A

A

2

2

S--

S

M

M

O

O

D

D

E

E

M

M

DII

D

D

E

D

E

USSEE

U

N--

N

S

K--

S

K

RSS

R

M

M

M

M

HAA

H

O

O

O

O

D

D

N

N

E

E

D

E

D

E

DBB

D

M--

M

M--

M

O

OKK

O

O

2

2

2

2

ISSUE 2

VERSION 2

A22SS,,

A

FORWARD

This handbook is a programming and function description for the A2S, DIN and

DESK-2 range of modems with system program version 1.2x.

©

LogiLink Ltd.2000

Unless Mitsubishi Electric Europe BV has accepted a contractual obligation in respect

of the permitted use of the information and data contained herein, such information

and data is provided without responsibility and Mitsubishi Electric Europe BV

disclaims all liability arising from its use.

All examples in this manual are used solely to promote understanding of how the

equipment works and its operation. Mitsubishi Electric Europe BV take no

responsibility if these examples are used in real applications.

Mitsubishi Electric Europe BV absolves itself of all responsibilities for damage and

injuries that may occur during installation or use of this equipment.

DII

D

N,,

N

DEESS

D

K--

K

M

M

O

O

DEE

D

M--22

M

Mitsubishi Electric Europe BV absolves itself of all responsibilities for any type of

modification made to the equipment.

i

Contents

FORWARD .............................................................................................................................................I

INTRODUCTION.................................................................................................................................. 1

SECTION 1 - MODEM STANDARDS AND COMPATIBILITY.................................................... 2

OMPATIBILITY

1.1 C

HAT YOU SHOULD HAVE IN YOUR PACKAGE

1.2 W

HAT TO DO NEXT

1.3 W

SECTION 2 – GETTING STARTED..................................................................................................3

..............................................................................................................................2

.................................................................................2

..........................................................................................................................2

NSTALLATION

2.1 I

& R

EMOVAL

...........................................................................................................3

2.1.1 Installation – A2S Version......................................................................................................3

2.2.2 Removal – A2S Version..........................................................................................................3

2.1.3 Installation – DIN Version .....................................................................................................3

2.1.4 Removal –DIN Version...........................................................................................................3

ONNECTION AND WIRING

2.2 C

.............................................................................................................3

2.2.1 Connection to a Link module (eg. A1SJ71C24-R2) ...............................................................3

2.2.2 Connection to FX2N-232-BD.................................................................................................4

2.2.3 Connection to MAC 50/90 and E range of HMI’s..................................................................4

2.2.4 Connection to FX-232AW / FX0N-232ADP...........................................................................5

2.2.5 Connection to DESK Version.................................................................................................5

2.2.6 Wiring.....................................................................................................................................6

NITIAL CONFIGURATION

2.3 I

.................................................................................................................6

SECTION 3 – USING THE ENHANCED FUNCTIONS .................................................................. 7

ETTING THE MODEM WITH TERMINAL SOFTWARE

3.1 S

........................................................................7

3.1.1 Connecting the Modem to a PC..............................................................................................7

3.1.2 Configuring the Modem..........................................................................................................7

Example 3-1 Protocol settings...............................................................................................................7

UTOMATIC SIMULTANEOUS VOICE AND DATA

3.2 A

.............................................................................8

3.2.1 Using Simultaneous Voice and Data with Other Modems......................................................8

NLINE MAINTENANCE USING MITSUBISHI

3.3 O

ROGRAMMING SOFTWARE

PLC P

................................9

3.3.1 Making a Connection.............................................................................................................9

Example 3-2 Dialling ............................................................................................................................9

3.3.2 Terminating a Call.................................................................................................................9

3.3.3 Communicating with Mitsubishi PLC’s................................................................................10

3.3.4 Communicating with E series and MAC HMI’s...................................................................10

3.3.5 Transferring files from/to the HMI.......................................................................................11

3.3.6 Communicating with other makes of PLC controllers..........................................................11

Example 3-3 Transparent settings........................................................................................................12

ECURITY

3.4 S

......................................................................................................................................13

3.4.1 Normal Operation................................................................................................................13

3.4.2 Installing the Access Codes ..................................................................................................14

IAL ON DEMAND

3.5 D

........................................................................................................................15

3.5.1 Setting Dial on Demand Commands....................................................................................15

Example 3-4 Command Block Address setting...................................................................................16

3.5.2 Online Configuration ...........................................................................................................16

3.5.3 Contents of the command block............................................................................................17

3.5.4 Control and Status Register..................................................................................................17

3.5.5 Setting telephone numbers....................................................................................................19

Example 3-5 Setting Speed-Dial numbers...........................................................................................19

Example 3-6 Directory Dialling (PLC programming).........................................................................19

3.5.6 Setting fixed messages in the modem....................................................................................20

Example 3-7 Setting Messages from the PLC..................................................................................... 20

IDE AREA TELEMETRY

3.6 W

(WAT)..................................................................................................21

ii

3.6.1 Setting the Start Address of WAT Information .....................................................................21

Example 3-8 Setting WAT addresses..................................................................................................21

3.6.2 Information in the WAT Header...........................................................................................22

Example 3-9 WAT settings in the PLC (Write Remote command).....................................................23

Example 3-10 WAT settings in the PLC (Read Remote command).....................................................23

3.7 WAT S

ETTINGS AND PROCEDURES BEFORE OPERATION

...............................................................24

SECTION 4 – TROUBLESHOOTING............................................................................................. 25

HE MODEM DOES NOT RESPOND TO COMMANDS

4.1 T

HE MODEM DIALS BUT DOES NOT CONNECT

4.2 T

HE MODEM DOES NOT DIAL

4.3 T

HE MODEM STOPS POLLING AFTER FIRST POLL

4.4 T

OLLING OCCURS, BUT WILL NOT DIAL ON DEMAND

4.5 P

ODEM OCCASIONALLY HANGS-UP DURING

4.6 M

CCASIONAL “RE-TRIES” OCCUR DURING PROGRAMMING/MONITORING

4.7 O

EPORTING

, R

..........................................................................25

..............................................................................25

“NO DIALTONE” ...................................................25

.........................................................................26

...................................................................26

DATA EXCHANGE

WAT

...........................................26

.....................................26

SECTION 5 – AT COMMAND SET AND S - REGISTERS........................................................... 27

TANDARD COMMANDS

5.1 S

5.2 ECC C

5.3 MNP 10 C

5.4 W-CLASS C

5.5 FAX C

5.6 FAX C

5.7 V

5.8 S-R

5.9 U

OMMANDS

OMMANDS

OMMANDS

LASS

1 ...............................................................................................................................30

LASS

2 ...............................................................................................................................30

OICE/AUDIO COMMANDS

EGISTERS

NIQUE

.................................................................................................................................32

AT C

OMMANDS

................................................................................................................27

..........................................................................................................................30

....................................................................................................................30

................................................................................................................30

...........................................................................................................31

...............................................................................................................33

SECTION 6 – SUPPORT SERVICE AND COMPLIANCE DETAILS......................................... 34

USTOMER SUPPORT

6.1 C

UROPEAN COMPLIANCE INFORMATION

6.2 E

INGER EQUIVALENCE NUMBER

6.3 R

PPROVED USAGE

6.4 A

.....................................................................................................................34

.......................................................................................34

...................................................................................................34

........................................................................................................................34

SECTION 7 – TECHNICAL DETAILS............................................................................................ 35

ODEM SERIAL CONNECTIONS

7.1 M

ECOMMENDED CABLE CONNECTIONS

7.2 R

.....................................................................................................35

.........................................................................................35

7.2.1 A1SJ71C24-R2 Communications Module............................................................................35

7.2.2 FX-232AW/AJ Communications Module..............................................................................36

7.2.3 PC Serial Port (9-way D-type).............................................................................................36

7.2.4 MAC / E-Range HMI’s.........................................................................................................36

7.3 LED F

UNCTIONS

...........................................................................................................................36

SECTION 8 – TECHNICAL SPECIFICATION.............................................................................. 37

ATED OPERATING LIMITS

8.1 R

...........................................................................................................37

SECTION 9 – ACCESSORIES AVAILABLE.................................................................................. 37

SECTION 10 – PLC PROGRAMMING EXAMPLE....................................................................... 38

iii

A22SS,,

A

INTRODUCTION

Your new modem is one of the most technologically advanced available. It combines

high-speed data, fax, voice and ASVD (Automatic Simultaneous Voice and Data)

functions in a single unit. The modem has been designed to complement the

Mitsubishi FX and A ranges of PLC’s, and provides a number of unique telemetry

features for handling data transfers between PLC’s.

The modem is capable of operating at data speeds of 33.6Kbps and has the ability to

store telephone numbers, fixed messages, etc.

This manual is divided into eleven sections covering (1) Modem Standards and

Compatibility, (2) Getting Started, (3) Enhanced Functions, (4) Troubleshooting,

(5) AT Command Set, (6) Support, Service and Compliance details, (7) Technical

Details, (8) Technical Specificati on, (9) Accessories, and (10) PLC Programming

Examples.

Please be sure to read section two carefully before installing your modem.

DII

D

N,,

N

DEESS

D

K--

K

M

M

O

O

DEE

D

M--22

M

1

Section 1 - Modem Standards and Compatibility

1.1 Compatibility

Your modem is compatible with the following communications standards:

!

V.34 (33600bps)

!

V.32bis (14400bps)

!

V.32 (9600bps)

!

V.22bis (2400bps)

!

V.22 (1200bps)

!

Bell 212A (1200bps)

!

Bell 103 (300bps)

!

V.17 (14400bps FAX)

!

V.29 (9600bps FAX)

!

V.27ter (4800bps FAX)

!

V.21 Channel 2 (300bps FAX)

!

V.42 (error correction)

!

MNP 2-4 (error correction)

!

V.42bis (data compression)

!

MNP 5 (data compression)

!

Class 1 Fax Command Set

!

Hayes AT Command Set

The modem has been designed to operate in all European Countries and complies with

standard TBR21.

1.2 What you should have in your package A2S-MODEM

One A2S-MODEM module

One PC Utilities Software Diskette *

One Telephone Cable (BT – UK only)

One 24 Volt dc connector

One Modem to C24 Data Cable (MODEM-R2-CAB)

DIN-MODEM-2

One DIN-MODEM-2 module

One PC Utilities Software Diskette *

One Telephone Cable (BT – UK only)

DESK-MODEM-2

One DESK-MODEM-2 module

One PC Utilities Software Diskette *

One Telephone Cable (BT – UK only)

One 12 Volt UK Mains adapter

One PC to Modem RS232 9 way Cable (MODEM-PC9-CAB)

* Includes manual in PDF format and Windows Terminal application

If any of the above items are missing please contact your supplier

1.3 What to do next

If you do not wish to use any of the enhanced features available in your modem go

straight to section 2 (Getting Started).

If you wish to use some of the enhanced features; i.e. Access Code Protection, Dial

On Demand and Wide Area Telemetry, also read section 3 (Using the Enhanced

Functions)

If you experience problems go to Section 4 (Troubleshooting).

2

Section 2 – Getting Started

CS

2.1 Installation & Removal

2.1.1 Installation – A2S Version

i)

Locate in a vacant I/O position, preferably adjacent to the Comms Link

module (A1SJ71C24-R2/A1SJ71UC24-R2/A1SJ71QC24-R2).

ii) Insert the module mounting-hook into the slot below the chosen I/O position

on the A1S Base and push the top of the module forward until fully located.

iii) Secure the module with the retained mounting screw at the top.

NOTE: Installing the A2S-MODEM on the backplane does not connect to the Bus or

take power or occupy I/O addresses. To avoid loosing any I/O addresses, assign “S0”,

under Parameters in the PLC software, for that slot.

2.2.2 Removal – A2S Version

i) Unscrew mounting screw then tilt the module backwards against the

mounting hook until clear of the A1S Base connector.

ii) Lift upwards and remove the module hook clear of the slot.

2.1.3 Installation – DIN Version

i) Locate the top of the DIN rail clip onto the DIN rail and push the module

down until the clip is secure.

2.1.4 Removal –DIN Version

i) Lever the bottom of the module upwards until the clip releases and un-hook

from the top.

2.2 Connection and Wiring

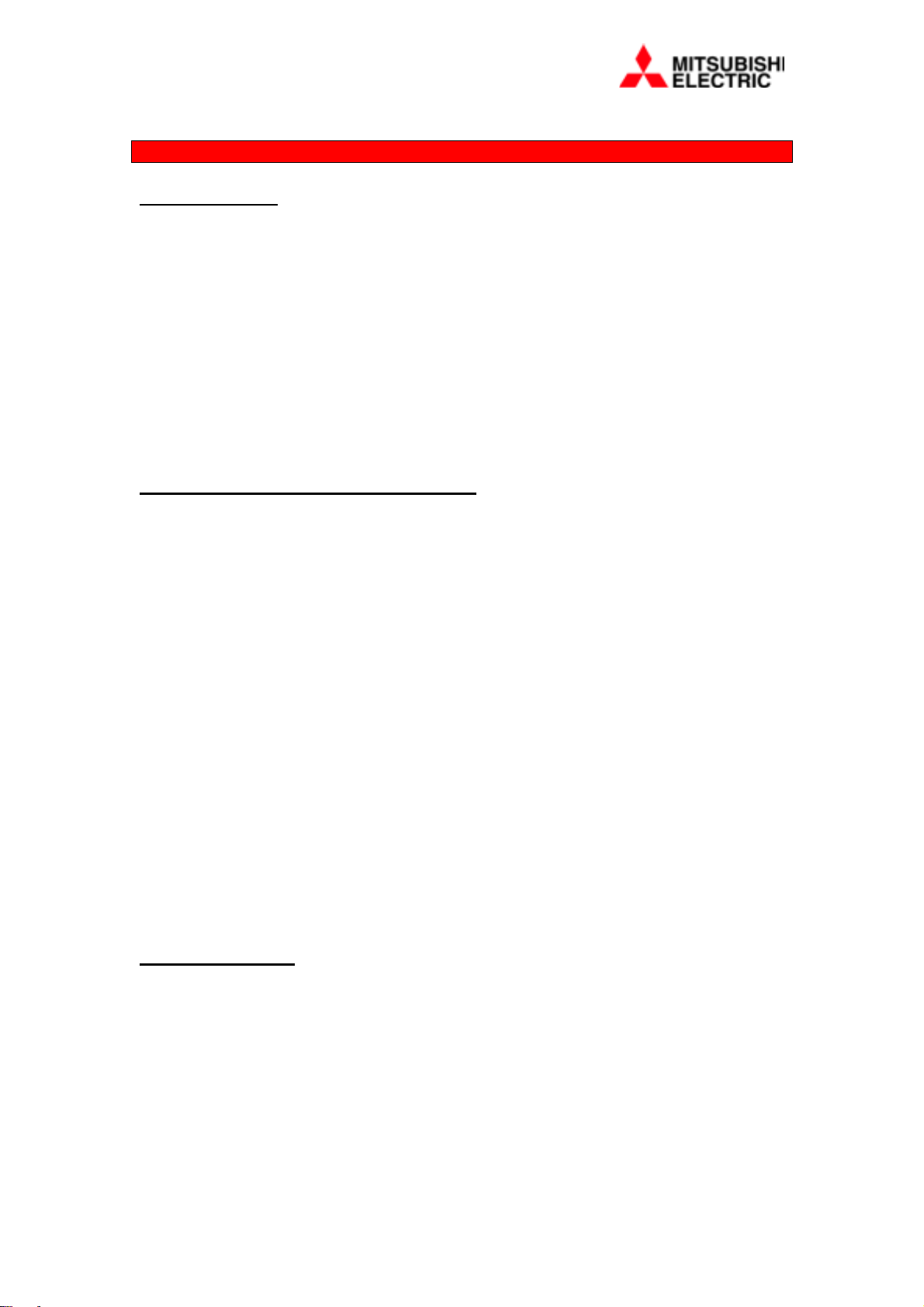

2.2.1 Connection to a Link module (eg. A1SJ71C24-R2)

Modem-A2S

RD

CD

MODEM-R2-

AnS/QnS/A via C24 (R2)

DATA

RS232

VOICE

LINE

24V

OV

i) Connect the 9-pin to 9-pin cable type (MODEM-R2-CAB), between the

Data RS232 port on the front of the DIN-MODEM-2 or A2S-MODEM and

to the RS232 connector on the front of the A1SJ71C24-R2 link module.

ii) Connect the telephone lead provided by plugging in the RJ11 type plug into

the socket labelled LINE, making sure that the connector is properly latched.

iii) When simultaneous voice and data is required, connect a suitable handset or

headset by plugging into the socket labelled VOICE.

iv) Connect a 24V or 12V dc supply via the connector provided. The dc

polarity is not important as it is corrected within the MODEM.

3

continued

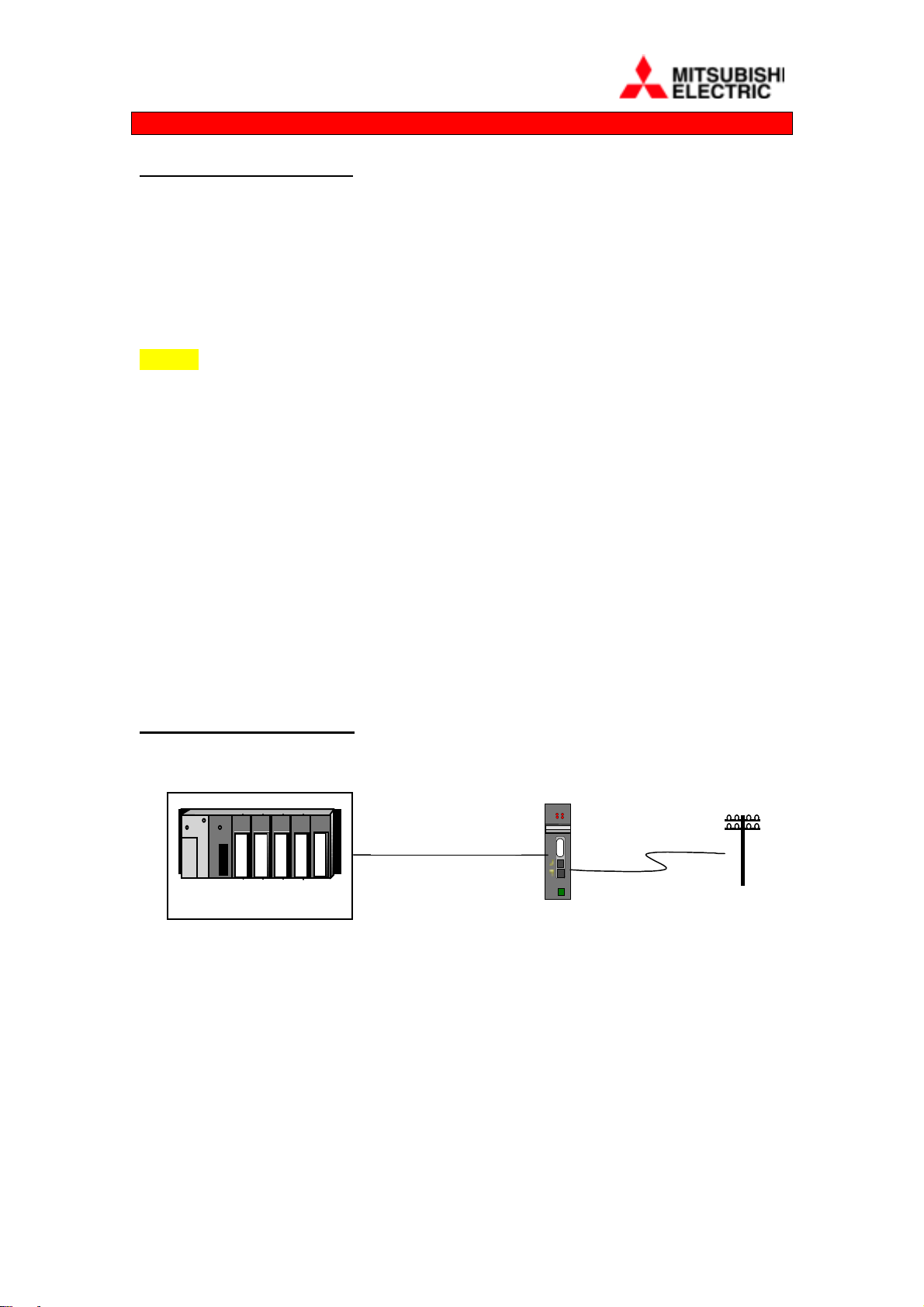

S

T

O

2.2.1

NOTE 1: Modems cannot be connected directly to the CPU programming port.

NOTE 2: Set the Link module to protocol 1, Write during run, 9600 baud, 8 data bits,

No parity, 1 Stop bit and Sum Check ON. Eg. MODE=1, SW04,05,07,08 &12 = ON,

all other switches OFF. After changing these switches turn the power to the PLC off

MITSUBISHI

MODEM-FX2-CAB

FX1S/FX1N/FX2N

+ 232-BD

MODEM-PC9-CAB

and back on alternatively reset the CPU.

2.2.2 Connection to FX2N-232-BD

i) Connect a 9-pin male to 9-pin female cable, type MODEM-FX2-CAB or

MODEM-PC9-CAB, wired to the schematic shown in Section 7, between

the Data RS232 port on the front of the MODEM and the serial port at the

top of the FX2N-232-BD plug-in module.

ii) Then follow the instructions in Section 2.2.1 ii) to iv) above

2.2.3 Connection to MAC 50/90 and E range of HMI’s

MAC 40+ CAB

Modem-A2S

RD

CD

OR

AnS/QnS/A

MITSUBISHI

MODEMMAC-CAB

FX-20P-CAB

CS

DATA

RS232

VOICE

LINE

24V

OV

FX0S/FX1S

FX0N/FX1N/FX2N

MAC 40+ CAB

MITSUBISHI

FX

iii) Connect a 9-pin male to 9-pin female cable, type MODEM-MAC-CAB,

wired to the schematic shown in Section 7, between the Data RS232 port on

the front of the MODEM and PRINTER serial port at the back of the MAC

or E range terminal.

iv) Then follow the instructions in Section 2.2.1 ii) to iv) above

4

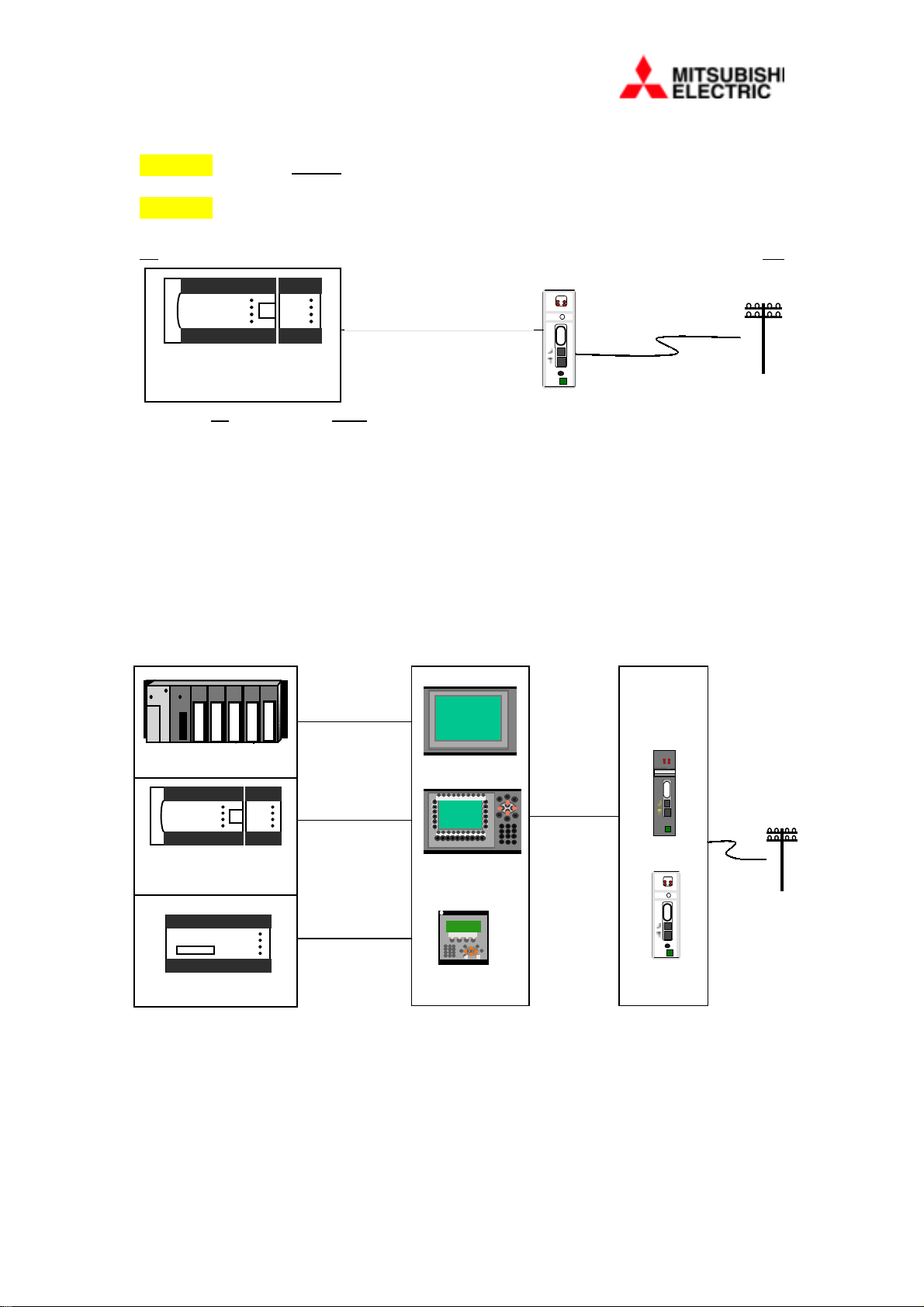

2.2.4 Connection to FX-232AW / FX0N-232ADP

MITSUBISHI

MODEM-R2A-CAB

FX1S/FX1N/FX2N

+ FX2N-CNV-BD +

FX0N-232-ADP

MITSUBISHI

FX + FX-232AW

i)

Connect the 9-pin to 25-pin cable, type MODEM-R2A-CAB, between the

Data RS232 port on the front of the MODEM and the RS232C Connector

on the FX232AW / FX0N-232ADP module.

ii)

Then follow the instructions in Section 2.2.1 ii) to iv) above

2.2.5 Connection to DESK Version

MODEM-PC9-CAB

i)

Connect the PC to Modem Data cable, type MODEM-PC9-CAB, between

the Data RS232 port at the rear of the MODEM and a spare

communication port on your PC.

ii)

Then follow the instructions in Section 2.2.1 ii) to iv) above.

logilink

336

RDSDCDTRCSOH

5

2.2.6 Wiring 24V dc Supply A2S and DIN Versions

i)

ii)

12V dc Supply DESK Version

i)

2.3 Initial configuration

Wire 24 dc from a suitable supply, usually from terminals on a nearby

module to the miniature screw terminal plug provided.

Check the specification for the 24V supply before making connection.

However, reversing the polarity of the dc will cause no harm.

Plug the 12V dc power supply provided into a mains supply and connect

the jack plug into the connector at the rear of the MODEM.

i)

ii)

Set the Modem to the correct local protocol (see 5.9 for a list of codes),

with the command:

AT%ADP=x (where x = protocol setting)

Read section 3.1 for more details.

6

Section 3 – Using the Enhanced Functions

In order to configure your modem and use its enhanced functions it must be connected

to the serial port of a PC running terminal software such as Terminal, HMI Tools

\Modem, Hyper-Terminal or ProComm Plus. This section describes how this is done.

3.1 Setting the Modem with Terminal Software The modem is pre-set to communicate at 9600 Baud with 8 data bits, 1 stop bit and

No parity. Flow control or Hardware Handshake is OFF. The terminal software must

therefore be set to match these parameters in order to communicate at all.

eg. 9600,8,N,1

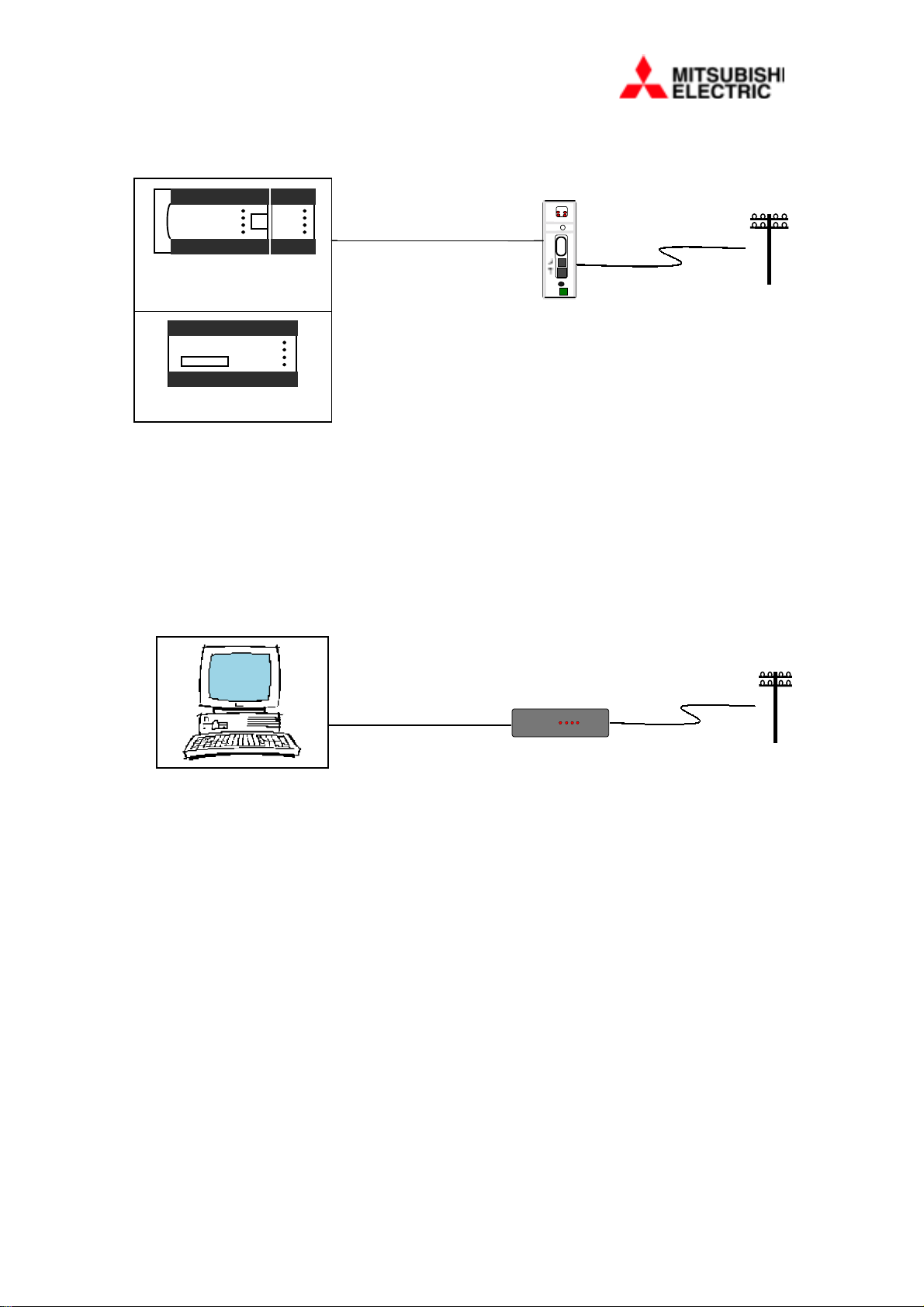

3.1.1 Connecting the Modem to a PC

To connect the modem to a PC, use a suitable RS232 modem cable (accessory

MODEM-PC9-CAB), wiring for such a cable is shown in section 7.2.3.

When the modem is connected, any characters typed at the terminal software will be

echoed back by the modem.

When the modem is communicating with PC terminal software it can be configured

using AT commands, so called because they are all preceded with the letters AT. A

full list of these commands is given in section 5. The modem is supplied with all

essential parameters for plug and pla y already set, but if t hese are lost for any reason

the device can be reprogrammed with the following command string:

AT&F&D0S0=1 &W0 (all 0’s are zeros)

or

AT%F (version 1.20 or later)

3.1.2 Configuring the Modem

Before the modem can be connected to a PC/Laptop, PLC or an HMI it will be

necessary to set the modem to the correct protocol. Just as the HMI, for example,

requires to know what PLC it is connected to, the modem has special protocol settings

for different configurations. Refer to

the following command string,

AT%ADP=x (x = protocol setting)

Example 3-1 Protocol settings

AT%ADP=0 (or 1) Modem connected to a PC/Laptop (default)*

AT%ADP=3 Modem connected to an FX PLC

AT%ADP=A Modem connected to an AnS PLC via an E HMI

section 5.9 for a list of protocol settings and use

* Earlier versions before 1.20 were set to protocol 1.

7

3.2 Automatic Simultaneous Voice and Data

To use the ASVD function, simply plug a suitable handset or headset into the front

panel socket marked with a handset symbol. Voice and data communication will be

made automatically during the period that the modem is connected.

3.2.1 Using Simultaneous Voice and Data with Other Modems

Not all modems available support simultaneous voice and data functions. First ensure

that the other modem is capable of supporting this feature. Refer to the other

modem’s handbook to see if it supports analogue or Audio Span voice and data.

NOTE:

It is highly recommended that the ASVD feature be always used when any on-line

changes are made to the PLC code. A risk of damage to equipment connected to the

PLC or even injury may occur if alterations are made to the program or data without

continuous voice contact with a local operator.

8

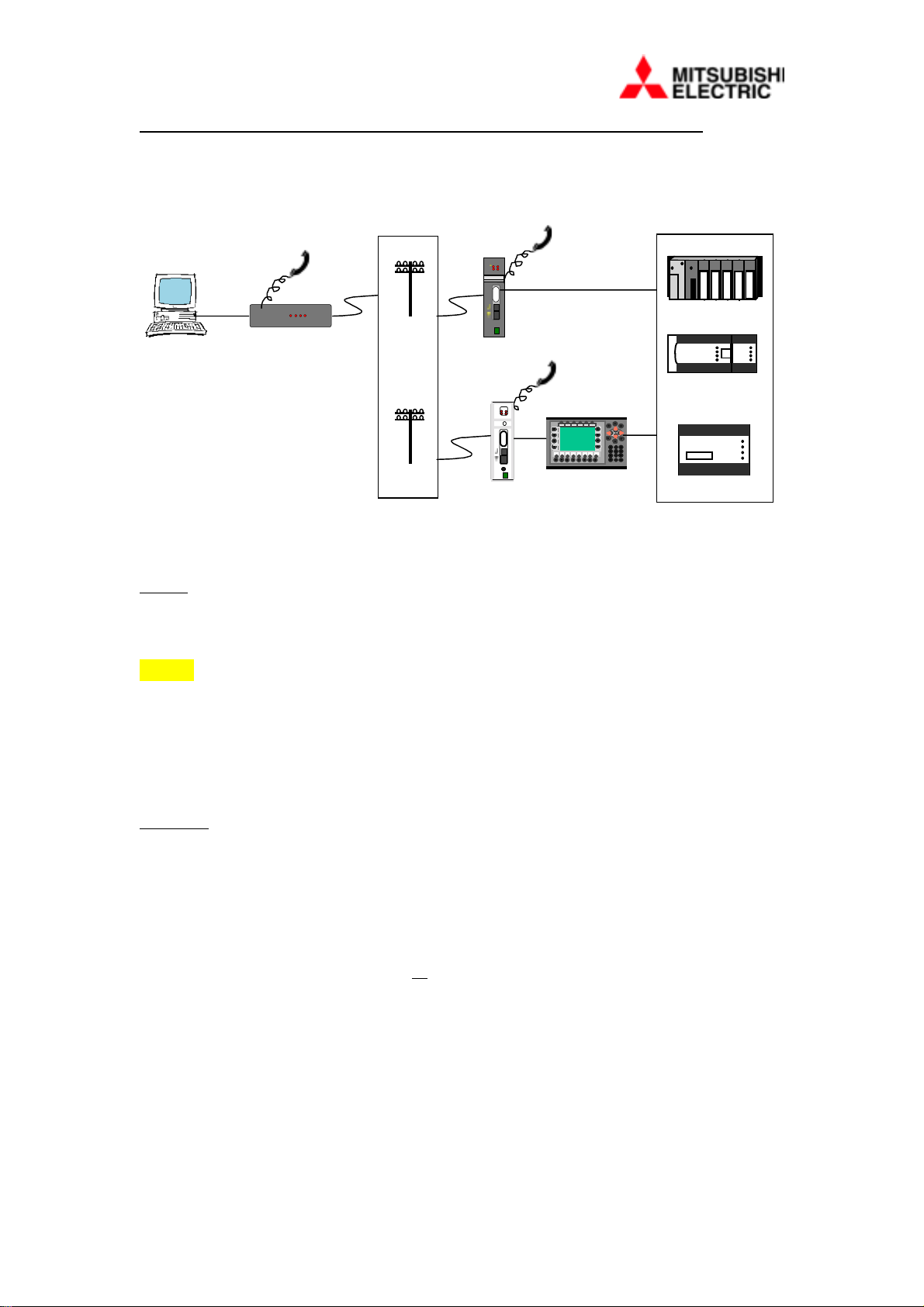

3.3 Online Maintenance Using Mitsubishi PLC Programming Software

24

LINE

One of the most commonly used features of th e modem is to contact a remote PLC

and then use programming software to interrogate operation. To do this requires a

two-stage operation.

Modem-A2S

RD

CD

CS

DATA

RS232

logilink

336

RDSDCDTRCSOH

VOICE

OV

MITSUBI

SHI

FX0S/FX1S

FX0N/FX2N

MITSUBI

SHI

FX

3.3.1 Making a Connection

Firstly, with the modem connected to your PC running terminal software, dial the

remote modem. Entering the command ATD followed by the telephone number of

the remote site is one way of doing this.

NOTE: Ensure the settings in the terminal software have been set to 9600,8,N,1.

Example 3-2 Dialling

ATD 0123456789 <enter> to dial a site on 0123456789

ATDT 0123456789 <enter> forces tone dialling (default)

ATDP 0123456789 <enter> forces pulse dialling

Secondly, close the terminal application (do not minimise). The modem will hold the

connection. Then run your Mitsubishi programming software from Windows, for

example, GPPWIN.

3.3.2 Terminating a Call

To terminate the connection, exit the programming software and r estart the terminal

application. Then select “Hang-up” or type:

+++ (3 pluses) followed by a pause of at least 1 second, or until the modem returns

“OK”

Then type ATH <enter> to ‘hang up’, the modem will close the connection and go onhook.

If the modem does not respond with OK after the three + symbols, try again.

9

3.3.3 Communicating with Mitsubishi PLC’s

Using the A2S/DIN/DESK Modems you will be able to transfer data between a

PC/Laptop and a PLC, seamlessly without making any changes to the default settings

in the HMI or Programming software. The modem can be connected directly to the

PLC via a suitable RS-232 interface or through an HMI port in the “Transparent”

mode, refer to section 2.

A simple test would be that if you are able to programme or monitor the PLC or HMI

when directly connected using the appropriate cable, then the same settings will apply

for the A2S Modems. The intelligence within the modem automatically adjusts

formats, even speeds to suit the individual PLC and HMI configuration. These unique

features, for example, include the ability to recognise when the software is addressing

the HMI and allow “high speed” data transfers.

3.3.4 Communicating with E series and MAC HMI’s

There are two methods of communication between the HMI and PC using Modems.

a) Method 1 (preferred):

Using two Mitsubishi A2S/DIN/DESK MODEMs at both ends.

This unique method provides the following features:

• transfer rates of up to 38400 baud.

• uses default software settings

• allows switching between HMI and PLC without having to redial.

NOTE:

1) Prior to installation, each modem must be set to a protocol matching the local

device with the protocol command, for example, AT%ADP=F for FX series and A

for A/Q series via HMI, refer to section 3.1.

2) If “HMI File transfers” (see section 3.3.5) are also required, when the HMI is

connected to an FX series PLC,

9600,8,N,1. This can be altered via the HMI software in “Set-up/Peripherals” or

via the HMI Front Panel.

Firstly, make connection in the normal way, (see 3.3.1, above), then close the

Terminal application (do not minimise).

Secondly, load the HMI programming software and select the speed “settings” to a

baud rate up to 38400 then, with the “Automatic terminal RUN/PROG” selected,

Transfer your Project in the normal way.

After each successful transfer the modems will automatically return to 9600 baud to

allow normal transparent mode to take place.

the RS232 port in the HMI must be changed to

b) Method 2:

Dialling from another manufacturers make of modems connected at the PC end.

Firstly, select 2400 baud in the terminal software before making a connection then

close the Terminal application (do not minimise).

10

Secondly, load the HMI programming software and adjust the speed ‘Settings’ to

2400 baud in the ‘Transfer \ Project’ window before starting the transfer.

NOTE: After each successful transfer the call must be terminated and redialled at

9600 baud before normal transparent mode to the PLC can be resumed.

CAUTIONARY NOTE:

At the time of writing. it is only possible to communicate with the E range and certain

versions of the MAC range of HMI’s, using either method 1 or 2.

3.3.5 Transferring files from/to the HMI

It is also possible to download files held in the E HMI, for example, “Trends”,

“Recipes” and “Alarm Lists”. To do this requires the HMI to be dialled from the

Windows HMI Tools program “Filetran”.

Firstly, enter your telephone numbers in the Connections list by selecting ‘Edit’,

under ‘Options\Comm Settings’. Then check that the communication is set to

9600,8,N,1.

a) Method 1 (preferred):

Using two Mitsubishi A2S/DIN/DESK MODEMs at both ends.

To dial your chosen telephone number click ‘Connect’ and wait for the Files to be

displayed before selecting the files to receive or send..

To “Hang-up”, click on the ‘Close’ button and the modems will return to their normal

“command mode” state.

b) Method 2:

Dialling from another manufacturers make of modems connected at the PC end.

Firstly, make sure that the RS232 port in the HMI is set to 9600,8,N,1 then dial as

described in

NOTE:

The RS232 port in the HMI will need to be changed back to the FX or AnS format

every time it is required to program a PLC through the transparent mode.

3.3.6 Communicating with other makes of PLC controllers

Because the purpose of the Modems’ on-board intelligence is to communicate

specifically with the Mitsubishi range of PLC’s there may be some difficulty in

transferring data between other makes. Until a local protocol has been written for the

device being connected, setting another code will confuse the modem and it will

incorrectly convert the serial format.

method 1

, above.

To allow the A2S type modem to be used for non-Mitsubishi equipment, for example

On-line Maintenance operation, it will be necessary to set the remote A2S Modem

into the special transparent protocol, as follows:

11

AT%ADP=T,<Baud rate,No. Data bits,Parity,No. Stop bits><enter>

Example 3-3 Transparent settings

AT%ADP=T,9600,7,E,1

AT%ADP=T,19200,8,O,2

You can check your setting by typing:

AT%ADP?<enter>

Example response,

Transparent – 19200,8,O,2

The local Modem must also be set to the Baud rate and format to match the remote

Modem. Depending on the type of modems there are two different wa ys of achieving

this, as follows.

1) For the A2S MODEM set the transparent m ode, as above, then after connecting

quit the Terminal software and load and run the equipment software to transfer data.

Before you can “hang-up” the A2S Modem, the Terminal software must be set to the

adjusted baud rate and format.

NOTE: The Terminal must be returned to the default setting of 9600,8,N.1 before

redialling, each time.

2) For another make of modem set the Terminal software to the new format

matching the “Transparent” settings, then type AT<enter> to set the modem. The

modem should respond with “OK” to indicate synchronisation.

Then Dial or Hang-up the remote modem in the normal way, whilst retaining the new

settings.

12

3.4 Security

Your modem has the powerful facility of a two level access code (password) facility

we call “User” and “Administrator” levels. The codes will both protect your system

from unauthorised connection/communication and allow the on-line configuration of

the remote modem’s parameters. Once set, anyone dialling in must enter the correct

User access code before data will be allowed to pass through to your system. The

modem will disconnect the line after the third ‘wrong code’.

3.4.1 Normal Operation

1) User Access Code Installed

!

Dial the modem in the normal way from a PC and after connection has

been established the modem will make the request ‘ENTER

PASSWORD’.

!

Enter your access code (up to 8 characters, UPPER CASE ONLY) plus

a carriage return <enter>.

!

If the correct code has been entered the modem will establish full

connection, providing an open line to your system. If an incorrect code

has been entered the modem will repeat the ‘ENTER PASSWORD’

prompt for a total of three attempts.

!

Failure to enter the correct code on the third attempt will cause the

modem to hang up and the ‘NO CARRIER’ message will be displayed.

2) User Access Code Disabled (default)

!

No request for a code will be displayed and an open data connection to

your system is made.

3) Administrator Access Code

!

Dial the modem in the normal way from a PC Terminal application and

wait for the usual ‘CONNECTED’ prompt to be returned.

!

If the User Access Code had been previously enabled you will be

prompted with ‘ENTER PASSWORD’, as normal. Do not enter the

“User” code.

!

Enter the Administrator code (up to eight characters, UPPER CASE

ONLY) followed by <enter>. The default code is ADMIN.

!

If the correct code has been entered, “OK” will be returned and you

will then be allowed to access the specialised modem settings of the

remote modem. This is referred to as the “Online Configuration”

mode, (see section 3.5.2).

!

You only have one chance to type the correct code, unless you h ave the

“User” code enabled, then there will be three chances.

!

When you have completed any changes, t ype *** (three stars ) and wait

until the remote modem responds with “OK”. The modem will then

effect any changes made and establish an open line to your system.

NOTE: To be able to use the password facility the user should use a terminal

application, such as the Terminal programme, provided. Using software with built-in

Modem support may not provide password facility.

13

3.4.2 Installing the Access Codes

To install or change an access code it will be necessary to connect a PC directly to the

modem via the PC serial port and the RS232 data connector. Use the MODEM-PC9CAB or suitable lead and run your terminal software.

1) Installing for the first time

!

The factory default setting is no user code set.

!

To install your user code for the first time use the following command:

AT%ACU = *,<new code> [Enter]

!

(Where the new code can be one to eight characters long)

2) Changing the user code

!

To change the user code you will require either the current user or

administrator codes and use the following command:

AT%ACU = <current code>,<new code> [Enter]

!

The modem will respond with

OK (when accepted) or

ERROR (when current code is incorrect)

!

Current code may be either the user or administrator codes.

3) Disabling the user code

!

To disable the user code enter * in the new code field and the current code in

the following command:

AT%ACU = <current code>,* [Enter]

!

The modem will respond with

OK (when accepted) or

ERROR (when current password is incorrect)

!

Current code may be either the user or administrator codes.

4) Changing the administrator code

!

To change the administrator code you will need to know the current

administrator code (default = ADMIN) and use the following command:

AT%ACA = <current admin code>,<new admin code > [Enter]

!

The modem will respond with

OK (when accepted) or

ERROR (when current admin code is incorrect)

!

Current admin code must be the administrator code.

NOTE: The codes are not case sensitive as all codes are converted to upper case.

Also, the administrator code cannot be disabled.

5) In case of problems

In the unfortunate event that the password has been lost or the modem has been

sabotaged, contact your supplier for assistance. It may be possible to return the

password back to the original factory setting.

14

3.5 Dial On Demand

The dial on demand facility enables an FX or AnS PLC to command the modem to

dial pre-stored telephone numbers and automatically exchange data with a remote site.

IMPORTANT NOTE:

The facilities described in sections 3.5 and 3.6 will not operate from an An(S)/QAn(S)

PLC when connected via an HMI.

The pre-stored telephone numbers may be either speed dial numbers (stored in the

modem) or located within PLC registers. How to set up the telephone numbers is

explained in section 3.5.5.

The data exchanged may be to either send fixed text messages stored within the

modem or to read/write blocks of data from within the PLC. The process of setting up

fixed text messages is explained in section 3.5.6, while data transfers are dealt with in

section 3.6. Alternatively the modem can be commanded to stay on line either to

repeat the data transaction, or wait on line until instructed to hang up by either end.

Dial on demand operates by configuring the modem to poll a block of PLC

(command) registers, which provide the modem with instructions, explained in

section 3.5.3.

NOTE: Throughout this section the Local system is the one making the call, while the

Remote system is the one being called.

3.5.1 Setting Dial on Demand Commands

To set up Dial On Demand it will be necessary to connect a PC directly to the modem

via the PC serial port and the RS232 data connector. Use the MODEM-PC9-CAB or

suitable lead and run your terminal software.

1) Defining the local PLC type

Because different PLC’s use different communications protocols it is necessary to set

the modem to the type of PLC that it is connected. This is done by entering a protocol

code with the command:

AT%ADP = x

Where x =0 No protocol/Desk (factory default version 1.20 or later)

All other protocols are listed in section 5.9.

15

2) Locating the command registers

The command registers may be located in any valid D-type register within the PLC. A

contiguous block of 7 registers is required. The modem will need to know the start

address of this block and this is done with the command:

AT%ADR = xxxxxx

Where xxxxxx is the address from 1 to 6 digits.

Example 3-4 Command Block Address setting

AT%ADR = 1000 Defines the command block at D1000

AT%ADR = 20 Defines a command block at D20

Also, the command block need not be within the same PLC connected to the modem.

It may be in another PLC connected over a local network. The PLC network number

may be defined using the command:

AT%ADN = FF FF is the default setting.

3) Starting the poll

Polling is started by the command:

AT%ADO = 1

And stopped by the command:

AT%ADO = 0

Polling will start approximately 10 seconds after the next modem reset.

If the modem does not receive a response to its poll request, polling will be

temporarily suspended until the next reset.

If the modem is still connected to a PC terminal when it starts to poll, then you should

see a formatted read request strin g appear. If you are able to interpret such strings,

this can be used as a useful tool to check your settings are correct.

3.5.2 Online Configuration

Any of the parameters listed in the whole of section 3 may be modified in a remote

modem by calling it and entering the Administrator Access Code. For a full

explanation of how to do this see

section 3.4.1 3).

16

3.5.3 Contents of the command block

The contents of the command block within the PLC are shown in the following

figures.

For a sample program that uses the dial on demand facility see section 10 at the end of

this manual.

COMMAND BLOCK

MSB LSB

D(x) E

R

R

D(x+1) Tel. No.#1 Tel. No. #2 Tel. No. #3 Tel. No. #4 Telephone Number

S

Y

N

N

R

S

Error code

PLC

Comms

N

A

N

N

D

T

N

C

D

B

S

Y

TCPFS

RQStatus register

T

P

register

D(x+2) Message#1Message

#2

D(x+3) [D]0~1999 Directory A Telephone

D(x+4) [D]0~1999 Directory B Telephone

D(x+5) [D]0~1999 Directory C Telephone

D(x+6) [D]0~1999 Directory D Telephone

Where

D(x) = Head address of the Control Block as specified by the AT%ADR command.

3.5.4 Control and Status Register

The first resister of the command block read back from the PLC is dealt with on a bit

by bit basis, the break down of which is detailed below.

Message

#3

Message#4Message register

No. head address

No. head address

No. head address

No. head address

D(x)

Erro r Flag

Sy ntax Error b13

N o R espo nse b 12

PLC co mms er ro r co d e b 1 1 -8

b0 D ial Request

b1 Stopped Polling

b2 P o llin g Flag

b3 Tran s miss io n Comple te

b4 L ine Busy

b5 No C arrie r

b6 N o D ial Tone

b7 No Answer

17

1) Dial Request Bit (bit 0)

In order to trigger a dial on demand action, the PLC program needs only to set

the Dial Request (RQ) bit in the first register of the command block. When

the RQ bit is set the telephone and action data is retrieved by the modem in the

same poll, so remember to set these values before the bit!

2) Stopped Polling bit (bit 1)

The Stopped Polling bit (STP) is set by the modem while it is performing a

dial out operation. It may be used in conjunction with the poll flag below to

indicate that polling has been temporarily suspended.

3) Polling Flag bit (bit 2)

The poll bit is toggled by the modem after every successful poll has been

made. This feature may be used by the PLC (particularly one at a remote site)

to determine if the modem has stopped polling it for some reason.

CAUTIONARY NOTE:

The polling bit is set and reset by a word write command. The remaining bits

in the register are overwritten with the data they contained at the time of the

poll read request. Therefore, take care when setting the RQ bit; perhaps by

triggering on the rising/falling edge of the poll bit.

4) Transmission Complete bit (bit 3)

The Transmission Complete bit (TC) is set by the modem when it has; made a

successful dial out, connected, and has performed all the transactions indicated

in the message registers. Used by the PLC as an indicator that the modem has

dealt with the request, and may be used to trigger a new set of transactions.

5) Error bits (bits 15-7)

The first address of the command block has a number of bits allocated for

error reporting by the modem. These bits are set by the modem in the event of

an error and presented to the PLC on an information only basis.

Bit 15 – General error – set when any error occurs

Bit 13 – Syntax error – set when either the local or remote PLC responds with

three consecutive NAK messages.

Bit 12 – No response – set when the remote PLC has not responded in three

seconds to a WAT request, in three consecutive attempts.

Bits 11 to 8 – PLC communication error – accompanies the syntax error flag,

the least two significant characters returned by a NAK response are copied

here. (AnS PLC only).

Bits 4 to 7 – dial errors – these flags are set when a dial attempt has failed for

one of the following reasons: Line busy, no carrier, no dial tone, or no answer.

18

3.5.5 Setting telephone numbers

When dial on demand is required, the modem uses the first telephone number v alue

from the command block to determine the number to dial. If this value is in the range

of 1 to 9 a speed-dial number is selected. If the value is in the range A to D (hex) then

the modem will read a block of registers from the PLC, then dial the returned value.

b15 b0

D(x+1) Tel. No.#1 Tel. No. #2 Tel. No. #3 Tel. No. #4 Telephone No. address

Where (x+1) = Command Block address +1

1-9h for Speed Dial addresses

A-Dh for Directory addresses

0h for NO telephone number

Telephone addresses are stored in HEX and must include all 4 numbers, e.g. 2300 not

23, [call telephone number in speed-dial address 2, then 3 if 2 is busy, etc.]

1) Setting speed-dial numbers in the modem

These numbers are stored within the modem, so must be pre-set by connecting

the modem to a PC terminal, and using the command:

AT&Zn = <telephone number>

Where n is the speed-dial address in the range of 1 to 9

<telephone number> may be 15 characters long

Example 3-5 Setting Speed-Dial numbers

AT&Z3=01234567890 [Tel. No. 01234 567890 set at address 3]

When a value of 1 to 9 is found in the data returned from the PLC the

corresponding number is looked up then dialled.

2) Setting directory numbers in the PLC

The start addresses of the four possible PLC locations (A-D) are included in

the command block and returned with each poll request. A block of five

registers is read from the start address indicated in the command block. Each

register holds up to four (hex) digits of the phone number, therefore the

number can be twenty digits long.

Entering a value of F (hex) indicates the end of the telephone number.

Example 3-6 Directory Dialling (PLC programming)

Command Block address D1000 and Directory Telephone No. in D405-409.

MOVP D405 D1003

Set Directory A header address

MOVP HA000 D1001

MOVP K1 D1000

19

Set Telephone address A

Set Dial Request bit 0=1

By either swapping the value of the address in the command block, or by

swapping the value at the directory address before making a dial request; a

huge directory of telephone numbers becomes available, limited only by the

amount of free data registers within the PLC.

3.5.6 Setting fixed messages in the modem

Fixed (text) messages are stored within the modem, so must be pre-set by connecting

the modem to a PC terminal, and using the command:

AT%MSGn = <message>

Where n = the message address in the range 1 to 9

<message> may be up to 48 characters long.

Example

: AT%MSG2=Pumping Station No. 2 [stores message in address2]

b15 b0

D(x+2) Msg. #1 Msg. #2 Msg. #3 Msg. #4 Message register

Where (x+2) = Command Block address +2

1-9h for Fixed Message addresses

A-Dh for WAT Messages/Data addresses (see section 3.6 for more information)

Eh for On-Line polling

Fh for Stay On-Line

0h for end of messages, hang up

Message addresses are stored in HEX and must include all 4 numbers, e.g. 12F0 not

12F. [send 2 messages from addresses 1 and 2, then Stay On-Line (F)]

When a value of 1 to 9 is found in the returned data, the corresponding message is

looked up then sent to the remote site.

The modem will automatically hang up when a value of 0 (zero) is found or after all

four messages have been actioned.

When the hexadecimal value E is found; the modem stops processing messages, sets

the Transmission Complete bit in the PLC command register, then resumes polling.

However, the modem does not hang-up, terminating the call. This feature is useful

when more than four transactions are required, and is particularl y useful when doing

Wide Area Telemetry.

When the hexadecimal value F is found; the modem stops processin g messages, sets

the transmission complete flag, but does not resume polling. Again the modem does

not hang-up, terminating the call. This feature is useful when an error has occurred

that requires operator intervention from a remote site.

Example 3-7 Setting Messages from the PLC

MOVP H12F0 D1002

Set Fixed messages 1,2 and

Stay on-line.

MOVP HABE0 D1002

Set WAT A,B then On-line

monitoring.

20

3.6 Wide Area Telemetry (WAT)

One of the most exciting features of your modem is its ability is not just to

automatically dial on demand, but also exchange information with another, remote

PLC. We refer to this process as Wide Area Telemetry (WAT) as it gives you the

possibility of setting up a wide area network of PLC’s.

AnS, A

MITSUBIS

MITSUBIS

MITSUBIS

MITSUBIS

FX0S/FX1S

FX0N/FX2N

FX

Modem-A2S

RD SD

CD TR

CS OH

DATA

RS232

VOICE

LINE

24V

OV

Modem-A2S

RD SD

CD TR

CS OH

DATA

RS232

VOICE

LINE

24V

OV

AnS, A

MITSUBIS

MITSUBIS

MITSUBIS

MITSUBIS

FX0S/FX1S

FX0N/FX2N

FX

In the previous section (3.5) it was mentioned that placing the values A to D (hex)

into one of the message slots of the command block would enable a WAT transaction.

3.6.1 Setting the Start Address of WAT Information

The information used to perform a WAT operation is stored in a WAT header; any

contiguous block of three D type registers within the PLC may be used. All the

modem needs to know is the first address.

To program the start address in the modem, use a PC terminal to communicate with it

and type an AT command in the following format:

AT%WATn = 1234

Where n is the letter A to D and corresponds to the hexadecimal value set in the

message register of the control block above.

1234 is an example start address

Example 3-8 Setting WAT addresses

AT%WATA = 500 when hexadecimal A is found in the message register

the modem will read address D500 for instructions.

AT%WATD = 22 when hexadecimal D is found in the message register

the modem will read address D22 for instructions.

21

3.6.2 Information in the WAT Header

The instructions read by the modem from t he WAT header are in the form shown in

the two figures below. It is the responsibility of the PLC program to transfer the

correct information into these registers before requesting the transaction.

WAT REGISTERS

MSB LSB

D(y) Number of data words to

transfer (hex value)

Read/Write

Remote

Remote

Protocol

Header #1

D(y+1) Remote Register/Device Prefix

Header #2

(One ASCII Number or letter)

D(y+2) Remote Head Address

Header #3

(0-1999 decimal)

D(y+3) 1st Data Word Data #1

D(y+4) 2nd Data Word Data #2

D(y+x) (x) Data Word

Data #x

(where x = 16 (10 hex) maximum)

Where D(y) = Head Address of the WAT Message data area specified with the

AT%WAT command.

The contents of Header #1 are further described below.

b15

D(y)

b0

WAT Header Address#1

b0-3 Remote Protocol No.

b 4-7 Remote Read/Wri te bit

b8-15 Number of words

Where D(y) Is the first WAT header address.

Bits 15 to 8 - The number of words to Transmit or Receive are limited to 16 (1 to 10h)

Bits 7 to 4 - Read/Write Remote, 0 = Read from Remote and 1 = Write to Remote.

Bits 3 to 0 - Remote Protocol Number refers to the remote PLC type, e.g. 1 = AnS PLC,

3 = FX PLC.

22

Detail of WAT header address’ #2 & 3.

b15b

)

b

b

0

WAT Head er A ddr ess # 2D(y+1)

b0-7 D evi ce pr efix l etter

Bits 7 to 0 – The Device Prefix letter in ASCII Hexadecimal, eg. X,Y,M,B,D,W, etc.

15

D(y+2)

0

WAT Hea d er A ddr ess # 3

b0-15 Device Address

Bits 15 to 0 – Device address in Decimal, Hexadecimal or Octal, eg. 1000, 3F, etc.

Example 3-9 WAT settings in the PLC (Write Remote command)

WAT Header address = D200, Writing 1 word to outputs Y0 to Y17 on an FX PLC.

MOV H0113 D0200

ASC Y D0201

MOV K0 D0202

MOV H5555 D0203

Set 1word,Write, FX protocol

Set Device = Y

Set Device address = 0

Set Data (Y0 and all even numbers to

Y26 will be switched ON, odd

numbers OFF

Example 3-10 WAT settings in the PLC (Read Remote command)

WAT Header address = D300, Read 16 (10h) words from D500 in an AnS PLC.

MOV H1001 D0300

ASC D D0301

MOV K500 D0302

BMOV K0 D0303 K16

Set 10h words, Read, AnS protocol

Set Device = D

Set Device address = 500

Clear 16 registers from D303 (not

obligatory). Data from D500 to 515 in

the remote AnS PLC will be read

directly into registers D303 to 318.

23

3.7 WAT Settings and Procedures before operation

Start

1.Reserve 7 (D) registers for the Command Block

(see 3.5.3)

2.Reserve 3 (D) registers for the WAT header +

16 registers for the WAT data (see 3.6.2)

Set-up the A2S Modem using the

following commands:

AT%ADP=<PLC type>

AT%ADR=<command block Addr.>

AT%WATA to D

AT%ADO=1

Yes No

Speed Dial

Set telephone numbers in the Set-up a Directory in the

A2S Modem with command PLC (5 registers per teleAT&Z1 to 9 (see 3.5.5 1)) phone No. (see 3.5.5 2))

Programme the PLC to transfer the WAT

strategy, eg. Read or Write, No. words and

the remote PLC Type (see Examples 3-9 & 10).

Set the Message register for the order in which

the WAT addresses are to be transmitted

(see Example 3-7)

Set the Telephone register

Set the “Dial Request” bit to start operation.

End

24

Section 4 – Troubleshooting

Your modem is designed to provide reliable and trouble free functionality. However,

should you experience any difficulty, the information in this section may assist you in

determining and resolving the source of the problem. If you cannot resolve your

situation after reading this chapter, contact your dealer of the Technical Support

Centre at the number provided on the last page of this manual.

4.1 The modem does not respond to commands

1. Ensure that the PC is not configured to a conflicting COM port and/or IRQ

setting. Your modem cannot be connected to a COM port currently in use by

another device in your system (e.g. mouse). Similarly IRQ settings must not

overlap.

2. Make sure that the communication software is configured with the correct COM

and IRQ settings (i.e. the same as the modem). Your communication software

will not be able to send or receive data if it is not configured to match the COM

settings of the modem

3. Check that the modem is not configured to echo off or command reporting off.

This can be done by typing the commands ATE1 to restore echo and ATQ0 to

restore command reporting. By default, the modem will be set to echo off and

reporting off.

4. The modem will not respond to commands if Dial On Demand is enabl ed, for the

first ten seconds after power up.

4.2 The Modem Dials but Does Not Connect

1. The best method of diagnosing this kind of problem is always to connect a

suitable head or handset to the modem as it is dialling.

2. Check that you are dialling the right number.

3. Check that the remote modem has the correct line cable connected.

4. If the remote site keeps ringing without picking up, it may either be unplugged or

it has not been programmed to auto-answer. Setting the modem with the

command ATS0=1 instructs auto answer after 1 ring.

5. Check that the line connected to the remote modem is not part of a digital miniexchange, this type of system requires an analogue (2-wire) adapter.

4.3 The Modem Does Not Dial, Reporting “NO DIALTONE”

Problems of this type are almost always due to the telephone cable/connection.

1. Check that the telephone cable is connected correctly to the modem and phone

socket.

2. Check that the cable used is the correct type for the country you are in, the one

supplied is only suitable for connection in the UK. Line connections are delivered

on pins 3 & 4 of the line socket.

25

4.4 The Modem Stops Polling After First Poll

1. Only applies to Dial On Demand polling

2. Check that the serial cable that you are using to connect to the PLC is right for the

PLC.

3. If using a communications module, check that its settings are correct

4. If connected to an HMI terminal, check that its communications settings are

correct

4.5 Polling Occurs, but will not Dial On Demand

1. Check that the register address polled is correct, AT%ADR setting.

2. Check that the PLC program is setting the RQ bit.

3. Check that there is at least one value in the telephone register of the command

block, and that it the value has sufficient trailing 0’s, i.e. 1000 not 1.

4. If using speed-dial numbers, check that the number requested is set in the modem,

At&Zn setting.

4.6 Modem occasionally hangs-up during WAT data exchange.

This is usually caused by an unacceptable number of data errors, detected during a

WAT operation.

1. Check cable connections.

2. The problem may be caused by poor Telephone Network connections, for

example, Exchange faults or old lines.

3. Try reducing the Baud rate between the A2s Modems on the Network by

changing the AT%NET setting from the default 28800 rate.

4.7 Occasional “Re-tries” occur during Programming/Monitoring.

This is probably due to poor Telephone Network connections.

1. Try another Line or redial.

2. If you are dialling from a Mitsubishi A2S/DESK Modem try reducing the Baud

rate, using the AT%NET command.

26

Section 5 – AT Command Set and S - Registers

All commands below are preceded with AT. The commands are not case sensitive.

5.1 Standard Commands

Command Function

A/ Re-execute command

A Go off-hook and attempt to answer an incoming call

B0 Select V.22 connection at 1200bps

B1 Select Bell 212A connection at 1200bps

C1 Return OK Message

Dn Dial modified by parameter n

E0 Turn off command echo to terminal

E1 Turn on command echo to terminal

F0 Select auto-detect mode (equivalent to N1)

F1 Select V.21 or Bell 103 line modulation

F2 Reserved

F3 Select V.23 line modulation

F4 Select V.22 or Bell 212A 1200bps line modulation / speed

F5 Select V.22bis line modulation

F6 Select V.32bis or V32 4800bps line modulation / speed

F7 Select V.32bis 7200bps line modulation / speed

F8 Select V.32bis or V.32 9600bps line modulation / speed

F9 Select V.32bis 12000bps line modulation / speed

F10 Select V.32bis 14400bps line modulation / speed

H0 Initiate hang-up sequence

H1 If on-hook go off-hook and enter command mode

I0 Report product code

I1 Report pre-computed checksum

I2 Report OK

I3 Report firmware revision and interface type

I4 Report response programmed by an OEM

I5 Report the country code parameter

I6 Report modem data pump model and code revision

I7 Reports the DAA code

L0 Set low speaker volume

L1 Set low speaker volume

L2 Set medium speaker volume

L3 Set high spea ker volume

M0 Turn speaker volume off

M1 Turn speaker on during handshaking and turn speaker off

M2 Turn speaker on during handshaking and while receiving carrier

M3 Turn speaker off during dialling and receiving carrier and on during answering

N0 Turn off auto-mode detection

N1 Turn on auto-mode detection

O0 Go on-line

O1 Go on-line and initiate a retrain sequence

P Dial modifier, force pulse dialling

Q0 Allow result codes to DTE

Q1 Inhibit result codes to DTE

Sn Select S-Register n

=v Set the value of S-Register to value v

? Return the current value of parameter

T Dial modifier, force DTMF dialling

V0 Report short form (terse) result codes

V1 Report long form (verbose) result codes

W0 Report DTE speed in EC mode

W1 Report line speed. EC protocol and DTE speed

W2 Report DCE speed in EC mode

X0 Report basic call progress result codes i.e. OK, CONNECT, RING, NO CARRIER

(also for busy if enabled, and dial tone not detected), NO ANSWER and ERROR.

27

X1 Report basic call progress result codes and connection speeds i.e. OK, CONNECT,

RING, NO CARRIER (also, for busy, if enabled, and dial tone not detected), NO

ANSWER, CONNECT XXXX and ERROR.

X2 Report basic call progress result codes and connection speeds i.e. OK, CONNECT,

RING, NO CARRIER (also, for busy, if enabled, and dial tone not detected), NO

ANSWER, CONNECT XXXX and ERROR.

X3 Report basic call progress report codes and connection speeds i.e. OK, CONNECT,

RING, NO CARRIER, NO ANSWER, CONNECT XXXX, B USY, and ERROR.

X4 Report all call progress codes and connection speeds i.e. OK, CONNECT, RING, NO

CARRIER, NO ANSWER, CONNECT XXXX, NO DIAL TONE and ERROR.

Y0 Disable long space disconnect before on-hook

Y1 Enable long space disconnect before on-hook

Z0 Restore stored profile 0 after warm reset

Z1 Restore stored profile 1 after warm reset

&C0 Force RLSD active regardless of the carrier state

&C1 Allow RLSD to follow the carrier state

&D0 Interpret DTR on " off transition per &Qn setting:

&Q0, &Q5, &Q6 the modem ignores DTR

&Q1, &Q4 the modem hangs up

&Q2, &Q3 the modem hangs up

&D1 Interpret DTR on " off transition per &Qn setting:

&Q0, &Q1, &Q4, &Q5, &Q6 Asynchronous escap e

&Q2, &Q3 the modem hangs up

&D2 Interpret DTR on " off transition per &Qn setting:

&Q0 through &Q6 the modem hangs up

&D3 Interpret DTR on " off transition per &Qn setting:

&Q0, &Q1, &Q4, &Q5, &Q6 the modem performs soft reset

&Q2, &q3 the modem hangs up

&F0 Restore factory configuration 0

&F1 Restore factory configuration 1

&G0 Disable guard tone

&G1 Disable guard tone

&G2 Enable 1800Hz guard tone

&J0 Set S-register response only for compatibility

&J1 Set S-register response only for compatibility

&K0 Disable DTE/DCE flow control

&K3 Enable RTS/CTS, DTE/DCE flow control

&K4 Enable XON/XOFF DTE/DCE flow control

&K5 Enable transparent XON/XOFF flow control

&K6 Enab le b oth RTS/CTS and XON/XOFF flow control

&L0 Not Used

&M0 Select direct asynchronous mode

&M1 Select synchronous connect with asynchronous off line command mode*

&M2 Select synchronous connect with asynchronous off line command mode and enable

DTR dialling of directory zero*

&M3 Select synchronous connect with asynchronous off line command mode and enable

DTR to act as Talk/Data switch

&P0 Set 10pps pulse dial with 39/61 make/break ratio

&P1 Set 10pps pulse dial with 33/67 make/break ratio

&P2 Set 20pps pulse dial with 39/61 make/break ratio

&P3 Set 20pps pulse dial with 33/67 make/break ratio

&Q0 Select direct asynchronous mode

&Q1 Select synchronous connect with asynchronous off-line command mode*

&Q2 Select synchronous connect with asynchronous off-line command mode and enable

DTR dialling of directory zero*

&Q3 Select synchronous connect with asynchronous off-line command mode and enable

PTR to act as Talk/Data switch*

&Q4 Select Hayes Auto Sync mode

&Q5 Modem negotiates an error corrected link

&Q6 Select asynchronous operation in normal mode

&R0 CTS tracks RTS (asynchronous) or acts per V.25 (synchronous)

&R1 CTS is always active

28

&S0 DSR is always active

&S1 DSR acts per V.25

&T0 Terminate any test in progress

&T1 Initiate local analogue loop-back test

&T2 Returns ERROR result code

&T3 Initiate local digital loop-back test

&T4 Allow remote digital loop-back test

&T5 Disallow remote digital loop-back request

&T6 Request an RDL without self-test

&T7 Request an RDL with self-test

&T8 Initiate local analogue loop-back with self-test

&V Display current modem configurations

&W0 Store the active profile in NVRAM profile 0

&W1 Store the active profile in NVRAM profile 1

&X0 Select internal timing for transmit clock

&X1 Select external timing for the transmit clock

&X2 Select slave receive timing for the transmit clock

&Y0 Recall stored profile 0 upon power up

&Y1 Recall stored profile 1 upon power up

&Zn-x Store dial string x (to 34 chars) to location n (0-3)

%E0 Disable line quality monitor and auto-retrain

%E1 Enable line quality monitor and auto retrain

%E2 Enable line quality monitor and fall back / fall forward

%L Return received signal level

%Q Report the line signal quality

%TTn PTT certification test signals

\Kn Controls break handling during three states:

When modem receives a break from the DTE:

\K0.2.4 Enter on-line command mode, no break sent to the remote modem

\K1 Clear buffer and send break to remote modem

\K3 Send break to remote modem immediately

\K5 Send break to remote modem in sequence with transmitted data

When modem receives \B in on-line command state:

\K0.1 Clear buffer and send break to remote modem

\K2.3 Send break to remote modem immediately

\K4.5 Send break to remote modem in sequence with transmitted data

When modem receives break from the remote modem:

\K0.1 Clear data buffers and send break to DTE

\K2.3 Send break immediately to DTE

\K4.5 Send a break with received data to the DTE

\N0 Select normal speed buffered mode

\N1 Select direct mode

\N2 Select reliable link mode

\N3 Select auto reliable mode

\N4 Force LAPM mode

\N5 Force MNP mode

\V0 Connect messages are controlled by the command settings X, W, and S95

\V1 Connect messages are displayed in the single line format

+MS Select modulation

+H0 Disable RP I

+H1 Enable RPI and set DTE speed to 9600bps

+H2 Enable RPI and set DTE speed to 38400bps

+H3 Enable RPI and set DTE speed to 57600bps

+H11 Enable RPI+ mode

**0 Download to flash memory at last sensed speed

**1 Download to flash memory at 38.4kbps

**2 Download to flash memory at 57.6kbps

29

-SDR=0 Disable distinctive ring

-SDR=1 Enable distinctive ring type 1

-SDR=2 Enable distinctive ring type 2

-SDR=3 Enable distinctive ring type 1 and 2

-SDR=4 Enable distinctive ring type 3

-SDR=5 Enable distinctive ring type 1 and 3

-SDR=6 Enable distinctive ring type 2 and 3

-SDR=7 Enable distinctive ring type 1, 2 and 3

5.2 ECC Commands

%C0 Disable data compression

%C1 Enable MNP 5 data compression

%C2 Enable V.42bis data compression

%C3 Enable both V.42bis and MNP 5 data compression

\A0 Set maximum block size in MNP to 64

\A1 Set maximum block size in MNP to 128

\A2 Set maximum block size in MNP to 192

\A3 Set maximum block size in MNP to 256

\Bn Send break of n x 100ms

5.3 MNP 10 Commands

-K0 Disable MNP 10 extended services

-K1 Enable MNP 10 extended services

-K2 Enable MNP 10 extended services, detection only

-SEC=0 Disable MNP 10-EC

-SEC=1,[<tx level>] Enable MNP 10-EC and set transmit level

<tx level> 0 to 30 (0dBm to –30dBm).

5.4 W-CLASS Commands

*B Display list of permanently blacklisted numbers

*D Display list of delayed numbers

*NCn Change country code to one of eight in NVRAM

5.5 FAX Class 1

+FCLASS=n Service class

+FAE=n Data/Fax auto answer

+FRH=n Receive data with HDLC framing

+FRM=n Receive data

+FRS=n Receive silence

+FTH=n Transmit data with HDLC framing

+FTM=n Transmit data

+FTS=n Stop transmit and wait

5.6 FAX Class 2

+FAA=n Adaptive answer

+FAXERR Fax error value

+FBOR Phase C data bit order

+FBUF? Buffer size (read only)

+FCFR Indicate confirmation to receive

+FCON Facsimile connection response

+FCIG Set the polled station identification

+FCIG: Report the polled station identification

+FCR Compatibility to receive

+FCSI: Report the called station ID

+FDCC= DCE capabilities parameters

+FDCS: Report current session

+FDIS: Report remote capabilities

+FDIS= Current sessions parameters

+FDR Begin of continue phase C receive data

30

+FDT= Data transmission

+FDTC: Report the polled station capabilities

+FET: Post page message response

+FET=n Transmit page punctuation

+FHNG Call ter minatio n with status

+FK Session termination

+FLID= Local ID string

+FLPL Document for polling

+FMDL? Identify model

+FMFR? Identify manufacturer

+FPHCTO Phase C time-out

+FPOLL Indicates polling request

+FPTS Page transfer status

+FREV? Report identity revision

+FSPL Enable polling

+FTSI: Report the transmit station ID

5.7 Voice/Audio Commands

#BDR Select Baud rate (turn off au t o Baud)

#CLS Select data fax or voice

#MDL? Identify model

#MFR? Identify manufacturer

#REV? Identify revision level

#SPK= Speakerphone setting

#TL Audio output transmit level

#VBQ? Query buffer size

#VBS Bits per sample

#VBT Beep tone timer

#VCI? Identify compression method

#VGT Set playback volume in the command state

#VLS Voice line select

#VRA Ring back goes away (originat e)

#VRN Ring back never came timer (originate)

#VRX Voice receive mode

#VSK Buffer skid setting

#VSP Silence detection period (voice receive)

#VSR Sampling rate selection

#VSS Silence detection tuner (voice receive)

#VTD DTMF/tine reporting

#VTM Enable timing mark placement

#VTS Generate tone signals

#VTX Voice transmit mode

31

5.8 S-Registers

Registry No. Function

S0 Number of rings to auto answer

S1 Ring counter

S2 Escape character

S3 Carriage return character

S4 Line feed character

S5 Back Space character

S6 Wait time for dial tone before blind dialling, or after ‘W’ modifier

S7 Wait time for carrier after dial, for silence, or for dial time after ‘W’ dial

modifier

S8 Pause time for dial delay

S9 Carrier detect response time

S10 Lost carrier to hang up delay

S11 DTMF tone duration

S12 Escape prompt delay

S13 Reserved

S14 General bit mapped option status

S15 Reserved

S16 General bit mapped test option status

S17 Reserved

S18 Test timer

S19 Auto sync bit mapped options

S20 Auto sync HDLC address or BSC sync character

S21 V.24 / General bit mapped option status

S22 Speaker / Results bit mapped option status

S23 General bit mapped option status

S24 Sleep inactivity timer

S25 Delay to DTR

S26 RTS to CTS delay

S27 & S28 Bit mapped option status

S29 Flash dial modifier time

S30 Disconnect inactivity timer

S31 Bit mapped option status

S32 XON character

S33 XOFF character

S34 & S35 Reserved

S36 LAPM failure control

S37 Desired line connection speed

S38 Delay before forced hang-up

S39 Flow control bit mapped option status

S40 & S41 General bit mapped option status

S46 Data compression control

S48 V.42 negotiation action

S82 Break handli ng options

S86 Call failure reason code

S91 PSTN Transmit attenuation level

S92 Fax transmit attenuation level

S95 Extended result code

32

5.9 Unique AT Commands

(Commands specific to the A2S/DIN-MODEM-2)

%ACA= <old>, <new> Replace Administrator level Access Code

%ACU= *, <new> Enable User level Access Code, set to <new>

%ACU= <old>, * Disable user level access code

%ACU= <old>, <new> Replace user level access code

%ADO=0 Disable PLC polling

%ADO=1 Enable PLC polling

%ADN= nn Set PLC network number to poll

%ADP= x Set local PLC protocol

x = 1 An(S) PLC through C24 comms module

x = 2 AnA(S)/QA(S) PLC via C24 comms module

x = 3 FX/FX0/FX2N PLC

x = A A/Q series via E type HMI

x = F FX series via E type HMI

x = T,bbbbb,d,p,s Transparent mode

where,

bbbbb = Baud rate (max. 38800)

d = no. of Data bits (7,8,9)

p = Parity

(N = None, E = Even, O = Odd)

s = no. of Stop bits (1or 2)

%ADR= xxxxxx Set PLC polling register address from x to xxxxxx

%F Returns the Modem to the default settings

eg. AT%ADO=0

%MSGn = <message> set fixed message n to string <message>

n = 1 to 9

<message> up to 48 ASCII characters

%NET = xxxxx Set the Telephone network Baud Rate to 2400,

4800, 9600, 19200 & 28800 (default)

%VER Report current A2S software revision

%WATn = xxxxxx Set PLC register for telemetry header n to value x to

xxxxxx

n = A to D

&V1 Report current A2S enhanced operating parameters

Reset the Modem after setting this command.

33

Section 6 – Support Service and Compliance Details

6.1 Customer Support

If after installing as per the instructions and trying the recommended troubleshooting

techniques, you are still unable to resolve a problem, you should contact either (1)

Your authorised distributor or (2) the Technical Support Centre at the number

provided at the end of this manual.

6.2 European Compliance Information

This modem has been approved for pan-European use by KCS as compliant with

telecommunications standard TBR21.

6.3 Ringer Equivalence Number

The ringer equivalence of this modem is 1.

REN is a guide to the maximum number of apparatus that can be simultaneously

connected to one telephone line. The REN value of each apparatus is added together

and should not exceed 4. Unless otherwise marked, a telephone can be assumed to

have a REN of 1.

6.4 Approved Usage

This modem is only approved for the following facilities:

Storage of telephone numbers for retrieval by a predetermined code

This modem is NOT suitable for use as an extension to a payphone

This modem is not approved for connection to UK private speech band services or

leased lines.

Any other usage will invalidate the approval of your modem, if as a result, it then

ceases to conform to the standards against which approval was granted.

The approval of this modem is invalidated if the apparatus is subject to modification

in any material way not authorised by KCS or if it is used with, or connected to,