Mitsubishi FR-S520-0.1K to 3.7K(-R)(-C), FR-S520-0.1K to 3.7K-NA(R), FR-S520S-0.2K to 1.5K-EC(R), FR-S520S-0.1K to 1.5K(-R) Instruction Manual

TRANSISTORIZED INVERTER

FR-

S

500

INSTRUCTION MANUAL (BASIC)

FR-S520-0.1K to 3.7K(-R)(-C)

FR-S520-0.1K to 3.7K-NA(R)

FR-S520S-0.1K to 1.5K(-R)

FR-S520S-0.2K to 1.5K-EC(R)

Thank you for choosing this Mitsubishi Transistorized inverter.

If this is the first time for you to use the FR-S500 series, please read through

this instruction manual (basic) carefully and use the inverter safely.

If you are going to use the inverter for higher-level applications, the FR-S500

instruction manual (detailed) [IB(NA)-0600027] is separately available from

where you purchased the inverter or your Mitsubishi sales representative.

CONTENTS

1. CONNECTION OF PERIPHERAL DEVICES......................................2

2. INSTALLATION METHOD ..................................................................4

3. SPECIFICATIONS OF WIRING AND TERMINALS............................5

4. OPERATION/CONTROL...................................................................15

5. ADJUSTMENT OF THE FREQUENCY SETTING

POTENTIOMETER AND INDICATOR..............................................21

6. FUNCTION LIST ...............................................................................25

7. ERRORS AND PROTECTIVE FUNCTIONS.....................................37

8. SPECIFICATIONS.............................................................................40

9. OUTLINE DRAWINGS......................................................................44

Appendix 1 Instructions for Compliance with the European

Appendix 2 Instructions for compliance with U.S. and Canadian

Standards...........................................................................46

Electrical Codes..................................................................48

This instruction manual (basic) provides handling information and precautions for

use of the equipment.

Please forward this instruction manual (basic) to the end user.

This instruction manual uses the International System of Units (SI). The

measuring units in the yard and pound system are indicated in parentheses as

reference values.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you have

read through this instruction manual (basic) and appended documents carefully

and can use the equipment correctly. Do not use the inverter until you have a

full knowledge of the equipment, safety information and instructions.

In this instruction manual (basic), the safety instruction levels are classified into

"WARNING" and "CAUTION".

WARNING

Assumes that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

CAUTION

Note that even the CAUTION level may lead to a serious consequence

according to conditions. Please follow the instructions of both levels because

they are important to personnel safety.

1. Electric Shock Prevention

Assumes that incorrect handling may cause hazardous

conditions, resulting in medium or slight injury, or may

cause physical damage only.

WARNING

! While power is on or when the inverter is running, do not open the front

cover. You may get an electric shock.

! Do not run the inverter with the front cover removed. Otherwise, you may

access the exposed high-voltage terminals or the charging part of the

circuitry and get an electric shock.

! If power is off, do not remove the front cover except for wiring or periodic

inspection. You may access the charged inverter circuits and get an electric

shock.

! Before starting wiring or inspection, check for residual voltages with a meter

etc. more than 10 minutes after power-off.

! Earth the inverter.

! Any person who is involved in the wiring or inspection of this equipment

should be fully competent to do the work.

! Always install the inverter before wiring. Otherwise, you may get an electric

shock or be injured.

! Perform setting dial and key operations with dry hands to prevent an electric

shock.

! Do not subject the cables to scratches, excessive stress, heavy loads or

pinching. Otherwise, you may get an electric shock.

! Do not change the cooling fan while power is on.

It is dangerous to change the cooling fan while power is on.

! When you have removed the front cover, do not touch the connector above

the 3-digit monitor LED display. Doing so can cause an electric shock.

A - 1

2. Fire Prevention

CAUTION

! Mount the inverter to incombustible material. Mounting it to or near

combustible material can cause a fire.

! If the inverter has become faulty, switch off the inverter power. A continuous

flow of large current could cause a fire.

! Do not connect a resistor directly to the DC terminals P(+), N(−). This could

cause a fire.

3. Injury Prevention

CAUTION

! Apply only the voltage specified in the instruction manual to each terminal to

prevent damage etc.

! Ensure that the cables are connected to the correct terminals. Otherwise,

damage etc. may occur.

! Always make sure that polarity is correct to prevent damage etc.

! While power is on and for some time after power-off, do not touch the inverter

or brake resistor as they are hot and you may get burnt.

4. Additional instructions

Also note the following points to prevent an accidental failure, injury, electric

shock, etc.

(1) Transportation and installation

CAUTION

! When carrying products, use correct lifting gear to prevent injury.

! Do not stack the inverter boxes higher than the number recommended.

! Ensure that installation position and material can withstand the weight of the

inverter. Install according to the information in the Instruction Manual.

! Do not operate if the inverter is damaged or has parts missing.

! When carrying the inverter, do not hold it by the front cover or setting dial; it

may fall off or fail.

! Do not stand or rest heavy objects on the inverter.

! Check the inverter mounting orientation is correct.

! Prevent screws, wire fragments, other conductive bodies, oil or other

flammable substances from entering the inverter.

! Do not drop the inverter, or subject it to impact.

A - 2

CAUTION

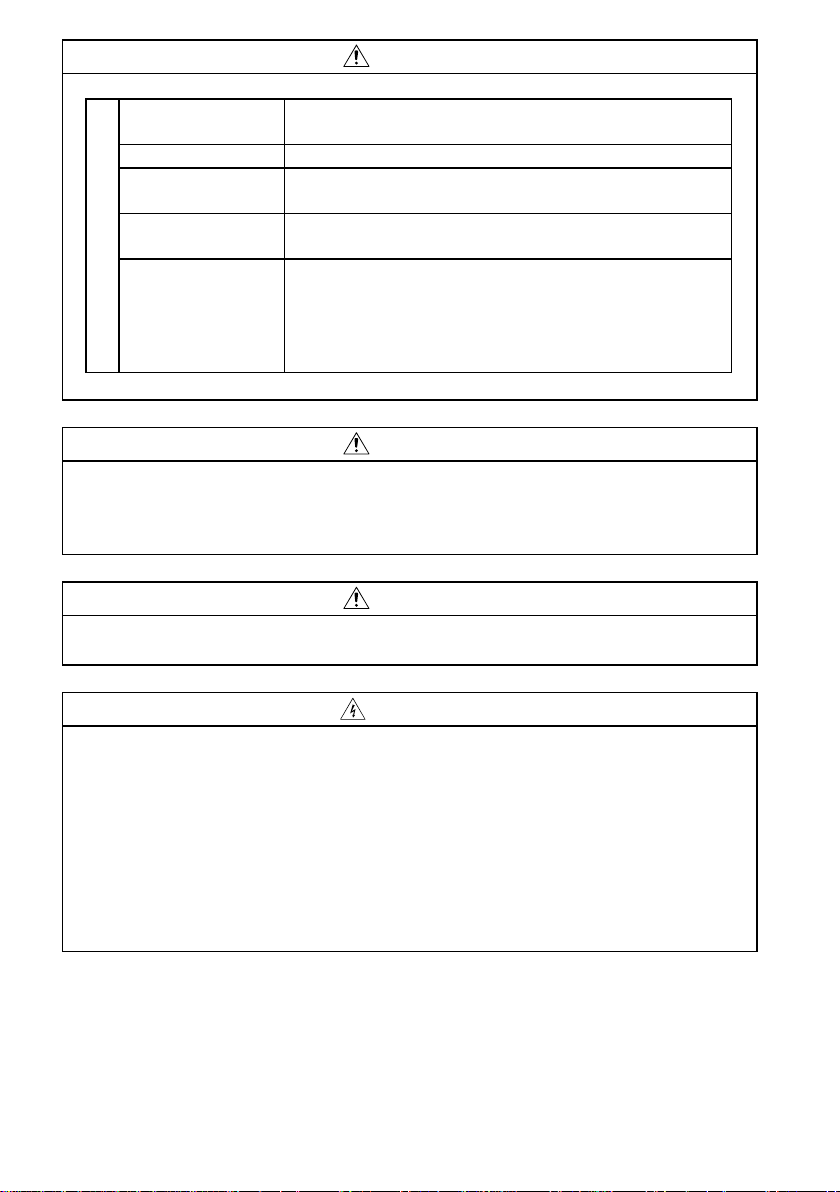

! Use the inverter under the following environmental conditions:

Ambient

temperature

Ambient humidity 90%RH or less (non-condensing)

Storage

temperature

Ambience

Environment

Altitude,

vibration

*Temperatures applicable for a short time, e.g. in transit.

(2) Wiring

-10°C to + 50°C (14°F to 122°F) (non-freezing)

-20°C to +65°C (-4°F to 149°F) *

Indoors (free from corrosive gas, flammable gas,

oil mist, dust and dirt)

Maximum 1000m (3280.80feet) above sea level

for standard operation. After that derate by 3% for

every extra 500m (1640.40feet) up to 2500m

(8202.00feet) (91%).

2

5.9m/s

or less (conforming to JIS C0911)

CAUTION

! Do not fit capacitive equipment such as power factor correction capacitor,

radio noise filter or surge suppressor to the output of the inverter.

! The connection orientation of the output cables U, V, W to the motor will

affect the direction of rotation of the motor.

(3) Trial run

CAUTION

! Check all parameters, and ensure that the machine will not be damaged by a

sudden start-up.

(4) Operation

WARNING

! When you have chosen the retry function, stay away from the equipment as it

will restart suddenly after an alarm stop.

! The [STOP] key is valid only when the appropriate function setting has been

made. Prepare an emergency stop switch separately.

! Make sure that the start signal is off before resetting the inverter alarm. A

failure to do so may restart the motor suddenly.

! The load used should be a three-phase induction motor only. Connection of

any other electrical equipment to the inverter output may damage the

equipment.

! Do not modify the equipment.

A - 3

CAUTION

! The electronic overcurrent protection does not guarantee protection of the

motor from overheating.

! Do not use a magnetic contactor on the inverter input for frequent

starting/stopping of the inverter.

! Use a noise filter to reduce the effect of electromagnetic interference.

Otherwise nearby electronic equipment may be affected.

! Take measures to suppress harmonics. Otherwise power harmonics from the

inverter may heat/damage the power capacitor and generator.

! When parameter clear or all clear is performed, each parameter returns to

the factory setting. Re-set the required parameters before starting operation.

! The inverter can be easily set for high-speed operation. Before changing its

setting, fully examine the performances of the motor and machine.

! In addition to the inverter's holding function, install a holding device to ensure

safety.

! Before running an inverter which had been stored for a long period, always

perform inspection and test operation.

(5) Emergency stop

CAUTION

! Provide a safety backup such as an emergency brake which will prevent the

machine and equipment from hazardous conditions if the inverter fails.

(6) Maintenance, inspection and parts replacement

CAUTION

! Do not carry out a megger (insulation resistance) test on the control circuit of

the inverter.

(7) Disposing of the inverter

CAUTION

! Treat as industrial waste.

(8) General instructions

Many of the diagrams and drawings in this instruction manual (basic) show the

inverter without a cover, or partially open. Never run the inverter in this status.

Always replace the cover and follow this instruction manual (basic) when

operating the inverter.

A - 4

Japanese Power Supply Harmonic Suppression Guideline

r

The "harmonic suppression guideline for household appliances and generalpurpose products" issued by the Ministry of International Trade and Industry in

September, 1994 applies to the FR-S500 series. By installing the FR-BEL or FRBAL power factor improving reactor, this product complies with the "harmonic

suppression techniques for transistorized inverters (input current 20A or less)"

established by the Japan Electrical Manufacturers' Association.

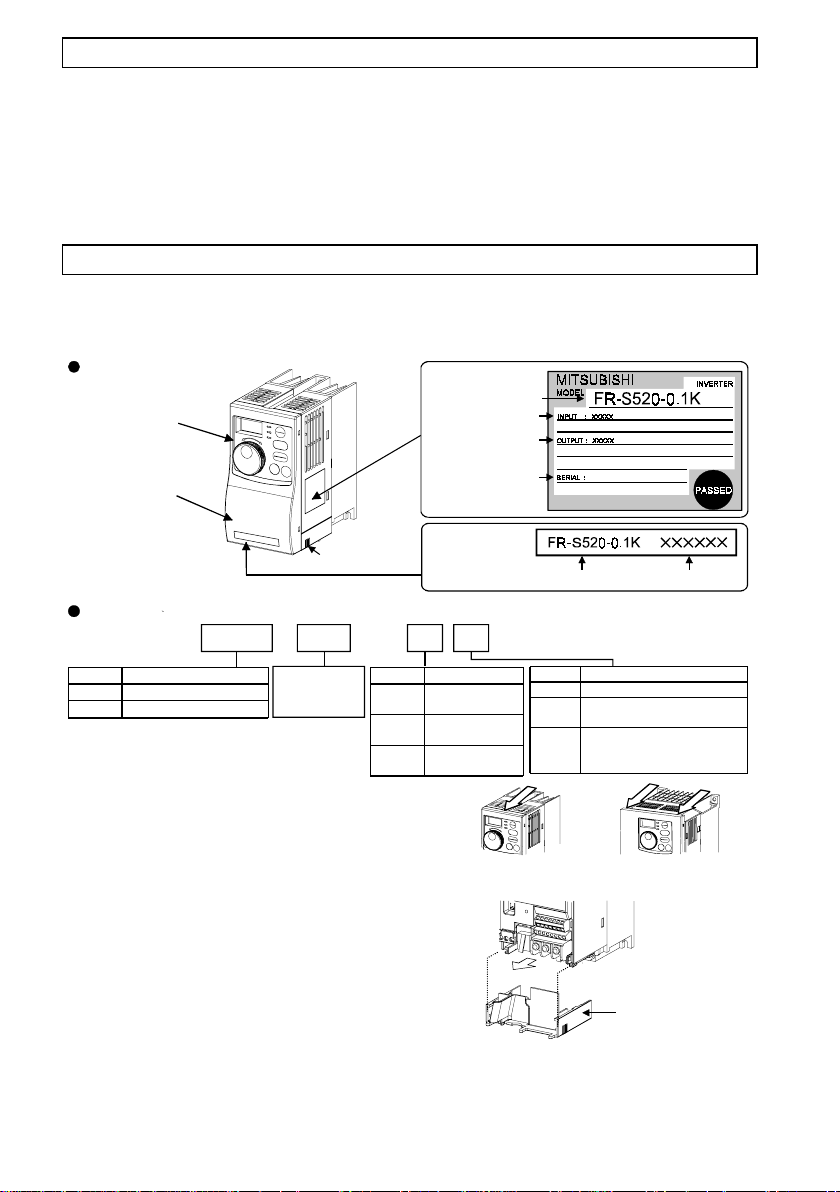

Product Checking and Parts Identification

Unpack the inverter and check the capacity plate on the front cover and the rating

plate on the inverter side face to ensure that the product agrees with your order

and the inverter is intact.

Part names and plates

Operation panel

Rating plate

Inverter type

Input rating

Output rating

Front cover

Wiring cover

Inverter type

FR - S520 -K -0.1

Symbol Voltage Class

Three-phase 200V class

S520

Single-phase 200V class

S520S

Represents

the inverter

capacity "kW ".

Removal and reinstallation of the front cover

Remove the front cover by pulling it toward

you in the direction of arrow.

To reinstall, match the cover to the inverter

front and i nsta ll it stra ight .

Removal and reinstallation of the wiring cover

The cover can be removed easily by pulling it

toward you.

To reinstall, fi t the cover to the invert er along

the guides.

Symbol Version

None

NA

EC

Serial number

Capacity plate

Inverter type

Symbol Protective Structure

Japanese

specification

North American

specification

European

specification

FR-S520(S)-0.1K to 0.75K FR-S520(S)-1.5K

None

R

C

Serial number

Standard structure

With RS-485 communication

function

Totally enclosed structure

IP40

Only for Japanese version

FR-S520-2.2K, 3.7K

Wiring cove

1

< Type with RS-485 communication function >

When using the RS-485 connector to wire the

cable, you can cut off the lug of the wiring cover

to wire it. (Cutting off the lug provides protective

Lug

structure IP10.)

CAUTION

The connector above the operation panel is for

manufacturer use. Do not touch it as doing so

may cause an electric shock.

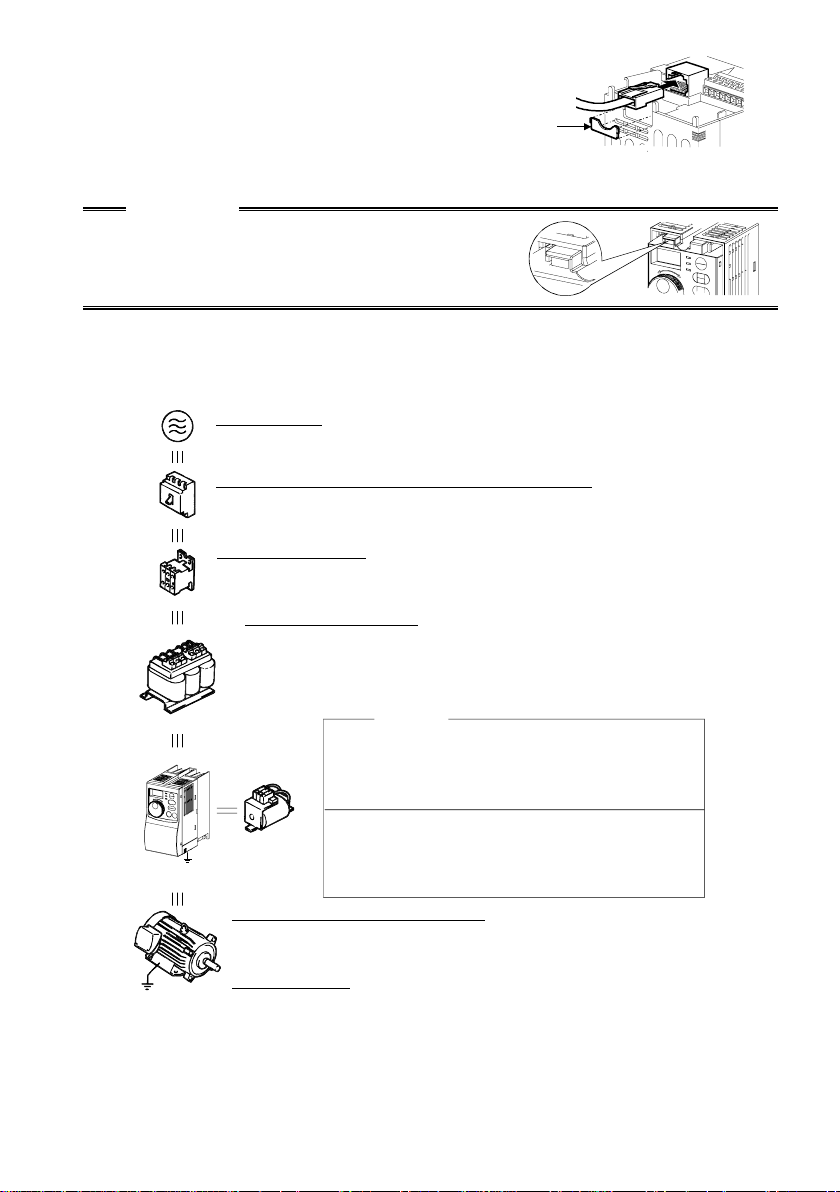

1.

CONNECTION OF PERIPHERAL DEVICES

1.1 Basic Configuration

Power supply

Use within the permissible power supply specifications

(NFB)

or

(ELB)

(MC)

C reactor

(FR-BAL)

Earth (Ground)

Earth (Ground)

of the inverter. (Refer to page 40.)

No-fuse breaker or earth leakage circuit breaker

The breaker must be selected carefully since

an in-rush current flows in the inverter at power-on.

Magnetic contactor

Do not use this magnetic contactor to start and stop the

inverter. Doing so will cause the inverter life to be shorter.

Installation of reactors

The reactors must be used when the power factor is to be

improved or the inverter is installed near a large power supply

system (500kVA or more and wiring distance within 10m (32.81feet)).

Make selection carefully.

Inverter

The inverter life is influenced by ambient

temperature. The ambient temperature should

be as low as possible within the permissible

range. (Refer to page 42.)

Wrong wiring might lead to inverter dam age. The

DC reactor

(FR-BEL)

Devices connected to the output

Do not connect a power capacitor, surge suppressor

or radio noise filter to the output side.

Earth (Ground)

To prevent an electric shock, always ground the motor

and inverter.

For reduction o f in duction noise from the power line of the inverter,

it is recommend ed t o wire the ground cable by returnin g i t to t he

ground terminal of the inverter. (For details of noise reduction

techniques , refer to the instruc t ion manual (detailed).)

control signal lines must be kept fully away f r om

the main circuit to protect them from noise.

(Refer to page 5.)

2

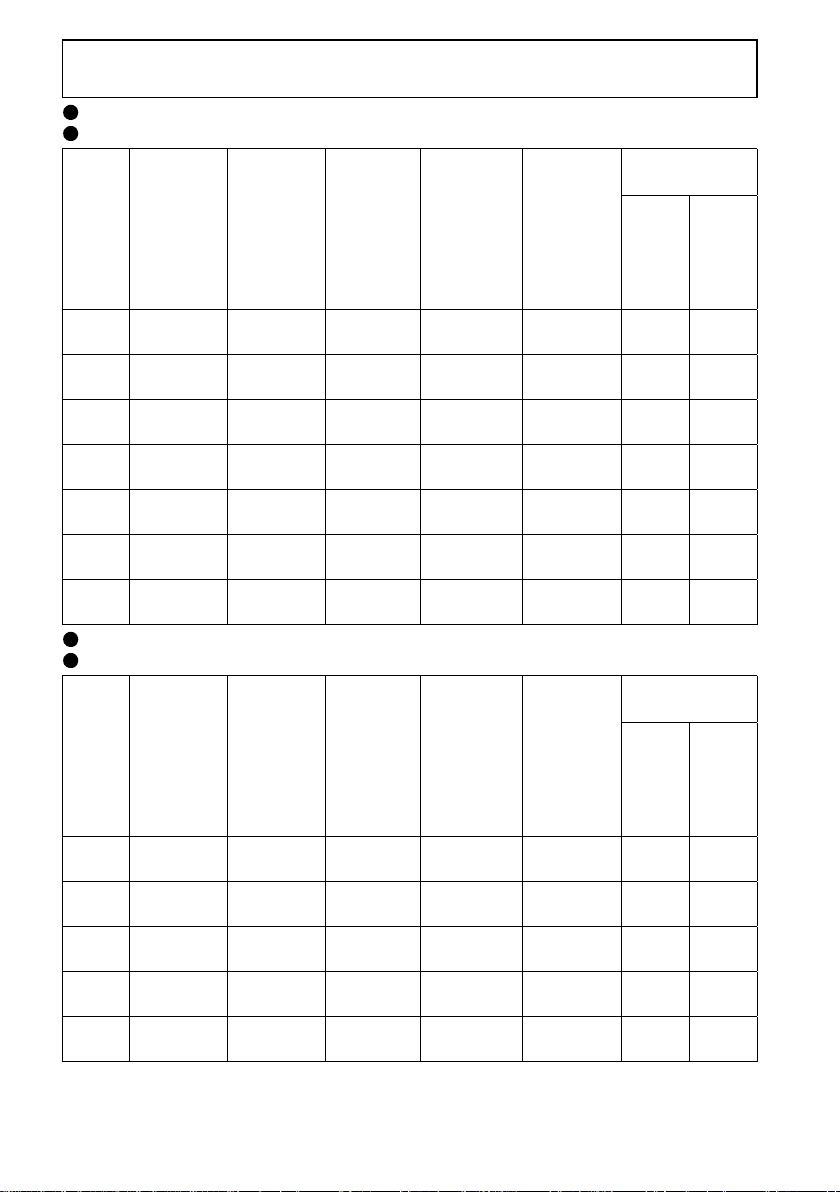

Selection of peripheral devices (Selection changes with the

power supply input specifications of the inverter.)

FR-S520-0.1K to 3.7K(-R)(-C)

FR-S520-0.1K to 3.7K-NA(R)

No-Fuse

Motor

Output

(kW

(HP))

0.1

(1/8)

0.2

(1/4)

0.4

(1/2)

0.75

(1)

1.5

(2)

2.2

(3)

3.7

(5)

Inverter

Type

FR-S520-

0.1K

FR-S520-

0.2K

FR-S520-

0.4K

FR-S520-

0.75K

FR-S520-

1.5K

FR-S520-

2.2K

FR-S520-

3.7K

Breaker

(NFB*1) or

Earth

Leakage

Circuit

Breaker

(ELB)

30AF/5AT

30AF/5AT

30AF/5AT

30AF/10AT

30AF/15AT

30AF/20AT

30AF/30AT

Power

Factor

Improving

AC

Reactor

FR-BAL-

0.4K (*3)

FR-BAL-

0.4K (*3)

FR-BAL-

0.4K

FR-BAL-

0.75K

FR-BAL-

1.5K

FR-BAL-

2.2K

FR-BAL-

3.7K

Power

Factor

Improving

DC

Reactor

FR-BEL-

0.4K (*3)

FR-BEL-

0.4K (*3)

FR-BEL-

0.4K

FR-BEL-

0.75K

FR-BEL-

1.5K

FR-BEL-

2.2K

FR-BEL-

3.7K

Magnetic

Contactor

(MC)

S-N10 2 2

S-N10 2 2

S-N10 2 2

S-N10 2 2

S-N10 2 2

S-N11,

S-N12

S-N20 3.5 3.5

FR-S520S-0.1K to 1.5K(-R)

FR-S520S-0.2K to 1.5K-EC(R)

No-Fuse

Motor

Output

(kW

(HP))

0.1

(1/8)

0.2

(1/4)

0.4

(1/2)

0.75

(1)

1.5

(2)

*1 Choose the NFB type to meet the power supply capacity.

*2 The size of the cabl e indicated assumes the wiring length of 20m (65.62feet).

*3 The power factor may be slightly lower.

Inverter

Type

FR-S520S-

0.1K

FR-S520S-

0.2K

FR-S520S-

0.4K

FR-S520S-

0.75K

FR-S520S-

1.5K

Breaker

(NFB*1) or

Earth

Leakage

Circuit

Breaker

(ELB)

30AF/5AT

30AF/10AT

30AF/10AT

30AF/15AT

30AF/20AT

Power

Factor

Improving

AC

Reactor

FR-BAL-

0.4K (*3)

FR-BAL-

0.4K (*3)

FR-BAL-

0.75K (*3)

FR-BAL-

1.5K (*3)

FR-BAL-

2.2K (*3)

Power

Factor

Improving

DC

Reactor

FR-BEL-

0.4K (*3)

FR-BEL-

0.4K (*3)

FR-BEL-

0.75K (*3)

FR-BEL-

1.5K (*3)

FR-BEL-

2.2K (*3)

Magnetic

Contactor

(MC)

S-N10 2 2

S-N10 2 2

S-N20 2 2

S-N20 2 2

S-N21 2 2

Cables (mm2)

R, S, T U, V, W

22

Cables (mm2)

R, S

1

, N>

<L

(*2)

(*2)

U, V, W

3

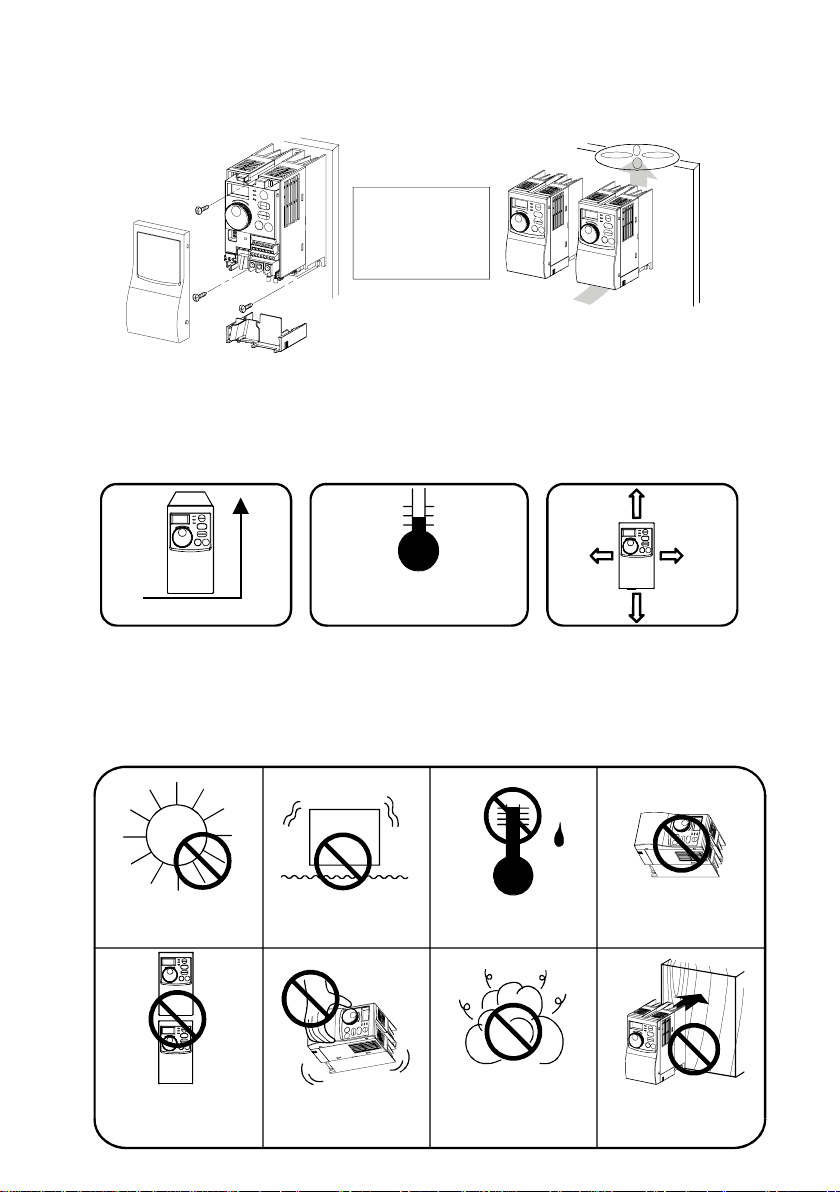

2.

INSTALLATION METHOD

2.1 Installation of the Inverter

Enclosure surface mounting Mounting inside enclosure

Fix the front

cover and wiring

cover after

removing them.

When containing two or more

Leave enough clearances

and provide cooling measures.

• Install the inverter under the following conditions.

Ambient temperature

Vertical mounting

Vertical

and humidity

Temperature: -10°C to 50°C

(14°F to 122°F)

Humidity: 90%RH maximum

• The inverter consists of precision mechanical and electronic parts. Never install

or handle it in any of the following conditions as doing so could cause an

operation fault or failure.

inverters, install them in parallel

and provide cooling measures.

Enough clearances

10cm

1cm

(0.39inch)

or more

10cm

(3.94inch)

or more

These clearances are also necessary

for changing the cooling fan.

(1.5K or more)

(3.94inch)

or more

1cm

(0.39inch)

or more

Direct sunlight

Vertical mounting

(When mounted

inside enclosure)

Vibration

2

(5.9m/s or more)

Transportation by

holding front cover

or dial

High temperature,

high humidity

Oil mist, flammable

gas, corrosive gas,

fluff, dust, etc.

4

Horizontal placement

Mounting to

combustible

material

3.

SPECIFICATIONS OF WIRING AND TERMINALS

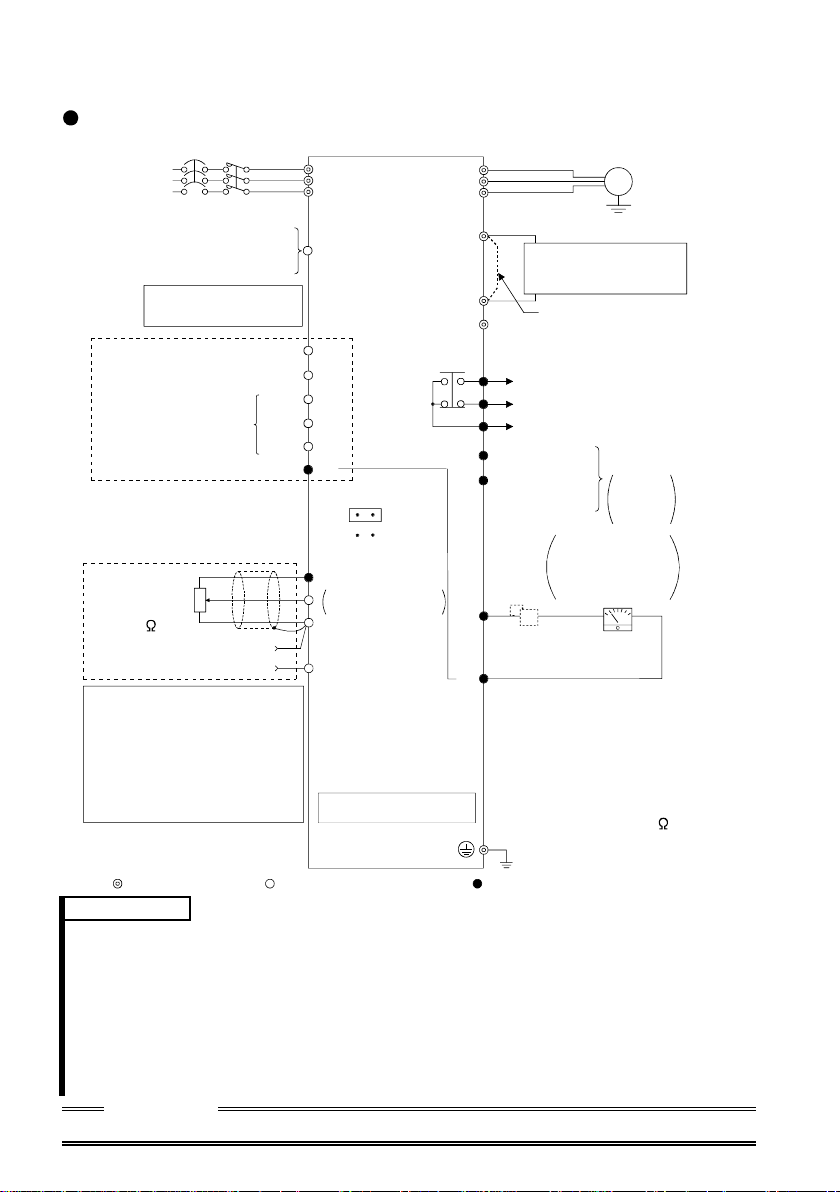

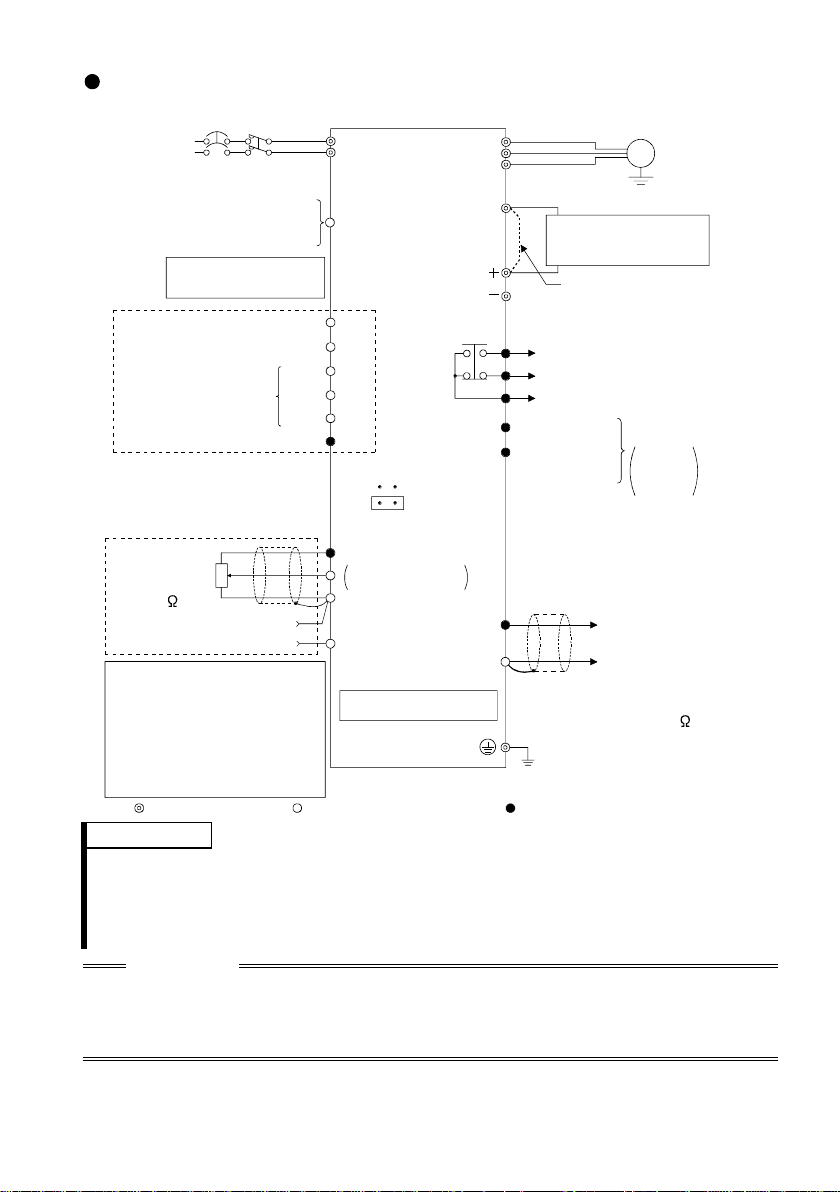

3.1 Terminal connection diagram (Japanese version)

FR-S520-0.1K to 3.7K (-R) (-C)

NFB

3-phase AC

power suppl y

External transistor common

Contact input common (source)

Frequency setting signals (Analog)

When using current input as the

frequency setting signal, set "4"

in any of Pr. 60 to Pr. 63 (input

terminal function selection) and

assign AU (current input selection)

to any of terminals RH, RM, RL

and STR.

24VDC power supply

Take care not to short

terminal s P C -SD.

Forward rotation start

Reverse rotation start

Multi-speed selection

Contact input common

Control input signals

(No voltage input allowed)

Frequency

setting

potentiometer

1/2W1k

(*4)

4 to 20mADC (+)

MC

3

2

1

Current input (-)

High

Middle

Low

Inverter

R

S

T

PC

STF

STR

RH

RM

RL

SD

SINK

(*3)

SOURCE

10 (+5V)

0 to 5VDC

2

0 to 10VDC

5 (Common)

4 (4 to 20mADC)

RS-485 Connector (*1)

Selected

U

V

W

P1

N

A

B

C

RUN

SE

FM

SD

Power factor improving

DC reactor

(FR-BEL: Option)

P

Alarm

output

Running

Open collector

output common

Calibration

resistor (*2)

Earth (Ground)

Grounding resistanc e 100 maximum

Grounding cable size: 2mm

Motor

IM

Ground

: Remove this

Jumper

jumper when FR-BEL

is connected.

Operation status

output

Open

collector

outputs

Indicator

1mA full-scale

Analog meter

(Digital indicator)

1mA

(+) (-)

2

Main circuit terminal, Control circuit input terminal,

Control circuit out put terminal

Remarks

*1 Only the type with RS-485 communication function

*2 Not needed when the setting dial is used for calibration. Used when

calibration must be made near the frequency meter for such a reason as a

remote frequency meter. However, the frequency meter needle may not

deflect to full-scale if the calibration resistor is connected. In this case, use

this resistor and setting dial together.

*3 You can switch between the sink and source logic positions. For details, refer

to the instruction manual (detailed).

*4 When the setting potentiometer is used frequently, use a 2W1kΩ potentiometer.

CAUTION

Keep the signal cables m ore th an 1 0cm (3.9 4inches) away from the power ca bles.

5

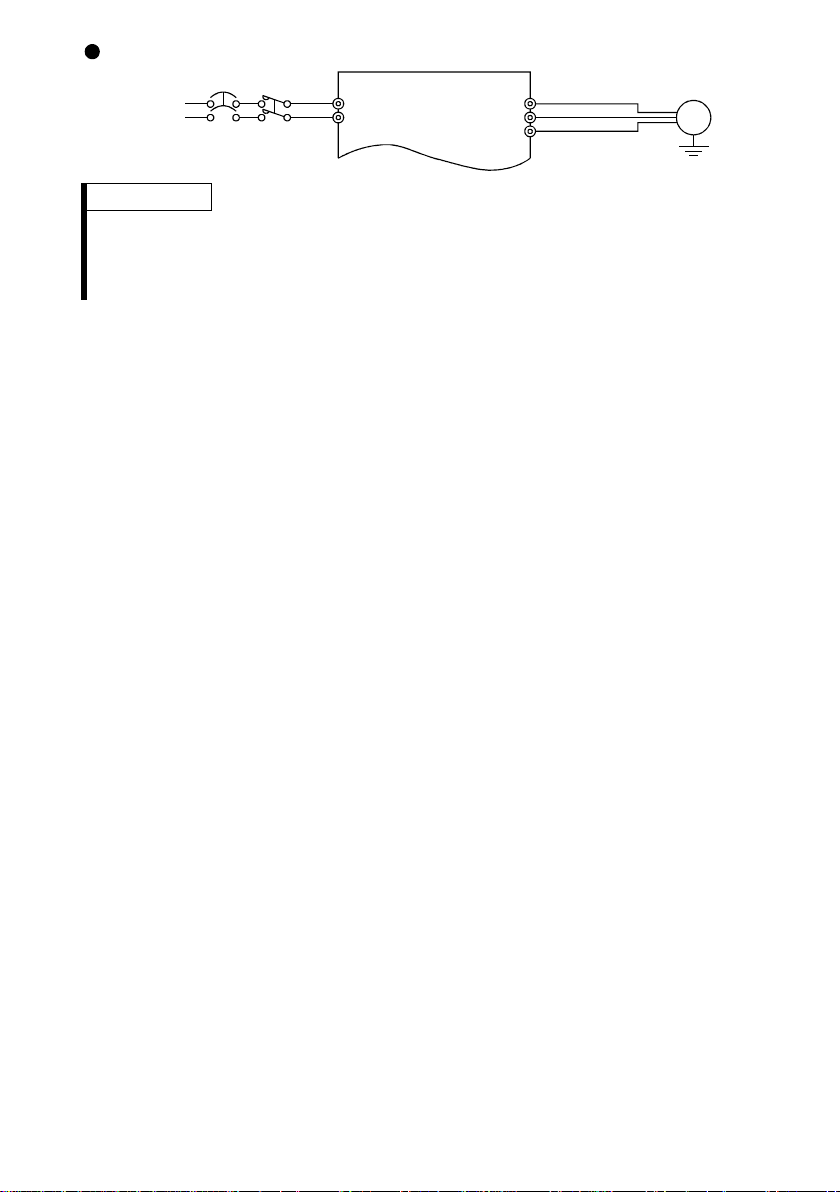

FR-S520S-0.1K to 1.5K (-R) (-C)

(

)

NFB

Power supply

MC

R

S

U

V

W

Motor

Remarks

• To ensure safety, connect the power input to the inverter via a magnetic

contactor and earth leakage circuit breaker or no-fuse breaker, and use the

magnetic contactor to switch power on-off.

• The output is three-phase 200V.

IM

Earth

Ground

6

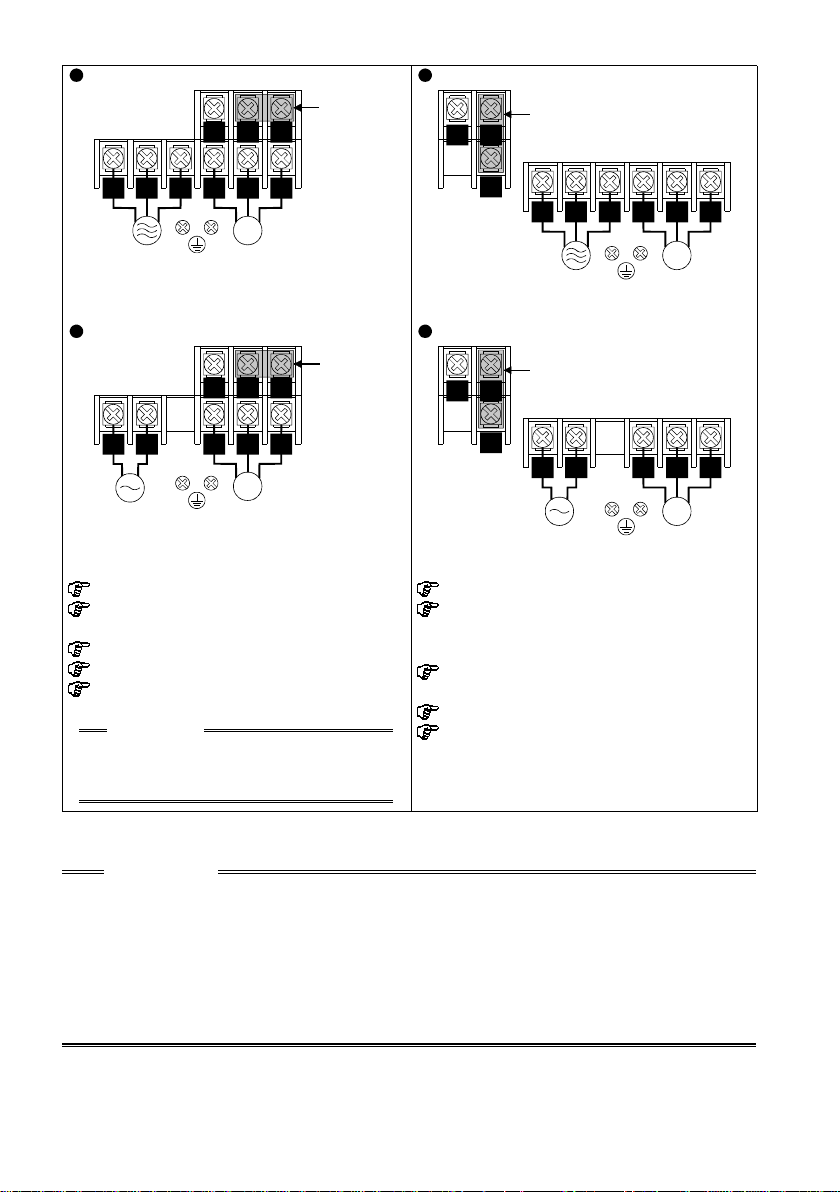

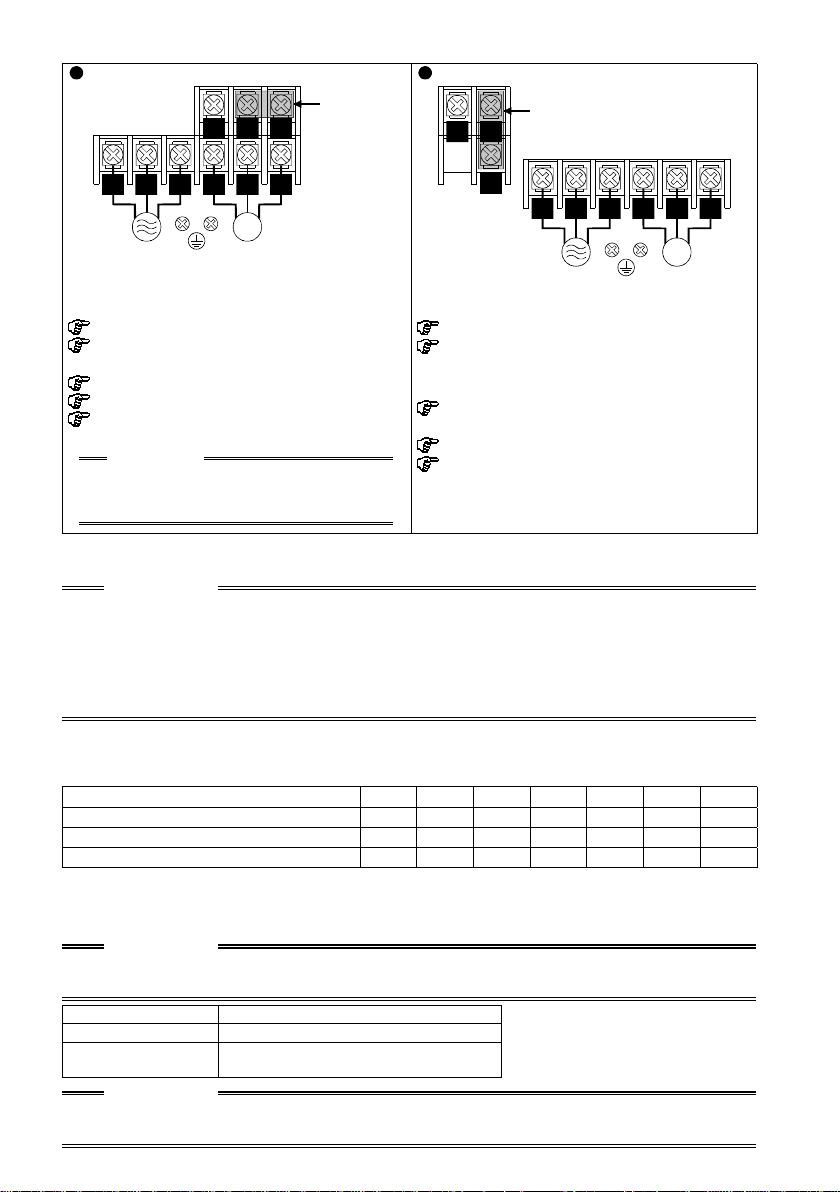

3.1.1 Layout and wiring of main circuit terminals

r

FR-S520-0.1K, 0.2K, 0.4K, 0.75K (-R) (-C) FR-S520-1.5K, 2.2K, 3.7K (-R) (-C)

RST

Jumper

P1

NP

NP

Jumper

RST

Power

supply

U V W

IM

Motor

P1

R S T

Power

supply

FR-S520S-0.1K, 0.2K, 0.4K, 0.75K (-R) FR-S520S-1.5K (-R)

RS

Power

supply

Jumpe

NP

P1

U V W

IM

Motor

NP

Jumper

P1

RS

Power

supply

Screw size: M3.5

Recommended cable size:

Crimping terminal : 2-3.5

Screw tightening torque: 1.2 N⋅m

Overall wiring lengt h:

2mm

2

(14 AWG)

100m (328.08feet) maximum *

CAUTION

If the wiring length of the 0.1K or 0.2K is

Screw size: M4

Recommended cable size:

Crimping terminal :

2

2mm

(14 AWG) (1.5K, 2.2K)

2

3.5mm

2-4 (1.5K, 2.2K), 5.5-4 (3.7K)

Screw tightening torque: 1.5N⋅m

Overall wiring lengt h:

100m (328.08feet)

30m (98.43feet) or more, reduce the

carrier frequency to 1kHz.

U V W

IM

Motor

U V W

IM

Motor

(12 AWG) (3.7K)

maximum *

* When automatic torque boost is selected i n Pr. 98 "automatic torque boost selection

(motor capacit y)": 30m (98.43feet) maximum.

CAUTION

The power supply cables must be connected to R, S, T. If they are connected

•

to U, V, W, the inverter will be damaged. (Phase sequence need not be

matched.)

(For use with a single-phase power supply, the power supply cables must be

connected to R and S.)

Connect the motor to U, V, W.

•

Turning on the forward rotation switch (signal) at this time rotates the motor

counterclockwise when viewed from the load shaft.

7

3.2 Terminal connection diagram (North America version)

FR-S520-0.1K to 3.7K-NA (R)

MC

3-phase AC

power supply

External transistor common

Contact input common (source)

Multi-speed selection

Control input signals

(No voltage input allowed)

Frequency setting signals (Analog)

Frequency

setting

potentiometer

1/2W1k

(*3)

When using current input as the

frequency setting signal, set "4"

in any of Pr. 60 to Pr. 63 (input

terminal function selection) and

assign AU (current input selection)

to any of terminals RH, RM, RL

and STR.

NFB

24VDC power supply

Take care not to short

terminals PC-SD.

Forward rotation start

Reverse rotation start

High

Middle

Low

Contact input common

3

2

1

Current input (-)

4 to 20mADC (+)

Main circuit terminal, Control circuit input terminal, Control circuit output terminal

Inverter

R

S

T

PC

STF

STR

RH

RM

RL

SD

SINK

(*2)

SOURCE

10 (+5V)

0 to 5VDC

2

0 to 10VDC

5 (Common)

4 (4 to 20mADC)

RS-485 Connector (*1)

Selected

U

V

W

P1

N

A

B

C

RUN

SE

AM

Power factor improving

DC reactor

(FR-BEL: Option)

P

Alarm

output

Running

Open collector

output common

5

Earth (Ground)

Grounding resistanc e 100 maximum

Grounding cable size: 2mm

Motor

IM

Earth

(Ground)

Jumper:

jumper when FR-BEL

is connected.

Remove this

Operation status

output

Open

collector

outputs

(+)

Analog signal

output

(0 to 5VDC)

(-)

2

Remarks

*1 Only the type with RS-485 communication function

*2 You can switch between the sink and source logic positions. For details, refer

to the instruction manual (detailed).

*3 When the setting potentiometer is used frequently, use a 2W1kΩ potentiometer.

CAUTION

Keep the signal cables m ore th an 1 0cm (3.9 4inches) away from the power ca bles.

8

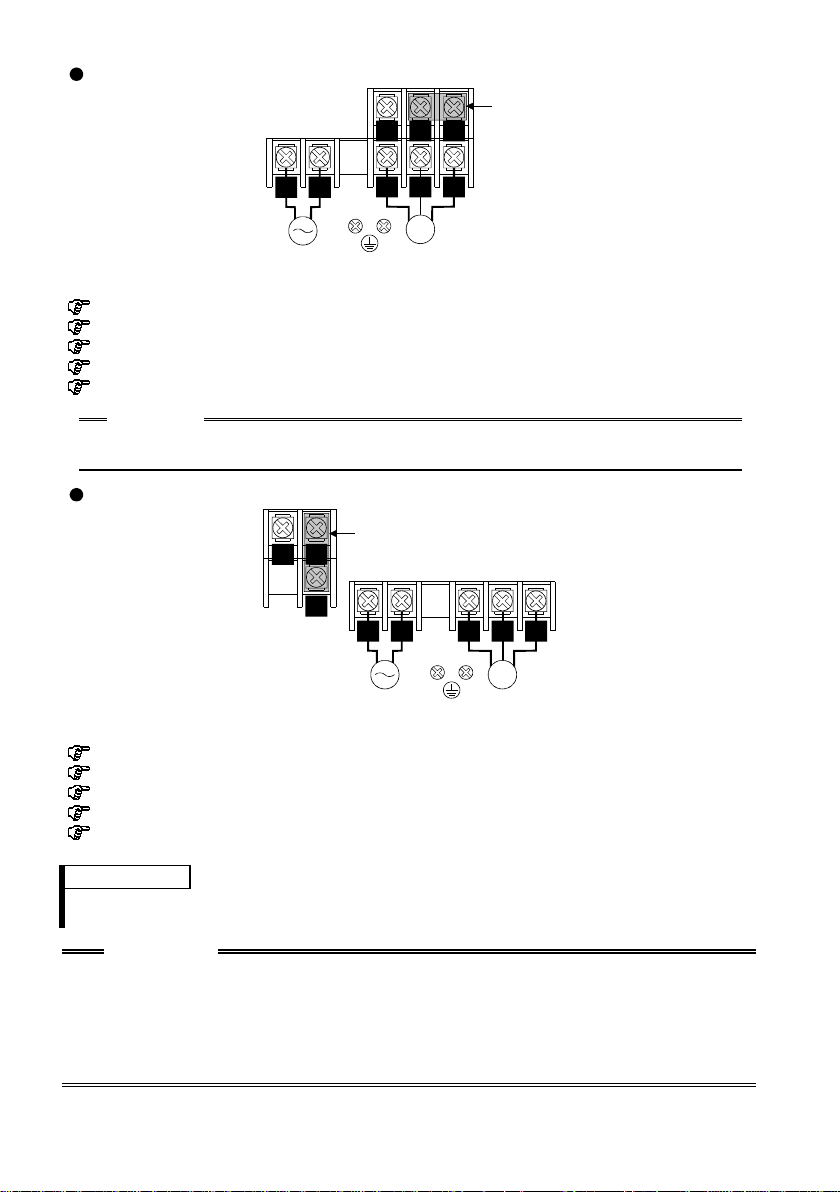

3.2.1 Layout and wiring of main circuit terminals

r

FR-S520-0.1K, 0.2K, 0.4K, 0.75K-NA (R) FR-S520-1.5K, 2. 2K, 3.7K-NA (R)

Jumpe

NP

P1

NP

Jumper

RST

Power

supply

Screw size: M3.5

Recommended cable size:

Crimping terminal : 2-3.5

Screw tightening torque: 1.2 N⋅m

Overall wiring lengt h:

CAUTION

If the wiring length of the 0.1K or 0.2K is

30m (98.43feet) or more, reduce the

carrier frequency to 1kHz.

* When automatic torque boost is selected i n Pr. 98 "automatic torque boost selection

(motor capacit y)": 30m (98.43feet) maximum.

U V W

IM

Motor

2

2mm

(14 AWG)

100m (328.08feet) maximum *

P1

R S T

Power

supply

Screw size: M4

Recommended cable size:

Crimping terminal :

Screw tightening torque: 1.5N⋅m

Overall wiring lengt h:

2

2mm

(14 AWG) (1.5K, 2.2K)

2

3.5mm

2-4 (1.5K, 2.2K), 5.5-4 (3.7K)

100m (328.08feet)

U V W

Motor

(12 AWG) (3.7K)

IM

maximum *

CAUTION

The power supply cables must be connected to R, S, T. If they are connected

•

to U, V, W, the inverter will be damaged. (Phase sequence need not be

matched.)

Connect the motor to U, V, W.

•

Turning on the forward rotation switch (signal) at this time rotates the motor

counterclockwise when viewed from the load shaft.

<When single-phase power input is provided for three-phase power input inverter

(NA version only)>

Reduce the output current.

•

FR-S520-"K-NA inverter 0.1 0.2 0.4 0.75 1.5 2.2 3.7

Rated output current (A) 0.4 0.8 1.5 2.5 4.0 5.0 7.0

Power supply capacity (kVA) 0.4 0.8 1.5 2.5 4.5 5.5 9.0

AC input power (kW ) 1.1 6.4 4.5 6.4 11.2 12.9 17.4

Set m9 (Pr. 637) "current detection filter".

•

Setting "801" in the manufacturer setting parameter C8 enables you to set the

m9 parameter.

CAUTION

Parameters other than m9 can also be made to be displayed, but never alter

these since they are manufacturer setting parameters.

m9 Setting Description

0 Single-phase pow er input

- - -

(Factory setting)

Three-phase power input

CAUTION

Always return the C8 parameter to 0 (factory setting) after you have finished the

setting of m9.

9

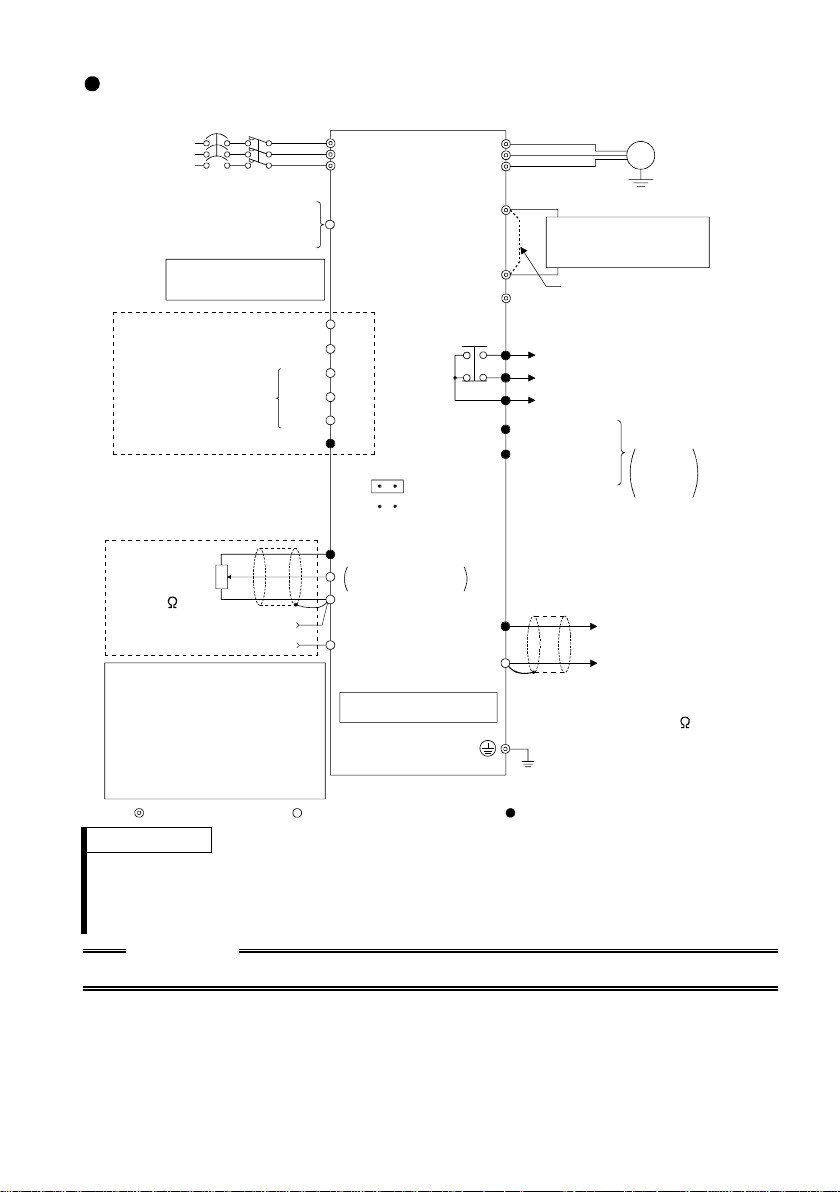

3.3 Terminal connection diagram (European version)

FR-S520S-0.2K to 1.5K-EC (R)

MC

NFB

Power supply

External transistor common

Contact input common (source)

Frequency setting signals (Analog)

24VDC power supply

Take care not to short

terminals PC-SD.

Forward rotation start

Reverse rotation start

High

Multi-speed selection

Contact input common

Control input signals

(No voltage input allowed)

Frequency

setting

potentiometer

1/2W1k

(*3)

When using current input as the

frequency setting signal, set "4"

in any of Pr. 60 to Pr. 63 (input

terminal function selection) and

assign AU (current input selection)

to any of terminals RH, RM, RL

and STR.

Main circuit terminal, Control circuit input terminal, Control circuit output terminal

3

1

Current input (-)

4 to 20mADC (+)

Middle

Low

2

Inverter

L

1

N

PC

STF

STR

RH

RM

RL

SD

SINK

(*2)

SOURCE

10 (+5V)

0 to 5VDC

2

0 to 10VDC

5 (Common)

4 (4 to 20mADC)

RS-485 Connector (*1)

Selected

U

V

W

P1

A

B

C

RUN

SE

AM

Power factor improving

DC reactor

(FR-BEL: Option)

Alarm

output

Running

Open collector

output common

5

Earth (Ground)

Grounding resistanc e 100 maximum

Grounding cable size: 2mm

Motor

IM

Earth

(Ground)

: Remove this

Jumper

jumper when FR-BEL

is connected.

Operation status

output

Open

collector

outputs

(+)

Analog signal

output

(-)

(0 to 5VDC)

2

Remarks

*1 Only the type with RS-485 communication function

*2 You can switch between the sink and source logic positions. For details, refer

to the instruction manual (detailed).

*3 When the setting potentiometer is used frequently, use a 2W1kΩ potentiometer.

• The output is three-phase 200V.

CAUTION

• Keep the signal cables more tha n 10cm (3.94inches) away from the power cables.

• To ensure safety, connect the power input to the inverter via a magnetic

contactor and earth leakage circuit breaker or no-fuse breaker, and use the

magnetic contactor to switch power on-off.

10

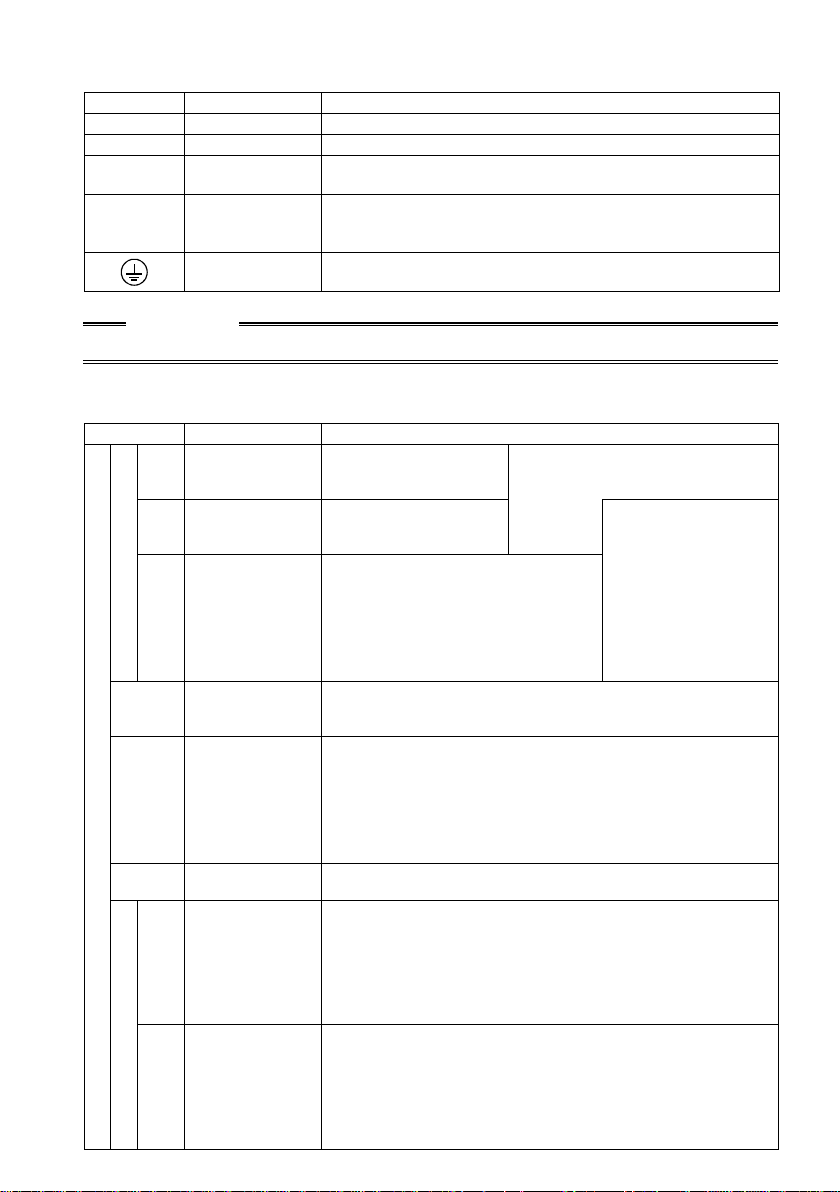

3.3.1 Layout and wiring of main circuit terminals

r

FR-S520S-0.2K, 0.4K, 0. 75K-EC (R)

Jumpe

P1

-

+

L1 N

Power

supply

Screw size: M3.5

Recommended cable size: 2mm

Crimping terminal : 2-3.5

Screw tightening torque: 1.2 N⋅m

Overall wiring length: 100m (328.08feet) maximum *

CAUTION

If the wiring length of the 0.2K is 30m (98.43fe et) or more, reduce the carrier frequency

to 1kHz.

FR-S520S-1.5K-EC (R)

+

-

P1

Screw size: M4

Recommended cable size:2mm

Crimping terminal : 2-4

Screw tightening torque: 1.5N⋅m

Overall wiring lengt h: 100m (328.08feet)

U V W

2

(14 AWG)

Jumper

L1 N

Power

supply

2

(14 AWG)

IM

Motor

maximum *

U V

Motor

W

IM

Remarks

* When automatic torque boost is selected in Pr. 98 "automatic torque boost

selection (motor capacity)": 30m (98.43feet) maximum.

CAUTION

For power input wiring, connect L1 to R/L1 of the terminal block and N to

•

S/L2 of the terminal block.

Connect the motor to U, V, W.

•

Turning on the forward rotation switch (signal) at this time rotates the motor

counterclockwise when viewed from the load shaft.

Do not connect the power supply to U, V and W.

•

11

3.4 Main Circuit

3.4.1 Explanation of main circuit terminals

Symbol Terminal Name Description

R, S, T* AC power input Connect to the commercial power supply.

U, V, W Inverter output Connect a three-phase squirrel-cage motor.

N <->

P <+>, P1

* R, S, <L1, N> terminals for single-phase power input.

DC voltage

common

Power factor

improving DC

reactor connection

Earth (Ground)

CAUTION

< > Terminal names in parentheses are those of the EC version.

DC voltage common terminal. Not isolated from the power

supply and inverter output.

Remove the jumper from across terminals P <+> -P1 and

connect the optional power factor improving DC reactor (FRBEL).

For grounding the inverter chassis.

Must be earthed.

3.5 Control Circuit

3.5.1 Explanation of control circuit terminals

Symbol Terminal Name Description

Forward rotation

STF

start

Reverse rotation

STR

start

RH

Contact input

Multi-speed

RM

selection

RL

SD

Contact input

(*1)

common (sink)

External transistor

common

PC

24VDC power

supply

(*1)

Frequency setting

10

2

4

Contact input

common (source)

Frequency setting

power supply

Frequency

setting

(Voltage signal)

Frequency

setting

(Current signal)

Input signals

Turn on the STF signal

to start forward rotation

and turn it off t o stop.

Turn on the STF signal

to start reverse rotation

and turn it off t o stop.

You can select mult iple speeds by

shorting any of terminals RH, RM

and RL signal.

The priorities of the speed

commands are in order of jog,

multi-speed sett ing (RH, RM, RL,

REX) and AU.

Common terminal for contact inputs (terminal s STF, STR,

RH, RM, RL) and indicator connection (terminal FM).

Isolated from terminals 5 and SE.

When connecting t he transistor output (open collector

output) of a programma ble controller (PLC) etc., connect

the positive external power supply for transistor output to

this terminal to prevent a malfunction due to l eakage

current. It can be used as a 24V 0.1A DC power supply

across PC-SD termi nals. Acts as the common termi nal of

the contact input signals when source l ogic is selected.

5VDC, permissible l oad current 10mA.

Inputting 0 to 5VDC (0 to 10V) provides the maximum

output frequency at 5V (10V) and makes input and output

proportional.

Use Pr. 73 "0 to 5V, 0 to 10V selection" to switch between

5V and 10V.

Input resistance 10kΩ. Maximum permissible input voltage

20V.

Input 4 to 20mA DC. Factory-adjusted to be 0Hz at 4mA

and 60Hz <50Hz for EC version> at 20mA. Maximum

permissible input current 30mA. Input resistance

approximately. 250Ω.

Turn ON signal AU for current input.

Use any of Pr. 60 to Pr. 63 (input terminal function

selection) t o set the AU signal.

A stop command is given if STF

and STR signal turn ON at the

same time.

12

The terminal function

changes with the

setting of input

terminal function

selection (Pr. 60 to

Pr. 63). (*4)

Loading...

Loading...