Mitsubishi Electric QJ71C24-R2, QJ71C24N-R2, QJ71C24N-R4, QJ71C24, GX Configurator-SC User Manual

Q Corresponding Serial Communication Module

User's Manual (Basic)

-QJ71C24N

-QJ71C24N-R2

-QJ71C24N-R4

-QJ71C24

-QJ71C24-R2

-GX Configurator-SC (SW2D5C-QSCU-E)

SAFETY PRECAUTIONS

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the user's manual of the CPU module to use.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

[Design Precautions]

!

WARNING

For the operation status of each station at communication error in each station, refer to the

respective manual for each station.

The communication error may result in an accident due to incorrect output or malfunction.

When using the notification function, the pager receiver may not be contacted due to the frequency

transmission status from the system setup environment and error on the receiver side.

To ensure the safety of the programmable controller system, install a call circuit with a lamp

display or buzzer sound.

When connecting a peripheral with the CPU module or connecting an external device, such as a

personal computer, with an intelligent function module to modify data of a running

programmable controller, configure an interlock circuit in the program to ensure that the entire

system will always operate safely.

For other forms of control (such as program modification or operating status change) of a

running programmable controller, read the relevant manuals carefully and ensure that the

operation is safe before proceeding.

Especially, when a remote programmable controller is controlled by an external device,

immediate action cannot be taken if a problem occurs in the programmable controller due to a

communication failure.

To prevent this, configure an interlock circuit in the program, and determine corrective actions to

be taken between the external device and CPU module in case of a communication failure.

A - 1 A - 1

[Design Precautions]

!

WARNING

Do not write any data to the "system area" of the buffer memory in the intelligent function

module.

Also, do not use any "use prohibited" signals as an output signal from the programmable

controller CPU to the intelligent function module.

Doing so may cause malfunction of the programmable controller system.

!

CAUTION

Do not install the control lines or communication cables together with the main circuit lines or

power cables.

Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise.

When using the module while values, such as buffer memory set values, are registered in the

Flash ROM, do not turn off the power supply for the module loading station nor reset the

programmable controller CPU.

If the power supply for the module loading station is turned off or the programmable controller

CPU is reset while any values are registered, the data contents in the Flash ROM become

inconsistent and as a result the values must be set again in the buffer memory, etc. and

reregistered to the Flash ROM.

Also, this may cause failure and malfunction of the module.

[Installation Precautions]

!

CAUTION

Use the programmable controller in an environment that meets the general specifications in the

user's manual for the CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of

the product.

To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect mounting may cause malfunction, failure or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the

module with a screw.

Tighten the screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

Shut off the external power supply (all phases) used in the system before mounting or removing

a module.

Failure to do so may result in damage to the product.

Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

A - 2 A - 2

[Wiring Precautions]

!

CAUTION

When turning on the power and operating the module after installation and wiring are completed,

always attach the terminal cover that comes with the product.

There is a risk of electric shock if the terminal cover is not attached.

Perform correct pressure-displacement, crimp-contact or soldering for external wire connections

using the tools specified by the manufactures.

Incorrect connection may cause short circuits, fire, or malfunction.

Attach connectors to the module securely.

Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunction due to poor contact.

Before connecting the cables, check the type o f interface to be connected.

Connecting or erroneous wiring to the wrong interface may cause failure to the module and

external devices.

Tighten the terminal screws within the specified torque range.

Undertightening the terminal screws can cause short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

When disconnecting the cable from the module, do not pull the cable by the cable part. For the

cable with connector, hold the connector part of the cable.

For the cable connected to the terminal block, loosen the terminal screw.

Pulling the cable that is still connected to the module may cause malfunction or damage to the

module or cable.

Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

A protective film is attached to the top of the module to prevent foreign matter, such as wire

chips, from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

A - 3 A - 3

[Startup/Maintenance Precautions]

!

CAUTION

Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

Shut off the external power supply (all phases) used in the system before mounting or removing

the module.

Failure to do so may cause the module to fail or malfunction.

After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module more than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit may cause malfunction.

Do not touch any terminal while power is on.

Doing so may cause malfunction.

Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws or module fixing screws.

Failure to do so may cause the module to fail or malfunction.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

Before handling the module, touch a conducting object such as a grounded metal to discharge

the static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

[Operation Precautions]

!

CAUTION

When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent

function module, read relevant manuals carefully and ensure the safety before operation.

Failure to perform correct operations to change data, program, or the status may result in

system malfunction, machine damage, or an accident.

[Disposal Precautions]

!

CAUTION

When disposing of this product, treat it as industrial waste.

A - 4 A - 4

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO

ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION NOT

INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING CONTAINED IN

MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL BULLETINS AND

GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general specifications

of the PRODUCTs are required. For details, please contact the Mitsubishi representative in your region.

A - 5 A - 5

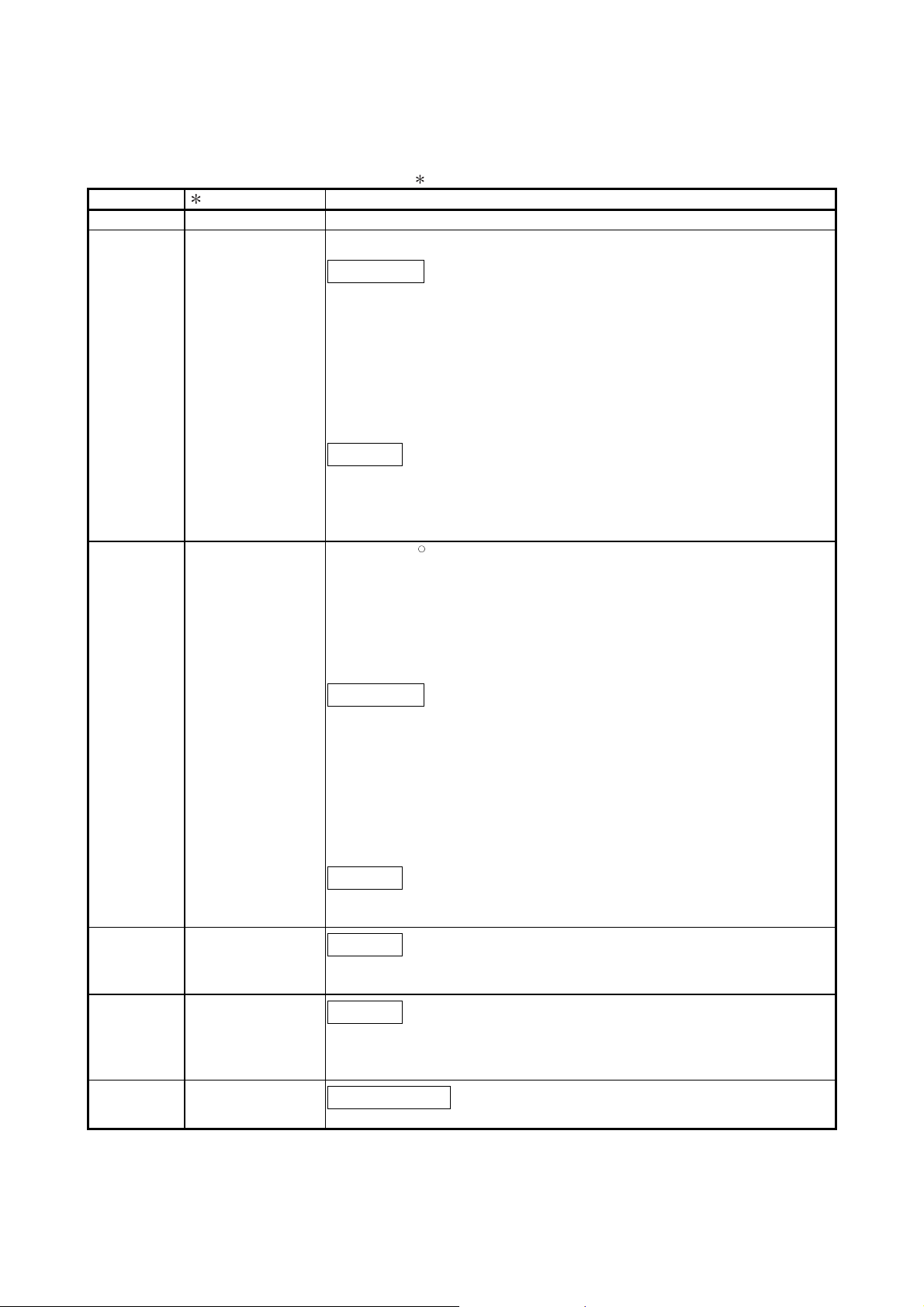

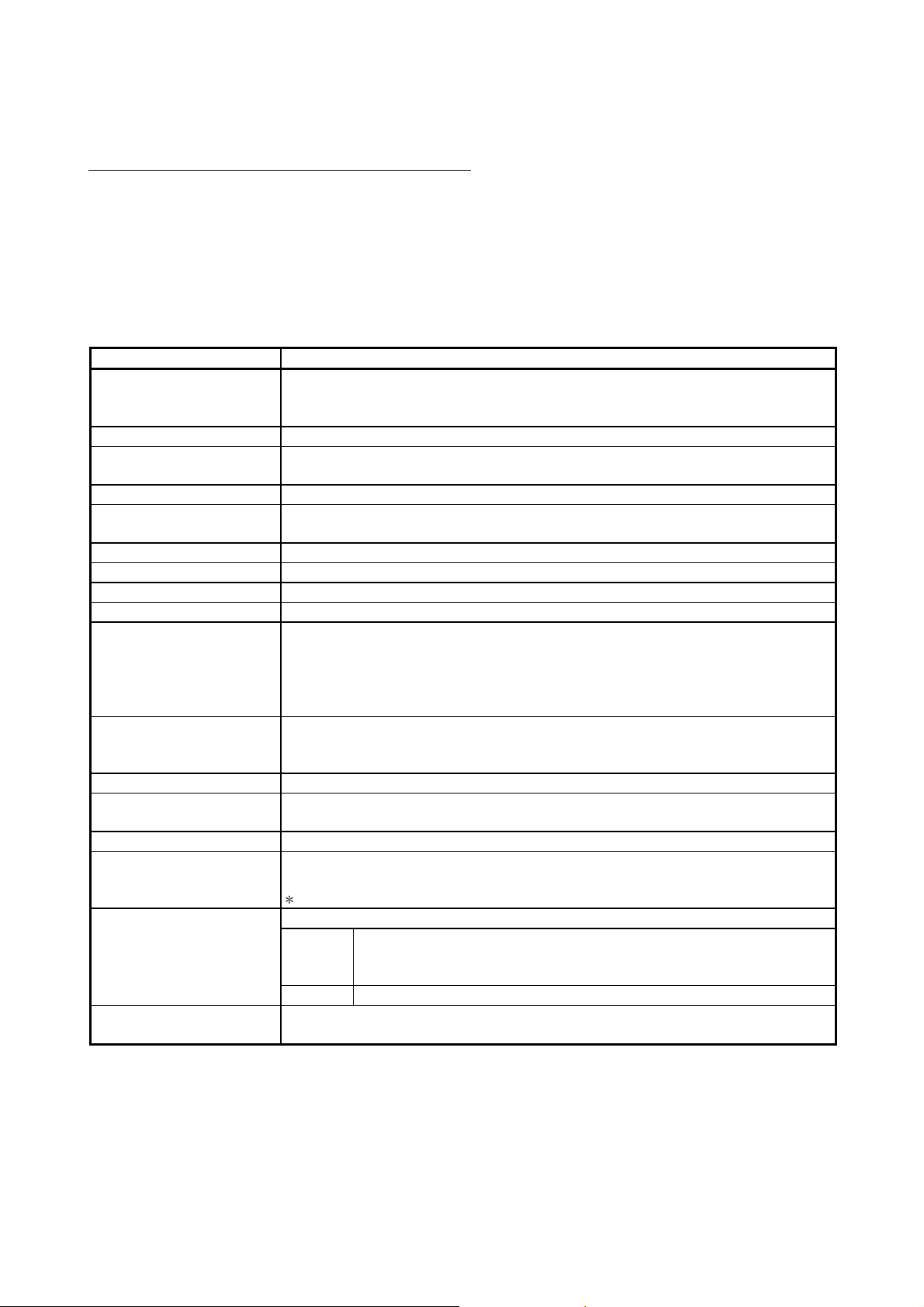

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Dec., 1999 SH (NA)-080006-A First edition

Oct., 2000 SH (NA)-080006-B Add the contents of the function version B.

Correction

Contents, Entire manual (change MELSECNET/10H to MELSECNET/H),

About Manuals, About The Generic Terms and Abbreviations, Product

Configuration, Section 1.2, 1.2(8), 1.3 POINT, Section 2.2, 2.3, 2.5, 2.6,

Section 3.1, 3.6, 3.9, Section 4.2, 4.4.1(2)(a)(Figure), 4.6(1), Chapter

5(all), Section 6.1.1, 6.1.3, 6.1.4, Section 7.1.1, 7.1.2, 7.2.2, Section 8.1,

8.2.1, 8.2.2, 8.3.1, 8.3.2, Section 9.2 to 9.7, Section 10.1.1, 10.2.1,

10.3.8, 10.3.18, Appendix 1.1(2), Appendix 2(all), Appendix 3(2),

Appendix 7, Appendix 8

Addition

Entire manual (add the explanation on MELSECNET/H remote I/O

station), The Manual's Use and Structure, Section 2.1, Section

3.1(Table), Section 4.4.2(1)(d), 4.9.2, Section 8.3.2 POINT, Section

10.2.1 (7164

Jun., 2001 SH (NA)-080006-C Put Windows base software product together from Mitsubishi

H, 7E70H), Appendix 3(1)

R

Programmable Controller MELSEC Series to Mitsubishi integrated FA

Software MELSOFT Series.

Standardize the name from software package (GPP function) to Product

name (GX Developer).

Standardize the name from utility package (QSCU) to Product name (GX

Configurator-SC).

Correction

Conformation to the EMC Directive and Low Voltage Instruction, About

the Generic Terms and Abbreviations, Product Configuration, Program

Examples (Section 6.1.4, 6.2.3, Section 7.2.3, Section 9.3, 9.5, Appendix-

8), Section 1.2(1)(d), 1.2(4)(b)(Diagram), 1.2(8)(b), 1.3, Section 2.1, 2.3,

2.4, 2.5, 2.7, Section 3.1(Table), 3.2.1(3), 3.3.3(2), 3.4(Table), 3.9,

Section 4.3, 4.5.2, Section 5.1.5(3), 5.2, Section 6.1.4, Section 8.2, 8.3.2

POINT, 8.4.2, 8.4.9(Table), 8.6.3(Table), 8.6.7(Table), Section 10.1.2(b),

10.3(Table), Appendix 1.1, 2.1, 6, 7, 9

Addition

Section 2.6, Section 8.4.4, 8.6.2(Table), Section 10.2.1(716FH, 7FEFH),

H), 10.3.14, Appendix 3

Feb., 2002 SH (NA)-080006-D

10.2.3(7FE9

Addition

About The Generic Terms and Abbreviations, Section 1.2, Section 2.1,

2.7, Section 4.5.2, Section 8.2.1, 8.2.2, Section 10.2.1, Appendix 1.1, 6

Oct., 2002 SH (NA)-080006-E

Addition

The Manual's Use and Structure, About The Generic Terms and

Abbreviations, Section 1.2(1)(4), Section 2.1, 2.4, Section 5.2, Section

6.1.4, Section 9.8, Appendix 7

Jan., 2003 SH (NA)-080006-F

Addition model

QJ71C24N, QJ71C24N-R2, QJ71C24N-R4

A - 6 A - 6

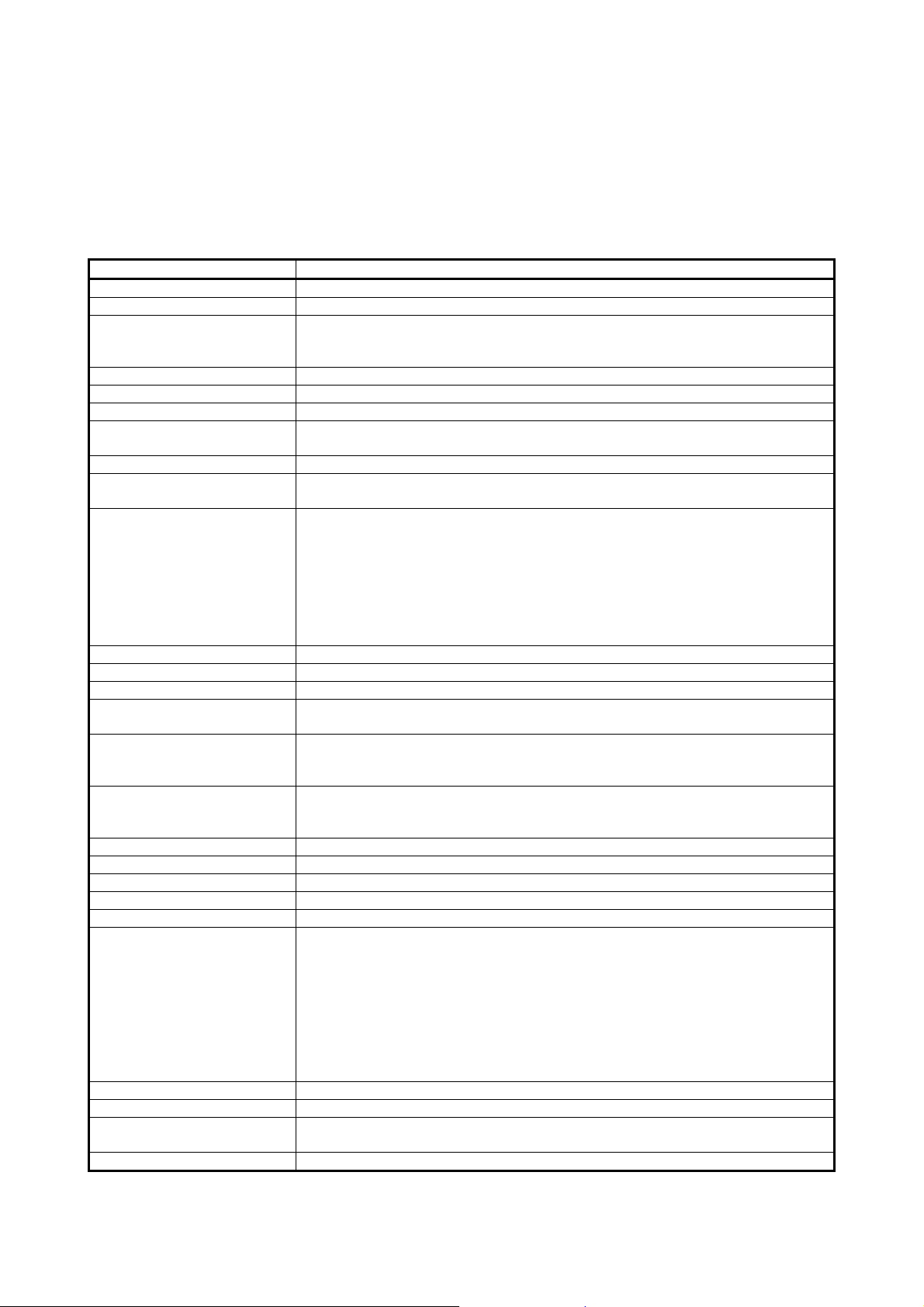

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Jan., 2003 SH (NA)-080006-F

Addition

SAFETY PRECAUTIONS, About Manuals, About The Generic Terms

and Abbreviations, Product Configuration, Section 1.3, Section 2.1, 2.2,

2.3, 2.5, 2.6, 2.7, Section 3.1, 3.2.1, 3.3.1, 3.6, 3.8, 3.9, Section 4.1, 4.3,

4.4, 4.5, 4.6, 4.7.1, Section 6.1.1, 6.1.2, Section 7.1, 7.2.2, Chapter 8(all),

Section 9.1, 9.6, Section 10.1.2(b), 10.1.3(1), 10.2, Appendix 1, Appendix

2.1, Appendix 3, Appendix 5, Appendix 9

Jun., 2004 SH (NA)-080006-G

Correction

About The Generic Terms and Abbreviations, Product Configuration,

Chapter 2 (all), Section 3.8, Section 4.2.2 (1), Section 5.1.3 POINT,

Section 5.1.4, Chapter 8 (screen change), Section 8.6.10, Section 10.1.1,

Section 10.2

Addition

Appendix 9

Sep., 2004 SH (NA)-080006-H

Correction

Section 1.3, Section 2.5, 2.6, Section 3.5, 3.6, 3.9, Section 4.1, Chapter 8

(screen change), Section 8.6.9, 8.6.10, Section 10.1, 10.2, Appendix 1.1

Addition

Appendix 9.12

Feb., 2005 SH (NA)-080006-I

Correction

Section 2.1 (1), Section 3.1, Section 4.5.2 (1) ©, Chapter 9 (Simultaneous

execution of dedicated instructions), Section 10.2.1

Aug., 2005 SH (NA)-080006-J

Correction

SAFETY PRECAUTIONS, Section 3.3.1, 3.3.3, Section 8.2.2,

Section 9.4, Appendix 5, Appendix 7.1, 7.2

Feb., 2006 SH (NA)-080006-K

Mar., 2006 SH (NA)-080006-L

Correction

Section 2.6, Section 3.9, Section 8.2.1, 8.3.3, Section 9.1, Appendix 5

Correction

SAFETY PRECAUTIONS, Section 1.3, Section 2.6, Section 3.2.1, 3.8,

3.9, Section 8.6.9, Section 10.2.1, 10.3.11, Appendix 1

Addition

Section 10.1.7

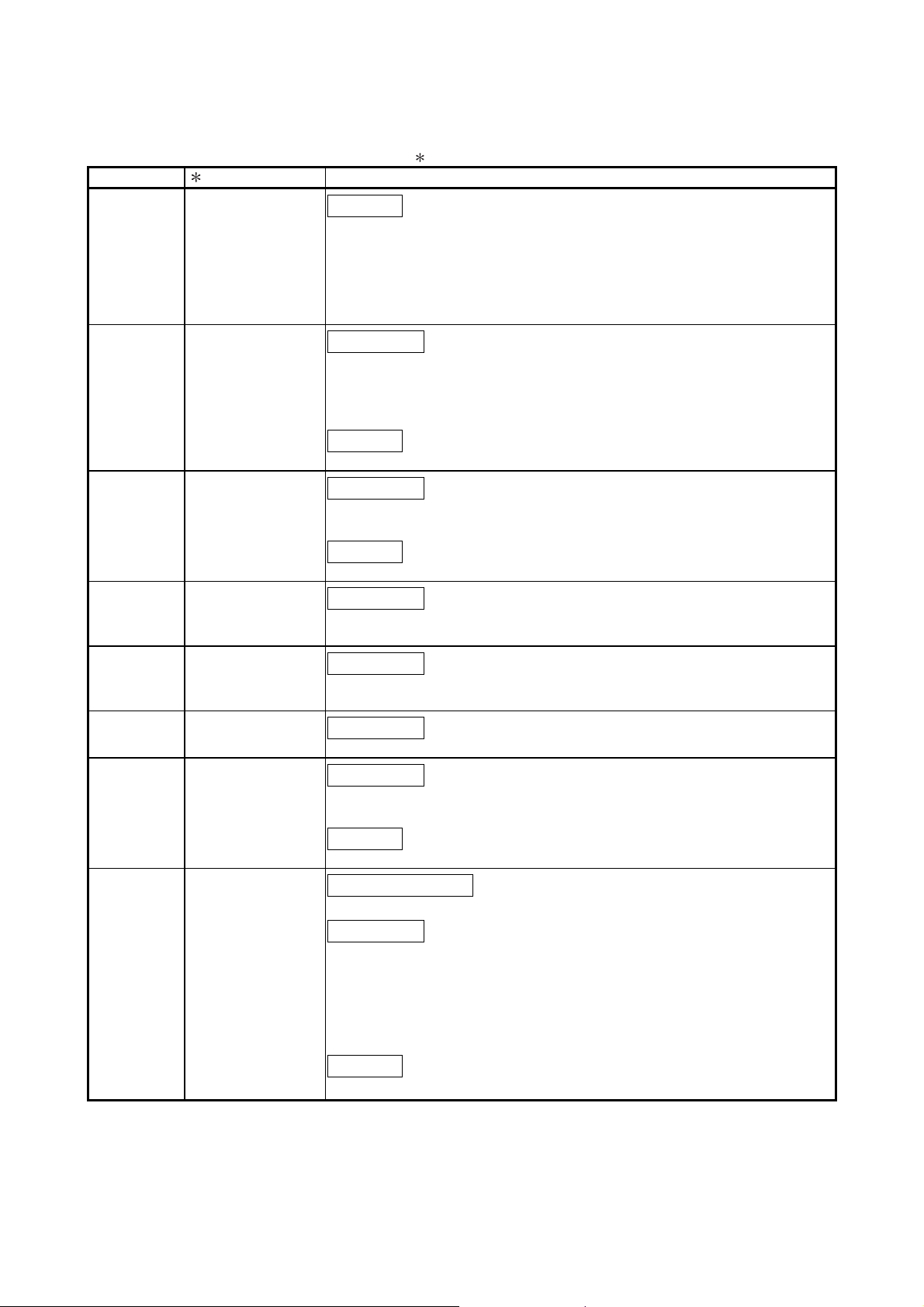

Jan., 2008 SH (NA)-080006-M

Change of a term

"PLC" was changed to "programmable controller".

Correction

About The Generic Terms and Abbreviations, Section 1.2, 1.3, Section

2.1, 2.5, 2.7, Section 3.2.1, 3.2.2, 3.3.1, 3.9, Section 4.1, 4.3, 4.4, 4.5.2,

4.6, 4.9.2, Section 5.1.4, 5.2, Section 6.1.6, Chapter 8, Section 9.2 to 9.8,

Section 10.1.1, 10.1.6, 10.2.1,10.2.3, 10.3.3, 10.3.4, 10.3.8, 10.3.11,

10.3.19, Appendix 1.1, Appendix 2.1, Appendix 3, Appendix 5, Appendix

7.1

Addition

Section 2.5, Appendix 1.3

A - 7 A - 7

A

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

May, 2008 SH (NA)-080006-N

Correction

SAFETY PRECAUTIONS, About Manuals, Compliance with the EMC

and Low Voltage Directives, About The Generic Terms and

bbreviations, Section 1.2, 1.3, Section 2.1 to 2.3, 2.8, Section 4.1, 4.5.2,

Section 5.1.1, Section 8.2.1, 8.3.2, 8.3.3, Section 9.8, Section 10.1.1,

10.2.1, 10.3.3, 10.3.6, Appendices 1.1, 2.1, 3

Addition

Section 2.7

June, 2009 SH (NA)-080006-O

Correction

About Manuals, Manual's Use and Structure, About The Generic Terms

and Abbreviations, Definitions and Descriptions of Terminology,

Sections 1.2, 1.3, 2.1, 2.2, 2.4 to 2.6,

2.8, 3.1, 3.2.1, 3.3.4, 3.4 to 3.6, 3.8, 3.9, 4.1 to 4.3,

4.4.2, 4.5.2, 4.5.3, 4.6, 4.7, 4.7.1, 5.1.4, 5.1.5, 6.1.2,

6.1.4, 6.2.2, 7.1.2, and 7.2.2, Chapter 9, Sections 9.1, 9.2.1, 9.2.2,

9.3.1, 9.4, 9.4.5, 9.6.1, 9.6.3, 10.2 to 10.8, 11.1.1, 11.1.2, 11.1.5,

11.1.6, 11.2.1, 11.3, 11.3.1 to 11.3.3,

and 11.3.5 to 11.3.22, Appendices 1.1, 2.1, 3, 9.6, and 10

Partial addition

Section 3.3.4, Chapter 8, Sections 9.4.9, 9.6.7, 11.3.4, and 11.3.6

Section number change

Chapters 8 to 10 9 to 11, Sections 9.6.7 to 9.6.10 9.6.8 to 9.6.11,

Sections 9.4.9 to 9.4.11 9.4.10 to 9.4.12,

Section 11.3.4 11.3.5, Sections 11.3.5 to 11.3.20 11.3.7 to 11.3.22

Apr., 2011 SH (NA)-080006-P

Correction

SAFETY PRECAUTIONS, About The Generic Terms and Abbreviations,

Sections 1.2, 1.3, 2.1, 2.2, 2.8, 3.2.1, 3.2.2, 3.3.1, 3.3.2, 3.8, 4.4, 5.2,

6.1.1, 6.1.3, 9.2.1, 9.2.2, 10.1, 10.4, 11.2.1, 11.3.3, 11.3.8, 11.3.21,

Appendices 1.1, 3, 6, 7.1

Addition

CONDITIONS OF USE FOR THE PRODUCT, Sections 8.1.5, 8.1.6, 10.7

Section number change

Section 10.8 10.9

Nov., 2012 SH (NA)-080006-Q

Correction

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES,

Sections 1.3, 3.2.1, 8.1.5, 8.1.6, 9.2.2, 11.2.1, 11.3.1, Appendix 3

Partial addition

Appendix 6

A - 8 A - 8

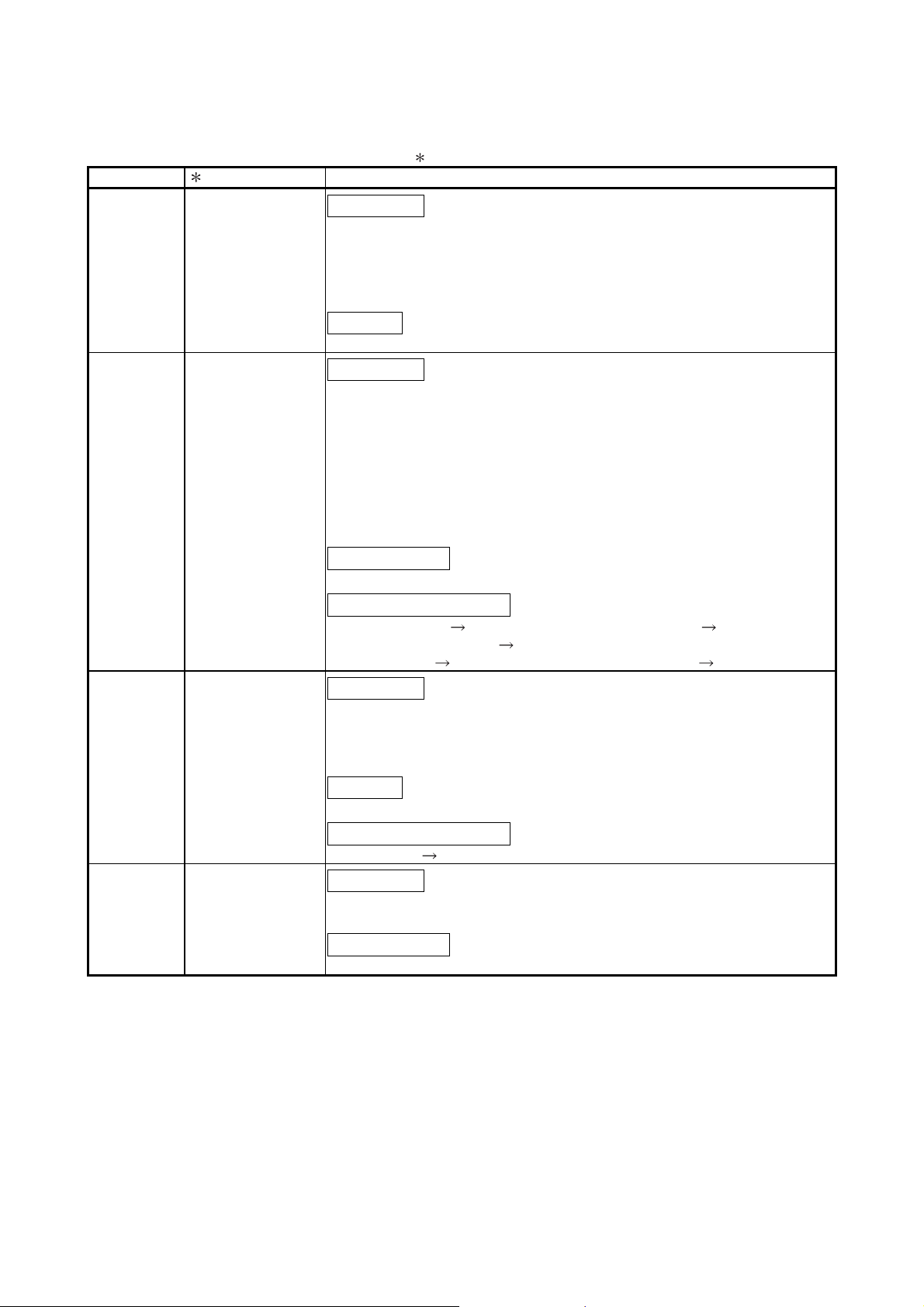

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Mar., 2015 SH (NA)-080006-R

Correction

ABOUT MANUALS, ABOUT THE GENERIC TERMS AND

ABBREVIATIONS, DEFINITIONS AND DESCRIPTIONS OF

TERMINOLOGY, Sections 1.2, 2.1, 2.8, 3.3.1, 3.3.2, 3.8, 3.9, 4.3, 4.4,

4.4.1, 4.5.2, 4.7, 4.7.1, 6.1.4, Chapters 8, Sections 8.1.6, 9.2.1, 9.2.2,

9.3.3, 10.7, 11.2.1, 11.3.14, Appendices 1.1, 2.3.1, 5, 6.1, 6.2, 9.1, 9.8

Deletion

Section 2.7

Section number change

Section 2.8 2.7

Jan., 2016 SH (NA)-080006-S

Correction

Section 2.1

Dec., 2016 SH (NA)-080006-T

Correction

ABOUT THE GENERIC TERMS AND ABBREVIATIONS, DEFINITIONS

AND DESCRIPTIONS OF TERMINOLOGY, DISCONTINUED MODELS,

Section 2.7, 6.1.1, 9.2.2, 11.2, Appendices 7.1

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

1999 MITSUBISHI ELECTRIC CORPORATION

Japanese Manual Version SH-080001-AD

A - 9 A - 9

INTRODUCTION

Thank you for purchasing the MELSEC-Q series programmable controller.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the Q series programmable controller you have purchased, so as to ensure correct use.

Please forward a copy of this manual to the end user.

CONTENTS

SAFETY PRECAUTIONS ............................................................................................................................ A- 1

CONDITIONS OF USE FOR THE PRODUCT ........................................................................................... A- 5

REVISIONS .................................................................................................................................................. A- 6

CONTENTS .................................................................................................................................................. A- 10

ABOUT MANUALS ...................................................................................................................................... A- 16

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES ..................................................... A- 16

THE MANUAL'S USE AND STRUCTURE ................................................................................................. A- 17

ABOUT THE GENERIC TERMS AND ABBREVIATIONS ......................................................................... A- 20

DEFINITIONS AND DESCRIPTIONS OF TERMINOLOGY ...................................................................... A- 22

DISCONTINUED MODELS ....................................................................................................................... A- 23

PRODUCT CONFIGURATION ................................................................................................................... A- 24

1 OVERVIEW 1- 1 to 1-15

1.1 Overview of the Serial Communication Module ................................................................................. 1- 1

1.2 Features of the Serial Communication Module .................................................................................. 1- 2

1.3 About Added/Changed Functions in Function Version B .................................................................. 1- 13

2 SYSTEM CONFIGURATION AND AVAILABLE FUNCTIONS 2- 1 to 2-20

2.1 Applicable Systems ............................................................................................................................. 2- 1

2.2 Combinations of Programmable Controller CPU and External Device, and Available Functions .... 2- 4

2.3 For Use in Multiple CPU System ........................................................................................................ 2- 8

2.4 Use with Basic Model QCPU .............................................................................................................. 2- 9

2.5 Use with Redundant CPUs ................................................................................................................. 2- 10

2.6 Use on MELSECNET/H Remote I/O Stations .................................................................................... 2- 12

2.7 Checking the Function Version, Serial No., and Software Version ................................................... 2- 16

3 SPECIFICATIONS 3- 1 to 3-42

3.1 Performance Specifications ................................................................................................................ 3- 1

3.2 RS-232 Interface Specification ........................................................................................................... 3- 3

3.2.1 RS-232 connector specifications ................................................................................................. 3- 3

3.2.2 RS-232 cable specification ........................................................................................................... 3- 6

3.3 RS-422/485 Interface Specifications .................................................................................................. 3- 7

3.3.1 RS-422/485 terminal block specifications .................................................................................... 3- 7

3.3.2 RS-422/485 cable specifications .................................................................................................. 3- 8

3.3.3 Precautions when transferring data using RS-422/485 circuit .................................................... 3- 9

3.3.4 Enabling or disabling echo back of the RS-422/485 interface .................................................... 3- 12

3.4 Serial Communication Module Function List ...................................................................................... 3- 14

3.5 Dedicated Instruction List .................................................................................................................... 3- 16

3.6 Utility Package (GX Configurator-SC) Function List .......................................................................... 3- 17

3.7 List of GX Developer Setting Items for Serial Communication Modules ........................................... 3- 19

3.8 List of Input/Output Signals for the Programmable Controller CPU .................................................. 3- 20

3.9 List of Applications and Assignments of the Buffer Memory ............................................................. 3- 23

A - 10 A - 10

4 SETTINGS AND PROCEDURES PRIOR TO OPERATION 4- 1 to 4-35

4.1 Handling Precautions .......................................................................................................................... 4- 1

4.2 Settings and Procedures Prior to Operation ....................................................................................... 4- 2

4.3 Part Names and Functions ................................................................................................................. 4- 3

4.4 External Wiring .................................................................................................................................... 4- 5

4.4.1 Connecting the RS-232 interface (full-duplex communications) ................................................. 4- 6

4.4.2 Connecting the RS-422/485 interface.......................................................................................... 4- 8

4.5 Settings for GX Developer .................................................................................................................. 4- 13

4.5.1 I/O assignment settings ................................................................................................................ 4- 13

4.5.2 Switch settings for I/O and intelligent functional module ............................................................. 4- 14

4.5.3 The Intelligent function module interrupt pointer setting ............................................................. 4- 21

4.6 Settings with the Utility Package (GX Configurator-SC) .................................................................... 4- 23

4.7 Individual Station Test ......................................................................................................................... 4- 26

4.7.1 ROM/RAM/switch tests ................................................................................................................ 4- 26

4.7.2 Individual station loopback test .................................................................................................... 4- 29

4.8 Loopback Test ..................................................................................................................................... 4- 31

4.9 Maintenance and Inspection ............................................................................................................... 4- 33

4.9.1 Maintenance and inspection ........................................................................................................ 4- 33

4.9.2 When mounting/dismounting the module .................................................................................... 4- 34

5 DATA COMMUNICATION USING THE MELSEC COMMUNICATION PROTOCOL 5- 1 to 5- 6

5.1 Data Communication Functions .......................................................................................................... 5- 1

5.1.1 Accessing the programmable controller CPUs using the MC protocol ...................................... 5- 1

5.1.2 Message format and control procedure for data communication ............................................... 5- 2

5.1.3 Programmable controller CPU setting for performing data communication ............................... 5- 2

5.1.4 Support of multiple CPU system or redundant system ............................................................... 5- 3

5.1.5 Support for the QCPU remote password functio n ....................................................................... 5- 4

5.2 Utilizing the MX Component ............................................................................................................... 5- 6

6 DATA COMMUNICATION USING THE NON PROCEDURE PROTOCOL 6- 1 to 6-33

6.1 Data Reception from the External Device .......................................................................................... 6- 2

6.1.1 Receiving methods ....................................................................................................................... 6- 2

6.1.2 The receive area and the received data list ................................................................................. 6- 6

6.1.3 Sequence program for data reception ......................................................................................... 6- 11

6.1.4 Receive data clear ........................................................................................................................ 6- 15

6.1.5 How to detect reception errors ..................................................................................................... 6- 19

6.1.6 Received data count and receive complete code settings .......................................................... 6- 22

6.2 Sending Data to the External Device .................................................................................................. 6- 24

6.2.1 Transmission methods ................................................................................................................. 6- 24

6.2.2 Arrangement and contents of the transmission area and the transmission data ....................... 6- 25

6.2.3 Sequence program for transmission data .................................................................................... 6- 27

6.2.4 How to detect transmission errors ............................................................................................... 6- 30

6.3 Data Communications Precautions .................................................................................................... 6- 32

A - 11 A - 11

7 DATA COMMUNICATION USING THE BIDIRECTIONAL PROTOCOL 7- 1 to 7-28

7.1 Data Reception from the External Device .......................................................................................... 7- 2

7.1.1 Receiving methods ....................................................................................................................... 7- 2

7.1.2 Arrangement and contents of the receive area and the receive data ......................................... 7- 4

7.1.3 Sequence program for data reception ......................................................................................... 7- 10

7.1.4 How to detect reception errors ..................................................................................................... 7- 13

7.1.5 Receive data clear ........................................................................................................................ 7- 14

7.2 Sending Data to the External Device .................................................................................................. 7- 15

7.2.1 Transmission methods ................................................................................................................. 7- 15

7.2.2 Arrangement and contents of the transmission area and the transmission data ....................... 7- 16

7.2.3 Sequence program for data transmission .................................................................................... 7- 19

7.2.4 How to detect transmission errors ............................................................................................... 7- 22

7.3 Processing when Simultaneous Transmission Performed During Full-Duplex Communications .... 7- 24

7.3.1 Processing when simultaneous transmissions occur .................................................................. 7- 24

7.3.2 Communication data processing when simultaneous transmissions occur ............................... 7- 25

7.4 Data Communications Precautions .................................................................................................... 7- 27

8 DATA COMMUNICATION USING THE PRE-DEFINED PROTOCOL 8- 1 to 8-21

8.1 Function of the Pre-Defined Protocol ................................................................................................. 8- 3

8.1.1 Data communication procedure ................................................................................................... 8- 3

8.1.2 Pre-defined protocol system setting ............................................................................................ 8- 5

8.1.3 Pre-defined protocol monitor/test ................................................................................................. 8- 6

8.1.4 Protocol execution log storage function ....................................................................................... 8- 7

8.1.5 Executing Condition of Predefined Protocol Communication ..................................................... 8- 8

8.1.6 Programming Example ................................................................................................................. 8- 13

9 UTILITY PACKAGE (GX Configurator -SC) 9- 1 to 9-56

9.1 Functions Available with Utility Package ............................................................................................ 9- 3

9.2 Installing and Uninstalling the Utility Package .................................................................................... 9- 4

9.2.1 Handling precautions .................................................................................................................... 9- 4

9.2.2 Operating environment ................................................................................................................. 9- 7

9.3 Utility Package Operation .................................................................................................................... 9- 9

9.3.1 Operation overview ....................................................................................................................... 9- 9

9.3.2 Starting the Intelligent function module utility ............................................................................ 9- 13

9.3.3 Common utility package operations ............................................................................................. 9- 16

9.4 System Registration to Flash ROM .................................................................................................... 9- 19

9.4.1 User frame registration ................................................................................................................. 9- 21

9.4.2 Data for modem initialization registration ..................................................................................... 9- 22

9.4.3 Data for modem connection registration ...................................................................................... 9- 23

9.4.4 Modem function system setting/registration ................................................................................ 9- 24

9.4.5 Transmission control and others system setting ......................................................................... 9- 25

9.4.6 MC protocol system setting .......................................................................................................... 9- 27

9.4.7 Non procedure system setting ..................................................................................................... 9- 28

9.4.8 Bidirectional system setting .......................................................................................................... 9- 29

9.4.9 Pre-defined protocol system setting ............................................................................................ 9- 30

9.4.10 Programmable controller CPU monitoring system setting ........................................................ 9- 31

A - 12 A - 12

9.4.11 Transmission user frame No. designation system setting ........................................................ 9- 33

9.4.12 Resetting the buffer memory/flash ROM setting values to the default values ......................... 9- 34

9.4.13 Flash ROM write allow/prohibit setting ...................................................................................... 9- 34

9.5 Auto Refresh Setting ........................................................................................................................... 9- 35

9.6 Monitor/Test ......................................................................................................................................... 9- 36

9.6.1 X/Y monitor/test ............................................................................................................................ 9- 37

9.6.2 Modem function monitor/test ........................................................................................................ 9- 38

9.6.3 Transmission control and others monitor/test ............................................................................. 9- 41

9.6.4 MC protocol monitor ..................................................................................................................... 9- 43

9.6.5 Non procedure monitor/test .......................................................................................................... 9- 45

9.6.6 Bidirectional monitor ..................................................................................................................... 9- 47

9.6.7 Pre-defined protocol monitor/test ................................................................................................. 9- 48

9.6.8 PLC CPU monitoring monitor ....................................................................................................... 9- 49

9.6.9 Transmission user frame No. designation monitor ...................................................................... 9- 51

9.6.10 Monitor/test others ...................................................................................................................... 9- 52

9.6.11 Display LED off and communication error information/error code initialization ........................ 9- 54

9.7 Non Procedure Protocol Receive Data Clear ..................................................................................... 9- 56

10 DEDICATED INSTRUCTIONS 10- 1 to 10-34

10.1 Dedicated Instruction List and Available Devices .......................................................................... 10- 1

10.2 G(P).ONDEMAND ........................................................................................................................... 10- 3

10.3 G(P).OUTPUT ................................................................................................................................. 10- 7

10.4 G.INPUT .......................................................................................................................................... 10- 11

10.5 G(P).BIDOUT .................................................................................................................................. 10- 15

10.6 G(P).BIDIN....................................................................................................................................... 10- 18

10.7 G(P). CPRTCL ................................................................................................................................ 10- 21

10.7.1 Functional protocol ...................................................................................................................... 10- 28

10.8 G(P).SPBUSY ................................................................................................................................. 10- 29

10.9 ZP.CSET (Receive data clear) ....................................................................................................... 10- 31

11 TROUBLESHOOTING 11- 1 to 11-57

11.1 Checking the Status of the Serial Communication Module ........................................................... 11- 1

11.1.1 Checking the LED ON status, communications error status, and switch setting status of

the serial communication module ............................................................................................ 11- 1

11.1.2 Initializing error information of the serial communication module ........................................... 11- 6

11.1.3 Reading the RS-232 control signal status ............................................................................... 11- 10

11.1.4 Reading the data communication status (Transmission sequence status) ............................ 11- 11

11.1.5 Reading the switch setting status ............................................................................................ 11- 12

11.1.6 How to read the current operation status ................................................................................ 11- 14

11.1.7 Clearing the programmable controller CPU information ......................................................... 11- 16

11.2 Error Code Tables ........................................................................................................................... 11- 18

11.2.1 Error code table ........................................................................................................................ 11- 18

11.2.2 A compatible 1C frame communications error code table ...................................................... 11- 30

11.2.3 Error code list while modem function is used .......................................................................... 11- 32

11.3 Troubleshooting by Symptom ......................................................................................................... 11- 34

11.3.1 The "RUN" LED is turned OFF ................................................................................................ 11- 36

11.3.2 The "RD" LED does not blink even after message transmission from the external device ... 11- 37

A - 13 A - 13

11.3.3 No response message is returned even though the external device transmitted a message

and the "RD" LED blinked ........................................................................................................ 11- 38

11.3.4 Transmission request does not make the "SD" LED blink ...................................................... 11- 39

11.3.5 Read request signal does not turn ON even though the external device transmitted

a message and the "RD" LED was blinking ............................................................................ 11- 40

11.3.6 The CPRTCL instruction execution is not completed although the “RD” LED blinked .......... 11- 41

11.3.7 Communication error "NAK"..................................................................................................... 11- 42

11.3.8 Communication error "C/N" ...................................................................................................... 11- 42

11.3.9 Communication error "P/S" ...................................................................................................... 11- 43

11.3.10 Communication error "PRO." ................................................................................................. 11- 44

11.3.11 Communication error "SIO" .................................................................................................... 11- 45

11.3.12 Communication error "CH1 ERR." or "CH2 ERR." ............................................................... 11- 46

11.3.13 Communication is intermittent ................................................................................................ 11- 49

11.3.14 Undecidable data are transmitted or received ...................................................................... 11- 51

11.3.15 Whether the communication error is caused on the Q series C24 or external device is unclear

................................................................................................................................................. 11- 52

11.3.16 Communication is not available via the modem .................................................................... 11- 53

11.3.17 Communication is not available with the ISDN sub-address ................................................ 11- 54

11.3.18 Periodic transmission is not performed normally .................................................................. 11- 54

11.3.19 Condition agreement transmission is not performed normally ............................................. 11- 54

11.3.20 Data cannot be received due to by an interrupt program ..................................................... 11- 54

11.3.21 Data cannot be written to the flash ROM .............................................................................. 11- 55

11.3.22 Troubleshooting on protocol setting data reading/writing ..................................................... 11- 56

11.3.23 The "ERR" LED is lit ............................................................................................................... 11- 57

APPENDICES App.- 1 to App.-63

Appendix 1 Functional Improvements of the Q Series C24 ................................................................ App.- 1

Appendix 1.1 Comparison of Q series C24/GX Configurator-SC/GX Works2 ............................... App.- 1

Appendix 1.2 Precautions when updating the module from function version A to B...................... App.- 7

Appendix 1.3 Precautions when replacing the QJ71C24(-R2) with the QJ71C24N(-R2/R4) ........ App.- 7

Appendix 2 QnA/A Series Module ....................................................................................................... App.- 8

Appendix 2.1 Functional comparison with the Q series C24 and the QnA/A series modules ....... App.- 8

Appendix 2.2 Using programs designed for the QC24 (N) and installing the Q series C24

into existing systems .................................................................................................. App.- 10

Appendix 2.2.1 Using programs designed for the QC24 (N) .................................................. App.- 10

Appendix 2.2.2 Installing on existing systems ........................................................................ App.- 11

Appendix 2.3 Using programs designed for the computer link module and installing

the Q series C24 into existing systems ..................................................................... App.- 12

Appendix 2.3.1 Using programs designed for the computer link module ............................... App.- 12

Appendix 2.3.2 Installing the Q series C24 into existing systems .......................................... App.- 15

Appendix 3 Processing Time ............................................................................................................... App.- 16

Appendix 4 ASCII-Code Table ............................................................................................................. App.- 19

Appendix 5 External Dimensions ......................................................................................................... App.- 20

Appendix 6 Interfaces ........................................................................................................................... App.- 22

Appendix 6.1 RS-232 interfaces used for the Q series C24 ........................................................... App.- 22

Appendix 6.2 Connection examples when using a converter ......................................................... App.- 22

Appendix 7 Communication Support Tool (MX Component) .............................................................. App.- 25

Appendix 7.1 Overview of MX Component ...................................................................................... App.- 25

Appendix 7.2 Usage procedure of MX Component ......................................................................... App.- 28

A - 14 A - 14

Appendix 8 Example of Clear Process Program for Receive Data .................................................... App.- 35

Appendix 9 Program Examples for Using Q Series C24 at MELSECNET/H Remote I/O Station .... App.- 37

Appendix 9.1 System configuration and program conditions .......................................................... App.- 37

Appendix 9.2 When accessing buffer memory using sequence program ...................................... App.- 39

Appendix 9.3 When sending on-demand data ................................................................................ App.- 40

Appendix 9.4 When receiving data using nonprocedural or bidirectional protocol ........................ App.- 42

Appendix 9.5 When sending data using nonprocedural or bidirectional protocol .......................... App.- 44

Appendix 9.6 When clearing received data ..................................................................................... App.- 46

Appendix 9.7 When sending data using user frames ...................................................................... App.- 48

Appendix 9.8 When performing initial setting .................................................................................. App.- 51

Appendix 9.9 When registering user frame ..................................................................................... App.- 53

Appendix 9.10 When reading user frame ........................................................................................ App.- 55

Appendix 9.11 When deleting user frame ........................................................................................ App.- 57

Appendix 9.12 When changing the communication protocol and transmission setting ................. App.- 59

Appendix 10 Setting Value Recording Sheet ...................................................................................... App.- 62

INDEX Index- 1 to Index- 2

A - 15 A - 15

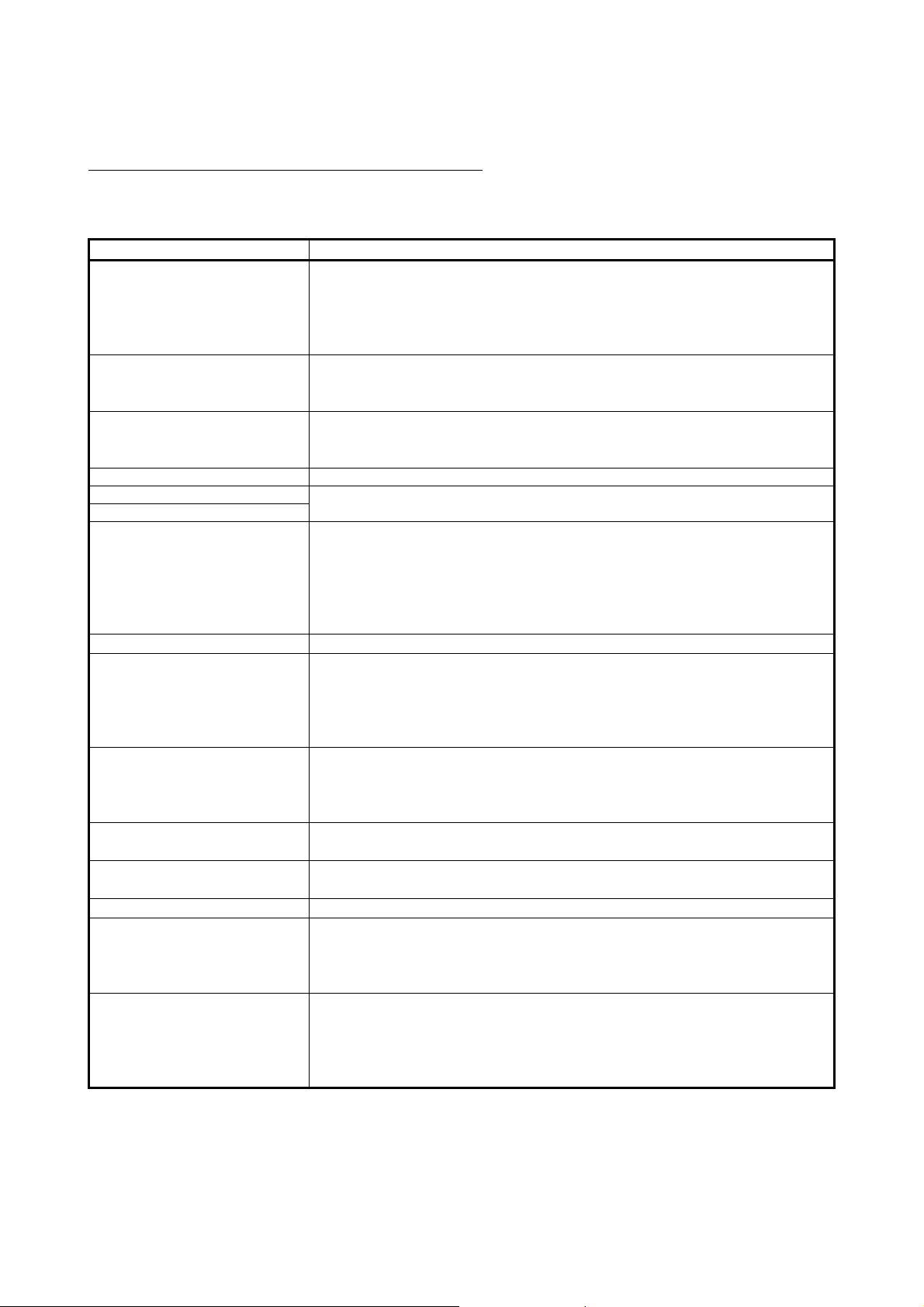

ABOUT MANUALS

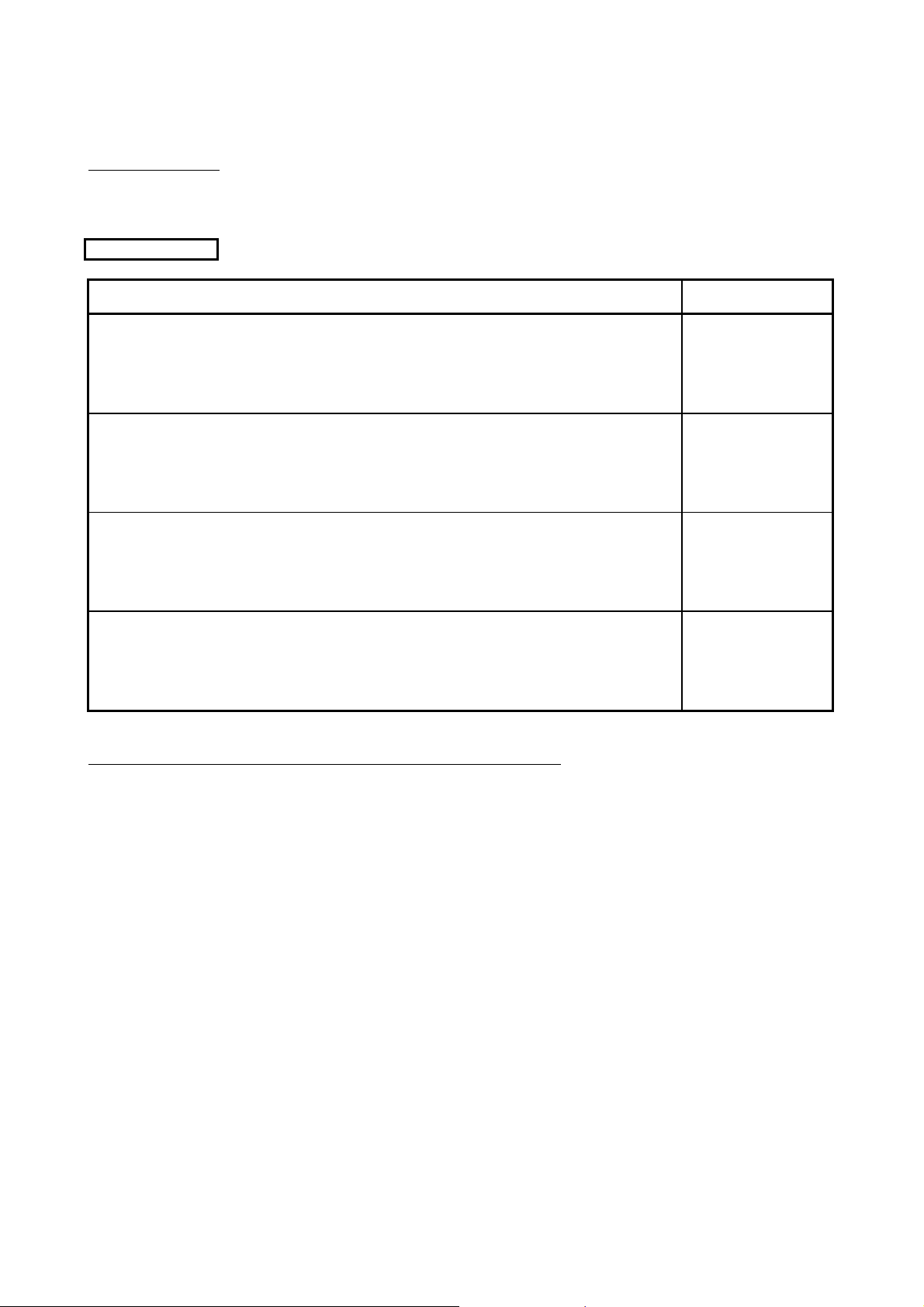

The following table lists the manuals relating to this product. Please order the desired manual(s) as needed.

Related manuals

Manual Name

MELSEC-Q/L Serial Communication Module User's Manual (Application)

Details of the special functions (specifications, usage, and settings) of the serial communication module

and the data communication methods between the module and external devices

(sold separately)

MELSEC Communication Protocol Reference Manual

Details of MELSEC communication protocol (MC protocol) that is used for data communication between

an external device and a CPU module

(sold separately)

GX Configurator-SC Version 2 Operating Manual (Protocol FB support function)

Details of the protocol FB support function (specifications, usage, and parameter settings) that enables

users to easily create data communication programs of the serial communication module

(sold separately)

Manual Number

(Model Code)

SH-080007

(13JL87)

SH-080008

(13JF89)

SH-080393E

(13JU46)

GX Configurator-SC Version 2 Operating Manual (Pre-defined protocol support function)

Details of the pre-defined protocol support function (specifications, usage, and protocol setting method)

of the serial communication module

(sold separately)

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low

Voltage Directives when incorporated into other machinery or equipment, certain

measures may be necessary. Please refer to one of the following manuals.

• QCPU User's Manual (Hardware Design, Maintenance and Inspection)

• Safety Guidelines

(This manual is included with the CPU module or base unit.)

The CE mark on the side of the programmable controller indicates compliance

with EMC and Low Voltage Directives.

(2) Additional measures

No additional measures are necessary for the compliance of this product with

EMC and Low Voltage Directives.

SH-080850ENG

(13JU66)

A - 16 A - 16

THE MANUAL'S USE AND STRUCTURE

How to use this manual

In this manual, details of the serial communication modules (QJ71C24N,

QJ71C24N-R2, QJ71C24N-R4, QJ71C24 and QJ71C24-R2) are organized as

shown below, according to their applications.

Please use this manual using the contents below as a reference.

(1) To learn about features, functions and component parts

(a) To learn about features and functions

• Chapter 1 describes the features of the serial communication modules.

• Chapter 3 describes the common specifications and functions of the serial

(b) To learn about the packed items and system-configured items

communication modules.

• The section prior to Chapter 1, "Product Configuration", describes the

parts that are packed along with the serial communication module.

• Parts and components other than those packed with the module must be

prepared separately by the user.

(2) To learn about processing required to start up the serial

communication module

(a) To learn about the startup procedure

• Section 4.2 describes the general procedures prior to starting the

(b) To learn about the connection with the external devices

(c) To learn about processing required prior to operation of the serial

(d) To check for failure in the serial communication module

(e) To learn how to check for a connection error with the external devices

operation of the serial communication module.

• Section 4.4 describes the connection methods for each type of interface.

communication module

• Section 4.5 explains the parameter settings with GX Developer in order to

use the serial communication module.

• Section 4.6 and Chapter 9 describe the settings from GX Configurator-SC

to perform the initial setting of the serial communication module.

To change an initial value, follow the procedure described in Chapter 9.

• Section 4.7 describes the test of the individual serial communication

module.

• Section 4.8 describes how to perform the individual module test and the

loopback test using MC protocol-based communication.

Details of the loopback test command are described in the reference

manual.

A - 17 A - 17

(3) To learn about data communication functions and detailed

explanations

(a) To learn about the communication functions

• Section 3.4 describes an overview of the serial communication module

(b) To learn about detailed explanations of the communication functions

functions.

• The basic communication methods are described in Chapters 5 to 7.

• Special functions are described in the User's Manual (Application).

(4) To learn about data communication functions and programming

(a) To learn how to read data from and written to the programmable controller

CPU

• Data is read from and written to the programmable controller CPU with a

communication function using the MC protocol.

Details are described in the Reference Manual.

• Appendix 7 describes an overview of the communication support tool (MX

(b) To learn how to send and receive data between the programmable controller

(c) To learn how to transfer data between a programmable controller CPU and

Component) that supports communication using the MC protocol.

CPU and the external devices

• Data communication between the programmable controller CPU and the

external devices is performed with a communication function using the

non procedure protocol or the bidirectional protocol.

• Chapter 6 explains details of the communication functions and

programming using the non procedure protocol.

• Chapter 7 explains details of the communication functions and

programming using the bidirectional protocol.

an external device using the protocol of the external device

• With the pre-defined protocol function, data can be transferred between

the QJ71C24N(-R2/R4) and external devices.

The details are described in the Operating Manual (Pre-defined protocol

support function).

(5) To learn how to check for error occurrences and take corrective

actions

Chapter 11 describes troubleshooting, how to check for errors, and detailed

explanations of error codes.

(6) To learn about functions that have been added or changed in

function version B

• Section 1.3 lists the functions that have been added or changed as well as

manuals that provide detailed explanations hereof.

• Appendix 1.1 provides a breakdown of the functions of Q series C24/GX

Configurator-SC by function version/software version.

A - 18 A - 18

The structure of this manual

The module's buffer memory stores default values that are used as initial settings

to execute the data send/receive functions in order to communicate with the

external devices.

Data can be sent to or received from the external devices using these default

values. However, it may be necessary to change the default values, depending on

system specifications.

This manual explains how to perform the initial settings in order to use each

function of the utility package available for this module (GX-Configurator-SC).

When changing a default value for sending and receiving data to/from an opposite

device, first see the section describing the applicable function to verify the initial

setting item and setting value you wish to change, then change the default value

as explained in Chapter 9.

A - 19 A - 19

ABOUT THE GENERIC TERMS AND ABBREVIATIONS

This manual uses the following generic terms and abbreviations to describe the serial communication

modules, unless otherwise specified.

(1) Generic terms and abbreviations of relevant modules

In this manual, the following generic terms and abbreviations are used to indicate

the programmable controller CPU and other modules used for the datacommunication functions of the serial communication modules. Module model

names are provided when relevant model names are needed to be shown.

Generic term/abbreviation Description of generic term/abbreviation

The abbreviation for QJ71C24N, QJ71C24N-R2, QJ71C24N-R4, QJ71C24 and QJ71C24-R2 type

Q series C24 (C24)

QC24 A generic term for AJ71QC24, AJ71QC24-R2, AJ71QC24-R4, A1SJ71QC24, and A1SJ71QC24-R2

QC24N

QC24(N) A generic term for QC24, and QC24N

QCPU

Basic model QCPU A generic term for Q00JCPU, Q00CPU, and Q01CPU

High Performance model QCPU A generic term for Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU

Process CPU A generic term for Q02PHCPU, Q06PHCPU, Q12PHCPU, and Q25PHCPU

Redundant CPU A generic term for Q12PRHCPU, and Q25PRHCPU

Universal model QCPU

Built-in Ethernet port QCPU

QCPU station The abbreviation for the programmable controller with QCPU installed

QnACPU

Q/QnACPU A generic term for QCPU, and QnACPU

UC24

Computer link module

Serial communication module

C Controller module

serial communication modules

(Indicated as "C24" in the diagrams)

A generic term for AJ71QC24N, AJ71QC24N-R2, AJ71QC24N-R4, A1SJ71QC24N1,

A1SJ71QC24N1-R2, A1SJ71QC24N, and A1SJ71QC24N-R2

A generic term for the Basic model QCPU, High Performance model QCPU, Process CPU,

Redundant CPU, and Universal model QCPU

A generic term for the Q00UJCPU, Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU, Q03UDVCPU,

Q03UDECPU, Q04UDHCPU, Q04UDVCPU, Q04UDEHCPU, Q06UDHCPU, Q06UDVCPU,

Q06UDEHCPU, Q10UDHCPU, Q10UDEHCPU, Q13UDHCPU, Q13UDVCPU, Q13UDEHCPU,

Q20UDHCPU, Q20UDEHCPU, Q26UDHCPU, Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and

Q100UDEHCPU

A generic term for the Q03UDVCPU, Q03UDECPU, Q04UDVCPU, Q04UDEHCPU, Q06UDVCPU,

Q06UDEHCPU, Q10UDEHCPU, Q13UDVCPU, Q13UDEHCPU, Q20UDEHCPU, Q26UDVCPU,

Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

A generic term for Q2ACPU, Q2ACPU-S1, Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU, Q2ASHCPU-S1,

Q3ACPU, Q4ACPU, and Q4ARCPU

A generic term for AJ71UC24, A1SJ71UC24-R2, A1SJ71UC24-R4, A1SJ71UC24-PRF,

A1SJ71C24-R2, A1SJ71C24-R4, A1SJ71C24-PRF, A2CCPUC24, and A2CCPUC24-PRF

A series computer link modules.

A generic term for the module below

AJ71QC24, AJ71QC24-R2, AJ71QC24-R4, A1SJ71QC24, A1SJ71QC24-R2,

QnA series

Q series QJ71C24N, QJ71C24N-R2, QJ71C24N-R4, QJ71C24, QJ71C24-R2.

A generic term for the C Controller modules: Q06CCPU-V, Q06CCPU-V-B, Q12DCCPU-V,

Q24DHCCPU-V, and Q24DHCCPU-LS

AJ71QC24N, AJ71QC24N-R2, AJ71QC24N-R4, A1SJ71QC24N1, A1SJ71QC24N1-R2,

A1SJ71QC24N, A1SJ71QC24N-R2.

A - 20 A - 20

(2) Other generic terms and abbreviations

This manual uses the following generic terms and abbreviations to explain the

data-communication devices for the serial communication module. The

names/model names are provided when it is necessary to explicitly identify the

model being discussed.

Generic term/abbreviation Description of generic term/abbreviation

BIDIN The abbreviation for G.BIDIN or GP.BIDIN

BIDOUT The abbreviation for G.BIDOUT or GP.BIDOUT

A generic term for memory of the intelligent function modules/special function modules used for

Buffer memory

BUFRCVS The abbreviation for Z.BUFRCVS

CPRTCL The abbreviation for G.CPRTCL or GP.CPRTCL

CSET The abbreviation for ZP.CSET

Data communication function

GETE The abbreviation for G.GETE or GP.GETE

Intelligent function module devices

Intelligent function modules

MELSECNET/10 The abbreviation for MELSECNET/10 network system

MELSECNET/H The abbreviation for MELSECNET/H network system

ONDEMAND The abbreviation for G.ONDEMAND or GP.ONDEMAND

Operating Manual

(Protocol FB support function)

Operating Manual

(Pre-defined protocol support

function)

Opposite devices

(external devices)

OUTPUT The abbreviation for G.OUTPUT or GP.OUTPUT

PRR The abbreviation for G.PRR or GP.PRR

PUTE The abbreviation for G.PUTE or GP.PUTE

Reference Manual Q Corresponding MELSEC Communication Protocol Reference Manual

SPBUSY The abbreviation for G.SPBUSY or GP.SPBUSY

Special function modules

Switch setting A generic term for intelligent function module switch setting

UINI The abbreviation for ZP.UINI

User's Manual (Application) or

Application

User's Manual (Basic) or Basic Q Corresponding Serial Communication Module User's Manual (Basic)

A - 21 A - 21

storing data sent to or received from the programmable controller CPU. (setting values, monitor

values, etc.)

A generic term for MC protocol, non procedure protocol, and bidirectional protocol, and pre-defined

protocol

A generic term for buffer memory of the intelligent function modules used for storing data sent to or

received from the programmable controller CPU. (setting values, monitor values, etc.)

A generic term for the Q series programmable controller modules that are operated by commands

from the programmable controller CPU (equivalent to the A series programmable controller special

function modules)

Examples:

• CC-Link interface module

• A/D and D/A conversion modules

• Ethernet interface module

• Serial communication module

GX Configurator-SC Version 2 Operating Manual (Protocol FB support function)

GX Configurator-SC Version 2 Operating Manual (Pre-defined protocol support function)

A generic term for computers, indicators, measuring instruments, ID modules, bar code readers,

regulators, other serial communication modules, UC24, etc. that are connected to this serial

communication module for data communication

A generic term for the A/QnA series programmable controller modules that are operated by

commands from the programmable controller CPU (equivalent to the Q series programmable

controller intelligent function modules)

Examples:

• CC-Link interface module

• A/D and D/A conversion modules

• High-speed counter module

• Ethernet interface module

• Computer link module and serial communication module

MELSEC-Q/L Serial Communication Module User's Manual (Application)

DEFINITIONS AND DESCRIPTIONS OF TERMINOLOGY

The following table lists the definitions and descriptions of terminology used in this manual and related

manuals for the Q series serial communication modules.

Terms Description

One of the message formats for the serial communication module for performing communication

A compatible 1C frame

(Formats 1 to 4)

Bidirectional protocol

Independent operation

GX Configurator-SC Setting and monitoring tool for the serial communication module (MELSOFT product)

GX Developer

GX Works2

Linked operation

MX Component Active X® control library for serial communication (MELSOFT product)

MELSEC communication protocol

(MC protocol)

Message send function

(Printer function)

Multidrop connection

Non procedure protocol

Packet A string of data used for communication with external devices by the pre-defined protocol.

Pre-defined protocol

Pre-defined protocol support function

using the MC protocol and ASCII code data.

This is the same message format as when communicating using the protocol for the A series

computer link modules. Device memory read/write operations for the QCPU are allowed within

the device range of the AnACPU.

A communication procedure for the serial communication modules and one of the data

communication functions for communicating any data between the programmable controller CPU

and an opposite device.

A mode of interface operation to communicate data with external devices using a function

specified in each communication protocol setting. Two interfaces of serial communication

modules do not interact.

The product name of the software package for the MELSEC programmable controllers

The operation mode of each of the two interfaces for a serial communication module that are

connected to external devices and linked to one another in order to send/receive data to/from the

external devices.

The two interfaces communicate data using the identical data-communication function (MC

protocol (identical format) or non procedure protocol) and the identical transmission

specifications. (Linked operation using the bidirectional or pre-defined protocol is not allowed.)

A communication procedure for the Q series serial communication modules or the Ethernet

interface modules, and a name of communication method for accessing to the programmable

controller CPU from an opposite device. (This is called the MC protocol in this manual.)

There are two communication methods; one uses ASCII code data and the other uses binary

code data.

This function registers character data (messages) to be sent to external devices (mainly printers)

in the serial communication module as a user frame in advance, and sends the registered data

for multiple user frames using the non-procedure protocol (sent by an instruction from the

programmable controller CPU).

A name of the connection when multiple external devices or other serial communication modules are

connected in a 1:n or m:n mode using the serial communication module's RS-422/485 interface.

A user's communication procedure and one of the data communication functions for

communicating any data between the programmable controller CPU and an opposite device.

One of the data communication functions available for the QJ71C24N(-R2/R4).

In data communication between the QJ71C24N(-R2/R4) and an external device, data can be

sent and received by using a protocol for the external device.

This must be set in GX Configurator-SC (Pre-defined protocol support function).

A function available in GX Configurator-SC (Pre-defined protocol support function), which

includes:

• Registration of the protocol appropriate to each external device

• Writing protocol setting data to or reading them from the flash ROM of the QJ71C24N(-R2/R4)

• Debug support function

A - 22 A - 22

Terms Description

QnA compatible 2C frame

(Formats 1 to 4)

QnA compatible 3C frame

(Formats 1 to 4)

QnA compatible 4C frame

(Formats 1 to 4)

QnA compatible 4C frame

(Format 5)

User frame

DISCONTINUED MODELS

One of the message formats for the serial communication module for performing communication

using the MC protocol and ASCII code data.

This is the same message format as the communication frame using the protocol for the QnA

series serial communication modules.

• QnA compatible 2C frame (Formats 1 to 4): QnA simplified frame (Formats 1 to 4)

• QnA compatible 3C frame (Formats 1 to 4): QnA frame (Formats 1 to 4)

• QnA compatible 4C frame (Formats 1 to 4): QnA extension frame (Formats 1 to 4)

One of the message formats for the serial communication module for performing communication

using the MC protocol and binary code data.

This is the same message format as the communication frame using the protocol for the QnA

series serial communication modules.

• QnA compatible 4C frame (Format 5): QnA extension frame (Format 5)

Data name when the fixed format portion of messages to be sent or received between a serial

communication module and an external device is registered in the module and used for sending

and receiving data. (The contents of a user frame data should conform to the specifications of the

external device.)

The data array of the head and tail sections of a message (transmission control code, serial

communication module station No., sum check, fixed data, etc.) to be sent and received is

registered in the serial communication module before use.

User frame is used in MC protocol on-demand functions and data communication functions which

use the non procedure protocol.

The following models are described in this manual, but have no longer been produced.

For the onerous repair term after discontinuation of production, refer to "WARRANTY" in this manual.

Model Production discontinuation

QJ71C24 January 2004

QJ71C24-R2 January 2004

A - 23 A - 23

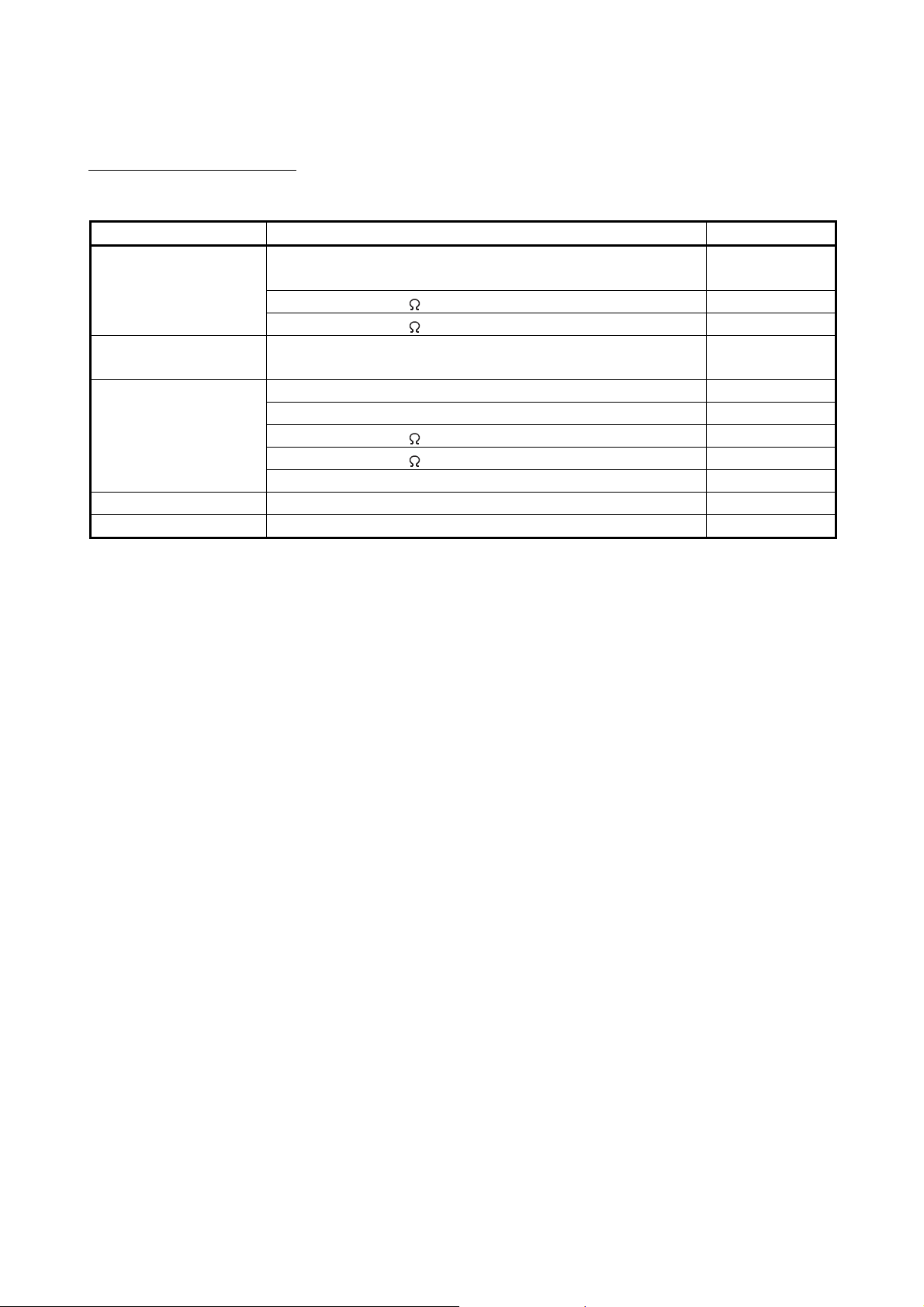

PRODUCT CONFIGURATION

The following lists the product configuration of the Q series serial communication modules.

Model Item name Quantity

QJ71C24N serial communication module or QJ71C24 serial

QJ71C24N or QJ71C24

QJ71C24N-R2 or

QJ71C24-R2

QJ71C24N-R4

SW2D5C-QSCU-E GX Configurator-SC Version 2 (1-license product) (CD-ROM) 1

SW2D5C-QSCU-EA GX Configurator-SC Version 2 (Multiple-license product) (CD-ROM) 1

communication module

Terminal resistor 330 ¼ W (for RS-422 communication) 2

Terminal resistor 110 ½ W (for RS-485 communication) 2

QJ71C24N-R2 serial communication module or QJ71C24-R2 serial

communication module

QJ71C24N-R4 serial communication module 1

RS-422/485 plug-in connector socket block 2

Terminal resistor 330 ¼ W (for RS-422 communication) 4

Terminal resistor 110 ½ W (for RS-485 communication) 4

Plate terminal (for connecting a braided shield cable) 4

1

1

A - 24 A - 24

1 OVERVIEW

MELSEC-Q

1 OVERVIEW

This manual describes the specifications for the QJ71C24N, QJ71C24N-R2,

QJ71C24N-R4, QJ71C24, QJ71C24-R2 serial communication module (hereinafter

referred to as "Q series C24"), as well as the procedures prior to starting the operation,

maintenance, inspection, data communication methods for use with external devices

and troubleshooting.

When applying the following program examples to the actual system, make sure to

examine the applicability and confirm that it will not cause system control problems.

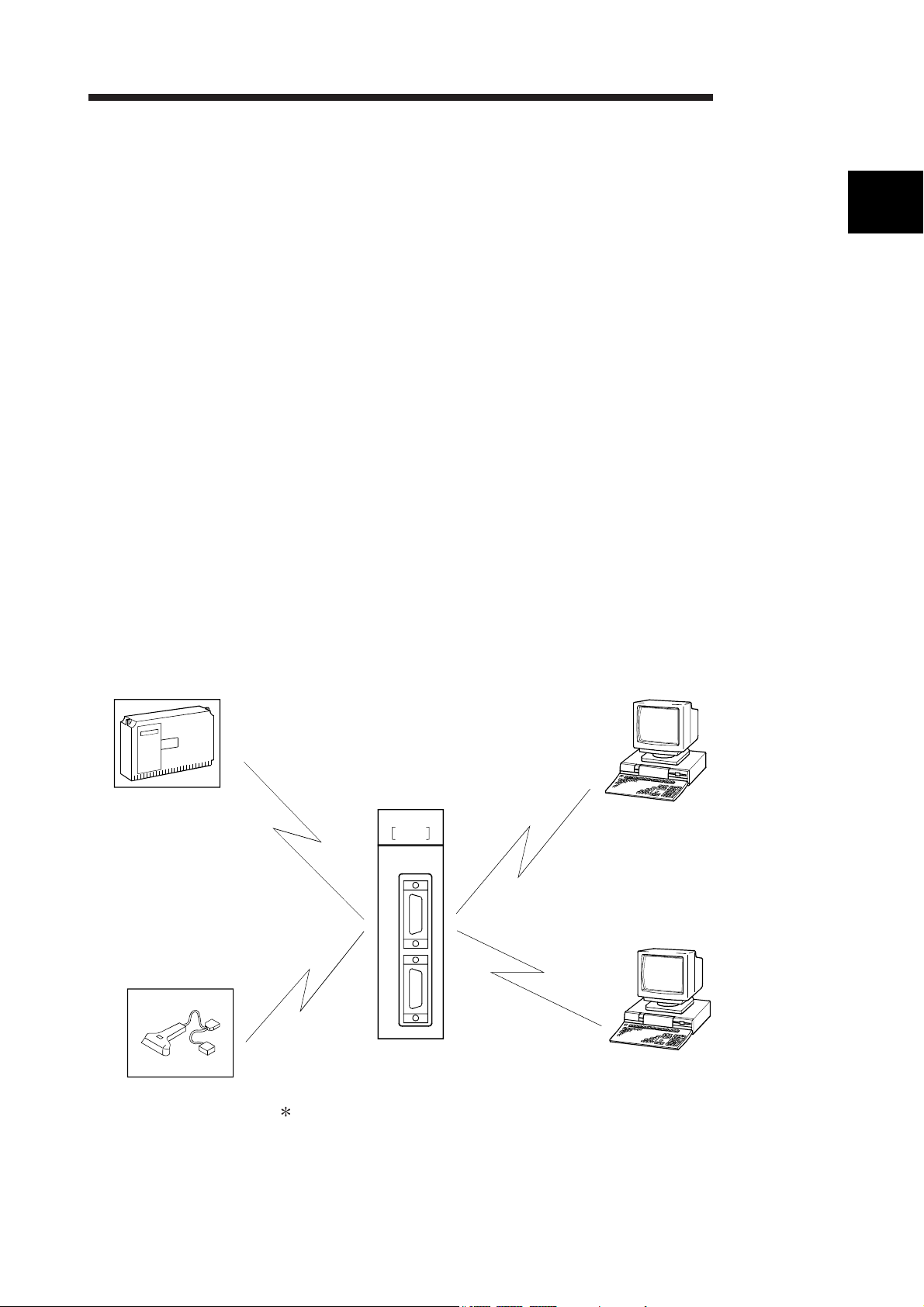

1.1 Overview of the Serial Communication Module

The Q series C24 is a module that connects the Q series programmable controller

CPU and an external device using an RS-232 or RS-422/485 line for serial

communication, in order to achieve the data communication described below.

By using a modem/terminal adapter, a public line (analog/digital) can be used for data

communication with a remote location.

• Programmable controller data collection/change from the external devices

(See the MELSEC Communication Protocol Reference Manual.)

• Programmable controller monitoring and control from the external devices (See the

User's Manual (Application).)

• Data receiving and sending in any formats that conform to the external device

specifications (See Section 1.2. (2), (3), and (4).)

• Collection of measured data from a measuring device (See Section 1.2. (2) and (4).)

• Operation of a programmable controller CPU that is connected to a personal

computer installed with GX Developer. (See the GX Developer Manual.)

1

• Collection of measured

data

• Collection of read data

QJ71C24-R2

RUN

ERR.

NEU

NEU

SD

SD

CH.1 CH.2

RD

RD

CH. 1

Being a convenient means of connection among different devices (personal

computers, display devices, printers, etc.), the serial communication line is the

most widely used medium on the market today.

• Programmable controller data

collection/change

• Programmable controller monitoring

and control from an external device

• Data receiving and sending in any

formats that conform to the external

device specifications

• GX Developer

• File writing/reading

• Device monitoring/testing

1 - 1 1 - 1

1 OVERVIEW

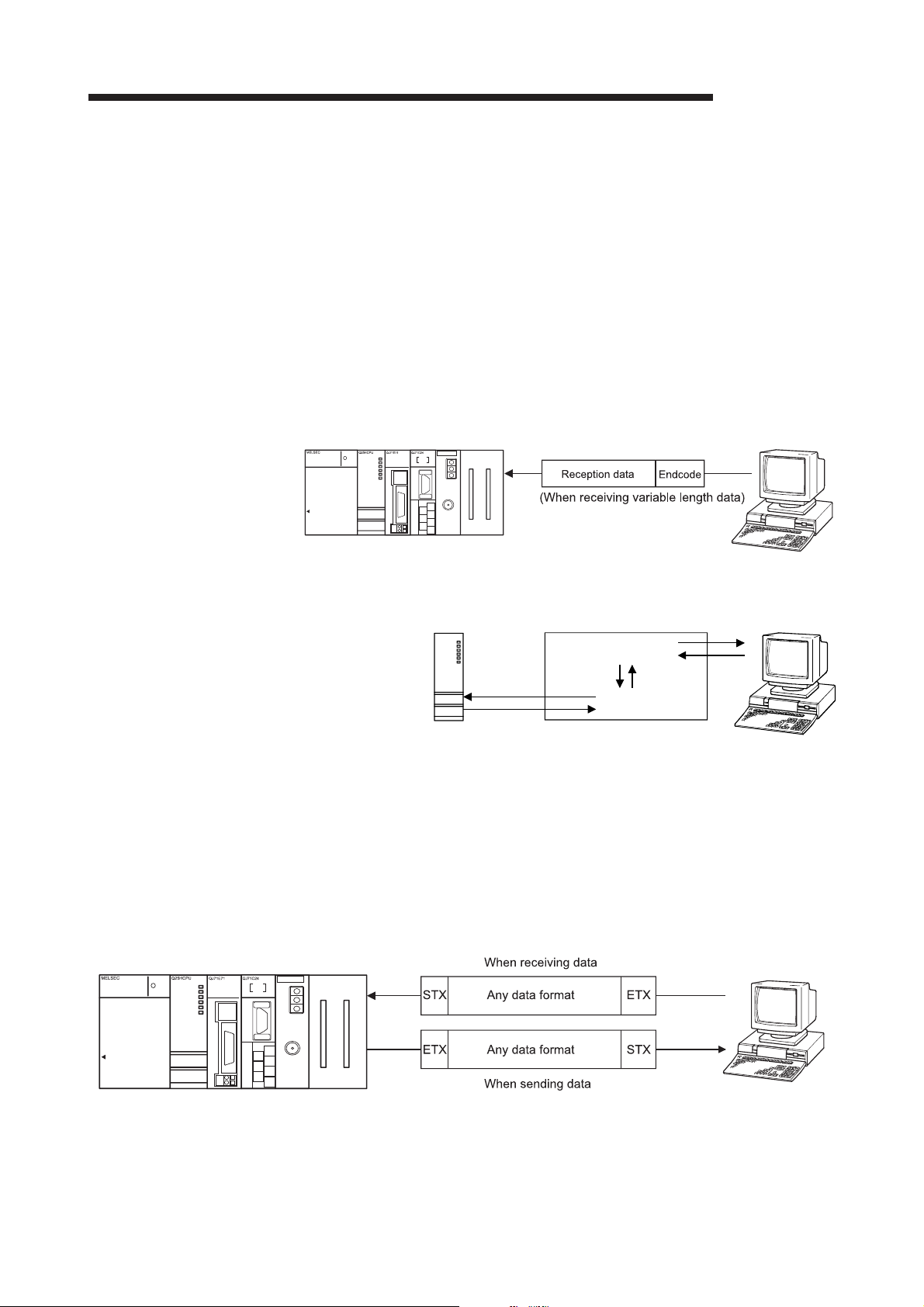

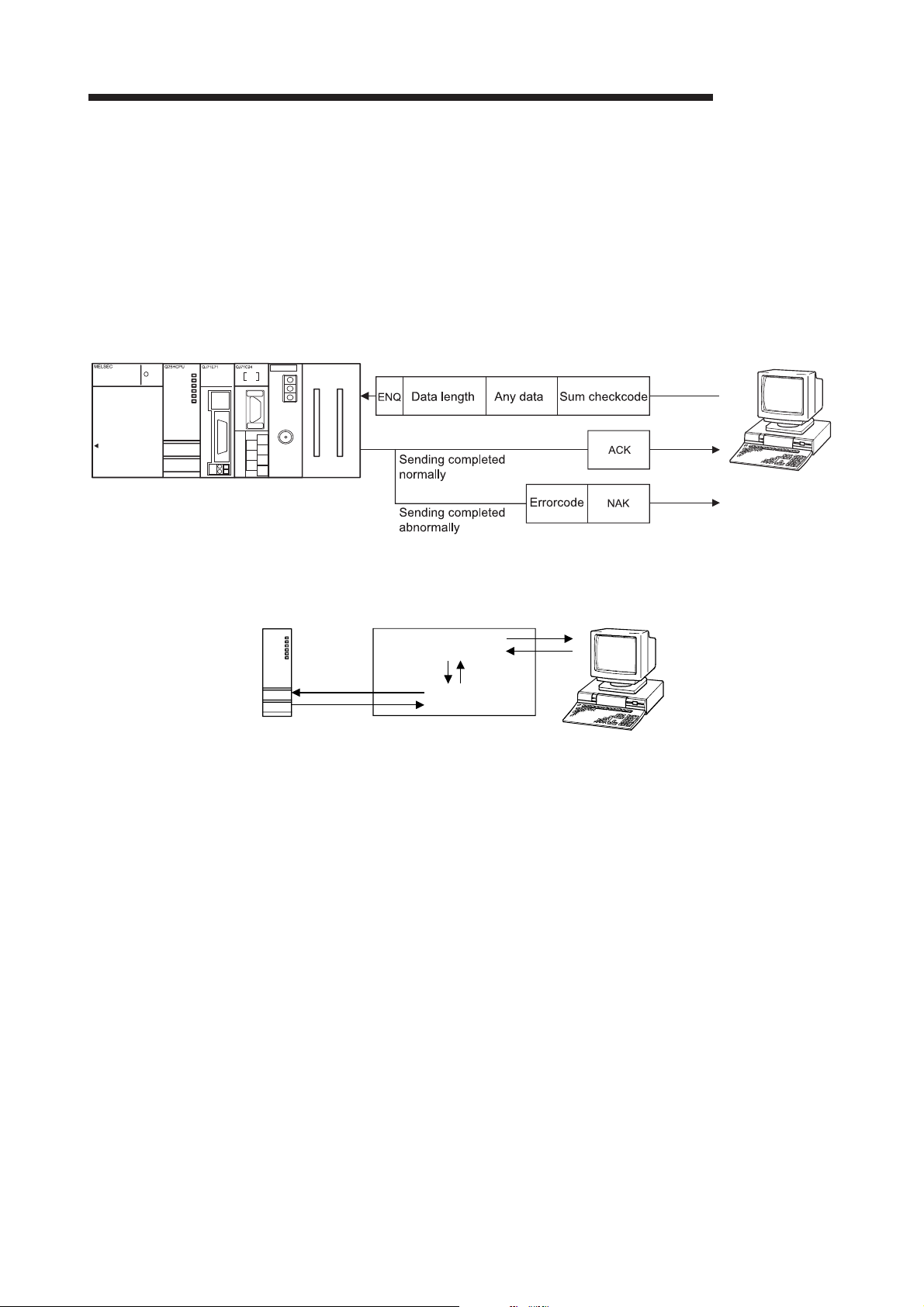

1.2 Features of the Serial Communication Module

The following describes the features of the Q series C24.

1

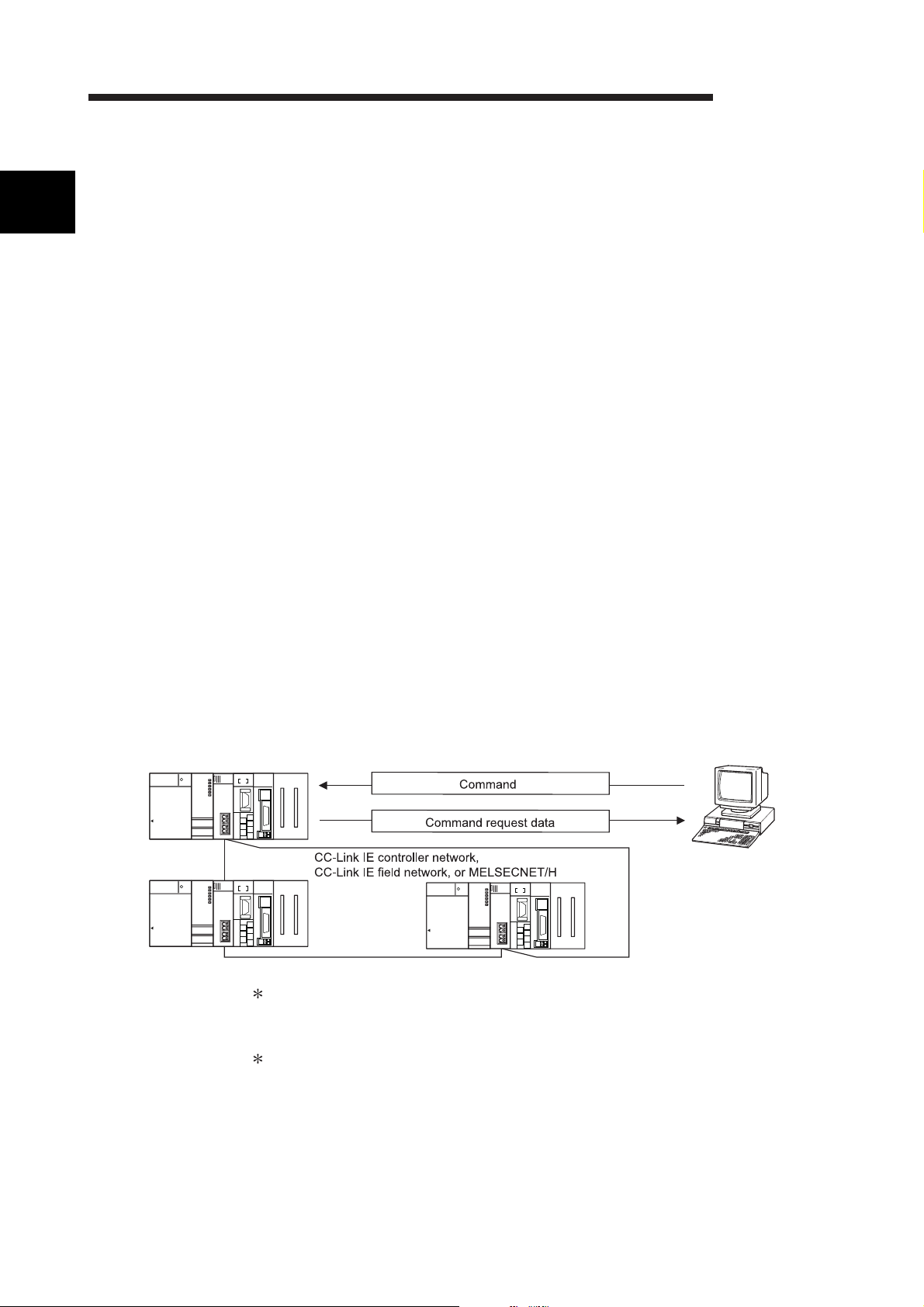

(1) Data communication based on the MELSEC communication

Q25HCPU

MELSEC

protocol (hereinafter referred to as the MC protocol)

(Details are explained in the MELSEC Communication Protocol Reference

Manual.)

(a) External devices can read/write the programmable controller device data

and sequence programs, and can monitor programmable controller

equipment status.

With the exception of the on-demand function described below, the

programmable controller does not require a sequence program because the

programmable controller sends and receives data based solely on

commands from external devices.

(b) Using the on-demand function, data can be sent from the programmable

controller CPU to the external devices in each frame format of the MC

protocol.

(c) Data communication can be performed using a program at the external

device side that has been created for communicating data with conventional

A/QnA series computer link module/serial communication modules.

(d) When an external device is a personal computer, use separately sold

communication support tools (MX Component). This allows a communication

program for the external device to be created, regardless of MC protocol's

transmitting/receiving procedure.

For details on MX Component, refer to Appendix 7 and the operating manual

of MX Component.

QJ71E71QJ71C24

MELSEC-Q

Q25HCPU

MELSEC

QJ71E71QJ71C24

Q25HCPU

MELSEC

QJ71E71QJ71C24

In the MELSECNET/H (MELSECNET/10 mode), other stations (including the

A/QnA series programmable controller CPUs) can be accessed during data link

operation.

The MC protocol is equivalent to the communication function using a dedicated