Mitsubishi Electric GS2110-WTBD, GS2107-WTBD General Description Manual

Side

JY997D518BDC

B

Side

A

CHINESE ENGLISH

Side

B

GS2110-WTBD, GS2107-WTBD

GS21 General Description

Manual Number JY997D518BDC

Date Dec. 2013

This manual describes the part names, dimensions, mounting, and

specifications of the product. Before use, read this manual and manuals o f

relevant products fully to acquire proficiency in handling and operating the

product. Make sure to learn all the product information, safety information, and

precautions.

And, store this manual in a safe place so that you can take it out and read it

whenever necessary. Always forward it to the end user.

Registration

Ethernet is a trademark of Xerox Corporation in the United States.The company

name and the product name to be described in this manual are the registered

trademarks or trademarks of each company.

Effective Dec. 2013

Specifications are subject to change without notice.

Safety Precaution

Before using this product, please read this manual and the relevant manuals

introduced in this manual carefully and pay full attention to safety to handle the

product correctly.

The precautions given in this manual are concerned with this product.

In this manual, the safety precautions are ranked as "WARNING" and

"CAUTION".

Indicates that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous

conditions, resulting in medium or slight personal injury

or physical damage.

Depending on circumstances, procedures indicated by "CAUTION" may also be

linked to serious results. In any case, it is important to follow the directions for

usage

DESIGN PRECAUTIONS

Some failures of the GOT or cable may keep the outputs on or off. Some

failures of a touch panel may cause malfunction of the input objects such as a

touch switch. An external monitoring circuit should be provided to check for

output signals which may lead to a serious accident. Not doing so can cause

an accident due to false output or malfunction.

Do not use the GOT as the warning device that may cause a serious

accident. An independent and redundant hardware or mechanical interlock is

required to configure the device that displays and outputs serious warning.

Not doing so can cause an accident due to false output or malfunction.

When the GOT detects its backlight failure, the GOT disables the input

operation on the touch switch(s). Thus, operators cannot operate the GOT

with touches. The GOT backlight failure can be checked with a system si gnal

of the GOT.

Even when the display section has dimmed due to a failure of the liquid

crystal section or the backlight on the GOT, the input operation of the touch

switches may still be enabled. This may cause an incorrect operation of the

touch switches. For example, if an operator assumes that the display section

has dimmed because of the screen save function and touches the display

section to cancel the screen save, a touch switch may be activated.h

touches. The GOT backlight failure can be checked with a system signal of

the GOT.

The display section of the GOT is an analog-resistive type touch panel.

Simultaneous pressing of two or more areas on the display section may

activate the switch between those areas. Do not press two or more areas

simultaneously on the display se ction. Doing so may cause an acc ident due

to incorrect output or malfunction.

When programs or parameters of the controller (such as a PLC) that is

monitored by the GOT are changed, be sure to shut off the power of the GOT

promptly and power on the GOT again. Not doing so can cause an accident

due to false output or malfunction.

If a communication fault (including cable disconnection) occurs during

monitoring on the GOT, communication between the GOT and PLC CPU is

suspended and the GOT becomes inoperative. A system where the GOT is

used should be configured to perform any significant operation to the system

by using the switches of a device other than the GOT on the assumption that

a GOT communication fault will occur. Not doing so can cause an accident

due to false output or malfunction.

2013 Mitsubishi Electric Corporation

(Read these precautions before using.)

DESIGN PRECAUTIONS

Do not bundle the control and communication cables with main-circuit, power or

other wiring. Run the above cables separately from such wiring and keep them a

minimum of 100mm apart. Not doing so noise can cause a malfunction.

Do not press the GOT display section with a pointed material as a pen or driver.

Doing so can result in a damage or failure of the display section.

When the GOT is connected to the Ethernet network, the available IP address is

restricted according to the system configuration.

- Wh en multiple GOTs are connected to the Ethernet network: Do not set the IP

address (192.168.3.18) for the GOTs and the controllers in the network.

- Wh en a single GOT is connected to the Ethernet network: Do not set the IP

address (192.168.3.18) for the controllers except the GOT in the network.

Doing so can cause the IP address duplication. The duplication can negatively

affect the communication of the device with the IP address (192.168.3.18). The

operation at the IP address duplication depends on the devices and the

system.

Turn on the controllers and the network devices to be ready for communication

before they communicate with the GOT. Failure to do so can cause a

communication error on the GOT.

When the GOT is subject to shock or vibration, or some colors appear on the

screen of the GOT, the screen of the GOT might flicker.

MOUNTING PRECAUTIONS

Be sure to shut off all phases of the external power supply used by the system

before mounting or remov ing the GOT main unit to/ from the panel. Not doing so

can cause the unit to fail or malfunction.

MOUNTING PRECAUTIONS

Use the GOT in the environment that satisfies the general specifications

described in this manual.Not doing so can cause an electric shock, fire,

malfunction or product damage or deterioration.

When mounting the GOT to the control panel, tighten the mounting screws in the

specified torque range (0.36N·m to 0.48N·m) with a Phillips-head screwdriver

No.2. Undertightening can cause the GOT to drop, shor t circuit or malfunction.

Overtightening can cause a drop , short circuit or malfunction du e to the damage

of the screws or the GOT.

Remove the protective film of the GOT. When the user continues using the GOT

with the protective film, the film may not be removed.

Operate and store the GOT in environments without direct sunlight, high

temperature, dust, humidity, and vibrations.

Do not use the GOT in an environment with oil or chemicals. Doing so may cause

failure or malfunction due to the oil or chemical entering into the GOT.

WIRING PRECAUTIONS

Be sure to shut off all phases of the external power supply used by the system

before wiring. Failure to do so may result in an electric shock, product damage or

malfunctions.

WIRING PRECAUTIONS

Please make sure to ground FG terminal of the GOT power supply section by

applying 100Ω or less which is used exclusively for the GOT. Not doing so may

cause an electric shock or malfunction.

Correctly wire the GOT power supply section after confirming the rated voltage

and terminal arrangement of the product. Not doing so can cause a fire or failure.

Tighten the terminal screws of the GOT power supply section in the specified

torque range (0.5N•m to 0.6N•m) . Undertightening can cause a short circuit or

malfunction. Overtightening can cause a short circuit or malfunction due to the

damage of the screws or the GOT.

Exercise care to avoid foreign matter such as chips and wire offcuts entering the

GOT. Not doing so can cause a fire, failure or malfunction.

Plug the communication cable into the GOT interface or the connector of the

connected unit, and tighten the mounting screws and the terminal screws in the

specified torque range. Undertighten ing can cause a short circuit or malfunctio n.

Overtightening can cause a short circuit or malfunction dueto the damage of the

screws or unit.

TEST OPERATION

PRECAUTIONS

Before performing the test operations of the user creation monitor screen (such as

turning ON or OFF bit device, changi ng the word device current value, c hanging

the settings or current values of the timer or counter, and changing the buffer

memory current value), read through the manual carefully and make yourself

familiar with the operation m ethod. During test operatio n, never change the data

of the devices which are used to perform significant operation for the system.

False output or malfunction can cause an accident.

STARTUP/MAINTENANCE

PRECAUTIONS

When power is on, do not touch the terminals. Doing so can cause an electric

shock or malfunction.

Before starting cleaning or terminal screw retightening, always switch off the

power externally in all phases. Not doing so can cause the unit to fail or

malfunction. Undertight ening can cause a short cir cuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the

screws or unit.

STARTUP/MAINTENANCE

PRECAUTIONS

Do not disassemble or modify the unit. Doing so can cause a failure,

malfunction, injury or fire.

Do not touch the conductive and electronic parts of the unit directly. Doing so

can cause a unit malfunction or failure.

The cables connected to the unit must be run in ducts or clamped. Not doing so

can cause the unit or cable to be damaged due to the dangling, motion or

accidental pulling of the cables or can cause a malfunction due to a cable

connection fault.

When unplugging the cable connected to the unit, do not hold and pull from the

cable portion. Doing so can cause the unit or cable to be damaged or can cause

a malfunction due to a cable connection fault.

Do not drop the module or subject it to strong shock. A module damage may

result.

Before touching the unit, always touch grounded metals, etc. to discharge static

electricity from human body, etc. Not doing so can cause the unit to fail or

malfunction.

TOUCH PANEL

PRECAUTIONS

For the analog-resistive film type touch panels, normally the adjustment is not

required.However, the difference between a touched position and the object

position may occur as the period of use elapses. When any difference between

a touched position and the ob ject position occurs, exec ute the touch panel

calibration.

When any difference between a touched position and the object position occurs,

other object may be activated. This may cause an unexpected operation due to

incorrect output or malfunction.

PRECAUTIONS WHEN THE

DATA STORAGE IS IN USE

If the SD card mounted on drive A of the GOT is removed while the GOT is

accessed, processing for the GOT might be interrupted about for 20 seconds.

The GOT cannot be operated during this period. The functions that run in the

background including a screen updating, alarm, logging, scripts, and others are

also interrupted. Since this interruption makes an impact to the system

operation, it might cause failure. After inhibiting access to the SD card on the

GOT utility screen, check that the SD card access LED is off and remove the SD

card.

PRECAUTIONS WHEN THE

DATA STORAGE IS IN USE

If the data storage mounted on the GOT is removed while the GOT is accessed,

the data storage and files are damaged. To remove the data storage from the

GOT, check that the access to the data storage in SD card access LED, the

system signal, and others is not performed.

When removing the SD card from the GOT, make sure to support the SD card

by hand as it may pop out. Failure to do so may cause the SD card to drop from

the GOT, resulting in a failure or break.

Before removing the USB device from the GOT, follow the procedure for

removal on the utility screen of the GOT. After the successful completion dialog

is displayed, remove the USB device by hand carefully. Failure to do so may

cause the USB device to drop from the GOT, resulting in a failure or break.

DISPOSAL PRECAUTIONS

When disposing of this product, treat it as industrial waste.

TRANSPORTATION

PRECAUTIONS

Make sure to transport the GOT main unit and/or relevant unit(s) in the manner

they will not be exposed to the impact exceeding the impact resistance

described in the general specifications of this manual, as they are precision

devices. Failure to do so may cause the unit to fail. Check if the unit operates

correctly after transportation.

When fumigants that contain halogen materials such as fluorine, chlorine,

bromine, and iodine are used for disinfecting and protecting wooden packaging

from insects, they cause malfunction when entering our products. Please take

necessary precautions to ensure that remaining materials from fumigant do not

enter our products, or treat packaging with methods other than fumigation (heat

method). Additionally, disinfect and protect wood from insects before packing

products.

Associated Manuals

The following manuals are relevant to this product. When these loose manuals are

required, please consult with our local distributor.

Manual name Contents

GT Works3 Installation

Instructions

GOT SIMPLE series User's

*1

Manual

(sold separately)

GT Designer3 (GOT2000) Help

GOT2000 Series Connection

Manual (Mitsubishi Products) for

GT Works3 Version1

(sold separately)

GOT2000 Series Connection

Manual (Non-Mitsubishi Products

1) for GT Works3 Version1*

(sold separately)

GOT2000 Series Connection

Manual (Non-Mitsubishi Products

2) for GT Works3 Version1*

(sold separately)

GOT2000 Series Connection

Manual (Microcomputer, MODBUS Products, Peripherals) for GT

Works3 Version1*

(sold separately)

*1 The manual in PDF-format is included in the GT Works3/GT Designer3 products.

For details of a PLC to be connected, refer to the PLC user's manual respectively.

*1

1

Installation Instructions BCN-P5999-0066

Describes the Handy GOT

hardware-relevant content

such as part names,

external dimensions,

mounting, power supply

wiring, specifications, and

introduction to option

devices

Describes methods of the

GT Designer3 basic

operation for drawing,

transmitting data to GOT

SIMPLE series, and

specifications and settings

of the object functions

used in GT Designer3

Describes system

configurations of

connection methods

applicable to GOT2000

series and cable creation

methods

Describes system

configurations of

connection methods

1

applicable to GOT2000

series and cable creation

methods

Describes system

configurations of

connection methods

1

applicable to GOT2000

series and cable creation

methods

Describes system

configurations of

connection methods

applicable to GOT2000

series and cable creation

methods

Manual Number

(Model Code)

JY997D52901

-

SH-081197ENG

(1D7MJ8)

SH-081198ENG

(1D7MJ9)

SH-081199ENG

(1D7MK1)

SH-081200ENG

(1D7MK2)

Bundled Items

Model Name Specifications

GS2110-WTBD

GS2107-WTBD

Mounting fitting 4

GS21 General Description (This manual) 1

10"[800 480 dots], TFT color (65536 colors), 24VDC,

Memory size 9MB, Ethernet interface built-in

7"[800 480 dots], TFT color (65536 colors), 24VDC,

Memory size 9MB, Ethernet interface built-in

Bundled item Quantity

1. Specifications

1.1 General Specifications

Operating ambient temperature 0 to 50C

Storage ambient temperature -20 to 6 0C

Operating/Storage ambient humidity

Vibration resistance

Shock resistance

Operating atmosphere

Operating altitude

Overvoltage category

Pollution degree

Cooling method Self-cooling

Grounding Class D grounding (100Ω or less), To be connected to the panel when grounding is not possible.

*1 Do not use or store the GOT under pressures higher than the atmospheric pressure of altitude 0m (0ft). Failure to observe this instruction may cause a malfunction.

When the air inside the control panel is purged by pressurization, the surface sheet may be lifted by high pressure. As a result, the touch panel may be difficult to press,

and the sheet may be peeled off.

*2 This indicates the section of the power supply to w hich the equipment is assumed to be connected between the public electrical power distribution network and the

machinery within the premises. Category II applies to equipment f or which electrical power is supplied from fixed facilities. The surge voltage withstand level for up to the

raged voltage of 300V is 2500V.

*3 This index indicates the degree to which conductive pollution is generated in the environment where the equipment is used. In pollution degree 2, only non-conductive

pollution occurs but temporary conductivity may be produced due to condensation.

1.2 Performance Specifications

Display

*1

section

Backlight

Touch

*2

panel

Memory C drive

Built-in

interface

Buzzer output

Protective structure

External dimensions W272(10.71) H214(8.43) D56(2.21) [mm] (inch) W206(8.11) H155(6.11) D50(1.97) [mm] (inch)

Item Specifications

10 to 90%RH, non-condensing (The wet bulb temperature is 39°C)

When the ambient temperature exceeds 40°C, maintain the absolute humidity at 40°C and 90%.

Conforms to

IEC 61131-2

Conforms to IEC 61131-2 (147m/s

Must be free of lamp black, corrosive gas, flammable gas, or excessive amount of electro conductive dust particles.

*1

*2

*3

Item

Type TFT color liquid crystal display

Screen size 10" 7"

Resolution 800 480 dots

Display size W222(8.74) H132.5(5.22) [mm](inch) (Horizontal format) W154(6.06) H85.9(3.38) [mm](inch) (Horizontal format)

Display character 16-dot standard font: 50 characters 30 lines (Horizontal format)

Display color 65536 colors

Brightness 32-level adjustment

Type Analog-resistive film type

Key size Minimum 2 2 [dots] (per key)

Number of points touched

simultaneously

Life 1 million times (operating force 0.98N max.)

RS-422

RS-232

Ethernet

USB

SD card

*3

Must be no direct sunlight. (Same as for saving)

2000m (6562ft) max.

or less

2 or less

LED-type (no replacement required)

Backlight off/screen saving time can be set.

Simultaneous 2-point presses prohibited (Only one point can be touched.)

Flash memory (Internal) (9Mbytes), for storing project data, OS

Life (Number of write times) 100,000times

RS-422, 1ch

Transmission speed: 115200/57600/38400/19200/9600/4800bps

Connector shape: D-sub 9 pins (Female)

Application: For communicating with controllers

Terminating resistor: 330Ω fixed

RS-232, 1ch

Transmission speed: 115200/57600/38400/19200/9600/4800bps

Connector shape: D-sub 9 pins (Male)

Application: For communication with controllers and a bar code reader

For PC connection (Project data upload/download, FA transparent function)

Data Transfer method: 100BASE-TX, 10BASE-T, 1ch

Connector shape: RJ-45 (modular jack)

Application: For communication with controllers

For PC connection (Project data upload/download, FA transparent function)

USB (Full Speed 12Mbps) 1ch

Connector shape: Mini-B

Application: For PC connection (Project data upload/download, FA transparent function)

Conforms to the SD standard, 1ch

Supported memory card: SDHC memory card, SD memory card

Application: Project data upload/download, logging data save

Single tone (LONG/SHORT/OFF adjustable)

IP65F (only the front part of the panel)

Under intermittent

vibration

Under continuous

vibration

GS2110-WTBD GS2107-WTBD

Frequency Acceleration Half-amplitude Sweep Count

5 to 8.4Hz -- 3.5mm

8.4 to 150Hz 9.8m/s

5 to 8.4Hz -- 1.75mm

8.4 to 150Hz 4.9m/s

2

, 3times each in the X, Y, and Z directions)

Specifications

2

2

--

--

10times each in X,

Y and Z directions

--

Item

Panel cutting dimensions W258(10.16) H200(7.88) [mm] (inch) (Horizontal format) W191(7.52) H137(5.40) [mm](inch) (Horizontal format)

Weight Approx. 1.3kg (Excluding mounting fixtures) Approx. 0.9kg (Excluding mounting fixtures)

Compatible software package

(Version of GT Designer3)

*1 Bright dots (always lit) and dark dots (unlit) may appear on a liquid crystal display panel. It is impossible to completely avoid this symptom, as the liquid crystal display

comprises of a great number of display elements. Flickers and partial discoloration may be generated on the liquid crystal display panel due to individual differences of

panels. Please note that these phenomena appear due to its characteristic and are not caused by product defect.

*2 The touch panel is an analog-resistive type. Simultaneous pressing of two or more areas on the touch panel may activate the switch between those areas. Do not press

two or more areas simultaneously on the touch panel.

*3 Note that this does not guarantee all users ' operation environment. In addition, the product may not be used in environments under exposition of oil or chemicals for a

long period of time, or in environments filled with oil-mist.

Version1.104J or later

GS2110-WTBD GS2107-WTBD

Specifications

1.3 Power Supply Specifications

Item

Input power supply voltage 24VDC (+10% -15%), ripple voltage 200mV or less

Power consumption 7.6W (317mA/24V) or less 6.5W (271mA/24V) or less

At backlight off 3.8W (158mA/24V) or less 3.8W (158mA/24V) or less

Inrush current 17A or less (6ms, 25°C, at the maximum load)

Permissible instantaneous power failure time

Noise immunity Conforms to IEC61000-4-4, 2kV (power supply line)

Dielectric withstand voltage 350VAC for 1 minute (across power supply terminals and earth)

Insulation resistance 500VDC across power terminals and earth, 10 MΩ or more by an insulation resistance tester

Within 5ms

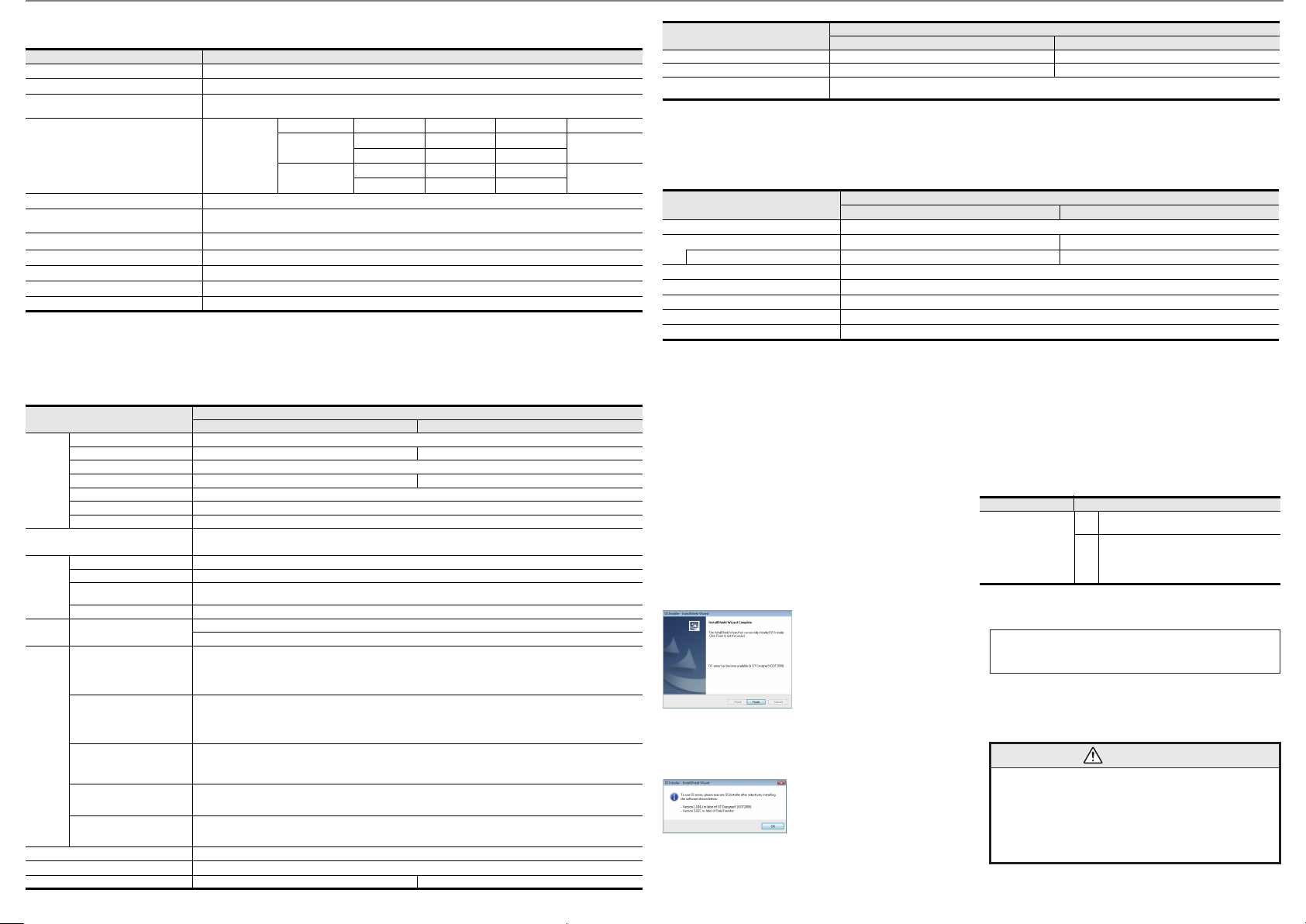

2. GT Works3 Version1 (compatible with GS Series) Installation Procedure

This chapter explains how to install and uninstall GT Works3 Version1 (compatible

with the GS Series). Make sure to read this chapter before introducing GT Works3

Version1 (compatible with the GS Series) into the personal computer.

2.1 Before installation

1) Prepare the product disc (CD-ROM or DVD-ROM) of GT Works3 Version 1.104J

or later at hand.

2) Install GT Designer3 (GOT2000) Version 1.104J or later in advance.

* For using the GS Series in the data transfer tool, it is necessary to install

in advance the data transfer tool Version 3.02C or later. For installation of

GT Designer3 (GOT2000)/data transfer tool, refer to "GT Works3

Version1 Installation Procedure" packed together with the product disc of

GT Works3 Version 1.104J or later.

3) GS Installer storage place

The installer is stored in the following folder saved in the product disc (CD-ROM or

DVD-ROM) of GT Works3 Version 1.104J or later:

CD-ROM:<Root>\TOOL\GS\GS Installer.exe

DVD-ROM:<Root>\Disk1\TOOL\GS\GS Installer.exe

4) For installing GS Installer, set to OFF the automatic playback function of the drive

before inserting the product disc into the drive, or finish the started installation if

GT Works3 Installer was automatically started by the automatic playback function.

2.2 Installation procedure

2.3 Uninstallation procedure

When GT Designer3 (GOT2000) is uninstalled, the GS Series is automatically

uninstalled.For uninstallation of GT Designer3 (GOT2000), refer to "GT Works3

Version1 Installation Procedure" packed together with the product disc of GT Works3

Version 1.104J or later.

1. Click GS Installer (GS Installer.exe) in

the folder shown in 2.1(3) above to start

GS Installer.Operate the personal

computer in accordance with

instructions given on the screen.

2. When the completion screen shown on

the left appears, click the [Finish] button

to quit GS Installer.

GS2110-WTBD GS2107-WTBD

This product is designed for use in industrial applications

Manufactured by: MITSUBISHI ELECTRIC AUTOMATION MANUFACTURING

Manufactured at: MITSUBISHI ELECTRIC AUTOMATION MANUFACTURING

Authorized Representative in the European Community:

EN61131-2 : 2007

Programmable

controllers - Equipment,

requirements and tests

For more details please contact your local Mitsubishi Electric sales site.

For details of CE marking, refer to the following.

GOT SIMPLE series User's Manual

2.4 Precautions

When the following screen appears after

startup of GS Installer, operate the

personal computer in accordance with

instructions given on the screen.

3. Notification of CE marking

The following products have shown compliance through direct testing (to the

identified standards) and design analysis (forming a technical construction file) to the

European Directive for Electromagnetic Compatibility (2004/108/EC) when used as

directed by the appropriate documentation.

Specifications

(CHANGSHU) CO.,LTD.

No.3 Southeast Road, Changshu New & Hi-tech Industrial

Development Zone of Jiangsu, 215500 China

(CHANGSHU) CO.,LTD.

No.3 Southeast Road, Changshu New & Hi-tech Industrial

Development Zone of Jiangsu, 215500 China

Mitsubishi Electric Europe B.V.

- Type: Graphic Operation Terminal

- Models : GOT SIMPLE series

Standard Remark

This manual confers no industrial property rights or any rights of any other kind,

nor does it confer any patent licenses. Mitsubishi Electric Corporation cannot be

held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

Warranty

Mitsubishi will not be held liable for damage caused by factors found not to be

the cause of Mitsubishi; opportunity loss or lost profits caused by faults in the

Mitsubishi products; damage, secondary damage, accident compensation

caused by special factors unpredictable by Mitsubishi; damages to products

other than Mitsubishi products; and to other duties.

Gothaer Str. 8, 40880 Ratingen, Germany.

Compliance with all relevant aspects of the

EMI

standard. (Radiated Emissions)

Compliance with all relevant aspects of the

standard.

EMS

(ESD, RF electromagnetic field, EFTB, Surge, RF

conducted disturbances and Power frequency

magnetic field)

For safe use

This product has been manufactured as a general-purpose part for general

industries, and has not been designed or manufactured to be incorporated in

a device or system used in purposes related to human life.

Before using the product for special purposes such as nuclear power, electric

power, aerospace, medicine or passenger movement vehicles, consult with

Mitsubishi Electric.

This product has been manufactured under strict quality control. However

when installing the product where major accidents or losses could occur if the

product fails, install appropriate backup or failsafe functions in the system.

MITSUBISHI ELECTRIC

AUTOMATION MANUFACTURING (CHANGSHU) CO.,LTD.

No.3 Southeast Road, Changshu New & Hi-tech Industrial Development Zone of Jiangsu, 215500 China

Loading...

Loading...