Page 1

Page 2

Page 3

SAFETY INSTRUCTIONS

(Always read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the CPU module user's manual.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

DANGER

!

CAUTION

!

Note that the !CAUTION level may lead to a serious consequence according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[Design Instructions]

!

DANGER

If a communication error occurs in the data link, the following will occur in the station having the

communication error.

Use the communication status information, and configure an interlock circuit in the sequence

program so that the system will operate safely.

Incorrect outputs and incorrect operations can lead to accidents.

(1) All points of the general-purpose input from this module will turn OFF.

(2) All points of the general-purpose output from this module will turn OFF.

The input/output may turn ON or OFF depending on the module trouble.

Provide a circuit that externally monitors input/output signals that could lead to serious trouble.

A - 1

Page 4

!

k

CAUTION

Do not bind the control wire or communication cable with the main circuit or power wire, or

place the control wire near these.

Separate by at least 100mm or more.

Failure to observe this could lead to malfunctions caused by noise.

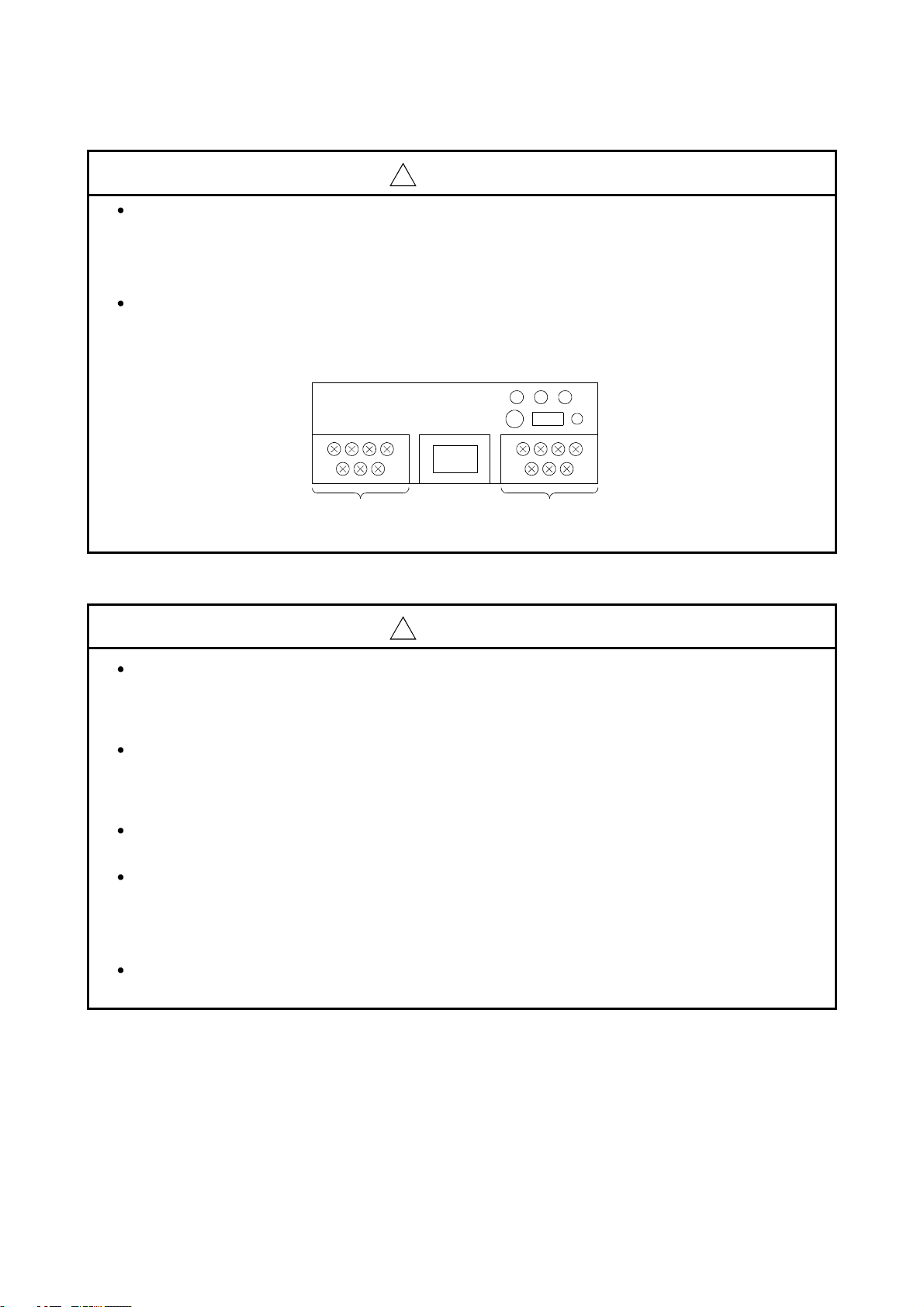

Always connect the master module and CC-Link dedicated cable at the data link terminal block.

If the data link terminal block and general-purpose input/output terminal block are incorrectly

inserted, module trouble could occur.

Data link terminal

bloc

General-purpose input/

output terminal block

[Mounting Instructions]

!

CAUTION

Use this module within the general specification environment described in the manual.

Use in an environment outside the general specification range could lead to electric shocks,

fires, malfunctioning, product damage or deterioration.

Always connect the crimp, press-fit or solder the connector wire connections with the maker-

designated tools, and securely connect the connector to the module.

An incomplete connection could lead to short-circuits or malfunctioning.

Do not directly touch the conductive section of the module.

Failure to observe this could lead to module malfunctioning or trouble.

Securely fix the module with the DIN rail or installation screw. Tighten the installation screw

within the designated torque range.

A loose screw could lead to dropping, short-circuiting or malfunctioning.

If the screw is too tight, dropping or short-circuiting could occur due to screw damage.

Securely mount the connector of each connection cable to the mounting section.

An incomplete connection could lead to malfunctioning caused by an incorrect contact.

A - 2

Page 5

[Wiring Instructions]

!

CAUTION

Before starting installation or wiring work, be sure to shut off all phases of external power supply

used by the system.

Failure to shut off all phases could lead to electric shocks, product damage or malfunctioning.

Always install the terminal covers enclosed with the product before turning ON the power or

operating the product after installation or wiring work.

Failure to install the terminal cover could lead to electric shocks.

Always ground the FG terminal with Class D grounding (Class 3 grounding) dedicated of the

programmable controller.

Failure to do so could lead to malfunctioning.

Always confirm the product's rated voltage and terminal layout before wiring the module.

Connecting with a power supply other than the rated power supply, or incorrect wiring could

lead to fires or trouble.

Tighten the terminal screws within the specified torque range.

A loose terminal screw could lead to short-circuiting or malfunctioning.

If the terminal screw is too tight, dropping or short-circuiting could occur due to screw damage.

Make sure that foreign matter, such as cutting chips or wire scraps, do not enter the module.

Failure to observe this could lead to fires, trouble or malfunctioning.

The communication cables and power supply cable connected to the module must be placed in

a conduit or fixed with a clamp.

If the cable is not placed in a conduit or fixed with a clamp, the module or cable could be

damaged by the cable variation, movement or unintentional pulling leading to malfunctioning

caused by an improper cable connection.

Do not install the control lines together with the communication cables, or bring them close to

each other. Failure to do so may cause malfunctions due to noise.

Do not remove the communication cable or power supply cable connected to the module by

pulling on the cable section.

If the cable has a connector, hold the connector at the section connected to the module, and

remove.

If the cable does not have a connector, loosen the screws at the section connected to the

module, and remove.

Pulling on the cable while connected to the module could lead to module or cable damage, or

malfunctioning caused by an improper cable connection.

A - 3

Page 6

[Startup/Maintenance Instructions]

!

CAUTION

When power is ON, do not touch the terminals.

Doing so can cause an electric shock or malfunction.

Before cleaning or tightening the terminal screws and module mounting screws, be sure to shut

off all phases of external power supply used by the system.

Failure to shut off all phases could lead to module trouble or malfunctioning.

Do not touch the connector inside the lid at the front of the module.

Failure to observe this could lead to module trouble or malfunctioning.

Never disassemble or modify the module.

Failure to observe this could lead to trouble, malfunctioning, injuries or fires.

Do not drop or apply any strong impact to the module. Doing so may damage the module.

Before installing or removing the module on the panel, be sure to shut off all phases of external

power supply used by the system.

Failure to shut off all phases could lead to module trouble or malfunctioning.

Do not install/remove the terminal block more than 50 times after the first use of the product.

(IEC 61131-2 compliant)

[Disposal Instructions]

!

CAUTION

When disposing of the product, handle it as industrial waste.

A - 4

Page 7

REVISIONS

*

The instruction manual No. is described on the lower left of the back cover of this instruction manual.

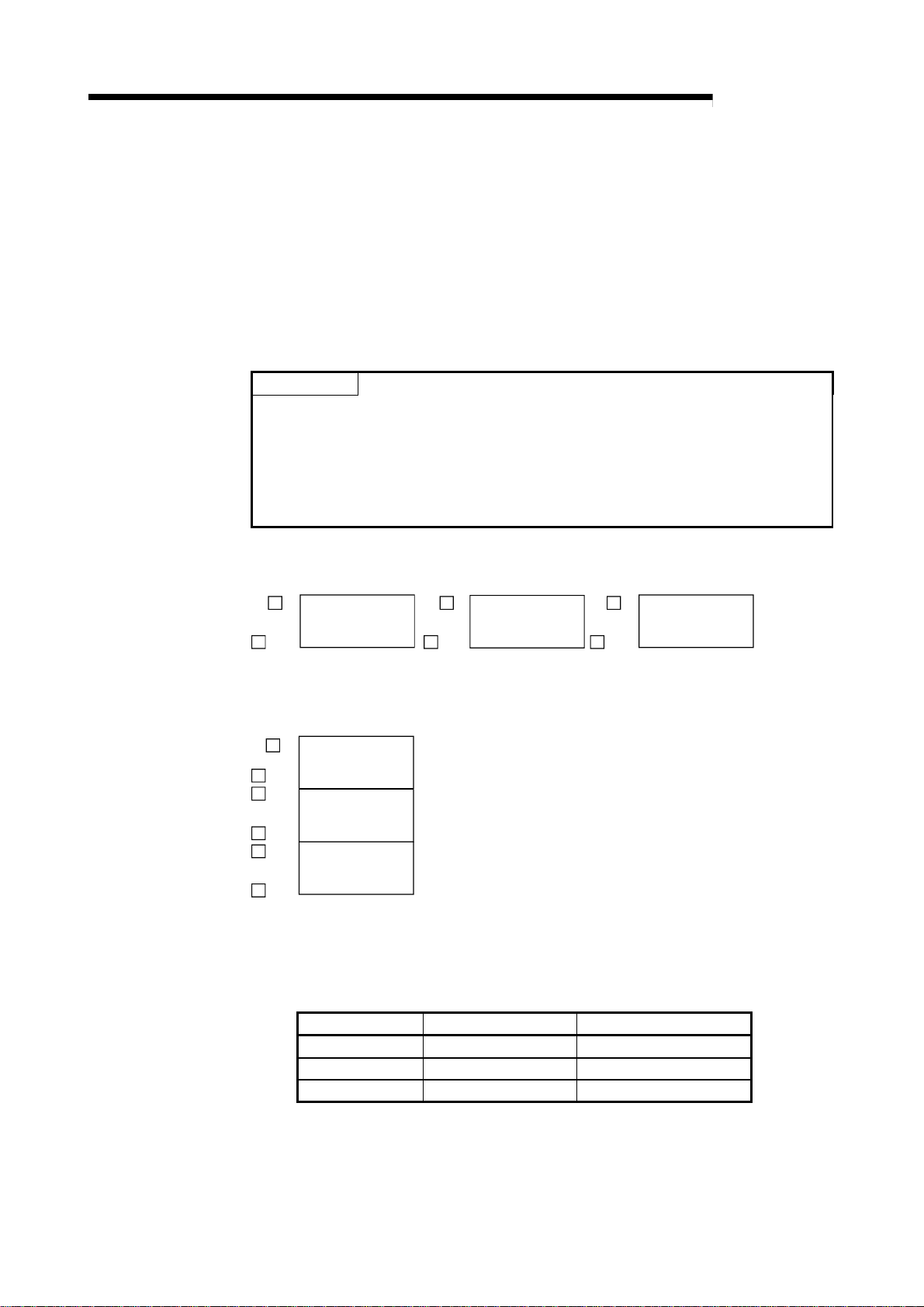

Date of print * Instruction manual No. Revision details

Jul., 1997 IB (NA)-66781-A Initial print

Apr., 1999 IB (NA)-66781-B Complete review

Sep., 2002 IB (NA)-66781-C Equivalent to Japanese version D

Addition of description for use of the QCPU (Q mode)

Addition

Compliance with the EMC/Low Voltage Directive, Section 4.5.1,

Section 5.2.2

Deletion

Section 2.3

Partial Correction

SAFETY INSTRUCTIONS, About Manuals, Chapter 1, Section 2.1,

Section 2.2, Section 3.1, Section 3.2, Section 3.3, Section 3.4, Section

3.7, Section 4.1, Section 4.2, Section 4.4, Section 4.5.2, Section 4.5.3,

Section 4.6, Section 5.2, Section 5.6.2, Section 8.3, Section 9.1,

Section 9.2.4, Section 10.1.2, Section 10.2

Nov., 2005 IB (NA)-66781-D

Partial Correction

SAFETY INSTRUCTIONS, About Manuals, Generic Terms and

Abbreviations, Definitions and Details of Terms, Section 1.1, Section

2.1, 2.2, Section 3.1, 3.2, 3.4, 3.6.1, 3.6.2, 3.7, 3.8, 3.9.1, 3.9.2,

Section 4.2, 4.4, 4.5.2, 4.5.3, Section 5.2.1, 5.3, 5.4, 5.5.1, 5.5.2,

5.7.1, 5.7.2, 5.7.3, 5.7.4, Section 6.3.1, 6.3.2, 6.4.1, 6.4.2, Section

7.3.1, 7.4.3, 7.5.2, Section 8.2, 8.3, 8.4, 8.5, 8.9.2, Section 9.1, 9.2.1,

9.2.2, 9.2.3, 9.2.4, 9.3.2, 9.3.3, Section 10.1.2, 10.3

Addition

INDEX

Oct., 2006 IB (NA)-66781-E

Partial Correction

SAFETY INSTRUCTIONS, Section 3.2, 3.4, 4.4, 7.3

Nov., 2007 IB (NA)-66781-F

Change of a term

"PLC" was changed to "programmable controller".

Partial Correction

Section 4.2, 4.4, Section 5.1, 5.2.1, 5.5.1, 5.6.2, 5.7.3, Section 6.2,

6.3, 6.4.1, 6.4.2, Section 7.4.3, Section 8.10, Section 9.2.1, 9.2.2,

9.2.4, 9.3.1, 9.3.3, Section 10.1.2, 10.3, 10.4

Japanese Manual Version SH-3633-G

This manual does not guarantee the implementation of industrial rights or other rights, and does not authorize the

implementation rights. Mitsubishi shall not be held liable for any problems regarding industrial rights that occur through

the use of the contents given in this manual.

© 1997 MITSUBISHI ELECTRIC CORPORATION

A - 5

Page 8

INTRODUCTION

Thank you for purchasing the Mitsubishi general-purpose programmable controller MELSEC-A.

Always read through this manual, and fully comprehend the functions and performance of the A Series

programmable controller before starting use to ensure correct usage of this product.

Make sure that this manual is delivered to the final user.

CONTENTS

Safety Instructions..........................................................................................................................................A- 1

Revisions ........................................................................................................................................................A- 5

About Manuals ...............................................................................................................................................A- 9

Compliance with the EMC/Low Voltage Directive.........................................................................................A- 9

Using This Manual.........................................................................................................................................A- 10

Generic Terms and Abbreviations ................................................................................................................A- 11

Definitions and Details of Terms...................................................................................................................A- 12

1. OUTLINE 1- 1 to 1- 4

1.1 Features ................................................................................................................................................... 1- 2

2. SYSTEM CONFIGURATION 2- 1 to 2- 2

2.1 System configuration ............................................................................................................................... 2- 1

2.2 Applicable systems .................................................................................................................................. 2- 2

3. SPECIFICATIONS 3- 1 to 3- 26

3.1 General specifications.............................................................................................................................. 3- 1

3.2 Performance specifications...................................................................................................................... 3- 2

3.3 RS-232-C interface specifications ...........................................................................................................3- 3

3.4 General-purpose input/output specifications........................................................................................... 3- 4

3.5 List of functions ........................................................................................................................................ 3- 6

3.6 Input/output signals for master module ................................................................................................... 3- 7

3.6.1 List of input/output signals................................................................................................................. 3- 7

3.6.2 Details of input/output signals ........................................................................................................... 3- 8

3.7 R2 buffer memory list .............................................................................................................................. 3- 13

3.8 Transmission delay time ......................................................................................................................... 3- 19

3.9 Transmission/reception time................................................................................................................... 3- 20

3.9.1 When using buffer memory automatic update function .................................................................. 3- 20

3.9.2 When using transmission/reception buffer ...................................................................................... 3- 23

4. PROCEDURES AND SETTINGS BEFORE OPERATIION 4- 1 to 4- 12

4.1 Procedures before operation ...................................................................................................................4- 1

4.2 Precautions for handling ..........................................................................................................................4- 3

4.3 Installation environment ........................................................................................................................... 4- 5

4.4 Names of each part, and settings............................................................................................................ 4- 6

4.5 Wiring........................................................................................................................................................ 4- 8

A - 6

Page 9

4.5.1 Precautions for handling the CC-Link dedicated cables .................................................................. 4- 8

4.5.2 Connection of the CC-Link dedicated cables ................................................................................... 4- 8

4.5.3 Connection with external device ....................................................................................................... 4- 9

4.6 Checking the module’s state (Hardware test) ........................................................................................ 4- 11

5. PRELIMINARY INFORMATION 5- 1 to 5- 46

5.1 System used in this manual ..................................................................................................................... 5- 1

5.2 Programming Precautions ....................................................................................................................... 5- 3

5.2.1 About bank changing of the A series master module ...................................................................... 5- 3

5.2.2 About dedicated commands for use of the buffer memory automatic update function .................. 5- 5

5.3 Program basic format............................................................................................................................... 5- 6

5.4 Initializing the master station.................................................................................................................... 5- 9

5.5 Initializing the R2 ..................................................................................................................................... 5- 12

5.5.1 Using the buffer memory automatic update function ......................................................................5- 12

5.5.2 Using the transmission/reception buffer ..........................................................................................5- 15

5.6 Reading and writing the buffer memory (using the buffer memory automatic update function) .......... 5- 18

5.6.1 Outline............................................................................................................................................... 5- 18

5.6.2 Understanding the roles of each area ............................................................................................. 5- 19

5.7 Reading and writing the buffer memory (using the transmission/reception buffer) ..............................5- 28

5.7.1 Outline............................................................................................................................................... 5- 28

5.7.2 About control data ............................................................................................................................5- 29

5.7.3 Reading the R2 buffer memory........................................................................................................ 5- 40

5.7.4 Writing to the R2 buffer memory...................................................................................................... 5- 43

6. EXCHANGING DATA WITH AN EXTERNAL DEVICE 6- 1 to 6- 30

6.1 Matters to understand before transmitting data ...................................................................................... 6- 1

6.2 Matters to know before receiving data .................................................................................................... 6- 5

6.3 Exchanging data using the buffer memory automatic update function .................................................. 6- 9

6.3.1 Transmitting data to an external device .......................................................................................... 6- 9

6.3.2 Receiving data from an external device .......................................................................................... 6- 14

6.4 Exchanging data using the transmission/reception buffer.....................................................................6- 18

6.4.1 Transmitting data to an external device ..........................................................................................6- 18

6.4.2 Receiving data from an external device .......................................................................................... 6- 24

7. USING FRAMES WHEN EXCHANGING DATA 7- 1 to 7- 38

7.1 What are frames?..................................................................................................................................... 7- 1

7.2 Transmitting data using frames ............................................................................................................... 7- 2

7.2.1 Transmitting using transmission frame 1 area .................................................................................7- 2

7.2.2 Transmitting using the transmission frame 2 area........................................................................... 7- 4

7.3 Receiving data using frames ................................................................................................................... 7- 6

7.3.1 Reception data ..................................................................................................................................7- 8

7.3.2 Reading the reception data.............................................................................................................. 7- 10

7.4 Transmitting data at the device and status change ............................................................................... 7- 13

7.4.1 Outline............................................................................................................................................... 7- 13

7.4.2 Devices and statuses that can be designated................................................................................. 7- 14

7.4.3 Setting the R2 buffer memory.......................................................................................................... 7- 15

A - 7

Page 10

7.4.4 Precautions....................................................................................................................................... 7- 21

7.5 Registration frames ................................................................................................................................. 7- 22

7.5.1 List of default registration frames..................................................................................................... 7- 23

7.5.2 Details of user registration frames ................................................................................................... 7- 25

8. OTHER FUNCTIONS 8- 1 to 8- 24

8.1 Canceling data communication to an external device ............................................................................ 8- 1

8.2 Forcibly completing reception .................................................................................................................. 8- 3

8.3 Flow control .............................................................................................................................................. 8- 6

8.4 ASCII-BIN conversion of transmission data ........................................................................................... 8- 10

8.5 RW update function ................................................................................................................................ 8- 12

8.6 Initializing the R2 ..................................................................................................................................... 8- 15

8.7 Clearing the OS reception area ..............................................................................................................8- 16

8.8 Registering and initializing the R2 EEPROM ......................................................................................... 8- 19

8.9 Controlling the RS-232-C signal ............................................................................................................. 8- 22

8.9.1 Correspondence of RS-232-C control signal and remote input/output signal ............................... 8- 22

8.9.2 Precautions for using RS-232-C control signal read/write function ................................................ 8- 23

8.10 Confirming the R2 switch states and software version........................................................................ 8- 24

9. PROGRAM EXAMPLES 9- 1 to 9- 48

9.1 Conditions for program examples ........................................................................................................... 9- 1

9.2 Example of program for using buffer memory automatic update function ............................................. 9- 2

9.2.1 When using FROM/TO command with ACPU / QCPU-A (A mode) ...............................................9- 2

9.2.2 When using dedicated commands with ACPU / QCPU-A (A mode) .............................................. 9- 6

9.2.3 When using dedicated commands with QCPU (Q mode) / QnACPU............................................ 9- 11

9.2.4 When using the FROM/TO commands with ACPU / QCPU-A (A mode)

(Three R2 modules connected) ......................................................................................................9- 14

9.3 Example of program for using transmission/reception buffer ................................................................ 9- 28

9.3.1 When using FROM/TO command with ACPU / QCPU-A (A mode) ..............................................9- 28

9.3.2 When using dedicated commands with ACPU / QCPU-A (A mode) ............................................. 9- 37

9.3.3 When using dedicated commands with QCPU (Q mode) / QnACPU............................................ 9- 43

10. TROUBLESHOOTING 10- 1 to 10- 12

10.1 Error codes ........................................................................................................................................... 10- 1

10.1.1 Error code storage area ................................................................................................................10- 1

10.1.2 List of error codes.......................................................................................................................... 10- 2

10.2 Confirming the error with the LED ....................................................................................................... 10- 5

10.3 Examples of trouble in general-purpose input circuit.......................................................................... 10- 7

10.4 Troubleshooting per symptom............................................................................................................. 10- 9

10.5 Troubleshooting when the master station's ERR. LED flashes......................................................... 10- 10

APPENDIX Appendix- 1 to Appendix- 2

Appendix 1 Outline dimension drawing ............................................................................................Appendix- 1

INDEX INDEX- 1 to INDEX 3

A - 8

Page 11

About Manuals

Related Manuals

The following manuals are also related to this product.

In necessary, order them by quoting the details in the tables below.

Manual Name

Control & Communication Link System Master/Local Module Type AJ61BT11/A1SJ61BT11

User's Manual

Explains the configuration, performance and specifications, functions, handling, wiring and

troubleshooting of the AJ61BT11 and A1SJ61BT11 system.

Control & Communication Link System Master/Local Module Type

AJ61QBT11/A1SJ61QBT11 User's Manual

Explains the configuration, performance and specifications, functions, handling, wiring and

troubleshooting of the AJ61QBT11 and A1SJ61QBT11 system.

CC-Link System Master/Local Module User's Manual QJ61BT11N

Explains the configuration, performance and specifications, functions, handling, wiring and

troubleshooting of the QJ61BT11N system. (Sold separately)

AnSHCPU/AnACPU/AnUCPU/QCPU-A (A mode) Programming Manual QJ61BT11

(Dedicated Instructions)

Explains the configuration, performance and specifications, functions, handling, wiring and

troubleshooting of the QJ61BT11 system. (Sold separately)

(Sold separately)

(Sold separately)

Compliance with the EMC/Low Voltage Directive

Manual Number

(Model Code)

IB-66721

(13J872)

IB-66722

(13J873)

SH-080394E

(13JR64)

IB-66251

(13J742)

When incorporating the Mitsubishi programmable controller into other machinery or

equipment and keeping compliance with the EMC and low voltage directives, refer to

Chapter 3, "EMC Directives and Low Voltage Directives" of the User's Manual

(Hardware) included with the CPU module or base unit used.

The CE logo is printed on the rating plate of the programmable controller, indicating

compliance with the EMC and low voltage directives.

To conform this product to the EMC Directive and Low Voltage Directive, refer to the

Section of "CC-Link Modules" in Chapter 3 "EMC Directive and Low Voltage Directive"

in the User’s Manual (Hardware) of the CPU module used or the programmable

controller CPU supplied with the base unit.

A - 9

Page 12

Using This Manual

This section "Using this manual" describes the R2 usage in categories of purpose.

Refer to the following details when using this manual.

(1) To find the characteristics of R2 (Section 1.1)

The features are described in section 1.1.

(2) To find the system configuration (Section 2.1)

The configuration of a system using R2 is explained in section 2.1.

(3) To find the master module that can use R2, and the CPU version that can use the

CC-Link dedicated commands (Section 2.2)

The master module that can use R2, and the CPU version that can use the CCLink dedicated commands are explained in section 2.2.

(4) To find the R2 specifications (Chapter 3)

The R2 specifications are described in Chapter 3.

(5) To find the time for transmitting/receiving data with R2 (Sections 3.8, 3.9)

The R2 transmission delay time and transmission/reception time are explained in

sections 3.8 and 3.9.

(6) To find the procedures for operating R2 (Chapter 4)

The procedures for operating the R2, and the methods of checking the module

state are explained in Chapter 4.

(7) To find how to access the R2 buffer memory (Sections 5.6, 5.7)

The methods of accessing the buffer memory are described in sections 5.6 and

5.7.

(8) To exchange data with an external device (Chapter 6)

The methods of exchanging data with an external device are explained in Chapter

6.

(9) To add a frame when exchanging data (Chapter 7)

The details of the frame, and the methods of adding a frame are explained in

Chapter 7.

(10) To find sample programs (Chapter 9)

Sample programs are described in Chapter 9.

(11) When trouble occurs (Chapter 10)

The error code list and troubleshooting are described in Chapter 10.

"How to Use This Manual" is described by purposes of using CSKP.

Refer to the following and use this manual.

A - 10

Page 13

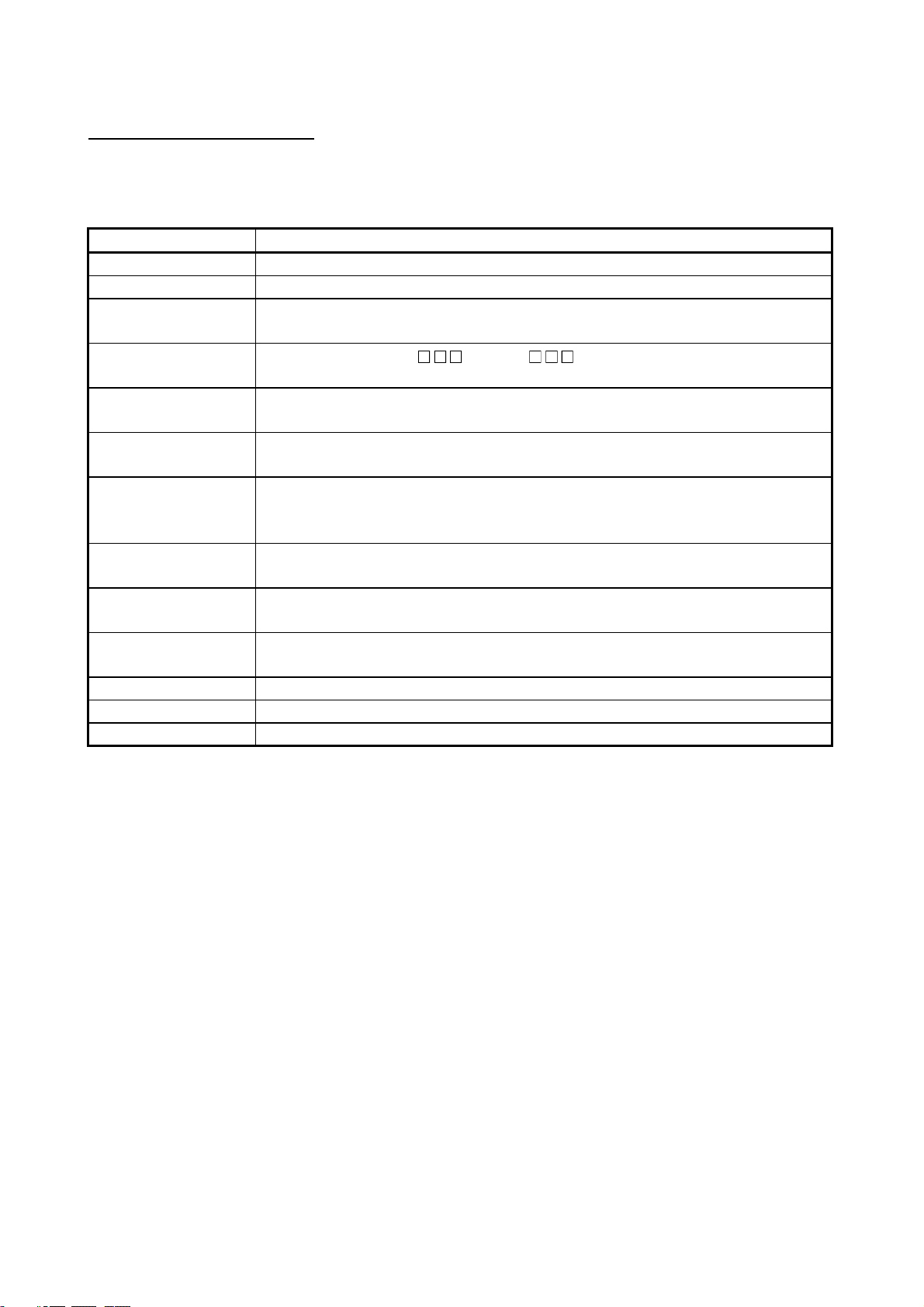

Generic Terms and Abbreviations

Unless specially noted, the following generic terms and abbreviations are used in this

manual to explain the AJ65BT-R2 type RS-232-C interface module.

Generic term/abbreviation Details of generic term/abbreviation

R2 Abbreviation for AJ65BT-R2 type RS-232-C interface module.

CC-Link Abbreviation for Control & Communication Link system.

Master module Generic term when using AJ61QBT11, A1SJ61QBT11, AJ61BT11, A1SJ61BT11, QJ61BT11

and QJ61BT11N as the master station.

Remote module Generic term for AJ65BTB - , AJ65BTC - , AJ65BT-64AD, AJ65BT-64DAV and

AJ65BT-64DAI.

External device Generic term for devices such as ID controller, bar code reader and general-purpose personal

computer, connected to R2 for data communication.

GPPW Generic term for model names: SWnD5C-GPPW, SWnD5C-GPPW-A, SWnD5C-GPPW-V

and SWnD5C-GPPW-VA. (“n” included in the model name indicates a number “4” or more.)

AnNCPU Abbreviation of A0J2HCPU, A1SCPU, A1SCPUC24-R2, A1SHCPU, A1SJCPU, A1SJCPU-

S3, ASJHCPU, A1NCPU, A2CCPU, A2CCPUC24, A2CCPUC24-PRF, A2CJCPU, A2NCPU,

A2NCPU-S1, A2SCPU, A2SHCPU and A2FXCPU

AnACPU Abbreviation of A2ACPU, A2ACPU-S1, A2ACPUP21/R21, A2ACPUP21/R21-S1,

A3ACPUP21/R21, A3NCPU and A3ACPU

AnUCPU Abbreviation of A2UCPU, A2UCPU-S1, A2USCPU, A2USCPU-S1, A2USHCPU-S1, A3UCPU

and A4UCPU

QnACPU Abbreviation of Q2ACPU, Q2ACPU-S1, Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU,

Q2ASHCPU-S1, Q3ACPU, Q4ACPU and Q4ARCPU

ACPU Abbreviation of AnNCPU, AnACPU and AnUCPU

QCPU (Q mode) Generic term for Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU and Q25HCPU

QCPU-A (A mode) Generic term for Q02CPU-A, Q02HCPU-A and Q06HCPU-A

A - 11

Page 14

Definitions and Details of Terms

The definitions and details of terms used in this manual are explained below.

(1)

M

H

This indicates the buffer memory address of the master station.

(2)

R2

H

This indicates the buffer memory address of R2.

(3) Master station

The station that controls the remote station, local station and intelligent device

station.

(4) Intelligent device station

Slave station on CC-Link system that can carry out transient transmission with R2,

etc.

(5) Transient transmission

Function that communicates data with a designated station when access is

requested from the programmable controller CPU, etc.

(6) Buffer memory automatic update function

Function that automatically updates the data between the R2 buffer memory and

master stations' automatic update buffer.

(7) Automatic update buffer

Buffer memory in master station used for the buffer memory automatic update

function in respect to R2.

(8) Registration frame

Row of data targeted for the fixed format section of the statement transmitted and

received between the external device and R2.

The registration frames include the default registration frame registered in the R2,

and the user registration frame registered by the user using EEPROM.

(9) Transmission frame 1 area

Buffer memory address

R2

118H to 119H.

With frame transmission that uses the transmission frame 1 area, a frame can be

added each to the head and end of a random data item when transmitting the

data.

(10) Transmission frame 2 area

Buffer memory address

R2

120H to 185H.

With frame transmission that uses the transmission frame 2 area, up to 100

frames can be added when transmitting the data.

A - 12

Page 15

A

1 OUTLINE

1. OUTLINE

MELSEC-

1

This User's Manual explains the features and specifications of the R2 used as the

intelligent device station of the CC-Link, communication with an external device, and

the special specifications, etc.

R2 can exchange data with an external device, such as an RS-232-C connection type

barcode reader, ID controller or general-purpose personal computer.

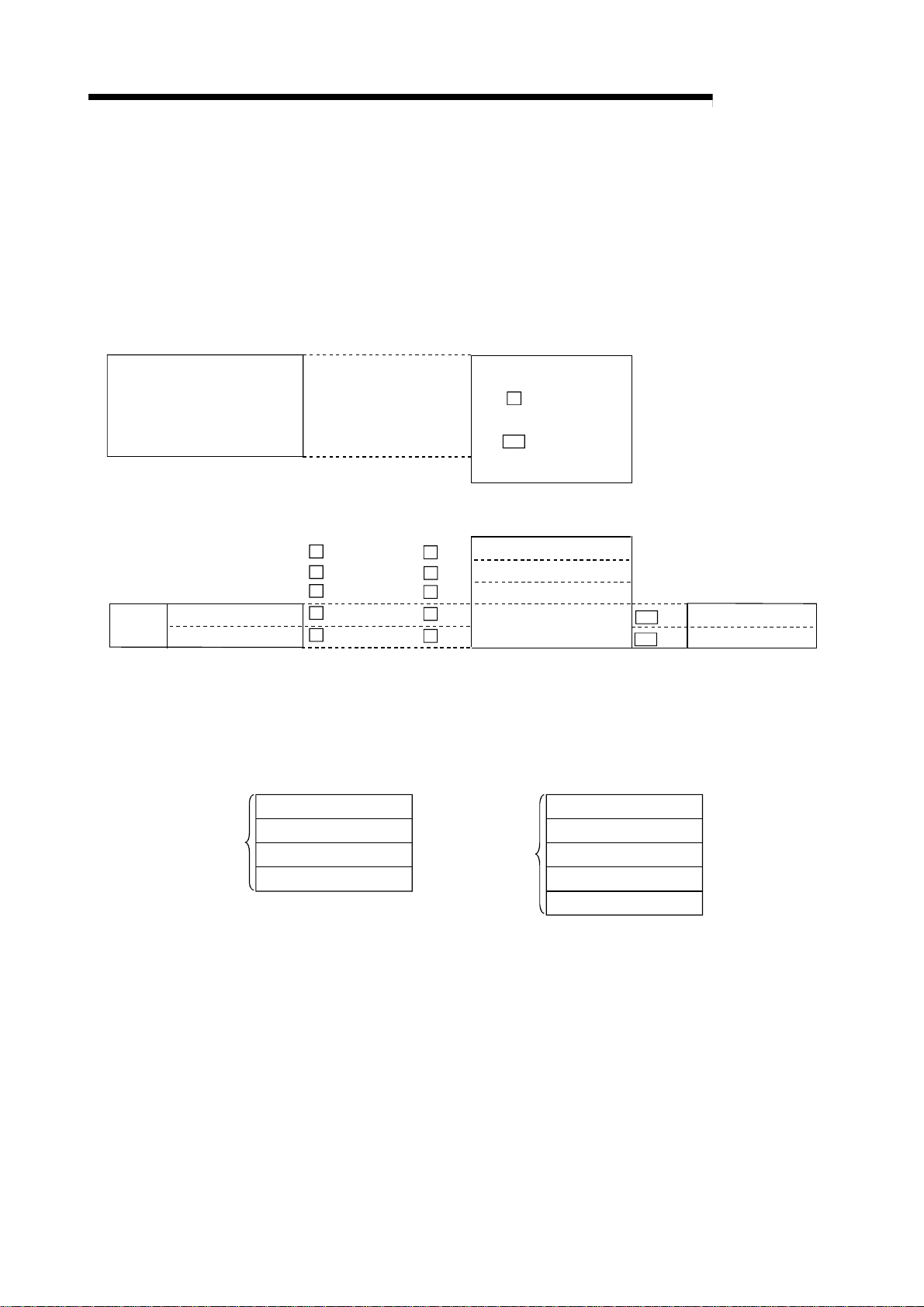

When a barcode reader is connected

Programmable controller

Master station

R2

Data reception

Barcode reader

Reading!

1 - 1

Page 16

A

1 OUTLINE

1.1 Features

MELSEC-

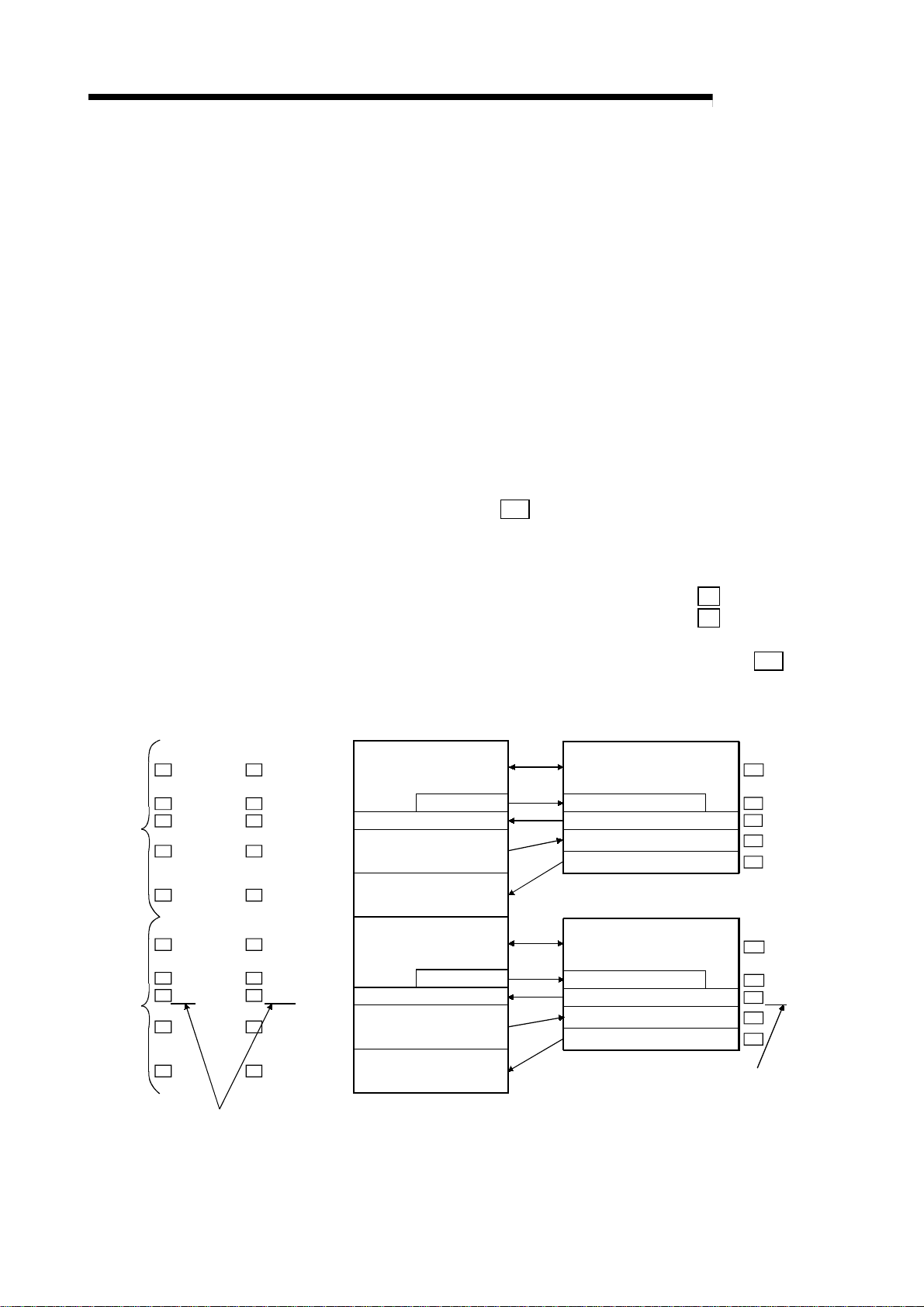

(1) Easy communication by using the buffer memory automatic update

function.

This function automatically updates the buffer memory between the R2 and

master station at the timing set in R2.

With this, a program to read and write between the R2 and master station can be

eliminated. As the data can be read and written with just the FROM/TO

command, the program is simplified.

(This can be used with all CPUs.)

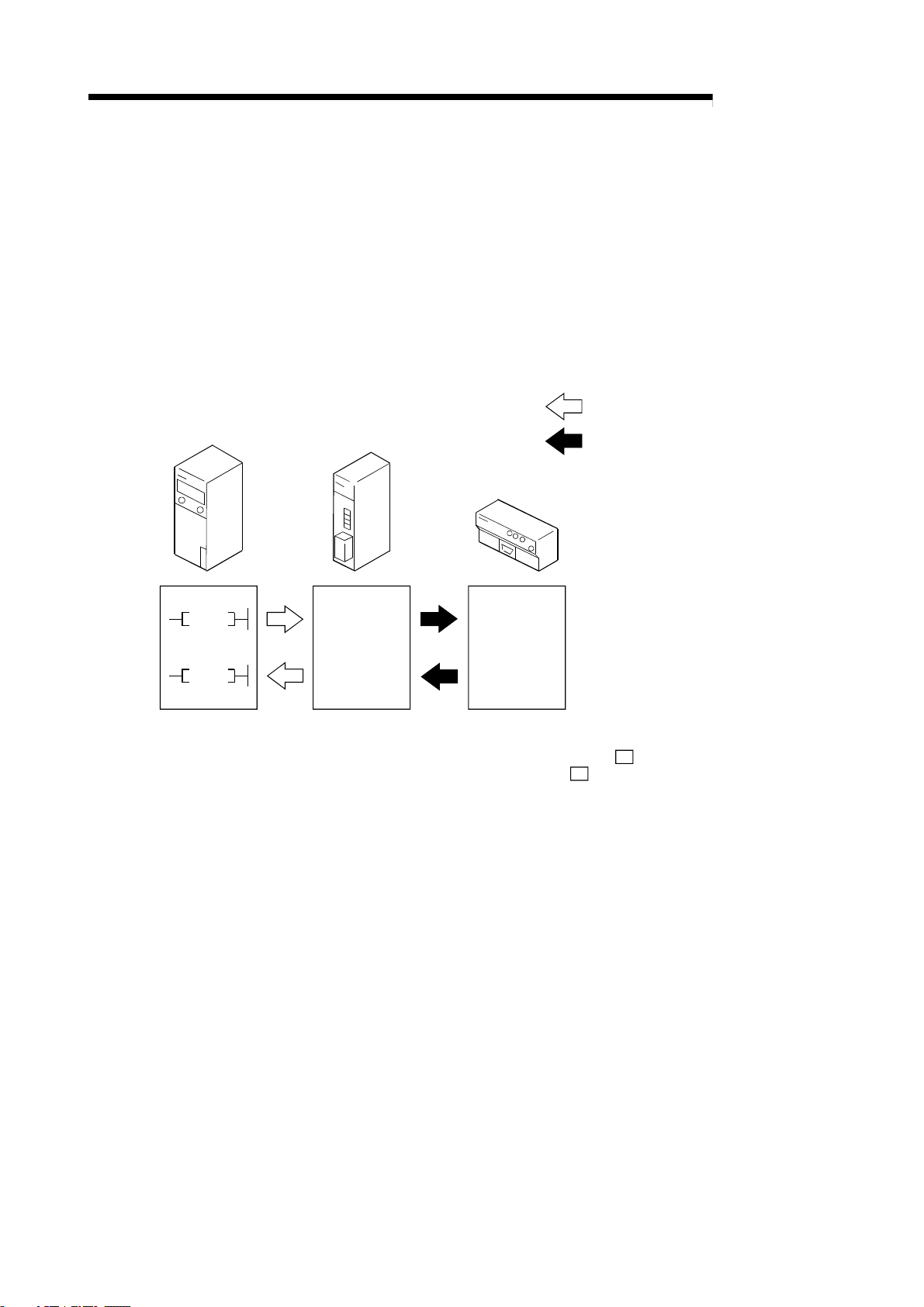

Carried out with sequence program

Programable controller CPU

1)

TO

FROM

4)

Master station

Buffer memory

(Automatic

update

1

buffer )

*

R2

2)

Buffer

memory

3)

*1 The address differs as shown below

for the A Series and Q/QnA Series.

A Series : Bank 2 M 0

Q/QnA Series : M 2000H to 2FFF

Automatically updated

to FFF

H

H

H

1) The data to be stored in the R2 buffer memory is written into the master

station's automatic update buffer.

2) The data is automatically written in at the R2 timing.

3) The data is automatically read at the R2 timing.

4) The corresponding master station's buffer memory is read to the data in the

R2 buffer memory to be read out.

1 - 2

Page 17

A

1 OUTLINE

MELSEC-

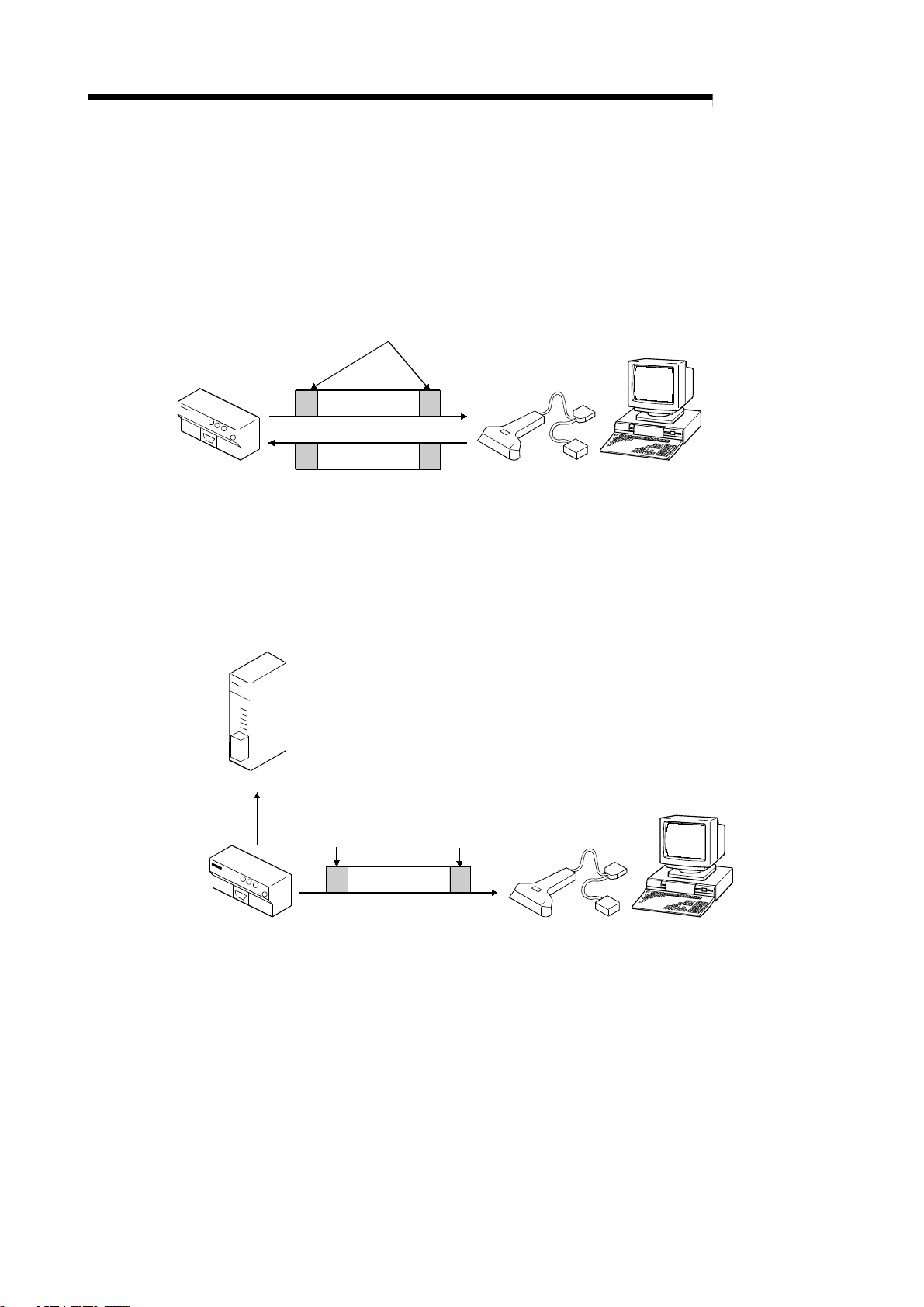

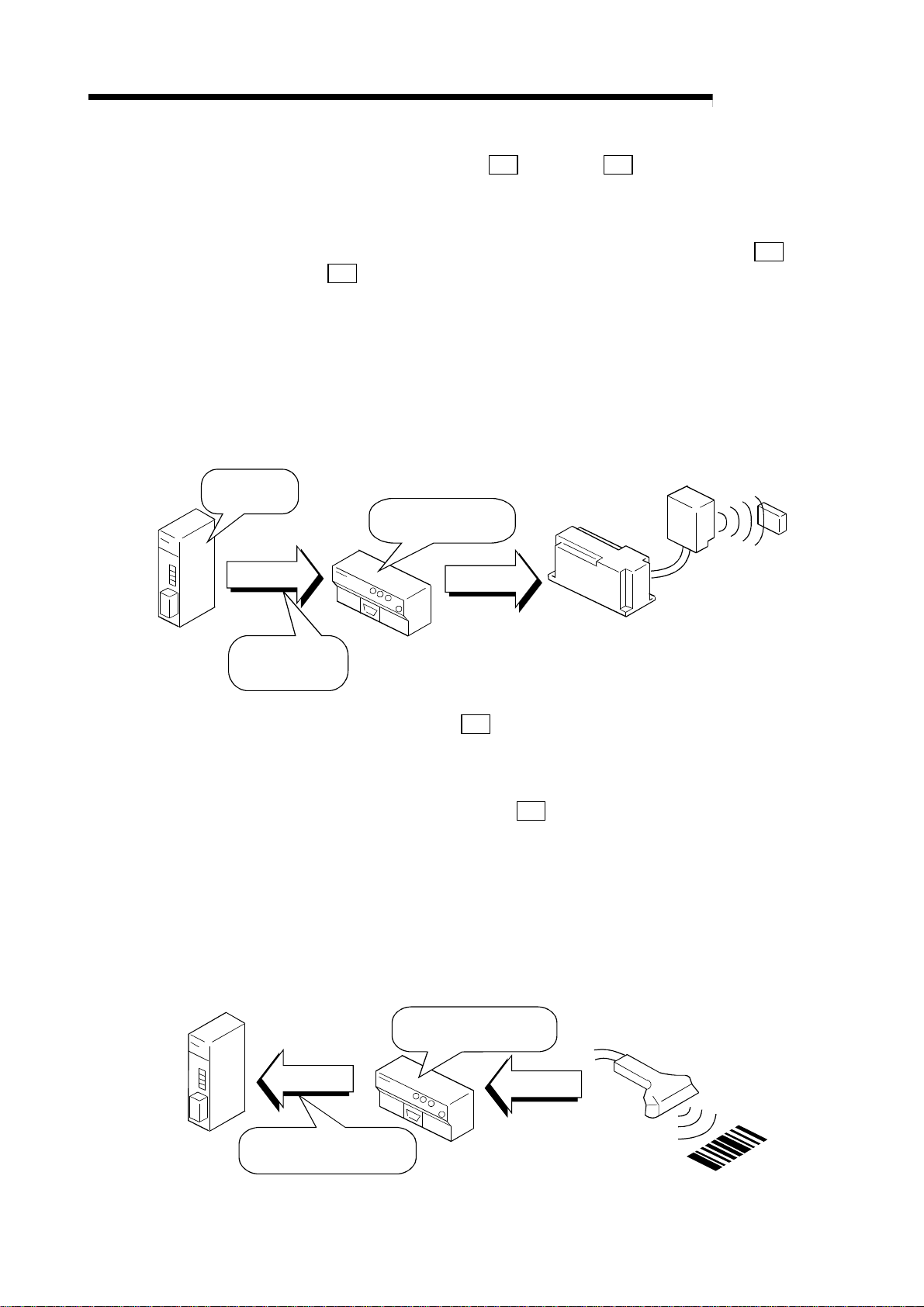

(2) Addition of frame during data transmission/reception with external

device

By adding a frame to the head and end, a statement format matching the

specifications of the external device, such as the barcode reader or ID controller,

can be created and communicated.

The frames include those that are set as the default, and the frames that can be

randomly created by the user (user registration frame).

A random frame can be added!

Random data

Data transmission

R2

Master station

Monitors the status

of RX, RY and RW,

etc.

Random data

Data reception

External device such as barcode reader,

ID controller, general-purpose personal computer

(3) Automatic transmission possible when user-set transmission

conditions are established

When the user-designated transmission conditions (changes in RX, RY, RW,

etc.), are established, data can be automatically transmitted to the external

device.

Head frame

External device such as barcode reader,

ID controller, general-purpose personal computer

R2

Final frame

Random data

Transmit data after conditions

are established!

(4) Two general-purpose input/output points each provided as a

standard

Two points each are provided for the general-purpose input and output so the

synchronous signal with the barcode reader and ID controller, etc., can be

directly input and output without providing a separate remote I/O module.

1 - 3

Page 18

A

1 OUTLINE

MEMO

MELSEC-

1 - 4

Page 19

A

2 SYSTEM CONFIGURATION

2. SYSTEM CONFIGURATION

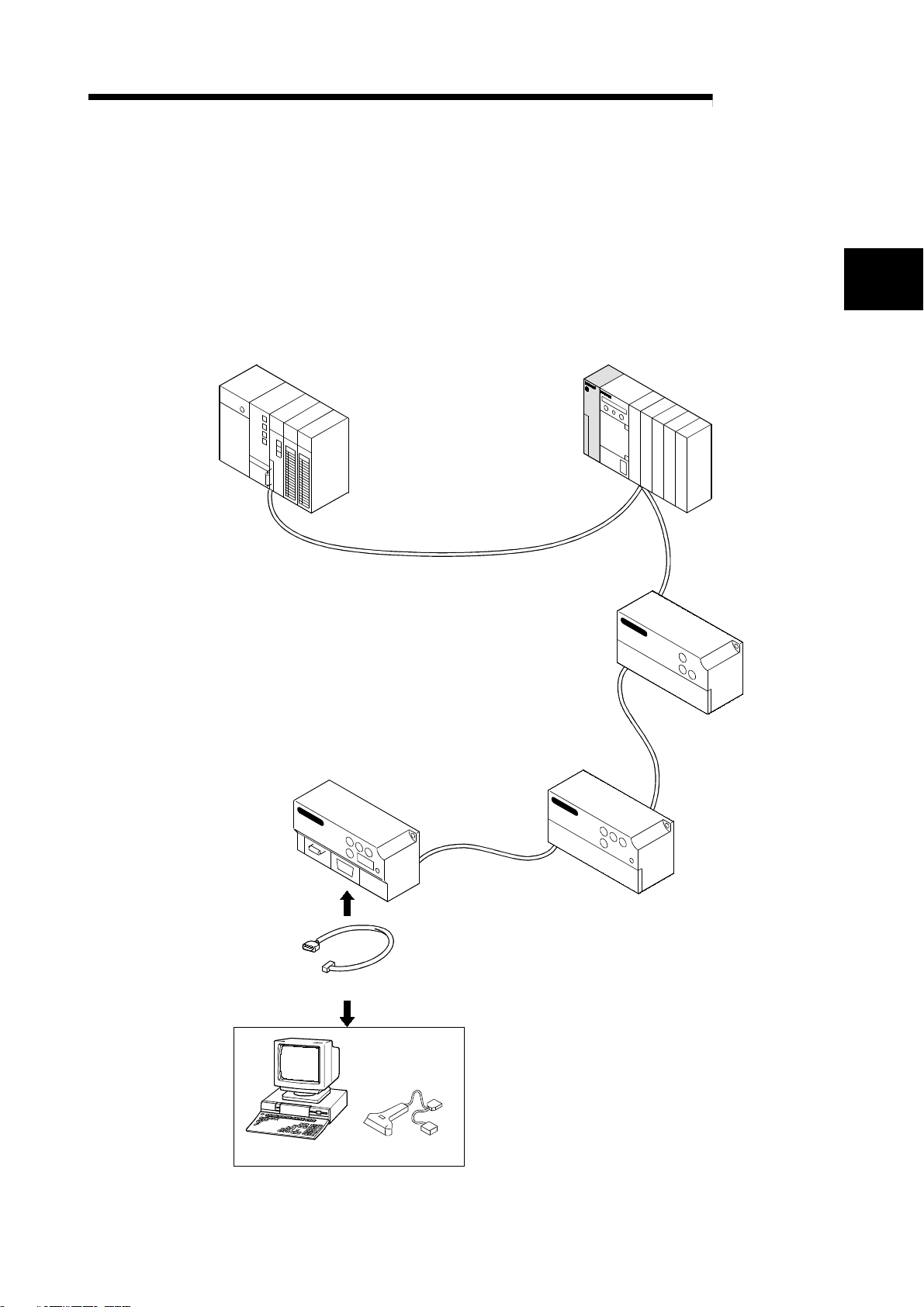

The system configuration for using R2 is shown explained in this section.

2.1 System configuration

The system configuration for using R2 is shown below.

Up to 26 R2 modules can be connected to one master station.

CC-Link master/local station (master station) CC-Link master/local station (local station)

MELSEC-

2

CC-Link dedicated cable

AJ65BT-R2

(Intelligent device station)

RS-232-C cable

Remote I/O station

Remote device station

1-station occupation

RX/RY 32 points each

RWr/RWw 4 points each

Personal computer Bar code reader

External device

2 - 1

Page 20

A

2 SYSTEM CONFIGURATION

2.2 Applicable systems

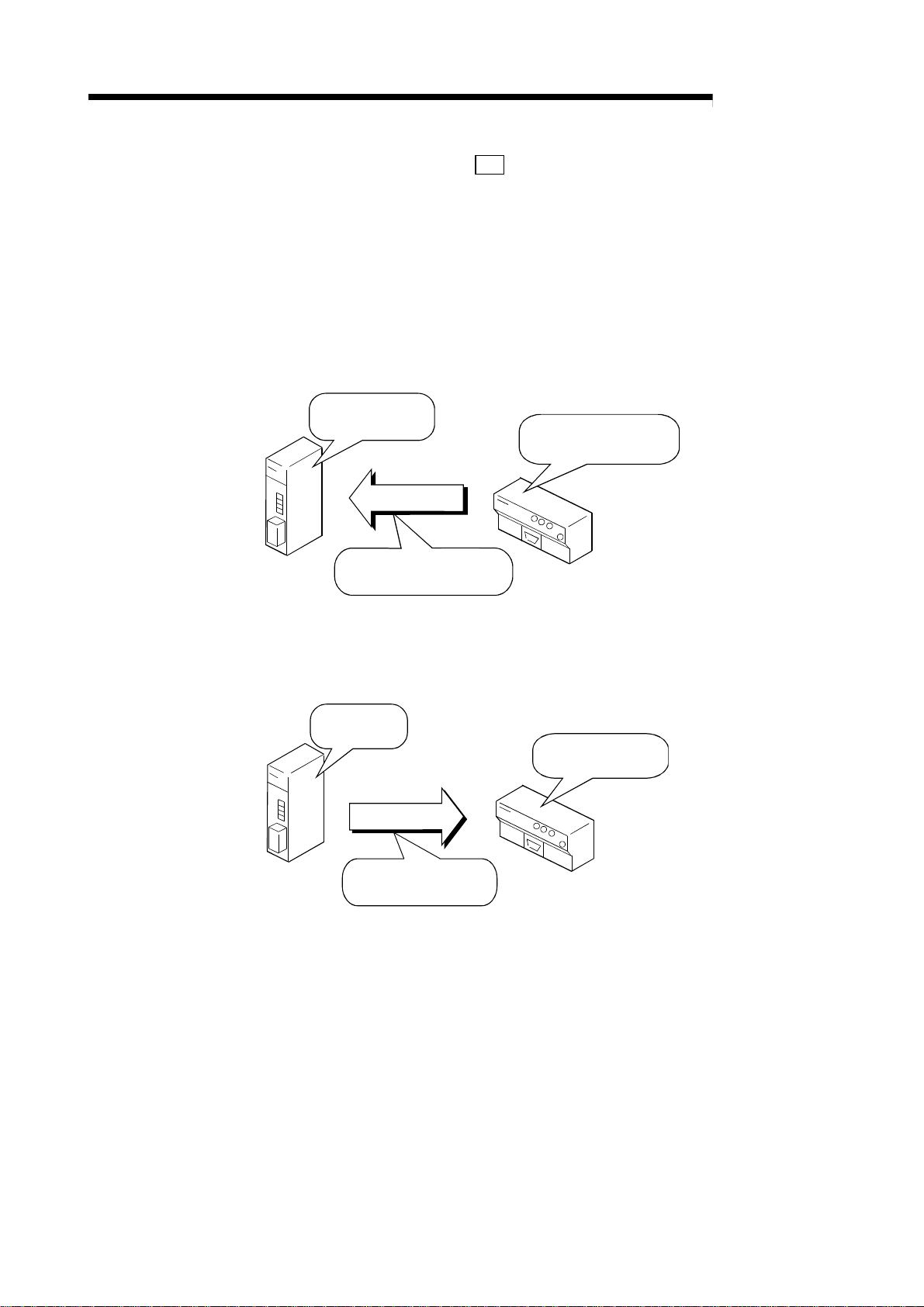

The master module of the CC-Link system that can use R2, and the programmable

controller CPU that can use the CC-Link dedicated commands are explained in this

section.

(1) Applicable master modules

The following indicates the master modules that can use the R2.

AJ61BT11

A1SJ61BT11

AJ61QBT11

A1SJ61QBT11

QJ61BT11N

QJ61BT11

POINT

When using any of the AJ61BT11, A1SJ61BT11, AJ61QBT11 and A1SJ61QBT11,

use the one that has the following number (9707 B or later) in the DATE field of the

rating plate.

The module that does not have "9707 B" in the DATE field cannot use the R2.

MELSEC-

<Large type>

<Compact type>

Date of Function version Date of Function version

manufacture manufacture

(2) Restrictions on use of CC-Link dedicated commands

Depending on the used programmable controller CPU and master module, the

CC-Link dedicated commands may be unusable.

For details of the restrictions, refer to the A Series Master Module User's Manual

(Details) and AnSHCPU/AnACPU/AnUCPU Programming Manual (Dedicated

Instructions).

For program examples using the dedicated commands, refer to Section 9.2.2,

Section 9.2.3, Section 9.3.2 and Section 9.3.3.

2 - 2

Page 21

A

3 SPECIFICATIONS

3. SPECIFICATIONS

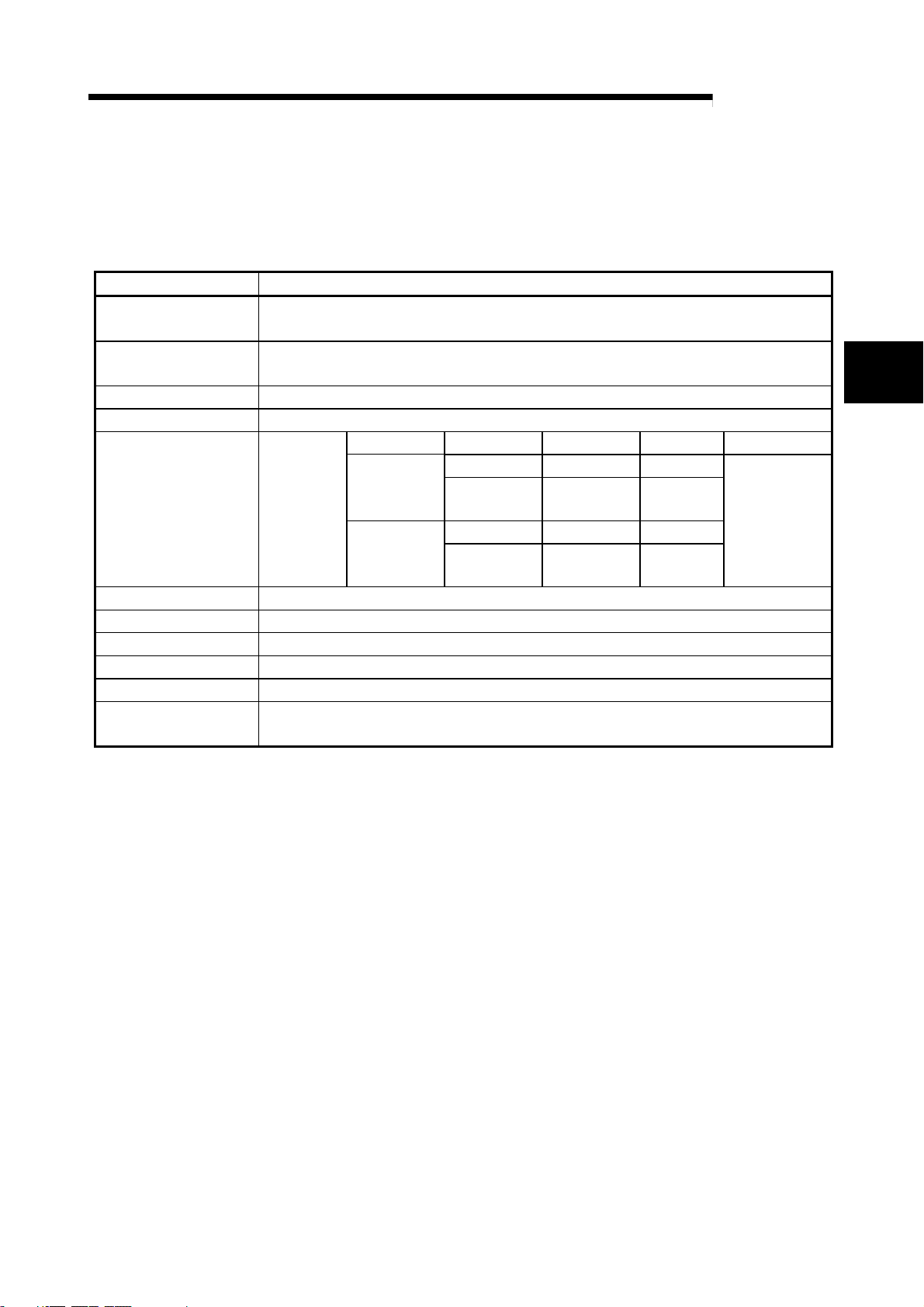

3.1 General specifications

The general specifications of the R2 are shown below.

Item Specifications

Working ambient

temperature

Storage ambient

temperature

Working ambient humidity 10 to 90%RH, with no dew condensation

Storage ambient humidity 10 to 90%RH, with no dew condensation

Frequency Acceleration Amplitude No. of sweeps

10 to 57Hz – 0.075mmWhen there is

JIS B 3502,

Vibration resistance

Impact resistance

Working atmosphere No corrosive gases

Working altitude *

Installation place Inside control panel

Overvoltage category *

Degree of contamination

2

*

3

IEC 61131-2

compliant

JIS B 3502, IEC 61131-2 compliant (147m/s

1

intermittent

vibration

When there is

continuous

vibration

57 to 150Hz

10 to 57Hz – 0.035mm

57 to 150Hz

-20 to 75°C

2000m or less

0 to 55

II or less

2 or less

°

C

2

9.8m/s

2

4.9m/s

2

, 3 times each in X, Y and Z directions)

–

–

MELSEC-

3

10 times each in

X, Y and Z

directions

(for 80 minutes)

*1 Indicates to which power distribution section, from the public power distribution network to the in-plant

machine device, the device is assumed to be connected.

Category II applies to a device fed power from a fixed facility.

The withstand surge voltage level for a device with a rating up to 300V is 2500V.

*2 Exponential indicating the degree of conductive matter generated in the environment where device is

used.

In the degree of contamination level 2, only non-conductive contaminants are generated. However,

temporary conductivity could occur due to rare condensation.

*3 Do not use or store the programmable controller in the environment where the pressure is higher than the

atmospheric pressure at sea level. Otherwise, malfunction may result. To use the programmable controller

in high-pressure environment, contact your nearest Mitsubishi representative.

3 - 1

Page 22

A

3 SPECIFICATIONS

×

×

⋅

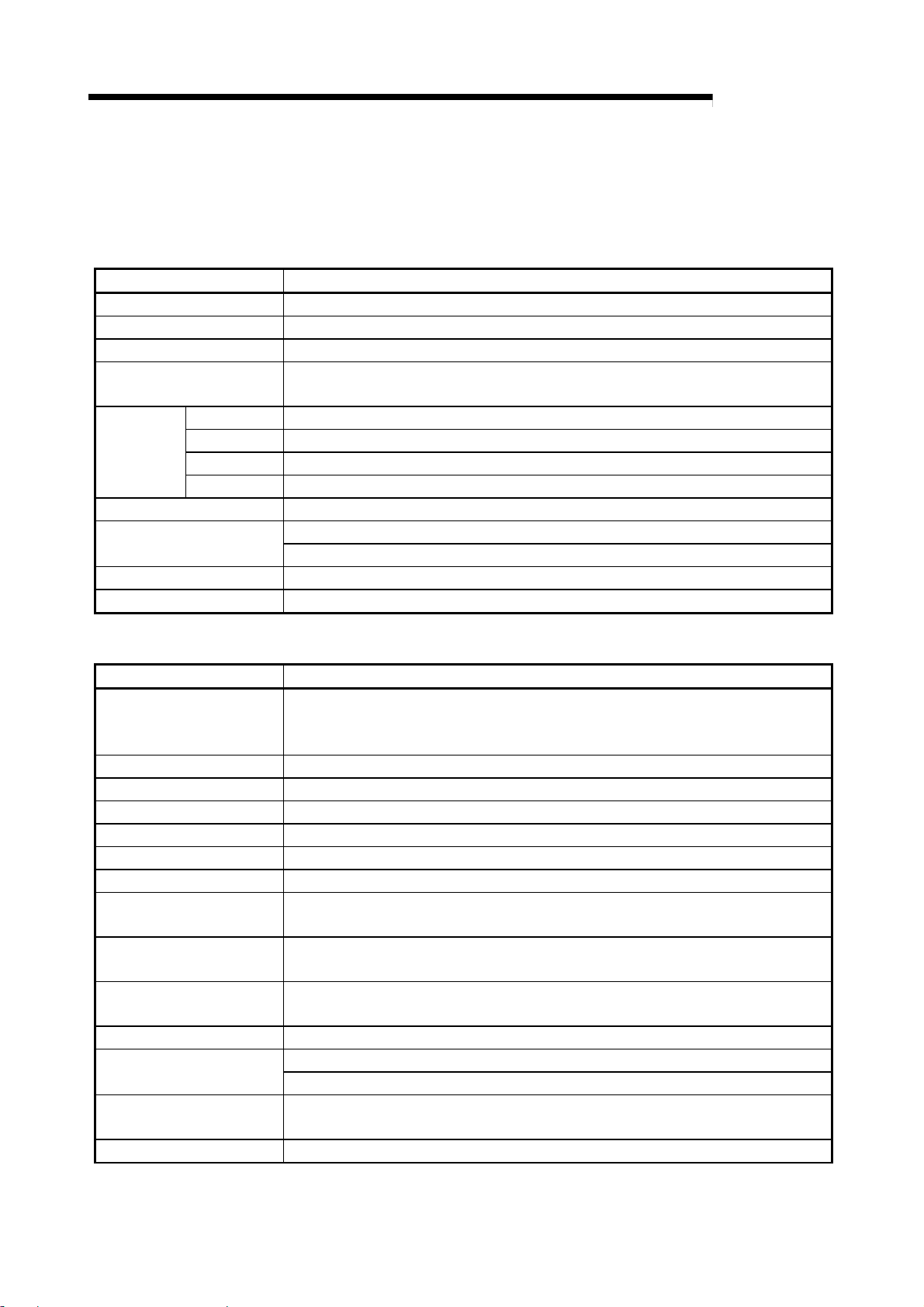

3.2 Performance specifications

The R2 performance specifications are shown below.

(1) RS-232-C specifications

Item Specifications

Interface specifications RS-232-C compliant, 1 channel (Refer to section 3.3)

Transmission method Full duplex communication method

Synchronization method Start-stop synchronization method

Transmission speed 300, 600, 1200, 2400, 4800, 9600, 19200bps

(Select with RS-232-C transmission specification setting switch)

Data format

Error detection With parity check (even/odd)/None

(flow control)

Transmission distance 15m

OS reception area 5120 bytes

Star bit 1

Data bit 7/8

Parity bit 1 (Yes)/0 (No)

Stop bit 1/2

DTR/DSR (ER/DR) controlCommunication control

DC1/DC3 control

MELSEC-

(2) Data link specifications

Item Specifications

General-purpose input/output

specifications

Transmission path Bus (RS-485)

EEPROM writing life 100,000 times

CC-Link station type Intelligent device station

No. of occupied stations 1 station (RX/RY 32 points each, RWw/RWr 4 points each)

Connection cable CC-Link dedicated cable

Withstand voltage One minute at 500VAC between DC external terminal batch and grounding

Insulation resistance

Noise withstand level DC type noise voltage 500Vp-p

Module installation screw

Applicable DIN rail TH35-7.5Fe, TH35-7.5Al, TH35-15Fe (JIS C 2812 compliant)

External power supply

Tolerable instantaneous

power failure time

Weight 0.40kg

Input side : 24VDC (Positive common/negative common shared type) 2 points

Output side : Transistor output (sink type) 12/24VDC 2 points Terminal block (Refer to

section 3.4)

Ω

or more with 500VDC insulation resistance meter between DC external terminal

10M

batch and grounding

μ

With noise width 1

(Tightening torque range 0.78 to 1.18N

s, noise frequency 25 to 60Hz noise simulator

0.7mm

M4

Current consumption: 0.11A

16mm or more screw

24VDC

1ms

m)

3 - 2

Page 23

A

3 SPECIFICATIONS

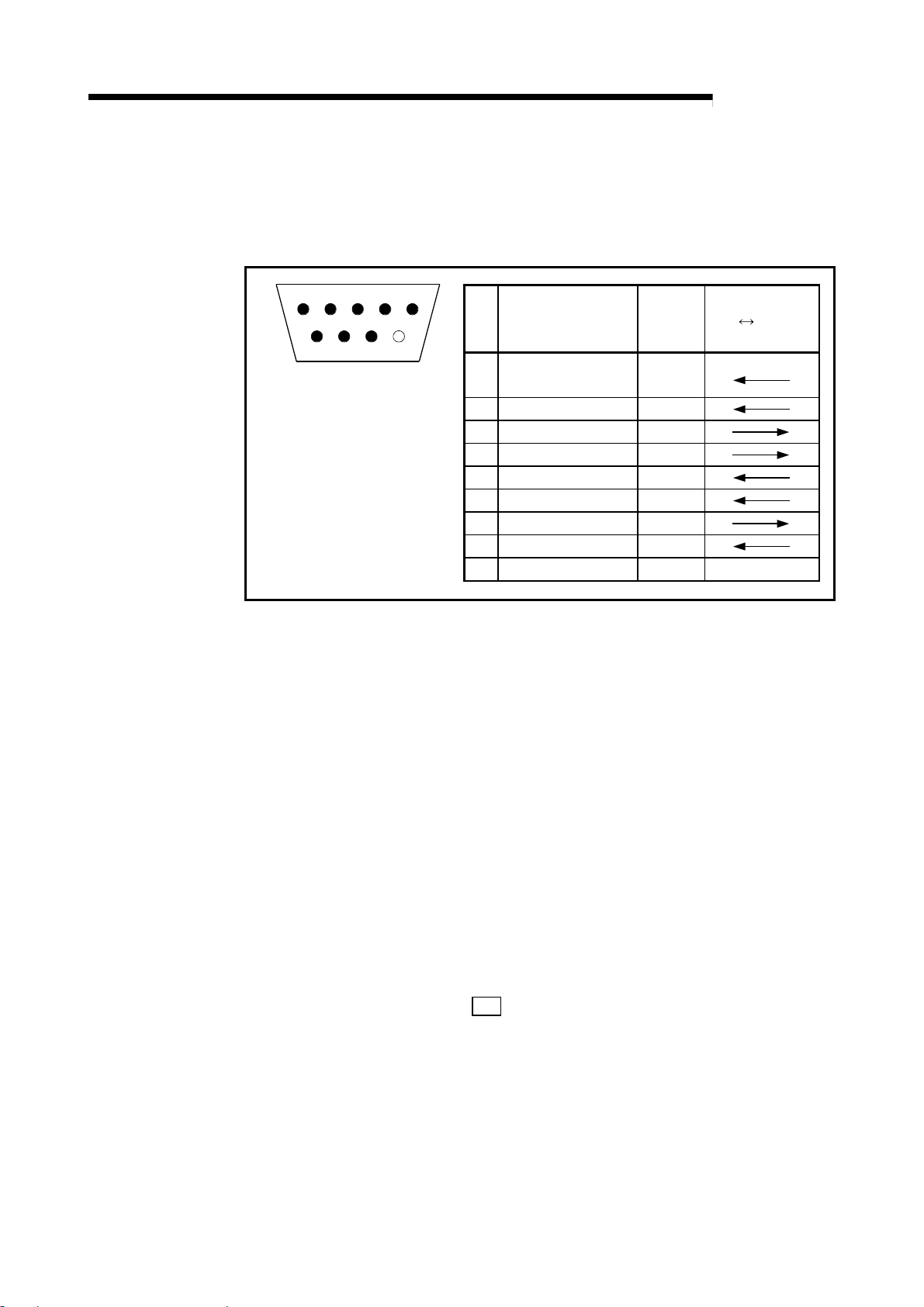

3.3 RS-232-C interface specifications

The specifications of the RS-232-C interface for connection with an external device are

shown below.

MELSEC-

1 2 3 4 5

6

7 8 9

The following type of connector

is mounted on the R2 side, so

use a mate connector that

matches this type.

9-pin D-SUB (female) screw-

fixed type

DDK Ltd.

17L-10090-27-D9AC

Pin

No.

Reception carrier

1

detection

2 Reception data RD(RXD)

3 Transmission data SD(TXD)

4 Data terminal ready ER(DTR)

5 Signal ground SG

6 Data set ready DR(DSR)

7 Transmission request RS(RTS)

8 Transmission enable CS(CTS)

9 Not used – –

Name

Signal

abbrev.

CD

Signal direction

external

R2

device

The details of each signal are explained below.

CD.................. The CD signal status can be read with the input signal RXnB.

ER (DTR) ....... When using DTR/DSR control, this is turned ON and OFF according

to the empty size of the OS reception area for storing the received

data.

(The DTR signal turns ON when the RS can receive data.)

When not using DTR/DSR control, the output signal RYnA is followed.

DR (DSR) ...... When using DTR/DSR control, if this is OFF, data will not be

transmitted from R2 to the external device.

Set this to be always ON when the external device is in the reception

enabled state.

When not using DTR/DSR control, the DSR signal status will be

ignored.

RS .................. This follows the

R2 101H setting and output signal RYn9.

CS .................. When the CS signal is OFF, data will not be transmitted from R2 to

the external device.

Set this to be always ON when the external device is in the reception

enabled state.

A standard connection example of the RS-232-C cable is given in section 4.5.2.

3 - 3

Page 24

A

3 SPECIFICATIONS

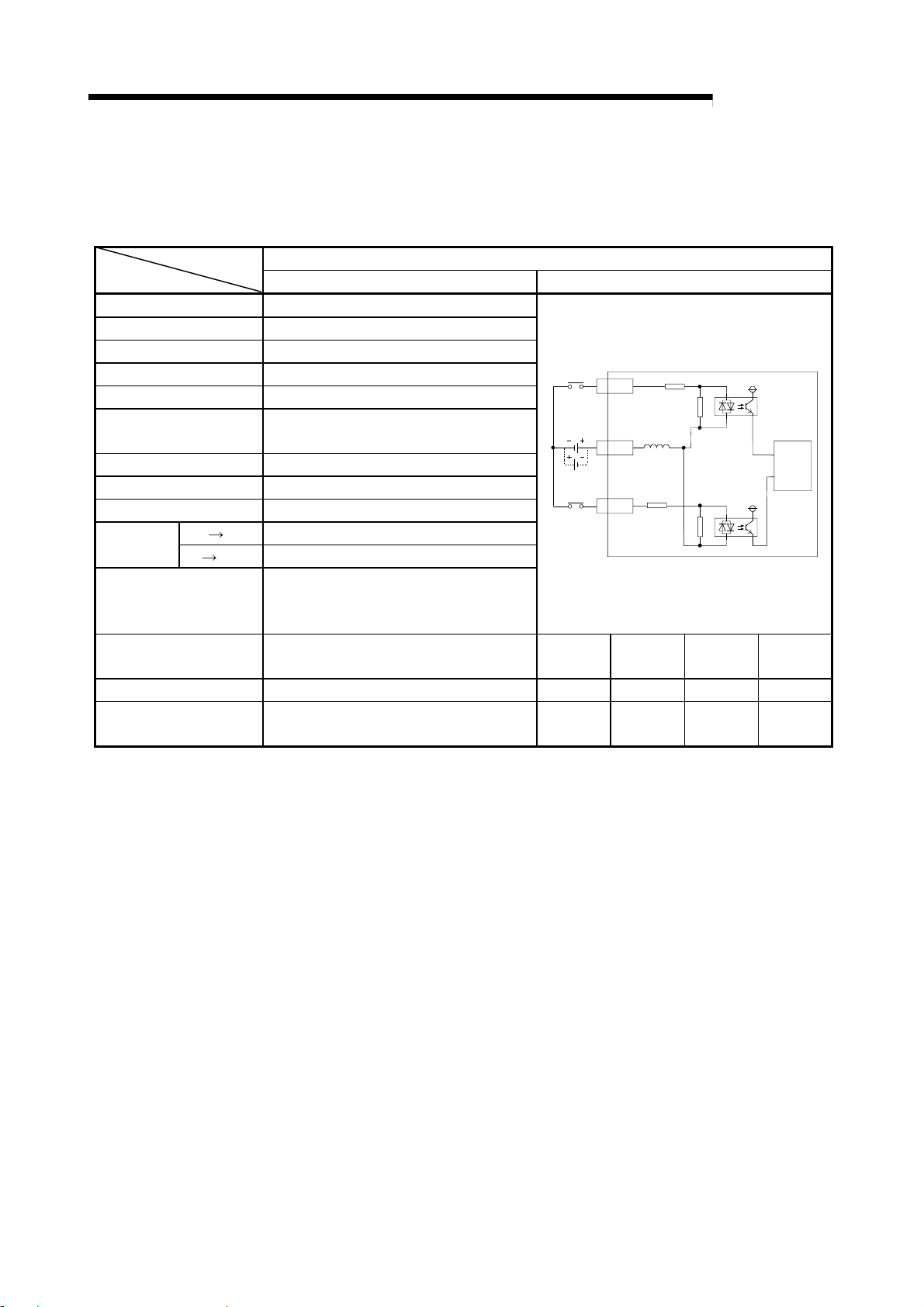

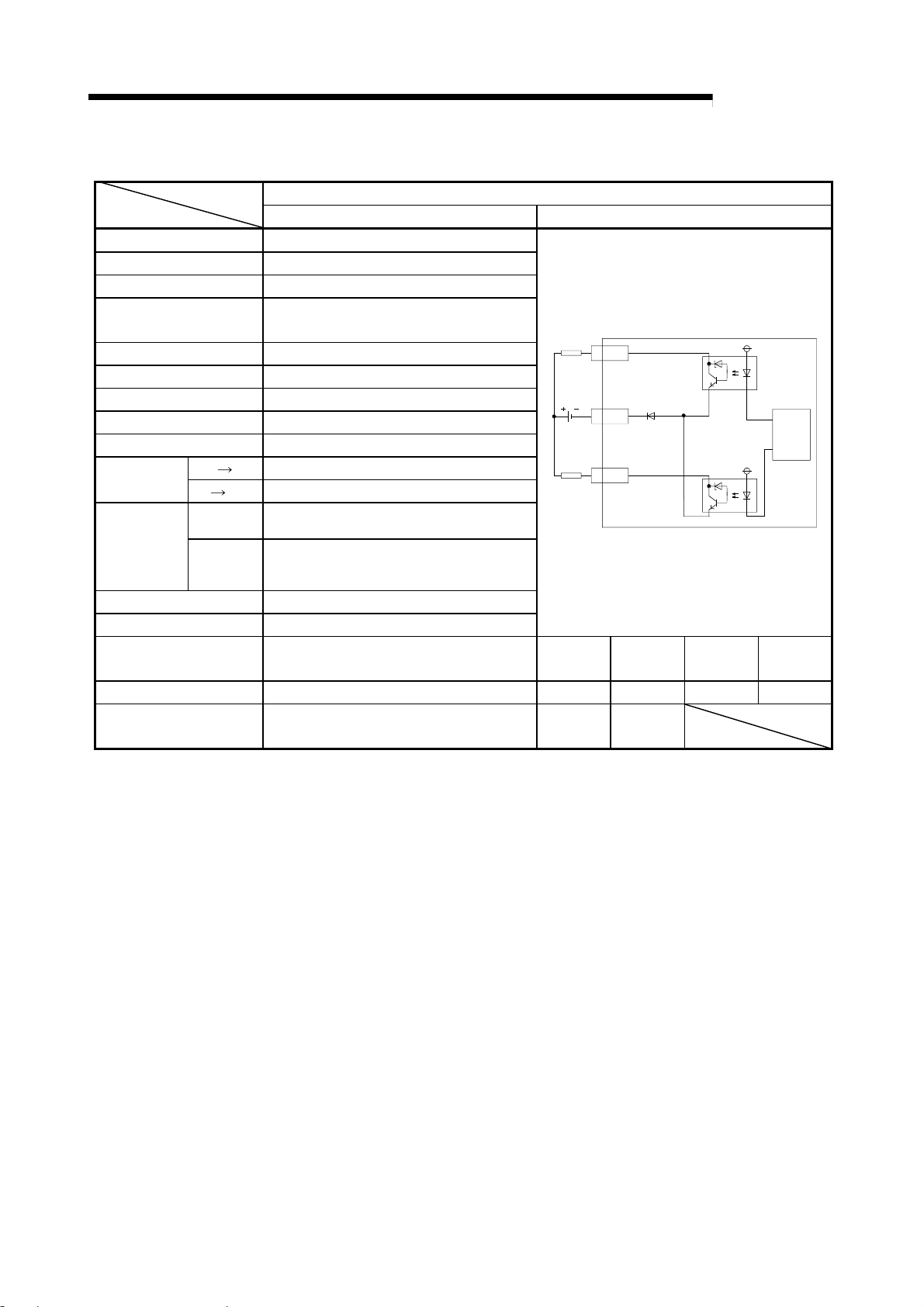

3.4 General-purpose input/output specifications

The general-purpose input/output specifications of the R2 are shown below.

(1) General-purpose input specifications

DC input (Positive common/negative common shared type)

R2 External connection view

No. of input points 2 points

Insulation method Photo coupler insulation

Rated input voltage 24VDC

Rated input current Approx. 7mA

Working voltage range 19.2 to 28.8VDC (ripple rate within 5%)

Max. No. of simultaneous

input points

ON voltage/ON current 14V or more/3.5mA or more

OFF voltage/OFF current 6V or less/1.7mA or less

Input resistance

Response

time

Common method

External connection

method

Applicable wire size

Applicable crimp terminal

OFF ON 10ms or less

ON OFF 10ms or less

100%

Approx. 3.3k

2 points/common (COM1)

Positive common/negative common shared

type

7-point terminal block (M3.5 screw)

0.75 to 2mm

RAV1.25-3.5, RAV2-3.5 (JIS C 2805

compliant)

Ω

2

MELSEC-

1XC

24VDC

COM1

2

3XD

Terminal

No.

TB1 XC TB3 XD

TB2 COM1 TB4 NC

Signal

name

Terminal

No.

Internal

Signal

name

circuit

3 - 4

Page 25

A

3 SPECIFICATIONS

(2) General-purpose output specifications

R2 External connection view

No. of output points 2 points

Insulation method Photo coupler insulation

Rated load voltage 12/24VDC

Working load voltage

range

Max. load current 0.1A/point 0.2A/common

Max. rush current 0.4A 10ms or less

Leakage current at OFF 0.1mA or less

Max. voltage drop at ON 1.5VDC or less (MAX) 0.1A

Output type Sink type

Response

time

Output section

OFF ON 2ms or less

ON OFF 2ms or less (resistance load)

Voltage 10.2 to 28.8VDC (ripple rate within 5%)

externally

supplied

Current

power

Surge killer Zener diode

Common method 2 points/common (COM2)

External connection

method

Applicable wire size

Applicable crimp terminal

10.2 to 28.8VDC (ripple rate within 5%)

50mA or less (TYP. 24VDC, per common)

Not including external load current.

7-point terminal block (M3.5 screw)

0.75 to 2mm

2

RAV1.25-3.5, RAV2-3.5 (JIS C 2805

compliant)

Transistor output (sink type)

L

5YC

12/24VDC

COM2

6

L

7YD

Terminal

No.

TB5 YC TB7 YD

TB6 COM2

Signal

name

MELSEC-

Terminal

No.

Internal

Signal

name

circuit

3 - 5

Page 26

A

3 SPECIFICATIONS

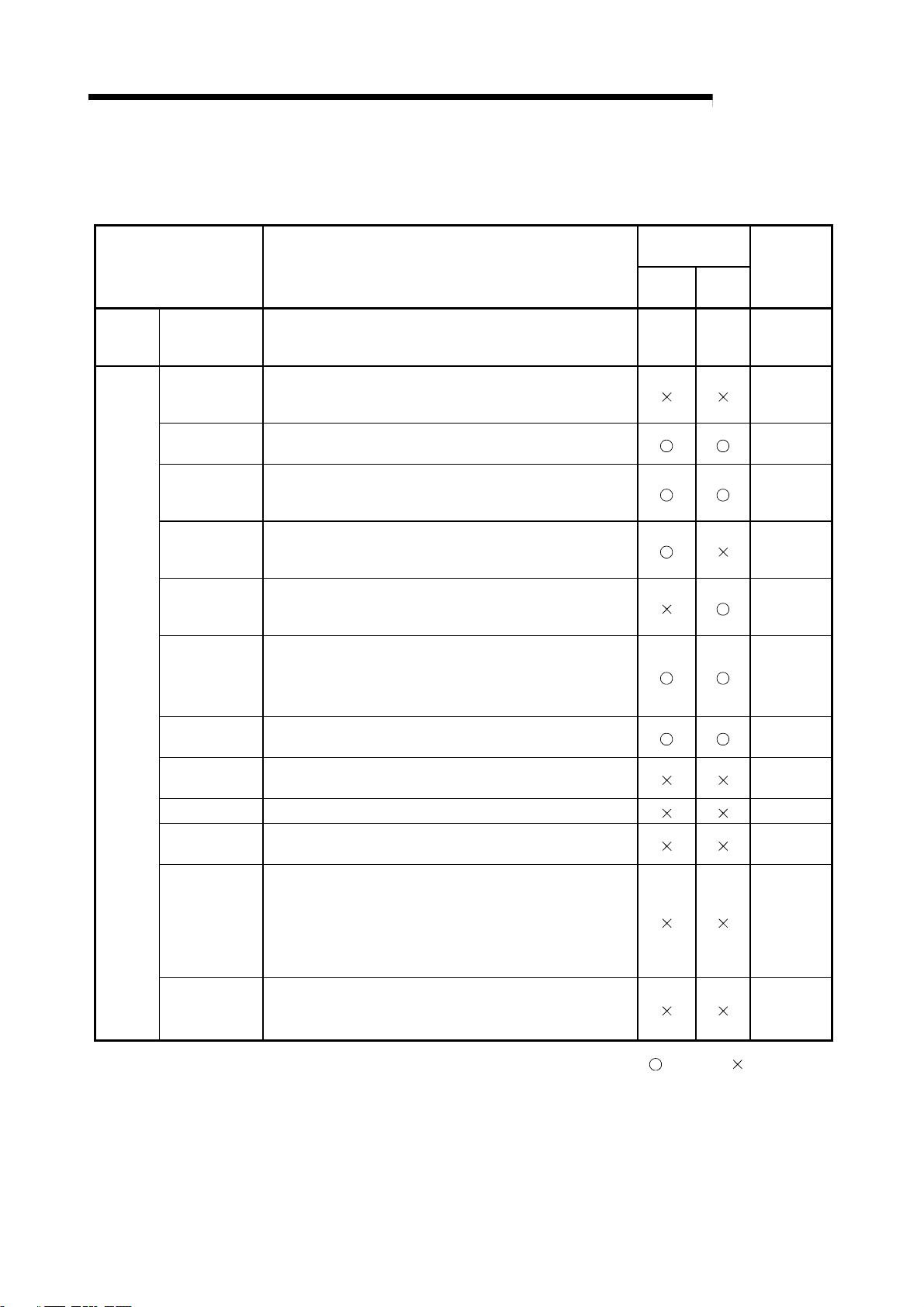

3.5 List of functions

Function Explanation

Main

function

Auxiliary

functions

Non-procedural

communication

function

Buffer memory

automatic

update

Frame addition

Monitor

transmission

Transmission

cancellation

Forced

reception

complete

Flow control

ASCII-BIN

conversion

RW update

R2 initialization Initializes the R2. Section 8.6

OS reception

area clear

Registration to

RS EEPROM

The R2 functions are shown below.

Non-procedural data transmission/reception with external

device such as barcode reader, ID controller, generalpurpose personal computer.

Automatically updates the buffer memory between the R2

and master station at the update timing set in each area of

the R2 buffer memory.

Adds a frame registered for R2 at the head and end of the

transmission data when transmitting data.

Automatically transmits data to the external device when the

user-designated transmission conditions (changes in RX, RY,

RW and status) are established.

After transmission request is issued from the master station

to R2, forcibly cancels the transmission before R2 completes

transmission to external device.

Forcibly completes the reception when reception data from

external device has not reached the reception complete data

size, etc., and reads out the currently received data.

Stops/resumes transmission of data from external device

according to open space in R2 OS reception area.

Stops/resumes transmission of data from R2 according to

requests from external device.

Carries out ASCII-BIN conversion on the

transmitted/received data.

Assigns master station remote register (RW) and R2 side

area to be automatically updated in the buffer memory.

Clears the received data stored in the R2 OS reception area.

Registers a setting value for the R2 buffer memory's specific

application area in the EEPROM, or returns the value

registered in the EEPROM to the R2 default value.

The value for the R2 buffer memory registered in the

EEPROM (including the setting values changed by the user)

is used as an initial value at the time of the R2 startup.

MELSEC-

Relation with

main function

Trans-

mission

Recep-

tion

– – Chapter 6

Reference

Section 5.6

Chapter 7

Section 7.4

Section 8.1

Section 8.2

Section 8.3

Section 8.4

Section 8.5

Section 8.7

Section 8.8

RS-232-C

signal control

Reads the status of the RS-232-C interface signal

stored in the R2 buffer memory, and controls the

output.

Section 8.9

: Related, : Not related

3 - 6

Page 27

A

3 SPECIFICATIONS

MELSEC-

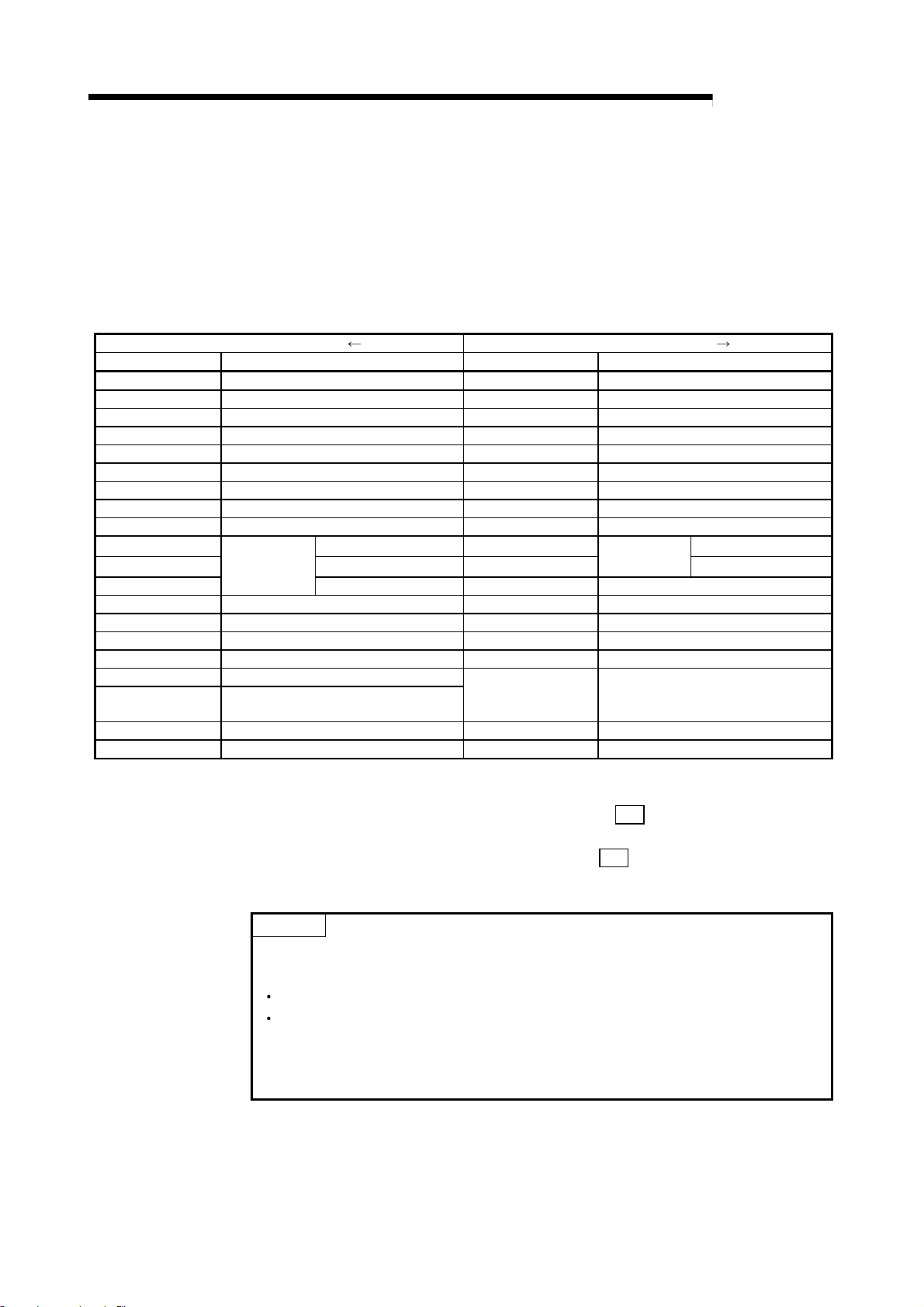

3.6 Input/output signals for master module

The input/output signals (RX/RY) for the R2 master module are explained in this

section.

3.6.1 List of input/output signals

A list of the R2 input/output signals is shown below.

Signal direction Master module R2 Signal direction Master module R2

Device No. (input) Signal name Device No. (output) Signal name

RXn0 Transmission normal complete RYn0 Transmission request

RXn1 Transmission error complete RYn1 Transmission cancel request

RXn2 Reception normal read request RYn2 Reception read complete

RXn3 Reception error read request RYn3 Forced reception complete request

RXn4 Initialization normal complete RYn4 Initialization request

RXn5 Initialization error complete RYn5 Use prohibited

RXn6 OS reception area clear complete RYn6 OS reception area clear request

RXn7 EEPROM function normal complete RYn7 EEPROM function request

RXn8 EEPROM function error complete RYn8 Use prohibited

RXn9 CS (CTS) signal RYn9

RXnA DR (DSR) signal RYnA

RXnB

RXnC to RXnD General-purpose external input signal RYnC to RYnD General-purpose external output signal

RXnE to RX(n+1)8 Use prohibited RYnE to RY(n+1)8 Use prohibited

RX(n+1)9 Initial data read complete RY(n+1)9 Initial data read request

RX(n+1)A Error state RY(n+1)A Error reset request

RX(n+1)B Remote station ready

RX(n+1)C to

RX(n+1)D

RX(n+1)E Intelligent device station access complete RY(n+1)E Intelligent device station access request

RX(n+1)F Use prohibited RY(n+1)F Use prohibited

Signal status

Use prohibited

CD signal RYnB Use prohibited

RY(n+1)B to RY(n+1)D Use prohibited

Signal setting

n: Address assigned to master module with station No. setting.

RS (RST) signal *

ER (DTR) signal *

1

2

*1 The RS signal setting is valid when the "RS signal status designation (

RYn9 ON/OFF (1)". (Refer to section 8.9.)

*2 The ER signal setting is invalid when the "Flow control designation (

flow control. (DTR/DSR/ (ER/DR) control) (1)".

Important

Do not designate the RXn0 to RXn8, RXnE to RX(n+1)F, RYn0 to RYn9, RYnB, or RYnE to

RY (N+1)F signals to the following functions.

Monitor target RX/RY for monitor transmission function

Reference RX/RY for registration frame RX/RY/RW reference special character.

Do not output (turn ON) the usage-prohibited signals.

If an output is carried out to a usage-prohibited signal, the programmable controller system

could malfunction.

3 - 7

R2 101H)" is set to "Follow

R2 100H)" is set to "Carry out

Page 28

A

3 SPECIFICATIONS

t

t

3.6.2 Details of input/output signals

A detailed explanation of the R2 input/output signals is given below.

The lines in the timing chart indicate the following details.

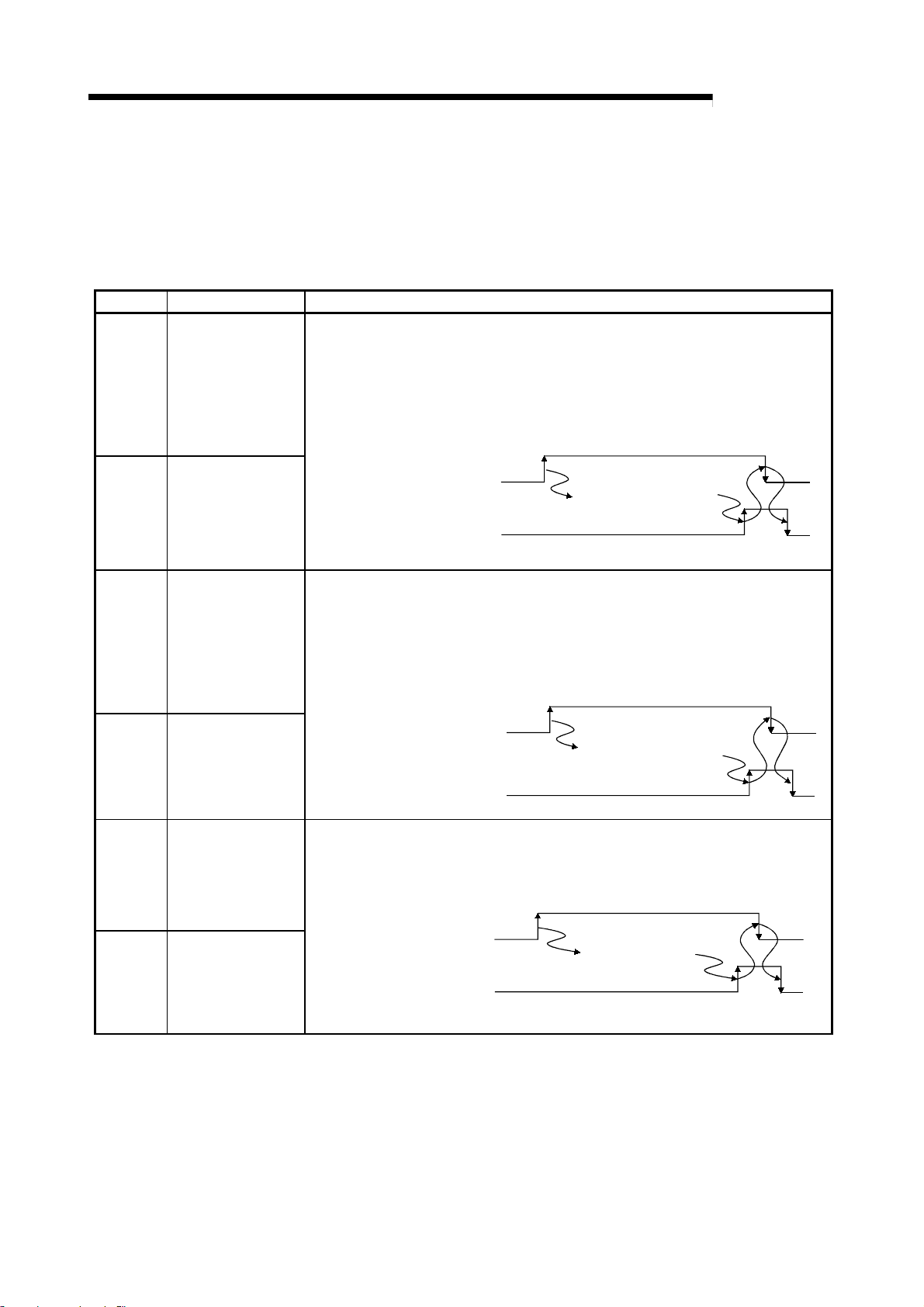

(1) Remote input (RX)

Device No. Signal name Details

When transmitting data to an external device connected to R2, after the transmission

data is written into the R2 transmission area, the transmission request (RYn0) is

turned ON.

RXn0

Transmission normal

complete

When the transmission is completed normally, transmission normal complete (RXn0)

turns ON, and if the transmission is completed abnormally, transmission error

complete (RXn1) turns ON.

The transmission request (RYn0) turns OFF when these signals turn ON.

MELSEC-

RXn1

RXn2

RXn3

RXn4

Transmission error

complete

Reception normal

read request

Reception error read

request

Initialization normal

complete

Transmission request (RYn0)

Transmission normal complete

(RXn0)

or Transmission error complete

(RXn1)

R2 transmits contents

of transmission area to

external device.

When data is received from an external device connected to R2 and the transmission

is completed normally, reception normal read request (RXn2) turns ON. If the

transmission is completed abnormally, reception error read request (RXn3) turns ON.

The reception data is stored in the R2 reception area at this time.

The data in the R2 reception area is read out when these signals turn ON, and read

complete (RYn2) turns OFF when the reading is completed.

Reception normal read reques

(RXn2)

or Reception error read reques

(RXn3)

Reception read complete (RYn2)

Reception area is read

with sequence program.

The initialization request (RYn4) is turned ON to initialize R2.

When the R2 is correctly initialized, initialization correct complete (RXn4) turns ON,

and when the process ends abnormally, initialization error complete (RXn5) turns ON.

The initialization request signal (RYn4) turns OFF when these signals turn ON.

RXn5

Initialization error

complete

Initialization request (RYn4)

Initialization normal complete

(RXn4)

or Initialization error complete

(RXn5)

3 - 8

R2 is initialized.

Page 29

A

3 SPECIFICATIONS

Device No. Signal name Details

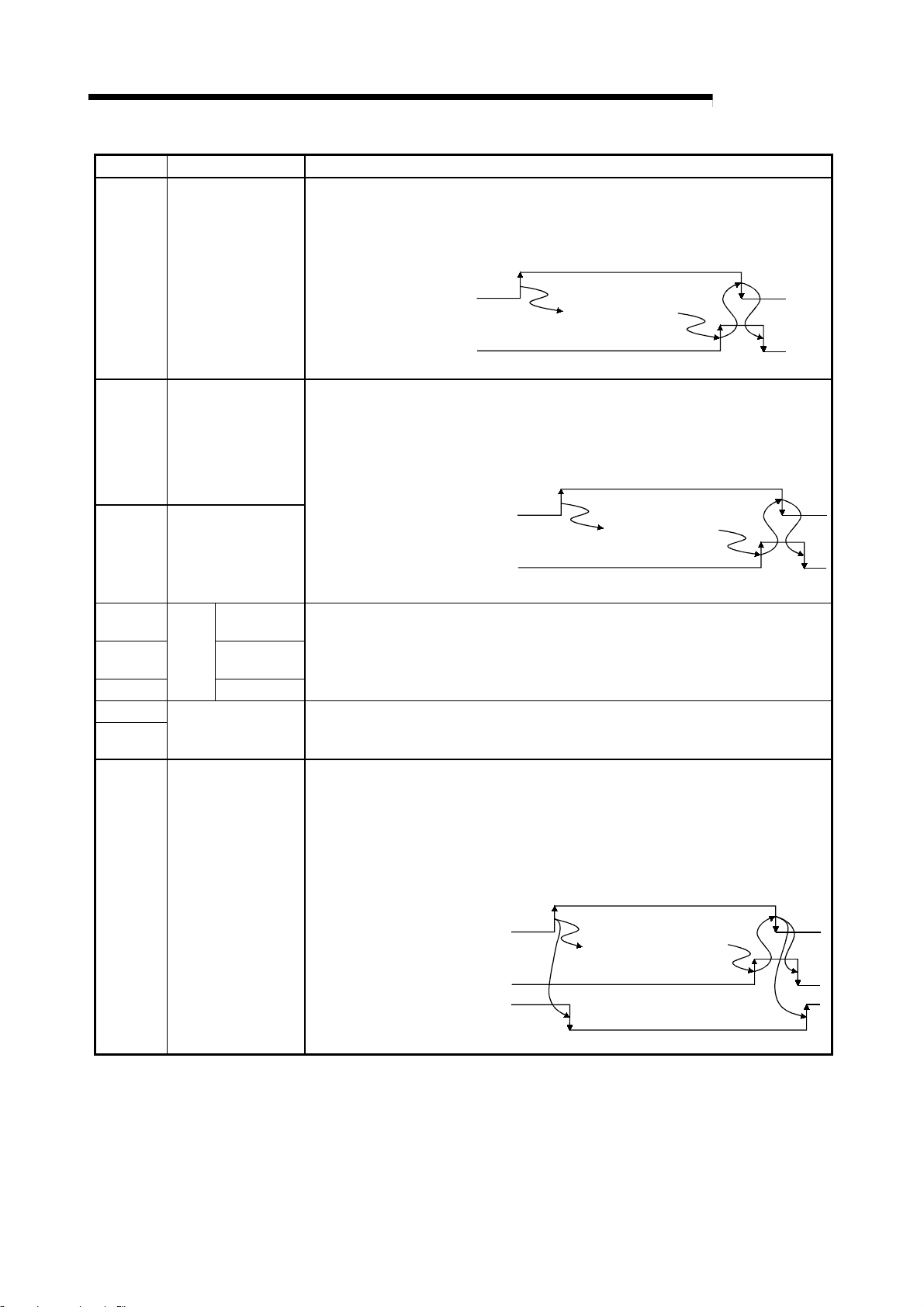

The OS reception area clear request (RYn6) is turned ON to abort the data in the R2

OS reception area.

When OS reception area clear is completed, the R2 turns the OS reception area clear

complete (RXn6) ON, so the OS reception area clear request (RYn6) will turn OFF.

MELSEC-

RXn6

RXn7

RXn8

RXn9

RXnA

RXnB

RXnC

RXnD

OS reception area

clear complete

EEPROM function

normal complete

EEPROM function

error complete

CS (CTS)

signal

Signal

status

DR (DSR)

signal

CD signal

General-purpose

external input signal

OS reception area

clear request (RYn6)

OS reception area

clear complete (RXn6)

R2 clears the OS

reception area.

When the R2 EEPROM function is executed, after the data is read into the R2 buffer

memory (1C0

H), EEPROM function request (RYn7) turns ON.

When completed normally, EEPROM function normal complete (RXn7) turns ON.

When completed abnormally, EEPROM function error complete (RXn8) turns ON.

When these signals turn ON, EEPROM function request (RYn7) turns OFF.

EEPROM function request (RYn7)

EEPROM function normal complete

(RXn7)

or EEPROM function error complete

(RXn8)

R2 executes

EEPROM function.

This signal indicates the control signal status (CS, DR, CD signal) during RS-232-C

communication with an ON or OFF state.

This signal indicates the status of the R2 general-purpose external input (XC, XD)

status with an ON or OFF state.

RXnC: Corresponds to XC RXnD: corresponds to XD

When writing in the initialization data before executing initialization, the initial data read

request (RY(N+1)9) turns ON, and the initialization data is written to the master station.

At this time, remote station ready (RX(n+1)B) turns OFF.

When the writing is completed, initial data read complete (RX(n+1)9) turns ON, and

the initial data read request (RY(n+1)9) turns OFF.

When these turn OFF, initial data read complete (RX(n+1)9) turns OFF, and remote

station ready (RX(n+1)B) turns ON.

RX(n+1)9

Initial data read

complete

Initial data read request (RY(n+1)9)

Initial data read complete

(RX(n+1)9)

Remote station ready (RX(n+1)B)

3 - 9

R2 writes initialization

data to master station.

Page 30

A

3 SPECIFICATIONS

Device No. Signal name Details

This signal indicates the R2 error state.

If the R2 ERR.LED is lit, the error status (RX(n+1)A) turns ON, and when the

ERR.LED is OFF, the status turns OFF.

When an error occurs, the R2 stores the error code in the error code storage area

R2

1A8H to 1B2H).

(

When the error reset request (RY(n+1)A) is turned ON after remedying the error

cause, the error status (RX(n+1)A) can be turned OFF.

When the initialization error complete (RXn5) is ON, review the R2 initial setting and

turn ON the initialization request (RYn4) again to reinitialize the setting.

RX(n+1)A Error state

When the reinitialization is completed normally and the initialization normal complete

(RXn4) turns ON, the error state (RX(n+1)A) turns OFF.

(When the initialization error complete (RXn5) is ON, turning ON the error reset

request (RY(n+1)A) will not turn OFF the error state (RX(n+1)A).)

Error state (RX(n+1)A)

Any error cause

Error reset request (RY(n+1)A)

MELSEC-

RX(n+1)B Remote station ready

Intelligent device

RX(n+1)E

station access

complete

This signal indicates that the R2 can operate. (Refer to the section for RX(n+1)9.)

ON : The R2 is in the operatable state, and the initial data read request (RY(n+1)9)

is OFF.

OFF : An R2 initialization error occurred (R2 buffer memory setting value error), or

when the initial data read request (RY(n+1)9) is turned ON.

This signal indicates the R2 access complete state in response to the intelligent device

station access request (RY(n+1)E).

If not using dedicated commands and directly reading/writing from the programmable

controller CPU to the master station buffer memory, when accessing to the R2 is

completed, the R2 will turn intelligent device station access complete (RX(n+1)E) ON.

With this signal, the intelligent device station access request (RY(n+1)E) will turn OFF.

Intelligent device station

access request (RY(n+1)E)

Intelligent device station

access complete (RX(n+1)E)

Access to the intelligent

device station

3 - 10

Page 31

A

3 SPECIFICATIONS

(

)

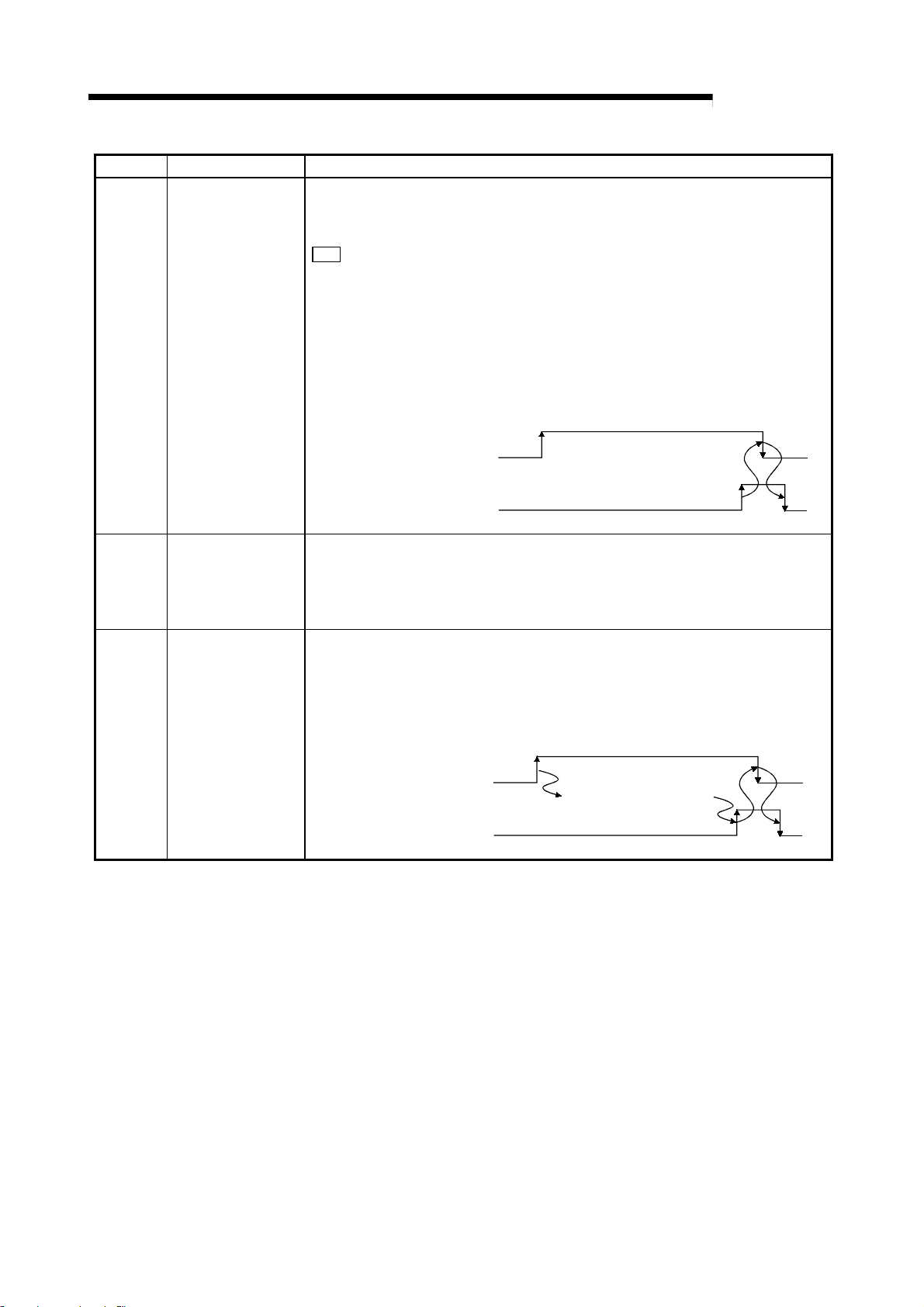

(2) Remote output (RY)

Device No. Signal name Details

RYn0 Transmission request Refer to the sections on RXn0 and RXn1.

To cancel the transmission after requesting transmission from R2, the transmission

will be canceled when the transmission cancel request (RYn1) turns ON.

When the transmission is forcibly canceled, the transmission normal complete (RXn0)

or transmission error complete (RXn1) will turn ON.

When these turn ON, the transmission request (RYn0) and transmission cancel

request (RYn1) will turn OFF.

MELSEC-

RYn1

RYn2

RYn3

Transmission cancel

request

Reception read

complete

Forced reception

complete request

Transmission request (RYn0)

Transmission normal complete

(RXn0)

or Transmission error complete

(RXn1)

Transmission cancel request

RYn1

R2 is transmitting

contents of transmission

area to external device.

Forcibly cancels transmission.

Refer to the sections on RXn2 and RXn3.

When the forced reception complete request (RYn3) turns ON, reception from the

external device will be forcibly completed.

When the forced reception is completed, the reception normal read request (RXn2)

and reception error read request (RXn3) will turn ON.

When these turn ON, forced reception complete request (RYn3) will turn OFF and

reception read complete (RYn2) will turn ON.

When the reception read complete (RYn2) turns ON, the reception normal read

request (RXn2) and reception error read request (RXn3) will turn OFF.

When this turns OFF, reception read complete (RYn2) will turn OFF.

Forced reception complete

request (RYn3)

Reception normal read request

(RXn2)

or Reception error read request

(RXn3)

Forcibly completes

the reception.

Receiving data

Reception read complete (RYn2)

Reads reception area with program.

RYn4 Initialization request Refer to the sections on RXn4 and RXn5.

RYn6

RYn7

OS reception area

clear request

EEPROM function

request

Refer to the section on RXn6.

Refer to the sections on RXn7 and RXn8.

3 - 11

Page 32

A

3 SPECIFICATIONS

Device No. Signal name Details

This signal turns the RS (RTS) signal of the RS-232-C line ON or OFF.

RYn9

Signal

setting

RYnA

RYnC

RYnD

RY(n+1)9

RY(n+1)A Error reset request Refer to the section on RX(n+1)A.

RY(n+1)E

General-purpose

external output signal

Initial data read

request

Intelligent device

station access

request

RS(RTS)

signal *

ER(DTR)

signal *

Note that when "RS (RTS) signal status designation (

(0)", the signal will remain ON even if the RS signal setting (RYn9) is turned ON or

1

OFF.

When controlling the RS signal with the RS (RTS) signal, set the above buffer memory

to "Follow RYn9 ON/OFF (1)".

This signal turns the ER (DTR) signal of the RS-232-C line ON or OFF.

When using DTR/DSR (ER/DR) control, even if the ER (DTR) signal (RYnA) is turned

ON or OFF, the process will follow the flow control designation (R2 100H) setting.

2

If the ER signal is being controlled with the ER (DTR) signal (RYnA) set the above

buffer memory to "No flow control (0)" or "Executing flow control by the DC code

control (2)".

This signal indicates the status of the R2 general-purpose output (YC, YD) with an ON

or OFF state.

RYnC: Corresponds to YC RYnD: Corresponds to YD

Refer to the section on RX(n+1)9.

Refer to the section on RX(n+1)E.

MELSEC-

R2

101H)" is set to "Always ON

3 - 12

Page 33

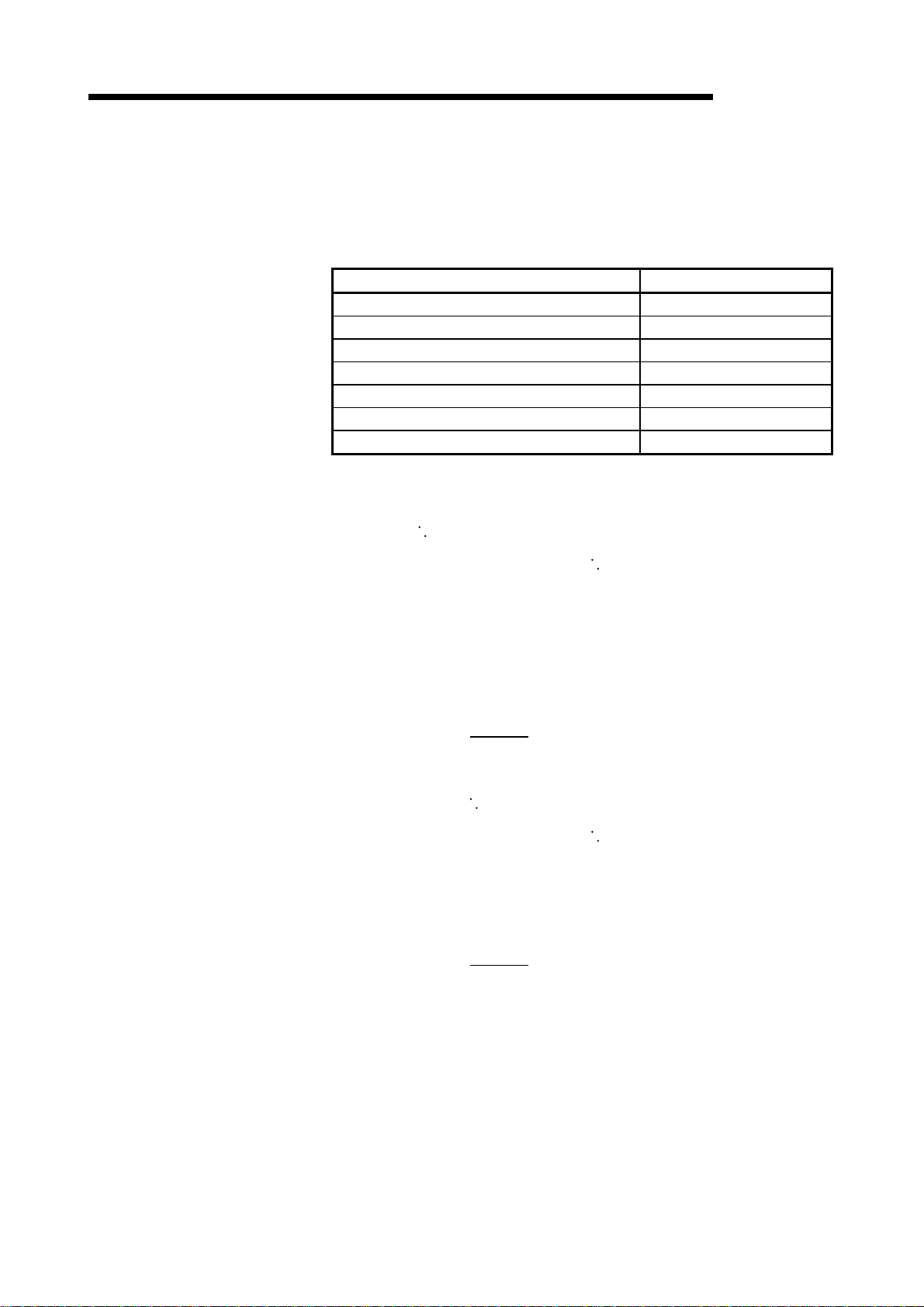

3 SPECIFICATIONS

3.7 R2 buffer memory li st

The entire configuration of the R2 buffer memory is explained in this section.

The contents of the R2 buffer memory are cleared to the default values when the

power is turned OFF.

However, if the user has registered the default values in the R2 EEPROM, the

EEPROM default values will be written in when the power is turned ON.

Refer to section 8.8 for details on writing to the R2 EEPROM.

Refer to the buffer memory list in the following manner.

MELSEC-A

Address

(hexadecimal)

Name

Default

value

Update

Initializa tion

EEPROM

registration

Referenc

(7)(1) (2) (3) (4) (5) (6)

e

No. Name Details

(1) Address Indicates R2 buffer memory address as a hex adecimal.

(2) Name Indicates the name of the R2 buffer memory.

(3) Default value Indicates the default value at R2 shipment.

Indicates whether the R2 buffer memory value is updated by the master

station or R2.

(4) Update

M station : Updated by the master station

R2 : Updated by R2

Both : Updated by both master stati on and R2

Indicates whether initialization is required when the R2 buffer memory

values have been changed.

(5) Initialization

Refer to section 8.6 for details on initialization.

Required : Initialization is required.

Not required : Initialization is not re quired.

Indicates whether the contents of the R2 buffer memory can be

registered in the R2 EEPROM.

Refer to section 8.8 for details on registering to the EEPROM.

Possible : Registration to the EEPROM is possible.

Not possible : Registration to the EEPROM is not possible.

(6)

EEPROM

registration

(7) Reference Indicates the chapter, section or page containing detailed explanations.

3 - 13

Page 34

3 SPECIFICATIONS

(1) Area for designating various assignments

MELSEC-A

Address

(hexadecimal)

R2

H

H

H

H

4H to F

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

R2 0

R2 1

R2 2

R2 3

R2 10

R2 11

R2 12

R2 13

R2 14

R2 15

R2 16

R2 17

R2 18

R2 19

R2 1A

R2 1B

R2 1C

R2 1D

R2 1E

R2 1F

R2 20

R2 21

R2 22

R2 23

R2 24

R2 25

R2 26

R2 27

Name

Transmission area head

address designation

Transmission area size

Head address

designation area

designation

Reception area head

address designation

Reception area size

designation

H

System area (Use prohibited) – – – – –

Transmission size 20

Status

storage

area

R2 side head address 1A0

(Fixed value: 4004H) 4004

Master station side offset

address

Transmission size 88

Transmission area 1

R2 side head address 118

(Fixed value: 4004H) 4004

Master station side offset

address

Transmission size 200

Transmission area 2

Automatic

update area

designation

Reception

area

R2 side head address 200

(Fixed value: 4004H) 4004

Master station side offset

address

Transmission size 200

R2 side head address 400

(Fixed value: 4004H) 4004

Master station side offset

address

Transmission size 1A0

Initial setting

area

R2 side head address 0

(Fixed value: 4004H) 4004

Master station side offset

address

Transmission size 30

EEPROM

function

area

R2 side head address 1C0

(Fixed value: 4004H) 4004

Master station side offset

address

Default

value

200

200

400

200

H

1A0

H

118

200

400

H

H

0

H

1C0

Update

H

H

M station Required Possible

H

H

H

H

H

H

H

H

H

H

H

H

M station Required Possible

H

H

H

H

H

H

H

H

H

Initializa-

tion

EEPROM

registration

Reference

Section

6.1

Section

6.2

Section

5.6.2

3 - 14

Page 35

3 SPECIFICATIONS

MELSEC-A

Address

(hexadecimal)

R2

R2

R2

R2

R2

R2

34H to

H

4BH to

H

72H to

H

7CH to

H

F8H to

H

30

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

R2 28

R2 29

R2 2A

R2 2B

R2 2C

R2 2D

R2 2E

R2 2F

R2 31

R2 32

R2 33

3F

R2 40

R2 41

R2 42

R2 43

R2 44

R2 45

R2 46

R2 47

R2 48

R2 49

R2 4A

6F

R2 70

R2 71

77

R2 78

R2 79

R2 7A

R2 7B

F5

R2 F6

R2 F7

FF

Automatic

update area

designation

User

registration

frame area

Monitor

transmission area 1

Monitor

transmission area 2

Name

Transmission size 29

R2 side head address 1C7

(Fixed value: 4004H) 4004

Master station side offset

address

Transmission size 88

R2 side head address 118

(Fixed value: 4004H) 4004

Master station side offset

address

Transmission size 200

R2 side head address 200

(Fixed value: 4004H) 4004

Master station side offset

address

Default

value

H

1C7

H

118

200

Update

H

H

H

H

M station Required Possible

H

H

H

H

H

H

Initializa-

tion

EEPROM

registration

Reference

Section

5.6.2

System area (Use prohibited) – – – – –

RW update interval time designation 1

RWw update validity designation 0

RWr update validity designation 1

H

H

H

M station Required Possible

H

H

H

H

H

Section

8.5

RW refresh

destination address

designation

Master station R2 (RWw0) 118

R2 Master station (RWr0) 1B0

Master station R2 (RWw1) 119

R2 Master station (RWr1) 1B1

Master station R2 (RWw2) 120

R2 Master station (RWr2) 1B2

Master station R2 (RWw3) 121

Master station (RWr3) 1B6

R2

System area (Use prohibited) – – – – –

Monitor interval time designation 0

No. of monitor designation 0

M station Required Possible

Section

7.4

System area (Use prohibited) – – – – –

Monitor

designation –1

Monitor

designation –2

Monitor target designation 0

Transmission data designation 0

Monitor target designation 0

Transmission data designation 0

M station Required Possible

Section

7.4

0

Monitor

designation –64

Monitor target designation 0

Transmission data designation 0

System area (Use prohibited) – – – – –

3 - 15

Page 36

3 SPECIFICATIONS

(2) Parameter area

MELSEC-A

Address

(hexadecimal)

106H to

H

113H to

H

11BH to

H

120

123H to

H

186H to

H

19DH to

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

R2 100

R2 101

R2 102

R2 103

R2 105

R2

107

R2 108

R2 109

R2 10A

R2 10B

R2 10C

R2 10D

R2 10E

R2 10F

R2 110

R2 111

R2 112

R2

117

R2 118

R2 119

R2 11A

R2

11F

R2

R2 121

R2 122

R2

184

R2 185

R2

18F

R2

19F

Name

Default

value

Flow control designation 1

RS (RTS) signal status designation 0

Word/byte unit designation 0

ASCII-BIN conversion designation 0

Transient timeout time designation 0

Update

M station Required Possible

Initializa-

tion

EEPROM

registration

Reference

Section

8.3

Section

8.9

Section

6.1, 6.2

Section

8.4

Section

5.6.1

System area (Use prohibited) – – – – –

0

Reception head frame No.

0

0

0

Section

7.3

Reception end frame No.

H

A

H

D

M station Required Possible

0

0

Reception head frame/reception end frame abort

designation

Reception end data size designation 0

Reception timeout time designation 0

1

Section

6.2

System area (Use prohibited) – – – – –

Transmission

frame - 1 area

Transmission timeout time designation 0

Transmission head frame No. 0

Transmission end frame No. 0

M station

Not

required

Possible

Section

7.2.1

Section

6.1

System area (Use prohibited) – – – – –

Transmission table head No.

designation

0

No. of transmission tables 0

Transmission

frame - 2 area

Transmission table

designation

No. 1

M station

0

Not

required

Possible

Section

7.2.2

No.100

System area (Use prohibited) – – – – –

System area (Use prohibited) – – – – –

3 - 16

Page 37

3 SPECIFICATIONS

(3) Setting status storage area

MELSEC-A

Address

(hexadecimal)

R2 1A0

R2 1A1

R2 1A2

R2 1A3

R2 1A4

R2 1A5

R2 1A6

R2 1A7

H

Station No. setting switch

H

Data link transmission speed setting sw itch

H

Mode setting switch

H

RS-232-C transmission speed

H

RS-232-C data bit length

H

RS-232-C parity bit presence

H

RS-232-C stop bit length

H

Buffer memory default value setting status storage 0

*1 Follows switch setting

Address

(hexadecimal)

R2

1A8H to

H

1AF

Error code

1B7H to

H

H

storage area

H

H

H

System area (Use prohibited) – – – – –

H

Actual transmission data size storage 0

H

Reception frame index No. storage 0

No. of data items in OS reception area data size

H

storage

System area (Use prohibited) – – – – –

H

Software version storage

R2 1B0

R2 1B1

R2 1B2

R2 1B3

R2 1B4

R2 1B5

R2 1B6

R2

1BE

R2 1BF

Name

Default

value

1

*

(4) Communication status storage area

Name

Error code history 0

General error code 0

Error code at transmission 0

Error code at reception 0

Default

value

0

Follows

version

Update

R2

Update

R2

R2

R2

Initializa-

tion

Not

required

Initializa-

tion

Not