Page 1

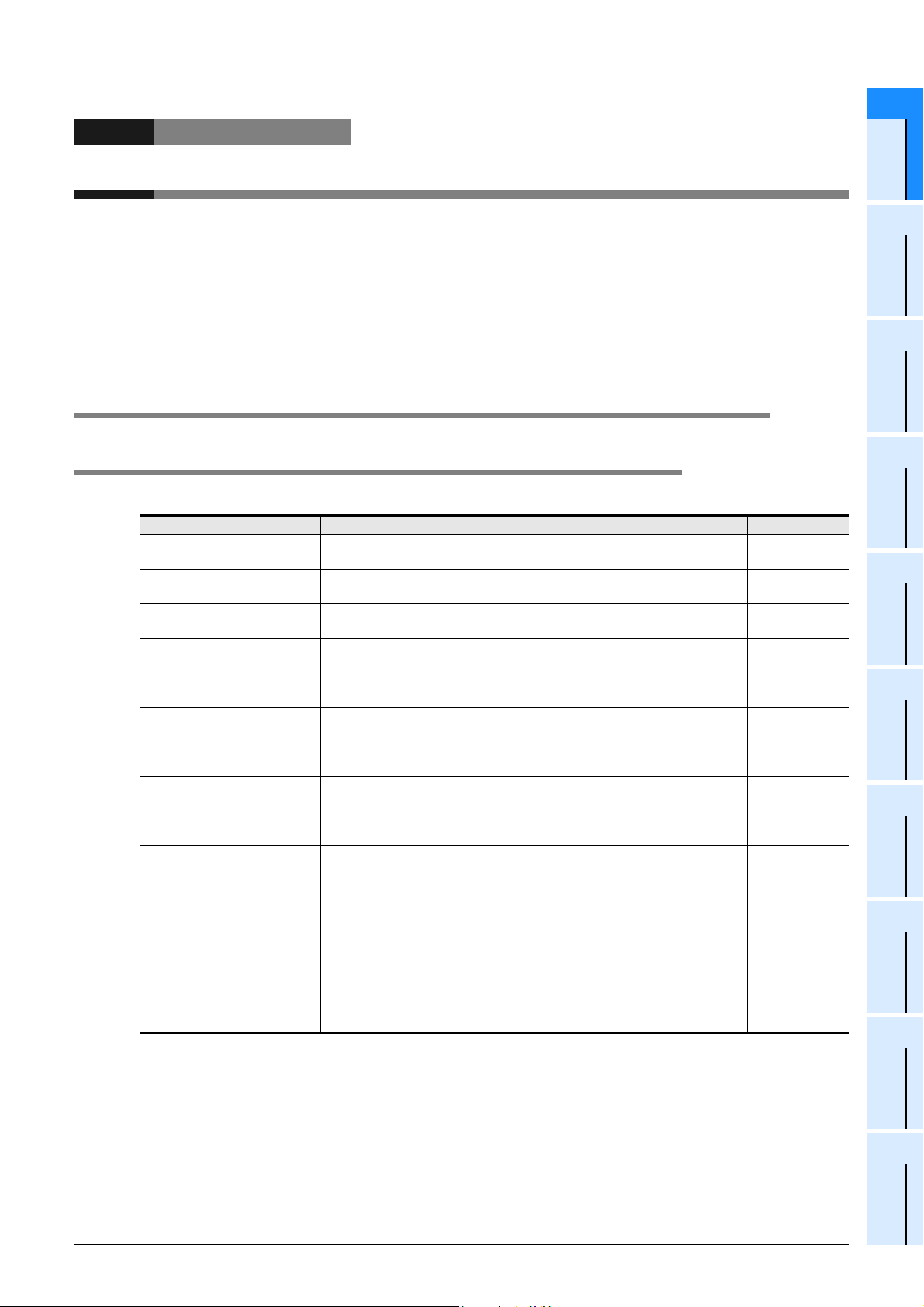

FX3G SERIES PROGRAMMABLE CONTROLLERS

USER'S MANUAL

Hardware Edition

Main Unit

AC Power Type

FX3G-MR/ES

FX3G-MT/ES

FX3G-MT/ESS

DC Power Type

FX3G-MR/DS

FX3G-MT/DS

FX3G-MT/DSS

Input/Output Powered

Extension Unit

FX2N-E-

Input/Output Extension Block

FX2N-8E-

FX2N-16E-

Display Module

FX3G-5DM

Memory Cassette

FX3G-EEPROM-32L

Page 2

Page 3

Safety Precautions

(Read these precautions before use.)

Before installation, operation, maintenance or inspection of this product, thoroughly read through and

understand this manual and all of the associated manuals. Also, take care to handle the module properly and

safely.

This manual classifies the safety precautions into two categories: and .

Indicates that incorrect handling may cause hazardous conditions, resulting in death or severe

injury.

Indicates that incorrect handling may cause hazardous conditions, resulting in medium or slight

personal injury or physical damage.

Depending on the circumstances, procedures indicated by may also cause severe injury. It is

important to follow all precautions for personal safety. Store this manual in a safe place so that it can be taken

out and read whenever necessary. Always forward it to the end user.

1. DESIGN PRECAUTIONS

Reference

• Make sure to have the following safety circuits outside of the PLC to ensure safe system operation even during

external power supply problems or PLC failure.

Otherwise, malfunctions may cause serious accidents.

1) Most importantly, have the following: an emergency stop circuit, a protection circuit, an interlock circuit for

opposite movements (such as normal vs. reverse rotation), and an interlock circuit (to prevent damage to the

equipment at the upper and lower positioning limits).

2) Note that when the PLC CPU detects an error, such as a watchdog timer error, during self-diagnosis, all outputs

are turned off. Also, when an error that cannot be detected by the PLC CPU occurs in an input/output control

block, output control may be disabled.

External circuits and mechanisms should be designed to ensure safe machinery operation in such a case.

3) Note that the output current of the 24V DC service power supply varies depending on the model and the

absence/presence of extension blocks. If an overload occurs, the voltage automatically drops, inputs in the PLC

are disabled, and all outputs are turned off.

External circuits and mechanisms should be designed to ensure safe machinery operation in such a case.

4) Note that when an error occurs in a relay, triac or transistor output device, the output could be held either on or

off.

For output signals that may lead to serious accidents, external circuits and mechanisms should be designed to

ensure safe machinery operation in such a case.

• Do not bundle the control line together with or lay it close to the main circuit or power line. As a guideline, lay the

control line at least 100mm (3.94") or more away from the main circuit or power line.

Noise may cause malfunctions.

• Install module so that excessive force will not be applied to peripheral device connectors.

Failure to do so may result in wire damage/breakage or PLC failure.

98

121

139

172

186

224

245

284

352

Reference

98

121

139

172

186

224

245

284

352

(1)

Page 4

Safety Precautions

(Read these precautions before use.)

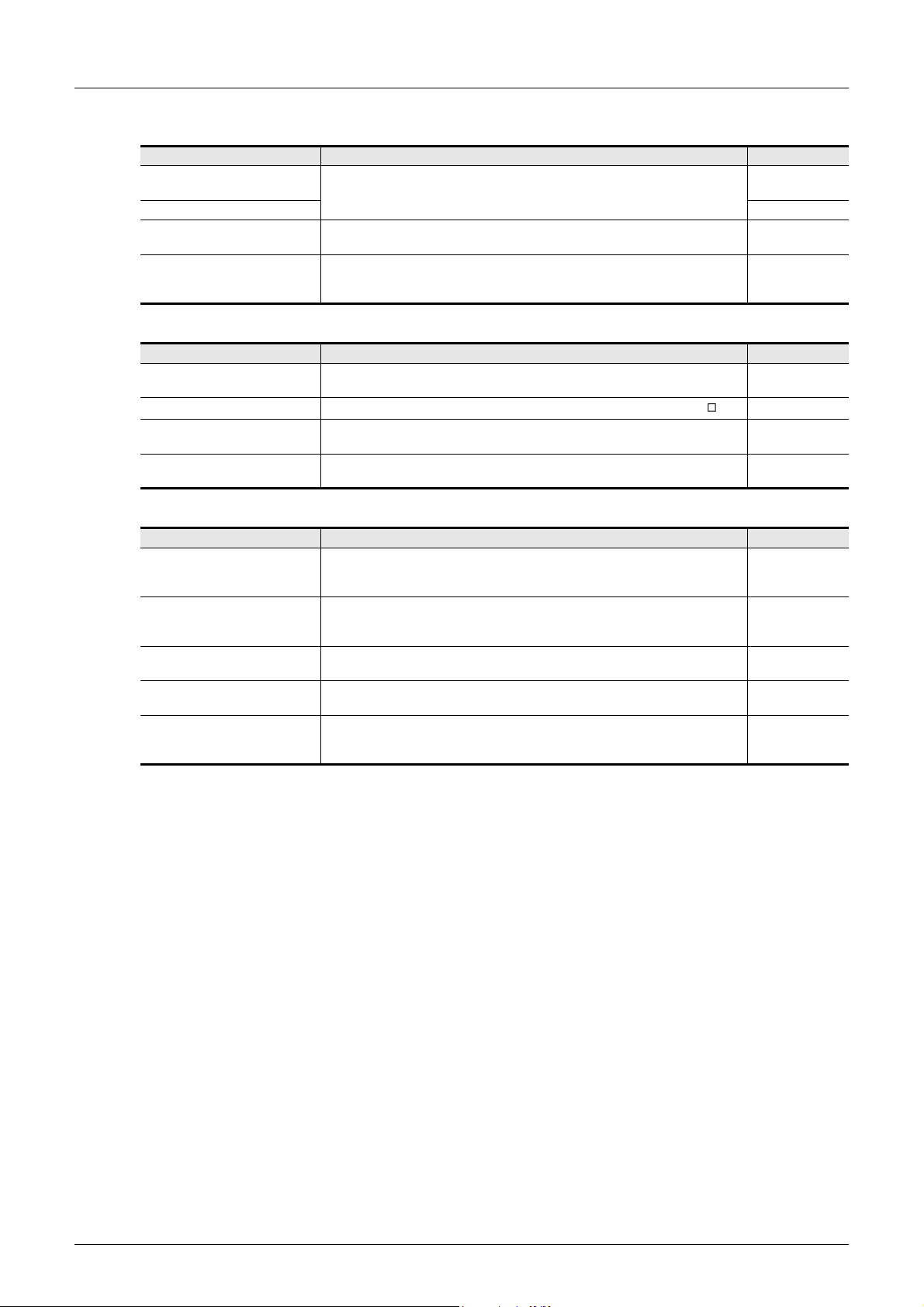

2. INSTALLATION PRECAUTIONS

Reference

• Make sure to cut off all phases of the power supply externally before attempting installation or wiring work.

Failure to do so may cause electric shock or damage to the product.

• Use the product within the generic environment specifications described in section 4.1 of this manual.

Never use the product in areas with excessive dust, oily smoke, conductive dusts, corrosive gas (salt air, Cl2, H2S,

SO2 or NO2), flammable gas, vibration or impacts, or expose it to high temperature, condensation, or rain and wind.

If the product is used in such conditions, electric shock, fire, malfunctions, deterioration or damage may occur.

• Do not touch the conductive parts of the product directly.

Doing so may cause device failures or malfunctions.

• Install the product securely using a DIN rail or mounting screws.

Terminal block DIN rail only

Main unit, FX2N Series I/O extension unit/block, FX2N/FX3U Series special

function block, and special adapter

• Install the product on a flat surface.

If the mounting surface is rough, undue force will be applied to the PC board, thereby causing nonconformities.

• Make sure to affix the expansion board with tapping screws.

Tightening torque should follow the specifications in the manual.

Loose connections may cause malfunctions.

• When drilling screw holes or wiring, make sure that cutting and wiring debris do not enter the ventilation slits.

Failure to do so may cause fire, equipment failures or malfunctions.

• Be sure to remove the dust proof sheet from the PLC’s ventilation port when installation work is completed.

Failure to do so may cause fire, equipment failures or malfunctions.

• Connect the extension cables, peripheral device cables, input/output cables and battery connecting cable securely

to their designated connectors.

Loose connections may cause malfunctions.

• Connect the display module, memory cassette, and expansion board securely to their designated connectors.

Loose connections may cause malfunctions.

• Turn off the power to the PLC before attaching or detaching the following devices.

Failure to do so may cause device failures or malfunctions.

- Peripheral devices, display modules, expansion boards and special adapters

- Extension units/blocks and FX Series terminal blocks

- Battery and memory cassette

• Connect the memory cassette securely to the appropriate connector.

Loose connections may cause malfunctions.

Installing the cassette in a raised or tilted posture can also cause malfunctions.

DIN rail or direct mounting

98

352

Reference

99

353

3. WIRING PRECAUTIONS

• Make sure to cut off all phases of the power supply externally before attempting installation or wiring work.

Failure to do so may cause electric shock or damage to the product.

• Make sure to attach the terminal cover, offered as an accessory, before turning on the power or initiating operation

after installation or wiring work.

Failure to do so may cause electric shock.

(2)

Reference

99

121

139

172

186

224

245

353

Page 5

Safety Precautions

(Read these precautions before use.)

• Do not supply power to the [24+] and [24V] terminals (24V DC service power supply) on the main unit or extension

units.

Doing so may cause damage to the product.

• Perform class D grounding (grounding resistance: 100 or less) to the grounding terminal on the main unit and

extension units with a wire 2 mm2 or thicker.

Do not use common grounding with heavy electrical systems (refer to section 9.3).

• Connect the AC power supply wiring to the dedicated terminals described in this manual.

If an AC power supply is connected to a DC input/output terminal or DC power supply terminal, the PLC will burn

out.

• Connect the DC power supply wiring to the dedicated terminals described in this manual.

If an AC power supply is connected to a DC input/output terminal or DC power supply terminal, the PLC will burn

out.

• Do not wire vacant terminals externally.

Doing so may damage the product.

• When drilling screw holes or wiring, make sure cutting or wire debris does not enter the ventilation slits.

Failure to do so may cause fire, equipment failures or malfunctions.

• Make sure to properly wire the FX3G Series main unit and FX2N/FX3U Series extension equipment in accordance

with the following precautions.

Failure to do so may cause electric shock, equipment failures, a short-circuit, wire breakage, malfunctions, or

damage to the product.

- The disposal size of the cable end should follow the dimensions described in the manual.

- Tightening torque should follow the specifications in the manual.

- Tighten the screws using a Phillips-head screwdriver No.2 (shaft diameter 6mm (0.24”) or less). Make sure that

the screwdriver does not touch the partition part of the terminal block.

• Make sure to properly wire to the terminal block (European type) in accordance with the following precautions.

Failure to do so may cause electric shock, equipment failures, a short-circuit, wire breakage, malfunctions, or

damage to the product.

- The disposal size of the cable end should follow the dimensions described in the manual.

- Tightening torque should follow the specifications in the manual.

- Twist the end of strand wire and make sure that there are no loose wires.

- Do not solder-plate the electric wire ends.

- Do not connect more than the specified number of wires or electric wires of unspecified size.

- Affix the electric wires so that neither the terminal block nor the connected parts are directly stressed.

• Make sure to properly wire to the FX Series terminal blocks in accordance with the following precautions.

Failure to do so may cause electric shock, equipment failures, a short-circuit, wire breakage, malfunctions, or

damage to the product.

- The disposal size of the cable end should follow the dimensions described in the manual.

- Tightening torque should follow the specifications in the manual.

- Tighten the screws using a Phillips-head screwdriver No.2 (shaft diameter 6mm (0.24”) or less). Make sure that

the screwdriver does not touch the partition part of the terminal block.

Reference

100

122

140

173

176

181

182

185

187

224

245

353

362

4. STARTUP AND MAINTENANCE PRECAUTIONS

• Do not touch any terminal while the PLC's power is on.

Doing so may cause electric shock or malfunctions.

• Before cleaning or retightening terminals, cut off all phases of the power supply externally.

Failure to do so may cause electric shock.

• Use the battery for memory backup correctly in conformance to this manual.

- Use the battery only for the specified purpose.

- Connect the battery correctly.

- Do not charge, disassemble, heat, put in fire, short-circuit, connect reversely, weld, swallow or burn the battery,

or apply excessive forces (vibration, impact, drop, etc.) to the battery.

- Do not store or use the battery at high temperatures or expose to direct sunlight.

- Do not expose to water, bring near fire or touch liquid leakage or other contents directly.

- Incorrect handling of the battery may cause heat excessive generation, bursting, ignition, liquid leakage or

deformation, and lead to injury, fire or failures and malfunctions of facilities and other equipment.

• Before modifying or disrupting the program in operation or running the PLC, carefully read through this manual and

the associated manuals and ensure the safety of the operation.

An operation error may damage the machinery or cause accidents.

• Do not change the program in the PLC from two or more peripheral equipment devices at the same time. (i.e. from

a programming tool and a GOT)

Doing so may cause destruction or malfunction of the PLC program.

Reference

199

307

385

(3)

Page 6

Safety Precautions

(Read these precautions before use.)

• Turn off the power to the PLC before attaching or detaching the memory cassette. If the memory cassette is

attached or detached while the PLC’s power is on, the data in the memory may be destroyed, or the memory

cassette may be damaged.

• Do not disassemble or modify the PLC.

Doing so may cause fire, equipment failures, or malfunctions.

For repair, contact your local Mitsubishi Electric representative.

• Turn off the power to the PLC before connecting or disconnecting any extension cable.

Failure to do so may cause equipment failures or malfunctions.

• Turn off the power to the PLC before attaching or detaching the following devices.

Failure to do so may cause equipment failures or malfunctions.

- Peripheral devices, display module, expansion boards, and special adapters

- Extension units/blocks and FX Series terminal blocks

- Battery and memory cassette

5. DISPOSAL PRECAUTIONS

• Please contact a certified electronic waste disposal company for the environmentally safe recycling and disposal of

your device.

When disposing of batteries, separate them from other waste according to local regulations.

(For details of the Battery Directive in EU countries, refer to Appendix E)

Reference

199

307

375

385

Reference

199

6. TRANSPORTATION AND STORAGE PRECAUTIONS

• When transporting the FX3G Series PLC incorporating the optional battery, turn on the PLC before shipment,

confirm that the battery mode is set using a parameter and the ALM LED is OFF, and check the battery life.

If the PLC is transported with the ALM LED on or the battery exhausted, the battery-backed data may be unstable

during transportation.

• The PLC is a precision instrument. During transportation, avoid impacts larger than those specified in the general

specifications (section 4.1). Failure to do so may cause failures in the PLC.

After transportation, verify the operations of the PLC.

• When transporting lithium batteries, follow required transportation regulations.

(For details of the regulated products, refer to Appendix D)

Reference

199

385

(4)

Page 7

FX3G Series Programmable Controllers

User’s Manual - Hardware Edition

FX3G Series Programmable Controllers

User's Manual [Hardware Edition]

Manual number JY997D31301

Manual revision J

Date 9/2013

Foreword

This manual contains text, diagrams and explanations which will guide the reader in the correct installation,

safe use and operation of the FX

before attempting to install or use the unit.

And, store this manual in a safe place so that you can take it out and read it whenever necessary. Always

forward it to the end user.

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses. Mitsubishi

Electric Corporation cannot be held responsible for any problems involving industrial property rights which may occur as a result of

using the contents noted in this manual.

© 2008 MITSUBISHI ELECTRIC CORPORATION

3G Series Programmable Controllers and should be read and understood

1

Page 8

FX3G Series Programmable Controllers

User’s Manual - Hardware Edition

Outline Precautions

• This manual provides information for the use of the FX3G Series Programmable Controllers. The manual

has been written to be used by trained and competent personnel. The definition of such a person or

persons is as follows;

1) Any engineer who is responsible for the planning, design and construction of automatic equipment

using the product associated with this manual should be of a competent nature, trained and qualified

to the local and national standards required to fulfill that role. These engineers should be fully aware of

all aspects of safety with regards to automated equipment.

2) Any commissioning or service engineer must be of a competent nature, trained and qualified to the

local and national standards required to fulfill that job. These engineers should also be trained in the

use and maintenance of the completed product. This includes being completely familiar with all

associated documentation for the said product. All maintenance should be carried out in accordance

with established safety practices.

3) All operators of the completed equipment should be trained to use that product in a safe and

coordinated manner in compliance to established safety practices. The operators should also be

familiar with documentation which is connected with the actual operation of the completed equipment.

Note: The term 'completed equipment' refers to a third party constructed device which contains or uses

the product associated with this manual

• This product has been manufactured as a general-purpose part for general industries, and has not been

designed or manufactured to be incorporated in a device or system used in purposes related to human life.

• Before using the product for special purposes such as nuclear power, electric power, aerospace, medicine

or passenger movement vehicles, consult with Mitsubishi Electric.

• This product has been manufactured under strict quality control. However when installing the product

where major accidents or losses could occur if the product fails, install appropriate backup or failsafe

functions in the system.

• When combining this product with other products, please confirm the standard and the code, or regulations

with which the user should follow. Moreover, please confirm the compatibility of this product to the system,

machine, and apparatus with which a user is using.

• If in doubt at any stage during the installation of the product, always consult a professional electrical

engineer who is qualified and trained to the local and national standards. If in doubt about the operation or

use, please consult the nearest Mitsubishi Electric representative.

• Since the examples indicated by this manual, technical bulletin, catalog, etc. are used as a reference,

please use it after confirming the function and safety of the equipment and system. Mitsubishi Electric will

accept no responsibility for actual use of the product based on these illustrative examples.

• This manual content, specification etc. may be changed without a notice for improvement.

• The information in this manual has been carefully checked and is believed to be accurate; however, if you

have noticed a doubtful point, a doubtful error, etc., please contact the nearest Mitsubishi Electric

representative.

Registration

•Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

• Ethernet is a trademark of Xerox Corporation.

®

•MODBUS

• Phillips is a registered trademark of Phillips Screw Company.

• The company name and the product name to be described in this manual are the registered trademarks or

trademarks of each company.

is a registered trademark of Schneider Electric SA.

2

Page 9

FX3G Series Programmable Controllers

User's Manual - Hardware Edition

Table of Contents

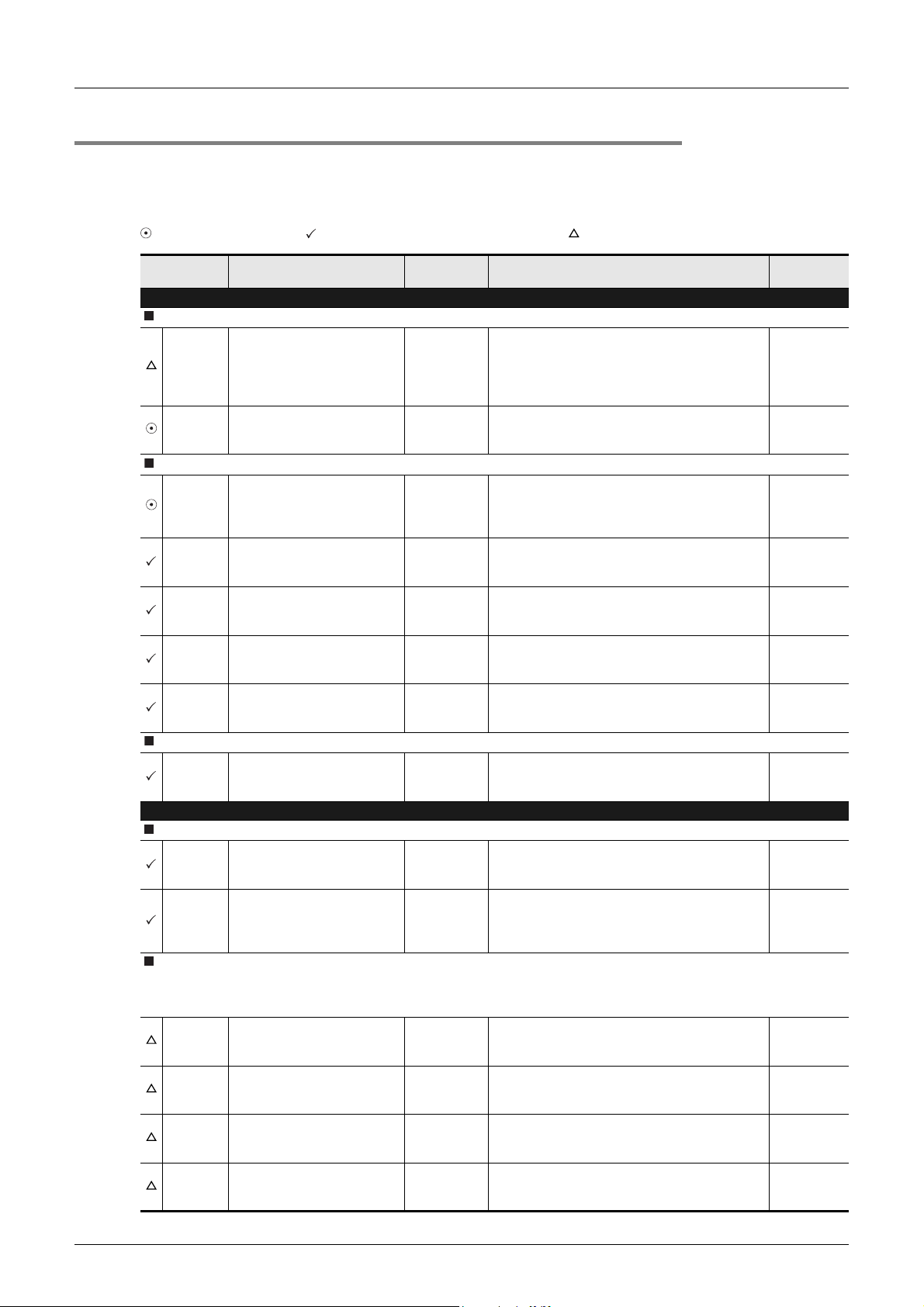

SAFETY PRECAUTIONS ..................................................................................................(1)

Standards 14

Certification of UL, cUL standards ....................................................................................................... 14

Compliance with EC directive (CE Marking) ........................................................................................ 14

Requirement for Compliance with EMC directive................................................................... 14

Requirement for Compliance with LVD directive.................................................................... 17

Caution for compliance with EC Directive .............................................................................. 18

1. Introduction 19

1.1 Introduction of Manuals................................................................................................................. 19

1.1.1 Classification of major components in this manual........................................................................19

1.1.2 Manual organization and position of this manual ..........................................................................21

1.1.3 List of manuals ..............................................................................................................................22

1.2 Generic Names and Abbreviations Used in Manuals.................................................................... 27

Table of Contents

2. Features and Part Names 29

2.1 Major Features.............................................................................................................................. 29

2.2 Names and Functions of Parts...................................................................................................... 31

2.2.1 Front Panel.................................................................................................................................... 31

2.2.2 Sides.............................................................................................................................................. 33

3. Introduction of Products 34

3.1 List of Products and Interpretation of Model Names..................................................................... 34

3.1.1 Main units ...................................................................................................................................... 35

3.1.2 Input/output powered extension units............................................................................................36

3.1.3 Input/output extension blocks........................................................................................................37

3.1.4 Special function blocks.................................................................................................................. 38

3.1.5 Display module.............................................................................................................................. 38

3.1.6 Expansion boards..........................................................................................................................38

3.1.7 Connector conversion adapter ...................................................................................................... 39

3.1.8 Special adapters............................................................................................................................ 39

3.1.9 Extension power supply unit.......................................................................................................... 39

3.1.10 Extension cables and connector conversion adapter/ Battery/Memory cassettes ...................... 39

3.1.11 FX Series terminal blocks (cables and connectors) .................................................................... 40

3.1.12 Remote I/O .................................................................................................................................. 40

3.1.13 Power supply unit ........................................................................................................................ 40

3.2 Connector Types and Cables for Program Communication.......................................................... 41

3.2.1 Programming tool .......................................................................................................................... 42

3.2.2 Communication cables ..................................................................................................................42

3.2.3 Converters and interface ............................................................................................................... 42

3.2.4 The accessing path to the FX

3G from CC-Link ............................................................................. 43

4. Specifications, External Dimensions and Terminal Layout (Main Units) 44

4.1 Generic Specifications .................................................................................................................. 44

4.1.1 Dielectric withstand voltage test and insulation resistance test..................................................... 45

4.2 Power Supply Specifications......................................................................................................... 46

4.2.1 AC Power Supply Type ................................................................................................................. 46

4.2.2 DC Power Supply Type .................................................................................................................46

3

Page 10

FX3G Series Programmable Controllers

User's Manual - Hardware Edition

4.3 Input Specifications....................................................................................................................... 47

4.3.1 24V DC Input (sink/source) ........................................................................................................... 47

4.4 Output Specifications .................................................................................................................... 48

4.4.1 Relay output ..................................................................................................................................48

4.4.2 Transistor output............................................................................................................................ 49

4.5 Performance Specifications .......................................................................................................... 50

4.6 External Dimensions (Weight/Accessories/Installation) ................................................................ 52

4.6.1 Main units ...................................................................................................................................... 52

4.7 Terminal Layout ............................................................................................................................ 53

4.7.1 Interpretation of terminal block layout............................................................................................ 53

4.7.2 FX3G-14M ..................................................................................................................................54

4.7.3 FX3G-24M ..................................................................................................................................54

4.7.4 FX

4.7.5 FX3G-60M ..................................................................................................................................55

3G-40M ..................................................................................................................................55

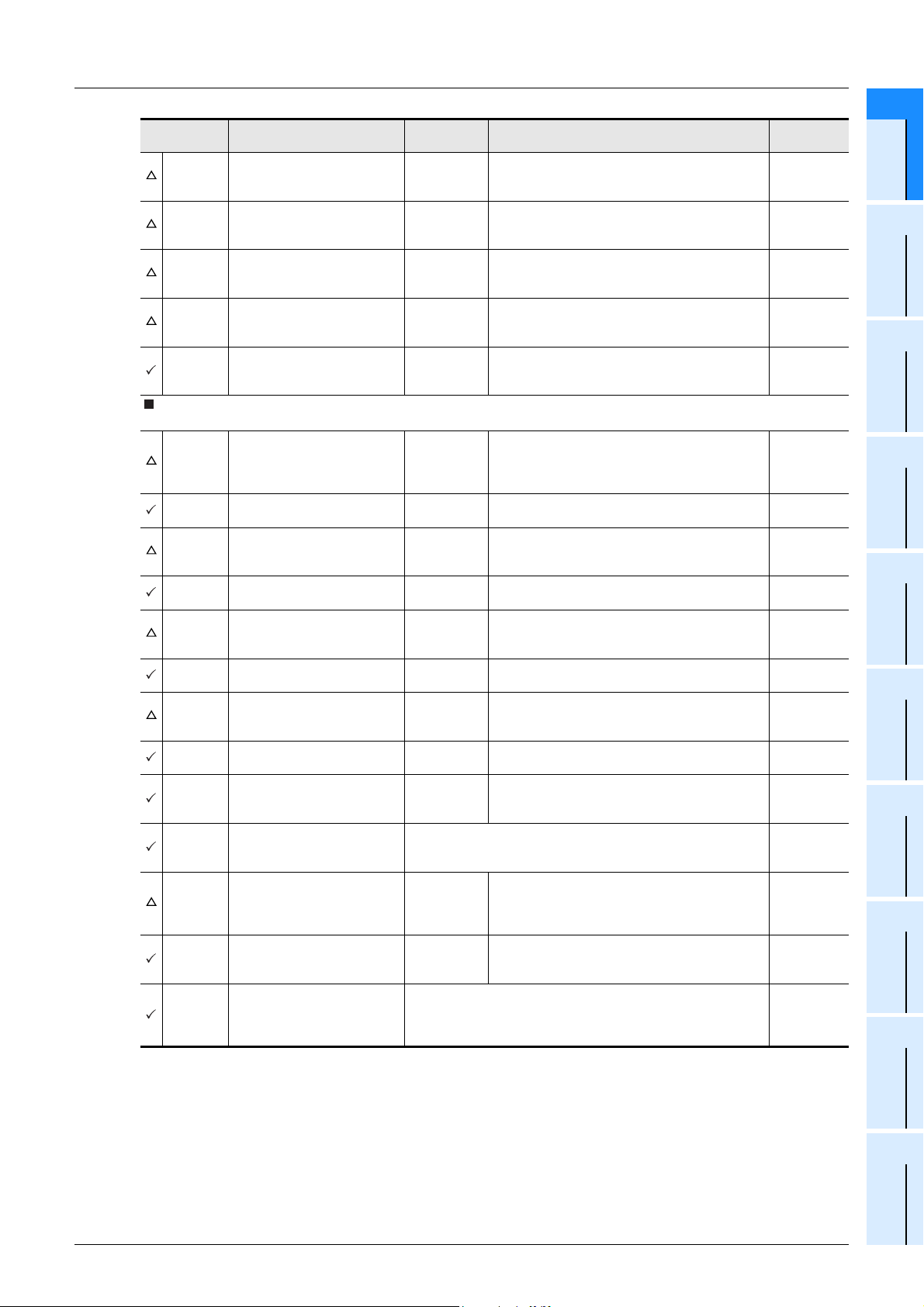

5. Version Information and Peripheral Equipment Connectability 56

5.1 Version Information....................................................................................................................... 56

5.1.1 Manufacturer's serial number check method................................................................................. 56

5.1.2 Version check method................................................................................................................... 57

5.1.3 Version upgrade history................................................................................................................. 57

5.2 Programming Tool Applicability..................................................................................................... 58

5.2.1 Applicable versions of programming tool....................................................................................... 58

5.2.2 In the case of programming tool (version) not applicable..............................................................59

5.2.3 Program transfer speed and programming tools ........................................................................... 59

5.2.4 Cautions on connecting peripheral equipment by way of expansion board or special adapter..... 60

5.2.5 Cautions on write during RUN.......................................................................................................60

5.3 Use of (Built-in USB) Programming Port....................................................................................... 63

5.3.1 Installation of USB driver............................................................................................................... 63

5.3.2 Setting in GX Developer ................................................................................................................63

5.4 Cautions on using transparent function by way of USB in GOT1000 Series ................................ 64

5.5 Cautions on using transparent port (2-port) function of GOT-F900 Series ................................... 65

5.6 Other Peripheral Equipment Applicability...................................................................................... 66

5.6.1 Other Peripheral Equipment Applicability ...................................................................................... 66

Table of Contents

6. Examination of System Configuration 67

6.1 Configuration of a Whole System.................................................................................................. 67

6.1.1

Expansion board/connector conversion adapter/memory cassette/display module configuration

6.2 Rules of System Configuration...................................................................................................... 70

6.3 Number of Input/Output Points and Maximum Number of Input/Output Points ...........................72

6.3.1 Calculation of number of input/output points .................................................................................72

6.3.2 Maximum number of input/output points when CC-Link master is used ....................................... 74

6.4 Number of Connected Extension Devices (Including Extension Cable) .......................................75

6.4.1 Number of connectable expansion boards and special adapters.................................................. 75

6.4.2 Input/output powered extension units............................................................................................75

6.4.3 Extension Power Supply Unit ........................................................................................................ 75

6.4.4 Special function blocks.................................................................................................................. 75

6.4.5 Extension cable ............................................................................................................................. 75

6.5 Expansion of Main Unit ................................................................................................................. 76

6.5.1 When adding input/output extension blocks using the 24V DC service power supply of

the main unit.................................................................................................................................. 77

6.5.2 Selection example 1 using the 24V DC service power supply of the main unit............................. 79

6.5.3 Selection example 2 using the 24V DC service power supply of the main unit............................. 80

6.6 Expansion of FX2N Series I/O Powered Extension Unit ............................................................... 81

6.6.1 Quick reference matrix (when only input/output devices are added)............................................. 81

6.6.2 When special extension devices are also added (calculation of current consumption)................. 84

6.7 Expansion of Extension Power Supply Unit (FX3U-1PSU-5V)...................................................... 86

... 68

4

Page 11

FX3G Series Programmable Controllers

User's Manual - Hardware Edition

6.8 Number of Input/Output (Occupied) Points and Current Consumption......................................... 88

6.8.1 [A] Main units................................................................................................................................. 88

6.8.2 [B] Input/output powered extension units/blocks ...........................................................................89

6.8.3 [C] Special function devices .......................................................................................................... 90

6.8.4 [D] Extension Power Supply Unit................................................................................................... 90

7. Assignment of Input/Output Numbers and Unit Numbers 91

7.1 Assignment of Input/Output Numbers (X/Y).................................................................................. 91

7.1.1 Concept of assigning..................................................................................................................... 91

7.1.2 Example of assigning .................................................................................................................... 92

7.1.3 Application of I/O number label .....................................................................................................92

7.2 Unit Numbers of Special Function Blocks ..................................................................................... 93

7.2.1 Concept of assigning..................................................................................................................... 93

7.2.2 Example of assigning .................................................................................................................... 93

7.2.3 Application of unit number labels................................................................................................... 94

7.3 Assignment of Communication Channels ..................................................................................... 95

7.3.1 Assignment of communication channels ....................................................................................... 95

7.4 "Station No." Label of FX3G-485-BD............................................................................................. 96

7.5 "Station No." Label of FX

7.6 Trimmer Layout Label of FX

3G-485-BD-RJ ....................................................................................... 96

3G-8AV-BD ....................................................................................... 97

Table of Contents

8. Installation In Enclosure 98

8.1 Installation location...................................................................................................................... 101

8.1.1 Installation location in enclosure.................................................................................................. 101

8.1.2 Spaces in enclosure ....................................................................................................................102

8.2 Layout in Enclosure..................................................................................................................... 102

8.2.1 1-stage layout.............................................................................................................................. 102

8.2.2 2-stage layout.............................................................................................................................. 103

8.3 Examination for Installing Method in Enclosure .......................................................................... 104

8.3.1 Installing methods........................................................................................................................ 104

8.3.2 Cautions on examining installing method .................................................................................... 104

8.3.3 Examples of installation...............................................................................................................104

8.4 Procedures for Installing on and Detaching from DIN Rail.......................................................... 106

8.4.1 Preparation for installation........................................................................................................... 106

8.4.2 Installation of main unit................................................................................................................ 107

8.4.3 Installation of input/output powered extension unit/block and special function block .................. 108

8.4.4 Removal of main unit...................................................................................................................109

8.5 Procedures for Installing Directly (with M4 Screws).................................................................... 110

8.5.1 Hole pitches for direct mounting.................................................................................................. 110

8.5.2 Example of mounting hole pitches...............................................................................................112

8.5.3 Installation of main unit................................................................................................................ 113

8.5.4 Installation of input/output powered extension unit/block and special function block .................. 113

8.6 Connecting Methods for Main Unit and Extension Devices ........................................................ 114

8.6.1 Connection of extension devices................................................................................................. 114

8.6.2 Connecting method A - connection of expansion board.............................................................. 115

8.6.3 Connecting method B - connection of connector conversion adapter ......................................... 116

8.6.4 Connecting method C - connection of special adapter ................................................................ 118

8.6.5 Connecting method D - connection of powered extension units/blocks to main unit................... 118

8.6.6 Connecting method E - connection of powered extension units/blocks ......................................119

8.6.7 Connecting method F - connection of extension cable and FX

8.6.8 Connecting method G - connection of input/output powered extension unit ............................... 120

8.6.9 Connecting method H - connection of extension block to input/output powered extension unit.. 120

2N-CNV-BC................................ 119

9. Preparation for Wiring and Power Supply Wiring Procedures 121

9.1 Preparation for Wiring ................................................................................................................. 123

9.1.1 Wiring procedures ....................................................................................................................... 123

9.1.2 Removal and installation of quick-release terminal block............................................................ 123

5

Page 12

FX3G Series Programmable Controllers

User's Manual - Hardware Edition

9.2 Cable Connecting Procedures .................................................................................................... 124

9.2.1 Input/output terminal block (power supply and input/output wiring).............................................124

9.2.2 Input/output connectors............................................................................................................... 127

9.2.3 Terminal block for Europe [expansion board and special adapters]............................................ 128

9.2.4 Grounding terminal of the FX

9.2.5 Grounding terminal of the FX3U-ENET-ADP ............................................................................... 130

3G-485-BD-RJ ............................................................................... 129

9.3 Grounding ...................................................................................................................................131

9.4 Examples of External Wiring [AC Power Supply Type]............................................................... 132

9.4.1 Example of input/output wiring with 24V DC service power supply.............................................132

9.4.2 Example of sink input [-common] wiring...................................................................................... 133

9.4.3 Example of source input [+common] wiring................................................................................. 134

9.4.4 An external wiring example for the extension power supply unit (sink input [-common]) ............ 135

9.4.5 An external wiring example for the extension power supply unit (source input [+common]) ....... 136

9.5 Examples of External Wiring [DC Power Supply Type]............................................................... 137

9.5.1 Example of sink input [-common] wiring...................................................................................... 137

9.5.2 Example of source input [+common] wiring................................................................................. 138

10. Input Wiring Procedures 139

10.1 Before Starting Input Wiring...................................................................................................... 141

10.1.1 Sink and source input ................................................................................................................ 141

10.2 24V DC input (Sink and source input type)............................................................................... 143

10.2.1 Handling of 24V DC input..........................................................................................................143

10.2.2 Instructions for connecting input devices...................................................................................144

10.2.3 Examples of external wiring (sink input) [AC Power Supply Type]............................................146

10.2.4 Examples of external wiring (source input) [AC Power Supply Type] ....................................... 148

10.2.5 Examples of external wiring (sink input) [DC Power Supply Type]............................................ 149

10.2.6 Examples of external wiring (source input) [DC Power Supply Type] .......................................151

10.3 100V AC Input........................................................................................................................... 152

10.3.1 Input specifications .................................................................................................................... 152

10.3.2 Handling of 100V AC Input ........................................................................................................ 152

10.3.3 Examples of external wiring (100V AC input) ............................................................................ 153

10.4 Input Interruption (I00 to I50) .............................................................................................. 154

10.4.1 Allocation of pointers to input numbers (input signal ON/OFF duration) ................................... 154

10.4.2 Cautions for input interruption ................................................................................................... 154

10.4.3 Examples of external wiring....................................................................................................... 155

10.5 Pulse Catch (M8170 to M8175) ................................................................................................ 156

10.5.1 Allocation of special memories to input numbers (ON duration of input signals) ...................... 156

10.5.2 Cautions for pulse catch ............................................................................................................ 156

10.5.3 Examples of external wiring....................................................................................................... 157

10.6 Pulse width/Pulse period measurement function (Supported in Ver. 1.10 or later)................... 158

10.6.1 Allocation of special memories to input numbers ......................................................................158

10.6.2 Cautions for pulse width/period measurement function............................................................. 158

10.6.3 Examples of external wiring....................................................................................................... 159

Table of Contents

11. Use of High-speed Counters 160

11.1 Outline....................................................................................................................................... 160

11.2 Types of Counting and Operations ........................................................................................... 160

11.2.1 Types and input signal forms..................................................................................................... 160

11.2.2 High-speed counter device notations ........................................................................................ 160

11.2.3 Cautions in connecting mating device ....................................................................................... 160

11.3 List of Device Numbers and Functions .....................................................................................161

11.4 Allocation of Device Numbers to Input Numbers ......................................................................162

11.4.1 Allocation table .......................................................................................................................... 162

11.4.2 Restriction of redundant use of input numbers..........................................................................162

11.5 Handling of High-speed Counters............................................................................................. 163

11.5.1 1-phase 1-count input................................................................................................................ 163

11.5.2 1-phase 2-count input................................................................................................................ 164

11.5.3 2-phase 2-count input................................................................................................................ 165

6

Page 13

FX3G Series Programmable Controllers

User's Manual - Hardware Edition

11.6 Timing of Updating of Current Value and Comparison of Current Value .................................. 166

11.6.1 Timing of updating of current value ........................................................................................... 166

11.6.2 Comparison of current value ..................................................................................................... 166

11.7 Response Frequency and Overall Frequency........................................................................... 167

11.8 Examples of External Wiring (Rotary Encoder)......................................................................... 168

11.8.1 1-phase 1-input [C235 to C245] ................................................................................................ 168

11.8.2 2-phase 2-input [C251 to C255] ................................................................................................ 169

11.9 Related Devices and Function Switching Procedures .............................................................. 170

11.9.1 Related devices ......................................................................................................................... 170

11.9.2 [Function switching] switching of allocation and functions of input terminals ............................ 171

11.10 Cautions on Use...................................................................................................................... 171

12. Output Wiring Procedures 172

12.1 External Wiring for Relay Output Type...................................................................................... 174

12.1.1 Product life of relay contacts .....................................................................................................174

12.1.2 Handling of relay output............................................................................................................. 174

12.1.3 External wiring precautions .......................................................................................................175

12.1.4 Example of external wiring ........................................................................................................ 176

12.2 External Wiring of Transistor Output (Sink/Source) Type ......................................................... 177

12.2.1 Transistor Output Sink and Source ........................................................................................... 177

12.2.2 Handling of transistor output...................................................................................................... 178

12.2.3 External wiring precautions .......................................................................................................180

12.2.4 Example of external wiring ........................................................................................................ 181

12.3 External Wiring for Triac (SSR) Output Type ............................................................................ 183

12.3.1 Handling of triac output.............................................................................................................. 183

12.3.2 External wiring precautions .......................................................................................................184

12.3.3 Example of external wiring ........................................................................................................ 185

Table of Contents

13. Examples of Wiring for Various Uses 186

13.1 Notes about Examples of Wiring............................................................................................... 187

13.2 Digital Switch [DSW Instructions (FNC72)/BIN Instructions (FNC19)]...................................... 188

13.2.1 When DSW instructions are used.............................................................................................. 188

13.2.2 When BIN instructions are used................................................................................................ 191

13.3 Input Matrix [MTR Instructions (FNC 52)] .................................................................................192

13.4 Seven Segment with Latch [SEGL Instructions (FNC74)/BCD Instructions (FNC18)].............. 195

13.4.1 When SEGL instructions are used ............................................................................................ 195

13.4.2 When BCD instructions are used .............................................................................................. 197

14. Test Operation, Adjustment, Maintenance and Troubleshooting 199

14.1 Preparation for Test Operation.................................................................................................. 200

14.1.1 Preliminary inspection [power OFF] .......................................................................................... 200

14.1.2 Connection to built-in programming connector (RS-422) .......................................................... 200

14.1.3 Connection to built-in programming connector (USB) ............................................................... 201

14.1.4 Writing of program and program check [power ON and PLC stopped] .....................................202

14.2 Running and Stopping Procedures [Power ON]........................................................................ 203

14.2.1 Methods of running and stopping .............................................................................................. 203

14.2.2 Use of several running/stopping methods .................................................................................204

14.3 Operation and Test [Power ON and PLC Running] ..................................................................205

14.3.1 Self-diagnostic function ............................................................................................................. 205

14.3.2 Test functions ............................................................................................................................ 205

14.3.3 Program modification function ................................................................................................... 206

14.3.4 Built-in variable analog potentiometer function.......................................................................... 206

14.4 Maintenance and Periodic Inspection ....................................................................................... 207

14.4.1 Procedures for checking model name ....................................................................................... 207

14.4.2 Periodic inspection - battery life, etc. .........................................................................................207

14.4.3 Maintenance - product life of relay contacts............................................................................. 208

7

Page 14

FX3G Series Programmable Controllers

User's Manual - Hardware Edition

14.5 Troubleshooting with LEDs ....................................................................................................... 210

14.5.1 POW LED [on/flashing/off]......................................................................................................... 210

14.5.2 ALM LED [on/off] ....................................................................................................................... 210

14.5.3 ERR LED [on/flashing/off].......................................................................................................... 211

14.6 Judgment by Error Codes and Representation of Error Codes ................................................212

14.6.1 Operation and check by GX Works2 ......................................................................................... 212

14.6.2 Operation and check on display module (FX3G-5DM) ..............................................................213

14.6.3 Representation of errors............................................................................................................ 214

14.6.4 Error Code List and Action ........................................................................................................ 215

14.7 Troubleshooting ........................................................................................................................ 222

14.7.1 Output does not operate (main unit and input/output extension blocks) ................................... 222

14.7.2 24V DC input does not operate (main unit and input/output extension blocks)......................... 222

14.7.3 Cautions in registering keyword ................................................................................................ 223

15. Input/Output Powered Extension Units 224

15.1 Outline....................................................................................................................................... 225

15.1.1 Product configuration................................................................................................................. 225

15.1.2 Product list................................................................................................................................. 225

15.2 Power supply specifications ...................................................................................................... 226

15.2.1 Weight, accessories, etc............................................................................................................ 226

15.2.2 Part names ................................................................................................................................ 227

15.3 FX2N-32ER-ES/UL, FX2N-48ER-ES/UL, FX2N-48ER-DS ........................................................ 229

15.3.1 Product specifications................................................................................................................ 229

15.3.2 External dimensions .................................................................................................................. 230

15.3.3 Terminal layout.......................................................................................................................... 231

15.4 FX2N-32ET-ESS/UL, FX2N-48ET-ESS/UL, FX2N-48ET-DSS.................................................. 232

15.4.1 Product specifications................................................................................................................ 232

15.4.2 External dimensions .................................................................................................................. 233

15.4.3 Terminal layout.......................................................................................................................... 234

15.5 FX2N-32ER, FX2N-48ER, FX2N-48ER-D.................................................................................. 235

15.5.1 Product specifications................................................................................................................ 235

15.5.2 External dimensions .................................................................................................................. 236

15.5.3 Terminal layout.......................................................................................................................... 237

15.6 FX2N-32ET, FX2N-48ET, FX2N-48ET-D................................................................................... 238

15.6.1 Product specifications................................................................................................................ 238

15.6.2 External dimensions .................................................................................................................. 239

15.6.3 Terminal layout.......................................................................................................................... 240

15.7 FX2N-32ES ...............................................................................................................................241

15.7.1 Product specifications................................................................................................................ 241

15.7.2 External dimensions .................................................................................................................. 242

15.7.3 Terminal layout.......................................................................................................................... 242

15.8 FX2N-48ER-UA1/UL ................................................................................................................. 243

15.8.1 Product specifications................................................................................................................ 243

15.8.2 External dimensions .................................................................................................................. 244

15.8.3 Terminal layout.......................................................................................................................... 244

Table of Contents

16. Input/Output Extension Blocks 245

16.1 Outline....................................................................................................................................... 246

16.1.1 Product configuration................................................................................................................. 246

16.1.2 Product list................................................................................................................................. 246

16.2 FX2N-8ER-ES/UL (24V DC Sink/Source Input, Relay Output) ................................................. 248

16.2.1 Product specifications................................................................................................................ 248

16.2.2 Parts identification and terminal arrangement ........................................................................... 249

16.2.3 External dimensions .................................................................................................................. 250

16.3 FX2N-8ER (24V DC Sink Input, Relay Output) ......................................................................... 251

16.3.1 Product specifications................................................................................................................ 251

16.3.2 Parts identification and terminal arrangement ........................................................................... 252

16.3.3 External dimensions .................................................................................................................. 253

8

Page 15

FX3G Series Programmable Controllers

User's Manual - Hardware Edition

16.4 FX2N-8EX-ES/UL, FX2N-16EX-ES/UL (24V DC Sink/Source Input) ........................................ 254

16.4.1 Product specifications................................................................................................................ 254

16.4.2 Parts identification and terminal arrangement ........................................................................... 255

16.4.3 External dimensions .................................................................................................................. 256

16.5 FX2N-8EX, FX2N-16EX and FX2N-16EX-C .............................................................................. 257

16.5.1 Product specifications................................................................................................................ 257

16.5.2 Parts identification and terminal arrangement ........................................................................... 258

16.5.3 External dimensions .................................................................................................................. 259

16.6 FX2N-16EXL-C (5V DC Input: 16 Points).................................................................................. 261

16.6.1 Product specifications................................................................................................................ 261

16.6.2 Parts identification and terminal arrangement ........................................................................... 262

16.6.3 External dimensions .................................................................................................................. 262

16.6.4 Example of wiring ...................................................................................................................... 262

16.7 FX2N-8EX-UA1/UL (100V AC Input)......................................................................................... 264

16.7.1 Product specifications................................................................................................................ 264

16.7.2 Parts identification and terminal arrangement ........................................................................... 265

16.7.3 External dimensions .................................................................................................................. 265

16.8 FX2N-8EYR-ES/UL, FX2N-8EYR-S-ES/UL, FX2N-16EYR-ES/UL (Relay Output) ................... 266

16.8.1 Product specifications................................................................................................................ 266

16.8.2 Parts identification and terminal arrangement ........................................................................... 267

16.8.3 External dimensions .................................................................................................................. 269

16.9 FX2N-8EYT-ESS/UL, FX2N-16EYT-ESS/UL (Transistor Output) ............................................. 270

16.9.1 Product specifications................................................................................................................ 270

16.9.2 Parts identification and terminal arrangement ........................................................................... 271

16.9.3 External dimensions .................................................................................................................. 272

16.10 FX2N-8EYR, FX2N-16EYR (Relay Output) ............................................................................. 273

16.10.1 Product specifications.............................................................................................................. 273

16.10.2 Parts identification and terminal arrangement ......................................................................... 274

16.10.3 External dimensions ................................................................................................................ 275

16.11 FX2N-8EYT, FX2N-16EYT, FX2N-16EYT-C (Transistor Output) ............................................ 276

16.11.1 Product specifications.............................................................................................................. 276

16.11.2 Parts identification and terminal arrangement ......................................................................... 277

16.11.3 External dimensions ................................................................................................................ 278

16.12 FX2N-8EYT-H (Transistor Output) .......................................................................................... 280

16.12.1 Product specifications.............................................................................................................. 280

16.12.2 Parts identification and terminal arrangement ......................................................................... 281

16.12.3 External dimensions ................................................................................................................ 281

16.13 FX2N-16EYS (Triac Output: 16 Points)................................................................................... 282

16.13.1 Product specifications.............................................................................................................. 282

16.13.2 Parts identification and terminal arrangement ......................................................................... 283

16.13.3 External dimensions ................................................................................................................ 283

Table of Contents

17. Extension Power Supply Unit 284

17.1 Outline....................................................................................................................................... 284

17.2 Specifications............................................................................................................................ 285

17.2.1 Generic Specifications............................................................................................................... 285

17.2.2 Performance Specifications....................................................................................................... 285

17.2.3 External Dimensions.................................................................................................................. 285

17.3 Extension Power Supply Unit Related Precaution .................................................................... 286

18. Other Extension Devices and Optional Units

(External Dimensions and Terminal Arrangement) 287

18.1 Special Function Units/Blocks................................................................................................... 287

18.1.1 FX2N-2AD.................................................................................................................................. 287

18.1.2 FX

18.1.3 FX

18.1.4 FX3U-4DA.................................................................................................................................. 288

18.1.5 FX2N-4AD.................................................................................................................................. 289

2N-2DA..................................................................................................................................287

3U-4AD.................................................................................................................................. 288

9

Page 16

FX3G Series Programmable Controllers

User's Manual - Hardware Edition

18.1.6 FX2N-4DA.................................................................................................................................. 289

18.1.7 FX2N-4AD-PT............................................................................................................................ 290

18.1.8 FX

18.1.9 FX2N-5A .................................................................................................................................... 291

18.1.10 FX3U-4LC ................................................................................................................................ 291

18.1.11 FX

18.1.12 FX2N-8AD................................................................................................................................ 292

18.1.13 FX3U-16CCL-M .......................................................................................................................293

18.1.14 FX

18.1.15 FX2N-32CCL ........................................................................................................................... 294

18.1.16 FX

18.1.17 FX2N-64CL-M.......................................................................................................................... 295

18.2 Special Adapters....................................................................................................................... 296

18.2.1 FX3U-4AD-ADP ......................................................................................................................... 296

18.2.2 FX3U-4DA-ADP ......................................................................................................................... 296

18.2.3 FX3U-3A-ADP............................................................................................................................ 296

18.2.4 FX

18.2.5 FX3U-4AD-PNK-ADP ................................................................................................................ 297

18.2.6 FX3U-4AD-TC-ADP ...................................................................................................................297

18.2.7 FX

18.2.8 FX3U-485ADP(-MB) ..................................................................................................................298

18.2.9 FX3U-ENET-ADP ......................................................................................................................299

18.3 Expansion Board....................................................................................................................... 300

18.3.1 FX3G-4EX-BD ........................................................................................................................... 300

18.3.2 FX3G-2EYT-BD ......................................................................................................................... 300

18.3.3 FX

18.3.4 FX3G-422-BD ............................................................................................................................ 301

18.3.5 FX3G-485-BD ............................................................................................................................ 302

18.3.6 FX

18.3.7 FX3G-2AD-BD ...........................................................................................................................303

18.3.8 FX3G-1DA-BD ...........................................................................................................................303

18.3.9 FX

18.4 Power Supply............................................................................................................................ 305

18.4.1 FX2N-20PSU ............................................................................................................................. 305

18.5 Connector Conversion Adapter................................................................................................. 305

18.5.1 FX3G-CNV-ADP ........................................................................................................................ 305

18.5.2 FX2N-CNV-BC...........................................................................................................................306

18.6 Interface Module ....................................................................................................................... 306

18.6.1 FX-232AWC-H...........................................................................................................................306

2N-4AD-TC............................................................................................................................ 290

2N-2LC ................................................................................................................................ 292

2N-16CCL-M .......................................................................................................................293

3U-64CCL ........................................................................................................................... 294

3U-4AD-PT(W)-ADP ............................................................................................................. 297

3U-232ADP(-MB) ..................................................................................................................298

3G-232-BD ............................................................................................................................ 301

3G-485-BD-RJ....................................................................................................................... 302

3G-8AV-BD ........................................................................................................................... 304

Table of Contents

19. Display Module (FX3G-5DM) 307

19.1 Specifications............................................................................................................................ 307

19.1.1 Applicable PLC .......................................................................................................................... 307

19.1.2 Display/switch specifications ..................................................................................................... 307

19.1.3 Part Names................................................................................................................................ 308

19.1.4 External Dimensions.................................................................................................................. 308

19.2 Installation and Removal........................................................................................................... 309

19.2.1 Installation (when the expansion board/connector conversion adapter is not used together)... 309

19.2.2 Installation (when the expansion board/connector conversion adapter is used together)......... 310

19.3 Summary of Functions .............................................................................................................. 311

19.4 Procedure for Accessing the Menu Screen from the Title Screen ............................................ 312

19.4.1 Title screen ................................................................................................................................ 312

19.4.2 Top screen (time display) .......................................................................................................... 312

19.4.3 Menu screen.............................................................................................................................. 312

19.5 Menu Structure.......................................................................................................................... 313