -

Service Specifications/Sealant

GENERAL

OUTLINE OF CHANGES

The following service procedures have been

established due to the addition of the 4G13-SOHC

16 valve MPI engine. Furthermore, other items are

the same as for the 4G13-SOHC 12 valve MPI

engine.

D The basic ignition timing has been changed

as a direct-mounted crank angle sensor has

been used.

D The compression pressure has been changed.

D An auto-lash adjuster has been adopted.

D Camshaft and camshaft oil seal removal and

installation

D Crankshaft front oil seal removal and installation

D Cylinder head gasket removal and installation

GENERAL INFORMATION

Items 4G13

Compression ratio 10.0

Combustion chamber Pentroof type

Number of valve Intake 8

11A-3

Exhaust 8

V alve timing Intake Opening BTDC 17

Closing ABDC 39

Exhaust Opening BBDC 49

Closing ATDC 7

Auto-lash adjuster Equipped

_

_

_

_

SERVICE SPECIFICATIONS

Items Standard value Limit

Basic ignition timing 5_BTDC±3

Compression pressure (250 – 400 r/min) kPa 1,598 Min. 1,161

Cylinder head bolt shank length mm - 103.2

_

-

SEALANT

Items Specified sealant Remarks

Camshaft position sensor support MITSUBISHI GENUINE PART

MD970389 or equivalent

Semi-drying sealant

Page 10

11A-4

ENGINE <4G1> -

Special Tools

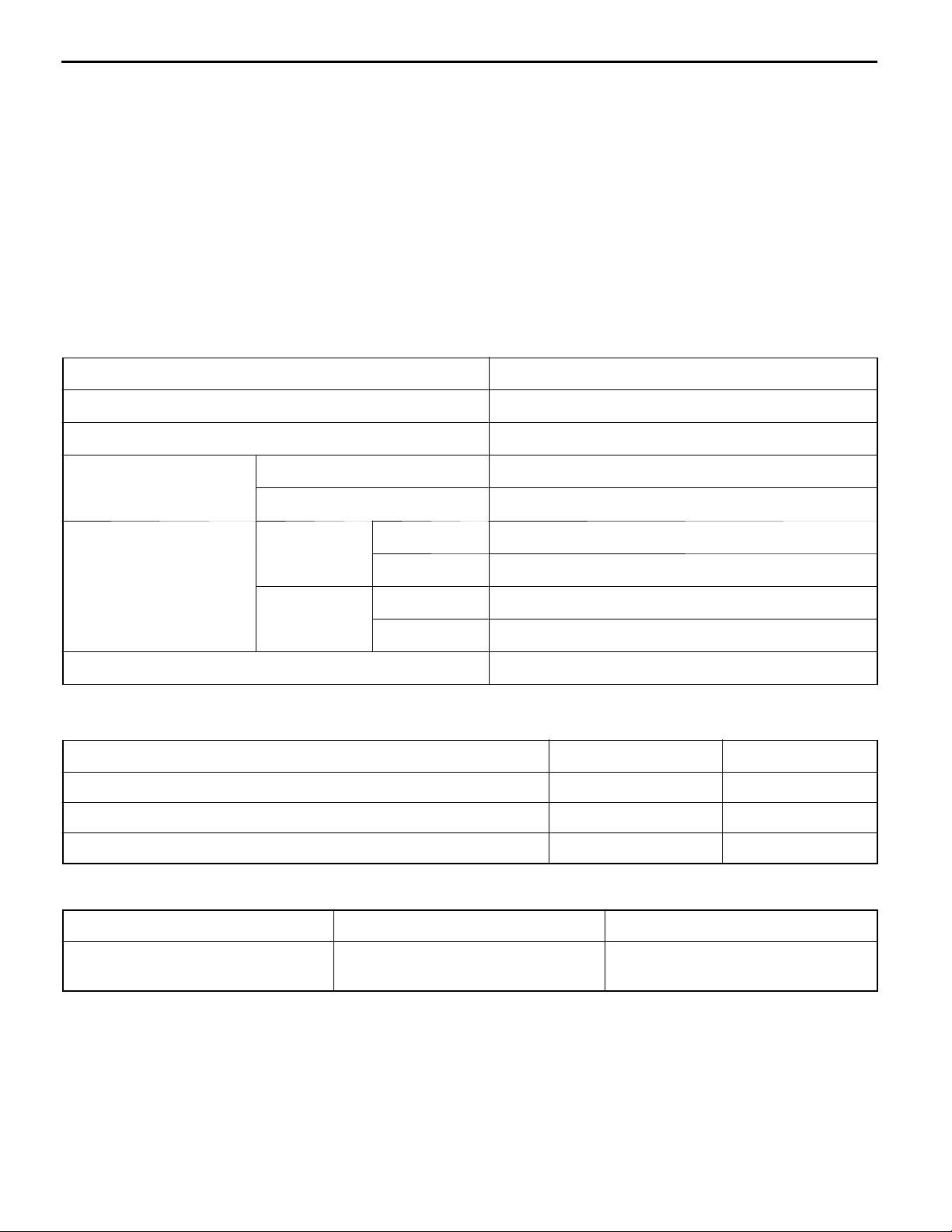

SPECIAL TOOLS

Tool Number Name Use

MB990767 Front hub and

flange yoke holder

MD998719 Crankshaft pulley

holder pin

MD998443 Auto-lash adjuster

holder

MD998713 Camshaft oil seal

installer

Holding the camshaft sprocket

Supporting of lash adjuster

Press-in of the camshaft oil seal

MD998304 Crankshaft front oil

seal installer

MD998305 Crankshaft front oil

seal guide

MB991653 Cylinder head bolt

wrench

Press-fitting the crankshaft front oil seal

Cylinder head bolt removal and installation

Page 11

ENGINE <4G1> -

ON-VEHICLE SERVICE

COMPRESSION PRESSURE CHECK

The disconnection of the distributor connector has been

changed to the disconnection of the crank angle sensor

connector due to the change of the crank angle sensor. Other

service procedures are the same as before.

Standard value (at engine speed of 250 - 400 r/min):

Limit (at engine speed of 250 - 4 00 r/min):

LASH ADJUSTER CHECK

If an abnormal noise (knocking) that seems to be coming

from the lash adjuster is heard after starting the engine and

does not stop, carry out the following check.

NOTE

(1) The abnormal noise which is caused by a problem

(2) If there is a problem with the lash adjusters, the noise

On-vehicle Service

1,598 kPa

Min. 1,161 kPa

with the lash adjusters is generated after the engine

is started, an d will vary according to the engine speed.

However, this noise is not related to the actual engine

load.

Because of this, if the noise does not occur

immediately after the engine is started, if it does not

change in accordance with the engine speed, or if

it changes in accordance with the engine load, the

source of the noise is not the lash adjusters.

will almost never disappear, even if the engine has

been run at idle to let it warm up.

The only case where the noise might disappear is

if the oil in the engine has not been looked after

properly and oil sludge has caused the lash adjusters

to stick.

11A-5

1. Start the engine.

2. Check that the noise occurs immediately after the engine

is started, and that the noise changes in accordance

with changes in the engine speed.

If the noise does not occur immediately after the engine

is started, or if it does not change in accordance with

the engine speed, the problem is not being caused by

the lash adjusters, so check for some other cause of

the problem. Moreover, if the noise does not change in

accordance with the engine speed, the cause of the

problem is probably not with the engine. (In these cases,

the lash adjusters are normal.)

3. While the engine is idling, check that the noise level does

not change when the engine load is varied.

If the noise level changes, the cause of the noise is

probably parts striking because of worn crankshaft

bearings or connecting rod bearings. (In such cases, the

lash adjusters are normal.)

Page 12

11A-6

ENGINE <4G1> -

4. After the engine has warmed up, run it at idle and check

if any noise can be heard.

If the noise has become smaller or disappeared, oil sludge

could make the lash adjusters stick. Clean the lash

adjusters. (Refer to the Engine Workshop Manual.) If not

improved, go to step 5.

5. Bleed air from the lash adjusters.

6. If the noise has not disappeared even after the air

bleeding, clean the lash adjusters. (Refer to the Engine

Workshop Manual.)

<LASH ADJUSTER AIR BLEEDING>

NOTE

(1) If the vehicle is parked on a slope for a long period

(2) After parking the vehicle for long periods, the oil drains

(3) If either of the above situations occur, the abnormal

On-vehicle Service

of time, the amount of oil inside the lash adjuster

will decrease, and air may get into the high pressure

chamber when starting the engine.

out of the oil passage, and it takes time for the oil

to be supplied to th e lash adjuster, so air can get

into the high pressure chamber.

noise can be eliminated by bleeding the air from inside

the lash adjusters.

Good

Highpressure

chamber

1. Check the engine oil and replenish or replace the oil

if necessary.

NOTE

(1) If there is a only small amount of oil, air will be drawn

in through the oil screen and will get into the oil

passage.

(2) If the amount of oil is greater than normal, then the

oil will being mixed by the crankshaft and a large

amount of air may get mixed into the oil.

(3) If the oil is degenerated, air and oil will not separate

easily in oil, and the amount of air mixed into the

oil will increase.

(4) If the air which has been mixed in with the oil due

to any of the above reasons gets into the high pressure

chamber of the lash adjuster, the air inside the high

pressure chamber will be compressed when the valve

is open and the lash adjuster will over-compress,

resulting in abnormal noise when the valve closes.

This is the same effect as if the valve clearance is

adjusted to be too large by mistake. If the air inside

the lash adjusters is then released, the operation

of the lash adjusters will return to normal.

Page 13

ENGINE <4G1> -

On-vehicle Service

11A-7

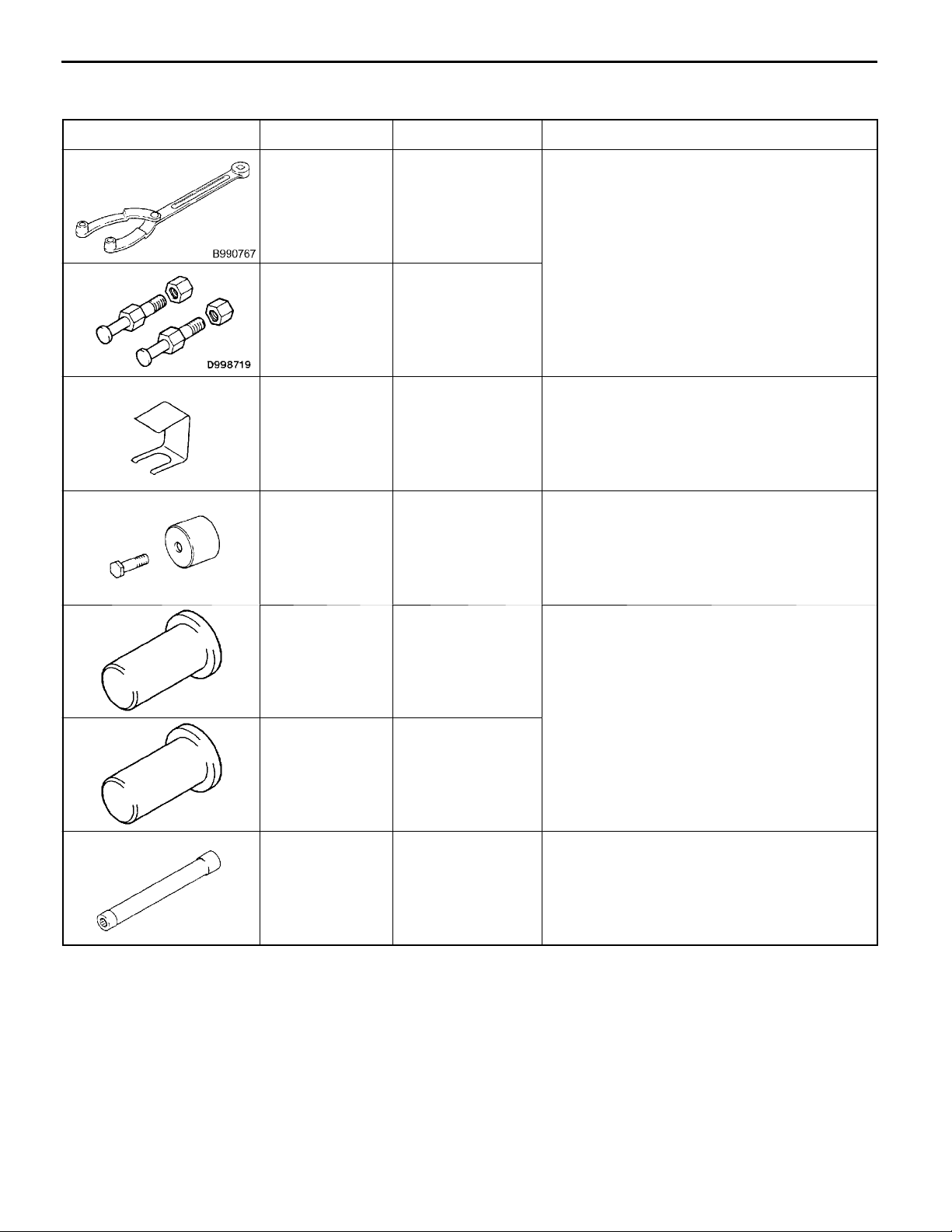

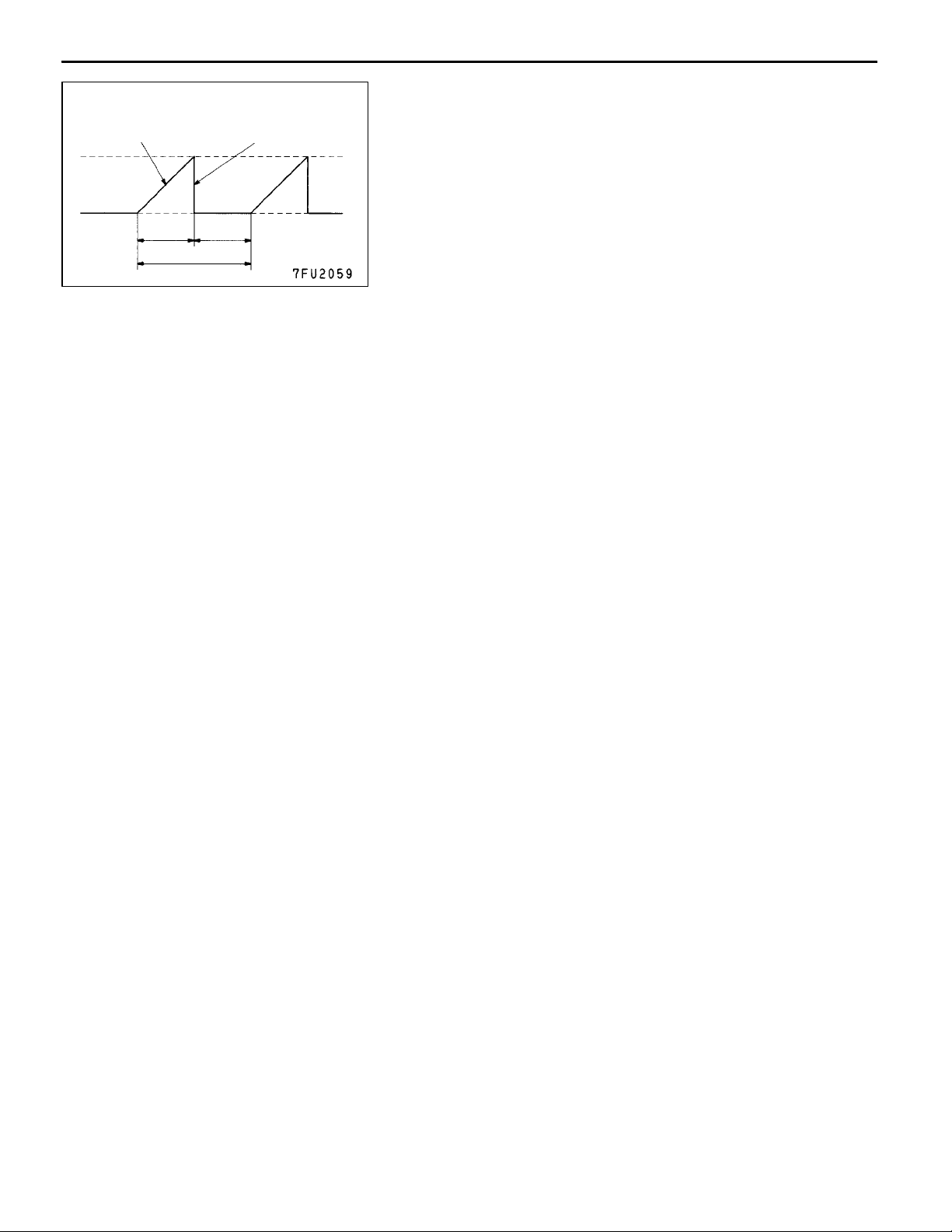

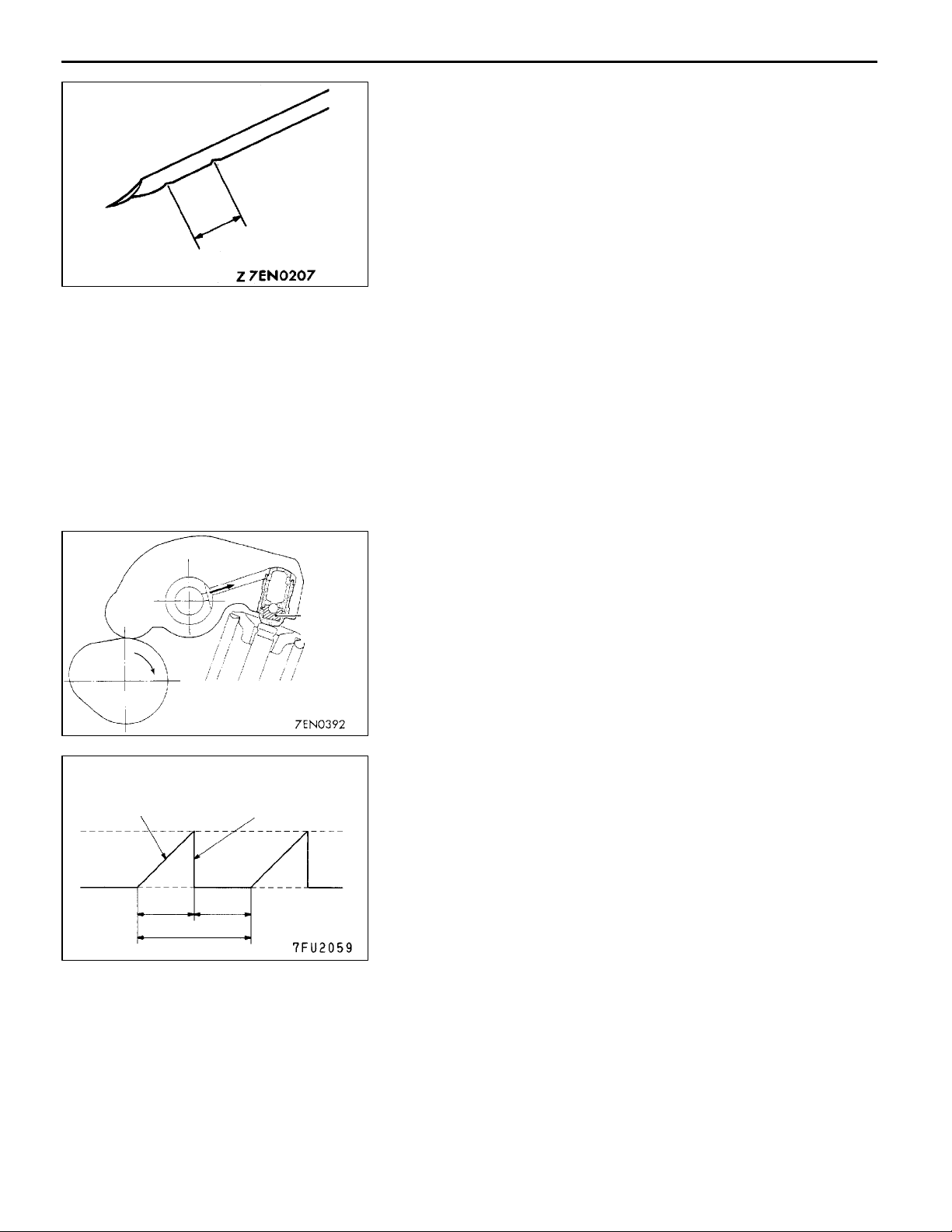

Drive pattern for air bleeding

Gradually open the

throttle valve.

Approx.

3,000 r/min

Idle speed

15

seconds

Once

Close the throttle

valve.

15

seconds

2. Run the engine at idle for 1 - 3 minutes to let it warm

up.

3. With no load on the engine, repeat the drive pattern shown

in the illustration at left and check if the abnormal noise

disappears. (The noise should normally disappear after

10 - 30 repetitions, but if there is no change in the noise

level after 30 repetitions or more, the problem is probably

not due to air inside the lash adjusters.)

4. After the noise has disappeared, repeat the drive pattern

shown in the illustration at left a further 5 times.

5. Run the engine at idle for 1 - 3 minutes and check that

the noise has disappeared.

Page 14

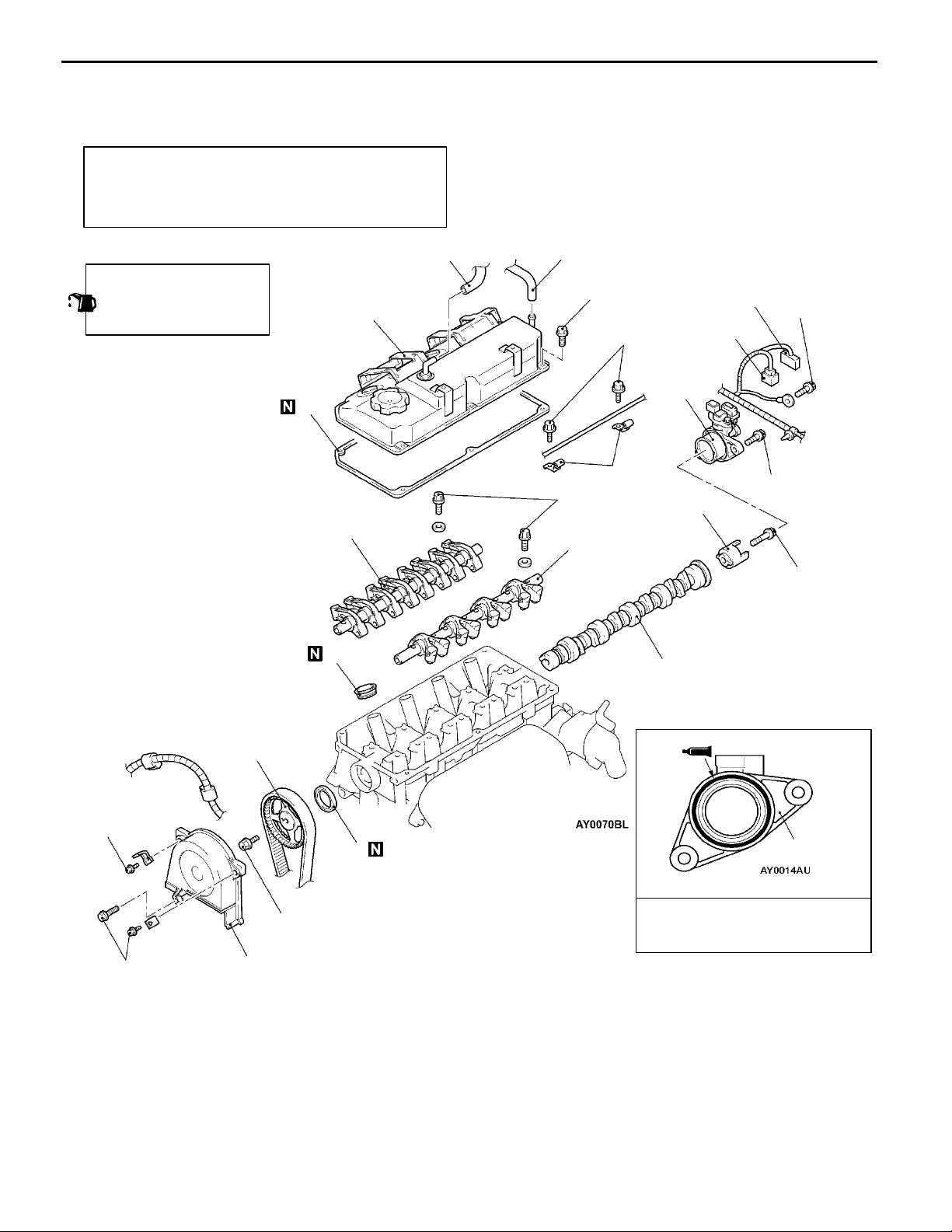

11A-8

ENGINE <4G1> - Camshaft and Camshaft Oil Seal

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Air Cleaner Removal and Installation

D Ignition Coil Removal and Installation

(Refer to GROUP16.)

12

Apply engine oil to all

moving parts during

installation.

3.5 Nm

4

10 - 12 Nm

13

12

5.0 Nm

14

5

3

28 - 34 Nm

10

11

6

16

15

12 - 15 Nm

22 Nm

10 - 12 Nm

10 - 12 Nm

AA""CA

"BA

8

9

88 Nm

7

Removal steps

1. Breather hose connection

2. PCV hose connection

3. Accelerator cable clamp

<LH drive vehicles>

4. Rocker cover

5. Rocker cover gasket

6. Spark plug guide

7. Timing belt front upper cover

8. Camshaft sprocket

9. Camshaft oil seal

AB""AA

AB""AA

14

Sealant:

MITSUBISHI GENUINE PART

MD970389 or equivalent

10. Lash adjuster, intake rocker arm

and shaft assembly

11. Lash adjuster, exhaust rocker arm

and shaft assembly

12. Ignition failure sensor connector

13. Camshaft position sensor connector

14. Camshaft position sensor support

15. Camshaft

16. Camshaft position sensing cylinder

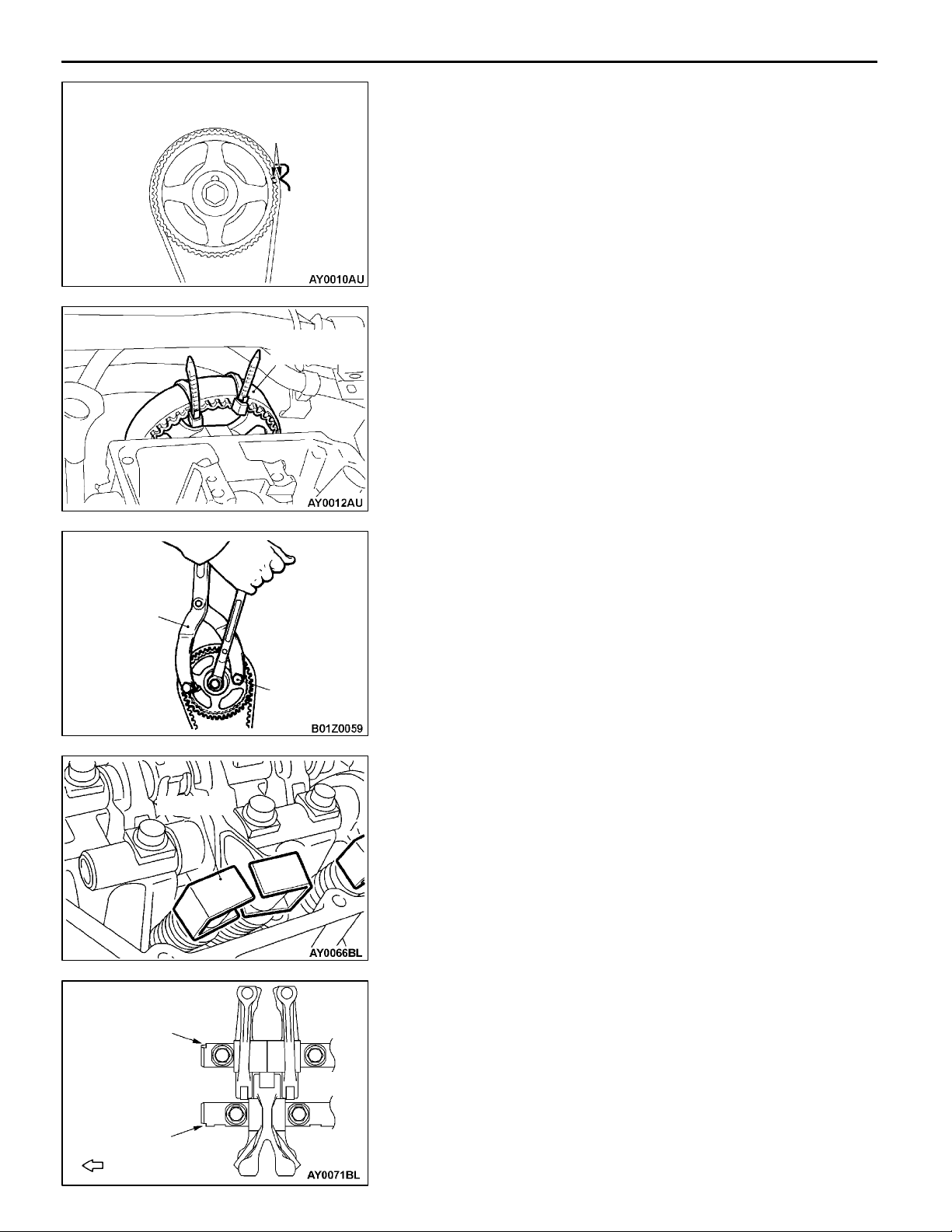

Page 15

ENGINE <4G1> - Camshaft and Camshaft Oil Seal

REMOVAL SERVICE POINTS

Timing mark

Camshaft

sprocket

AA"

1. Turn the crankshaft in the forward direction (clockwise)

2. Secure the camshaft sprocket and the timing belt with

CAMSHAFT SPROCKET REMOVAL

to align the timing mark so that No.1 cylinder is at the

compression TDC.

Caution

Always turn the crankshaft in the forward direction

(clockwise).

band cables to prevent deviation from the relative positions

between the camshaft sprocket and the timing belt.

11A-9

MB990767

MD998443

MD998719

3. Use the special tool to stop the camshaft sprocket from

turning.

4. Remove the camshaft sprocket with the timing belt

attached.

Caution

Do not turn the crankshaft after the camshaft sprocket

is removed.

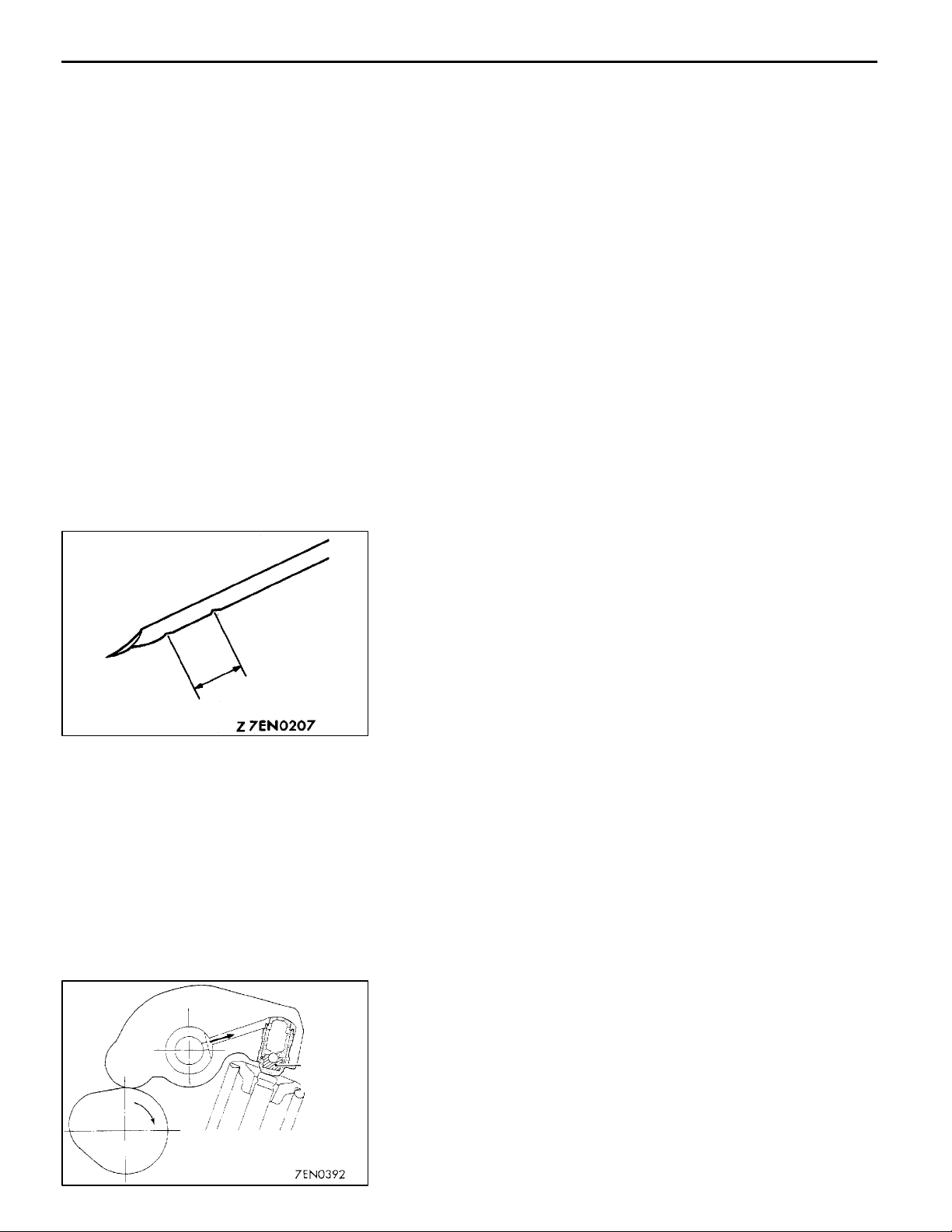

AB"

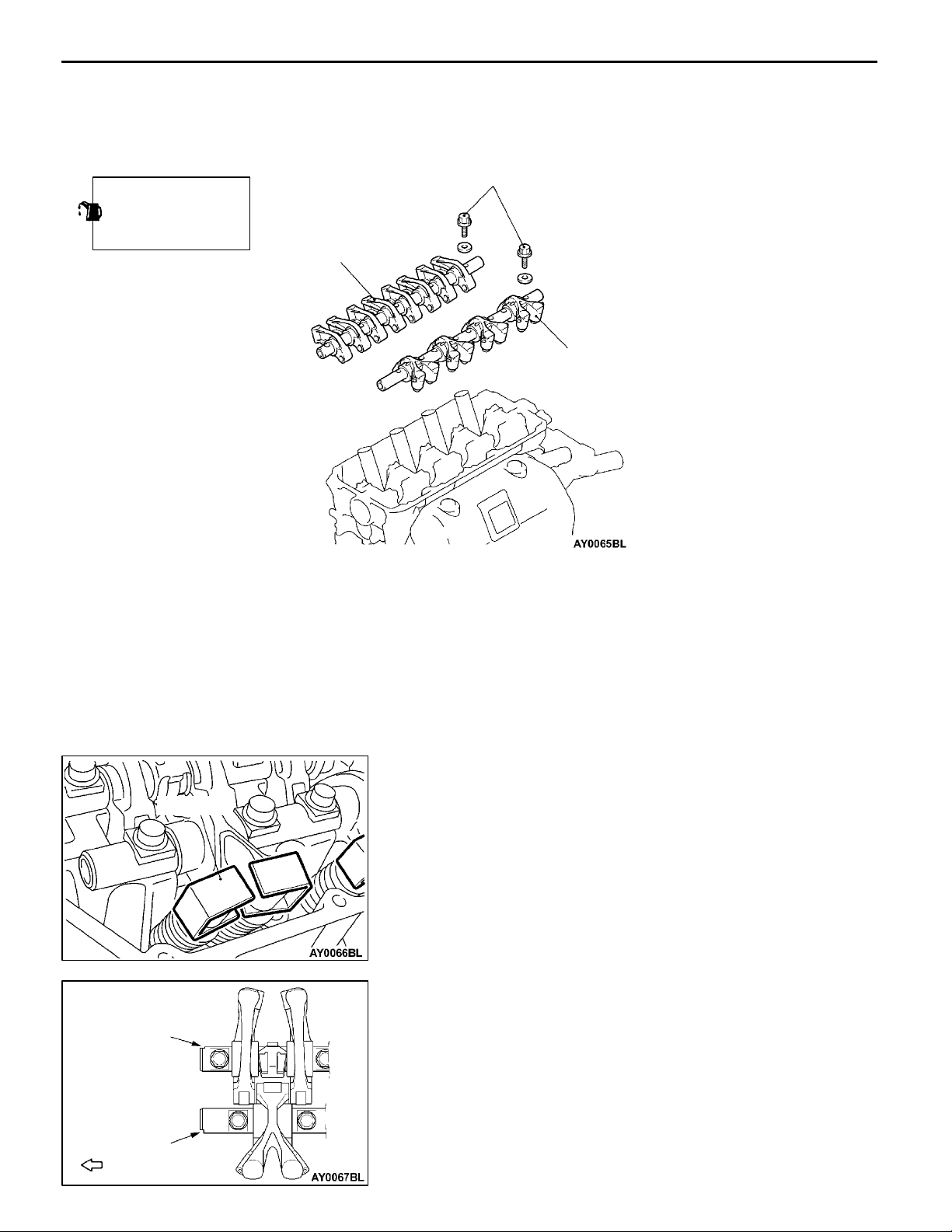

LASH ADJUSTER, INTAKE ROCKER ARM AND

SHAFT ASSEMBLY/LASH ADJUSTER, EXHAUST

ROCKER ARM AND SHAFT ASSEMBLY

REMOVAL

Before removing the lash adjuster, rocker arm a nd shaft

assembly, install the special tools as shown in the illustration

so that the lash adjusters will not fall out.

Notch

Notch

Front of engine

INSTALLATION SERVICE POINTS

"AA

Position the rocker arm shaft so that their notches point the

direction shown, an d install the lash adjuster, rocker arm

and shaft assembly.

LASH ADJUSTER, EXHAUST ROCKER ARM AND

SHAFT ASSEMBLY/LASH ADJUSTER, INTAKE

ROCKER ARM AND SHAFT ASSEMBLY

INSTALLATION

Page 16

11A-10

ENGINE <4G1> - Camshaft and Camshaft Oil Seal

MD998713

"BA

1. Apply engine oil to the camshaft oil seal lip.

2. Use the special tool to press-fit the camshaft oil seal.

"CA

Use the special tool to stop the camshaft sprocket from turning

in the same way as was done during removal, and then tighten

the bolts to the specified torque.

Tightening torque: 88 Nm

CAMSHAFT OIL SEAL INSTALLATION

CAMSHAFT SPROCKET INSTALLATION

Page 17

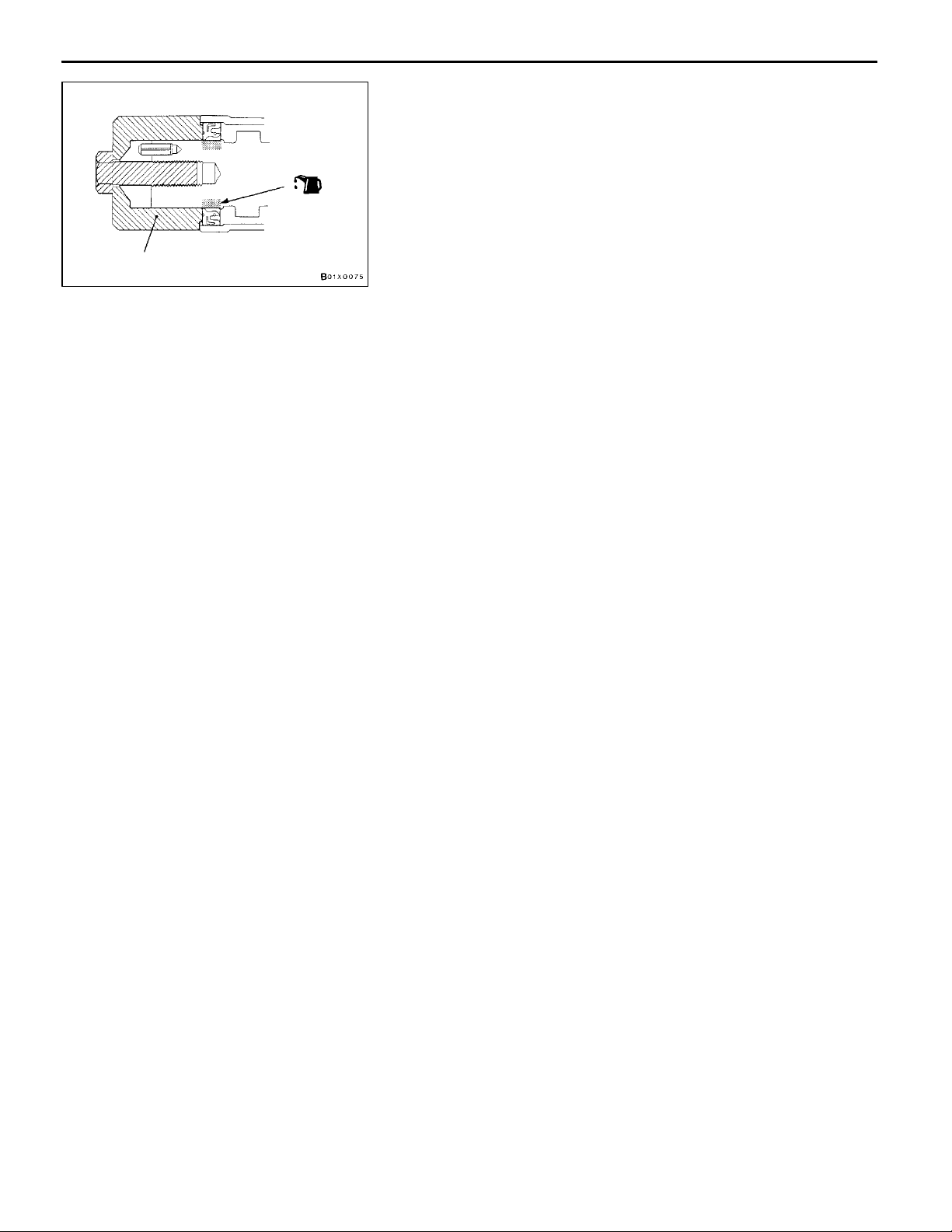

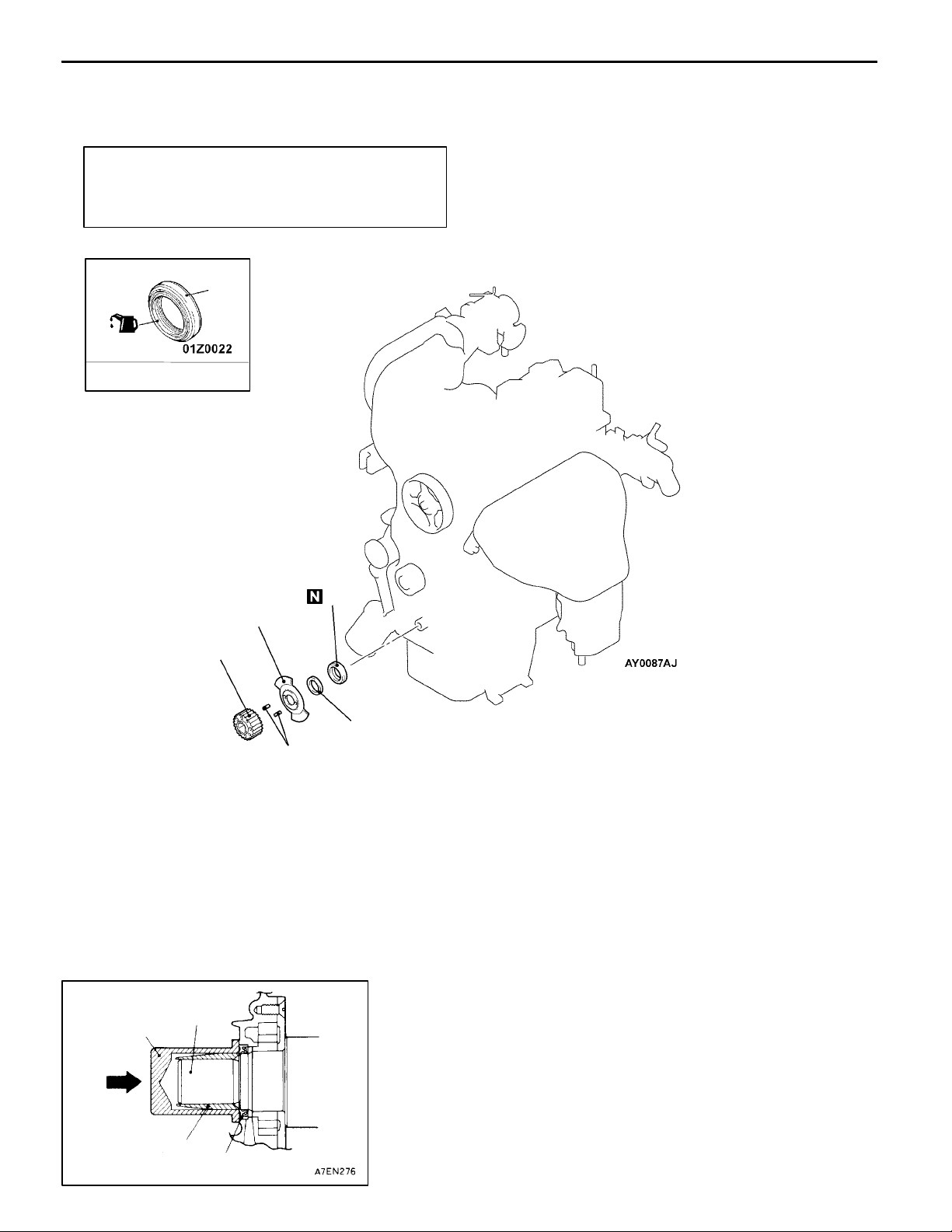

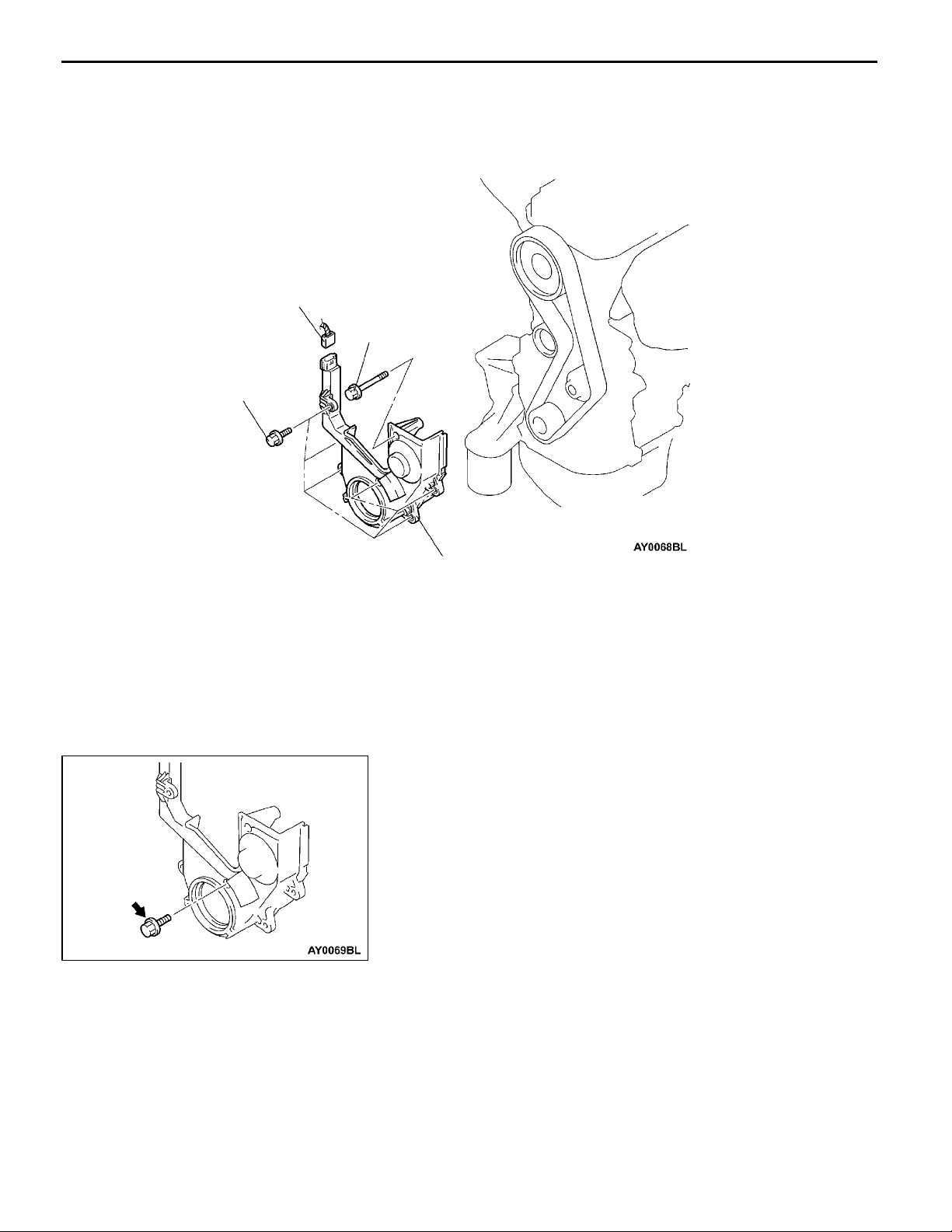

ENGINE <4G1> - Crankshaft Front Oil Seal

CRANKSHAFT FRONT OIL SEAL

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Timing Belt Removal and Installation

D Crank angle sensor Removal and Installation

(Refer to GROUP16.)

5

(Lip)

Engine oil

11A-11

"BA

"BA

"BA

MD998304

5

3

1

2

Removal steps

1. Crankshaft sprocket

2. Spring pin

3. Crankshaft sensing blade

Crankshaft

4

"BA

"AA

4. Crankshaft spacer

5. Crankshaft front oil seal

INSTALLATION SERVICE POINTS

"AA

1. Apply a small amount of engine oil to the entire

2. Tap the oil seal unit it flushes with the oil seal case.

CRANKSHAFT FRONT OIL SEAL INSTALLATION

circumference of the oil seal lip.

MD998305

Oil seal

Page 18

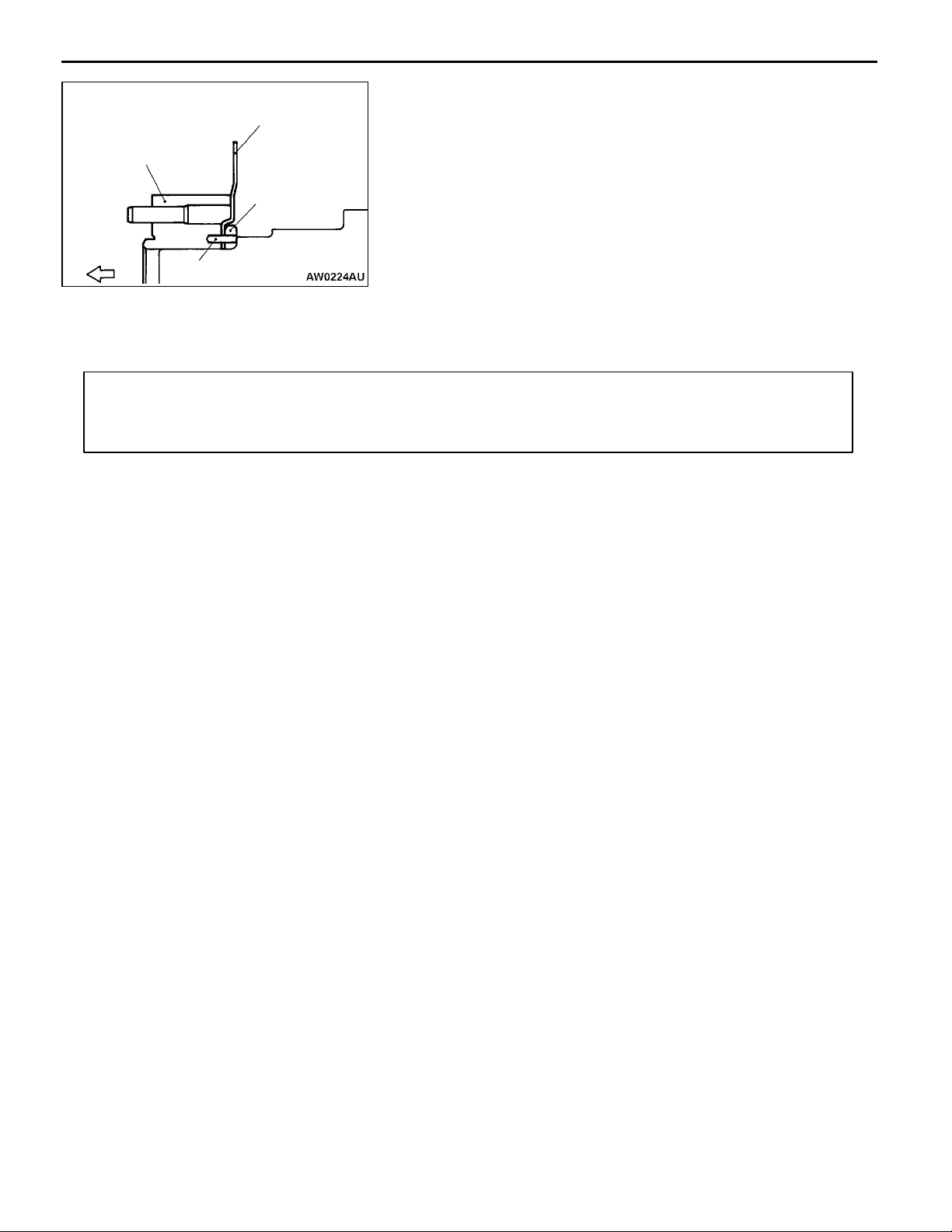

11A-12

ENGINE <4G1> - Crankshaft Front Oil Seal/Cylinder Head Gasket

Crankshaft

sensing blade

Crankshaft

sprocket

Crankshaft

spacer

Front of

engine

Spring pin

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Prevention of Fuel Discharge <before removal only>

D

Fuel Leak Check <after installation only>

D

Under Cover Removal and Installation

D

"BA

CRANKSHAFT SPACER/CRANKSHAFT SENSING

BLADE/SPRING PIN/CRANKSHAFT SPROCKET

INSTALLATION

Install t he crankshaft sprocket assembled with the spring pin,

the crankshaft sensing blade, and the crankshaft spacer to

the crankshaft.

Engine Coolant Draining and Supplying

D

Engine Oil Draining and Supplying

D

Air Cleaner Removal an d Installation

D

Page 19

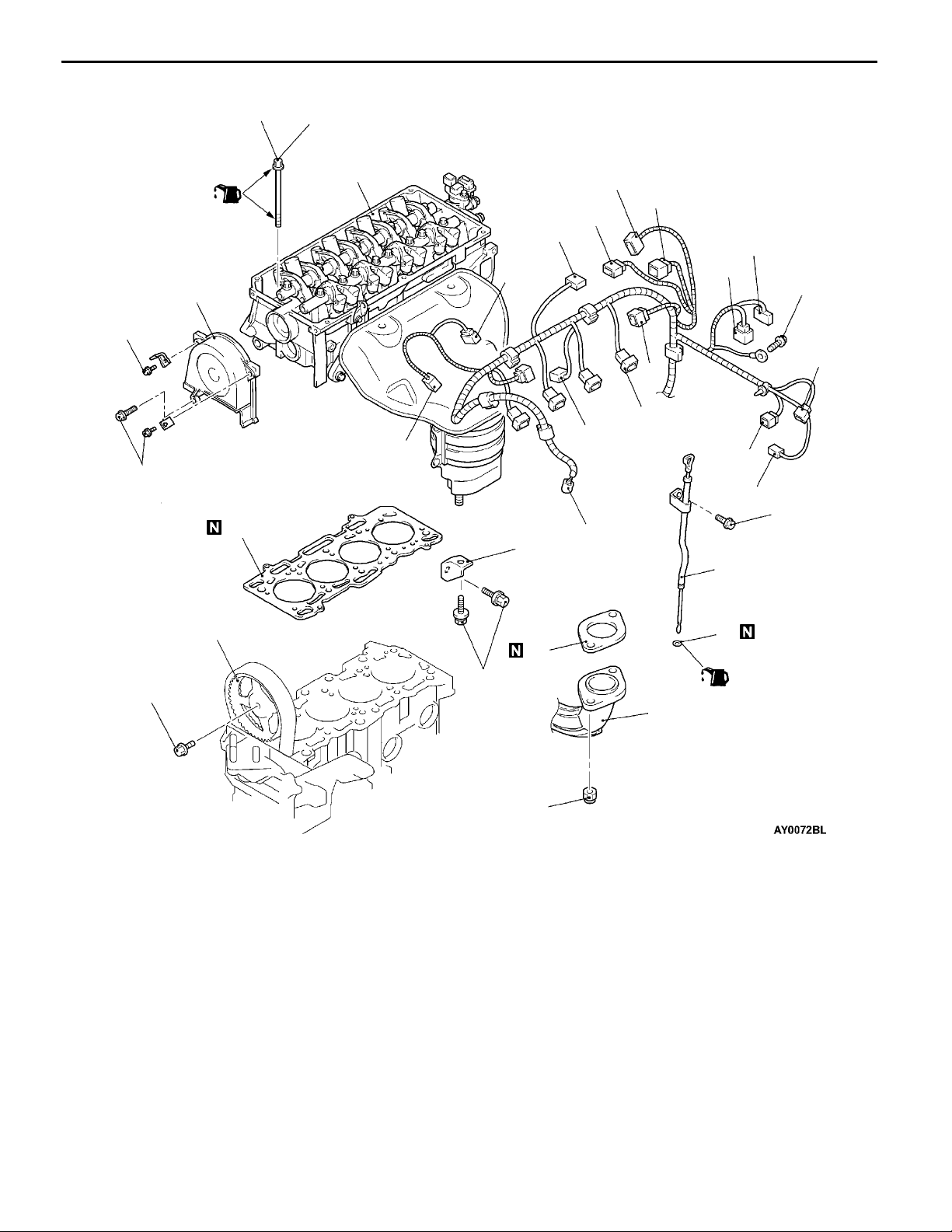

ENGINE <4G1> - Cylinder Head Gasket

11A-13

(Engine oil)

10 - 12 Nm

10 - 12 Nm

21

25

23

49 Nm®0Nm®20 Nm®+90°®+90°(Cold engine)

24

8

9

10

4

2

5

6

7

3

1

18

14

15

5.0 Nm

12

13

11

24 Nm

19

88 Nm

22

Removal steps

1. Crank angle sensor connector

2. Detonation sensor connector

3. Oxygen sensor (rear) connector

4. Vacuum sensor connector

5. Ignition coil connector

6. Injector connector

7. EGR solenoid valve connector

8. Throttle position sensor connector

9. Idle speed control servo connector

10. Purge control solenoid valve

connector

11. Engine coolant temperature gauge

unit connector

12. Oxygen sensor (front) connector

13. Engine coolant temperature sensor

connector

35 Nm

50 Nm

AA""CA

AB""BA

17

"AA

20

(Engine oil)

16

14. Ignition failure sensor connector

15. Camshaft position sensor connector

D

Rocker cover (Refer to P.11A-8.)

D

Intake manifold

(Refer to GROUP 15.)

D

Water inlet pipe (Refer to GROUP 14.)

16. Front exhaust pipe connection

17. Front exhaust pipe gasket

18. Exhaust manifold bracket

19. Oil level gauge assembly

20. O-ring

21. Timing belt front upper cover

22. Camshaft sprocket

23. Cylinder head bolts

24. Cylinder head assembly

25. Cylinder head gasket

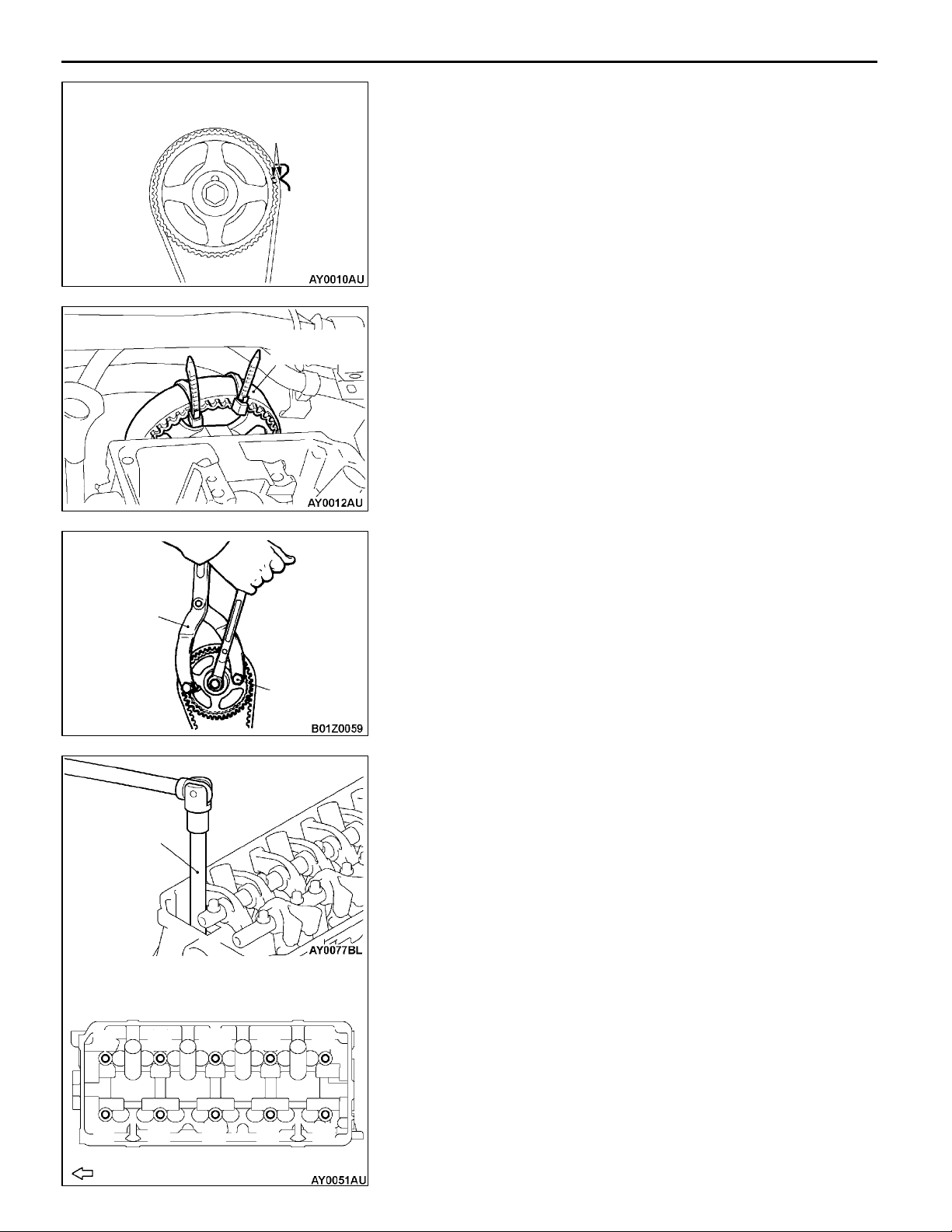

Page 20

11A-14

ENGINE <4G1> - Cylinder Head Gasket

REMOVAL SERVICE POINTS

Timing mark

Camshaft

sprocket

AA"

1. Turn the crankshaft in the forward direction (clockwise)

2. Secure the camshaft sprocket and the timing belt with

CAMSHAFT SPROCKET REMOVAL

to align the timing mark so that No.1 cylinder is at the

compression TDC.

Caution

Always turn the crankshaft in the forward direction

(clockwise).

band cables to prevent deviation from the relative positions

between the camshaft sprocket and the timing belt.

MB990767

MB991653

MD998719

3. Use the special tool to stop the camshaft sprocket from

turning.

4. Remove the camshaft sprocket with the timing belt

attached.

Caution

Do not turn the crankshaft after the camshaft sprocket

is removed.

AB"

CYLINDER HEAD BOLT REMOVAL

Use the special tool to loosen the bolts in 2 or 3 steps in

order of the numbers shown in the illustration, a nd remove

the cylinder head assembly.

3

1

Front of engine

5

7

10

9

8

6

2

4

Page 21

ENGINE <4G1> - Cylinder Head Gasket

INSTALLATION SERVICE POINTS

"AA

1. Wipe off all oil and grease from the gasket mounting

2. Install so that the shapes of the cylinder head holes match

CYLINDER HEAD GASKET INSTALLATION

surface.

Caution

Do not allow foreign material to enter the engine

coolant or oil passages and the cylinder.

the shapes of the respective cylinder head gasket holes.

11A-15

(Engine oil)

MB991653

"BA

CYLINDER HEAD BOLT INSTALLATION

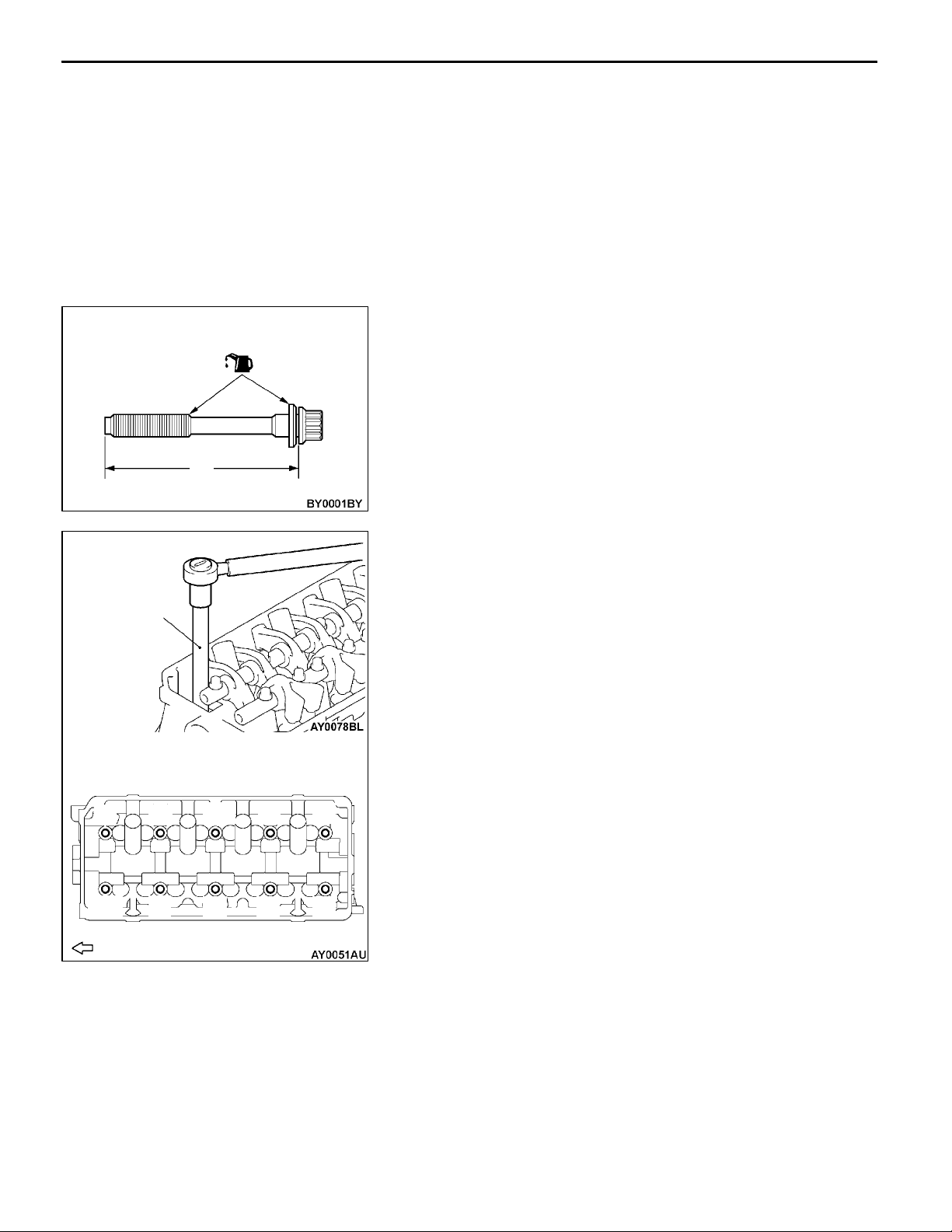

1. When installing the cylinder head bolts, the length below

the head of the bolts should be within the limit.

If it is outside the limit, replace the bolts.

Limit (A): 103.2 mm

2. Apply a small amount of engine oil to the thread section

and the washer of the cylinder head bolt.

A

3. Use the special tool to tighten the bolts by the following

procedure (angle-tightening procedure).

(1) Tighten the cylinder head bolts in the shown sequence

to 49 Nm.

(2) Loosen the cylinder head bolts completely in the

reverse of the shown sequence.

(3) Tighten the cylinder head bolts in the shown order

to 20 Nm.

8

10

Front of engine

6

4

1

2

3

5

9

7

Page 22

11A-16

ENGINE <4G1> - Cylinder Head Gasket

Step (4)

90

Painted mark

Step (5)

_

90

_

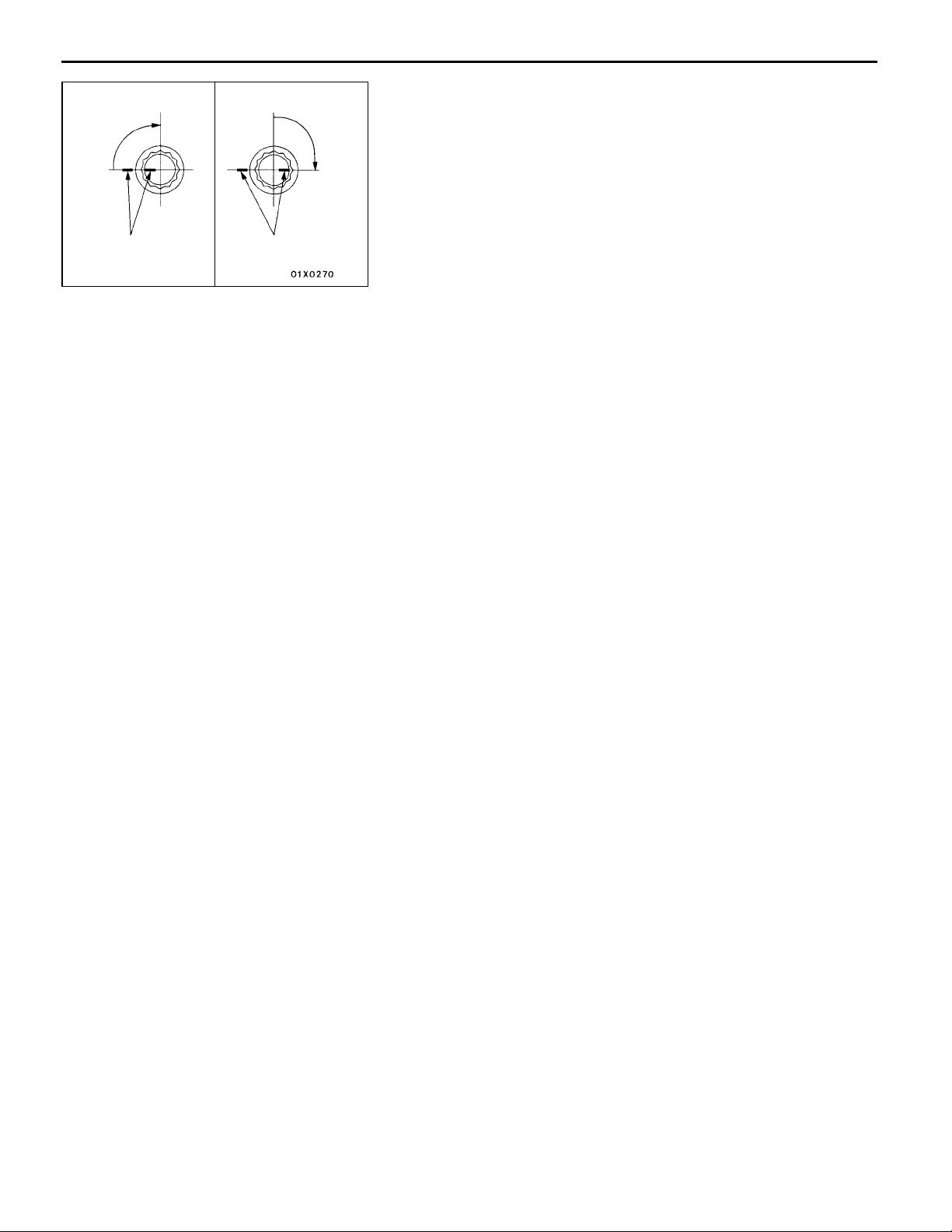

(4) Mark the cylinder head bolts and the cylinder head with

paint, and then tighten the bolts in the shown

sequence to 90°.

(5) Tighten the bolts in the shown sequence to additional

90°, and check that the paint marks on the cylinder

head bolts are flush with the paint marks on the

cylinder head.

Caution

Painted mark

1) If the tightening angle is less than 90°, the

bolt is loose.

2) If the tightening angle is more than 90°, loosen

the bolt and repeat the procedure from step

1.

"CA

CAMSHAFT SPROCKET INSTALLATION

Use the special tool to stop the camshaft sprocket from turning

in the same way as was done during removal, and then tighten

the bolts to the specified torque.

Tightening torque: 88 Nm

Page 23

ENGINE <4G9>

CONTENTS

11B-1

GENERAL 2.................................

Outline of Changes 2..........................

GENERAL INFORMATION 2..................

SPECIAL TOOL 2............................

ON-VEHICLE SERVICE 2.....................

Ignition Timing Check 2........................

Lash Adjuster Check 2.........................

CAMSHAFT AND CAMSHAFT OIL SEAL 5....

TIMING BELT 6..............................

Page 24

11B-2

ENGINE <4G9> -

General/General Information/

Special Tool/On-vehicle Service

GENERAL

OUTLINE OF CHANGES

The following service procedures have been

changed. Furthermore, other items are the same

as before.

D The valve timing has been changed.

D The ignition timing has been changed.

D An auto-lash adjuster has been added.

D The timing belt lower cover has been changed.

GENERAL INFORMATION

Items 4G9

V alve timing Intake Opening BTDC 12

Closing ABDC 46

Exhaust Opening BBDC 46

Closing ATDC 2

SPECIAL TOOL

Tool Number Name Use

MD998443 Auto-lash adjuster

holder

ON-VEHICLE SERVICE

_

_

_

_

Supporting of lash adjuster

IGNITION TIMING CHECK

The ignition timing has been changed. Other service

procedures are the same as before.

Standard value: Approx. 8_BTDC

LASH ADJUSTER CHECK

If an abnormal noise (knocking) that seems to be coming

from the lash adjuster is heard after starting the engine and

does not stop, carry out the following check.

NOTE

(1) The abnormal noise which is caused by a problem

with the lash adjusters is generated after the engine

is started, an d will vary according to the engine speed.

However, this noise is not related to the actual engine

load.

Page 25

ENGINE <4G9> -

(2) If there is a problem with the lash adjusters, the noise

1. Start the engine.

2. Check that the noise occurs immediately after the engine

is started, and that the noise changes in accordance

with changes in the engine speed.

If the noise does not occur immediately after the engine

is started, or if it does not change in accordance with

the engine speed, the problem is not being caused by

the lash adjusters, so check for some other cause of

the problem. Moreover, if the noise does not change in

accordance with the engine speed, the cause of the

problem is probably not with the engine. (In these cases,

the lash adjusters are normal.)

3. While the engine is idling, check that the noise level does

not change when the engine load is varied (for example,

by shifting from N ® D).

If the noise level changes, the cause of the noise is

probably parts striking because of worn crankshaft

bearings or connecting rod bearings. (In such cases, the

lash adjusters are normal.)

4. After the engine has warmed up, run it at idle and check

if any noise can be heard.

If the noise has become smaller or disappeared, oil sludge

could make the lash adjusters stick. Clean the lash

adjusters. (Refer to the Engine Workshop Manual.) If not

improved, go to step 5.

5. Bleed air from the lash adjusters.

6. If the noise has not disappeared even after the air

bleeding, clean the lash adjusters. (Refer to the Engine

Workshop Manual.)

On-vehicle Service

Because of this, if the noise does not occur

immediately after the engine is started, if it does not

change in accordance with the engine speed, or if

it changes in accordance with the engine load, the

source of the noise is not the lash adjusters.

will almost never disappear, even if the engine has

been run at idle to let it warm up.

The only case where the noise might disappear is

if the oil in the engine has not been looked after

properly and oil sludge has caused the lash adjusters

to stick.

11B-3

<LASH ADJUSTER AIR BLEEDING>

NOTE

(1) If the vehicle is parked on a slope for a long period

of time, the amount of oil inside the lash adjuster

will decrease, and air may get into the high pressure

chamber when starting the engine.

(2) After parking the vehicle for long periods, the oil drains

out of the oil passage, and it takes time for the oil

to be supplied to th e lash adjuster, so air can get

into the high pressure chamber.

(3) If either of the above situations occur, the abnormal

noise can be eliminated by bleeding the air from inside

the lash adjusters.

Page 26

11B-4

Good

ENGINE <4G9> -

1. Check the engine oil and replenish or replace the oil

if necessary.

NOTE

(1) If there is a only small amount of oil, air will be drawn

(2) If the amount of oil is greater than normal, then the

(3) If the oil is degenerated, air and oil will not separate

On-vehicle Service

in through the oil screen and will get into the oil

passage.

oil will being mixed by the crankshaft and a large

amount of air may get mixed into the oil.

easily in oil, and the amount of air mixed into the

oil will increase.

Drive pattern for air bleeding

Gradually open the

throttle valve.

Approx.

3,000 r/min

Idle speed

15

seconds

Once

Close the throttle

valve.

15

seconds

Highpressure

chamber

(4) If the air which has been mixed in with the oil due

to any of the above reasons gets into the high pressure

chamber of the lash adjuster, the air inside the high

pressure chamber will be compressed when the valve

is open and the lash adjuster will over-compress,

resulting in abnormal noise when the valve closes.

This is the same effect as if the valve clearance is

adjusted to be too large by mistake. If the air inside

the lash adjusters is then released, the operation

of the lash adjusters will return to normal.

2. Run the engine at idle for 1 - 3 minutes to let it warm

up.

3. With no load on the engine, repeat the drive pattern shown

in the illustration at left and check if the abnormal noise

disappears. (The noise should normally disappear after

10 - 30 repetitions, but if there is no change in the noise

level after 30 repetitions or more, the problem is probably

not due to air inside the lash adjusters.)

4. After the noise has disappeared, repeat the drive pattern

shown in the illustration at left a further 5 times.

5. Run the engine at idle for 1 - 3 minutes and check that

the noise has disappeared.

Page 27

ENGINE <4G9> - Camshaft and Camshaft Oil Seal

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

28 - 34 Nm

Apply engine oil to all

sliding parts during

installation.

1

11B-5

2

AA""AA

AA""AA

Notch

Notch

Front of engine

Removal steps

1. Lash adjuster, intake rocker arm

and shaft assembly

2. Lash adjuster, exhaust rocker arm

and shaft assembly

MD998443

REMOVAL SERVICE POINT

AA"

Before removing the lash adjuster, rocker arm a nd shaft

assembly, install the special tools as shown in the illustration

so that the lash adjusters will not fall out.

LASH ADJUSTER, INTAKE ROCKER ARM AND

SHAFT ASSEMBLY/LASH ADJUSTER, EXHAUST

ROCKER ARM AND SHAFT ASSEMBLY

REMOVAL

INSTALLATION SERVICE POINT

"AA

Position the rocker arm shafts so that their notches point

the direction shown, and install the lash adjuster, rocker arm

and shaft assembly.

LASH ADJUSTER, EXHAUST ROCKER ARM AND

SHAFT ASSEMBLY/LASH ADJUSTER, INTAKE

ROCKER ARM AND SHAFT ASSEMBLY

INSTALLATION

Page 28

11B-6

ENGINE <4G9> - Timing Belt

TIMING BELT

REMOVAL AND INSTALLATION

1

10 Nm

10 Nm

Removal steps

1. Crank angle sensor connector

"AA 2. Timing belt lower cover

2

INSTALLATION SERVICE POINT

"AA

1. Mount the bolt shown in the illustration (M6´20 mm)

2. Mount the other bolts, and tighten them to the specified

TIMING BELT LOWER COVER INSTALLATION

first.

torque.

Tightening torque: 10 Nm

Page 29

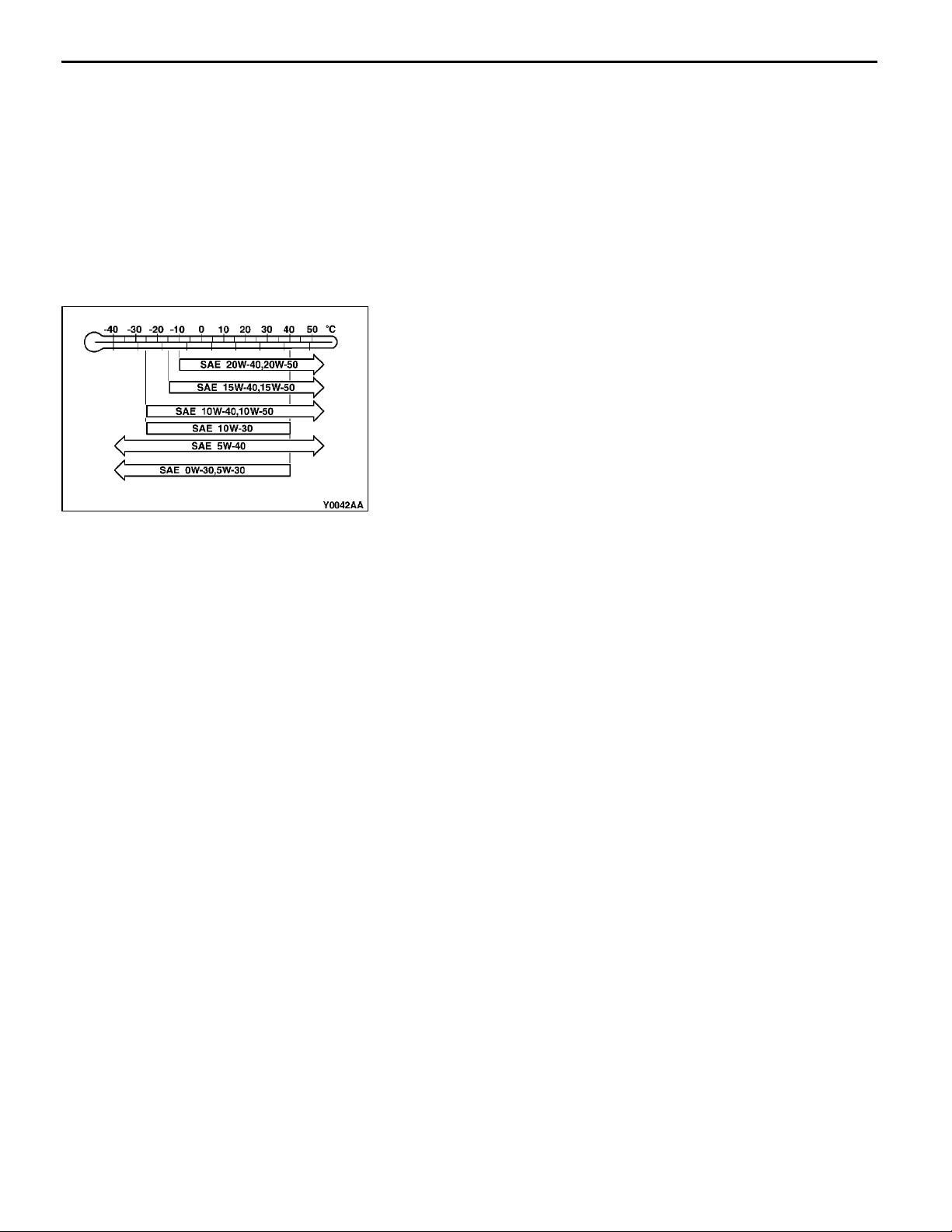

ENGINE LUBRICATION -

GROUP 12

ENGINE LUBRICATION

GENERAL

OUTLINE OF CHANGE

A quality of the engine oil has been changed.

ON-VEHICLE SERVICE

Specified Engine Oil (ACEA and API classification):

General/On-vehicle Service

ACEA A1, A2, A3/API SG or higher

12-1

Page 30

NOTES

Page 31

13A-1

MULTIPOINT FUEL

INJECTION (MPI)

CONTENTS

MULTIPOINT FUEL INJECTION (MPI)

<4G1> 2..............................

GENERAL 2...............................

Outline of Changes 2........................

GENERAL INFORMATION 2................

Self-diagnosis Function 2.....................

General Specifications 2......................

Multi-point Fuel Injection System

Diagnosis 3.................................

SERVICE SPECIFICATIONS 4..............

SPECIAL TOOLS 4........................

TROUBLESHOOTING 5....................

Diagnosis Function 5.........................

Fail-safe Function Reference Table 8...........

Inspection Chart for Diagnosis Codes 9........

Inspection Procedure Classified by Diagnosis

Code 10....................................

Inspection Chart for Trouble Symptoms 39......

Inspection Procedure for Trouble

Symptoms 40...............................

Data List Reference Table 65..................

Actuator Test Reference Table 70..............

Check at the Engine-ECU Terminals 71.........

Inspection Procedure Using an Analyzer 72.....

ON-VEHICLE SERVICE 78.................

Basic Idle Speed Adjustment 78...............

Component Location 79......................

Intake Air Temperature Sensor Check 80.......

Oxygen Sensor Check 80....................

INJECTOR 82............................

MULTIPOINT FUEL INJECTION (MPI)

<4G9> 84.............................

GENERAL 84.............................

Outline of Changes 84.......................

GENERAL INFORMATION 84..............

Self-diagnosis Function 84....................

General Specifications 84.....................

TROUBLESHOOTING 85..................

Diagnosis Function 85........................

Fail-safe Function Reference Table 89..........

Inspection Chart for Diagnosis Codes 90.......

Inspection Procedure Classified by Diagnosis

Code 92....................................

Inspection Chart for Trouble Symptoms 125.....

Inspection Procedure for Trouble

Symptoms 126..............................

Data List Reference Table 153.................

Actuator Test Reference Table 158.............

Check at the Engine-ECU Terminals 159........

Inspection Procedure Using an Analyzer 166....

Page 32

13A-2

MPI <4G1> -

General/General Information

MULTIPOINT FUEL INJECTION (MPI) <4G1>

GENERAL

OUTLINE OF CHANGES

The service procedures have been established to describe revised sections due to the changed items

shown below.

D On-board Diagnostics System has been adopted, diagnostic items have been expanded, and diagnostic

code numbering system has been changed.

D Non-distributor two-coiled ignition system has been adopted.

D Crank angle sensor attached to the crank shaft has been adopted.

D Camshaft position sensor has been added.

D Ignition failure sensor has been added.

D Intake air temperature sensor built in the vacuum sensor (manifold absolute pressure sensor) has

been adopted.

D Oxygen sensor (front, rear) has been changed.

D Ignition timing adjustment terminal has been abolished.

D Delivery pipe has been changed.

GENERAL INFORMATION

SELF-DIAGNOSIS FUNCTION

The following functions have been added.

D The engine-ECU records the engine operating condition when the diagnosis code is set.

This data is called “freeze frame” data.

This data can be read by using the MUT-II, are can then be used in simulation tests for troubleshooting.

GENERAL SPECIFICATIONS

Item Specifications

Engine-ECU Identification No. E6T31372 <Vehicles with immobilizer system>

E6T31373 <Vehicles without immobilizer system>

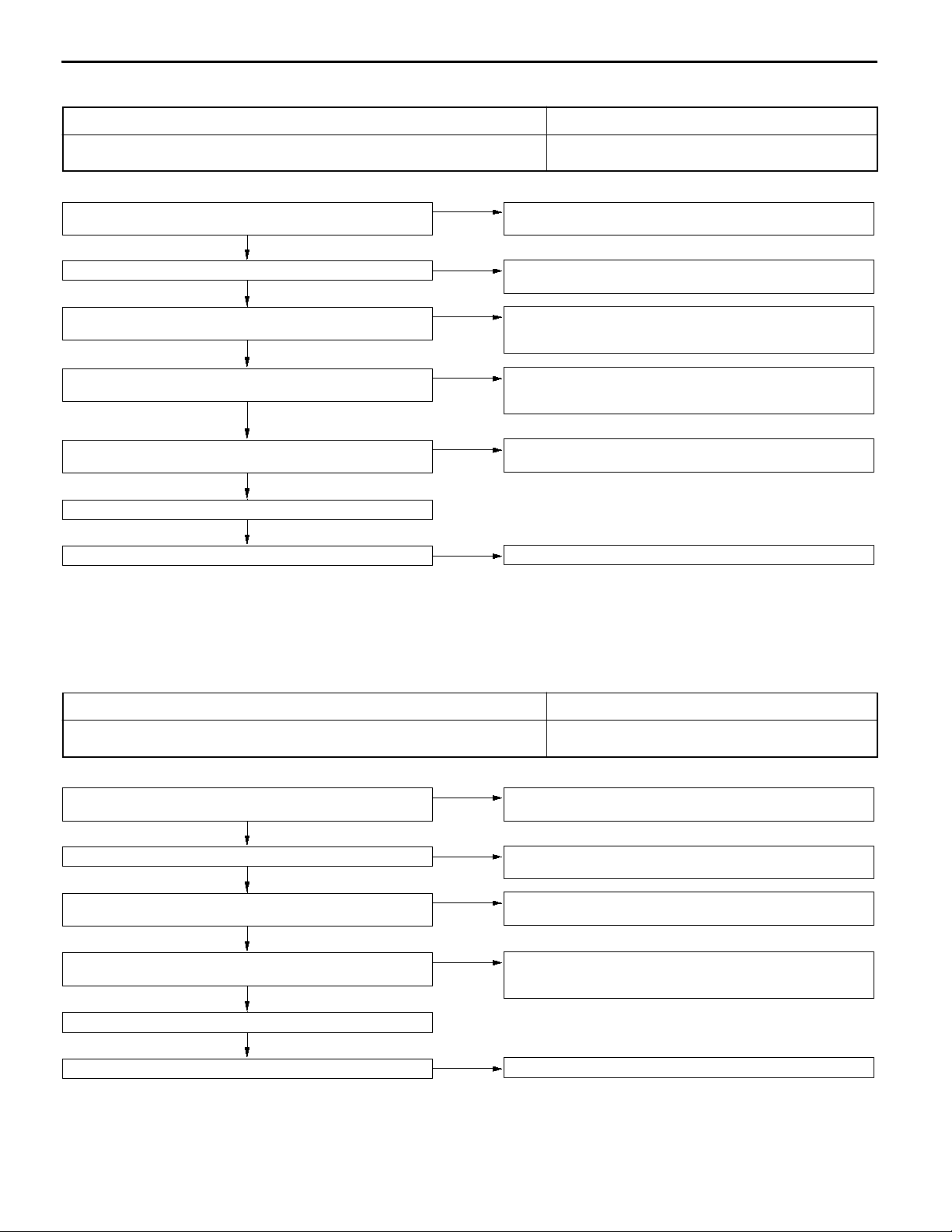

Page 33

MPI <4G1> -

General Information

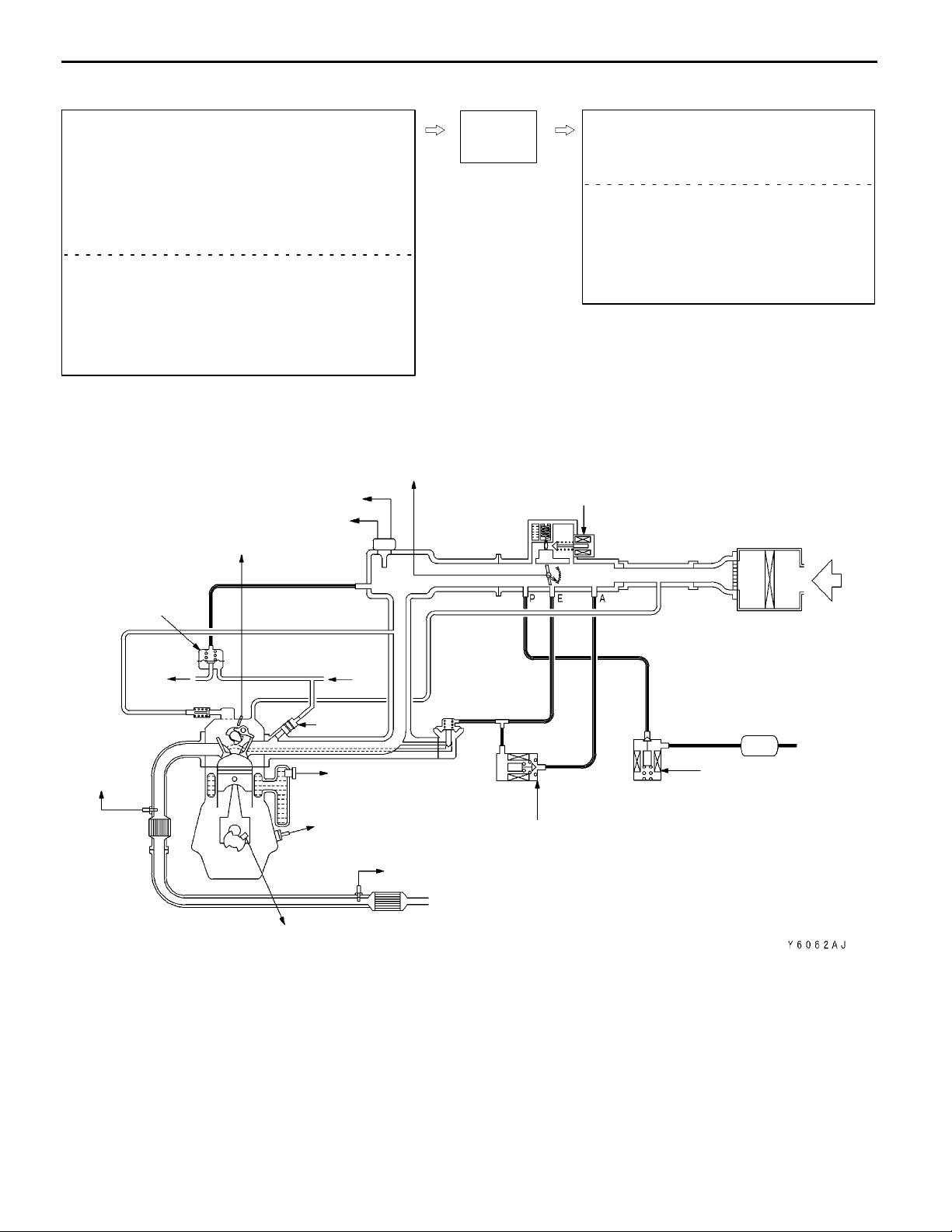

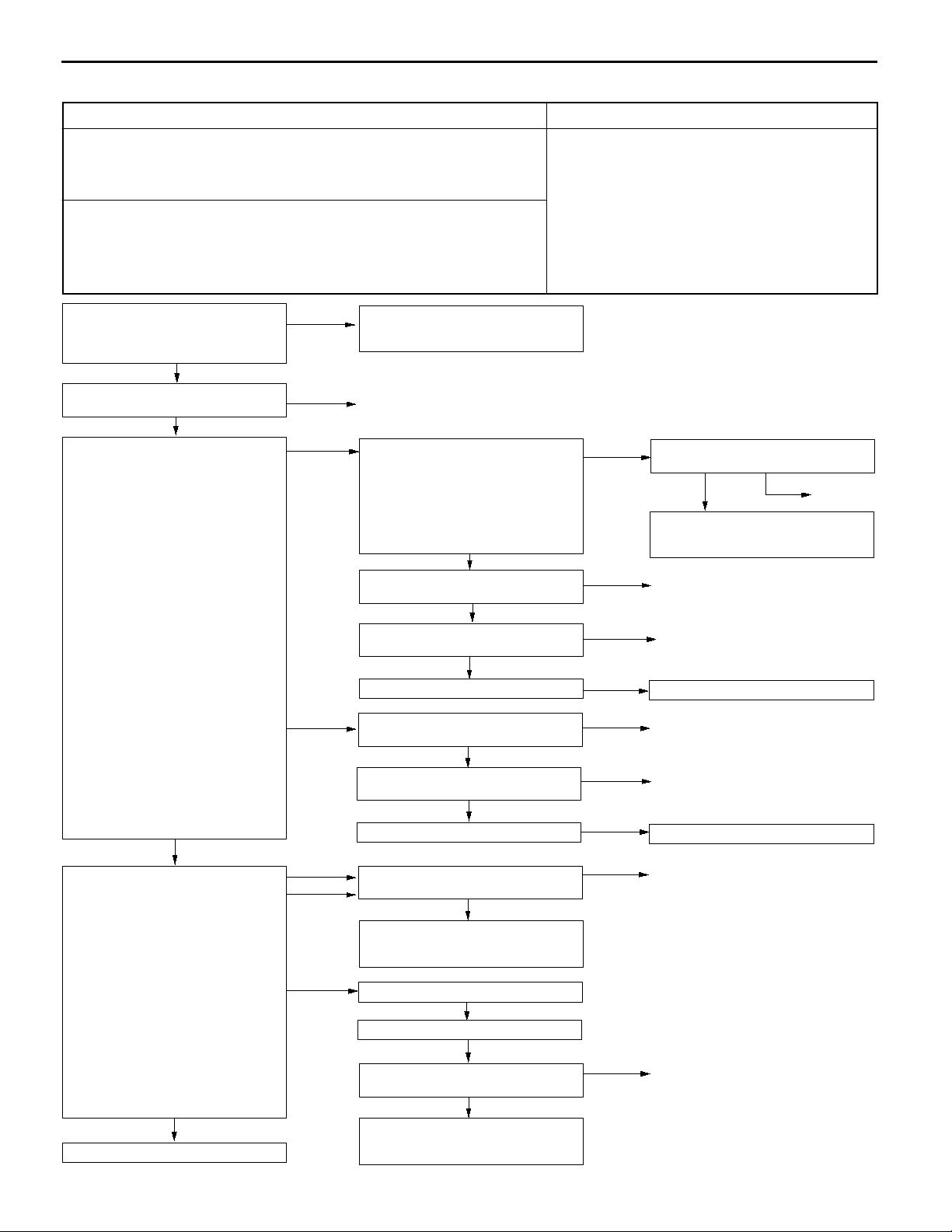

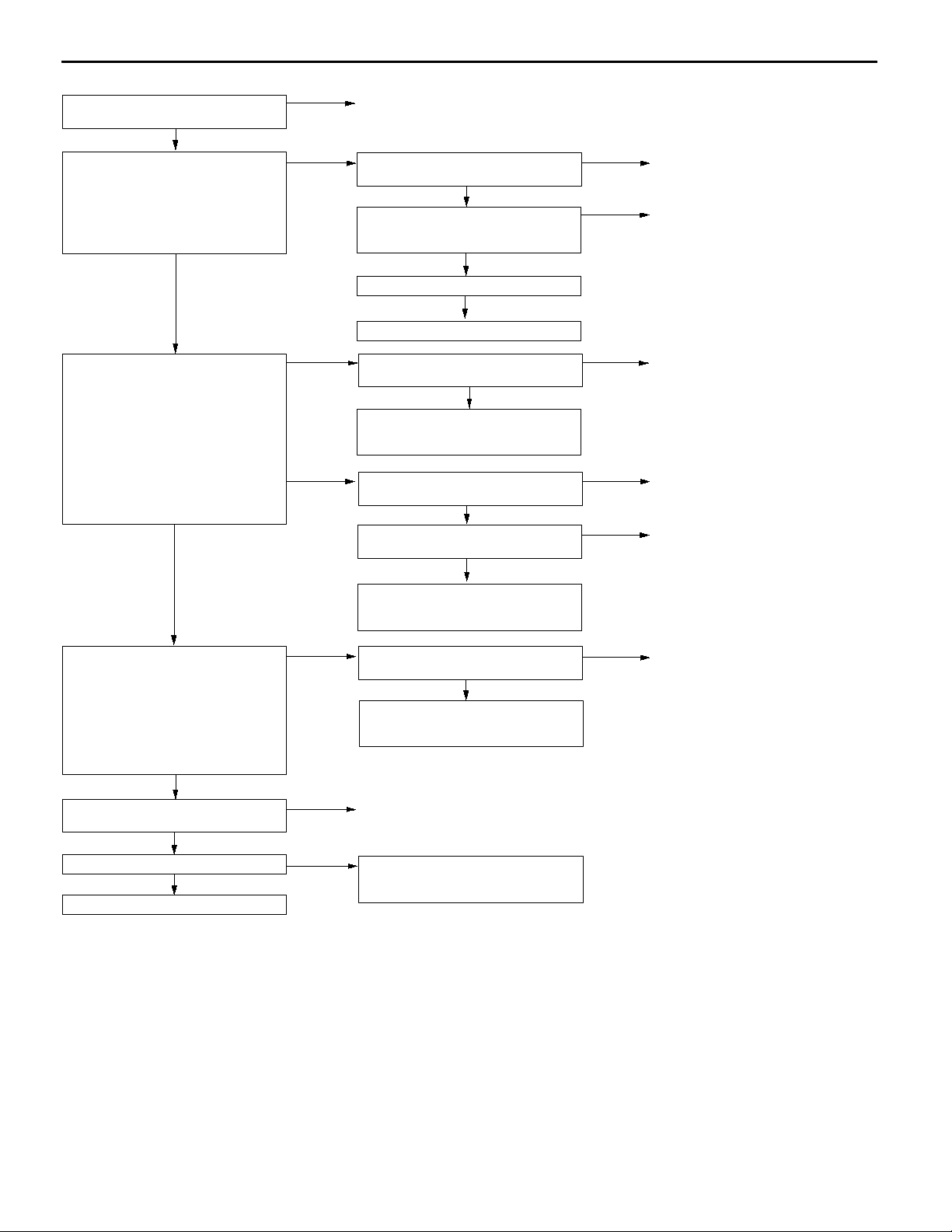

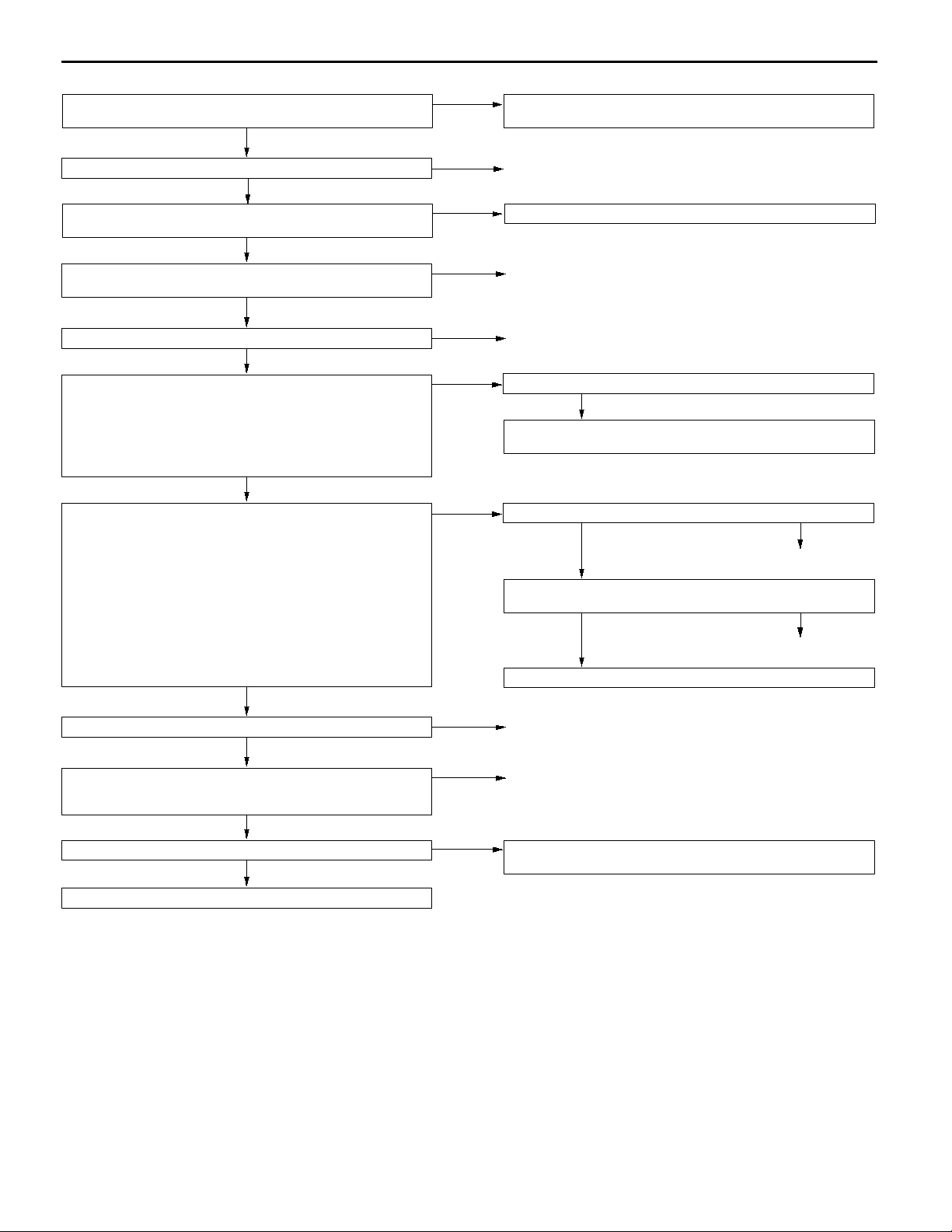

MULTI-POINT FUEL INJECTION SYSTEM DIAGRAM

13A-3

L1 Oxygen sensor (front)

L2 Vacuum sensor

L3 Intake air temperature sensor

L4 Throttle position sensor

L5 Camshaft position sensor

L6 Crank angle sensor

L7 Engine coolant temperature sensor

L8 Detonation sensor

L9 Oxygen sensor (rear)

D Power supply voltage

D Vehicle speed sensor

D A/C switch

D Power steering fluid pressure switch

D Vehicle speed sensor

D Ignition switch - ST

D Ignition switch - IG

L2 Vacuum sensor

L3 Intake air temperature sensor

L5 Camshaft position sensor

Engine-

ECU

L4 Throttle position sensor

l1 Injector

l2 Purge control solenoid valve

l3 Idle speed control valve

l4 EGR control servo valve

D Fuel pump relay

D Engine control relay

D A/C power relay

D Engine warning lamp

D Diagnosis signal

D Ignition coil (power transistor)

D Fan controller

l3 Idle speed control valve

Air cleaner

Fuel pressure

regulator

PCV valve

L1 Oxygen

sensor

(front)

Catalytic

converter

To fuel

tank

From fuel

pump

l1

Injector

L7 Engine coolant

L8 Detonation

L6 Crank angle sensor

EGR valve

temperature sensor

sensor

L9 Oxygen

sensor (rear)

Catalytic

converter

Air

Canister

l2 Purge control

solenoid valve

l4 EGR control solenoid valve

Page 34

13A-4

MPI <4G1> -

Service Specifications/Special Tools

SERVICE SPECIFICATIONS

Items Standard value

Intake air temperature sensor resistance kW 20_C 2.3 - 3.0

80_C 0.30 - 0.42

Oxygen sensor output voltage (during revving) V 0.6 - 1.0

Oxygen sensor heater resistance (at 20_C) W Front 4.5 - 8.0

Rear 11 - 18

SPECIAL TOOLS

Tool Number Name Use

MB991536 Throttle position

sensor adjustment

harness

MB991658 Test harness set D Measurement of voltage during trouble-

MD998464 Test harness

(4-pin, square)

MD998478 Test harness

(3-pin, triangle)

D Measurement of voltage during trouble-

shooting

shooting

D Measurement of voltage during trouble-

shooting

D Inspection of oxygen sensor (front)

D Measurement of voltage during trouble-

shooting

D Inspection using an analyzer

Page 35

MPI <4G1> -

TROUBLESHOOTING

DIAGNOSIS FUNCTION

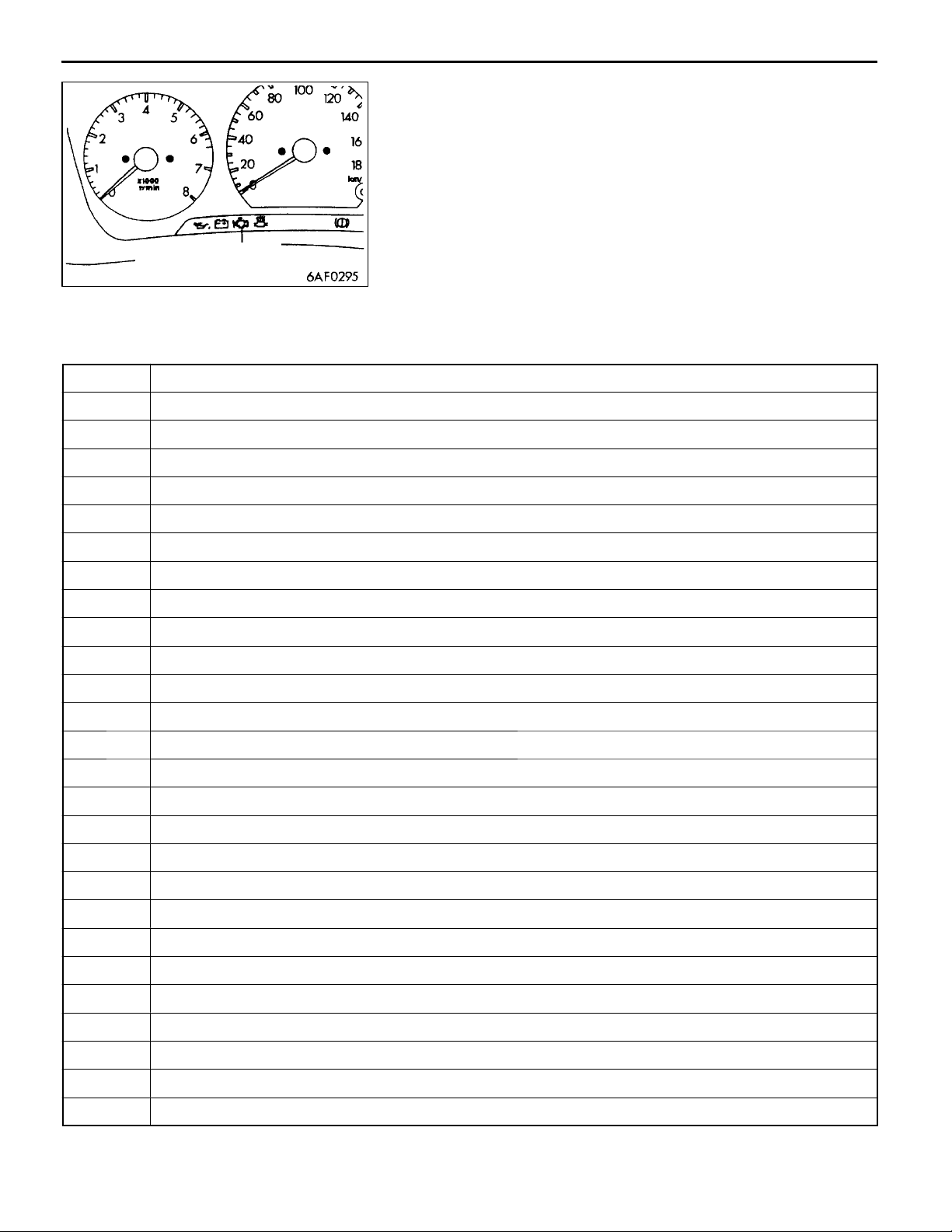

ENGINE WARNING LAMP (CHECK ENGINE LAMP)

If an abnormality occurs in any of the following items related

to the Multipoint Fuel Injection (MPI) system, the engine

warning lamp will illuminate. If th e lamp remains illuminated

Engine warning lamp

(check engine lamp)

Engine warning lamp inspection items

Code No. Diagnosis item

- Engine-ECU

P0105 Vacuum sensor system

P0110 Intake air temperature sensor system

P0115 Engine coolant temperature sensor system

or if the lamp illuminates while the engine is running, check

the diagnosis code output.

However, the warning lamp will illuminate as bulb check for

five seconds whenever the ignition switch is turned to the

ON position.

Troubleshooting

13A-5

P0120 Throttle position sensor system

P0125 Feedback system

P0130 Oxygen sensor (front) system <sensor 1>

P0135 Oxygen sensor heater (front) system <sensor 1>

P0136 Oxygen sensor (rear) system <sensor 2>

P0141 Oxygen sensor heater (rear) system <sensor 2>

P0170 Abnormal fuel system

P0201 No. 1 injector system

P0202 No. 2 injector system

P0203 No. 3 injector system

P0204 No. 4 injector system

L

P0300

P0301 No. 1 cylinder misfire detected

P0302 No. 2 cylinder misfire detected

P0303 No. 3 cylinder misfire detected

P0304 No. 4 cylinder misfire detected

Random cylinder misfire detected

P0335 Crank angle sensor system

P0340 Camshaft position sensor system

P0403 EGR control solenoid valve system

P0420 Catalyst malfunction

P0443 Purge control solenoid valve system

P0505 Idle speed control system

Page 36

13A-6

NOTE

1. If the engine warning lamp illuminates because of a malfunction of the engine-ECU, communication

between MUT-II and the engine-ECU is impossible. In this case, the diagnosis code cannot be read.

2. After the engine-ECU has detected a malfunction, the engine warning lamp illuminates when the

engine is next turned on and the same malfunction is re-detected. However, for items marked with

a“L” in the diagnosis code number column, the engine warning lamp illuminates only on the first

detection of the malfunction.

3. After the engine warning lamp illuminates, it will be switched off under the following conditions.

(1) When the engine-ECU monitored t he power train malfunction three times* and met set condition

requirements, it detected no malfunction.

*: In this case, “one time” indicates from engine start to stop.

(2) For misfiring malfunction, when driving conditions (engine speed, engine coolant temperature,

etc.) are similar to those when the malfunction was first recorded.

4. Sensor 1 indicates the sensor mounted at a position closest to the engine, and sensor 2 indicates

the sensor mounted at the position second closest to the engine.

MPI <4G1> -

Troubleshooting

METHOD OF READING AND ERASING DIAGNOSIS

CODES

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.

DIAGNOSIS USING DIAGNOSIS 2 MODE

1. Switch the diagnosis mode of the engine control unit

to DIAGNOSIS 2 mode using the MUT-II.

2. Carry out a road test.

3. Take a reading of the diagnosis code a n d repair the

problem location.

4. Turn the ignition switch to OFF and then back to ON

again.

NOTE

By turning the ignition switch to OFF, the engine-ECU

will switch the diagnosis mode from DIAGNOSIS 2 mode

to DIAGNOSIS 1 mode.

5. Erase the diagnosis codes.

INSPECTION USING MUT-IIDATA LIST AND

ACTUATOR TESTING

1. Carry out inspection by means of the data list and the

actuator test function. If there is an abnormality, check

and repair the chassis harnesses and components.

2. After repairing, re-check using the MUT-II and check that

the abnormal input and output have returned to normal

as a result of t he repairs.

3. Erase the diagnosis code memory.

4. Remove the MUT-II, and then start the engine again and

carry out a road test to confirm that the problem has

disappeared.

Page 37

MPI <4G1> -

FREEZE FRAME DATA

When the engine-ECU detects a malfunction and stores a

diagnosis code, it also stores a current status of the engine.

This function is called “freeze frame data.” By analyzing

this “freeze frame” data with the MUT-II, an effective

troubleshooting can be performed.

Displayed items of freeze frame data are shown in the

following:

DISPLAYED ITEM LIST

Data item Unit

Troubleshooting

13A-7

Engine coolant temperature sensor

Engine speed r/min

Vehicle speed km/h

Long-term fuel compensation (long-term

fuel trim)

Short-term fuel compensation (short-term

fuel trim)

Fuel control condi- Open loop OL

tion

Closed loop CL

Open loop owing to

drive condition

Open loop owing to

system malfunction

Closed loop based

on one oxygen sensor

Calculation load value %

_

C

%

%

OL-DRV.

OL-SYS.

CL-H02S

Diagnosis code during data recording -

NOTE

If malfunctions have been detected in multiple systems, store

one malfunction only, which has been detected first.

READINESS TEST STATUS

The engine-ECU monitors the following main diagnosis items,

judges if these items are in good condition or not, and the

stores its history. This history can be read out by using MUT-II.

(If the ECU has judged a item before, the MUT-II displays

“Complete.”)

In addition, if diagnosis codes are erased or the battery

cable is disconnected, this history will also be erased (the

memory will be reset).

D Catalyst: P0421

D Oxygen sensor: P0130

D Oxygen sensor heater: P0135, P0141

Page 38

13A-8

MPI <4G1> -

Troubleshooting

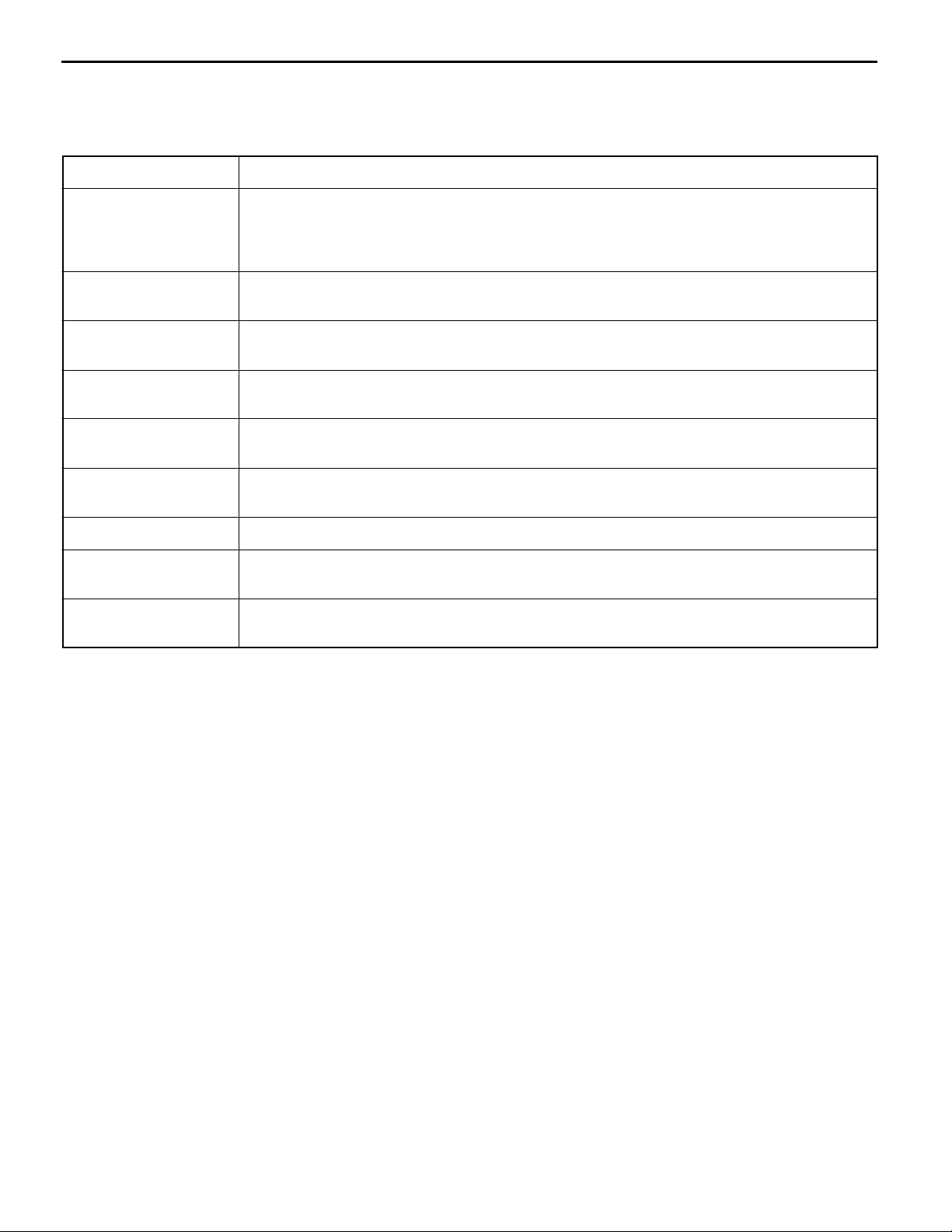

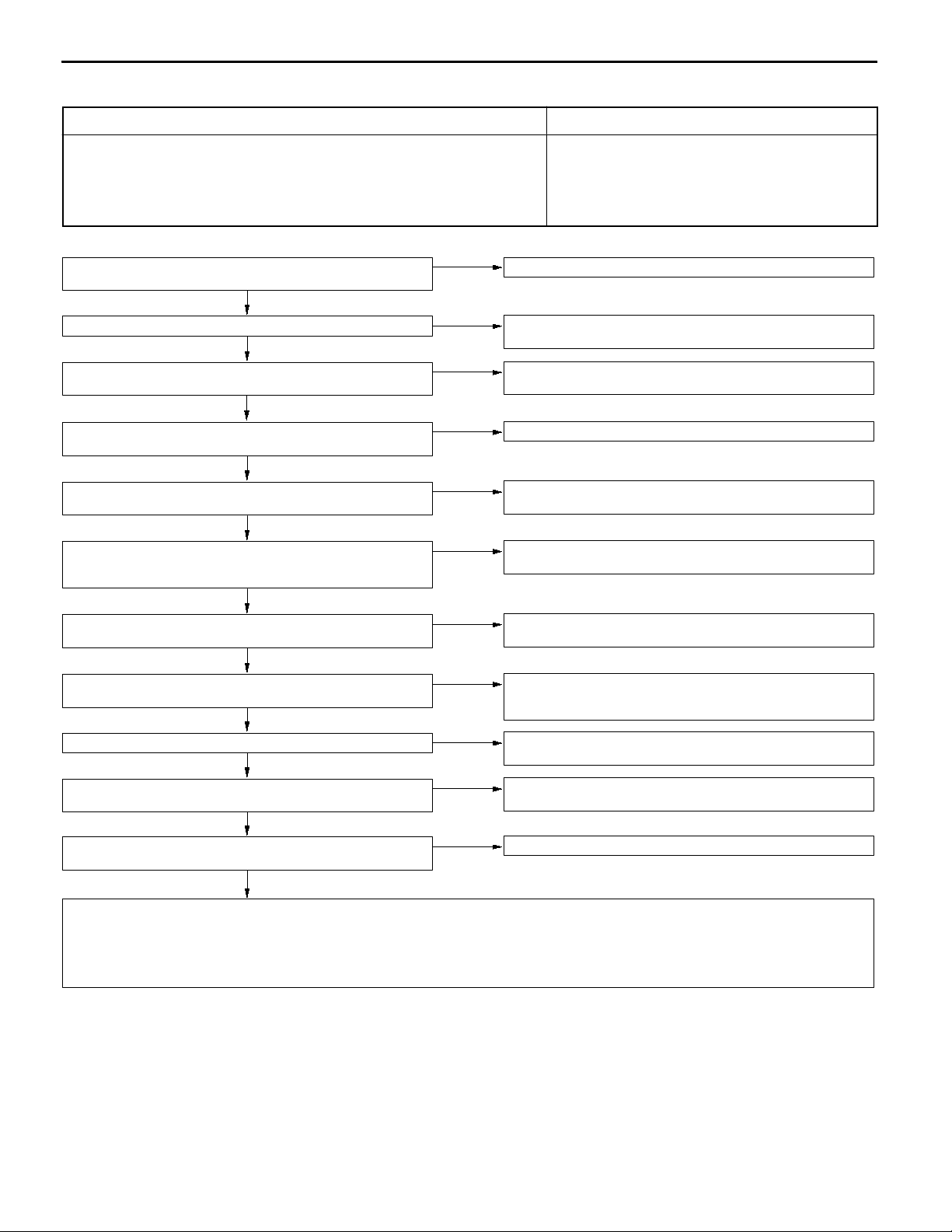

FAIL-SAFE FUNCTION REFERENCE TABLE

When the main sensor malfunctions are detected by the diagnosis function, the vehicle is controlled

by means of the pre-set control logic to maintain safe conditions for driving.

Malfunctioning item Control contents during malfunction

V acuum sensor 1. Uses the throttle position sensor signal and engine speed signal (crank angle sensor

signal) to take reading of the basic injector drive time and basic ignition timing from

the pre-set mapping.

2. Fixes the ISC servo in the appointed position so idle control is not performed.

Intake air temperature

sensor

Throttle position sensor (TPS)

Engine coolant temperature sensor

Camshaft position

sensor

Detonation sensor Switches the ignition timing from ignition timing for super petrol to ignition timing for standard

Oxygen sensor (front) Air/fuel ratio feedback control (closed loop control) is not performed.

Oxygen sensor (rear) Performs the feedback control (closed loop control) of the air/fuel ratio by using only the

Misfire detection The engine-ECU stops supplying fuel to the cylinder with the highest misfiring rate if a

Controls as if the intake air temperature is 45_C.

No increase in fuel injection amount during acceleration due to the throttle position sensor

signal.

Controls as if the engine coolant temperature is 80_C.

Injects fuelinto the cylinders inthe order 1-3-4-2with irregular timing. (After the ignitionswitch

is turned to ON, the No. 1 cylinder top dead centre is not detected at all.)

petrol.

signal of the oxygen sensor (front) installed on the front of the catalytic converter.

misfiring that could damage the catalytic converter is detected.

Page 39

MPI <4G1> -

Troubleshooting

INSPECTION CHART FOR DIAGNOSIS CODES

Code No. Diagnosis item Reference page

P0105 Vacuum sensor system 13A-10

P0110 Intake air temperature sensor system 13A-12

P0115 Engine coolant temperature sensor system 13A-13

P0120 Throttle position sensor system 13A-16

P0125 Feedback system 13A-18

P0130 Oxygen sensor (front) system <sensor 1> 13A-19

P0135 Oxygen sensor heater (front) system <sensor 1> 13A-21

P0136 Oxygen sensor (rear) system <sensor 2> 13A-22

P0141 Oxygen sensor heater (rear) system <sensor 2> 13A-24

P0170 Abnormal fuel system 13A-25

P0201 No. 1 injector system 13A-26

P0202 No. 2 injector system 13A-26

P0203 No. 3 injector system 13A-26

13A-9

P0204 No. 4 injector system 13A-26

P0300L Random cylinder misfire detected 13A-27

P0301 No. 1 cylinder misfire detected 13A-28

P0302 No. 2 cylinder misfire detected 13A-28

P0303 No. 3 cylinder misfire detected 13A-28

P0304 No. 4 cylinder misfire detected 13A-28

P0325 Detonation sensor system 13A-29

P0335 Crank angle sensor system 13A-29

P0340 Camshaft position sensor system 13A-31

P0403 EGR control solenoid valve system 13A-32

P0421 Catalyst malfunction 13A-33

P0443 Purge control solenoid valve system 13A-34

P0500 Vehicle speed sensor system 13A-35

P0505 Idle speed control system 13A-36

P1610 Immobilizer system 13A-38

NOTE

1. Do not replace the engine-ECU until a through terminal check reveals there are no short/open circuit.

2. Check that the engine-ECU earth circuit is normal before checking for the cause of the problem.

3. After the engine-ECU has detected a malfunction, a diagnosis code is recorded the next time the

engine is started and the same malfunction is re-detected. However, for items marked with a “L”,

the diagnosis code is recorded on the first detection of the malfunction.

4. Sensor 1 indicates the sensor mounted at a position closest to the engine, and sensor 2 indicates

the sensor mounted at the position second closest to the engine.

Page 40

13A-10

MPI <4G1> -

Troubleshooting

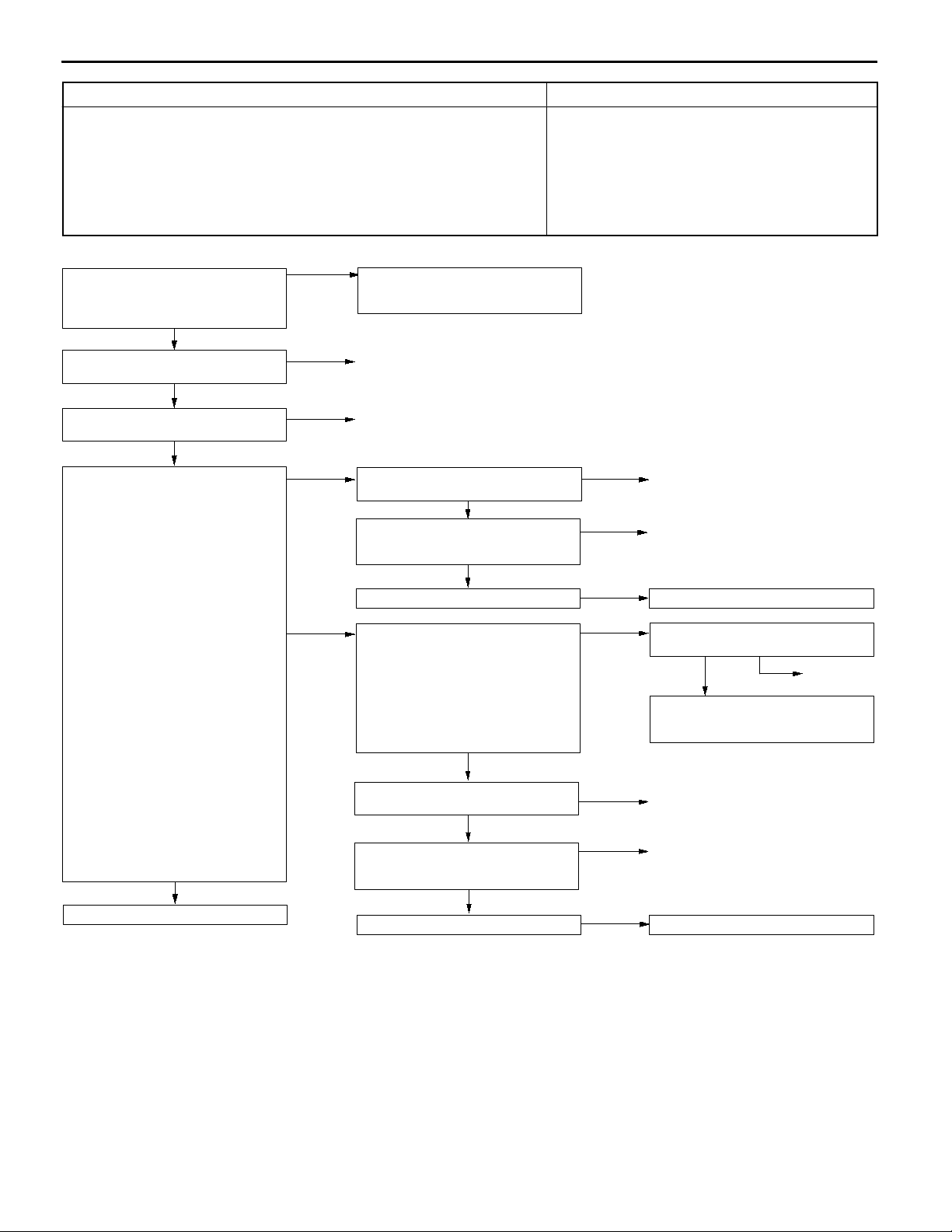

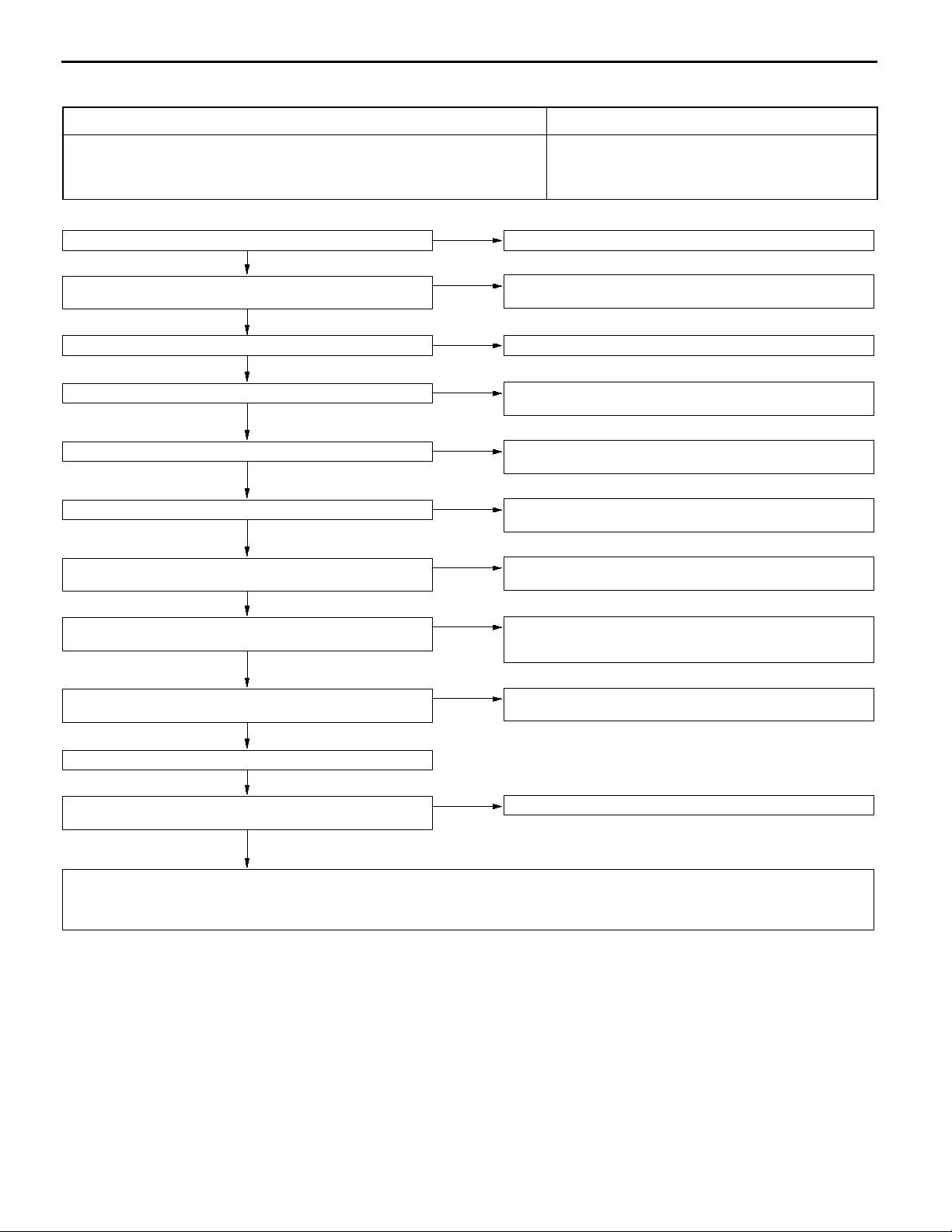

INSPECTION PROCEDURE CLASSIFIED BY DIAGNOSIS CODE

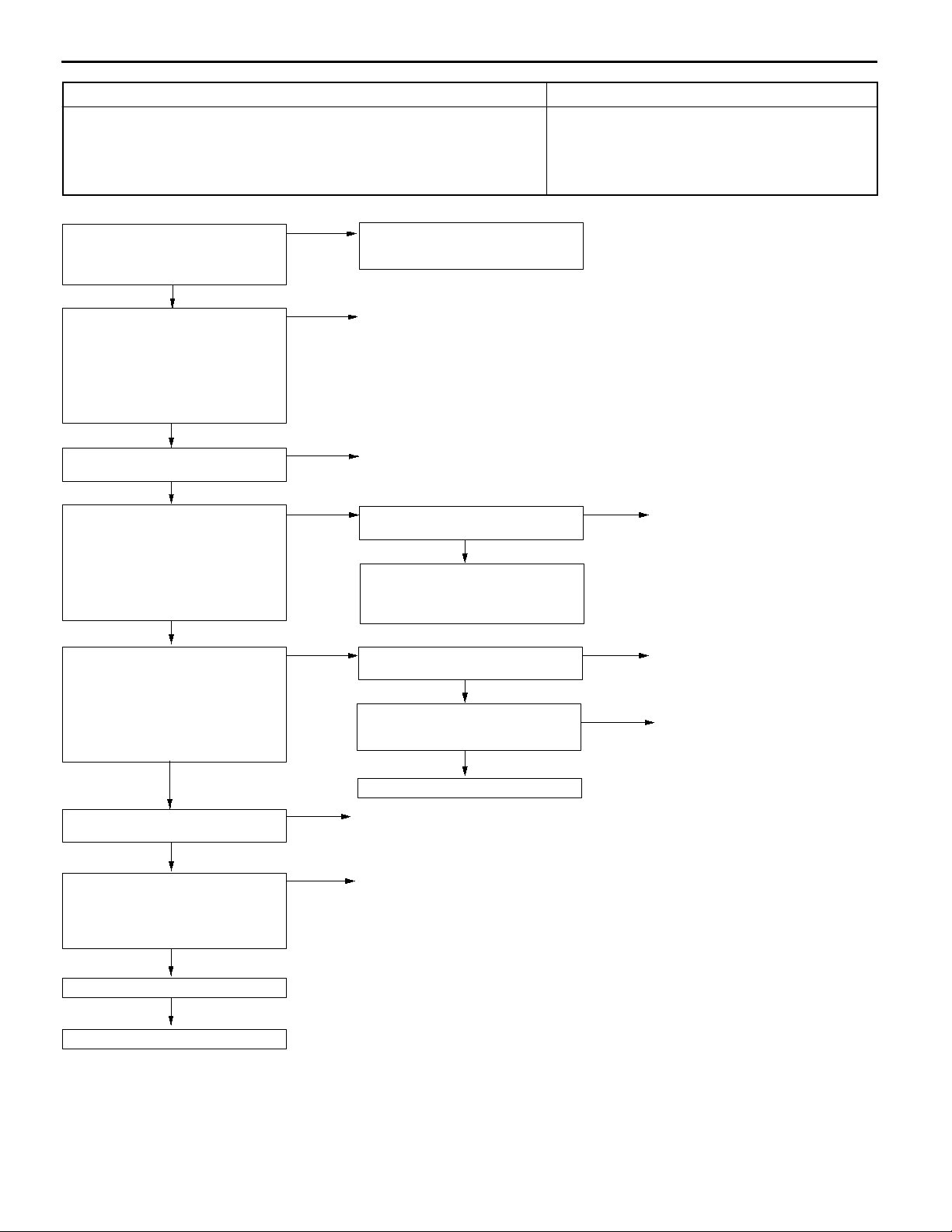

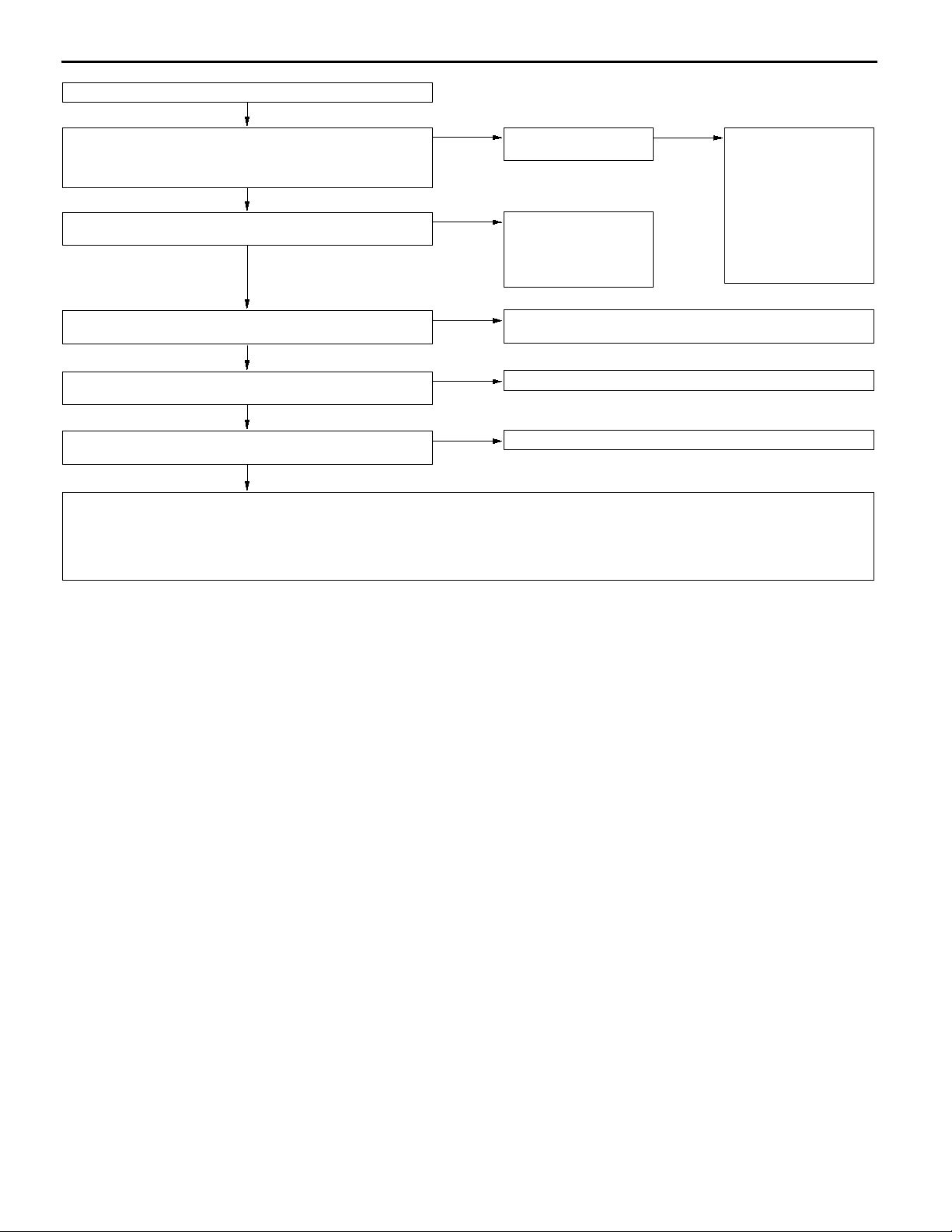

Code No. P0105 Vacuum sensor system Range of Check

Range of Check

D Ignition switch: ON

Set Conditions

D The output voltage of the vacuum sensor is 4.5 V or more for 2 seconds.

(This corresponds to the absolute manifold pressure of 115 kPa or more.)

Range of Check

D The output voltage of the throttle position sensor is 1.25 V or more.

or

D The vehicle is stationary.

Set Conditions

D The output voltage of the vacuum sensor is 0.2 V or less for 2 seconds.

(This corresponds to the absolute manifold pressure of 4.9 kPa or less.)

D Malfunction of the vacuum sensor

D Improper connector contact, open circuit or

short-circuited harness

D Malfunction of the engine-ECU

MUT-IIData list

32 Barometric pressure sensor

(Refer to P.13A-65, DATA LIST

REFERENCE TABLE.)

NG

Check the following connector:

A-54

OK

Measure at vacuum sensor

connector A-54.

D Disconnect the connector and

measure at the harness side.

(1) Voltage between terminal 3 and

earth (Ignition switch: ON)

OK:

(2) Resistance between terminal 2

Measure at vacuum sensor

connector A-54.

D Connect connector terminals No.

D Ignition switch: ON

(1) Voltage between terminal 3 and

(2) Voltage between terminal 1 and

(3) Voltage between terminal 2 and

To the next page

4.8 - 5.2 V

and earth

OK:

2 W or less

OK

1, No. 2 and No. 5 only by using

test harness (MB991348), and

measure at the pick-up harness.

earth

OK:

4.8 - 5.2 V

earth

OK:

Altitude 0 m: 3.7 - 4.3 V

Altitude 1,200 m:

3.2 - 3.8 V

earth

OK:

0.5 V or less

OK

OK

NG

(1) NG

(2) NG

(1) NG

(3) NG

(2) NG

Transient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Repair

Measure at engine-ECU connector

B-34.

D Measure the voltage at the

engine-ECU terminal.

D Ignition switch: ON

D Voltage between terminal 81 and

earth

OK:

4.8 - 5.2 V

NG

Check the following connector:

B-34

OK

Check the harness between the

vacuum sensor and the engine-ECU.

OK

Check the trouble symptoms.

Check the following connector:

B-34

OK

Check the harness between the

vacuum sensor and the engine-ECU.

OK

Check the trouble symptoms.

Check the following connector:

B-34

OK

Check the harness between the

vacuum sensor and the engine-ECU,

and repair if necessary.

Replace the vacuum sensor.

Check the trouble symptoms.

NG

Check the following connector:

B-34

OK

Check the harness between the

vacuum sensor and the engine-ECU,

and repair if necessary.

OK

NG

NG

NG

NG

NG

NG

NG

NG

Check the following connector:

B-34

OK

Check the harness between the

vacuum sensor and the engine-ECU,

and repair if necessary.

Repair

Repair

Replace the engine-ECU.

Repair

Repair

Replace the engine-ECU.

Repair

Repair

NG

Repair

Page 41

From the previous page

OK

Measure at engine-ECU connector

B-34.

D Measure the voltage at the

engine-ECU terminal.

D Ignition switch: ON

D Voltage between terminal 85 and

earth

OK:

Altitude 0 m: 3.7 - 4.3 V

Altitude 1,200 m:

3.2 - 3.8 V

MPI <4G1> -

NG

OK

Check the following connector:

B-34

Check the harness between the

vacuum sensor and the engine-ECU,

and repair if necessary.

Check the following connector:

B-34

Check the trouble symptoms.

Replace the engine-ECU.

Troubleshooting

NG

OK

NG

OK

NG

13A-11

Repair

Repair

Page 42

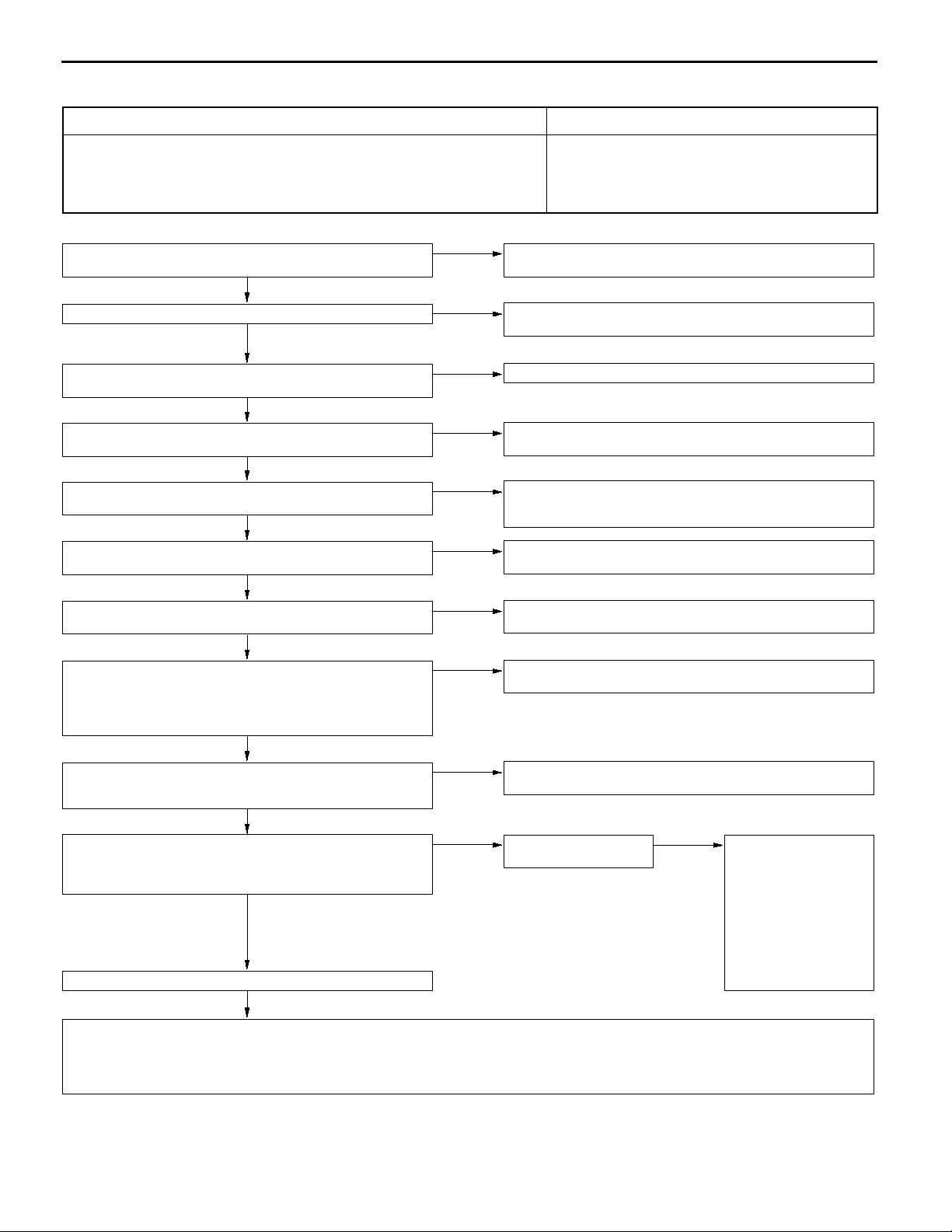

13A-12

MPI <4G1> -

Troubleshooting

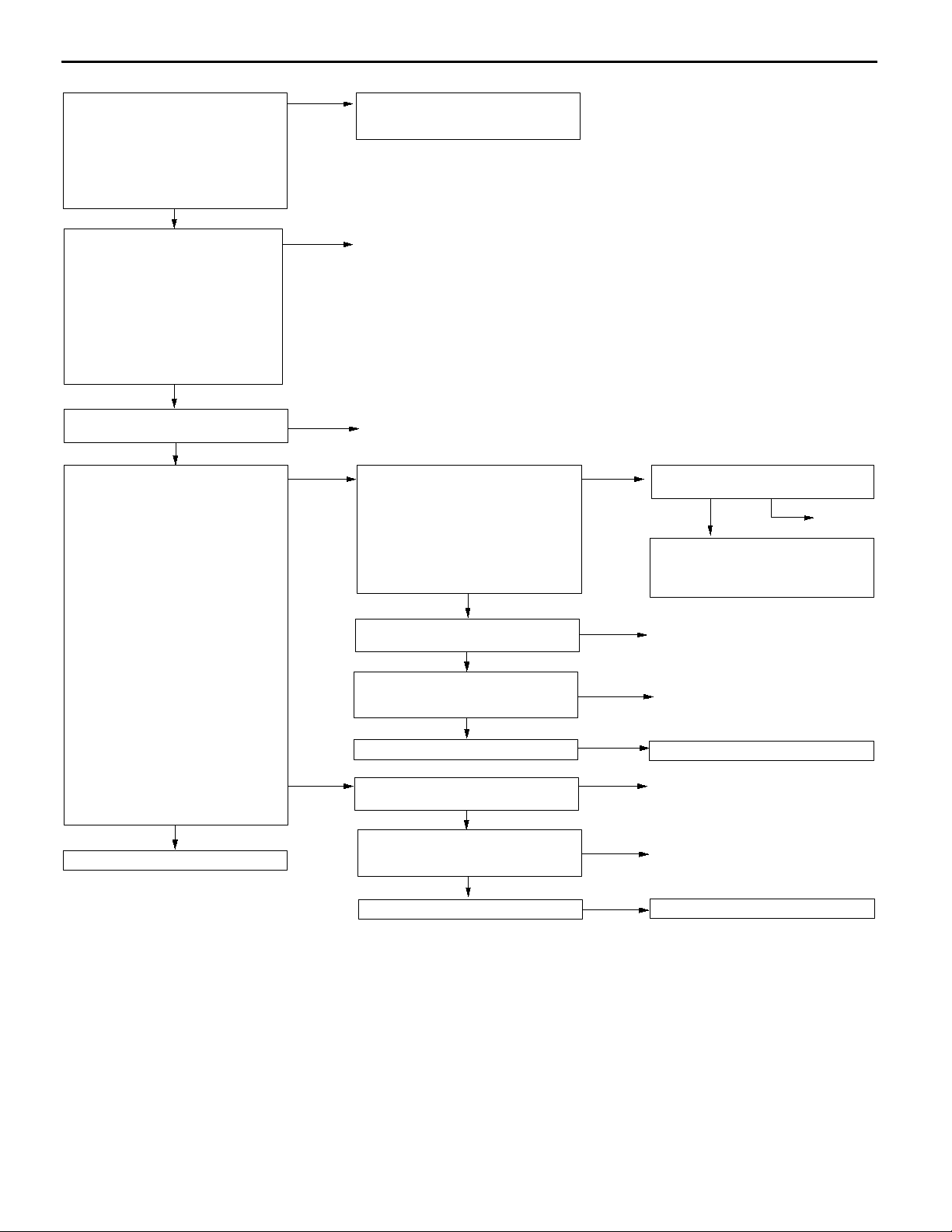

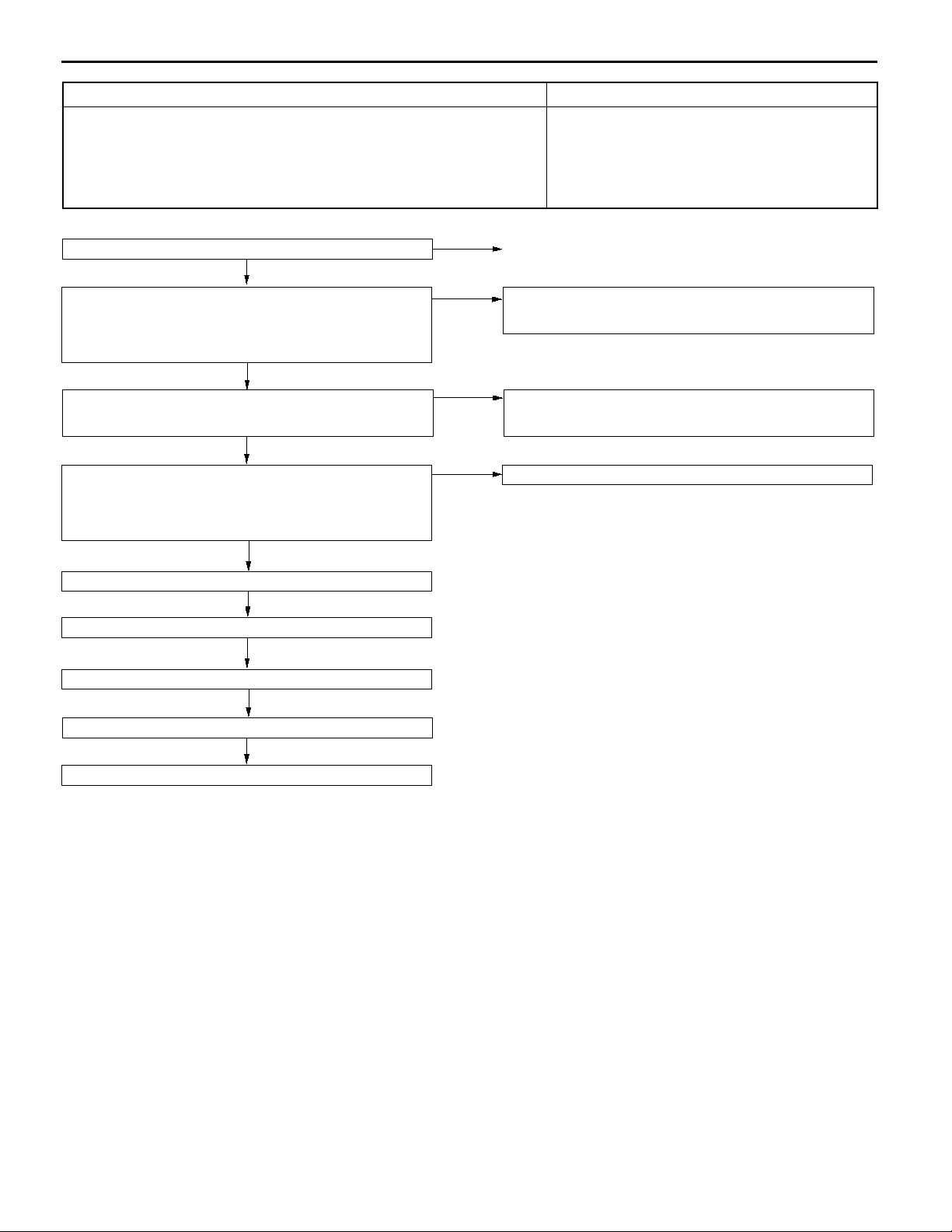

Code No. P0110 Intake air temperature sensor system Probable cause

Range of Check

D Two seconds have passed since the ignition switch is turned ON or the

engine starting process is completed.

Set Conditions

D The sensor output voltage is 4.6 V or more for two seconds (equivalent to

-45_C of intake air temperature)

or

D The sensor output voltage is 0.2 V or more for two seconds (equivalent to

125_C of intake air temperature)

D Malfunction of intake air temperature sensor

D Open or short circuit in intake air temperature

sensor or loose connector contact

D Malfunction of engine-ECU

MUT-IIData list

13 Intake air temperature sensor

OK:

Roughly the same as ambient temperature.

NG

Check the intake air temperature

sensor. (Refer to P.13A-80.)

OK

Check the following connector:

A-54

OK

Measure at vacuum sensor

connector A-54.

D Disconnect the connector and

measure at the harness side.

(1) Resistance between terminal 2

and earth

OK:

(2) Voltage between terminal 3 and

2 W or less

earth

(Ignition switch: ON)

OK:

4.8 - 5.2 V

OK

NG

NG

(1) NG

(2) NG

Transient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Repair

Repair

B-34

OK

Check the harness between the

intake air temperature sensor and

the engine-ECU.

OK

Check the trouble symptoms.

Measure at engine-ECU connector

B-34.

D Measure the voltage at the

engine-ECU terminal.

D Disconnect connector A-54.

D Ignition switch: ON

D Voltage between terminal 81 and

earth

OK:

4.8 - 5.2 V

NG

NG

NG

NG

OK

RepairCheck the following connector:

Repair

Replace the engine-ECU.

Check the following connector:

B-34

OK

Check the harness between the air

flow sensor and the engine-ECU,

and repair if necessary.

NG

Repair

To the next page

OK

Check the following connector:

B-34

OK

Check the harness between the

intake air temperature sensor and

the engine-ECU.

OK

Check the trouble symptoms.

NG

NG

NG

Repair

Repair

Replace the engine-ECU.

Page 43

From the previous page

OK

Measure at intake air temperature

sensor connector A-54.

D Use the test harness (MB991348)

to connect only terminals 1 and

3, and then measure at the

pick-up harness.

D Ignition switch: ON

D Voltage between terminal 1 and

earth

OK:

Ambient temperature 0_C:

3.2 - 3.8 V

Ambient temperature 20_C:

2.3 - 2.9 V

Ambient temperature 40_C:

1.5 - 2.1 V

Ambient temperature 80_C:

0.4 - 1.0 V

OK

Check the trouble symptoms.

MPI <4G1> -

NG

NG

Check the following connector:

B-34

Check the harness between the

intake air temperature sensor and

the engine-ECU, and repair if

necessary.

Replace the engine-ECU.

Troubleshooting

NG

OK

13A-13

Repair

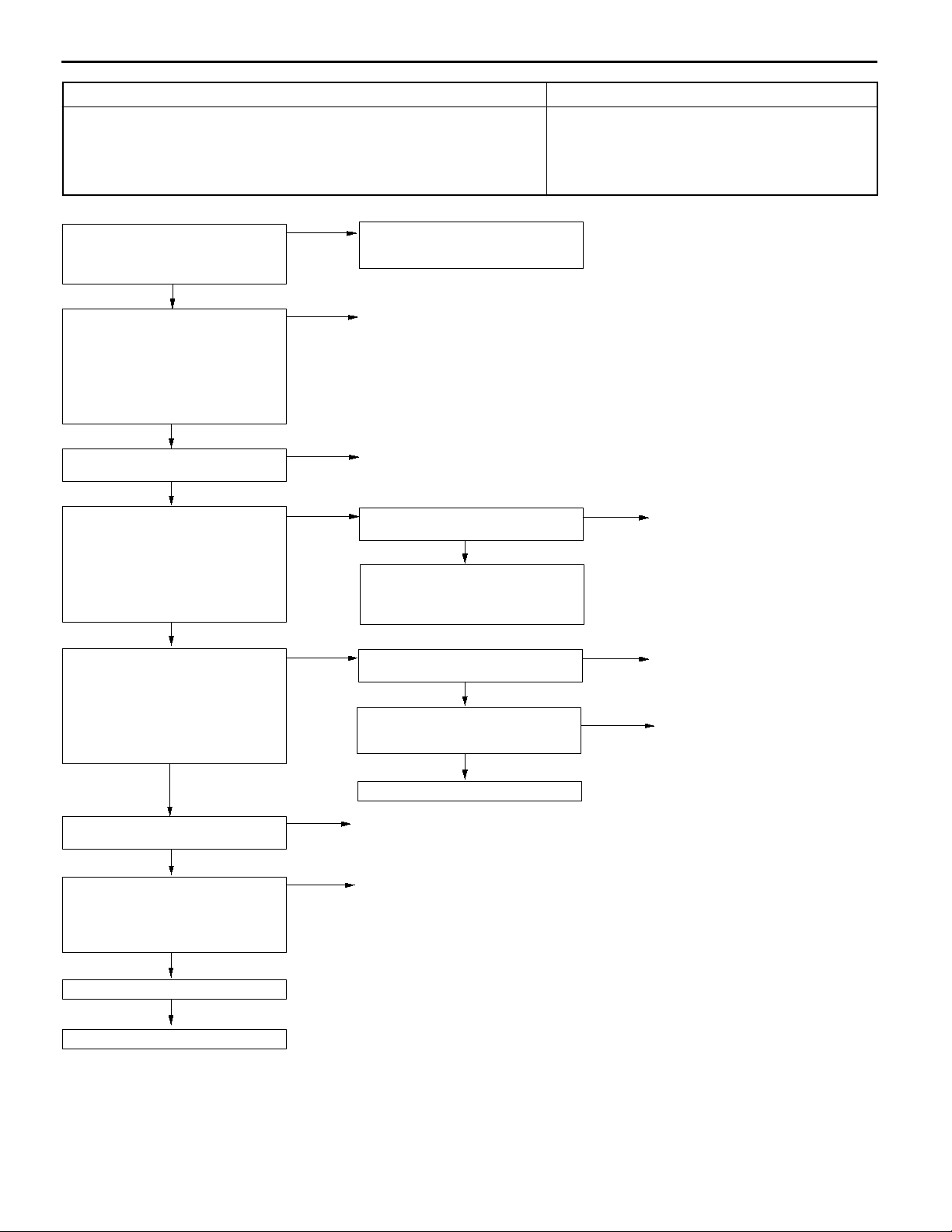

Code No. P0115 Engine coolant temperature sensor

system

Range of Check

D Engine: Two seconds after the engine has been started

Set Conditions

D The sensor output voltage is 4.6 V or more for two seconds (equivalent to

-45_C of engine coolant temperature)

or

D The sensor output voltage is 0.1 V or less for two seconds (equivalent to

140_C of engine coolant temperature)

Range of Check

D Engine: After starting

Set Conditions

D The engine coolant temperature has reduced from over 40_C to less than

40_C, and that condition has lasted for five minutes or more.

Probable cause

D Malfunction of engine coolant temperature sensor

D Open or short circuit in the engine coolant

temperature sensor circuit or loose connector

contact

D Malfunction of engine-ECU

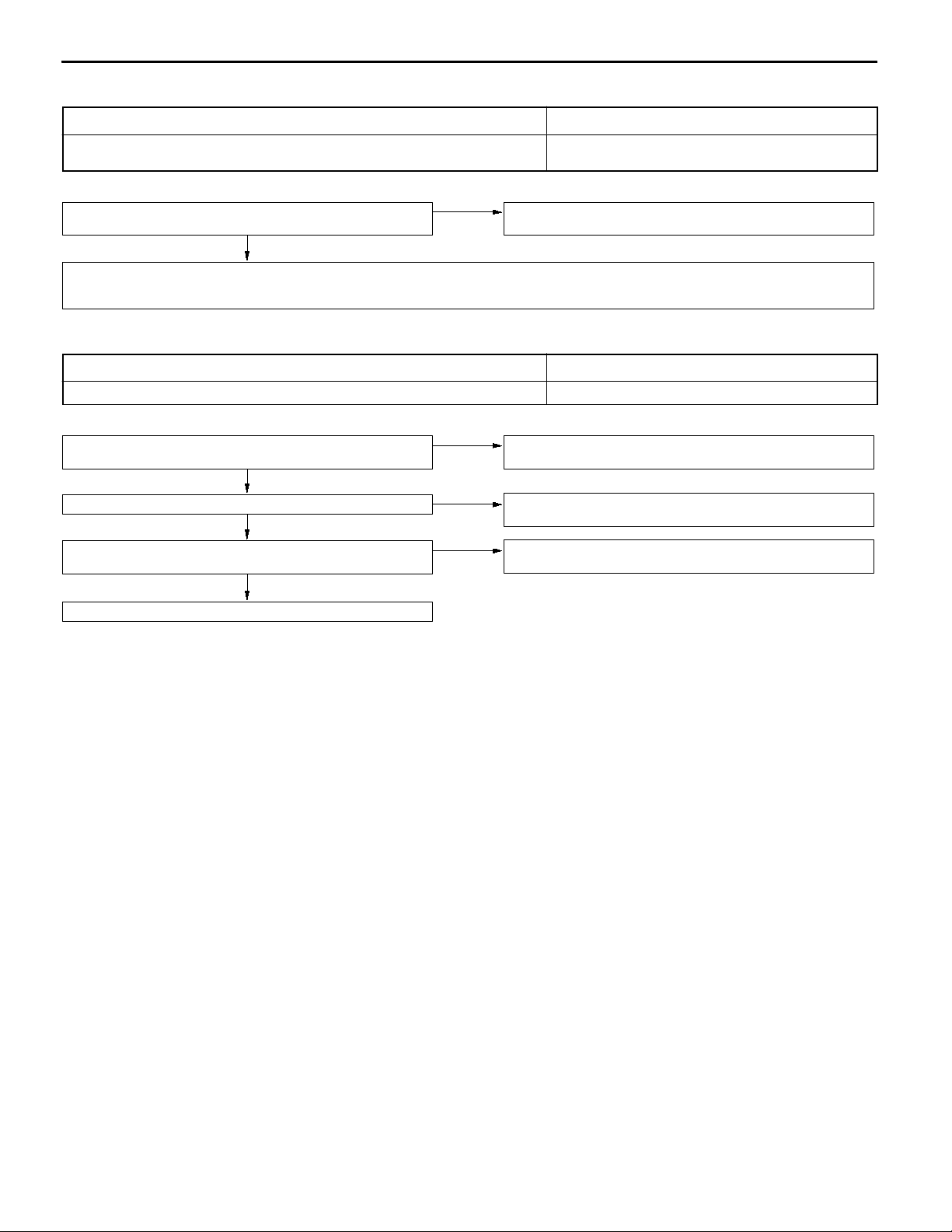

Page 44

13A-14

MPI <4G1> -

Troubleshooting

MUT-IIData list

21 Engine coolant temperature

sensor

OK:

When the engine is cold,

the temperature is roughly

the same as ambient temperature. If warm, it is 80 120_C.

NG

Measure at engine coolant

temperature sensor connector A-72.

D Disconnect the connector and

measure at the harness side.

D Resistance between terminals 1

and 2

OK:

At 20_C of engine coolant

temperature: 2.1 - 2.7 kW

At 80_C of engine coolant

temperature: 0.26 - 0.36

kW

OK

Check the following connector:

A-72

OK

Measure at engine coolant

temperature sensor connector A-72.

D Disconnect the connector and

measure at the harness side.

(1) Voltage between terminal 1 and

earth

(Ignition switch: ON)

OK:

(2) Resistance between terminal 2

To the next page

4.8 - 5.2 V

and earth

OK:

2 W or less

OK

OK

NG

NG

(1) NG

(2) NG

Transient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Replace

Repair

Measure at engine-ECU connector

B-34.

D Measure the voltage at the

engine-ECU terminal.

D Disconnect connector A-72.

D Ignition switch: ON

D Voltage between terminal 44 and

earth

OK:

4.8 - 5.2 V

NG

Check the following connector:

B-34

OK

Check the harness wire between the

engine coolant temperature sensor

and the engine-ECU.

OK

Check the trouble symptoms.

Check the following connector:

B-34

OK

Check the harness wire between the

engine coolant temperature sensor

and the engine-ECU.

OK

Check the trouble symptoms.

NG

NG

NG

NG

NG

OK

NG

Check the following connector:

B-34

OK

Check the harness wire between the

engine coolant temperature sensor

and the engine-ECU, and repair if

necessary.

Repair

Repair

Replace the engine-ECU.

Repair

Repair

Replace the engine-ECU.

NG

Repair

Page 45

From the previous page

OK

Measure at engine coolant

temperature sensor connector A-72.

D Use test harness (MB991658) to

connect the connector, and

measure at the pick-up harness.

D Ignition switch: ON

D Voltage between terminal 1 and

earth

OK:

At 0_C of engine coolant

temperature: 3.2 - 3.8 V

At 20_C of engine coolant

temperature: 2.3 - 2.9 V

At 40_C of engine coolant

temperature: 1.3 - 1.9 V

At 80_C of engine coolant

temperature: 0.3 - 0.9 V

OK

Check the trouble symptoms.

MPI <4G1> -

NG

NG

Check the engine coolant

temperature sensor.

(Refer to P.13A-83*.)

Check the following connector:

B-34

Check the harness wire between the

engine coolant temperature sensor

and the engine-ECU, and repair if

necessary.

Replace the engine-ECU.

Troubleshooting

NG

OK

OK

NG

Repair

Repair

NOTE:

*: Refer to the ’96 COLT/LANCER Workshop Manual (Pub. No. PWME9511).

13A-15

Page 46

13A-16

MPI <4G1> -

Troubleshooting

Code No. 0120 Throttle position sensor system Probable cause

Range of Check

D Ignition switch: ON

D Excluding 2 seconds after the ignition switch is turned to ON or immediately

after the engine starts.

Set Conditions

D Engine speed is 1,000 r/min or less, and intake air pressure is 48 kPa or

less, TPS output voltage is 4.6 V or more for 2 seconds.

or

D The sensor output voltage is 0.2 V or less for 2 seconds.

D Malfunction of throttle position sensor

D Open or short circuit in the throttle position sensor

circuit or loose connector contact

D Malfunction of the engine-ECU

MUT-IIData list

14 Throttle position sensor

OK:

Refer to P.13A-65, DATA

LIST REFERENCE TABLE.

NG

Check throttle position sensor.

(Refer to P.13A-84*.)

OK

Check the following connector:

A-05

OK

Measure at throttle position sensor

connector A-05.

D Disconnect the connector and

measure at the harness side.

(1) The voltage between terminal 1

and earth

(Ignition switch: ON)

OK:

(2) Resistance between terminal 4

4.8 - 5.2 V

and earth

OK:

2 W or less

OK

NG

NG

(1) NG

Intermittent malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Replace

Repair

Measure at engine-ECU connector

B-34.

D Measure the voltage at the

engine-ECU connector terminal.

D Ignition switch: ON

D The voltage between terminal 81

and earth

OK:

4.8 - 5.2 V

NG

Check the following connector:

B-34

OK

Check the harness wire between the

throttle position sensor and the

engine-ECU.

OK

Check the trouble symptoms.

OK

NG

NG

NG

Check the following connector:

B-34

OK

Check the harness wire between the

throttle position sensor and the

engine-ECU, and repair if necessary.

Repair

Repair

Replace the engine-ECU.

NG

Repair

NG

NG

NG

Repair

Repair

Replace the engine-ECU.

To the next page

OK

(2) NG

Check the following connector:

B-34

OK

Check the harness wire between the

throttle position sensor and the

engine-ECU.

OK

Check the trouble symptoms.

NOTE:

*: Refer to the ’96 COLT/LANCER Workshop Manual (Pub. No. PWME9511).

Page 47

From the previous page

OK

Measure at throttle position sensor

connector A-05.

D Use test harness (MB991536) to

connect the connector, and

measure at the pick-up harness.

D Ignition switch: ON

(1) The voltage between terminal 1

and earth

OK:

(2) The voltage between terminal 4

(3) The voltage between terminal 2

Measure at engine-ECU connector

B-34.

D Measure the voltage at the

D Ignition switch: ON

D The voltage between terminal 84

4.8 - 5.2 V

and earth

OK:

0.5 V or less

and earth

OK:

Accelerator pedal fully released: 0.3 - 1.0 V

Accelerator pedal fully depressed: 4.5 - 5.5 V

OK

engine-ECU terminal.

and earth

OK:

Accelerator pedal fully released: 0.3 - 1.0 V

Accelerator pedal fully depressed: 4.5 - 5.5 V

MPI <4G1> -

(1), (2) NG

(3) NG

NG

OK

Check the following connector:

B-34

Check the harness wire between

throttle position sensor and the

engine-ECU.

Adjust the throttle position sensor.

(Refer to P.13A-84*.)

Check the following connector:

B-34

Check the harness wire between

throttle position sensor and the

engine-ECU, and repair if necessary.

Troubleshooting

OK

OK

Check the following connector:

B-34

OK

Check the harness wire between

throttle position sensor and the

engine-ECU, and repair if necessary.

Check the following connector:

B-34

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

NG

NG

NG

NG

13A-17

Repair

Repair

Repair

Repair

NOTE:

*: Refer to the ’96 COLT/LANCER Workshop Manual (Pub. No. PWME9511).

Page 48

13A-18

MPI <4G1> -

Troubleshooting

Code No. P0125 Feedback system Probable cause

Range of Check

D The engine coolant temperature is approx. 80_C or more.

D During stoichiometric feedback control

D The vehicle is not being decelerated.

Set Conditions

D Oxygen sensor (front) output voltage has been higher or lower than 0.5 V for

at least thirty seconds.

D Malfunction of oxygen sensor (front)

D Open or short circuit in the oxygen sensor (front)

circuit or loose connector contact

D Malfunction of engine-ECU

Check the following connector:

A-106

OK

Measure at oxygen sensor (front)

connector A-106.

D Disconnect the connector and

measure at the harness side.

D Resistance between terminal 2

and earth

OK:

2 W or less

OK

Measure at oxygen sensor (front)

connector A-106.

D Use the test harness

(MD998464) to connect the

connector, and measure at the

pick-up harness side.

D Engine: 2,500 r/min (after

warming up)

(1) Voltage between terminal 2 and

earth

OK:

(2) Voltage between terminal 4 and

Measure at engine-ECU connector

B-34.

D Measure the voltage at the

D Engine: 2,500 r/min (after

D Voltage between terminal 76 and

Check the following connector:

B-34

Check the trouble symptoms.

Replace the engine-ECU.

0.5 V or less

earth

OK:

0 V and 0.8 V alternate.

OK

engine-ECU terminal.

warming up)

earth

OK:

0 V and 0.8 V alternate.

OK

OK

NG

NG

NG

(1) NG

(2) NG

NG

NG

OK

Repair

Check the following connector:

B-34

OK

Check the harness wire between the

oxygen sensor (front) and the

engine-ECU.

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

Check the following connector:

B-34

OK

Check the harness wire between the

oxygen sensor (front) and the

engine-ECU, and repair if necessary.

Check the oxygen sensor (front).

(Refer to P.13A-80.)

OK

Check the following connector:

B-34

OK

Check the harness wire between the

oxygen sensor (front) and the

engine-ECU, and repair if necessary.

Check the following connector:

B-34

OK

Check the harness wire between the

oxygen sensor (front) and the

engine-ECU, and repair if necessary.

Repair

Transient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

NG

NG

NG

NG

NG

Repair

Repair

Repair

Replace

Repair

Repair

Page 49

MPI <4G1> -

Troubleshooting

13A-19

Code No. P0130 Oxygen sensor (front) system

<sensor 1>

Range of Check

D Three minutes have been passed since the engine has been started.

D The engine coolant temperature is approx. 80_C or more.

D Intake air temperature is 20 - 50_C

D Engine speed is 1,200 r/min or more

D Driving on a level surface at constant speed.

Set Conditions

D The oxygen sensor (front) output voltage is 4.5 V or more when the sensor

output voltage is 0.2 V or less and a voltage of 5 V is applied to the oxygen

sensor (front) inside the engine-ECU.

Range of Check

D Engine speed is 2,800 r/min or less

D During driving

D During air/fuel ratio feedback control

Set Conditions

D The oxygen sensor (front) output frequency is six or less per 10 seconds on

average.

Probable cause

D Malfunction of oxygen sensor (front)

D Open or short circuit in the oxygen sensor (front)

circuit or loose connector contact

D Malfunction of engine-ECU

Page 50

13A-20

MPI <4G1> -

Troubleshooting

Check the following connector:

A-106

OK

Measure at oxygen sensor (front)

connector A-106.

D Disconnect the connector and

measure at the harness side.

D Resistance between terminal 2

and earth

OK:

2 W or less

OK

Measure at oxygen sensor (front)

connector A-106.

D Use the test harness

(MD998464) to connect the

connector, and measure at the

pick-up harness side.

D Engine: 2,500 r/min (after

warming up)

(1) Voltage between terminal 2 and

earth

OK:

(2) Voltage between terminal 4 and

Measure at engine-ECU connector

B-34.

D Measure the voltage at the

D Engine: 2,500 r/min (after

D Voltage between terminal 76 and

Check the following connector:

B-34

Check the trouble symptoms.

Replace the engine-ECU.

0.5 V or less

earth

OK:

0 V and 0.8 V alternate.

OK

engine-ECU terminal.

warming up)

earth

OK:

0 V and 0.8 V alternate.

OK

OK

NG

NG

NG

(1) NG

(2) NG

NG

NG

OK

Repair

Check the following connector:

B-34

OK

Check the harness wire between the

oxygen sensor (front) and the

engine-ECU.

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

Check the following connector:

B-34

OK

Check the harness wire between the

oxygen sensor (front) and the

engine-ECU, and repair if necessary.

Check the oxygen sensor (front).

(Refer to P.13A-80.)

OK

Check the following connector:

B-34

OK

Check the harness wire between the

oxygen sensor (front) and the

engine-ECU, and repair if necessary.

Check the following connector:

B-34

OK

Check the harness wire between the

oxygen sensor (front) and the

engine-ECU, and repair if necessary.

Repair

Transient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

NG

NG

NG

NG

NG

Repair

Repair

Repair

Replace

Repair

Repair

Page 51

MPI <4G1> -

Troubleshooting

13A-21

Code No. P0135 Oxygen sensor heater (front) system

<sensor 1>

Range of Check

D The engine coolant temperature is approx. 20_C or more.

D The oxygen sensor heater (front) remains on.

D The engine speed is 50 r/min or more.

D Battery voltage is 11 - 16 V.

Set Conditions

D The current, which flows through the oxygen sensor heater (front), is 0.2 A

or less or 3.5 A or more for six seconds.

Measure at oxygen sensor (front)

connector A-106.

D Disconnect the connector and

measure at the harness side.

D Resistance between terminals 1

and 3

OK:

4.5 - 8.0 W

OK

Check the following connector:

A-106

OK

Measure at oxygen sensor (front)

connector A-106.

D Disconnect the connector and

measure at the harness side.

D Ignition switch: ON

D Voltage between terminal 1 and

earth

OK:

System voltage

OK

Measure at engine-ECU connector

B-35.

D Measure the voltage at the

engine-ECU terminal.

D Ignition switch: ON

D Voltage between terminal 60 and

earth

OK:

System voltage

OK

Check the following connector:

B-35

OK

Check the harness wires between

the oxygen sensor (front) and the

engine-ECU and between the oxygen

sensor (front) and the engine control

relay.

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

NG

NG

NG

NG

NG

NG

OK

Replace

Repair

Check the following connector:

B-13

OK

Check the harness wires between

the oxygen sensor (front) and the

engine control relay, and repair if

necessary.

Check the following connector:

B-35

OK

Check the harness wire between the

oxygen sensor (front) and the

engine-ECU.

OK

Replace the engine-ECU.

Repair

Repair

Transient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Probable cause

D Malfunction of oxygen sensor heater (front)

D Open or short circuit in the oxygen sensor heater

(front) circuit or loose connector contact

D Malfunction of engine-ECU

NG

NG

NG

Repair

Repair

Repair

Page 52

13A-22

MPI <4G1> -

Troubleshooting

Code No. P0136 Oxygen sensor (rear) system

<sensor 2>

Range of Check

D Three minutes have been passed since the engine has been started.