Page 1

FX

2NC

-ENET-ADP Ethernet adapter

USER'S MANUAL

Manual Number JY997D12301

Revision D

Date May 2007

• This manual contains text, diagrams and explanations which guide the

reader in the correct installation and operation of the FX

Ethernet adapter. It should be read and understood before attempting to use

the unit.

• If in doubt at any stage of the installation of FX

professional electrical technician who is qualified and trained to the local

and national standards which apply to the installation site.

• If in doubt about the operation or use of the FX

consult the nearest Mitsubishi Electric distributor.

• This manual is subject to change without notice.

®

• Microsoft

and Windows® are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

• The company name and the product name described in this manual are the

registered trademarks or trademarks of each company.

Guideline for the safety of the user and protection of the FX2NC-ENET-ADP.

This manual provides usage information for the FX

adapter. The manual has been written to be used by trained and competent

personnel.

Notes on the symbols used in this manual

At various times throughout out this manual certain symbols will be used to

highlight points of information which are intended to ensure the users personal

safety and protect the integrity of equipment. Whenever any of the following

symbols are encountered, its associated note must be read and understood. Each

of the symbols used will now be listed with a brief description of its meaning.

Hardware Warnings

1) Indicates that the identified danger WILL cause physical and

property damage.

2) Indicates that the identified danger could POSSIBLY cause

physical and property damage.

3) Indicates a point of further interest or further explanation.

DISPOSAL PRECAUTIONS

• When disposing of this product, treat it as industrial waste.

INSTALLATION PRECAUTIONS

• Use the module in an environment that meets the general

specifications contained in this manual. U sing this module in a n

environment outside the range of the general specifications could

result in electric shock, fire, erroneous operati on, and damage to or

deterioration of the product.

• Do not disassemble or modify the module. Doing so may cause

failure, malfunction, injury, or fire.

TRANSPORTATION AND MAINTENANCE PRECAUTIONS

• During transportation avoid any impact as the module is a precision

instrument. Doing so could cause trouble in the module.

• It is necessary to check the operation of module after transportation,

in case of any impact damage.

2NC-ENET-ADP

2NC-ENET-ADP, consult a

2NC-ENET-ADP, please

2NC-ENET-ADP Ethernet

The CE marking does not guarantee that an entire mechanical module produced in

accordance with the co ntents of t he notificati on comply with the f ollowing sta ndards.

Compliance to EMC standards of the entire mechanical module should be checked by

the user / manufacturer.

Standards with which this product complies

Type: Programmable Controller (Open Type Equipment)

Models: Products manufactured:

from April 1st, 2004 to April 30th, 2006 are compliant with

EN61000-6-4 and EN61131-2:1994+A11:1996+A12:2000 and EN61000-6-2

after May 1st, 2006 are compliant with EN61131-2:2003

Electromagnetic Compatibility

EN61000-6-4:2001

Electromagnetic compatibility

-Generic standards - Emission standard

for Industrial environment

EN61131-2:1994/A11:1996/A12:2000

Programmable controllers

-Equipment requirements and tests

EN61000-6-2:2001

Electromagnetic compatibility

-Generic standards Immunity for

industrial environments.

EN61131-2: 2003

Programmable controllers

-Equipment requirements and tests

For more details please contact the local Mitsubishi Electric sales site.

- Notes for compliance to the EMC regulation.

It is necessary to install the FX

panel.

●Note Concerning the C E Marking●

Standards (EMC)

2NC-ENET-ADP module in a shielded metal control

Remark

Compliance with all relevant aspects of the

standard. (Radiated Emissions and Mains

Terminal Voltage Emissions)

Compliance with all relevant aspects of the

standard. (RF Immunity, Fast transients,

ESD and Damped oscillatory wave)

Compliance with all relevant aspects of the

standard. (RF immunity, Fast transients,

ESD, Conducted, Surges, Power

magnetic fields, Voltage dips and Voltage

interruptions)

Compliance with all relevant aspects of the

standard.

(Radiated Emissions, Mains Terminal

Voltage Emissions, RF immunity, Fast

Transients, ESD, Surge, Voltage drops

and interruptions, Conducted and Power

magnetic fields)

1. Associated Manuals

Manual name Manual No. Description

FX1S HARDWARE MANUAL JY992D83901

1N HARDWARE MANUAL JY992D89301

FX

FX

2N HARDWARE MANUAL JY992D66301

2NC HARDWARE MANUAL

FX

(DSS/DS)

(D/UL)

JY992D76401

JY992D87201

FX PROGRAMMING MANUAL II JY992D88101

FX Configurator-EN

OPERATION MANUAL

1N-CNV-BD Special Adapter

FX

Connection Board

2N-CNV-BD Special Adapter

FX

Connection Board

JY997D20501

JY992D84701

JY992D63601

For GX Developer and MX Component, refer to the operation manual respectively.

2. Outline of Product

The FX2NC-ENET-ADP is an Ethernet adapter of 10BASE-T specifications for the

1S, FX1N, FX2N and FX2NC Series.

FX

The FX

2NC-ENET-ADP enables the upload, download, monitor, and test of a program

from the personal computer (GX Developer or MX Component) via Ethernet.

3. Installation

Caution

• Use only in the environments specified under the gene ral specifications

in the manual.

Do not use the product in environments with excessive or conductive

dust, corrosive (including salt breeze, Cl

flammable gas, oily smoke, moisture or rain, exces sive heat, regular

impact shocks or excessive vibration, as it may result in electrical shock,

fire, malfunction, damage or deterioration of the product.

• Make sure to shut off the external power before installing or wiring it.

Electric shock or serious damage to the product may occur, if the external

power is not disconnected.

• Never drop wire chips or shavings into the ventilation slits when drilling

screw holes or performing wiring, as they may caus e fire, breakdown, or

malfunction.

• Securely install the FX

A poor connection may result in malfunction.

2NC-ENET-ADP to the designated port.

Describes the hardware of the

FX Series PLC such as

specification s, wiring, and

installation.

Describes the instructions

available in the FX

2N/FX2NC Series PLC.

FX

Describes operation details of

FX Configurator-EN

Configuration Software.

Describes matters related to the

installation of the boards.

2, H2S, SO2, NO2, etc.) or

1S/FX1N/

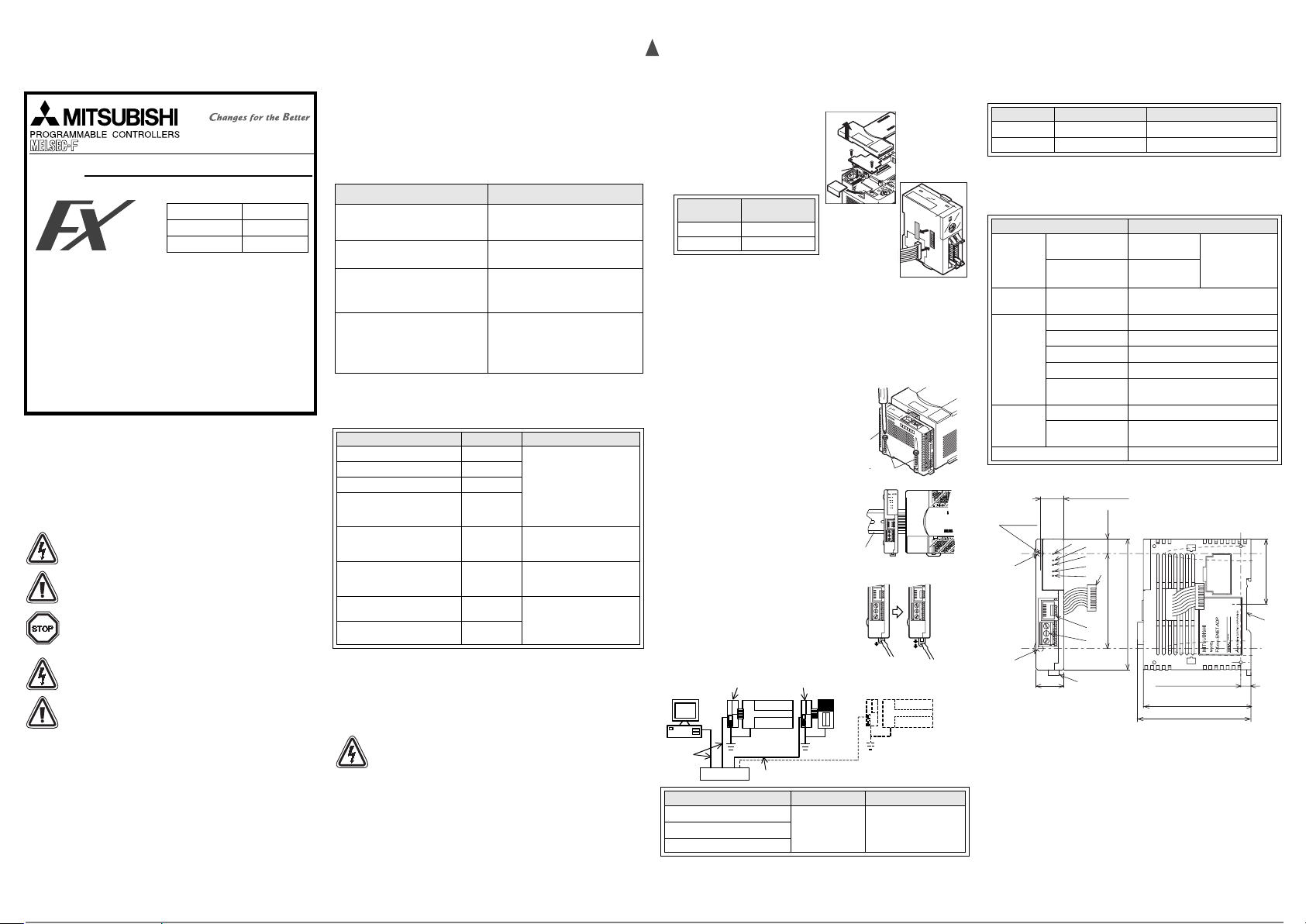

3.1 How to Ins tall to FX Series PLC

Installation to FX1S/FX1N/FX2N

Turn OFF the PLC before beginning any

work.

1) Remove the panel cover fr om the top

face of the main unit.

2) Take off the resin cover from the left

side of the main unit.

3) Install the following board to the port

on the main unit.

Board name

Corresponding

model

1)

4)

5)

FX1N-CNV-BD FX1S/FX1N

FX2N-CNV-BD FX2N

4) Affix the above board using th e

supplied M3 screws.

Tightening torque: 0.3 to 0.6 N·m

5) Connect the built-in cable of the

FX

2NC-ENET-ADP to the port on the left side of the board.

Installation to FX

Turn OFF the PLC before beginning any work.

1) Remove the cover from the special adapter port provided on the left side of the

main unit.

2) Connect the built-in cable of the FX

3.2 Installation to a Panel Face

Direct installation to the panel face

Directly attach to the panel face using 2 sets of a

screw (M4), a spring washer, and a flat washer

in the mounting holes.

Tightening torque: 0.7 to 1.0 N·m

For the pitch and positions of mounting screw

holes, refer to the external dimensions.

2NC

Installation to

FX

2NC-ENET-ADP to the special adapter port.

ENET

-ADP

2NC

Installation to

FX

1S/FX1N/FX2N

X3

1

X

3)

2

Y

1

Y

0

Y

2)

1)

2)

FX Series

PLC

Screws

Mounting on DIN rail

Affix the FX

DIN46277 (35 mm (1.37") wide).

Dismounting from DIN rail

Slightly pull down the DIN rail mounting clip

using a tool such as a slotted screwdriver. Pull

down the clip further, and the rail will be locked

with the clip left open.

4. System Configuration

2NC-ENET-ADP to the DIN rail,

FX

PC

2NC

FX1S,FX1N,FX

-ENET-ADP

2N

DIN rail

Detach

FX

2NC

ENET

-ADP

FX Series

PLC

To lock the tab

. . . .

LAN

cables

HUB

FX1S/FX1N PLC + FX 1N-CNV-BD

FX2N PLC + FX 2N-CNV-BD

2NC PLC

FX

LAN cables

PLC Ethernet adapter LAN cable

2NC-ENET-ADP

FX

Twisted pair cable

Category 5(e) STP or 3

STP (straight cable)

• Applicable version of GX Developer/MX Component

Software Applicable Version W ith FX Configurato r-EN

GX Developer Ver. 8.12N or later Ver. 8.25B or later

MX Component Ver. 3.05F or later Ver. 3.08J or later

5. Product Specification

5.1 Specifications

The general specifications of FX2NC-ENET-ADP are same as those of the FX

Series PLC except the following items.

Item Description

General

specifications

Power supply

specifications

Withstand voltage

Insulation resistance

Supply voltage/

current

500V AC for 1

min

5 MΩ or more by

500V DC megger

5V DC, 135 mA (supplied from PLC)

Baud rate 10Mbps

Protocol CSMA/CD(IEEE802.3)

Performance

specifications

Transmission media 10BASE-T

Topology Star type

Communication

method

Full duplex

To Ethernet RJ45 connector

Connector

To ground

3 pins

(However, internally short-circuited)

Mass 0.1 kg (0.22 lbs)

5.2 Outside dimensions and name of each part

16.1(0.64")

(to screw holes)

2-φ4.2(0.17")

2NC

FX -ENET-ADP

POWER

LINK

ACT

1)

SD

RD

1)

19.1

(0.76")

1) Mounting hole (2-φ4.2)

Used when FX

Not used when the module is mounted on DIN rail.

2) POWER LED (green)

Lit while 5V DC power is supplied from the PLC.

3) LINK LED (green)

Lit while the HUB is connected by an RJ45 connector and the power is on.

4) ACT LED (red)

Lit while transferring data with connected Ethernet.

5) SD LED (red)

Lit while sending data to the connected PLC.

6) RD LED (red)

Lit while receiving data from the connected PLC.

7) Connecting cable

Used to connect the main unit.

8) RJ45 connector

Connects the Ethernet cable.

2NC-ENET-ADP is mounted directly.

2)

3)

4)

5)

6)

8)

9)

10)

10

(0.40")

7)

90(3.35")

65.5(2.58")

(between screw holes)

(Height of screw hole)

7(0.28")

74(2.92")

78(3.08")

Conforms to JEM1021, between all

terminals together

and grounding

terminal

Unit: mm (inches)

45 (1.78")

11)

(to center of DIN rail)

Page 2

9) Terminal block for grounding

Internally short-circuited.

Applicable cable: AWG 17 to 14

Tightening torque: 0.4 to 0.5 N·m

10)DIN rail mounting hook

11)DIN rail mounting groove

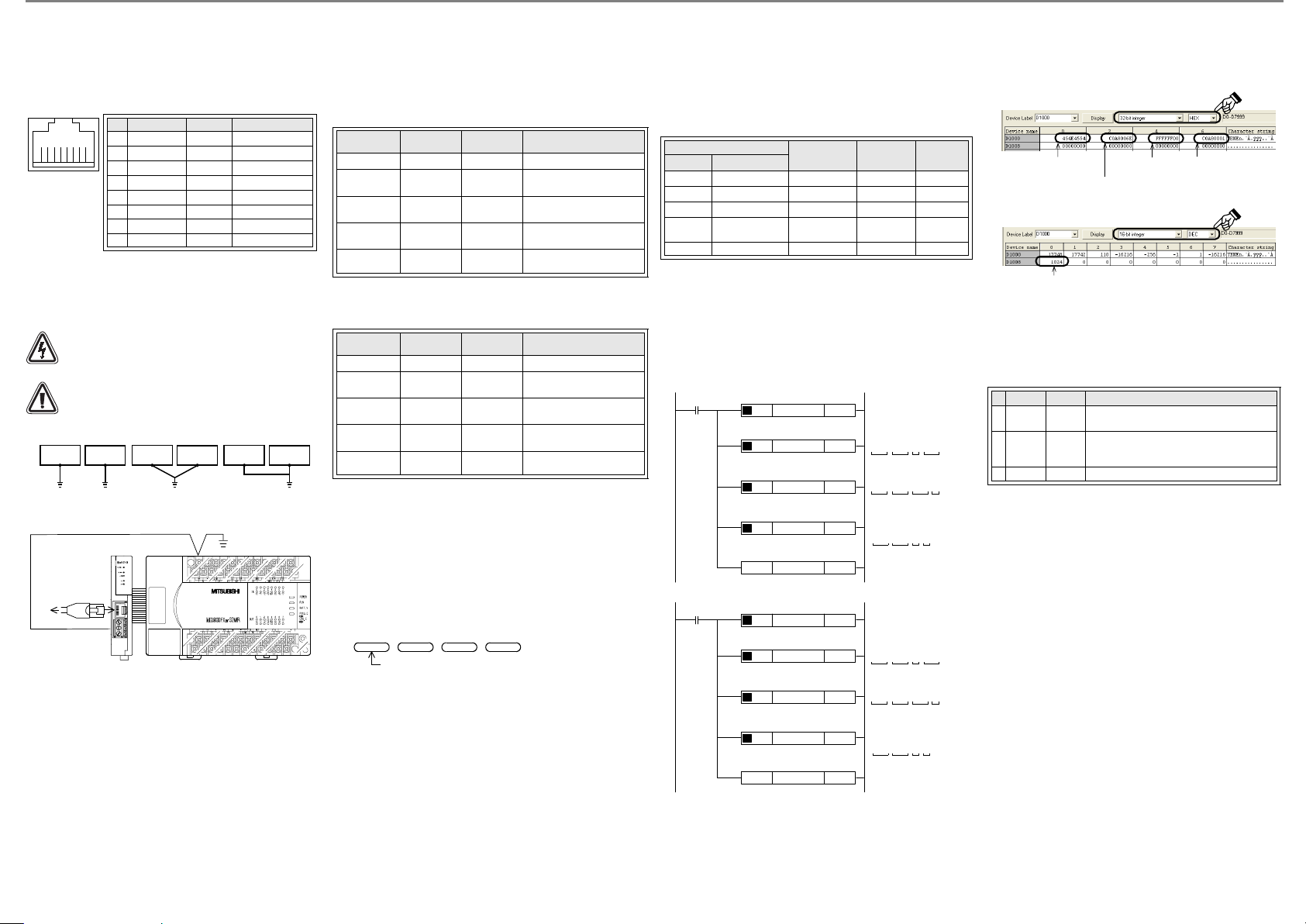

5.3 Connector pin arrangement

The RJ45 connector in the FX2NC-ENET-ADP has the following pin arrangement.

Pin Signal name Direction Description

1 TD+ Out + side of send data

2 TD- Out - side of send data

81

3 RD+ In + side of receive data

4 U nused -

5 U nused -

6 RD- In - side of receive data

7 U nused -

8 U nused -

5.4 Used cable

STP (Shielded twisted pair) cable Category 5(e) or 3

6. Wiring

6.1 Cautions on wiring

Wiring Precaution

• Cut off all phases of external power source before installation or

performing wiring work in order to avoid electric shock or damage to

the product.

Wiring Precaution

• The grounding terminal in the main unit should be connected to a

grounding resistance of 100Ω or less.

• Do not drop cuttings and wire chips into the ventilation slits of the

PLC when drilling screw holes or performing wiring work.

Otherwise, fire, failure, or malfunction may occur.

Another

PLC

equipment

Dedicated grounding

(best)

6.2 Wiring ex ample

To

HUB

Shared grounding (good) Common grounding

PLC

Another

equipment

PLC

(not possible)

Grounding

Ω

or less)

(100

Another

equipment

7. Parameter Settings for FX2NC-ENET-ADP

To connect the FX2NC-ENET-ADP to the Ethernet, it is necessary to set the Ethernet

parameters, including the Header, IP address, Subnet mask, Gateway address and

TCP port number.

Set the Ethernet parameters to the 'D' data registers in the PLC.

Immediately after the power is turned on, the FX

parameters stored in the 'D' data registers in the PLC, and configures itself.

7.1 Used devices

[FX1S]

Set the Ethernet parameters to nine data registers from D128 to D136.

Data register Setting item

D128, D129 Header

D130, D131 IP address

*1*5

*4

192.168.0.100

D132, D133 Subnet mask*4255.255.255.0

D134, D135

D136

[FX

1N/FX2N/FX2NC]

Set the Ethernet parameters to nine data registers from D1000 to D1008.

If these data registers are used for any other purpose, the Ethernet parameters can be

set to nine data registers 'D' starting from D2000, D3000, D4000, D5000, D6000 or

D7000.

Gateway

address

TCP port

number

*4

Data register Setting item

D000,D001 Header

D002,D003 IP address

*1

*4

192.168.0.100

D004,D005 Subnet mask*4255.255.255.0

D006,D007

D008

Gateway

address

TCP port

number

*4

2NC-ENET-ADP reads the Ethernet

Default

paramete r

Description

- Set H454E4554 ("ENET").

Set the IP address for

connecting to Ethernet.

Set the sub-net mask for

connecting to Ethernet.

192.168.0.1

Default

paramete r

Set the gateway address for

connecting to Ethernet.

Set the TCP ports within the

1024

range from 1024 to 65535.

Description

- Set H454E4554 ("ENET").

Set the IP address for

connecting to Ethernet.

Set the sub-net mask for

connecting to Ethernet.

192.168.0.1

Set the gateway address for

connecting to Ethernet.

Set the TCP ports within the

1024

range from 1024 to 65535.

*2

*3

*2

*2

*3

*2

: Indicates any number in the range from 1 to 7.

• If "ENET" is not found or the parameters such as IP address, Gateway address,

Subnet mask are incorrect, the default parameters are valid.

• If FX

2NC-ENET-ADAP cannot read out the specified data register stored i n the PLC,

the default parameters are used. In such a case, the SD or RD LED is lit.

(Refer to 7.4.)

Note

*1 This is the header identifier required when FX

Ethernet parameters.

Make sure to set H454E4554 ("ENET") to D128/D129 or D000/D001.

*2 The first 8 bits used for the IP address and Gateway address must be in the

range from 1 to 223.

If any number outside this range is used, the RD LED will be lit when the FX

ENET-ADP is turned on and Ethernet communication will not be performed.

2NC-ENET-ADP identifies the

2NC-

. . .

Set numbers from 1 to 223.

*3 In the following cases (and as explained in *2) concerning the Subnet mask data,

the RD LED will be lit when the FX

occur and Ethernet communication will not be performed.

(The following conditions are expressed in binary form.)

1) If 1 is set for all bits

2) If 0 is set for all bits

3) If 1 is set immediately after 0 is set

Example: 111...11000100...

*4 The settings of the IP address, Subnet mask and Gateway address depend on

the network environment. For the contents of these parameters, see the network

administrator.

*5 The FX

2NC-ENET-ADP searches for the header in the order "D1000 → D7000".

The values described in lowest data resister numbers are set as the Ethernet

parameters.

2NC-ENET-ADP is turned on, an error will

7.2 Parameter setting methods

Set the Ethernet parameters using either of the following methods through serial

communication:

• Setting using the PLC program

• Setting using file registers

For each setting example, refer to Section 7.3.

7.3 Parameter setting examples for FX2NC-ENET-ADP

Two examples of setting the Ethernet parameters for the FX2NC-ENET-ADP are shown

below:

Example of parameter settings

Data register

FX1S FX 1N/FX2N/FX2NC

Setting item Parameter Set data

D128,D129 D1000,D1001 Header "ENET" H454E4554

D130,D131 D1002,D1003 IP ad dress 192.168.0 .110 HC0A8006E

D132,D133 D1004,D1005 Subnet mask 255.255.255.0 HFFFFFF00

D134,D135 D1006,D1007

Gateway

address

192.168.0.1 HC0A80001

D136 D1008 TCP port number 1024 K1024

When the PLC program is used to set the Ethernet parameters

The Ethernet parameters for the FX

shown below:

Note

In the FX

2NC-ENET-ADP, the Ethernet parameters become valid only when the power

is turned ON and the setting data is stored in specified data registers.

In either of the following cases, turn off the power of the PLC once, and then turn it on

again.

• When a parameter is set for the first time

• When the setting of a parameter is changed during operation

1S]

[FX

M8002

D MOV

D MOV

D MOV

D MOV

MOV D136K1024

1N/FX2N/FX2NC]

[FX

M8002

D MOV

D MOV

D MOV

D MOV

MOV D1008K1024

When connecting two or more PLCs to a network, do not use the same IP

*6

address twice.

Example: Personal computer (GX Developer)

PLC1

PLC2

2NC-ENET-ADP can be set using the program

Setting of Header:

D128H454E4554

ASCII codes to specify

"ENET"

*6

D130HC0A8006E

D132HFFFFFF00

D134HC0A80001

Setting of IP address

192 . 168 . 0 . 110

C0 A8 00 6E

Setting of Subnet mask:

255 . 255 . 255 . 0

FF FF FF 00

Setting of Gateway

address:

192 . 168 . 0 . 1

C0 A8 00 01

:

TCP Port number:1024

Setting of Header:

D1000H454E4554

ASCII codes to specify

"ENET"

D1002HC0A8006E

D1004HFFFFFF00

D1006HC0A80001

Setting of IP address

192 . 168 . 0 . 110

C0 A8 00 6E

Setting of Subnet mask:

255 . 255 . 255 . 0

FF FF FF 00

Setting of Gateway

address:

192 . 168 . 0 . 1

C0 A8 00 01

*6

:

TCP Port number:1024

192 . 168 . 0 . 10

192 . 168 . 0 . 110

192 . 168 . 0 . 111

When file registers are used to set the Ethernet parameters

Select [Parameter] - [PLC parameter] - [Memory capacity] in GX Developer, and

set the file register capacity to 1 block or more.

Then, right-click [Device memory], add the device memory data, and set the

parameters as shown below:

• Settings of D128 to D135 or D1000 to D1007 (32-bit HEX mode)

Header: ENET

IP address: 192.168.0.110

Subnet mask:

255.255.255.0

Gateway address:

192.168.0.1

• Settings of D136 or D1008 (16-bit DEC mode)

TCP port number: 1024

7.4 Check of configuration using SD LED and RD LED

The SD LED and the RD LED can be used to check whether the c urrent

configuration is functioning properly or not.

At startup (reset)

After power is turned on, the SD LED and RD LED are lit for 2 seconds, and the

FX2NC-ENET-ADP reads the configuration data from the PLC.

If the configuration data is read correctly, the SD LED and RD LED turn off. If an

error occurs, the SD LED and RD LED indicate the error status as shown below:

SD LED RD LED Description

1) ON OFF

2) OFF ON

The contents of data registers in the PLC cannot be

read.

The header "ENET" cannot be detected.

A parameter such as IP address, Gateway address,

Subnet mask and TCP port number is invalid.

3) OFF OFF Valid

Note

In case of 1) or 2), the parameters such as IP address, Gate way address, Subnet

mask are incorrect and the default parameters are valid.

Page 3

8. Settings in GX Developer

Set the IP address, the TCP port number and the connec tion route, etc. on the

Transfer setup dialog box, when accessing FX

PLC via Ethernet from GX Developer.

Note:

• GX Developer must be Version 8.25B or later.

• FX Configurator-EN must be installed on the personal computer.

For details on th e installation method of FX Configurato r-EN, refer to the FX

Configurator-EN Operation Manual.

8.1 Setting metho d

Select [Online] → [Transfer setup]

1S, FX1N, FX2N, or FX2NC Series

Click “Ethernet board”

Double-click “Ethernet module”

9. Setting in MX Component

Note:

• MX Component must be Version 3.08J or later.

• FX Configurator-EN must be installed on the personal computer.

For details on the installation method of FX Configurator-EN, refer to the FX

Configurator-EN Operation Manual.

Note; In case of Virtual COM Port (VCP) Driver

If using Virtual COM Port (VCP) Driver, add the Logical station number for Ethernet.

9.1 Setting method

Select [Programs] - [MELSOFT Application] - [MX Component] - [Communication

Setup Utility].

[Wizard]

First, set "Ethernet board" at [PC

side I/F]. Next, set "FX-ENET

(-ADP)" at [Connect module].

[Next]

First, set "Ethernet module" at [PLC side I/F].

Next, set "FX-ENET-ADP" at [Module type].

[Next]

Set FX1S, FX1N, FX2N or

2NC at [CPU type].

FX

Select FX

2NC

-ENET-ADP.

Set the TCP Port Number (Port

No.) connection destination as

assigned to the FX

by the sequence program.

For details on the TCP port Number

setting for the FX

refer to Chapter 7.

8.2 Operations

In GX Developer, operations such as upload, download, monitoring and test of a

program are performed in the same way as with serial communication.

2NC

-ENET-ADP

2NC

-ENET-ADP,

Set the IP address connection

destination as assigned to the

FX

2NC

-ENET-ADP by the sequence

program. (When using the Host

Name, set the name assigned by

the hosts file within 64 characters.)

For details on the IP address

setting for the FX

refer to Chapter 7.

2NC

-ENET-ADP,

[Next]

Select the "Logical station number".

Set the TCP Port Number (Port No)

connection destination as assigned

2NC-ENET-ADP by the

to the FX

sequence program.

For details on the TCP port Number

setting for the FX

refer to Chapter 7.

2NC-ENET-ADP,

[Next]

Set the IP address connection

destination as assigned to the

2NC-ENET-ADP by the sequence

FX

program. (When using the Host

Name, set the name assigned by

the hosts file.)

For details on the IP address setting

2NC-ENET-ADP, refer to

for the FX

Chapter 7.

[Finish]

Enter a comment.

Page 4

10. Troubleshooting

Turn ON power of PLC.

Is POWER

LED ON?

Yes

Is LINK

LED ON?

Yes

Two seconds after

FX

2NC

-ENET-ADP is

turned ON

SD LED:ON

RD LED:OFF

Yes

Are FX

2NC

-ENET-ADP

and PLC connected

correctly?

Yes

Is communication

port set for computer

link or no protocol

communication?

(Value other than 0

stored in D8120.)

Yes

Clear communication

parameter check box,

and download

program.

Clear the check box.

No

Check the cable connection between

2NC

-ENET-ADP and PLC.

FX

Check if FX

2NC

SD LED:OFF

RD LED:ON

Check Ethernet

parameters.

For details, refer

to "7. Parameter

Settings for

FX

ADP".

-ENET-ADP and HUB are

2NC

-ENET-

No

connected correctly.

Check if power of HUB is ON.

No No

Connect

No

cable

correctly.

SD LED:OFF

RD LED:OFF

Yes Yes

Parameters

are read

correctly

from PLC.

Execute PING

command for IP

address set to PLC.*

1) Check again IP address set to PLC.

2) Confirm that network address in PLC

No

Any response?

matches network address in PC.

3) Confirm connection of Ethernet

between PC and PLC.

Yes

Confirm that TCP port number set in GX

Developer or MX Component matches TCP

port number set in PLC.

Turn ON power again.

Is any

numeric value

other than 0 stored in

D8120?

No

Yes

Set 0 to D8120.

Turn ON power again.

[Reference]

*

The PING command confirms confirmation whether the communication

between Ethernet devices using the IP address of TCP/IP is possible.

Execute the PING command from the personal computer connected to

Ethernet, and check whether the FX

Refer to the PING command described below.

Executing the PING command

Open the MS-DOS prompt (command prompt in the Windows2000/XP).

In the example parameter settings in Section 7.3, the IP address is set

to "192.168.0.110".

PING 192.168.0.110

Check if PLC and PC

are connected

correctly.

2NC

-ENET-ADP sends a response.

This manual confers no industrial property rights or any rights of any other kind, nor does it

confer any patent licenses. Mitsubishi Electric Corporation cannot be held responsible for any

problems involving industrial property rights which may occur as a result of using the contents

noted in this manual.

HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310,

HIMEJI WORKS : 840, CHIYODA CHO, HIMEJI, JAPAN

JAPAN

Page 5

FX

2NC

-ENET-ADP Ethernet adapter

USER'S MANUAL

Manual Number JY997D12301

Revision D

Date May 2007

• This manual contains text, diagrams and explanations which guide the

reader in the correct installation and operation of the FX

Ethernet adapter. It should be read and understood before attempting to use

the unit.

• If in doubt at any stage of the installation of FX

professional electrical technician who is qualified and trained to the local

and national standards which apply to the installation site.

• If in doubt about the operation or use of the FX

consult the nearest Mitsubishi Electric distributor.

• This manual is subject to change without notice.

®

• Microsoft

and Windows® are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

• The company name and the product name described in this manual are the

registered trademarks or trademarks of each company.

Guideline for the safety of the user and protection of the FX2NC-ENET-ADP.

This manual provides usage information for the FX

adapter. The manual has been written to be used by trained and competent

personnel.

Notes on the symbols used in this manual

At various times throughout out this manual certain symbols will be used to

highlight points of information which are intended to ensure the users personal

safety and protect the integrity of equipment. Whenever any of the following

symbols are encountered, its associated note must be read and understood. Each

of the symbols used will now be listed with a brief description of its meaning.

Hardware Warnings

1) Indicates that the identified danger WILL cause physical and

property damage.

2) Indicates that the identified danger could POSSIBLY cause

physical and property damage.

3) Indicates a point of further interest or further explanation.

DISPOSAL PRECAUTIONS

• When disposing of this product, treat it as industrial waste.

INSTALLATION PRECAUTIONS

• Use the module in an environment that meets the general

specifications contained in this manual. U sing this module in a n

environment outside the range of the general specifications could

result in electric shock, fire, erroneous operati on, and damage to or

deterioration of the product.

• Do not disassemble or modify the module. Doing so may cause

failure, malfunction, injury, or fire.

TRANSPORTATION AND MAINTENANCE PRECAUTIONS

• During transportation avoid any impact as the module is a precision

instrument. Doing so could cause trouble in the module.

• It is necessary to check the operation of module after transportation,

in case of any impact damage.

2NC-ENET-ADP

2NC-ENET-ADP, consult a

2NC-ENET-ADP, please

2NC-ENET-ADP Ethernet

The CE marking does not guarantee that an entire mechanical module produced in

accordance with the co ntents of t he notificati on comply with the f ollowing sta ndards.

Compliance to EMC standards of the entire mechanical module should be checked by

the user / manufacturer.

Standards with which this product complies

Type: Programmable Controller (Open Type Equipment)

Models: Products manufactured:

from April 1st, 2004 to April 30th, 2006 are compliant with

EN61000-6-4 and EN61131-2:1994+A11:1996+A12:2000 and EN61000-6-2

after May 1st, 2006 are compliant with EN61131-2:2003

Electromagnetic Compatibility

EN61000-6-4:2001

Electromagnetic compatibility

-Generic standards - Emission standard

for Industrial environment

EN61131-2:1994/A11:1996/A12:2000

Programmable controllers

-Equipment requirements and tests

EN61000-6-2:2001

Electromagnetic compatibility

-Generic standards Immunity for

industrial environments.

EN61131-2: 2003

Programmable controllers

-Equipment requirements and tests

For more details please contact the local Mitsubishi Electric sales site.

- Notes for compliance to the EMC regulation.

It is necessary to install the FX

panel.

●Note Concerning the C E Marking●

Standards (EMC)

2NC-ENET-ADP module in a shielded metal control

Remark

Compliance with all relevant aspects of the

standard. (Radiated Emissions and Mains

Terminal Voltage Emissions)

Compliance with all relevant aspects of the

standard. (RF Immunity, Fast transients,

ESD and Damped oscillatory wave)

Compliance with all relevant aspects of the

standard. (RF immunity, Fast transients,

ESD, Conducted, Surges, Power

magnetic fields, Voltage dips and Voltage

interruptions)

Compliance with all relevant aspects of the

standard.

(Radiated Emissions, Mains Terminal

Voltage Emissions, RF immunity, Fast

Transients, ESD, Surge, Voltage drops

and interruptions, Conducted and Power

magnetic fields)

1. Associated Manuals

Manual name Manual No. Description

FX1S HARDWARE MANUAL JY992D83901

1N HARDWARE MANUAL JY992D89301

FX

FX

2N HARDWARE MANUAL JY992D66301

2NC HARDWARE MANUAL

FX

(DSS/DS)

(D/UL)

JY992D76401

JY992D87201

FX PROGRAMMING MANUAL II JY992D88101

FX Configurator-EN

OPERATION MANUAL

1N-CNV-BD Special Adapter

FX

Connection Board

2N-CNV-BD Special Adapter

FX

Connection Board

JY997D20501

JY992D84701

JY992D63601

For GX Developer and MX Component, refer to the operation manual respectively.

2. Outline of Product

The FX2NC-ENET-ADP is an Ethernet adapter of 10BASE-T specifications for the

1S, FX1N, FX2N and FX2NC Series.

FX

The FX

2NC-ENET-ADP enables the upload, download, monitor, and test of a program

from the personal computer (GX Developer or MX Component) via Ethernet.

3. Installation

Caution

• Use only in the environments specified under the gene ral specifications

in the manual.

Do not use the product in environments with excessive or conductive

dust, corrosive (including salt breeze, Cl

flammable gas, oily smoke, moisture or rain, exces sive heat, regular

impact shocks or excessive vibration, as it may result in electrical shock,

fire, malfunction, damage or deterioration of the product.

• Make sure to shut off the external power before installing or wiring it.

Electric shock or serious damage to the product may occur, if the external

power is not disconnected.

• Never drop wire chips or shavings into the ventilation slits when drilling

screw holes or performing wiring, as they may caus e fire, breakdown, or

malfunction.

• Securely install the FX

A poor connection may result in malfunction.

2NC-ENET-ADP to the designated port.

Describes the hardware of the

FX Series PLC such as

specification s, wiring, and

installation.

Describes the instructions

available in the FX

2N/FX2NC Series PLC.

FX

Describes operation details of

FX Configurator-EN

Configuration Software.

Describes matters related to the

installation of the boards.

2, H2S, SO2, NO2, etc.) or

1S/FX1N/

3.1 How to Ins tall to FX Series PLC

Installation to FX1S/FX1N/FX2N

Turn OFF the PLC before beginning any

work.

1) Remove the panel cover fr om the top

face of the main unit.

2) Take off the resin cover from the left

side of the main unit.

3) Install the following board to the port

on the main unit.

Board name

Corresponding

model

1)

4)

5)

FX1N-CNV-BD FX1S/FX1N

FX2N-CNV-BD FX2N

4) Affix the above board using th e

supplied M3 screws.

Tightening torque: 0.3 to 0.6 N·m

5) Connect the built-in cable of the

FX

2NC-ENET-ADP to the port on the left side of the board.

Installation to FX

Turn OFF the PLC before beginning any work.

1) Remove the cover from the special adapter port provided on the left side of the

main unit.

2) Connect the built-in cable of the FX

3.2 Installation to a Panel Face

Direct installation to the panel face

Directly attach to the panel face using 2 sets of a

screw (M4), a spring washer, and a flat washer

in the mounting holes.

Tightening torque: 0.7 to 1.0 N·m

For the pitch and positions of mounting screw

holes, refer to the external dimensions.

2NC

Installation to

FX

2NC-ENET-ADP to the special adapter port.

ENET

-ADP

2NC

Installation to

FX

1S/FX1N/FX2N

X3

1

X

3)

2

Y

1

Y

0

Y

2)

1)

2)

FX Series

PLC

Screws

Mounting on DIN rail

Affix the FX

DIN46277 (35 mm (1.37") wide).

Dismounting from DIN rail

Slightly pull down the DIN rail mounting clip

using a tool such as a slotted screwdriver. Pull

down the clip further, and the rail will be locked

with the clip left open.

4. System Configuration

2NC-ENET-ADP to the DIN rail,

FX

PC

2NC

FX1S,FX1N,FX

-ENET-ADP

2N

DIN rail

Detach

FX

2NC

ENET

-ADP

FX Series

PLC

To lock the tab

. . . .

LAN

cables

HUB

FX1S/FX1N PLC + FX 1N-CNV-BD

FX2N PLC + FX 2N-CNV-BD

2NC PLC

FX

LAN cables

PLC Ethernet adapter LAN cable

2NC-ENET-ADP

FX

Twisted pair cable

Category 5(e) STP or 3

STP (straight cable)

• Applicable version of GX Developer/MX Component

Software Applicable Version W ith FX Configurato r-EN

GX Developer Ver. 8.12N or later Ver. 8.25B or later

MX Component Ver. 3.05F or later Ver. 3.08J or later

5. Product Specification

5.1 Specifications

The general specifications of FX2NC-ENET-ADP are same as those of the FX

Series PLC except the following items.

Item Description

General

specifications

Power supply

specifications

Withstand voltage

Insulation resistance

Supply voltage/

current

500V AC for 1

min

5 MΩ or more by

500V DC megger

5V DC, 135 mA (supplied from PLC)

Baud rate 10Mbps

Protocol CSMA/CD(IEEE802.3)

Performance

specifications

Transmission media 10BASE-T

Topology Star type

Communication

method

Full duplex

To Ethernet RJ45 connector

Connector

To ground

3 pins

(However, internally short-circuited)

Mass 0.1 kg (0.22 lbs)

5.2 Outside dimensions and name of each part

16.1(0.64")

(to screw holes)

2-φ4.2(0.17")

2NC

FX -ENET-ADP

POWER

LINK

ACT

1)

SD

RD

1)

19.1

(0.76")

1) Mounting hole (2-φ4.2)

Used when FX

Not used when the module is mounted on DIN rail.

2) POWER LED (green)

Lit while 5V DC power is supplied from the PLC.

3) LINK LED (green)

Lit while the HUB is connected by an RJ45 connector and the power is on.

4) ACT LED (red)

Lit while transferring data with connected Ethernet.

5) SD LED (red)

Lit while sending data to the connected PLC.

6) RD LED (red)

Lit while receiving data from the connected PLC.

7) Connecting cable

Used to connect the main unit.

8) RJ45 connector

Connects the Ethernet cable.

2NC-ENET-ADP is mounted directly.

2)

3)

4)

5)

6)

8)

9)

10)

10

(0.40")

7)

90(3.35")

65.5(2.58")

(between screw holes)

(Height of screw hole)

7(0.28")

74(2.92")

78(3.08")

Conforms to JEM1021, between all

terminals together

and grounding

terminal

Unit: mm (inches)

45 (1.78")

11)

(to center of DIN rail)

9) Terminal block for grounding

Internally short-circuited.

Applicable cable: AWG 17 to 14

Tightening torque: 0.4 to 0.5 N·m

10)DIN rail mounting hook

11)DIN rail mounting groove

5.3 Connector pin arrangement

The RJ45 connector in the FX2NC-ENET-ADP has the following pin arrangement.

Pin Signal name Direction Description

1 TD+ Out + side of send data

2 TD- Out - side of send data

81

3 RD+ In + side of receive data

4 U nused -

5 U nused -

6 RD- In - side of receive data

7 U nused -

8 U nused -

5.4 Used cable

STP (Shielded twisted pair) cable Category 5(e) or 3

6. Wiring

6.1 Cautions on wiring

Wiring Precaution

• Cut off all phases of external power source before installation or

performing wiring work in order to avoid electric shock or damage to

the product.

Wiring Precaution

• The grounding terminal in the main unit should be connected to a

grounding resistance of 100Ω or less.

• Do not drop cuttings and wire chips into the ventilation slits of the

PLC when drilling screw holes or performing wiring work.

Otherwise, fire, failure, or malfunction may occur.

Another

PLC

equipment

Dedicated grounding

(best)

6.2 Wiring ex ample

To

HUB

Shared grounding (good) Common grounding

PLC

Another

equipment

PLC

(not possible)

Grounding

Ω

or less)

(100

Another

equipment

7. Parameter Settings for FX2NC-ENET-ADP

To connect the FX2NC-ENET-ADP to the Ethernet, it is necessary to set the Ethernet

parameters, including the Header, IP address, Subnet mask, Gateway address and

TCP port number.

Set the Ethernet parameters to the 'D' data registers in the PLC.

Immediately after the power is turned on, the FX

parameters stored in the 'D' data registers in the PLC, and configures itself.

7.1 Used devices

[FX1S]

Set the Ethernet parameters to nine data registers from D128 to D136.

Data register Setting item

D128, D129 Header

D130, D131 IP address

*1*5

*4

192.168.0.100

D132, D133 Subnet mask*4255.255.255.0

D134, D135

D136

[FX

1N/FX2N/FX2NC]

Set the Ethernet parameters to nine data registers from D1000 to D1008.

If these data registers are used for any other purpose, the Ethernet parameters can be

set to nine data registers 'D' starting from D2000, D3000, D4000, D5000, D6000 or

D7000.

Gateway

address

TCP port

number

*4

Data register Setting item

D000,D001 Header

D002,D003 IP address

*1

*4

192.168.0.100

D004,D005 Subnet mask*4255.255.255.0

D006,D007

D008

Gateway

address

TCP port

number

*4

2NC-ENET-ADP reads the Ethernet

Default

paramete r

Description

- Set H454E4554 ("ENET").

Set the IP address for

connecting to Ethernet.

Set the sub-net mask for

connecting to Ethernet.

192.168.0.1

Default

paramete r

Set the gateway address for

connecting to Ethernet.

Set the TCP ports within the

1024

range from 1024 to 65535.

Description

- Set H454E4554 ("ENET").

Set the IP address for

connecting to Ethernet.

Set the sub-net mask for

connecting to Ethernet.

192.168.0.1

Set the gateway address for

connecting to Ethernet.

Set the TCP ports within the

1024

range from 1024 to 65535.

*2

*3

*2

*2

*3

*2

: Indicates any number in the range from 1 to 7.

• If "ENET" is not found or the parameters such as IP address, Gateway address,

Subnet mask are incorrect, the default parameters are valid.

• If FX

2NC-ENET-ADAP cannot read out the specified data register stored i n the PLC,

the default parameters are used. In such a case, the SD or RD LED is lit.

(Refer to 7.4.)

Note

*1 This is the header identifier required when FX

Ethernet parameters.

Make sure to set H454E4554 ("ENET") to D128/D129 or D000/D001.

*2 The first 8 bits used for the IP address and Gateway address must be in the

range from 1 to 223.

If any number outside this range is used, the RD LED will be lit when the FX

ENET-ADP is turned on and Ethernet communication will not be performed.

2NC-ENET-ADP identifies the

2NC-

. . .

Set numbers from 1 to 223.

*3 In the following cases (and as explained in *2) concerning the Subnet mask data,

the RD LED will be lit when the FX

occur and Ethernet communication will not be performed.

(The following conditions are expressed in binary form.)

1) If 1 is set for all bits

2) If 0 is set for all bits

3) If 1 is set immediately after 0 is set

Example: 111...11000100...

*4 The settings of the IP address, Subnet mask and Gateway address depend on

the network environment. For the contents of these parameters, see the network

administrator.

*5 The FX

2NC-ENET-ADP searches for the header in the order "D1000 → D7000".

The values described in lowest data resister numbers are set as the Ethernet

parameters.

2NC-ENET-ADP is turned on, an error will

7.2 Parameter setting methods

Set the Ethernet parameters using either of the following methods through serial

communication:

• Setting using the PLC program

• Setting using file registers

For each setting example, refer to Section 7.3.

7.3 Parameter setting examples for FX2NC-ENET-ADP

Two examples of setting the Ethernet parameters for the FX2NC-ENET-ADP are shown

below:

Example of parameter settings

Data register

FX1S FX 1N/FX2N/FX2NC

Setting item Parameter Set data

D128,D129 D1000,D1001 Header "ENET" H454E4554

D130,D131 D1002,D1003 IP ad dress 192.168.0 .110 HC0A8006E

D132,D133 D1004,D1005 Subnet mask 255.255.255.0 HFFFFFF00

D134,D135 D1006,D1007

Gateway

address

192.168.0.1 HC0A80001

D136 D1008 TCP port number 1024 K1024

When the PLC program is used to set the Ethernet parameters

The Ethernet parameters for the FX

shown below:

Note

In the FX

2NC-ENET-ADP, the Ethernet parameters become valid only when the power

is turned ON and the setting data is stored in specified data registers.

In either of the following cases, turn off the power of the PLC once, and then turn it on

again.

• When a parameter is set for the first time

• When the setting of a parameter is changed during operation

1S]

[FX

M8002

D MOV

D MOV

D MOV

D MOV

MOV D136K1024

1N/FX2N/FX2NC]

[FX

M8002

D MOV

D MOV

D MOV

D MOV

MOV D1008K1024

When connecting two or more PLCs to a network, do not use the same IP

*6

address twice.

Example: Personal computer (GX Developer)

PLC1

PLC2

2NC-ENET-ADP can be set using the program

Setting of Header:

D128H454E4554

ASCII codes to specify

"ENET"

*6

D130HC0A8006E

D132HFFFFFF00

D134HC0A80001

Setting of IP address

192 . 168 . 0 . 110

C0 A8 00 6E

Setting of Subnet mask:

255 . 255 . 255 . 0

FF FF FF 00

Setting of Gateway

address:

192 . 168 . 0 . 1

C0 A8 00 01

:

TCP Port number:1024

Setting of Header:

D1000H454E4554

ASCII codes to specify

"ENET"

D1002HC0A8006E

D1004HFFFFFF00

D1006HC0A80001

Setting of IP address

192 . 168 . 0 . 110

C0 A8 00 6E

Setting of Subnet mask:

255 . 255 . 255 . 0

FF FF FF 00

Setting of Gateway

address:

192 . 168 . 0 . 1

C0 A8 00 01

*6

:

TCP Port number:1024

192 . 168 . 0 . 10

192 . 168 . 0 . 110

192 . 168 . 0 . 111

When file registers are used to set the Ethernet parameters

Select [Parameter] - [PLC parameter] - [Memory capacity] in GX Developer, and

set the file register capacity to 1 block or more.

Then, right-click [Device memory], add the device memory data, and set the

parameters as shown below:

• Settings of D128 to D135 or D1000 to D1007 (32-bit HEX mode)

Header: ENET

IP address: 192.168.0.110

Subnet mask:

255.255.255.0

Gateway address:

192.168.0.1

• Settings of D136 or D1008 (16-bit DEC mode)

TCP port number: 1024

7.4 Check of configuration using SD LED and RD LED

The SD LED and the RD LED can be used to check whether the c urrent

configuration is functioning properly or not.

At startup (reset)

After power is turned on, the SD LED and RD LED are lit for 2 seconds, and the

FX2NC-ENET-ADP reads the configuration data from the PLC.

If the configuration data is read correctly, the SD LED and RD LED turn off. If an

error occurs, the SD LED and RD LED indicate the error status as shown below:

SD LED RD LED Description

1) ON OFF

2) OFF ON

The contents of data registers in the PLC cannot be

read.

The header "ENET" cannot be detected.

A parameter such as IP address, Gateway address,

Subnet mask and TCP port number is invalid.

3) OFF OFF Valid

Note

In case of 1) or 2), the parameters such as IP address, Gate way address, Subnet

mask are incorrect and the default parameters are valid.

Page 6

8. Settings in GX Developer

Set the IP address, the TCP port number and the connec tion route, etc. on the

Transfer setup dialog box, when accessing FX

PLC via Ethernet from GX Developer.

Note:

• GX Developer must be Version 8.25B or later.

• FX Configurator-EN must be installed on the personal computer.

For details on th e installation method of FX Configurato r-EN, refer to the FX

Configurator-EN Operation Manual.

8.1 Setting metho d

Select [Online] → [Transfer setup]

1S, FX1N, FX2N, or FX2NC Series

Click “Ethernet board”

Double-click “Ethernet module”

9. Setting in MX Component

Note:

• MX Component must be Version 3.08J or later.

• FX Configurator-EN must be installed on the personal computer.

For details on the installation method of FX Configurator-EN, refer to the FX

Configurator-EN Operation Manual.

Note; In case of Virtual COM Port (VCP) Driver

If using Virtual COM Port (VCP) Driver, add the Logical station number for Ethernet.

9.1 Setting method

Select [Programs] - [MELSOFT Application] - [MX Component] - [Communication

Setup Utility].

[Wizard]

First, set "Ethernet board" at [PC

side I/F]. Next, set "FX-ENET

(-ADP)" at [Connect module].

[Next]

First, set "Ethernet module" at [PLC side I/F].

Next, set "FX-ENET-ADP" at [Module type].

[Next]

Set FX1S, FX1N, FX2N or

2NC at [CPU type].

FX

Select FX

2NC

-ENET-ADP.

Set the TCP Port Number (Port

No.) connection destination as

assigned to the FX

by the sequence program.

For details on the TCP port Number

setting for the FX

refer to Chapter 7.

8.2 Operations

In GX Developer, operations such as upload, download, monitoring and test of a

program are performed in the same way as with serial communication.

2NC

-ENET-ADP

2NC

-ENET-ADP,

Set the IP address connection

destination as assigned to the

FX

2NC

-ENET-ADP by the sequence

program. (When using the Host

Name, set the name assigned by

the hosts file within 64 characters.)

For details on the IP address

setting for the FX

refer to Chapter 7.

2NC

-ENET-ADP,

10. Troubleshooting

Turn ON power of PLC.

[Next]

Select the "Logical station number".

Set the TCP Port Number (Port No)

connection destination as assigned

2NC-ENET-ADP by the

to the FX

sequence program.

For details on the TCP port Number

setting for the FX

refer to Chapter 7.

2NC-ENET-ADP,

[Next]

Set the IP address connection

destination as assigned to the

2NC-ENET-ADP by the sequence

FX

program. (When using the Host

Name, set the name assigned by

the hosts file.)

For details on the IP address setting

2NC-ENET-ADP, refer to

for the FX

Chapter 7.

[Finish]

Enter a comment.

Is POWER

LED ON?

Yes

Is LINK

LED ON?

Yes

Two seconds after

FX

2NC

-ENET-ADP is

turned ON

SD LED:ON

RD LED:OFF

Yes

Are FX

2NC

-ENET-ADP

and PLC connected

correctly?

Yes

Is communication

port set for computer

link or no protocol

communication?

(Value other than 0

stored in D8120.)

Yes

Clear communication

parameter check box,

and download

program.

Clear the check box.

No

Check the cable connection between

2NC

-ENET-ADP and PLC.

FX

Check if FX

2NC

SD LED:OFF

RD LED:ON

Check Ethernet

parameters.

For details, refer

to "7. Parameter

Settings for

FX

ADP".

-ENET-ADP and HUB are

2NC

-ENET-

No

connected correctly.

Check if power of HUB is ON.

No No

Connect

No

cable

correctly.

SD LED:OFF

RD LED:OFF

Yes Yes

Parameters

are read

correctly

from PLC.

Execute PING

command for IP

address set to PLC.*

1) Check again IP address set to PLC.

2) Confirm that network address in PLC

No

Any response?

matches network address in PC.

3) Confirm connection of Ethernet

between PC and PLC.

Yes

Confirm that TCP port number set in GX

Developer or MX Component matches TCP

port number set in PLC.

Turn ON power again.

Is any

numeric value

other than 0 stored in

D8120?

No

Yes

Set 0 to D8120.

Turn ON power again.

[Reference]

*

The PING command confirms confirmation whether the communication

between Ethernet devices using the IP address of TCP/IP is possible.

Execute the PING command from the personal computer connected to

Ethernet, and check whether the FX

Refer to the PING command described below.

Executing the PING command

Open the MS-DOS prompt (command prompt in the Windows2000/XP).

In the example parameter settings in Section 7.3, the IP address is set

to "192.168.0.110".

PING 192.168.0.110

Check if PLC and PC

are connected

correctly.

2NC

-ENET-ADP sends a response.

This manual confers no industrial property rights or any rights of any other kind, nor does it

confer any patent licenses. Mitsubishi Electric Corporation cannot be held responsible for any

problems involving industrial property rights which may occur as a result of using the contents

noted in this manual.

HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310,

HIMEJI WORKS : 840, CHIYODA CHO, HIMEJI, JAPAN

JAPAN

Loading...

Loading...