Mitsubishi Electric AJ65BTS-RPH User Manual

CC-Link System

Spring Clamp Termnal Block Type

Repeater Hub Module

User’s Manual

AJ65BTS-RPH

Thank you for buying the Mitsubishi general-purpose programmable

logic controller MELSEC-A series.

Prior to use, please read both this manual and related manuals

thoroughly and familiarize yourself with the product.

MODEL AJ65BTS-RPH-U

MODEL

13JP97

CODE

IB(NA)-0800346-B(0612)MEE

© 2006 MITSUBISHI ELECTRIC CORPORATION

zSAFETY PRECAUTIONSz

(Read these precautions before using.)

When using Mitsubishi equipment, thoroughly read this manual and the

associated manuals introduced in this manual. Also pay careful attention to safety

and handle the module properly.

The precautions given in this manual are concerned with this product. Refer to the

user's manual of the network system to use for a description of the network

system safety precautions.

These SAFETY PRECAUTIONS classify the safety precautions into two

categories: “DANGER” and “CAUTION”.

Indicates that incorrect handling may cause hazardous

DANGER

conditions, resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous

CAUTION

Depending on circumstances, procedures indicated by may also

be linked to serious results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read it whenever

necessary. Always forward it to the end user.

conditions, resulting in medium or slight personal

injury or physical damage.

CAUTION

A-1

[DESIGN PRECAUTIONS]

DANGER

z Input/output could be switched on or off when a problem occurs in the

repeater module.

So build an external monitoring circuit that will monitor any input/output

signals that could cause a serious accident.

CAUTION

z Use the module in an environment that meets the general specifications

contained in this manual. Using this module in an environment outside the

range of the general specifications could result in electric shock, fire,

erroneous operation, and damage to or deterioration of the product.

z Do not install the control wires or communication cables together with the

main circuit or power wires.

Keep a distance of 100mm (3.94inch) or more between them.

Not doing so could result in malfunctions due to noise.

[INSTALLATION PRECAUTIONS]

CAUTION

z Do not directly touch the module's conductive parts.

Doing so may cause malfunctions or failure of the module.

z Fix the module securely with a DIN rail or screws, and when using screws,

tighten them within the specified torque range.

Undertightening can cause a drop, short circuit or malfunction. Overtightening

can cause a drop, short circuit or malfunction due to damage to the screw or

module.

A-2

[WIRING PRECAUTIONS]

DANGER

z Before installation or wiring, be sure to shut off all phases of the external

power supply used in the system.

If the power is not disconnected at all phases an electric shock or product

damage may result.

CAUTION

z Always earth the FG terminal to the protective earth conductor. Otherwise

there will be an electric shock or misoperation.

z Perform correct wiring for the module according to the product’s rated voltage

and terminal arrangement. Connecting to a power supply different from rating

or miss-wiring may cause fire and/or product failure.

z Ensure that no foreign matter such as chips and wire-offcuts enter the module.

Foreign matter can cause a fire, failure or malfunction.

z Be sure that the communication cable connected to the module is kept in the

duct or is fixed with cramps.

Failure to do so may cause a damage to the module or cables due to

dangling, shifting or inadvertent handling of cable, or malfunction because of

bad cable contacts.

z Do not install the control lines together with the communication cables, or

bring them close to each other. Failure to do so may cause malfunctions due

to noise.

z When disconnecting the communication and power supply cables from the

module, do not hold and pull the cable part.

Disconnect the cables after loosening the screws in the portions connected to

the module.

Pulling the cables connected to the module can damage the module and

cables or can cause a malfunction due to a cable connection fault.

A-3

[STARTING AND MAINTENANCE PRECAUTIONS]

CAUTION

z Do not disassemble or modify the modules.

Doing so could cause failure, erroneous operation, injury, or fire.

z Be sure to shut down all the phases of the externally supplied power used in

the system before cleaning the module, retightening the module fixing screws,

and attaching/removing the module.

Not doing so can cause the module to fail or malfunction.

z Do not install/remove the terminal block more than 50 times after the first use

of the product. (IEC 61131-2 compliant)

z Before handling the module, make sure to touch a grounded metal object to

discharge the static electricity from the human body.

Failure to do say cause a failure or malfunctions of the module.

[DISPOSAL PRECAUTIONS]

CAUTION

z When disposing of this product, treat it as industrial waste.

A-4

REVISIONS

* The manual number is given on the bottom right of the cover.

Print Date *Manual Number Revision

Oct., 2006 IB(NA)-0800346-A First edition

Dec., 2006 IB(NA)-0800346-B

Correction

SAFETY PRECAUTIONS, About the

Manual, Section 2.2, 2.3, 3.1, 3.2, 4.2.1

This manual confers no industrial property rights or any rights of any other kind,

nor does it confer any patent licenses. Mitsubishi Electric Corporation cannot be

held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

© 2006 MITSUBISHI ELECTRIC CORPORATION

A-5

CONTENTS

1. OVERVIEW ....................................................................................................1

1.1 Features ..................................................................................................1

2. SYSTEM CONFIGURATION .........................................................................3

2.1 Total configuration ...................................................................................3

2.2 Applicable system .................................................................................... 4

2.3 Cautions on system configuration ........................................................... 5

3. SPECIFICATION .........................................................................................12

3.1 General specifications ...........................................................................12

3.2 Performance specifications ................................................................... 14

3.3 Specifications of connection cable ........................................................17

3.4 Maximum transmission distance ........................................................... 18

4. PROCEDURE UP TO START OF DATA LINK ............................................19

4.1 Procedure up to start of data link ...........................................................19

4.2 Mounting and installation .......................................................................20

4.2.1 Cautions on handling .................................................................... 20

4.2.2 Installation environment ................................................................ 25

4.3 Names and settings of parts ..................................................................26

4.4 Connection of module through CC-Link dedicated cable ...................... 30

4.5 Check for state of connection (line test) ................................................ 31

5. TROUBLESHOOTING ................................................................................. 34

6. EXTERNAL DIMENSIONS ..........................................................................38

A-6

About the Manuals

The following manuals are also related to this product.

Order them if necessary.

Related Manual

Manual name

CC-Link System Master/Local Module Type AJ61BT11/

A1SJ61BT11 User’s Manual

CC-Link System Master/Local Module Type AJ61QBT11/

A1SJ61QBT11 User’s Manual

CC-Link System Master/Local Module User’s Manual

QJ61BT11N

CC-Link System Repeater (T-junction) Module Type

AJ65SBT-RPT User’s Manual

CC-Link System Optical Repeater Module Type AJ65SBTRPS/AJ65SBT-RPG User’s Manual

CC-Link System Space Optical Repeater Module Type

AJ65BT-RPI-10A/AJ65BT-RPI-10B User’s Manual

Manual No.

(Model code)

IB-66721

(13J872)

IB-66722

(13J873)

SH-080394E

(13JR64)

IB-0800078

(13JQ81)

IB-0800089

(13JQ85)

IB-0800090

(13JQ86)

CC-Link System Low Profile Waterproof Type Repeater

Hub Module User’s Manual

Compliance with the EMC and Low Voltage Directives

When incorporating the Mitsubishi PLC into other machinery or equipment and

keeping compliance with the EMC and low voltage directives, refer to Chapter 3,

"EMC Directives and Low Voltage Directives" of the User's Manual (Hardware)

included with the CPU module or base unit used.

The CE logo is printed on the rating plate of the PLC, indicating compliance with

the EMC and low voltage directives.

To conform this product to the EMC Directive and Low Voltage Directive, refer to

the Section of “CC-Link Modules” in Chapter 3 “EMC Directive and Low Voltage

Directive” of the User’s Manual (Hardware) of the CPU module used.

IB-0800288

(13JP55)

A-7

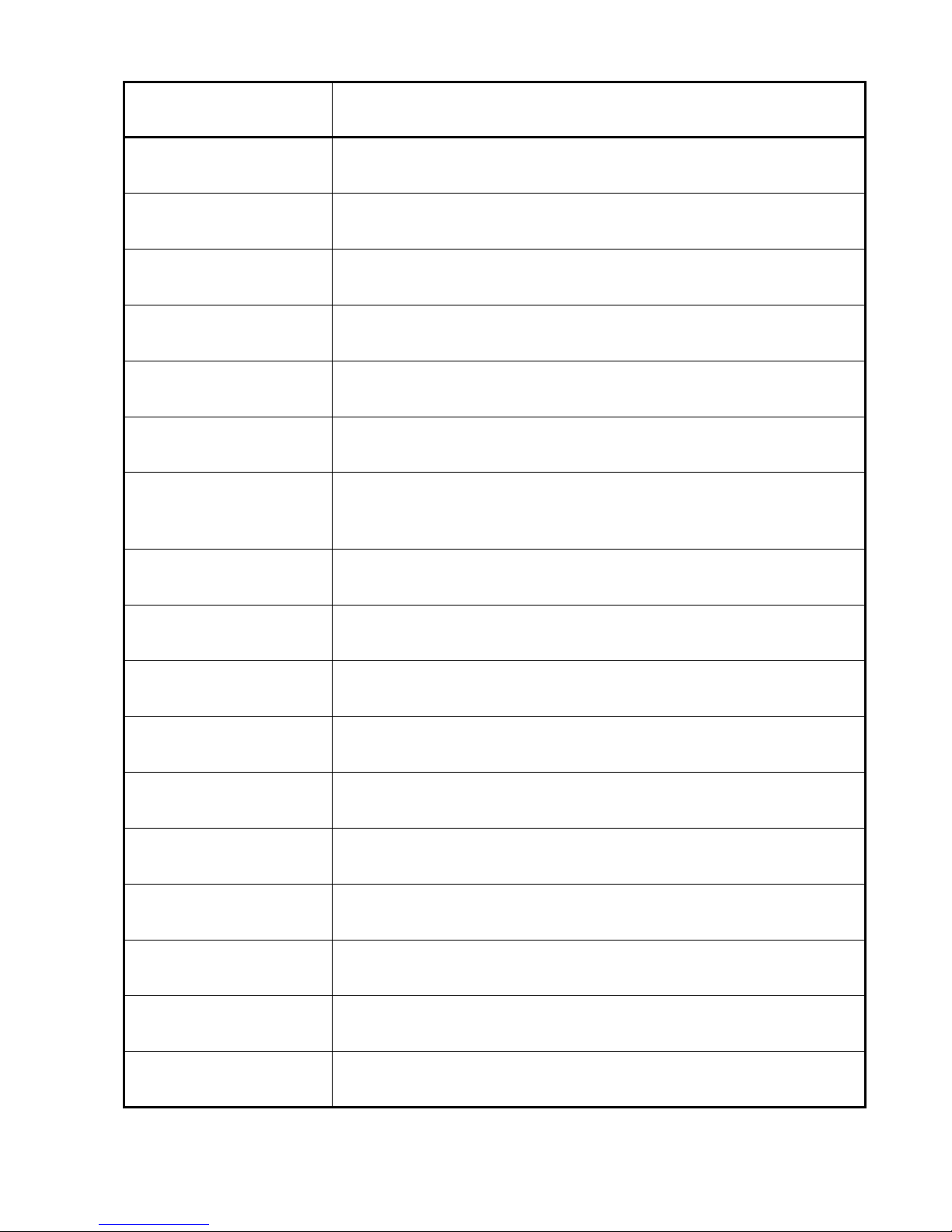

Abbreviated names, generic names and terms

Abbreviated names,

generic names and terms

AJ-65BTS-RPH

AJ65FBTA-RPH

AJ65SBT-RPT

AJ65SBT-RPS/RPG

AJ65BT-RPI-10A/10B

AJ65SBT-CLB

Segment

Description

Abbreviation of AJ65BTS-RPH type CC-Link system spring clamp

terminal Block type Repeater hub module.

Abbreviation of AJ65FBTA-RPH type CC-Link system low profile

waterproof type repeater hub module.

Abbreviation of AJ65SBT-RPT type CC-Link system repeater (Tjunction) module.

Abbreviation of AJ65SBT-RPS/AJ65SBT-RPG type CC-Link

system optical repeater module.

Abbreviation of AJ65BT-RPI-10A/AJ65BT-RPI-10B type CC-Link

system space optical repeater module.

Abbreviation of AJ65SBT-CLB CC-Link - CC-Link/LT bridge

module.

System between terminating resistors connected to each other

through cross-over cables.The conventional CC-Link system can be

said to be configured with one segment.

Master station

Local station

Remote I/O station

Remote device station

Remote station

Intelligent device station

Repeater

Standby master station

Slave station

Station to control the data link system. One station is required for

each system.

Station which has a sequencer CPU and can communicate with the

master station and the other local stations.

Remote station processing only information in unit of bit.

(AJ65BTB1-16D, AJ65SBTB1-16D, etc.)

Remote station processing only information in unit of bit and in unit

of word. (AJ65BT-64AD, AJ65BT-64DAV, AJ65BT-64DAI, etc.)

Generic name of remote I/O station and remote device station.

Controlled by the master station.

Station allowing transient transmission such as AJ65BT-R2.

(Including local stations)

Module for expanding the CC-Link system by connecting the

segments to each other.

Backup station which inherits data link control when the master

station comes off parallel due to error.

Generic term of remote I/O station, remote device station, local

station, intelligent device station, and standby master station.

Master local module

Generic name of QJ61BT11N, QJ61BT11, AJ61BT11,

A1SJ61BT11, AJ61QBT11 and A1SJ61QBT11.

A-8

Abbreviated names,

generic names and terms

Generic name of QJ61BT11N, QJ61BT11, AJ61BT11,

Master module

Local module

Intelligent device module Module allowing transient transmission such as AJ65BT-R2.

A1SJ61BT11, AJ61QBT11 and A1SJ61QBT11 when these are

used as the master station.

Generic name of QJ61BT11N, QJ61BT11, AJ61BT11,

A1SJ61BT11, AJ61QBT11 and A1SJ61QBT11 when these are

used as the local station.

Description

Product structure

The product structure of AJ65BTS-RPH is as shown below.

Product name Quantity

AJ65FBTA-RPH module 1

Terminating resistor kit 1

For a trunk line (Bar terminal type): 110Ω (brown,

brown, brown)

For a trunk line (Bar terminal type): 130Ω (brown,

orange, brown)

For a branch line (Y terminal type): 110Ω (brown,

brown, brown)

1

1

8

A-9

1. OVERVIEW

This User’s Manual describes the specifications, names of parts, and

settings of the AJ65BTS-RPH type CC-Link system spring clamp terminal

block type repeater hub module (hereafter abbreviated as AJ65BTS-RPH)

used in the CC-Link system.

1.1 Features

The AJ65BTS-RPH is the module designed for improving flexibility in

cable wiring of the CC-Link system.

Using the AJ65BTS-RPH allows the extension of the transmission

distance and star-topology wiring (with 8 branch lines) in the CC-Link

system.

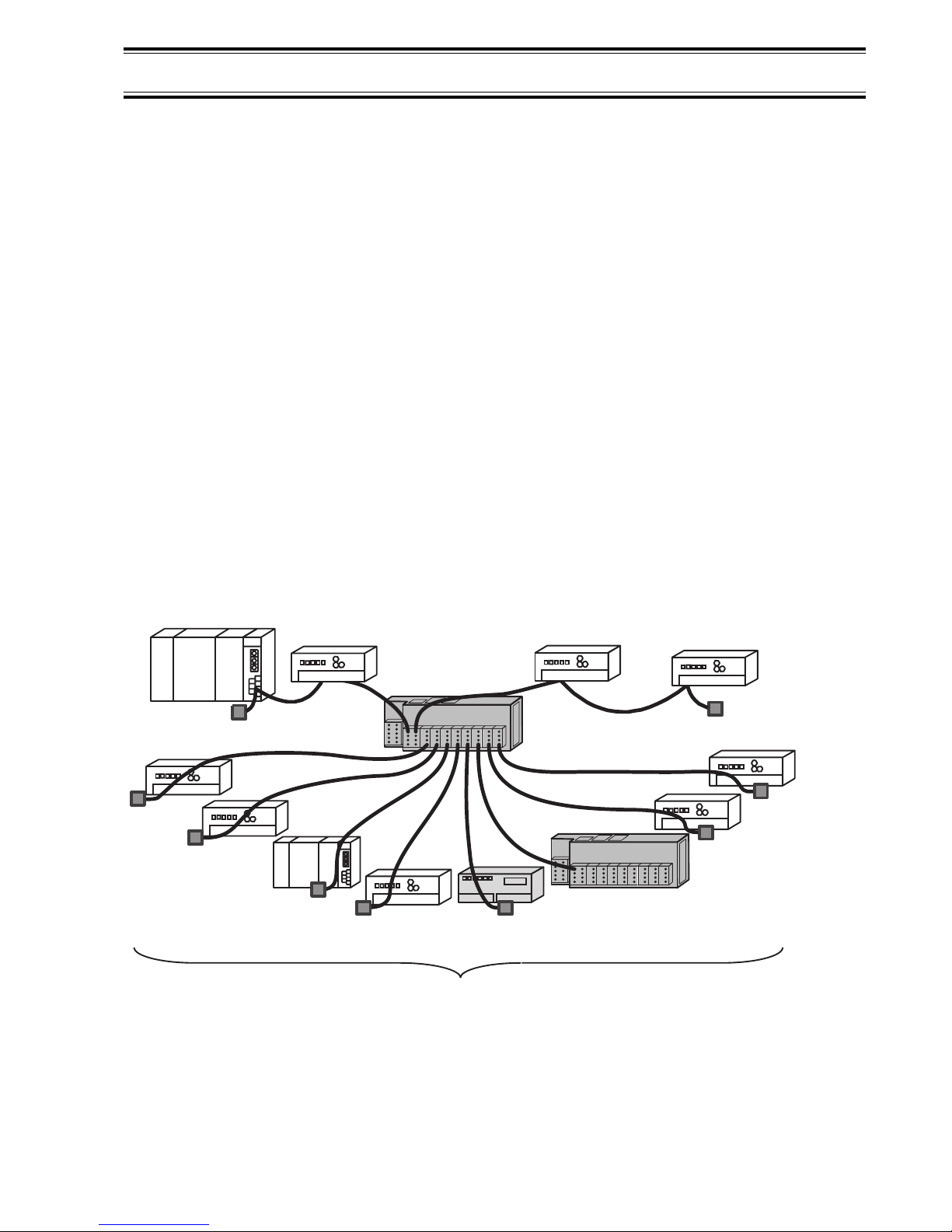

(1) Star-topology wiring (T-branch) with 8 branch lines (segments)

available in CC-Link system

By placing the AJ65BTS-RPH between modules of the CC-Link

system, star-topology wiring (T-branch) with up to 8 branch lines

Master station

Remote I/O

station

Remote device

station

(segments) can be used in the CC-Link system of all transmission

rates (10Mbps, 5Mbps, 2.5Mbps, 625kbps, and 156kbps).

Remote I/O

station

Local station

Repeater

(AJ65

Remote I/O

station

Intelligent device

BTS

-RPH)

IN

OUT

Repeater

(AJ65SBT-RPT)

station

Repeater

(

AJ65BTS-RPH

Remote device

station

Remote

device station

Intelligent device

station

)

Star-topology wiring with 8 branch lines can be used!!

1

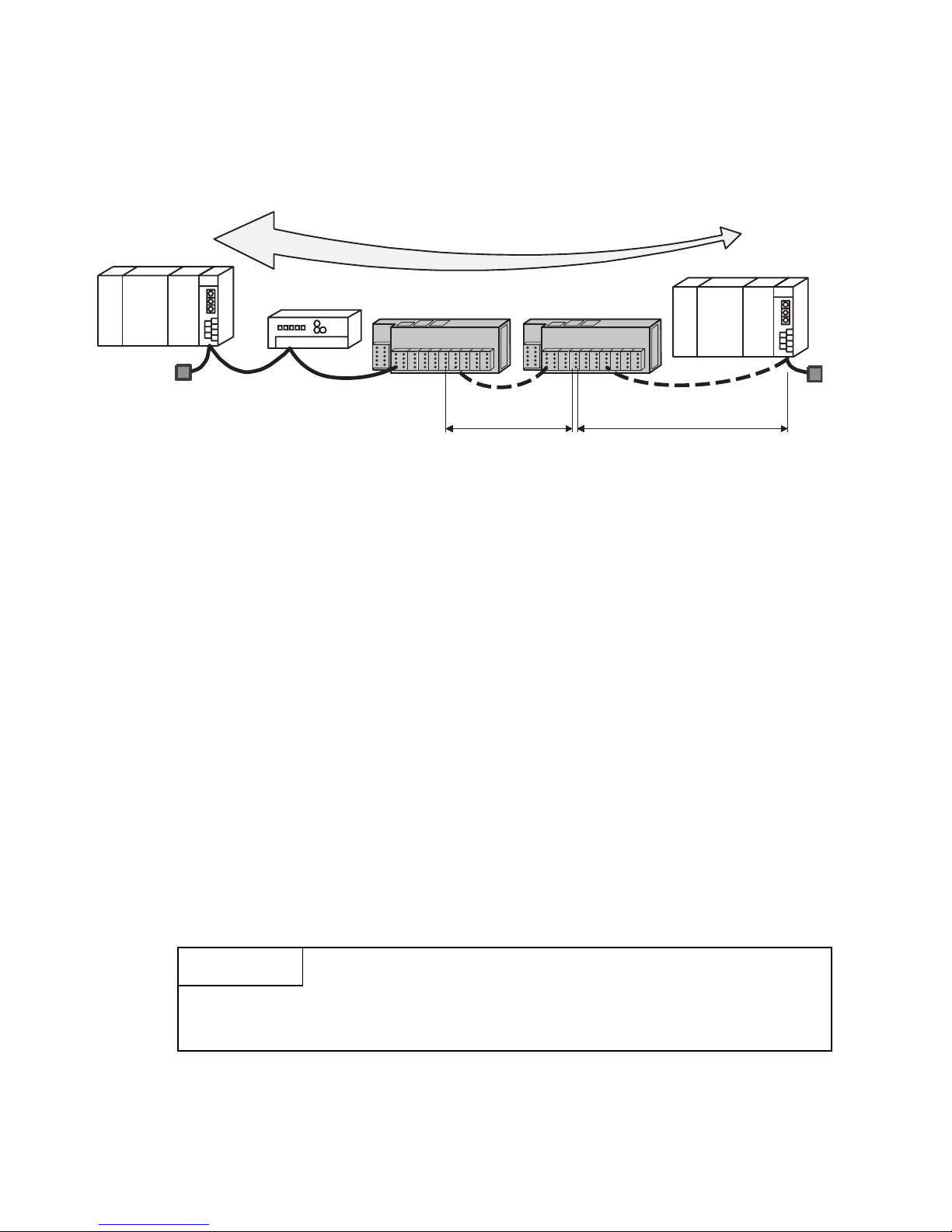

(2) Extended transmission distance in CC-Link system

Use of AJ65BTS-RPH enables the transmission distance of the CCLink system to be extended.

In addition, use of multiple modules enables the transmission

distance of the CC-Link system to be extended up to 2 stages.

Master station

*1 Max. transmission distance at a transmission speed of 156kbps.

*2 Though it is not shown here, the other remote stations can be

(3) Energy saving realized by adoption of a spring clamp terminal block

Extended to 3.6km (11811.02ft.) max !!

Remote I/O

station

Repeater (AJ65BTS-RPH)

*2

1st stage

*1

Remote

station

*2

2nd stage

connected between the repeaters.

(a) The AJ65BTS-RPH has adopted a spring clamp terminal block.

Because screw tightening is not needed, working steps can be

reduced.

(b) The terminal block can be installed to or removed from the

module, which reduces the maintenance cost and improves the

maintainability.

(c) All the operation and wiring parts are placed on the module front,

allowing easier operation and wiring.

(4) Improved maintenability by system separation

By using the AJ65BTS-RPH, any of the systems can be separated

and error location can be identified quickly.

This prevents the whole system from being seriously affected by an

error.

POINT

Branch lines with no error can send/receive data normally, not

influenced by each other.

2

2. SYSTEM CONFIGURATION

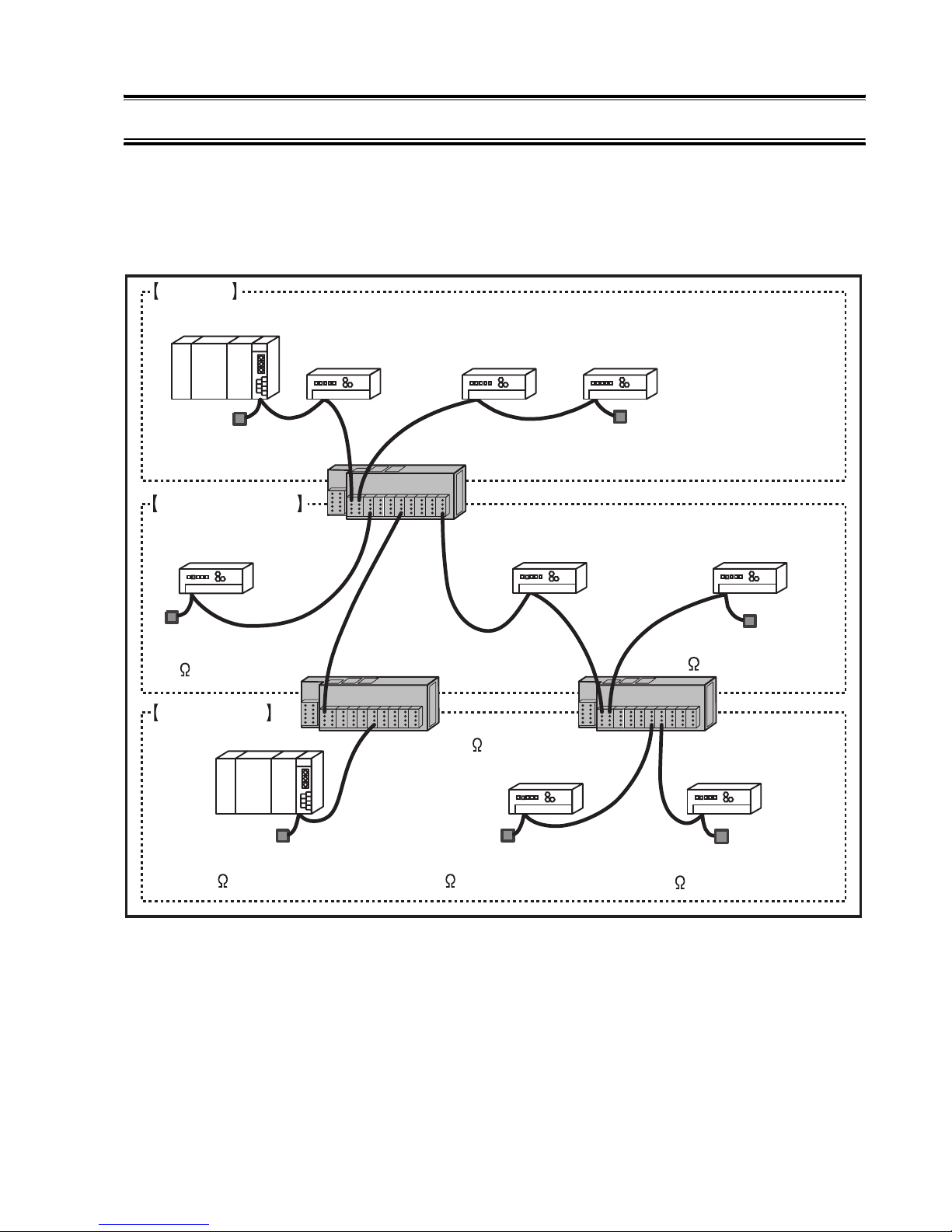

2.1 Total configuration

The total configuration employed when the AJ65BTS-RPH is used is as

shown below.

Segment

Master station

*1

I/O station

Remote

Remote

device station

Intelligent

device station

Terminating resistor

(indispensable)

Segment (1st stage)

Remote

I/O station

Terminating rresistor,

110 (indispensable)

Segment (2nd stage)

Local station

Terminating resistor,

110 (indispensable)

*3

*2

*3

Terminating resistor

(indispensable)

Repeater (AJ65BTS-RPH)

Intelligent

device station

Repeater (AJ65BTS-RPH)

Terminating resistor,

110 (built-in)

Remote

I/O station

Terminating resistor,

110 (indispensable)

*3

*3

Remote

device station

Terminating resistor,

110 (indispensable)

Repeater (AJ65BTS-RPH)

Remote

device station

Terminating resistor,

110 (indispensable)

*3

*3

*1 The transmission speed of each segment must be matched with that

of the master station.

*2 2 stages of segments max. are allowed to be used.

*3 The 130Ω terminating resistor is not usable for a segment connected

on the branch line side of the AJ65BTS-RPH.

Use the 110Ω terminating resistor that is included with the AJ65BTS-

RPH.

3

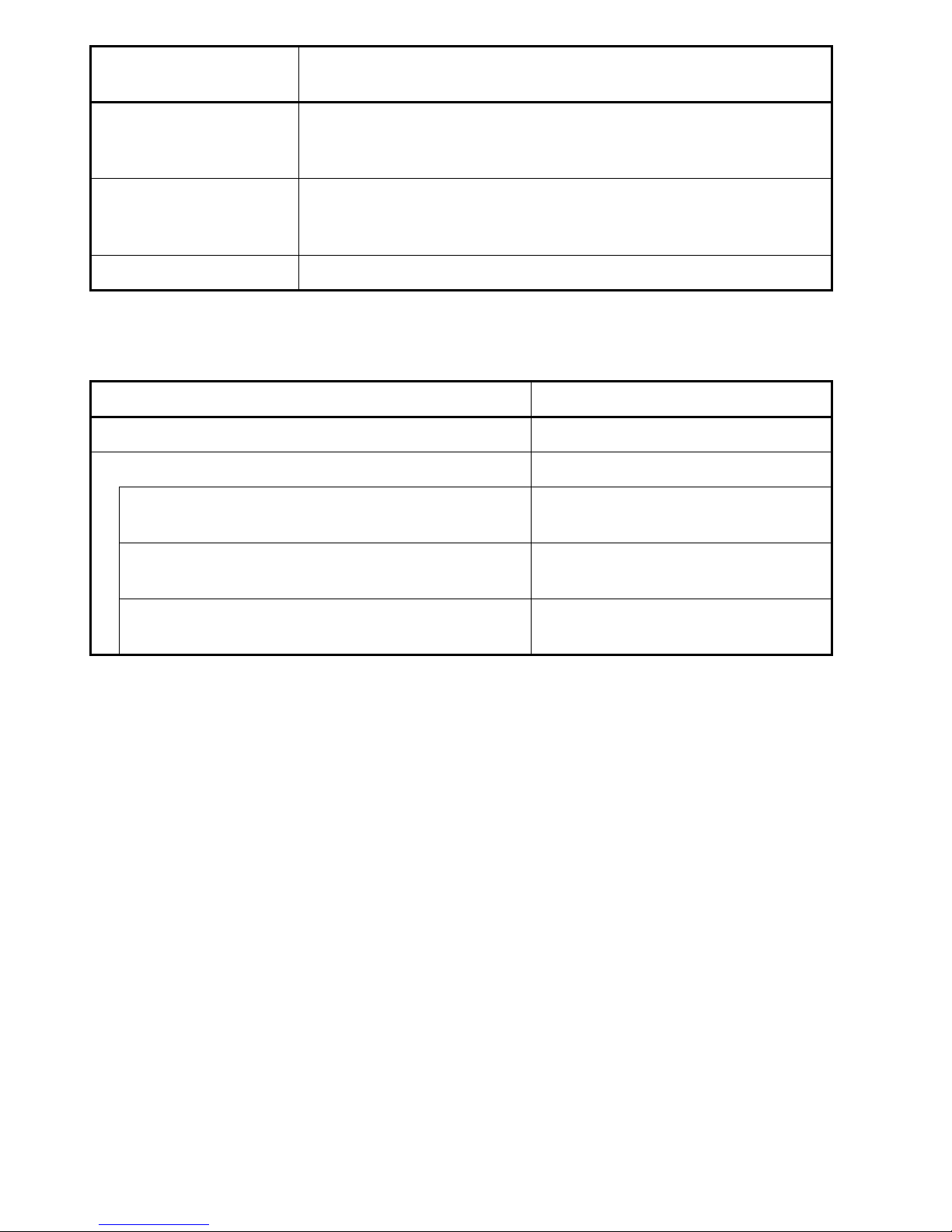

2.2 Applicable system

This section describes usable modules and cables.

(1) Modules connectable on the branch line side

The types of the modules connectable on the branch line side of the

AJ65BTS-RPH are shown below.

Table 2.1 Modules connectable on the branch line side

Category Module types

Remote I/O station

Remote device station

Slave station

Intelligent device station

Local station

AJ65BTS-RPH

AJ65FBTA-RPH

Repeater

Bridge AJ65SBT-CLB

AJ65SBT-RPT

AJ65SBT-RPS/RPG

AJ65BT-RPI-10A/10B

(2) Applicable communication cables

The communication cables connectable to the AJ65BTS-RPH are

shown below.

Table 2.2 Applicable communication cables

Connector

name

Trunk line side

Branch line side

CC-Link version Name

Ver.1.00

Ver.1.10 CC-Link dedicated cable

Ver.1.00 CC-Link dedicated cable

Ver.1.10 CC-Link dedicated cable

Applicable cable

resistance

CC-Link dedicated

high-performance cable

CC-Link dedicated cable

Terminal

130Ω

110Ω

POINT

The master station and stand by master station can not be connected

to the branch line side.

4

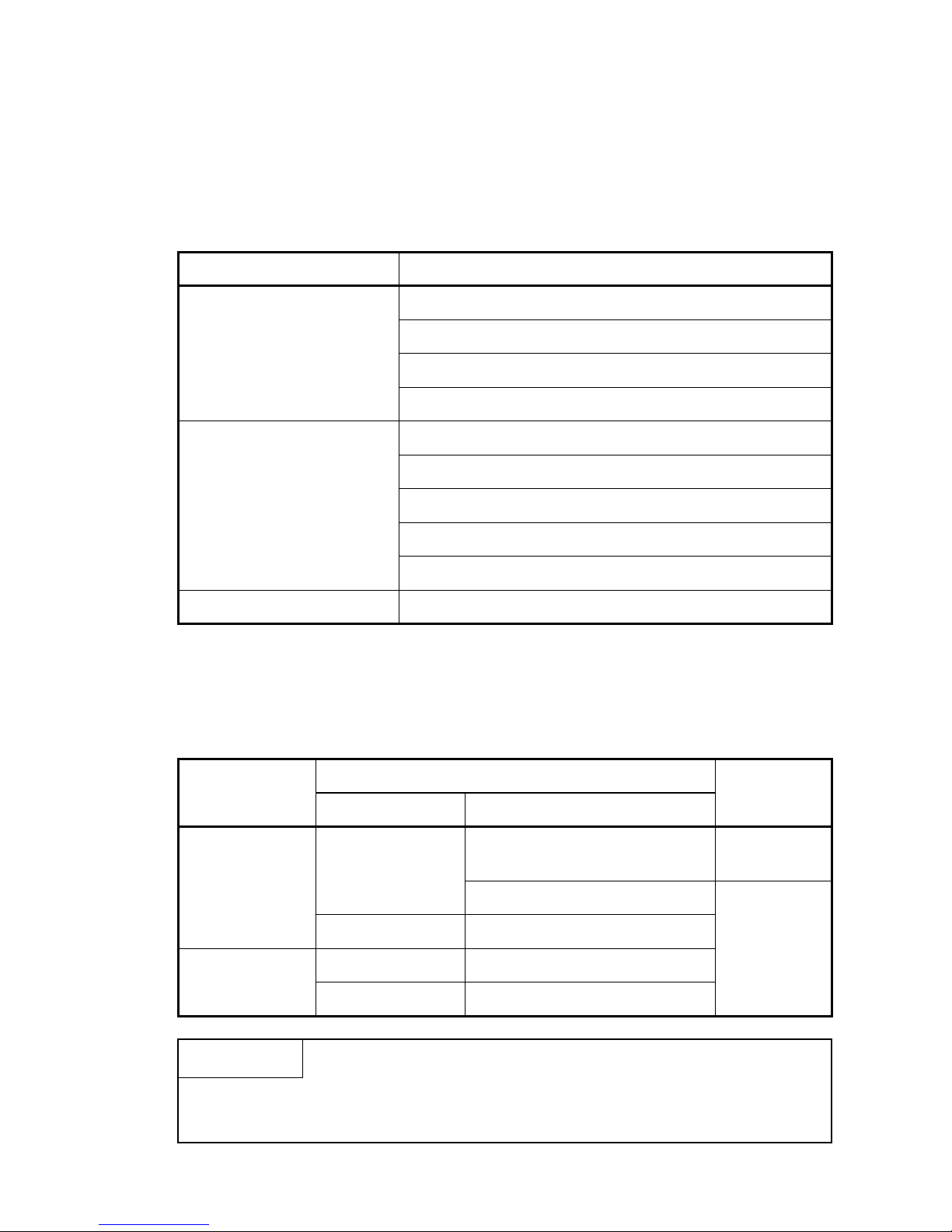

2.3 Cautions on system configuration

(1) Conditions of usable master module

When the AJ61BT11, A1SJ61BT11, AJ61QBT11 and A1SJ61QBT11

modules are used, those of the functional version B or later must be

employed. Use the master module bearing the version 9707 B or

later in the DATE column of the name plate as shown in the figure

below.

When the QJ61BT11N, QJ61BT11 module are used, any module

can be used irrespective of the version.

(a) Rating plate of AJ61BT11 or AJ61QBT11

PROGRAMMABLE CONTROLLER

DATE

yymm

MADE IN JAPAN BD992C077H01

B

Year and month of manufacture

(Use a master module of

9707 or later.)

Function version

Conformed standard

(b) Rating plate of A1SJ61BT11 or A1SJ61QBT11

Year and month of manufacture

MODEL

POWER

DATE

MADE IN JAPAN BD992C077H01

yymm

B

(Use a master module of

9707 or later.)

Function version

Conformed standard

5

Loading...

Loading...