Mitsubishi FREQROL-SFJ Maintance Manual

r‘

LiC SPINDLE DRl.i/E

. . . .

t .,.

. .

-SFJ L

*’

P

MAINTENANCE -MANUAL

:

BNP-A282 l-02-A-E

ADVANCED AND EVER ADVANCING

n/lmJBlsHl

ELEcTmc

-CO.NTENTS-

1.

GENERAL

1.1

Introduction

1.2

Safety during

maitenance

and troubleshooting

1.3

Storage

2. WIRING

2.1

External wiring

2.2

Parts arrangement

3. ADJUSTMENT

3.i

Preliminary check

3.2

Power feeding

3.3 FR-SFJ status display and parameter settings

. . . . .

1

. . . . .

1

. . . . .

1

. . . . .

2

. . . . .

3

. . . . .

3

. . . . .

10

. . . . .

12

. . . . .

12

. . . . .

13

. . . . .

15

3.3.1 (A) Status display and parameter setting

for ROM version A

. . . . .

17

3.3.2

(B)

Status display and parameter setting

for ROM versions after BO

3.4 Spindle control monitor on NC CRT dispaly

. . . .

when FR-SFJ is connected to M300 CNC

through bus line

3.5 Spindle control monitor on NC CRT display

. . . .

when FR-SFJ is not connected to M300

CNC through bus line

3.6 Test operation

3.7 Adjustment of motor speed

3.8 Adjustment of oriented spindle stop function

3.9 Parameter list

4. CARD SETTINGS AND CHECK TERMINALS

4.1

Card SFJ-CA1

4.2

Card SF-ORJ

4.3

Card SF-TLJ

4.4 Card SF-DAJ

5. ADDITION AND REPLACEMENT OF COMPONENT

5.1 Addition of option card (SF-ORJ, SF-DAJ and

SF-TLJ)

5.2 Replacement of card

5.3 Replacement of ROM

5.4 Replacement of diode moduie and transistor

module

. . . . .

2C

. . . . .

26

. . . . .

29

. . . . .

32

. . . . .

32

. . . . .

34

. . . . .

42

. . . . .

50

. . . . .

50

. . . . .

55

. . . . .

56

. . . . .

57

. . . . .

58

. . . . .

58

. . . . .

59

. . . . .

60

. . . . .

61

5.5 Disassembly and assembly of SJ-J type AC spindle motor

. . . . .

63

-

1/2-

6.

INSTALLATICN OF ORIENTED SPINDLE STOP POSITION

DETECTOR

6.1 Magnesensor l-point oriented spindle stop

7.

DISCHARGE RESISTOR UNIT

a.

TROUBLESHOOTING

a.1

General information

,a.2

First step of troubleshooting

a.3

Second step of troubleshooting

8.4 Alarm and warning table

a.5

"Alarm/warning"

display by LED readout

9. PERIODIC INSPECTION

9.1

Inspection of control equipment

9.2

Inspection of motor

9.3

Inspection of discharge resistor unit

10. PARTS LIST

. . . . .

72

. . . . .

72

. . . . .

a2

. . . . .

a3

. . . . .

a3

. . . . .

a4

. . . . .

86

. . . . .

a9

. . . . .

94

. . . .

115

. . . .

115

. . . .

116

. . . .

ii8

. . . .

119

-2/2-

$1.

GENERAL

1.1

Introduction

AC spindle drive unit, FR-SFJ series, is the inverter use,?

,-

to control a machine tool spindle drive AC motor.

It is capable of

contro.lling

widely ranged motor speeds ac-

curately and quietly.

Discharge resistors are

connectec t-:

the drive unit to disperse regenerative energy for regenerative braking of motor.

This manual mainly describes periodic maintenance and trou-

bleshooting which are very important to assure successful

use of your AC spindle

drive.unit.

1.2

Safety during

maitenance

and troubleshooting

The maintenance and troubleshooting should be done with the

following safety consideration:

o The control system should be maintained and remedied by

qualified electrician.

o When a person who maintains or remedy the control system

must touch a part of control system under live condition,

he should take off finger ring, wristwatch, necktie pin,

and other metallic goods before starting the work.

o Electric shock may cause fatal accident.

When a circuit at high voltage must be checked, due care

should be taken to select appropriate test/inspection

equipment, tools, etc.

and to use them safetly (no matter

whether or not the circuit is grounded).

When a test equipment is applied to a part, component, or

circuit of the unit,

operator should pay attention not to

touch a grounded part.

In general,

test equipment should not be grounded.

During test or measurement, it is likely that high voltage

is present across the test equipment and the ground.

When motor is run during adjustment or remedy, due care

should be taken in this respect.

o Person who carries out maintenance or remedy of rotative

machinery should not wear loosely (otherwise loose wear

-

l-

might be involved into the running machine.

o DO NOT TURN OFF THE POWER IMMEDIATELY AFTER OPERATION IS

TERMINATED.

THE UNIT SHOULD BE HELD TURNED ON FOR AT

LEAST 10 MIN.

FOR COOLING THE DISCHARGE RESISTOR UNIT

(BY COOLING FAN), AFTER THE OPERATION.

IF THE DRIVE UNIT IS TURNED OFF IMMEDIATELY AFTER THE

TERMINATION OF OPERATION, THE RESISTOR UNIT COOLING FAN

STOPS AND RESIDUAL HEAT, OF RESISTOR UNIT MIGHT CAUSE BURN-

ING OR DAMAGE TO OTHER COMPONENTS OF DRIVE UNIT.

o Do not touch the drive unit immediately after the opera-

tion is terminated (maintenance or remedy should be started in about 5 min.

after the operation is terminated).

1.3

Storage

When your AC spindle drive unit is not used, store it in

clean and dry environment.

Note that humidity and dust entering into the control unit

may adversely affect insulation resistance of the drive unit.

When your, AC spindle drive unit is left out of operation for

any length of time,

the same cautions should be taken.

It is recommended,

if the storage is humid, to use a heater

to keep the environment dry.

.

-

2

-

f-

c

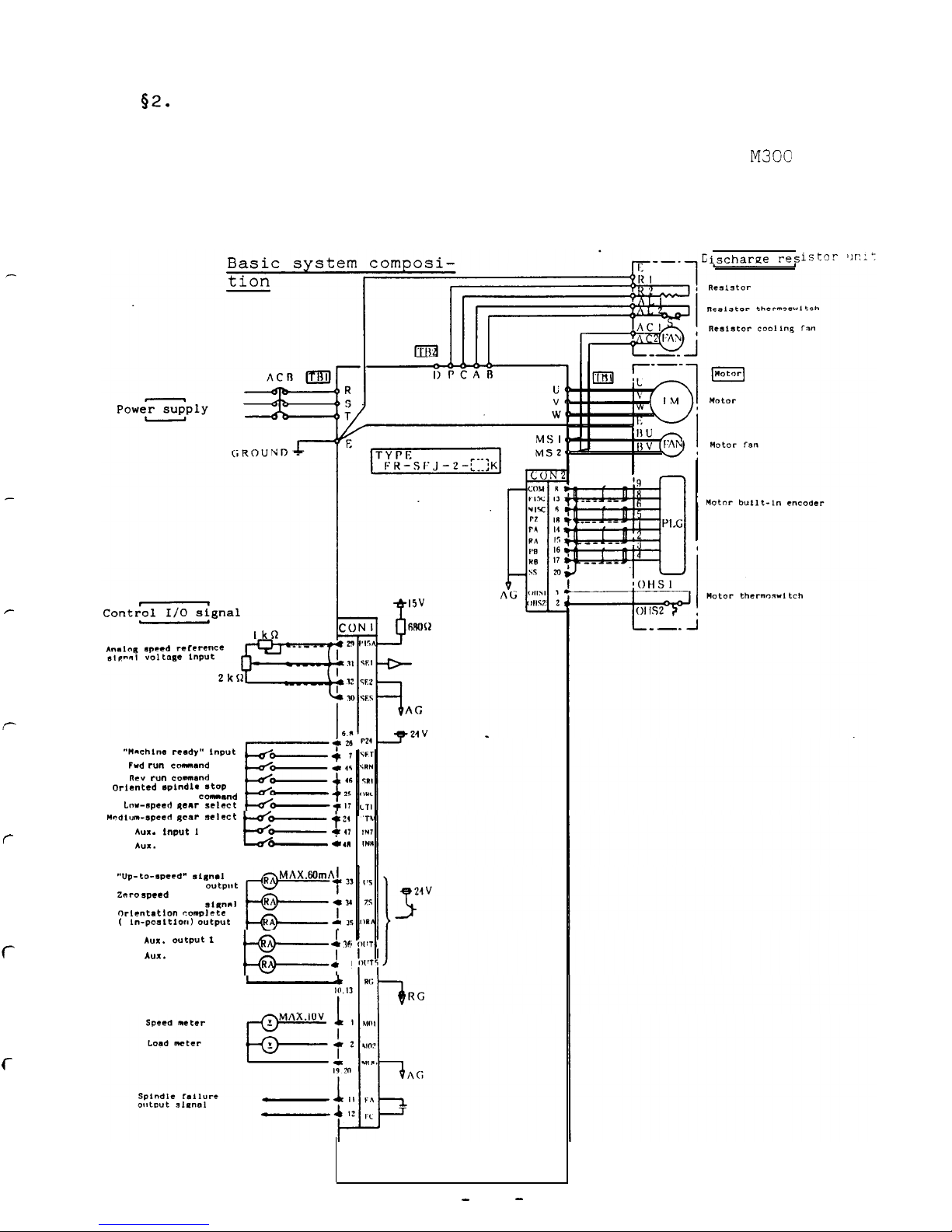

92.

WIRING

2.1

External wiring

2.1.1 Control system.where FR-SFJ is not connected

through bus line

a. Analog speed reference

signal

“““chins rc*dy” Input

FWd

r””

command

R.3” run

command

orlsnttd

eplndl*

atoP

commmd

I.“*-spewi qsllr

select

“rdlum-specrl

genr select

AUI .

Input I

E

Yir:

AUX.

input 2

A

C4I

I

“Up-to-speed”

st.m.1

O”tpUt

Zero

speed

output

5111”“1

“rlcntation complete

(

In-po~ltIorl)

output

-

AUX.

output

1

I

.

36

*“I.

output 2

Is=_

R

I

e

21

to

M300

Nischarne r-es

-

3

-

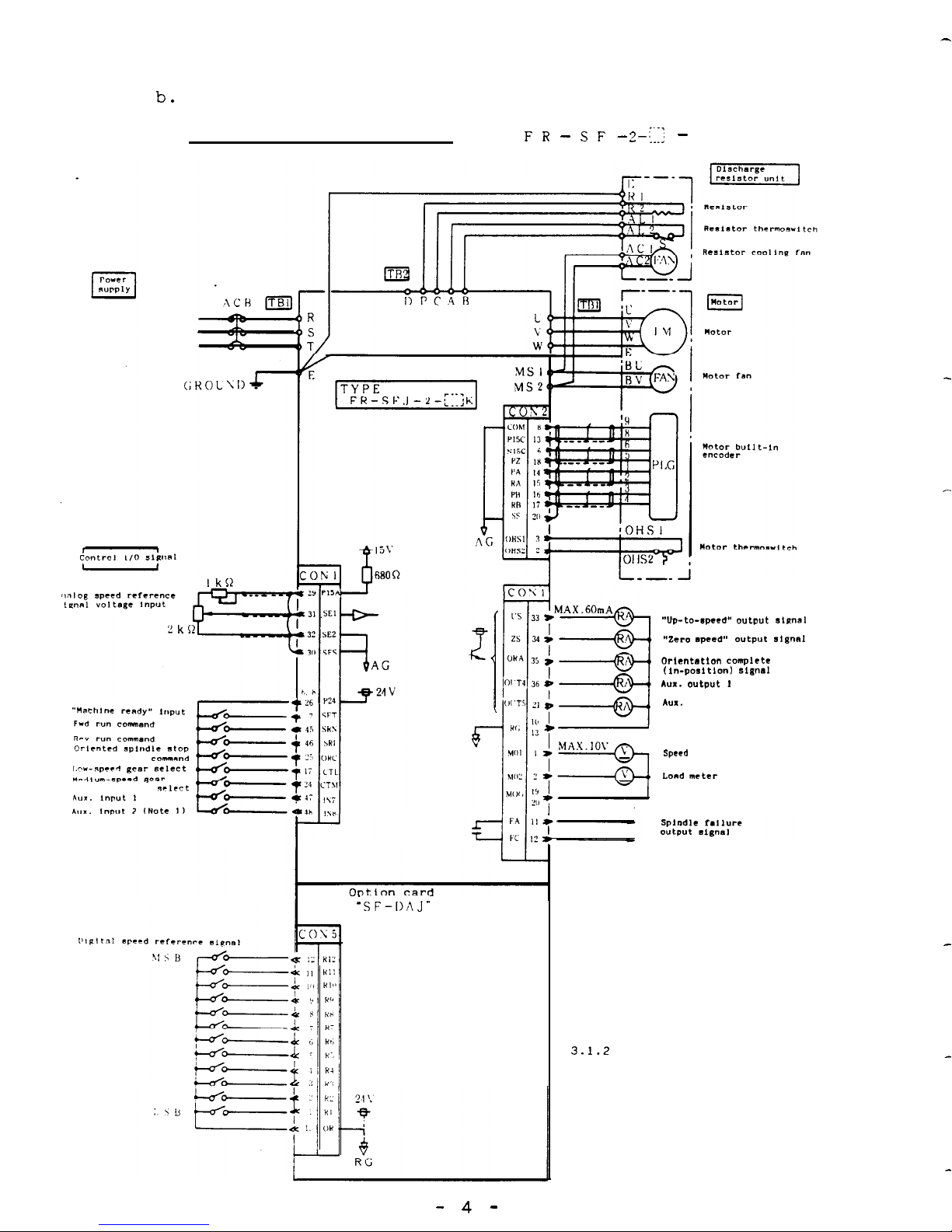

b.

Digital speed reference signal (option card SF-DAJ is used)

Basic system composition

F R - S F

J - 2

-;;I;

K - D

“VP-to-epee.9, OUrpUt

aima,

“Zero speed”

output

signal

tJr,entstion ccmplett

(in-porrItIon~ signal

A”X. O”Ip”t

I

A”X.

output 2

speed

meter

Lord rnCtCr

‘SF-DAJ”

Note 1:

This input port is used for speed

reference signal selection

between “analog” and “digital”.

For details,

refer to paragraph

3.1.2

“Auxiliary input signals”

in the Standard Specifications.

- 4 -

f---

c

c

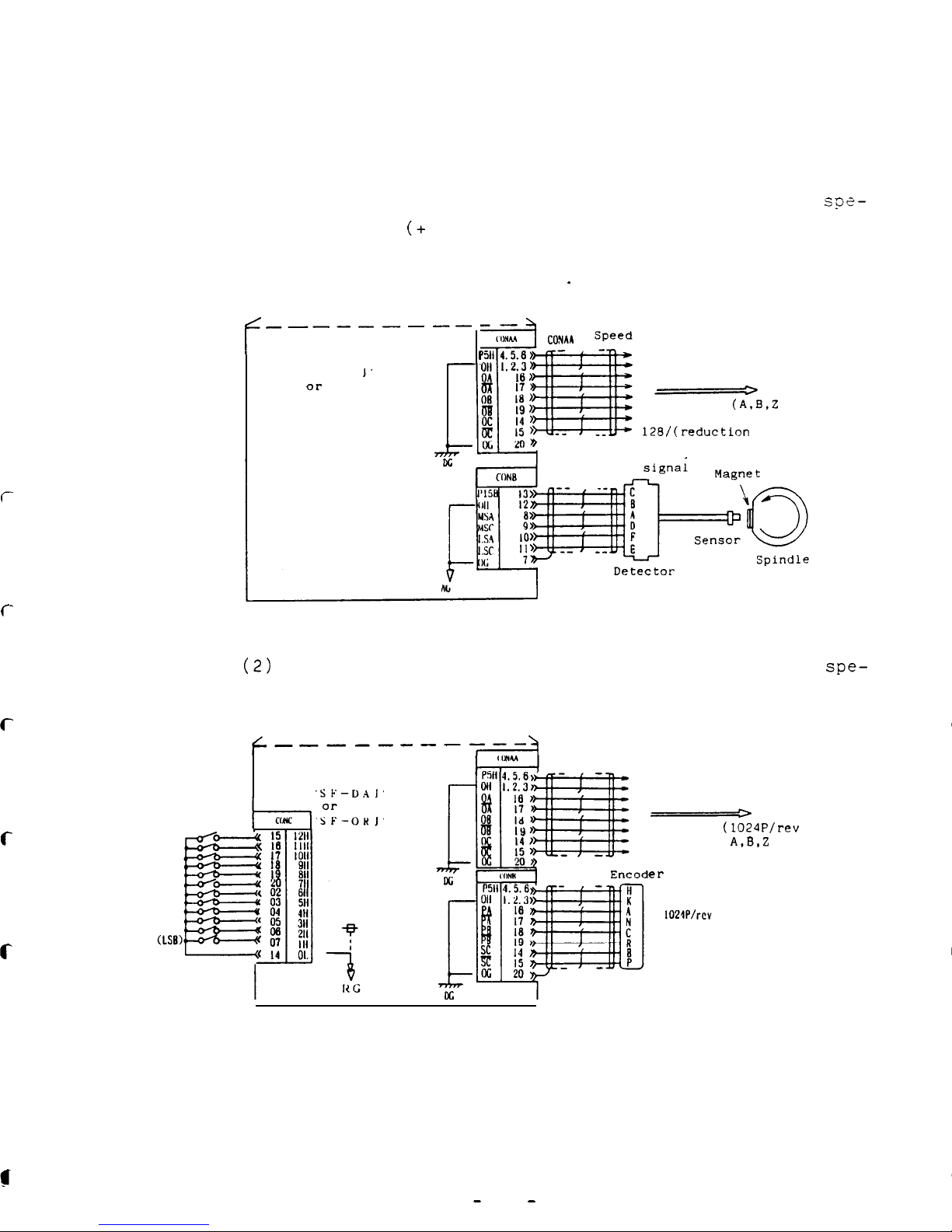

c. Control system equipped with oriented spindle stop func-

tion

A circuit

illustrated below is added to the basic system.

(1) Magnesensor type oriented spindle stop (1 point)

see-

cification (+ motor

speed feedback signal output)

(For spindle speed display/sync. feed

signal)

.

f

_---

---

--

Option card

I

‘SF-DA

1’

OI-

'SF-OHJ'

.!.

_^

Maqnesensor

display/sync. feed signal

_____h

To NC

(A.B,Z

phases)

Pulse nu Number of pulses is

128/(reduction ratio).

detect

Magnesensor

(2)

Encoder type oriented spindle stop (4096

cification,

equipped with index function

+_----_--_T_~

points)

spe-

Option card

'SF-D41'

Oriented stop

position command

Speed display/sync. feed signal

e

To NC

(1024P/rev

A.B.2

phases)

er

detect signal

-

5

-

(3)

Z-phase controlled motor built-in encoder type ori-

ented spindle stop (4096 points) specification, equipped with index function

Motor detector signal

_______----------

Option card

'iented

spindle

'5

F-DA

1’

top

position

ed display/sync. feed signal

Tmmand

SF-OKJ'

-----hTo

NC

(128P/rev

A,B,Z

phases)

-.

-

6

-

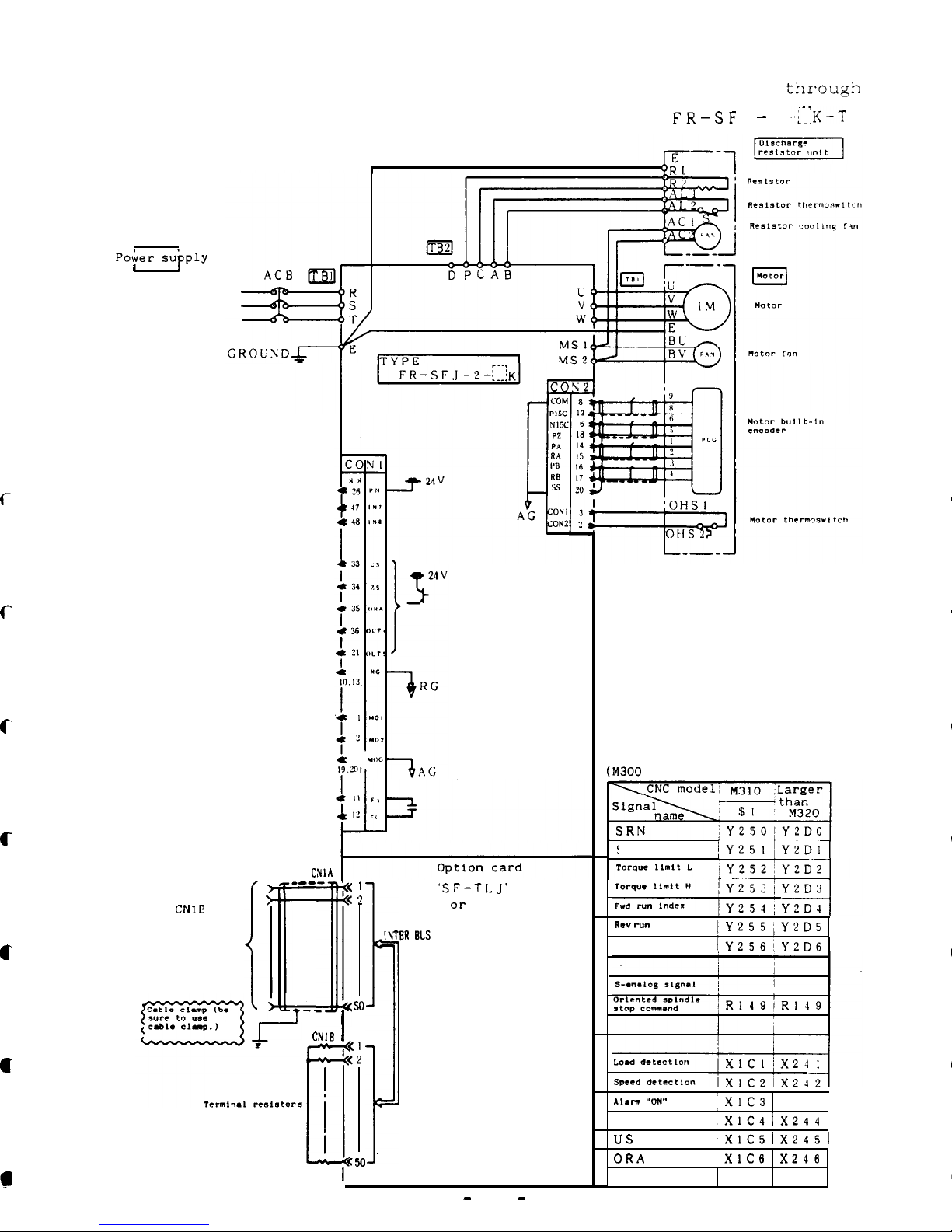

2.1.2 Control system where FR-SFJ is connected to M300

,through

bus line (option card SF-TLJ is used)

FR-SF

J - 2

$K-T

a. Basic system composition

I

QR

I

I

Poker supply

I

J

Connection is not

required for CON1

signal in usual

operation.

c

c

c

I/O signal assignment

CM300

series interface)

c

SRI

jY251~Y2DI

CNI

____

A

‘<

1

‘<

2

,I

IVEIl

I

so

CNll7 ,

‘<2

!

le

7

:

'SF-TL.J'

Ot-

'SF-RSJ'

To

CNlB

of

final axis

MR-S servo

amplifier

Rev

run Index

/Y255;Y2D5

ORC

lY256!Y2D6

BLS

c

*,.rm

“on”

jXIC3

X243

ZS

IXIC4/X244

us

lxlc5ix2451

ORA

/XlC61X246

J

-

7

-

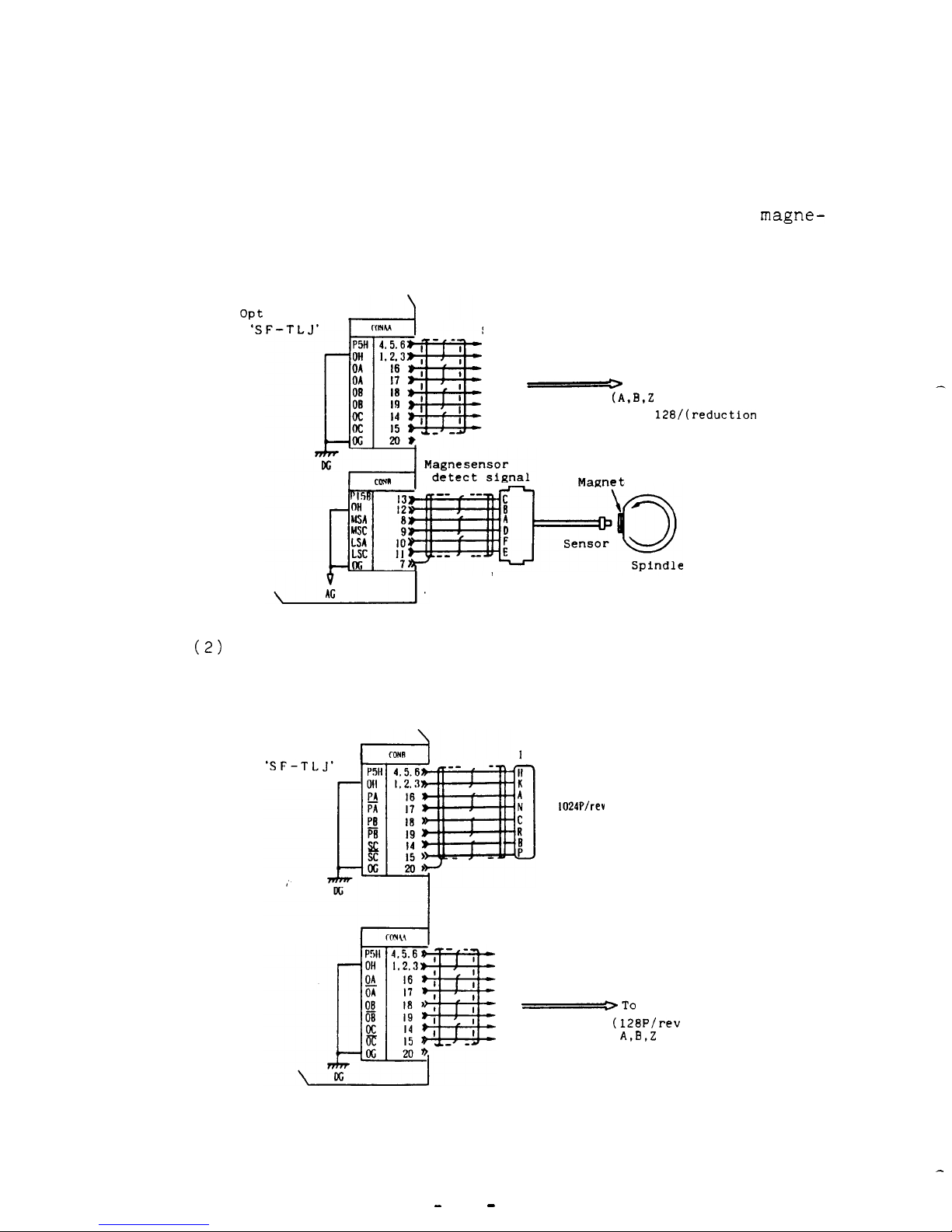

b.

Control system equipped with oriented spindle stop func-

tion

A circuit illustrated below is added to the basic system.

(1) Motor built-in encoder high-speed sync. TAP and

magne-

sensor type oriented spindle stop (1 point) specification

Opt

'S

ion card

Speed display/sync. feed signal

-

To NC

(A.El.2

phases)

Number of pulses is

128/(reduction

ratio).

Magnet

Detector

Magnesensor

(2)

Encoder high-speed

sync.

TAP and multi-point (4096

points) oriented spindle stop specification, equipped

with 'index function

Option card

Encoder detect signal

1024P/rev

Speed display/sync. feed signal

-To

NC

(128P/rev

A,B.Z

phases)

-

8

-

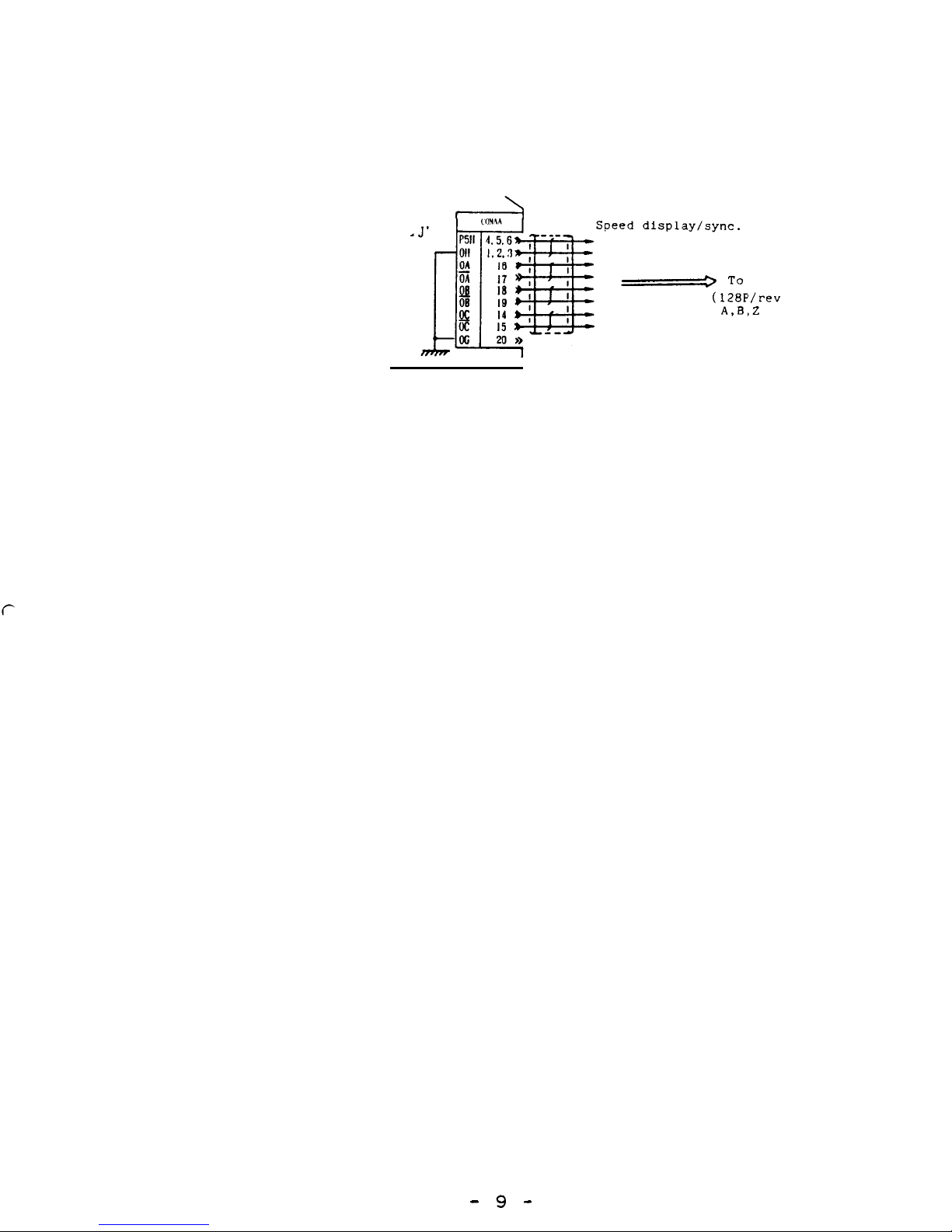

(3) Z-phase controlled motor built-in encoder high-speed

sync.

TAP and multi-point oriented spindle stop spe-

cification,

equipped with index function

Option

‘SF-71

card

A

-

To

NC

(128P

‘/rev

A,B,

,Z

phases)

feed signal

- 9 -

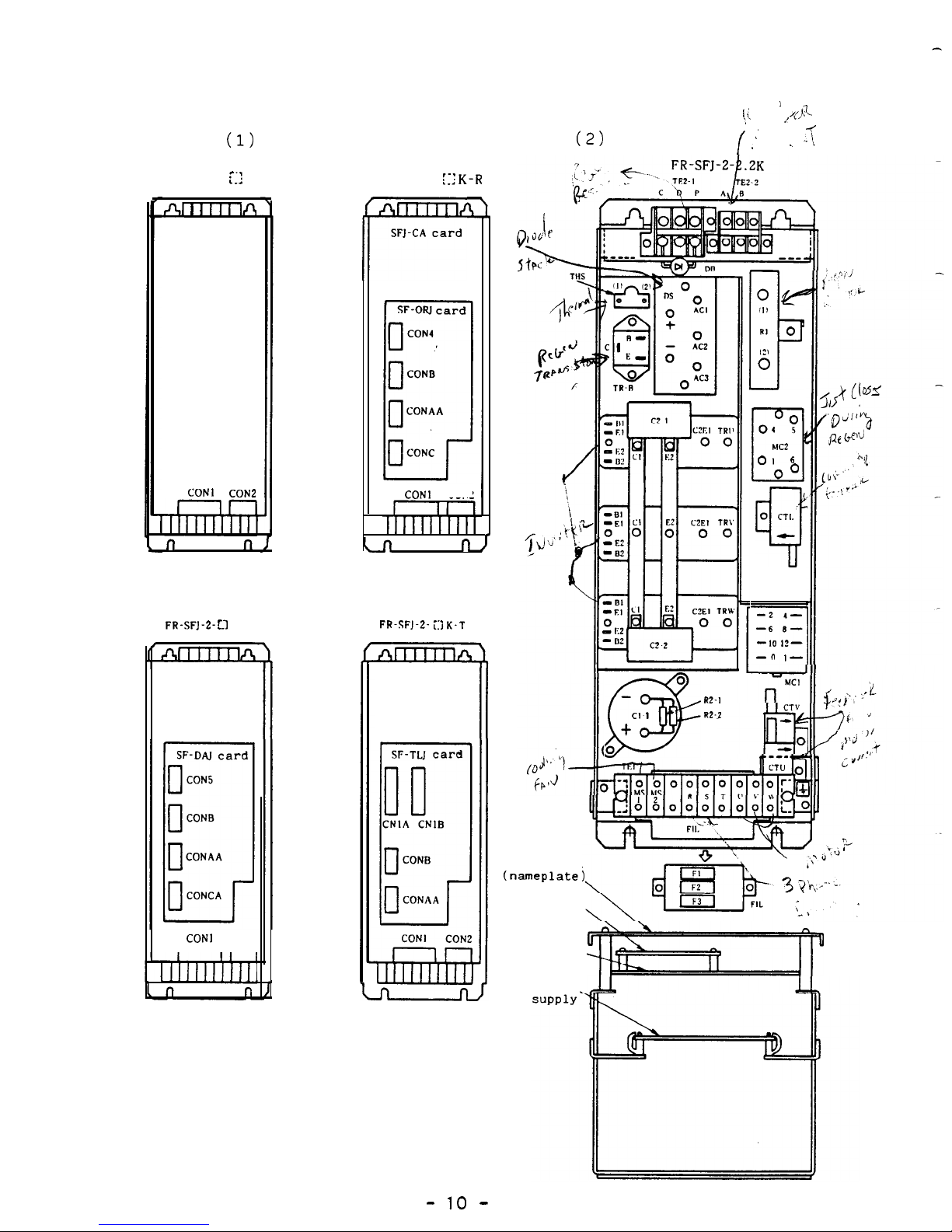

2.2 Parts arrangement

(1)

SFJ-CA card and option

card

1

‘,’

,,

,&

(2)

Main board

L

f I’

\ -1

FR-SFJ-2-

:::

K

fit 1 1 II1lA

SFI-CA card

FR-SFJ-2-

:::K-R

SFJ-CA card

r

Option

CON1 CON2

In

n,

r

OP

II!

b

RI

0

6

04 ?

Et

MC2

01

6

O0

0 Cfl.

%f

-2

I-

-6 .3-

1

-10 12-

-” ,-

CON1

CON2

n

n

FR-SFJ-2- Ll K-D

FR-SFJ-2-

i:IK-T

SFJ-CA card SFJ-CA card

option

0

@

w-1

Cl

I

R2.2

t

0

CTV

IQ?

0

Option

Front

panel

(namer

Ilate)

Option card

Card SFJ-CA

z

CON1

CON2

nn

r

IP-PM power

-

10

-

c

c

c

c

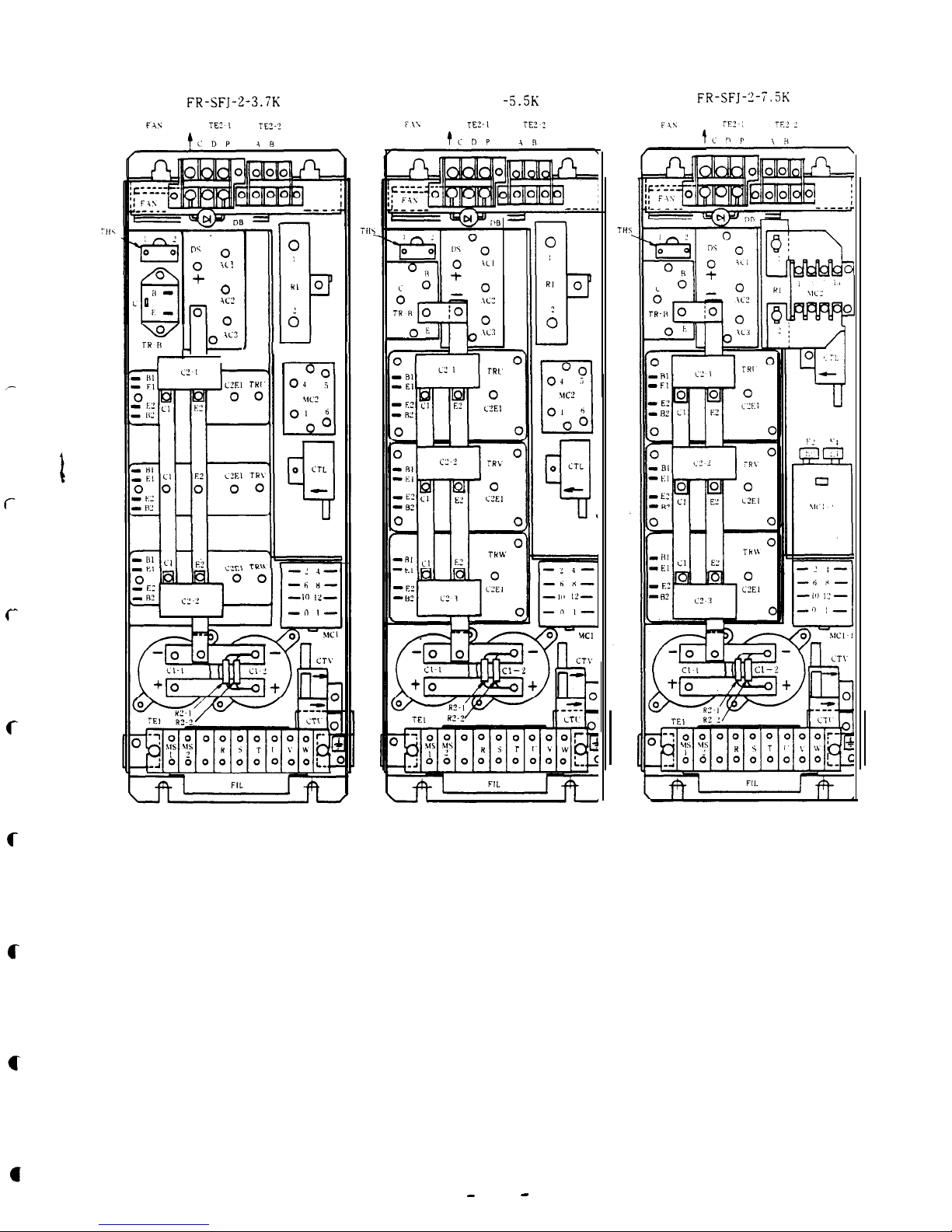

FR-SFJ-Z-3.7K

0

“\

0

:

3‘ !

0

KL’

0

1

l-l-

.c?

J

I

I

’

-L 4-

-Ii

n-

-111

,z-

-n ,-

FR-SFJ- -5.5K

-

11

-

$3.

ADJUSTMENT

3.1

Preliminary check

Before turning on FR-SFJ, perform the following check:

(1) Is the external wiring in conformity with the relevant

wiring diagram?

(2) Are the motor and the drive unit grounded properly?

(3) Are all shielding wires terminated properly?

o Is each shield

armour

connected to the corresponding

terminal'?

o Is each shield

armour

not looped?

(4)

Is any component or part not loose?

(5) Is any foreign matter is not involved in the drive unit?

(6) Is there any damage or defect on

each,P.C.

board?

(7) Do ROM No.

and jumper pin settings meet the order sheet?

-

12

-

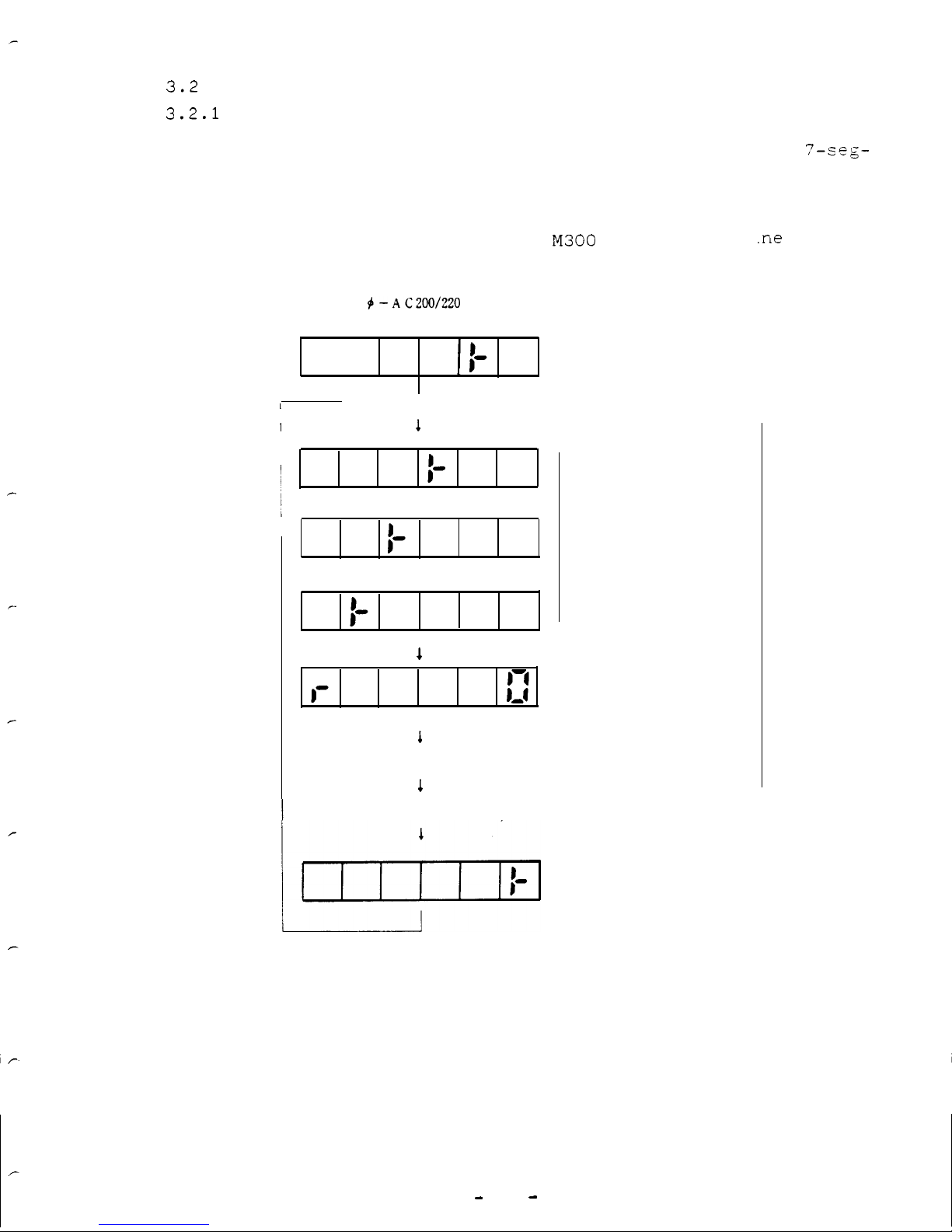

3.2

Power feeding

3.2.1

Turning on the power

Immediately after the FR-SFJ is turned on, see the

?-seg-

.ment LED readout at the center of front panel to check

conditions:

(1) For FR-SFJ connected to

M300

through bus 1

.ne

3

4-AC200/220

ON

1

I

1

+ NC power is turned on.

I

1

1

1

Normal operation

1

NC power is turned off.

Wait for turning on NC power

Initial data communication with NC (momentary

display)

Initial data communication

complete

Wait for "ready ON".

Wait for turning on NC

Alarm code is

displayed in

case of failure.

-

13

-

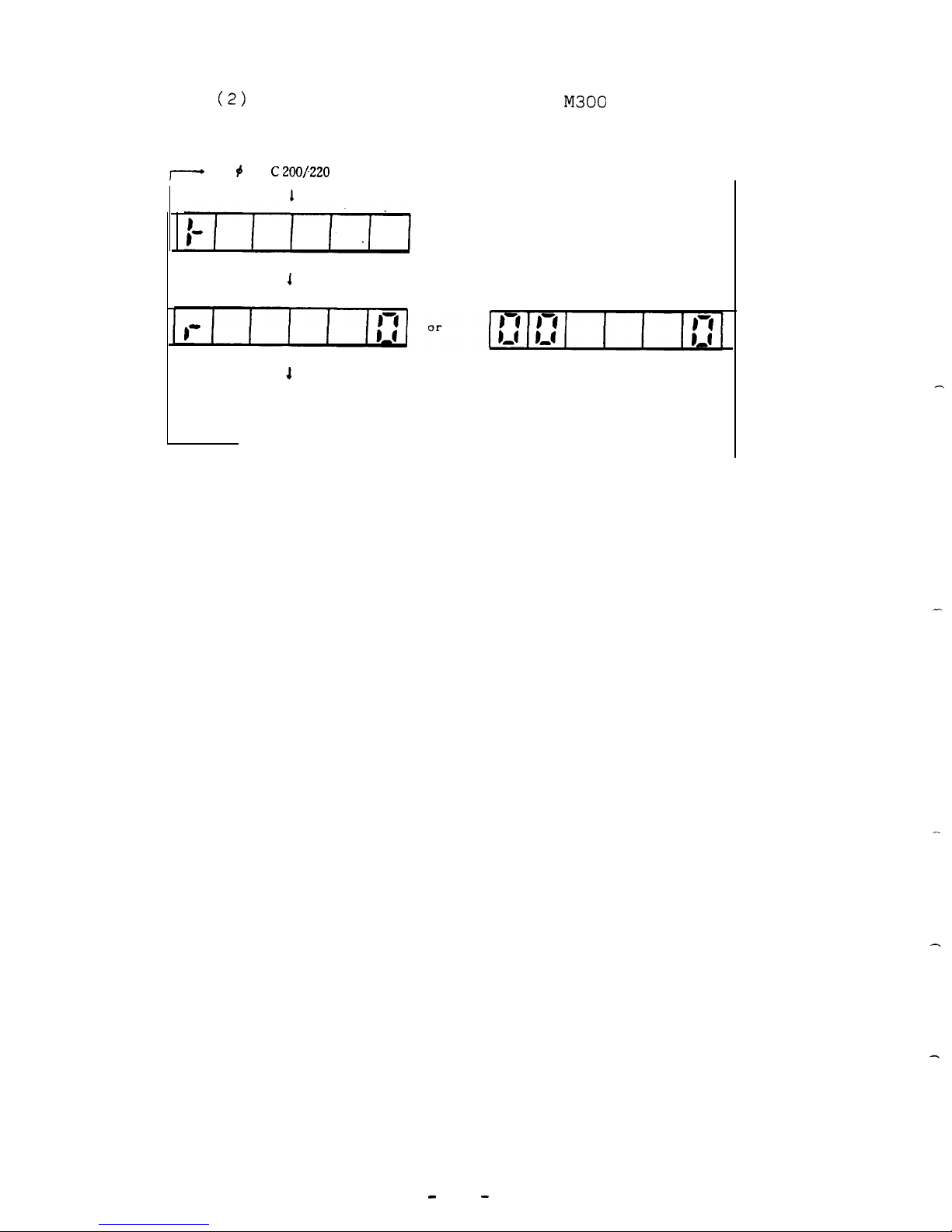

(2)

For FR-SFJ not connected to

M300

I_

3 # -A

C200~220

0 N

1

1

Normal operation

1

Power is turned off.

Alarm code is

displayed in

case of failure.

-

14

-

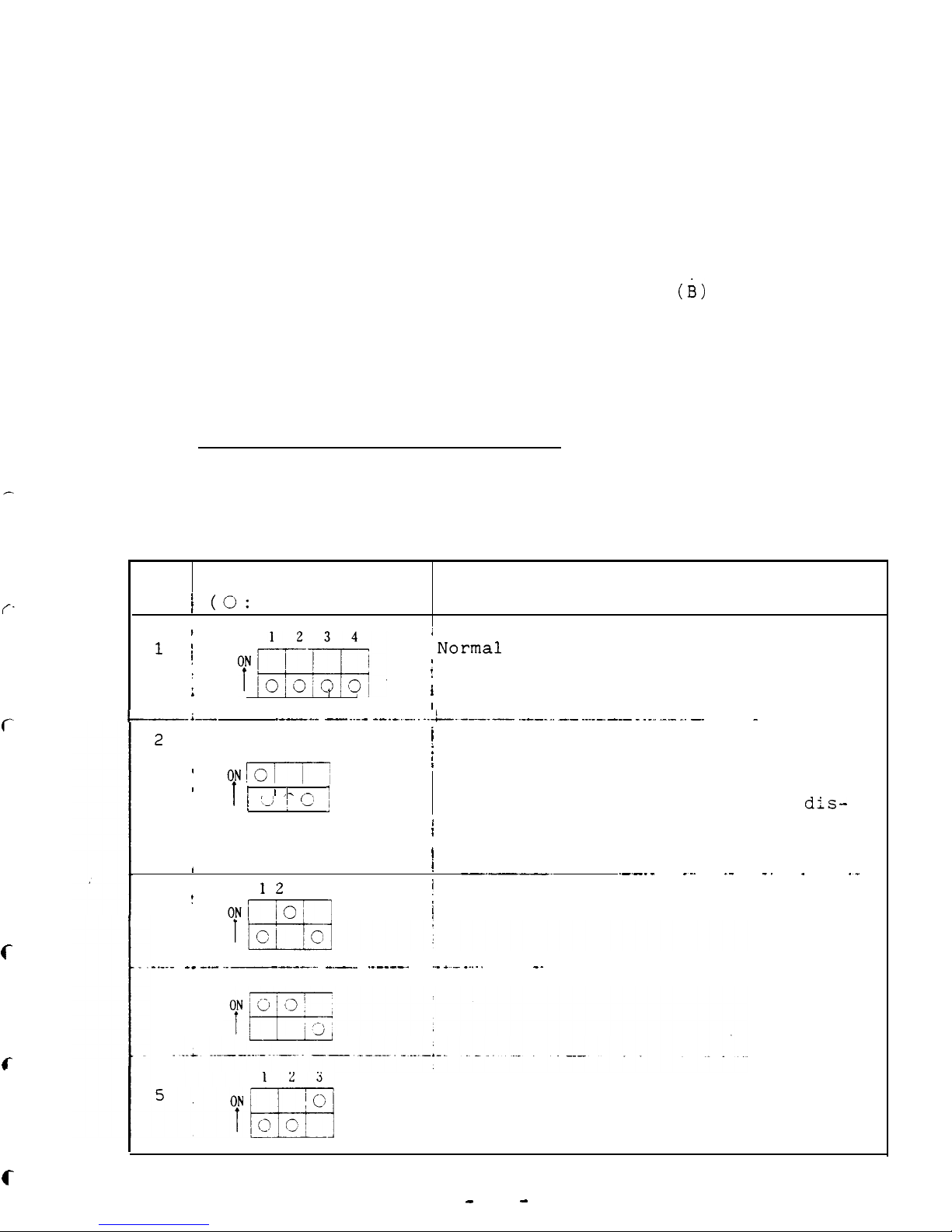

3.3 FR-SFJ status display and parameter settings

c

c

Operation status is displayed by the 7-segment LED readout

on card SFJ-CA1 and parameters can be set by DIP switches.

Status display and parameter settings depend on ROM version

of card SFJ-CA1 card.

For ROM version A@ . . . . .

(A) 3. 3. 1

For ROM version BO and thereafter . . . .

(B)

3. 3. 1

When FR-SFJ is connected to M300 CNC through bus line, sta-

tus can be displayed and parameter can be set on the NC CRT.

(For details,

refer to 3.5.)

DIP switch settings and functions

Since DIP switch settings must be changed only when test operation is required, they should not be changed during normal

operation.

Mode

DIP switch setting

Function

/ (0:

Set position)

1

I

1 j

i

Normal

operation

;

g@$

!

I ,

I

I_i_

_--_._ -.._- _-._._...

.__!_-_-_-_- ._-_.._ -_ __.__-__ ___. ___ _. __

_

2

i

1

2 3

[

Spindle parameters displayed by NC

/

CRT are ignored.

,

ON !o/

I

I

;

I

,-

j ‘A j c ]

When FR-SFJ is connected to M300 CNC,

the spindle parameters set and

dis-

I

I

played on the CNC side are ignored

!

and the parameters set on the FR-SFJ

side are used.

I

!

-.--.

.--__

_.. ._ _. .

._

3

!

1 2

3

I

Setting prohibited (for manufacturer's

1

test operation)

_._._

4

__ __-

-~_--.-.

-.-

._-_--_ .._

&_

_....

-.

1

2 3

Setting prohibited (for manufacturer's

c

-

15

-

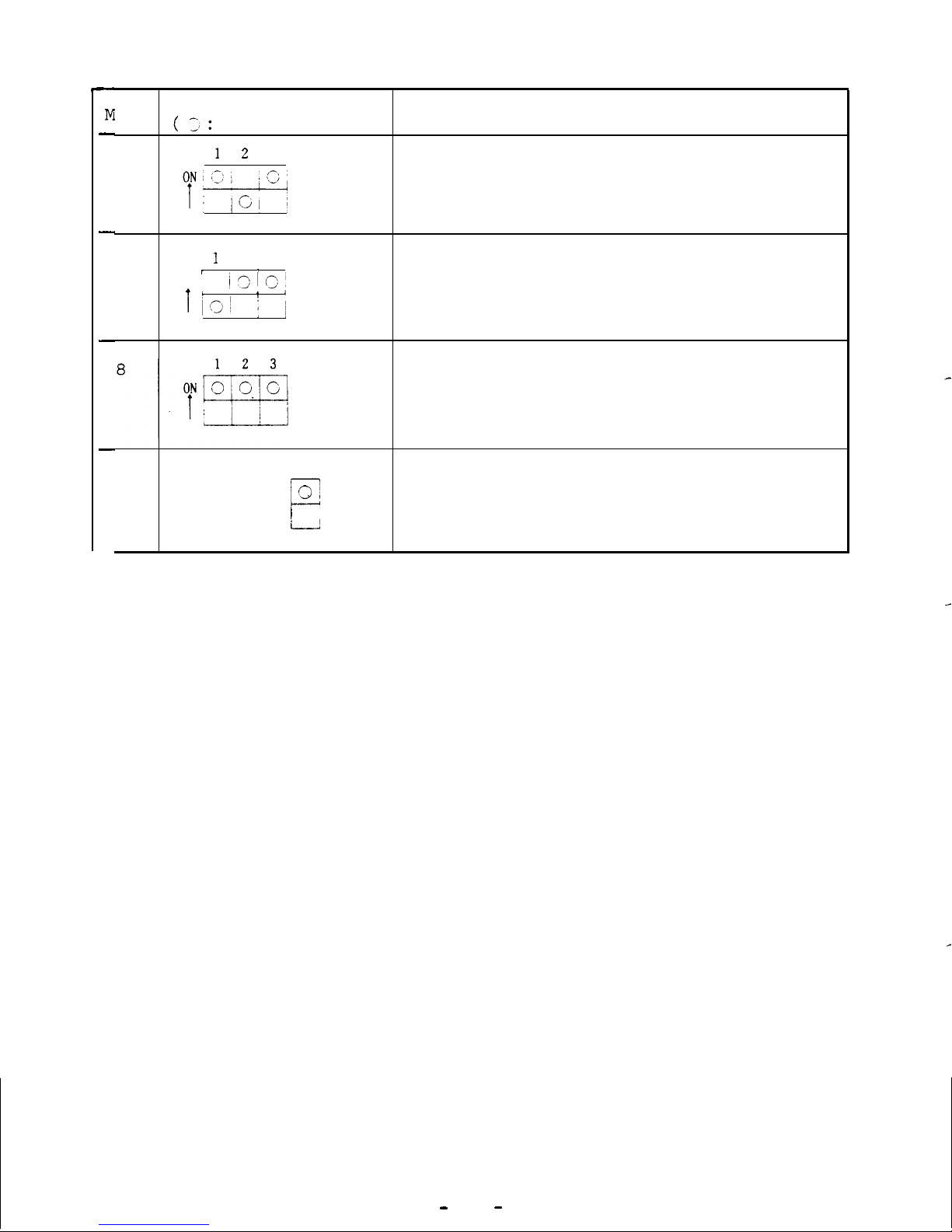

M

-

-

-

-

ode

DIP switch setting

(

3:

Set position)

Function

1

2

3

6

1

2 3

7

I

1

ON; ,

i3lC!

I’

v!

I’JI

’

j j

Initialization of parameters

The standard values (manufacturer's)

are set for all parameters.

User should not use this setting.

9

4

Meter test mode

c

931

Speed meter/load meter output

I

;

(for ROM versions after BO)

-

16

-

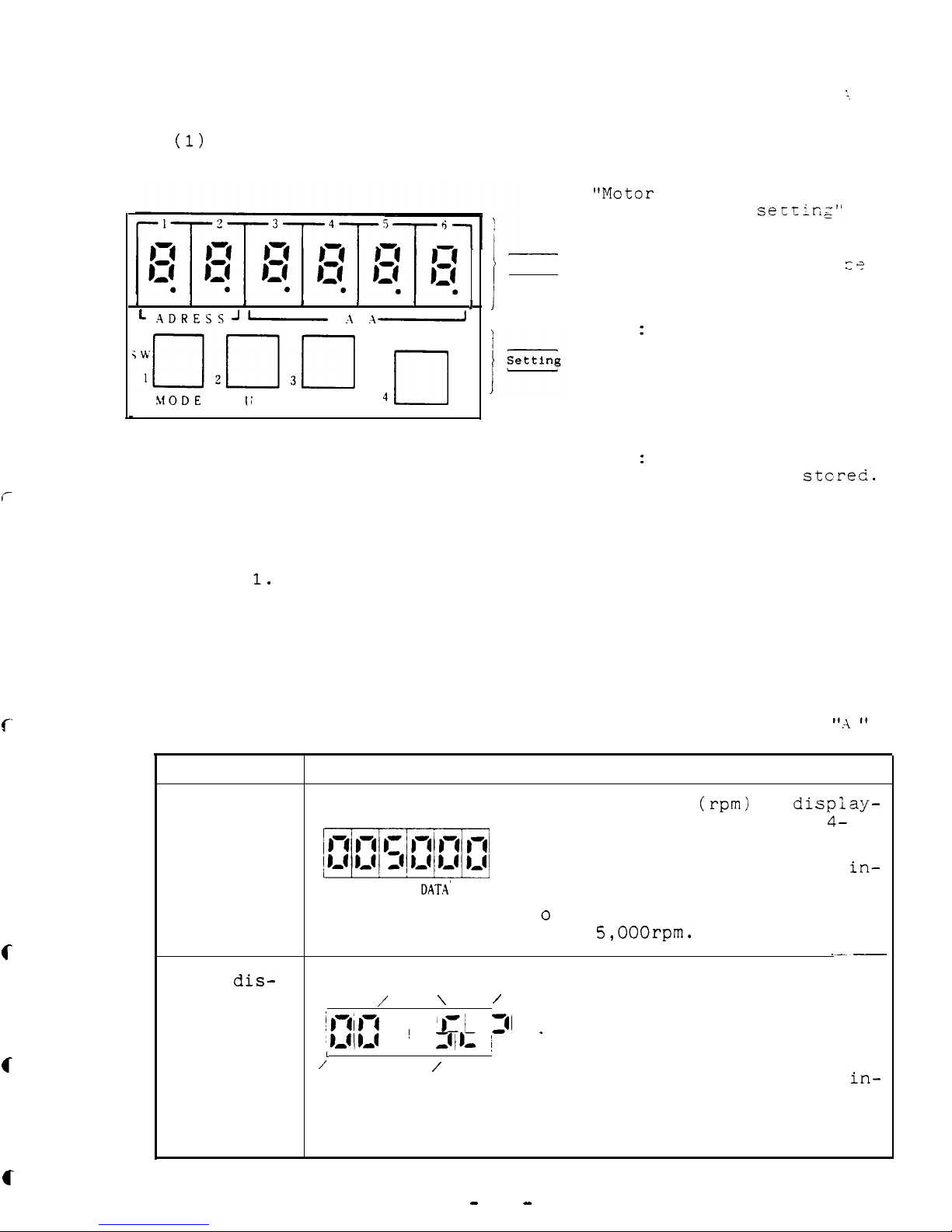

3.3.1 (A)

Status display and parameter setting for ROM version

1

(1)

Readout and switches

I

I

I

I I

I

I

L

ADRESSJ

-

D A T

.A-

clr13~

4n

!dODE

Ii

P

DOWN

SET

"Motor

speed", "alar::"

and

"parameter

seLting"

are displayed.

I-

1

Display

MODE:

Display mode can

c?

selected between

ADDRESS and DATA.

UP

:

Value displayed in

ADDRESS and DATA

can be incremented.

DOWN: Value displayed in

ADDRESS and DATA

can be decremented.

SET

:

Data set for para-

meter can be

stcred.

1) The display modes include "motor speed" display, "alarm"

display, and

"parameter setting",

as described in Table

2) After turning on the power, "motor speed" is displayed

unless alarm occurs.

3) In case of alarm,

alarm code is displayed.

c

c

c

Table 1

Display modes and information for ROM version

I'.\ I'

Display mode

Display example and information

Motor speed

o Motor speed

(rpm)

is

dispiay-

display

mi

ed in DATA section with

4-

digit numerals.

ADD

DAT.A'

o Display in ADD section is

in-

significant.

o In this example, motor speed

is

5,OOOrpm.

Alarm

dis-

o In case of alarm, alarm No.

play

\

/

\

/

and alarm code are displayed

'RI;-!

~

‘,:I

31

.

in DATA section with 2-digit

J/L

~

numerals (for details, refer

1,-

L

to APPENDIX 1).

/

\

/

\

o Display in ADD section is

in-

They flicker.

significant.

o This example shows occurrence

of

"excess error".

-

17

-

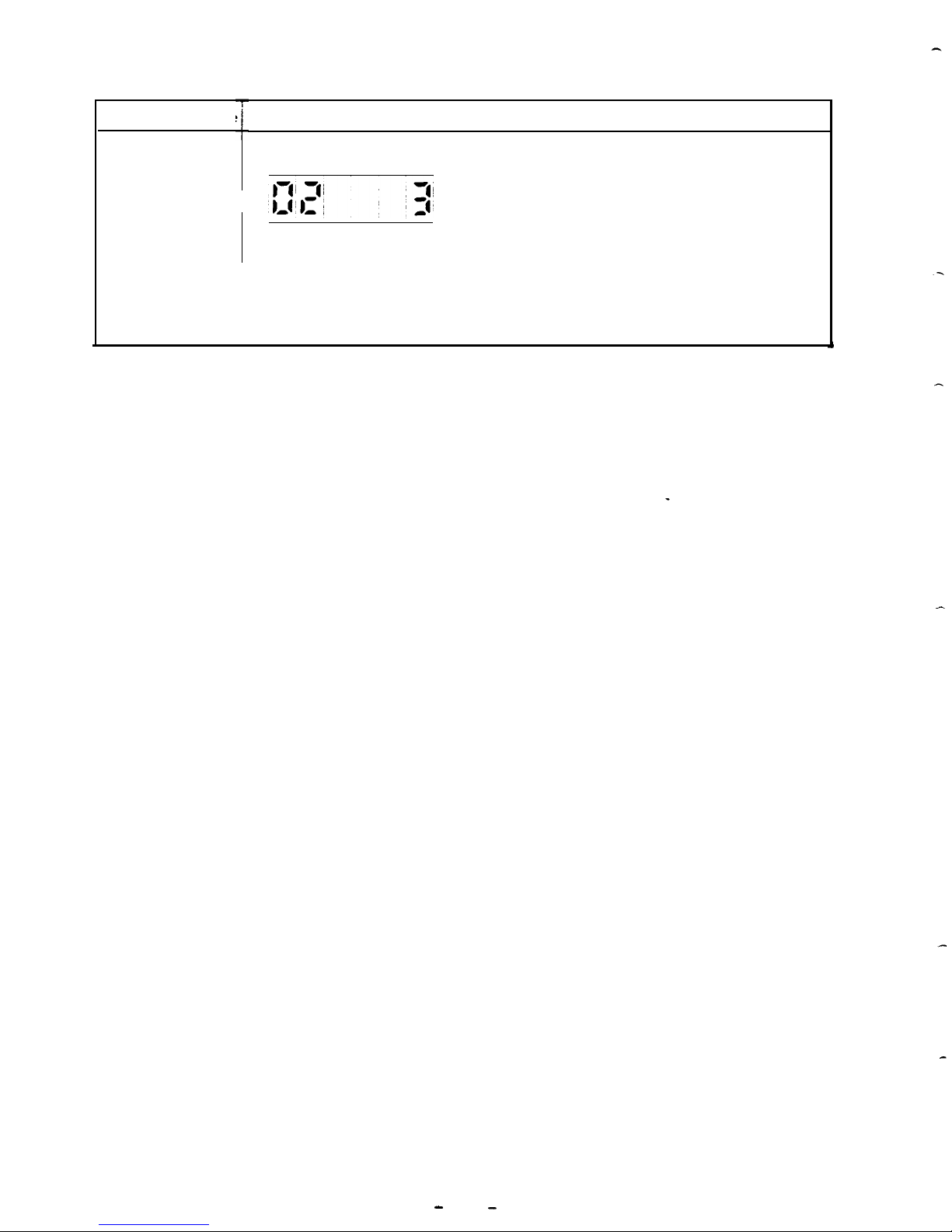

Display mode

Parameter

display

Display example and information

0

0

0

Parameter address (parameter

No.) and data value are dis-

played in ADD and DATA re-

spectively.

For methods of setting para-

meter,

and checking set para-

meter,

refer to the next page.

For details of each parameter,

refer to 3.9.

1

-

18

-

f

(2) Parameter setting

Set parameters with READY signal (SET) turned off.

o Motor speed is displayed

(Fig.

1) when alarm does

not occur.

ADD

DATA

Fig.

1 Motor speed

display

0 Each time @ switch is pressed, ADDRESS and

DATA alternate.

'0

Desired address can be selected in ADD section

Selecting the

by pressing

morH

switch.

Data at the

selected

address is displayed in DATA section.

(G&p->

Note:

If display in ADD

section does not

change,

but DATA

f;;=$$;~~:,

press w switch

t;

Fig. 2

I

1

*

changemode

from

DATA to ADDRESS.

(Data at address

"02 II

is displayed

Ex.:

In example shown

in **.)

in Fig. 1, ADD dis-

play changes to

S

I

when

cl

UP

switch is

pressed, and to

SZ

when the switch is

pressed again (Fig. 2).

o Display in

DATA section can be incremented

or decremented by pressing

@*or @

switch.

to set desired value for DA

o E;tB;zzsing a switch, the set data can be

.

o After the desired data has been set, press

mlfll

E

switch on card SFJ-CA1 or turn off and

en on the power to reset FR-SFJ.

Now data setting (parameter setting) has been

completed.

f

-

19

-

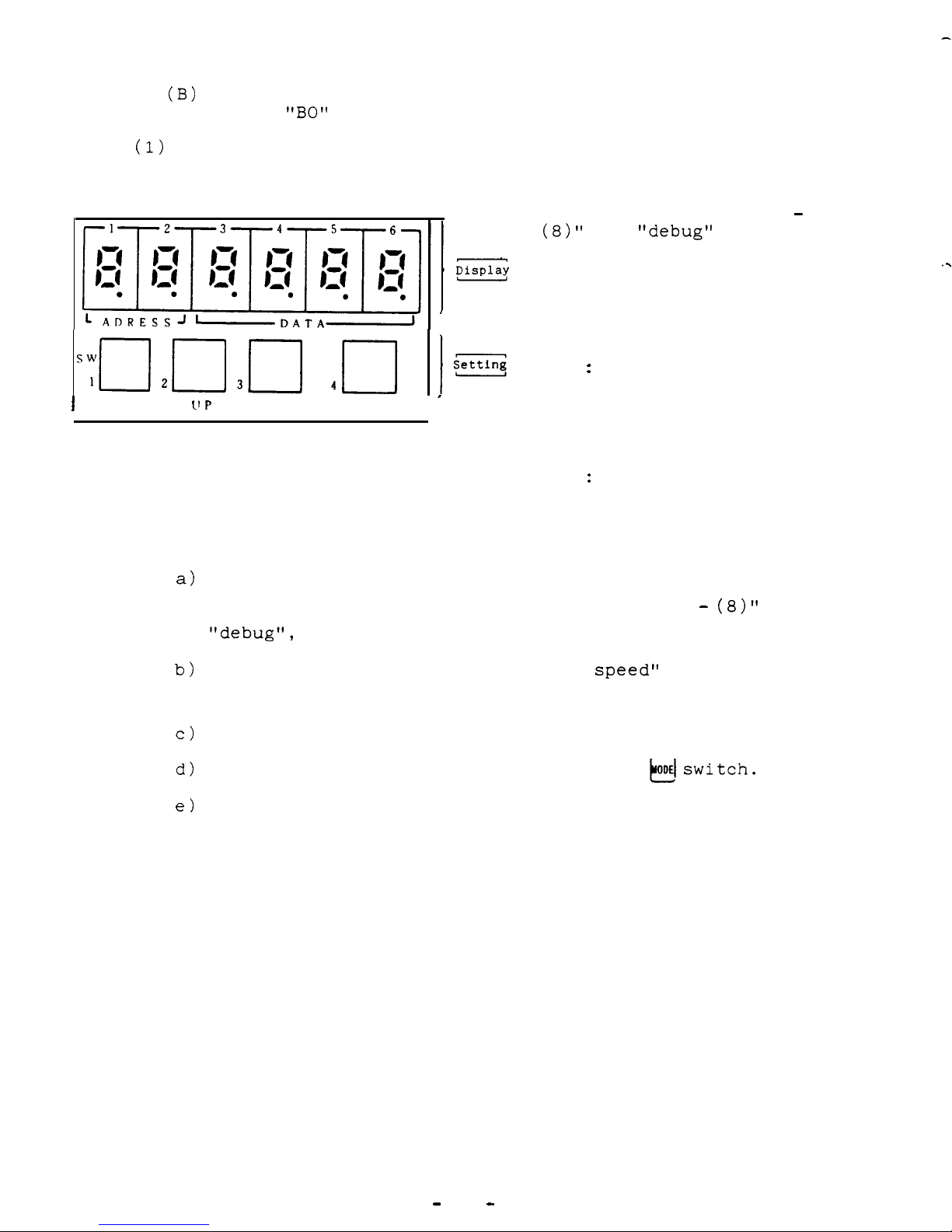

3.3.1

(B)

Status display and parameter setting for ROM versions

after

"BO"

(1)

Readout and switches

I

MODE

If P

DOWN

SET

I

’

Located on card SFJ-CA1

a)

b)

c)

d)

e)

"Operation status",

"dia-

gnosis",

"error alarm",

"parameter setting (1)

-

(8)"

and

"debug"

can be

displayed.

Function of each switch is

as follows:

MODE:

UP

:

DOWN:

SET

:

Display mode can be

changed.

Value displayed in

ADDRESS and DATA can

be incremented.

Value displayed in

ADDRESS and DATA can

be decremented.

Data set for parameter is stored when

this switch is pressed.

12 display modes, namely, "operation status", "diagnosis",

"error alarm",

"parameter setting (1) -

(8)"

and

"debug",

are selectable.

After turning on the power, "motor

speed"

is displayed

automatically unless alarm occurs.

In case of alarm, alarm code is displayed.

Display mode can be changed by pressing

kdswitch.

For display mode sequence and display content, refer

to the chart on the next page.

. .

-

20

-

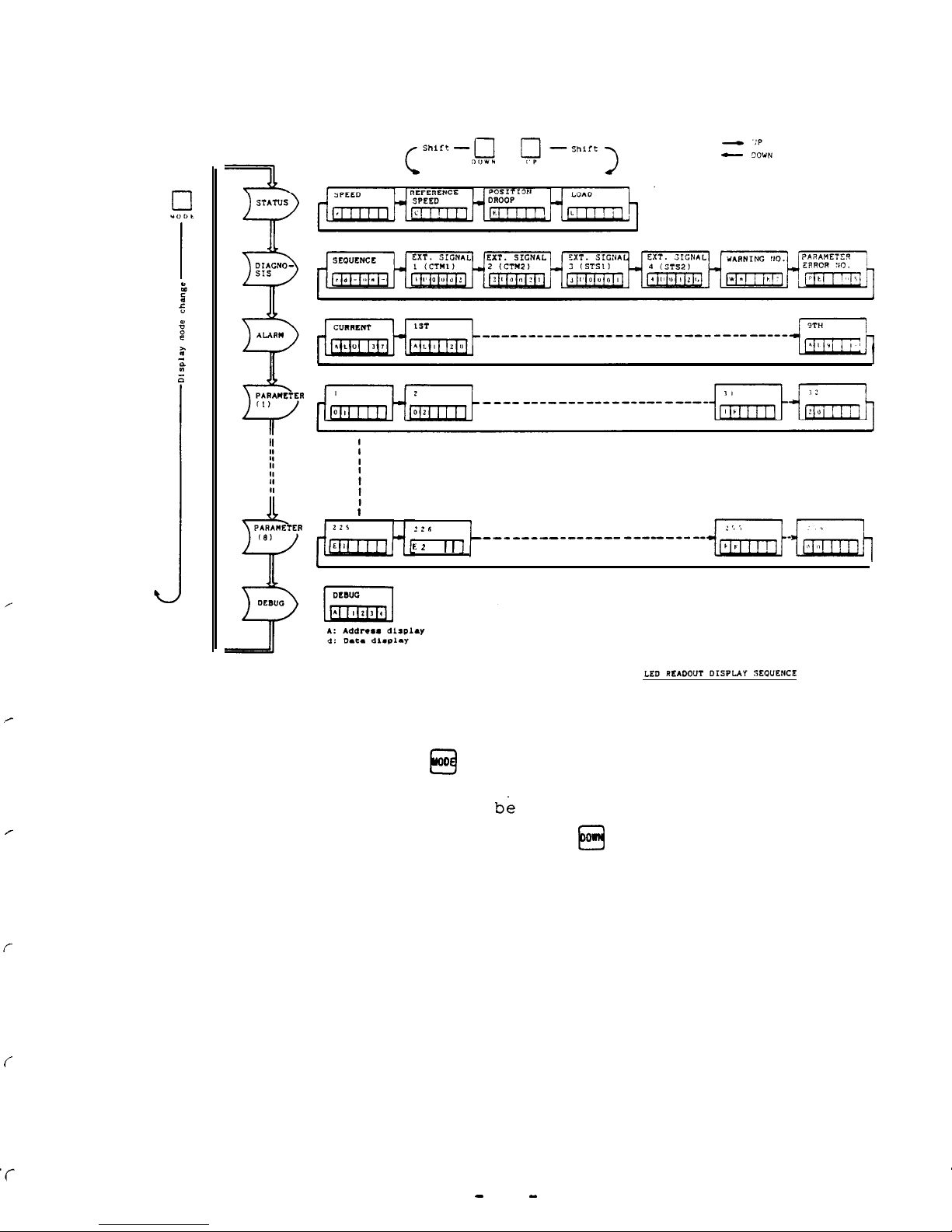

(2) Readout display mode sequence

1

L

2

, , ]

t_______-________________~~~_~~~

o Display mode can be selected in the sequence shown above

by pressing

EEI

D

switch.

o Display content can be changed within the same'display

mode by pressing UP or o

0

El

switch.

f

-

21

-

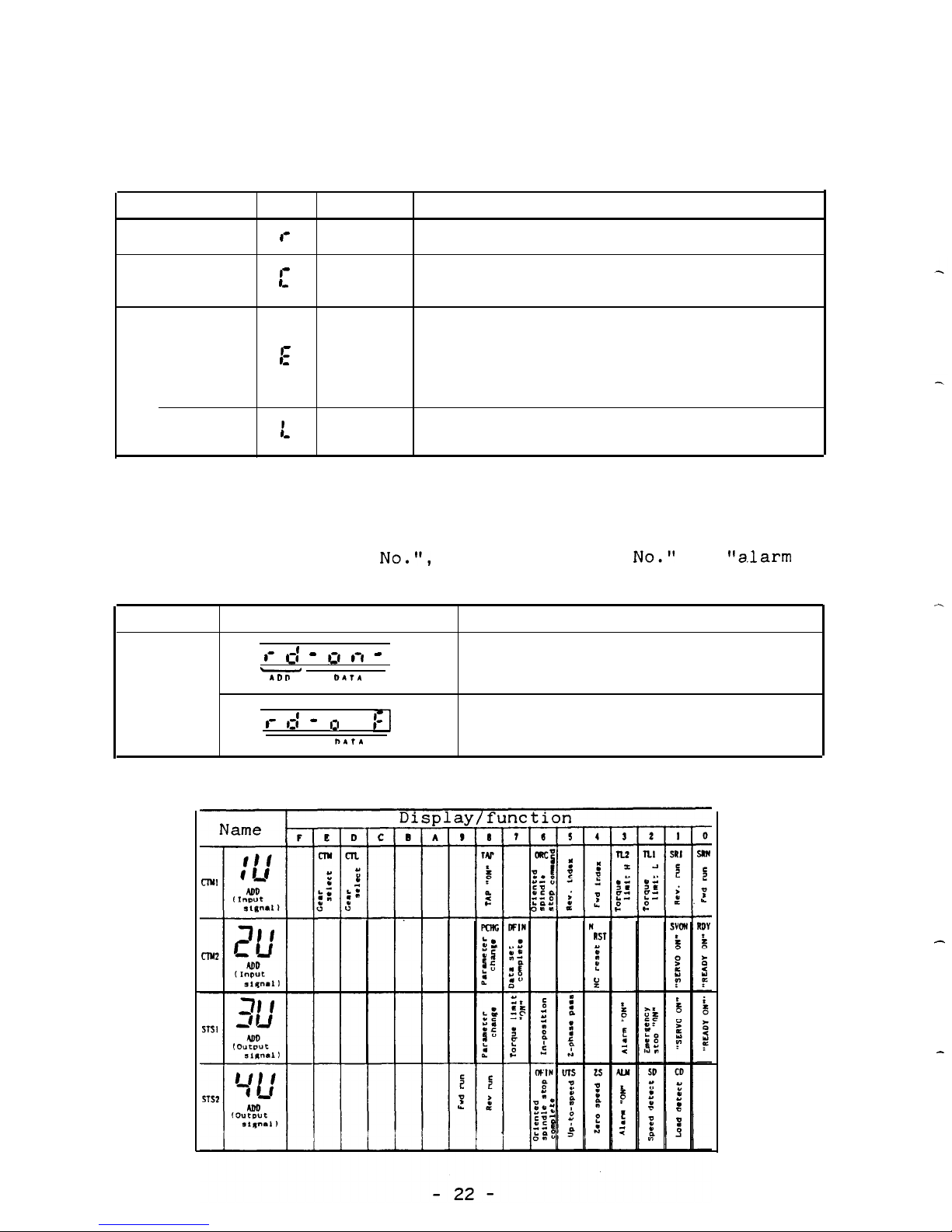

(3) Operation status display mode

In operation status display mode,

codes listed below are

displayed.

Item

Code

Unit

Description

Motor speed

I-

rpm

Motor speed is displayed.

Reference

-

I_

rpm

Commanded reference motor speed is

speed

displayed.

Position

Pulses

Number of 'remaining pulses (delay

control

pulses) on deviation counter is

droop

%

displayed.

For pulses (minus) in reverse rota-

tion,

decimal point lights.

-Load

I_

%

Load condition is displayed (100%

for 30min.

rated output).

(4) Diagnosis display mode

In diagnosis display mode, "control sequence", "external

signal",

"warning

NO.",

"parameter error

No."

and

"alarm

No."

can be displayed.

Item

Display

Description

Control

,- c

_I -

0 1-l -

Indicates that the controller

sequence

-

ID" DATA

is ready for operation.

I- ,=: -

I:1

I-

Indicates that the'controller

ADD

nlfl

is not ready for operation.

(5) External I/O signals . . . . .

I/O signal can be monitored.

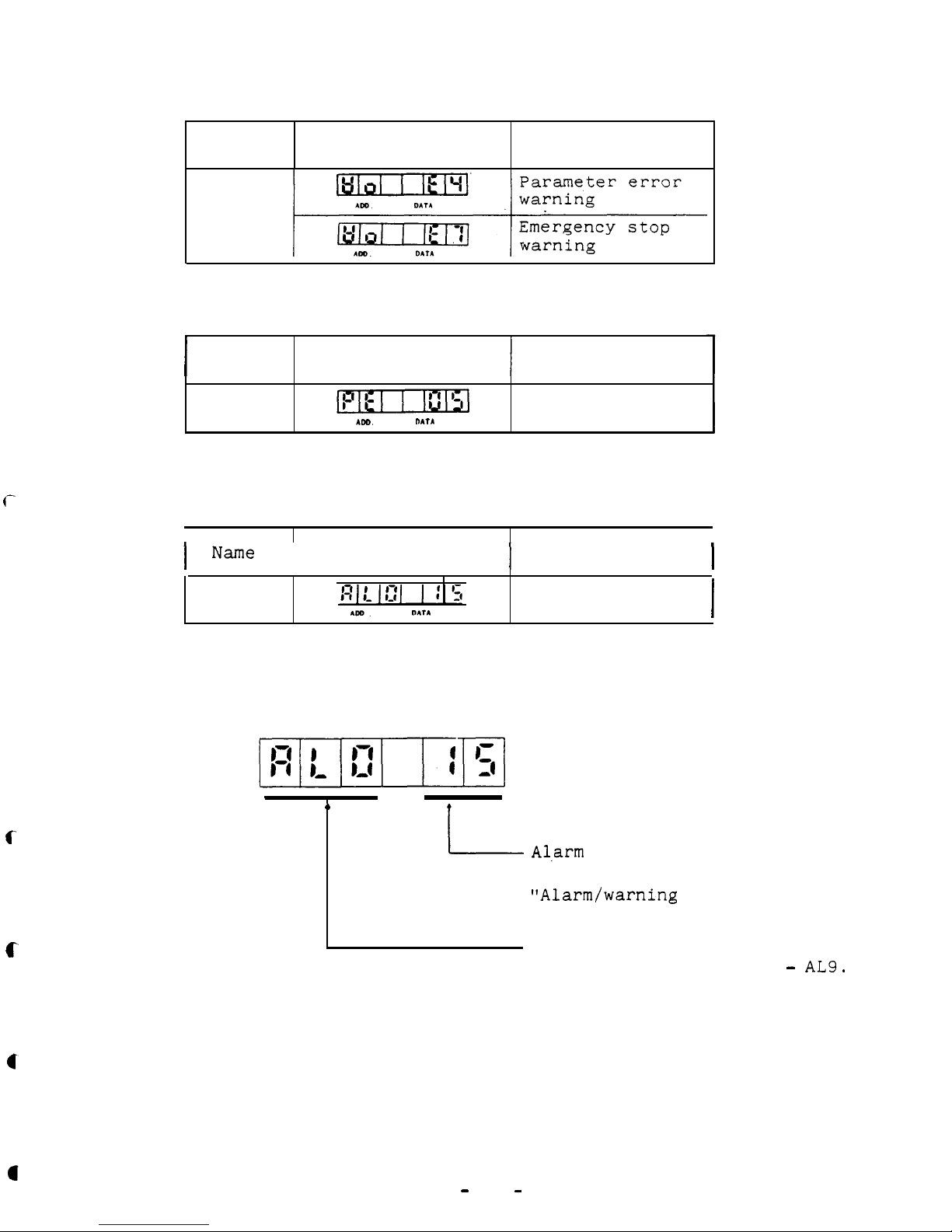

Warning No.

c

Name

Display

Description

Warning

No.

e

'Parameter error No.

I

Name

Display

Description

Parameter

error No.

Parameter error

IDD.

MT*

No. is displayed.

(5) Alarm display mode

Alarm No.

1

Name

i

Display

I

Description

I

Alarm No.

Alarm No. is

displayed.

I

c

.

I-

c

Alarm display

Al.arm

No.

is displayed.

For details,

refer to a.4

t'Alarm/warning

table".

Concurrent alarms are display-

ed in the order of AL0 -

AL9.

-

23

-

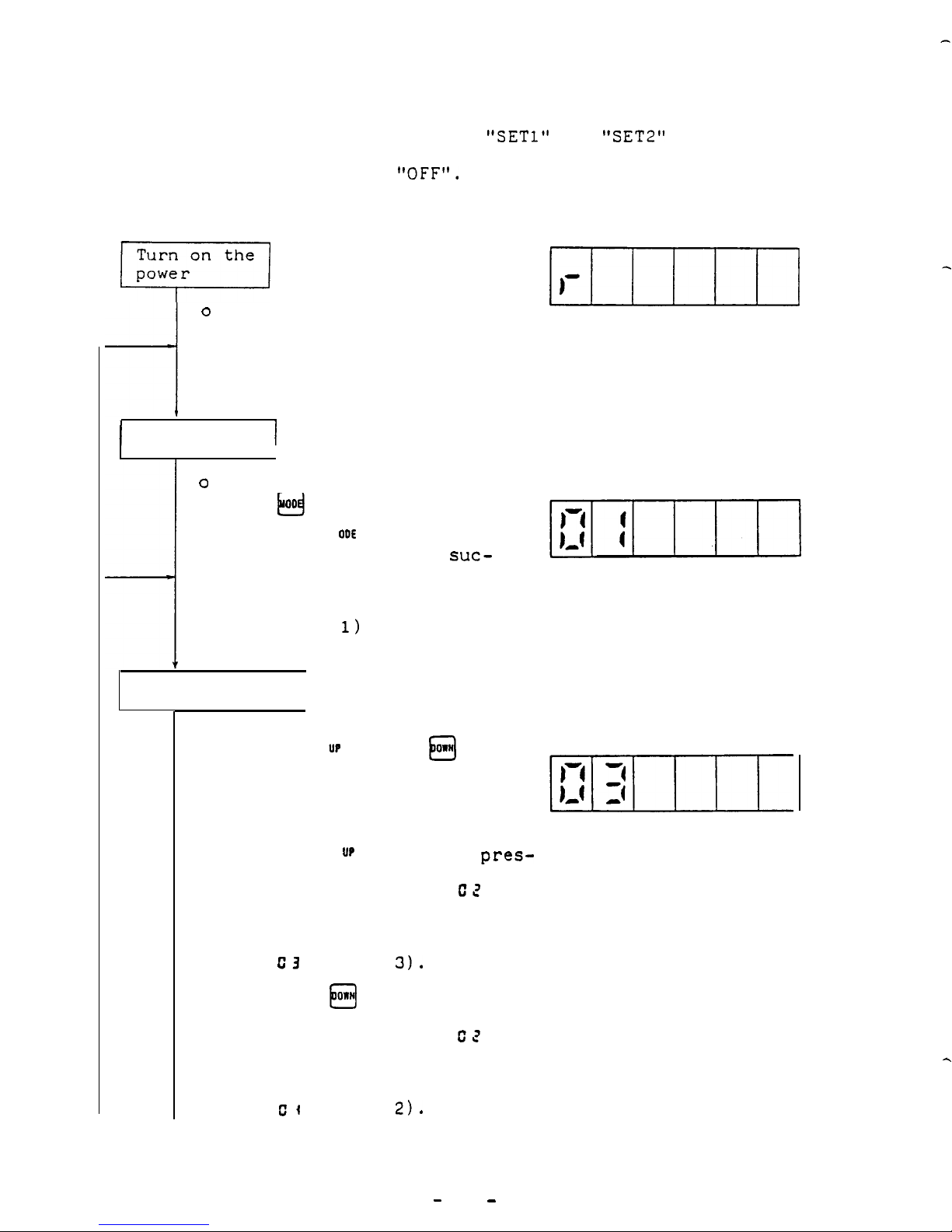

(6) Parameter setting

To specify parameter, set

"SETl"

and

"SET2"

(machine ready

for operation) to

"OFF".

p+xj

Unless alarm occurs, speed

BIIIII

A

0

is displayed in operation

status mode by the readout

ADD

DATA

(Fig. 1).

Fig. 1

SPEED display

I

Select mode.

1

o

Mode

when

Ex.:

changes step by step

k-3

00

switch is pressed.

When

El

ODE

switch is

pressed 3 times

suc-

cessively, display

mode changes from op-

eration status mode

ADD

DATA

(Fig. 1) to parameter (1)

mode' (Fig. 2).

Fig. 2

Select address.

J

o Address can be selected by

pressing UP and/or

0"~

switches.

0

Q

When address is selected,

the data at that address is

displayed.

Ex.:

When

up

0

switch is

pres-

Fig. 3

sed while display is as

shown in Fig. 2, CZ appears.

Another one touch of

switch causes display of,

c3

(Fig.

3).

When

OnH0switch is pres-

sed while display is as

shown in Fig. 3, CZ ap-

pears.

Another one touch of

switch causes display of

CI

(Fig.

2).

-

24

-

I

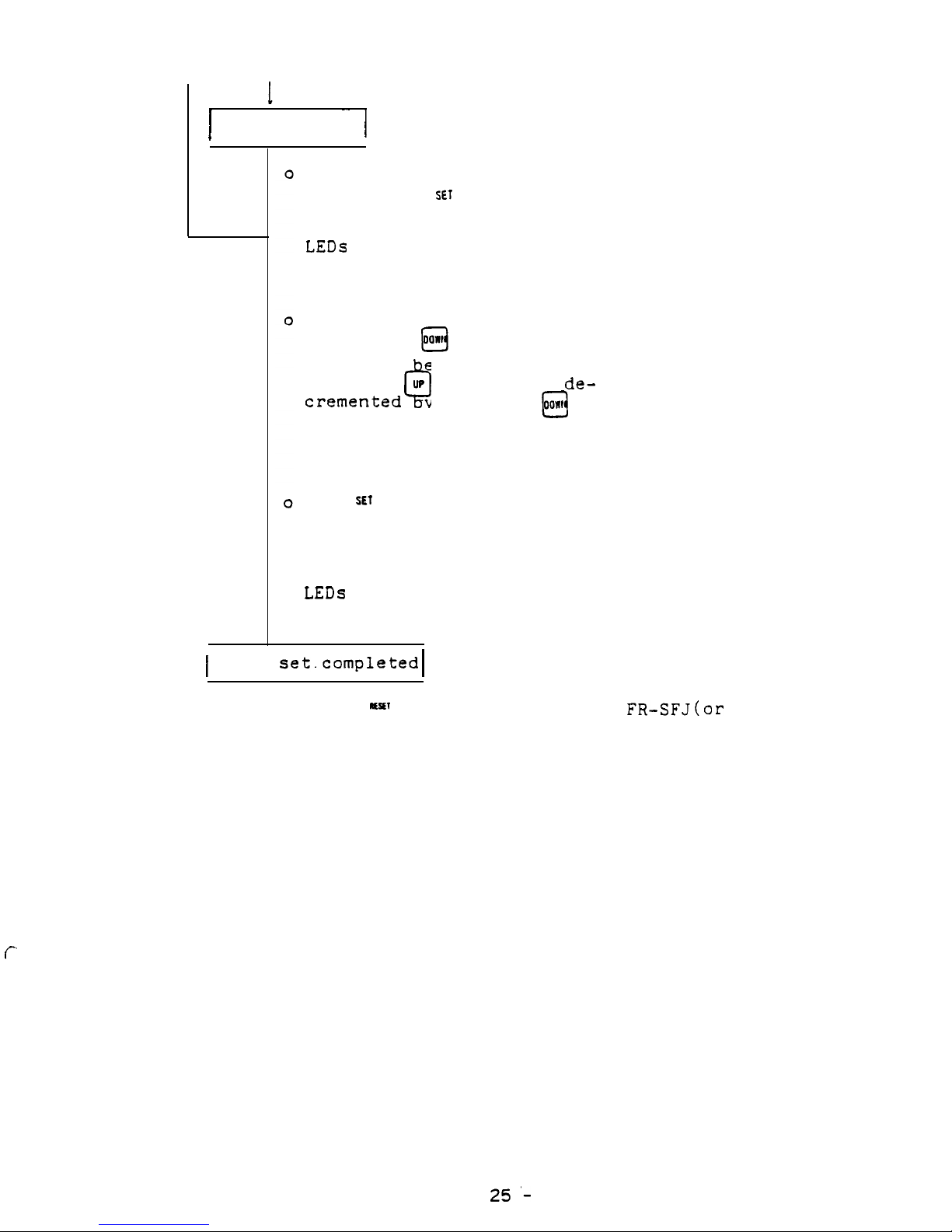

Data rewrite

~~

I

To rewrite previously set

data, press

SET

switch.

0

When the switch is pressed,

LEDs

ADD flickers indicating that data can be rewritten.

Set desired data by pressing

0

UP

and/or

oawt

switches.

Cl

Value can

e incremented by

pressing

0

UP

switch, and

decremented

switch.

y pressing

@j

Value changes continuously

while switch is held down.

When

SEf

switch i's pressed

0

again,

newly set data is

stored.

After the switch is pressed,

LEDs

ADD light continuously.

1

Data

set.completed

1

o Press

~ESU

switch and reset the FR-SFJ(or turn off and

0

then on the power).

Now data setting has been completed.

f-

-

25'-

3.4

Spindle control monitor on NC CRT display . . . when FR-SFJ is

connected to M300 CNC through bus line

Since display (format, content,

etc.) and setting method dif-

fer from NC to NC,

refer to the instruction manual for your

NC system.

Typical examples of NC CRT display are described here.

3.4.1

Status display

For status display, "SPINDLE

MONITOR" is selected from

the menu.

For use of this display

f

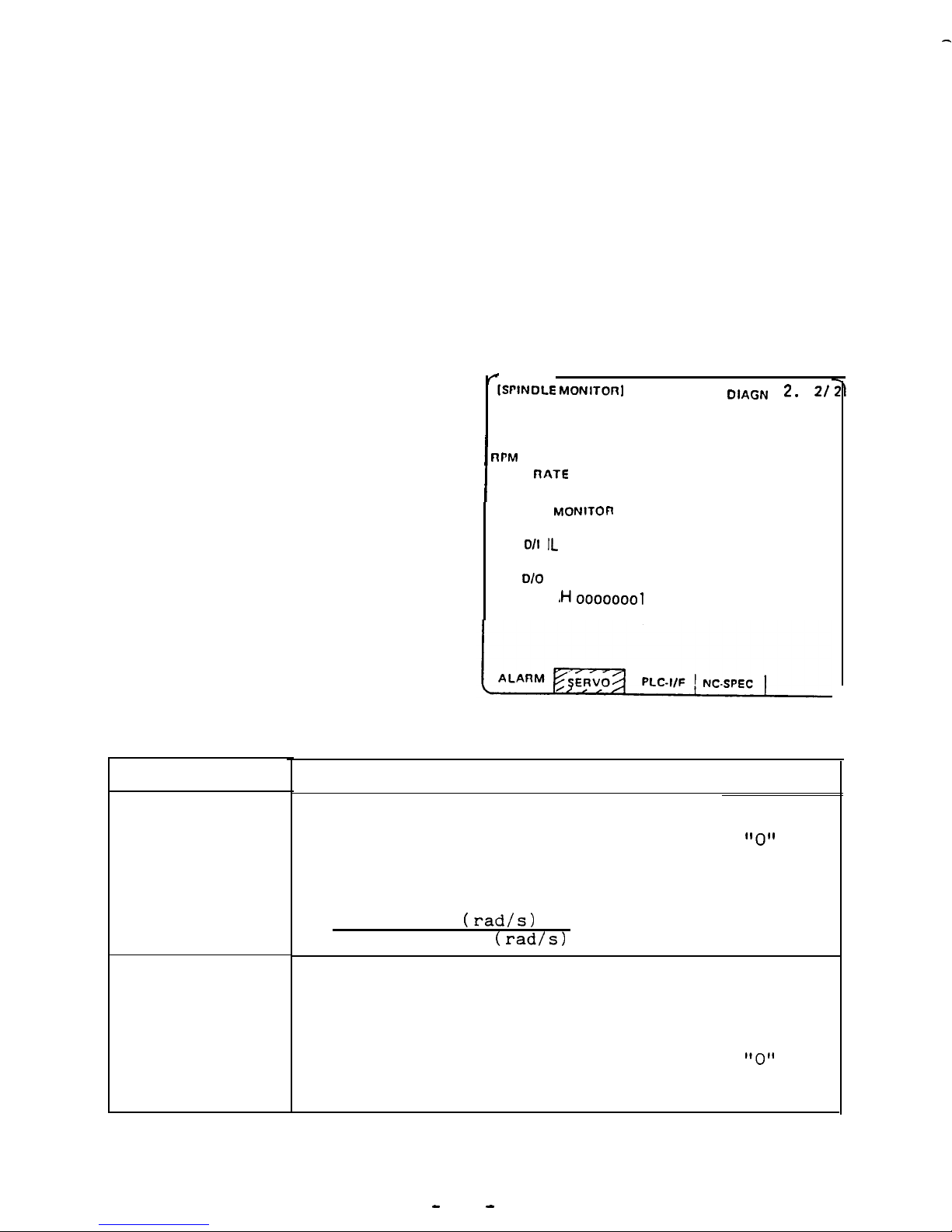

-(SPINDLE MONlTOn]

DIAGN 2. 21

GAIN

10.0

function,

FR-SFJ should be

I

DROOP

nPM

line.

connected to NC through bus

I

LOAD

nATE

80

ALARM NO.

46 23

DATA BIT

MONlTOn

76543210

o/I IL

oooooool

H

ollooooo

0'0

Looololoo

~Hoooooool

123456

6000

Display

GAIN

DROOP

Description

Position control loop gain is displayed.

When position control loop is not used,

"0"

is

displayed.

The standard position control loop gain is,

Motor speed

(rad/s)

Response delay

(rad/s)

= 10

Error in true spindle angle from referenced

spindle angle is called "droop".

Droop is expressed in number of pulses.

When position control loop is not used,

"0"

is

displayed.

-

26

-

Display

Description

MOTOR SPEED

True motor speed is displayed in rpm.

MOTOR LOAD

Load is displayed in ratio(%) to motor rated output (capacity).

The output rated for 30 min. is 100%.

Range of display is from 0 to 120%.

SPINDLE ALARM

If fault occurs with spindle amplifier, alarm

is displayed with code No. (current alarm and

previous alarm are displayed).

For alarm contents,

refer to Appendix 2.

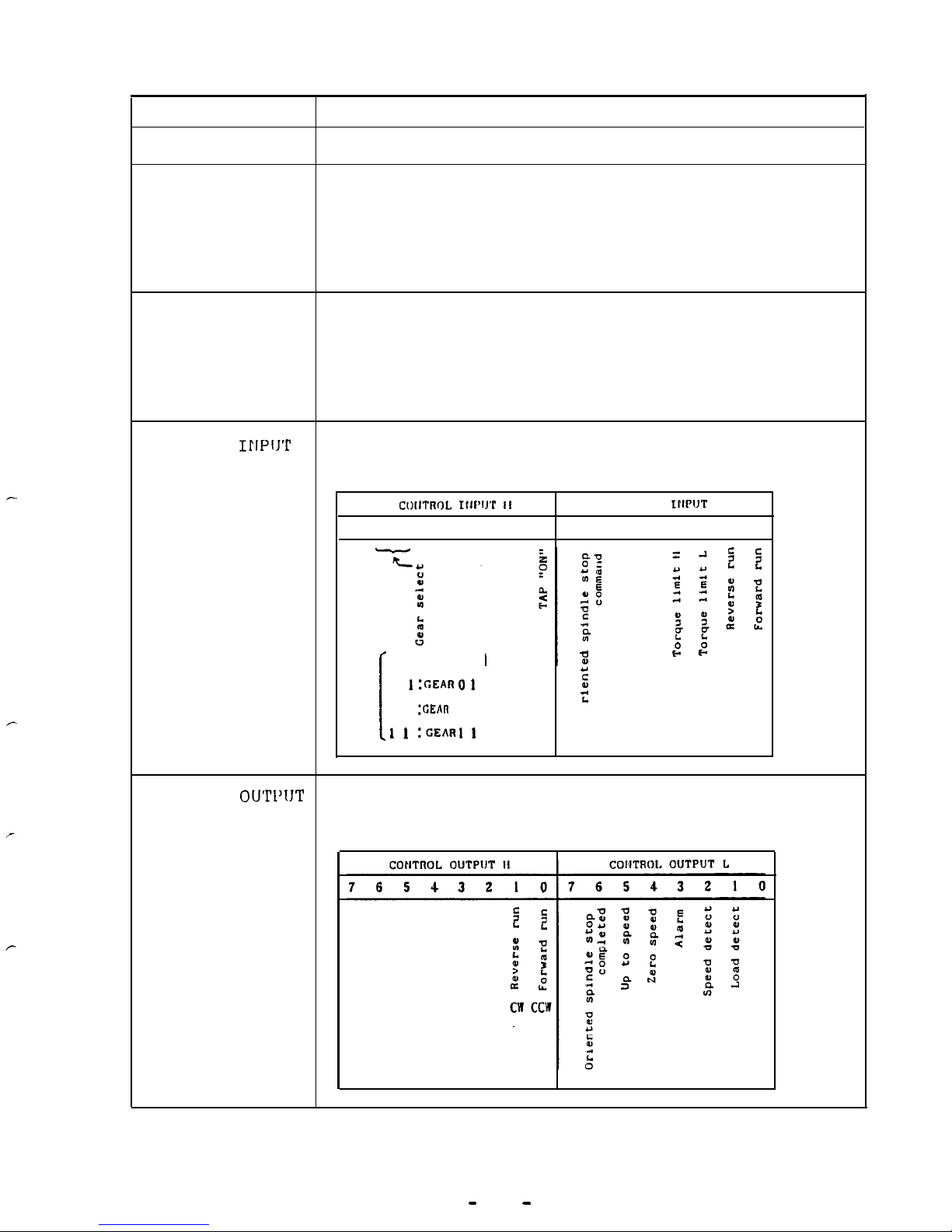

CONTROL

I!IPiJT

Signal input to spindle amplifier is displayed

by bit.

CI)IITROL IIII’IJ’P II

CONTROL

IWUT

L

7654321076543210

0 I

:c;EAnO 1

1

I

-3

2 :

,”

5

II L SRISRN

z

1 0 :-An 1 0

0

1 1 :GEARI

I

CONTROL

OUTl'lJT

Signal output from spindle amplifier is display-

ed by bit.

-

27

-

Loading...

Loading...