Page 1

INVERTER FR-F700-EC INSTRUCTION MANUAL (BASIC)

E

INVERTER

INSTRUCTION MANUAL (BASIC)

FR-F740-00023 to 12120-EC

Thank you for choosing this Mitsubishi Inverter.

This Instruction Manual (basic) is intended for users who "just want to run the inverter".

If you are going to utilize functions and performance, refer to the Instruction Manual (applied) [IB-0600193ENG].

Please read the provided CD-ROM for the instruction manual (applied).

CONTENTS

1

PRODUCT CHECKING AND PARTS IDENTIFICATION..............................1

2

INSTALLATION AND WIRING......................................................................2

2.1 Peripheral devices .....................................................................................................3

2.2 Method of removal and reinstallation of the front cover ............................................4

2.3 Installation of the inverter and instructions ................................................................6

2.4 Wiring.........................................................................................................................7

2.5 Power-off and magnetic contactor (MC)..................................................................24

2.6 Precautions for use of the inverter...........................................................................25

DRIVE THE MOTOR .................................................................................... 27

3

3.1 Step of operation .....................................................................................................27

3.2 Operation panel (FR-DU07) ....................................................................................28

3.3 Overheat protection of the motor by the inverter (Pr. 9)..........................................33

3.4 Start/stop from the operation panel (PU operation mode) ......................................34

3.5 Make a start and stop with terminals (external operation) ......................................42

ADJUSTMENT .............................................................................................50

4

4.1 Simple mode parameter list.....................................................................................50

4.2 Increase the starting torque (Pr. 0) ..........................................................................51

4.3 Limit the maximum and minimum output frequency (Pr. 1, Pr. 2)...........................52

4.4 When the rated motor frequency is 60Hz (Pr. 3).....................................................53

4.5 Change acceleration and deceleration time (Pr. 7, Pr. 8) .......................................54

4.6 Energy saving operation (Pr. 60).............................................................................55

4.7 Selection of the operation command and frequency command locations (Pr. 79) .57

4.8 Parameter clear, all parameter clear .......................................................................58

4.9 Parameter copy and parameter verification ............................................................59

4.10 Parameter list...........................................................................................................61

4.11 Extended parameters ..............................................................................................63

4.12 Parameter list...........................................................................................................64

5

TROUBLESHOOTING ................................................................................. 89

5.1 Reset method of protective function........................................................................89

5.2 List of alarm display .................................................................................................90

5.3 Causes and corrective actions ................................................................................91

5.4 Correspondences between digital and actual characters .....................................102

5.5 Check and clear of the alarm history .....................................................................103

5.6 Check first when you have troubles ......................................................................105

6

PRECAUTIONS FOR MAINTENANCE AND INSPECTION .....................108

6.1 Inspection item.......................................................................................................108

SPECIFICATIONS .....................................................................................116

7

7.1 Rating.....................................................................................................................116

7.2 Common specifications .........................................................................................117

7.3 Outline dimension drawings ..................................................................................119

7.4 Heatsink protrusion attachment procedure ...........................................................128

700

1

2

3

4

5

6

7

Page 2

This instruction manual (basic) provides handling information and precautions for use of the equipment.

Please forward this instruction manual (basic) to the end user.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you

have read through this instruction manual (basic) and appended

documents carefully and can use the equipment correctly. Do not use the

inverter until you have a full knowledge of the equipment, safety

information and instructions. In this instruction manual (basic), the safety

instruction levels are classified into "WARNING" and "CAUTION".

Assumes that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Assumes that incorrect handling may cause

hazardous conditions, resulting in medium or

slight injury, or may cause physical damage only.

Note that even the level may lead to a serious consequence

according to conditions. Please follow strictly the instructions of both levels

because they are important to personnel safety.

1. Electric Shock Prevention

• While power is on or when the inverter is running, do not open the front cover.

Otherwise you may get an electric shock.m

• Do not run the inverter with the front cover or wiring cover removed.

Otherwise, you may access the exposed high-voltage terminals or the

charging part of the circuitry and get an electric shock.

•

Even if power is off, do not remove the front cover except for wiring or periodic

inspection.You may access the charged inverter circuits and get an electric shock.

• Before starting wiring, inspection or switching EMC filter on/off connector,

switch off the inverter power, check to make sure that the operation panel

indicator is off, wait for at least 10 minutes after the power supply has been

switched off, and check that there are no residual voltage using a tester or the

like. The capacitor is charged with high voltage for some time after power off

and it is dangerous.

• This inverter must be earthed. Earthing must conform to the requirements of

national and local safety regulations and electrical codes. (NEC section 250,

WARNING

CAUTION

CAUTION

WARNING

(2) Wiring

• Do not install a power factor correction capacitor, surge suppressor or radio

noise filter on the inverter output side.

• The connection orientation of the output cables U, V, W to the motor will affect

the direction of rotation of the motor.

(3) Test operation and adjustment

• Before starting operation, confirm and adjust the parameters. A failure to do

so may cause some machines to make unexpected motions.

(4) Operation

• When you have chosen the retry function, stay away from the equipment as it

will restart suddenly after an alarm stop.

• The key is valid only when the appropriate function setting(refer to page

71) has been made. Prepare an emergency stop circuit (power off,

mechanical brake operation for an emergency stop, etc.) and switch

separately.

• Make sure that the start signal is off before resetting the inverter alarm. A

failure to do so may restart the motor suddenly.

• The load used should be a three-phase induction motor only. Connection of any

other electrical equipment to the inverter output may damage the inverter as well

as equipment.

• Do not modify the equipment.

• Do not perform parts removal which is not instructed in this manual. Doing so

may lead to fault or damage of the inverter.

• The electronic thermal relay function does not guarantee protection of the

motor from overheating.

• Do not use a magnetic contactor on the inverter input for frequent starting/

CAUTION

CAUTION

WARNING

CAUTION

Page 3

1 PRODUCT CHECKING AND PARTS IDENTIFICATION 1

2 INSTALLATION AND WIRING 2

2.1 Peripheral devices ...................................................................................................... 3

2.2 Method of removal and reinstallation of the front cover............................................. 4

2.3 Installation of the inverter and instructions................................................................. 6

2.4 Wiring.......................................................................................................................... 7

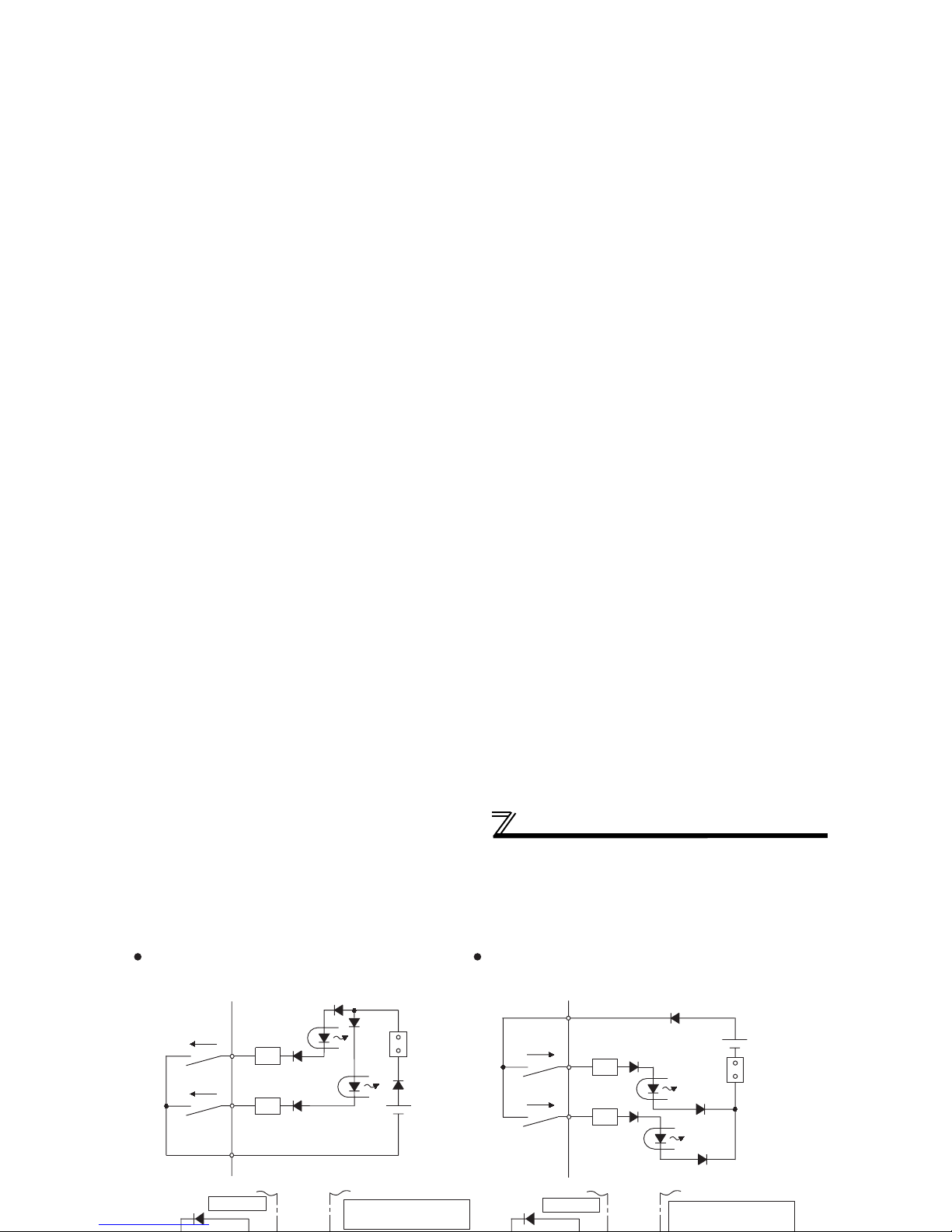

2.4.1 Terminal connection diagram .................................................................................................... 7

2.4.2 EMC filter................................................................................................................................... 8

2.4.3 Specification of main circuit terminal ......................................................................................... 9

2.4.4 Terminal arrangement of the main circuit terminal, power supply and the motor wiring. .......... 9

2.4.5 Control circuit terminals ........................................................................................................... 16

2.4.6 Changing the control logic ....................................................................................................... 18

2.4.7 Wiring of control circuit ............................................................................................................ 20

— CONTENTS —

Page 4

CONTENTS

3.5.6 Change the frequency (50Hz) of the maximum value of potentiometer (at 20mA) ................. 49

4 ADJUSTMENT 50

4.1 Simple mode parameter list ..................................................................................... 50

4.2 Increase the starting torque (Pr. 0) .......................................................................... 51

4.3 Limit the maximum and minimum output frequency (Pr. 1, Pr. 2) ...........................52

4.4 When the rated motor frequency is 60Hz (Pr. 3) .....................................................53

4.5 Change acceleration and deceleration time (Pr. 7, Pr. 8)........................................ 54

4.6 Energy saving operation (Pr. 60) .............................................................................55

4.6.1 Energy saving operation mode (setting "4") ............................................................................ 55

4.6.2 Optimum excitation control mode (setting "9")......................................................................... 55

4.7 Selection of the operation command and frequency command locations (Pr. 79).. 57

4.8 Parameter clear, all parameter clear....................................................................58

4.9 Parameter copy and parameter verification ......................................................... 59

Page 5

6 PRECAUTIONS FOR MAINTENANCE AND INSPECTION 108

6.1 Inspection item .......................................................................................................108

6.1.1 Daily inspection ..................................................................................................................... 108

6.1.2 Periodic inspection ................................................................................................................ 108

6.1.3 Daily and periodic inspection................................................................................................. 109

6.1.4 Display of the life of the inverter parts ................................................................................... 110

6.1.5 Cleaning ................................................................................................................................ 111

6.1.6 Replacement of parts ............................................................................................................ 111

6.1.7 Inverter replacement.............................................................................................................. 115

7 SPECIFICATIONS 116

7.1 Rating .....................................................................................................................116

7.2 Common specifications .......................................................................................... 117

Page 6

1

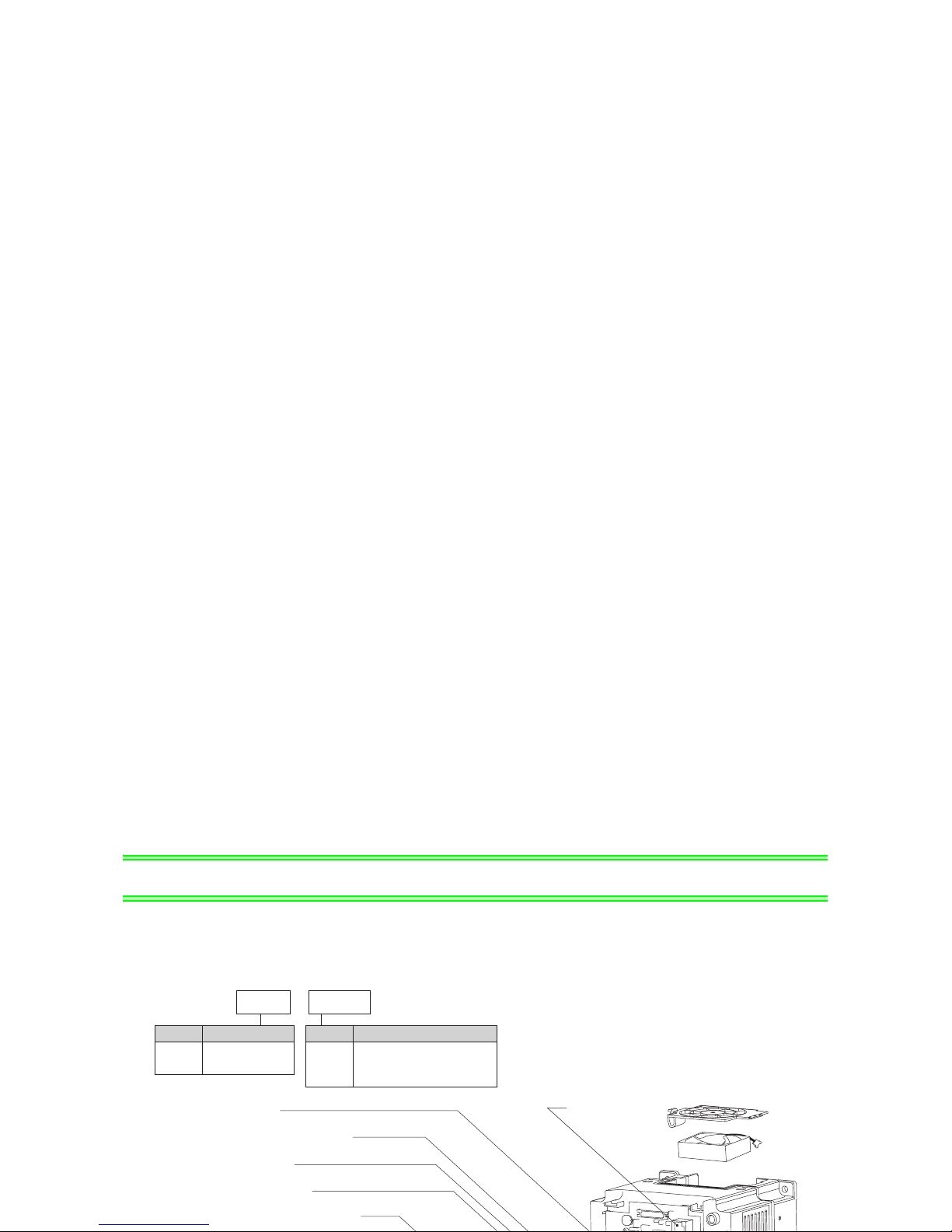

PRODUCT CHECKING AND PARTS IDENTIFICATION

Unpack the inverter and check the capacity plate on the front cover and the rating plate on the inverter side face to

ensure that the product agrees with your order and the inverter is intact.

EMC filter ON/OFF connector

AU/PTC switchover switch

Cooling fan

PU connector

RS-485 terminals

Connector for plug-in option connection

(Refer to the instruction manual of options.)

Voltage/current input switch

- EC

00126

Symbol

00023

to

12120

Displays the rated current

Type Number

FR --F740

Symbol

F740

Voltage Class

Three-phase

400V class

• Inverter Type

(Refer to page 23)

(Refer to the Instruction Manual (applied).)

(Refer to page 8)

(Refer to page 22)

(Refer to page 7)

(Refer to page 112)

Page 7

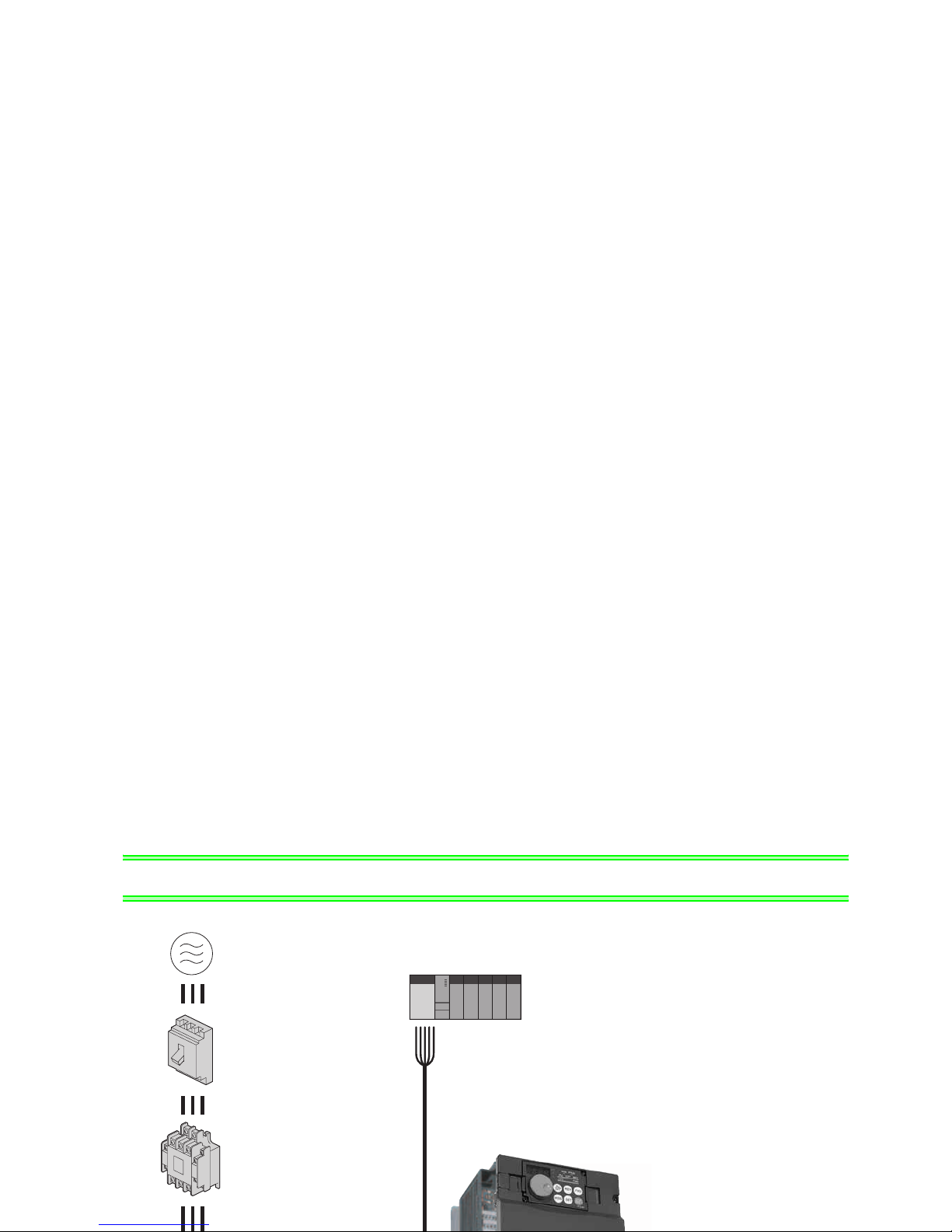

2 INSTALLATION AND WIRING

PLC

Three-phase AC power supply

Moulded case circuit

breaker (MCCB)

or earth leakage current

breaker (ELB), fuse

Magnetic contactor(MC)

RS-485 terminal block

Use within the permissible power supply

specifications of the inverter.

Install the magnetic contactor to ensure safety.

Do not use this magnetic contactor to start and

stop the inverter.

Doing so will cause the inverter life to be shorten.

The inverter can be

connected with computers

such as PLC.

It supports Mitsubishi inverter

protocol and Modbus-RTU

(binary) protocol.

The breaker must be selected carefully since

an in-rush current flows in the inverter at

power on.

Reactor (FR-HAL, FR-HEL)

Reactors (option) should be used when power

harmonics measures are taken, the power factor

(Refer to page 116)

(Refer to page 3)

(Refer to page 3)

Inverter

(FR-F700)

The life of the inverter is influenced by ambient

temperature. The ambient temperature should be as low

as possible within the permissible range. Especially when

mounting the inverter inside an enclosure, take cautions

of the ambient temperature. (Refer to page 6)

Wrong wiring might lead to damage of the inverter. The

control signal lines must be kept fully away from the main

circuit to protect them from noise.(Refer to page 7)

Refer to page 8 for the built-in EMC filter.

Page 8

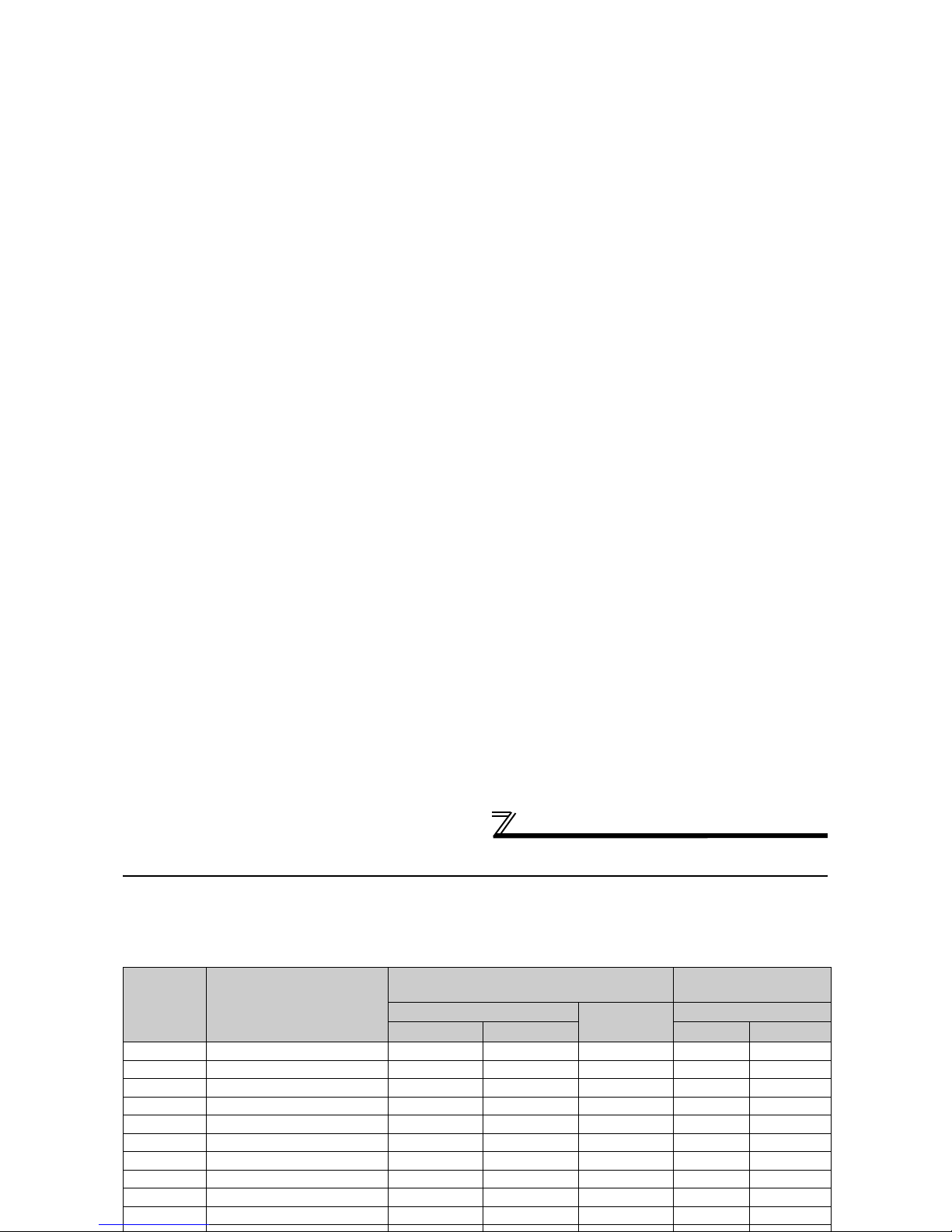

Peripheral devices

2.1 Peripheral devices

Check the motor capacity of the inverter you purchased. Appropriate peripheral devices must be selected according

to the capacity. Refer to the following list and prepare appropriate peripheral devices:

400V class

Motor

Output

(kW)

*1

Applicable Inverter Type

Breaker Selection*2,4

Input Side Magnetic

Contactor*3

Reactor connection

with commercial

power-supply

operation

Reactor connection

without with

without

with

0.75 FR-F740-00023-EC 30AF 5A 30AF 5A 30AF 5A S-N10 S-N10

1.5 FR-F740-00038-EC 30AF 10A 30AF 10A 30AF 10A S-N10 S-N10

2.2 FR-F740-00052-EC 30AF 10A 30AF 10A 30AF 15A S-N10 S-N10

3.7 FR-F740-00083-EC 30AF 20A 30AF 15A 30AF 20A S-N10 S-N10

5.5 FR-F740-00126-EC 30AF 30A 30AF 20A 30AF 30A S-N20 S-N11, N12

7.5 FR-F740-00170-EC 30AF 30A 30AF 30A 30AF 30A S-N20 S-N20

11 FR-F740-00250-EC 50AF 50A 50AF 40A 50AF 50A S-N20 S-N20

15 FR-F740-00310-EC 100AF 60A 50AF 50A 100AF 60A S-N25 S-N20

18.5 FR-F740-00380-EC 100AF 75A 100AF 60A 100AF 75A S-N25 S-N25

22 FR-F740-00470-EC 100AF 100A 100AF 75A 100AF 100A S-N35 S-N25

Page 9

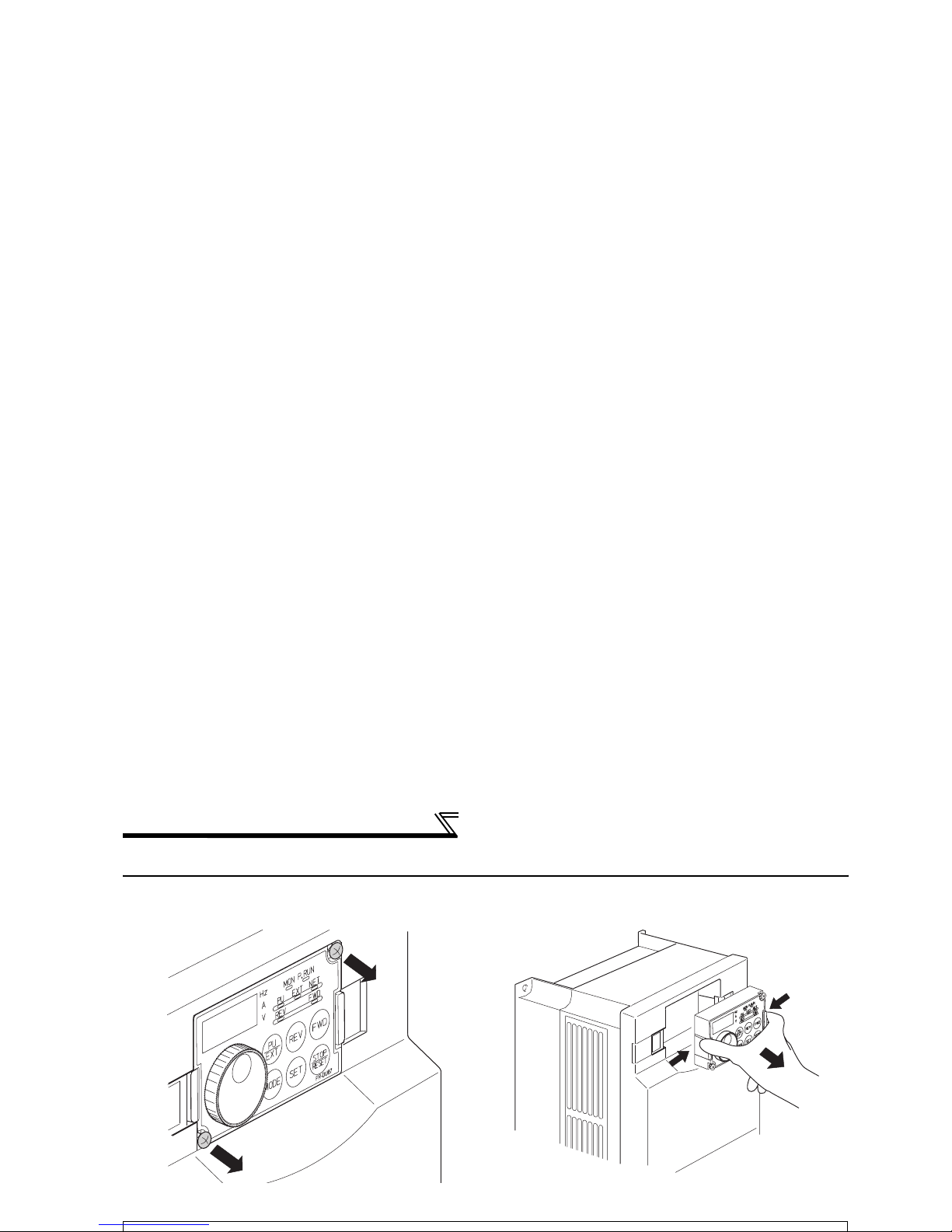

Method of removal and reinstallation of the

front cover

2.2 Method of removal and reinstallation of the front cover

•Removal of the operation panel

1) Loosen the two screws on the operation panel.

(These screws cannot be removed.)

2) Push the left and right hooks of the operation panel

and pull the operation panel toward you to remove.

When reinstalling the operation panel, insert it straight to reinstall securely and tighten the fixed screws of the

operation panel.

Page 10

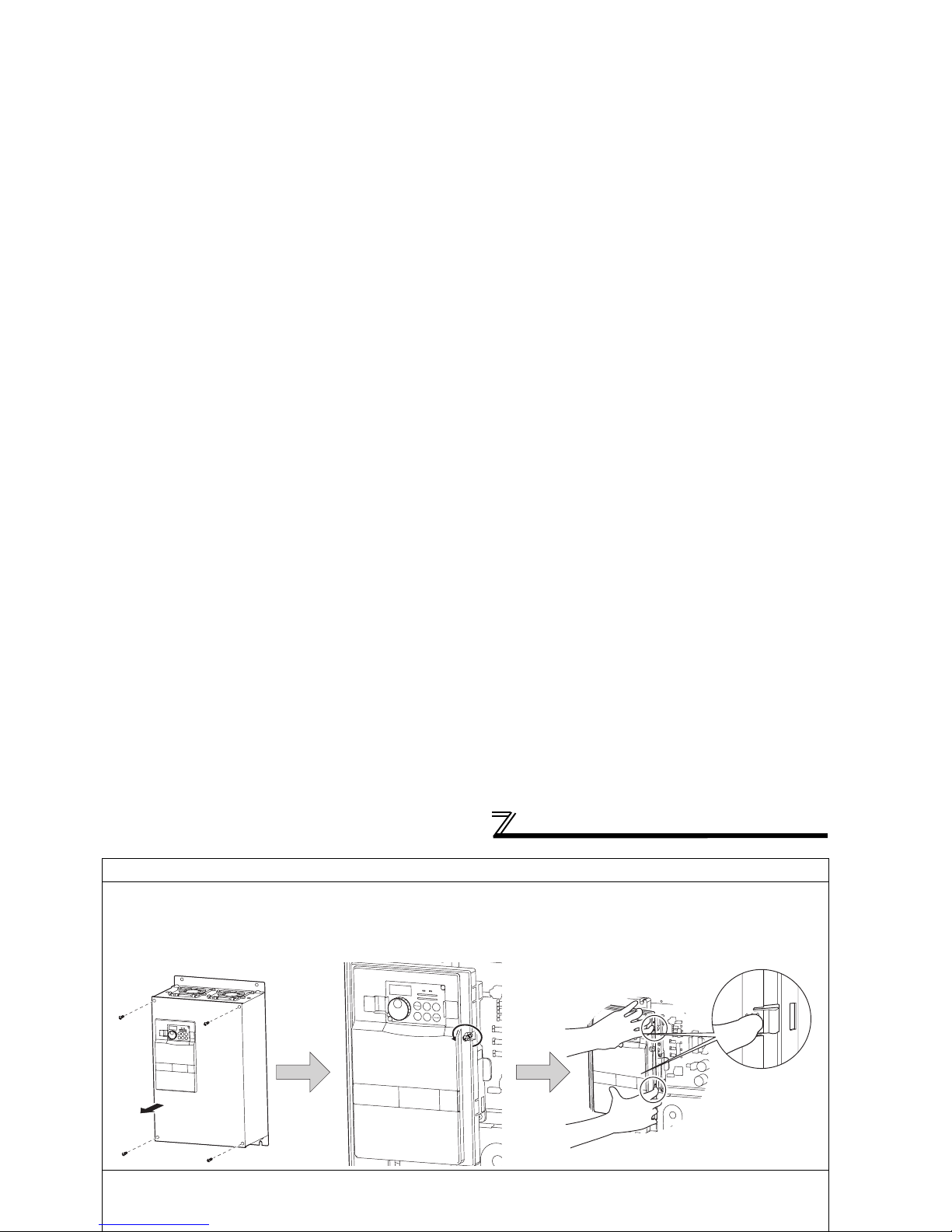

Method of removal and reinstallation of the

front cover

FR-F740-00770-EC or more

•

Removal

•Reinstallation

Front cover 2

Front cover 1

Installation hook

1) Remove installation screws on

the front cover 1 to remove the

front cover 1.

2) Loosen the installation

screws of the front cover 2.

3) Pull the front cover 2 toward you to

remove by pushing an installation

hook on the right side using left

fixed hooks as supports.

1) Insert the two fixed hooks on the left side of the

front cover 2 into the sockets of the inverter.

2) Using the fixed hooks as supports, securely

press the front cover 2 against the inverter.

Page 11

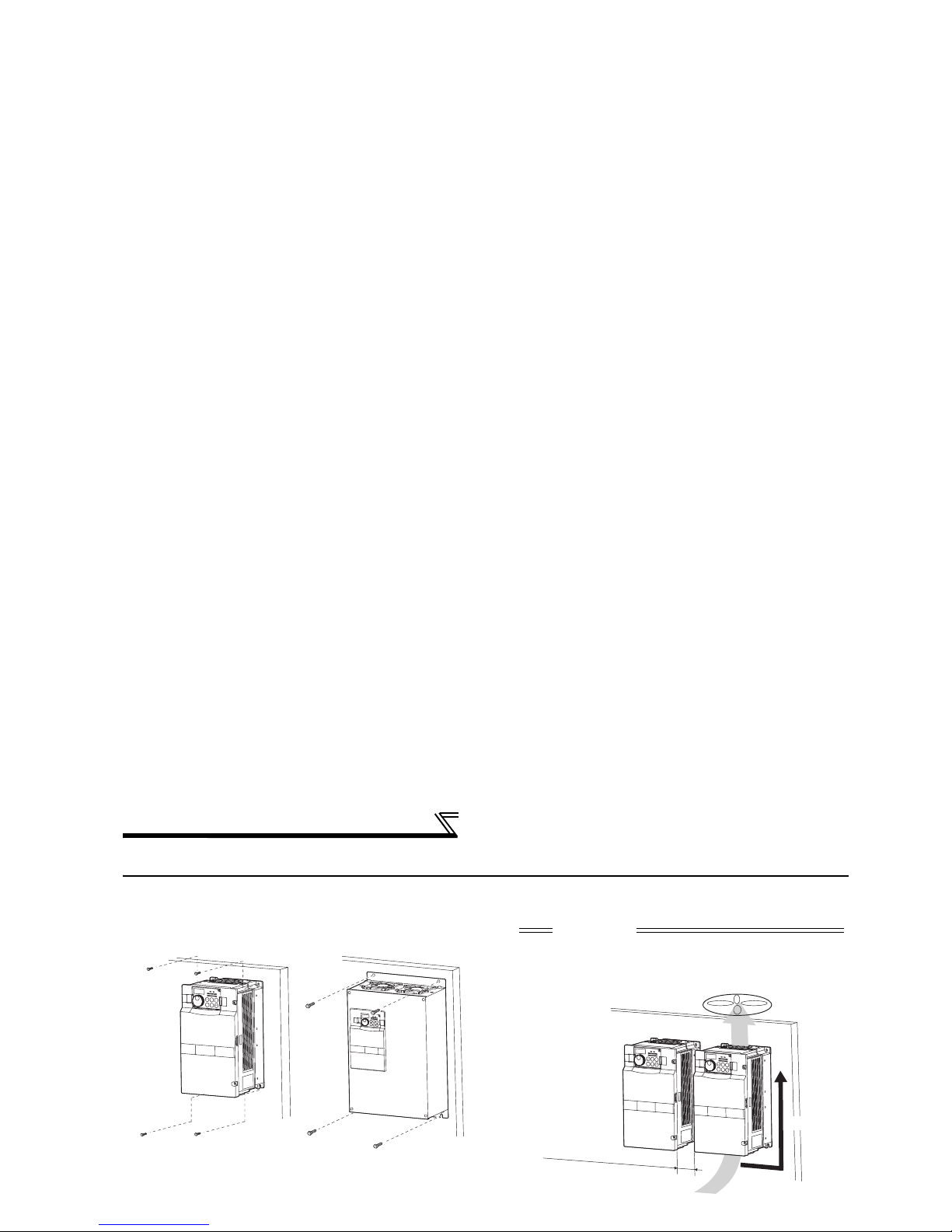

Installation of the inverter and instructions

2.3 Installation of the inverter and instructions

• Installation of the Inverter

• Install the inverter under the following conditions.

Installation on the enclosure

00620 or less 00770 or more

CAUTION

⋅ When encasing multiple inverters, install them in

parallel as a cooling measure.

⋅ Install the inverter vertically.

Refer to the clearances below.

Vertical

Fix six positions for the FR-F74004320 to 08660 and fix eight positions

for the FR-F740-09620 to 12120.

Page 12

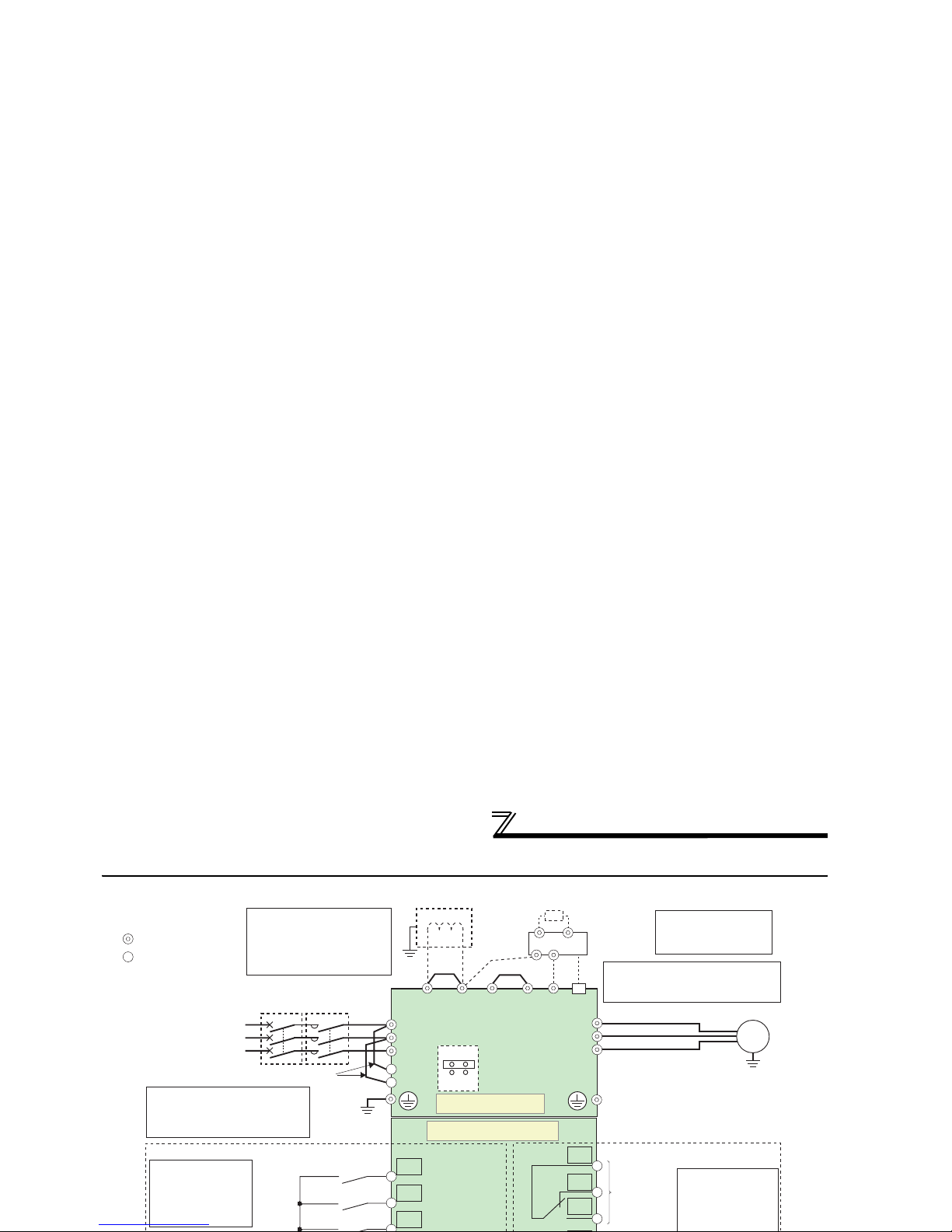

Wiring

2.4 Wiring

2.4.1 Terminal connection diagram

Three-phase AC

power supply

MCCB

Jumper

R/L1

S/L2

T/L3

R1/L11

S1/L21

Control input signals (No voltage input allowed)

Jumper

Motor

Relay output 1

(Alarm output)

C1

B1

A1

U

V

W

*1

Main circuit terminal

Control circuit terminal

MC

Main circuit

Control circuit

Relay output

IM

Terminal functions

vary with the output

terminal assignment

(Pr. 195, Pr. 196)

Terminal functions

vary with the input

terminal assignment

(Pr. 178 to Pr. 189)

STF

STR

STOP

EMC filter

ON/OFF

connector

ON

OFF

Forward

rotation

start

Reverse

rotation

start

PR*7

PX*7

Jumper

*7.

*2. To supply power to the

control circuit separately,

remove the jumper across

R1/L11 and S1/L21.

*2

Do not use PR and PX terminals.

Please do not remove the jumper

connected to terminal PR and PX.

N/-

P/+

P1

Resistor unit

(Option)

Brake unit

(Option)

CN8

*6

Source logic

Earth

Earth

Earth

*6. A CN8 connector is

provided with the

01800 or more.

*1. DC reactor (FR-HEL)

Be sure to connect the DC reactor

supplied with the 01800 or more.

When a DC reactor is connected

to the 01160 or less, remove the

jumper across P1-P/+.

(Refer to the Instruction

Manual (applied))

(Refer to the

Instruction Manual

Page 13

Wiring

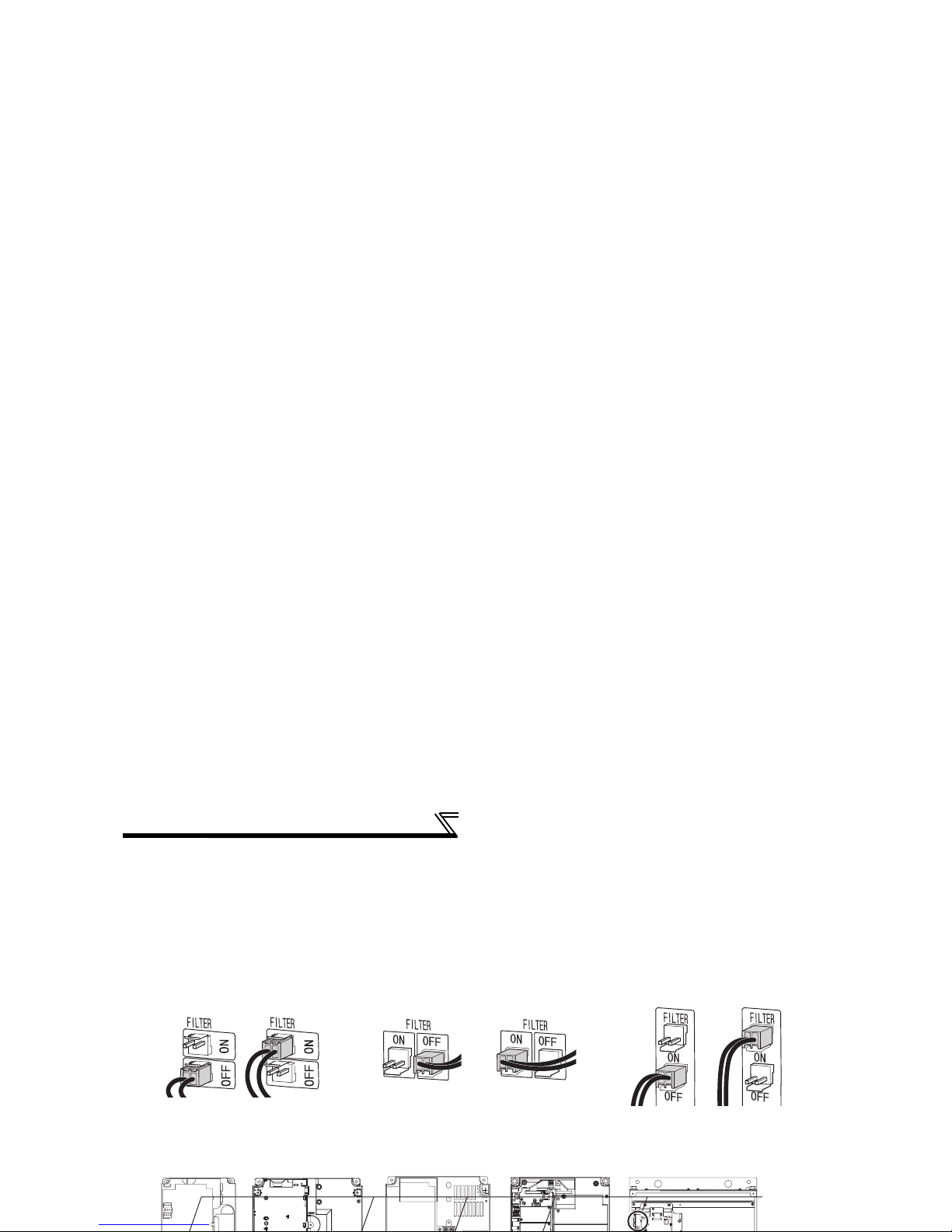

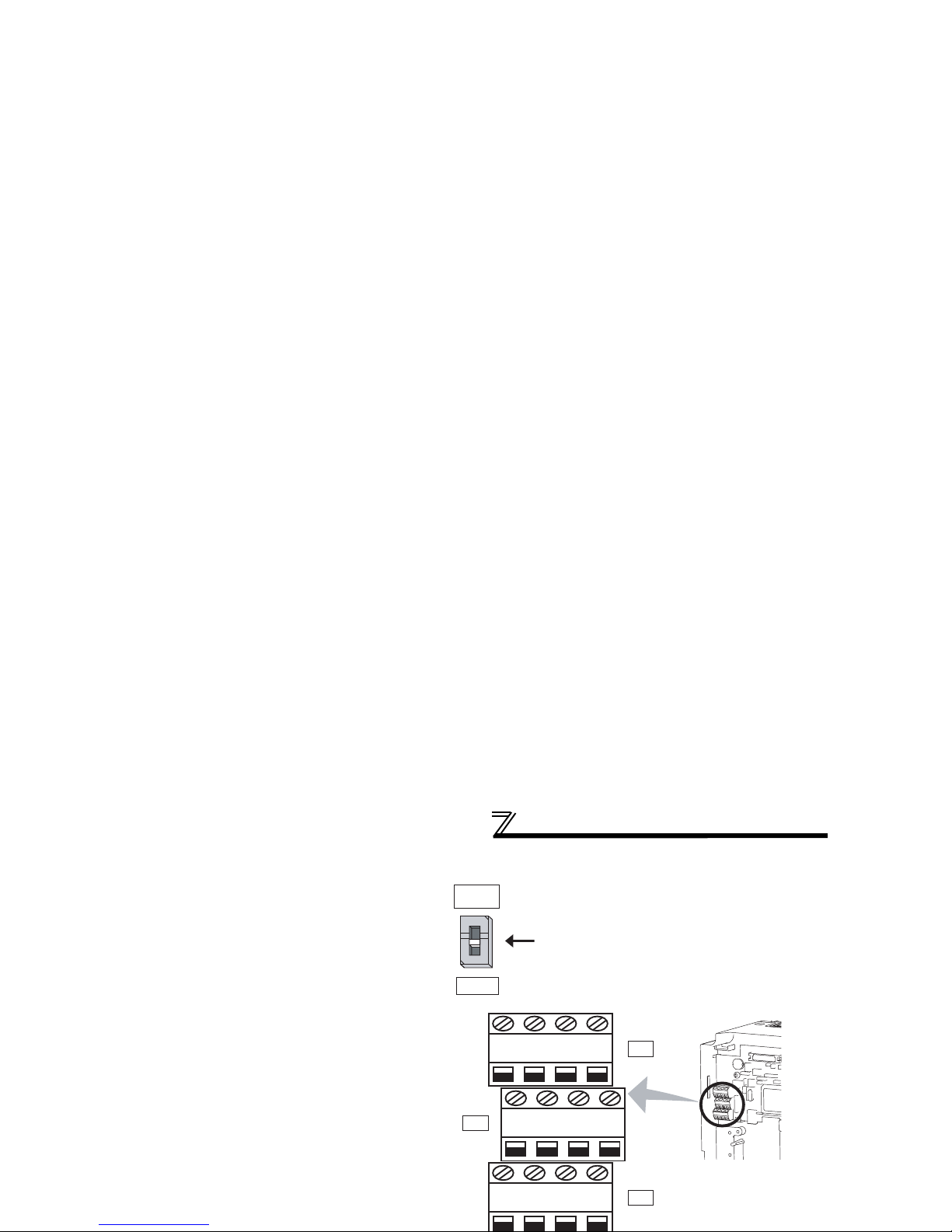

2.4.2 EMC filter

This inverter is equipped with a built-in EMC filter (capacitive filter) and common mode core.

The EMC filter is effective for reduction of air-propagated noise on the input side of the inverter.

The EMC filter is factory-set to enable (ON). To disable it, fit the EMC filter ON/OFF connector to the OFF position.

The input side common mode core, built-in the FR-F740-01160 or less inverter, is always valid regardless of on/off of

the EMC filter on/off connector.

EMC filter OFF EMC filter OFF EMC filter OFFEMC filter ON EMC filter ON EMC filter ON

(initial setting) (initial setting) (initial setting)

EMC filte

r

ON/OFF

connecto

r

00023 to 00126

00170, 00250

00310 or more

00170, 00250

00310, 00380

00470, 00620

00770 or more

00023 to 00126

Page 14

Wiring

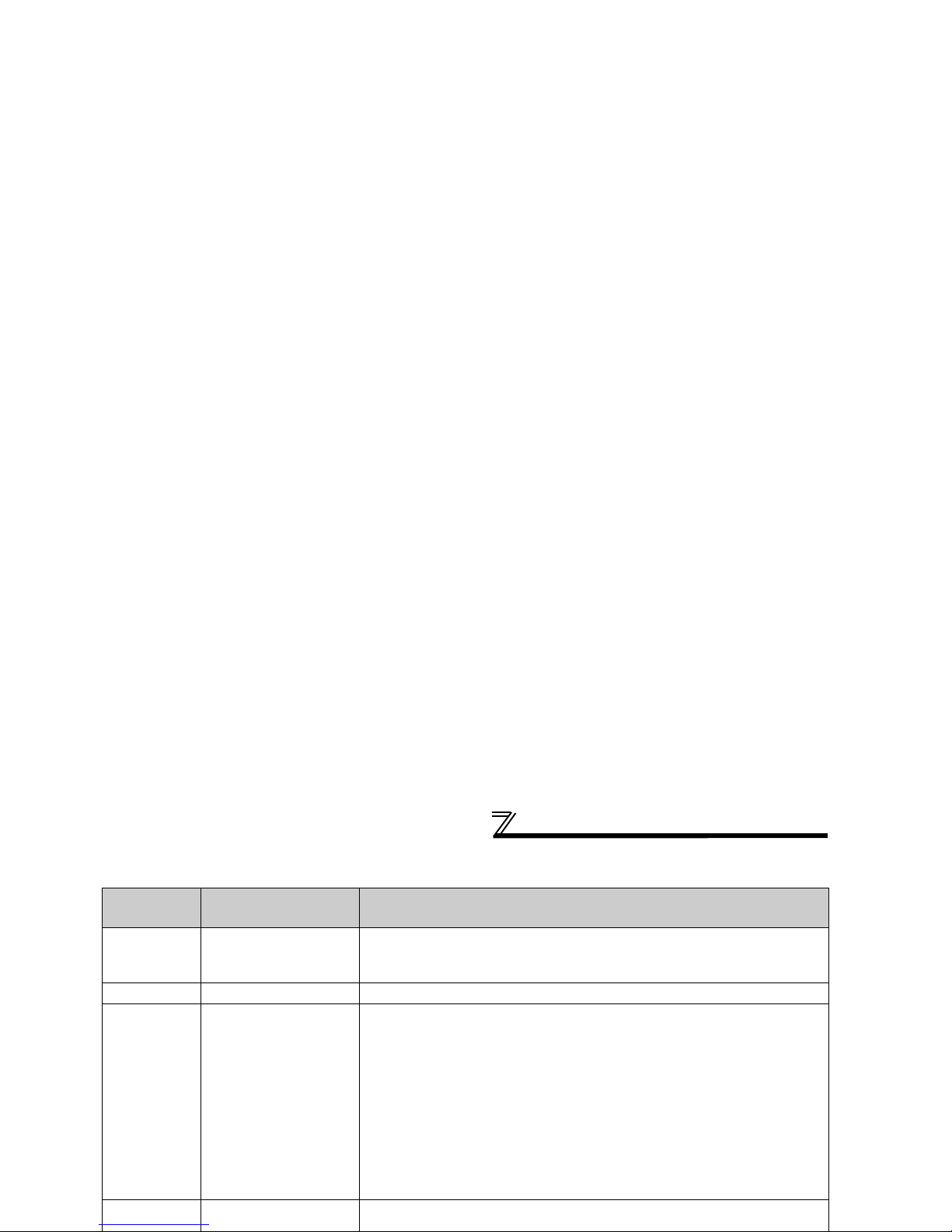

2.4.3 Specification of main circuit terminal

Term inal

Symbol

Term inal Name Description

R/L1,

S/L2,

T/L3

AC power input

Connect to the commercial power supply.

Keep these terminals open when using the high power factor converter

(FR-HC, MT-HC) or power regeneration common converter (FR-CV).

U, V, W Inverter output Connect a three-phase squirrel-cage motor.

R1/L11,

S1/L21

Power supply for

control circuit

Connected to the AC power supply terminals R/L1 and S/L2. To retain the

alarm display and alarm output or when using the high power factor

converter (FR-HC, MT-HC) or power regeneration common converter (FRCV), remove the jumpers from terminals R/L1-R1/L11 and S/L2-S1/L21

and apply external power to these terminals.

Do not turn off the power supply for control circuit (R1/L11, S1/L21) with the

main circuit power (R/L1, S/L2, T/L3) on. Doing so may damage the

inverter. The circuit should be configured so that the main circuit power (R/

L1, S/L2, T/L3) is also turned off when the power supply for control circuit

(R1/L11, S1/L21) is off.

00380 or less : 60VA, 00470 or more : 80VA

P/+, N/-

Brake unit

Connect the brake unit (FR-BU, BU and MT-BU5), power regeneration

common converter (FR-CV), high power factor converter (FR-HC and

Page 15

Wiring

FR-F740-00310, 00380-EC FR-F740-00470, 00620-EC

FR-F740-00770 to 01160-EC FR-F740-01800 to 02600-EC

R1/L11 S1/L21

R/L1 S/L2 T/L3

N/-

P/+

PR

Charge lamp

Jumper

Jumper

Screw size

(M4)

Screw size (M5)

Screw size (M5)

Power supply

IM

Motor

R/L1 S/L2 T/L3

N/-

P/+

PR

R1/L11 S1/L21

IM

Screw size (M4)

Screw size (M6)

Screw size (M6)

Jumper

Jumper

Charge lamp

Power supply

Motor

Screw size(M4)

R1/L11 S1/L21

Page 16

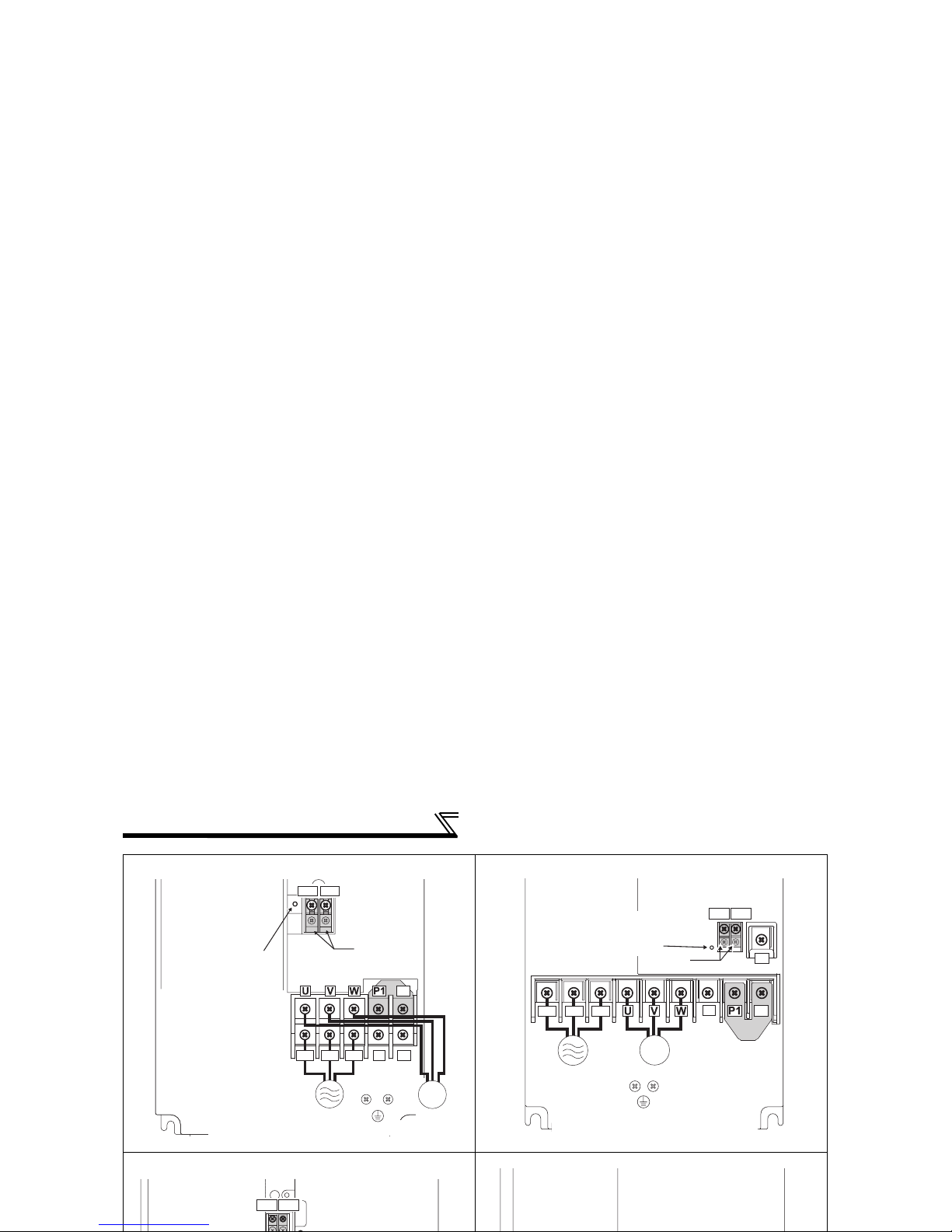

Wiring

FR-F740-03250 to 04810-EC FR-F740-05470 to 12120-EC

IM

R/L1 S/L2 T/L3

N/-

P/+

R1/L11 S1/L21

P/+

P/+

Screw size (M4)

Jumper

Charge lamp

Screw size

(M10)

Motor

Screw size (M12)

(for option)

Power supply

DC reactor

Screw size

(03250/03610: M10

04320/04810: M12)

IM

R/L1 S/L2 T/L3

N/-

R1/L11 S1/L21

P/+

P/+

Screw size (M4)

Jumper

Charge lamp

Motor

Power supply

DC reactor

Screw size (M12)

Page 17

Wiring

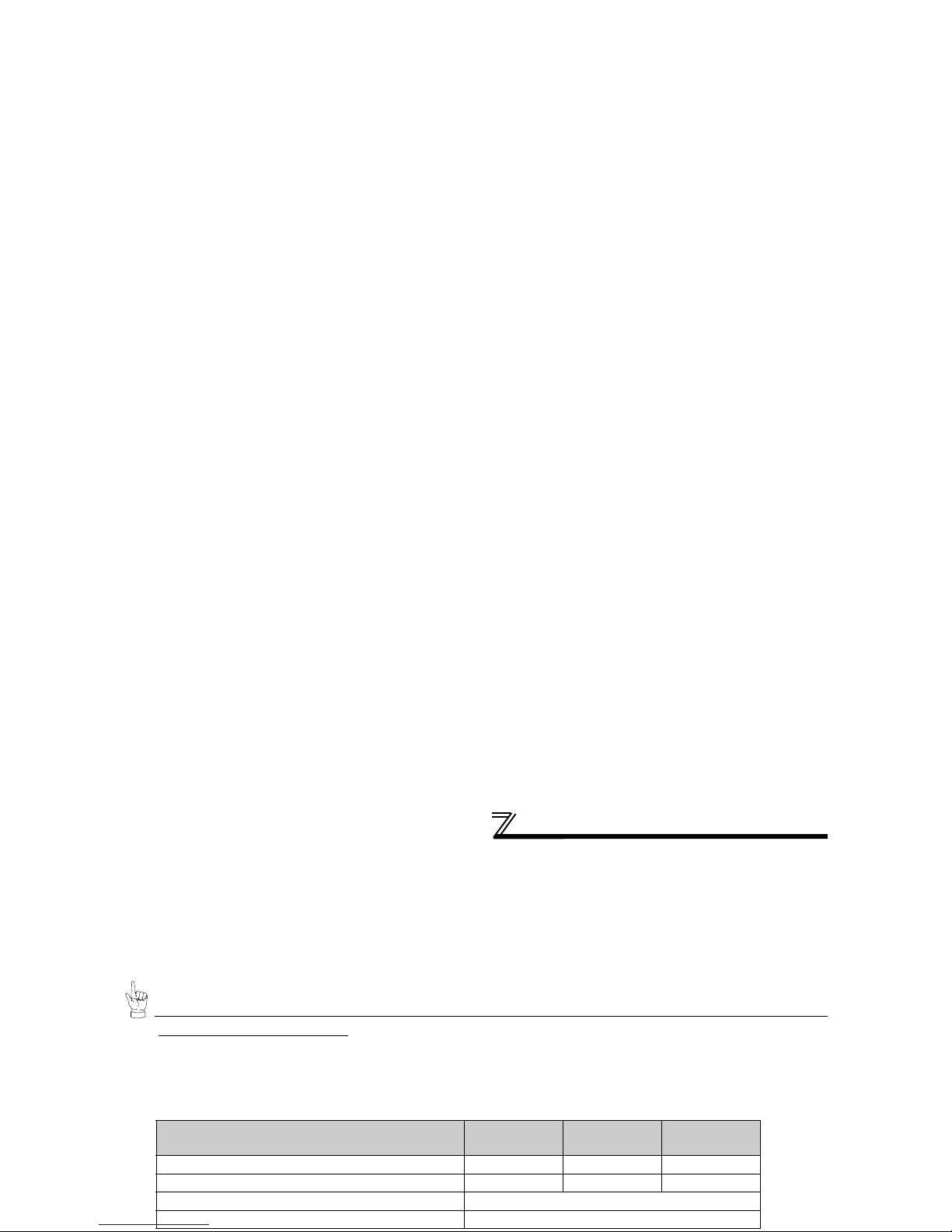

(1) Cable sizes etc., of the main control circuit terminals and earth terminals

Select the recommended cable size to ensure that a voltage drop will be 2% max.

If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause the motor

torque to decrease especially at the output of a low frequency.

The following table indicates a selection example for the wiring length of 20m.

400V class (when input power supply is 440V based on the rated current for 110% overload for 1 minute)

Applicable Inverter

Typ e

Ter min al

Screw Size

*4

Tightening

Tor que N· m

Crimping

(Compression)

Ter mina l

Cable Sizes

HIV, etc. (mm2) *1 AWG/MCM *2 PVC, etc. (mm2) *3

R/L1,

S/L2,

T/L3

U, V,

W

R/L1,

S/L2,

T/L3

U, V,

W

cable

R/L1,

S/L2,

T/L3

U, V, W

R/L1,

S/L2,

T/L3

U, V, W cable

FR-F740-00023 to

00083-EC

M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-F740-00126-EC M4 1.5 2-4 2-4 2 2 3.5 12 14 2.5 2.5 4

FR-F740-00170-EC M4 1.5 5.5-4 5.5-4 3.5 3.5 3.5 12 12 4 4 4

FR-F740-00250-EC M4 1.5 5.5-4 5.5-4 5.5 5.5 8 10 10 6 6 10

FR-F740-00310-EC M5 2.5 8-5 8-5 88888101010

FR-F740-00380-EC M5 2.5 14-5 8-5 14 8 14 6 8 16 10 16

FR-F740-00470-EC M6 4.4 14-6 14-6 14 14 14 6 6 16 16 16

FR-F740-00620-EC M6 4.4 22-6 22-6 22 22 14 4 4 25 25 16

FR-F740-00770-EC M6 4.4 22-6 22-6 22 22 14 4 4 25 25 16

FR-F740-00930-EC M8 7.8 38-8 38-8 38 38 22 1 2 50 50 25

Page 18

Wiring

(2) Notes on earthing

• Leakage currents flow in the inverter. To prevent an electric shock, the inverter and motor must be earthed. This inverter

must be earthed. Earthing must conform to the requirements of national and local safety regulations and electrical

codes. (NEC section 250, IEC 536 class 1 and other applicable standards)

• Use the dedicated earth terminal to earth the inverter.

(Do not use the screw in the casing, chassis, etc.)

• Use the thickest possible

earth

cable. Use the cable whose size is equal to or greater than that indicated in the above

table, and minimize the cable length. The earthing point should be as near as possible to the inverter.

To be compliant with the European Directive (Low Voltage Directive), earth the inverter according to

the instructions on page 135.

(3) Total wiring length

The overall wiring length for connection of a single motor or multiple motors should be within the value in the table below.

Pr. 72 PWM frequency selection Setting

(carrier frequency) *

00023 00038

00052 or

More

2 (2kH) or less 300m 500m 500m

3 (3kHz), 4 (4kHz) 200m 300m 500m

5 (5kHz) to 9 (9kHz) 100m

10 (10kHz) or more 50m

Page 19

Wiring

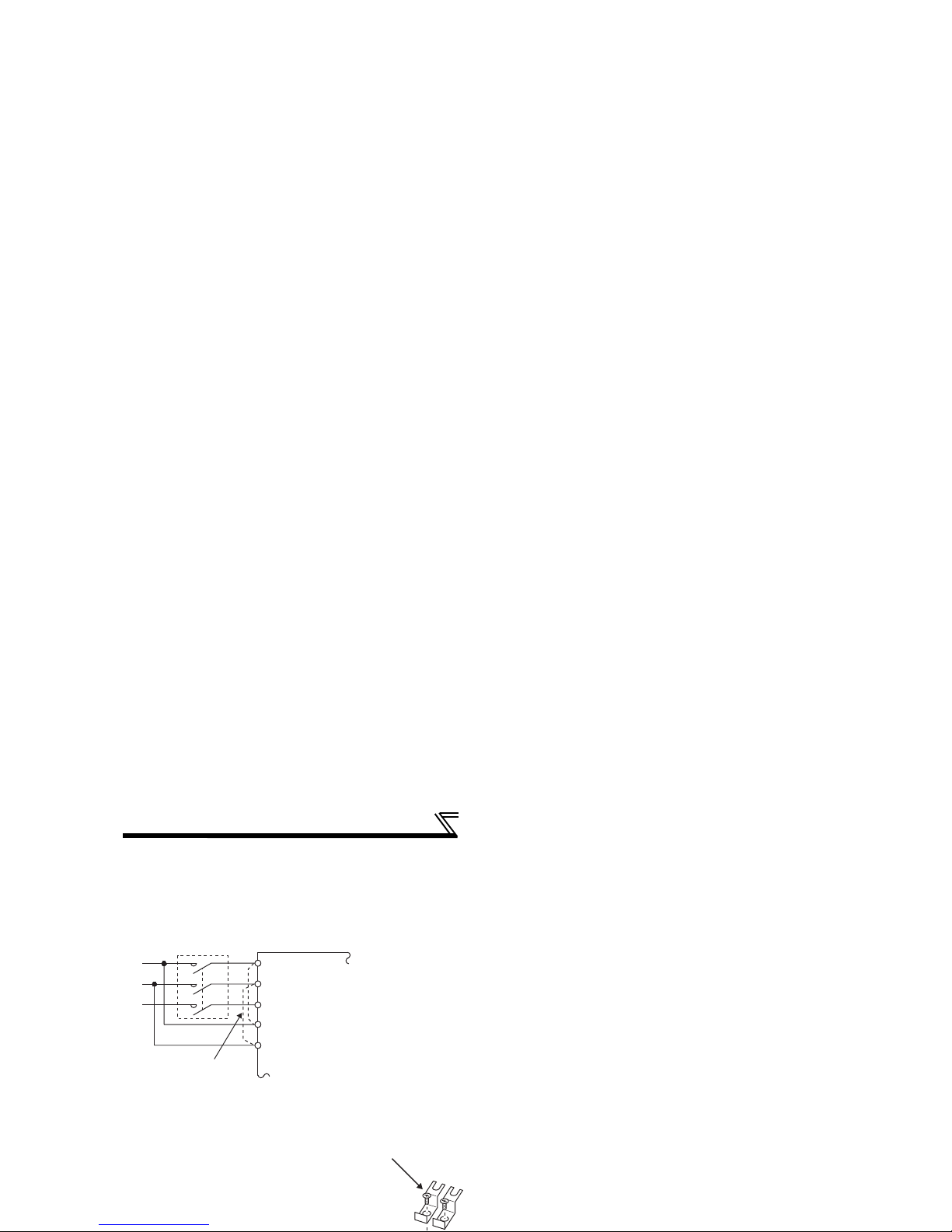

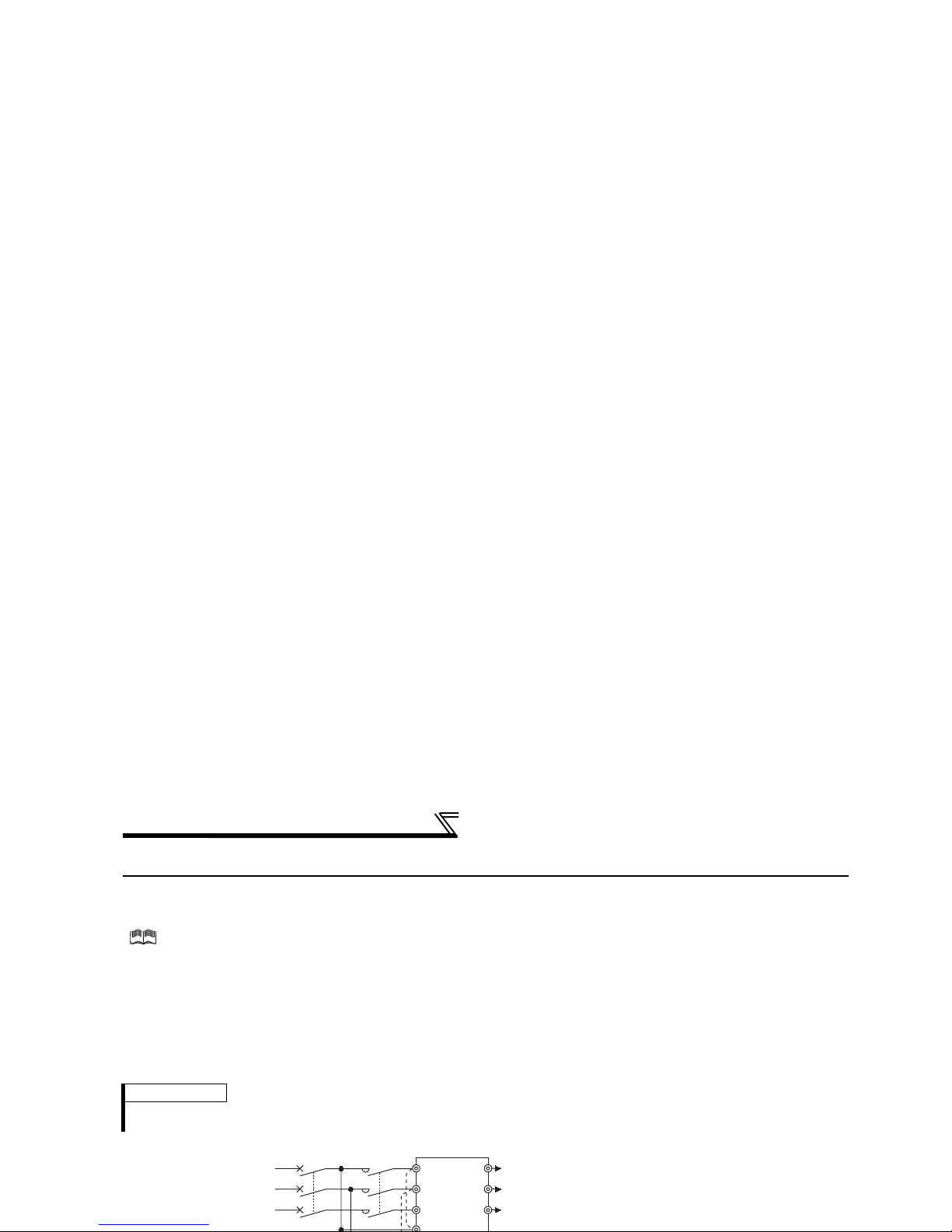

(5) When connecting the control circuit and the main circuit separately to the power supply

(separate power)

• FR-F740-00023 to 00126

<Connection diagram> When the protected circuit is activated, opening of the electromagnetic

contactor (MC) on the inverter power supply side results in power loss in the

control circuit, disabling the alarm output signal retention. Terminals R1/L11

and S1/L21 are provided to hold an alarm signal. In this case, connect the

power supply terminals R1/L11 and S1/L21 of the control circuit to the

primary side of the MC.

1)Loosen the upper screws.

2)Remove the lower screws.

3)Remove the jumper

4)Connect the separate power

supply cable for the control

circuit to the lower terminals

Inverter

MC

R/L1

S/L2

T/L3

R1/L11

S1/L21

Remove the jumper

3)

Page 20

Wiring

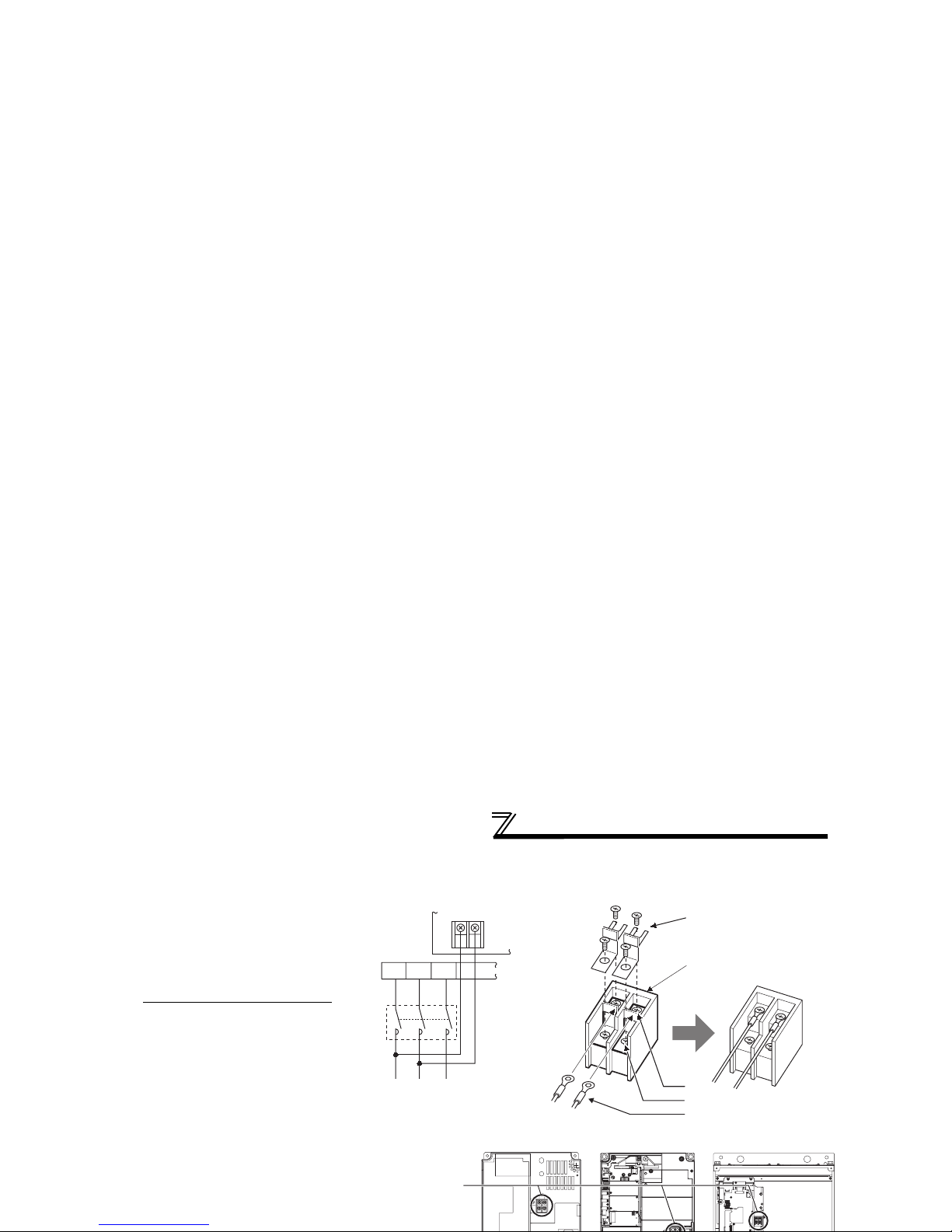

• FR-F740-00310 or more

1)Remove the upper screws.

2)Remove the lower screws.

3)Pull the jumper toward you to

remove.

4)

Connect the separate power supply

cable for the control circuit to the

upper terminals (R1/L11, S1/L21)

.

Never connect the power cable to

the terminals in the lower stand.

Doing so will damage the inverter.

S1/L21

R1/L11

3)

4)

1)

2)

Power supply

terminal block for

the control circuit

Power supply terminal block

for the control circuit

R/L1

S/L2

T/L3

R1/

L11

S1/

L21

Power supply

terminal block

for the control circuit

Main power supply

MC

00310, 00380

00470, 00620

00770 or more

Page 21

Wiring

2.4.5 Control circuit terminals

indicates that terminal functions can be selected using Pr. 178 to Pr. 196 (I/O terminal function selection) (Refer to

Instruction Manual (applied).)

(1) Input signals

Typ e

Terminal

Symbol

Ter min al

Name

Description

Rated

Specifications

Refer to

STF

Forward

rotation start

Turn on the STF signal to start forward

rotation and turn it off to stop.

When the STF and

STR signals are turned

on simultaneously, the

stop command is given.

42

STR

Reverse

rotation start

Turn on the STR signal to start reverse

rotation and turn it off to stop.

STOP

Star t selfholding

selection

Turn on the STOP signal to self-hold the start signal.

Instruction

Manual

(applied)

RH,

RM, RL

Multi-speed

selection

Multi-speed can be selected according to the combination of RH,

RM and RL signals.

44

JOG

Jog mode

selection

Turn on the JOG signal to select Jog operation (initial setting) and

turn on the start signal (STF or STR) to start Jog operation.

Instruction

Manual

(applied)

Second

Turn on the RT signal to select second function.

When the second function such as "second torque boost" and

Instruction

Page 22

Wiring

Frequency setting

10E

Frequency

setting power

supply

When connecting the frequency setting potentiometer at an initial

status, connect it to terminal 10.

Change the input specifications of terminal 2 when connecting it

to terminal 10E. (Refer to Pr. 73 Analog input selection in

Instruction Manual (applied).)

10VDC

Permissible load

current 10mA

Instruction

Manual

(applied)

10

5VDC

Permissible load

current 10mA

38, 46

2

Frequency

setting

(voltage)

Inputting 0 to 5VDC (or 0 to 10V, 0 to 20mA) provides the

maximum output frequency at 5V (10V, 20mA) and makes input

and output proportional. Use Pr. 73 to switch from among input 0

to 5VDC (initial setting), 0 to 10VDC, and 0 to 20mA.

Set the voltage/current input switch in the ON position to select

current input (0 to 20mA).

*1

Voltage input:

Input resistance

10kΩ ± 1kΩ

Maximum

permissible

voltage 20VDC

Current input:

Input resistance

245Ω ± 5Ω

Maximum

permissible

current 30mA

38, 46

4

Frequency

setting

(current)

Inputting 4 to 20mADC (or 0 to 5V, 0 to 10V) provides the

maximum output frequency at 20mA (5V, 10V) makes input and

output proportional. This input signal is valid only when the AU

signal is on (terminal 2 input is invalid). Use Pr. 267 to switch from

among input 4 to 20mA (initial setting), 0 to 5VDC, and 0 to

10VDC. Set the voltage/current input switch in the OFF position

to select voltage input (0 to 5V/0 to 10V).

*1

(Refer to Instruction Manual (applied).)

40, 48

1

Frequency

setting

Inputting 0 to ±5 VDC or 0 to ±10VDC adds this signal to terminal

2 or 4 frequency setting signal. Use Pr.73 to switch between the

Input resistance

10kΩ ± 1kΩ

Maximum

Instruction

Manual

Typ e

Terminal

Symbol

Terminal

Name

Description

Rated

Specifications

Refer to

Page 23

Wiring

*2 Low indicates that the open collector output transistor is on (conducts).

High indicates that the transistor is off (does not conduct).

*3 Not output during inverter reset.

(3) Communication

Analog

CA

Analog current

output

Select one e.g. output frequency from

monitor items.

*3

The output signal is proportional to the

magnitude of the corresponding

monitoring item.

Output item:

Output frequency

(initial setting)

Load impedance

200Ω to 450Ω

Output signal 0 to

20mADC

Instruction

Manual

(applied)

AM

Analog voltage

output

Output signal 0 to

10VDC

Permissible load

current 1mA

(load impedance

10kΩ or more)

Resolution 8 bit

Instruction

Manual

(applied).

Type

Terminal

Symbol

Terminal

Name

Description Refer to

—

PU

With the PU connector, communication can be made through RS-485.

(for connection on a 1:1 basis only)

. Conforming standard : EIA-485(RS-485)

22

Typ e

Terminal

Symbol

Terminal

Name

Description

Rated

Specifications

Refer to

Page 24

Wiring

Sink logic and source logic

⋅ In sink logic, a signal switches on when a current flows from the corresponding signal input terminal.

Terminal SD is common to the contact input signals. Terminal SE is common to the open collector output signals.

⋅ In source logic, a signal switches on when a current flows into the corresponding signal input terminal.

Terminal PC is common to the contact input signals. Terminal SE is common to the open collector output signals.

Current

PC

STF

R

STR

R

Source logic

Source

connecto

r

Current

SD

STF

R

STR

R

Sink

connector

Sink logic

Current flow concerning the input/output signal

when sink logic is selected

Current flow concerning the input/output signal

when source logic is selected

DC input (source type)

<Example: AX80>

Inverter

DC input (sink type)

<Example: AX40>

Inverter

Page 25

Wiring

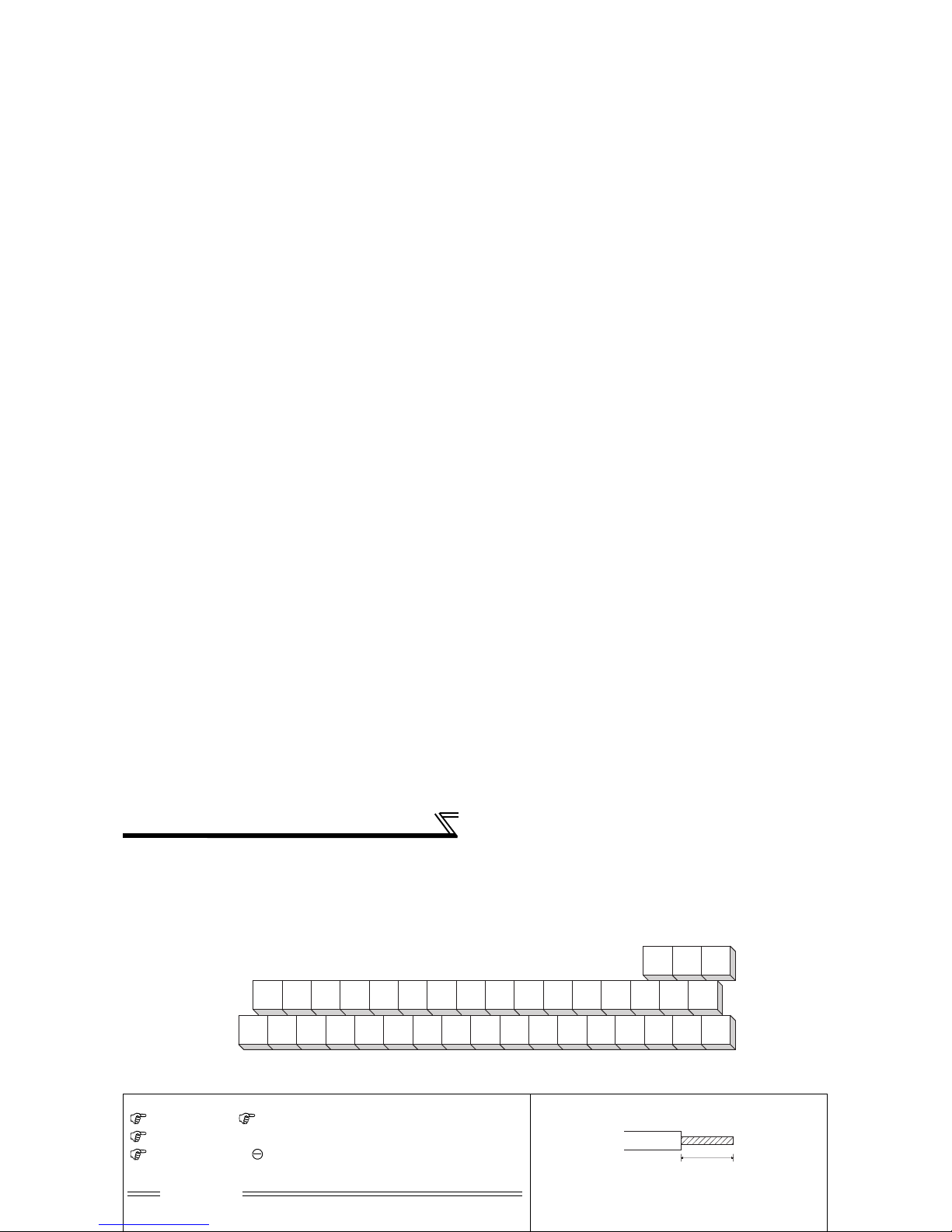

2.4.7 Wiring of control circuit

(1) Control circuit terminal layout

(2) Wiring method

Loosen the terminal screw and insert the cable into the terminal.

Screw Size: M3 Tightening Torque: 0.5N·m to 0.6N·m

Cable size: 0.3mm

2

to 0.75mm

2

Screwdriver:Small flat-blade screwdriver (Edge thickness: 0.4mm/

Edge width: 2.5mm)

Wire the stripped cable after twisting it to

prevent it from becoming loose. In addition, do

not solder it.

STOP

AURHRM

RL

C2B2A2C1B1A1

OLIPFSURUNSE14521010EAMPC

FU

MRS

JOG CS

RES STF STR PC

CA SD PC

RT

CAUTION

Undertightening can cause cable disconnection or malfunction.

Overtightening can cause a short circuit or malfunction due to

Cable stripping size

6mm

Page 26

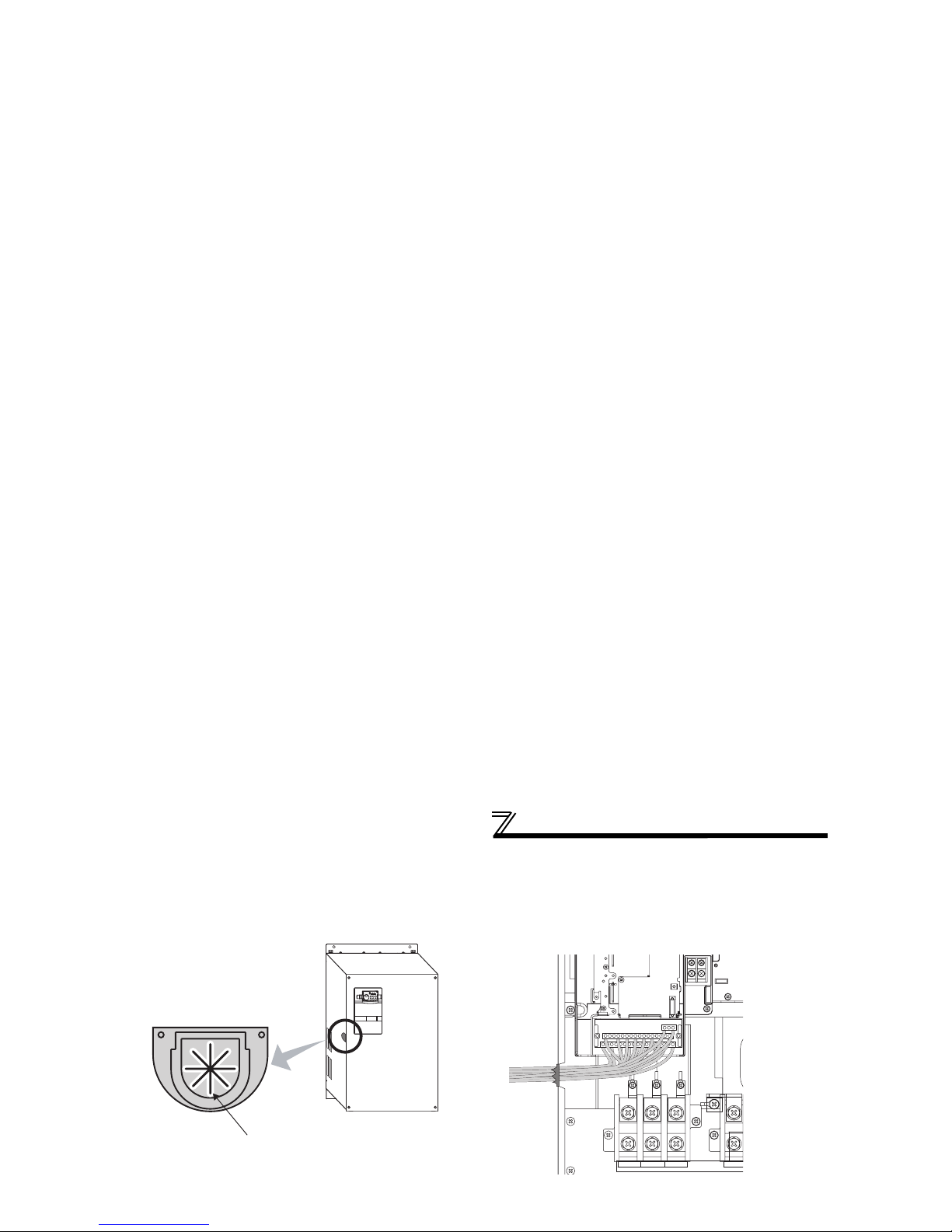

Wiring

z Wiring of the control circuit of the 01800 or more

For wiring of the control circuit of the 01800 or more, separate away from wiring of the main circuit.

Make cuts in rubber bush of the inverter side and lead wires.

<Wiring>

Rubber bush

(view from the inside)

Make cuts along the lines inside with

a cutter knife and such.

Page 27

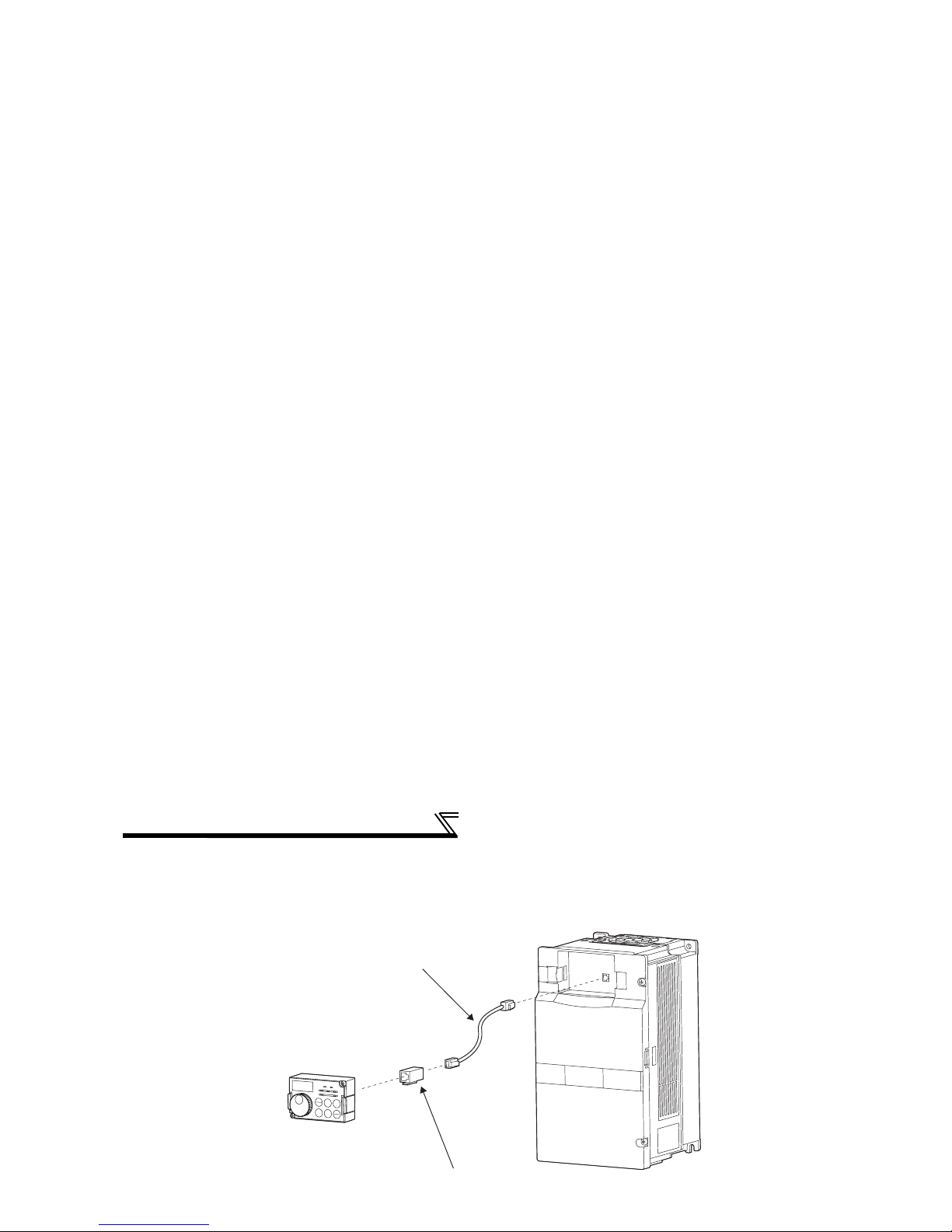

Wiring

2.4.8 When connecting the operation panel using a connection cable

When connecting the operation panel (FR-DU07) to the inverter using a cable, the operation panel can be mounted

on the enclosure surface and operationality improves.

Parameter unit connection cable

(FR-CB2)(option)

Operation panel(FR-DU07)

Operation panel connection connector

(FR-ADP)(option)

Page 28

Wiring

2.4.9 RS-485 terminal block

⋅ Conforming standard: EIA-485(RS-485)

⋅ Transmission format: Multidrop link

⋅ Communication speed: MAX 38400bps

⋅ Overall length: 500m

⋅ Connection cable:Twisted pair cable

(4 paires)

RXD

RDA1

(RXD1+)

RDB1

(RXD1-)

RDA2

(RXD2+)

RDB2

(RXD2-)

SDA1

(TXD1+)

SDB1

(TXD1-)

SDA2

(TXD2+)

SDB2

(TXD2-)

P5S

(VCC)SG(GND)

P5S

(VCC)SG(GND)

VCC

TXD

OPEN

100Ω

Terminating resistor switch

Factory-set to "OPEN".

Set only the terminating resistor switch of

the remotest inverter to the "100Ω" position.

Page 29

Power-off and magnetic contactor (MC)

2.5 Power-off and magnetic contactor (MC)

(1) Inverter input side magnetic contactor (MC)

On the inverter input side, it is recommended to provide an MC for the following purposes.

(

Refer to page 3 for selection.)

1)To release the inverter from the power supply when the inverter's protective function is activated or when the drive is

not functioning (e.g. emergency stop operation).

2)

To prevent any accident due to an automatic restart at restoration of power after an inverter stop made by a power failure

3)The control power supply for inverter is always running and consumes a little power. When stopping the inverter for an

extended period of time, powering off the inverter will save power slightly.

4)To separate the inverter from the power supply to ensure safe maintenance and inspection work

The inverter's input side MC is used for the above purpose, select class JEM1038-AC3MC for the inverter input side

current when making an emergency stop during normal operation.

REMARKS

Since repeated inrush current at powering on will shorten the life of the converter part (switching life is 100 million times), frequent

on/off must be avoided. Turn on/off the inverter start controlling terminals (STF, STR) to run/stop the inverter.

• Inverter start/stop circuit example

As shown on the left, always use the start signal

(ON or OFF across terminals STF or STR-PC) to

make a start or stop.

*1 When the power supply is 400V class, install a step-

Power

supply

MCCB

U

V

W

To the

motor

MC

R/L1

S/L2

T/L3

Page 30

Precautions for use of the inverter

2.6 Precautions for use of the inverter

The FR-F700 series is a highly reliable product, but incorrect peripheral circuit making or operation/handling method

may shorten the product life or damage the product.

Before starting operation, always recheck the following items.

(1) Use crimping terminals with insulation sleeve to wire the power supply and motor.

(2) Application of power to the output terminals (U, V, W) of the inverter will damage the inverter. Never perform such wiring.

(3) After wiring, wire offcuts must not be left in the inverter.

Wire offcuts can cause an alarm, failure or malfunction. Always keep the inverter clean. When drilling mounting holes in

an enclosure etc., take care not to allow chips and other foreign matter to enter the inverter.

(4) Use cables of the size to make a voltage drop 2% maximum.

If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause the motor torque

to decrease especially at the output of a low frequency.

Refer to page 12 for the recommended cable sizes.

(5) The overall wiring length should be 500m maximum.

Especially for long distance wiring, the fast-response current limit function may decrease or the equipment connected to the

secondary side may malfunction or become faulty under the influence of a charging current due to the stray capacity of the

wiring. Therefore, note the overall wiring length. (Refer to page 13.)

Page 31

Precautions for use of the inverter

(13) If the machine must not be restarted when power is restored after a power failure, provide a magnetic contactor in the

inverter's input side and also make up a sequence which will not switch on the start signal.

If the start signal (start switch) remains on after a power failure, the inverter will automatically restart as soon as the

power is restored.

(14) Instructions for overload operation

When performing an operation of frequent start/stop of the inverter, increase/decrease in the temperature of the

transistor element of the inverter may repeat due to a continuous flow of large current, shortening the life from thermal

fatigue. Since thermal fatigue is related to the amount of current, the life can be increased by reducing bound current,

starting current, etc. Decreasing current may increase the life. However, decreasing current will result in insufficient

torque and the inverter may not start. Therefore, increase the inverter capacity to have enough allowance for current.

(15) Make sure that the specifications and rating match the system requirements.

Page 32

Step of operation

3 DRIVE THE MOTOR

3.1 Step of operation

The inverter needs frequency command and start command. Turning the start command on

start the motor rotating and the motor speed is determined by the frequency command (set

frequency).

Refer to the flow chart below to perform setting.

Step of operation

o

p

Step of operation

Installation/mounting

System examination

Wiring of the power

supply and motor

{Refer to page 9}

{Refer to page 6}

Page 33

Operation panel (FR-DU07)

3.2 Operation panel (FR-DU07)

3.2.1 Parts of the operation panel (FR-DU07)

PU: Lit to indicate PU operation mode.

EXT: Lit to indicate external operation mode.

NET: Lit to indicate network operation mode.

Rotation direction indication

REV: Lit during reverse rotation

FWD: Lit during forward rotation

Unit indication

· Hz: Lit to indicate frequency.

· A: Lit to indicate current.

Operation mode indication

On: Forward/reverse operation

Flickering: When the frequency command is

not given even if the

forward/reverse command is given.

Page 34

Operation panel (FR-DU07)

3.2.2 Basic operation (factory setting)

At powering on (external operation mode)

PU operation mode

(output frequency monitor)

PU Jog operation mode

Output current monitor

Output voltage monitor

Value change

(Example)

Frequency setting has been

written and completed!!

and frequency flicker.

Operation mode switchover

Monitor/frequency setting

(Refer to page 32)

Page 35

Operation panel (FR-DU07)

3.2.3 Operation lock (Press [MODE] for an extended time (2s))

· Set "10 or 11" in Pr. 161, then press for 2s to make the setting dial and key operation invalid.

· When the setting dial and key operation is made invalid, appears on the operation panel.

When the setting dial and key operation is invalid, appears if the setting dial or key operation is

performed. (When the setting dial or key operation is not performed for 2s, the monitor display appears.)

· To make the setting dial and key operation valid again, press for 2s.

Operation using the setting dial and key of the operation panel can be made invalid to prevent parameter

change and unexpected start and stop.

POINT

Set "0" (extended mode parameter valid) in Pr.160 User group read selection.

Set "10 or 11" (key lock mode valid) in Pr.161 Frequency setting/key lock operation selection.

1.Screen at powering on

Display

Operation

Page 36

Operation panel (FR-DU07)

3.2.4 Monitoring of output current and output voltage

POINT

Monitor display of output frequency, output current and output voltage can be changed by pushing during

monitoring mode.

2.Independently of whether the inverter is running

in any operation mode or at a stop, the output

current monitor appears by pressing .

3.Press to show the output voltage monitor.

1.Press during operation to choose the output

frequency monitor

Display

Operation

Page 37

Operation panel (FR-DU07)

3.2.7 Change the parameter setting value

Changing example Change the Pr. 1 Maximum frequency .

1.Screen at powering on

The monitor display appears.

Display

Operation

3.Press to choose the parameter

setting mode.

4. Pr. 1) appears.

5.Press to read the currently set value.

" "(initial value) appears.

PU indication is lit.

2.Press to choose the PU operation

mode.

The parameter

number read

previously appears.

Page 38

Overheat protection of the motor by the inverter (Pr. 9)

3.3 Overheat protection of the motor by the inverter (Pr. 9)

Set the rated motor current in Pr. 9 Electronic thermal O/L relay to protect the motor from overheat.

Parameter

Number

Name Initial Value Setting Range *2 Description

9 Electronic thermal O/L relay

Inverter rated

current

*1

01160 or less

0 to 500A

Set the rated motor current.

01800 or more

0 to 3600A

*1 Refer to page 116 for the rated inverter current value.

*2 The minimum setting increments are 0.01A for the

01160

or less and 0.1A for the

01800

or more.

Changing example

Change the Pr. 9 Electronic thermal O/L relay setting to 2.0A according to the motor rated current.

(FR-F740-00023)

1.Screen at powering on

The monitor display appears.

2.Press to choose the PU

operation mode.

PU indication is lit.

Display

Operation

Page 39

Start/stop from the operation panel (PU

operation mode)

3.4 Start/stop from the operation panel (PU operation mode)

3.4.1 Set the set frequency to operate (example: performing operation at 30Hz)

POINT

From where is the frequency command given?

· Operation at the frequency set in the frequency setting mode

of the operation panel →Refer to 3.4.1 (Refer to page 34)

· Operation using the setting dial as the volume

→Refer to 3.4.2 (Refer to page 35)

· Change of frequency with ON/OFF switches connected to

terminals →Refer to 3.4.3 (Refer to page 36)

· Frequency setting with a voltage output device

→Refer to 3.4.4 (Refer to page 38)

· Frequency setting with a current output device

→Refer to 3.4.5 (Refer to page 40)

Three-phase

A

C power supply

Motor

Inverter

R/L1

S/L2

T/L3

U

V

W

FR-DU07

,

,

[Connection diagram]

1.

Screen at powering on

The monitor display appears.

2.

Press to choose the PU

PU indication is lit.

Display

Operation

Page 40

Start/stop from the operation panel (PU

operation mode)

3.4.2 Use the setting dial like a potentiometer to perform operation.

POINT

Set "0" (extended mode parameter valid) in Pr. 160 User group read selection.

Set "1" (setting dial potentiometer mode) in Pr. 161 Frequency setting/key lock operation selection.

Operation example Change the frequency from 0Hz to 50Hz during operation

DisplayOperation

PU indication is lit.

The parameter number

previously read appears.

1. Screen at powering on

The monitor display appears.

2. Press to choose the PU operation

mode.

3. Press to choose the parameter

setting mode.

4. Turn until (Pr. 160) appears.

Page 41

Start/stop from the operation panel (PU

operation mode)

3.4.3 Use switches to give a start command and a frequency setting (multi-speed

setting)

[Connection diagram]

POINT

· Use / to give a start command.

· Pr. 79 Operation mode selection must be set to "4" (external/PU combined operation mode 2)

· The initial values of the terminals RH, RM, RL are 50Hz, 30Hz, and 10Hz. (Refer to page 44 to change frequencies

using Pr. 4, Pr. 5 and Pr. 6.)

· Operation at 7-speed can be performed by turning on two (or three) terminals simultaneously.

(Refer to Instruction Manual (applied).)

ON

ON ON ON ON

ON ON

ONONON

ON

Output frequency (Hz)

Speed 1

(High speed)

Speed 2

(Middle speed)

Speed 3

(Low speed)

Speed 4

Speed 5

Speed 6

Speed 7

Time

RH

RM

RL

Three-phase

AC power supply

Moto

r

Inverter

R/L1

S/L2

T/L3

U

V

W

High speed

Middle speed

Low speed

RH

RM

RL

FR-DU07

PC

Page 42

Start/stop from the operation panel (PU

operation mode)

50Hz for the RH, 30Hz for the RM and 10Hz for the RL are not output when they are turned on ... Why?

Check for the setting of Pr. 4, Pr. 5, and Pr. 6 once again.

Check for the setting of Pr. 1 Maximum frequency and Pr. 2 Minimum frequency once again.

(Refer to page 52.)

Check that Pr. 180 RL terminal function selection = "0", Pr. 181 RM terminal function selection = "1", Pr.

182 RH terminal function selection ="2", and Pr. 59 Remote function selection = "0". (all are initial values)

[FWD (or REV)] lamp is not lit ... Why?

Check that wiring is correct. Check the wiring once again.

Flickering

9. Turn on the low speed switch (RL).

The output frequency increases to " "

(10Hz) according to Pr. 7 Acceleration time.

10. Turn off the low speed switch (RL).

The output frequency decreases to " "

(0Hz) according to Pr. 8 Deceleration time.

11. Turn off the start switch .

FWD (or REV) turns off.

Low speed

Low speed

Operation Display

Page 43

Start/stop from the operation panel (PU

operation mode)

3.4.4 Perform frequency setting by analog (voltage input)

[Connection diagram]

(The inverter supplies 5V of power to the frequency setting potentiometer.(Terminal 10)

)

POINT

· Use / to give a start command.

· Pr. 79 Operation mode selection must be set to "4" (external/PU combined operation mode 2)

Three-phase

AC power supply

Moto

r

Frequency setting

potentiometer

Inverter

R/L1

S/L2

T/L3

U

V

W

5

10

2

FR-DU07

,

DisplayOperation

Page 44

Start/stop from the operation panel (PU

operation mode)

Change the frequency (50Hz) of the maximum value of potentiometer (at 5V)

Adjust the frequency in Pr. 125 Terminal 2 frequency setting gain frequency. (Refer to page 47.)

Change the frequency (0Hz) of the minimum value of potentiometer (at 0V)

Adjust the frequency in calibration parameter C2 Terminal 2 frequency setting bias frequency. (Refer to

Instruction Manual (applied).)

Stop

Flickering

DisplayOperation

10.

Deceleration

Turn the volume (frequency setting potentiometer)

counterclockwise slowly to full.

The frequency value on the indication decreases

according to Pr. 8 Deceleration time unitl

" "

(

0.00Hz) is displayed and operation status indication

of FWD or REV flickers.

The motor stops.

11. Stop

Press .

Operation status indication of FWD (or REV)

turns off.

Page 45

Start/stop from the operation panel (PU

operation mode)

3.4.5 Perform frequency setting by analog (current input)

[Connection diagram]

POINT

· Use / to give a start command.

· Turn the AU signal on.

· Pr. 79 Operation mode selection must be set to "4" (external/PU combined operation mode 2)

Three-phase

AC power supply

Moto

r

5(-)

4(+)

AU

Inverter

R/L1

S/L2

T/L3

U

V

W

A

U signal

FR-DU07

,

Output of the

adjustment meter

(4 to 20mADC)

PC

Page 46

Start/stop from the operation panel (PU

operation mode)

REMARKS

Stop

Flickering

DisplayOperation

10.

Deceleration

Perform 4mA input.

The frequency value on the indication

decreases according to Pr. 8 Deceleration time

until

" " (

0.00Hz) is displayed and the

operation status indication of FWD or REV

flickers.

The motor stops.

11.

Stop

Press .

FWD or REV of the operation status indication

turns off.

Output of the

adjustment meter

(4 to 20mADC)

Output of the

adjustment meter

(4 to 20mADC)

9.

Acceleration → constant speed

Perform 20mA input.

The frequency value on the indication increases

according to Pr. 7 Acceleration time

until

" " (

50.00Hz) is displayed.

Page 47

Make a start and stop with terminals

(external operation)

3.5 Make a start and stop with terminals (external operation)

3.5.1 Use the set frequency set by the operation panel (Pr. 79 = 3)

POINT

From where is the frequency command given?

· Operation at the frequency set in the frequency setting mode of the operation panel → Refer to 3.5.1(Refer to page 42)

· Give a frequency command by switch (multi-speed setting) → Refer to 3.5.2 (Refer to page 44)

· Perform frequency setting by a voltage output device → Refer to 3.5.3 (Refer to page 46)

· Perform frequency setting by a current output device → Refer to 3.5.5 (Refer to page 48)

POINT

[Connection diagram]

· Switch terminal STF(STR)-PC on to give a start

command.

·Set "3" in Pr. 79 (External/PU combined

operation mode 1).

· Refer to page 34 for the set frequency by the

operation panel.

Three-phase

AC power supply

Moto

r

Inverter

R/L1

S/L2

T/L3

U

V

W

FR-DU07

STR

Forward rotation

start

Reverse rotation

start

STF

PC

Page 48

Make a start and stop with terminals

(external operation)

REMARKS

· Pr. 178 STF terminal function selection must be set to "60" (or Pr. 179 STR terminal function selection must be set to "61").

(all are initial values)

· When Pr. 79 Operation mode selection is set to "3", multi-speed operation (refer to page 44) is also made valid.

When the inverter is stopped by of the operation panel (FR-DU07), and are

Display

Operation

Stop

10.Turn the start switch (STF or STR) off.

The motor decelerates according to

Pr. 8 Deceleration time to stop.

OFF

Flicker ··· Frequency setting complete!!

9.While the value is flickering,

press to set the frequency.

If you do not press ,the value flickers

for about 5s and the display then returns

to 0.00 (display) Hz. At this time, return to

"Step 3" and set the frequency again.

Forward

rotation

Reverse

rotation

Page 49

Make a start and stop with terminals

(external operation)

3.5.2 Use switches to give a start command and a frequency setting

(multi-speed setting) (Pr. 4 to Pr. 6)

[Connection diagram]

POINT

· Start command by terminal STF (STR)-PC

· Frequency command by terminal RH, RM, RL and STR-PC

· [EXT] must be lit. (When [PU] is lit, switch it to [EXT] with .)

· The initial values of the terminals RH, RM, RL are 50Hz, 30Hz, and 10Hz. (Use Pr. 4, Pr. 5 and Pr. 6 to change.)

· Operation at 7-speed can be performed by turning two (or three) terminals simultaneously. (Refer to

Instruction Manual (applied).)

Three-phase

AC power supply

Moto

r

Inverter

R/L1

S/L2

T/L3

U

V

W

Forward

rotation start

Reverse

rotation start

STF

STR

Output frequency (Hz)

Speed 1

(High speed)

Speed 2

(Middle speed)

Speed 3

(Low speed)

Speed 4

Speed 5

Speed 6

Speed 7

Page 50

Make a start and stop with terminals

(external operation)

ON

ON

Stop

OFF

Forward rotation

Reverse rotation

High speed

Middle speed

Low speed

DisplayOperation

8.

Turn on the high speed switch (RH).

10.

Stop

Turn the start switch (STF or STR) off.

The motor stops according to Pr. 8

Deceleration time.

• 30Hz appears when RM is on and 10Hz

appears when RL is on.

Forward

rotation

Reverse

rotation

7.

Mode/monitor check

Press twice to choose the

monitor/frequency monitor.

9.

Turn the start switch (STF or STR) on.

" " (40Hz) appears.

Page 51

Make a start and stop with terminals

(external operation)

3.5.3 Perform frequency setting by analog (voltage input)

[Connection diagram]

(The inverter supplies 5V of power to frequency setting potentiometer. (Terminal 10))

Three-phase

AC power supply

Moto

r

Frequency setting

potentiometer

Inverter

R/L1

S/L2

T/L3

U

V

W

5

10

2

Forward rotation

start

Reverse rotation

start

STF

STR

PC

1.Power on → operation mode check

For the initial setting, the inverter operates

in the external operation mode [EXT] when

powering on. Check that the operation

ON

DisplayOperation

Page 52

Make a start and stop with terminals

(external operation)

3.5.4 Change the frequency (50Hz) of the maximum value of potentiometer (at 5V)

<How to change the maximum frequency?>

The motor will not rotate ... Why?

Check that [EXT] is lit.

[EXT] is valid when Pr. 79 = "0" (initial value).

Use to lit [EXT].

Check that wiring is correct. Check once again.

Change the frequency (0Hz) of the minimum value of potentiometer (at 0V)

Adjust the frequency in calibration parameter C2 Terminal 2 frequency setting bias frequency. (Refer to

Instruction Manual (applied).)

When you want to compensate frequency setting, use terminal 1.

For details, refer to Instruction Manual (applied).

Changing example When you want to use the 0 to 5VDC input frequency setting potentiometer to change the 5V-

time frequency from 50Hz (initial value) to 40Hz

Adjust to output 40Hz at 5V voltage input.

Set "40Hz" in Pr. 125.

Displ

ay

O

peration

Page 53

Make a start and stop with terminals

(external operation)

3.5.5 Perform frequency setting by analog (current input)

[Connection diagram]

POINT

· Switch terminal STF(STR)-PC on to give a start command.

· Turn the AU signal on.

· Set "2" (external operation mode) in Pr. 79 Operation mode selection

5(-)

4(+)

Three-phase

AC power supply

AU

Moto

r

Inverter

R/L1

S/L2

T/L3

U

V

W

AU signal

STF

Forward rotation start

Reverse rotation start

STR

Output of the

adjustment meter

(4 to 20mADC)

PC

Page 54

Make a start and stop with terminals

(external operation)

3.5.6 Change the frequency (50Hz) of the maximum value of potentiometer (at 20mA)

<How to change the maximum frequency?>

The motor will not rotate ... Why?

Check that [EXT] is lit.

[EXT] is valid when Pr. 79 = "0" (initial value).

Use to lit [EXT].

Check that the AU signal is on.

Turn the AU signal on.

Check that wiring is orrect. Check it again.

Change the frequency (0Hz) of the minimum value of potentiometer (at 4mA)

Adjust the frequency in calibration parameter C5 Terminal 4 frequency setting bias frequency.

(Refer to Instruction Manual (applied).)

Changing example When you want to use the 4 to 20mA input frequency setting potentiometer to change the 20mA-

time frequency from 50Hz (initial value) to 40Hz

Adjust to output 40Hz at 20mA current input.

Set "40Hz" in Pr. 126.

PU

EXT

DisplayOperation

Page 55

Simple mode parameter list

4ADJUSTMENT

4.1 Simple mode parameter list

For simple variable-speed operation of the inverter, the initial setting of the parameters may be used as they are. Set the

necessary parameters to meet the load and operational specifications. Parameter setting, change and check can be made from

the operation panel (FR-DU07). For details of parameters, refer to Instruction Manual (applied).

POINT

Only simple mode parameters are displayed by the initial setting of Pr. 160 User group read selection. Set Pr. 160 User

group read selection as required. (Refer to page 63.)

Pr. 160 Description

9999

(Initial Value)

Only the simple mode parameters can be displayed.

0 Simple mode and extended mode parameters can be displayed.

1 Only the parameters registered in the user group can be displayed.

Page 56

Increase the starting torque (Pr. 0)

4.2 Increase the starting torque (Pr. 0)

Set this parameter when "the motor with a load will not rotate", "an alarm [OL] is output, resulting in an inverter

trip due to [OC1], etc.

Parameter

Number

Name Initial Value

Setting

Range

Description

0 Torque boost

00023

6%

0 to 30%

Motor torque in the lowfrequency range can be

adjusted to the load to increase

the starting motor torque.

00038 to 00083

4%

00126, 00170

3%

00250 to 00770

2%

00930, 01160

1.5%

01800 or more

1%

Changing example

When the motor with a load will not rotate,

increase the Pr. 0 value 1% by 1% unit by

looking at the motor movement. (The guideline

is for about 10% change at the greatest.)

Output

voltage

P

r. 0

P

r.46

Setting

range

Base

frequency

0

100%

Output

frequency

Page 57

Limit the maximum and minimum

output frequency (Pr. 1, Pr. 2)

4.3 Limit the maximum and minimum output frequency (Pr. 1, Pr. 2)

Parameter

Number

Name Initial Value

Setting

Range

Description

1 Maximum frequency

01160 or less

120Hz

0 to 120Hz

Set the upper limit of the output

frequency.

01800 or more

60Hz

2 Minimum frequency

0Hz 0 to 120Hz

Set the lower limit of the output

frequency.

Changing example

Limit the frequency set by the potentiometer,

etc. to 50Hz maximum.

(Set "50"Hz in Pr. 1 Maximum frequency.)

Output frequency

(Hz)

Pr.1

Pr.18

Pr.2

Frequency setting

Clamped at the

maximum frequenc

y

Clamped at the

minimum frequency

5, 10V

(20mA)

0

(4mA)

Display

Operation

Page 58

When the rated motor frequency is 60Hz

(Pr. 3)

4.4 When the rated motor frequency is 60Hz (Pr. 3)

First, check the motor rating plate. If a frequency given on the rating plate is "60Hz" only, always set Pr. 3 Base frequency

to "60Hz".

Parameter

Number

Name Initial Value Setting Range Description

3 Base frequency

50Hz 0 to 400Hz

Set the frequency when the motor

rated torque is generated.

Changing example Change Pr. 3 Base frequency to 60Hz according to the motor rated frequency.

3.Press to choose the parameter

setting mode.

1.Screen at powering on

The monitor display appears.

2.Press to choose the PU operation

mode.

PU indication is lit.

Display

Operation

The parameter

number

read previously

Page 59

Change acceleration and deceleration time

(Pr. 7, Pr. 8)

4.5 Change acceleration and deceleration time (Pr. 7, Pr. 8)

* Depends on the Pr. 21 Acceleration/deceleration time increments setting. Τηε ινιτιαλ ϖαλυε φορ τηε σεττινγ ρανγε ισ ∀0 το 3600σ∀

ανδ σεττινγ ινχρεµεντσ ισ ∀0.1σ∀.

Set in Pr. 7 Acceleration time a larger value for a slower speed increase and a smaller value for a faster speed increase.

Set in Pr. 8 Deceleration time a larger value for a slower speed decrease and a smaller value for a faster speed decrease.

Parameter

Number

Name Initial Value

Setting

Range

Description

7 Acceleration time

00170 or less

5s

0 to 3600/

360s

*

Set the motor acceleration time.

00250 or more

15s

8 Deceleration time

00170 or less

10s

0 to 3600/

360s

*

Set the motor deceleration time.

00250 or more

30s

Changing example Change the Pr. 7 Acceleration time setting from "5s"

to "10s".

Running

frequenc

y

Acceleration

time

Deceleration

time

Time

Pr.20

Pr.7

Pr.8

Output

frequency

(Hz)

(50Hz)

Page 60

Energy saving operation (Pr. 60)

4.6 Energy saving operation (Pr. 60)

4.6.1 Energy saving operation mode (setting "4")

· When "4" is set in Pr. 60, the inverter operates in the energy saving operation mode.

· In the energy saving operation mode, the inverter automatically controls the output voltage to minimize the

inverter output voltage during a constant operation.

Without a fine parameter setting, the inverter automatically performs energy saving operation.

This inverter is appropriate for fan and pump applications

Parameter

Number

Name

Initial

Value

Setting

Range

Remarks

60 Energy saving control selection

0

0 Normal operation mode

4 Energy saving operation mode

9 Optimum excitation control mode

REMARKS

· For applications a large load torque is applied to or machines repeat frequent acceleration/deceleration, an energy saving

effect is not expected.

Page 61

Energy saving operation (Pr. 60)

1.Screen at powering on

The monitor display appears.

Display

Operation

3.Press to choose the parameter

setting mode.

4.

Turn until (

Pr. 60)

appears

.

5.Press to read the currently set value.

" "(initial value) appears.

6.

Turn to change it to the set

value " ".

PU indication is lit.

2.Press to choose the PU operation

mode.

The parameter

number previously

read appears.

Page 62

Selection of the operation command and

frequency command locations (Pr. 79)

4.7 Selection of the operation command and frequency

command locations (Pr. 79)

Select the start command location and frequency command location.

Parameter

Number

Name

Initial

Value

Setting

Range

Description

LED Indication

: Off

: On

0

Use external/PU switchover mode (press to switch

between the PU and external operation mode. (Refer to

page 34))

At power on, the inverter is in the external operation

mode.

External operation mode

PU operation mode

1 Fixed to PU operation mode

2

Fixed to external operation mode

Operation can be performed by switching between the

external and NET operation mode.

External operation mode

NET operation mode

Page 63

Parameter clear, all parameter clear

4.8 Parameter clear, all parameter clear

POINT

· Set "1" in Pr. CL parameter clear, ALLC All parameter clear to initialize parameters. (Parameters are not cleared

when "1" is set in Pr. 77 Parameter write selection. )

· Refer to the parameter list on page 64 for parameters to be cleared with this operation.

1.

Screen at powering on

The monitor display appears.

Display

Operation

3.

Press to choose the parameter

setting mode.

PU indication is lit.

2.

Press to choose the PU operation

mode.

4.

Turn until " ", " "

The parameter

number read

previously appears.

Page 64

Parameter copy and parameter verification

4.9 Parameter copy and parameter verification

4.9.1

Parameter copy

PCPY Setting Description

0 Cancel

1 Copy the source parameters to the operation panel.

2 Write the parameters copied to the operation panel into the destination inverter.

3 Verify parameters in the inverter and operation panel. (Refer to page 60.)

Multiple inverters and parameter settings can be copied.

REMARKS

· When the copy destination inverter is not the FR-F700 series or parameter copy write is performed after parameter read is stopped,

“model error ( )” is displayed.

· Refer to the parameter list on

page 64 and later for availability of parameter copy.

· When the power is turned off or an operation panel is disconnected, etc. during parameter copy write, perform write again or check the

values by parameter verification.

Display

Operation

Page 65

Parameter copy and parameter verification

4.9.2 Parameter verification

appears...Why? Parameter read error. Perform operation from step 3 again.

appears...Why? Parameter write error. Perform operation from step 8 again.

and flicker alternately

Appears when parameters are copied between the inverter of 01160 or less and 01800 or more.

1. Set "0" in Pr. 160 User group read selection.

2. Set the following setting (initial value) in Pr. 989 Parameter copy alarm release.

3. Reset Pr. 9, Pr. 30, Pr. 51, Pr. 52, Pr. 54, Pr. 56, Pr. 57, Pr. 70, Pr. 72, Pr. 80, Pr. 90, Pr. 158, Pr. 190 to Pr. 196, Pr. 893.

Whether same parameter values are set in other inverters or not can be checked.

01160 or less 01800 or more

Pr. 989 Setting 10 100

Display

Operation

1.Replace the operation panel on the

inverter to be verified.

Page 66

Parameter list

4.10Parameter list

4.10.1 List of parameters classified by purpose of use

Set the parameters according to the operating conditions. The following list indicates purpose of use and

corresponding parameters.

Purpose of Use Parameter Number

Adjust the output torque of

the motor (current)

Manual torque boost Pr. 0, Pr. 46

Simple magnetic flux vector control Pr. 80, Pr. 90

Slip compensation Pr. 245 to Pr. 247

Stall prevention operation

Pr. 22, Pr. 23, Pr. 48, Pr. 49, Pr. 66, Pr.

148, Pr. 149, Pr. 154, Pr. 156, Pr. 157

Multiple rating setting Pr. 570

Limit the output frequency

Maximum/minimum frequency Pr. 1, Pr. 2, Pr. 18

Avoid mechanical resonance points (frequency jump) Pr. 31 to Pr. 36

Set V/F pattern

Base frequency, voltage Pr. 3, Pr. 19, Pr. 47

V/F pattern matching applications Pr. 14

Adjustable 5 points V/F Pr. 71, Pr. 100 to Pr. 109

Pr. 4 to Pr. 6, Pr. 24 to Pr. 27,

Page 67

Parameter list

Operation selection at power

failure and instantaneous

power failure

Restart operation after instantaneous power failure/Flying

start

Pr. 57, Pr. 58, Pr. 162 to Pr. 165, Pr.

299, Pr. 611

Decelerate the motor to a stop at instantaneous power failure Pr. 261 to Pr. 266

Operation setting at alarm

occurrence

Retry function at alarm occurrence Pr. 65, Pr. 67 to Pr. 69

Output function of alarm code Pr. 76

Input/output phase failure protection selection Pr. 251, Pr. 872

Regeneration avoidance function Pr. 882 to Pr. 886

Energy saving operation

Energy saving control selection Pr. 60

How much energy can be saved (energy saving monitor) Pr. 891 to Pr. 899

Reduction of the motor noise

Measures against noise and

leakage currents

Carrier frequency and SoftPWM selection Pr. 72, Pr. 240, Pr. 260

Noise elimination at the analog input Pr. 74

Frequency setting by analog

input

Analog input selection Pr. 73, Pr. 267, Pr. 573

Override function Pr. 73, Pr. 252, Pr. 253

Noise elimination at the analog input Pr. 74

Change of analog input frequency,

adjustment of voltage, current input and frequency

(calibration)

Pr. 125, Pr. 126, Pr. 241,

C2 to C7 (Pr. 902 to Pr. 905)

Purpose of Use Parameter Number

Page 68

Extended parameters

4.11Extended parameters

4.11.1 Used to display the extended parameters

1. Screen at powering on

The monitor display appears.

DisplayOperation

3. Press to choose the parameter

setting mode.

4. Tu

Pr. 160)

appears.

PU indication is lit.

2. Press to choose

the PU operation mode.

The parameter

number read

previously appears.

5. Press to read the currently set value.

" " (initial value) appears.

Page 69

Parameter list

4.12Parameter list

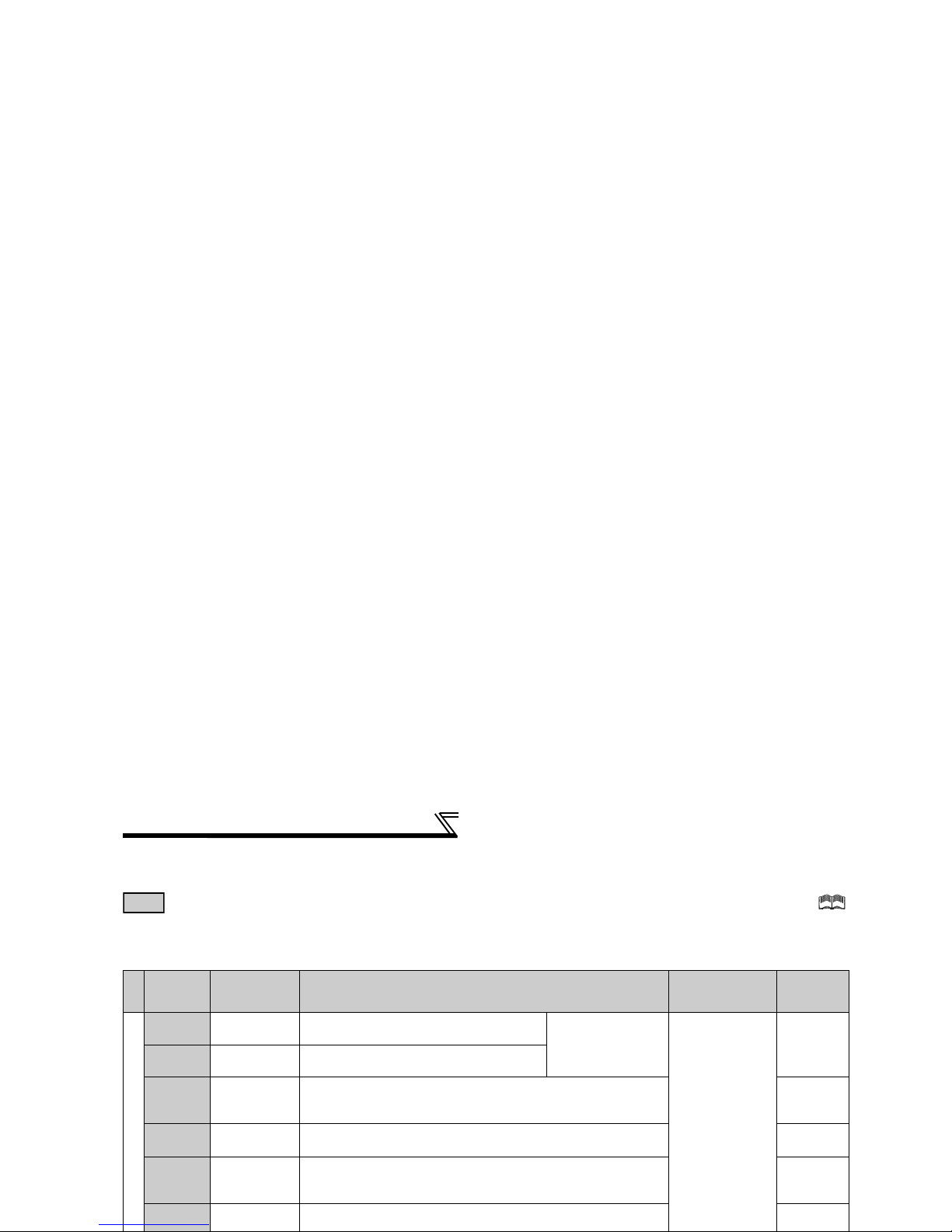

indicates simple mode parameters.

Func

t

ion

Parameter

Name

Incre

ments

Initial

Val ue

Range Description

Param

eter

copy

Param

eter

clear

All

param

eter

clear

Related

parameters

{: enabled

× : disabled

Manual torque boost

0

Torque boost

0.1%

6/4/3/2/

1.5/1%

*1

0 to 30%

Set the output voltage at 0Hz as %.

*1 Initial values differ according to the

inverter capacity.

{{{

46

Second torque

0.1% 9999

0 to 30%

Set the torque boost when the RT signal

is on.

{{{

Inverter capacity

Initial value

400V class

00023 6%

00038 to 00083 4%

00126, 00170 3%

00250 to 00770 2%

00930, 01160 1.5%

01800 or more 1%

Page 70

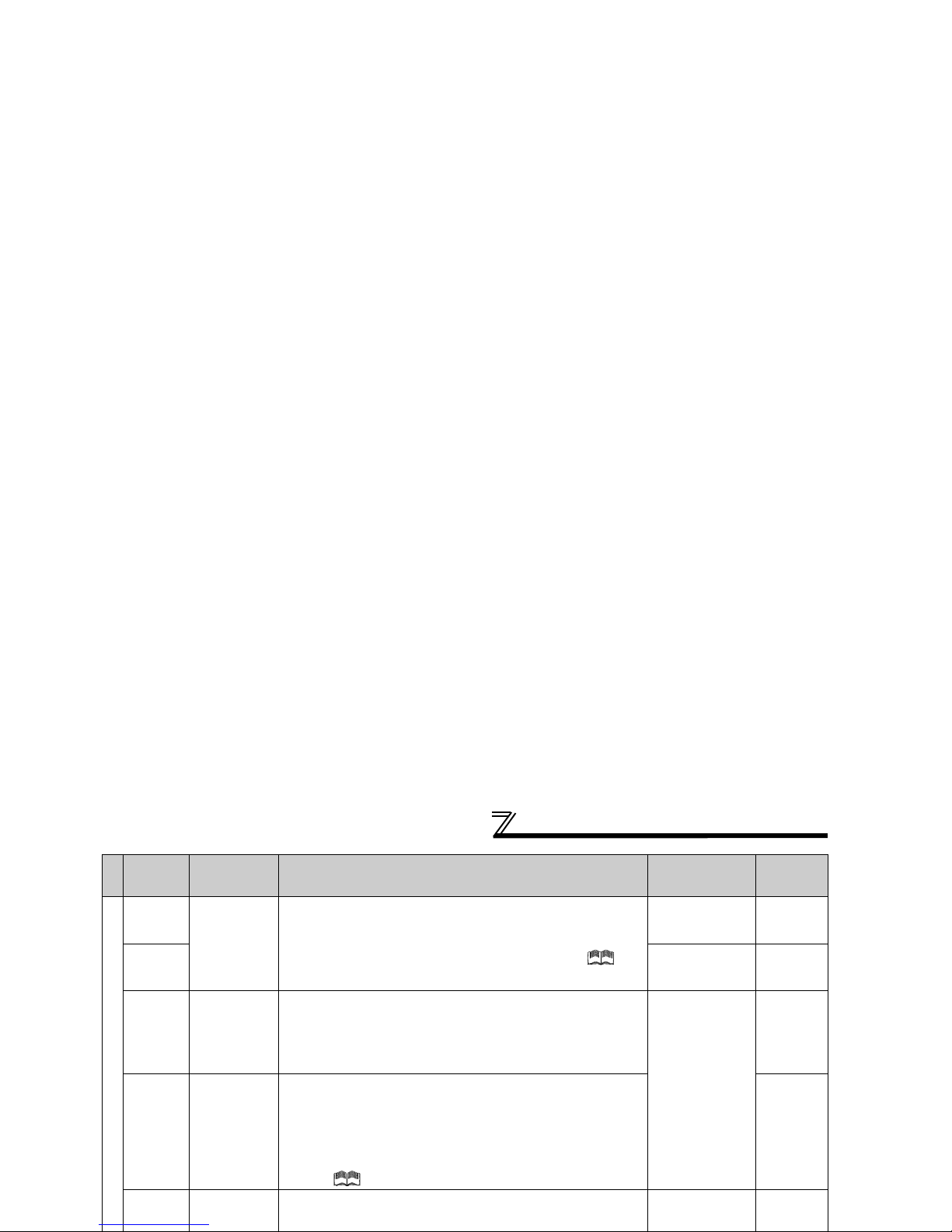

Parameter list

Parameter list

Acceleration/deceleration time setting

7

Acceleration time

0.1/

0.01s

5/15s

*4

0 to 3600/

360s

Set the motor acceleration time.

*4 Initial values differ according to the inverter

capacity. (

00170

or less/

00250

or more)

{{{

8

Deceleration time

0.1/

0.01s

10/30s

*5

0 to 3600/

360s

Set the motor deceleration time.

*5 Initial values differ according to the inverter

capacity. (

00170

or less/

00250

or more)

{{{

20

Acceleration/

deceleration

reference frequency

0.01Hz 50Hz 1 to 400Hz

Set the frequency referenced as

acceleration/deceleration time. Set the

frequency change time from stop to Pr. 20

for acceleration/deceleration time.

{{{

21

Acceleration/

deceleration time

increments

10

0

Increments: 0.1s

Range: 0 to 3600s

Increments and

setting range of

acceleration/

deceleration time

setting can be

changed.

{{{

1

Increments: 0.01s

Range: 0 to 360s

44

Second

acceleration/

deceleration time

0.1/

0.01s

5s

0 to 3600/

360s

Set the acceleration/deceleration time

when the RT signal is on.

{{{

Func

t

ion

Parameter