Page 1

SERVICE MANUAL

HYDROBOX

No. OCH503

CONTENTS

1. REFERENCE MANUAL

...................................

2

2. SAFETY PRECAUTION

...................................

3

3. SPECIFICATIONS

............................................

7

4. PART NAMES AND FUNCTIONS

..................

8

5. OUTLINES AND DIMENSIONS

.....................

10

6. WIRING DIAGRAM

........................................

12

7. FIELD WIRING

...............................................

16

8. WATER SYSTEM DIAGRAM

.........................

20

9. CONTROLS

...................................................

21

10. TROUBLESHOOTING

...................................

36

11. DISASSEMBLY PROCEDURE

......................

49

12. SUPPLEMENTARY INFORMATION

.............

63

13. SERVICE AND MAINTENANCE

...................

64

July 2011

Note:

• This manual describes only

service data of Hydrobox.

• RoHS compliant products have

<G> mark on the spec name

plate.

R410A

MAIN CONTROLLER

PARTS CATALOG (OCB503)

[Model name]

EHSC-VM6A

EHSC-YM9A

EHPX-VM2A

[Service Ref.]

EHSC-VM6A.UK

EHSC-YM9A.UK

EHPX-VM2A.UK

HYDROBOX

TENTATIVE

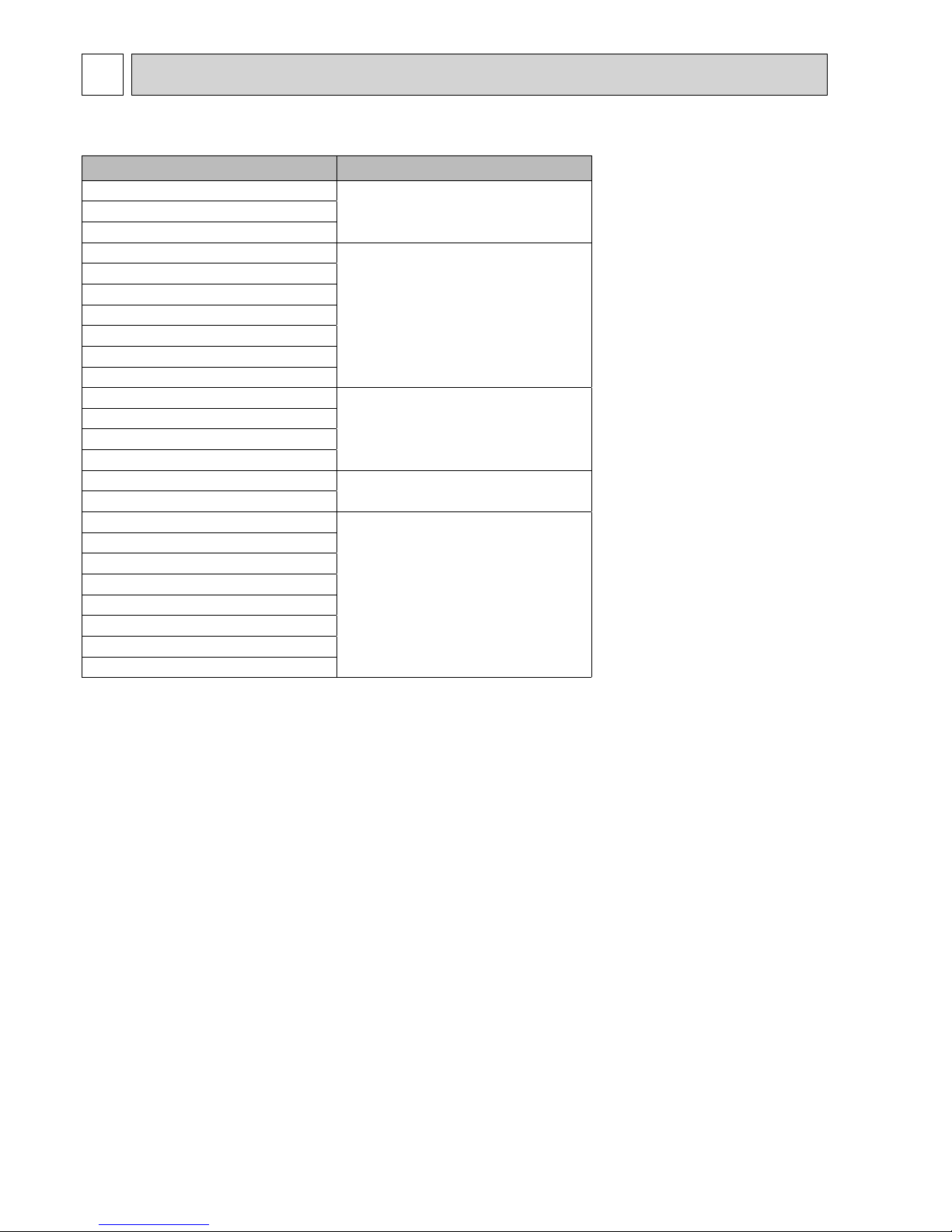

Page 2

2

REFERENCE MANUAL

1

OUTDOOR UNIT'S SERVICE MANUAL

Service Ref. Service Manual No.

PUHZ-RP35/50/60/71VHA4

OCH451PUHZ-RP100/125/140VKA

PUHZ-RP100/125/140YKA

PUHZ-HRP71/100VHA

OCH425

PUHZ-HRP71/100VHA2

PUHZ-HRP71/100VHA2R1

PUHZ-HRP100VHA2R2

PUHZ-HRP100/125YHA

PUHZ-HRP100/125YHA2

PUHZ-HRP100/125YHA2R1

PUHZ-W50/85VHA

OCH439

PUHZ-W50/85VHA-BS

PUHZ-W85VHAR1

PUHZ-W85VHAR1-BS

PUHZ-W85VHA2.UK

OCH465

PUHZ-W85VHA2-BS.UK

PUHZ-HW112/140YHA

OCH439

PUHZ-HW112/140YHA-BS

PUHZ-HW112/140YHA2

PUHZ-HW112/140YHA2-BS

PUHZ-HW140VHA

PUHZ-HW140VHA-BS

PUHZ-HW140VHA2

PUHZ-HW140VHA2(R1)-BS

Page 3

3

SAFETY PRECAUTION

2

Please read the following safety precautions carefully.

WARNING:

Precautions that must be observed to prevent injuries or death.

CAUTION:

Precautions that must be observed to prevent damage to unit.

This installation manual along with the user manual should be left with the product after installation for future reference.

Mitsubishi Electric is not responsible for the failure of locally or fi eld-supplied parts.

Be sure to perform periodical maintenance.

Be sure to follow your local regulations.

Be sure to follow the instructions provided in this manual.

•

•

•

WARNING

Mechanical

The hydrobox and outdoor units must not be installed, disassembled, relocated, altered or repaired by the user. Ask an authorised installer or technician. If the

unit is installed improperly or modifi ed after installation by the user water leakage, electric shock or fi re may result.

The outdoor unit should be securely fi xed to a hard level surface capable of bearing its weight.

The hydrobox should be positioned on a hard vertical surface capable of supporting its fi lled weight to prevent excessive sound or vibration.

Do not position furniture or electrical appliances below the outdoor unit or hydrobox.

The discharge pipework from the emergency/safety devices of the hydrobox should be installed according to local law.

Only use accessories and replacement parts authorised by Mitsubishi Electric and employ a qualifi ed technician to fi t the parts.

Electrical

All electrical work should be performed by a qualifi ed technician according to local regulations and the instructions given in this manual.

The units must be powered by a dedicated power supply and the correct voltage and circuit breakers must be used.

Wiring should be in accordance with national wiring regulations. Connections must be made securely and without tension on the terminals.

Earth unit correctly.

General

Keep children and pets away from both the hydrobox and outdoor units.

Do not use the hot water produced by the heat pump directly for drinking or cooking. This could cause illness to the user.

Do not stand on the units.

Do not touch switches with wet hands.

Annual maintenance checks on both the hydrobox and the outdoor unit should be done by qualifi ed person.

Do not place items containing liquid in on top of the hydrobox. If they leak or spill onto the hydrobox damage to the unit and or fi re could occur.

Do not place any heavy items on top of the hydrobox.

When installing or relocating, or servicing the hydrobox, use only the specifi ed refrigerant (R410A) to charge the refrigerant lines. Do not mix it with any other

refrigerant and do not allow air to remain in the lines. If air is mixed with the refrigerant, then it can be the cause of abnormal high pressure in the refrigerant

line, and may result in an explosion and other hazards.

The use of any refrigerant other than that specifi ed for the system will cause mechanical failure or system malfunction or unit breakdown. In the worst case, this

could lead to a serious impediment to securing product safety.

CAUTION

Use clean water that meets local quality standards on the primary circuit.

The outdoor unit should be installed in an area with suffi cient airfl ow according to the diagrams in the outdoor unit installation manual.

The hydrobox should be located inside to minimise heat loss.

Water pipe-runs on the primary circuit between outdoor and indoor unit should be kept to a minimum to reduce heat loss.

Ensure condensate from outdoor unit is piped away from the base to avoid puddles of water.

Remove as much air as possible from water circuit.

Refrigerant leakage may cause suffocation. Provide ventilation in accordance with EN378-1.

Be sure to wrap insulation around the piping. Direct contact with the bare piping may result in burns or frostbite.

Never put batteries in your mouth for any reason to avoid accidental ingestion.

Battery ingestion may cause choking and/or poisoning.

Install the unit on a rigid structure to prevent excessive sound or vibration during operation.

If power to the hydrobox is to be turned off (or system switched off) for a long time, the water should be drained.

Preventative measures should be taken against water hammer, such as installing a Water Hammer Arrestor on the primary water circuit, as directed by the manufacturer.

Page 4

4

CAUTION (SPLIT MODELS ONLY)

<Using R410A refrigerant heat pumps>

Use C1220 copper phosphorus, for copper and copper alloy seamless pipes, to connect the refrigerant pipes. Make sure the insides of the pipes are clean and

do not contain any harmful contaminants such as sulfuric compounds, oxidants, debris, or dust. Use pipes with the specifi ed thickness. (Refer to 4.4.) Note the

following if reusing existing pipes that carried R22 refrigerant.

- Replace the existing fl are nuts and fl are the fl ared sections again.

- Do not use thin pipes. (Refer to 4.4.)

Store the pipes to be used during installation indoors and keep both ends of the pipes sealed until just before brazing. (Leave elbow joints, etc. in their packaging.) If dust, debris, or moisture enters the refrigerant lines, oil deterioration or compressor breakdown may result.

Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration oil applied to the fl ared sections. If mineral oil is mixed in the refrigeration oil, oil dete-

rioration may result.

Do not use refrigerant other than R410A refrigerant. If another refrigerant is used, the chlorine will cause the oil to deteriorate.

Use the following tools specifi cally designed for use with R410A refrigerant. The following tools are necessary to use R410A refrigerant. Contact your nearest

dealer for any questions.

Tools (for R410A)

Gauge manifold Flare tool

Charge hose Size adjustment gauge

Gas leak detector Vacuum pump adapter

Torque wrench Electronic refrigerant charging scale

Be sure to use the correct tools. If dust, debris, or moisture enters the refrigerant lines, refrigeration oil deterioration may result.

Do not use a charging cylinder. If a charging cylinder is used, the composition of the refrigerant will change and system effi ciency will be reduced.

WARNING (SPLIT MODELS ONLY)

Do not discharge refrigerant into the atmosphere if refrigerant leaks during installation, ventilate the room.

Use appropriate tools for high pressure refrigerant.

When pumping down refrigerant , stop the compressor before disconnecting the refrigerant pipes.

During installation securely fasten the refrigerant pipes before starting the compressor.

Check that refrigerant gas does not leak after the completion of installation.

Use R410A refrigerant only. Do not allow air to enter the lines. Failure to observe these instructions will cause mechanical failure, system failure or, in the worst

case, serious breach of product safety.

Page 5

5

Cautions for units utilizing refrigerant R410A

CAUTIONS RELATED TO NEW REFRIGERANT

Use new refrigerant pipes.

If using the existing R22, be careful of the followings.

· For RP100, 125 and 140, be sure to perform replacement

operation before test run.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Only use R410A refrigerant.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Handle tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

If dirt, dust or moisture enters into refrigerant cycle, it can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amounts of mineral oil enters, it can cause deterioration of refrigerant oil etc.

The refrigerant oil applied to flare and flange

connections must be ester oil, ether oil or

alkylbenzene oil in a small amount.

Store the piping to be used indoors during

installation, and both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Make sure that the inside and outside of refrigerant piping is clean and it has no contaminants

such as sulfur, oxides, dirt, shaving particles, etc,

which are hazard to refrigerant cycle.

In addition, use pipes with specified thickness.

Use the specified refrigerant only.

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the

unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the

spec labels provided with our products.

We will not be held responsible for mechanical failure,

system malfunction, unit breakdown or accidents caused

by failure to follow the instructions.

Page 6

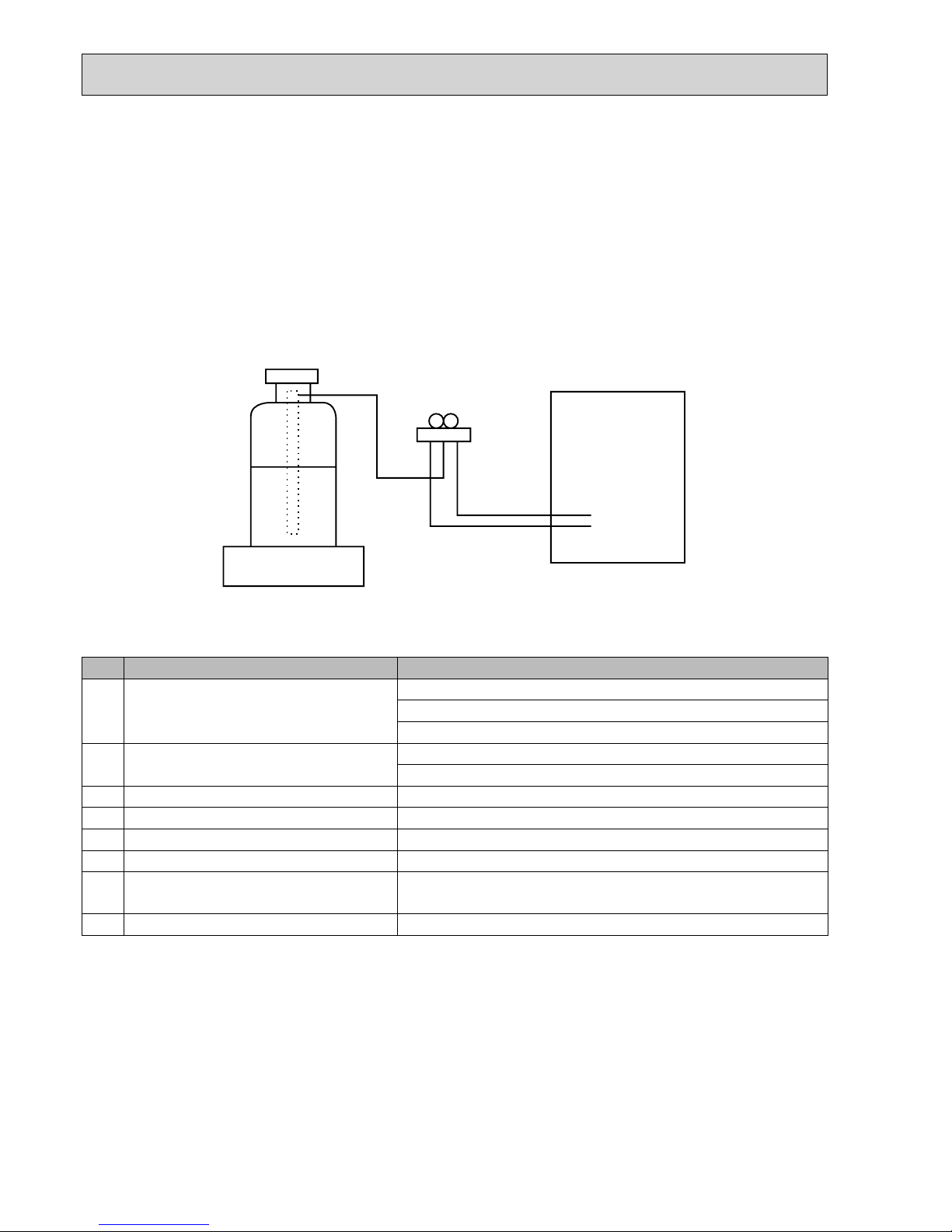

Gravimeter

Unit

6

[1] Cautions for service

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

[3] Service tools

Use the service tools below as exclusive tools for R410A refrigerant.

No. Tool name Specifications

1

Gauge manifold

· Only for R410A

· Use the existing fitting

specifications

. (UNF1/2)

· Use high-tension side pressure of 5.3 MPa·G or over.

2

Charge hose

· Only for R410A

· Use pressure performance of 5.09 MPa·G or over.

3

Electronic scale

—

4

Gas leak detector · Use the detector for R134a, R407C or R410A

5

Adaptor for reverse flow check · Attach on vacuum pump.

6

Refrigerant charge base

—

7

Refrigerant cylinder

· Only for R410A ·Top of cylinder (Pink)

· Cylinder with syphon

8

Refrigerant recovery equipment

—

Page 7

7

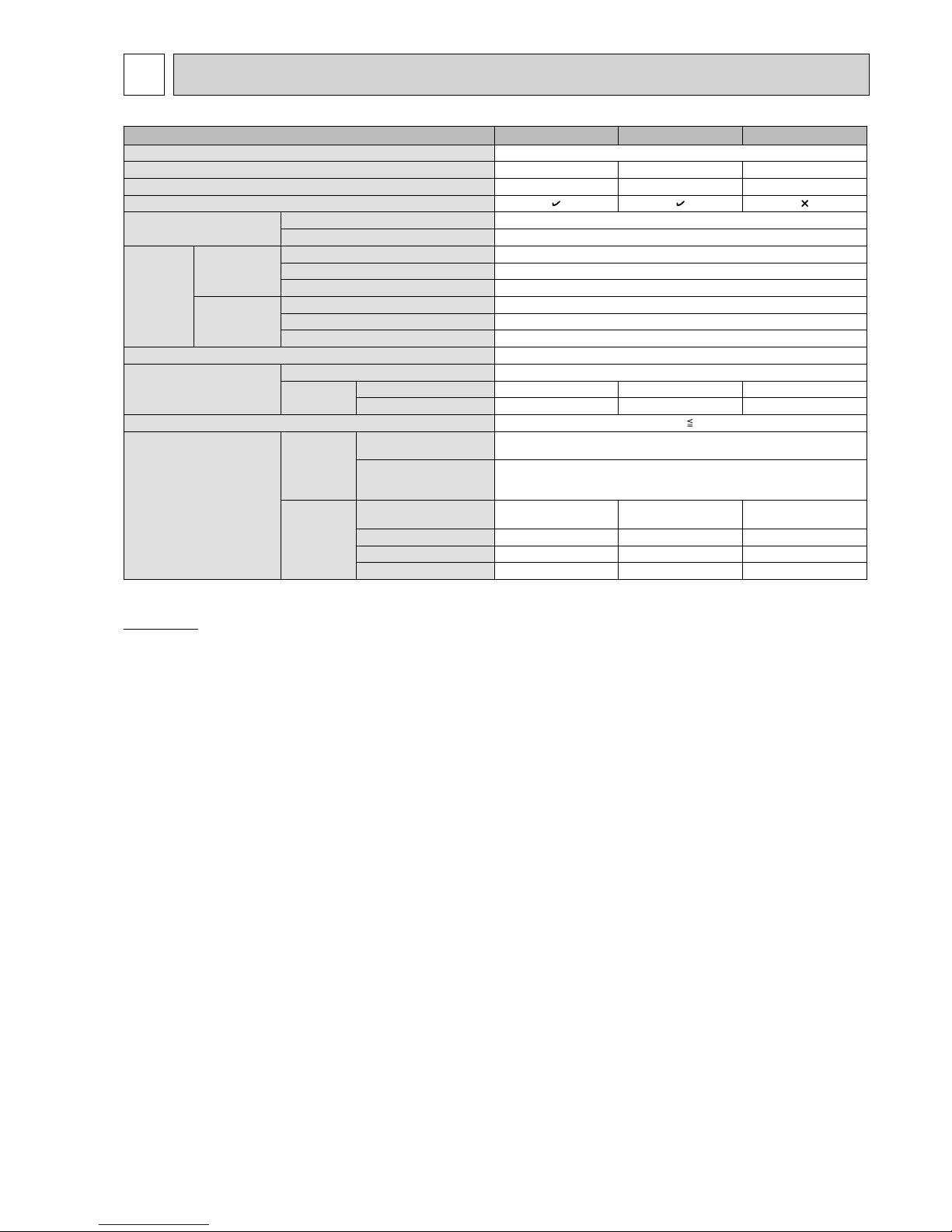

SPECIFICATIONS

3

Model name EHSC-VM6A EHSC-YM9A EHPX-VM2A

Overall unit dimensions 800 × 530 × 360 mm (Height × Width × Depth)

Weight (empty) 54 kg 54 kg 39 kg

Weight (full) 60 kg 60 kg 44 kg

Plate heat exchanger

Unvented expansion vessel

(Primary circuit)

Nominal volume 10 L

Charge pressure 0.1 MPa (1 bar)

Safety device Water circuit

(Primary)

Control thermistor 1 - 80°C

Pressure relief valve 0.3 MPa (3 bar)

Flow switch Min fl ow 5.5 l/min

Booster heater Control thermistor 80°C

Manual reset thermostat 90°C

Thermal Cut Off (for dry run prevention) 121°C

Primary circuit circulating Pump Grundfos UPSO 25-70 180

Connections Water 28 mm compression primary circuit

Refrigerant

(R410A)

Liquid 9.52 mm 9.52 mm —

Gas 15.88 mm 15.88 mm —

Operating ambient condition 0 (*1) - 35°C ( 80 %RH)

Electrical data Control board Power supply

(Phase, voltage, frequency)

~/N, 230 V, 50 Hz

Breaker

(*when powered from

independent source)

10A

Booster heater Power supply

(Phase, voltage, frequency)

~/N, 230 V, 50 Hz 3~, 400 V, 50 Hz ~/N, 230 V, 50 Hz

Capacity 2 kW+4 kW 3 kW+6 kW 2 kW

Current 26 A 13 A 9 A

Breaker 32 A 16 A 16 A

*1 The environment must be frost-free.

Optional extras

• Wireless Remote Controller PAR-WT40R-E • Joint pipe (15.88 12.7) PAC-SH50RJ-E

• Wireless Receiver PAR-WR41R-E • Joint pipe (9.52 6.35) PAC-SH30RJ-E

• Remote sensor PAC-SE41TS-E

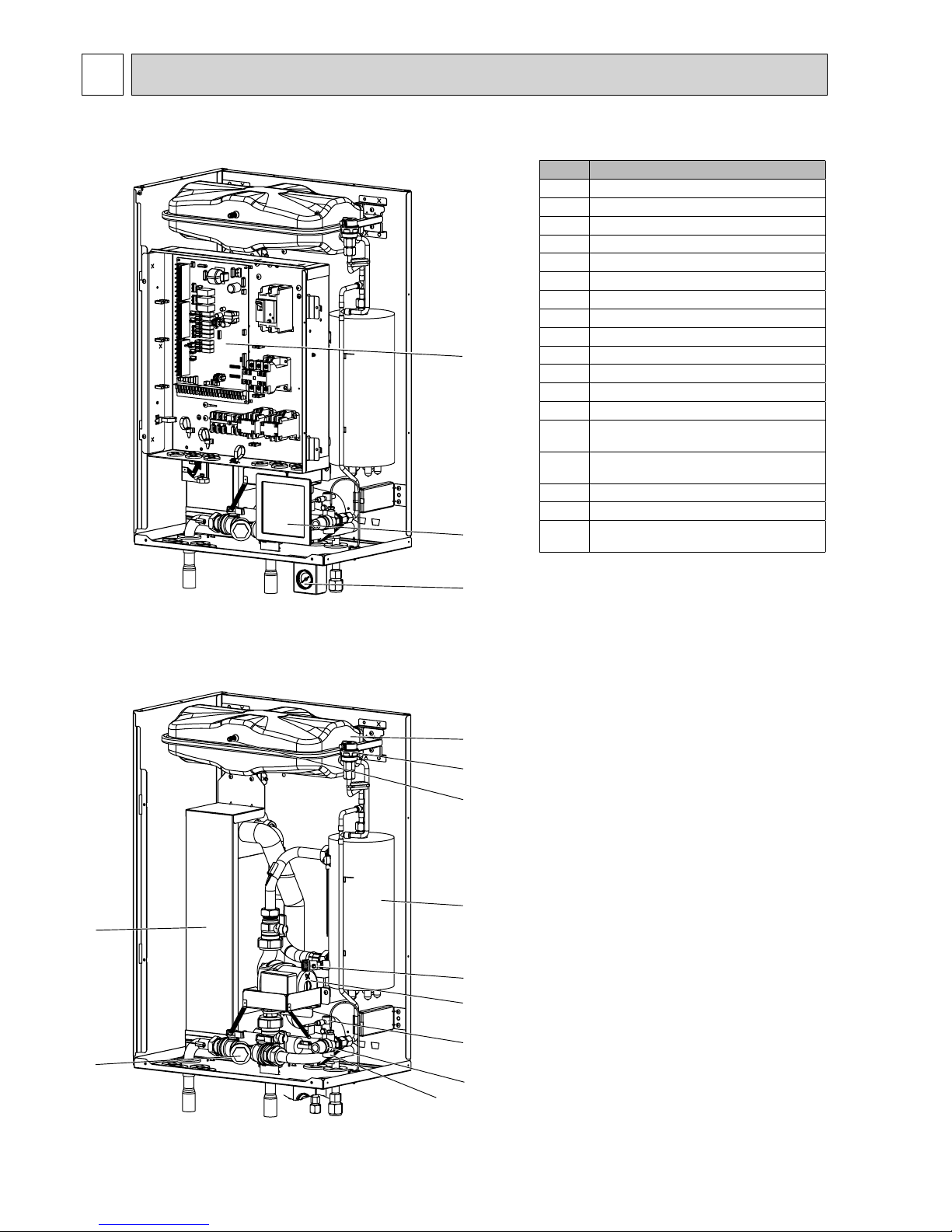

Page 8

8

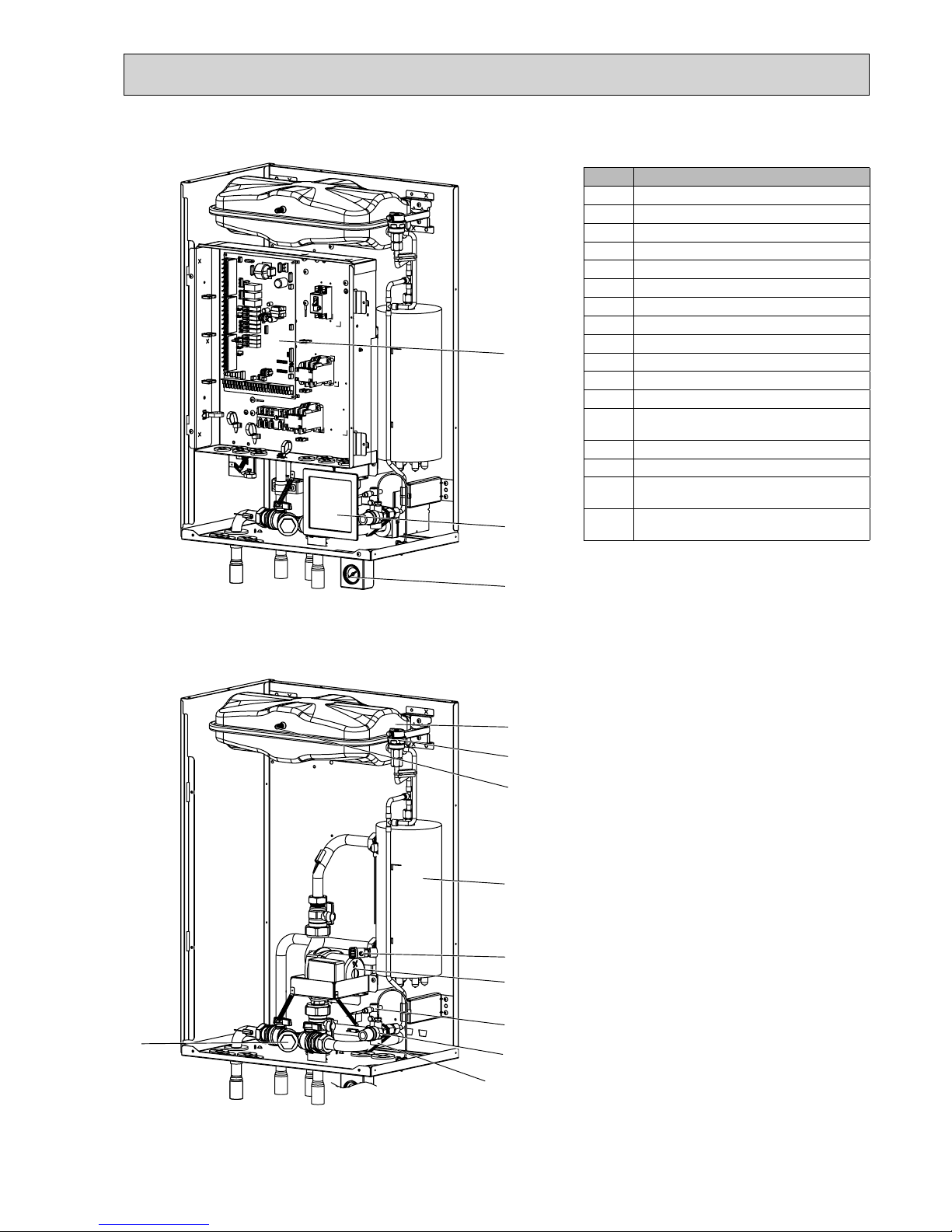

PART NAMES AND FUNCTIONS

4

Number Component

1 Control and electrical box

2 Main controller

3 Manometer

4 Expansion vessel

5 Expansion vessel charge valve

6 Automatic air vent

7 Booster heater

8 Drain cock

9 Water circulation pump

10 Pressure relief valve

11 Flow switch

12 Plate heat exchanger

13 Strainer valve

A

Inlet from space heating/Indirect DHW cylinder

(primary return)

B

Outlet to space heating/Indirect DHW cylinder

(primary fl ow)

C Refrigerant (Liquid)

D Refrigerant (Gas)

E

Discharge from pressure relief valve (installer to

pipe connect to suitable drain point)

1

2

3

4

6

5

7

8

9

11

10

12

13

A

B

C

D

E

<EHSC> (Split model system)

Figure 4-1

Figure 4-2

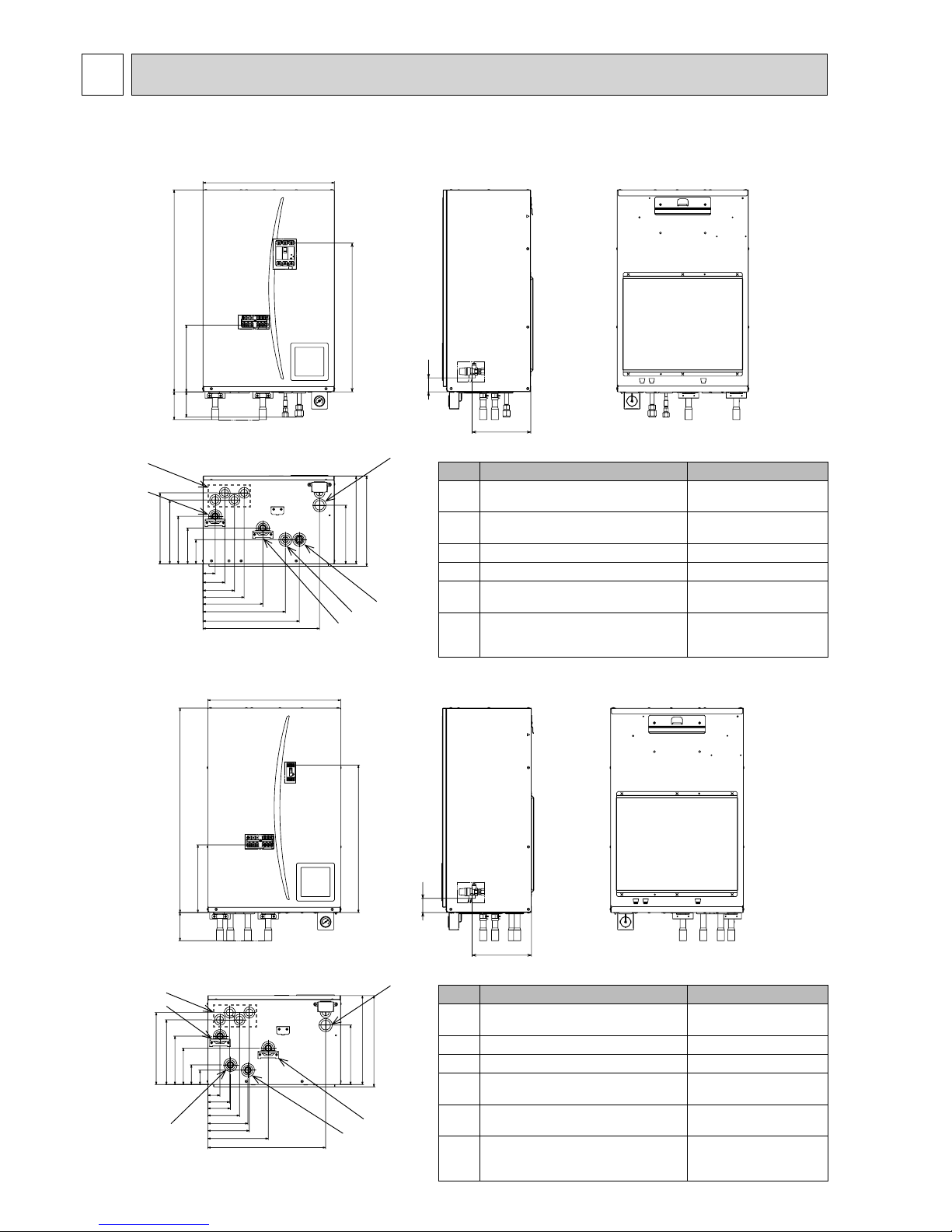

Page 9

9

Figure 4-3

Figure 4-4

Number Component

1 Control and electrical box

2 Main controller

3 Manometer

4 Expansion vessel

5 Expansion vessel charge valve

6

Automatic air vent

7 Booster heater

8 Drain cock

9 Water circulation pump

10 Pressure relief valve

11 Flow switch

13 Strainer valve

A

Inlet from space heating/Indirect DHW cylinder

(primary return)

B Inlet from heat pump

C Outlet to heat pump

D

Outlet to space heating/Indirect DHW cylinder (primary fl ow)

E

Discharge from pressure relief valve (installer to

pipe connect to suitable drain point)

1

2

3

7

8

9

10

11

13

A

B

C

D

E

<EHPX> (Packaged model system)

4

6

5

Page 10

48

357

348

381

237

326

142

96

189

86

124

163

461

233

253

282

55.5

(233)

590

520

264.5

800

110±5

100±5

56

77

142

189

233

253

282

48

89

86

124

157

163

237

461

348

357

520

800

264.5

577

110±5

55.5

(233)

10

OUTLINES AND DIMENSIONS

5

5-1. Technical Drawings

(Unit: mm)

Letter Pipe description Connection size/type

A

Space heating/Indirect DHW cylinder (primary) return connection

28 mm/Compression

B

Space heating/Indirect DHW cylinder (primary) fl ow connection

28 mm/Compression

C Refrigerant (Liquid) 9.52 mm/Flare

D Refrigerant (Gas) 15.88 mm/Flare

E

Discharge pipe (by installer) from pressure

relief valve

G1/2” female (valve port

within hydrobox casing)

F Electrical cable inlets

—

*The leftmost inlet is for

wireless receiver (option)

Letter Pipe description Connection size/type

A

Space heating/Indirect DHW cylinder (primary) return connection

28 mm/Compression

B Flow connection from heat pump 28 mm/Compression

C Return connection to heat pump 28 mm/Compression

D

Space heating/Indirect DHW cylinder (primary) fl ow connection

28 mm/Compression

E

Discharge pipe (by installer) from pressure

relief valve

G1/2” female (valve port

within hydrobox casing)

F Electrical cable inlets

—

*The leftmost inlet is for wire-

less receiver (option)

F

A

B

C

D

E

F

A

B

C

D

E

<EHSC> (Split model system)

<EHPX> (Packaged model system)

<Front>

<Side> <Rear>

<View from below>

<Front>

<Side> <Rear>

<View from below>

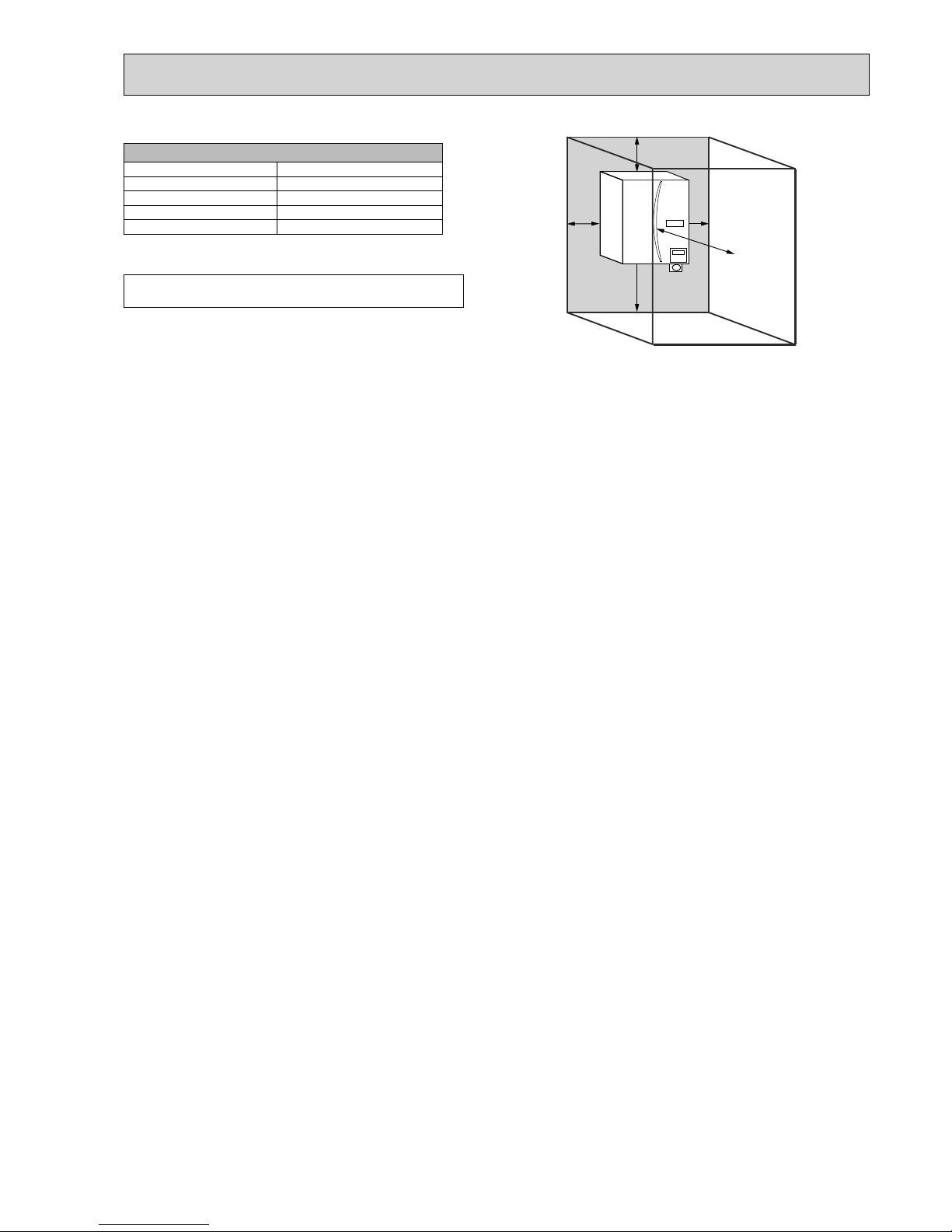

Page 11

a

b

b

d

c

11

Service access

5-2. Service access diagrams

Service access

Parameter Dimension (mm)

a 200

b 150

c 500

d 500

Suffi cient space MUST be left for the provision of discharge pipework as

detailed in National and Local building regulations.

The hydrobox must be located indoors and in a frost-free environment,

for example in a utility room.

Page 12

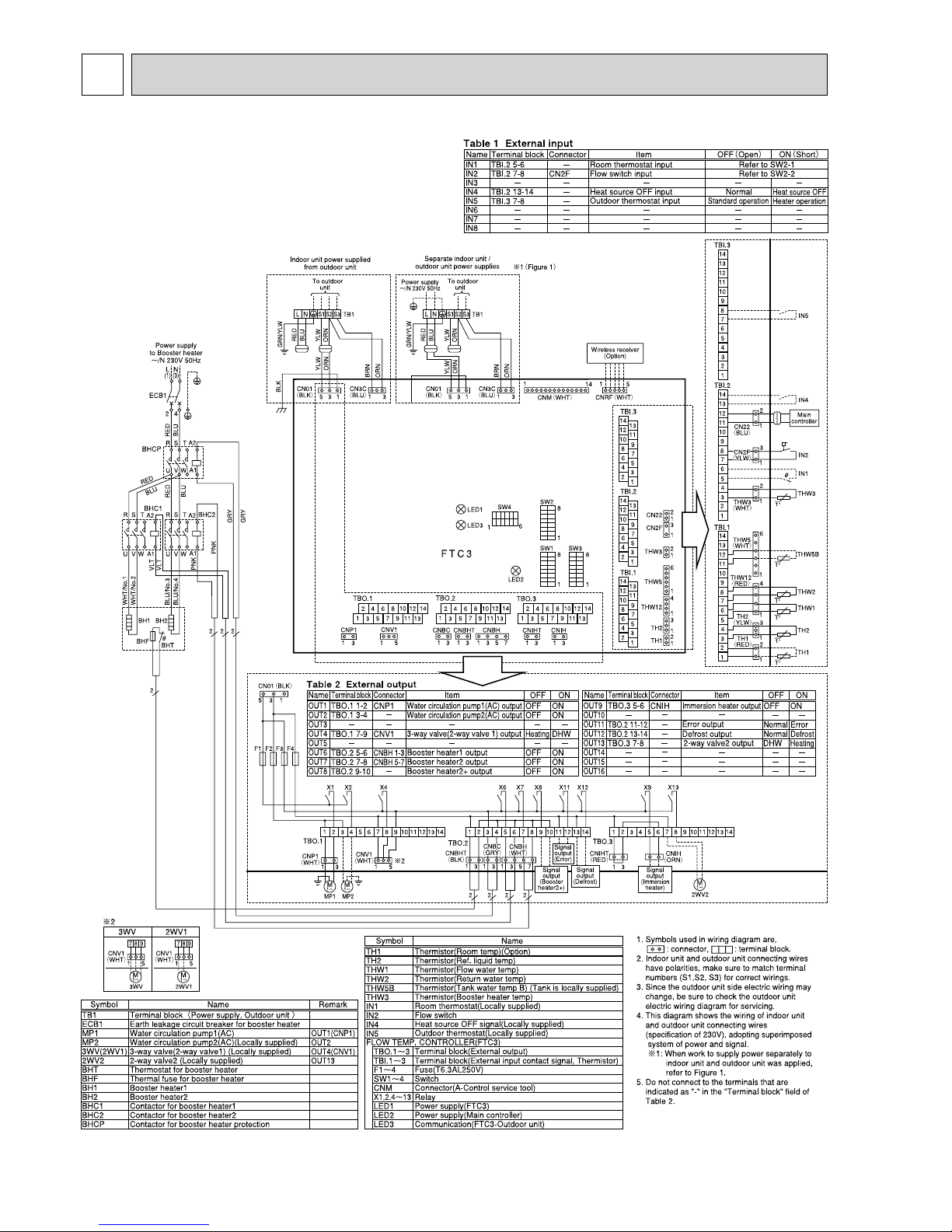

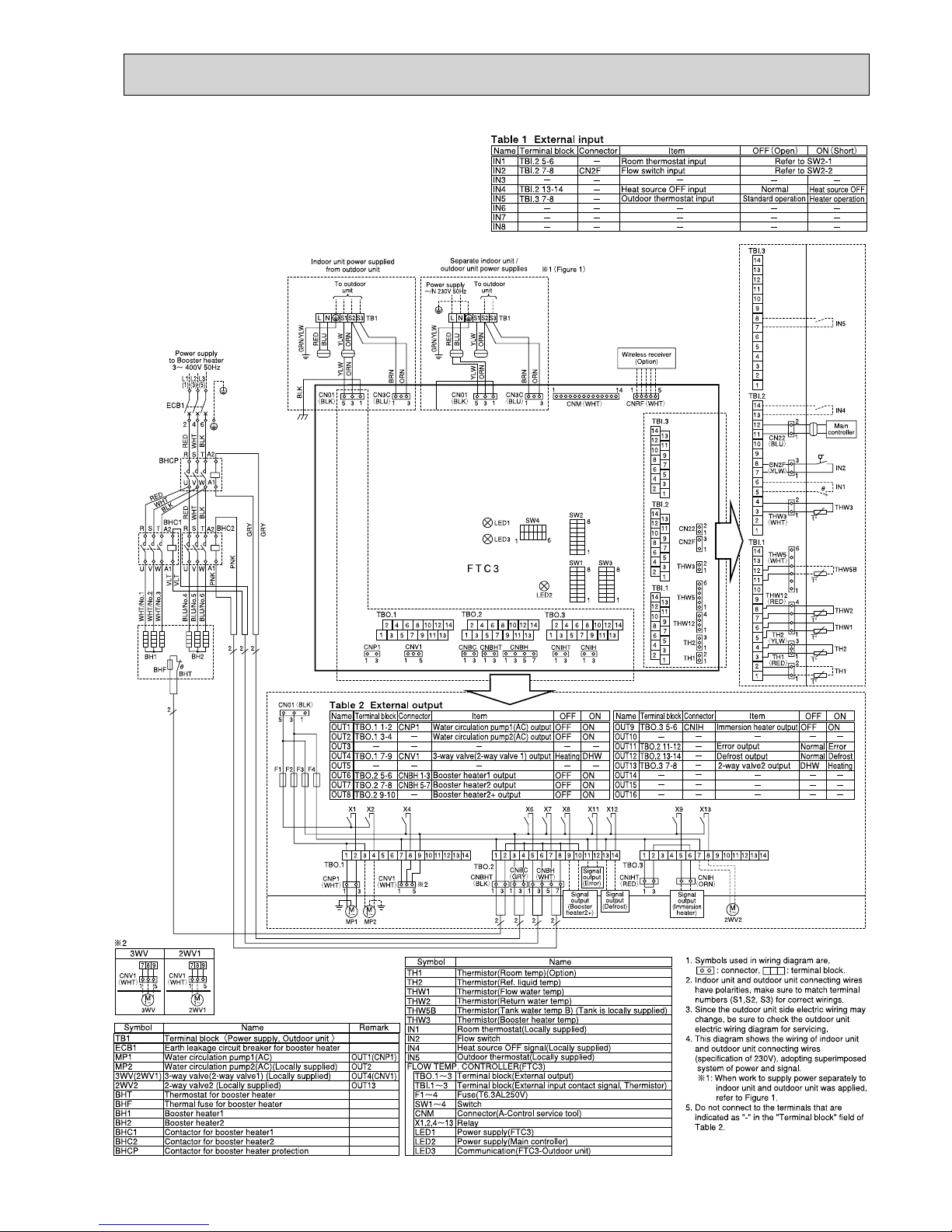

* See Chapter 6-4.

12

6 WIRING DIAGRAM

6-1. EHSC-VM6A

Page 13

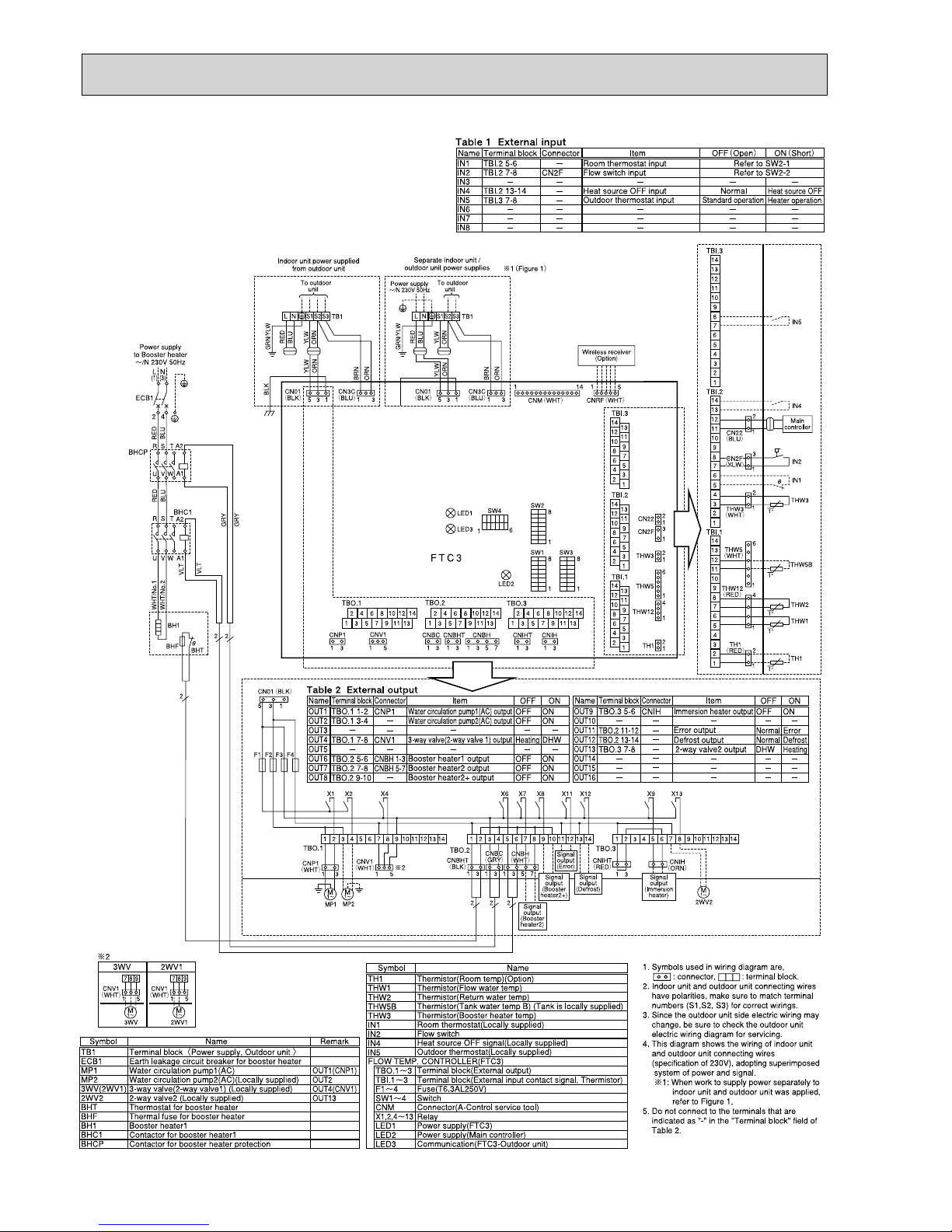

* See Chapter 6-4.

13

6-2. EHSC-YM9A

Page 14

* See Chapter 6-4.

14

6-3. EHPX-VM2A

Page 15

15

Automatic switch to backup heater only operation

Back-up heater operation (*1) will automatically run when the indoor unit stops abnormally.

To enable the function, switch Dip SW 2-5 to ON.

During the back-up operation, an error code(s) and the contact number will be displayed alternately.

External output (OUT11) will be available.

To clear the fault(s), reset the power breakers on the indoor and outdoor units.

<Applicable error codes (*2)>

E6 to E9, Ed, P8, U1 to U8, Ud, UE, UF, UL, UP

(*1) Prolonged running of the back-up operation may affect the life of the heater.

(*2) For safety reasons, this function is not available for certain faults. (System operation must be stopped and only pump keeps running.)

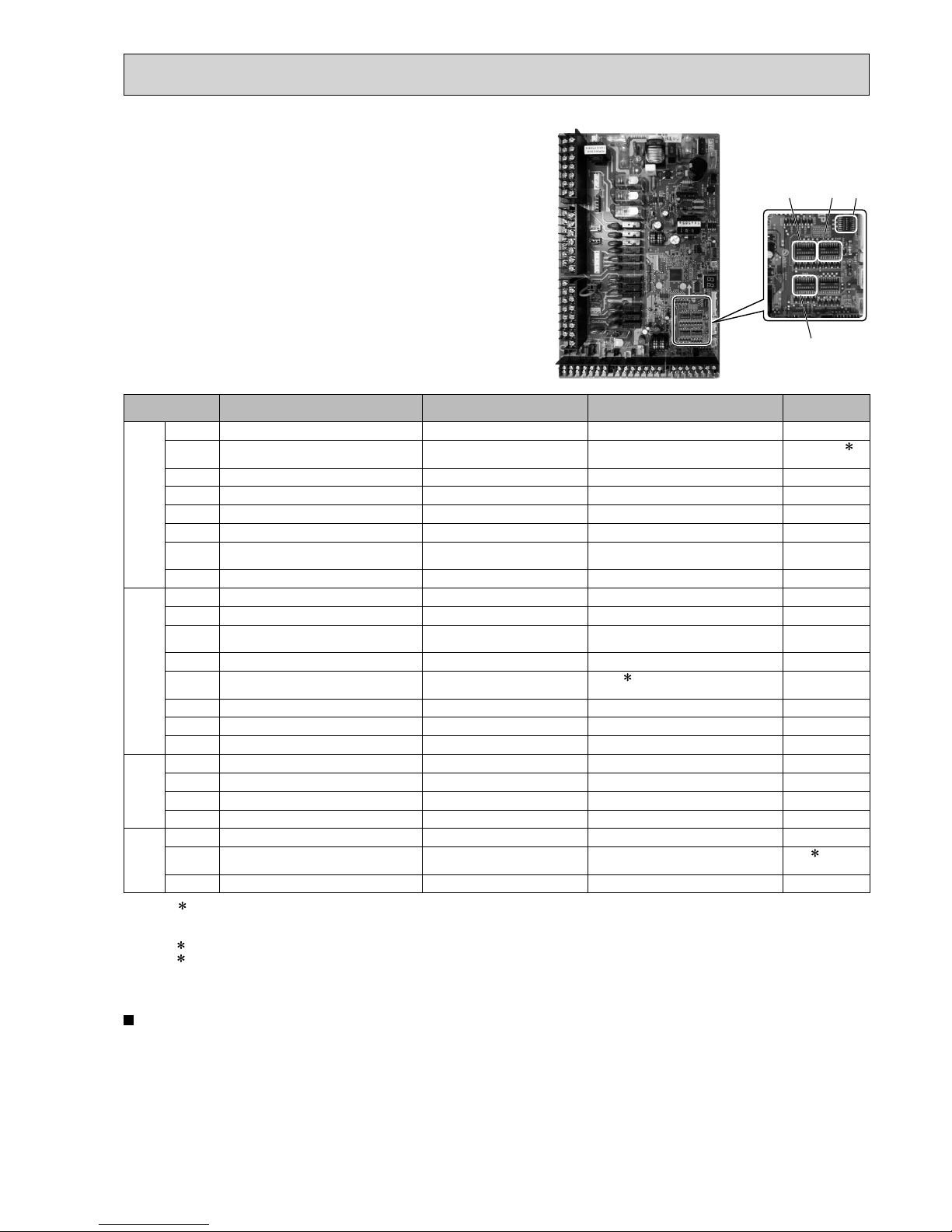

6-4. Dip switch setting

<Dip Switch Functions>

Located on the FTC3 printed circuit board are 4 sets of small white switches

known as Dip switches. The Dip switch number is printed on the circuit board

next to the relevant switches. The word ON is printed on the circuit board and on

the Dip switch block itself. To move the switch you will need to use a pin or the

corner of a thin metal ruler or similar.

Dip switch settings are listed below in the table below.

SW1 SW2

SW3

SW4

Dip switch Function OFF ON

Default

(Indoor unit Ref.)

SW1

SW1-1 — — —

OFF

SW1-2

Heat pump maximum outlet water

temperature

55 °C 60 °C

OFF: EHSC ( 1)

ON : EHPX

SW1-3

DHW tank WITHOUT DHW tank WITH DHW tank OFF

SW1-4

Immersion heater WITHOUT immersion heater WITH immersion heater OFF

SW1-5

Booster heater WITHOUT booster heater WITH booster heater ON

SW1-6

Booster heater function For heating only For heating and DHW OFF

SW1-7

Outdoor unit type Split type Packaged type OFF: EHSC

ON : EHPX

SW1-8

Wireless remote controller

WITHOUT wireless remote controller

WITH wireless remote controller OFF

SW2

SW2-1

Room thermostat input (IN1) logic change Operation stop at thermostat short Operation stop at thermostat open OFF

SW2-2

Flow switch input (IN2) logic change Failure detection at short Failure detection at open ON

SW2-3

Booster heater capacity restriction Inactive Active OFF: EHSC

ON : EHPX-VM2A

SW2-4 — — —

OFF

SW2-5

Automatic switch to backup heater only operation (When outdoor unit stops by error)

Inactive

Active (

3)

OFF

SW2-6 — — —

OFF

SW2-7 — — —

OFF

SW2-8 — — —

OFF

SW3

SW3-1 — — —

OFF

SW3-2 — — —

OFF

SW3-3

— — — OFF

SW3-4~8

— — — OFF

SW4

SW4-1~4

— — — OFF

SW4-5

Emergency mode (Heater only operation) Normal Emergency mode (Heater only operation)

(To be activated only when powered ON)

OFF (

2)

SW4-6 — — —

OFF

Notes:

1. For packaged model system, the max outlet water temperature is always 60°C so default Dip switch SW1-2 is ON.

For split model system, the max outlet water temperature is usually 55°C except in the case of PUHZ-HRP outdoor model where the max

outlet water temperature is 60°C and DIP switch SW1-2 should be changed to ON.

2.

If emergency mode is no longer required, please turn off both outdoor and indoor unit power supply before returning SW4-5 to OFF position.

3. For safety reasons, this function is not available for certain errors. (System operation must be stopped and only pump keeps running.)

External output (OUT11) will be available.

Page 16

Power

supply

~/N

230V

50Hz

Earth

leakage

breaker

Wiring

circuit

breaker

or

Isolating

switch

L

N

S1

S2

S3

Outdoor unit

S1

S2

S3

TB1

L

N

ECB1

Wiring

circuit

breaker

or

Isolating

switch

To control

board

ELB for

booster

heater

(Primary circuit)

Power

supply

~/N

230V

50Hz

Hydrobox

L

N

16

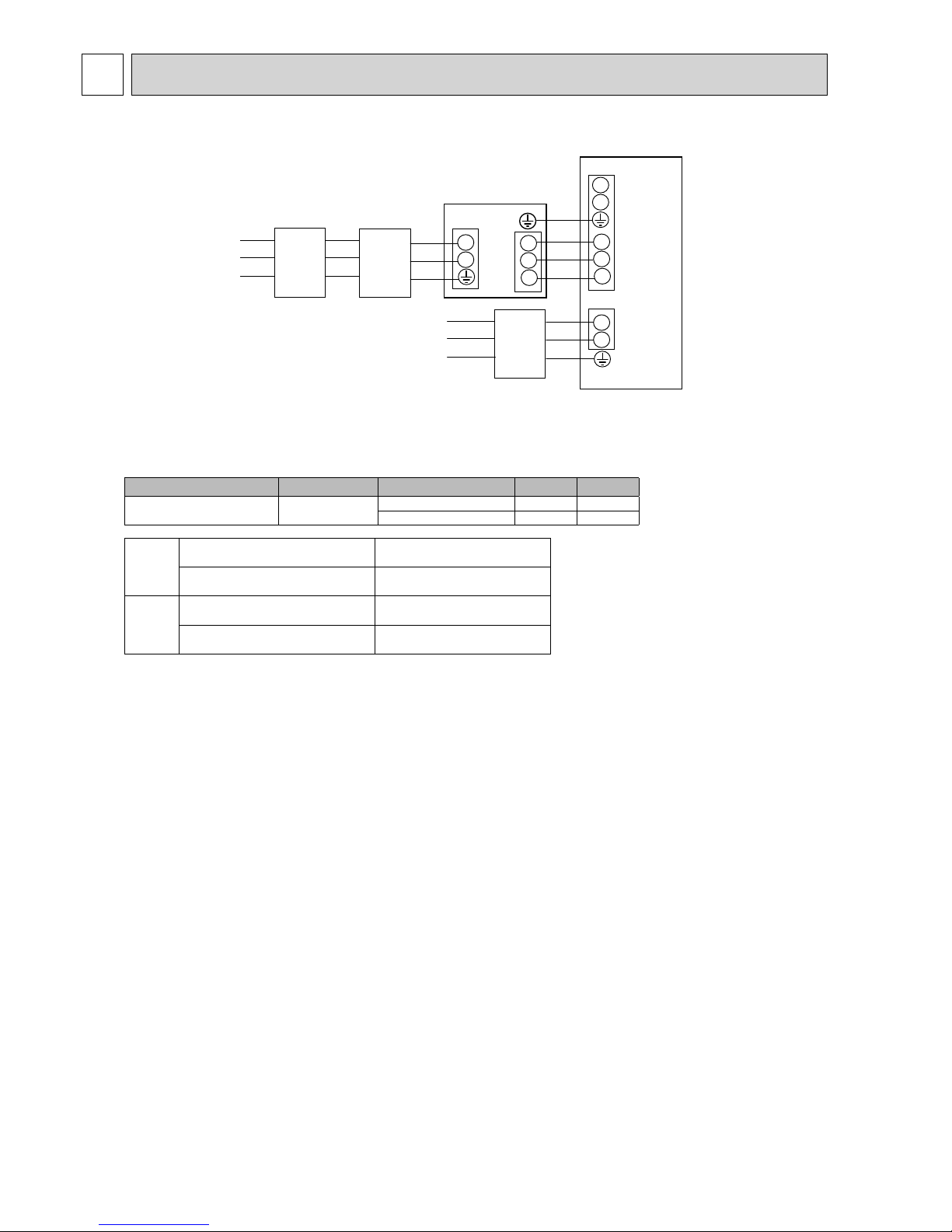

FIELD WIRING

7

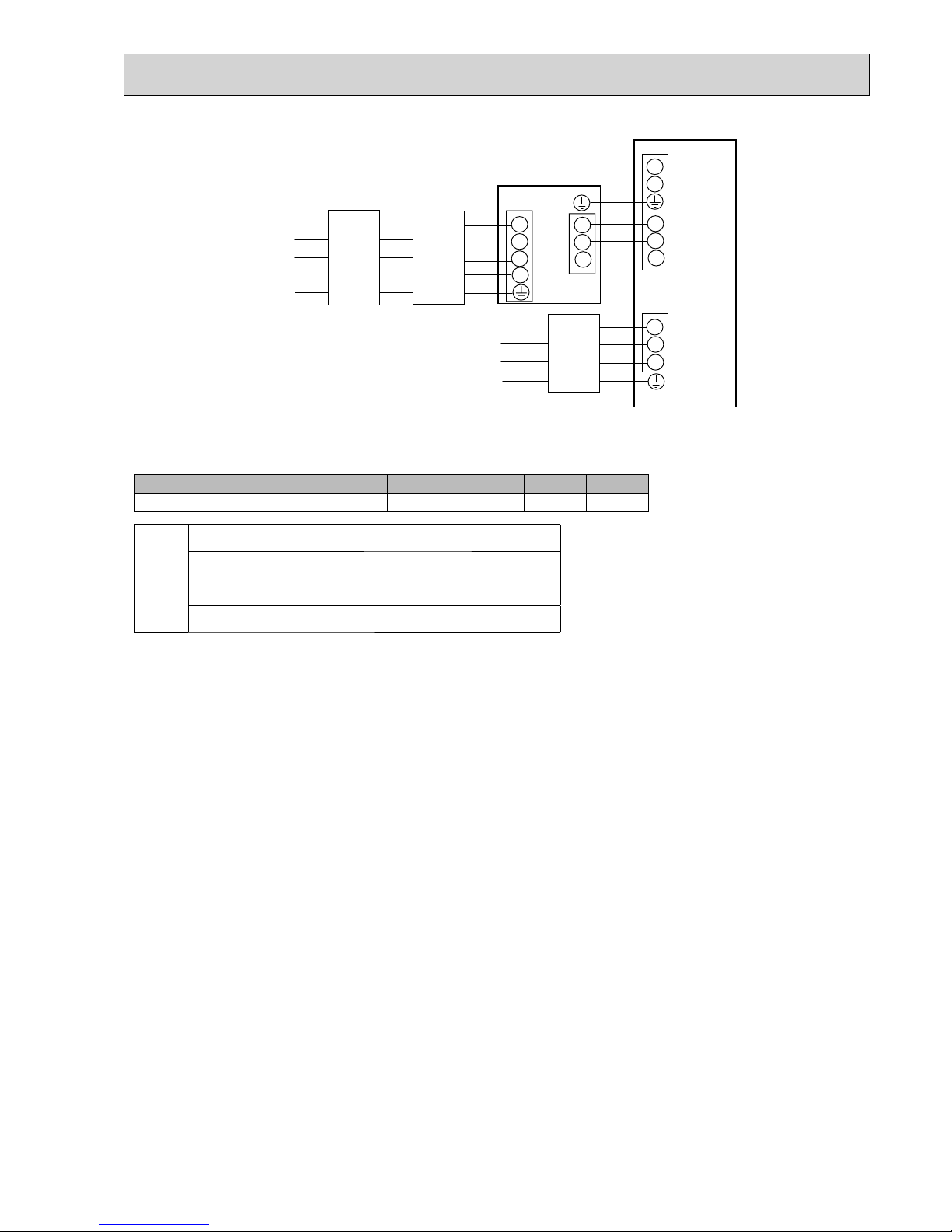

Option 1: Hydrobox powered via outdoor unit

<1 phase>

<Figure 7-1>

Electrical connections 1 phase

Description Power supply Capacity (Indoor unit Ref.) Breaker Wiring

Booster heater (Primary circuit) ~/N 230 V 50 Hz 2 kW (EHPX-VM2A) 16 A *1 2.5 mm²

6 kW (EHSC-VM6A) 32 A *1 6.0 mm²

Wiring

Wiring No.

× size (mm²)

Hydrobox - Outdoor unit *2 3 × 1.5 (polar)

Hydrobox - Outdoor unit earth *2 1 × Min. 1.5

Circuit

rating

Hydrobox - Outdoor unit S1 - S2 *3 AC230V

Hydrobox - Outdoor unit S2 - S3 *3 DC24V

*1. A breaker with at least 3.0 mm contact separation in each pole shall be provided. Use earth leakage breaker (NV).

The breaker shall be provided to ensure disconnection of all active phase conductors of the supply.

*2. Max. 45 m

If 2.5 mm² used, Max. 50 m

If 2.5 mm² used and S3 separated, Max. 80 m

*3. The values given in the table above are not always measured against the ground value.

Notes: 1. Wiring size must comply with the applicable local and national codes.

2. Indoor unit/outdoor unit connecting cords shall not be lighter than polychloroprene sheathed fl exible cord. (Design 60245 IEC 57)

Indoor unit power supply cords shall not be lighter than polychloroprene sheathed fl exible cord. (Design 60227 IEC 53)

3. Install an earth longer than other cables.

4. The power supply MUST have suffi cient capacity for each heater and ALL electrical loads. Insuffi cient power supply may result in

chattering of load contactor(s).

* Installer MUST affi x label A that is included with the manuals near each wiring diagram for hydrobox and outdoor units.

Page 17

Power

supply

3N~

400V

50Hz

Earth

leakage

breaker

Wiring

circuit

breaker

or

Isolating

switch

L1

L2

S1

S2

S3

Outdoor unit

S1

S2

S3

TB1

L2

L3

ECB1

Wiring

circuit

breaker

or

Isolating

switch

To control

board

ELB for

booster

heater

(Primary circuit)

Power

supply

3~

400V

50Hz

N

L3

L1

Hydrobox

L2

L1

17

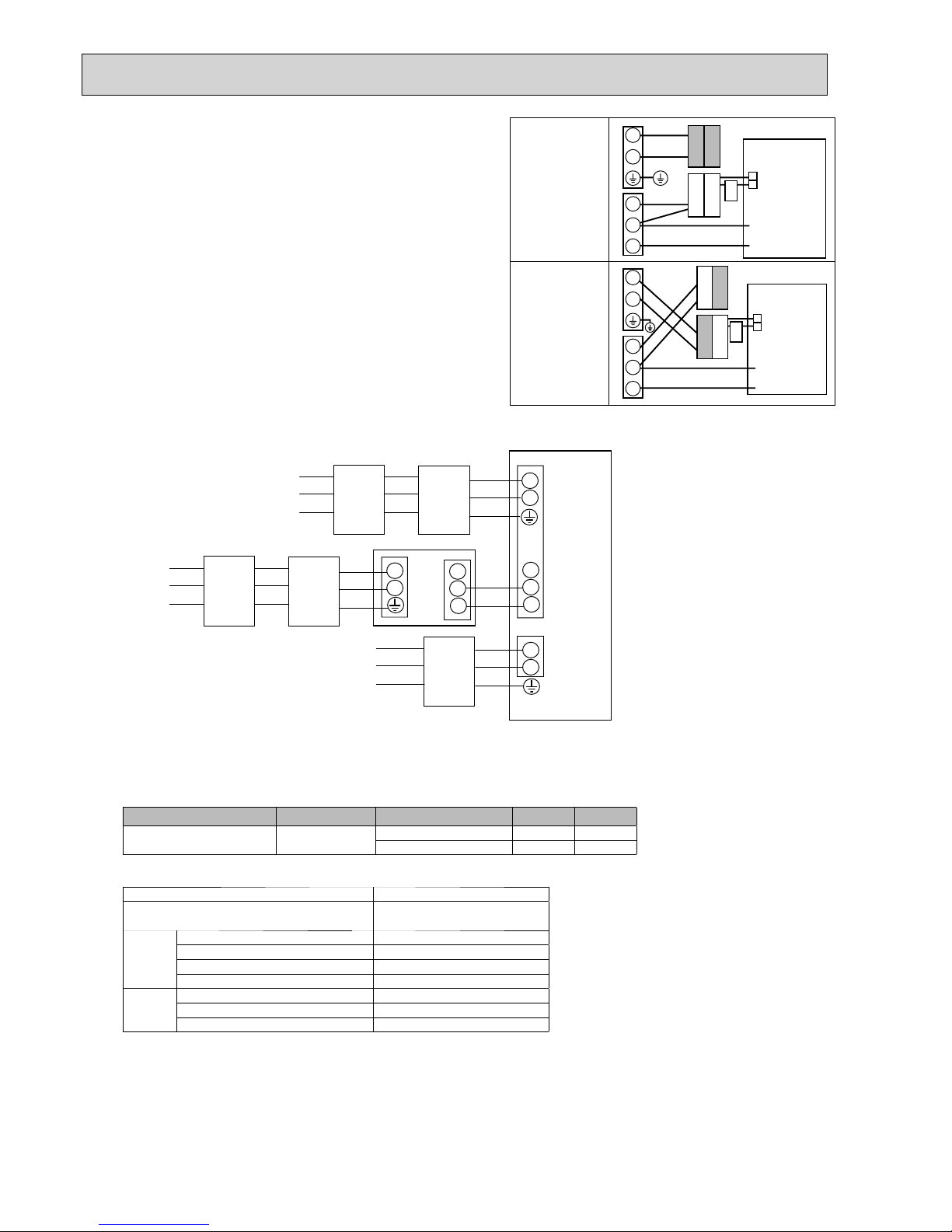

<3 phase>

<Figure 7-2>

Electrical connections 3 phase

Description Power supply Capacity (Indoor unit Ref.) Breaker Wiring

Booster heater (Primary circuit)

3~ 400V 50Hz 9 kW (EHSC-YM9A) 16 A *1 2.5 mm²

Wiring

Wiring No.

× size (mm²)

Hydrobox - Outdoor unit *2 3 × 1.5 (polar)

Hydrobox - Outdoor unit earth *2 1 × Min. 1.5

Circuit

rating

Hydrobox - Outdoor unit S1 - S2 *3 AC230V

Hydrobox - Outdoor unit S2 - S3 *3 DC24V

*1. A breaker with at least 3.0 mm contact separation in each pole shall be provided. Use earth leakage breaker (NV).

The breaker shall be provided to ensure disconnection of all active phase conductors of the supply.

*2. Max. 45 m

If 2.5 mm² used, Max. 50 m

If 2.5 mm² used and S3 separated, Max. 80 m

*3. The values given in the table above are not always measured against the ground value.

Notes: 1. Wiring size must comply with the applicable local and national codes.

2. Indoor unit/outdoor unit connecting cords shall not be lighter than polychloroprene sheathed fl exible cord. (Design 60245 IEC 57)

Indoor unit power supply cords shall not be lighter than polychloroprene sheathed fl exible cord. (Design 60227 IEC 53)

3. Install an earth longer than other cables.

4. The power supply MUST have suffi cient capacity for each heater and ALL electrical loads. Insuffi cient power supply may result in

chattering of load contactor(s).

* Installer MUST affi x label A that is included with the manuals near each wiring diagram for hydrobox and outdoor units.

Page 18

S1

S2

S3

L

N

L

N

BLACK

BLACK

YELLOW

YELLOW

YELLOW

YELLOW

BLACK

BLACK

CNO1

CNO1

CNO1

Black

CNO1

Black

Hydrobox

control board

Hydrobox

control board

S1

S2

S3

Initial settings

(Power supplied

by outdoor unit)

Modified settings

(Separate power

supply to

the hydrobox)

Power

supply

~/N

230V

50Hz

Earth

leakage

breaker

Wiring

circuit

breaker

or

Isolating

switch

L

N

S1

S2

S3

Outdoor unit

S1

S2

S3

TB1

L

N

ECB1

Wiring

circuit

breaker

or

Isolating

switch

To control

board

ELB for

booster

heater

(Primary circuit)

L

N

Power

supply

~/N

230V

50Hz

Earth

leakage

breaker

Wiring

circuit

breaker

or

Isolating

switch

Power

supply

~/N

230V

50Hz

Hydrobox

18

Option2: Hydrobox powered by independent source.

If the hydrobox and outdoor units have separate power supplies, the following

requirements MUST be carried out:

• Hydrobox electrical box connector connections changed (see Figure

4.5.6)

• Outdoor unit DIP switch settings changed to SW8-3 ON.

• Turn on the outdoor unit BEFORE the hydrobox.

<1 phase>

<Figure 7-4>

Electrical connections 1 phase

<Figure 7-3>

Description Power supply Capacity (Indoor unit Ref.) Breaker Wiring

Booster heater (Primary circuit) ~/N 230 V 50 Hz 2 kW (EHPX-VM2A) 16 A *1 2.5 mm²

6 kW (EHSC-VM6A) 32 A *1 6.0 mm²

Hydrobox power supply ~/N 230 V 50 Hz

Hydrobox input capacity

Main switch (Breaker)

*1

16 A

Wiring

Wiring No.

× size (mm²)

Hydrobox power supply 2 × Min. 1.5

Hydrobox power supply earth 1 × Min. 1.5

Hydrobox - Outdoor unit *2 2 × Min. 0.3

Hydrobox - Outdoor unit earth —

Circuit

rating

Hydrobox L - N *3 AC230V

Hydrobox - Outdoor unit S1 - S2 *3 —

Hydrobox - Outdoor unit S2 - S3 *3 DC24V

*1. A breaker with at least 3.0 mm contact separation in each pole shall be provided. Use earth leakage breaker (NV).

The breaker shall be provided to ensure disconnection of all active phase conductors of the supply.

*2. Max. 120 m

*3. The values given in the table above are not always measured against the ground value.

Notes: 1. Wiring size must comply with the applicable local and national codes.

2. Indoor unit/outdoor unit connecting cords shall not be lighter than polychloroprene sheathed fl exible cord. (Design 60245 IEC 57)

Indoor unit power supply cords shall not be lighter than polychloroprene sheathed fl exible cord. (Design 60227 IEC 53)

3. Install an earth longer than other cables.

4. The power supply MUST have suffi cient capacity for each heater and ALL electrical loads. Insuffi cient power supply may result in

chattering of load contactor(s).

* Installer MUST affi x label B that is included with the manuals near each wiring diagram for hydrobox and outdoor units.

Page 19

Earth

leakage

breaker

Wiring

circuit

breaker

or

Isolating

switch

L1

L2

S1

S2

S3

Outdoor unit

S1

S2

S3

TB1

L2

L3

ECB1

Wiring

circuit

breaker

or

Isolating

switch

To control

board

ELB for

booster

heater

(Primary circuit)

N

L3

L1

L

N

Earth

leakage

breaker

Wiring

circuit

breaker

or

Isolating

switch

Power

supply

~/N

230V

50Hz

Power

supply

3N~

400V

50Hz

Power

supply

3~

400V

50Hz

Hydrobox

19

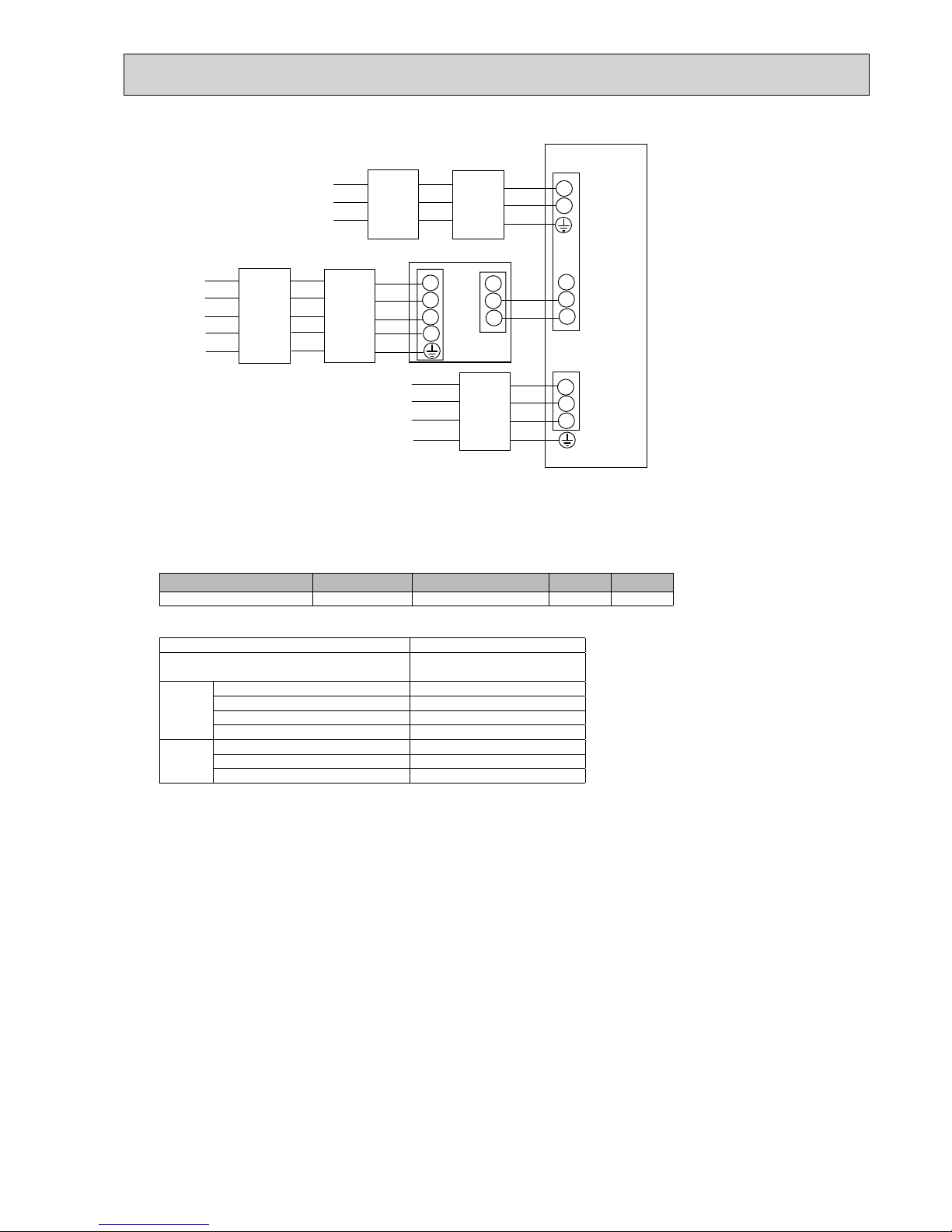

<3 phase>

<Figure 7-5>

Electrical connections 3 phase

Description Power supply Capacity (Indoor unit Ref.) Breaker Wiring

Booster heater (Primary circuit) 3~ 400V 50Hz 9 kW (EHSC-YM9A) 16 A *1 2.5 mm²

Hydrobox power supply ~/N 230 V 50 Hz

Hydrobox input capacity

Main switch (Breaker)

*1

16 A

Wiring

Wiring No.

× size (mm²)

Hydrobox power supply 2 × Min. 1.5

Hydrobox power supply earth 1 × Min. 1.5

Hydrobox - Outdoor unit *2 2 × Min. 0.3

Hydrobox - Outdoor unit earth —

Circuit

rating

Hydrobox L - N *3 AC230V

Hydrobox - Outdoor unit S1 - S2 *3 —

Hydrobox - Outdoor unit S2 - S3 *3 DC24V

*1. A breaker with at least 3.0 mm contact separation in each pole shall be provided. Use earth leakage breaker (NV).

The breaker shall be provided to ensure disconnection of all active power (i.e. phase AND neutral) conductors of the supply.

*2. Max. 120 m

*3. The values given in the table above are not always measured against the ground value.

Notes: 1. Wiring size must comply with the applicable local and national codes.

2. Indoor unit/outdoor unit connecting cords shall not be lighter than polychloroprene sheathed fl exible cord. (Design 60245 IEC 57)

Indoor unit power supply cords shall not be lighter than polychloroprene sheathed fl exible cord. (Design 60227 IEC 53)

3. Install an earth longer than other cables.

4. The power supply MUST have suffi cient capacity for each heater and ALL electrical loads. Insuffi cient power supply may result in

chattering of load contactor(s).

* Installer MUST affi x label B that is included with the manuals near each wiring diagram for hydrobox and outdoor units.

Page 20

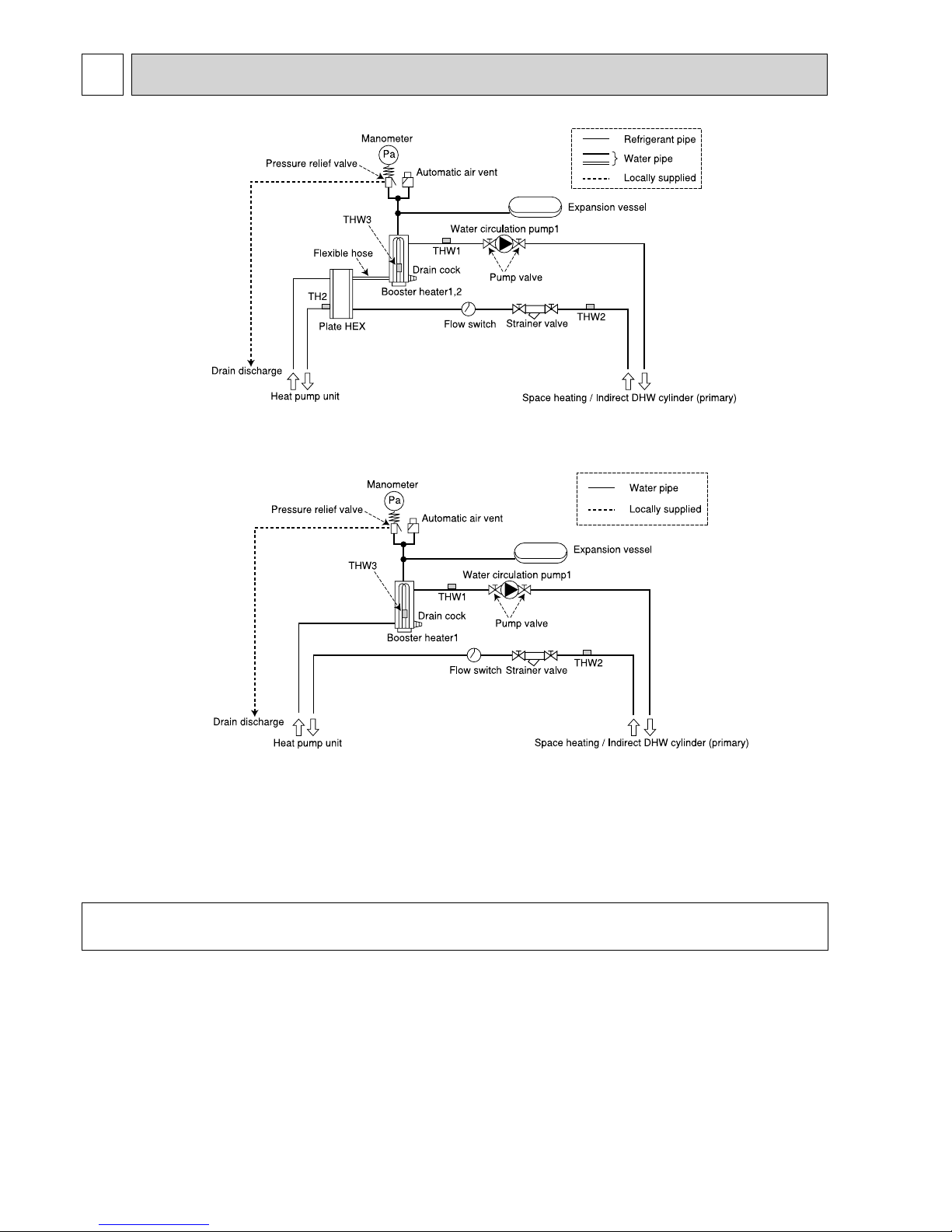

20

WATER SYSTEM DIAGRAM

8

EHSC-VM6A

EHSC-YM9A

EHPX-VM2A

1. Check all connections including factory fi tted ones are tight.

2. Insulate pipe work between hydrobox and outdoor unit.

3. Thoroughly clean and fl ush, system of all debris. (see section 4.2 for detailed instructions.)

4. Fill primary heating circuit with water and suitable anti-freeze and inhibitor as necessary. Always use a fi lling loop with double check valve when fi lling the

primary circuit to avoid back fl ow contamination of water supply.

Anti-freeze should always be used for package systems. It is the responsibility of the installer to decide if anti-freeze solution should be used in split systems

depending on each site’s conditions. Corrosion inhibitor should be used in both split and package systems.

When connecting metal pipes of different materials insulate the joints to prevent a corrosive reaction taking place which will damage the pipework.

•

•

5. Check for leaks. If leaks are found, retighten the screws on the connections.

6. Pressurise system to 1 bar.

7. Release all trapped air using air vents during and following heating period.

8. Top up with water as necessary. (If pressure falls below 1 bar)

Filling the System (Primary Circuit)

Draining the Hydrobox

WARNING: DRAINED WATER MAY BE VERY HOT

1. Before attempting to drain the hydrobox islolate from the electrical supply to prevent booster heater burning out.

2. Isolate hydrobox from primary water circuit and drain water from hydrobox. Use a suitable heat resistant hose to assist in these operations.

3. Drain any remaining water from booster heater using fi tted drain cock and hose, and the drain valve on the primary circuit to safely drain the unit.

4. After the hydrobox is drained, water remains in the following component parts. Drain water completely by checking the inside of the parts.

• Strainer (Remove the strainer cover.)

• Pressure relief valve (Operate the valve.)

Page 21

21

CONTROLS

9

F1 F2 F3 F4

9-1. Main Controller

<Main controller parts>

Letter Name Function

A Screen Screen in which all information is displayed

B Menu Access to system settings for initial set up and

modifi cations.

C Back Return to previous menu.

D Confi rm Used to select or save. (Enter key)

E Power/Holiday If system is switched off pressing once will turn sys-

tem on. Pressing again when system is switched on

will enable Holiday Mode. Holding the button down

for 3 secs will turn the system off. (*1)

F1-4 Function keys Used to scroll through menu and adjust settings.

Function is determined by the menu screen visible

on screen A.

*1

When the system is switched off or the power supply is disconnected, the

cylinder protection functions (e.g. freeze stat. function) will NOT operate.

Please beware that without these safety functions in operation the cylinder

may be damaged.

<Main screen icons>

Icon Description

1 Legionella

prevention

When this icon is displayed ‘Legionella Prevention

mode’ is active. (if DHW tank in system)

2 Heat pump When this icon is displayed the ‘Heat pump’ is in

use.

3 Electric heater When this icon is displayed the ‘Electric heaters’ are

in use.

4 Target

temperature

Target fl ow temperature

Target room temperature

Compensation curve

5 OPTION Pressing the function button below this icon will dis-

play the quick view menu.

6 + Increase desired temperature.

7 - Decrease desired temperature.

8 Information Pressing the function button below this icon displays

the information screen.

9 Space heating

mode

Heating mode

10 DHW mode Normal or ECO mode displayed (if DHW tank in

system)

11 Holiday mode

When this icon is displayed ‘Holiday mode’ time is

set.

12 Timer

Prohibited

Stand-by

Stop

Operating

BCD

E

A

8

765

12 11 1 3

2

10

9

4

Page 22

22

}

Unrestricted access

Installer only

Shaded items relate

to DHW functions.

These are only available if the system

includes a DHW tank.

F1

F4

F1

F2

F3

F4

F2 (PREVIEW)

F3 (EDIT)

F2

F4

F1

F2

F3 (EDIT)

(Password protected)

<Main Controller Menu Tree>

Initial

Main screen

Information

Option

Forced DHW ON/OFF

DHW ON/OFF/Timer

Heating ON/OFF/Timer

Holiday Active/Non active

Set time

Main menu

DHW Normal

Eco

Edit

DHW max. temp

DHW max. temperature drop

DHW max. operation time

DHW mode restriction

Legionella Active/Non active

Edit

Hot water temp.

Frequency

Start time

Max. operation time

Duration of max. temp.

Heating mode Heating Flow temp

Room temp

Compensation curve

Compensation curve preview

Compensation curve edit

Curve parameters

Adjustment

Schedule timer menu

Heating

DHW Schedule timer preview

Day select Time select Time setting

Temp. setting

Holiday setting

DHW active /non active

Heating active/non active

Holiday menu

Heating room temp.

Heating fl ow temp.

Initial settings

Date/Time yyyy/mm/dd/hh:mm

Language ENG/GER/FR/NL/SP/IT/PT/DA/SW/NOR/FIN

°C/°F °C/°F

Temp. display ON/OFF

Contact number

Time display hh:mm/hh:mm AM/AM hh:mm

Room sensor setting

Sensor setting

TH1/Main controller/Room RC1-8/Time/Zone

Select Time/Zone

Service menu

Manual operation

Function setting

Thermistor adjustment

Auxiliary setting

Economy setting for pump

ON

Delay

Freeze stat function Flow t.

Ambient

Electric heater (Heating) ON

Delay

Electric heater (DHW) ON

Delay

Heat source setting Standard (Heat pump & electric heaters)

Heater (Electric heaters only)

Operation setting Simultaneous operation

Running information Cold weather function

Thermistor reading

Room temp. control (Heating)

Temp. control interval

Summary of setting Flow temperature range

Error history

Password protection

Manual reset Main controller Yes/No

FTC3 Yes/No

Page 23

23

9-2. Service Menu

The service menu provides functions for use by installer or service engineer. It

is NOT intended the home owner alters settings within this menu. It is for this

reason password protection is required to prevent unauthorised access to the

service settings.

From the main setting menu use F2 and F3 to highlight the service icon then

press CONFIRM.

You will be prompted to enter a password. THE FACTORY DEFAULT PASS-

WORD IS 0000.

Press CONFIRM.

(It takes approx. 30 secs to load the service menu.)

The service menu is navigated using the F1 and F2 buttons to scroll through the

functions. The menu is split across two screens and is comprised of the following

functions;

Manual operation

Function setting

Thermistor adjustment

Auxiliary setting

Heat source setting

Operation setting

Running information

Thermistor reading

Summary of setting

Error history

Password protection

Manual reset

In this Installation Manual instructions will be given only for the following functions;

Auxiliary setting

Manual operation

Heat source setting

Password protection

Manual reset

Information on the other functions can be found by consulting the technical or

service manuals.

1.

2.

3.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

1.

2.

3.

4.

5.

Screen 1 of service menu

Screen 2 of service menu

System off prompt screen

Action requires confi rmation Action is confi rmed

<General operation>

Many functions can not be set whilst the indoor unit is running. The installer

should turn OFF the unit before trying to set these functions. If the installer attempts to change the settings whilst the unit is running the main controller will

display a reminder message prompting the installer to stop operation before continuing. By selecting Yes the unit will cease operation and changes can be made

to the service settings.

If text is displayed in white on a black background CONFIRM button must be

pressed to save this choice.

Page 24

24

Auxiliary setting menu screen

Economy settings for pump screen

Auxiliary Setting

This function is used to set the parameters for any auxiliary parts used in the system.

From the service menu use F1 and F2 buttons to highlight Auxiliary setting then

press CONFIRM.

<Frost prevention>

From the Auxiliary setting menu highlight Freeze Stat Function.

Press CONFIRM.

The freeze stat function screen will be displayed.

Use buttons F3 and F4 to adjust the minimum outdoor temperature which

freeze stat function will begin to operate, (3 - 20 °C) or choose .

If asterisk ( ) is chosen freeze stat function is deactivated/disabled (i.e. freeze

risk).

1.

2.

3.

4.

<Electric heater (Space heating)>

From the Auxiliary Setting menu highlight Electric heater (Space heating).

Press CONFIRM.

The Electric heater (Space heating) screen is displayed.

Press F1 button to switch the function ON/OFF.

Use F3 and F4 buttons to adjust the time period of heat pump-only operation

before the booster heater will assist in space heating. (5 -180mins)

<Electric heater (DHW)>

From the Auxiliary Setting menu highlight Electric heater (DHW).

Press CONFIRM.

The Electric heater (DHW) screen is displayed.

Press F1 button to switch the function ON/OFF.

Use F3 and F4 buttons to adjust the time period of heat pump-only operation

before the booster heater and the immersion heater (if present) will assist in

DHW heating. (15 -30mins)

1.

2.

3.

4.

5.

1.

2.

3.

4.

5.

<Economy settings for pump>

From the Auxiliary setting menu highlight Economy Settings for pump.

Press CONFIRM.

The economy settings for pump screen will be displayed.

Use button F1 to switch the pump ON/OFF.

Use buttons F3 and F4 to adjust the time the pump will run. (3 - 60 mins)

1.

2.

3.

4.

5.

Freeze stat function screen

Electric heater (Heating) screen

Electric heater (DHW) screen

Page 25

25

<Manual operation>

During the fi lling of the system the pump and 3-way valve can be manually over-

ridden using manual operation mode.

When manual operation is selected a small timer icon appears in the screen. The

function selected will only remain in manual operation for a maximum of 2 hours.

This is to prevent accidental permanent override of the FTC3.

From the service menu use F1 and F2 buttons to scroll through list until Manual Operation is highlighted.

Press CONFIRM.

Manual operation menu screen is displayed.

To activate manual operation press the function button under the desired part.

To return to service menu press MENU or BACK button.

Example

Pressing F3 button will switch manual operation mode ON for the main 3-way

valve. When fi lling of the tank is complete the installer should access this menu

again and press F3 to deactivate manual operation of the part. Alternatively after

2 hours manual operation mode will no longer be active and FTC3 will resume

control of the part.

NOTE:

Manual operation and heat source setting can not be selected if the system

is running. A screen will be displayed asking the installer to stop the system before these modes can be activated.

The system automatically stops 2 hours after last operation.

The OUT13 output of the 2-way valve 2 constitutes an inversion of the OUT4

output of the 2-way valve 1.

1.

2.

3.

4.

5.

Manual operation menu screen

System off prompt screen

<Function Setting>

Function Setting allows the setting of auto recovery after power failure only.

1. From the service menu use F1 and F2 to highlight Function Setting.

2. Press CONFIRM.

3. Ensure the Ref address and unit number are displayed to the right.

4. Press CONFIRM.

NB Changes can ONLY be made to Mode 1.

6. Use F3 and F4 to highlight either 1/2/3 (see below).

7. Press CONFIRM.

Mode 1 Setting number meanings

1 - Power failure automatic recovery NOT available

2 - Power failure automatic recovery AVAILABLE

(Aprox 4-minute delay after power is restored.)

3 - NO FUNCTION

<Thermistor Adjustment>

This function allows adjustments to be made to the thermistor readings from

-10 – 10 °C in 0.5 °C intervals.

1. From the Service menu highlight Thermistor Adjustment

2. Press CONFIRM.

3. Use F1 and F2 to select thermistor.

4. Press CONFIRM.

5. Use F2 and F3 to change the thermistor temperature.

6. Press CONFIRM.

Page 26

26

<Running Information>

This function shows current temperature and other data of main component parts

of both the indoor and outdoor units.

1. From the Service menu highlight Running information.

2. Press CONFIRM.

3. Use the function buttons to enter index code for the component to be viewed.

(See the Table 9-2-1 for component index codes.)

4. Press CONFIRM.

Note

Refer to outdoor unit service manual for request code 0 to 149.

As only four digits can be displayed at one time the software version number is displayed in two halves.

Enter code 190 to see the fi rst four digits and code 191 to see the last four digits.

For example software version No. 5.01 A000, when code 190 is entered 0501 is displayed, when code 191 is entered A000 is displayed.

<Thermistor reading> shows all the thermistor temperature except THW3.

<Table 9-2-1>

Request

code

Request content Range Unit

154 Indoor unit pump - Accumulated operating time (after reset) 0 - 9999 10 hours

162 Indoor unit - Dip SW1 setting information Refer to detail contents described hereinafter —

163 Indoor unit - Dip SW2 setting information Refer to detail contents described hereinafter —

164 Indoor unit - Dip SW3 setting information Refer to detail contents described hereinafter —

165 Indoor unit - Dip SW4 setting information Refer to detail contents described hereinafter —

175 Indoor unit - Output signal information Refer to detail contents described hereinafter —

176 Indoor unit - Input signal information Refer to detail contents described hereinafter —

190 Indoor unit - Software version 1st 4 digits Refer to Note below —

191 Indoor unit - Software version last 4 digits Refer to Note below —

340 Indoor unit pump - Accumulated operating time reset — —

512 Indoor unit - Booster heater temp. (THW3) 3 - 217 °C

Heat source setting screen

Cancel last action screen

<Heat source setting>

The default heat source setting is heat pump and all electric heaters present in

the system to be operational. This is referred to as Standard operation on the

menu.

From the service menu use F1 and F2 buttons to scroll through list until

H

e

a

t

S

o

u

r

c

e

S

e

t

t

i

n

g

is highlighted.

Press CONFIRM.

Heat source setting menu screen is displayed.

Press F3 button until preferred heat source is displayed.

Press CONFIRM.

To return to service menu press MENU or BACK button.

If you wish to return to the service menu without saving the setting press return button. You will be asked if you are sure you wish to cancel the changes.

Choose Yes or No as appropriate.

1.

2.

3.

4.

5.

6.

7.

Page 27

27

Operation Setting Menu

To access the Operation setting menu use F1 and F2 buttons to scroll through

the service menu until Operation setting is highlighted.

Press CONFIRM.

Operation setting menu is displayed.

1.

2.

3.

<Cold weather function>

For extremely low outdoor temperature conditions when the heat pump’s capacity is severely restricted the heating or DHW is provided by only the electric

booster heater (and immersion if present). This function is intended for use during

extreme cold periods only. Extensive use of direct electrical heaters ONLY will

result in higher electric usage and may reduce working life of heaters and related

parts.

From the Operation setting menu use F1 and F2 buttons to scroll through the

list until Cold weather function is highlighted.

Press CONFIRM.

Cold weather function screen is displayed.

To switch Cold weather function ON/OFF press F1.

To alter the temperature at which heater switching function starts use F3 and F4.

Note: Range of ambient (outdoor) temperature is -15°C to -10°C (default -15°C)

To return to Operation setting menu press BACK.

1.

2.

3.

4.

5.

6.

<Room Temp Control (Heating)>

This function allows operational setting of fl ow temperature range from the Eco-

dan and also the time interval at which the FTC3 collects and processes data for

the auto adaptation mode.

From the Operation setting menu use F1 and F2 buttons to scroll through the

list until Room temp. control (HEATING) is highlighted.

Press CONFIRM.

Room temp. control (HEATING) screen is displayed.

To alter the time period at which date will be collected use F1 and F2 buttons

to highlight ‘Temp. control interval’.

Press CONFIRM.

Use F3 and F2 buttons to alter the time interval.

Note: Range 10 – 60 minutes at 10 minute intervals (default 10 minutes).

To alter the fl ow temperature limits, use F1 and F2 buttons to highlight ‘Flow

temperature range’.

Press CONFIRM.

Flow temperature range screen is displayed.

To alter minimum fl ow temp. use F1 and F2 buttons.

Note: Range of minimum fl ow temp. is 25°C to 40°C (default 30°C).

To alter maximum fl ow temp. use F3 and F4 buttons.

Note: Range of maximum fl ow temp. is 35°C to 60°C (default 50°C)

To return to Operation setting menu press BACK twice.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Operation setting menu screen

Simultaneous operation screen

Cold weather function screen

Room temp. control (HEATING) screen

<Simultaneous Operation>

For periods of very low outside temperature this mode can be used. Simultaneous operation allows both DHW and space heating to be provided simultaneously

by using the heat pump to provide space heating whilst only the immersion heater

(if fi tted) provides heating for DHW. This operation is only available if BOTH a

DHW tank AND immersion heater are present on the system.

From the Operation setting menu use F1 and F2 buttons to scroll through the

list until Simultaneous operation is highlighted.

Press CONFIRM.

Simultaneous operation screen is displayed.

To switch simultaneous operation ON/OFF press F1.

To alter the temperature at which simultaneous operation starts use F3 and F4.

Note: Range of ambient (outdoor) temperature is -15°C to 10°C (default -15°C).

To return to Operation setting menu press BACK.

1.

2.

3.

4.

5.

6.

Page 28

28

Indoor unit switch setting display (Request code: 162 to 165)

0: OFF 1: ON

SW1, SW2, SW3, SW4

Display

1 2345678

0 0000000 00 00

1 0000000 00 01

0 1000000 00 02

1 1000000 00 03

0 0100000 00 04

1 0100000 00 05

0 1100000 00 06

1 1100000 00 07

0 0010000 00 08

1 0010000 00 09

0 1010000 00 0A

1 1010000 00 0B

0 0110000 00 0C

1 0110000 00 0D

0 1110000 00 0E

1 1110000 00 0F

0 0001000 00 10

1 0001000 00 11

0 1001000 00 12

1 1001000 00 13

0 0101000 00 14

1 0101000 00 15

0 1101000 00 16

1 1101000 00 17

0 0011000 00 18

1 0011000 00 19

0 1011000 00 1A

1 1011000 00 1B

0 0111000 00 1C

1 0111000 00 1D

0 1111000 00 1E

1 1111000 00 1F

0 0000100 00 20

1 0000100 00 21

0 1000100 00 22

1 1000100 00 23

0 0100100 00 24

1 0100100 00 25

0 1100100 00 26

1 1100100 00 27

0 0010100 00 28

1 0010100 00 29

0 1010100 00 2A

1 1010100 00 2B

0 0110100 00 2C

1 0110100 00 2D

0 1110100 00 2E

1 1110100 00 2F

0 0001100 00 30

1 0001100 00 31

0 1001100 00 32

1 1001100 00 33

0 0101100 00 34

1 0101100 00 35

0 1101100 00 36

1 1101100 00 37

0 0011100 00 38

1 0011100 00 39

0 1011100 00 3A

1 1011100 00 3B

0 0111100 00 3C

1 0111100 00 3D

0 1111100 00 3E

1 1111100 00 3F

0: OFF 1: ON

SW1, SW2, SW3, SW4

Display

1 2345678

0 0000010 00 40

1 0000010 00 41

0 1000010 00 42

1 1000010 00 43

0 0100010 00 44

1 0100010 00 45

0 1100010 00 46

1 1100010 00 47

0 0010010 00 48

1 0010010 00 49

0 1010010 00 4A

1 1010010 00 4B

0 0110010 00 4C

1 0110010 00 4D

0 1110010 00 4E

1 1110010 00 4F

0 0001010 00 50

1 0001010 00 51

0 1001010 00 52

1 1001010 00 53

0 0101010 00 54

1 0101010 00 55

0 1101010 00 56

1 1101010 00 57

0 0011010 00 58

1 0011010 00 59

0 1011010 00 5A

1 1011010 00 5B

0 0111010 00 5C

1 0111010 00 5D

0 1111010 00 5E

1 1111010 00 5F

0 0000110 00 60

1 0000110 00 61

0 1000110 00 62

1 1000110 00 63

0 0100110 00 64

1 0100110 00 65

0 1100110 00 66

1 1100110 00 67

0 0010110 00 68

1 0010110 00 69

0 1010110 00 6A

1 1010110 00 6B

0 0110110 00 6C

1 0110110 00 6D

0 1110110 00 6E

1 1110110 00 6F

0 0001110 00 70

1 0001110 00 71

0 1001110 00 72

1 1001110 00 73

0 0101110 00 74

1 0101110 00 75

0 1101110 00 76

1 1101110 00 77

0 0011110 00 78

1 0011110 00 79

0 1011110 00 7A

1 1011110 00 7B

0 0111110 00 7C

1 0111110 00 7D

0 1111110 00 7E

1 1111110 00 7F

Page 29

29

Indoor unit switch setting display (Request code: 162 to 165)

0: OFF 1: ON

SW1, SW2, SW3, SW4

Display

12345678

00000001 00 80

10000001 00 81

01000001 00 82

11000001 00 83

00100001 00 84

10100001 00 85

01100001 00 86

11100001 00 87

00010001 00 88

10010001 00 89

01010001 00 8A

11010001 00 8B

00110001 00 8C

10110001 00 8D

01110001 00 8E

11110001 00 8F

00001001 00 90

10001001 00 91

01001001 00 92

11001001 00 93

00101001 00 94

10101001 00 95

01101001 00 96

11101001 00 97

00011001 00 98

10011001 00 99

01011001 00 9A

11011001 00 9B

00111001 00 9C

10111001 00 9D

01111001 00 9E

11111001 00 9F

00000101 00 A0

10000101 00 A1

01000101 00 A2

11000101 00 A3

00100101 00 A4

10100101 00 A5

01100101 00 A6

11100101 00 A7

00010101 00 A8

10010101 00 A9

01010101 00 AA

11010101 00 AB

00110101 00 AC

10110101 00 AD

01110101 00 AE

11110101 00 AF

00001101 00 B0

10001101 00 B1

01001101 00 B2

11001101 00 B3

00101101 00 B4

10101101 00 B5

01101101 00 B6

11101101 00 B7

00011101 00 B8

10011101 00 B9

01011101 00 BA

11011101 00 BB

00111101 00 BC

10111101 00 BD

01111101 00 BE

11111101 00 BF

0: OFF 1: ON

SW1, SW2, SW3, SW4

Display

12345678

00000011 00 C0

10000011 00 C1

01000011 00 C2

11000011 00 C3

00100011 00 C4

10100011 00 C5

01100011 00 C6

11100011 00 C7

00010011 00 C8

10010011 00 C9

01010011 00 CA

11010011 00 CB

00110011 00 CC

10110011 00 CD

01110011 00 CE

11110011 00 CF

00001011 00 D0

10001011 00 D1

01001011 00 D2

11001011 00 D3

00101011 00 D4

10101011 00 D5

01101011 00 D6

11101011 00 D7

00011011 00 D8

10011011 00 D9

01011011 00 DA

11011011 00 DB

00111011 00 DC

10111011 00 DD

01111011 00 DE

11111011 00 DF

00000111 00 E0

10000111 00 E1

01000111 00 E2

11000111 00 E3

00100111 00 E4

10100111 00 E5

01100111 00 E6

11100111 00 E7

00010111 00 E8

10010111 00 E9

01010111 00 EA

11010111 00 EB

00110111 00 EC

10110111 00 ED

01110111 00 EE

11110111 00 EF

00001111 00 F0

10001111 00 F1

01001111 00 F2

11001111 00 F3

00101111 00 F4

10101111 00 F5

01101111 00 F6

11101111 00 F7

00011111 00 F8

10011111 00 F9

01011111 00 FA

11011111 00 FB

00111111 00 FC

10111111 00 FD

01111111 00 FE

11111111 00 FF

Page 30

30

Output signal display (Request code: 175)

Please refer to Table 2 on relevant wiring diagram whilst using the following.

0: OFF 1: ON

OUT

Display

1 2345678

0 0000000 xx 00

1 0000000 xx 01

0 1000000 xx 02

1 1000000 xx 03

0 0100000 xx 04

1 0100000 xx 05

0 1100000 xx 06

1 1100000 xx 07

0 0010000 xx 08

1 0010000 xx 09

0 1010000 xx 0A

1 1010000 xx 0B

0 0110000 xx 0C

1 0110000 xx 0D

0 1110000 xx 0E

1 1110000 xx 0F

0 0001000 xx 10

1 0001000 xx 11

0 1001000 xx 12

1 1001000 xx 13

0 0101000 xx 14

1 0101000 xx 15

0 1101000 xx 16

1 1101000 xx 17

0 0011000 xx 18

1 0011000 xx 19

0 1011000 xx 1A

1 1011000 xx 1B

0 0111000 xx 1C

1 0111000 xx 1D

0 1111000 xx 1E

1 1111000 xx 1F

0 0000100 xx 20

1 0000100 xx 21

0 1000100 xx 22

1 1000100 xx 23

0 0100100 xx 24

1 0100100 xx 25

0 1100100 xx 26

1 1100100 xx 27

0 0010100 xx 28

1 0010100 xx 29

0 1010100 xx 2A

1 1010100 xx 2B

0 0110100 xx 2C

1 0110100 xx 2D

0 1110100 xx 2E

1 1110100 xx 2F

0 0001100 xx 30

1 0001100 xx 31

0 1001100 xx 32

1 1001100 xx 33

0 0101100 xx 34

1 0101100 xx 35

0 1101100 xx 36

1 1101100 xx 37

0 0011100 xx 38

1 0011100 xx 39

0 1011100 xx 3A

1 1011100 xx 3B

0 0111100 xx 3C

1 0111100 xx 3D

0 1111100 xx 3E

1 1111100 xx 3F

0: OFF 1: ON

OUT

Display

1 2345678

0 0000010 xx 40

1 0000010 xx 41

0 1000010 xx 42

1 1000010 xx 43

0 0100010 xx 44

1 0100010 xx 45

0 1100010 xx 46

1 1100010 xx 47

0 0010010 xx 48

1 0010010 xx 49

0 1010010 xx 4A

1 1010010 xx 4B

0 0110010 xx 4C

1 0110010 xx 4D

0 1110010 xx 4E

1 1110010 xx 4F

0 0001010 xx 50

1 0001010 xx 51

0 1001010 xx 52

1 1001010 xx 53

0 0101010 xx 54

1 0101010 xx 55

0 1101010 xx 56

1 1101010 xx 57

0 0011010 xx 58

1 0011010 xx 59

0 1011010 xx 5A

1 1011010 xx 5B

0 0111010 xx 5C

1 0111010 xx 5D

0 1111010 xx 5E

1 1111010 xx 5F

0 0000110 xx 60

1 0000110 xx 61

0 1000110 xx 62

1 1000110 xx 63

0 0100110 xx 64

1 0100110 xx 65

0 1100110 xx 66

1 1100110 xx 67

0 0010110 xx 68

1 0010110 xx 69

0 1010110 xx 6A

1 1010110 xx 6B

0 0110110 xx 6C

1 0110110 xx 6D

0 1110110 xx 6E

1 1110110 xx 6F

0 0001110 xx 70

1 0001110 xx 71

0 1001110 xx 72

1 1001110 xx 73

0 0101110 xx 74

1 0101110 xx 75

0 1101110 xx 76

1 1101110 xx 77

0 0011110 xx 78

1 0011110 xx 79

0 1011110 xx 7A

1 1011110 xx 7B

0 0111110 xx 7C

1 0111110 xx 7D

0 1111110 xx 7E

1 1111110 xx 7F

Page 31

31

Indoor unit switch setting display (Request code: 175)

Please refer to Table 2 on relevant wiring diagram whilst using the following.

0: OFF 1: ON

OUT

Display

12345678

00000001 xx 80

10000001 xx 81

01000001 xx 82

11000001 xx 83

00100001 xx 84

10100001 xx 85

01100001 xx 86

11100001 xx 87

00010001 xx 88

10010001 xx 89

01010001 xx 8A

11010001 xx 8B

00110001 xx 8C

10110001 xx 8D

01110001 xx 8E

11110001 xx 8F

00001001 xx 90

10001001 xx 91

01001001 xx 92

11001001 xx 93

00101001 xx 94

10101001 xx 95

01101001 xx 96

11101001 xx 97

00011001 xx 98

10011001 xx 99

01011001 xx 9A

11011001 xx 9B

00111001 xx 9C

10111001 xx 9D

01111001 xx 9E

11111001 xx 9F

00000101 xx A0

10000101 xx A1

01000101 xx A2

11000101 xx A3

00100101 xx A4

10100101 xx A5

01100101 xx A6

11100101 xx A7

00010101 xx A8

10010101 xx A9

01010101 xx AA

11010101 xx AB

00110101 xx AC

10110101 xx AD

01110101 xx AE

11110101 xx AF

00001101 xx B0

10001101 xx B1

01001101 xx B2

11001101 xx B3

00101101 xx B4

10101101 xx B5

01101101 xx B6

11101101 xx B7

00011101 xx B8

10011101 xx B9

01011101 xx BA

11011101 xx BB

00111101 xx BC

10111101 xx BD

01111101 xx BE

11111101 xx BF

0: OFF 1: ON

OUT

Display

12345678

00000011 xx C0

10000011 xx C1

01000011 xx C2

11000011 xx C3

00100011 xx C4

10100011 xx C5

01100011 xx C6

11100011 xx C7

00010011 xx C8

10010011 xx C9

01010011 xx CA

11010011 xx CB

00110011 xx CC

10110011 xx CD

01110011 xx CE

11110011 xx CF

00001011 xx D0

10001011 xx D1

01001011 xx D2

11001011 xx D3

00101011 xx D4

10101011 xx D5

01101011 xx D6

11101011 xx D7

00011011 xx D8

10011011 xx D9

01011011 xx DA

11011011 xx DB

00111011 xx DC

10111011 xx DD

01111011 xx DE

11111011 xx DF

00000111 xx E0

10000111 xx E1

01000111 xx E2

11000111 xx E3

00100111 xx E4

10100111 xx E5

01100111 xx E6

11100111 xx E7

00010111 xx E8

10010111 xx E9

01010111 xx EA

11010111 xx EB

00110111 xx EC

10110111 xx ED

01110111 xx EE

11110111 xx EF

00001111 xx F0

10001111 xx F1

01001111 xx F2

11001111 xx F3

00101111 xx F4

10101111 xx F5

01101111 xx F6

11101111 xx F7

00011111 xx F8

10011111 xx F9

01011111 xx FA

11011111 xx FB

00111111 xx FC

10111111 xx FD

01111111 xx FE

11111111 xx FF

Page 32

32

Output signal display (Request code: 175)

Please refer to Table 2 on relevant wiring diagram whilst using the following.

0: OFF 1: ON

OUT

Display

9 10111213141516

0 0000000 00 xx

1 0000000 01 xx

0 1000000 02 xx

1 1000000 03 xx

0 0100000 04 xx

1 0100000 05 xx

0 1100000 06 xx

1 1100000 07 xx

0 0010000 08 xx

1 0010000 09 xx

0 1010000 0A xx

1 1010000 0B xx

0 0110000 0C xx

1 0110000 0D xx

0 1110000 0E xx

1 1110000 0F xx

0 0001000 10 xx

1 0001000 11 xx

0 1001000 12 xx

1 1001000 13 xx

0 0101000 14 xx

1 0101000 15 xx

0 1101000 16 xx

1 1101000 17 xx

0 0011000 18 xx

1 0011000 19 xx

0 1011000 1A xx

1 1011000 1B xx

0 0111000 1C xx

1 0111000 1D xx

0 1111000 1E xx

1 1111000 1F xx

Input signal display (Request code: 176)

Please refer to Table 1 on relevant wiring diagram whilst using the following.

0: OFF (open) 1: ON (short)

IN

Display

1 2345678

0 0000000 00 00

1 0000000 00 01

0 1000000 00 02

1 1000000 00 03

0 0100000 00 04

1 0100000 00 05

0 1100000 00 06

1 1100000 00 07

0 0010000 00 08

1 0010000 00 09

0 1010000 00 0A

1 1010000 00 0B

0 0110000 00 0C

1 0110000 00 0D

0 1110000 00 0E

1 1110000 00 0F

0 0001000 00 10

1 0001000 00 11

0 1001000 00 12

1 1001000 00 13

0 0101000 00 14

1 0101000 00 15

0 1101000 00 16

1 1101000 00 17

0 0011000 00 18

1 0011000 00 19

0 1011000 00 1A

1 1011000 00 1B

0 0111000 00 1C

1 0111000 00 1D

0 1111000 00 1E

1 1111000 00 1F

Page 33

33

<Thermistor Reading>

This function shows the current readings of thermistors located on the water and refrigerant circuit

Thermistor Description

TH1 Room temperature

TH2 Refrigerant return temperature

THW1 Water flow temperature

THW2 Water return temperature

TH5A —

TH5B Tank temperature

TH5C —

TH7 Ambient (outdoor) temperature

<Summary of Settings>

This function shows the current installer/user entered settings.

Abbreviation

Explanation

Abbreviation

Explanation

HWtemp DHW max temp mode Operation mode

HWdrop DHW temperature drop - HER (Heating room temp)

HWtime DHW max operation time - HE (Heating flow temp)

NO HW DHW mode restriction - HCC (Heating compensation curve)

HWset DHW operation mode (Normal/Eco) - COR (—)

- CO (—)

Ltemp Legionella hot water temp Hroom Heating target room temp

Lfreq Legionella operation Frequency Hflow Heating target flow temp

Lstart Legionella mode start time Croom —

Ltime Legionella max. operation time Cflow —

Lkeep Duration of max (Legionella) hot

water temp

FSflow Freeze stat function flow temp

FSout Freeze stat function ambient temp

<Error History>

Error history allows the service engineer to view previous Error codes, the unit

address and the date on which they occurred. Up to 16 Error codes can be stored

in the history the most recent Error event is displayed at the top of the list.

From the service menu select Error history

Press CONFIRM.

Please see chapter 10-4. for error code diagnosis and actions.

To delete an Error history item;

From Error history screen press F4 button (Rubbish bin icon)

Then press F3 button (Yes).

1.

2.

1.

2.

Page 34

34

<Password protection>

Password protection is available to prevent unauthorised access to the service

menu by untrained persons.

From the service menu use F1 and F2 buttons to scroll through list until

P

a

s

s

-

w

o

r

d

p

r

o

t

e

c

t

i

o

n

is highlighted.

Press CONFIRM.

When password input screen is displayed use buttons F1 and F2 to move left

and right between the four digits, F3 to lower the selected digit by 1, and F4 to

increase the selected digit by 1.

When you have input your password press CONFIRM.

The password verify screen is displayed.

To verify your new password press button F3.

Your password is now set and the completion screen is displayed.

To return to service menu press MENU or BACK button.

1.

2.

3.

4.

5.

6.

7.

8.

Password input screen

<Resetting the password>

If you forget the password you entered, or have to service a unit somebody else

installed, you can reset the password to the factory default of 0000.

From the main settings menu scroll down the functions until Service Menu is

highlighted.

Press CONFIRM.

You will be prompted to enter a password.

Hold down buttons F3 and F4 together for 3 secs

You will be asked if you wish to continue and reset the password to default setting.

To reset press button F3.

The password is now reset to 0000.

1.

2.

3.

4.

5.

6.

7.

Password verify screen

Completion screen

<Manual reset>

Should you wish to restore the factory settings at any time you should use the

manual reset function. Please note this will reset ALL functions to the factory default settings.

From the service menu use F1 and F2 buttons to scroll through list until Manual Reset is highlighted.

Press CONFIRM.

The manual reset screen is displayed.

Choose either Manual Reset for FTC3 or Main Controller.

Press F3 button to confi rm manual reset of chosen device.

1.

2.

3.

4.

5.

Page 35

35

F1 F2 F3 F4

<Emergency operation>

In Emergency operation mode the outdoor heat pump unit will not operate. Heating for DHW and space heating is provided by the booster heater and the tank

immersion heater (if installed). Space heating flow temp is restricted 40°C if an

immersion heater is not present on the DHW tank then the booster heater will

also indirectly heat the DHW.

When in Emergency operation the main control has NO control functions. It's only

function is to display the Main screen and Information screen by pressing F1, all

other buttons are disabled.

• Activating Emergency operation mode

To activate Emergency operation see the following:

Switch OFF the breaker for the outdoor unit (or both breakers if cylinder powered independently).

Change DIP switch SW4-5 to ON.

Switch ON the breaker(s).

Emergency Operation is now activated.

• Deactivating Emergency operation mode

To deactivate Emergency operation see the following:

Switch OFF the breaker for the outdoor unit (or both breakers if cylinder powered independently).

Change DIP switch SW4-5 to OFF.

Switch ON the breaker(s).

Emergency operation is now deactivated.

WARNING

Do not attempt to change the DIP switches whilst the breaker(s) are ON as

this could result in ELECTROCUTION.

1.

2.

3.

4.

1.

2.

3.

4.

Page 36

36

TROUBLESHOOTING

10

10-1. Troubleshooting

<Summary of self diagnosis based on Error Codes and Service Procedures>

Present and past Error codes are logged and displayed on the main controller or control board of the outdoor unit.

Please refer to the table below and subsequent explanations to diagnose and remedy typical problems that may occur in the fi eld.

Unit Condition Error Code Action

Reoccurring problem

Displayed Use table 10-4. "Self diagnosis and action" to identify fault and correct.

Not Displayed Use table 10-5. "Troubleshooting by inferior phenomena" to identify fault and correct.

Non reoccurring problem Logged 1. Check temporary causes of defects such as the operation of safety devices on the re-

frigerant/water circuit including compressor, poor wiring, electrical noise etc. Re-check

the symptom and the installation environment, refrigerant amount (Split systems only),

weather conditions at time of fault etc.

2. Reset Error code logs, Service the unit and restart system.

Not Logged

1. Recheck the abnormal symptom

2. Identify cause of problem and take corrective action according to Table 10-5. "Troubleshooting by inferior phenomena"

3. If no obvious problem can be found continue to operate the unit.

NOTE

Electrical components should only be replaced as a fi nal option. Please follow instructions in Tables 10-4. and 10-5. Error Codes and Inferior Phenom-

ena fully before resorting to replacing parts.

10-2. Test Run

Before a test run

• After installation of outdoor unit, pipework and electrical wiring, recheck that there is no water leakage, loosened connections or miswiring.

• Measure impedance between the ground and the power supply terminal block (L,N) on the outdoor and indoor units with suitable (500V) ohmmeter. Resistance

should be 1.0M .

• Read the Installation and Operation Manuals fully especially the safety requirements before carrying out any test runs.

10-3. Malfunction diagnosis method by main controller

If during start up or operation a malfunction occurs the error code screen may be displayed on the main controller.

The error code screen shows the following; code, unit, ref. address, and telephone number of installer (only if previously entered by the installer)

Please not in the case of some malfunctions an error code is not generated please refer to table 10-5. for more details.

To reset

1. To reset the main controller press F4 button (Reset).

2. Then press F3 (Yes) to confi rm.

Page 37

37

Error code Title and display conditions Possible Cause Diagnosis and action

L1 Booster heater overheat detection

<DHW/Heating/LP/FS/OS>

Error code displayed when THW3 detects

temp. of 85ºC for 10 consecutive seconds.

1

Insuffi cient system head

1

Refer to table in section 10-6. to determine

if system pump meets requirements.

If more head required either add an pump