Page 1

MITSUBISHI

VVVF TRANSISTOR INVERTER

-

INSTRUCTION MANUAL

-

0

MlTSUBlSHl

A

ELECTRIC

Page 2

Introduction

Thank you for your purchase of MiBubishi Micro-Inverter

Before operating the inverter, read this manual carefully. Please deliver

actual

user

of

the inverter.

FREQROL-2024-UL.

this

instruction manual

to

the

Page 3

Instructions

1

.

Precautions

2

.

Block Diagram and Description

3

.

Preparation before Operation

CONTENTS

......................................................................................................

......................................................................

.........................................................................

1

7

11

4 . Apparatus and Components

5

.

Installation

6

.

Wiring

7

.

Pre-Operation Settings

8

.

Operation

9

.

Using the Parameter Unit

10

.

Parameter Unit Installation

11 . Outline

.......................................................................................................

...............................................................................................................

...................................................................................

.........................................................................................................

of

Parameter Unit Functions

to

be Prepared before Operation

...............................................................................

.............................................................................

..............................................................

....................

13

15

17

26

30

38

40

42

Page 4

12

.

Operation

.........................................................................................................

43

Selecting operation mode

Operating the motor with the parameter unit

of

Settings

Monitor

Frequency meter calibration

Adjusting bias and gain for frequency reference signal

Cautions for

13

.

Details

14 .

Maintenance and Inspection

15

.

Troubleshooting

16 . Specifications

17

.

DIMENSIONS

18

.

Selection of Peripheral Devices

control variables (Parameters)

.............................................................................................................

PU

operation

of

Each Parameter

..............................................................................................

................................................................................................

..................................................................................................

...............................................................................

.................................................

....................................................

...........................................................................

..............................................................................

..............................................................................

...........................................................................

.....................................................................

................................

43

46

51

55

64

66

69

72

102

109

113

127

133

Page 5

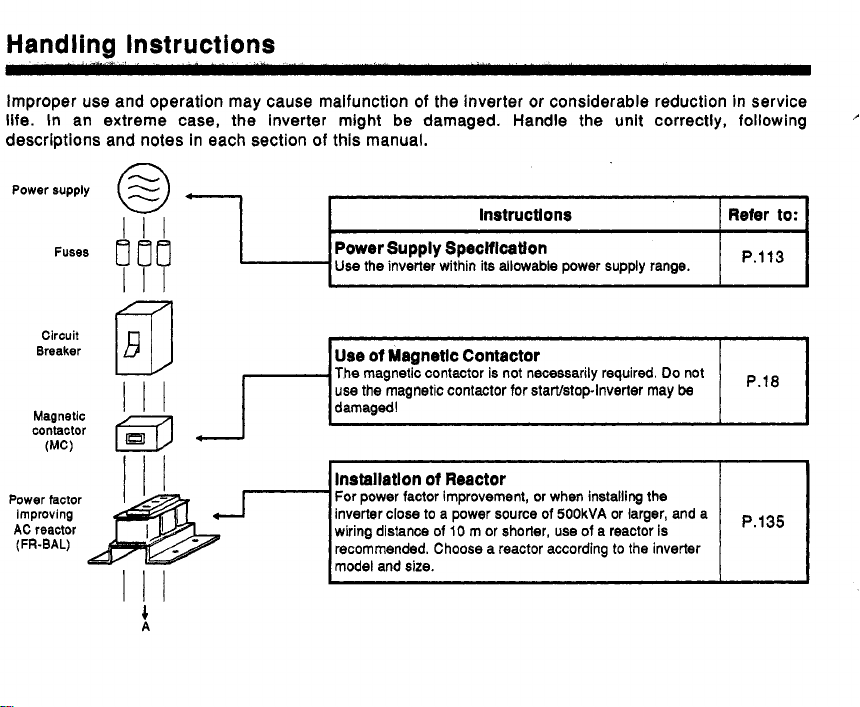

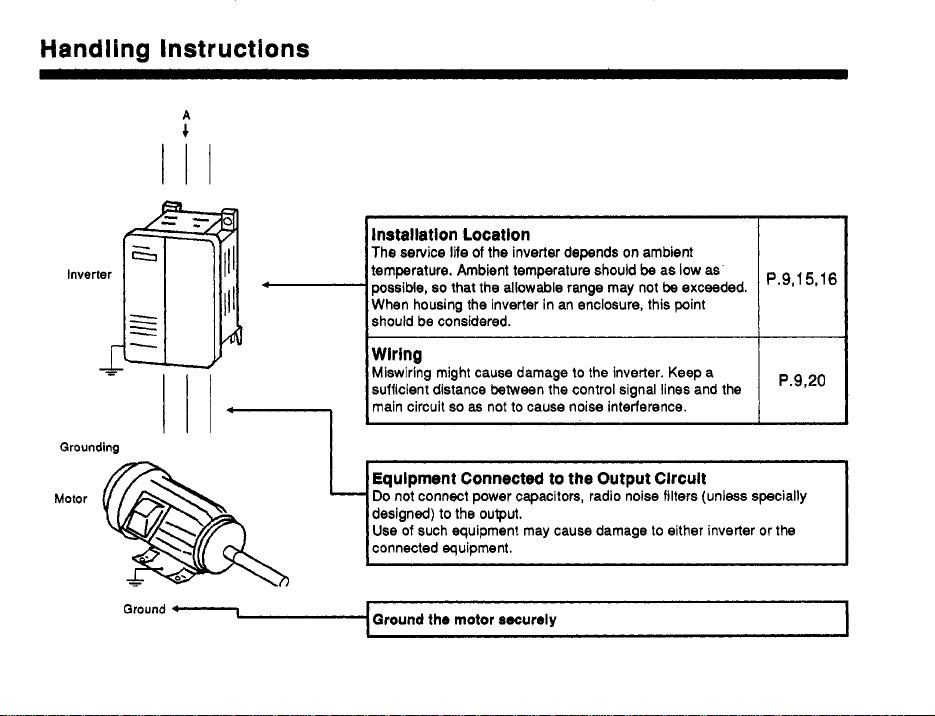

Handling Instructions

Improper use and operation may cause malfunction of the inverter

or

considerable reduction in service

life. In an extreme case, the inverter might be damaged. Handle the unit correctly, following

descriptions and notes in each section

Power supply

Fuses

Circuit

Breaker

Magnetic

contactor

(MC)

Power factor

improving

AC

reactor

(FR-BAL)

BUR

Ill

I

I

of

this manual.

~ ~~

Instructlons

Power Supply Speclflcatlon

.

Use

the

inverter within

I

lnstallatlon

For power factor improvement, or when installing the

wiring distance of

recommended. Choose a reactor according

model and size.

of

Reactor

10

its

allowable power supply range.

m

or

shorter,

use

of a reactor

to

the

is

inverter

I

Refer

P.113

to:

Ill

-'

I

I

Page 6

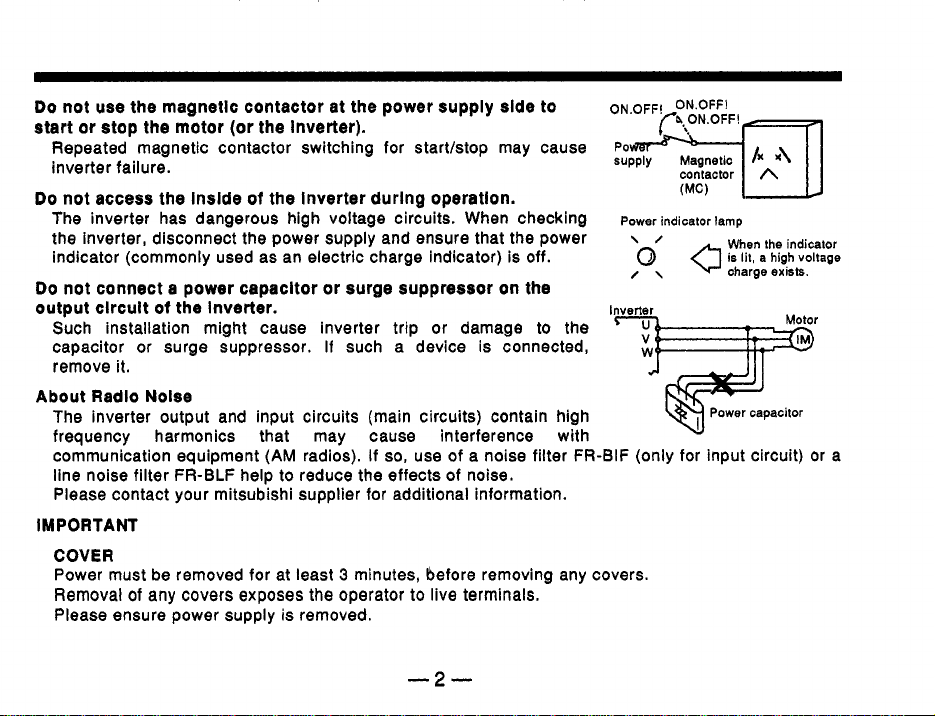

Handling Instructions

A

til

Grounding

installation Location

The service life

temperature. Ambient temperature should

possible,

When housing the inverter in an enclosure, this point

should be considered.

of

the inverter depends

so

that the allowable range may

on

ambient

be

not

as low as

be exceeded.

Wirlng

Miswiring might cause damage

sufficient distance between the control signal lines and the

main circuit

so

as

not

to

cause

to

the inverter. Keep a

noise

interference.

p.9,,

P.9,20

5,,6

Motor

designed)

Use

Ground the motor securely

to

the

of

such equipment may cause damage

output.

to

either inverter or the

Page 7

1.

PRECAUTIONS

Use

the Inverter wlthln the allowable ambient temperature range.

The service life of the inverter depends on ambient temperature.

Ambient temperature should be as low as possible, such that the

allowable range is not exceeded. Care should be taken for installation

direction and the environment.

(See page

Do

not perform Inverter contlnulty test.

When measuring isolation resistance

connections

Do

If

power

be damaged.

If

the power voltage is applied to terminals

damaged. Check to ensure that wiring and operation sequence (such as

commercial power source selector circuit) are correct.

voltage exceeding the allowable voltage range.

1516.)

of

to

not perform a continuity test on the control circuit.

voltage

the inverter

Is

applied to the output circuit

or

short-circuit across terminals as follows.Pow

power line or motor, disconnect

of

the Inverter, it will

U,

V,

W,

the inverter will be

Do

not supply a

FREQROL

--

Motor

Conlinuily Continuity

tester tester

-1-

Page 8

Do

not use the magnetic contactor at the power supply side to

start or stop the motor (or the inverter).

Repeated magnetic contactor switching for startktop may cause

inverter failure.

Do

not access the inside

of

the inverter during operatlon.

The inverter has dangerous high voltage circuits. When checking

the inverter, disconnect the power supply and ensure that the power

indicator (commonly used as an electric charge indicator) is off.

Do

not connect a power capacltor

output circuit

of

the inverter.

or

surge suppressor on the

Such installation might cause inverter trip or damage to the

If

capacitor or surge suppressor.

such a device is connected,

remove it.

About Radio Nolse

The inverter output and input circuits (main circuits) contain high

frequency harmonics that may cause interference with

communication equipment

(AM

radios).

If

so,

use of a noise filter FR-BIF (only for input circuit) or a

line noise filter FR-BLF help to reduce the effects of noise.

Please contact your mitsubishi supplier for additional information.

I

M

PORT ANT

COVER

Power must be removed for at least 3 minutes, before removing any covers.

Removal

of

any covers exposes the operator to live terminals.

Please ensure power supply is removed.

-2-

oN’oFF+.,ON.OFF!

supply

Po~~~n

I

0N.OFFI

Magnetic

contactor

(MC)

Power indicator lamp

\ /

/\

When

charge

A

the

exisIs.

indicator

r

Page 9

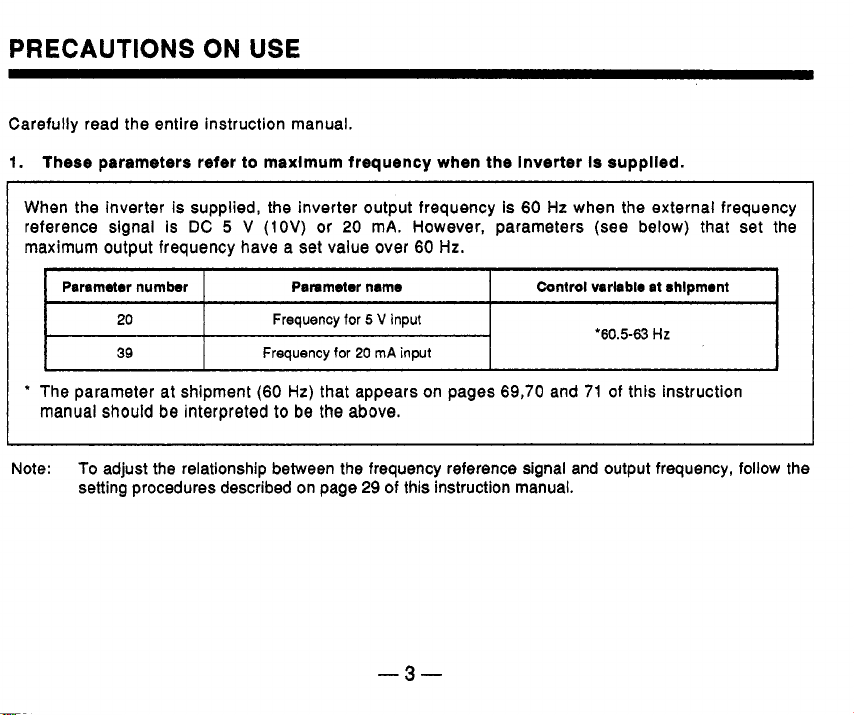

PRECAUTIONS ON USE

Carefully read the entire instruction manual.

1.

These parameters refer to maximum frequency when the Inverter is supplied.

When the inverter is supplied, the inverter output frequency is 60 Hz when the external frequency

reference signal is DC

maximum output frequency have a set value over

5

V

(1OV)

or

20

mA.

However, parameters (see below) that set the

60

Hz.

Parsmetar number

20

39

‘

The parameter at shipment

manual should be interpreted to

Note:

To

adjust the relationship between the frequency reference signal and output frequency, follow the

setting procedures described on page

Panmeter name

Frequency

Frequency

(60

for

for

Hz) that appears

be

the above.

5

V

input

20

rnA

input

on

pages 69,70 and 71 of this instruction

29

of this instruction manual.

-3-

Control varlabie at shipment

‘60.5-63

HZ

.

Page 10

~~

Frequency reference potentiometer

(voltage signal)

Pr.20

Frequency reference signal

(current signal)

Pr.39

-b4

r

(>

(>

(

(

,.

,.

/’

/’

Inverter

10

10

2

(0-5Vor0-10

2

(0-5Vor0-10

5

5

(4-20mA)

V)

V)

common

common

-4-

Page 11

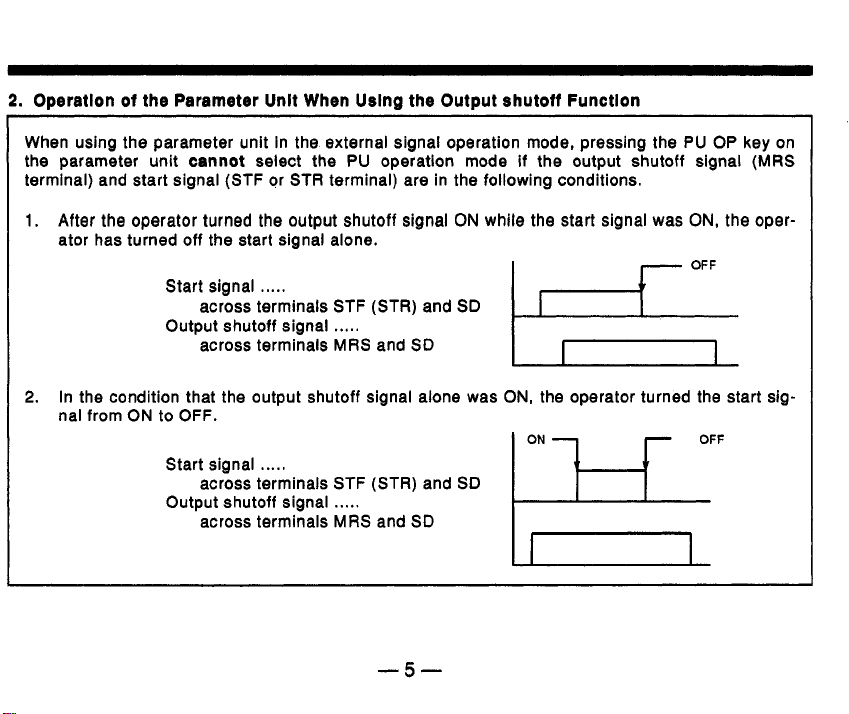

2.

Operation of the Parameter Unit When

Using

the Output shutoff Function

When using the parameter unit in the external signal operation mode, pressing the

the parameter unit

terminal) and start signal (STF or STR terminal) are in the following conditions.

1.

After the operator turned the output shutoff signal

ator has turned off the start signal alone.

2.

In the condition that the output shutoff signal alone was

nal from

ON

cannot

Start sianal

OutDut shutoff sianal

'across terminals MRS and

to OFF.

Start signal

Output shutoff signal

select the

PU

.....

across terminals STF (STR) and

.....

across terminals STF (STR) and

across terminals MRS and

.....

.....

operation mode

ON

while the start signal was

SD

SD

SD

SD

if

the output shutoff signal (MRS

I

1

In

ON,

the operator turned the start sig-

EF

-5-

PU OP

key on

ON,

the oper-

OFF

Page 12

To

select the

First, break connection between terminals

Note: When the operator has changed the function of terminal

accelerationldeceleration

condition that the start signal is

3.

Attachlng the Front Cover

When

Bring the upper part

it will “click” when in the correct position.

PU

operation

attaching the front cover, locate the lower lugs first, into the main cover.

mode:

MRS

and

SD,

then press the

time selection’, it is possible to select the

OFF.

of

front cover to the main cover and press firmly.

-6-

PU

OP

key.

MRS

from ’output shutoff’ to ’second

PU

operation mode on the

Page 13

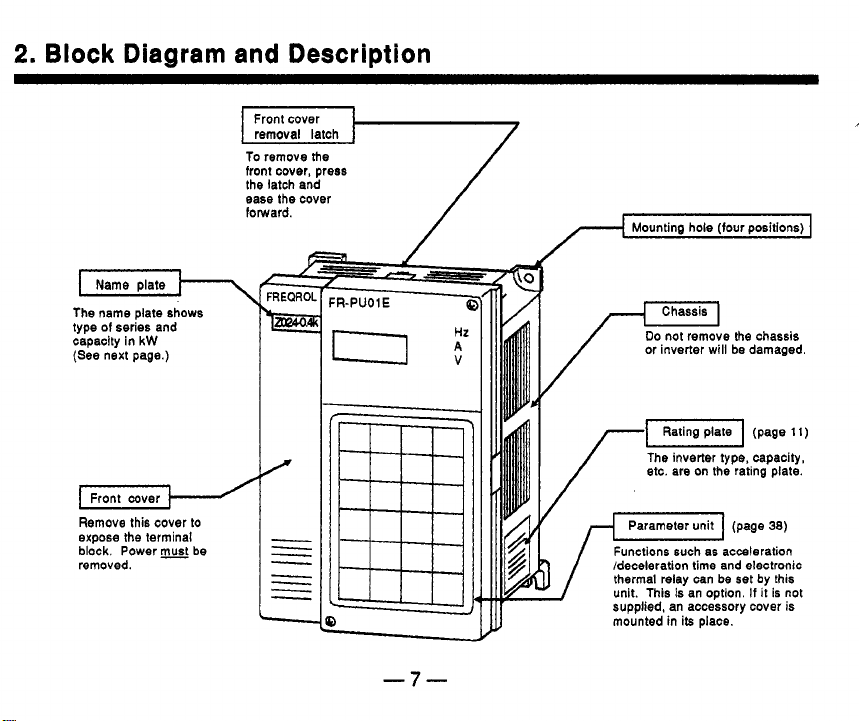

2.

Block Diagram and Description

Front cover

To

remove

the

Name plate

The

name plate

type

of

capacity

(See

next page.)

k.

Front cover

Remove this cover

expose the terminal

block.

removed.

series and

in

kW

Power

shows

to

be

front cover, press

the latch and

ease the cover

forward.

/

Mounting

hole

(four positions)

The inverter type, capacity,

etc. are on the rating plate.

-7-

w

supvlied. an accessory cover

mounted

in

its place

is

Page 14

2.

Block

Diagram

Model

and

Description

Size

FR-2024-

Symbol

0.1

K

to

3.7K

3.7K

T

I

Applicable

Inverter

capacity

in

kW.

-8-

caeacltv

is

shown

motor

Page 15

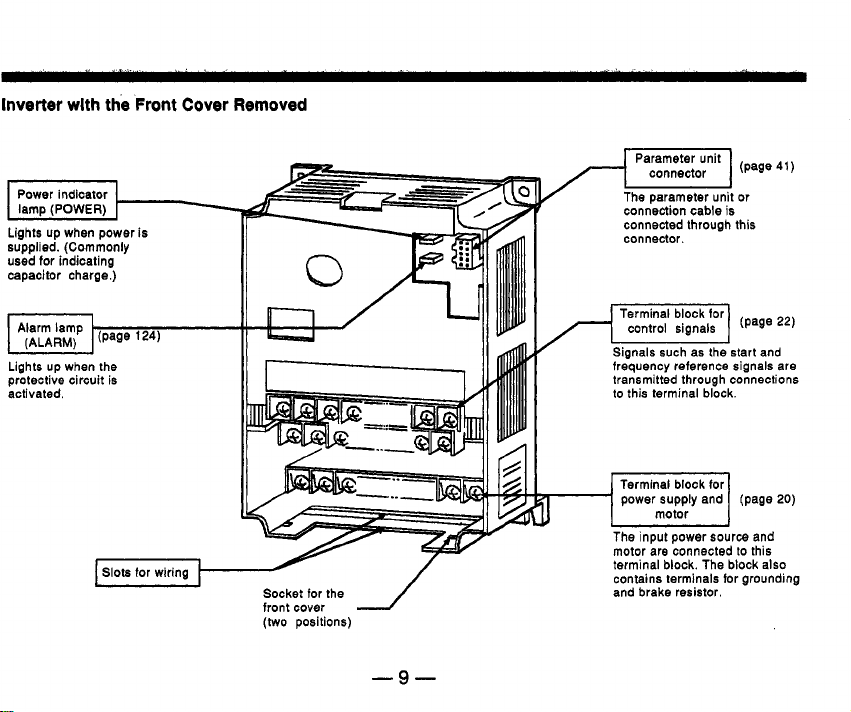

Inverter

wlth the

Front

Cover

Removed

I

Power indicator

I

lam0 (POWER)

Lights up when power is

supplied. (Commonly

used for indicating

capacitor charge.)

Lights up when the

protective circuit is

activated.

1

front cover

(two

positions)

1

-9-

11

The parameter unit or

connection cable is

connected through this

connector.

Signals such as the start and

frequency reference signals are

transmitted through connections

to this terminal block.

Terminal block for

power supply and (page

motor

The

input power source and

motor are connected to this

20)

J

Page 16

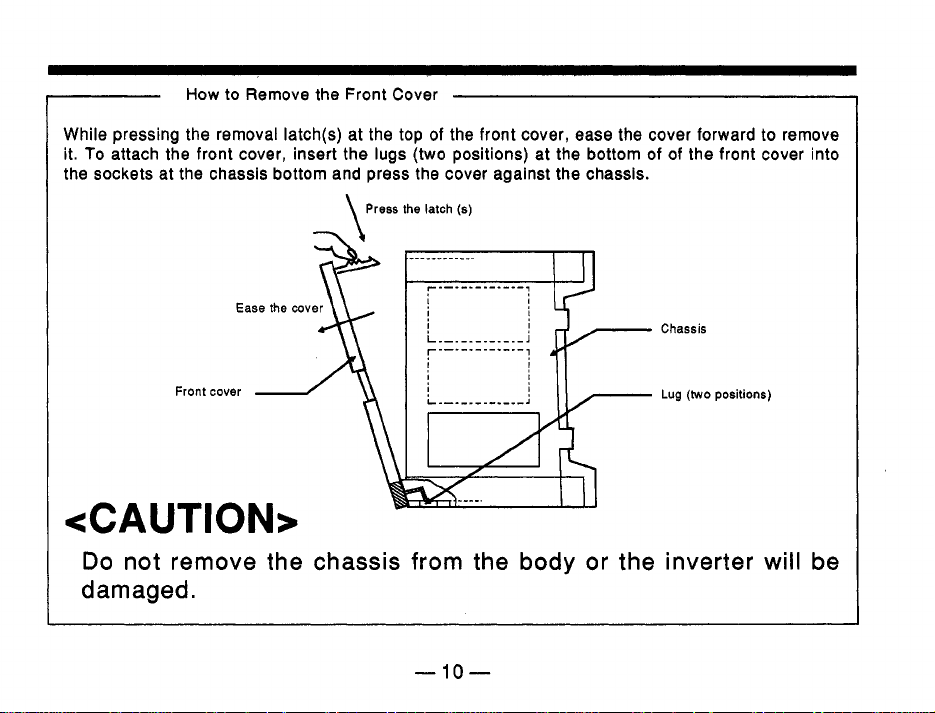

How

to Remove the Front Cover

While pressing the removal latch(s) at the top of the front cover, ease the cover forward to remove

To

attach the front cover, insert the lugs (two positions) at the bottom

it.

the sockets at the chassis bottom and press the cover against the chassis.

\

Press the latch

Ease the cover

(8)

of

of the front cover into

Chassis

Front cover

<CAUTION>

Do

not remove the chassis from the body or the inverter will be

damaged.

b

-10-

Lug

(two

positions)

Page 17

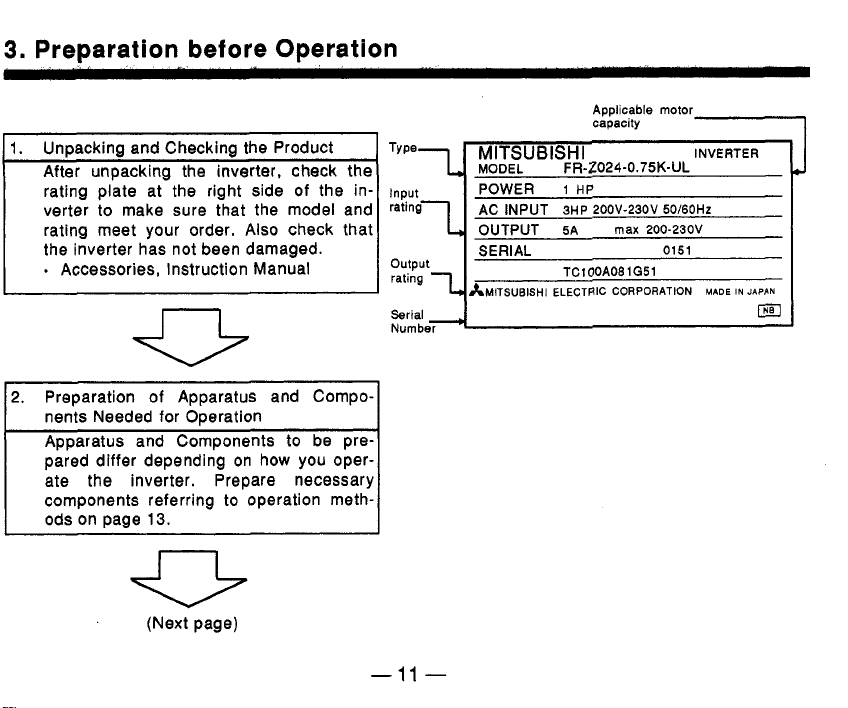

3.

PreDaration before Operation

Unpacking and Checking the Product

1.

After unpackina the inverter, check the

rating plate at-the right side of the inverter to make sure that the model and

rating meet your order.

Also

check that

the inverter has not been damaged.

.

Accessories, Instruction Manual

n

2.

Preparation of Apparatus and Compo-

nents Needed for Operation

Apparatus and Components

pared differ depending on how you operate the inverter. Prepare necessary

components referring

ods on page

13.

to

(Next page)

to

operation meth-

be pre-

Type

Input

output

ratina

-11

7

1

AMITSUBISHI

-

MlTSUBlSHl

MODEL

POWER

AC

OUTPUT

SERIAL

FR-2024-0.75K-UL

1

INPUT

3HP 2OOV-230V

5A max 200-230V

TC100A08

ELECTRIC

HP

Applicable

capacity

1051

CORPORATION

motor

1-

INVERTER

50/60Hz

0151

MADE

IN

JAP~N

I3

Page 18

stallation location, installation direction, and

surrounding space

so

as not

to

cause a re-

duction in the inverter service life or perfor-

mance.

4.

~~ ~

Wiring

Connect the power source, motor, and oper-

to

ation signal (control signals)

the terminal

block. Improper wiring may cause damage

to

the inverter.

-12-

Page 19

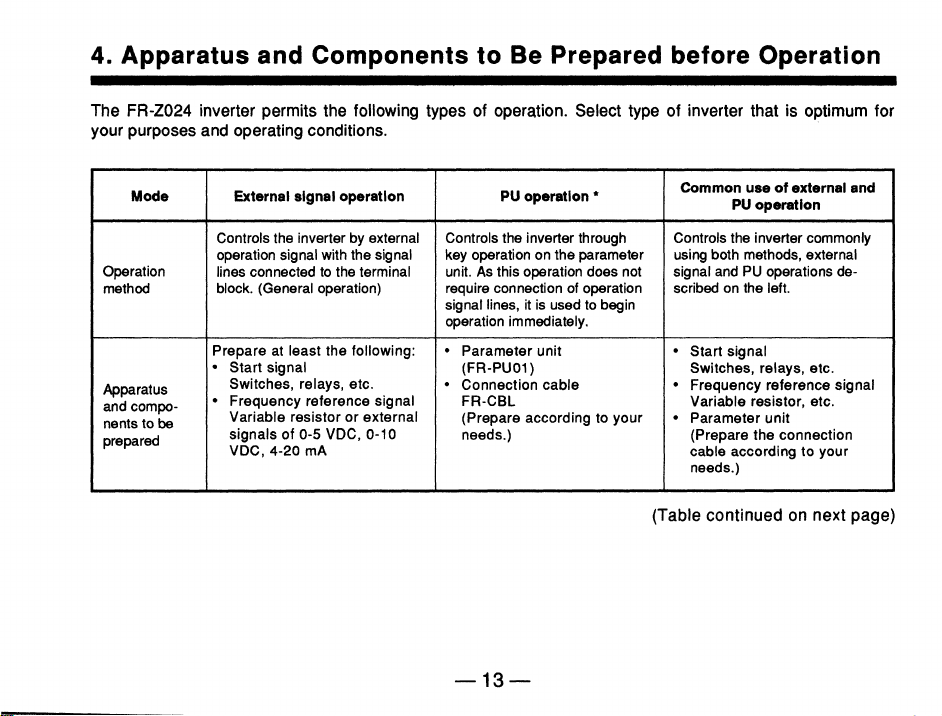

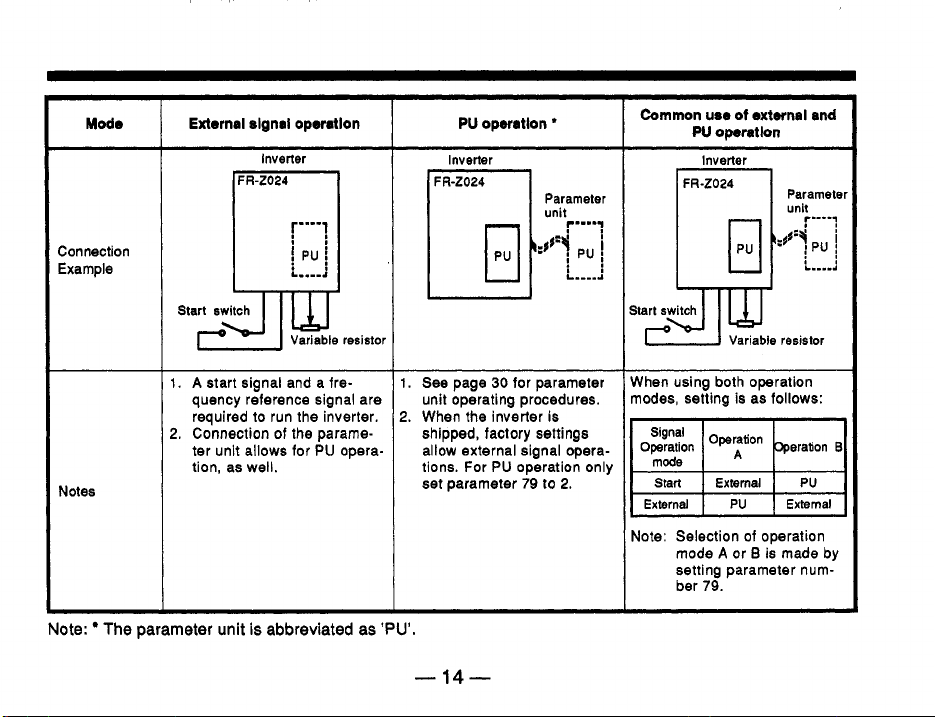

Page 20

Mode

Connection

Example

External signal opemtlon

Inverter

!

PU

i

PU

Inverter

FR-Z024

opsrrtlon

:q

Parameter

unit

r"":

p"

.I

,I

L.--..l

Common

Start

switch

use of

external end

PU

oparatlon

Inverter

I I

FR

-2024

El

Notes

Note:

The

parameter

I.

A

start signal and a fre-

quency reference signal are

to

unit

is

run the inverter.

PU

abbreviated

required

2.

Connection of the parameter unit allows for

tion, as well.

opera-

as

I.

See

page

30

the

inverter is

for parameter

unit operating procedures.

?.

When

shipped, factory settings

allow external signal operations. For PU operation only

set

parameter

'PU'.

-14-

79

to

When using both operation

modes, setting is as follows:

I

Ex;;d

I

Exteel

I

PU

2.

Note: Selection of operation

mode A or 0 is made by

setting parameter number

79.

1

External

Page 21

Page 22

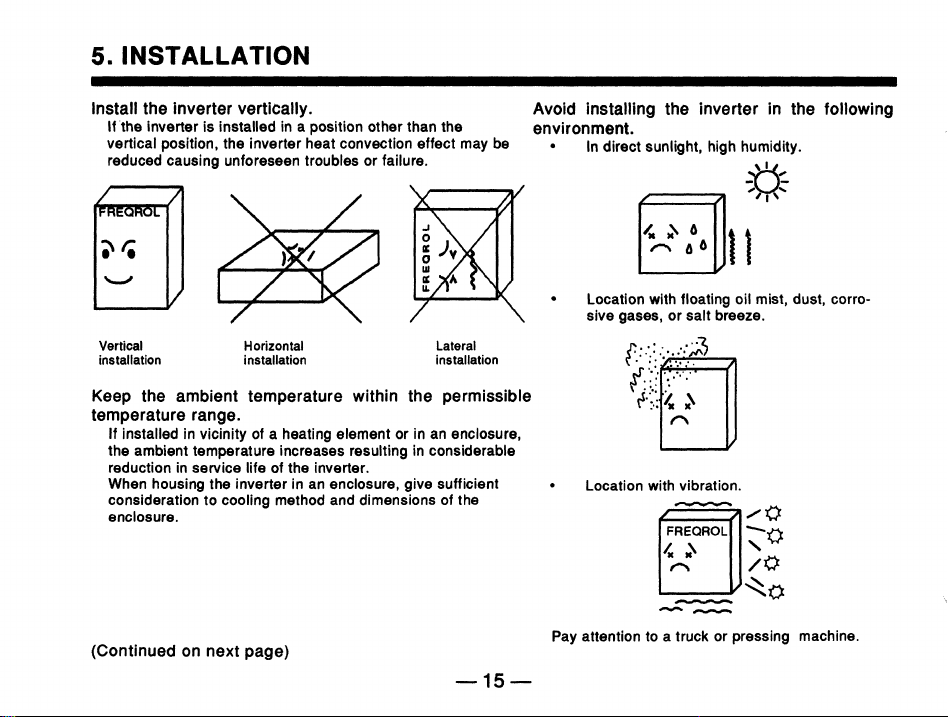

Permissive ambient temperature:-1 0 to

Measuring points

of

the ambient temperature.

+5OoC

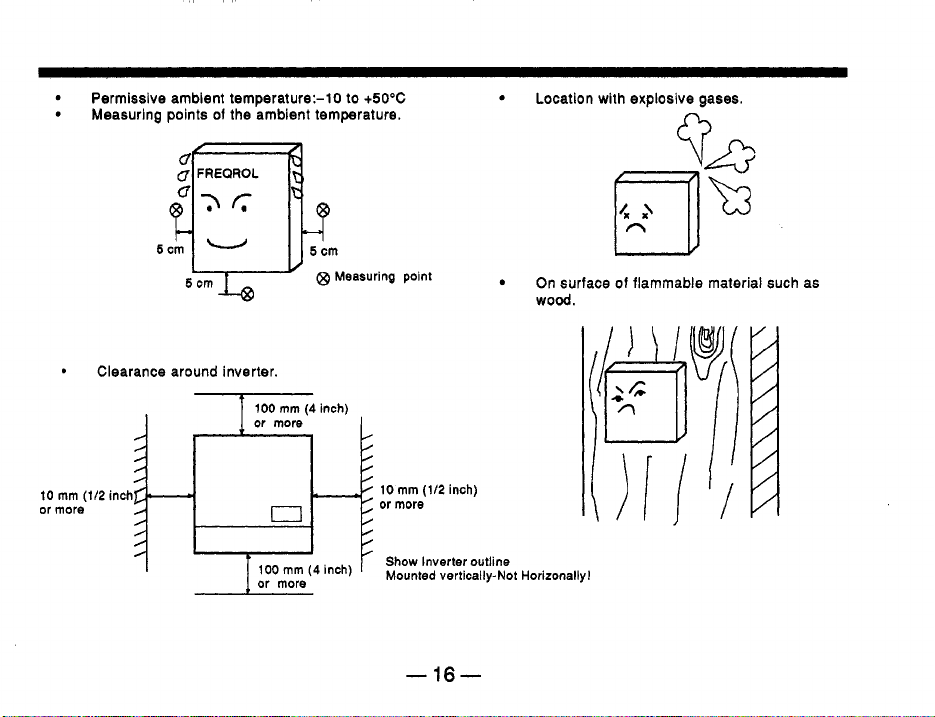

Location with explosive gases.

10

mm

or more

(112

/

0

.

/

/

inchc-

/

/

/

/

/

tTv

or more

,oo

I

mm

Q9

-0

(4

Measuring point

0

0

0

0

0

0

0

/

inch)

’

10

mm

(112

more

-

inch)

16-

or

Show Inverter outline

On surface of flammable material such as

wood.

Page 23

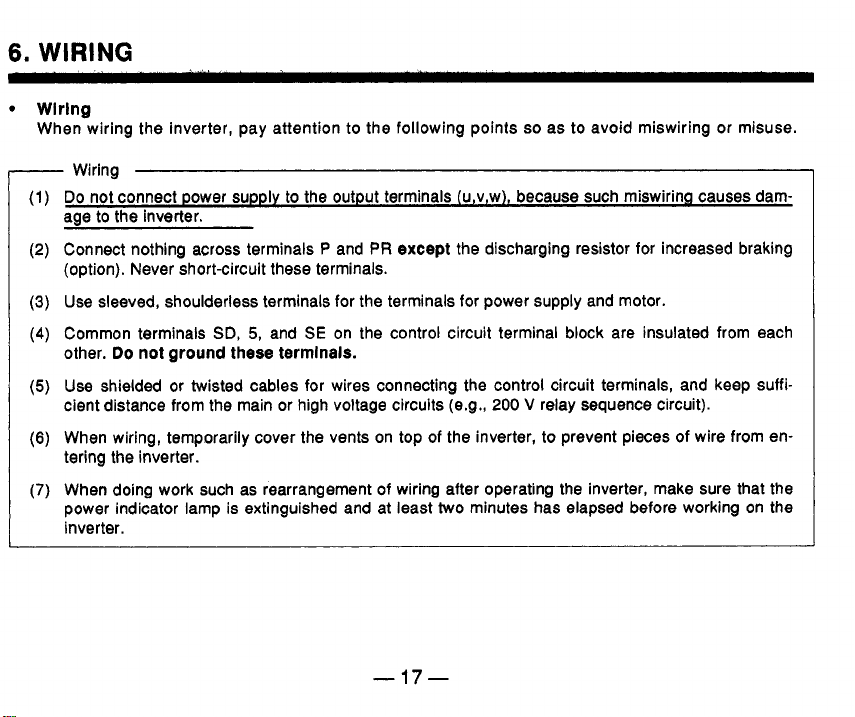

6.

WIRING

Wlrlng

When wiring the inverter, pay attention

-

Wiring

(1)

Do

not connect power supply to the output terminals (u,v,w), because such miswiring causes dam-

aae to the inverter.

(2)

Connect nothing across terminals P and

(option). Never short-circuit these terminals.

(3)

Use sleeved, shoulderless terminals for the terminals for power supply and motor.

(4)

Common terminals

Do

other.

(5)

Use shielded or twisted cables for wires connecting the control circuit terminals, and keep suffi-

cient distance from the main or high voltage circuits (e.g.,

(6)

When wiring, temporarily cover the vents on top of the inverter,

tering the inverter.

(7)

When doing work such as rearrangement

power indicator lamp is extinguished and at least two minutes has elapsed before working on the

inverter.

not

SD,

ground

5,

these

and

termlnals.

to

the following points

PR

except

the discharging resistor for increased braking

SE

on the control circuit terminal block are insulated from each

of

wiring after operating the inverter, make sure that the

-

17-

so

as

to

avoid miswiring

200

V

relay sequence circuit).

to

prevent pieces of wire from en-

or

misuse.

h

Page 24

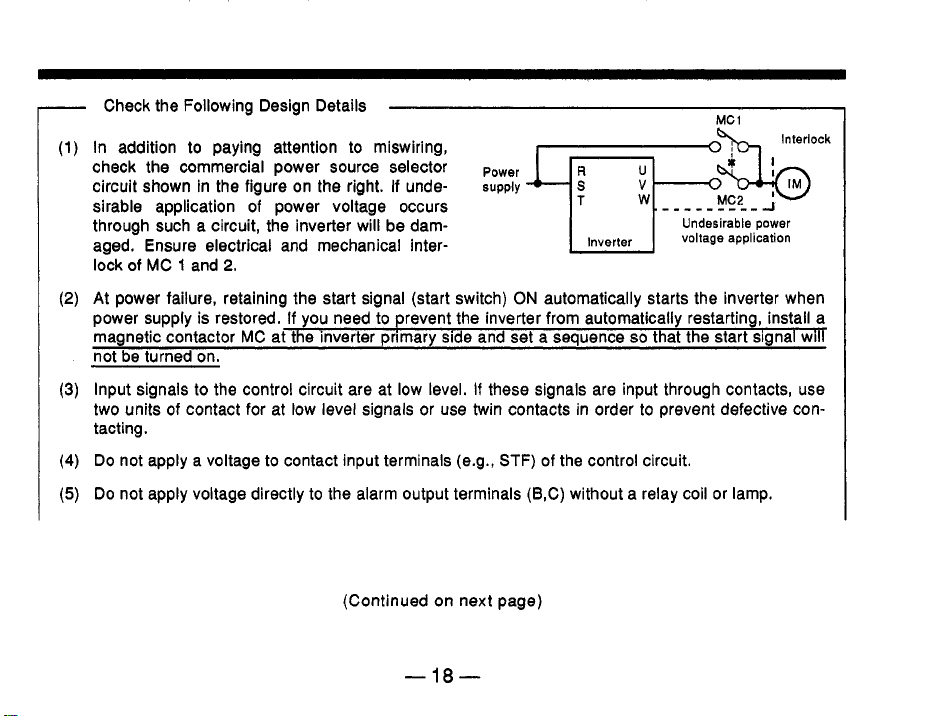

-

Check the Following Design Details

(1)

In addition

check the commercial power source selector

circuit shown In the figure on the right.

sirable application

to

paying attention

of

power voltage occurs

to

miswiring,

If

unde-

Power

supply

through such a circuit, the inverter will be damaged. Ensure electrical and mechanical inter-

lock of MC

(2)

At

power failure, retaining the start signal (start switch)

(3)

Input signals

1

and

2.

to

the control circuit are at

low

ON

level.

If

these signals are input through contacts, use

two units of contact for at low level signals or use twin contacts in order

tacting.

(4)

Do

not apply a voltage

(5)

Do not apply voltage directly

to

contact input terminals (e.g.,

to

the alarm output terminals (B,C) without a relay coil or lamp.

STF)

(Continued on next page)

-18-

Interlock

W

Undesirable power

automatically starts the inverter when

to

prevent defective con-

of

the control circuit.

Page 25

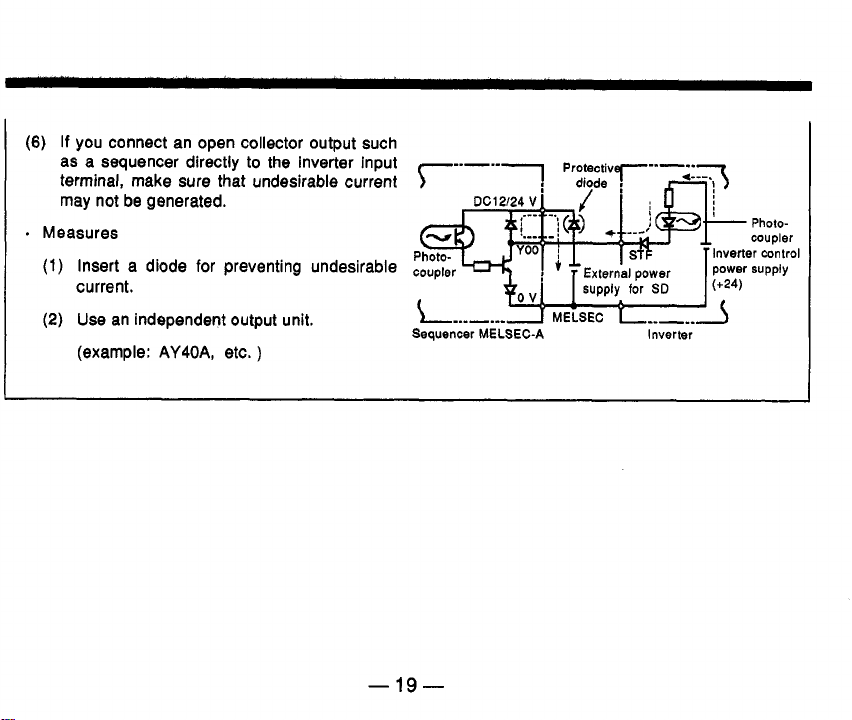

(6)

If

you connect an open collector output such

as a sequencer directly

terminal, make sure

may not be generated.

e

Measures

(1)

Insert a diode for preventing undesirable

current.

(2)

Use an independent output unit.

(example:

AY40A,

to

the inverter input

that

undesirable current

etc.

)

r---.-l

coupler

Sequencer

-19-

uv

MELSEC-A

ProtectivT--;-q

diode

,

MELSEC

L..,..

Inverter

h

n

Page 26

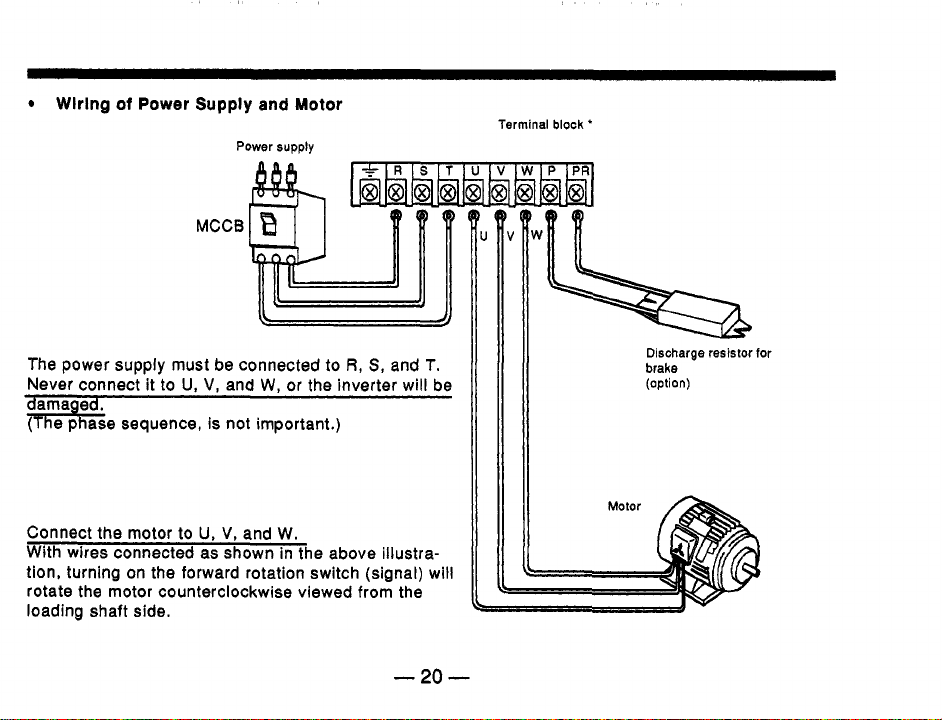

Wlrlng

of

Power

Supply

Power supply

and

Motor

Terminal

block

'

The Dower

Never connect'it-to

su~~lv

must be connected

U,

V,

to

R.

S.

and T.

and W, or the inverter will be

me sequence, is not important.)

U,

V,

Connect the motor to

and W.

With wires connected as shown in the above illustration, turning on the forward rotation switch (signal) will

rotate the motor counterclockwise viewed from the

loading shaft side.

Discharge resistor for

brake

(option)

Page 27

Notes:

1.

Terminal block

Terminal arrangement

Screw size

Terminal specification

2.

Using wire

3. The shape

4. Motor overload protection must be provided in accordance with the National Electrical Code.

5.

This drive is not intended to provide overspeed protection.

.....

size

of

terminal block differs according to inverter capacity.

.....

as shown on the previous page.

M3.5 screws (FR-Z024-0.1 K to

.....

see description of terminal specification (page 120).

See Selection

of

Peripheral Devices (page 133).

-21

-

1.5

K),

M4 screw (FR-Z024-2.2

K,

3.7

K)

h

Page 28

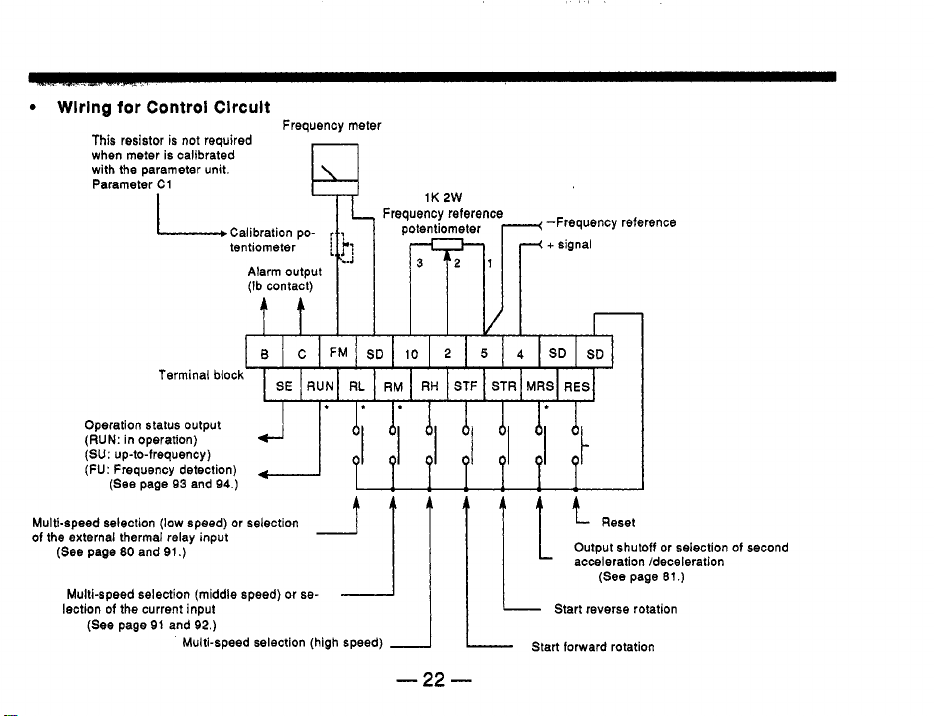

Wlrlng for Control Clrcult

is

not

This resistor

when meter

with the parameter unit

Parameter C1

Operation

(RUN: in operation)

(SU: up-to-frequency)

(FU: Frequency detection)

(See

page

Multi.

.speed selection (low speed) or selection

of

the

external thermai relay input

(See

page

80

and

Multi-speed selection (middle speed) or

lection of the current input

(See

page

required

is

calibrated

ICalibration tentlometer pol potentiometer

block

Terminal

status

output

93

and

94.)

91.)

91

and

92.)

Multi-speed selection (high speed)

Frequency meter

Alarm output

(Ib

contact)

t

t

B

c

SE

RUN

I

se-

_~_

1K

Frequency reference

I I

FM

SD

RL

RM

I

...

I

f

2W

i

I

io

2

RH

I1

t t

'j

~-

-Frequency reference

VI

5

4

SD

SD

STF STR

I

t

LL

MRS

RES

11.1

f

t

t

Reset

Output shutoff or selection of second

acceleration /deceleration

(See

Start reverse rotation

Start forward rotation

page

81.)

-22-

Page 29

Notes:

1.

Terminal block

Terminal arrangement

size

.....

Screw

2.

Input and output specifications for terminals marked with an asterisk

controlled via the parameter unit.

3.

Three terminals named

M3

.....

as shown in the above illustration (two-row).

screws

SD

are connected in the inverter.

-

23

-

"I

may be

Page 30

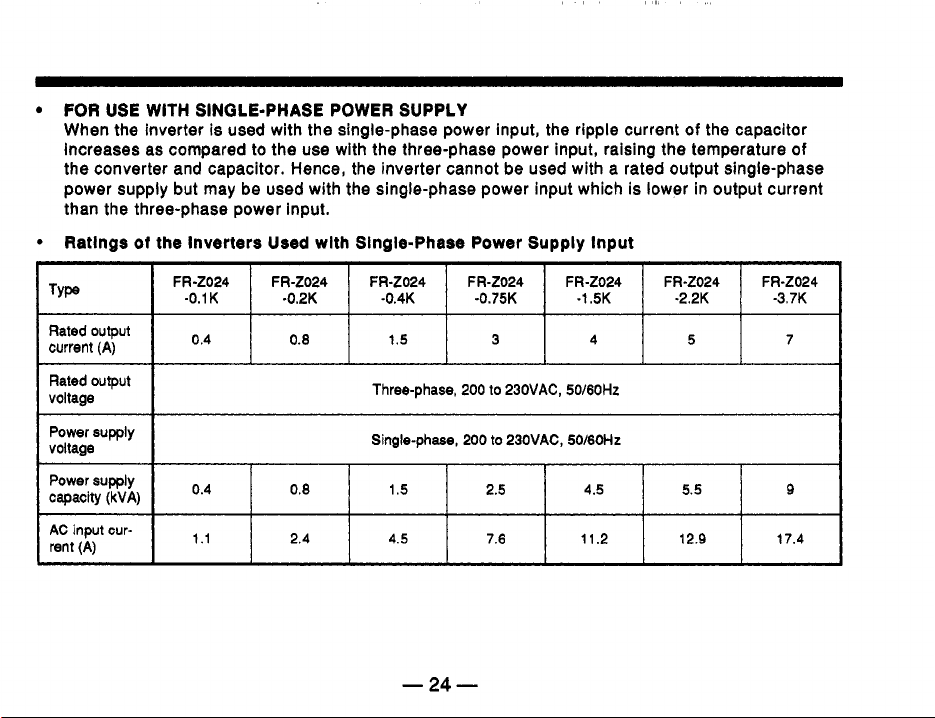

FOR

USE

WITH

When the inverter is used with the single-phase power input, the ripple current

SINGLE-PHASE POWER SUPPLY

of

the capacitor

Increases as compared to the use with the three-phase power input, raising the temperature

the converter and capacitor. Hence, the inverter cannot be used with a rated output single-phase

power supply but may be used with the single-phase power input which is lower in output current

than the three-phase power input.

Type

Rated output

current

(A)

Rated output

voltage

Power supply

voltage

Power

supply

capacity

(kVA)

AC

input

cur-

rent

(A)

FR-2024 FR-2024 FR-2024 FR-2024 FR-Z024 FR-Z024 FR-Z024

-0.1 K -0.2K -0.4K -0.75K -1.5K -2.2K -3.7K

0.4

0’4

1.1 2.4 4.5 7.6 11.2 12.9 17.4

0.6

0.8

1.5

Three-phase,

Single-phase,

1.5 2.5 4.5 5.5

3

200

to

230VAC, 50/60Hz

200

to

23OVAC,

4 5 7

50/60Hz

-24-

of

*

9

Page 31

Notes

on

Use

wlth

Slngle-Phase

(1)

The single-phase power supply must be connected to the power supply side terminals R and

of

the inverter.

(2)

The inverter must be used with the power supply

power supply capacity

Is

Power

Supply

of

sufficient power supply capacity. If the

small, the output voltage will be varied greatly by the load.

*

S

Single-phase

200

50

AC

to

/

60HZ

power

230V

supply

NFB

Circuit

-25-

Motor

Example1

Page 32

7.

PRE-OPERATION SETTINGS

Principal parameters and descriptions are as

requirements.

-

Setting Method: Use the parameter unit for setting parameters. See page

of

settings.

5.

DC

0-10

Set

parameter num-

ber 73

to

1.

v

4""

sure

to

select

V

(Continued on next page)

Parsmetere

Frequency reference signal

Select

5V

or

1OV

descriptions

Set the frequency reference voltage signals input across termi-

2

and

nals

0-10

Note:

Be

auencv reference Dotentiometer (variable resistor).

follows.

D-crlptlon

I*

I

the

0-5

Set these parameters according to operational

DC

05

V

Set

parameter nurn-

to

ber 73

VDC

input if you connect a fre-

0.

The inverter

shown above when

isshipped.

is

set

as

it

-26-

30

for

Related

Functlons

Input selection

rameter number 73)

5

V/10

V

(pa-

Page 33

Parametem

Maximum output

frequency

Deecrlptlon

Set this parameter when you operate the inverter with a value

other than that set when the inverter is shipped.

control variables set at shipment.

put frequency higher than

reference must be changed.

‘(Control Variables Set at Shipment)

’

Voltage signal

’

Current signal

PU

operation

.....

.....

.......

If

60Hz,

60

0

up to the maximum frequency of

120

it is necessary to obtain out-

the maximum output trequency

Hz

at 5 VDC (or

Hz

at 4 mADC,

Hz

60

10

Hz

See

VDC)

at

below for

20

mA

Related

Functlonil

Frequency for input

voltage signal

(parameter number

Frequency for input

current signal

(parameter number

Maximum frequency at

PU

operation

(parameter number

of

of

5

V

20)

20

mA

39)

1)

Maximum

frequency

Minimum

frequency

Set this parameter only when you set the maximum or minimum

-frequency.

Although it is possible to set the maximum frequency within the

range indicated above, the inverter may not operate correctly if

the maximum frequency is set incorrectly.

Note:lf the minimum frequency is set, the motor will run at thc

minimum frequency by just turning the start signal on.

(Continued

on

next

page)

-27-

*

Maximum frequency

(parameter number

*

Minimum frequency

(parameter number

1)

2)

Page 34

Electronic thermal

relay

Acceleration/

Deceleration time

Descrlption

Set

the relay in accordance with the rated current

speed of the motor.

Note:Operation characteristics, are based on operation with

standard squirrel cage motor. They are

special motors.

nal thermal relay

to

mutiple motors.

If

you perform

other than the value

acceleration/deceleration

the

set

Value

Note:The

at shipment: 5 sec.

set

If

you use a special motor, mount an

to

protect your motor. This also appliei

acceleration/deceleration

set

when the inverter

time.

value is the time from start

operation with a time

at

the base

not

applicable

is

shipped, change

to

the maximum outpu

extei

frequency stated before.

-28-

Related

'

Electronic thermal relay

(parameter number

i

'

Selection

ti

load

(parameter number

'

External thermal relay

Input selection

(parameter number

*

Acceleration time

(parameter number

'

Deceleration time

(parameter number

Second acceleration

/deceleration time

(parameter number

'

Second deceleration timc

26

(parameter number

Functions

of

applicable

9)

14)

46)

7)

8)

17)

47)

Page 35

In order to monitor the output status accurately, calibrate the frequency meter before operation. Use of

the parameter unit allows precise adjustment. (See page

64

for calibration procedures.)

-

Changing usage of an inverter (Previouly set up)

Because such an inverter might have parameters set previously according

parameters before operation

Mitsubishi).

The inverter may be factory reset on the parameter unit. (See page

Note, however, that the parameters that follow may not be initialized even

parameters using the parameter unit. Read each control variable and change

'

Parameter number

'

Parameter number

*

Parameter number

Parameter number

'

Parameter number

Parameter number C-5

(reset parameters to values set when the inverter was supplied by

20

'frequency for 5 V input signal'

39

'frequency for

C-2

'frequency reference voltage bias'

'frequency reference voltage gain'

C-3

C-4

'frequency reference current bias'

'frequency reference current gain'

20

mA input signal'

-

29

-

61

for

to

a specific operation, reset

initialization.)

if

you all clear

it

to

a needed value.

Page 36

8.

OPERATION

Check Points before Swltchlng Power On

e

Check that the power lines are connected to terminals

Check that the source voltage meets the rated value, and is not exceeding the specification of the

inverter. (See page

Check that the setting of the maximum output frequency is within the load (machine) specification

range. (See page

-

Check that short-circuit or ground fault do not exist in the output circuit or sequence.

Bask Operating Procedures

After the inverter has been wired, follow the procedures on pages

correctly.

11

3

for specifications.)

78

for setting conditions.)

R,

S,

T.

Also

check that terminals are tight.

31,

32

and

33

to check that it operates

-30-

Page 37

-

Operation with External Signals

Example

of

setting frequency

Start

Switch power on.

I

(The power indicator lamp is lit.)

Turn the start switch on. (Short-circuit across terminals

STF and SD or

with

4

STR

I

a

voltage

and SD.)

signal

'

1

h

I

I

Acceleration

Constant

Deceleration

I

4

stop

speed

Slowly turn

tentiometer) clockwise

Slowly turn the variable resistor (frequency reference

tentiometer) counterclockwise

'2,'3

Turn the start switch off. (Open across terminals STF and

SD or

the

variable resistor (frequency reference

to

the

maximum position.

to

the maximum position

STR

and

SD.)

*

1

-31

-

po-

po-

Page 38

-

Operation with the Parameter Unit

Using the parameter unit.

Switch power on.

(The power indicator lamp is lit.)

Selecting the PU

operation mode

Setting output

frequency

I

Start

and

ation

Press the PU OP key to select the PU operation mode.

(The indicator lamp next to the PU OP key is lit.)

Enter the frequency value with which you want to operate

the inverter using the numeric keys, then press the WRITE

key, or hold down

i

is reached.

I

Press the

FWD

or

I

1

REV

or

[El

until desired output frequency

key.

Frequency

change

eration

during

stop

After pressing the PU OP key, enter the frequency value to

which you want to change, with the numeric keys, then

op-

.4

press theWRlTE key, or hold down

sired output frequency is reached.

and

Press the STOP key.

'3

[El

or

until the de-

-32-

Page 39

Notes:

The inverter will not start

1.

if

both forward and reverse rotation switches are turned on.

switches are turned on during operation, the inverter will decelerate and stop the motor.

2.

If

the start switch is turned off with the variable resistor turned clockwise to the maximum

position, the inverter will decelerate and stop the motor.

3.

A

high pitch sound is generated just before the motor stops, this is normal. The sound is

generated because the

4.

If

the parameter unit

DC

dynamic brake is in operation.

is

removed from the inverter during operation, normal operation wiii

continue, however, the motor cannot stop, therefore, do not remove the parameter unit

during operation.

-33-

If

both

,-

F

Page 40

Using both External Signals and PU Operatlon

The

2024

follows:

The start signal is controlled externally, while the output frequency is set on PU.

1.

2.

Notes:

inverter permits use of both external signal and PU operations. The details are as

To

select this configuration, first, set parameter number

to

11.

selection'

After turning the start switch on, output frequency is set on PU during operation.

(See page

1.

2.

3.

(See page

44

and

45

The external frequency reference signal or PU forwardlreverse rotation and stop keys

are not accepted.

The operation mode lamp indicates PU operation. The external signal operation mode

cannot be selected.

If

the start switch is turned on, the inverter

automatically. To monitor data, press the MONITOR key.

51

and

52

for detailed procedures.)

for detailed procedures.)

79

'operation mode

is

not switched

to

the monitoring mode

Start switch I Inverter

-34-

I

Page 41

-

The start and multi-speed selection signals are externally controlled, while setting

speed is done by using the

When the inverter is supplied, setting allows for this configuration.

1.

After turning the start switch

(short-circuit terminals

2.

Control multi-speed frequency on

If

you selet high speed (short-circuit

ter number

and

Note: Control variables of multi-speed other than those in-operation, may be changed during

operation.

4

'third speed setting (high speed)' alters speed during operation. (See page

49

for detailed operations.)

PU.

on,

select multi-speed signal needed for operation

RH-SD,

RM-SD,

PU

Start

or

RL-SD).

during operation.

RH

and

SD),

for

example, a change in value

switch

qM

-

35

Inverter

-

of

of

multi-

parame-

48

Page 42

The output frequency is controlled externally, while start/stop is controlled using.the PU.

1.

To select this configuration, first, set parameter number

'operation mode selection'

tailed operations.)

2.

While inputting output frequency (analog or

multi-speed selection stated above) signal externally,

runlstop is controlled by the FWD/REV and STOP key on

PU.

Notes:

1.

The start terminals (STF, STR) on the inverter are

disabled.

2.

The operation mode lamp indicates PU operation.

The external signal operation mode cannot be selected.

3.

When not in the monitoring mode, the PU display

shows the frequency corresponding

nal frequency setting signal. Note that this frequency is not displayed unless the PU OP key is

pressed.

4.

The inverter may also be started by pressing the FWD or

external frequency setting signal set to

signal. (Note that

PU

OP

to

12.

(See page

O.01Hz

key after the FWD or REV key of the PU has been pressed.)

43

and

44

to

is displayed when the set frequency is called by pressing the

79

for de-

Frequency reference

potentiometer

Current input

selector Inverter

the exter-

0,

and then increasing the frequency setting

REV

1

Inverter

10

2

d

1-1

key

of

the PU, with the

-36-

i

Page 43

In-operation Check Points

that the motor rotates in the correct direction.

Check that the motor does not generate unusual noises or vibration.

.

Check that the pointer

.

Check

if

the

ALARM

See

page

109

and

of

the frequency meter swings smoothly and correctly.

lamp lights, and the inverter stops (inverter trip).

1

10

for causes and measures.

-37-

h

Page 44

9.

How

to Use the Parameter Unit

Parameter unit, model FR-PUOI, is attached to the inverter

the cable (option). The parameter unit permits the operator

(parameters), and to monitor operational status and alarm messages through its readout.

In this manual, parameter unit

FR-PUO1

is

abbreviated as

(FR-Z

series), or connected

to

set (read and write) various control variables

'PU'.

-38-

to

the inverter with

Page 45

DISPLAY(READ0UT)

Frequency, motor

control variables, alarm message,

etc. are displayed by this 7-segment 4-digit readout.

2nd

or

3rd

group

key

(2nd)

Press this key after pressing the

key to read or change (write)

9

con rot variables for the 2nd group

selected by

function

KEY

after this

SHIFT KEY

Variable (frequency, motor current,

alarm message) to be monitored is

shifted or 3rd group function is

Iected.

se-

CLEAR KEY

If

incorrect key is pressed during

setting, it can be cancelled by

pressing this key.

FUNCTlONlNUMERAL KEYS

Parameter

value or frequency can

No.

of

1st

group function and

be

specified.

-

‘R-PUOI

PARAMETER

0000

.b

I

-

39

L

-

MOUNTING SCREW

By loosening two screws, the unit

can be separated from the inverter.

A

VARIABLE INDICATOR LAMP

Control variable to be monitored (frequency, motor current, etc.) is indicated.

L

OPERATION MODE KEYS

Operation mode can be selected

from: operation by the parameter

unit, operation by external signals,

readlwrite

4

toring frequency, motor current,

alarm messages.

Note:

of

control variables, moni-

The parameter unit is abbrevi-

‘PU’

ated as

FREQUENCY ADJUST KEYS

4

Whilst it is held down, frequency continuously increases or decreases.

OPERATION KEYS

Direction of motor rotation can be

lected and operation can be

stopped.

I

READlWRlTE KEYS

J

Variable setting can be read

se-

Page 46

10.

INSTALLATION

The

PU

remb,te+in#aH$tion~on an enclosure or control with the parameter unit held

attached Waonnbetw even when the Inverter is in-operation.

can be attached directly to the inverter, or connected to the inverter with the approved cable for

DLrset

Attachment

Attach PU to the inverter front cover for use (it is electrically connected through the plug and

receptacle).

For

Ffivetters

Io

without

to

Inverter

PU,

replace the accessory cover

(1

(2)

on

the inverter front cover.

)

Connection

Engage the plug of PU with the inverter receptacle and

gently press the

Securing the PU in position

Lightly tighten

PU

two

against

screws

in

the opetator’s hands.

the inverter.

to

secure the

PU

It

can be

in position.

-

40

-

Page 47

Remote

In

held by hand for adjustment or maintenance. In this case, use the approved cable (option) to

connect PU and the inverter.

lnstallatlon

addition to attaching PU to the inverter, it

Uslng

the Approved

(1)

(2)

Cable

Connector

is

possible to install it

Connection

Plug one end

inverter, and the other end into PU. When plugging, fit

the guides

left.) (Improper connection may damage the inverter.)

Locking

The plug on the inverter side should be locked with

screws as shown on the left. On the PU side, secure

the cable

its own weight.

to

the grooves. (See the illustration on

of

Plugs

so

that the cable cannot be disconnected by

to

an enclosure

of

the cable into the receptacle

or

to control it

a:::::

Fit

the

guides

to

the

grooves

of

the

Note: The extension cable, must

be

a Mitsubishi type, and is available as an option.

-41

-

Page 48

11.

OUTLINE

OF

FUNCTIONS

Monitoring

Operation status and alarm message can be monitored.

Output frequency

Direction

Motor current

Operation mode

Alarm information

See

procedures

Additional control variables can

be accessed and changed.

See

operating procedures.

of

motor rotation

page

55

for operating

Setting of control variables

page

51

and

52

for

1

-42-

Selection of operation mode

It

is possible

nal signal operation or

tion mode.

See

page

procedures.

-I

The

put frequency can be

Operation on

Jog

Motor control

motor starts or stop or out-

operation

able.

See

page

operating procedures.

I

to

select

43

for operating

PU.

is

also

51

and

52

the

PU

set

for

exter-

opera-

by key

avail-

Page 49

12.

OPERATION

How

to

Select

Operation

1.

Operating the Inverter with External Signals (External Signal Operation)

When the inverter

signal operation function),

To

select the PU operation mode from the external signal operation mode, press them key.

2.

Operating the Inverter with the Parameter Unit (PU Operation)

Press thep key to select the PU operation mode.

To

select e external signal operation mode from the PU operation mode, press them key.

3.

Operating the Inverter Using both the External and PU Operation Modes

using the external and PU operation modes, for example, the start signal is input externally and

output frequency is set on PU, set parameter number

only by this setting. See page

Mode:

is

supplied,

it

is set to this operation mode (when power is turned on, external

so

it is not necessary

26

for detailed operating procedures.

to

Selecting Operation Mode

select operation mode on PU.

To

control the inverter

79

to

11

or

12.

Such operation is available

-43-

Page 50

How

to Set Operation Mode

It is possible to set only one mode

When power

mode is prohibited.

L

is

turned on, the set operation mode is selected, and selection

Press

the

PU

key.

ul

Press

the

of

operation using either external signal or

-44-

key.

I

PU

of

oparation.

other operation

1

I

Page 51

Note:

1.

Caution at changing operation mode

Operation mode cannot be changed when the start signal is on

closed).

2.

Caution for removing PU during operation

In the PU operation mode, do not remove PU during operation. The inverter will stay in

operation even

operating the motor.

if

PU is removed. In that case, the operator cannot stop the inverter from

(STF-SD

or

STR-SD is

-45-

Page 52

OPERATING THE MOTOR

The operator can startlstop the motor with PU, without any external frequency reference

potentiometer, or start switch.

below

to

control the motor.

Operating Procedures

JOG

WITH

operation is also available with PU. Follow the key operation

THE PARAMETER UNIT

Frequency setting

The increase (or decrease) of frequency is slow initially, after the key is pressed, but increases

as the key is held depressed.

.....

By repeating this procedure during operation, it is possible to vary the

rotation rate.

-46-

Page 53

Note: Be sure to press them key when desired frequency

stored.

u

is

set, otherwise the set frequency

is

not

h

The motor starts and runs only while the

motor stops.

JOG

operation frequency is the value set with the parameter unit. (Parameter number

WD

or

El0

REV

key

is

held down. If the key

-47-

is

released, the

15)

Page 54

To

return to external signal operation, press the

stopped.

(If

the external signal operation cannot be selected, see page

(4)

Method to Vary Speed with

PU

during Multi-speed Operation.

key, then press the key after the motor has

69

and

70.)

Operating procedure

pressing the key is unnecessary.

Example of Operation

*

Example where

60

(1)

Hz

is set for desired output frequency (from start to

I

f

cation

or

(2)

on page

51

and

Set

to

11"''

-48-

52

permits such variation. Note, however, that

60

Hz)

60

Hz

I

Stari

I

I

I

stoa

I

I

Page 55

*

Example where speed

is

changed during operation

(from

60

Hz

to

30

Hz):

Note: Direct setting of output frequency is impossible while the

To

'

JOG

set output frequency, press the

Operation

Indi-

cation

I

i

PU

key

Ll

oaaX

i

to

cancel the

mlt

Xook

I

-49-

MONITOR

MONITOR

I

mode indicator lamp is lit.

mode.

Page 56

Notes:

1.

The JOG mode cannot be selected while the motor is in operation. Press the key to

stop the motor, then select the

2.

To cancel the JOG mode operation, press the qkey.

3.

Desired frequency and

are the same) for the JOG mode operation can be set by specifying the corresponding

parameter (control variable). (See page

When the inverter is shipped, the JOG frequency and acceleration/ deceleration time are set

to

5

Hz

and

0.5

4.

If

the motor does not start, check the starting frequency.

*

When the motor is started by pressing the start key

automatically selected and output frequency is displayed.

While the inverter output

flickers (the same occurs during

sec., respectively (it takes

is

on (motor in rotation), the mode indicator lamp just above the

JOG

mode.

acceleration/deceleration

90.)

0.04

DC

dynamic brake operation).

ime (acceleration and deceleration times

sec. for increase of frequency up to

(m

orm), the MONITOR mode is

5

Hz).

key

Page 57

SETTINGS

OF

CONTROL VARIABLES (PARAMETERS)

The inverter has a variety of control functions. It is possible

check control variables.

The parameters(contro1 variables) are factory-set

parameters should only reguire adjustment

Such as: AcceVDecel rates or min/max frequency are grouped into three categories, from

functions.

Setting procedures that follow differ according

Setting procedures

(1)

Setting of

most often used.

r-------I------------I------~----------------------

Parameter name (abbreviations) are indicated on the numeral keys

1st

functions (parameter numbers

to

to

to

suit

individual application requirements.

this classification.

-551

to

choose individual parameters

run a standard

0-9)

.....

These are main function and are the

-

AC

induction motor, therefore

(0-9).

to

alter or

1st

to

3rd

Page 58

(2)

Setting of 2nd functions (parameter numbers

applications.

lo-)

.....

These are used

in

advanced

(3) Setting of 3rd functions

*'

Desired parameter may be called by pressing theB key several times. See page

To

read a set value:

In the above procedure, press the

(Example)

To end or cancel settings:

To control the motor with

.....

Calibration

READ

key instead

PU

at the middle of setting, or when settlng is complete, press the key.

p]

of

the

(The case of 2nd function)

key without entering

-52-

49

for details.

a

set value.

Page 59

Examples

(1)

of

Operatlon

Setting of 1st Function (acceleration time setting)

.....

To

change from 5 sec. to

10

sec.

Key

Indi-

cation

Note:

When another

can be called by

unnecessary.

Solsotton

1st

-1g;z

0

;.:

of

tunctlon eccelontlon time

lpl.11

0

;.,

/ov

1st

function is

just

pressing the corresponding parameter key,

Settlng

of

Read

lzJ

W]

to

be set after setting a

-53-

premnt

value

(5

sec.)

Initial setting

1st

Change

to

10

Sec.

mm

rr-pTq

(1Osec)

function, the new desired arameter

so

repressing theb key

ml

Write

pJ

*

Alternate

is

Page 60

(2)

Setting of 2nd function (frequency reference for

JOG

operation)

.....

To

change from

5

Hz

to

10

Hz:

Setting

2nd

Indi-

cation

Note:

1.

A

dot is placed after

2.

When another 2nd function is to be set after setting a 2nd function, the new desired

parameter can be called by just pressing the

so

repressing the

*

If

changing parameter or reading is impossible:

See page

71

when an error message is displayed and a new value cannot be written.

of

funct'on

frequency

JOG

,!D

,-when the 2nd function is selected, ex.

key is unnecessary.

Of

for

operation

-54-

Read present Change to

value

2nd

key and specifying the parameter number,

0

10

Hz

(

i-7

,-.,)

Write

Page 61

MONITOR

Conditions

protectlve function at occurrence of an abnormality can be monitored

LED

Type

I

I

Engineering Display Unit

I

External signaVPU operation

I

of

load such as output frequency and motor power, and information about activated

lamps).

of

Yonltored

monnored

Information

Output frequency

Output current

Direction

In-operation Operation mode

MONITOR

Setting mode

JOG

of

rotation

mode

mode

lnlotmatlon

1

Unlt I lndlcator devlce

Hz

A

I

I

I

-

IVaJa;ble

I

-

IReadout

Readout and

variable indicator

lamp

Indicator

indicator lamps

lamp

indicator

1

In the MONITOR mode shift the display information with the

Switched from the monitoring of the output frequency when

I

the function number

The lamp is lit at forward rotation and is flickering at reverse

I

rotation.

The lamp above the operation mode key corresponding

selected mode is lit. When the motor is running, the lamp

flickers, when stopping, the lamp is just

I

If

-55-

Dleplay/operetlon/se~lng

key

37

the

JOG

meration mode is selected,

with

is

set.

PU

(by

segment display and

In

brief,

lit.

'JOG'

etc.

is

displayed.

I

I

I

to

the

I

Page 62

Readout (7-segment 4-digit

\

LED)

Parameter Unit

-56-

Variable indicator lamps

Control variable

/-

indicated.

All

when

readout.

Operation mode indicator

/lamps

When an operation mode

pressed,

lit.

Operation mode

lamps are turned

alarm information is on

the

corresponding lamp is

/

to

be

monitored is

off

the

key

is

keys

Page 63

lndlcator

In

this manual, the variable indicator lamps are described

;e:

lamps.

is

Lamp

in

the

MONITOR

a

"lit"

lamp, and 0 is an extinguished lamp. The same is applicable

Mode

in

the following layout.

to

the operation mode indicator

lndlcatlon

0

0

0

Note

1:

Descriptlon

Frequency is displayed.

Hz

Motor current is displayed.

A

Not used.

V

The engineering display unit is displayed when the function number

other than

0.

If

the stall prevention function is activated during MONITOR mode, all

MODE

lamps except that selected flicker.

reverse rotation, these lamps are

lit

or

-57-

If

the motor

flicker, respectively.

37

is

in forward

is set to any value

or

Page 64

Example

*

of

Output frequency, motor current (constant), alarm condition (checking)

Operation

-

Output frequency

I

Note:

By pressing the

time of the alarm

-

To

check

Up

to

four alarm codes are stored.

condition displaying status.

I

(60

Hz)

the

stored alarm information:

Fl-

2nd latest alarm 3rd latest alarm Oldest alarm (Returns

SHIFT

L7

IS

isp ayed.

Motor

current

c

0

HZ

A

/'

'do

/'

key when an alarm condition is indicated, the output frequency at the

To

0

(6.5

check them follow the procedure below in the above alarm

0

A)

ov

................

~I-~IREAD------*/

................

Alarm

(Returns

to

-

READ

/

-

to

the latest alarm.)

condltlon

the latest alarm.)

I

-558-

Page 65

Notes

:

1.

To erase an alarm code:

@

With an alarm code displayed, press the

displayed code will be erased from memory, and the next code

be

displayed.

will

key, the

A

2.

To

check operatlon

conditions immediately

before Occurrence of an

alarm:

At Occurrence of an alarm, the parameter unit automatically

displays the activated protective function. In this condition if

you press them key (without resetting), output frequency

is

displayed. Thus it is possible to check output frequency

immediately before the alarm Occured. Motor current will also

be checked similarly, but these values will not be stored.

-59-

Page 66

Alarm

Dlsplay

If

failure occurs

readout

as

during

follows

operation of

(See

page

124

for details):

the

inverter,

an

alarm

code

is

automatically displayed

on

the

PU

I

I

c

DIaplay

c

1-1

E

2:

L

1-1

f-

1:

I-/

1-1 1-1

11

1- (-1

I-

1- I 11

1,’

I-

1-

I I 11

c

L

.

I-

c

I-

c

I-/ I-

1-

-/

-?

I I-

1-1

c

L

Code

EOC1 Inverter output current exceeded the overcurrent limit during acceleration.

/

EOC2 I inverter output current exceeded the overcurrent limit during constant-speed operation.

I

1

EOC3

1

EOVT

I

I

Inverter output current exceeded the overcurrent limit during deceleration.

I

Braking regenerative power from motor exceeded the regenerative overvoltage limit.

Electronic thermal relay in the inverter was activated (current is below

current).

Electronic thermal relay in the inverter was activated (current is over 150%

current).

Brake transistor in the inverter fault detection. E. BE

-

60

Dwrlption

-

150%

of preset

of

preset

Page 67

Dlaplry

/:

I7

1-

1-1

/-I

I

Code

I-

I

/

EOHT

External thermal relay was activated.

De6crlption

1:

I

1-

I

E

11

1-

1-1

I I-

1-1

1-

.

a’1

I

I7

I:/

1-1

I

I

L

I

I-

Stall prevention function was activated during constant-speed operation and

1

E.PE I Data memory in the inverter and corresponding

EOPT

Indicates that the retry function has been activated or any error other than the error selected

by

the retry selection has occurred and

-61

-

stopped

to

parameter number

the inverter.

is

corrupted,

stopped

the

Page 68

Characters Appearlng In Readout

The alphanumeric which appear in the readout are listed below.

Letter

Dlsplay

-

62

-

Page 69

~~~~~~~~~~

It is possible to reset (initialize) control variables to those set when the inverter is supplied except for

some parameters. This procedure is called ’ALL CLEAR’.

Operating procedure

When writing is complete,

Note : The following control variables are

Parameter number

‘20

‘39

c-

c

-2

c-3

c-4

c-5

-1

not

initialized through the all clear operation stated above.

~~~~

Frequency for

1

Frequency for

Frequency meter calibration

Frequency reference voltage bias

Frequency reference voltage gain

Frequency reference current bias

Frequency reference current gain

is displayed and flickers.

~~~~ ~ ~ ~

Parameter name

5

V

input signal

20

mA input signal

*These control variables set the maximum output frequency using external signal operation, and also

are reference frequencies for

acceleration/deceleration

time. After carrying out ALL CLEAR, check

these values and reset to optimum values.

-

63

-

Page 70

FREQUENCY METER CALIBRATION

It

is possible

FM

and

may be adjusted.

to

calibrate any frequency meter connected

SD

on the inverter, by operating the PU.

If

it is a digital indicator, pulse train signal frequency

to

the frequency meter connection terminals,

Preparation

(1)

Connect the frequency meter across terminals

to

attention

(2)

If

a calibration resistor has already been connected, remove it or adjust it

resistance reads zero.

polarity matching.)

Inverter

Calibration

resistor

-

64

Frequency meter

-

FM

and

SD

on

the inverter. (Pay

so

that its

Page 71

Operatlng Procedure

1.

Operate

frequency for meter fullscale reading.

2.

Select the meter calibration

mode.

3.

Calibrate the meter.

PU

to set the

(*)

(Set to

60

inverter is shipped.)

of the frequency meter,

Hz when the

'The motor need not be connected.

If

Note:

a signal relative to magnitude of motor current is to be output from the

95),

install a calibration resistor at the position shown on the previous page. Output of the

terminal is not adjusted with the above procedure.

When the meter has been calibrated, press the

key.

FM

terminal (see page

-65-

WRI

FM

Page 72

ADJUSTING BIAS AND GAIN

FOR

FREQUENCY REFERENCE

SIGNAL

Using 'bias' and 'gain', the operator can adjust the relationship between output frequency and

leference input signals such as

This function is classified as 3rd function and is set through the procedure that follows:

SETTI

NO

PROCEDURE

0-5

VDC,

0-1

0

VDC, or

4-20

mA DC, which set the output frequency.

r

.....(

Frequency meter calibration mode C-1)

lwmp-lpJ7

,..Bias setting for frequency

reference voltage ((3-2)

...

1'

I.

Gain setting

reference voltage

1

...

Bias setting for frequency

reference current

I

..Gain setting for frequency

reference current

for

frequency

(C-3)

(C-4)

(C-5)

-

66

-

Page 73

Example

-

of

Bias setting for frequency reference voltage

frequency will be

60Hz

Adjustment

10

Output frequency

I

Hz.

.....

when the reference voltage

-67-

is

0

V,

the output

Page 74

Note: Setting should be made with voltage across the frequency reference input terminals

and 5 using 5 V

shown in the illustration on the previous page.)

If

a voltage is being applied, output frequency relative to that voltage is set. In the above

procedure, for example,

characteristics become as shown in the illustration below (solid line).

/?-

10

Hz

.A

0

1'v

(or

10

V)

or with input lines disconnected. (When setting characteristics

if

1

V

is being applied across terminals 2 and

If

,

I

5'v

you want to set 0 Hz

input, set 0 Hz

in the above procedure.

against

1

V

5,

output

-68-

2

Page 75

CAUTIONS FOR PU OPERATION

Pay attention to the following points

PU operation.

Operation

Motor control

by PU Operation

Becomes effective only after pressing the

When PU

setting the

Press the

An error indication (Err.) will be displayed, or the value you entered will not

the conditions that follow

(1)

(2)

(3)

(4)

JOG Operation

(1)

(2)

is

LJ

When

(setting value for parameter number

When prohibition of parameter entry is effective (parameter number

When PU is in the external signal operation mode (the indicator lamp above the

key is lit)

When PU is in the monitor mode (stated above). (Note, however, step setting is

possible.)

The JOG Operation is not available when the motor is running.First, stop the motor

perform the JOG Operation.

If

the motor does

the start frequency (parameter number

so

as to avoid incorrect setting or entry of a wrong value during

Cautlona

PU

key.

in the monitcr mode (when the indicator lamp above the MONITOR key is lit),

ou

ut

frequency is impossible.

PU

key to leave the monitor mode and enter a new value.

:

you

have entered a value exceeding the maximum or minimum frequency

la

be

written under

1

or

2)

:

77

is set

to

:

not

start, check whether the JOG Operation frequency is lower than

13).

-69-

1)

;

M

to

Page 76

Opmtlon

Writing values

Writing values

Ceutlonr

1.

Writing is effective only when PU is in the PU Operation mode, accordingly,

in the external signal Operation mode. (Set values can

2.

Writing is impossible when the motor is running. First, stop the motor to write values. The

following parameters, however, may

(1)

Multi-speed setting (speed

(2)

PWM mode

Setting values cannot

3.

displayed)

When

(1)

When the motor is running (except the above

(2)

When prohibition of parameter entry is effective;

(3)

When a number not on the parameter list

(4)

When a value exceeding the setting range

(5)

When a value exceeding the maximum or minimum frequency is set.

(6)

When an error message is displayed, press the[E]key, or repeat the procedures from

1

the first sten

......

parameter number

be

:

PU

written under the conditions that follow (an error message will

is in the external signal Operation mode;

-

70

be

written even when the motor is running.

1-7)

......

Parameters number

10

-

be

(only in the

two

is

selected:

i5

entered;

read in either mode.)

4-6, 24-27

PU

Operation mode)

parameters):

it

is ineffective

be

Page 77

Operation

Reading

values

Monitor

Common -Operation

mode.

Maximum number of

digits stored and the

decimal point.

I

1.

It

is possible

Operation modes.

In addition, reading is possible

Reading the

2.

Operation mode.

1.

When the Operator uses the PU

after setting frequency automatically

Selecting PU or external signal Operation

Pressing the

that follow

(1)

(2)

(3)

Switching

RES and

The maximum number

disregarded. (Example

Pressing.

be

disreaarded.

to

read the

set

set

values for the 3rd functions is possible only when the inverter is in PU

PU

key (or

:

mm

When the motor is running

When the start signal (across terminals

signal Operation

When Operation mode (parameter number

signal Operation.

on

the power of the inverter after switching it off or resetting (across terminals

SD)

the external Operation mode. (Initial setting)

1

for

0.1,

Do

rn

is

ON.

of

digits for entry

:

Pressing 12345 will

as is done for a calculator, is regarded as

not

omit

-71

Cautlonr

values for the

if

the motor is running.

to

key) is not allowed for mode change under the conditions

a

0.

1st

and 2nd functions in both PU and external

control the motor, pressing the start key (FWD or

selects

the

monitor mode.

;

STF

and

SD

or

STR

and

SD)

for the external

79)

is

set

to

PU operation or external

is

four.

If

this

is

be

exceeded, the first digit is

set

as 2345.)

1,

and the decimal point

-

REV)

will

Page 78

13.

DETAILS

PARAMETER LIST

OF

EACH PARAMETER

-72-

Page 79

Parameter

2nd

function

No.

Jog acceieration/deceleration time

2nd

I

High-speedmaximum frequency

I

1

I

16

17

18

19

20

21

*24 Multi-speed setting (speed 4) 0-360

.

*25

‘26

*27 Multi-speed setting (speed 7) 0-360 Hz,

Parameter

acceIeratiotVdeceleration

Base frequency voltage

5

V

Frequency a

Stall prevention

Multi-speed setting (speed

Multi-speed setting (speed 6) 0-360

input voltage 1-360 HZ 60 Hz 78

time

level

5)

0,

0,

0.1-3600 sec.,

1

I

Setting

0.1-3600

120-360Hz

Oto500V,

0-360 Hz,

0-200%

range

S~C.

9999 9999

initial eettttlng

I

9999

HZ,

9999 9999

9999 9999

Hz,

9999 9999

9999 9999

I

0.5

sec.

120Hz

9999

150% 88

1

I

page:

90

81

78

84

91

Acceleration/deceleration

29

37

39

42

Engineering display unit display

Frequency at 20

Up-to-frequency sensitivity

pattern selection

0,

2,

4,

6, 8, 10,

mA

input 1-360 HZ

0,

1-1

1,2

00%

11

to

9998

0

0

60

Hz 78

1

0%

82

101

94

Page 80

Parameter

No.

43

44

Parameter Setting range lnltlal setting Refer

Output frequency detection 0.5-360

Output frequency detection at reverse

rotation

0.5-360

HZ

Hz,

9999 9999

to

page:

6

Hz

94

I

53

69

70

72

Retry execution count display erase

Parameter set by the manufacturer.

FM

output terminal function selection

Current monitoring output gain 0-200%

1

-74-

0

0,

1

Must

not be

0 100

set.

0

150%

95

Page 81

I

ParameterNo.

2nd

function

I

I

73

74

75

-

76

79

77

Selection

I

Parameter

5

V/10

V

input selection

Current input selection

Reset selection

Output signal selection

Operation mode selection

of

prohibition

writing

of

parameter

-

I

75

-

Setting range

0,

1

0%

1

0,

1

0,1,2

0,

1,2,

11, 12

1

initial setting

0

0

0

0

0

I

O

I

77

92

92

93

83

Ig7

Page 82

Notes

:

1.

Set values differ depending on inverter capacity.

2.

For parameters marked with a star, it is possible

setting)

Minimum setting step

3.

.

Frequency

.

Time

.

Current

.

Yo

......................................

4.

The set value of

.......................

.................................

............................

9999