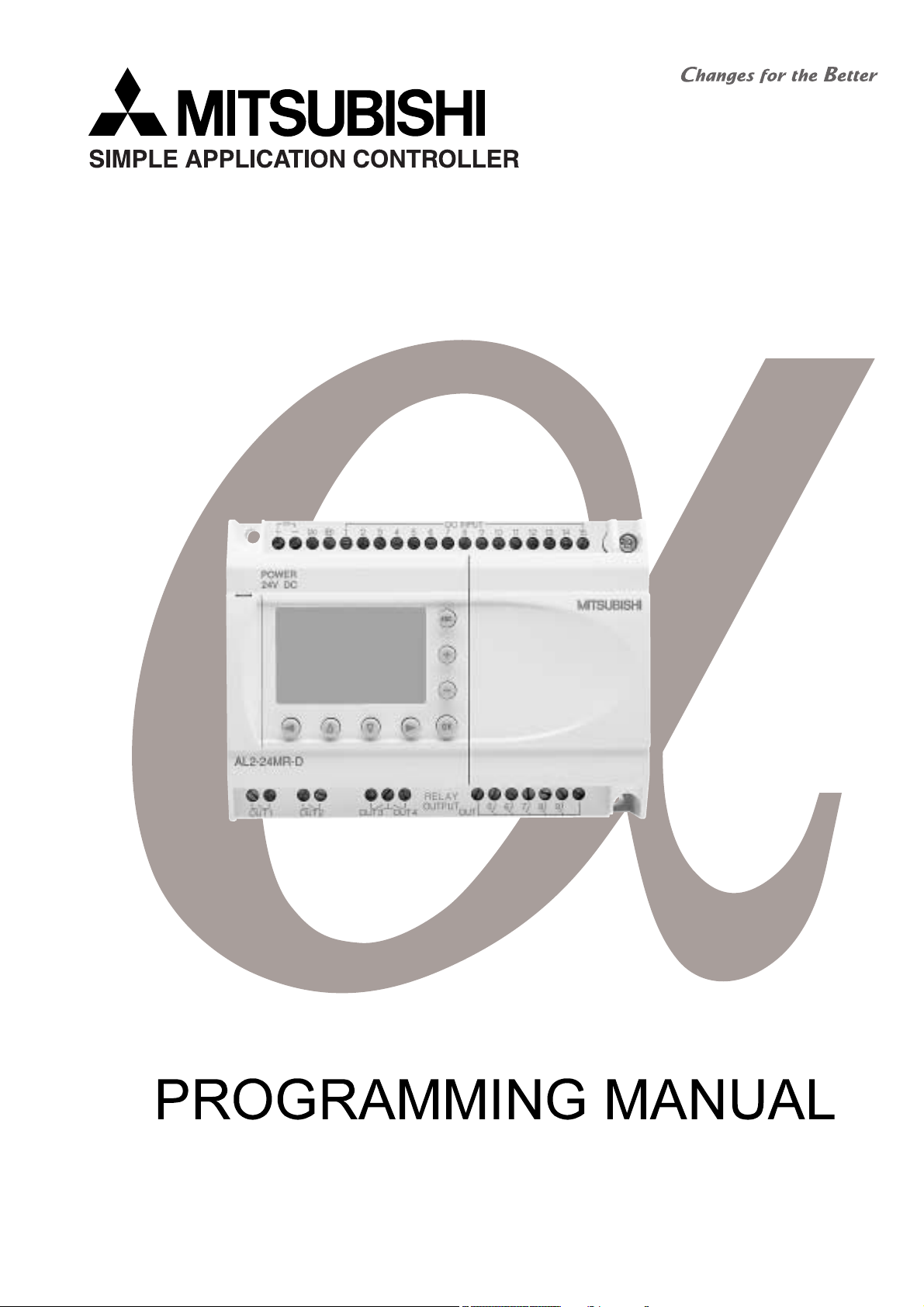

Page 1

α

2 SIMPLE APPLICATION CONTROLLER

Page 2

α2 Simple Application Controllers

Foreword

• This manual contains text, diagrams and explanations which will guide the reader in the

correct programming and operation of the

• Before attempting to install or use the

understood.

• If in doubt at any stage of the installation of the

professional electrical engineer who is qualified and trained to local and national standards

which apply to the installation site.

• If in doubt about the operation or use of the

Mitsubishi Electric distributor.

• This manual is subject to change without notice.

α2 series controller.

α2 Series Controller this manual should be read and

α2 Series Controller always consult a

α2 Series Controller please consult the nearest

Page 3

α

2

Simple Application Controllers

α2 SIMPLE APPLICATION

CONTROLLERS

PROGRAMMING MANUAL

Manual number : JY992D97101

Manual revision : A

Date : Apr. 2002

i

Page 4

α

2

Simple Application Controllers

FAX BACK

Mitsubishi has a world wide reputation for its efforts in continually developing and pushing back

the frontiers of industrial automation. What is sometimes overlooked by the user is the care

and attention to detail that is taken with the documentation. However,to continue this process

of improvement, the comments of the Mitsubishi users are always welcomed. This page has

been designed for you,the reader,to fill in your comments and fax them back to us. We look

forward to hearing from you.

Fax numbers: Your name....................................................

Mitsubishi Electric.... .....................................................................

America (708)298-1834 Your company ..............................................

Australia (02)638 7072 .....................................................................

Germany (0 21 02)4 86-1 12 Your location: ...............................................

Spain (34)93-589-1579 .....................................................................

United Kingdom (01707)278695

Please tick the box of your choice

What condition did the manual arrive in?

Will you be using a folder to store the manual?

What do you think to the manual presentation?

Are the explanations understandable?

Which explanation was most difficult to understand: ..................................................................

....................................................................................................................................................

Are there any diagrams which are not clear?

If so,which: ..................................................................................................................................

What do you think to the manual layout?

If there one thing you would like to see improved,what is it?......................................................

....................................................................................................................................................

....................................................................................................................................................

Could you find the information you required easily using the index and/or the contents, if

possible please identify your experience: ...................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

¨Good ¨Minor damage ¨Unusable

¨Yes ¨No

¨Tidy ¨Un-friendly

¨Yes ¨Not too bad ¨Unusable

¨Yes ¨No

¨Good ¨Not too bad ¨Un-helpful

Do you have any comments in general about the Mitsubishi manuals?.....................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Thank you for taking the time to fill out this questionnaire. We hope you found both the product

and this manual easy to use.

ii

Page 5

α

2

Simple Application Controllers

Guidelines for the safety of the user and protection of α2 Simple Application

controllers

This manual provides information for the use of α2 Simple Application controllers. The manual

has been written to be used by trained and competent personnel. The definition of such a

person or persons is as follows;

a ) Any engineer who is responsible for the planning, design and construction of automatic

equipment using the product associated with this manual should be of a competent

nature, trained and qualified to the local and national standards required to fulfill that

role. These engineers should be fully aware of all aspects of safety with regards to

automated equipment.

b ) Any commissioning or service engineer must be of a competent nature, trained and

qualified to the local and national standards required to fulfill that job. These engineers

should also be trained in the use and maintenance of the completed product. This

includes being completely familiar with all associated documentation for the said product.

All maintenance should be carried out in accordance with established safety practices.

c ) All operators of the completed equipment should be trained to use that product in a safe

and co-ordinated manner in compliance to established safety practices. The operators

should also be familiar with documentation which is connected with the actual operation

of the completed equipment.

Note : the term ‘completed equipment’ refers to a third party constructed device which

contains or uses the product associated with this manual.

Notes on the symbology used in this manual

At various times through out this manual certain symbols will be used to highlight points of

information which are intended to ensure the users personal safety and protect the integrity of

equipment. Whenever any of the following symbols are encountered its associated note must

be read and understood. Each of the symbols used will now be listed with a brief description of

its meaning.

Hardware warnings

1 ) Indicates that the identified danger WILL cause physical and property damage.

2 ) Indicates that the identified danger could POSSIBLY cause physical and property

damage.

3 ) Indicates a point of further interest or further explanation.

Software warning

4 ) Indicates special care must be taken when using this element of software.

5 ) Indicates a special point which the user of the associate software element should

be aware of.

6 ) Indicates a point of interest or further explanation.

iii

Page 6

α

2

Simple Application Controllers

iv

Page 7

α

2

Simple Application Controllers

Table of Contents

Safety Guidelines ................................................................................ iii

1. Introduction ..............................................................................1-1

1.1 Special Features Display messages and Function Block data ............. 1-1

1.2 Model Name ..........................................................................................1-2

2. Function Block Programming .................................................... 2-1

2.1 Block Type and the FBD base ..............................................................2-1

2.1.1 Inputs ........................................................................................... 2-2

2.1.2 Front Panel Keys ..........................................................................2-2

2.1.3 System Memory Bits ....................................................................2-3

2.1.4 Function Blocks ............................................................................2-3

2.1.5 Outputs ........................................................................................2-4

2.1.6 Function Block Diagram (FBD) base ............................................2-4

2.2 Programming Methods ..........................................................................2-5

2.2.1 Direct Programming .....................................................................2-5

2.2.2 AL-PCS/WIN-E Programming Software Ver 2.00 ........................ 2-5

3. System Menu ............................................................................ 3-1

3.1 Menu Options Instructions ....................................................................3-1

3.2 The Stop Mode ..................................................................................... 3-1

3.2.1 Top Menu .....................................................................................3-1

3.2.2 The “Others... ...............................................................................3-3

3.3 The Run Mode Top Menu ..................................................................... 3-7

3.4 The Edit Menu ..................................................................................... 3-13

3.5 The Function Block Edit Menu ............................................................3-13

3.6 Option Screen Setup ........................................................................... 3-13

3.6.1 ProgEdit ..................................................................................... 3-13

3.6.2 Change the Language Setting ...................................................3-13

3.6.3 ClockSET ...................................................................................3-14

3.6.4 SummerTime ..............................................................................3-14

3.6.5 Password ................................................................................... 3-15

3.6.6 Serial Com ................................................................................. 3-15

3.6.7 Memory cassette ........................................................................3-16

3.7 LCD Displays ......................................................................................3-17

3.7.1 Image Table ...............................................................................3-17

3.7.2 LCD Function .............................................................................3-17

3.8 Block Items .........................................................................................3-18

3.8.1 Input Blocks ...............................................................................3-18

3.8.2 Function Blocks .......................................................................... 3-18

3.8.3 Output Blocks .............................................................................3-18

3.8.4 Connected Blocks ......................................................................3-18

v

Page 8

α

2 Series Applications Controller

4. Direct Programming .................................................................. 4-1

4.1 Block Availability ...................................................................................4-1

4.2 Connecting Blocks ................................................................................4-1

4.2.1 To connect the blocks from the left block to right block. .............. 4-1

4.2.2 To connect the blocks from the right block to left block. .............. 4-2

4.3 Disconnect Two Blocks ......................................................................... 4-2

4.4 Methods to Create a Function Block .....................................................4-3

4.4.1 New FB ........................................................................................4-3

4.4.2 AddFB .......................................................................................... 4-3

4.5 Function Block Editing ..........................................................................4-3

4.5.1 Setup Function Block ...................................................................4-3

4.5.2 Change No. (of a Function Block) ................................................ 4-3

4.5.3 Delete FB .....................................................................................4-3

4.6 Movement between Function Blocks ....................................................4-4

4.6.1 Movement Between Unconnected Blocks .................................... 4-4

4.6.2 Movement Between Connected Blocks ....................................... 4-4

4.6.3 The Jump Command .................................................................... 4-4

4.7 Using Keys as Inputs ............................................................................ 4-4

4.8 The Monitor Mode ................................................................................. 4-5

4.8.1 Monitor/Update Function Block Values ........................................4-5

4.8.2 Forcing Outputs ON/OFF ............................................................. 4-6

4.8.3 Add/Delete Function Blocks in the Monitor Mode ........................4-6

5. The Logic Function Blocks ........................................................5-1

5.1 The AND Block ..................................................................................... 5-2

5.2 The OR Block ........................................................................................ 5-3

5.3 The NOT Block ..................................................................................... 5-4

5.4 The XOR Block (Exclusive OR) ............................................................5-4

5.5 The NAND Block (Not AND) .................................................................5-5

5.6 The NOR Block (Not OR) ......................................................................5-6

6. Function Blocks ......................................................................... 6-1

6.1 Definitions ............................................................................................. 6-6

6.2 Abbreviations ........................................................................................ 6-6

6.3 Boolean block ....................................................................................... 6-7

6.4 Set/Reset Block .................................................................................... 6-9

6.5 Pulse Block .........................................................................................6-11

6.6 Alternate Block ....................................................................................6-13

6.7 Delay Block .........................................................................................6-14

6.8 One Shot Block ................................................................................... 6-16

6.9 Flicker Block ........................................................................................6-18

6.10 TimeSW Block ..................................................................................6-21

6.10.1 Setting the First Time Switch ................................................... 6-21

6.10.2 For the Date operation: ............................................................ 6-22

6.10.3 For the Weekly Operation: .......................................................6-22

6.10.4 To Enter New Time Switches ...................................................6-22

6.10.5 To Edit Time Switches ............................................................. 6-23

6.10.6 To Delete Time Switch Data .................................................... 6-23

vi

Page 9

α

2 Series Applications Controller

6.11 Counter Block ...................................................................................6-24

6.12 Up/Down Counter Block ....................................................................6-25

6.13 Compare Block ................................................................................. 6-27

6.14 OFFSET Block .................................................................................. 6-29

6.15 Display Block ....................................................................................6-32

6.15.1 Displaying Data Onscreen ....................................................... 6-32

6.15.2 Editing Data Onscreen ............................................................. 6-33

6.16 Zone Compare Block ........................................................................ 6-36

6.17 Schmitt Trigger Block ........................................................................6-38

6.18 Hour Meter Block ..............................................................................6-41

6.19 Speed Detect Block .......................................................................... 6-43

6.20 Pulse Width Modulation .................................................................... 6-48

6.21 Retentive Alternate Block ..................................................................6-50

6.22 Addition Block ................................................................................... 6-51

6.23 Subtraction Block .............................................................................. 6-52

6.24 Multiplication Block ........................................................................... 6-53

6.25 Division Block ....................................................................................6-54

6.26 Calculation Block ..............................................................................6-55

6.27 Shift Block ......................................................................................... 6-57

6.28 GSM SMS Block ............................................................................... 6-59

6.28.1 Input Signal .............................................................................. 6-61

6.28.2 Output Signal ........................................................................... 6-61

6.28.3 Word Output .............................................................................6-61

6.28.4 Short Message Service (SMS) ................................................ 6-62

6.28.5 Comment/Signal Number ......................................................... 6-62

6.28.6 Setting ......................................................................................6-62

6.28.7 Destination ...............................................................................6-62

6.28.8 SMS Setting Dialog Box ........................................................... 6-63

6.28.9 SMS Service Center ................................................................ 6-63

6.28.10 Valid Period ............................................................................ 6-63

6.28.11 Destination ............................................................................. 6-63

6.28.12 Error Messages ...................................................................... 6-64

6.29 Random One Shot Block ..................................................................6-70

6.30 Delayed One Shot Block ................................................................... 6-72

6.31 Delayed Alternate Block ....................................................................6-75

6.32 Retentive Set Reset Block ................................................................ 6-77

6.33 Control Display Manager ..................................................................6-79

6.33.1 Operation Image: ..................................................................... 6-80

6.33.2 To Set Display Manager: .......................................................... 6-81

6.34 Connect Block ................................................................................... 6-87

vii

Page 10

α

2 Series Applications Controller

7. Lets Make a Program ................................................................ 7-1

7.1 Option Settings ..................................................................................... 7-1

7.2 The Function Block Diagram .................................................................7-1

7.3 Input the Program ................................................................................. 7-2

7.3.1 Adding Function Blocks by the Left to Right method (Section 4.2.1) 7-2

7.3.2 Scroll through the Function Blocks by Number (Section 4.6.1) .... 7-3

7.3.3 Use the Jump Command (Section 4.6.3) ..................................... 7-3

7.3.4 Use the NewFB command ...........................................................7-4

7.3.5 Connect the Function Blocks from Right to Left (Section 4.2.2) .. 7-4

7.4 Set up the Function Block Parameters (Section 4.5.1) .........................7-5

7.5 Exit the Function Block Diagram board ................................................. 7-6

8. Appendix ...................................................................................8-1

8.1 Associated Manuals .............................................................................. 8-1

8.2 System Keys .........................................................................................8-2

8.3 System Bits ...........................................................................................8-2

8.4 Boolean Gates ...................................................................................... 8-3

8.5 Function Blocks .....................................................................................8-4

viii

Page 11

α

2

Simple Application Controllers

1. Introduction

The α2 Series Controllers provides supervisory control for use in the home, office, factory or

wherever you need it. The

applications:

Applications

The

α2 Series is designed to be used for automatic applications including:

- Lighting, air-conditioning or watering control

- Opening and shutting of gates

- Security systems

- Domestic systems

- Temperature control

Introduction 1

α2 Series Controllers offers flexible I/O control for varied

However, the

- Applications where high reliabilities such as nuclear power control, railway facilities,

airline facilities, vehicles, combustion equipment and medical equipment are required.

- Applications in life critical situations

Please contact a Mitsubishi distributor for more information.

α2 Series Controllers is not designed to be used in the following applications:

1.1 Special Features Display messages and Function Block data

1 ) Display messages and Function Block data

The

α2 Series can display the state of operation and the alarm on the LCD screen as a

message. The values of timers and counters can be changed in RUN mode.

- Total characters on LCD display: 12 characters x 4 lines

- Display items: Message, values (current or set) of timers and counters, analogue

values, etc.

2 ) Program Input

The user can program directly from the front panel or use the windows based

AL-PCS/WIN-E programming software Ver2.00. Pictorial representation of data is used to

connect function blocks. Please refer to the

α Software Manual.

3 ) Enhancement of clock function

The weekly and daily calendar timer function allows switch inputs that set the powerful

time dependent control capabilities.

4 ) Analog input, 0-10V/0-500

The DC input type for the

5 ) High Speed Counter, max 1kHz

The

α2 Series has two dedicated high speed counters when using AL2-4EX EI1 and EI2.

6 ) High current output

Relay output is 8A/COM in the main unit AL2-14MR-*: O01-6, AL2-24MR-D: O01-04 and

the transistor output is 1A/point in the extension module.

α2 Series accepts 0-10V signals with a resolution of 0-500.

1 - 1

Page 12

α

2

Simple Application Controllers

7 ) GSM Function

The

α2 Series Controller uses GSM to send a SMS to a mobile phone or a dedicated

E-mail account via a standard service provider.

8 ) Dedicated Protocol

Introducing a Communication Device concept in the

user to monitor, modify and enter current and set values in Function Blocks via dedicated

protocol controlled from a personal computer.

9 ) Built-in EEPROM

The built in EEPROM eliminates the need for battery backed data.

10 )Supports 6 languages

The language option under the TopMenu can be changed to display: English, German,

French, Italian, Spanish and Swedish.

11 ) LCD Screen

Enhanced LCD screen size allows the user to view data clearer and permits the

Controller to display bar graphs and other new intricate data representation items.

Introduction 1

α2 Series Controllers allowing the

α2 Series

12 )Increased Memory

The CPU memory for the new

blocks to create a program algorithm and contains a 5000 byte capacity memory on board.

This manual will describe the procedure by which the

programmed from the front panel, the functions of the keys, and the powerful function block

capabilities.

1.2 Model Name

The α2 Series Controllers can be identified using the following format:

AL2 - α2 Series Controller

** - Total number of I/O

M - Main Unit

α2 Series Controller allows a maximum of 200 function

α2 Series Controllers can be

AL2- ** M R - A/D

A - 100~240V AC

D - +24V DC

R - Relay Type output

1 - 2

Page 13

α

2

Simple Application Controllers

2. Function Block Programming

The α2 Series Controller is programmed with a user-friendly method of combining special

dedicated purpose function blocks. The task is broken down into various stages which can be

represented by a number of function blocks. Function Block Programming simplifies

application representation but ensures complete process control. The program can be

developed in very simple steps but even a complex task can be represented in this way. For

ease of use, the function blocks have been preprogrammed to perform certain tasks yet offer

flexibility to be tailored to individual requirements.

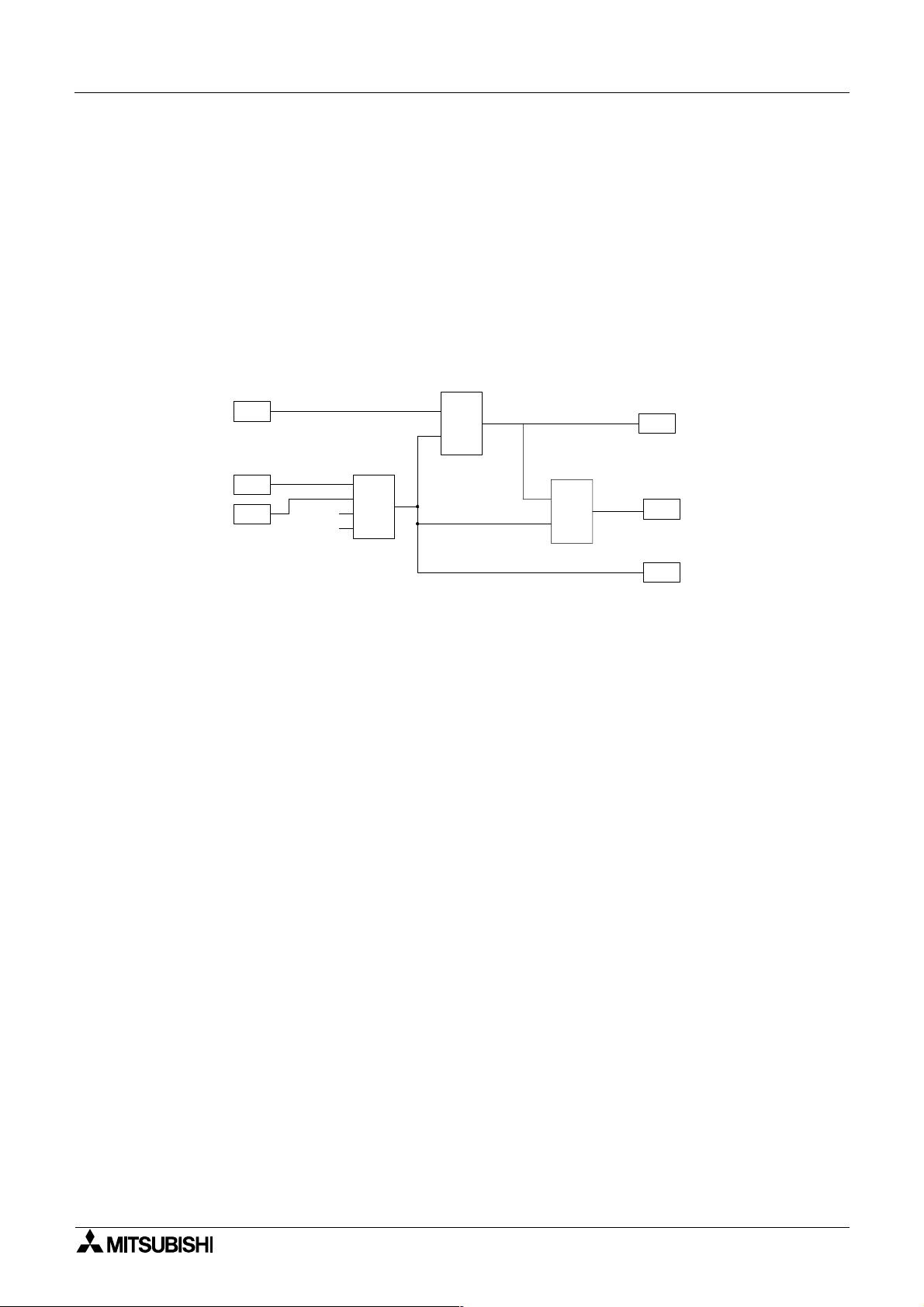

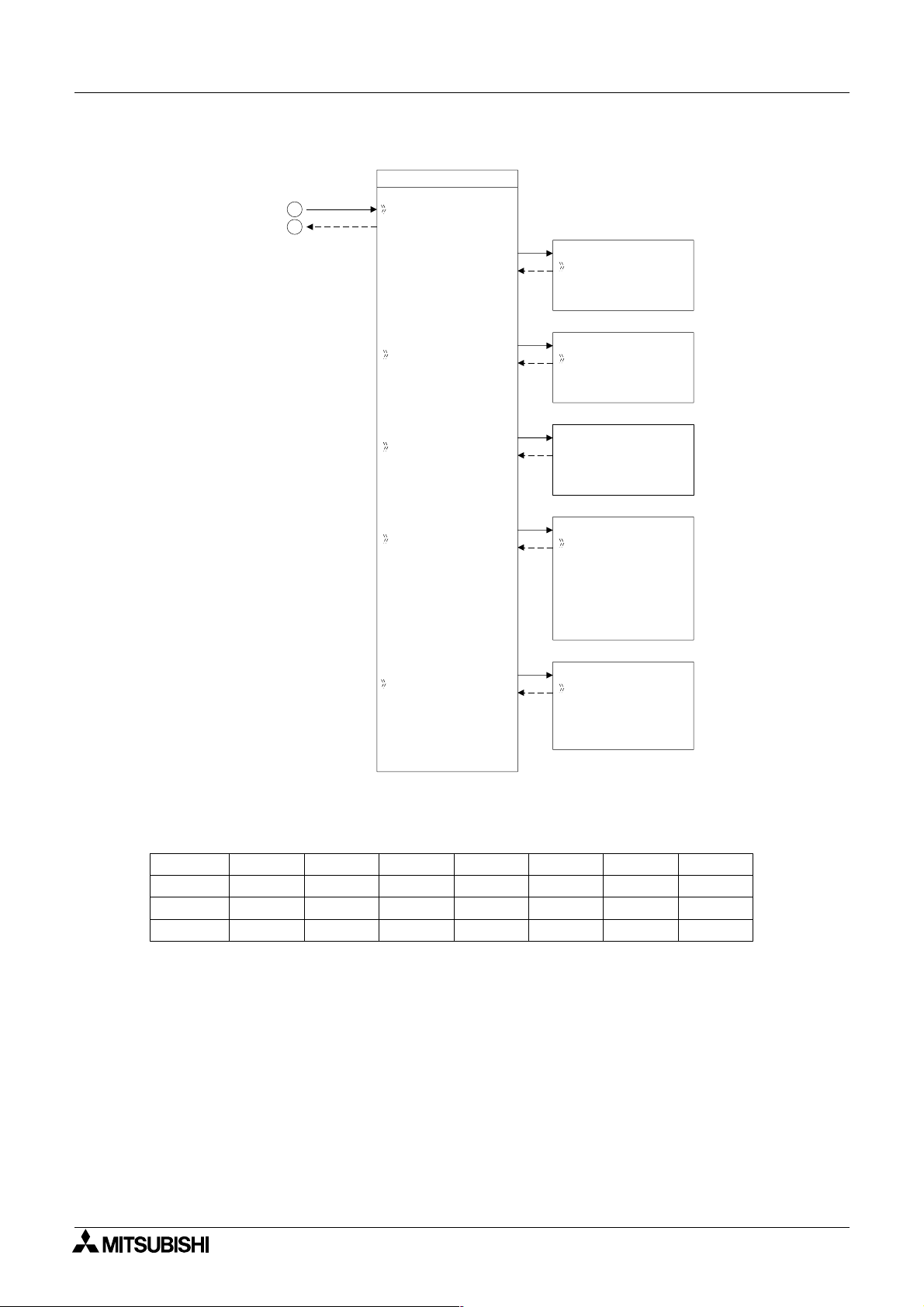

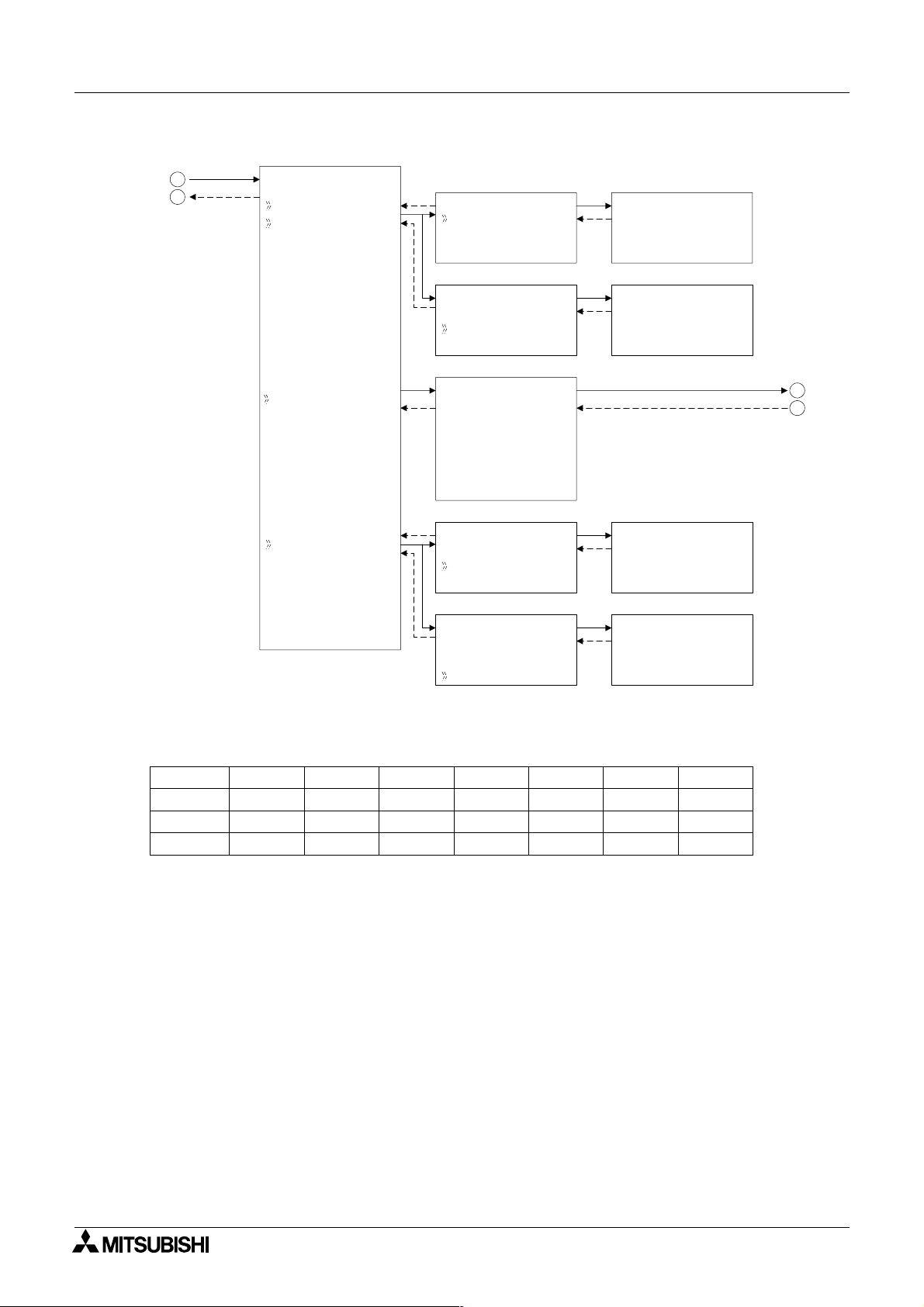

Figure 1.1: Principle of Function Block Programming

B001

I01

S

OS

C

Function Block Programming 2

O01

One Shot

I02

I03

1

2

3

4

B002

OR

I0n - Input n

O0n - Output n

OR - OR Boolean Function Block

SR - Set/Reset Function Block

OS - One Shot Function Block

The user can build a complex circuit in small easy steps by starting at the input and working

forward in a logical manner. The

α2 will gather and process information and provide the

necessary control for the application according to the system algorithm. Each individual

function block provides specific control parameters, accessible by the user, to tailor each program for complete application suitability. The function blocks are connected together to form a

circuit using the Function Block Diagram (FBD.)

2.1 Block Type and the FBD base

B003

S

SR

R

Set/Reset

O02

O03

There are seven sets of items that can be used in the function block program: Inputs, Front

Panel Keys, System Memory Bits, Logic Blocks, Function Blocks, User-defined Function

Blocks and Outputs. A brief description of each follows.

2 - 1

Page 14

α

2

Simple Application Controllers

2.1.1 Inputs

The α2 Series Controller will accept both digital (On/Off) and analog (mV value based)

electrical information through the system Inputs. Please refer to the

electrical information, wiring diagrams and input specifications. Depending on the chosen

controller there are either 14 or 24 input version types of the

are referenced to I01, I02, ..., I15.

Function Block Programming 2

α2 Hardware Manual for

α2 Series Controller. The Inputs

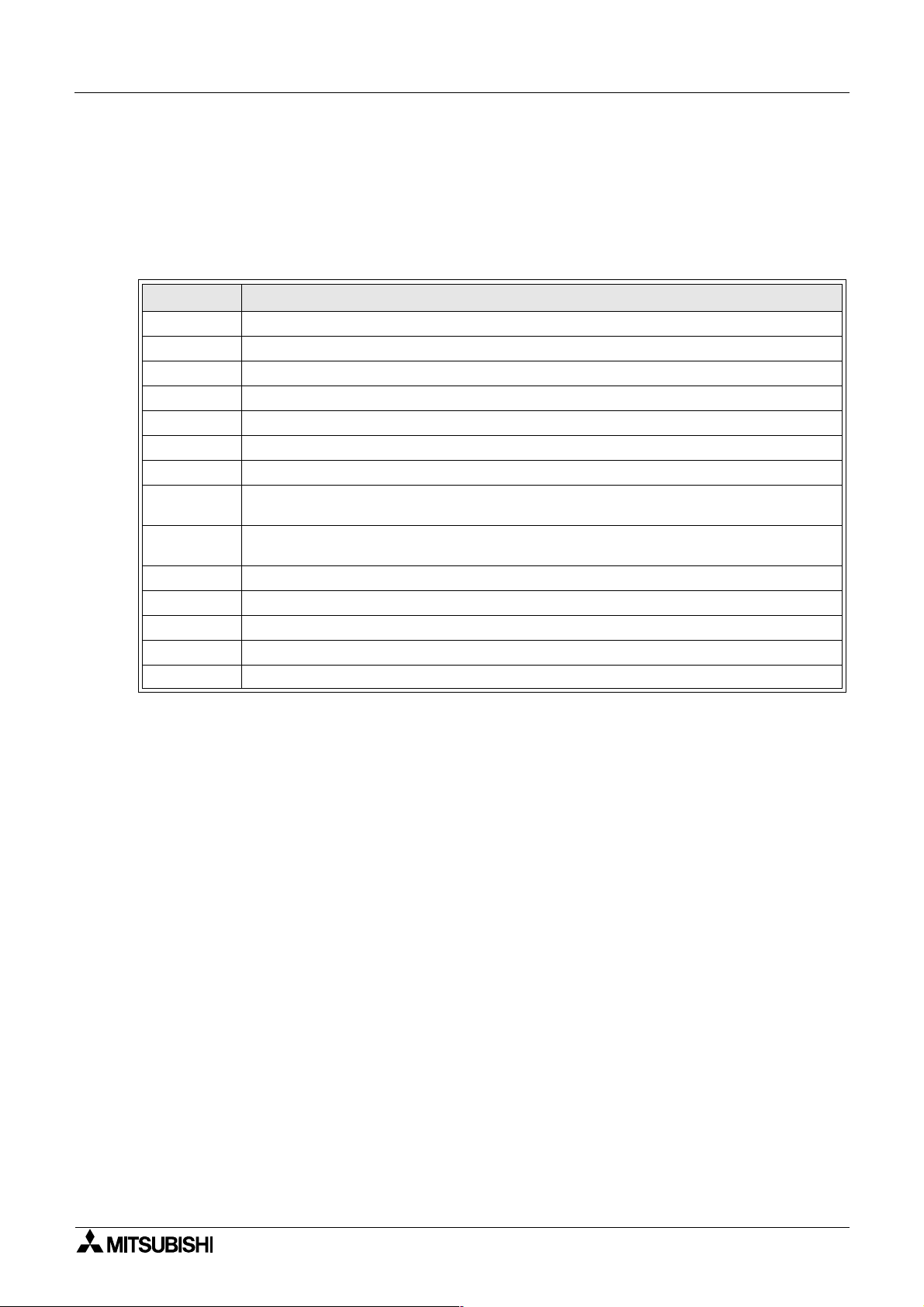

Table 2.1: Input type for the

Input Input Number Description

Signal I01 - I15 Maximum of 15 Inputs are allocated for use.

AS-i E01 - E04 Maximum of 4 AS-interface inputs are allocated for use.

Analog A01 - A08 Maximum of 8 Analog inputs are allocated for use on input I01 to I08.

Extension EI01 - EI04 Maximum of 4 Extension inputs are allocated for use.

2.1.2 Front Panel Keys

The front panel keys can enter data into the program memory, move through menus or

programs, select programming options, or be used as extra inputs when the program is

running. There are eight keys which are referenced as K01 - K08.

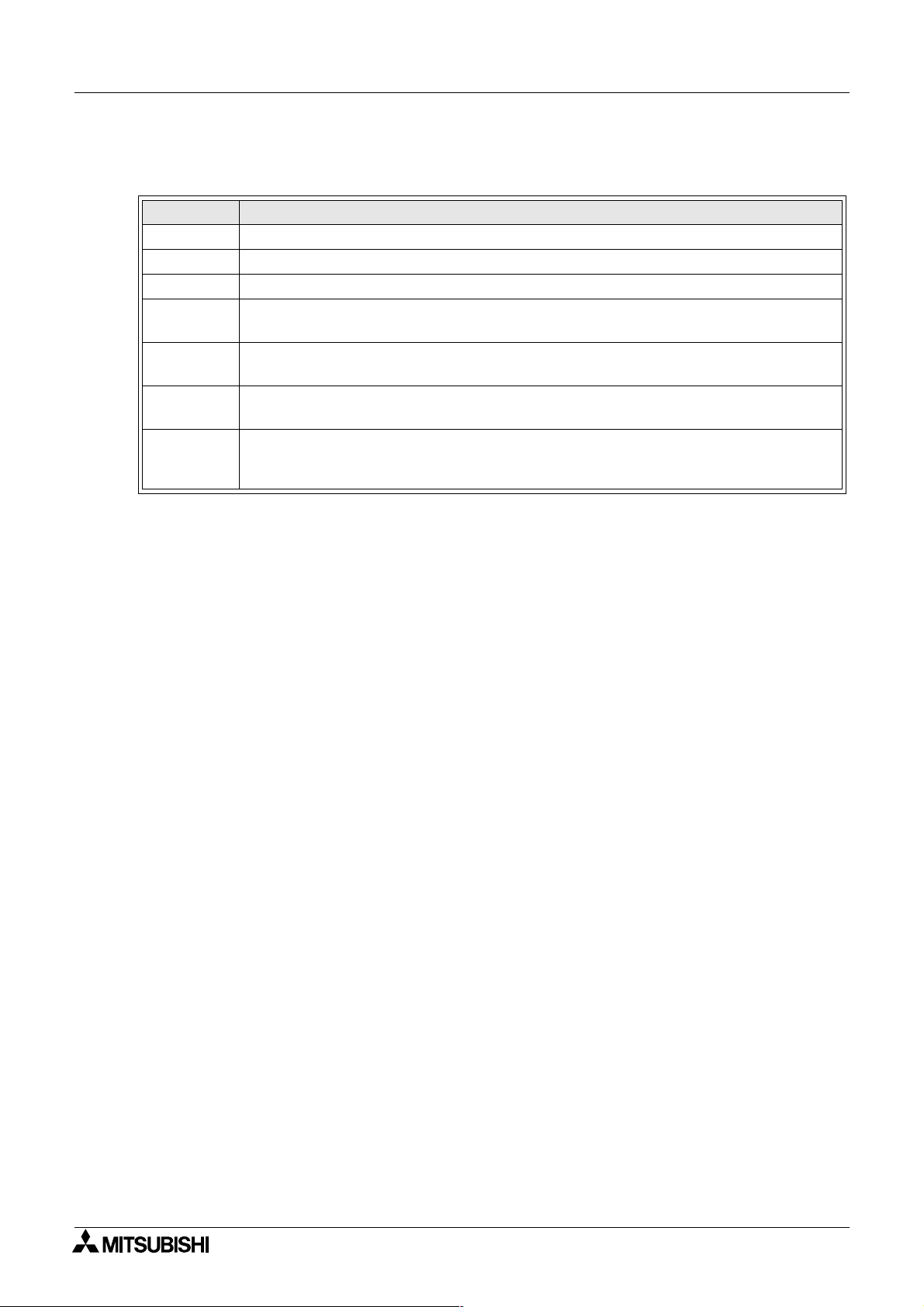

Table 2.2: Front panel keys for the

Key Name Key number Key Function

OK K01

ESC K02

“+” K03

“-” K04

( ) K05

( ) K06

( ) K07 Move to the right on the LCD display, FB program, or Jump command

( )

K08 Move to the left on the LCD display, FB program, or Jump command

α2 Series Controller

α2 Series Controller

Used to enter menu options, confirm data entry, and manually force

inputs ON/OFF in the monitor function.

Used to cancel an operation, move to a higher level screen, or to

move to a new menu.

Used to connect (or “add”) function blocks, increase Direct Set input

values or times, or move through programs or menus.

Used to disconnect function blocks, decrease Direct Set values or

times, or move through programs or menus.

Scroll up through menu options (menus, keys, FB, Inputs, Outputs,

etc.)

Scroll down through menu options (menus, keys, FB, Inputs, Outputs,

etc.)

2 - 2

Page 15

α

2

Simple Application Controllers

2.1.3 System Memory Bits

These System Memory Bits can provide predefined signals - Always On, Always Off, 0.5

second On, 0.5 second Off, or provide information about the Real Time Clock time or errors

etc. There are fourteen Memory bits that are referenced to M01, M02, ... M14.

Function Block Programming 2

Table 2.3: System Bits for the

System Bit Description

M01 Always “ON”.

M02 Always “OFF”.

M03 Alternate - 0.5 seconds “ON”, 0.5 seconds “OFF”.

M04 “ON” when Real Time Clock data error occurs.

M05 “ON” when Summer time schedule is activated.

M06 “ON” when AS-interface communication Error occurs.

M07 “ON” when communication Error caused by AS-interface power failure occurs.

M08

M09

M10 Reserved

M11 Reserved

M12 “ON” when CD (DCD) signal is turned ON (receiving CD signal from the modem.)

M13 “ON” when it is possible to access the GSM network.

M14 “ON” when the α2 series controller is accessed via GSM

“ON” when Stop mode turns to Run mode in the α2 Series. The “ON” signal acts as a

pulse output and then turns “OFF”.

“OFF” when Stop mode turns to Run mode in the α2 Series. The “OFF” signal acts as

a pulse output and then turns “ON”.

α2 Series Controller

2.1.4 Function Blocks

Programming the α2 Series Controller is based upon the combination of different function

blocks. They process the information received from the previously mentioned inputs and

control the system Outputs. They can also provide input signals or information to other

function blocks using word outputs pins. To make programming easier, the Function Blocks

have all been preprogrammed. Therefore, parameters within each function block dialog box

can be set according to the intended application. There are 38 Function Blocks available, they

are described in detail throughout Chapters 5 and 6.

2 - 3

Page 16

α

2

Simple Application Controllers

2.1.5 Outputs

Table 2.4: Outputs for the α2 Series Controller

Outputs Description

O01 - 09 Signal output

A01 - 04 AS-interface Output

EO1 - E04 Extension Output

N01

N02*1

N03*1

N04

Note: *1 When both N02 and N03 are ON and hence the back light is “ON” because N03 is

given the priority.

Function Block Programming 2

ON: Disconnected to AS-interface network

OFF: Connect to AS-interface network

ON: The back light is “OFF” in LCD.

OFF: The back light is controlled by the “Light Time” setting in Menu.

ON: The back light is “ON” in LCD.

OFF: The back light is controlled by the “Light Time” setting in Menu.

ON: The user screen is controlled by the setting of “Display Manager” with AL-PCS/

WIN-E.

OFF: The user screen is controlled by user program.

2.1.6 Function Block Diagram (FBD) base

The Function Block Diagram provides the base for which all programming actions for the α2 is

performed. Both the

FBD base contains a Title rectangle on the top, Input rectangles on the left and Output

rectangles on the right. The FBD base is also known as FBD wiring area. All the components

should be placed only within the FBD base rectangle except for the input and output signals

which can be placed in the FBD wiring area or in the Input or Output rectangles.

α2 controller and the AL-PCS/Win-E software use the FBD base. The

2 - 4

Page 17

α

2

Simple Application Controllers

2.2 Programming Methods

2.2.1 Direct Programming

Direct Programming uses the keys on the front panel to create the program and enter any

required data values. The method for Direct Programming is explained in this manual

beginning at Chapter 4.

2.2.2 AL-PCS/WIN-E Programming Software Ver 2.00

This windows based software allows the user to drag and drop the desired Function Block

icons onto the FBD base and construct a program. The program is downloaded to the

controller via the AL-232CAB cable. The visual on-screen connections make the software

easy to grasp for beginners and experienced users alike. The AL-PCS/WIN-E Programming

Software is fully explained in the

Figure 2.1: AL-PCS/WIN-E Programming Software Ver 2.00

α Software Manual.

Function Block Programming 2

α2

Note: Do not simultaneously program the

programming keys and AL-PCS/WIN-E Ver 2.00 methods as this may cause harm.

α2 Series Controller from the direct

2 - 5

Page 18

α

2

Simple Application Controllers

Function Block Programming 2

MEMO

2 - 6

Page 19

α

2

Simple Application Controllers

3. System Menu

3.1 Menu Options Instructions

There are Systems Menus to help guide the user through the options available in the α2. The

TopMenu has a Run Mode that is accessed while the

accessed when the

The Edit Menu and the Function Block Edit Menu can be accessed when in either ProgEdit or

Monitor. These menus can be used to create and/or change programs steps or values.

Use the “OK” key to enter a programming option or to enter data into memory.

Set all the data on the screen before using the “OK” key to write the data to the system

memory. If there are multiple data screens in an option, enter the required data and accept

each screen with the “OK” key.

The “ESC” key will move the screen back to a higher menu option. It will cancel any data input

that has not been accepted with the “OK” key.

α2 is idle.

System Menu 3

α2 is in operation or a Stop Mode that is

Note

Use the “ESC” key to exit the option to the higher menu; at times, it will be necessary to press

the “ESC” key a number of times to move to through multiple programming layers.

3.2 The Stop Mode

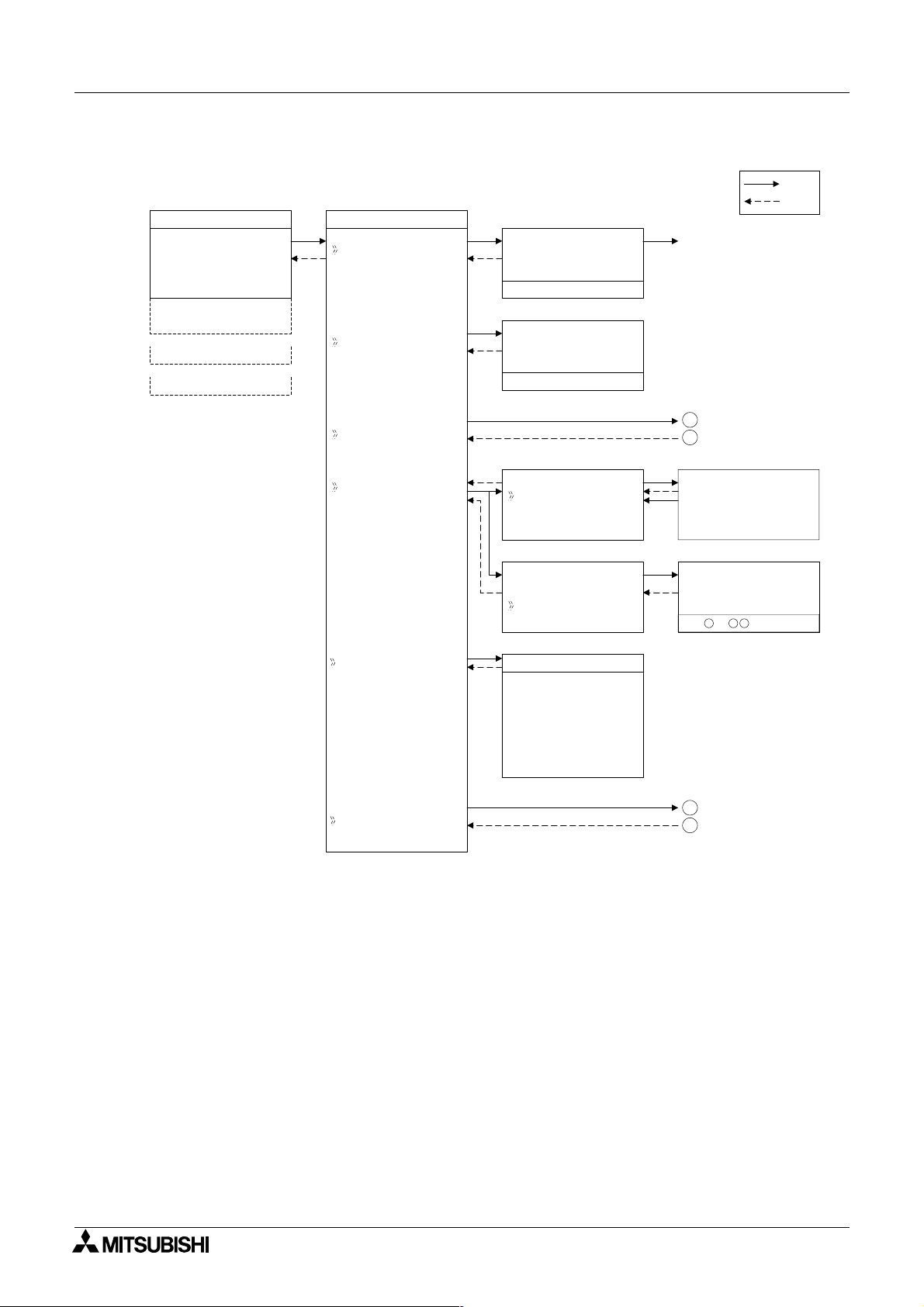

3.2.1 Top Menu

When the α2 is first turned On, the Input/Output Image Table will appear. Press the “OK” and

“ESC” keys simultaneously to move to the TopMenu.

(If the TopMenu cannot be accessed the Menu Key has been set to “Not Use”),

• Run:

Places the controller in Run mode.

•Setup TS:

Provides a simple method to edit Time Switches from the Top Menu (only selectable if a

TSm function block has been chosen.)

• ProgEdit:

Allows program editing/creation on the display using the front panel keys. The current

memory will be overwritten as changes are made to the program. Programs can be saved

on an AL2-EEPROM-2 memory cassette or in the AL-PCS/WIN-E software Version 2.0 or

above.

• ClockSet:

Set the Real Time Clock or input a daily clock adjustment.

• LANGUAGE:

Choose from 6 onscreen languages: English, German, French, Italian, Spanish, or

Swedish.

• Others...

3 - 1

Page 20

α

2

Simple Application Controllers

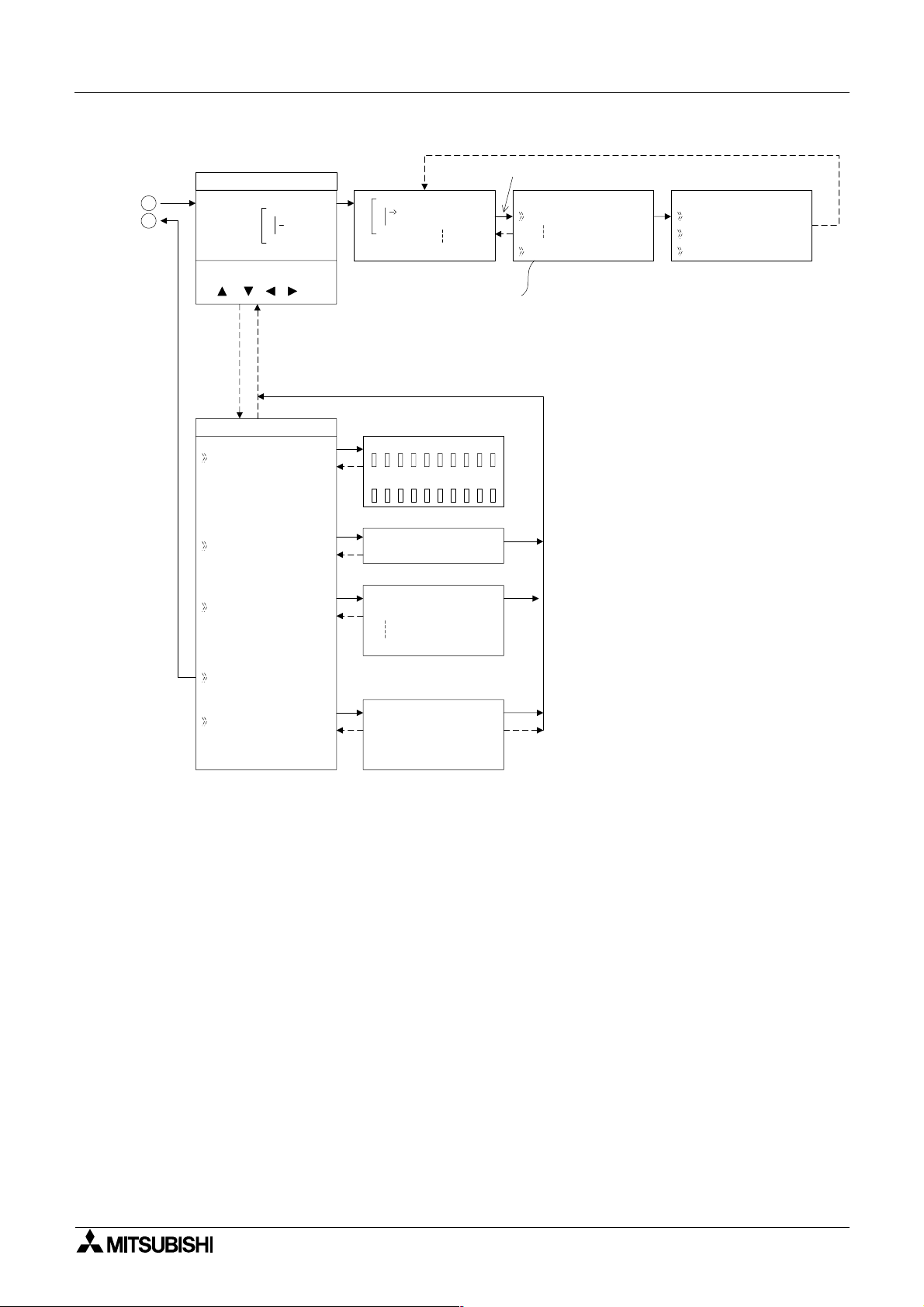

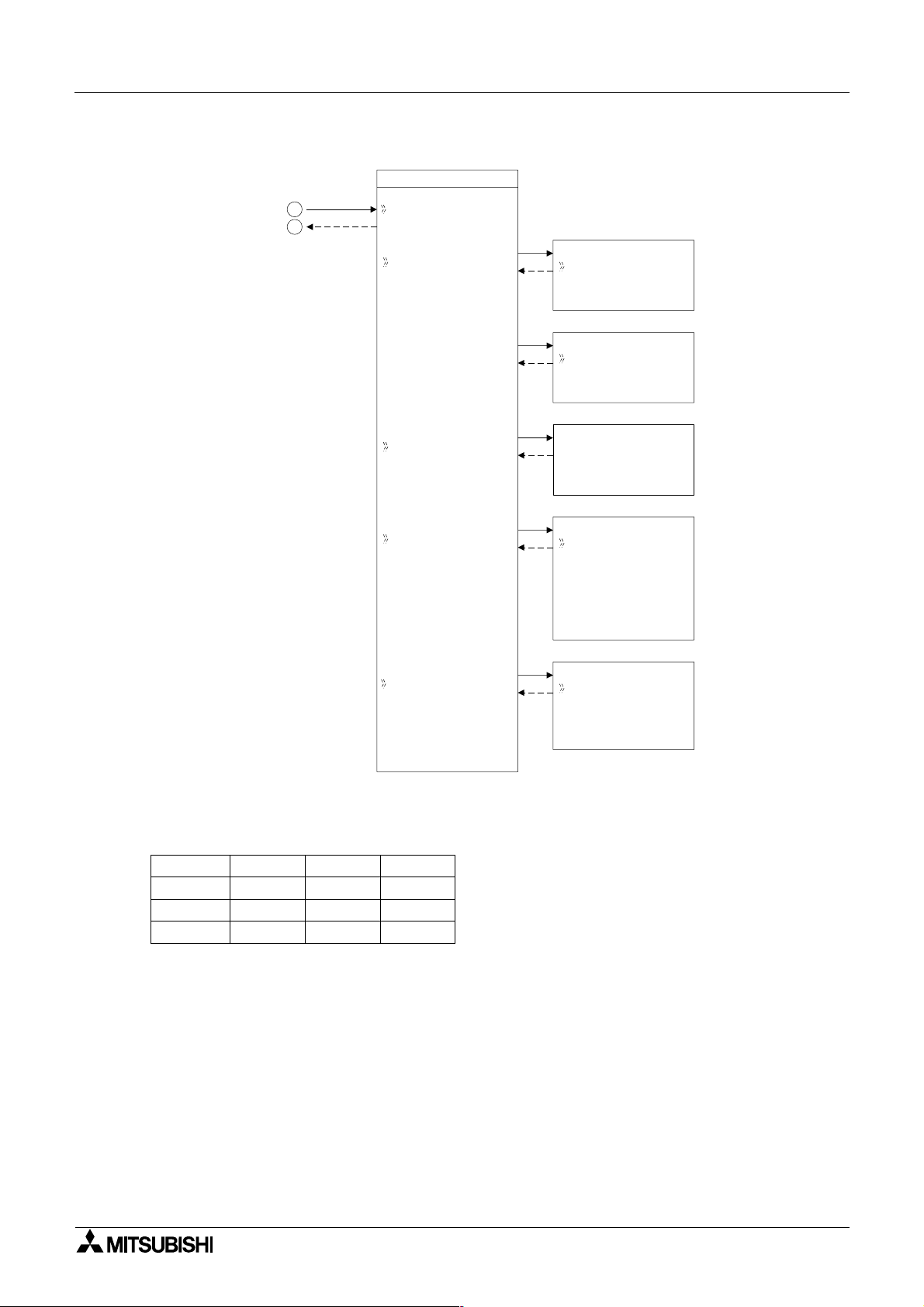

Figure 3.1: TopMenu in Stop Mode operation

10: 19 Fr i

•2••5 • •9

I:

•1••••5

O: 1• • 4 • • 8•

E:1• •4

A: •23

EI : • •41

EO : 2 3 ••

•

TopMenu

Run

Se t upTS

Run / S t op

OK o r ESC

Se t up

Stop

NoDa t a

→

Run

ST

System Menu 3

OK

ESC

Run Mode

ProgEd i t

Cl ockSet

LANGUAGE

Ot he r s

Cl ockSe t

Cl ockSet

Co r r ec t

Cl ockSe t

Cl ockSet

Co r r ec t

LANGUAGE

Eng l i s h

Ge r man

French

Italian

Spani sh

e

Sw d i s h

1

2

Cl ockSe t

dd/mm/ yyyy

30/ 11 / 2001

10: 45 Fr i

Co r r e c t

•s/d

3

4

3 - 2

Page 21

α

2

Simple Application Controllers

3.2.2 The “Others...

• Version:

Displays CPU Version of the

• Scan Time:

Monitor the Current, Maximum, or Minimum program scan times. Upon controller reset

current, Maximum and Minimum values for scan times are reset to 0.

• Password:

Restrict entry to the ProgEdit and Monitor mode with a four digit password.

• DispPass:

Set up to three Passwords for Display function blocks.

• Menu Key:

Two settings are possible, “Not Use” or “OK + ESC”. “Not Use” is designed so that

unauthorised people cannot access the

setting is selected, simultaneously depress the “OK” and the “ESC” keys to access the Top

Menu.

• Summertime:

Choose the preferred daylight savings time: Cancel, Manual On, Date Type, UK type, US

type, or EU type.

• Serial Com:

Choose the type of communication to be used for the right hand side serial communication

port - Not Use, Modem, GSM or Other Com.

• Light Time:

Set the backlight off delay time.

• ProgClear:

Completely clears the system memory including Password protected programs. Only the

active memory is cleared, i.e. if a memory cassette is installed, the memory cassette program will be erased but the controller memory will be retained.

• ProgTran. (only appears if a cassette is installed):

Verify,

Cassette à (the cassette writes to the α2), Cassette ß(the cassette reads

from the α2), and ProtectSW are the options available.

System Menu 3

α2 Series Controller.

α2 Top Menu in Run mode. If the “OK + ESC” key

3 - 3

Page 22

α

2

Simple Application Controllers

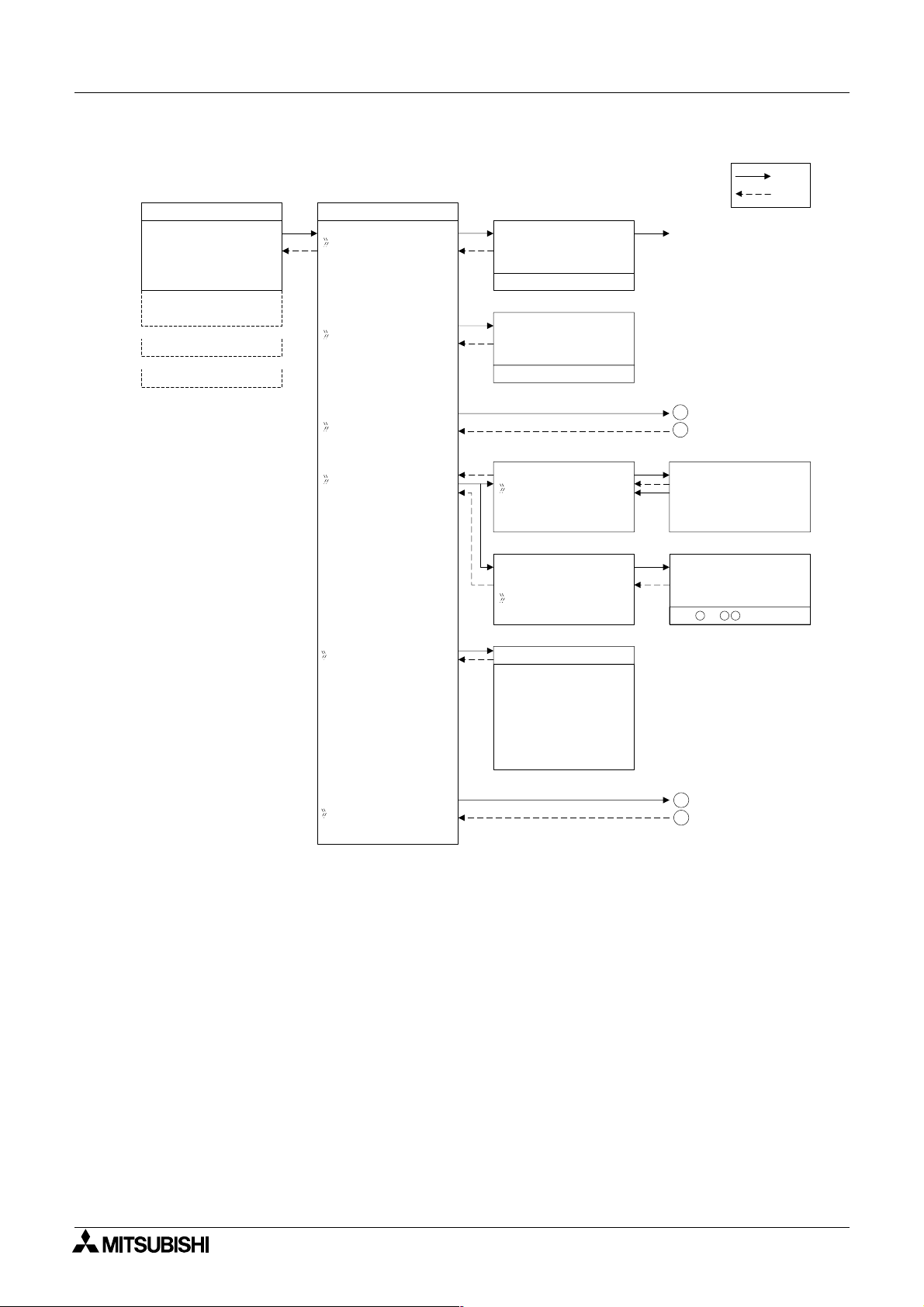

Figure 3.2: Others Menu in Stop Mode operation

3

4

System Menu 3

Others...

Ve r s i on

Ve r s i on

Ve r * . * *

ScanT i me

Pas swo r d

Di spPass

Me n u K e y

ScanT i me

Mo n i t o r

Res e t

ScanT i me

Mo n i t o r

Res e t

Se t u p

Pas swo r d

Di spPass

Leve l 1

Leve l 2

Leve l 3

MenuKey

No

Use

ON+

ESC

Key

ScanT i me

Cu r . 0ms

Ma x .

Mi n

Re s e t

ScanT i me

OK o r ESC

Se t up

Di spPass

Leve l 1

12ms

0ms

Summe r T ime

Se r i a l Com

LightTime

Progcl ear

ProgTran

Summe r T ime

Can c e l

Ma n u a l On

Da t aTy p e

UK T y p e

US T y p e

EU T y p e

Se t up

LightTime

2m

Pr ogCl ea r

OK o r E SC

Summe r T ime

31/ 03

~30 / 10

+60mi n

5

6

3 - 4

Page 23

α

2

Simple Application Controllers

Figure 3.3: Serial Com in Stop Mode operation

System Menu 3

5

6

Se r i a l Com

No t Us e

Modem

GSM

Ot he rCom

ModemIn i t

Command

De l y T i me

a

ModemIn i t

Command

De l y T i mea

GSM

Comf o rma t

GSM I n i t

GS Re mo t e

M

P NCode

I

Se t SMS

GSMStatus

Ot he rCom Ot he rCom

Comf o rma t *

Stat i onNo

Li nkBl ock

Ot he rCom

Comf o rma t *

Stat i onNo

Li nkBl ock

ModemIn i t01

Command

[]

yz{ | } ! "#$

ModemIn i t

De l y T i mea

0s

Stat i onNo

No . 0

Ot he rCom

Li nkBl ock

0.

7

8

Figure 3.4: Communication Format in Stop Mode Operation

* Comformat

Datalengt h

Parity

Stopbit

Baudrate

8 bits

None

1 bit

300 bps 600 bps 1200 bps

7 bits

Odd

2 bits

---

Even

---

---

---

---

2400 bps

---

---

---

4800 bps

---

---

---

9600 bps

---

---

---

19200 bps

3 - 5

Page 24

α

2

Simple Application Controllers

Figure 3.5: GSM Menu in Stop Mode operation

System Menu 3

GSM

7

8

Comf o rma t *

GSM I n i t

M

GS Re mo t e

I

P NCode

Se t SMS

GSM I n i t

Commnd

De l ay T i me

M

GS Re mo t e

Fo r b i t

Pe rmi t

PI NCode

Se t up

[****]

Se t SMS

SMSC1

SMSC2

DA1

DA2

DA3

VP

GSMStatus

GSMStatus

Status

CMEE r r o r

CMSE r r o r

SigSei ng

Figure 3.6: Communication Format in Stop Mode operation

* Comformat

Datalengt h

Parity

Stopbit

Baudrate

8 bits

None

1 bit

300 bps 600 bps 1200 bps

7 bits

Odd

2 bits

---

Even

---

---

---

---

2400 bps

---

---

---

4800 bps

---

---

---

9600 bps

---

---

---

19200 bps

3 - 6

Page 25

α

2

Simple Application Controllers

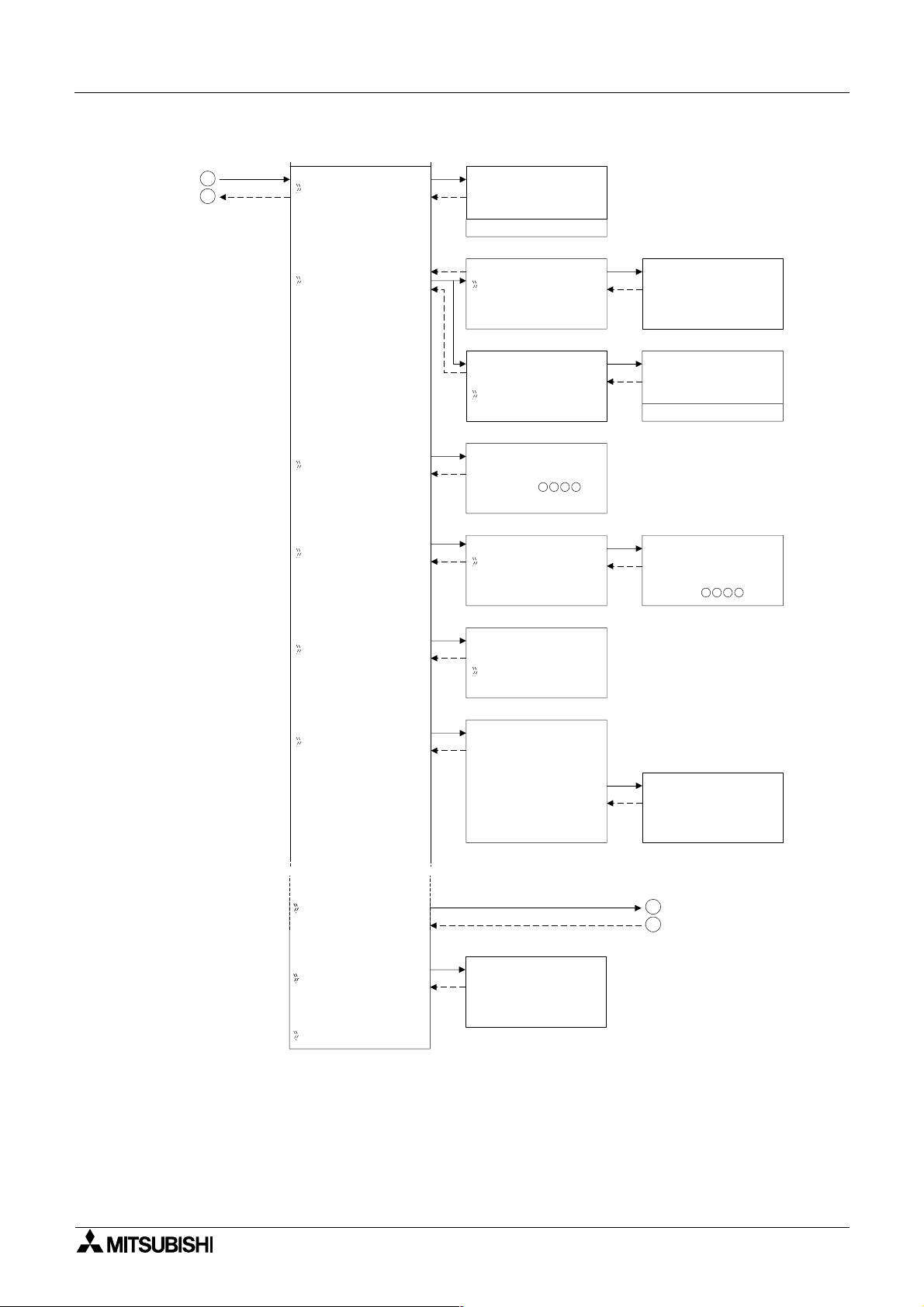

System Menu 3

Pr ogr amScr een

1

2

(OK, ESC, +, -,

, , , )

Edi tMenu

ProgSi ze

Jump

NewFB

01

In

01

Add FB

O 01

Connect EO 04

Bl ock 0FB

Memo r y 0%

Jump

MIOKEANEIEOB

FBSe l ec t

AND

Adding Function Blocks

FBSe l ec t

AND

De l ay edA

(+) or (-) Skips to

the next topic

upFB

ter

*1

*3

FBPa r ame

Se t

ChangeN*2o

L

*1

Function Block Specific

*2

Changes Function Block Number

*3

Deletes Functi on Block from

FBD

De l e t eFB

De l ay edA

Ex i t

Mn e mo n i c

M0 1 -

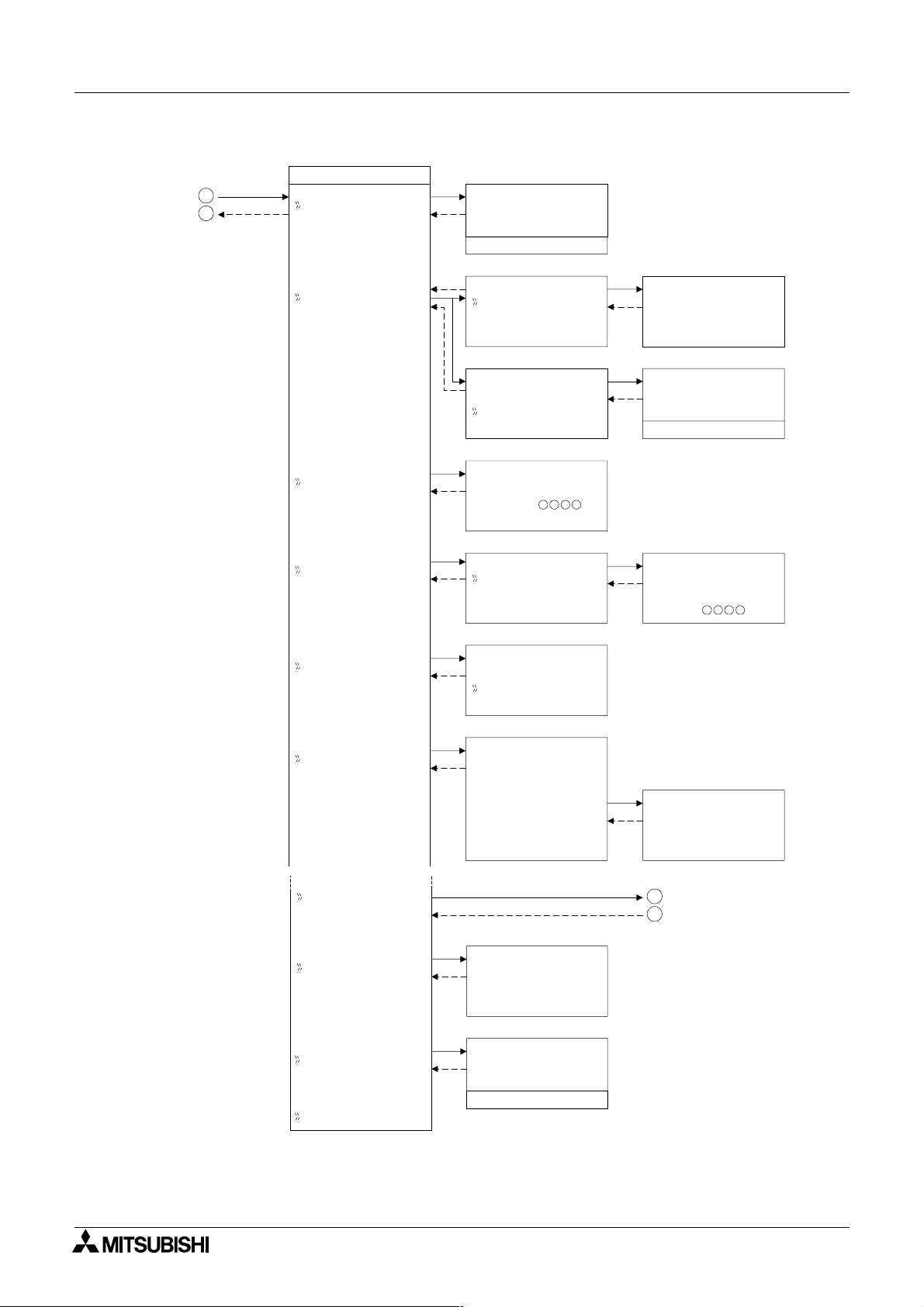

3.3 The Run Mode Top Menu

When the α2 program is running, the LCD defaults to the Image Table screen. According to

the Menu Key setting, proceed to the Stop Mode of the Top Menu by using the “OK” and the

“ESC” keys or reset the controller by powering down.

• Stop:

Takes the

•Setup TS:

Provides a simple method to edit Time Switches from the Top Menu.

• Monitor:

Monitor the program settings while in the Run mode and perform limited editing to FB

parameters. The existing programming steps cannot be modified.

•ClockSet:

Set the Real Time Clock or input a daily clock adjustment.

• LANGUAGE:

Choose the on-screen language from English, German, French, Italian, Spanish, or

Swedish.

•Others

α2 out of Run mode.

L

3 - 7

Page 26

α

2

Simple Application Controllers

Figure 3.8: TopMenu in Run Mode Operation

10: 19 Fr i

I :•2••5 ••9

•1••••5

O: 1• • 4 • • 8•

E:1• •4

A: •23

EI : • •41

EO : 2 3 ••

•

TopMenu

Stop

Se t upTS

Run / S t op

→

Run

Stop

OK o r ESC

Se t up

TS

NoDa t a

System Menu 3

OK

ESC

Stop Mode

Mo n i t o r

Cl ockSet

LANGUAGE

Others

Cl ockSe t

Cl ockSet

Co r r ec t

Cl ockSe t

Cl ockSet

Co r r ec t

LANGUAGE

Eng l i s h

Ge r man

French

Italian

Spani sh

e

Sw d i s h

1

2

Cl ockSe t

dd/mm/ yyyy

30/ 11 / 2001

10: 45 Fr i

Co r r e c t

•s/d

3

4

3 - 8

Page 27

α

2

Simple Application Controllers

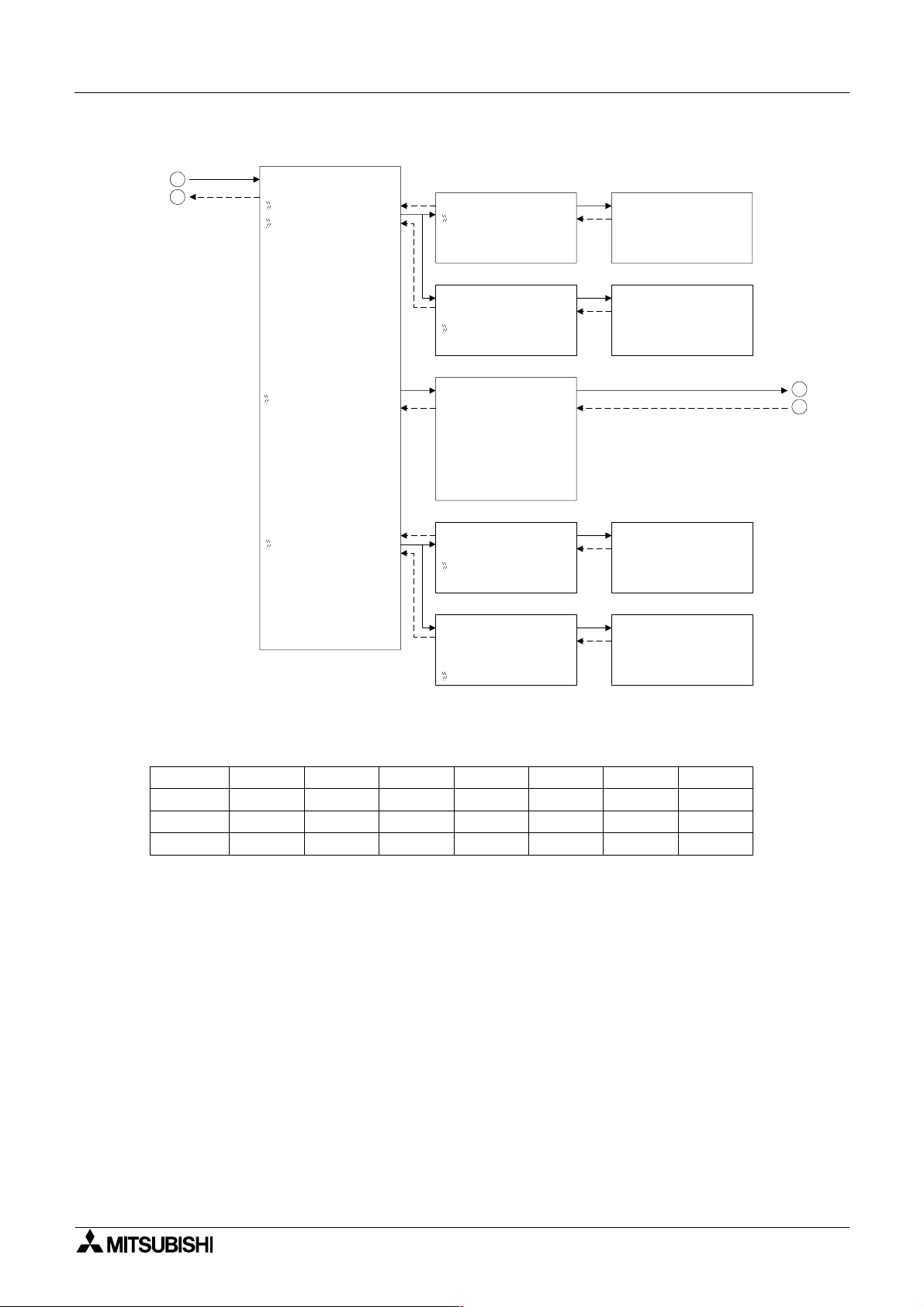

Figure 3.9: Others Menu in Run Mode operation

System Menu 3

3

4

Ve r s i on

ScanT i me

Pas swo r d

Di spPass

Ve r s i on

Ve r * . * *

ScanT i me

Mo n i t o r

Res e t

ScanT i me

Mo n i t o r

Res e t

Se t up

Pas swo r d

Di spPass

Leve l 1

Leve l 2

Leve l 3

ScanT i me

Cu r . 0ms

Ma x .

Mi n

Res e t

ScanT i me

OK o r ESC

Se t up

Di spPass

Leve l 1

12ms

0ms

MenuKey

Summer T i me

Se r i a l Com

LightTime

Pr ogTr an

MenuKey

No

Use

ON+

ESC

Key

Summer T i me

Can c e l

Ma n u a l On

Da t aTy pe

UK T y p e

US T y p e

EU T y p e

Se t up

LightTime

2m

Summer T i me

31/ 03

~30 / 10

+60mi n

5

6

3 - 9

Page 28

α

2

Simple Application Controllers

Figure 3.10: Serial Com in Run Mode operation

System Menu 3

5

6

Se r i a l Com

No t Us e

Modem

GSM

Ot he rCom

ModemIn i t

Command

De l ay

ModemIn i t

Command

GSM

Comf o rma t

GSM I n i t

GS Re mo t e

P NCode

Se t SMS

GSMStatus

Ot he rCom Ot he rCom

Comf o rma t *

Stat i onNo

Li nkBl ock

Ot he rCom

Comf o rma t *

Stat i onNo

Li nkBl ock

Time

TimeDe l ay

M

I

ModemIn i t01

Command

[]

yz{ | } ! "#$

ModemIn i t

TimeDe l ay

0s

Stat i onNo

No . 0

Ot he rCom

Li nkBl ock

0.

7

8

Figure 3.11: Communication Format in Run Mode Operation

* Comformat

Datalengt h

Parity

Stopbit

Baudrate

8 bits

None

1 bit

7 bits

Odd

2 bits

---

Even

---

---

---

---

2400 bps 4800 bps 9600 bps 19200 bps300 bps 600 bps 1200 bps

---

---

---

---

---

---

---

---

---

3 - 10

Page 29

α

2

Simple Application Controllers

Figure 3.12: GSM Menu in Run Mode operation

System Menu 3

GSM

7

8

Comf o rma t *

GSM I n i t

M

GS Re mo t e

I

P NCode

Se t SMS

GSM I n i t

m

Com and

De l ay T i me

GSR emo t e

Fo r b i t

Pe rmi t

PI NCode

Se t up

[****]

Se t SMS

SMSC1

SMSC2

DA1

DA2

DA3

VP

GSMStatus

GSMStatus

Status

CMEE r r o r

CMSE r r o r

SigSt ing

Figure 3.13: Communication Format in Run Mode operation

* Comformat

Datalengt h

Parity

Stopbit

Baudrate

8 bits

None

1 bit

9600 bps

7 bits

Odd

2 bits

19200 bps

---

Even

---

---

r

3 - 11

Page 30

α

2

Simple Application Controllers

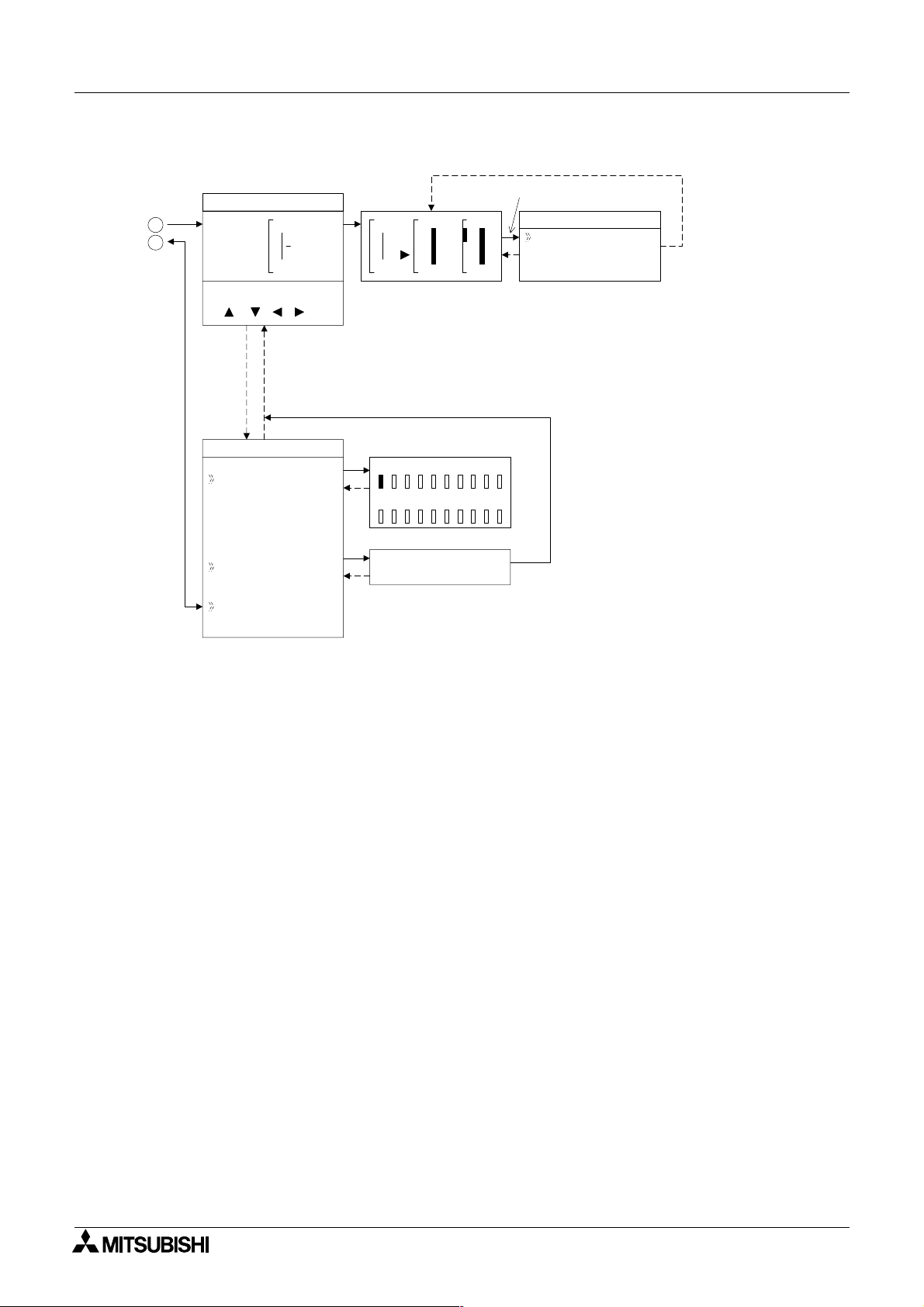

Figure 3.14: Monitor Screen in Run Mode.

System Menu 3

Moni t o r Sc reen

1

2

(OK, ESC, +, -,

, , , )

Edi tMenu

ProgSi ze

Jump

Ex i t

01

B002

B003

In

Bl ack 4FB

Memo r y 1%

Jump

MIOKEANEIEOB

01

In

=S

003

P- I

RSR

Setti ngs for Function Blocks

02

Out

FBSe t t i n

-

Se t

*1

Individual for each Function Block.

g

up

3 - 12

Page 31

α

2

Simple Application Controllers

3.4 The Edit Menu

The Edit Menu can be entered when the α2 is in the ProgEdit or Monitor main programming

screen. If entering options or connecting FBs, these procedures have to be finished or

canceled before the Edit Menu can be entered. Press the “ESC” key at any place in the main

programming screen to enter the Edit Menu.

• ProgSize:

Shows the numbers of FBs used and percentage of program memory used.

• Jump:

Leads to a screen that shows available places to go in the program. “M” - system bits; “I” system Inputs; “O” - System Outputs; “K” - Keys (1-8); “E” - ASi Inputs; “A” - ASi Outputs;

“N” - Control bits; “EI” - External Board inputs; “EO” - External Board outputs; and “B” Function Blocks existing in the program. Choose the desired block with the arrow keys

and press the “OK” key to jump to that spot in the program.

• New FB:

Create a new Function Block from one of the available FBs.

• Exit: Exits to the Top Menu.

• Mnemonic:

Gives a mnemonic display of the current programming rung. Enter the programming

mode by pressing the “OK” key or return to the Edit Menu using the “ESC” key. (Not

available in Monitor Mode).

System Menu 3

3.5 The Function Block Edit Menu

The Function Block Edit Menu can be entered only while in the ProgEdit or Monitor mode.

Move to the Function Block to edit and press the “OK” key when the Function Block number is

flashing.

• Setup FB:

Optimise variables in the Function Blocks for your application. See Chapter 6 for more

details on each Function Block’s Options. The logic functions in Chapter 5 do not have

Setup Options.

• Change No: Change the Function Block Number

• Delete FB: Delete Selected Function Block

3.6 Option Screen Setup

Various options have been provided for ease of use or for safety purposes. Please set as your

needs require. All of the options in this section can be accessed from either the Run or the

Stop Menu.

3.6.1 ProgEdit

Refer to the Direct programming chapter 4 for detailed combinations of key presses to be able

to program the

3.6.2 Change the Language Setting

α2 Series Controller.

1 ) Turn the α2 On.

2 ) Press the “OK” and “ESC” button to go to the Top Menu or reset the controller.

3 ) Scroll to the “LANGUAGE” option and press the “OK” key. The spelling for “LANGUAGE”

does not change.

4 ) Scroll to the desired language and press the “OK” key. The languages available are

English, German, French, Italian, Spanish, and Swedish.

5 ) Use the “ESC” key to exit to the Topmenu.

3 - 13

Page 32

α

2

Simple Application Controllers

3.6.3 ClockSET

To set the Clock:

1 ) From the TopMenu, scroll to “ClockSet” and press the “OK” key.

2 ) From the options that appear, choose “ClockSet” and press the “OK” key.

3 ) Use the arrow keys to move an area that needs to be changed.

4 ) Adjust with the “+” or “-” keys.

5 ) Repeat steps 3-4 until ALL changes have been accomplished.

6 ) Press the “OK” key to accept all the changes.

7 ) Press the “ESC” key to return to the Top Menu having discarded the clockset options.

To set the daily correction:

1 ) From the TopMenu, scroll to “ClockSet” and press the “OK” key.

2 ) From the options that appear, choose “Correct” and press the “OK” key.

3 ) Set the daily correction time with the “+” or “-” keys.

4 ) Press the “OK” key to accept the value and press the “ESC” key to return to the Top Menu.

Note: The date setting can be displayed as yyyy/mm/dd, dd/mm/yyyy, or mm/dd/yyyy

by manipulating the “+” and “-” keys. The day of the week will update automatically as

the date is changed.

System Menu 3

3.6.4 SummerTime

The Summertime menu will display six choices when entered.

Cancel - Turns off the Summertime clock setting.

Manual On - Moves the clock one hour ahead immediately and will remain ON until cancelled.

Date Type - Set the On date, Off date, and Time adjustment.

UK Type - Last Sunday of March to the last Sunday of October.

US Type - First Sunday of April to the last Sunday of October.

EU Type - Last Sunday of March to the last Sunday of October.

The time changes for the UK type take place at 1:00 AM in the Spring and 2:00 AM in the

Autumn. Time changes in the EU setting take place at 2:00 AM in the Spring and 3:00 AM in

the Autumn. The date settings are equivalent.

If the display time has been adjusted for the Summertime setting, an “s” will precede hour

number on the screen.

How to Set the Summertime Setting:

1 ) Select “Others” from the Top Menu.

2 ) Select “Summertime”.

3 ) Scroll to the desired setting (see above for information on settings).

4 ) Press the “OK” key to accept.

5 ) If the display time has been adjusted, an “s” will precede hour number on the screen. If

the date is outside of the adjustment range, no visible sign will appear.

3 - 14

Page 33

α

2

Simple Application Controllers

3.6.5 Password

The password consists of four digits and will prohibit entry into the ProgEdit, Monitor, Disp

Pass and Serial Com modes only. All other menu options can be accessed when a Password

is used.

To Enter a Password:

1 ) Select “Other” Menu Option.

2 ) Select “Password” from the “Other” Menu Options

3 ) Use the “+” and “-” keys to enter the desired password.

4 ) Press the “OK” key to accept and activate the password.

5 ) A key symbol will now be displayed at the top of the

To Cancel a Password:

1 ) Select the “Other” Menu Option.

2 ) Select “Password” from the “Other” Menu Options. “Cancel Password” should appear on

the top of the screen.

3 ) Use the “+” and “-” keys to enter the current password.

4 ) Press the “OK” key to accept and deactivate the password.

5 ) The key symbol will be removed from the

System Menu 3

α2 display.

α2 display.

Note 1: A Password protected program in an AL2-EEPROM-2 Cassette can be run from and

be downloaded into the main body of the controller.

Note 2: A controller containing a Password protected program can accept or transfer

programs to an AL2-EEPROM-2.

Note 3: The Password can also be set/deleted from the AL-PCS/WIN-E software or deleted by

the “PROGCLEAR” command.

3.6.6 Serial Com

The modem function capability of the α2 allows remote monitoring via a PC and program

upload/download. The communication must take place using the Visual Logic Software (VLS)

and the communication must be initiated accordingly. (The modem connected to the

initialised upon the

available).

Command - Enter the AT command for the modem to be connected to the controller.

Reference the Modem User manual for details on that unit’s AT command. Choose the first

letter or symbol by using the ( ) and ( ) arrows. When the symbol is showing in the

command line, use the

symbols and accept the whole string with the “OK” key when finished inputting the data.

(There is no need to accept each letter with the “OK” key).

α2 is

α2 start-up. Dialing options from a command or specific conditions are not

( ) and ( ) arrows to move to adjoining spaces. Enter up to 64 letters/

Delay - The Delay function sets the length of time the α2 will wait after entering the Run mode

before turning on the modem. Choose a value of 0 - 10 seconds using the “+” or “-” keys. The

modem connected to the Personal Computer with the VLS software must be set ON prior to

the

α2 modem turning on.

The GSM function allows a SMS (Short Message Service) message to be sent to either a

mobile telephone or an email account. The SMS provides the remote user with the identical

LCD screen’s data. Refer to the

concerning GSM parameters.

α2 Communication Manual for detailed explanation

3 - 15

Page 34

α

2

Simple Application Controllers

The OtherCom function provides the user with an on-line programming feature using

dedicated protocol. Refer to the

concerning Dedicated Protocol parameters.

3.6.7 Memory cassette

The Memory Cassette EEPROM is the active memory whenever it is properly installed in

the

α2 controller. The controller must be Powered down before installing/removing the

memory cassette or an error will occur.

To Verify a Program:

1 ) Install the AL2-EEPROM-2. Refer to the AL2-EEPROM-2 instruction manual.

2 ) Select “Others” in the Top Menu.

3 ) Select “ProgTran.”

4 ) Select “Verify”.

5 ) Choose “OK” to proceed or “ESC” to exit.

6 ) If the program is successfully verified, the work “Completed” will blink on screen.

7 ) If the programs are not the same, the words “Verify Error” will blink onscreen.

System Menu 3

α2 Communication Manual for detailed explanation

To Transfer a Program from the Cassette to the

1 ) Install the AL2-EEPROM-2. Refer to the AL2-EEPROM-2 instruction manual.

2 ) Select “Others” in the Top Menu.

3 ) Select “ProgTran.”

4 ) Select “Cassette

5 ) Choose “OK” to proceed or “ESC” to exit.

6 ) When the program is successfully transferred, “Completed” will blink on the display.

To Transfer a Program from the

1 ) Install the AL2-EEPROM-2. Refer to the AL2-EEPROM-2 instruction manual.

2 ) Select “Others” in the Top Menu.

3 ) Select “ProgTran.”

4 ) Select “Cassette

5 ) Choose “OK” to proceed or “ESC” to exit.

6 ) When the program is successfully transferred, “Completed” will blink on the display.

To apply the “ProtectSW” Feature:

The “ProtectSW” will write protect the program in the memory cassette. The program cannot

be edited nor erased when the feature is ON.

1 ) Install the AL2-EEPROM-2 per the instruction manual.

2 ) Select “Others” in the Top Menu.

3 ) Select “ProgTran.”

4 ) 4. Select “ProtectSW”.

5 ) Choose “On“ to activate the feature.

→”.

α2 to the Cassette:

←”.

α2:

3 - 16

Page 35

α

2

Simple Application Controllers

To Remove the “ProtectSW” Feature:

1 ) Install the AL2-EEPROM-2. Refer to the AL2-EEPROM-2 instruction manual.

2 ) Select “Others” in the Top Menu.

3 ) Select “ProgTran.”

4 ) Select “ProtectSW”.

5 ) Choose “Off“ to de-activate the feature.

3.7 LCD Displays

There are a number of types of data and/or information that can be displayed on the LCD

display besides the menus listed previously.

3.7.1 Image Table

The first LCD display to appear is the Input/Output image table and the Real Time Clock. The

clock shows the current time as Set by the User. The Summertime mode is shown by an “s”

preceding the time if activated.

3.7.2 LCD Function

System Menu 3

Display up to 12 different letters or characters on each of four lines. Options include character

strings (design your own message), function block data, or analog data.

3 - 17

Page 36

α

2

Simple Application Controllers

3.8 Block Items

Each block item contains an individual diagram that shows the block number, available number

of input pins, the output pin if applicable, and the block mnemonic. Connections between

blocks can be viewed at the pin locations when connected blocks are shown individually on the

LCD.

3.8.1 Input Blocks

The Input Blocks consist of System Inputs (I01 - I15), Key Inputs (K01-K08), and System Bits

(M01-M14). The input number is shown in the top right hand corner, the type of input in the

lower right hand corner, and the output pin is shown on the far right of the block. Input Blocks

provide information to the Function Blocks or Outputs.

3.8.2 Function Blocks

The individual Function Blocks are described in detail in Chapters 5 and 6. Function Blocks

can have from 0 to 4 input pins shown on the left of the diagram and an output shown on the

far right. Some function blocks have data that can be used for comparison purposes only or

are used to display data onscreen. These blocks have no output pins. The number and block

mnemonic are shown in the top right and bottom right locations respectively.

System Menu 3

3.8.3 Output Blocks

Output Blocks have one input and one output pin. They only have the capacity for one input

signal through the input pin. The Output Block number and Mnemonic are shown in the top

right and lower right hand corner of the diagram respectively.

3.8.4 Connected Blocks

Blocks that are connected can be shown simultaneously onscreen. The block providing the

output signal will be shown on the left of the screen. The input pin accepting the signal will

flash. Any input pin that is already connected will be shown as a solid triangle.

3 - 18

Page 37

α2

Simple Application Controllers

4. Direct Programming

The α2 can be programmed using the front panel keys on the α2 series controller. When the

function block diagram is complete, the program can be logically entered into the

following sections will describe how to connect/disconnect function blocks, set program

parameters, add Function Blocks, and move around within the program.

The ProgEdit mode in the Stop Menu has full programming capability. The Monitor mode in the

Run Menu has the capability to manipulate Function Block values and settings but cannot edit,

change, or delete the existing program.

4.1 Block Availability

The number of System Inputs and Outputs is determined by the type of controller being

programmed. Configurations include 8 In / 6 Out and 15 In / 9 Out. Up to 200 Function Blocks

can be used in a program or 5000 bytes of memory. The Function Blocks must be added in the

course of programming. The 8 Keys and the 14 system M bits are automatically available for

every program.

Inputs, Outputs, System Memory Bits, Extended Inputs, Extended Outputs, AS-i Outputs,

Control Bits, and Keys do not count in the Function Block total.

Direct Programming 4

α2. The

4.2 Connecting Blocks

Any block that has an output pin can be connected to any block that has an (unused) input pin.

System Inputs, Keys, and Memory M bits have output pins only.

Function Blocks and Outputs both contain input and output pins (the Display and TimeSwitch

Blocks are exceptions). Blocks can be connected beginning with an output pin, from “left to

right” on the display, or beginning with an input pin, from “right to left” on the display.

4.2.1 To connect the blocks from the left (signal provider) block to right (signal receiver) block.

It is necessary to choose the block to provide the output (step 1), the block to accept the signal

(step 2), and the pin with which to accept the signal (step 3).

1 ) Step 1: Select the block providing the data to be output and move to the right until the

output pin is flashing. Press the “+” button to “add” a block.

1nI0

2 ) Step 2: Choices will appear on the right side of the screen that include System Outputs (if

available), existing Function Blocks that have free input pins, and the option to add a new

function block (AddFB, see section 4.4). Scroll to the preferred option and select using the

“OK” key.

1oC0

nncet

4 - 1

dAFdB

0O1

Page 38

α2

Simple Application Controllers

Direct Programming 4

3 ) Step 3: The block accepting the signal will display as many of its input pins as possible (at

times they will not all fit on-screen). Pins that have been used will show as filled triangles;

pins that are open will show as “>” signs. A “Connect” prompt will appear on-screen, either

above or below the left hand block. The current input choice will flash. Scroll to the desired

pin and press the “OK” key to accept. The process is complete.

1oC0

nncet

4.2.2 To connect the blocks from the right (signal receiver) block to left (signal provider) block.

It is necessary to choose the block input pin (Step 1), the signal provider (Step 2), and to

accept the connection (Step 3).

1 ) Step 1: Select the block that will be receiving the signal and move left until an input pin is

flashing. Scroll to the desired unused input pin (“>”). Press the “+” key to begin the

connection process.

10

010

P

010

P

2 ) Step 2: Because output pins may have multiple connections, all the Keys, Function Blocks,

System Inputs, Outputs will show on the left of the screen as well as an option to “AddFB”.

Scroll to the preferred option and Press the “OK” key.

3 ) Step 3: The chosen connection will be flashing on-screen along with the “Connect” prompt.

Press the “OK” key to accept.

4.3 Disconnect Two Blocks

Blocks can be disconnected by implementing the following procedure.

Move to the connection that is to be disconnected. Enter “-” as the disconnect command. A

“Disconnect” prompt will appear on-screen. Press the “OK” key to accept the disconnect.

nI

oCtc

e

nn

FddAB

1

0M

oCtce

nn

nI

NC

P

NC

P

NC

4 - 2

Page 39

α2

Simple Application Controllers

4.4 Methods to Create a Function Block

The two methods of creating a Function Block. The New FB option in the Edit Menu and

AddFB option when connecting two blocks.

4.4.1 New FB

To use the New FB option, proceed to the Edit Menu (Chapter 3) using the “ESC” key. Scroll to

the New FB option and press the “OK” key. Scroll to the desired Function Block and press the

“OK” key to create a New FB. The block will appear on the Function Block Diagram board.

4.4.2 AddFB

Direct Programming 4

eleSBFtc

ADN

OR

naeloBo

R

/teSsete

eteRtnRS

aleDeyAd L

When connecting a Function Block, scroll to the AddFB prompt and press the “OK” key. This

invokes the Function Block list. Scroll to the desired Function Block and choose by pressing

the “OK” key. The Function Block will be shown on the screen with the connecting block.

4.5 Function Block Editing

To enter the Function Block editing menu (Chapter 3), press the “OK” key when the Function

Block number and name is flashing on the screen. Up to three options appear on-screen:

Setup FB, Change No, and Delete FB. The Setup Function option is not valid for some

Function blocks and so will not always appear and certain function blocks will also contain a

Time unit option (refer to chapter 6 for function block specification).

4.5.1 Setup Function Block

Each Function Block has its own individual parameters outlined in Chapter 6. The Function

Blocks might have multiple data screens that can be optimised. As with other menu options,

the “ESC” key will move the screen back to a higher menu option without changing the option

parameters for that screen. If there are multiple data screens in an option, enter the required

data and accept each screen using the “OK” key. Use the “ESC” key to exit the Function Block

“OK” button.

4.5.2 Change No. (of a Function Block)

Change the number of an existing Function Block with this screen. The current FB number is

shown on-screen when the option is entered. Scroll up or down with the “+” or “-” keys to find

an open FB number. Press the “OK” key to accept the new number.

4.5.3 Delete FB

This menu option will Delete the current Function Block. After the Delete FB is chosen, confirm

the delete operation with “OK” or use the “ESC” key to cancel the function. All connections to

the Function Block will be removed with the block.

4 - 3

Page 40

α2

Simple Application Controllers

4.6 Movement between Function Blocks

There are a number of ways to move from one item to another when in the ProgEdit or Monitor

modes.

4.6.1 Movement Between Unconnected Blocks

Movement between System Inputs, System Outputs, Keys, and M bits can be accomplished

with the “+” and “-” keys. When the block number is flashing on-screen, press the “+” key to

scroll to the higher value of the same block type; e.g. move from I01 to I02 to I03...until the

highest value is reached. The scroll will then proceed to the lowest value of the next block

type. The same technique will work for the “-” key in the opposite direction.

Function Blocks can be scrolled through in the same manner, although only the Function

Blocks are rotated through in this case.

4.6.2 Movement Between Connected Blocks

The Right arrow moves horizontally (to the right) along the path of connections between

blocks. If an output pin is connected to multiple input pins, the current path will flash. The Up

and Down arrows can be used to choose the desired path. The left arrow will move back along

the path of the connections to the left.

Direct Programming 4

4.6.3 The Jump Command

The “ESC” key can be used to enter the Edit Menu at anytime when a function block is

displayed on the LCD screen. (The “ESC” key will cancel in process commands first. Keep

pressing the “ESC” key until the Edit Menu has been entered). Enter the Jump Command.

Choose any system M

E

xtended Output, or existing Function Block by using the front panel keys. Press “OK” to

emory Bit, Input, Output, Key, AS-i Input, AS-i Output, Extended Input,

“Jump” to the chosen block in the programming mode.

4.7 Using Keys as Inputs

Connect the Keys for use as Manual Inputs by using the Jump command to access the desired

key, by connecting a Function Block or Output as described in Chapter 3, or by scrolling

through the blocks as described in section 4.6.1.

The programmed Key(s) will give an output signal for as long as the key is depressed.

i

weNBF

eMtdEun

ziSgrPo

e

pmuJ

tixE

inomnMe c

4 - 4

Page 41

α2

Simple Application Controllers

4.8 The Monitor Mode

Function Block values and Output status can be manipulated from the Monitor option.

When placed in the Run mode, the

and OK” keys together to enter the Top Menu and then enter Monitor. The program will now be

displayed on-screen. Movement among the function blocks is the same as in the ProgEdit

mode.

4.8.1 Monitor/Update Function Block Values

Move to the function block to monitor and enter Setup FB. The Function Block Values can be

updated and monitored. Changes to current values will be valid only while in the Monitor

Mode. Changes to Set point data and the comparison values will be written to the system

memory.

Type Abbreviated Terms Forcing Conditions

Input I 1

Output O 2

Key K 3

System bit M 3

Control bit N 2

Function Block B 3

α2 defaults back to the I/O status screen. Press the “ESC

EI 1

E2

E0 2

A2

Direct Programming 4

(1) It is possible to force ON/OFF, however, the status is decided by hardware control.

(2) It is possible to force ON/OFF, however, the status is decided by programming control.

(3) It is not possible to force ON/OFF.

4 - 5

Page 42

α2

Simple Application Controllers

4.8.2 Forcing Outputs ON/OFF

Outputs can be forced ON/OFF if they do not have a direct conflict with the program. To force

an Output On, proceed to the position where the Output name and number are flashing and

press the “OK” key. A solid rectangle will appear underneath the block number to signify that

the block is ON.

A solid rectangle will appear underneath the block number to signify that the block is ON. Input

pins will have a smaller solid block next to their arrow to show that they are activated. In the

block at right, the Delay output pins are ON, along with the input and output pins for the system

Output O01.

Direct Programming 4

An example of a block that cannot be forced follows.

Ex. Output O01 is connected to System Bit M01. M01 is constantly ON, therefore Output O01

is constantly ON and cannot be forced OFF.

4.8.3 Add/Delete Function Blocks in the Monitor Mode

The user cannot Add or Delete Function Blocks while in the Monitor mode.

001

1uO0

t

1M0\

_

\

0O2

?

4 - 6

Page 43

α2

Simple Application Controllers

5. The Logic Function Blocks

Logic Function Blocks operate by reading whether signals are ON or OFF and then setting the

status of their Outputs accordingly. There are six types of logic blocks available in the

Series - AND, OR, NAND, NOT, NOR, XOR. Analog signals cannot be processed by the Logic

blocks. This chapter has been formulated to have a description of the Function Block, a

diagram of the Function Block as seen on the LCD Display, and a logic table to show how the

Output is controlled by the input signals.

Table 5.1: Boolean Logic function blocks

The Logic Function Blocks 5

α2

Logic

Block

State

AND

OR

NOT

XOR

Logic Block

Displayed

1

00

2

3

AND

4

1

00

2

3

OR

4

00

1

NT

00

1

2

XOR

Description

This function executes logical AND

operation on given input signals. The input

O

signals connected should be of bit input

type only. 4 Bit input pins and 1 Bit output

pin. If all the inputs are ON then the output

is ON, otherwise output is OFF.

This function executes logical OR operation

on given input signals. The input signals

O

connected should be of bit input type only. 4

Bit input pins and 1 Bit output pin. If all the

inputs are OFF then output is OFF,

otherwise output is ON.

This function executes logical NOT operation on given input signal. The input signal

O

connected should be of bit input type only. 1

Bit input pin and 1 Bit output pin. Output is

negation of Input given.

This function executes logical XOR operation on given input signals. The input sig-

O

nals connected should be of bit input type