ADVANCED

AND

EVER

ADVANCING

MITSUBISHI

ELECTRIC

MITSUBISHI

General Purpose Inverter

mm®rnOO[loU100

Instruction ManuaI

Thank you

for

choosing this Mitsubishi Inverter.

This manual gives handling, safety and operating instructions.

Th is section is

specifica

Ily a bout

safety

matters

Read

this

manual

carefully

and become

familiar

with

the

inverterbefore

operation, pay special

attention

to the

safety

information

marked

Warning.

This

warning

symbol indicates the presence

of

LtWARNING

dangerous voltage.

It

informs

you

of

high

HIGH VOLTAG

voltage conditions,

situations

and

locations

that

may

cause death

or

serious

injury

if you

do

not

follow

precautions.

&WARNING

This

symbol

indicates a general

warning.

Serious

injury

may

occur

if

precautions

are

not

followed.

Where these Wamings

are

written,

pay special

attention

to

the

precautions detailed.

A-l

Operator

Safety

1. Electric shock prevention

it

WARNING HIGH

VOLTAGE

&. Do

not

remove th,e

front

cover while

there

is

power

supplied

to

the

inverter,

there

are

high voltage

terminals

which can be

accessed. Please check

the

wiring when

the

inverter

is

not

powered.

&.

There

are

high voltage

capacitors

in

the

main circuit which

remain

charged

after

the

inverter

has

been

turned

off,

wait

10

minutes

after

the

Power

Lamp

has

gone

out

and

check

for

no

residual voltage

actoss

terminals

"P!+"

and

<::

("P"

and

"N")

before

touching wires.

&. Use good

earthing.

Earth

the

inverter

before wiring

the

Power

circuits

and

control

circuits.

&. Do

not

operate

with wet hands.

&. Do

not

damage,

cut,

trap,

or

degrade

the

cables.

A-2

2.

Fire

Prevention

it. WARNING

6 Do

not

mount

on

or

near

combustible

material

(such

as

wood)

6 Use a

circuit

breaker

on

the

supply

side

of

the

inverter

to

prevent

high

current

flow in

the

case

of

a fault.

6 Do

not

connect

a

resistor

directly

to

terminals

"P"

and

"N".

3. I

njury

Prevention

it. WARNING

6

Only

supply

the

inverter

with

the

voltage

on

the

nameplate

and

in

the

Manual

Specification

section.

6

Other

voltages

may

cause

the

inverter

to

fail.

6

Care

should

be

taken

when

wiring

to

ensure

correct

terminals

are

used. Check

polarity

etc

...

6 Do

not

touch

the

inverter

while it is

powered

as

certain

parts

become

hot.

A-3

4.

Other

points

To prevent injury. damage.

or

product

failure please note

the

following points.

(1)

Transportation

and mounting

~WARNING

&

Take

care

when

carrying

products.

use

correct

lifting

gear.

& Do

not

stack

the

inverter

boxes higher

than

the

number

recommended.

&

Ensure

the

installation

position

and

material

can

with

stand

the

weight

of

the

inverter. Install

according

to

the

information

in

theInstruction

Manual.

& Do

not

operate

if

the

inverter

is

damaged

or

has

parts

missing.

& Do

not

life

the

inverter

with

the

front

cover

attached.

it

may

falloff.

& Do

not

stand

or

rest

heavy objects on

the

inverter.

& Check

the

inverter

mounting

orientation

is

correct.

&

Prevent

any

dust.

wire

fragments

or

other

foreign

bodies

from

dropping

into

the

inverter

during

wiring up

and

commissioning.

A-4

LhWARNING

Lt:.

Do

not

drop

the

inverter.

or

subject

it

to

impacts.

Lt:.

Environmental

limitations. Check

the

ambient

temperature.

humidity.

storage

temperature.

atmosphere,

altitude.

vibration.

-10°C

to +50°C

(without

freezing)

-10"C

to +40°C

for

enclosed specification.

Less

than

90% Relative Humidity

without

condensation.

Ensure

the

environment

is

-20°C

to +65°C

(short

time

storage

temperature).

no

corrosive

or

flammable

gasses,

altitude

less

than

1000m

above

sea

level,

vibration

is less

than

5.9m/s 2 {0.6

G)

(based

on

JIS

C 0911)

------------------'

(2)

Wiring

LhWARNING

Lt:.

Do

not

fit

power

factor

correction

capacitor.

or

RFI filter

to

the

output

of

the

inverter.

Lt:.

The

connection

orientation

of

the

output

cables

U. V. W

to

the

motor

will

effect

the

direction

of

rotation

of

the

motor.

A-5

(3)

Trial run

LhWARNING

.&

Check all

parameters.

and

ensure

that

the machine will

not

be

dameged

by sudden

start-up.

(4)

Operation

LhWARNING

.&

When

retry

function is selected the inverter will

try

to

restart

the

machine up to 10 times over a 1 hour period. Ensure

operator

safety

with

other

devices.

.&

The

stop

key can only be used

at

all times to

stop

the

inverter

when a

parameter

has been set.

therefore

use an

external

emergency

stop

button. Switch off

start

signal when resetting

the

inverter. failure to do so

may

start

the

motor

immediately

after

reset.

.&

The Electronic

motor

thermal

protection does not

guarantee

to prevent

motor

burn out.

A-6

LhWARNING

.6';

Do

not

use a

contactor

in

the

inverter

input

for

frequent

start

/stopping

of

the

inverter. use

control

signals

.

.6';

To reduce

the

effect of

mains

conducted

electromagnetic

interference

use a RFI noise filter .

.6';

Take

care

to

ensure

electromagnetic

radiation

from

the

inverter

does

not

damage

or

effect

the

operation

of

nearby

electrical equipment.

.6';

Use an

input

line

reactor

when

the

power

supply

capacity

is

large.

or

where

harmonics

from

the

inverter

will

cause

problems

.

.6';

Take

countermeasures

to

prevent

motor

insulation

damage

from

micro

surge

voltages

in

the

supply

cable.

.6';

Reset

the

inverter

before

starting

set-up. initialises

the

parameters

to

factory

set

values.

.6';

Do

not

use

the

inverter

and

motor

at

high speed until

the

machine

has

been checked.

.6';

The

inverter

does

not have a holding

stop

facility.

For

emergency

stop

another

circuit

must

be used.

A-7

(5) Emergency

stop

~WARNING

.&.

Use a

circuit

and

mechanical

brake

etc. which will

protect

the

operator

of

the

machine should

the

inverter

fail.

(6)

Maintenance

and

inspection

~WARNING

.&.

Do not

carry

out

a

megga

(insulation

resistance)

test

on

the

control

circuit

of

the

inverter.

(7) Disposing of

the

inverter.

~WARNING

.&.

Treat

as

industrial

waste.

A-a

(8)

General

Many

of

the

diagrams

and

drawings

in the

instruction

manual

show the

inverter

without

a cover,

or

partially

open, never

run

the

inverter

like this.

Always

replace the cover and ensure

adequate cooling etc. before using the inverter.

A-9

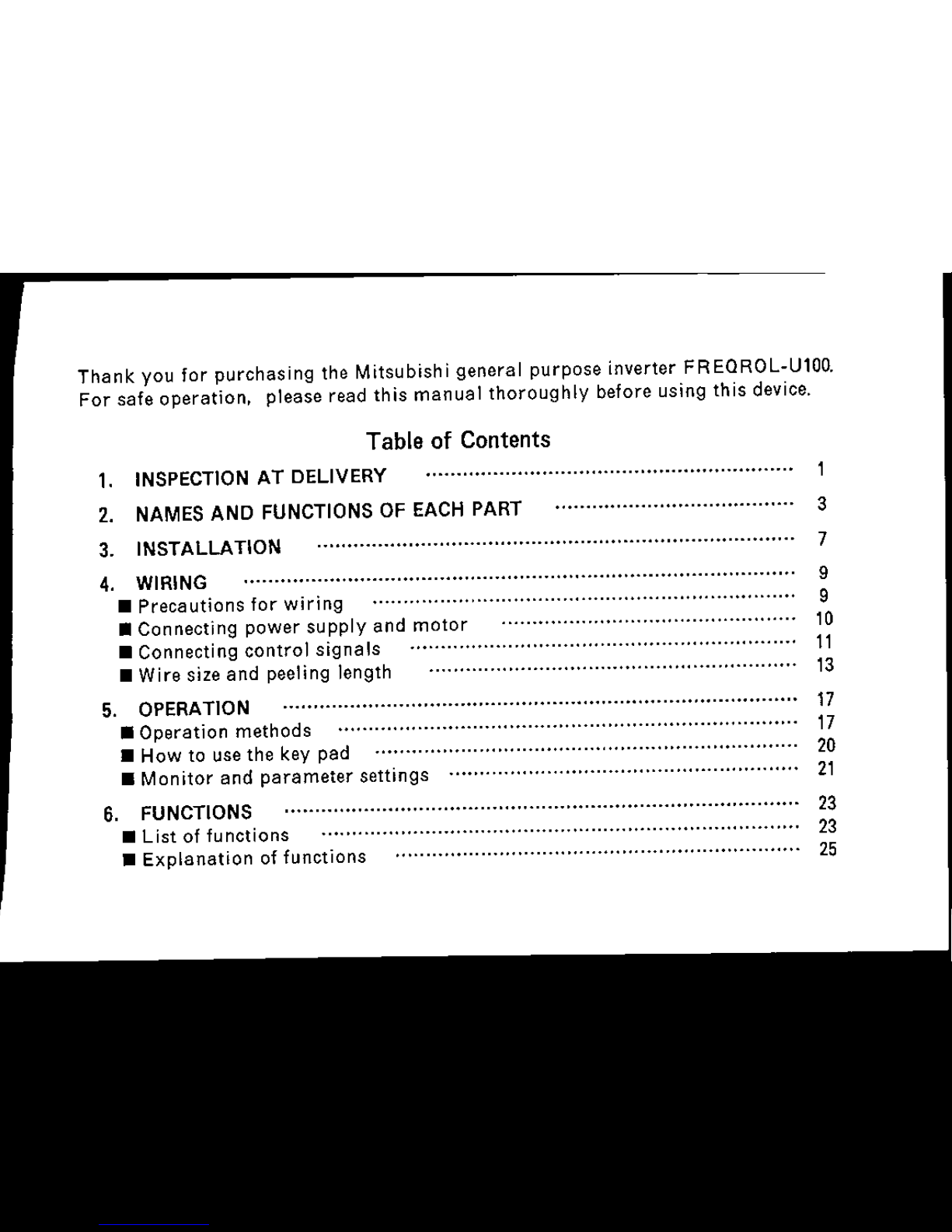

Thank

you

for

purchasing

the

Mitsubishi

general

purpose

inverter

FREQROL-U100.

For

safe

operation,

please

read

this

manual

thoroughly

before

using

this

device.

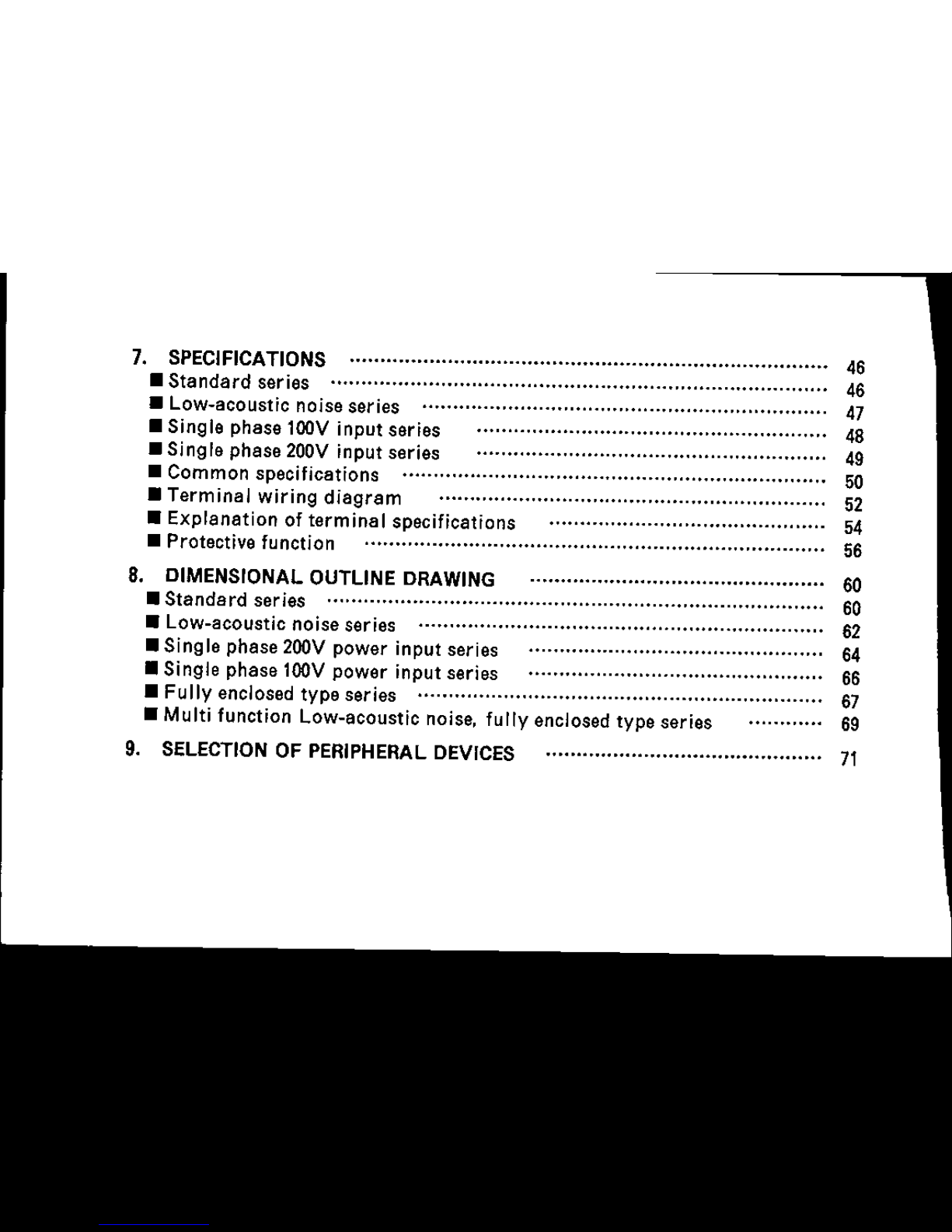

Table of Contents

1. INSPECTION AT

DELIVERy·

..···..··..·..· ·· · ····..· ··........ ,

2. NAMES AND FUNCTIONS OF EACH PART 3

3. INSTALLATION 7

4. WIRING 9

•

Precautions

for

wiring

,....................................................

9

•

Connecting

power

supply

and

motor

10

•

Connecting

control

signals

11

•

Wire

size

and

peeling

length

13

5. OPERATION 17

•

Operation

methods

,

,.....

17

•

How

to use

the

key

pad

20

•

Monitor

and

parameter

settings

21

6. FUNCTIONS 23

•

List

of

functions

23

•

Explanation

of

functions

25

7.

SPECIFICATIONS

46

• Standard series 46

• Low-acoustic noiseseries 47

• Single phase100V input series 48

• Single phase

20DV

input series 49

• Common specifications 50

• Terminal wiring diagram 52

• Explanation of terminal specifications 54

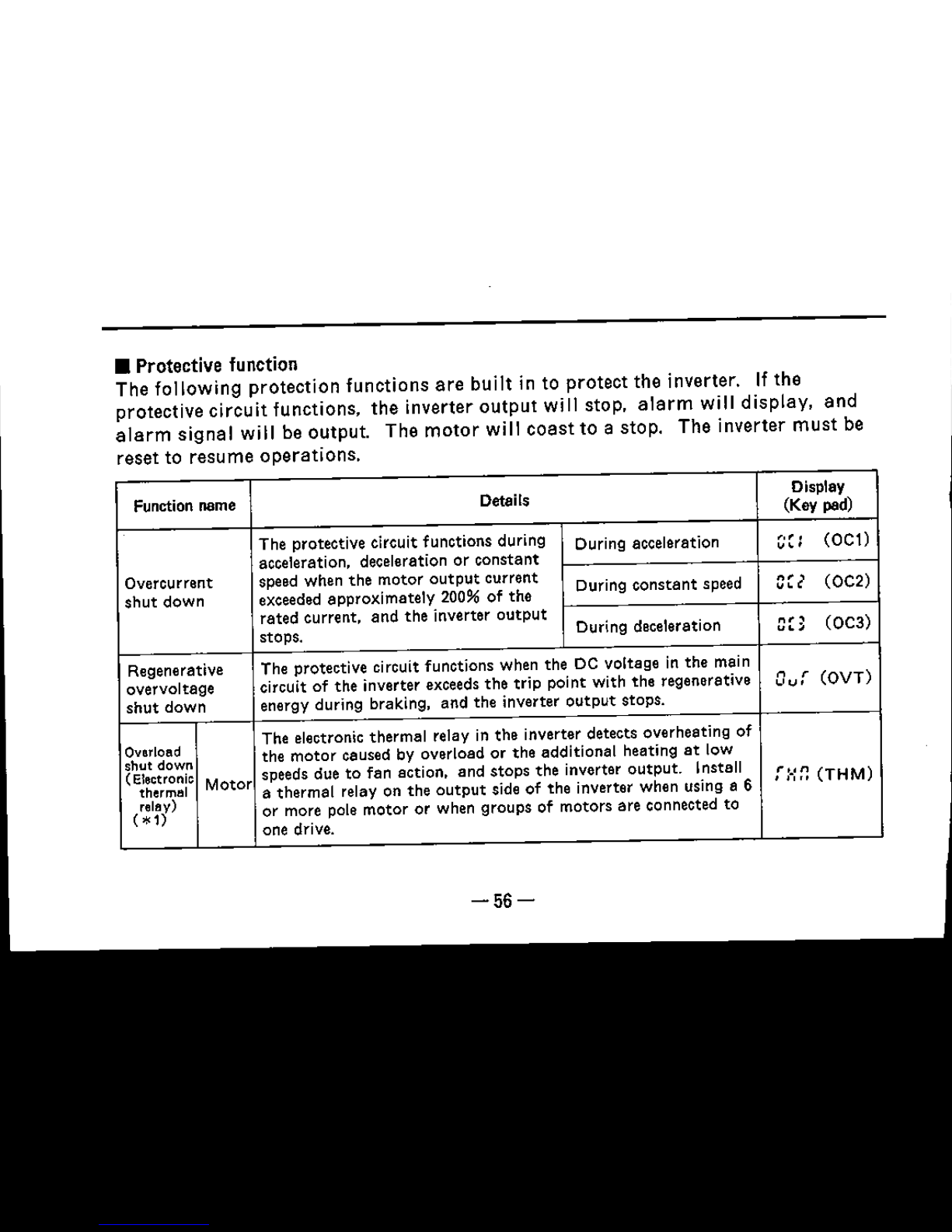

• Protectivefunction 56

8.

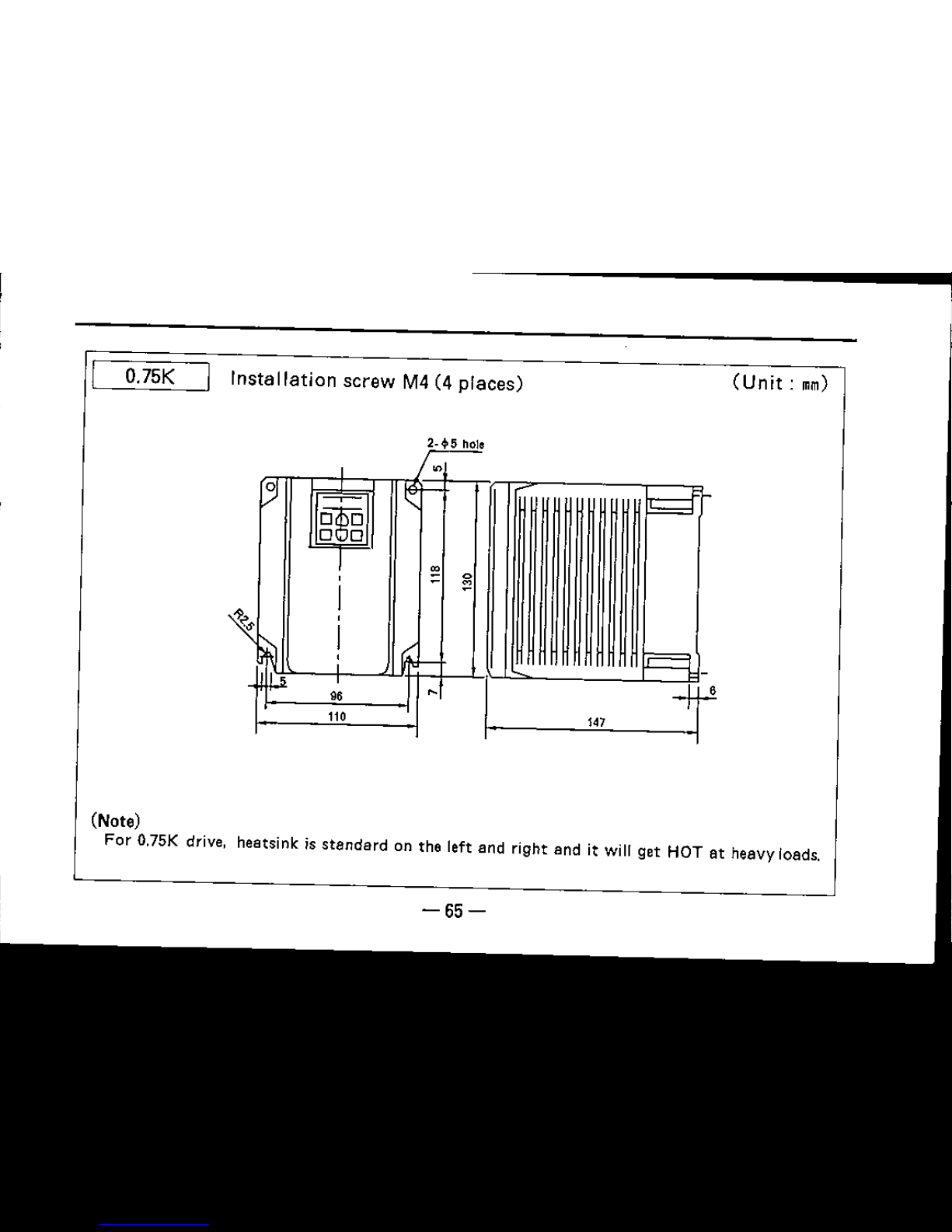

OIMENSIONAL

OUTLINE

ORA

WING

60

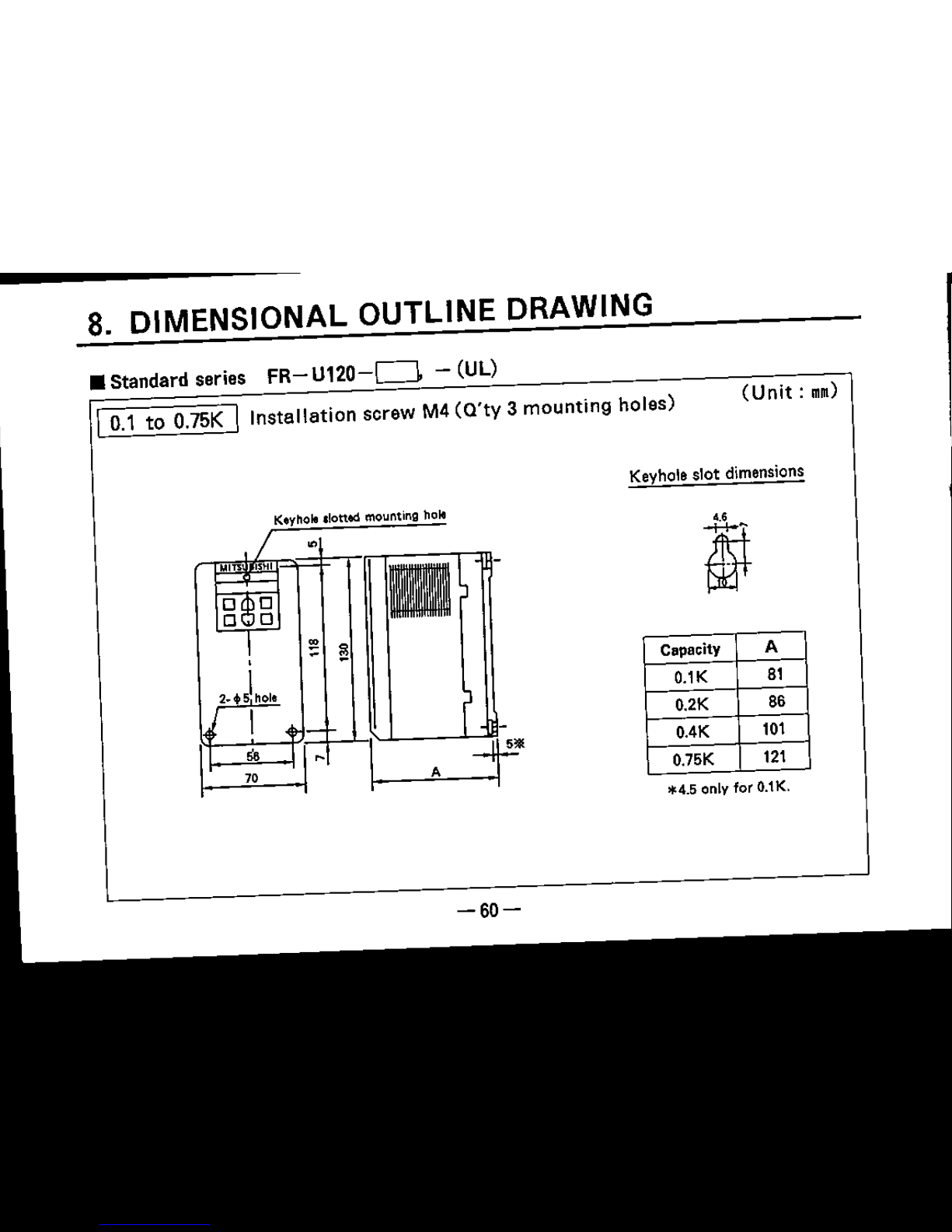

• Standard series 60

• Low-acoustic noise

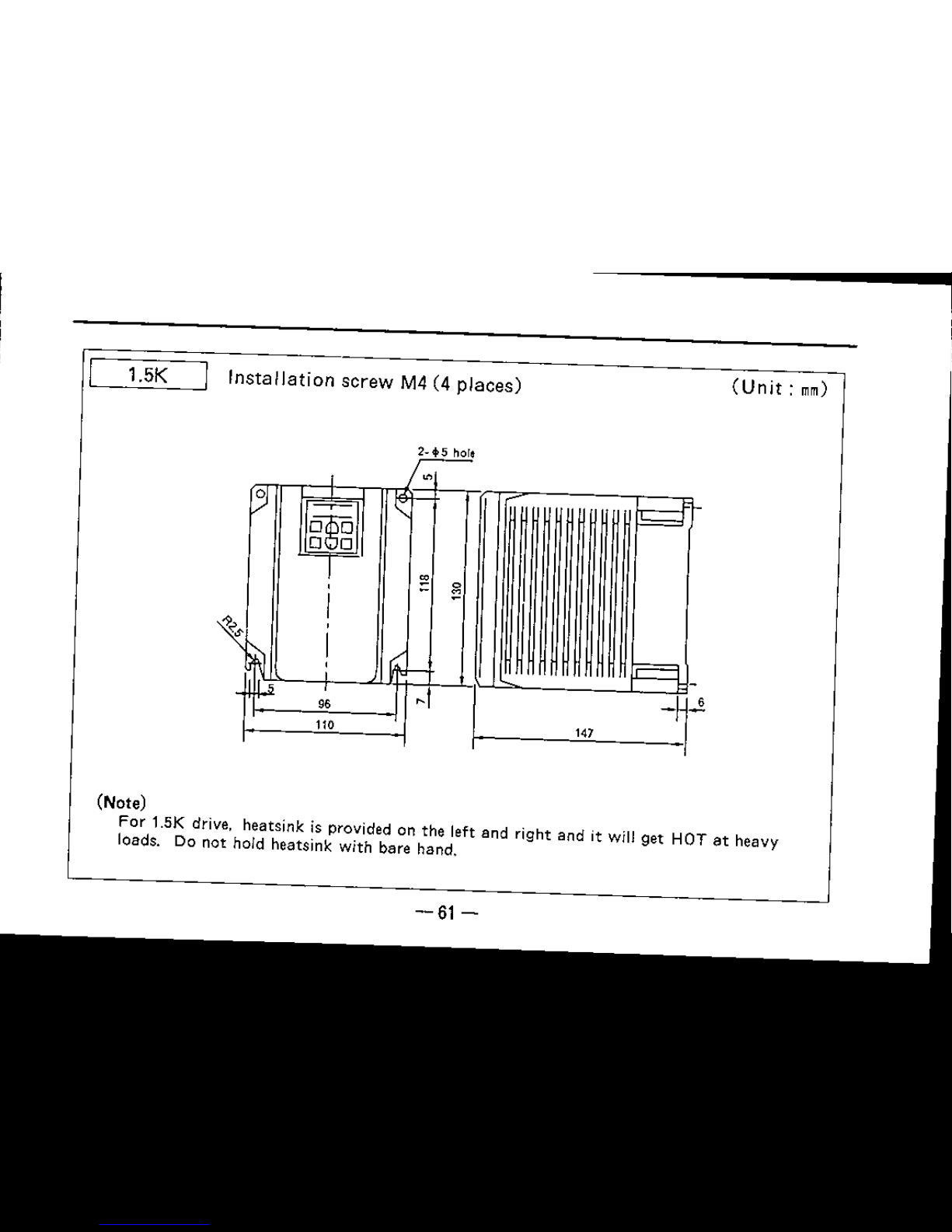

series

62

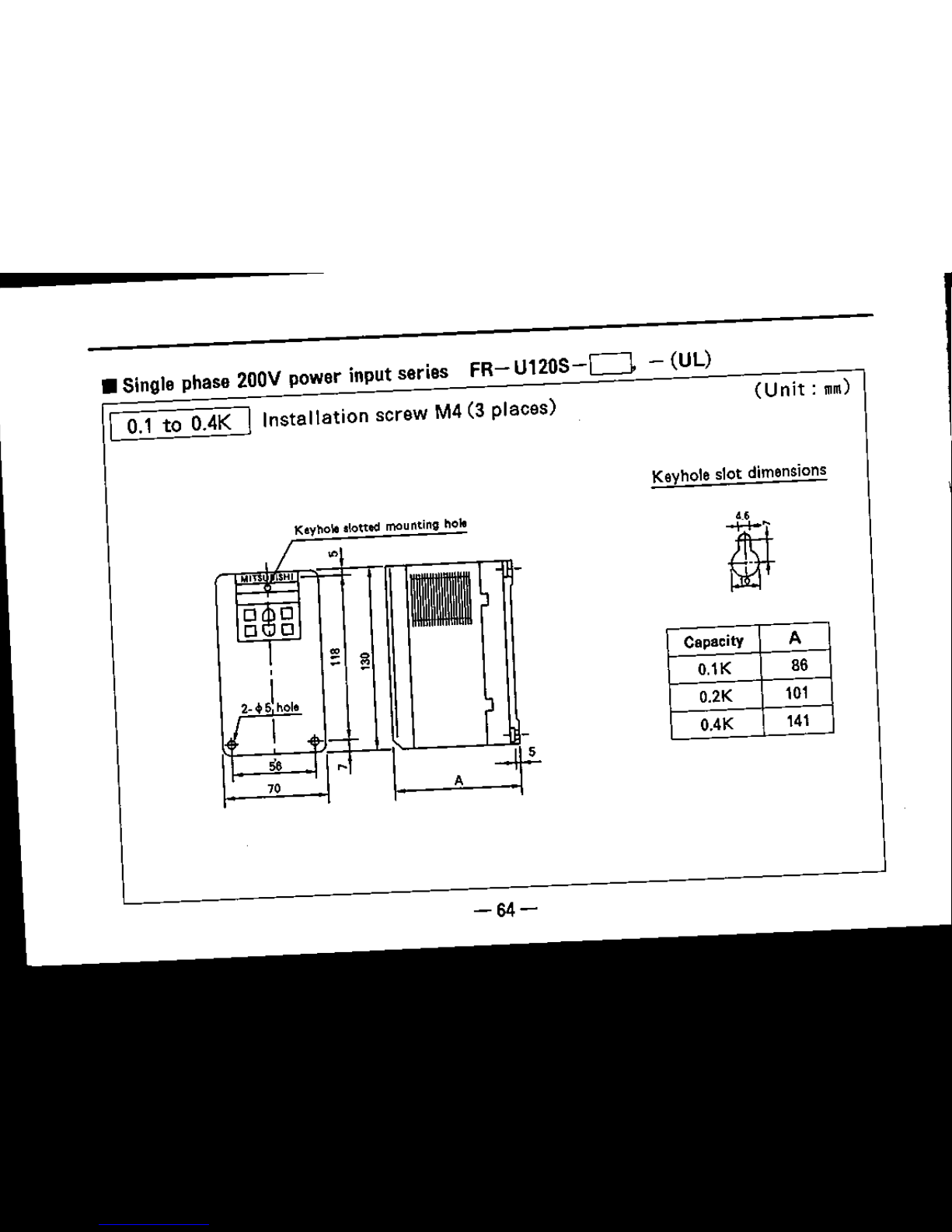

• Single phase200V power input

series

64

• Single phase100V power input series 66

• Fully

enclosed

type series 67

• Multi function Low-acoustic

noise,

fully

enclosed

type series 69

9.

SELECTION

OF

PERIPHERAL

OEVICES

71

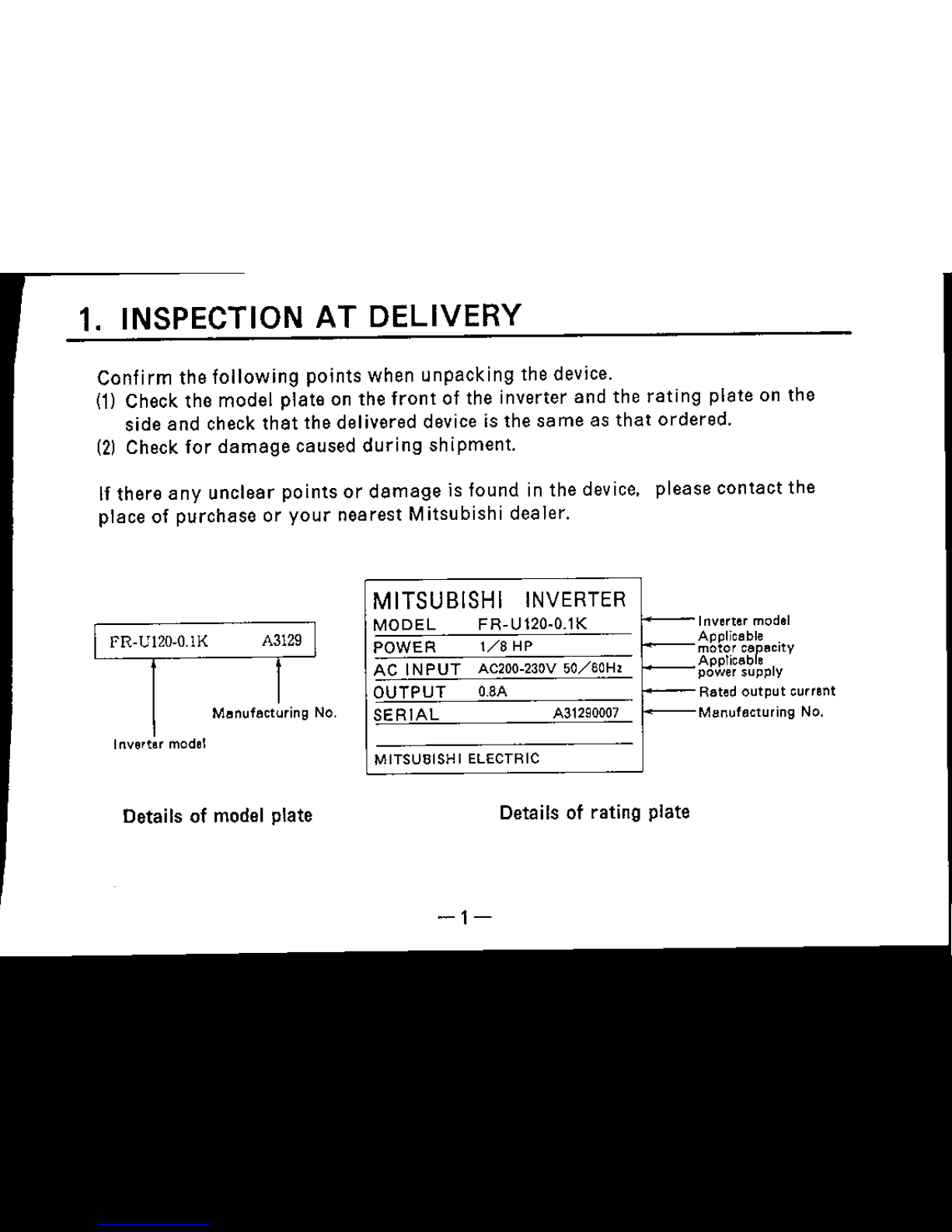

1. INSPECTION AT DELIVERY

Confirm the

following

points when unpacking the device.

(1)

Check

the

model

plate

on

the

front

of the

inverter

and

the

rating

plate

on

the

side

and

check

that

the delivered device is the

same

as

that

ordered.

(2)

Check

for

damage caused

during

shipment.

If

there

any

unclear

points

or

damage

is

found

in

the

device,

please

contact

the

place

of

purchase

or

your

nearest

Mitsubishi

dealer.

FR-U120-0.1K

Menufecturing No.

Inverter model

Details of model plate

MITSUBISHI

INVERTER

MODEL

FR-U120·0.1K

I---

POWER

1/8

HP

I--

ACINPUT

AC200-230V

50/60Hz

I--

OUTPUT

a.8A

~

SERIAL

A31290007

MITSUBISHI

ELECTRIC

Details of rating plate

-1-

Inverter model

Applicable

A~~~i~;~Pe"citY

power supply

Rated

output

current

Manufacturing No.

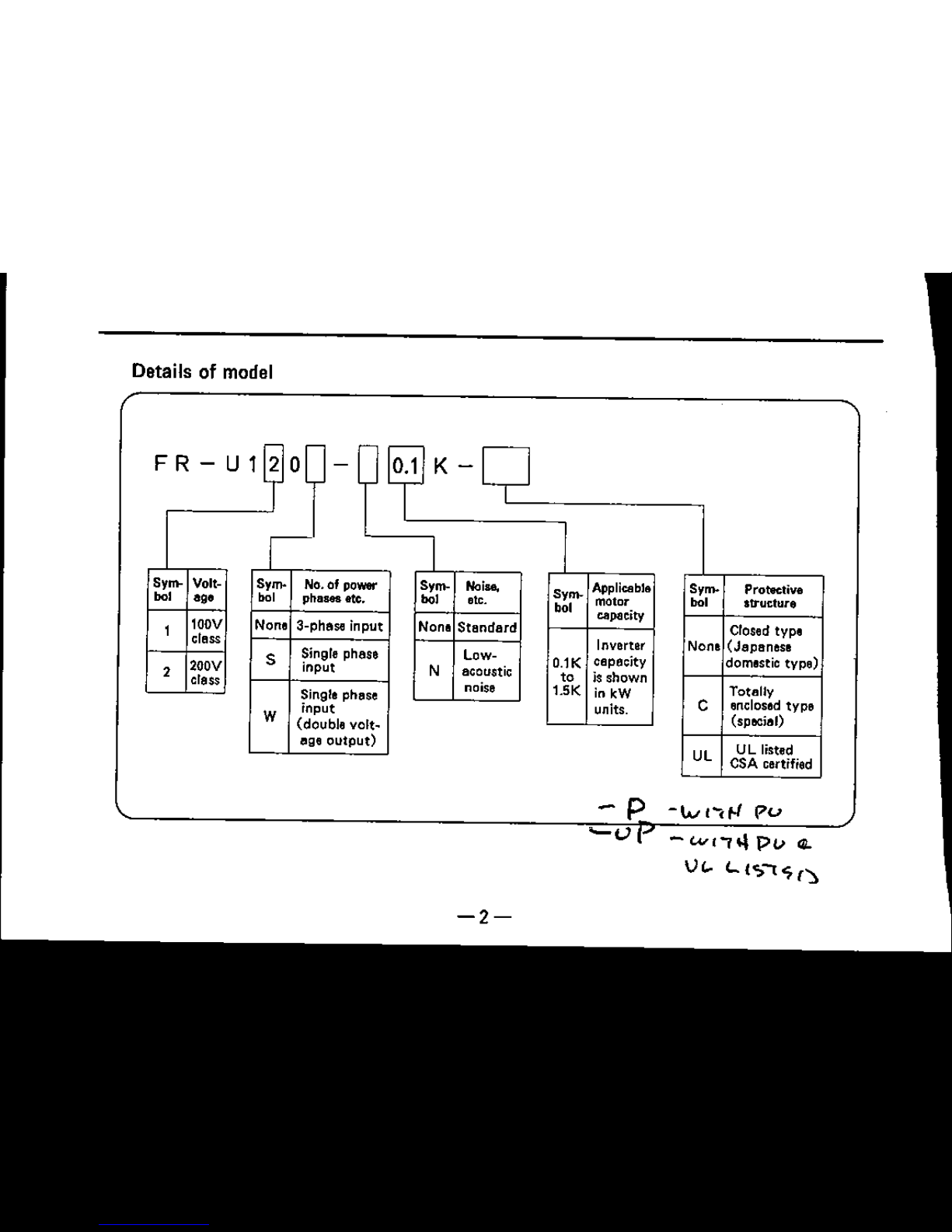

Details of model

K-

Sy~

Volt-

Sy~

No.of pow.-

Sy~

Noise,

Sy~

Applicable

Sy~

Protective

001

'g'

001

plleS&S

etc. 001 etc.

,"

motor 001

structure

capacity

100V None a-phase

input

None

Standard

Closed type

class

Inverter None

(Japanese

S

Single phese Low-

O.1K

capacity

domestic

type)

2

200V

input

N

acoustic

'0

is

shown

class

noise

1.5K

in leW

Totolly

Single phose

units.

C

enclosed

type

W

input

(special)

(double

vert-

eae

output)

Ul

UL listed

CSA certified

-

p

-tv

l~t-I

pv

~l..1

-WI,,,,

pv

...

V<-

'-

{Sol

'7

(~

-2-

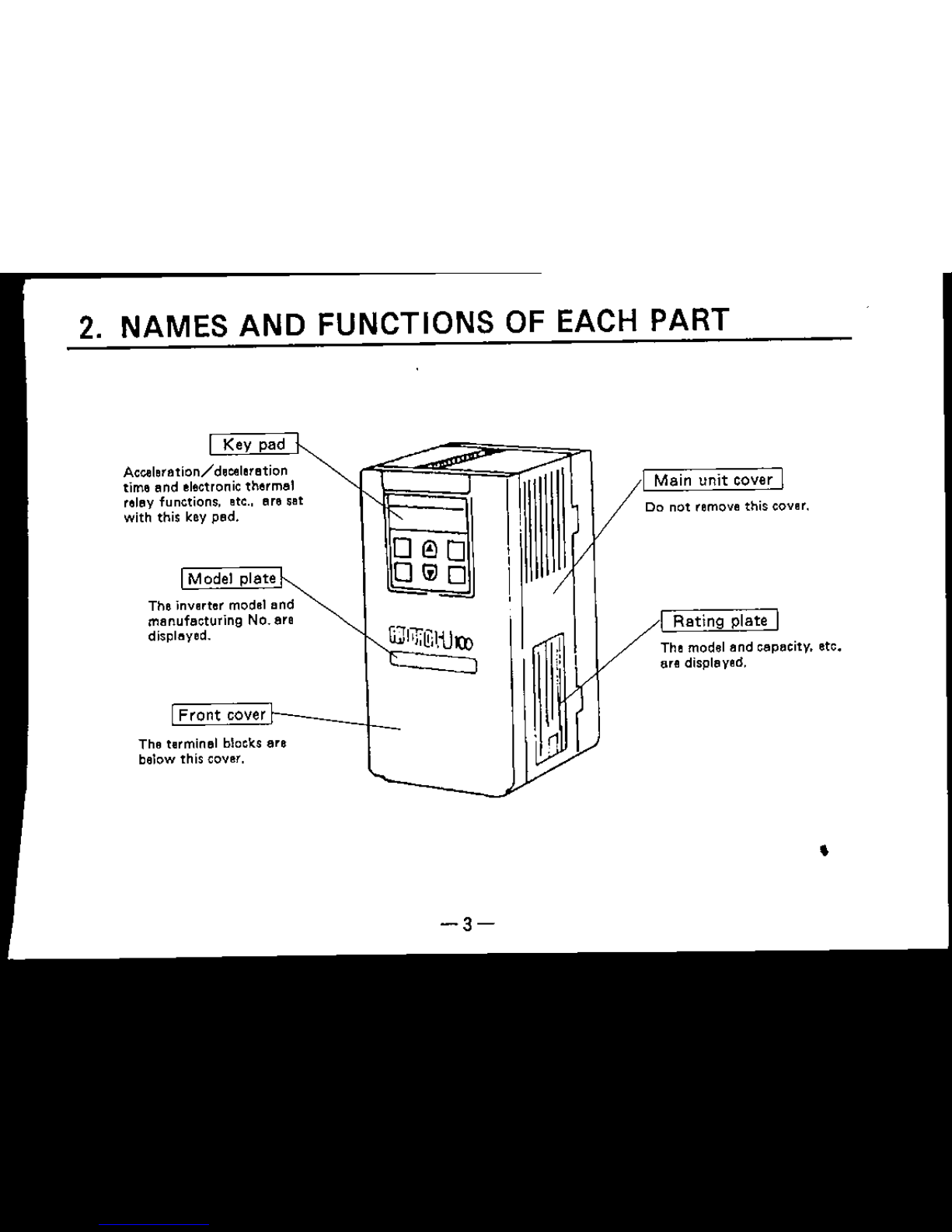

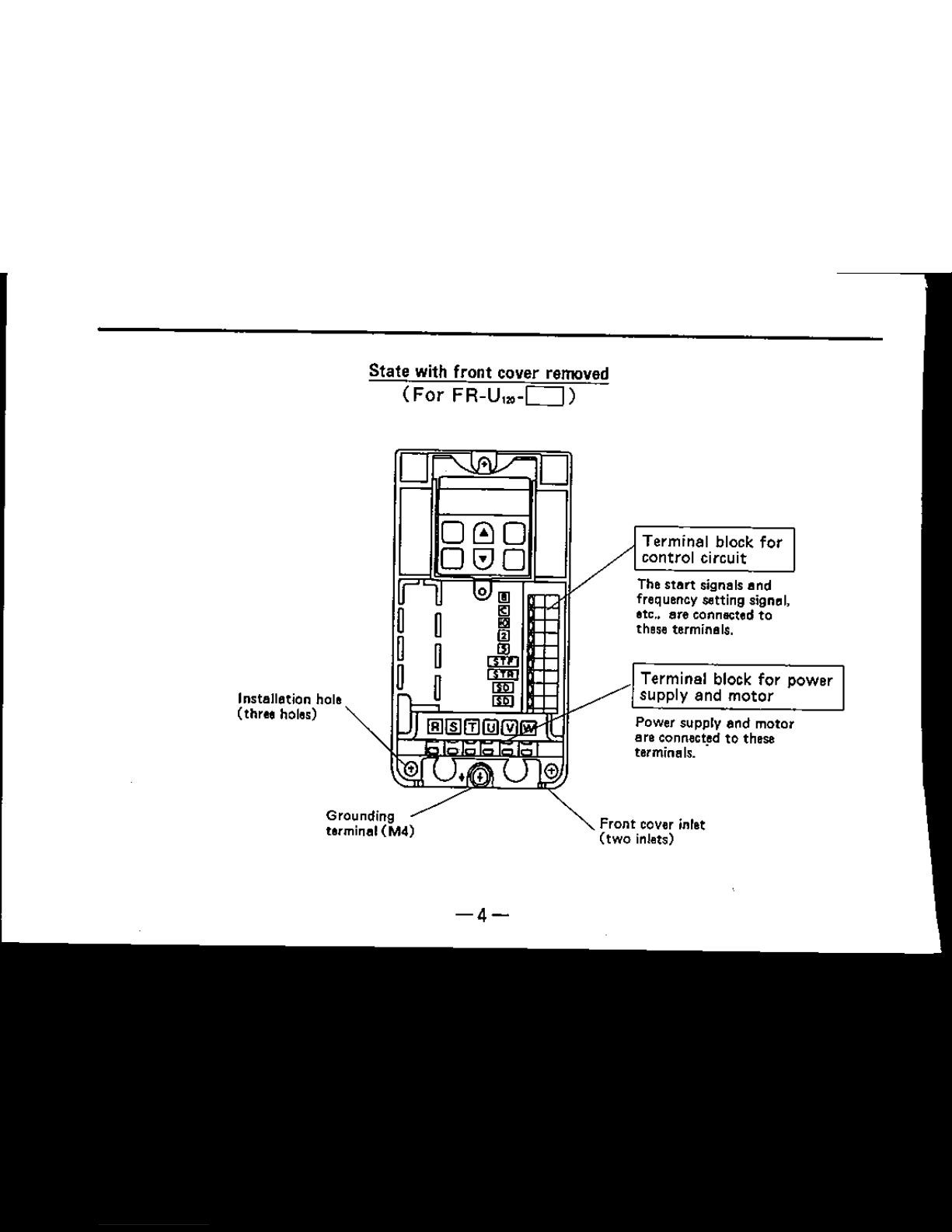

2. NAMES AND FUNCTIONS OF EACH PART

Key pad

Acceleration/deceleration

time and electronic thermal

relay functions. etc.. are set

with this key pad.

Model plate

The inverter model lind

manufacturing No. are

displayed.

Front

cover

The terminal blocks are

below this cover.

-3-

'n

I Main

unit

cover I

Do not remove this cover.

I

Rating

plate I

The model and cepecitv, etc.

lire dlspleved.

•

Front

cover inlet

(two

inlets)

Grounding

terminlll(M4)

Terminal block

for

power

supply and

motor

Terminal block

for

control circuit

The

start

signals lind

frequency settlng signal,

etc.. lire connected to

these terminals.

Power supply lind motor

lire connected to these

terminals

..

000

O(VO

State with front cover removed

(For

FR-U,.-D)

Instlllllltion hole

(three holes)

-4-

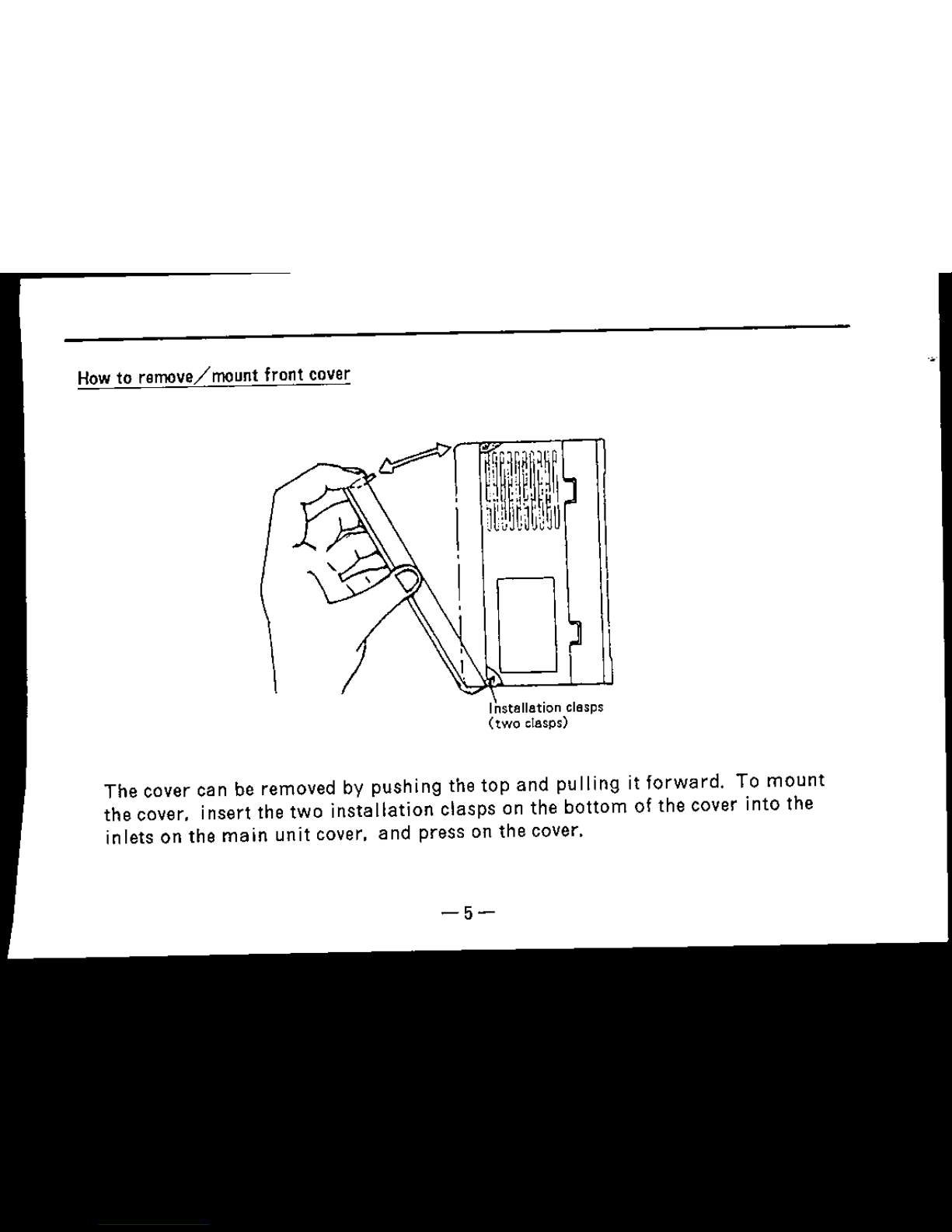

How

to

remove/

mountfront cover

Installation clasps

(two

clasps)

The

cover can be removed by

pushing

the

top

and

pulling

it

forward.

To

mount

the

cover.

insert

the

two

installation

clasps

on

the

bottom

of

the

cover

into

the

inlets

on

the

main

unit

cover.

and

press

on

the

cover.

-5-

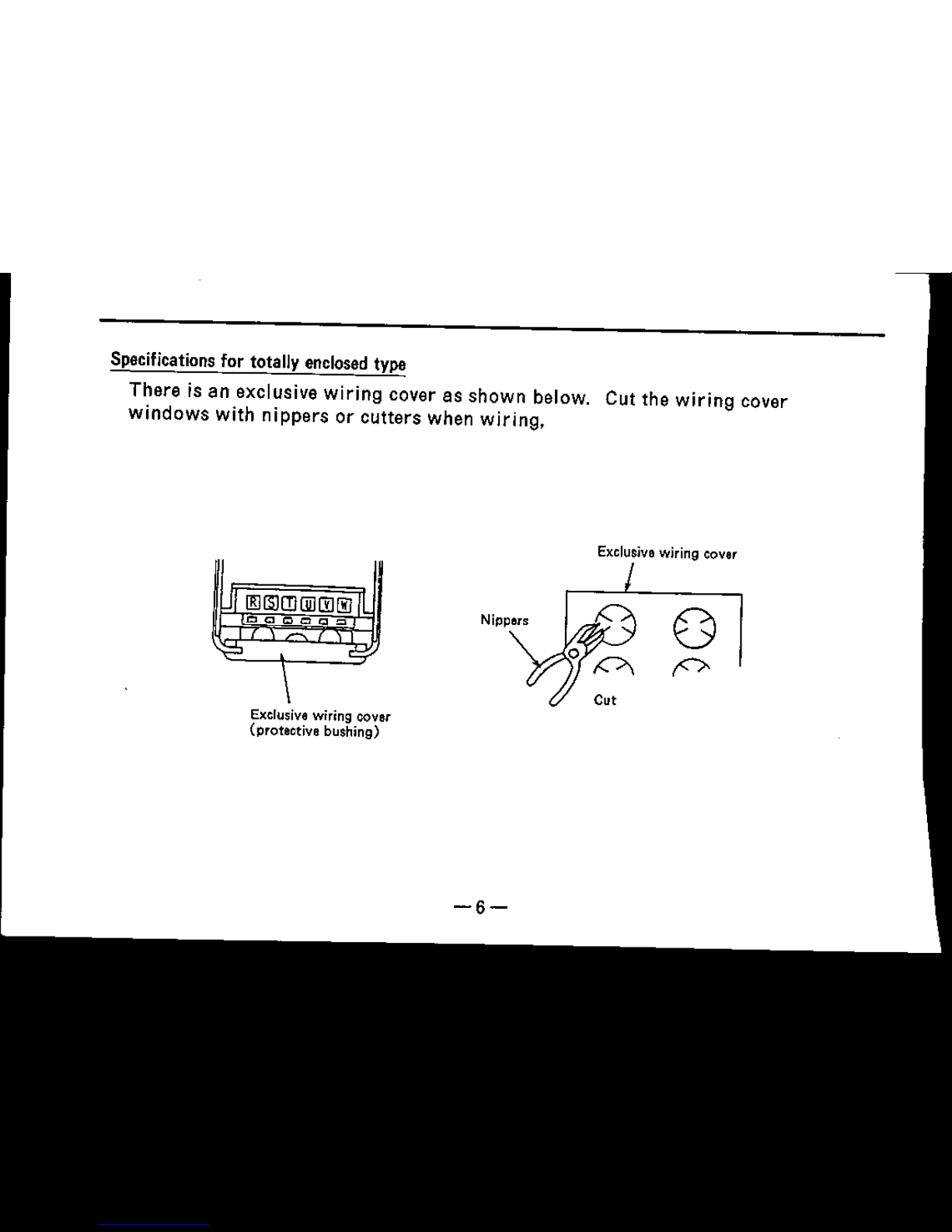

Exclusive wiring cover

Excrusive wiring cover

(protective bushing)

~llEJlSlrn(jjJmoo

II

OCl

ClOCl

!:I

""

\

Specifications for totally

enclosed

type

There

is an exclusive

wiring

cover

as

shown

below. Cut the

wiring

cover

windows

with

nippers

or

cutters

when

wiring,

-6-

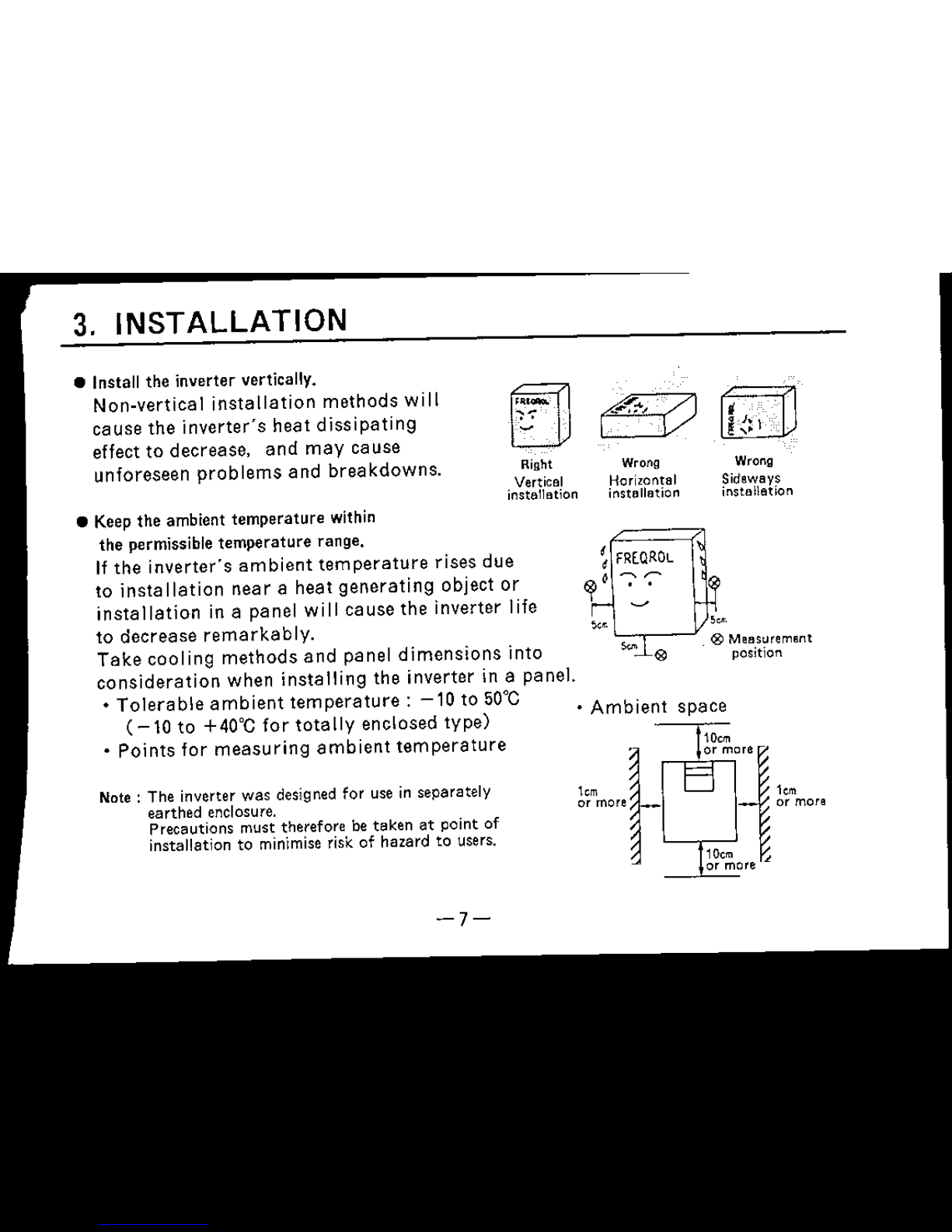

Wrong

Sideways

installation

Wrong

Horizontal

installation

~

FR[QROL

.

~~

If

.,

Right

Vertical

installation

Note:

The inverter was designed for use in separately

earthed enclosure.

Precautions must therefore be

taken

at

point of

installation to minimise risk.

of

hazard to users.

• Keep

the

ambient

temperature

within

the permissible

temperature

range.

If

the

inverter's

ambient

temperature

rises

due

to

installation

near

a

heat

generating

object

or

installation

in a panel

will

cause the inverter

life

to

decrease

remarkably.

Take

cooling

methods

and

panel

dimensions

into

consideration

when

installing

the

inverter

in a

panel.

•

Tolerable

ambient

temperature:

-10

to

50°C

(-10

to

+40°C

for

totally

enclosed

type)

•

Points

for

measuring

ambient

temperature

• Install the inverter vertically.

Non-vertical

installation

methods

will

cause

the

inverter's

heat

dissipating

effect

to

decrease,

and

may

cause

unforeseen problems and breakdowns.

3.

INSTALLATION

-]-

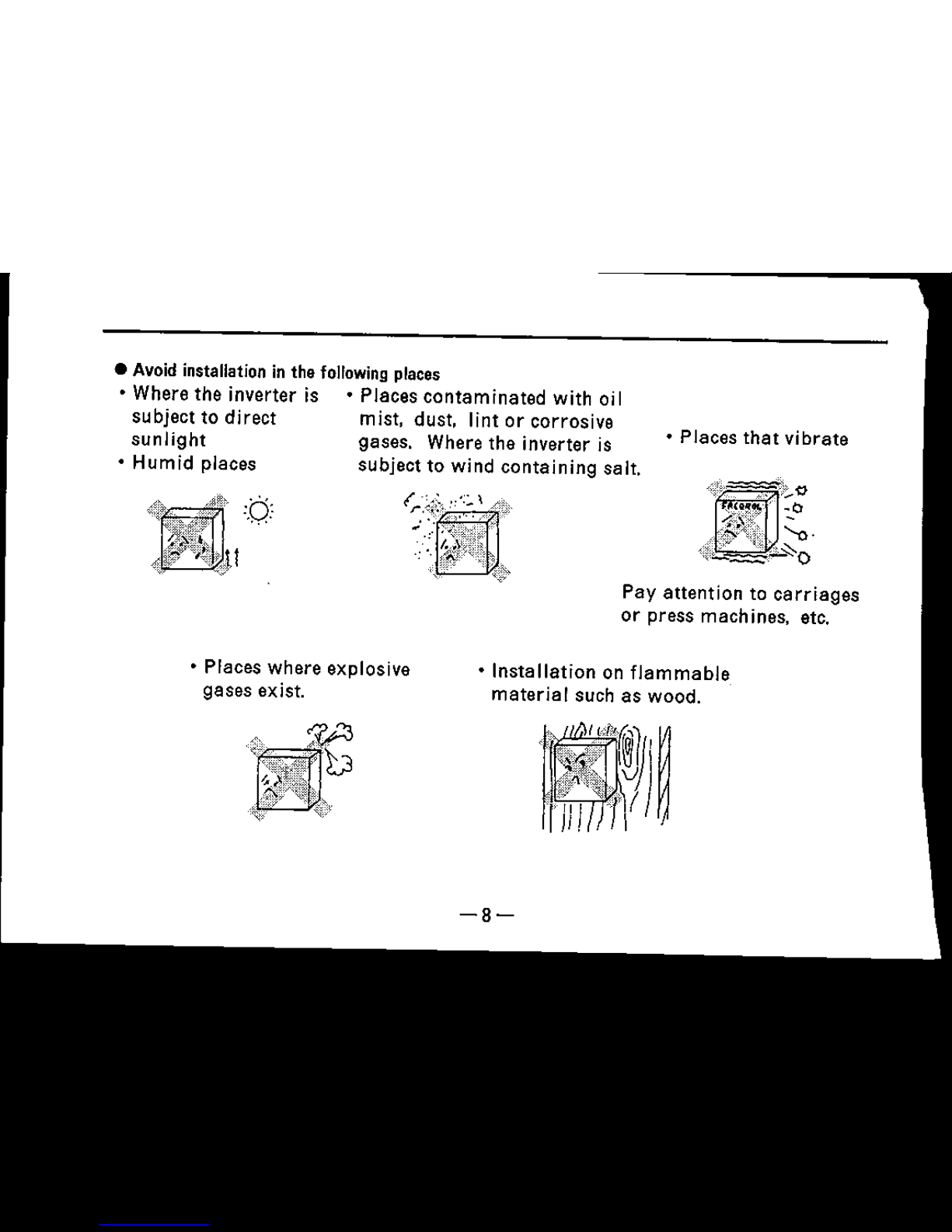

•

Places

that

vibrate

Pay

attention

to

carriages

or

press

machines, etc.

•

Installation

on

flammable

material

such

as

wood.

• Places where explosive

gases

exist.

• Avoid installation in the following places

• Where the inverter is •

Places

contaminated

with oil

subject to

direct

mist, dust, lint or corrosive

sunlight

gases. Where the inverter is

• Humid places subject to wind

containing

salt.

-8-

4.

WIRING

• Precautions for wiring

Pay attention to the

following

items

during

wiring

to prevent mistaken

wiring

and mistaken usages.

,------------

Precautions

for

wirlng-------------..

(1)

When the power supply is applied on the inverter

output

terminals

CU,

Vand

W), the inverter will be damaged. Never wire the power

supply

to these

terminals.

(2)

Use a shield or twisted wire for the wiring to the control circuit

terminal,

and separate the

wires

from

the

main

circuit

or power

distribution

circuit

(200V

relay

sequence

circuit, etc.).

(3)

Cover

the

slits

on the inverter so

that

the

wire

waste

does

not

enter

the

inverter

during

wiring.

(4)

Confirm

that

the

display

lamp

on the key pad has gone out before changing

the

wiring

after

operation,

and

wait

at

least

two

minutes

before

starting

the

wiring.

(It

takes

more

than

one

minutes

for

discharge

of

the

internal

capacitors

after

disconnecting

power

supply.

)

-9-

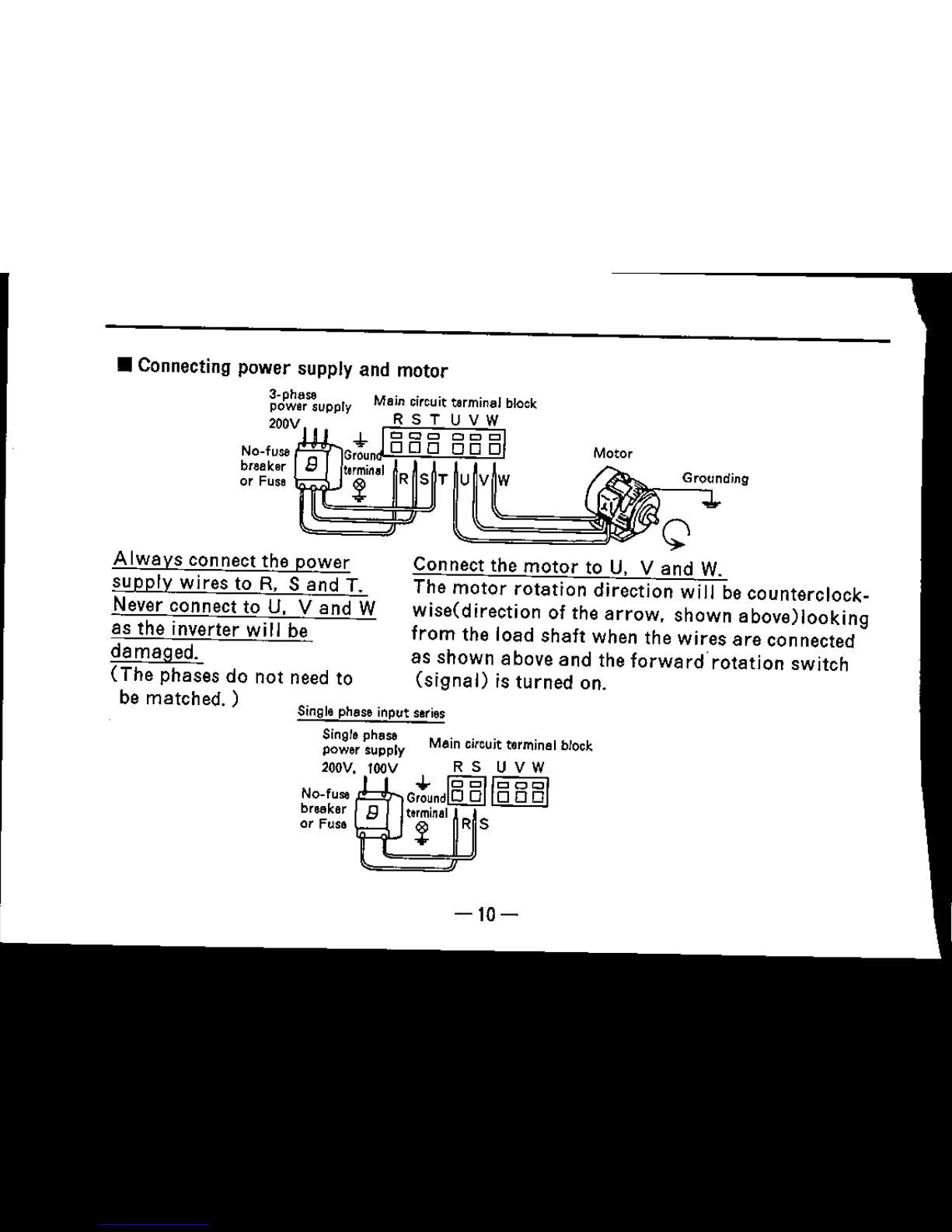

Motor

~~~~~':t,g

Connect the

motor

to U. V

and

W.

The

motor

rotation

direction will be counterclock-

wlsefdlrectlon of the

arrow.

shown

above)looking

from

the load

shaft

when the

wires

are

connected

as

shown

above

and

the forward"

rotation

switch

(signal)

is

turned

on.

No-fuse

breaker

or Fuse

Single phase input series

Single phase Main circuit terminal block

power supply

200V.

tOOV

R 5 U V W

G:undMlooo!

£)

t~rminel

Z

No-fuse

breaker

or Fuse

• Connecting power supply and motor

a-phese

power supply

200V

AI

ways

con nect the power

supply

wires

to R.

Sand

T.

Never connect to U. V and W

as the inverter will be

damaged.

(The

phases

do not need to

be

metched)

-10-

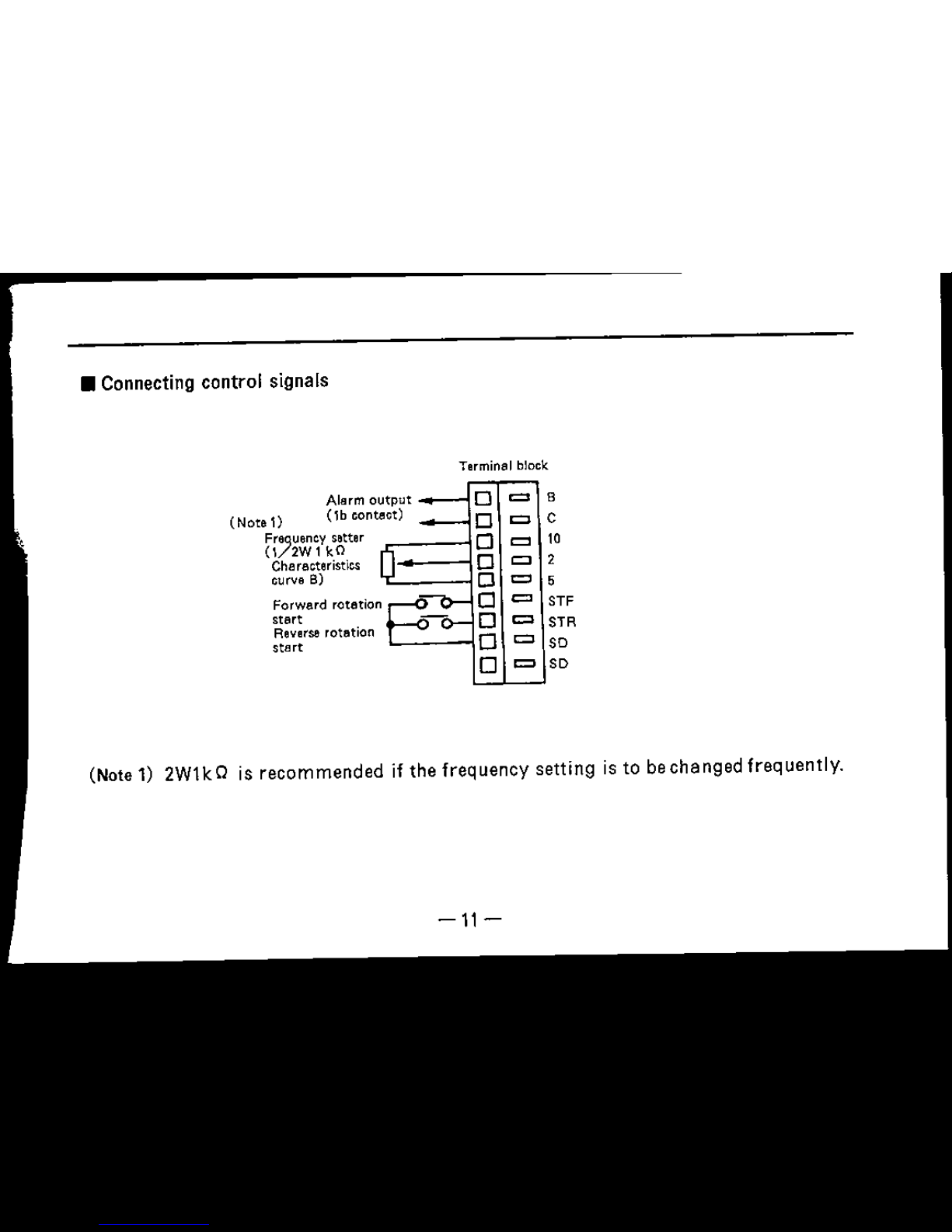

•

Connecting

control

signals

Terminal block

Alarm

output

0

=

8

(Note 1)

(lb

contact)

0

=

C

Fr,uenc

y

setter

0

=

10

(\

2WlkO

0

=

2

Characteristics

curve B)

0

=

5

Forward rotation

0

=

ST'

start

0

=

ST"

Reverse rotation

0

=

start

SD

0

=

SD

(Note 1) 2Wl k Q is

recommended

if

the

frequency

setting

is to be

changed

frequently.

-11-

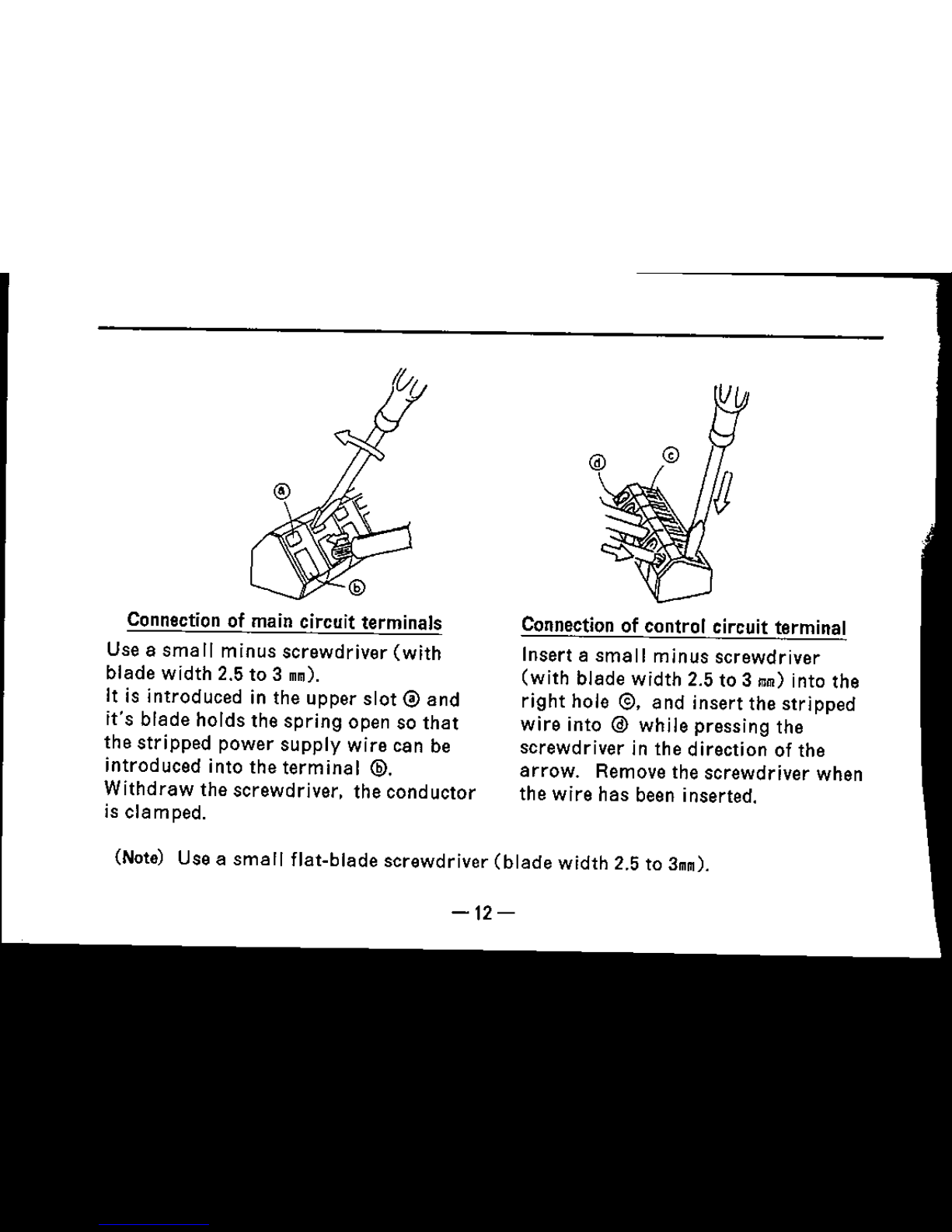

Connection of main circuit terminals

Use a

small

minus

screwdriver

(with

blade

width

2.5 to 3

mm).

It is

introduced

in the

upper

slot@

and

it's

blade

holds

the

spring

open so

that

the

stripped

power

supply

wire

can be

introduced

into

the

terminal

@.

Withdraw

the

screwdriver,

the

conductor

is

clamped.

Connection of control circuit terminal

Insert a

small

minus

screwdriver

(with

blade

width

2.5 to 3

mm)

into the

right

hole

<9,

and

insert

the

stripped

wire

into @

while

pressing

the

screwdriver

in the

direction

of the

arrow.

Remove the

screwdriver

when

the

wire

has

been inserted.

(Note) Use a

small

flat-blade

screwdriver

(blade

width

2.5 to

3mm).

-12-

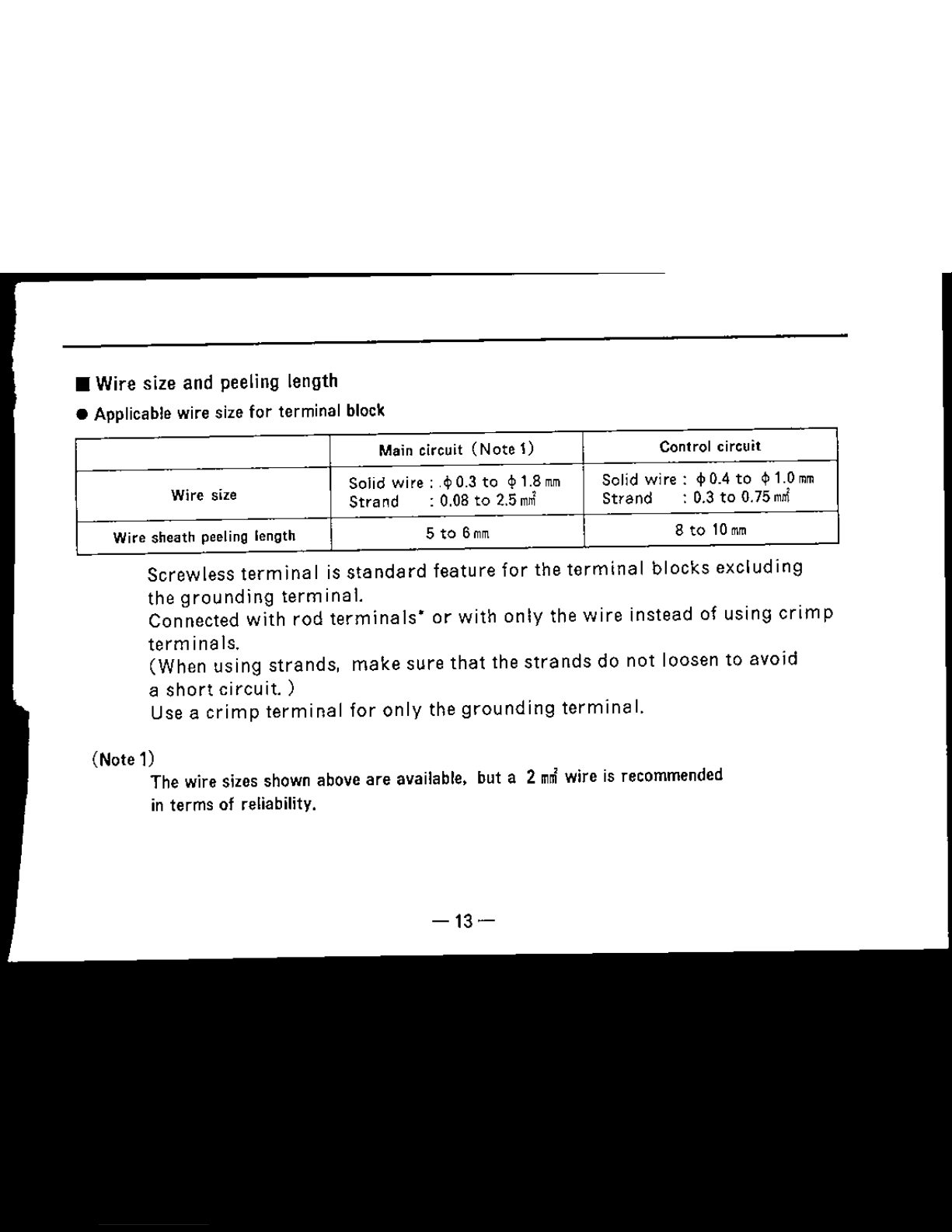

eeling length

lze

for

terminal block

Maincircuit (Note

1) Controlcircuit

ze

Solid

wire:

,$0.3 to

~1.8mm

Solid

wire:

<fl

0.4to ¢l1.0

mm

Strand

:

0.08

to 2.5

mnl

Strand

: 0.3 to

0.75mnl

ling

length

5 to

6mm

8tol0mm

S

terminal

is

standard

feature

for

the

terminal

blocks

excluding

ndinq

terminal.

d

with

rod

terminals"

or

with

only

the

wire

instead

of

using

crimp

s.

ing

strands,

make

sure

that

the

strands

do

not

loosen

to

avoid

ircuit.

)

mp

terminal

for

only

the

grounding

terminal.

lzes shown aboveare available. but a 2

m~

wire is

recommended

f reliability,

-13-

Screwles

the

grou

Ccnnecte

term

ina I

(When

us

a

short

c

Use

a

cri

Wire si

Wire

sheath

pee

(Note 1)

The wire s

in terms 0

•

Wire

size and p

• Applicable wire

s

"Example

of rod

terminals

Applicable

Applicable wire size

Circuit Manufacturer

terminal name

Solid wira

(11m)

Strand wire

(mnl)

TC-1.25

(S)

cjlO.57

to cjl1.44 0.25to1.65

Main

Nichifu Terminal

circuit

TC-2

(S)

cjl1.14to e

t.aa

1.04 to 2.36

terminal

TUB-1.25

cjlO.57tocjl1.44

0.55to1.65

Japan

SolderJess Terminal

Control

TC-0.5

cjl

0.57

to

cjl

0.7

0.25

to

0.75 Nichifu Terminal

circuit

terminal

HO.25/10

.0.57

0.25

Japan

Weidmuller

-14-

Mel

~

nterloC

k

, ,

Power R U

'1M

su

P

P:;y1}

~

~

~~-~

Current

~

loop

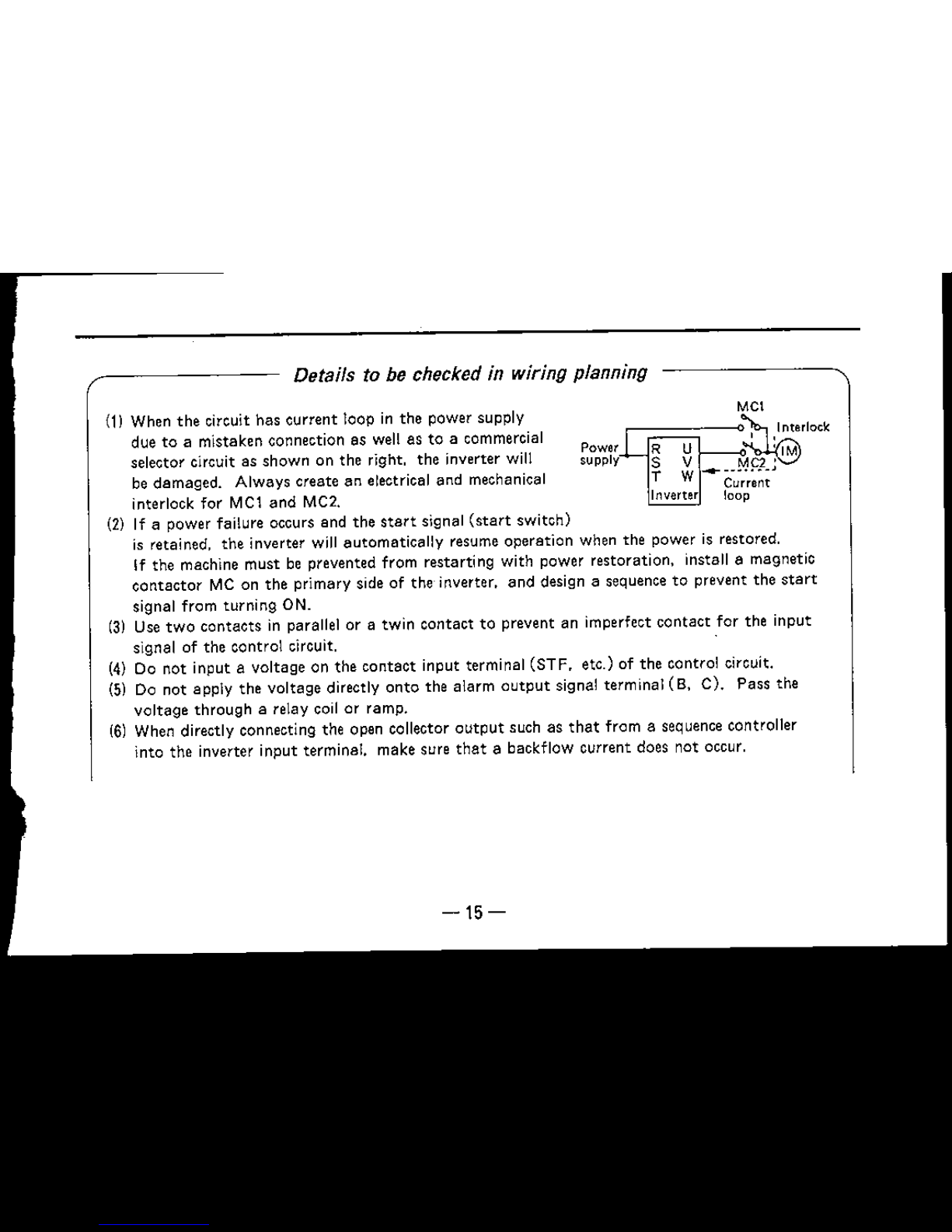

Details to be checked in wiring planning

(1) When

the

circuit has current loop in the power supply

due to a mistaken connection as well as to a commercial

selector circuit as shown on the right, the inverter will

be damaged. Always create an electrical and mechanical

interlock

for

MCl and MC2.

(2) If a power failure occurs and the

start signal

(start

switch)

is retained. the inverter will automatically resume operation when the power is restored.

If the machine must be prevented from restarting with power restoration, install a magnetic

ccntector

MC on the primary side of the inverter, and design a sequence to prevent the

start

signal from turning ON.

(3) Use

two

contacts

in parallel or a twin contact to prevent an imperfect

contact

for the input

signal of the control circuit.

(4) Do not input a voltage on the

contact

input terminal (STF, etc.) of the control circuit.

(5) Do not apply the voltage directly

onto

the alarm

output

signal terminal

(8,

C). Pass the

voltage

through

a relay coil or ramp.

(6) When directly connecting the open collector

output

such as

that

from a sequence controller

into the inverter input terminal. make sure

that

a backflow current does not occur.

-15-

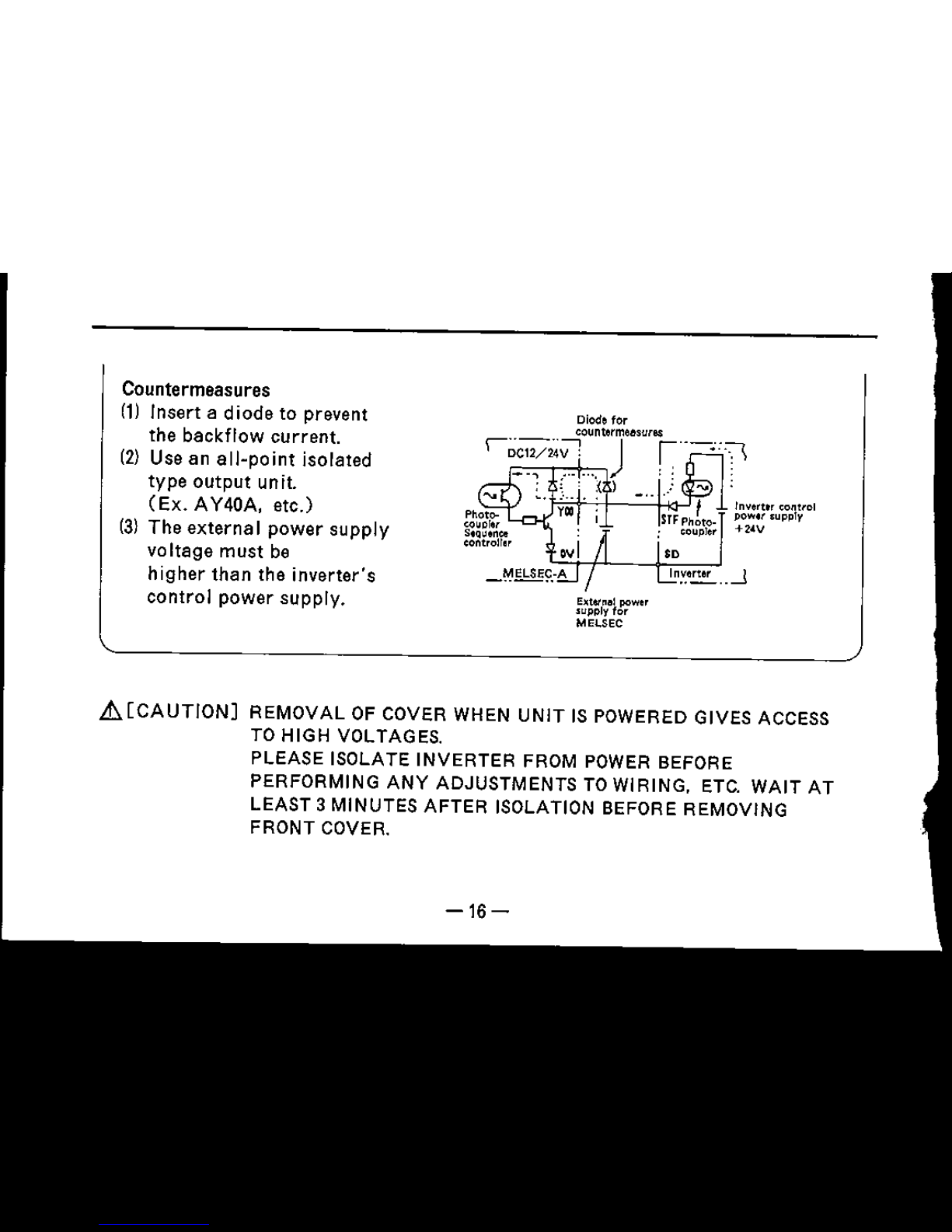

Countermeasures

(1)

Insert a diode to prevent

the backflow current.

(2) Use an

all-point

isolated

type output unit.

(Ex.

AY40A,

etc.)

(3) The external power supply

voltage must be

higher than the inverter's

control power supply.

Diode for

ecuntermeeswee

r~W2~;-1

...

, j

r'--~:T\

,{ 1

Invert" control

pow"

supply

+2~V

.-.1

E~W"al

power

.upply for

MELSEC

L!I.[CAUTION]

REMOVAL

OF COVER WHEN

UNIT

IS POWERED GIVES ACCESS

TO HIGH VOLTAGES.

PLEASE ISOLATE

INVERTER

FROM POWER BEFORE

PERFORMING

ANY

ADJUSTMENTS TO WIRING, ETC.

WAIT

AT

LEAST 3 MINUTES

AFTER

ISOLATION BEFORE REMOVING

FRONT COVER.

-16-

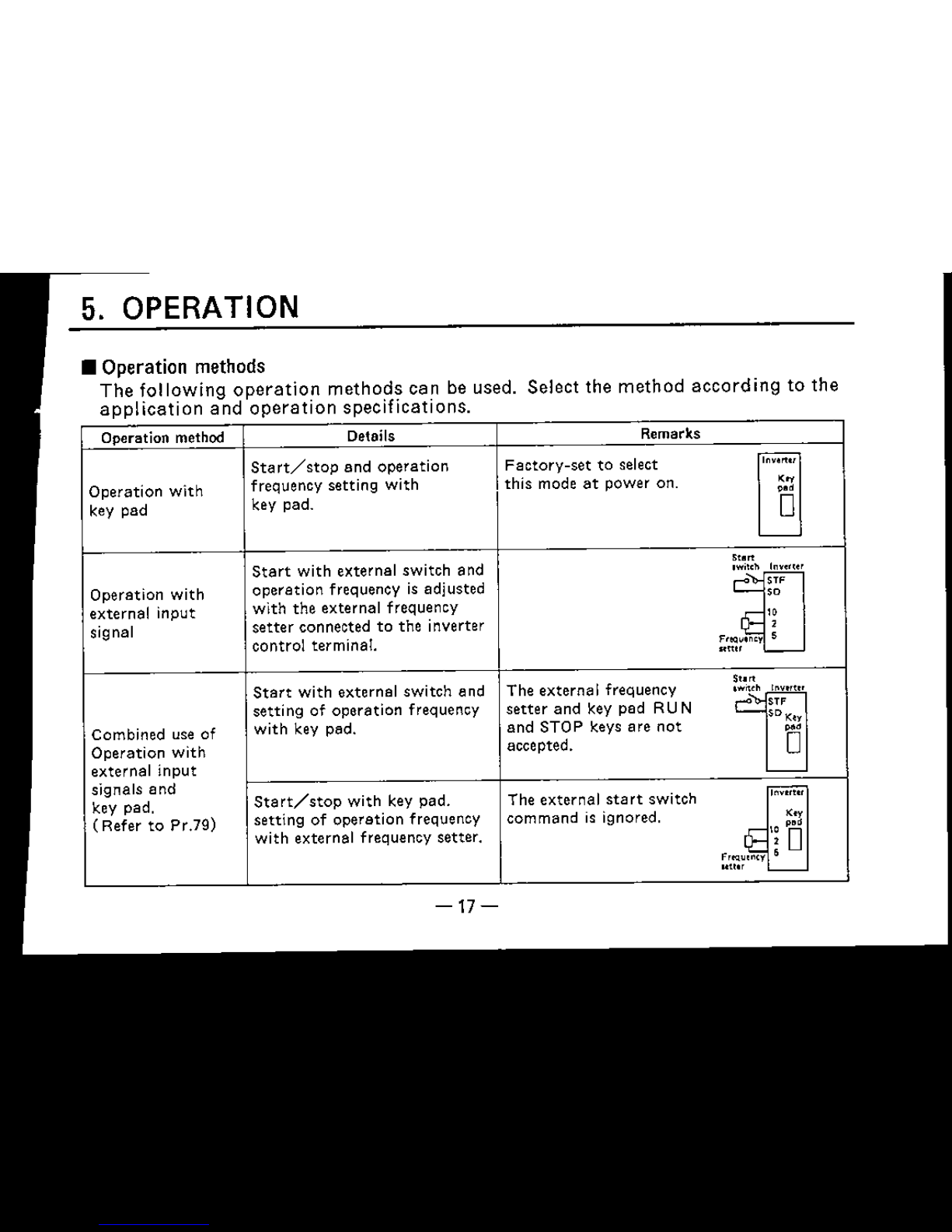

5. OPERATION

•

Operation

methods

The

following

operation

methods

can be used. Select the

method

according

to the

application

and

operation

specifications

Operation method

Details Remarks

Start/stop

and operation

Factory-settoselect

rn

Operation

with

frequency

setting

with

this

mode

at

power

on.

'"

key pad

key pad.

Qa

Start

with

external

switch

and

Sto

..

In''''''

,w;lCh

Operation

with

operation

frequency is adjusted

C':

'"

'0

external

input

with

the

external

frequency

.~"

signal

setter

connectedtothe

inverter

F'!Q""cy

~

control

terminal.

Sf""

l-.-

Start

with

external

switch

and The

external

frequency

St."

'WMh

10""'''

settingofoperation

frequency setter and key pad RU N

C':

err

SDK,.

Combined use of

with

key pad.

and

STOP

keys

are

not

~.

Operation

with

accepted.

0

external

input

signals

and

Start/stop

with

key

pad.

The

external

start

switch

lov"'"

key

pad.

(Refer

to

Pr.79)

setting

of

operation

frequency

command

is ignored.

"

''""~

~.

with

external

frequency

setter.

\~

D

s

uUor

'-----

-17-

(Operation

with key

pad)

The key pad

operation

(parameter

No. 79 "1" ) is selected

as

the factory setting.

8 Frequency setting mode is entered.

o

~

Set

frequencyischanged.

8 Setfrequency is fixed.

8 Motor

starts

(forward

rotation)

(Note),

rsroP1

Motor stops.

~

(Note)

To

drive

the

motor

in

the

reverse

direction

with

thelRUNlkey,

short-circuit

between STR

and

SO on the

terminal

block, or set

parameter

No.la to "2".

-18-

( Operation with external input

signal)

Frequency

setter

Motor

NFB

·Inverter

Power

-::~~~====~

R U

supply S V

T W

Forward

rotation_"----J

8TF

Reverse rotation STR

'-----180

10

,

5

• Set

external

operation

mode

(parameter

No.79 "2" ).

(Refer

to the

following

explanation

for the

setting

method.

)

The

start

signals

and

frequency

are

input

with

external

switches

and

frequency

setting

potentio-

meter. The

motor

wi II

operate

when a

signal

is

input

into

STF

(forward

rotation)

or

STR

(reverse

rotation)

and

the

frequency

setterisoperated.

-19-

£[CAUTIONJ

DO NOT USE

ANY

SHARP

OBJECTS ON THE

KEY

PAD,

OR IT

MAY

DAMAGE

THE

MEMBRANE.

Operation command keys

Theseare the RU N and STOP

command keys

for

operating

with

the key pad.

The stop key also functions as the

resetkey when an

alarm

occurs in

the inverter.

I UP key I

IDOWN key

Thesekeys continuously increment

or decrementthe operation

frequency setting or setting value

of variousfunctions.

The value

will

change

only

when

the key is

pressed.

t:

o

8

This key is usedto select

the frequency monitor,

frequency setting and

parameter setting mode.

This key is usedto confirm

and changethe frequency

and setting value

of

various functions.

Display

The frequency,

motor

current

setting value of

various functions. and

alarm

codeare shown

on a 7-segment,

3.digit

display.

MODE key

SET key

•

How

to usethe key

pad

-20-

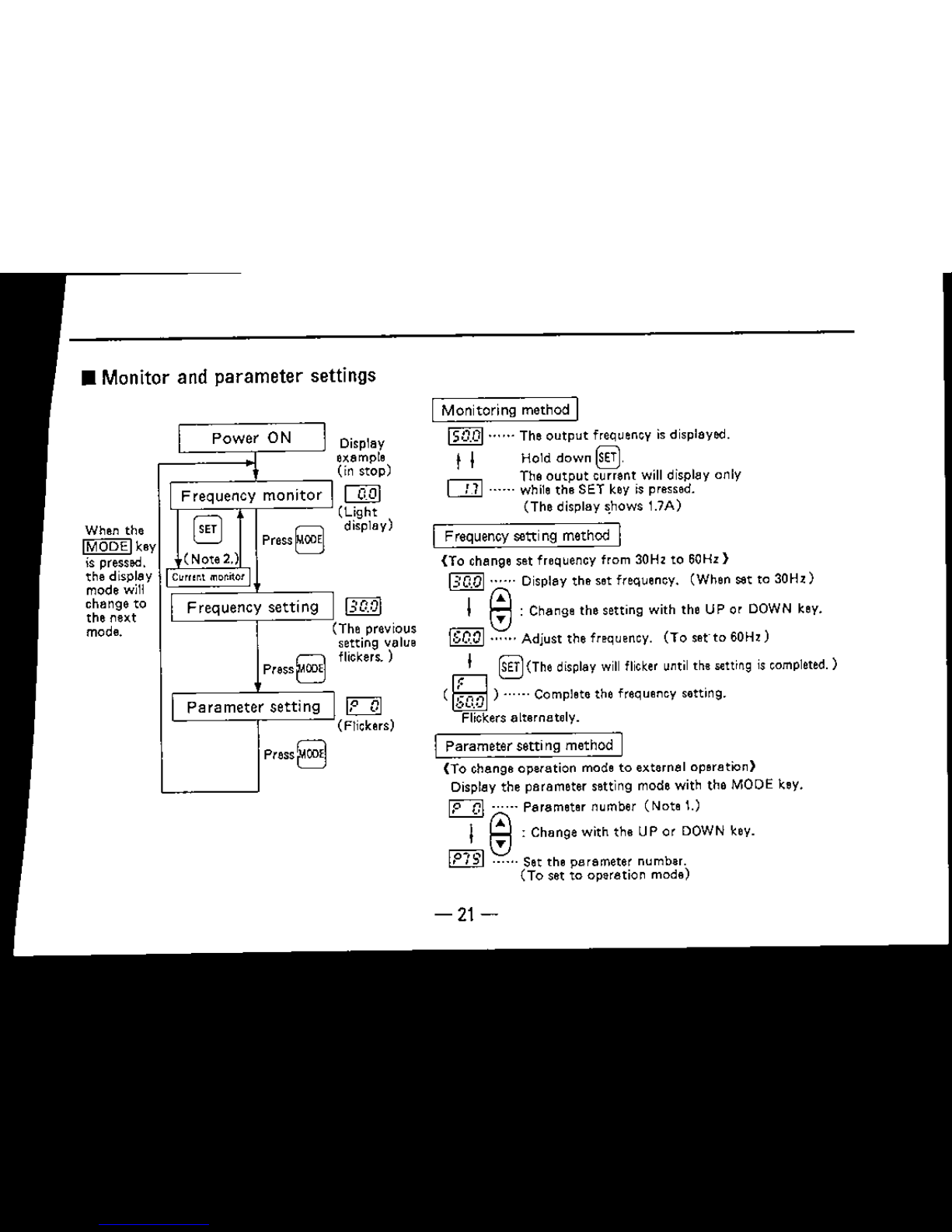

• Monitor and parameter settings

[IQQI.

.The

output

frequency isdisplayed.

t I Hold down

~

The

output

current willdisplay only

[J]

......

whilethe SET key is pressed.

(The display

shows 1.7A)

Monitoring mathOd I

I

Parameter

setti ng method I

(To change operation mode to external operation)

Display the parameter setting mode with the MODE key.

~

...... Parameter number (Note t.)

I

@:

Change with the UP or DOWN key.

rn

......

Set the parameter number.

(To set to operation mode)

[lQ]]

The previous

setting value

flickers.)

~

(Flickers)

Display

example

(in stop)

ITQJ

(light

display)

I

Power

ON

I

Frequency

monitor

I

y

8,,1

Press8

(Note 2.)

y

C",,,r.t

mor.ilor

II

Frequency

setting

I

(

press8

Ir

Parameter

setting

I

press8

When the

IMODElke

is pressed.

the displa

mode will

change to

the next

mode.

-21-

• When

alarm

(Er

1 to 3) is

displayed

(The

alarm

can be canceled by pressing the mode key.

not

canceled by

RESET

key.)

Alarm

Type Details

display

E,

I

Write prohibit alarm

Writing

was

attempted during the pr.77

M1

M

state

(write prohibit)

E,'

Write alarm

Pr.79 was rewritten or all clear was executed during operation.

during operation

Ed

Calibration

error

The calibration value for C-2 and C-3 was

too

close,

.

(Note)

1) Pressing UP or DOWN key will increment

or

decrement displayed parameter number

by one in order of the parameter list.

(PO

will display if the UP key is pressed

when

ct.r

is displayed. )

2) The

current

monitor

displays only when

the SET key is pressed in the frequency

monitor mode.

press~.

r-il

The setting value of the selected

L---!..J

parameter

will display.

I @:Change with

the

UP or DOWN key.

Set the

parameter

satting value.

D······

(The

displ8y will flicker until

the

setting is completed. )

prass§.

(

IlliJ) . .

U The

parameter

settmg

IScompleted.

Flickers alternately.

• The calibration error

Will

occur If the difference of the Input voltage for the C-2 to C·3 calibration

value is approximately

O.5V

or less.

-22-

6. Functions

•

List

of functions

~~~~~i:t~)'

Function name Setting range

Setting Factory

Uw

unit

setting setting

0

Torque

boost

(manual)

o

to

15%

1%

6%

1

Upper limit frequency

Oto120Hz

1

H'

120 Hz

2

Lower

limit

frequency oto60 Hz 1 H, oH,

3

Base frequency

50to120 Hz

1 H,

60 Hz

7

Acceleration time 0, 0.1

to

999 sec. 0.1 sec. 5.0 sec

8

Deceleration

time

0, 0.1to

999

sec.

0.1

sec.

5.0 sec

9

Electronic

thermal

relay

o

to

15A 0.1 A

Rated

current

10

PWM

mode

(Note

4)

Ot015,---

1

3

11 DC

dynamic

braking

operation

time

Oto

tOsee. 0.1sec.

0.5 sec.

12

DC

dynamic

braking

voltage

o

to

15%

1%

8%

-'

Acceleration/deceleration

reference

20

frequency

1to120Hz

1

H'

60 Hz

~

Frequency

setting

voltage

bias o to 60 Hz

1

H'

oH,

22

Frequency

setting

voltage

gain

Oto120Hz

1

H'

60Hz

23

Stall

prevention

operation

level

o

to

10

1

5

-23-

~g;;~t:'"

Function name

Setting range

~~irg

Factory

User

setting setting

*71

Frequency meter scale

calibration

0,

1 1

0

*72

PWM carrier frequency 2.3

to

14.5kHz 0.1 kHz 7.0kHz

75

Stop

key function

0,

,.

1

"

77

Write

prohibit

selection

0,

1

1

0

78

Reverse

rotation

prevention selection

0, I,

2

1

0

79

Operation mode selection

"

2, 3,

•

1 1

CL,

Parameter

clear

0,

1.

2

1

0

C-2 Frequency setting bias

calibration

o

to

60 Hz

1

H,

o

H'

C-3 Frequency

setting

gain calibration o to 120Hz

1 H,

60 Hz

(Note)

1.

The

factory

setting for Pr.79 operation mode selection is -1- (key pad mode).

2. All parameters. excluding Pr.79. and Pr.CLr parameter clear, can be written during

cperettcr;

(When Pr.77

=

0)

Writing is invalid when

Pr.77=l,

except for Pr.77.

3. The parameters marked with

*

are displayed only for the low-acoustic noise model.

4. The Pr.10 setting

--

-

--

can

be

set only for the low-acoustic noise model.

Pr.72 can be read and written when - - -

.:»

is set in Pr.10.

The

factory

setting for the low-acoustic noise model is -

--,

-24-

/

• Upper limit frequency

rn

•Lower limit frequency

rn

The

upper

and

lower

limit

clamps

of

the

output

frequency

can

be set.

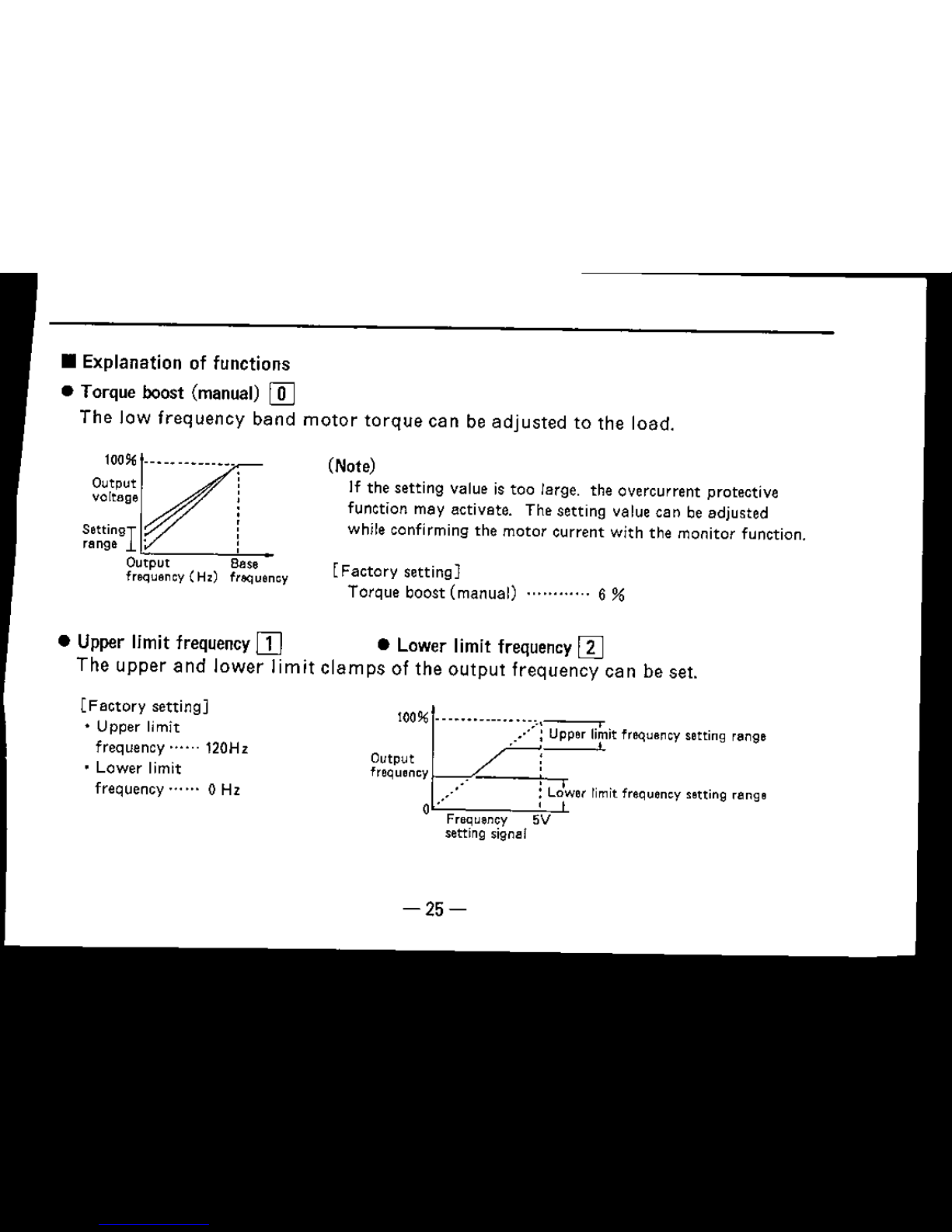

• Explanation of functions

• Torque boost (manual)

[[]

The

Jaw

frequency

band

motor

torque

can

be

adjusted

to the

load.

-25-

lOO%~

'~

..•..•

:~it

frequency setting range

Output :

frequency ,

.•.••. :

Lo1wer

limit frequency setting range

o- ,

Frequency 5V

setting signal

[Factory

setting)

Torque boost

(manual)

6 %

(Note)

If

the

setting

value is

too

large. the overcurrent protective

function may activate. The setting value can be adjusted

while confirming the

motor

current

with

the

monitor

function.

[Factory

setting)

• Upper limit

frequency"""120Hz

• Lower limit

frecuencv-. ... 0 Hz

O~::~~-·----·---··-1

""""?T

Settingr

. [

range :

Output Base

frequency (Hz) frbQuency

• VIF(base frequency)

rn

The base frequency (reference frequency

at

motor

rated

power)

can be

set

freely

between 50

and

120Hz

according

to the

motor

rating.

[Factory

setting]

V/F

{base frequency) .... ···.. 60Hz

aese frequency setting fange

I 'I

Output

voltage

50 Base 120

frequency

Output

frequency (Hz)

-26-

• Acceleration time (I] • Deceleration time

[[]

• Acceleration/deceleration reference frequency

~

Pr.7

and

8 can be

set

between 0.1

and

999seconds.

Acceleration

time

is the

time

(inclination)

taken

for

acceleration

to the

frequency

(fm)

setinacc./dec.

reference

frequency

Pr.20.

If the

acceleration/deceleration

time

is set to 0, the

time

will be 0.04 seconds.

5.0sec.

5.0 sec.

[Factory

setting]

Acceleration time

Deceleration time

Acceleration/deceleration

reference

frequency··········

60Hz

Deceleration

time

W

Acceleration

time

[II

'1'--1---++....1- Time

-27-

[Factory

settmg]

......3(Low

eccousnc norse

type

......

-28-

•

PWM

mode

I!ID

By

changing

PWM

mode

setting, it is

possible

to select

motor

sound

appropriate

for load

and

to reduce

resonant

vibration

for the

standard

acoustic

noise model.

Available

in sixteen settings.

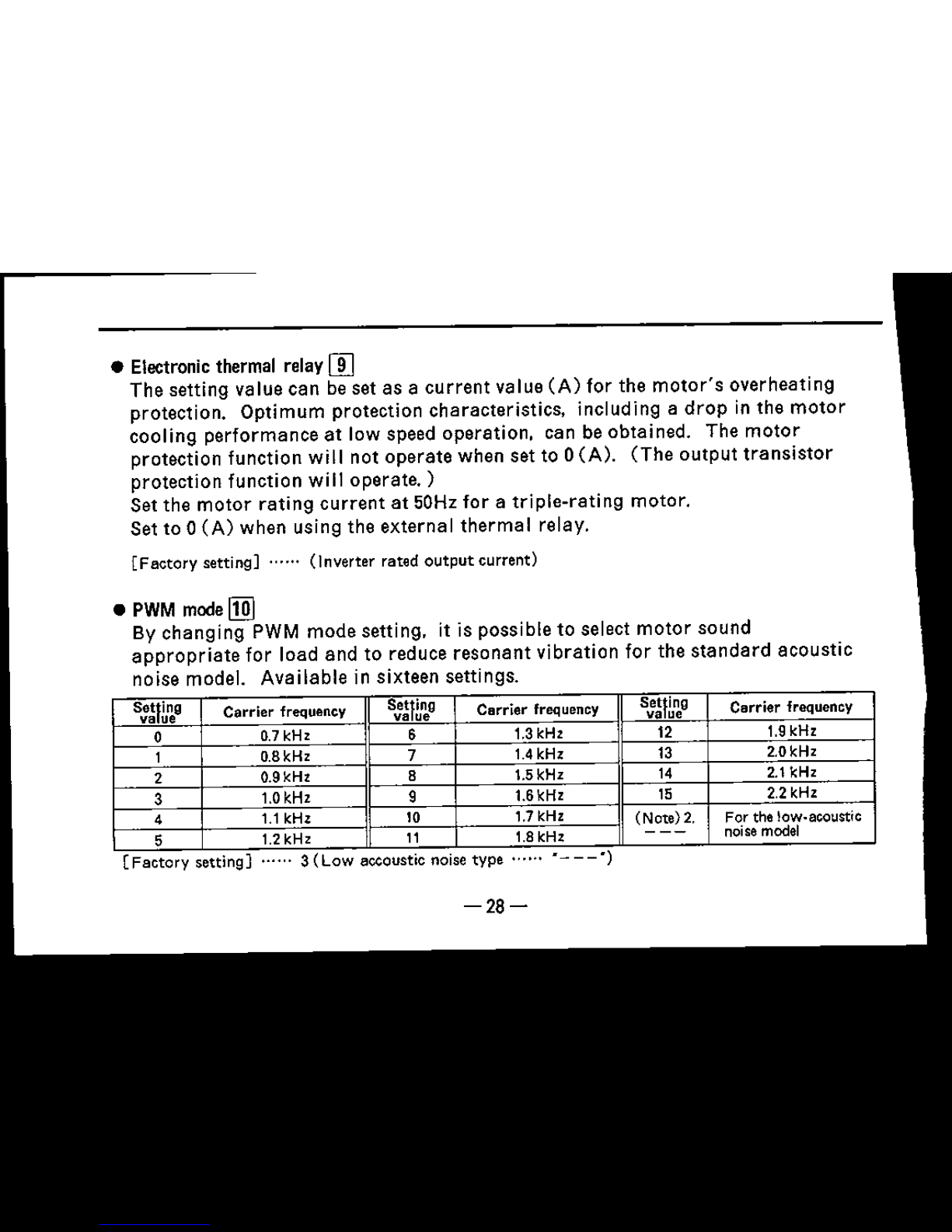

• Electronic thermal relay

rn

The

setting

value

can

be set as a

current

value

(A)

for the

motor's

overheating

protection.

Optimum

protection

characteristics.

including a

drop

in

the

motor

cooling

performance

at

low speed

operation.

can be

obtained.

The

motor

protection function will not

operate

when

set

to 0

(A).

(The

output

transistor

protection

function will

operate.)

Set the

motor

rating

current

at

50Hz

foratriple-rating

motor.

Set to 0

(A)

when using the

external

thermal

relay.

[Factory

setting]

......

(Inverter

rated

output

current)

s:~n~g

Carrier frequency

S:~n~g

Carrier frequency

s::n~g

Carrier frequency

0

0.7kHz

6 1.3kHz 12 1.9kHz

1 0.8kHz

7 1.4kHz 13

2.0kHz

2 0.9kHz

8 1.5kHz 14 2.1kHz

3

1.0kHz

9

1.6kHz 15 2.2kHz

4

1.1kHz 10 1.7kHz

(Nctel

z.

For the row-acoustic

6

1.2kHz 11

1.8kHz

---

noisemodel

.

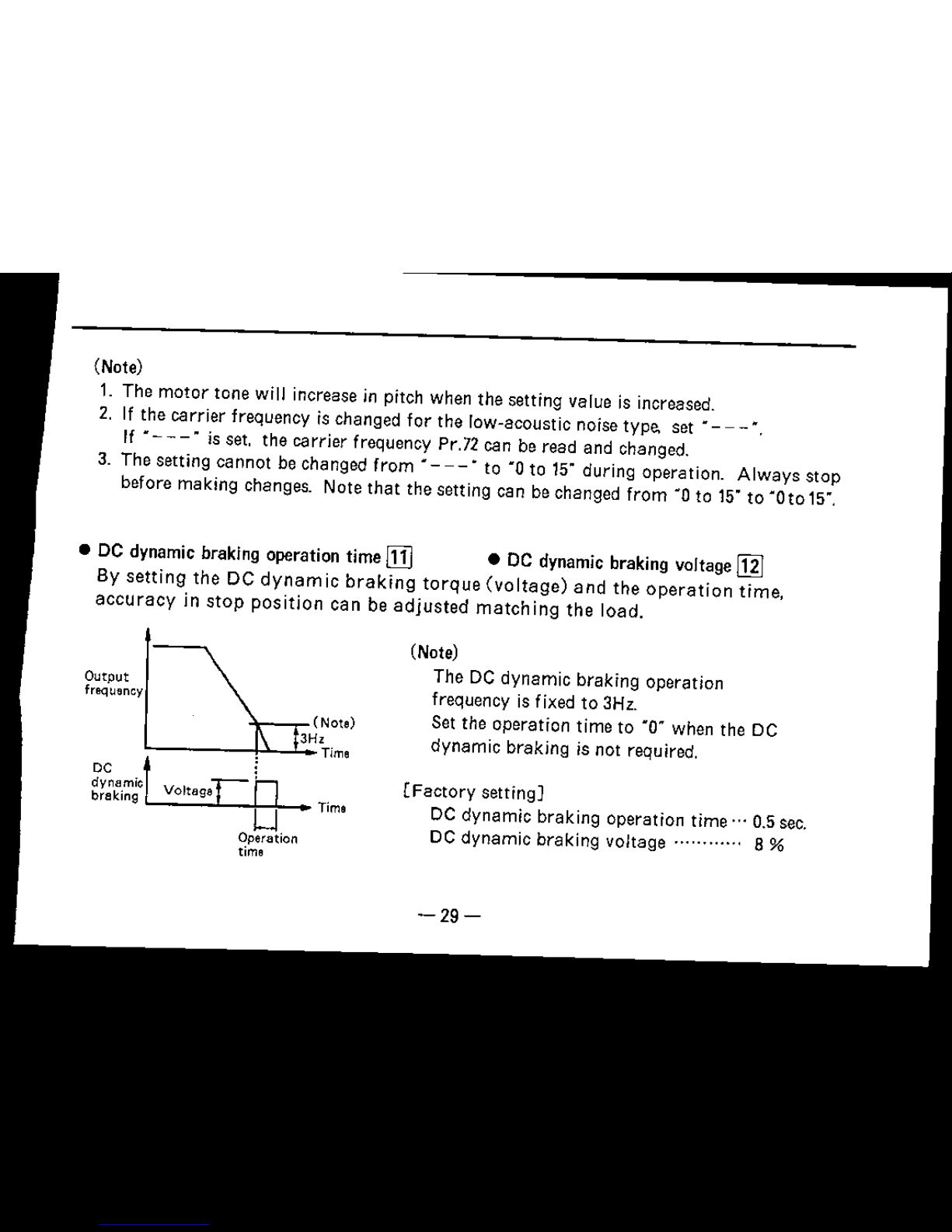

• DC dynamic braking operation

time

[1J

•

DC dynamic braking voltage

[gJ

By

setting

the

DC

dynamic

braking

torque

(voltage)

and

the

operation

time,

accuracy

in

stop

position

can

be

adjusted

matching

the

load.

(Note)

1.

The

motor

tone

will

increase in pitch when the setting value is increased.

2. If the carrier frequency is changed

for

the row-acoustic noise type. set

~

- - -:",

If

M "

is set.

the

carrier

frequency Pr.72 can be

read

and changed.

3. The setting

cannot

be changed

from

M "

to·O

to 15"

during

operation.

Always

stop

before

making

changes. Note

that

the setting can be changed

from

·0 to 15"to ·0 to 15",

Output

frequ~ncy

(Note)

3H'

L

p.......l"-'

Time

~y~a.mlc

t

Voltage-

L

braking

~

Time

U

Operation

time

(Note)

The DC

dynamic

braking

operation

frequency

is fixed to 3Hz.

Set the

operation

time

to

·0·

when the DC

dynamic

braking

is not required.

(Factory

setting]

DC

dynamic

braking

operation

time

.., 0.5 sec.

DC

dynamic

braking

voltage

8

%

-29-

• Frequencysetting voltage bias [1]

• Frequencysetting voltage gain

~

The

output

frequency

(ratio)

for

the frequency setting

signal

(DC

0 to 5V)

can

be

set freely.

Output

frequency

(Hz)

Bias

-30-

*When

setting

the

bias

and

gain.

the

frequency

setting

signal

need

not

be input.

• Stall prevention operation levle

~

An

overload

(excessive

torque)

can be prevented when

driving

a

motor

with

a

capacity

smaller

than

the

inverter

by

changing

the

stall

prevention

operation

current

level.

This

will

also

function

during

acceleration/deceleration.

The

operation

current

level is

set

with

setting

values

(codes).

Setting

Operation level

Setting

Operation level

Setting

Operation level

value

value value

,

110%

5

150%

9

190%

2

120%

6

160%

'0

200%

3

130%

7

170%

Stall

preventiqn

0

is

not

activated.

4

140%

8

180%

[Factory

setting]

.....

5

(150%)

• The

operation

level

%

indicates the

ratio

to the inverter

rated

output

current

-31-

[Factory

setting] •....• 0

Setting value

Tone selection

0

No tone control

1

Tone control

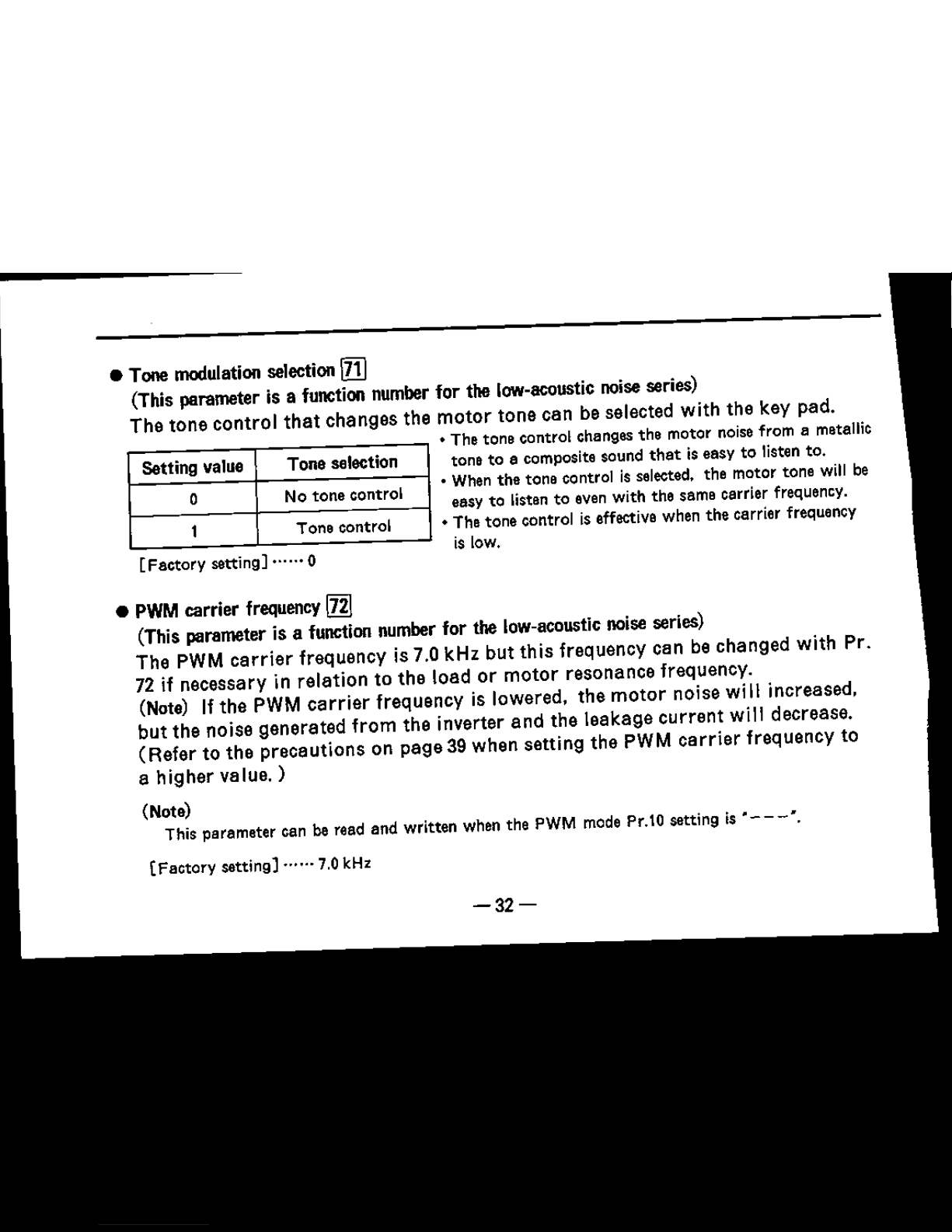

• Tone modulation selection

ITIJ

(This parameter is a function numberfor the low-acoustic noiseseries)

The

tone

control

that

changes

the

motor

tone

can

be selected

with

the key

pad

.

• The tone control changes the motor noisefrom a metallic

tone to a composite sound

that

is easy to listen to.

o

When the tone control is selected. the motor tone will be

easy to listen to even with the same carrier frequency,

• The tone control is effective when the carrier frequency

is low.

•

PWM

carrier

frequency

IllJ

(This parameter is a function number for

the

low-acoustic noise series)

The PWM

carrier

frequency is 7.0 kHz

but

this

frequency can be

changed

with

Pro

72

if necessary in

relation

to

the

load or

motor

resonance

frequency.

(Note)

If

the

PWM

carrier

frequency is lowered,

the

motor

noise

wi

II increased,

but

the

noise

generated

from

the

inverter

and

the

leakage

current

will decrease.

(Refer

to

the

precautions

on

page

39 when

setting

the

PWM

carrier

frequency

to

a

higher

vefue.)

(Note)

This parameter can

be

read and written when the PWM mode Pr.10 setting is

"-

- -:",

(Factory

setting]

......

7.0kHz

-32-

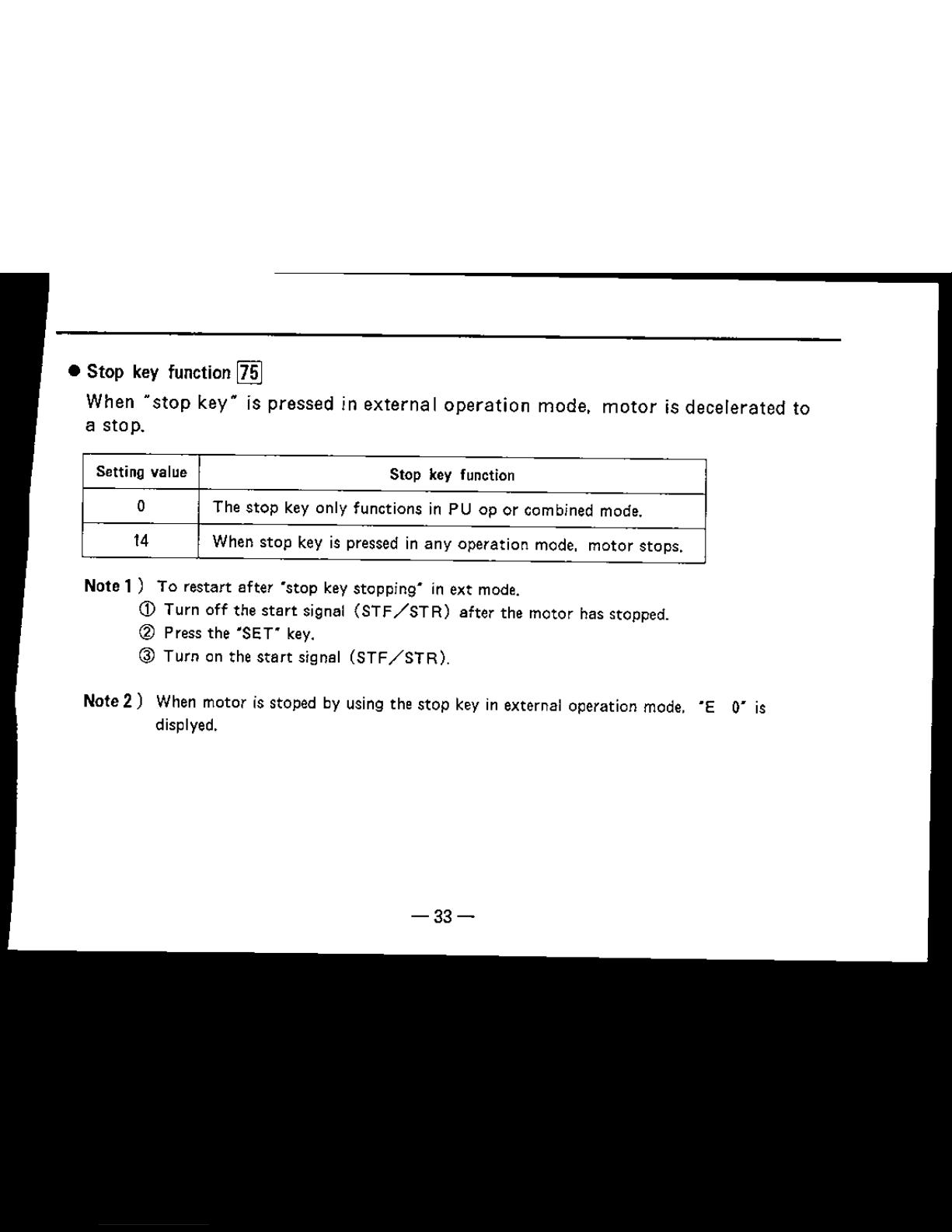

• Stop key function

IZID

When

"stop

key" is pressed in external

operation

mode,

motor

is decelerated to

a stop.

Setting value Stop key function

o The

stop

key

only

functions in PU op or combined mode.

14 When

stop

key is pressed in

any

operation

mode,

motor

stops.

Note

1)

To restart after

'stop

key stopping" in ext mode.

CD

Turn off the

start

signal

(STP/STR)

after the

motor

has stopped.

@ Press the 'SET" key.

@ Turn on the

start

signal

(STF/STR).

Note

2)

When motor is stoped by using the stop key in external operation

mode.

"E O' is

displyed.

-33-

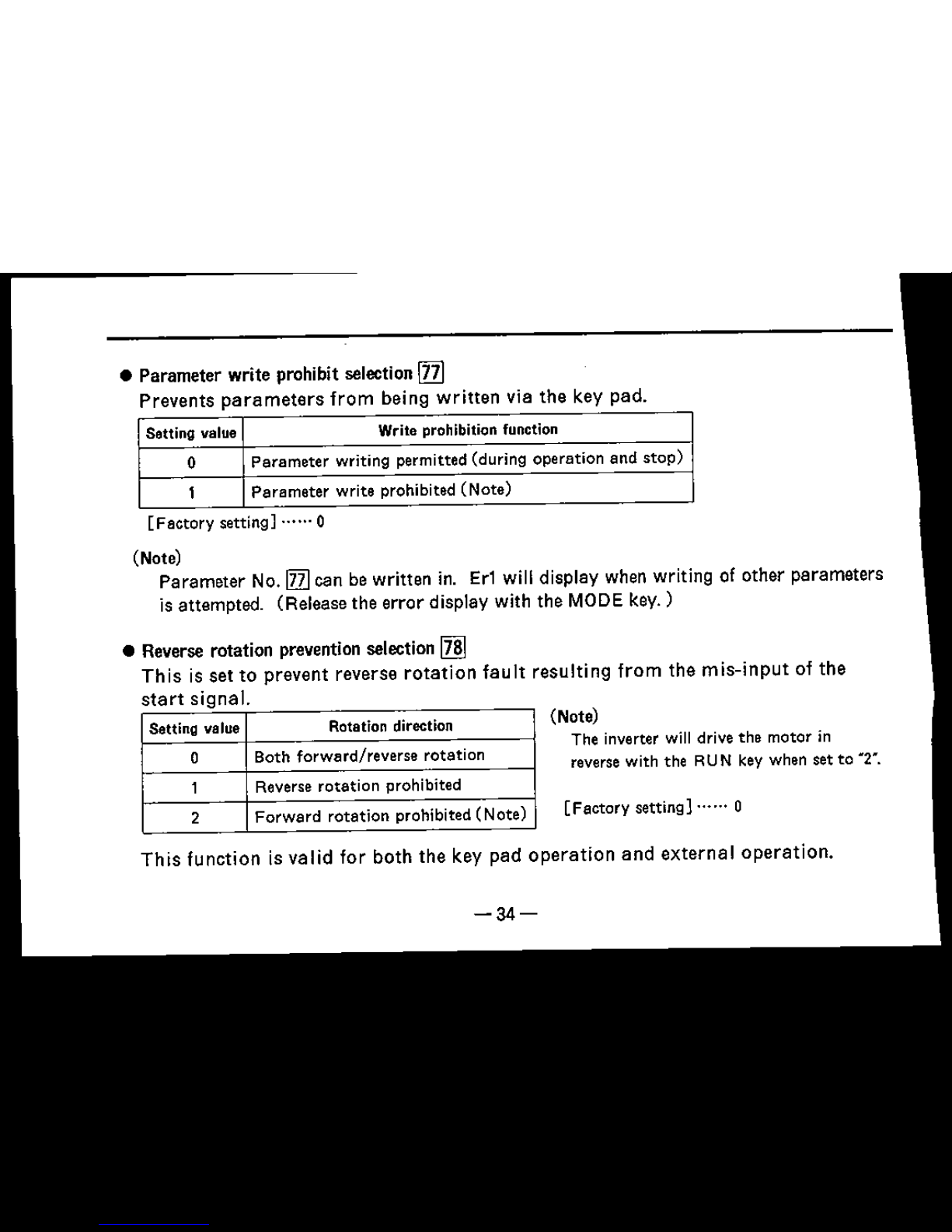

• Parameter write prohibit selection[ll]

Prevents

parameters

from

being

written

via the key pad.

Setting value Write prohibition function

0

Parameter

writing permitted (during operation and

stop)

1

Parameter

write prohibited

(Note)

[F actory setting] ..•". 0

(Note)

Parameter No. Ill]can be written in.

Er1

will display when writing of other parameters

is attempted. (Release the error display with the MODEkev.)

• Reverse rotation preventionselection

IIID

This

is set to prevent reverse

rotation

fault

resulting

from

the

mis-input

of the

start

signal

Setting value Rotation direction

0 Both forward/reverse

rotation

1 Reverse

rotation

prohibited

2

Forward

rotation

prohibited

(Note)

(Note)

The inverter will drive the motor in

reverse with the RUN key when set to

M2

M•

[Factory

setting)

......

0

This

function is

valid

for both

the

key pad

operation

and

external

operation.

-34-

• Operation

mode

selection

lZID

The

inverter

operation

modes

include

operation

with

external

signals

and

operation

with

key

pad.

Operation

can

be

limited

to one

mode

or

can

be

carried

out

with

both

modes.

Setting value 1 Operation only

with

key pad

Setting value 2 Operation

only

with

external signals

Setting value 3

Operation trecuencv-: Set with key pad (direct setting or

~l!J

keys)

Start

signal",

External signal

input

(STF.

STR

terminals)

Setting value 4

Operation

frequency""

External

signal

input

(DCOto5V between

termtnalsz-s)

Start

signal'"

Input

with

key pad

(RUN

key)

(Note)

4.

[Factory

setting) 1

(Note)

1.

This

parameter

cannotberewritten

during

operation. Er2

will

display if

writingisattempted.

2. Setting values 3 and 4 are set to use the external signals and key pad operation for the

operation frequency setting and

start

signals.

3. When set to 3, the operating frequency is set via key pad and analog signa! input is ignored.

4. When set to 4, the operating frequency is set via analog signal input.

-35-

-36-

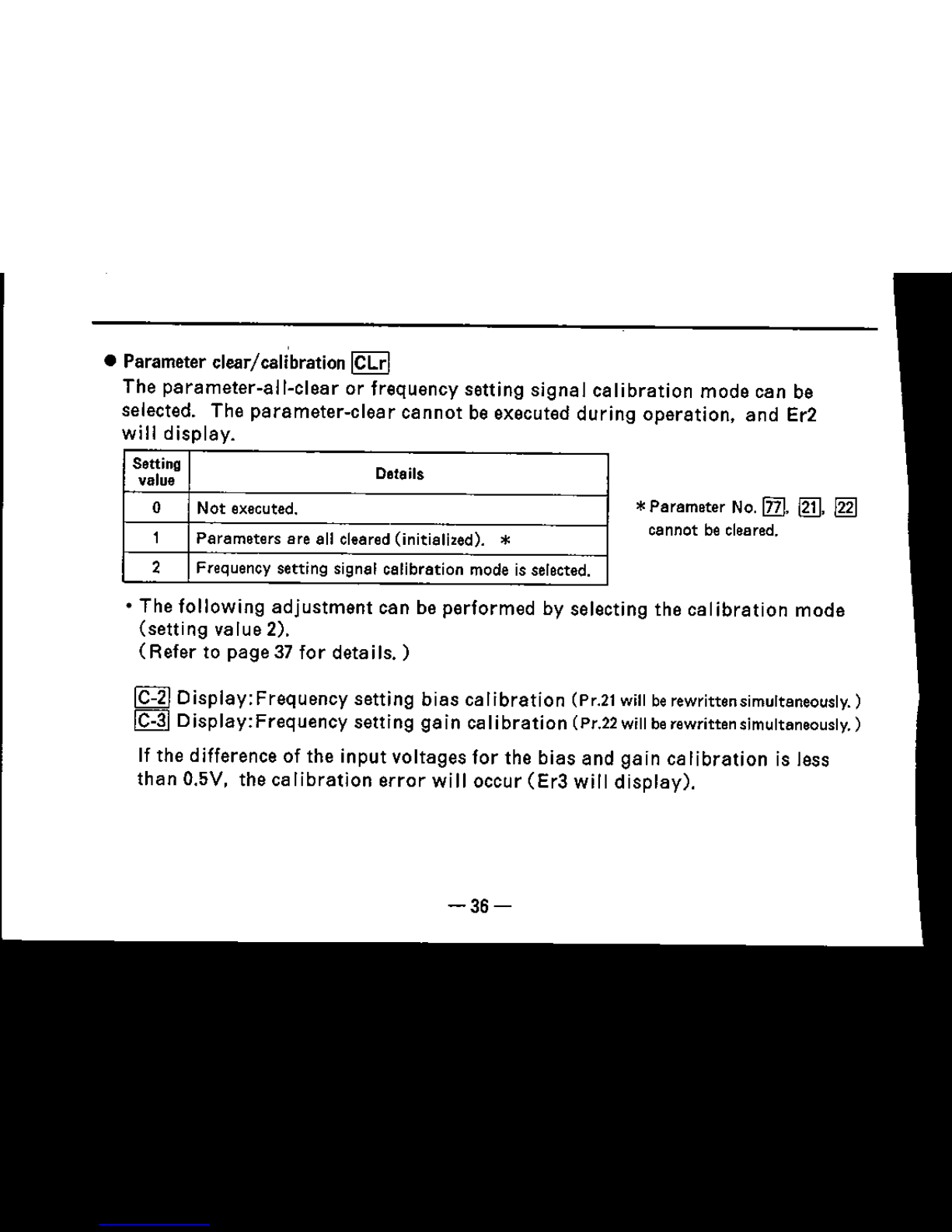

• The following

adjustment

can be

performed

by selecting the

calibration

mode

(setting

value 2),

(Refer

to

page37for

details.)

• Parameter clear/cali'bration

ICLrl

The

parameter-all-clear

or frequency

setting

signal

calibration

mode

can be

selected. The

parameter-clear

cannot

be executed

during

operation.

and

Er2

will

display.

*Parameter No.lllI,

1m,

~

cannot be cleared.

~

Display:Frequency

setting

bias

calibration

(Pr.21 willberewrittensimultaneously. )

~

0 isplay:Frequency

setting

ga in caIi

bration

(Pr.22 will be rewritten slmultenecuslv,)

If the difference of the

input

voltages

for

the

bias

and

gain

calibration

is less

than

O.5V,

the

calibration

error

will occur

(Er3

will

display).

Setting

Details

value

0 Not executed.

1

Parameters are all cleared (initiefieed).

*

2

Frequency setting signal calibration mode is selected.

o Example of parameter-all-clear!calibration operation

Selection of

setectlcn

Read

out

Change

to 1

Write

in

display

mode

of function

of

current

number

value

0

Parameter-clear

[SIT]

Koy

!MODEI

......

IMODEI

-

~ -

[ill]

operation

ICL,-I

Display

1'-"01

Ip

01

lCL,·1

c::::m

0

A

Displays

0 ...•.

+

elternately

0

To

change

Pr.C-2

from

0 Hzto3 Hz,

Write

in

Read

out

of

Change to

Change

to 2

(Select

Write

in

Chang

calibration

current

value

3H,

mode)

..

Changes

Output

4

0

0

ISETI

I

SETI

frequency

o

whil~

h~td

ISETI

(Hz)

down

IC-,?I

3

Q

Ic-.?\

c::::m

OJ

t

~1;:~~':I:IY

OJ

0

Frequency setti

signal

-37-

09

Gain

If-'

i

NOU

)

,v

frequenoy setting signal

(Note)

• When this C-2 or C-3 is specified, value set for 'frequency setting voltage bias"

(function No. 21)

or

'frequency setting voltage

gain-

(function No.22) will be

automatically

rewritten.

-38-

• Frequency setting bias calibration §

• Frequency setting gain calibration

fC=3l

Allows

the

output

frequency

to be

set

in

relation

to

the

frequency

setting

signal

(DC

Oto

5V).

(Bias)

The

output

frequency

for

the

setting

signal

input

between

terminals

2-5

will

be set.

(Gain)

The

output

frequency

for

the

setti

ng sig naJ

input

between

term

ina

Is 2-5 wi II be

set

If

the

input

signal

is

av,

it is

judged

to be 5V

input.

To set frequency with

current

input

(4 to 20mA)

(60Hz)

--------------

. ,

,

,

,

/ 1

/'

L

When4to!

~20mAis

,

;'

used I

Fa~tory

setting

Output

fr&quen~y

(Hz)

2.

Adjust

C-2

(bias)

as below.

(Pr.21 will be

rewritten

simultaneously.)

1. Place a

resistor

between 2-5.

and

convert

the

current

into a voltage. (4 to

zoma->

1 to 5V)

Install a resistor

(2500

lW)

(-)-~-=:~

(+

)1-----,,..1

Remarks

1

(4)

5V

(20mA)

-39-

)PrecautionsI

1. It is necessary to accept a reduction of load torque when

setting the

PWM

carrier

frequency to a higher value.

PWM carrier frequency (kHz)

o

2.37

8

910

11

12131414.5

-~-Ijl-.

-.-~-.~

- r-,-

-.-

-0_

-~- - -

-.-

- r _

0.-.

_..-~-

=:=

=~=~==

=~

---

.~

100

-;--""

'l!

li

~

60

SO

Derating

to rated

current

(%)

-40-

(1)

When setting the PWM

carrier

Ireq uenoy

(Pr

.72) to 7.1kHz or

more

to lower the

motor

acoustic

noise, the rated

output

should

be derated as

shown

on the right.

Also change the electronic

thermal

relay

(Pr.

9) setting.

(2)

If the PWM

carrier

frequency

is increased, the

acoustic

noise from the

motor

will

lower, but the noise qenerated

by the inverter

and

the leakage

current

will increase.

2. Noise

Thereisnoise

that

enters

from

outside

and

causes

the inverter to

malfunction

and

that

which is

generated

from

the

inverter

and

causes

the

peripheral

equipment

to

malfunction.

The inverter is

designed

so

that

it is not

easily

affected by noise.

but

as it is

an

electronic

device which

handles

weak

signals.

the

following

general

countermeasures

will be

required.

+General

countermeasures

• Avoid

laying

the

inverter's

power

cables

(input/output)

in

parallel

with

the

signal

wires

and

avoid

bundling

the

power

cables

and

signal

wires.

• Use

twisted

pair

shield

wires

for

the

connection

wires

with

the

sensor

and

for

the

control

signal

wires.

Connect the

sheath

of the

shield

wire

to

terminal

SO.

• Use

one-point

grounding

for

the inverter

and

motor.

etc.

-41-

+Example

of noise

countermeasures

Motor

Sensor

Use a s-ecre cable for the

motor power cable, and use

one wire for the grounding.

Install a filter (FR·BSFOl)

on the inverter

output

side.

Do not ground the shield,

but instead

connllGt

to the

common wirefor the signals.

Use twisted pair shield wires.

lower

carrier

frequency

Do not

dirllGtly

ground

to the control panel.

~~

:~t~~e~];e.9rOund

'-_"'-

-'tJ

Separate the inverter

unit",

....

_

power cables and sensor

circuit by

30cm

or more

(at

least

lDem).

Install a filter

(FR.BSFOl) on the

Power _ inverter input side.

supply-o

Install a fHur

(FR.

elF)

on the

inverter input side

Control

panel

-42-

3. Leakage

current

Leakage

current

will

flow

through

stray

capacity

which

exists

between the

ground

and

a cable,

motor,

etc. The

value

of the

leakage

current

depends

on the

cable

length,

wiring

method

and

inverter

carrier

frequency, and will

increase

when

using

a

low-acoustic

noise inverter, so use the

following

countermeasures.

(1)

Leakage

current

to the

ground

The

leakage

current

will not

affect

only

the

inverter

but

may

pass

into

other

equtpments

through

the

grounding

cables

and

may

cause

a

leakage

breaker

or

relay

unnecessary

trip.

_Countermeasures

Route

of

leakage

current

•

Lower

the

inverter's

carrier

frequency

(Pr.

72). Note

that

this

will

increase

the

motor

acoustic

noise

.

• Use a

leakage

breaker

that

corresponds

to high

harmonics

and

surges

(Mitsubishi

New

Super

NV Series,

etc.)

for the inverter

or

other

lines

when

using

the

low-acoustic

noise model

(with

high

carrier

frequency).

-43-

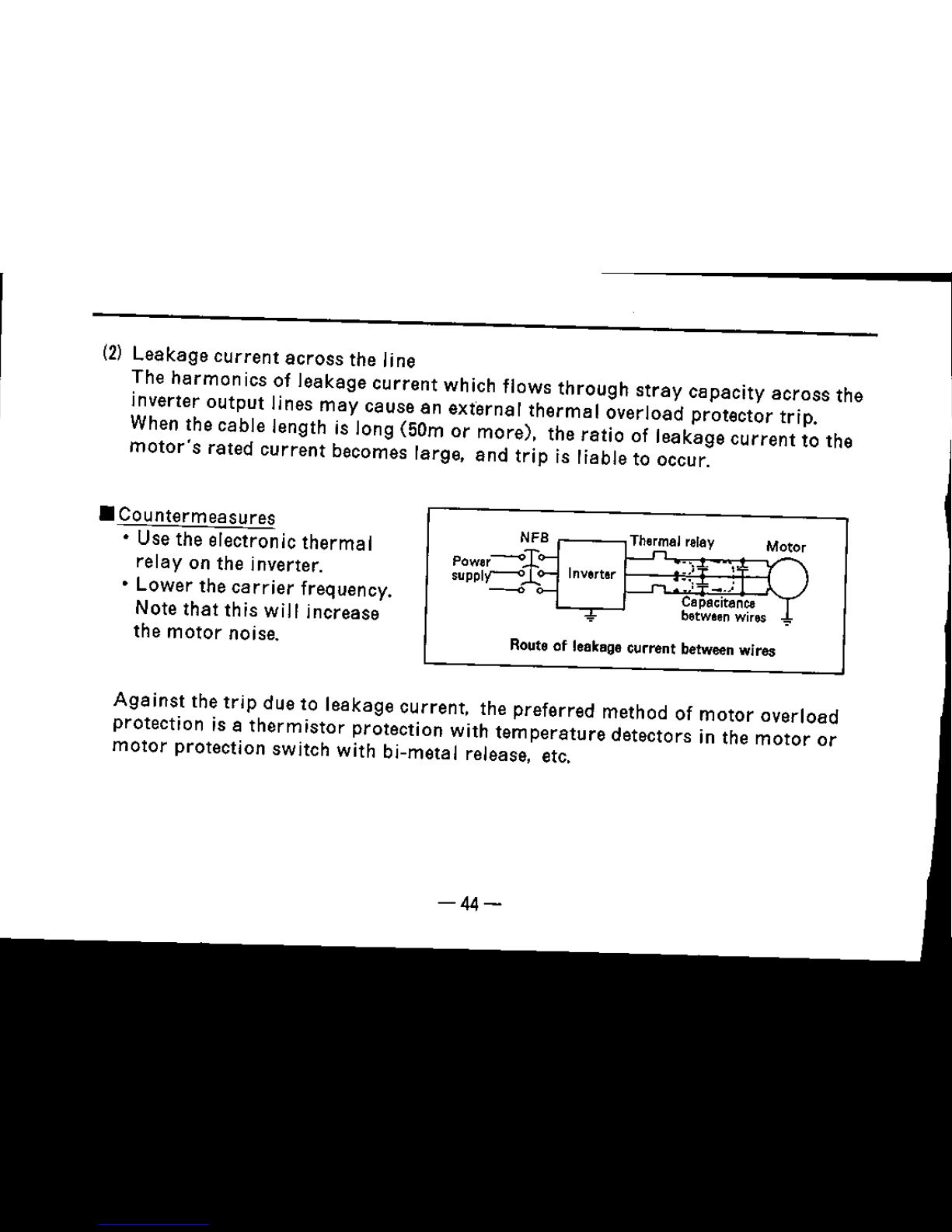

(2)

Leakage

current

across

the line

The

harmonics

of leakage

current

which flows

through

stray

capacity

across

the

inverter output lines

may

cause an external

thermal

overload protector trip.

When the cable length is long (50m or more), the

ratio

of leakage

current

to the

motor's

rated

current

becomes large.

and

trip

is liable to occur.

• Countermeasures

• Use the electronic

thermal

relay on the inverter.

• Lower the

carrier

frequency.

Note

that

this will increase

the

motor

noise.

NFB

The~al

relay

M~r

power~

Inverter

.)

,

SUPPIC""O-

'

_

....

Capacitance

T

between

wires ':'

Routa of leakage current between wires

Against

the

trip

due to leakage current, the preferred method of

motor

overload

protection is a

thermistor

protection with

temperature

detectors in the

motor

or

motor

protection switch with bi-metal release, etc.

-44-

4. Carrier frequency

The parameter of carrier frequency (Pr.l0) must be changed for the operation

frequency range as following:

Operation frequency range

Pro

10 setting value

0.5 to 77 Hz

oto 15.

---

0.5 to 88 Hz

1 to 15.

---

0.5 to 99 Hz

2 to 15.

---

0.5 to 111 Hz

3 to

15.

---

0.5 to 120 Hz

4 to

15.

---

-45-

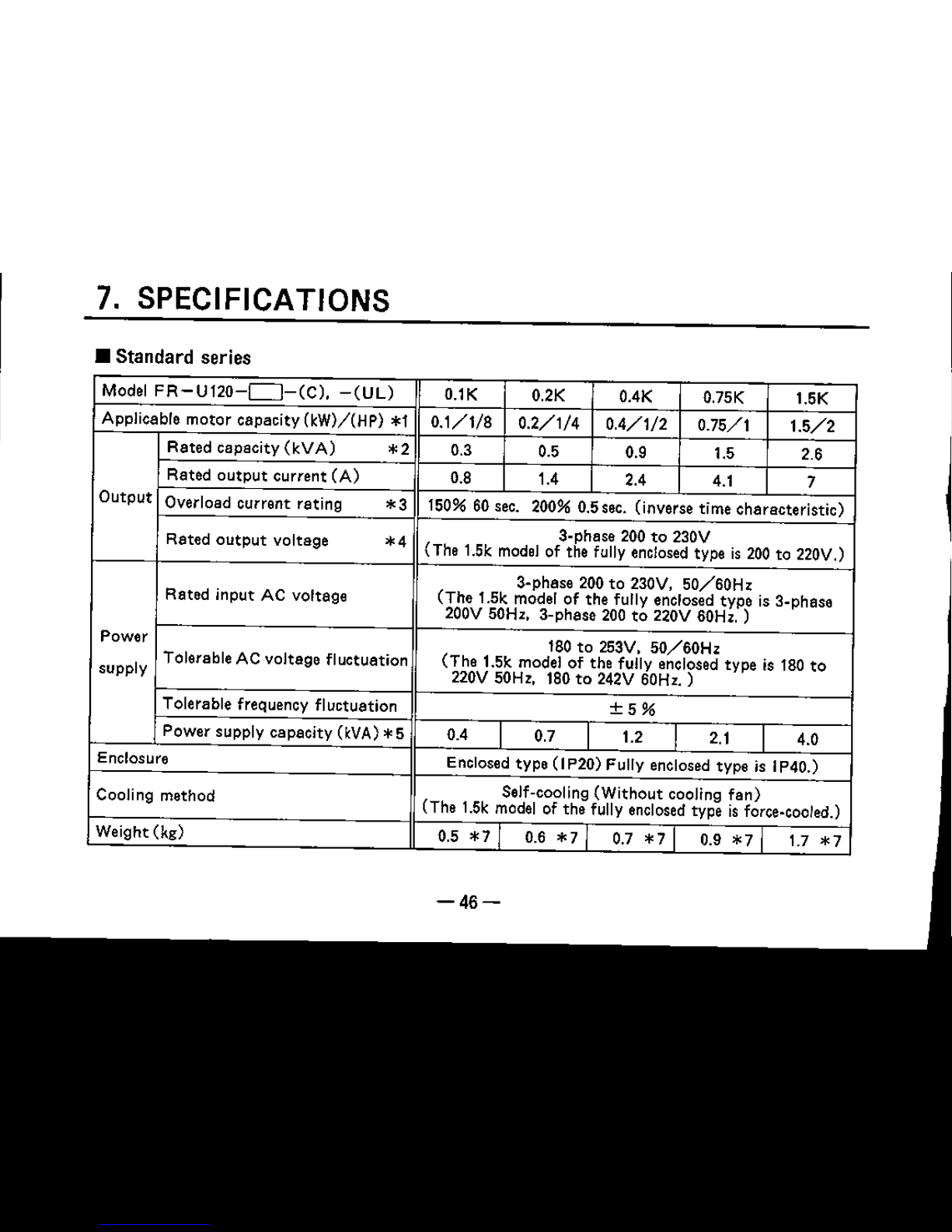

7. SPECIFICATIONS

• Standard series

Model

FR-U120-C]-(C).

-CULl

O.1K

0.2K 0.4K

a.75K

1.5K

Applicable

motor

capacity

(kW)/(HP)

*1

0.1/1/8 0.2/1/4 0.4/1/2

0.75/1

1.5/2

Rated

capacity

(kVA)

*'

0.3

0.5

0.9 1.5 2.6

Rated

output

current

(A)

0.8

1.4 2.4

4.1

7

Output

Overload current rating

*3

150%60sec. 200% 0.5sec. (inverse time

characteristic)

Rated

output

voltage

*4

a-pheee 200to230V

(The 1.5k model of the fully enclosed type is 200 to 220V.)

a-phase 200 to 230V,

SO/60Hz

Rated

input

AC

voltage

(The

1.5k model of the fully enclosed

typeisa-phase

200V 50Hz, 3-phase 200to220V 60Hz. )

Power

180to253V.

SO/60Hz

supply

Tolerable AC

voltage

fluctuation

(The

1.5k model of the fully enclosed type is 180

to

220V 50Hz, 180to242V 60Hz. )

Tolerable frequency

fluctuation

±5%

Power

supply

capacity

O:VA)

*5 0.4

0.7

I

1.2 2.1

4.0

Enclosure

Enclosed

type

(I P20) Fully enclosed type is IP40.)

Cooling method

Self-cooling

(Without

cooling

fan)

(The 1.5k model of the fully enclosed type isforce-cooled.)

Weight

(kg)

0.5

*7

0.6

*7

0.7 * 7 I

0.9

*7

1.7

*7

-46-

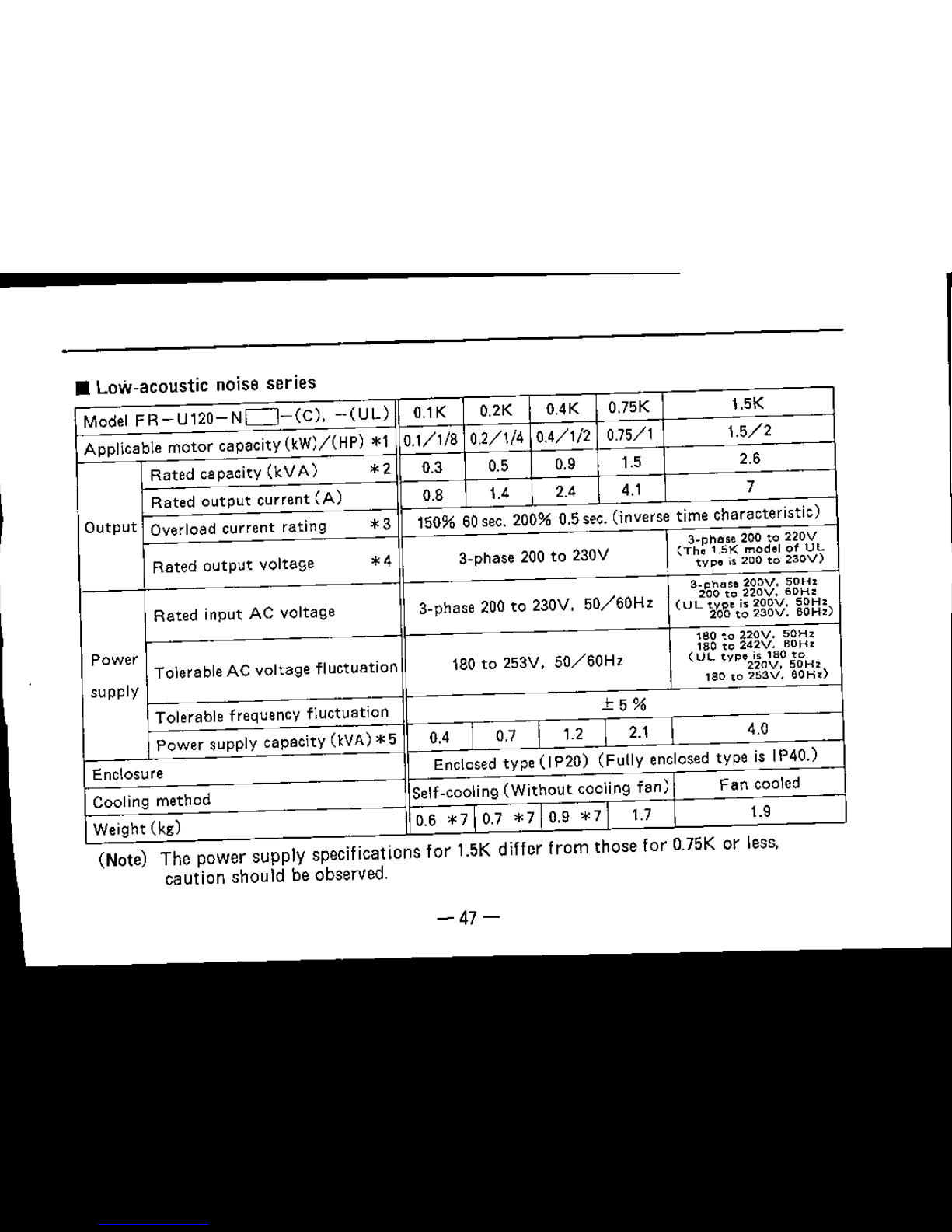

• Low-acoustic noise series

Model

FR-U120-ND-(C),

-(UL)

0.1K

0.2K

0.4K 0.75K 1.5K

Applicable

motor

capacity (kW)/(HP) *1

0.111/8

0.2/1/4

0.4/1/2

0.75/1

1.5/2

Rated

capacity

(kVA)

*2

0.3 0.5 0.9 1.5

2.6

Rated

output

current

(A)

0.8 1.4 2.4 4.1

7

Output

Overload current rating

*3

150% 60sec. 200% 0.5sec.

(inverse time characteristic)

a-cbe

se

200

to

220V

Rated

output

voltage

*4

3-phase 200 to 230V

(Tho

1,5K

model

of

UL

typo

is

200

to

230V)

3_p!'>as.200V.

50Hz

Rated

input AC voltage

3-phase 200 to 230V,

SO/60Hz

200

to

220V.

60Hz

(UL

typo

is

200V.

50Hz

200

to

230V.

60Hz)

Power

vee

to

220V.

50Hz

180

to

242V.

60Hz

Tolerable AC voltage fluctuation 180 to 253V.

50/60Hz

(UL

typo

is 180

to

220V,

50Hz

supply leo

to

253V.

80Hz)

Tolerable frequency fluctuation

±5%

Power

supply capacity (kVA)

*5

0.4

0.7 1.2 2.1 4.0

Enclosure

Enclosed type

(IP20)

(Fully enclosed type is IP40.)

Cooling method

Self-cooling

(Without

cooling

fan)

Fan

cooled

Weight (kg) 0.6

*7

0.7

*7

0.9

*7

1.7

1.9

(Note) The power supply specifications

for

1.5K differ

from

those for

a.75K

or

less.

caution should be

observed.

-47-

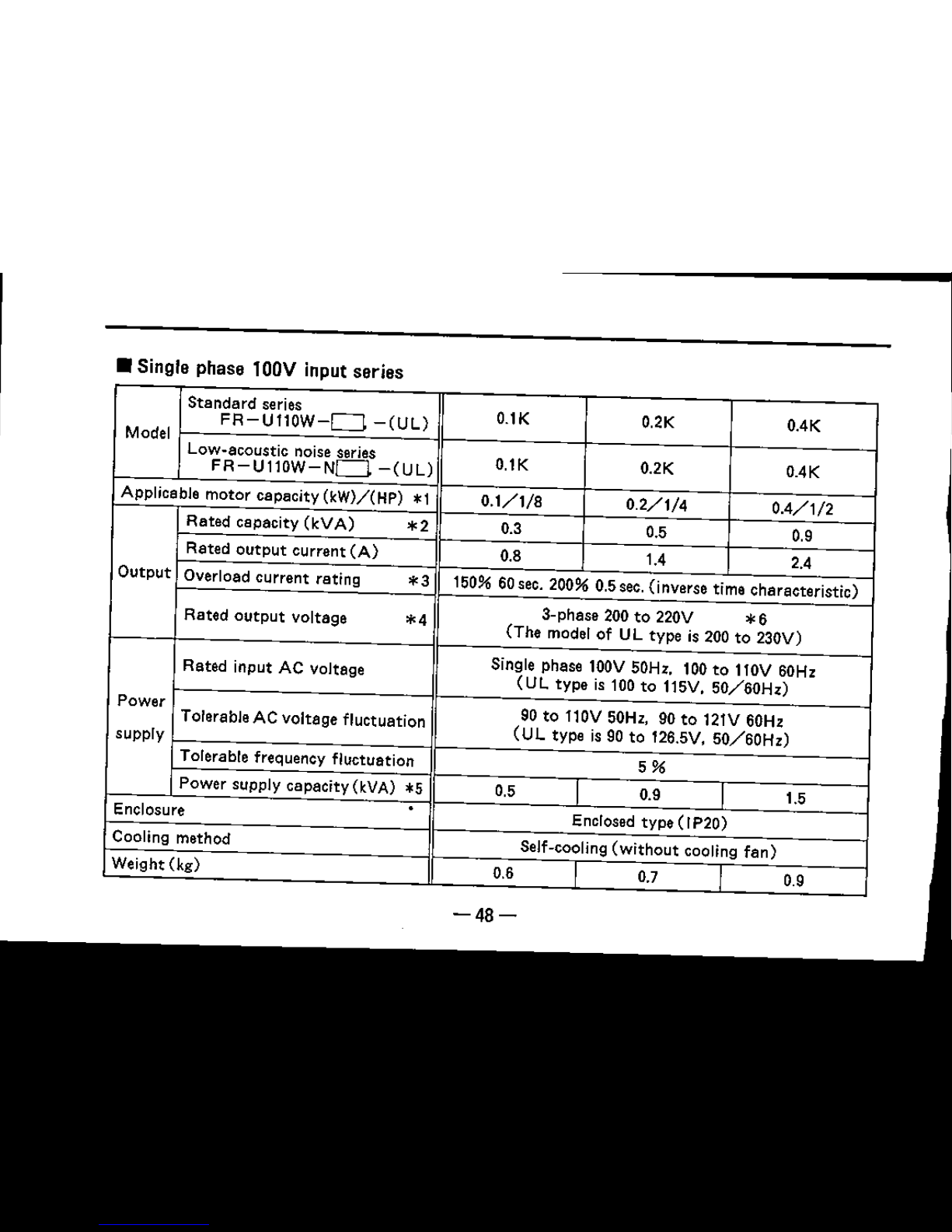

• Single phase lOOV input

series

Standard

series

O.IK

0.2K 0.4K

Model

FR-Ull0W-D

-CUL)

Low-acoustic noise series

O.lK 0.2K OAK

FR-Ull0W-ND

-(UL)

Applicable motor capacity

(kW)/(HP)

*1

0.1/1/8

0.2/1/4

0.4/1/2

Rated capacity

(kVA)

*2

0.3 0.5 0.9

Rated

output

current

(A)

0.8 1.4

2.4

Output

Overload current rating

*3

150% 60sec. 200% 0.5sec.(inverse time characteristic)

Rated

output

Voltage

*4

3-phase 200

to

220V

*6

(The model of UL type is 200 to 230V)

Rated input AC voltage

Single phase 100V50Hz. 100

to

110V 60Hz

(UL

type is 100 to 115V.

50/60Hz)

Power

90 to 110V 50Hz, 90

to

121V 60Hz

Tolerable AC voltage fluctuation

(UL

type is 90 to 126.5V,

50/60Hz)

supply

Tolerable frequency fluctuation

5%

Power supply capacity

(kVA)

*'

0.5

I

0.9

1.5

Enclosure

Enclosed type

(rP20)

Cooling method

Self-cooling

(without

cooling

fan)

Weight (kg)

0.6

0.7

0.9

-48-

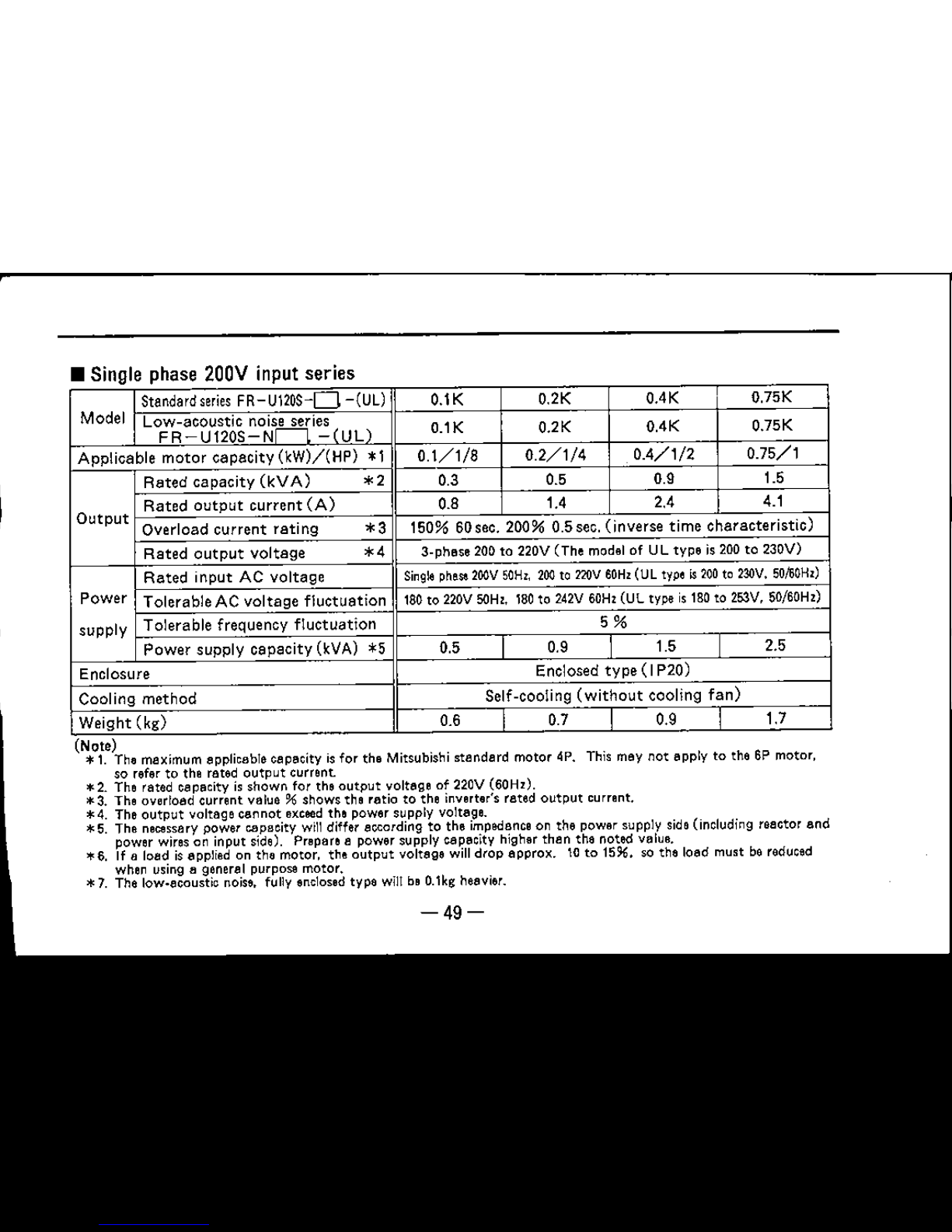

• Single phase 200V input

series

IStandard series FR

U120S

0 (UL)

O.lK

O.2K OAK

O.75K

Model

Low-acoustic

no~s~ie~

(I 1 )

O.1K

O.2K OAK

0.75K

FR-U120S-N

- UL

Applicable

motor

capacity

(kW)/(HP)

* 1

0.1/1/8

0.2/1/4 0.4/1/2

0.75/1

Rated

capacity

(kVA)

*2

0.3

0.5 0.9 1.5

Rated

output

current

(A)

0.8

1.4 2.4 4.1

Output

Overload

current

rating

*3

150%

60 sec.

200%

u.s

sec.

(inverse

time

characteristic)

Rated

output

voltage

*4

s-pnese

200 to 220V (The model of UL type is 200 to 230V)

Rated

input

AC

voltage

Single

ohese

200V

50Hz.

200to zarv

60Hz

(ULtype~200

to

230V,

50/60Hz)

Power

Tolerable

AC

voltage

fluctuation

180to 220V

SOHz,

180to 242V

60Hz

(UL type is180to 253V, 50/60Hz)

supply

Tolerable

frequency

fluctuation

5%

Power

supply

capacity

(kVA) *5

0.5

I

0.9

I

1.5

I

2.5

Enclosure

Enclosed

type(IP20)

Cooling

method

Self-cooling

(without

cooling

fan)

Weight

(kg)

0.6

I

0.7

I

0.9

I

1.7

(Note)

*1. The maximum applicable capacity isfor the Mitsubishi standard motor 4p, This may not apply to the 6P motor.

so refer to the rated

output

current.

*2. The rated capacity isshown for the

output

voltage of 220V (60Hz).

*3. The overload current value

% shows the ratio to the inverter's rated

output

current.

*4. The

output

voltage cannot

exceed

the power supply voltage.

*5. The necessary power capacity willdiffer according to the impedanceon the power supply side(including reactor and

power wires on input side). Prepare a power supply capacity higher than the noted value.

*6. If a load isapplied on the motor. the

output

voltage will drop approx. \0 to 15%. so the load must be reduced

when using a general purpose motor.

*7. The lcw-ecoustio noise. fully enclosedtype

wl11

be O.lkgheavier.

-49-

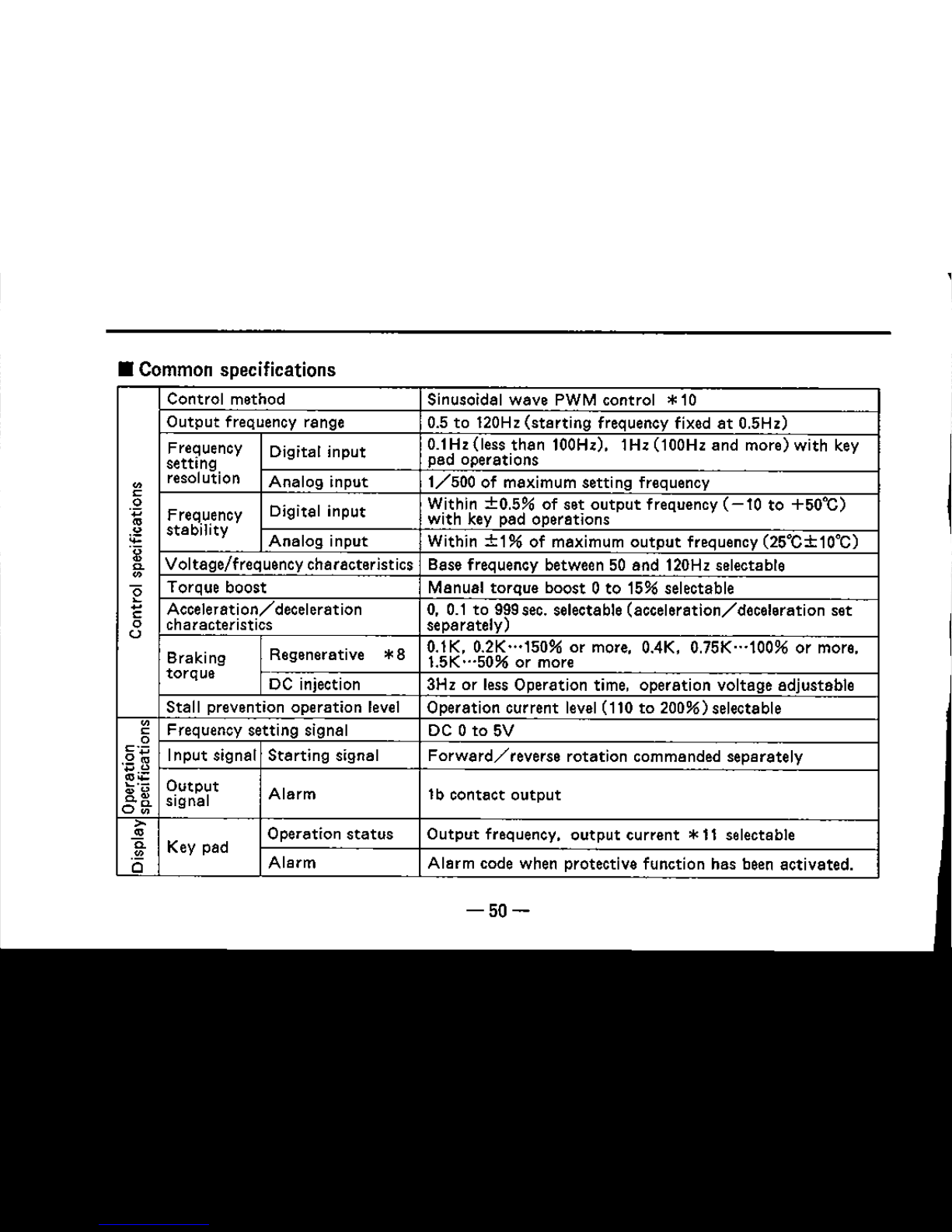

• Common specifications

Control method Sinusoidal wave PWM control

*10

Output

frequency range

0.5 to 120Hz

(starting

frequency fixedat0.5Hz)

Frequency

Digital input

0.1Hz (less

than

100Hz).

1Hz (100Hz and more) with key

setting

pad operations

"

resolution

Analog input

1/500

of maximum setting frequency

0

Within

±0.5%

of set

output

frequency (

10 to +50OC)

0

Digital input

.~

Frequency

with key pad operations

~

stability

Analog input

Within

+1%

of maximum

output

frequency (25°C±10°C)

g

Voltage/frequency characteristics Base frequency between 50 and 120Hz selectable

~

e

Torque boost

Manual torque boost 0 to 15% selectable

"

Acceleration/deceleration 0.0.1 to 999sec. selectable (acceleration/deceleration set

0

characteristics separately)

u

0.1K.

O.2K

"'150% or more.

OAK,

0.75K···100% or more.

Braking

Regenerative

*8

1.5K

"'50%

or more

torque

IDC injection

3Hz or less Operation time, operation voltage adjustable

Stall prevention operation level

Operation current level(110 to 200%)selectable

"

Frequency setting signal

DC 0 to 5V

0

0

.~~

Input signat Starting signal

Forward/reverse

rotation commanded separately

i;:'u

Output

Alarm 1b contact

output

~.

signal

o~

>

•

Operation

status

Output frequency.

output

current *11 selectable

~

Key pad

i5

Alarm

Alarm code when protective function has been activated.

-50-

Overcurrent

shut

down

(during

acceleration/deceleration/

Protection/warning

function

constant

speed), regenerative overvoltage

shut

off.

electronic thermal overload. stall prevention

Ambient temperature

-10

to +50°C

(-10

to +40°C for

totally

enclosed

type)

(with

no freezing)

»,

Ambient humidity 90% RH or less

(with

no dew condensation)

•

fr

Storage

temperature

*9

-20

to +65°C

is

Indoors

with

no corrosive or flammable gases. oil mist or

Atmosphere

dust

Altitude/vibration

Less

than

1000m above sea level.

5.9m/S'(O.6G)

or less

-51-

1,000

5,000

HP

rating

o to ,

(Note)

*8.

The braking torque shows the

short

time average deceleration torque when the motor

without

load is decelerated in the shortest time from 60Hz (changes due to motor's loss), and is not

the continuous regenerative torque. For deceleration from a frequency

that

exceeds the base

frequency. the average deceleration torque value will decrease.

A brake resister is not built-in and

cannot

be extemally installed.

1.5K is not available for the single phase input series.

*9. This is a

short

time temperature

for

during transportation, etc.

*10. The low-acoustic noise series use the high carrier frequency sinusoidal PWM control.

*11. The

output

current is displayed only while the SET key is being pressed.

*12. Short Cirunit Ratings

The drive is suitable

for

use on a circuit capable of delivering not move

than

* RMS

symmetrical Amperes.

•

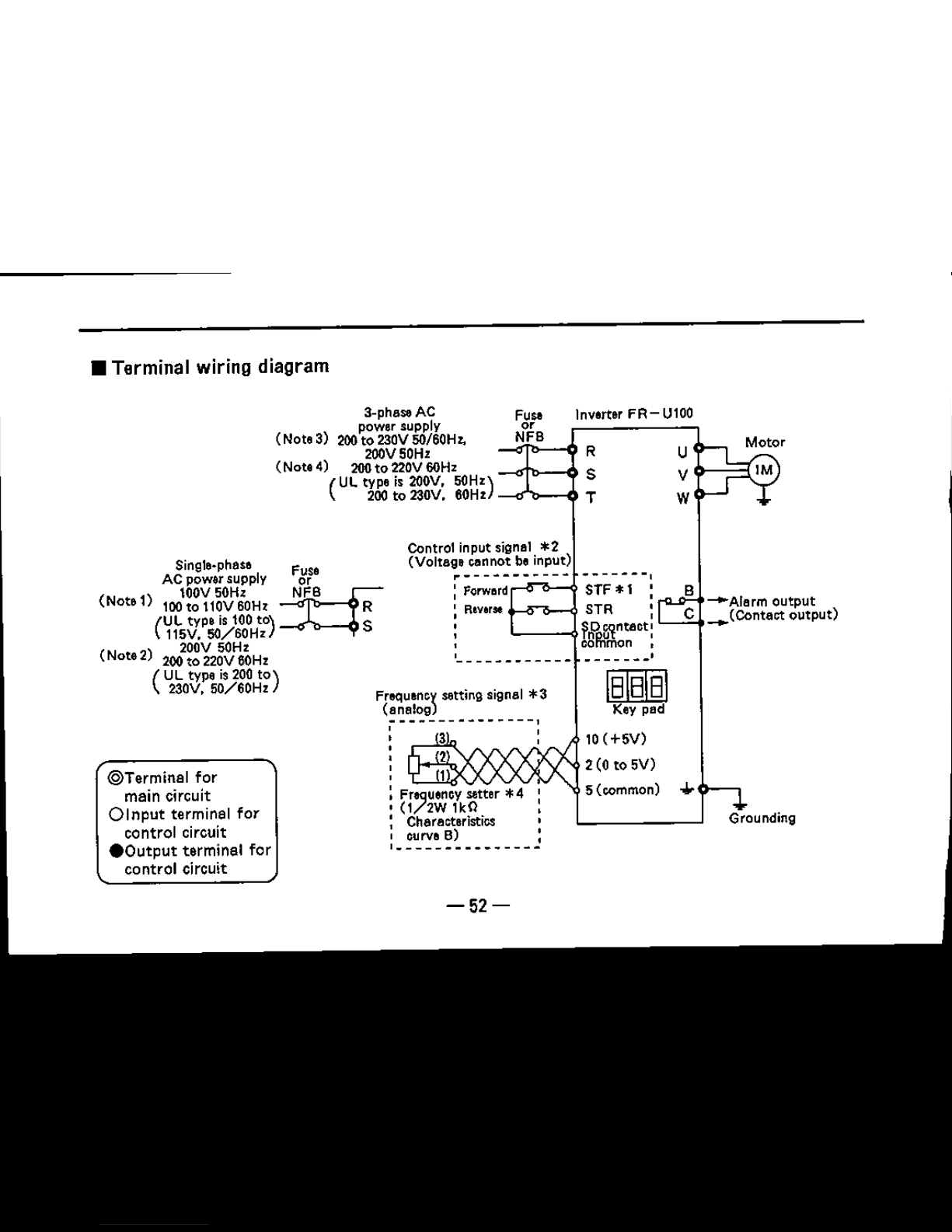

Terminal

wiring

diagram

Inverter

FR-U100

F".

0'

NFB

3-phase AC

(Note 3)

2OO~~";;~Vu:)$OHl,

2OOV50Hz

R

(Note 4) 200to 220V60Hz

(

UL tYpe is 200V. 50HZ)

S

200to 230V. 60Hz

_-"'_--<10

T

u

V

W

Motor

1M

Control input signal

*2

(Voltage cannot be input)

~-----------

-------,

:

Forwerd

STF *1 :

:

Rlverse

l-

..........J STR '

,

frPra

ntact

:

, common

I

,

------------

B

-e-Aterm

output

C

_(Contact

output)

Grounding

mill]

Key pad

10(+5V)

2(Oto5V)

5 (common)

FreqUenC\

setting signal

*3

(analog

~--------------'

: 3 :

, 2

: 1

: Frequencysetter *4

,

(l/2W

1kO

: Characteristics

, curve B) :

,---------------

@Terminal

for

main circuit

Olnput

terminal

for

control circuit

.Output

terminal

for

control circuit

Single-phase fuse

AC power supply or

)

100V50Hz

~FB