Mitsubishi Electric F930GOT-BWD, F940GOT-SWD, F940WGOT-TWD, F940GOT-SBD-H, F940GOT-LBD-H Operation Manual

...

OPERATION MANUAL

GOT-F900

Graphic Operation Terminal GOT-F900

Foreword

• This manual contains text, diagrams and explanations which will guide the reader in the

correct installation and operation of GOT -F900.

• Before attempting to install or use GOT-F900 this manual should be read and understood.

• If in doubt at any stage of the installation of GOT-F900 always consult a professional

electrical engineer who is qualified and trained to the local and national standards which

apply to the installation site.

• If in doubt about the operation or use of GOT-F900 please consult the nearest Mitsubisi

Electric distributor.

• This manual is subject to change without notice.

Graphic Operation Terminal GOT-F900

GRAPHIC OPERATION TERMINAL

GOT-F900

OPERATION MANUAL

Manual number : JY992D94701

Manual revision : A

Date : April 2001

i

Graphic Operation Terminal GOT-F900

ii

Graphic Operation Terminal GOT-F900

FAX BACK

Mitsubishi has a world wide reputation for its efforts in continually developing and pushing

back the frontiers of industrial automation. What is sometimes overlooked by the user is the

care and attention to detail that is taken with the documentation. However, to continue this

process of improvement, the comments of the Mitsubishi users are a lways welcomed. This

page has been designed for you, the reader, to fill in your comments and fax them back to us.

We look forward to hearing from you.

Fax numbers: Your name....................................................

Mitsubishi Electric.... .....................................................................

America (01) 847-478-2253 Your company ..............................................

Australia (02) 638-7072 .....................................................................

Germany (0 21 02) 4 86-1 12 Your location:................................................

South Africa (0 27) 11 444-0223 .................... ................................. .. ..............

United Kingdom (01707) 278-695

Please tick the box of your choice

What condition did the manual arrive in?

Will you be using a f o lder to store the manual?

What do you think to the manual presentation?

Are the explanations understandable?

Which explanation was most difficult to understand:..................................................................

....................................................................................................................................................

Are there any diagrams which are not clear?

If so,which:..................................................................................................................................

What do you think to the manual layout?

If there one thing you would li ke to see improved, what is it?.....................................................

....................................................................................................................................................

....................................................................................................................................................

Could you find the information you required easily using the index and/or the contents, if

possible please identify your experience: ...................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

¨

¨

¨

¨

¨

¨

Good

Yes

Tidy

Yes

Yes

Good

Minor damage

¨

No

¨

Unfriendly

¨

Not too bad

¨

No

¨

Not too bad

¨

Unusable

¨

Unusable

¨

Unhelpful

¨

Do you have any comments in general about the Mitsubishi manuals? ............... .. ....................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Thank you for taking the time to fill out this questionnaire. We hope you found both the product

and this manual easy to use.

iii

Graphic Operation Terminal GOT-F900

iv

Graphic Operation Terminal GOT-F900

Guidelines for the Safety of the User and Protection of the Graphic operation

terminal GOT-F900

This manual provides information for the use of the Graphic operation terminal GOT-F900. The

manual has been writte n to be use d by trained and compe tent personnel. T he definition of

such a person or persons is as follows;

a) Any engineer who is responsible for the planning, design and construction of automatic

equipment using the product associated w ith this manual should be of a com petent

nature, trained and qualified to the loc al and national sta ndards required to fulfill that

role. These engineers should be fully aware of all aspects of safety with regards to

automated equipment.

b) Any commissioning or service engineer must be of a competent nature, trained and

qualified to the local an d nationa l standards required to fulfill tha t job. These engineers

should also be trained in the use and maintenance of the completed product. This

includes being completely f amili ar with all ass ociated docume ntation for the said product.

All maintenance should be carried out in accordance with established safety practi ces.

c) All operators of the completed equipment should be trained to use that product in a safe

and coordinated manner in compliance to established safety practices. The operators

should also be familiar with documentation which is connected with the actual operation

of the completed equipment.

Note : Note: the term ‘completed equipment’ refers to a third party constructed device which

contains or uses the product associated with this manual.

Notes on the Symbols Used in this Manual

At various times through out this manual cer tain s ymbols will be used to highlight p oints of

information which are intended to ensure the users personal safety and protect the integrity of

equipment. Whenever any of the following symbols are encountered its associated note must

be read and understood. Each of the symbols used will no w be lis ted with a brief description of

its meaning.

Hardware Warnings

1) Indicates that the identified danger WILL cause physical and property damage.

2) Indicates that the identified danger could POSSIBLY cause physical and property

damage.

3) Indicates a point of further interest or further explanation.

Software Warnings

4) Indicates special care must be taken when using this element of software.

5) Indicates a special point which the user of the associate software element should

be aware of.

6) Indicates a point of interest or further explanation.

v

Graphic Operation Terminal GOT-F900

• Under no circumstances will Mitsubishi Electric be liable or responsible for any

consequential damage that may arise as a result of the installation o r use of t his equi pment.

• All examples and diagrams shown in this manual are intended only as an aid to

understanding the text, not to guarantee operation. Mitsubishi Electric will accept no

responsibility for actual use of the product based on these illustrative examples.

• Owing to the very great variety in possible application of this equipment, you must satisfy

yourself as to its suitability for your specific application.

vi

Graphic Operation Terminal GOT-F900 Contents

Manual configuration and various data ........................................................1

1. Introduction .........................................................................................1-1

1.1 Outline..............................................................................................................1-1

1.2 Format of manual.......................................................... .. .................................1-3

1.2.1 Contents described in manual.............................................................................1-3

1.2.2 Abbreviations used in text ...................................................................................1-3

1.3 Expressions and basic functions of operation keys ......................................... 1-4

1.3.1 Expressions of operation keys ............................................................................1-4

1.3.2 Basic operations..................................................................................................1-4

1.4 System configuration .......................................................................................1-5

1.4.1 Connection of peripheral units of GOT................................................................1-5

1.5 Connectable PLC.............................................................................................1-6

1.6 GOT version upgrade history........................... ................................. .. .............1-9

1.7 Screen creation software version upgrade history.........................................1-11

1.8 Preservation of screen data and backup .......................................................1-13

2. Specifications......................................................................................2-1

2.1 General specifications......................................................................................2-1

2.2 Display section specifications ..........................................................................2-2

3. Outside dimensions.............................................................................3-1

4. Part names..........................................................................................4-1

4.1 Front panel.......................................................................................................4-1

4.2 Rear panel.......................................................................................................4-1

4.3 Functions of connectors........................ .......................... ......................... ........4-2

5. Installation...........................................................................................5-1

5.1 Panel cut dimension.........................................................................................5-1

5.2 Installation........................................................................................................5-2

6. Function ..............................................................................................6-1

6.1 Function list......................................................................................................6-1

7. Start up ...............................................................................................7-1

7.1 Start up procedure...........................................................................................7-1

7.2 Operation environment setting.........................................................................7-3

7.3 Each mode selection procedure ......................................................................7-9

7.4 Security function (screen protection function)................................................7-11

7.4.1 Upgrading of security function...........................................................................7-13

8. Creation of Display Screens................................................................8-1

8.1 Outline of compatibility of screen data.......................... ...................................8-2

8.1.1 Functions dedicated to screen creation software FX-PCS-DU/WIN-E................8-3

8.1.2 Common functions ..............................................................................................8-4

8.1.3 Functions dedicated to GT Designer...................................................................8-7

8.2 Transfer of screen data........................... ......................... ................................8-8

8.3 Misappropriation of screen data.....................................................................8-10

8.4 Use of data in FX-50DU-TK(S)-E...................................................................8-10

8.5 Concept on screen display........... ..................................................................8-11

8.5.1 Screen display position .....................................................................................8-11

8.5.2 Number of display screens and screen Nos......................................................8-11

8.5.3 Number of display elements and data capacity ................................... ...... ........8-11

8.5.4 Attribute of display element............................................. ....... ...... ....... ...... ....... . 8-12

8.6 Screen call function and overlay functio n......................................................8-15

8.6.1 The writing function of the initial display screen number

(GT Designer is used). ......................................................................................8-16

8.6.2 Screen call function...........................................................................................8-17

8.6.3 Overlay function ................................................................................................8-18

vii

Graphic Operation Terminal GOT-F900 Contents

8.7 Control devices and system inf o rmation........................................................8-26

8.7.1 Control device (setting in FX-PCS-DU/WIN-E) .................................................8-26

8.7.2 System information (setting in GT Designer) ....................................................8-29

9. Screen mode .... ............ ............ ............ ............ ............ ............ ...........9-1

9.1 Display format..................................................................................................9-1

9.2 Display size......................................................................................................9-2

9.3 Outline of screen mode................................ ................................. .. .................9-4

9.4 Number of registered screen construction elements .......................................9-6

9.5 Change of displ a ye d d ata .................... .. .. .............. .. .. ............. ... ......................9-8

9.5.1 Common contents in data change.......................................................................9-8

9.5.2 Decimal point input function ..............................................................................9-10

9.5.3 Key window display position specification.........................................................9-11

9.5.4 Creation of key window .....................................................................................9-13

9.6 Numeric setting completion flag.....................................................................9-16

9.6.1 When FX-PCS-DU/WIN-E is used ....................................................................9-16

9.6.2 When GT Designer is used ............................................................................... 9-17

10. HPP Mode.........................................................................................10-1

10.1 O utline of HPP mode ........................................................................ .. ...........10-1

10.2 PROGRAM LIST............................................................................................10-2

10.3 PARAMETER...............................................................................................10-11

10.4 DEVICE MONITOR................................. .. ...................................................10-12

10.4.1 Device/comment monito r .................................... ....... ...... ....... ...... ....... ...... ...... 10-12

10.4.2 Changing set values and current values of T, C and D................................... 10-14

10.4.3 Forced ON/OFF.................................................. ....... ...... ....... ...... ....... ...... ...... 10-16

10.5 LIST MONITOR ...........................................................................................10-17

10.6 ACTIVE STATE MONITOR .........................................................................10-18

10.7 BFM MONITOR ...........................................................................................10-19

10.8 PC DIAGNOSIS...........................................................................................10-20

11. Sampling Mode.................................................................................11-1

11.1 Outline of sampling mode ..............................................................................11-1

11.2 Outline of sampling condition setting .............................................................11-3

11.2.1 SAMPLE COND. ...............................................................................................11-5

11.2.2 START COND...................................................................................................11-6

11.2.3 END COND.......................................................................................................11-7

11.2.4 SAMPLING DEV. ..............................................................................................11-9

11.3 Display of sampling result............................................................................11-10

11.3.1 DISPLAY LIST.................................................................................................11-10

11.3.2 DISPLAY GRAPH ........................................................................................... 11-10

11.4 CLEAR DAT A..............................................................................................11-11

11.5 Control signals in PLC ............... ................................. .. ...............................11-12

11.5.1 When FX-PCS-DU/WIN-E is used ..................................................................11-12

11.5.2 When GT Designer..........................................................................................11-12

12. Alarm Mode.......................................................................................12-1

12.1 Outline of alarm function................................................................................12-1

12.2 Alarm function in screen mode............................. .........................................12-2

12.2.1 Set item.............................................................................................................12-3

12.2.2 Alarm history clear using key code....................................................................12-5

12.3 Alarm function in alarm mode ........................................................................12-7

12.3.1 Operation when alarms have occurred .............................................................12-8

12.3.2 Alarm list............................................................................................................12-9

12.3.3 Alarm history display .......................................................................................12-11

12.3.4 Alarm frequency display.................................................................................. 12-12

12.3.5 Alarm history clear...........................................................................................12-13

viii

Graphic Operation Terminal GOT-F900 Contents

13. Test Mode.........................................................................................13-1

13.1 Outline of test mode.......................................................................................13-1

13.2 USER SCREEN........................................................................ ...... ...............13-2

13.3 DATA BANK...................................................................................................13-3

13.4 DEBUG..........................................................................................................13-4

13.5 Communication monitor (F940GOT, F940WGOT)........................................13-7

14. Other Mode.......................................................................................14-1

14.1 Outline of other mode ....................................................................................14-1

14.2 SET TIME SWITCH .......................................................................................14-2

14.3 DATA TRANSFER.........................................................................................14-3

14.4 PRINT OUT.................. .. .. ............. ... .. ............. .. .. .............. .. .. ............. ... .. .......14-4

14.5 ENTRY CODE ...............................................................................................14-6

14.6 SET UP MODE ..............................................................................................14-7

15. Connection to Bar Code Reader.......................................................15-1

15.1 Outline of function..........................................................................................15-1

15.2 Applicable version..........................................................................................15-1

15.3 Connection.....................................................................................................15-1

16. Screen Hard Copy Function..............................................................16-1

16.1 Outline of hardware copy operation...............................................................16-1

16.2 Applicable version..........................................................................................16-2

16.3 Starting and aborting printing.........................................................................16-2

16.3.1 Start and abortion by triggers............................................................................16-2

16.3.2 Start and abortion by touch switches ................................................................16-2

16.3.3 Hard copy output signal (GT Designer).............................................................16-3

16.3.4 Printing image ...................................................................................................16-5

17. Observe status function ....................................................................17-1

17.1 Outline of observe status function..................................................................17-1

17.2 Applicable version..........................................................................................17-2

17.3 Observe status cycle......................................................................................17-2

17.4 Setting the triggers.................................. .......................................................17-2

17.4.1 Setting the operation .........................................................................................17-3

17.5 Trigger and number of devices.......................... .. ..........................................17-6

17.6 Cautions.........................................................................................................17-7

17.7 Use example (utilization of clock data) ..........................................................17-8

18. Creation of Display Screens (FX-PCS-DU/WIN-E)...........................18-1

18.1 Element li st ............. .. ... ............. .. .. .............. .. .. ............. .. ... ............. .. .. ............18 -1

18.2 Application and setting item............................... .. ..........................................18-4

18.3 Registration of object .....................................................................................18-6

18.4 Display objects...............................................................................................18-7

18.4.1 Text ...................................................................................................................18-7

18.4.2 Line....................................................................................................................18-8

18.4.3 Box....................................................................................................................18-9

18.4.4 Filled Box.........................................................................................................18-10

18.4.5 Circle...............................................................................................................18-11

18.4.6 Filled Circle......................................................................................................18-12

18.4.7 Image .............................................................................................................. 18-13

18.4.8 Date and time..................................................................................................18-14

18.5 Data display objects.....................................................................................18-15

18.5.1 Library Text .....................................................................................................18-15

18.5.2 Number............................................................................................................18-17

18.5.3 Bar Graph........................................................................................................18-20

18.5.4 Circle Graph ....................................................................................................18-23

ix

Graphic Operation Terminal GOT-F900 Contents

18.5.5 Proportional Bar Graph ................................................................................... 18-24

18.5.6 Proportional Pie Graph....................................................................................18-25

18.5.7 Panel Meter..................................................................................................... 18-26

18.5.8 Indicator...........................................................................................................18-27

18.5.9 Label Indicator.................................................................................................18-28

18.5.10 Text Indicator...................................................................................................18-29

18.5.11 Image Indicator................................................................................................ 18-30

18.5.12 Overlay Screen................................................................................................ 18-31

18.5.13 Library Image ..................................................................................................18-32

18.5.14 Trend Graph (Sampling)..................................................................................18-33

18.5.15 Trend Graph (Total).........................................................................................18-36

18.5.16 Ascii................................................................................................................. 18-38

18.6 Data transfer objects....................................................................................18-41

18.6.1 Touch Key.......................................................................................................18-42

18.6.2 Switch..............................................................................................................18-46

18.6.3 Send Data Bank (recipe function) ...................................................................18-48

18.6.4 Write Constant.................................................................................................18-49

18.6.5 Increment ........................................................................................................ 18-50

18.6.6 Decrement....................................................................................................... 18-51

18.6.7 Data Setting.....................................................................................................18-52

18.6.8 Keyboard.........................................................................................................18-55

18.6.9 Change Screen ...............................................................................................18-59

18.6.10 Alarm history display function..........................................................................18-60

18.6.11 Alarm list display function................................................................................ 18-62

18.6.12 Buzzer.............................................................................................................18-64

18.7 Text library ...................................................................................................18-65

18.8 Image library................................................................................................18-66

18.9 Data file........................................................................................................18-67

19. Changeover of Display Screen (FX-PCS-DU/WIN-E).......................19-1

19.1 Outline of changeover of display screen............................ ............................19-1

19.2 "Change Screen" object.................... .. ................................. .. ........................19-2

19.2.1 Contents of setting ............................................................................................ 19-2

19.2.2 Operation of screen changeover.......................................................................19-4

19.2.3 Timing of screen changeover............................................................................19-5

19.3 Screen changeover by touch key.............................................. .....................19-6

19.4 Screen changeover from PLC......................................... ...............................19-9

19.4.1 Screen changeover using bit devices................................................................19-9

19.4.2 Screen changeover by data ............................................................................ 19-11

19.5 Screen changeover by screen No. stored in memory..................................19-13

19.6 Changeover to system screen.....................................................................19-15

19.6.1 Display of system screen ................................................................................19-15

19.7 Application of screen changeover................................................................19-16

20. Creation of Display Screen (GT Designer)........................................20-1

20.1 Project auxiliary settings ................................................................................20-1

20.2 Element li st ............. .. ... ............. .. .. .............. .. .. ............. .. ... ............. .. .. ............20 -6

20.3 Application and setting item............................... .. ..........................................20-8

20.4 Figure display function.................................................................................20-10

20.5 Data display function....................................................................................20-11

20.5.1 Display of numerics.........................................................................................20-11

20.5.2 ASCII code display function ............................................................................ 20-13

20.5.3 Clock display function... ...... ....... ...... ....... ...................................... ....... ...... ...... 20 -1 6

20.5.4 Comment display function...............................................................................20-17

20.5.5 Alarm history display function..........................................................................20-18

20.5.6 Alarm list display function................................................................................20-20

20.5.7 Part display function........................................................................................ 20-22

x

Graphic Operation Terminal GOT-F900 Contents

20.5.8 Lamp display function......................................................................................20-23

20.5.9 Panel meter display function...........................................................................20-24

20.6 Graph display function.................................................................................20-25

20.6.1 Trend graph..................................................................................................... 20-26

20.6.2 Line graph .......................................................................................................20-27

20.6.3 Bar graph.........................................................................................................20-28

20.6.4 Statistics graph display function...................................................................... 20-30

20.7 Touch ke y s................... .. .. ............. ... .. ............. .. .. .............. .. .. ............. ... .. .....20-31

20.7.1 Common items for all touch keys....................................................................20-32

20.7.2 Bit function.................... ...... ....... ...... ....... ...... ...... ....... ...... ....... .........................20-34

20.7.3 Word function ..................................................................................................20-36

20.7.4 Creation of keys to enter numerics and ASCII codes......................................20-37

20.8 Data input function.................................. ................................. ....................20-38

20.8.1 Numerical input function.................................................................................. 20-38

20.8.2 ASCII code input function................................................................................20-40

20.9 Creation of comment....................................................................................20-43

20.10 Recipe function ............................................................................................20-44

21. Changeover of Display Screen (GT Designer)..................................21-1

21.1 Outline of changeover of display screen............................ ............................21-1

21.2 Changeover of display screen .......................................................................21-2

21.2.1 Contents of setting ............................................................................................ 21-2

21.2.2 Contents of screen changeover operation ........................................................21-2

21.3 Changeover of base screen (changeover from PLC) ....................................21-3

21.3.1 Outline of changeover of base screen...............................................................21-3

21.3.2 Example of basescreen changeover.................................................................21-4

21.4 Screen changeover by touch key.............................................. .....................21-5

21.4.1 Changeover using a fixed value........................................................................ 21-5

21.4.2 Changeover to upper hierarchy.........................................................................21-6

21.5 Changeover to system screen.......................................................................21-7

21.5.1 Display example of system screen....................................................................21-7

21.6 Application of screen changeover..................................................................21-8

21.6.1 Application example 1.......................................................................................21-8

21.6.2 Application example 2.....................................................................................21-10

22. Appendix...........................................................................................22-1

22.1 Number of registered screen construction elemen ts................................... ..22-1

22.2 Comparison with screen creation software....................................................22-3

22.2.1 Differences in functions among display units and connected PLC....................22-5

22.3 System Screen No.........................................................................................22-8

22.4 Key Code List.................................................................................................22-9

22.5 Key code list used in each object.................................................................22-10

xi

Graphic Operation Terminal GOT-F900 Contents

xii

Graphic Operation Terminal GOT-F900

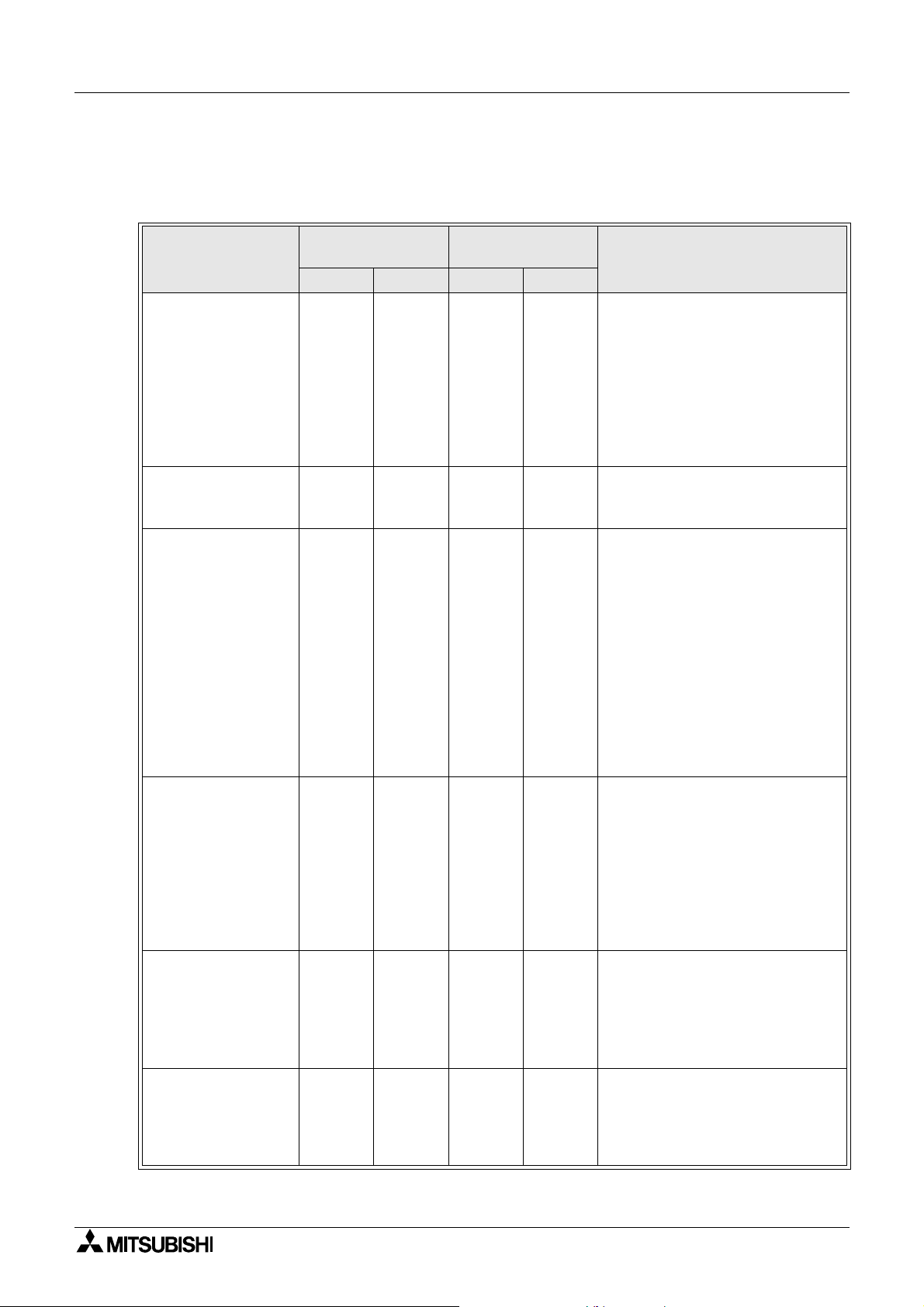

Manual configuration and various data

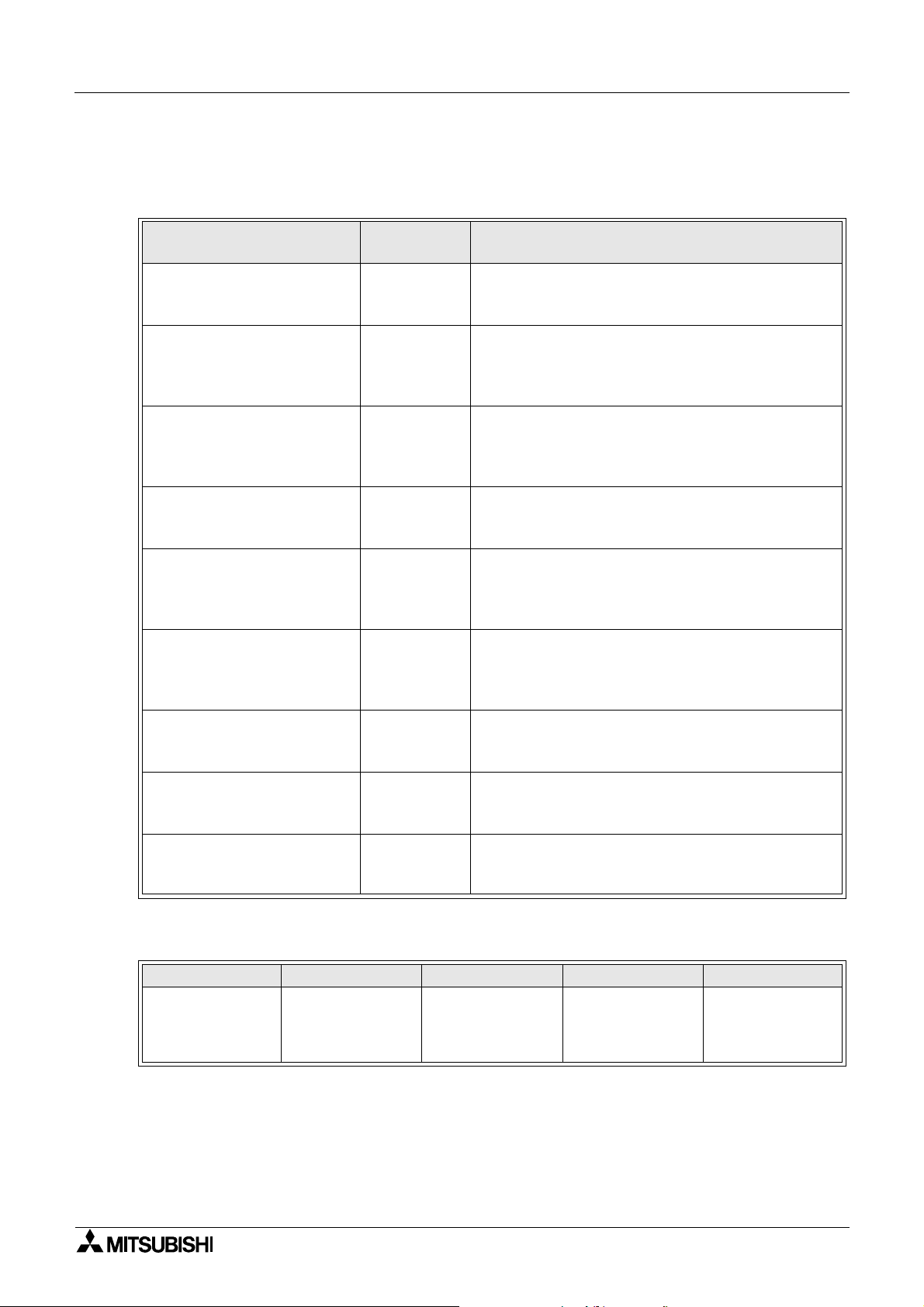

The configuration of the manual s relating to this product is as shown below.

Manual configuration and various data

Manual name

Manual

number

F930GOT Series

Installation Manual

JY992D95701

(supplied with product)

F940GOT Series

(F940GOT-*WD-E)

Installation Manual

JY992D94201

(supplied with product)

F940GOT Handy Series

(F94*GOT-BD-H-E)

HARDWARE MANUAL

JY992D86901

(supplied with product)

F940WGOT Series

Instllation Manual

JY992D93901

(supplied with product)

SW¨D5C-GOTR-PACKE

OPERATING MANUAL

(supplied with screen creation

software)

FX-PCS-DU/WIN-E

SOFTWARE MANUAL

(supplied with screen creation

JY992D68301

software)

GOT-F900 SERIES

OPERATION MANUAL

JY992D94701

(this manual)

GOT-F900 SERIES

HARDWARE MANUAL

JY992D94801

(separate volume)

F9GT-40UMB MANUAL JY992D74101

Description

This manual contains explanations for the

specifications, installation and maintenance, etc of

F930GOT Series graphic operation terminals.

This manual contains explanations for the

specifications, installation and maintenance, etc of

F940GOT Series graphic operation terminals.

This manual contains explanations for the

specifications, installation and maintenance, etc of

F940GOT Handy Series handy graphic operation

terminals.

This manual contains explanations for the

specifications, installation and maintenance, etc of

F940WGOT Series graphic operation terminals.

This manual contains explanations for the operation

of GT-Designer (SW*D5C-GOTR-PACKE) screen

design software.

This manual contains explanations for the operation

of FX-PCS-DU/WIN-E screen design software.

This manual contains explanations for the operation

and use of the GOT-F900 Series graphic operation

terminals.

This manual contains explanations for the wining and

installation, etc of the GOT-F900 series graphic

operation terminals.

This manual contains explanations for installation and

operating procedure of F9GT-40UMB data transfer

adapter.

Applicable type

F930GOT F940GOT F943GOT F940W Handy GOT

F940GOT-SBD-H

F930GOT-BWD

F940GOT-SWD

F940GOT-LWD

F943GOT-LWD

F943GOT-SWD

F940WGOT-TWD

F940GOT-LBD-H

F943GOT-SBD-H

F943GOT-LBD-H

1

Graphic Operation Terminal GOT-F900 Manual configuration and various data

MEMO

2

Graphic Operation Terminal GOT-F900

1. Introduction

This section describes the product and system configuration of the graphic operation terminal.

1.1 Outline

The graphic operation terminal (he reafter abbreviated to

GOT) is to be mounted on the face of a control panel or

operations panel, and connected to a programmable

controller (hereafter abb re viat ed to PLC (e xcept t he A0J2))

Various devices can be monitored and PLC data changed

through the screens of the GOT.

There are several display screens built-in to the GOT

which offer various functions. In addition user defined

screens can be created.

The user defined screens and the built-in screens (system

screens) have the following respective functions.

Introduction 1

PLC

Program

port

G O T m ain body

User screens

• Screen display function

The following functions can be assigned to each screen. Also the available screens can be

limited using the security function.

Both software packages, FX-PCS-DU/WIN-E, and SWoD5C-GOTRE-PACK ("o" indicates

a numeric not less than "1".) can be used to create user screens.

Display function

- Up to 500 user defined screens can be displayed. In screen creation, two or more

screens can be overlaid or changed over arbitrarily.

- Simple graphics such as straight lines, circles and rectangles can be displayed, along

with numerics and English, Japanese, Chinese and Korean text. Also bitmaps can be

imported and displayed as well as pre-defined screen components.

Monitor function

- Set values and current values of word devices in the PLC can be displayed in numerics

or bar graphs for monitoring.

- The specified range of the screen components can be displayed in reverse in

accordance with the ON/OFF status of bit devices in the PLC.

Data change function

- The numeric data being monitored can be changed.

Switch function

- By manipulating the operation keys in the GOT, bit devices in the PLC can be set to ON

and OFF.

The display panel face can be assigned as touch keys to offer switch functions.

1-1

Graphic Operation Terminal GOT-F900 Introduction 1

System screens

• Monitor function

List program (only in the FX Series)

- Programs can be read, written and monitored in the form of an instruction list program.

Buffer memory (only in the FX

and FX

2N

2NC

Series)

- The contents of buffer memories (BFMs) of special blocks can be read, written and

monitored.

Device monitor

- The ON/OFF status of each device, the set value and current value of each timer,

counter and data register in the PLC can be monitored and changed.

- Specified bit devices can be forced ON or OFF.

Unlike the monitor function described previously, screen data can be edited by inputting

a desired device No. from the keyboar d.

• Data sampling function

The current value of spe cified data re gisters are ac quired in a con stant cyc le or w hen the

trigger condition is satisfied.

- Sampling data can be displayed in the form of list or graph.

- Sampling data can be output to a printer in the form of list.

• Alarm function

Alarm messages can be assigned to up to 256 consecutive bit devices in the PLC. When a

bit device becomes ON, the assigned message is displayed (overlapped) on the user

screen.

In addition, a specified user screen can be displayed by setting a corresponding bit device

to ON.

- When a bit device becomes ON, a corresponding message is displayed on the user

screen. The message list can be also displayed.

- Up to 1,000 alarms (turning ON of bit devices) can be stored as the alarm history.

- The alarm frequency of each device can be stored as historical data.

- Alarm history can be output to a printer using the screen creation software.

• Other functions

Many other functions are built in.

- A real-time clock, current time and data can be set and displayed.

- The GOT can function as an interface to enable data communication between the PLC

and a personal computer in which the relay ladder creation software is operating. At this

time, the GOT screen can also be displayed.

- The screen contrast and the buzzer sound volume can be adjusted.

1-2

Graphic Operation Terminal GOT-F900 Introduction 1

1.2 Format of manual

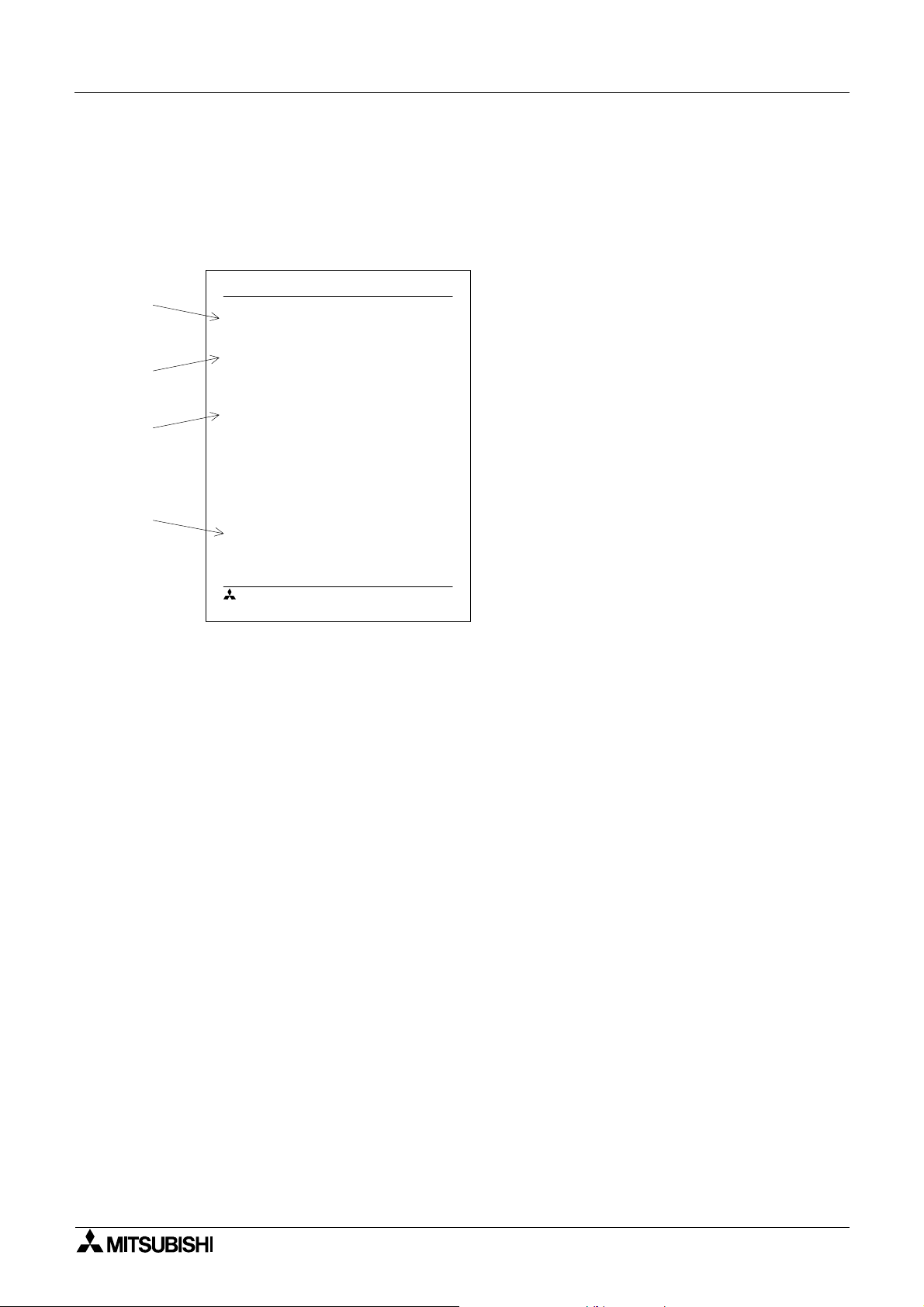

1.2.1 Contents described in manual

This manual is described in the foll owing format. Use each element of the format for index.

Example:

Graphic Operation Terminal F940G OT

a)

b)

c)

d)

2. Startup

2.1 Startup procedure

2.1.1 GOT setup

n

Important point

MITSUBISHI

1.2.2 Abbreviations used in text

The following terms may be abbreviated in the text.

Startup 2

a) Section title

Sections 1 to 17 describe operations.

Sections 18 to 21 describe the contents

required to create screens.

b) Title

The title explains the contents of each

paragraph.

c) Sub title

d) Important point

Ter ms used in the text are explained and

supplemented.

2-1

1) MELSEC FX series, A Series, QnA series, Q series unit and programmable controllers of

other companies may be abbreviated as "programmable controller" or "PLC".

2) The software kit to create display screens FX-PCS-DU/WIN-E or GT Designer may be

abbreviated as "screen creation software".

3) A general-purpose computer may be abbreviated as "PC".

4) A floppy disk may be abbreviat ed as "FD". A f loppy disk drive ma y be ab b reviated as "FDD".

5) The graphic operation terminal GOT-F900 Series may be abbreviated as "GOT".

6) Devices in side the PLC may be abbreviate d as "X" (i nput ), "Y" (ou tput), "M" (aux ili ary rela y),

"S" (state), "T" (timer), "C" (counter) and "D" (data register). Output contacts of X,Y, M, S, T

and C are called "bit devices". T, C and D are called "word devices". All of them may be

called "devices".

1-3

Graphic Operation Terminal GOT-F900 Introduction 1

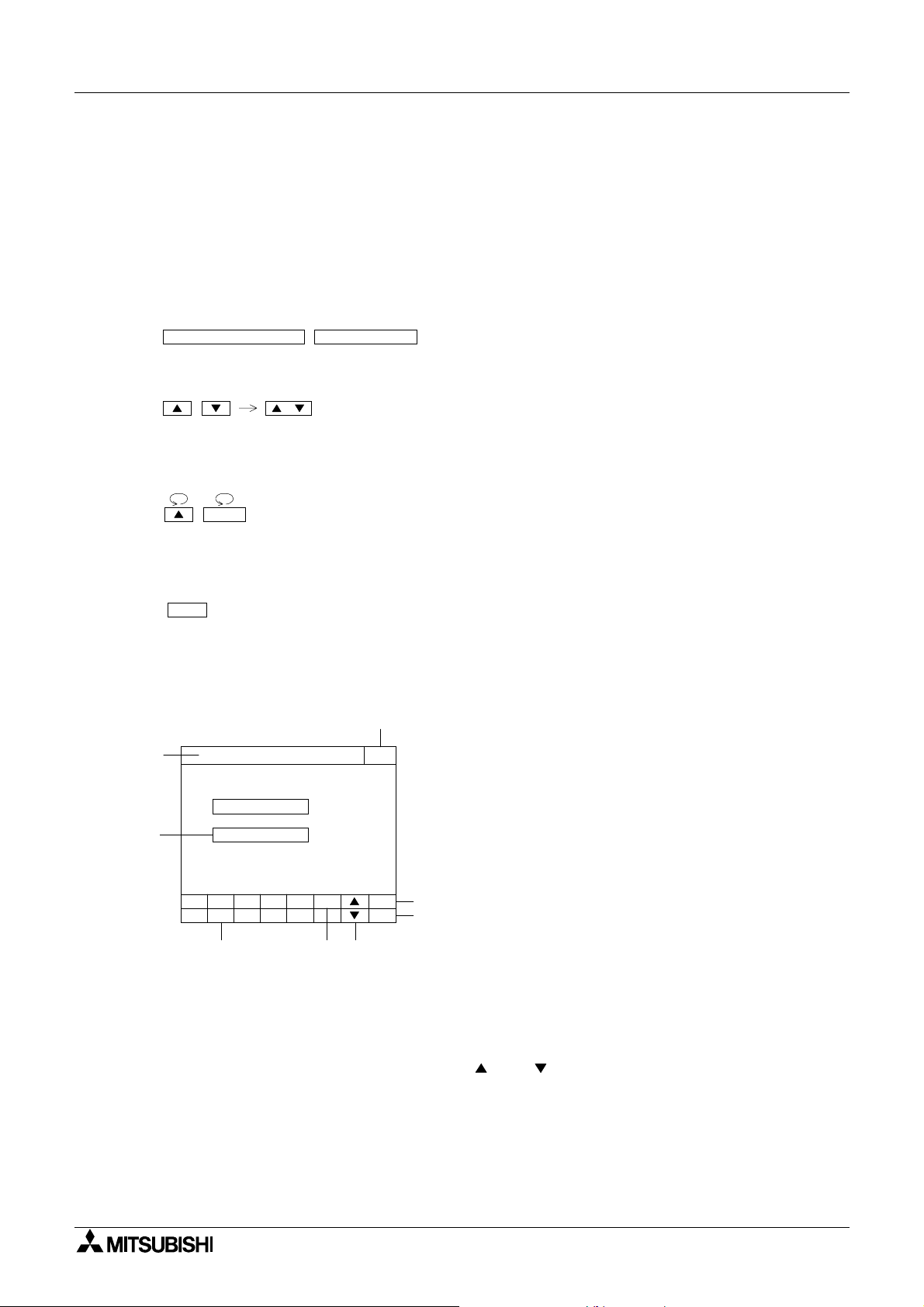

1.3 Expressions and basic functions of operation keys

The operation keys are expressed as follows in the text.

The example of the screen display and key operation are described as an example of

F940GOT when there is no description.

1.3.1 Expressions of operation keys

1) Touch keys on the screen which are actuated when being touched by fingers are enclosed

with a frame.

USER SCREEN MODE,PROGRAM LIST

2) Cursor control keys to be pressed may be expressed as follows.

, ,

3) When a same key is pressed several times or a same operation is repeated, the following

expression may be used.

MORE,

4) When an arbitrary numeric within the range of 0 to 9 is to be entered, the following

expression may be used.

0 to 9

1.3.2 Basic operations

The common operations in the GOT are shown below.

a)

h)

[ SET CONDITION ] END

SAMPLE COND.

START COND.

END COND.

506

789- CLR

1234

e) f) g)

b)

ENT

a) Function display

The selected mode or function is displayed here.

b) END key

This key terminates the displayed function, and

returns to the previous screen.

c) CLR (clear ) key

This key cancels the input of characters and

numeri cs.

c)

d)

d) ENT (enter) key

This key determines the input of alphabets and

numeri cs.

e) Ten-key pad

This pad allows to enter numerics .

f) - (minus) key

g) and (cursor control) keys

h) SET key

When this key is pressed after a character or

numeric has been entered, the keyboard is

displayed.

1-4

Graphic Operation Terminal GOT-F900 Introduction 1

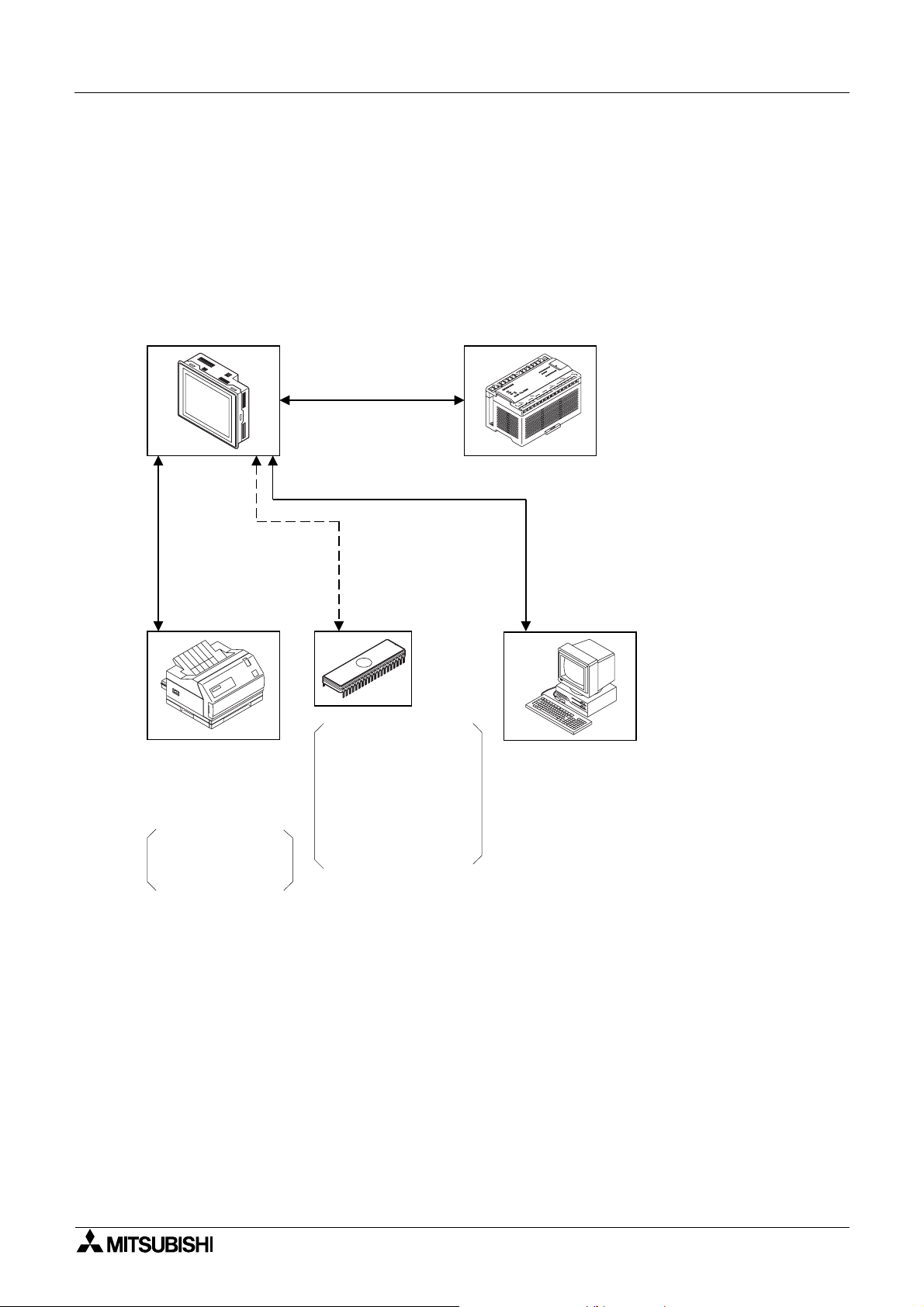

1.4 System configuration

The method of connecting the GOT to PLC and peripheral devices is described below.

1.4.1 Connection of peripheral units of GOT

The figure below shows the system configuration required to use the GOT with peripheral

devices.

F930GOT, F940GOT,

F943GOT and F940WGOT

graphic operation terminals

RS-422 or RS-232C

communication.

PLC

Data transfer

cable

F2-232CAB-1

(3m)

RS-232C communication.

·Printer

Bar code reader

<General-purpose printers>

ESC/P

Printer equipped with

RS-232C interface

Prints out sampling data,

alarm history, alarm

message and screen

hard copy

RS-232C communication.

The ROM is attached to

F9GT-40UMB and inserted

into the connector on the

back of the GOT.

(F940GOT and F943GOT

only)

·EPROM memory

User screens can be stored

using a general-purpose

ROM writer.

(FX-EPROM-4M)

FX-PCS-DU/WIN-E is used

to put screen data in the form

of ROM chips.

(In the case of GT Designer,

data cannot be saved on to a

ROM chip.)

·Data transfer cable FX-232CAB-1 (3 m)

(when the RS-232C port in the PC is 9-pin

type)

·Data transfer cable FX-232CAB-2 (3m)

(when the RS-232C port in the PC is half pitch, 14-pin type)

·Data transfer cable F2-232CAB-1 (3m)

(when the RS-232C port in the PC is 25-pin

type)

·General-purpose personal computer

(screen creation software)

FX-PCS-DU/WIN-E or GT Designer

·For the screen creation software

versions corresponding to each GOT, refer

to Section 1.7.

• When the GOT is CPU-connected to a PLC and a general purpose PC is used as a

program edit tool for the PLC, the 2-port interface function of the GOT can be used.

(In the case of connection using a communication unit of QnA Series or Q Series, the 2-port

interface function can be used when the setting of the GOT is fo r CPU connection.)

When using the GOT and peripheral devices dedicated to sequence program edit (such as

FX-20P and A6GPP that performs RS-422 communication) for one PLC, connect the GOT

to an extension communication board or extension communication adapter of FX Series, a

computer link unit of A Series or a communication unit of QnA Series or Q Series.

(The FX-2PIF type 2-port interface is not compatible with the PLCs of Q Series and QnA

Series or with PLCs or microcomputer boards manufactured by other companies.)

When connected to a PLC or microcomputer board manufactured by other companies, the

2-port interface function of the GOT cannot be used.

1-5

Graphic Operation Terminal GOT-F900 Introduction 1

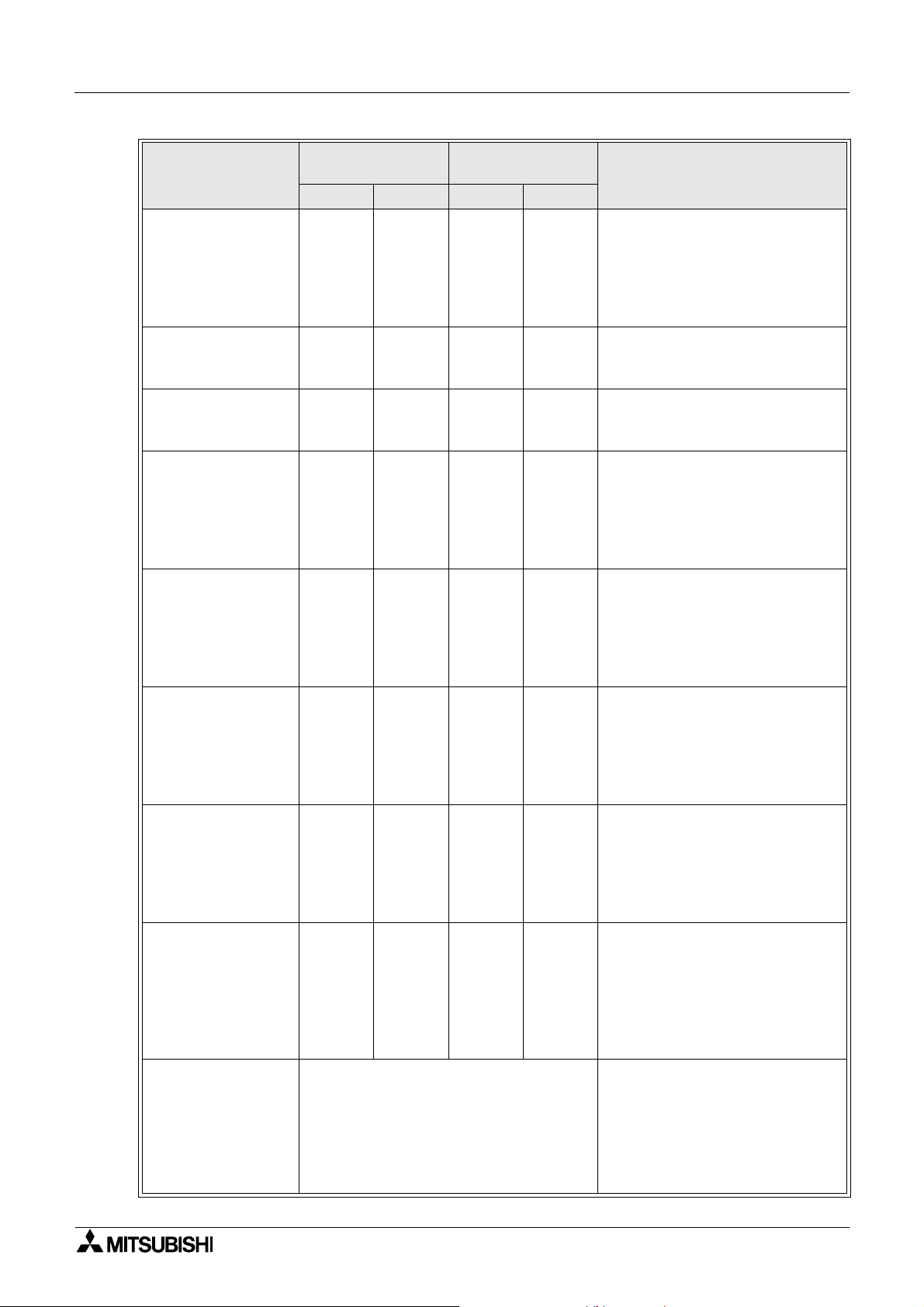

1.5 Connectable PLC

Setting of the PLC to be connected is made according to "PLC TYPE" in "Operation

environment setting (see Section 7)".

Connectable PLC

MELSEC FX

FX

, FX0, FX0S,

2C

FX

, FX0N, FX1N,

1S

FX

and FX

2N

, FX2,

1

2NC

Series manufactured

by Mitsubishi Erectric

MELSEC A Series

manufactured by

Mitsubishi Erectric

MELSEC QnA Series

manufactured by

Mitsubishi Erectric

MELSEC Q Series

manufactured by

Mitsubishi Erectric

MELSEC FX-10GM,

FX-20GM, E-20GM,

FX

-10GM, FX2N-

2N

20GM positioning

units

Motion controllers

A171SCPU-S3,

A171SHCPU,

A172SHCPU and

A272UHCPU

Direct connection

to CPU

Computer link

Upper link

RS-232C RS-422 RS-232C RS-422

¡¡

✕

✕

¡

✕

✕

¡¡¡

¡¡¡

✕

¡

¡

✕✕

¡¡

✕✕

✕✕

Remarks

For connection to FX

and FX1N

1S

Series, the following versions

should be used.

F930GOT, V2.10 or later should be

used.

F940GOT and F943GOT, V4.00 or

later should be used.

F940WGOT, any version may be

used.

Any version may be used.

When a communication unit is

used, settings for direct connection

to CPU should be made.

F930GOT, V2.00 or later should be

used.

F940GOT and F943GOT, V3.00 or

later should be used. (When a

version is former than V3.00 and

computer link connection is made,

only setting for computer link for A

Series is available.)

F940WGOT, any version may be

used.

When a communication unit is

used, settings for direct connection

to CPU should be made.

F930GOT, V2.20 or later should be

used.

F940GOT and F943GOT, V4.10 or

later should be used.

F940WGOT, any version may be

used.

F930GOT, V4.10 or later should be

used.

F940GOT, V6.10 or later should be

used.

F940WGOT, V1.10 or later should

be used.

Any version may be used.

1-6

Graphic Operation Terminal GOT-F900 Introduction 1

Connectable PLC

Inverter FREQROLA500, E500 and

S500 Series

manufactured by

Mitsubishi Erectric

SYSMAC C Series

manufactured by

Omron Corp.

FLEX-PC N Series

manufactured by Fuji

Electric Co., Ltd.

FP Series FP0 and

FP2SH manufactured

by Matsushita

Electric Works

Machine controllers

CP9200SH, MP920

and MP930

manufactured by

Yasukawa Electric

Corp.

SLC500 Series

manufactured by

Allen-Bradley Co.,

Inc.

MicroLogix 1000/

1200/1500 Series

manufactured by

Allen-Bradley Co.,

Inc.

S7-300/400 Series

manufactured by

Siemens AG

Microcomputer board

Direct connection

to CPU

Computer link

Upper link

RS-232C RS-422 RS-232C RS-422

✕

✕✕

✕✕

¡

¡¡

¡

¡

¡

¡

✕✕

¡¡

¡¡

✕✕✕

✕✕

✕✕✕

✕✕✕

✕✕✕

Select a communication procedure

according to the GOT (RS-232C/RS-422).

Remarks

F930GOT, V4.10 or later should be

used.

F940GOT, V6.10 or later should be

used.

F940WGOT, V1.10 or later should

be used.

Any version may be used.

Any version may be used.

F930GOT, V4.10 or later should be

used.

F940GOT and F943GOT, V6.10 or

later should be used.

F940WGOT, V1.10 or later should

be used.

F930GOT, V3.00 or later should be

used.

F940GOT and F943GOT, V5.00 or

later should be used.

F940WGOT, any version may be

used.

F930GOT, V2.00 or later should be

used.

F940GOT and F943GOT, V5.00 or

later should be used.

F940WGOT, any version may be

used.

F930GOT, V4.00 or later should be

used.

F940GOT and F943GOT, V5.00 or

later should be used.

F940WGOT, any version may be

used.

HMI Adapter is necessary.

F930GOT, V3.00 or later should be

used.

F940GOT and F943GOT, V5.00 or

later should be used.

F940WGOT, any version may be

used.

When connecting two or more units

F930GOT, V3.00 or later should be

used.

F940GOT and F943GOT, V5.00 or

later should be used.

F940WGOT, any version may be

used.

1-7

Graphic Operation Terminal GOT-F900 Introduction 1

• In the case of F943GOT, connection to a PLC is limited to RS-232C communication.

The types connectable through RS-422 communication shown in the table above are not

applicable.

• For the method of wiring to a PLC, refer to "GOT-F900 SERIES HARDWARE MANUAL.

1-8

Graphic Operation Terminal GOT-F900 Introduction 1

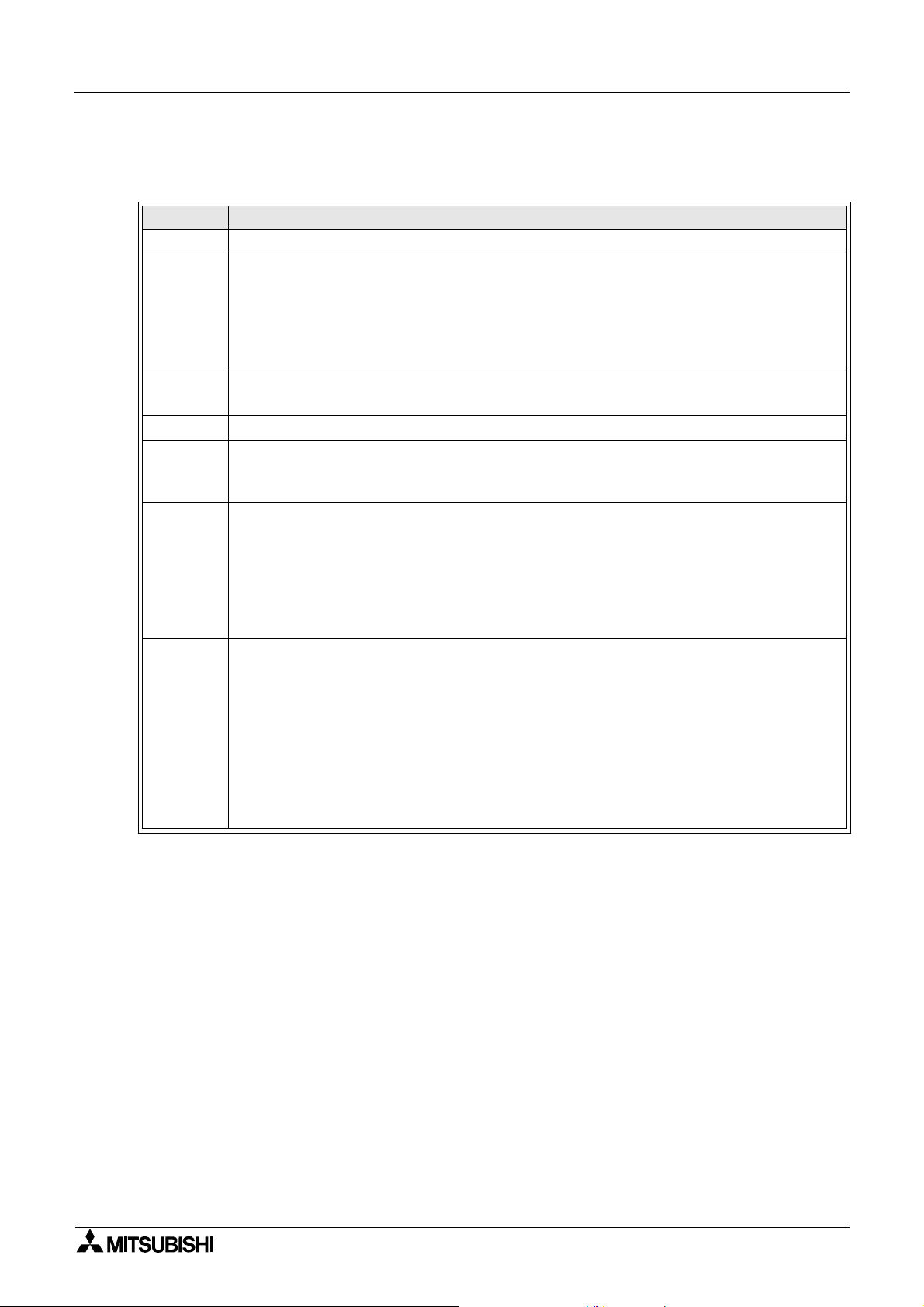

1.6 GOT version upgrade history

F930GOT

Version Description

V1.00 • First version

• Addition of function, connecting to QnA Series PLC

• Addition of function, bar code connection

V2.00

V2.10

V2.20 • Addition of function, connecting to Q Series PLC

V3.00

V4.00

V4.20

• Addition of function, observe status

• Touch key and lamp graphic extension

• Compatible with SLC500 Series manufactured by Allen-Bradley Co., Inc.

• Addition of rectangle and circle daubing pattern

• Addition of function, connecting to two or more units for microcomputer board

connection

• Addition of function, connecting to S7-300/400 Series manufactured by Siemens AG

• Addition of function, connecting to machine controller manufactured by Yasukawa

Electric Corp.

• Addition of function, connecting to MicroLogix 1000/1200/1500 Series manufactured

by Allen-Bradley Co., Inc.

• Addition of function, connecting to CS1 Series (CS1G/H-CPU¨¨-V1) manufactured

by Omron Corp.

(Connection condition: Link connection)

• Addition of function, entering numeric values including decimal points

• Addition of security function (screen protection)

• Addition of function, connecting to MELSEC positioning units FX-10/20GM, FX

20GM, E-20GM

• Addition of function, connecting to inverter FREQROL-A500, E500 and S500 Series

• Addition of function, connecting to FP0 and FP2SH Series manufactured by

Matsushita Electric Works

• Addition of function, connecting to S7-200 Series manufactured by Siemens AG

• Addition of function, displaying alarms in alarm list in order of occurrence

• Addition of function, high-definition font display

• Addition of function, "6dots × 8dots" font display

• Coping with customizing of key window

2N

-10/

1-9

Graphic Operation Terminal GOT-F900 Introduction 1

F940GOT and F943GOT (including handy GOT)

Version Description

V1.00 • First version

V1.10 • Compatible with QnA Series (A Series mode)

V2.00

V3.00

V3.10

V4.00 • Addition of function, connecting to FX

V4.10 • Addition of function, connecting to Q Series PLC

V5.00

V6.00

V6.20

• Compatible with SLC500 Series manufactured by Allen-Bradley Co., Inc.

• Addition of function of bar code connection

• Addition of function, connecting to QnA Series PLC

• Addition of hard-copy function

• Addition of setting of key window initial display position

• Addition of key code for alarm history

• Addition of observe status function

• Compatible with customizing of key window

• Touch key and lamp graphic extension

• Addition of rectangle and circle daubing pattern

and FX1N Series PLC

1S

• Addition of function, connecting to S7-300/400 Series manufactured by Siemens AG

• Addition of function, connecting to machine controller manufactured by Yasukawa

Electric Corp.

• Addition of function, connecting to MicroLogix 1000/1200/1500 Series manufactured

by Allen-Bradley Co., Inc.

• Addition of function, connecting to CS1 Series (CS1G/H-CPU¨¨-V1) manufactured

by Omron Corp.

(Connection condition: Link connection)

• Addition of function, entering numeric values including decimal points

• Addition of security function (screen protection)

• Addition of function, connecting to MELSEC positioning units FX-10/20GM, FX

2N

-10/

20GM, E-20GM

• Addition of function, connecting to inverter FREQROL-A500, E500 and S500 Series

• Addition of function, connecting to FP0 and FP2SH Series manufactured by

Matsushita Electric Works

• Addition of function, connecting to S7-200 Series manufactured by Siemens AG

• Addition of function, displaying alarms in alarm list in order of occurrence

• Addition of function, high-definition font display

• Addition of function, "6dots × 8dots" font display

F940WGOT

Version Description

V1.00 • First version

• Addition of function, connecting to MELSEC positioning units FX-10/20GM, FX

20GM, E-20GM

• Addition of function, connecting to inverter FREQROL-A500, E500 and S500 Series

V1.10

• Addition of function, connecting to FP0 and FP2SH Series manufactured by

Matsushita Electric Works

• Addition of function, displaying alarms in alarm list in order of occurrence

• Addition of function, high-definition font display

• Addition of function, "6dots × 8dots" font display

1-10

2N

-10/

Graphic Operation Terminal GOT-F900 Introduction 1

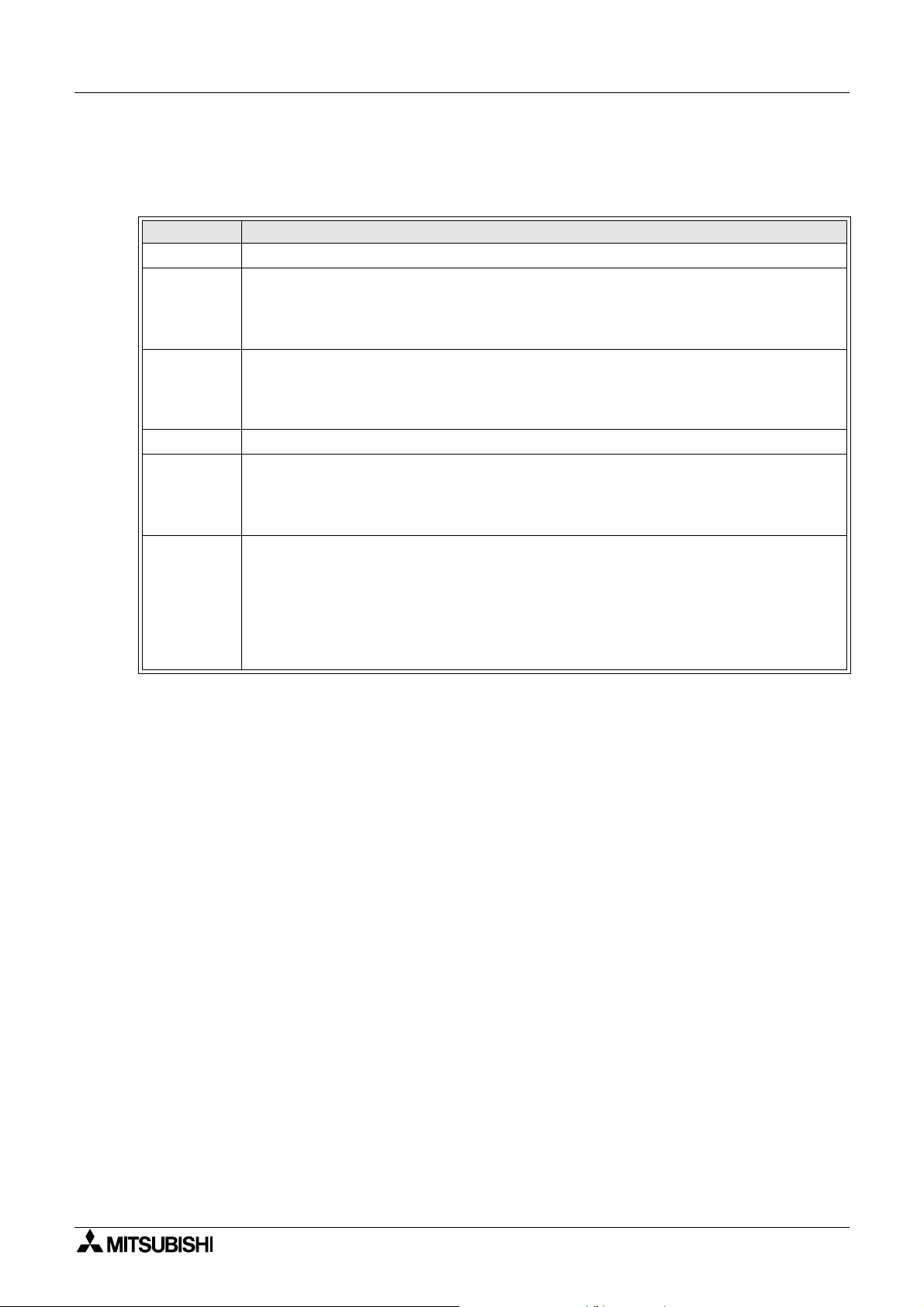

1.7 Screen creation software version upgrade history

The following software is used to create display screens.

FX-PCS-DU/WIN-E

Version Description

V1.00 • First version (not compatible with F900 Series GOT)

• Addition of function, programming F940GOT

V2.00

V2.10

V2.20

V2.30

V2.41

V2.50

V2.52 • Addition of function of connecting to S7-200 Series manufactured by Siemens AG

• Addition of setting, display of line graph (batch) object and outer frame

• Addition of function, programming ET-940BH (-L) display unit

• Addition of key code for alarm history

• Compatible with label color inversion of lamp (label) and touch key on black-and-white

liquid crystal display unit

• Addition of function, programming handy display unit (F940GOT-SBD-H/LBD-H)

• Addition of function, programming F930GOT display unit

• Improving of graphic size (320 × 240 dots) registered in image library

• Addition of function, connecting to bar code reader

• Addition of function, connecting to QnA Series PLC

• Addition of function, connecting to SLC500 Series manufactured by Allen-Bradley Co.,

Inc.

• Addition of function, hard-copy setting on F940GOT display screen

• Addition of graphic type to touch key and lamp (label) object

• Addition of hatching pattern of rectangle and circle object

• Addition of line type, straight line and rectangle object

• Compatible with European font display

• Addition of function, connecting to Q Series PLC

• Addition of function, connecting to S7-300/400 Series manufactured by Siemens AG

• Addition of alarm list and alarm history object

• Addition of display, alarm mode flow

• Addition of function, programming F940WGOT displayunit.

• Addition of PLC connectable to GOT

MELSEC positioning unit FX-10/20GM, FX

E500, S500 Series

Extension of support device of SLC500 Series manufactured by Allen-Bradley Co., Inc.

MicroLogix Series manufactured by Allen-Bradley Co., Inc.

• Addition of setting, observe status function

• Compatible with high-definition font display

• Compatible with "6 × 8 dots" font display

• Addition of GOT-F900 internal device (GB, GD)

-10/20GM, E-20GM, FREQROL A500,

2N

1-11

Graphic Operation Terminal GOT-F900 Introduction 1

GT Designer (Main items relating to F900 Series GOT)

SW

¨

: Abbreviation of SW¨D5C-GOTR-PACKE

(A), (B)... : Abbreviation of screen creation software package version name

Version Description

SW0D5C(A) • First version (not compatible with F900 Series GOT)

•Usable for F940GOT

SW1D5C(E)

SW1D5C(H)

SW2D5C(A) • Addition of hard-copy function

SW5D5C(F)

V5.05F

SW5D5C(K)

V5.09K

(Usable for F940GOT whose main unit version is V1.10 or later)

• Addition of function, connecting to C Series manufactured by Omron Corp.

• Addition of function, connecting to microcomputer

•Usable for F930GOT

• Addition of function, connecting to bar code reader

• Addition of function, connecting to SLC500 Series manufactured by Allen-Bradley

Co., Inc.

• Compatible with connecting to MicroLogix 1000/1200/1500 Series manufactured by

Allen-Bradley Co., Inc.

• Compatible with connecting to CS1 Series (CS1G/H-CPU¨¨-V1) manufactured by

Omron Corp.

• Compatible with connecting to MELSEC positioning units FX-10/ 20GM, FX

20GM and E-20GM

• Compatible with connecting to FREQROL A500, E500 and S500 Series

• Compatible with connecting to FP Series manufactured by Matsushita Electric

Works

• Compatible with high-definition font display

• Compatible with "6 × 8 dots" font display

2N

-10/

• The items shown above are main items relating to F900 Series GOT.

For further details abou t the version upgrade of each pie ce of software, refer to the result

operation manual (operating manual).

* Usable fer F940WGOT

1-12

Graphic Operation Terminal GOT-F900 Introduction 1

1.8 Preservation of screen data and backup

The undermentioned data is stored in RAM of GOT or the flash memory.

RAM area: Data is backed up with the built in battery.

1) Content set by system setting requirements of GOT main unit.

2) Alarm history

3) Sampling collection data

4) Operating time

Flash memory area: Battery is unnecessary.

1) Data made with screen creation software.

Screen data, system requirement settings, alar m element settings, and sampling element

settings.

GOT

Create screen software

RAM

➀

RAM ➁ to

Flash memory

➃

➁

Read only

Personal computer

Transfer

• Transfer between the screen creation software and GOT is done between RAM area ➁, ➂,

➃

and the flash memory.

Neither “RAM area” nor “Time now” is read to the personal computer.

• The systems requirements can be set with the GOT main unit (a default content is stored in

RAM ➀) or the screen creation software (a set content is preserved in flash memory ➀).

The content set later is given priority.

User set data may be last if the back up battery power runsout. In thi s situation , it ma y not be

possible to communicate with the programmable controller.

If possible set the system requirements in the screen creation software.

1-13

Graphic Operation Terminal GOT-F900 Introduction 1

MEMO

1-14

Graphic Operation Terminal GOT-F900

2. Specifications

For the power supply specifications, refer to "GOT-F900 SERIES HARD WARE MANUAL".

2.1 General specifications

Item Specifications

Use: 0 to 50°C (32 to 122°F) (0 to 40°C when using an extension interface or for handy

GOT)

Temperature

Humidity

Vibration

resistance

Shock

resistance

Noise

resistance

Withstand

voltage

Insulation

resistance

Grounding

Working

atmosphere

Protective

structure

Storage: -20 to 60°C (-4 to 140°F)

In the case of F940WGOT, ambient temperature should be 0 to 50°C for vertical

mounting; 0 to 40°C for horizontal mounting.

35 to 85%RH (non-condensing) (35 to 80%RH for F930GOT)

Conforms to

IEC 1131-2

Conforms to IEC 1131-2 (147m/s

1,000Vp-p, 1µs, 30 to 100Hz, tested by noise simulator.

500V AC for 1 min

5MΩ or more at 500V DC

Class D (100Ω or less)

No corrosive gas and no significant dust

Equivalent to IP65F (Handy GOT: IP54)

With

intermittent

vibration

With

continuous

vibration

Frequency Acce lerat ion Amplitude

10 to 57Hz

57 to 150Hz 9.8m/s

10 to 57Hz

57 to 150Hz 4.9m/s

2

, 3 times in each direction X, Y and Z)

2

2

0.075mm

0.035mm

Tested between power terminals and ground

Specifications 2

10 times in each

of X, Y and Z

directions

(for 80 minutes)

2-1

Graphic Operation Terminal GOT-F900 Specifications 2

2.2 Display section specifications

Specifications

Item

LCD type

Display

element

Screen

Life of liquid crystal

Back light

Key

Interface

Number of screens

User memory

Dot pitch

Horizontal

Vertical (mm)

Display color

Number of

keys used

Configuration

(Horizontal

Vertical)

RS-422

RS-232C

F930GOT-BWD

STN-type full dot matrix LCD

0.47 × 0.47 0.36 × 0.36

××××

Monochrome

(Blue/White)

"240 × 80 dots"

liquid crystal

Valid display

dimension: 117 × 42

mm (4”-type)

Approximately 50,000 hours (Ordinary temperature: 25°C/77°F, Ordinary

humidity)

Guaranteed term is 1 year.

Cold cathode

(life of 50,000 hours

or more at 25°C/

77°F)

Guaranteed term is 1 year.

Touch key Max. 50 keys/1 screen

"15 × 4" matrix

××××

configuration

In conformity with RS-422 standard, 1 channel and for PLC communication

(F943GOT has no RS-422 connector.)

In conformity with RS-232C standard, 1-channel and for

screen data transfer.

(F943GOT: In conformity with RS-232C standard, 2

channel and for screen data transfer and for PLC

communication)

User created screen: Max. 500 screens (Screen number: No.0 to No. 499)

System screen: 25 screens (Screen number: No.1001 to No. 1030)

Flash memory

256KB

F940GOT-LWD

F943GOT-LWD

Monochrome

(Black/White)

"320 × 240 dots" liquid crystal

Valid display dimension: 115 × 86

mm (6”-type)

Cold cathode

(life of 40,000 hours or more at

25°C/77°F)

"20 × 12" matrix configuration

Flash memory 512KB Flash memory 1MB

F940GOT-SWD

F943GOT-SWD

8 colors 256 colors

F940WGOT-TWD

TFT-type full dot

matrix LCD

0.324 × 0.375

"480 × 234 dots"

liquid crystal

Valid display

dimension: 155.5 ×

87.8 mm (7”-type)

Cold cathode

(life of 40,000 hours

or more at 25°C/

77°F)

"30 × 12" matrix

configuration (last

column composed of

14 dots)

In conformity with

RS-232C standard,

2-channel and for

screen data transfer

and for PLC

communication

*1

*1 In the case of F940WGOT, when used in the vertical position, characters name a ratio of

about 1: 1.16.

2-2

Graphic Operation Terminal GOT-F900

Outside dimensions 3

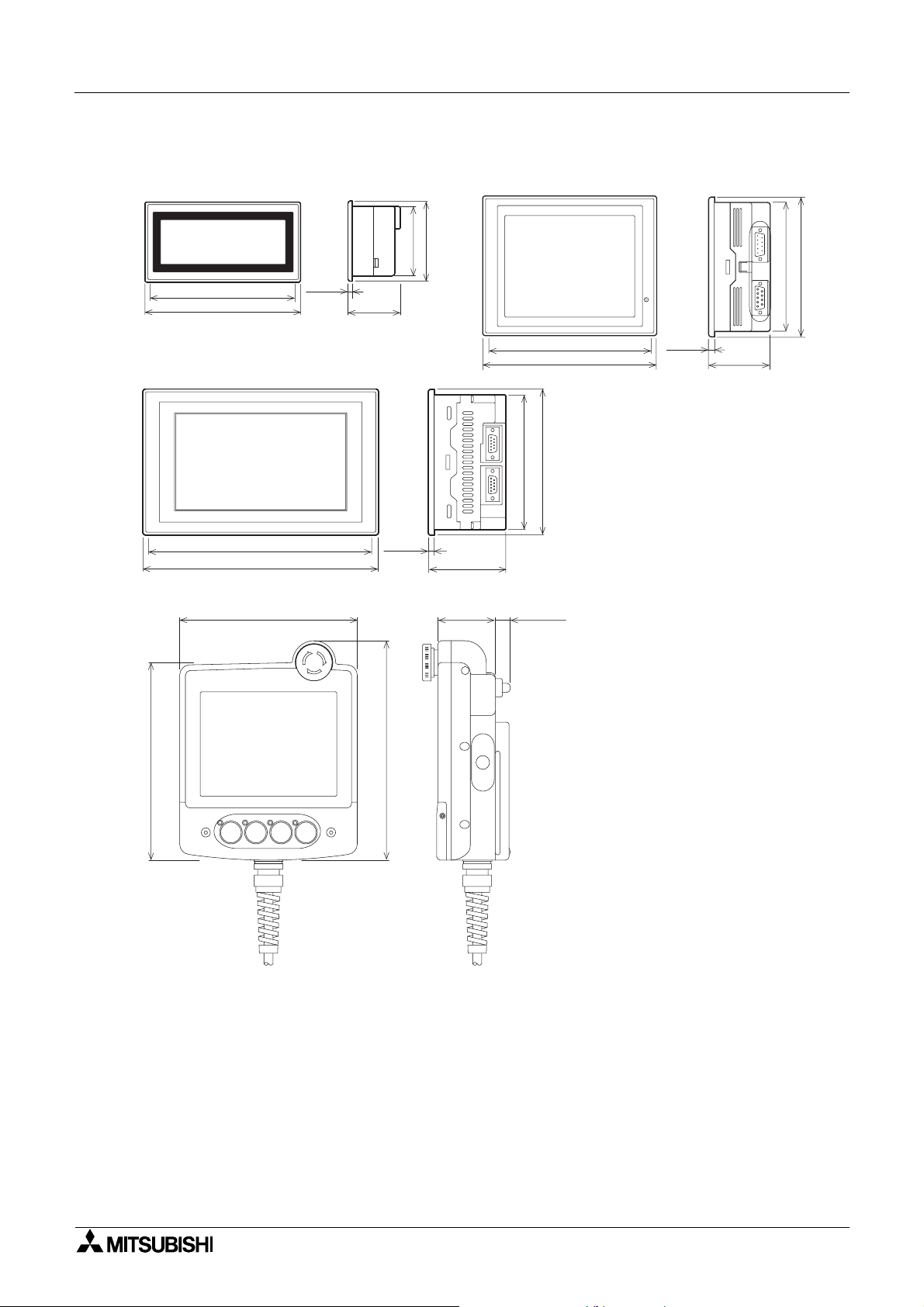

3.

Outside dimensions

F930GOT

136(5.35")

146(5.75")

F940WGOT

205(0.79")

215(8.46")

Handy GOT

156 (6.14")

5(0.20")

49(1.93")

65(2.56")

5(0.20")

75(2.95")

F940GOT,F943GOT

123(4.84")

133(5.24")

70.6(2.78")

50.5

(1.99")

13 (0.51")

152(5.98")

162(6.38")

RS232C RS422

130(5.12")

POWER

5(0.20")

57(2.24")

120(4.72")

)

)

"

172 (6.71

POW ER GRIP SW

"

191 (7.45

Dimensions: mm (inches)

MASS: F930GOT 0.3kg (0.66lbs)

F940GOT, F943GOT 1kg (2.2lbs)

F940WGOT 1kg(2.2lbs)

Handy GOT 0.79kg(1.74lbs)

Accessory: F930GOT, F940GOT, F943GOT, F940WGOT

- Mouting brackets.

- Tightning bolt (M3 (0.12”), 4bolts)

- packing seal (for dust and water resistance)

Handy GOT

- Sheets to change switch names

3-1

Graphic Operation Terminal GOT-F900 Outside dimensions 3

MEMO

3-2

POW ER

1)

<Example>

Front panel of F940GOT

2)

1)

Graphic Operation Terminal GOT-F900

4. Part names

4.1 Front panel

1) Display

- F930GOT

"240 × 80 dots" graphic display

Character string:30 characters × 5 lines

- F940GOT, F943GOT

"320 × 240 dots" graphic display

Character string:40 characters × 15 lines

- F940WGOT

"480 × 234 dots" graphic display

Character string:

60 characters × 14 lines / Horizontal display

29 characters × 30 lines / Vertical display

• Alphabetic characters and numeric characters can be enlarged by 1/2 to 4 times ver tically

and by 1 to 4 times horizontally.

Part names 4

4.2 Rear panel

2)

3)

1) Power terminal : Used to supply power to the GOT and for grounding.

2) Battery : Used to store sampling data, alarm history and current time.

3) Extension interf ace :Used to connect optional extension devices.

4) CN↔OP selector switch : Not used (F940GOT, F943GOT)

F930GOT

F940GOT

4)

F943GOT

2)

3)

24VDC

+

-

4)

2)

3)

24VDC

+

-

1)

1)

F940WGOT

Screen data is stored in the built-in flash memory, for which no

battery power is needed.

A F9GT-40UMB type data transfer adapter is connected to

transfer screen data stored in the EPROM.

4-1

Graphic Operation Terminal GOT-F900 Part names 4

4.3 Functions of connectors

A PLC and peripheral devices are connected to the following connectors of the GOT.

F930GOT F943GOT F940WGOTF940GOT

4)

1) 2)

2)

RS232C

1)

RS422

4)

RS232C

3)

RS232C

1) Port for PLC (RS-422 connector) D-sub, 9-pin, female

- Used for RS-422 connection to a PLC.

- Also used to connect two or more GOT units (RS-422 connection).

2) Port for PC (RS-232C connector) D-sub, 9-pin, male

- For connection to PC when transferring screen data created by the screen creation

software.

- Used for RS-232C connection to a PLC or microcomputer board.

- Also used to connect two or more GOT units (RS-232C connection) or for

communication with bar code reader or printer.

- 2-port interface function can be used. (A PC on which the ladder support software has

been started can be connected.)

3)

1)

3) Port for PLC (RS-232C connector) D-sub, 9-pin, male

- Used for RS-232C connection to a PLC or microcomputer board.

- Also used to connect two or more GOT units (RS-232C connection) or for

communication with a bar code reader or printer.

4) Port for PC (F940WGOT) (RS-232C connector) D-sub, 9-pin, male

- For connection to PC when transferring screen data created by the screen creation

software.

- Not used for connection to a PLC.

- When the GOT is connected to a PLC through Port 3) (RS-232C), it can be used to

connect two or more GOT units (RS-232C connec tion) or for communication with a bar

code reader or printer.

- 2-port interface function can be used. (A PC on which the ladder support software has

been started can be connected.)

4-2

Graphic Operation Terminal GOT-F900 Part names 4

• When connecting to a PLC through a computer link unit, the connector 1), 2) or 3) shoul d be

used.

• When two or more GOT units are connected, 2-system connection cannot be made.

It is not possible to connect two or more PLCs to one GOT.

PLC

PLC

PLC

GOT

GOTGOT GOT GOT

GOTGOT GOT

GOT

PLC

4-3

Graphic Operation Terminal GOT-F900 Part names 4

MEMO

4-4

Graphic Operation Terminal GOT-F900

5. Installation

5.1 Panel cut dimension

On the panel face, drill an installation hole of the dimension shown below.

W 137 (5.39”) 153 (6.02”) 206 (8.11”)

H 66 (2.60”) 121 (4.76”) 124 (4.88”)

Installation 5

Space for m etal fixture

H

H2

W

W2

Unit: mm (inches)

F930GO T F940GOT, F943GOT F940WGOT

- Make sure that the processing accuracy is 0 to +1 mm (0 to +0.04”).

- Make sure that the thickness of the installation panel is 5 mm or less.

5-1

Graphic Operation Terminal GOT-F900 Installation 5

Enlarged view

a)

b)

5.2 Installation

GOT-F900 units are designed as to be embedded in a panel. Instal l the GOT using the procedure