Satellite Training Series

PART

2

Your First Inverter

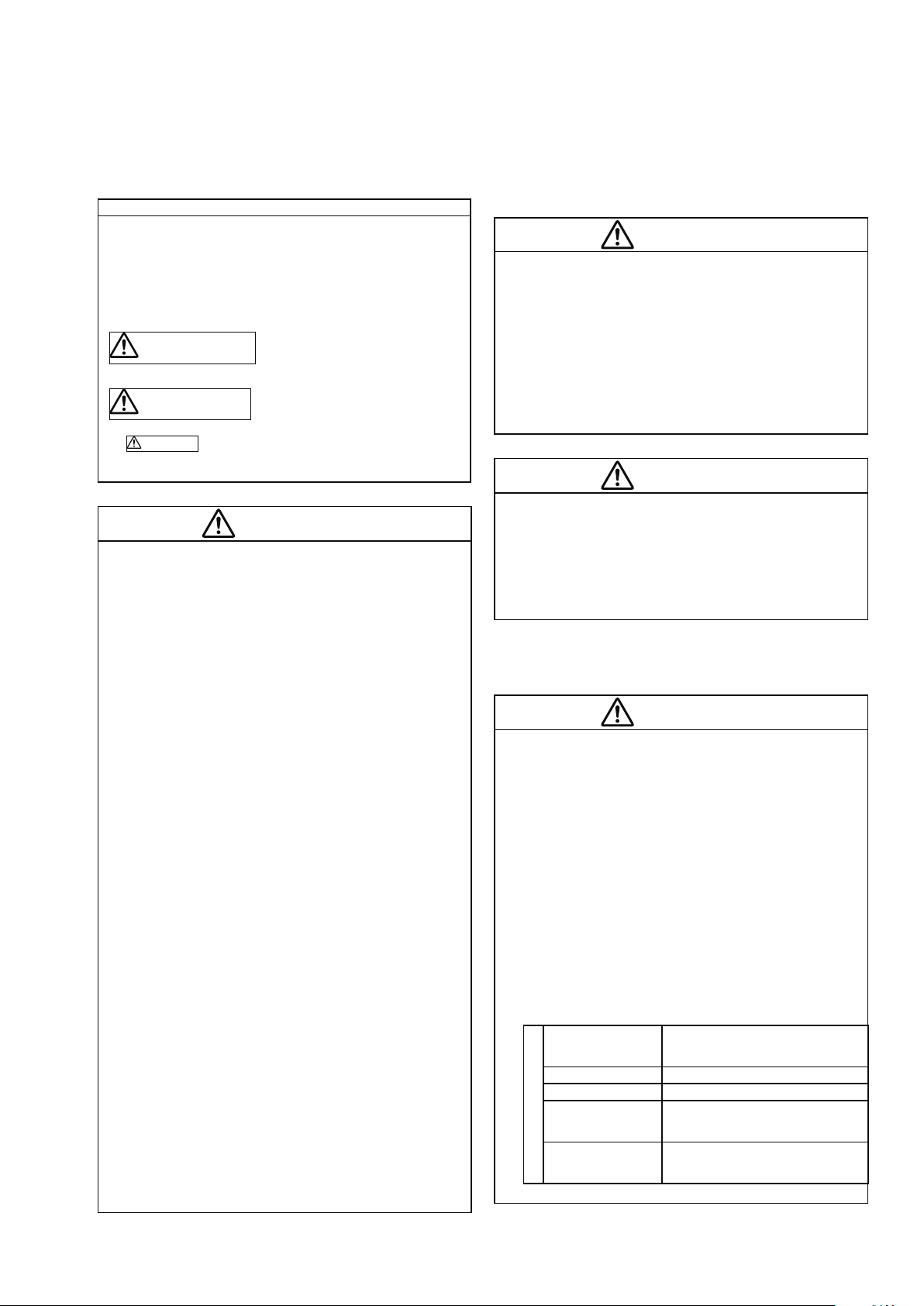

SAFETY PRECAUTIONS

:$51,1*

Always read these precautions

before using this equipment.

Before designing your system, make sure to read the related manuals of your

products to ensure that you exercise appropriate caution with regards to safety.

Take the following precautions and use the equipment correctly when practicing

and learning the material.

The Mitsubishi general-purpose inverter FR-E700 series is used for this training. If

the equipment in your actual environment is different, make sure to read the specif-

ic manual for your device as operation methods and parameter type differ depend-

ing on the specic model of inverter.

Training precautions

● Do not touch the terminals when the power is on to prevent electric shock.

● Before opening the cover, either turn off the power or ensure that it is safe to

open the cover.

● Do not insert your hands into moving parts.

This section is specically about safety matters

:$51,1*

&$87,21

&$87,21

:$51,1*

&$87,21

&$87,21

&$87,21

Do not attempt to install, operate, maintain or inspect the inverter

until you have read through the Instruction Manual and appended

documents carefully and can use the equipment correctly. Do not

use this product until you have a full knowledge of the equipment,

safety information and instructions.

In this Instruction Manual, the safety instruction levels are

classied into "WARNING" and "CAUTION".

Incorrect handling may cause hazardous conditions, resulting in death or

severe injury.

Incorrect handling may cause hazardous

conditions, resulting in medium or slight

injury, or may cause only material damage.

The

according to conditions. Both instruction levels must be followed

because these are important to personal safety.

level may even lead to a serious consequence

1. Electric shock prevention

● While power is ON or when the inverter is running, do not

open the front cover. Otherwise you may get an electric shock.

● Do not run the inverter with the front cover or wiring cover

removed. Otherwise you may access the exposed high voltage

terminals or the charging part of the circuitry and get an electric

shock.

● Even if power is OFF, do not remove the front cover except

for wiring or periodic inspection. You may access the charged

inverter circuits and get an electric shock.

● Before wiring or inspection, power must be switched OFF.

To conrm that, LED indication of the operation panel must

be checked. (It must be OFF.) Any person who is involved in

wiring or inspection shall wait for at least 10 minutes after the

power supply has been switched OFF and check that there

are no residual voltage using a tester or the like. The capacitor

is charged with high voltage for some time after power OFF,

and it is dangerous.

● This inverter must be earthed (grounded). Earthing (grounding)

must conform to the requirements of national and local safety

regulations and electrical code (NEC section 250, IEC 536

class 1 and other applicable standards). A neutral-point earthed

(grounded) power supply for 400V class inverter in compliance

with EN standard must be used.

● Any person who is involved in wiring or inspection of this

equipment shall be fully competent to do the work.

● The inverter must be installed before wiring. Otherwise you

may get an electric shock or be injured.

● M Dial and key operations must be performed with dry hands

to prevent an electric shock. Otherwise you may get an electric shock.

● Do not subject the cables to scratches, excessive stress,

heavy loads or pinching. Otherwise you may get an electric

shock.

● Do not change the cooling fan while power is ON.

It is dangerous to change the cooling fan while power is ON.

● Do not touch the printed circuit board with wet hands.

Otherwise you may get an electric shock.

● When measuring the main circuit capacitor capacity, the DC

voltage is applied to the motor for 1s at powering OFF. Never

touch the motor terminal, etc. right after powering OFF to

prevent an electric shock.

2. Fire prevention

● Inverter must be installed on a nonammable wall without holes

(so that nobody touches the inverter heatsink on the rear side,

etc.). Mounting it to or near ammable material can cause a re.

● If the inverter has become faulty, the inverter power must be

switched OFF. A continuous ow of large current could cause a re.

● When using a brake resistor, a sequence that will turn OFF

power when a fault signal is output must be congured.

Otherwise the brake resistor may excessively overheat due to

damage of the brake transistor and such, causing a re.

● Do not connect a resistor directly to the DC terminals P/+ and

N/-. Doing so could cause a re.

3. Injury prevention

● The voltage applied to each terminal must be the ones specied in

the Instruction Manual. Otherwise burst, damage, etc. may occur.

● The cables must be connected to the correct terminals.

Otherwise burst, damage, etc. may occur.

● Polarity must be correct. Otherwise burst, damage, etc. may occur.

● While power is ON or for some time after power-OFF, do not touch

the inverter as they will be extremely hot. Doing so can cause burns.

4. Additional instructions

Also the following points must be noted to prevent an ac-

cidental failure, injury, electric shock, etc.

(1)

Transportation and mounting

● The product must be transported in correct method that cor-

responds to the weight. Failure to do so may lead to injuries.

● Do not stack the boxes containing inverters higher than the

number recommended.

● The product must be installed to the position where withstands

the weight of the product according to the information in the

Instruction Manual.

● Do not install or operate the inverter if it is damaged or has

parts missing.

● When carrying the inverter, do not hold it by the front cover or

M Dial; it may fall off or fail.

● Do not stand or rest heavy objects on the product.

● The inverter mounting orientation must be correct.

● Foreign conductive bodies must be prevented to enter the

inverter. That includes screws and metal fragments or other

ammable substance such as oil.

● As the inverter is a precision instrument, do not drop or subject

it to impact.

● The inverter must be used under the following environment.

Otherwise the inverter may be damaged.

Surrounding air

temperature

Ambient humidity 90%RH or less (non-condensing)

Storage temperature -20°C to +65°C

Atmosphere Indoors (free from corrosive gas,

Environment

Altitude/vibration Maximum 1,000m above sea level.

*1 Temperature applicable for a short time, e.g. in transit.

-10°C to +50°C (non-freezing)

(-10°C to +40°C for totally-enclosed

structure feature)

*1

ammable gas,

oil mist, dust and dirt)

2

5.9m/s

or less at 10 to 55Hz (direc-

tions of X, Y, Z axes)

(2) Wiring

&$87,21

&$87,21

:$51,1*

&$87,21

&$87,21

&$87,21

&$87,21

&$87,21

● Do not install a power factor correction capacitor or surge sup-

pressor/capacitor type lter on the inverter output side. These

devices on the inverter output side may be overheated or burn

out.

● The connection orientation of the output cables U, V, W to the

motor affects the rotation direction of the motor.

(3) Trial run

● Before starting operation, each parameter must be conrmed

and adjusted. A failure to do so may cause some machines to

make unexpected motions.

(4) Usage

● Any person must stay away from the equipment when the

retry function is set as it will restart suddenly after trip.

● Since pressing

the function setting status, separate circuit and switch that

make an emergency stop (power OFF, mechanical brake

operation for emergency stop, etc.) must be provided.

● OFF status of the start signal must be conrmed before

resetting the inverter fault. Resetting inverter alarm with the

start signal ON restarts the motor suddenly.

● The inverter must be used for three-phase induction motors.

Connection of any other electrical equipment to the inverter

output may damage the equipment.

● Do not modify the equipment.

● Do not perform parts removal which is not instructed in this

manual. Doing so may lead to fault or damage of the product.

key may not stop output depending on

● The inverter can be easily set for high-speed operation. Before

changing its setting, the performances of the motor and machine must be fully examined.

● Stop status cannot be hold by the inverter's brake function. In

addition to the inverter’s brake function, a holding device must

be installed to ensure safety.

● Before running an inverter which had been stored for a long

period, inspection and test operation must be performed.

● For prevention of damage due to static electricity, nearby

metal must be touched before touching this product to eliminate static electricity from your body.

● If you are installing the inverter to drive a three-phase device

while you are contracted for lighting and power service, consult your electric power supplier.

(5) Emergency stop

● A safety backup such as an emergency brake must be provid-

ed to prevent hazardous condition to the machine and equipment in case of inverter failure.

● When the breaker on the inverter input side trips, the wiring

must be checked for fault (short circuit), and internal parts of the

inverter for a damage, etc. The cause of the trip must be identi-

ed and removed before turning ON the power of the breaker.

● When any protection function is activated, appropriate cor-

rective action must be taken, and the inverter must be reset

before resuming operation.

(6) Maintenance, inspection and parts replacement

● Do not carry out a megger (insulation resistance) test on the

control circuit of the inverter. It will cause a failure.

(7) Disposal

● The electronic thermal O/L relay function does not guarantee pro-

tection of the motor from overheating. It is recommended to install

both an external thermal and PTC thermistor for overheat protection.

● Do not use a magnetic contactor on the inverter input for

frequent starting/stopping of the inverter. Otherwise the life of

the inverter decreases.

● The effect of electromagnetic interference must be reduced

by using a noise lter or by other means. Otherwise nearby

electronic equipment may be affected.

● Appropriate measures must be taken to suppress harmonics.

Otherwise power supply harmonics from the inverter may heat/

damage the power factor correction capacitor and generator.

● When driving a 400V class motor by the inverter, the motor

must be an insulation-enhanced motor or measures must be

taken to suppress surge voltage. Surge voltage attributable to

the wiring constants may occur at the motor terminals, deteriorating the insulation of the motor.

● When parameter clear or all parameter clear is performed, the

required parameters must be set again before starting operations because all parameters return to the initial value.

● The inverter must be treated as industrial waste.

General instruction

Many of the diagrams and drawings in this Instruction Manual show

the inverter without a cover or partially open for explanation. Never

operate the inverter in this manner. The cover must be always reinstalled and the instruction in this Instruction Manual must be followed when operating the inverter.

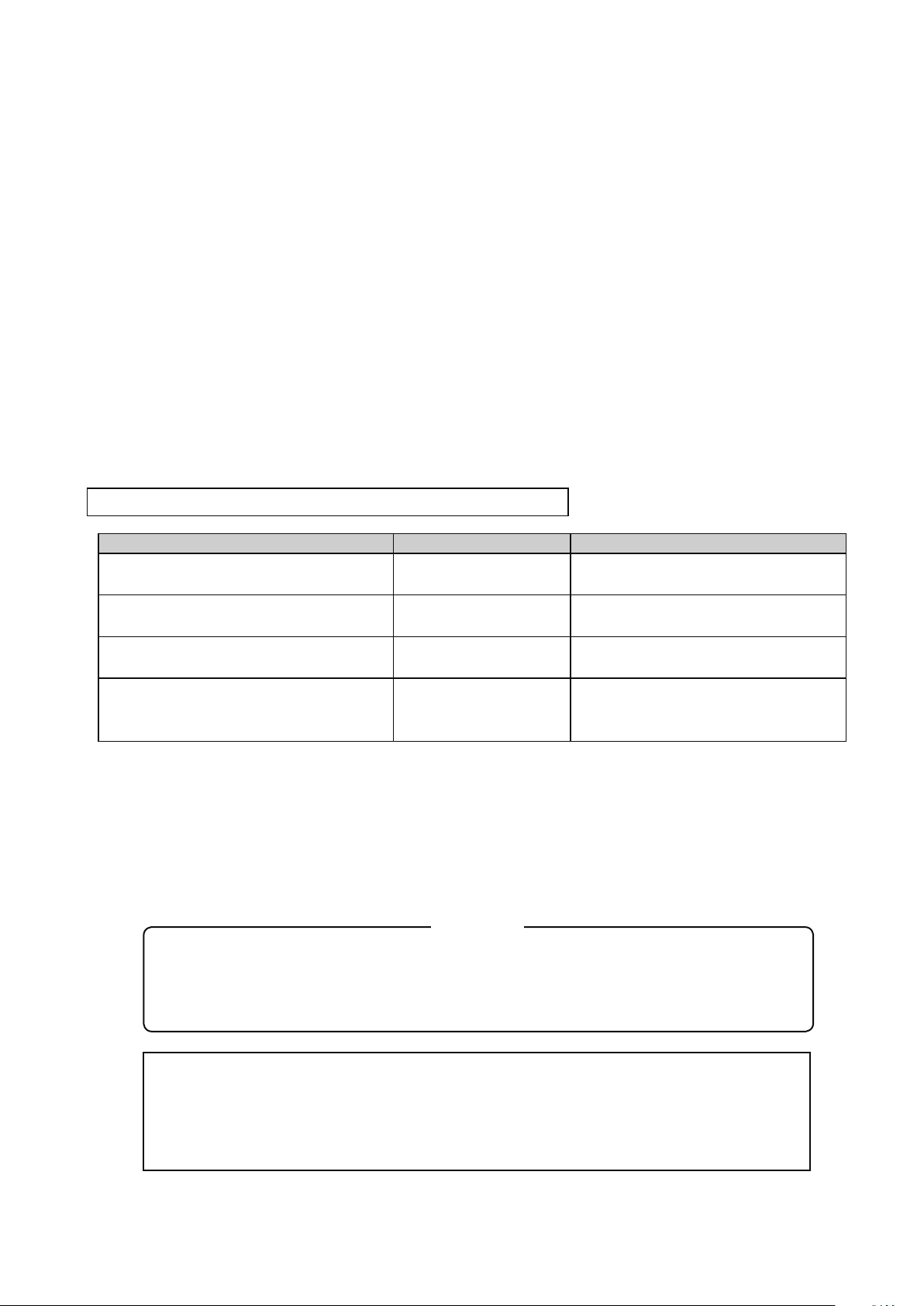

Introduction

This document covers some fundamentals of inverters that rst-time users of inverters should

know.

This document was created on the premise that the Mitsubishi general-purpose inverter FR-E700

series would be used for training.

Before wiring your inverter, make sure to read the related manuals of your products to ensure

that you exercise appropriate caution with regards to safety.

The following table lists some related documentation.

Manual name Manual number Description

Inverter FREQROL-E700

Instruction Manual (Basic Edition)

Inverter FREQROL-E700

Instruction Manual (Practical Use Edition)

Inverter setup software

FR Congurator SW 3 Instruction Manual

GOT2000 series

Connection Manual (Connecting with

Mitsubishi Devices Edition)

IB-0600441ENG Excerpts from E700 usage precautions

and the parameter list

IB-0600277ENG Excerpts from E700 specications,

wiring, and installation

IB-0600306ENG Excerpts from content regarding

starting the inverter setup

SH-081197ENG Excerpts from content regarding

connections between the inverter and

GOT

• Windows

United States and other countries of Microsoft Corporation.

• Other company names or product names are trademarks or registered trademarks of their

respective companies.

This manual confers no industrial property rights or any rights of any other kind, nor does it

confer any patent licenses.

Mitsubishi Electric Corporation shall not be held responsible for any problems involving

industrial property rights which may occur as a result of using the content described in this

manual.

®

, Windows 7®, and Windows 8® are trademarks and registered trademarks in the

Trademarks

Contents

Chapter 1 Brief description of inverters 1-1

1.1 What is an inverter? ..................................................................................................................... 1-2

1.1.1 Basic functions of the inverter ............................................................................................. 1-2

1.1.2 Benets of the inverter ........................................................................................................ 1-2

1.1.3 Familiar examples where inverters are used ...................................................................... 1-3

1.2 Motor drive force .......................................................................................................................... 1-6

1.2.1 Motor and frequency ........................................................................................................... 1-6

1.2.2 Principles of the motor ........................................................................................................ 1-7

1.3 Changing frequency..................................................................................................................... 1-8

1.3.1 Structure of the inverter ...................................................................................................... 1-8

Chapter 2 Specic models of the inverter 2-1

2.1 Mitsubishi general-purpose inverters ........................................................................................... 2-2

2.1.1 Lineup ................................................................................................................................. 2-2

2.2 Detailed description of the inverter .............................................................................................. 2-5

2.2.1 Parts identication for the Mitsubishi general-purpose inverter FR-E700 series ................ 2-5

2.3 Connecting the inverter................................................................................................................ 2-6

2.3.1 Removing and installing the cover ...................................................................................... 2-6

2.3.2 Connecting the power cable ............................................................................................... 2-7

2.3.3 Control terminals ................................................................................................................. 2-8

2.4 Inverter usage precautions ........................................................................................................ 2-10

2.4.1 Installation of the inverter .................................................................................................. 2-10

2.4.2 Troubleshooting ................................................................................................................ 2-13

1

2

3

4

Chapter 3 Parameters 3-1

3.1 Setting basic parameters ............................................................................................................. 3-2

3.1.1 Brief description of parameters ........................................................................................... 3-2

3.1.2 Typical parameters .............................................................................................................. 3-2

3.2 Operation panel ........................................................................................................................... 3-3

3.2.1 Names and functions of the operation panel ...................................................................... 3-3

3.3 Selecting the operation mode and command source .................................................................. 3-4

3.3.1 Various operation modes .................................................................................................... 3-4

3.3.2 Operation mode selection (Pr. 79) ...................................................................................... 3-5

3.4 Basic operation modes ................................................................................................................ 3-6

3.4.1 External operation mode ..................................................................................................... 3-6

3.4.2 PU operation mode ............................................................................................................. 3-6

3.4.3 External/PU operation mode 1 ............................................................................................ 3-7

3.4.4 External/PU operation mode 2 ............................................................................................ 3-7

5

6

Appendix

3.5 How to congure parameters....................................................................................................... 3-8

3.5.1 Parameter clear/All parameter clear ................................................................................... 3-8

3.5.2 Pr. 9 Electronic thermal O/L relay ....................................................................................... 3-9

3.5.3 Pr. 3 Base frequency......................................................................................................... 3-10

3.5.4 Pr. 0 Torque boost ..............................................................................................................3-11

3.5.5 Pr. 1, 2 Upper-limit/lower-limit frequency .......................................................................... 3-12

3.5.6 Pr. 7, 8 Acceleration/deceleration time.............................................................................. 3-13

Chapter 4 How to use FR Congurator 4-1

4.1 Fundamental knowledge to operate FR Congurator .................................................................. 4-2

4.1.1 Items needed for connectivity ............................................................................................. 4-2

4.1.2 Connection method ............................................................................................................. 4-2

4.1.3 Startup ................................................................................................................................ 4-3

4.1.4 Screen conguration (Main frame)...................................................................................... 4-4

4.1.5 Screen conguration (Navigation area) .............................................................................. 4-5

4.1.6 Screen conguration (System area) ................................................................................... 4-6

4.1.7 Screen conguration (Monitor area) ................................................................................... 4-7

4.2 Easy Setup .................................................................................................................................. 4-8

4.2.1 Conguration method.......................................................................................................... 4-8

4.2.2 System property .................................................................................................................. 4-9

4.2.3 Communication setting ..................................................................................................... 4-10

4.2.4 Inverter setting method ......................................................................................................4-11

4.2.5 Automatic detection........................................................................................................... 4-12

4.2.6 Inverter selection............................................................................................................... 4-13

4.2.7 Control method ................................................................................................................. 4-14

4.2.8 Motor setting ..................................................................................................................... 4-15

4.2.9 Start command and frequency (speed) setting method .................................................... 4-16

4.2.10 Parameter List................................................................................................................. 4-17

4.3 Parameter List operations.......................................................................................................... 4-18

4.3.1 Parameter List functions ................................................................................................... 4-18

4.3.2 Read (Batch Read), write (Batch Write) and verication .................................................. 4-19

4.3.3 Parameter clear and all parameter clear........................................................................... 4-20

Chapter 5 Inverter external connections 5-1

5.1 Connecting GOT with the inverter ............................................................................................... 5-2

5.1.1 Function overview ............................................................................................................... 5-2

5.1.2 System conguration .......................................................................................................... 5-2

5.1.3 Cable connection diagram .................................................................................................. 5-3

5.1.4 Inverter communication settings ......................................................................................... 5-4

5.1.5 GOT communication settings .............................................................................................. 5-5

1

2

3

4

Appendix

5

6

5.2 Connecting MELSEC iQ-F series with the inverter ...................................................................... 5-7

5.2.1 Function overview ............................................................................................................... 5-7

5.2.2 System conguration .......................................................................................................... 5-8

5.2.3 Connecting terminating resistors ...................................................................................... 5-10

5.2.4 Cable wiring diagram .........................................................................................................5-11

5.2.5 Inverter communication settings ....................................................................................... 5-13

5.2.6 FX5 programmable controller communication settings ..................................................... 5-14

5.3 External potentiometer operation............................................................................................... 5-15

5.3.1 Analog conguration of frequency (voltage and current input) ......................................... 5-15

Chapter 6 Review 6-1

Review 1 Belt conveyor control .......................................................................................................... 6-2

Review 2 Writing parameters using FR Congurator ......................................................................... 6-3

Review 3 Comprehension test ............................................................................................................ 6-4

Appendix

Appendix 1 Parameter List (FR-E700).........................................................................................App.1-1

Appendix 2 List of fault displays (FR-E700).................................................................................App.2-1

Appendix 3 Final assembly of training devices ............................................................................ App.3-1

Appendix 4 Terminal connection diagram (FR-E700) .................................................................. App.4-1

MEMO

1

Inverter basics

Chapter 1

Brief description of inverters

Inverter basics

As we will cover in more detail throughout this document, "inverters" are devices

used to control motor speed.

While this is not a term often heard in typical conversation, inverters are used in

many of the devices used on a daily basis.

Inverters are used in trains, for example. "Inverters" control the speed of motors in

trains to control the speed of the train itself to ensure safe operation.

This chapter describes the fundamentals of "inverters".

1-1

1.1 What is an inverter?

1.1.1 Basic functions of the inverter

◎Inverter

Motors are used to operate many of the devices and products we use on a daily basis.

The reason devices do not suddenly start to operate when power switches are turned on is because the inverter

controls the speed of motors.

In basic terms, the inverter is a device that changes the speed of standard motors without restriction.

1.1.2 Benets of the inverter

The inverter can freely changes the speed of standard motors. They can be

1

also connected to the already-installed standard motors.

2

3

4

5

The inverter can drive standard motors at a set speed regardless the power

supply frequency.

The inverter can save energy (electricity).

The inverter can improve productivity by changing the standard motor speed

to match the application.

The inverter can perform smooth start and stop operations by reducing the

starting current of standard motors.

1-2

1.1.3 Familiar examples where inverters are used

Belt conveyors used in factories

1

☆Improve efciency of work, braking at specic positions, automatic operation

● The inverter improves efciency of work and enable conveyors to be stopped at specic

positions.

● Conveyor speeds can be optimally adjusted depending on the work conditions.

● Soft starts and stops prevent products from moving around and falling off the conveyor.

● Conveyor acceleration and deceleration can be controlled such that shock to machines is

reduced or removed completely.

1-3

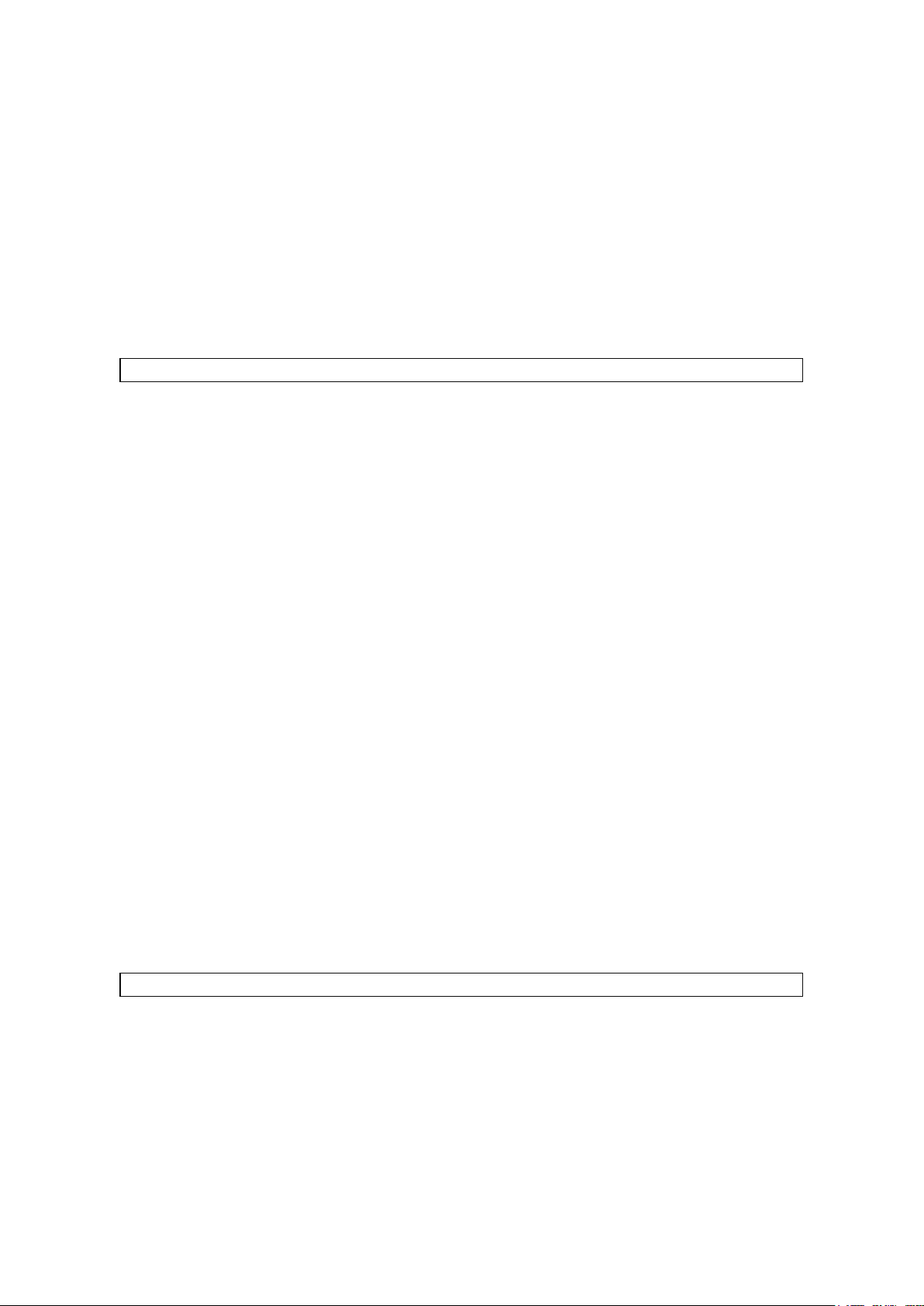

Fan, blower

Ventilation fans used in buildings

● Pump

● Fan, blower

● Ventilation fan

● Cooling tower

● Drying machine

(Furnace fan)

Switch

Inverter

Standard motor

Standard motor

Damper control

Damper

Fan, blower

Inverter control

☆The inverter achieves energy efciency and automation.

● Useful for air ow control (ow amount control)

● Automatic control over air ow (pressure or ow amount)

● Necessary amount can be changed according to seasons and day/night.

1-4

Inverters are used in these and many

devices we use every day.

other applications.

1

Air conditioner

Train

Electric vehicle

Washing machine

As you can see, inverters are used in the products and

1-5

1.2 Motor drive force

1.2.1 Motor and frequency

Motor speed is changed by varying the frequency of current owing through motors.

Frequency is discussed in more detail in this section.

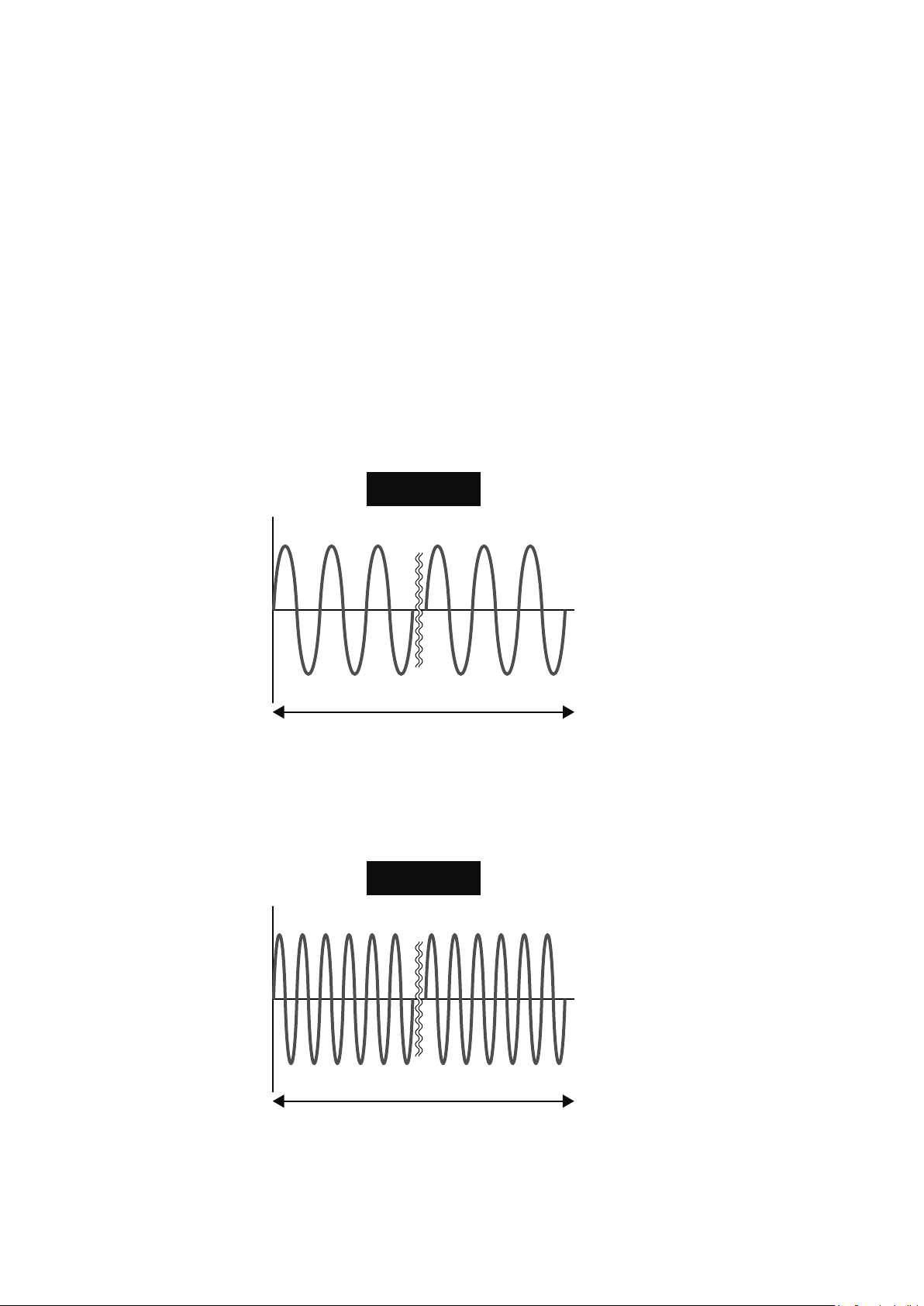

◎Frequency

Outlets in homes, for example, supply power at 100V/50Hz and 200V/60Hz specications.

"V" represents voltage and "Hz" represents the frequency.

Frequency values are usually shown in a graph like this. For example, frequency 60Hz means that there are 60

waves between positive and negative per second.

V

V

60Hz

t

60 cycles

1 sec

120Hz

1 sec

t

120 cycles

1-6

1

1.2.2 Principles of the motor

When a motor is connected to a source of power, current ows through the stator winding, or stator coil, within

the motor, which creates a rotating magnetic eld. This rotating magnetic eld causes the stator (rotor) to rotate.

Motor speed is proportional to the frequency of the power source.

Basically, the motor rotates by electromagnetic force.

Fan

Core

Rotor

Frame

Coil

Structure of the motor

1-7

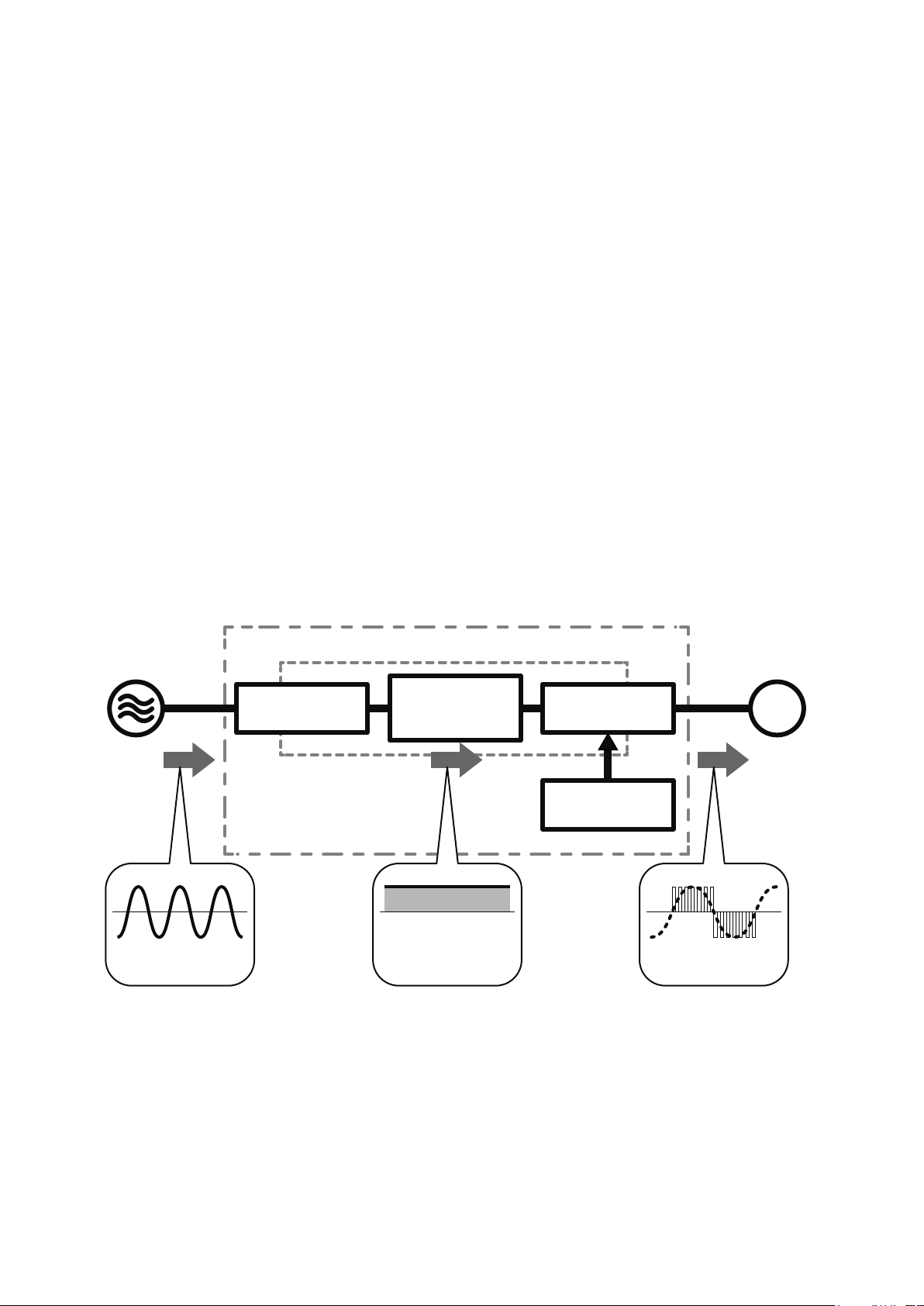

1.3 Changing frequency

1.3.1 Structure of the inverter

The inverter is generally comprised of 3 sections: converter section, inverter section, and control circuit.

◎Converter section

The converter section converts an AC of an AC power supply into a DC, and then smooths out the pulses of

current by the smoothing capacitor.

◎Inverter section

The inverter section converts the DC converted by the converter section into a pulsed current of

alternating current having variable frequency.

* Pulsed current refers to current that ows intermittently for short periods of time.

◎Control circuit

The control circuit controls the converter and inverter sections.

AC power supply

AC DC

Converter

section

Inverter

Main circuit

Smoothing

capacitor

Inverter

section

Control circuit

Standard

motor

IM

Variable voltage

Variable frequency

1-8

2

Inverter basics

Chapter 2

Specic models of the inverter

Mitsubishi general-purpose inverters

This chapter introduces several types of actual "inverters".

Mitsubishi offers many types of inverters to suit different purposes.

This chapter will cover the compact and high functionality FR-E700 model in detail.

Make sure the power is not turned on before connecting the power cable.

2-1

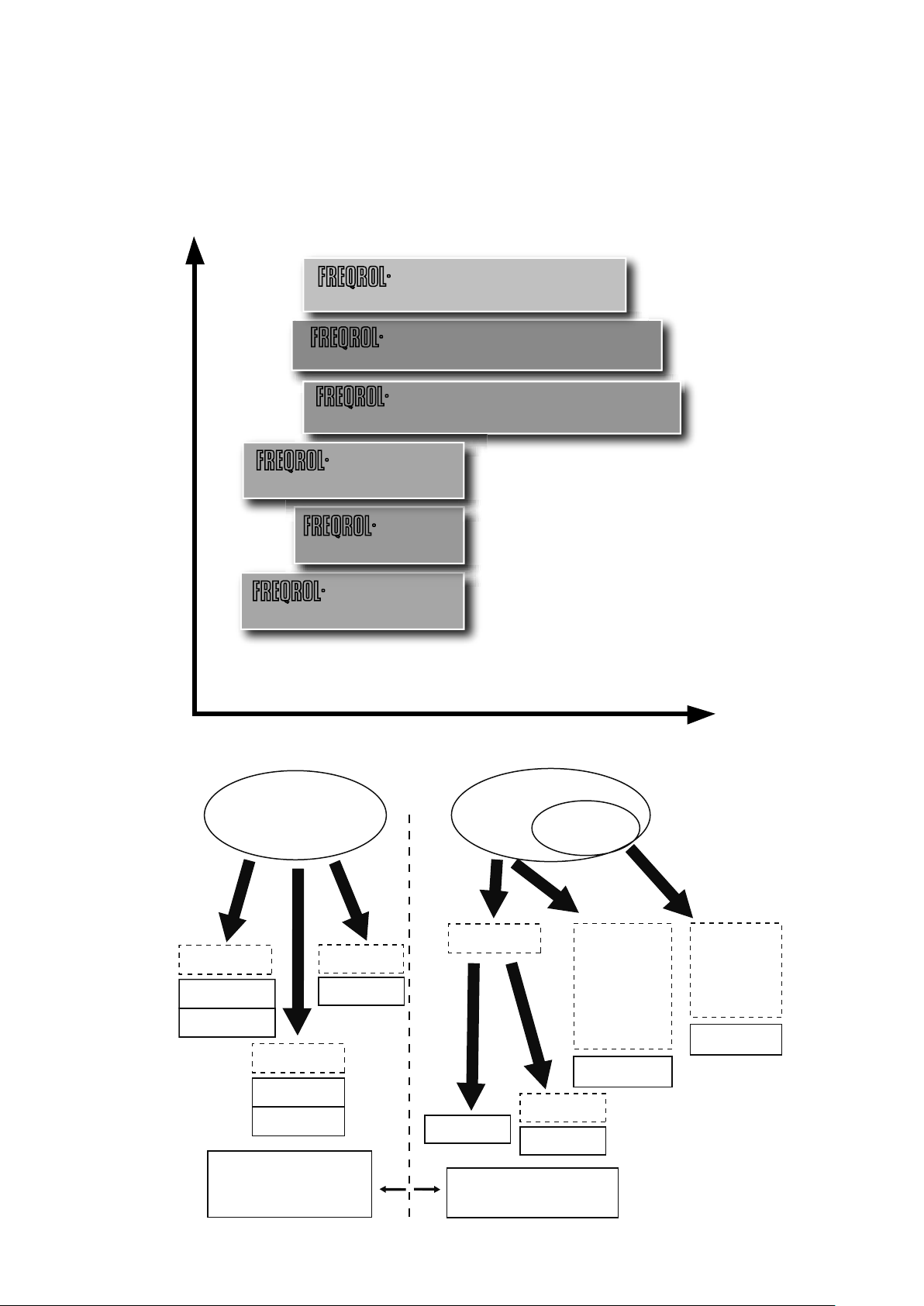

2.1 Mitsubishi general-purpose inverters

Three-phase 400V class

Three-phase 200V class

0.75kW to 55kW

0.75kW to 55kW

Three-phase 400V class

Three-phase 200V class

0.4K to 15K

0.4K to 15K

FR-F700PJ

Three-phase 400V class

Three-phase 200V class

0.75K to 110K

0.75K to 560K

FR-F800

●Service life of parts is extended. It comes with the service life diagnose function as standard.

●Compatible with various plug-in options.

Compatible with networks, such as LONWORKS and CC-Link, via plug-in options.

For fans and pumps

●Spring clamp terminals provide high reliability and easy wiring.

●Drives both the general-purpose motors and IPM motors. When it drives an IPM motor

(MM-EFS), which has permanent magnets embedded in its rotor, the energy saving and

high efficiency can be further achieved.

●Drives both the general-purpose motors and IPM motors. When it drives an IPM motor

(MM-EFS), which has permanent magnets embedded in its rotor, energy savings and high

efficiency can be further achieved.

SF-PR

●This model achieves the IE3 efficiency class with the same dimensions as those of

conventional models using our unique steel plate frame technology and new core materials.

●It maintains interchangeability with our standard-efficiency motor SF-JR for easy

replacement.

Three-phase 400V class

Three-phase 200V class

0.75kW to 55kW (75kW is to be released soon.)

0.75kW to 55kW (75kW to 160kW are to be released soon.)

MM-EFS (75kW or less)

MM-THE4 (75kW or more)

●This is an IPM motor, which has permanent magnets embedded in its rotor. It is more

efficient than an induction motor.

●Compared with the "MM-EF series", the motor loss (iron loss and primary copper loss) is

further reduced, and thus achieving higher efficiency. This motor satisfies the highest

efficiency standard IE4 (super premium efficiency).

●This inverter is suitable for fans and pumps, and has the various functions: optimum

excitation control, variable torque acceleration/deceleration patterns, PID control,

commercial power supply switching, adjustable 5 points V/F, continuous operation at an

instantaneous power failure, regeneration avoidance function, etc.

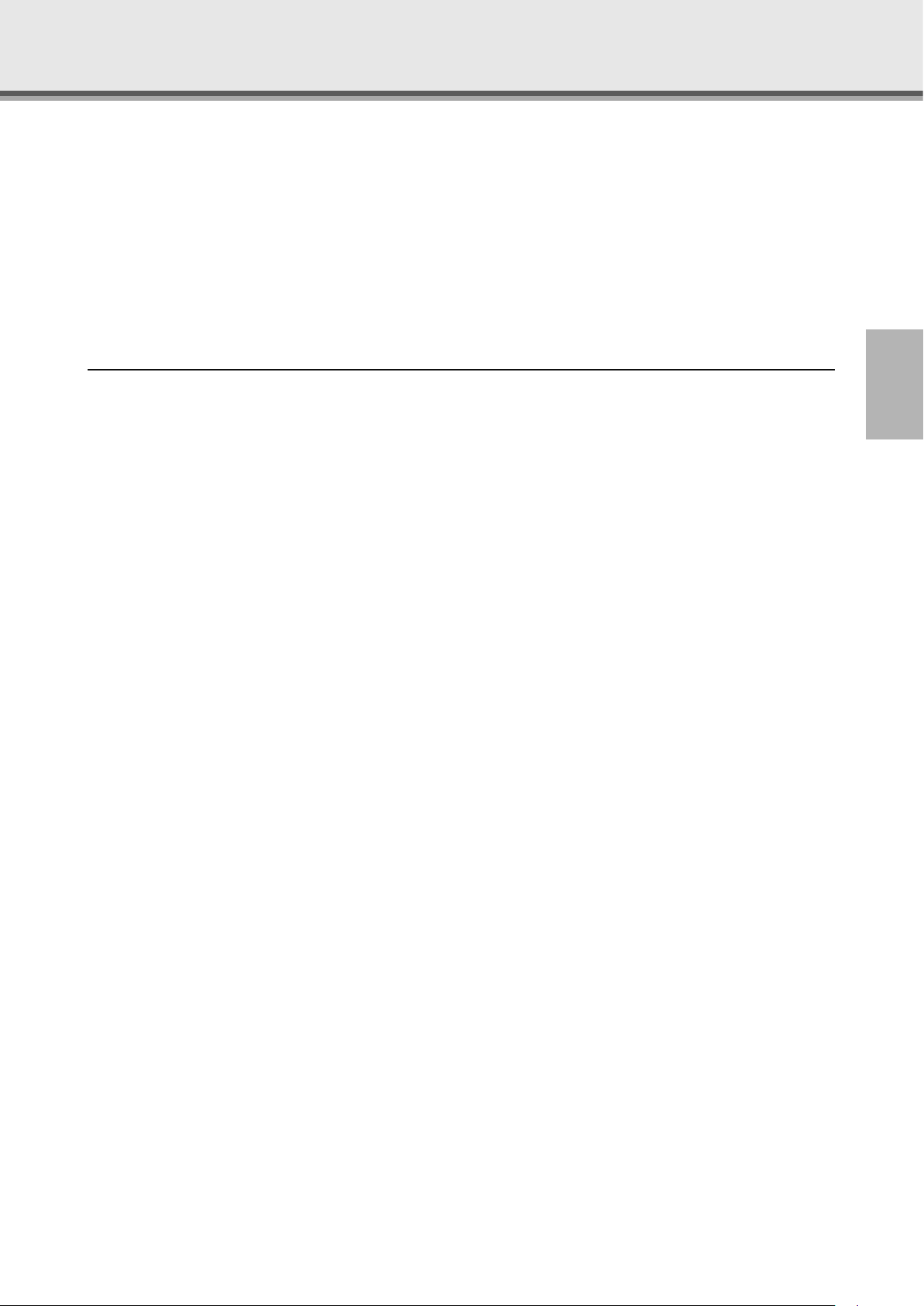

2.1.1 Lineup

Inverter line-up

Functions and performance

Simple and compact inverter

Vector inverter

V500 (L)

Advanced functionality and high-performance inverter

A800

Energy-saving premium inverter

F800

Compact and powerful inverter

E700

F700PJ

Air conditioning inverter

D700

Applicable series for each industry

Fans and pumps

General industrial machine

Compact

FR-D700

Overcurrent shutdown level

is approx. 200% of the rated

current.

Compact

FR-D700

FR-F700PJ

More energy

saving

FR-F800

FR-F700PJ

Overcurrent shutdown

level is approx. 170%

(approx. 200% for FR-D700)

of the rated current.

High-

functionality

FR-F800

Web handling,

machine tool,

etc.

Highfunctionality

Highperformance

Closed-loop

(built-in option)

Torque control

Powerful

FR-E700

Capacity

Highperformance

Closed-loop

Torque control

FR-V500(L)

FR-A800

2-2

For fans and pumps

FR-F800

Three-phase 200V class

Three-phase 400V class

●Drives both the general-purpose motors and IPM motors. When it drives an IPM motor

(MM-EFS), which has permanent magnets embedded in its rotor, energy savings and high

efficiency can be further achieved.

●This inverter is suitable for fans and pumps, and has the various functions: optimum

excitation control, variable torque acceleration/deceleration patterns, PID control,

commercial power supply switching, adjustable 5 points V/F, continuous operation at an

instantaneous power failure, regeneration avoidance function, etc.

●Service life of parts is extended. It comes with the service life diagnose function as standard.

●Compatible with various plug-in options.

Compatible with networks, such as LONWORKS and CC-Link, via plug-in options.

FR-F700PJ

Three-phase 200V class

Three-phase 400V class

●Drives both the general-purpose motors and IPM motors. When it drives an IPM motor

(MM-EFS), which has permanent magnets embedded in its rotor, the energy saving and

high efficiency can be further achieved.

●Spring clamp terminals provide high reliability and easy wiring.

MM-EFS (75kW or less)

MM-THE4 (75kW or more)

●This is an IPM motor, which has permanent magnets embedded in its rotor. It is more

efficient than an induction motor.

●Compared with the "MM-EF series", the motor loss (iron loss and primary copper loss) is

further reduced, and thus achieving higher efficiency. This motor satisfies the highest

efficiency standard IE4 (super premium efficiency).

0.75K to 110K

0.75K to 560K

0.4K to 15K

0.4K to 15K

Three-phase 200V class

Three-phase 400V class

2

0.75kW to 55kW (75kW is to be released soon.)

0.75kW to 55kW (75kW to 160kW are to be released soon.)

SF-PR

Three-phase 200V class

Three-phase 400V class

0.75kW to 55kW

0.75kW to 55kW

●This model achieves the IE3 efficiency class with the same dimensions as those of

conventional models using our unique steel plate frame technology and new core materials.

●It maintains interchangeability with our standard-efficiency motor SF-JR for easy

replacement.

2-3

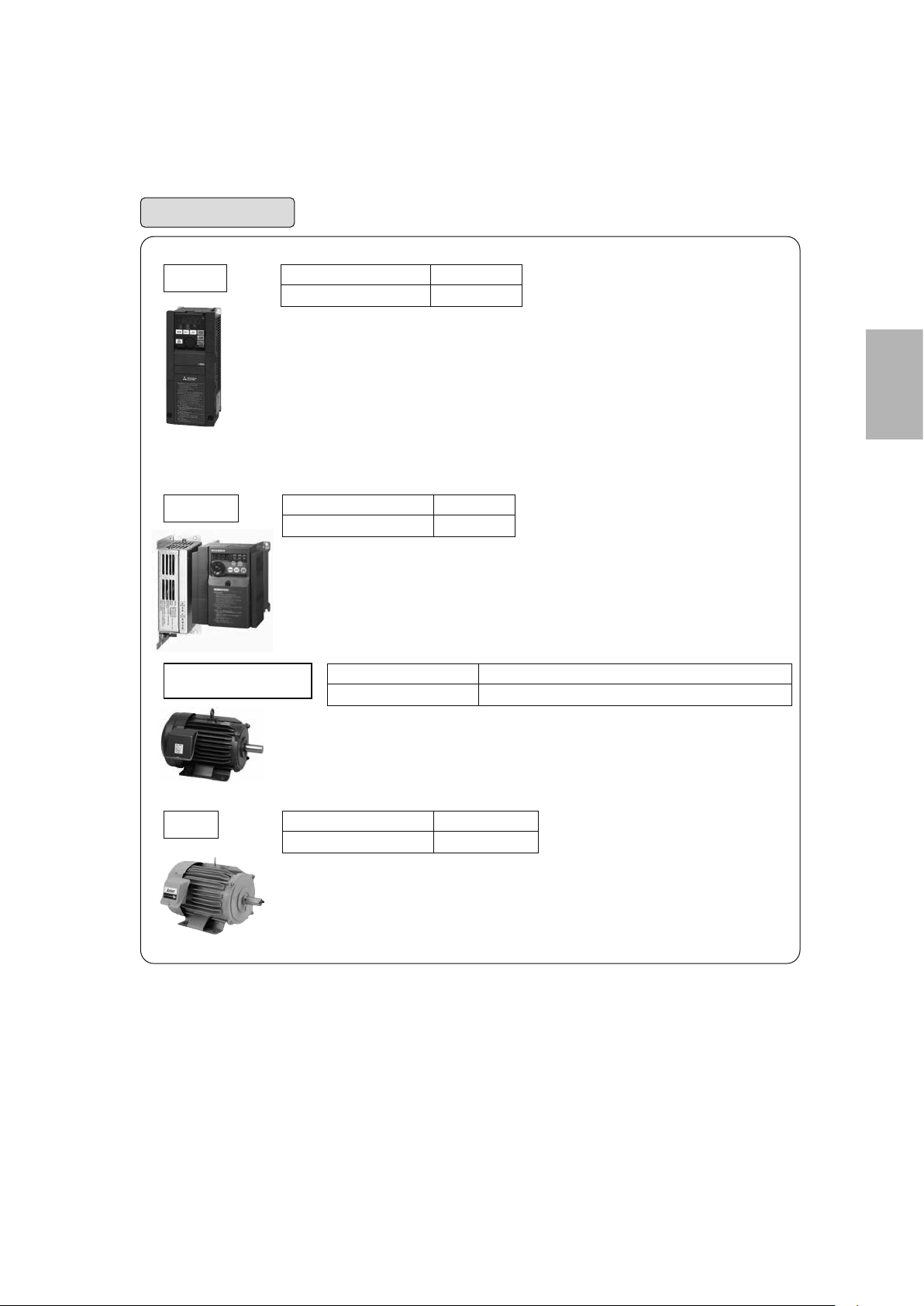

General industrial applications

(Suitable for transfer, conveyor, food packaging,

and standard machine tools, etc.)

FR-E700

General industrial applications

FR-D700

General industrial applications

Single-phase 100V class

Single-phase 200V class

● 0.5Hz 200% torque (0.1K to 3.7K) can be generated under Advanced magnetic flux

vector control.

● The non-slip M Dial with adaptive stroke speed allows for quick jumps or precise

increments based on turning speed.

● Compatible with various plug-in options.

The inverter is compatible with networks, such as CC-Link, PROFIBUS-DP, DeviceNet,

via plug-in options.

Single-phase 100V class

Single-phase 200V class

● Spring clamp terminals provide high reliability and easy wiring.

● It features the safety stop function and can comply with safety standards at a low cost.

● 1Hz 150% torque can be generated under General-purpose magnetic flux and with the

auto tuning function.

● The non-slip M Dial with adaptive scroll speed allows for quick jumps or precise

increments based on turning speed.

0.1K to 0.75K

0.1K to 2.2K Three-phase 400V class

(Suitable for transfer, conveyor, food packaging,

fans and pumps, etc.)

0.1K to 0.75K

0.1K to 2.2K Three-phase 400V class

(Suitable for lift, web line control, machine tools, etc.)

Three-phase 200V class

Three-phase 200V class

0.1K to 15K

0.4K to 15K

0.1K to 15K

0.4K to 15K

FR-A800

FR-V500 (L)

Three-phase 200V class

Three-phase 400V class

● PM sensorless vector control enables combinations with PM (magnetic) motor.

The auto-tuning function enables operation of other manufacturers' PM motors.

● Many useful features such as USB memory connectivity and PLC function

● True vector control possible through combinations with PLG motors

(requires the FR-A8AP internal option)

● Compatible with various plug-in options.

Also compatible with networks, such as CC-Link and SSCNETⅢ/H, via plug-in options.

Three-phase 200V class

Three-phase 400V class

● High-performance and quick-response operation via vector control of specialized motors

● Improved torque precision through high-precision calculations of internal

motor magnetic flux

● Adjustment-free speed control gain and position loop gain

● Compatible with operation over SSCNET communication via internal options

0.4K to 90K

0.4K to 500K

1.5 to 55K, 75K

1.5 to 55K and 75 to 250K

2-4

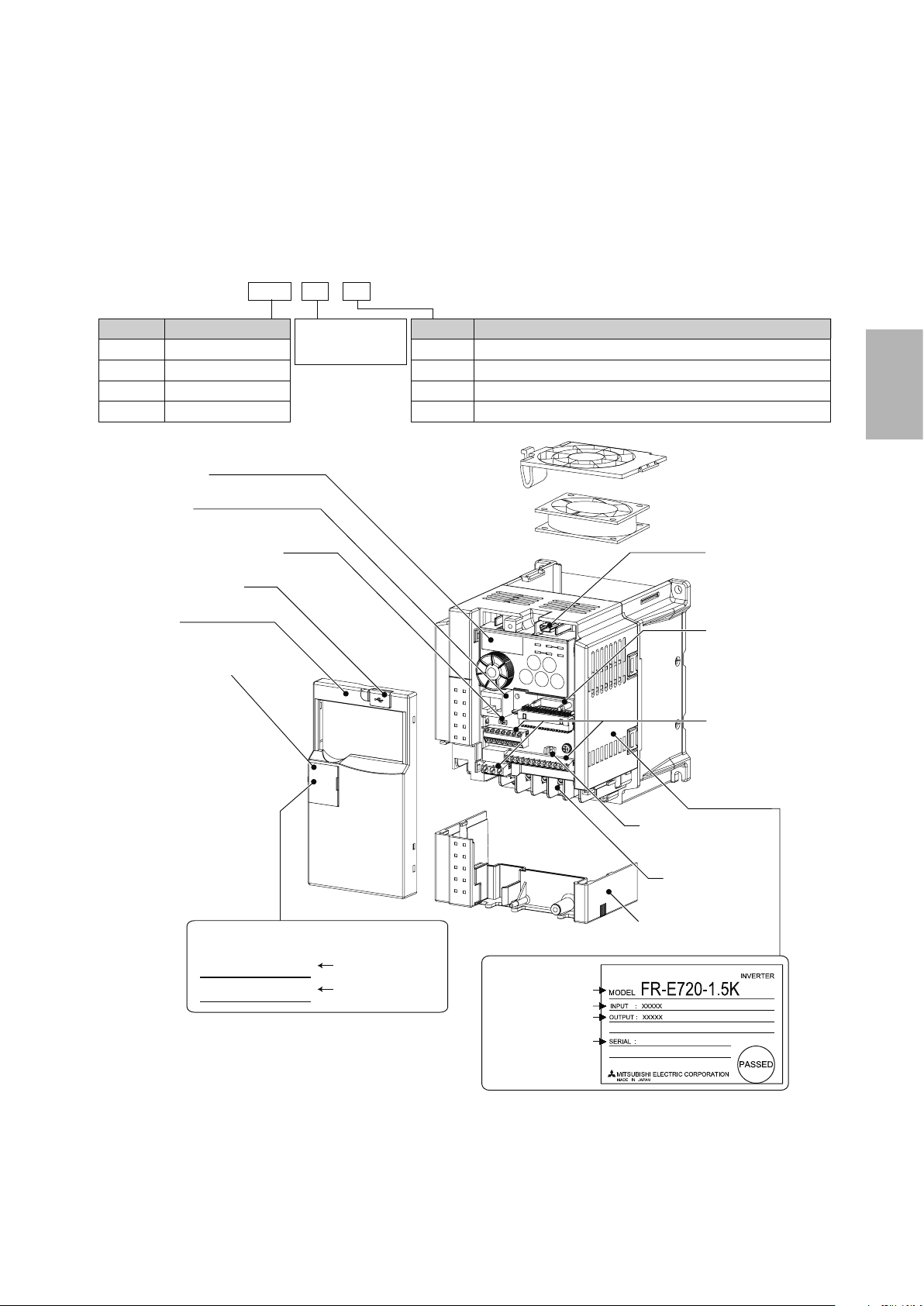

2.2 Detailed description of the inverter

2.2.1 Parts identication for the Mitsubishi

general-purpose inverter FR-E700 series

● Inverter model

FR - E720 - 1.5 K

No.

E720

E740

E720S

E710W

Operation panel

PU connector

Voltage/current input switch

USB connector cover

Front cover

PU connector cover

Voltage class

Three-phase 200V class

Three-phase 400V class

Single-phase 200V class

Single-phase 100V class

Represents the

inverter capacity [kW]

Symbol

None

SC

NF

NC

Control circuit terminal specification

Standard control circuit terminal (screw plug)

Models equipped with Safety Stop functionality

Models equipped with FL remote communication functionality

Models equipped with CC-Link communication functionality

Cooling fan

USB connector

(mini-B connector)

Connector for plug-in

option connection

Control circuit

terminal block

2

Capacity plate *

FR-E720-1.5K

SERIAL:

* Location of the capacity plate and the rating plate

differs according to the inverter capacity.

Refer to the outline dimension drawing.

● Accessory

Fan cover fixing screws (M3 × 35mm)

XXXXXX

Inverter model

Serial number

Changing the control

logic jumper connector

Main circuit

terminal block

Combed shaped

wiring cover

Rating plate *

Inverter model

Input rating

Output rating

Serial number

2-5

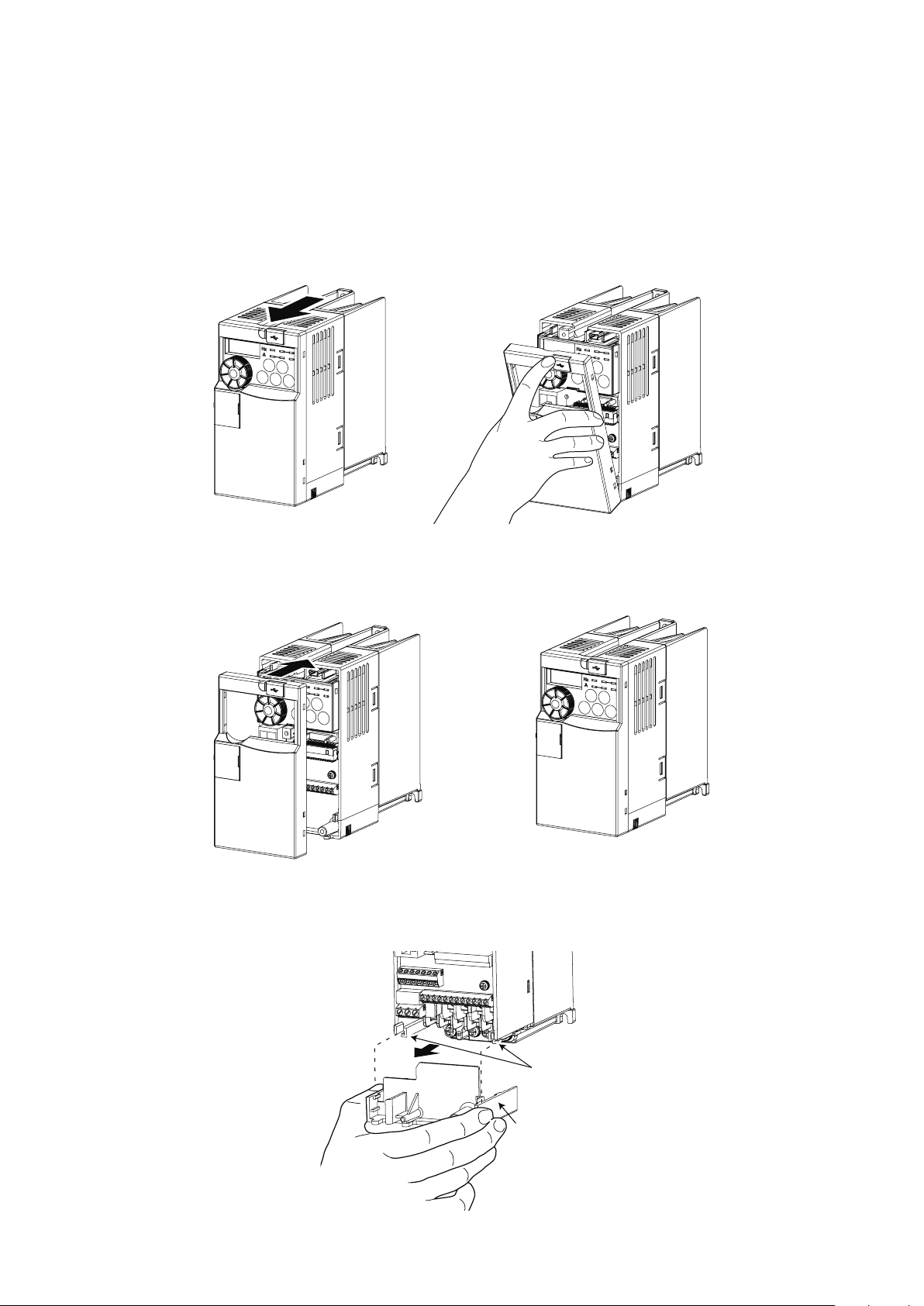

2.3 Connecting the inverter

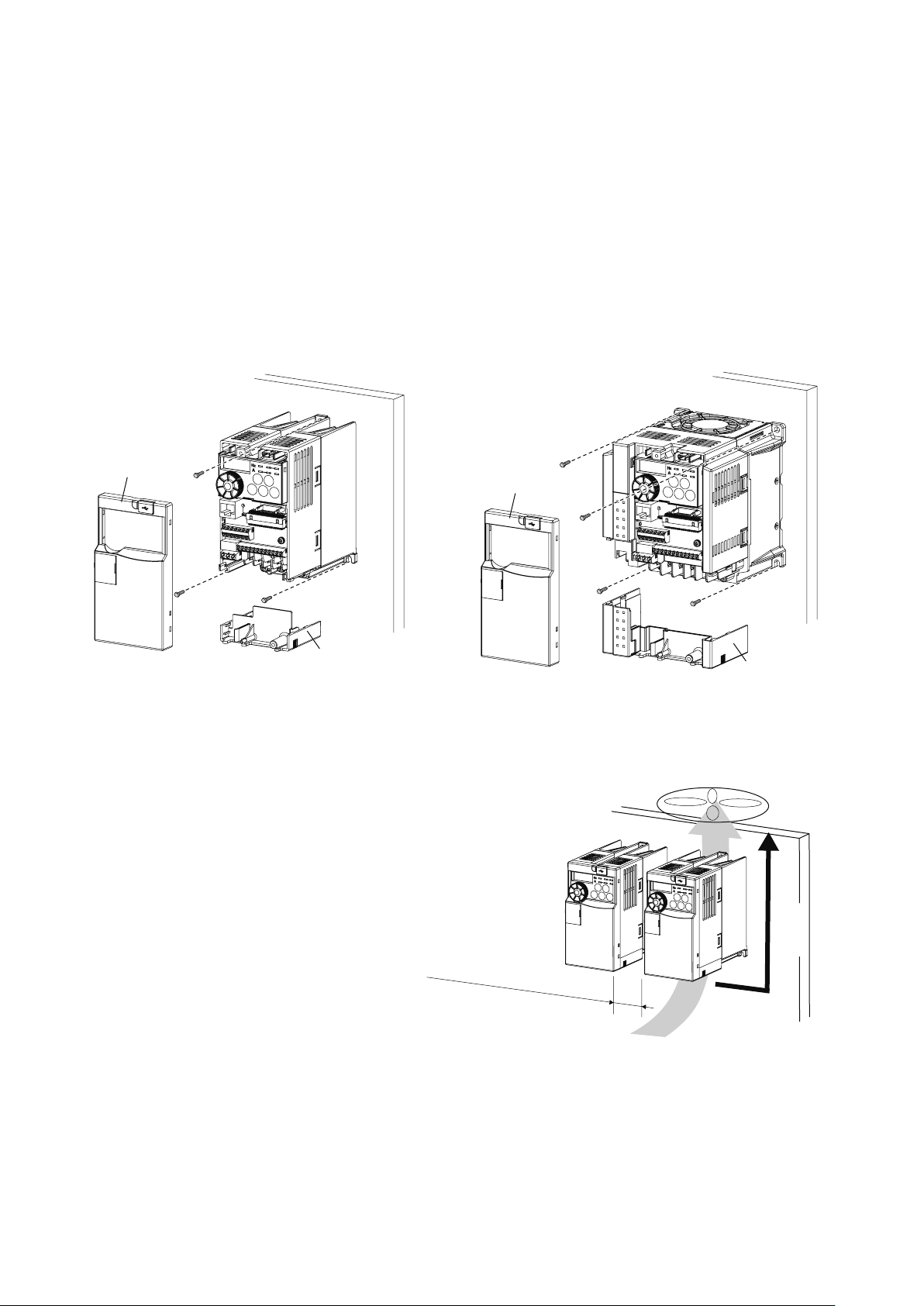

2.3.1 Removing and installing the cover

Removal

Remove the front cover by pulling it toward you in the direction of arrow.

Reinstallation

To reinstall, match the cover to the inverter front and install it straight.

Wiring cover

Removes easily when pulled toward the front. Install the cover to the unit in alignment with the guide.

2-6

Guide

Wiring

cover

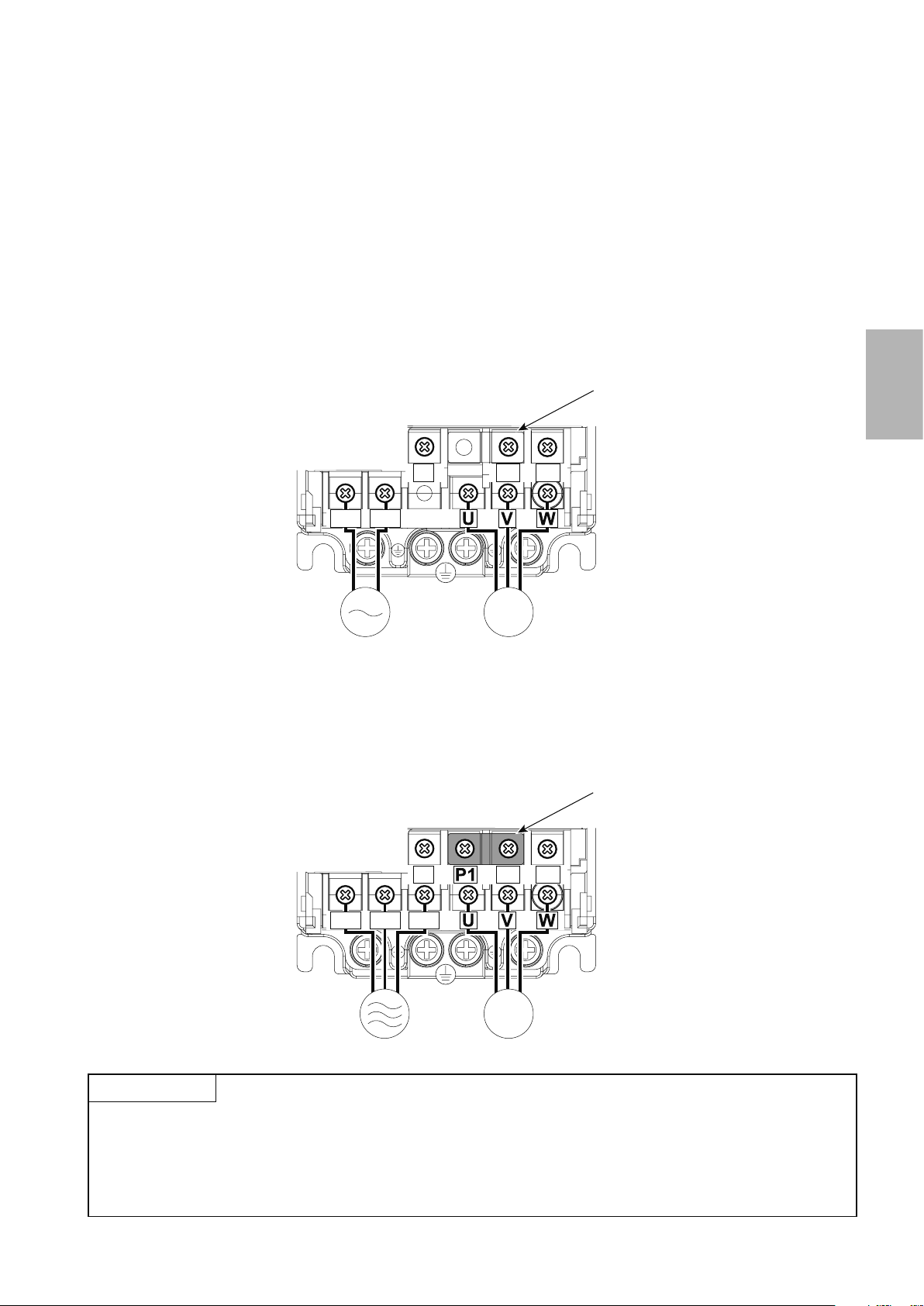

2.3.2 Connecting the power cable

Motor

Power supply

MotorPower supply

There are two types of power cables that can be used to connect to the inverter.

*Either the single-phase input type or three-phase input type cable is used depending on your power supply.

The single-phase input type is also further separated in 200V and 100V inputs. The output in either case is three-phase at 200V.

Single-phase two-wire power supply

This power supply is used for home electric appliances and small electric equipment.

The power supply is connected to the main circuit terminals R and S, and the motor is connected to terminals U, V,

and W.

Jumper

Screw size (M3.5)

2

N/-

P/+ PR

R/L1 S/L2

Screw size

(M3.5)

IM

Three-phase three-wire power supply

This power supply is for large electric equipment in factories.

The power supply is connected to the main circuit terminals R, S, and T, and the motor is connected to terminals U, V,

and W.

Jumper

Screw size (M3.5)

N/-

R/L1 S/L2 T/L3

P/+ PR

CAUTION

Screw size

(M3.5)

● Make sure the power cables are connected to the R/L1, S/L2, and T/L3 terminals. (Phase need not be matched.)

Never connect the power cable to the U, V, and W terminals on the inverter. Doing so will damage the inverter.

● Do not touch the main circuit terminals directly as this could cause electric shock.

IM

2-7

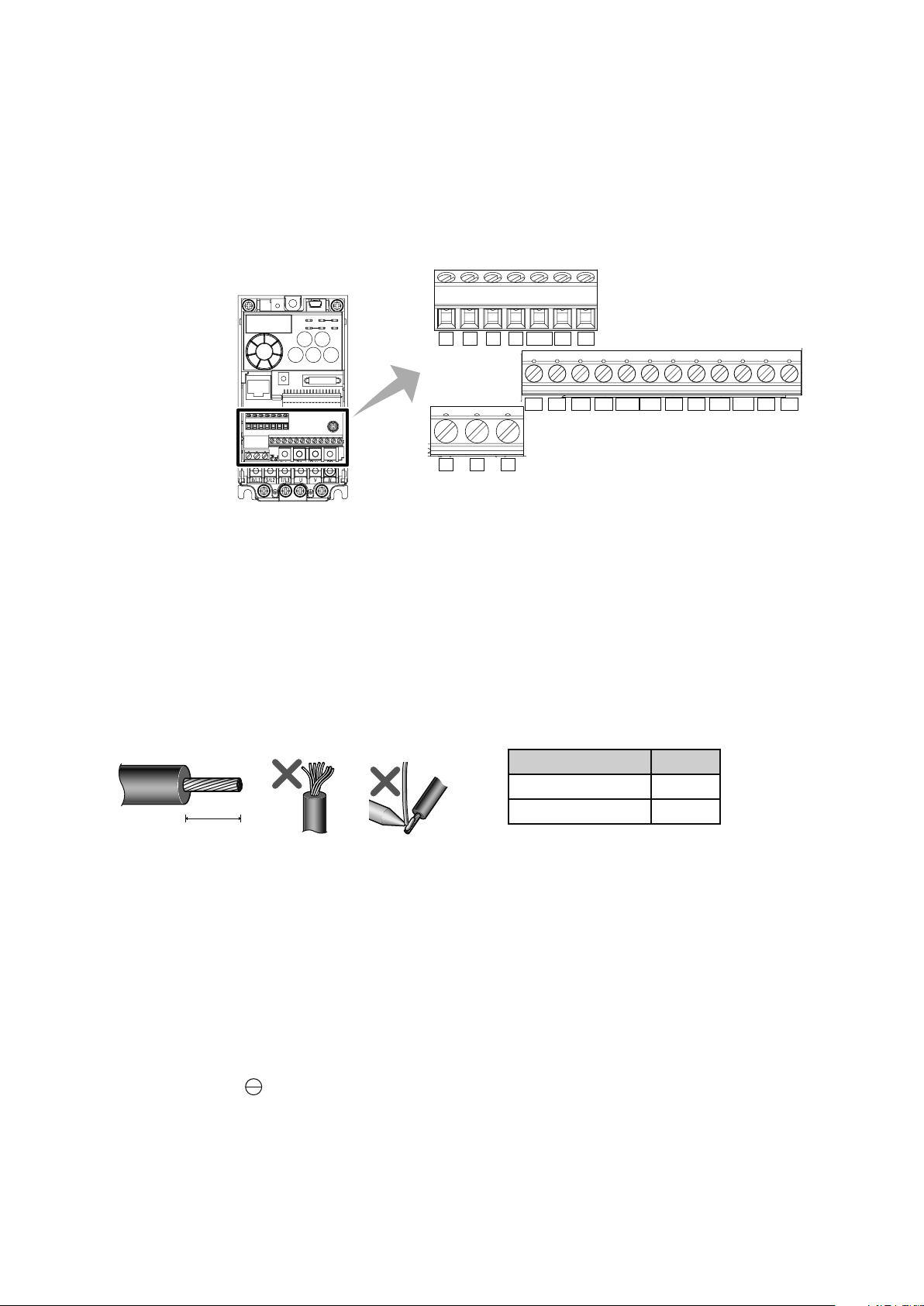

2.3.3 Control terminals

Cable sheath stripping length

Terminal screw size

M3: (Terminals A, B, and C)

M2: (All others)

Terminal layout

10 2 5 4 RUN FU SE

STF STR

RESMRS

FM

CBA

RHRMRL

PCSD

Wiring method

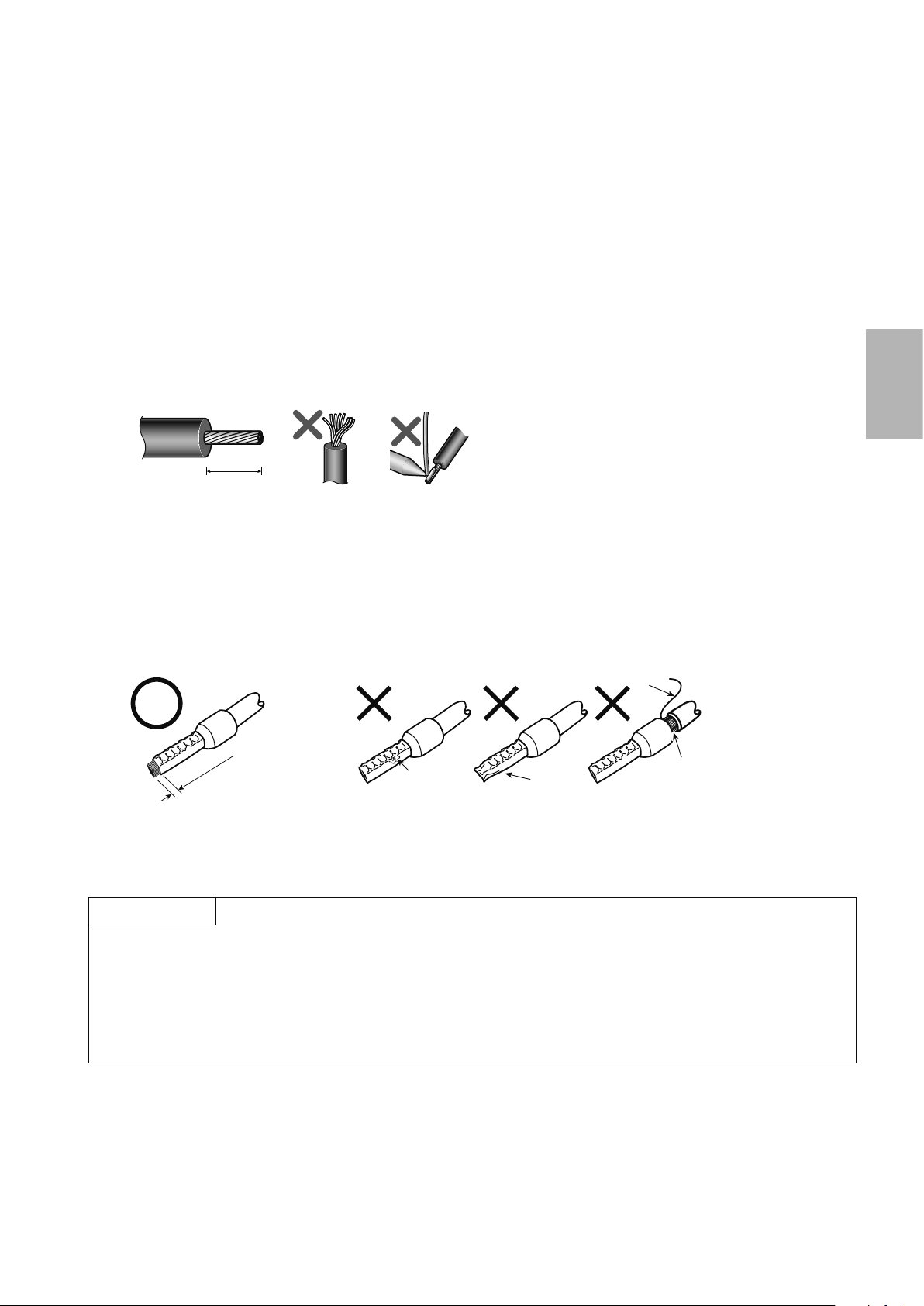

For the control circuit wiring, strip off the sheath of a cable and use as it is.

1.

Strip off the sheath about the size below. If the length of the sheath peeled is too long, a short circuit may

occur among neighboring wires. If the length is too short, wires might come off.

Wire the stripped wire after twisting it to prevent it from becoming loose. In addition, do not solder it.

L (mm)

Terminals A, B, and C 6

All others 5

L

SDSD

Loosen the terminal screw and insert the cable into the terminal.

2.

Tighten the screw according to the specied tightening torque.

3.

Under tightening may cause cable disconnection or malfunction. Over tightening may cause a short circuit

or malfunction due to damage to the screw or unit.

Tightening torque: 0.5N m to 0.6N m (terminals A, B, and C),

0.22N m to 0.25N m (terminals other than described above)

Screwdriver: small, at-blade screwdriver (tip thickness: 0.4mm/tip width: 2.5mm)

2-8

● Blade terminals

0 to 0.5m

Unstranded wires

Wires are not inserted

10mm

Cable sheath stripping length

Strip the sheath off of wires, and connect them to a blade terminal.

Strip off the sheath about the size below. If the length of the sheath peeled is too long, a short circuit may

1.

occur among neighboring wires. If the length is too short, wires might come off.

Wire the stripped wire after twisting it to prevent it from becoming loose. In addition, do not solder it.

Crimp the blade terminal.

2.

Insert wires to a blade terminal, and check that the wires come out for about 0 to 0.5mm from a sleeve.

Check the condition of the blade terminal after crimping. Do not use a blade terminal of which the crimp-

ing is inappropriate, or the face is damaged.

2

Wire

Shell

Sleeve

m

Damaged

Crumpled tip

into the shell

CAUTION

● When using stranded wires without a blade terminal, twist enough to avoid short circuit with a nearby

terminals or wires.

● Place the athead screwdriver vertical to the open/close button. In case the blade tip slips, it may cause an

inverter damage or injury.

2-9

2.4 Inverter usage precautions

Front cover

Wiring cover

ەFR-E720-0.1K (SC) - 0.75K (SC)

ە

ە

ەFR-E720-1.5K (SC) or later

2.4.1 Installation of the inverter

Enclosure surface mounting

Remove the front cover and wiring cover to x the inverter to the surface.

FR-E720S-0.1K (SC) - 0.4K (SC)

FR-E710W-0.1K - 0.4K

ەFR-E740-0.4K (SC) or later

ەFR-E720S-0.75K (SC) or later

ەFR-E710W-0.75K

Front cover

Wiring cover

Install the inverter vertically.

Re

f

er t

o

the clearances be

low.

Vertical

2-10

Surrounding air temperature

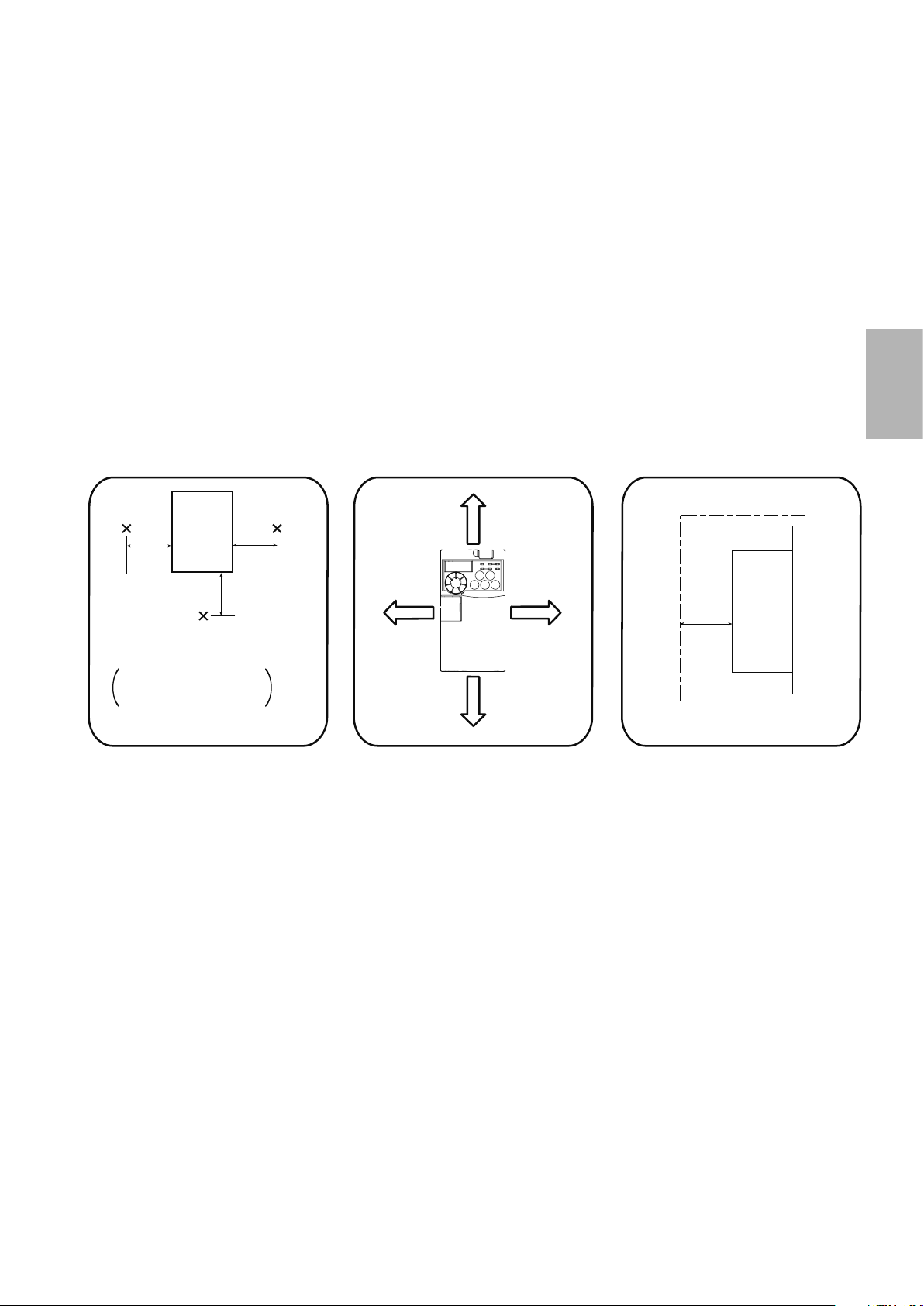

Installation orientation of the inverter

Install the inverter on a wall as specied. Do not mount it horizontally or in any other way.

Clearance around the inverter

To ensure ease of heat dissipation and maintenance, leave at least the shown clearances around the inverter.

At least the following clearances are required under the inverter as a wiring space, and above the inverter as a

heat dissipation space.

2

and humidity

Inverter

5cm 5cm

Measurement

position

Temperature: -10°C to +50°C

-10°C to +40°C for

totally enclosed

structure feature

Humidity: 90% RH or less

Leave enough clearances and take

cooling measures.

Measurement

position

5cm

Clearances (front)

10cm or

more

1cm or

more*

1cm or

more*

10cm or

more

* When using the inverters at the

surrounding air temperature of 40°C

or less, the inverters can be installed

without any clearance between them

(0cm clearance).

When surrounding air temperature

exceeds 40°C, clearances between

the inverters should be 1cm or more

(5cm or more for the 5.5K or more).

Clearances (side)

1cm

Inverter

or

more *

* 5cm or more for the 5.5K (SC) or

more

2-11

Above inverter

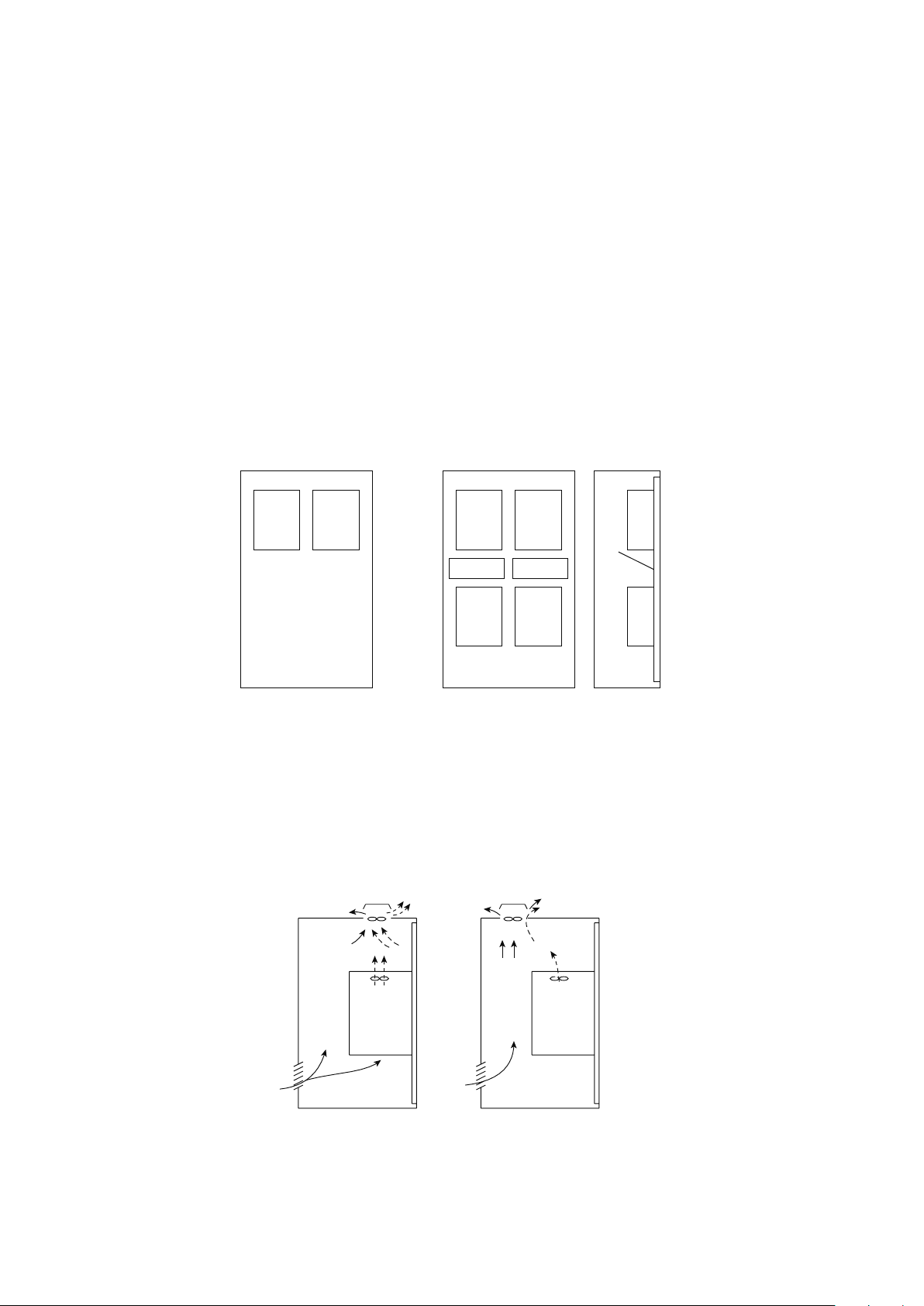

Arrangement of multiple inverters

Arrangement of the ventilation fan and inverter

Heat is blown up from inside the inverter by the small fan built in the unit.

Any equipment placed above the inverter should be heat resistant.

Arrangement of multiple inverters

When multiple inverters are placed in the same enclosure, generally arrange them horizontally as shown below in the

gure (a). When it is inevitable to arrange them vertically to minimize space, take such measures as to provide guides

since heat from the bottom inverters can increase the temperatures in the top inverters, causing inverter failures.

When mounting multiple inverters, fully take caution not to make the surrounding air temperature of the inverter

higher than the permissible value by providing ventilation and increasing the panel size.

InverterInverterInverter Inverter

Guide Guide

Inverter

Inverter

Guide

Enclosure Enclosure

(a) Arranged horizontally

(b) Arranged vertically

Arrangement of ventilation fan and inverter

Heat generated in the inverter is blown up from the bottom of the unit as warm air by the cooling fan. When installing a ventilation fan for that heat, determine the place of ventilation fan installation after fully considering an air ow.

(Air passes through areas of low resistance. Make an airway and airow plates to expose the inverter to cool air.)

Inverter Inverter

<Good example>

<Bad example>

2-12

2

2.4.2 Troubleshooting

When a fault occurs in the inverter, the inverter trips and the PU display automatically changes to one of the following fault or alarm indications.

◎Retention of fault output signal

When the magnetic contactor (MC) provided on the input side of the inverter is opened when a fault occurs,

the inverter's control power will be lost and the fault output will not be held.

◎Fault or alarm indication

When a fault or alarm occurs, the operation panel display automatically switches to the fault or alarm indication.

◎Resetting method

When a fault occurs, the inverter output is kept stopped. Unless reset, therefore, the inverter cannot restart.

When any fault occurs, take the appropriate corrective action, then reset the inverter, and resume operation.

Not doing so may lead to the inverter fault and damage.

Inverter fault or alarm indications are roughly categorized as below.

Error message

1

A message regarding operational fault and setting fault by the operation panel and parameter unit

(FR-PU04 /FR-PU07) is displayed. The inverter does not trip.

Warning

2

The inverter does not trip even when a warning is displayed. However, failure to take appropriate

measures will lead to a major fault.

Minor failure

3

The inverter does not trip. You can also output a minor failure signal by making parameter setting.

Major fault

4

<Reference>

Refer to Appendix 2 as it contains a list of fault displays and the appropriate troubleshooting steps to resolve the issue.

When a fault occurs, the inverter trips and a fault signal is output.

2-13

MEMO

2-14

3

Inverter basics

Chapter 3

Parameters

Inverter basics

You must have an understanding of parameters in order to congure "inverters".

We will use the belt conveyor example described in Chapter 1 again here. If the motor

moving the belt conveyor is not rotated smoothly, items on the belt conveyor could

fall off and break. The motor must be started slowly to ensure that the conveyor

moves smoothly.

The motor can be rotated smoothly in such a manner by conguring inverter parameters.

This chapter will introduce typically used parameters.

3-1

3.1 Setting basic parameters

3.1.1 Brief description of parameters

Parameters are the values used to congure inverter operation. These are notated as "Pr.". The type and number of parameters available differ depending on inverter model.

For simple variable-speed operation of the inverter, the initial values of the parameters may be used as they are.

Congure the necessary parameters in accordance with loads and operational specications. Parameters can

be congured, changed, and conrmed from the operation panel.

3.1.2 Typical parameters

The following table lists the most commonly used parameters.

Pr. Name Unit Initial value Range Application

Set when you want to increase a starting torque

0 Torque boost 0.1%

1 Upper-limit frequency 0.01Hz 120Hz 0 to 120Hz

2 Lower-limit frequency 0.01Hz 0Hz 0 to 120Hz

3 Base frequency 0.01Hz 60Hz 0 to 400Hz

Multi-speed setting

4

(high speed)

Multi-speed setting

5

(middle speed)

Multi-speed setting

6

(low speed)

7 Acceleration time 0.1 s 5s/10s/15s* 0 to 3600 s

8 Deceleration time 0.1 s 5s/10s/15s* 0 to 3600 s

Electronic thermal O/L

9

relay

79

Pr.CL Parameter clear 1 0 0, 1

ALLC All parameter clear 1 0 0, 1

Operation mode

selection

0.01Hz 60Hz 0 to 400Hz

0.01Hz 30Hz 0 to 400Hz

0.01Hz 10Hz 0 to 400Hz

0.01A

1 0

6%/4%/

3%/2%*

Inverter rated

current

0 to 30%

0 to 500A

0 External/PU switchover mode

1 Fixed to PU operation mode

2 Fixed to External operation mode

3

4

6 Switchover mode

7 External operation mode (PU operation interlock)

or when the motor with a load will not rotate,

resulting in an alarm [OL] and a trip [OC1].

* Initial values differ according to the inverter

capacity. (0.75K or lower/1.5K to 3.7K/5.5K,

7.5K/11K, 15K)

Congure this to set a limit on the maximum

output frequency.

Congure this to set a limit on the minimum out-

put frequency.

Congure this when the rate frequency of the

motor is not 60Hz.

Check the motor rating plate.

Congure this to change the preset speed

parameter with a terminal.

Acceleration/deceleration time can be set.

* Initial values differ according to the inverter

capacity.

(3.7K or lower/5.5K, 7.5K/11K, 15K)

External/PU operation mode 1

(Start command from External, frequency com-

mand from PU)

External/PU operation mode 2

(Frequency command from External, start com-

mand from PU)

Setting "1" returns all parameters except calibra-

tion parameters to the initial values.

Setting "1" returns all parameters to the initial

values.

POINT

● Parameters are congured with initial values so that inverters can operate without specic conguration.

Parameters can be congured in accordance with the motors and devices used in your environment.

3-2

3.2 Operation panel

3.2.1 Names and functions of the operation panel

The operation panel cannot be removed from the inverter.

Operation mode indication

PU: Lit to indicate PU operation mode.

EXT: Lit to indicate External operation

mode.

(Lit at power-ON at initial setting.)

NET: Lit to indicate Network operation

mode.

PU, EXT: Lit to indicate External/PU

These turn OFF when command

source is not on operation panel.

Unit indication

・Hz: Lit to indicate frequency.

・A: Lit to indicate current.

Monitor (4-digit LED)

Shows the frequency, parameter

number, etc.

M Dial

(M Dial: Mitsubishi inverter dial)

Used to change the frequency setting

and parameter values.

Press to display the following.

・Displays the set frequency in the

・Present set value is displayed during

・Displays the order in the faults history

Mode switchover

Used to change each setting mode.

Pressing simultaneously

changes the operation mode.

Pressing for a while (2s) can lock

operation.

Determination of each setting

If pressed during operation,

monitor changes as below;

operation mode 1, 2.

(Flickers when the set frequency

monitor is displayed.)

(Both "Hz" and "A" turn OFF when

other than the above is displayed.)

monitor mode

calibration

mode

Running frequency

Operating status indication

Lit or flicker during inverter operation.

* ON: Indicates that forward rotation

operation is being performed.

Slow flickering (1.4s cycle):

Reverse rotation operation

Fast flickering (0.2s cycle):

When was pressed or the

start command was given, but the

operation can not be made.

・When the frequency command is

less than the starting frequency.

・When the MRS signal is input.

Parameter setting mode

Lit to indicate parameter setting mode.

3

Monitor indication

Lit to indicate monitoring mode.

Stop operation

Used to stop Run command.

Fault can be reset when protective

function is activated (major fault).

Operation mode switchover

Used to switch between the PU and

External operation mode.

When using the External operation

mode (operation using a separately

connected frequency setting

potentiometer and start signal), press

this key to light up the EXT indication.

(Press simultaneously (0.5s),

or change Pr. 79 setting.)

PU: PU operation mode

EXT: External operation mode

Cancels PU stop also.

Start command

The rotation direction can be selected

by setting Pr. 40.

Output current

Output voltage

3-3

3.3

Potentiometer

Switch

)

Selecting the operation mode and command source

3.3.1 Various operation modes

One of the key features of the inverter is the capability to be controlled with various signals.

The operation mode species the source of start commands and frequency commands.

PU operation mode

PC

(FR Configurator

GOT

POINT

Parameter unit

FR-PU07

PC

Programmable controller

PU operation mode

Network

operation mode

Operation panel

PU connector

Communication

option card

Control terminal

Inverter

USB

connector

PU operation mode

External

operation mode

5

4

6

3

7

2

8

1

9

10

● Mitsubishi Electric factory automation devices such as programmable controllers and GOTs are equipped

with Mitsubishi general-purpose inverter protocols for easy integration by simply connecting cables and con-

guring communication settings.

3-4

3.3.2 Operation mode selection (Pr. 79)

Used to select the operation mode of the inverter. Mode can be changed as desired among operation using external command signals (External operation), operation from the operation panel and PU (FR-PU07/FR-PU04)

(PU operation), combined operation of PU operation and External operation (External/PU combined operation),

and Network operation (when RS-485 communication or a communication option is used).

Initial

Pr. Name

value

Setting

range

Description LED Indication

79

Operation

mode

selection

Use External/PU switchover mode (

between the PU and External operation mode.

0

At power on, the inverter is in the External operation

mode.

Fixed to PU operation mode

1

Fixed to External operation mode

Operation can be performed by switching between the

2

External and NET operation mode.

External/PU operation mode 1

Frequency command Start command

Operation panel and PU

(FRPU04/FR-PU07)

3

setting or external signal

input (multi-speed setting,

across terminals 4-5 (valid

when AU signal turns ON)).*

0

External/PU operation mode 2

Frequency command Start command

External signal input

(terminal STF, STR)

) to switch

External operation mode

PU operation mode

External operation mode

NET operation mode

3

External signal input

4

(terminal 2, 4, JOG,

multi-speed selection, etc.)

Switchover mode

Switchover between PU operation, External operation,

and NET operation is available while keeping the same

6

operation status.

External operation mode (PU operation interlock)

X12 signal ON

Operation mode can be switched to the PU operation

7

mode. (output stop during external operation)

X12 signal OFF

Operation mode can not be switched to the PU

operation mode.

Enter from

operation panel and

and

(FR-PU04/FR-PU07)

of the

of the PU

PU operation mode

External operation mode

NET operation mode

PU operation mode

External operation mode

* The priority of frequency commands when Pr. 79="3" is: Multi-speed operation (RL/RM/RH/REX) > PID control

(X14) > terminal 4 analog input (AU) > Digital input from the operation panel.

3-5

3.4 Basic operation modes

5

6

3.4.1 External operation mode

External operation mode is used to input start and frequency commands with external potentiometers and

switches connected to the control circuit terminal.

4

7

3

Forward

rotation start

Reverse

rotation start

8

9

10

Hz

Inverter

STF

STR

SD

Frequency setting

potentiometer

3.4.2 PU operation mode

PU operation mode is used to input start and frequency

commands with operation panels or parameter units

(FR-PU04/FR-PU07).

10

2

5

3-6

Operation panel

3.4.3 External/PU operation mode 1

Select the External/PU operation mode 1 when

applying frequency command from the operation panel

or parameter unit (FR-PU04/FRPU07) and inputting

the start command with the external start switch.

Inverter

Forward

rotation start

Reverse

STF

STR

rotation start

SD

3.4.4 External/PU operation mode 2

Select the External/PU operation mode 2 to input

frequency commands from an external potentiometer

or multi-speed and JOG signals,

or to input start commands via key operation of the

operation panel or parameter unit (FR-PU04/FR-PU07).

• Select "4" for Pr. 79. You cannot change to the other

operation mode.

5

6

4

7

3

8

9

10

Hz

Operation panel

3

Frequency setting

potentiometer

3-7

Inverter

Operation panel

10

2

5

3.5 How to congure parameters

3.5.1 Parameter clear/All parameter clear

Parameter settings may have been changed if the inverter is used.

Use this procedure to restore parameters to their initial values.

Operation Display

Screen at power-ON

1

2

The monitor display appears.

Changing the operation mode

Press to choose the PU operation mode.

PU indication is lit.

Parameter setting mode

3

Press to choose the parameter setting

mode.

Selecting the parameter number

4

Turn until ( ) appears

Reading settings

5

Press to read the present setting.

"

"(initial value) appears.

Changing the setting

6

Turn to change it to the set value " ".

Parameter settings

7

Press to nalize the setting.

"1" and "Pr.CL"/"ALLC" ashes.

PRM indication is lit.

(The parameter number read previously appears.)

Parameter clear

All parameter clear

Parameter clear

All parameter clear

Setting Description

0 Not executed.

Set parameters back to the initial values. (Parameter clear sets back all parameters except calibration

1

parameters, terminal function selection parameters to the initial values.) Refer to the parameter list for

information on the availability of clear parameter and clear all parameters functions for each parameter.

POINT

● Check the values of several parameter settings when the clear all parameters function cannot be performed.

Pr. 77 "0", Pr. 79 "0", Pr. 340 "10", and Pr. 551 "9999"

3-8

3.5.2 Pr. 9 Electronic thermal O/L relay

Congure the current value for the electronic thermal O/L relay to enable motor overheating protection. This can

help you achieve optimal protection capability for various operating conditions such as low-speed operation and

reduced motor cooling capacity.

Pr. Name Initial value Setting range Description

*1

9 Electronic thermal O/L relay Inverter rated current

*1 The inverter rated current is congured to 85% for values of 0.75K or less.

This function detects the motor overload (overheating) and trips the inverter by stopping the operation of the

transistor at the inverter output side.

● Set the rated current value (A) of the motor in Pr. 9.

(If the motor has both 50Hz and 60Hz rating and the Pr. 3 Base frequency is set to 60Hz, set the 1.1 times of

the 60Hz rated motor current.)

● Set "0" in Pr. 9 when you do not want to operate the electronic thermal O/L relay, e.g. when using an external

thermal relay with the motor. (Note that the output transistor protection of the inverter functions (E.THT).)

Operation example

0 to 500A Set the rated motor current.

3

Screen at power-ON

1

The monitor display appears.

Changing the operation mode

2

Press to choose the PU operation mode. The [PU] indicator turns on.

Parameter setting mode

3

Press to choose the parameter setting mode.

Selecting the parameter number

4

Turn until (Pr. 9) is selected.

Reading settings

5

Press to read the present setting. " " (0.68A (initial value)) appears.

Changing the setting

6

Turn to change the setting to " " (0.63A).

Parameter settings

7

Press to nalize the setting.

The parameter number and setting ashes.

* Congure parameter settings in accordance with your environment.

3-9

3.5.3 Pr. 3 Base frequency

Use this function to adjust the inverter output (voltage, frequency) to match the motor rating.

Pr. Name Initial value Setting range Description

3 Base frequency 60Hz 0 to 400Hz

● When operating a standard motor, generally set the rated frequency of the motor to Pr. 3 Base frequency.

When running the motor using commercial power supply-inverter switch-over operation, set Pr. 3 to the same

value as the power supply frequency.

● If the frequency given on the motor rating plate is "50Hz" only, always set to "50Hz". Leaving the base fre-

quency unchanged from "60Hz" may make the voltage too low and the torque insufcient. It may result in an

inverter trip due to overload.

Rated motor frequency.

(50Hz/60Hz)

Screen at power-ON

1

The monitor display appears.

Changing the operation mode

2

Press to choose the PU operation mode. The [PU] indicator turns on.

Parameter setting mode

3

Press to choose the parameter setting mode.

Selecting the parameter number

4

Turn until (Pr. 3) is selected.

Reading settings

5

Press to read the present setting. " " (60.00Hz (initial value)) appears.

Changing the setting

6

Turn to change the setting to " " (50.00Hz).

Parameter settings

7

Press to nalize the setting.

Operation example

The parameter number and setting ashes.

* Congure parameter settings in accordance with your environment.

3-10

3.5.4 Pr. 0 Torque boost

Pr

y

Output frequency (Hz)

This parameter is used to correct voltage drops in low-frequency ranges and improve decreases in motor torque

during low speeds.

•

Motor torque during low-frequency ranges can be adjusted in accordance with load and can be increased during startup.

Pr. Name Initial value Setting range Description

0.1K to 0.75K 6%

0 Torque boost

1. Starting torque adjustment

● On the assumption that Pr. 19 Base frequency

voltage is 100%, set the output voltage at 0Hz in %

to Pr. 0.

1.5K to 3.7K 4%

5.5K, 7.5K 3%

11K, 15K 2%

0 to 30% Set the output voltage at 0Hz as %.

100%

● Adjust the parameter little by little (about 0.5%),

and check the motor status each time. If the setting

is too large, the motor will overheat. The guideline

is about 10% at the greatest.

Operation example

Screen at power-ON

1

The monitor display appears.

Changing the operation mode

2

Press to choose the PU operation mode. The [PU] indicator turns on.

Parameter setting mode

3

Press to choose the parameter setting mode.

Selecting the parameter number

4

Turn until (Pr. 0) is selected.

Reading settings

5

Press to read the present setting. " " (6.0% (initial value)) appears.

Output voltage

.0 Setting range

3

0

Base

frequenc

Changing the setting

6

Turn to change the setting to " " (3.0%).

Parameter settings

7

Press to nalize the setting.

The parameter number and setting ashes.

* Congure parameter settings in accordance with your environment.

3-11

3.5.5 Pr. 1, 2 Upper-limit/lower-limit frequency

Output frequency

Frequency setting value

lower-limit frequency

These parameters can be used to restrict motor speed.

These parameters are used to set upper and lower limits on output frequency.

Pr. Name Initial value Setting range Description

1 Upper-limit frequency 120Hz 0 to 120Hz Upper limit of the output frequency

2 Lower-limit frequency 0Hz 0 to 120Hz Lower limit of the output frequency

(1) Set upper-limit frequency

● Use Pr. 1 Upper-limit frequency to set the maximum

frequency. If the frequency of the frequency

command

output frequency is clamped at the upper-limit

frequency.

(2) Set lower-limit frequency

● Use Pr. 2 Lower-limit frequency to set the minimum

frequency.

● If the set frequency is less than Pr. 2, the output

frequency is clamped at Pr. 2 (will not fall below Pr. 2 ).

entered is higher than the setting, the

Operation example

Screen at power-ON

1

The monitor display appears.

(Hz)

Pr.1

Pr.18

Pr.2

Clamped at the

0

(4mA)

Clamped at the

upper-limit frequency

5, 10V

(20mA)

2

3

4

5

6

7

* Congure parameter settings in accordance with your environment.

Changing the operation mode

Press to choose the PU operation mode. The [PU] indicator turns on.

Parameter setting mode

Press to choose the parameter setting mode.

Selecting the parameter number

Turn until (Pr. 1) is selected.

Reading settings

Press to read the present setting. " " (120.0Hz (initial value)) appears.

Changing the setting

Turn to change the setting to " " (60.00Hz).

Parameter settings

Press to nalize the setting.

The parameter number and setting ashes.

3-12

3

3.5.6 Pr. 7, 8 Acceleration/deceleration time

e

Pr.20

Pr.7 Pr.8

frequency

Pr.44 Pr.45

These parameters are used to congure the motor acceleration/deceleration time.

Set larger values for slower acceleration/deceleration and smaller values for faster acceleration/deceleration.

Pr. Name Initial value Setting range Description

3.7K or less 5s

7 Acceleration time

11K, 15K 15s

3.7K or less 5s

8 Deceleration time

11K, 15K 15s

Acceleration/

20

(1) Acceleration time setting (Pr. 7, Pr. 20)

● Pr. 7 acceleration time congures the acceleration

time required to reach the Pr. 20 acceleration/

deceleration reference frequency from a stopped state.

deceleration

reference

frequency

60Hz 1 to 400Hz

0 to 3600/360s Motor acceleration time5.5K, 7.5K 10s

0 to 3600/360s Motor deceleration time5.5K, 7.5K 10s

Frequency that will be the basis of

acceleration/deceleration time

As acceleration/deceleration time, set the

frequency change time from stop to Pr. 20.

Running

frequency

(Hz)

(2) Deceleration time setting (Pr. 8, Pr. 20)

● Pr. 8 acceleration time congures the deceleration

time required to stop from the Pr. 20 acceleration/

deceleration reference frequency.

Operation example

Screen at power-ON

1

The monitor display appears.

Changing the operation mode

2

Press to choose the PU operation mode. The [PU] indicator turns on.

Parameter setting mode

3

Press to choose the parameter setting mode.

Selecting the parameter number

4

Turn until (Pr. 7) is selected.

Reading settings

5

Press to read the present setting. " " (5.0 seconds (initial value)) appears.

Changing the setting

6

Turn to change the setting to " " (10.0 seconds).

Parameter settings

Output

Accelerationtime

Tim

Decelerationtime

7

Press to nalize the setting.

The parameter number and setting ashes.

* Congure parameter settings in accordance with your environment.

3-13

MEMO

3-14

4

Controlling inverters using a PC

Chapter 4

How to use FR Congurator

Using FR Congurator makes parameter

conguration even easier.

Many parameters can be congured in single batch operations with the software

"FR Congurator".

This chapter will cover how to connect the inverter to a PC, Easy Setup, and nally

basic operation of the software.

Using this software also enables you to save conguration data for devices.

You can easily take congurations created for testing and prototype environments

and copy them to mass-production equipment and devices.

4-1

4.1

Example of FR-E700

Pull the cover in the direction of arrow. Then turn it upward.

Inverter PC (FR Configurator) USB cable

Fundamental knowledge to operate FR Congurator

4.1.1 Items needed for connectivity

4.1.2 Connection method

All you need to connect a PC and inverter is a single USB cable. Only peer-to-peer connections can be

established. USB hubs cannot be used to make connections.

USB cable

USB connector

<How to open the USB connector cover>

4-2

4.1.3 Startup

The "Startup" window is displayed when FR Congurator is started. Each function can be directly selected from

the "Startup" window.

A

B

C

D

E

No. Name Function and description

Shows up to ve recent used les.

A Open

B Easy Setup

C Functions Shows a list of functions.

D Help Displays Help window.

E Cancel Click to close this window, and returns to Main frame.

Point a cursor on "Open", and ve recent used les are shown. Click the le name, then

"Startup" window is closed, and Main frame is displayed with the le contents reected.

Click to start Easy Setup.

From System Property setting to Model setting and parameter setting, the system setting

up is easily made with wizard style (interactive manner).

4

4-3

4.1.4 Screen conguration (Main frame)

The Main frame (main window) of FR Congurator consists of three areas.

• Navigation area

An area for showing information of the registered inverter, or for making settings. "Test Operation", "System

Settings", "Setting Wizard", and "Troubleshooting" are available in this area.

• Monitor area

An area for showing obtained monitor data of the inverter. "Graph", "I/O Terminal Monitor", "Machine Analyzer",

"Batch Monitor" are available in this area.

• System area

An area for showing and read/write parameters, or for converting from parameter setting of conventional model.

"Parameter List", "Diagnosis" and "Convert" are available in this area.

H

A

B

C

G

I

F

Navigation area

D

No. Name Function and description

A Title bar

B Menu bar Each function is available by selecting from the menu.

C Tool bar Each function is available by clicking icons of the tool bar.

D Status bar The model name, Operating status, etc. are shown.

"FR Congurator SW3" is displayed on the title bar. If a system le has been read, or has been

saved, the le name is displayed.