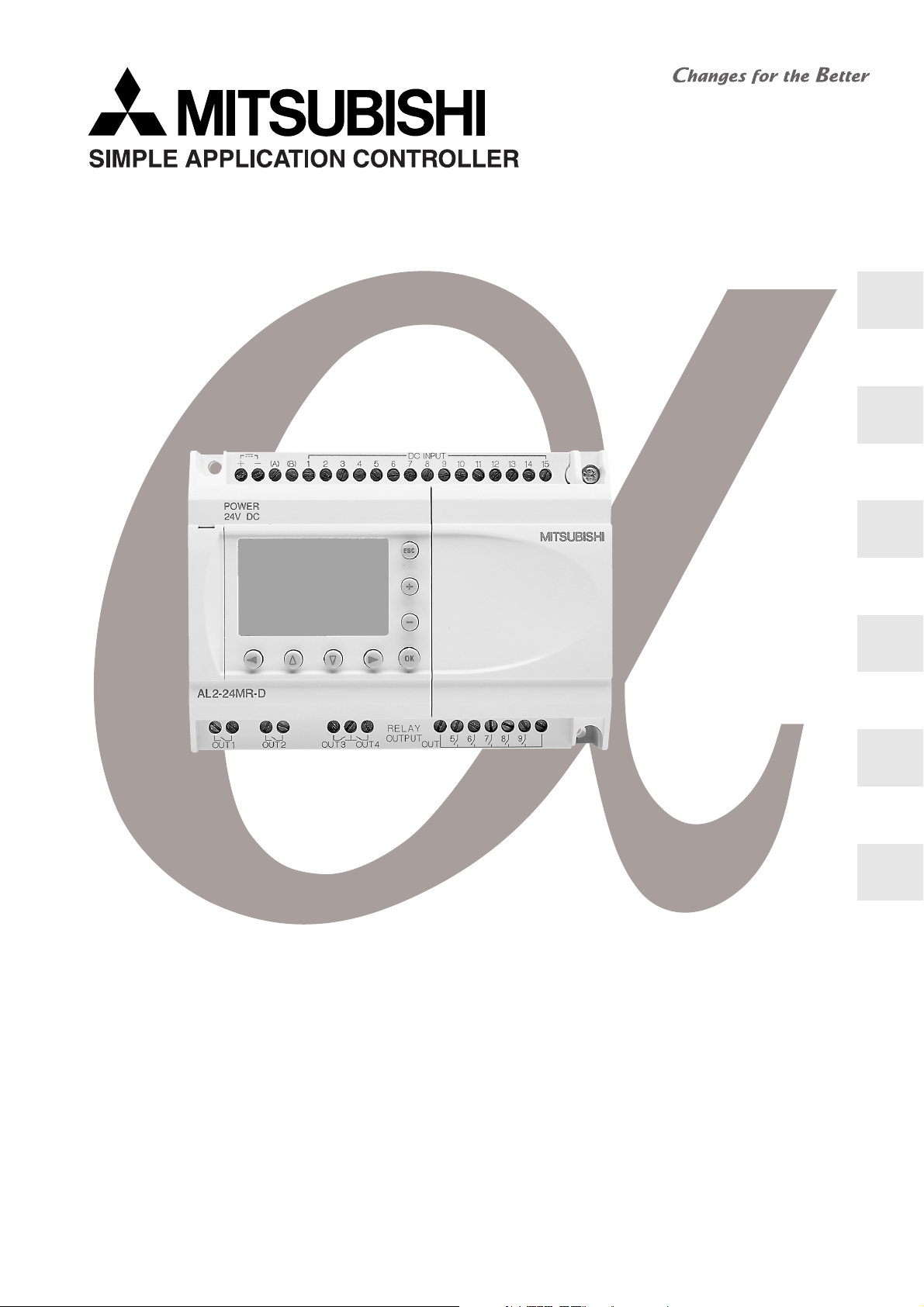

Page 1

ENG

GER

FRE

ITL

α

2 Simple Application Controller

HARDWARE MANUAL

HARDWARE-HANDBUCH

MANUEL DU MATÉRIEL

MANUALE HARDWARE

MANUAL DE HARDWARE

ESP

SWE

MASKINVARUHANDBOK

Page 2

α

2 Simple Application Controllers

Foreword

• This manual contains text, diagrams and explanations which will guide the reader in the correct installation,

safe use and operation of the

use the unit.

α

2 series and should be read and understood before attempting to install or

• If in doubt at any stage of the installation of the

who is qualified and trained to the local and national standards. If in doubt about the operation or use of the

a series controller please consult the nearest Mitsubishi Electric distributor.

• This manual is subject to change without notice.

α

2 series always consult a professional electrical engineer

Page 3

2 Simple Application Controller

α

2 Simple Application Controller

α

Hardware Manual

ENG

Manual number: JY992D97301

Manual revision: B

Date: 06/2002

ENG-i

Page 4

2 Simple Application Controller

α

ENG-ii

Page 5

α

2 Simple Application Controller

FAX BAC K

Mitsubishi has a world wide reputation for its efforts in continually developing and pushing back

the frontiers of industrial automation. What is sometimes overlooked by the user is the care

and attention to detail that is taken with the documentation. However, to continue this process

of improvement, the comments of the Mitsubishi users are always welcomed. This page has

been designed for you, the reader, to fill in your comments and fax them back to us. We look

forward to hearing from you.

Fax numbers: Your name....................................................

Mitsubishi Electric.... .....................................................................

America (01) 847-478-2253 Your company ..............................................

Australia (02) 638-7072 .....................................................................

Germany (0 21 02) 4 86-11 20 Your location: ...............................................

Spain (0 34) 93 589-1579 .....................................................................

United Kingdom (01707) 278-695

ENG

Please tick the box of your choice

What condition did the manual arrive in?

Will you be using a folder to store the manual?

What do you think to the manual presentation?

Are the explanations understandable?

Which explanation was most difficult to understand: ..................................................................

....................................................................................................................................................

Are there any diagrams which are not clear?

If so,which:..................................................................................................................................

What do you think to the manual layout?

If there one thing you would like to see improved, what is it?.....................................................

....................................................................................................................................................

....................................................................................................................................................

Could you find the information you required easily using the index and/or the contents, if

possible please identify your experience: ...................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Good

Yes No

Tidy Unfriendly

Yes Not too bad Unusable

Yes No

Good

Minor damage

Not too bad

Unusable

Unhelpful

Do you have any comments in general about the Mitsubishi manuals?.....................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Thank you for taking the time to fill out this questionnaire. We hope you found both the product

and this manual easy to use.

ENG-iii

Page 6

2 Simple Application Controller

α

ENG-iv

Page 7

2 Simple Application Controller

α

Guidelines for the Safety of the User and Protection of equipment

This manual provides information for the use of theα2 Series Controllers. The manual has

been written to be used by trained and competent personnel. The definition of such a person

or persons is as follows;

a) Any engineer who is responsible for the planning, design and construction of automatic

equipment using the product associated with this manual should be of a competent

nature, trained and qualified to the local and national standards required to fulfill that

role. These engineers should be fully aware of all aspects of safety with regards to

automated equipment.

b) Any commissioning or service engineer must be of a competent nature, trained and

qualified to the local and national standards required to fulfill that job. These engineers

should also be trained in the use and maintenance of the completed product. This

includes being completely familiar with all associated documentation for the said

product. All maintenance should be carried out in accordance with established safety

practices.

c) All operators of the completed equipment should be trained to use that product in a safe

and coordinated manner in compliance to established safety practices. The operators

should also be familiar with documentation which is connected with the actual operation

of the completed equipment.

ENG

Note :

NotesontheSymbolsUsedinthisManual

At various times through out this manual certain symbols will be used to highlight points of

information which are intended to ensure the users personal safety and protect the integrity of

equipment. Whenever any of the following symbols are encountered its associated note must

be read and understood. Each of the symbols used will now be listed with a brief description of

its meaning.

Hardware Warnings

Software Warnings

The term ‘completed equipment’ refers to a third party constructed device which

contains or uses the product associated with this manual.

1) Indicates that the identified danger

2) Indicates that the identified danger could

damage.

3) Indicates a point of further interest or further explanation.

4) Indicates special care must be taken when using this element of software.

WILL

cause physical and property damage.

POSSIBLY

cause physical and property

5) Indicates a special point which the user of the associate software element should

be aware of.

6) Indicates a point of interest or further explanation.

ENG-v

Page 8

2 Simple Application Controller

α

• Under no circumstances will Mitsubishi Electric be liable or responsible for any

consequential damage that may arise as a result of the installation or use of this equipment.

• All examples and diagrams shown in this manual are intended only as an aid to

understanding the text, not to guarantee operation. Mitsubishi Electric will accept no

responsibility for actual use of the product based on these illustrative examples.

• Owing to the very great variety in possible application of this equipment, you must satisfy

yourself as to its suitability for your specific application.

Further Information Manual Lists

Manual Name Manual No. Description

α

2 Hardware Manual

(This manual)

α2 Programming Manual

<English only>

JY992D97301

JY992D97101

This manual contains hardware explanations for

wiring, installation and specification for

Series controllers.

This manual contains instruction explanations for

α

the

2 Series controllers.

α2

α

Software Manual

<English only>

α

2 Series Communication

User’s Manual

<English only>

α

2 Series Installation Manual

AL2-4EX, AL2-4EX-A2,

AL2-4EYR, AL2-4EYT

Installation Manual

AL2-EEPROM-2

Hardware Manual

AL-232CAB

Hardware Manual

AL2-GSM-CAB

Hardware Manual

AL-ASI-BD, AL2-ASI-BD

Hardware Manual

Refer to these manuals.

JY992D74001

JY992D97701

JY992D97501

JY992D97401

JY992D96801

JY992D76001

JY992D97201

JY992D81401

This manual contains explanations of operation

of AL-PCS/WIN-E Programming Software.

This manual contains explanations for the setup,

messaging, diagnostics, bit assignments, etc for

communications using the

This manual contains hardware explanations of

α

installation for

This manual contains hardware explanations of

installation for AL2-4EX, AL2-4EX-A2, AL24EYR and AL2-4EYT extension module.

This manual contains hardware explanations of

installation for AL2-EEPROM-2.

This manual contains hardware explanations of

installation for AL-232CAB.

This manual contains hardware explanations of

installation for AL2-GSM-CAB.

This manual contains hardware explanations of

wiring, installation and specification, etc. for ALASI-BD and AL2-ASI-BD.

2 Series controller.

α

2 series controller.

Refer to this manual if necessary.

Refer to the content of these manuals if necessary though it is included in

Manual.

α

2 Hardware

ENG-vi

Page 9

2 Simple Application Controllers

α

Table of Contents

Guidelines of Safety....................................................................ENG-v

1. Introduction......................................................................................ENG-1

1.1 Special Features of theα2 Series System.................................................... ENG-2

1.2 Available Models ........................................................................................... ENG-3

1.3 Dimensions and Each Part Name ................................................................. ENG-4

1.4 System Configuration .................................................................................... ENG-5

1.5 Applicable Programming Software ................................................................ ENG-5

2. Specifications ..................................................................................ENG-7

2.1 Power Supply Specification ........................................................................... ENG-7

2.2 Input Specification ........................................................................................ ENG-8

2.3 Output Specification .................................................................................... ENG-10

2.4 General Specification .................................................................................. ENG-11

ENG

3. Installation .....................................................................................ENG-13

3.1 Installation Mounting Notes ......................................................................... ENG-13

3.2 DIN RAIL Mounting of Main Unit ................................................................. ENG-14

3.2.1 Installation ......................................................................................................... ENG-14

3.2.2 Remove ............................................................................................................. ENG-14

3.3 Direct Mounting of Main Unit ....................................................................... ENG-15

3.4 Install Extension Module.............................................................................. ENG-15

4. Wiring ............................................................................................ENG-17

4.1 Installation Wiring Notes.............................................................................. ENG-17

4.2 Wire Size ..................................................................................................... ENG-18

4.3 Power Supply .............................................................................................. ENG-19

4.4 AC Power Supply and Input Wiring ............................................................. ENG-20

4.4.1 AC Power Supply and Input Wiring ................................................................... ENG-20

4.4.2 AL2-4EX-A2 Input Wiring .................................................................................. ENG-20

4.5 DC Power Supply and Input Wiring ............................................................. ENG-21

4.5.1 DC Power Supply and Source (“+” Common) Input Wiring Diagram ................ ENG-21

4.5.2 AL2-4EX Source (“+” Common) Input Wiring Diagram ..................................... ENG-21

4.5.3 DC Power Supply and Sink (“-” Common) Input Wiring Diagram...................... ENG-22

4.5.4 AL2-4EX Sink (“-” Common) Input Wiring Diagram........................................... ENG-22

4.6 Output Relay and Transistor Wiring ............................................................ ENG-23

4.6.1 Relay Output Wiring Diagram main unit (AC and/or DC) .................................. ENG-23

4.6.2 Relay Output Wiring Diagram AL2-4EYR (AC and/or DC) ................................ ENG-24

4.6.3 Transistor Output (Source or “+”CommonOnly) Wiring Diagram AL2-4EYT... ENG-25

5. Terminal Layout............................................................................ENG-27

6. AL2-EEPROM-2............................................................................ENG-29

6.1 Installation ................................................................................................... ENG-30

ENG-vii

Page 10

2 Simple Application Controllers

α

7. AL-232CAB ...................................................................................ENG-31

7.1 Introduction.................................................................................................. ENG-31

7.1.1 External Dimensions ......................................................................................... ENG-31

7.2 Connected to AL-232CAB cable.................................................................. ENG-32

8. AL2-GSM-CAB..............................................................................ENG-35

8.1 Introduction.................................................................................................. ENG-35

8.1.1 External Dimensions ......................................................................................... ENG-35

8.1.2 System Configuration with using AL2-GSM-CAB.............................................. ENG-36

8.2 Installation ................................................................................................... ENG-37

8.3 Remote Maintenace with a Modem ............................................................. ENG-39

8.3.1 Recommended Modems ................................................................................... ENG-39

8.3.2 RS-232C Straight Cable Between Modem and AL2-GSM-CAB........................ ENG-39

8.3.3 Modem Setting .................................................................................................. ENG-40

9. AL2-ASI-BD...................................................................................ENG-43

9.1 Introduction.................................................................................................. ENG-43

9.1.1 External Dimensions ......................................................................................... ENG-43

9.1.2 System Configuration ........................................................................................ ENG-44

9.2 Specifications .............................................................................................. ENG-44

9.3 Wiring & Installation..................................................................................... ENG-45

9.3.1 Installation ......................................................................................................... ENG-45

9.3.2 Wiring ................................................................................................................ ENG-46

9.4 Slave Address Setting & Diagnostics .......................................................... ENG-46

9.4.1 Setting Slave Address ....................................................................................... ENG-46

9.4.2 Applicable Error checks..................................................................................... ENG-46

10.Key, System Bit and Function Block Lists ....................................ENG-47

10.1 Key Lists ...................................................................................................... ENG-47

10.2 System Bit Lists ........................................................................................... ENG-48

10.2.1 System Bit Lists................................................................................................. ENG-48

10.2.2 Control Bit Lists ................................................................................................. ENG-48

10.3 Function Block Lists..................................................................................... ENG-49

11.Diagnostics...................................................................................ENG-53

11.1 Input Status Error ........................................................................................ ENG-54

11.2 Output Status Error...................................................................................... ENG-54

11.3 TOP MENU is not Displayed ....................................................................... ENG-55

11.4 Cannot enter Run Mode. ............................................................................. ENG-56

11.5 Incorrect Clock Data .................................................................................... ENG-56

11.6 The “?” appears on the Display ...................................................................ENG-56

11.7 Cannot Use an Operation Key..................................................................... ENG-57

11.8 Incorrect LCD display .................................................................................. ENG-58

11.9 Memory Cassette Is Not Working Correctly................................................. ENG-58

11.10Cannot Communicate with the AS-interface Master Module ...................... ENG-59

11.11Cannot Communicate with AL-PCS/WIN-E. ............................................... ENG-60

ENG-viii

Page 11

α

2 Simple Application Controllers

1. Introduction

Theα2 series can be easily used in all places where control is needed for the home, office, or

factory. The controller outputs cycle ON/OFF to control electrical equipment per the Function

Block program.

The explanation of the instructions and the operation of main unit can be found in

Programming Manual. An explanation of the AL-PCS/WIN-E programming software can be

found in the

Applications

α

The

- Automation of lights, air-conditioning, or watering systems

- The opening and shutting of gates

- Easy security systems

- Domestic animal and pet food distribution systems

- Control of stockyards and greenhouses

α

Series Software Manual.

2 series is designed to be used in automatic applications including those listed below.

Introduction 1

α

2

ENG

α

However, the

a Mitsubishi distributor for more information.

- Applications where high reliabilities such as nuclear power control, railway facilities,

airline facilities, vehicles, combustion equipment, and medical equipment are required.

- Applications in life critical situations.

2seriesisnotdesignedtobeusedinthefollowingapplications.Pleasecontact

ENG-1

Page 12

α

2 Simple Application Controllers

1.1 Special Features of theα2SeriesSystem

1) Display message and Function Block data

α

The

message. It can display the following contents by the using display function block. The

value of displayed timers and counters can be changed in the RUN mode.

- Total characters on LCD display: 12 characters×4 lines

- Display Items: Message, value (current or set) of timer and counter, analog values, etc

2) The programming in the personal computer is fast and easy

The programming software AL-PCS/WIN-E for Windows can make and save programs.

The programming can be done using a pictorial method in which lines are used to connect

function blocks on a programming screen.

Direct programming using the

3) LCD image send via GSM modem

The

can monitor application status by accessing the diagnostic message sent as an E-mail via

GSM modem

2 series can display the state of operation and the alarm on the LCD display as a

α

2 controller front panel keys is also available.

α

2 series is able to send the LCD image as an E-mail using a GSM modem. The user

Introduction 1

4) Supports computer link using dedicated protocol

α

The

software using computer link (dedicated protocol) can change schedule data, parameters

within Function Blocks and provide condition monitoring of the application.

5) Enhancement of clock function

The weekly timer and the calendar timer function have many switches that can be set and

provide powerful time dependant control capabilities.

6) Analog input, 0 - 10V/0 - 500:

The DC input for the

7) High speed counter, Max. 1kHz

The

8) High current output capability

2 series supports computer link (dedicated protocol). User-specific application

α

2 series can accept of 0 - 10V signals with a resolution of 0 - 500.

α

2 series has high speed counters (Max. 2 points) when using AL2-4EX (EI1, EI2).

Table 1.1: High Current Output Capability

Output Type Capability

AL2-14MR-*: O01-06

Relay

Transistor AL2-4EYT: EO1-EO41A/Point

AL2-24MR-*: O01-04

AL2-24MR-*: O05-09

AL2-4EYR: EO1-EO4

8A/Common

2A/Point (4A/Common)

9) Built-in EEPROM

The built in EEPROM eliminates the need for battery backed data.

10)Supports 6 languages:

α

The

Swedish). The displayed language can be selected in the TOP MENU.

2 series supports 6 languages (English, German, French, Italian, Spanish, and

ENG-2

Page 13

α

2 Simple Application Controllers

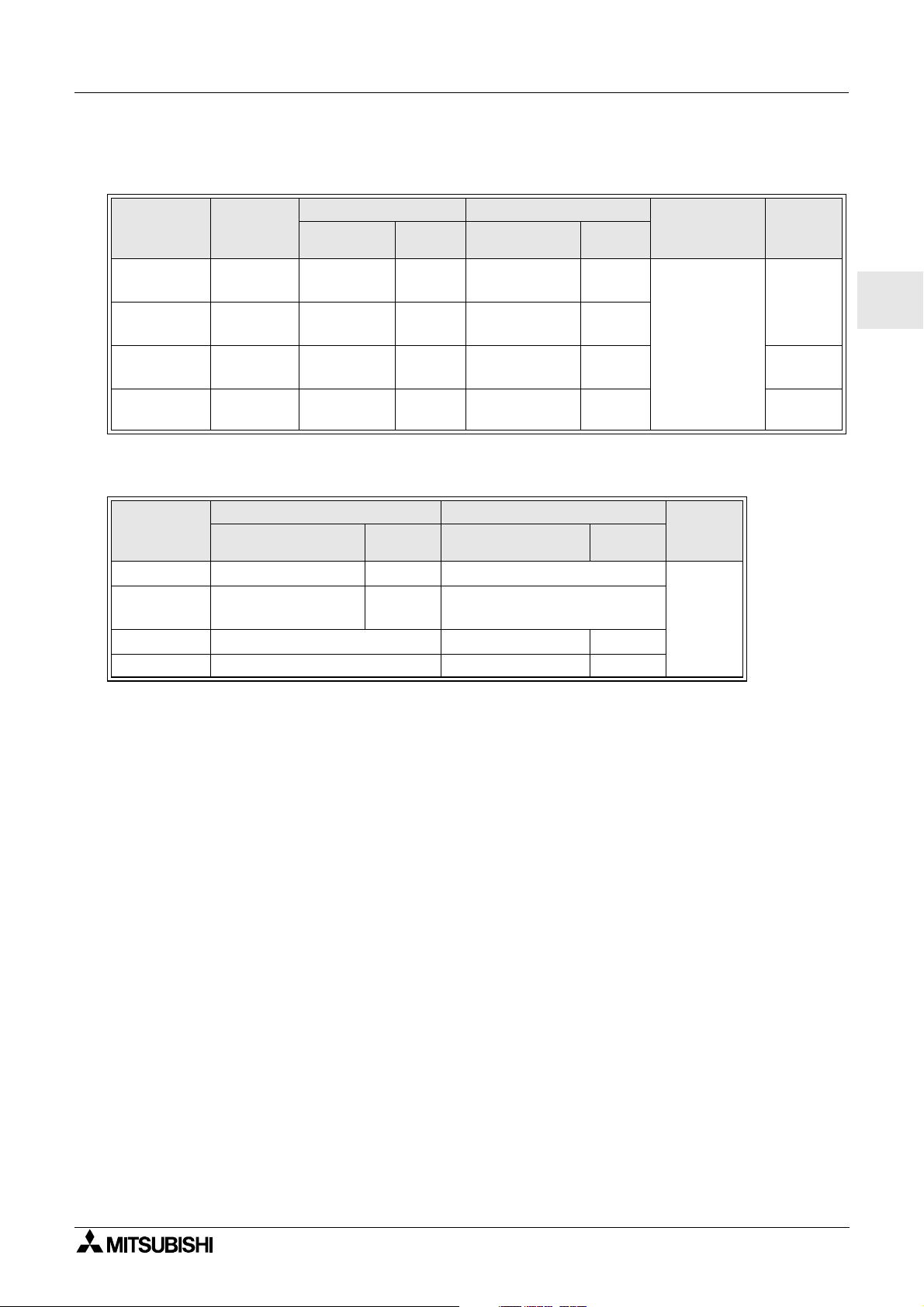

1.2 Available Models

Table 1.2:Main Units

Model

AL2-14MR-A

AL2-14MR-D 24V DC

AL2-24MR-A

AL2-24MR-D 24V DC

Power

Supply

100 - 240V

AC~

100 - 240V

AC~

100 - 240V

Sink/Source

100 - 240V

Sink/Source

*1 Without extension modules.

Table 1.3:Extension Modules

Input Output MASS

Model

AL2-4EX-A2 220 - 240V AC~ 4

AL2-4EX

AL2-4EYR RELAY 4

AL2-4EYT TRANSISTOR4

Type Number Type Number

24V DC, Sink/

Source

Input Output

Type Number Type Number

AC~

24V DC

AC~

24V DC

8RELAY6

8RELAY6

15 RELAY 9

15 RELAY 9

4

Dimensions

mm (inches)

124.6 x 90 x 52

(4.91 x 3.54

x 2.05)

(Weight)

kg (lbs)

0.05

(0.11)

Introduction 1

MASS

(Weight)

kg (lbs)

*1

0.30

(0.66)

*1

0.35

(0.77)

*1

0.30

(0.66)

ENG

ENG-3

Page 14

α

2 Simple Application Controllers

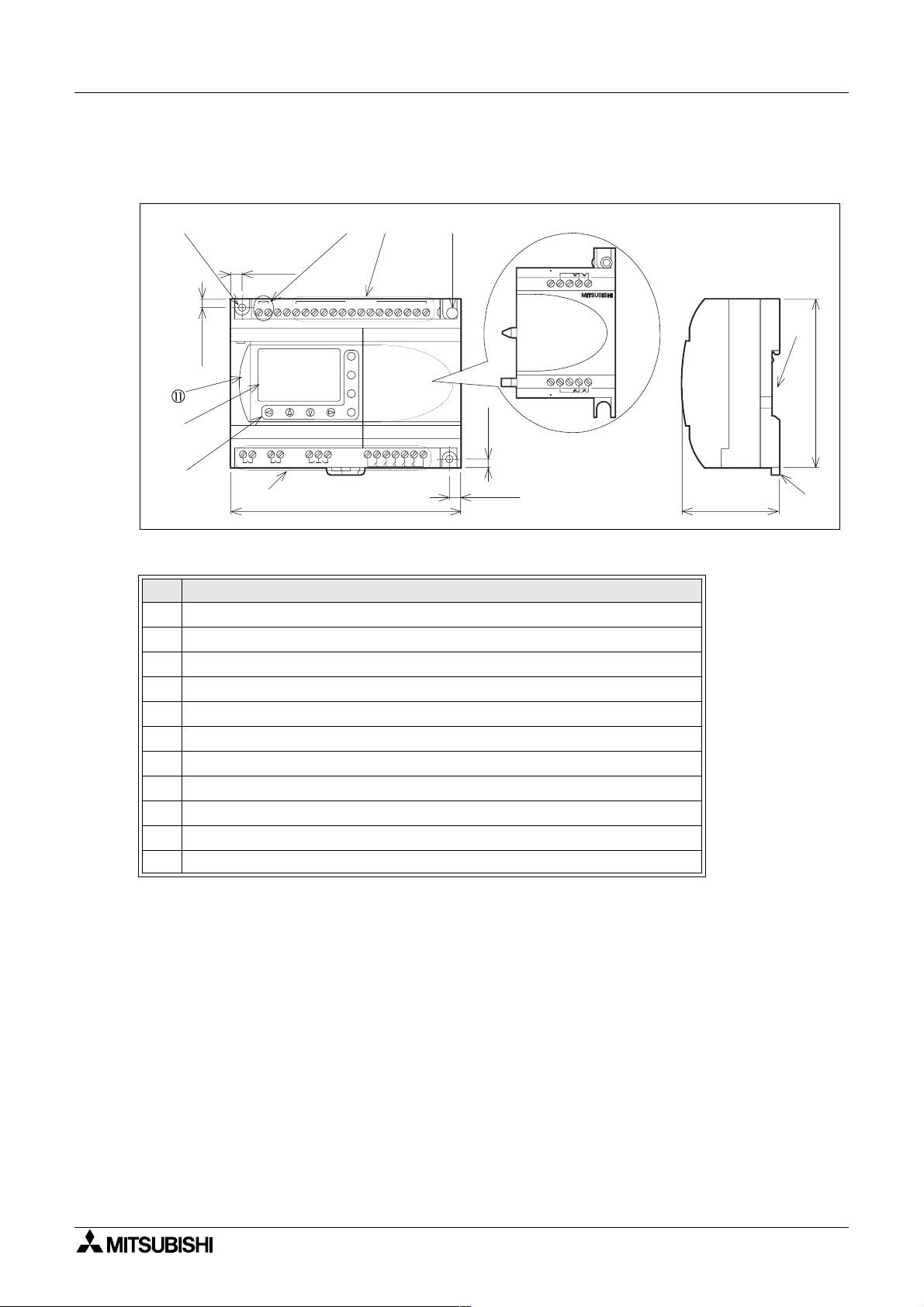

1.3 Dimensions and Each Part Name

Figure 1.1: Each Part Name

Introduction 1

6(0.24")

+-

POW ER

24V DC

4(0.16")

AL2-24MR -D

OUT1

OUT2 OUT4

D C IN P U T

ESC

+

-

OK

RELAY

OUTPUT

OUT3

124.6(4.91")

65

7

OUT

+-E01E02

151413121110987654321(B )(A )

9

8

4(0.16")

+E03-E04

6(0.24")

Table 1.4: Each Part Name

Ref. Item Description

1 Mounting hole, φ4.2 mm

2 Power terminals

3 Input terminals

4 Mounting screw for the extension cover or extension module

5 Extension cover or extension module

6 Groove for DIN rail mounting (Width of DIN rail 35mm <DIN EN 50022>)

7 DIN-RAIL mounting clips

8 Output terminals

9 Operation keys

10 Liquid crystal display

11 Programming port cover

52(2.05")

90(3.54")

ENG-4

Page 15

α

2 Simple Application Controllers

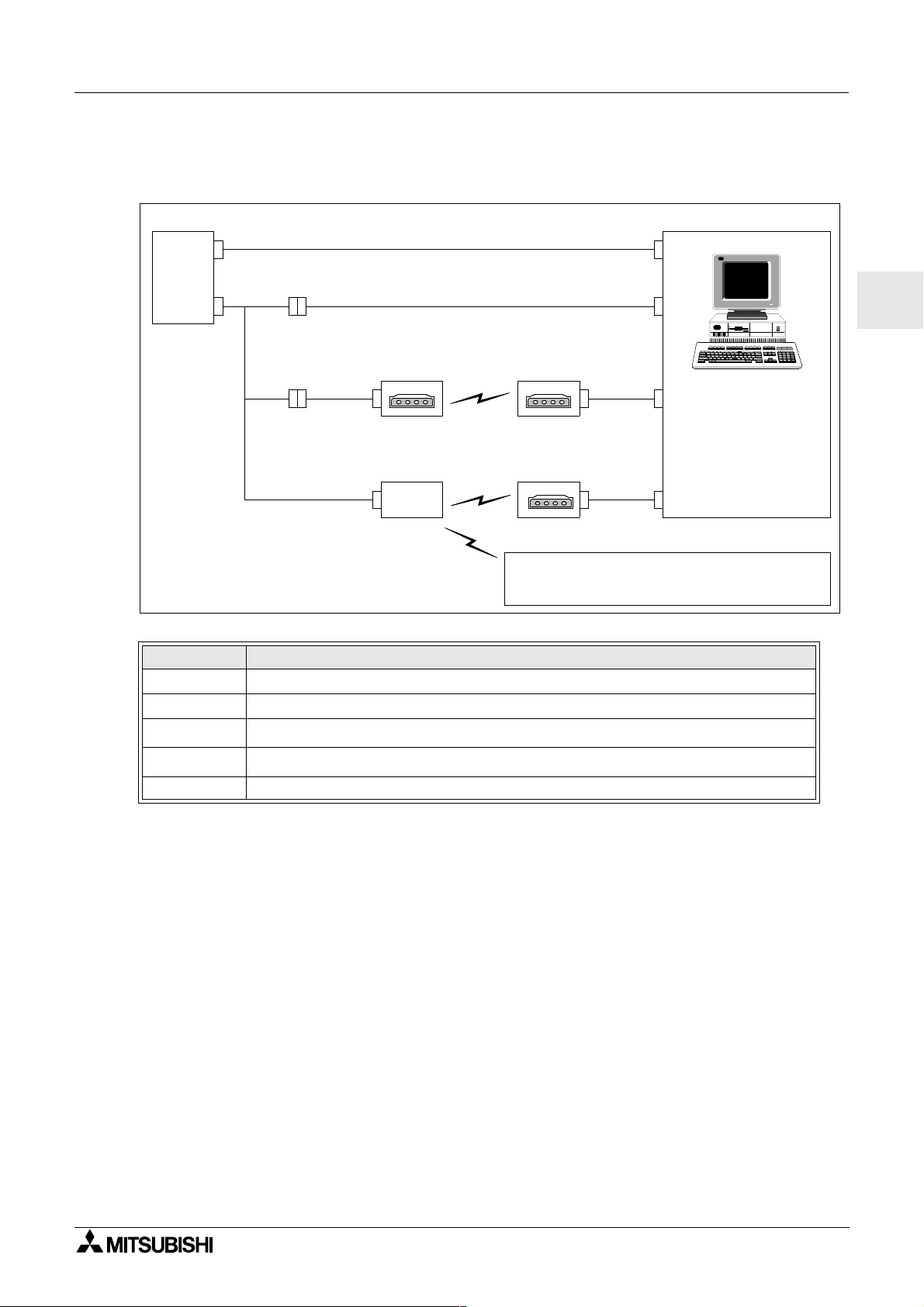

1.4 System Configuration

Figure 1.2: System Configuration

Standard Connection to the Programming Softoware

α

2

Series

Introduction 1

UsingDedicatedProtocol

ENG

Remote Maintenance (via Telephone Line)

Normal Modem Normal Modem

Remote Maintenance, e-Mail (via GSM)

Normal Modem

GSM

Modem

Personal computer

- Programming Software

(AL-PCS/WIN-E)

- Dedicated protocol

- e-Mail application

Sending SMS Message

Table 1.5: System Configuration

Item Using Cable

1 AL-232CAB

2AL2-GSM-CAB

3

4

RS-232C cross cable

RS-232C straight cable for the modem

*1

5 RS-232C straight cable for the modem (specified by Modem manufacture)

*1 Further information can be found in chapter 8.

1.5 Applicable Programming Software

Theα2 series is supported by the programming software (AL-PCS/WIN-E) V2.00 or

later. Versions lower than V2.00, do not communicate with the

Cellular Phone

(Supporting SMS message)

*1

α

2series.

ENG-5

Page 16

α

2 Simple Application Controllers

Introduction 1

MEMO

ENG-6

Page 17

α

2 Simple Application Controllers

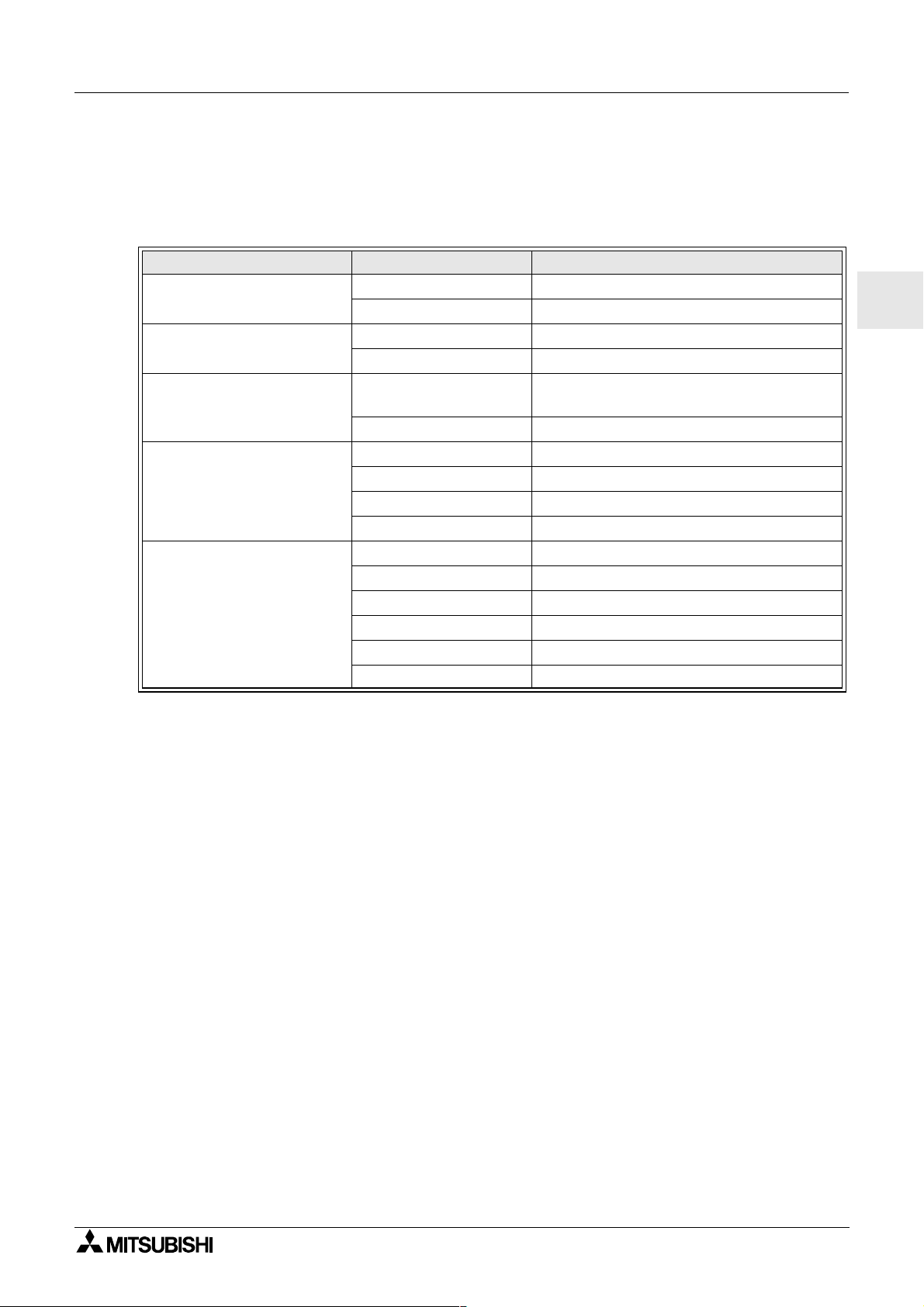

2. Specifications

2.1 Power Supply Specification

Table 2.1: Power Supply Specifications

Description Code Specification

Power Supply

Maximum Momentary Power

Failure

In-rush Current

Maximum Power

Consumption

Typical Power Consumption

(without Special Connection

Modules)

AL2-***-A 100 - 240V AC~, +10% -15%, 50/60 Hz

AL2-***-D 24V DC, +20% -15%

AL2-***-A 10ms

AL2-***-D 5ms

AL2-***-A,

240V AC~ (120V AC~)

AL2-***-D, 24V DC ≤ 7.0 A

AL2-14MR-A, 264V AC~ 5.5 W

AL2-14MR-D, 28.8V DC 7.5 W

AL2-24MR-A, 264V AC~ 7.0 W

AL2-24MR-D, 28.8V DC 9.0 W

AL2-14MR-A, 240V AC~ I/O all On-4.5W;I/O all Off - 2.0 W

AL2-14MR-A, 120V AC~ I/O all On-3.5W;I/O all Off - 1.5 W

AL2-14MR-D, 24V DC I/O all On-4.0W;I/O all Off - 1.0 W

AL2-24MR-A, 240V AC~ I/O all On-5.5W;I/O all Off - 2.5 W

AL2-24MR-A, 120V AC~ I/O all On-4.5W;I/O all Off - 2.0 W

AL2-24MR-D, 24V DC I/O all On-5.0W;I/O all Off - 1.0 W

Specifications 2

ENG

≤ 6.5 A (3.5 A)

ENG-7

Page 18

α

2 Simple Application Controllers

2.2 Input Specification

Table 2.2: AC Input Specifications

Description

Input Voltage 100 - 240V AC~, +10% -15%, 50/60 Hz

Input Current

Input Impedance ≥ 800 kΩ

OFF → ON/ ON → OFF ≥ 80V / ≤ 40V ≥ 160V / ≤ 40V

Response

Time

Isolation Circuit None Photocoupler

Operation Indication Liquid Crystal Display

OFF → ON

ON → OFF

main unit AL2-4EX-A2

I01 -I08 I09 -I15 EI1 -EI4

0.13mA / 120V AC~

0.25mA / 240V AC~

35-85ms, 120V AC~

25-55ms, 240V AC~

35-85ms, 120V AC~

50-130ms, 240V AC~

AC Input Specification

*1

0.15mA / 120V AC~

*1

0.29mA / 240V AC~

Specifications 2

220 - 240V AC~, +10% -15%,

50/60 Hz

*1

7.5mA / 240V AC~ 50Hz

*1

9.0mA / 240V AC~ 60Hz

32kΩ (50Hz)

27kΩ (60Hz)

15 - 40ms / 240V AC~

*1 Current leakage from the sensors connected to the inputs might provide enough current

to turn the controller On. Do not use two wire sensors

Table 2.3: DC Input Specifications

Description Sink(“-” Common) Source (“+”Common)

Input Voltage 24V DC +20% -15% 24V DC +20% -15%

Input

Current

main unit

I01 - I08

I09 - I15 5.5mA, 24V DC

5.5mA, 24V DC

6.0mA, 24V DC

AL2-4EX EI1 - EI4 5.4mA, 24V DC 5.4mA, 24V DC

OFF → ON/

ON → OFF

main unit I01 - I15

Current: ≥ 4.7mA / ≤ 1.1 mA

Voltage: ≤ 4V / ≥ 18V

Voltage: ≥ 18V / ≤ 4V

AL2-4EX EI1 - EI4 Voltage: ≥ 18V / ≤ 4VVoltage: ≥ 18V / ≤ 4V

Response

Time

Isolation

Circuit

main unit 10 - 20ms

AL2-4EX

*1

10 - 20ms

main unit None

AL2-4EX Photocoupler

Operation Indication Liquid Crystal Display

0

*1 EI1 and EI2 in AL2-4EX canbeusedasHighSpeedCounters.

When using the High Speed Counter function, the input response time is 0.5ms or less.

ENG-8

Page 19

α

2 Simple Application Controllers

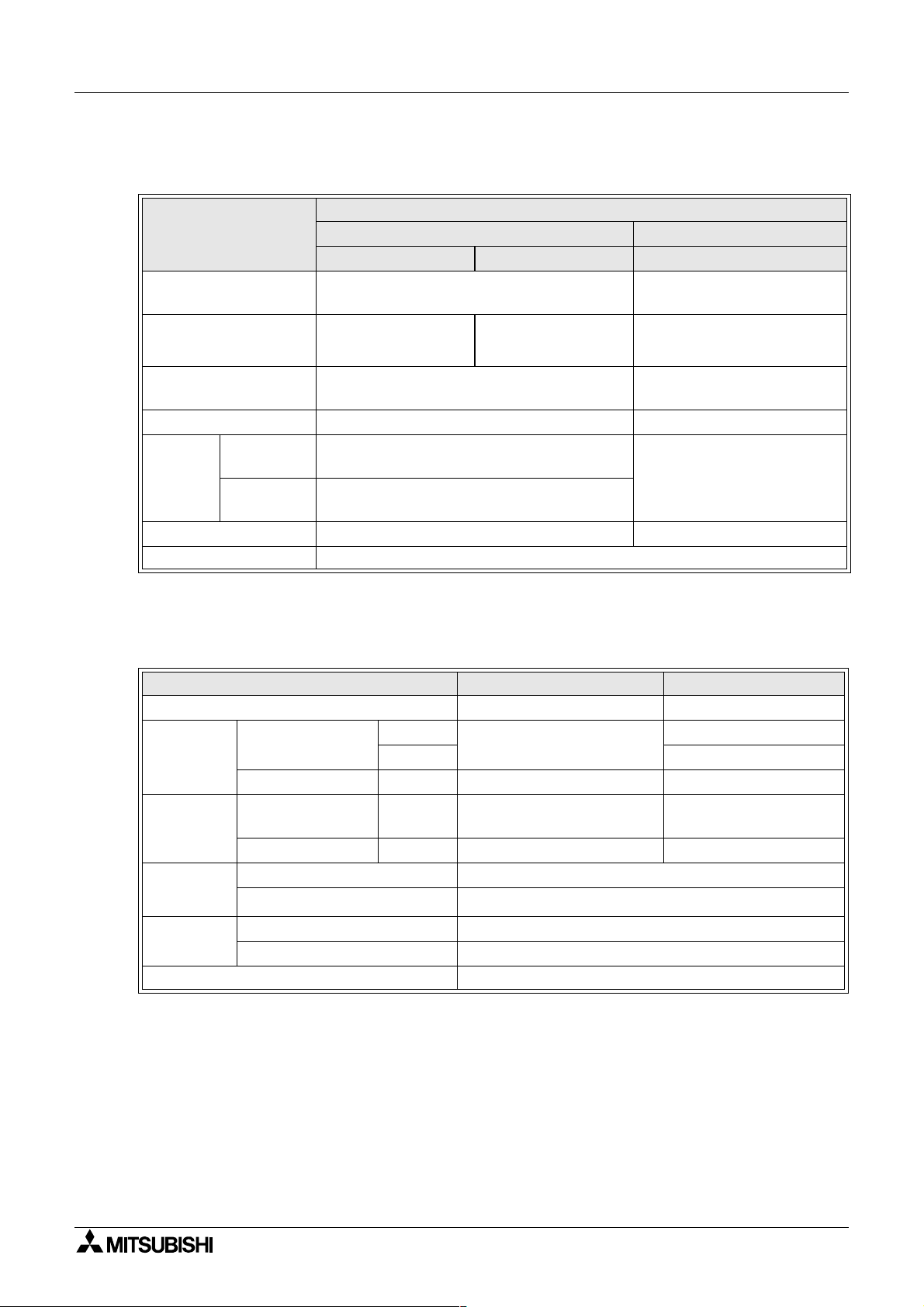

Table 2.4: Analog Input Specifications (Only AL2-***-D Type Unit)

Description Analog Input Specification

Number of Input Points 8 (I01 - I08)

Analog Input Range 0 - 500

Resolution 9 bit, 20mV (10000/ 500mv)

Conversion Speed 8ms

Input Voltage 0 - 10V DC

Input Impedance 142kΩ ± 5%

Overall Accuracy ± 5% (0.5V DC)

Offset/Gain

Temperature Drift ± 3LSB

Specifications 2

ENG

Offset Value = 0at0V DC

Gain Value: 0 - 10V=0-500

These default values can be changed in the OffsetGain FB

ENG-9

Page 20

α

2 Simple Application Controllers

2.3 Output Specification

Table 2.5: Relay Output Specifications

Description Relay Specification

Switched Voltage 250V AC~ or less, 30V DC or less

AL2-14MR-* (O01 - O06)

Max. Resistive Load

Contact Life Cycle /

Resistance Load

Minimum Load 50mW (10mA at 5V DC)

Max. Inductive Load

Response Time ≤ 10 ms

Operation Indication Liquid Crystal Display

Isolation Circuit By Relay

AL2-24MR-* (O01 - O04)

AL2-24MR-* (O05 - O09) 2A/point (4A/COM)

AL2-4EYR (EO1-EO4) 2A/point

AL2-14MR-* (O01 - O06)

AL2-24MR-* (O01 - O04)

AL2-24MR-* (O05 - O09)

AL2-4EYR (EO1-EO4)

AL2-14MR-* (O01 - O06)

AL2-24MR-* (O01 - O04)

AL2-24MR-* (O05 - O09)

AL2-4EYR (EO1-EO4)

Specifications 2

8A/COM

100,000 Cycles at 8 Amps / 240V AC~ or 24V DC

100,000 Cycles at 2 Amps / 240V AC~ or 24V DC

249 VA (1/3 hp) / 125V AC~,

373 VA (1/2 hp) / 250V AC~

93 VA(1/8hp)/125V AC~,

93 VA(1/8hp)/250V AC~

Table 2.6: Transistor Output Specifications (Source Type only) of AL2-4EYT

Description Transistor Specification

Switched Voltage 5 - 24V DC (+20%,-5%)

Max. Resistive Load 1A / point (8 - 24V DC), 0.1A / point (5 - 8V DC)

Minimum Load 1.0mA

Max. Inductive Load 1A / 24V DC (24 W)

Response Time On/Off, Off/On (approx) ≤ 1ms

Open Circuit Current Leakage ≤ 0.1mA / 24V DC

Operation Indication Liquid Crystal Display

Isolation Circuit Photocoupler

ENG-10

Page 21

α

2 Simple Application Controllers

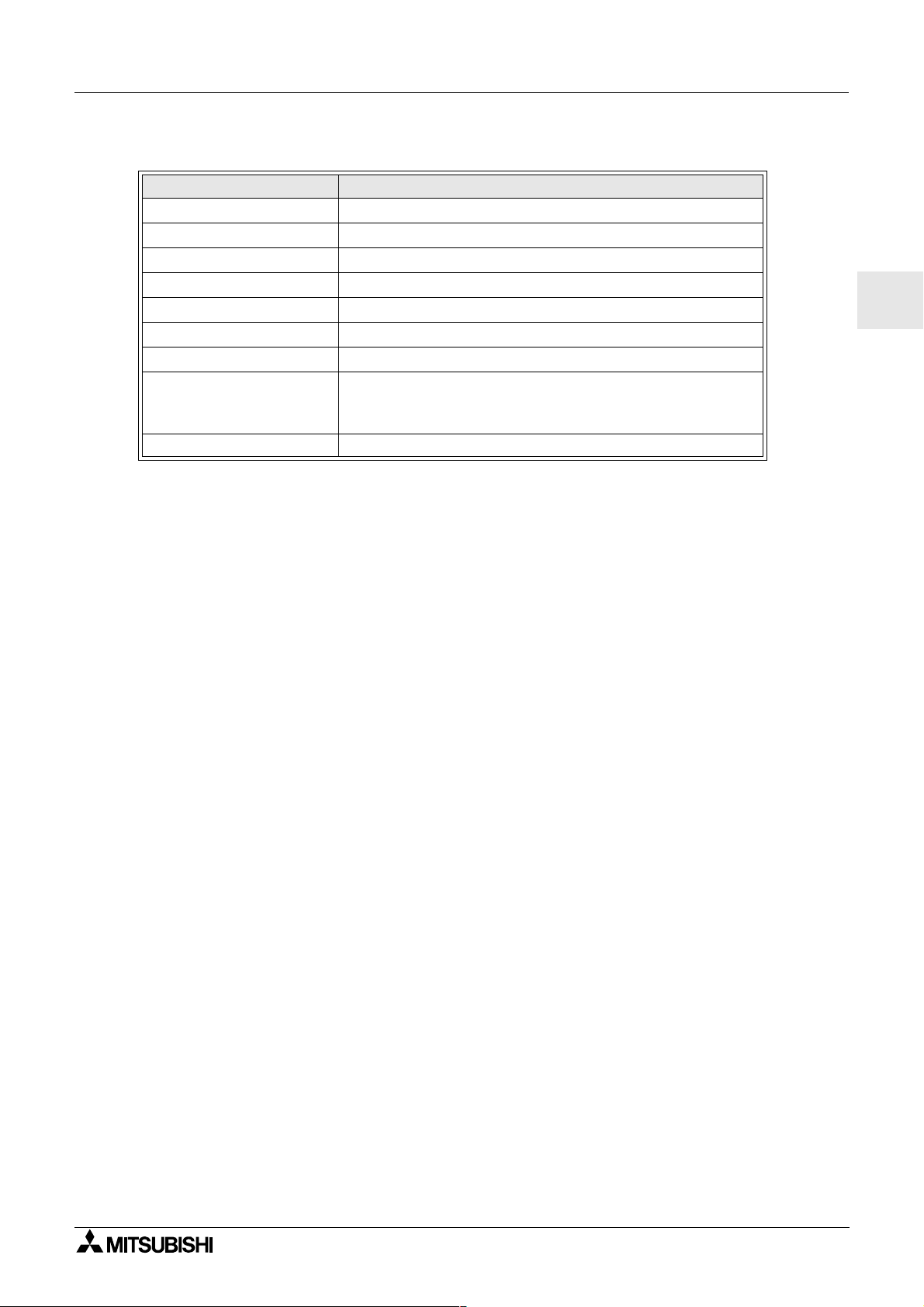

2.4 General Specification

Table 2.7: Environmental and Electrical Specifications

Description Specification

Programming Method Function Block

Program Capacity 200 Function Blocks or 5000 bytes

Program Storage

Device Backup 20 Days at 25°C / 77°F (by capacitor)

RTC Backup 20 Days at 25°C / 77°F (by capacitor)

RTC Accuracy 5 s / day (25°C / 77°F)

Operating Temperature

Storage Temperature (-30) - 70°C / (-22) - 158°F

Vibration Resistance

- Direct Mounting

Vibration Resistance

- DIN Rail mounting

Shock Resistance

Noise Immunity 1000Vpp, 1 µs, 30 - 100Hz, tested by noise simulator

Humidity 35 - 85% Relative Humidity, no condensation

Dielectric withstand

voltage

Insulation Resistance

Type of Action IEC 60730-1, Section 6.4.3 - Type 1C (Relay Output)

Type of Action IEC 60730-1, Section 6.4.3 - Type 1Y (Transistor Output)

Software Class IEC 60730-1, Section H6.18 - Class A

Purpose of Control IEC 60730-1, Section 2.2 - Electrical Control

Construction of Control IEC 60730-1, Section 6.15 - Incorporated Control

Whether the Control is

electric

Safety Class ΙΙ

Pollution Degree 2

Grounding None

Electrical Isolation Reinforced primary/secondary insulation

Operation Ambience To be free of corrosive gases. Dust should be minimal.

Protection IP 20

Specifications 2

Built in EEPROM (no battery backup required) or optional EEPROM

cassette (AL2-EEPROM-2)

Controller Hardware: (-25) - 55°C / (-13) - 101°F

Controller Display: (-10) - 55°C / 14 - 101°F

Conforms to IEC 68-2-6; 10-57Hz: 0.15mm Constant Amplitude

2

57-150Hz: 19.6m/s

Sweep Count for X,Y,Z: 10 times (80 minutes in each direction)

Conforms to IEC 68-2-6; 10-57Hz: 0.075mm Constant Amplitude

57-150Hz:9.8m/s

Sweep Count for X,Y,Z: 10 times (80 minutes in each direction)

2

Conforms to IEC 68-2-27: 147m/s

3 times in each direction X,Y, and Z

3750V AC~>1min per IEC 60730-1 between the following points:

Power/Input Terminals and Relay Output Terminals

Relay Output Terminal and Relay Output Terminal

All Terminals and the DIN 43880 Control box or equivalent

7MΩ at 500V DC per IEC60730-1 between the following points:

Power/Input Terminals and Relay Output Terminals

Relay Output Terminal and Relay Output Terminal

All Terminals and the DIN 43880 Control box or equivalent

IEC 60730-1, Section H2.5.7 - Electronic Control

Acceleration, Action Time: 11ms

Acceleration

2

Acceleration

ENG

ENG-11

Page 22

α

2 Simple Application Controllers

Table 2.7: Environmental and Electrical Specifications

Description Specification

Temperature for the Ball

Pressure Test

EC Directive EMC, LVD

Certifications UL/cUL

Attestation of Conformity TÜV PRODUCT SEVICE

Complies with

Liquid Crystal Display

*1 AL2-ASI-BD is not complied with these standards.

Specifications 2

75°C (167°F)

UL 508

IEC 60730-1

*1

*1

EN 61010-1

EN 50081-1

*1

EN 50082-1

EN 61000-6-2

Will display 4 lines of 12 characters per line, Program Run On/Off mode,

Password Protection, Image Table, and Function Blocks during

programming.

ENG-12

Page 23

α

2 Simple Application Controllers

3. Installation

3.1 Installation Mounting Notes

Theα2 Series’ safe design means the user can install it almost anywhere but please take

the following points into consideration.

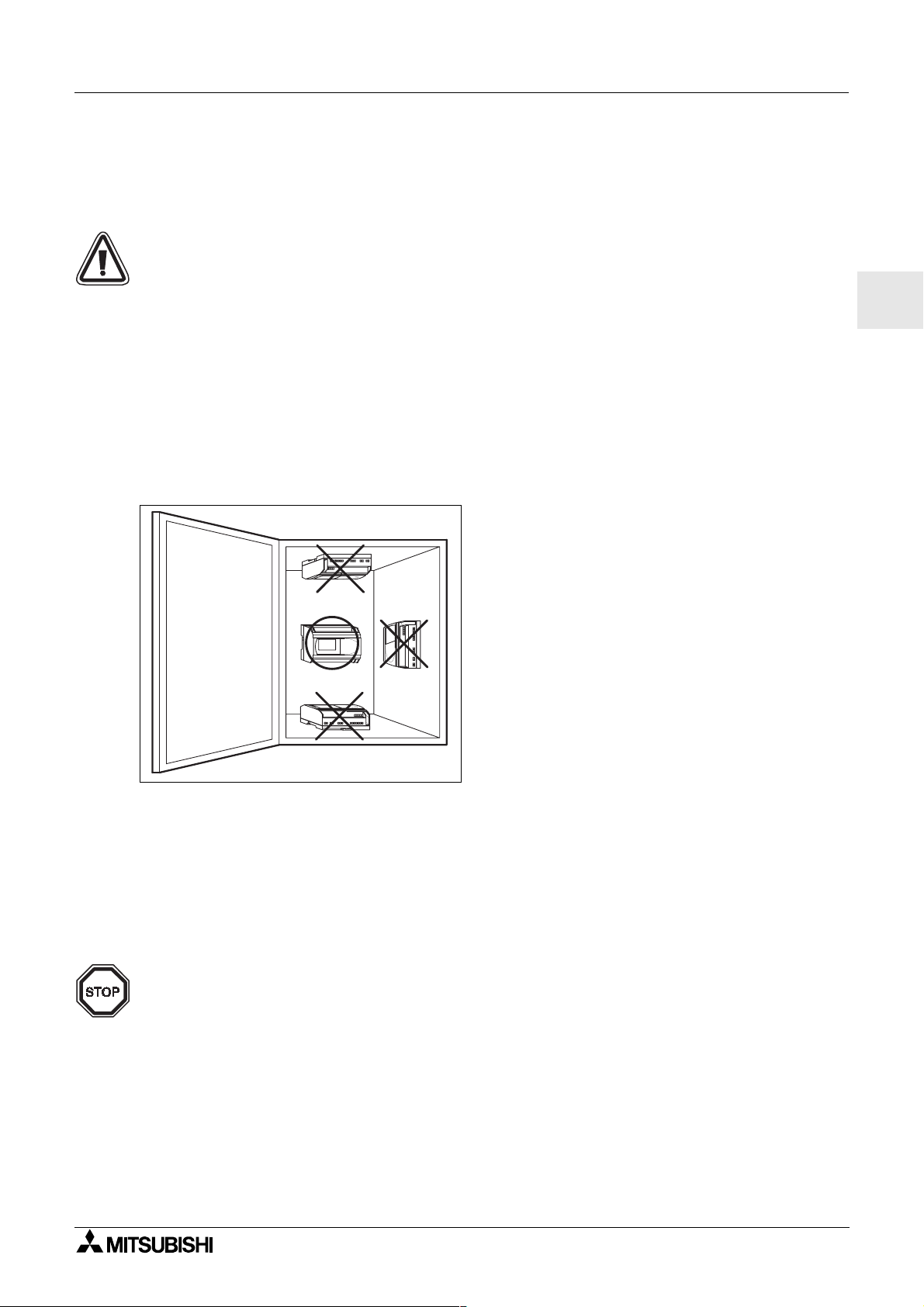

Installation 3

• Do not install in areas with excessive or conductive dust, corrosive or flammable gas,

moisture or rain, excessive heat, regular impact shocks or excessive vibration. Do not

place in water or let water leak onto the controller.

• Do not allow debris to fall inside the unit during installation.

• Keep as far as possible from high-voltage cables and power equipment.

•The

α

2 Series Controller must be installed in cabinets which are designed for the

assembly of devices complying to DIN 43880 or in a control box

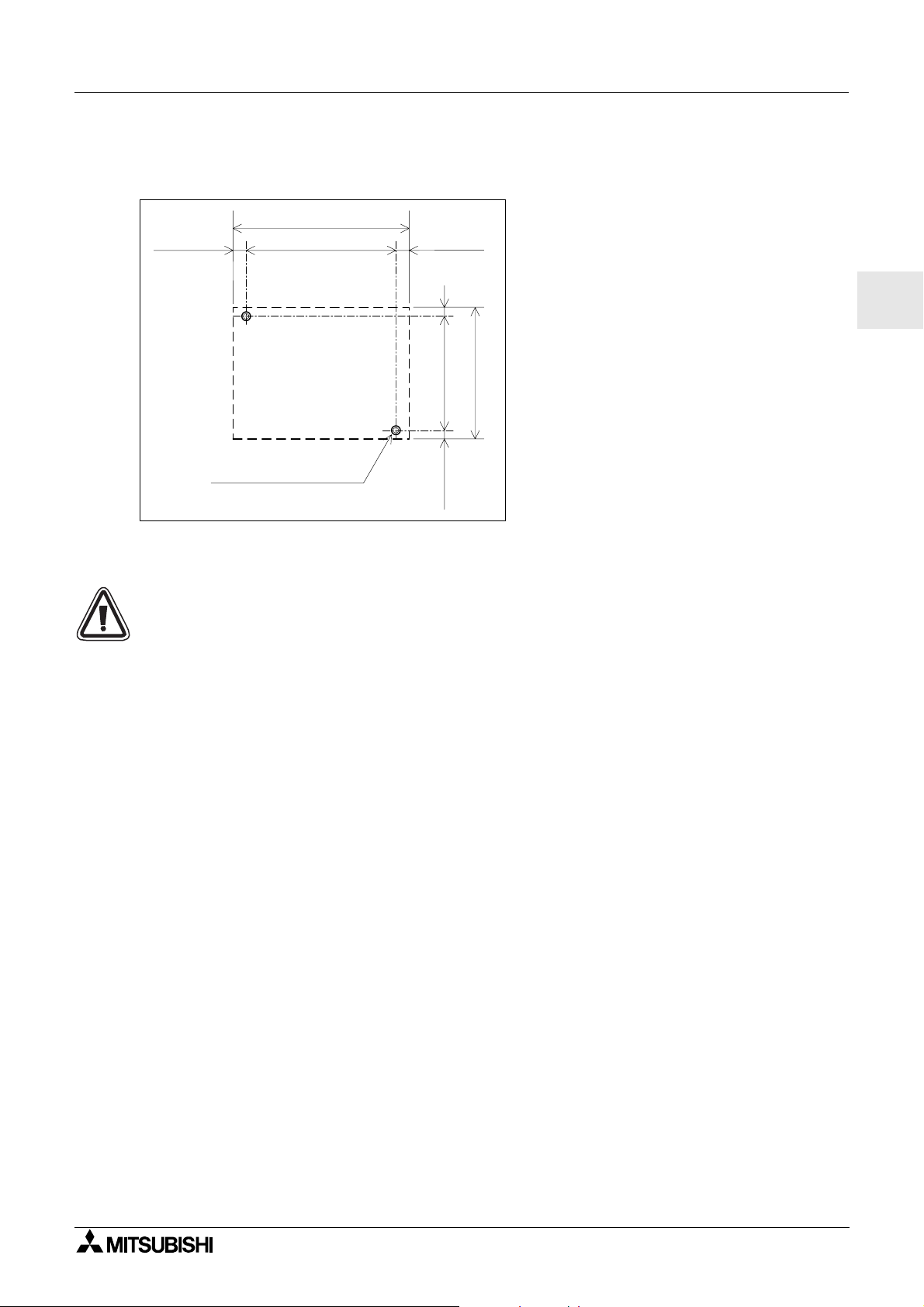

Figure 3.1: Mounting Arrengement.

ENG

•Usesize M4 screws when mounting by screw holes.

• The connectors must be covered to prevent injury from contact with “live” wires.

• Leave a minimum of 10mm of space for ventilation between the top and bottom edges of

α

the

2 Series Controller and the enclosure walls.

• Do not disassemble the

α

2 Series controller.

Note;

• Refer to chapter 6 when installing or removing the AL2-EEPROM-2.

• Refer to chapter 7 when installing or removing the AL-232CAB.

• Refer to chapter 8 when installing or removing the AL2-GSM-CAB.

ENG-13

Page 24

α

2 Simple Application Controllers

3.2 DINRAILMountingofMainUnit

Units can be snap mounted to 35mm DIN rail (DIN EN 50022). To release pull the spring

loaded clips away from the rail and slide the unit off and up.

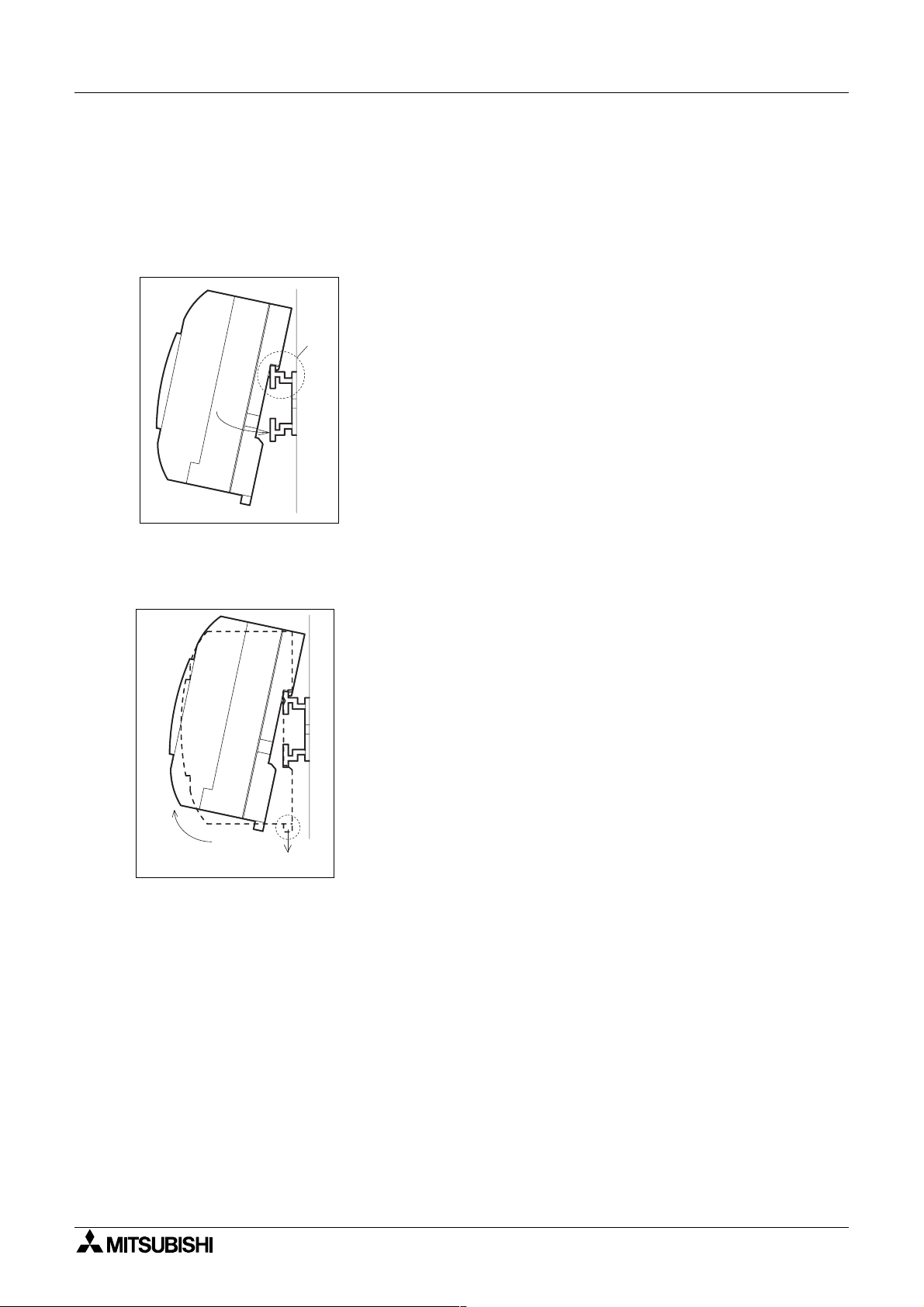

3.2.1 Installation

Figure 3.2: Installation

Align the upper side of theα2 DIN rail mounting groove with the

DIN rail () and push it onto the rail ().

Installation 3

3.2.2 Remove

Figure 3.3: Remove

Pull the DIN rail hook () and remove theα2 series main unit()

ENG-14

Page 25

α

2 Simple Application Controllers

3.3 Direct Mounting of Main Unit

Figure 3.4: Direct Mounting

124.6 (4.91")

6(0.24")

M4 Mounting Screw

112.6 (4.43")6(0.24")

Main Unit

Installation 3

4

(0.16")

90 (3.54")

82 (3.23")

4 (0.16")

ENG

3.4 Install Extension Module

Caution:

Disconnect all terminals from the power supply before removing the cover.

ENG-15

Page 26

α

2 Simple Application Controllers

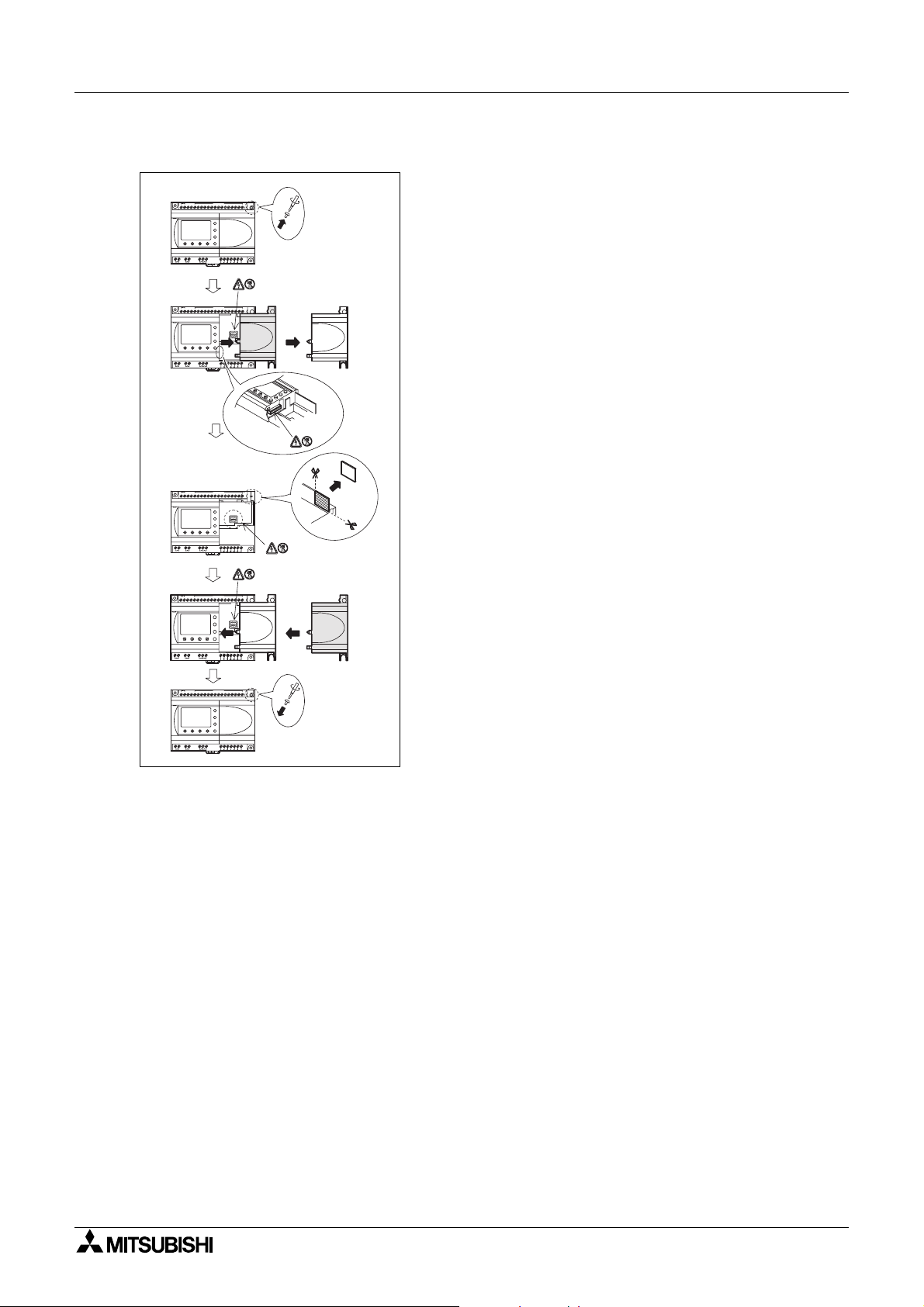

Figure 3.5: Installation

Installation 3

1)

2)

3)

4)

+-

POWER

24V DC

AL2-24MR-D

OUT1

OUT3

OUT2 OUT4

(A)(B)123456789101112131415

-+

POWER

24V DC

AL2-24MR-D

OUT4OUT28OUT

OUT3

OUT1

(A)(B)123456789101112131415

-+

POWER

24V DC

AL2-24MR-D

OUT4OUT28OUT

OUT3

OUT1

(A) (B) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

-+

POWER

24V DC

AL2-24MR-D

OUT4OUT28OUT

OUT3

OUT1

DC INPUT

151413121110987654321(B )(A)

ESC

+

-

OK

RELAY

OUTPUT

9

65

8

7

OUT

DC INPUT

ESC

+

-

OK

RELAY

OUTPUT

7

5

9

DC INPUT

ESC

+

-

OK

RELAY

OUTPUT

7

56

9

DC IN P U T

ESC

+

-

OK

RELAY

OUTPUT

6

7

5

9

A

B

1) Release screw ‘A’ and keep.

2) Carefully remove the factory fitted expansion

port cover.

3) Cut away section ‘B’ from the

α

2series

controller main unit.

4) Attach the expansion module to the main unit.

5) Tighten screw ‘A’ to a torque of 0.4 N·m.

5)

AL2-24MR-D

OUT1

+-

POWER

24V DC

OUT2 OUT4

DC INPUT

151413121110987654321(B )(A)

ESC

+

-

OK

RELAY

OUTPUT

9

65

8

7

OUT3

OUT

A

ENG-16

Page 27

α

2 Simple Application Controllers

4. Wiring

4.1 Installation Wiring Notes

The wiring ofα2 Series has been designed to be safe and easy. A technician or engineer

trained in the local and national electrical standards should perform all tasks associated

with the electrical wiring of the

performing any wiring operations.

• Input and output cables should not be run through the same multicore cable or share the

same wire.

• Do not lay input/output cables near high voltage power cables.

• Input and output cable length must be than 30m (98' 5").

Allow for voltage drop and noise interference with input/output lines used over an extended

distance. Please use wire that is properly sized for the current load.

The terminal will accept a 3 mm flathead screwdriver.

α

2 Series controllers. Turn OFF the Power before

Wiring 4

ENG

ENG-17

Page 28

α

2 Simple Application Controllers

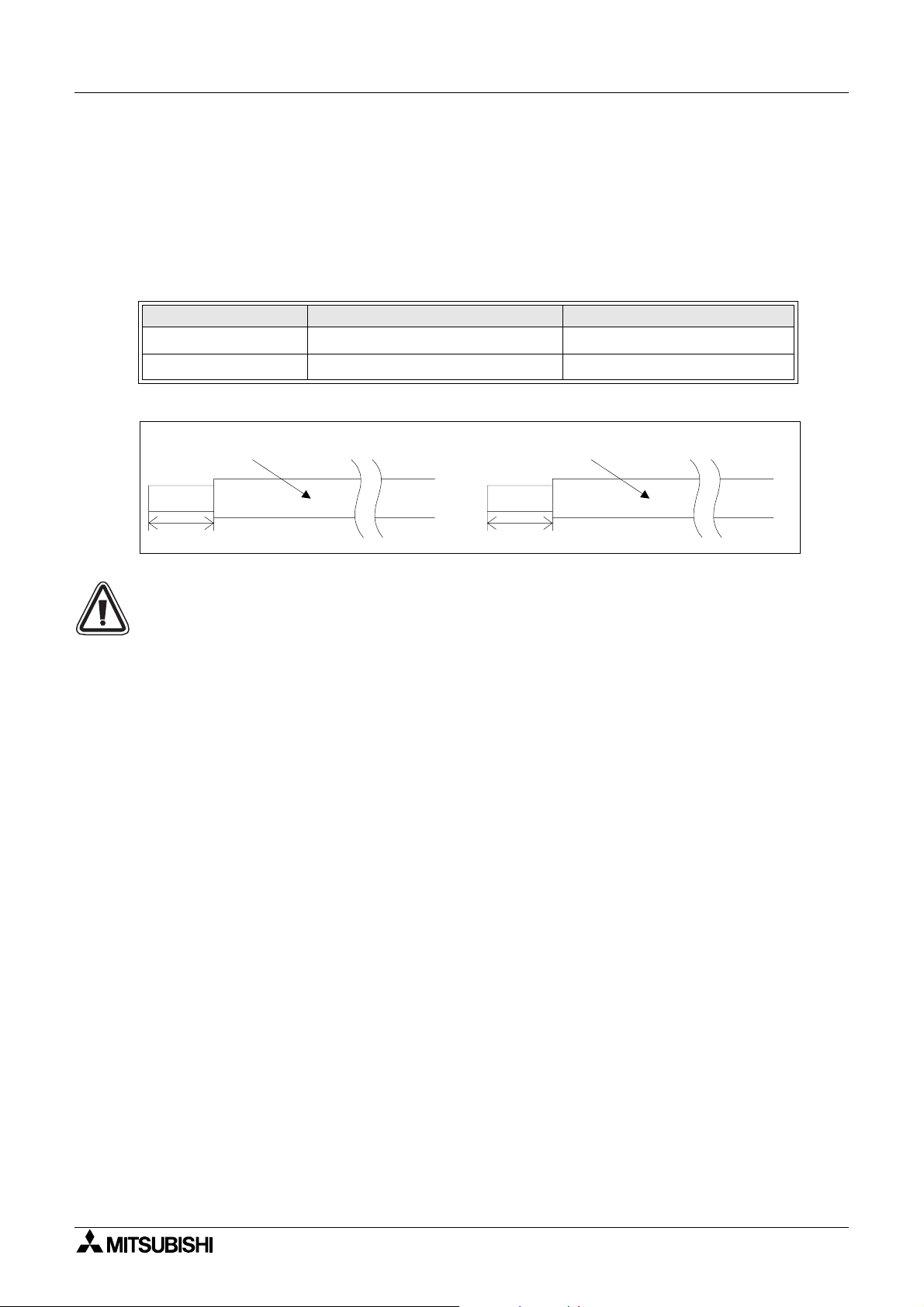

4.2 Wire Size

Wire of the Inputs and Outputs using the following wire. Strip the wire to the following length

(See Table 4.1 and Figure 4.1). Please unscrew the terminal to its widest position before

inserting a wire. Insert the wire completely into the terminal to ensure that a proper connection

canbemade.

The terminals will accept a 3mm flathead screwdriver.

Table 4.1: Wire Size

Main Unit

Extension Module

Figure 4.1: Wire Size

Main unit Extension module

Wire Size Strip Wire Length

26 - 12 AWG (0.13 - 3.31mm

24 - 14AWG (0.2 - 2.5mm

2

)

Wiring 4

2

)

7mm ± 0.5mm

6mm ± 0.5mm

26 -12 AWG

7mm(0.276") ± 0.5mm(0.02")

24 -14 AWG

6mm(0.236")

Note;

• To avoid damaging the wire, tighten to a torque of 0.5 - 0.6 N⋅m.

• Please do not use tin, solder, or any other substance on the stripped wire that might

causethewirestrandtobreak.

- Stranded cable:

Remove sheath, twist core wires, then connect cable (or use a crimp terminal).

- Single cable:

Remove sheath, then connect cable.

ENG-18

Page 29

α

2 Simple Application Controllers

4.3 Power Supply

• When wiring AC supplies the “Live” cable should be connected to the “L” terminal and

the “Neutral” cable should be connected to the “N” terminal. Do NOT connect the “Live”

wire to the “N” terminal, the user might receive a dangerous shock on powerup.

• When wiring DC supplies the “positive” cable should be connected to the “+” terminal

and the negative cable should be connected to the “-” terminal. On no account should

the power supply terminals be connected to any other terminal on the unit. DC Power

Supply units should be capable of providing 4 Amperes of current to the controller.

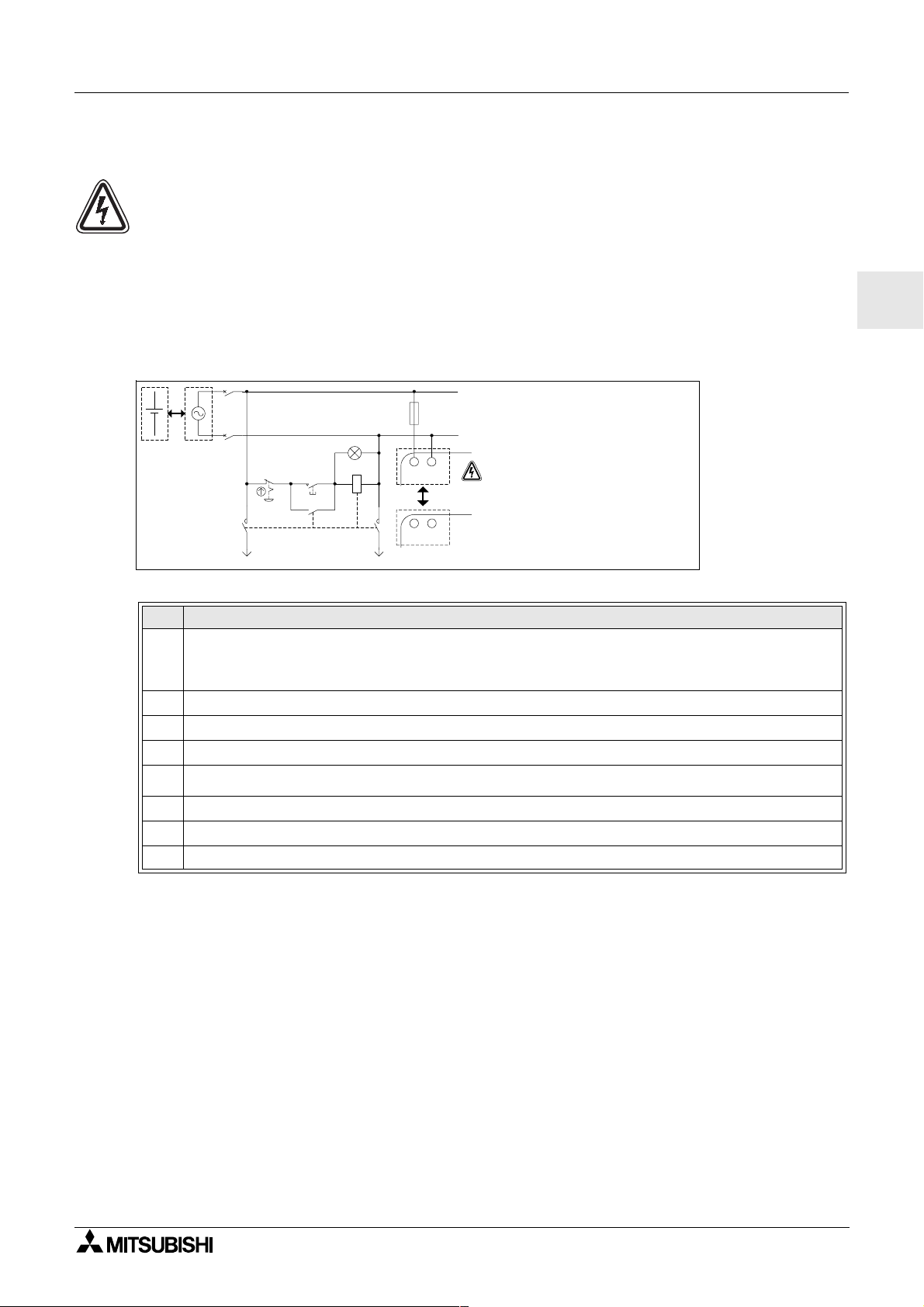

Figure 4.2: Recommended Power Input Wiring Diagram

L

+

N

Start

MC

MC

L

+ -

Wiring 4

ENG

N

"L" and "N" terminals are

not reversible.

Table 4.2: Recommended Power Wiring

Ref. Item Description

Power supply

1

AL2-***-A: 100-240V AC, 50/60Hz

AL2-***-D: 24V DC

2 Circuit isolation device

3 Power ON pilot indicator

4 Circuit protection device - Limit to 1.0A

5

α

2mainunit

6 Emergency stop

7 Magnetic switch contact

8 Power supply for loads

ENG-19

Page 30

α

2 Simple Application Controllers

4.4 AC Power Supply and Input Wiring

4.4.1 AC Power Supply and Input Wiring

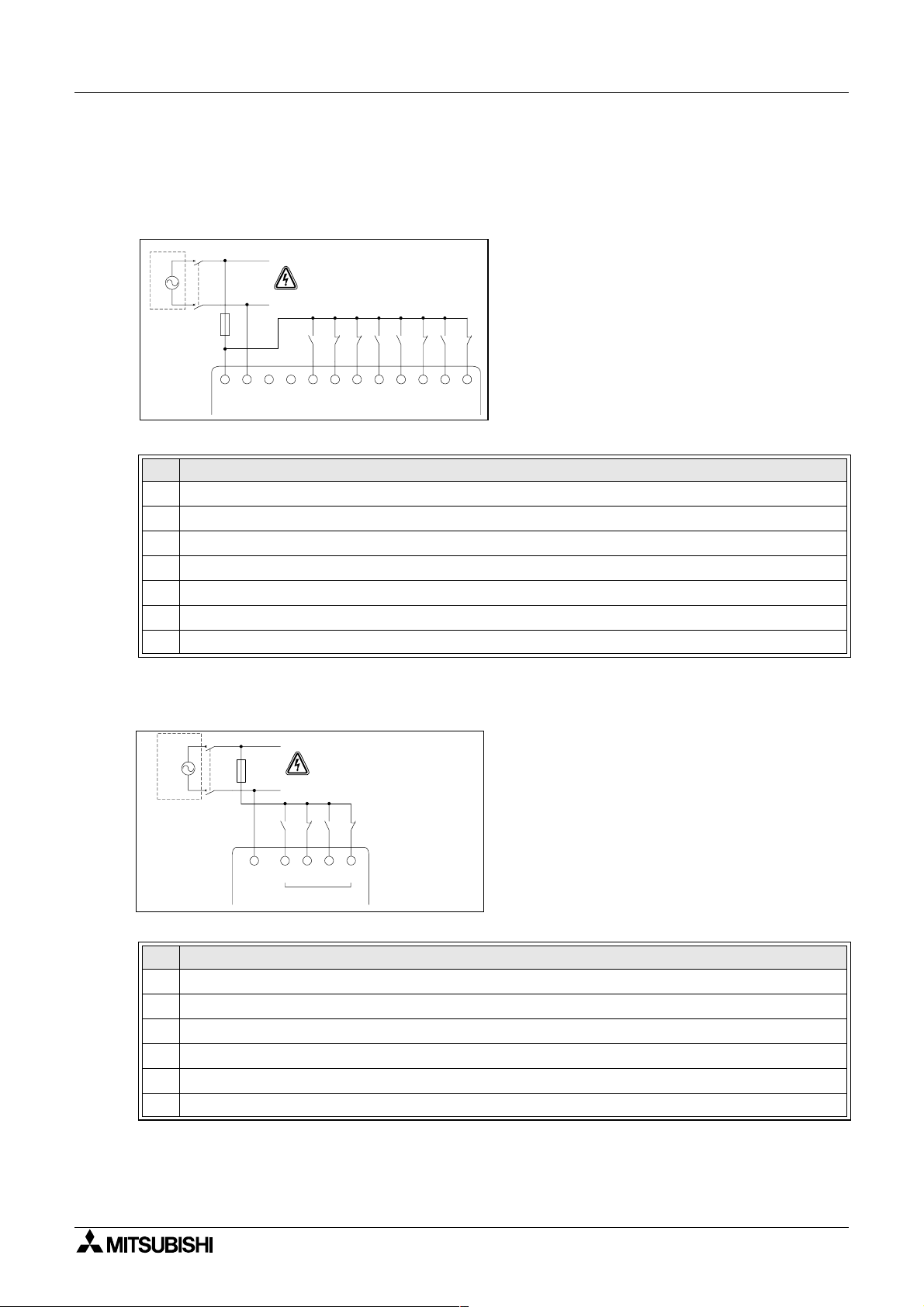

Figure 4.3: AC Power Supply and Input Wiring Diagram

L

N

"L" and "N" terminals

are not reversible.

Wiring 4

LN 123456

Table 4.3: AC Power Supply and Input Wiring

Ref. Item Description

1 AC power supply, 100 - 240V AC~, 50/60Hz

2 Circuit isolation device

3 Circuit protection device - Limit to 1.0 Amp

4 AC power terminals

5 Unused terminals

6 Input terminals

7 Digital input switches

4.4.2 AL2-4EX-A2 Input Wiring

Figure 4.4: AL2-4EX-A2 Input Wiring Diagram

L

N

"L" and "N" terminals

are not reversible.

INPUTS

78

EI1 EI2

COM

(N)

EI3 EI4

Table 4.4: AC Power Supply and Input Wiring

Ref. Item Description

1 AC power supply, 220 - 240V AC~,50/60Hz

2 Circuit isolation device

3 Circuit protection device - Limit to 1.0 Amps

4COM (N) terminal

5 Input terminals

6 Digital input switches

ENG-20

Page 31

α

2 Simple Application Controllers

4.5 DC Power Supply and Input Wiring

4.5.1 DC Power Supply and Source (“+” Common) Input Wiring Diagram

Figure 4.5: DC Power Supply and Source (“+” Common) Input Wiring Diagram

Wiring 4

+ -

(A) (B)

2

1

456

3

INPUTS

78

Table 4.5: DC Power Supply and Source (“+” Common) Input Wiring

Ref. Item Description

DC power supply, 24V DC

1

2 Circuit isolation device

Circuit protection device - Limit to 1.0A

3

DC power terminals

4

Sink/Source input wiring terminals

5

Sensor input switches

6

Input terminals

7

Analog input

8

4.5.2 AL2-4EX Source (“+”Common) Input Wiring Diagram

Figure 4.6: AL2-4EX Source (“+” Common) Input Wiring Diagram

ENG

EI1

EI1

EI2

EI2

EI3

EI3

(+)

(-)

(+)

(-)

(+)

EI4

(-)

(+)

EI4

(-)

Table 4.6: DC Power Supply and Source (“+” Common) Input Wiring

Ref. Item Description

DC power supply, 24V DC

1

2 Circuit isolation device

Input terminals

3

Sensor input switches

4

Note:

Each input terminal (EI1 ~ EI4) can be used as either Source input or Sink input.

ENG-21

Page 32

α

2 Simple Application Controllers

4.5.3 DC Power Supply and Sink(“-” Common) Input Wiring Diagram

Figure 4.7: DC Power Supply and Sink (”-” Common) Input Wiring Diagram

Wiring 4

+ -

(A) (B)

2

1

456

3

INPUTS

78

Table 4.7: DC Power Supply and Sink (“-” Common) Input Wiring

Ref. Item Description

DC power supply, 24V DC

1

2 Circuit isolation device

Circuit protection device - Limit to 1.0 Amps

3

DC power terminals

4

Sink/Source input wiring terminals

5

Sensor input switches

6

Input terminals

7

4.5.4 AL2-4EX Sink(“-” Common) Input Wiring Diagram

Figure 4.8: AL2-4EX Sink (”-” Common) Input Wiring Diagram

EI1

(+)

EI1

EI2

EI2

(-)

(+)

EI3

(-)

(+)

EI3

(-)

EI4

(+)

EI4

(-)

Table 4.8: DC Power Supply and Sink (“-” Common) Input Wiring

Ref. Item Description

DC power supply, 24V DC

1

2 Circuit isolation device

Input terminals

3

Sensor input switches

4

Note:

Each input terminal (EI1 ~ EI4) can be used as either Source input or Sink input.

ENG-22

Page 33

α

2 Simple Application Controllers

4.6 Output Relay and Transistor Wiring

4.6.1 Relay Output Wiring Diagram main unit (AC and/or DC)

Figure 4.9: Relay Output Wiring Diagram main unit (AC and/or DC)

OUT1

Table 4.9: Relay Output Wiring main unit (AC and/or DC)

Ref. Item Description

1

2mainunit

α

2 Mutually exclusive outputs

3 Output devices

4 Circuit protection device (SeeTable 4.10)

5 Emergency stop

6 DC power supply

7 AC power supply

OUT2 OUT3 OUT4

OUT5 OUT6

Wiring 4

ENG

Table 4.10: Relay Output Circuit Protection Table

Model

AL2-14MR-*O01~O06

AL2-24MR-*

Number of

Output

O01~O04 ≤ 10A / Circuit

O05~O09 2A/point (4A/common) ≤ 3A / Circuit

Max. ResistiveLoad

8A/common

Circuit Protection

(Fuse)

≤ 10A / Circuit

ENG-23

Page 34

α

2 Simple Application Controllers

4.6.2 Relay Output Wiring Diagram AL2-4EYR (AC and/or DC)

Figure 4.10: Relay Output Wiring Diagram AL2-4EYR (AC and/or DC)

EO1 EO2 EO3 EO4

Table 4.11: Relay Output Wiring AL2-4EYR (AC and/or DC)

Ref. Item Description

1 DC power supply

2 Emergency stop

3 Circuit protection device (Fuse: ≤ 3A)

4 Mutually exclusive outputs

5 Output devices

6 AC power supply

Wiring 4

Table 4.12: Relay Output Circuit Protection Table

Model

AL2-4EYR EO1~EO4 2A/common ≤ 3A / Circuit

Number of

Output

Max. ResistiveLoad

Circuit Protection

(Fuse)

ENG-24

Page 35

α

2 Simple Application Controllers

4.6.3 Transistor Output (Source or “+” Common Only) Wiring Diagram AL2-4EYT

Figure 4.11: Transistor Output (Source/ “+” Common Only) Wiring Diagram AL2-4EYT

Wiring 4

EO1 EO2 EO3 EO4

-

+

-+

Table 4.13: Transistor Output Wiring

Ref. Item Description

1 DC Power Supply: 24V DC

2 Emergency Stop

3 Circuit Protection Device - See Table 4.14 for Specifications

4 Power Supply Terminal

5 Output Devices

6 DC Power Supply: 12V DC

Table 4.14: Transistor Output Circuit Protection Table

Circuit

Volt age

5V DC <

12V DC <

24V DC < 2.0A/Circuit

Circuit Protection (Fuse)

0.3A/Circuit

2.0A/Circuit

*1

*1

ENG

*1 Power Source capacity≥Fuse size×2

Figure 4.12: Example Fuse Size Calculation

12V,8A

(8A

≥1A×2×

4)

Fuse

1A

O01

Fuse1AFuse1AFuse

1A

O02 O03 O04

Note;

Table 4.15: Output Terminal Notes

Volt Output Terminal Notes

5 Each circuit can contain from one output terminal up to every output terminal.

12-24 Each circuit can contain from one output terminal up to every output terminal.

5,12,24

Using any combination of 5 Volt, 12 Volt, and 24 Volt outputs can be accomplished on the

2 Series Controller if separate circuits are used for each voltage level.

α

same

ENG-25

Page 36

α

2 Simple Application Controllers

Wiring 4

MEMO

ENG-26

Page 37

α

2 Simple Application Controllers

5. Terminal Layout

Figure 5.1: AL2-14MR-A, AC Input, Relay Output

LN

1

IN

34567

2

Terminal Layout 5

8

AL2-14MR-A

OUT1

OUT2

OUT3

OUT4 OUT6

OUT5

Figure 5.2: AL2-14MR-D, DC Input, Relay Output

IN

+ -

AL2-14MR-D

OUT1

(A)

(B)

OUT2

1

34567

2

OUT3

8

OUT4 OUT6

OUT5

Figure 5.3: AL2-24MR-A, AC Input, Relay Output

IN

LN

1

34567

2

8

9

10 11

12

13 14

ENG

15

AL2-24MR-A

OUT1

OUT2

OUT3

OUT4

OUT

Figure 5.4: AL2-24MR-D, DC Input, Relay Output

IN

+ -

AL2-24MR-D

OUT1

(A)

(B)

OUT2

1

34567

2

OUT3

OUT4

8

OUT

9

5

10 11

5

67

12

67

8

13 14

8

9

15

9

ENG-27

Page 38

α

2 Simple Application Controllers

Figure 5.5: AL2-4EX-A2, 220 - 240V AC Input

IN

EI1

COM(N)

AL2-4EX-A2

EI2 EI3

Figure 5.6: AL2-4EX, DC Input

Terminal Layout 5

EI4

+

+

EI2

-

-

EI1

-

+

AL2-4EX

+

-

EI3 EI4

Figure 5.7: AL2-4EYR, Relay Output

EO1

AL2-4EYR

EO3EO4

EO2

Figure 5.8: AL2-4EYT, Transistor Output

-

+

AL2-4EYT

+

EO1

EO2

-

EO3

EO4

ENG-28

Page 39

α

2 Simple Application Controllers

6. AL2-EEPROM-2

The AL2-EEPROM-2 memory cassette is for use only with theα2 series controller

(Model: AL2-**M*-*).

Caution

AL2-EEPROM-2 6

• Persons trained in the local and national electrical standards must replace the memory

cassette.

• Turn off the power supply when installing or removing the memory cassette.

• Replace the cover after removing the memory cassette.

α

• When installing the connector cover or the memory cassette of

to pinch your finger.

•DO NOT touch the following part when removing the cover or memory cassette.

2series,becarefulnot

ENG

ENG-29

Page 40

α

2 Simple Application Controllers

6.1 Installation

1) Remove the cover or the memory cassette

2) Install on the cover or the memory cassette

AL2-EEPROM-2 6

ENG-30

Page 41

α

2 Simple Application Controllers

7.AL-232CAB

7.1 Introduction

The AL-232CAB is an RS-232C cable used to connect anαseries controller (α,α2) and a

personal computer that is running the programming software (AL-PCS/WIN-E).

AL-232CAB 7

Note:

• AL-232CAB cable cannot be used for any other applications.

• AL-232CAB cable rises about 40mm (1.57") above the top panel when connecting to an

α

2 series controller.

7.1.1 External Dimensions

α

2seriesside

30.8(1.21")

47.8(1.88")

46(1.81")

11.5(0.45")

2500(8'2")

RXD(RD)

TXD (SD)

D T R (E R )

GND(SG)

Dimensions: mm (inches)

0

Personal computer side

(9-pin D-Sub female)

*1 Set this signal to

*1

high-level.

ENG

ENG-31

Page 42

α

2 Simple Application Controllers

7.2 Connected to AL-232CAB cable

Removecover and memory cassette

• Be careful of personal safety when removing theα2cover.

Caution

• Turn off the power supply when you install or detach the AL-232CAB cable.

• Install the cover or the memory cassette after removing the AL-232CAB cable.

• When installing the connector cover or the memory cassette of

to pinch your finger.

• Please hold the protective case when detaching the cable. DO NOT pull on the cord.

•DO NOT touch the following part when removing the cover, memory cassette or this

cable.

AL-232CAB 7

α

2series,becarefulnot

1) Removing the cover or the memory cassette

ENG-32

Page 43

α

2 Simple Application Controllers

2) Connecting the AL-232CAB cable

3) Removing the AL-232CAB cable

AL-232CAB 7

ENG

ENG-33

Page 44

α

2 Simple Application Controllers

4) Installing on the cover or the memory cassette

AL-232CAB 7

ENG-34

Page 45

α

2 Simple Application Controllers

AL-232CAB 7

MEMO

ENG

ENG-35

Page 46

α

2 Simple Application Controllers

8. AL2-GSM-CAB

8.1 Introduction

The AL2-GSM-CAB can be used to connectα2 Series Controllers to a normal or GSM

modem. The AL2-GSM-CAB can transfer Short Message Service (SMS) data to a GSM

modem for transmission to mobile phones and mail addresses or can facilitate remote

monitoring functions and program transfers via normal modems. RS-232C communication to a

personal computer can also be accomplished if an adaptor or cable is used.

Further information can be found in the

Note:

• This cable cannot be used for any other applications.

AL2-GSM-CAB 8

α

2 Programming Manual andαSoftware Manual.

• This cable does not attach to the

• Simultaneous communication through both ports of theα2 Series Controllers may result

in a damaged program or a malfunction in the controller.

8.1.1 External Dimensions

Figure 8.1: External Dimensions Dimensions: mm (inches)

α

2seriesside

34.2

(1.35")

(1.82")

46.3

α

Series Controller (Model: AL-**M*-*).

1500(4'11")

10.2(0.4")

modem side

(9-pin D-Sub male)

ENG-36

Page 47

α

2 Simple Application Controllers

8.1.2 System Configuration with using AL2-GSM-CAB

Figure 8.2: System Configuration with AL2-GSM-CAB

UsingDedicatedProtocol

α

2

Series

AL2-GSM-CAB 8

Remote Maintenance (Via Telephone Line)

Normal Modem Normal Modem

Remote Maintenance, E-Mail (Via GSM)

Normal Modem

GSM

Modem

Sending SMS Message

Table 8.1: System Configuration with AL2-GSM-CAB

Item Using Cable

1AL2-GSM-CAB

2 RS-232C cross cable (See Figure 8.3)

3 RS-232C straight cable for the modem (See Figure 8.5)

4 RS-232C straight cable for the modem (specified by modem manufacturer)

Personal computer

- Programming Software

(AL-PCS/WIN-E)

Cellular Phone

(Supporting SMS message)

- Dedicated protocol

- E-Mail application

ENG

Figure 8.3: RS-232C Cross Cable Reference

(9-pin D-Sub female) (9-pin D-Sub female)

2

3

4

5

6

7

8

3

2

6

5

4

8

7

Note:

The 4 and 7 signals must be set to high-level on the personal computer side.

If these signals are not set, it will not communicate to

α

2series.

ENG-37

Page 48

α

2 Simple Application Controllers

8.2 Installation

When installing AL2-GSM-CAB refer to Figure 8.4.

Caution

• Persons trained in the local and national electrical standards must install or remove the

AL2-GSM-CAB.

• Turn off the power supply when installing or removing the AL2-GSM-CAB.

• Put the cover back on after either installing or removing the AL2-GSM-CAB.

• Under no circumstances will Mitsubishi Electric be liable or responsible for any

consequential damage that may arise as a result of the installation or use of this

equipment.

• Do not pull on the cord, otherwise the cable may be damaged.

AL2-GSM-CAB 8

• When communicating to

must be turned ON at the same time. If they are not started up at same time, the

series will not communicate via GSM modem.

• Disconnect all terminals from the power supply before removing the cover.

α

2 series via GSM modem, the power supply for both units

α

2

ENG-38

Page 49

α

2 Simple Application Controllers

Figure 8.4: Installation

AL2-GSM-CAB 8

1)

2)

3)

4)

+-

POWER

24V DC

AL2-24MR-D

OUT1

OUT3

OUT2 OUT4

(A)(B)1 23 45 678 9101112131415

-+

POWER

24V DC

AL2-24MR-D

OUT4OUT28OUT

OUT3

OUT1

(A)(B)1 23 45 6 78 9101112131415

-+

POWER

24V DC

AL2-24MR-D

OUT4OUT28OUT

OUT3

OUT1

(A)(B)123456789101112131415

-+

POWER

24V DC

AL2-24MR-D

RELAY

OUTPUT

OUT4OUT28OUT

OUT3

OUT1

DC INPUT

151413121110987654321(B )(A)

ESC

+

-

OK

RELAY

OUTPUT

9

65

8

7

OUT

DC INPUT

ESC

+

-

OK

RELAY

OUTPUT

7

5

9

A

1) Release screw ‘A’ and keep.

2) Carefully remove the factory fitted

α

2 expansion

port cover or special module cover.

3) Install the AL2-GSM-CAB

into the cavity,

carefully placing the cable in the channel located

on the input terminal side.

α

4) Attach the

2 cover or expansion module taking

ENG

care that there is no interference with the AL2GSM-CAB.

5) Tighten screw ‘A’ to a torque of 0.4 Nm.

In s ta ll

DC INPUT

ESC

+

-

OK

RELAY

OUTPUT

7

56

9

DC INPUT

ESC

+

-

OK

6

7

5

9

Remove

5)

AL2-24MR-D

OUT1

+-

POWER

24V DC

OUT2 OUT4

DC INPUT

151413121110987654321(B )(A)

ESC

+

-

OK

RELAY

OUTPUT

9

65

8

7

OUT3

OUT

A

ENG-39

Page 50

α

2 Simple Application Controllers

8.3 Remote Maintenace with a Modem

Further information of the modem setup procedures can be found in theα2 Programming

Manual. The programming software (AL-PCS/WIN-E) provides the easiest method to setup

the modem.

8.3.1 Recommended Modems

Thefollowingmodemshavebeensuccessfullytested.

Table 8.2: Tested Modems

Maker name Model name Modem command (AT c ommand )

3com SP560V-P ATE0Q1&B1&D0H0&I0&R1&S0S0=2S15=8&W

OMRONME3314ATE0S0=2Q1&D0S15=8&R1&H0&W

AIWA PV-AF3360 ATE0S0=2Q1&D0&M5\Q0\J0&W

Siemens M20T ATE0S0=2&S0;+IFC=0,0;+CMEE=1;+IPR=9600&W

8.3.2 RS-232C Straight Cable Between Modem and AL2-GSM-CAB

Figure 8.5: RS-232C Straight Cable Reference Between a Modem and AL2-GSM-CAB

AL2-GSM-CAB 8

AL2-GSM-CAB Side

(9-pin D-Sub female)

1

2

3

4 20

5

6

7

8

9

Modem Side

(25-pin D-Sub male)

1

8

3

2

7

6

4

5

22

ENG-40

Page 51

α

2 Simple Application Controllers

8.3.3 Modem Setting

1) Setting of personal computer side

Install the file for the setting of the attachment in the modem.

AL2-GSM-CAB 8

2) Setting of

The modem on the

α

2seriesside

α

2 series side is set by the ModemInit command of the main unit.

a) About the modem command (AT command)

Use the AT command to initialize the modem. Confirm details of the AT command in the

manual of the modem to be used. AT commands have been prepared for select modems

in the table 8.4 (normal modem) and 8.5 (GSM modem) below.

Table 8.3: Tested Modems

Maker name Model name Modem command (AT command)

3com SP560V-P ATE0Q1&B1&D0H0&I0&R1&S0S0=2S15=8&W

OMRON ME3314 ATE0S0=2Q1&D0S15=8&R1&H0&W

AIWA PV-AF3360 ATE0S0=2Q1&D0&M5\Q0\J0&W

Siemens M20T ATE0S0=2&S0;+IFC=0,0;+CMEE=1;+IPR=9600&W

Further information on the method to initialize a modem can be found in the

Programming Manual.

When modems not listed in the table above are used, set the AT command to meet the

following requirements.

Table 8.4: AT Command for Modem (Normal Modem)

Setting Item Set content

Setting of command echo None E0 E0 E0

Call frequency of auto-answering Twice S0=2S0=2S0=2

Displayed result code None Q1 Q1 Q1

DTR control Always on &D0 &D0 &D0

DSR control Always on &S0

Communicate mode V.42bis mode S15=8S15=8 &M5

Speed of terminal fixed dimension Fixed &B1 \J0

Terminal flow control scheme None -&R1 \Q0

Flow control of transmission data None &H0 &H0 Flow control of received data

(software)

Flow control of received data

(RTS control)

Writing in nonvolatile memory

None &I0

None &R1

Writeinthe

nonvolatile

memory.

SP560V-P ME3314 PV-AF3360

&W &W &W

Example Setting

α

ENG

2

ENG-41

Page 52

α

2 Simple Application Controllers

Table 8.5: AT Command for GSM Modem

Setting Item Set content

Enable command echo Echo mode OFF E0

Set number of ring before

automatically answering the call

Set circuit data set ready (DSR)

function mode

Set TE-TA local data flow control

Report mobile equipment error Enable result code and use numeric value +CMEE=1

Set fixed local rate Baud Rate: 9600 bps +IPR=9600

Set circuit data carrier detect

(DCD) function mode

Select bearer service type

Store current parameter to use

defined profile

AL2-GSM-CAB 8

Example Setting

M20T

Enable automatic answering on the ring

twice

DSR always ON &S0

• Specifies the method which will be used

by TE when data is received fromTA:

None

• Specifies the method which will be used

by TA when data is received from TE:

None

*1

*1

DCD line is ON only in the presence of

Data Carrier

9600 bps (V.32), asynchronous modem,

non-transparent

The user profile is stored in non-volatile

memory

S0=2

+IFC=0,0

&C1

+CBST=7,0,1

&W

*1 In Siemens M20T case, these settings are not necessary because they are default

settings. If using other GSM Modem, maybe these settings are necessary.

b) Timing to initialize the modem during system startup

α

In the

2 series, there is a function to delay the transmission of the modem command

(AT command) to initialize the modem from the main unit at start up. The delay can

range from 0 - 10 seconds. This command can be useful to ensure the AT command is

correctly transmitted when the

Further information for the modem operation can be found in the

Manual and the

α

Software Manual.

α

2 series start up is faster than the modem start up.

α

2 Programming

ENG-42

Page 53

α

2 Simple Application Controllers

AL2-GSM-CAB 8

MEMO

ENG

ENG-43

Page 54

α

2 Simple Application Controllers

9. AL2-ASI-BD

The AL2-ASI-BD Actuator Sensor Interface board module is used in conjunction withα2

series controller for data communication over an Actuator Sensor Interface (AS-interface)

network.

Further information can be found in the

Caution

• Persons trained in the local and national electrical standards must replace the

AL2-ASI-BD.

• Turn off the power supply when you install or remove the AL2-ASI-BD.

• Replace the cover after removing the AL2-ASI-BD.

• Under no circumstances will Mitsubishi Electric be liable or responsible for any

consequential damage that may arise as a result of the installation or use of this

equipment.

9.1 Introduction

α

2 Series Programming Manuals.

AL2-ASI-BD 9

The AL2-ASI-BD connects onto the main unit of theα2 series controller, forming a slave

station for an AS-interface network (Input 4 points, Output 4 points). A maximum of 31 slaves

can be connected to form an AS-interface network. Power for the communication is supplied

over the AS-interface bus by the AS-interface power supply. The communication signal is

superimposed over the power supply on the AS-interface bus.

9.1.1 External Dimensions

Figure 9.1:

External

Dimensions Unit: mm (inches)

ASI+

ASI+

ASI-

ASI-

90(3.54")

24.5(0.96")

5 3 .1 (2 .0 9 ")

ENG-44

Page 55

α

2 Simple Application Controllers

9.1.2 System Configuration

Figure 9.2: System Configuration

AL2-ASI-BD 9

AS-interface Master

Module

AS-interface

Power Supply

9.2 Specifications

For general specifications please refer to the Chapter 2.

Table 9.1: Hardware Communication Specifications

Number of I/O 4 Input (E01-E04) 4 Output (A01-A04)

I/O Refresh Time Max. 5ms

Network Distance Max. 100m

External Power Voltage Typ. 30.5V DC (AS-interface Power supply)

External Power Current Consumption 40 mA or less

EC Directive EMC

Complies with AS-interface Certification

AS-interface Slave

(Sensor / Actuator)

AS-interface Slave

(Sensor / Actuator)

Item Content

AS-interface Slave

α

2Series

(

+ AL2-ASI-BD)

AS-interface Slave

(Sensor / Actuator)

ENG

Table 9.2: Software Communication Specifications

Item Content

Station Number Set by Master Station (Factory default 0)

IO Code 7

ID Code F

Data Bit D0 - D3 Input/Output 01 - 04 (E01 - E04, A01 - A04)

Parameter Bit

System Bit

Control Bit N1

P0

P1,P2,P3 Unused

M6 “ON” when communication Error of AS-interface occurs

M7 “ON” when communication Error by AS-interface power fail occurs

Communication monitor (set by default).

ON: Connect to AS-interface network

OFF: Unconnected to AS-interface network

*1

*1 Function to reset input signal (E01 - E04) when AS-interface communication is cut for 70

ms or more.

ENG-45

Page 56

α

2 Simple Application Controllers

9.3 Wiring & Installation

9.3.1 Installation

Caution

Disconnect all terminals from the power supply before removing the cover.

Figure 9.3: Installation

AL2-ASI-BD 9

1)

2)

3)

4)

+-

POWER

24V DC

AL2-24MR-D

OUT1

OUT3

OUT2 OUT4

(A)(B)123456789101112131415

-+

POWER

24V DC

AL2-24MR-D

OUT4OUT28OUT

OUT3

OUT1

(A)(B)1 23 45 678 9101112131415

-+

POWER

24V DC

AL2-24MR-D

OUT4OUT28OUT

OUT3

OUT1

(A)(B)123456789101112131415

-+

POWER

24V DC

AL2-24MR-D

RELAY

OUTPUT

OUT4OUT28OUT

OUT3

OUT1

DC IN P U T

151413121110987654321(B )(A)

ESC

+

-

OK

RELAY

OUTPUT

9

65

8

7

OUT

DC INPUT

ESC

+

-

OK

RELAY

OUTPUT

7

5

9

DC IN P U T

ESC

+

-

OK

RELAY

OUTPUT

7

56

9

DC INPUT

ESC

+

-

OK

6

7

5

9

A

B

1) Release screw ‘A’ and keep.

2) Carefully remove the factory fitted expansion

port cover.

3) Cut away section ‘B’ from the

α

2series

controller main unit.

4) Attach the expansion module to the main unit.

5) Tighten screw ‘A’ to a torque of 0.4 Nm.

5)

AL2-24MR-D

OUT1

+-

POWER

24V DC

OUT2 OUT4

DC IN P U T

151413121110987654321(B )(A)

ESC

+

-

OK

RELAY

OUTPUT

9

65

8

7

OUT3

OUT

A

ENG-46

Page 57

α

2 Simple Application Controllers

9.3.2 Wiring

Use the AS-interface flat cable (yellow) for connecting the AL2-ASI-BD to the network.

When connecting AS-interface cable to the module, tighten communication connector pin

Figure 9.4: Wiring

AL2-ASI-BD 9

AS-interface Flat cable (Yellow)

ASI+ ASI-

AS-interface Master

Module

ASI+ ASI- ASI+ ASI-

AL2-ASI-BD

9.4 Slave Address Setting & Diagnostics

9.4.1 Setting SlaveAddress

The address of AL2-ASI-BD must be set from the AS-interface master module. The setting

range of the slave address is 1 to 31. New modules are preset to 0 before shipping, if a module

has been previously assigned an address other than 0, it must be reset to 0 before it need to

add into new AS-interface network.

Refer to the AS-interface master module's manual for details of how to set station address

from the AS-interface master.

Many modules can be added to a network at one time, all but one of them should be set in their

passive state (set N1=1). Once the network has been powered up the modules can be

individually activated (set N1=0), where the Master station will assign a slave address.

ENG

ASI+ ASI-

AS-interface Power

Supply

9.4.2 Applicable Error checks

1) If a Communication error (M6) occurs;

- Check connections to the AS-interface master, and that the slave station number is

correct.

2) If a Communications power supply error (M7) occurs;

- Check the connection of the AS-interface Bus cable at each affected unit, also the ASinterface power supply and its operation.

ENG-47

Page 58

α

2 Simple Application Controllers

Key, System Bit and Function Block Lists 10

10.Key, System Bit and Function Block Lists

10.1 Key Lists

The following table is the keys to use operation in the Menu and user program. Further

information can be found in

Table 10.1: Operation Key Lists

Key Name Key Number Description

OK K01 Acceptance of data entry, menu options, program choices

ESC K02 Cancel current operation, move to higher screen or menu

+ K03

-K04

K05

K06 Scroll to lower numbered items (keys, FB, Inputs, Outputs, etc.)

K07 Move to the right on the LCD display, FB program or Jump command

K08 Move to the left on the LCD display, FB program or Jump command

α

2 Programming Manual.

Connect function blocks, move to higher numbered blocks, increment

values

Disconnect function blocks, move to lower numbered blocks,

decrement values

Scroll to higher number numbered items (keys, FB, Inputs, Outputs,

etc.)

ENG-48

Page 59

α

2 Simple Application Controllers

10.2 System Bit Lists

There is the system bit controlled by system and the control bit to control from user program.

10.2.1 System Bit Lists

Table 10.2: System Bit Lists

System Bit Description

M01 Always “ON”

M02 Always “OFF”

M03 Alternate - 0.5 seconds “ON”, 0.5 seconds “OFF”

M04 “ON” when Real Time Clock data error occurs

M05 “ON” when Summer time schedule is activated

M06 “ON” when communication Error of AS-interface occurs

M07 “ON” when communication Error by AS-interface power failure occurs

Key, System Bit and Function Block Lists 10

ENG

M08

M09

M10 Reserved

M11 Reserved

M12 “ON” when CD (DCD) signal is turned ON (receiving CD signal from modem)

M13 “ON” when it is possible to access the GSM network.

M14

ONwhenturnStopmodeturnstoRunmodeinthe

pulse output and then turns OFF .

OFF when turn Stop mode turns to Run mode in the

as a pulse output and then turns ON.

“ON” when the

10.2.2 Control Bit Lists

Table 10.3: Control Bits

Control Bit Description

N01

*1

N02

*1

N03

N04

2 Series. The ON signal acts as a

α

2 Series. The OFF signal acts

α

2seriesisaccessedviaGSM.

α

ON: Disconnected to AS-interface network

OFF: Connect to AS-interface network

ON: The back light is “OFF”inLCD.

OFF: The back light is controlled by the “Light Time” setting in Menu.

ON: The back light is “ON” in LCD.

OFF: The back light is controlled by the “Light Time” setting in Menu.

ON: The user screen is controlled by the setting of “Display Manager” with AL-

PCS/WIN-E.

OFF: The user screen is controlled by user program.

*1 When both N02 and N03 are ON and hence the back light is “ON” because N03 is given

the priority.

ENG-49

Page 60

α

2 Simple Application Controllers

10.3 Function Block Lists

Further information for function blocks can be found in theα2 Series Programming Manual.

Table 10.4: Function Block Lists

Function Block Memory

Name Symbol

AND AND 19

OR OR19

NOTNOT10

XOR XOR13

NAND NAND 19

NORNOR19

Boolean BL *1 Logic equation using AND, OR, XOR, NOT

Set/Reset SR 14

Pulse PL 10 Send a Pulse on the Rising, Falling, or both Edges

Alternate AL 13

Delay DL 19 Delay a signal on the Rising, Falling, or both Edges

One Shot OS17

Flicker FL 19

Time Switch TS *2

Time Switch

Maintenance

Counter CN 16 Count upwards on pulses, can reset at a signal

Up/Down

Counter

Compare CP 17

Offset Gain OG22

Display DP *3

Zone