FRONT

SUSPENSION

33A-1

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

SPECIAL TOOLS 3..........................

ON-VEHICLE SERVICE 4.....................

Wheel Alignment Check and Adjustment 4.......

Ball Joint Dust Cover Check 5..................

33109000094

STRUT ASSEMBLY 6........................

LOWER ARM ASSEMBLY 10................

STABILIZER BAR 14........................

33A-2

FRONT SUSPENSION -

General Information/Service Specifications

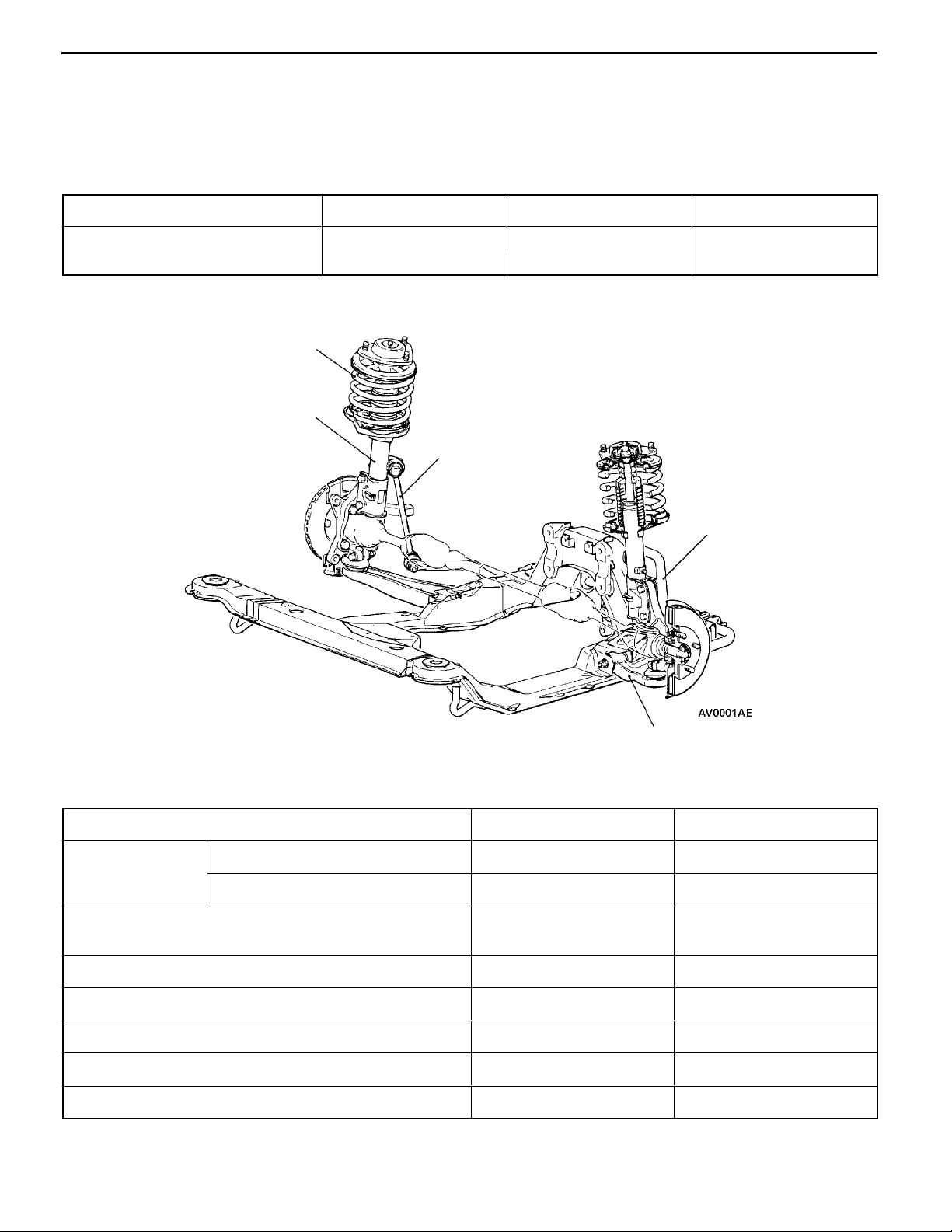

GENERAL INFORMATION

33100010089

The front suspension is a McPherson strut with coil spring. The shock absorber is hydraulic double-acting

type.

COIL SPRING

Items SPACE RUNNER SPACE WAGON - 2WD SPACE WAGON - 4WD

Wire diameter´average diameter

´

free length mm

13.6´160´368 14.0´160´371 14.1´160´381

CONSTRUCTION DIAGRAM

Coil spring

Strut assembly

Stabilizer link

Stabilizer bar

Lower arm assembly

SERVICE SPECIFICATIONS

Items SPACE RUNNER SPACE WAGON

Toe-in At the centre of tyre tread mm 0±3 0±3

Toe-angle (per wheel) 0_00’±08’ 0_00’±08’

Toe-out angle on turns

(inner wheel when outer wheel at 20_)

Camber 0_00’±30’ * -0_10’±30’ *

Caster 2_45’±30’ * 2_50’±30’ *

Kingpin inclination 11_27’ 12_49’

Lower arm ball joint rotation starting torque Nm 2.0 - 8.8 2.0 - 8.8

Stabilizer link ball joint turning torque Nm 1.7 - 3.1 1.7 - 3.1

NOTE

*: difference between right and left wheel: less than 30’

22_10’ 21_50’

33100030115

FRONT SUSPENSION -

Special Tools

33A-3

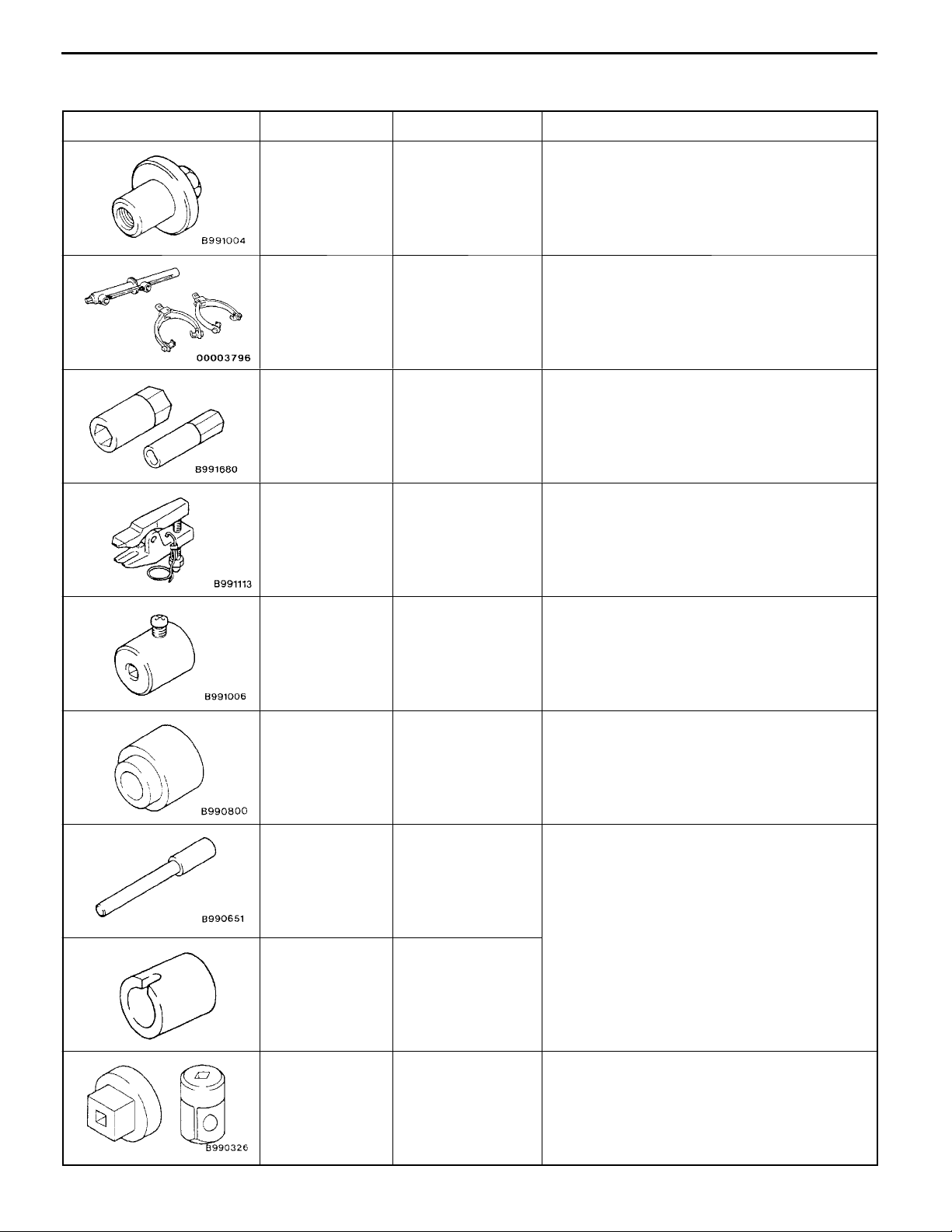

SPECIAL TOOLS

Tools Number Name Use

MB991004 Wheel alignment

gauge attachment

A: MB991237

B: MB991238

A

B

A

A: MB991619

B: MB991682

B

MB991406,

MB990635 or

MB991113

A: Spring compres-

sor body

B: Arm set

A: Wrench

B: Socket

Steering linkage

puller

33100060077

Wheel alignment measurement

<Vehicles with aluminium type wheelsd

Coil spring compression

Strut assembly disassembly and reassembly

Tie rod end disconnection

MB991006 Preload socket Lower arm ball joint rotation starting torque

measurement

MB990800 Ball joint remover

and installer

MB990651 Bar Driving out and press-fitting of lower arm

MB998716 Crankshaft wrench

Lower arm ball joint dust cover installation

bushing

MB990326 Preload socket Stabilizer link ball joint turning torque measure-

ment

33A-4

Tools UseNameNumber

FRONT SUSPENSION -

Special Tools/On-vehicle Service

MB991 164 Door adjusting

wrench

ON-VEHICLE SERVICE

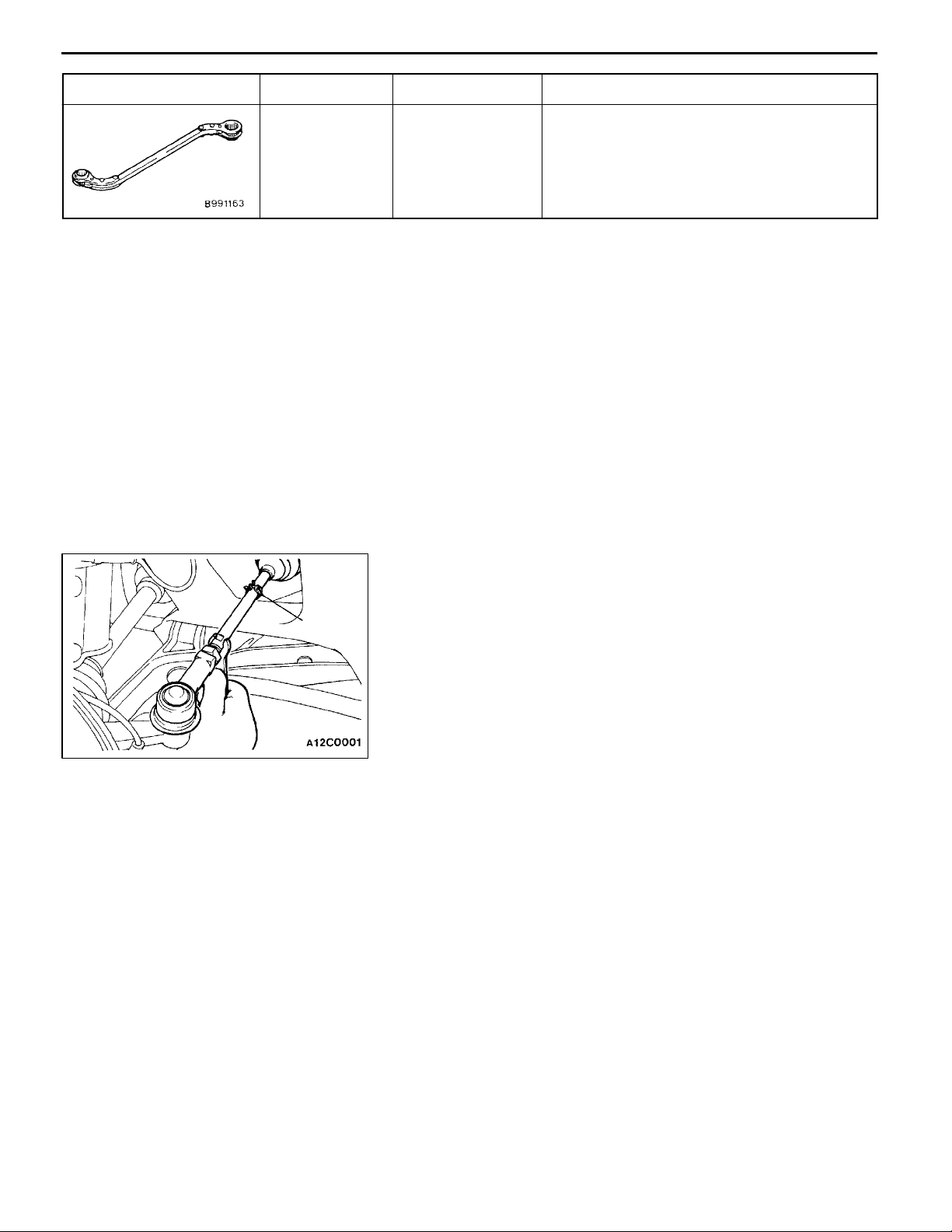

WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

Measure the wheel alignment with the vehicle parked on a

level surface.

The front suspension, steering system, and wheels should

be serviced to normal condition prior to measurement of wheel

alignment.

TOE-IN

Standard value:

At the centre of tyre tread 0±3mm

Toe angle (per wheel) 0_00’±08’

Clip

1. If the toe-in is not within t h e standard value, adjust the

toe-in by undoing the clip and turning the left and right

tie rod turnbuckles by the same amount (in opposite

directions).

Stabilizer bar bracket mounting bolt removal

and installation

33100090267

NOTE

The toe will move out as the left turnbuckle is turned

toward the front of the vehicle and the right turnbuckle

is turned toward the rear of the vehicle.

2. Use a turning radius gauge to check that the steering

angle is at the standard value.

(Refer to GROUP37A - On-vehicle Service.)

TOE-OUT ANGLE ON TURNS

To check the steering linkage, especially after the vehicle

has been involved in an accident or if an accident is presumed,

it is advisable to check the toe-out angle on turns in addition

to the wheel alignment.

Conduct this test on the left turn as well as on the right turn.

Standard value (inner wheel when outer wheel

at 20_):

<SPACE RUNNER> 22_10’

<SPACE WAGON> 21_50’

FRONT SUSPENSION -

CAMBER, CASTER AND KINGPIN INCLINATION

On-vehicle Service

33A-5

MB991004

Standard value:

Item SPACE

RUNNER

Camber (difference between right

and left wheel: less than 30’)

Caster (difference between right

and left wheel: less than 30’)

Kingpin inclination 11_ 27’ 12_ 49’

0_00’ ± 30’ -0_10’ ± 30’

2_45’ ± 30’ 2_50’ ± 30’

SPACE

WAGON

NOTE

1. Camber and caster are preset at the factory and cannot

be adjusted.

2. If camber is no t within the standard value, check and

replace bent or damaged parts.

3. For vehicles with aluminium type wheels, attach the

camber/caster/kingpin gauge to the drive shaft by using

the special tool. Tighten the special tool to the same

torque 196 - 255 Nm as the drive shaft nut.

Caution

To prevent the wheel bearing from damage, never

subject the wheel bearings to the vehicle load when

the drive shaft nuts are loosened.

BALL JOINT DUST COVER CHECK

33200860090

1. Check the dust cover for cracks or damage by pushing

it with finger.

2. If the dust cover is cracked or damaged, replace the

upper arm assembly, compression lower arm assembly,

lateral lower arm assembly or stabilizer link.

NOTE

Cracks or damage of the dust cover may cause damage

of the ball joint.

33A-6

FRONT SUSPENSION -

Strut Assembly

STRUT ASSEMBLY

REMOVAL AND INSTALLATION

Pre-removal Operation

Injector Driver Removal (Refer to GROUP 13.)

44 Nm

33200110126

Post-installation Operation

D Injector Driver Installation (Refer to GROUP 13.)

D Check the Dust Cover for Cracks or Damage by

Pushing it with Finger.

D Wheel Alignment Check and Adjustment

(Refer to P.33A-4.)

5

6

3

1

4

Removal steps

1. Brake hose bracket

2. Front wheel speed sensor harness

<Vehicles with ABS>

3. Stabilizer link connection

INSPECTION

D

D

39 Nm

2

106 Nm

4. Knuckle connection

5. Strut mounting nut

6. Strut assembly

33200120020

Check for oil leaks from the strut assembly.

Check the strut assembly for damage or deformation

FRONT SUSPENSION -

Strut Assembly

33A-7

DISASSEMBLY AND REASSEMBLY

8

9

10

33200130139

69 - 78 Nm

2

1

3

4

5

6

7

Disassembly steps

AA""AA 1. Self-locking nut

2. Washer

3. Strut insulator assembly

4. Bearing

5. Upper spring seat

6. Upper spring pad

7. Bump rubber

8. Coil spring

9. Spring tube

10. Strut assembly

33A-8

FRONT SUSPENSION -

Strut Assembly

MB991237

MB991682

MB991238

MB991619

DISASSEMBLY SERVICE POINT

AA"

1. Use the special tools to compress the coil spring.

2. Use the special tools to remove the self-locking nut.

SELF-LOCKING NUT REMOVAL

Caution

(1) To compress the coil spring sufficiently, install

the special tools evenly,and so that the maximum

lengthwill beattainedwithintheinstallation range.

(2) To prevent the special tool from damage, do not

use an impact wrench to tighten the special tool

bolt.

Caution

Do not use an impact wrench as internal parts of

the strut assembly will be loosened.

Pipe

REASSEMBLY SERVICE POINT

"AA

1. Check that the bearing is properly assembled.

2. With the coil spring held compressed by the special tools

3. Line up the holes in the strut assembly lower spring seat

4. Correctly align both ends of the coil spring with the grooves

SELF-LOCKING NUT INSTALLATION

(MB991237 and MB991238), provisionally tighten the selflocking nut.

Caution

To prevent the special tool from damage, do not use

an impact wrench to tighten the special tool bolt.

with the hole in the upper spring seat.

NOTE

The job is easily accomplished with a pipe.

in the spring seat, and then loosen the special tools

(MB991237 and MB991238).

MB991682

FRONT SUSPENSION -

5. Using the special tool, tighten the self-locking nut to the

specified torque.

Specified torque: 69 - 78 Nm

Strut Assembly

33A-9

MB991619

Caution

Do not use an impact wrench as internal parts of

the strut assembly will be loosened.

INSPECTION

D Check the bearing for wear or rust.

D Check the rubber parts for damage or deterioration.

D Check the spring for deformation, deterioration or damage.

D Check the shock absorber for deformation.

33200140064

33A-10

FRONT SUSPENSION -

Lower Arm Assembly

LOWER ARM ASSEMBLY

33200160121

REMOVAL AND INSTALLATION

Caution

*: To prevent bushings from breakage”the parts indicated by * should be temporarily tightened,

and then fully tightened with the vehicle on the ground in the unladen condition.

Post-installation Operation

D Check the Dust Cover for Cracks or Damage by

Pushing it with Finger.

D Wheel Alignment Check and Adjustment

(Refer to P.33A-4.)

6

5

88 - 108 Nm

39 Nm

2

1

88 - 108 Nm*

AA"

AB"

5

3

177 Nm

Removal steps

1. Tie rod end connection

2. Stabilizer link connection

3. Stay

4. Lower arm and knuckle connection

6

78 Nm

AC"

"AA

24 - 33 Nm

98 - 118 Nm

4

5. Lower arm and front member

connection

6. Lower arm assembly

Ball joint

Nut

MB991406,

MB990635 or

MB991113

FRONT SUSPENSION -

REMOVAL SERVICE POINTS

Cord

AA"

Caution

1. Loosen the nut of the special tool, but do not remove

2. Tie the special tool with a cord not to let it fall off.

TIE ROD END DISCONNECTION

it.Ifit isremoved, theballjoint threadwill be damaged.

Lower Arm Assembly

33A-11

Front member

Front member

mounting bolts

Stay

AB"

STAY REMOVAL

The stay is tightened together with the front member. After

the stay is removed, tighten the bolts loosely to hold the

front member.

NOTE

If the lower arm assembly has been removed, tighten the

bolts loosely to hold the front member.

AC"

LOWER ARM AND FRONT MEMBER

DISCONNECTION

To remove the connection bolts of the lower arm at the vehicle

rear side, remove the front member mounting bolts, and then

lower the front member.

Knuckle

A

Lower arm

assembly

INSTALLATION SERVICE POINT

"AA

1. Install the lower arm assembly to the knuckle.

2. If grease has flown out of the dust cover by pushing

3. Check that there is no clearance between the knuckle

LOWER ARM ASSEMBLY INSTALLATION

Caution

When installing the lower arm assembly, make sure

that the ball joint stud (A) does not protrude 4 mm

or more from the knuckle in order to prevent grease

from flowing out.

the lower arm in the knuckle excessively, replace the

dust cover. (Refer to P.33A-12.)

and the dust cover.

33A-12

FRONT SUSPENSION -

Lower Arm Assembly

MB991006

INSPECTION

33200170117

D Check the bushing for wear and deterioration.

D Check the lower arm for bend or breakage.

D Check the stay for deterioration or damage.

D Check all bolts for condition and straightness.

LOWER ARM BALL JOINT ROTATION STARTING

TORQUE CHECK

1. After shaking the ball joint stud several times, install the

nut to the stud and use the special tool to measure the

rotation starting torque of the ball joint.

Standard value: 2.0 - 8.8 Nm

2. When the measured value exceeds the standard values,

replace the lower arm assembly.

3. When the measured value is lower than the standard

value, check that the ball joint turns smoothly without

excessive play. If so, it is possible to use that ball joint.

MB990800

Dust cover

Snap ring

LOWER ARM BALL JOINT DUST COVER CHECK

1. Check the dust cover for cracks or damage by pushing

it with finger.

2. If the dust cover is cracked or damaged, replace the

lower arm assembly.

NOTE

Cracks or damage of the dust cover may cause damage

of the ball joint. When it is damaged during service work,

replace the dust cover.

LOWER ARM BALL JOINT DUST COVER

REPLACEMENT

Only when the dust cover is damaged accidentally during

service work, replace the dust cover as follows:

1. Remove the dust cover.

2. Apply multipurpose grease to the lip and inside of the

dust cover.

3. Using the special tool, press the dust cover until it contacts

the snap ring.

4. Check the dust cover for cracks or damage by pushing

it with finger.

33200820098

FRONT SUSPENSION -

Lower Arm Assembly

33A-13

Bushing

Lower arm

assembly

MB990651

MD998716

Piece

of

metal

MB990651

MD998716

BUSHING REPLACEMENT

33200810118

Replace the rear bushing by the following procedure.

1. Use the special tools to drive out the bushing.

2. Use the special tools to presss in the bushing.

3. Position the bushing so that its hollow part is as shown.

4. Press in the bushing until its outer tube top surface is

lined up with the lower arm assembly.

Lower arm

assembly

Bushing

Hollow

part

Lower arm assembly

Outer

tube

Piece

of

metal

60

_

33A-14

FRONT SUSPENSION -

Stabilizer Bar

STABILIZER BAR

REMOVAL AND INSTALLATION

Post-installation Operation

Check the Dust Cover for Cracks or Damage by Pushing

it with Finger.

4

33200190137

39 Nm

2

3

39 Nm

"AA

"AA

"AA

Front side of

vehicle

Approx. 20 mm

39 Nm

Removal steps

1. Stabilizer link

D

Front member (Refer to GROUP 32.)

2. Stabilizer bar bracket

3. Bushing*

4. Stabilizer bar

Bushing

1

NOTE

*: If only the bushing is removed and installed, refer to

P.33A-15.

INSTALLATION SERVICE POINT

"AA

1. Position the bushing so that its cut is aligned as shown.

2. Position the stabilizer at the left side of the vehicle so

STABILIZER BAR/BUSHING/STABILIZER BAR

BRACKET INSTALLATION

that its identification mark is as shown, and then tighten

the stabilizer bar bracket mounting bolts.

FRONT SUSPENSION -

Stabilizer Bar

33A-15

MB990326

INSPECTION

332000200076

D Check the bushing for wear and deterioration.

D Check the stabilizer bar for deterioration or damage.

D Check all bolts for condition and straightness.

STABILIZER LINK BALL JOINT TURNING TORQUE

CHECK

1. After shaking the ball joint stud several times, install the

nut to the stud and use the special tool to measure the

turning torque of the ball joint.

Standard value: 1.7 - 3.1 Nm

2. When the measured value exceeds the standard value,

replace the stabilizer link.

3. When the measured value is lower than the standard

value, check that the ball joint turns smoothly without

excessive play. If so, it is possible to use that ball joint.

Front member mounting bolts

Side cover

mounting clip

STABILIZER LINK BALL JOINT DUST COVER CHECK

1. Check the dust cover for cracks or damage by pushing

it with finger.

2. If the dust cover is cracked or damaged, replace the

stabilizer link.

NOTE

Cracks or damage of the dust cover may cause damage

of the ball joint. When it is damaged during service work,

replace the dust cover.

BUSHING REPLACEMENT

33201010012

1. Remove the side cover mounting clip.

2. Remove the front member mounting bolt and stay.

Stay

33A-16

Bushing

Stabilizer bar bracket

FRONT SUSPENSION -

3.Use the special tool to remove the stabilizer bar bracket

mounting bolt.

4. Remove the stabilizer bar bracket.

MB991164

Stabilizer Bar

Front side of

the vehicle

Approx. 20 mm

Clip ring

Bushing

5. Position a new bushing so that its cut is as shown.

6. Position the stabilizer at the left side of the vehicle so

that its identification mark is as shown, and then tighten

the stabilizer bar bracket mounting bolts.

7. Install the stay, front member, side cover mounting clip

in that order.

STABILIZER LINK BALL JOINT DUST COVER

REPLACEMENT

Only when the dust cover is damaged accidentally during

service work, replace the dust cover as follows:

1. Remove the clip ring and the dust cover.

2. Apply multipurpose grease to the inside of the dust cover.

3. Use plastic tape on the stabilizer link threads as shown

in the illustration, and then install the dust cover to the

stabilizer link.

4. Secure the dust cover by the clip ring.

5. Check the dust cover for cracks or damage by pushing

it with finger.

33201020015

Loading...

Loading...