Mitsubishi CMB-P-NU-G1, CMB-P-NU-HA1, CMB-P-NU-GA1, CMB-P-NU-GB1, CMB-P-NU-HB1 Installation Manual

Air-Conditioners For Building Application

INDOOR UNIT

CMB-P-NU-G1

CMB-P-NU-GA1 (MAIN BC CONTROLLER)

CMB-P-NU-GB1 (SUB BC CONTROLLER)

CMB-P-NU-HA1 (MAIN BC CONTROLLER)

CMB-P-NU-HB1 (SUB BC CONTROLLER)

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

GBF

Contents

1. Safety precautions ........................................................................................2

1.1. Before installation and electric work ............................................ 2

1.2. Precautions for devices that use R410A refrigerant .................... 2

1.3. Before installation ........................................................................ 3

1.4. Before installation (relocation) - electrical work ........................... 3

1.5. Before starting the test run .......................................................... 3

2. Items to be used ........................................................................................... 3

2.1. Package contents ........................................................................ 3

2.2. Commercially available items ...................................................... 3

3. Selecting an installation site ......................................................................... 4

3.1. About the product ........................................................................ 4

3.2. Installation site ............................................................................ 4

3.3. Securing installation and service space ...................................... 4

3.4. Checking the installation site ....................................................... 5

1. Safety precautions

1.1. Before installation and electric work

Before installing the unit, make sure you read all the “Safety

u

precautions”.

The “Safety precautions” provide very important points

u

regarding safety. Make sure you follow them.

GB

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the unit.

Symbols used in the illustrations

:

Indicates an action that must be avoided.

:

Indicates that important instructions must be followed.

:

Indicates a part which must be grounded.

:

Beware of electric shock. (This symbol is displayed on the main unit label.) <Color: Yellow>

Warning:

Carefully read the labels afxed to the main unit.

HIGH VOLTAGE WARNING:

• Control box houses high-voltage parts.

• When opening or closing the front panel of the control box, do not let it

come into contact with any of the internal components.

• Before inspecting the inside of the control box, turn off the power, keep

the unit off for at least 10 minutes.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric

shock, or re.

• Install the unit at a place that can withstand its weight.

- Failure to do so may cause the unit to fall down, resulting in injuries and

damage to the unit.

• Use the specied cables for wiring. Make the connections securely so

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a re.

• Prepare for earthquakes and install the unit at the specied place.

- Improper installation may cause the unit to fall down and result in injury

and damage to the unit.

• Always use accessories specied by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper installa-

tion by the user may result in water leakage, electric shock, or re.

• Never attempt to repair the unit without the proper qualications. If the

air conditioner must be repaired, consult the dealer, contractor or quali-

ed Refrigeration Engineer.

- If the unit is repaired improperly, water leakage, electric shock, or re may

result.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a ame, poisonous gases will

be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or re may

result.

4. Installing BC controller .................................................................................8

4.1. Installing BC controllers .............................................................. 8

5. Connecting refrigerant pipes and drain pipes...............................................8

5.1. Pipe connecting method .............................................................. 8

5.2. Connecting refrigerant pipes ....................................................... 9

5.3. Refrigerant piping work ............................................................. 10

5.4. Insulating refrigerant pipes ........................................................ 11

5.5. Drain piping work ...................................................................... 11

6. Electrical work ............................................................................................ 11

7. Setting addresses and operating units ....................................................... 12

8. Checklist after installation ...........................................................................12

9. Test run ....................................................................................................... 12

10. Important information to be passed on to the end users ............................ 12

• Have all electric work done by a licensed electrician according to “Electric Facility Engineering Standard” and “Interior Wire Regulations”and

the instructions given in this manual and always use a dedicated power

supply.

- If the power source capacity is inadequate or electric work is performed

improperly, electric shock and re may result.

• Securely install the cover of control box.

- If the cover is not installed properly, dust or water may enter the outdoor

unit and re or electric shock may result.

• When installing and moving the air conditioner to another site, do not

charge it with a refrigerant different from the refrigerant specied on

the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the re-

frigerant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must be taken to prevent the refrigerant concentration from exceeding the safety

limit if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the

safety limit from being exceeded. Should the refrigerant leak and cause

the safety limit to be exceeded, hazards due to lack of oxygen in the room

could result.

• When moving and reinstalling the air conditioner, consult the dealer or

an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock,

or re may result.

• After completing installation work, make sure that refrigerant gas is not

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted

or operated forcibly, or parts other than those specied by Mitsubishi Electric are used, re or explosion may result.

• To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety against leakage

according to local regulation or standards.

- Choose the appropriate wire size and the switch capacities for the main

power supply described in this manual if local regulations are not available.

• Pay special attention to the place of installation, such as basement, etc.

where refrigeration gas can accumulate, since refrigerant is heavier

than the air.

1.2. Precautions for devices that use

R410A refrigerant

Caution:

• Do not use existing refrigerant piping.

- The old refrigerant and refrigerant oil in the existing piping contains a large

amount of chlorine which may cause the refrigerant oil of the new unit to

deteriorate.

- R410A is a high-pressure refrigerant and can cause the existing piping to

burst.

• Use refrigerant piping made of phosphorus deoxidized copper and

copper alloy seamless pipes and tubes. In addition, be sure that the

inner and outer surfaces of the pipes are clean and free of hazardous

sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or any other

contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refrig-

erant residual oil to deteriorate.

2

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor failure may result.

• Apply a small amount of ester oil, ether oil, or alkyl benzene to ares. (for

indoor unit)

- Inltration of a large amount of mineral oil may cause the refrigerant oil to

deteriorate.

• Use liquid refrigerant to ll the system.

- If gas refrigerant is used to ll the system, the composition of the refriger-

ant in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R410A.

- If another refrigerant (R22, etc.) is mixed with R410A, the chlorine in the

refrigerant may cause the refrigerant oil to deteriorate.

• Use a vacuum pump with a reverse ow check valve.

- The vacuum pump oil may ow back into the refrigerant cycle and cause

the refrigerant oil to deteriorate.

• Do not use the following tools that are used with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse ow check

valve, refrigerant charge base, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerant oil are mixed in the R410A,

the refrigerant may deteriorate.

- If water is mixed in the R410A, the refrigerant oil may deteriorate.

- Since R410A does not contain any chlorine, gas leak detectors for conven-

tional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Do not use antioxidant or leak-detection additive.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets into the refrigerant cycle, the refrigerant may de-

teriorate.

1.3. Before installation

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can signicantly reduce the performance of

the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufcient protection against noise.

- Inverter equipment, private power generator, high-frequency medical

equipment, or radio communication equipment may cause the air conditioner to operate erroneously, or fail to operate. On the other hand, the

air conditioner may affect such equipment by creating noise that disturbs

medical treatment or image broadcasting.

• Do not install the unit on or over things that are subject to water damage.

- When the room humidity exceeds 80 % or when the drain pipe is clogged,

condensation may drip from the indoor unit or BC controller. Perform collective drainage work together with the outdoor unit, as required.

1.4. Before installation (relocation) - electrical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a re.

• Install a leak circuit breaker, as required.

- If a leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufcient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a re.

• Use only a circuit breaker and fuse of the specied capacity.

- A fuse or circuit breaker of a larger capacity, or the use of substitute simple

steel or copper wire may result in a general unit failure or re.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury or property damage.

• Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage causing damage to furni-

ture and other possessions.

• Be very careful about transporting the product.

- One person should not carry the product. Its weight is in excess of 20 kg

[45 LBS].

- Some products use PP bands for packaging. Do not use any PP bands as

a means of transportation. It is dangerous.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may

cause stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which has not been torn

apart, they face the risk of suffocation.

1.5. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch

can result in irreversible damage to internal parts. Keep the power switch

turned on during the operational season.

• Do not touch the switches with wet ngers.

- Touching a switch with wet ngers can result in an electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes may be hot or

cold, depending on the condition of the refrigerant owing through the refrigerant piping, compressor, and other refrigerant cycle parts. Your hands

may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least 5 minutes before turning off the power. Otherwise,

drainage water leakage or mechanical failure of sensitive parts may occur.

GB

2. Items to be used

2.1. Package contents

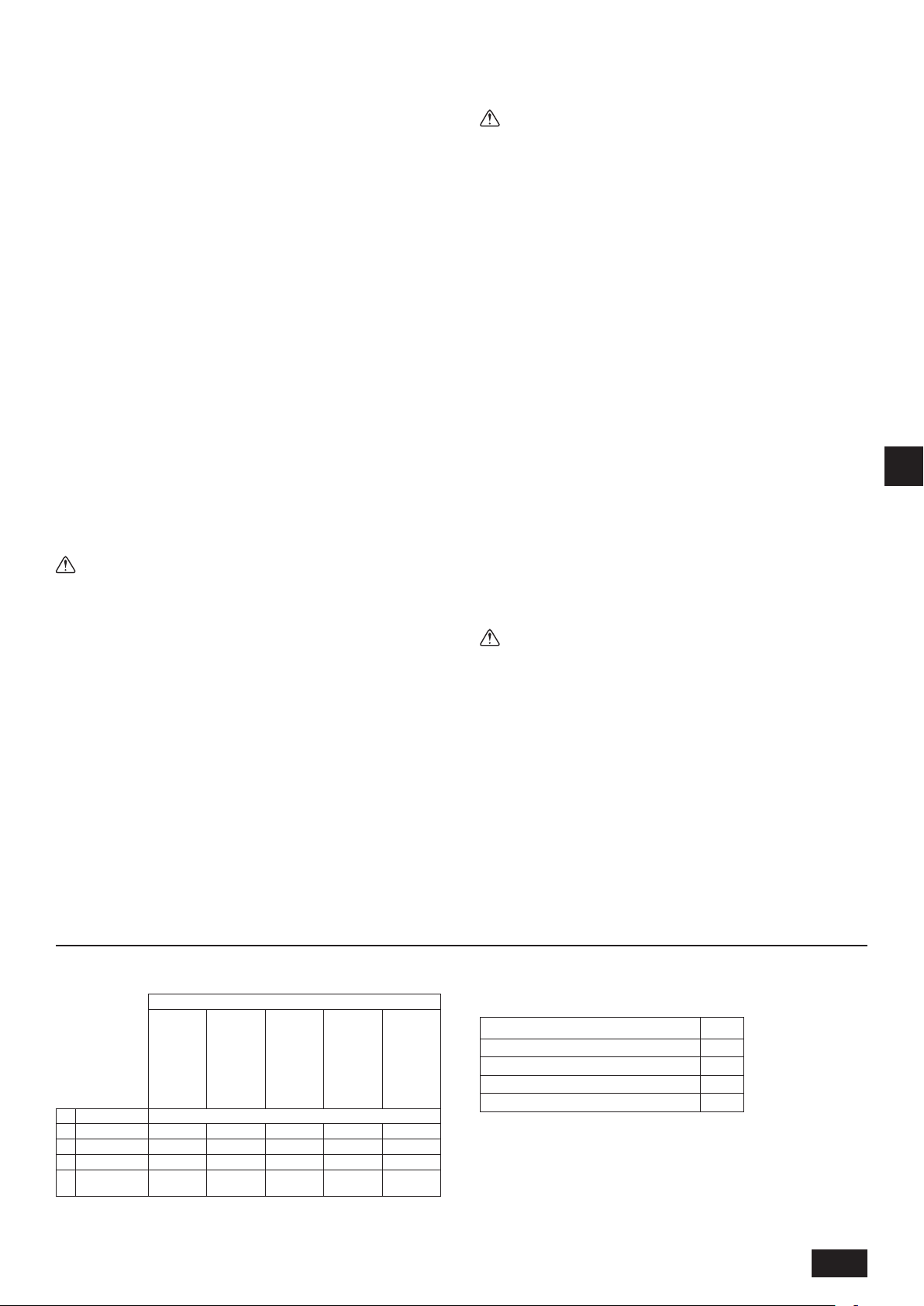

The table below lists all the items and their quantities included in the package.

CMBP104NU-G1

P105NU-G1

P106NU-G1

P108NU-G1

P1010NU-G1

P1013NU-G1

Item Qty

Drain hose 1 1 1 1 1

1

Tie band 1 1 1 1 1

2

Hose band 1 1 1 1 1

3

Refrigerant

4

connection pipe

P1016NU-G1

CMBP108NU-GA1

P1010NU-GA1

P1013NU-GA1

P1016NU-GA1

3 3 8 1 8

Model name

CMBP104NU-GB1

P108NU-GB1

CMBP108NU-HA1

P1010NU-HA1

P1016NU-HA1

CMBP1016NU-HB1

2.2. Commercially available items

The table below lists the items not included in the package but required for installation, and their required quantity.

Hanging bolt ø10 or Anchor bolt M10 4

Nut 4

Washer 8

Double nuts 4

Insulating material 1

3

3. Selecting an installation site

200

]

3.1. About the product

• This unit uses R410A-type refrigerant.

• Piping for systems using R410A may be different from that for systems us-

ing conventional refrigerant because the design pressure in systems using

R410A is higher. Refer to the Data Book for more information.

• Some of the tools and equipment used for installation with systems that use

other types of refrigerant cannot be used with the systems using R410A. Refer to the Data Book for more information.

• Do not use the existing piping, as it contains chlorine, which is found in

conventional refrigerating machine oil and refrigerant. This chlorine will deteriorate the refrigerant machine oil in the new equipment. The existing piping

must not be used as the design pressure in systems using R410A is higher

than that in the systems using other types of refrigerant and the existing

pipes may burst.

3.2. Installation site

• Install the unit in a place not exposed to rain. The BC controller is designed

to be installed indoors.

• Install the unit with adequate space around it for servicing.

• Do not install the unit in a place that would result in the piping length restric-

tions being exceeded.

• Install the unit in a place not exposed to direct radiant heat from other heat

sources.

• Do not install the unit in any oily steamy place or near any machine that generates high frequencies. Doing so may cause a risk of re, erroneous opera-

tion or dew drop.

• Install the unit in a location where the noise from the unit will not be a prob-

GB

lem. (Install indoor unit and BC controller at least 5 m [16-3/8 ft] away from

each other when installed in a space with low background noise, e.g., hotel

rooms).

• Allow enough space and access to ensure water piping, refrigerant piping

and electrical wiring can be easily connected.

• Avoid places exposed to the generation, inow, accumulation or leakage of

ammable and sulfuric gases.

• Ensure a downward gradient of at least 1/100 for drain piping.

• Properly install the unit on a stable, load-bearing surface.

• Some combination of BC controller and outdoor unit cannot be used.

Refer to the table below for details.

Combination of BC controller and outdoor unit

Outdoor unit

G type GA type GB type HA type HB type

P72 to P126 A A A A A

P127 to P240 N/A A A A A

P241 to P288 N/A N/A A A A

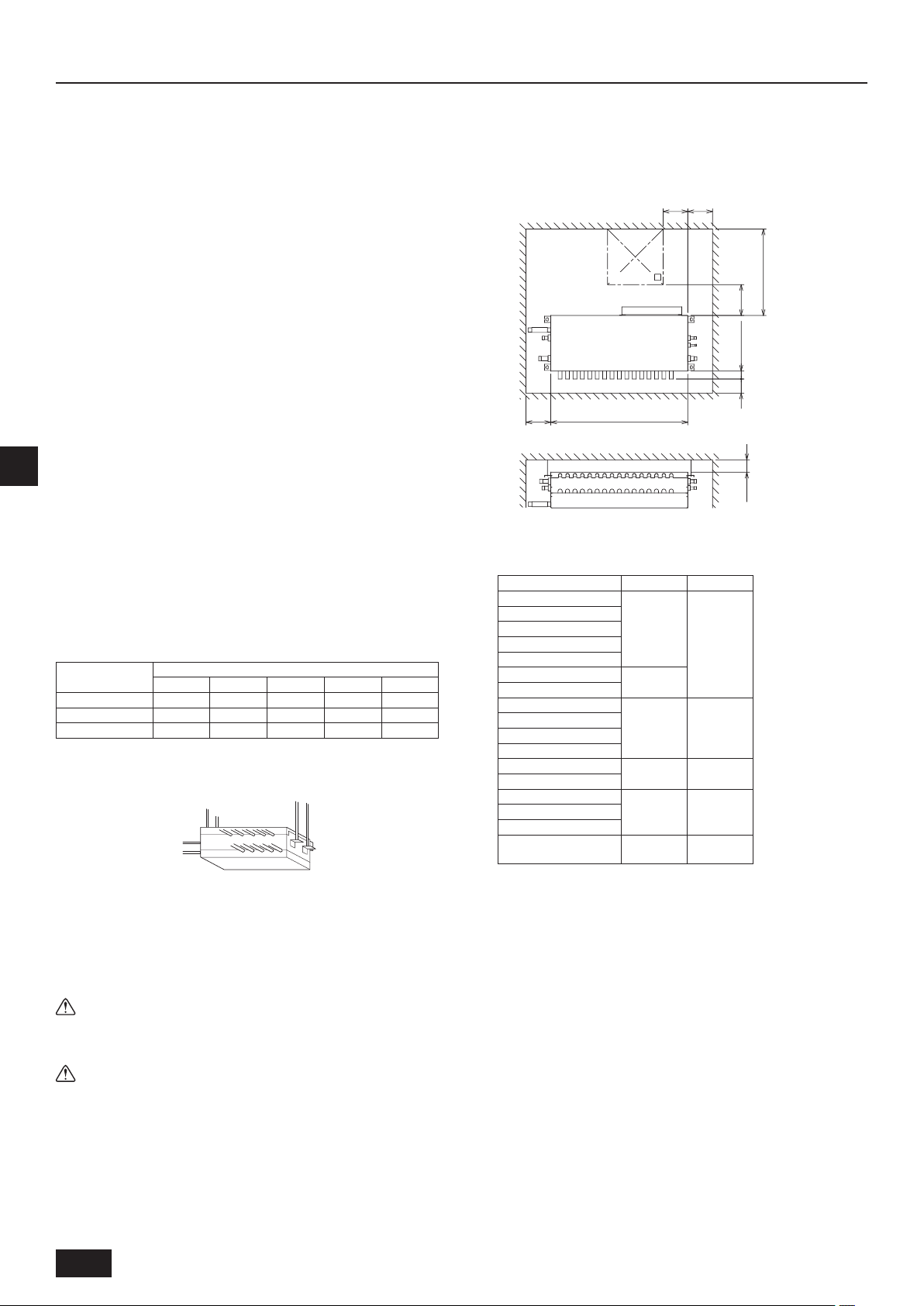

1. For hanging from the ceiling

[Fig. 3.2.1]

BC controller

A:available N/A:Not available

3.3. Securing installation and service

space

1. For hanging from the ceiling

(This is a reference view showing the least installation space.)

[Fig. 3.3.1] (Unit: mm [in])

<Top view>

450 (17-23/32)

B

D

INDOOR UNIT SIDE

200

[7-7/8]

<Front view>

B

Inspection hole

A

Control box

C

A

*1 Dimensions with which pipe connection can be handled at site

Model name A B

CMB-P104NU-G1

CMB-P105NU-G1

CMB-P106NU-G1

CMB-P108NU-G1

CMB-P1010NU-G1

CMB-P1013NU-G1

CMB-P1016NU-G1

CMB-P108NU-GA1

CMB-P1010NU-GA1

CMB-P1013NU-GA1

CMB-P1016NU-GA1

CMB-P104NU-GB1

CMB-P108NU-GB1

CMB-P108NU-HA1

CMB-P1010NU-HA1

CMB-P1016NU-HA1

CMB-P1016NU-HB1

[7-7/8]

A

C

648

[25-17/32]

1098

[43-1/4]

1110

[43-23/32]

648

[25-17/32]

1110

[43-23/32]

1098

[43-1/4]

B

[27-9/16]

(700)

250

9-27/32

[9-27/32]

[2-17/32][2-17/32]

64*1

100

[3-15/16]

On the side of outdoor unit piping

B

On the side of indoor unit piping

D

-

200

[7-7/8]

-

200

[7-7/8]

-

• Provide an inspection hole 450 mm [17-23/32 in] square in the ceiling surface as shown in [Fig.3.2.1].

• Install the unit in a suitable location (such as in the ceiling of a corridor or in

the bathroom etc) away from places regularly occupied. Avoid installing in

the center of a room.

• Ensure a pull out strength of at least 60 kg [133 LBS] per bolt for hanging

bolts.

• Be sure to install BC controllers level.

Warning:

Be sure to install the unit in a place that can sustain the entire weight.

If there is a lack of strength, it may cause the unit to fall down, resulting in

an injury.

Caution:

Be sure to install the unit level.

4

Loading...

Loading...