Page 1

Page 2

EZMotion, MELDAS and MELSEC are registered trademarks of Mitsubishi Electric

Corporation.

Other company and product names that appear in this manual are trademarks or

registered trademarks of the respective company.

Page 3

Introduction

This manual is referred to when using the EZMotion-NC E60/E68.

This manual explains how to operate, run and set up this NC unit. Read this manual

thoroughly before using the NC unit. To safely use this NC unit, thoroughly study the

"Precautions for Safety" on the next page before use.

Details described in this manual

CAUTION

For items described as "Restrictions" or "Usable State" in this manual, the instruction

manual issued by the machine maker takes precedence over this manual.

Items not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added. Confirm

with the specifications issued by the machine maker before starting use.

Refer to the Instruction Manual issued by each machine maker for details on each

machine tool.

Some screens and functions may differ depending on the NC system (or its version),

and some functions may not be possible. Please confirm the specifications before use.

Refer to the following documents.

EZMotion-NC E60/E68 Alarm / Parameter Manual

・・・・・・・・・

IB-1500175(ENG)

EZMotion-NC E60/E68 Programming Manual (M TYPE)

・・・・

IB-1500174(ENG)

EZMotion-NC E60/E68 Programming Manual (L TYPE)

・・・・・

IB-1500173(ENG)

In this NC unit, the machining programs, param eters and tool compensation data are saved in

the memory (mem ory elements). This NC unit's mem ory is backed up by lithium batteries, and

under normal conditions will last 6 years from the date of m anufacture. However, data contents

could be lost under the conditions described below.

To prevent data loss, output important programs, parameters, etc., to a serial input/output device

and save them. Refer to Section "

III

-8 Maintenance Functions" in this manual for inform ation on

how to do this.

Data in the memory can be lost under these kinds of conditions.

(1) Incorrect operation

Data can be lost if the operator inadvertently changes data while editing a program or setting

parameters.

(This is not really a data loss, but it is a loss from the standpoint that the original data is gone.)

Data can be lost if the operator inadvertently deletes data or initializes NC unit.

(2) Battery life expires

When the battery life expires and there is not enough voltage to store the data in the memory,

data can be lost by turning the power OFF.

(3) Faults

Data can be lost when faults occur and the control unit must be replaced.

< Important Usage Notes >

Page 4

Precautions for Safety

Always read the specifications issued by the machine maker, this manual, related

manuals and attached documents before installation, operation, programming,

maintenance or inspection to ensure correct use.

Understand this numerical controller, safety items and cautions before using the unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

When the user may be subject to imminent fatalities or major

injuries if handling is mistaken.

WARNING

When the user may be subject to fatalities or major injuries if

handling is mistaken.

CAUTION

When the user may be subject to bodily injury or when physical

damage may occur if handling is mistaken.

Note that even items ranked as "

CAUTION

", may lead to major results depending on

the situation. In any case, important information that must always be observed is

described.

DANGER

Not applicable in this manual.

WARNING

Not applicable in this manual.

CAUTION

1. Items related to product and manual

For items described as "Restrictions" or "Usable State" in this manual, the instruction

manual issued by the machine maker takes precedence over this manual.

Items not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added. Confirm

with the specifications issued by the machine maker before starting use.

Refer to the Instruction Manual issued by each machine maker for details on each

machine tool.

Some screens and functions may differ depending on the NC system (or its version),

and some functions may not be possible. Please confirm the specifications before

use.

(Continued on next page)

Page 5

CAUTION

2. Items related to installation and assembly

Ground the signal cables to ensure stable system operation. Also ground the NC unit

main frame, power distribution panel and machine to one point, so they all have the

same potential.

If the control unit's rotary switch is set to "7", all data in the NC will be erased and the

system will not start up.

3. Items related to preparation before use

Always set the stored stroke limit. Failure to set this could result in collision with the

machine end.

Always turn the power OFF before connecting/disconnecting the I/O device cable.

Failure to do so could damage the I/O device and NC unit.

4. Items related to screen operation

If the tool offset and workpiece coordinate system offset are changed during automatic

operation (including during single block stop), they are validated from the command of

the next block or blocks onwards.

When forcibly setting (forcibly outputting) data on the I/F diagnosis screen during

machine operation, pay careful attention to the sequence operation.

All of the various data in the NC memory is erased when formatting. Be sure to use

the transfer function to transfer all necessary data to another storage device before

formatting.

Even if the tool compensation amount write command, parameter write command or

variable data write command is executed with graphic check, the data will be actually

written in, and the original data will be overwritten.

To prevent influence from data omission and data transformation in the communication

circuit, always verify the data after inputting and outputting machining programs.

Do not change setup parameters without prior approval from the machine maker.

5. Items related to programming

Because of key chattering, etc., during editing, "NO NOS. FOLLOWING G" commands

become a "G00" operation during running.

";" "EOB" and "%" "EOR" are expressions used for explanation. Under ISO, the actual codes

are "CR, LF" or "LF" for ";" "EOB" and "%" for "%" "EOR".

Programs created on the Edit screen are stored in the NC memory in a "CR, LF" format, but

programs created with external devices may be stored in an "LF" format.

The actual codes for EIA are: "EOB (End of Block)" and "EOR (End of Record)".

Do not change the fixed cycle program without prior approval from the machine maker.

(Continued on next page)

Page 6

CAUTION

6. Items related to operation

Stay out of the moveable range of the machine during automatic operation. During

rotation, keep hands, feet and face away from the spindle.

Carry out dry operation before actually machining, and confirm the machining program,

tool offset and workpiece coordinate system offset.

If the operation start position is set from a block in the program and the program is

started, the program before the set block is not executed. If there are coordinate

system shift commands or M, S, T, and B commands before the block set as the

starting position, carry out the required commands using the MDI, etc. There is a

danger of interference with the machine if the operation is started from the set starting

position block without carrying out these operations.

Program so the mirror image function is turned ON/OFF at the mirror image center.

The mirror image center will deviate if the function is turned ON/OFF at a position

other than the mirror image center.

7. Items related to faults and abnormalities

If the BATTERY LOW alarm is output, save the machining programs, tool data and parameters

to an input/output device, and then replace the battery. If the BATTERY alarm occurs, the

machining programs, tool data and parameters may be damaged. After replacing the battery,

reload each data item.

If the axis overruns or emits an abnormal noise, immediately press the emergency

stop button and stop the axis movement.

8. Items related to maintenance

Incorrect connections may damage the devices, so connect the cables to the

specified connectors.

Do not apply voltages other than those indicated in this manual on the connector.

Doing so may lead to destruction or damage.

Do not connect or disconnect the connection cables between each unit while the

power is ON.

Do not connect or disconnect the PCBs while the power is ON.

Do not connect the cable by pulling on the cable wire.

Do not short circuit, charge, overheat, incinerate or disassemble the battery.

Dispose the spent battery according to local laws.

Do not replace the control unit while the power is ON.

Do not replace the base I/O unit while the power is ON.

Do not replace the control section power supply PCB while the power is ON.

Do not replace the expansion PCB while the power is ON.

Do not replace the memory cassette while the power is ON.

Be careful that metal cutting chips, etc., do not come into contact with the connector

contacts of the memory cassette.

Page 7

- i -

Contents

I.

OPERATION SECTION

1. Setting and Display Unit Operation.........................................................................................1

1.1 Appearance of Setting and Display Unit...........................................................................1

1.2 Functions of Display Areas...............................................................................................2

1.3 Screen Transition Diagram...............................................................................................4

1.3.1 Screen Transition when Power Is Turned ON.......................................................4

1.3.2 Screen Transition Diagram (Lathe system)...........................................................5

1.3.3 Screen Transition Diagram (Machining center system)........................................7

1.4 Screen Selection Procedure.............................................................................................9

1.5 Data Setting Method.......................................................................................................12

1.6 Screen Saver..................................................................................................................16

2. Monitor..................................................................................................................................18

2.1 POSITION ......................................................................................................................19

2.1.1 Total Clear of Screen ..........................................................................................21

2.1.2 Position Display Counter Zero and Origin Zero ..................................................21

2.1.3 Manual Numeric Command (S, T, M) .................................................................22

2.1.4 Displaying Automatic Operation Program...........................................................25

2.2 COORDINATE ...............................................................................................................26

2.2.1 Correcting the Buffer ...........................................................................................29

2.3 COMMAND ....................................................................................................................41

2.3.1 Execution Program Monitor.................................................................................41

2.3.2 Execution Modal Monitor.....................................................................................42

2.3.3 Total Integrating Time Display ............................................................................44

2.4 PROGRAM SEARCH.....................................................................................................46

2.4.1 Memory Search...................................................................................................47

2.4.2 Tape Search........................................................................................................48

2.4.3 IC Card Search ...................................................................................................50

2.4.4 Compare Stop.....................................................................................................51

2.5 Resuming the Program ..................................................................................................53

2.5.1 Operation Sequences for Program Restart.........................................................55

2.5.2 Restart Search Operations..................................................................................58

2.5.3 Restart Position Return System..........................................................................64

2.5.4 Manual Numeric Commands with Program Restart............................................65

2.5.5 Checkpoints for Program Restart........................................................................66

2.6 PLC SWITCH .................................................................................................................68

2.6.1 PLC Switch ON and OFF Operation ...................................................................68

2.7 COMMON VARIABLE....................................................................................................69

2.7.1 Common Variable Display...................................................................................70

2.7.2 Common Variable Setting ...................................................................................71

2.7.3 Common Variable Data Deleting.........................................................................71

2.8 LOCAL VARIABLE.........................................................................................................72

2.8.1 Local Variable Data Display................................................................................73

3 (I). Tool Offset (L system)......................................................................................................75

3.1 Wear Data ......................................................................................................................76

3.1.1 Setting Tool Offset Data......................................................................................77

3.1.2 Erasing the Tool Offset Data...............................................................................77

3.1.3 Tool Wear and Tool Length Data Setting Mode (incremental/absolute)...............78

Page 8

- ii -

3.2 Tool Length Data............................................................................................................80

3.2.1 Manual Tool Length Measurement I ...................................................................81

3.2.2 Manual Numeric Command Operation on the TOOL DATA Screen (M, T) ........87

3.2.3 Manual Tool Length Measurement II ..................................................................88

3.3 Tool Nose Data ..............................................................................................................95

3.4 Tool Life Management I (#1096 T_L type is 1)...............................................................96

3.4.1 Tool Life Management Method ...........................................................................97

3.4.2 Conditions for Counting (incrementing)...............................................................97

3.4.3 Setting Tool Life Management Data....................................................................98

3.4.4 Erasing Tool Life Management Data in Display Screen Units ............................98

3.4.5 Precautions .........................................................................................................98

3.5 Tool Life Management II (#1096 T_Ltype is 2)...............................................................99

3.5.1 Group Registration..............................................................................................99

3.5.2 Tool Life Incrementation Methods.....................................................................102

3.5.3 Parameters........................................................................................................104

3.6 Tool Registration ..........................................................................................................105

3.6.1 Outline of Functions ..........................................................................................105

3.6.2 Tool Registration in the Magazine Pot ..............................................................105

3.6.3 Tool Registration in the Spindle, Standby and Indexing Areas.........................106

3.6.4 Deleting Tool Registration Data ........................................................................107

3.6.5 Manual Numeric Command Operation (M, T) on the TOOL

REGISTRATION Screen...................................................................................107

3 (II). Tool Offset (M system)..................................................................................................109

3.1 Tool Offset....................................................................................................................110

3.1.1 Tool Offset Data Setting....................................................................................111

3.1.2 Tool Offset Data Clear ......................................................................................111

3.1.3 Tool Offset Data Setting Modes (Absolute and Incremental)............................111

3.1.4 Manual Tool Length Measurement ...................................................................114

3.1.5 Manual Numeric Command Operation on the TOOL OFFSET Screen

(M, T).................................................................................................................117

3.2 Tool Registration ..........................................................................................................118

3.2.1 Function Outline................................................................................................118

3.2.2 Tool Registration in Magazine Pot ....................................................................119

3.2.3 Tool Registration in HEAD, NEXT, and INDEX.................................................120

3.2.4 Tool Registration Data Clear.............................................................................120

3.2.5 Manual numeric Command Operation on the TOOL REGISTRATION

Screen (M, T)....................................................................................................121

3.3 Tool Life........................................................................................................................122

3.3.1 Function Outline................................................................................................122

3.3.2 TOOL LIFE Screen Data Display......................................................................123

3.3.3 TOOL LIFE Data Display and Setting (TOOL LIFE Data Screen Page 2) ........127

3.3.4 Clear of All TOOL LIFE Data (HEAD, NEXT, GROUP LIST Screen

Page 1)..............................................................................................................128

4. Parameters (User) ..............................................................................................................129

4.1 Workpiece Coordinate..................................................................................................130

4.1.1 Setting Workpiece Coordinate System Offset Data ..........................................132

4.1.2 Setting External Workpiece Coordinate System Offset Data............................132

4.1.3 Displaying Machine Position Data.....................................................................132

4.1.4 Workpiece Coordinate Offset Measurement Function (L System)....................133

4.1.5 Workpiece Coordinate Offset Measurement Function (M System)......................137

4.1.6 Workpiece Position Measurement Function (M System) ..................................138

Page 9

- iii -

4.2 Machining Parameters .................................................................................................144

4.2.1 PROCESS PARAMERTER...............................................................................144

4.2.2 Control Parameters...........................................................................................150

4.2.3 Axis Parameters................................................................................................152

4.2.4 Barrier Data.......................................................................................................154

4.2.5 Tool Measurement Parameters.........................................................................155

4.3 I/O Parameters.............................................................................................................156

4.3.1 I/O BASE PARAM .............................................................................................156

4.3.2 I/O DEVICE PARAM .........................................................................................157

4.3.3 COMPUTER LINK PARAMETER .....................................................................160

4.4 Setup Parameters ........................................................................................................163

4.5 BACKUP Screen ..........................................................................................................164

4.5.1 Backup Operations............................................................................................165

4.5.2 Restoration Operations .....................................................................................166

4.5.3 Restoring Individual Data ..................................................................................167

5. Program..............................................................................................................................168

5.1 Function Outline ...........................................................................................................169

5.2 Menu Function..............................................................................................................170

5.2.1 MDI Screen Menu Function ..............................................................................170

5.2.2 EDIT Screen Menu Function.............................................................................173

5.3 Program Edit Operation................................................................................................175

5.3.1 Data Display Update (One Screen Scroll).........................................................175

5.3.2 Data Display Update (One Line Scroll) .............................................................176

5.3.3 Data Change.....................................................................................................177

5.3.4 Data Insertion....................................................................................................178

5.3.5 Deletion of One Character ................................................................................179

5.3.6 Deletion of One Block .......................................................................................180

5.3.7 Deletion of Data on One Screen .......................................................................181

5.4 MDI Screen Extension Operation.................................................................................182

5.4.1 MDI Data Registration in Memory.....................................................................182

5.5 Edit Screen Extension Operation .................................................................................183

5.5.1 Edit Data Call ....................................................................................................183

5.5.2 New Program Registration and Preparation .....................................................188

5.6 PLAYBACK ..................................................................................................................189

5.6.1 Playback Operation...........................................................................................190

5.6.2 Edit Operation ...................................................................................................195

5.6.3 Limitations.........................................................................................................196

5.7 Word Editing.................................................................................................................197

5.7.1 Handling of the Various Keys During Word Editing...........................................200

5.7.2 Searching Word Units .......................................................................................201

5.7.3 Word Search .....................................................................................................202

5.7.4 Character String Search....................................................................................203

5.7.5 Deleting Words..................................................................................................204

5.7.6 Deleting Lines ...................................................................................................205

5.7.7 Replacing Words...............................................................................................206

5.7.8 Inserting Words.................................................................................................207

5.7.9 Copying Words..................................................................................................209

5.7.10 Program ..........................................................................................................210

5.7.11 Deleting Programs ..........................................................................................211

5.7.12 Newly Creating Programs ...............................................................................212

5.7.13 Operation Search............................................................................................213

5.7.14 B. G Search.....................................................................................................214

5.7.15 B. G Quit .........................................................................................................215

Page 10

- iv -

5.7.16 Comments.......................................................................................................215

5.7.17 Setting the Program Operation Start Position.................................................216

6. Data In/Out .........................................................................................................................217

6.1 DATA INPUT................................................................................................................218

6.1.1 Change of Input and Comparison .....................................................................219

6.1.2 Machining Program Input ..................................................................................220

6.1.3 Inputting Tool Offset Data .................................................................................222

6.1.4 Inputting Parameter Data ..................................................................................223

6.1.5 Inputting Common Variables.............................................................................224

6.1.6 Inputting History Data........................................................................................225

6.1.7 Inputting Auxiliary Axis Parameter Data............................................................226

6.2 DATA OUTPUT............................................................................................................227

6.2.1 Machining Program Output ...............................................................................229

6.2.2 Outputting Tool Offset Data ..............................................................................232

6.2.3 Outputting Parameter Data ...............................................................................233

6.2.4 Outputting Common Variable Data ...................................................................236

6.2.5 Outputting History Data.....................................................................................237

6.2.6 Outputting Waveform Data................................................................................238

6.2.7 Outputting Auxiliary Axis Parameter Data.........................................................239

6.3 PROGRAM ERASE......................................................................................................242

6.4 PROGRAM COPY........................................................................................................246

6.4.1 Machining Program Copy..................................................................................246

6.4.2 Machining Program Condense..........................................................................247

6.4.3 Machining Program Merge................................................................................248

6.4.4 Changing the Machining Program Number.......................................................249

6.5 PROGRAM FILE ..........................................................................................................250

6.6 RS-232C I/O Device Connection..................................................................................251

6.6.1 Connection of Tape Reader, Tape Puncher, Printer, FLD................................251

6.7 Data Protection.............................................................................................................252

6.7.1 Data Protection Key ..........................................................................................252

6.7.2 Edit Lock B, C ................................................................................................... 254

7. Diagnosis............................................................................................................................256

7.1 ALARM MESSAGE......................................................................................................257

7.1.1 Tracing of Alarm and Stop Codes.....................................................................257

7.2 SERVO MONITOR.......................................................................................................259

7.2.1 Servo Monitor....................................................................................................259

7.2.2 Servo Monitor (2) ..............................................................................................260

7.2.3 Servo Diagnosis................................................................................................261

7.2.4 Servo Diagnosis (2)...........................................................................................262

7.2.5 PW Diagnosis....................................................................................................263

7.3 SPINDLE MONITOR....................................................................................................264

7.4 PLC Interface Diagnosis...............................................................................................268

7.4.1 PLC-I/F Setting and Display..............................................................................268

7.4.2 PLC Device Data Display..................................................................................270

7.4.3 PLC Interface Signal Forcible Definition (Single-shot Type).............................271

7.4.4 PLC Interface Signal Forcible Definition (Modal Type) .....................................272

7.4.5 Diagnosis Executed When an Emergency Stop Status Occurs........................273

7.5 Absolute Position Monitor.............................................................................................274

7.5.1 ABS SERVO MONITOR....................................................................................274

7.5.2 Absolute Position Initialization...........................................................................275

Page 11

- v -

7.6 Adjustment ...................................................................................................................277

7.6.1 Adjustment Preparation.....................................................................................277

7.6.2 Automatic Analog Output Adjustment ...............................................................277

7.6.3 Adjustment Procedure.......................................................................................278

7.6.4 Parameter Input/Output.....................................................................................279

7.7 OPERATION HISTORY ...............................................................................................280

7.8 Configuration................................................................................................................281

7.8.1 S/W MODULE TREE ........................................................................................281

7.8.2 H/W MONITOR .................................................................................................281

7.9 Auxiliary Axis Parameter ..............................................................................................282

7.9.1 Auxiliary Axis Parameter Screen.......................................................................282

7.9.2 Backup ..............................................................................................................283

7.10 Auxiliary Axis Monitor .................................................................................................287

7.10.1 Alarm History Display......................................................................................288

7.10.2 Auxiliary Axis Adjustment Function.................................................................288

7.10.3 Operation Method for the Auxiliary Axis Adjustment Function........................291

7.11 NC Data Sampling......................................................................................................294

7.12 PLC Signal Trace..........................................................................................................295

7.12.1 Device Setting Screen.......................................................................................295

7.12.2 Device Monitor Screen ......................................................................................297

8. IC Card Operation...............................................................................................................299

8.1 IC Data Screen.............................................................................................................301

8.1.1 IC Card Input/Output............................................................................................301

8.1.2 File Selection Screen ........................................................................................303

8.1.3 NC Data File Name...........................................................................................305

8.1.4 IC Card I/O Screen Operation...........................................................................306

9. Graphics .............................................................................................................................314

9.1 Outline of Functions .....................................................................................................314

9.2 Menu Function..............................................................................................................315

9.3 Use of the Trace Mode.................................................................................................317

9.4 Use of the Check Modes..............................................................................................319

9.5 GRF MODE..................................................................................................................328

9.6 SCALE..........................................................................................................................330

9.6.1 Changing the Scale...........................................................................................330

9.6.2 Changing the Display Position ..........................................................................331

9.7 STANDARD..................................................................................................................337

9.8 ROTATION (M system) ................................................................................................338

9.9 ERASE ( ).....................................................................................................................339

9.10 PROGRAM.................................................................................................................340

10. Ladder Circuit Monitor [for PLC built-in specification only] ...............................................341

10.1 Parameter Setting ......................................................................................................341

11. Visual Analyzer (Waveform display).................................................................................342

11.1 Menu Function............................................................................................................344

11.2 Synchronous Tap Error Display .................................................................................345

II.

MACHINE OPERATION MANUAL

1. Operation State.......................................................................................................................2

1.1 Operation State Transition Diagram.................................................................................2

1.2 Power OFF.......................................................................................................................2

1.3 Run Not Ready.................................................................................................................3

Page 12

- vi -

1.4 Ready...............................................................................................................................3

1.4.1 Reset.....................................................................................................................3

1.4.2 Automatic Operation Start.....................................................................................3

1.4.3 Automatic Operation Pause ..................................................................................4

1.4.4 Automatic Operation Stop .....................................................................................4

2. Indicator Lamps ......................................................................................................................4

2.1 Control Unit Ready ...........................................................................................................4

2.2 Automatic Operation Busy................................................................................................4

2.3 Automatic Operation Start Busy.......................................................................................4

2.4 Automatic Operation Pause Busy ....................................................................................4

2.5 Return to Reference Position ...........................................................................................5

2.6 Alarm................................................................................................................................5

2.7 M00 ..................................................................................................................................5

2.8 M02/M30 ..........................................................................................................................5

3. Reset Switch and Emergency Stop Button.............................................................................6

3.1 Reset Switch ....................................................................................................................6

3.2 Emergency Stop Button ...................................................................................................6

4. Operation Mode......................................................................................................................7

4.1 Mode Selection Switch .....................................................................................................7

4.2 Jog Feed Mode ................................................................................................................7

4.3 Rapid Traverse Feed Mode..............................................................................................8

4.4 Return to Reference Position Mode .................................................................................9

4.5 Incremental Feed Mode .................................................................................................11

4.6 Handle Feed Mode.........................................................................................................12

4.7 Memory Mode ................................................................................................................13

4.8 MDI Operation Mode ......................................................................................................14

5. Operation Panel Switches in Operation Mode......................................................................15

5.1 Rapid Traverse Override ................................................................................................15

5.2 Cutting Feed Override ....................................................................................................15

5.3 Manual Feedrate ............................................................................................................15

5.4 Handle/Incremental Feed Magnification Factor..............................................................16

5.5 Handle Feed Axis Selection ...........................................................................................16

5.6 Manual Pulse Generator ................................................................................................16

5.7 Cycle Start and Feed Hold .............................................................................................17

5.8 Feed Axis Selection........................................................................................................17

6. Operation Panel Switch Functions........................................................................................18

6.1 Chamfering.....................................................................................................................18

6.2 Miscellaneous Function Lock .........................................................................................18

6.3 Single Block....................................................................................................................18

6.4 Dry Run ..........................................................................................................................18

6.5 Manual Override.............................................................................................................18

6.6 Override Cancel .............................................................................................................19

6.7 Optional Stop..................................................................................................................19

6.8 Optional Block Skip ........................................................................................................19

6.9 Manual Absolute.............................................................................................................20

6.10 Error Detect..................................................................................................................21

6.11 Follow-up Function.......................................................................................................21

6.12 Axis Removal ...............................................................................................................21

6.13 Manual/Automatic Synchronous Feed .........................................................................21

6.14 Handle Interruption.......................................................................................................22

6.14.1 Outline...............................................................................................................22

6.14.2 Interruptible Conditions .....................................................................................22

Page 13

- vii -

6.14.3 Interruption Effective Axis .................................................................................22

6.14.4 Axis Movement Speed Resulting from Interruption...........................................23

6.14.5 Path Resulting after Handle Interruption...........................................................24

6.14.6 Handle Interruption in Tool Radius Compensation ...........................................26

6.14.7 Interrupt Amount Reset .....................................................................................28

6.14.8 Operation Sequence .........................................................................................28

6.15 Machine Lock ...............................................................................................................29

6.16 Deceleration Check......................................................................................................30

6.16.1 Functions...........................................................................................................30

6.16.2 Deceleration Check Method..............................................................................30

6.16.3 Deceleration Check when Opposite Direction Movement is Reversed.............33

6.16.4 Parameters........................................................................................................34

6.16.5 Precautions .......................................................................................................36

III.

SETUP

1. Switches .................................................................................................................................1

1.1 Layout Diagram of the Control Unit Rotary Switch...........................................................1

2. Start up and Adjustment Procedure........................................................................................4

2.1 Confirmation of Connections ............................................................................................4

2.2 Setting of Various Switches..............................................................................................4

2.3 Turning Power ON, Memory Initialization and Parameter Settings ..................................6

3. Adjustment of Dog-type Reference Point Return....................................................................7

3.1 Outline..............................................................................................................................7

3.2 Dog-type Reference Point Return ....................................................................................7

3.3 Reference Point Return Parameters ................................................................................9

3.4 Dog-type Reference Point Return Adjustment Procedures............................................14

4. Absolute Position Detection System.....................................................................................15

4.1 Outline............................................................................................................................15

4.2 Coordinate System of Absolute Position System...........................................................15

4.3 Starting up Absolute Position Detection System............................................................16

5. Stored Stroke Limit ...............................................................................................................26

5.1 Stored stroke limit I.........................................................................................................28

5.2 Stored stroke limit II........................................................................................................29

5.3 Stored stroke limit IB ......................................................................................................31

5.4 Stored stroke limit IC......................................................................................................31

5.5 Movable Range during Inclined Axis Control .................................................................32

5.6 Stored Stroke Limit for Rotation Axis .............................................................................33

5.7 Precautions ....................................................................................................................34

6. Daily Maintenance and Periodic Inspection and Maintenance................................................35

6.1 Maintenance Tools.........................................................................................................35

6.2 Maintenance Items.........................................................................................................35

6.2.1 Escutcheon .........................................................................................................36

6.2.2 Handling the CRT................................................................................................36

6.2.3 Handling the LCD Panel......................................................................................36

6.2.4 IC Card ..................................................................................................................37

6.3 Replacement Methods ...................................................................................................38

6.3.1 Cable...................................................................................................................38

6.3.2 Durable Parts ......................................................................................................40

6.3.3 Unit......................................................................................................................42

Page 14

- viii -

7. Troubleshooting....................................................................................................................44

7.1 Confirmation of Trouble State ........................................................................................44

7.2 When in Trouble .............................................................................................................45

8. Maintenance Functions.........................................................................................................50

8.1 Data Input/Output Function ............................................................................................50

8.1.1 Data Format ........................................................................................................51

8.1.2 Data Output.........................................................................................................54

8.1.3 Data Input and Compare.....................................................................................58

8.1.4 Parameter Backup ..............................................................................................63

8.2 Data Sampling................................................................................................................64

8.2.1 Specifications......................................................................................................64

8.2.2 Operation Procedures.........................................................................................65

8.2.3 Setting and Display Items ...................................................................................66

8.2.4 Data Output Procedures .....................................................................................72

IV.

APPENDIXES

Appendix 1 List of Function Codes.............................................................................................1

Appendix 2 Table of Command Value Ranges...........................................................................2

Appendix 3 Circular Cutting Radius Error...................................................................................3

Appendix 4 Registering/Editing the Fixed cycle Program...........................................................4

4.1 Fixed Cycle Operation Parameters ..................................................................................4

4.2 Inputting the Fixed Cycle Program...................................................................................4

4.3 Outputting the Fixed Cycle Program ................................................................................4

4.4 Erasing the Fixed Cycle Program.....................................................................................4

4.5 Standard Fixed Cycle Subprogram (For L system) ..........................................................5

4.6 Standard Fixed Cycle Subprogram (For M system) .......................................................12

Appendix 5 RS-232C I/O Device Parameter Setting Examples and Cable Connection...........17

Appendix 6 Operation Messages on Setting and Display Unit .................................................18

Page 15

I. OPERATION SECTION

Page 16

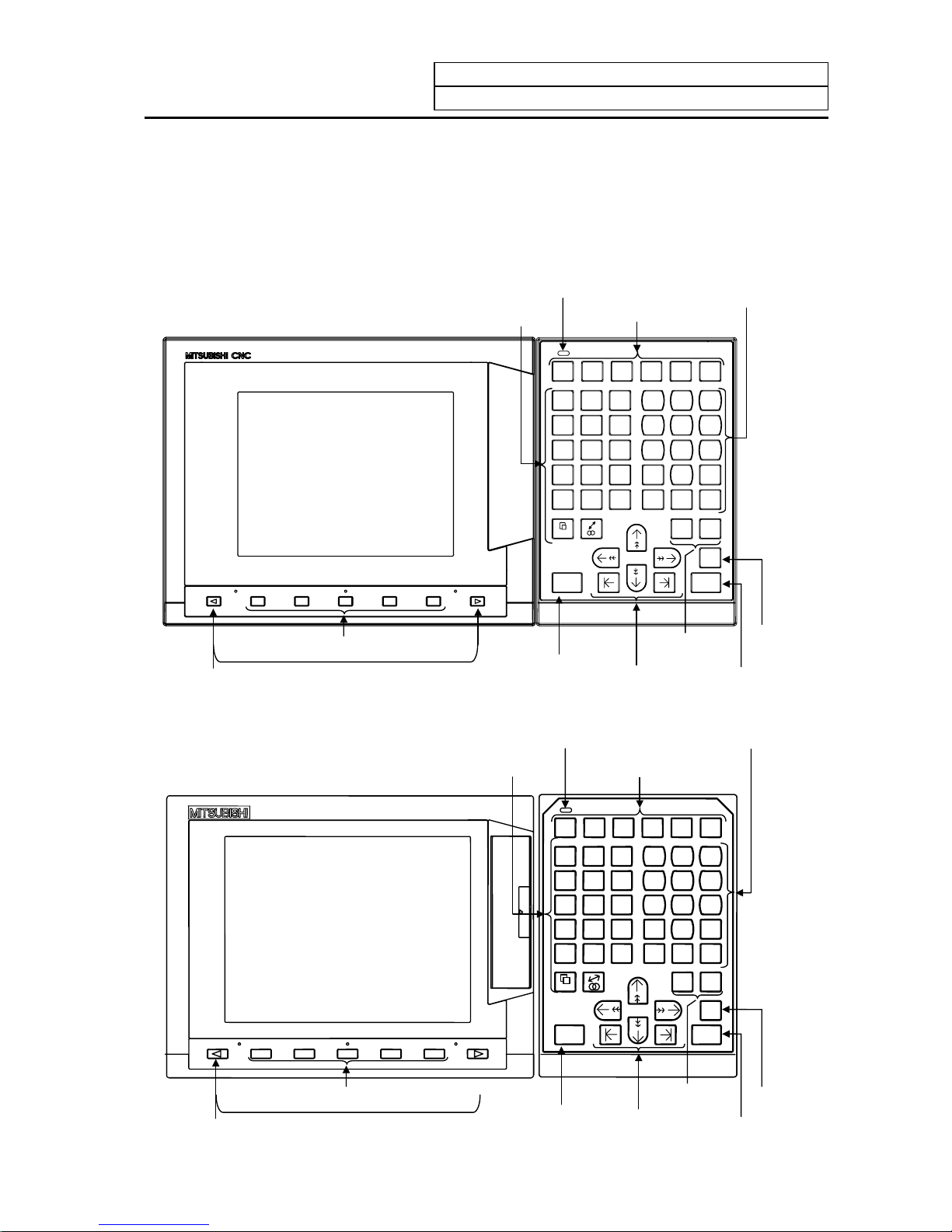

1. Setting and Display Unit Operation

1.1 Appearance of Setting and Display Unit

I-1

1. Setting and Display Unit Operation

1.1 Appearance of Setting and Display Unit

The setting and display unit consists of a display unit, keys, and menu keys, as illustrated below:

(1) Appearance of the Setting and Display Unit (For E60)

MONITOR

TOOL

PARAM

EDIT

MDI

DIAGN

IN/OUT

SFG F0

OANBG

C

XUYVZ

W

FEDLH

!

PIQJR

K

M(S)T

[

EOB

]

=#/

*

-

+

.

,

789

456

123

0

SP

DELETE

INS

C.B

CAN

SHIFT

INPUT

CALC

RESET

?

READY

Data correction

keys

Input key (calculation)

Shift key

Menu keys

Reset key

Cursor keys

Setting keys

READY LED

Function selection keys

Page keys

A

lphabetic character,

numerical character,

and symbol keys

(2) Appearance of the Setting and Display Unit (For E68)

READY

MONITOR

TOOL

PARA M

EDIT

MDI

DIAGN

IN/OUT

SFG F0

9

6

3

・

8

5

2

7

4

1

,

-

+

0

SP

= # /

*

EOB

]

DELETE

INS

C.B

CAN

SHIFT

INPUT

CALC

Z

W

G

C

H

!

R

K

T

[

Y

V

N

B

D

L

Q

J

S

)

X

U

O

A

F

E

P

I

M

(

RESET

?

Page keys

Menu keys

Reset key

Cursor keys

Data correction

keys

Input key (calculation)

Shift key

A

lphabetic character,

numerical character,

and symbol keys

READY LED

Setting keys

Function selection keys

Page 17

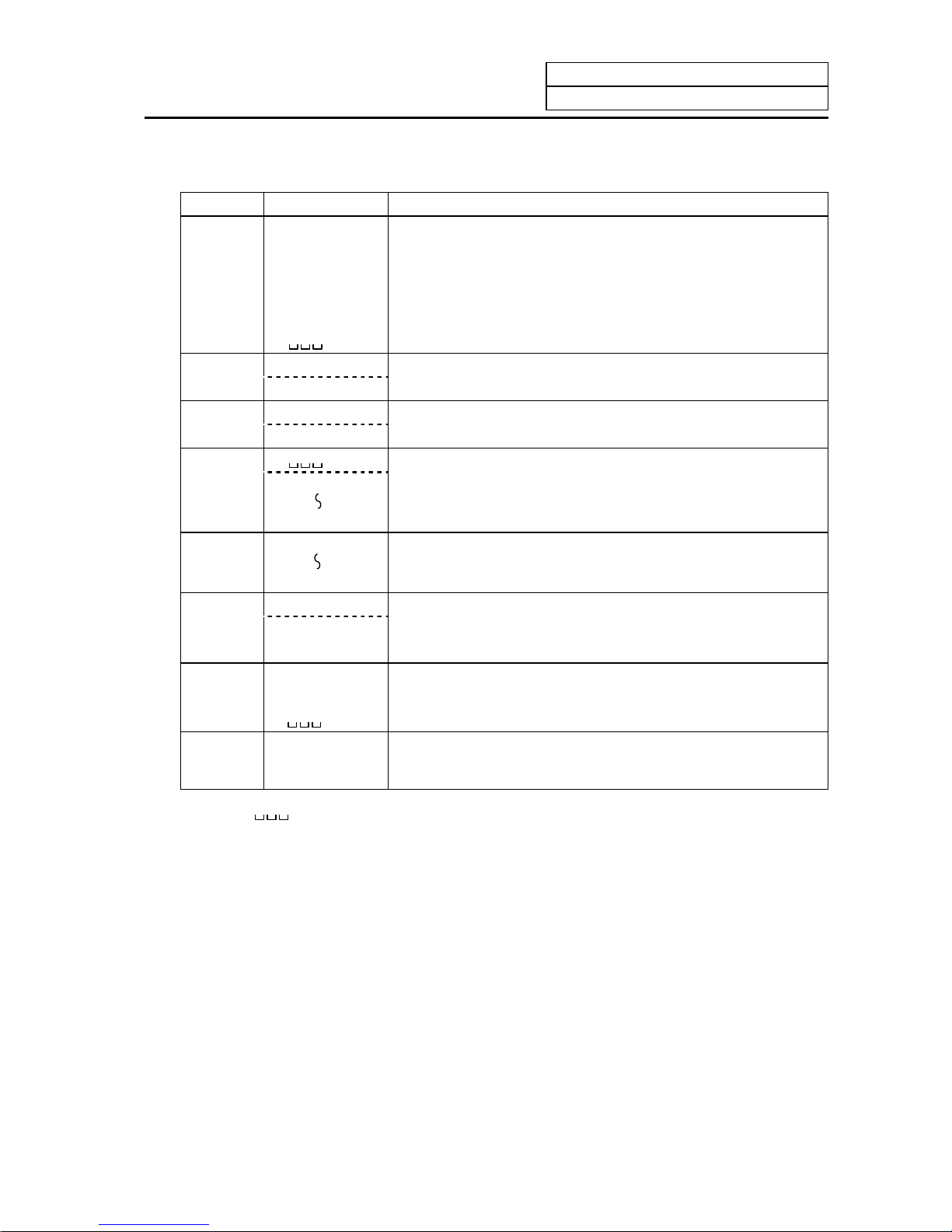

1. Setting and Display Unit Operation

1.2 Functions of Display Areas

I-2

1.2 Functions of Display Areas

Screen display is divided into the following four areas:

(1) Data display area

(2) Operation status mode and alarm message area

(3) Menu display area

(4) Setting area and key operation message area

.......Function.......

name

Data display area

Key operation message area..........

...Setting area........................................................................................................

...Operation status mode/alarm display area.........................................................

...Menu display area..............................................................................................

MONITOR 3. 1/4

Maximum

number

of pages

Pa

g

e number

Menu number

Function name

Menu 1 Menu 2 Menu 3 Menu 4 MENU

ST1 ST2 ST3 ST4 ST5 ST6 ST7 ST8

Operation mode

Operation status mode display and menu display

(during normal operation)

Menu 1 Menu 2 Menu 3 Menu 4 Menu 5

Alarm 1 (19 characters)

A

larm message display (during alarm occurrence

)

Alarm 2 (19 characters)

This is displayed when 6 or more

menus exist.

The selected menu is reversedisplayed.

A

larm is highlighted and message

(warning) is normally displayed.

Page 18

1. Setting and Display Unit Operation

1.2 Functions of Display Areas

I-3

Explanation of operation status display

Position Display symbol Explanation

ST1 EMG During emergency stop

RST During reset

LSK When paper tape reader is in label skip state

HLD During feed hold stop

STP During single block stop

Normal operation state other than the above

ST2 mm Metric command

in. Inch command

ST3 ABS Absolute command mode G90

INC Incremental comman d mod e G91

ST4

This indicates that subprogram is not executed.

SB1

SB8

Machining program execution is controlled according to subprogram

data. Each value of 1 to 8 indicates the subprogram depth.

ST5

G54

G59

Selection of the workpiece coordinate system is indicated.

ST6 G40 Tool radius compensation cancel state

G41 During tool R compensation (left)

G42 During tool R compensation (right)

ST7 fix Fixed cycle is being executed.

PR State in which power must be rebooted to validate set parameter.

State other than the above.

ST8

(Note 1)

denotes blank display.

Page 19

1. Setting and Display Unit Operation

1.3 Screen Transition Diagram

I-4

1.3 Screen Transition Diagram

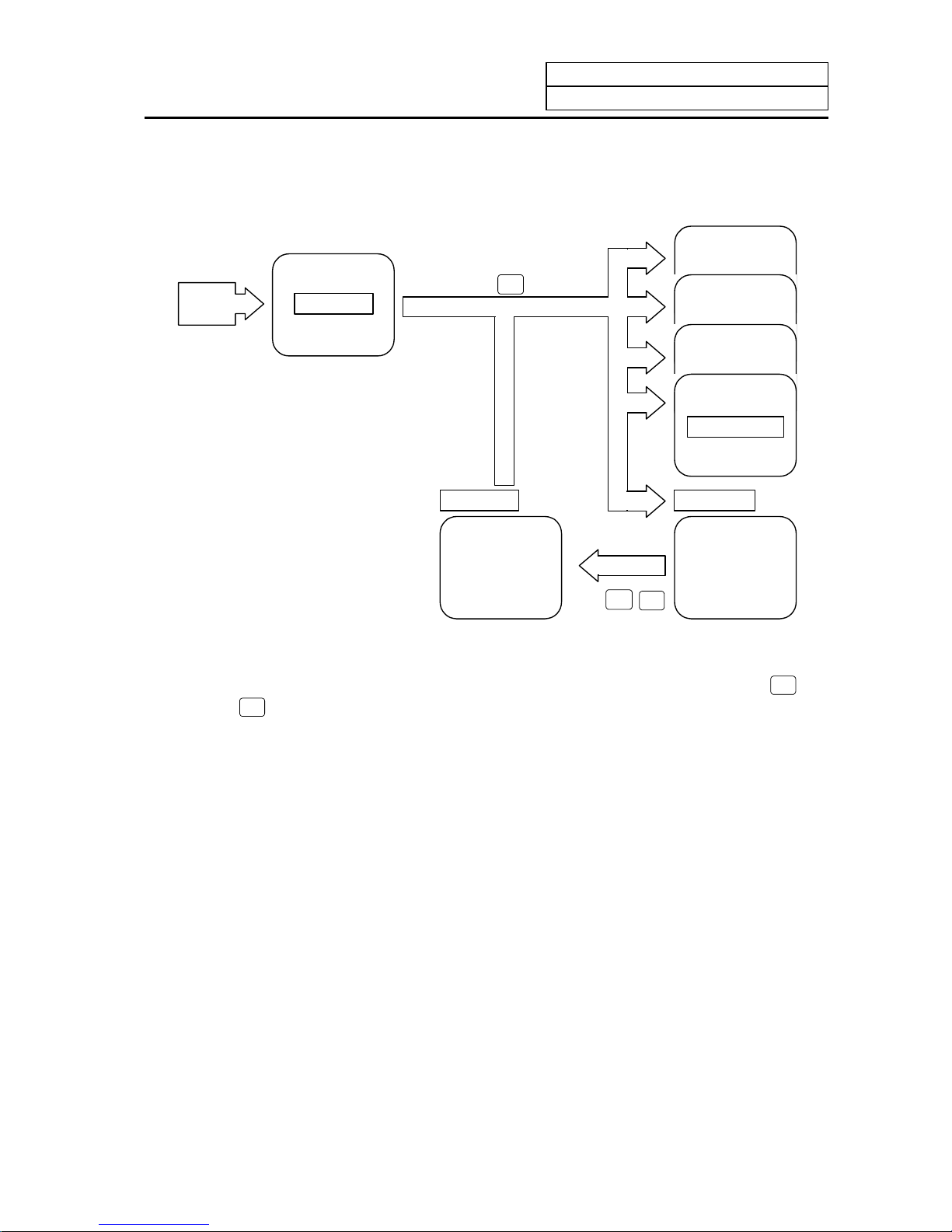

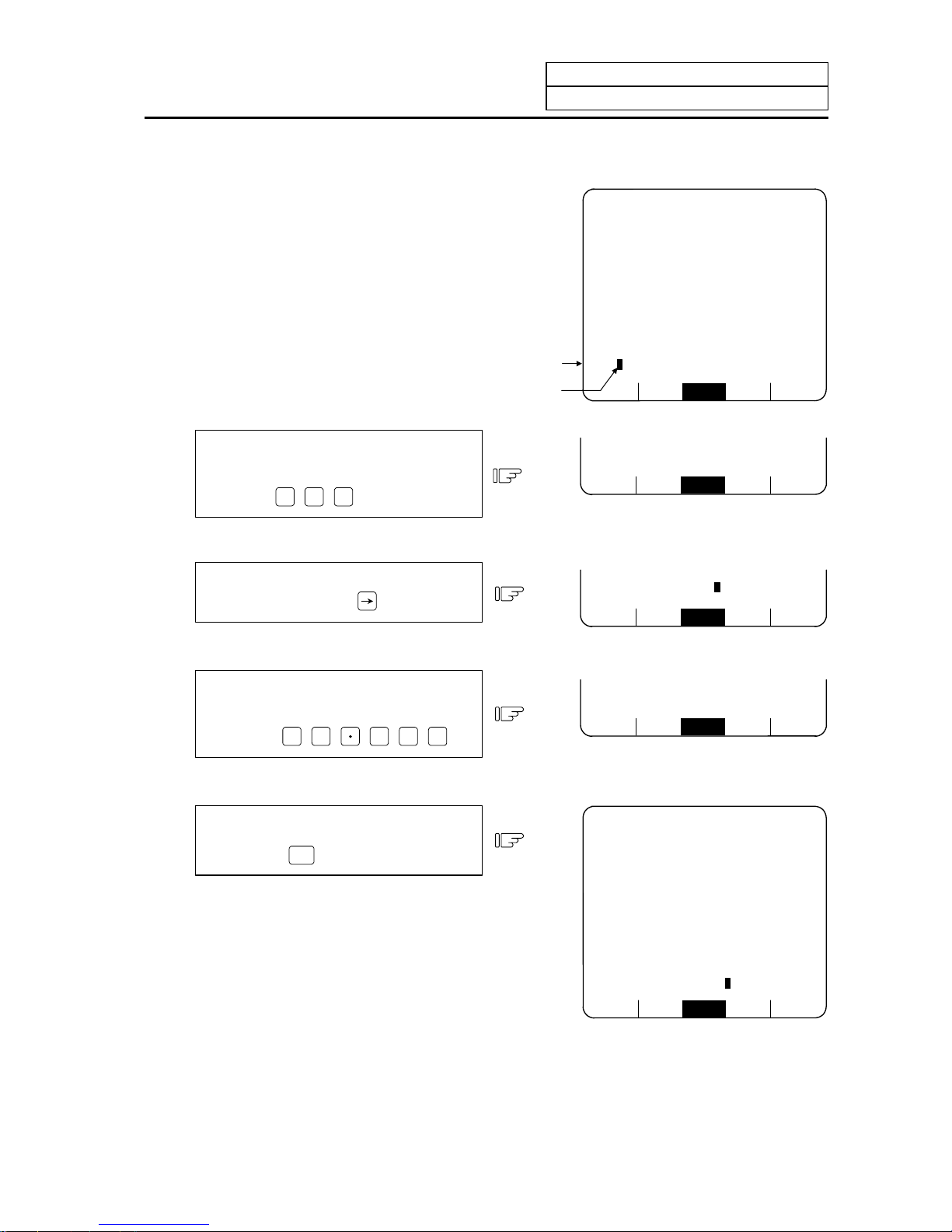

1.3.1 Screen Transition when Power Is Turned ON

MONI-

TOR

etc.

Power ON

O··1234 N12345

X -12000.000 M3

Y -3400.000 S100

Z -560.000 T12

N1

N2

MONITOR 1

Blank screen

Title screen

SHIFT

C.B

CAN

Display scree n

(1) When the power is turned ON, the "Title" screen is displayed. To select a display screen on the

"Title" screen, press the corresponding "function selection" key.

(2) To select a blank screen on a display screen, select the "MONITOR 1" screen and press

SHIFT

key,

then

C.B

CAN

key.

To select a display screen on the "blank screen", press the corresponding "function selection" key.

Page 20

1. Setting and Display Unit Operation

1.3 Screen Transition Diagram

I-5

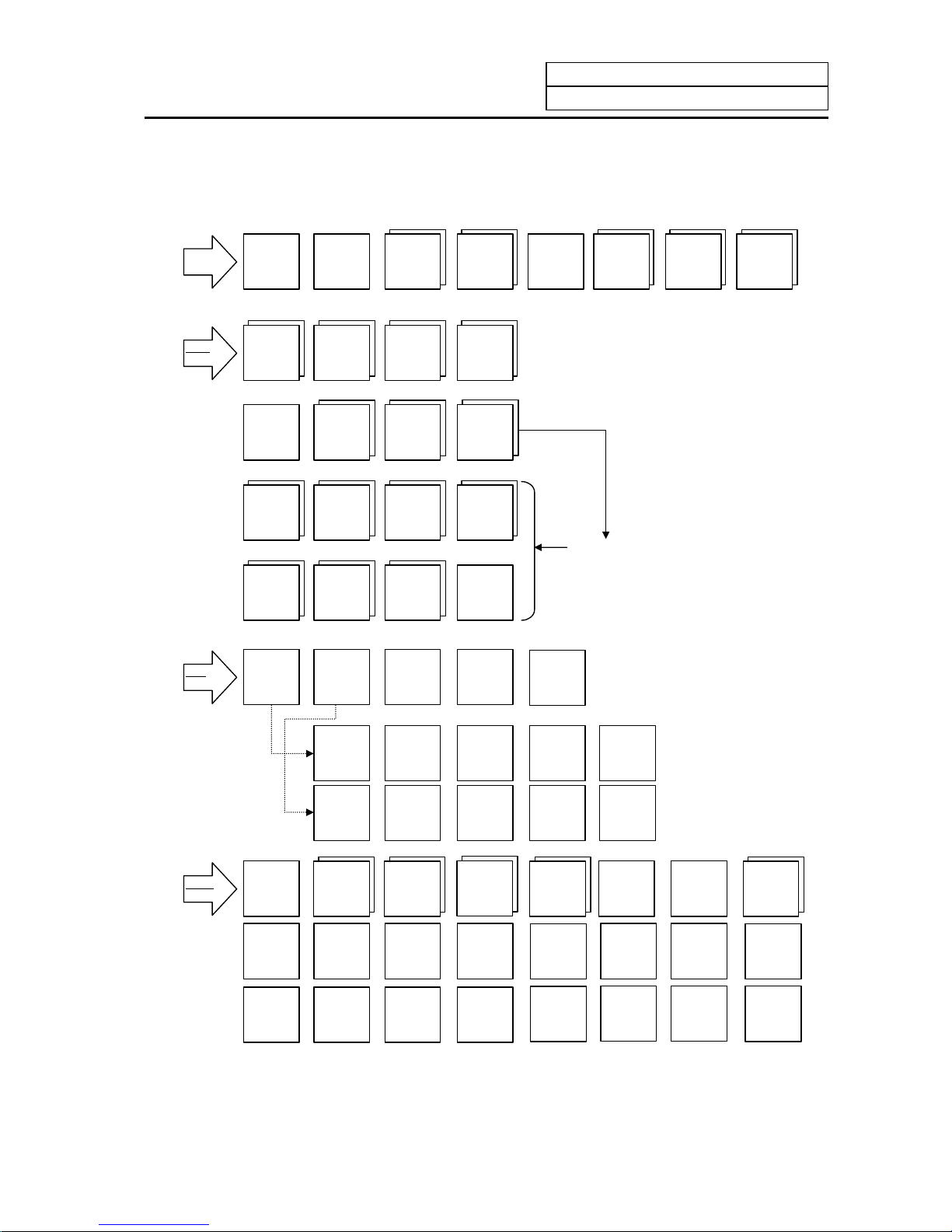

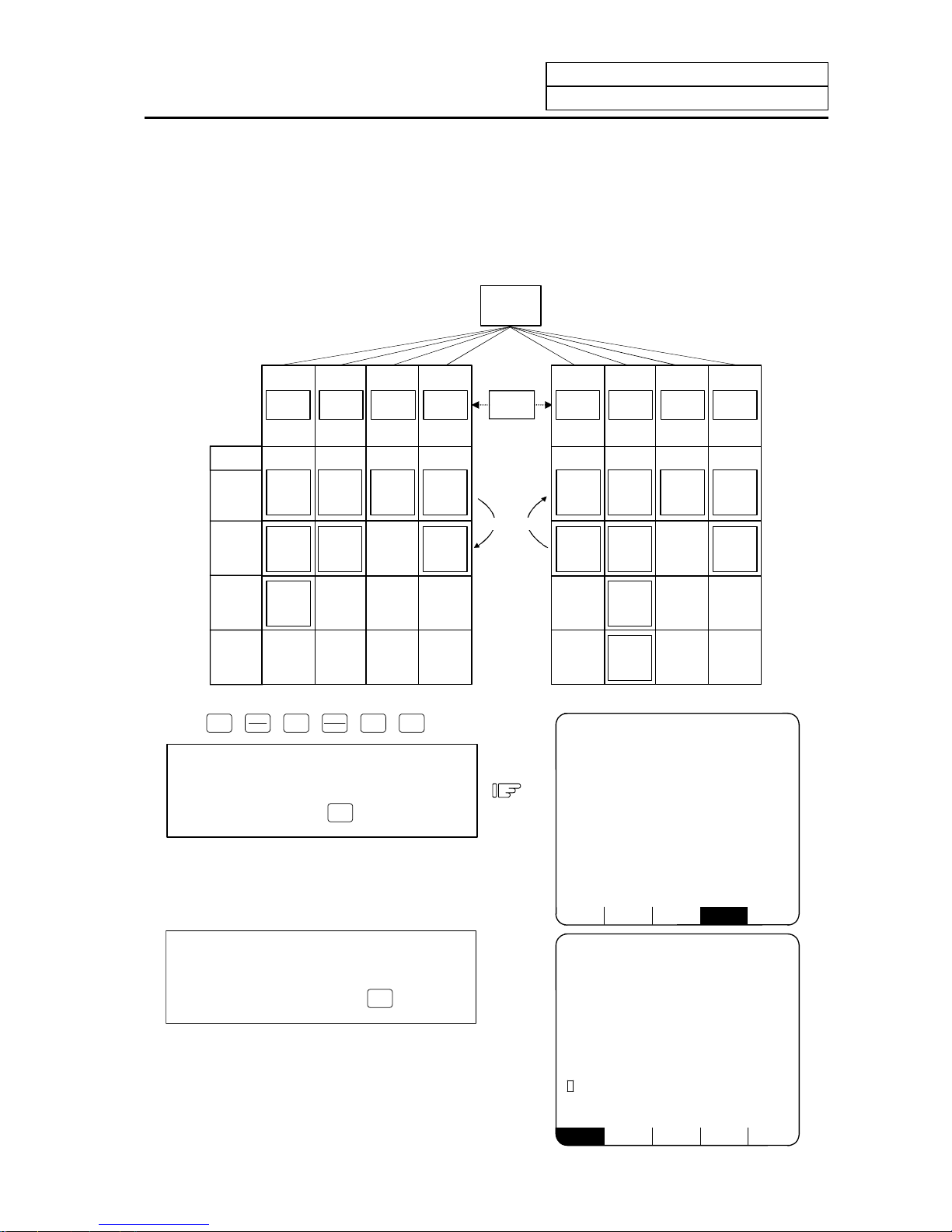

1.3.2 Screen Transition Diagram (Lathe system)

MDI

MONITOR

POSITION COORDINATE

COMMAND

MODAL

INFORM.

TIME

PLC

SWITCH

COMMON

VARIABLE

LOCAL

VARIABLE

PROGRAM

SEARCH

TOOL

PARAM

NOSE-R

TOOL

LIFE

DATA

TOOL TIP

OFFSET

TOOL

DATA

I/O BASE

PARAM

SETUP

PARAM

BACKUP

SERVO

PARAM

SPINDLE

PARAM

BASE

SPEC.

PARAM

AXIS

SPEC.

PARAM

MACRO

FILE

PSW

MC-ERR.

CMP.

PLC

TIMER

#1000

#9000

#2000 #2200 #3000

#4000,#5000 #6000 #7000 #7000

The setting can be displayed when SETUP

PARAM is selected.

EDIT

MDI

MDI

EDIT

MDI-ENT

PROGRAM

SMALL

LARGE

FILE

SEARCH

DIAGN

IN/OUT

SPINDLE

MONITOR

PLC-I/F

ALARM

MESSAGE

SERVO

MONITOR

SERVO

DIAGNOSIS

ABS SERVO

MONITOR

A

BS. POSITION

SET

ERASE

FILE

INPUT

OUTPUT

SUPPORT

(Not used)

NC-DATA

SAMPLING

NSK-

TERMINAL

(Not used)

AUX-PRM

AUX-MON

PLC

TRACE

ADJUST

S-ANALOG

OPERATION

HISTORY

CONFIG

[MENU 1]

[MENU 2] [MENU 3] [MENU 4] [MENU 5] [MENU 6] [ME NU 7] [MENU 8]

#8000

EDIT

WORK

PROCESS

CONTROL

AXIS

BARRIER

TLM

COPY

IC-CARD

I/O

RESERCH

(Note) The 1st page of SUPPORT menu and the NSK TERMINAL screen are not used.

Page 21

1. Setting and Display Unit Operation

1.3 Screen Transition Diagram

I-6

SFG

PROGRAM

ERASE

TRACE

STEP

OPERATION

SEARCH

ERASE

CHECK

STANDARD

GRF

MODE

ROTATION

SCALE

F0

VISUAL

ANALYZER

LADDER

MONITOR

ON

OFF

PARAMETER

#1222/2

ON

OFF

PARAMETER

#6451/5 OFF

and #6451/0

Page 22

1. Setting and Display Unit Operation

1.3 Screen Transition Diagram

I-7

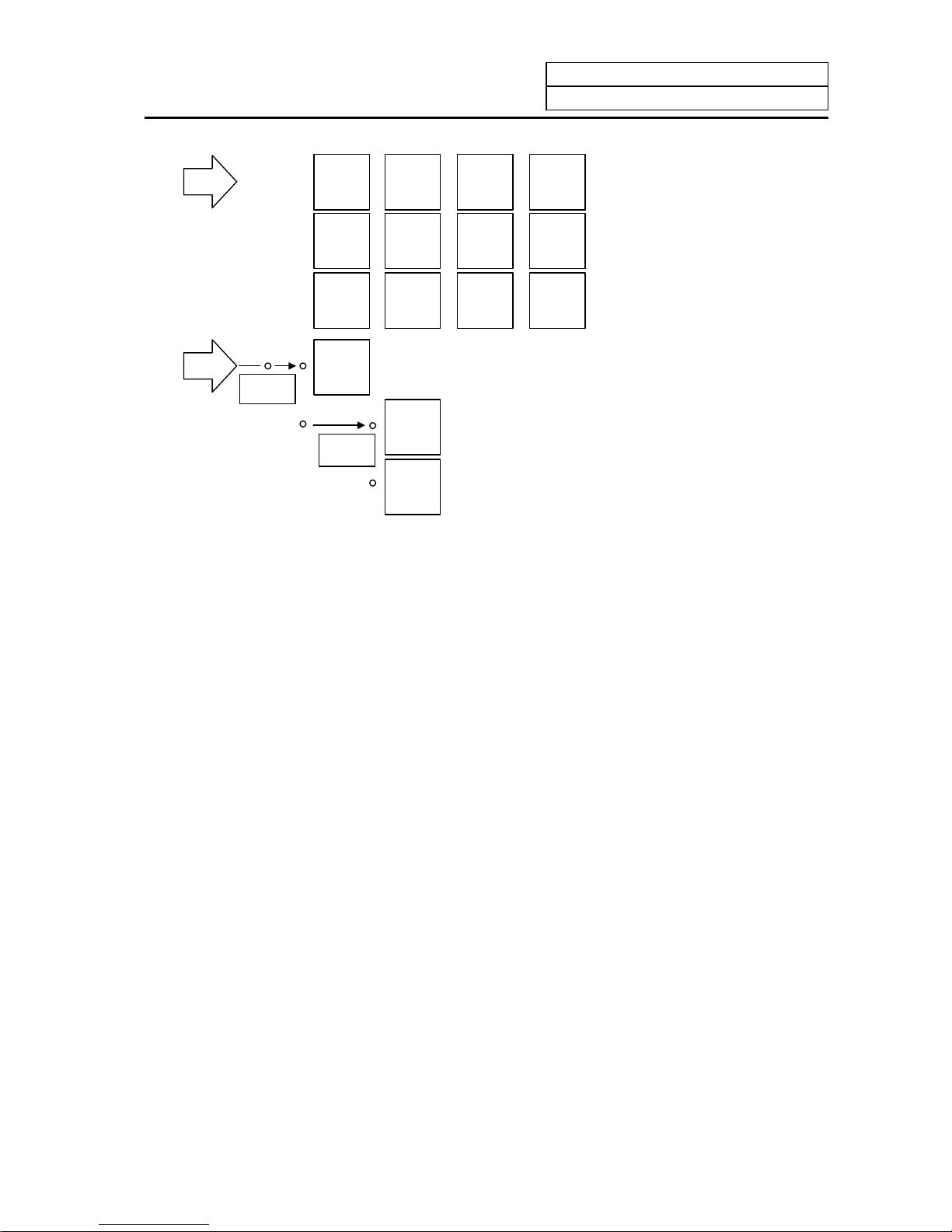

1.3.3 Screen Transition Diagram (Machining center system)

MONITOR

POSITION COORDINATE

COMMAND

MODAL

INFORM.

TIME

RESERCH

PLC

SWITCH

COMMON

VARIABLE

LOCAL

VARIABLE

PROGRAM

SEARCH

TOOL

PARAM

TOOL

LIFE

DATA

TOOL

OFFSET

T-

REGIST-

RATION

I/O BASE

PARAM

SETUP

PARAM

BACKUP

WORK

PROCESS

CONTROL

AXIS

BARRIER

TLM

BASE

SPEC.

PARAM

AXIS

SPEC.

PARAM

MACRO

FILE

PSW

MC-ERR.

CMP.

PLC

TIMER

#1000

#9000

#2000 #2200 #3000

#4000,#5000 #6000 #7000 #7000

EDIT

MDI

MDI

EDIT

MDI-ENT

PROGRAM

SMALL

LARGE

FILE

SEARCH

DIAGN

IN/OUT

SPINDLE

MONITOR

PLC-I/F

ALARM

MESSAGE

SERVO

MONITOR

SERVO

DIAGNOSIS

ABS SERVO

MONITOR

A

BS. POSITION

SET

SUPPORT

(Not used)

NC-DATA

SAMPLING

NSK-

TERMINAL

(Not used)

AUX-PRM

AUX-MON

ERASE

FILE

INPUT

OUTPUT

PLC

TRACE

ADJUST

S-ANALOG

OPERATION

HISTORY

CONFIG

[MENU 1]

[MENU 2] [MENU 3] [MENU 4] [MENU 5] [MENU 6]

#8000

SPINDLE

PARAM

SERVO

PARAM

MDI

EDIT

[MENU 7] [MENU 8]

The setting can be displayed when SETUP

PARAM is selected.

COPY

IC-CARD

I/O

(Note) The 1st page of SUPPORT menu and NSK TERMINAL screen are not used.

Page 23

1. Setting and Display Unit Operation

1.3 Screen Transition Diagram

I-8

SFG

PROGRAM

ERASE

TRACE

STEP

OPERATION

SEARCH

ERASE

CHECK

STANDARD

RANGE

GRF

MODE

ROTATION

SCALE

F0

VISUAL

ANALYZER

LADDER

MONITOR

ON

OFF

PARAMETER

#1222/2

ON

OFF

PARAMETER

#6451/5 OFF

and #6451/0

Page 24

1. Setting and Display Unit Operation

1.4 Screen Selection Procedure

I-9

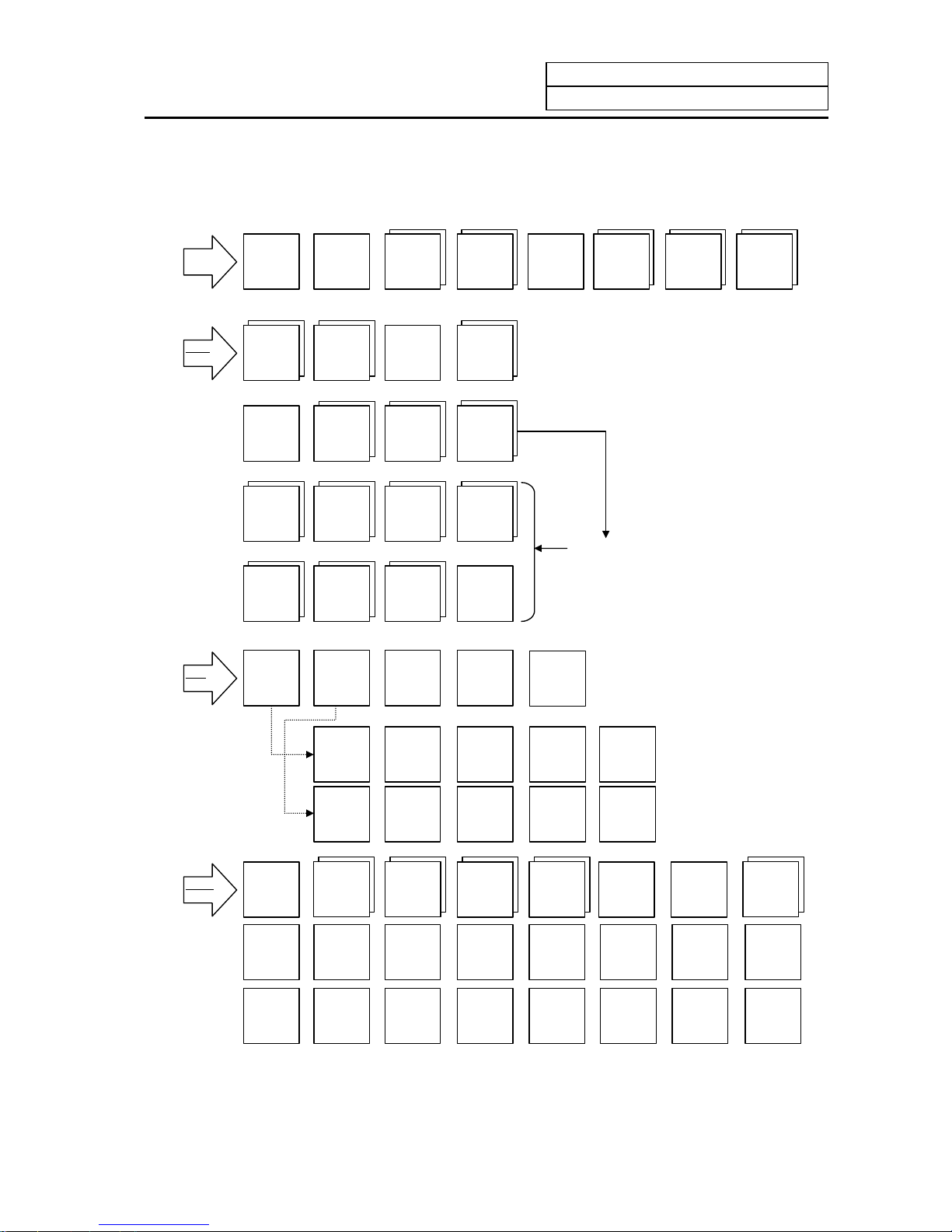

1.4 Screen Selection Procedure

The following operation methods are based on using the exclusive setting and display unit.

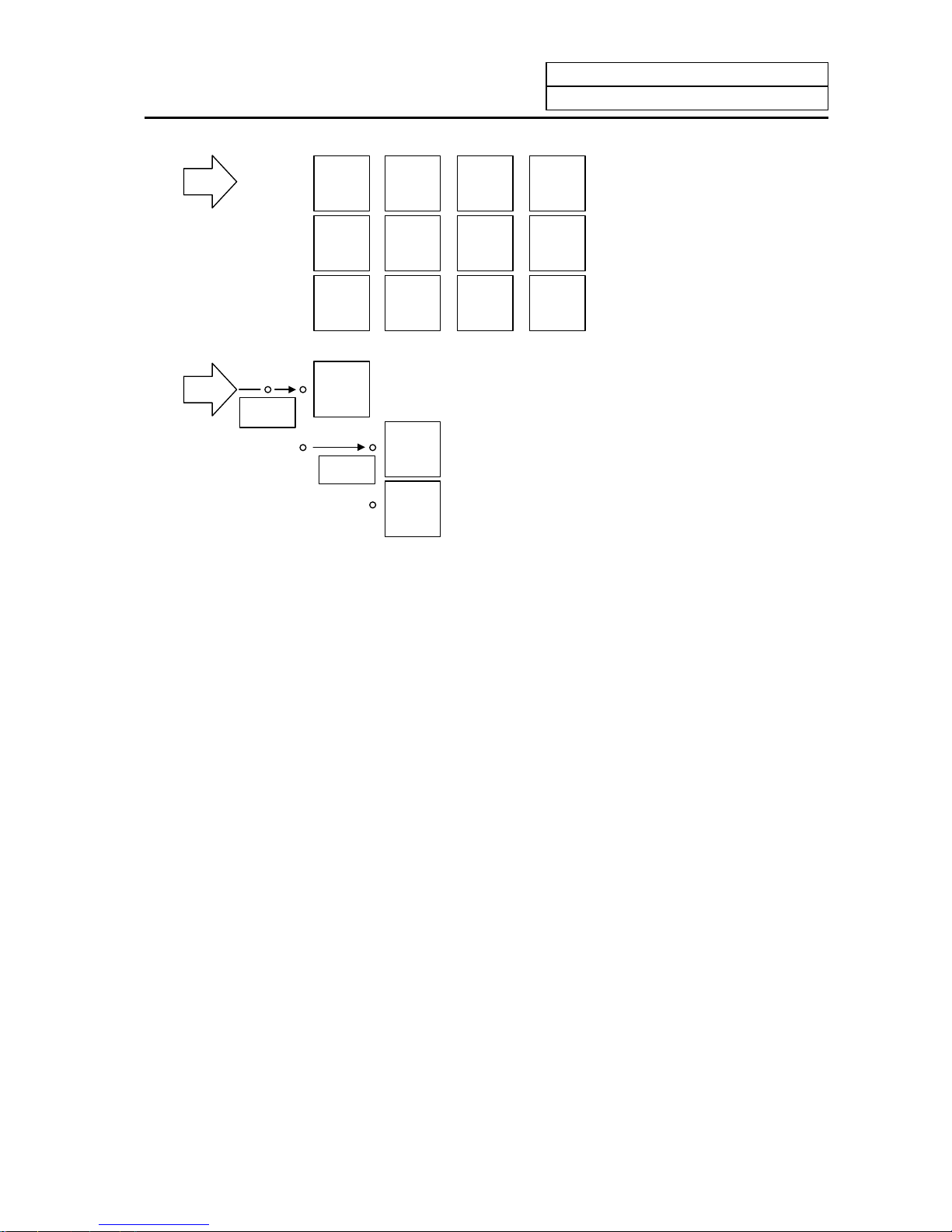

Select a screen according to the following procedure:

(1) Select a function screen by using the appropriate function key.

(2) Select a menu screen in the function by using the appropriate menu key.

(3) Select a page in the menu screen by using the page key.

FUNCTION

MENU

Page

First

page

Page Page

Menu 1 Menu 2 Menu 3 Menu 4 Menu 5 Menu 6 Menu 7 Menu 8

1.1

screen

2.1

screen

3.1

screen

4.1

screen

5.1

screen

6.1

screen

7.1

screen

8.1

screen

5.2

screen

6.2

screen

1.3

screen

6.3

screen

6.4

screen

4.2

screen

1.2

screen

2.2

screen

8.2

screen

Second

page

Third

page

Fourth

page

(1) Select a function screen.

MONI-

TOR

TOOL

PARAM

EDIT

MDI

DIAGN

IN/OUT

SFG

F0

Press the function selection key

corresponding to the function screen to be

displayed.

(Example)

Press the

MONI-

TOR

key.

1) The previously displayed menu screen is

displayed in the data display area.

2) Th e first display screen after power is turned

ON is the screen on the first menu.

If the same function selection key is again

pressed, a return is made to the first page

screen of the first menu.

(Example)

Again press the

MONI-

TOR

key.

POSI COORDI COMMAND SEARCH MENU

[PROGRAM SEARCH] MONITOR 4.1/4

O12345678 N12345-12

<SUB> O 1000 N 200-30

[PROGRAM FILE]

100 1500 50 000 1234 567

200 2000 70 000 2000 000

300 3000 1 23456 3000000

400 7000 2 00000 4000000

1234 10000 300000 5000000

[COL.BLOCK]

O N -

N20 G91 G28X0 Y0 Z0;

O( )N( )-( ) TAPE( )

[POSITION] 12/14 13:27 MONITOR 1

O12345678 N12345-12

<SUB> O 1000 N 200-30

S 12345

( 2000)

#1 T 1234

M 12

Fc 12000.00

G00 X-345.67 Y345.67;

T1234;

N100 S5000 M3;

N200 G00 Z-100;

X -12345 .678

Y 12345.678

Z 0.000

POSI COORDI COMMAND SEARCH MENU

Page 25

1. Setting and Display Unit Operation

1.4 Screen Selection Procedure

I-10

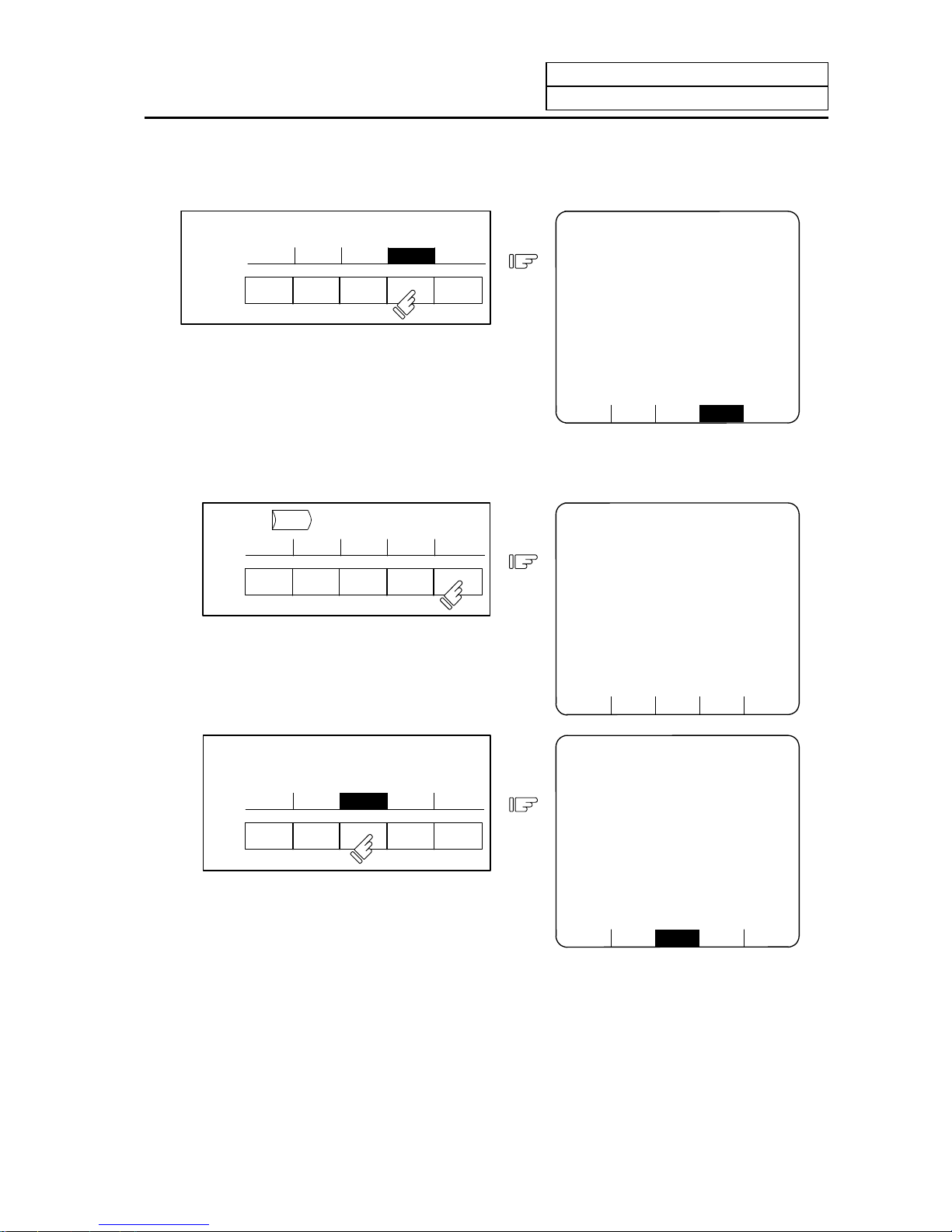

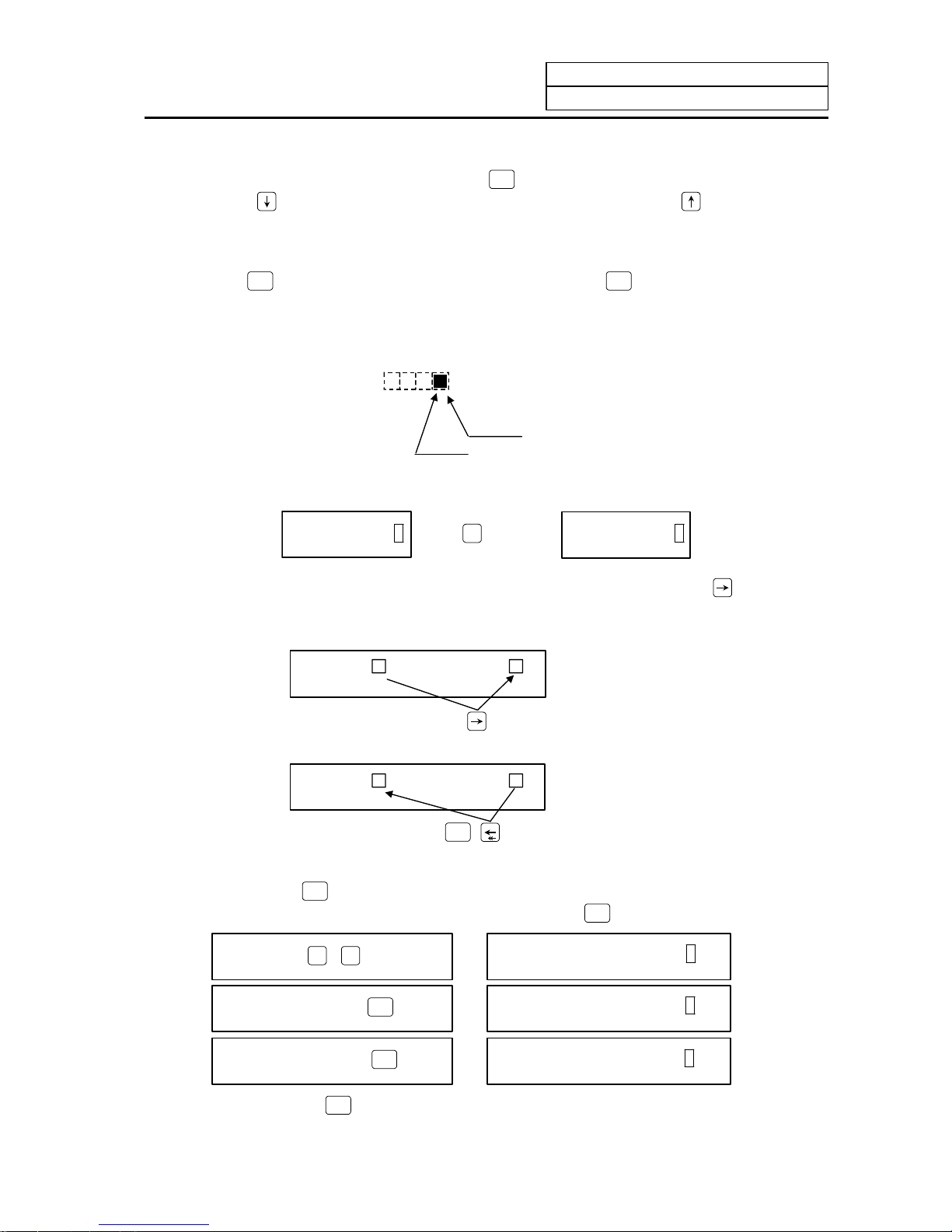

(2) Select a menu screen in the function.

Up to five menus are displayed at a time. When a menu key below the menu display is pressed,

the menu screen corresponding to the menu key is displayed.

Press the menu key corresponding to the menu

display.

Menu display

Menu key

POSI COORDI COMMAND SEARCH MENU

1) The selected menu screen is displayed

in the data display area.

2) The selected menu is highlighted in the

menu display area.

POSI COORDI COMMAND SEARCH MENU

[PROGRAM SEARCH] MONITOR 4.1/4

O12345678 N12345-12

<SUB> O 1000 N 200-30

[PROGRAM FILE]

100 1500 50 000 1234 567

200 2000 70 000 2000 000

300 3000 1 23456 3000000

400 7000 2 00000 4000000

500 10000 300000 5000000

[COL.BLOCK]

O N -

N20 G91 G28X0 Y0 Z0;

O( )N( )-( ) TAPE( )

When the rightmost menu in the menu display area is "MENU", it indicates that other menus than the

displayed menus exist. Make menu change by pressing the menu key below "MENU", then select the

menu screen to be displayed.

Press the

MENU

key.

POSI COORDI COMMAND SEARCH MENU

(1)

1) Only the menu display area is changed

and the remaining menu group is

displayed.

RESERCH PLC-SW COM-VAR LOC-VAR MENU

[PROGRAM SEARCH] MONITOR 4.1/4

O12345678 N12345-12

<SUB> O 1000 N 200-30

[PROGRAM FILE]

100 1500 50 000 1234 567

200 2000 70 000 2000 000

300 3000 1 23456 3000000

400 7000 2 00000 4000000

500 10000 300000 5000000

[COL. BLOCK]

O N -

N20 G91 G28X0 Y0 Z0;

O( )N( )-( ) TAPE( )

Press the menu key corresponding to the

menu display.

RESERCH PLC-SW COM-VAR LOC-VAR MENU

(2)

RESERCH PLC-SW COM-VAR LOC-VAR MENU

[COMMON VARIABLE] MONITOR 7.1/11

# 110

100 -123456.7890 111

101 12.3456 112

102 113

103 114

104 115

105 116

106 117

107 118

108 119

109

#( )DATA( )NAME( )

Page 26

1. Setting and Display Unit Operation

1.4 Screen Selection Procedure

I-11

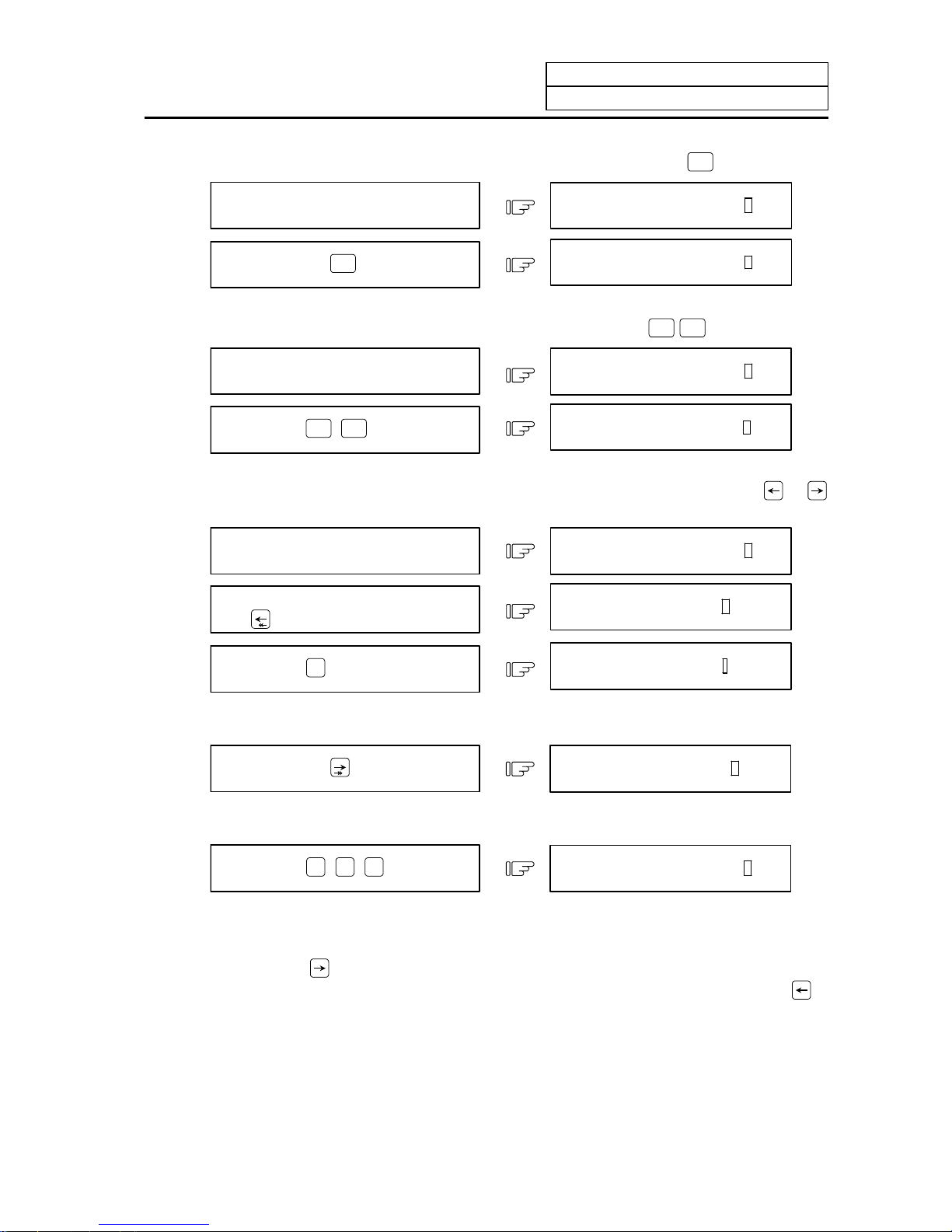

When the screen selection menu is selected, the screen that " ↓ " mark is displayed after the menu

means that the operation menu exists.

Press the menu key corresponding to the

menu display.

T-OFSET T-DATA NOSE-R LIFE MENU

(1)

1) The selected menu screen is displayed

in the data display area.

2) The selected menu is highlighted and

" ↓ " mark is displayed after the menu.

T-OFSET T-DATA NOSE-R ↓ LIFE NENU

[NOSE-R] TOOL 3.1/4

#1 R 0.000 r 0.000 P 0

2 R 0.000 r 0.000 P 0

3 R 0.000 r 0.000 P 0

: : :

: : :

#( ) R( ) r( ) P( )

Press the menu key again.

(2)

T-OFSET T-DATA

NOSE-R ↓

LIFE MENU

1) The operation menu is displayed in the

menu display area.

+INPUT =INPUT RETURN

[NOSE-R] TOOL 3.1/4

#1 R 0.000 r 0.000 P 0

2 R 0.000 r 0.000 P 0

3 R 0.000 r 0.000 P 0

: : :

: : :

#( ) R( ) r( ) P( )

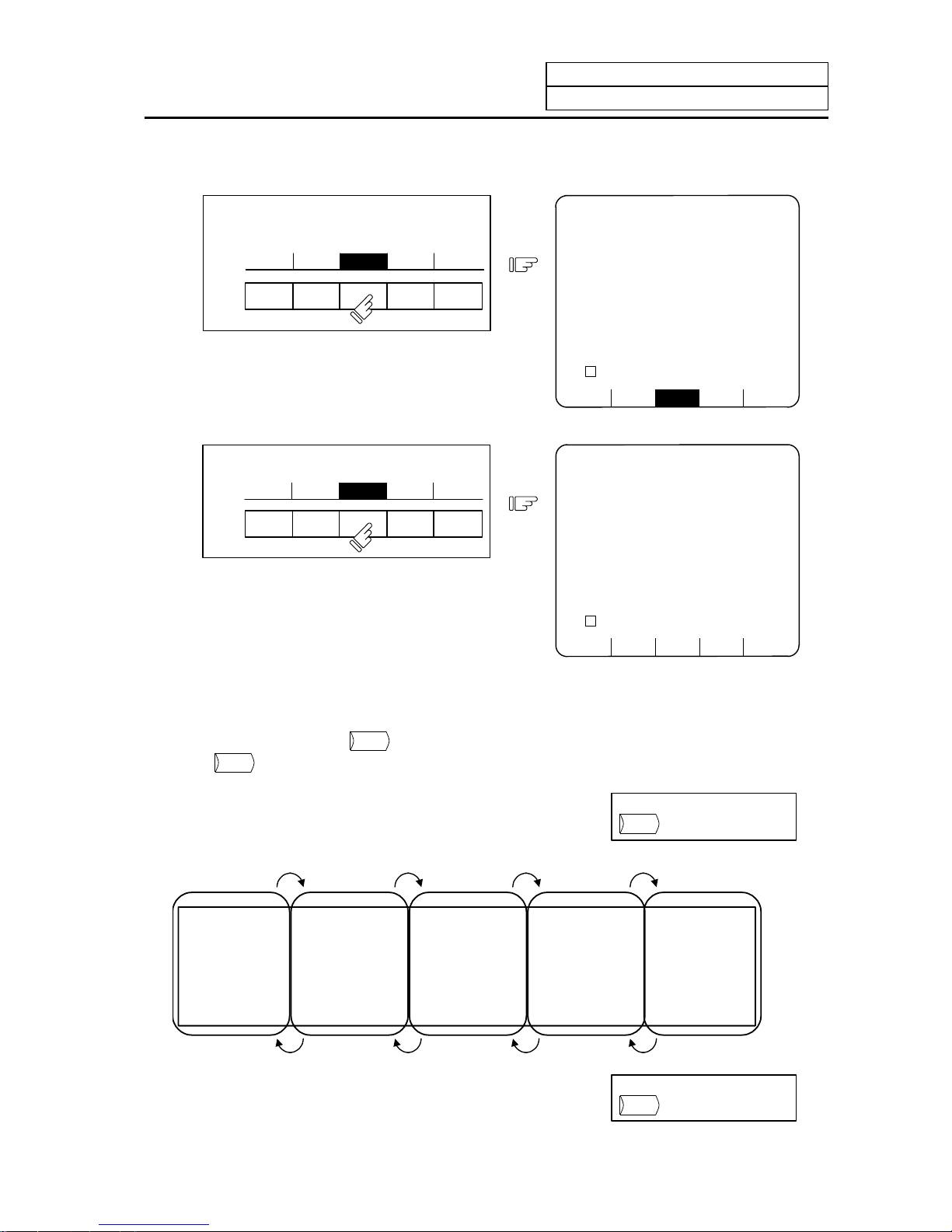

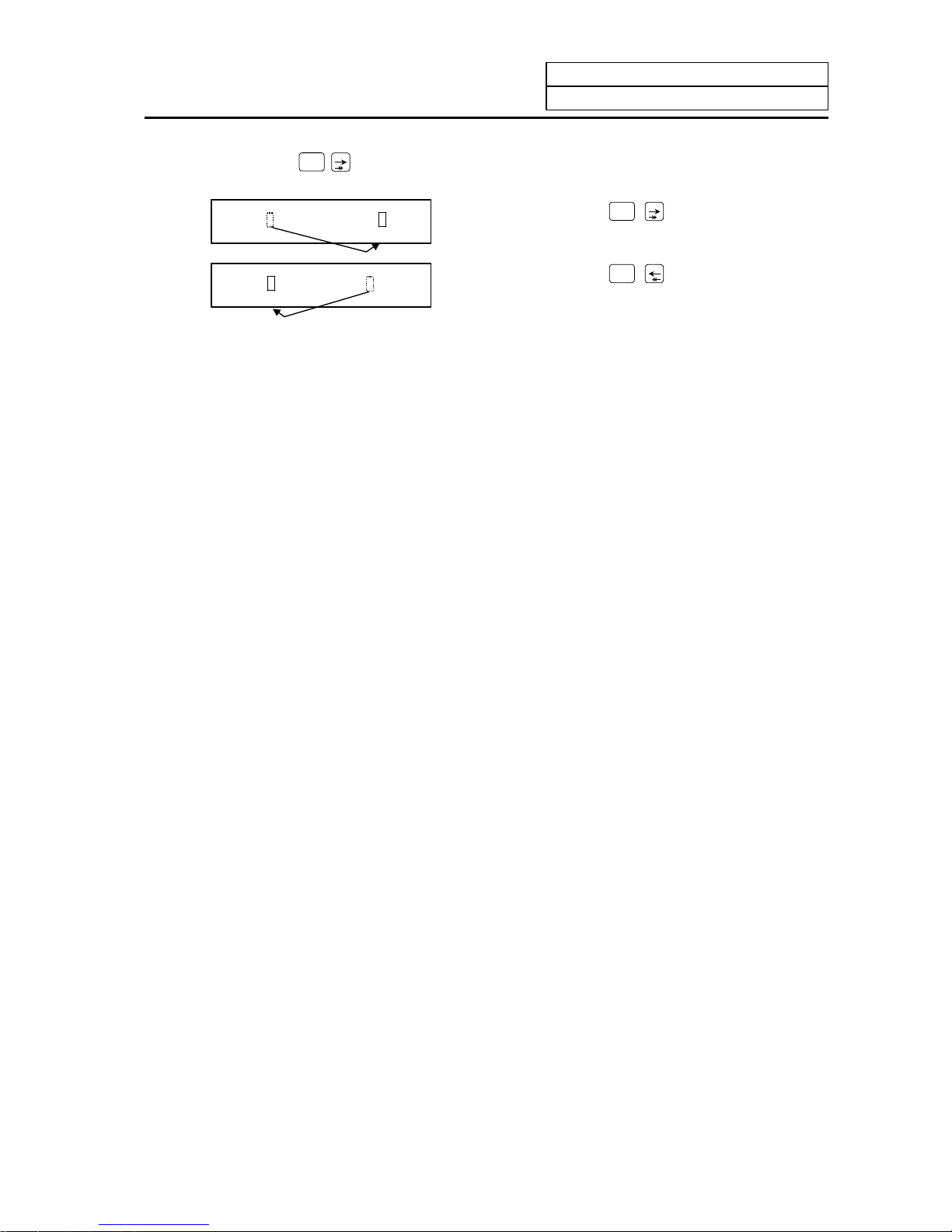

(3) Select a page in the menu screen.

When the menu screen contains a number of pages, feed pages by using the page key, the

rightmost page key (

NEXT

) is the "next page" screen selection key. The leftmost page key

(

BACK

) is the "previous page" screen selection key.

Using the rightmost key

NEXT

, feed page.

Using the leftmost key

BACK

,

feed page.

# 1 #1

#10 #20

#21 #31

#30 #40

#41 #51

#50 #60

First page Second page Third page Fourth page Fifth page

#81 #91

#90 #100

#61 #71

#70 #80

to to to to to to to to to to

Page 27

1. Setting and Display Unit Operation

1.5 Data Setting Method

I-12

1.5 Data Setting Method

(1) Outline of data setting

The data setting method consists

mainly of the following steps:

(1) Enter the data number.

(2) Move the cursor.

(3) Press data keys.

(4) Press the INPUT key.

When a screen is selected, the cursor

is displayed in the right end within the

first parentheses in the setting area.

RESERCH PLC-SW COM-VAR LOC-VAR MENU

[COMMON VARIABLE] MONITOR 7.1/11

# 110

100 -123456.7890 111

101 12.3456 112

102 113

103 114

104 115

105 116

106 117

107 118

108 119

109

#( )DATA( )NAME( )

Data setting

area

Curso

r

(1) Enter the data number.

Enter the number of the data to be set by

using the numeric keys.

(Example)

To set data in #104, press

1

0

4

.

RESERCH P LC-SW COM-VAR LOC-VAR MENU

#( 104 )DATA( )NAME( )

(2) Move the cursor.

To move the cursor to the next

parentheses, press the

key.

RESERCH P LC-SW COM-VAR LOC-VAR MENU

#( 104 )DATA( )NAME( )

(3) Press data keys.

Seeing the data display area contents,

enter new data by using the keys.

(Example)

To change to 12.345, press

1

2

3

4

5

.

RESERCH P LC-SW COM-VAR LOC-VAR MENU

#( 104 )DATA( 12.345 )NAME( )

(4) Press the INPUT key.

Check the setup contents displayed in the

setting area and set the data in memory by

pressing the

INPUT

key.

1) Data setting processing is performed

according to the setting area contents,

and the result is displayed in the data

display area.

2) The data number in the setting area is

incremented by one, and the cursor is

displayed in the right end within the

second parentheses.

After the last data number is input, it is

not displayed. At this time, the cursor is

displayed in the right end of the first

parentheses.

RESERCH PLC-SW COM-VAR LOC-VAR MENU

[COMMON VARIABLE] MONITOR 7.1/11

# 110

100 -123456.7890 111

101 12.3456 112

102 113

103 114

104 115

105 116

106 117

107 118

108 119

109

#( 105)DATA( )NAME( )

Page 28

1. Setting and Display Unit Operation

1.5 Data Setting Method

I-13

3) To consecutively set data, repeat (3) and (4).

4) To change the data number, press the

INPUT

key. The number is incremented by one. When

the

key is pressed, the number is incremented by one. When the

key is pressed, the

number is decremented by one. The data number can also be directly changed by moving th e

cursor to the data number setting area.

(Note 1) Data in the setting area is only displayed on the screen and is not set in memory until the

INPUT

key is pressed. If the screen is changed before the

INPUT

key is pressed, the data in the

setting area becomes invalid.

(2) Cursor control and operation examples

1) Data write into the display screen (by keying) is made at the position indicated by the cursor.

When the cursor is not displayed, keying is not effective.

Data ( )

Cursor

This position enables keying.

2) When any key is pressed, already displayed data is moved one column to the left and the dat a

corresponding to the key pressed at the cursor position is displayed.

DATA ( 12) When

3

is pressed, DATA ( 123)

3) If a number of parentheses exist in the data setting area, pressing the

key when the

cursor is in the right end within a parenthesis causes the cursor to move to the right end within

the next pair.

When the

key is pressed, the cursor is moved

to the right end within the next parentheses.

# ( ) DATA ( )

When the

SHIFT

key are pressed, the cursor is

moved to the preceding parentheses.

# ( ) DATA ( )

4) When the

DELETE

INS

key is pressed, the data at the cursor position is deleted. To cancel one

character entered by using any data key, etc., use the

DELETE

INS

key.

If you press

3

,

3

by mistake,

# ( 12) DATA ( 1233)

If you once press the

DELETE

INS

key,

# ( 12) DATA ( 123)

If you again press the

DELETE

INS

key,

# ( 12) DATA ( 12)

Each time the

DELETE

INS

key is pressed, one character of data at the cursor position is deleted and

the data to the left of the deleted character is moved one column to the right.

Page 29

1. Setting and Display Unit Operation

1.5 Data Setting Method

I-14

5) Data in parentheses where the cursor exists is erased by pressing the

C.B

CAN

key.