Page 1

FX3U-CF-ADP

USER'S MANUAL

Page 2

Page 3

Safety Precautions

(Read these precautions before using.)

Before installation, operation, maintenance or inspection of this product, thoroughly read through and

understand this manual and the associated manuals. Also, take care to handle the module properly and

safely.

This manual classifies the safety precautions into two categories: and .

Indicates that incorrect h andling may cause hazardous conditions, result ing in death or severe

injury.

Indicates that incorrect h andling may cause hazardous conditio ns, resulting in medium or slight

personal injury or physical damage.

Depending on the circumstances, procedures indicated by may also cause severe injury. In

any case, it is important to follow all usage directions. Store this manual in a safe place so that it can be taken

out and read whenever necessary. Always forward it to the end user.

1. DESIGN PRECAUTIONS

Reference

• Make sure to include the f ollowing safety circuits outside the PLC to ensure safe system op eration even during

external power supply problems o r PLC failure.

Otherwise, malfunctions may cause serio u s ac cid ents.

1) Above all, the following components should be included: an emergency stop circuit, a protection circuit, an

interlock circuit for opposite movements (such as normal vs. reverse rotation), and an interlock circuit (to prevent

damage to the equipment at the upper and lower positioning limits ).

2) Note that when the PLC main unit de tects an error during self diagnosis , such as a watchdog timer error, all

outputs are turned off. Also, when an error that cannot be detected by the PLC main unit occurs in an input/

output control block, output control may be disabled.

External circuits and mechanisms should be designed to ensure safe machinery operation in such cases.

• Observe the following items. Fai lure t o do so may c ause incor rect data- writi ng th roug h nois e to the PLC and result

in PLC failure, machine damage or other accident.

1) Do not bundle the control line together with or lay it close to the main circuit or power line. As a guideline, lay the

control line at least 100mm (3.94") or more away from the main circuit or power line.

Noise may cause malfunctions.

2) Ground the shield wire or shield of a shielded cable. Do not use common grounding with heavy electrical

systems

• During access (ACCESS LED is lit or flickering) to CompactFlash

or power off the FX

Failure to do so may cause CompactFlash

• If the power is turned OFF while the CompactFlash

buffered data is erased. Als o files or CompactFlashTM card itself may be damaged. Do not turn the power OFF

while the ACCESS LED is lit or flickering.

• Do not apply excessive pressure to the power supply cable or power supply connector.

Excessive pressure may cause damage or error.

3U-CF-ADP.

TM

card failures or malfunctions.

TM

card is being accessed (ACCESS LED is lit or flickering), the

TM

card, do not remove the CompactFlashTM card

15

28

Reference

15

28

(1)

Page 4

Safety Precautions

(Read these precautions before using.)

2. INSTALLATION PRECAUTIONS

Reference

• Make sure to shut down all phases of the power supply externally before i nstalling the FX3U-CF-ADP.

Failure to do so may cause electric shock or damage to the product.

• Use the product within the generic environment specifications described in PLC main unit manual (Hardware

Edition). Never use the product in areas with excessive dust, oily smoke, conductive dusts, corrosive gas (salt air,

Cl2, H2S, SO2, or NO2), flammable gas, vibration or impacts, or expose i t to high temperature, condensa tion, or

rain and wind. If the prod uct is used in s uch condition s, electric sh ock, fire, malf unctions, dete rioration or d amage

may occur.

• Do not touch the conductive part s of the product directly.

Doing so may cause device failures or malfunctions.

• Install the product securely usin g a DI N ra il or mounting screws.

• Install the product on a flat surface.

If the mounting surface is rough, undue force will be applied to the PC board, thereby causing nonconformities.

• When drilling screw holes or wiring, make sure that cutting and wiri ng debris do not enter the ventilation slits.

Failure to do so may cause fire, equipment failures or malfunctions.

• Be sure to remove the dust proof sheet from the PLC's ventilation port when installation work is completed.

Failure to do so may cause fire, equipment failures or malfunctions.

• Connect the FX3U-CF-ADP securely to special adapter connector.

Loose connections may cause malfunctions.

• Connect the power connector of the power supply cable securely to the CF-ADP power supply connector.

Loose connections may cause malfunctions.

• When inserting a CompactFlashTM card into the FX3U-CF-ADP, push it into the CF card slot until the EJECT button

pops out.

Loose connections may cause malfunctions.

• Before inserting/removing a CompactFlashTM card into/from the FX3U-CF-ADP, set the CF card ACCESS switch to

OFF and confirm that the BUFFER LED and ACCE SS LED are both OFF.

Failure to do so may corrupt data within the CompactFlashTM card.

• When removing a CompactFlashTM card from the FX3U-CF-ADP, make sure to support the CompactFlashTM card

by hand, as it may pop out.

Failure to do so may cause the CompactFlashTM card to fall from the FX3U-CF-ADP an d break.

• Turn off the power to the PLC befor e attaching or detaching the foll owing devices.

Failure to do so may cause device failures or malfunctions.

- Peripheral devices, display modules, expansion boa rds and special adapters

- I/O extension units/blocks, FX Series terminal block and the special function units/blocks

- Battery and memory cassette

22

99

Reference

22

99

3. WIRING PRECAUTIONS

• Make sure to cut off all phases of the power supply externally bef ore attempting wiring work.

Failure to do so may cause electric shock or damage to the product.

• Connect the DC power supply wiring to the dedicated terminal described in this manual.

If an AC power supply is connected to a DC input/output terminal or DC power supply terminal, the PLC will burn

out.

• Connect the DC power supply wiring to the dedicated connector descri bed in this manual.

If an AC power supply is connected to a DC power supply connecto r, the PLC will bu rn out .

• When drilling screw holes or wiring, make sure that cutting and wiri ng debris do not enter the ventilation slits.

Failure to do so may cause fire, equipment failures or malfunctions.

(2)

Reference

28

99

Reference

28

99

Page 5

Safety Precautions

(Read these precautions before using.)

4. STARTUP AND MAINTENANCE PRECAUTIONS

• Make sure to connect the battery co rre c tly . Do n ot c ha rg e, disassemble, heat, short-circuit, or exp o se the battery to

fire.

Doing so may rupture or ignite it.

• Do not touch any terminal while the PLC's power is on.

Doing so may cause electric shock or malfunctions.

• Before modifying or disrupting th e progr am i n opera t ion or runn ing t he PL C, ca ref ul ly rea d th roug h th is manual and

the associated manuals and ensure the safety of the operation.

An operation error may damage the machinery or cause accidents.

• Do not disassemble or modify the PLC.

Doing so may cause fire, equipment failures, or malfunctions.

For repair, contact your local Mitsubishi Electric distributor.

• Turn off the power to the PLC befor e attaching or detaching the foll owing devices.

Failure to do so may cause device failures or malfunctions.

- Peripheral devices, display modules, expansion boa rds and special adapters

- I/O extension units/blocks, FX Series terminal block and the special function units/blocks

- Battery and memory cassette

Reference

28

81

100

Reference

29

81

100

5. DISPOSAL PRECAUTIONS

• Please contact a certified elect r onic wast e dis pos al compan y fo r t he envir on ment all y safe re cy cl ing an d di sp osal of

your device.

6. TRANSPORTATION PRECAUTIONS

• The PLC is a precision instrument. Dur ing transportation, avoid impacts larger tha n those specified in th e general

specifications of the PLC main uni t manual.

Failure to do so may cause failures in the PLC.

After transportation, verify the operations of the PLC.

Reference

15

Reference

15

(3)

Page 6

(4)

Page 7

FX3U-CF-ADP User's Manual

FX3U-CF-ADP

User's Manual

Manual number JY997D35401 Manual revision A Date 6/2009

Foreword

This manual describes the FX3U-CF-ADP CF card special adapter and should be read and understood before

attempting to install the hardware.

Store this manual in a safe place so that you can take it out and read it whenever necessary. Always forward

it to the end user.

This manual confers no industrial property rights or any ri ghts of any other kind, nor does it confer any patent lic enses. Mitsubishi

Electric Corporation cannot be held resp onsible for any problems involving ind ustrial pro perty rights which may oc cur as a resu lt of

using the contents noted in thi s manual.

© 2009 MITSUBISHI ELECTRIC CORPORATION

1

Page 8

FX3U-CF-ADP User's Manual

Outline Precautions

• This manual provides information for the use of the FX3U-CF-ADP CF card special adapter.

The manual has been written to be used by trained and competent personnel. The definition of such a

person or persons is as follows;

1) Any engineer who is responsible for the planning, design and construction of automatic equipment using

the product associated with this manual should be of a competent nature, trained and qualified to the

local and national standards required to fulfill that role. These engineers should be fully aware of all

aspects of safety with aspects regarding to automated equipment.

2) Any commissioning or maintenance engineer must be of a competent nature, trained and qualified to the

local and national standards required to fulfill the job. These engineers should also be trained in the use

and maintenance of the completed product. This includes being familiar with all associated manuals and

documentation for the product. All maintenance sho uld be carried out in accordance with est ablished

safety practices.

3) All operators of the completed equipment should be trained to use that product in a safe and coordinated

manner in compliance with established safety practices. The operators should also be familiar with

documentation that is connected with the actual operation of the completed equipment.

Note: the term 'completed equipment' refers to a third party constructed device that contains or uses the

product associated with this manual.

• This product has been manufactured as a general-purpose part for general industries, and has not been

designed or manufactured to be incorporated in a device or system used in purposes related to human life.

• Before using the product for special purposes such as nuclear power, electric power, aerospace, medicine

or passenger movement vehicles, consult with Mitsubishi Electric.

• This product has been manufactured under strict quality control. However when installing the product

where major accidents or losses could occur if the product fails, install appropriate backup or failsafe

functions into the system.

• When combining this product with other products, please confirm the standards and codes of regulation to

which the user should follow. Moreover, please confirm the compatibility of this product with the system,

machines, and apparatuses to be used.

• If there is doubt at any stage during installation of the product, always consult a professional electrical

engineer who is qualified and trained in the local and national standards. If there is doubt about the

operation or use, please consult the nearest Mitsubishi Electric distributor.

• Since the examples within this manual, technical bulletin, catalog, etc. are used as reference; please use it

after confirming the function and safety of the equipment and system. Mitsubishi Electric will not accept

responsibility for actual use of the product based on these illustrative examples.

• The content, specification etc. of this manual may be changed for improvement without notice.

• The information in this manual has been carefully checked and is believed to be accurate; however, if you

notice any doubtful point, error, etc., please contact the nearest Mitsubishi Electric distributor.

Registration

• CompactFlash is a trademark of SanDisk Corporation in the United States and other countries.

• The company name and the product name to be described in this manual are the registered trademarks or

trademarks of each company.

2

Page 9

FX3U-CF-ADP User's Manual

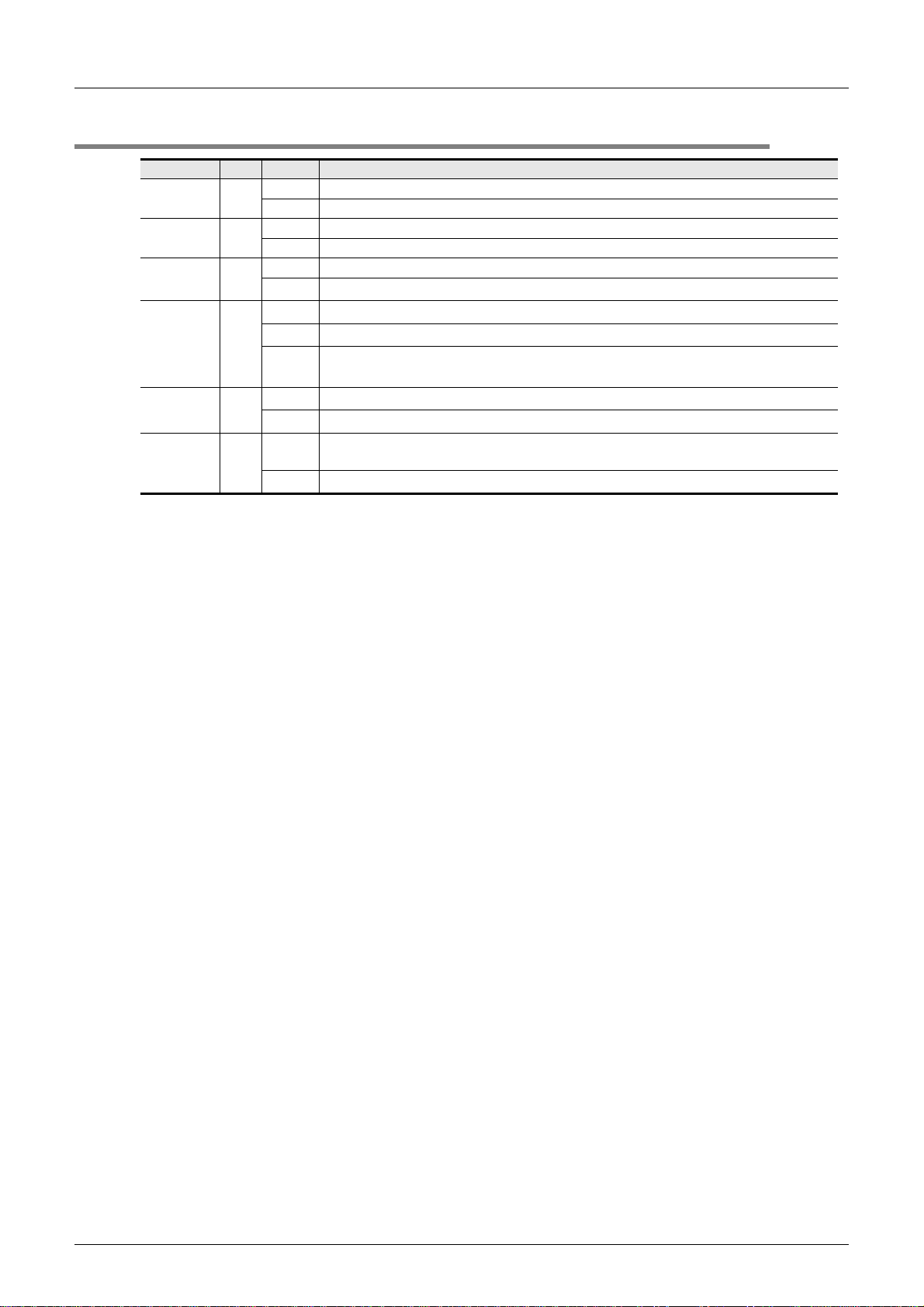

Table of Contents

SAFETY PRECAUTIONS..................................................................................................(1)

Standards...................................................................................................................................7

Certification of UL, cUL standards .......................................................................................................7

Compliance with EC directive (CE Marking)........................................................................................7

Associated Manuals..................................................................................................................9

Generic Names and Abbreviations Used in the Manual......................................................10

Reading the Manual .................................................... ............................................................ 12

1. Introduction 13

1.1 Outline...........................................................................................................................................13

1.2 External Dimensions and Part Names..........................................................................................13

1.3 Power and status LEDs.................................................................................................................14

2. Specification 15

2.1 General specifications...................................................................................................................16

2.2 Power supply specification............................................................................................................16

2.3 Performance specification.............................................................................................................16

2.4 CF card ACCESS switch specification..........................................................................................17

TM

2.5 CompactFlash

2.6 Applicable CompactFlash

card specification.............................................................................................. 17

TM

card.................................................................................................17

Table of Contents

3. System Configuration 18

3.1 General configuration....................................................................................................................18

3.2 Applicable PLC..............................................................................................................................19

3.2.1 Connectable PLC ..........................................................................................................................19

3.2.2 Applicable versions of the programming tool.................................................................................19

3.3 Connection with PLC.....................................................................................................................19

3.4 Assignment of channels................................................................................................................20

4. Installation 22

4.1 CF-ADP Connection......................................................................................................................23

4.2 DIN rail mounting ..........................................................................................................................24

4.3 Direct mounting.............................................................................................................................25

4.4 Inserting and Removal Procedures...............................................................................................26

4.4.1 Inserting the CompactFlashTM card .................................................... ... .......................................26

4.4.2 Removing the CompactFlash

TM

card............................................................. ... ............................27

3

Page 10

FX3U-CF-ADP User's Manual

5. Wiring 28

5.1 Which Power Supply Cable to Use...............................................................................................29

5.1.1 Power supply cable .......................................................................................................................29

5.1.2 Preparing the power cable by yourself ..........................................................................................29

5.2 Power Supply Wiring.....................................................................................................................30

5.2.1 Power supply wiring.......................................................................................................................30

5.3 Grounding .....................................................................................................................................30

5.4 Power OFF procedure...................................................................................................................31

5.4.1 Power OFF procedure using the CF card ACCESS switch...........................................................31

5.4.2 Power OFF procedure using the applied instruction for the CF-ADP............................................31

5.4.3 Caution on power OFF..................................................................................................................31

5.5 Connection of the power supply cable..........................................................................................32

5.5.1 Connection/removal of the power supply cable.............................................................................32

6. Functions 33

6.1 Details of functions........................................................................................................................33

6.2 Status information.........................................................................................................................34

Table of Contents

7. Before Programming 35

7.1 File format available in the CF-ADP..............................................................................................35

7.1.1 Files created by the CF-ADP.........................................................................................................35

7.1.2 Files created by the user........................ ... ... .................................... ... ..........................................36

7.1.3 Characters available in files...........................................................................................................37

7.1.4 Data size calculation......................................................................................................................38

7.1.5 Data writing destination.................................................................................................................39

7.1.6 File ID............................................................................................................................................40

7.1.7 FIFO file.........................................................................................................................................41

7.2 Directory structure.........................................................................................................................42

7.3 Date/time setting...........................................................................................................................42

7.4 General Rules for Applied Instructions..........................................................................................43

7.4.1 Expression and operation type of applied instructions..................................................................43

7.4.2 Programming using "Instruction execution complete" flag and

"Instruction execution abnormal end" flag ................................................................................44

8. CF-ADP Applied Instructions Explanation 46

8.1 CF-ADP Instructions types............................................................................................................46

8.2 Common Items in CF-ADP Instructions........................................................................................46

8.2.1 Function and operation..................................................................................................................46

8.2.2 Cautions on programming.............................................................................................................47

8.3 FNC 300 - FLCRT / File create•check ..........................................................................................48

8.3.1 Detailed explanation of setting data..............................................................................................49

8.4 FNC 301 - FLDEL / File delete•CF card format ............................................................................51

8.4.1 Detailed explanation of setting data..............................................................................................52

8.5 FNC 302 - FLWR / Data write.......................................................................................................54

8.5.1 Detailed explanation of setting data..............................................................................................56

8.5.2 Writing data of same type..............................................................................................................57

8.5.3 Writing data of different types........................................................................................................61

8.6 FNC 303 - FLRD / Data read ........................................................................................................68

8.6.1 Detailed explanation of setting data..............................................................................................69

8.6.2 Reading data of the same type from a file.....................................................................................70

8.6.3 Reading data of different types from a file.....................................................................................71

4

Page 11

FX3U-CF-ADP User's Manual

8.7 FNC 304 - FLCMD / FX3U-CF-ADP command............................................................................. 74

8.7.1 Detailed explanation of setting data..............................................................................................75

8.8 FNC 305 - FLSTRD / FX3U-CF-ADP status read ......................................................................... 76

8.8.1 Detailed explanation of setting data..............................................................................................77

8.9 Contents of Related Devices.........................................................................................................80

9. Program Examples 81

9.1 System Configuration....................................................................................................................81

9.2 Program Example 1 ......................................................................................................................82

9.2.1 Operation details ...........................................................................................................................82

9.2.2 Example of a 32-bit decimal type file in "csv" format after writing.................................................82

9.2.3 Device Assignments......................................................................................................................83

9.2.4 Sequence Program........................................................................................................................84

9.3 Program Example 2 ......................................................................................................................89

9.3.1 Operation details ...........................................................................................................................89

9.3.2 Example of a mixed type file in "csv" format after writing..............................................................89

9.3.3 Device Assignments......................................................................................................................89

9.3.4 Sequence Program........................................................................................................................91

9.4 Program Example 3 ......................................................................................................................97

9.4.1 Operation details ...........................................................................................................................97

9.4.2 Device Assignments......................................................................................................................97

9.4.3 Sequence Program........................................................................................................................98

Table of Contents

10. Troubleshooting 99

10.1 Troubleshooting procedure.......................................................................................................101

10.1.1 LED status check.......................................................................................................................101

10.1.2 Troubleshooting by error code...................................................................................................101

10.1.3 Error Code List and Action........................................................................................................102

10.2 Diagnostics on the PLC Main Unit ............................................................................................107

10.2.1 POWER(POW) LED [on/flashing/off].........................................................................................107

10.2.2 BATT(BAT) LED [on/off]............................................................................................................107

10.2.3 ERROR(ERR) LED [on/flashing/off]..........................................................................................108

Appendix A: Related Devices 109

Appendix A-1 Related Device List ............................................................................................ 109

Appendix A-2 Details of related devices...................................................................................110

Appendix A-2-1 Instruction execution complete [M8029] .....................................................................110

Appendix A-2-2 Instruction execution abnormal end [M8329]..............................................................110

Appendix A-2-3 CF-ADP instruction executing [M8402, M8422]..........................................................110

Appendix A-2-4 CF-ADP unit ready [M8404, M8424]...........................................................................110

Appendix A-2-5 CF card mount status [M8405, M8425] ......................................................................111

Appendix A-2-6 CF-ADP status renewal stop [M8410, M8430] ...........................................................111

Appendix A-2-7 CF-ADP instruction error [M8418, M8438] .................................................................111

Appendix A-2-8 CF-ADP status [D8406, D8426]..................................................................................111

Appendix A-2-9 CF-ADP version [D8408, D8428]................................................................................111

Appendix A-2-10 Step number of an instruction for the CF-ADP where an error has occurred

[D8415, D8414][D8435, D8434]..............................................................................112

Appendix A-2-11 Error code in detail for CF-ADP instructions [D8417, D8437]...................................112

Appendix A-2-12 Error code for CF-ADP instructions [D8418, D8438]................................................112

Appendix A-2-13 Operation mode display [D8419, D8439]..................................................................112

5

Page 12

FX3U-CF-ADP User's Manual

Appendix B: Version Information 113

Appendix B-1 Version information ............................................................................................113

Appendix B-1-1 Version check method................................................................................................113

Appendix B-1-2 Version upgrade history..............................................................................................113

Warranty.................................................................................................................................115

Revised History.....................................................................................................................116

Table of Contents

6

Page 13

FX3U-CF-ADP User's Manual

Standards

Certification of UL, cUL standards

FX3U-CF-ADP units comply with the UL standards (UL, cUL).

UL, cUL File number :E95239

Regarding the standards that comply with the main unit, please refer to either the FX series product catalog or

consult with your nearest Mitsubishi product provider.

Compliance with EC directive (CE Marking)

This document does not guarantee that a mechanical system including this product will comply with the

following standards.

Compliance to EMC directive and LVD directive for the entire mechanical module should be checked by the

user / manufacturer. For more information please consult with your nearest Mitsubishi product provider.

Regarding the standards that comply with the main unit, please refer to either the FX series product catalog or

consult with your nearest Mitsubishi product provider.

Standards

Requirement for Compliance with EMC directive

The following products have shown compliance through direct testing (of the identified standards below) and

design analysis (through the creation of a technical construction file) to the European Directive for

Electromagnetic Compatibility (89/336/EEC) when used as directed by the appropriate documentation.

Type: Programmable Controller (Open Type Equipment)

Models: MELSEC FX

from June 1st, 2009 FX

EN61131-2:2003

Programmable controllers

- Equipment requirements and tests

3U series manufactured

3U-CF-ADP

Standard Remark

Compliance with all relevant aspects of the standard.

EMI

• Radiated Emissions

• Conducted Emissions

EMS

• Radiated electromagnetic field

• Fast Transient burst

• Electrostatic discharge

• High-energy surge

• Voltage drops and iterruptions

• Conducted RF

• Power frequency magnetic field

7

Page 14

FX3U-CF-ADP User's Manual

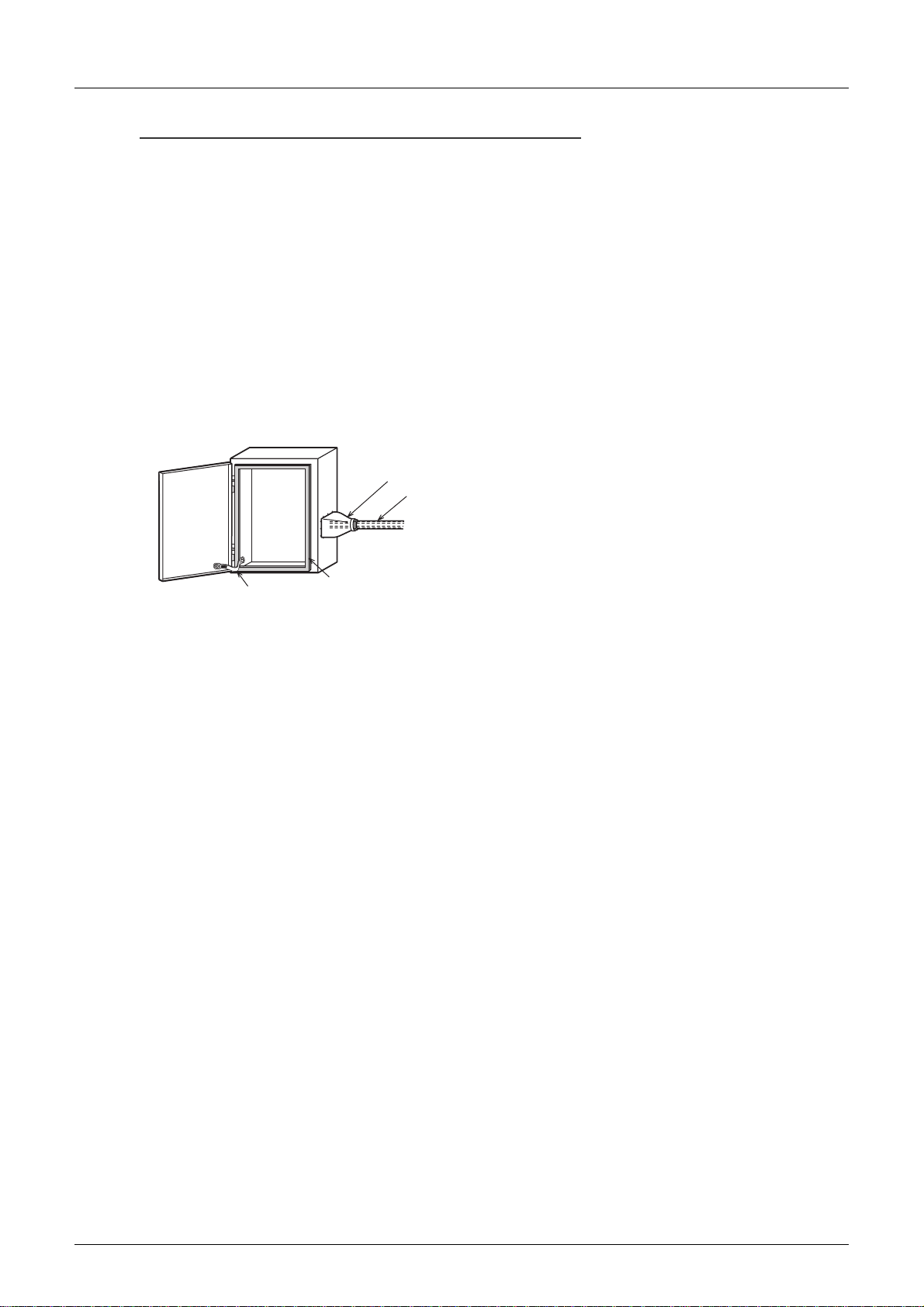

Caution to conform with EC Directives

• Installation in Enclosure

Programmable logic controllers are open-type devices that must be installed and used within conductive

control cabinets. Please use the programmable logic controller while installed within a conductive shielded

control cabinet. Please secure the cabinet door to the control cabinet (for conduction).

Installation within a control cabinet greatly affects the safety of the system and aids in shielding noise from

the programmable logic controller.

• Control cabinet

- The control cabinet must be conductive.

- Ground the control cabinet with the thickest possible grounding cable.

- To ensure that there is electric contact between the control cabinet and its door, connect the cabinet and

its doors with thick wires.

- In order to suppress the leakage of radio waves, the control cabinet structure must have minimal

openings. Also, wrap the cable holes with a shielding cover or other shielding devices.

- The gap between the control cabinet and its door must be as small as possible by attaching EMI gaskets

between them.

Standards

Shielding cover

Shielded cable

Wires*1

EMI gasket

*1. These wires are used to improve the conductivity between the door and control cabinet.

8

Page 15

FX3U-CF-ADP User's Manual

Associated Manuals

Only the installation manual is packed together with the FX3U-CF-ADP special adapter.

For a detailed explanation of the FX

For the hardware information and instructions on the PLC main unit, refer to the respective manuals.

Title of manual

Manual for the Main Unit

FX3U Series PLCs Main Unit

Supplied

Manual

Additional

Manual

FX3UC Series PLCs Main Unit

Supplied

Manual

Supplied

Manual

Supplied

Manual

Additional

Manual

Programming for FX

Additional

Manual

Manuals for communication control

Additional

Manual

Manuals for FX3U-CF-ADP CF card special adapter

Supplied

Manual

Additional

Manual

3U Series

FX

Hardware Manual

FX3U Series

User's Manual

- Hardware Edition

FX3UC(D,DSS) Series

Hardware Manual

FX3UC-32MT-LT-2

Hardware Manual

FX3UC-32MT-LT

Hardware Manual

(Only Japanese document)

FX3UC Series

User's Manual

- Hardware Edition

3G/FX3U/FX3UC Series

FX

3G/FX3U/FX3UC Series

Programming Manual

- Basic & Applied

Instruction Edition

FX Series User's Manual Data Communication

Edition

FX3U-CF-ADP

Installation Manual

FX3U-CF-ADP

User's Manual

(This Manual)

3U-CF-ADP special adapter, refer to this manual.

Refer to these manuals

Refer to the appropriate equipment manual

For a detailed explanation, refer to an additional manual

Document

number

JY997D18801

JY997D16501

JY997D28601

JY997D31601

JY997D12701

JY997D28701

JY997D16601

JY997D16901

JY997D35201

JY997D35401

Describes FX

and installation extracted from the FX

Hardware Edition.

For details, refer to FX

Hardware Edition.

Describes FX3U Series PLC specification details for I/O,

wiring, installation and maintenance.

Describes FX3UC(D,DSS) Series PLC specification for I/

O, wiring and installation extracted from the FX3UC

Series User's Manual - Hardware Ed ition.

For details, refer to FX3UC Series User's Manual Hardware Edition.

Describes FX3UC-32MT-LT-2 specification for I/O,

wiring and installation extracted from t he FX3UC User's

Manual - Hardware Edition.

For details, refer to FX3UC Series User's Manual Hardware Edition.

Describes FX3UC-32MT-LT specification for I/O, wiring

and installation extracted from the FX3UC User's Manual

- Hardware Edition.

For details, refer to FX3UC Series User's Manual Hardware Edition.

Describes FX3UC Series PLC specification details

for I/O, wiring, installation an d maintenance.

Describes FX3G/FX3U/FX3UC Series PLC

programming for basic/applied

instructions and devices.

Details of N:N Network, parallel link, computer link and

non-protocol communication (RS instructions, FX2N-

232IF)

Describes installation specifications for the FX3U-CF-

ADP CF card special adapter extracted from the FX3U-

CF-ADP User's Manual.

For details, refer to FX3U-CF-ADP User's Manual.

Describes details of the FX3U-CF-ADP C F card special

adapter.

Description Model code

3U Series PLC specification for I/O, wiring

3U User's Manual -

3U Series User's Manual -

Associated Manuals

-

09R516

-

-

-

09R519

09R517

09R715

-

09R720

9

Page 16

FX3U-CF-ADP User's Manual

Generic Names and Abbreviations Used in the Manual

Generic Names and Abbreviations Used in the Manual

Generic name or abbreviation Description

PLC

FX3U series Generic name for FX3U Series PLC

FX3U PLC or main unit Generic name for FX3U Series PLC main unit

FX3UC series Generic name for FX3UC Series PLC

FX3UC PLC or main unit Generic name for FX3UC Series PLC main unit

Expansion board

Generic name for expansion board

Expansion board

Special adapter

Special adapter

CF-ADP Abbreviated name for FX3U-CF-ADP

Extension equipment

I/O extension unit/block

Special function unit/block or

Special extension unit

Special function unit Generic name for special function unit

Special function block

Optional unit

Memory cassette Generic name for FX3U-FLROM-16, FX3U-FLROM-64, FX3U-FLROM-64L

CF card or CompactFlashTM card

Memory card adaptor Generic name for GT05-MEM-ADPC

Peripheral unit

Peripheral unit Generic name for programming software, handy programming panel, and indicator

Programming tool

Programming tool Generic name for programming softwar e and handy programming panel

Programming software Generic name for programming softw are

GX Developer

FX-PCS/WIN(-E) Generic name for FX-PCS/WIN or FX-PCS/WIN-E programming software package

Handy programming panel (HPP) Generic name for FX-30P, FX-20P(-E) and FX-10P(-E)

Indicator

GOT1000 series Generic name for GT15, GT11 and GT10

GOT-900 series Generic name for GOT-A900 series and GOT-F900 series

GOT-A900 series Generic name for GOT-A900 series

GOT-F900 series Generic name for GOT-F900 series

ET-940 series

The number of connectable units, how ever, depends on the type of main unit .

To check the number of connectable units, refer to the User's Manual - Hardware Editon of the main

unit to be used for your system.

Generic name for high-speed input/ output special adapter, communic ation special adapter, analog

special adapter, and CF card special adapter.

The number of connectable units, how ever, depends on the type of main unit .

To check the number of connectable units, refer to the User's Manual - Hardware Editon of the main

unit to be used for your system.

Generic name for input/output p owered extension unit and input /output extension block

The number of connectable units, how ever, depends on the type of main unit .

To check the number of connectable units, refer to the User's Manual - Hardware Edition of the main

unit to be used for your system.

Generic name for special function unit and special function block

The number of connectable units, how ever, depends on the type of main unit .

To check the number of connectable units, refer to the User's Manual - Hardware Edition of the main

unit to be used for your system.

Generic name for special function block

The number of connectable units, how ever, depends on the type of main unit .

To check the number of connectable units, refer to the User's Manual - Hardware Edition of the main

unit to be used for your system.

Generic name for GT05-MEM-128MC, GT05-MEM-256MC, GT05-MEM-512MC, GT05-MEM-1GC,

GT05-MEM-2GC

Generic name for SW D5C-GPPW-J/SW D5C-GPPW-E programming software package

Generic name for ET-940 series

Only manuals in Japanese are available for these products

10

Page 17

FX3U-CF-ADP User's Manual

Generic name or abbreviation Description

Manual

FX3U Hardware Edition FX3U Series User's Manual - Hardware Edition

FX3UC Hardware Edition FX3UC Series User's Manual - Hardware Edition

Programming manual FX3G/FX3U/FX3UC Series Programming Manual - Basic and App lied Instructions Edition

Communication control Edition FX Series User's Manual - Data Communication Edition

Analog control Edition FX3G/FX3U/FX3UC Series User' s Manual - Analog Control Edition

Positioning control Edition FX3G/FX3U/FX3UC Series User's Manual - Positioning Control Edition

Generic Names and Abbreviations Used in the Manual

11

Page 18

FX3U-CF-ADP User's Manual

Reading the Manual

In this manual, the following formats are used for describing the common items.

Reading the Manual

Shows the manual title.

This area shows the

manual title for the current

page.

Shows the title of the chapter and the title

of the section.

This area shows the title of the chapter and the

title of the section for the current page.

Indexes the chapter number.

The right side of each page

indexes the chapter number

for the page currently opened.

Shows the reference.

The " " mark indicates

a reference destination

and reference manual.

12

The above is different from the actual page, as it is provided for explanation only.

Page 19

FX3U-CF-ADP User's Manual

1. Introduction

1.1 Outline

The CF card special adapter FX3U-CF-ADP (hereinafter abbreviated as "CF-ADP") stores data to and reads

data from the CompactFlash

3U/FX3UC PLC.

FX

Data is stored in CSV format on the CompactFlash

Only one CF-ADP unit can be connected to a single main unit.

• Data can be saved in the CompactFlash

• Data can be saved in a specified file stored in the CompactFlash

• Data can be read from the CompactFlash

1 Introduction

1.1 Outline

TM

card in accordance with applied instructions for the CF-ADP sent from the

TM

card.

→ For system configuration, refer to Chapter 3.

TM

card in files with the FIFO (first in, first out) function.

TM

card.

TM

card.

→ For details on the functions, refer to Chapter 6.

Configuration

1

Introduction

2

Specification

3

System

4

Installation

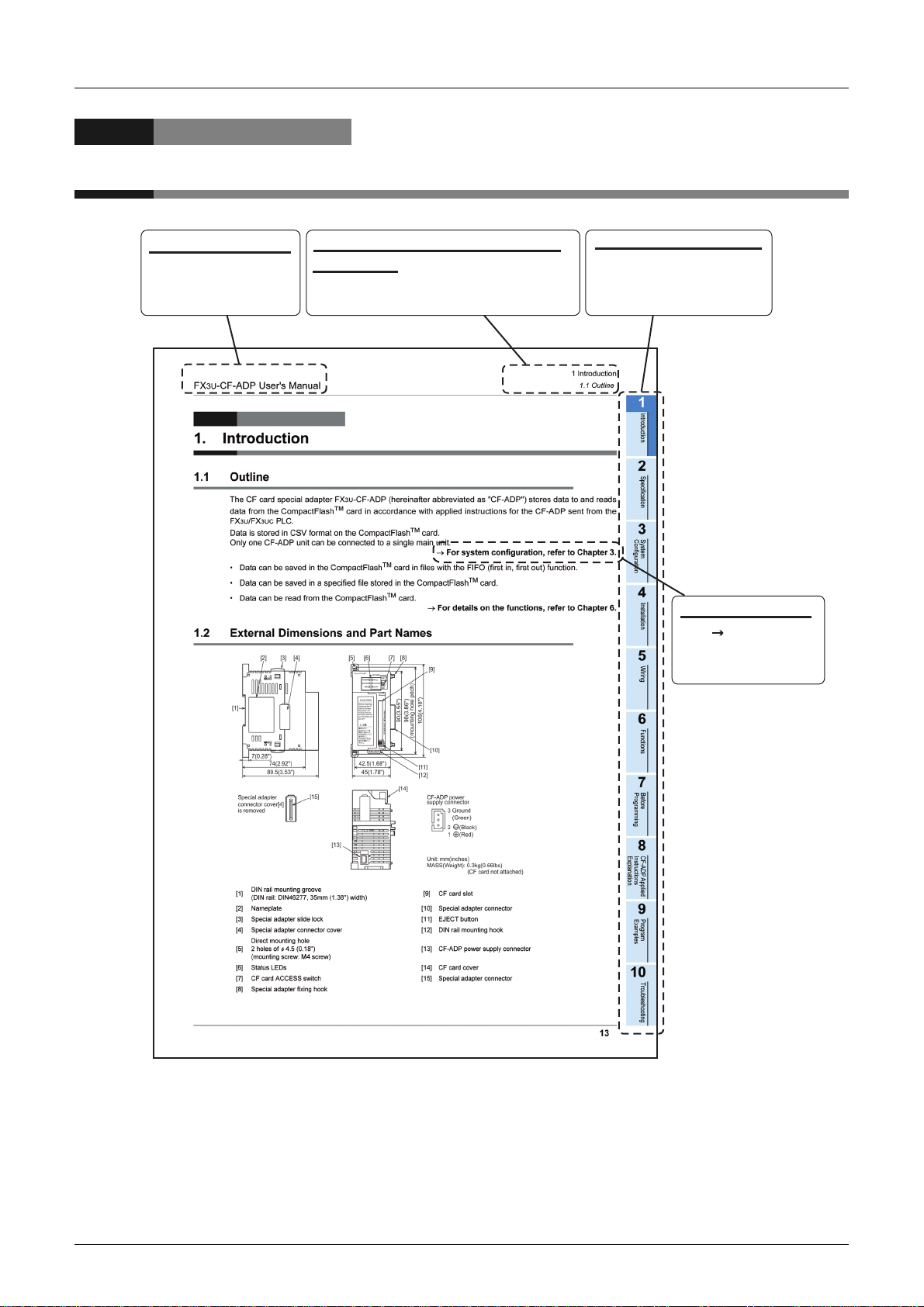

1.2 External Dimensions and Part Names

[6][5] [8][7]

42.5(1.68")

45(1.78")

90(3.55")

98(3.86")

106(4.18")

(mounting hole pitch)

[11]

[12]

[14]

[1]

7(0.28")

89.5(3.53")

Special adapter

connector cover[4]

is removed

[3][2] [4]

74(2.92")

[15]

[13]

[9]

[10]

CF-ADP power

supply connector

3 Ground

(Green)

21(Black)

(Red)

Unit: mm(inches)

MASS(Weight): 0.3kg(0.66lbs)

(CF card not attached)

5

Wiring

6

Functions

7

Before

Programming

8

CF-ADP Applied

Instructions

Explanation

DIN rail mounting groove

[1]

(DIN rail: DIN46277, 35mm (1.3 8") width)

[2] Nameplate [10] Special adapter connector

[3] Special adapter slide lock [11] EJECT button

[4] Special adapter connector cover [12] DIN rail mounting hook

Direct mounting hole

[5]

2 holes of 4.5 (0.18")

(mounting screw: M4 screw)

[6] Status LEDs [14] CF card cover

[7] CF card ACCESS switch [15] Special adapter connector

[8] Special adapter fixing hook

[9] CF card slot

[13] CF-ADP power supply connector

13

9

Program

Examples

10

Troubleshooting

Page 20

FX3U-CF-ADP User's Manual

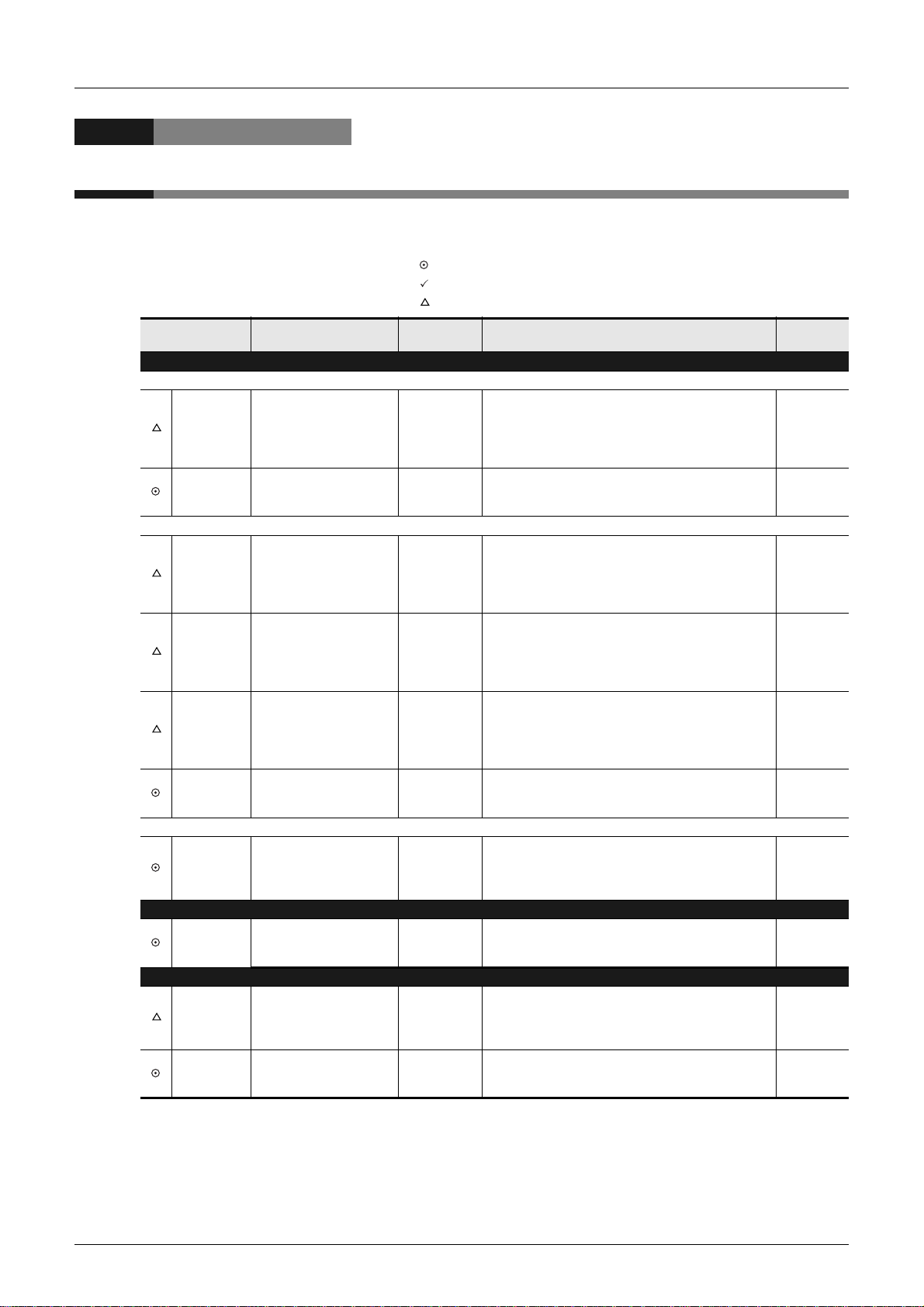

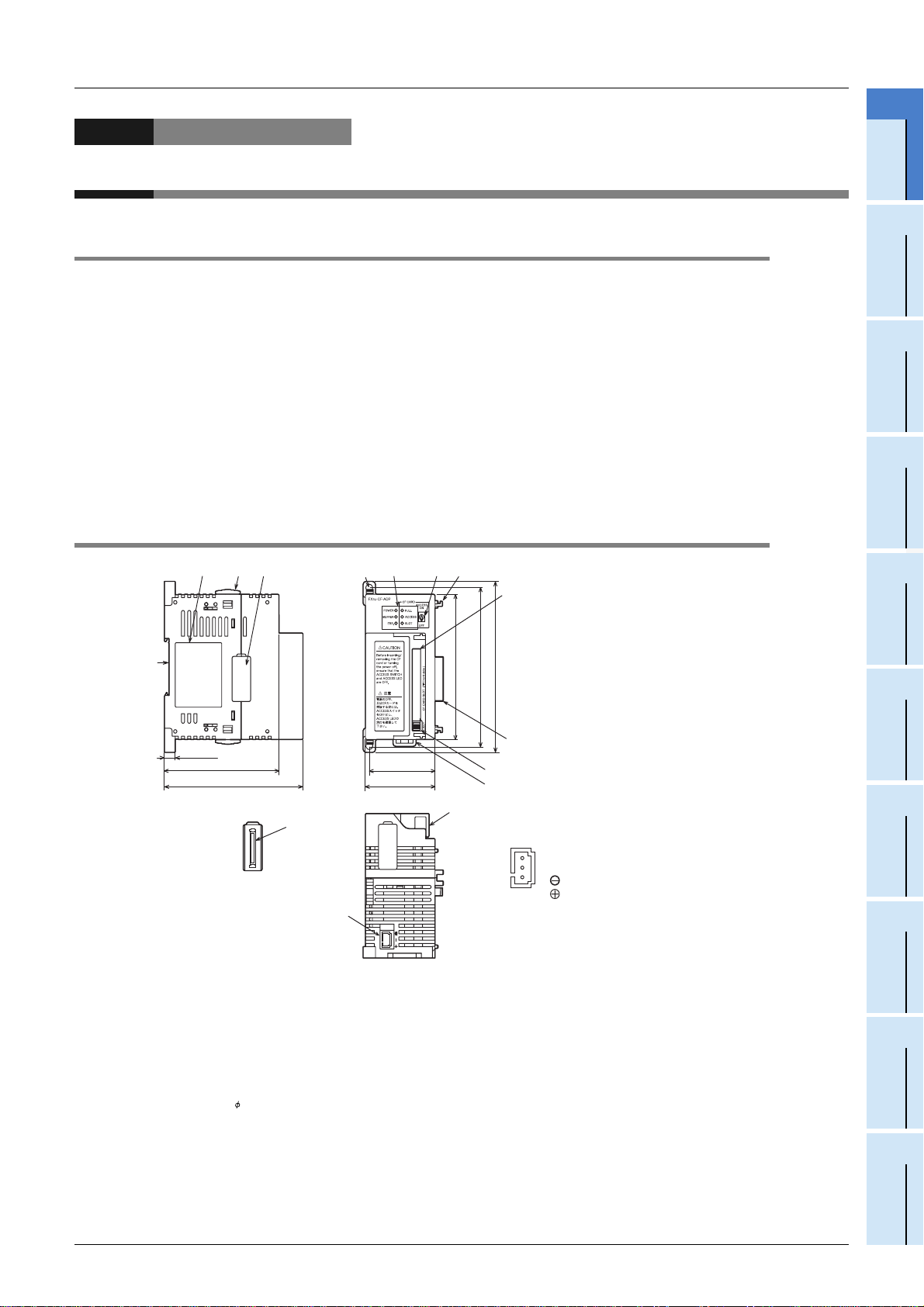

1.3 Power and status LEDs

LED display Color Status Description

POWER Green

BUFFER Green

ERR. Red

FULL Red

ACCESS Red

SLOT Green

OFF Power is not being supplied fro m the external power supply (24V D C ).

ON Power is being supplied from the external power supply (24V DC).

OFF Data is not stored in the internal buffer.

ON Data is stored in the internal buffer.

OFF No errors.

ON

CF write error, CompactFlashTM card error, etc. has occurred.

OFF

The CompactFlashTM card has free space.

Flicker

The free space in the CompactFlashTM card is 20% or less of the full capacity.

The CompactFlashTM card has no free space.

ON

The free space in the CompactFlashTM card is 1% or less of the full capacity.

OFF

CompactFlashTM card not accessed.

ON

CompactFlashTM card being accessed.

The CompactFlashTM card is not inserted, or the slot is in the CompactFlashTM card unmounted

OFF

status.

ON

The CompactFlashTM card is inserted, or the slot is in the CompactFlashTM card mounted status.

1 Introduction

1.3 Power and status LEDs

14

Page 21

FX3U-CF-ADP User's Manual

2. Specification

DESIGN PRECAUTIONS

• Make sure to include the following safety circuits outside the PLC to ensure safe system operation even during external power supply

problems or PLC failure.

Otherwise, malfunctions may caus e serious accidents.

1) Above all, the followi ng components should be included: an emerg ency stop circuit, a protection circuit , an interlock circuit for

opposite movements (such as normal vs. r everse r otation), and an int erlock cir cuit (to pr event da mage to the e quipment at the

upper and lower positioning limits).

2) Note that when the PLC main unit detects an error during self diagnosis, such as a watchdog timer error, all outputs are turned off.

Also, when an error th at ca nnot be detec ted by t he PLC main u nit occ urs i n an inp ut/ out put c ontrol bloc k, outp ut cont rol ma y be

disabled.

External circuits and mechanisms should be designed to ensure safe machinery operation in such cases .

DESIGN PRECAUTIONS

2 Specification

Configuration

1

Introduction

2

Specification

3

System

4

Installation

• Observe the following items. F ailure to do so may cause i ncorrect data-writing th rough noise to the PLC and result in PLC failure,

machine damage or other accident.

1) Do not bundle the control line together with or lay it close to the main circuit or power line. As a guideline, lay the control line at

least 100mm (3.94") or more away from the main circuit or power line.

Noise may cause malfunctions.

2) Ground the shield wire or shield of a shielded cable. Do not use common grounding with heavy electrical systems

• During access (ACCESS LED is l it or fli ckering) to Compac tFlashTM card, do not remove the CompactFlashTM card or power off the

CF-ADP.

Failure to do so may cause CompactFlashTM card failures or malfunctions.

• If the power is turned OFF wh ile the Compa ctFlashTM card is being accessed (ACCE SS LED is lit or flicke ring), the buffere d data is

erased. Also files or CompactFlashTM card itself may be damaged. Do not turn the power OFF while the ACCESS LED is lit or

flickering.

• Do not apply excessive pressu re to the power supply cable or power supply connector.

Excessive pressure may cause da mage or error.

DISPOSAL PRECAUTIONS

• Please contact a certified el ectronic waste disposal company for the environmentally safe recycling and disposal of your devi ce.

TRANSPORTATION PRECAUTIONS

• The PLC is a precision instrument. During transportation, avoid impacts larger than those specified in the general specifications of the

PLC main unit manual.

Failure to do so may cause failures in the PLC.

After transportation, verify the operations of the PLC.

5

Wiring

6

Functions

7

Before

Programming

8

CF-ADP Applied

Instructions

Explanation

15

9

Program

Examples

10

Troubleshooting

Page 22

FX3U-CF-ADP User's Manual

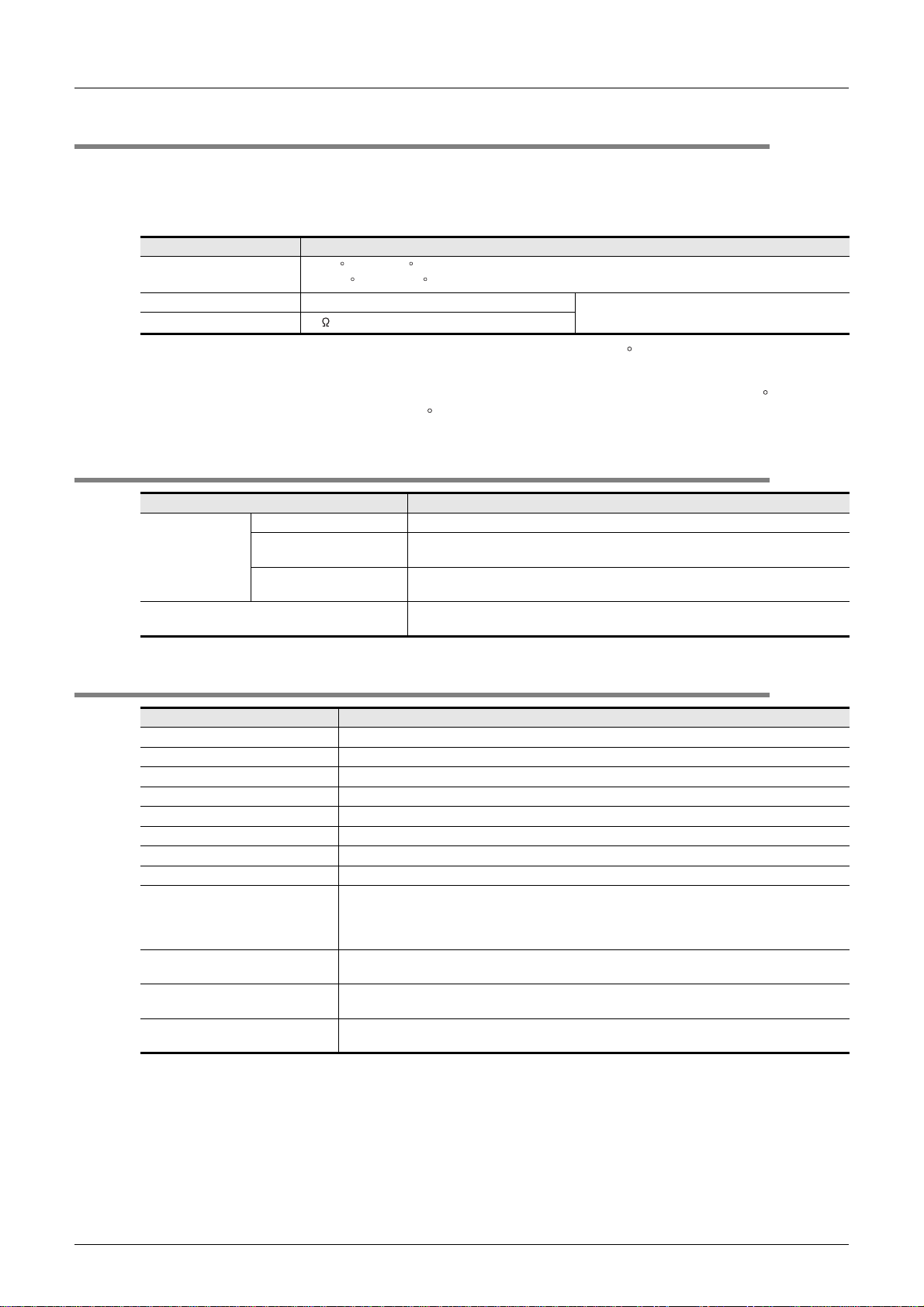

2.1 General specifications

For items not listed below, specifications are the same as the of the PLC main unit.

For general specifications, refer to the manual of the PLC main unit.

Item Specification

0 to 55 C (32 to 131 F) ••••• when operating,

Ambient temperature

Dielectric withstand voltage 500V AC for one minute

Insulation resistance

*1

-25 to 75 C (-13 to 167 F) ••••• when stored

5M or more by 500V DC Megger

*1. The upper limit of the ambient temperature shall not exceed "20 C" below the upper limit of the

CompactFlash

TM

card operating temperature.

Example : When the upper limit of the CompactFlash

limit of the ambient temperature is 55 C.

2.2 Power supply specification

2 Specification

2.1 General specifications

→ Refer to the FX

→ Refer to the FX

Between all terminals and ground terminal

TM

card operating temperature is 75 C, the upper

3U Hardware Edition

3UC Hardware Edition

Item Specification

Power supply voltage 24V DC +20% -15% Ripple (p-p) within 5%

Adapter driving

power supply

Interface driving power supply

Permitted instantaneous

power failure time

Current consumption

2.3 Performance specification

Item Specification

Data transfer method Depends on the applied instruction sent from the main un it.

Clock data Operates based on the clock data in the main unit.

DOS file system FAT16

The maximum data capacity 2GB

The maximum file size 512MB (Per 1 file)

Data format CSV format

The number of the maximum files 63 file (When the FIFO function is not used)

FIFO functional file 1 pattern. The file name is automatically assigned.

• Standard file

Data storage directory

File name type

Number of I/O occupied points

Number of connectable units to the

main unit

\FX3U_CF\DATA\. (The directory name is fixed.)

• FIFO file

\FX3U_CF\DATA\FIFO\. (The directory name is fixed.)

8.3 file name (The extensi on is fixe d to " CSV" .) (Hal f-w idth a lpha numer ic c haract ers a nd s ymbols

and character strings allowed in the MS-DOS)

0 point

(This number is not related to the maximum number of input/o utput points of the PLC.)

*1

1 unit

Operation continues when the instantaneous power failure is shorter than 1ms.

130mA

Connect a 24V DC power supply to the power supply connector.

50mA / 5V DC

5V DC power is supplied internally from the main unit.

16

*1. The CF-ADP is handled in the same way as communication expansion boards and communication

special adapters, and occupies 1 communication channel.

Page 23

FX3U-CF-ADP User's Manual

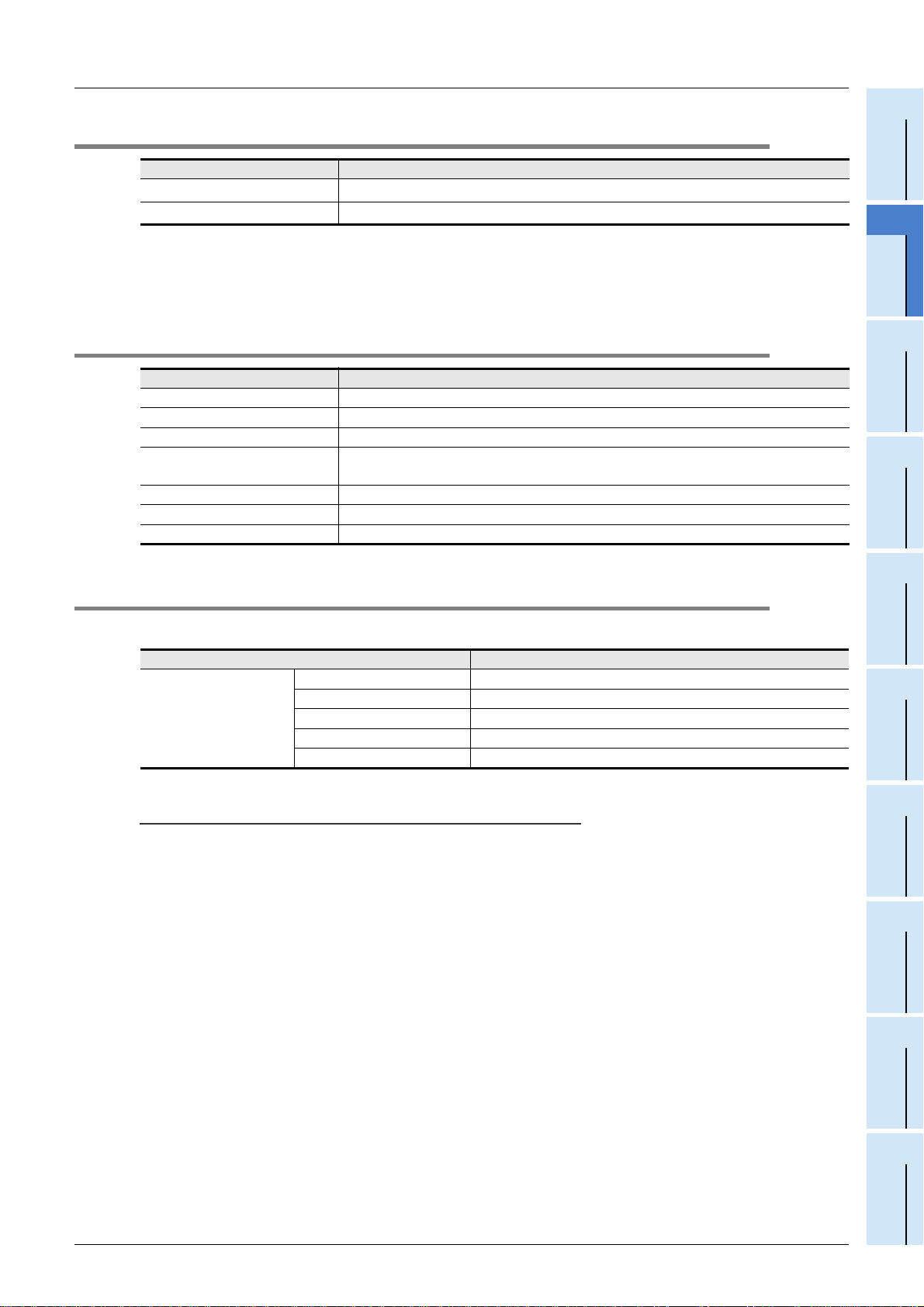

2.4 CF card ACCESS switch specification

Setting item Description

ON

*1

OFF

*1. Turn OFF the CF card ACCESS switch, and then confirm that the BUFFER LED and ACCESS LED

are completely OFF before removing the CompactFlash

ADP.

Access to the CompactFlashTM card enabled

Access to the CompactFlashTM card disabled

2 Specification

2.4 CF card ACCESS switch spec if ic a t io n

TM

card or turning OFF the power of the CF-

1

Introduction

2

Specification

2.5 CompactFlashTM card specification

Item Specification

Operating ambient humidity 5 to 95%RH (no condensation)

Power supply voltage 3.3V 150mA or less

Connector shape Type I

Format form

Data capacity 2GB or less

Connector terminal Gilding

No. of installable cards 1

FAT16

(The CompactFlashTM card shall be formatted in accordance with the FAT16 in advance.)

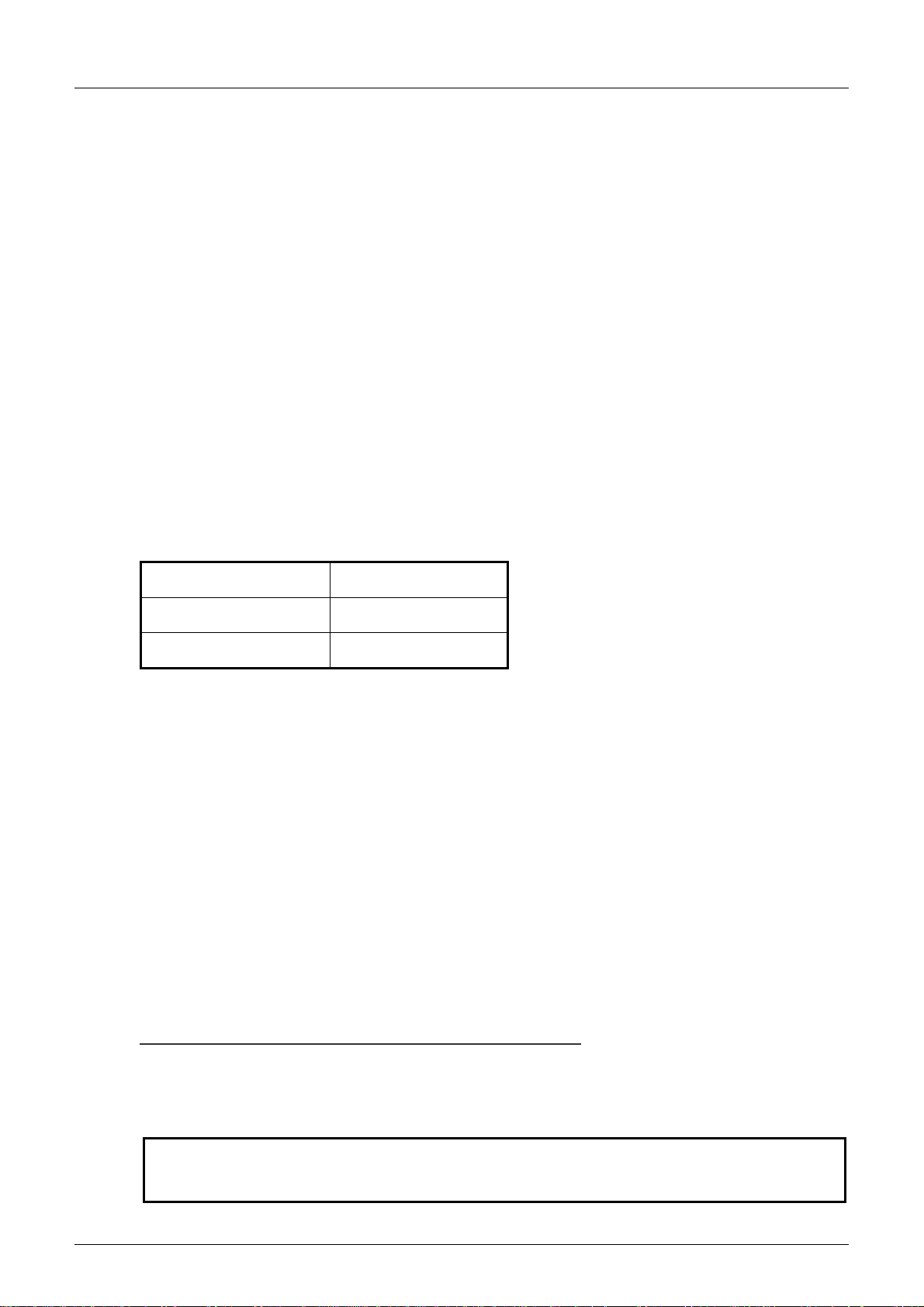

2.6 Applicable CompactFlashTM card

The following CompactFlashTM card are applicable for the CF-ADP.

Model Description

GT05-MEM-128MC Flash ROM 128MB

GT05-MEM-256MC Flash ROM 256MB

CompactFlashTM card

GT05-MEM-512MC Flash ROM 512MB

GT05-MEM-1GC Flash ROM 1GB

GT05-MEM-2GC Flash ROM 2GB

Configuration

3

System

4

Installation

5

Wiring

6

Functions

Caution

The life of a CompactFlash

Generally, at the end of the operational life, the CompactFlash

Please use it ensuring sufficient availability.

TM

card is expired when data is written to it a specified number of times.

TM

card has reduced capabilities.

7

Before

Programming

8

CF-ADP Applied

Instructions

Explanation

9

Program

Examples

10

Troubleshooting

17

Page 24

FX3U-CF-ADP User's Manual

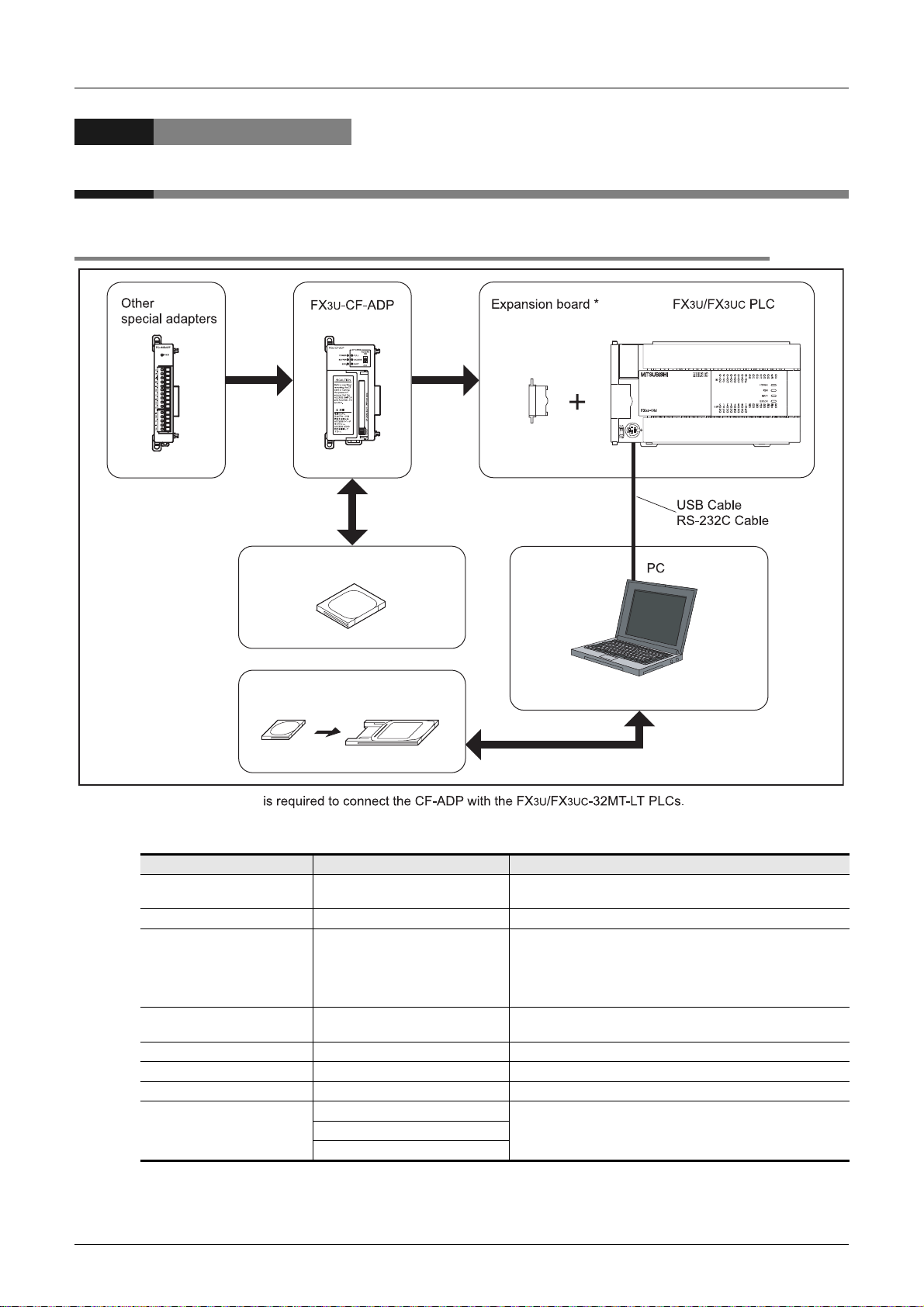

3. System Configuration

3.1 General configuration

3 System Configuration

3.1 General configuration

CompactFlashTM card

TM

CompactFlash

card

Memory card

adapter

*An expansion board

Component list

Part name Model name Remarks

CF card special adapter FX3U-CF-ADP

PLC FX

CompactFlashTM card

Memory card adapter GT05-MEM-ADP

PC software GX Developer PLC programming software.

PC - USB cable FX-USB-AW Cable with RS-422/USB converter between a FX PLC and PC.

RS-232C cable

3U/FX3UC PLC -

GT05-MEM-128MC,

GT05-MEM-256MC,

GT05-MEM-512MC,

GT05-MEM-1GC,

GT05-MEM-2GC

F2-232CAB-1

FX-422CAB0

An expansion board is requir ed to connect th e CF-ADP with the

3U/FX3UC-32MT-LT PLCs.

FX

CompactFlashTM cards available for the CF-ADP.

The memory card adapter is used to convert a CF card into a

memory card (Type II).

PC connection cable and interface.FX-232AWC-H

18

Page 25

FX3U-CF-ADP User's Manual

3.2 Applicable PLC

3.2.1 Connectable PLC

Model name Applicability

FX3U Series PLC

FX3UC Series PLC

The version number can be checked by reading the last three digits of device D8001.

*1. An expansion board is required to connect the CF-ADP with FX

*2. The FX

*1

*1*2

3UC-32MT-LT-2 PLC is due to be upgraded later.

3.2.2 Applicable versions of the programming tool

Ver. 2.61 and later

Only one CF-ADP unit can be connected to a mai n un it.

Ver. 2.61 and later

Only one CF-ADP unit can be connected to a mai n un it.

3 System Configuration

3.2 Applicable PLC

3U/FX3UC-32MT-LT PLCs.

Configuration

1

Introduction

2

Specification

3

System

1. GX Developer

Use the programming tool with the following version number to create programs for the CF-ADP of the FX3U/

3UC Series PLC.

FX

Software Applicability

GX Developer

• SW D5C(F)-GPPW-J

• SW D5C(F)-GPPW-E

Caution

If a programming tool with the wrong version number is used, programming will not be possible.

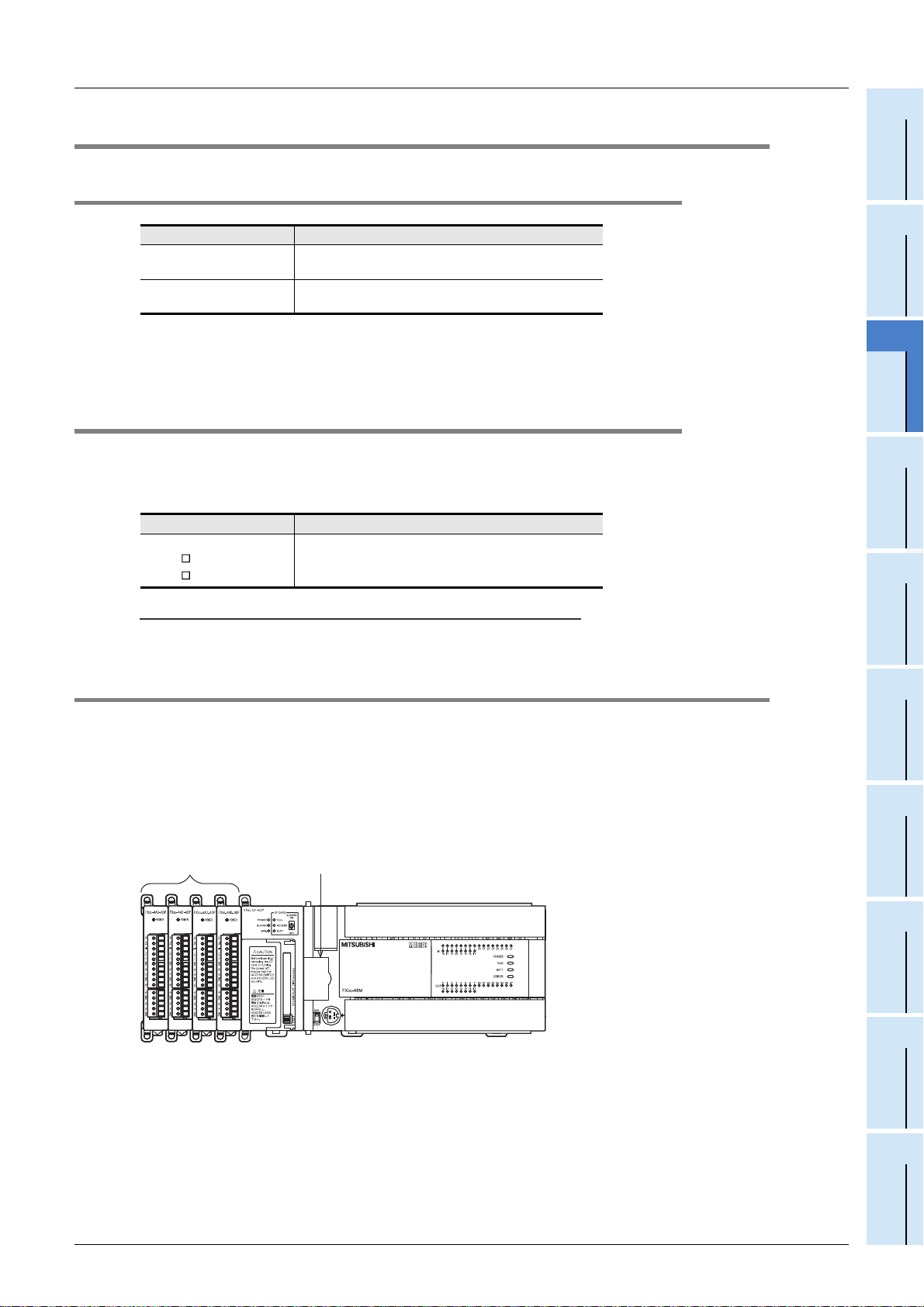

3.3 Connection with PLC

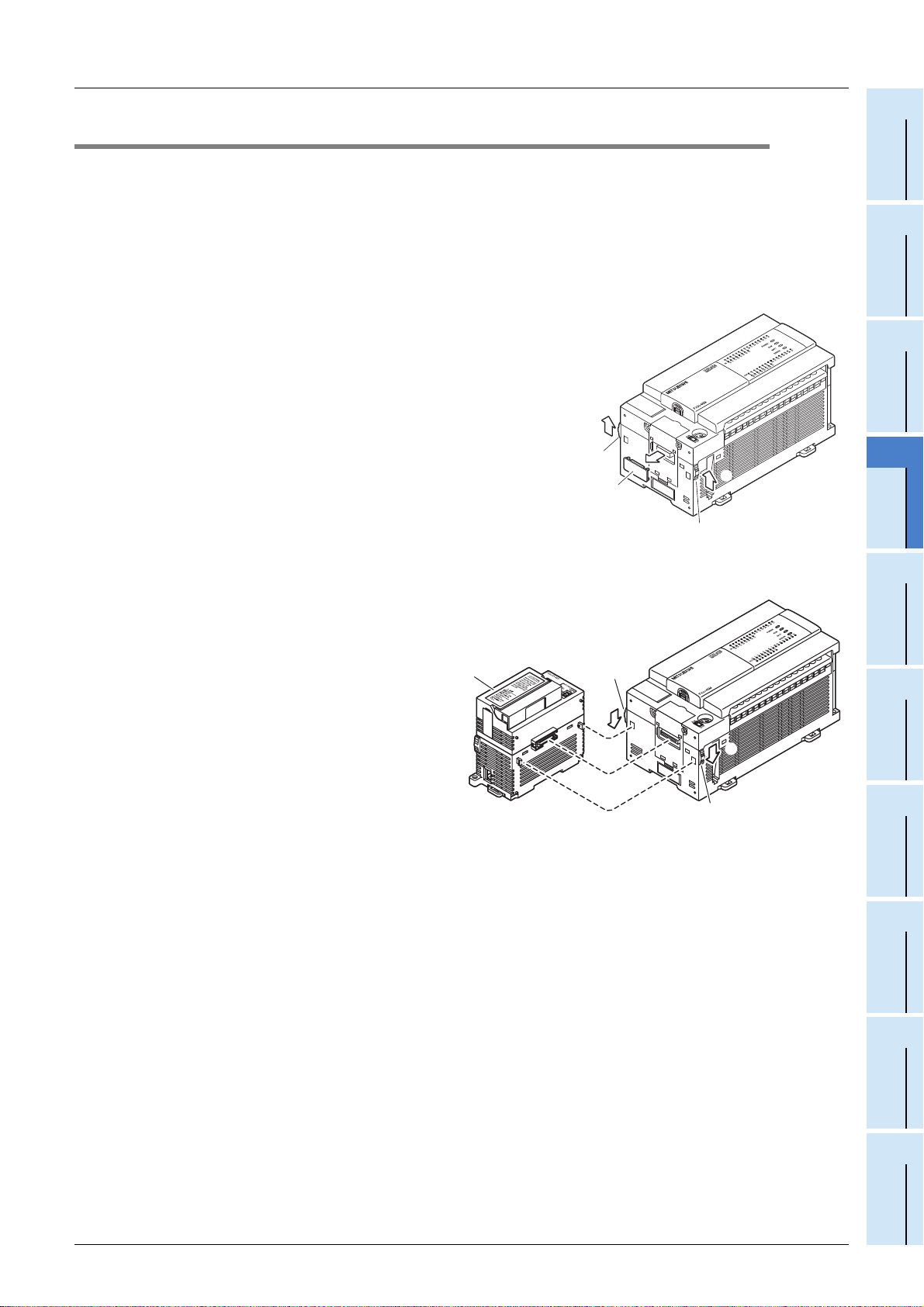

The CF-ADP connects with a FX3U/FX3UC PLC via an interface connector.

Only one CF-ADP unit can be connected to the FX

the CF-ADP with the FX

For details of assignment of channel numbers in the main unit, refer to the following.

1. FX3U/FX3UC-32MT-LT PLC

Other

special adapters

3U/FX3UC-32MT-LT PLCs.

Expansion board

Ver.8.82L or later

3U/FX3UC PLC. An expansion board is required to connect

Main unit

→ Refer to Section 3.4

Programming

4

Installation

5

Wiring

6

Functions

7

Before

FX

3U

-CF-ADP

19

8

CF-ADP Applied

Instructions

Explanation

9

Program

Examples

10

Troubleshooting

Page 26

FX3U-CF-ADP User's Manual

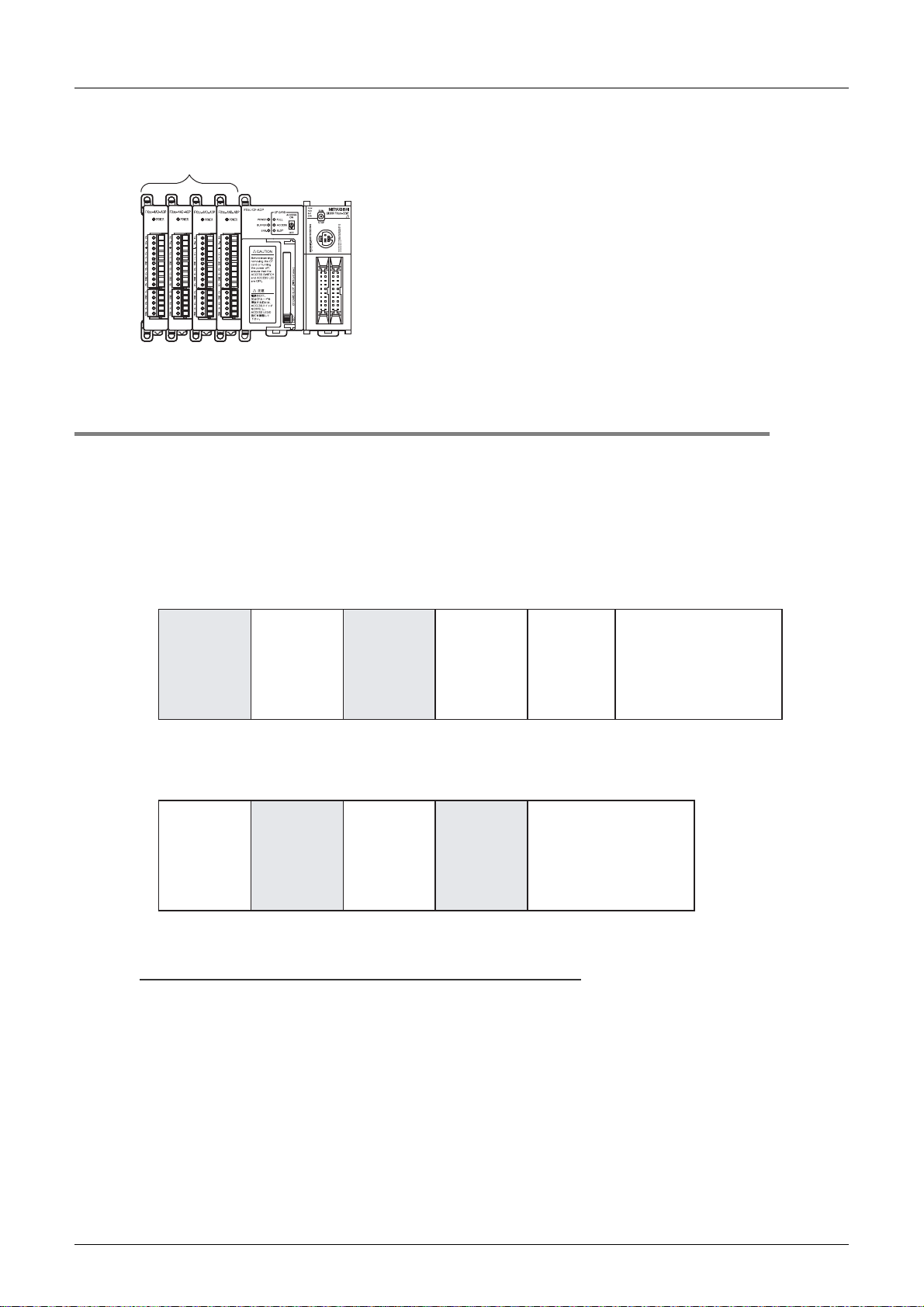

2. FX3UC(D, DSS) PLC

Other

special adapters

Main unit

3U

-CF-ADP

FX

3.4 Assignment of channels

The CF-ADP is handled in the same way as communication expansion boards and communication special

adapters for PLCs. Its channel number ("ch1" or "ch2") is assigned automatically in the order of the position

from the main unit. This channel number is used in applied instructions for the CF-ADP.

The channel number is assigned as shown below.

3 System Configuration

3.4 Assignment of channels

1. FX3U/FX3UC-32MT-LT(-2) PLC

• When using channel 1 (ch1)

(ch2)

Communication

special adapter

• When using channel 2 (ch2)

Analog

special adapter

Caution on using the CF-ADP

Analog

special adapter

ch2 (ch1)

CF-ADP

special adapter

ch1

Analog

Analog

special adapter

Communication

expansion

board

FX3U-CNV-BDCF-ADP

FX3U, FX

3UC

-32MT-LT(-2)

Main unit

FX3U, FX

3UC

-32MT-LT(-2)

Main unit

20

The CF-ADP is handled in the same way as communication expansion boards and communication special

adapters, and occupies one communication channel.

Page 27

FX3U-CF-ADP User's Manual

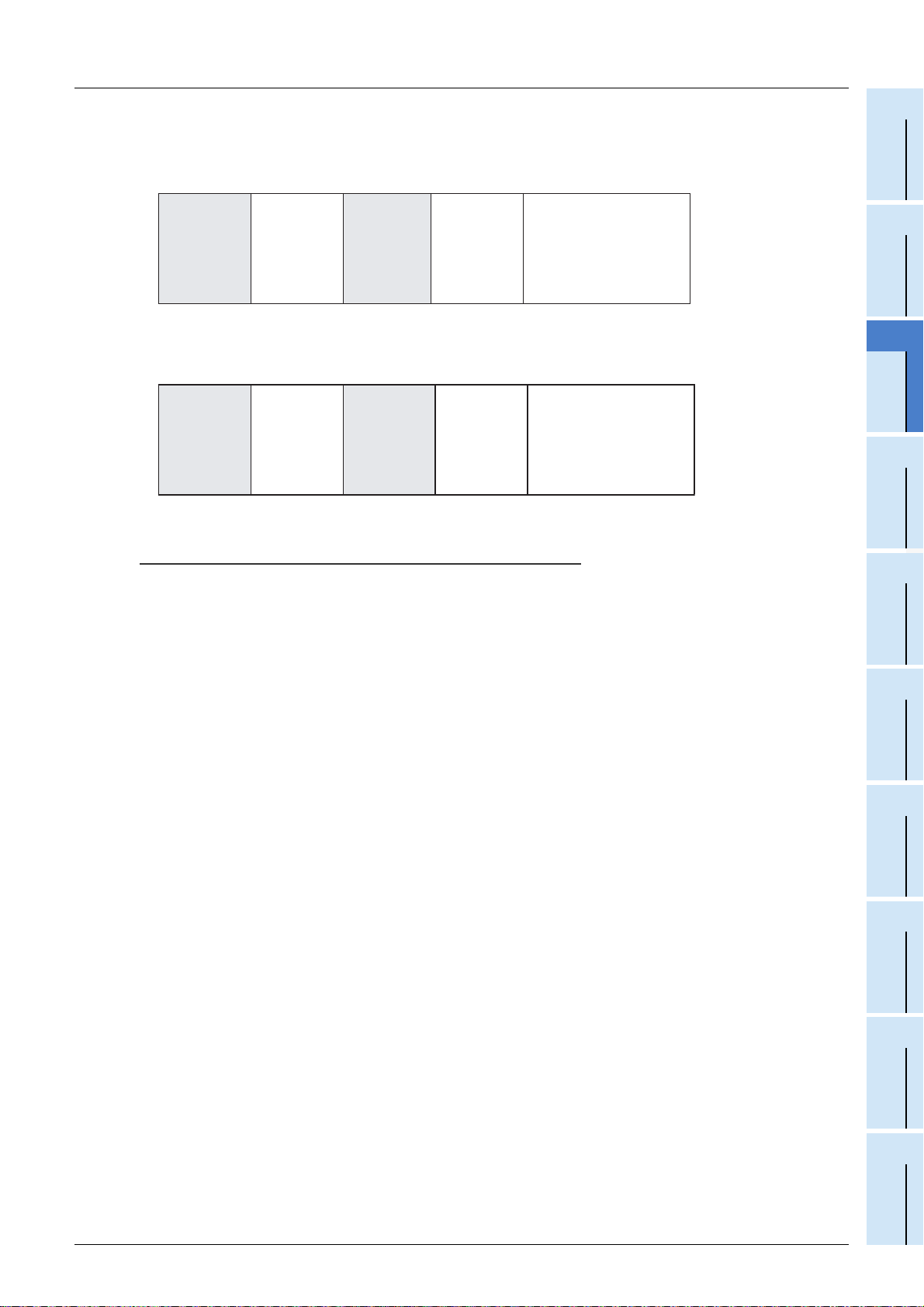

2. FX3UC(D, DSS) PLC

• When using channel 1 (ch1)

(ch2) ch1

Communication

special adapter

Analog

special adapter

CF-ADP

Analog

special adapter

FX

3UC

Main unit

(D, DSS)

3 System Configuration

3.4 Assignment of channels

1

Introduction

2

Specification

• When using channel 2 (ch2)

ch2 (ch1)

FX

3UC

CF-ADP

Caution on using the CF-ADP

The CF-ADP is handled in the same way as communication special adapters, and occupies one

communication channel.

Analog

special adapter

Communication

special adapter

Analog

special adapter

(D, DSS)

Main unit

Configuration

3

System

4

Installation

5

Wiring

6

Functions

7

Before

Programming

8

CF-ADP Applied

Instructions

Explanation

9

Program

Examples

10

Troubleshooting

21

Page 28

FX3U-CF-ADP User's Manual

4. Installation

INSTALLATION PRECAUTIONS

• Make sure to shut down all phases of the power supply externally before i nstalling the FX3U-CF-ADP.

Failure to do so may cause electric shock or damage to the product.

INSTALLATION PRECAUTIONS

• Use the product within the gener ic env ironmen t sp ecifi catio ns de scribe d in PLC main uni t manual (Ha rdware Edit ion). Never use the

product in areas with ex cessive dust , oily smoke, conductive dusts, cor rosive gas ( salt air, C l2, H2S, SO2, or NO2), flammable gas,

vibration or impacts, or expose it to high temperature, condensation, or rain and wind. If the product is used in such conditions, electric

shock, fire, malfunctions, deterioration or damage may occur.

• Do not touch the conductive part s of the product directly.

Doing so may cause device failures or malfunctions.

• Install the product securely usin g a DI N ra il or mounting screws.

• Install the product on a flat surface.

If the mounting surface is rough, undue force will be applied to the PC board, thereby causing nonconformities.

• When drilling screw holes or wiring, make sure that cutting and wiri ng debris do not enter the ventilation slits.

Failure to do so may cause fire, equipment failures or malfunctions.

• Be sure to remove the dust proof sheet from the PLC's ventilation port when installation work is completed.

Failure to do so may cause fire, equipment failures or malfunctions.

• Connect the FX3U-CF-ADP securely to special adapter connector.

Loose connections may cause malfunctions.

• Connect the power connector of the power supply cable securely to the CF-ADP power supply connector.

Loose connections may cause malfunctions.

• When inserting a CompactFlashTM card into the FX3U-CF-ADP, push it into the CF card slot until th e EJECT button pops out.

Loose connections may cause malfunctions.

• Before inserting/removing a CompactFlashTM card into/from the FX3U-CF-ADP, set the CF card ACCESS switch to OFF and confirm

that the BUFFER LED and ACCESS LED are both OFF.

Failure to do so may corrupt data within the CompactFlashTM card.

• When removing a CompactFlashTM card from the FX3U-CF-ADP, make sure to support the CompactFlashTM card by hand, as it may

pop out.

Failure to do so may cause the CompactFlashTM card to fall from the FX3U-CF-ADP and break.

• Turn off the power to the PLC befor e attaching or detaching the foll owing devices.

Failure to do so may cause device failures or malfunctions.

- Peripheral devices, display modules, expansion boa rds and special adapters

- I/O extension units/blocks, FX Series terminal block and the special function units/blocks

- Battery and memory cassette

4 Installation

22

Only one CF-ADP unit can be connected to the left side of the main unit or special adapter.

An expansion board is required to connect the CF-ADP with the FX

3U/FX3UC-32MT-LT PLCs.

For details, refer to the respective PLC manual.

→ Refer to the FX

→ Refer to the FX

3U Hardware Edition

3UC Hardware Edition

The CF-ADP may be installed in a control cabinet with a 35mm (1.38") wide DIN46277 DIN rail mounting or

M4 screw direct mounting.

When the CF-ADP is connected to a FX

3UC PLC, the direct mounting method is not possible.

Page 29

FX3U-CF-ADP User's Manual

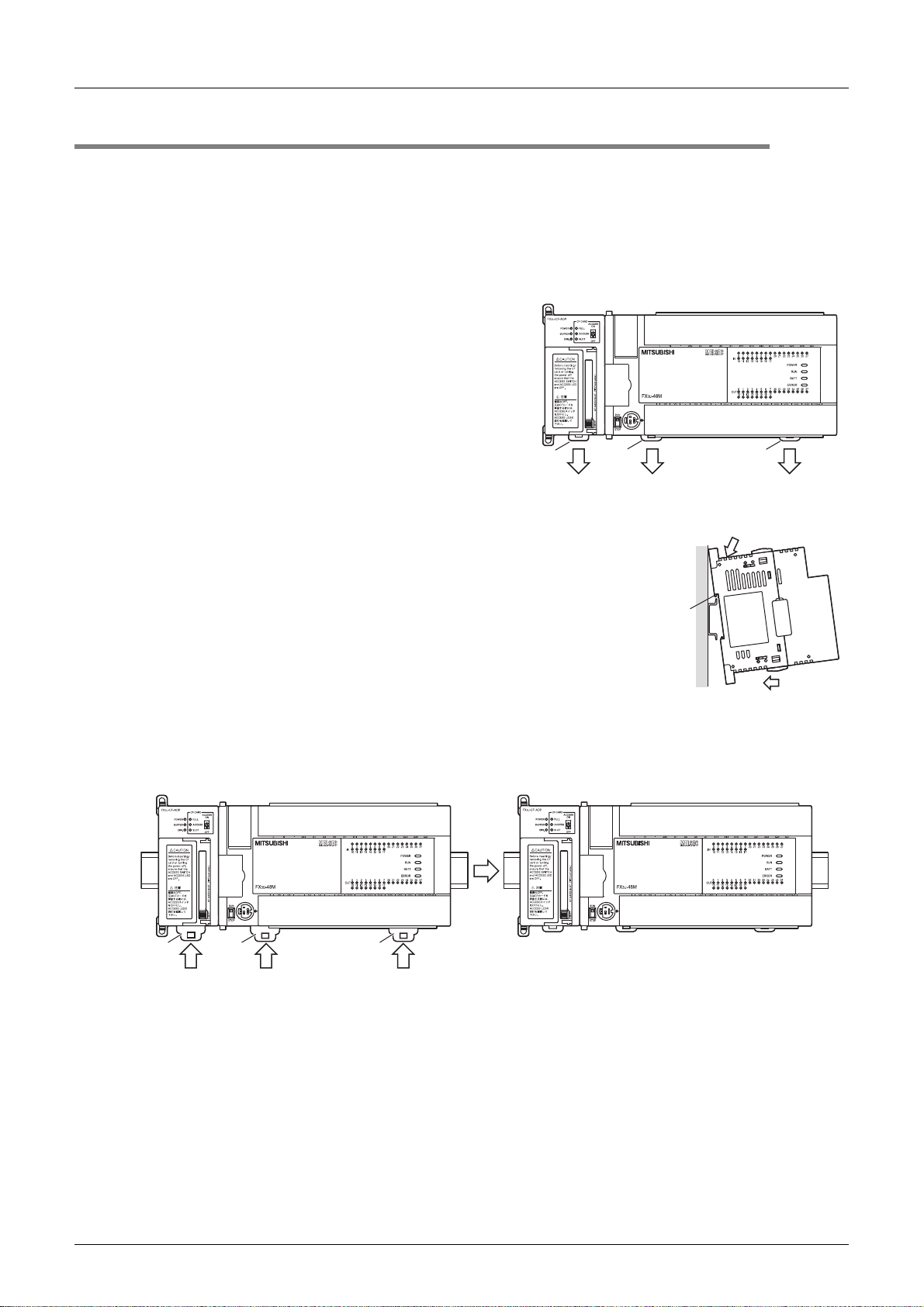

4.1 CF-ADP Connection

An expansion board should be installed before connection of the CF-ADP. An expansion board is not required

when the CF-ADP is connected to a FX

This section explains an example where the CF-ADP is connected to a FX

PLC, refer to the respective PLC manual.

3UC(D, DSS) PLC.

1 Remove the special adapter connector cover

(A in the figure on the right) from the expansion

board.

It is assumed that an expansion board has been installed in

advance. For the expansion board installation method, refer

to the respective PLC manual.

→ Refer to the FX3U Hardware Edition

→ Refer to the FX

3UC Hardware Edition

2 Slide the special adapter connecting hooks

(B in the figure on the right) of the main unit

upwards.

4.1 CF-ADP Connection

3U PLC. For connection to another

→ Refer to the FX

→ Refer to the FX

2

1

B

A

3U Hardware Edition

3UC Hardware Edition

2

B

4 Installation

Configuration

1

Introduction

2

Specification

3

System

4

Installation

3 Connect the CF-ADP (C in the

figure on the right) to the main

unit as shown in the figure on the

right.

4 Slide the special adapter

connecting hooks (B in the figure

on the right) of the main unit

downwards to secure the CF-ADP

(C in the figure on the right).

5

Wiring

C

B

4

3

3

3

4

B

6

Functions

7

Before

Programming

8

CF-ADP Applied

Instructions

Explanation

23

9

Program

Examples

10

Troubleshooting

Page 30

FX3U-CF-ADP User's Manual

4.2 DIN rail mounting

The CF-ADP may be mounted on a 35mm (1.38") wide DIN46277 (DIN rail).

Connect the CF-ADP to the PLC main unit before attaching the CF-ADP to a DIN rail.

This section explains an example where the CF-ADP is connected to a FX

method for other PLCs, refer to the respective PLC manual.

1 Push out all DIN rail mounting hooks (A

in the figure on the right).

It is assumed that the CF-ADP has been connected

in advance. For the CF-ADP connection method,

refer to the following.

→ Refer to Section 4.1.

3U PLC. For the DIN rail mounting

→ Refer to the FX

→ Refer to the FX

4 Installation

4.2 DIN rail mounting

3U Hardware Edition

3UC Hardware Edition

A

A

2 Fit the upper edge (B in the figure on the right) of the DIN

A

2

111

rail mounting groove onto the DIN rail.

3 Push the product onto the DIN rail.

B

3

4 Lock the DIN rail mounting hooks (A in the following figure) while pressing

the PLC against the DIN rail.

24

A

A

4

4

A

4

Page 31

FX3U-CF-ADP User's Manual

4.3 Direct mounting

When the CF-ADP is connected to a FX3U PLC, the CF-ADP may be mounted directly on a pan el surface

using screws. The direct mounting method is not available when the CF-ADP is connected to a FX

Connect the CF-ADP to the main unit before attaching it to the panel surface.

For mounting, refer to the following manual.

1 Create mounting holes in the

mounting surface according to the

external dimensions diagram.

2 Fit the CF-ADP to the mounting

holes and tighten with M4 screws

(A in the figure on the right).

Also fit the main unit to the mounting holes

and tighten with M4 screws. For the main unit

connection method, refer to the following.

→ Refer to the FX3U Hardware Edition

It is assumed that the CF-ADP has been

connected in advance.

For the CF-ADP connection method, refer to

the following.

→ Refer to Section 4.1.

→ Refer to the FX

A

A

4 Installation

4.3 Direct mounting

3UC PLC.

3U Hardware Edition

Configuration

1

Introduction

2

Specification

3

System

4

Installation

5

Wiring

For the screw positions and number of screws in the CF-ADP, refer to the dimensional outline

drawing as follows.

→ Refer to Section 1.2.

For the screw positions and number of screws in the main unit, refer to the following manual.

→ Refer to the FX3U Hardware Edition

6

Functions

7

Before

Programming

8

CF-ADP Applied

Instructions

Explanation

9

Program

Examples

25

10

Troubleshooting

Page 32

FX3U-CF-ADP User's Manual

4.4 Inserting and Removal Procedures

4.4.1 Inserting the CompactFlashTM card

The CompactFlashTM card can be inserted when the CF-ADP is power off.

When the power supply of CF-ADP is ON and it inserts the CompactFlash

the following procedures.

4 Installation

4.4 Inserting and Removal Procedures

TM

card, make sure to perform of

1 Set the CF card ACCESS switch to OFF (A in

the figure on the right) in the CF-ADP . Confirm

that the POWER LED is lit.

2 Open the CF card cover.

TM

Insert the CompactFlash

card slot with the front side (side B in the

figure on the right) facing the right side of the

CF-ADP until the EJECT button (side C in the

figure on the right) pops out.

card into the CF

CompactFlash

card

CF-ADP

TM

(A)(D)

3 Confirm that the CF card ACCESS LED

is lit or flickers and turns OFF, and then the

SLOT LED (D in the figure on the right) turns

ON.

4 Close the CF card cover.

Set the CF card ACCESS switch to ON.

26

Front

side (B)

EJECT button (C)

Page 33

FX3U-CF-ADP User's Manual

4.4.2 Removing the CompactFlashTM card

The CompactFlashTM card can be removed when the CF-ADP is power off.

When the power supply of CF-ADP is ON and it removes the CompactFlash

the following procedures.

1 Set the CF card ACCESS switch of the CF-

ADP to OFF (A in the figure on the right), and

make sure that the CF card ACCESS LED and

BUFFER LED (B in the figure on the right)

both turn off.

(When the CF card ACCESS LED turns off, the

TM

CompactFlash

when the CF-ADP is powering on.)

When the CF card ACCESS LED is lit or flickering, do not

removing the CompactFlash card or power off the CF-ADP.

Doing so may cause data corruption or malfunction.

card can be removed even

TM

4 Installation

4.4 Inserting and Removal Procedures

TM

card, make sure to perform of

(A)(B)

Configuration

1

Introduction

2

Specification

3

System

4

Installation

2 Open the CF card cover.

Push the EJECT button (C in the figure on the

right) of the CF-ADP to push out the

TM

CompactFlash

When ejecting the CompactFlash card, support it by hand

since it may pop out.

Failure to do so may cause the CompactFlash card to fall

leading to failure or damage of the card.

card and remove it.

TM

TM

CF-ADP

CompactFlashTM

card

Push

EJECT button (C)

5

Wiring

6

Functions

7

Before

Programming

8

CF-ADP Applied

Instructions

Explanation

27

9

Program

Examples

10

Troubleshooting

Page 34

FX3U-CF-ADP User's Manual

5. Wiring

DESIGN PRECAUTIONS

• Make sure to include the following safety circuits outside the PLC to ensure safe system operation even during external power supply

problems or PLC failure.

Otherwise, malfunctions may caus e serious accidents.

1) Above all, the followi ng components should be included: an emerg ency stop circuit, a protection circuit , an interlock circuit for

opposite movements (such as normal vs. r everse r otation), and an int erlock cir cuit (to pr event da mage to the e quipment at the

upper and lower positioning limits).

2) Note that when the PLC main unit detects an error during self diagnosis, such as a watchdog timer error, all outputs are turned off.

Also, when an error th at ca nnot be detec ted by t he PLC main u nit occ urs i n an inp ut/ out put c ontrol bloc k, outp ut cont rol ma y be

disabled.External circuits and mechanisms should be designed to ensure safe machinery operation in such cases.

DESIGN PRECAUTIONS

• Observe the following items. F ailure to do so may cause i ncorrect data-writing th rough noise to the PLC and result in PLC failure,

machine damage or other accident.

1) Do not bundle the control line together with or lay it close to the main circuit or power line. As a guideline, lay the control line at

least 100mm (3.94") or more away from the main circuit or power line.

Noise may cause malfunctions.

2) Ground the shield wire or shield of a shielded cable. Do not use common grounding with heavy electrical systems

• During access (ACCESS LED is l it or fli ckering) to Compac tFlashTM card, do not remove the CompactFlashTM card or power off the

CF-ADP.

Failure to do so may cause CompactFlashTM card failures or malfunctions.

• If the power is turned OFF wh ile the Compa ctFlashTM card is being accessed (ACCE SS LED is lit or flicke ring), the buffere d data is

erased. Also files or CompactFlashTM card itself may be damaged. Do not turn the power OFF while the ACCESS LED is lit or

flickering.

• Do not apply excessive pressu re to the power supply cable or power supply connector.

Excessive pressure may cause da mage or error.

5 Wiring

WIRING PRECAUTIONS

• Make sure to cut off all phases of the power supply externally bef ore attempting wiring work.

Failure to do so may cause electric shock or damage to the product.

WIRING PRECAUTIONS

• Connect the DC power supply wiring to the dedicated terminal described in this manual.

If an AC power supply is connected to a DC input/output terminal or DC power supply terminal, the PLC will burn out.

• Connect the DC power supply wiring to the dedicated connector descri bed in this manual.

If an AC power supply is connected to a DC power supply connecto r, the PLC will bu rn out .

• When drilling screw holes or wiring, make sure that cutting and wiri ng debris do not enter the ventilation slits.

Failure to do so may cause fire, equipment failures or malfunctions.

STARTUP AND MAINTENANCE

PRECAUTIONS

• Make sure to connect the battery correctly. Do not charge, disassemble, heat, short-circuit, or expose the battery to fire.

Doing so may rupture or ignite it.

• Do not touch any terminal while the PLC's power is on.

Doing so may cause electric shock or malfunctions.

• Before modifying or disrup ting the program in operation or runni ng the PLC, careful ly read through th is manual and the associated

manuals and ensure the safety of the operation.

An operation error may damage the machinery or cause accidents.

28

Page 35

FX3U-CF-ADP User's Manual

STARTUP AND MAINTENANCE

PRECAUTIONS

• Do not disassemble or modify the PLC.

Doing so may cause fire, equipment failures, or malfunctions.

For repair, contact your local Mitsubishi Electric distributor.

• Turn off the power to the PLC befor e attaching or detaching the foll owing devices.

Failure to do so may cause device failures or malfunctions.

- Peripheral devices, display modules, expansion boa rds and special adapters

- I/O extension units/blocks, FX Series terminal block and the special function units/blocks

- Battery and memory cassette

5 Wiring

5.1 Which Power Supply Cable to Use

1

Introduction

2

Specification

5.1 Which Power Supply Cable to Use

The cable for connecting the CF-ADP power supply connector with the power supply is described here.

5.1.1 Power supply cable

A dedicated power supply cable offered as an accessory of the CF-ADP is available.

Model name Length Remarks

FX2NC-100MPCB 1m (3’3") Accessory of CF-ADP

5.1.2 Preparing the power cable by yourself

To prepare the power cable by yourself, use the following wiring material and connector type.

Model name Specifications/model name

Wire size

Crimp terminal 1602-0069 (Manufactured by Molex Incorporated)

Housing 51030-0330 (Manufactured by Molex Incorporated)

AWG 24(0.2mm2)

Configuration

3

System

4

Installation

5

Wiring

6

Functions

7

Before

Programming

8

CF-ADP Applied

Instructions

Explanation

9

Program

Examples

10

Troubleshooting

29

Page 36

FX3U-CF-ADP User's Manual

5.2 Power Supply Wiring

5.2.1 Power supply wiring

Grounding

CF-ADP

Expansion

board

FX

3U

PLC

[Main unit]

CF-ADP

Expansion

*1

board

5 Wiring

5.2 Power Supply Wiring

FX

3UC

PLC

[Main unit]

Power connector

GreenRedBlack

24+24-

Stabilized

power supply

24V DC

*1. The expansion board is required when connecting with the FX3UC-32MT-LT PLC.

Power-on/off timing

The CF-ADP power supply should be turned ON simultaneously with or before the power supply of the PLC

main unit. Before turning the power OFF, ensure the safety of the system and then simultaneously turn the

main unit, CF-ADP, and other extension equipment (the special extension equipment is included) OFF.

For details, refer to the respective PLC manual.

5.3 Grounding

Ground the cables as follows

• The grounding resistance should be 100 or less.