Page 1

AC SPINDLE

USA-E99991-075-*

DRIV

TROUBLESHOOTING

,

i

./’

{‘Z

i

]

._

ADVANCED

MITSUBISHI

AND

EVER AOVAkCfNG

ELECTRKZ

Page 2

1.

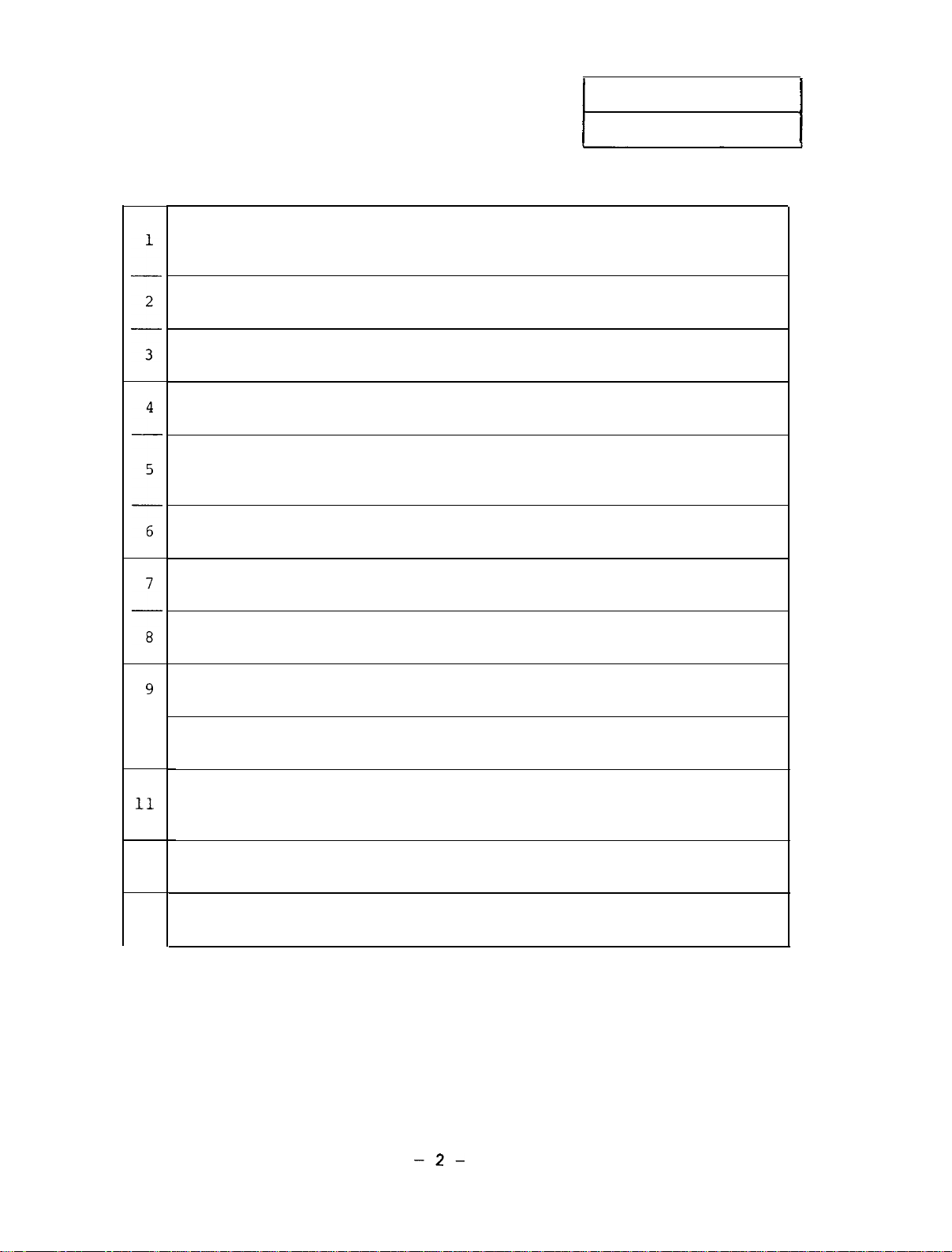

Troubleshooting

1.1

1.1.1

1.1.2

Status display and diagnosis . . . . . . . . . . . . . . . . . . . . . . . . .

Status display and diagnosis from spindle amplifier.

Status display and diagnosis from NC . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Checking method and countermeasures of trouble

classification A .._..................................

1.2.1

When the amplifier is turned on at the first time,

it does not correctly work

. . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 The motor which has normally rotated stops

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Although an

after turning on and off the power

1.2.3

abruptly

The equipment does not work in occasions.

orientation stop position deviates.

alarm appears,

or resetting the equipment, the equipment normally

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3

1.3.1

works

Checking method and remedy of trouble classification

B

.

..I................................................

When the power is turned on, the display of the

operation panel does not appear at all . . . . . . . . . . . . .

1.3.2

When the power is turned on, the display on the

operation panel does not indicated the speed in

the status display mode (as shown in the following

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3

figure)

An alarm appears ont he display on the printed

circuit board (SF-CA card) of the amplifier . . . . . . . .

1.3.4

1.3.5

The motor does not rotate . . . . . . . . . . . . . . . . . . . . . . . . . .

The motor does not rotate at a speed being

specified

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The

. . . . . . . . .

1

5

5

10

13

13

15

16

17

17

18

20

41

43

1.3.6

1.3.7

1.3.8

The motor vibrates and is getting noisier during

rotations . . . .

.._...._._........_...................

The motor overshoots in speed or hours . . . . . . . . . . . . .

The cutting force degrades . . . . . . . . . . . . . . . . . . . . . . . . .

44

46

47

Page 3

1.3.9 The orientation of the spindle is not correct . . . . . .

1.3.10 The acceleration/deceleration time increases . . . . . . .

1.3.11 The speed detection signal, up to speed signal,

or zero speed signal is not issued . . . . . . . . . . . . . . . . .

1.3.12 The tapping operation cannot be correctly performed. 55

1.3.13 The threading operation cannot be correctly

performed

. . . . . . . . . . . . . . . ..I...........

. . . . . . . . . . . . .

48

53

54

57

2. Checking and replacing parts

2.1

2.2

2.3

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.5 Checking transistor module (This method is the same

2.6

2.7

2.8

2.9

2.9.1

2.9.2

Replacing fuses

Replacing thermal protectors

Replacing amplifier cooling fan

Replacing printed circuit board

Replacing SF-PW module

Replacing SF-OR or SF-10 card

Replacing SF-TL card

Replacing SF-CA card

both in the power side and regeneration side)

Checking diode stack

Replacing transistor module and diode stack

Replacing motor cooling

Adjusting and replacing motor built-in encoder

Adjusting printed circuit board

Replacing encoder and printed circuit board

......................................

.................................

............................

.........................

......................

......................

.............................

......................

...............................

...............................

........

..........

..............................

....................

........

.......

58

59

59

59

61

61

62

63

64

65

68

70

71

74

74

77

3. Spindle orientation control circuit . . . . . . . . . . . . . . . . . . . . .

3.1

3.1.1 Spindle orientation using magnesensor (1 point) . . . . 80

3.1.2

3.2

3.2.1 Where the speed selection signal function is

3.2.2 Where the equipment is linkedwith the NC through

Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spindle orientation using encoder . . . . . . . . . . . . . . . . . .

(4096 points,

Control circuit and parameter setting . . . . . . . . . . . . . . . .

provided (SF-OR card)

the bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with index function)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

79

80

82

84

84

89

Page 4

3.2.3 Where the equipment is linked with the NC using

analog or digital signals ..........................

3.3 Mounting position detector

3.3.1

3.3.2

3.4

3.4.1

3.4.2

3.5

3.5.1

3.5.2

In the case of magnesensor type ....................

In the case of encoder type ........................

Adjustment ...........................................

In the case of magnesensor .........................

Encoder type .......................................

Operation mode and motions ...........................

In the case of magnesensor .........................

Encoder type .......................................

...........................

96

97

97

104

106

106

110

113

113

115

4. Adjusting synchronous tap ...............................

4.1

4.2

Appendix 1

Appendix l-l

Appendix l-2

Appendix l-3

Setting parameters ...................................

Checking operation ...................................

Machine Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Connection with motor (for standard motor) . . . 122

Machine connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

(without orientation (standard))

Appendix l-4

Appendix l-5

Machine connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Machine connection(Bus linkage with NC) . . . . . . 124

(Magnesensor orientation (1 point)

specification)

Appendix l-6

Machine connection(Bus linkage with NC) . . . . . . 125

(with encoder synchronous tap,

orientation

(4096 points) specification/indexing

funtion)

Appendix l-7

Machine connection . . . . . . . . . . . . . . . . . . . . . . . . . . .

(with encoder orientation rather than NC)

(with 4096 point orientation/indexing function)

117

117

118

120

126

Appendix 2

Appendix 2-l

Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(without orientation (standard)

1

127

127

Page 5

Appendix 2-2

Appendix 2-3

Cable connection .............................

Cable connections (Bus linkage with NC)

...... 129

128

Appendix 3

Appendix 4

Appendix 5

Cable and Connector Specifications

Main Circuit Configuration .....................

Spindle Part Layout ............................

.............

(Excluding printed circuit boards)

Appendix 6

Control Circuit Printed Circuit Board Part

Layout .........................................

Appendix 7

Appendix 8

Appendix 9

Appendix 10

Appendix 11

Appendix 12

Reference:

Major Part Table ...............................

Display Lamps (LED diodes) .....................

Check Terminals ................................

Parameter Setting List and Short Pin Switch . . .

Structural Components . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Instruments . . . . . . . . . . . . . . . . . . . . . . .

Setting and Adjustment

1.1 Set switches, set pins, and variable resistors

1.1.1

1.1.2

SF-CA card

SF-GR card

.........................................

.........................................

.......

130

138

139

144

148

154

155

169

172

175

176

176

179

1.1.3

1.2

1.2.1

1.2.2

SF-TL card .........................................

Setting parameters

Display and set switches (on SF-CA card)

Setting parameters from spindle amplifier

...................................

...........

..........

1.2.3 Setting parameters from NC (On 9" CRT screen)

1.3

Adjusting speed and load meter

.......................

1.4 Setting and adjusting spindle orientation control

circuit

..............................................

......

180

182

183

185

204

214

214

Page 6

1 Troubleshooting

Troubleshooting

1.

If any trouble occurs, before checking the cause, make sure

to read and follow the contents of Table 1.1, "Precautions"

for safety,

Table 1.1 Precautions for safety

o

After turning off the power,

the controller.

tion lamp LED 10 (SF-CA card) puts off, conduct the maintenance and inspection work (waiting for 3 minutes or

more).

0

An electric shock may result in a death accident.

Regardless of whether the power supply is grounded or

not,

exposed to a high voltage,

apparatus.

When installing any test apparatus on a portion to be

tested,

Generally, when conducting a test,

of any test apparatus.

be applied between the test apparatus case and the

ground,

repairing it, take care of it.

o

While the power is supplied to the equipment or when the

equipment is operated,

circuit board.

o

Do not put on a loose close which may be caught by the

rotating portion of the equipment.

since each component of the equipment may be

take care not to touch any portion being grounded.

when operating the equipment while adjusting/

After checking that the power indica-

Thus,

do not attach/detach any printed

Otherwise,

do not immediately touch

carefully select and use test

do not ground the case

because a high voltage may

the equipment may be damaged.

1

Next,

Items upon Occurrence of Trouble".

with Service Department of Mitsubishi Electric.

thoroughly check the contents of Table 1.2, "Check

They will help you contact

-l-

Page 7

/

1 Troubleshooting

/

Table 1.2

Check items upon occurrence of trouble

Check what alarm the alarm display of theamplifier indicates.

In addition, check old alarms in the alarm mode

of the indication lamp (see Appendix 8).

At which of phase R, S, and T a fuse is blown?

(Control circuit input fuse)

Does the trouble or fault repeatedly occur?

Is the ambient temperature and temperature in the

panel normal?

(Is that 55°C or less?)

During what situation does the trouble or fault occur?

During acceleration, deceleration, or constant speed?

At what speed it occurs?

Does the trouble or fault differ between the forward

rotation and reverse rotation?

Is there an instantaneous power failure?

Does the trouble or fault occur when a special opera-

tion or instruction is executed?

9

How often does the trouble or fault occur?

10

At what load situation does the trouble or fault occurs?

Whether a load is applied or removed?

Is a suspicious part replaced with a new one or a

11

temporary repair conducted against the trouble or

fault?

12

13

How many years has the equipment been operated?

Is the power voltage normal?

Does it vary remarkably depending on the time zone?

By referencing the trouble classification shown in Table 1.4,

check the power voltage listed in Table 1.3 before conducting

troubleshooting and countermeasures.

-2-

Page 8

1

1 Troubleshooting

~1

Table 1.3

Checking

AC power voltage

Checking DC power

supply voltage on

printed circuit

board

Table 1.4

E;$-

cation

When the amplifier is powered on at the first

1

time,

The equipment which has normally worked does

2

not abruptly work.

A.

The equipment does not work in occasions.

The orientation stop position deviates from

3

the specific position.

lights,

then on the equipment or by resetting it.

Checking power voltage

Amplifier input pins

Xl, X2, X3, and E

Checking DC output

voltage at check

pins on SF-PW card

Trouble classification

Situation

it does not normally work.

Although an alarm

it is recovered by turning off and

See Appendix l-l

See Appendixes 5,

h(4),

and

g(4).

1

r-

1.2.1

1.2.2

1.2.3

When the power is turned on, the display of

the operation panel does not appear at all.

1

Alternatevely,

circuit board is not correct.

When the power is turned on, the display on

the operation panel does not indicate

2

tions in the status display mode (as shown in

B

the following figure).

)-

The display on the amplifier printed circuit

board (SF-CA card) indicates an alarm (as

shown in the following figure).

3

the DC voltage of the printed

rota-

::

Continued

on the next page.

1.3.1

1.3.2

1.3.3

-3-

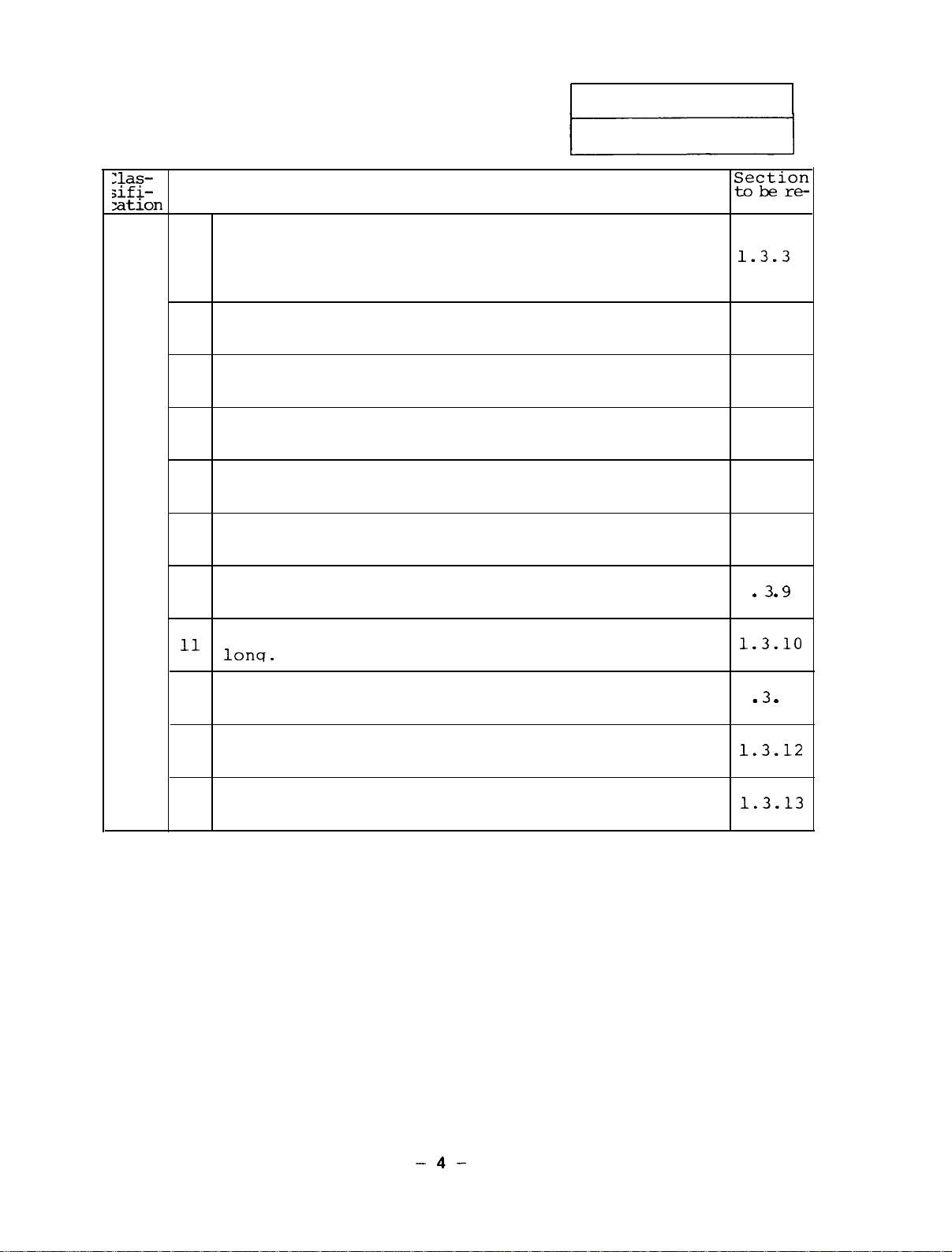

Page 9

1 Troubleshooting

:kEi-

;ifiation

B

Situation

The NC CRT (spindle monitor screen) indicates

an alarm (as shown in the following figure).

4

Spindle alarm 15 01

5 The motor does not rotate.

The motor speed do not conform with that being

6

specified.

The motor vibrates with a large noise during

7

rotations.

8

The motor overshoots at speed or hunts.

9

The cutting force degrades.

The orientation of the spindle is not correctly 1 3

10

performed.

EcikiZ

ferenced

1.3.3

1.3.4

1.3.5

1.3.6

1.3.7

1.3.8

g

. .

The acceleration/deceleration time becomes

11

lonq.

The speed detection signal, up to speed signal, 1 3 11

12

or zero speed signal is not issued.

13 The tapping work is not correctly performed.

The threading work is not correctly

14

performed.

1.3.10

. .

1.3.12

1.3.13

-4-

Page 10

1.1 Status display and diagnosis The status display and diagnosis are executed with the

display and switches on the SF-CA card.

an NC and bus line,

the status display and diagnosis can

be executed on the NC CRT.

When linking

1.1.1

Status display and diagnosis from spindle amplifier

For instructions for operating the display and switches,

see Reference

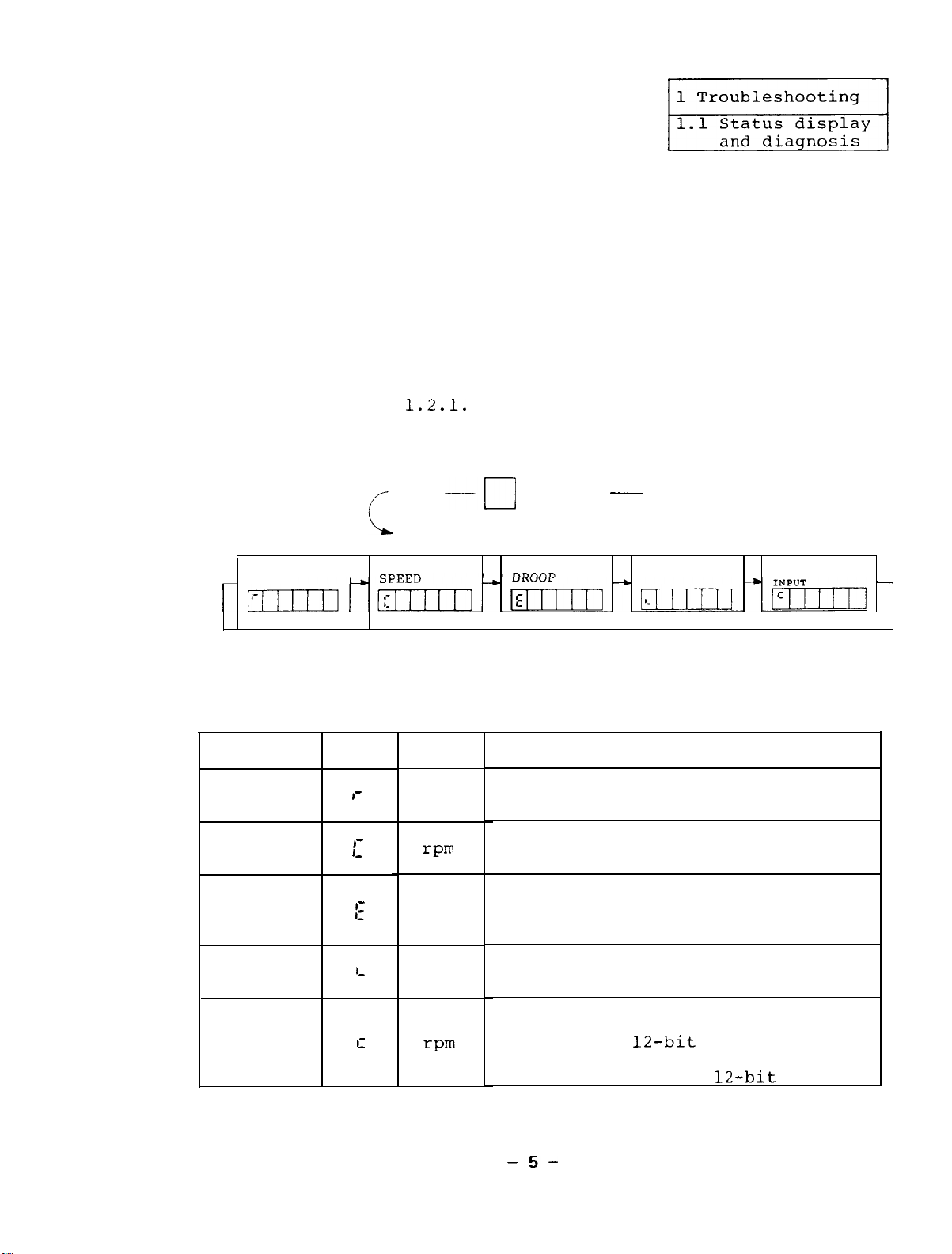

(1) Status display

SPEED

The following table lists the contents of the four types

of status display modes.

Item

SPEED

Code

I'

1.2.1.

Shift

REFERENCE

Unit

rpm

-I

DOWN UP

Represents the motor speed.

q

POSITION

___

Shift

LOAD

Description

3

SPEED

REFERENCE

7

REFERENCE

SPEED

POSITION

DROOP

LOAD

SPEED

REFERENCE

INPUT

1-

1,

-

1:

L

I-

_

rpm

Pulse

%

rpm

Represents the motor reference

speed.

Represents remaining pulses on the

deviation counter.

In the case of

reverse side pulse (negative number),

the decimal point indicator lights.

Represents the load status assuming

that 30-minute rating output is

100%.

Bus linkage with NC . . . 2-port data

of speed reference inputted from NC

S analog . . .

12-bit conversion value

of A/D converter

Digital control . . . 12-bit value

-5-

Page 11

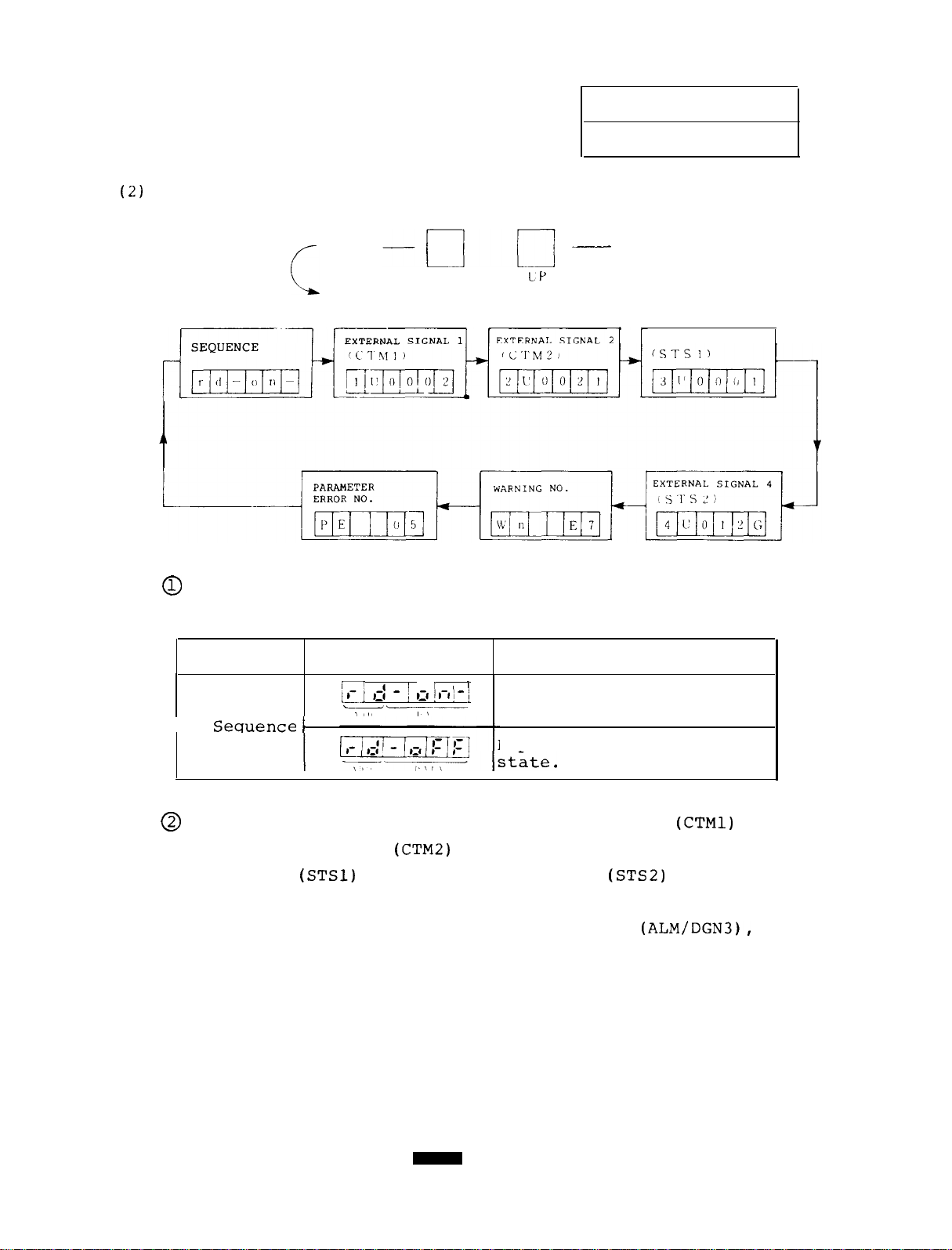

(2)

Diagnosis

Shift

1 Troubleshooting

1.1 Status display

and diagnosis

-

Shift

DOWN

LP

‘,

0

The following table lists the contents of the

sequence diagnosis.

I

Item

Sequence

1

Display

1

k, ,j - j III!

MM__

\ ,I,

II

l-l ] - j

Description

Represents the ready

state.

Represents the non-ready

3

EXTERNAL SIGNAL 3

Check the contents of the external signal 1

0

external signal 2

signal 3

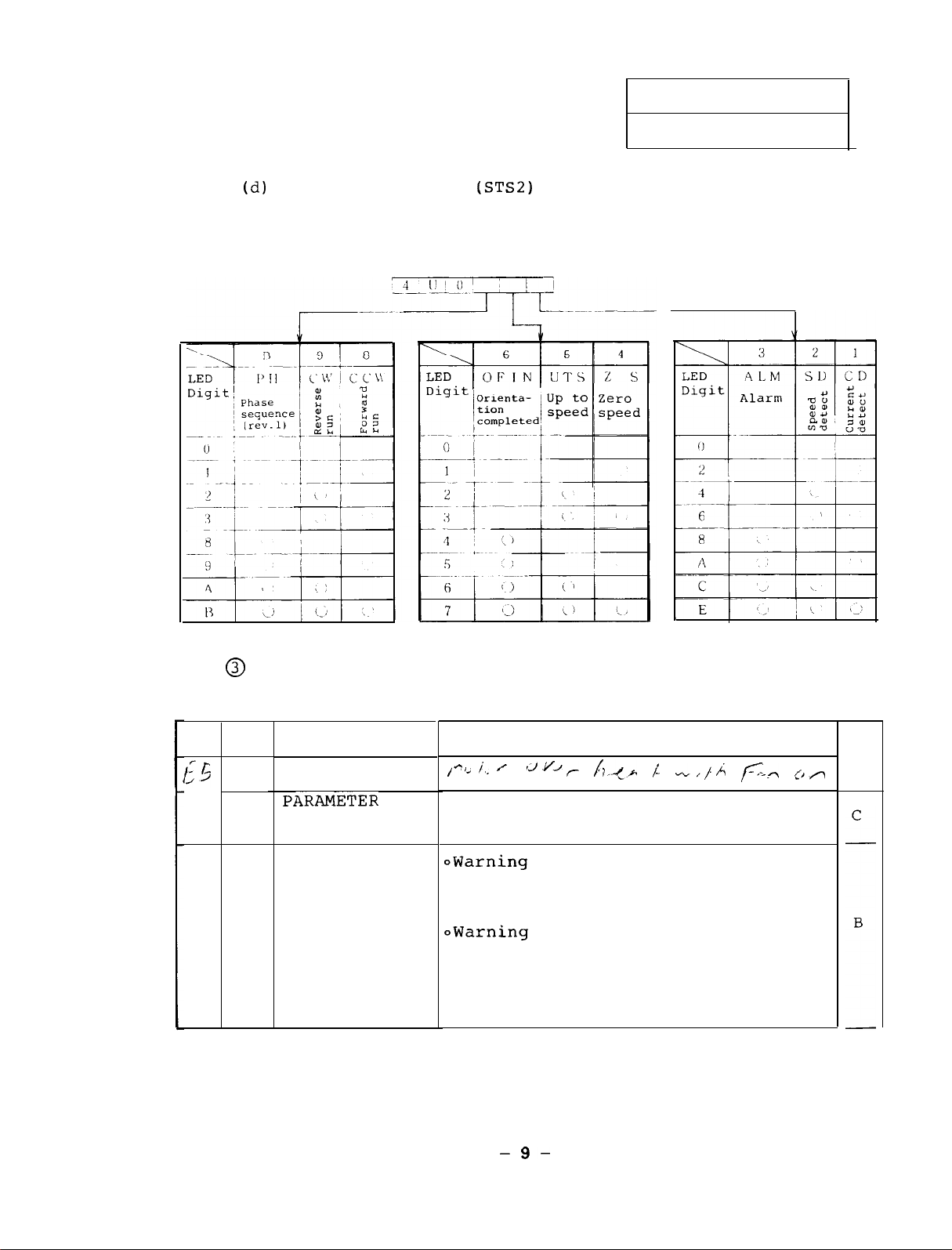

(STSl)

(CTM2)

of input signals and external

and external signal 4

(STS2)

of output

signals by comparing them with the following table.

(Note) On the NC spindle monitor display

(ALM/DGN3),

the external signal 1 and external signal 4 are

checked as a control input and control output,

respectively.

-6-

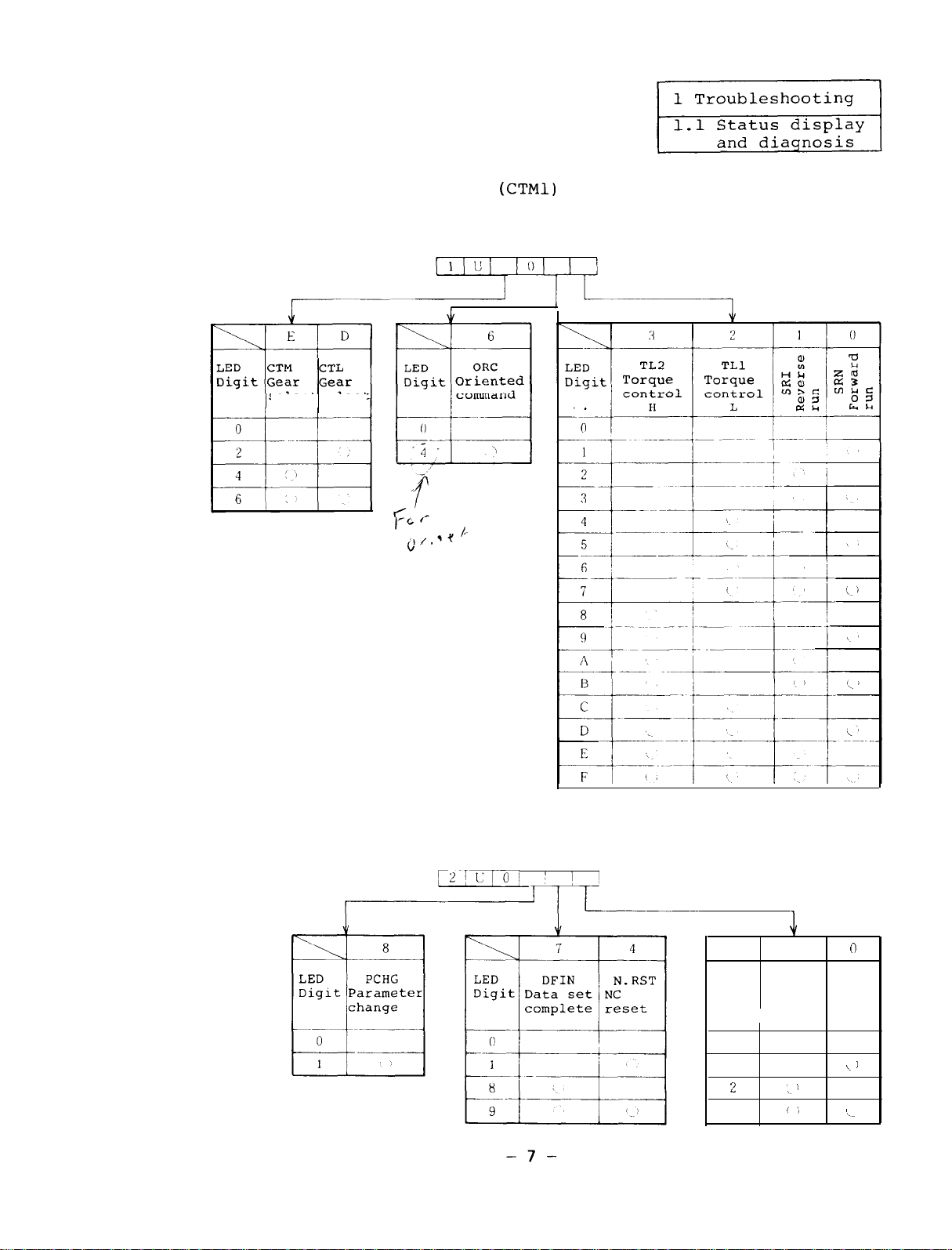

(CTMl)

and

Page 12

(a) External signal 1

(CTMl)

Check the contents of signals by each digit of LED

using the following table.

selectselect

(b) External signal 2 (CTM2)

Check the signal contents by each digit of LED using

the following table.

[2/1;10/

LED

Digit Servo Ready

SVON

ON

0

1

:!

3

J

1

: '

'j

n

RDY

ON

k. J

I_

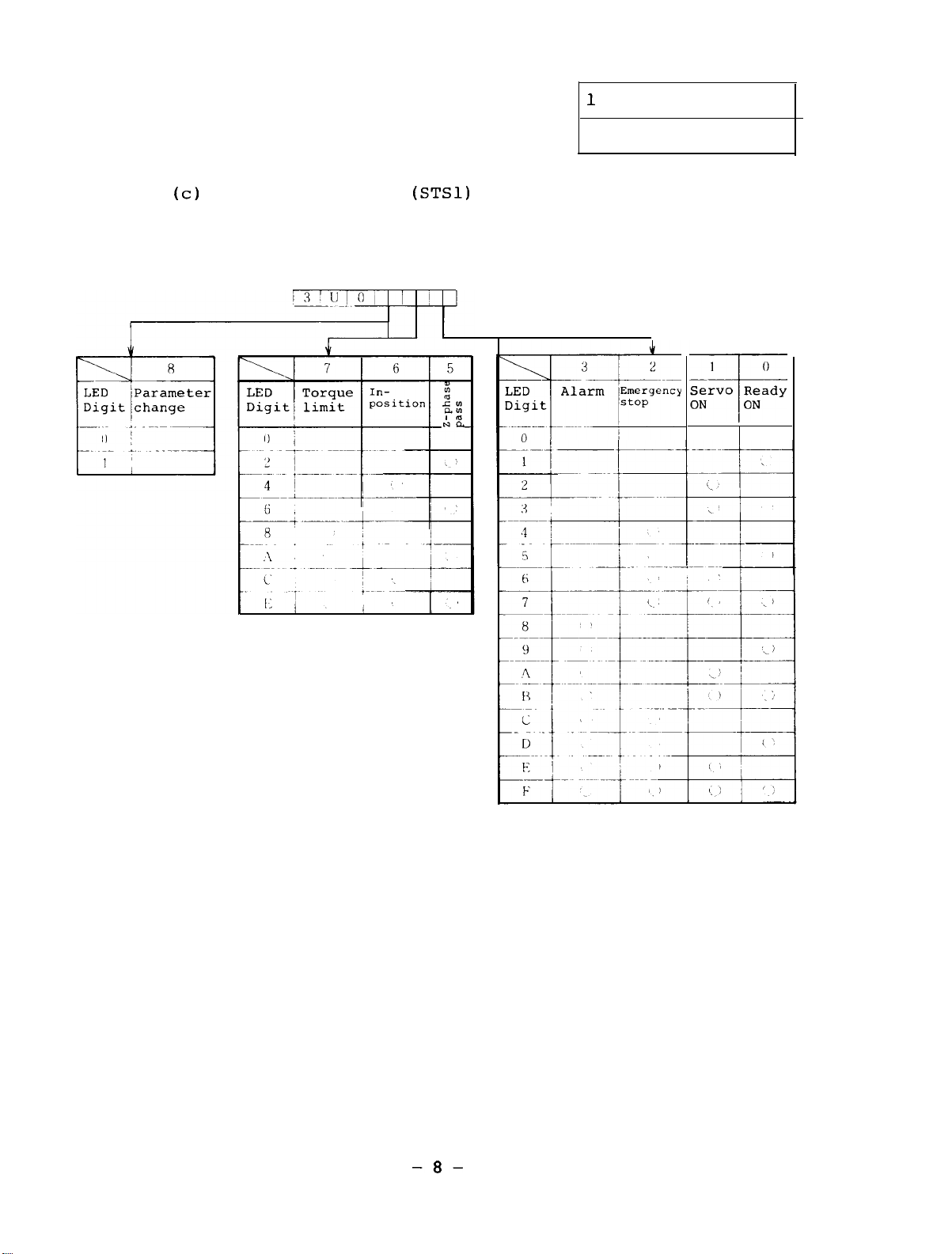

Page 13

1

Troubleshooting

1.1 Status display

and diagnosis

(c)

External signal 3

(STSl)

Check the signal contents by each digit of LED using

the following table.

1

Servo Ready

ON

f

0

ON

-8-

Page 14

1 Troubleshooting

1.1 Status display

(d)

External signal 4

(STS2)

Check the signal contents by each digit of LED

using the following table.

and diagnosis

@

There are three types of warnings as listed in the

EO

IPF

E4E7WPE

NCE

table.

INSTANTANEOUS

POWER FAILURE

PARAMETER

SETTING ERROR

NC EMERGENCY

STOP

Warning which is issued when the

power voltage temporarily drops.

/cl'

i.. y

12vJr Lp> /- "",/.A /c_* [,A

Warning which is issued when a

parameter value exceeds the allow-

able range

OWarning which is issued when an

emergency stop signal is inputted

from the CNC in bus linkage with

the M300 series CNC.

owarning which is issued when an

emergency stop signal is inputted

from the outside while the external emergency stop signal is

validated with the related para-

meter being set.

C

-9-

Page 15

1 Troubleshooting

1.1 Status display

and diagnosis

(Note 1) Motion B - The motor decelerations and stops

with regenerative braking and then base

shut-off takes place.

Whether to open

the trouble signal contact FA-FC can be

selected with a parameter.

Nos.

Motion C

11 and

Only the alarm lamp lights, but

-

12",

Appendixes l-4 and l-5.)

(See

"CON Pin

the operation continues.

(Note 2) An example of the display is as follows.

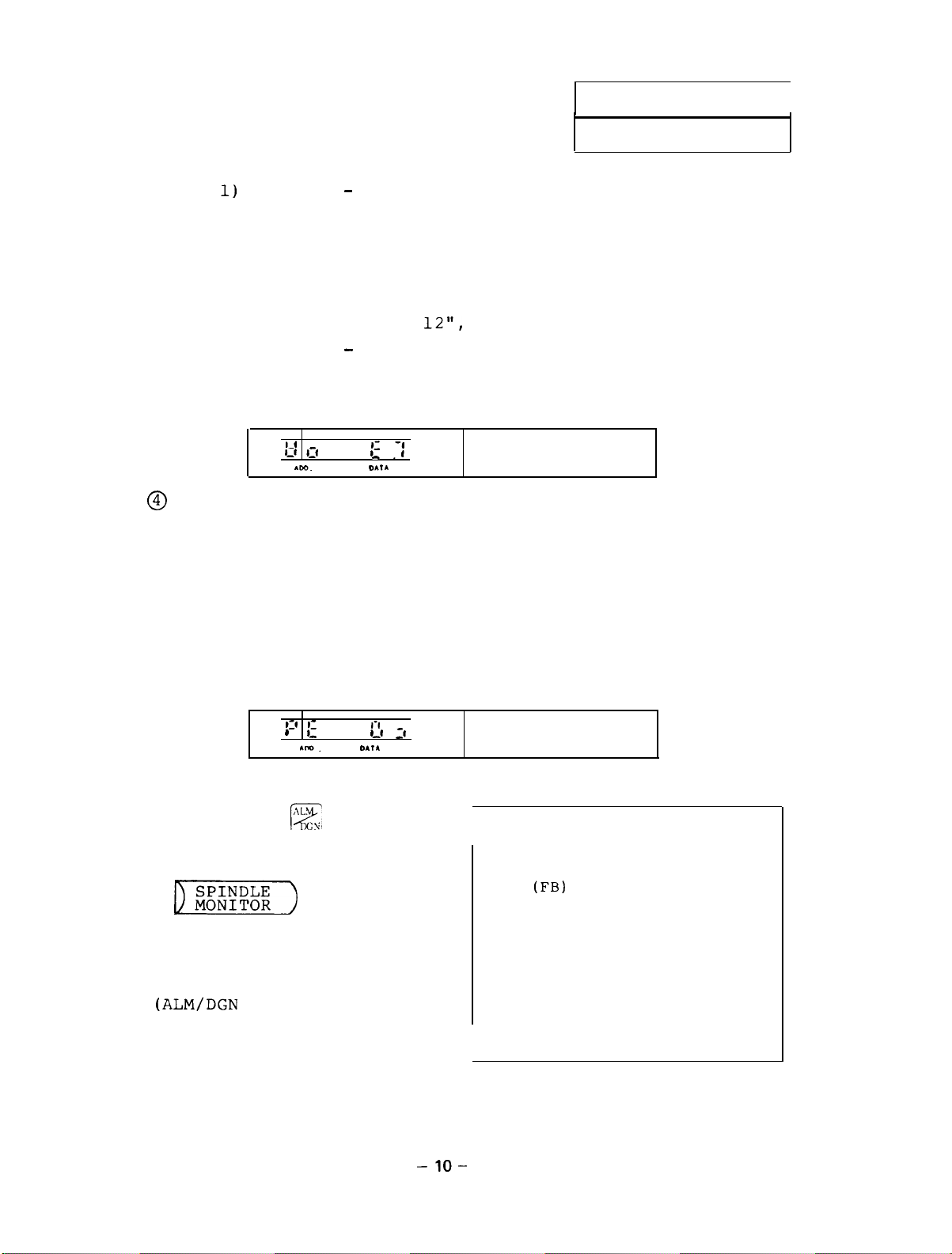

1.1.2

1-4

I-1 111

rm.

@

The parameter error No. represents which parameter

;'

_ .-1'

DA,&

NC emergency stop

is defective when the alarm No. 37 (PE, parameter

error) occurs.

(Note 1) If a multiple of parameters is defective, check

and correct the parameters in accordance with

the parameter error Nos. until the alarm No.

37 does not occur.

(Note 2) An example of display is as follows:

19 :'

’ ^

Am.

Status display and diagnosis

Pressing the

E,

is one of function

selection keys and the

D))

key

which is one of menu

keys causes the following spindle monitor screen

(ALM/DGN

3) to appear.

l-l

I-

,,I :I

D.,l

which

Indicating parameter

error No.

from NC

[SPINDLE MONITOR]

GAIN

DROOP

Srpm

RPM

LOAD RATE

ALARM NO.

D/I L

D/O L

ALARM SERVO

(FB)

H

H

00 00

76543210

00000100

00000001

00000100

00000010

SPINDLE

MONITOR PLC-I/F

ALM/DGN

10.0

675

100

100

40

3

-lO-

Page 16

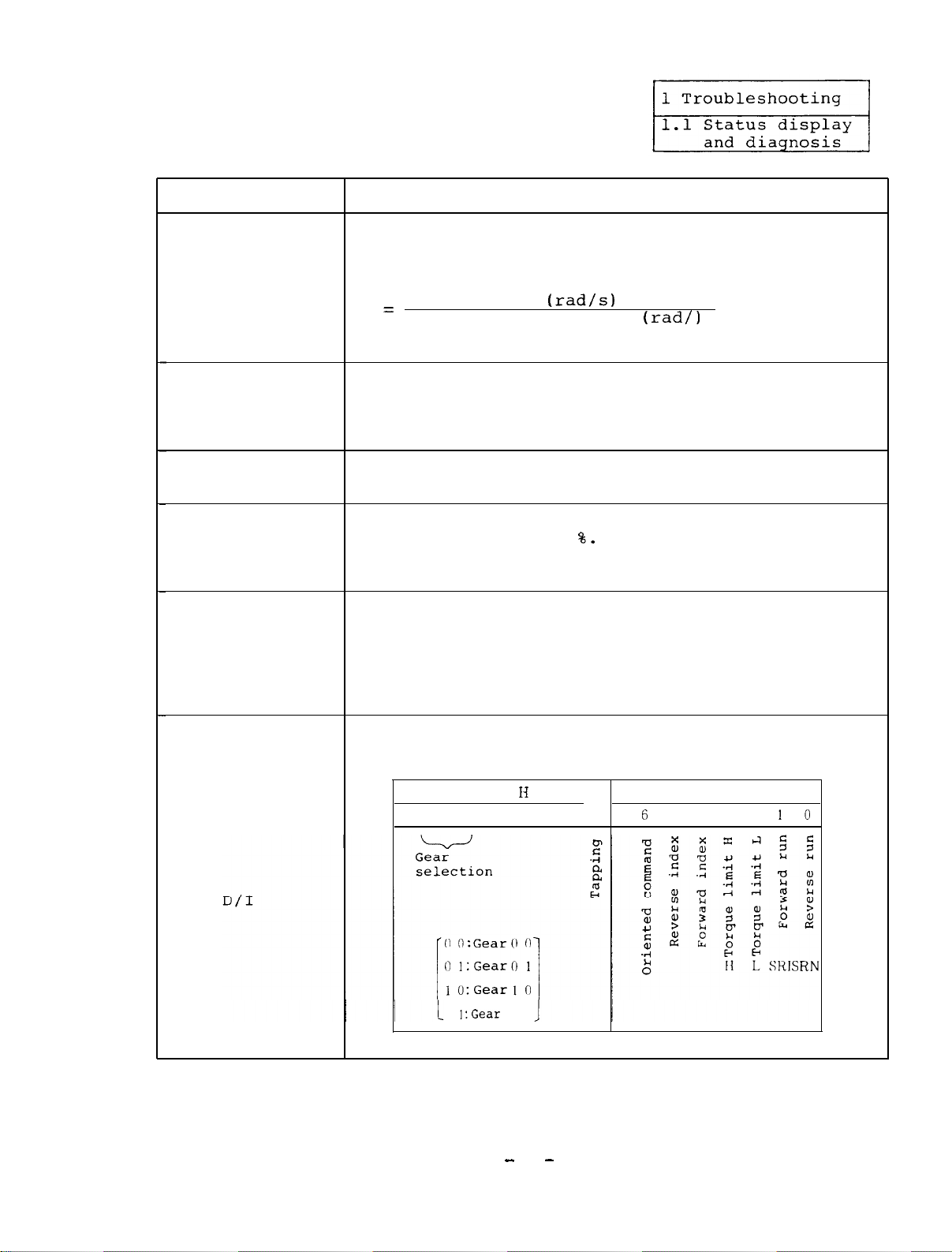

Display

Description

Represents the position loop gain state. It

represents 0 when no position loop is formed.

GAIN

Position loop gain is obtained from the equation

Motor speed

=

Followed delay error

(rad/s)

(rad/)

The standard value is 10.

An error of real spindle rotation angle against

POSITION DROOP

referred spindle rotation angle is named droop.

The unit is in pulses. When no position loop is

formed,

the position droop is 0.

RPM Represents the real motor speed.

(Motor speed)

The unit is in rpm.

Represents a ratio of load against the rating

MOTOR RATE

output.

The unit is

output is 100%. The motor rate is in the range

The 30-minute rating

8.

0 to 120%.

Represents the contents of alarms which occurred

in the spindle amplifier this time and last time

ALARM NO.

with code numbers.

However,

the last alarm is

(Spindle alarm) the smallest number alarm which differs from

this time alarm.

For details of the contents

of alarms, see 1.3.3.

Represents an input command to be issued to the

spindle amplifier corresponding to bits.

D/I

7

6 5 4 3 2 10 7 6 5 4 3 2

1

1:Gear

13

1 1

D/I L

10

Continued on the next page.

-

11

-

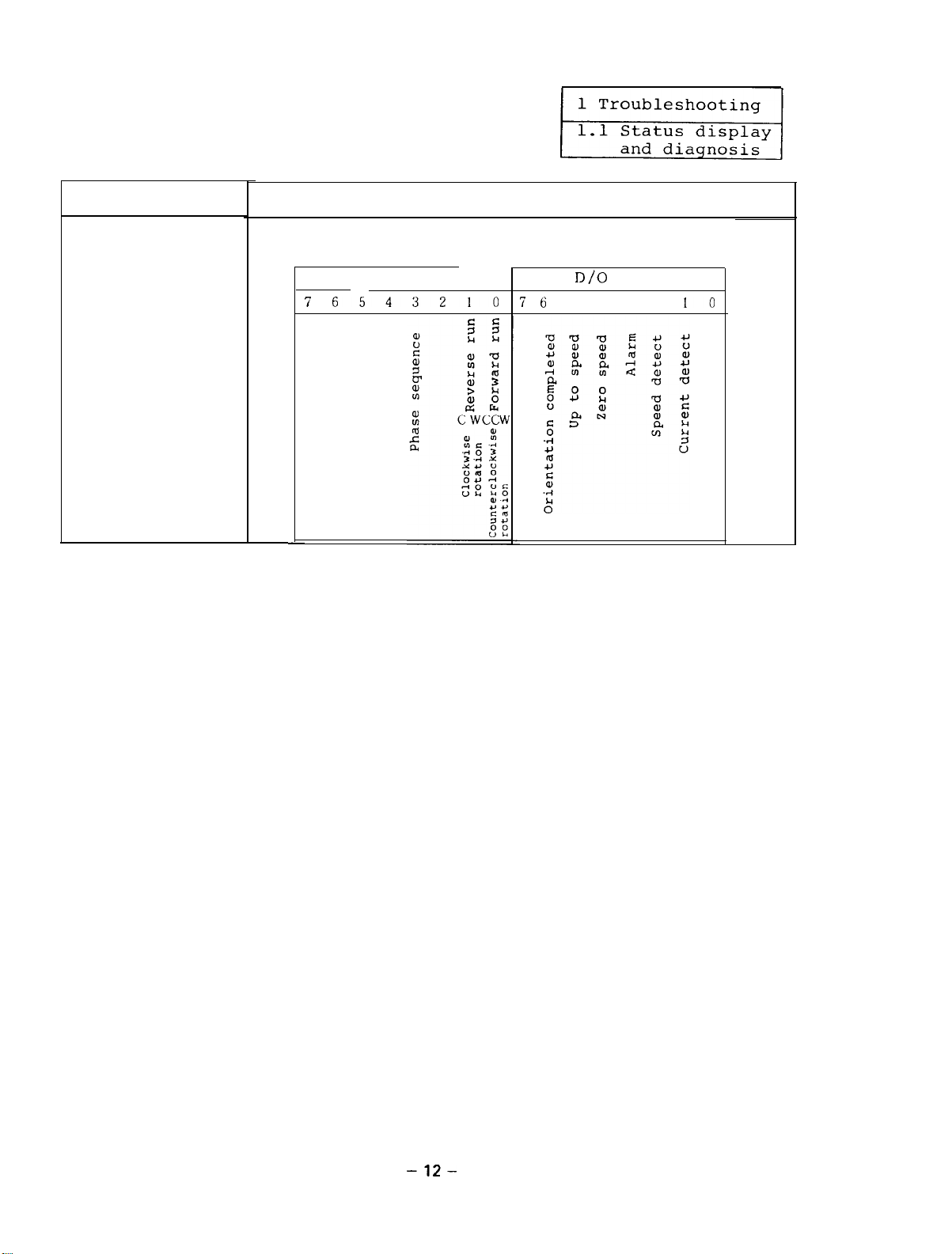

Page 17

Display

Description

Represents a control output being outputted from

the spindle amplifier corresponding to bits.

D/O

D/O H

7

6543210

-

7 6

D/O L

5 4 3 2

10

-12-

Page 18

1 Troubleshooting

1.2 Checking method and countermeasures of trouble classification A

1.2.1 When the amplifier is turned on at the first time, it

[tern

The amplifier is

knocked and damaged

1

when the equipment is

operated or installed.

The external wiring

is incorrect or broken

2

The signal ON/OFF

sequence is incorrect.

3

-The ground wiring is

not conducted.

4

The

5

incorrect.

The switch and setting

pins are incorrectly

6

set.

Cause

ElPROM

number is

l-

Visually check there is an abnormal portion on the amplifier.

Visually check the external wiring.

Check that the indication lamp

LED 1 on the SF-PW card lights

(see Appendix

Check the sequence among the NC

ready ON signal, spindle ampli-

fier CON1 ready signal

SETZ),

reverse rotation signal, and

orientation signal taking care

of the following items.

DThe

NC ready ON signal and

spindle amplifier CON1 ready

signal

ready when both the signals are

turned on.

BIt

takes 1

command of the forward rotation

signal,

or orientation signal is

received after the ready ON

state.

BWhen

both the forward rotation

signal and reverse rotation

signal are turned on at a time,

the motor does not rotate (it

becomes the DC exciting state).

BWhen

the forward rotation

or reverse rotation signal is

inputted when the speed reference is 0,

DC exciting State.

BUnless

Check the ground wirings of the

power,

shield ground wiring of the

detector command.

Check that the

conforms with the amplifier mode

name and motor type name.

Check the set positions of the

switches and setting pins by

comparing them with the attached setting pin list (Reference

1.11.

the forward rotation

signal,

or orientation signal is input-

ted the motor is in the free

run state where the base

shut-off takes place.

Check

6(411.

forward rotation signal,

(SETl, SET21

set

or more until tht

reverse rotation signal

the motor becomes the

reverse rotation signal

amplifier, and motor and

E'PROM

(SETl,

become

signa

number

-13-

Remedy

D

Replace the broken wire

with a new one.

0

Change the signal sequence.'

D

Correctly connect the

ground wirings (see

Appendix

o

Replace the incorrect

ElPROM

o

Correctly set the switches

and setting pins.

Continued on the next page.

1).

with a correct one.

Page 19

1

Item 1

Cause

Check

Remedy

The parameters are0 Check the parameters by comparing oCorrectly set the

incorrectly set.

7

them with the parameter list

vided by the machine manufacturer

pro-

meters.

(Reference 1.2).

The motor speed cannot DCheck that the phase sequence of . oCorrect the phase sequence.

a

be increased (the

alarm No.

23 occurs).

The motor does not

correctly rotate only

9

when the orientation

D‘ v,

and motor is correct.

1

Check and readjust the spindle orientation control

referencing Chapter 7.

and W between the amplifier

circuyt

stop takes place (a

runout

occurs).

The alarm disply

10

of the amplifier

)

Check the cause and take the proper remedy by referencing

Section 1.3.3 which describes the contents of alarms.

lights.

An alarm appears on

11

the NC CRT screen.

0

Check the cause and take the proper remedy by referencing

Section 1.1.2 which describes the status display and diagnosis.

The

LED3(red)

amplifier lights.

12

The spindle does not

rotate.

13

on the

0

ROM is defective or incorrectly attached.

0

The power supply (SF-PW Module) is defective.

o

No data is transferred from NC in bus linkage state.

o

Check that the spindle parameters

o

Check that the connection constants

slimit

and smax are not 0.

(MCW

and inching) of the

connection parameters are not 0.

para-

by

-14-

Page 20

1 Troubleshooting

1.2.2 The motor which has normally rotated stops abruptly.

Item

The fuse

or

Alternatively, the NF

(CBl)

1

The power voltage is

out of the range.

2

An input signal from

the sequencer is

mal.

3

The input signal from

the NC is abnormal.

4

Cause Check

F3)

is blown.

is tripped.

(Fl,

F2, and/

abnor-

Remedy

0

Check the conductivity using

a circuit tester (see

Appendix 5).

0

Check the power voltage using0 Adjust the related control

the circuit tester.

(See Table 1.3)

0

Check each bit of the

external signals 1 and 2 in

the diagnosis mode of the

amplifier indicator. received.

For example, the bits of

ready ON,

and reverse rotation signals.

(See Section

0

Check each bit of a control0 Conduct the same

input by referencing Section

1.1.2 which describes the

status display and diagnosis.

0

At the same time, check the

same items as the Item 3

above.

forward rotation,

1.1.1(2).)

0

Replace the fuse

and/or

(See Section 2.1).

0

After replacing the fuse

with a new one or resetting

the NF,

tion takes place, see Section 1.2.3.

so that the input power

votlage is in the specified

range.

0

Check the input signal where

bits are abnormal so that

the signal is correctly

measures as the Item 3 above,

F3)

with a new one.

if the same situa-

(Fl,

F2,

counter-

The signal from the

encoder which contains

a motor is abnormal.

5

(Note)

The parameter 00 is valid just after 1 is set. Since the parameter 00 is cleared

when the power is turned off or the equipment is reset, after setting 1, immediately

input the speed reference and start command.

0

Set the parameter of the

amplifier as follows.

(Note) _

In an open loop state, input

the speed reference and

start command to rotate the0 If the above adjustment

motor at a slow speed and

check the signal from the

encoder. (See Section 2.9.) printed circuit board with

I 8 t-1

l-1 ,_I

I I I

:

0

Adjust the related control

by referencing Section 2.9

which describes the

ing procedure of motor

built-in encoder so that the

output signal is in the

specified level.

not be conducted, replace

the sensor section and

new ones.

adjust-

-15-

can-

Page 21

1 Troubleshooting

1.2

Checking method and

countermeasures of

trouble

tion

calssifica-

A

1.2.3

The equipment does not work in occassions.

tation stop position deviates.

appears,

after turning on and off the power or resetting

the equipment, the equipment normally works.

[tern

An instantaneous power

failure or voltage

1

drop of the input power

occurs. (Alarm No.101

The machine is

loaded instantaneously

due to affect of

rations and so forth. the status display.

2

(Note) This trouble

The equipment malfunc-

tions with a too large

noise.

(Power supply line)

3

Cause

over-

vib-

often occurs when

orientation is

correctly conducted.

in-

o

Check that an instantaneous

power failure occurred in

another facility in the same

plant.

0

Rotate the motor at a slow

speed and check that the

motor load changes through

(See Section

o

Check the backlash between

the spindle encoder and

spindle.

o

Check the voltage waveform

of the amplifier input pins

Xl, x2,

oscilloscope.

o

While removing suspicious

noise sources one by one,

check the voltage waveform

and find the real noise

source.

Check

1.1.1

or

and X3 with an

The orien-

Although an alarm

Remedy

0

Check the cause of the

instantaneous power failure

and take the proper

measures so that the same

situation will not occur.

o

Remove the cause of the load

change.

o

Adjust the related control

1.1.2)

so that the backlash becomes

small.

o

Place a serge killer near

the noise source.

(For example, 200 VAC,

DCR-2-12003-5041, made by

MATSUO)

counter-

The equipment malfunc-D Check the signal waveforms

tions by noise which

enters a signal from

the motor built-in

encoder.

4

at check pins

AGA)

for phase A signal and

CH45-CH9

B signal using an

scope.

(See

9(l).)

(Note) When measuring the

(or

Appendixes

waveforms, turn off the

power of the amplifier

before using the check

pins.

CH44-CH9 (or

AGA)

for phase

6(l)

OscillO-

and

o

Correctly connect the ground

wires of the power supply,

amplifier, and motor.

(See Appendix

o

Correctly connect the shield

ground wire of the signal

line

(CON21

built-in encoder

referencing Appendix 1-4.

1.)

to the motor

(PLG)

by

-16-

Page 22

1.3

Checking method and remedy of trouble classification B

1.3.1 When the power is turned on,

tion panel does not appear at all.

the display of the opera-

Item Cause

The AC power is not

1

supplied.

The fuse

F3)

of the control power lamp LED1 on the SF-PW module

is blown.

2

The power

N15A,

the printed circuit outside of the SF-CA card in

board SF-CA card is the order of

shortcircuited.

3

The power supply inside0 Disconnect the connectors

the printed circuit

board SF-CA card is

4

shortcircuited.

or

(Fl,

F2, and/or 0 Check that the indication

(PSA, PlSA,

P24)

outside

D

Check the input pins Xl, X2,o Supply the power.

and X3 of the amplifier using

a circuit tester.

lights.

o

Check the electric continuity

using the circuit tester.

0

Disconnect the connectors

which are connected to the

and so on by referencing

Appendixes 1-4 or 1-5, turn

on the power again, and then

check that the indication

lamp LED1 on the SF-PW module

lights.

which are connected between

the SF-CA card and SF-PW

module (CON21 to

on the power again, and check

that the indication lamp

lights.

Check

(See Appendix

CONl,

6(4)

CON3,

CON24),

Remedy

o

Replace the fuse

and/or

.)

turn (See Section

LED1

(See

o

Open the shortcircuited

tion of a circuit outside

the SF-CA card.

(See Appendix 1.2).

D

Replace the printed circuit

board SF-CA card with a new

one.

F3)

with a new one.

Section 2.1.)

(Fl,

2.4.4)

F2,

por-

o

The control power SF-PWo Check that 200 VAC power is

module is defective.

5

All the dip switches

~~5-1

to

Sw5-4

printed circuit board

6

are not placed in the

OFF position.

-

When the equipment is

not

linked with the NC

through the bus, the

setting pins PIN1 and attached setting pin list

PIN2 on the SF-CA card

are not placed as 1.1.1(4).

follows.

7

3

2

1

PIN I PIN

on the

2

supplied to the input

nals of the SF-PW module.

0

Disconnect the connectors

(CON21 to

the power again, and check

that the indication lamp

LED1 does not light.

(See Appendix

o

Check the switch position of

switch SW5 by referencing

Reference

0

Compare the positions of the

setting pins on the SF-CA

card with those on the

by referencing Reference

CON24),

6(4).)

1.1.1(l).

-

17-

termi-

turn on

Replace the control power

with a new one.

(See Section 2.4.1.)

o

Correctly set the dip

switches

(See Appendix

o

Correctly set the setting

pins.

SWS-1

to SWS-4.

6(l))

Page 23

1.3.2 When the power is turned on,

tion panel does not indicate

display mode (as shown in the following figure).

the display on the opera-

the speed in the status

Item

When the equipment is

linked with the NC

through the bus, the

power of the NC is not

1

turned on.

When the equipment is

linked with the NC

through the bus, the

rotary switch

printed circuit board

2

SF-TL card is not placed

in the correct position.

When the equipment is

connected with the NC

through the bus, the bus

cable connectors

and

3

CNlB)

circuit board SF-TL card

are not correctly connected.

Cause

CSl

on the

on the printed

(CNlA

I,-r-rr-rTl

o

While the display on the

operation panel is as

lows,

and check that the display

indicates the speed (as shown

in the above figure).

Even after the power of the

' EC

play on the operation panel

turn on the NC power

is turned

is as follows.

Ill

o

Check the position of the

rotary switch

TL card by referencing Sec-

tion 3.1.3.

(See Appendix

o

Even after the power of the

NC is turned on, the display

on the operation panel is as

follows.

D

Check the position of the

rotary switch

TL card by referencing Reference

1.1.3.

(See Appendix

Check

--

I-

on,

the

I-

I

III

CSl

6t31.1

I-

CSl

6t31.1

fol-

dis-

on the

i

on the

SF-

SF-

Remedy

D

Turn on the power of the

NC.

D

Correctly set the rotary

switch

o

Correctly connect the

nectars CNlA

CSl.

and

con-

CNlB.

When the equipment is

linked with the NC

through the bus, the

connectors

on the printed circuit

board SF-TL card are nqt

4

correctly connected.

All the positions of the

dip switches

SW5-4

on the printed

circuit board SF-CA

card are not turned

5

off.

CNlA

SW5-1

and

to

o

Even after the power of the

N

C is turned on, the display

on the operation panel is as

CNlB

follows.

D

Check the connections by

referencing Appendixes l-6

to l-9.

that a termination resistor

is connected to the connector

CNlB.

Even after the power of the

0

NC is turned on, the display

on the operation panel is as

follows.

I

I I I

o

Check the positions of the

switch SW5 by referencing

Reference

Especially, check

I

1.1.1(l).

-18-

t

1-

II

o

Correctly connect the

nectars CNlA

I

o

Correctly set the positions

of the dip switches

sw5-4.

(See Appendix

Continued on the next

and

6(l).)

CNlB.

SWS-1

con-

to

page

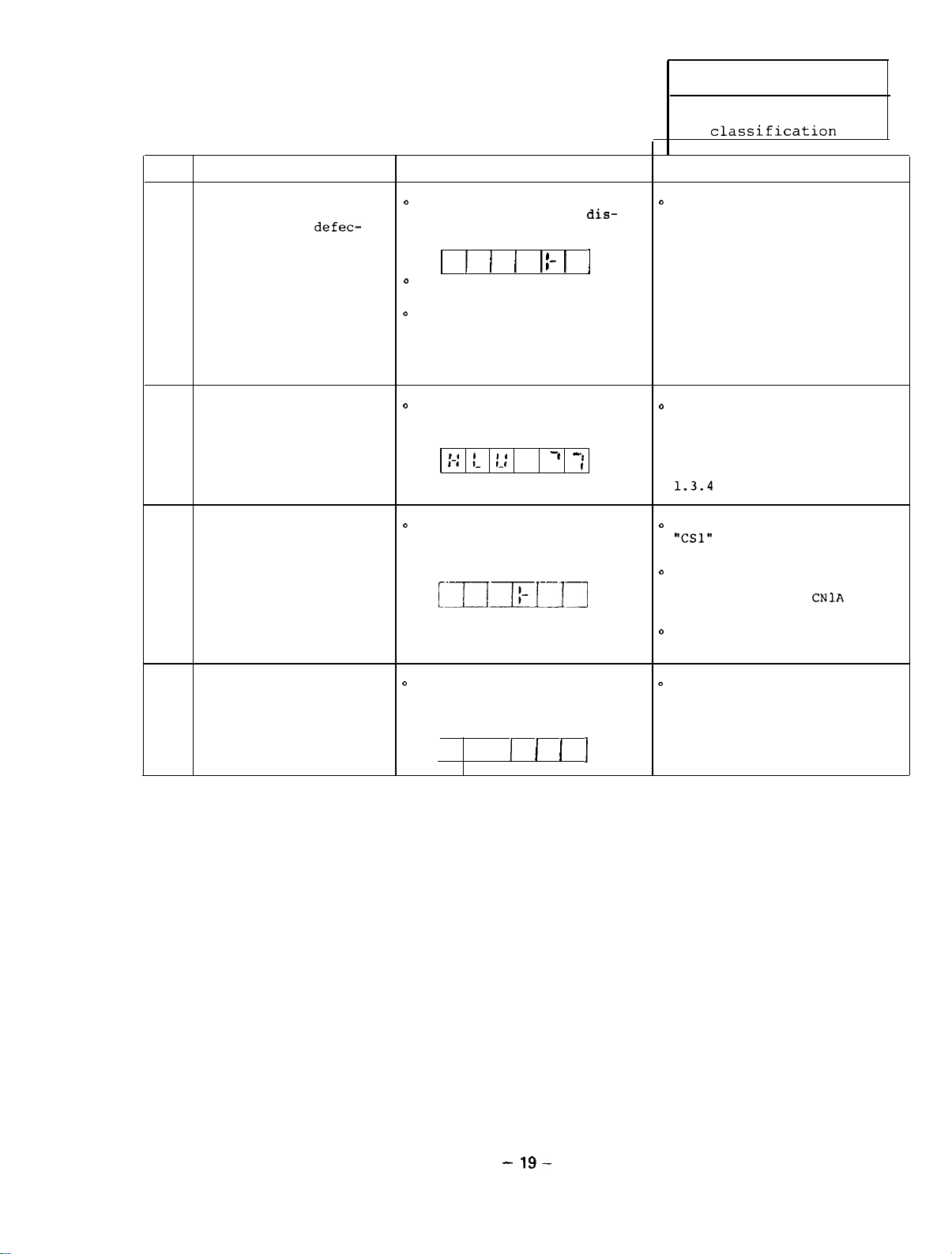

Page 24

1 Troubleshooting

1.3 Checking method and

remedy of trouble

classification

B

Item

The printed circuit

board SF-CA card or

SF-TL card is

tive.

6

An alarm occurs.

7

The transmission of

parameters is required.

8

Cause

defec-

Check Remedy

o

0

Even after the power of the

NC is turned on, the

play on the operation panel

is as follows.

0

The above Items 1 to 5 cannot

0

Replace the printed circuit

0

Check that the display on

o

Even after the power of theo Check that the rotary switch

NC is turned on ,the display

on the operation panel is as

1 I I I I I

be applied.

boards SF-CA card and/or

SF-TL card with new ones and

check that the correct display appears.

the operation panel is as

follows.

:-::I_:

follows.

czfzlxi-_11

1-

-I

3

dis-

7

Replace the printed circuit

boards with the new ones.

0

Check the cause and take the

proper countermeasures by

referencing the description

relating to alarm display,

Section 1.3.3 (on display of

the amplifier) and Section

1.3.4

(On NC CRT).

"CSl"

on the SF-TL card is

placed in thecorrectposition

0

Check that the bus cable

CAM11 is securely connected

to the connector

SF-TL card.

o

Replace the SF-TL card with

a new one.

CNlA

on the

The equipment waits for

the IT start of the

servo amplifier. on the operation panel is as start up.

9

o

Even after the power of theD The amplifier of the servo

NC is turned on, the display

follows.

I-

I I I I

motor does not correctly

Check an alarm of

the servo amplifier.

- 19-

Page 25

1.3.3

An alarm appears on the display on the

board (SF-CA card) of the amplifier.

1-e

As an example:

,

8-1 ,_ c

, I-

,

3

printed circuit

Alternatively,

an alarm appears on the

NC CRT.

As an example: Spindle alarm 15 32

The contents of the alarm which appears on the spindle

amplifier are the same as those which appear on the NC

CRT.

The contents of alarms are listed in the following table.

The details of each alarm are described in the following.

(Note) If the alarm No.12

(MEl)

memory error 1 occurs,

it should be reset by turning off the power of

the spindle amplifier.

On the other hand, other alarm Nos. should be

reset by turning off the NC power.

-

20

-

Page 26

1 Troubleshooting

1.3 Checking method and

remedy of trouble

classification B

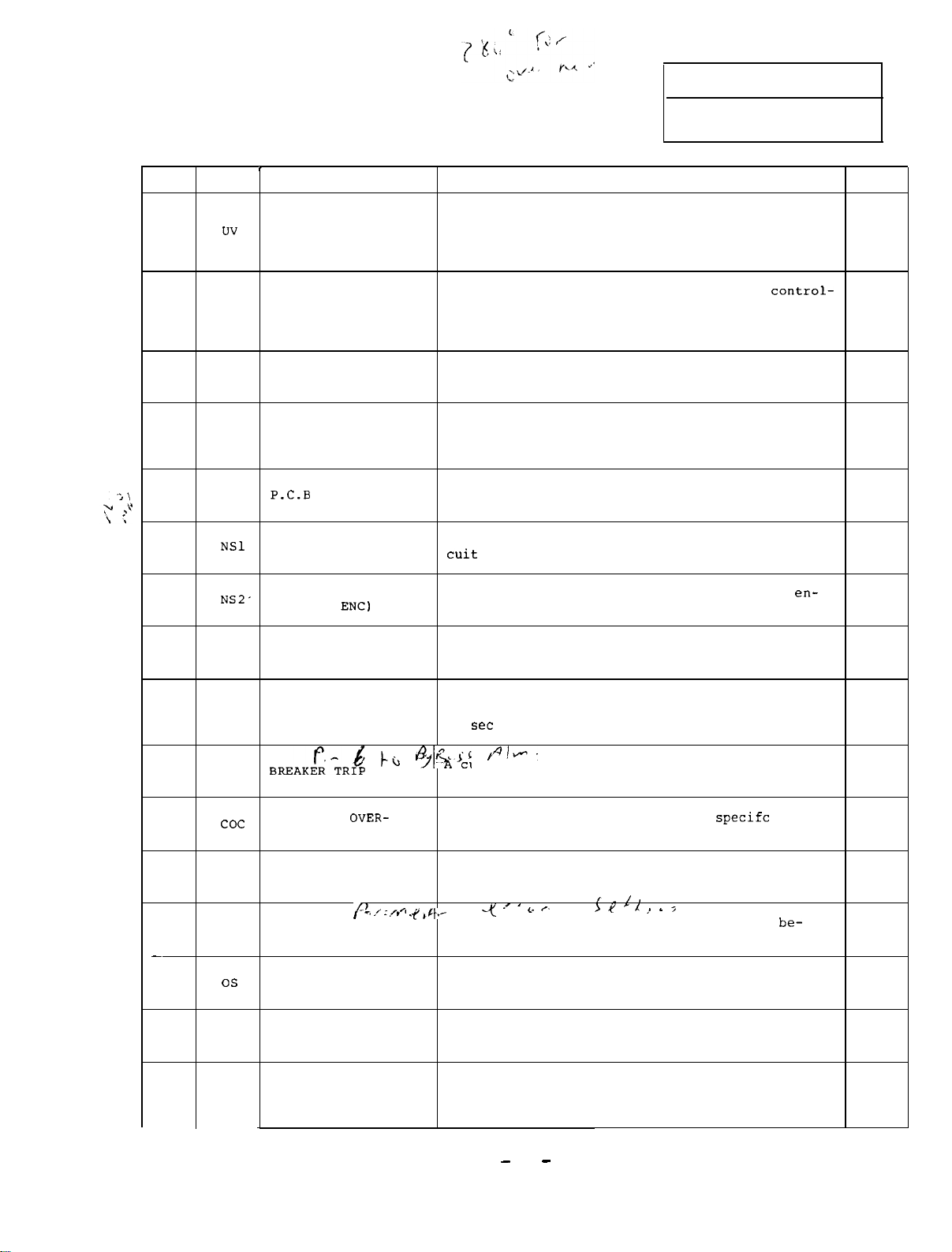

Alarm

No.

10

12

13

15

17

20

21

Abbr.

UV

ME1

ME2

BE

NSl

NSZ'

,

UNDER VOLTAGE

MEMORY ERROR 1

EXTERNAL CLOCK

ERROR

MEMORY ERROR 2

P.C.B

IC MAC007 ERROR

NO SIGNAL 2

(SPINDLE

Name

ERROR

ENS)

Description

The input power voltage drops to a value less

than the specification assured value or an

instantaneous power failure occurs for 15 ms or

more.

The internal memory for controlling the

ler is not correclty read and written.

(It is checked when the power of the controller

is turned on.)

The system clock which is sent from the NC is

defective.

The 2-port memory for communication which is

used for linkage with the M300 series CNC through

the bus does not correctly work.

Any part on the controlling printed circuit

board does not correctly work.

The part ICMACOO7 on the controlling printed cir-

cuit

board does not correctly work.

A signal is not input from the orientation

coder or the signal is not in the correct level.

control-

en-

Motion

(Note)

A

A

A

A

A

A

A

22

23

24

25

26

NSS IC MAC012 ERROR

OSE

BRT

cot

PL

SPEED CONTROL ERROR

EXCESS

B,,,L-,,&

CONVERTER

CURRENT flows in the converter.

POWER PHASE LACK

OVER-

j-a +%$I

4 / ; .,,4 .y

27

-

31

32

33

CPUE

OS

oc

ov

CPU ERROR

(DIVISION ERROR)

OVERSPEED

INVERTER OVERCURRENT

OVER VOLTAGE

'

The part IC MAC012 on the controlling printed

circuit board does not correctly works.

The difference between the referenced speed and

motor speed is 50 rpm or more and it takes for

12

set

or more.

fli@-

current which exceeds the specific value flows

in the main circuit.

An overcurrent which exceeds the

One or more of 3 phases is missed in 3-phase

power.

,‘.,_

-< .’ ‘ c- (’

A division error occurs in CPU operation

cause of incorrect parameters being set.

The motor speed exceeds 115% of the maximum speed

An overcurrent which exceeds the specific value

flows in the controller.

The voltage of the main circuit condenser exceeds

the specific value because of regenerative energy

in motor deceleration state.

I.

>i/ ‘I

/,

,, I

;

specifc

Continued on the next page.

value

be-

A

A

A

A

A

A

A

A

A

-

21 -

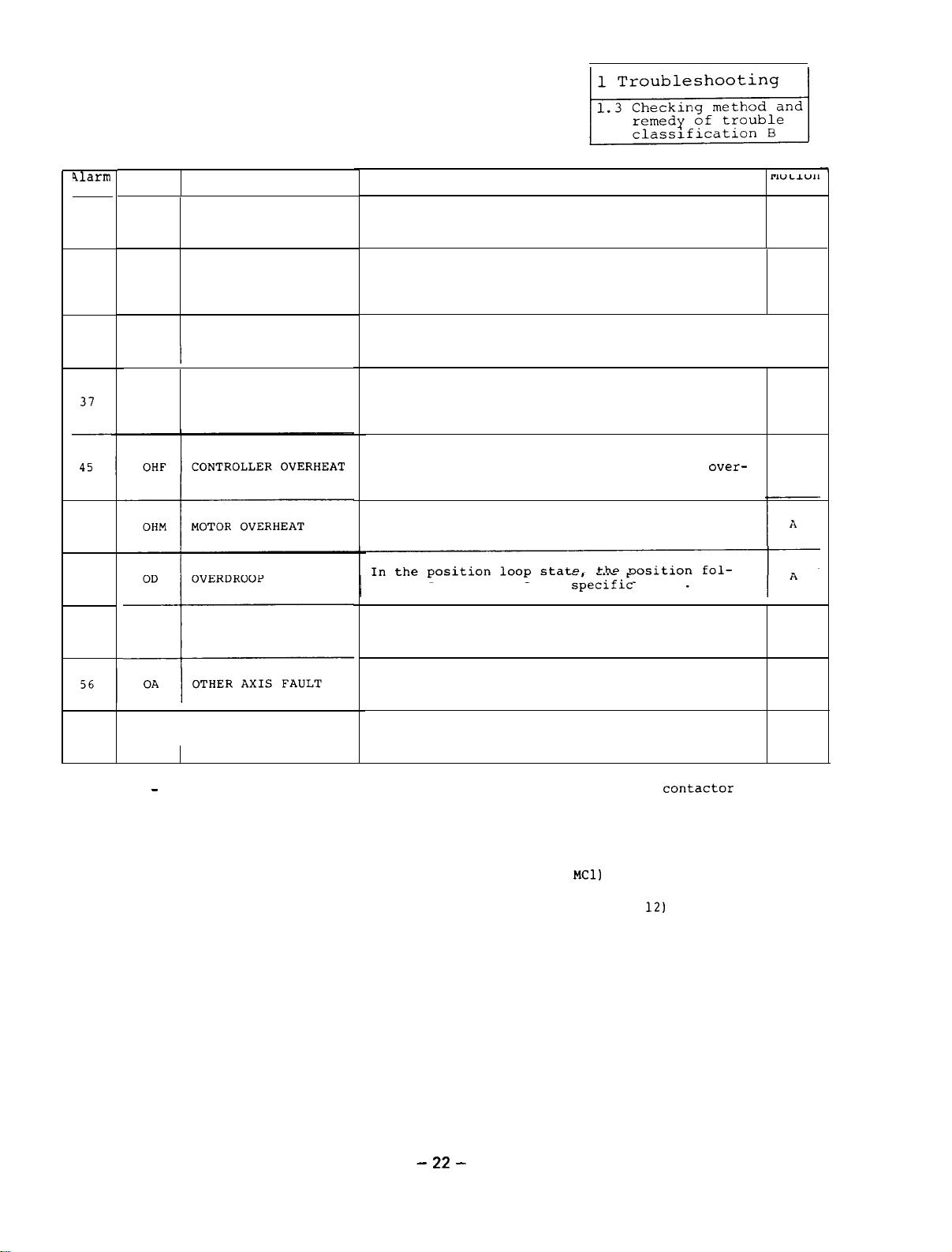

Page 27

Alarm

uo.

34

35

Abbr.

DP

DE

Name

DATA PARITY

DATA ERROR

Description

Parity error occurs in bus linkage with the M300

series CNC.

In bus linkage with the M300 series CNC, the

shift command which exceeds the specific value

is issued from the CNC.

Pl"CJ."ll

(Note)

A

A

36

46

52

57

Motion A - The base shut-off occurs in the controller, the main circuit

TE

PE

OPE

TRANSFER ERROR

PARAMETER ERROR

OPTION CARD ERROR

turned off,

trouble signal contacts FA-FC are open.

and the motor stops in the free-run state.

In the bus linkage with the M300 series CNC,

data is not correctly transferred.

A parameter value which exceeds the allowable

range is set.

the controller is turned on.)

The ambient temperature is abnormal or the main

circuit devices are overheated because an

load is applied or the air cooling fan stops.

The motor is overheated because an overload

is applied or the motor cooling blower stops.

lowing error exceeds the

In the bus linkage with the M300 series CNC,

any fault occurs in an other servo axis.

Any function which is not provided with the

option card is selected.

(It is set when the power of

sbecific

value.

COntaCtor

In additon, the

over-

is

A

A

A

A

A

(Note)

For the main circuit contactor

For the trouble signal contacts FA and FC :

: See Appendixes l-4 and l-5

- 22 -

(contact

See Appendixes l-4 and 1-5

(CON1 pins 11 and

MC11

12)

Page 28

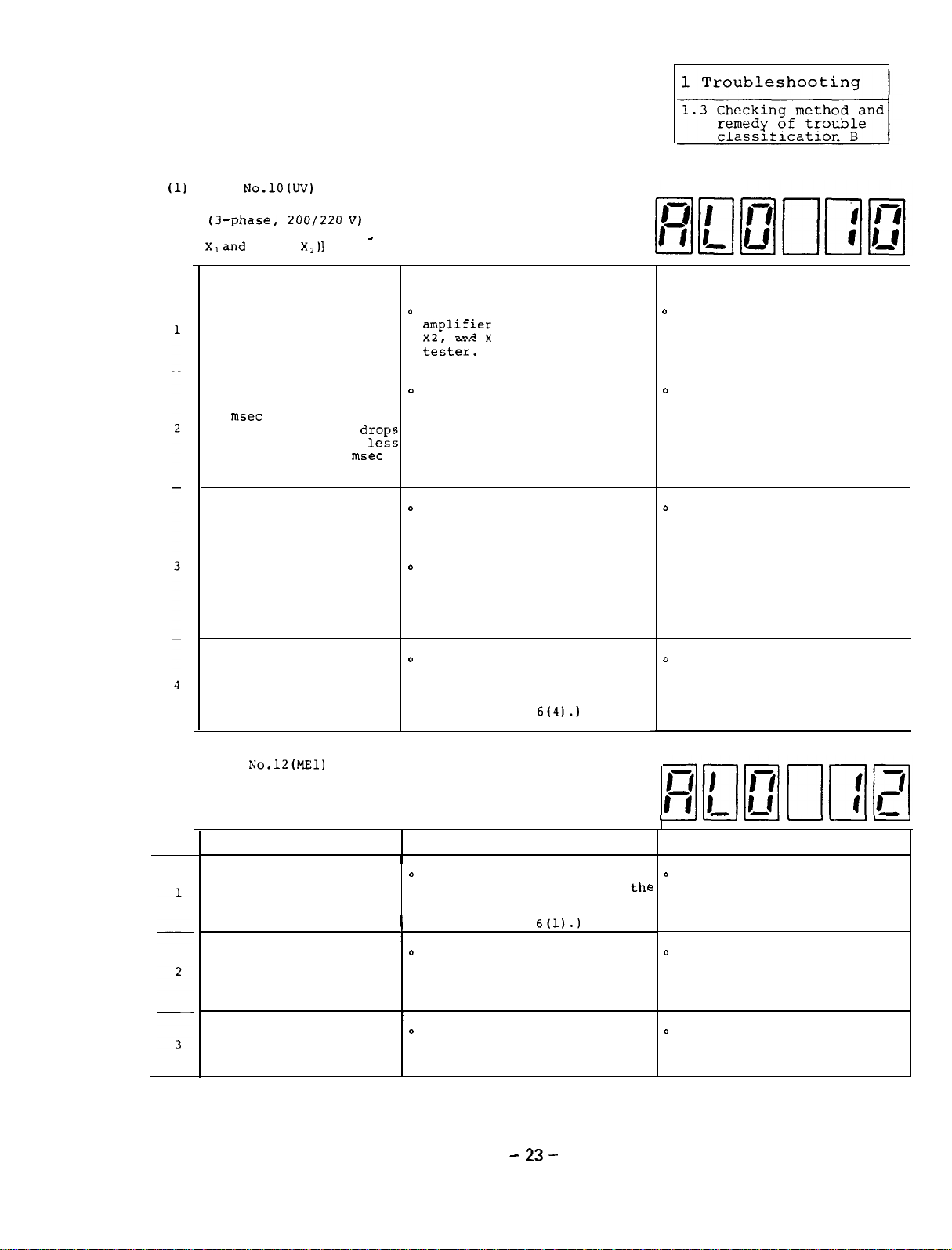

(1)

Alarm

No.lO(UV)

Under Voltage

[The voltage drop of the input voltage

(3-phase,

ZOO/220 V)

to the amplifier

is detected. (Voltage between phase

Xland

phase

X,)1

_

Item

Cause Check

The AC input votlage of

the amplifier drops to

a voltage which is less

than 170 V.

An instantaneous power

failure which lasts for

15

msec

(the input votlage

to a value which is

than 170 V for 15

or more occurs

drop2

less

msec

or more).

The power capacity is

insufficient.

The control power

(SF-PW module) is defec-

tive.

0

Check the voltage at the

;plifier

input terminals Xl,

and X3 using a circuit

teiter.

0

Check the voltage waveforms

at the amplifier input terminals Xl, X2, and X3 using an

oscilloscope.

0

Check the voltage waveforms

at the amplifier input terminals Xl, X2, and X3 using an

oscilloscope.

0

Check that the input voltage

drops while the spindle

motor is in the acceleration/

deceleration state or while

an overload is applied.

0

Check that the voltage bet-

ween ACDOW and DO24 of the

block A in the SF-PW module

is + 5V.

(See Appendix

6(4).)

Remedy

0

Check the cause of which the

input voltage drops and take

proper countermeasures.

0

Check the cause of the

instantaneous power failure

and take porper counter-

measures.

o

Increase the power capacity.

o

Replace the SF-PW module

with a new one.

(2) Alarm

No.l20l!Zll

Memory Error 1

[The integrify of the contents Of

RO

M are compared with those of RAM

during initialization.]

Item Cause

Check

I

EPROM is not installed

in the correct position.

0

Visually check that ROM's 1,

2, and 3 are installed at

correct positions on SF-CA

card.

1

(See Appendix

I

0

There is an imperfect

connection between pins

of EPROM and the socket.

Visually check that pins of

ROM's 1, 2, and 3 are not

bent and they are correctly

inserted into the sockets.

The printed circuit

board SF-CA card is

0

Replace the SF-CA card with

a new one and check that the

defective. new one correctly works.

- 23 -

6(l).)

-II-II-II

Remedy

o

Install each ROM in the cor-

rect position.

e

thl

D

Straighten the pins being

bent and securely insert

them into the socket.

o

Replace the SF-CA card with

the new one.

(See Section 2.4.4).

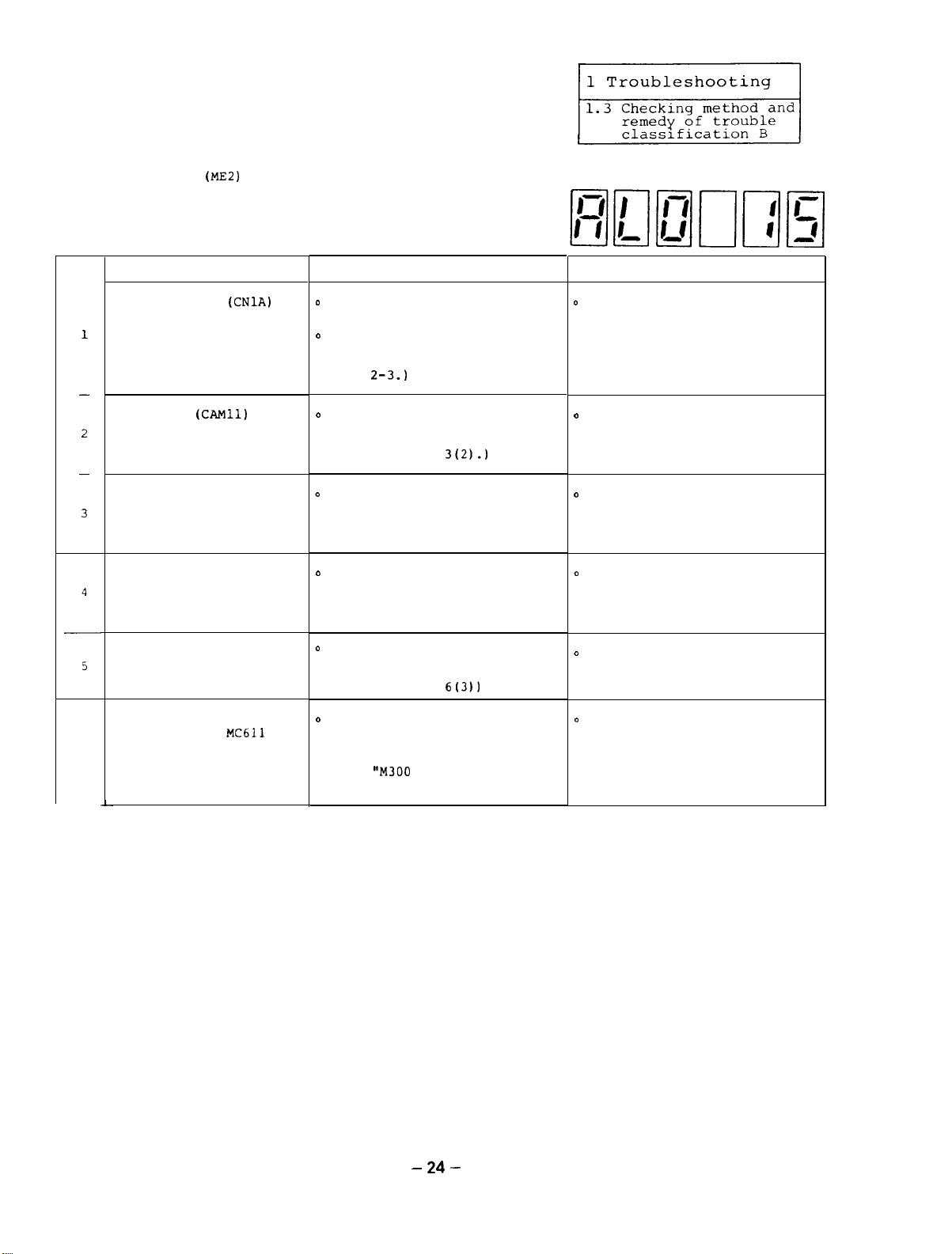

Page 29

(3) Alarm No.15

(ME2)

Memory Error 2

[The integrity of the contents of

the 2-port RAM which communicates

with the NC during initialization

is checked.1

Item

The connector

which is linked with the

NC through the bus is

not securely connected.

Cause Check Remedy

D

(CNlA)

Check the looseness of the

connector.

o

Check that the set screws of

the connector are not loosen.

(See Appendixes l-6 to l-9

and

2-3.)

The cable

is connected with the NC

(CAM11)

which0 Replace the cable with a new

one and check that the equip-

through the bus is ment correctly works.

defective.

(See Appendix

The ground wires of theo Visually check that the

amplifier, and motor

NC,

are not correctly con- connected by referencing

nected.

The signal cable is not

correclty shielded.

ground wires are correctly

Appendix 1.

0

Visually check that the

signal cable is correctly

shielded by referencing

Appendix 1.

o

The printed circuit

board SF-TL card is

defective_

The NC side printed

circuit board

MC632 is defective.

6

~~611

or

Replace the SF-TL card with

a new one and check that the

equipment correctly works.

(See Appendix

o

Replace the MC611 or MC632

cards with new ones and check

that the equipment correctly

work.

(See

"M300

Series Maintenance

Manual".)

L

3(2).)

6(3)1

D

Securely connect the connec-

tor and tighten the screws.

o

Replace the cable with the

new one.

o

Correclty connect the

ground wires.

o

Correctly shield the signal

cable.

o

Replace the SF-TL card with

a new one.

(See Section 2.4.3.)

D

Replace the MC611 or UC632

cards with the new ones.

MC632: M310

MC611: All other

- 24 -

Page 30

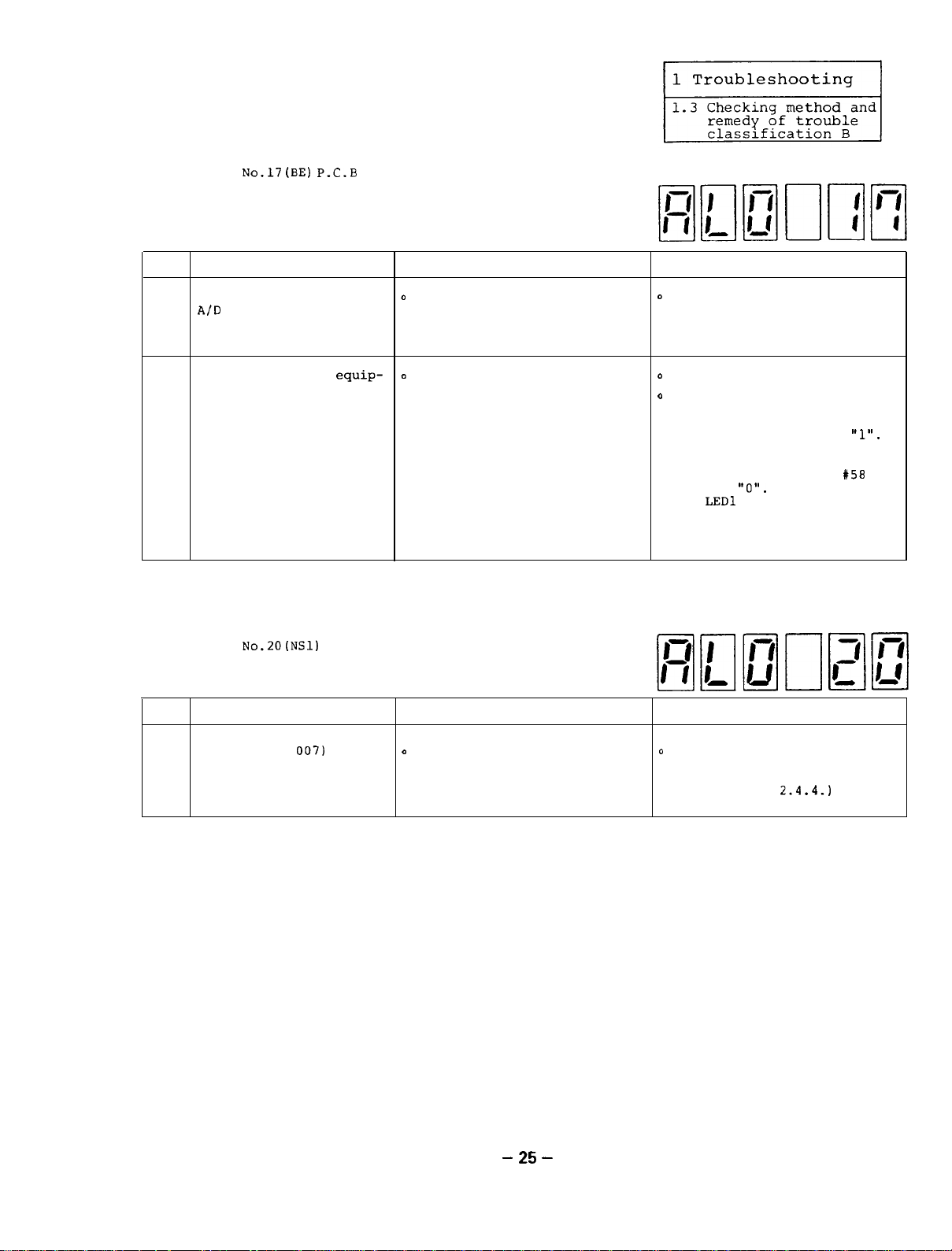

(4) Alarm

[Whether a component (especially

A/D converter) on the printed circuit board is normal or abnormal

is checked.

No.l7(BE) P.C.B

1

error

Item

A component (especially,

A/D

1

2

(5) Alarm

Item

converter) on the

printed circuit board

SF-CA card is defective. works.

The power of the

ment is turned on while

the NF in the unit is

turned off.

[The internal codes of the IC MAC007

on the SF-CA card are checked.]

Cause Check Remedy

equip-

No.20(NSl)

IC MAC007 Error

Cause Check

D

Replace the SF-CA card with

the new one and check that

the equipment correctly

D

Check that the NF is turned

off.

o

Replace the SF-CA card with

the new one.

(See Section 2.4.4.)

o

Turn on the NF.

o

To check only the control

circuit without appearance

of alarm No.17, set the

parameter X58 CVHS to

However,

the normal operation mode,

make sure to set the

CVHS to

the

ing regeneration) on the

SF-CA card continuously

lights.

to return back to

"0".

LED1

(which lights dur-

Otherwise,

Remedy

"1".

158

The IC (MAC

printed circuit board

1

SF-CA card does not

correctly work.

007)

on the

o

D

Replace the SF-CA card with a

new one and check that the board SF-CA card with the

equipment correctly works. new one.

Replace the printed circuit

(See Section

2.4.4.)

- 25 -

Page 31

1 Troubleshooting

1.3

Checking method and

remedy of trouble

r

classification B

(6) Alarm

[The signals of

Item Cause Check

1

2

NO.~~(NS~)

spindle orientation encoder are checked

during orientation and synchronous tapping

state.1

The cable

the spindle orientation

encoder is defective. oscilloscope. (See Appendix 3

The encoder for the

spindle orientation is same manner as Item 1 above. new one.

defective.

NO Signal 2 (Spindle

phases

(MR-ZOLF)

A, B, and C of the

toD Observe the signal waveform

from the encoder using an

o

Check the check pins on the

printed circuit board SF-TL

card.

.

Between

.

Between CH2 and DGA, for

.

Between CH3 and DGA, for

(See Appendixes

o

Replace the cable with a new

one and check that the equipment correctly works.

(See Appendix 1 - 7.)

o

Check the wave form in the

o

Replace the encoder with a

new one and check that the

equipment correctly works.

(See Appendix 7.)

phase A

phase B

phase

9(3).)

ENC)

CHl

and DGA, for

2

6(3)

and

Remedy

o

Replace the cable to the

encoder with the new one.

(2j.l

*

D

Replace the encoder with the

The printed circuit

board SF-TL card is from the encoder at CONB

defective.

3

The 5V power is not

supplied from the NC NC side.

side to the encoder.

4

o

Observe the signal waveform

on the SF-TL card using the

oscilloscope and check that

it is normal.

(See Appendix 1 -

o

Check the 5V power on the

o

Replace the cable with a new

one and check that the

ment correctly works.

7.1

equip-

o

Replace the printed circuit

board SF-TL card with a

new one.

(See Section

o

Repair the power supply on

the NC side.

Refer to M300 series

Maintenance

o

Replace the cable with a new

one.

o

If the 5 V power is not

plied from the NC side

(namely,

connected with the NC),

shortcircuit the pin 5 on

the SF-TL card to pins 2 and

3 (no power supply form the

NC).

2.4.3.)

manual

sup-

when CONAA is not

- 26 -

Page 32

(Note) The correct output waveform of the encoder is as follows:

@

When the spindle of the machine rotates counterclockwise at approx. 500 rpm

while the bit 8 of the parameter

Phase A

ORSZ

is 0:

Phase

Phase

@

When the spindle of the machine rotates clockwise at approx. 500 rpm and when

the bit 8 of the parameter OSR2 is 0,

occurs.

(7) Alarm

[The internal codes of the IC MAC012

Item Cause Check Remedy

1

No.22(NSS)

are checked. 1

The IC (MAC 012) and

the related circuits on

the printed circuit

board SF-CA card do

not correctly work.

B

2

___.

IC MAC012 Error

I

o

Replace the SF-CA card with ao Replace the printed circuit

new one and check that the board SF-CA card with the

equipment correctly works.

(See Appendix

the same waveform as the above figure

new one.

6(l))

(See Section 2.4.4.)

- 27 -

Page 33

>‘I / c

4

,P+

(13) Alarm

[The difference between the speed reference

4

No.23(OSE)

value and real speed is checked and if the

deviation which is 50 rpm or more lasts

for 12 sec. or more, an alarm occurs.1

c

Speed Control Error Excess

/)

0

ir

Item

The phase sequence of

wires U, V,

are connected between

the amplifier and the

motor is incorrect.

One of the wires U, V,

and W which are

netted

amplifier and the motor

is broken.

The motor is overloaded.

The printed circuit

board SF-CA card is

defective.

The integration gain

parameter VKI (amplifier

parameter X37; NC

meter:

loop is set to 0.

Cause

and W which

between the

#23)

of the speed

con-

para-

Check

o

Increase the reference speedD Correctly connect the wires

and check that the motor

rotates at a low speed.

o

Visually check the phase

sequence of wires U. V,

and W.

o

Check that the motor does not

smoothly rotate.

o

Remove the wires U, V, and W

on the amplifier side and

check that there is no electric discontinuity in the

wires U, V, and W.

o

Check whether the motor iso Review the cutting condition

overloaded using a load meter

or load display in the status

display mode.

(See Section 1.1.1)

D

Replace the SF-CA card with ao Replace the printed circuit

new one and check that the board SF-CA card with the

equipment correctly works.

D

Check the parameters beingo Set the parameters to the

set by referencing Section

1.1.1

or 1.1.2.

U, V,

amplifier and the motor.

0

Replace the power wire which

is broken with a

and tool being used.

new one.

(See Chapter 2.)

standard values by refer-

encing Reference 1.2.2 or

1.2.3.

0

If the motor unstably

rotates,

to correct values by refer-

encing Alarm No. 31 Item 2.

Remedy

and W between the

new one.

set the parameters

The volume on the

printed circuit board

for the motor built-in

encoder (in the motor

terminal box) is not

correctly adjusted.

o

Check that the motor rotates

at several

speed display is

o

Set the parameters of the

amplifier as follows and

put the speed reference and

start command to rotate the

motor at a low speed.

parameter 00 becomes valid

just after it is set to

Since the parameter is

cleared when the power is

turned off or reset, after

it is set to

speed reference and start

command.

ten

rpm and the

"0".

"l",

input the

in-

The

"ll..

- 28 -

0

Adjust the volume

and VR4 so that the

VR3,

output waveforms of phases

A and B are in the

ard value range by referencing the section

ing to adjustment and

replacement of motor

built-in encoder (Section

6.9).

Continued on the next page.

VRl, VR2.

standrelat-

Page 34

1 Troubleshooting

1.3

Checking method and

remedy of trouble

classification 0

Item

The printed circuit

board in the motor

built-in encoder speed display indicates

(motor terminal box) is

defective.

7

Cause

Check Remedy

o

Check the signal waveform at

the check pins on the printed

circuit board SF-CA card

using an oscilloscope.

Phase A signal:

Phase B signal:

(See Appendixes

9(l).)

(Note) Before using the check

pins,

amplifier should have been

turned off.

0

Check that the motor rotates

at several ten rpm and the

o

Like the same manner as the

Item 6 above, in the open

loop state, rotate the motor

at a low speed.

0

Like the same manner as the

Item 6,

waveform of the check pins on

the SF-CA card using an

oscilloscope.

0

By referencing the descrip-

tion relating to adjustment

and replacement of the motor

built-in encoder described

in Section 2.9, observe the

waveforms between PA and PGA

and between PB and PGA using

an oscilloscope and check

that they can be in the

standard value range using

volume resistors

VR3 and

the power of the

check the signal

VR4).

CH44-CH9

(or AGA)

CH45-CH9

(or AGA)

6(l)

and

(VRl, VR2,

"0".

0

Replace the printed circuit

board in the motor terminal

box and adjust the controls

by referencing Section 2.9.

The sensor in the motoro Check that the output

built-in encoder is forms between PA and PGA and

defective.

a

(9)

(10)

Alarm

Alarm

No.24tBRT)

No_25(COC)

Breaker Trip

Converter Overcurrent

between PB and PGA on the

encoder printed circuit board

cannot be adjusted in the

standard value range even

after the printed circuit

board has been replaced in

the manner described in the

Item 7 above.

- 29 -

wave-

o

Replace the entire motor

with a new one.

o

If the motor cannot be

replaced, replace it

together with the sensor

and printed circuit board

by referencing Section

2.9.

Page 35

(111

Alarm

No.32(OC)

Inverter Overcurrent

Item Cause

The input power voltage

waveform is defective.

1

Check

o

Observe the voltage waveforms

at the input terminals Xl, X2,

and X3 of the amplifier using

an oscilloscope.

0

Check that the voltage wave-

forms are as follows even in

the acceleration or

tion state.

(al

If the waveform is

tially lost:

It should be

If the peak value drops:

(bl

t.-

100 us or less.

<-.

decelera-

par-

-L

It should be

2 to 3% or

less.

Remedy

Increase the power capacity.

0

0

Thicken the size of the

cable between the input

power supply and amplifier.

0

Check other semiconductor

devices which generate

distorted waveforms and

install surge killers and

so force.

(For example, MATSUO made,

rating 200 VAC,

12003-5041, etc.)

DCRZ-

The input power

ante

is high.

(Example,

that two transformers

2

are connected in series

or a variable

transformer is con-

netted)

The input power

quency remarkably

3

changes.

The motor selection

parameters

4

are not correctly set.

The transistor module

is defective.

5

in the cases

#Ol

imped-

auto-

fre-

and

102

0

o

Check that the alarm occurs

only when the motor speed

decelerates from a high

speed.

0

Check that the input voltage

temporarily drops to 170 V power supply and amplifier.

or less when the motor

decelerates.

0

Check the voltage frequencies

at the input terminals Xl,

and X3 of the amplifier

x2,

using a frequency counter.

o

Check that the parameters are0 Correctly set the

correctly set by referencing

Reference 1.2.2.

0

Check that this alarm occurs

even after the equipment is unit of the amplifier with

reset.

0

Disconnect the cable between

the amplifier and motor and

check that this alarm occurs

when only the amplifier is

operated.

(See Appendix l-2.1

-

30

-

Replace the power supply

with an other one whose

power impedance is low.

0

Tighten the screws of

nections

0

Check the cause of the fre-

quency

the related controls so

that it is in the specification range.

meters.

(See Reference

0

Replace the main circuit

a new one.

between the input

variation and

1.2.3.)

Continued on the next page.

con-

adlust

para-

Page 36

1 Troubleshooting

1.3 Checking method and

remedy of trouble

classification B

Cause

The diode stack is

defective.

The surge absorbers and

condensers are defective.

The current detection

circuit is defective.

8

The motor is overloaded.

9

Check

o

Check the diode stack in the

same manner as the Item 5

above.

o

Check them in the same manner

as the Item 5 above.

0

Observe the waveforms at the

following check pins using an

oscilloscope and check that

the peak value exceeds 10 V.

Between CH39 and AGA:

Regenerative converter

side

Between CH42 and AGA:

Converter side

Between CH43 and AGA:

Inverter side

(See Appendix

0

Check that the motor is over-

loaded using a load meter or

the load display in the

status display

Section

1.1.1).

9(l).)

mode (see

Remedy

0

Replace the main circuit

unit of the amplifier with

a new one.

(Note)

See Section 2.6 and

2.7.

0

Replace the main circuit

unit of the amplifier with

a new one.

0

Replace the printed circuit

board SF-CA card with a new

one.

(See Section 2.4.4.)

(Note) Normally, the peak

voltage is in the range

from 6 to 7 V while the

motor accelerates or

decelerates.

D

Review the cutting condition

and tool being used.

The cable connections

between the amplifier

and motor are incorrect.

10

The wiring of the motor

is rare-shortcircuited

or earth-grounded.

11

3

Visually check the cable con-

nections.

0

Check that the screws of the

cable connection terminal are

loosen.

Disconnect the cables between

the amplifier and motor and

check the insulation resistance between the following

leads.

Between U and W; between V

and W; between U and W;

between each of U, V, and

W and E

3

Correctly connect the

cables.

s

Tighten the screws being

loosen.

)

Replace the motor with a

new one.

-

31

-

Page 37

1 Troubleshooting

1.3 Checking method and

remedy of trouble

classification

B

(12) Alarm

Item

1

2

(13) Alarm

Item

1

No.26(PL)

[When R and T of phases R, S, and T are

normal,

checked.]

One of phases R, S, and

T is lacked when the

power is turned on.

One of the fuses

and F3 has been blown

when the power is turned

on.

No.27(CPUE)

[This alarm occurs when an CPU operation where

a value is divided by 0 is executed or the

result of division is overflowed.)

The parameter relating

to gear ratio is

correctly set.

Power Phase Lack

whether there is phase S is

Cause

D

Check the voltage between any

two phases of R, S, and T at

the input power terminals

and X3 using a circuit

X2,

tester.

o

Check the electric continuity

of each fuse using the

cuit

tester.

D

Check the parameter by

encing

Reference 1.2.2 for

that which is set from the

amplifier and Reference 1.2.3

for that which is set from

the NC.

Cause

Fl,

F2,

CPU Error (Division error)

in-

Check

Check

Sl,

cir-

refer-

Remedy

o

Check the cause of the phase

lack and take proper

countermeasures.

Replace the fuse being blown

0

with a new one.

(See Section 2.1.)

Remedy

o

Correctly set the parameter.

(Note) Compare the parameter

in the parameter list on

the cover of the amplifier

with that being set.

(See Appendix 10)

The connector

which is linked with the

2

NC through the bus is

loose.

The cable

is linked with the NC

3

through the bus is

defective.

The following parameterso Check the parameters by

relating to the gain of

the speed loop are

4

correct.

When a special motor iso Compare the

used (when

5

are set), the motor

constants

incorrect.

(CNlA)

(CAMll)

VKP,VKI,ORSl.

181

whichD Check the cable in the same

in-

X01

and 02

to

XAF

are

o

Check the cable in the same

manner as the alarm No. 15

(k=2).

manner as the alarm No. 15

(-2).

referencing Reference 1.2.3.

the parameter list on the

amplifier cover with those

being set.

(See Appendix 10.)

parameters.in

- 32 -

o

Securely connect the

tor and the set screws.

o

Replace the cable with a new

one.

o

Correctly set the parameters.

(Note) Compare the parameters

in the parameter list on

the amplifier cover with

those being set.

(See Appendix 10.)

D

Correctly set the parameters

connec-

Page 38

1 Troubleshooting

I

1.3 Checking method and

remedy of trouble

classification

B

I

(14) Alarm

(The real speed of the motor is checked

Item Cause Check

1

No.31(0S)

and when it exceeds 115% of the motor

maximum speed,

The reference speed

exceeds 115% of the

maximum speed. speed being set.

The speed control system oObserve and check the signal

is unstable and an

shoot occurs.

Overspeed

this alarm occurs.)

o

Compare the reference speed

with the following maximum

Parameter being set from

the amplifier:

Parameter being set from

the NC: #17(TSP)

(See References

and

over-

between the speed signal

terminals SMO and OM using

an oscilloscope (See

dixes l-4 and l-5).

1.2.3(3).)

#31(TSP)

l-2.2(2)

Appen-

-~-

0

Decrease the reference

speed.

o

Correctly set the parameter

for motor maximum speed.

0

Decrease the parameter

values of the speed loop

gain VKP and VKI (amplifier

parameter

parameters

(Note) To check the occurrence

Remedy

Y36

and

#22

and X23).

--

#37

or NC

The motor built-in

coder is defective.

3

The printed circuit

board SF-CA card is

4

defective.

en-

o

If the signal output is

saturated when it exceeds

10 V because a too high speed

is set,

age rises to around 115% in

the speed mode of the status

display (see Section

or using the NC CRT monitor.

D

In the same manner as the

alarm

encoder output signal

form using the oscilloscope.

o

Rotate the motor using the

reference speed which is

slower than

and check that the frequencies of the signals of the

phase

following relation.

f(Bs) = +

o

Replace the SF-CA card with

a new one and check that it

correctly

check that the

1.1.1)

No_23(OSE),

A or B satisfy the

works.

check the

the

middle speed

x

(motor

speed(rpm)

wave-

volt-

(b) If the alarm does not

occur,

decrease the parameter

values of VKP and VKI.

o

In the same manner as the

alarm

replace the motor built-in

encoder with a new one.

No.23(OSE),

adjust or

1

o

Replace the printed circuit

board with a new one.

(See

Section 2.4.4.)

!

-

33

-

Page 39

(15) Alarm

No.33(OV)

OVerVOltage

[The voltage in the converter circuit is

checked and if it exceeds 400 V, this alarm

occurs.)

Item

The input power voltage

Cause Check

0

In the same manner as the

waveform is abnormal.

1

0

The input power

ante

is high. alarm

imped-

In the same manner as the

2

o

An instantaneous power

In the same manner as the

failure occurs in the

input voltage or the input power.

3

voltage drops when the

motor decelerates.

alarm No.24, No.25, and

No.32, check the waveform.

check the input power.

alarm

No.24/NoW25/No.32,

No.lO(LJV),

check the

Remedy

0

See the alarm

No.24/No.25/

No.32.

0

Increase the power capacity.

0

Thicken the size of the

cable between the input

power supply and the ampli-

fier.

0

Improve other components

which generate distorted

waves by installing surge

killers and so forth.

0

See the alarm

No.24/No.25/

No.32.

0

Replase the power supply

with that whose impedance

is low.

o

Tighten the screws of the

cable connections between

the input power and amplifier.

o

See the alarm

o

Check the cause of the

No.lO(UV).

instantaneous power failure

or voltage drop and improve

the power condition.

The printed circuit

board SF-CA card is

4

defective.

0

Replace the SF-CA card witho Replace the printed circuit