Page 1

0-1

GROUP 0

GENERAL

CONTENTS

VEHICLE IDENTIFICATION . . . . . . . 0-2 MAJOR SPECIFICATIONS . . . . . . . . 0-2

Page 2

VEHICLE IDENTIFICATION

GENERAL

0-2

VEHICLE IDENTIFICATION

M4000001000264

MODELS

MAJOR SPECIFICATIONS

M4000003000174

Model code Engine model Price

class

Transmission model Fuel supply

system

NA4W LNUYL6/R6 4G69-SOHC-MIVEC

(2,378 mL)

GLX F5M42 <2WD, 5M/T> MPI

LRUYL6/R6 F4A4B <2WD, 4A/T with sport mode>

LNHYL6/R6 F5M42 <2WD, 5M/T>

LRHYL6/R6 F4A4B <2WD, 4A/T with sport mode>

Item NA4W

LNUYL6/R6LNHYL6/R6LRUYL6/R6LRHYL6/

R6

Vehicle

dimension mm

Overall length 4,765

Overall width 1,795

Overall height Without roof rails

1,655/1,665

*1

With roof rails

1,690/1,700

*1

Wheelbase 2,830

Track Front 1,550

Rear 1,555

Front overhang 900

Rear overhang 1,035

Ground clearance 155

Vehicle

wheel

alignment

Front Toe-in (at the centre of tyre tread) mm 0 ± 3

Toe angle (per wheel) 0°00' ± 08'

Camber

*3

0°00' ± 30'

Caster

*3

2°46' ± 1°00', 2°54' ± 1°00'

*1

Kingpin inclination angle

13°12' ± 1°30', 12°54' ± 1°30'

*1

Rear Toe-in (at the centre of tyre tread) mm 3 ± 2

Toe angle (per wheel) 0°08' ± 05'

Camber

*3

-0°45' +45'/-15', -0°05' ± 30'

*1

Wheels and tyres Tyre size

215/60 R16 95H, 215/55 R17 94V

*2

Wheel size

16 × 6 1/2JJ, 17 × 7JJ

*2

Offset mm 46

Page 3

MAJOR SPECIFICATIONS

GENERAL

0-3

NOTE: .

*1

: Vehicles with high ground suspensions <LH drive vehicles>.

*2

: Vehicles with aluminium wheels.

*3

: Difference between right and left wheels must be less than 30'.

Page 4

1-1

GROUP 1

BODY

CONSTRUCTION

CONTENTS

BODY COMPONENTS. . . . . . . . . . . . 1-2

BODY MAIN CROSS-SECTIONAL VIEWS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

MAINTENANCE, SERVICEABILITY . 1-6

BODY CONSTRUCTION CHARACTERISTICS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

FRONT BODY. . . . . . . . . . . . . . . . . . . . . . . 1-7

SIDE BODY. . . . . . . . . . . . . . . . . . . . . . . . . 1-12

REAR BODY . . . . . . . . . . . . . . . . . . . . . . . . 1-14

ROOF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

UNDER BODY. . . . . . . . . . . . . . . . . . . . . . . 1-16

DOOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

SILENCER APPLICATION LOCATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

LOCATIONS USING URETHANE FOAM AND

FOAM MATERIAL . . . . . . . . . . . . . . . 1-21

STIFFENER AND DAMP SHEET

APPLICATION LOCATIONS . . . . . . . 1-22

Page 5

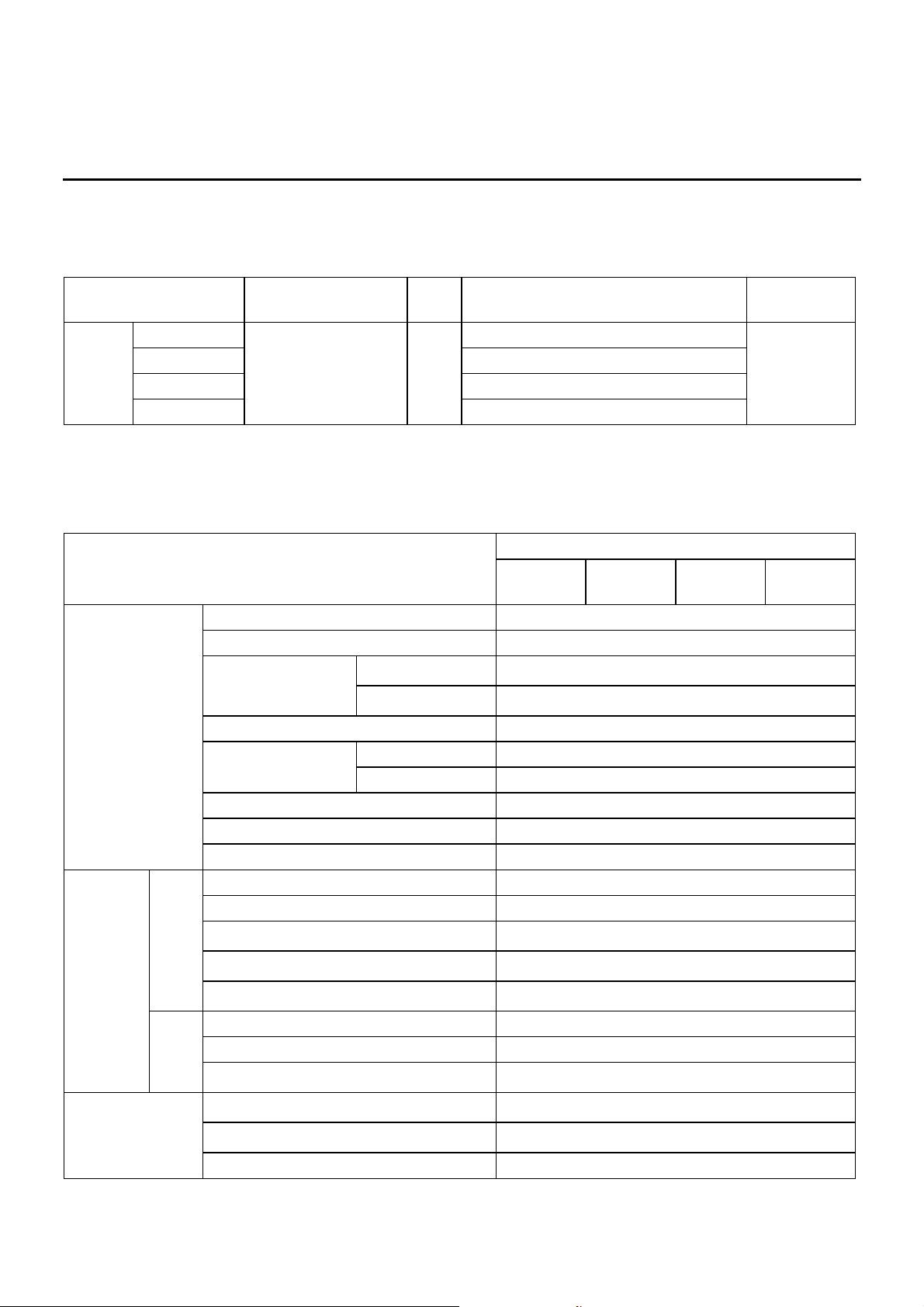

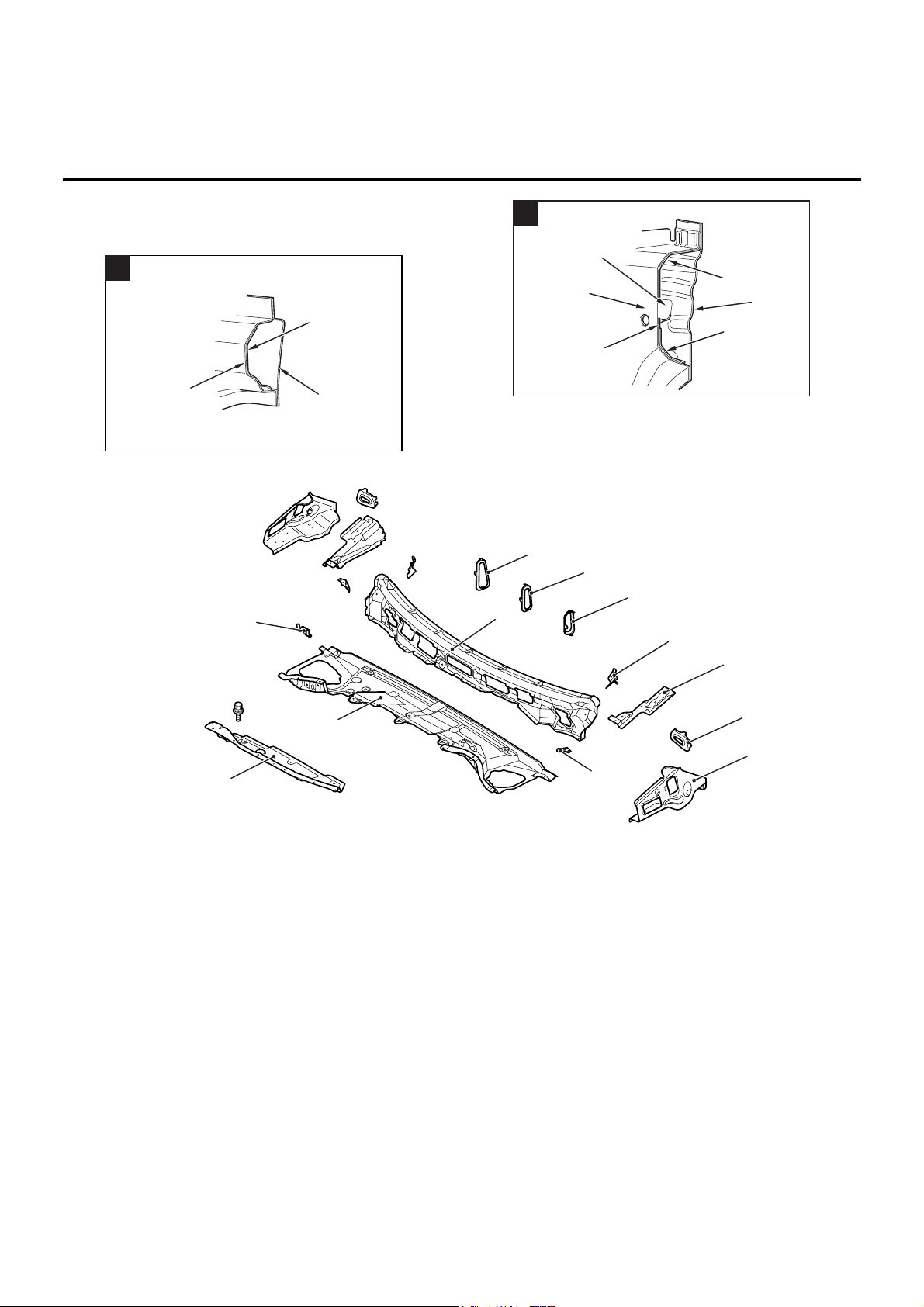

BODY COMPONENTS

BODY CONSTRUCTION

1-2

BODY COMPONENTS

M4010001000221

AB301830

AB

1

2

3*

4

5

6

7

8*

9*

10*

11*

12

13

14

15

16

17

18

19

20

21

22

23

24

25*

26

27

28

29

30

31

41

51

61

71*

72

73

74*

75

76

77

78

70

62

63

64

65

66

67

68

69

60

52

53

54

55

56

57

58

59

50

40

42

43

44

45

46

47

48

49

32

33

34

35

36

37

38

39

79

80

81

82

84

85

86

83

: High-tensile steel panels (*: Indicates 590MPa-high-tensile steel panels.)

: Anti-corrosion steel panels

1. Front end crossmember

2. Hood lock stay

3. Front end beam

4. Front end upper bar

5. Front upper bar side

6. Headlamp support brace upper

Page 6

BODY COMPONENTS

BODY CONSTRUCTION

1-3

7. Dash panel extension

8. Front floor sidemember

9. Front floor sidemember reinforcement

10. Front sidemember inner

11. Front sidemember outer

12. Headlamp bracket

13. Front fender shield

14. Spring house panel

15. Front upper frame inner

16. Front upper frame outer

17. Dash panel crossmember upper

18. Dash panel

19. Upper frame extension

20. Front deck

21. Deck crossmember

22. Guide bracket

23. Front pillar inner lower

24. Front pillar reinforcement outer lower

25. Side sill reinforcement

26. Centre pillar reinforcement outer

27. Centre pillar inner

28. Front pillar reinforcement outer upper

29. Front pillar inner upper

30. Hood inner panel

31. Hood outer panel

32. Front door panel inner

33. Front door side door beam

34. Front door panel outer

35. Rear door panel inner

36. Rear door side door beam

37. Rear door panel outer

38. Roof panel

39. Front roof rail

40. Roof bow A

41. Roof bow B

42. Roof bow C

43. Roof bow D

44. Roof bow E

45. Rear roof rail

46. Tailgate panel inner

47 Tailgate panel outer

48 Quarter extension inner

49. Quarter inner panel

50. Roof reinforcement centre

51. Roof side rail inner

52 Rear wheel house inner panel

53. Shield plate front

54. Shield plate rear

55 Rear pillar reinforcement outer

56. Gate pillar reinforcement

57. Quarter extension outer

58 Fuel filler door panel

59. Side outer panel

60. Rear end outer panel

61 Rear end inner panel

62 Quarter inner extension lower

63. Seat pan reinforcement

64. Rear floor side pan

65 Rear floor side member rear extension

66. Rear floor crossmember D

67. Rear floor sidemember

68. Rear floor crossmember C

69. Rear floor crossmember B

70. Front stringer

71. Rear floor crossmember A

72. Front floor crossmember rear

73. Front floor pan

74. Front floor side sill

75. Front fender

76. Front floor crossmember front centre

77. Buttery tray stay

78. Buttery bracket

79. Buttery tray

80. Foot rest bracket

81. Front floor crossmember front

82. Back bone reinforcement

83. Rear floor pan

84. Front fender bracket

85. Front fender bracket lower

86. Front floor side sill inner front

Page 7

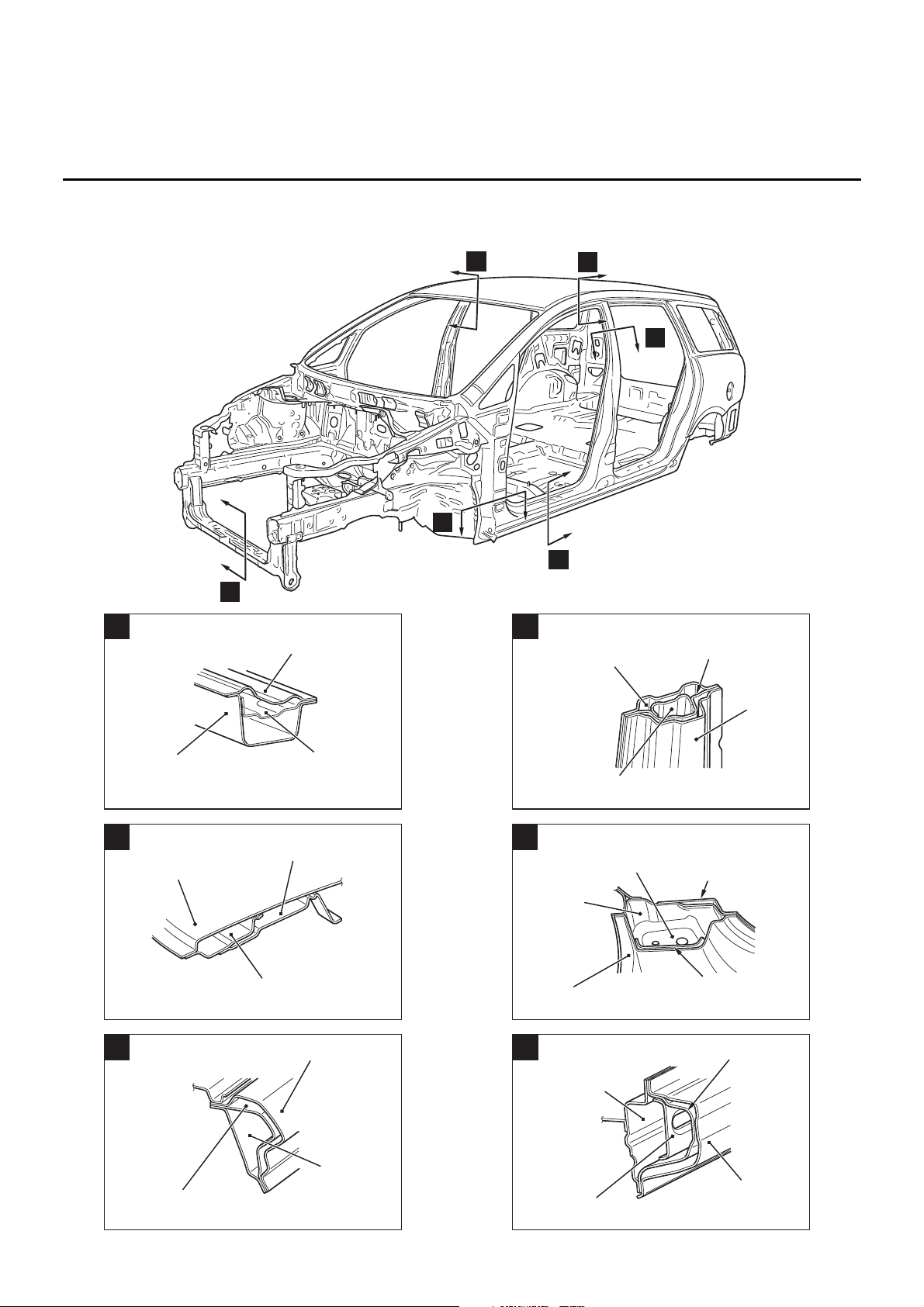

BODY MAIN CROSS-SECTIONAL VIEWS

BODY CONSTRUCTION

1-4

BODY MAIN CROSS-SECTIONAL VIEWS

M4010002000246

AB300191

AD

A

B

D

E

C

F

AB300345

AC

A

Front end

crossmember lower

Front end

crossmember upper

Front end crossmember

reinforcement

AB300343

AC

B

Roof panel

Over head console bracket

Front roof rail inner

AB300344

AC

C

Side outer panel

Front pillar

reinforcement outer upper

Side roof

rail inner

AB300346

AC

D

Centre pillar

reinforcement outer

Seat belt anchor

reinforcement

Centre pillar inner

Side outer

panel

AB300347

AD

Front floor

side sill

inner front

Side outer panel

Front pillar

reinforcement

bulkhead lower

Front door hinge

reinforcement lower

E

Front floor side sill

reinforcement upper

AB300348

AC

Side outer panel

Front floor

side sill inner

Side sill

reinforcement front

Side sill reinforcement

F

Page 8

BODY MAIN CROSS-SECTIONAL VIEWS

BODY CONSTRUCTION

1-5

AB300192

AD

G

H

I

J

K

L

AB300349

Front pillar

inner upper

Front pillar reinforcement

outer upper

Side outer panel

AC

G

Front pillar support

(Drivers side)

AB300351

Seat belt reinforcement

rear pillar

Side outer

panel

Rear pillar reinforcement

H

AE

Quarter inner

panel

AB300352

Side

outer panel

Quarter inner panel

Gate pillar

reinforcement

Quarter outer

extension

AC

Quarter inner

extension upper

I

AB300350

Rear roof rail outer

Rear roof

rail inner

Roof panel

AC

J

AB300353

AC

Side outer panel

Quarter inner panel

K

Rear wheel house inner

front panel

AB300354

Rear floor pan

Rear end panel

inner

Rear end

panel outer

Tailgate striker

reinforcement

AC

L

Page 9

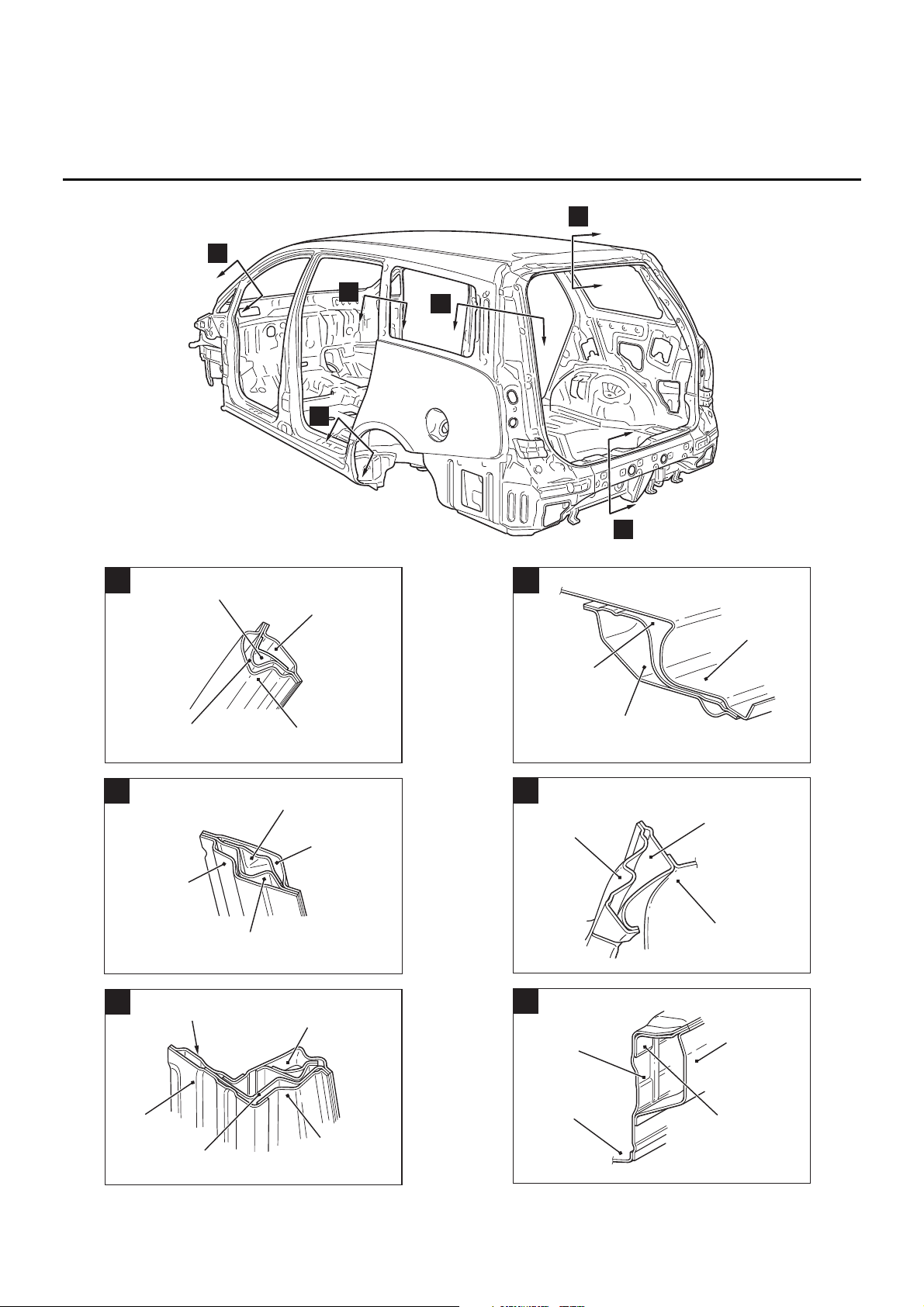

MAINTENANCE, SERVICEABILITY

BODY CONSTRUCTION

1-6

MAINTENANCE, SERVICEABILITY

M4010003000238

SIDE STRUCTURE

A panel positioning notch has been added on the

door opening to improve assembling workability

when replacing the panel.

SIDE OUTER PANEL

The extra parts are supplied in 4 different cut forms

as a result of employing the integrated side-frame

side outer panel.

AB301701

AB

Panel positioning notch

AB301702

AB

AB301703

Quarter outer

Floor side sill outer

Centre pillar outer

Front pillar outer

AB

Page 10

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-7

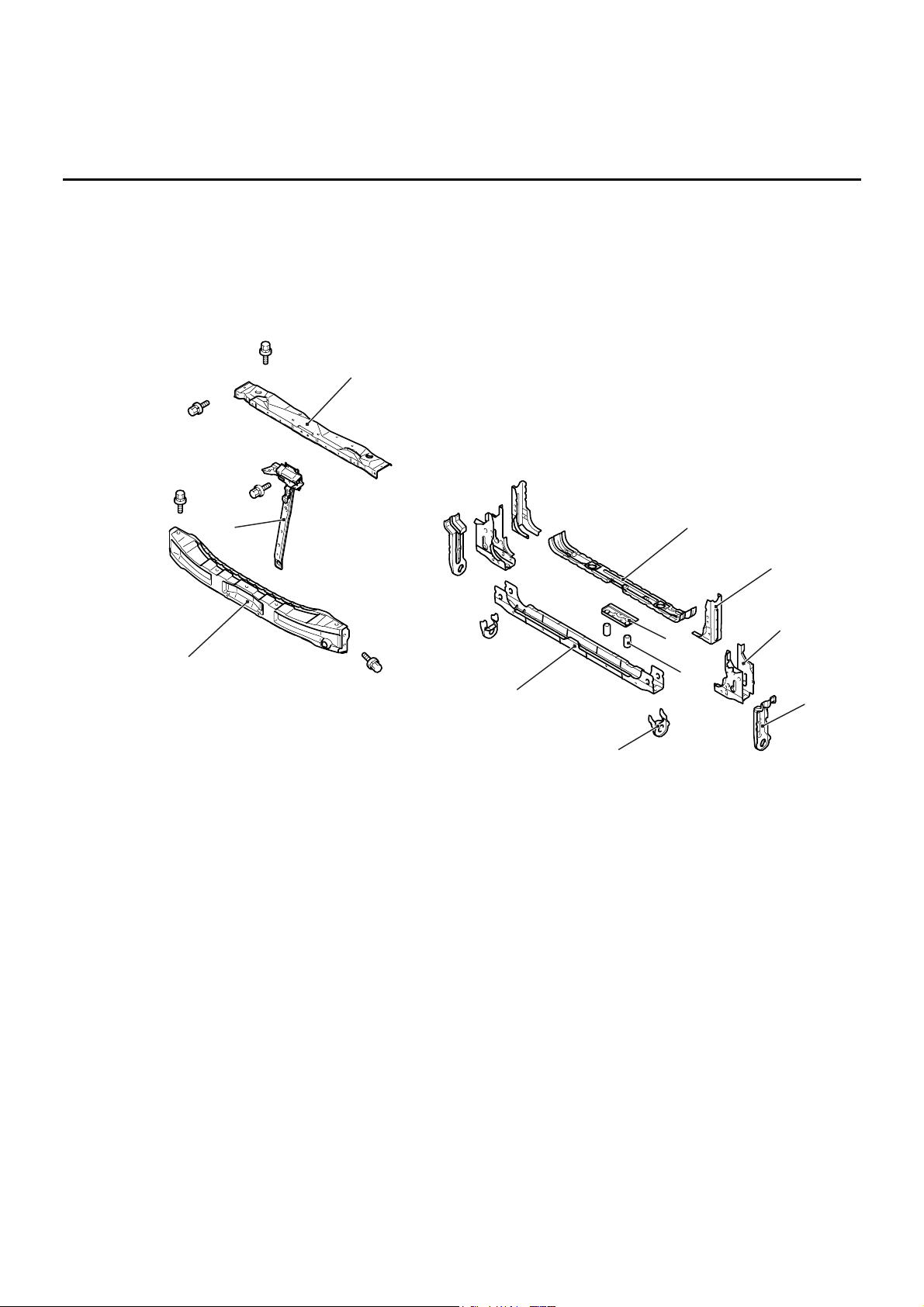

BODY CONSTRUCTION CHARACTERISTICS

FRONT BODY

M4010010000263

HEADLAMP SUPPORT

• A front end beam with a large cross section has

been adopted to improve safety upon impact.

• The bolt-on front end beam, bolt-on hood lock

stay and bolt-on front end upper bar are used to

improve maintainability.

FENDER SHIELD

• The front frame structure is supported in three

directions by the front floor side members with a

large section, dash braces and dash upper

crossmember (dash panel area) to improve body

rigidity.

• An uneven thickness steel sheet* in which the

sheet thickness is thicker in the forward part of

the vehicle was employed for the front side

member reinforcement to ensure safety upon

impact and improve body rigidity.

NOTE: *: A steel sheet of varying thickness that is

welded into one steel sheet.

AB301705

AB

1

2

3

4

5

9

8

7

6

10

11

1. Front end beam

2. Hood lock stay

3. Front end upper bar

4. Front end crossmember upper

5. Headlamp support brace lower

6. Front end crossmember brace

7. Shipping bracket

8. Front end crossmember reinforcement

9. Front No2 crossmember pipe

10. Shipping reinforcement

11. Front end crossmember lower

Page 11

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-8

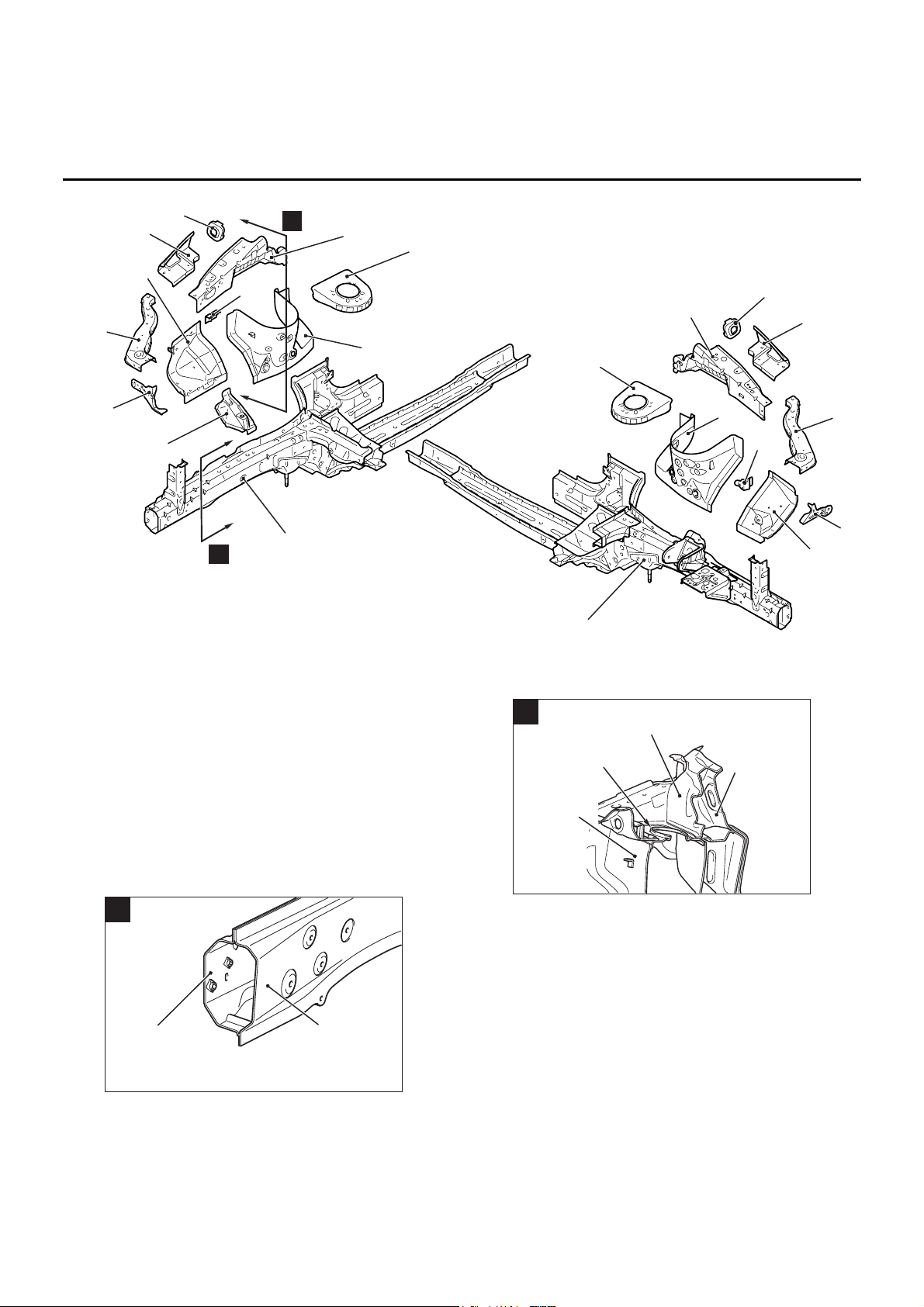

The front part of the front side member has octagonal

section that efficiently absorbs energy upon impact.

The coupling between the cowl tops with a large

cross section and the spring house brackets has

been strengthened to heighten body rigidity of the

suspension assembling support area and improve

driving stability.

AB301677

AB

Light side

Right side

A

B

1

10

4

3

5

6

9

2

3

5

8

1

4

6

7

8

7

11

10

11

12

1. Front sidemember

2. Engine mount reinforcement (Right side)

3. Headlamp bracket

4. Front end upper bar side

5. Front fender shield

6. Front upper frame outer

7. Upper frame bulkhead front

8. Front upper frame inner

9. Power steering reservoir tank bracket (Right side)

10. Spring house bracket

11. Spring house panel

12. Relay box bracket (Left side)

AB301688

AB

A

Front sidemember

inner

Front sidemember

outer

AB301689

AB

B

Spring house

bracket

Cowl top

panel inner

Cowl top

panel outer

Spring house

panel

Page 12

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-9

FRONT SIDEMEMBER REINFORCEMENT

AB302050

AB

Right side

1

2

3

4

5

7

8

9

10

11

12

13

14

15

16

19

20

27

22

6

29

25

28

26

21

30

23

24

18

17

AB300245

AC

A

B

3

9

19

15

12

25

4

5

2

18

27

17

1. Front sidemember inner

2. Front sidemember inner reinforcement front

3. Pipe support front

4. Engine mounting bulkhead rear

5. Engine mounting bulkhead front

6. Headlamp support brace upper

7. Brake hose bracket

8. Front sidemember outer

9. Kick up reinforcement

10. Dash brace

11. Accel stopper bracket (R.H. drive vehicles)

12. Front floor side sill inner reinforcement upper

13. Hood opener bracket (R.H. drive vehicles)

14. Front floor side sill inner front

15. Front floor side sill inner reinforcement lower

16. Dash panel extension

17. Front floor sidemember reinforcement upper

18. Front floor sidemember reinforcement middle (R.H.

drive vehicles)

19. Front floor sidemember reinforcement

20. Front floor sidemember

21. Suspension crossmember bracket rear

22. Dash crossmember extension lower

23. Front sidemember brace lower

24. Pipe nut

25. Pipe support rear

26. Accel pedal bracket (R.H. drive vehicles)

27. Stay reinforcement

28. Dash crossmember upper reinforcement extension

(R.H. drive vehicles)

29. Dash crossmember extension upper

30. Suspension crossmember bracket front

AB301690

AB

A

1

8

4

2

Page 13

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-10

AB302054

AB

B

1

9

8

19

3

10

AB302049

Light side

1

2

3

4

6

9

10

11

12

13

14

15

16

17

18

20

22

23

24

25

26

27

AB

28

29

30

31

33

32

8

7

5

19

21

AB302053

A

B

AB

18

4

10

9

30

31

20

13

17

5

7

1. Dash crossmember extension lower

2. Suspension crossmember bracket rear

3. Front floor sidemember

4. Front floor sidemember reinforcement

5. Front floor sidemember reinforcement upper

6. Dash panel extension

7. Front floor sidemember reinforcement middle (L.H.

drive vehicles)

8. Dash crossmember upper reinforcement extension

(L.H. drive vehicles)

9. Front floor side sill inner reinforcement lower

10. Front floor side sill inner reinforcement upper

11. Dash brace

12. Front floor side sill inner front

13. Kick up reinforcement

14. Brake house bracket

15. Headlamp support brace upper

16. Front sidemember outer

17. Towing reinforcement

18. Transmission mounting reinforcement

19. Front sidemember outer reinforcement (L.H. drive

vehicles)

20. Pipe support front

21. Front sidemember inner reinforcement (L.H. drive

vehicles)

22. Front sidemember inner

23. Battery bracket

24. Transmission mounting stay front

25. Transmission mounting gusset

26. Transmission mounting bracket

27. Transmission mounting stay rear

28. Suspension crossmember bracket front

29. Dash crossmember extension upper

30. Stay reinforcement

Page 14

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-11

FRONT DECK

31. Pipe support rear

32 Pipe nut

33. Front sidemember brace lower

AB302055

AB

22

16

18

A

AB302056

AB

22

16

11

B

13

20

4

AB301706

2

3

5

6

AB

7

8

9

12

4

10

11

1

1. Cowl top panel front

2. Cowl top panel inner

3. Wiper bracket A

4. Cowl top bulkhead A

5. Cowl top panel outer

6. Cowl top bulkhead B

7. Cowl top bulkhead C

8. Cowl top gusset side

9. Front upper frame extension inner

10. Upper frame bulkhead rear

11. Front upper frame extension outer

12. Fender bracket

Page 15

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-12

DASH PANEL

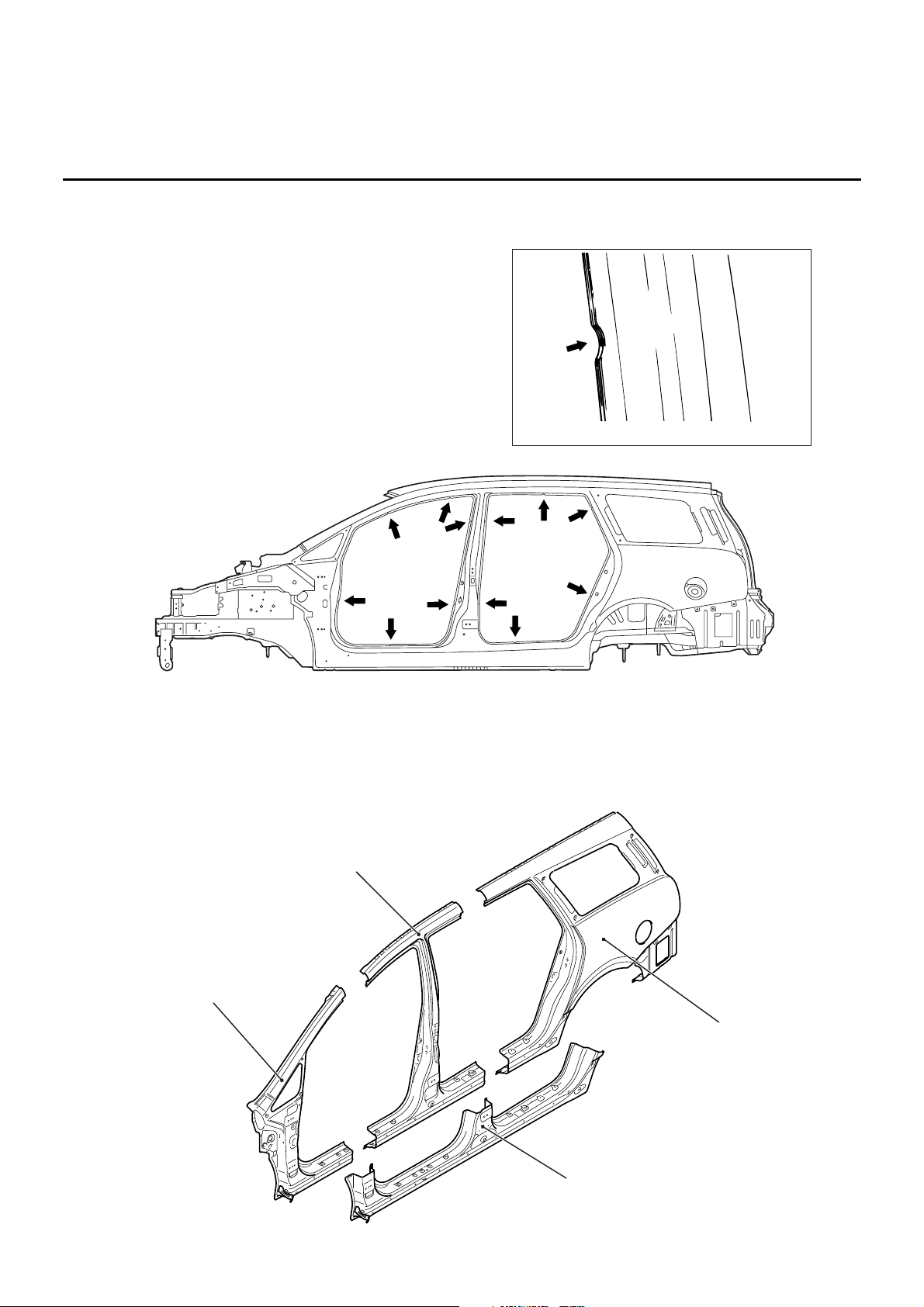

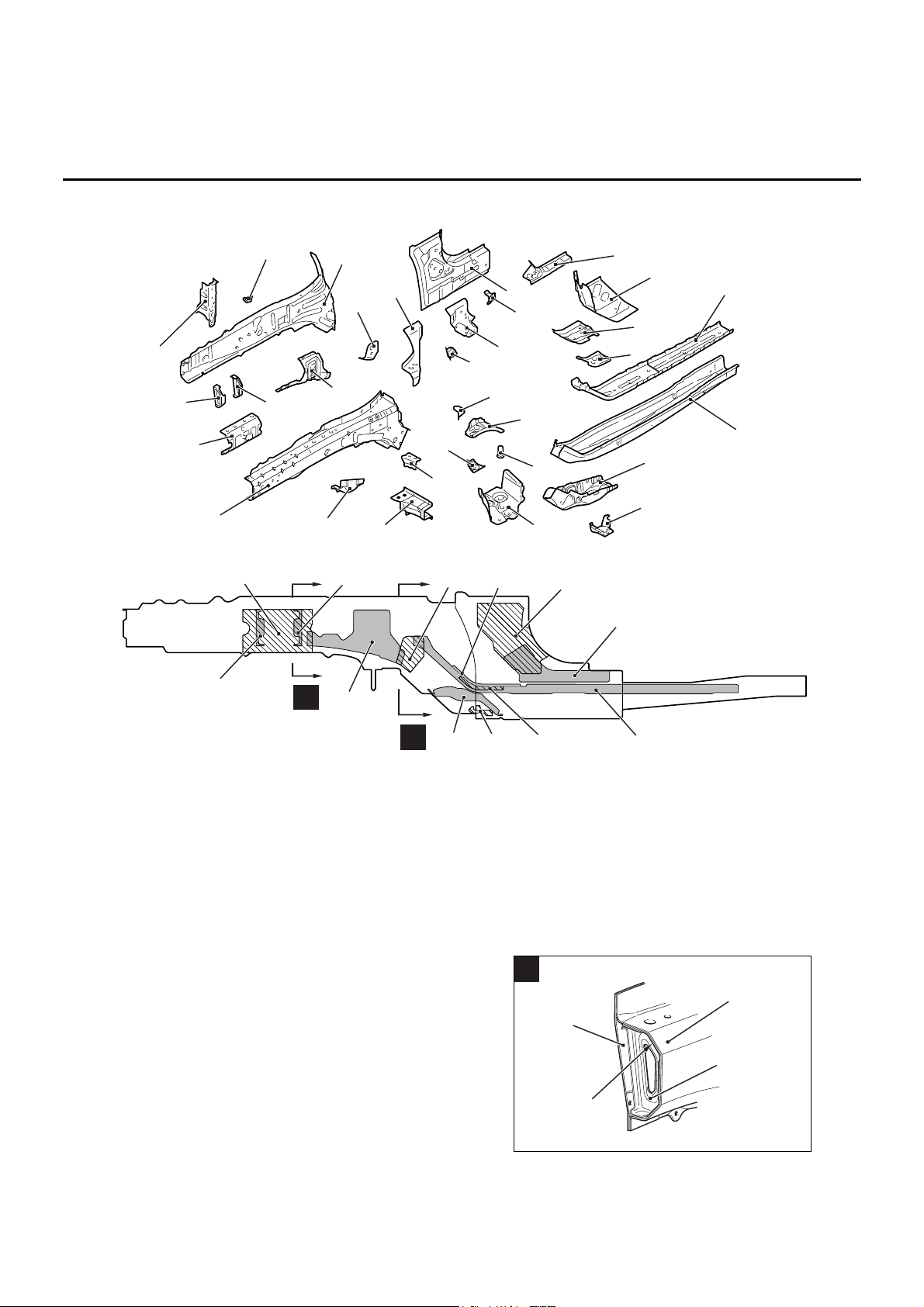

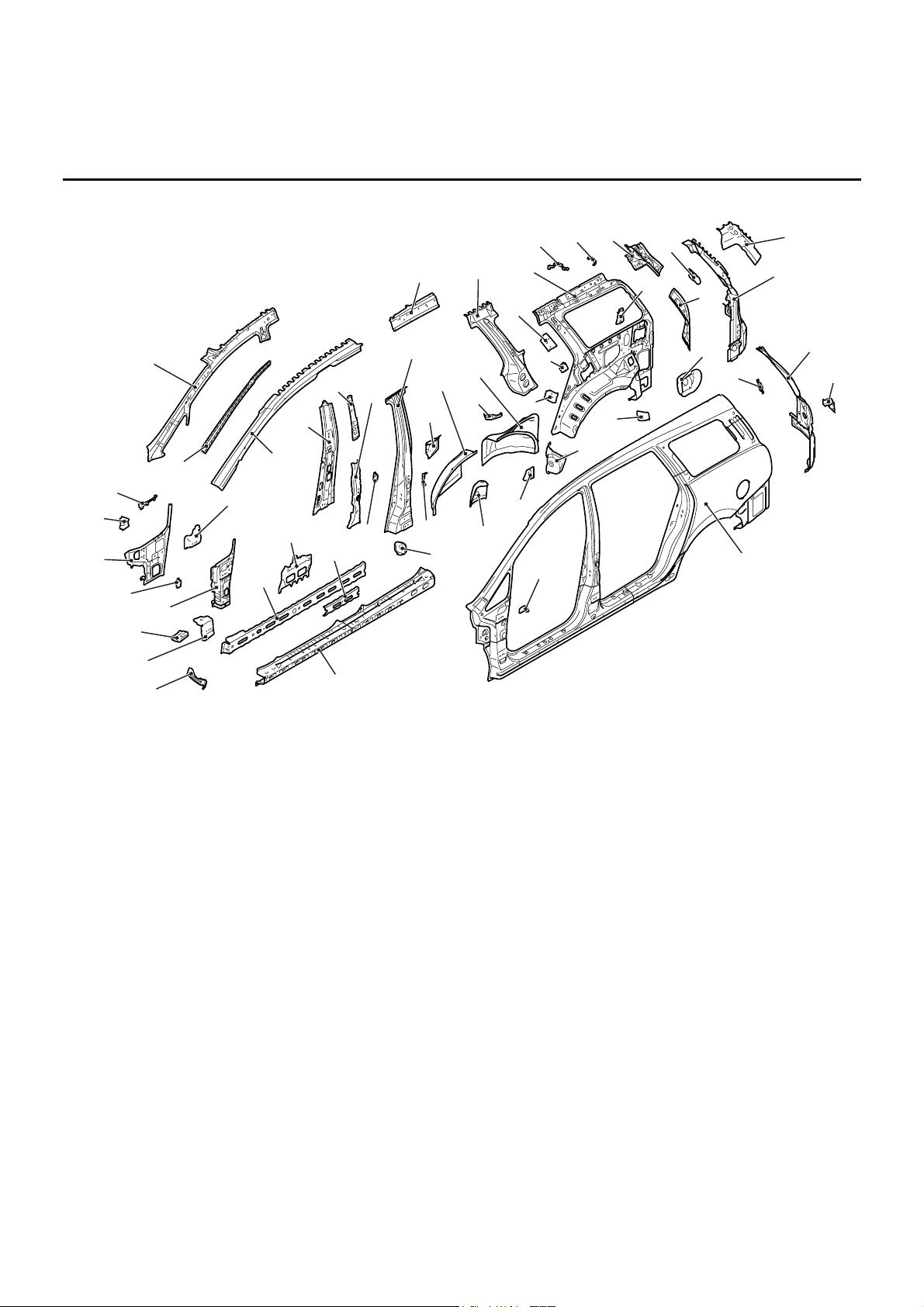

SIDE BODY

M4010011000233

SIDE STRUCTURE

• An uneven thickness steel sheet* in which the

sheet thickness is thicker in the order of the

upper section, rear section, and lower section

was employed for the side outer panel to ensure

safety upon side impact.

• The rear wheel houses each consist of a front

and a rear panel, and thick steel plates are used

for the rear wheel house panels where the rear

suspensions are installed, in order to heighten

the body rigidity and improve driving stability.

NOTE: *: A steel sheet of varying thickness that is

welded into one steel sheet.

AB301685

AB

1

7

11

2

9

8

4

3

6

5

10

1. Dash crossmember upper

2. Dash crossmember reinforcement upper

3. Dash panel plate (RH drive vehicles, A/T lever type)

4. Dash panel

5. Dash crossmember lower

6. Accel pedal upper bracket (LH drive vehicles)

7. Clutch pedal support bracket (Vehicle for M/T)

8. Dash panel reinforcement

9. Clutch pedal stopper bracket (RH drive vehicles,

M/T)

10. Accel pedal bracket (LH drive vehicles)

11. Steering shaft bracket

Page 16

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-13

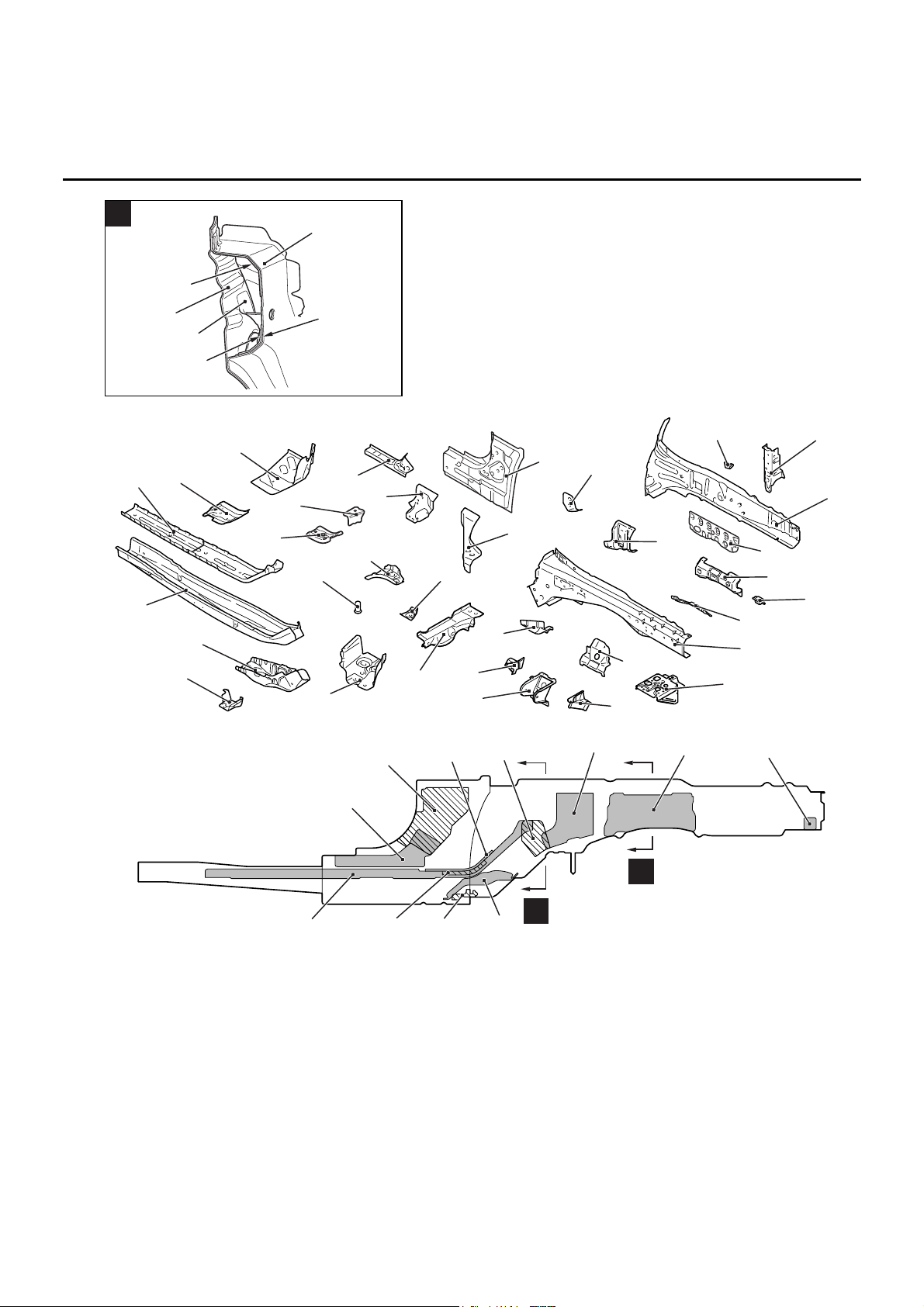

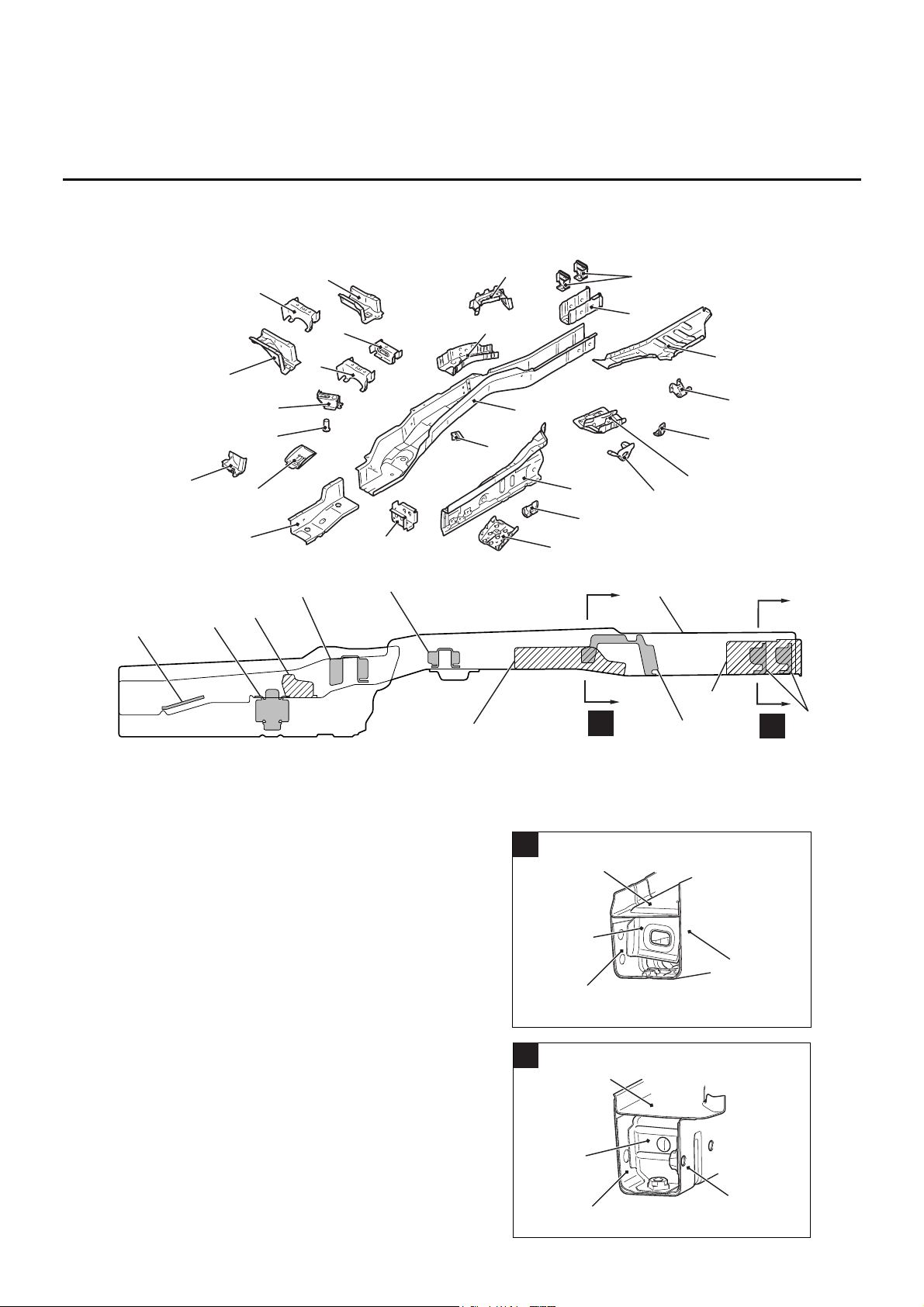

SIDE STRUCTURE REINFORCEMENT

An uneven thickness steel sheet* in which the sheet

thickness is thicker in the forward part of the vehicle

was employed for the side sill reinforcement to

ensure safety upon side impact.

NOTE: *: A steel sheet of varying thickness that is

welded into one steel sheet.

AB301697

AB

1

2

3

4

5

6

7

8

9

10

12

13

14

15

16

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

35

36

37

38

39

40

44

34

17

41

42

43

33

46

45

48

51

50

49

11

47

1. Front fender lower bracket

2. Front door hinges reinforcement lower

3. Front pillar reinforcement bulkhead lower

4. Front pillar reinforcement outer lower

5. Front door checker bulkhead

6. Front door hinges reinforcement upper

7. Front pillar inner lower

8. Deck crossmember bracket

9. Instrument panel side bracket

10. Front pillar inner upper

11. Front pillar support (Driver’s side)

12. Front pillar reinforcement outer upper (Passenger’s

side)

13. Centre pillar inner

14. Seat belt anchor reinforcement

15. Rear door hinges reinforcement upper

16. Side roof rail inner

17. Centre pillar reinforcement outer

18. Third seat anchor reinforcement

19. Rear wheel house inner front panel

20. Shock absorber reinforcement

21. Rear wheel house inner rear panel

22. Rear door striker reinforcement

23. Seat belt reinforcement lower second

24. Seat belt reinforcement rear pillar

25. Rear pillar reinforcement outer

26. Quarter inner panel

27. Radio tuner amplifier bracket (Right side)

28. TV tuner amplifier bracket (Left side)

29. Quarter inner extension upper

30. Seat belt reinforcement lower third

31. Seat belt reinforcement upper

32. Quarter inner extension

33. Gate pillar upper reinforcement

34. Gate pillar reinforcement

35. Fuel filler neck bracket (Left side)

36. Gas spring reinforcement

37. Quarter outer extension

38. Tailgate dumper reinforcement side

39. Side outer panel

40. Fender bracket

41. Side sill reinforcement

42. Side sill reinforcement front

43. Seat belt front anchor reinforcement

44. Side sill reinforcement centre

45. Rear door check bulkhead

46. Side sill bulkhead rear

47. Harness bracket

48. Shock absorber support

49. Rear seat belt reinforcement wheel house

50. Shield plate front

51. Shield plate rear

Page 17

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-14

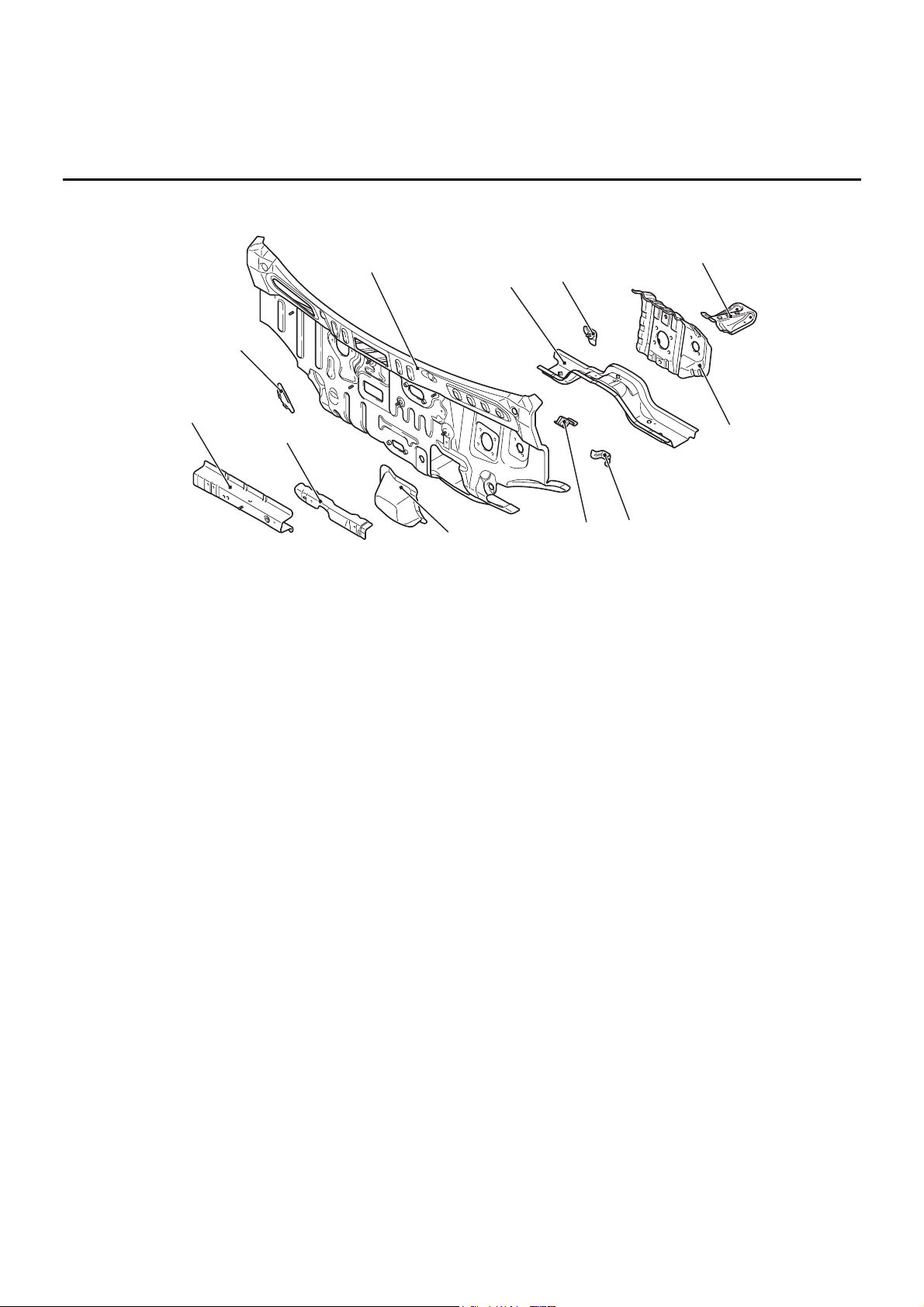

REAR BODY

M4010012000203

REAR END CROSSMEMBER

AB301707

AB

Side sill reinforcement

AB301708

AB

1

2

3

4

5

6

7

8

9

10

11

12

1. Rear end panel inner

2. Heat protector bracket

3. Muffler hanger bracket rear

4. Tailgate striker reinforcement

5. Rear end panel outer

6. Jack rear bulkhead

7. Spare tyre reinforcement rear end

8. Jack rear bracket A

9. Jack rear bracket B

10. Bumper bracket

11. Rear floor side brace

12. Quarter inner extension lower

Page 18

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-15

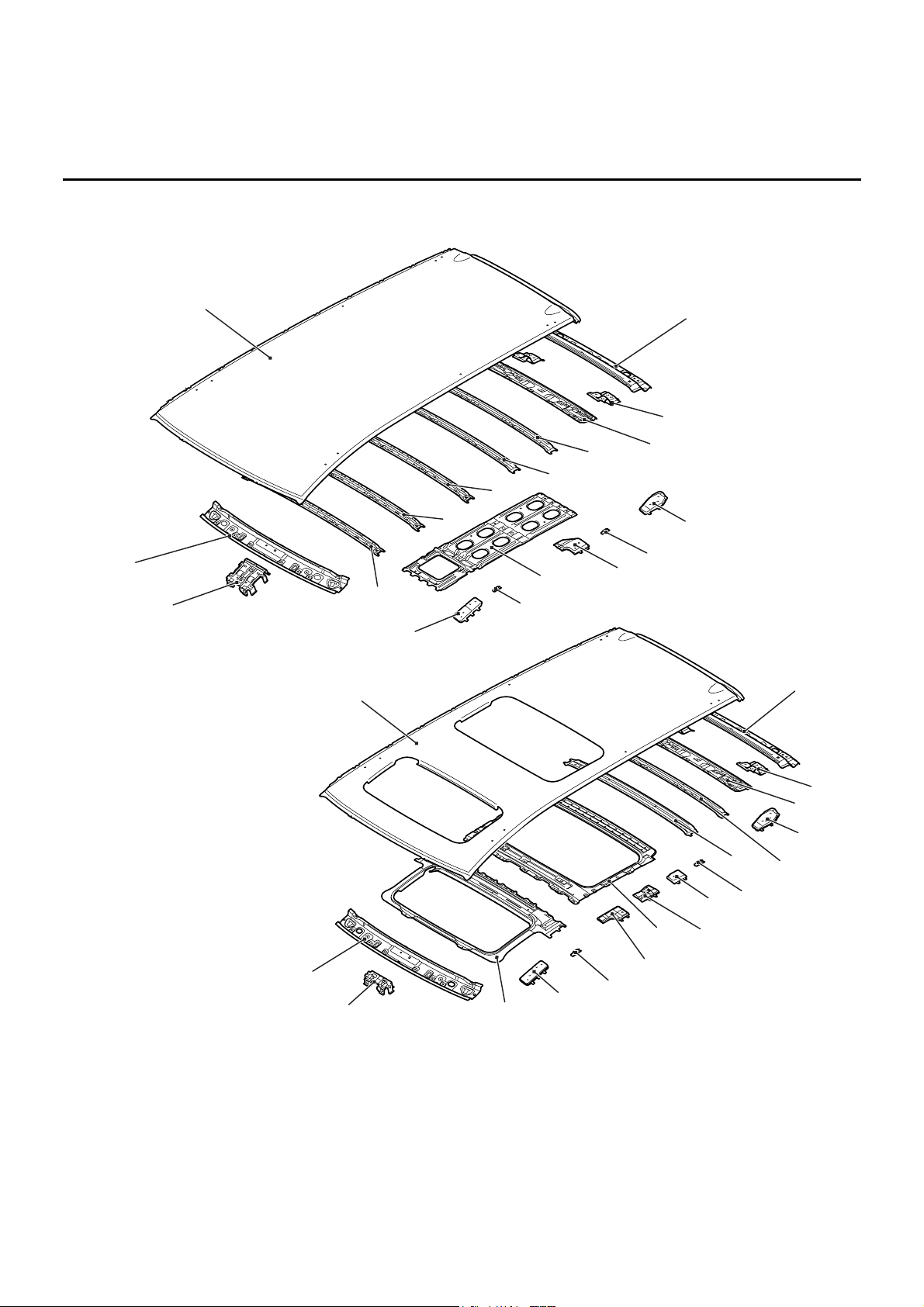

ROOF

M4010013000217

AB300305

AB301710

AB300304

Except for sun roof

Vehicles with sun roof

AB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

2

3

4

5

6

18

19

20

7

11

8

16

15

8

9

8

21

1. Overhead console bracket

2. Front roof rail inner

3. Roof panel

4. Rear roof rail outer

5. Tailgate hinge reinforcement

6. Rear roof rail inner

7. Roof rack reinforcement rear (Vehicles with roof rail)

8. Roof carrier bracket

9. Roof rack reinforcement centre (Vehicles with roof

rail)

10. Roof centre reinforcement

11. Roof rack reinforcement front (Vehicles with roof rail)

12. Roof bow A

13. Roof bow B

14. Roof bow centre

15. Roof bow D

16. Roof bow E

17. Set bracket rear

18. Roof reinforcement rear

19. Set bracket front

20. Roof reinforcement front

21. Room lamp bracket

Page 19

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-16

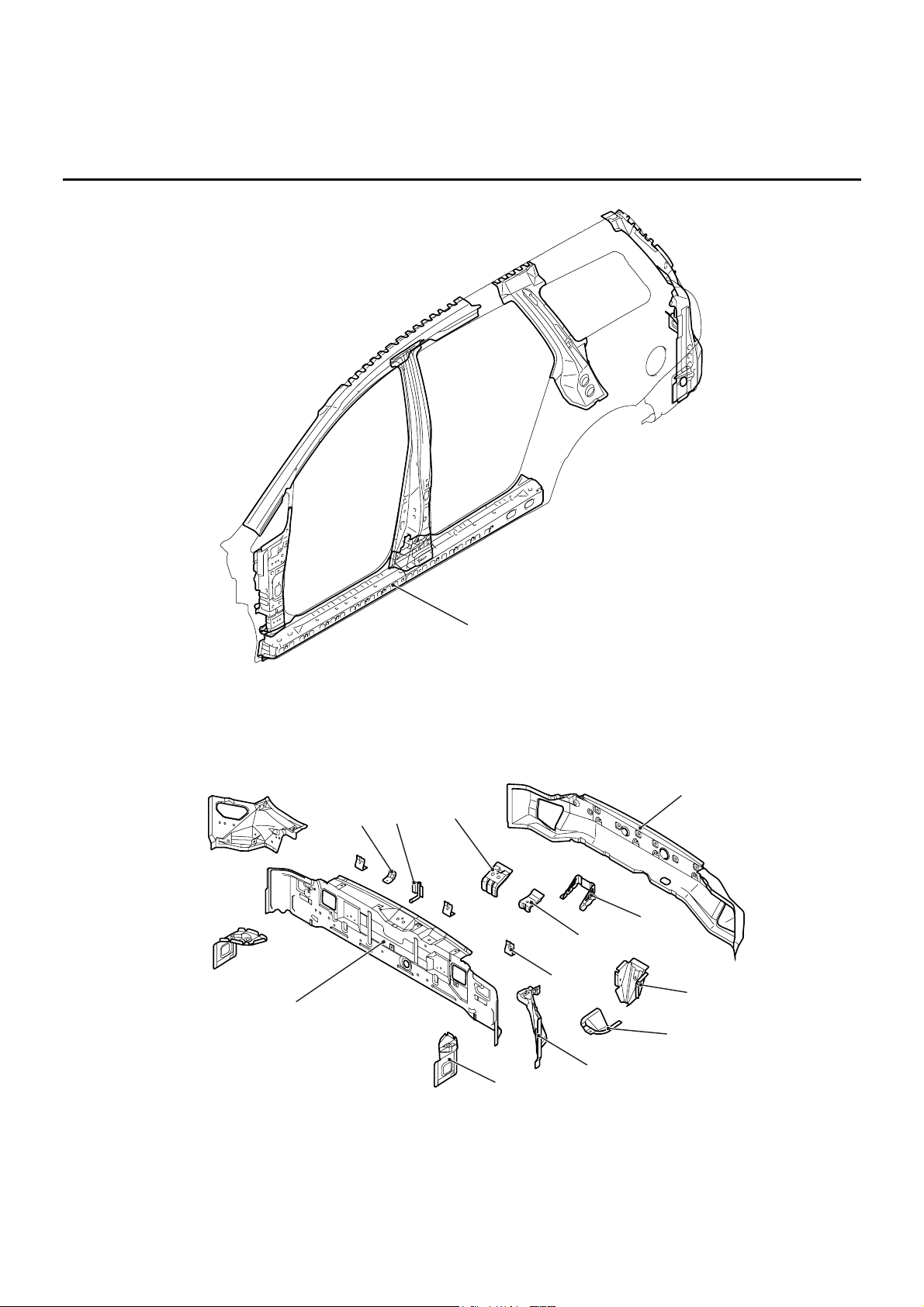

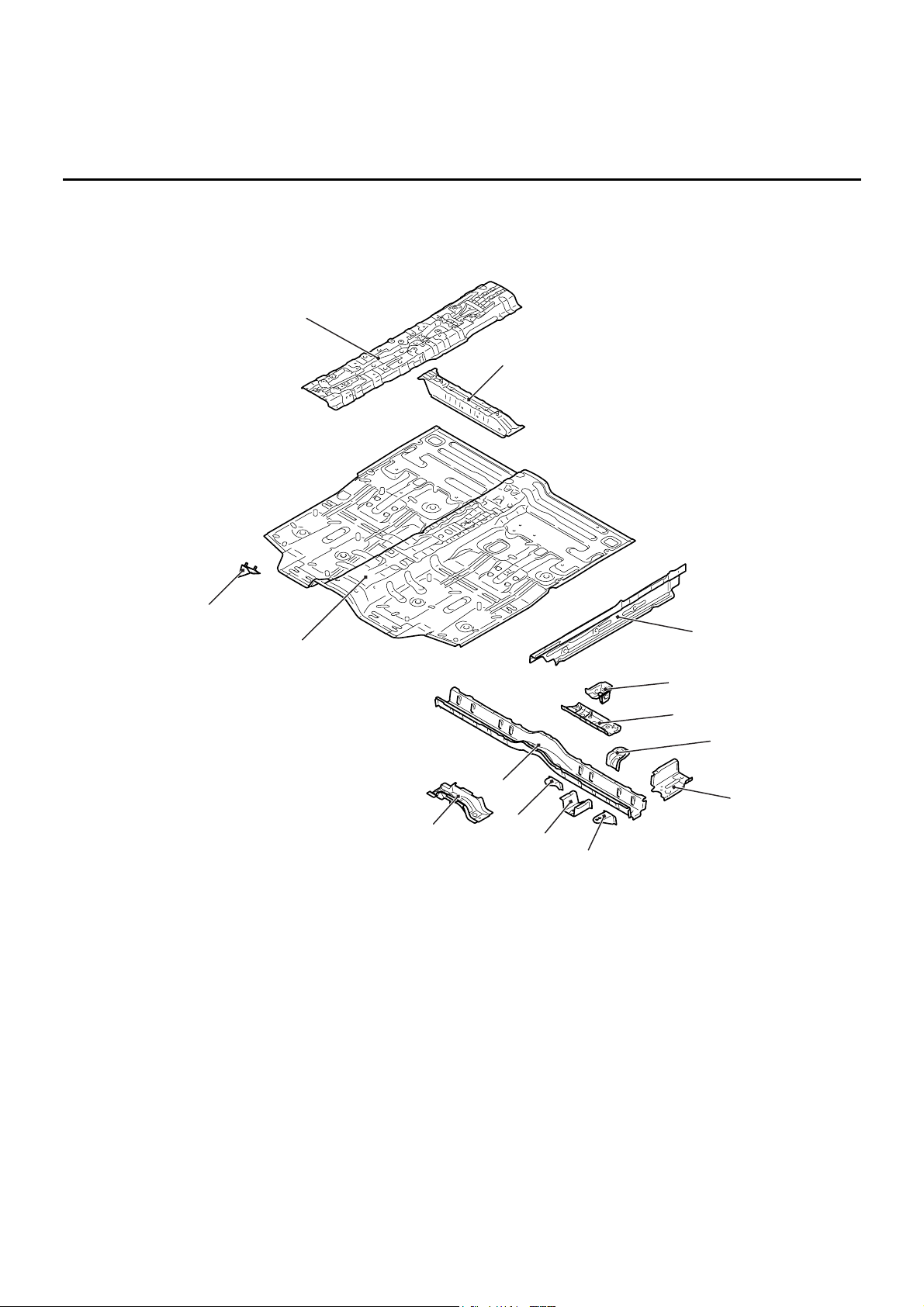

UNDER BODY

M4010014000265

FRONT FLOOR

REAR FLOOR

• An uneven thickness steel sheet* in which the

sheet thickness is thicker in the forward part of

the vehicle was employed for the rear floor side

member to ensure safety upon impact.

NOTE: *: A steel sheet of varying thickness that is

welded into one steel sheet.

AB301673

AB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1. Front floor pan

2. Foot rest bracket (R.H. drive vehicles)

3. Backbone reinforcement

4. Front floor crossmember front

5. Front floor side sill inner

6. Front floor crossmember rear bulkhead

7. Front floor crossmember rear reinforcement

8. Fuel tank support bracket front

9. Front floor sidemember extension rear

10. Front seat reinforcement rear side

11. Front floor sidemember extension front

12. Front seat anchor reinforcement centre

13. Front floor crossmember rear

14 Front floor crossmember front centre

Page 20

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-17

AB301667

AB

1

2

3

4

5

6

7

8

9

10

11

12

13

15

17

18

14

16

1. Rear floor crossmember A

2. Seat anchor reinforcement front centre A

3. Seat anchor front reinforcement

4. Rear floor pan

5. Rear floor crossmember D

6. Seat anchor reinforcement D

7. Seat pan reinforcement

8. Rear suspension crossmember bulkhead

9. Mounting bolt

10. Rear floor crossmember C

11. Spring sheet

12. Seat anchor reinforcement B

13. Rear floor crossmember centre reinforcement B

(Seven-passenger model)

14. Rear floor crossmember B

15. Fuel tank support bracket rear

16. Flange reinforcement (Seven-passenger model)

17. Front stringer

18. Rear floor sidemember

Page 21

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-18

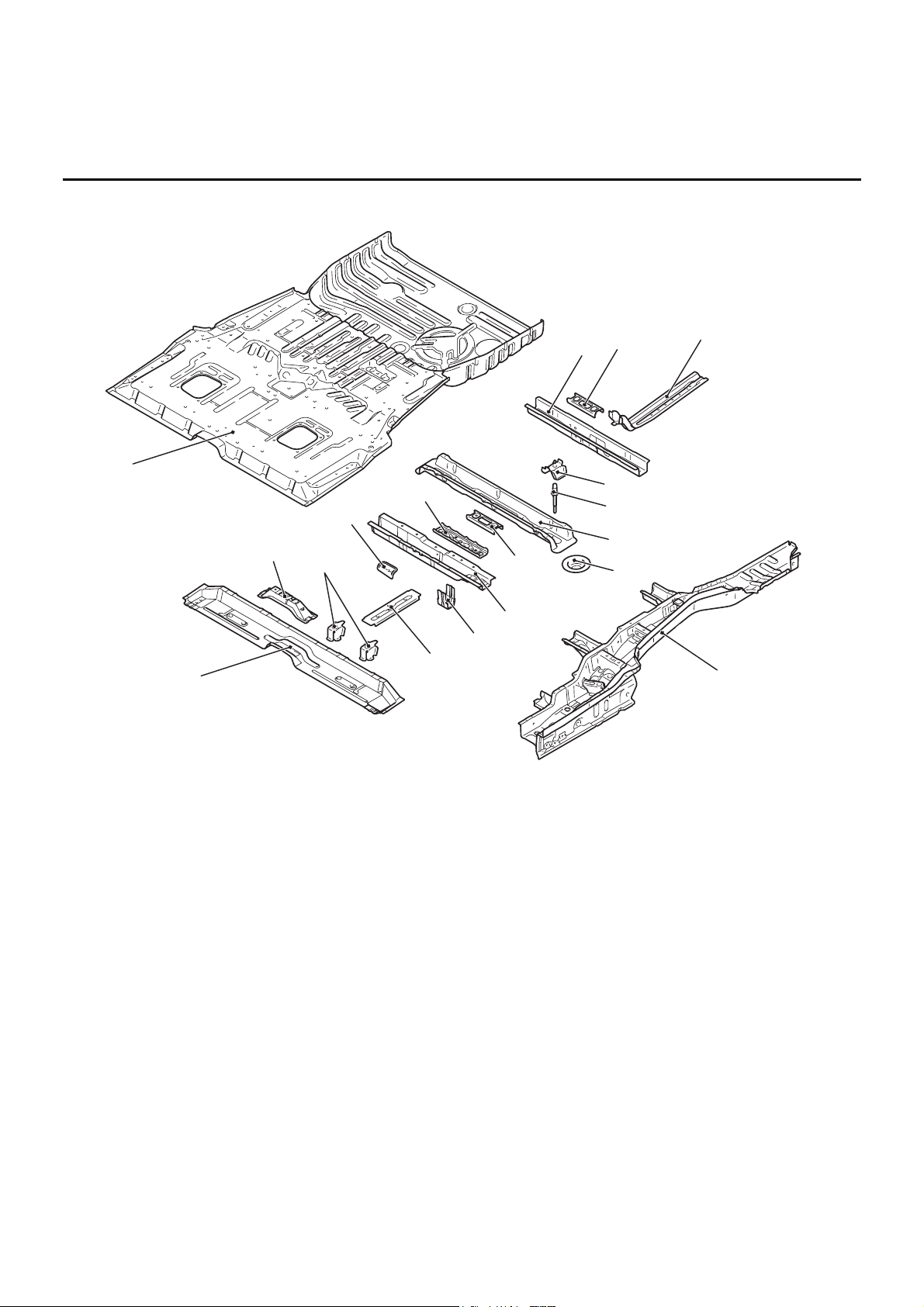

REAR FLOOR SIDEMEMBER

REINFORCEMENT

AB301668

AB

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

20

21

22

23

25

17

19

24

18

7

AB301675

A

B

AB

12

11

13

2

25

5

7

9

14

20

1. Rear floor sidemember extension front

2. Tie down hook plate

3. Fuel tank support bracket

4. Pipe nut

5. Pipe support front

6. Rear floor crossmember extension B

7. Seat anchor rear reinforcement (Seven-passenger

model right side)

8. Seat anchor rear reinforcement (Except for seven

passenger model right side)

9. Rear floor sidemember front bulkhead

10. Rear floor crossmember extension D

11. Rear floor sidemember reinforcement

12. Third seat anchor reinforcement

13. Rear floor sidemember rear bulkhead (Left side)

14. Rear floor sidemember extension rear

15. Rear floor side pan

16. Muffler hanger bracket rear (Right side)

17. Heat protector bracket (Right side)

18. Spare tyre support (Left side)

19. Shipping bracket (Right side)

20. Rear floor sidemember

21. Brake hose bracket

22. Rear floor side sill inner

23. Jack up side reinforcement

24. Sidemember front bulkhead

25. Rear suspension crossmember stopper bracket

AB300434

A

20

12

11

AC

15

AB300435

B

AC

15

14

13

20

Page 22

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

1-19

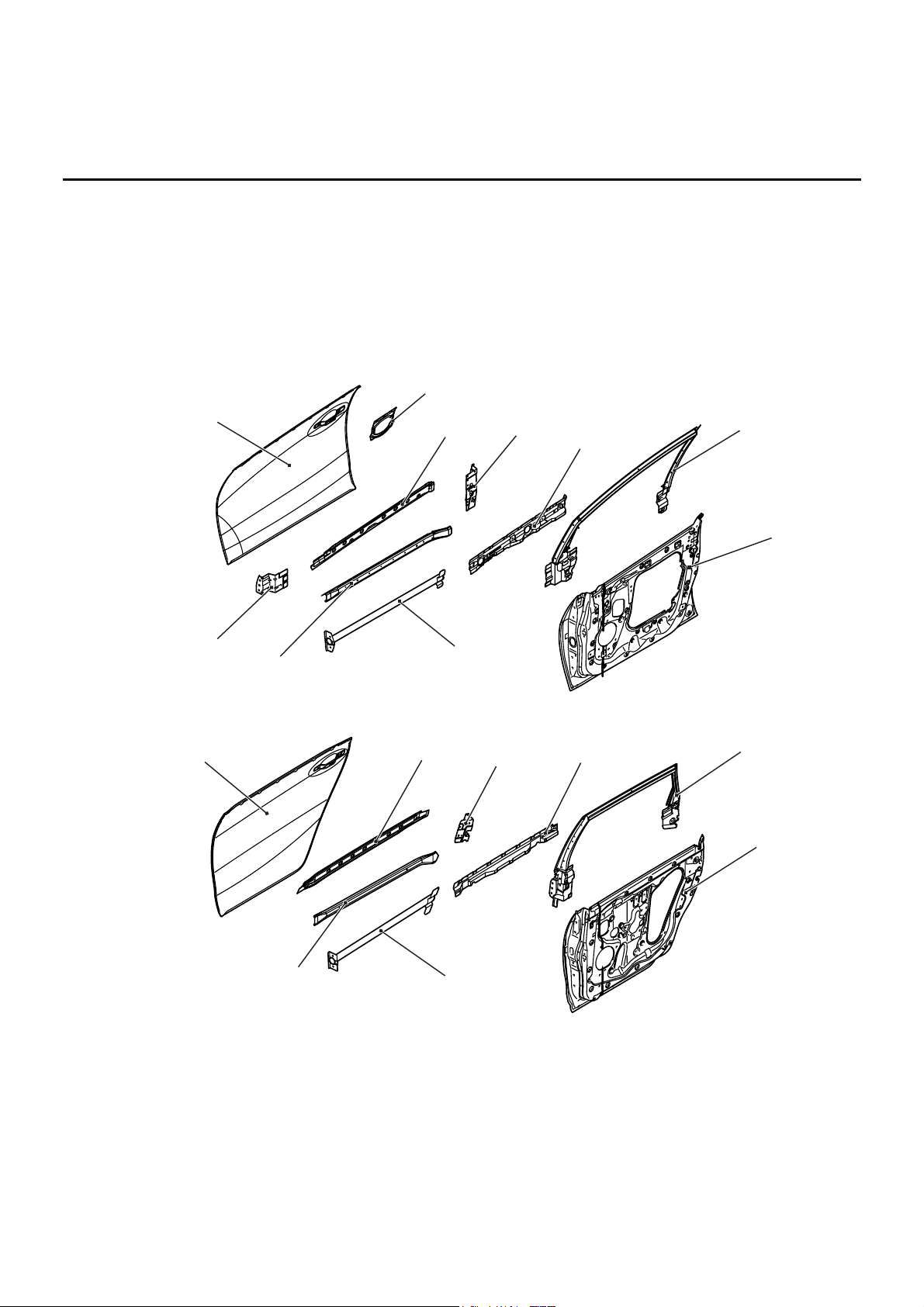

DOOR

M4010015000213

• An uneven thickness steel sheet* in which the

sheet thickness is thicker in the forward part of

the vehicle was employed for the inner panel to

improve rigidity.

• The front and rear side door beam was located in

the bumper position of the vehicle to improve

cabin protection upon side impact.

• A belt line inner reinforcement has been adopted

to improve cabin protection upon impact.

• The bottom section of the door sash pillar was

enlarged and the couplings between the hinge,

latch and door sash were strengthened to

improve sash rigidity.

NOTE: *: A steel sheet of varying thickness that is

welded into one steel sheet.

AB301700

1

2

3

4

5

6

AB

7

8

9

10

Front door

AB301699

AB

Rear door

12

13

14

15

16

17

18

11

1. Front door outer panel

2. Front door outside handle reinforcement

3. Front door belt line outer reinforcement

4. Front door latch reinforcement

5. Front door belt line inner reinforcement

6. Front door window sash

7. Front door inner panel

8. Front side door beam

9. Front door outer stiffener

10. Front door hinge upper reinforcement

11. Rear door outer panel

12. Rear door belt line outer reinforcement

13. Rear door latch reinforcement

14. Rear door belt line inner reinforcement

15. Rear door window sash

16. Rear door inner panel

17. Rear side door beam

18. Rear door outer stiffener

Page 23

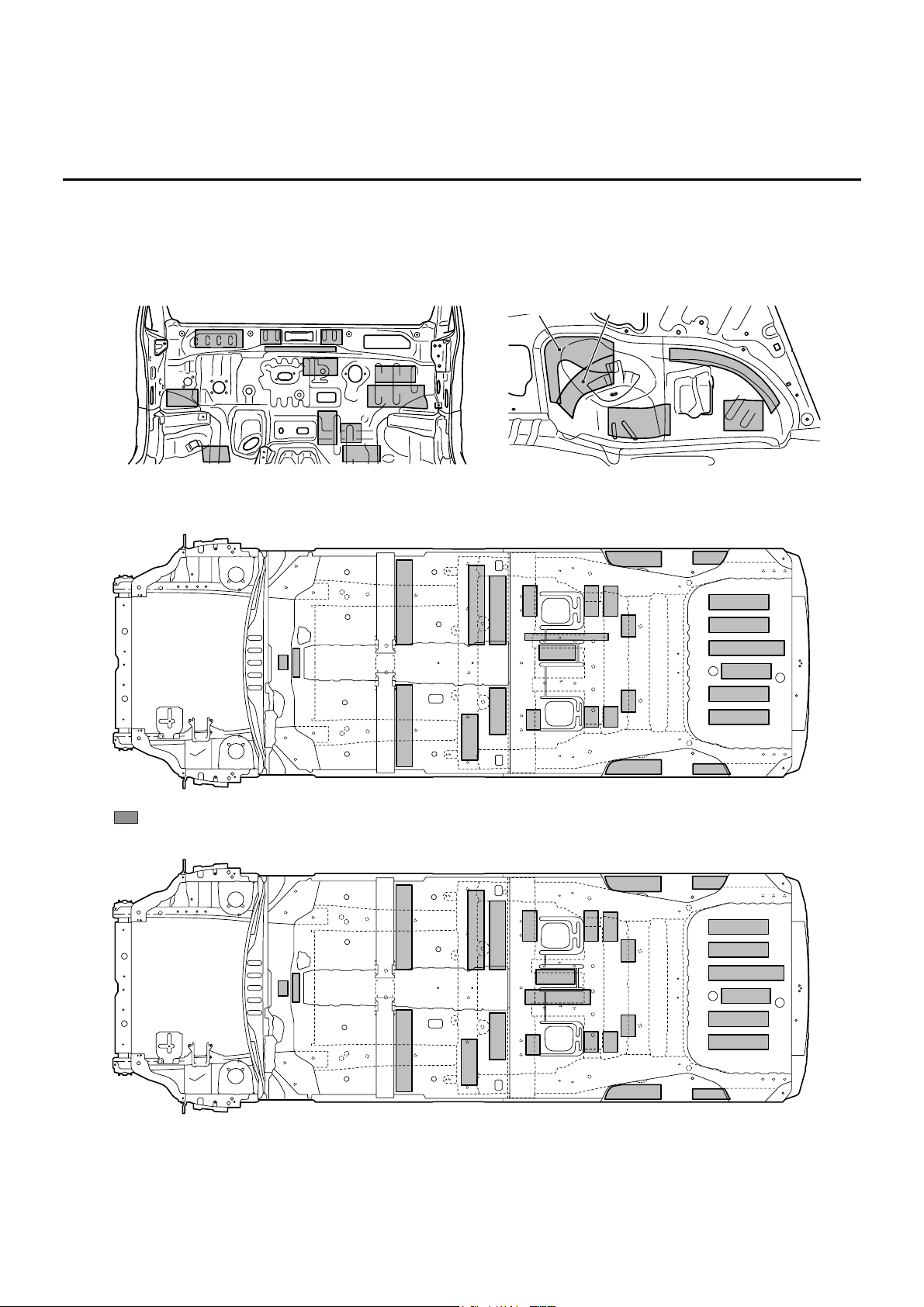

SILENCER APPLICATION LOCATIONS

BODY CONSTRUCTION

1-20

SILENCER APPLICATION LOCATIONS

M4010005000278

Sound insulation was improved by using a

spray-type anti-vibration agent on the cabin side of

the dash panel, rear wheel house and rear floor.

Use a melting sheet for repair.

NOTE: ( ) indicates the number of melting sheets that are used for repair.

AB300368

AB301712

AB

Rear wheel house inner

Dash panel

<Left side>

<Right side>

AB301714

AB

Six-passenger model

: 3.2 mm thick melting sheet and RSS (Place two 1.6 mm melting sheet one on top of another.)

AB301713

AB

Seven-passenger model

Page 24

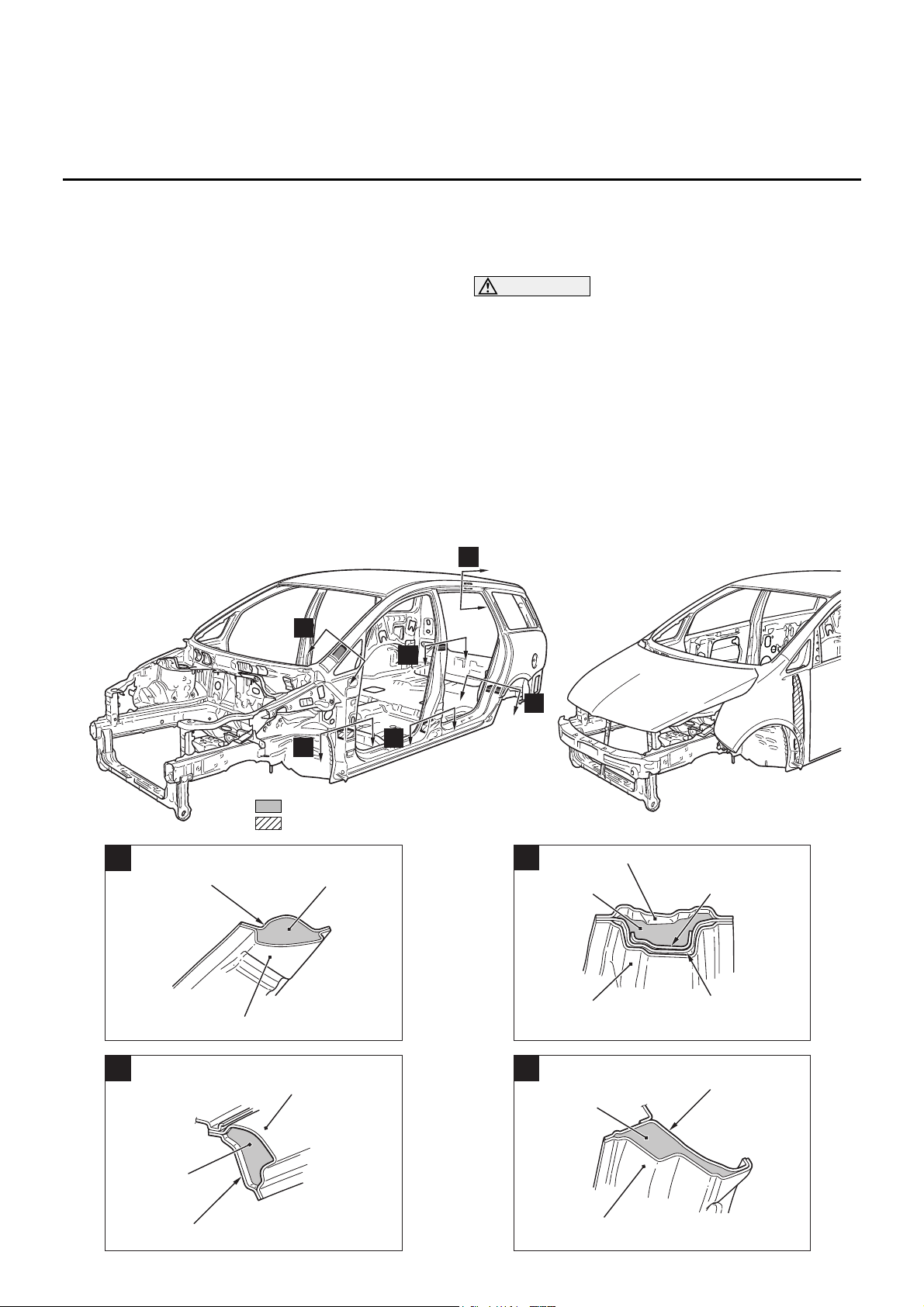

LOCATIONS USING URETHANE FOAM AND FOAM MATERIAL

BODY CONSTRUCTION

1-21

LOCATIONS USING URETHANE FOAM AND FOAM

MATERIAL

M4010007000177

• Introduction of noise was prevented by adding

acoustic foam materials inside the front pillar,

centre pillar, side roof rail and wheel house arch.

• Introduction of noise was prevented by inserting

urethane foam inside the front pillar, centre pillar

and front fender.

CAUTION

The foam materials may burn when heated.

Always observe the following instructions.

• Never use a gas burner or burn the areas

using foam materials.

• When cutting the parts using foam materials,

ensure to use tools (air saw, etc.) that do not

generate fire.

• If there is residual foam materials remaining

on the cut section (body side) then weld after

removing the foam materials from periphery

of the welding area.

AB300554

AB300416

AB300490

AC

A

B

C

E

F

D

: Acoustic foam

: Urethane foam

AB300446

AC

Acoustic foam

material

Side outer panel

Front pillar

inner upper

A

AB300448

AC

B

Acoustic foam

material

Roof side rail inner

Side outer panel

AB300447

AC

Centre pillar

reinforcement outer

Centre pillar inner

Acoustic foam

material

C

Seat belt anchor

reinforcement

Side outer panel

AB300449

AC

Side outer panel

Quarter inner panel

Acoustic foam

material

D

Page 25

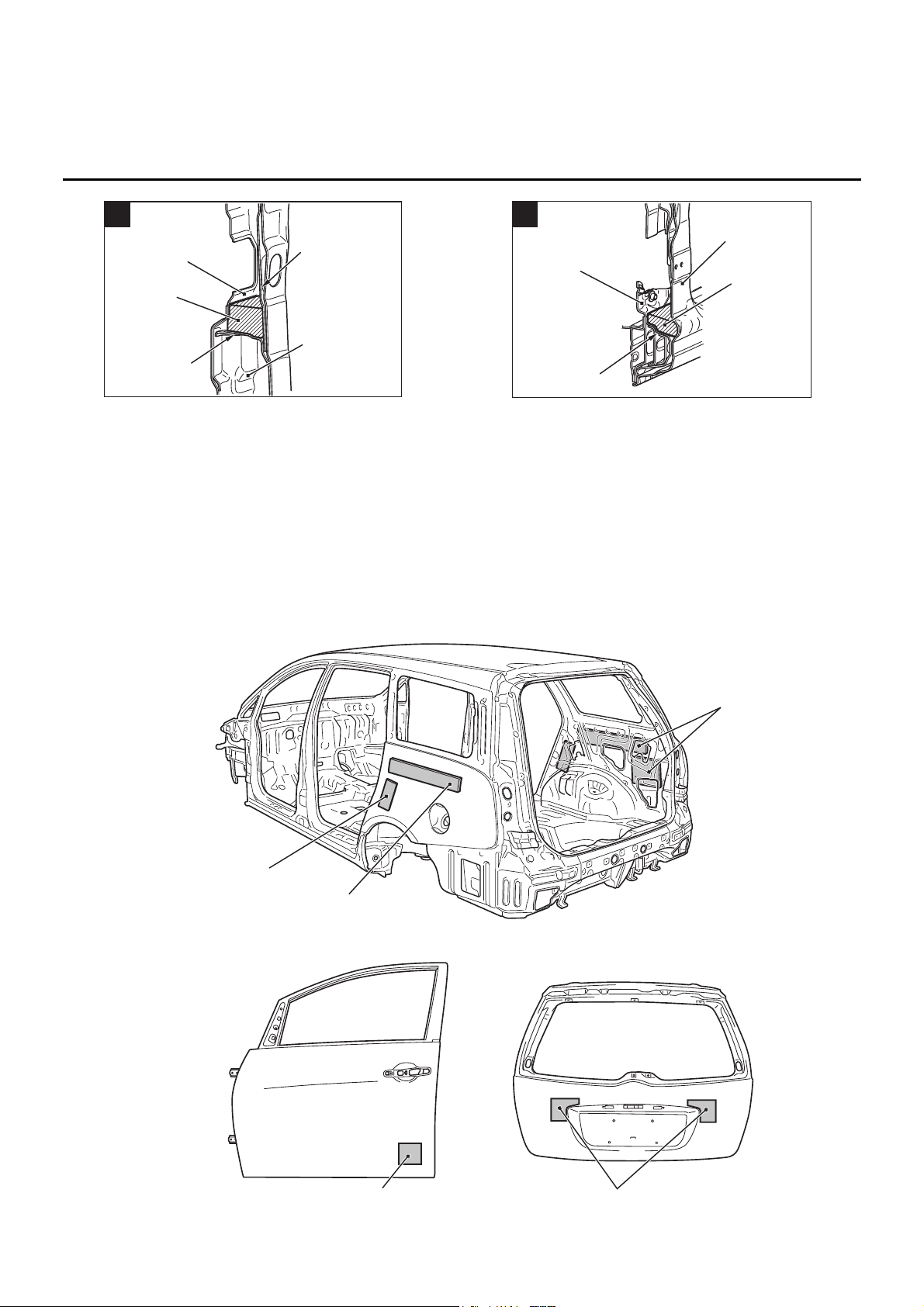

STIFFENER AND DAMP SHEET APPLICATION LOCATIONS

BODY CONSTRUCTION

1-22

STIFFENER AND DAMP SHEET APPLICATION LOCATIONS

M4010008000192

Sound insulation was improved with anti-vibration

effects and heightening surface rigidity with a

stiffener on the inner side of the side outer panel and

the tailgate outer panel, as well as a damping sheet

adhered to the inner side of the front door and the

rear door outer panel.

NOTE: The main contents of a stiffener are epoxy

resin. It comes in a sheet form and contains a

mixture of glass fibre and filler, and cures (stiffens)

when heated. It is used to improve the rigidity of the

outer plate.

AB300450

AC

Urethane foam

Front pillar

reinforcement

outer lower

Front pillar inner lower

Front door hinge

reinforcement

lower

Front floor side

sill inner front

E

AB300451

AC

Side outer panel

Urethane

foam

Side sill

reinforcement

Seat belt front

anchor reinforcement

F

AB301882

AB

Stiffener

Stiffener

Damp sheet

AB301881

AB

Stiffener

Damp sheet

Front door

Tailgate

Page 26

2-1

GROUP 2

BODY DIMENSIONS

CONTENTS

BODY DIMENSIONS AND MEASUREMENT

METHODS . . . . . . . . . . . . . . . . . . . . . 2-2

TYPE A (PROJECTED DIMENSIONS)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

UNDER BODY . . . . . . . . . . . . . . . . . . . . . . 2-3

SUSPENSION INSTALLATION DIMENSIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

TYPE B (ACTUAL-MEASUREMENT

DIMENSIONS). . . . . . . . . . . . . . . . . . . 2-7

UNDER BODY. . . . . . . . . . . . . . . . . . . . . . . 2-7

SUSPENSION INSTALLATION DIMENSIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

FRONT BODY . . . . . . . . . . . . . . . . . . . . . . . 2-10

SIDE BODY . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

REAR BODY . . . . . . . . . . . . . . . . . . . . . . . . 2-13

INTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Page 27

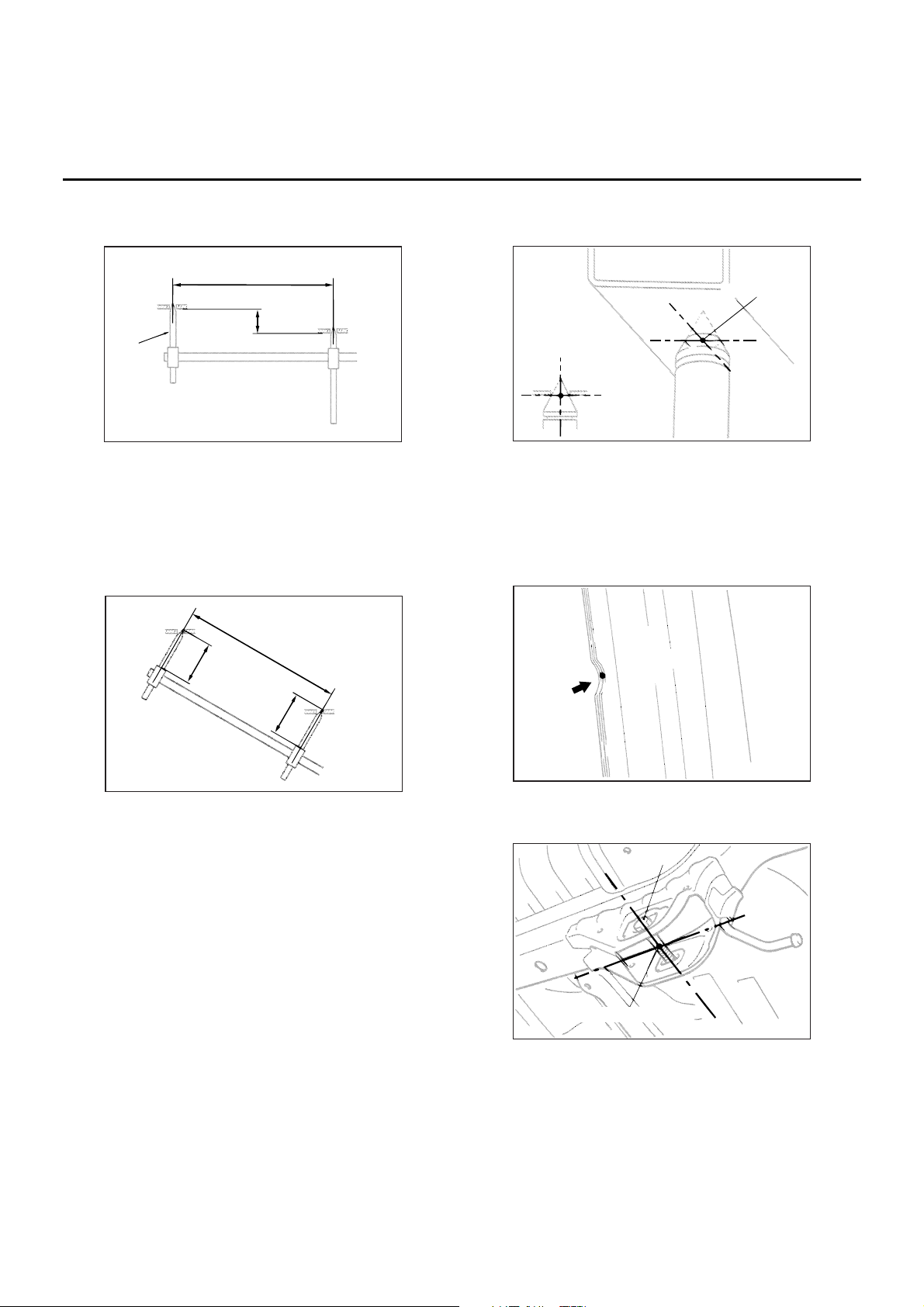

BODY DIMENSIONS AND MEASUREMENT METHODS

BODY DIMENSIONS

2-2

BODY DIMENSIONS AND MEASUREMENT METHODS

M4020001000255

1. Type A (projected dimensions)

Indicates the dimension when a measurement

location is projected onto the plane.

The difference in height of the measurement

points should be taken into consideration when

measuring.

2. Type B (actual-measurement dimensions)

Indicates the actual distance between the

measurement points.

Measure using a tracking gauge or a measuring

tape, etc.

NOTE: .

•

Make the lengths of the tracking gauge probes

the same (A=A’).

•

Do not bend or twist the measuring tape.

3. Insert the tracking gauge probes securely into the

measurement holes.

4. When the standard dimensions in the illustration

are enclosed by rectangle, this indicates that the

symmetrical left and right positions have the same

dimensions.

5. When using a notch for dimension measurement,

set the measuring point at the centre of the notch.

6. When measuring the suspension mounting arm,

or link mounting position, use the suspension

mounting bolt, etc. (Type B only)

7. The body centre points are shown for the purpose

of checking the position of the left and right

symmetry location.

AB100778

Projected dimension

Height

Probe

AB

AB100779

AB

Actual-measured dimension

A

A'

AB100780

AD

Centre of hole

AB100781

AB

AB100782

AB

Bolt

Measurement point

Page 28

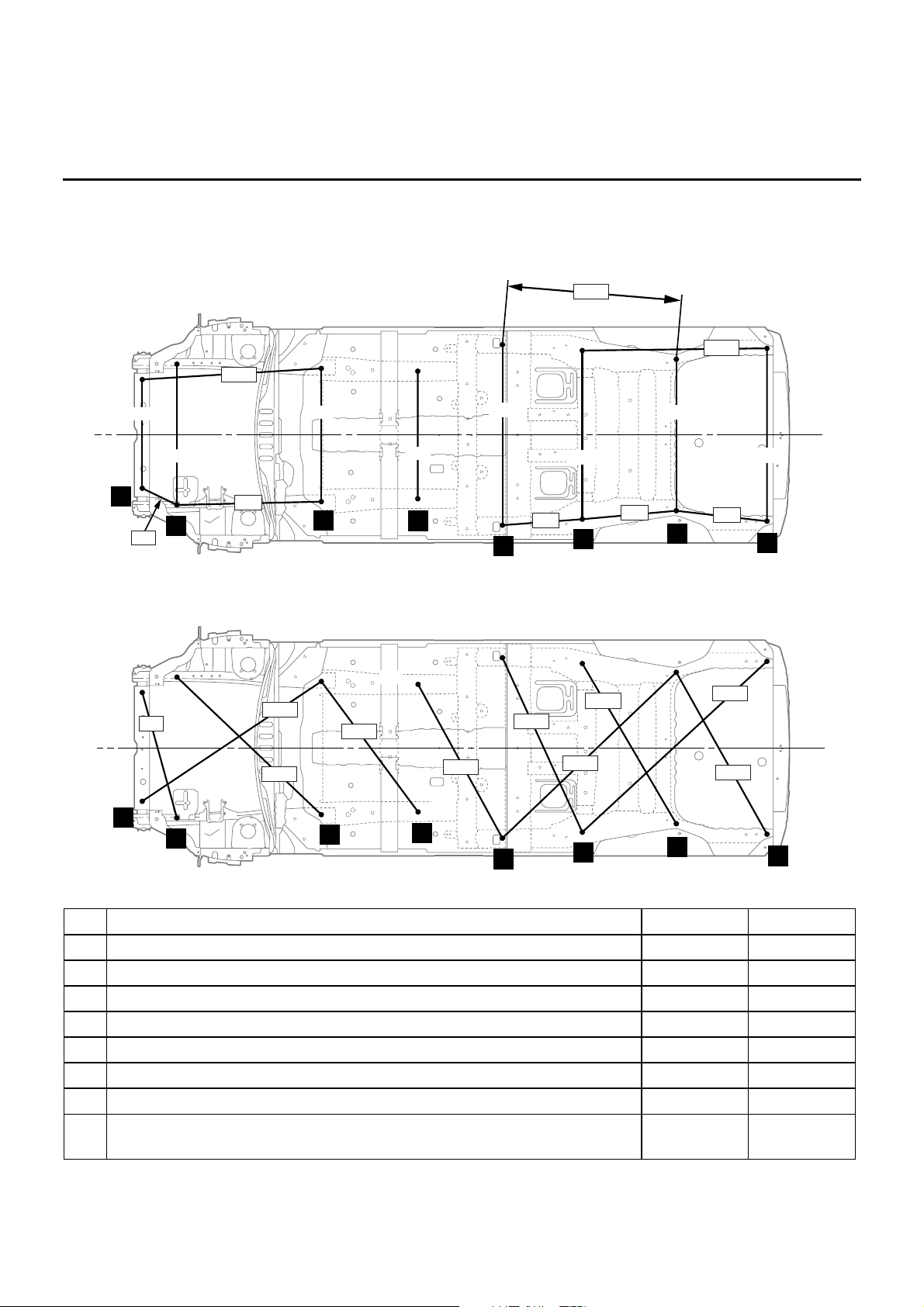

TYPE A (PROJECTED DIMENSIONS)

BODY DIMENSIONS

2-3

TYPE A (PROJECTED DIMENSIONS)

UNDER BODY

M4020005000536

NOTE: The * mark indicates the mounting position for the frame centring gauge.

AB301815

AB

2

1

5

3

4

7

6

8

740

960

908

979

271

870

1200

558

642

628

1261

1230

1240

1160

1030

1180

mm

AB301816

AB

2

1

5

3

4

7

6

8

885

1478

1353

1323

1268

1648

1721

1269

1117

1216

No. Standard measurement point Hole shape Size mm

1* Centre of front end crossmember brace positioning hole Round 12

2* Centre of front sidemember inner positioning hole Round 25

3* Centre of suspension crossmember stay mounting hole Round 14

4* Centre of front floor sidemember positioning hole Round 16

5* Centre of rear floor sidemember extension front positioning hole Round 25

6* Centre of rear floor sidemember water draining hole Round 25

7* Centre of rear floor sidemember positioning hole Round 35

8* Centre of hichmember mounting hole (This hole also serves as a

shipping bracket mounting hole on left side.)

Round 16

Page 29

TYPE A (PROJECTED DIMENSIONS)

BODY DIMENSIONS

2-4

AB301817

1195

676

128

330

100

150

165

219

282 269

605 557

1655

1903

1818

AB

2

1

5

3

4

7

6

8

mm

AB300200

AB

1

AB300201

AB

2

AB300195

AB

3

AB300196

AB

4

AB300197

AB

5

AB300194

AB

6

AB301814AB301814

AB

7

AB300199

AB

8

Page 30

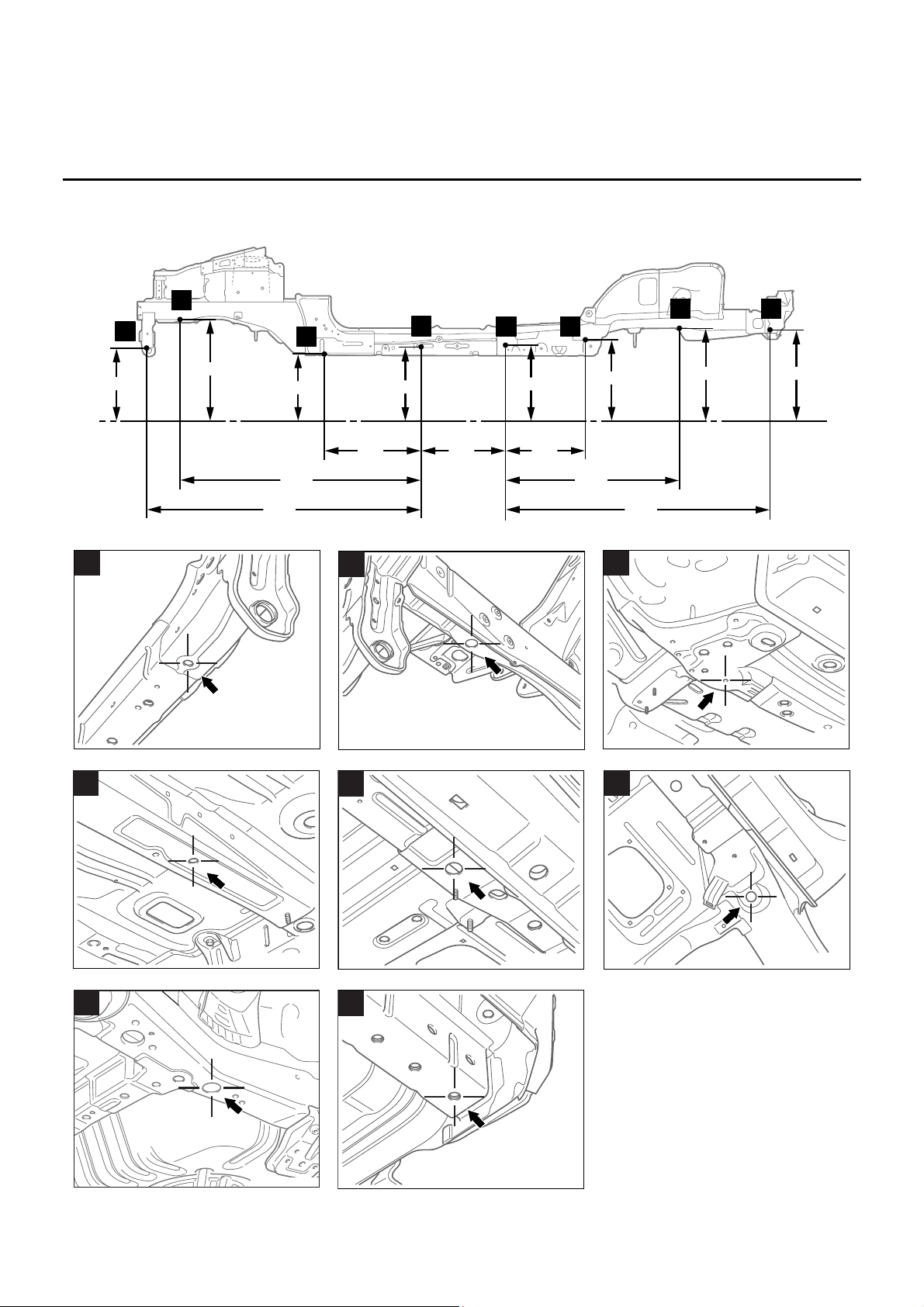

TYPE A (PROJECTED DIMENSIONS)

BODY DIMENSIONS

2-5

SUSPENSION INSTALLATION

DIMENSIONS

M4020013000467

AB301820

AB

9

12

11

392

297

181

206

154

940

908

970

1250

474

89

574

480

1192

1230

13

3

14

15

16

mm

10

1145

1165

AB301821

AB

12

11

13

3

14

15

16

1000

1153

1085

1112

1214

959

985

956

No. Standard measurement point Hole shape Size mm

3 Centre of suspension crossmember stay mounting hole Round 14

9 Centre of front shock absorber mounting hole Round 104.6

10 Centre of rear shock absorber mounting hole Round 22

11 Tip of front suspension crossmember mounting bolt

−−

12 Centre of suspension crossmember positioning hole Round 15.5

13 Centre of suspension crossmember stay mounting hole Round 16

14 Centre of rear suspension stopper front mounting hole Round 11

15 Centre of rear suspension crossmember mounting hole Round 15.5

16 Tip of rear suspension crossmember mounting bolt

−−

Page 31

TYPE A (PROJECTED DIMENSIONS)

BODY DIMENSIONS

2-6

AB300297

AB300220

AB300221

AB

A

Centre of vehicle

AB

B

Centre of vehicle

AB

500

mm

750

183 106 106 100 123 200 149

864

87

521

114

178

474

1639

546

9

12

11

13

3

14

15

16

10

A

B

7˚54´

7˚36´

1˚42´

13˚18´

AB300632

AB

12

13

3

3, 12, 13

AB202307

AB

9

AB300202

AB

10

Page 32

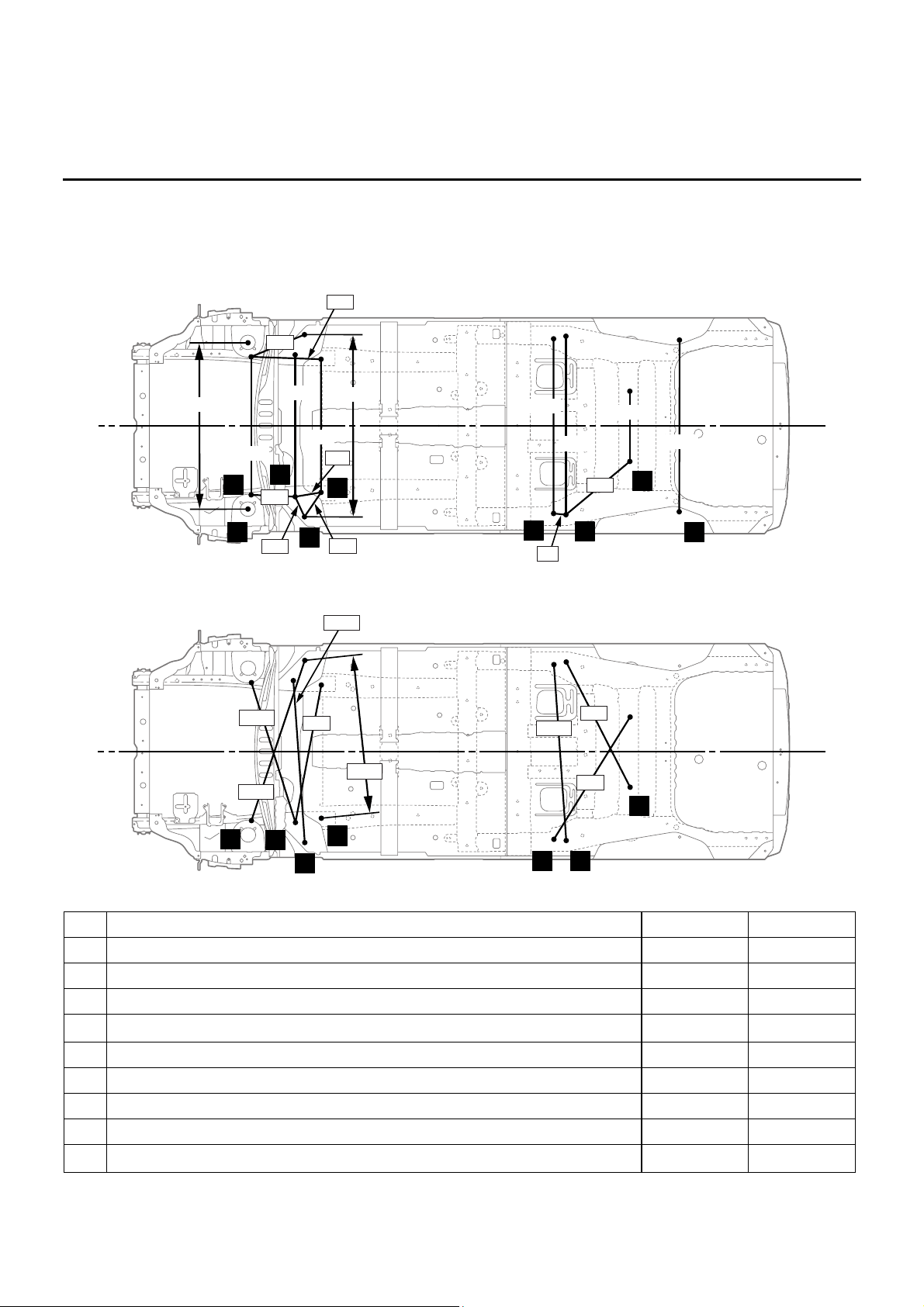

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

BODY DIMENSIONS

2-7

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

UNDER BODY

M4020005000547

AB301818

AB

2

1

5

3

4

7

6

8

740 960

908

338

1205

561

645

628

1262

1230

1240 1160 1030

1180

mm

1006

870

AB301819

AB

2

1

5

3

4

7

6

8

908

1478

1373

1324

1269

1652

1721

1269

1118

1216

No. Standard measurement point Hole shape Size mm

1 Centre of front end crossmember brace positioning hole Round 12

2 Centre of front sidemember inner positioning hole Round 25

3 Centre of suspension crossmember stay mounting hole Round 14

4 Centre of front floor sidemember positioning hole Round 16

5 Centre of rear floor sidemember extension front positioning hole Round 25

6 Centre of rear floor sidemember water draining hole Round 25

7 Centre of rear floor sidemember positioning hole Round 35

8 Centre of hichmember mounting hole (This hole also serves as a

shipping bracket mounting hole on left side.)

Round 16

Page 33

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

BODY DIMENSIONS

2-8

SUSPENSION INSTALLATION

DIMENSIONS

M4020013000478

AB300200

AB

1

AB300201

AB

2

AB300195

AB

3

AB300196

AB

4

AB300197

AB

5

AB300194

AB

6

AB301814AB301814

AB

7

AB300199

AB

8

AB301820

AC

12

11

400

306

181

206

154

940

908

970

1250

482

117

576

480

1192

1230

13

3

14

15

16

mm

Page 34

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

BODY DIMENSIONS

2-9

AB301821

AC

12

11

13

3

14

15

16

1003

1155

1085

1112

1217

960

985

956

No. Standard measurement point Hole shape Size mm

3 Centre of suspension crossmember stay mounting hole Round 14

11 Tip of front suspension crossmember mounting bolt

−−

12 Centre of suspension crossmember positioning hole Round 15.5

13 Centre of suspension crossmember stay mounting hole Round 16

14 Centre of rear suspension stopper front mounting hole Round 11

15 Centre of rear suspension crossmember mounting hole Round 15.5

16 Tip of rear suspension crossmember mounting bolt

−−

AB300632

AB

12

13

3

3, 12, 13

AB300205

AB

11

AB300593

AB

14

15

14, 15

AB300206

AB

16

Page 35

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

BODY DIMENSIONS

2-10

FRONT BODY

M4020006000261

AB301825

Body centre point

768

Body centre point

524

277

1010

1176

1046

1683

1478

763

770

822

1439

1011

1583

1577

931

927

1001

710

1528

1535

874

863

783

159

353

505

392

653

453

17

18

19

20

19

20

17

21

22

23

24

25

26

27

28

29

21

23

24

25

26

28

937

1000

20

21

23

24

25

27

874

467

468

413

1191

1198

22

409

969

1403

981

974

AB

mm

Page 36

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

BODY DIMENSIONS

2-11

No. Standard measurement point Hole shape Size mm

17 Centre of dynamic damper mounting hole Round 11

18 Centre of hood lock stay mounting hole Round 9

19 Centre of front end beam mounting hole Round 13

20 Centre of front end beam mounting hole Round 13

21 Centre of front end beam mounting hole Round 13

22 Centre of front end upper bar mounting hole Round 6.6

23 Centre of front end upper bar mounting hole Round 10

24 Centre of front end upper bar side positioning hole Round 8

25 Centre of front end upper bar side positioning hole Round 8

26 Centre of cowl top front panel mounting hole (Body centre point) Round 6.6

27 Centre of front strut mounting hole Round 11.5

28 Centre of hood hinge mounting hole Round 9

29 Corner of roof panel

−−

AB300337

AB

19

17

18

17, 18, 19

AB202310

20

AB

23

22

20, 22, 23

AB300333

AB

21

AB202305

AB

24

AB300328

AB

25

AB301829

AB

26

AB202306

AB

28

27

27, 28

AB300247

AB

29

Page 37

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

BODY DIMENSIONS

2-12

SIDE BODY

M4020007000264

AB300224

AB

mm

30

31

32

33

35

34

36

37

38

39

619

608

1142

1180

1138

1018

1051

1244

930

624

749

832

848

AB300225

AB

41

40

32

43

42

46

44

852

370

410

940

990

1135

1109

1192

1109

1059

No. Standard measurement point Hole shape Size mm

30 Front pillar positioning notch (upper)

−−

31 Front pillar positioning notch (lower)

−−

32 Side roof rail positioning notch (front)

−−

33 Side sill positioning notch (front)

−−

34 Centre pillar positioning notch (upper)

−−

35 Centre pillar positioning notch (lower)

−−

36 Side roof rail positioning notch (rear)

−−

37 Side sill positioning notch (rear)

−−

38 Quarter panel positioning notch (upper)

−−

39 Quarter panel positioning notch (lower)

−−

40 Centre of front door hinge mounting hole (upper) Round 11

41 Centre of front door hinge mounting hole (lower) Round 11

42 Centre of front door hinge mounting hole (lower) Round 11

43 Centre of rear door hinge mounting hole (lower) Round 12

44 Centre of rear door switch mounting hole Round 5

Page 38

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

BODY DIMENSIONS

2-13

REAR BODY

M4020008000278

AB300596

AB

41

40

31

31, 40, 41

AB300235

AB

43

35

35, 43

AB300250

AB

44

39

39, 44

AB300231

mm

730

1266

900

562

1206

792

765

1122

1323

1045

579

1021

1033

AB

45

46

48

47

No. Standard measurement point Hole shape Size mm

45 Centre of tailgate hinge mounting hole Round 11

46 Centre of gas spring mounting hole Round 11

47 Centre of tailgate striker mounting hole Oblong 11×14

48 Centre of rear bumper mounting hole Square 9

AB300251

AB

45

AB300252

AB

46

AB300338

AB

47

48

47, 48

Page 39

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

BODY DIMENSIONS

2-14

INTERIOR

M4020009000282

AB300227

mm

1308

1217

1382

1203

1336

1484

1484

1484

1484

1472

AB

31

30

32

34

35

37

39

38

36

33

AB300228

1280

973

774

810

1323

1242

1186

1462

1349

1131

AB

30

31

32

33

34

35

37

36

38

39

49

Body centre point

AB300232

50

51

10

995

736

711

1165

1168

AB

Body centre point

Page 40

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

BODY DIMENSIONS

2-15

No. Standard measurement point Hole shape Size mm

10 Centre of rear shock absorber mounting hole Round 22

30 Front pillar positioning notch (upper)

−−

31 Front pillar positioning notch (lower)

−−

32 Side roof rail positioning notch (front)

−−

33 Side sill positioning notch (front)

−−

34 Centre pillar positioning notch (upper)

−−

35 Centre pillar positioning notch (lower)

−−

36 Side roof rail positioning notch (rear)

−−

37 Side sill positioning notch (rear)

−−

38 Quarter panel positioning notch (upper)

−−

39 Quarter panel positioning notch (lower)

−−

49 Centre of parking brake cable bracket mounting hole (Body centre point) Round 9

50 Body centre point of rear floor

−−

51 Centre of rear end trim mounting hole Round 8.5

AB300595

AB

10

AB300597

AB

31

AB300598

AB

35

AB300259

AB

49

AB300256

AB

50

AB300258

51

AB

Page 41

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

BODY DIMENSIONS

2-16

AB300260

AB301813

AB

52

54

55

53

(L.H. drive vehicles)

100

151

1435

1437

1439

1444

AB300260

AD

56

57

58

59

100

151

1435

1437

1439

1444

(R.H. drive vehicles)

No. Standard measurement point Hole shape Size mm

52 Centre of deck crossmember mounting hole (left-upper) Round 11

53 Centre of deck crossmember mounting hole (left-lower) Round 11

54 Centre of deck crossmember mounting hole (right-upper) Round 9

55 Centre of deck crossmember mounting hole (right-lower) Round 9

56 Centre of deck crossmember mounting hole (left-upper) Round 9

57 Centre of deck crossmember mounting hole (left-lower) Round 9

58 Centre of deck crossmember mounting hole (right-upper) Round 11

59 Centre of deck crossmember mounting hole (right-lower) Round 11

AB301826

52

53

AB

52, 53

AB301827

54

55

AB

54, 55

AB300261

56

57

AB

56, 57

Page 42

TYPE B (ACTUAL-MEASUREMENT DIMENSIONS)

BODY DIMENSIONS

2-17

AB300262

58

59

AB

58, 59

Page 43

3-1

GROUP 3

WELDED PANEL

REPLACEMENT

CONTENTS

HEADLAMP SUPPORT . . . . . . . . . . . 3-2

FENDER SHIELD. . . . . . . . . . . . . . . . 3-2

FRONT SIDEMEMBER (PARTIAL

REPLACEMENT) . . . . . . . . . . . . . . . . 3-6

FRONT PILLAR (DRIVERS SIDE). . . 3-7

FRONT PILLAR (PASSENGERS SIDE)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

CENTRE PILLAR . . . . . . . . . . . . . . . . 3-15

SIDE SILL . . . . . . . . . . . . . . . . . . . . . . 3-19

QUARTER OUTER . . . . . . . . . . . . . . . 3-21

ROOF . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

REAR FLOOR. . . . . . . . . . . . . . . . . . . 3-25

REAR END PANEL. . . . . . . . . . . . . . . 3-27

QUARTER, INNER . . . . . . . . . . . . . . . 3-29

FRONT DOOR OUTER PANEL . . . . . 3-33

REAR DOOR OUTER PANEL . . . . . . 3-34

Page 44

HEADLAMP SUPPORT

WELDED PANEL REPLACEMENT

3-2

HEADLAMP SUPPORT

M4030003000274

FENDER SHIELD

M4030004000307

AB300463

AB

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

Symbol

Operation description

AB300525

A

AB

A

Right side

REPAIR WELDS

AB300475

AB

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

Symbol

Operation description

Page 45

FENDER SHIELD

WELDED PANEL REPLACEMENT

3-3

NOTE: .

•

Refer to the Headlamp Support Section on P.3-2

for the welding point with headlamp support.

AB302007

AB301896

AB300306

AB301898

AB300307

A

AB

A

G

REPAIR WELDS

(R. H. Drive vehicles)

(R. H. Drive vehicles)

Page 46

FENDER SHIELD

WELDED PANEL REPLACEMENT

3-4

AB302008

AB300313

AB300395

AB301899

AB300309

AB301897

AB300308

E

B

B

C

AB

C

D

(R. H. Drive vehicles)

(R. H. Drive vehicles)

H

D

F

Page 47

FENDER SHIELD

WELDED PANEL REPLACEMENT

3-5

NOTE ON REPAIR WORK

REMOVAL

The welding point between front sidemember inner

and dash panel extension is hidden by the dash

crossmember extension upper. Therefore, when

removing the front sidemember, remove the dash

crossmember extension upper in advance.

INSTALLATION

1. Remove the front sidemember brace lower,

suspension crossmember bracket rear and dash

crossmember extension lower from the new front

sidemember.

2. Remove the dash crossmember extension upper

from the new front sidemember and install the

front sidemember, and then install the dash

crossmember extension upper.

AB302016

AB300312

AB300314

AB300310

AB300311

AB

E

F

H

G

(With the front upper frame extension outer removed)

AB302030

AB

Dash crossmember

extension upper

AB302029

AB

Dash crossmember

extension upper

Front sidemember

Page 48

FRONT SIDEMEMBER (PARTIAL REPLACEMENT)

WELDED PANEL REPLACEMENT

3-6

FRONT SIDEMEMBER (PARTIAL REPLACEMENT)

M4030000100175

NOTE: Refer to the Headlamp Support Section on

P.3-2 for the welding point with headlamp support.

NOTE ON REPAIR WORK

REMOVAL

To reinforce the strength of the front sidemember cut

area, cut the front sidemember outer 50 mm behind

the cut-out part.

AB300507

AB

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

Symbol

Operation description

AB300511

AB

A

85 mm (Right side)

105 mm (Left side)

A

Centre of front sidemember

inner positioning hole

REPAIR WELDS

AB300491

AB

50 mm

Front sidemember outer

Page 49

FRONT PILLAR (DRIVERS SIDE)

WELDED PANEL REPLACEMENT

3-7

FRONT PILLAR (DRIVERS SIDE)

M4030005300011

AB300474

AB

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

Symbol

Operation description

AB301982

AB300392

AB300393

AB300427

AB300426

B

A

C

A

C

B

120 ± 10 mm

115 ± 10 mm

AB

E

F

D

REPAIR WELDS

Foam acoustic

material

(With the front upper frame extension outer removed)

Page 50

FRONT PILLAR (DRIVERS SIDE)

WELDED PANEL REPLACEMENT

3-8

CAUTION

When repairing the area using foam materials do not use firing tools since the foaming materials may

burn.

NOTE: .

•

Refer to the Fender Shield Section on P.3-2 for

the welding point with front upper frame

extension outer.

NOTE ON REPAIR WORK

AB301984

AB300394

AB300424

AB300425

AB

D

E

F

(With the side sill outer reinforcement removed)

Page 51

FRONT PILLAR (DRIVERS SIDE)

WELDED PANEL REPLACEMENT

3-9

INSTALLATION

1. To reinforce the strength of the front pillar cut

area, cut the side outer panel 100 mm above the

cut-out part and front pillar reinforcement outer

upper 50 mm above the cut-out part.

2. To reinforce the strength of the side sill cut area,

cut the side outer panel 100 mm behind the

cut-out part and the side sill reinforcement 50 mm

behind the cut-out part.

3. Cut the new front pillar inner upper by aligning it

with the body side, and then assemble it with the

new front pillar inner lower and install it to the

body. After that, install the front floor side sill inner

front.

CAUTION

Weld and repair if the front pillar support is

damaged.

4. Cut the new front pillar reinforcement outer upper

and the front pillar support by aligning them with

the front pillar reinforcement outer upper of the

body side. Next, cut only the front pillar

reinforcement outer upper 100 mm downwards

from the cut area to create a cover, and then cut

the front pillar support 50 mm above the cut area.

5. To install the front pillar reinforcement outer upper,

weld the front pillar support, and then weld the

cover of front pillar reinforcement outer upper.

6. To prevent the foam materials dripping in filling

them, apply urethane in the area shown in the

figure to bury the inside of the front pillar.

AB301996

AB

Front pillar

reinforcement

outer upper

Side outer

panel

100 mm

50 mm

AB300381

AB

50 mm

100 mm

Side outer panel

Side sill

reinforcement

AB301997

AB

100 mm

Front pillar

reinforcement

outer upper

Front pillar

support

50 mm

Cover

AB301998

AB

Cover

Front pillar

support

AB300383

AB

Urethane

Page 52

FRONT PILLAR (DRIVERS SIDE)

WELDED PANEL REPLACEMENT

3-10

CAUTION

Weld and repair if the side sill reinforcement front

is damaged.

7. Cut the new side sill reinforcement and the side

sill reinforcement front by aligning them with the

cut area of side sill reinforcement in the body side.

Next, cut only the side sill reinforcement 100 mm

forwards from the cut area to create a cover, and

then cut the side sill reinforcement front 50 mm

backwards from the cut area.

8. To install the side sill reinforcement, weld the side

sill reinforcement front, and then weld the cover of

side sill reinforcement.

9. When assembling the new front pillar outer

reinforcement lower, apply structural adhesives in

the areas shown in the figure.

Adhesive: Epoxyayresin adhesive

Brand: 3M ATD Part No.8115 or equivalent

10.When assembling the new front pillar outer, apply

body sealant in the areas shown in the figure of

body side.

AB300384

AB

50 mm

100 mm

Side sill

reinforcement

Cover

Side sill

reinforcement

front

AB300385

AB

Cover

Side sill

reinforcement front

AB300386

AB

: Adhesive

AB302110

AB

: Body sealant

AB300389

AB

Page 53

FRONT PILLAR (PASSENGERS SIDE)

WELDED PANEL REPLACEMENT

3-11

11.Assemble the front pillar outer, then bolt and tape

the hole and flange with aluminium tape and fill

the hole with foam materials as shown in the

figure of the instructions.

FOAM: 3M ATD ULTRAPRO Panel

foam-Yellow

12.Wait 2 hours after filling the foam materials to

remove the bolt and aluminium tape, then melt the

foam materials with a soldering gun so a clip, etc.

can thoroughly be inserted in the hole filled with

foam materials.

FRONT PILLAR (PASSENGERS SIDE)

M4030005400018

AB200418

AB300652

AB

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

Symbol

Operation description

Page 54

FRONT PILLAR (PASSENGERS SIDE)

WELDED PANEL REPLACEMENT

3-12

CAUTION

When repairing the area using foam materials do

not use firing tools since the foaming materials

may burn.

NOTE: .

•

Refer to the Fender Shield Section on P.3-2 for

the welding point with front upper frame

extension outer.

AB301983

AB300392

AB300427

AB300426

AB300393

AB

D

B

F

E

A

B

C

A

C

115 ± 10 mm

120 ± 10 mm

REPAIR WELDS

Foam acoustic

material

(With the front upper frame extension outer removed)

Page 55

FRONT PILLAR (PASSENGERS SIDE)

WELDED PANEL REPLACEMENT

3-13

NOTE ON REPAIR WORK

INSTALLATION

1. To reinforce the strength of the front pillar cut

area, cut the side outer panel 100 mm above the

cut-out part and front pillar reinforcement outer

upper 50 mm above the cut-out part.

2. To reinforce the strength of the side sill cut area,

cut the side outer panel 100 mm behind the

cut-out part and the side sill reinforcement 50 mm

behind the cut-out part.

AB301985

AB300394

AB300424

AB300425

AB

D

E

F

(With the side sill outer reinforcement removed)

AB301993

AB

Side outer

panel

Front pillar

reinforcement

outer upper

50 mm

100 mm

AB300642

AB

100 mm

50 mm

Side outer panel

Side sill

reinforcement

Page 56

FRONT PILLAR (PASSENGERS SIDE)

WELDED PANEL REPLACEMENT

3-14

3. Cut the new front pillar inner upper by aligning it

with the body side, and then assemble it with the

new front pillar inner lower and install it to the

body. After that, install the front floor side sill inner

front.

4. Cut the new front pillar reinforcement outer upper

in alignment with the body-side and install it.

5. To prevent the foam materials dripping in filling

them, apply urethane in the area shown in the

figure to bury the inside of the front pillar.

CAUTION

Weld and repair if the side sill reinforcement front

is damaged.

6. Cut the new side sill reinforcement and the side

sill reinforcement front by aligning them with the

cut area of side sill reinforcement in the body side.

Next, cut only the side sill reinforcement 100 mm

forwards from the cut area to create a cover, and

then cut the side sill reinforcement front 50 mm

backwards from the cut area.

7. To install the side sill reinforcement, weld the side

sill reinforcement front, and then weld the cover of

side sill reinforcement.

8. When assembling the new front pillar outer

reinforcement lower, apply structural adhesives in

the areas shown in the figure.

Adhesive: Epoxyayresin adhesive

Brand: 3M ATD Part No.8115 or equivalent

AB301994

AB

Front pillar

reinforcement upper

AB300643

AB

Urethane

AB300644

AB

100 mm

Side sill

reinforcement

Cover

Side sill

reinforcement front

50 mm

AB300645

AB

Cover

Side sill

reinforcement front

AB300649

AB

: Adhesive

Page 57

CENTRE PILLAR

WELDED PANEL REPLACEMENT

3-15

9. When assembling the new front pillar outer, apply

body sealant and structural adhesives in the

areas shown in the figure of body side.

Adhesive: Epoxyayresin adhesive

Brand: 3M ATD Part No.8115 or equivalent

10.Assemble the front pillar outer, then bolt and tape

the hole and flange with aluminium tape and fill

the hole with foam materials as shown in the

figure of the instructions.

FOAM: 3M ATD ULTRAPRO Panel

foam-Yellow

11.Wait 2 hours after filling the foam materials to

remove the bolt and aluminium tape, then melt the

foam materials with a soldering gun so a clip, etc.

can thoroughly be inserted in the hole filled with

foam materials.

CENTRE PILLAR

M4030006000284

AB301995

AB

: Adhesive

: Body sealant

AB300660

AB

AB200418

AB300464

AB

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

Symbol

Operation description

Page 58

CENTRE PILLAR

WELDED PANEL REPLACEMENT

3-16

CAUTION

When repairing the area using foam materials do not use firing tools since the foaming materials may

burn.

NOTE ON REPAIR WORK

REMOVAL

After removing the centre pillar, remove the centre

pillar inner left on the body side.

AB300517

A

C

A

D

C

195 mm

125 mm

160 mm

B

AB

B

D

REPAIR WELDS

Foam acoustic

material

AB300443

AB

Centre pillar

inner

Page 59

CENTRE PILLAR

WELDED PANEL REPLACEMENT

3-17

INSTALLATION

1. To reinforce the strength of the centre pillar cut

area, cut the side outer panel 50 mm above the

cut-out part.

2. To reinforce the strength of the side sill cut area,

cut the side outer panel 90 mm forwards and the

side sill reinforcement 40 mm forwards from the

cut-out part in the front side. Cut the side outer

panel 50 mm behind the cut-out part in the rear

side.

CAUTION

Weld and repair if the side sill reinforcement front

is damaged.

3. Cut the new side sill reinforcement and the side

sill reinforcement front by aligning them with the

cut area of side sill reinforcement in the body side.

Next, cut only the side sill reinforcement 100 mm

behind the cut area to create a cover, and then cut

the side sill reinforcement front 60 mm forwards

from the cut area of the side sill reinforcement.

4. To install the side sill reinforcement, weld the side

sill reinforcement front, and then weld the cover of

side sill reinforcement.

AB300444

AB

50 mm

Side outer panel

AB300515

AB

Side sill reinforcement

Side outer panel

50 mm

40 mm

90 mm

Front side

Rear side

Side outer panel

AB300440

AB

60 mm

100 mm

Cover

Side sill

reinforcement

Side sill

reinforcement

front

AB300441

AB

Cover

Page 60

CENTRE PILLAR

WELDED PANEL REPLACEMENT

3-18

5. Cut the new centre pillar reinforcement outer and

the rear door hinge reinforcement upper by

aligning them with the cut-out part of body side,

and then weld the centre pillar reinforcement

outer from outside and rear door hinge

reinforcement upper from inside respectively.

6. After assembling the new centre pillar outer, to

prevent the foaming materials from dripping in the

area shown in the figure of the instructions,

adhere urethane foam to fill (bury) the centre pillar

interior.

7. After assembling the new centre pillar inner, seal

the hole and flange with bolt and sheet-metal

tape, and then fill the hole with foam materials as

shown in the figure of the instructions.

Foam: 3M ATD ULTRAPRO Panel

foam-Yellow

8. Wait 2 hours after filling the foam materials to

remove the bolt and sheet-metal tape, then melt

the foam materials with a soldering gun so a clip,

etc. can thoroughly be inserted in the hole filled

with foam materials.

AB300516

AB

Centre pillar

reinforcement

outer

Outside

Inside

Rear door hinge

reinforcement

upper

AB300445

AB

Urethane

foam

AB300470

AB

AB200418

Page 61

SIDE SILL

WELDED PANEL REPLACEMENT

3-19

SIDE SILL

M4030007000340

AB300476

AB

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

Symbol

Operation description

Page 62

SIDE SILL

WELDED PANEL REPLACEMENT

3-20

NOTE:

Partial replacement of side sill is possible depending

on the range of damage.

CAUTION

Cut the side sill reinforcement by displacing 50

mm from the butt welding area with the side

outer panel.

AB300534

AB300456

AB300459

AB300455

AB300457

AB300636

AB300452

D

F

A

B

C

D

E

F

A

B

C

50 mm

260 mm

50 mm

AB

E

REPAIR WELDS

Foam

acoustic

material

AB300454AB300454

AB

Side sill reinforcement

: Cuttable range

(With the side outer panel removed)

Page 63

QUARTER OUTER

WELDED PANEL REPLACEMENT

3-21

QUARTER OUTER

M4030008000279

AB300377

AB

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

Symbol

Operation description

AB300522

AB

A

B

C

D

B

C

D

A

250 ± 100 mm

300 mm

410 mm

4 points

right side

Foam acoustic material

REPAIR WELDS

3 points

left side

Page 64

QUARTER OUTER

WELDED PANEL REPLACEMENT

3-22

CAUTION

When repairing the area using foam materials do not use firing tools since the foaming materials may

burn.

NOTE ON REPAIR WORK

REMOBAL

When replacing the gate pillar reinforcement, cut it

50 mm downwards from the cut area of rear gate

pillar.

INSTALLATION

1. To reinforce the strength of the rear gate pillar cut

area, cut the side outer panel 100 mm above the

cut-out part.

2. When assembling the new rear quarter outer

panel, apply in advance body sealant to the areas

shown in the figure of the instructions. In addition,

to prevent the foam materials from dripping, apply

urethane foam to bury the inside of the wheel

arch.

3. Assemble the quarter outer panel, bolt and tape

the hole and flange with aluminium tape, then fill

the hole with foam materials as shown in the

figure of the instructions.

Foam: 3M ATD ULTRAPRO Panel

foam-Yellow

4. Wait 2 hours after filling the foam materials to

remove the bolt and aluminium tape. Then melt

the foam materials with a soldering gun so a clip,

etc. can thoroughly be inserted in the hole that

was clogged with foam materials, to bore open

the hole.

AB300548

AB

50 mm

Gate pillar

reinforcement

AB300360

AB

Side

outer

panel

100 mm

AB300183

Left side

AB

: Body sealant

Urethane foam

AB300361

AB

AB200418

Page 65

ROOF

WELDED PANEL REPLACEMENT

3-23

ROOF

M4030011000280

Adhesive: Urethane body sealer

Brand: 3M ATD Part No.8542 or equivalent

AB300478

AB

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

Symbol

Operation description

AB302123

AB300494

AB300493

A

B

C

D

AB

H

E

F

G

E

F

H

Except for sun roof

Repair welds

: Adhesive

Vehicles with sun roof

7 Points

vehicles with roof rail

4 Points

vehicles with roof rail

6 Points

vehicles with roof rail

7 Points

vehicles with roof rail

4 Points

vehicles with roof rail

6 Points

vehicles with roof rail

Vehicles with

roof rail

Page 66

ROOF

WELDED PANEL REPLACEMENT

3-24

AB300536

AB300500

AB300495

AB300496

AB300497

AB300498

AB300499

AB300501

AB300502

B

C

D

E

AB

A

G

F

H

Page 67

REAR FLOOR

WELDED PANEL REPLACEMENT

3-25

REAR FLOOR

M4030010000287

NOTE: Refer to the Rear End Panel Section on P.3-27 for the welding points with the rear end panel.

AB300417

AB

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

Symbol

Operation description

AB302125

AB300410

AB

A

D

B

C

A

E

REPAIR WELDS

Page 68

REAR FLOOR

WELDED PANEL REPLACEMENT

3-26

NOTE ON REPAIR WORK

REMOVAL

1. When cutting the rear floor pan, cut it 40 mm

behind the body centre point as shown.

AB301940

AB300411

AB301669

AB

C

D

E

B

Left side

(With the rear floor pan removed)

(With the rear floor pan removed)

(With the rear floor sidemember

and rear floor side pan removed)

AB300396

AB

40 mm

Body centre point

Page 69

REAR END PANEL

WELDED PANEL REPLACEMENT

3-27

2. Remove the seat pan support and shipping

bracket (right side) on the cut area in advance

when cutting the rear floor sidemember.

3. Cut the rear floor sidemember 280 mm forward

from the hitch member mounting hole (This hole

also serves as a shipping bracket mounting hole

on left side). In addition, cut the rear floor side pan

in the same area.

INSTALLATION

1. Remove the seat pan reinforcement from the new

rear floor crossmember (D).

2. When assembling the new quarter inner

extension lower, apply in advance body sealant to

the areas shown in the figure of the instructions.

REAR END PANEL

M4030000300038

AB301941

AB300408

AB301671

AB300407

AB301670

AB

Left side

Right side

Seat pan support

Shipping bracket

AB300406

280 mm

AB

AB300404

Seat pan reinforcement

AB

AB300405

AB

: Body sealant

AB300379

AB

Spot welding

MIG plug welding : indicates two panels to be welded

: indicates three panels to be welded

MIG spot welding

MIG arc welding (continuous)

Braze welding

Anti-corrosion agent application locations

(Use access holes to apply liberally to butt-welded joints.)

( )

Symbol

Operation description

Page 70

REAR END PANEL