Page 1

CITY MULTI® H2I® Y-SERIES HYPER-HEATING INVERTER

SYSTEM DESIGN

1. ELECTRICAL WORK ...........................................................................................................................................H2iSD-2

1-1. General Cautions ....................................................................................................................................... H2iSD-2

1-2. Power Supply for Indoor Unit and Outdoor Unit ......................................................................................... H2iSD-3

2. M-NET CONTROL................................................................................................................................................H2iSD-6

2-1. Transmission Cable Length Limitation .......................................................................................................H2iSD-6

2-2. TransmissionCableSpecications ............................................................................................................H2iSD-7

2-3. SystemCongurationRestrictions ............................................................................................................. H2iSD-8

2-4. Address Setting .........................................................................................................................................H2iSD-11

3. PIPING DESIGN ................................................................................................................................................ H2iSD-22

3-1. R410A Piping Material ..............................................................................................................................H2iSD-22

3-2. PUHY-HP-T/Y(S)JMU’s Piping Design ..................................................................................................... H2iSD-23

3-3. Refrigerant Charge Calculation ................................................................................................................ H2iSD-25

4. INSTALLATION ..................................................................................................................................................H2iSD-26

4-1. Installation Site Requirements ................................................................................................................. H2iSD-26

4-2. Installation Clearance Space ................................................................................................................... H2iSD-27

4-3. Piping Direction ........................................................................................................................................ H2iSD-29

4-4. Weather Countermeasures ...................................................................................................................... H2iSD-34

4-5. Low Ambient Kit Application Guidelines ...................................................................................................H2iSD-35

5. STANDARD AND SEACOAST PROTECTION (-BS) TREATMENT ..................................................................H2iSD-37

5-1. H2i Y-Series .............................................................................................................................................H2iSD-37

6. CAUTIONS ......................................................................................................................................................... H2iSD-38

6-1. Refrigerant Properties .............................................................................................................................. H2iSD-38

6-2. ConrmtheCriticalConcentrationandPerformCountermeasures ......................................................... H2iSD-38

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-1

Page 2

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

1. ELECTRICAL WORK

1-1. General Cautions

Follow ordinance of your governmental organization for technical standard related to electrical equipment, wiring

regulations, and guidance of each electric power company.

Wiring for control (hereinafter referred to as transmission ) shall be (50mm[1-5/8in] or more) apart from power source

wiring so that it is not influenced by electric noise from power source wiring. (Do not insert transmission and power

source wire in the same conduit.)

Be sure to provide designated grounding work to outdoor unit.

Give some allowance to wiring for electrical part box of indoor and outdoor units, because the box is sometimes removed

at the time of service work.

Never connect 100V, 208~230,460V power source to terminal block of transmission . If connected,electrical parts will

be burnt

Use

multiplecore

out.

2-conductor

cable, the resultant poor transmitting and receiving will cause erroneous operations.

shield cable for transmission . If transmission of different systems are wired with the same

cable

cable

cable

cable

cables

Outdoor

unit

2-conductor shield cable

OK NO

Outdoor

unit

2-conductor shield cable

BC controller

Indoor unit

Remote

controller

Indoor unit

Remote

controller

Outdoor

unit

Outdoor

unit

Multiple-

core cable

Remote

controller

BC controller

controller

Indoor unit

Indoor unit

Remote

H2iSD-2

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

Page 3

1. ELECTRICAL WORK

1-2. Power Supply for Indoor and Outdoor Units

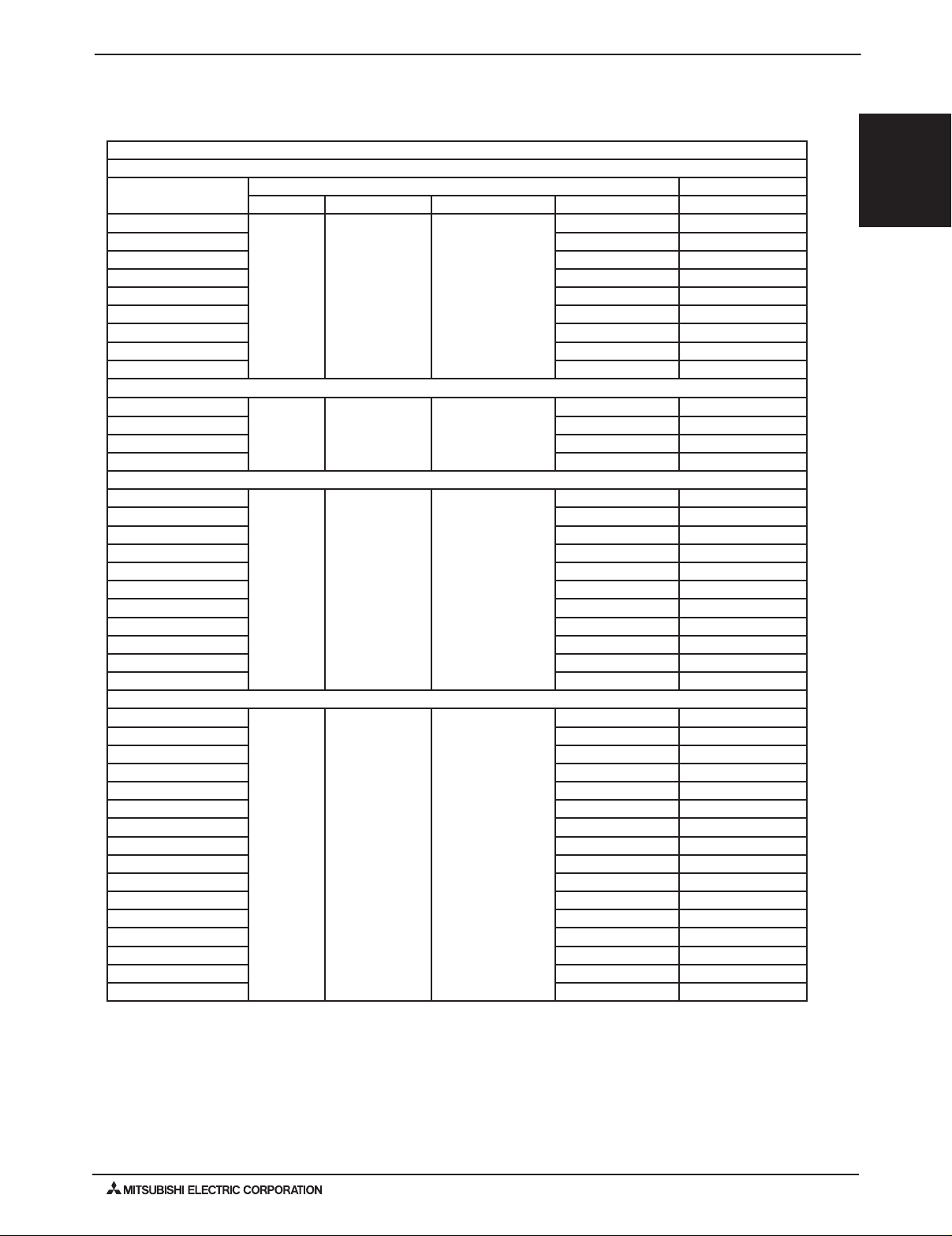

1-2-1. Electrical Characteristics of the Indoor Units

Symbols: MCA : Min.Circuit Amps (=1.25xFLA) FLA : Full Load Amps

IFM :Indoor Fan Motor Output : Fan motor rated output

Model

PLFY-P08NCMU-E

PLFY-P12NCMU-E 0.35 / 0.35 0.28 / 0.28

PLFY-P15NCMU-E 0.35 / 0.35 0.28 / 0.28

PLFY-P12NBMU-E 0.64 / 0.64 0.51 / 0.51

PLFY-P15NBMU-E 0.64 / 0.64 0.51 / 0.51

PLFY-P18NBMU-E 0.64 / 0.64 0.51 / 0.51

PLFY-P24NBMU-E 0.64 / 0.64 0.51 / 0.51

PLFY-P30NBMU-E 0.64 / 0.64 0.51 / 0.51

PLFY-P36NBMU-E 1.25 / 1.25 1.00 / 1.00

Hz Volts Voltage range MCA(A) FLA(A)

60Hz 208 / 230V 188 to 253V

Indoor Unit IFM

0.29 / 0.29 0.23 / 0.23

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

PMFY-P06NBMU-E

PMFY-P08NBMU-E 0.25 / 0.25 0.20 / 0.20

PMFY-P12NBMU-E 0.26 / 0.26 0.21 / 0.21

PMFY-P15NBMU-E 0.33 / 0.33 0.26 / 0.26

PEFY-P06NMAU-E

PEFY-P08NMAU-E 1.05 / 1.05 0.84 / 0.84

PEFY-P12NMAU-E 1.21 / 1.21 0.97 / 0.97

PEFY-P15NMAU-E 1.45 / 1.45 1.16 / 1.16

PEFY-P18NMAU-E 1.56 / 1.56 1.25 / 1.25

PEFY-P24NMAU-E 2.25 / 2.25 1.80 / 1.80

PEFY-P27NMAU-E 2.49 / 2.49 1.99 / 1.99

PEFY-P30NMAU-E 2.50 / 2.50 2.00 / 2.00

PEFY-P36NMAU-E 3.33 / 3.33 2.66 / 2.66

PEFY-P48NMAU-E 3.41 / 3.41 2.73 / 2.73

PEFY-P54NMAU-E 3.31 / 3.31 2.65 / 2.65

PEFY-P06NMSU-E

PEFY-P08NMSU-E 0.47 / 0.50 0.41 / 0.39

PEFY-P12NMSU-E 0.68 / 0.74 0.46 / 0.43

PEFY-P15NMSU-E 1.20 / 1.33 0.47 / 0.45

PEFY-P18NMSU-E 1.20 / 1.33 0.64 / 0.60

PEFY-P24NMSU-E 1.57 / 1.73 0.88 / 0.83

PEFY-P15NMHU-E 1.20 / 1.33 0.96 / 1.06

PEFY-P18NMHU-E 1.20 / 1.33 0.96 / 1.06

PEFY-P24NMHU-E 1.57 / 1.73 1.25 / 1.38

PEFY-P27NMHU-E 1.72 / 1.89 1.37 / 1.51

PEFY-P30NMHU-E 2.08 / 2.29 1.66 / 1.83

PEFY-P36NMHU-E 4.23 / 4.67 3.38 / 3.73

PEFY-P48NMHU-E 4.23 / 4.67 3.38 / 3.73

PEFY-P54NMHU-E

PEFY-P72NMHU-E 5.60 / 6.18 4.48 / 4.94

PEFY-P96NMHU-E 7.12 / 7.85 5.69 / 6.28

60Hz 208 / 230V 188 to 253V

60Hz 208 / 230V 188 to 253V

60Hz 208 / 230V 188 to 253V

0.25 / 0.25 0.20 / 0.20

1.05 / 1.05 0.84 / 0.84

0.47 / 0.50 0.32 / 0.31

4.29 / 4.73 3.43 / 3.78

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-3

Page 4

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

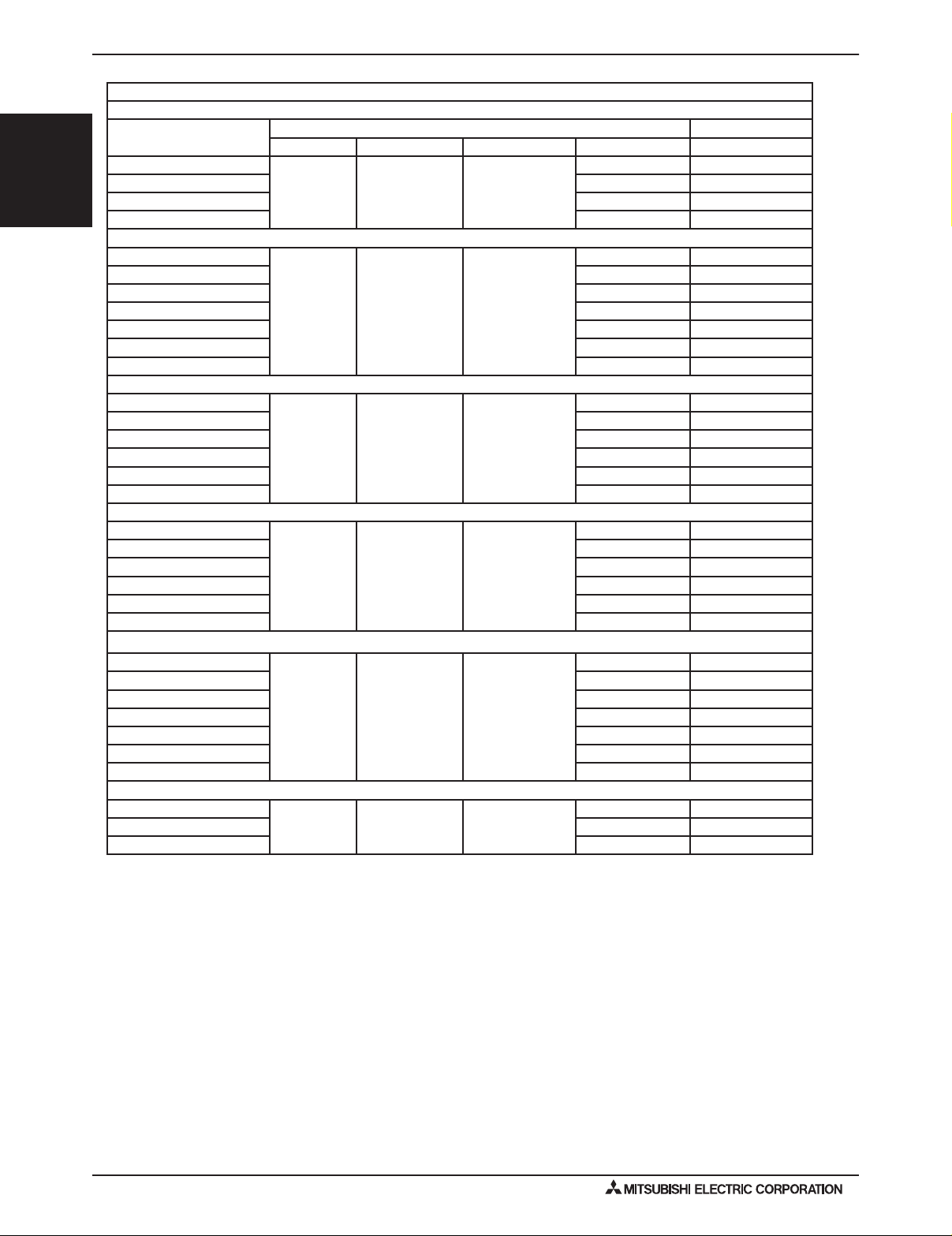

1. ELECTRICAL WORK

Symbols: MCA : Min.Circuit Amps (=1.25xFLA) FLA : Full Load Amps

IFM :Indoor Fan Motor

Model

PCFY-P15NKMU-E

PCFY-P24NKMU-E 0.52 / 0.52 0.41 / 0.41

PCFY-P30NKMU-E 1.22 / 1.22 0.97 / 0.97

PCFY-P36NKMU-E 1.22 / 1.22 0.97 / 0.97

Hz Volts Voltage range MCA(A) FLA(A)

60Hz 208 / 230V 188 to 253V

Indoor Unit IFM

0.44 / 0.44 0.35 / 0.35

PKFY-P06NBMU-E

PKFY-P08NBMU-E 0.19 / 0.19 0.15 / 0.15

PKFY-P12NHMU-E 0.38 / 0.38 0.30 / 0.30

PKFY-P15NHMU-E 0.38 / 0.38 0.30 / 0.30

PKFY-P18NHMU-E 0.38 / 0.38 0.30 / 0.30

PKFY-P24NKMU-E 0.37 / 0.37 0.29 / 0.29

PKFY-P30NKMU-E 0.54 / 0.54 0.43 / 0.43

PFFY-P06NEMU-E

PFFY-P08NEMU-E 0.32 / 0.34 0.25 / 0.27

PFFY-P12NEMU-E 0.34 / 0.38 0.27 / 0.30

PFFY-P15NEMU-E 0.40 / 0.44 0.32 / 0.35

PFFY-P18NEMU-E 0.48 / 0.53 0.38 / 0.42

PFFY-P24NEMU-E 0.59 / 0.64 0.47 / 0.51

PFFY-P06NRMU-E

PFFY-P08NRMU-E 0.32 / 0.34 0.25 / 0.27

PFFY-P12NRMU-E 0.34 / 0.38 0.27 / 0.30

PFFY-P15NRMU-E 0.40 / 0.44 0.32 / 0.35

PFFY-P18NRMU-E 0.48 / 0.53 0.38 / 0.42

PFFY-P24NRMU-E 0.59 / 0.64 0.47 / 0.51

PVFY-P12E00A

PVFY-P18E00A 1.53 / 1.38 1.22 / 1.10

PVFY-P24E00A 1.39 / 1.85 1.11 / 1.00

PVFY-P30E00A 2.50 / 2.25 2.00 / 1.80

PVFY-P36E00A 2.09 / 1.88 1.67 / 1.50

PVFY-P48E00A 2.23 / 2.00 1.78 / 1.60

PVFY-P54E00A 2.64 / 2.38 2.11 / 1.90

60Hz 208 / 230V 188 to 253V

60Hz 208 / 230V 188 to 253V

60Hz 208 / 230V 188 to 253V

60Hz 208 / 230V 188 to 253V

0.19 / 0.19 0.15 / 0.15

0.32 / 0.34 0.25 / 0.27

0.32 / 0.34 0.25 / 0.27

0.56 / 0.50 0.45 / 0.40

PWFY-P36NMU-E-BU

PWFY-P36NMU-E-AU 0.09 PWFY-P72NMU-E-AU 0.09 -

H2iSD-4

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

60Hz 208 / 230V 188 to 253V

25 -

Page 5

1. ELECTRICAL WORK

1-2-2. Electrical characteristics of Outdoor unit of cooling mode

Symbols: MCA : Min. Circuit Amps

PUHY-HP-T(S)JMU

Model

PUHY-HP72TJMU-A

PUHY-HP96TJMU-A

PUHY-HP

144TSJMU-A

PUHY-HP

192TSJMU-A

Tosizebreakers,see“RecommendedFuse/BreakerSize”intheSpecicationstable.

Unit Combination

PUHY-HP72TJMU-A

PUHY-HP72TJMU-A

PUHY-HP96TJMU-A

PUHY-HP96TJMU-A

60Hz

60Hz

60Hz

60Hz

60Hz

60Hz

VoltsHz

208 / 230V

208 / 230V

208 / 230V

208 / 230V

208 / 230V

208 / 230V

Voltage range

188 to 253V

SC : Starting Current RLA

Outdoor Units

RLA(A)

19.4 / 17.6

28.2 / 25.5

19.4 / 17.6

19.4 / 17.6

28.2 / 25.5

28.2 / 25.5

RLA(MAX)(A)

38.4 / 38.4

52.4 / 52.4

38.4 / 38.4

38.4 / 38.4

52.4 / 52.4

52.4 / 52.4

MOCP : Max. Over Current Protection

: Rated Load Amps

MCA(A)

59 / 54

74 / 68

59 / 54

59 / 54

74 / 68

74 / 68

101 / 92

127 / 116

101 / 92

101 / 92

127 / 116

127 / 116

MOCP

Compressor

15

15

15

15

15

15

Fan

Output(kW)SC(A)

0.92

0.92

0.92

0.92

0.92

0.92

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-5

Page 6

2. M-NET CONTROL

2-1. Transmission Cable Length Limitations

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

2-1-1. Using MA Remote controller

Long transmission cable causes voltage down, therefore, the length limitation should be obeyed to secure proper transmission.

Max. length via Outdoor (M-NET cable) L1+L2+L3+L4, L1+L2+L6+L7, L3+L4+L6+L7 <=500m[1640ft.] 1.25mm

Max. Total M-NET Wiring

Max. length to Outdoor (M-NET cable)

(L1 → 8) <=2km [6,560ft.] 1.25mm2 [AWG16] or thicker

∑

L1+L8, L3+L4, L6, L2+L6+L8, L7 <=200m[656ft.] 1.25mm2 [AWG16] or thicker

Max. length from MA to Indoor a1+a2, a1+a2+a3+a4 <=200m[656ft.] 0.3-1.25 mm

24VDC to AG-150A n <=50m[164ft.] 0.75-2.0 mm

L

8

Group1 Group3 Group5

OS

(52)

TB3

M2

TB7

M2SM2M1 M1 S

2

L

6

L

7

L

(51)

OC

TB3

M2M1 M1

TB7

AG-150A

Shielded wire

OC

(54 )

TB7

M1M2

S

TB3

M2M1

Power Supply Unit

PAC-SC51KUA

AB

S

V+V-FG

AB

S

V+V-FG

L

3

IC

(01)

TB5 TB15

M1 M2 12S

a1

AB

a2

MA

IC

(02)

TB15

TB5

12

M1 M2 S

n

OC, OS : Outdoor unit controller; IC: Indoor unit controller; MA: MA remote controller

L

1

M1 M2 S

M1 M2 S

IC

(04)

TB15

TB5

12

a2

L

4

IC

(03)

TB 15

TB5

12

a1

AB

MA

M1 M2 S

M1 M2 S

IC

(05)

TB15

TB5

12

a1

AB

MA

IC

(07)

TB15

TB5

12

2

[AWG16] or thicker

2

[AWG22-16]

2

[AWG18-14]

IC

(06)

TB5

M1 M2 S

a2

a4

AB

MA

TB15

12

a3

2-1-2. Using ME Remote controller

Long transmission cable causes voltage down, therefore, the length limitation should be obeyed to secure proper transmission.

Max. length via Outdoor (M-NET cable)

Max. Total M-NET Wiring

Max. length to Outdoor (M-NET cable) L1+L8, L3+L4, L6, L2+L6+L8, L7, L3+L5 <=200m[656ft.] 1.25mm

Max. length from ME to Indoor e1, e2+e3, e4 <=10m[32ft.]*1 0.3-1.25 mm

24VDC to AG-150A n <=50m[164ft.] 0.75-2.0 mm

*1. If the length from ME to Indoor exceed 10m [33ft.], use 1.25 mm

L

8

OS

(52)

TB3

M2

TB7

S

M2

OC, OS : Outdoor unit controller; IC: Indoor unit controller; ME: ME remote controller

H2iSD-6

OC

(51)

TB3

M2M1 M1

TB7

M2M1 M1

S

Shielded wire

2

L

TB7

M1 M2

L6L7

Power Supply Unit

PAC-SC51KUA

AG-150A

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

L1+L2+L3+L4, L1+L2+L6+L7,L1+L2+L3+L5, L3+L4+L6+L7

∑ (L1 → 8) <=2km [6,560ft.] 1.25mm

2

[AWG16] shielded cable, but the total length should be counted into Max. length via Outdoor.

L1

Group1 Group3

IC

(01)

TB5

M1 M2 S

e1

AB

(101)

ME

OC

(54 )

S

TB3

M2M1

AB

S

V+V-FG

L3

TB5

M1 M2 S

IC

(02)

n

AB

S

V+V-FG

IC

(04)

TB5

M1 M2 S

IC

(03)

TB5

M1 M2 S

L5

e4

AB

(103)

ME

<=500m[1640ft.] 1.25mm2 [AWG16] or thicker

2

[AWG16] or thicker

2

[AWG16] or thicker

2

[AWG22-16] *1

2

[AWG18-14]

Group5

IC

(05)

TB5

M1 M2 S

e2

AB AB

(105)

ME

L4

M1 M2 S

e3

IC

(07)

TB5

M1 M2 S

(155)

ME

IC

(06)

TB5

Page 7

2. M-NET CONTROL

2-2. Transmission Cable Specications

(Li)

—

Type of cable

Cable size

Remarks

Connected with simple remote controller.

Transmission cablesME Remote controller cables

Shielding wire (2-core)

CVVS, CPEVS or MVVS

1.25 [AWG16]

MA Remote controller cables

Sheathed 2-core cable (unshielded)

CVV

2

1.25 [AWG16]

1.25 [AWG16]

When 10m [32ft] is exceeded, use cables with

the same specification as transmission cables.

2

CVVS, MVVS : PVC insulated PVC jacketed shielded control cable

PE insulated PVC jacketed shielded communication cable

CPEVS :

CVV : PV insulated PVC sheathed control cable

1.25 [AWG16]

1.25 [AWG16]

Max length : 200m [656ft]

SYSTEM DESIGN

2010 H2i

Y-SERIES

2

2

®

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-7

Page 8

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

2. M-NET CONTROL

2-3. System Conguration Restrictions

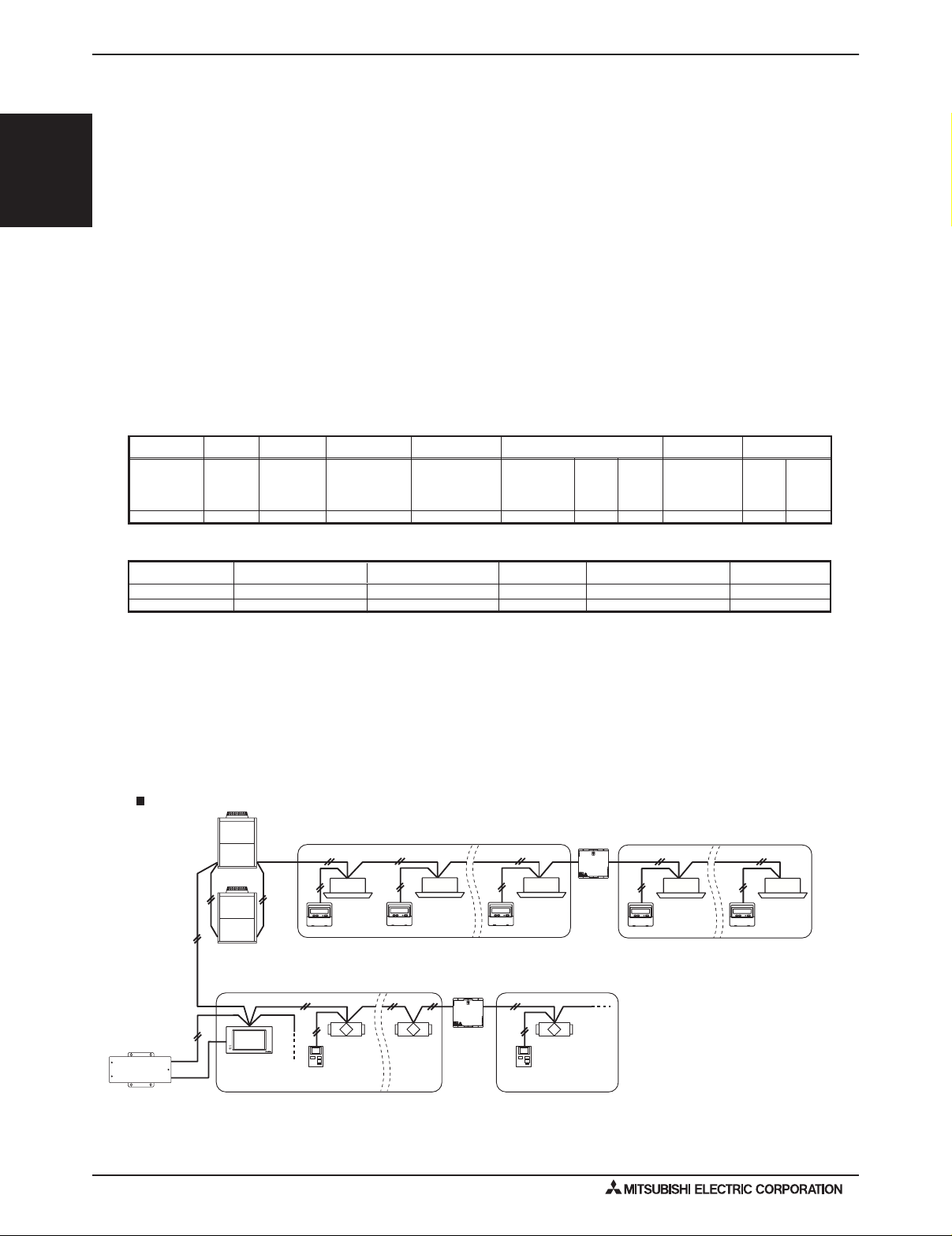

2-3-1. Common restrictions for the CITY MULTI system

For each Outdoor unit, the maximum connectable quantity of Indoor unit is specified at its Specifications table.

A) 1 Group of Indoor units can have 1-16 Indoor units;

B) Maximum 2 remote controllers for 1 Group; (MA/ME remote controllers cannot be present together in 1group.)

C) 1 LOSSNAY unit can interlock maximum 16 Indoor units; 1 Indoor unit can interlock only 1 LOSSNAY unit.

D) Maximum 3 System controllers are connectable when connecting to TB3 of the Outdoor unit.

E) Maximum 3 System controllers are connectable when connecting to TB7 of the Outdoor unit, if the transmission

power is supplied by the Outdoor unit.

F) 4 System controllers or more are connectable when connecting to TB7 of the Outdoor unit, if the transmission

power is supplied by the power supply unit PAC-SC51KUA. Details refer to 2-3-3-C.

*System controller connected as described in D) and E) would have a risk that the failure of connected Outdoor

unit would stop power supply to the System controller.

2-3-2. Ensuring proper communication power for M-NET

In order to ensure proper communication among Outdoor unit, Indoor unit, LOSSNAY and Controllers, the transmission

power situation for the M-NET should be observed. In some cases, Transmission booster should be used. Taking the

power consumption index of Indoor unit sized P06-P54 as 1, the equivalent power consumption index and supply

capability index of others are listed at Table 2-3-1 and Table 2-3-2.

Table 2-3-1 The equivalent power consumption by index Indoor units, LOSSNAY, controllers

Indoor, OA unitIndoor unit

Sized P06-P54

Sized P72,

P96

BC controller

CMB

1 701/41/2 31 21/2

*RC : Remote Controller

Table 2-3-2 The equivalent power supply capability index of Trans.Booster, Power supply unit, Connector TB3, TB7 of Outdoor unit.

Transmission Booster

PAC-SF46EPA

25

*If PAC-SC51KUA is used to supply power at TB7 side, no power supply need from Outdoor unit at TB7, Connector TB3 itself will therefore have 32.

Not applicable to the PUMY model.

Power supply unit

PAC-SC51KUA

With the equivalent power consumption values in Table 2-3-1 and Table 2-3-2, PAC-SF46EPA can be designed into the airconditioner system to ensure proper system communication according to 2-3-2-A, B, C.

2-3-2-A) Firstly, count from TB3 at TB3 side the total quantity of Indoor units and ME remote controller, Timers and System

controllers.If the total quantity reaches 40, a PAC-SF46EPA should be set.In this case, Indoor unit sized P72, 96 is

counted as 7 Indoor units, but MA remote controller(s), LOSSNAY is NOT counted.

2-3-2-B) Secondly, count from TB7 side to TB3 side the total transmission power consumption index. If the total power consumption

reaches 32, a PAC-SF46EPA should be set.Yet, if a PAC-SC51KUA is used to supply power at TB7 side, count from

index TB3 side only.

2-3-2-C) Thirdly, count from TB7 at TB7 side the total transmission power consumption index, If the total power consumption reaches

6, a PAC-SF46EPA should be set.

System example

2

5

MA RC.LOSSNAY

PAR-21MAA

PAC-YT51CRB

PAR-FA32MA

LGH-RX-E

PZ-41SLB

BM ADAPTER

BAC-HD150

ME Remote Contr. Timers, System Contr. ON/OFF Contr MN Converter.

PAR-F27MEA

PZ-52SF

PAC-SF44SRA

PAC-YT34STA

AG-150A

TC-24A

PAC-YT40ANRA CMS

GB-24A

4

System Controller

GB-50ADA

6

6

Outdoor unit

Connector TB3 and TB7 total *

32

-MNF-B

Outdoor unit

Connector TB7 only

6

CMS

-MNG-E

Power supply unit

PAC-SC51KUA

H2iSD-8

TB7 TB3

ME remote

TB7 TB3

Outdoor unit

M-NET

24VDC

CENTRALIZED CONTROLLER AG-150A

Centralized controller

(AG-150A)

Transmission booster (No.2) should be used,

if the total equivalent transmission power consumption reaches 5.

controller

Transmission booster (No.1) should be used,

if the total quantity of Indoor units and ME remote controllers

reaches 40, (Indoor unit sized P72, 96 is counted as 7);

or if the total equivalent transmission power consumption reaches 32.

LOSSNAY

unit

PZ-52SF

N3

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

N1

0201

UP

TRANSMISSION BOOSTER

MODEL

PAC-SF46EPA

220-240V:0.7A ~/N

POWER RATING

50

3.4kg

WEIGHT

MADE IN JAPAN

Transmission

booster

PAC-SF46EPA

(No.2)

LOSSNAY

unit

PZ-52SF

Within N4, the total equivalent transmission

power consumption should not exceed 25.

N4

UP

TRANSMISSION BOOSTER

MODEL

PAC-SF46EPA

220-240V:0.7A ~/N

POWER RATING

50

3.4kg

WEIGHT

MADE IN JAPAN

Transmission

booster

(No.1)

ME remote

controller

Within N2, conditions 1,2 should be followed.

1.The total quantity of Indoor units and ME remote controller

should not exceed 40.

*Indoor unit sized P72, 96 is counted as 7 units.

2.The total equivalent transmission power consumption

should not exceed 25.

N2

Page 9

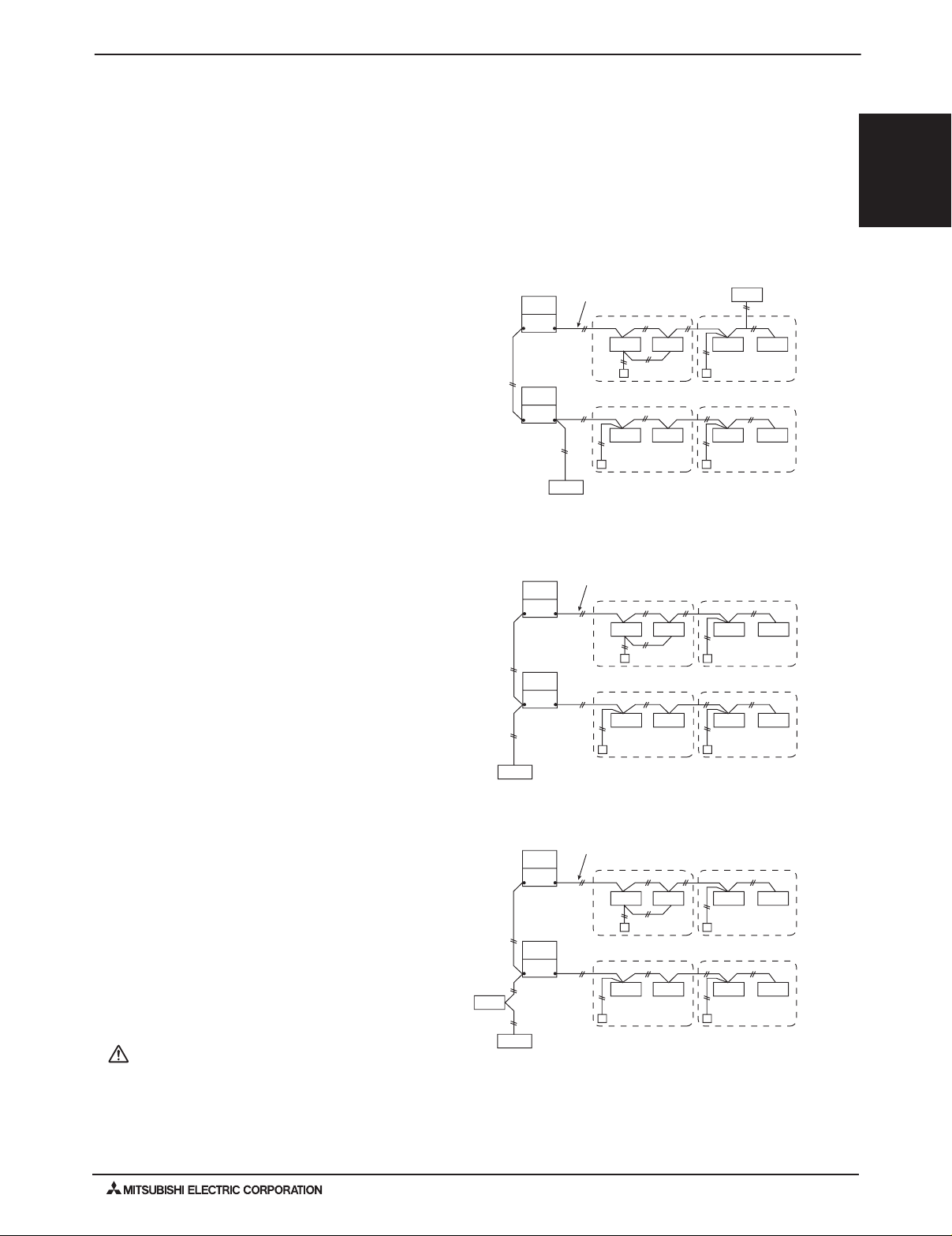

2. M-NET CONTROL

The power to System controller (excluding LMAP03-U) is supplied via M-NET transmission line. M-NET transmission line

at TB7 side is called Central control transmission line while one at TB3 side is called Indoor-Outdoor transmission line.

There are 3 ways to supply power to the System controller .

A) Connecting to TB3 of the Outdoor unit and receiving power from the Outdoor unit.

B) Connecting to TB7 of the Outdoor unit and receiving power from the Outdoor unit.

C) Connecting to TB7 of the Outdoor unit but receiving power from power supply unit PAC-SC51KUA.

Maximum 3 System controllers can be connected to TB3.

If there is more than 1 Outdoor unit, it is necessary to

replace power supply switch connector CN41 with CN40

on one Outdoor unit.

Maximum 3 System controllers can be connected to TB7

and receiving power from the Outdoor unit.

It is necessary to replace power supply switch connector

CN41 with CN40 on one Outdoor unit.

2-3-3-A. When connecting to TB3 of the Outdoor unit and receiving power from the Outdoor unit.

2-3-3-B. When connecting to TB7 of the Outdoor unit and receiving power from the Outdoor unit.

2-3-3-C. When connecting to TB7 of the Outdoor unit but receiving power from PAC-SC51KUA.

2-3-3. Ensuring proper power supply to System controller

Outdoor unit

MA remote controller

Group Group

Indoor unit

M-NET transmission lines

(transmission lines

for central controller)

Outdoor unit

ME remote controller

Group Group

Indoor unit

Replacement of

CN41 with CN40

Use CN41

as it is.

TB7

TB3

System controller

(excluding LMAP03-E)

M-NET transmission lines

(Indoor-Outdoor transmission lines)

TB7

TB3

System

controller

Maximum 3 System controllers can be connected to TB3.

Fig. 2-3-3-A

M-NET transmission lines

(transmission lines

for central controller)

MA remote controller

ME remote controller

Group Group

Group Group

Indoor unit

Indoor unit

TB3

Outdoor unit

Outdoor unit

Replacement of

CN41 with CN40

Use CN41

as it is.

System

controller

TB7

TB7

TB3

Maximum 3 System controllers can be connected to TB7.

M-NET transmission lines

(Indoor-Outdoor transmission lines)

Fig. 2-3-3-B

PAC-SC51KUA

M-NET transmission lines

(transmission lines

for central controller)

MA remote controller

ME remote controller

Group Group

Group Group

Indoor unit

Indoor unit

TB3

Outdoor unit

Outdoor unit

Use CN41

as it is.

Use CN41

as it is.

System

controller

TB7

TB7

TB3

CAUTION

M-NET transmission lines

(Indoor-Outdoor transmission lines)

Fig. 2-3-3-C

When using PAC-SC51KUA to supply transmission

power, the power supply connector CN41 on the Outdoor

units should be kept as it is. It is also a factory setting.

1 PAC-SC51KUA supports maximum 1 AG-150A unit

due to the limited power 24VDC at its TB3.

However, 1 PAC-SC51KUA supplies transmission power

at its TB2 equal to 5 Indoor units, which is referable at

Table 2-3-2.

If PZ-52SF, Timers, System controller, ON/OFF controller

connected to TB7 consume transmission power more

than 5 (Indoor units), Transmission booster

PAC-SF46EPA is needed. PAC-SF46EPA supplies

transmission power equal to 25 Indoor units.

AG-150A*1 is recommended to connect to TB7 because it performs back-up to a number of data.

In an air conditioner system has more than 1 Outdoor units, AG-150A receiving transmission power through TB3 or TB7 on one of the Outdoor units would

have a risk that the connected Outdoor unit failure would stop power supply to AG-150A and disrupt the whole system.

When applying apportioned electric power function, AG-150A is necessary to connected to TB7 and has its own power supply unit PAC-SC51KUA.

Note: Power supply unit PAC-SC51KUA is for AG-150A.

*1: AG-150A is an example model of system controllers.

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-9

Page 10

2. M-NET CONTROL

2-3-4. Power supply to LM adapter LMAP03U

1-phase 208-230V AC power supply is needed.

®

The power supply unit PAC-SC51KUA is not necessary when connecting only the LMAP03U. Yet, make sure to change

the power supply changeover connector CN41 to CN40 on the LM adapter.

2-3-5.

Y-SERIES

2010 H2i

SYSTEM DESIGN

2-3-6.

Power supply to BM ADAPTER

1-phase 100-240VAC power supply is needed.

The power supply unit PAC-SC51KUA is not necessary when only BM ADAPTER is connected.

Yet, make sure to move the power jumper from CN41 to CN40 on the BM ADAPTER.

Power supply to GB-50ADA-A

1-phase 100-240VAC power supply is needed.

The power supply unit PAC-SC51KUA is not necessary.

GB-50ADA-A supplies power through TB3, which equals 6 indoor units. (refer to Table 2-3-2)

H2iSD-10

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

Page 11

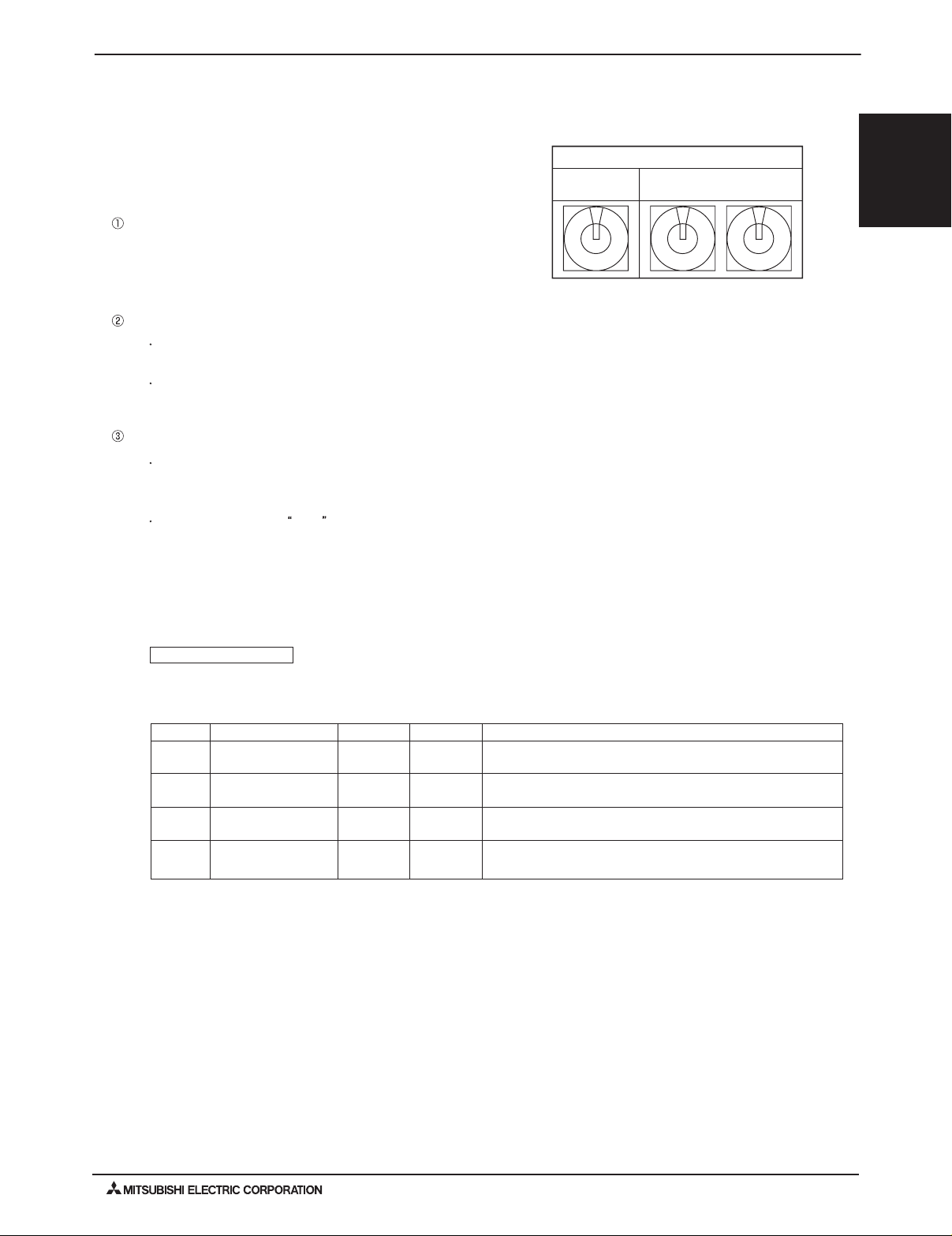

2. M-NET CONTROL

Branch

No. setting

Unit address No. setting

Rotary switch

In order to constitute CITY MULTI in a complete system, switch

operation for setting the unit address No. and connection No. is

required.

À Address No. of outdoor unit, indoor unit and remote controller.

The address No. is set at the address setting board.

In the case of R2 system, it is necessary to set the same No. at the

branch No. switch of indoor unit as that of the BC controller

connected. (When connecting two or more branches, use the lowest

branch No.)

Á Caution for switch operations

MA remote controller

¥ Be sure to shut off power source before switch setting. If operated with power source on, switch can

not operate properly.

¥ When connecting only one remote controller to one group, it is always the main remote controller.

When connecting two remote controllers to one group, set one remote controller as the main remote controller

and the other as the sub remote controller.

¥ No units with identical unit address shall exist in one whole air conditioner system. If set erroneously,

the system can not operate.

¥ The factory setting is Main .

2-4-1. Switch operation

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

PAR-21MAA

The MA remote controller does not have the switches listed above.

Refer to the installation manual for the function setting.

Setting the dip switches

There are switches on the front of the remote controller. Remote controller Main/Sub and other function settings

are performed using these switches. Ordinarily, only change the Main/Sub setting of SW1.

(The factory settings are all “ON”.)

SW No

1

2

3

SW contents Main

Remote controller

Main/Sub setting

Temperature display

units setting

Cooling/heating display in AUTO mode

ON

Main

Celsius

Yes

OFF

Sub

Fahrenheit

No

Comment

Set one of the two remote controllers at one group to “Main”

When the temperature is displayed in [Fahrenheit], set to “No”.

When you do not want to display “Cooling” and “Heating” in the

Auto mode, set to “No”.

PAC-YT51CRB

4

Intake temperature

display

YesNo

When you do not want to display the intake temperature, set to

“No”.

2-4. Address Setting

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-11

Page 12

2. M-NET CONTROL

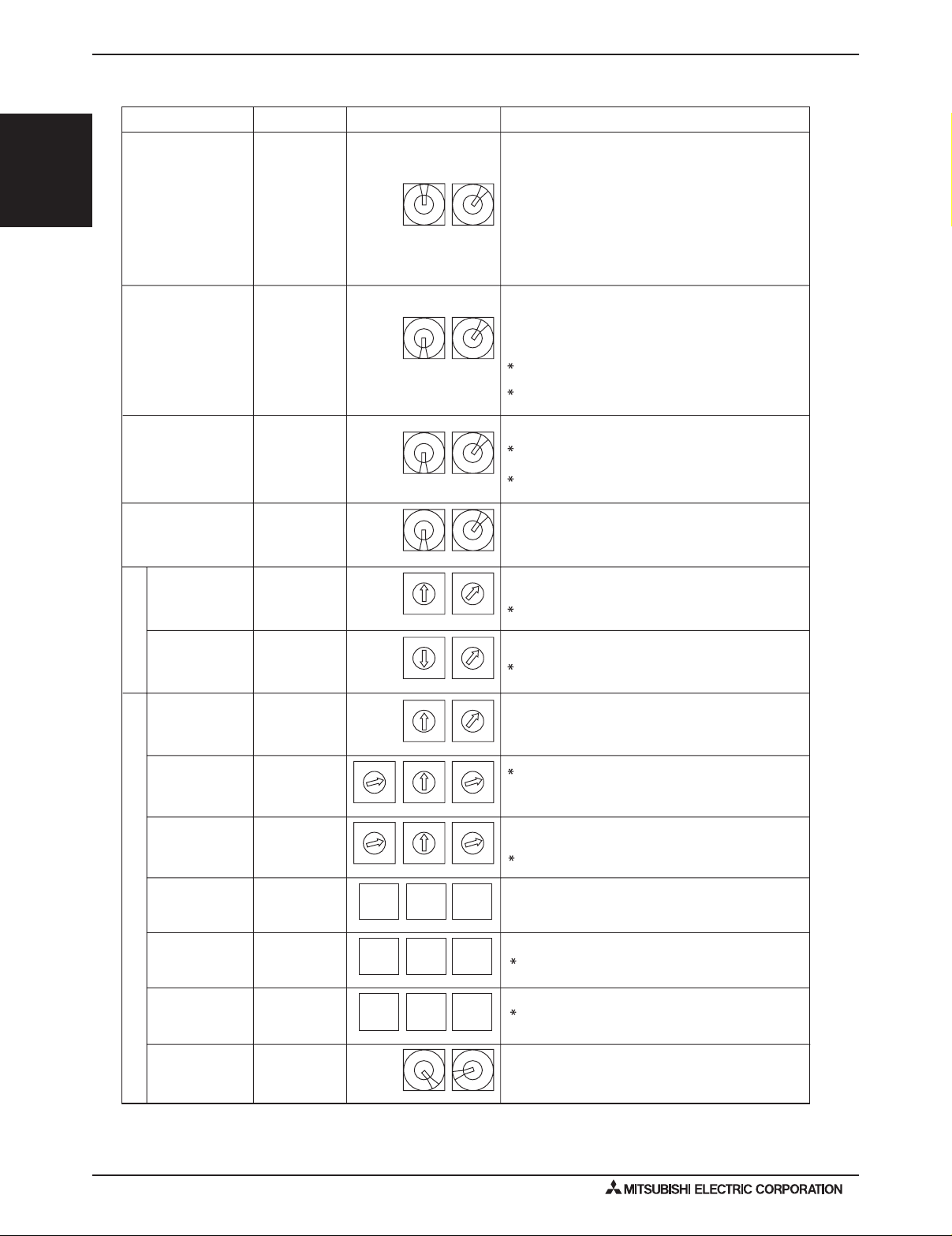

2-4-2. Rule of setting address

Unit

Indoor unit

ME, LOSSNAY

Remote controller

(Main)

ME, LOSSNAY

Remote controller

(Sub)

Address setting

01 ~ 50

52 ~ 99, 100

101 ~ 150

151 ~ 199, 200

NoteExample

The address of outdoor unit + 1

Please reset one of them to an address between 51

and 99 when two addresses overlap.

The address automatically becomes "100" if it is set

as "01~ 50"

The smallest address of indoor unit in the group + 100

The place of "100" is fixed to "1"

System remote

controller

ON/OFF remote

controller

000, 201 ~ 250

000, 201 ~ 250

Local remote controller

System controller

The address of main remote controller + 50

The address automatically becomes "200" if it is set

as "00"

10 1

10 1

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

10 1

10 1

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

10 1

10 1100

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

10 1100

LMAP03U

201 ~ 250

1

1

Fixed

Fixed

Group remote

controller

201 ~ 250

The smallest group No. to be managed + 200

For TC-24A, the address is set on the screen.

10 1

2

Fixed

2

Fixed

Outdoor unit

BC controller

(Main)

52 ~ 99, 100

Lowest address within the indoor units connected to

the BC controller (Sub) plus 50.

10 1

BC controller

(Sub)

51 ~ 99, 100

The smallest address of indoor unit in same refrigerant

system + 50

Assign sequential address numbers to the outdoor

units in one refrigerant circuit system. OC and OS are

automatically detected. (Note 2)

Please reset one of them to an address between 51

and 99 when two addresses overlap.

The address automatically becomes "100" if it is set

as "01~ 50"

Use the most recent address within the same group of

indoor units. Make the indoor units address connected

to the BC controller (Sub) larger than the indoor units

address connected to the BC controller (Main).

If applicable, set the sub BC controllers in an PURY

system in the following order:

(1)

Indoor unit to be connected to the BC controller (Main)

(2)

Indoor unit to be connected to the BC controller (No.1 Sub)

(3)

Indoor unit to be connected to the BC controller (No.2 Sub)

Set the address so that (1)<(2)<(3)

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

10 1

(Note1)

The smallest group No. to be managed is changeable.

The smallest group No. to be managed + 200

Note1: To set the address to "100", set it to "50"

Note2: Outdoor units OC and OS in one refrigerant circuit system are automatically detected.

OC and OS are ranked in descending order of capacity. If units are the same capacity, they are ranked in ascending

order of their address.

AG-150A

GB-50ADA

GB-24A

000, 201 ~ 250

10 1100

00 0

PAC-YG50ECA

000, 201 ~ 250

10 1100

BAC-HD150

000, 201 ~ 250

10 1100

Settings are made on the initial screen of AG-150A.

Settings are made with setting tool of BM ADAPTER.

00 0

00 0

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

H2iSD-12

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

Page 13

2. M-NET CONTROL

2-4-3. System examples

Factory setting

Original switch setting of the outdoors, indoors, controllers and LMAP at shipment is as follows.

Outdoor unit : Address: 00, CN41: U (Jumper), DipSW2-1: OFF

Indoor unit : Address: 00

ME remote controller : Address: 101

LMAP : Address: 247, CN41: U (Jumper), DipSW1-2: OFF

Setting at the site

DipSW2-1(Outdoor) : When the System Remote Controller is used, all the Dip SW2-1 at the outdoor units should be

set to "ON".

DipSW1-2(LMAP) : When the LMAP is used together with System Remote Controller, DipSW1-2 at the LMAP

should be set to "ON".

CN40/CN41 : Change jumper from CN41 to CN 40 at outdoor control board will activate central transmission

power supply to TB7;

(Change jumper at only one outdoor unit when activating the transmission power supply

without using a power supply unit.)

Change jumper from CN41 to CN 40 at LMAP will activate transmission power supply to LMAP

itself;

Power supply unit is recommended to use for a system having more than 1 outdoor unit,

because the central transmission power supply from TB7 of one of outdoor units is risking that

the outdoor unit failure may let down the whole system controller system.

2-4-3-1. MA remote controller, Single-refrigerant-system, No System Controller

<Two outdoor units>

PUHY-HP-TSJMU

OC OS

<One outdoor unit>

PUHY-HP-TJMU

0000

CN41CN40CN41CN40 CN41CN40

* Dip SW2-1 remains OFF when only LMAP03U is used.

OC

00

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

DipSW2-1

OFF

*1

To *1 or *2

DipSW2-1

OFF

TB3TB3

DipSW2-1

OFF

TB3

*2

Indoor unit

Group 2Group 1 Group 3 Group 4

00 00 00 00 00

SRU

*3

*3

TB15

TB15 TB15 TB15 TB15

MA R/C MA R/C MA R/C

(Main) (Sub)

TB5 TB5TB5 TB5 TB5

Wireless R/C

*3 For Wireless R/C and Signal receiver unit (SRU), channel 1, 2 and 3 are selectable and should be set to same channel.

NOTE:

1. Outdoor units OC and OS in one refrigerant circuit system are automatically detected.

OC and OS are ranked in descending order of capacity. If units are the same capacity, they are ranked in ascending order

of their address.

2. No address setting is needed.

3. For a system having more than 16 indoor unit, confirm the need of Booster at 2-3 "System configuration restrictions".

MA R/C

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-13

Page 14

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

2. M-NET CONTROL

2-4-3-2. MA remote controller, Single-refrigerant-system, System Controller

<Two outdoor units>

PUHY-HP-TSJMU

OC OS

5251

CN41CN40CN41CN40 CN41CN40

DipSW2-1

ON

*1 *2

DipSW2-1

ON

TB3TB3

<One outdoor unit>

PUHY-HP-TJMU

OC

51

DipSW2-1

ON

TB3

To *1 or *2

Indoor unit

Group 2Group 1 Group 3 Group 4

01 02 03 04 05

SRU

*3

*3

TB15

TB15 TB15 TB15 TB15

MA R/C MA R/C MA R/C

(Main) (Sub)

MA R/C

TB5 TB5TB5 TB5 TB5

201

SC

Wireless R/C

*3 For Wireless R/C and Signal receiver unit (SRU), channel 1, 2 and 3 are selectable and should be set to same channel.

*SC can be connected to TB3 side or TB7 side;

Should SC connected to TB7 side, change Jumper from CN41 to CN40 at the Outdoor unit module so as to supply power to the SC.

NOTE:

1. Outdoor units OC and OS in one refrigerant circuit system are automatically detected.

OC and OS are ranked in descending order of capacity. If units are the same capacity, they are ranked in ascending order

of their address.

2. Address should be set to Indoor units and central controller.

3. For a system having more than 16 indoor unit, confirm the need of Booster at 2-3 "System configuration restrictions".

H2iSD-14

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

Page 15

2. M-NET CONTROL

2-4-3-3. MA remote controller, Multi-refrigerant-system, System Controller at TB7 side, Booster for long M-NET wiring

PUHY-HP-TSJMU

OC OS

DipSW2-1

ON

TB3

TB7TB7 TB7 TB7

TB3

PUHY-HP-TSJMU

OC OS

5251

CN41CN40CN41CN40 CN41CN40CN41CN40 CN41CN40

DipSW2-1

ON

Indoor unit

DipSW2-1

ON

9291

DipSW2-1

ON

TB3TB3

Group 2Group 1 Group 21

PUHY-HP-TJMU

OC

TB7

97

DipSW2-1

ON

TB3

01 02 03 30

PSU

Power supply

unit (PSU)

(PAC-SC51KUA)*2

000 or 201

SC*3

TB5 TB5TB5 TB2

Wireless R/C

SRU

*1

TB15

TB15 TB15 TB3

Transmission Booster

PAC-SF46EPA

MA R/C MA R/C

TB5

TB15

MA R/C

(Main) (Sub)

*1

Group 31 Group 34 Group 35

Group 33Group 32

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

Indoor unit

41 45 46

SRU

TB15

*1

TB5 TB5 TB5

203

SC*3

42

TB5

142 143

ME R/CPZ-52SF

LOSSNAY

TB5

43

TB15

MA R/C

TB15

MA R/C

MA R/C

(Main) (Sub)

*1

Wireless R/C

*1 For Wireless R/C and Signal receiver unit (SRU), channel 1, 2 and 3 are selectable and should be set to same channel.

*2 System controller should connect to TB7 at Outdoor and use power supply unit together in Multi-Refrigerant-System.

For AG-150A, 24V DC should be used with the PAC-SC51KUA.

*3 When multiple system controllers are connected in the system, set the controller with more functions than others as a "main"

controller and others as "sub".

TC-24A is for exclusive use as a "main" system controller and cannot be used as a "sub" system controller.

Make the setting to only one of the system controllers for "prohibition of operation from local remote controller".

NOTE:

1. Outdoor units OC and OS in one refrigerant circuit system are automatically detected.

OC and OS are ranked in descending order of capacity. If units are the same capacity, they are ranked in ascending order

of their address.

2. Address should be set to Indoor units, LOSSNAY and central controller.

3. M-NET power is supplied by the Outdoor unit at TB3, while Indoor unit and

transmission use. The power balance is needed to consider for long M-NET wiring. Details refer to 2-3 "System configuration

restrictions".

ME remote controller consume the M-NET power for

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-15

Page 16

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

2. M-NET CONTROL

2-4-3-4. ME remote controller, Single-refrigerant-system, No system controller

<Two outdoor units>

PUHY-HP-TSJMU

OC OS

DipSW2-1

OFF

TB3TB3

*1

5251

CN41CN40CN41CN40 CN41CN40

DipSW2-1

OFF

<One outdoor unit>

PUHY-HP-TJMU

OC

51

DipSW2-1

OFF

TB3

*2

To *1 or *2

Indoor unit

Group 2Group 1 Group 3 Group 4

01 02 03 04 05

TB5 TB5TB5

101

ME R/C

NOTE:

1. Outdoor units OC and OS in one refrigerant circuit system are automatically detected.

OC and OS are ranked in descending order of capacity. If units are the same capacity, they are ranked in ascending order of their

address.

2. Address should be set to Indoor units,

3. M-NET power is supplied by the Outdoor unit at TB3, while Indoor unit and ME RC consume the M-NET power for transmission

use. The power balance is needed to consider for long M-NET wiring. Details refer to 2-3 "System configuration restrictions".

controller and ME remote controllers.

system

102

ME R/C ME R/C ME R/C

2-4-3-5. ME remote controller, Single-refrigerant-system, System controller, LOSSNAY

<Two outdoor units>

PUHY-HP-TSJMU

OC OS

DipSW2-1

ON

TB3TB3

*1

5251

CN41CN40CN41CN40 CN41CN40

DipSW2-1

ON

<One outdoor unit>

PUHY-HP-TJMU

OC

51

DipSW2-1

ON

TB3

*2

TB5 TB5

104 105 155

ME R/C

To *1 or *2

201

SC

*SC can be connected to TB3 side or TB7 side;

Should SC connected to TB7 side, change Jumper from CN41 to CN40 at the Outdoor unit module so as to supply power to the SC.

NOTE:

1. Outdoor units OC and OS in one refrigerant circuit system are automatically detected.

OC and OS are ranked in descending order of capacity. If units are the same capacity, they are ranked in ascending order of their

address.

2. Address should be set to Indoor units, LOSSNAY central controller, ME remote controllers.

3. For a system having more than 16 indoor unit, confirm the need of Booster at 2-3 "System configuration restrictions".

H2iSD-16

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

Group 1 Group 4 Group 5

Indoor unit

01 04 05

TB5 TB5 TB5

101

ME R/C

Group 2Group 3

LOSSNAY

02

TB5

102 103

ME R/CPZ-52SF

TB5

03

104 105 155

ME R/C

ME R/C ME R/C

Page 17

2. M-NET CONTROL

2-4-3-6.

TB3

Power supply

unit (PSU)

(PAC-SC51KUA)

ME remote controller, Multi-refrigerant-system, System Controller at TB 7side, LOSSNAY, Booster for M-NET wiring

PUHY-HP-TSJMU

OC OS

DipSW2-1

ON

201

SC

PSU

*1

PUHY-HP-TSJMU

TB7TB7 TB7 TB7

OC OS

5251

CN41CN40CN41CN40 CN41CN40CN41CN40 CN41CN40

DipSW2-1

TB3TB3

Group 2Group 1 Group 21

TB3

DipSW2-1

ON

DipSW2-1

ON

Indoor unit

01 02 03 30

TB5 TB5TB5 TB2

202

SC *2

101

ME R/C

Group 31 Group 34 Group 35

Indoor unit

41 44 45

TB5 TB5 TB5

102

ME R/C

Group 32 Group 33

42

TB5

9291

ON

TB5

LOSSNAY

43

PUHY-HP-TJMU

OC

TB7

96

DipSW2-1

ON

TB3

Transmission Booster

PAC-SF46EPA

TB3

TB5

130 180

ME R/C ME R/C

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

203

SC *2

*1 System controller should connect to TB7 at Outdoor and use power supply unit together in Multi-Refrigerant-System.

For AG-150A, 24V DC should be used with the PAC-SC51KUA.

*2 When multiple system controllers are connected in the system, set the controller with more functions than others as a "main"

controller and others as "sub".

TC-24A, AG-150A, GB-50ADA and GB-24A are for exclusive use as a "main" system controller and cannot be used as a "sub"

system controller.

Make the setting to only one of the system controllers for "prohibition of operation from local remote controller".

NOTE:

1. Outdoor units OC and OS in one refrigerant circuit system are automatically detected.

OC and OS are ranked in descending order of capacity. If units are the same capacity, they are ranked in ascending order of their address.

2. M-NET power is supplied by the Outdoor unit at TB3, while Indoor unit and ME

transmission use. The power balance is needed to consider for M-NET wiring. Details refer to "System configuration

restrictions".

141

ME R/C

142 143

ME R/C PZ-52SF

remote controller

144 145 195

ME R/C

consume the M-NET power for

ME R/C ME R/C

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-17

Page 18

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

2. M-NET CONTROL

2-4-3-7. ME remote controller, Multi-refrigerant-system, No Power supply unit

PUHY-HP-TSJMU PUHY-HP-TJMU

OC OCOS

TB7

CN40

DipSW2-1

OFF

TB3

TB7

5251

CN41CN40CN41

DipSW2-1

OFF

TB3

01 02 03 04 05

TB7

56

CN41CN40

DipSW2-1

OFF

TB3

Group 1

Group 2

101

ME R/C

Group 3Group 4

105

ME R/C

0910 08 07 06

110

NOTE

It is necessary to change the connecter to CN40 on the outdoor unit control board (only one outdoor unit) when the group is set between other refrigerant systems.

It is necessary to set on the remote controller by manual when group sets on the different refrigerant system. Please refer to remote controller installation manual

ME R/C

107

ME R/C

2-4-3-8. ME remote controller, Multi-refrigerant-system, System Controller at TB7 side, No Power supply unit

PUHY-HP-TSJMU PUHY-HP-TJMU

OC OCOS

TB7

CN40

DipSW2-1

ON

TB3

TB7

5251

CN41CN40CN41

DipSW2-1

ON

TB3

TB7

DipSW2-1

TB3

56

ON

CN41CN40

Group 1

Group 2

01 02 03 04 05

.

201

SC

101

ME R/C

Group 3Group 4

105

ME R/C

0910 08 07 06

110

NOTE

It is necessary to change the connecter to CN40 on the outdoor unit control board (only one outdoor unit) when the group is set between other refrigerant systems.

It is necessary to set on the remote controller by manual when group sets on the different refrigerant system. Please refer to remote controller installation manual

H2iSD-18

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

ME R/C

107

ME R/C

.

Page 19

2. M-NET CONTROL

CM

2-4-3-9. TG-2000A + AG-150A/GB-50A

AG-150A/GB-50A can control max. 50 indoor units.

AG-150A can control max. 50 indoor units. AG-150A can control max. 150 indoor units via expansion controllers (PAC-YG50ECA).

TG-2000A can control max. 40 pieces of AG-150A*2 or GB-50A;

TG-2000A can control max. 40 pieces of AG-150A*1 or GB-50A;

TG-2000A can control max. 2000 indoor units.

TG-2000A can control max. 2000 indoor units.

AG-150A

000

24VDC

PUHY-HP-TJMU

OC

TB7

51

CN41CN40

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

HUB

PC with

TG-2000A

*3

LAN

PSU

(PAC-SC51KUA)

AG-150A

000

24VDC

PSU

(PAC-SC51KUA)

DipSW2-1

ON

TB3

Group 2Group 1 Group 40

Indoor unit

01 02 03 42

TB5 TB5TB5 TB2

Wireless R/C

PUHY-HP-TSJMU PUHY-HP-TJMU

TB15

SRU

*2

*2

OC OS

TB7 TB7

DipSW2-1

ON

TB3TB3

MA R/

9291

CN41CN40CN41CN40 CN41CN40

DipSW2-1

ON

TB15 TB15 TB3

Transmission Booster

PAC-SF46EPA

OC

TB7

51

DipSW2-1

ON

TB3

TB5

TB15

A R/C

(Main) (Sub)

MA R/C

Group 2Group 1 Group 21

Indoor unit

01 02 03 30

TB5 TB5TB5 TB2

Transmission Booster

101

ME R/C

Indoor unit

41 42

TB5 TB5

141

ME R/C

NOTE

It is planned that GB-50ADA will be supported on TG-2000A Ver. 6.3* or later.

*1 When AG-150A is connected with expansion controllers (PAC-YG50ECA), AG-150A here means PAC-YG50ECA.

*2 For Wireless R/C and Signal receiver unit (SRU), channel 1, 2 and 3 are selectable and should be set to same channel.

*3 AG-150A connected with PAC-YG50ECA is compatible with TG-2000A Ver.6.10* or later.

102 130 180

ME R/C ME R/C ME R/C

Group 32Group 31 Group 33 Group 34

Interlocked

LOSSNAY

43

TB5 TB5 TB5

142

ME R/C

PAC-SF46EPA

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

TB3

44 45

144 145 195

ME R/C

TB5

ME R/C ME R/C

H2iSD-19

Page 20

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

2. M-NET CONTROL

2-4-3-10. LMAP

LMAP can transmit max. 50 indoor units;

If system controller (SC) is used, DipSW1-2 at LMAP and DipSW2-1 at Outdoor unit should set to "ON".

Change Jumper from CN41 to CN40 to activate power supply to LMAP itself for those LMAP connected without system

controller (SC).

LMAP can transmit for max.

50 indoor units in single-refrigerant-system or multi-refrigerant-system.

CN41

PUHY-HP-TSJMU

OC OS

TB7 TB7

5251

CN41CN40CN41CN40

(LONWORKS adapter)

LMAP(01)

identified by Neuron ID

247

CN40

DipSW1-2

OFF

Power supply unit

(PAC-SC51KUA)

PSU

LMAP(02)

identified by Neuron ID

247

CN40

LONWORKS

DipSW1-2

24VDC

CN41

ON

TB3

DipSW2-1

OFF

Group 2Group 1

Group 40

DipSW2-1

OFF

TB3

Indoor unit

01 02 03 42

SRU

TB15

*1

TB15 TB15 TB3

MA R/C MA R/C

*1

TB7TB7 TB7 TB7

5251

CN41CN40CN41CN40

DipSW2-1

ON

TB3

Group 2

OC OS

DipSW2-1

ON

Transmission Booster

PAC-SF46EPA

9291

CN40CN41CN40 CN41CN40

CN41

DipSW2-1

ON

TB3TB3

TB5

(Main) (Sub)

TB3

Group 21

TB5 TB5TB5 TB2

AG-150A

000

Wireless R/C

PUHY-HP-TSJMU PUHY-HP-TSJMU PUHY-HP-TJMU

OC OS

DipSW2-1

ON

TB3

Group 1

Indoor unit

01 02 03 30

TB5 TB5TB5 TB2

TB3

TB5

TB15

MA R/C

OC

TB7

96

DipSW2-1

ON

LONW

LONW

LONW

H2iSD-20

PC

ORKS

ORKS

ORKS

Transmission Booster

101

ME R/C

Group 31 Group 34 Group 35

Indoor unit

41 44 45

TB5 TB5 TB5

102 130 180

ME R/C ME R/C ME R/C

Group 32 Group 33

LOSSNAY

42

TB5

43

TB5

PAC-SF46EPA

card

card

card

*1 For Wireless R/C and Signal receiver unit (SRU), channel 1, 2 and 3 are selectable and should be set to same channel.

For other equipments (Lighting, security, elevator etc.)

141

ME R/C

142 143

ME R/CPZ-52SF

144 145 195

ME R/C

ME R/C ME R/C

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

Page 21

2. M-NET CONTROL

2-4-3-11. BM ADAPTER

BM ADAPTER(01)

HUB

For other equipments (Lighting, security, elevator etc.)

BM ADAPTER can transmit for max.

50 indoor units in single-refrigerant-system or multi-refrigerant-system.

000

BAC net

BM ADAPTER(02)

201

CN41

CN40

BM ADAPTER can transmit max. 50 indoor units;

Change Jumper from CN41 to CN40 to activate power supply to BM ADAPTER itself for those BM ADAPTER connected

without the power supply unit.

Indoor unit

MA R/CMA R/C

(Main)(Sub)

MA R/C

SRU

Wireless R/C

*1

*1

01 02 03 42

TB15

TB5TB5TB5TB2

Transmission Booster

PAC-SF46EPA

TB5

TB15 TB15 TB3

TB15

Group 2Group 1

Group 40

Indoor unit

ME R/C ME R/CME R/C

01 02 03 30

TB5TB5TB5TB2

Transmission Booster

PAC-SF46EPA

TB5

ME R/C

101

102 130 180

TB3

Group 2

Group 1

Group 21

TB3

TB7TB7

TB7

TB3

OC OS

5251

TB3

91

OC

CN41CN40CN41CN40 CN41CN40

ON

DipSW2-1

ON

DipSW2-1

ON

DipSW2-1

ME R/CME R/C

Indoor unit

ME R/C

ME R/C

PZ-52SF-E

142 143

144 145 195

41 42

43

44 45

TB5TB5

LOSSNAY

TB5TB5 TB5

Group 32 Group 33Group 31 Group 34 Group 35

ME R/C

141

PUHY-HP-TSJMU PUHY-HP-TJMU

*1 For Wireless R/C and Signal receiver unit (SRU), channel 1, 2 and 3 are selectable and should be set to same channel.

HUB

CN41

CN40

TB3

TB7TB7

TB7

TB3

5251

OC OS

TB3

51

OC

CN41CN40CN41CN40 CN41CN40

OFF

DipSW2-1

OFF

DipSW2-1

OFF

DipSW2-1

PUHY-HP-TSJM

U

PUHY-HP-TJMU

<Two outdoor units>

<One outdoor unit>

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-21

Page 22

3. PIPING DESIGN

3-1. R410A Piping Material

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

Refrigerant pipe for CITY MULTI shall be made of phosphorus deoxidized copper, and has two types.

A. Type-O : Soft copper pipe (annealed copper pipe), can be easily bent with human's hand.

B. Ty pe-1/2H pipe : Hard copper pipe (Straight pipe), being stronger than Type-O pipe of the same radical thickness.

The maximum operation pressure of R410A air conditioner is 4.30 MPa [623psi] . The refrigerant piping should ensure the safety

under the maximum operation pressure. MITSUBISHI ELECTRIC recommends pipe size as Ta ble 3-1, or You shall follow the local

industrial standard. Pipes of radical thickness 0.7mm or less shall not be used.

Table 3-1. Copper pipe size and radial thickness for R410A CITY MULTI.

Size (mm) Size (inch)Radial thickness (mm) Pipe type

ø6.35 ø1/4"0.8 Ty pe-O

ø9.52 ø3/8"0.8 Ty pe-O

ø12.7 ø1/2"0.8 Ty pe-O

ø15.88 ø5/8"1.0 Ty pe-O

ø19.05 ø3/4"1.2 Ty pe-O

ø19.05 ø3/4"1.0 Ty pe-1/2H or H

ø22.2 ø7/8"1.0 Ty pe-1/2H or H

ø25.4ø1" 1.0Type-1/2H or H

ø28.58 ø1-1/8" 1.0Type-1/2H or H

ø31.75 ø1-1/4" 1.1Type-1/2H or H

ø34.93 ø1-3/8" 1.2Type-1/2H or H

ø41.28 ø1-5/8" 1.4

* F

or pipe sized ø19.05 (3/4") for R410A air conditioner, choice of pipe type is up to you.

* The figures in the radial thickness column are based on the Japanese standards and provided only as a reference. Use pipes that meet the

local standards.

Radial thickness (mil)

[32]

[32]

[32]

[40]

[48]

[40]

[40]

[40]

[40]

[44]

[48]

[56] Type-1/2H or H

Flare

Due to the relative higher operation pressure of R410A compared to R22, the flare connection should follow dimensions

mentioned below so as to achieve enough the air-tightness.

Flare pipe Pipe sizeA (For R410A) Flare nut Pipe size

ø6.35 [1/4"]

ø9.52 [3/8"]

A

ø12.70 [1/2"]

ø15.88 [5/8"]

ø19.05 [3/4"]

9.1 [3/8"]

13.2 [9/16"]

16.6 [11/16"]

19.7 [13/16"]

24.0 [1"]

B

ø6.35 [1/4"]

ø9.52 [3/8"]

ø12.70 [1/2"]

ø15.88 [5/8"]

ø19.05 [3/4"]

B (For R410A)

17.0 [3/4"]

22.0 [7/8"]

26.0 [1-1/16"]

29.0 [1-1/8"]

36.0 [1-7/16"]

(mm[in.]) (mm[in.])

H2iSD-22

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

Page 23

3. PIPING DESIGN

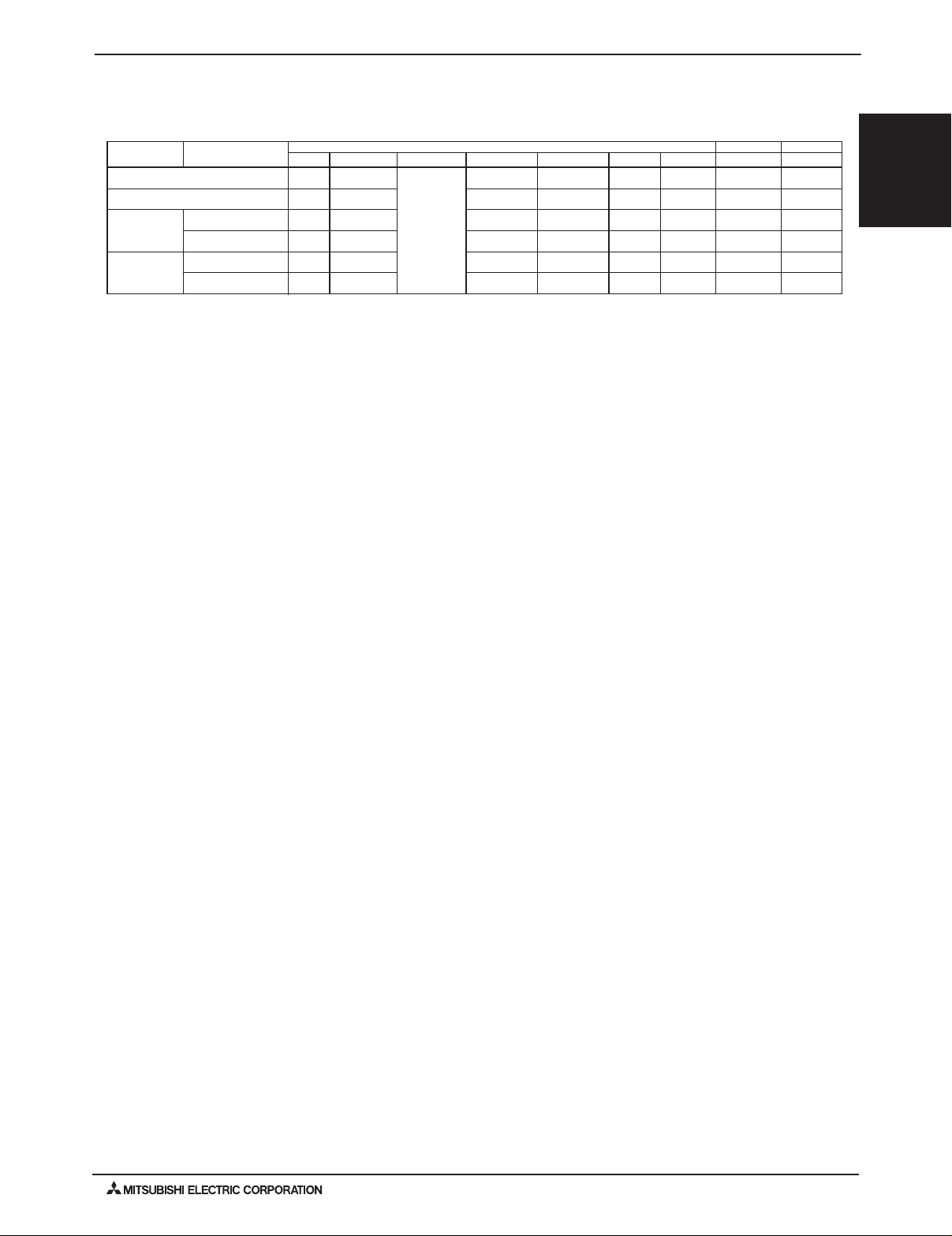

Table3-2-1-6. R410A Joint selection rule

Total down-stream Indoor capacity Joint

~ P72 CMY-Y102S-G2

P73 ~ P144 CMY-Y102L-G2

P145 ~ P234 CMY-Y202-G2

P235 ~ CMY-Y302-G2

*Concerning detailed usage of Joint parts, refer to its Installation Manual.

Table3-2-1-7. R410A Header selection rule

4-branch Header 8-branch Header 10-branch Header

CMY-Y104-G CMY-Y108-G CMY-Y1010-G

Total down-stream Indoor capacity

<=P72 <=P144 <=P234

* CMY-Y104-G can directly connect PUHY-HP72TJMU, but can NOT directly connect PUHY-HP96TJMU or above;

* CMY-Y108-G can directly connect PUHY-HP72-144T(S)JMU, but can NOT directly connect PUHY-HP192TSJMU

* CMY-Y1010-G can directly connect PUHY-HP72-192T(S)JMU;

* CMY-Y104-G can NOT connect P72, P96 Indoor, but CMY-Y108, Y1010-G can do;

* Concerning detailed usage of Header parts, refer to its Installation Manual.

H

h

H'

The first joint

Joint

b ca

L2

L1

IU

IU IUIU

d

IU

IU

f

IU

e

C

D

A

OU

B

Header

Note1. No Joint after Header; Piping direct to Indoor Unit from Header;

Note2. If the A/C system is designed to use Cooling-mode under Outside temperature 10°C [50°F], H'<=40m [131ft.];

Note3. As bents cause pressure loss on transportation of refrigerant, fewer bents design is better;

Piping length needs to consider the actual length and equivalent length which bents are counted.

Equivalent piping length = Actual piping length + "M" x Quantity of bent.

IU : Indoor unit , OU : Outdoor unit

g

Fig. 3-2-1A Piping scheme

3-2-1. PUHY-HP-72, 96TJMU Piping

Table3-2-1-1. Piping length (m [ft.])

Item Piping in the figure Max. length

Max. equivalent length

Total piping length A+B+C+D+a+b+c+d+e+f+g 300 [984'] Farthest IU from OU (L1) A+C+D+g / A+B+d 150 [492'] 175 [574']

Farthest IU from first Joint (L2) C+D+g / B+d 40 [131'] 40 [131']

Height between OU and IU (OU above IU)

H 50 [164'] -

Height between OU and IU (OU under IU)

H' 40 [131'] -

Height between IU and IU h 15 [49'] -

OU: Outdoor Unit, IU: Indoor Unit

Table3-2-1-3. Piping "A" size selection rule (mm [in.])

Outdoor and the first Joint Pipe(Liquid) Pipe(Gas)

PUHY-HP72TJMU=CMY-Y102S-G2 ø12.70 [1/2"] ø19.05 [3/4"]

PUHY-HP96TJMU=CMY-Y102L-G2 ø12.70 [1/2"] ø22.20 [7/8"]

Table3-2-1-4. Piping "B","C","D"size selection rule

(mm [in.])

Total down-stream Indoor capacity Pipe(Liquid) Pipe(Gas)

~ P54 ø9.52 [3/8"] ø15.88 [5/8"]

P55 ~ P72 ø9.52 [3/8"] ø19.05 [3/4"]

P73 ~ P108 ø9.52 [3/8"] ø22.20 [7/8"]

P109 ~ P144 ø12.70 [1/2"] ø28.58 [1-1/8"]

P145 ~ P234 ø15.88 [5/8"] ø28.58 [1-1/8"]

Table3-2-1-5.

Piping "a","b","c","d","e","f","g"size selection rule (mm [in.])

Indoor Unit size Pipe(Liquid) Pipe(Gas)

P06,P08,P12,P15,P18 ø6.35 [1/4"] ø12.70 [1/2"]

P24,P27,P30,P36,P48,P54 ø9.52 [3/8"] ø15.88 [5/8"]

P72 ø9.52 [3/8"] ø19.05 [3/4"]

P96 ø9.52 [3/8"] ø22.20 [7/8"]

Table3-2-1-2.

Bent equivalent length "M"

Outdoor Model M (m/

bends

[ft./

bends

])

PUHY-HP72TJMU 0.30 [0.99]

PUHY-HP96TJMU 0.35 [1.15]

Note4. Indoor capacity is described as its model size;

For example, PEFY-P08NMAU-E, its capacity is P06;

Note5. Total down-stream Indoor capacity is the summary of the model size of Indoors downstream.

For example, PEFY-P06NMAU-E+PEFY-P08NMAU-E: Total Indoor capacity=P06+P08=P14

Note6. Piping sized determined by the Total down-stream indoor capacity is NOT necessary

to be bigger than the up-stream one.

i.e. A>=B; A>=C>=D

3-2. Piping Design

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-23

Page 24

3. PIPING DESIGN

Table3-2-2-4. R410A Joint selection rule

Total down-stream Indoor capacity Joint

~ P72CMY-Y102S-G2

P73~ P144 CMY-Y102L-G2

P145 ~ P234 CMY-Y202-G2

*First Joint is always CMY-Y202-G2;

*Concerning detailed usage of Joint parts, refer to its Installation Manual.

Outdoor Twinning Kit

CMY-Y100VBK2

Note1. No Joint after Header; Piping direct to Indoor Unit from Header;

Note2. If the A/C system is designed to use cooling-mode under outside temperature 10°C [50°F], H’<=40m [131ft].

Note3. As bents cause pressure loss on transportation of refrigerant, fewer bents design is better;

Piping length needs to consider the actual length and equivalent length which bents are counted.

Equivalent piping length=Actual piping length+"M" x Quantity of bent.

H (OU above IU)

h1

H' (OU under IU)

h2

1st Joint

Joint

ba

L2

L1

IU

IU IUIU

g

IU

e

IU

d

C

D

IU

f

E

T

S

A

B

Header

Capped

IU : Indoor unit , OU : Outdoor unit

Fig. 3-2-1B Piping scheme

c

2m [6.56ft]

To indoor unit

To indoor unit

To indoor unit

To indoor unit

2m [6.56ft] max

Trap (gas

pipe only)

Upward

incline

Downward

incline

Install the pipes from the outdoor unit to the branch

joint with a downward incline.

If the length of pipe between the branch joint and outdoor

unit exceeds 2m [6.56ft], provide at rap at a distance 2m [6.56ft] or

less from the branch joint.

OK

NO

3-2-2. PUHY-HP144-192TSJMU Piping

Table3-2-2-1. Piping length (m [ft.])

ItemPiping in the figureMax. length

Max. equivalent length

Total piping length

S+T+A+B+C+D+E+a+b+c+d+e+f+g

300 [984']Distance between OU and OU S+T 10[32']Height between OU and OU h2 0.1[0.3']Farthest IU from OU (L1)

S(T)+A+C+D+E+g / S(T)+A+B+c

150 [492'] 175 [574']

Farthest IU from the first Joint (L2) C+D+E+g / B+c 40 [131'] 40 [131']

Height between OU and IU (OU above IU)

H 50 [164']-

Height between OU and IU (OU under IU)

H' 40 [131']-

Height between IU and IU h1 15 [49']-

OU: Outdoor Unit, IU: Indoor Unit

Table3-2-2-3. Piping "A" size selection rule (mm [in.])

Outdoor and the first JointPipe(Liquid) Pipe(Gas)

CMY-Y100VBK2=CMY-Y202-G2 ø15.88[5/8"] ø28.58[1-1/8"]

For Piping size "S","T", please refer to specification of the Twining kit CMY-Y100VBK2 at the Outdoor unit's

external drawing.

Table3-2-2-2.

Bent equivalent length "M"

Outdoor Model M (m/bends [ft./bends])

PUHY-HP144TSJMU 0.50 [1.64]

PUHY-HP192TSJMU 0.50 [1.64]

OU

OU

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

H2iSD-24

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

Page 25

3. PIPING DESIGN

+++

++

++

3-3. Refrigerant Charge Calculation

At the time of shipping, the outdoor unit is charged with the refrigerant. As this charge does not include the amount needed

for extended piping, additional charging for each refrigerant line will be required on site. In order that future servicing may be

properly provided, always keep a record of the size and length of each refrigerant line and the amount of additional charge

by writing it in the space provided on the outdoor unit.

(1) Calculation of additional refrigerant charge

Calculate the amount of additional charge based on the length of the piping extension and the size of the refrigerant

line.

Use the table to the below as a guide to calculating the amount of additional charging and charge the system

accordingly.

If the calculation results in a fraction of less than 0.1kg, round up to the next 0.1kg. For example, if the result of the

12.38kg, round the result up to 12.4kg.

calculation was

If the calculation results in a fraction of less than 1oz, round up to the next 1oz. For example, if the result of the

calculation was 435.1oz, round the result up to 436oz.

<Additional Charge>

Additional

refrigerant charge

Table3-2-3-1. Value of

(kg)

(oz)

Total capacity of connecting indoor units

Total length of liquid

= ++

(m)

(ft.)

Models 27

Models 28 54

Models 55 126

Models 127 144

Models 145 180

Models 181 234

Models 235

Example: PUHY-HP96TJMU

m [kg]

Indoor 1: P48A: 40 m a: 10 m

2: P36B: 10 m b: 5 m

3: P15 15 m c: 10 m

4: P12 10 m d: 10 m

5: P24 e: 10 m

The total length of liquid pipe of each size is as follows:

12.7 : A = 40 = 40 m

9.52 : B + C + D + a + b + e = 10 + 15 + 10 + 10 + 5 + 10 = 60 m

A

6.35 : c + d = 10 + 10 = 20 m

Total capacity of connecting Indoor units Pt :

Pt = P48 + P36 + P15 + P12 + P24 = P135, therefore = 3.5kg

0.29 (kg/m)

x

x 3.1 [oz/ft.]

Total length of liquid

(m) x 0.20 (kg/m)

(ft.)

x 2.15 [oz/ft.]

2.0 kg [71 oz]

2.5 kg [89 oz]

3.0 kg [106 oz]

3.5 kg [124 oz]

4.5 kg [159 oz]

5.0 kg [177 oz]

6.0 kg [212 oz]

Total length of liquid

(m) x 0.12 (kg/m)

(ft.)

x 1.29 [oz/ft.]

ft. [oz]

Indoor 1: P48A: 131ft. 32ft.

The total length of liquid pipe of each line is as follows:

Total capacity of connecting Indoor units Pt :

Pt = P48 + P36 + P15 + P12 + P24 = P135, therefore = 124oz

Total length of liquid

(m) x 0.06 (kg/m)

(ft.)

x 0.65 [oz/ft.]

2: P36B: 32ft. b: 16ft.

3: P15C: 49ft. c: 32ft.

4: P12D: 32ft. d: 32ft.

5: P24 e: 32ft.

A = 131 = 131ft.

+ a + b + e = 32 + 49 + 32 + 32 + 16 + 32 = 193ft.

Total length of liquid

(m) x 0.024 (kg/m)

(ft.)

x 0.26 [oz/ft.]

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

m [kg]

Additional

refrigerant charge

(kg)

or

ft. [oz]

Additional

refrigerant charge

(oz)

B C D

e

a b c d

P15P36P48 P12

Total length of liquid

=+++

x 0.29 (kg/m)

0 (m) x 0.29 (kg/m)

=

0 0 40 x 0.12 60 x 0.06 20 x 0.024

= 12.4 kg

Total length of liquid

=+++

x 3.1 (oz/ft.)

0 (ft.) x 3.1 (oz/ft.)

=

0 0 131 x 1.29 193 x 0.65 64 x 0.26

= 436 [oz]

Total length of liquid

x 0.20 (kg/m)

0 (m) x 0.20 (kg/m)

++++

Total length of liquid

x 2.15 (oz/ft.)

0 (ft.) x 2.15 (oz/ft.)

++++

Total length of liquid

x 0.12 (kg/m)

40 (m) x 0.12 (kg/m)

Total length of liquid

x 1.29 (oz/ft.)

131 (ft.) x 1.29 (oz/ft.)

Total length of liquid

x 0.06 (kg/m)

60 (m) x 0.06 (kg/m)

Total length of liquid

x 0.65 (oz/ft.)

193 (ft.) x 0.65 (oz/ft.)

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

P24

Total length of liquid

x 0.024 (kg/m)

20 (m) x 0.024 (kg/m)

Total length of liquid

x 0.26 (oz/ft.)

64 (ft.) x 0.26 (oz/ft.)

H2iSD-25

3.5

+ 3.5

124

+ 124

Page 26

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

4. OUTDOOR INSTALLATION

4-1. Installation Site Requirements

1.

Do not install in an area where the unit could be subjected to direct heat.

2.

Avoid installing the unit in a location where the operating sound could be an annoyance.

3. Avoid the sites where strong winds blow.

4.

Install on a stable, load-bearing surface.

5.

Ensure there is adequate drain flow from the unit when in heating mode

6.

See space requirements for installation and maintenance.

7. Do not install the unit in an environment that may have combustible gas, oil, steam, chemical gas like acidic solutions,

sulfur gas, etc.

8. To ensure an adequate flow velocity for the exhaust pipe, make sure its horizontal gradient is higher than 1/100.

H2iSD-26

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

Page 27

4. OUTDOOR INSTALLATION

4-2. Installation Clearance Space

In case of single installation

• Secure enough space around the unit as shown in the figure.

<A> : Top view

<B> :Side view

<C> : When there is little space up to an obstruction

(1) If the distance is 300 mm [11-13/16 in.] or more between the rear side and the wall

:Front

A

Unit height

:

B

300*

[11-13/16]

Back

:

C

:Air outlet guide (Procured at the site)

D

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

A

450*

[17-23/32]

15* [19/32] 15* [19/32]

<A>

(2) If the distance is 100 mm [3-15/16 in.] or more between the rear side and the wall

100*

[3-15/16]

A

450*

[17-23/32]

50* [1-31/32] 50* [1-31/32]

<A>

(3) If the wall height (H) of the front, rear or side exceeds the wall height restriction

h

H

B

A

h

H

500

[19-11/16]

<B>

• When the height of the walls on the front, back or on the sides <H> exceeds the wall height limit as defined below,

add the height that exceeds the height limit <h> to the figures that are marked with an asterisk.

<Wall height limit> Front: Up to the unit height

Back: Up to 500mm [19-11/16 in.] from the unit bottom

Side: Up to the unit height

(4) If there are obstacles at the upper part of the unit

1000

45°

240

[39-3/8]

D

[9-15/32]

<C>

C

(Unit : mm [in.])

A

50 [1-31/32]

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-27

Page 28

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

4. OUTDOOR INSTALLATION

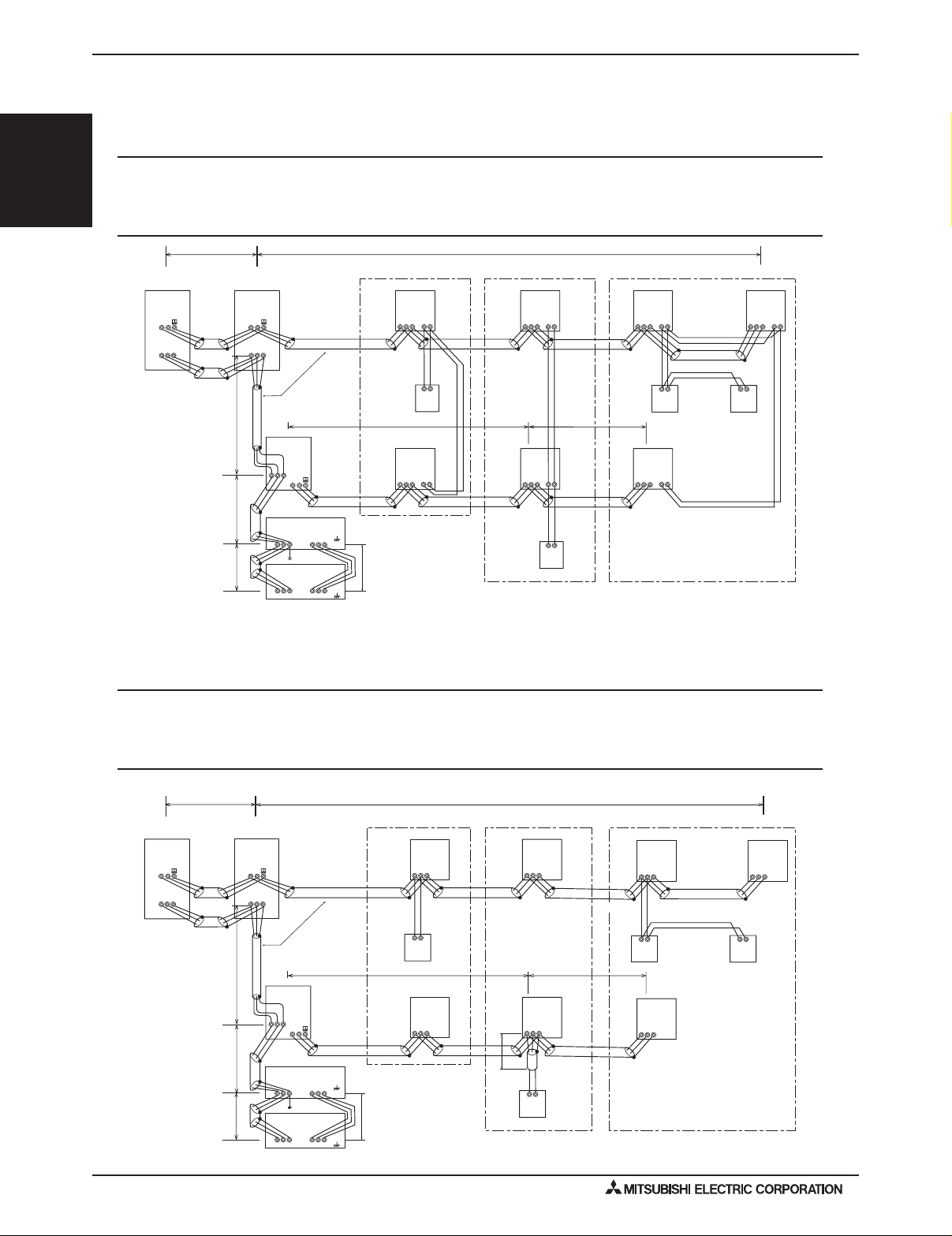

In case of collective installation and continuous installation

:Front

A

Must be open

:

B

• When multiple units are installed adjacent to each other, secure enough space to allow for air circulation and

passageways between groups of units as shown in the figures.

• At least two sides must be left open.

• As with the single installation, add the height that exceeds the height limit <h> to the figures that are marked with

an asterisk.

• If there is a wall at both the front and the rear of the unit, install up to six units consecutively in the side direction and

provide a space of 1000mm [33-3/8] or more as inlet space/passage space for each six units.

: Wall height (H)

C

C

B B

A

C

C

30

[1-3/16]

450* 300*

[17-23/32] [11-13/16]

[3-15/16]

B B

A

C

100

[3-15/16]

450* 100*

[17-23/32]

B

C

AAA

C

C

B B

A

C

C

A

1000*

[39-3/8]

B

300*300*

900

900 300*

[11-13/16] [11-13/16] [11-13/16]

[35-7/16]

B

[35-7/16]

H2iSD-28

450*

[17-23/32] [17-23/32] [17-23/32]

450 450

100*

[3-15/16]

B

C

15*

AAA

450 450

[17-23/32] [17-23/32]

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

(Unit : mm [in.])

Page 29

4. OUTDOOR INSTALLATION

-

4-3. Piping Direction

4-3-1. Lifting method

· When lifting the unit with ropes, run the ropes under the unit and use the lifting hole.

· Support the unit at four points with two ropes, and avoid giving mechanical shock.

· Suspension rope angle must be 40° or less, so as to avoid compressing fan guard.

· Use two ropes, each at least 8m [26 ft.] in length

· Use ropes strong enough to support the weight of the unit.

· Always suspend the unit from four corners. (It is dangerous to suspend a unit from two corners and must not be attempt

ed.)

· Use protective pads to keep the ropes from scratching the panels on the unit.

SYSTEM DESIGN

Y-SERIES

2010 H2i

®

1 HP72 HP96

8 [26]

°

40

8 [26]

2

8 [26]

40°

8 [26]

CAUTION

Exercise caution when transporting products.

· Products weighing more than 20 kg [45 LBS] should not be carried alone.

· Do not carry the product by the PP bands.

· To avoid the risk of injury, do not touch the heat exchanger fins.

· Plastic bags may pose a risk of choking hazard to children. Tear plastic bags into pieces before disposing of them.

· When lifting and transporting outdoor units with ropes, run the ropes through lifting hole at the unit base. Securely

fix the unit so that the ropes will not slide off, and always lift the unit at four points to prevent the unit from falling.

2010 Hyper-heating Y-SERIES SYSTEM DESIGN (Sept. 2010)

H2iSD-29

Page 30

4. OUTDOOR INSTALLATION

4-3-2. Installation

®

Y-SERIES

2010 H2i

SYSTEM DESIGN

· Secure the unit with anchor bolts as shown in the figure below so that the unit will not topple over with strong wind or during an earthquake.

· Install the unit on a durable base made of such materials as concrete or angle steel.

· Ta ke appropriate anti-vibration measures (e.g., vibration damper pad, vibration isolation base) to keep vibrations and

noise from being transmitted from the unit through walls and floors.

· Install the unit in such a way that the corner of the angle bracket at the base of the unit shown in the figure below is

securely supported.

· Install the anchor bolt in such a way that the top end of the anchor bolt do not stick out more than 30 mm [1-3/16in].