Mitsubishi GT05-70PCO, GT05-90PCO, GT05-80PCO, GT05-60PCO, GT05-50PCO User Manual

GT05 Protective Cover for Oil

WAR NING

CAUTION

WARNING

CAUTION

CAUTION

A

B

C

D

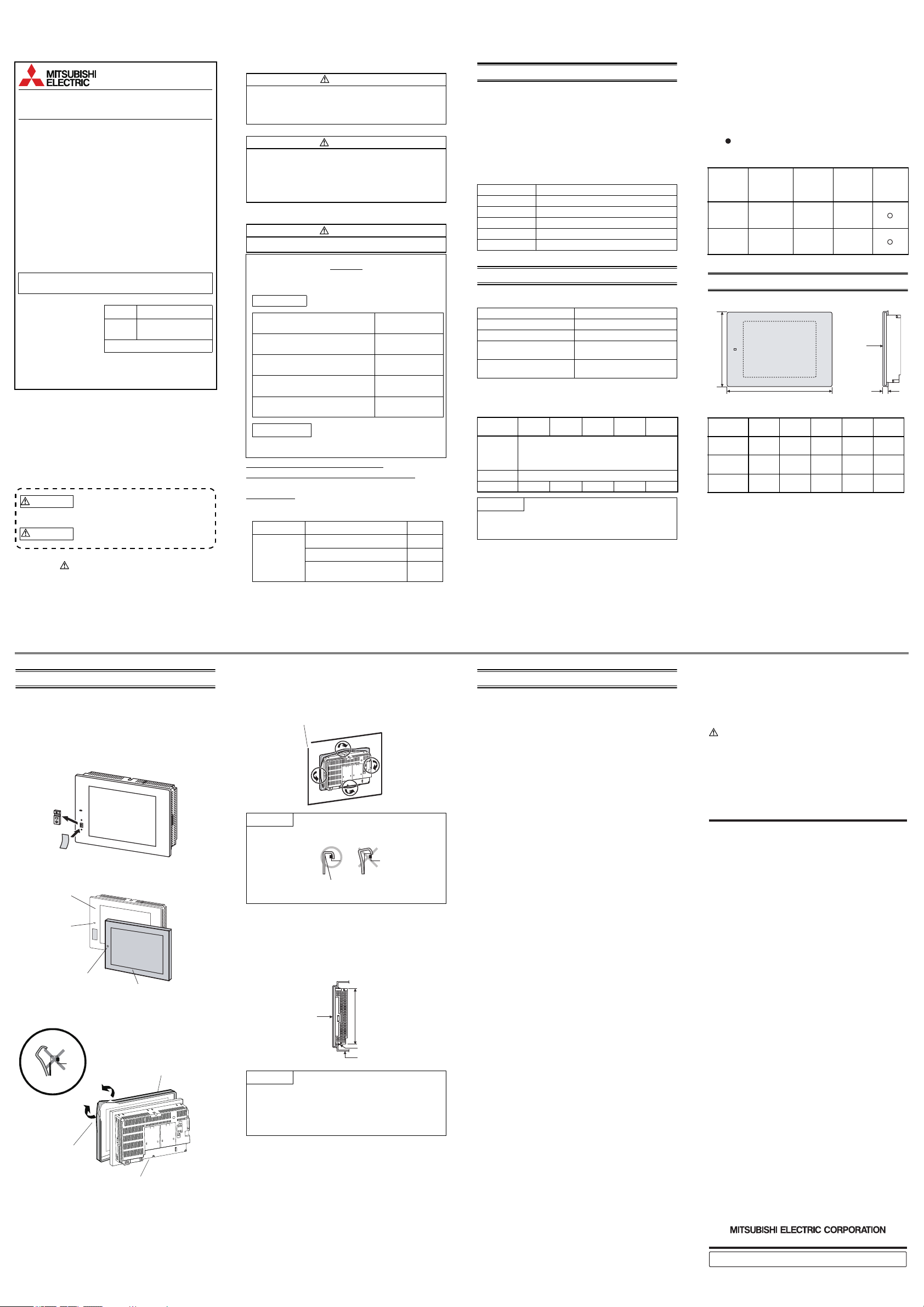

Starting from the upper left corner, fit the sides of the

protective cover for oil in the order from A to D.

User's Manual

GT05-90PCO

GT05-80PCO

GT05-70PCO

GT05-60PCO

GT05-50PCO

Thank you for choosing Mitsubishi Electric Graphic Operation

Terminal (GOT).

Prior to use, please read both this manual and detailed

manual thoroughly to fully understand the product.

MODEL GT05-PCO-U

MODEL

CODE

IB(NA)-0800390-G(1906)MEE

© 2007 MITSUBISHI ELECTRIC CORPORATION

SAFETY PRECAUTIONS

(Always read these precautions before using this equipment.)

Before using this product, please read this manual and the relevant

manuals introduced in this manual carefully and pay full attention to

safety to handle the product correctly.

The precautions given in this manual are concerned with this

product.

In this manual, the safety precautions are ranked as "WARNING"

and "CAUTION".

Indicates that incorrect handling may cause

hazardous conditions, resulting in death or

severe injury.

Indicates that incorrect handling may cause

hazardous conditions, resulting in medium or

slight personal injury or physical damage.

Note that the CAUTION level may lead to a serious accident

according to the circumstances.

Always follow the precautions of both levels because they are

important to personal safety.

Please save this manual to make it accessible when required and

always forward it to the end user.

1D7M71

[INSTALLATION PRECAUTIONS]

Be sure to shut off all phases of the external power supply used

by the system before mounting or removing the GOT main unit

to/from the panel.

Not doing so can cause the unit to fail or malfunction.

When mounting the GOT to the control panel, tighten the

mounting screws in the specified torque range.

Undertightening can cause the GOT to drop, short circuit or

malfunction.

Overtightening can cause a drop, short circuit or malfunction

due to the damage of the screws or the GOT.

[DISPOSAL PRECAUTIONS]

Dispose of the product as industrial waste.

Manuals

The following manuals are related to this product.

Detailed Manual

Manual name

GOT2000 Series User’s Manual

(Hardware) (Sold separately)

GT16 User's Manual (Hardware)

GT15 User's Manual

GT11 User's Manual

(Sold separately)

(Sold separately)

(Sold separately)

Manual Number

(Model code)

SH-081194ENG

(1D7MJ5)

SH-080928ENG

(1D7MD3)

SH-080528ENG

(1D7M23)

JY997D17501G

(09R815)

Relevant Manuals

For relevant manuals, refer to the PDF manuals stored in the GT

Designer3 DVD-ROM.

Referenced Standard: GB/T15969.2

(Requirement of Chinese standardized law)

Packing List

The following item is included.

Manual name Item Quantity

GT05-90PCO

GT05-80PCO

GT05-70PCO

GT05-60PCO

GT05-50PCO

Protective cover for oil 1

USB connector protective sticker 1

GT05 Protective Cover for Oil

User's Manual (This manual)

1

1. Overview

This user’s manual explains the GT05 protective cover for oil

(hereinafter referred to as protective cover for oil).

Use of the protective cover for oil improves oil resistance and

chemical resistance of the GOT.*1

*1:Note that the structure does not guarantee protection in all

users' environments. The protective cover for oil may not be

used in an environment where it is exposed to oil or

chemicals for a long time, or where oil mist fills the air.

The fo llowing ta ble sho ws protect ive covers for oil and the ap plicable

GOT.

Model Applicable GOT

GT05-90PCO GT1695, GT1595

GT05-80PCO GT1685, GT1585

GT05-70PCO GT1675, GT1672, GT1575, GT1572

GT05-60PCO GT1665, GT1662, GT1565, GT1562

GT05-50PCO GT1555, GT1550, GT1155, GT1150

2. Specifications

2.1 General specifications

Item Specifications

Operating ambient temperature 0°C to 50°C

Storage ambient temperature -20°C to 50°C

Operating ambient hum idity

Storage ambient humidity

2.2 Performance specifications

The performance specifications of the protective cover for oil are

indicated below.

Item

Level of

protection

Material Cover: Nitrile rubber, Display: PET sheet

Weight 0.310kg 0.195kg 0.185kg 0.135kg 0.080kg

POINT

For installing the GOT with the protective cover for oil, the control

panel thickness must be 2 to 3mm because of the cover

thickness. (Control panel thickness without the cover: 2 to 4mm)

GT05-

90PCO

Caution:The protective cover for oil may not be used

in an environment where it is exposed to oil or

chemicals for a long time, or where oil mist fills the air.

10% RH to 90% RH,

non-condensing

10% RH to 90% RH,

non-condensing

GT05-

80PCO

GT05-

70PCO

IP67

GT05-

60PCO

GT05-

50PCO

2.3 Oil resistance, chemical resistance

The protective cover for oil is made of materials with high oil and

chemical resistance so that the cover can be used in various oil and

chemical atmospheres.

Because oils, including cutting oils, contain a small amount of

additives depending on oil products, oil resistance of the cover

cannot be stated.

Prior to use the cover, test the cover in operating environments, and

then check the oil and chemical resistance of the cover.

Test contents and oil resistance of cover

The protective cover for oil is soaked in the following oils

for 2000 hours, and then oil resistance of the cover is

checked.

Oil type Product

Waterinsoluble

cutting oil

Water soluble

cutting oil

Grinding oil

(Yushiron oil

CL35)

Grinding oil

(Noritake cool

CG-50P)

Change in

appearance

dimension

and

Adhesion

between

cover and

sheet

No change No change

No change No change

Oil

resistance

3. External Dimensions

GT05-

70PCO

314

(12.36)

228

(8.98)

Protective

cover for oil

GT05-

60PCO

252

(9.92)

201

(7.91)

GT05-

50PCO

178

(7.01)

146

(5.75)

Unit: mm (inch)

H

Dimensions

W

H

D

WD

GT05-

GT05-

90PCO

80PCO

408

307

12

327

(12.87)

253

(9.96)

(16.06)

(12.09)

(0.47)12(0.47)12(0.47)12(0.47)12(0.47)

4. Installation Procedure

The following shows how to install the protective cover for oil on

GT1575 as an example.

To install the cover on GT16, the procedures (1) and (2) are not

required.

(1) When the USB environmental protection cover is installed on the

GOT, remove the cover.

(2) After removing the cover, put the USB connector protective

sticker on the USB connector.

(3) Align the POWER LED window of the cover and the POWER

LED of the GOT front panel to ensure that the cover orientation

is appropriate.

GOT

POWER LED

POWER LED window

(4) Stretch one corner of the cover, and fit it to the corner of the GOT

front panel.

Stretchthecornerof

thecoverandfititto

thecornerofthe

GOT.

Protective cover for oil

Donotoverstretchoroverbendthecover.

Doingsomaycauseaseparationbetween

thesheetandrubber.

Protective cover for oil

GOT

(5) Starting from one corner, fit the other corners of the cover

sequential ly to the corne rs of th e GOT, and th en the s ides (i n the

order of the arrows from A to D). Make sure that the gasket of

the GOT rear face is entirely covered.

POINT

• To prevent liquid ingress into the control panel, make sure that

the gasket is completely covered.

Make sure that the corners of the

protective cover for oil align those of the

GOT front panel.

(6) Mount the GOT onto the control panel.

When the control panel is dirty, clean the control panel.

The panel cutting dimensions and mounting screw tightening

torque with the protective cover for oil are the same as those

without the cover.

Mount the GOT onto the control panel by referring to GT16

User's Manual (Hardware), GT15 User's manual or GT11 user's

Manual.

Protective cover

for oil

Panel cut

dimensions

Mounting metal fixture

Control panel

POINT

For attaching the protective cover for oil to the GOT already

mounted on the control panel, follow the procedures as below.

• Remove the GOT from the control panel.

Make sure to externally shut off all phases of the power supply

and remove all cables from the GOT in advance.

• Clean dirt off surfaces of the GOT and control panel.

5. Precautions for Use

(1) The protective cover for oil is a consumable product.

Check the cover for scratch, damage or dirt at regular

intervals, and replace with new one if necessary.

(2) Do not push the protective cover for oil with pointed tools,

including mechanical pencils and screwdrivers. Doing so

causes scratches and damages of the cover.

(3) Do not clean the protective cover for oil with bleaches,

thinners, organic solvents, corrosive chemicals, and others.

Doing so causes changes in shape and color of the cover.

(4) When the protective cover for oil is attached to the GOT, do

not stretch and bend the cover too much.

Doing so may cause a separation between the sheet and

rubber.

(5) Do not place or use the protective cover for oil in direct

sunshine.

(6) When the protective cover for oil gets dusts, wipe the dusts

off with a damp cloth.

(7) White particles may adhere to the rubber frame of the

protective cover for oil, which does not affect the quality of the

cover.

Wipe the frame with a cloth moistened with isopropyl alcohol

or ethanol as necessary.

(8) When the protective cover for oil is used, the USB connector

on the GOT front face cannot be used.

(9) When the protective cover for oil is used, the human sensor

does not correctly operate.

Disable the human sensor with the utility.

For the human sensor setting, refer to GT15 User's Manual.

(10) Do not attach and remove the protective cover for oil

frequently. Doing so reduces oil resistance and chemical

resistance.

(11) Note that the structure does not guarantee protection in all

users' environments. The protective cover for oil may not be

used in an environment where it is exposed to oil or

chemicals for a long time, or where oil mist fills the air.

Warra nty

Mitsubishi Electric will not be held liable for damage caused by

factors found not to be the cause of Mitsubishi Electric; machine

damage or lost profits caused by faults in the Mitsubishi Electric

products; damage, secondary damage, accident compensation

caused by special factors unpredictable by Mitsubishi Electric;

damages to products other than Mitsubishi Electric products; and to

other duties.

For safe use

• This product has been manufactured as a general-purpose part for

general industries, and has not been designed or manufactured to

be incorporated in a device or system used in purposes related to

human life.

• Before using the product for special purposes such as nuclear

power, electric power, aerospace, medicine or passenger

movement vehicles, consult with Mitsubishi Electric.

• This product has been manufactured under strict quality control.

However, when installing the product where major accidents or

losses could occur if the product fails, install appropriate backup or

failsafe functions in the system.

Country/Region Sales office/Tel

USA

Brazil

Mexico

Germany

UK

Italy

Spain

France

Czech

Turkey

Poland

Russia

South Africa

China

Taiwan

Korea

Singapore

Thailand

Indonesia

Vietnam

India

Australia

HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

NAGOYA WORKS : 1-14, YADA-MINAMI 5-CHOME, HIGASHI-KU, NAGOYA, JAPAN

When exported from Japan, this manual does not require application to the Ministry

of Economy, Trade and Industry for service transaction permission.

Mitsubishi Electric Automation, Inc.

500 Corporate Woods Parkway, Vernon Hills, IL 60061, U.S.A.

Tel: +1-847-478-2100

Mitsubishi Electric do Brasil Comercio e Servicos Ltda.

Avenida Adelino Cardana, 293, 21 andar, Bethaville, Barueri SP,

Brasil CEP 06401-147

Tel: +55-11-4689-3000

Mitsubishi Electric Automation, Inc. Mexico Branch

Mariano Escobedo #69, Col. Zona Industrial, Tlalnepantla Edo. Mexico, C.P.54030

Tel: +52-55-3067-7511

Mitsubishi Electric Europe B.V. German Branch

Mitsubishi-Electric-Platz 1, 40882 Ratingen, Germany

Tel: +49-2102-486-0

Mitsubishi Electric Europe B.V. UK Branch

Travellers Lane, Hatfield, Hertfordshire, AL10 8XB, U.K.

Tel: +44-1707-28-8780

Mitsubishi Electric Europe B.V. Italian Branch

Centro Direzionale Colleoni - Palazzo Sirio, Viale Colleoni 7,

Agrate Brianza (MB), Italy

Tel: +39-039-60531

Mitsubishi Electric Europe B.V. Spanish Branch

Carretera de Rubi 76-80-Apdo.420, 08190 Sant Cugat del Valles (Barcelona), Spain

Tel: +34-935-65-3131

Mitsubishi Electric Europe B.V. French Branch

25, Boulevard des Bouvets, 92741 Nanterre Cedex, France

Tel: +33-1-55-68-55-68

Mitsubishi Electric Europe B.V. Czech Branch

Avenir Business Park, Radlicka 751/113e, 158 00 Praha 5, Czech Republic

Tel: +420-251-551-470

Mitsubishi Electric Turkey A.S. Umraniye Branch

Serifali Mahallesi Nutuk Sokak No:5, TR-34775 Umraniye / Istanbul, Turkey

Tel: +90-216-526-3990

Mitsubishi Electric Europe B.V. Polish Branch

ul. Krakowska 50, 32-083 Balice, Poland

Tel: +48-12-347-65-00

Mitsubishi Electric (Russia) LLC St. Petersburg Branch

Piskarevsky pr. 2, bld 2, lit “Sch”, BC “Benua”, office 720;

RU-195027 St. Petersburg, Russia

Tel: +7-812-633-3497

Adroit Technologies

20 Waterford Office Park, 189 Witkoppen Road, Fourways, Johannesburg, South Africa

Tel: +27-11-658-8100

Mitsubishi Electric Automation (China) Ltd.

No.1386 Hongqiao Road, Mitsubishi Electric Automation Center, Shanghai, China

Tel: +86-21-2322-3030

SETSUYO ENTERPRISE CO., LTD.

6F, No.105, Wugong 3rd Road, Wugu District, New Taipei City 24889, Taiwan

Tel: +886-2-2299-2499

Mitsubishi Electric Automation Korea Co., Ltd.

7F-9F, Gangseo Hangang Xi-tower A, 401, Yangcheon-ro, Gangseo-Gu,

Seoul 07528, Korea

Tel: +82-2-3660-9530

Mitsubishi Electric Asia Pte. Ltd.

307 Alexandra Road, Mitsubishi Electric Building, Singapore 159943

Tel: +65-6473-2308

Mitsubishi Electric Factory Automation (Thailand) Co., Ltd.

12th Floor, SV.City Building, Office Tower 1, No. 896/19 and 20 Rama 3 Road,

Kwaeng Bangpongpang, Khet Yannawa, Bangkok 10120, Thailand

Tel: +66-2682-6522 to 31

PT. Mitsubishi Electric Indonesia

Gedung Jaya 11th Floor, JL. MH. Thamrin No.12, Jakarta Pusat 10340, Indonesia

Tel: +62-21-3192-6461

Mitsubishi Electric Vietnam Co., LTD. Ho Chi Minh Head Office

Unit 01-04, 10th Floor, Vincom Center, 72 Le Thanh Ton Street, District 1,

Ho Chi Minh City, Vietnam

Tel: +84-8-3910-5945

Mitsubishi Electric India Pvt. Ltd. Pune Branch

Emerald House, EL -3, J Block, M.I.D.C., Bhosari, Pune - 411026, Maharashtra, India

Tel: +91-20-2710-2000

Mitsubishi Electric Australia Pty. Ltd.

348 Victoria Road, P.O. Box 11, Rydalmere, N.S.W. 2116, Australia

Tel: +61-2-9684-7777

Specifications subject to change without notice.

Printed in Japan, June 2019.

Loading...

Loading...