September. 2016

Model : TECHNICAL MANUAL

DIRECT EXPANSION COIL UNIT FOR LOSSNAY

GUG-01SL-E

GUG-02SL-E

GUG-03SL-E

Lossnay Return Air and Supply Air

Temperature Control

Now Possible!

i

CONTENTS

CHAPTER 1 What Dx-coil unit is

1. Basic function

...................................................................................................................................................

1

2. Two temperature control method

.....................................................................................................................

1

CHAPTER 2 System configurations

1. System pattern outline

....................................................................................................................................

3

2. Technical notes

.................................................................................................................................................

5

3. The conditions when Dx-coil unit is forcibly thermo-OFF

..................................................................................

9

4. Water level sensor

............................................................................................................................................

9

5. Drain pump operation

.......................................................................................................................................

9

CHAPTER 3 Specifications

1. Operation range

................................................................................................................................................

10

2. Connectable Lossnay unit and outdoor unit for each functions

........................................................................

10

3. Refrigerant pipe size information

......................................................................................................................

10

4. Specifications

....................................................................................................................................................

11

5. Characteristic curve

..........................................................................................................................................

13

CHAPTER 4 Outlines and Dimensions

1. Outlines and dimensions

...................................................................................................................................

16

2. Installation example

..........................................................................................................................................

18

CHAPTER 5 Wiring Diagram

1. Wiring diagram

..................................................................................................................................................

20

2. Connecting the power supply cable

..................................................................................................................

21

3. Connecting PZ-01RC

........................................................................................................................................

21

4. Connecting Lossnay unit

...................................................................................................................................

21

CHAPTER 6 Other Functions

1. Function setting

.................................................................................................................................................

22

2. Dip switch setting

..............................................................................................................................................

27

3. Lossnay functions

.............................................................................................................................................

27

CHAPTER 7 Remote Controller PZ-01RC

1. Remote controller PZ-01RC

..............................................................................................................................

28

2. Menu list

............................................................................................................................................................

28

3. Appearance

.......................................................................................................................................................

29

4. Outlines and dimensions

...................................................................................................................................

30

5. Initial setting

......................................................................................................................................................

31

6. Basic operations

...............................................................................................................................................

33

7. Troubleshooting

................................................................................................................................................

33

8. Timer and Weekly timer

....................................................................................................................................

34

9. Service

..............................................................................................................................................................

34

10. Others

...............................................................................................................................................................

34

CHAPTER 8 Refrigerant system diagram

1. Refrigerant system diagram

..............................................................................................................................

35

CHAPTER 9 Model selection and capacity calculation

...................................................................

36

CHAPTER 10 Performance Data

1. Air volume factor

..............................................................................................................................................

62

2. Performance curves

..........................................................................................................................................

62

3 . Capacity ratio against corrected refrigerant pipe length

...................................................................................

63

4. Quick reference for the air condition difference factor C2

.................................................................................

63

5. Cooling capacity and SHF (sensible heat factor) table against return and outdoor air temperature.

...............

65

ii

1

CHAPTER1

What Dx-coil unit is

PZ-01RC

SA

RA

OA

EA

Outdoor unit

Lossnay unit

Power supply

Power supply

Dx-coil unit

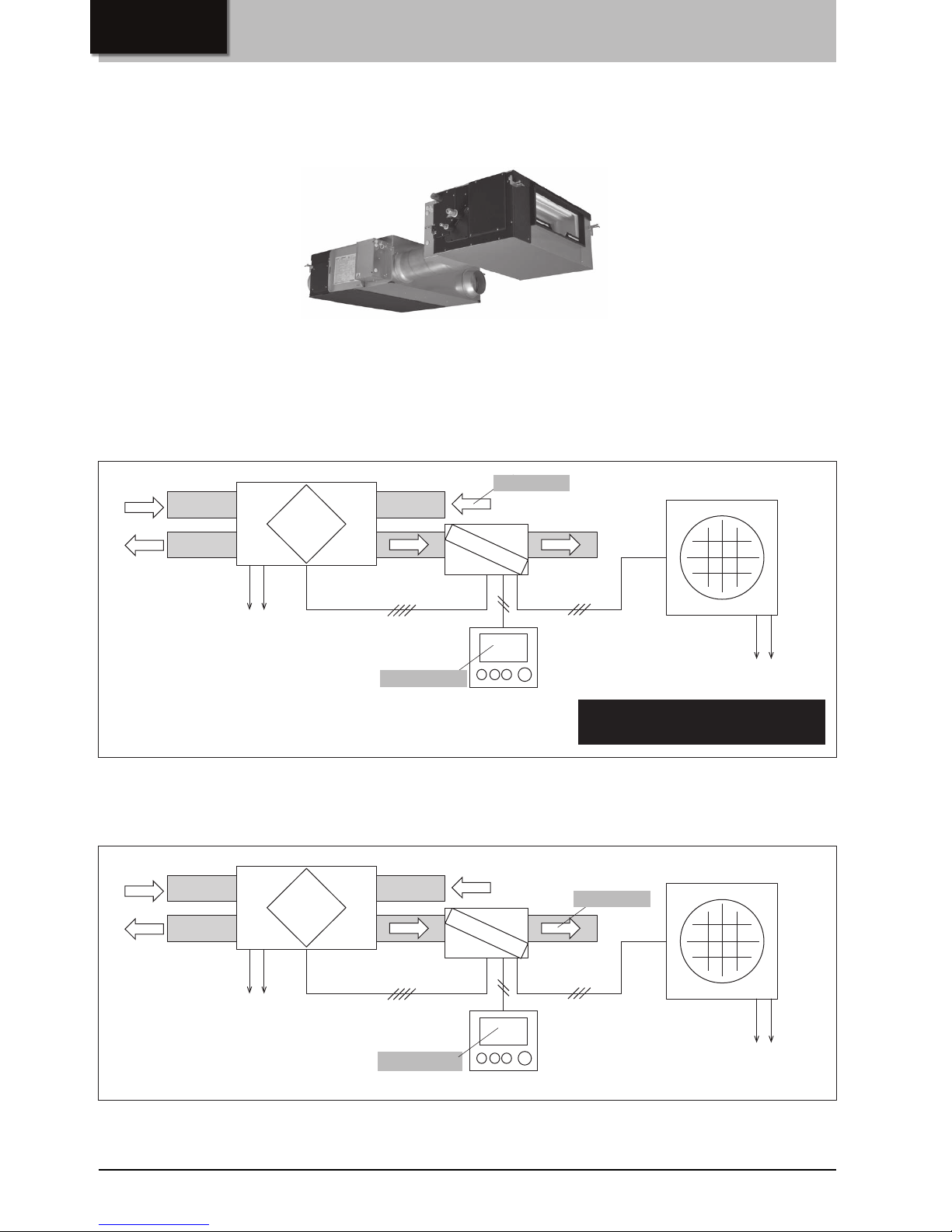

Dx-coil (Direct Expansion Coil) unit is a kind of temperature control equipment working with Lossnay unit and Mr.Slim outdoor

unit to control Return Air temperature or Supply Air temperature.

2.2 SA (Supply Air) temperature control

1. Basic function

2.Two temperature control method

2.1 RA (Return Air) temperature control

As same as air-conditioner, users set the target return air temperature on the remote controller and then Dx-coil unit will operate

to heat up or cool down the room temperature.

This picture shows the system of LGH-100RVX-E and GUG-02SL-E as example.

Users set the target supply air temperature on the remote controller and then Dx-coil unit will maintain the supply air

temperature close to the setting temperature.

Connection image

Lossnay unit

Dx-coil unit

PZ-01RC

SA

RA

OA

EA

Outdoor unit

Lossnay unit

Power supply

Power supply

Dx-coil unit

The dedicated remote controller for the Dx-coil unit is

described as “PZ-01RC” in this manual.

It is not an official model name.

OA: Outdoor air

EA: Exhaust air

SA: Supply air

RA: Return air

Setting temp.

Setting temp.

Target temp.

Target temp.

2

CHAPTER1 What Dx-coil unit is/ 2.Two temperature control method

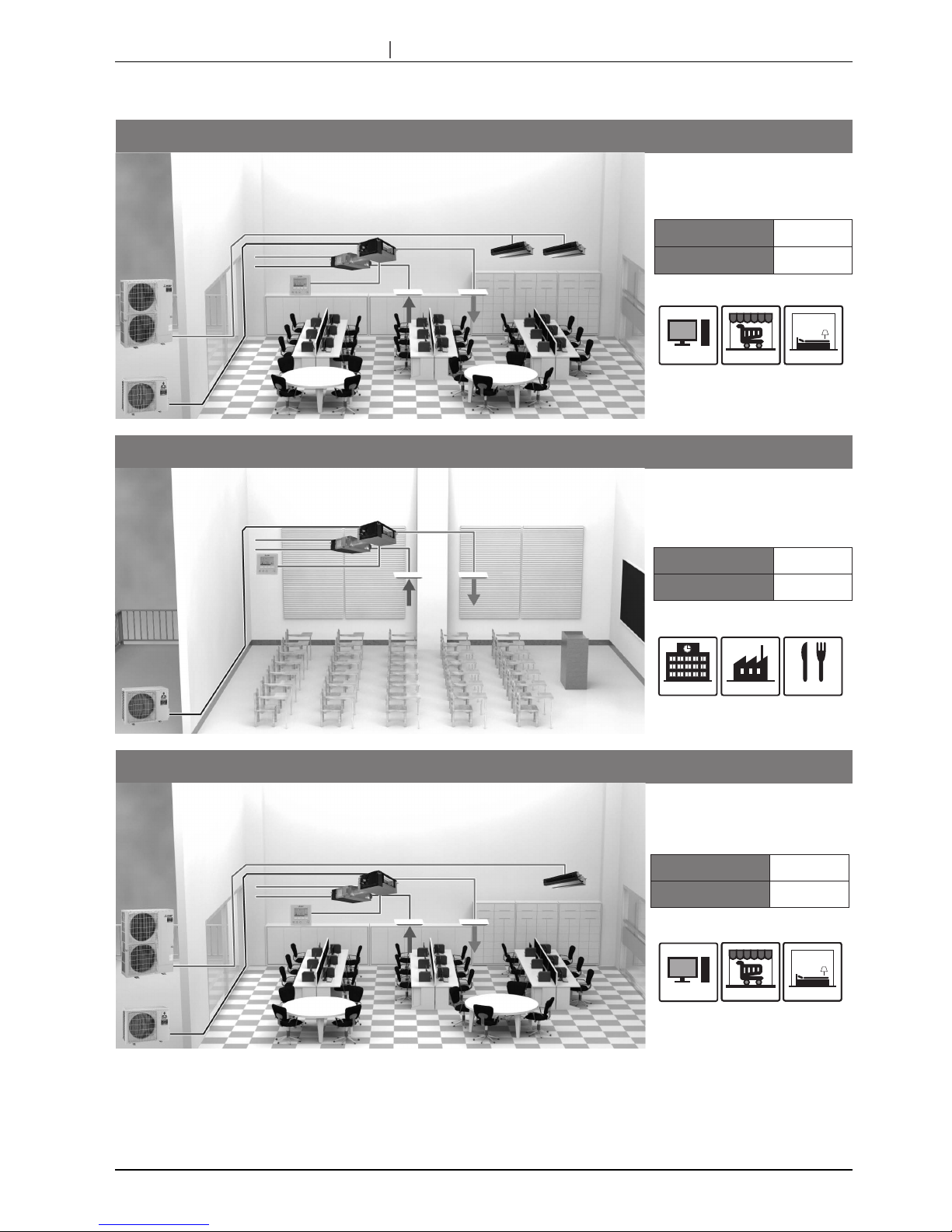

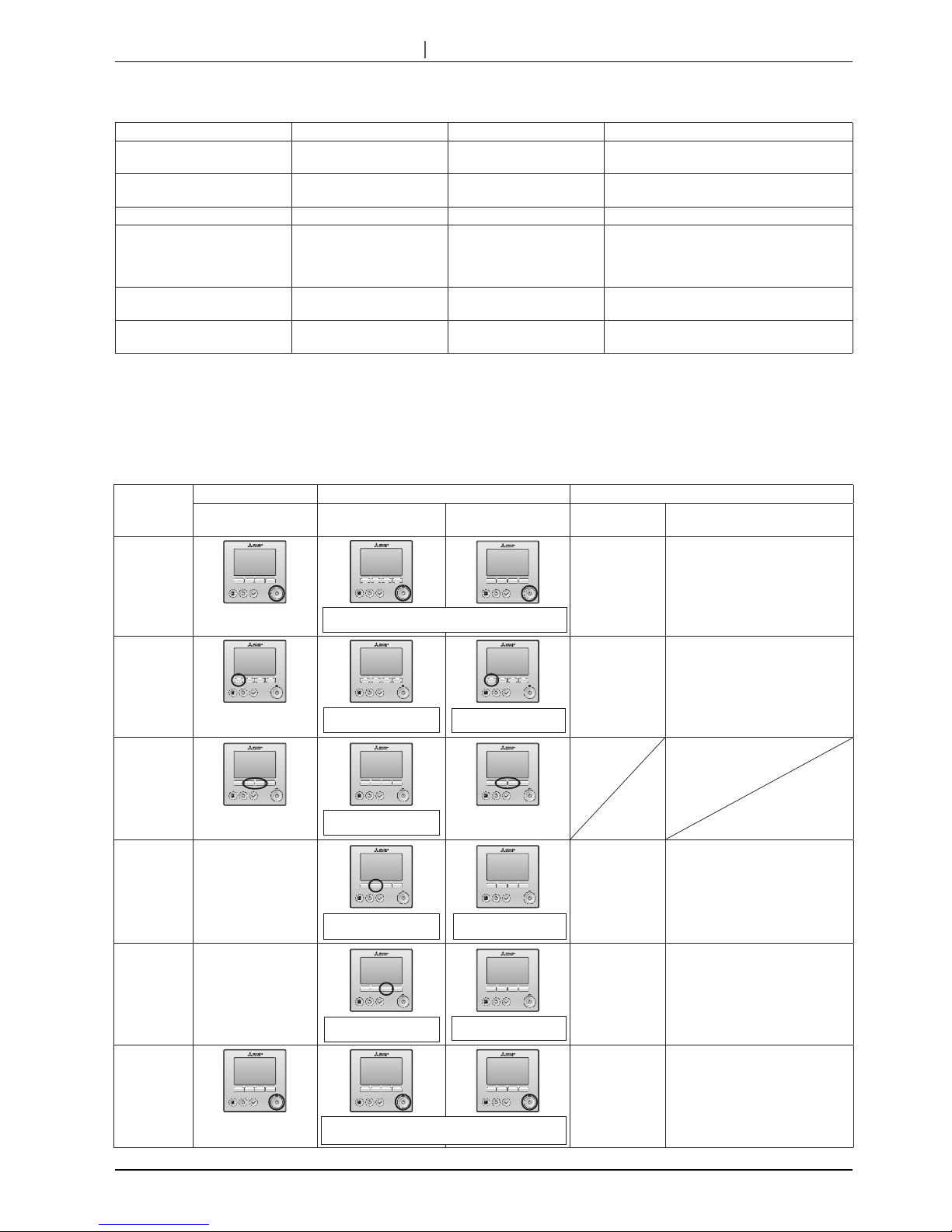

2.3 Application examples

Supplemental Air-conditioning System

Target Segment:

Supplemental air-conditioning systems

that combine the use of Dx-coil and

Lossnay units are now possible.

Offices

Small shops

Hotels

RA Temperature Control

Temperature setting range

Heating: 17-28°C / Cooling: 19-30°C / Auto: 19-28°C

Dx-coil unit

Dx-coil unit RC

Mr.Slim

Power lnverter

Series

Lossnay

Necessary fresh

air volume

Medium

Necessary Heating and

Cooling capacity

Medium

Main Air-conditioning System

Target Segment:

If the required heating and cooling

capacity is not so high, a Dx-coil and

Lossnay package solution is possible

for air-conditioning and ventilation

needs.

Schools Factories

Restaurants

RA Temperature Control

Temperature setting range

Heating: 17-28°C / Cooling: 19-30°C / Auto: 19-28°C

Necessary fresh

air volume

Large

Necessary Heating and

Cooling capacity

Small

Outdoor Air Treatment

Target Segment:

Controlling the temperature of outdoorair supplied via the Dx-coil and Lossnay

units simplifies air-conditioning design

and control.

Offices

Small shops

SA Temperature Control

Temperature setting range

Heating: 17-28°C / Cooling: 12-30°C

Hotels

Necessary fresh

air volume

Medium

Necessary Heating and

Cooling capacity

Medium

Dx-coil unit

Dx-coil unit RC

Lossnay

Mr.Slim

Power lnverter

Series

Mr.Slim

Power lnverter

Series

Dx-coil unit

Dx-coil unit RC

Lossnay

3

CHAPTER2

System configurations

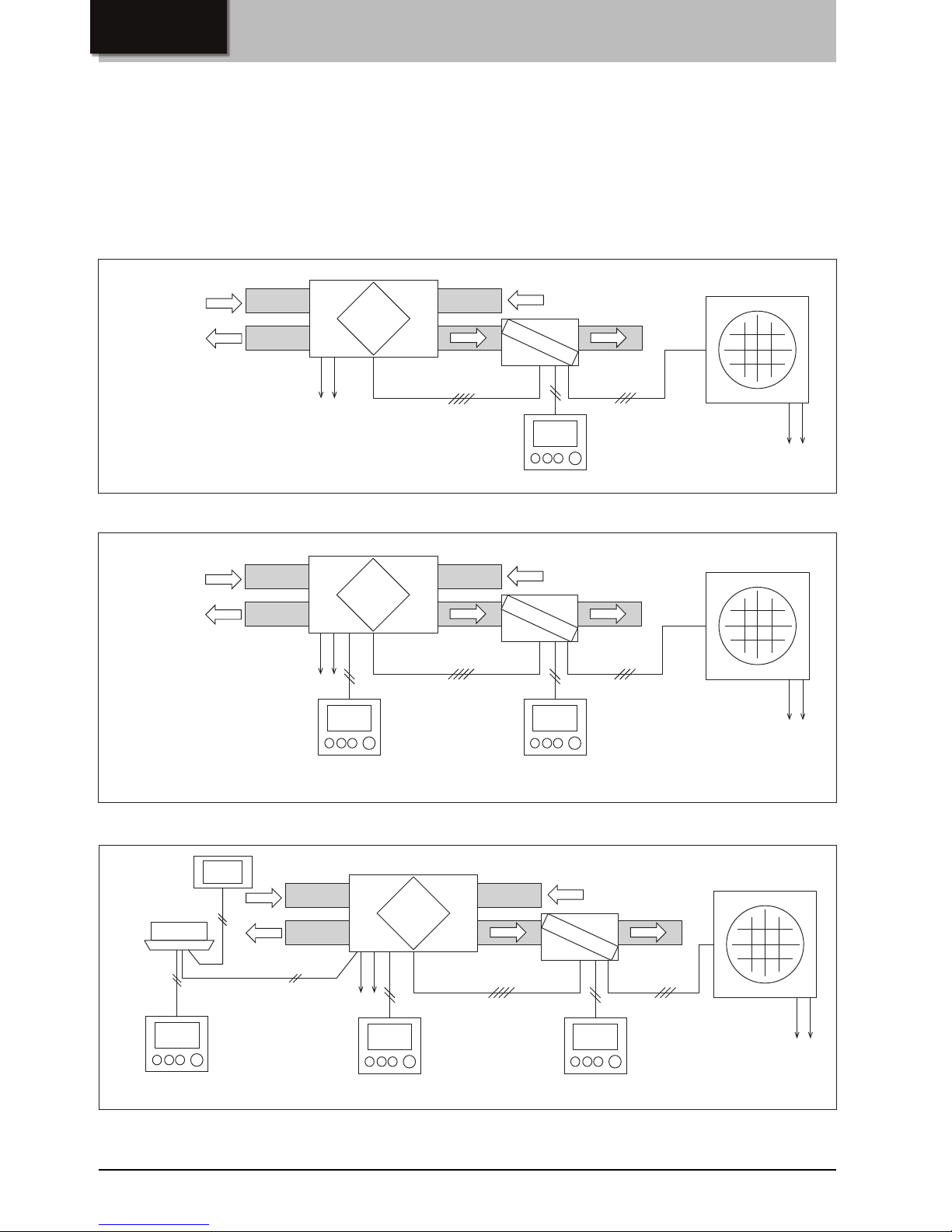

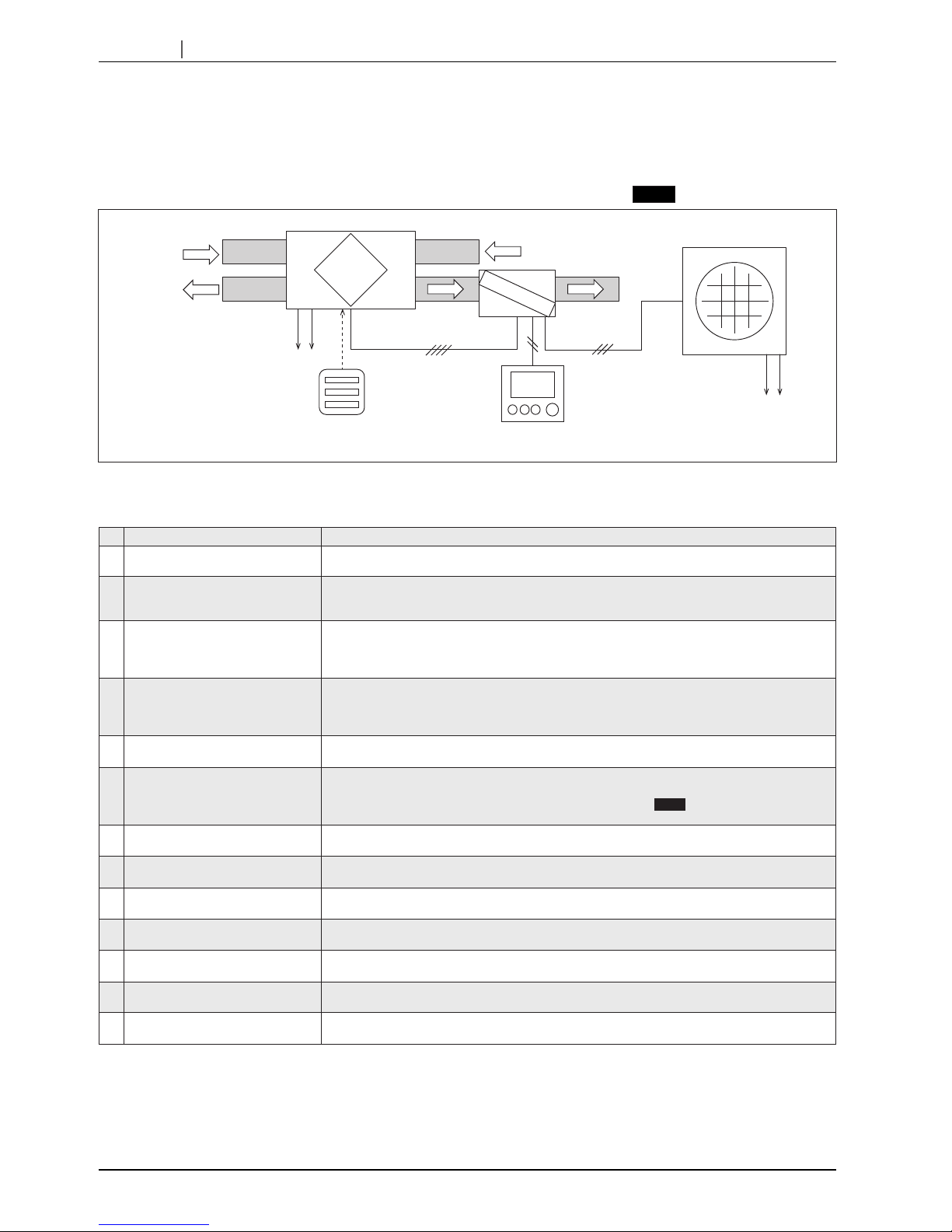

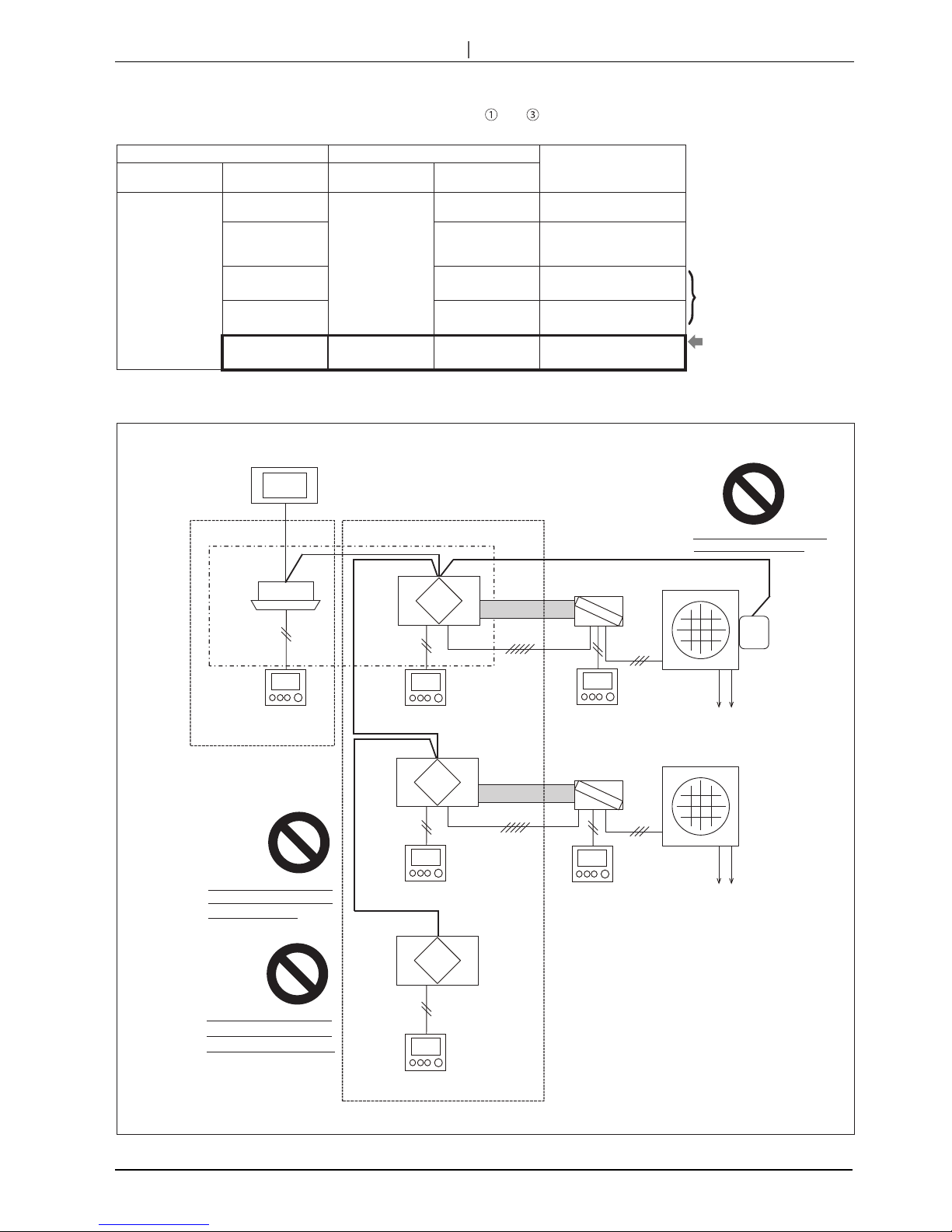

The system of Lossnay unit and Dx-coil unit can be used as a few system patterns.

• System pattern X: One remote controller

• System pattern Y: Two remote controllers

• System pattern Z: M-NET connection

Depending on the pattern, the way to operate system, available functions, information can be monitored etc. are different. See

the following gures and tables.

1. System pattern outline

1.1 System pattern X: One remote controller

1.2 System pattern Y: Two remote controllers

1.3

System pattern Z: M-NET connection

(Interlocked with City Multi indoor unit when necessary)

<CAUTION>

Dx-coil unit cannot be monitored nor operated from M-NET system controller.

PZ-01RC

SA

RA

OA

EA

Outdoor unit

Lossnay unit

Power supply

Power supply

Dx-coil unit

PZ-01RC

Lossnay remote controller

(PZ-61DR-E)

SA

RA

OA

EA

Outdoor unit

Lossnay unit

Power supply

Power supply

Dx-coil unit

Lossnay remote controller

(PZ-61DR-E if necessary)

MA remote controller

(If necessary)

M-NET system controller

(If necessary)

City Multi indoor unit

(Interlocked with Lossnay

when necessary)

PZ-01RC

SA

RA

OA

EA

Outdoor unit

Lossnay unit

Power supply

Power supply

Dx-coil unit

4

CHAPTER2 System configurations/ 1. System pattern outline

*1: When one of the two remote controllers is switched ON/OFF, the other remote controller switches ON/OFF synchronously.

*2: When one of the three remote controllers is switched ON/OFF, the other remote controllers switch ON/OFF synchronously.

Or when the indoor unit is switched ON/OFF, the system of the Lossnay unit and Dx-coil unit switches ON/OFF synchronously.

*3: Cannot be controlled by M-NET system controller nor MA remote controller of the indoor unit.

*4: Fan speeds can be changed by 0-10VDC input or a volt free contact and can be xed at the fan speed 3 if necessary.

*5: The ventilation mode is set to the heat recovery mode during the heating and fan modes.

The ventilation mode can be set to the bypass ventilation mode by a volt-free contact if necessary.

*6:

When Lossnay is interlocked with City Multi indoor unit, the target temperature information and the operation mode information from Dx-coil have a priority used for

automatic ventilation mapping or Night-purge starting condition etc..

1.4 Operation from each remote controller

System pattern X System pattern Y System pattern Z

ON/OFF From PZ-01RC From PZ-01RC or

PZ-61DR-E *1

From one of the remote controllers or when

the indoor unit is switched ON/OFF *2

Operation mode

[Heating/Cooling/Fan]

From PZ-01RC From PZ-01RC Only from PZ-01RC *3

Temp. setting From PZ-01RC From PZ-01RC Only from PZ-01RC *3

Fan speed

[FS1 / FS2 / FS3 / FS4]

Fixed at FS4 *4 Can be changed from

PZ-61DR-E.

Can be changed from PZ-61DR-E, M-NET

system controller or MA remote controller (for

the indoor unit). The selectable fan speeds

depend on the model of remote controller.

Ventilation mode

[Heat recovery / Bypass / Auto]

Fixed at automatic mode *5 Can be changed from

PZ-61DR-E.

Can be changed from PZ-61DR-E or M-NET

system controller.

Remarks - - Dx-coil unit cannot be monitored nor operated

from M-NET system controller.*6

Basic

operation

System pattern X System pattern Y Unit status

Dx-coil unit remote

controller (PZ-01RC)

Lossnay unit remote

controller (PZ-61DR-E)

Dx-coil unit remote

controller (PZ-01RC)

Lossnay unit Dx-coil unit

ON ON ON

Heating

Cooling

Fan

Auto

Ventilating

Heating and Cooling:

Thermo-ON or thermo-OFF depending

on temperature conditions

Fan: Always thermo-OFF (ventilatio only)

Auto: Only available at RA temp. control

Temperature

setting

Fan speed

Fixed at fan speed 4

(Fan speed can

be changed by the

external input to

Lossnay and be xed

at fan speed 3 if

necessary.)

Operating at

selected fan

speed

When Lossnay unit goes to fan

speed 1 or 2 during thermo-ON,

Dx-coil unit becomes thermo-OFF

forcibly.

Ventilation

mode

Fixed at automatic mode

(The ventilation mode is

always the heat recovery

mode during the heating

and fan mode.)

Operating

at selected

ventilation mode

The Dx-coil unit can be switched

thermo-ON in any ventilation

mode depending on temperature

conditions.

OFF OFF OFF

When one of the two remote controllers is switched ON,

the other remote controller switches ON synchronously.

Cannot be changed by

PZ-61DR-E.

Heating/Cooling/Fan/Auto

Cannot be changed by

PZ-61DR-E.

Fan speed 1, 2, 3 or 4

Cannot be changed by

PZ-01RC.

Heat recovery/Bypass/Auto

Cannot be changed by

PZ-01RC.

When one of the two remote controllers is switched OFF,

the other remote controller switches OFF synchronously.

For system pattern Z, the functions that can be used depend on the model of remote controllers.

5

CHAPTER2 System configurations/ 2.Technical notes

1.5 External fan speed control without Lossnay remote controller

When Lossnay remote controller (PZ-61DR-E) is not used in the system pattern X or Z, Lossnay fan speed can be controlled by

external input like 0-10VDC (CN26) or volt-free contact (CN17).

Refer to the installation manual and the technical manual of Lossnay unit for more detailed information such as how to set, how

to select.

The selection of Temp. priority mode or Fan speed priority mode can be set. Please refer to No.10 on page 25 and 26.

2. Technical notes

For the details of No.8, 9, 10, 11 and 12, see the following pages.

PZ-01RC

SA

RA

OA

EA

Outdoor unit

Lossnay unit

Power supply

Power supply

Dx-coil unit

0-10VDC input(CN26)

or

volt-free contact(CN17)

CO

2

sensor

(field supply)

No.

Item Contents

1

Fan speed 1 and 2 When Lossnay supply fan is the fan speed 1 or 2, Dx-coil unit always switches thermo-OFF.

2

Night purge When Lossnay is in Night purge mode, Dx-coil unit always switches thermo-OFF and PZ-01RC is

the same as the normal operation screen.

PZ-61DR-E or AE-200E is required for the Night-purge function.

3

Heating stops when the OA temp. is

19 ˚C or higher

[GUG-03SL-E, SA temperature control and heating mode only]

When the OA temperature is 19 ˚C or higher, Dx-coil unit switches thermo-OFF to protect the

compressor of the outdoor unit.(This “OA temperature” is the detected temperature by outdoor

unit. It is not the detected temperature by Lossnay unit.)

4

Intermittent operation - When the OA temperature is between -10 ˚C and -15 ˚C, Lossnay oparates 60 minutes ON and

10 minutes OFF. During the ‘10 minutes OFF’, Dx-coil unit switches thermo-OFF.

- When the OA temperature is lower than -15 ˚C, Lossnay operates 5 minutes ON and 55 minutes

OFF. During the ‘5 minutes ON’, Dx-coil unit switches thermo-OFF.

5

Defrost and heating standby mode During defrost and heating standby mode, Lossnay supply fan stops but exhaust fan continues to

run as factory setting.

6

Error indication During heating or cooling modes, PZ-01RC displays an error code on its screen.

During fan mode, PZ-01RC changes to heating mode and displays an error code. If automatic

change to heating mode is not required, please set the function

No.7

to pattern B. Refer to page

24 for details.

7

Drain pump The drain pump operates during cooling mode and operates for 6 minutes after Dx-coil unit stops.

The drain pump will make a noise while operating.

8

One-to-one connection For the system, the number of Lossnay unit, Dx-coil unit, PZ-01RC and outdoor unit must be one.

Multiple-units connection is prohibited.

9

PZ-43SMF-E

PZ-60DR-E

PZ-43SMF-E and PZ-60DR-E are prohibited to use in the system of Lossnay and the Dx-coil unit.

10

Interlocking with Mr. Slim indoor unit Interlocking Mr. Slim indoor unit with Lossnay unit by using CN2L connector is prohibited.

11

One system in one group If the system is on M-NET, only one system can be used within a group. Multiple systems in one

group is prohibited. One system and Lossnay unit(s) in one group is also prohibited.

12

M-NET adapter Do not use M-NET adapter for the outdoor unit.

13

Apportioned electricity charge

function of AE-200E

Not available

6

CHAPTER2 System configurations/ 2.Technical notes

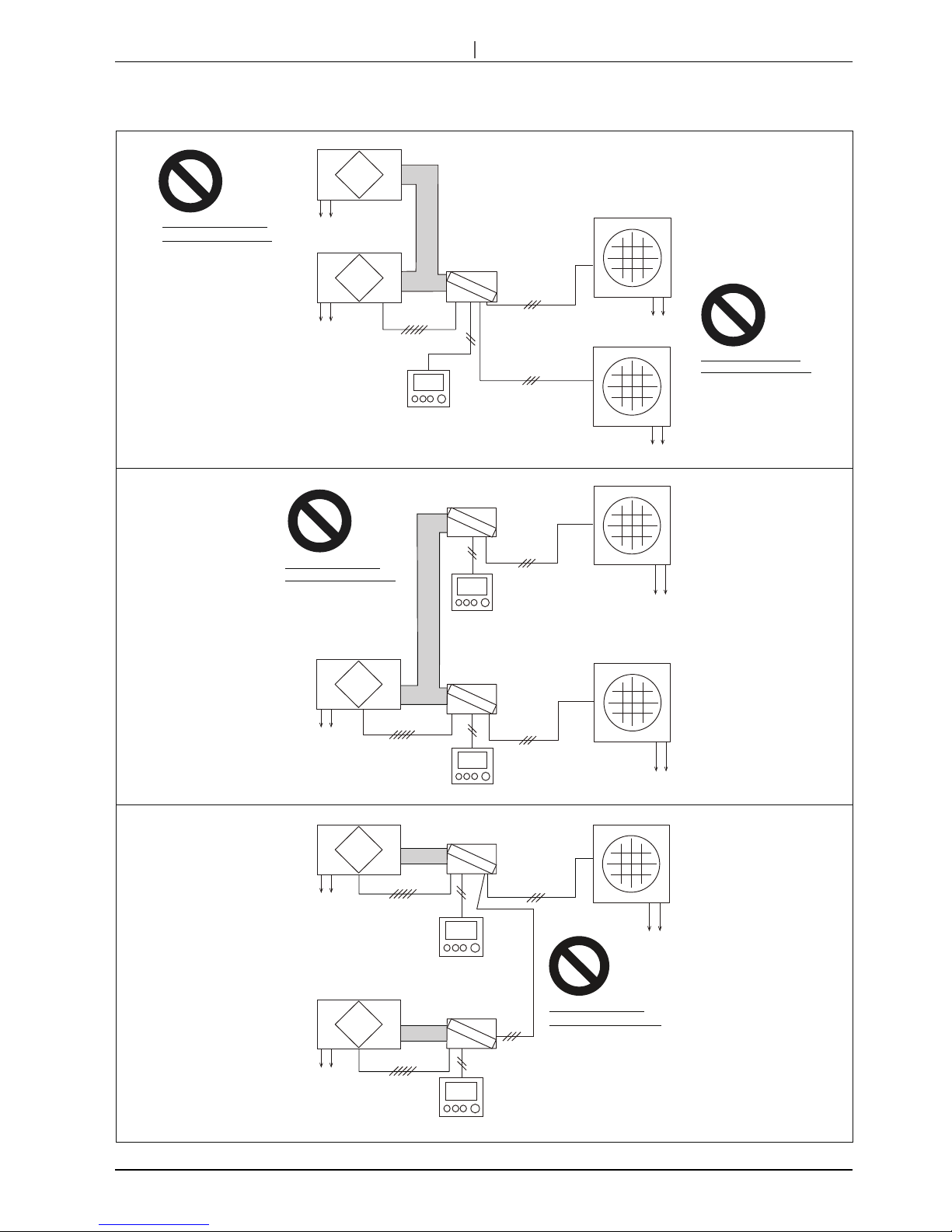

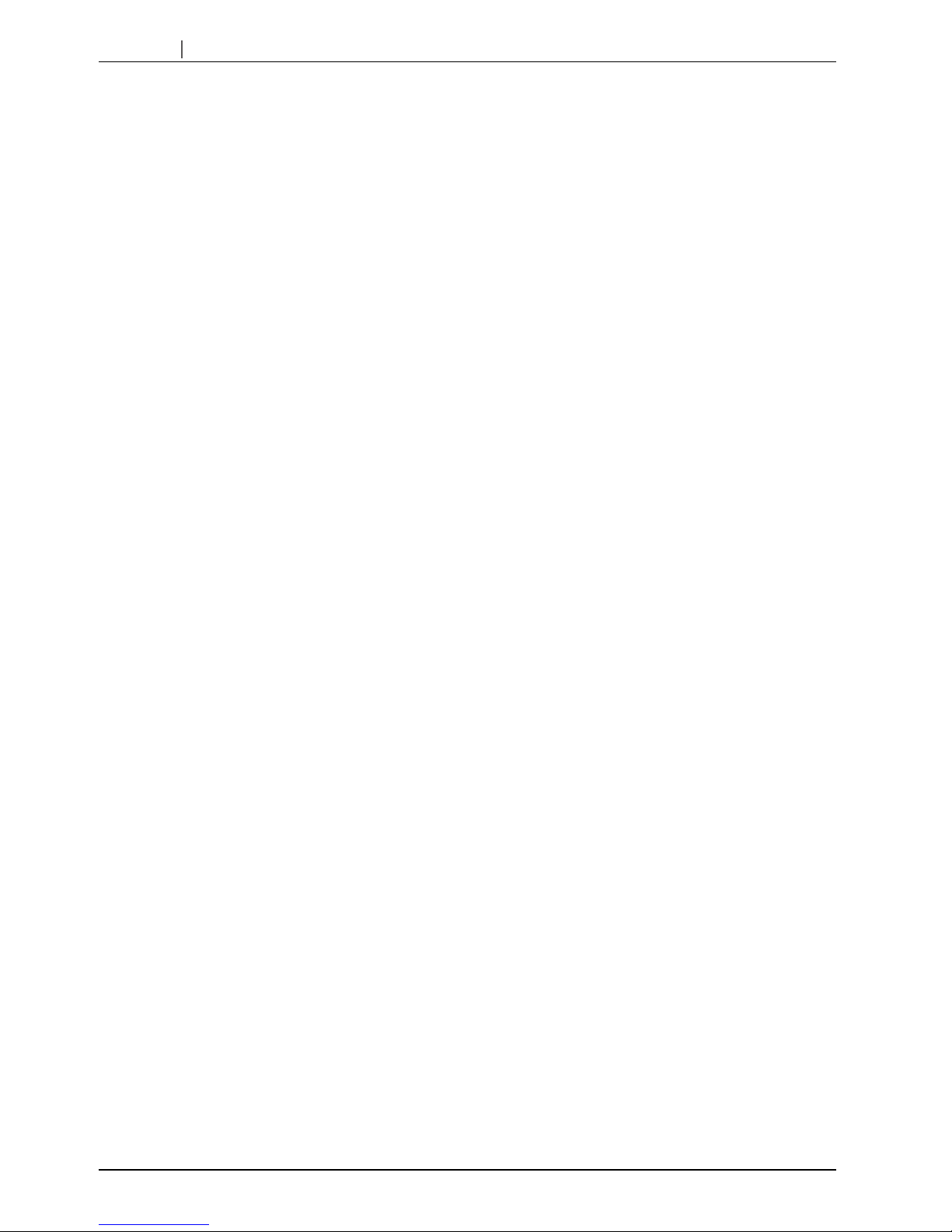

Following congurations are bad examples. Do not construct systems same as below.

Lossnay unit

Dx-coil unit

Dx-coil unit

Multiple Dx-coil units

connection is prohibited.

Dx-coil unit

Multiple Dx-coil units

connection is prohibited.

Dx-coil unit

Lossnay unit

Outdoor unit

Power supply

Power supply

Power supply

Lossnay unit

Power supply

Multiple Lossnay units

connection

is prohibited.

Outdoor unit

PZ-01RC

Multiple outdoor units

connection is prohibited.

Dx-coil unit

Outdoor unit

Power supply

PZ-01RC

Outdoor unit

Power supply

PZ-01RC

Power supply

PZ-01RC

Lossnay unit

Power supply

PZ-01RC

Lossnay unit

Power supply

Outdoor unit

Power supply

Prohibition for multiple connection.

7

CHAPTER2 System configurations / 2.Technical notes

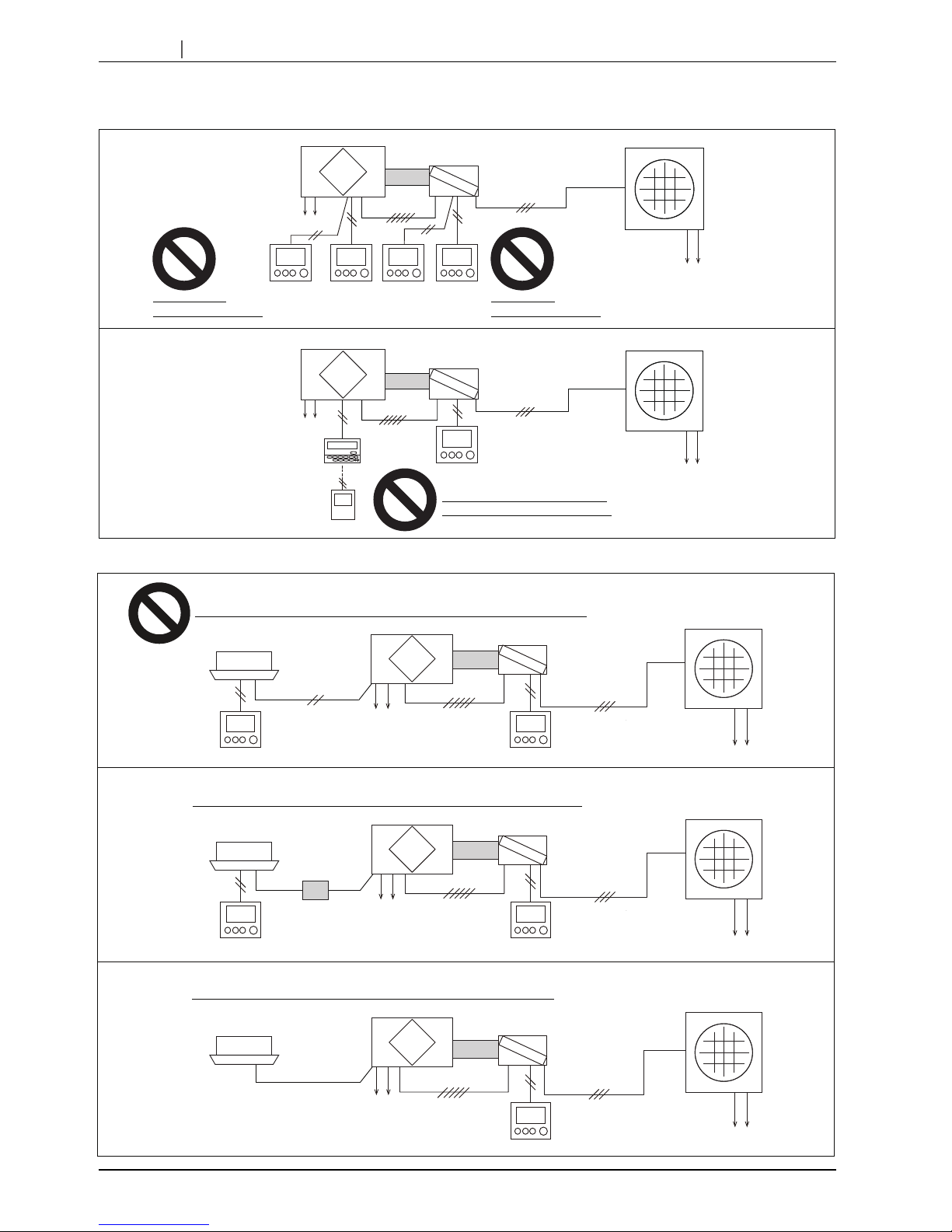

Following congurations are bad examples. Do not construct systems same as below.

Prohibition for TM2 connection of Lossnay.

Two PZ-01RC

connection is prohibited.

Two PZ-61DR-E

connection is prohibited.

Dx-coil unit

PZ-60DR-E

PZ-60DR-E connection is prohibited.

PZ-43SMF-E connection is prohibited.

PZ-43SMF-E

Dx-coil unit

PZ-01RC

Lossnay unit

Power supply

Outdoor unit

Power supply

PZ-01RC

PZ-01RC

Lossnay unit

Power supply

Power supply

Outdoor unit

PZ-61DR-EPZ-61DR-E

Mr. Slim

indoor unit

MA remote controller

Interlocking Mr. Slim indoor unit with Lossnay unit by using CN2L connector is prohibited.

CN2L

Dx-coil unit

External

device

Interlocking external device with Lossnay unit by using TM2 ①and ③is available.

OK

e.g. Non-Mitsubishi

Air-conditioner

Dx-coil unit

TM2 ①③

TM2 ①③

Mr. Slim

indoor unit

MA remote controller

CN2L

Dx-coil unit

PZ-01RC

Lossnay unit

Power supply

Outdoor unit

Power supply

PZ-01RC

PZ-01RC

Lossnay unit

Power supply

Power supply

Power supply

Power supply

(Optional)

Interlocking Mr. Slim indoor unit with Lossnay unit by using PAC-SF40RM-E is available.

OK

PAC-SF40RM-E

Lossnay unit

Outdoor unit

Outdoor unit

Prohibition for Lossnay remote controller.

8

CHAPTER2 System configurations / 2.Technical notes

<CAUTION>

When interlocking with Mr.Slim or external device through TM2 and , there is a restriction to use “ON interlock mode” ,

“OFF interlock mode” and “External priority ON/OFF interlock mode” of Lossnay unit.

DIP-SW PZ-61DR-E

Interlock setting

SW No. Setting Function No. Setting Data

SW5-7

SW5-8

-

15

0

(Factory setting)

DIP-SW priority

5-7 OFF

5-8 OFF

(Factory setting)

1 a) ON/OFF interlock mode

5-7 ON

5-8 OFF

2 b) ON interlock mode

5-7 OFF

5-8 ON

3 c) OFF interlock mode

5-7 ON

5-8 ON

4

d) External priority ON/

OFF interlock mode

Not available at anytime

with Dx-coil unit.

Available only when

PZ-61DR-E is connected

or M-NET system

controller is connected.

Following diagrams are bad examples. Do not construct systems same as below.

M-NET system

controller

Lossnay unit

Lossnay unit

Lossnay unit

Dx-coil unit

Outdoor unit

PZ-01RC

PZ-01RC

Lossnay remote controller

(PZ-61DR-E, if necessary)

Indoor unit

Power supply

Power supply

MA remote controller

(If necessary)

Group 1

Group 2

Lossnay remote controller

PZ-61DR-E, if necessary)

Lossnay remote controller

(PZ-61DR-E, if necessary)

M-NET

adapter

To use M-NET adapter for the

outdoor unit is prohibited.

Lossnay and Dx-coil system

and

normal Lossnay unit(s)

cannot be set in same group.

Multiple systems of Lossnay

unit and Dx-coil unit in one

group is prohibited.

Outdoor unit

Dx-coil unit

Prohibition for M-NET system.

9

CHAPTER2

System configurations

/

3. The conditions when Dx-coil unit is forcibly thermo-OFF/4. Water level sensor/5. Drain pump operation

3. The conditions when Dx-coil unit is forcibly thermo-OFF

4. Water level sensor

5. Drain pump operation

Under the conditions listed below, Dx-coil unit is always and forcibly thermo-OFF. Dx-coil unit cannot be thermo-ON for about 10

minutes after the condition is canceled.

• When the supply fan of Lossnay unit is stopping, fan speed 1 or fan speed 2.

• When the Lossnay unit is operating at Night-purge mode.

• When outdoor air temperature detected by a thermistor in Lossnay unit is less than -15˚C.

• When outdoor air temperature detected by a thermistor in Outdoor unit is more than 19˚C, if GUG-03SL-E is used at SA

temperature control and heating mode.

• When the system (Lossnay unit, Dx-coil unit, Outdoor unit) has an error.

The Dx-coil unit has a water sensor to detect the water level in the drain pan and has a drain pump to drain the condensation

water during cooling mode.

If the drain pump cannot drain the water properly, the water level in the drain pan increases and the water sensor detects the

water, and then nally an error occurs to avoid the water overow.

During the error is occurring, the supply fan of Lossnay unit will continue to run at fan speed 2 or 1 to avoid that the water y

out from the product.

The drain pump becomes ON at the conditions listed below.

• When Dx-coil unit is cooling mode.

• When the water sensor is detecting the water.

• When the lead wire connector that should be connected CN10 of PCB B is disconnected.

• When the drain pump test run switch is ON.

The drain pump continues to run for six minutes after the condition is canceled except for the test run.

10

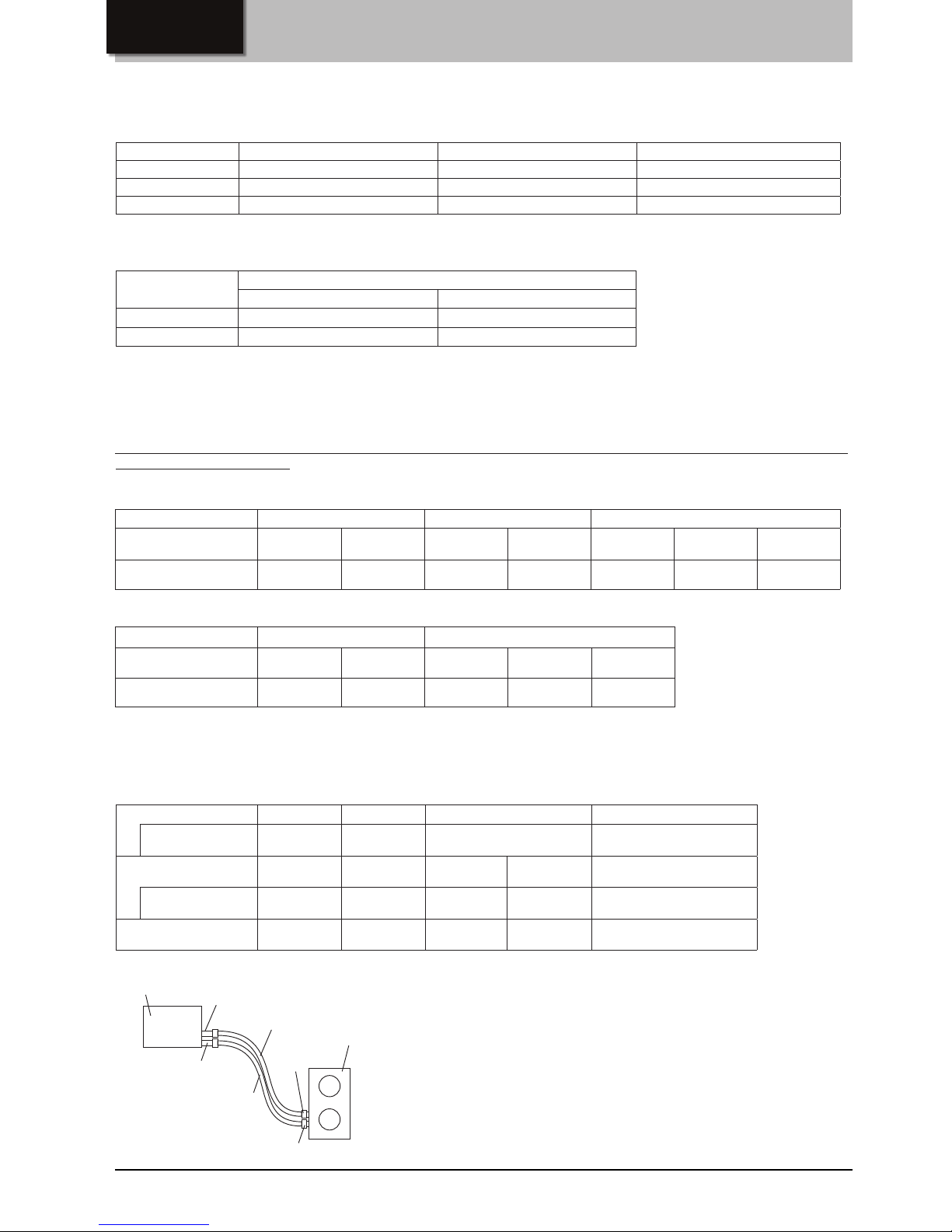

CHAPTER3

Specifications

1. Operation range

2.

Connectable Lossnay unit and outdoor unit for each functions

3. Refrigerant pipe size information

Note:

Dx-coil unit is only connectable to the Lossnay unit manufactured later than June 2016. Serial number of Lossnay unit

should be 16060001 or later.

The software version written in Lossnay PCB should be 05 or later.

Lossnay Dx-coil unit PZ-01RC

Outdoor air -15 ˚C to +40 ˚C *1 - -

Return air *2 +40 ˚C, 80 %RH or less - -

Ambient the unit 0 ˚C to +40 ˚C, 80 %RH or less 0 ˚C to +40 ˚C, 80 %RH or less 0 ˚C to +40 ˚C

*1: -15 ˚C to -10 ˚C : Intermittent operation takes 60 min. for ON and 10 min. for OFF.

-15 ˚C or lower : Intermittent operation takes 55 min. for OFF and 5 min. for ON.

*2: Air conditioned room air.

Guaranteed operation

ranges [Outdoor]

Outdoor unit

PUHZ-ZRP35 and 50 PUHZ-ZRP71, 100 and 125

Cooling *3

-15 ˚C to +46 ˚C -15 ˚C to +46 ˚C

Heating

-11 ˚C to +21 ˚C -20 ˚C to +21 ˚C

*3: The optional air protection guide is required where the ambient temperature is lower than -5 ˚C.

[RA (Return Air) temperature control]

Dx-coil unit GUG-01SL-E GUG-02SL-E GUG-03SL-E

Connectable Lossnay

LGH-50RVX-E LGH-65RVX-E LGH-80RVX-E LGH-100RVX-E

LGH-150RVX-E

LGH-150RVXT-E

LGH-200RVX-E

LGH-200RVXT-E

LGH-250RVXT-E

Connectable outdoor unit

PUHZ-ZRP35 PUHZ-ZRP35 PUHZ-ZRP50 PUHZ-ZRP71 PUHZ-ZRP100 PUHZ-ZRP100 PUHZ-ZRP125

[SA (Supply Air) temperature control]

Dx-coil unit GUG-02SL-E GUG-03SL-E

Connectable Lossnay

LGH-80RVX-E LGH-100RVX-E

LGH-150RVX-E

LGH-150RVXT-E

LGH-200RVX-E

LGH-200RVXT-E

LGH-250RVXT-E

Connectable outdoor unit

PUHZ-ZRP50 PUHZ-ZRP50 PUHZ-ZRP71 PUHZ-ZRP71 PUHZ-ZRP71

A

B

E

F

D

C

Dx-coil unit

Outdoor unit

Dx-coil unit -

GUG-01SL-E GUG-02SL-E GUG-03SL-E

Ref. pipe size of unit A / B

6.35 / 12.7 9.52 / 15.88 9.52 / 15.88

Outdoor unit -

PUHZ-ZRP35 PUHZ-ZRP50 PUHZ-ZRP71 PUHZ-ZRP71, 100, 125

Ref. pipe size of unit C / D

6.35 / 12.7 6.35 / 12.7 9.52 / 15.88 9.52 / 15.88

Pipe size between Dx-coil

unit and outdoor unit

E / F

6.35 / 12.7 6.35 / 12.7 *1 9.52 / 15.88 9.52 / 15.88

*1: To change the pipe size, PAC-SH30RJ and PAC-SH50RJ are needed to be installed at Dx-coil unit side.

Note:

GUG-01SL-E cannot be used for the SA temperature control function.

11

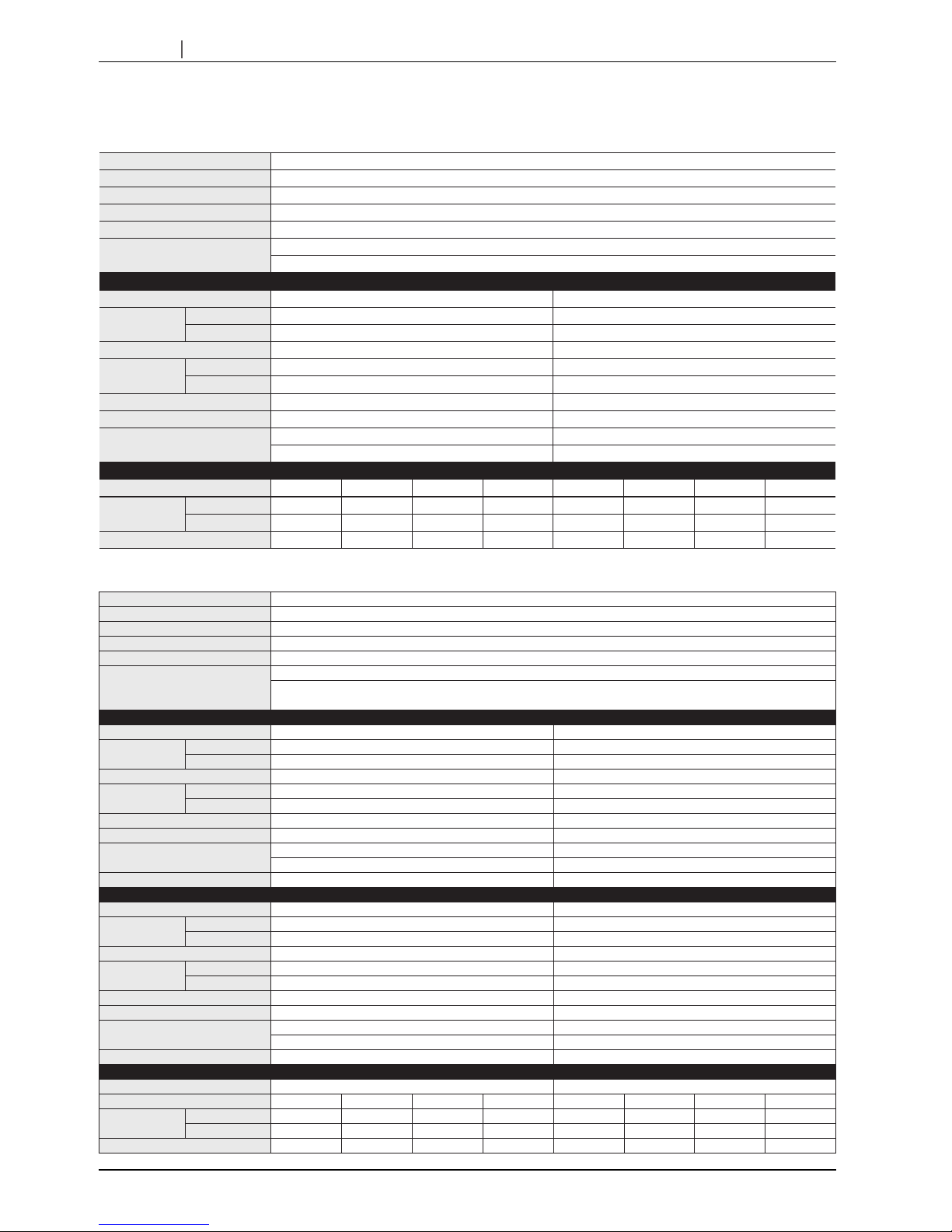

CHAPTER3 Specifications / 4. Specications

4. Specications

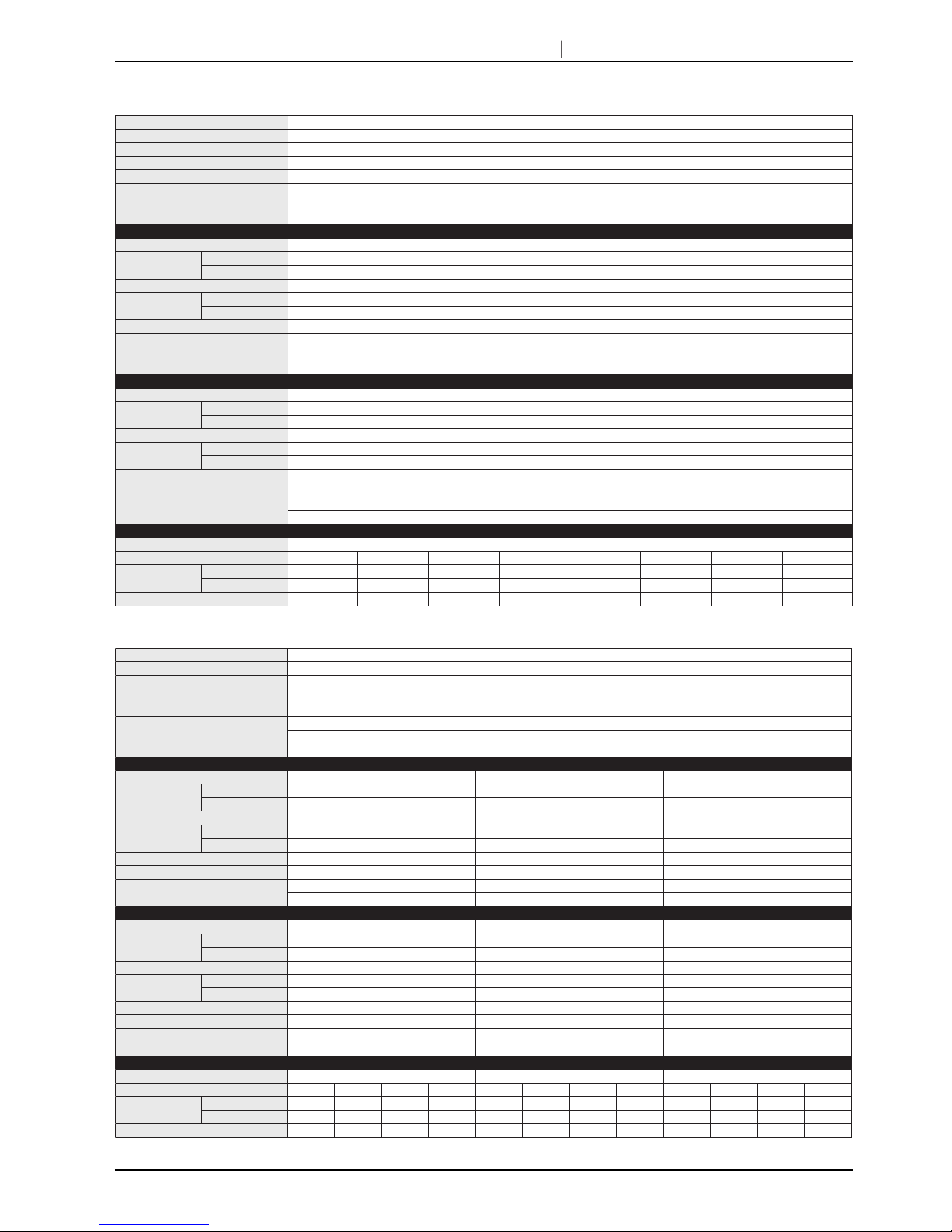

GUG-01SL-E (connection to LGH-50RVX-E or LGH-65RVX-E)

GUG-02SL-E (Connection to LGH-80RVX-E or LGH-100RVX-E)

Refrigerant R410A

Electrical power supply 220-240V / 50Hz, 220V / 60Hz (Supplied from outdoor unit)

Input power Heating / Fan: 2.5W, Cooling: 12.4W

Running current Less than 0.1A

Weight 21kg *Accessories: Approx. 1kg

Function

Heating / Cooling / Auto / Fan

RA (Return Air) temperature control

RA (Return Air) temperature control

Connectable Lossnay unit LGH-50RVX-E LGH-65RVX-E

Capacity [kW]

Heating 6.5 ( 2.4 + 4.1 ) 7.7 ( 3.2 + 4.5 )

Cooling 5.6 ( 2.0 + 3.6 ) 6.6 ( 2.6 + 4.0 )

SHF 0.66 0.69

Performance index

Heating 4.09 4.72

Cooling 4.69 5.03

Air flow range at SP3 and SP4 350 - 695 m3/h 350 - 900 m3/h

Connectable outdoor unit PUHZ-ZRP35 PUHZ-ZRP35

Ext. piping

Diameter Liquid / Gas: 6.35 / 12.7 Diameter Liquid / Gas: 6.35 / 12.7

Maximum length: 50m, Maximum height: 30m Maximum length: 50m, Maximum height: 30m

Ventilation specifications

Fan speed SP4 SP3 SP2 SP1 SP4 SP3 SP2 SP1

Air volume

[m3/h] 500 375 250 125 650 488 325 16 3

[L/s] 139 104 69 35 181 135 90 45

External static pressure [Pa] 105 59 26 7 95 53 24 6

Refrigerant R410A

Electrical power supply 220-240V / 50Hz, 220V / 60Hz (Supplied from outdoor unit)

Input power Heating / Fan: 2.5W, Cooling: 12.4W

Running current Less than 0.1A

Weight 26kg *Accessories: Approx. 1kg

Function

Heating / Cooling / Auto / Fan *Auto is only available for RA temperature control

RA (Return Air) temperature control / SA (Supply Air) temperature control

[Must be set at initial setting and not possible to change from remote controller]

RA (Return Air) temperature control

Connectable Lossnay unit LGH-80RVX-E LGH-100RVX-E

Capacity [kW]

Heating 10.0 ( 4.0 + 6.0 ) 13.2 ( 5.1 + 8.1 )

Cooling 8.3 ( 3.3 + 5.0 ) 11.3 ( 4.2 + 7.1 )

SHF 0.69 0.66

Performance index

Heating 4.62 4.42

Cooling 4.76 4.98

Air flow range at SP3 and SP4 560 - 1200 m3/h 700 - 1200 m3/h

Connectable outdoor unit PUHZ-ZRP50 PUHZ-ZRP71

Ext. piping

Diameter Liquid / Gas: 6.35 / 12.7 Diameter Liquid / Gas: 9.52 / 15.88

Maximum length: 50m, Maximum height: 30m Maximum length: 50m, Maximum height: 30m

Required optional parts PAC-SH30RJ-E and PAC-SH50RJ-E -

SA (Supply Air) temperature control

Connectable Lossnay unit LGH-80RVX-E LGH-100RVX-E

Capacity [kW]

Heating 10.0 ( 4.0 + 6.0 ) 11.4 ( 5.1 + 6.3 )

Cooling 8.3 ( 3.3 + 5.0 ) 9.5 ( 4.2 + 5.3 )

SHF 0.69 0.73

Performance index

Heating 4.62 5.09

Cooling 4.76 5.43

Air flow range at SP3 and SP4 560 - 1200 m3/h 700 - 1200 m3/h

Connectable outdoor unit PUHZ-ZRP50 PUHZ-ZRP50

Ext. piping

Diameter Liquid / Gas: 6.35 / 12.7 Diameter Liquid / Gas: 6.35 / 12.7

Maximum length: 50m, Maximum height: 30m Maximum length: 50m, Maximum height: 30m

Required optional parts PAC-SH30RJ-E and PAC-SH50RJ-E PAC-SH30RJ-E and PAC-SH50RJ-E

Ventilation specifications

Connectable Lossnay unit LGH-80RVX-E LGH-100RVX-E

Fan speed SP4 SP3 SP2 SP1 SP4 SP3 SP2 SP1

Air Volume

[m3/h] 800 600 400 200 1,000 750 500 250

[L/s] 222 167 111 56 278 208 139 69

External static pressure [Pa] 130 73 33 8 130 73 33 8

12

CHAPTER3 Specifications / 4. Specications

GUG-03SL-E (Connection to LGH-150RVX-E or LGH-200RVX-E)

GUG-03SL-E (Connection to LGH-150RVXT-E, LGH-200RVXT-E or LGH-250RVXT-E)

Refrigerant R410A

Electrical power supply 220-240V / 50Hz, 220V / 60Hz (Supplied from outdoor unit)

Input power Heating / Fan: 2.5W, Cooling: 12.4W

Running current Less than 0.1A

Weight 28kg *Accessories: Approx. 1kg

Function

Heating / Cooling / Auto / Fan *Auto is only available for RA temperature control

RA (Return Air) temperature control / SA (Supply Air) temperature control

[Must be set at initial setting and not possible to change from remote controller]

RA (Return Air) temperature control

Connectable Lossnay unit LGH-150RVX-E LGH-200RVX-E

Capacity [kW]

Heating 20.7 ( 7.7 + 13.0 ) 23.8 ( 10.3 + 13.5 )

Cooling 15.8 ( 6.3 + 9.5 ) 18.4 ( 8.4 + 10.0 )

SHF 0.68 0.76

Performance index

Heating 4.24 5.02

Cooling 5.27 5.86

Air flow range at SP3 and SP4 1050 - 2250 m3/h 1050 - 2600 m3/h

Connectable outdoor unit PUHZ-ZRP100 PUHZ-ZRP100

Ext. piping

Diameter Liquid / Gas: 9.52 / 15.88 Diameter Liquid / Gas: 9.52 / 15.88

Maximum length: 75m, Maximum height: 30m Maximum length: 75m, Maximum height: 30m

SA (Supply Air) temperature control

Connectable Lossnay unit

LGH-150RVX-E

LGH-200RVX-E

Capacity [kW]

Heating

16.6 ( 7.7 + 8.9 )

19.5 ( 10.3 + 9.2 )

Cooling

13.4 ( 6.3 + 7.1 )

15.9 ( 8.5 + 7.4 )

SHF

0.85

0.90

Performance index

Heating 5.46 6.30

Cooling 5.32 5.85

Air flow range at SP3 and SP4 1050 - 2250 m3/h 1050 - 2600 m3/h

Connectable outdoor unit PUHZ-ZRP71 PUHZ-ZRP71

Ext. piping

Diameter Liquid / Gas: 9.52 / 15.88 Diameter Liquid / Gas: 9.52 / 15.88

Maximum length: 50m, Maximum height: 30m Maximum length: 50m, Maximum height: 30m

Ventilation specifications

Connectable Lossnay unit LGH-150RVX-E LGH-200RVX-E

Fan speed SP4 SP3 SP2 SP1 SP4 SP3 SP2 SP1

Air Volume

[m3/h] 1,500 1,125 750 375 2,000 1,500 1,000 500

[L/s] 417 313 208 10 4 556 417 278 13 9

External static pressure [Pa] 150 84 38 9 10 5 59 26 7

Refrigerant R410A

Electrical power supply 220-240V / 50Hz, 220V / 60Hz (Supplied from outdoor unit)

Input power Heating / Fan: 2.5W, Cooling: 12.4W

Running current Less than 0.1A

Weight 28kg *Accessories: Approx. 1kg

Function

Heating / Cooling / Auto / Fan *Auto is only available for RA temperature control

RA (Return Air) temperature control / SA (Supply Air) temperature control

[Must be set at initial setting and not possible to change from remote controller]

RA (Return Air) temperature control

Connectable Lossnay unit LGH-150RVXT-E LGH-200RVXT-E LGH-250RVXT-E

Capacity [kW]

Heating 20.4 ( 7.4 + 13.0 ) 23.8 ( 10.3 + 13.5 ) 26.1 ( 12.1 + 14.0 )

Cooling 15.7 ( 6.2 + 9.5 ) 18.4 ( 8.4 + 10.0 ) 22.3 ( 9.8 + 12.5 )

SHF 0.68 0.76 0.87

Performance index

Heating 4.07 4.86 4.75

Cooling 5.03 5.59 4.59

Air flow range at SP3 and SP4 1050 - 2250 m3/h 1050 - 2600 m3/h 1750 - 2880 m3/h

Connectable outdoor unit PUHZ-ZRP100 PUHZ-ZRP100 PUHZ-ZRP125

Ext. piping

Diameter Liquid / Gas: 9.52 / 15.88 Diameter Liquid / Gas: 9.52 / 15.88 Diameter Liquid / Gas: 9.52 / 15.88

Maximum length: 75m, Maximum height: 30m Maximum length: 75m, Maximum height: 30m Maximum length: 75m, Maximum height: 30m

SA (Supply Air) temperature control

Connectable Lossnay unit LGH-150RVXT-E LGH-200RVXT-E LGH-250RVXT-E

Capacity [kW]

Heating 16.3 ( 7.4 + 8.9 ) 19.5 ( 10.3 + 9.2 ) 21.6 ( 12.1 + 9.5 )

Cooling 13.3 ( 6.2 + 7.1 ) 15.9 ( 8.5 + 7.4 ) 17.6 ( 9.8 + 7.8 )

SHF 0.86 0.90 0.95

Performance index

Heating 5.16 6.01 5.97

Cooling 5.03 5.54 5.31

Air flow range at SP3 and SP4 1050 - 2250 m3/h 1050 - 2600 m3/h 1000 - 2600 m3/h

Connectable outdoor unit PUHZ-ZRP71 PUHZ-ZRP71 PUHZ-ZRP71

Ext. piping

Diameter Liquid / Gas: 9.52 / 15.88 Diameter Liquid / Gas: 9.52 / 15.88 Diameter Liquid / Gas: 9.52 / 15.88

Maximum length: 50m, Maximum height: 30m Maximum length: 50m, Maximum height: 30m Maximum length: 50m, Maximum height: 30m

Ventilation specifications

Connectable Lossnay unit LGH-150RVXT-E LGH-200RVXT-E LGH-250RVXT-E

Fan speed SP4 SP3 SP2 SP1 SP4 SP3 SP2 SP1 SP4 SP3 SP2 SP1

Air Volume

[m3/h] 1,500 1,125 750 375 2,000 1,500 1,000 500 2,500 1,875 1,250 625

[L/s] 4 17 3 13 208 10 4 556 417 278 139 694 521 347 174

External static pressure [Pa] 150 84 38 9 145 82 36 9 14 0 79 35 9

13

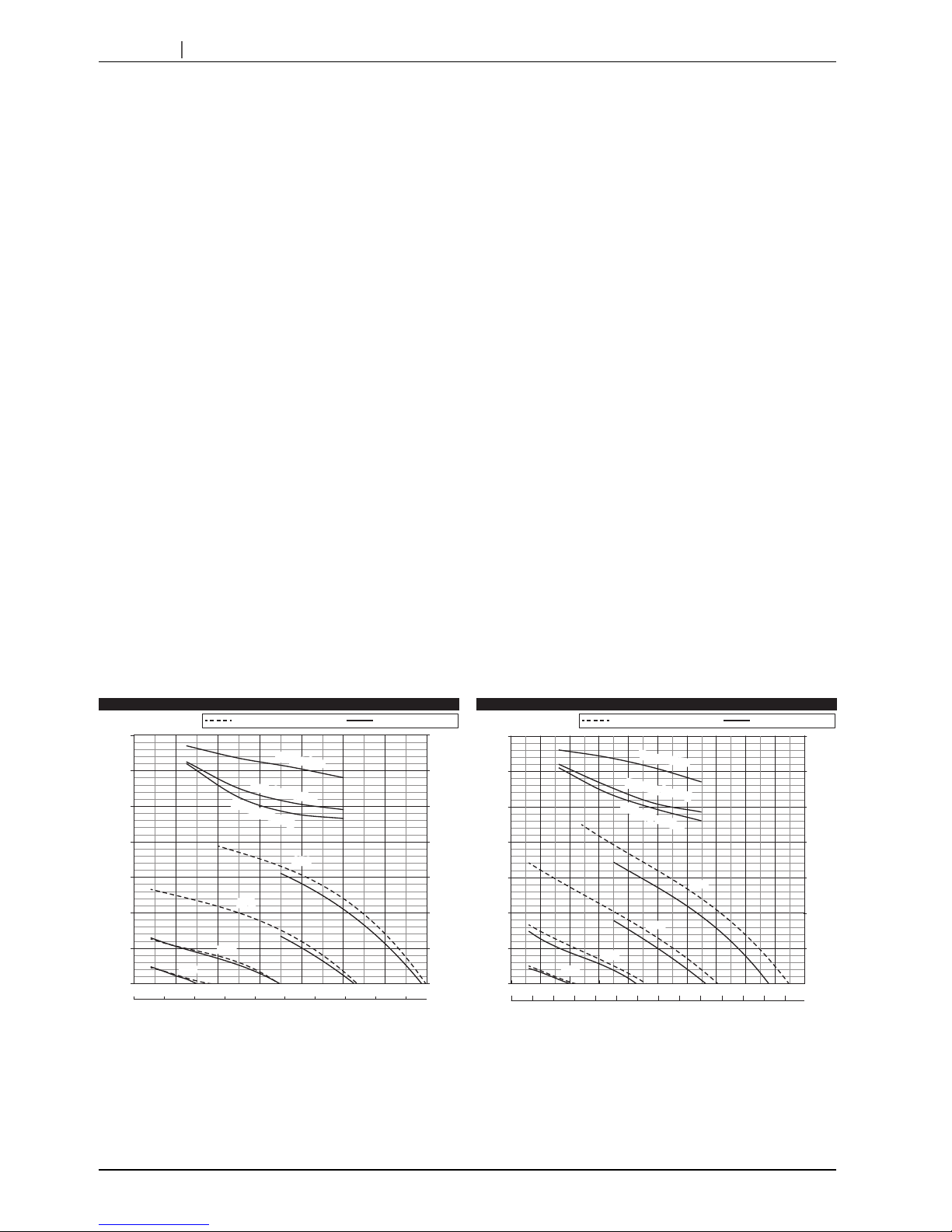

CHAPTER3 Specifications / 5. Characteristic curve

Attention

1. The running current and input power are based on 230V/50Hz.

2. The cooling and heating capacities are based on the air conditions listed below and the rated airow of fan speed 4.

Cooling Indoor: 27°CDB/19°CWB Outdoor: 35°CDB/24°CWB

Heating Indoor: 20°CDB/15°CWB Outdoor: 7°CDB/6°CWB

3. The rst gure in ( ) of the capacity specication is the heat recovery energy of the Lossnay unit. The second gure is the

capacity specication for the Dx-coil connected to the outdoor unit.

4. ”Performance index” is the calculated value at the temperature conditions above and is reference purpose only.

Performance index = Total capacity ÷ total power consumption of outdoor unit and Lossnay unit

5. The external static pressure listed above includes the static pressure loss of the Dx-coil unit when using a 50cm straight duct

between the Lossnay and Dx-coil units. When the duct work between the Lossnay and Dx-coil units is longer and/or bent,

the pressure loss of the duct work should be included in the pressure loss calculation.

6. The designed airow of the system (Lossnay, Dx-coil and duct work) at fan speed 3 and 4 should be kept within “Airow range

at SP3 and SP4” listed above. This range is shown as the solid line in graphs of the characteristics curve.

If the Lossnay airow is out of this range, the compressor of the outdoor unit may stop for self-protection purposes.

7. By installing the Dx-coil unit with a Lossnay unit, the air blow noise level is quieter at fan speed 4 as shown below.

LGH-50RVX-E: about 4dB quieter, LGH-65RVX-E: about 7dB quieter

LGH-80RVX-E: about 6dB quieter, LGH-100RVX-E: about 7dB quieter

LGH-150,200RVX-E: about 3dB quieter

LGH-150,200RVXT-E: about 3dB quieter, LGH-250RVXT-E: about 4dB quieter

8 .Refrigerant leakage contributes to climate change. Refrigerant with lower global warming potential (GWP) would contribute

less to global warming than a refrigerant with higher GWP, if leaked to the atmosphere.

This appliance contains a refrigerant uid with a GWP equal to 1975. This means that if 1kg of this refrigerant uid would be

leaked to the atmosphere, the impact on global warming would be 1975 times higher than 1kg of CO2, over a period of 100

years. Never try to interfere with the refrigerant circuit yourself or disassemble the product yourself and always ask a professional.

9.

On-site measurements by pitot tube method could be as much 20% difference from JIS test room conditions. If the measuring

point is close to sources of turbulence like bends, contractions and dampers etc., it is difficult to measure air volume correctly.

A straight duct length more than 10D (D=duct diameter or equivalent) from the source of turbulence is recommended for

correct measurement.

On-site measurement should therefore be measured in accordance with BSRIA guideline

(Commissioning Air Systems. Application procedures for buildings AG3/89.3(2001)).

5. Characteristic curve

LGH-50RVX-E

LGH-65RVX-E

0 20 40 60 80 100 120 140 160 180

0 100 200 300 400 500 600 700

Air volume

(m

3

/h)

(L/s)

SP1

SP2

SP3

SP4

Enthalpy cooling

Enthalpy heating

Without GUG-01SL-E With GUG-01SL-E

Temperature

60

70

80

90

Exchange efficiency (%)

0

50

100

150

200

250

300

350

Static pressure (Pa)

Air volume

Without GUG-01SL-E With GUG-01SL-E

(m3/h)

(L/s)

0 20 40 60 80 100 120 140 160 180 200 220 240 260

0 100 200 300 400 500 600 700 800 900 1000

SP1

SP2

SP3

SP4

Enthalpy cooling

Enthalpy heating

Temperature

0

50

100

150

200

250

300

350

Static pressure (Pa)

60

70

80

90

Exchange efficiency (%)

Following gures show air volume drop when connecting Dx-coil unit.

The air ow range is limited because of the protection for overload of outdoor unit when Dx-coil unit is connected.

14

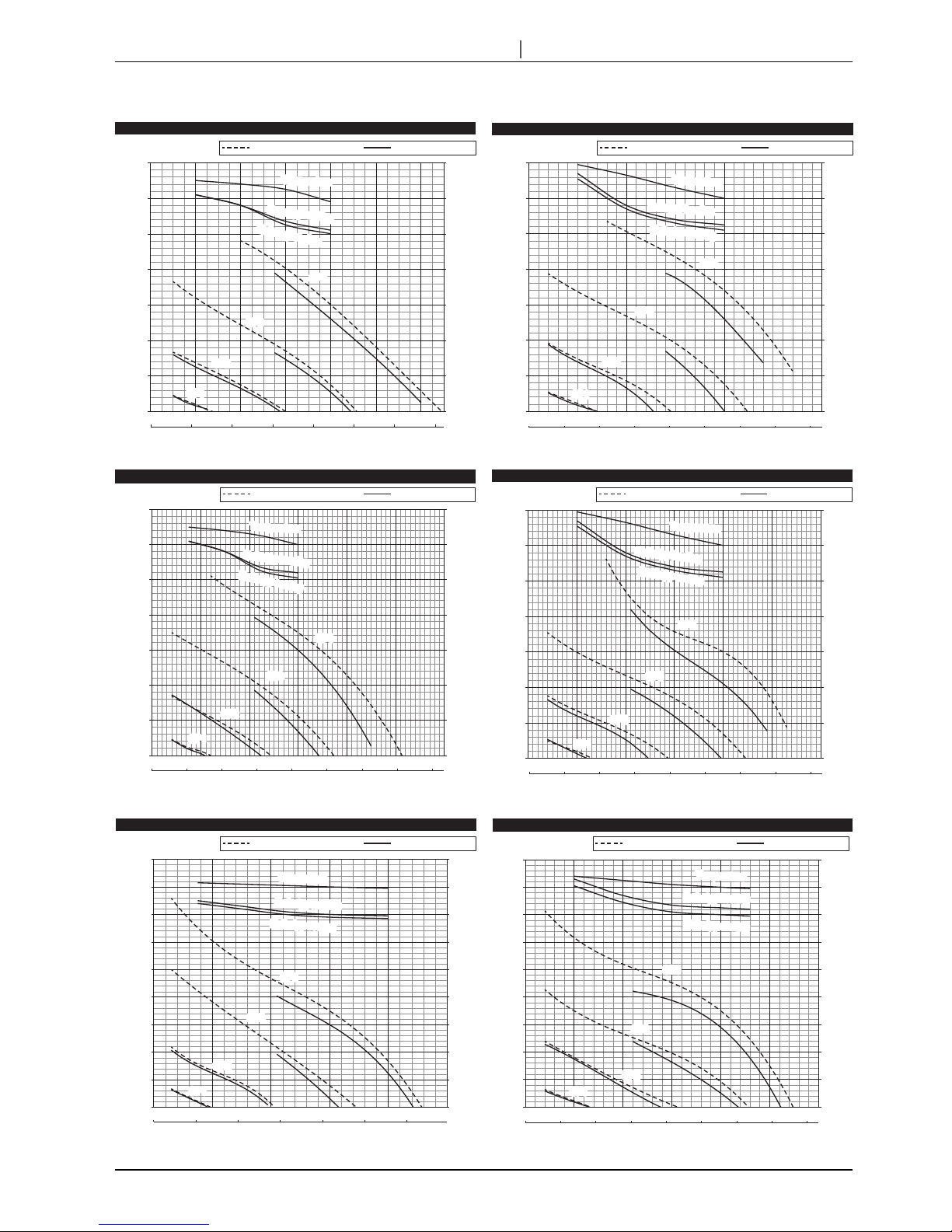

CHAPTER3 Specifications / 5. Characteristic curve

LGH-80RVX-E

LGH-100RVX-E

0 50 100 150 200 250 300 350

0 200 400 600 800 1000 1200

Without GUG-02SL-E With GUG-02SL-E

(m3/h)

(L/s)

Air volume

SP1

SP2

SP3

SP4

Enthalpy cooling

Enthalpy heating

Temperature

60

70

80

90

Exchange efficiency (%)

0

50

100

150

200

250

300

350

Static pressure (Pa)

0 50 100 150 200 250 300 350 400

0 500 1000 1500

Air volume

Without GUG-02SL-E With GUG-02SL-E

(m3/h)

(L/s)

SP1

SP2

SP3

SP4

Enthalpy cooling

Enthalpy heating

Temperature

60

70

80

90

Exchange efficiency (%)

0

50

100

150

200

250

300

350

Static pressure (Pa)

LGH-150RVX-E

0 100 200 300 400 500 600 700 800

0

500 1000 1500 2000 2500 3000

Air volume

Without GUG-03SL-E With GUG-03SL-E

SP1

SP2

SP3

SP4

Enthalpy cooling

Enthalpy heating

Temperature

60

70

80

90

Exchange efficiency (%)

0

50

100

150

200

250

300

350

Static pressure (Pa)

(m3/h)

(L/s)

LGH-200RVX-E

0 100 200 300 400 500 600 700 800

0 500 1000 1500 2000 2500 3000

Air volume

Without GUG-03SL-E With GUG-03SL-E

SP1

SP2

SP3

SP4

Enthalpy cooling

Enthalpy heating

Temperature

60

70

80

90

Exchange efficiency (%)

0

50

100

150

200

250

300

350

Static pressure (Pa)

(m

3

/h)

(L/s)

LGH-150RVXT-E

0 100 200 300 400 500 600

0 500 1000 1500 2000 2500

Air volume

0

50

100

150

200

250

300

350

450

400

Without GUG-03SL-E With GUG-03SL-E

SP1

SP2

SP3

SP4

Enthalpy cooling

Enthalpy heating

Temperature

Exchange efficiency (%)

60

70

80

90

Static pressure (Pa)

(m

3

/h)

(L/s)

LGH-200RVXT-E

0 100 200 300 400 500 600 700 800

0 500 1000 1500 2000 2500 3000

Air volume

Without GUG-03SL-E With GUG-03SL-E

SP1

SP2

SP3

SP4

Enthalpy cooling

Enthalpy heating

Temperature

0

50

100

150

200

250

300

350

450

400

Exchange efficiency (%)

60

70

80

90

Static pressure (Pa)

(m3/h)

(L/s)

LGH-100RVX-E

15

CHAPTER3 Specifications / 5. Characteristic curve

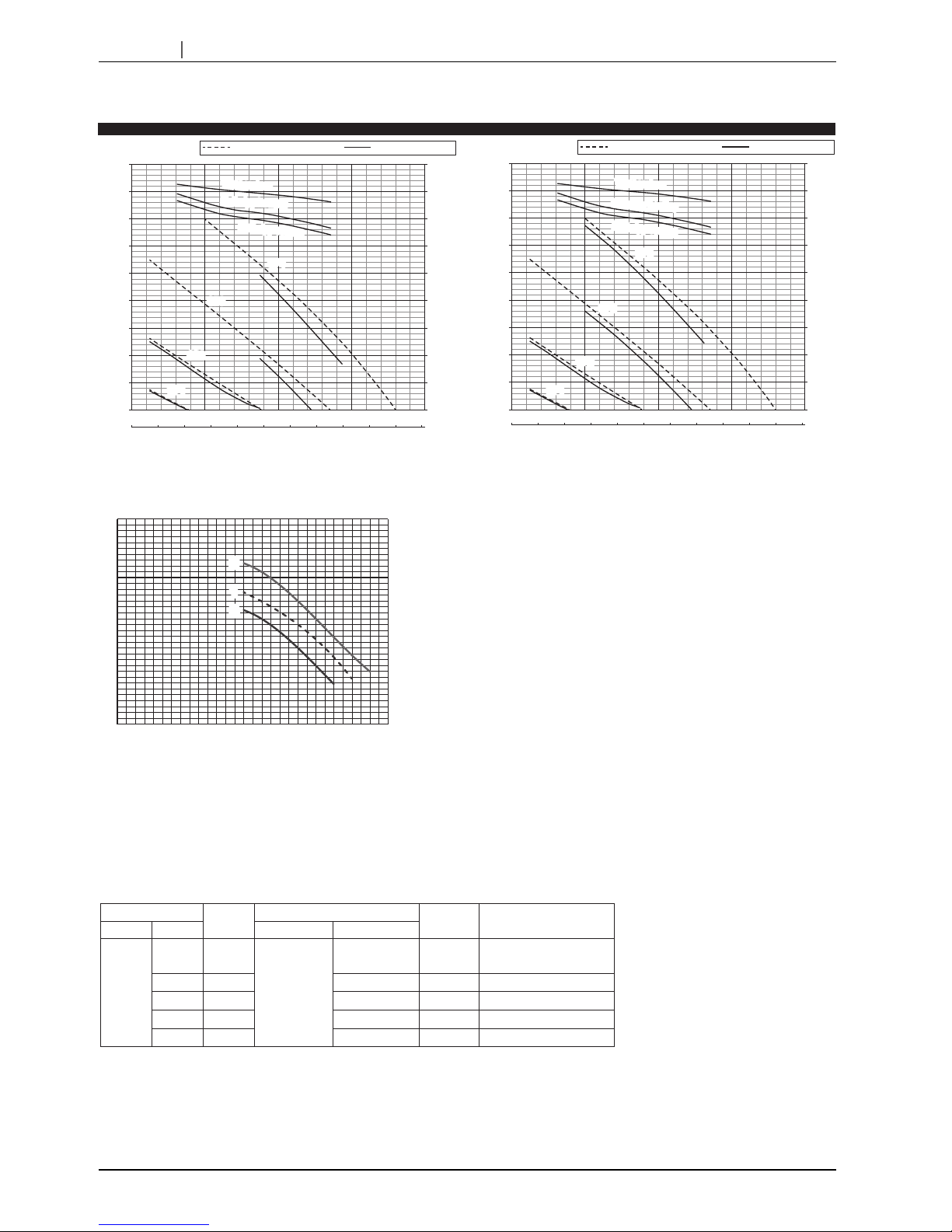

LGH-250RVXT-E

0 100 200 300 400 500 600 700 800 900 1000 1100

0 1000 2000 3000 4000

Air volume

Without GUG-03SL-E

RA temperature control

With GUG-03SL-E

SP1

SP2

SP3

SP4

Enthalpy cooling

Enthalpy heating

Temperature

Exchange efficiency (%)

60

70

80

90

0

50

100

150

200

250

300

350

450

400

Static pressure (Pa)

(m3/h)

(L/s)

0 100 200 300 400 500 600 700 800 900 1000 1100

0 1000 2000 3000 4000

Air volume

Without GUG-03SL-E

SA temperature control

With GUG-03SL-E

SP1

SP2

SP3

SP4

Enthalpy cooling

Enthalpy heating

Temperature

Exchange efficiency (%)

60

70

80

90

0

50

100

150

200

250

300

350

450

400

Static pressure (Pa)

(m3/h)

(L/s)

[Reference information]

P-Q curve image

1. Lossnay unit

2. Lossnay unit + Dx-coil unit

3. Lossnay unit (fan power up +4) + Dx-coil unit

Static pressure (Pa)

Air volume (m3/h)

3

3

1

1

2

2

Recovery of static pressure losing by Dx-coil unit.

*This graph is just for illustrative purposes.

When connecting Dx-coil unit to Lossnay unit, the original Lossnay P-Q curve (Curve.1) will decrease because of adding

pressure loss by Dx-coil unit (Curve.2).

One solution to recover this static pressure decrease is setting fan power up function of Lossnay unit (Curve.3).

This fan power up function is only available when Lossnay remote controller PZ-61DR-E is used.

Select adequate setting data number which is associated with fan power up level shown in below table at the function setting

page of PZ-61DR-E.

Refer to Lossnay and PZ-61DR-E installation manual for more detailed information.

DIP-SW

Setting

check

PZ-61DR-E

Setting

check

Supply fan power up

SW No. Setting Function No. Setting data

N/A

- -

55

0

(Factory setting)

N/A

- - 1 1 level up

- - 2 2 level up

- - 3 3 level up

- - 4 4 level up

16

CHAPTER4

Outlines and Dimensions

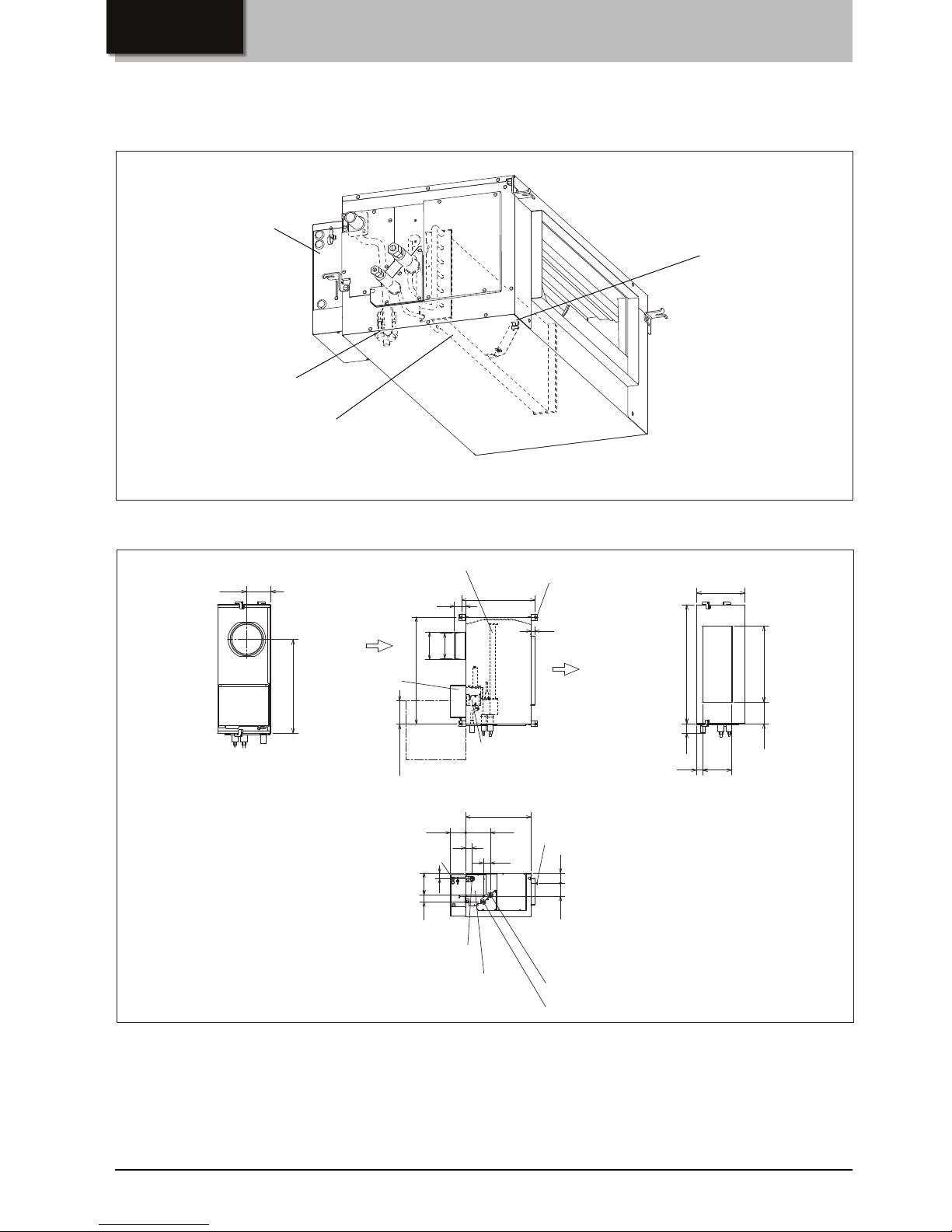

1. Outlines and dimensions

GUG-01SL-E

Names of the parts

Heat exchanger

Drain pump

Control box Supply air thermistor

(Only for GUG-02 and 03SL-E)

Note:

The drain pump always runs in the cooling mode and continues to run for six minutes after the unit stops.

63

593

30

492

85

146

166

812

330

φ208

φ192

520

200

41

551

147

Air inlet from

Lossnay

115 186

55

100 77

52

44

47

An inspection opening is required

for installation and regular

maintenance (check) of the drain

pump.

811

Unit (mm)

Ceiling suspension

fixture

Liquid pipe φ6.35

Gas pipe φ12.7Maintenance cover for drain pump, inlet air

thermistor and water sensor

Heat exchanger

Control box

150 to 200

Drain pump

Drain pipe (O.D φ32)

Inspection

opening

450 x 450 or

more

SA

(supply air)

Ceiling suspension fixture

(4-13 X 20 oval)

Power supply

cable opening

17

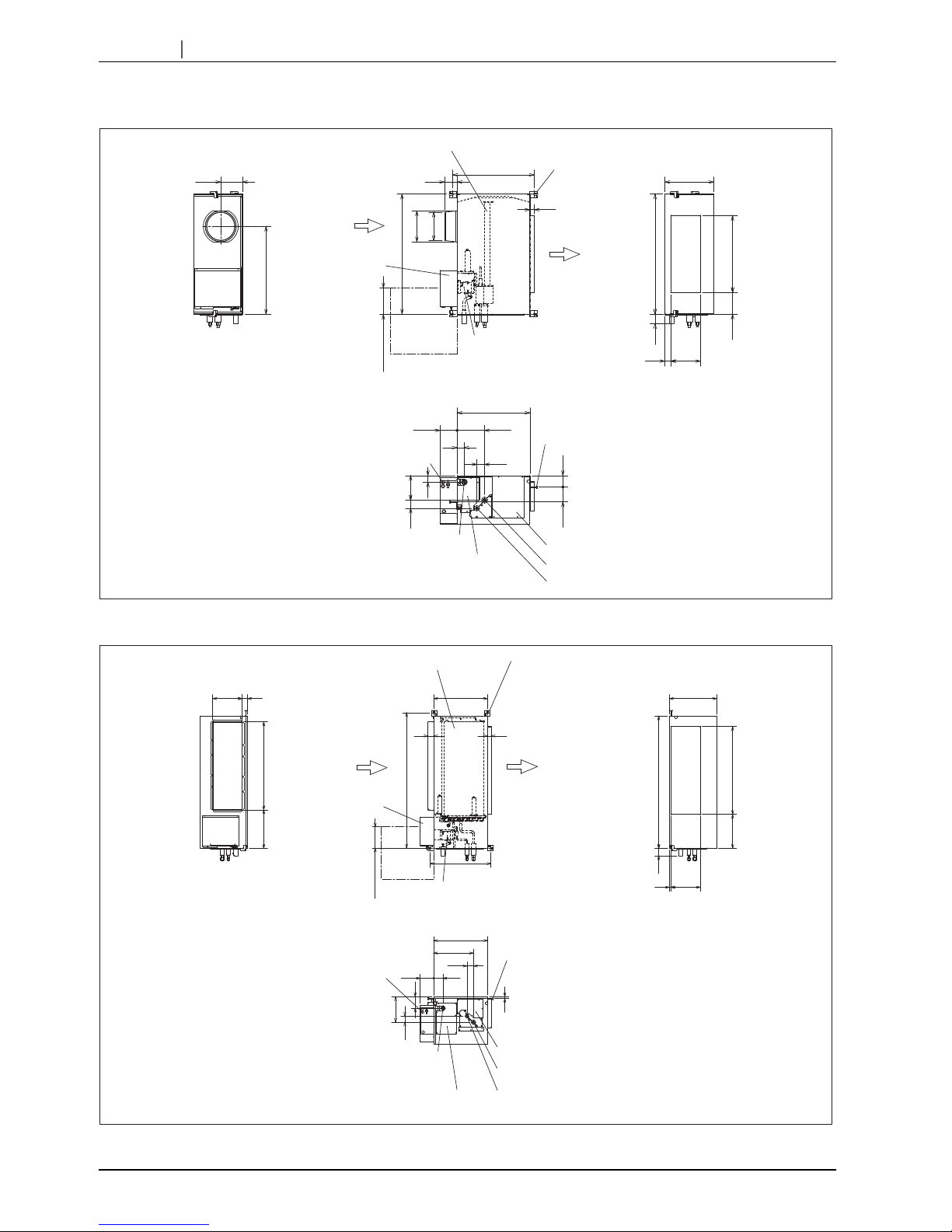

CHAPTER4 Outlines and Dimensions / 1. Outlines and dimensions

GUG-02SL-E

GUG-03SL-E

63

600

30

492

84

132

207

1034

394

φ258

φ242

750

25059

551

170

Air inlet from

Lossnay

115 186

55

165 56

52

86

47

An inspection opening is required for

installation and regular maintenance

(check) of the drain pump. When SA

temp. control is selected, another

inspection opening may be required in

front of the unit for SA thermistor

replacement only when an error

occurred on the SA thermistor.

1033

Ceiling suspension

fixture

Liquid pipe φ9.52

Gas pipe φ15.88Maintenance cover for drain pump, inlet air

thermistor and water sensor

Heat exchanger

Control box

150 to 200

Drain pump

Drain pipe (O.D φ32)

Inspection

opening

450 x 450 or

more

SA

(supply air)

Ceiling suspension fixture

(4-13 X 20 oval)

Power supply

cable opening

Maintenance cover for SA thermistor

Unit (mm)

An inspection opening is required for

installation and regular maintenance

(check) of the drain pump. When SA

temp. control is selected, another

inspection opening may be required in

front of the unit for SA thermistor

replacement only when an error

occurred on the SA thermistor.

Ceiling suspension

fixture

Liquid pipe φ9.52

Gas pipe φ15.88

Maintenance cover for drain pump, inlet air

thermistor and water sensor

Heat exchanger

Control box

150 to 200

Drain pump

Drain pipe (O.D φ32)

Inspection

opening

450 x 450

or more

Ceiling suspension fixture

(4-13 X 20 oval)

Power supply

cable opening

Maintenance cover for SA thermistor

Air inlet from

Lossnay

SA

(supply air)

63

217

518

1130

49

14 250

290

250 47

461

750329

750

1156

30

459

97

404

14

52

115

340

55

78

Unit (mm)

18

CHAPTER4 Outlines and Dimensions/ 2. Installation example

2.1 GUG-01SL-E and GUG-02SL-E

2. Installation example

Note:

•The distance between the Lossnay unit

and the Dx-coil unit must be between 25

cm and 5 m when the duct is straight.

•The length of the connection cable

(enclosed accessory) between the

Lossnay and Dx-coil units is about 6 m.

Please install the two units so that the

cable can be connected.

Note:

•The duct between the two units can

be bent like the gure.

* To take the control cover off.

Top view (to install straight duct)

Side view (to install with straight duct)

Side view (to minimize the space with slope duct)

Top view (to install with bent duct)

Connection cable

(Enclosed accessory)

Connection cable

(Enclosed accessory)

Duct (Field supply)

Duct (Field supply)

Min 150*

19

CHAPTER4 Outlines and Dimensions/ 2. Installation example

Note:

•The distance between the Lossnay unit

and the Dx-coil unit must be between 25

cm and 5 m when the duct is straight.

•The length of the connection cable

(enclosed accessory) between the

Lossnay and Dx-coil units is about 6 m.

Please install the two units so that the

cable can be connected.

Note:

•The distance between the Lossnay unit

and the Dx-coil unit must be between 25

cm and 5 m when the duct is straight.

•The length of the connection cable

(enclosed accessory) between the

Lossnay and Dx-coil units is about 6 m.

Please install the two units so that the

cable can be connected.

2.2 GUG-03SL-E with LGH-150/200RVX-E

Side view (with chamber box)

Following duct works is example using chamber box between LGH-150/200RVX-E and GUG-03SL-E.

Top view (with chamber box)

Top view (to install with rectangular duct)

2.3 GUG-03SL-E with LGH-150/200/250RVXT-E

Connection cable

(Enclosed accessory)

Duct (Field supply)

Connection cable (Enclosed accessory)

Chamber box (field supply)

Rectangular duct (field supply)

Duct

(field supply)

20

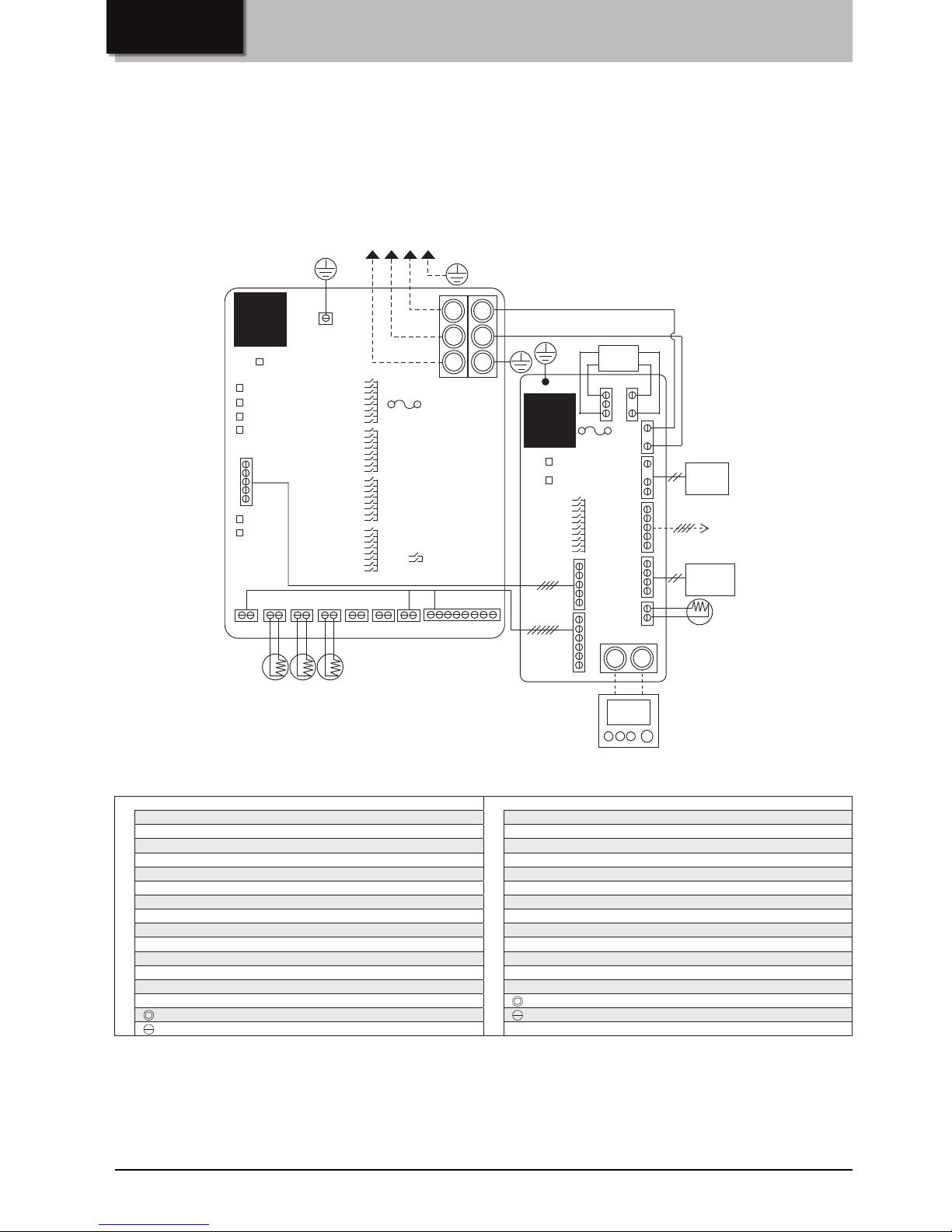

CHAPTER5

Wiring Diagram

1. Wiring diagram

Note:

1. TB6, TM104 and CN120 shown in dotted lines are eld work.

2. Make sure to connect the ground wire.

3. Prior to access the electrical parts cut off the power supply (all to Dx-coil unit, Lossnay unit and outdoor unit) more than ve

minutes.

4. The appliance shall be installed in accordance with national wiring regulations.

Printed circuit board A Printed circuit board B

TB6 : Terminal for power supply from the outdoor unit TM104 : Terminal for remote controller PZ-01RC

TAB1 : Connector (Ground) SW11 : Switch (Function selection)

SW1-SW4 : Switch (Function selection) LED11 : Inspection indicator lamp

SW6 : Switch (Function selection) LED12 : Power supply indicator lamp

LED1 : Power supply indicator lamp CN1 : Connector (Power supply)

LED2-5 : Operation status CN2 : Connector (Transformer primary)

LED6, 7 : Reading or writing data to SD card CN3 : Connector (Drain pump)

CN105 : Connector (IT communication) CN4 : Connector (Transformer secondary)

CN20 : Connector (TH1, software use) CN5 : Connector (IT communication)

CN21 : Connector (TH2, liquid pipe temp.) CN6 : Connector (Output to PCB A)

CN22 : Connector (Remote controller) CN9 : Connector (TH9, supply air temp.)

CN23 : Connector (TH11, inlet air temp.) CN10 : Connector (Water sensor)

CN29 : Connector (TH5, gas pipe temp.) CN120 : Connector (Communication to Lossnay)

CN82 : Connector (Forced comp. OFF)

: Terminal block

: Terminal block

: Connector on PCB

: Connector on PCB

Denition of symbols

Attention

1.With this product, the wiring installation method will vary according to the design of the system.

2.Perform electrical installation to meet local electrical regulations.

3.Always use double insulated PVC cable for the transmission cables.

4.Wiring work must be performed by qualied professionals.

CN105

LED1

S1

L

N

E

S2

S3

TB6

CN9

CN10

CN120

CN3

CN2CN4

CN6

CN5

CN1

SW11

TM104

LED12

LED11

SW1

SW6

TAB1

CN20

CN23 CN21 CN29

CN22 CN82

TH11

TH2

TH5

SW2

SW3

SW4

LED5

LED4

LED3

LED2

LED6

LED7

TH9

SA thermistor

(GUG-02 and GUG-03SL-E)

Dedicated remote controller PZ-01RC

(Enclosed accessory)

To Lossnay

(CN20)

(RED)

(RED)

CN20:RED

CN23:BROWN

CN29:BLACK

CN22:BLUE

Others: WHITE

(RED)

(YELLOW)

(WHITE)

(WHITE)

(WHITE)

(GREEN)

To outdoor unit

Printed

Circuit

Board B

Printed

Circuit

Board A

TRANS

DRAIN

PUMP

WATER

SENSOR

* PZ-61DR-E cannot be connected.

Fuse 15 A 250 V

Fuse

5 A 250 V

Loading...

Loading...