Page 1

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

H2i-R2-1

© 2014 Mitsubishi Electric US, Inc.

CITY MULTI® H2i® R2-SERIES HYPER-HEATING INVERTER SERIES

OUTDOOR UNITS

1. SPECIFICATIONS ..................................................................................................................................................H2i-R2-4

1-1. PURY-HP72~192T(S)KMU-A-H Specications .............................................................................................H2i-R2-4

1-2. PURY-HP72~192Y(S)KMU-A Specications ................................................................................................H2i-R2-7

2. EXTERNAL DIMENSIONS ...................................................................................................................................H2i-R2-11

3. CENTER OF GRAVITY ........................................................................................................................................H2i-R2-17

4. ELECTRICAL WIRING DIAGRAMS .....................................................................................................................H2i-R2-18

5. REFRIGERANT CIRCUIT DIAGRAMS ................................................................................................................H2i-R2-20

6. SOUND PRESSURE LEVELS .............................................................................................................................H2i-R2-22

7. CAPACITY TABLES .............................................................................................................................................H2i-R2-24

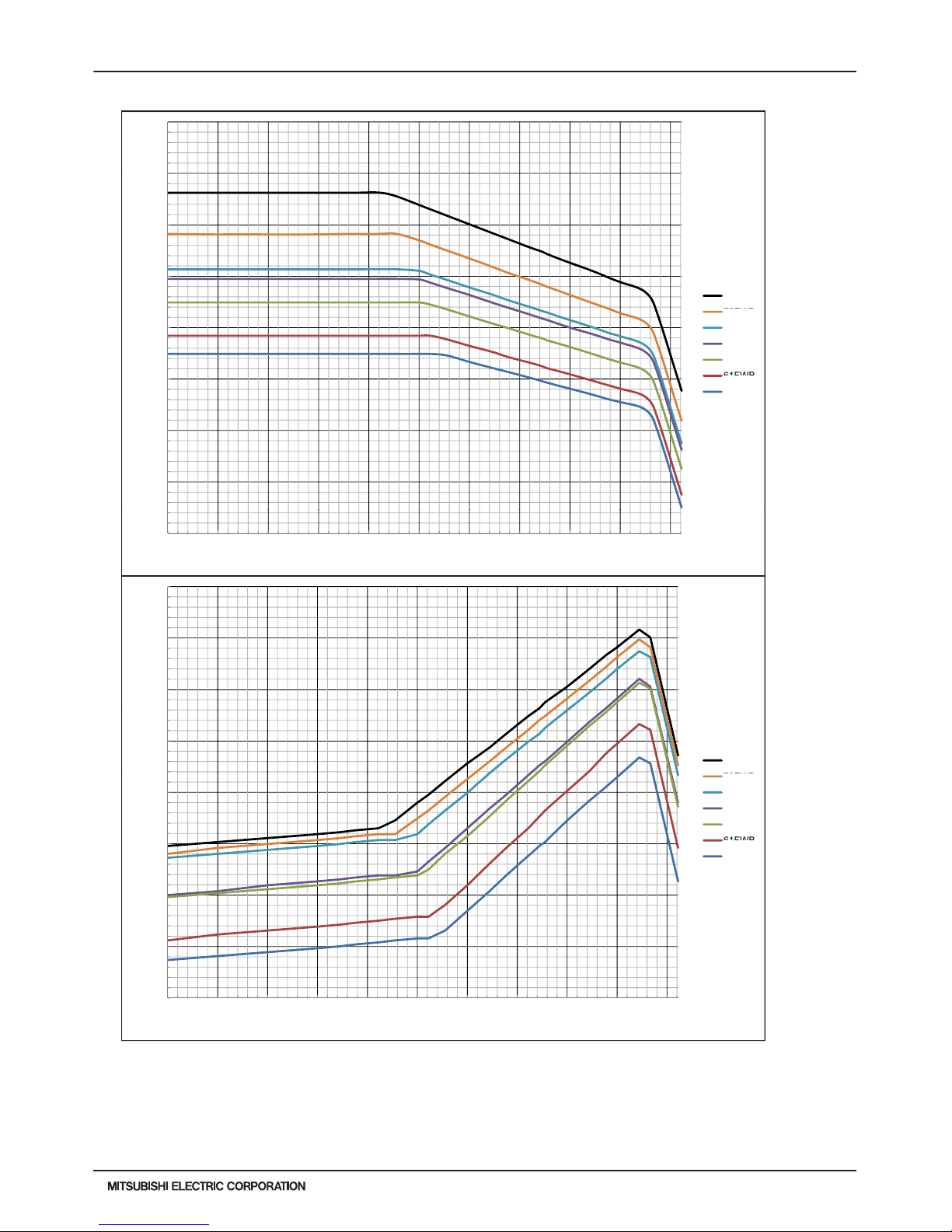

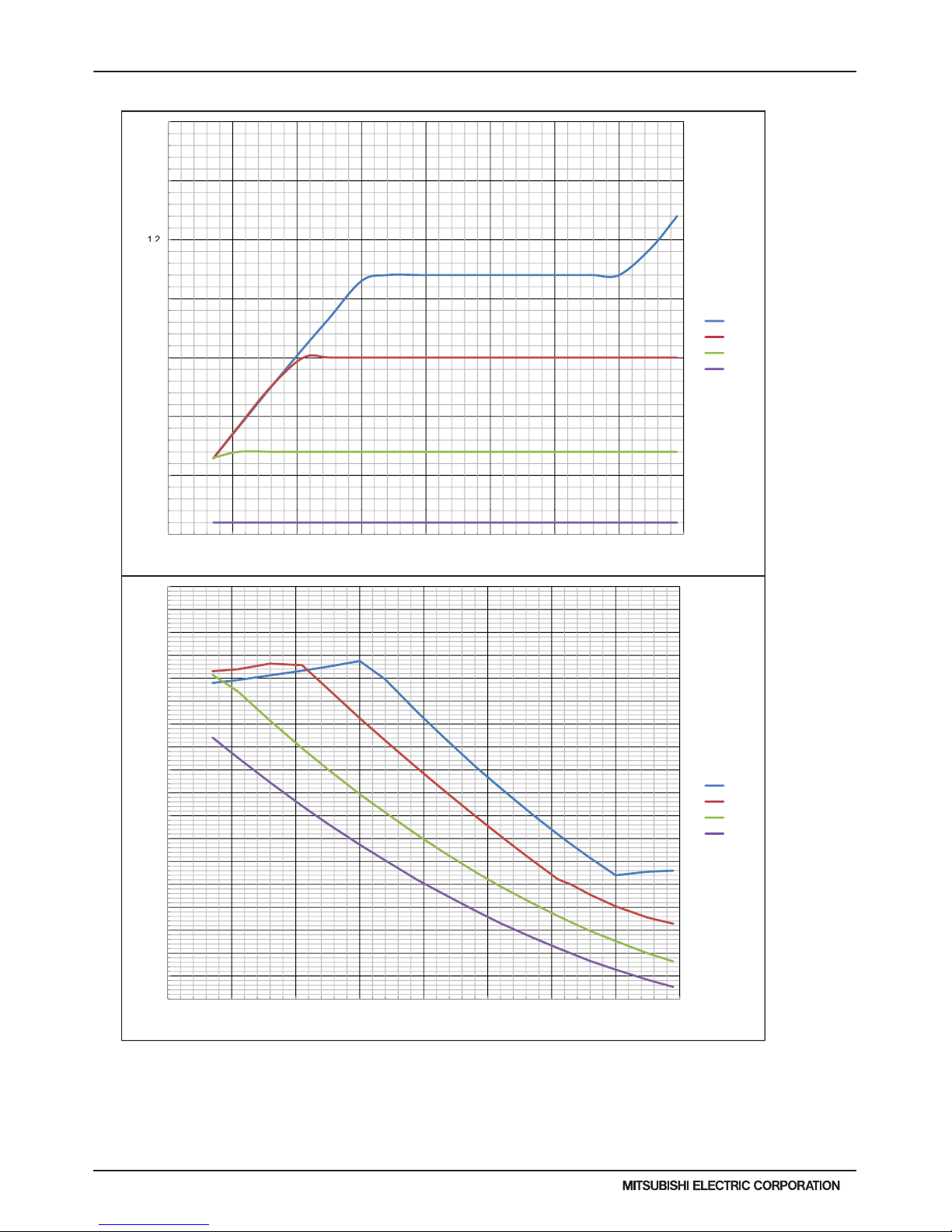

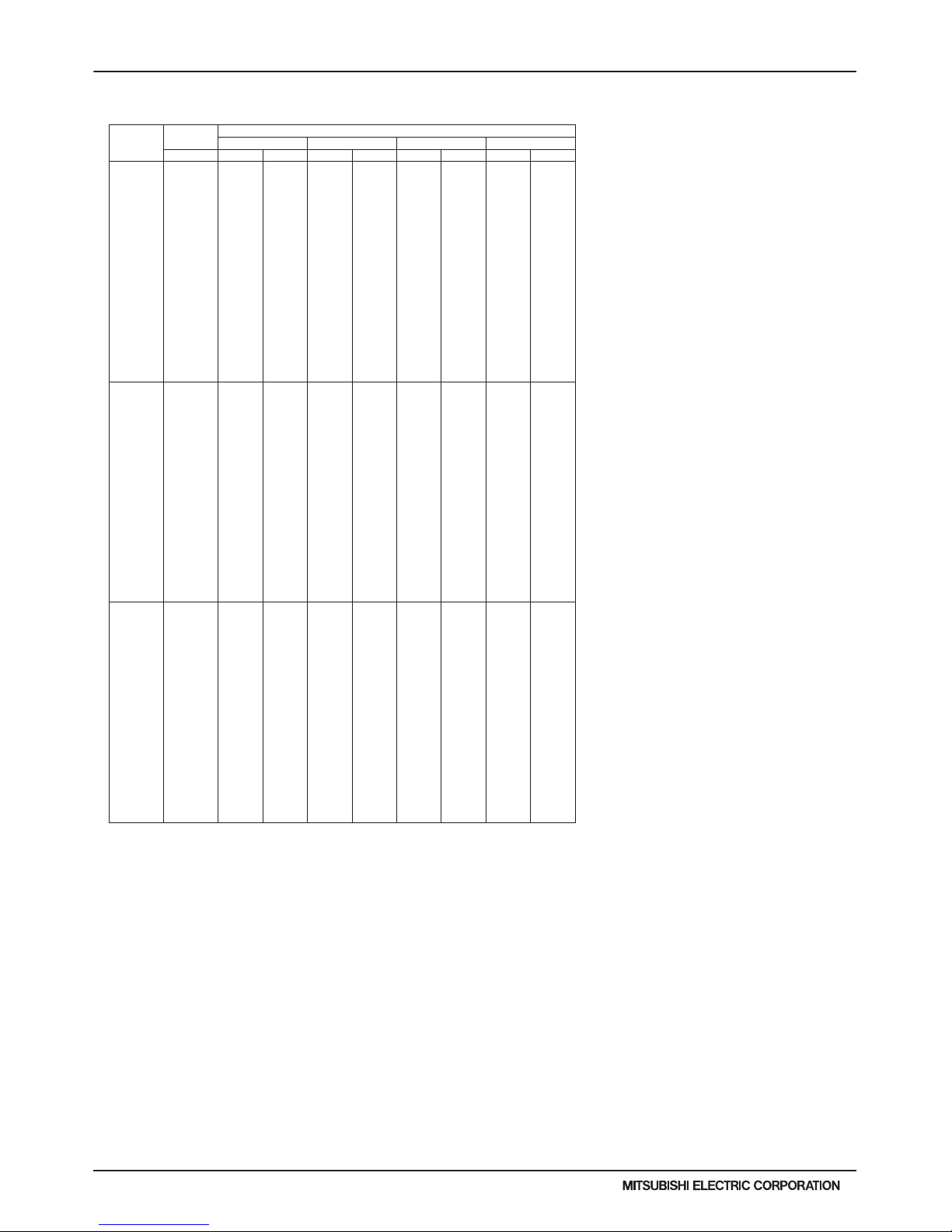

7-1. Correction by Temperature (Standard Performance) in Fahrenheit ............................................................H2i-R2-24

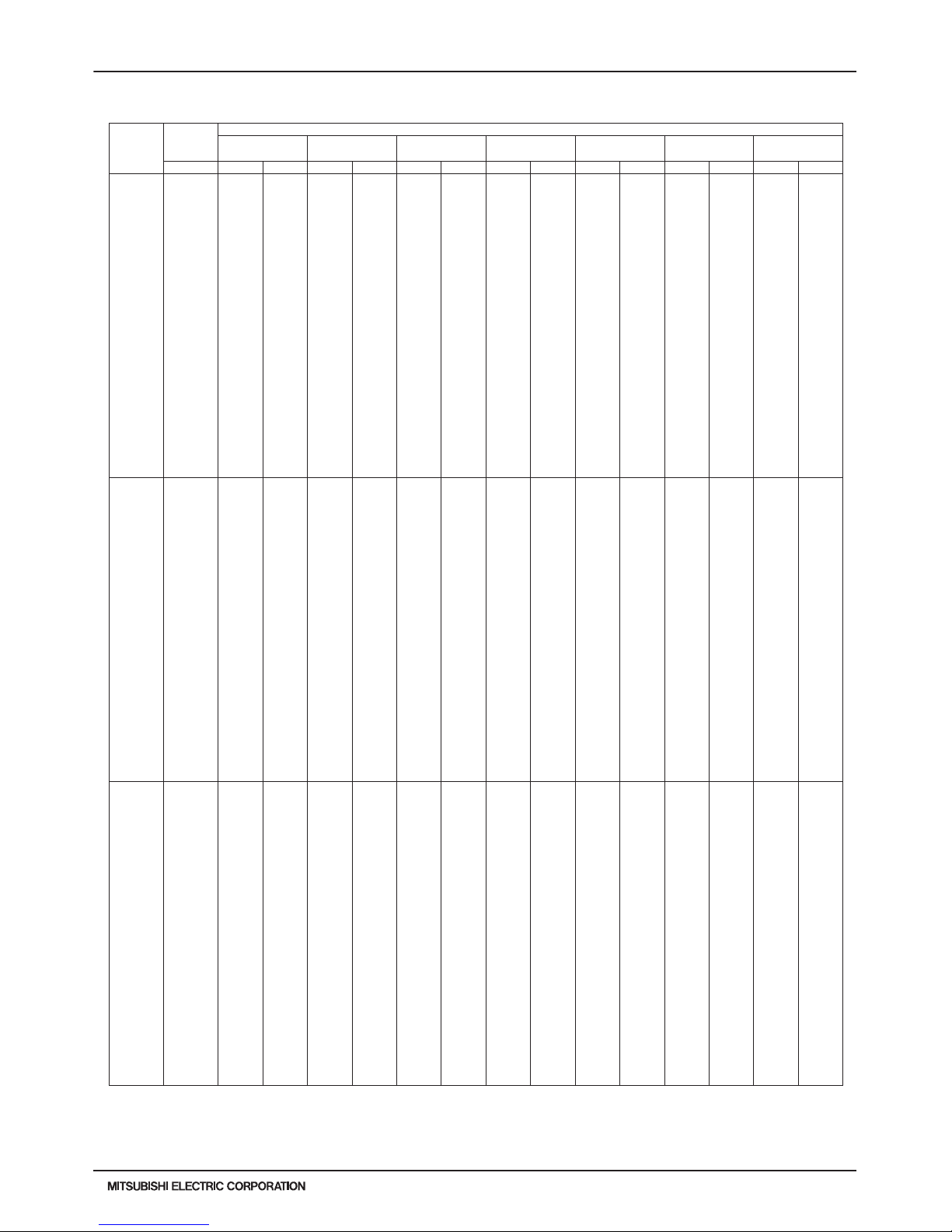

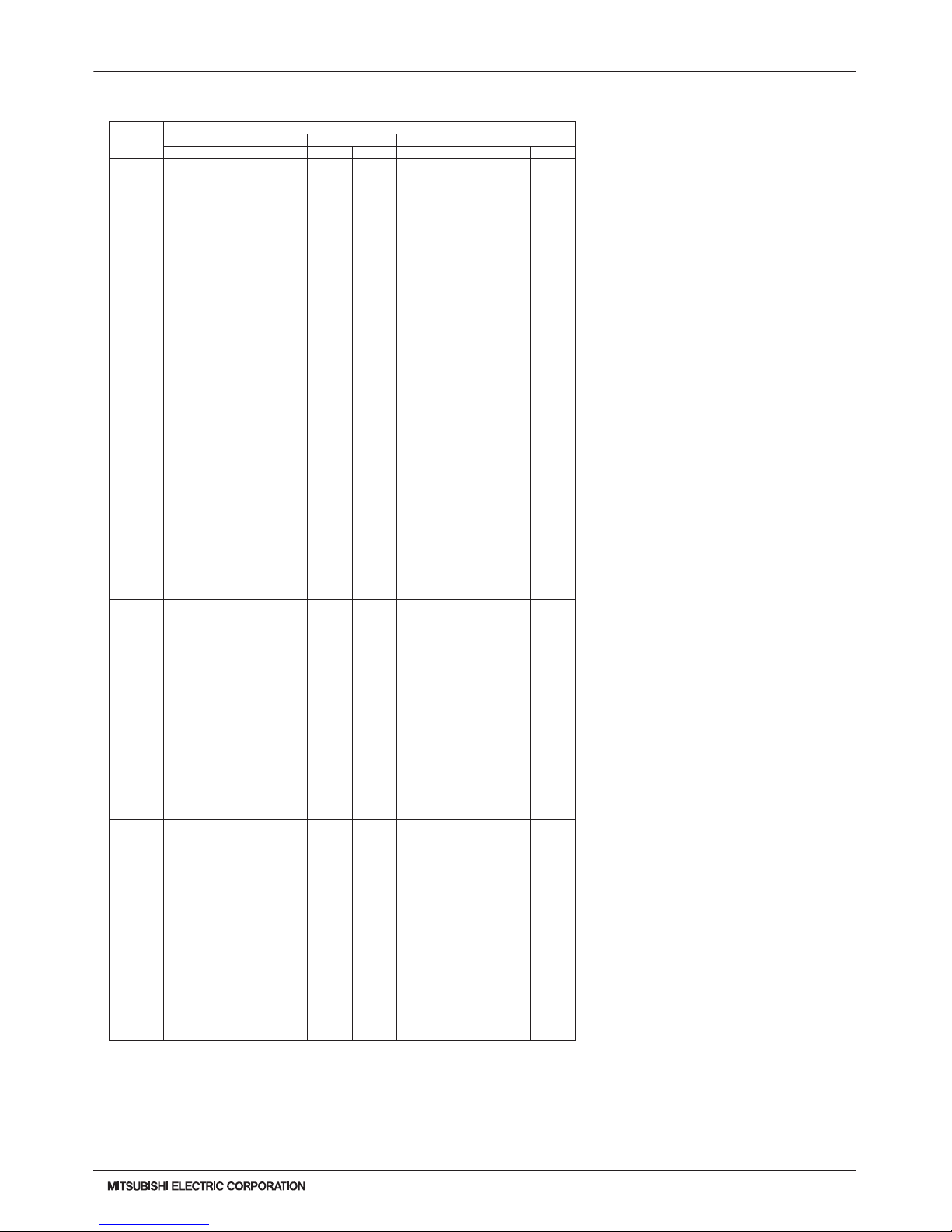

7-1-1. Cooling Capacity/Power Input with PURY-HP72TKMU-A-H ..........................................................H2i-R2-24

7-1-2. Cooling Capacity/Power Input with PURY-HP96TKMU-A-H ..........................................................H2i-R2-25

7-1-3. Cooling Capacity/Power Input with PURY-HP144TSKMU-A-H .....................................................H2i-R2-26

7-1-4. Cooling Capacity/Power Input with PURY-HP192TSKMU-A-H .....................................................H2i-R2-27

7-1-5. Heating Capacity/Power Input with PURY-HP72TKMU-A-H .........................................................H2i-R2-28

7-1-6. Heating Capacity/Power Input with PURY-HP96TKMU-A-H .........................................................H2i-R2-29

7-1-7. Heating Capacity/Power Input with PURY-HP144TSKMU-A-H .....................................................H2i-R2-30

7-1-8. Heating Capacity/Power Input with PURY-HP192TSKMU-A-H .....................................................H2i-R2-31

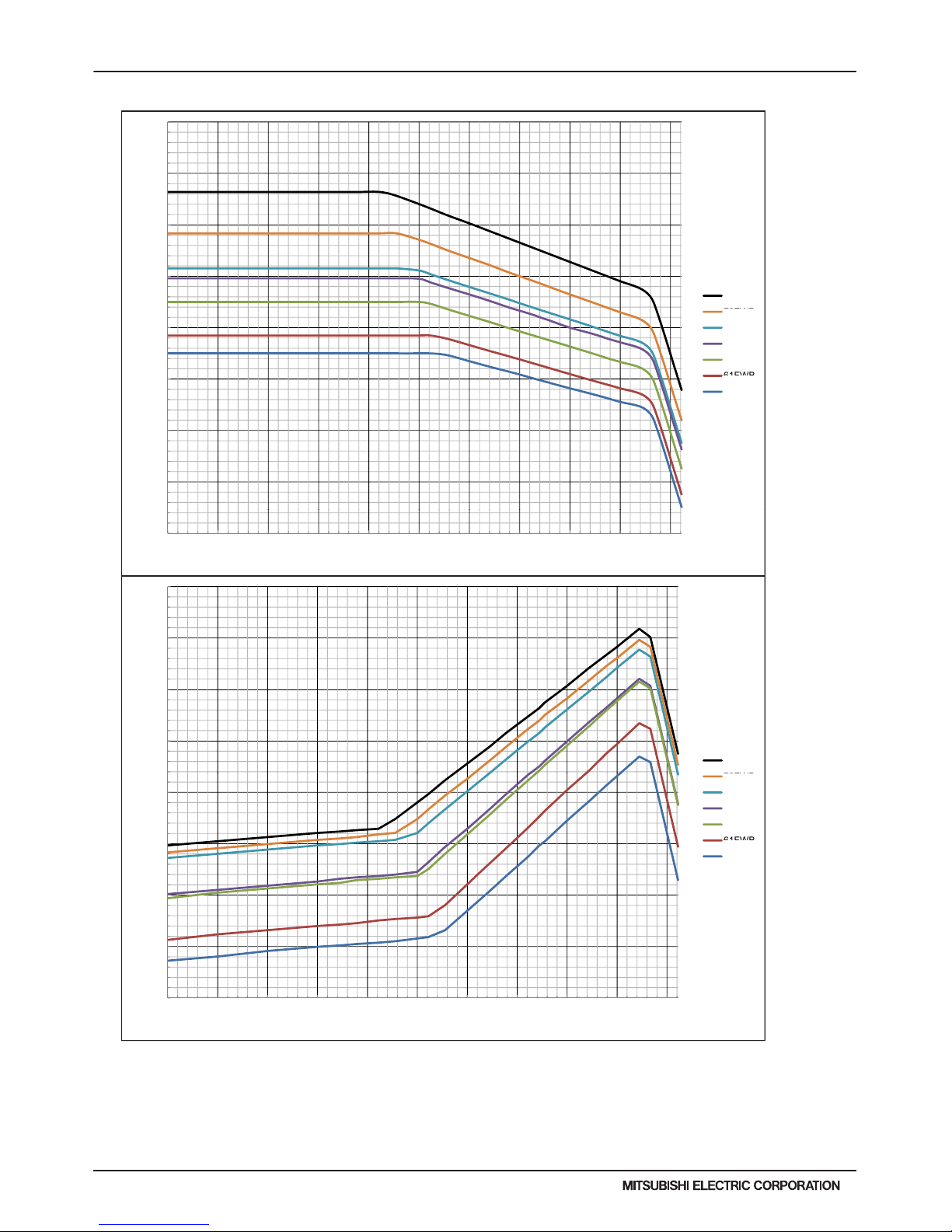

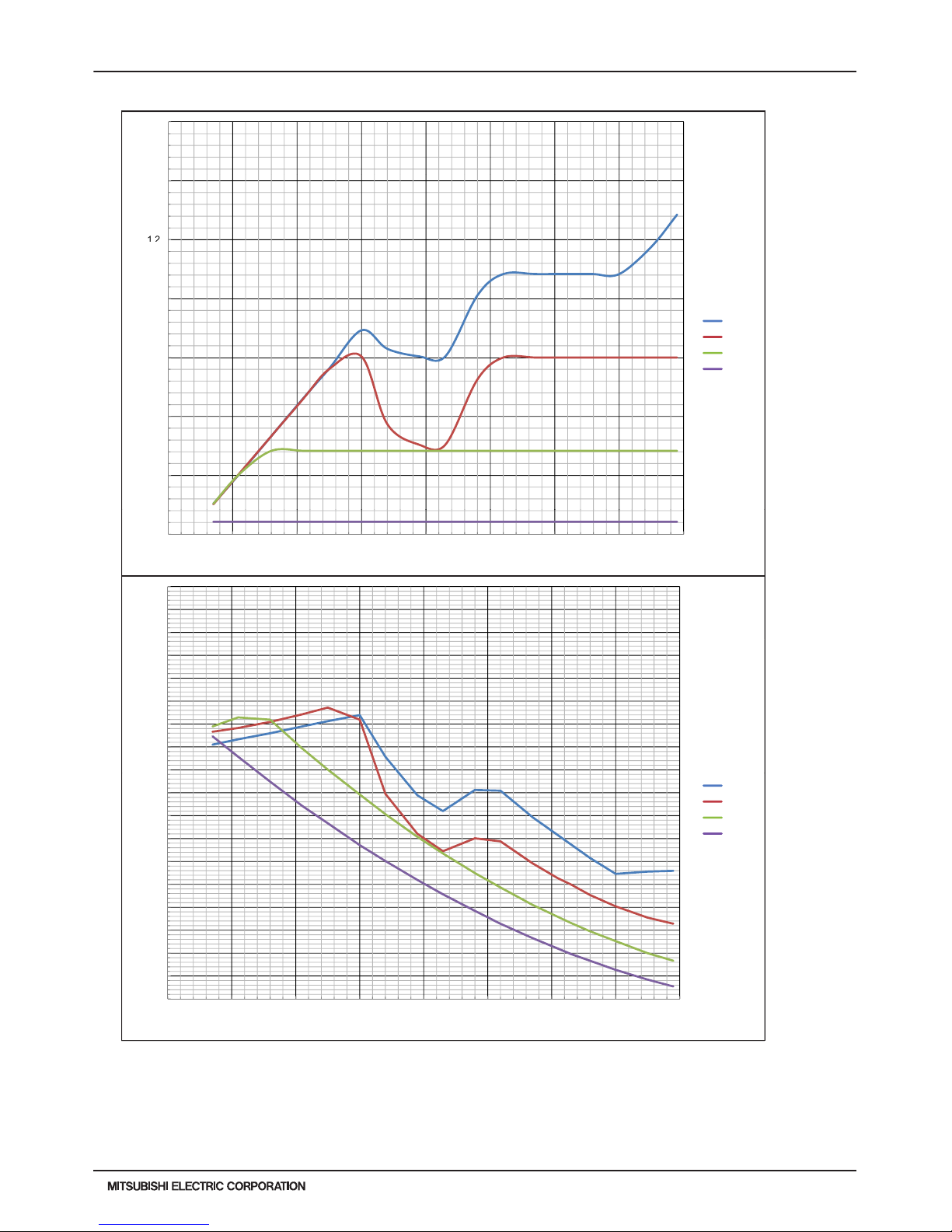

7-2. Correction by Temperature (High Heating Performance) in Fahrenheit ......................................................H2i-R2-32

7-2-1. Heating Capacity/Power Input (High Heat Performance) with PURY-HP72TKMU-A-H ...............H2i-R2-32

7-2-2. Heating Capacity/Power Input (High Heat Performance) with PURY-HP96TKMU-A-H ................H2i-R2-33

7-2-3. Heating Capacity/Power Input (High Heat Performance) with PURY-HP144TSKMU-A-H ............H2i-R2-34

7-2-4. Heating Capacity/Power Input (High Heat Performance) with PURY-HP192TSKMU-A-H ...........H2i-R2-35

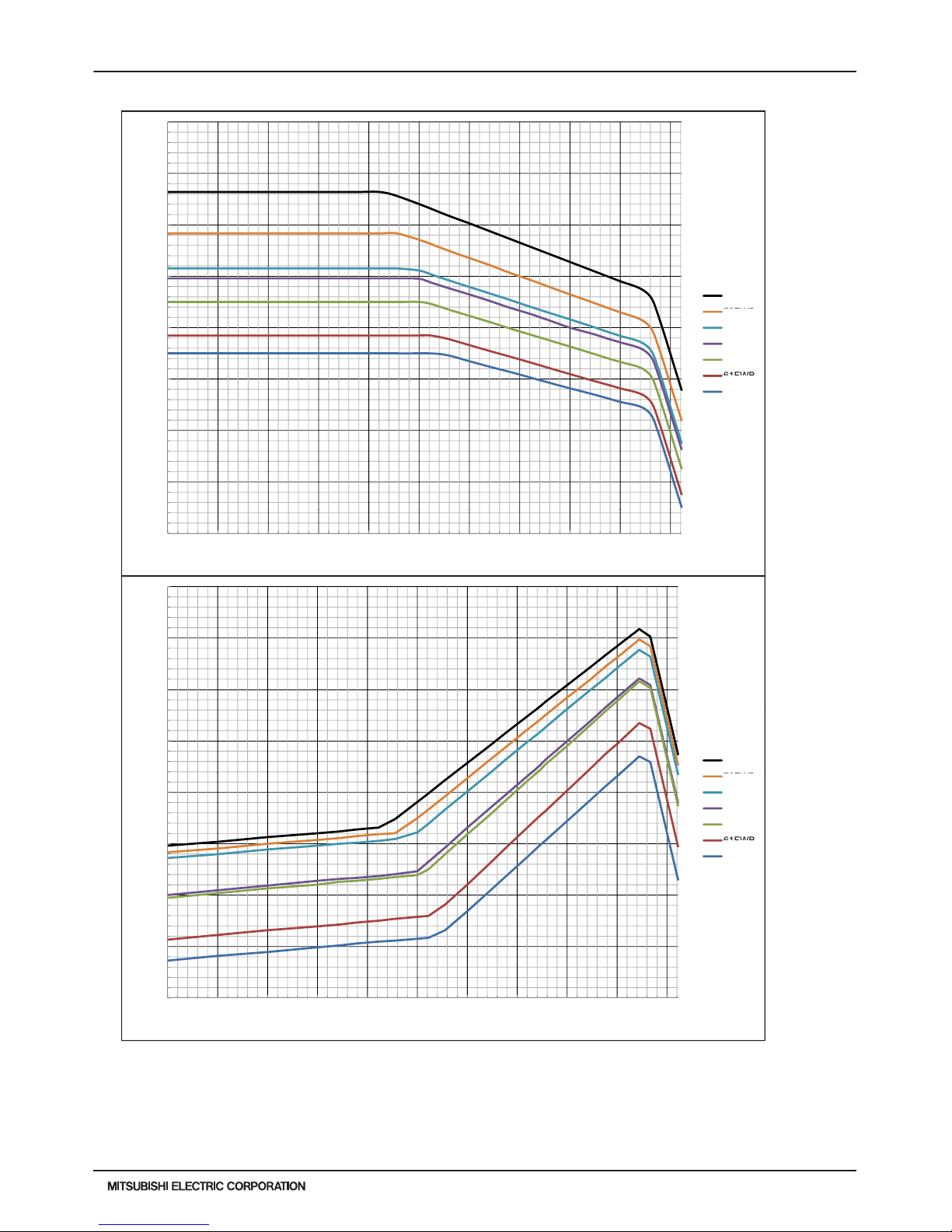

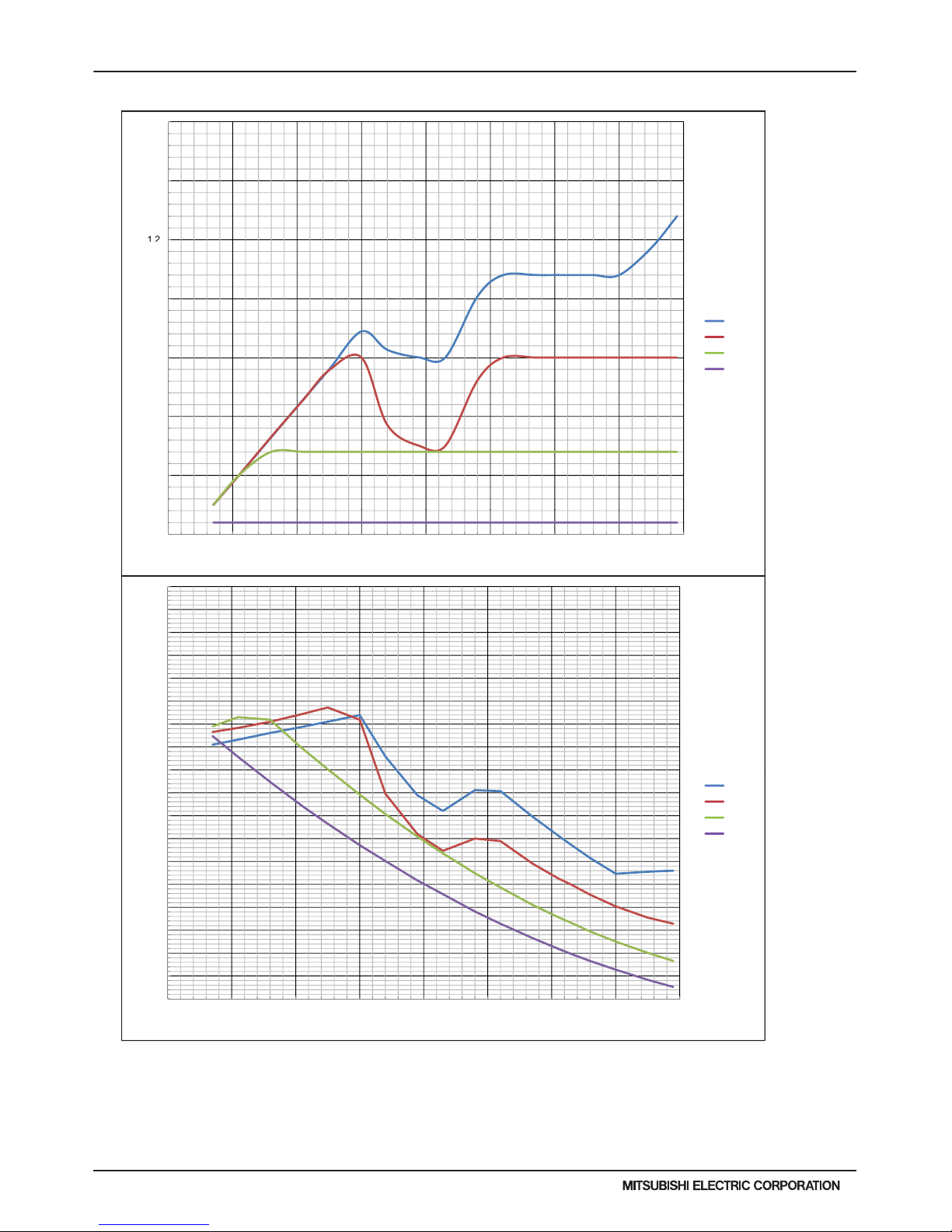

7-3. Correction by Temperature (Intelligent Heat Performance) in Fahrenheit ...................................................H2i-R2-36

7-3-1. Heating Capacity/Power Input (Intelligent Heat Performance) with PURY-HP72TKMU-A-H ........H2i-R2-36

7-3-2. Heating Capacity/Power Input (Intelligent Heat Performance) with PURY-HP96TKMU-A-H ........H2i-R2-37

7-3-3. Heating Capacity/Power Input (Intelligent Heat Performance) with PURY-HP144TSKMU-A-H ....H2i-R2-38

7-3-4. Heating Capacity/Power Input (Intelligent Heat Performance) with PURY-HP192TSKMU-A-H ....H2i-R2-39

7-4. Correction by Temperature/Total Indoor in Fahrenheit ................................................................................H2i-R2-40

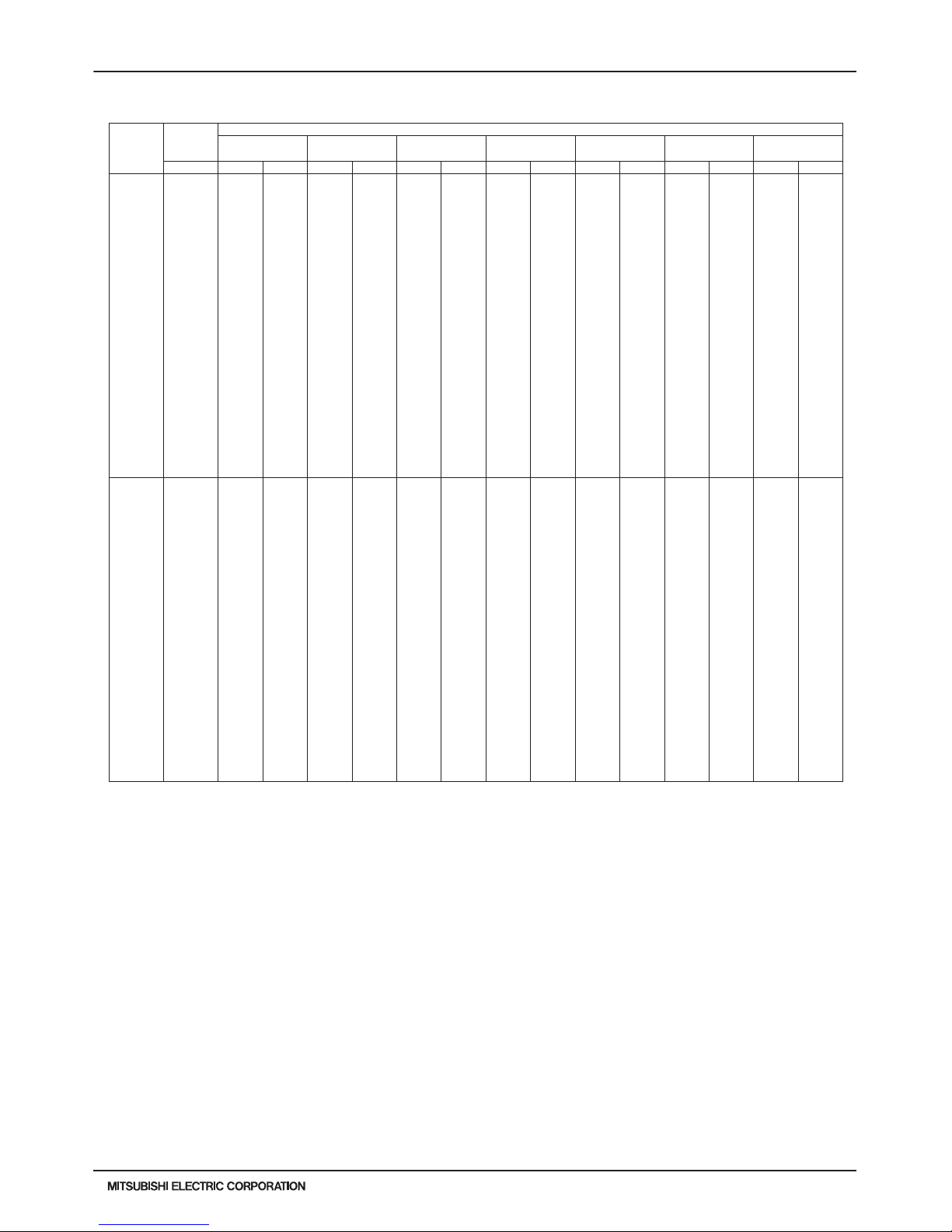

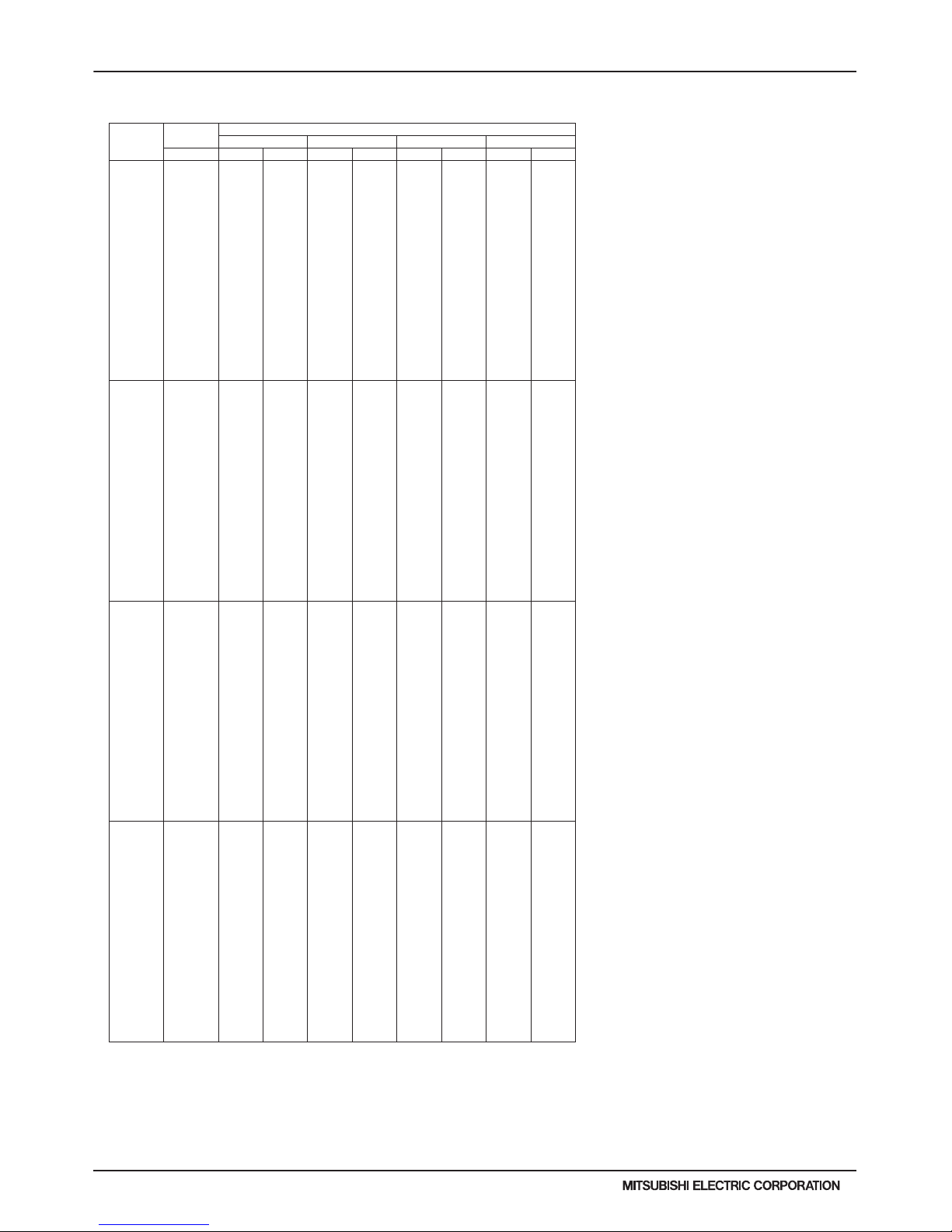

7-4-1. Cooling Capacity with PURY-HP72TKMU-A-H .............................................................................H2i-R2-40

7-4-2. Cooling Capacity with PURY-HP96TKMU-A-H ..............................................................................H2i-R2-44

7-4-3. Cooling Capacity with PURY-HP144TSKMU-A-H .........................................................................H2i-R2-48

7-4-4. Cooling Capacity with PURY-HP192TSKMU-A-H .........................................................................H2i-R2-52

7-4-5. Cooling Capacity with PURY-HP72YKMU-A ..................................................................................H2i-R2-56

7-4-6. Cooling Capacity with PURY-HP96YKMU-A ..................................................................................H2i-R2-60

7-4-7. Cooling Capacity with PURY-HP144YSKMU-A .............................................................................H2i-R2-64

7-4-8. Cooling Capacity with PURY-HP192YSKMU-A .............................................................................H2i-R2-68

7-4-9. Heating Capacity with PURY-HP72TKMU-A-H ..............................................................................H2i-R2-72

7-4-10. Heating Capacity with PURY-HP96TKMU-A-H ............................................................................H2i-R2-75

7-4-11. Heating Capacity with PURY-HP144TSKMU-A-H .......................................................................H2i-R2-78

7-4-12. Heating Capacity with PURY-HP192TSKMU-A-H .......................................................................H2i-R2-81

7-4-13. Heating Capacity with PURY-HP72YKMU-A ...............................................................................H2i-R2-84

7-4-14. Heating Capacity with PURY-HP96YKMU-A ..............................................................................H2i-R2-87

7-4-15. Heating Capacity with PURY-HP144YSKMU-A ...........................................................................H2i-R2-90

7-4-16. Heating Capacity with PURY-HP192YSKMU-A ...........................................................................H2i-R2-93

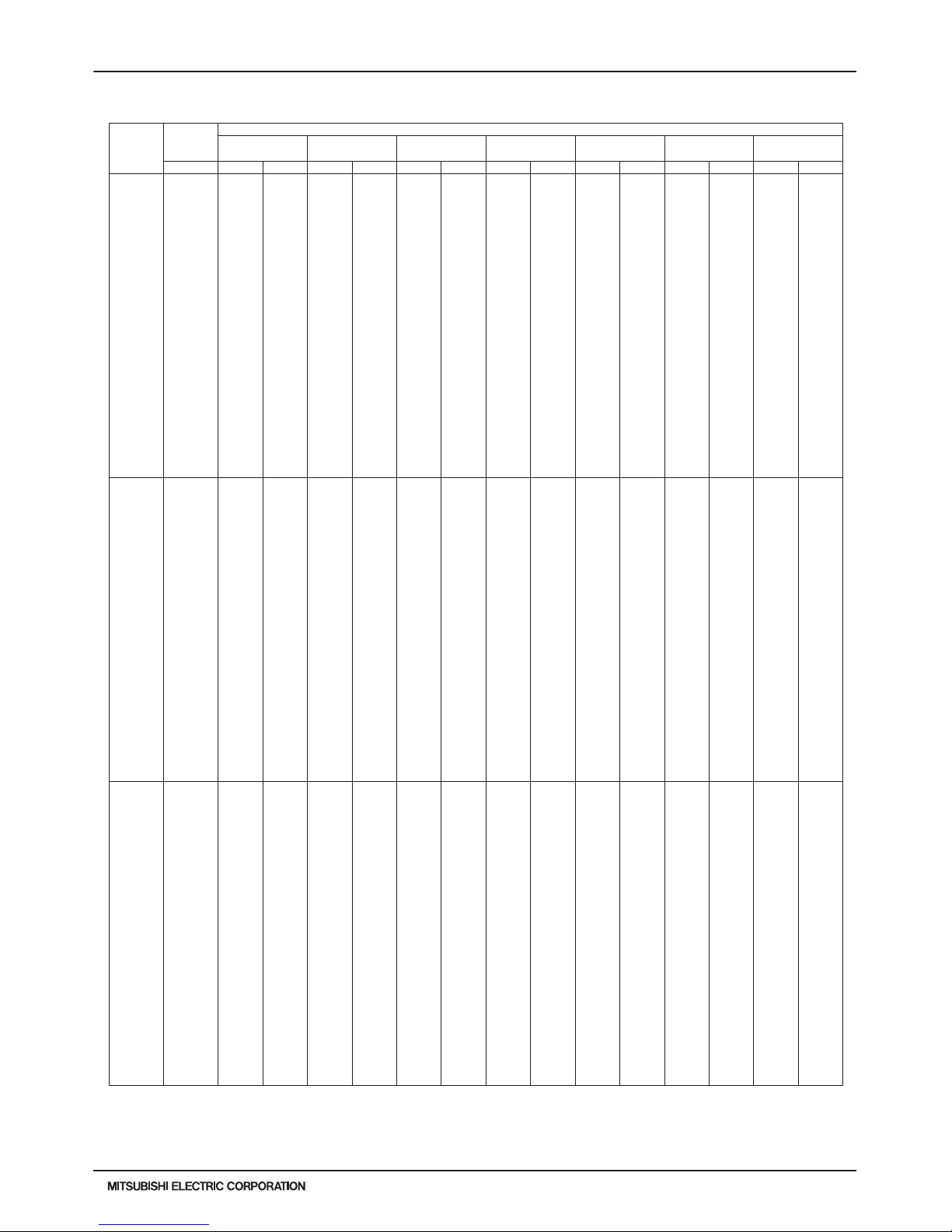

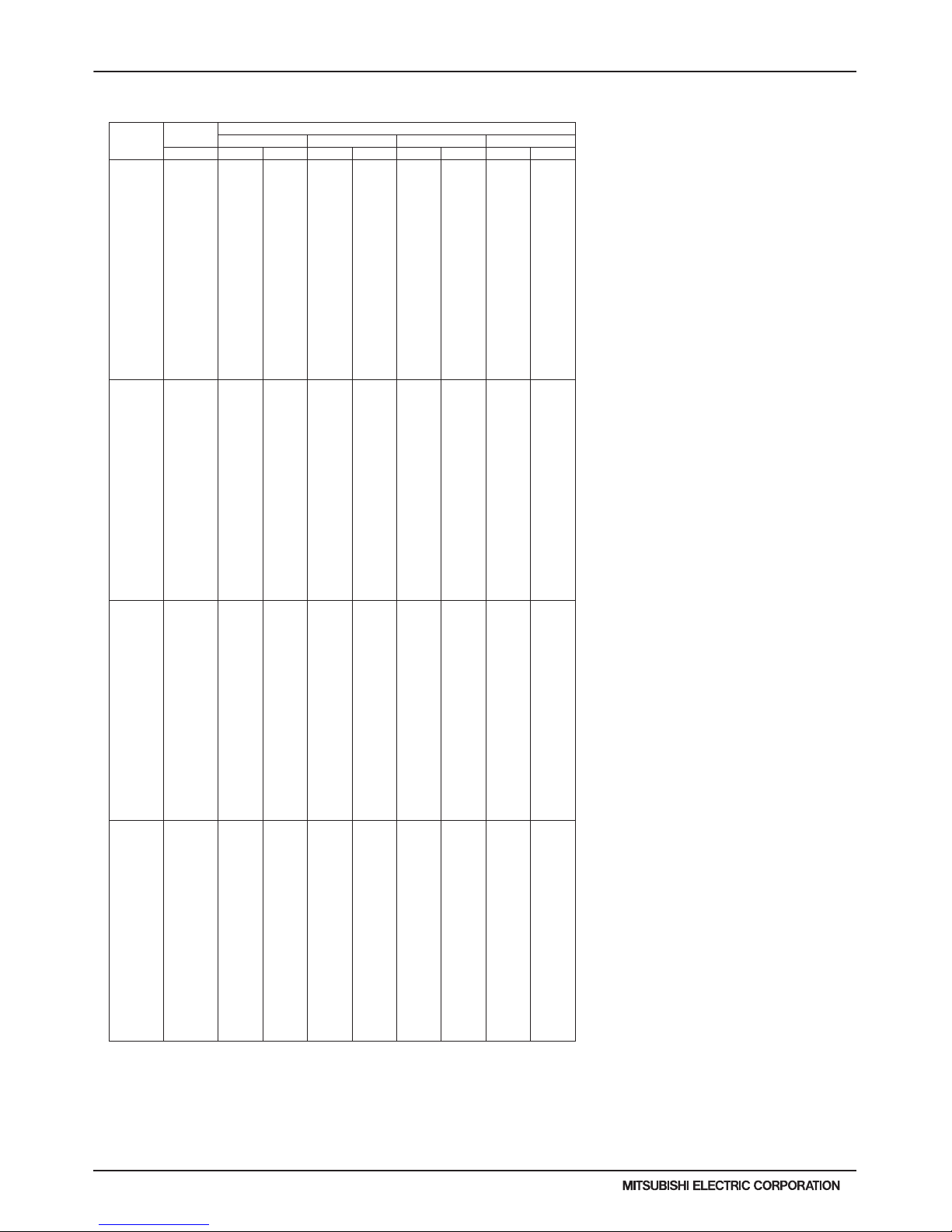

7-4-17. Heating Capacity [High Heat Performance Mode] with PURY-HP72TKMU-A-H .........................H2i-R2-96

7-4-18. Heating Capacity [High Heat Performance Mode] with PURY-HP96TKMU-A-H .........................H2i-R2-99

Page 2

H2i-R2-2

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

© 2014 Mitsubishi Electric US, Inc.

H2i® R2-SERIES HYPER-HEATING INVERTER SERIES

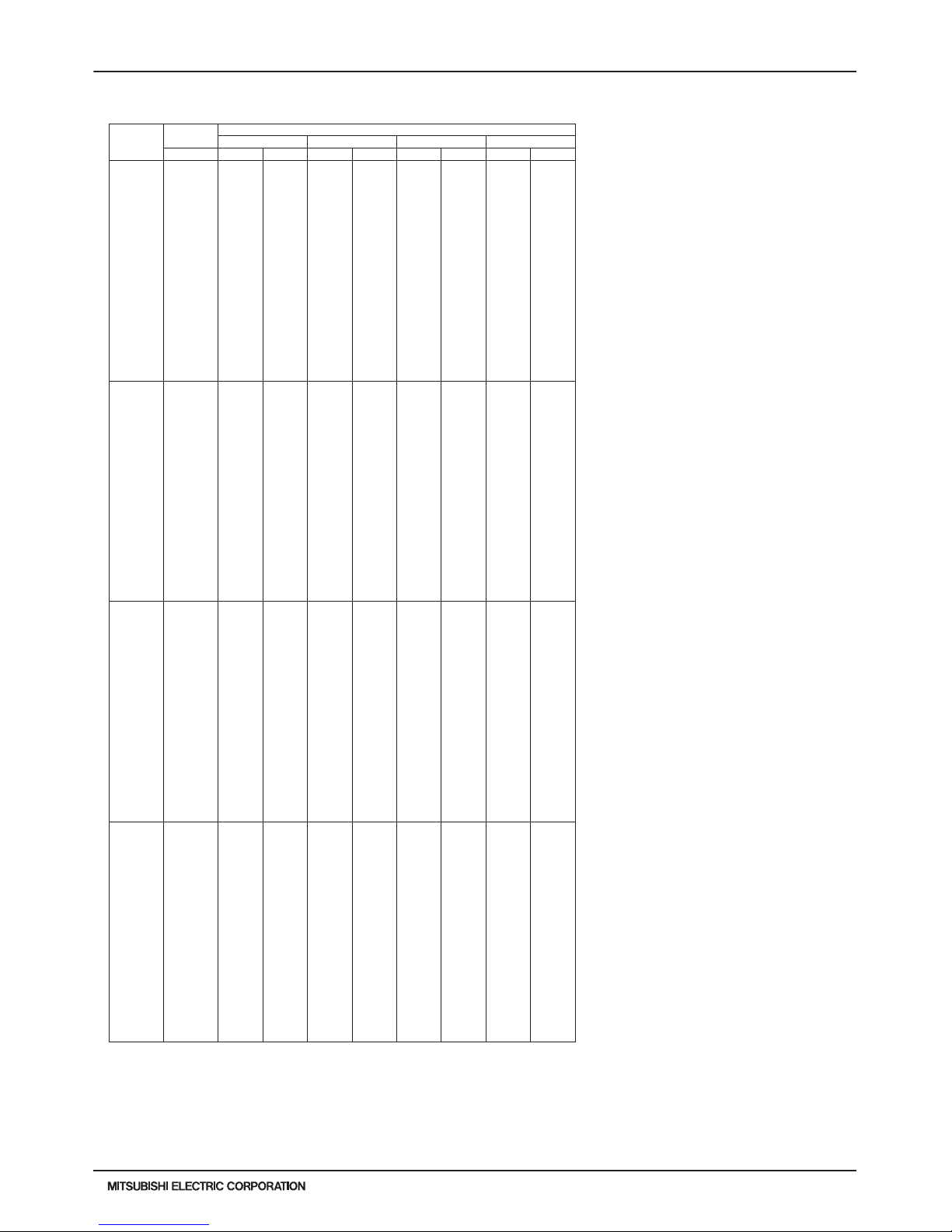

7-4-19. Heating Capacity [High Heat Performance Mode] PURY-HP144TSKMU-A-H .........................H2i-R2-102

7-4-20. Heating Capacity [High Heat Performance Mode] with PURY-HP192TSKMU-A-H ...................H2i-R2-105

7-4-21. Heating Capacity [High Heat Performance Mode] with PURY-HP72YKMU-A ...........................H2i-R2-108

7-4-22. Heating Capacity [High Heat Performance Mode] with PURY-HP96YKMU-A ........................... H2i-R2-111

7-4-23. Heating Capacity [High Heat Performance Mode] with PURY-HP144YSKMU-A ......................H2i-R2-11 4

7-4-24. Heating Capacity [High Heat Performance Mode] with PURY-HP192YSKMU-A ......................H2i-R2-11 7

7-4-25. Heating Capacity [Intelligent Heat Mode] with PURY-HP72TKMU-A-H .....................................H2i-R2-120

7-4-26. Heating Capacity [Intelligent Heat Mode] with PURY-HP96TKMU-A-H .....................................H2i-R2-123

7-4-27. Heating Capacity [Intelligent Heat Mode] with PURY-HP144TSKMU-A-H ................................H2i-R2-126

7-4-28. Heating Capacity [Intelligent Heat Mode] with PURY-HP192TSKMU-A-H ................................H2i-R2-129

7-4-29. Heating Capacity [Intelligent Heat Mode] with PURY-HP72YKMU-A ........................................H2i-R2-132

7-4-30. Heating Capacity [Intelligent Heat Mode] with PURY-HP96YKMU-A ........................................H2i-R2-135

7-4-31. Heating Capacity [Intelligent Heat Mode] with PURY-HP144YSKMU-A ....................................H2i-R2-138

7-4-32. Heating Capacity [Intelligent Heat Mode] with PURY-HP192YSKMU-A ....................................H2i-R2-141

7-5. Correction by Temperature (Standard Performance) in Celsius ...............................................................H2i-R2-144

7-6. Correction by Temperature (High Heating Performance) in Celsius .........................................................H2i-R2-145

7-7. Correction by Temperature (Intelligent Heat Performance) in Celsius ......................................................H2i-R2-146

7-8. Correction by Temperature/Total Indoor in Celsius ...................................................................................H2i-R2-147

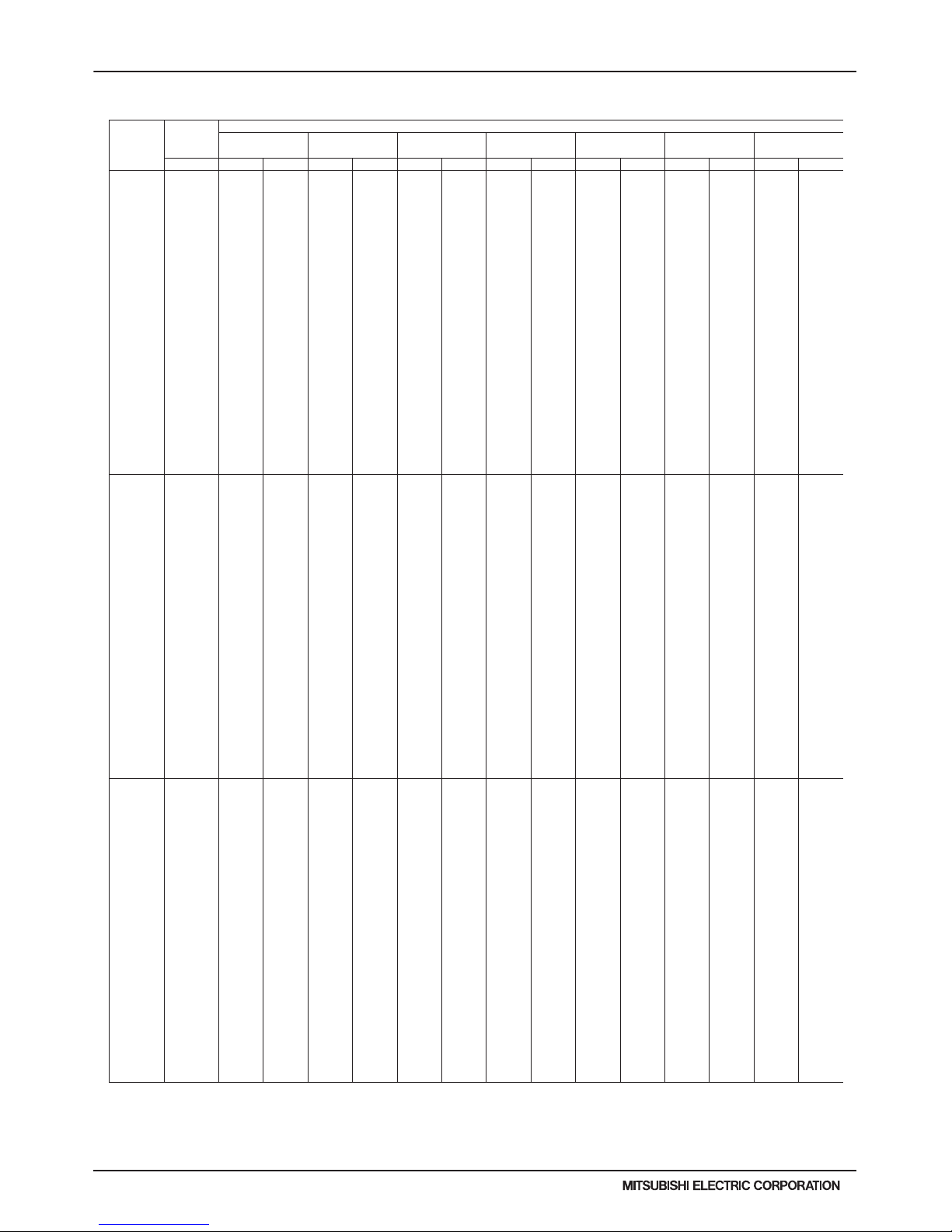

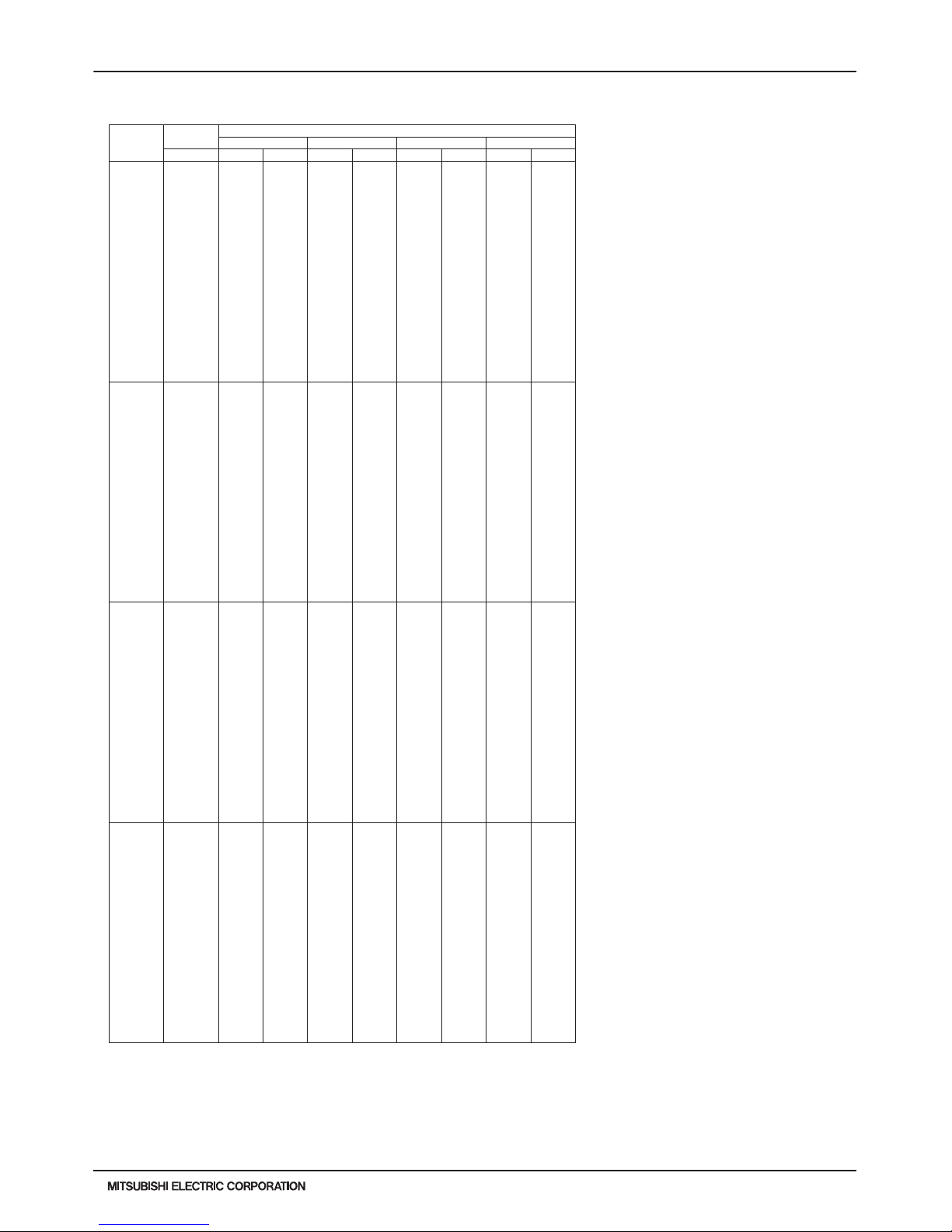

7-8-1. Cooling Capacity with PURY-HP72TKMU-A-H ............................................................................H2i-R2-147

7-8-2. Cooling Capacity with PURY-HP96TKMU-A-H ............................................................................H2i-R2-151

7-8-3. Cooling Capacity with PURY-HP144TSKMU-A-H .......................................................................H2i-R2-156

7-8-4. Cooling Capacity with PURY-HP192TSKMU-A-H .......................................................................H2i-R2-160

7-8-5. Cooling Capacity with PURY-HP72YKMU-A ................................................................................H2i-R2-164

7-8-6. Cooling Capacity with PURY-HP96YKMU-A ................................................................................H2i-R2-168

7-8-7. Cooling Capacity with PURY-HP144YSKMU-A ...........................................................................H2i-R2-172

7-8-8. Cooling Capacity with PURY-HP192YSKMU-A ...........................................................................H2i-R2-176

7-8-9. Heating Capacity with PURY-HP72TKMU-A-H ............................................................................H2i-R2-180

7-8-10. Heating Capacity with PURY-HP96TKMU-A-H ..........................................................................H2i-R2-183

7-8-11. Heating Capacity with PURY-HP144TSKMU-A-H .....................................................................H2i-R2-186

7-8-12. Heating Capacity with PURY-HP192TSKMU-A-H .....................................................................H2i-R2-189

7-8-13. Heating Capacity with PURY-HP72YKMU-A .............................................................................H2i-R2-192

7-8-14. Heating Capacity with PURY-HP96YKMU-A ............................................................................H2i-R2-195

7-8-15. Heating Capacity with PURY-HP144YSKMU-A .........................................................................H2i-R2-198

7-8-16. Heating Capacity with PURY-HP192YSKMU-A .........................................................................H2i-R2-201

7-8-17. Heating Capacity [High Heat Performance Mode] with PURY-HP72TKMU-A-H .......................H2i-R2-204

7-8-18. Heating Capacity [High Heat Performance Mode] with PURY-HP96TKMU-A-H .......................H2i-R2-207

7-8-19. Heating Capacity [High Heat Performance Mode] PURY-HP144TSKMU-A-H ..........................H2i-R2-210

7-8-20. Heating Capacity [High Heat Performance Mode] with PURY-HP192TSKMU-A-H ...................H2i-R2-213

7-8-21. Heating Capacity [High Heat Performance Mode] with PURY-HP72YKMU-A ...........................H2i-R2-216

7-8-22. Heating Capacity [High Heat Performance Mode] with PURY-HP96YKMU-A ...........................H2i-R2-219

7-8-23. Heating Capacity [High Heat Performance Mode] with PURY-HP144YSKMU-A ......................H2i-R2-222

7-8-24. Heating Capacity [High Heat Performance Mode] with PURY-HP192YSKMU-A ......................H2i-R2-225

7-8-25. Heating Capacity [Intelligent Heat Mode] with PURY-HP72TKMU-A-H .....................................H2i-R2-228

7-8-26. Heating Capacity [Intelligent Heat Mode] with PURY-HP96TKMU-A-H .....................................H2i-R2-231

7-8-27. Heating Capacity [Intelligent Heat Mode] with PURY-HP144TSKMU-A-H ................................H2i-R2-234

7-8-28. Heating Capacity [Intelligent Heat Mode] with PURY-HP192TSKMU-A-H ................................H2i-R2-237

7-8-29. Heating Capacity [Intelligent Heat Mode] with PURY-HP72YKMU-A ........................................H2i-R2-240

7-8-30. Heating Capacity [Intelligent Heat Mode] with PURY-HP96YKMU-A ........................................H2i-R2-243

7-8-31. Heating Capacity [Intelligent Heat Mode] with PURY-HP144YSKMU-A ....................................H2i-R2-246

7-8-32. Heating Capacity [Intelligent Heat Mode] with PURY-HP192YSKMU-A ....................................H2i-R2-249

Page 3

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

H2i-R2-3

© 2014 Mitsubishi Electric US, Inc.

H2i® R2-SERIES HYPER-HEATING INVERTER SERIES

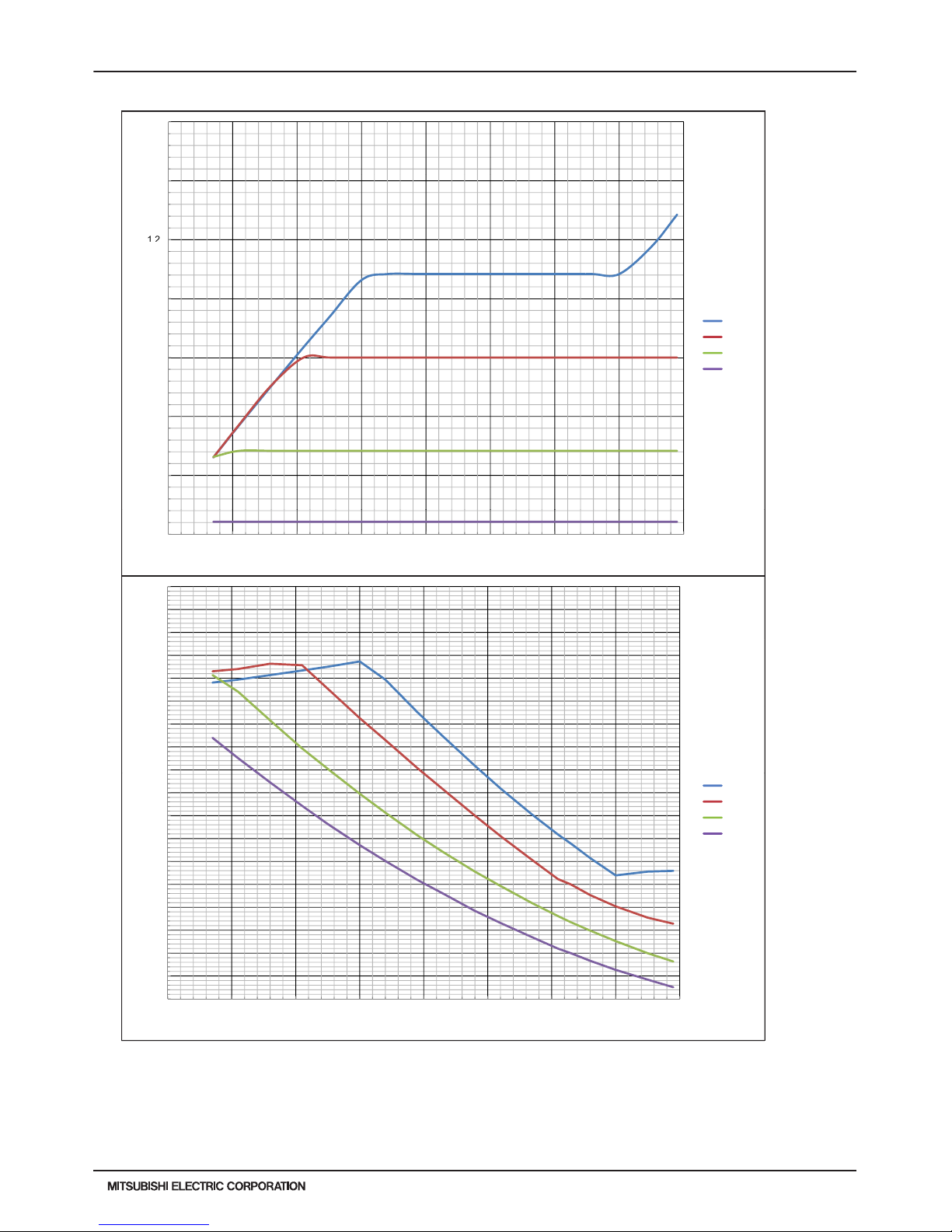

7-9. Correction by Refrigerant Piping Length ...................................................................................................H2i-R2-252

7-9-1. Cooling Capacity Correction .......................................................................................................H2i-R2-252

7-9-2. Heating Capacity Correction .......................................................................................................H2i-R2-253

7-9-3. How to obtain the equivalent piping length ..................................................................................H2i-R2-253

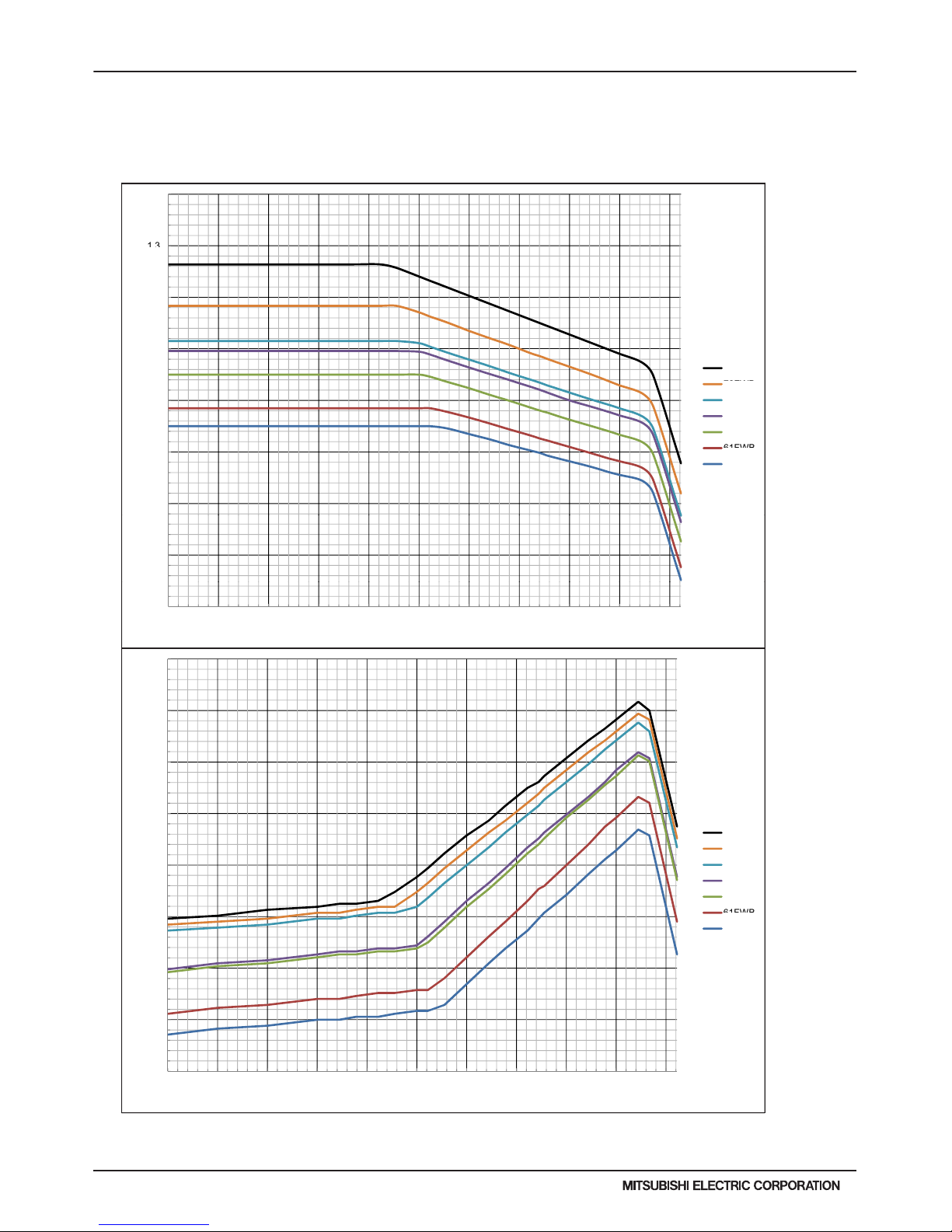

7-10. Correction at Frost and Defrost ...............................................................................................................H2i-R2-254

7-11. Operation Temperature Range ................................................................................................................H2i-R2-255

7-12. Extended Cooling Range with Low Ambient Kit ......................................................................................H2i-R2-256

8. OPTIONAL PARTS .............................................................................................................................................H2i-R2-257

8-1. Branch Joints ............................................................................................................................................H2i-R2-257

8-2. Twinning Kit ...............................................................................................................................................H2i-R2-258

8-3. Joint Adapter Kit ........................................................................................................................................H2i-R2-259

8-4. Low Ambient Kit ........................................................................................................................................H2i-R2-260

8-5. Snow/Hail Guards Kit ................................................................................................................................H2i-R2-263

Page 4

H2i-R2-4

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

© 2014 Mitsubishi Electric US, Inc.

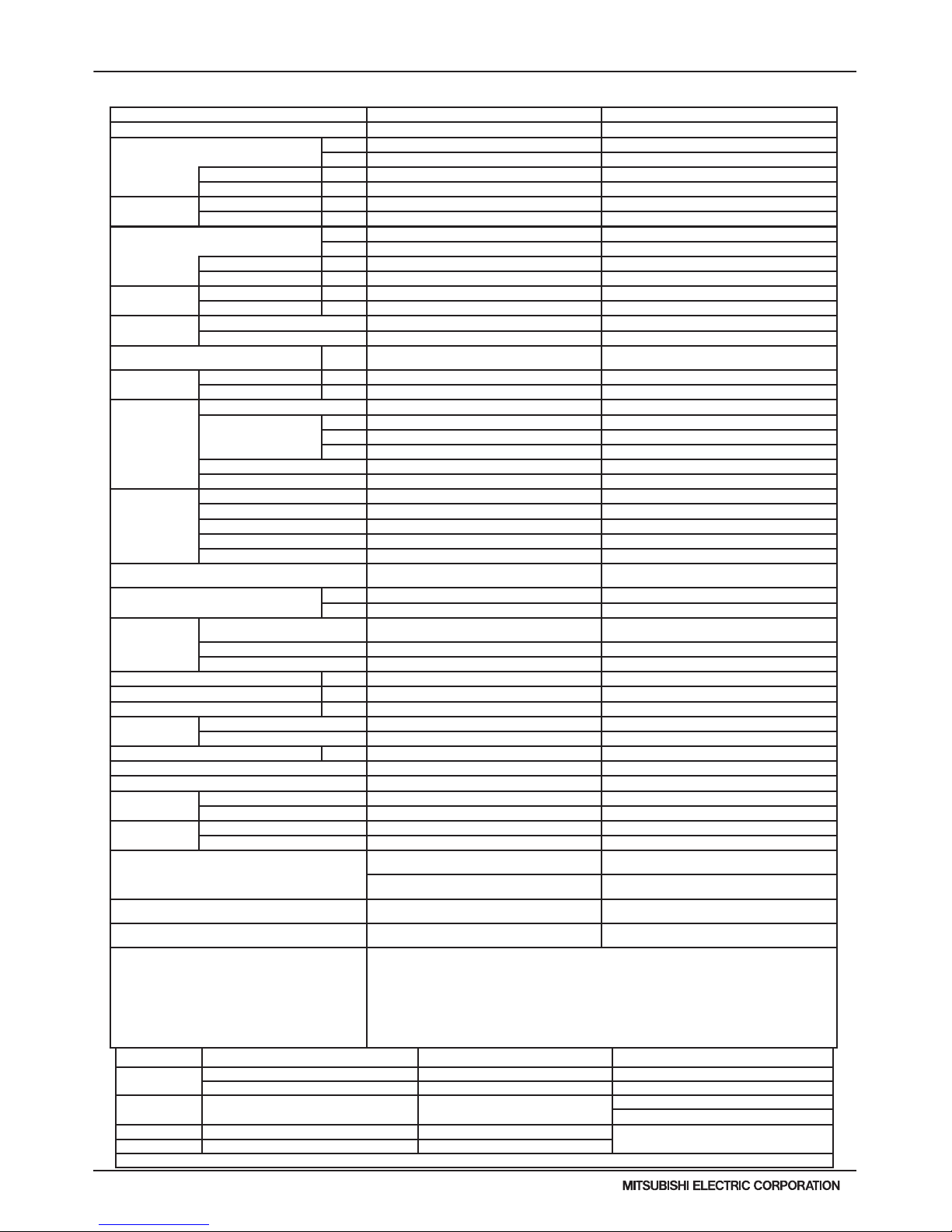

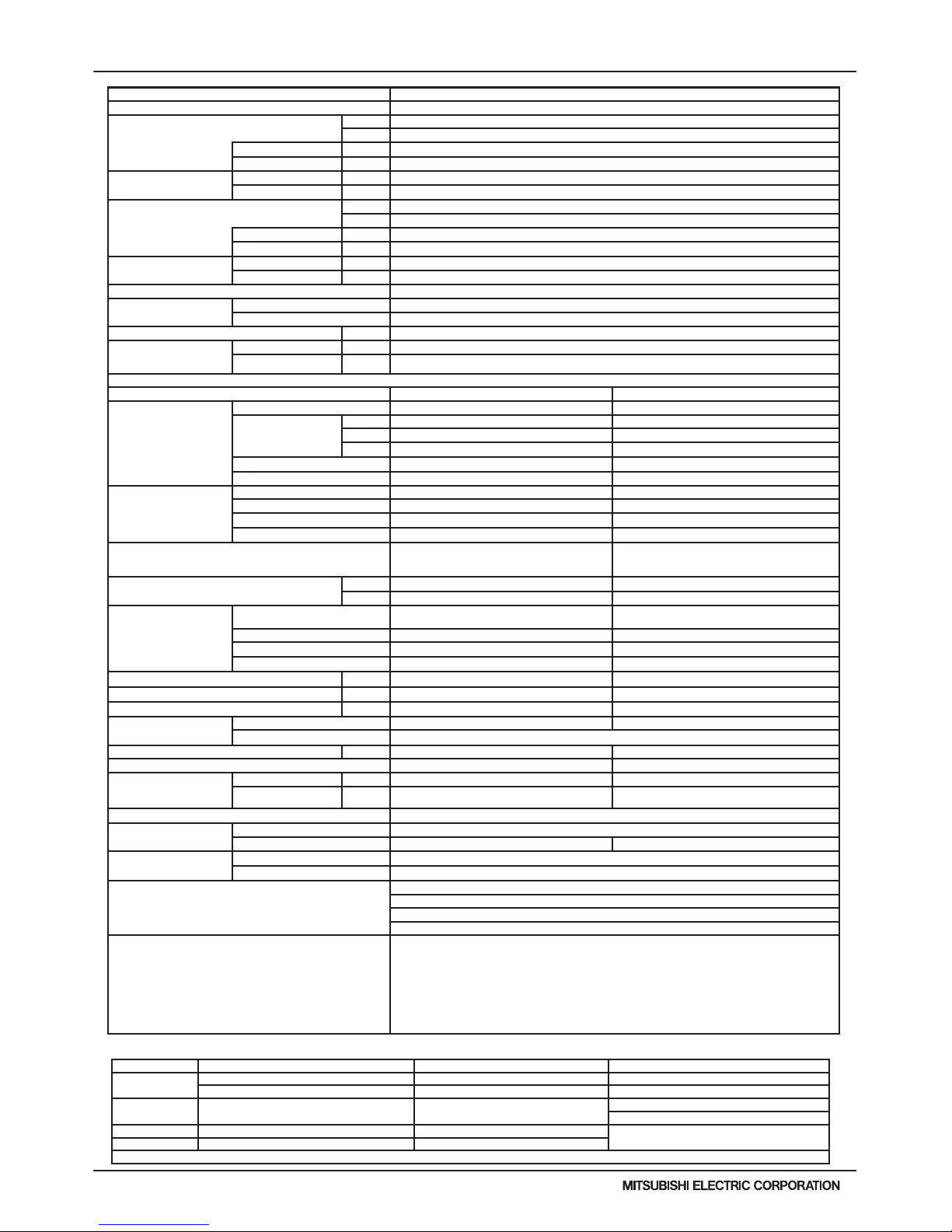

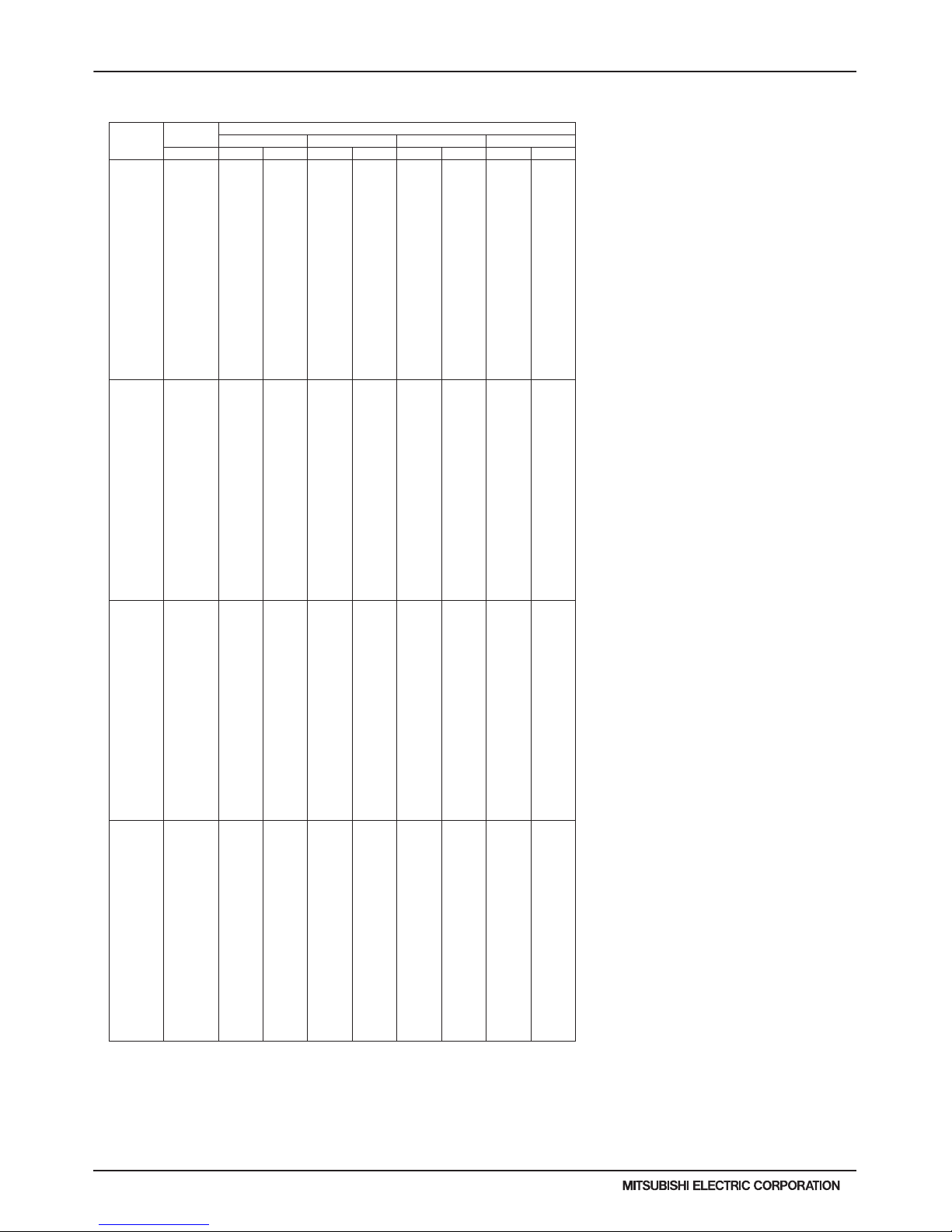

1. SPECIFICATIONS

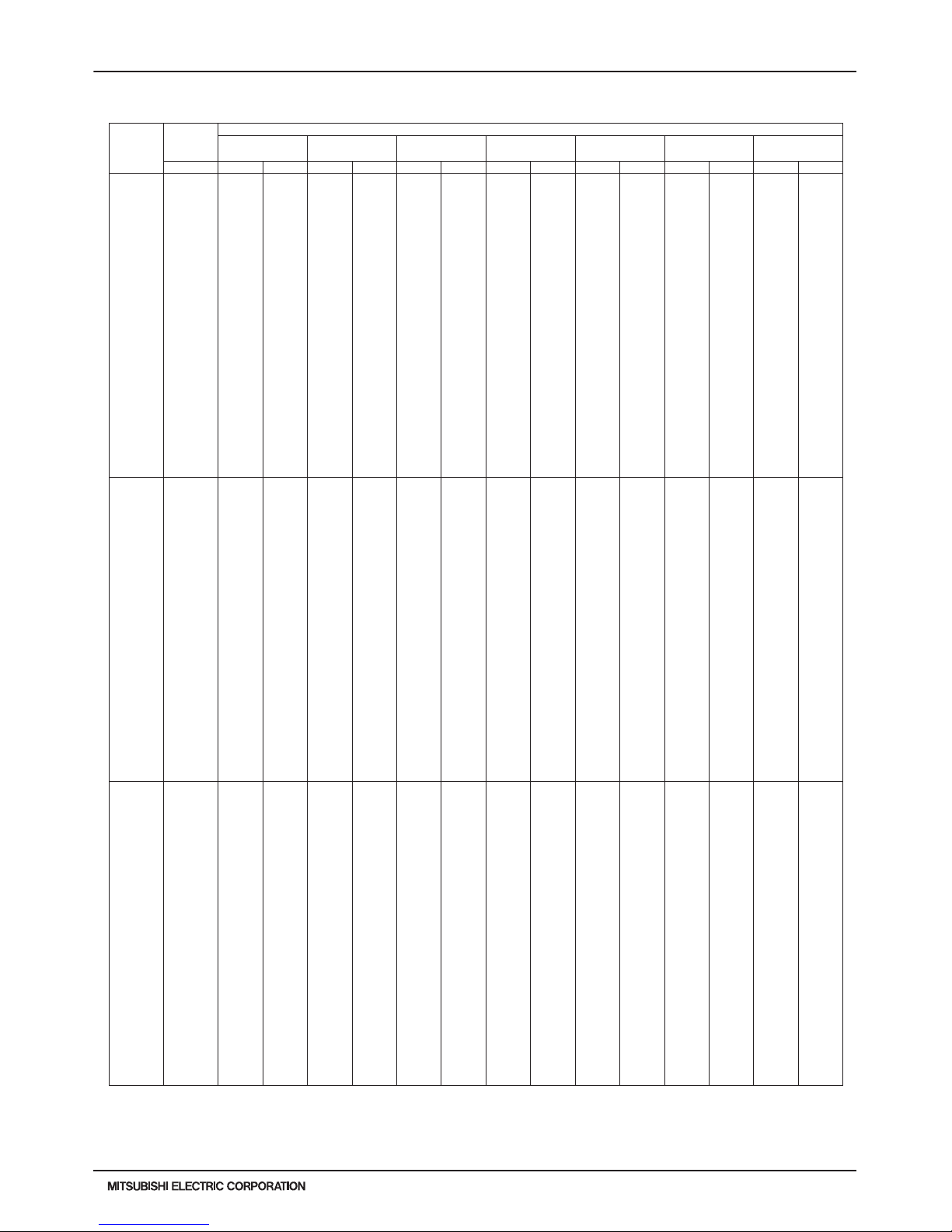

Model

PURY-HP72TKMU-A-H PURY-HP96TKMU-A-H

Power source

3-phase 3-wire 208 / 230V ±10% 60Hz 3-phase 3-wire 208 / 230V ±10% 60Hz

Cooling capacity (Nominal) *1 (208 / 230V)

Btu/h

72,000 96,000

kW

21.1 28.1

Power input kW

5.08 *4 7.66 *4

Current input A

15.6 / 14.1 *4 23.6 / 21.3 *4

Temp. range of

cooling *3

Indoor W.B.

59 ~ 75° F(15 ~ 24° C) 59 ~ 75° F(15 ~ 24° C)

Outdoor D.B.

23 ~ 115° F (-5 ~ +46° C) *5 23 ~ 115° F (-5 ~ +46° C) *5

Heating capacity (Nominal) *2 (208-230V)

Btu/h

80,000 108,000

kW

23.4 31.7

Power input kW

6.26 *4 8.88 *4

Current input A

19.3 / 17.4 *4 27.3 / 24.7 *4

Temp. range of

heating *3

Indoor D.B.

59~81°F(15~27°C) 59~81°F(15~27°C)

Outdoor W.B.

-13~60°F(-25~15.5°C) -13~60°F(-25~15.5°C)

Indoor unit

Total capacity

50~150 % of outdoor unit capacity 50~150 % of outdoor unit capacity

Model / Quantity

P06~P96 / 1~18 P06~P96 / 1~24

Sound pressure level (measured in

anechoic room)

dB <A>

58.0 58.0

Refrigerant

piping diameter

Liquid (High Pressure) In. (mm)

5/8 (15.88) Brazed 3/4 (19.05) Brazed

Gas (Low Pressure) In. (mm)

3/4 (19.05) Brazed 7/8 (22.2) Brazed

Fan

Type x Quantity

Propeller fan x 1 Propeller fan x 1

Airow rate

CFM

6,200 6,200

m3 / min

175 175

L/s

2,920 2,920

Control, Driving mechanism

Inverter-control, Brushless DC motor Inverter-control, Brushless DC motor

External static pressure *6

0 in.WG (0 Pa) *6 0 in.WG (0 Pa) *6

Compressor

Type x Quantity

Inverter scroll hermetic compressor x 1 Inverter scroll hermetic compressor x 1

Manufacturer

AC&R Works, MITSUBISHI ELECTRIC CORP. AC&R Works, MITSUBISHI ELECTRIC CORP.

Operating Range

Heating: 16-100%

Heating: 13-100%

Starting method

Inverter Inverter

Lubricant

MEL32 MEL32

External nish

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D

In.

64-31/32 x 48-1/16 x 29-15/16 64-31/32 x 48-1/16 x 29-15/16

mm

1,650 x 1,220 x 760 1,650 x 1,220 x 760

Protection

devices

High pressure protection

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

Inverter circuit (COMP. / FAN)

Over-current protection Over-current protection

Fan motor

Thermal switch Thermal switch

Minimum Circuit Ampacity (MCA) A 44 / 40 60 / 54

Recommended Fuse/Breaker Size A 50 65

Maximum Fuse Size A 60 80

Refrigerant

Type x original charge

R410A x 26 lbs + 1 oz (11.8 kg) R410A x 26 lbs + 1 oz (11.8kg)

Control

Indoor LEV and BC controller Indoor LEV and BC controller

Net weight lbs (kg)

552 (250) 552 (250)

Heat exchanger

Salt-resistant cross n & copper tube Salt-resistant cross n & copper tube

Defrost method

Auto-defrost mode (Reversed refrigerant cycle) Auto-defrost mode (Reversed refrigerant cycle)

Drawing

External

KJ94G386 KJ94G386

Wiring

KE94C883 KE94C883

Standard

attachment

Document

Installation Manual Installation Manual

Accessory

Details refer to External Drw Details refer to External Drw

Optional parts

Joint: CMY-Y102SS-G2,CMY-Y102LS-G2,

CMY-R160C-J

Joint: CMY-Y102SS-G2,CMY-Y102LS-G2,

CMY-R160C-J

BC controller: CMB-P104,105,106,108,1010,1013,

1016NU-G

BC controller: CMB-P104,105,106,108,1010,1013,

1016NU-G

Main BC controller: CMB-P108,1010,1013,

1016NU-GA,1016NU-HA

Main BC controller: CMB-P108,1010,1013,

1016NU-GA,1016NU-HA

Sub BC controller: CMB-P104,108NU-GB,

CMB-P1016NU-HB

Sub BC controller: CMB-P104,108NU-GB,

CMB-P1016NU-HB

Remark

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

*3 Harsh weather environments may demand performance enhancing equipment.

Ask your Mitsubishi Electric representative for more details on your region.

*4 For details on the electrical data needed for installing these units,

see the H2i R2-Series System Design section.

*5 For details on extended ambient cooling operation range down to -10°FDB (-23°CDB),

see Low Ambient Cooling Kit information.

*6 External static pressure is adjustable via dipswitch setting

(0.12 in.WG, 0.24 in.WG / 30Pa, 60Pa).

Note: *1 Nominal cooling conditions *2 Nominal heating conditions

Unit converter

Indoor:

80degF D.B./ 67degF W.B. 70degF D.B.

kcal =kW x 860

(26.7degC D.B./ 19.4degC W.B.) (21.1degC D.B.)

BTU/h =kW x 3,412

Outdoor: 95degF D.B. (35degC D.B.)

47degF D.B./ 43degF W.B.

(8.3degC D.B./ 6.1degC W.B.)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 25ft.(7.6m) 25ft.(7.6m)

* Above specification data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specifications may be subject to change without notice.

1-1. PURY-HP72~192T(S)KMU-A-H Specications

Page 5

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

H2i-R2-5

© 2014 Mitsubishi Electric US, Inc.

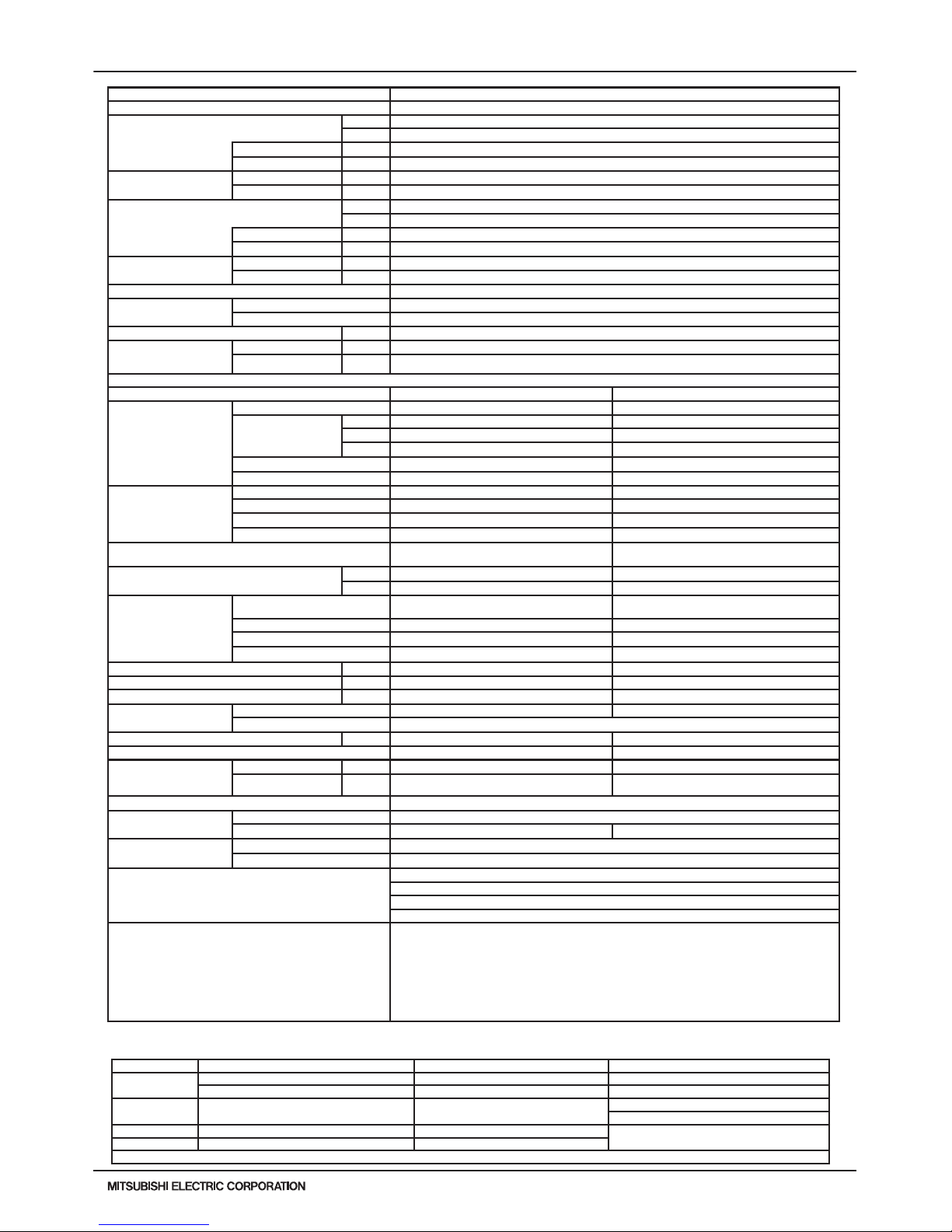

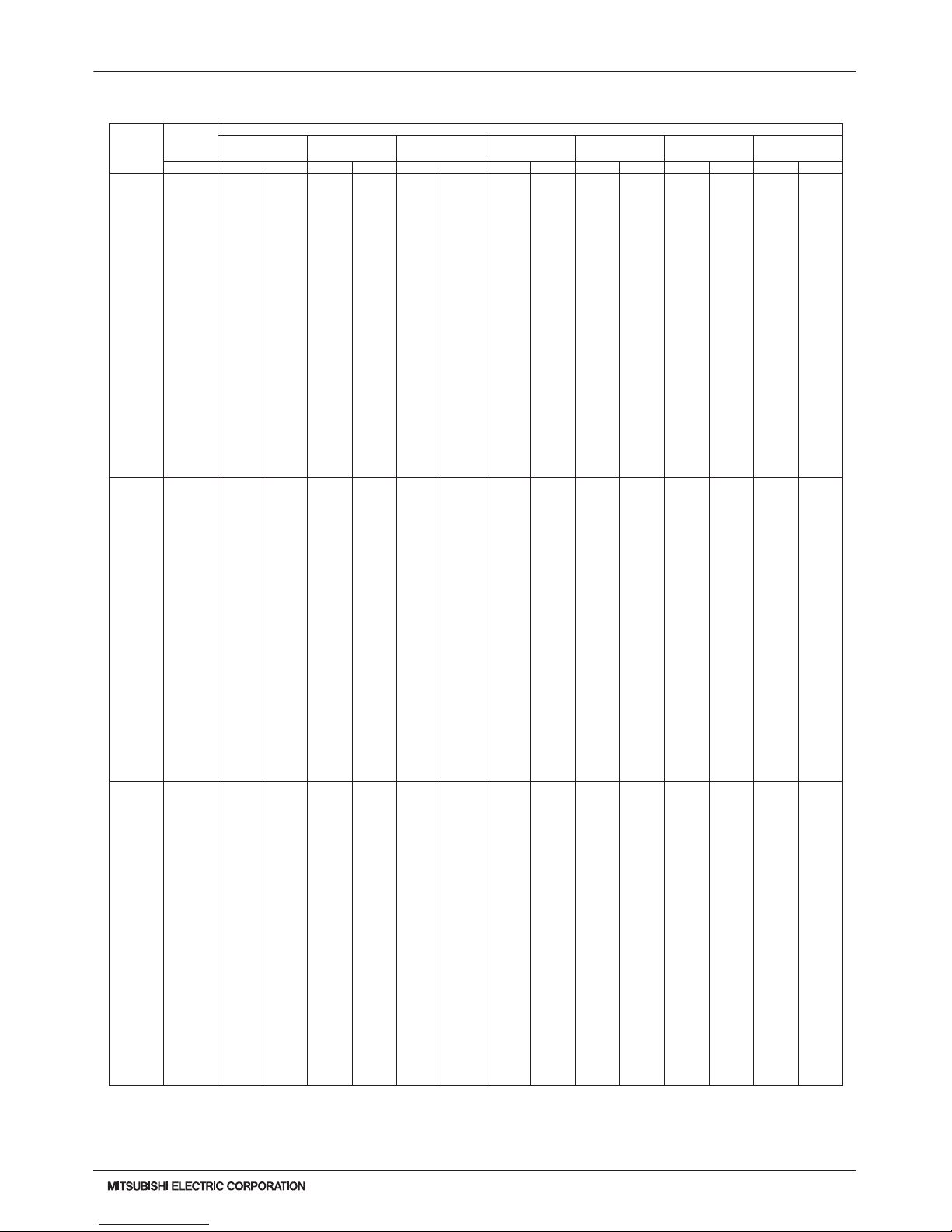

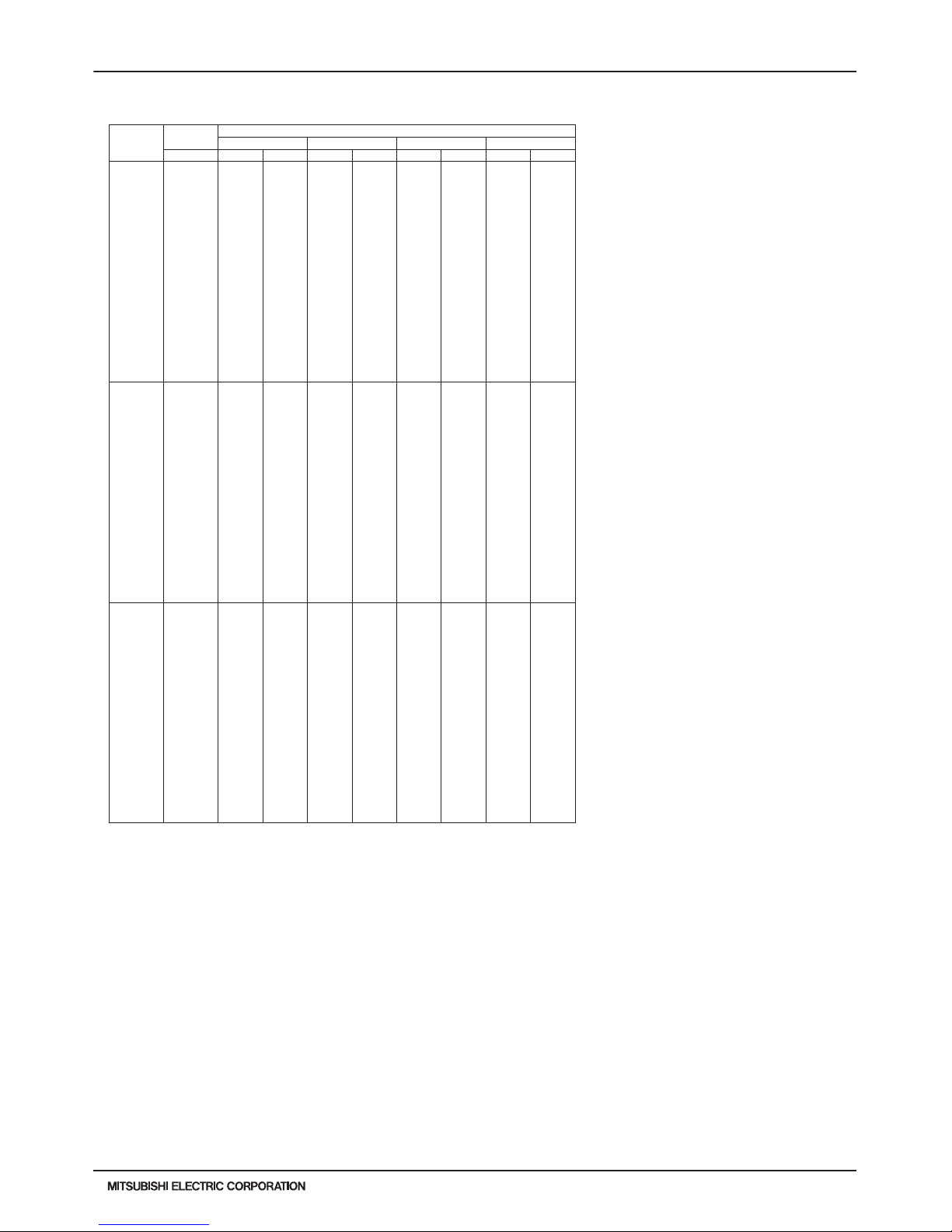

1. SPECIFICATIONS

Model PURY-HP144TSKMU-A-H

Power source 3-phase 3-wire 208 / 230V ±10% 60Hz

Cooling capacity (Nominal) *1 (208 / 230V)

Btu/h 144,000

kW 42.2

Power input

kW 10.85 *4

Current input

A 33.4 / 30.2 *4

Temp. range of cooling *3

Indoor

W.B. 59 ~ 75° F(15 ~ 24° C)

Outdoor

D.B. 23 ~ 115° F (-5 ~ +46° C) *5

Heating capacity (Nominal) *2 (208-230V)

Btu/h 160,000

kW 46.9

Power input

kW 13.16 *4

Current input

A 40.5 / 36.7 *4

Temp. range of heating *3

Indoor

D.B. 59~81°F(15~27°C)

Outdoor

W.B. -13~60°F(-25~15.5°C)

System Compressor Operating Range Heating: 8-100%

Indoor unit

connectable

Total capacity 50~150 % of outdoor unit capacity

Model / Quantity P06~P96 / 1~36

Sound pressure level (measured in anechoic room) dB <A> 61.0

Refrigerant piping

diameter from Twinning

Kit to Indoor Units

Liquid (High Pressure) In. (mm) 7/8 (22.2) Brazed

Gas (Low Pressure) In. (mm) 1-1/8 (28.58) Brazed

Set Model

Model PURY-HP72TKMU-A-H PURY-HP72TKMU-A-H

Fan

Type x Quantity Propeller fan x 1 Propeller fan x 1

Airflow rate

CFM 6,200 6,200

m3 / min 175 175

L/s 2,920 2,920

Control , Driving mechanism Inverter-control, Brushless DC motor Inverter-control, Brushless DC motor

External static pressure *6 0 in.WG (0 Pa) *6 0 in.WG (0 Pa) *6

Compressor

Type x Quantity Inverter scroll hermetic compressor x 1 Inverter scroll hermetic compressor x 1

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORP. AC&R Works, MITSUBISHI ELECTRIC CORP.

Starting method Inverter Inverter

Lubricant MEL32 MEL32

External finish

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D

In. 64-31/32 x 48-1/16 x 29-15/16 64-31/32 x 48-1/16 x 29-15/16

mm 1,650 x 1,220 x 760 1,650 x 1,220 x 760

Protection

devices

High pressure protection

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

Inverter circuit (COMP. / FAN)

Over-heat protection,Over-current protection Over-heat protection,Over-current protection

Compressor Over-heat protection Over-heat protection

Fan Motor Thermal switch Thermal switch

Minimum Circuit Ampacity (MCA) A 44 / 40 44 / 40

Recommended Fuse/Breaker Size A 50 50

Maximum Fuse Size A 60 60

Refrigerant

Type x original charge R410A x 26 lbs + 1 oz (11.8 kg) R410A x 26 lbs + 1 oz (11.8 kg)

Control LEV and HIC circuit

Net weight lbs (kg) 552 (250) 552 (250)

Heat exchanger Salt-resistant cross n & copper tube Salt-resistant cross n & copper tube

Refrigerant piping

diameter from Module to

Twinning Kit

Liquid (High Pressure) In. (mm) 5/8”(15.88)Brazed 5/8”(15.88)Brazed

Gas (Low Pressure) In. (mm) 3/4”(19.05)Brazed 3/4”(19.05)Brazed

Defrosting method Auto-defrost mode (Reversed refrigerant cycle)

Drawing

External KJ94G492

Wiring KE94C883 KE94C883

Standard attachment

Document Installation Manual

Accessory Details refer to External Drw

Optional parts

Outdoor Twinning kit: CMY-Y100CBK2

Joint: CMY-Y102SS-G2,CMY-Y102LS-G2,CMY-Y202S-G2,CMY-R160C-J

Main BC controller: CMB-P108,1010,1013,1016NU-GA,1016NU-HA

Sub BC controller: CMB-P104,108NU-GB,CMB-P1016NU-HB

Remark

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

*3 Harsh weather environments may demand performance enhancing equipment.

Ask your Mitsubishi Electric representative for more details on your region.

*4 For details on the electrical data needed for installing these units,

see the H2i R2-Series System Design section.

*5 For details on extended ambient cooling operation range down to -10°FDB (-23°CDB),

see Low Ambient Cooling Kit information.

*6 External static pressure is adjustable via dipswitch setting

(0.12 in.WG, 0.24 in.WG / 30Pa, 60Pa).

Note: *1 Nominal cooling conditions *2 Nominal heating conditions Unit converter

Indoor:

80degF D.B./ 67degF W.B. 70degF D.B. kcal =kW x 860

(26.7degC D.B./ 19.4degC W.B.) (21.1degC D.B.) BTU/h =kW x 3,412

Outdoor: 95degF D.B. (35degC D.B.)

47degF D.B./ 43degF W.B.

(8.3degC D.B./ 6.1degC W.B.)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 25ft.(7.6m) 25ft.(7.6m)

* Above specification data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specifications may be subject to change without notice.

Page 6

H2i-R2-6

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

© 2014 Mitsubishi Electric US, Inc.

1. SPECIFICATIONS

Model

PURY-HP192TSKMU-A-H

Power source

3-phase 3-wire 208 / 230V ±10% 60Hz

Cooling capacity (Nominal) *1 (208 / 230V)

Btu/h

192,000

kW

56.3

Power input kW

15.86 *4

Current input A

48.9 / 44.2 *4

Temp. range of cooling *3

Indoor W.B.

59 ~ 75° F(15 ~ 24° C)

Outdoor D.B.

23 ~ 115° F (-5 ~ +46° C) *5

Heating capacity (Nominal) *2 (208-230V)

Btu/h

215,000

kW

63.0

Power input kW

18.52 *4

Current input A

55.9 / 50.5 *4

Temp. range of heating *3

Indoor D.B.

59~81°F(15~27°C)

Outdoor W.B.

-13~60°F(-25~15.5°C)

System Compressor Operating Range

Heating: 6-100%

Indoor unit

connectable

Total capacity

50~150 % of outdoor unit capacity

Model / Quantity

P06~P96 / 1-48

Sound pressure level (measured in anechoic room) dB <A>

61.0

Refrigerant piping diameter

from Twinning Kit to Indoor

Units

Liquid (High Pressure) In. (mm)

7/8”(22.2) Brazed

Gas (Low Pressure) In. (mm)

1-1/8”(28.58) Brazed

Set Model

Model

PURY-HP96TKMU-A-H PURY-HP96TKMU-A-H

Fan

Type x Quantity

Propeller fan x 1 Propeller fan x 1

Airow rate

CFM

6,200 6,200

m3 / min

175 175

L/s

2,920 2,920

Control , Driving mechanism

Inverter-control, Brushless DC motor Inverter-control, Brushless DC motor

External static pressure *6

0 in.WG (0 Pa) *6 0 in.WG (0 Pa) *6

Compressor

Type x Quantity

Inverter scroll hermetic compressor x 1 Inverter scroll hermetic compressor x 1

Manufacturer

AC&R Works, MITSUBISHI ELECTRIC CORP. AC&R Works, MITSUBISHI ELECTRIC CORP.

Starting method

Inverter Inverter

Lubricant

MEL32 MEL32

External nish

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D

In.

64-31/32 x 48-1/16 x 29-15/16 64-31/32 x 48-1/16 x 29-15/16

mm

1,650 x 1,220 x 760 1,650 x 1,220 x 760

Protection

devices

High pressure protection

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

Inverter circuit (COMP. / FAN)

Over-current protection Over-current protection

Fan Motor

Thermal switch Thermal switch

Minimum Circuit Ampacity (MCA) A

60 / 54 60 / 54

Recommended Fuse/Breaker Size A

65 65

Maximum Fuse Size A

80 80

Refrigerant

Type x original charge

R410A x 26 lbs + 1oz (11.8kg) R410A x 26 lbs + 1oz (11.8kg)

Control

LEV and HIC circuit

Net weight lbs (kg)

552 (250) 552 (250)

Heat exchanger

Salt-resistant cross n & copper tube Salt-resistant cross n & copper tube

Refrigerant piping diameter

from Module to Twinning Kit

Liquid (High Pressure) In. (mm)

3/4”(19.05)Brazed 3/4”(19.05)Brazed

Gas (Low Pressure) In. (mm)

7/8”(22.2)Brazed 7/8”(22.2)Brazed

Defrosting method

Auto-defrost mode (Reversed refrigerant cycle)

Drawing

External

KJ94G492

Wiring

KE94C883 KE94C883

Standard attachment

Document

Installation Manual

Accessory

Details refer to External Drw

Optional parts

Outdoor Twinning kit: CMY-Y100CBK2

Joint: CMY-Y102SS-G2,CMY-Y102LS-G2,CMY-Y202S-G2,CMY-R160C-J

Main BC controller: CMB-P108,1010,1013,1016NU-GA,1016NU-HA

Sub BC controller: CMB-P104,108NU-GB,CMB-P1016NU-HB

Remark

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

*3 Harsh weather environments may demand performance enhancing equipment.

Ask your Mitsubishi Electric representative for more details on your region.

*4 For details on the electrical data needed for installing these units,

see the H2i R2-Series System Design section.

*5 For details on extended ambient cooling operation range down to -10°FDB (-23°CDB),

see Low Ambient Cooling Kit information.

*6 External static pressure is adjustable via dipswitch setting

(0.12 in.WG, 0.24 in.WG / 30Pa, 60Pa).

Note: *1 Nominal cooling conditions *2 Nominal heating conditions Unit converter

Indoor:

80degF D.B./ 67degF W.B. 70degF D.B. kcal =kW x 860

(26.7degC D.B./ 19.4degC W.B.) (21.1degC D.B.) BTU/h =kW x 3,412

Outdoor: 95degF D.B. (35degC D.B.)

47degF D.B./ 43degF W.B.

(8.3degC D.B./ 6.1degC W.B.)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 25ft.(7.6m) 25ft.(7.6m)

* Above specification data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specifications may be subject to change without notice.

Page 7

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

H2i-R2-7

© 2014 Mitsubishi Electric US, Inc.

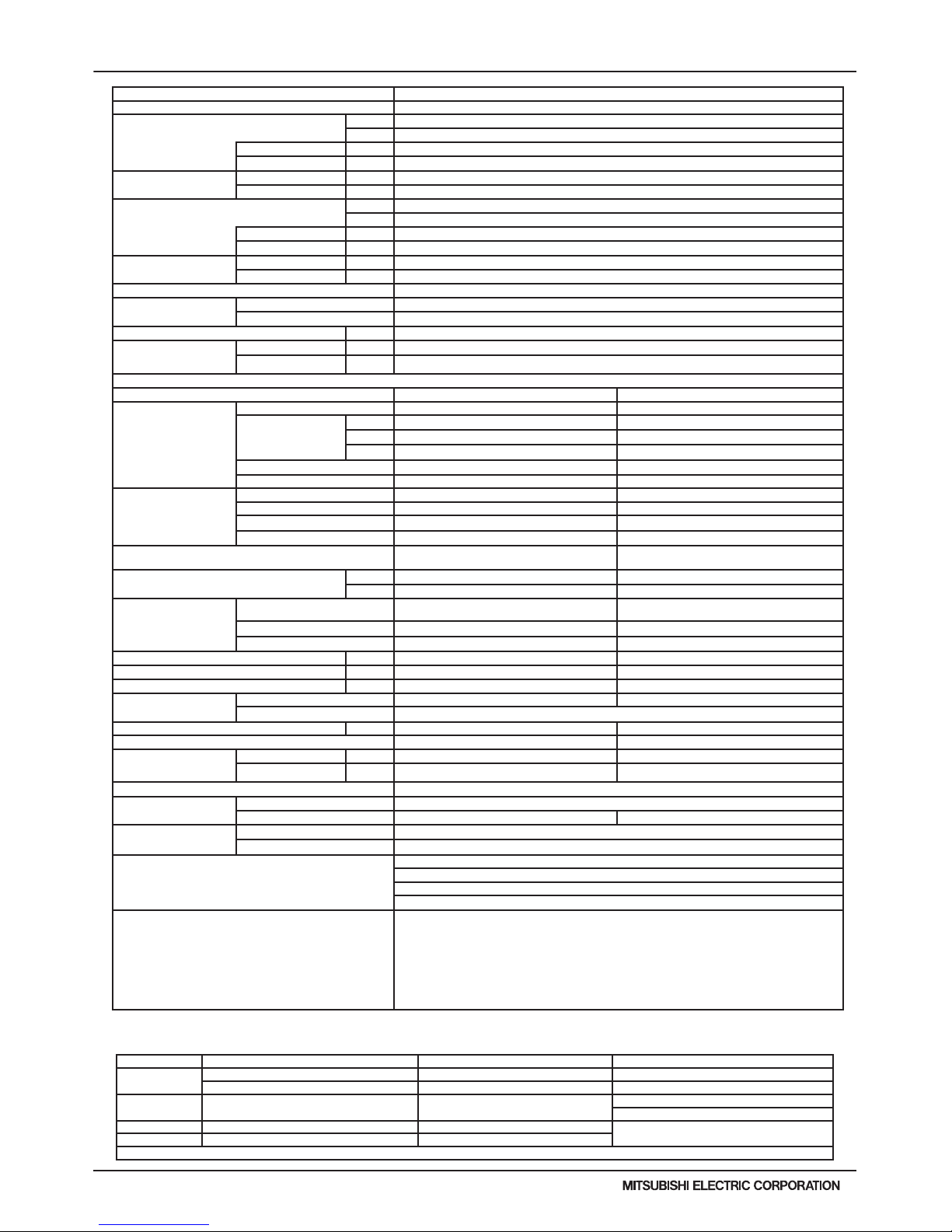

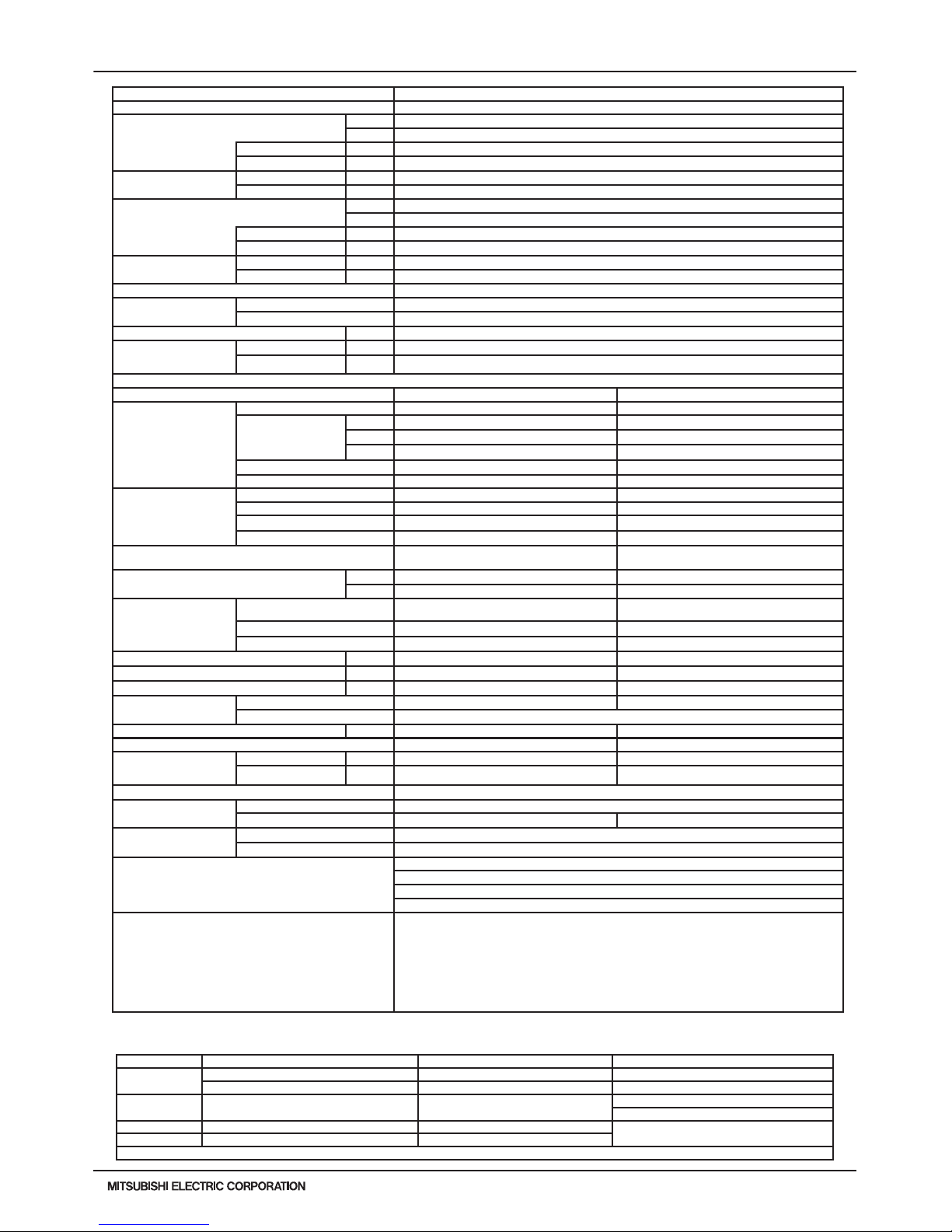

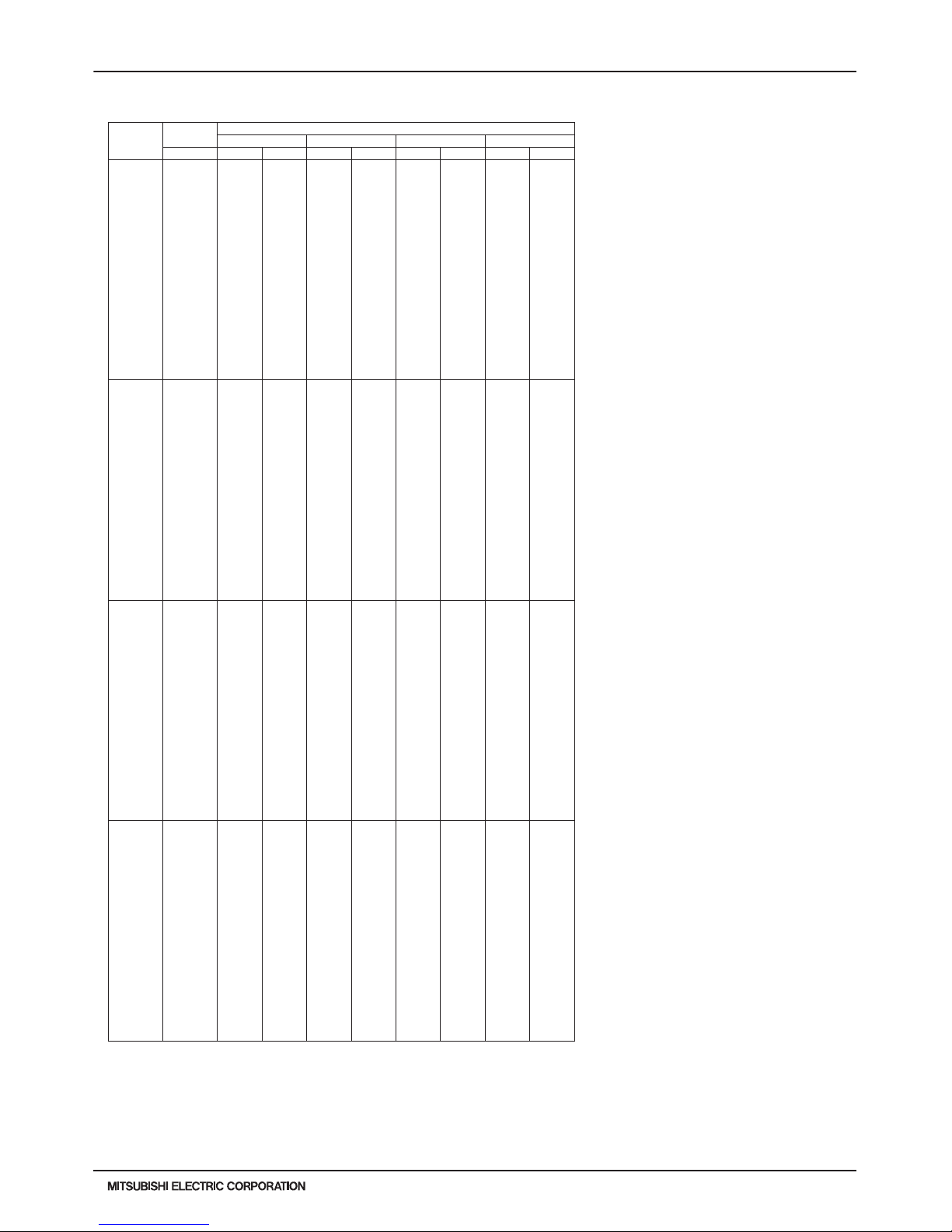

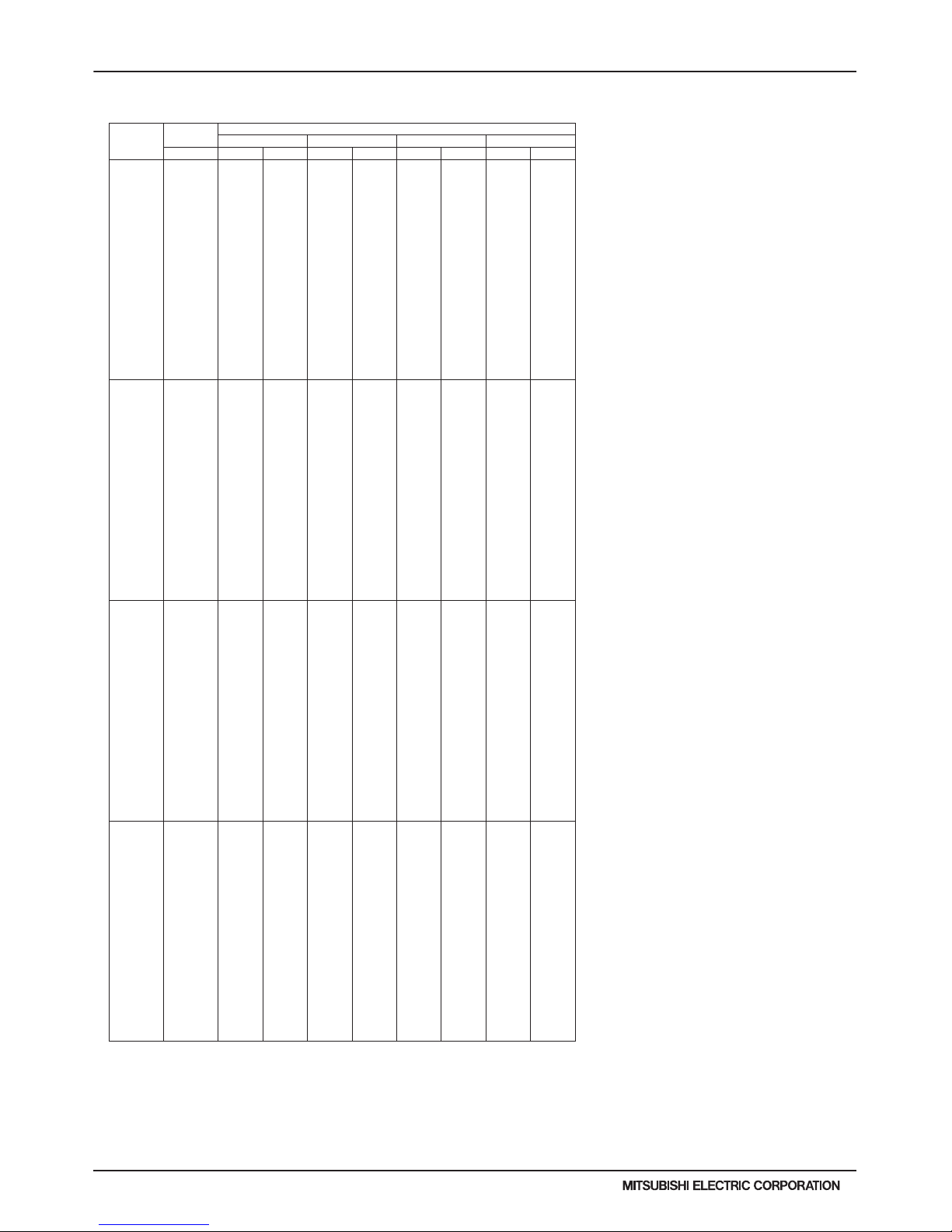

1. SPECIFICATIONS

Model

PURY-HP72YKMU-A PURY-HP96YKMU-A

Power source

3-phase 3-wire 460V ±10% 60Hz 3-phase 3-wire 460V ±10% 60Hz

Cooling capacity (Nominal) *1 (460V)

Btu/h

72,000 96,000

kW

21.1 28.1

Power input kW

5.08 *4 7.66 *4

Current input A

7.0 *4 10.6 *4

Temp. range of

cooling *3

Indoor W.B.

59 ~ 75° F(15 ~ 24° C) 59 ~ 75° F(15 ~ 24° C)

Outdoor D.B.

23 ~ 115° F (-5 ~ +46° C) *5 23 ~ 115° F (-5 ~ +46° C) *5

Heating capacity (Nominal) *2 (460V)

Btu/h

80,000 108,000

kW

23.4 31.7

Power input kW

6.26 *4 8.88 *4

Current input A

8.7 *4 12.3 *4

Temp. range of

heating *3

Indoor D.B.

59~81°F(15~27°C) 59~81°F(15~27°C)

Outdoor W.B.

-13~60°F(-25~15.5°C) -13~60°F(-25~15.5°C)

Indoor unit

Total capacity

50~150 % of outdoor unit capacity 50~150 % of outdoor unit capacity

Model / Quantity

P06~P96 / 1~18 P06~P96 / 1~24

Sound pressure level (measured in

anechoic room)

dB <A>

58.0 58.0

Refrigerant

piping diameter

Liquid (High Pressure) In. (mm)

5/8 (15.88) Brazed 3/4 (19.05) Brazed

Gas (Low Pressure) In. (mm)

3/4 (19.05) Brazed 7/8 (22.2) Brazed

Fan

Type x Quantity

Propeller fan x 1 Propeller fan x 1

Airow rate

CFM

6,200 6,200

m3 / min

175 175

L/s

2,920 2,920

Control, Driving mechanism

Inverter-control, Brushless DC motor Inverter-control, Brushless DC motor

External static pressure *6

0 in.WG (0 Pa) *6 0 in.WG (0 Pa) *6

Compressor

Type x Quantity

Inverter scroll hermetic compressor x 1 Inverter scroll hermetic compressor x 1

Manufacturer

AC&R Works, MITSUBISHI ELECTRIC CORP. AC&R Works, MITSUBISHI ELECTRIC CORP.

Operating Range

Heating: 16-100%

Heating: 13-100%

Starting method

Inverter Inverter

Lubricant

MEL32 MEL32

External nish

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D

In.

64-31/32 x 48-1/16 x 29-15/16 64-31/32 x 48-1/16 x 29-15/16

mm

1,650 x 1,220 x 760 1,650 x 1,220 x 760

Protection

devices

High pressure protection

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

Inverter circuit (COMP. / FAN)

Over-current protection Over-current protection

Fan motor

Thermal switch Thermal switch

Minimum Circuit Ampacity (MCA) A 26 32

Recommended Fuse/Breaker Size A 30 35

Maximum Fuse Size A 30 35

Refrigerant

Type x original charge

R410A x 26 lbs + 1 oz (11.8 kg) R410A x 26 lbs + 1 oz (11.8kg)

Control

Indoor LEV and BC controller Indoor LEV and BC controller

Net weight lbs (kg)

574 (260) 576 (261)

Heat exchanger

Salt-resistant cross n & copper tube Salt-resistant cross n & copper tube

Defrost method

Auto-defrost mode (Reversed refrigerant cycle) Auto-defrost mode (Reversed refrigerant cycle)

Drawing

External

KJ94G387 KJ94G387

Wiring

KE94C884 KE94C884

Standard

attachment

Document

Installation Manual Installation Manual

Accessory

Details refer to External Drw Details refer to External Drw

Optional parts

Joint: CMY-Y102SS-G2,CMY-Y102LS-G2,

CMY-R160C-J

Joint: CMY-Y102SS-G2,CMY-Y102LS-G2,

CMY-R160C-J

BC controller: CMB-P104,105,106,108,1010,1013,

1016NU-G

BC controller: CMB-P104,105,106,108,1010,1013,

1016NU-G

Main BC controller: CMB-P108,1010,1013,

1016NU-GA,1016NU-HA

Main BC controller: CMB-P108,1010,1013,

1016NU-GA,1016NU-HA

Sub BC controller: CMB-P104,108NU-GB,

CMB-P1016NU-HB

Sub BC controller: CMB-P104,108NU-GB,

CMB-P1016NU-HB

Remark

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

*3 Harsh weather environments may demand performance enhancing equipment.

Ask your Mitsubishi Electric representative for more details on your region.

*4 For details on the electrical data needed for installing these units,

see the H2i R2-Series System Design section.

*5 For details on extended ambient cooling operation range down to -10°FDB (-23°CDB),

see Low Ambient Cooling Kit information.

*6 External static pressure is adjustable via dipswitch setting

(0.12 in.WG, 0.24 in.WG / 30Pa, 60Pa).

Note: *1 Nominal cooling conditions *2 Nominal heating conditions

Unit converter

Indoor:

80degF D.B./ 67degF W.B. 70degF D.B.

kcal =kW x 860

(26.7degC D.B./ 19.4degC W.B.) (21.1degC D.B.)

BTU/h =kW x 3,412

Outdoor: 95degF D.B. (35degC D.B.)

47degF D.B./ 43degF W.B.

(8.3degC D.B./ 6.1degC W.B.)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 25ft.(7.6m) 25ft.(7.6m)

* Above specification data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specifications may be subject to change without notice.

1-2. PURY-HP72~192Y(S)KMU-A Specications

Page 8

H2i-R2-8

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

© 2014 Mitsubishi Electric US, Inc.

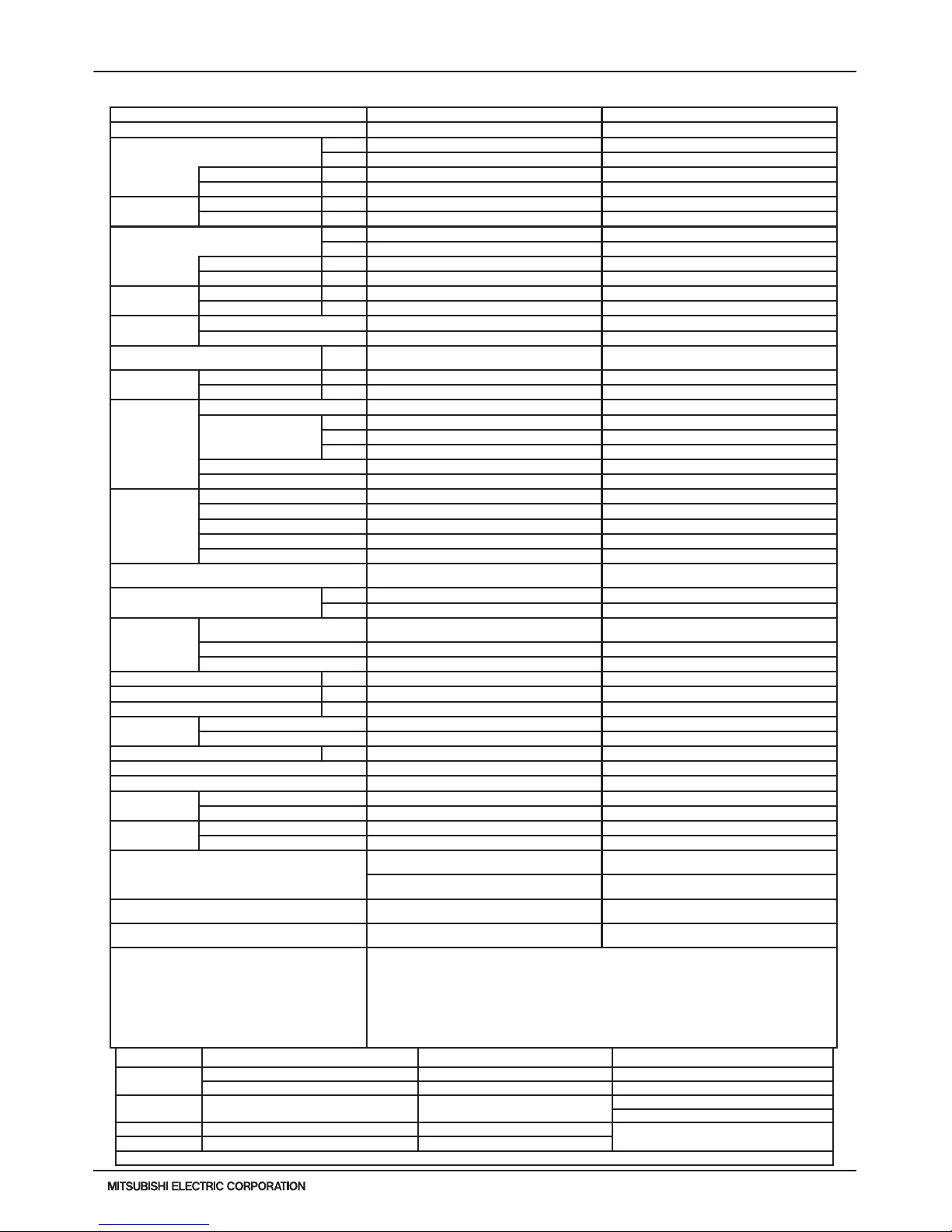

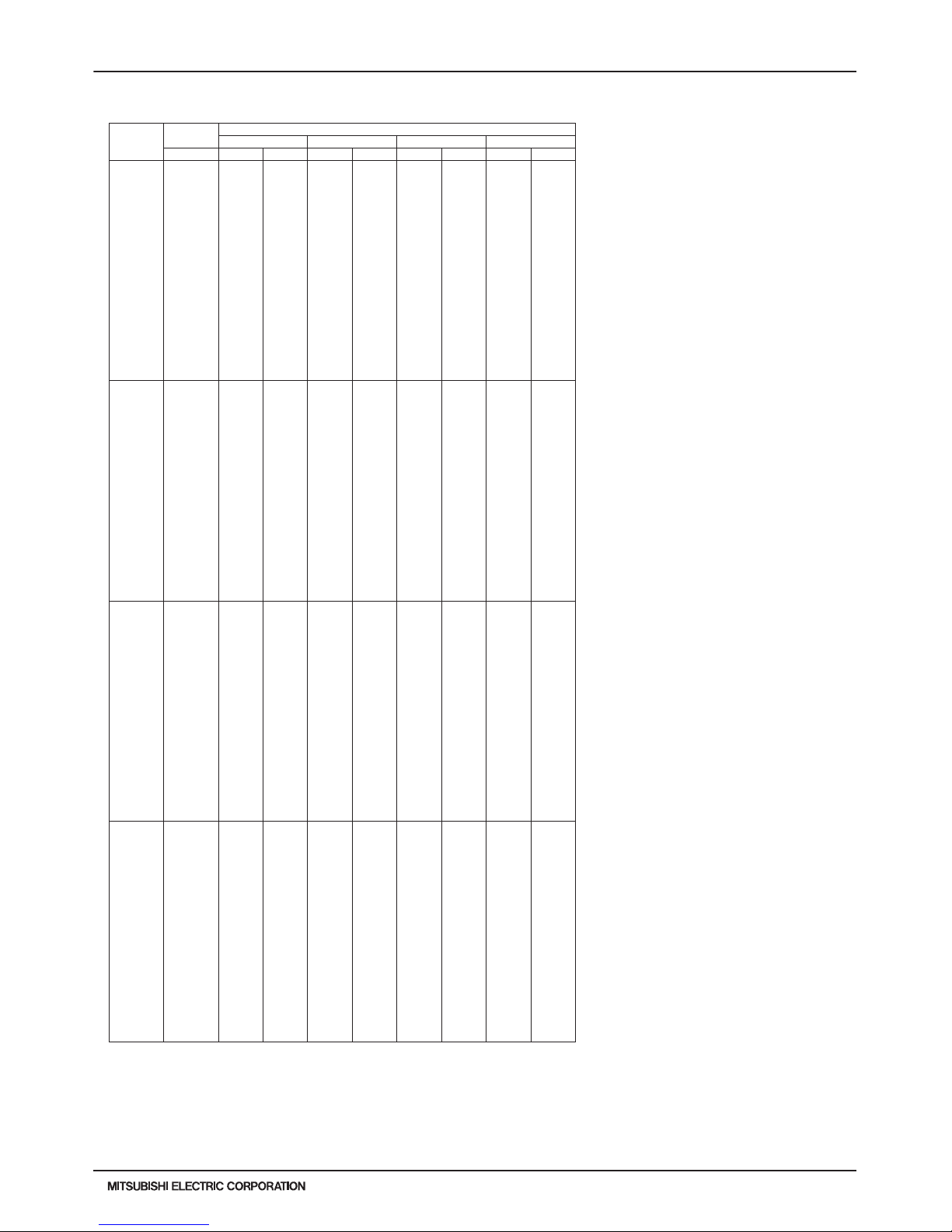

1. SPECIFICATIONS

Model PURY-HP144YSKMU-A

Power source 3-phase 3-wire 460V ±10% 60Hz

Cooling capacity (Nominal) *1 (460V)

Btu/h 144,000

kW 42.2

Power input

kW 10.85 *4

Current input

A 15.1 *4

Temp. range of cooling *3

Indoor

W.B. 59 ~ 75° F(15 ~ 24° C)

Outdoor

D.B. 23 ~ 115° F (-5 ~ +46° C) *5

Heating capacity (Nominal) *2 (460V)

Btu/h 160,000

kW 46.9

Power input

kW 13.16 *4

Current input

A 18.3 *4

Temp. range of heating *3

Indoor

D.B. 59~81°F(15~27°C)

Outdoor

W.B. -13~60°F(-25~15.5°C)

System Compressor Operating Range Heating: 8-100%

Indoor unit

connectable

Total capacity 50~150 % of outdoor unit capacity

Model / Quantity P06~P96 / 1~36

Sound pressure level (measured in anechoic room) dB <A> 61.0

Refrigerant piping

diameter from Twinning

Kit to Indoor Units

Liquid (High Pressure) In. (mm) 7/8 (22.2) Brazed

Gas (Low Pressure) In. (mm) 1-1/8 (28.58) Brazed

Set Model

Model PURY-HP72YKMU-A PURY-HP72YKMU-A

Fan

Type x Quantity Propeller fan x 1 Propeller fan x 1

Airflow rate

CFM 6,200 6,200

m3 / min 175 175

L/s 2,920 2,920

Control , Driving mechanism Inverter-control, Brushless DC motor Inverter-control, Brushless DC motor

External static pressure *6 0 in.WG (0 Pa) *6 0 in.WG (0 Pa) *6

Compressor

Type x Quantity Inverter scroll hermetic compressor x 1 Inverter scroll hermetic compressor x 1

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORP. AC&R Works, MITSUBISHI ELECTRIC CORP.

Starting method Inverter Inverter

Lubricant MEL32 MEL32

External finish

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D

In. 64-31/32 x 48-1/16 x 29-15/16 64-31/32 x 48-1/16 x 29-15/16

mm 1,650 x 1,220 x 760 1,650 x 1,220 x 760

Protection

devices

High pressure protection

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

Inverter circuit (COMP. / FAN)

Over-heat protection,Over-current protection Over-heat protection,Over-current protection

Compressor Over-heat protection Over-heat protection

Fan Motor Thermal switch Thermal switch

Minimum Circuit Ampacity (MCA) A

26 26

Recommended Fuse/Breaker Size A

30 30

Maximum Fuse Size A

30 30

Refrigerant

Type x original charge R410A x 26 lbs + 1 oz (11.8 kg) R410A x 26 lbs + 1 oz (11.8 kg)

Control LEV and HIC circuit

Net weight lbs (kg) 574 (260) 574 (260)

Heat exchanger Salt-resistant cross n & copper tube Salt-resistant cross n & copper tube

Refrigerant piping

diameter from Module to

Twinning Kit

Liquid (High Pressure) In. (mm) 5/8 (15.88)Brazed 5/8 (15.88)Brazed

Gas (Low Pressure) In. (mm) 3/4 (19.05)Brazed 3/4 (19.05)Brazed

Defrosting method Auto-defrost mode (Reversed refrigerant cycle)

Drawing

External KJ94G493

Wiring KE94C884 KE94C884

Standard attachment

Document Installation Manual

Accessory Details refer to External Drw

Optional parts

Outdoor Twinning kit: CMY-Y100CBK2

Joint: CMY-Y102SS-G2,CMY-Y102LS-G2,CMY-Y202S-G2,CMY-R160C-J

Main BC controller: CMB-P108,1010,1013,1016NU-GA,1016NU-HA

Sub BC controller: CMB-P104,108NU-GB,CMB-P1016NU-HB

Remark

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

*3 Harsh weather environments may demand performance enhancing equipment.

Ask your Mitsubishi Electric representative for more details on your region.

*4 For details on the electrical data needed for installing these units,

see the H2i R2-Series System Design section.

*5 For details on extended ambient cooling operation range down to -10°FDB (-23°CDB),

see Low Ambient Cooling Kit information.

*6 External static pressure is adjustable via dipswitch setting

(0.12 in.WG, 0.24 in.WG / 30Pa, 60Pa).

Note: *1 Nominal cooling conditions *2 Nominal heating conditions Unit converter

Indoor:

80degF D.B./ 67degF W.B. 70degF D.B. kcal =kW x 860

(26.7degC D.B./ 19.4degC W.B.) (21.1degC D.B.) BTU/h =kW x 3,412

Outdoor: 95degF D.B. (35degC D.B.)

47degF D.B./ 43degF W.B.

(8.3degC D.B./ 6.1degC W.B.)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 25ft.(7.6m) 25ft.(7.6m)

* Above specification data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specifications may be subject to change without notice.

Page 9

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

H2i-R2-9

© 2014 Mitsubishi Electric US, Inc.

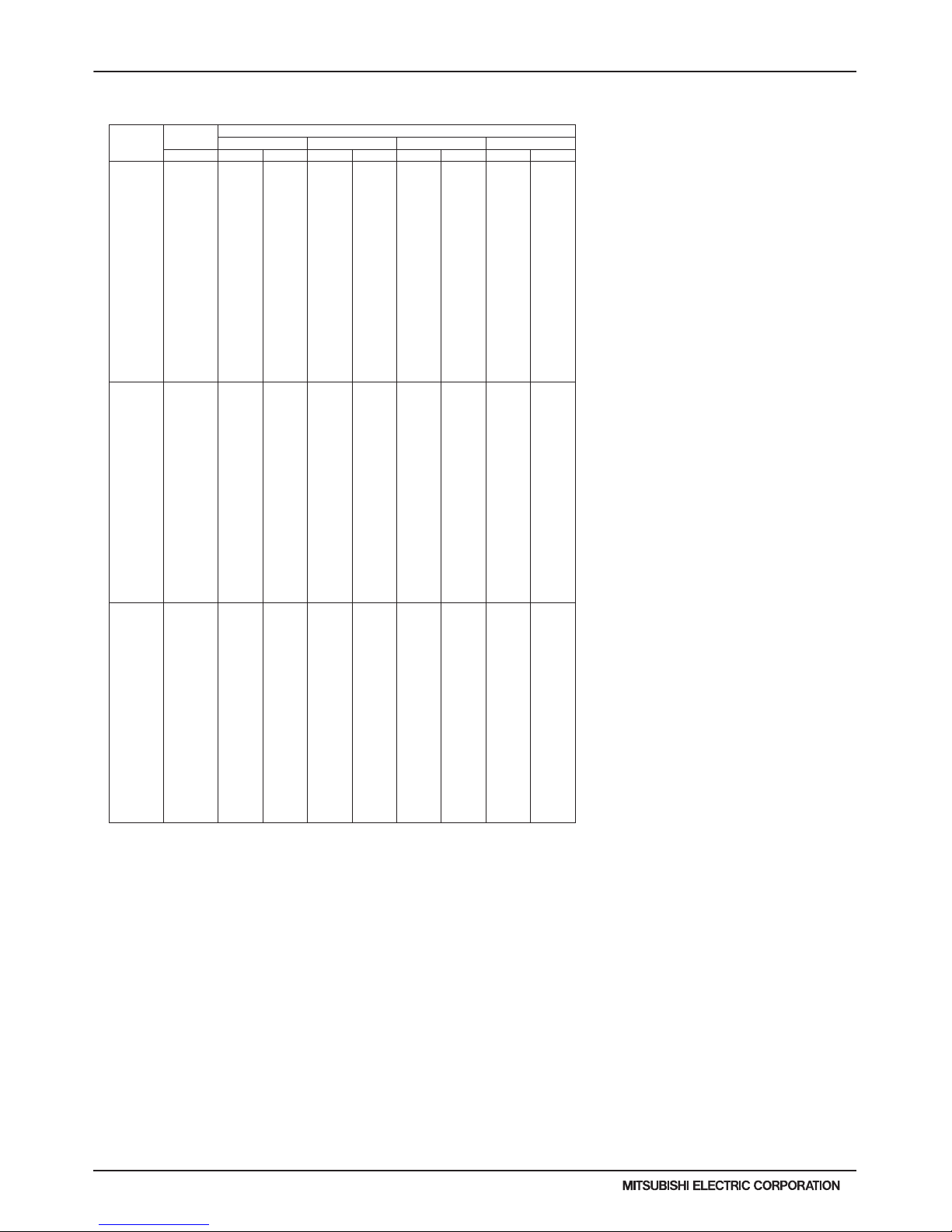

1. SPECIFICATIONS

Model

PURY-HP192YSKMU-A

Power source

3-phase 3-wire 460V ±10% 60Hz

Cooling capacity (Nominal) *1 (460V)

Btu/h

192,000

kW

56.3

Power input kW

15.86 *4

Current input A

22.1 *4

Temp. range of cooling *3

Indoor W.B.

59 ~ 75° F(15 ~ 24° C)

Outdoor D.B.

23 ~ 115° F (-5 ~ +46° C) *5

Heating capacity (Nominal) *2 (460V)

Btu/h

215,000

kW

63.0

Power input kW

18.52 *4

Current input A

25.8 *4

Temp. range of heating *3

Indoor D.B.

59~81°F(15~27°C)

Outdoor W.B.

-13~60°F(-25~15.5°C)

System Compressor Operating Range

Heating: 6-100%

Indoor unit

connectable

Total capacity

50~150 % of outdoor unit capacity

Model / Quantity

P06~P96 / 1-48

Sound pressure level (measured in anechoic room) dB <A>

61.0

Refrigerant piping diameter

from Twinning Kit to Indoor

Units

Liquid (High Pressure) In. (mm)

7/8 (22.2) Brazed

Gas (Low Pressure) In. (mm)

1-1/8 (28.58) Brazed

Set Model

Model

PURY-HP96YKMU-A PURY-HP96YKMU-A

Fan

Type x Quantity

Propeller fan x 1 Propeller fan x 1

Airow rate

CFM

6,200 6,200

m3 / min

175 175

L/s

2,920 2,920

Control , Driving mechanism

Inverter-control, Brushless DC motor Inverter-control, Brushless DC motor

External static pressure *6

0 in.WG (0 Pa) *6 0 in.WG (0 Pa) *6

Compressor

Type x Quantity

Inverter scroll hermetic compressor x 1 Inverter scroll hermetic compressor x 1

Manufacturer

AC&R Works, MITSUBISHI ELECTRIC CORP. AC&R Works, MITSUBISHI ELECTRIC CORP.

Starting method

Inverter Inverter

Lubricant

MEL32 MEL32

External nish

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D

In.

64-31/32 x 48-1/16 x 29-15/16 64-31/32 x 48-1/16 x 29-15/16

mm

1,650 x 1,220 x 760 1,650 x 1,220 x 760

Protection

devices

High pressure protection

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

Inverter circuit (COMP. / FAN)

Over-current protection Over-current protection

Fan Motor

Thermal switch Thermal switch

Minimum Circuit Ampacity (MCA) A 32 32

Recommended Fuse/Breaker Size A 35 35

Maximum Fuse Size A 35 35

Refrigerant

Type x original charge

R410A x 26 lbs + 1oz (11.8kg) R410A x 26 lbs + 1oz (11.8kg)

Control

LEV and HIC circuit

Net weight lbs (kg)

576 (261) 576 (261)

Heat exchanger

Salt-resistant cross n & copper tube Salt-resistant cross n & copper tube

Refrigerant piping diameter

from Module to Twinning Kit

Liquid (High Pressure) In. (mm)

3/4 (19.05)Brazed 3/4 (19.05)Brazed

Gas (Low Pressure) In. (mm)

7/8 (22.2)Brazed 7/8 (22.2)Brazed

Defrosting method

Auto-defrost mode (Reversed refrigerant cycle)

Drawing

External

KJ94G493

Wiring

KE94C884 KE94C884

Standard attachment

Document

Installation Manual

Accessory

Details refer to External Drw

Optional parts

Outdoor Twinning kit: CMY-Y100CBK2

Joint: CMY-Y102SS-G2,CMY-Y102LS-G2,CMY-Y202S-G2,CMY-R160C-J

Main BC controller: CMB-P108,1010,1013,1016NU-GA,1016NU-HA

Sub BC controller: CMB-P104,108NU-GB,CMB-P1016NU-HB

Remark

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

*3 Harsh weather environments may demand performance enhancing equipment.

Ask your Mitsubishi Electric representative for more details on your region.

*4 For details on the electrical data needed for installing these units,

see the H2i R2-Series System Design section.

*5 For details on extended ambient cooling operation range down to -10°FDB (-23°CDB),

see Low Ambient Cooling Kit information.

*6 External static pressure is adjustable via dipswitch setting

(0.12 in.WG, 0.24 in.WG / 30Pa, 60Pa).

Note: *1 Nominal cooling conditions *2 Nominal heating conditions Unit converter

Indoor:

80degF D.B./ 67degF W.B. 70degF D.B. kcal =kW x 860

(26.7degC D.B./ 19.4degC W.B.) (21.1degC D.B.) BTU/h =kW x 3,412

Outdoor: 95degF D.B. (35degC D.B.)

47degF D.B./ 43degF W.B.

(8.3degC D.B./ 6.1degC W.B.)

cfm =m3/min x 35.31

lb =kg / 0.4536

Pipe length: 25ft.(7.6m) 25ft.(7.6m)

* Above specification data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specifications may be subject to change without notice.

Page 10

H2i-R2-10

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

© 2014 Mitsubishi Electric US, Inc.

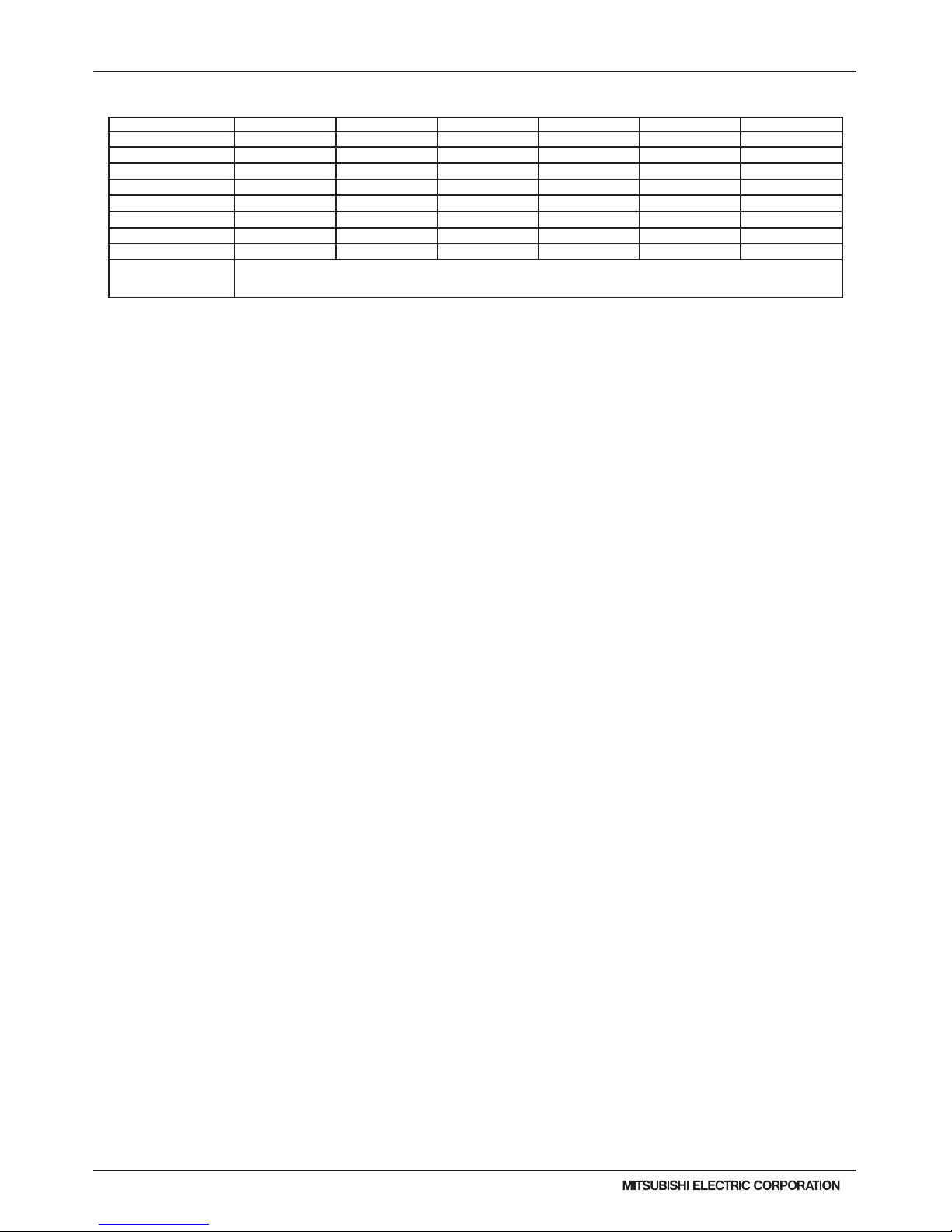

Model

IDU Type EER (95° F) *1 IEER *1 HI COP (47° F) *1 LOW COP (17° F) *1 SCHE

PURY-HP72TKMU-A-H Ducted / Non-Ducted 12.9 / 13 17.2 / 18.4 3.61 / 3.55 2.39 / 2.25 22.7 / 22.6

PURY-HP96TKMU-A-H Ducted / Non-Ducted 11.4 / 12.5 16.5 / 17.1 3.46 / 3.44 2.31 / 2.25 17.4 / 22.0

PURY-HP144TSKMU-A-H Ducted / Non-Ducted 12.5 / 12.6 16.7 / 17.9 3.47 / 3.41 2.32 / 2.05 22.1 / 22.0

PURY-HP192TSKMU-A-H Ducted / Non-Ducted 11.1 / 12.1 16.1 / 16.6 3.32 / 3.31 2.24 / 2.05 16.9 / 21.4

PURY-HP72YKMU-A Ducted / Non-Ducted 12.9 / 13 17.2 / 18.4 3.61 / 3.55 2.39 / 2.25 22.7 / 22.6

PURY-HP96YKMU-A Ducted / Non-Ducted 11.4 / 12.5 16.5 / 17.1 3.46 / 3.44 2.31 / 2.25 17.4 / 22.0

PURY-HP144YSKMU-A Ducted / Non-Ducted 12.5 / 12.6 16.7 / 17.9 3.47 / 3.41 2.32 / 2.05 22.1 / 22.0

PURY-HP192YSKMU-A Ducted / Non-Ducted 11.1 / 12.1 16.1 / 16.6 3.32 / 3.31 2.24 / 2.05 16.9 / 21.4

Note:

*1. Efficiency values based on AHRI 1230 test method.

1. SPECIFICATIONS

Efciency Ratings

Page 11

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

H2i-R2-11

© 2014 Mitsubishi Electric US, Inc.

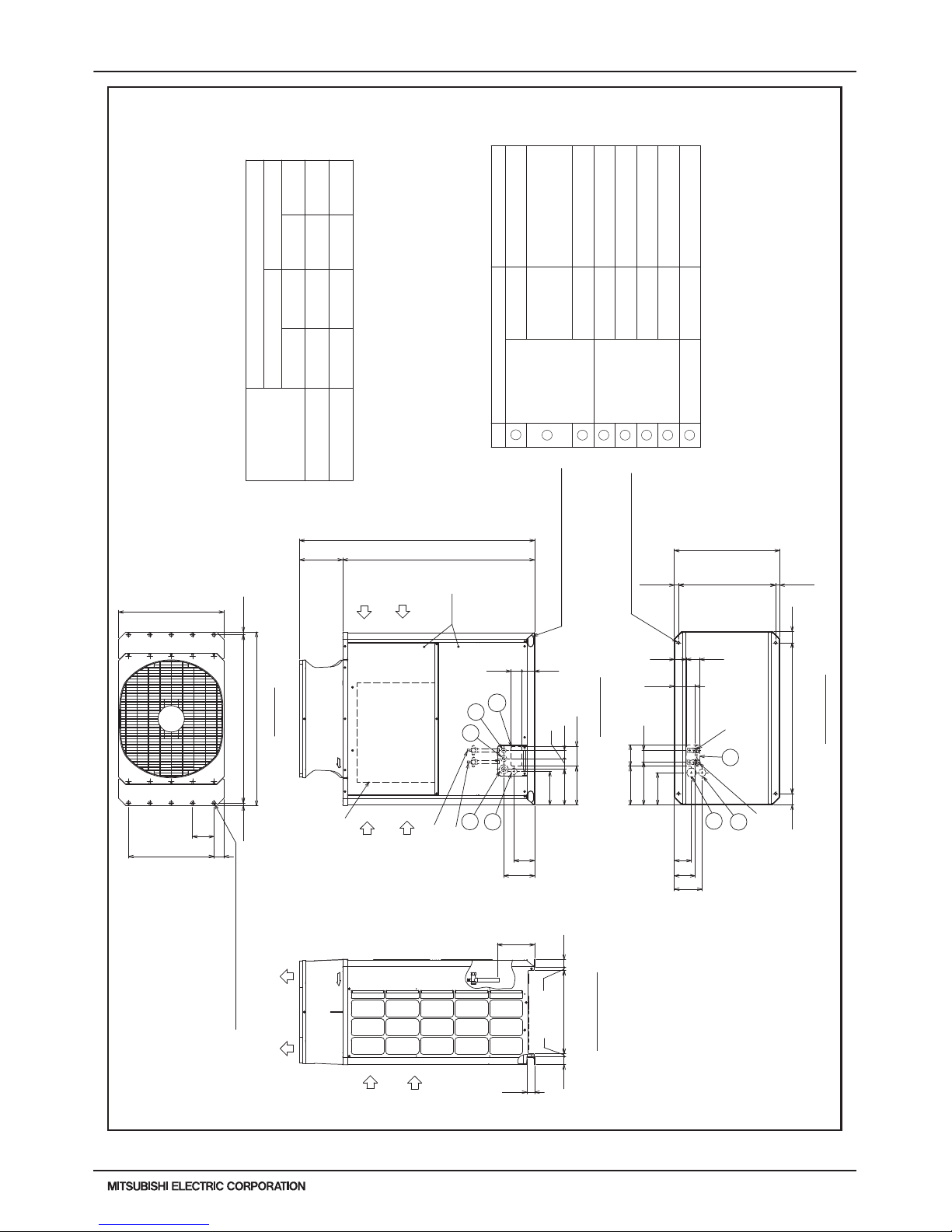

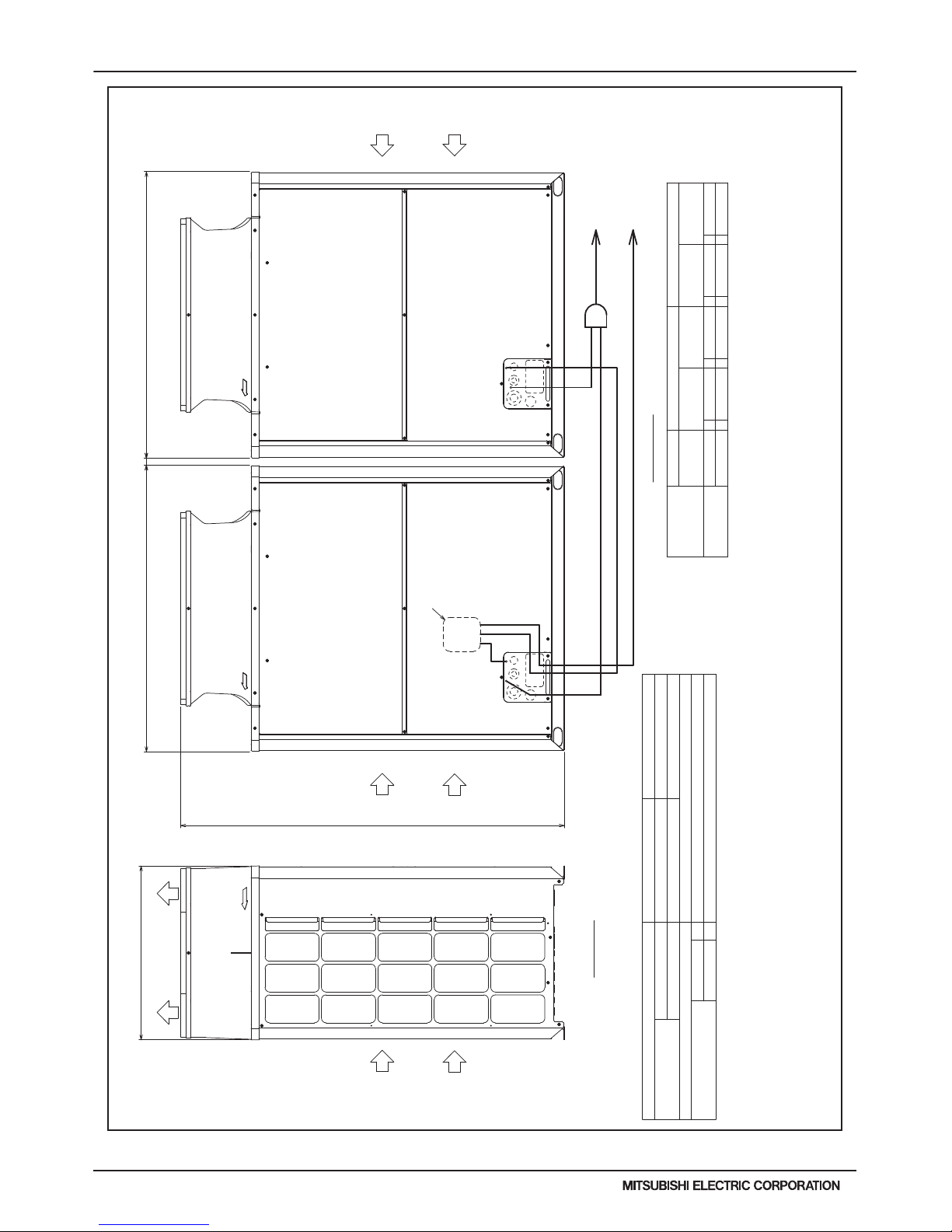

2. EXTERNAL DIMENSIONS

DATA U10

PURY-HP72, 96TKMU-A-H(-BS)

Unit : mm(in)

Refrigerant service

valve <High pressure>

Refrigerant service

valve <Low pressure>

Refrigerant service valve

<Low pressure>

Refrigerant service valve

<High pressure>

(5-3/4)

(5-3/4)

(1-3/16)

(1-3/16)

(Mounting pitch)

(26-23/32~26-15/16)

(26-13/16)

(Mounting pitch)

(3-5/32)

(3-5/32)

(4-25/32)

(8-9/16) 217

(5-23/32) 145

(10-11/32)

(7-23/32)

(3-5/16)

(3-23/32)

(10-23/32) 272

(11-7/8) 301

(8-15/16) 227

(2-1/4)

(2-1/4)

(13/16)

(13/16)

(3-17/32)

(3-1/16)

1

(9-29/32) 251

(9-5/16) 236

(10-23/32) 272

(11-15/16)

(25/32)(25/32)

(2-25/32)

=(5-29/32)X4

(23-5/8)

<Snow hood attachment hole>

4X5-ø4.6(3/16) Hole

(Make hole at the plastic fan guard

for snow hood attachment)

Intake

air

Discharge air

Control box

Intake

air

Service

panel

Intake

air

<Sling hole>

3

6

2

4

5

8

2X2-14(9/16)X20(13/16) Oval hole

2X2-80(3-5/32)X35(1-13/32) Oval hole

7

*1 Use the pipe joint(field supply) and connect to the refrigerant service

valve piping.

High

pressure

ø25.4

(1)

Low

pressure

Service valveRefrigerant pipe

Diameter

High

pressure

Low

pressure

Model

PURY-HP72TKMU-A-H(-BS)

ø25.4

(1)

ø19.05 Brazedø15.88 Brazed

ø45 Knockout hole

Specifications

ø43.7 or ø22.2 Knockout hole

ø62.7 or ø34.5 Knockout hole

Front through hole

Bottom through hole

Bottom through hole

Front through hole

Front through hole

For wires

Usage

Front through hole

Front through hole

(Uses when twinning

kit (optional

parts) is mounted.)

140 × 77 Knockout hole

150 × 94 Knockout hole

Bottom through hole

For pipes

ø52 Knockout hole

For transmission cables

ø34 Knockout hole

ø65 Knockout hole

PURY-HP96TKMU-A-H(-BS)

ø19.05 Brazed

ø25.4 ø25.4

ø22.2 Brazed

58(2-5/16)

75(2-31/32)

146

146

83 (3-9/32)

262

(740)(29-5/32)

150 (5-29/32)

57

54(2-5/32)

19.5

80

1060(41-3/4)

586(23-3/32)

19.5

57

94 84

121

600=150×4

20

1220(48-1/16)

150 (5-29/32)

1650(64-31/32)

196

1347(53-1/16)

89

303

20

740(29-5/32)

70

1181(46-1/2)

140(5-17/32)

80

77

681(678~684)29.5 29.5

Bottom view

Left side view

Front view

Top view

Note1. Please refer to the next page for information

regarding necessary spacing around the

unit and foundation work.

2. At brazing of pipes,wrap the refrigerant service valve

with wet cloth and keep the temperature of

refrigerant service valve under 120°C(248°F).

Connecting pipe specifications

(3/4)

*1

(5/8)

*

1

(1-25/32)

(2-9/16)

(1-3/4)

(2-15/32) (1-3/8)

(7/8)

(1-11/32)

(2-1/16)

(5-29/32) (3-23/32)

(5-17/32) (3-1/16)

(3/4)

*1

(1) (1)(7/8)

*1

NO.

1

2

3

4

5

6

7

8

Page 12

H2i-R2-12

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

© 2014 Mitsubishi Electric US, Inc.

2. EXTERNAL DIMENSIONS

DATA U10

H2i R2

PURY-HP72, 96TKMU-A-H(-BS)

Unit : mm(in)

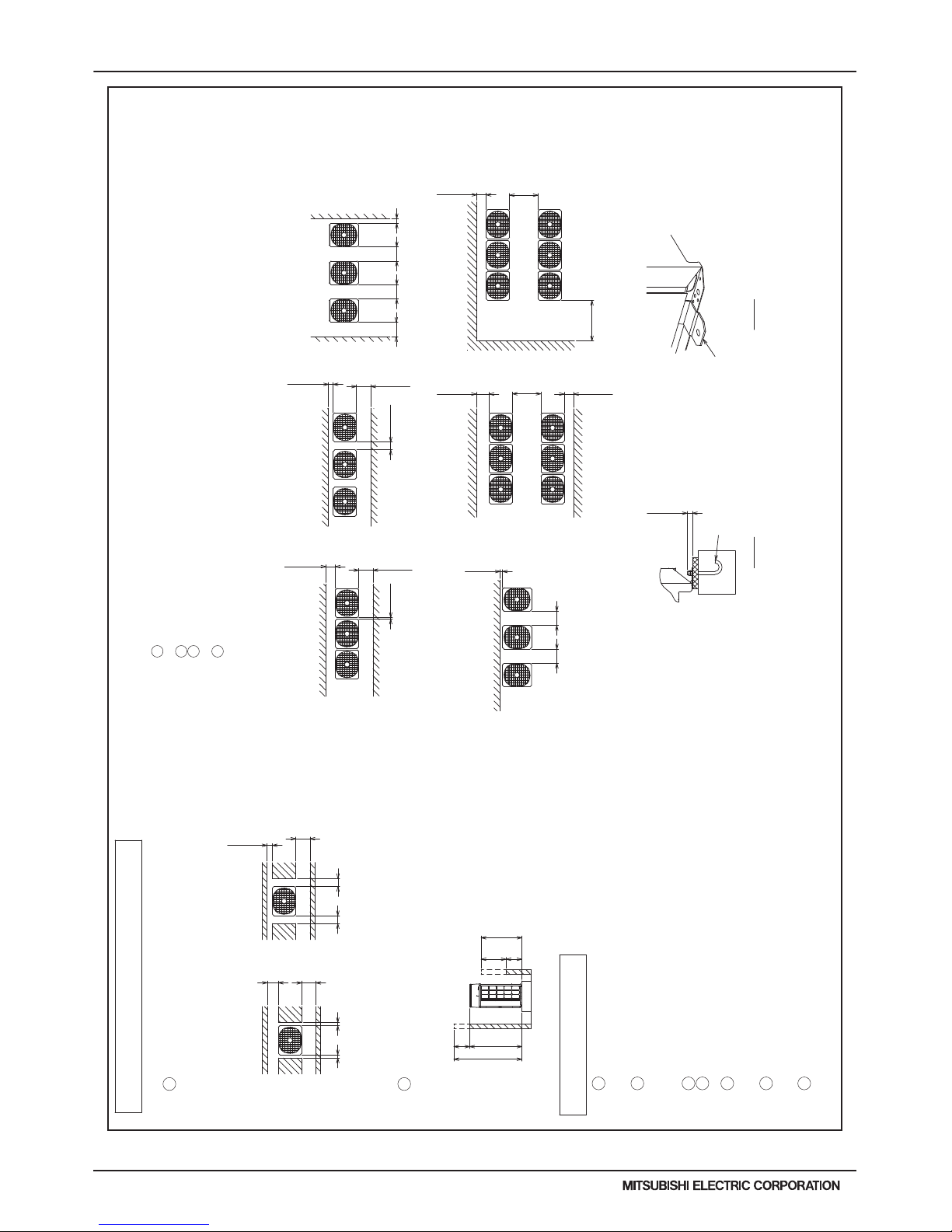

●In case of single installation

1. Required space around the unit

2 When the height of the walls on the front,back or on the sides<H>

exceeds the wall height limit as defined below

add the height that exceeds the height limit <h> to the figures that

are marked with an asterisk.

1 Secure enough space around the unit as shown in the figure below.

2. Foundation work

Wall <H>

Front

Front

Front

Front

Front

Front

Wall <H>

Wall<H>

Front

<Unit:mm(in)>

<To be left open>

Wall <H>

Front

<To be left open>

Wall <H>

Wall <H>

Wall <H>

Wall <H>

<To be left open>

Wall <H>

Wall <H>

Front

Front

<Unit:mm(in)>

1 When multiple units are installed adjacent to each other, secure enough space to allow

for air circulation and walkway between groups of units as shown in the figures below.

2 At least two sides must be left open.

3 As with the single installation, add the height that exceeds the height limit<h>

to the figures that are marked with an asterisk.

4 If there is a wall at both the front and the rear of the unit, install up to six units

consecutively in the side direction and provide a space of 1000mm or more as inlet space/

passage space for each six units.

●In case of collective installation

1 Take into consideration the surface strength, water drainage route,

piping route, and wiring route when preparing the installation site.

<Note that the drain water comes out of the unit during operation.>

2 Build the foundation in such way that the corner of the installation leg is

securely supported as shown in the right figure.(Fig.A)

When using a rubber isolating cushion, please ensure it is large enough

to cover the entire width of each of the unit's legs.

3 The protrusion length of the anchor bolt must not exceed 30mm(1-3/16).(Fig.A)

4 Use four fixing plates as shown in the right figure <field supply required>

when using post-installed anchor bolts.(Fig.B)

5 To prevent small animals and water and snow from entering the unit and damaging its parts,

close the gap around the edges of through holes for pipes and wires with

filler plates <field supply required>.

6 When the pipes or cables are routed at the bottom of the unit,

make sure that the through hole at the base of the unit does not get blocked

with the installation base.

7 Refer to the Installation Manual when installing units on an installation base.

(19-11/16)

(1-3/16)

(35-7/16)

(11-13/16)

(35-7/16) (11-13/16)(11-13/16)

(19/32)

(17-23/32) (17-23/32)

(39-3/8)

(17-23/32)

(17-23/32)

(17-23/32)

(3-15/16)

(3-15/16)

(1-3/16)

(11-13/16)

(3-15/16)

(17-23/32)

(17-23/32)

(1-31/32)(1-31/32)

(3-15/16)

(17-23/32)

(19/32)(19/32)

(11-13/16)

(17-23/32)

<To be left open>

<To be left open>

<To be left open>

<To be left open>

<To be left open>

<To be left open>

<To be left open>

Front

M10 anchor bolt

<field supply required>

Fixing plate

<field supply required>

Front

<Top view><Top view>

Front

<Side view>

• With a space of at least

300mm(11-13/16) to the wall on

the back of the unit

<Wall height limit> Front : Up to the unit height

Back : Up to 500mm(19-11/16) from

the unit bottom

Side : Up to the unit height

Fig.A Fig.B

Unit height

500

900 min.

300 min.*

1000 min.*

300 min.* 300 min.*900 min.

15 min.*

450 min.450 min.

100 min.*

450 min.

450 min.

450 min.*

100 min.

450 min.*

100 min.*

30 min.

300 min.*

450 min.*

100 min.*

450 min.*

450 min.*

300 min.*

15 min.* 15 min.* 50 min.*50 min.*

H

h

h

H

30mm max.

• With a space of at least

100mm(3-15/16) to the wall on

the back of the unit

Page 13

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

H2i-R2-13

© 2014 Mitsubishi Electric US, Inc.

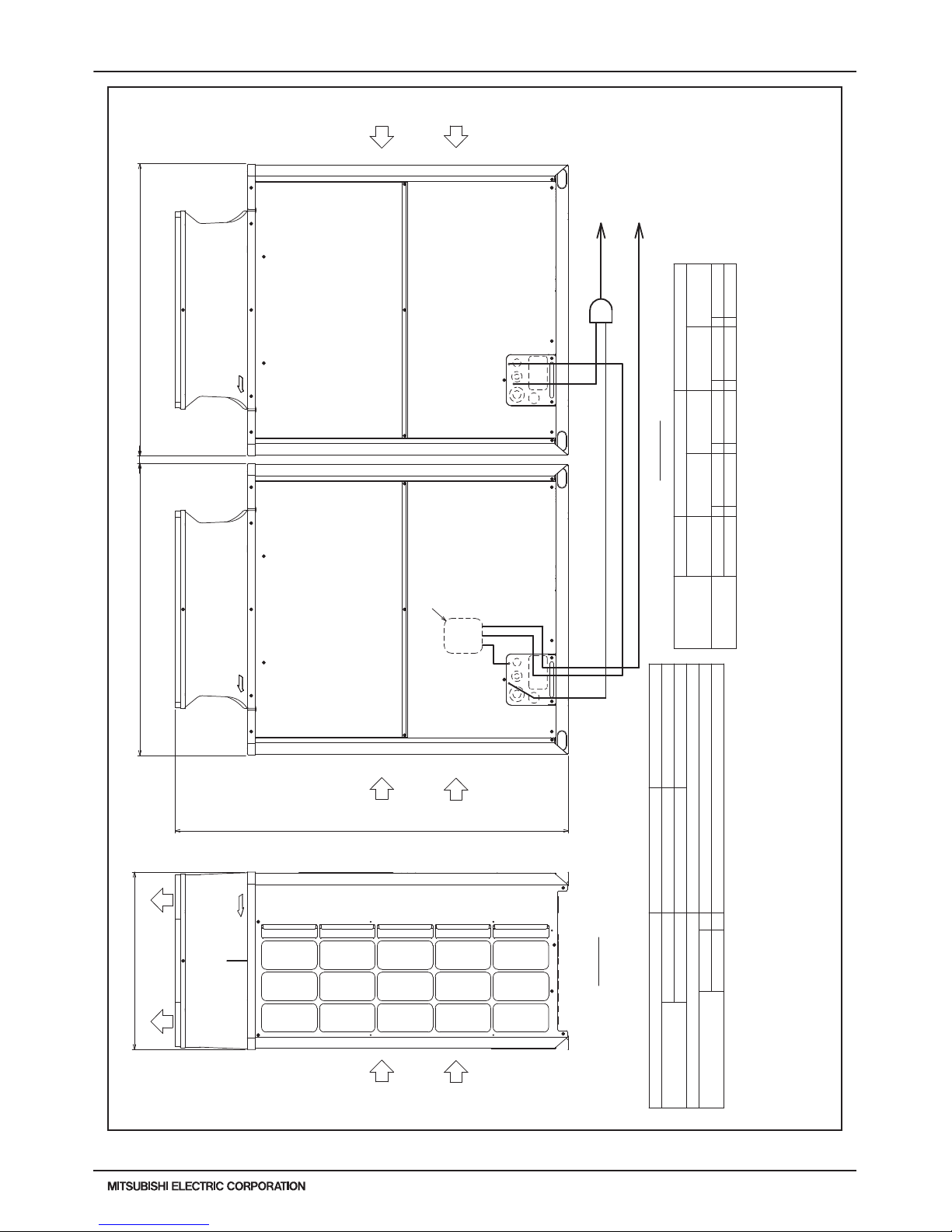

2. EXTERNAL DIMENSIONS

DATA U10

PURY-HP144, 192TSKMU-A-H(-BS)

Unit : mm(in)

30 (1-3/16)

1220 (48-1/16) 1220 (48-1/16)

1650 (64-31/32)

740 (29-5/32)

Front view

Left view

Outdoor unit 2Outdoor unit 1

To BC controller

To BC controller

a

b

e

f

c

d

Twinning pipe(High pressure)

<optional parts>

Twinning pipe(Low pressure)

<optional parts>

Intake

air

Intake

air

Discharge air

Intake

air

Low pressure

Unit model

Component

unit model

ø15.88(5/8) ø19.05(3/4)ccee

ddff

High pressure

HP72 HP96

Twinning Kit

~Outdoor unit

HP72 HP96

(Note 5) (Note 5)

--

ø19.05(3/4)

ø19.05(3/4)

HP144 HP192

Low pressure

Twinning pipe connection size

Outdoor unit 1

Component unit name

Package unit name

BC controller~Twinning pipe

a

b

High pressure

Outdoor Twinning Kit(optional parts)

CMY-R100CBK2

Outdoor unit 2

PURY-HP144TSKMU-A-H(-BS) PURY-HP192TSKMU-A-H(-BS)

PURY-HP72TKMU-A-H(-BS) PURY-HP96TKMU-A-H(-BS)

PURY-HP72TKMU-A-H(-BS) PURY-HP96TKMU-A-H(-BS)

ø28.58(1-1/8)

ø22.2(7/8)

ø15.88(5/8)

ø22.2(7/8)

Note 1. Connect the pipes as shown in the figure above. Refer to the table aboveforthe pipe size.

2. Twinning pipe (High pressure) should not be tilted more than 15 degrees from the horizontal plane.

Be sure to see the Installation Manual for details of Twinning pipe installation.

3. The pipe section before the Twinning pipe (section "a" in the figure) must have at least 500mm(19-11/16) of straight section

(*including the straight pipe that is supplied with the Twinning pipe).

4. Only use the Twinning pipe by Mitsubishi (optional parts).

5. Connect the outdoor unit 1 with the Twinning pipe (Low pressure) (section "d" in the figure).

Page 14

H2i-R2-14

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

© 2014 Mitsubishi Electric US, Inc.

2. EXTERNAL DIMENSIONS

DATA U10

H2i R2

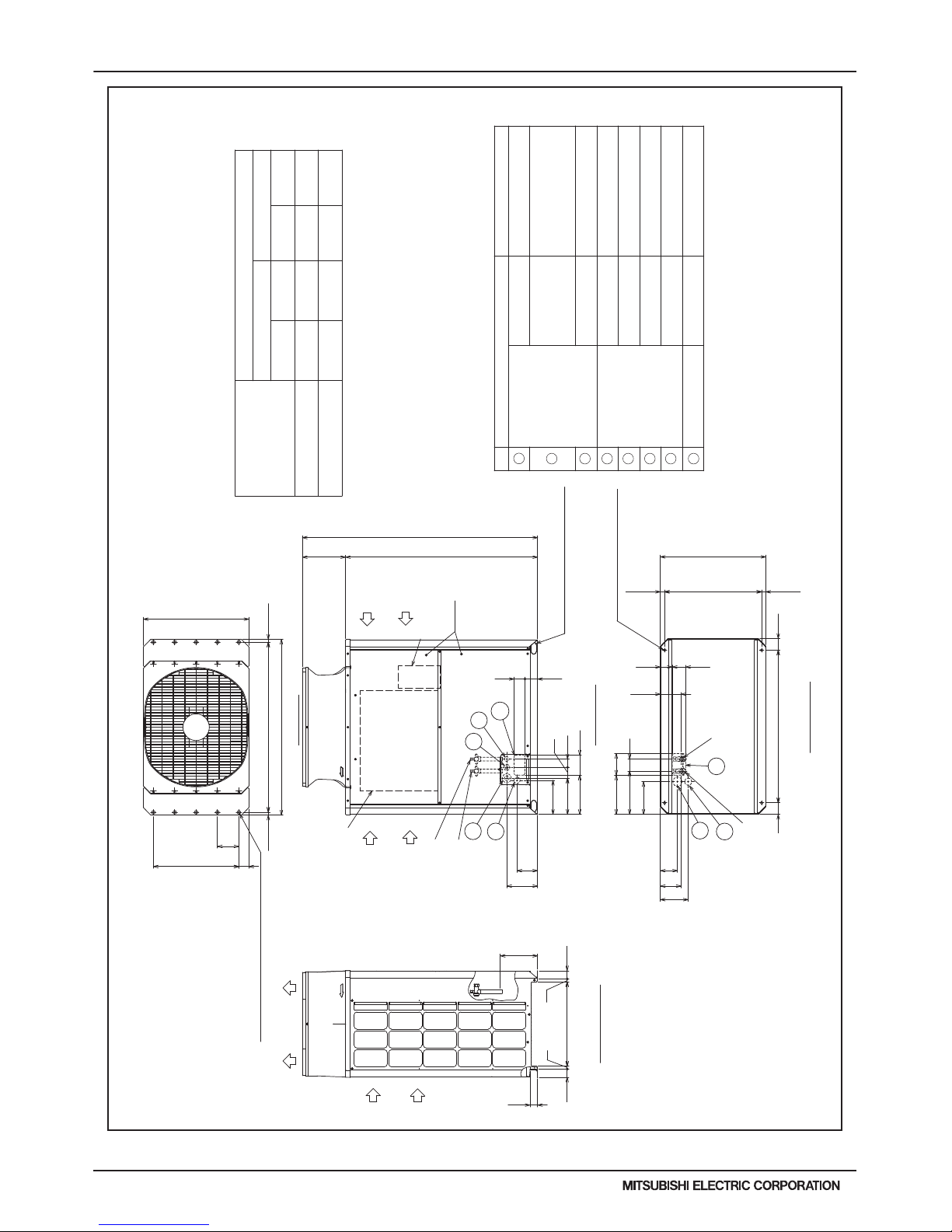

PURY-HP72, 96YKMU-A(-BS)

Unit : mm(in)

(1) (1)

(3/4)

(5/8)

(1-25/32)

(2-9/16)

(1-3/4)

(2-15/32)

(7/8)

(1-3/8)

(1-11/32)

(2-1/16)

(3-23/32)(5-29/32)

(3-1/16)(5-17/32)

(3/4) (1) (1)

(7/8)

Connecting pipe specifications

Note1. Please refer to the next page for information

regarding necessary spacing around the

unit and foundation work.

2. At brazing of pipes, wrap the refrigerant service valve

with wet cloth and keep the temperature of

refrigerant service valve under 120°C(248°F).

Refrigerant service

valve <High pressure>

Refrigerant service

valve <Low pressure>

Refrigerant service valve

<Low pressure>

Refrigerant service valve

<High pressure>

(5-3/4)

(1-3/16)

(1-3/16)

(29-5/32)

(Mounting pitch)

(26-23/32~26-15/16)

(26-13/16)

(Mounting pitch)

(3-5/32) (3-5/32)

(10-11/32)

(3-5/16)

(3-23/32)

(10-23/32) 272

(11-7/8) 301

(8-15/16) 227

(2-1/4)(2-1/4)

(13/16)

(13/16)

(3-17/32)

(3-1/16)

1

(9-29/32) 251

(9-5/16) 236

(10-23/32) 272

(11-15/16)

(25/32)(25/32)

(2-25/32)

=(5-29/32)X4

(23-5/8)

<Snow hood attachment hole>

4X5-ø4.6 (3/16) Hole

(Make hole at the plastic fan guard

for snow hood attachment)

Intake

air

Discharge air

Control box

Intake

air

Service

panel

Intake

air

<Sling hole>

3

6

2

4

5

8

2X2-14(9/16)X20(13/16) Oval hole

2X2-80(3-5/32)X35(1-13/32) Oval hole

7

*1 Use the pipe joint(field supply) and connect to the refrigerant service

valve piping.

High

pressure

ø25.4

Low

pressure

Service valveRefrigerant pipe

Diameter

*1

High

pressure

Low

pressure

Model

PURY-HP72YKMU-A(-BS)

ø25.4

ø19.05 Brazed

ø15.88 Brazed

*1

ø45 Knockout hole

Specifications

ø43.7 or ø22.2 Knockout hole

ø62.7 or ø34.5 Knockout hole

Front through hole

Bottom through hole

Bottom through hole

Front through hole

Front through hole

For wires

Usage

Front through hole

Front through hole

(Uses when twinning

kit (optional

parts) is mounted.)

140 × 77 Knockout hole

150 × 94 Knockout hole

Bottom through hole

For pipes

ø52 Knockout hole

For transmission cables

ø34 Knockout hole

ø65 Knockout hole

PURY-HP96YKMU-A(-BS)

ø19.05 Brazed

*1

ø25.4

*1

ø25.4

ø22.2 Brazed

Transformer box

58 (2-5/16)

75 (2-31/32)

(8-9/16) 217

(5-23/32) 145

146 (5-3/4)

146

83 (3-9/32)

262

(740)

150 (5-29/32)

57

54 (2-5/32)

19.5

80 1060 (41-3/4)

586 (23-3/32)

19.5

57

94 84

121 (4-25/32)

600=150×4

20

1220 (48-1/16)

150 (5-29/32)

1650 (64-31/32)

196 (7-23/32)

1347 (53-1/16)

89

303

20

740 (29-5/32)

70

1181 (46-1/2)

140 (5-17/32)

80

77

681(678~684)29.5 29.5

Bottom view

Left side view

Front view

Top view

NO.

1

2

3

465

8

7

Page 15

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

H2i-R2-15

© 2014 Mitsubishi Electric US, Inc.

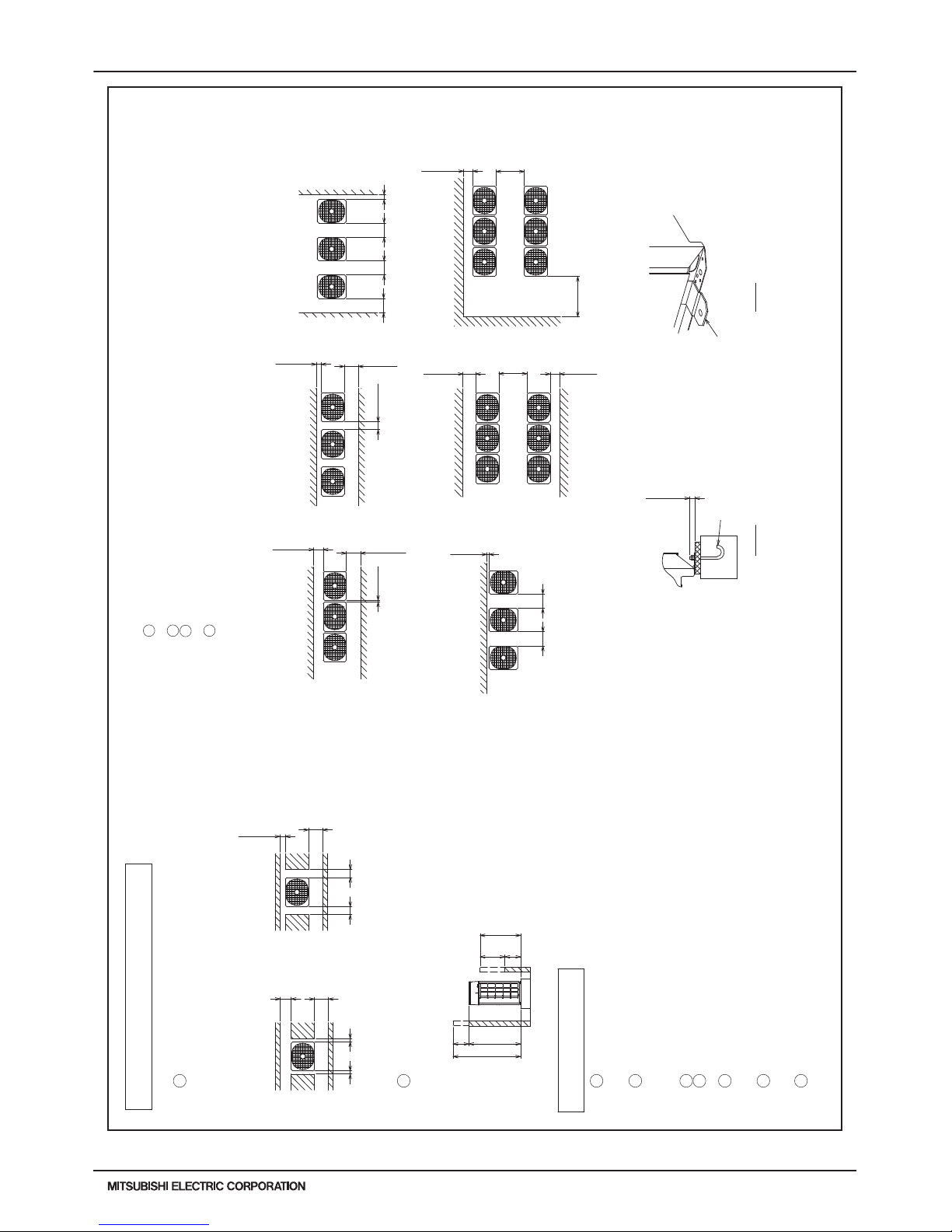

2. EXTERNAL DIMENSIONS

DATA U10

PURY-HP72, 96YKMU-A(-BS)

Unit : mm(in)

Front

Front

Front

Front

Front

Front

Wall <H>

Front

<Unit:mm(in)>

<To be left open>

Front

<To be left open>

<To be left open>

Wall <H>

Front

Front

<Unit:mm(in)>

1 When multiple units are installed adjacent to each other, secure enough space to allow

for air circulation and walkway between groups of units as shown in the figures below.

2 At least two sides must be left open.

3 As with the single installation, add the height that exceeds the height limit<h>

to the figures that are marked with an asterisk.

4 If there is a wall at both the front and the rear of the unit, install up to six units

consecutively in the side direction and provide a space of 1000mm or more as inlet space/

passage space for each six units.

●In case of collective installation

1 Take into consideration the surface strength,water drainage route,

piping route,and wiring route when preparing the installation site.

<Note that the drain water comes out of the unit during operation.>

2 Build the foundation in such way that the corner of the installation leg is

securely supported as shown in the right figure.(Fig.A)

When using a rubber isolating cushion, please ensure it is large enough

to cover the entire width of each of the unit's legs.

3 The protrusion length of the anchor bolt must not exceed 30mm(1-3/16).(Fig.A)

4 Use four fixing plates as shown in the right figure <field supply required>

when using post-installed anchor bolts.(Fig.B)

5 To prevent small animals and water and snow from entering the unit and damaging its parts,

close the gap around the edges of through holes for pipes and wires with

filler plates <field supply required>.

6 When the pipes or cables are routed at the bottom of the unit,

make sure that the through hole at the base of the unit does not get blocked

with the installation base.

7 Refer to the Installation Manual when installing units on an installation base.

Wall <H>

Wall <H>

Wall <H>

Wall <H>

Wall <H>

Wall <H>

Wall <H>

Wall <H>

●In case of single installation

1. Required space around the unit

2 When the height of the walls on the front,back or on the sides<H>

exceeds the wall height limit as defined below

add the height that exceeds the height limit <h> to the figures that

are marked with an asterisk.

1 Secure enough space around the unit as shown in the figure below.

2. Foundation work

(19-11/16)

(1-3/16)

(35-7/16)

(11-13/16)

(35-7/16)

(11-13/16)

(11-13/16)

(19/32)

(17-23/32)

(17-23/32)

(39-3/8)

(17-23/32)

(17-23/32)

(17-23/32)

(3-15/16)

(3-15/16)

(1-3/16)

(11-13/16)

(3-15/16)

(17-23/32)

(17-23/32)

(1-31/32)

(1-31/32)

(3-15/16)

(17-23/32)

(19/32)

(19/32)

(11-13/16)

(17-23/32)

<To be left open>

<To be left open>

<To be left open>

<To be left open>

<To be left open>

<To be left open>

<To be left open>

Front

M10 anchor bolt

<field supply required>

Fixing plate

<field supply required>

Front

<Top view>

<Top view>

Front

<Side view>

• With a space of at least

100mm(3-15/16) to the wall on

the back of the unit

• With a space of at least

300mm(11-13/16) to the wall on

the back of the unit

Fig.A Fig.B

Unit height

500

900 min.

300 min.*

1000 min.*

300 min.* 300 min.*

900 min.

15 min.*

450 min. 450 min.

100 min.*

450 min.

450 min.

450 min.*

100 min.

450 min.*

100 min.*

30 min.

300 min.*

450 min.*

100 min.*

450 min.*

450 min.*

300 min.*

15 min.*

15 min.*

50 min.*

50 min.*

H

h

h

H

30mm max.

<Wall height limit> Front : Up to the unit height

Back : Up to 500mm(19-11/16) from

the unit bottom

Side : Up to the unit height

Page 16

H2i-R2-16

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

© 2014 Mitsubishi Electric US, Inc.

2. EXTERNAL DIMENSIONS

DATA U10

H2i R2

PURY-HP144, 192YSKMU-A(-BS)

Unit : mm(in)

Low pressure

Unit model

Component

unit model

ø15.88(5/8) ø19.05(3/4)

ccee

ddff

High pressure

HP72 HP96

Twinning Kit

~Outdoor unit

HP72 HP96

(Note 5) (Note 5)

--

ø19.05(3/4)

ø19.05(3/4)

HP144 HP192

Low pressure

Twinning pipe connection size

Outdoor unit 1

Component unit name

Package unit name

BC controller~Twinning pipe

a

b

High pressure

Outdoor Twinning Kit(optional parts)

CMY-R100CBK2

Outdoor unit 2

PURY-HP144YSKMU-A(-BS) PURY-HP192YSKMU-A(-BS)

PURY-HP72YKMU-A(-BS) PURY-HP96YKMU-A(-BS)

PURY-HP72YKMU-A(-BS) PURY-HP96YKMU-A(-BS)

ø28.58(1-1/8)

ø22.2(7/8)

ø15.88(5/8)

ø22.2(7/8)

Note 1. Connect the pipes as shown in the figure above. Refer to the table above for the pipe size.

2. Twinning pipe (High pressure) should not be tilted more than 15 degrees from the horizontal plane.

Be sure to see the Installation Manual for details of Twinning pipe installation.

3. The pipe section before the Twinning pipe (section "a" in the figure) must have at least 500mm(19-11/16) of straight section

(*including the straight pipe that is supplied with the Twinning pipe).

4. Only use the Twinning pipe by Mitsubishi (optional parts).

5. Connect the outdoor unit 1 with the Twinning pipe (Low pressure) (section "d" in the figure).

30 (1-3/16)

1220 (48-1/16) 1220 (48-1/16)

1650 (64-31/32)

740 (29-5/32)

Front view

Left view

Outdoor unit 2Outdoor unit 1

To BC controller

To BC controller

a

b

e

f

c

d

Twinning pipe(High pressure)

<optional parts>

Twinning pipe(Low pressure)

<optional parts>

Intake

air

Intake

air

Discharge air

Intake

air

Page 17

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

H2i-R2-17

© 2014 Mitsubishi Electric US, Inc.

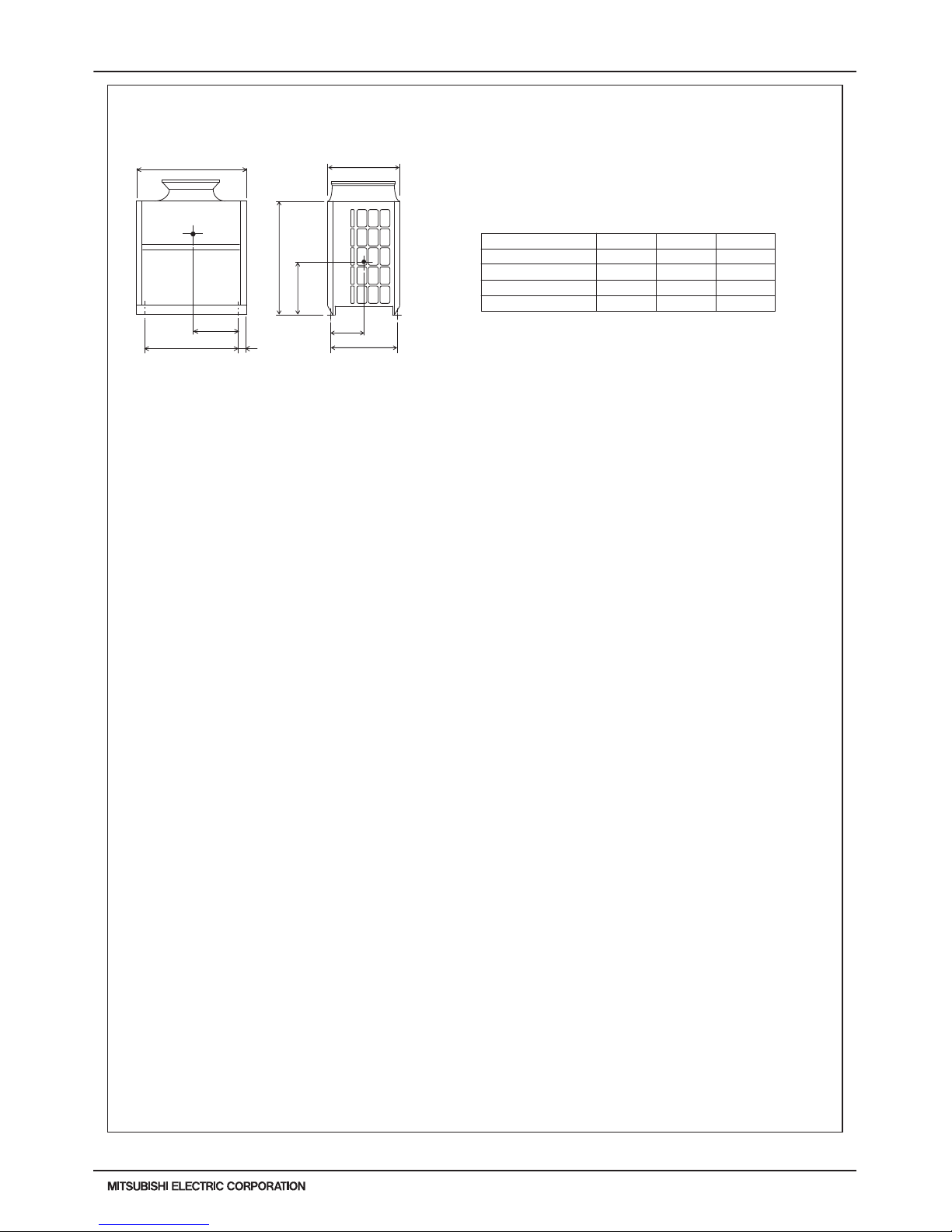

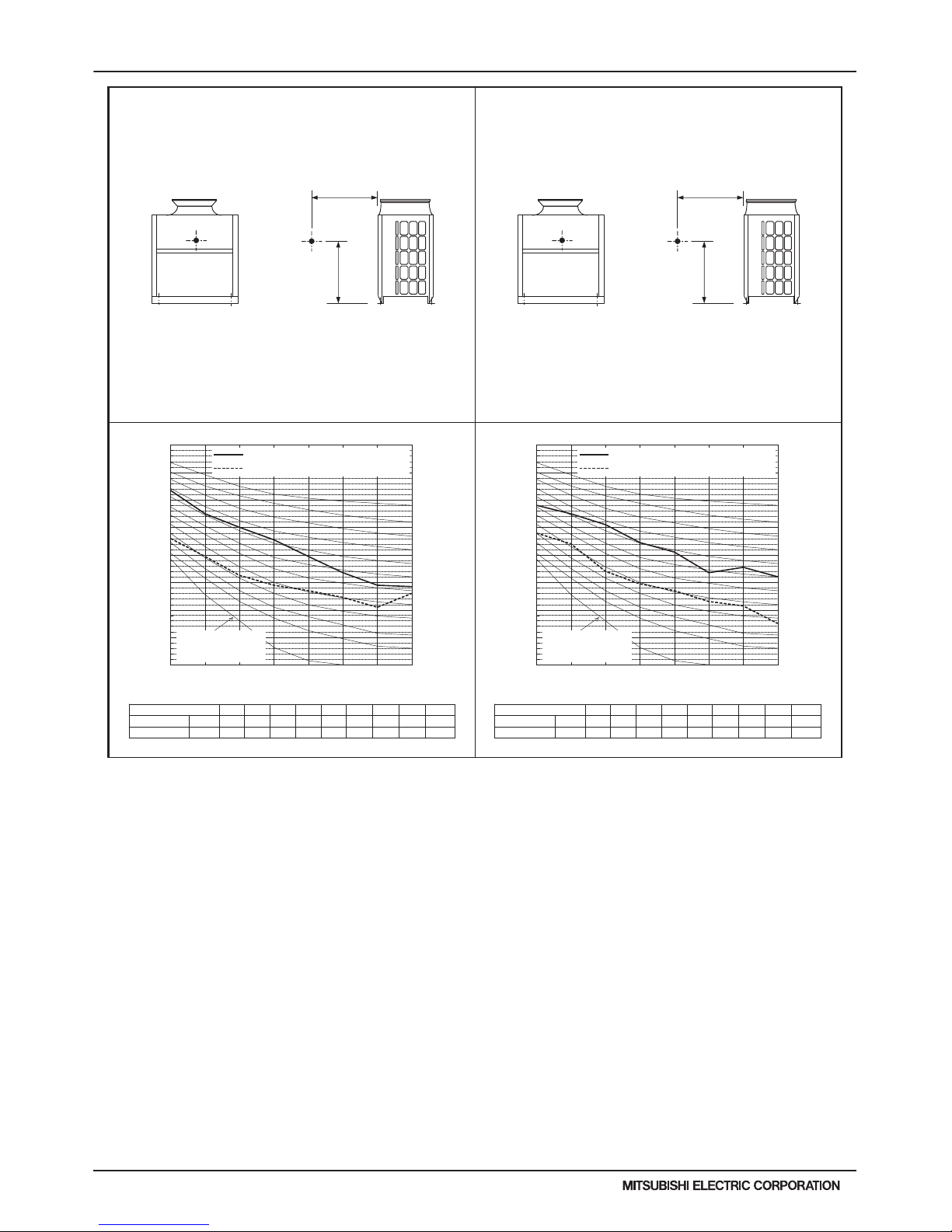

3. CENTER OF GRAVITY

DATA U10

1060

80

1220

X

Y

681

740

1347

Z

PURY-HP72, 96TKMU-A-H (-BS)

PURY-HP72, 96YKMU-A (-BS)

Model X Y Z

Unit : mm[in.]

PURY-HP72YKMU-A

PURY-HP96YKMU-A

460[18-1/8]

447[17-5/8]

447[17-5/8]

435[17-5/32]

320[12-5/8]

311[12-1/4]

310[12-7/32]

302[11-29/32]

609[23]

595[23-7/16]

623[24-17/32]

610[24-1/32]

PURY-HP72TKMU-A-H

PURY-HP96TKMU-A-H

Page 18

H2i-R2-18

PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

© 2014 Mitsubishi Electric US, Inc.

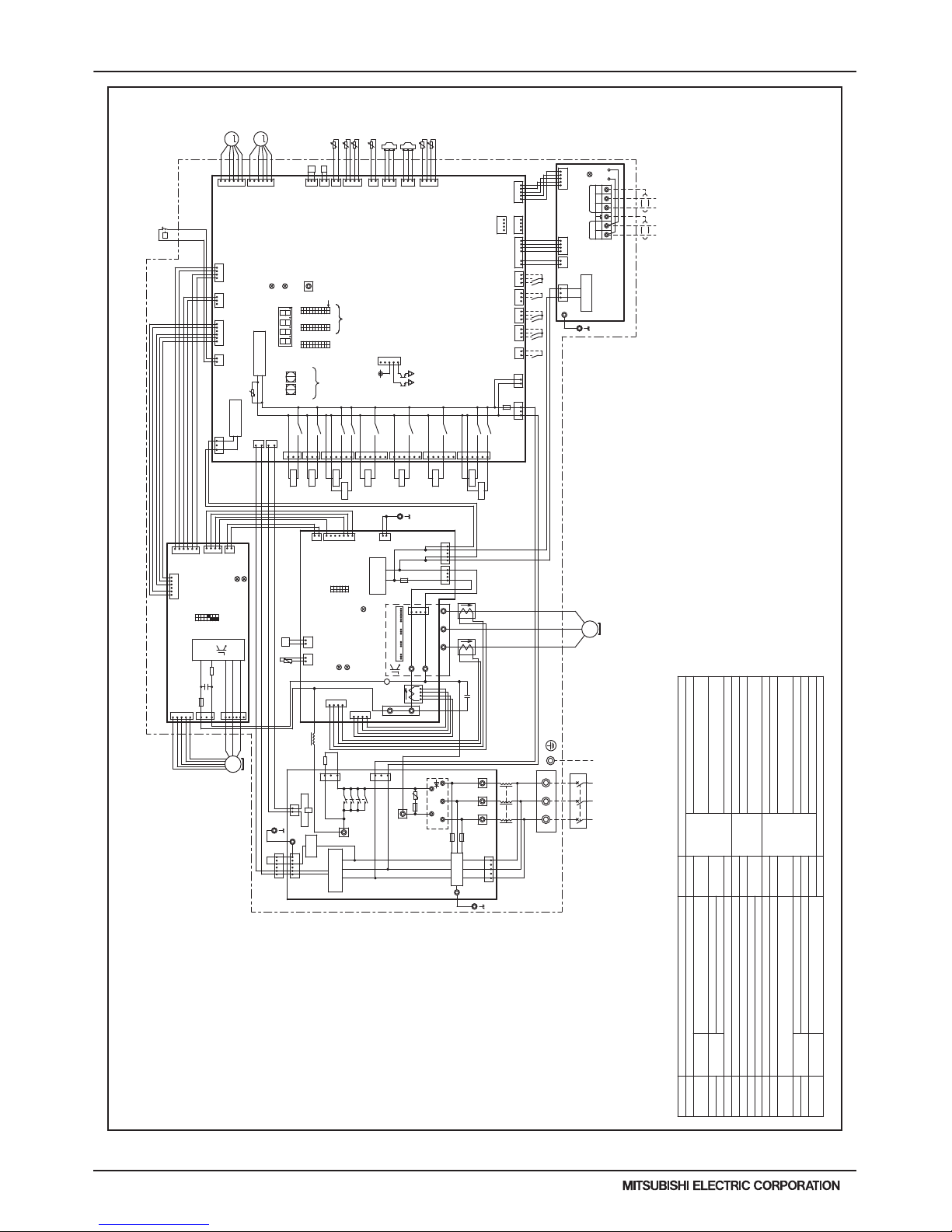

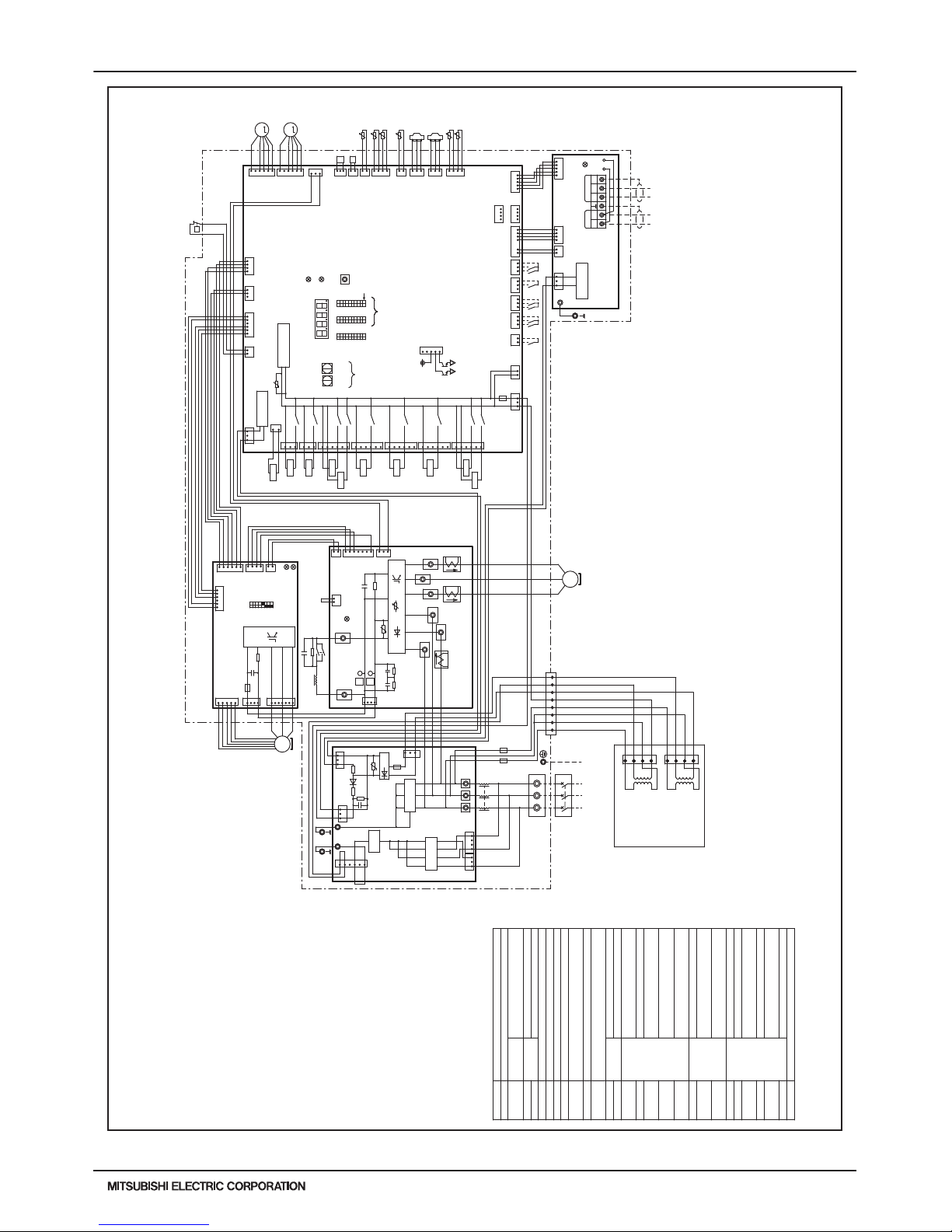

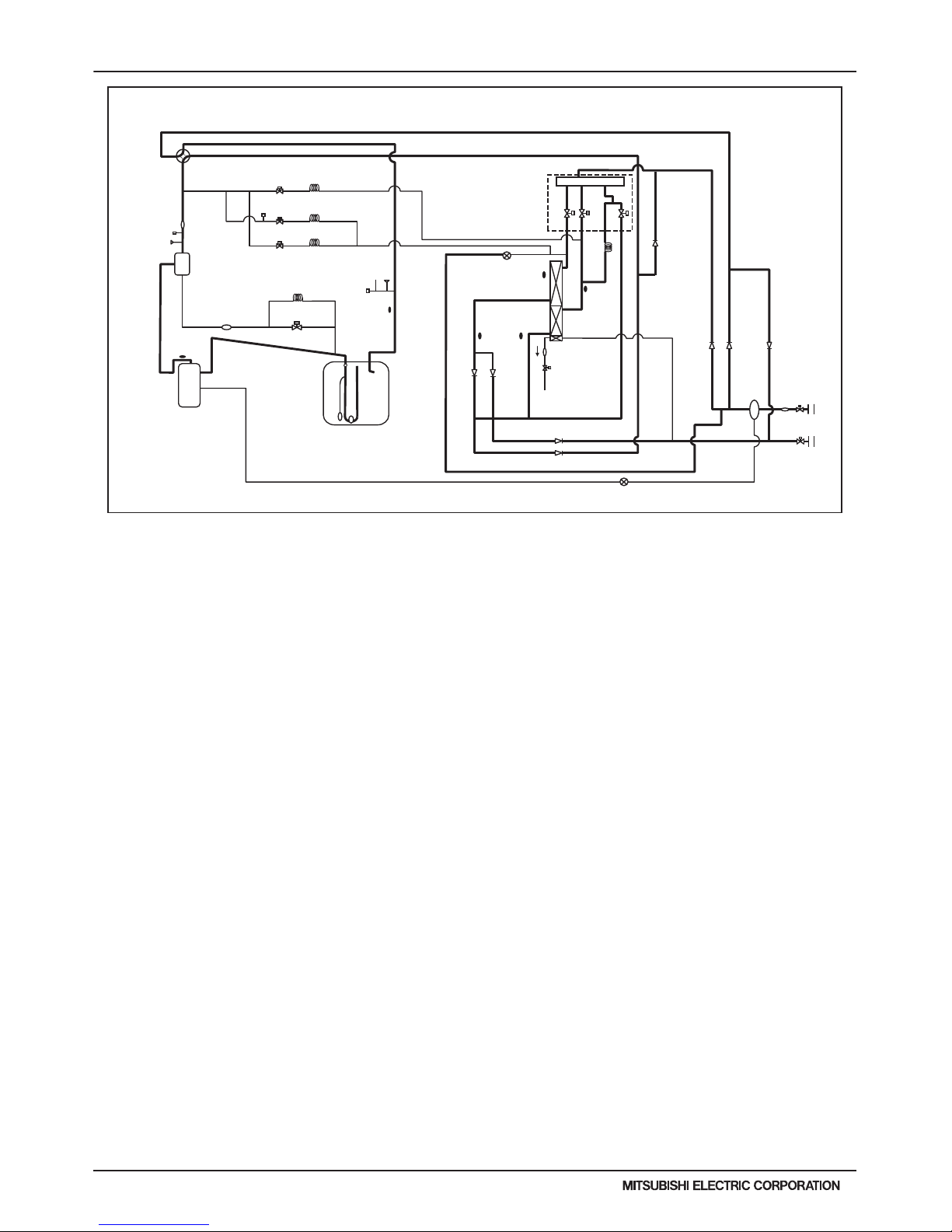

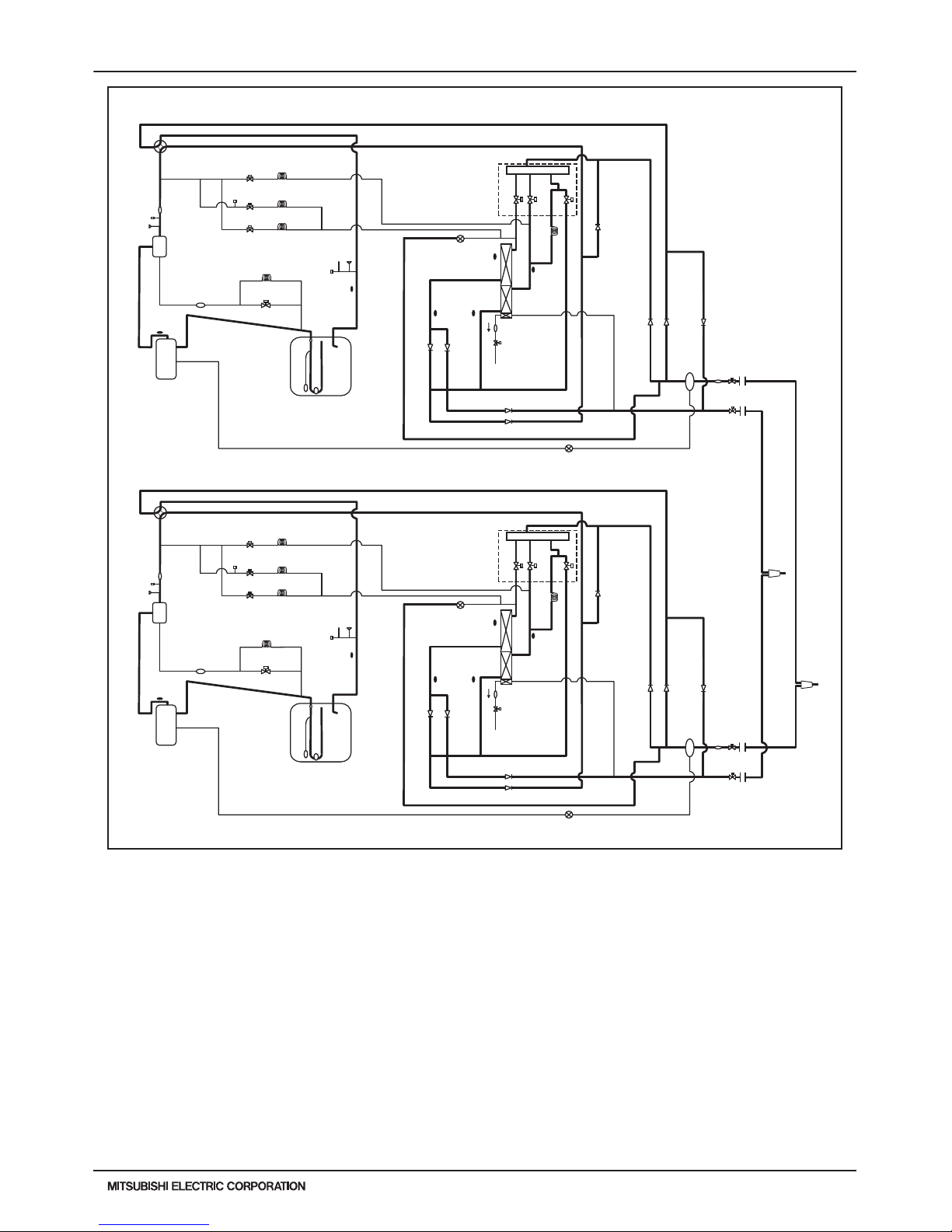

4. ELECTRICAL WIRING DIAGRAMS

DATA U10

H2i R2

PURY-HP72, 96TKMU-A-H(-BS)

For opening/closing the bypass

circuit

Terminal

block

Central control transmission

cable

Power supply

Function setting connector

IPM temperature

Heat exchanger outlet pipe temperature

ACC inlet pipe temperature

Discharge pipe temperature

Thermistor

SV9

TB1

TB3

TB7

TH4

TH5

TH6

THHS

Z24,25,26

DC reactor

Current sensor(AC)

Low pressure

Discharge pressure

High pressure protection for the

outdoor unit

Pressure

switch

Pressure

sensor

Explanation

Explanation

4-way valve (Cooling/Heating switching)

For opening/closing the bypass circuit

under the O/S

Solenoid

valve

Solenoid

valve

DCL

LEV5a

ACCT1,2

63LS

63HS1

63H1

<Symbol explanation>

Symbol

Symbol

21S4a

C1

DCCT1

SV1a

SV5b

Outdoor unit heat exchanger

capacity control

SV4a,b,d

Subcooled liquid refrigerant

temperature

*1. Single-dotted lines indicate wiring not

supplied with the unit.

*2. Dot-dash lines indicate the control box

boundaries.

*3. Refer to the Data book for connecting

input/output signal connectors.

*4. Daisy-chain terminals (TB3) on the outdoor

units in the same refrigerant system together.

*5. Faston terminals have a locking function.

Make sure the terminals are securely locked

in place after insertion. Press the tab on

the terminals to removed them.

*6. Control box houses high-voltage parts.

Before inspecting the inside of the control box,

turn off the power,keep the unit off for at

least 10 minutes, and confirm that the voltage

at both ends of the main capacitor (C1) has

dropped to DC20V or less.

X001

For inrush current preventionR1

Choke coil (for high frequency noise reduction)L

Indoor/Outdoor transmission cable

Magnetic relay (inverter main circuit)72C

Heat exchanger capacity control

Linear expansion valve (for the control of

evaporating temperature)

Resistor

For current detection

RSH01

Capacitor (inverter main circuit)

Current sensor(DC)

For opening/closing the injection circuitLEV4

For opening/closing the defrost circuit

SV10,11

OA temperature

TH7

TH9,11

Ground

L3L2

L1

X14

X13

613

5

12

red

CNPS

132

1

TP1 TP2

TB3

2

3

TB7

M1 M2 M1 M2 S

512 34

1

2

t

°

1

2

132

346

122

CN82

blue

134

CN83

black

31

6

X12

1

3

CN508

blue

CN4

black

231

t

SW001

1

3

°

CN2

7

12

1

3

31

432

2

3

1

1

TH4

t

4

°

1

1

CN211

green

23

123

321

6

CNSNR

54321

U

V

W

Fan motor

(Heat exchanger)

MS

3~

416

CNINV

2

SW1

1

6

OFF ON

3

2

23

Power failure

detection circuit

red

1

Surge

absorber

2

3

1

TB1

L3L2L1

21

INV Board

°

t

2

L

yellow

CNPOW

t

°

654

5

CNVDC

4

CNDC2

1

ACCT2

F02

AC250V

3.15A T

C1

IPM

4

X10

ON

X08

Unit address

setting

LED3:Charge

6

316

F001

AC250V

6.3A T

F002

AC250V

6.3A T

RSH01

CN001

531

TB22 TB23TB21

Diode stack

~~~

12

34

3

green

CN62

CN990

green

CNTYP4

CN201

Z25

1

TH5

2

SWU2

LED1

SW6

10

Control Board

CN40

63HS1

CN41

TH7

15

543

1

SW4

LED3

2

LEV5a

3

SET UP(SW6-10)

V

M

OFF

CN506

red

yellow

CN3K

*3

Compressor ON/OFF output

Error detection output

DC12V

CN51

SV5b

W

blue

CN3N

1

334

TB7 Power

selecting

connector

CNVDC

IPM

5

1

26

ON

OFF

M-NET power

supply circuit

12

M-NET Board

Power failure

detection circuit

Indoor/Outdoor

transmission

cable

ON

1's

digit

CN102

1

4

1

U

10's

digit

OFF

LED2:Normal operation(Lit)

/ Error(Blink)

yellow

CNDC

red

MS

3~

2

TH6

U

LED1:Power supply to

Indoor/Outdoor

transmission line

ZNR400

Central control

transmission

cable

ONOFF

Motor

(Compressor)

red

CN3S

1

CN04

red

CN43

yellow

CN61

green

CN202

red

8

/ Error(Blink)

*4

2

P

63H1

4

1

SW5

10

5

CN3D

1

CPU power

supply circuit

black

CNAC2

1

*3

ONOFF

10

SWU1

N

CN212

red

WU

P

6

CNDC1

1

4

V

1

CN80

25

F301

AC250V

15A T

CNIPM

CNTYP5

green

LED4:CPU in operation

FT-N

LED1:Normal operation(Lit)

/ Error(Blink)

CN801

red

SWP1

CN012

1

3

FAN Board

63LS

U

-

+

ZNR005

Z24

2

CN507

black

3

F003

AC250V

6.3A T

TB42

6

4

X001

CN213

green

black

*5

SV9

Function

setting

LED1

Display

setting/

Function

setting

red

LED4:CPU in operation

5

1

SC-P1

DCL

black

CN72C

red

3

1

DCCT1

1

2

1

4

1

CNLVA

1

CNR1

red

black

F01

AC250V

3.15A T

TB31

R1

white

red

CNIT

red

X001

12

Power Source

3~

60Hz

208/230V

CNCT

red

white

ACCT1

56

CN110

Noise filter

31

6412

IPM power

supply circuit

CNFG2

Noise

Filter

black

432

1

CNCT2

blue

432

1

X05

X06

351

6

CN505

13

12

CNFG

blue

1

2

black

redwhite

*5

black

red

THHS

°

t

Z26

CNTYP

2

CNTH

green

21

CN110

black

2

1

red

1

2

1

CNAC

CN81

green

12

5

134

4

SV4a

4

CN2

C310,C311

SV4d

SV1a

SV4b