Mitsubishi Electric Fresh Master GUF-50RD3, Fresh Master GUF-50RDH3, Fresh Master GUF-100RDH3, Fresh Master GUF-100RD3 Installation Instructions Manual

ENGLISH

Fresh Master

Models:

GUF-50RDH3 • GUF-50RD3

GUF-100RDH3

•

GUF-100RD3

Installation Instructions

(For use by dealer/contractor)

For use with the R410A&R407C&R22

• Please take the time to read through these instructions before commencing with the installation work.

They will help to install the Fresh Master properly and

safely.

• The separate Operating Instructions are for the user.

Make sure that they are handed over to the customer.

The warranty will not apply to damage resulting

from failure to follow the warnings and precautions set forth in the

Installation Instructions

.

GUF-50RDH3 shown above.

Humidifier function not available on GUF-50RD3 and

GUF-100RD3.

Contents

1. Safety precautions ............................................ 2-4

2. Accessories .......................................................... 5

3. Outline drawings .................................................. 5

4. Selecting an installation site ................................. 6

5. Installing the Fresh Master ................................6-7

6. Supply pipe and drain pipe work .......................... 8

7. Refrigerant pipe work ...................................... 9-11

8. Electrical wiring .............................................12-16

9. Feature settings ............................................ 17-19

10. Test run ......................................................... 19-20

11. Troubleshooting ................................................. 21

2

ENGLISH

1. Safety precautions

3 ) Remote controller

Warning:

The Remote controller should be installed in such a way that children cannot play with it.

4) Drain hose

Caution:

Make sure that the drain hose is installed so that drainage can go

ahead smoothly. Incorrect installation may result in water leakage, causing damage to furniture.

5 ) Power Supply, fuse or circuit breaker

Warning:

•

Make sure that the unit is powered by a dedicated power supply.

Other appliances connected to the same power supply could

cause an overload.

• Make sure that there is a mains power switch.

• Be sure to adhere to the unit’s voltage and fuse circuit breaker

ratings. Never use a cable or a fuse with a higher rating than

the one specified.

6 ) Grounding

Caution:

• The unit must be properly grounded. Never connect the

grounding wire to a gas pipe, water pipe, lightning conductor

or telephone grounding wire. If the unit is not grounded properly, electric shock may result.

• Check frequently that the ground wire from the outdoor unit is

properly connected to both the unit’s ground terminal and the

grounding electrode.

ss

ss

s Before operating the unit, make sure you read

all the “Safety precautions”.

ss

ss

s “Safety precautions” lists important points about

safety. Please be sure to follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to avoid the risk

of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the unit.

Symbols used in the illustrations

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock. (This symbol is displayed on the main

unit label.) <Colour: Yellow>

Warning:

Carefully read the labels affixed to the main unit.

1.1. Installation

ss

ss

s After you have read this manual, keep it and the Installation

Manual in a safe place for easy reference whenever a question

arises. If the unit is going to be operated by another person,

make sure that this manual is given to him or her.

Warning:

• The unit should not be installed by the user. Ask the dealer or

an authorized company to install the unit. If the unit is installed

improperly, water leakage, electric shock or fire may result.

• Use only accessories authorized by Mitsubishi Electric and

ask your dealer or an authorized company to install them. If

accessories are installed improperly, water leakage, electric

shock or fire may result.

• The Installation Manual details the suggested installation

method. Any structural alteration necessary for installation

must comply with local building code requirements.

• Never repair the unit or transfer it to another site by yourself.

If repair is performed improperly, water leakage, electric shock

or fire may result. If you need to have the unit repaired or

moved, consult your dealer.

1 ) Outdoor unit

Warning:

• The outdoor unit must be installed on a stable, level surface,

in a place where there is no accumulation of snow, leaves or

rubbish.

• Do not stand on, or place any items on the unit. You may fall

down or the item may fall, causing injury.

Caution:

The outdoor unit should be installed in a location where air and

noise emitted by the unit will not disturb the neighbours.

2) Fresh Master

Warning:

The Fresh Master should be securely installed. If the unit is loosely

mounted, it may fall, causing injury.

3

ENGLISH

1.2. Precautions for devices that use

R407C refrigerant

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping contains a large amount of chlorine which may cause the refrigerator

oil of the new unit to deteriorate.

• Use refrigerant piping made of C1220 (CU-DHP) phosphorus

deoxidized copper as specified in the JIS H3300 “Copper and

copper alloy seamless pipes and tubes”. In addition, be sure

that the inner and outer surfaces of the pipes are clean and

free of hazardous sulphur, oxides, dust/dirt, shaving particles,

oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause

the refrigerant residual oil to deteriorate.

• Store the piping to be used during installation indoors and

keep both ends of the piping sealed until just before brazing.

(Store elbows and other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of

the oil and compressor trouble may result.

• Use ester oil, ether oil or alkylbenzene (small amount) same

as the refrigerator oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount

of mineral oil.

• Use liquid refrigerant to fill the system.

-

If gas refrigerant is used to seal the system, the composition of the

refrigerant in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R407C.

- If another refrigerant (R22, etc.) is used, the chlorine in the refrig-

erant may cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle

and cause the refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional

refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow

check valve, refrigerant charge base, vacuum gauge, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the

R407C, the refrigerant may deteriorate.

-

If water is mixed in the R407C, the refrigerator oil may deteriorate.

- Since R407C does not contain any chlorine, gas leak detectors

for conventional refrigerants will not react to it.

• Do not use a charging cylinder.

-

Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant

may deteriorate.

1.3. Precautions for devices that use

R410A refrigerant

• Make sure to use new refrigerant piping.

- When using the existing piping which used R22, take care of the

following points.

• Replace the flare nut with that is attached to the product. Flare

section must be finished with the flare processing. (See P.10.)

• Use of piping with thin wall should be avoided. (See P.10.)

• Use refrigerant piping made of C1220 (CU-DHP) phosphorus

deoxidized copper as specified in the JIS H3300 “Copper and

copper alloy seamless pipes and tubes”. The pipes must have

the wall thickness as shown in the table below. In addition, be

sure that the inner and outer surfaces of the pipes are clean

and free of hazardous sulphur, oxides, dust/dirt, shaving

particles, oils, moisture, or any other contaminant.

It is strictly prohibited to use pipes with thin wall not listed in

the above table.

If the inside of pipe is contaminated, it could cause deterioration of

refrigerator oil, or other problems.

• Store the piping to be used during installation indoors and

keep both ends of the piping sealed until just before brazing.

(Store elbows and other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of

the oil and compressor trouble may result.

• Use ester oil, ether oil or alkylbenzene (small amount) same

as the refrigerator oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount

of mineral oil.

• Do not use a refrigerant other than R410A.

- If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant

may cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle

and cause the refrigerator oil to deteriorate.

• For the following tools, use only the tools special to the

refrigerant R410A.

- Tools as listed in the following table are required for the refrigerant

R410A.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant

may deteriorate.

• Do not use a charging cylinder.

-

Using a charging cylinder may cause the refrigerant to deteriorate.

1.4. Before conducting supply pipe

and drain pipe work

[Supply pipe work is not required for GUF-50 • 100RD3]

Caution:

• The water quality of the permeable film humidifier's supply

water should meet public waterworks standards, and have a

hardness less than 100 mg/

RR

RR

R. If the supply water does not

meet these standards, use a deionizer.

• The supply pressure must be within the range of 2×104pa to

49×104pa.

-

Supply pressure that is lower than the specified range will cause the

water to not supplied the permeable-film humiditier, and the humidifier may not work. Supply pressure that exceeds the specified range

may cause damage to the solenoid valve and result in water leaks.

• Drain pipe gradient must be more than 1/100.

- Drain water will not be properly discharged.

• For areas that are extremely cold in winter, perform freezeprevention on the supply pipe by wrapping a freeze prevention heater and thermal insulation.

- Cold temperatures may freeze water, and damage supply pipe.

• Install the drain piping according to this installation Manual

to ensure proper drainage. Wrap thermal insulation around

the pipes to prevent condensation.

- Improper drain piping may cause water leakage and damage to

furniture and other possessions.

ø6.35, Wall thickness 0.8 mm

ø12.7, Wall thickness 0.8 mm

ø9.52, Wall thickness 0.8 mm

ø15.88, Wall thickness 1.0 mm

Gauge manifold

Charging hose

Gas leak detector

Torque wrench

Tool name (For R410A)

Flare tool

Protrusion adjust copper pipe gauge

Vacuum pump adaptor

Balance for refrigerant charging

4

ENGLISH

1.5. Before getting installed

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion

may result.

• Do not use the Fresh Master where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the Fresh Master in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the per-

formance of the Fresh Master or damage its parts.

• When installing the unit in a hospital, communication station,

or similar place, provide sufficient protection against noise.

-

The inverter equipment, private power generator, high-frequency

medical equipment, or radio communication equipment may cause

the Fresh Master to operate erroneously, or fail to operate. On the

other hand, the Fresh Master may affect such equipment by creating noise that disturbs medical treatment or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80% or when the drain pipe is

clogged, condensation may drip from the Fresh Master. Perform

collective drainage work together with the outdoor unit, as required.

1.6. Before getting installed (moved) -

electrical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning

rods, or telephone ground lines. Improper grounding may result

in electric shock.

•

Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and

cause a fire.

• Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may re-

sult.

• Use power line cables of sufficient current carrying capacity

and rating.

-

Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper

wire may result in a general unit failure or fire.

• Do not wash the Fresh Master.

- Washing them may cause an electric shock.

•

Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause

personal injury or property damage.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more

than 20 kg.

- Fresh Master use PP bands for packaging. Do not use any PP

bands for a means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your

fingers.

- When transporting the outdoor unit, suspend it at the specified

positions on the unit base. Also support the outdoor unit at four

points so that it cannot slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts,

may cause stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that chil-

dren can not play with them. If children play with a plastic bag

which was not torn apart, they face the risk of suffocation.

1.7. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power

switch can result in severe damage to internal parts. Keep the

power switch turned on during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electrification.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes are

may be hot or cold, depending on the condition of the refrigerant

flowing through the refrigerant piping, compressor, and other refrigerant cycle parts. Your hands may suffer burns or frostbite if

you touch the refrigerant pipes.

• Do not operate the Fresh Master and outdoor unit with the

panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power.

Otherwise, water leakage and trouble may occur.

5

ENGLISH

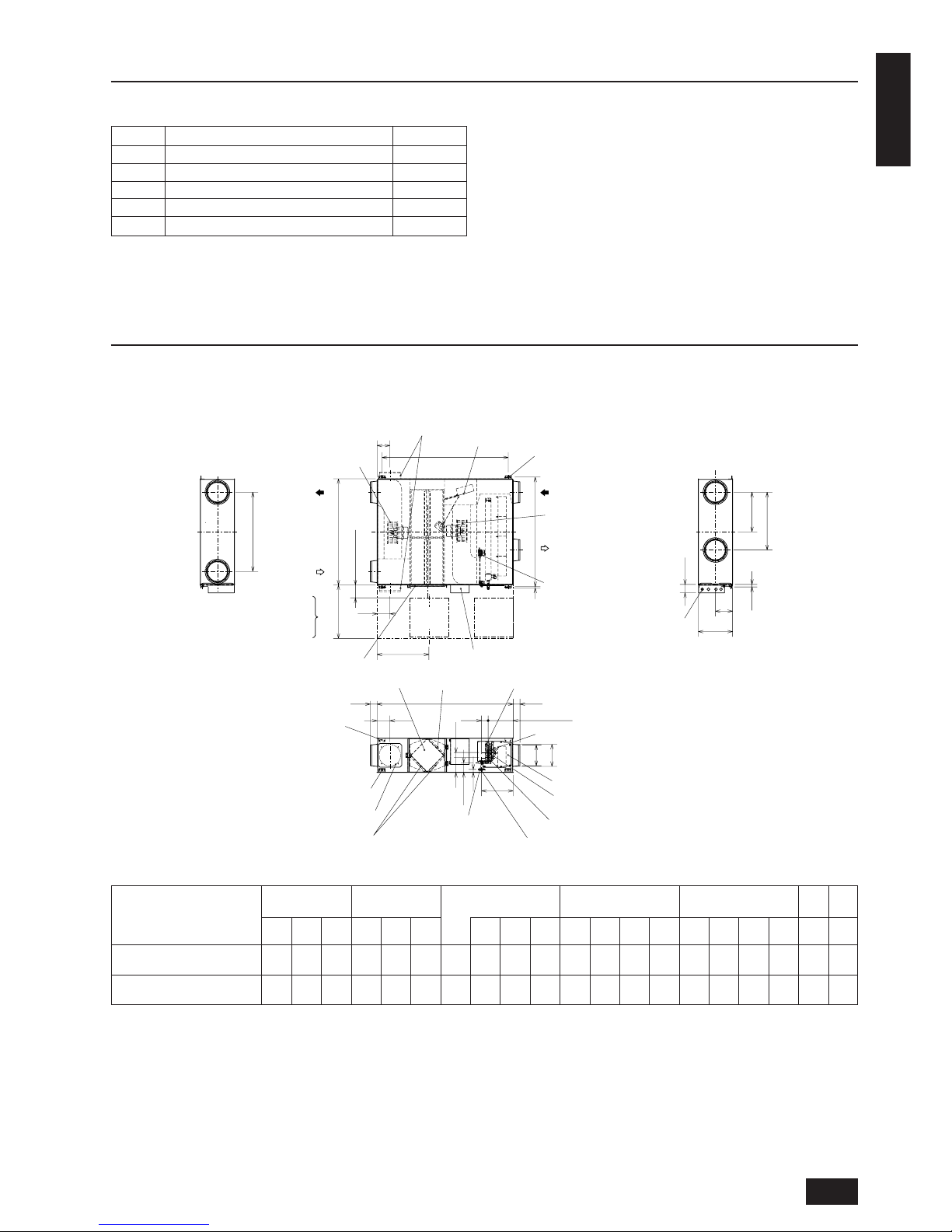

The unit is provided with the following accessories:

No. Accessories Qty

1 Pipe insulation 1

2 Flare insulation 1

3 Tie band 6

4 Duct connecting flanges 4

5 Mounting screws 16

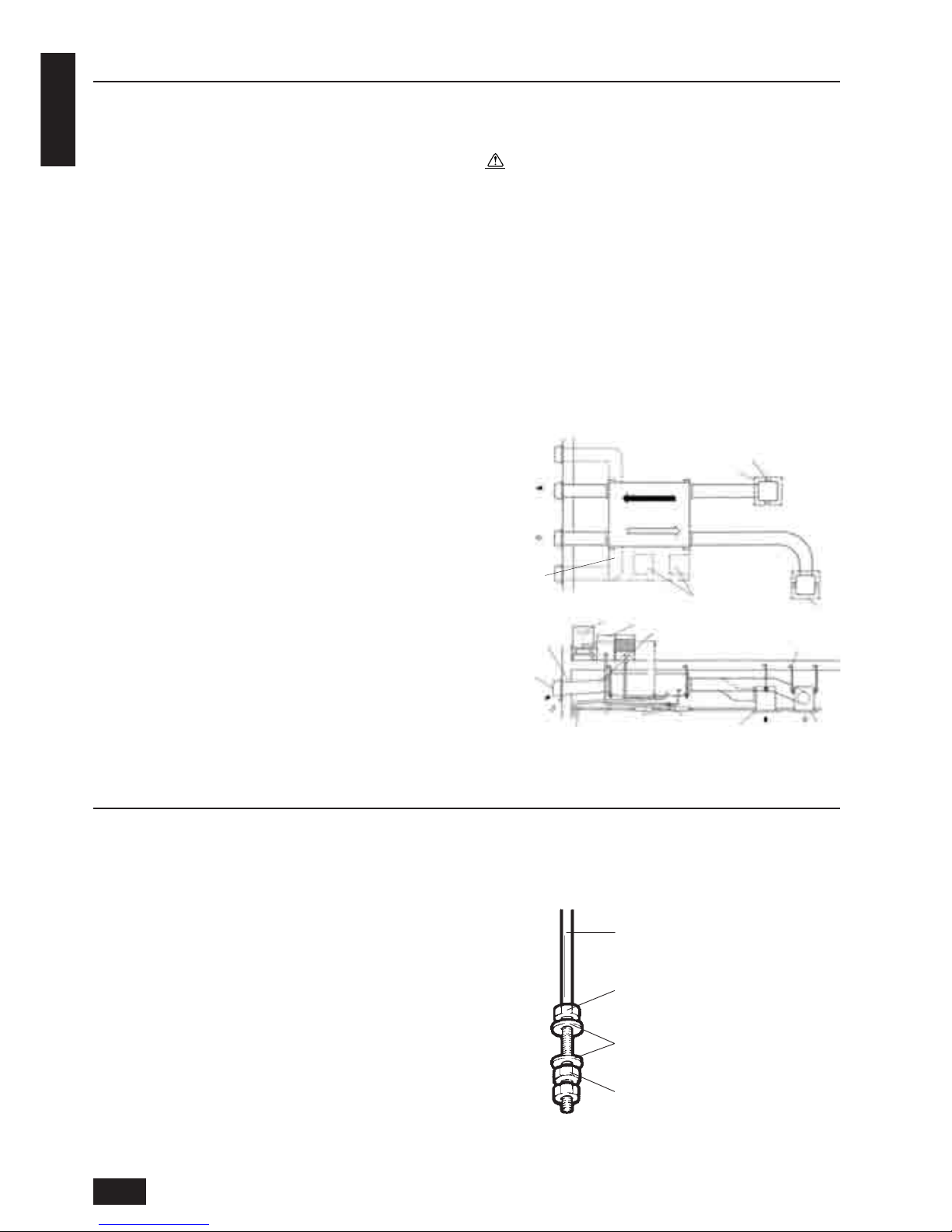

3. Outline drawings

2. Accessories

G

P

M

L

20

100

øH

øJ

C

(N)

A

F

E

N

D

B

79

79

N

T

150 to 250

60

Q

79

R

30

K

Air exhaust fan

Damper plate

Air supply fan

Ceiling suspension fixture (4-13×30 length hole for GUF-50RDH3 · 50RD3)

Ceiling suspension fixture (4-15×30 length hole for GUF-100RDH3 · 100RD3)

RA

(Return air)

Control box

Maintenance cover

EA

(Exhaust air)

High efficiency filter

(Optional part)

Gas pipe

Drain discharge hole

(VP25 connection)

Lossnay core

Liquid pipe

Heat exchanger

Air filters

SA

(Supply air)

OA

(Outdoor air)

Ceiling suspension fixture

Maintenance cover

Location at which the duct direction can be changed

Lossnay core

Air filter

High efficiency filter

Fan

Maintenance space

Inspection

opening

Inspection

opening

Solenoid valve unit with

pressure regulator*

Solenoid valve

Heat exchange unit

Humidifying element

Maintenance space

Power cable

installation port

Can install upper area of ceiling suspension fixture

(GUF-100RDH3 · 100RD3)

Location at which the duct direction can be changed

Humidifying element*

S (Water intake)

(Discharge hole)

Water intake strainer

with check valve*

(PT1/2 External thread)

More than 600

(* GUF-50, 100RDH3 only)

External

Ceiling suspension

Duct connection

Duct pitch Humidification

Inspection

Weight

Model

dimension

fixture pitch

flange

opening

ABCDEF

Nominal

G H J K L M N P Q R S T (kg)

diameter

GUF-50RDH3, GUF-50RD3 1288 1016 317 1185 1048 22 200 158.5 192 208 745 372.5 435 124 347 135 99 266 450

57

(54)

GUF-100RDH3, GUF-100RD3 1580 1231 398 1465 1271 16 250 199 242 258 920 460 670 149 361 169 110 280 600

98

(92)

Unit (mm)

*Values shown in parentheses “( )” are for RD3.

6

ENGLISH

4. Selecting an installation site

• Select a site with sturdy fixed surface sufficiently durable against

the weight of unit.

• Before installing unit, the route to carry the unit to the installation

site should be determined.

• Select a site where the unit is not affected by entering air.

• Select a site where the flow of supply, return, exhaust and outdoor

air is not blocked.

• Select a site where refrigerant piping and exhaust/outdoor ducts

can easily be led to the outside.

•

Select a site which allows the supply air to be distributed fully in room.

• Select a location where the inspection opening can be installed.

•

Do not install unit at a site with oil splashing or steam in large quantities

.

• Do not install unit at a site where combustible gas may generate,

flow in, stagnate or leak.

•

Do not install unit at a site where equipment generating high frequency

waves (a high frequency wave welder for example) is provided.

• Do not install unit at a site where fire detector is located at the

supply air side. (Fire detector may operate erroneously due to the

heated air supplied during heating operation.)

• When special chemical product may be scatter all around such as

site chemical plants and hospitals, full investigation is required before installing unit. (The plastic components may be damaged depending on the chemical product applied.)

• Do not install this product in a refrigerated warehouse, heated swimming pool or other location where the temperature and humidity

are significantly different.

(Failure to heed this warning may result in electrical shock or malfunction.)

• The electro-magnetic susceptibility has been chosen at a level that

gains proper operation in residential areas, on business and light

industrial premises and on small-scale enterprises, inside as well

as outside of the buildings. All places of operation are characterised by their connection to the public low voltage power supply

system.

5. Installing the Fresh Master

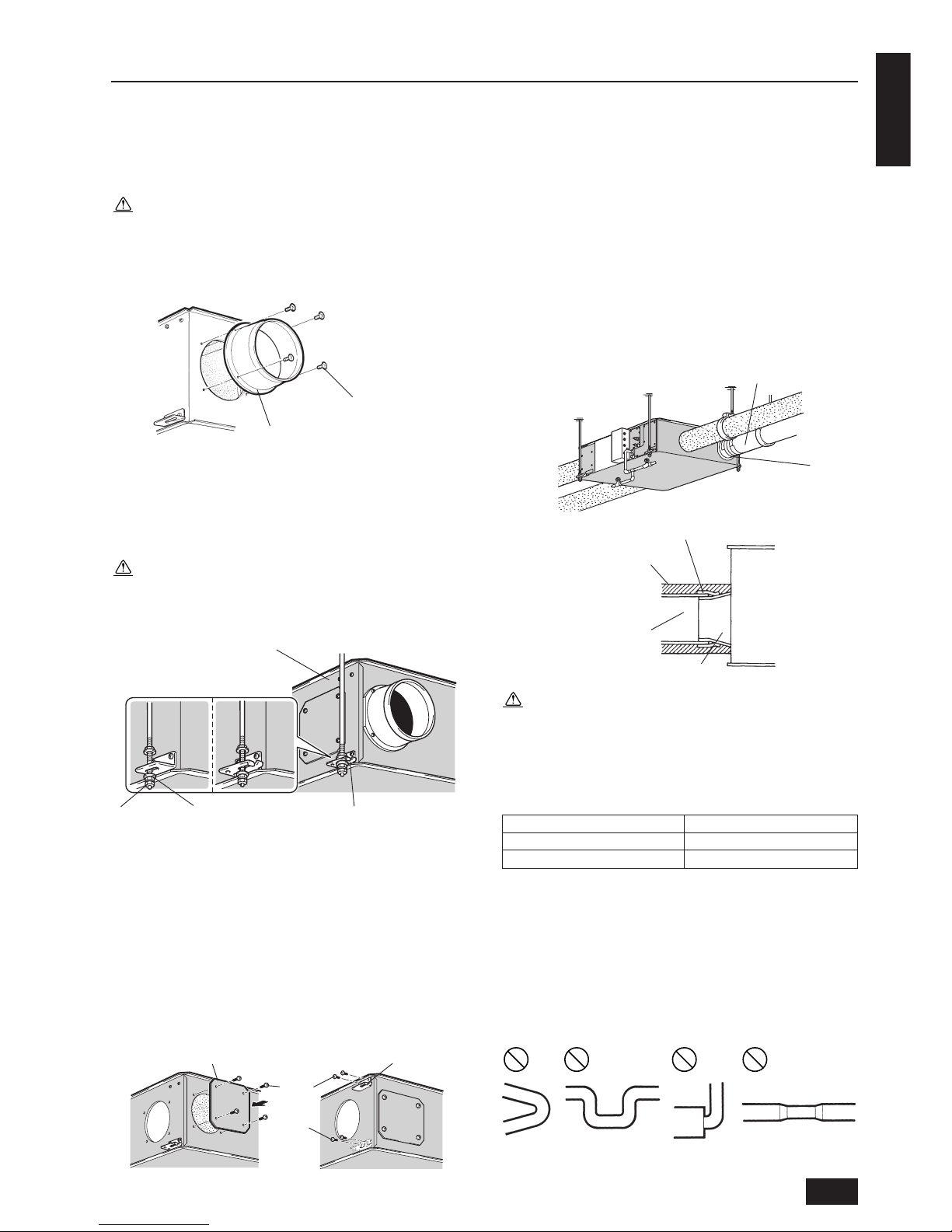

5.1. Fixing hanging bolts

(Use M10 or M12 hanging bolts. The bolts and washers should be

supplied in the field.)

(Give site of suspension strong structure.)

Hanging structure

• Ceiling: The ceiling structure varies from one building to another.

For detailed information, consult your construction company.

1 Reinforcing the ceiling with additional members (edge beam, etc.)

must be required to keep the ceiling at level and to prevent the

ceiling from vibrations.

2 Cut and remove the ceiling members.

3 Reinforce the ceiling members, and add other members for fixing

the ceiling boards.

• Mount the washers (outer diameter of >21 mm for M10, >24 mm

for M12) and nuts obtained from a field supply onto the pre-recessed

hanging bolts (M10 or M12) also obtained from a field supply, as

shown in the figure.

4.1.

Install the Fresh Master on a ceiling

strong enough to sustain its weight

Warning:

The unit must be securely installed on a structure that can sustain its weight. If the unit is mounted on an unstable structure, it

may fall down causing injuries.

4.2. Securing installation and service

space

• Select the optimum direction of supply airflow according to the configuration of the room and the installation position.

• As the piping and wiring are connected at the side surfaces, and

the maintenance is made at the same surfaces, allow a proper

space properly. For the efficient suspension work and safety, provide a space as much as possible.

4.3. Standard installation examples

Hanging bolt (M10 or M12)

Nut

Washer

Nut

EA

(exhaust)

Maintenance

space

Exhaust grille

Hanging bolt location

Inspection opening

Supply grille

OA

(outdoor)

Duct downward

gradient to wall

(more than 1/30)

Cistern tank

Deionizer

Duct (provided by

customer)

Hanging bolt

(provided by customer)

Deep hood or

weather cover

EA

(exhaust)

OA

(outdoor)

Drain pipe gradient to wall

(more than 1/100)

Supply pipe

Inspection

opening

Servicing

valve

Exhaust

grille

Supply

grille

RA

(return)SA(supply)

7

ENGLISH

5.2. Attaching the duct connecting

flanges

Use the screws supplied to secure the duct connecting flanges to the

Fresh Master.

Caution:

• Before attaching the duct connecting flanges, check that no

foreign matter (scraps of paper, vinyl, etc.) has found its way

inside the main unit.

• Replace the screws that were removed when the duct connect-

ing flange was removed back in place and securely tighten them.

5.3. Hanging the unit body

1. Hang the ceiling suspension fixtures on the hanging bolts and ad-

just in such a way that the main unit is level.

2. Tighten up securely using double nuts in order to prevent looseness.

Caution:

• When suspending the main unit from the ceiling, do not handle

it in such a way that force will be applied to the control box.

• Fasten the body so that it is oriented horizontally. (within 1˚)

5.4. When changing the direction of

the out door side duct (EA/OA)

Remove the flange cover and suspension fixture.

1. Remove the four mounting screws for the flange cover and remove

the flange cover.

2. Remove the screws at the top mounting position.

3. Remove the ceiling suspension fixtures and attach them at higher

mounting positions.

4. Tighten up the screws in the screw hole where the ceiling suspen-

sion fixtures were removed in order to prevent air leaks.

Mounting the duct connection flange

1. Use the mounting screws provided to mount the duct connection

flange to the main body.

2. Use the four mounting screws that were removed to attach the

flange cover.

5.5. Connecting the ducts

1. Fit the ducts securely into the duct connecting flanges, and wind

aluminium tape available from a field supply around them to prevent air leaks.

2. Suspend the ducts from the ceiling so that their weight will not be

applied to the Fresh Master.

3. The exhaust/outdoor and supply ducts must be covered with heatinsulating material in order to prevent condensation from forming.

Caution:

• The main unit is equipped with connection locations for

equipotential connection of ducts.

• Down ward gradient of outdoor duct: 1/30 or more (toward

wall side)

• Provision of distance for the exhaust/outdoor ducts in table

below (to prevent rain water from seeping in)

Model Distance

GUF-50RDH3, GUF-50RD3 1 m or more

GUF-100RDH3, GUF-100RD

3 2.5 m or more

• Before connecting the ducts, check that no sawdust or any

other foreign matter (scraps of paper, vinyl, etc.) has found its

way inside the ducts.

• Do not touch the damper plate inside the main unit when con-

necting the ducts.

• Do not install the ducts in the ways illustrated below. Doing

so will reduce the air volume and give rise to abnormal sounds.

Mounting screw

Duct connecting flange

Fresh Master

Nut Washer Celling suspension fixture

GUF-100RDH3

GUF-100RD3

GUF-50RDH3

GUF-50RD3

Screw

Flange cover Ceiling suspension fixture

Screw

Duct

Taping

Aluminium tape

Heat-insulating material

Exhaust/outdoor/supply ducts

Duct connecting flange

Main unit

• Extremely

sharp

bends

• Multiple bends

• Bends right next

to the outlet

• Extreme reduction in

the diameter of the

connected ducts

8

ENGLISH

6. Supply pipe and drain pipe work

Supply pipe work is not required for GUF-50 • 100RD3. Only perform

the drain pipe work.

6.1. Supply pipe work

1.

Connect a commercially available interlocked flexible metal hose or

the equivalent between the water supply pipe and the water filler

hole when performing pipe work for the water supply.

• Set the water pressure between 2×104Pa to 49×104Pa.

• Install the servicing valve near the strainer then install the sup-

ply pipe.

Caution:

•

The supply water should meet public waterworks standards, and have

a hardness less than 100 mg/

RR

RR

R, otherwise the humidifier will clog up.

• Install the discharge and servicing valve in locations accessible from the inspection opening.

• Securely lock the supply pipe so that no force is applied to the

strainer.

•

When performing the supply pipe work, wash the pipe with fresh

water prior to installation to prevent saw dust, etc. from entering, or install a discharge valve in the piping and sufficiently

conduct water discharge before using until the water is clear.

•

Take caution as to not let cutting oil or detergent from entering.

• The supply and drain pipes must be installed as such that they

do not rest on the Maintenance cover and cover (humidifier).

• The supply and drain pipes must be properly installed so that

there is no water leak.

• To prevent freezing when not using the unit for long periods

of time, close the servicing valve, open the discharge valve,

and remove the servicing valve and any water in the unitís

supply water entrance. After removing the servicing valve and

water, close the discharge valve.

2. Freeze-prevention work for extremely cold areas

Perform freeze prevention by wrapping a freeze-prevention heater

(field supply) on the supply pipe.

•

Wrap a freeze-prevention heater all the way to the Fresh Master.

• Insulation work must be performed upon the heater as well.

6.2. Drain pipe work

1. Connect a vinyl chloride VP25 elbow to the drain discharge port.

2. The drain pipe must be properly insulated from the drain discharge

port.

Caution:

• The pipe must be installed with gradient of more than 1/100.

• The drain pipe must be installed so that water does not accumulate inside.

• Check to make sure that the end of the drain pipe is at a location where discharge is possible and that the pipe can be properly drained.

• Do not install the drain pipe as shown below.

(This will result in insufficient drainage)

• Do not insert the tip of the drain pipe into a gutter or the like.

Doing so will cause the gutter to freeze in the event of heavy

snowfall, resulting in water leakage from the main unit.

3. Make sure the pipe drains water properly.

(1) Remove the maintenance cover (for humidifying).

• Remove the seven mounting screws, slide the maintenance

cover to the right, and remove it from the potbelly-shaped holes

(six locations for Model 50).

(2) Pull out the inner lid.

(3) Pour approximately 1,000 cc of water onto the drain tray.

(4) Confirm that the drain pipe drains away water at the pipe’s final

exit.

(5) Replace the inner lid and the maintenance cover (for humidifying).

* The diagram shows GUF-50 • 100RDH3

Wrapping the freeze-prevention

heater.

Supply pipe

Servicing valve

Discharge valve

→

Drained

water

Odor trap

Air-bleeding

→

Drained

water

Pass-over

Cap

Drain discharge port

VP25 elbow

Drain pipe (gradient: 1/100 or more)

Vinyl chloride pipe VP25

Maintenance Cover

(humidifier)

Drain tray

Water supply

hose

(field supply)

Innerlid

9

ENGLISH

7. Refrigerant pipe work

7.1. Refrigerant pipe specifications

To avoid dew drops, provide sufficient insulation to the refrigerant and

drain pipes.

When using commercially available refrigerant pipes, be sure to use

commercially available insulation (with a heat-resisting temperature of

more than 100°C and thickness given below) onto both liquid and gas

pipes.

Be also sure to use commercially available insulating material (with a

formed polyethylene’s specific gravity of 0.03 and thickness given below) onto all pipes which pass through rooms.

1 Select the thickness of insulating material by pipe size.

Pipe size Insulating material’s thickness

6.4 mm to 25.4 mm More than 12 mm

28.6 mm to 38.1 mm More than 15 mm

2 If the unit is used on the highest story of a building and under con-

ditions of high temperature and humidity, it is necessary to use

pipe size and insulating material’s thickness more than those given

in the table above.

3 If there are customer’s specifications, simply follow them.

4 Refrigerant pipe specifications

Model

GUF-50RDH3 GUF-100RDH3

Item

GUF-50RD3 GUF-100RD3

Liquid pipe ø6.35 ø9.52

Gas pipe ø12.7 ø15.88

5 Torque specifications

Outerdia of copper pipe Tightening torque

ø6.35 14 ~ 18 N•m

ø9.52 34 ~ 42 N•m

ø12.7 49 ~ 61 N•m

ø15.88 68 ~ 82 N•m

6 Refrigerant system diagram

Refrigerant pipe

(Flare connection)

7.2. Refrigerant piping work

This piping work must be done in accordance with the installation manuals for both outdoor unit and BC controller (simultaneous cooling and

heating series R2).

• With R2 systems connect Fresh Masters to BC controllers.

• For constraints on pipe length and allowable difference of eleva-

tion, refer to the outdoor unit manual.

• The method of pipe connection is flare connection.

Cautions On Refrigerant Piping

s Be sure to use non-oxidative brazing for brazing to ensure

that no foreign matter or moisture enter into the pipe.

s Be sure to apply refrigerating machine oil over the flare con-

nection seating surface and tighten the connection using a

double spanner.

s Provide a metal brace to support the refrigerant pipe so that

no load is imparted to the Fresh Master end pipe. This metal

brace should be provided 50 cm away from the Fresh Master’s

flare connection.

Warning:

When installing and moving the unit, do not charge

it with refrigerant other than the refrigerant (R410A

R407C or R22) specified on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant

cycle to malfunction and result in severe damage.

Caution:

• Use refrigerant piping made of C1220 (CU-DHP) phosphorus

deoxidized copper as specified in the JIS H3300 “Copper and

copper alloy seamless pipes and tubes”. In addition, be sure

that the inner and outer surfaces of the pipes are clean and

free of hazardous sulphur, oxides, dust/dirt, shaving particles,

oils, moisture, or any other contaminant.

• Never use existing refrigerant piping.

- The large amount of chlorine in conventional refrigerant and

refrigerator oil in the existing piping will cause the new refrigerant to deteriorate.

• Store the piping to be used during installation indoors and

keep both ends of the piping sealed until just before brazing.

- If dust, dirt, or water gets into the refrigerant cycle, the oil will

deteriorate and the compressor may fail.

• Use Suniso 4GS or 3GS (small amount) refrigerator oil to coat

the flare and flange connection part. (For using R22)

• Use ester oil, ether oil or alkylbenzene (small amount) as the

refrigerator oil to coat flares and flange connections. (For using R407C, R410A)

- The refrigerant used in the unit is highly hygroscopic and mixes

with water and will degrade the refrigerator oil.

Gas pipe thermistor TH3

Liquid pipe thermistor TH2

Strainer

Flare

connection

Heat exchanger

Strainer

Linear expansion valve

10

ENGLISH

• Make sure to use new refrigerant piping.

- When using the existing piping which used R22, take care of the

following points.

• Replace the flare nut with that is attached to the product. Flare

section must be finished with the flare processing.

• Use of piping with thin wall should be avoided.

* When applying the flare processing for the refrigerant R410A using conventional

tools, conduct the work referring to the above. If you use the copper pipe gauge

for the adjustment of protrusion margin, you can secure the dimension A.

Pipe Dia. (mm)

ø6.35 (1/4”)

ø9.52 (3/8”)

ø12.7 (1/2”)

ø15.88 (5/8”)

0~0.5

0~0.5

0~0.5

0~0.5

1.0~1.5

1.0~1.5

1.0~1.5

1.0~1.5

1.5~2.0

1.5~2.0

1.5~2.5

1.5~2.5

R410A Flare Tool

When using conventional flare tool (R22/R407C)

Dimension A (mm)

Rigid (clutch type)

Imperial (wing nut) type

Dice

Copper pipe

A

øB

R

0

.4

~

R

0

.8

Copper Pipe O.D.

ø6.35

ø9.52

ø12.7

ø15.88

8.7~9.1

12.8~13.2

16.2~16.6

19.3~19.7

Flare Dimension

Dimension øB (

mm

)

Coat small amount of ester oil, ether oil or hard alkylbenzen oil over

the entire periphery of flare seat surface.

* Do not coat at the threaded section.

(Otherwise, you cannot lock the flare nut securely.)

* Make sure to use only the flare nut attached to the main unit. (Off-the-shelf

product could be cracked.)

11

ENGLISH

No.

1

2

3

Reference drawing

Fig-1

Fig-2 (Note *2)

Fig-2

Fig-3 (Note *3)

Fig-3 (Note *4)

Detail of work

“IN” and “OUT” are marked on the

inside of the flare insulation. Mount the

portion marked “IN” near the unit body

and the portion marked “OUT” on the

field piping side.

• Fasten the insulated pipe with the

insulation tape.

• Firmly secure the insulation with the

provided tie band (4) at the position

indicated on the drawing.

• Fasten the flare insulation with the

provided tape (3).

• Fasten with the provided tie band (4)

at the position indicated on the

drawing.

Item to be observed

• Using the flare insulation of a different type

may result in condensation forming. Check

the type name on the insulation and be sure

to use the correct one.

• To prevent a gap from forming near the

unit’s side plate, be sure that the flare

insulation firmly contacts the unit’s side

plate before mounting.

• Incorrectly mounting the “INNER” and

“OUTER” sides of the insulation may result

in condensation forming.

Seal the slit securely so that there are no

openings. Be sure to mount the insulation so

that the slit is on the top.

Seal the slit securely so that there are no

openings. Be sure to mount the insulation so

that the slit is on the top.

Notes:

*1 Insert the flare nut into the field refrigerant piping. Pull the insulation material back at the area where it will be flared, then return

it to its original position after performing the flare work.

Exposing copper piping may result in condensation forming. Be extremely careful when performing this operation.

*2 There must be no gap.

*3, *4 There must be no gap. Slit should be on the top.

Work procedures

Mount the provided

pipe insulation (1) on

the liquid pipe of the

refrigerant piping, and

then mount the flare

insulation (2) on the

gas pipe.

Fixing of insulated pipe

Fixing of flare insulation

*2

7.3. Request for refrigerant piping connection

Description of parts to be used

*1

20

20

20

20

*3

*4

Fig-1

Fig-2 (figure showing the flare insulation)

Fig-3

“gas” mark

“IN” mark

“OUT” mark

Flare insulation (2)

Refrigerant piping (gas)

Refrigerant piping (liquid)

Field refrigerant piping

Pipe insulation (1)

Insulation material

Flare

Pull in this

direction.

Insulation material

Flare

There must be no gap.

Move to the

original position.

Field refrigerant piping

INNER

There must be no gap.

Unit body plate

OUTER

Unit body

Provided flare insulation

Tape (3)

Fasten with tape.

Provided tie band

12

ENGLISH

8. Electrical wiring

8.1. Precautions on electrical wiring

Warning:

Electrical work should be done by qualified electrical engineers

in accordance with “Engineering Standards For Electrical Installation” and supplied installation manuals. Special circuits should

also be used. If the power circuit lacks capacity or has an installation failure, it may cause a risk of electric shock or fire.

1. Be sure to take power from the special branch circuit.

2. Be sure to install an earth leakage breaker to the power.

3. Install the unit to prevent that any of the control circuit cables (Remote controller, transmission cables) is brought in direct contact

with the power cable outside the unit.

4. Ensure that there is no slack on all wire connections.

5. Some cables (power, Remote controller, transmission cables) above

the ceiling may be bitten by mice. Use as many metal pipes as

possible to insert the cables into them for protection.

6. Never connect the power supply cable to leads for the transmission cables. Otherwise the electronic circuit would be broken.

7. Be sure to connect control cables to the Fresh Master, Remote

controller, and the outdoor unit.

8. Put the unit to the ground on the outdoor unit side.

9. Select control cables from the conditions given below.

Caution:

Be sure to put the unit to the ground on the outdoor unit side. Do

not connect the earth cable to any gas pipe, water pipe, lightening rod, or telephone earth cable. Incomplete grounding may cause

a risk of electric shock.

8.2. Types of control cables

1. Wiring M-NET transmission cables

• Types of transmission cables

Design wiring in accordance with the following table <Table 1>.

• Cable cross-sectional area 1.25 mm2 to 2.00 mm

2

<Table 1>

2. Remote controller cables

Building, clinic, hospital or communications station without noise supposedly generated from inverter equipment, private power generator, highfrequency medical equipment, radioused communications equipment and

so on

Residence or independent

store without noise

Facility example

(for noise judgment)

VCTF, VCTFK, CVV, CVS,

VVR, VVF, VCT or shielding

wire CVVS or CPEVS

Shielding wire CVVS or CPEVS

Types of transmission

cables

System configuration

For a multi-refrigerant system

Transmission cable length Less than 120 m More than 120 m Regardless of length

All facilities

For a single-refrigerant system

MA Remote controller

(PAR-20MAA)

Wire Type

ME Remote controller

(PAR-F27MEA, PAC-SE51CRA)

10 m or shorter

VCTF, VCTFK, CVV, CVS,

VVR, VVF, VCT

If the length exceeds 10 m, keep

the length within the maximum

length of communications lines

between indoor and outdoor

units.

VCTF, VCTFK, CVV, CVS,

VVR, VVF, VCT

Type

2-conductor cable

Number of

conductors

0.3 ~ 1.25 mm2 (Note 1)

(0.75 ~ 1.25 mm2 )(Note 2)

0.3 ~ 1.25 mm2 (Note 1)

Wire diameter

Total Length

Max. 200 m Max. 10 m

M-NET transmission cable

Note1 For work purposes, a wire diameter of 0.75 mm2 is recommended.

Note2 If you are running the wires to the PAC-SE51CRA terminal block, use the wire diameter shown in ( ).

If the length exceeds 10 m.

13

ENGLISH

8.3. Electrical wiring diagram

■ GUF-50 • 100RDH3

• TM1, TM2, TM3 shown in dotted lines are field work.

• Be sure to connect the grounding wire.

• Breakers and controller switches should be provided by the customer.

■ SYMBOL EXPLANATION

■ NOTE 1. TM1,TM2,TM3 shown in dotted lines are field work.

2. Be sure to connect the grounding wire.

3. Breakers should be provided by the customer.

4. MARK : indicates terminal block, : connector, : board insertion connector or fastening connector of control board.

GUF50-100RDH3

M1

M2

C

W.S

SV1

SV2

TH1

TH2

TH3

TH4

LEV

RSV

Symbol Name Symbol Name Symbol Name

TM1

TM2

TM3

SW1

SW2

SW3

SW4

SW5

SW11

SW12

SW14

1, 2

A, B

S

CND1, CND2

X02–X09

TR

GM

LS

LED1

LED2

LED3

Fan motor (exhaust)

Fan motor (supply)

Capacitor

Water sensor

Solenoid valve (pressure regulator)

Solenoid valve (exhaust)

Thermistor (outdoor air temp. detection)

Thermistor (pipe temp. detection/liquid)

Thermistor (pipe temp. detection/gas)

Thermistor (room air temp. detection)

Electronic linear expansion valve

Resistance(solenoid valve)

Terminal block (power supply)

Terminal block (transmission)

Terminal block (humidistat, monitor)

Switch (function selection)

Switch (capacity code setting)

Switch (function selection)

Switch

Switch

Switch (1st digit address set)

Switch (2nd digit address set)

Switch (branch NO. set)

Remote control terminal

M-NET transmission terminal

Shield

Connector (power supply)

Relay

Transformer

Damper motor

Limit switch

Power supply monitor

MA Remote contoller Power supply monitor

M-NET Power supply monitor

1

12

11

10

9

8

7

2

A

B

S

GREEN/YELLOW

BLACK

PINK

ORANGE

WHITE

RED

GREEN/YELLOW

SUPPLY FAN

EXHAUST FAN

ORANGE

BLUE

WHITE

RED

BLACK

PINK

GREEN/YELLOW

M2

M1

BROWN

PINK

PINK

C

C

7

1

5

5

1

ZNR901

ZNR902

DSA1

X05

X04

X07

X06

FUSE1

PURPLE

FAN1

FAN4

CND1 CND2

BLACK

YELLOW

YELLOW

RED

WHITE

WHITE

ORANGE

PURPLE

FAN2

FAN3

SW4

SW5

SV2

SV1

DB901

1

6

1

X02

RSV (1KΩ)

RED

YELLOW

YELLOW

YELLOW

ORANGE

ORANGE

LS

W.S

GM

RED

RED

PURPLE

PURPLE

CN70

CNL

CN27

CN4D

RED

RED

Liquid

pipe

Gas

pipe

TH4 (RA)

TH1 (OA)

YELLOW

YELLOW

WHITE

WHITE

PINK

PINK

GRAY

GRAY

CN22

CN29

CN21

CN20

TH2

TH3

250V 6.3A

SW1

SW2

SW3

SW12

LED1

LED2

SW11

SW14

LED3

BROWN

RED

PURPLE

ORANGE

PINK

WHITE

LEV

CN60

31

TM1

BROWN

BROWN

BLUE

RED

BLUE

BROWN

/YELLOW

TR

CN3TCNT

GREEN

N

L

TM3

TM2

PE

N

L

BREAKER(16A)

220-240V ~ 50Hz

POWER SUPPLY

X09

X08

X03

<PAR-F27MEA>

<PAR-20MAA>

Remote Controller

Uncharged a-contact

Humidistat

240VAC more than 10mA

Operation monitor output

AC240V 1A AC220V 100mA

DC 24V 1A DC 5V 100mA

MAX MIN

Malfunction monitor output

MAX MIN

AC240V 1A AC220V 100mA

DC 24V 1A DC 5V 100mA

Shield wire

M-NET Remote controller

Fresh Master

To Outdoor Unit , BC Controller

M-NET transmissiion cable

■ Warning

Before obtaining access to terminals, all supply circuits

must be disconnected.

14

ENGLISH

■ SYMBOL EXPLANATION

■ GUF-50 • 100RD3

• TM1, TM2, TM3 shown in dotted lines are field work.

• Be sure to connect the grounding wire.

• Breakers and controller switches should be provided by the customer.

M1

M2

C

W.S

TH1

TH2

TH3

TH4

LEV

Symbol Name Symbol Name Symbol Name

TM1

TM2

TM3

SW1

SW2

SW3

SW4

SW5

SW11

SW12

SW14

1, 2

A, B

S

CND1, CND2

X02–X09

TR

GM

LS

LED1

LED2

LED3

Fan motor (exhaust)

Fan motor (supply)

Capacitor

Water sensor

Thermistor (outdoor air temp. detection)

Thermistor (pipe temp. detection/liquid)

Thermistor (pipe temp. detection/gas)

Thermistor (room air temp. detection)

Electronic linear expansion valve

Terminal block (power supply)

Terminal block (transmission)

Terminal block (humidistat, monitor)

Switch (function selection)

Switch (capacity code setting)

Switch (function selection)

Switch

Switch

Switch (1st digit address set)

Switch (2nd digit address set)

Switch (branch NO. set)

Remote control terminal

M-NET transmission terminal

Shield

Connector (power supply)

Relay

Transformer

Damper motor

Limit switch

Power supply monitor

MA Remote contoller Power supply monitor

M-NET Power supply monitor

PINK

PINK

C

C

5

1

5

1

SUPPLY FAN

EXHAUST FAN

BROWN

PURPLE

FAN1

FAN4

BLACK

YELLOW

YELLOW

RED

WHITE

WHITE

ORANGE

PURPLE

ORANGE

BLUE

WHITE

RED

BLACK

PINK

GREEN/YELLOW

GREEN/YELLOW

BLACK

PINK

ORANGE

WHITE

RED

GREEN/YELLOW

M1

M2

FAN2

FAN3

31

ZNR901

X05

X04

X07

X06

FUSE1

BROWN

BROWN

BLUE

RED

BLUE

BROWN

/YELLOW

TR

CN3TCNT

CND1

CND2

GREEN

SW4

SW5

TM3

TM2

X09

X08

X03

BREAKER(16A)

TM1

220-240V ~ 50Hz

POWER SUPPLY

N

L

PE

N

L

B

S

A

2

7

8

9

10

11

1

12

<PAR-F27MEA>

<PAR-20MAA>

Remote Controller

Operation monitor output

AC240V 1A AC220V 100mA

DC 24V 1A DC 5V 100mA

MAX MIN

Malfunction monitor output

MAX MIN

AC240V 1A AC220V 100mA

DC 24V 1A DC 5V 100mA

Shield wire

M-NET Remote controller

Fresh Master

To Outdoor Unit , BC Controller

M-NET transmissiion cable

1

6

X02

Liquid

piping

TH2

Gas

piping

TH3

TH4 (RA)

TH1 (OA)

YELLOW

YELLOW

WHITE

WHITE

RED

PINK

PINK

YELLOW

GRAY

GRAY

YELLOW

YELLOW

ORANGE

ORANGE

CN22

CN29

CN21

CN20

LS

W.S

GM

CNL

CN27

CN4D

DB901

7

1

ZNR902

DSA1

CN70

250V 6.3A

SW1

SW2

SW3

SW12

LED1

LED2

SW11

SW14

LED3

BROWN

RED

PURPLE

ORANGE

PINK

WHITE

LEV

CN60

■ NOTE 1. TM1,TM2,TM3 shown in dotted lines are field work.

2. Be sure to connect the grounding wire.

3. Breakers should be provided by the customer.

4. MARK : indicates terminal block, : connector, : board insertion connector or fastening connector of control board.

■ Warning

Before obtaining access to terminals, all supply circuits

must be disconnected.

15

ENGLISH

8.4. Power supply wiring

Power cable size: 1.5 mm2 or more

[Selecting non-fuse breaker (NF) or earth leakage breaker (NV)]

To select NF or NV instead of a combination of Class B fuse with switch,

use the following:

• In the case of Class B fuse rated 15 A or 20 A,

NF model name (MITSUBISHI): NF30-CS (15 A) (20 A)

NV model name (MITSUBISHI): NV30-CA (15 A) (20 A)

Use an earth leakage breaker with a sensitivity of less than 30 mA 0.1

sec.

Caution:

Do not use anything other than the correct capacity breaker and

fuse. Using fuse, wire or copper wire with too large capacity may

cause a risk of malfunction or fire.

8.5. Connecting the Remote controller,

the Fresh Master and outdoor

transmission cables

(The Remote controller is optionally available.)

• Connect Fresh Master TM2 and outdoor unit TB3. (Non-polarized

2-wire)

The “S” on Fresh Master TM2 is a shielding wire connection. For

specifications about the connecting cables, refer to the outdoor unit

installation manual.

• Install the Remote controller following the manual supplied with the

Remote controller.

[For using the ME Remote controller]

Connect the “A” and “B” on Fresh Master TM2 to the Remote controller. (Non-polarized 2-wire) Connect the Remote controller’s transmission cable within 200 m. If the distance is more than 10 m, use a 1.25

mm2 to 2.0 mm2 cable.

[For using the MA Remote controller]

Connect the “1” and “2” on Fresh Master TM2 to the Remote controller. (Non-polarized 2-wire) Connect the Remote controller’s transmission cable within 200 m.

SBA21 SBA2 1

SBA21

• 24 to 30 V DC between M1 and M2

Longest wiring length (L1+L2+L4 or L1+L3): less than 200 m

Longest wiring length (L2+L3+L4): less than 500 m

Length between the Fresh Master and the Remote controller (R): within

10 m

Notes:

*1 Put the transmission cable earth via the outdoor unit’s earth

terminal to the ground.

*2 If the Remote controller cable exceeds 10 m, use a 1.25 mm2 to

2.0 mm2 cable over the exceeded portion, and add that exceeded portion to within 200 m.

*3 The BC controller is required only for simultaneous cooling

and heating series R2.

[Constraints on transmission cable]

G

I

JJJ

KK

KK

JJ

L

K

H

*1

*3

L1

L2

L4

R

L3

*2

G Outdoor unit

H Earth

I BC controller

J Fresh Master

K Remote controller

L Non-polarized 2-wire

Switch 16 A

Over current

protection 16 A

Total operating current

be less than 16 A

Pull box

Fresh Master

Switch 16 A

Overcurrent

protection 16 A

Fresh Master

Terminal block for outdoor

transmission cable

TM2

(Fresh Master)

TM2

(after Fresh Master)

Terminal block for the

Fresh Master

transmission cable

TB3

MA Remote controller

(PAR-20MAA)

ME Remote

controller

(PAR-F27MEA)

16

ENGLISH

8.6. Connecting electrical connections

1. Remove the 4 screws to remove the control box cover.

2. Install a PG connection or the like, then connect the power supply

cable to the TM1 terminal block.

PE

N

L

Caution:

Wire the power supply so that no tension is imparted. Otherwise

disconnection, heating or fire may result.

3. Connect the transmission line to the TM2 terminal block as shown

in the diagram.

11

10

9

8

7

1

2

A

B

S

12

4. When connecting the humidistat input, remove the short-circuit piece

from the TM3 terminal block as shown in the diagram, then install a

PG connector and connect to the TM3 terminal block.

* The humidistat is the sensor designed specifically for the control of

moisture environment.

The suitable model in this stage :

Uncharged a-contact turns on when atmospheric moisture

content becomes less than your preset minimum allowable

percentage.

Screw

Controller box cover

Terminal block (TM1)

Terminal block for power

supply cable (for TM1)

Grounding wire

PG connection or the like

Power supply cable

Insulation sheet

Terminal block for TM2

M-NET

transmission

cable

Shield

wire

Terminal block (TM3)

Transmission cable

to terminal block for

Fresh Master

outdoor and BC

controller

Humidistat *

Uncharged acontact

240 V AC more

than 10 mA

Short-circuit

piece

Terminal block (TM2)

Humidistat cable

PVC insulated PVC

jacketed control cable 0.75

mm

2

. Recommended type

H03VV-F, H05VV-F.

PAR-20MAA

(Remote

controller)

PG connection

or the like

Terminal block for TM3

Humidistat

Malfunction

monitor

output

Operration

monitor

output

Remote

Controller

17

ENGLISH

9. Feature settings

Caution:

* Always turn off the main power supply.

* Remove the control box cover.

9.1. Address setting

(Determining the address depends on the own-site system. Please

see to technical references, etc.)

Remove the control box cover.

Turn the address setting switch on the board using a Phillips screwdriver.

• The left side (SW12) shows the second digit and the right side

(SW11) shows the first digit.

• The switch is set to 00 when factory shipped.

• Set the address between 1 and 50.

9.2. When using an R2 series external

unit, setting for the branch No. is

also required.

Turn the branch controller No. setting switch (SW14) on the board

using a Phillips screwdriver.

• Set the refrigerant pipe of the external unit and the connected branch

controller to the same number.

• The switch is set to 0 when factory shipped.

9.3. Feature select switches

(SW1, SW3, SW2)

* When shipped from the factory

Items concerning humidifying is for GUF-50 • 100RDH3 only.

SW1

OFF ON

Fan test operation switch (test operation when ON)

Filter maintenance display (displayed when ON)

Filter maintenance time setting switch

Do not touch

Damper motor test operation (test operation when

ON)

Solenoid valve test operation for humidifier water supply (test

operation when ON) Do not touch GUF-50

•

100RD3

Auto-recovery during power failure (active when on)

Power supply ON/OFF (test operation when on)

SW12 SW11 SW14

Second digit First digit Branch No.

SW3 ---- GUF-50 • 100RDH3

OFF ON

Synchronous air-conditioning switch (async when

ON)

Humidifier mode (OFF: humidifier; ON: heat save)

Heater operation during synchronous operation/

stop temperature switch

Exhaust fan operation when supply fan is stopped

(exhaust fan also stopped when ON)

Do not touch

Automatic humidifier control (active when ON)

Do not touch

SW3 ---- GUF-50 • 100RD3

OFF ON

Synchronous air-conditioning switch (async when

ON)

Do not touch

Exhaust fan operation when supply fan is stopped

(exhaust fan also stopped when ON)

Do not touch

Room temperature detected at main unit is decreased

by 4°C when heating. (OFF: active; ON: inactive)

Room-temperature sensor location (OFF: main

unit; ON: remote control)

Do not touch

SW2

OFF ON

Do not touch

Fan speed control method select switch

7: OFF, 8: ON fix to High speed.

Both ONs fix to Low speed.

Do not touch

Notes:

* The switches are vertical for explanation purposes.

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

18

ENGLISH

9.3.1. Filter maintenance time setting

Set the filter maintenance display ON/OFF and time according to use.

2

3

4

2

3

4

3

4

3

4

When the accumulated operation time reaches the set time, indication

for filter cleaning is notified to the Remote controller.

After cleaning, press the filter button twice to reset the accumulated

operation time.

9.3.2. Power-failure auto-recovery select

(independent of Fresh Master)

Set the Fresh Master operation condition when power failure is recovered.

9

9

9.3.3. Power ON feature

Set whether to operate the Fresh Master or not when the main power

is turned ON.

10

10

9.3.4. Indoor unit and synchronous setting

Setting to synchronize with the indoor unit.

1

1

Maintenance time

Filter maintenance display ON

Filter maintenance display OFF*

1,500 hours

3,000 hours*

4,500 hours

Unrestricted

Switch

SW1

OFF ON

Mode

Fresh Master stopped when power failure is

recovered.*

Fresh Master recovers to the prior state when

power failure is recovered.

Switch

SW1

OFF ON

Mode

Inactive: operates according to the SW1-9

setting*

Active: operation starts with power ON

Switch

SW1

OFF ON

9.3.5. Humidifier mode select (GUF-50

•

100RDH3 only)

Setting the humidifier mode.

2

2

Used when operating only the Fresh Master and the temperature during heating becomes too hot. The heating capability can be saved lower

temperature than normal.

9.3.6. Heat operation stop temperature setting

(GUF-50 • 100RDH3 only)

Stopping the heating operation when synchronous with the indoor unit.

It becomes invalid when SW3-1 is ON.

3

4

5

3

4

5

3

4

5

3

4

5

3

4

5

3

4

5

3

4

5

3

4

5

9.3.7. Exhaust fan operation setting

Setting the exhaust fan operation, although the supply fan will stop

when defrosting during heating or when withdrawing the refrigerant.

6

6

9.3.8. Automatic humidifier control setting

(GUF-50

•

100RDH3 only)

Although the permeable-film humidifier is supplied with water for humidifying when heating, there is a feature to automatically stop the

water supply depending on the outside temperature.

8

8

Mode

Synchronizing with the indoor unit*

Asynchronous with the indoor unit. The Remote controller operation only.

Switch

SW3

OFF ON

Mode

Standard humidifier mode*

Heat save humidifier mode (see below)

Switch

SW3

OFF ON

Switch

SW3

OFF ON

Set outside

temperature

6°C

7°C

8°C

9°C

OFF ON

Set outside

temperature

10°C*

12°C

14°C

16°C

Mode

Exhaust fan in operation even when the supply fan is stopped*

Exhaust fan is stopped wen the supply fan is

stopped

Switch

SW3

OFF ON

Mode

Automatic humidifier control prohibited*

Water is supplied to the permeable-film humidifier constantly when the heater is in operation.

Automatic humidifier control permitted

When the outside temperature is below 12°C

during heating operation, supply water to the

permeable-film humidifier.

Switch

SW3

OFF ON

19

ENGLISH

10. Test run

ss

ss

s Read the operation manual, too.

• After installing, piping and wiring the Fresh Master and outdoor

units, make sure again that there is no refrigerant leakage, no slack

on the power and transmission cables, or no polarity mistakes.

• Make sure using a 500 V DC megger that the resistance between

the power terminal bed and ground is more than 2.0 MΩ. If less

than 2.0 MΩ, do not operate the unit.

Warning:

Never measure the insulation resistance of the terminal block for

transmission cables.

Caution:

When operating the Fresh Master for a test run, be sure there is

no water leakage.

■

When operating the Fresh Master for a test run

1 Turn ON the test run switches (1, 7, 8) of the function changeover

switch (SW1).

1

7

8

Notes:

• When the test run switches (1, 7, 8) are turned on, the Remote

controller inspection code “0900” is displayed.

• The operating sound of the damper plate is generated when

the test run switch 7 is turned on. However, it is not abnormal.

2 Turn off the test run switches (1, 7, 8).

9.3.9. Selecting the fan speed control method

This setting is used to select whether to operate according to the fan

speed requested by the indoor unit, or to operate in high or low speed.

7

8

7

8

7

8

7

8

* When factory shipped.

9.3.10. Room temperature control (GUF-50

•

100RD3 only)

Room temperature detected at main unit is decreased by 4°C when

heating.

8

8

9.3.11. Room temperature sensor position

(GUF-50

•

100RD3 only)

9

9

Mode

Following the selected fan speed from controllers.*

Following the selected fan speed from controllers.

High fan speed mode (notch constantly on

high)

Low fan speed mode (notch constantly on

low)

Switch

SW2

OFF ON

Mode

Effective*

Ineffective

Switch

SW3

OFF ON

Mode

Fresh Master’s return air*

Built in the Remote controller.

Switch

SW3

OFF ON

■ When operating the Fresh Master directly

using the Remote controller (SW3-1 is ON)

Operational Procedure

1 Turn ON power at least 12 hours before operation

2 Press [TEST RUN] button twice → displaying “TEST RUN” on the

screen

3 Press [Selecting operation] button → Check that wind is blowing

out

4 Press [Selecting operation] button to change over to cooling (or

heating) → Check that cool (or warm) air is blowing out

5 Press [Fan speed adjustment] button → Check that the wind speed

is changed

6 → Check that the outdoor unit fan is operating

7 Press [ON/OFF] button to clear test run → Test run stops

PAR-F27MEA

ON/OFF

CENTRALLY CONTROLLED

DAILY

AUTO OFF

REMAINDER

CLOCK

ON OFF

˚C

CHECK MODE

FILTER

TEST RUN

LIMIT TEMP.

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

CLOCK→ON→OFF

CHECK

B

C

A

7

5

4

3

2

D

E

A Lighting in operation

B Displaying inspection code

C Displaying remaining test run time

D Displaying indoor unit’s liquid pipe temperature

E Displaying test run

Mode

Power is delivered to the fans for air supply

and exhaust, and they start operating.

The damper motor is powered on, and the

bypass ventilation is activated.

The solenoid valve unit with a pressure regulator that supplies water to the solenoid valve

unit with a pressure regulator for the humidifier is powered on, and water is supplied

(GUF-50·100RDH3 only).

Switch

SW1

OFF ON

20

ENGLISH

Notes:

• It takes a while until warm air comes out when heating. When

cooling, make sure that the display on the remote control

shows “Cooling”.

• The 2-hour-set timer is activated to automatically stop test run

after two hours.

■ When operating the Fresh Master by synchro-

nizing with the indoor unit

During test operation of the indoor unit, press the ventilation button

to operate the Fresh Master simultaneously.

Check to make sure that the mode is the same as the indoor unit

operation mode.

Notes:

• If the Remote controller shows an inspection code or does

not operate normally, refer to the outdoor unit installation

manual.

• The 2-hour-set timer is activated to automatically stop test run

after two hours.

• The Remote controller displays the remaining test run time on

the time display section during test run.

• The Remote controller displays the temperature of the indoor

unit’s liquid pipe on the temperature display section during

test run.

• Depending on the model, the Remote controller displays “This

function is not available” when pressing the [Up/down airflow

selection] button. This is not a malfunction.

Phenomenon

(1) No Remote controller

display appears at all.

(2) No Remote controller

display appears at all.

(3) Inspection code “6600”

flashes.

(4) Inspection code “7107”

flashes.

(5) Inspection code “7106”

flashes.

Cause

• The source power supply is

not turned on.

• Wiring error, short-circuit or

contact failure of transmission

line

• Error in setting the indoor unit

address

There are duplicate address

settings, meaning there are

indoor units with the same

address.

• Error in setting the branch exit

number.

• The Remote controller was

connected with the SW3-1

OFF.

■

In case of abnormality during a test-run operation

If the unit fails to operate normally, check the phenomena and causes

listed below, and correct the problem. (The phenomena listed below

are applicable to the test-run mode.)

21

ENGLISH

11. Troubleshooting

Error code

0900

2600

2601

3602

4116

5101

5102

5103

5104

H0

–

–

See below for possible remedies when there is an error during test operation and [Check] followed by a 4-digit number is displayed on the remote

controller.

Error content

Test run

Drain error

Disconnected water sensor

connector

Damper motor error

Fan motor error

Indoor temperature sensor

error

Liquid pipe temperature

sensor error

Gas pipe temperature sensor

error

Outdoor temperature sensor

error

Booting system

Unable to register.

Operation display comes up

with the Remote controller,

however it turns off immediately.

Cause

• Is the test operation SW of either the fan,

humidifier solenoid valve or bypass damper

turned ON?

• Drain water is not properly discharged.

• Is there a leak from the permeable-film

humidifier?

• Is there a leak from the permeable-film

humidifier?

• When no problem is discovered after

checking the above items.

• Is the CN4D connector firmly connected?

• Is the relay connector between the PCB and

water sensor firmly connected?

• When no problem is discovered after

checking the above item.

• Is the CNL connector firmly connected?

• Is the connector of the damper motor

section firmly connected?

• Does the damper operate when the damper

motor is running?

• When no problem is discovered after

checking the above items.

• The motor continues to run when the

operation is stopped.

• Are the connectors of each thermister firmly

connected?

• Is each relay connector firmly connected?

• When no problem is discovered after

checking the above item.

• Has 10 minutes passed since system bootup?

• Has group registration been made?

• Has the Fresh Master address been

changed?

• When no problem is discovered after

checking the above items.

• The Fresh Master which is linked with air

conditioner, cannot be group registered

other than the interlock setting with the

Remote controller.

• Main power hasn’t supplied to the Fresh

Master.

Remedy

• Set the test operation SW (SW1-1, 7, 8) to

OFF.

• The body must be levelly installed.

The drain pipe must be installed with

gradient of more than 1/100.

• Fix the water leak.

• Replace the permeable-film humidifier.

• Replace the PCB (printed circuit board).

• Firmly connect the connector.

• Firmly connect the connector.

• Replace the PCB (printer circuit board).

• Firmly connect the connector.

• Firmly connect the connector.

• Replace the damper motor if not working.

• Replace the PCB (printed circuit board).

• Replace the PCB (printed circuit board).

• Firmly connect each connector.

• Firmly connect each connector.

• Replace the PCB (printed circuit board).

• After system boot-up, HO may flash for a

maximum of 10 minutes. However, this is

not a malfunction.

• Conduct group registration. If there is a

master system controller such as the central

controller, use the controller to conduct

group registration.

• If the Fresh Master main unit address has

been changed, conduct the group registration again.

• If HO continues to flash for more than 10

minutes after reregistering the group and

rebooting, replace the PCB (printed circuit

board).

• Change the setting of the SW3-1 switch and

reset the registration or register it interlocked.

• Supply Main Power.

22

ENGLISH

Loading...

Loading...