Page 1

HC

HIGH POWER FACTOR CONVERTER

FR-HC-7.5K to 55K

FR-HC-H7.5K to H55K

INSTRUCTION MANUAL

Page 2

Thank you for choosing the Mitsubishi High Power Factor Converter.

This instruction manual gives handling information and precautions for use of this equipment. Incorrect

handling might cause an unexpected fault. Before using the invert er, please read this manual care fully to us e

the equipment to its optimum.

Please forward this manual to the end user.

Safety Instructions

Do not attempt to install, operat e, maintain or i nspec t the unit until you have read through this ins tr ucti on

manual and appended docu ments carefully and can use the equipme nt correctly. Do not use the unit

until you have a full knowledge of the equipment, safety information and instructions.

In this instruction manual, the safety instruction levels are classified into “WARNING” and “CAUTION”.

Assumes that incorrect handling may cause hazardous conditions,

WARNING

CAUTION

resulting in death or severe injury.

Assumes that in correc t handl ing may cause h azardou s cond itions, r esulti ng

in medium or slight injury, or may cause physical damage only.

Note that the level may lead to a serious consequen ce accordi ng to con ditions. Plea se

follow the instructions of both levels because they are important to personnel safety.

CAUTION

- A-1 -

Page 3

SAFETY INSTRUCTIO NS

1. Electric Shock Prevention

WARNING

• While power is on or when the equipment is running, do not open the front cover. You may get an

electric shock.

• Do not run the equipment with the front co ver remo ved. Oth erwis e, you may acces s the expo sed high voltage terminals and charging part and get an electric shock.

• If power is off, do not remove the front cover except fo r wiring or periodic inspection . You may access

the charged circuits of the inverter and high power factor converter and get an electric shock.

• Before starting wiring or ins pe ction, ch ec k fo r res i dual v oltages wi th a m ete r etc. more than 10 minutes

after power-off.

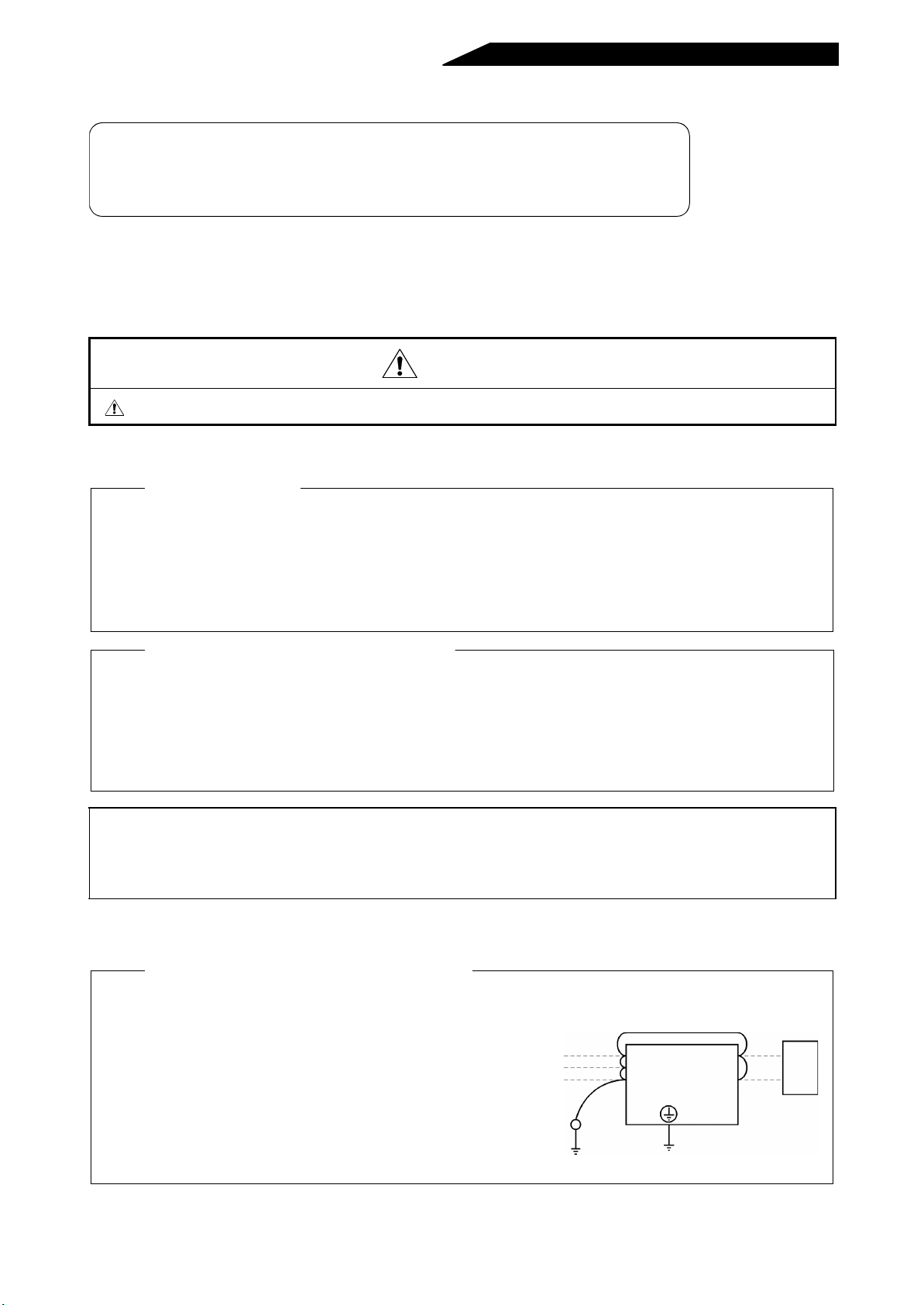

• This converter must be ear the d (gr ou nde d). Earthing (grounding) mu st be c on for m to the requi r eme nts

of national and local safety regul ations and electrical codes. (NEC section 250, IEC 536 class 1 and

other applicable standa rd s)

• Any person who is involved in th e wiring or inspection of this equipment should be fully competent to

do the work.

• Always install the equipment before wiring. Otherwise, you may get an electric shock or be injured.

• Operate the switches with dry hands to prevent an electric shock.

• Do not subject the c ab les to s cratc he s, ex ce ss iv e str ess , heavy loads or pi nchi ng. O th er wis e, you may

get an electric shock.

2. Fire Prevention

CAUTION

• Mount the high power fa ctor conver ter on a non- combustible sur face. Installing the equipment directly

on or near a combustible surface could lead to a fire.

• Power off the high power factor converter if it has failed. A continuous flow of a large current can cause

a fire.

• Do not connect a resistor directly to the DC terminals P, N. This could cause a fire.

• When a brake resistor is used, switch po wer off if an alarm signal app ears on the PU. Otherwi se, the

brake resistor may excessively overheat due to damage of the brake transistor, etc., causing a fire.

3. Injury Prevention

CAUTION

• Apply only the volta ge specified in the inst ruction manual to each te rminal to prevent bu rst, damage,

etc.

• Ensure that the cables are connected to the correct terminals. Otherwise, burst, damage, etc. may

occur.

• Always make sure that polarity is correct to prevent burst, damage, etc.

• While power is on or for some time after power-off, do not touch the inverter, high power factor

converter, reactors 1 and 2, or the external box as they are hot and you may get burnt.

- A-2 -

Page 4

4. Additional instructions

To prevent injury, damage or product failure, please note the following points.

(1)Transportation and mounting

CAUTION

• Please use common sense when carrying the product. Not doing so can cause injury.

• Do not stack the equipment higher than the number recommended.

• Install the product in a load-bearing place in accordance with the instruction manual.

• Do not operate if the high power factor converter is damaged or has parts missing.

• Do not lift the equipment with the front cover attached; it may fall off.

• Do not stand or rest heavy objects on the product.

• Check the equipment mounting orientation is correct.

• Prevent any dust, wire fragments or other foreign bodies from dropping into the high power factor

converter.

• Do not drop the high power factor converter, or subject it to impact.

• Use the equipment under the following environmental conditions:

Ambient

temperature

Ambient

humidity

Storage

temperature

Environment

Ambience Indoors (free from corrosive gas, flammable gas, oil mist, dust and dirt)

Altitude,

vibration

*Temperatures applicable for a short time, e.g. in transit.

(-10°C to +40°C when the d ust-protec tion structure attachment is used)

Maximum 1000m above sea level for standard operation.

After that derate by 3% for every extra 500m up to 2500m (91%).

-10°C to +50°C (non-freezing)

90%RH or less (non-condensing )

-20°C to +65°C*

2

5.9m/s

or less

(2)Trail run

CAUTION

• Check all parameters, and ensure that the machine will not be damaged by sudden start-up.

• Before starting operation, e nsure that each peripheral device is wired pr operly. Incorrect connection

may lead to unexpected operation.

(3)Operation

CAUTION

• The load used must be a three-phase induction motor. If any other electrical equipment is connected to

the inverter output, the equipment may be damaged.

• Do not modify the equipment.

- A-3 -

Page 5

(4)Emergency stop

CAUTION

• Provide a safety backup such as an emer gecy brake which will prevent the machine and equipment

from hazardous conditions if the high power factor converter fails.

• When any protective function is activated, take the corresponding corrective action, then reset the

inverter, and resume operation.

(5)Maintenance, inspection and parts replacement

CAUTION

• Do not carry out a megger (insulation resistance) test on the control circuit of the high power factor

converter.

(6)Disposal

CAUTION

• Treat the equipment as industrial waste.

(7)General instructions

Many of the diagrams and drawing in this instruction manual show the equipment without a cover, or

partiall y open. Never run the inverter like thi s. Always replace th e cover and ensure adequate coo ling,

etc. before using the product.

- A-4 -

Page 6

CONTENTS

1. OVERVIEW

1.1 PRECAUTIONS FOR OPERATION ................................ ...... ....................................... ...... ..... ...... ..........................1

1.1.1 Japanese harmonic suppression guideline .......................................................................................................1

1.1.2 Pre-operation procedure ....................................................................................................................................5

1.1.3 Handling precautions .........................................................................................................................................6

1.2 STRUCTURE ...........................................................................................................................................................7

1.2.1 Structure ............................................................................................................................................................7

1.2.2 Removal and reinstallation of the front cover ....................................................................................................8

1.2.3 Removal and reinstallation of the accessory cover .........................................................................................11

1.2.4 Removal and reinstallation of the parameter unit (FR-PU02) ..........................................................................12

1.3 INSTALLATION AND WIRING ................................... ..... ...... ....................................... ...... ..... ..............................13

1.3.1 Precautions for installation ................................... ....................................... ...... ..... .........................................13

1.3.2 Wiring instructions ...........................................................................................................................................16

1.3.3 Wiring of the main circuit ..................... ....................................... ...... ...............................................................17

1.3.4 Wiring of the control circuit .................. ....................................... ...... ...............................................................26

2. PARAMETERS

2.1 PARAMETER UNIT ...............................................................................................................................................29

2.1.1 Structure of the parameter unit ........................................................................................................................29

2.1.2 Setting and changing the parameter values ....................................................................................................30

2.2 PARAMETER FUNCTION DETAILS .....................................................................................................................31

2.2.1 Parameter list ..................................................................................................................................................31

2.2.2 Setting of parameters to improve the corresponding operational functions ....................................................32

Pr.1 “power supply frequency 1”, Pr.2 “power supply frequency 2” .......................................................................32

Pr.22 “overload signal detection level” ..................................................................................................................32

Pr.40 “output terminal assignment” .......................................................................................................................32

Pr. 51 “input power monitoring refer ence”, Pr. 53 “input voltage monitoring reference”, Pr. 55 “bus voltage monitori ng

reference”, Pr. 56 “current monitoring reference” ...................................................................................................33

Pr. 52 “PU main display data selection”, Pr. 54 “FM terminal function selection” ...................................................33

Pr.57 “restart selection” .........................................................................................................................................35

Pr. 65 “retry selection”, Pr. 67 “number of retries at al arm occurrence”, Pr. 68 “retry waiting t ime”, Pr. 69 “retry coun t

display erasure” ........................................................... ..... ........................................ ..... .........................................36

Pr.77 “parameter write disable selection” ..............................................................................................................37

Pr.145 “parameter unit language switching” ..........................................................................................................37

Pr.900 “FM terminal calibration” ............................................................................................................................38

2.3 HELP FUNCTIONS ................................................................................................................................................40

2.3.1 Definitions of the help function displays ..........................................................................................................40

2.4 CONVERTER RESET ............................................................ ...... ..... ...... ..... ...... ....................................................43

3. PROTECTIVE FUNCTIONS

3.1 ERRORS ................................................................................................................................................................44

3.1.1 Error (alarm) definitions and remedies .............................................................. ..... ...... ...................................44

3.1.2 Faults and check points ...................................................................................................................................45

- I -

Page 7

3.2 MAINTENANCE AND INSPECTION .....................................................................................................................46

3.2.1 Precautions for maintenance and inspection ...................................................................................................46

3.2.2 Check items .....................................................................................................................................................46

3.2.3 Replacement of parts ...................................................................................................................................... 49

3.2.4 Measurement of main circuit voltages, currents and powers ..........................................................................50

4. PRECAUTIONS FOR SELECTION

4.1 PRECAUTIONS FOR SELECTING PERIPHERAL DEVICES ..............................................................................52

4.1.1 Measures against noises .................................................................................................................................52

4.1.2 Peripheral device list .......................................................................................................................................55

4.1.3 Selecting the rated sensitivity current for the earth leakage circuit breaker ....................................................55

5. SPECIFICATIONS

5.1 SPECIFICATIONS .................................................................................................................................................56

5.1.1 Standard specifications ...................................................................................................................................56

5.1.2 Block diagram ..................................................................................................................................................57

5.1.3 Terminals .........................................................................................................................................................58

5.1.4 Terminal block arrangement ............................................................................................................................60

5.1.5 Outline drawings (400V class models have H in their type codes) ..................................................................61

5.1.6 Panel cutting dimension diagrams (For use of the heat sink outside mounting attachment) ...........................66

5.1.7 Parameter unit (FR-PU02-1/FR-PU02E-1/FR-PU02ER-1) dimension diagram ..............................................67

5.2 OPTIONS ...............................................................................................................................................................68

5.2.1 Option list .........................................................................................................................................................68

5.2.2 External dedicated options ..............................................................................................................................69

APPENDIX

APPENDIX 1 INSTRUCTIONS FOR COMPLIANCE WITH THE EUROPEAN STANDARDS .............................73

APPENDIX 2 Instructions for UL and cUL ..........................................................................................................74

- II -

Page 8

1. OVERVIEW

2. PARAMETERS

3. PROTECTIVE FUNCTIONS

4. PRECAUTIONS FOR SELECTION

5. SPECIFICATIONS

Page 9

1. OVERVIEW

This chapter provides an “overview” of this product.

Always read the precautions, etc. before starting use.

1

1.1 PRECAUTIONS FOR OPERATION........................................................... 1

1.2 STRUCTURE ............................................................................................. 7

1.3 INSTALLATION AND WIRING................................................................... 13

Page 10

1.1 PRECAUTIONS FOR OPERATION

Incorrect handling might cause the equipment to operate improperly, its life to be reduced

considerably, and in the worst case, the high power factor converter and inverter to be

damaged. Please handle the unit properly in accordance with the information on each

section as well as the precautions and instructions of this manual.

FR-HC Function

The FR-HC high power factor converter provides three functions

1) Inverter generated mains harmonics reduction

See the Power harmonic guideline section below.

2) Near unity power factor at 100% load

Gives better efficiency and lower stress on power line components.

3) Regeneration of load to the mains power supply

The FR-HC can con tinuously re generate conver ter rated current t o the power su pply, for example from

a ‘back-driving’ load such as a d own escalator. This gives very efficient full 4-quadrant control of the

AC motor from the inverter without the need for brake resistors or braking units etc.

1.1.1 Japanese harmonic suppression guideline

Harmonic c urrents flow from th e inverter to a power receiv ing point via a p ower transformer. The harmonic

suppression guideline was established to protect other consumers from these outgoing harmonics.

1) “Harmonic suppression guideline for household appliances and general-purpose products”

200V class inver ters of 3.7kW and less are covered by this guideline. Install a power factor improving

reactor to comply with this guideline.

2) “Harmonic suppression guideline for specific consumers”

This guideline sets forth the maximum values of harmonic currents outgoing from a high-voltage or

specially high-voltage con sumer who will install, add or renew harm onic generating equipment. If any

of the maximum values is exceeded, this g uideline requ ires that c onsumer to ta ke cer tain suppre ssion

measures.

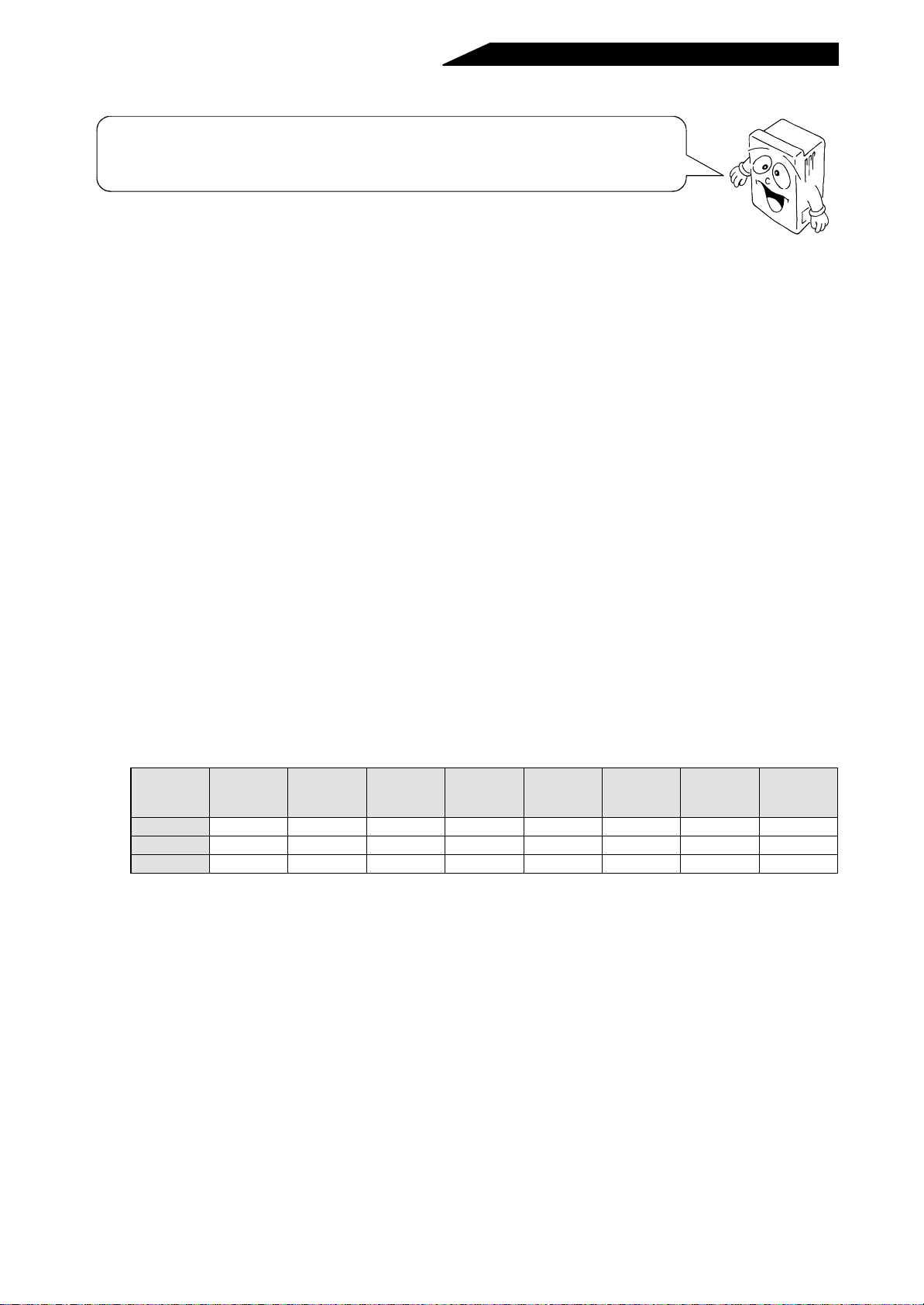

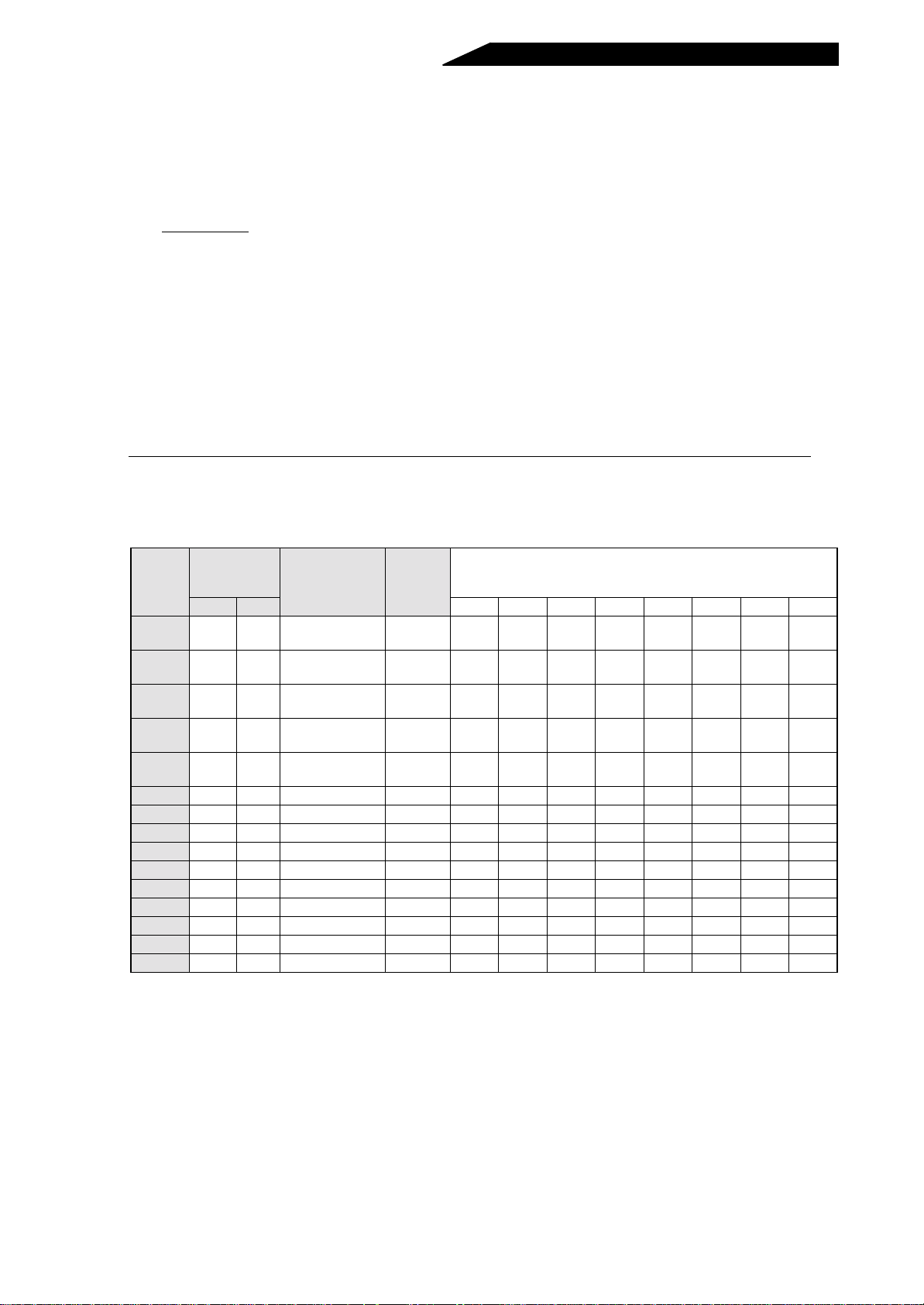

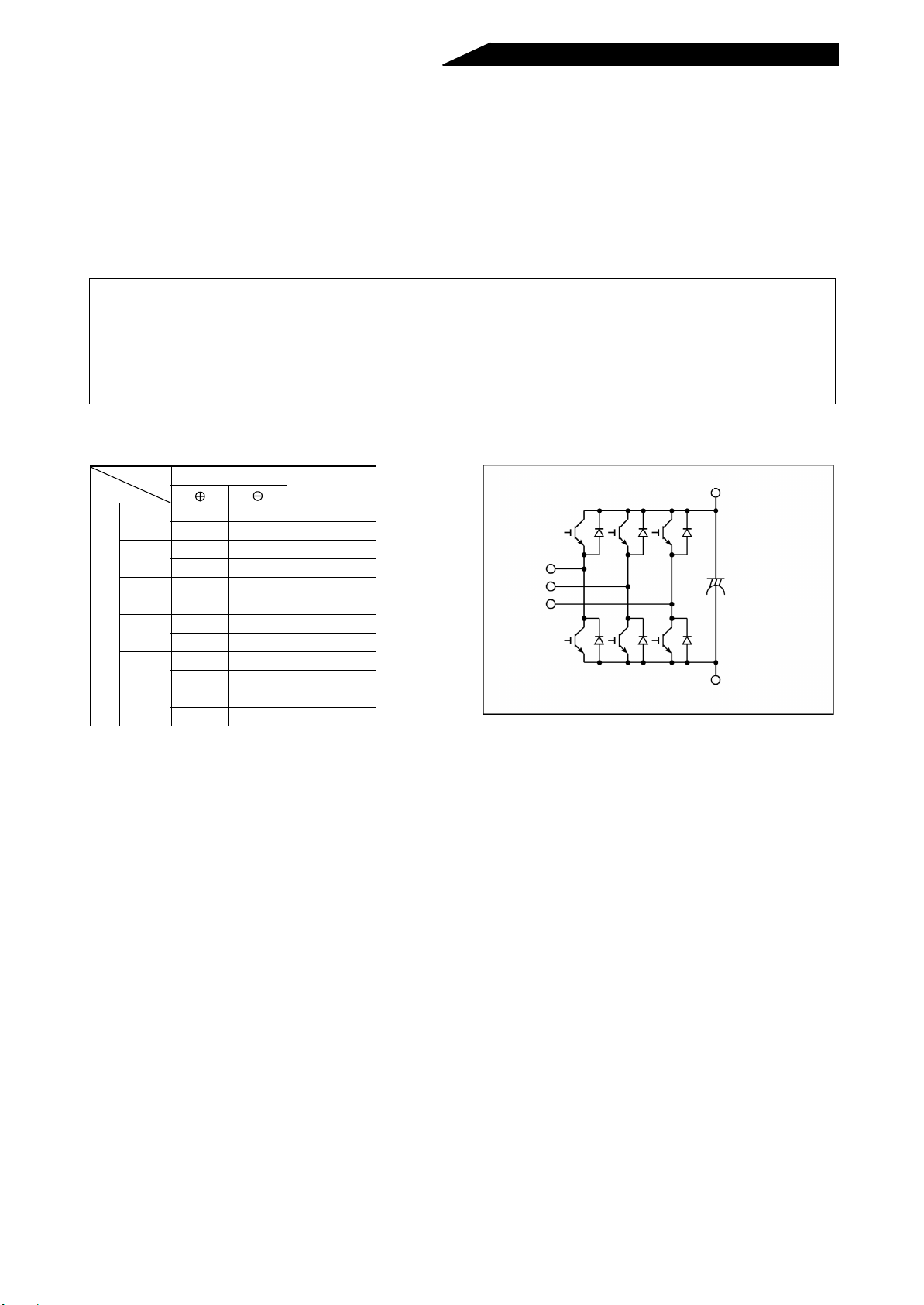

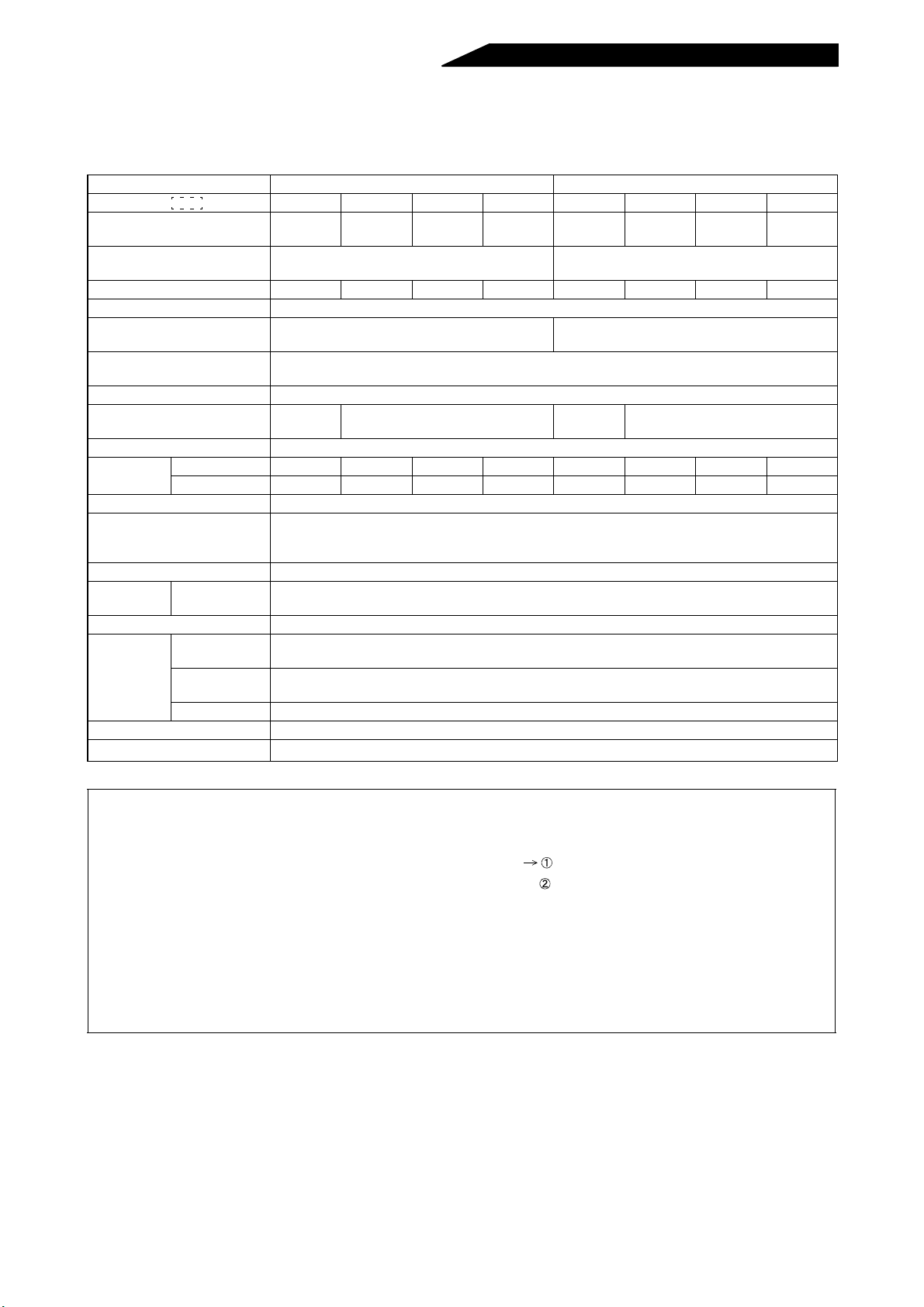

Table 1 Maximum Values of Outgoing Harmonic Currents per 1kW Contract Power

Received

Power

Voltage

6.6kV 3.5 2.5 1.6 1.3 1.0 0.9 0.76 0.70

22kV 1.8 1.3 0 .82 0.69 0.53 0.47 0.39 0.36

33kV 1.2 0.86 0.55 0.46 0.35 0. 32 0.26 0.2 4

5th 7th 11th 13th 17th 19th 23rd

over

23rd

- 1 -

Page 11

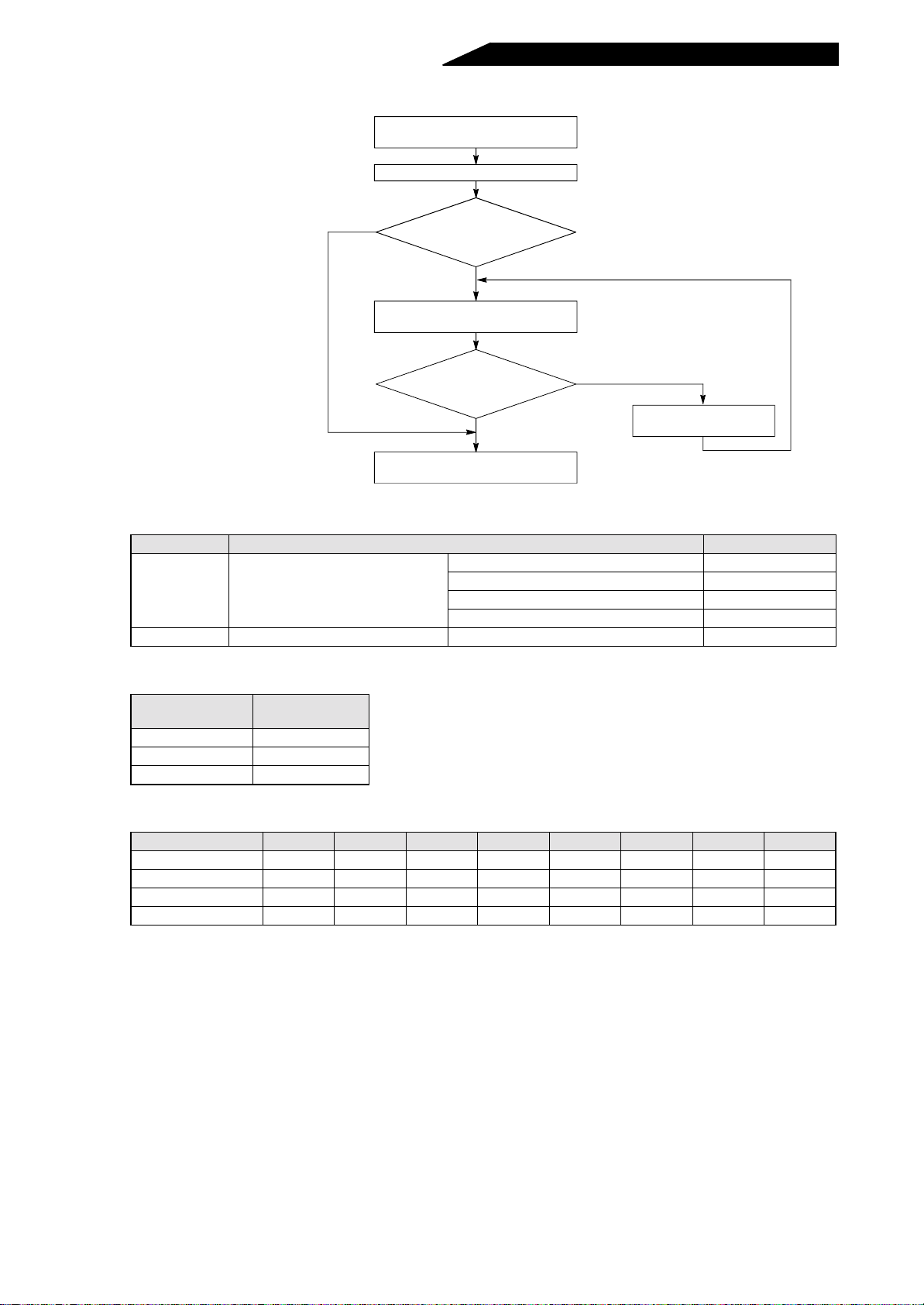

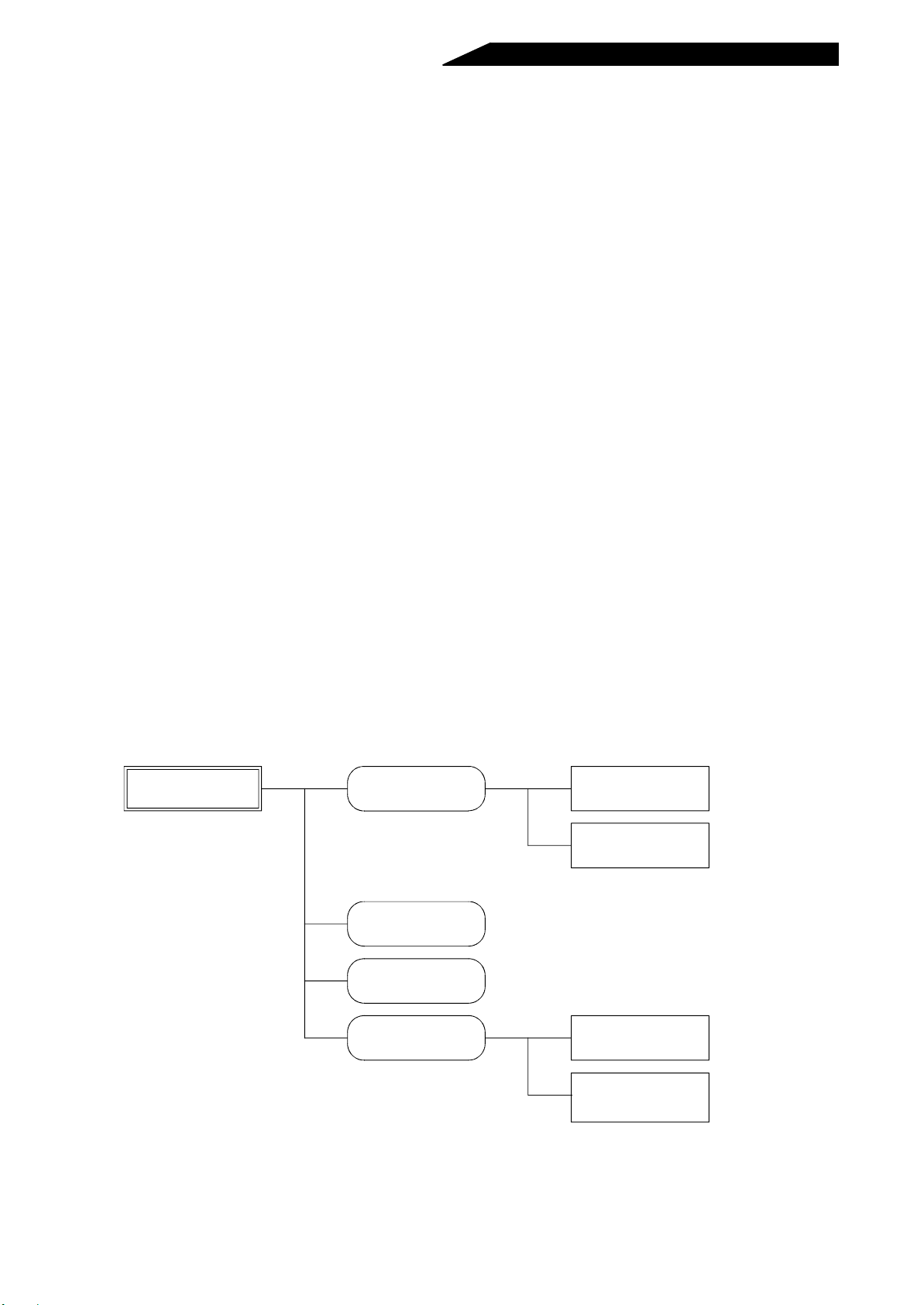

(1) Application of the harmonic suppression guideline for specific consumers

New installation/addition/renewal of

harmonic generating equipment

Calculation of equivalent capacity sum

Not more than

reference capacity

Over reference capacity

Sum of equivalent capacities

Calculation of outgoing harmon ic

current higher than maximum

Harmonic suppression techn iq ue is

current

Is outgoing harmonic

value?

Not more than

maximum value

not required.

Over maximum value

Harmonic suppression

technique is required.

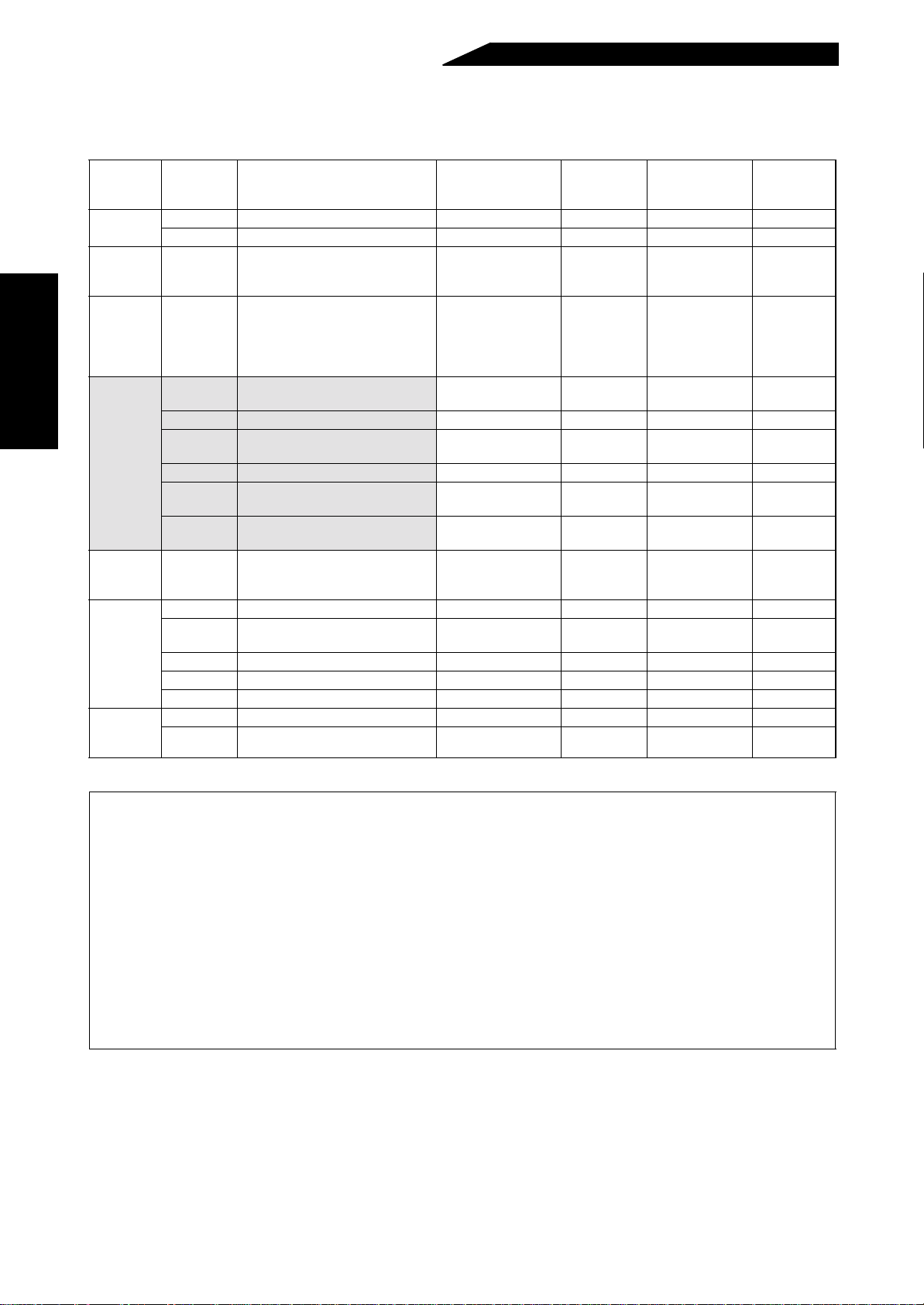

Table 2 Conversion Factors for FR-A500 Series

Classification Circuit Type Conversion Factor

Without reactor K31=3.4

3

Three-phase bridge

(Capacitor smoothed)

With reactor (on AC side) K32=1.8

With reactor (on DC side) K33=1.8

Without reactor (on AC/DC side) K34=1.4

5 Self-excited three-phase bridge When high power factor converter is used K5=0

Table 3 Equivalent Capacity Limits

Received Power

Voltage

6.6kV 50kVA

22/23kV 300kVA

66kV or more 2000kVA

Reference

Capacity

Table 4 Harmonic Content (Values at the fundamental current of 100%)

Reactor 5th 7th 11th 13th 17th 19th 23rd 25th

Not used 65 41 8.5 7.7 4.3 3.1 2.6 1.8

Used (AC side) 38 14.5 7.4 3.4 3.2 1.9 1.7 1.3

Used (DC side) 3 0 13 8.4 5.0 4.7 3.2 3.0 2.2

Used (AC, DC sides) 28 9.1 7.2 4.1 3.2 2.4 1.6 1.4

- 2 -

Page 12

1) Calculation of equivalent capacity P0 of harmonic generating equipment

Σ

The “equivalent capacity” is the capacity of a 6-pulse converter converted from the capacity of a

consumer’s harmonic generat ing equip ment and i s calcula ted with the following equation. If the s um of

equivalent capacities is hig her than the limit in Table 3, har monics must be calcul ated in the following

procedure:

P0 = (Ki×Pi) [kVA]

Ki: Conversion factor (refer to Table 2)

Pi: Rated capacity of harmonic

generating equipment* [kVA]

i: Number indicating the conversion

circuit type

* Rated capacity: Determined by the

capacity of the applied motor and found

in Table 5. It should be noted that the

rated capacity used here is used to

calculate generated harmonic amount

and is different from the power supply

capacity require d for actual inverter drive.

2) Calculati on of outgoi ng harmonic current

Outgoing harm oni c

current

=

(value converted from received power voltage)

fundamental wave current

operation

×

ratio

harmonic

×

content

• Operation ratio: Operation ratio = actual load factor × operation tim ratio during 30 minutes

• Harmonic content: Found in Table 4.

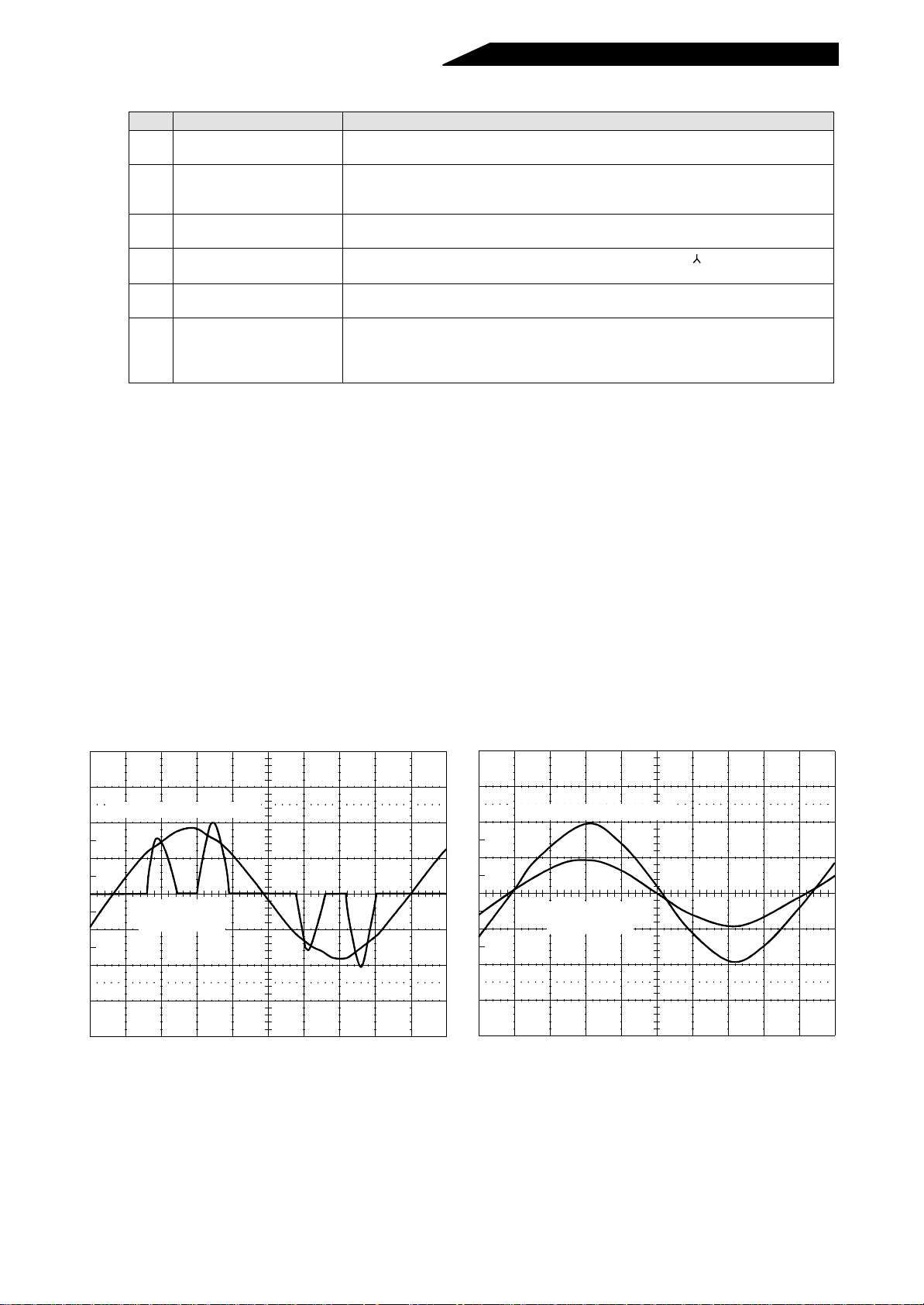

Table 5 Rated Capacities and Outgoing Harmonic Currents for Inverter Drive

Applied

Motor

(kW)

0.4

0.75

1.5

2.2

3.7

5.5 19.1 9.55 579 6.77 376.1 237.4 49.22 44.58 24.90 17.95 15.05 10.42

7.5 25.6 12.8 776 9.07 504.4 318.2 65.96 59.75 33.37 24.06 20.18 13.97

11 36.9 18.5 1121 13.1 728.7 459.6 95.29 86.32 48.20 34.75 29.15 20.18

15 49.8 24.9 1509 17.6 980.9 618.7 128.3 116.2 64.89 46.78 39.24 27.16

18.5 61.4 30.7 1860 21.8 1209 762.6 158.1 143.2 79.98 57.66 48.36 33.48

22 73.1 36.6 2220 25.9 1443 910.2 188.7 170.9 95.46 68.82 57.72 39.96

30 98.0 49.0 2970 34.7 1931 1218 252.5 228.7 127.7 92.07 77.22 53.46

37 121 60.4 3660 42.8 2379 1501 311.1 281.8 157.4 1 13.5 95.16 65.88

45 147 73.5 4450 52.1 2893 1825 378.3 342.7 191.4 1 38.0 115.7 80.10

55 180 89.9 5450 63.7 3543 2235 463.3 419.7 234.4 1 69.0 141.7 98.10

Rated

Current

[A]

200V 400V 5th 7th 11th 13th 17th 19th 23rd 25th

1.61

(Note)

(Note)

(Note)

(Note)

(Note)

0.81 49 0.57 31.85 2 0.09 4.165 3.773 2.107 1.519 1.274 0.882

2.74

1.37 83 0.97 53.95 3 4.03 7.055 6.391 3.569 2.573 2.158 1.494

5.50

2.75 167 1.95 108.6 68.47 14.20 12.86 7.181 5.177 4.342 3.006

7.93

3.96 240 2.81 156.0 98.40 20.40 18.48 10.32 7.440 6.240 4.320

13.0

6.50 394 4.61 257.1 161.5 33.49 30.34 16.94 12.21 10.24 7.092

Fundamental

Wave Current

Converted fr om

6.6kV (mA)

Rated

Capacity

(kVA)

Fundamental Wave Current Converted from 6.6kV(mA)

(No reactor, 100% operation ratio)

Note:When a motor of 3.7kW or less capaci ty is driven by a transistorized inverter of more than 3.7kW.

For example, when a 3.7kW or less motor is driven by a 5.5kW transistorized inverter, the

transistorized inverter is not the target of the household appliances/general-purpose products

guideline, but because they must be included in the calculation of the har monic current of the

guideline, the fundamental wave input currents are indicated.

3) Harmonic suppression technique requirement

contract

If the outgoing harmoni c current is higher than the maximum value per 1kW co ntract power ×

power, a harmonic suppression technique is required.

- 3 -

Page 13

4) Harmonic suppression techniques

No. Item Description

Reactor installation

1

(ACL, DCL)

High power factor

2

converter (FR-HC)

Installation of power

3

factor improving capacitor

Transformer multi-phase

4

operation

5AC filter

6 Active filter

Install a reactor (ACL) in the AC side of the inverter or a reactor (DCL) in its DC s ide or

both to suppress harmonic currents.

Designed to switch the converter circuit on-off to convert an input current waveform into

a sine wave, the high power factor converter (FR-HC) suppresses harmonic current

considerably. The FR-HC is used with the standard accessories.

When used with a series reactor, the power factor improving capacitor has an effect of

absorbing harmonic currents.

Use two transformers with a phase angle difference of 30° as in - , - combination to

provide an effect corresponding to 12 pulses, reducing low-degree harmonic currents.

A capacitor and a reactor are used together to reduce impedance at specific

frequencies, producing a great effect of absorbing harmonic currents.

This filter detects the current of a circuit generating a harmonic current and generates a

harmonic current equivalent to a difference between that current and a fundamental

wave current to suppress a harmonic current at a detection point, providing a great

effect of absorbing harmonic currents.

∆∆∆

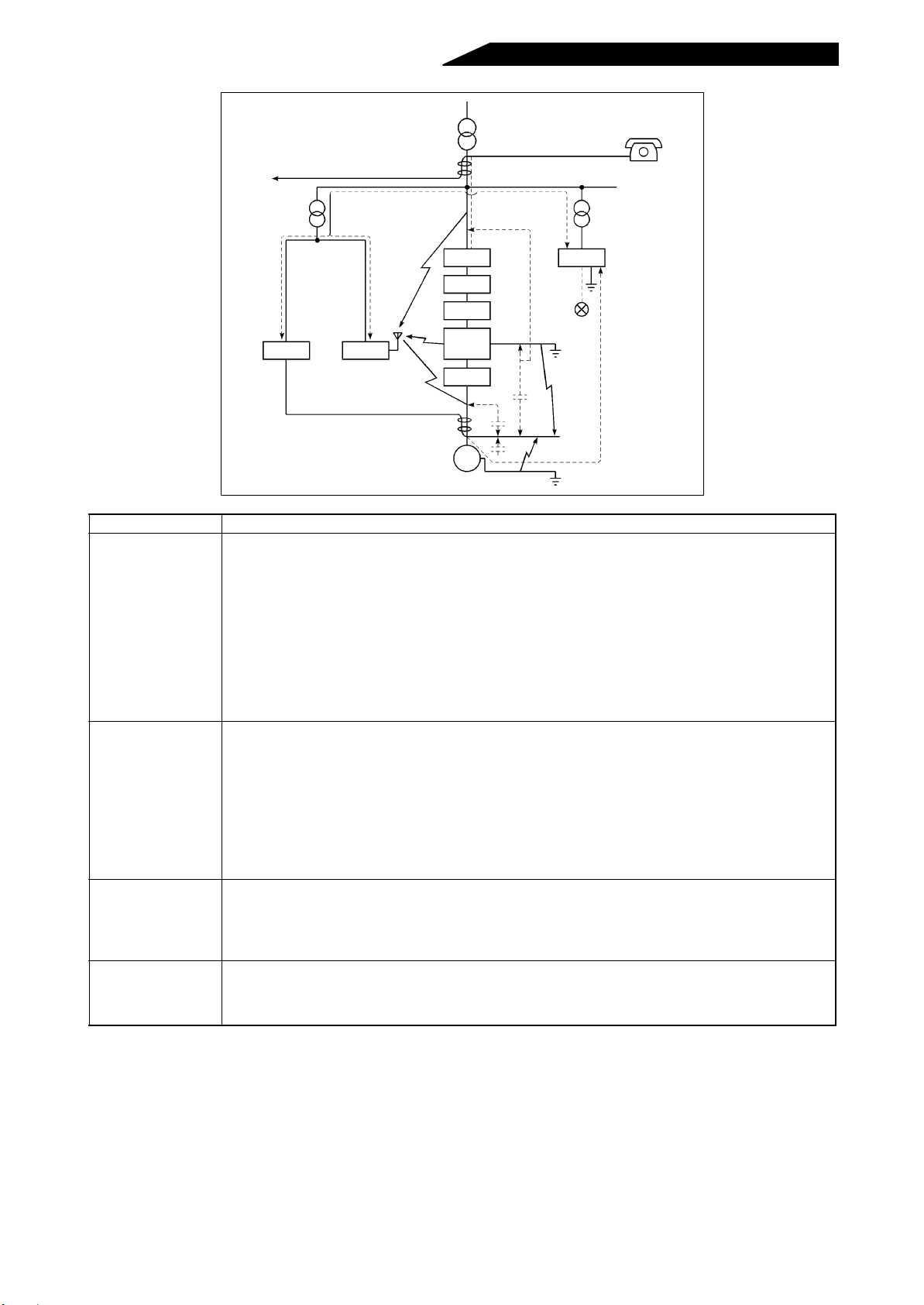

(2) Features of the FR-HC (high power factor converter)

The converter circuit of an inverter generates power harmonics, which may affect a generator, power

capacitor, etc. Power harmonics are different from noises and leakage currents in their sources,

frequency bands and transmission routes. Th erefore, securely connect the high power factor converter

(FR-HC) with the FR series inverter, and refer to the inverter instruction manual on how to set the

parameters. The conversion factor of the high power factor converter is K5=0 for a self-excited, threephase bridge circuit:

Making the above settings suppresses power harmonics to conform to the harmonic suppression

guidelines published by the Ministry of International Trade and Industry.

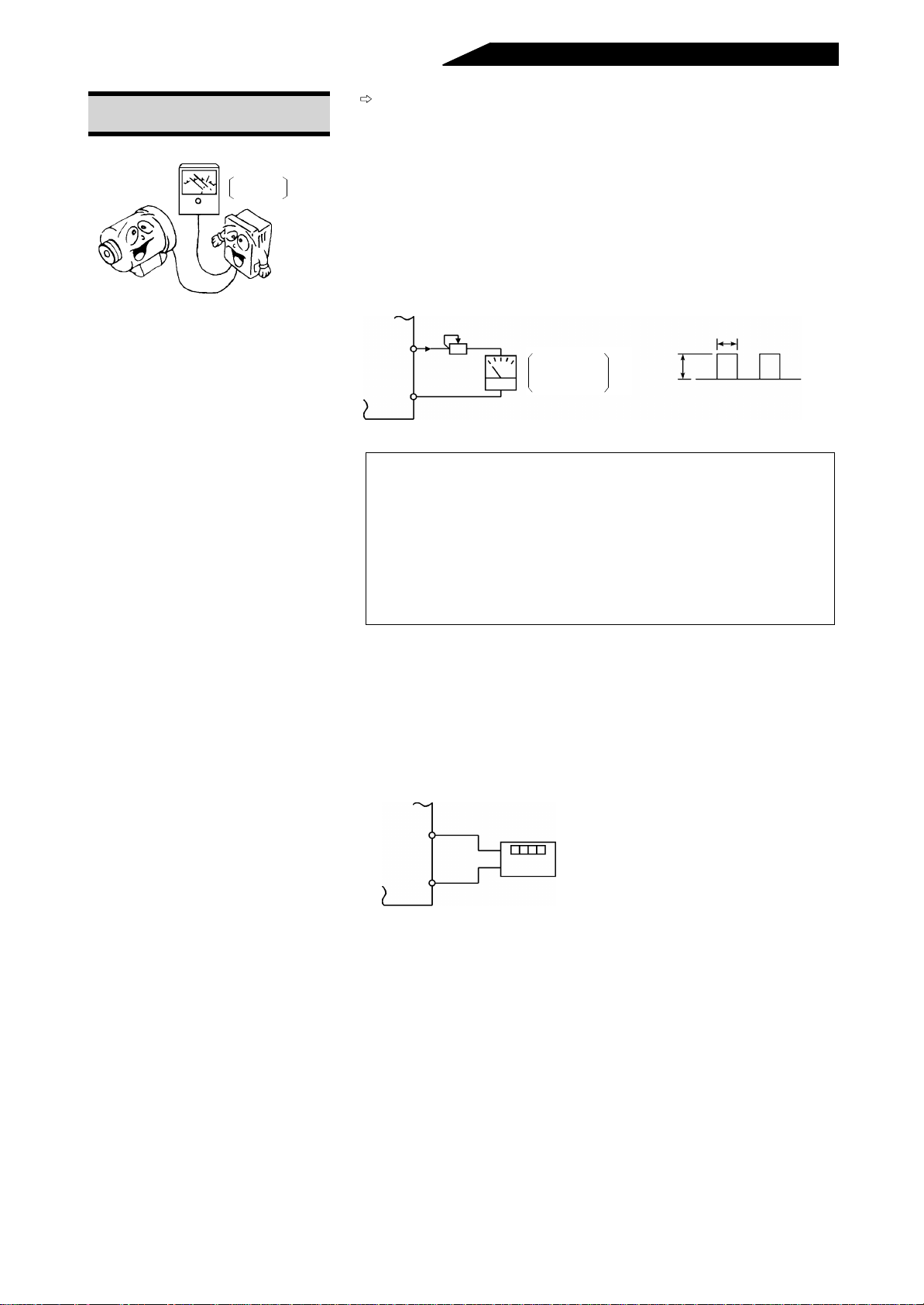

• Power harmonic su ppr ess ion effect

(Example) FR-HC-7.5K

(Environment) Load: 100%

Power factor: 1

[FR-HC not connected]

Phase voltage (100V/div)

Phase current

(50A/div)

Phase voltage (100V/div)

Phase current

[FR-HC connecte d]

(50A/div)

- 4 -

Page 14

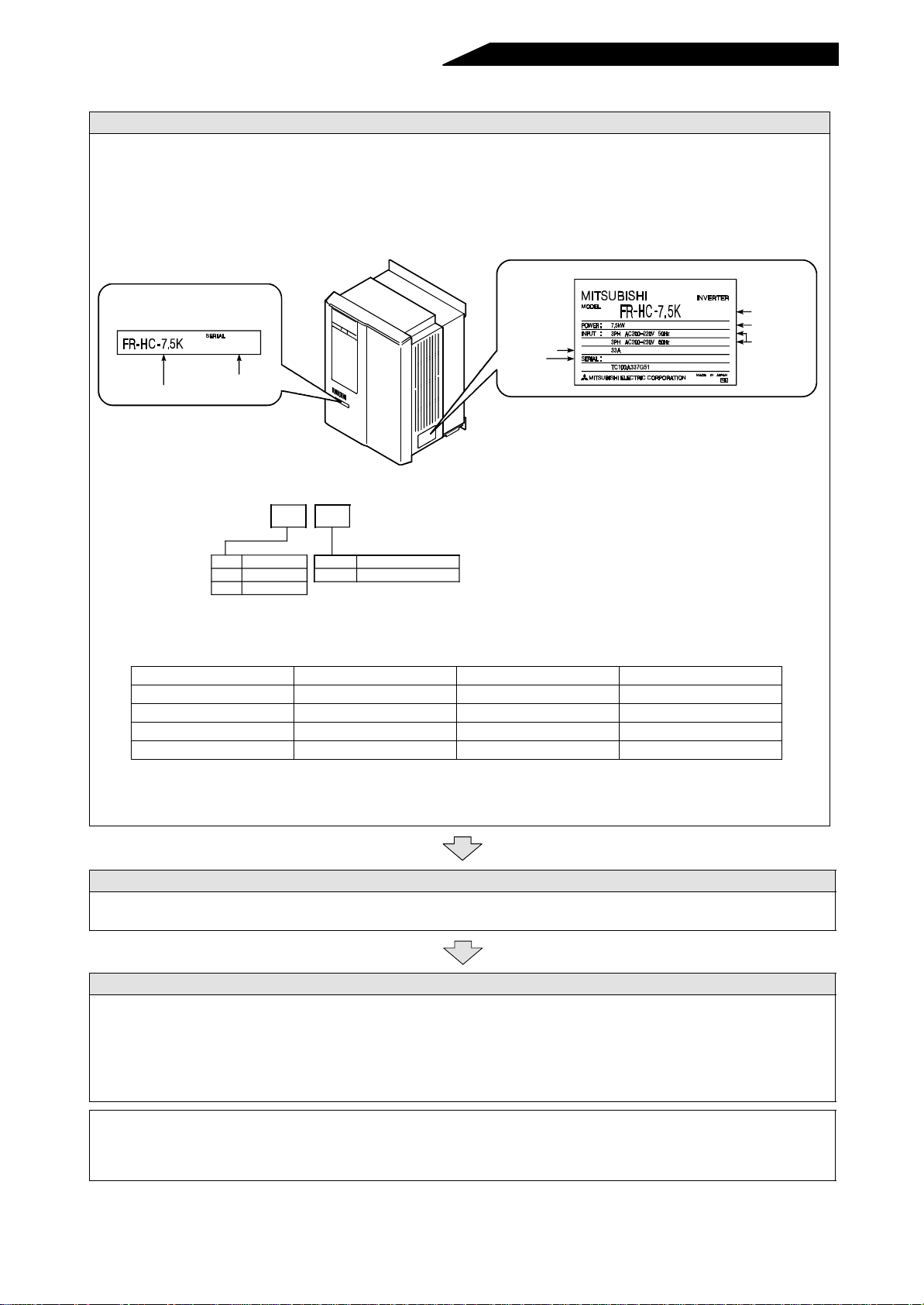

1.1.2 Pre-operation procedure

1. Unpacking and product check

Unpack the product and ch eck the ca pa ci ty plat e on t he fron t cover and the ratin g pl at e on the equ ip me nt

side face to ensure that the type and output rating agree with your order and the product is intact.

When using reactors 1, 2 and the external box, especially when they are used with the Mitsubishi

transistorized inverter be sure to us e them as a set and make sure they are securely con nected. This

high power factor converter suppresses har monics according to the harmonic suppressio n guidelines

published by Ministry of Economy Trade and Industry (formerly Ministry of International, Trade and

Industry). Pay attention to the applicable capacity, etc.

Rating plate

Capacity plate

High power factor

converter type

Serial number

Rated input

current

Serial number

Converter type

Applicable inverter

capacity

Applicable power

supply

• Definition of the high power factor converter type

FR-HC- K

Symbol

Symbol

None

H

Voltage class

200V class

400V class

7.5 to 55

Applicable inverter capacity

Capacity in "kW"

• Confirmation of the peripheral device types

The following three peripheral devices, FR-HCL01, FR-HCL02 and FR-HCB, must be installed.

Confirm their types:

High Power Factor Converter

FR-HC-7.5K FR-HCL01-7.5K FR-HCL02-7.5K FR-HCB-7.5K

FR-HC-15K FR-HCL01-15K FR-HCL02-15K FR-HCB-15K

FR-HC-30K FR-HCL01-30K FR-HCL02-30K FR-HCB-30K

FR-HC-55K FR-HCL01-55K FR-HCL02-55K FR-HCB-55K

Reactor 1 Reactor 2 External Box

Note: 400V class devices have capacity numbers preceded by H in their type codes.

• Accessory . . . . . . Instruction manual

If you have found any discrepancy, damage, etc., please contact your sales representative.

2. Installation

To operate the product with high performance for a long time, install it in a p roper place, in a correct

direction, and with proper clearances. (See page 13.)

3. Wiring

Securely connec t the p ower supply, reactors 1, 2, external box, high power factor converter a nd inver ter

to the terminal blocks.

If they are connected im properly, the periph eral devices and the high power factor converter itself may

be damaged. (See page 16.)

After making su re that the wiring is secured, refer to the i nverter instruc tion manual on how to set the

parameters.

Note: If the inverter is provided with a jum per connector for sink and source logic change, fit the jumpe r

connector to the sink logic (factor y settin g) when c onnecting a high power factor converter (FR-HC).

If the jumper connector is fitted to the source logic, the converter cannot be connected.

- 5 -

Page 15

1.1.3 Handling precautions

The following system is required to operate the inverter. Install the high power factor converter in a proper

position. For the selection and specifications of each peripheral device, refer to “Precautions for Selecting

Peripheral Devices” on page 52:

Name Description Refer to Page:

Use the power supply within the

Power supply

permissible power supply specifications

of the high power factor conve rter .

56

Earth leakage

circuit

breaker or no-fuse

breaker

Magnetic

contactor

Reactor 1

FR-HCL01

External box

FR-HCB

Reactor 2

FR-HCL02

High power factor

converter

The breaker should be selected with

care since a large inrush current flows

in the high power factor converter at

power on.

Install the magnetic contactor to

ensure safety.

When installed, do not use it to start

or stop the inverter. It might reduce

the high power factor converter life.

Make sure that the reactor has a

proper capacity which matches the

high power factor converter capacity.

Make sure that the external box has a

proper capacity which matches the

high power factor converter capacity.

Make sure that the reactor has a

proper capacity which matches the

high power factor converter capacity.

Install and wire the equipment

correctly.

Note: Do not install a no-fuse breaker

(NFB) across terminals P -P and

N-N of the high power factor

converter and the inverter.

55

55

62

64

62

13

Ground

Inverter

Devices

connected to the

output

Motor

Ground

Make sure that the inverter is

compatible with the FR-HC.

Connect the inverter suitable for the

capacity of the high power factor

converter.

Do not connect a power capacitor,

surge suppressor or radio noise filter

to the output side.

Note: When installing a no-fuse

breaker (NFB) on the output

side, contact the NFB

manufacturer for selection of

no-fuse breaker.

Connect the motor suitable for the

capacity.

To prevent an accidental electric shock,

always ground the high power factor

converter, external box, inverter and

motor.

56

Instruction

manuals of the

devices

connected on

the output side

Inverter

instruction

manual

Inverter

instruction

manual

- 6 -

Page 16

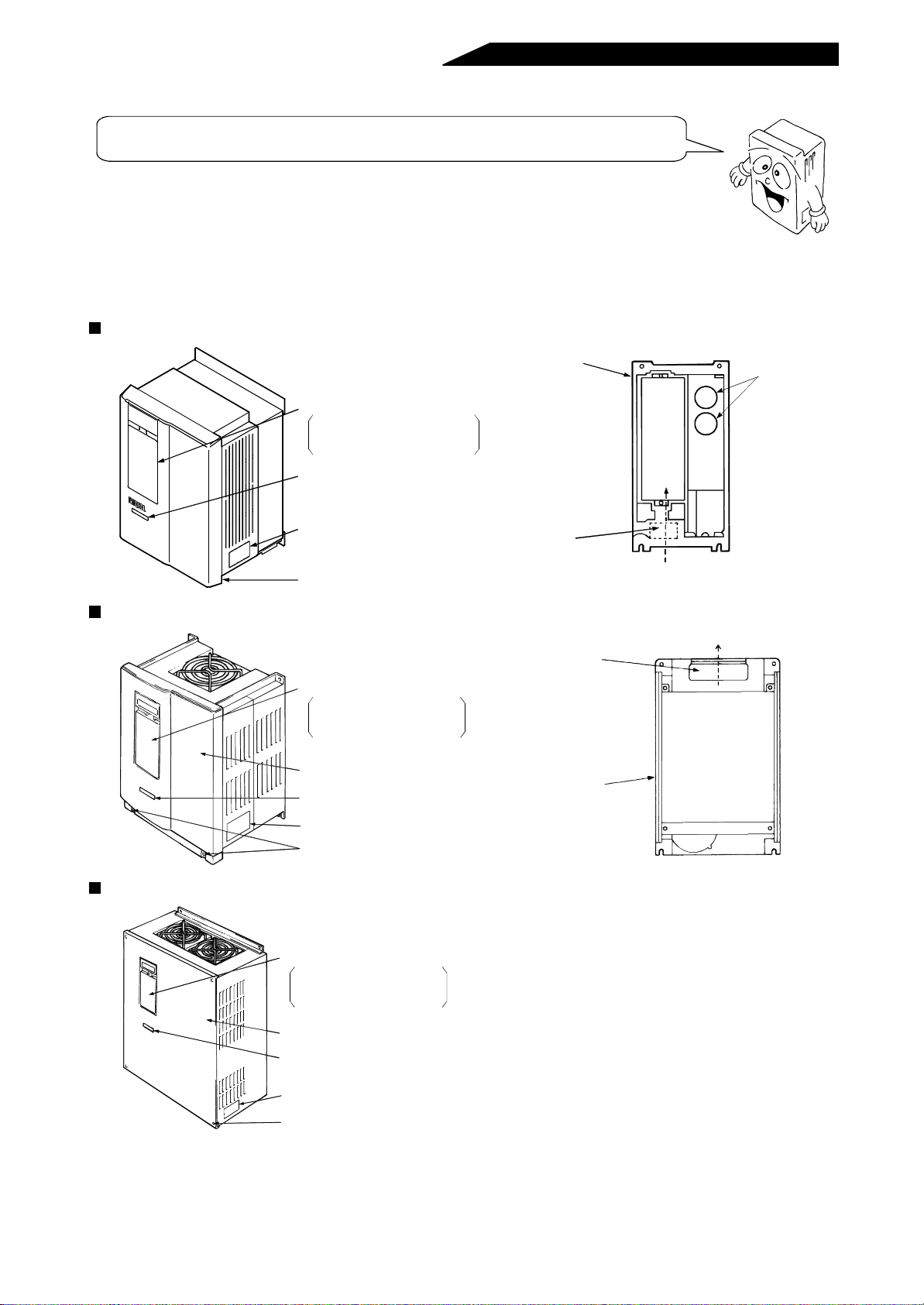

1.2 STRUCTURE

This section covers the structure, installation and removal of the equipment.

In this manual, equipment parts are described with the following names.

1.2.1 Structure

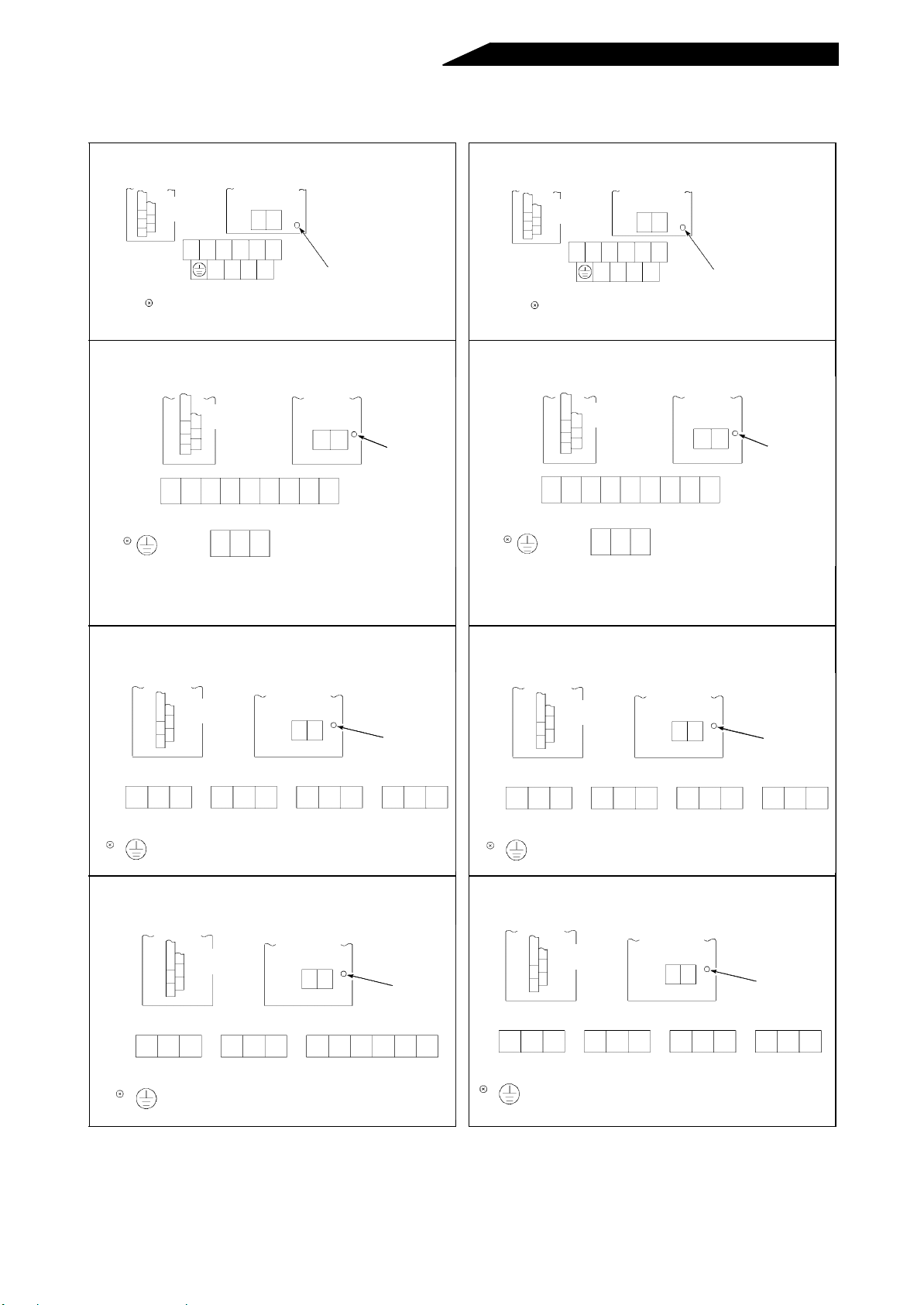

The high power factor converter models have the following parts as shown below.

For the location of the charge lamp, refer to “Terminal block arrangement” on page 60.

FR-HC-7.5K/H7.5K

Chassis

Accessory cover

When using the parameter unit, re-

move this accessory cover and install

the parameter unit in this position.

Capacity plate

Rating plate

Front cover

Cooling fan

Cooling air

Capacitors

FR-HC-15K/H15K

Cooling air

Cooling fan

Accessory cover

When using the parameter unit, remove this accesso ry cover and inst all

the parameter unit in this position.

Front cover

Capacity plate

Rating plate

Front cover installation screws

Chassis

(Plastic)

FR-HC-30K, 55K/H30K, H55K

Accessory cover

When using the parameter unit, remove this accessor y cover and instal l

the parameter unit in this position.

Front cover

Capacity plate

Rating plate

Front cover installation screws

Note:Dimensions vary with the capacity . F or full information, refer to “Outline Dimension Drawings” on page 61.

- 7 -

Page 17

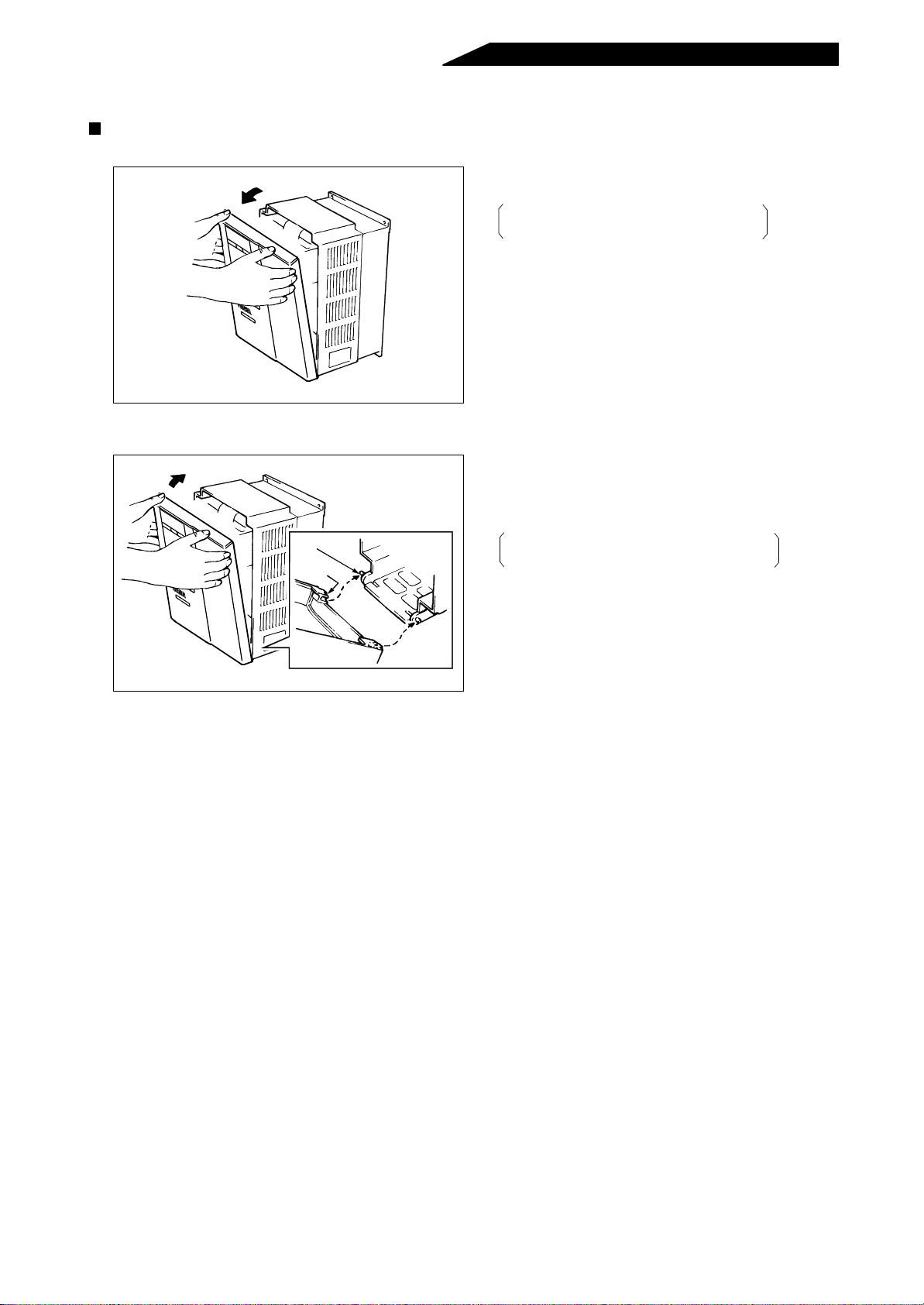

1.2.2 Removal and reinstallation of the front cover

FR-HC-7.5K/H7.5K

• Removal

• Reinstallation

Catch

Socket

1) Hold both sides of the front cover top.

2) Pull the cover toward you.

The cover may be removed with the

parameter unit on.

1) Fit the sockets at the cover bottom onto the

catches of the inverter.

2) Using the c atche s as supp orts, securely pr ess

the cover against the inverter.

The cover may be reinstalled with the

parameter unit on.

- 8 -

Page 18

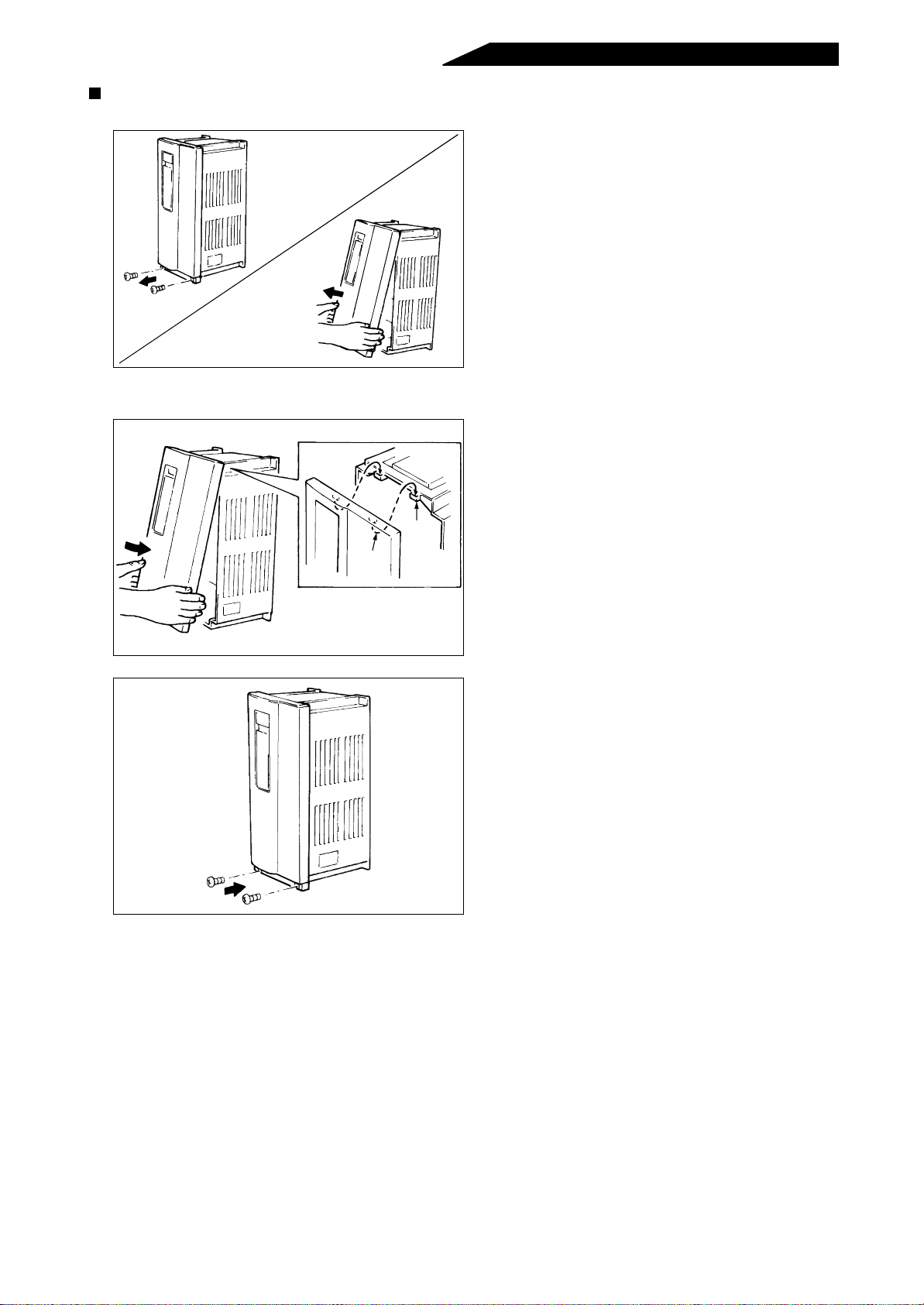

FR-HC-15K/H15K

• Removal

• Reinstallation

1) Remove the two installation screws at the

bottom of the front cover.

2) Hold both ends of the front cover bottom and

pull the cover toward you

1) Fit the catches on t he inside of the front cover

top into the sockets of the inverter.

2) Securely press the cover against the inverter.

Socket

Catch

3) Fix the cover with the bottom installation

screws.

- 9 -

Page 19

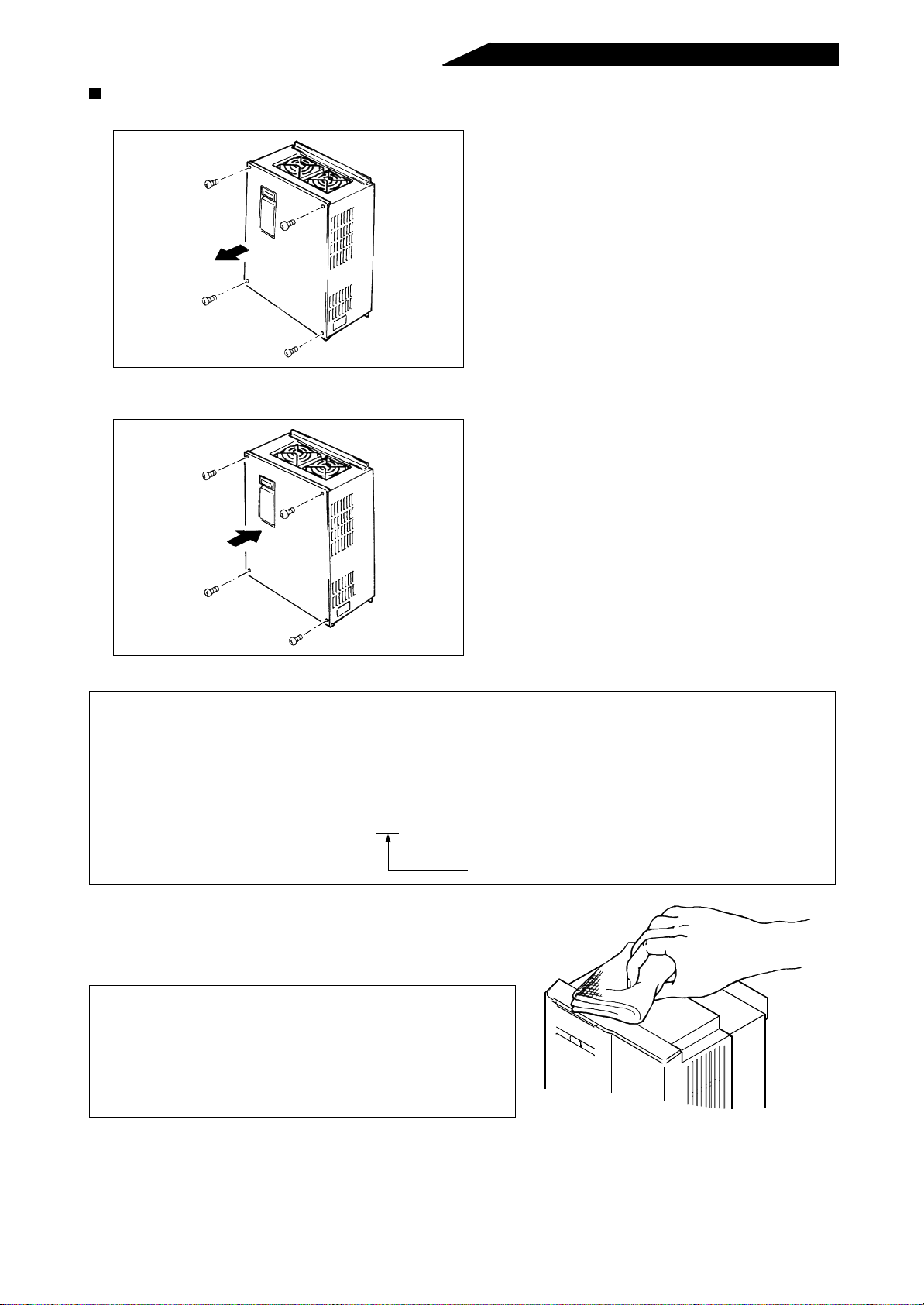

FR-HC-30K, 55K/H30K, H55K

• Removal

• Reinstallation

1) Remove the front cover installation screws.

1) Attach the front cover with the installation

screws.

Note: 1.Fully check that the front cover has been reinstalled securely.

2.The serial numbe r is printed on bot h the capacity plate o n the front cover and the rating plate on

the high power factor converter side face. Before reinstalling the front cover, check the serial

numbers are the same.

Example:

Capacity plate A46152

Rating plate A46152 001

3-digit serial number

If the high power factor converter surface is stained with

fingerma rks, oil, et c. dur ing removal and/or rei nstallation work,

gently clean it with a cloth soa ked with a neutral detergent or

ethanol.

Note: 1.Do not use any solvent, such as acetone, benzene,

toluene and alco hol, that will cause the hig h power

factor converter surface to dissolve and the paint to

peel.

2. Do not clean the lens of the high power factor

converter’s power lamp with a detergent or alcohol.

- 10 -

Page 20

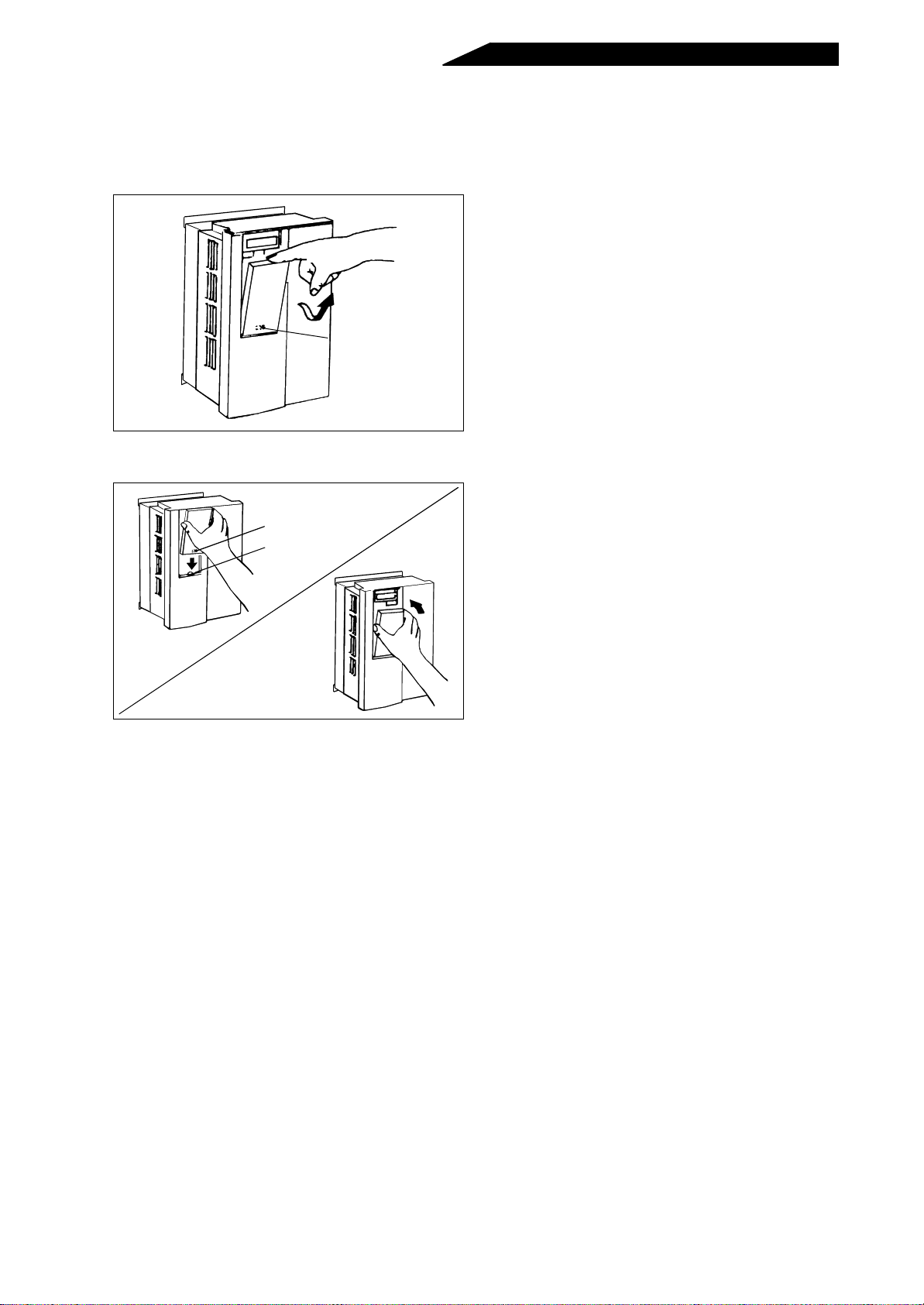

1.2.3 Removal and reinstallation of the accessory cover

To ensure safety, remove and reinstall the accessory cover after switching the power off.

• Removal

1) As in the re moval of the parameter unit, h old

down the top and pull the accessory cover

toward you, using the catch as a support.

Catch

• Reinstallation

1) After fitting th e fixing hole onto t he ca tch of the

cover, push it into the inverter.

Fixing hole

Catch

- 11 -

Page 21

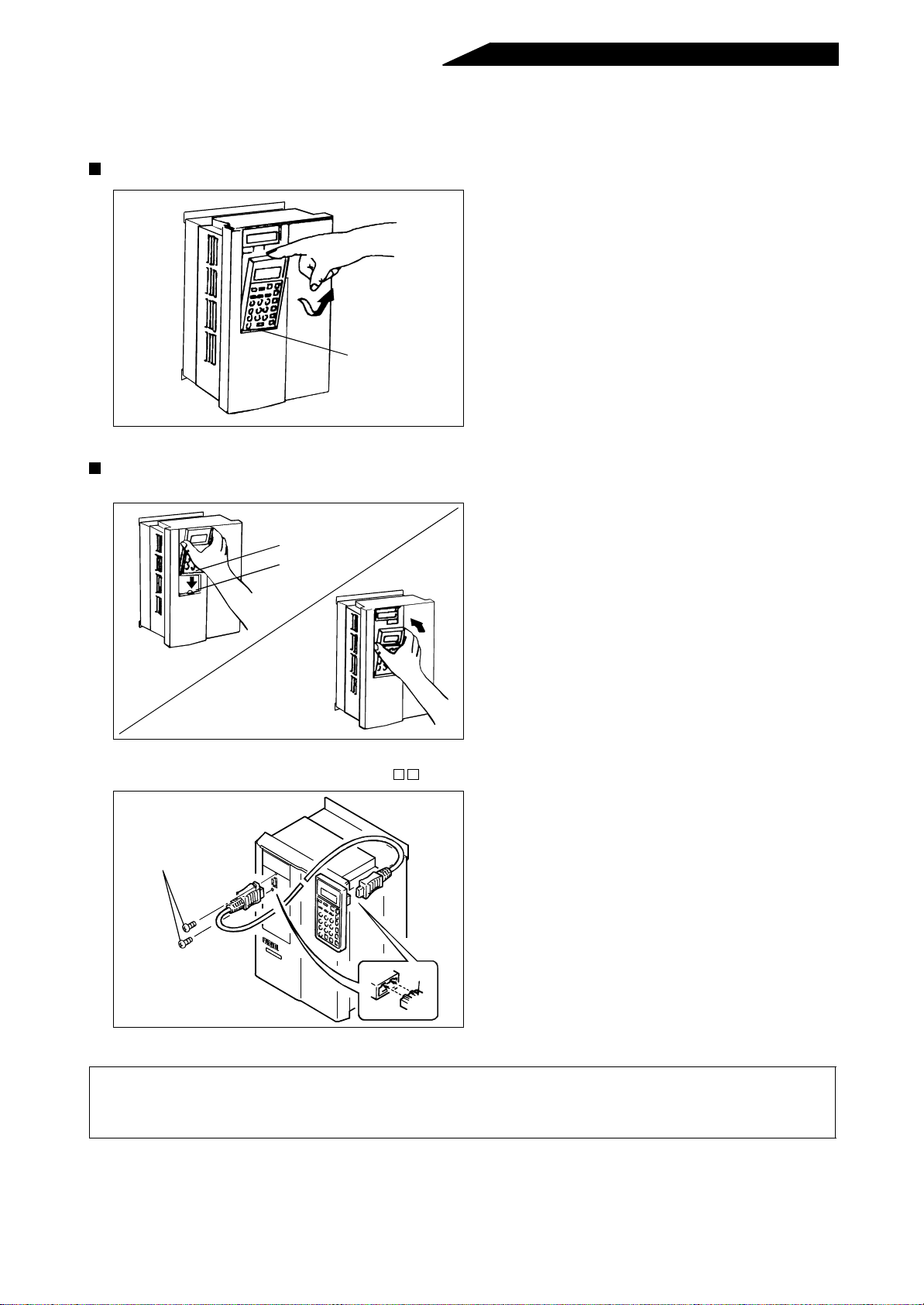

1.2.4 Removal and reinstallation of the parameter unit (FR-PU02)

To ensure safety, remove and reinstall the parameter unit after switching the power off.

Removal

1) Hold down the top button of the parameter unit

and pull the parameter unit toward you, using

the catch as a support.

Catch

Reinstallation

• Direct installation onto the high power factor converter

1) After fitting the fixing hole of the parameter unit

(PU) on the catch of the cover, confirm the

Fixing hole

Catch

connector position and push the parameter

unit into the inverter, using the catch as a

support.

• Installation using the cable (FR-CBL )

1) Securely inser t one connector of the cable into

the connector of the high power factor

converter and the other cable connector into

Installation screws

the PU connector. Insert the cable connector

along the guides. (If the orientation is

incorrect, the high power factor converter may

be damaged.)

2) After plugging the cable connector into the

high power factor converter connector, fix it

Guide

securely with the in stallation screws.

Note: 1.The parameter unit must only be installed on the high power factor converter when t he front cover

is fitted.

2.During installation, do not apply force to the display (liquid crystal).

- 12 -

Page 22

1.3 INSTALLATION AND WIRING

Incorrect handling might cause the equipment to operate improperly, its life to be reduced

considerably, and in the worst case, the high power factor converter and inverter to be

damaged. Please handle the unit properly in accordance with the information on each

section as well as the precautions and instructions of this manual.

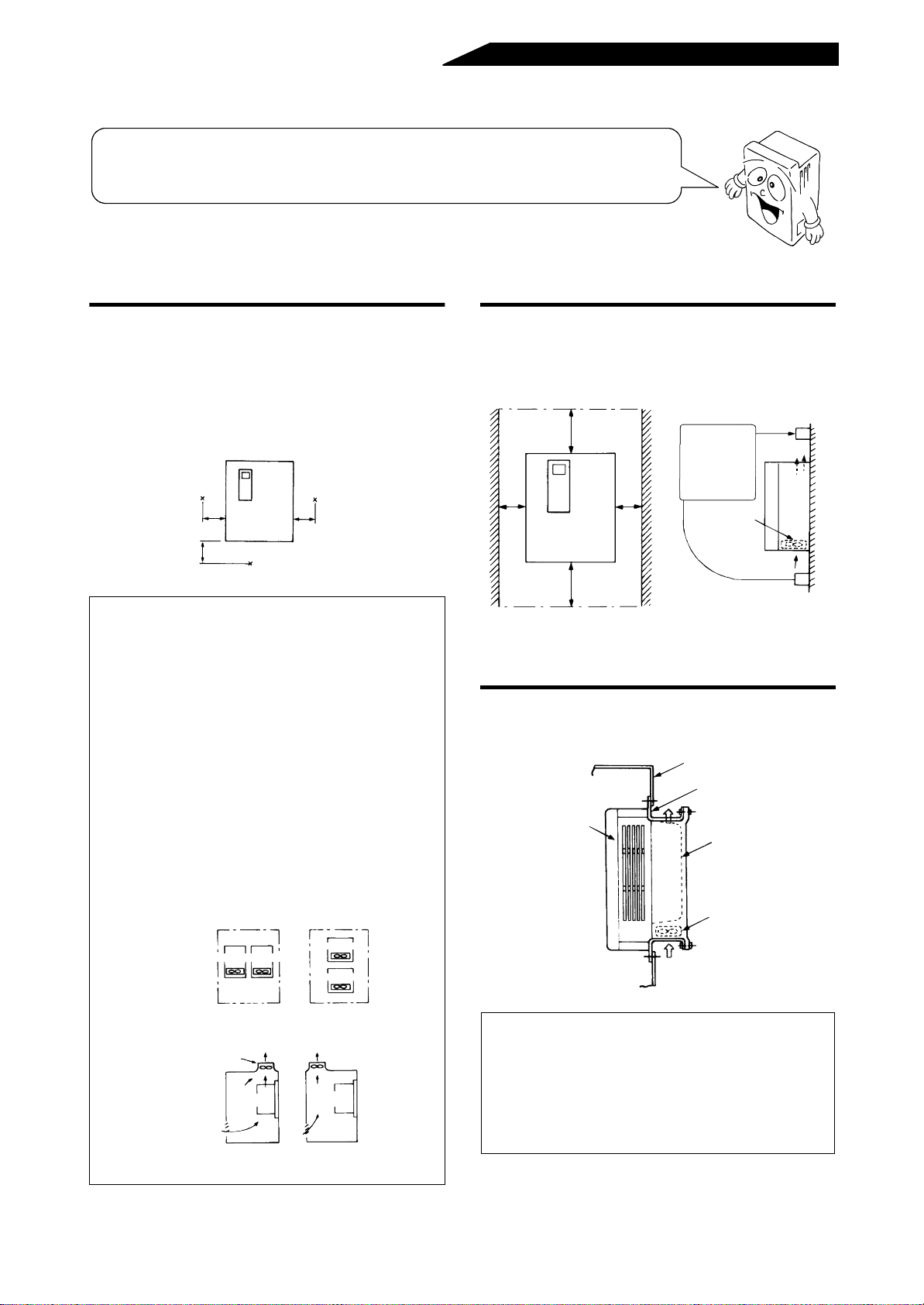

1.3.1 Precautions for installation (1) Installation of the high power factor converter

Instructions for ambient temperatures

The lives of the high power factor converter and

reactors 1, 2 are affected considerably by ambient

temperatures. Keep their ambient temperatures

below the permissible value (50°C). Measure the

ambient temperatures in the following positions to

make sure that they are within the permissible

range.:

Measurement position

5cm

5cm

FREQROL

Measurement position

Note: 1.When the high power factor converter is

installed in a panel, determine the cooling

method and panel dimensions so that the

ambient temperature of the high power factor

converter is within the permissible range

(specified value is given on page 56).

2.When the inverter and high power factor

converter are installed in the same panel or a

ventilation fan is mounted in the panel,

extreme care must be taken to keep the

ambient temperatures of the high power factor

converter and inverter below the permissible

value. If the high power factor converter,

inverter and/or ventilation fan is installed in an

improper position, the ambient temperature of

the high power factor converter will rise and

ventilation effects will reduce.

5cm

Leave sufficient space around the equipment.

For adequate heat dissipation, leave sufficient

space around the high power factor converter.

5cm

or

more

10cm or more

FREQROL

10cm or more

5cm

or

more

Leave sufficient

clearances ab o ve

and under the u nit

to ensure proper

ventilation.

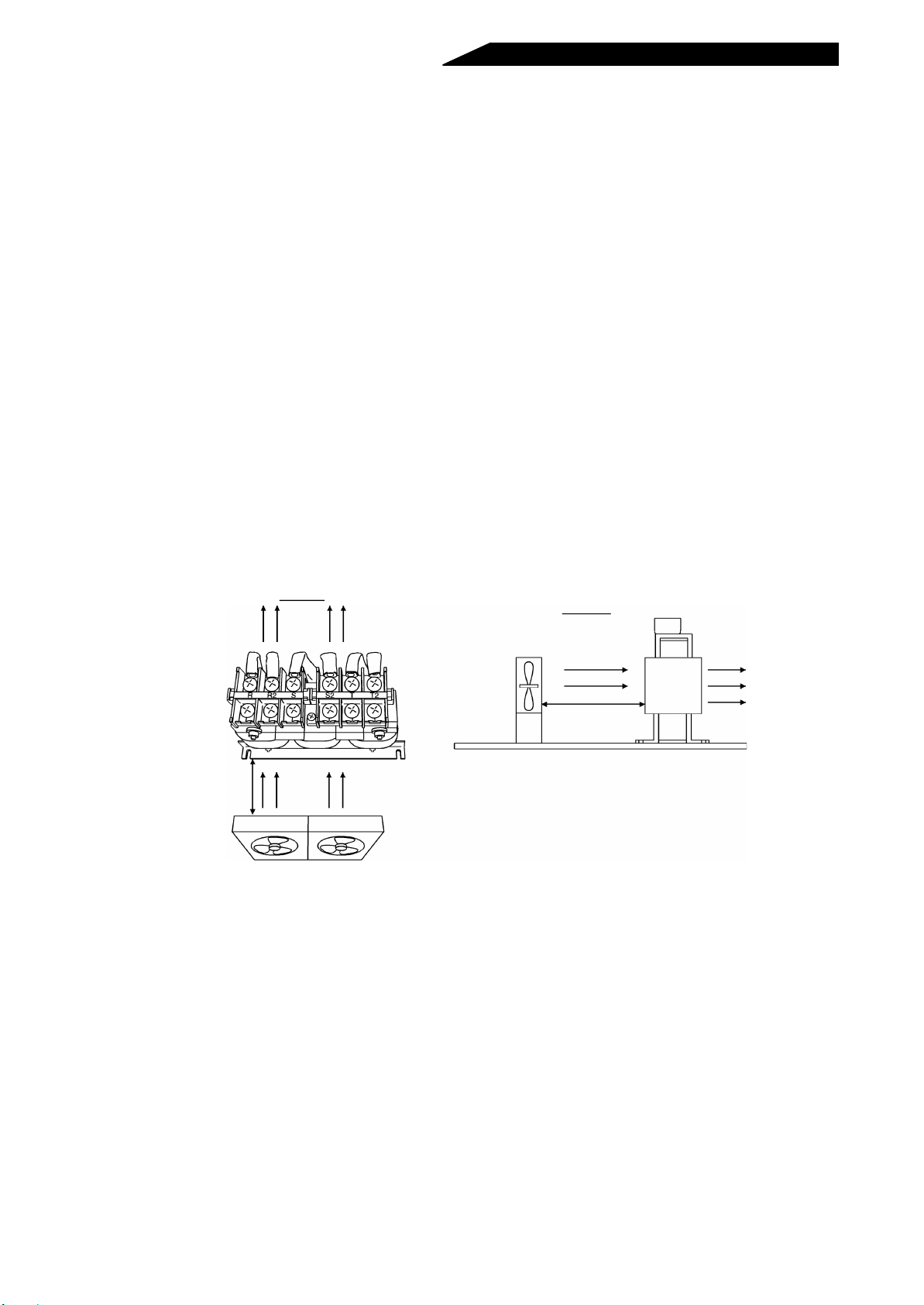

Cooling fan built

in converter

Cooling air

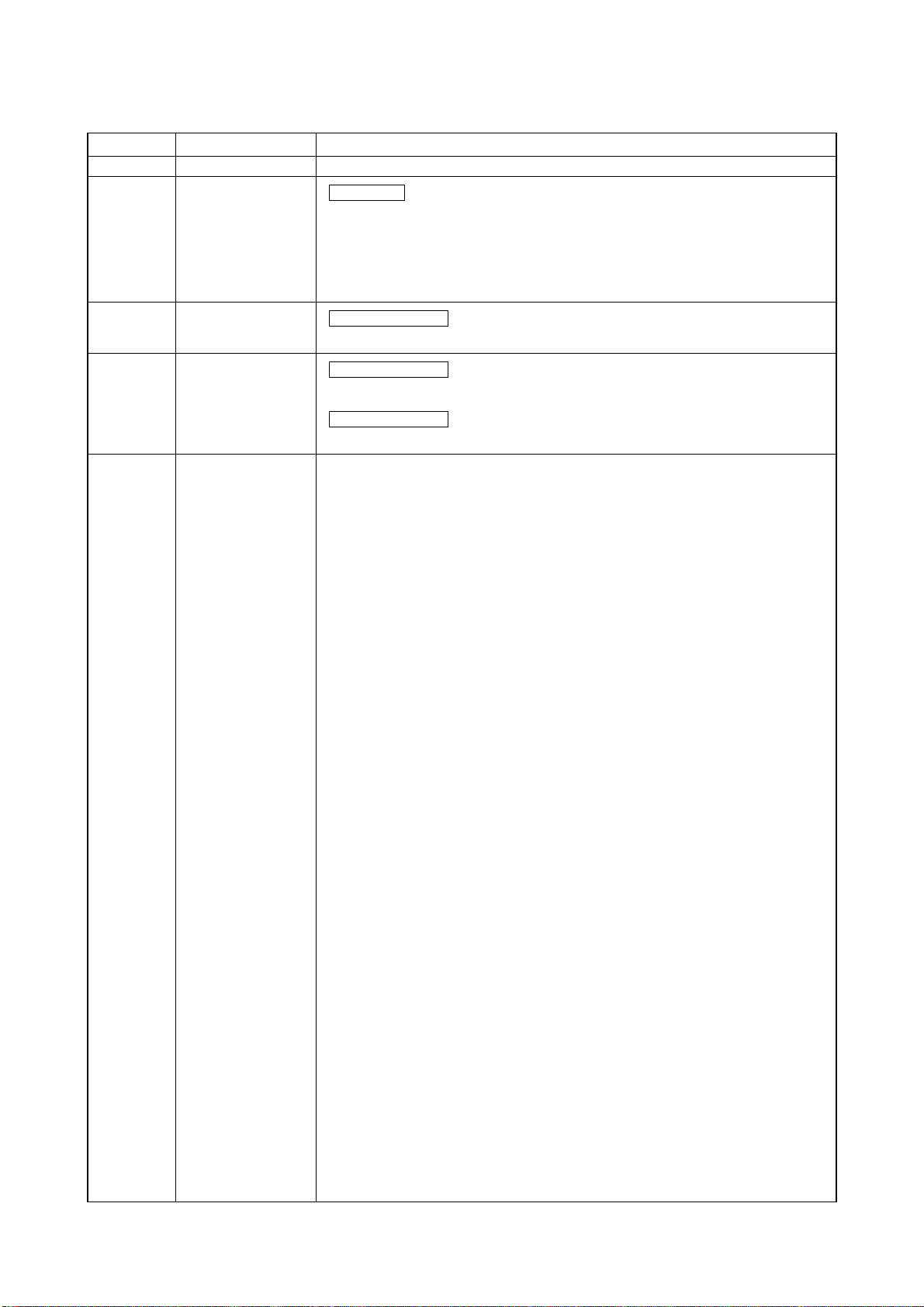

It is possible to place the heat sink outside the

enclosure to grea tl y reduce heat generated.

Inside

enclosure

High power factor

converter

Enclosure

Mounting bracket FR-ACN

(option)

Heat sink

Cooling fan

Inverter Converter

Built-in cooling fan

(Correct) (Incorrect)

Inverter

Converter

Installation of Converter and Inverter

Ventilation fan

Converter Converter

(Correct) (Incorrect)

Position of Ventilation Fan

Cooling air

Note: 1. Use the optional mounting bracket (FR-ACN)

(see page 70). The mounting area should be

machined to the panel cutting dimensions on

page 66.

2.The cooling section outside the panel has a

cooling fan. Do not use the inverter in damp,

oil mist or dust environments.

- 13 -

Page 23

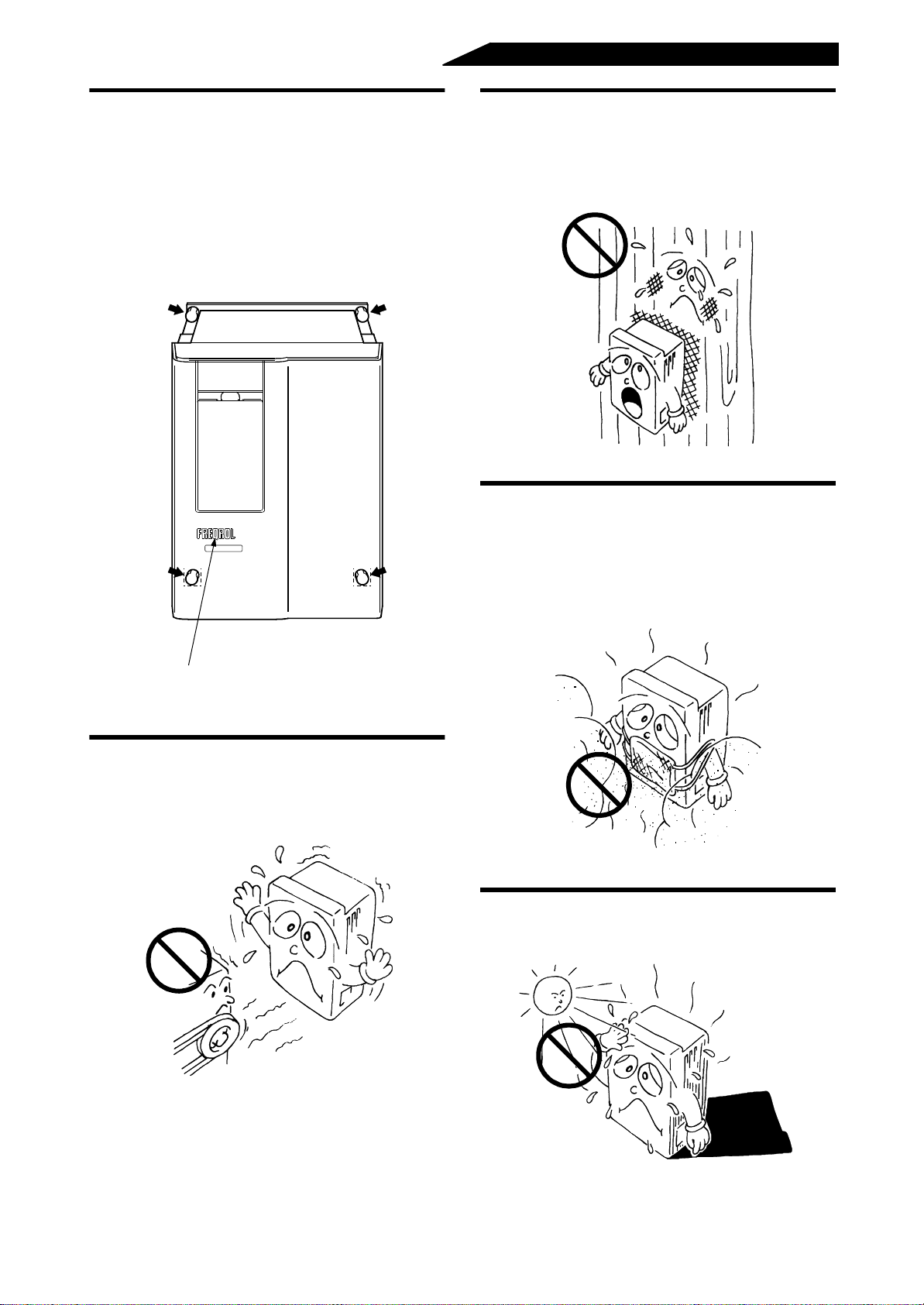

Bolt the unit sec u re ly and verticall y.

Install the un it on a non-combustible surface.

Install the high power factor converter on a surface

securely and vertically (so that the letters

FREQROL are located at the fro nt) with screws or

bolts.

Note: Hor izontal or side inst allation may cause the

high power factor converter to fail. Always

install the unit vertically.

Install the high power factor converter on a noncombustible. If it is installed directly on or near a

combustible, a fire may take place.

Avoid places where the equipment is subjected to

oil mist, flammable gases, fluff , dust, dirt, etc.

Install the unit in a clean place or inside an

“enclosure” which does no t accept any suspended

matter.

Located at front

Install the inverter where it is not subjected to

vibration.

Also take the vibration of a trolley, press, etc. into

consideration.

Avoid high temperature and high humidity.

Avoid direct sunlight, heat and humidity.

- 14 -

Page 24

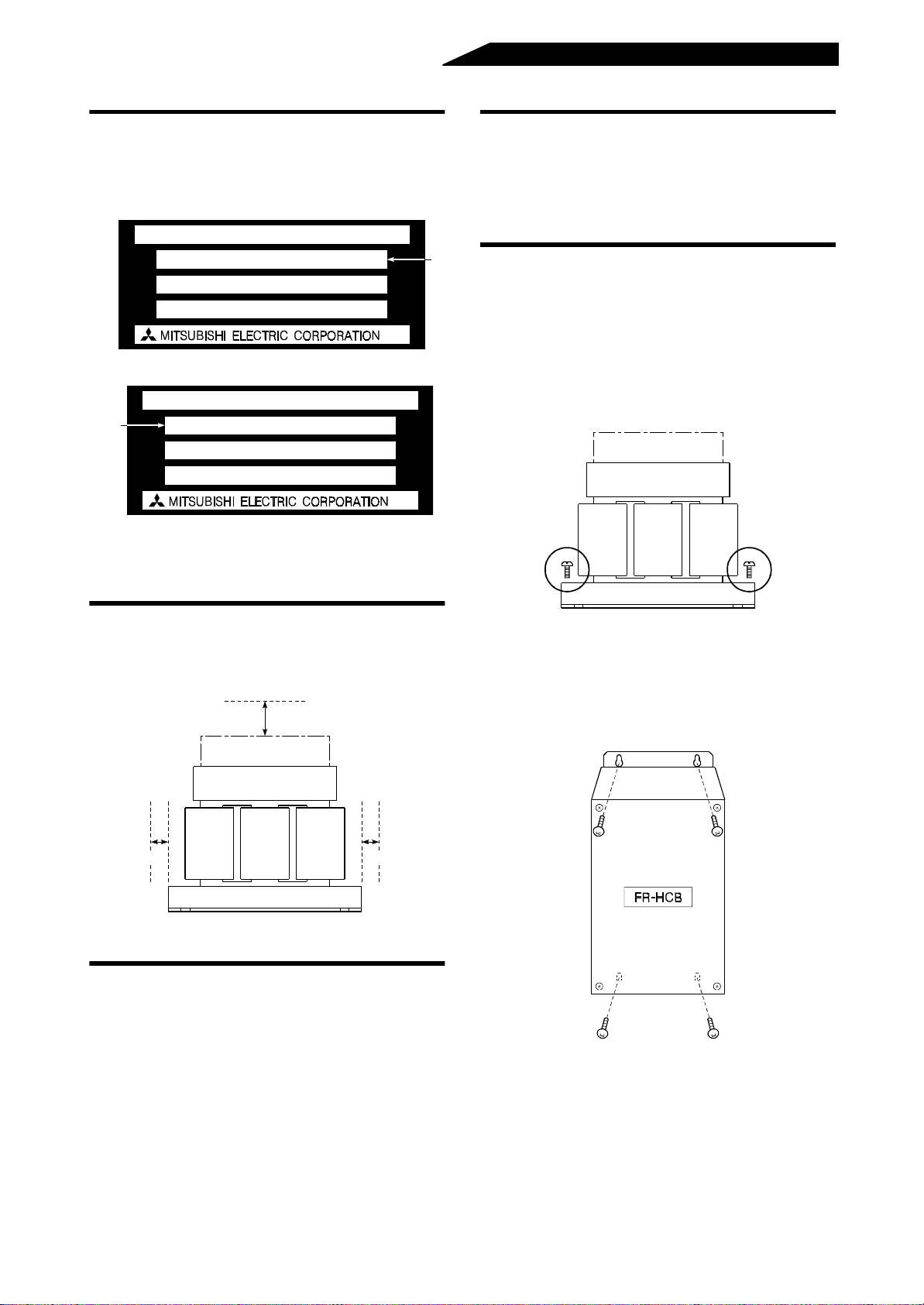

(2) Installation of the reactors 1, 2 and external box

Confirm th e types.

Note the types of the reactor 1 (FR-HCL01) and

reactor 2 (FR-HCL02) look alike in outline.

Reactor 1 (FR-HCL01)

AC REACTOR

TYPE FR-HCL01

BKO-CA

SERIAL

Reactor 2 (FR-HCL02)

AC REACTOR

(Note)

Note: For the reactor 1 (FR-HCL01) and reactor 2 (FR-

TYPE FR-HCL02

BKO-CA

SERIAL

HCL02), check the “TYPE” in the above rating

plates.

(Note)

Avoid places where the equipment is subjected to

oil mist, flammable gases, fluff , dust, dirt, etc.

Install the equipment in a clean place or protect

them from suspended matter.

Bolt the reactors securely and horizontally.

To prevent looseness, install the reactor 1 (FRHCL01) and reactor 2 (FR-HCL02) on a surface

securely and horizontally with screws or bolts.

Note:Avoid vertical or side installation and install

them on a mounting stand which can withstand

their weights.

Instructions for ambient temperatures

For adequate heat dissipation, leave sufficient

space around the reactor 1 (FR-HCL01) and

reactor 2 (FR-HCL02).

10cm or more

5cm or more5cm or more

Install the equipment on a non-combustible

surface.

Install the reactor 1 (FR-HCL01) an d reactor 2 (FRHCL02) on a non-combustible. Direct install ation on

a combustible may cause a fire.

Install the external box (FR-HCB) vertically.

Note:Install it vertically. Horizontal or side

installation may lead the external box to a

failure.

Note:Since the charged sections of the reactor 1,

reactor 2 and external box are uncovered, fully

protect them to prevent ground fault and

electric shock.

- 15 -

Page 25

1.3.2 Wiring instructions

During wiring, d o no t l eave wire off-cut s i n t he

high power fact or converter and external bo x.

Wire offcuts will cause a mal func ti on, failure or fault.

The high power factor converter should always be

kept clean.

Wire offcuts, etc.

Use the space on the left-hand side of the main

circuit terminal block to run the control circuit

cable.

Control circuit terminal block

Before starting wiring or inspection, switch

power off, make sure that the converter LED

indicator has gone off, wait for at least 10

minutes after the charge lamp on the printed

circuit board has gone off.

For some short time after power-off, there is a

dangerous voltage in the capacitor. Start work

about 10 minutes after ensuring that the charge

lamp is off.

When the power supply voltage is special for the

high power factor converter (the rated input voltage

is exceeded), change the connection of the jumper

in the internal transformer. (FR-HC-H7.5K H15K,

H30K, H55K)

If the connection is not changed, the 400V class

high power factor converter may be heated,

resulting in fault or burnout.

For the FR-HC-H7.5K, change the connection of

the jumper in the interna l transform er in the externa l

box.

Main circuit terminal block

Cable

Cut off the wiring cover (protective bush)

windows using nippers or a cutter when

running the cables. (FR-HC-7.5K/H7.5K)

Wiring cover

Nippers

Cut off.

Protective bush

Do not apply a voltage directly to the alarm

output signal terminals (A, B, C).

Always apply a voltage via a relay coil, lamp, etc. to

these terminals.

380 to 460V

The cable size for connection to the control

2

circuit terminals should be 0.75mm

If the cable size used is 1.25mm

or less.

2

or more, the front

cover may expand, resulting in a co ntact fault of the

parameter unit. This fault is indicated by the

following message displayed on the parameter unit

and disables operation from the parameter unit.

Run the cables so that they do not occupy much of

the control box terminal block space.

Parameter unit display

PU to Inverter

comms. Error

Inv. Reset ON

Use shielded or twisted cables for connection to

the control circuit terminals.

Voltage

Run them away from the main and power circuits

(such as the 200V relay sequence circuit).

A

B

C

Note:Connect the sheath of the shielded cable to

terminal SD.

- 16 -

Page 26

1.3.3 Wiring of the main circuit

• The high power factor converter (FR-HC) is a high-power factor, low-noise inverter option unit designed for

use with the transistorized inverters (FR-HC compatible models) in accordance with the harmonic

suppression guidelines published by Ministry of Economy Trade and Industry (formerly Ministry of

International, Trade and Industry). This high power factor converter is used for the suppression of

harmonics to an input power supply.

• To comply with the harmonic suppression guidelines published by the MITI, the system needs to be

configured as indicated and make sure that terminals P and N are sacurely connected to terminals P and N

of the inverter. An incorrect connection will cause th e high power factor converter to display an alar m or to

be faulty or damaged.

• Refer to the inverter instruction manual on how to wire the system to suppress har monics to the input

power supply. Especially note the wiring distance and cable size.

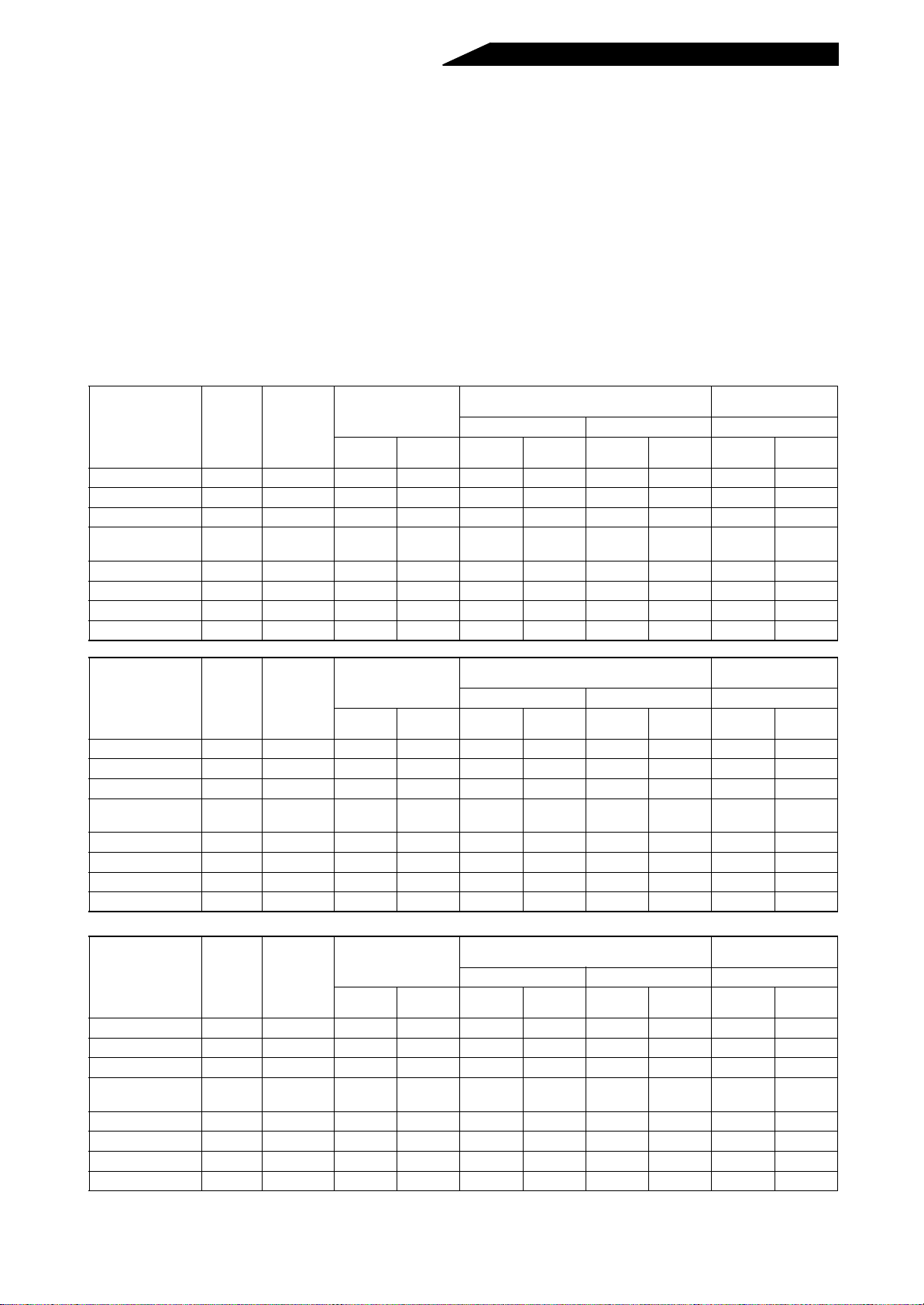

(1) Cable, Crimping terminals etc.

The following table lists the cables and crimping terminals used for each of the devices of the High

power factor converter system and the torques for tightening the screws:

Cables

2

P, N

AWG *1mm

R4, S4,

T4

P, N

Type

Terminal

screw

size

Tightening

torque

·

m *3

N

Crimping

terminal *2

R4, S4,

T4

P, N

mm

R4, S4,

T4

FR-HC-7.5K M4 1 8-4 8-4 8 8 8 8 6 6

FR-HC-15K M6 4 22-6 22-6 22 22 4 4 16 16

FR-HC-30K M8 7 60-8 60-8 60 60 1/0 1/0 50 50

FR-HC-55K M12 24 150-12 150-12 150 150

MCM

300

MCM

300

FR-HC-H7.5K M4 1 3.5-4 3.5-4 3.5 3.5 12 12 4 4

FR-HC-H15K M6 4 8-6 8-6 8 8 8 8 10 10

FR-HC-H30K M6 4 22-6 22-6 22 22 4 4 25 25

FR-HC-H55K M8 7 60-8 60-8 60 60 1/0 1/0 50 50

PVC insulated

Cables

2 *

4

R4, S4,

T4

P, N

––

PVC insulated

Cables

2 *

4

Type

Terminal

screw

size

Tightening

torque

·

N

m *3

Crimping

terminal *2

R2, S2, T2R3, S3, T3R2, S2, T2R3, S3, T3R2, S2, T2R3, S3, T3R2, S2, T2R3, S3,

mm

Cables

2

AWG *1mm

FR-HCB-7.5K M5 2 8-5 8-5 8 8 8 8 6 6

FR-HCB-15K M5 2 22-5 22-5 22 22 4 4 16 16

FR-HCB-30K M6 4 60-6 60-6 60 60 1/0 1/0 50 50

FR-HCB-55K M8 7 150-8 150-8 150 150

MCM

300

MCM

300

––

FR-HCB-H7.5K M5 2 3.5-5 3.5-5 3.5 3.5 12 12 4 4

FR-HCB-H15K M5 2 8-5 8-5 8 8 8 8 10 10

FR-HCB-H30K M5 2 22-5 22-5 22 22 4 4 25 25

FR-HCB-H55K M8 7 60-8 60-8 60 6 0 1/0 1/0 50 50

PVC insulated

Cables

2 *

R, S, T

4

R2, S2,

Type

Terminal

screw

size

Tightening

torque

N

·

m *3

terminal *2

R, S, T

Crimping

R2, S2,

T2

R, S, T

mm

2

R2, S2,

T2

Cables

AWG *1mm

R, S, T

R2, S2,

T2

FR-HCL01-7.5K M5 2 8-5 8-5 8 8 8 8 6 6

FR-HCL01-15K M6 4 22-6 22-6 22 22 4 4 16 16

FR-HCL01-30K M8 7 60-8 60-8 60 60 1/0 1/0 50 50

FR-HCL01-55K M12 24 150-12 150-12 150 150

MCM

300

MCM

300

––

FR-HCL01-H7.5K M4 1 3.5-4 3.5-4 3.5 3.5 12 12 4 4

FR-HCL01-H15K M5 2 8-5 8-5 8 8 8 8 10 10

FR-HCL01-H30K M6 4 22-6 22-6 22 22 4 4 25 25

FR-HCL01-H55K M8 7 60-8 60-8 60 60 1/0 1/0 50 50

T3

T2

- 17 -

Page 27

Cables PVC insulated Cables

2

AWG *1mm

2 *

Type

Terminal

screw

size

Tightening

torque

·

N

m *3

Crimping

terminal *2

R3, S3, T3R4, S4, T4R3, S3, T3R4, S4, T4R3, S3, T3R4, S4, T4R3, S3, T3R4, S4,

mm

FR-HCL02-7.5K M5 2 8-5 8-5 8 8 8 8 6 6

FR-HCL02-15K M6 4 22-6 22-6 22 22 4 4 16 16

FR-HCL02-30K M8 7 60-8 60-8 60 60 1/0 1/0 50 50

FR-HCL02-55K M12 24 150-12 150-12 150 150

MCM

300

MCM

300

––

FR-HCL02-H7.5K M4 1 3.5-4 3.5-4 3.5 3.5 12 12 4 4

FR-HCL02-H15K M5 2 8-5 8-5 8 8 8 8 10 10

FR-HCL02-H30K M6 4 22-6 22-6 22 22 4 4 25 25

FR-HCL02-H55K M8 7 60-8 60-8 60 60 1/0 1/0 50 50

Note: *1.The cable used should be 75°C copper cables.

*2.Use the UL approved round crimping terminals. Crimp the terminals with the crimping tool

recommended by the terminal manufacturer.

*3.Tighten the terminal screws to the specified torques. Undertigtening can cause a short or misoperation.

Overtigtening can cause the screws and unit to be damaged, resulting in a short or misoperation.

*4.This column is for Low Voltage Directive.

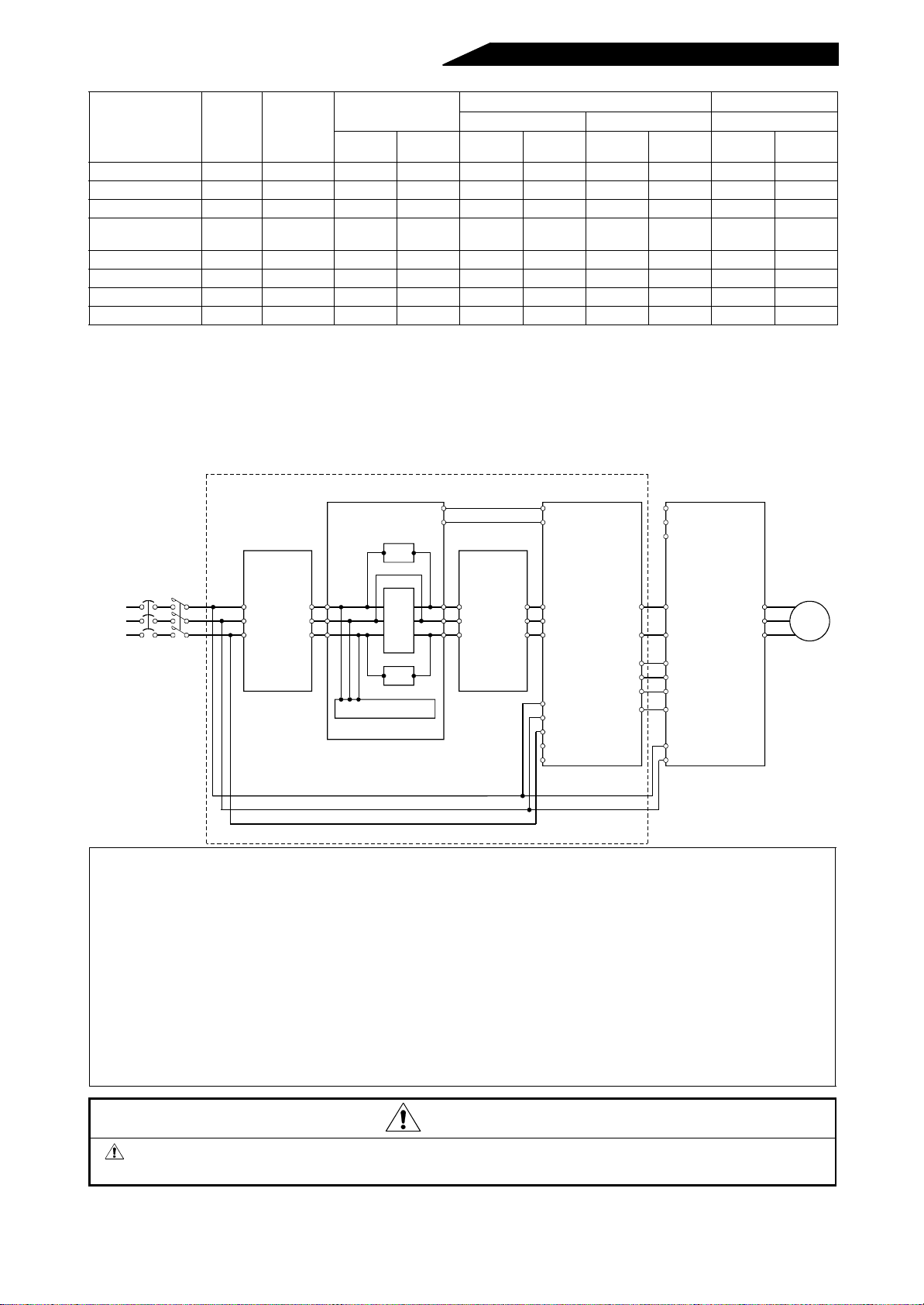

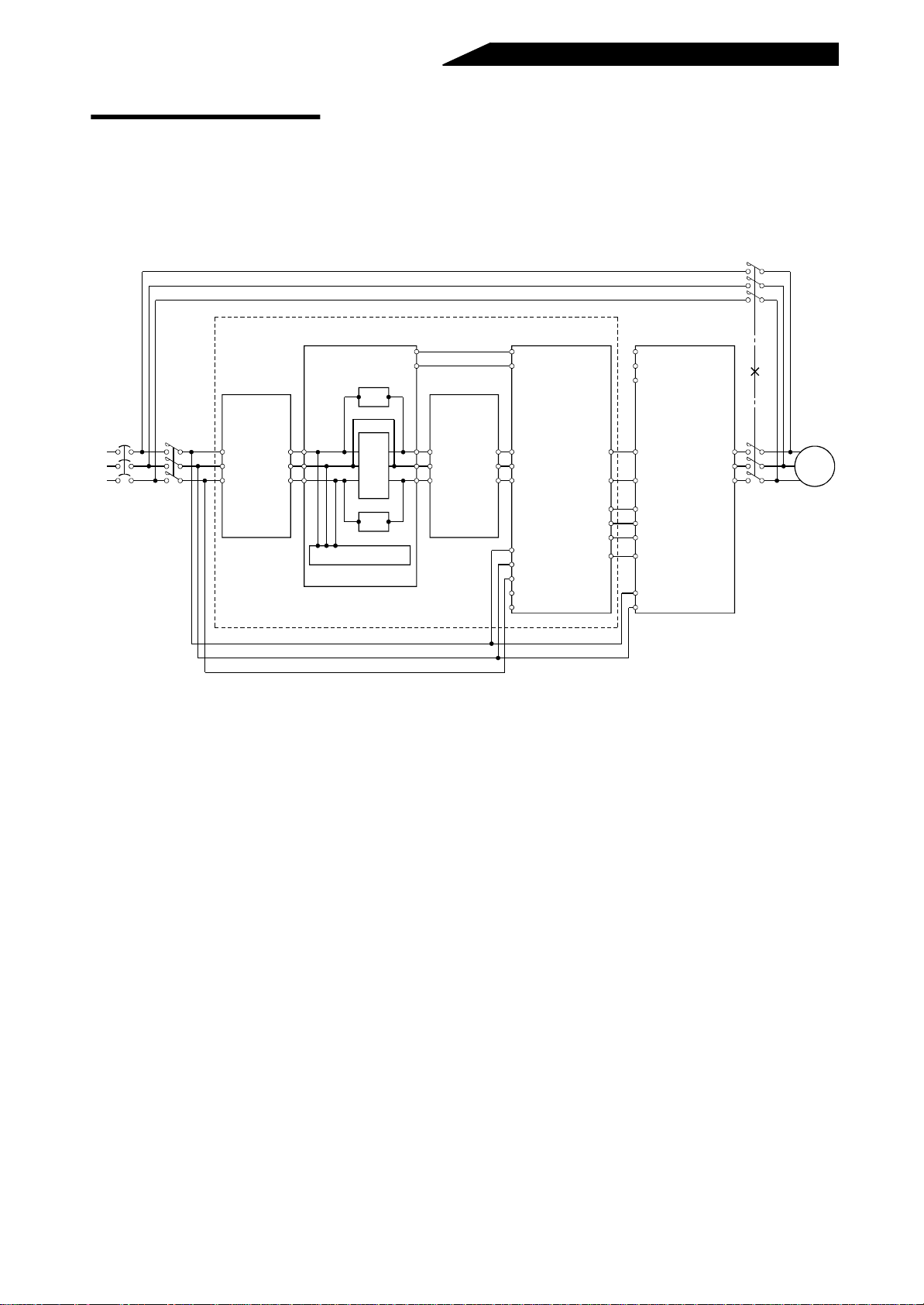

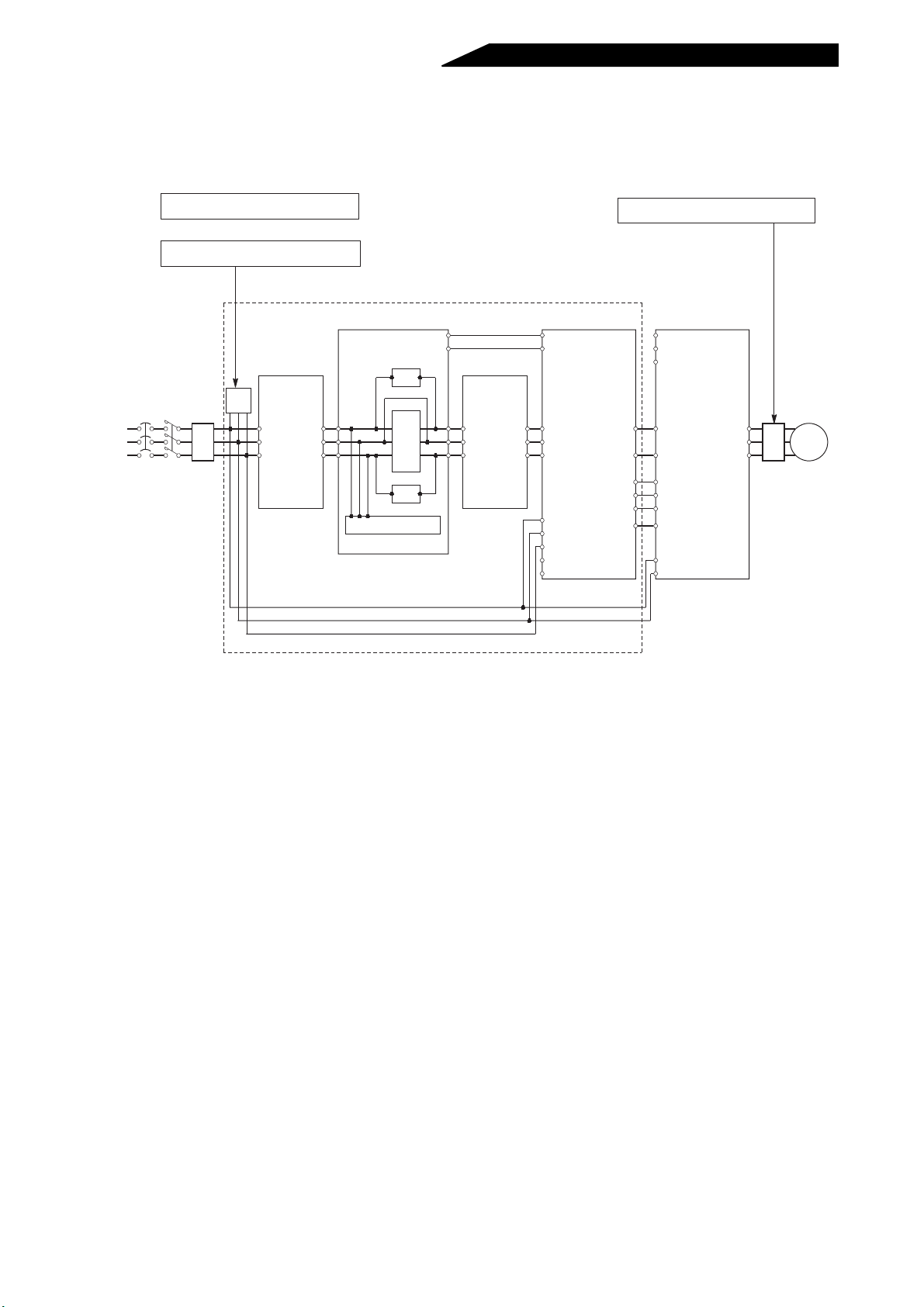

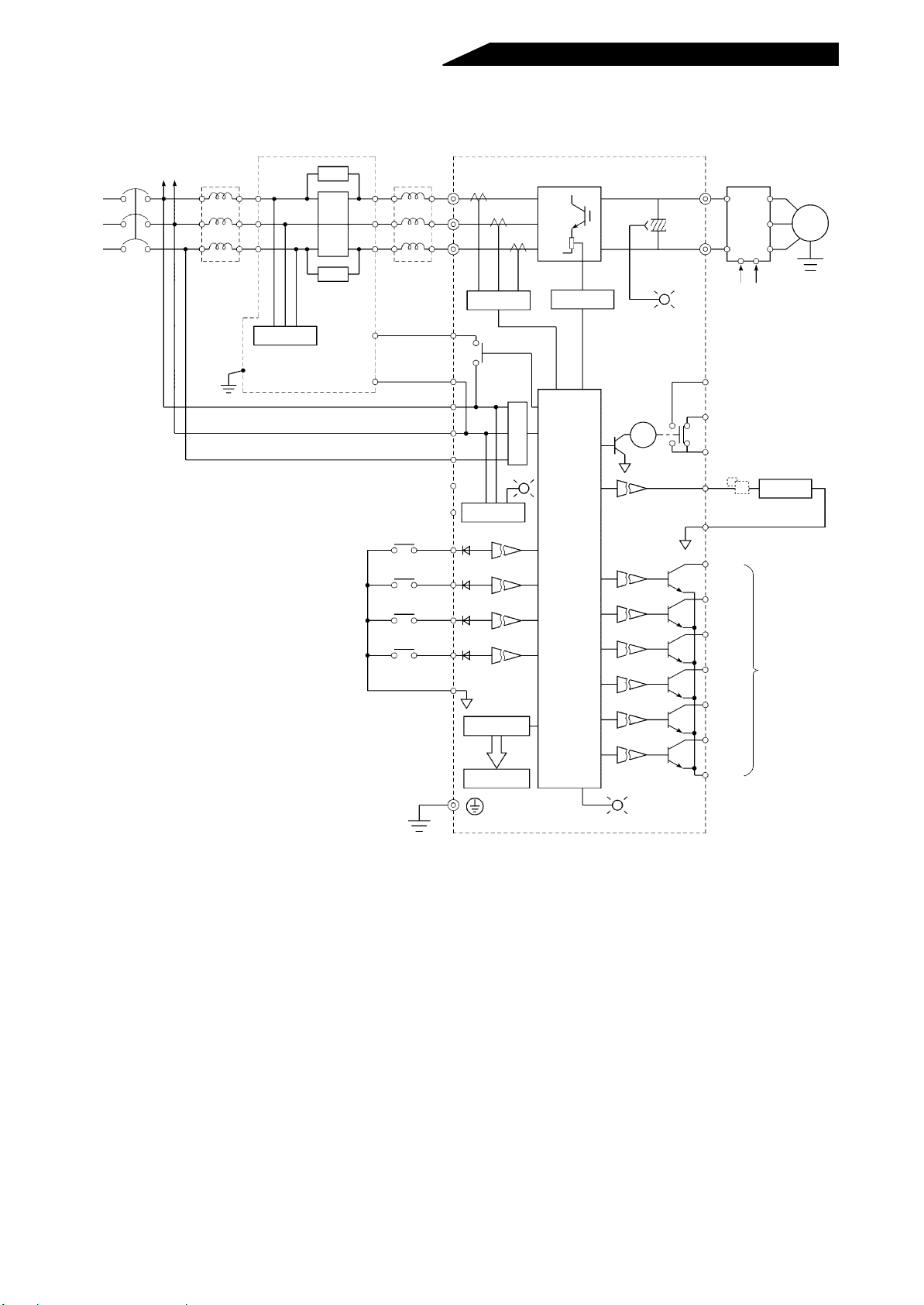

(2) Wiring example (FR-A500 series)

The wiring method varies with the inverter series.

Reactor 1

(FR-HCL01)

External box

(FR-HCB)

Resistor

MC1

MC2

Reactor 2

(FR-HCL02)

High power factor converter

(FR-HC)

MC1

MC2

Inverter

(FR-A500 series)

R

(Note 4)

S

T

4

T4

Power

supply

NFB MC

1)

R

S

T

R2

S2

T2

2)

R2

S2

T2

MC

Resistor

Filter capacitor

3) 4) 5)

R3

S3

T3

R3

S3

T3

R4

S4

T4

6)

S4

R

S

T

R1

S1

R4

T4

RDY

RSO

Y1 or Y2

(Note 8)

SE

P

P

(Note 9)

N

N

X10

(Note 5)

RES

X11

(Note 5)

SD

R1

(Note 7)

S1

7)

Note: 1.Use care to minimize the wiring distance between respective terminals.

2.Before starting wiring, cover the top ventilation hole to prevent wire offcuts from entering.

3.Use the ground terminal to ground the equipment securely.

4.Keep the inverter’s power input terminals R, S, T open. The i nverter will be damaged if they are

connected accidentall y. Also, opposite polar ity of term inals P, N will damage the high power factor

converter and inverter.

5.The terminals used with the X10, X11 signals require their functions to be set. (Refer to the inverter

instruction manual for details.)

6.Match the power supply phases before connecting terminals R4, S4, T4 and terminals R, S, T.

7.A different power supply may be supplied to terminals R1 and S1.

8.Keep the high power factor converter’s terminals R1, S1 unconnected.

9.Do not insert the NFB between terminals P-N (P-P, N-N).

10.The R, S , T terminals of the high pow er factor converter (FR-HC) must be connected to the po w er supply.

Running the inverter without connecting the terminals to the power supply will damage the high power

factor converter (FR-HC).

U

Motor

V

W

CAUTION

Confirm the connection sequence of the reactors 1 and 2. Incorrect connection will make

them abnormally hot.

- 18 -

Page 28

1) Wiring the power supply and reactor 1

Power

supply

NFB

MC

Reactor 1

R2

R

S2

S

T2

T

Reactor 1

RR2S S2T T2

RS T

Power supply

R

Power

supply

ST

FR-HCL01-55K appearance

(Note 2)

The cable size is dependent on the capacity of the high power factor converter. (Refer to page 17.)

Note: 1.Use the magnetic contactor (MC) and reactor 1 which match the high power factor converter capacity.

(Refer to page 62.)

2.Note that the FR-HCL01-55K is different in outline and terminal positions.

2) Wiring the reactor 1 and external box

Reactor 1 External box

R

R2

S

S2

T

T2

R2

S2

T2

R3

S3

T3

Reactor 1

Overall wiring distance: Within 10m

Transtormer

Capacitor

S2

R2 T2

Magnetic

Resistor

contactor

S3R3 T3

FR-HCL02

MC1.MC2

FR-HC

Resistor

Terminal block

Note: 1.The cable size is dependent on the capacity of the external box. (Refer to page 17.)

2.The reactor generates heat. When installing the reactor, exercise care not to heat the external box.

3.Run the cables to keep the reactor untouched by the sheaths of the cables.

- 19 -

Page 29

3) Wiring the external box and reactor 2

r

(Overall wiring distance should be not more than 10m.)

External box Reactor 2

R3

R2

S2

T2

S3

T3

R3

R4

S3

S4

T3

T4

Overall wiring distance: Within 10m

Reactor 2

Resistor

Note: The cable size is dependent on the capacity of the reactor. (Refer to page 17.)

4) Wiring the reactor 2 and high power factor converter

(Overall wiring distance should be not more than 10m.)

Power supply

FR-HCL01

Capacitor

S2

R2 T2

Magnetic

contactor

S3R3 T3

Transtormer

Resistor

Terminal block

MC1.MC2

FR-HC

Reactor 2

R4

R3

S4

S3

T4

T3

High power factor converte

R4

S4

T4PN

R3 R4 S3 S4 T3 T4

Reactor 2

High power factor converter

High power

factor converter

Screw size

M4

R1 S1

RSTR4S4T4

PN

Charge lamp

(yellow)

Note: The cable size is dependent on the capacity of the reactor. (Refer to page 17.)

5) Example of how to wire the high power factor converter and inverter (FR-A500 series)

These units should be connected to transmit commands from the high power factor converter to the

inverter securely.

The cable size varies with the inverter series. Refer to the inverter instruction manual for wiring

instructions.

(Overall wiring distance should be not more than 50m.)

High power factor converter

P

N

RDY

Control

circuit

RSO

Y1 or Y2

SE

P

N

X10

RES

X11

SD

Inverter

(Note 3)

Cable size: 0.75 to 2 mm

2

- 20 -

Page 30

Note: 1.The high power factor converter (FR-HC) operates as a common conver ter. Use terminals P, N to

r

t

connect it with the inverter. Always keep the inverter’s power input terminals R, S, T open. If they

are connected accidentally, the inverter will be damaged. Opposite po larity of terminals P, N will

damage the inverter and high power factor converter.

2.The size of the cables for connecti on of terminals P, N should be the same as that use d in the

power supply side of the inverter. (Refer to the inverter instruction manual.)

3.Refer to the inverter instruction manual for the invert er terminal to be c onne cted to termi na l R DY of

the high power factor converter.

4.Do not insert the NFB between terminals P-N (P-P, N-N).

6) Wiring the reactor 1 and high power factor converter

Supply power to the power detecting terminals (R, S, T) independently of the main circuit wiring.

High power factor converte

contro l ci rcuitReactor 1

R

S

T

R

S

T

Power

supply

Reactor 1

R

S

T

High power factor converter

control circuit terminals

S

R

T

Overall wiring distance: Within 10m

Cable size: 1.25mm

2

Note: 1.Ter minals R, S, T of the high power factor converter (FR-HC) are control terminals designed to

detect power supply phases. Be fore wiring, it is necessar y to match the phases of ter minals R4,

S4, T4 with those of terminals R, S, T. If wiring is inc orrect, the high power factor converter (F RHC) will not operate properly.

2.The R, S, T terminals of the high power factor converter (FR-HC) must be connected to the power

supply.

Running the inverter without c onnecting the terminals to the power supply will damag e the high

power factor con verter (FR-HC).

7) Wiring the power supply and inverter

Supply power to the inverter independently of the high power factor converter (FR-HC).

Terminal block for control circui

Pull out.

NFB

Power

supply

Cable size:0.75 to 2mm

Inverter control power supply

R1

S1

2

1) Loosen the upper screws.

2) Remove the lower screws.

3) Pull out the jumpers toward

you and remove.

4) Conncet the cables of the

other control circuit power

supply to the lower

terminals (R1, S1).

5) Tighten the upper

screws without fail.

Note: 1.Remove the jumpers across terminals R-R1 and S-S1 of the inverter control circuit.

2.Always connect the power supply to the inver te r wh ic h has the alternate power supply inp ut terminals

R1, S1. Power for the inverter’s control power and large-capacity cooling fan (200V 15K or more/

400V 11K or more) will be supplied. Otherwise the inverter may come to an alarm stop or be

damaged. Refer to the inverter instruction manual to check whether the inverter has the alternate

power supply input terminals or not.

- 21 -

Page 31

8) Wiring the external box and high power factor converter

Power supply

FR-HCL01

Capacitor

S2

R2 T2

S3R3 T3

FR-HCL02

External box

MC1

MC2

Cable size: 0.75 to 2mm

High power factor

converter

MC1

MC2

2

Resistor Magnetic contactor

Transformer

Resistor

Terminal

block

MC1.MC2

High power factor converter

Control circuit

terminal block

RSTR4S4T4

Overall wiring distance:

Within 10m

Screw size

M4

R1 S1

PN

Note:Ter minals MC1, MC2 of the high power factor converter provide contro l signals for the inrush cur rent

control circuit within the exter nal box. Always connect these ter minals with the external box. Otherwis e,

the external box’s internal circuit will be damaged.

Notes for grounding

• The high power factor converter lea ks cur rent. To prevent an electric shock, always

ground the converter before starting operation (200V class: class D grounding,

grounding resistance 1 00 maximum, 400V class: class C grounding, grounding

resistance 10 maximum).

Ω

Ω

• To ground the hi gh power factor converter, use the exclusive ground termina l. (Do

not use the screws in the casing, chassis, etc.)

• Use the thickest and shortest possible ground

cable that is equal to, or larger than the size

indicated in the right table. Ground the high

power factor converter at a point ne arest to itself

and the inverter.

High power factor

converter capacity

Ground cable size

200V class 400V class

7.5kW 5.5 3.5

15kW 14 8

30kW 22 14

55kW 38 22

(Unit:mm2)

Grounding

- 22 -

Page 32

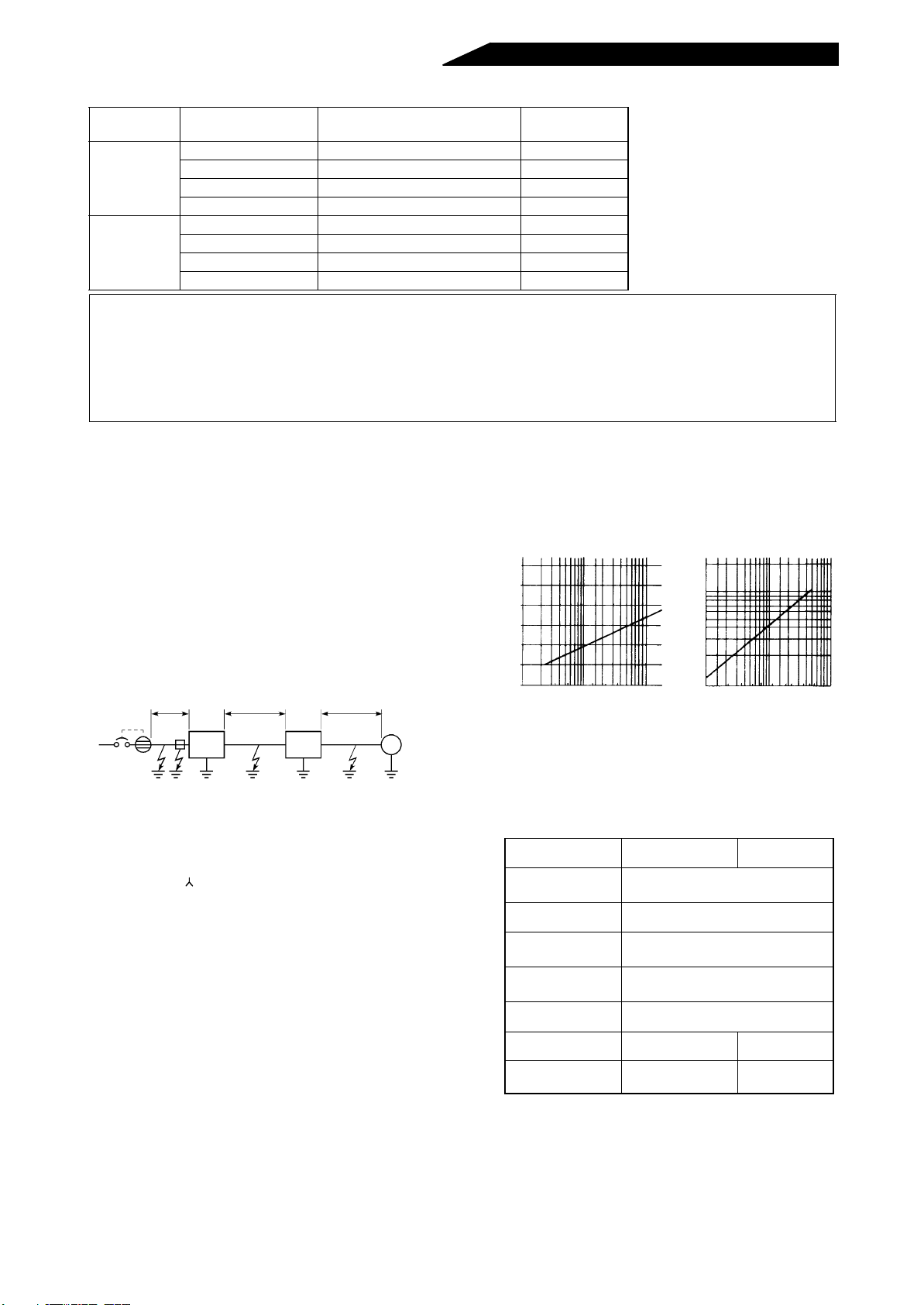

(3) Application of the high power factor converter and inverter

1) When one inverter is connected to the hig h power factor converter, the capacities of the inverters that

may be connected are as listed in the following selection table. : indicates that the high

power factor converter and inverter may be used together. –: indicates that they cannot be used

together. (Note)

Motor capacity (kW) 2.2 or less 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55

Inverter capacity (K) 2.2 or less 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55

FR-HC-7.5K –

2

FR-HC-15K –––

0

0

FR-HC-30K – ––––

V

FR-HC-55K – –––––––

FR-HC-H7.5K –

4

FR-HC-H15K –––

0

0

FR-HC-H30K – ––––

V

FR-HC-H55K – –––––––

Outside application range

Outside application range

Outside application range

Outside application range

Outside application range

Outside application range

Note: When the invert er connected has a capacity less tha n in the application range, the high power

factor converter may be used as a common conver ter or regenerative converter, but its capability

to suppress power harmonics will reduce.

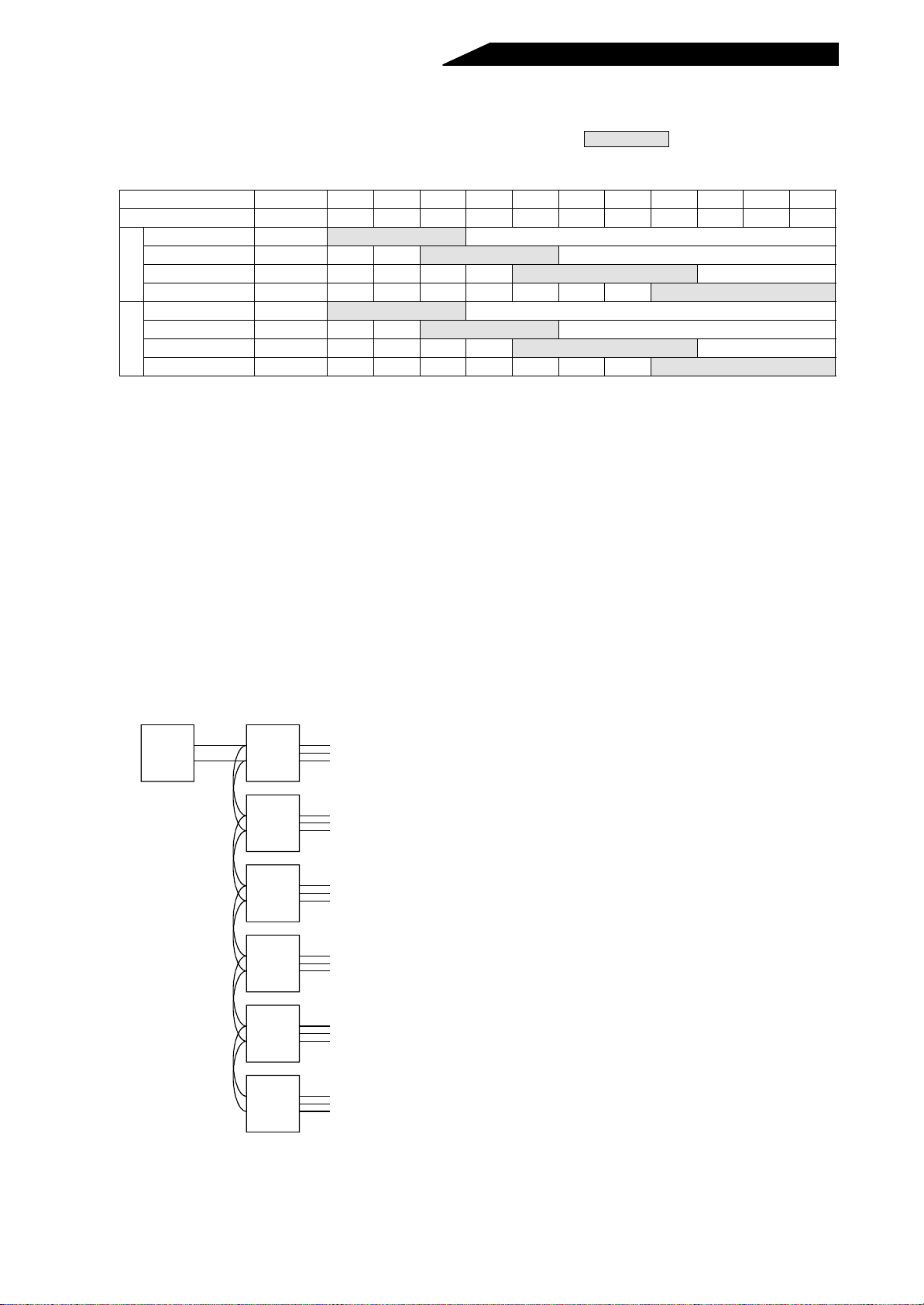

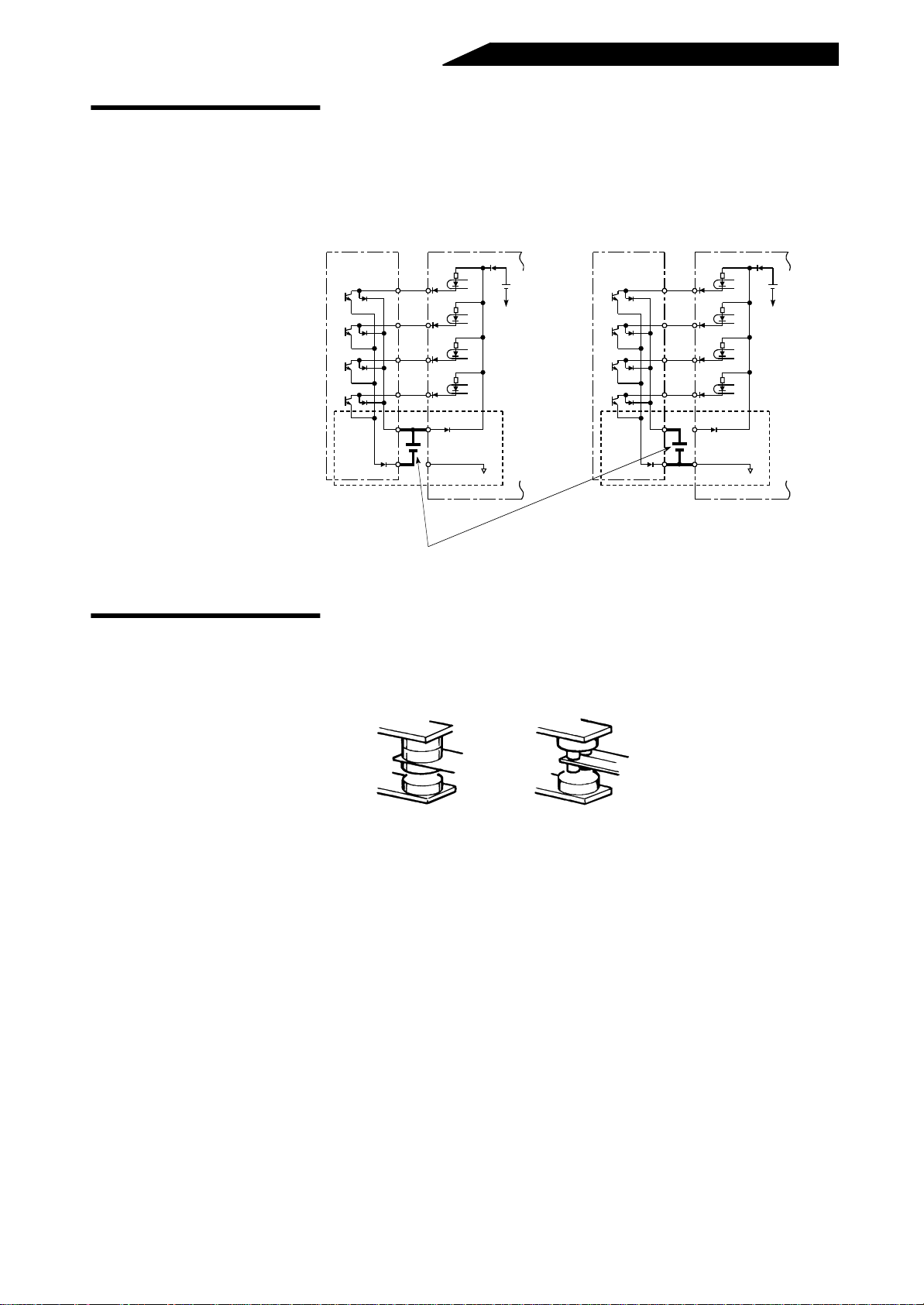

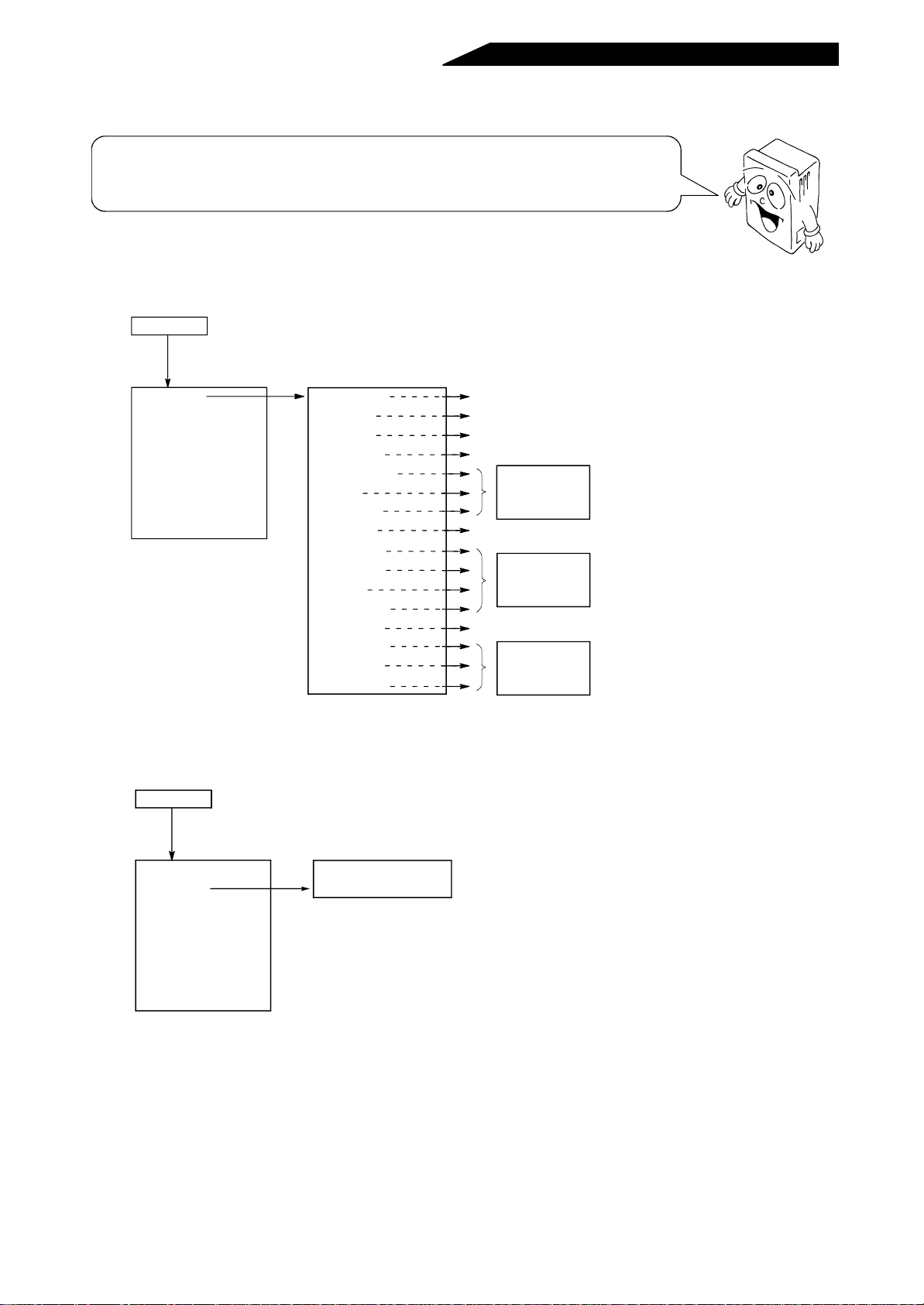

(4) Connection of more than one inverter to the high power factor conve rter

Up to six inverters may be connected to one high power factor converter. (Do not connect seven or more

inverters.) The capacity of the high power factor converter should always be higher than the sum of

those of the inverters connecte d. Also, one inverter connected should have a capacity more than half of

the high power factor converter capacity.

Note: Note that if the sum of the inver ter capacities is less than half of the high power factor converter

capacity, the high power factor converter may be used as a common conver ter or regenerative

converter, but its capability to suppress power harmonics will decrease.

1)For connection of more than one inverter, select the cable size carefully beca use the inverter termin als

P, N will be wired us ing junction ter mina ls or jumpers. Select the cable size so that inverter capacities

are added in order, beginning with the farthest inverter.

2)For connection of more than one inverter, connect them in sequence of larger capacities.

3)Specific example

FR-HC

55K

P

N

A520

30K

P

A520

15K

N

P

A520

5.5K

N

P

A520

2.2K

N

First: 125mm

Second: 15+5.5+2.2+1.5+0.75=24.95K

Hence, capacity is 30K, so 50mm

Third: 5.5+2.2+1.5+0. 75=9.95K

Hence, capacity is 11K, so 14mm

Fourth: 2.2+1.5+0.75=4.45K

Hence, capacity is 5.5K, so 5.5mm

2

cable from FR-HC capacity

2

cable is selected.

2

cable is selected.

2

cable is selected.

P

A520

1.5K

N

P

A520

0.75K

N

Fifth: 1.5+0.75=2.25K

Hence, capacity is 2.2K, so 2mm

2

Sixth: 2mm

cable from 0.75K

2

cable is selected.

Note: When the FR-E500, FR-A024 series inverters are connected to the high power

factor converter (FR-HC-7.5K), at least one of the inverter connected is

required t o be at least half the ratin g of the high power factor rating. In this

case, at least one of the inverter connected is 3.7K or greater.

- 23 -

Page 33

(5) Where the power supply is special (rated input voltage is exceeded) for the 400V class high

power factor converters (FR-HC-H15K, H30K, H55K, FR-HCB-H7.5K)

Change the connection of the j um per to the internal transfor me r a ccor ding to t he op erating power supply

voltage. For the FR-HC-H7.5K, change the connection of the internal transformer inside the external

box.

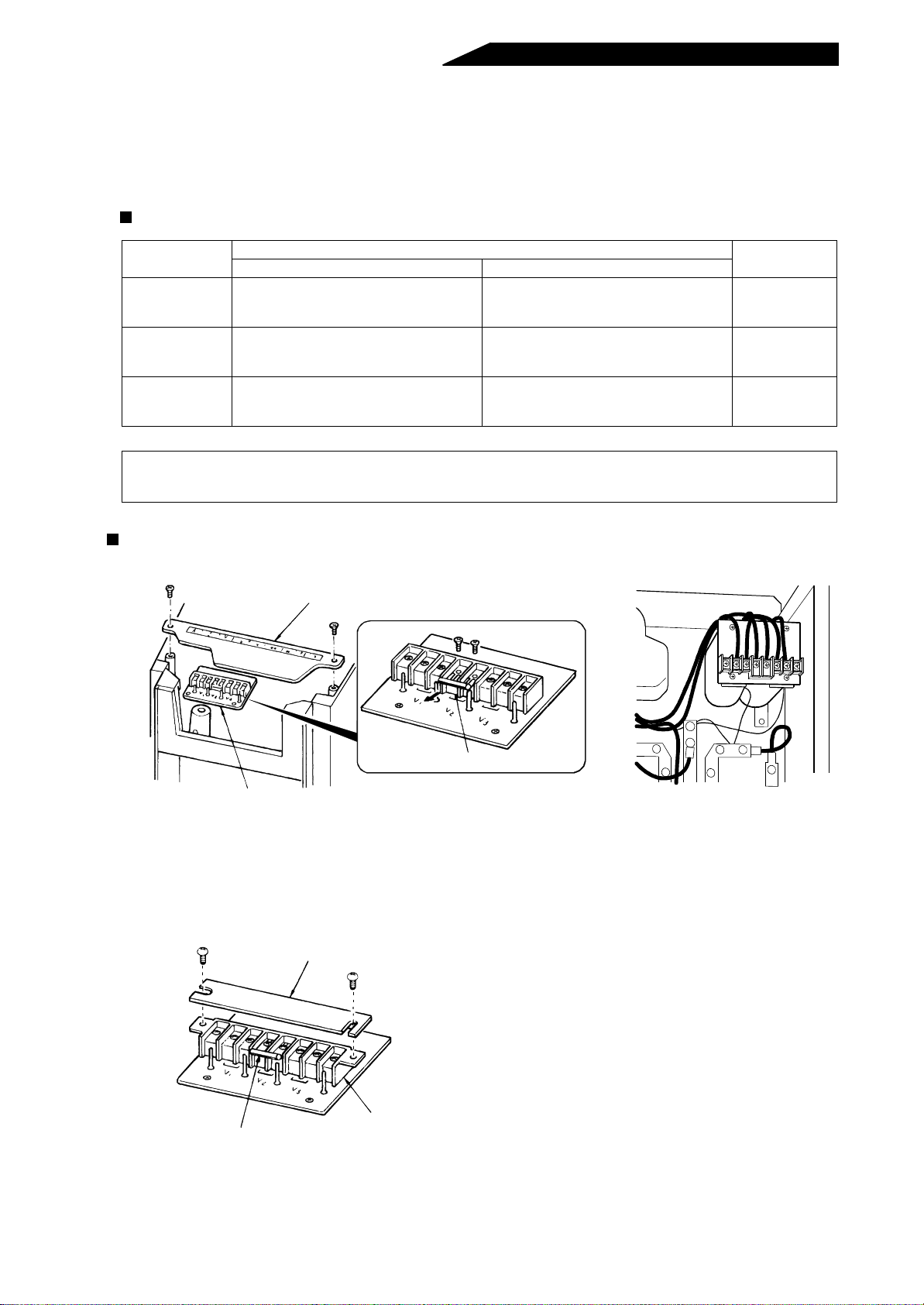

Operating power supply voltage range vs. jumper position

Jumper Position

323V(380V-15%)

V1

456V(415V+10%)

342V(380V-15%)

V2

484V(440V+10%)

391V(460V-15%)

V3

506V(460V+10%)

Operating Power Supply Voltage

50Hz 60Hz

to

to

to

As on the left

342V(380V-10%)

to

506V(460V+10%)

As on the left

Remarks

Factory setting

Note: Change the jumper position acco rding to the operatin g power supply. Otherwise the high power

factor converter will be heated and may become faulty or burn out.

Changing the jumper position

• Model: . . . . FR-HC-H15K, FR-HCB-H7.5K

Terminal symbol cover

Pull out.

Jumper

Transformer terminal block

Appearance of

FR-HCB-H7.5K

1) Remove the mounting screws of the terminal symbol cover and remove the cover.

2) This reveals the termi nal block of the inter nal transform er. After removing the screws from the jumper in

the terminal block, reconnect the jumper in accordance with the operating voltage in the above table.

• Model: . . . . FR-HC-H30K, H55K

Terminal cover

1) Remove the terminal cover of the internal

transformer located under the main circuit

terminal block (R, S, T).

2) Remove the screws from the jumper in the

terminal block, and reconnect the jumper.

Jumper

Transformer terminal block

- 24 -

Page 34

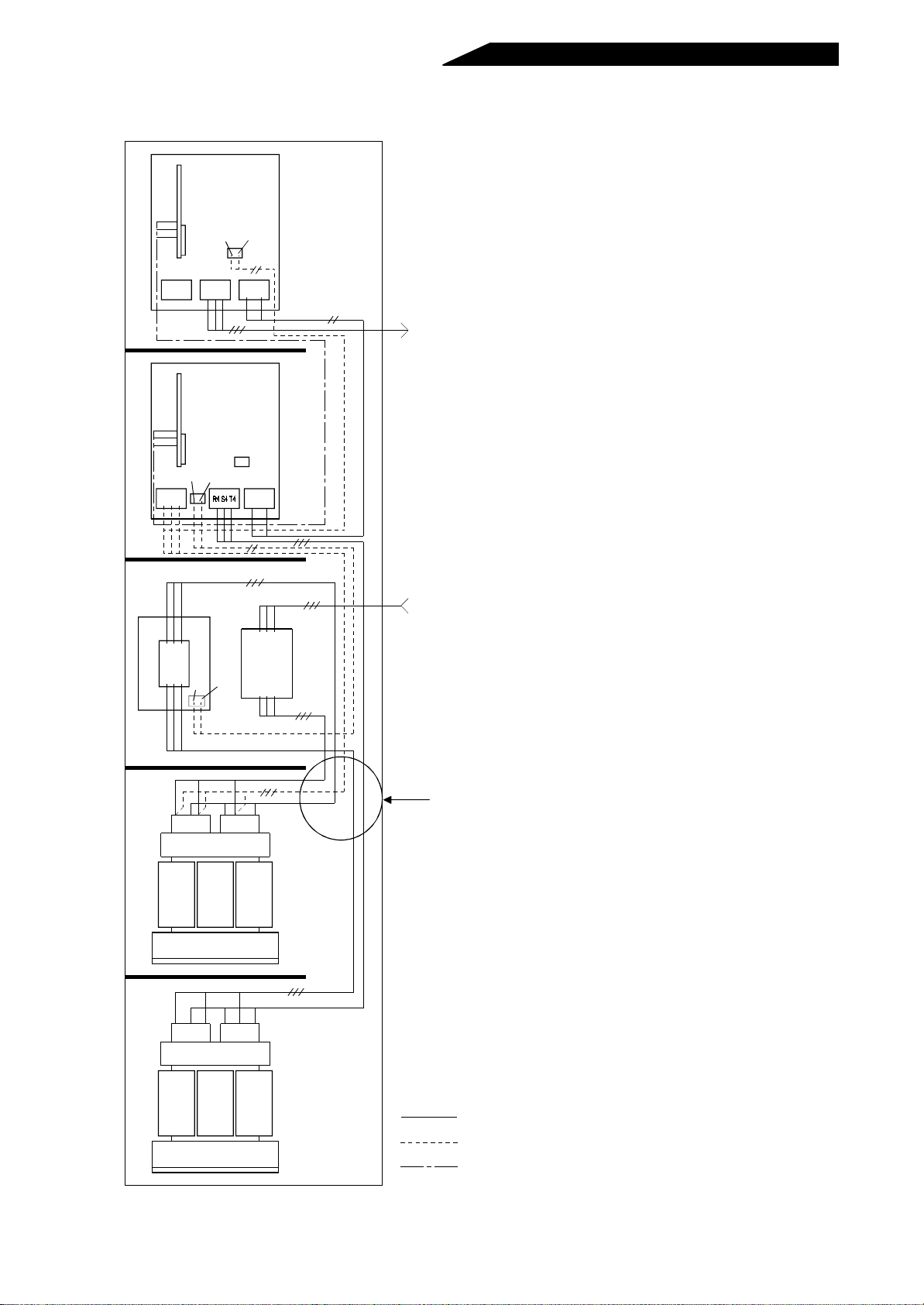

(6) Installation and wiring example

<Vertical mounting>

Inverter

R1

S1

N P

U V W

R S T

MC

MC1

HCB

MC1

Converter

(FR-HC)

MC2

MC2

N P

Motor

<Instructions>

1) Leave clearances of at least 10cm above

and below and 5cm o n the left and right

side of each unit.

2) Up to six cables may be bundled.

3) Install par titions to shut off heat given to

the upper units.

4) The reactors generate heat. Run cables

away from them.

5) When the installation place has enough

space, it is recommended to install the

units side by side.

Power supply

NFB

HCL01

HCL02

(Note 4)

Main circuit

High-voltage control circuit

Low-voltage control circuit

- 25 -

Page 35

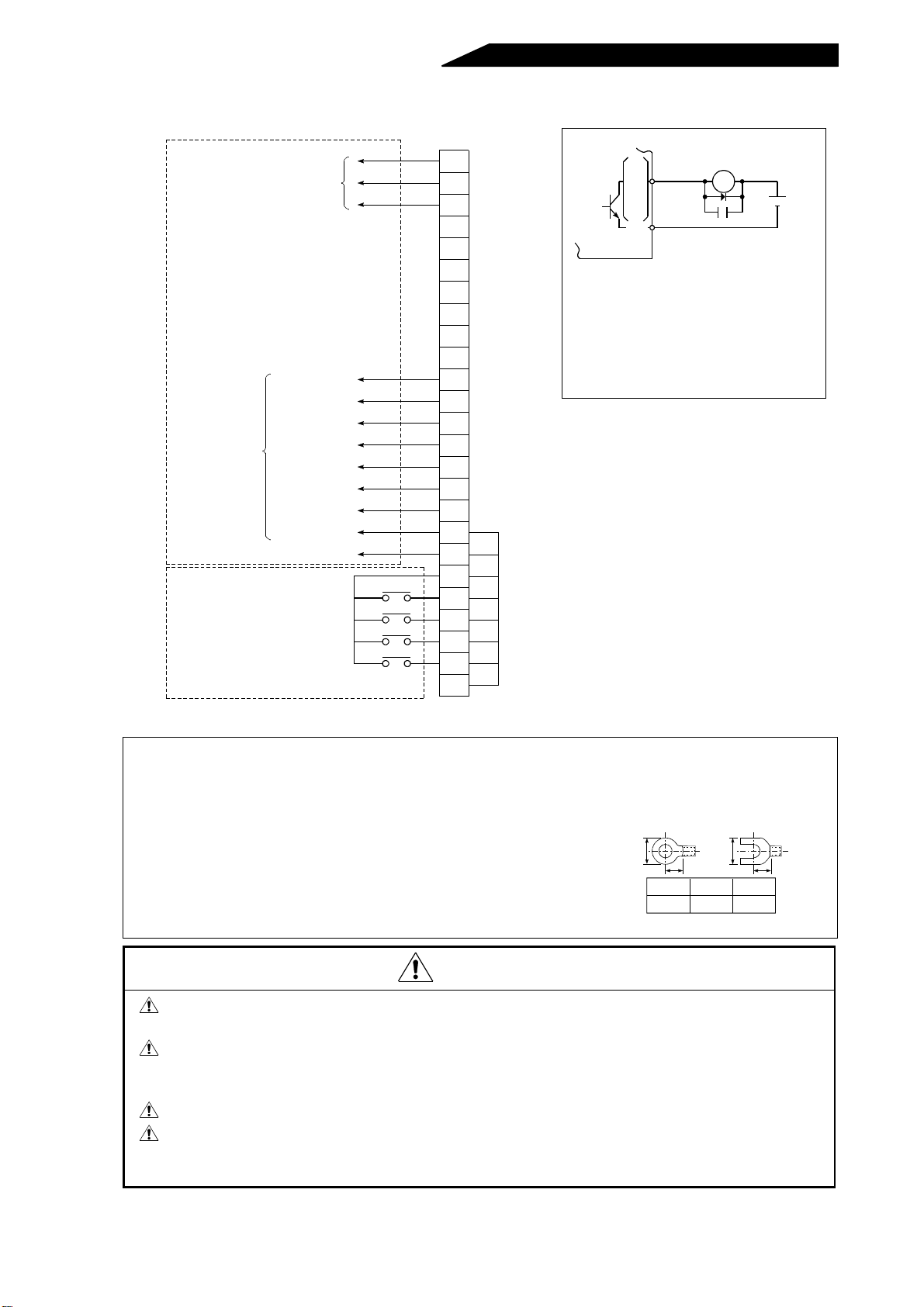

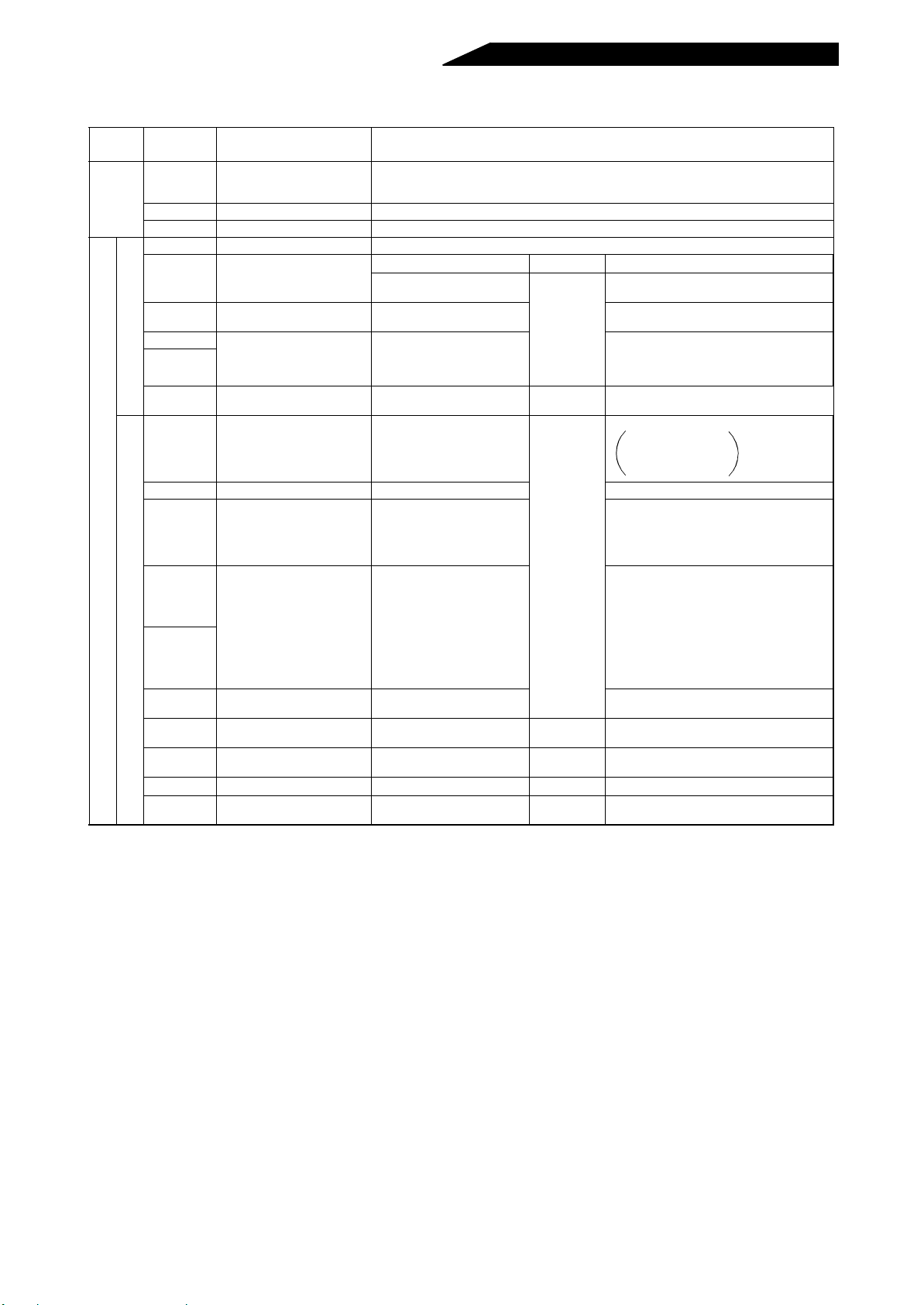

1.3.4 Wiring of the control circuit

)

)

)

)

)

)

Control input signals (voltage input disabled)

(Note)

r

y

r

C

3

(For terminal block functions, refer to “Terminals” on page 58.)

Output signals

Alarm output

(1 change-over contact output)

Open collector

output common

Multi-purpose

output terminal

Multi-purpose

output terminal

Open collector

outputs

Overload alarm

Converter reset

Converter operating

Inverter operation

Meter connection

common

Meter connection

Contact input common

Monitor switching

Monitor switching

Converter stop

External transistor common

enable

Reset

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

SE

Y2

Y1

OL

RSO

CVO

RDY

SD

FM

SD

X2

X1

SOF

RES

PC

A

B

C

High

power

factor

converter

RDY

CVO

RSO

OL

V1

Y2

SE

RA

Powe

suppl

24V o

12VD

Note: A voltage applied in the wrong

direction will damage the high

power factor converter. Beware

of miswiring such as the

direction of diode connection.

(NC)

(NC

(NC

(NC

(NC

(NC

(NC

Note: 1.Terminals SD and SE are common to the I/O signals and are isolated from each other. Do not

earth (ground) .

2.Use shielded or twisted cables for connection to the control circuit terminals and run them

away from the main and power circuits (including the 200V relay sequence circuit).

3.Since the control circuit input signals are micro currents, use two parallel micro signal contacts

or a twin contact to prevent a contact fault.

4.Keep the free termina ls ( NC) unc on nected. Otherwise, the high

power factor converter may become faulty.

5.When connecting two crimping terminals to one of the control

circuit terminals, round or square open-ended crimping terminals

of the size as shown on t he r igh t s hou ld be use d b ack to ba ck.

Do not use the free terminals (NC) of the control circuit. Using them will lead to the

failure of the high power factor converter and inverter.

Steep distortion or sinking in power may cause the reactor 2 (FR-HCL02) to generate

unusual noise. This phenomenon occurs due to a power fault and is not attributable to

a damaged high power factor converter (FR-HC).

When the load is light, harmonic suppression effects will decrease.

Be sure to connect terminal RDY of the FR-HC to the X10 or MRS signal assigned

terminal of the inverter, and connect terminal SE of the FR-HC to terminal SD of the

inverter. Without proper connecting, FR-HC will be damaged.

B

FF

Nominal

1.25-3

Note: Round crimping terminal V1.25-MS

(Japan Solderless Terminal)

B(mm)

6.4 or less

B

F(mm)

53 or more

CAUTION

- 26 -

Page 36

Using the PC terminal

This termi nal is used to connect transistor output (open coll ector output)

such as a pr ogrammable controller (P C). Connecting the external power

supply common for transistor outpu t to the PC terminal prevents a faulty

operation caused by a sneak current.

(The power supply voltage of the PC terminal should be 24VDC.)

Instruction for contact inputs

<Correct connection>

AY40 transistor

output module

10

1

2

3

4

9

DC

24V

DC

x2

x1

SOF

RES

PC

SD

High power factor converter

24V

(SD)

AY40 transistor

output module

<Incorrect connection>

1

x2

2

x1

3

SOF

4

RES

9

PC

10

DC

SD

24V

High power factor converter

DC

24V

(SD)

The AY40 module requires a 24VDC power supply.

Since input signals to the control circuit are at a low level, use two parallel

micro signal contacts or twin contact for contact inputs to prevent a contact

fault.

Micro signal contacts

- 27 -

Twin contact

Page 37

Wiring example for commercial

power supply-inverter switchover

• Complicated sequence circuit for commercial power supply-inverter

switch-over

The following example shows wiring for connection of a commercial

power supply. (FR-A500 series) When making connection, always

provide interlocks between magnetic contactors MC2 and MC3:

MC2

NFB MC1

Power supply

Reactor 1

(FR-HCL01)

R

S

T

R2

S2

T2

External box

(FR-HCB)

R2

S2

T2

Filter capacitor

Resistor

MC

Resistor

MC1

MC2

R3

S3

T3

Reactor 2

(FR-HCL02)

R3

S3

T3

converter (FR-HC)

MC1

MC2

R4

S4

S4

T4

R

S

T

R1

S1

High power fa ct or

R4

T4

RDY

RSO

Y1 or Y2

SE

(Note)

N

Inverter

(FR-A500 series)

R

S

T

PP

N

X10

RES

X11

SD

R1

S1

MC3

U

V

W

Motor

Note: Keep the high power factor converter’s terminals R1, S1 unconnected.

- 28 -

Page 38

2. PARAMETERS

This chapter presents details on the “parameters” of this

product.

Always read the precautions, etc. before starting use.

2

2.1 PARAMETER UNIT.................................................................................... 29

2.2 PARAMETER FUNCTION DETAILS .......................................................... 31

2.3 HELP FUNCTIONS........................ ............................................ .. .............. 40

2.4 CONVERTER RESET................................................................................ 43

Page 39

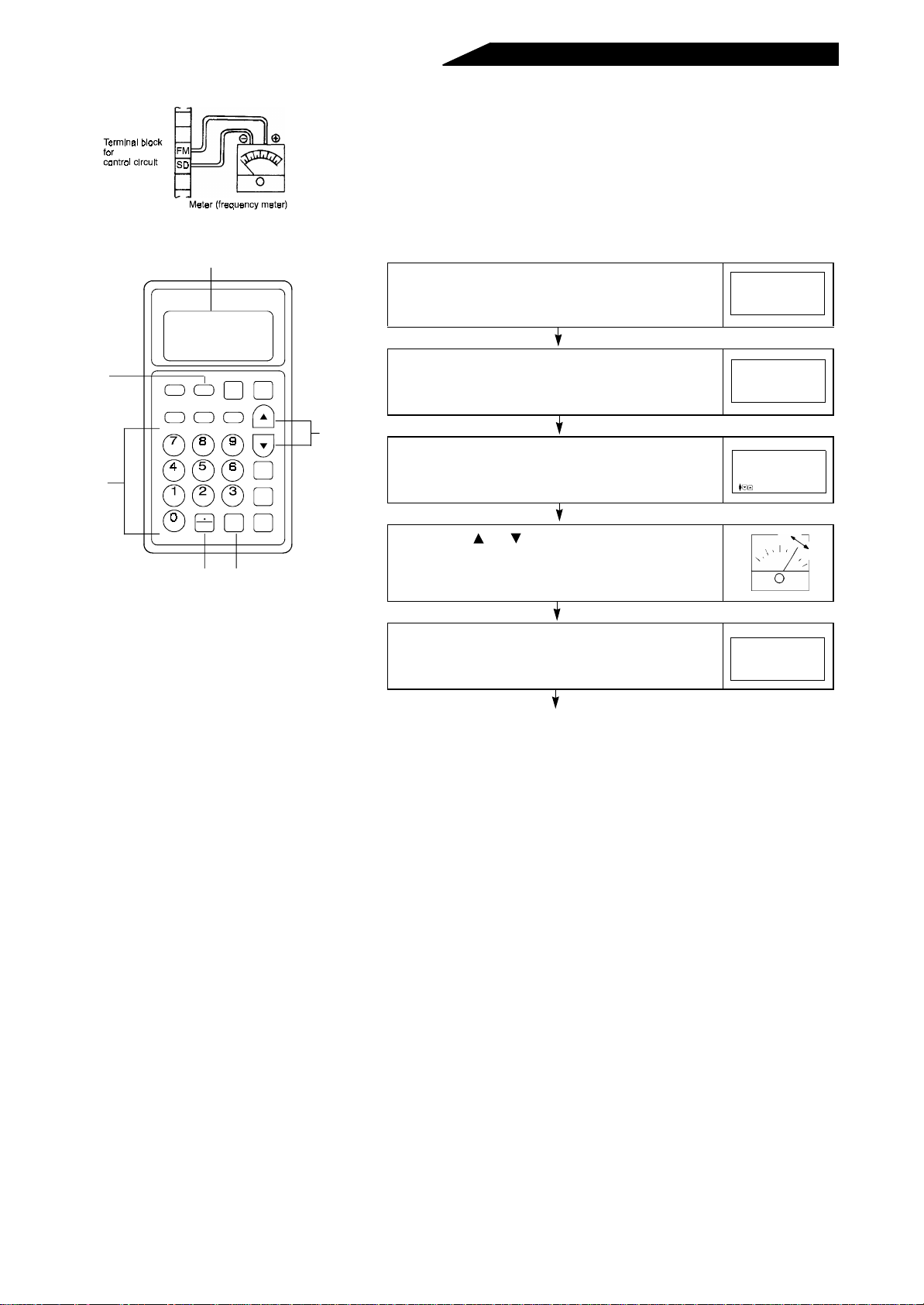

2.1 PARAMETER UNIT

g

The parameter unit (FR-PU02E-1) is installed directly to the high power factor converter or

connected to it by the cable (FR-CBL) to allow parameters to be set and data to be

monitored. Note that as compared to the inverter, there are restrictions on functions. In this

manual, the parameter unit may be referred to as the PU.

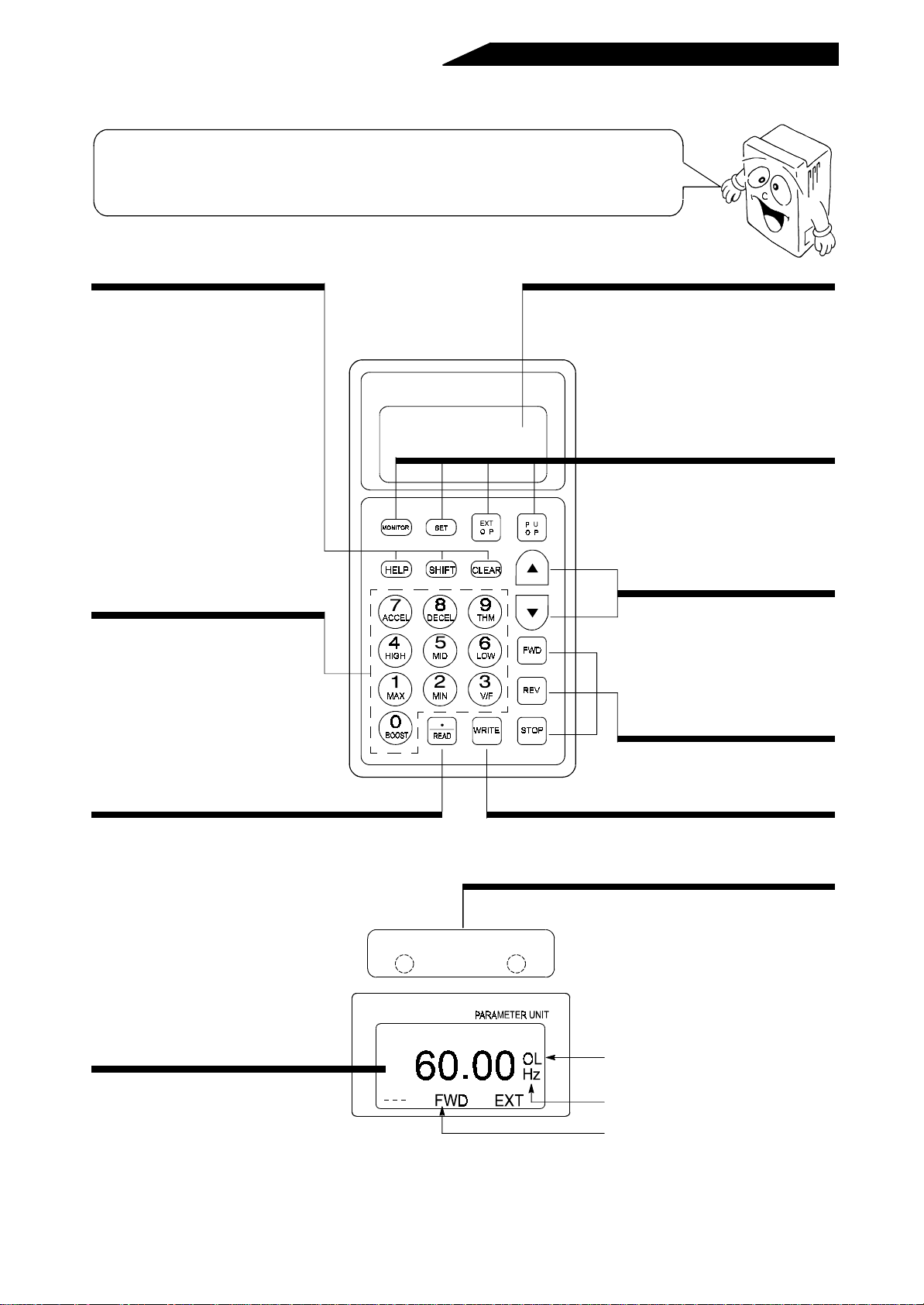

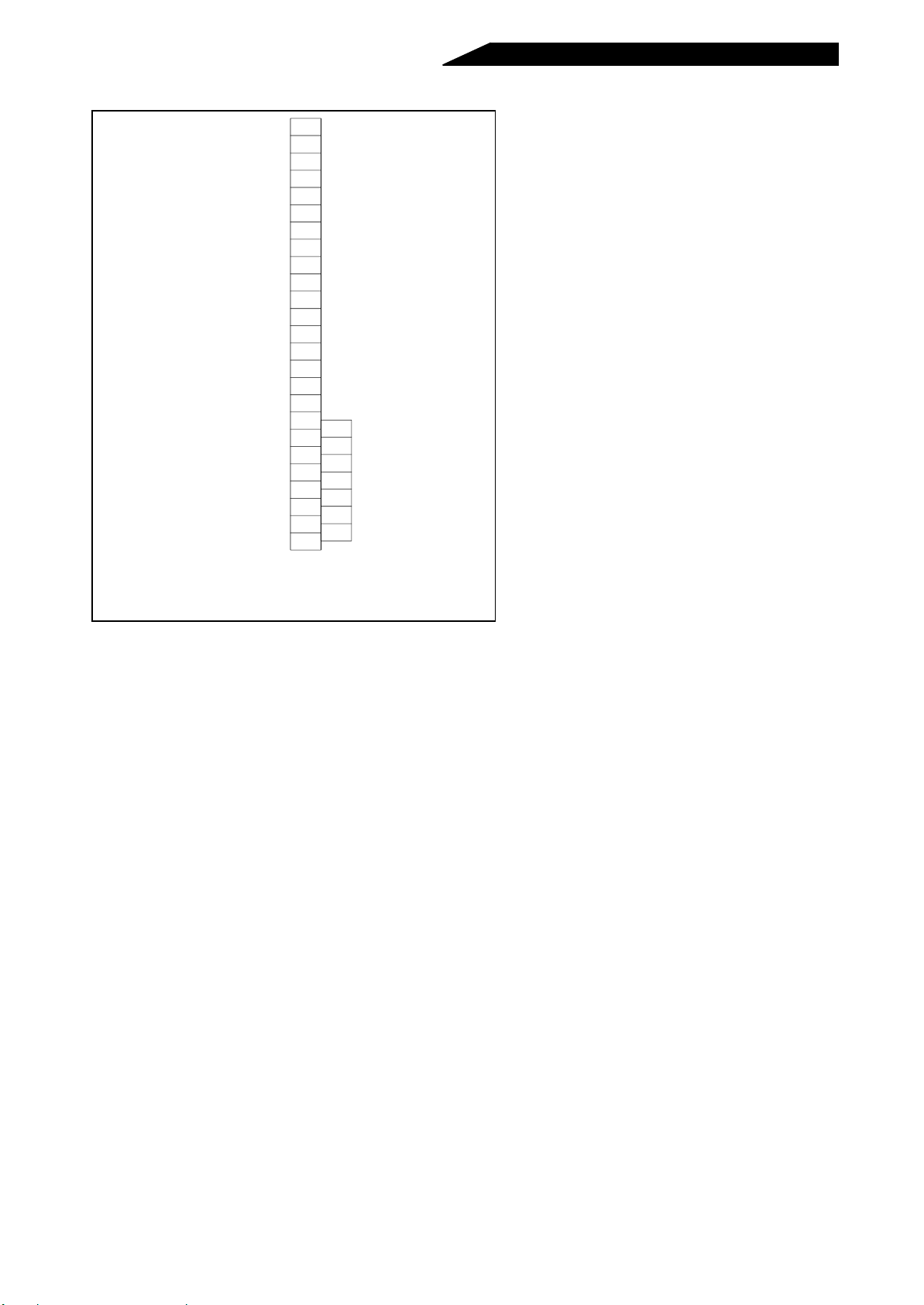

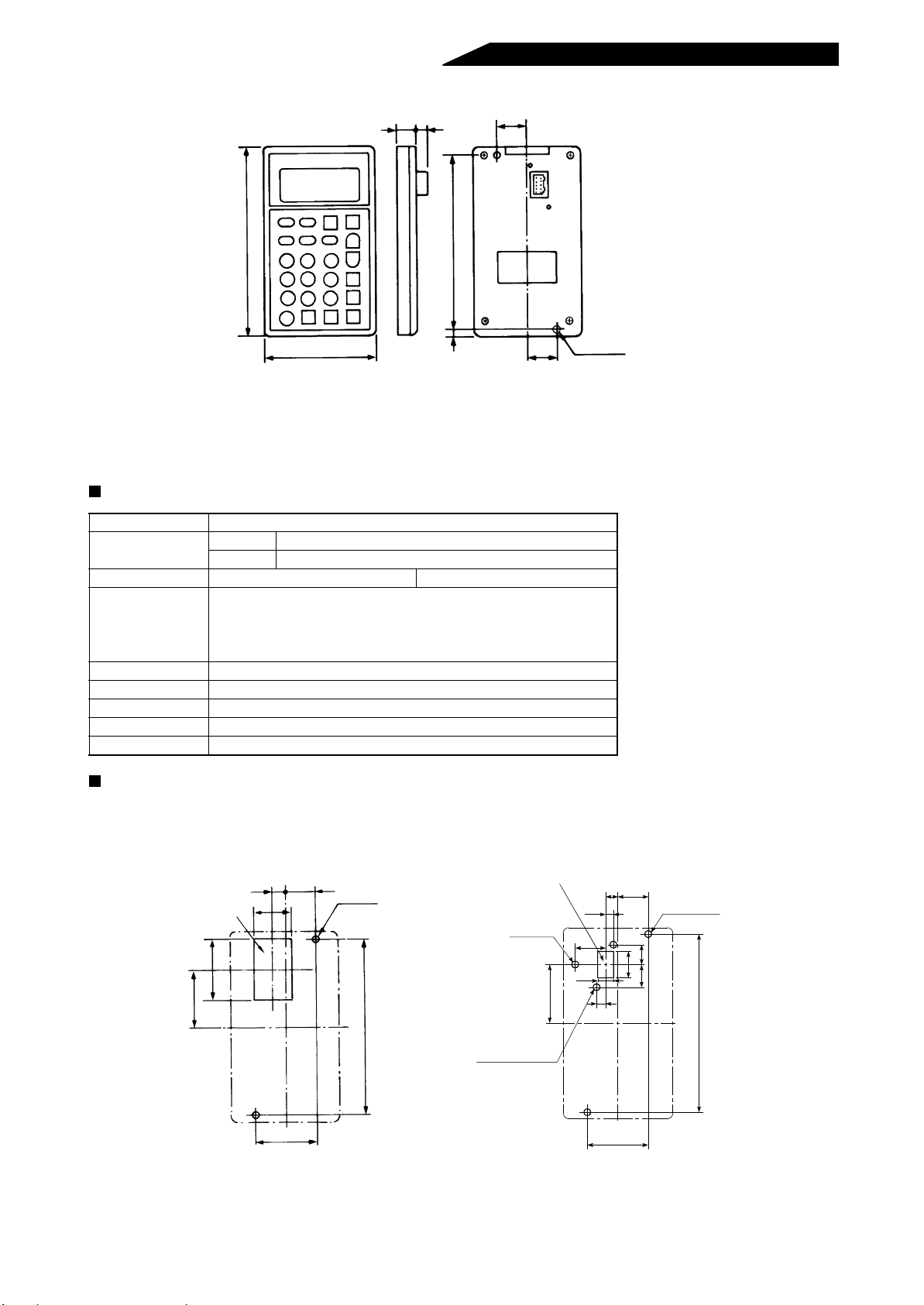

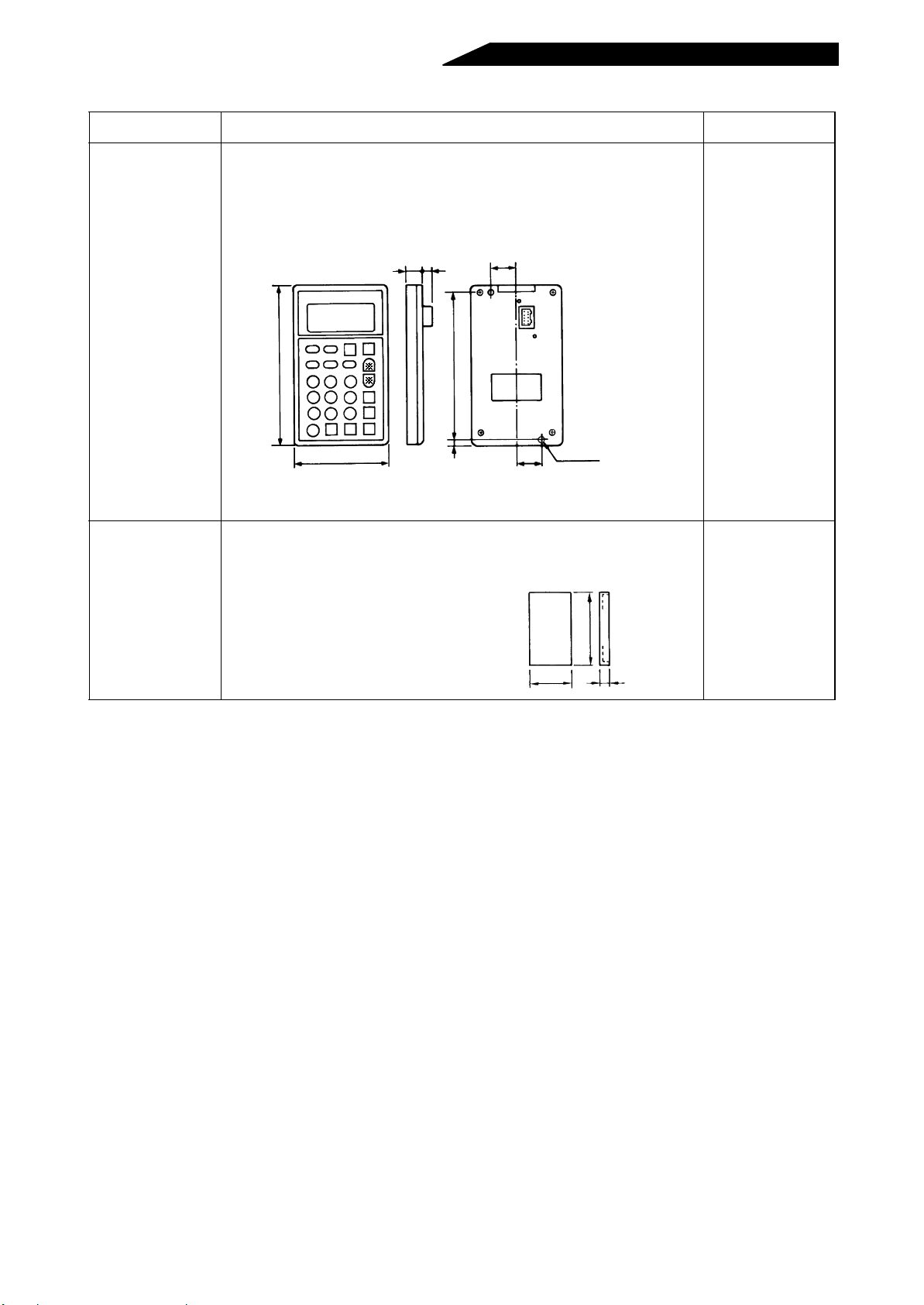

2.1.1 Structure of the parameter unit

Help key

• Used to call the help selection

screen.

• Note that there are restrictions.

Clear key

• Used to clear a set value entered.

• Used to return to the help

selection screen when you have

selected an invalid help item.

Shift key

• Used to shift to the next item in

the setting or monitoring mode.

Numeral keys

• Used to enter the parameter

number and set value.

FR-PU02E

PARAMETER UNIT

-1

Display

• Shows the monitor screen, etc.

Mode selecton keys

• Used to select the setting mode

and monitoring mode. The “EXT

OP” and “PU OP” keys are invalid.

Frequency change ke ys

• On the monitoring, parameter or

help item selection screen, these

keys are used to move the cursor.

Hold down the SHIFT key and

press either of these keys to

advance or return the display

screen one page.

Read key

• Used also as a decimal point key.

• Acts as a key to select or read any of various functions.

PU main monitor

• Three different monitors can be select ed

in sequence with the [SHIFT] key.

POWER ALARM

FR-PU02E

-1

Operation command key s

• Invalid.

Write key

• Used to write a set value in the

setting mode, etc.

Converter LED display

• POWER (yellow) indicates whether

power is supplied or not and ALARM

(red) indicates whether alarm output is

provided or not.

Overload signal detecting

indication

Display unit

Indicates the driving (FWD) or

re

enerative (RV) mode.

- 29 -

Page 40

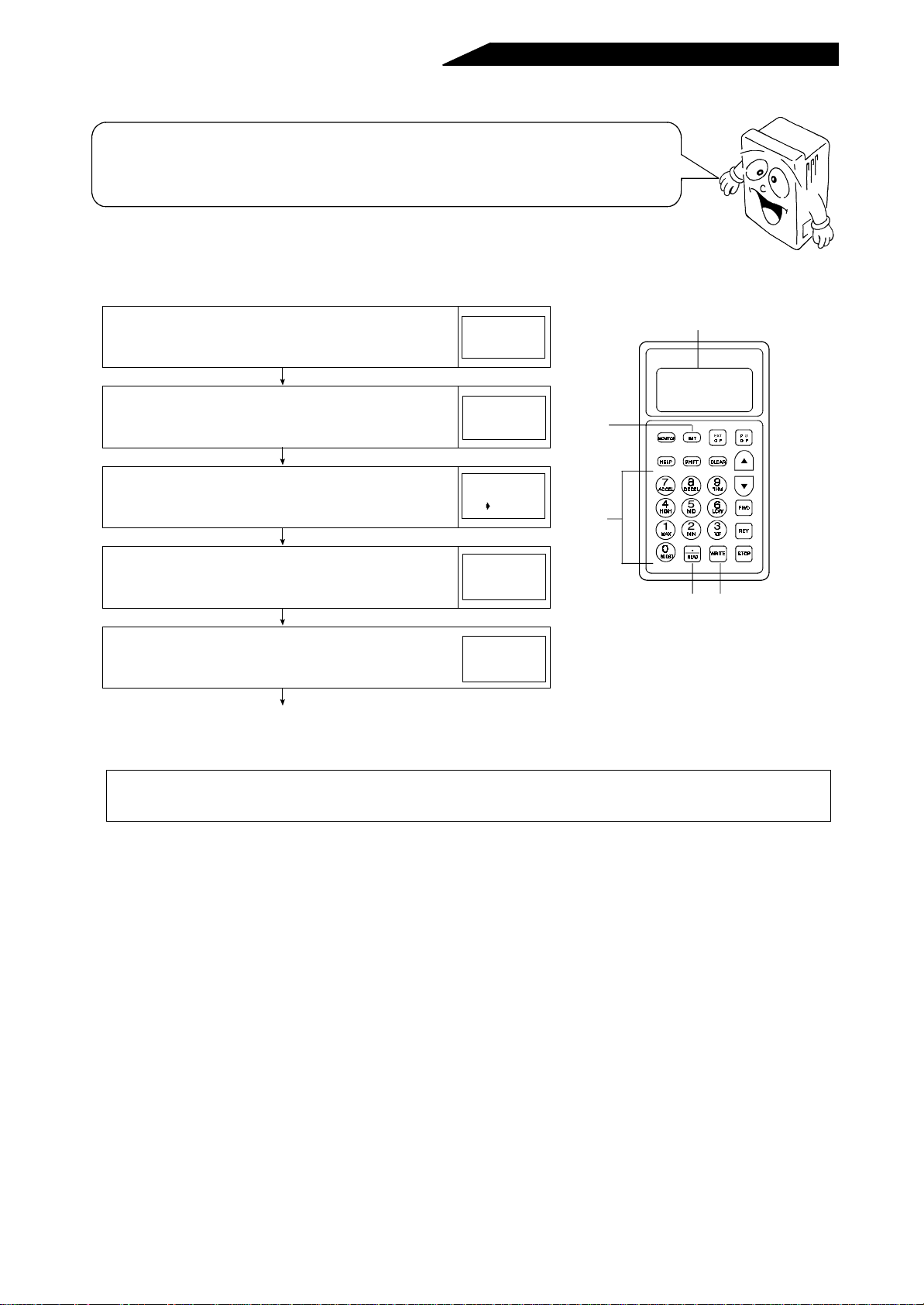

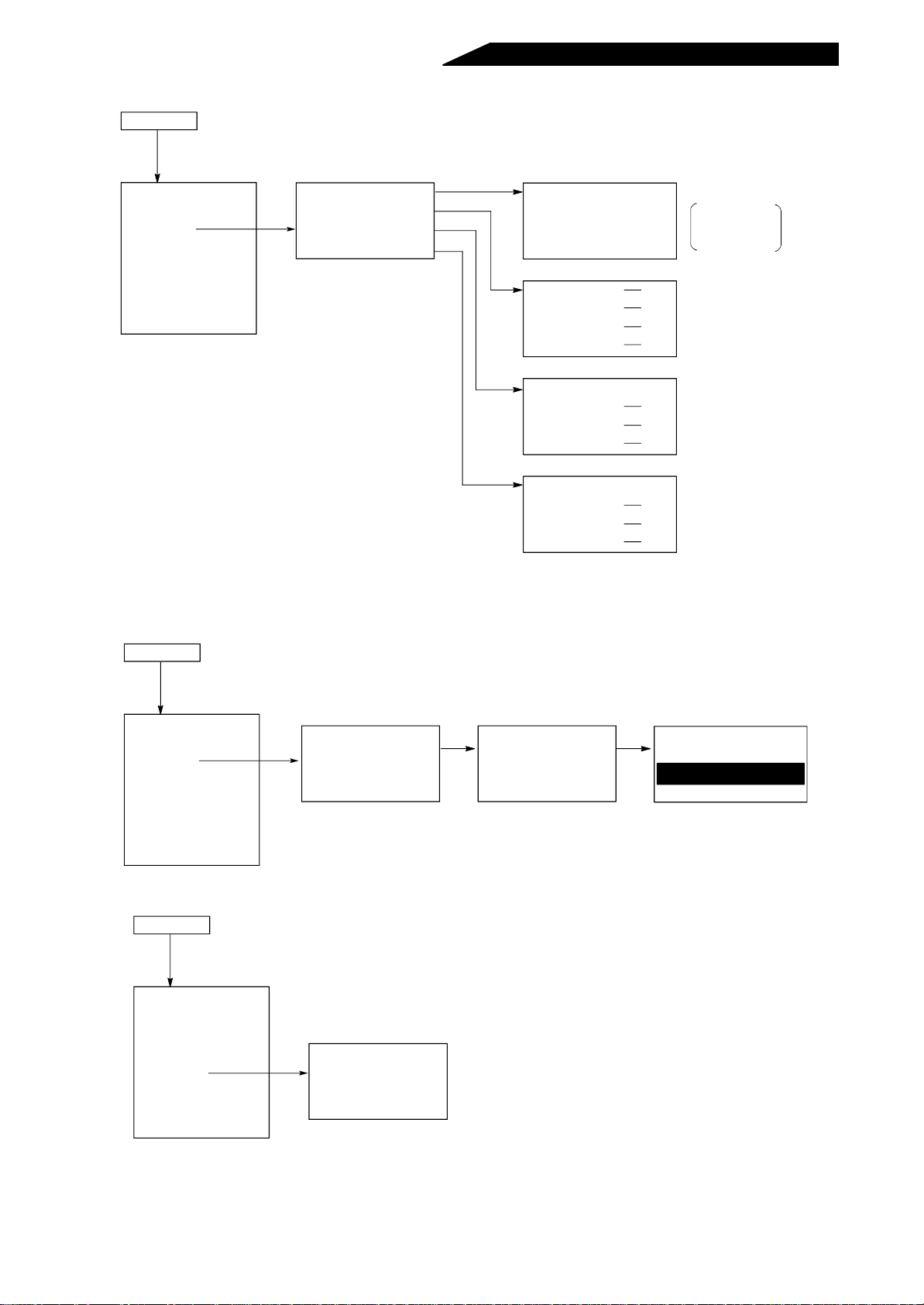

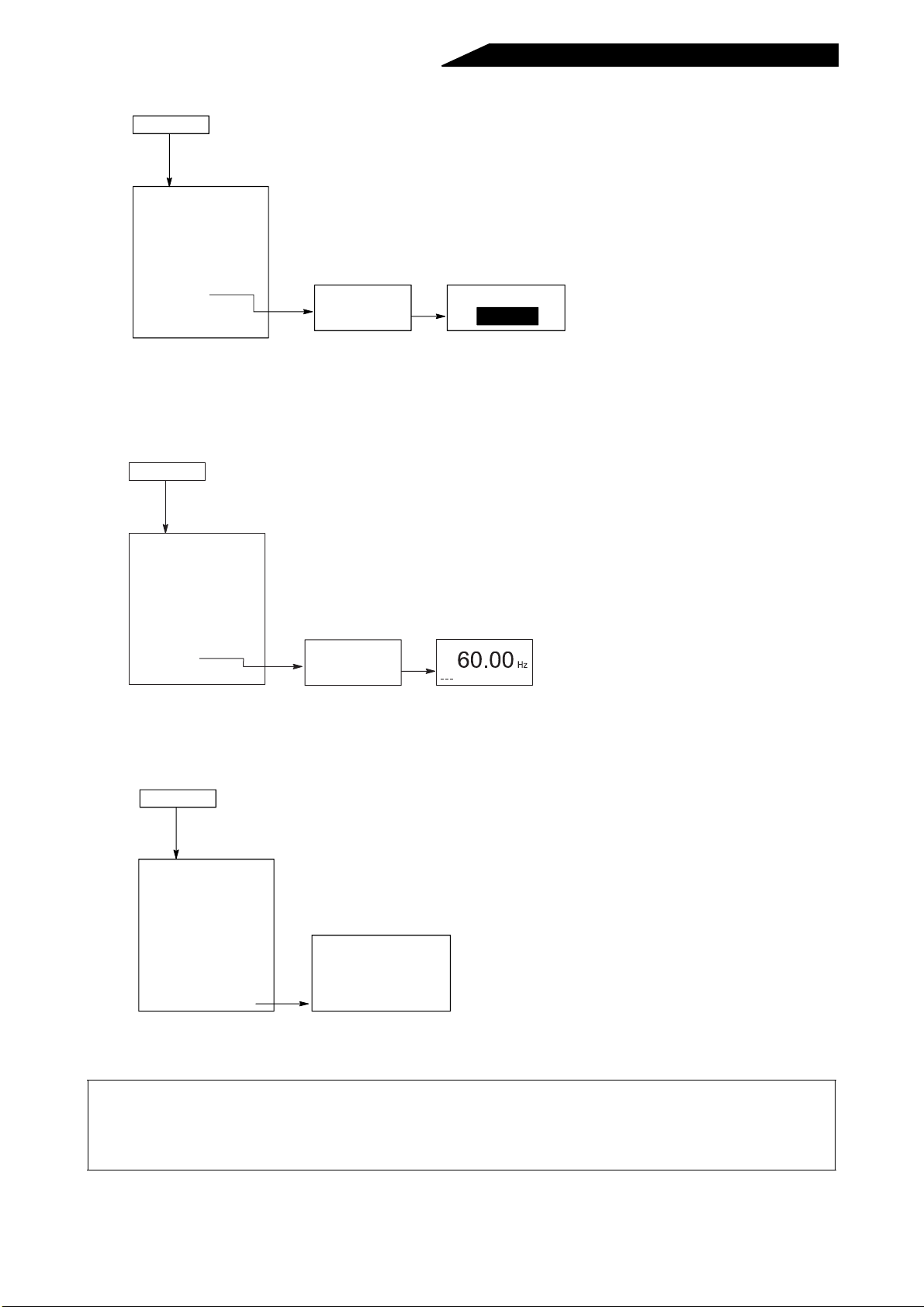

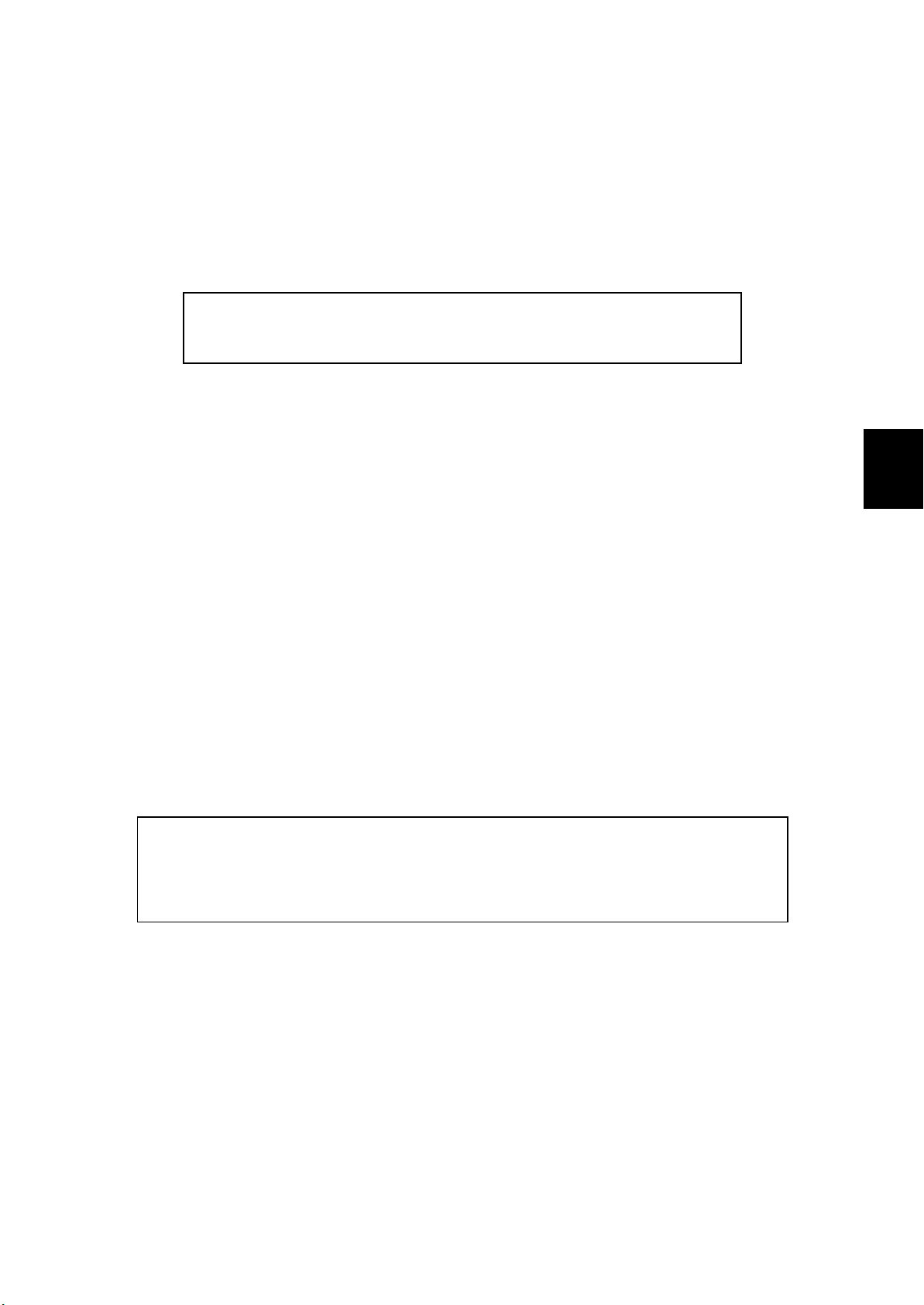

2.1.2 Setting and changing the parameter values

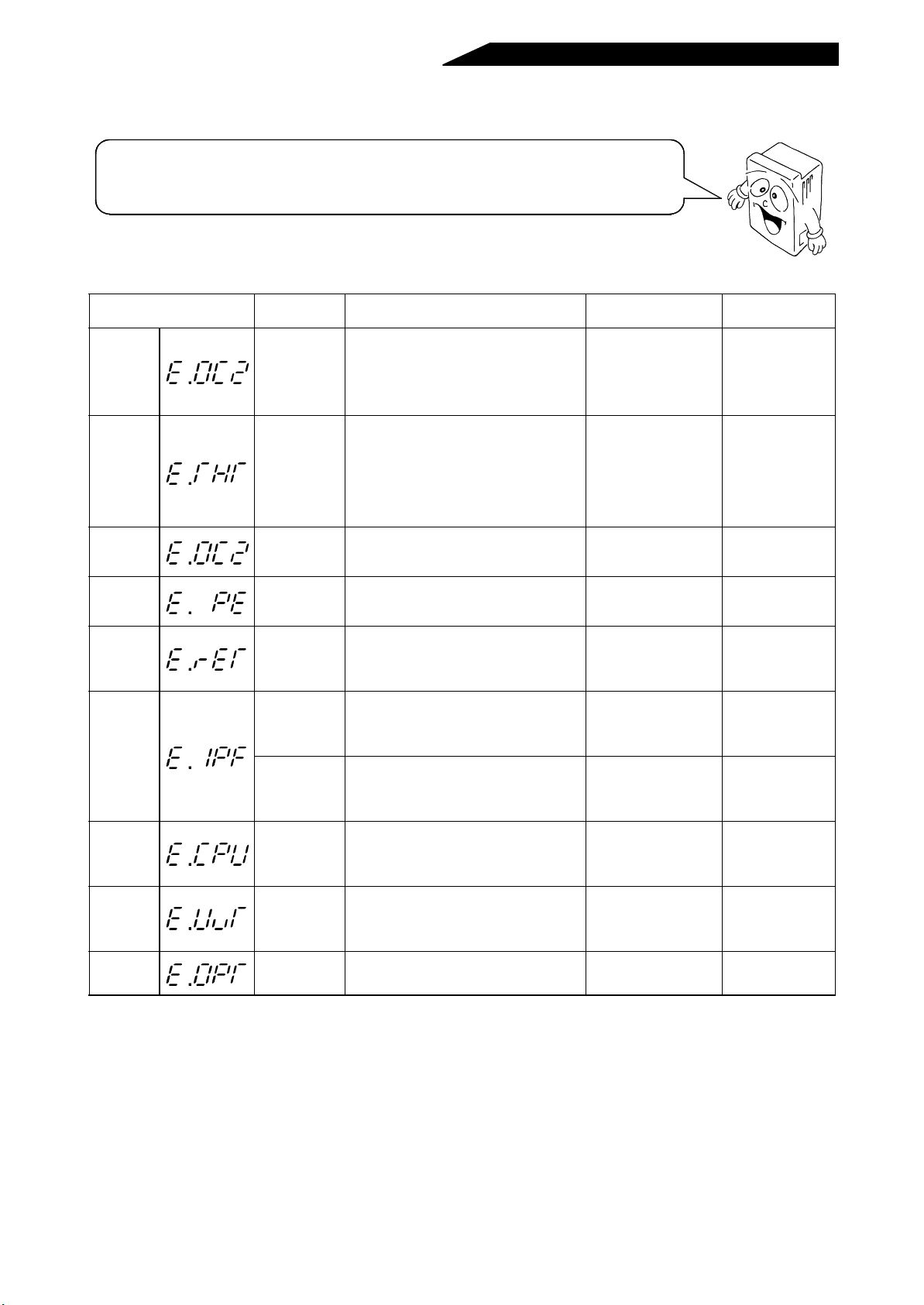

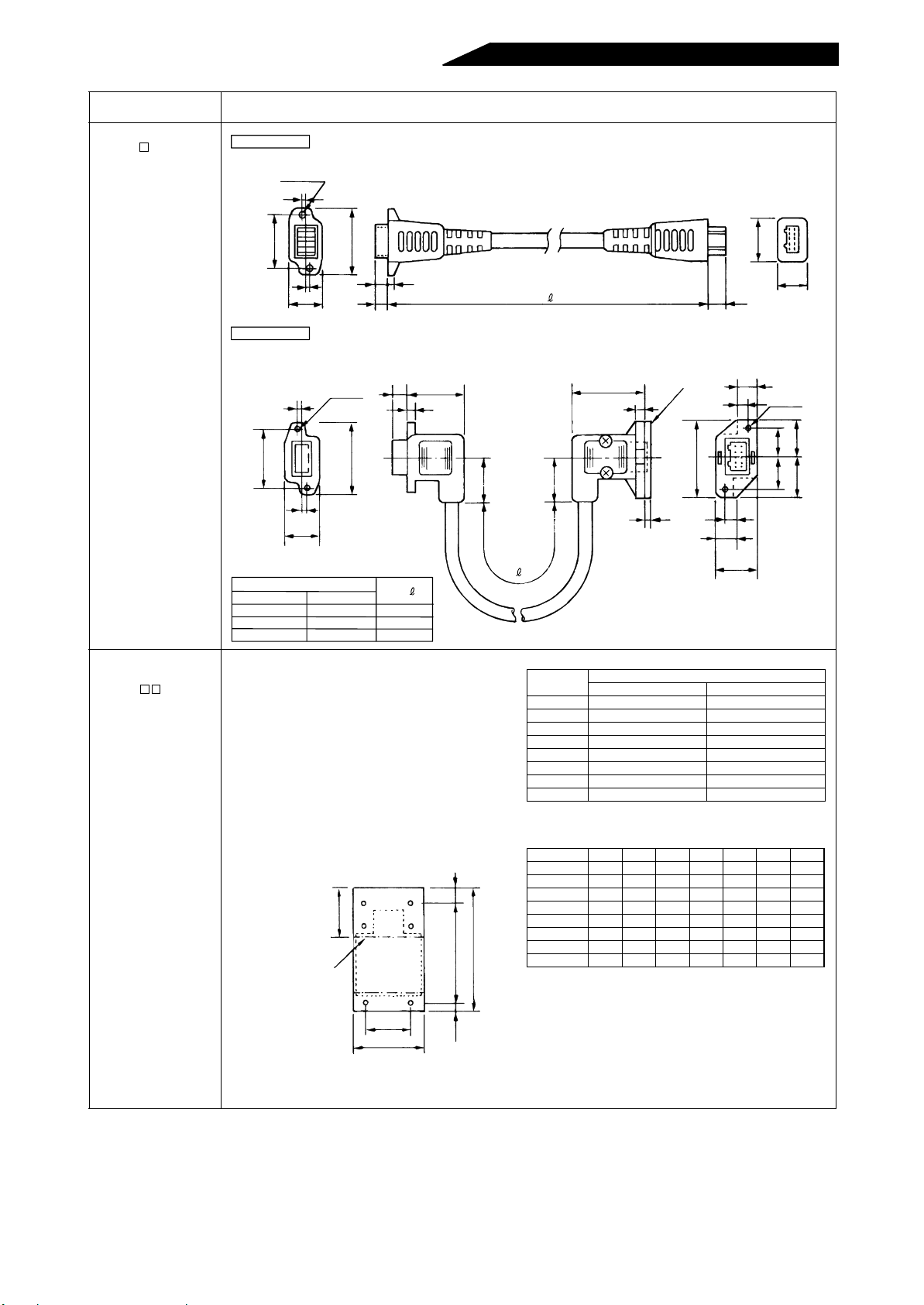

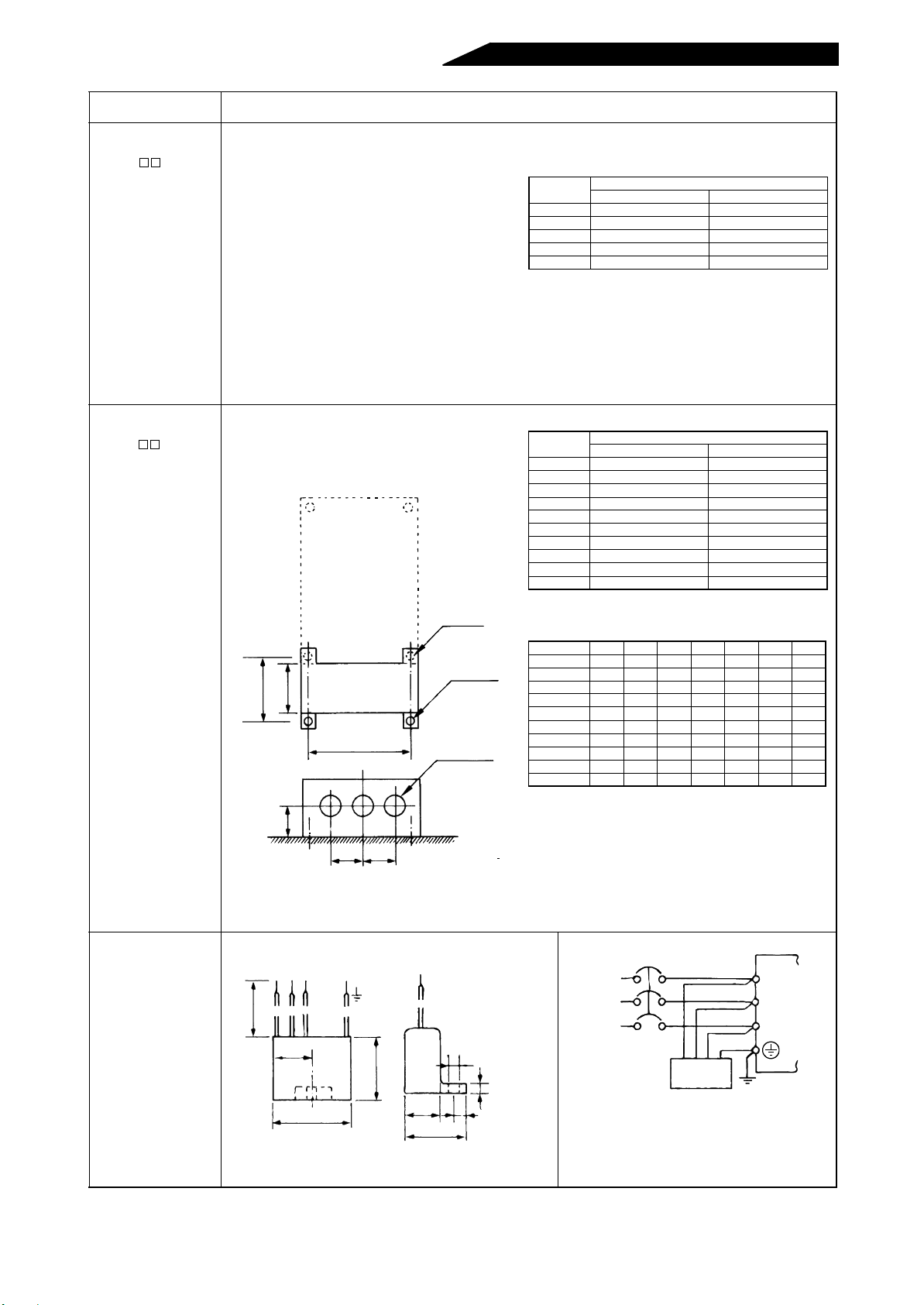

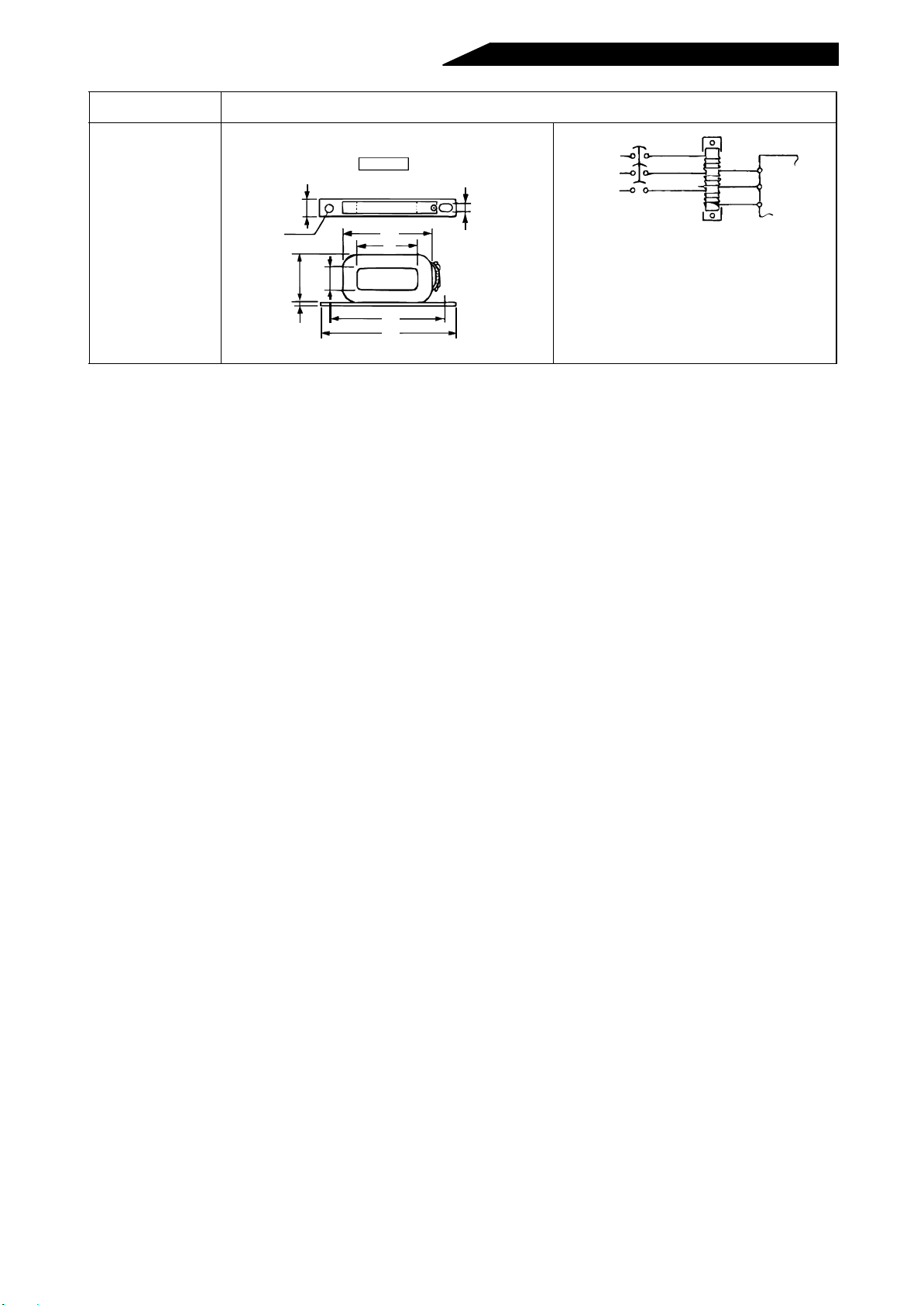

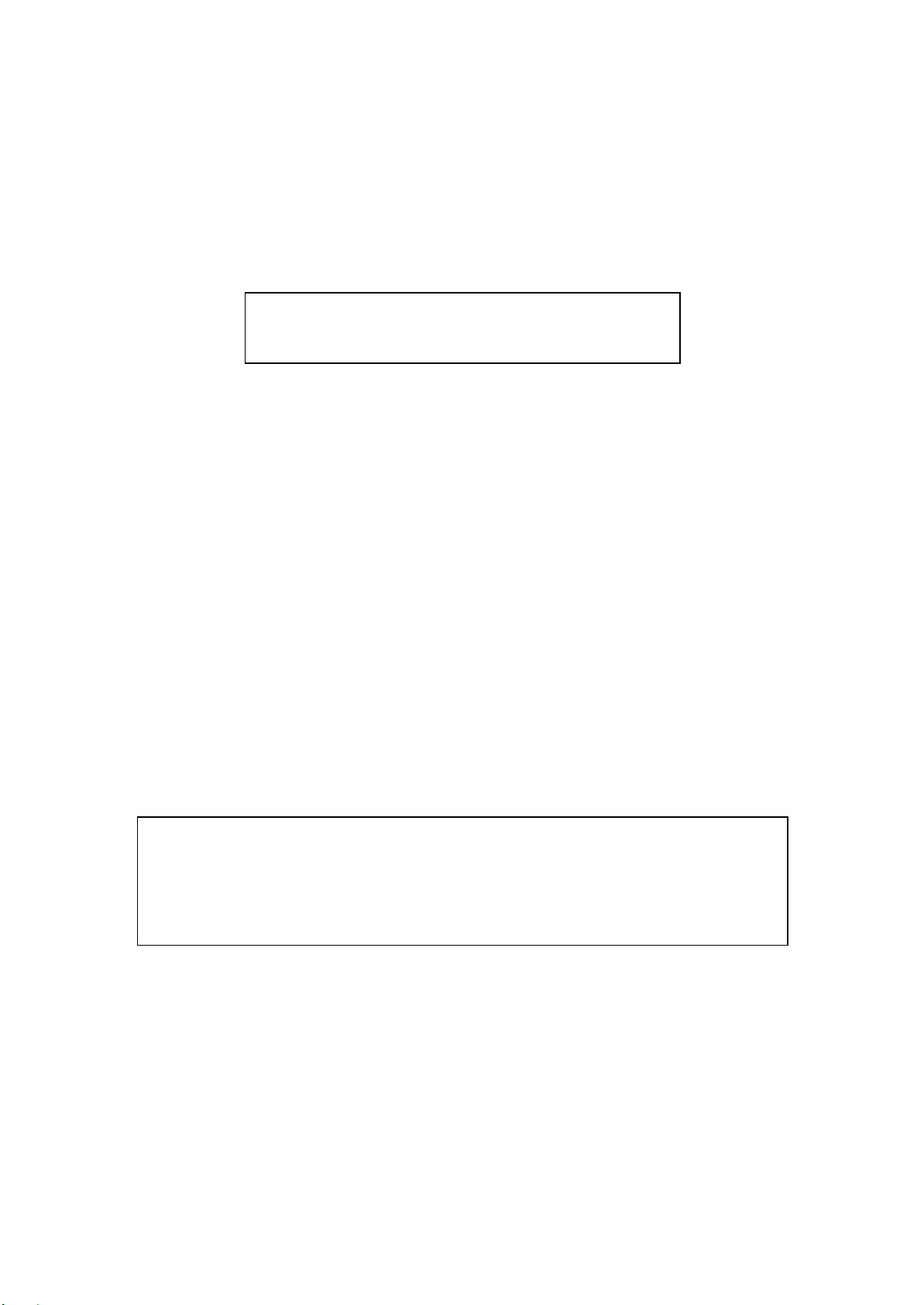

The high power factor converter has many parameters. Using the PU, the required