Page 1

AJ65BT-D75P2-S3 Positioning Module

User's Manual

Page 2

Page 3

SAFETY PRECAUTIONS

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full

attention to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of

the programmable controller system, refer to the user's manual for the CPU module used.

In this manual, the safety instructions are classified into two levels: "

WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

A - 1

Page 4

[Design Precautions]

WARNING

Failure to observe this could lead to accidents for incorrect outputs or malfunctioning.

Configure safety circuits external to the programmable controller to ensure that the entire

system operates safely even when a fault occurs in the external power supply or the

programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Configure an emergency stop circuit and interlock circuit such as a positioning upper

limit/lower limit to prevent mechanical damage outside the programmable controller.

(2) The machine zero point return operation is controlled by the zero point return direction

and zero point return speed data. Deceleration starts when the near-point dog turns ON.

Thus, if the zero point return direction is incorrectly set, deceleration will not start and the

machine will continue to travel. Configure an interlock circuit to prevent mechanical

damage outside the programmable controller.

(3) When the positioning module detects an error, the motion slows down and stops or the

motion suddenly stops, depending on the stop group setting in parameter.

Set the parameters to meet the specifications of the positioning control system used.

In addition, set the OPR parameters and positioning data within the specified setting range.

When a data link results in a communication error, the operating status of the station in

communication error changes depending on the type of the used data link. Using the

communication status information, configure an interlock circuit in the sequence program to

ensure that the system will operate safely.

For the method of checking the station in communication error and its operating status at

communication error, refer to the corresponding data link manual.

[Design Precautions]

CAUTION

Do not install the control lines or communication cables together with the main circuit lines or

power cables.

Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise.

A - 2

Page 5

[Installation Precautions]

CAUTION

Use the programmable controller in an environment that meets the general specifications in

this manual.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of

the product.

Securely fix the module using the DIN rail or mounting screws and fully tighten the mounting

screws within the specified torque range. If the screws are loose, it may result in fallout, short

circuits, or malfunctions. Tightening the screw too far may cause damages to the screws and/or

the module, resulting in a fallout, short circuits, or malfunctions.

Securely connect the external device connection connector and peripheral device connection

connector into the module connector until a click is heard.

Improper connection could lead to a connection fault, and to incorrect inputs and outputs.

When not connecting the drive unit and peripheral device, always install a cover on the

connector section.

Failure to observe this could lead to malfunctioning.

[Wiring Precautions]

WARNING

Check the rated voltage and terminal layout before wiring to the programmable controller, and

connect the cables correctly. Connecting a power supply with a different voltage rating or

incorrect wiring may cause a fire or failure.

Check the terminal layout before wiring to the module, and connect the cables correctly.

Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

[Wiring Precautions]

!

CAUTION

Tighten the terminal screws within the range of the specified torque.

If the terminal screws are loose, it may result in short circuits, or malfunctions. Tightening the

terminal screws too far may cause damages to the terminal screws and/or the module, resulting

in short circuits, or malfunctions.

Be sure there are no foreign substances such as sawdust or wiring debris inside the module.

Such debris could cause fires, failure, or malfunction.

Individually ground the FG terminal of the programmable controller with a ground resistance of

100 ohms or less. Failure to do so may result in malfunction.

Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module

or cables or malfunction due to poor contact.

Keep a certain distance between the control wires and the communication cables.

Noise can cause a malfunction.

When disconnecting a cable from the module, do not pull on the cable itself. Disconnect cables

not fitted with a connectors by holding and pulling the cable connector.

Disconnect cables not fitted with a connector by removing the screws from the part connected

to the module can cause damage to the module or cable, or ,malfunction due to cable

connection faults.

A - 3

Page 6

[Startup and Maintenance Precautions]

!

CAUTION

Do not touch any terminal while power is on.

Doing so will cause electric shock or malfunction.

Never disassemble or modify the module.

Failure to observe this could lead to trouble, malfunctioning, injuries or fires.

Switch off all phases of the externally supplied power used in the system before cleaning or

tightening the screws.

Failure to turn all phases OFF could lead to electric shocks.

Make sure to install or remove the module from the panel after switching off all phases of the

externally supplied power for the system.

Failure to turn all phases OFF could lead to module trouble or malfunctioning.

Before starting test operation, set the parameter speed limit value to the slowest value, and

make sure that operation can be stopped immediately if a hazardous state occurs.

Do not install/remove the terminal block more than 50 times after the first use of the product.

(IEC 61131-2 compliant)

Always make sure to touch the grounded metal to discharge the electricity charged in the body,

etc., before touching the module.

Failure to do so may cause a failure or malfunctions of the module.

[Precautions for use]

!

CAUTION

Note that when the reference axis speed is designated for interpolation operation, the speed of

the partner axis (2nd axis) may be larger than the set speed (larger than the speed limit value).

[Disposal Precautions]

!

CAUTION

When disposing of the product, handle it as industrial waste.

A - 4

Page 7

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED

TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION NOT

INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING CONTAINED IN

MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL BULLETINS AND

GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi representative

in your region.

A - 5

Page 8

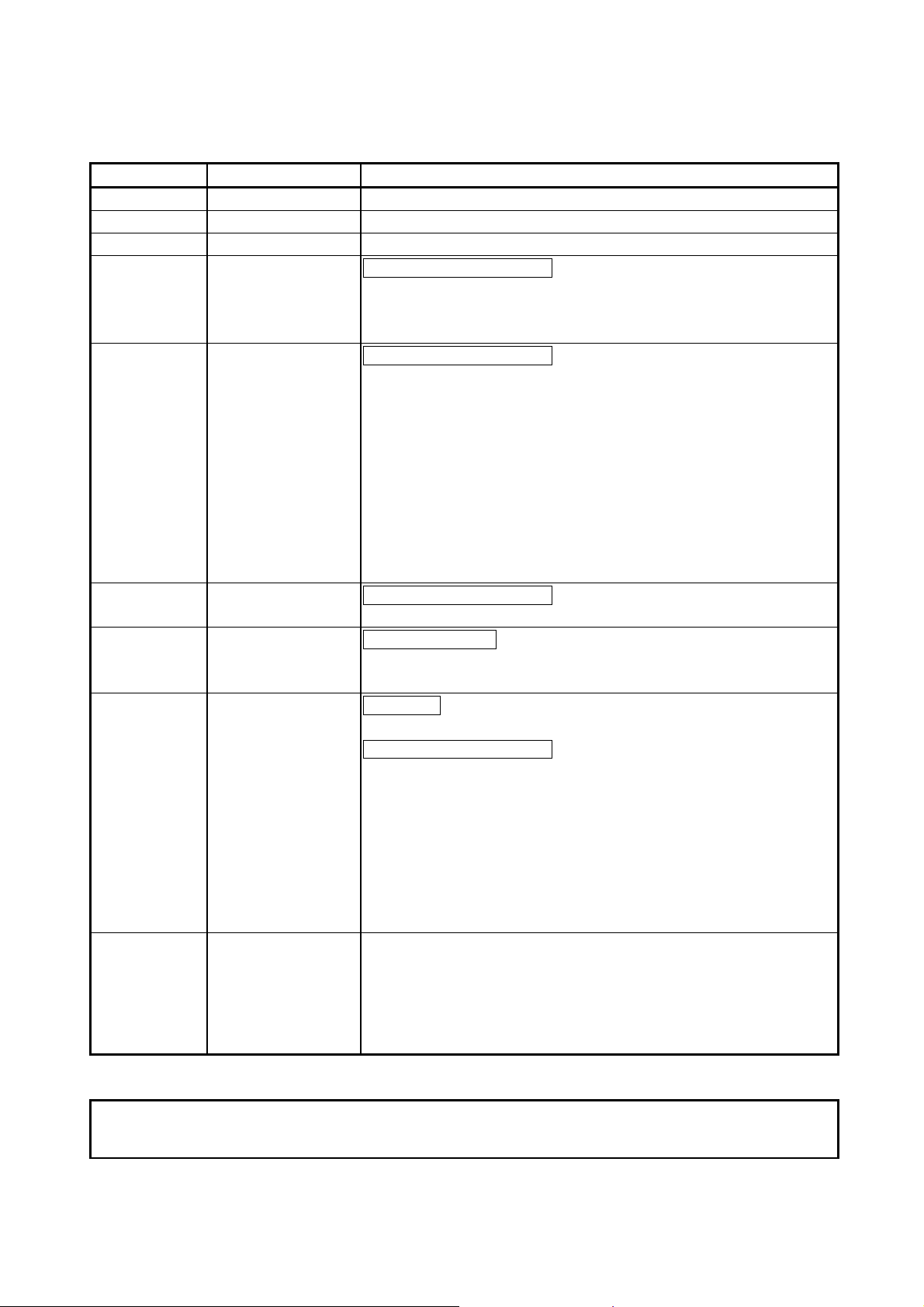

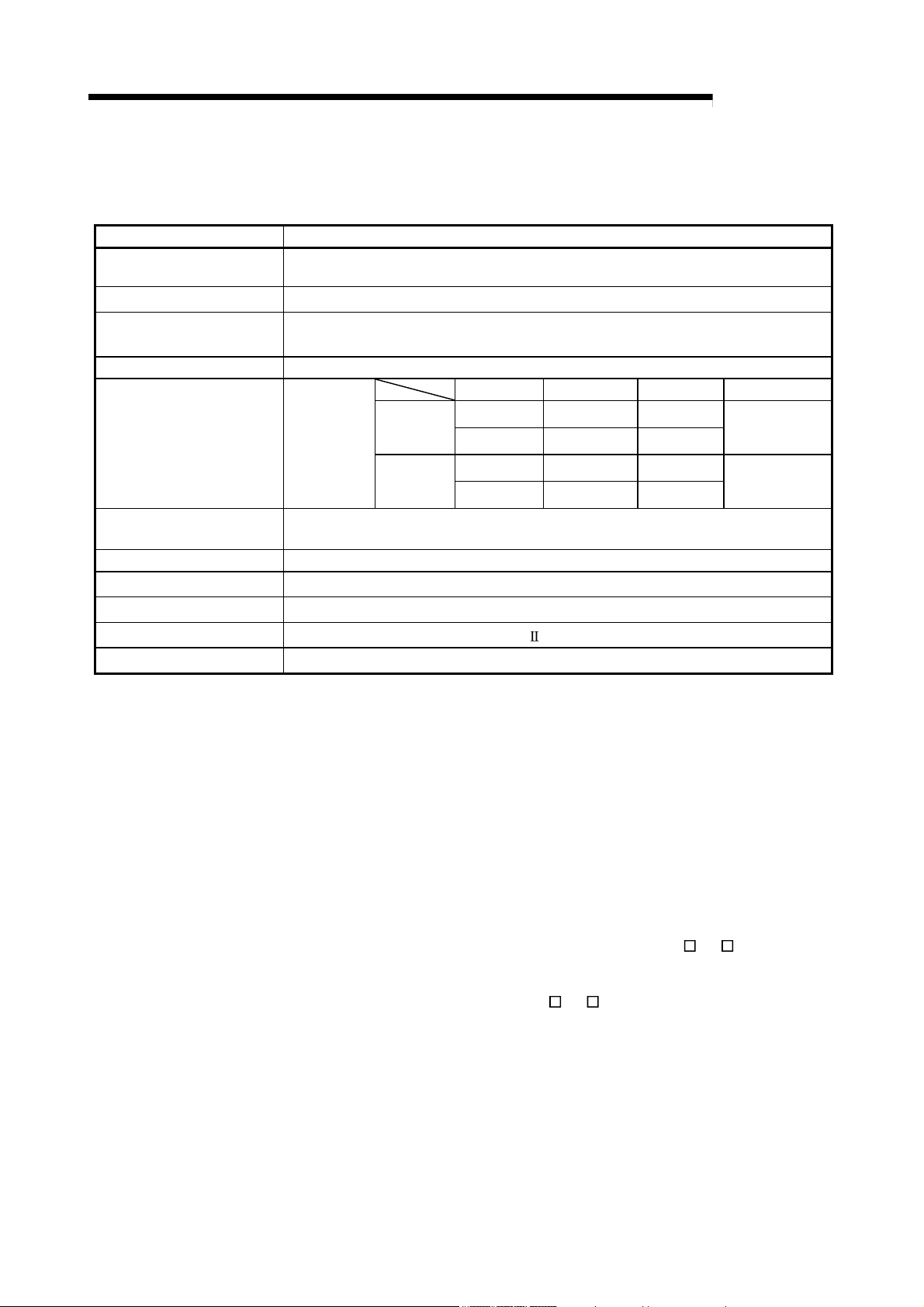

REVISIONS

The manual number is given on the bottom left of the back cover.

*

Print Date * Manual Number Revision

Apr., 1998 IB (NA)-66824-A First printing

Apr., 2003 IB (NA)-66824-B Complete review

Oct., 2003 IB (NA)-66824-C Complete review

Feb.,2004 IB (NA)-66824-D

Partial correction addition

CONTENTS, Section 3.5, Section 5.6.2, Section 7.1.2, Section 8.2.5,

Section 8.2.6, Section 10.1.2, Section 10.3.3 to Section 10.3.5,

Section 10.3.8, Appendix 13, INDEX

Jun., 2005 IB (NA)-66824-E

Partial correction addition

SAFETY INSTRUCTIONS, Generic Terms and Abbreviations,

Section 3.4.2, Section 4.2.2, Section 4.3, Section 4.5.1, Section 4.5.3,

Section 4.8.1, Section 5.1.2, Section 5.2.1, Section 5.3, Section 5.7.2,

Section 6.1.1, Section 6.6.1, Section 6.6.5, Section 8.1.1,

Section 8.2.4 to Section 8.2.8, Section 8.5, Section 9.1.2,

Section 9.15, Section 9.2.6, Section 9.2.8 to Section 9.2.11,

Section 10.3.9, Section 11.3.1, Section 12.2.1, Section 14.4.3,

Section 12.4.4, Section 12.5.1, Section 12.5.2, Section 12.7.1,

Section 12.7.5, Section 12.7.6, Section 13.4, Section 14.2,

Section 14.3, Appendix 5.1, Appendix 11, Appendix 12

Jul., 2006 IB (NA)-66824-F

Partial correction addition

Appendix 7.1, INDEX

Sep., 2007 IB(NA)-66824-G

Partial revisions

Section 5.1.2, Section 5.2.1, Section 5.6.1, Section 5.7.1

Apr., 2015 IB(NA)-66824-H

Addition

CONDITIONS OF USE FOR THE PRODUCT

Partial correction addition

SAFETY PRECAUTIONS, INTRODUCTION, ABOUT MANUALS,

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES,

GENERIC TERMS AND ABBREVIATIONS, Section 1.3, 2.3, 2.4, 3.1,

3.2, 3.7.1, 3.7.3, 3.7.4, 4.1.2, 4.1.3, 4.2.1, 4.3, 4.5.1, 4.5.2, 4.8.1,

5.1.1, 5.2.3, 5.3, 5.5, 6.1.1, 6.1.2, 9.1.4, 9.1.5, 9.2.7, 10.1.1, 10.1.2,

10.3.5, 10.3.8, 10.4.1, 10.4.2, 12.3.2, 12.4.3, 12.4.4, 12.5.3, 13.4,

Appendix 1, 2, 3.2, 5.1, 5.2, 5.3, 6.1, 7.1, 8.1, 9.1, 11, 12,

WARRANTY

Japanese Manual Version SH-3654-J

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which

may occur as a result of using the contents noted in this manual.

1998 MITSUBISHI ELECTRIC CORPORATION

A - 6

Page 9

MEMO

A - 7

Page 10

INTRODUCTION

Thank you for purchasing the Mitsubishi general-purpose programmable controller MELSEC-A Series.

Always read through this manual, and fully comprehend the functions and performance of the A Series PLC

before starting use to ensure correct usage of this product.

When applying the program examples introduced in this manual to an actual system, ensure the applicability

and confirm that it will not cause system control problems.

CONTENTS

SAFETY PRECAUTIONS ............................................................................................................................ A- 1

CONDITIONS OF USE FOR THE PRODUCT ........................................................................................... A- 5

REVISIONS .................................................................................................................................................. A- 6

INTRODUCTION .......................................................................................................................................... A- 8

CONTENTS .................................................................................................................................................. A- 8

ABOUT MANUALS ....................................................................................................................................... A- 15

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES ......................................................... A- 16

USING THIS MANUAL (1) ............................................................................................................................ A- 17

USING THIS MANUAL (2) ............................................................................................................................ A- 18

USING THIS MANUAL (3) ............................................................................................................................ A- 19

GENERIC TERMS AND ABBREVIATIONS ................................................................................................ A- 20

ENCLOSED PARTS ..................................................................................................................................... A- 21

SECTION 1 PRODUCT SPECIFICATIONS AND HANDLING

1. PRODUCT OUTLINE 1- 1 to 1- 20

1.1 Positioning control .................................................................................................................................. 1- 2

1.1.1 Features of D75P2 .......................................................................................................................... 1- 2

1.1.2 Purpose and applications of positioning control ............................................................................. 1- 4

1.1.3 Mechanism of positioning control ................................................................................................... 1- 6

1.1.4 Outline design of positioning system .............................................................................................. 1- 8

1.1.5 Communicating signals between D75P2 and each module ........................................................... 1- 10

1.2 Flow of system operation ........................................................................................................................ 1- 12

1.2.1 Flow of all processes ........................................................................................................................ 1- 12

1.2.2 Outline of starting ............................................................................................................................. 1- 14

1.2.3 Outline of stopping ........................................................................................................................... 1- 16

1.2.4 Outline for restarting ......................................................................................................................... 1- 17

1.3 Outline of communication ....................................................................................................................... 1- 18

1.3.1 Cyclic transmission........................................................................................................................... 1- 19

1.3.2 Transient transmission ..................................................................................................................... 1- 20

2. SYSTEM CONFIGURATION 2- 1 to 2- 12

2.1 General image of system ....................................................................................................................... 2- 2

2.2 List of configuration devices .................................................................................................................. 2- 4

2.3 Applicable system .................................................................................................................................. 2- 6

2.4 Precautions for use ................................................................................................................................ 2- 8

A - 8

Page 11

3. SPECIFICATIONS AND FUNCTIONS 3- 1 to 3- 44

3.1 General specifications ............................................................................................................................ 3- 2

3.2 Performance specifications .................................................................................................................... 3- 4

3.3 List of functions ..................................................................................................................................... 3- 6

3.3.1 D75P2 control functions .................................................................................................................. 3- 6

3.3.2 D75P2 main functions ..................................................................................................................... 3- 8

3.3.3 D75P2 auxiliary functions and common functions .......................................................................... 3- 10

3.3.4 Combination of D75P2 main functions and auxiliary functions ...................................................... 3- 12

3.4 Specifications of input/output signals for master module ...................................................................... 3- 14

3.4.1 List of input/output signals ............................................................................................................... 3- 14

3.4.2 Details of input signals (D75P2

3.4.3 Details of output signals (Master module

3.5 Remote registers ..................................................................................................................................... 3- 23

3.6 Transmission delay time ......................................................................................................................... 3- 32

3.7 Specifications of input/output interfaces with external devices ............................................................. 3- 35

3.7.1 Electrical specifications of input/output signals ............................................................................... 3- 35

3.7.2 Signal layout for external device connection connector.................................................................. 3- 38

3.7.3 List of input/output signal details ...................................................................................................... 3- 39

3.7.4 Input/output interface internal circuit ................................................................................................ 3- 42

Master module) ....................................................................... 3- 17

D75P2) .................................................................... 3- 21

4. INSTALLATION, WIRING AND MAINTENANCE OF THE PRODUCT 4- 1 to 4- 30

4.1 Outline of installation, wiring and maintenance ..................................................................................... 4- 2

4.1.1 Installation, wiring and maintenance procedures ........................................................................... 4- 2

4.1.2 Names of each part ......................................................................................................................... 4- 3

4.1.3 Handling precautions ...................................................................................................................... 4- 5

4.2 Installation .............................................................................................................................................. 4- 7

4.2.1 Precautions for installation .............................................................................................................. 4- 7

4.2.2 Installation/removal of module ........................................................................................................ 4- 9

4.3 Connection of CC-Link dedicated cable ................................................................................................. 4- 12

4.4 Module setting ......................................................................................................................................... 4- 14

4.4.1 Station number setting of module .................................................................................................... 4- 14

4.4.2 Transmission speed setting of module ............................................................................................ 4- 15

4.5 Wiring/connection .................................................................................................................................... 4- 16

4.5.1 Precautions for wiring/connection .................................................................................................... 4- 16

4.5.2 Wiring the external device connection connector pins.................................................................... 4- 20

4.5.3 Connecting the connector ................................................................................................................ 4- 24

4.6 Confirming the installation and wiring ..................................................................................................... 4- 25

4.6.1 Items to confirm when installation and wiring are completed ......................................................... 4- 25

4.7 Single module test ................................................................................................................................... 4- 26

4.8 Maintenance ............................................................................................................................................ 4- 30

4.8.1 Precautions for maintenance ........................................................................................................... 4- 30

4.8.2 Disposal instructions ........................................................................................................................ 4- 30

A - 9

Page 12

5. DATA USED FOR POSITIONING CONTROL (List of buffer memory addresses) 5- 1 to 5-112

5.1 Types of data .......................................................................................................................................... 5- 2

5.1.1 Parameters and data required for control....................................................................................... 5- 2

5.1.2 Setting items for positioning parameters ........................................................................................ 5- 4

5.1.3 Setting items for zero point return parameters ............................................................................... 5- 6

5.1.4 Setting items for positioning data .................................................................................................... 5- 7

5.1.5 Setting items for start block data .................................................................................................... 5- 9

5.1.6 Setting items for condition data ....................................................................................................... 5- 10

5.1.7 Types and roles of monitor data ...................................................................................................... 5- 11

5.1.8 Types and roles of control data ....................................................................................................... 5- 14

5.2 List of parameters ................................................................................................................................... 5- 18

5.2.1 Basic parameters 1 .......................................................................................................................... 5- 18

5.2.2 Basic parameters 2 .......................................................................................................................... 5- 24

5.2.3 Detailed parameters 1 ...................................................................................................................... 5- 28

5.2.4 Detailed parameters 2 ...................................................................................................................... 5- 36

5.2.5 Zero point return basic parameters ................................................................................................. 5- 45

5.2.6 Zero point return detailed parameters ............................................................................................. 5- 52

5.3 List of positioning data ............................................................................................................................ 5- 57

5.4 List of start block data ............................................................................................................................. 5- 71

5.5 List of condition data ............................................................................................................................... 5- 76

5.6 List of monitor data .................................................................................................................................. 5- 80

5.6.1 System monitor data ........................................................................................................................ 5- 80

5.6.2 Axis monitor data .............................................................................................................................. 5- 90

5.7 List of control data .................................................................................................................................. 5-100

5.7.1 System control data ........................................................................................................................ 5-100

5.7.2 Axis control data .............................................................................................................................. 5-106

6. SEQUENCE PROGRAM USED FOR POSITIONING CONTROL 6- 1 to 6- 66

6.1 Information necessary for program creation ............................................................................................ 6- 2

6.1.1 When ACPU/QCPU (A mode) is used .............................................................................................. 6- 2

6.1.2 When QCPU (Q mode)/QnACPU is used ....................................................................................... 6- 15

6.2 Precautions for creating program ........................................................................................................... 6- 2 2

6.3 List of devices used ................................................................................................................................. 6- 23

6.4 Creating a program ................................................................................................................................. 6- 29

6.4.1 General configuration of program .................................................................................................... 6- 29

6.4.2 Positioning control operation program ............................................................................................. 6- 30

6.5 Positioning program examples ............................................................................................................... 6- 3 3

6.5.1 When using FROM/TO command with ACPU/QCPU-A (A mode) ................................................ 6- 33

6.5.2 When using dedicated commands with ACPU/QCPU-A (A mode) ............................................... 6- 40

6.5.3 When using dedicated commands with QCPU (Q mode)/QnACPU .............................................. 6- 46

6.6 Program details ....................................................................................................................................... 6- 51

6.6.1 Initialization program ........................................................................................................................ 6- 51

6.6.2 Start details setting program ............................................................................................................ 6- 52

6.6.3 Start program .................................................................................................................................... 6- 53

6.6.4 Restart program ............................................................................................................................... 6- 61

6.6.5 Stop program .................................................................................................................................... 6- 64

A - 10

Page 13

7. MEMORY CONFIGURATION AND DATA PROCESS 7- 1 to 7- 16

7.1 Configuration and roles of D75P2 memory ........................................................................................... 7- 2

7.1.1 Configuration and roles of D75P2 memory .................................................................................... 7- 2

7.1.2 Buffer memory area configuration .................................................................................................. 7- 5

7.2 Data transmission process .................................................................................................................... 7- 6

SECTION 2 CONTROL DETAILS AND SETTING

8. ZERO POINT RETURN CONTROL 8- 1 to 8- 24

8.1 Outline of zero point return control ........................................................................................................ 8- 2

8.1.1 Three types of zero point return control ......................................................................................... 8- 2

8.2 Machine zero point return ...................................................................................................................... 8- 4

8.2.1 Outline of the machine zero point return operation ........................................................................ 8- 4

8.2.2 Machine zero point return method .................................................................................................. 8- 5

8.2.3 Zero point return method (1): Near-point dog method ................................................................... 8- 6

8.2.4 Zero point return method (2): Stopper stop method 1) .................................................................. 8- 8

8.2.5 Zero point return method (3): Stopper stop method 2) ................................................................... 8- 11

8.2.6 Zero point return method (4): Stopper stop method 3) ................................................................... 8- 14

8.2.7 Zero point return method (5): Count method 1) .............................................................................. 8- 16

8.2.8 Zero point return method (6): Count method 2) .............................................................................. 8- 18

8.3 Data setting method zero point return .................................................................................................... 8- 20

8.4 High-speed zero point return .................................................................................................................. 8- 21

8.4.1 Outline of the high-speed zero point return operation .................................................................... 8- 21

8.5 Positioning to the zero point ................................................................................................................... 8- 23

9. MAIN POSITIONING CONTROL 9- 1 to 9- 62

9.1 Outline of main positioning controls....................................................................................................... 9- 2

9.1.1 Data required for main positioning control ...................................................................................... 9- 3

9.1.2 Operation patterns of main positioning controls ............................................................................. 9- 4

9.1.3 Designating the positioning address................................................................................................ 9- 14

9.1.4 Confirming the current value ............................................................................................................ 9- 15

9.1.5 Control unit "degree" handling ......................................................................................................... 9- 17

9.1.6 Interpolation control .......................................................................................................................... 9- 19

9.2 Setting the positioning data ................................................................................................................... 9- 22

9.2.1 Relation between each control and positioning data ...................................................................... 9- 22

9.2.2 1-axis linear control .......................................................................................................................... 9- 23

9.2.3 2-axis linear interpolation control ..................................................................................................... 9- 25

9.2.4 1-axis fixed-dimension feed control ................................................................................................. 9- 29

9.2.5 2-axis fixed-dimension feed control (interpolation) ........................................................................ 9- 31

9.2.6 2-axis circular interpolation control with auxiliary point designation ............................................... 9- 33

9.2.7 2-axis circular interpolation control with center point designation .................................................. 9- 39

9.2.8 Speed control ................................................................................................................................... 9- 46

9.2.9 Speed/position changeover control ................................................................................................. 9- 48

9.2.10 Current value change ..................................................................................................................... 9- 56

9.2.11 JUMP command ............................................................................................................................. 9- 60

A - 11

Page 14

10. ADVANCED POSITIONING CONTROL 10- 1 to 10- 22

10.1 Outline of advanced positioning control ............................................................................................ 10- 2

10.1.1 Data required for advanced positioning control ......................................................................... 10- 3

10.1.2 "Start block data" and "condition data" configuration ................................................................. 10- 4

10.2 Advanced positioning control execution procedure ........................................................................ 10- 6

10.3 Setting the start block data ................................................................................................................ 10- 7

10.3.1 Relation between various controls and start block data ............................................................ 10- 7

10.3.2 Block start (normal start) ........................................................................................................... 10- 8

10.3.3 Condition start .............................................................................................................................. 10- 10

10.3.4 Wait start....................................................................................................................................... 10- 11

10.3.5 Simultaneous start ...................................................................................................................... 10- 12

10.3.6 Stop............................................................................................................................................... 10- 13

10.3.7 Repeated start (FOR loop) ......................................................................................................... 10- 14

10.3.8 Repeated start (FOR condition) ................................................................................................. 10- 15

10.3.9 Restrictions when using the NEXT start ...................................................................................... 10- 16

10.4 Setting the condition data ................................................................................................................... 10- 17

10.4.1 Relation between various controls and the condition data ......................................................... 10- 17

10.4.2 Condition data setting examples ................................................................................................. 10- 19

10.5 Starting advanced positioning control ................................................................................................ 10- 20

10.5.1 Starting advanced positioning control ......................................................................................... 10- 20

10.5.2 Example of start program for advanced positioning control ....................................................... 10- 21

11. MANUAL CONTROL 11- 1 to 11- 22

11.1 Outline of manual control ................................................................................................................. 11- 2

11.1.1 Two manual control methods ..................................................................................................... 11- 2

11.2 JOG operation .................................................................................................................................... 11- 4

11.2.1 Outline of JOG operation ............................................................................................................ 11- 4

11.2.2 JOG operation execution procedure .......................................................................................... 11- 7

11.2.3 Setting the required parameters for JOG operation ................................................................... 11- 8

11.2.4 Creating start programs for JOG operation ................................................................................. 11- 10

11.2.5 JOG operation example ............................................................................................................... 11- 12

11.3 Manual pulse generator operation ...................................................................................................... 11- 16

11.3.1 Outline of manual pulse generator operation .............................................................................. 11- 16

11.3.2 Manual pulse generator operation execution procedure ............................................................ 11- 19

11.3.3 Setting the required parameters for manual pulse generator operation .................................... 11- 20

11.3.4 Starting the manual pulse generator operation ........................................................................... 11- 21

12. CONTROL AUXILIARY FUNCTIONS 12- 1 to 12- 82

12.1 Outline of auxiliary functions .............................................................................................................. 12- 2

12.1.1 Outline of auxiliary functions ....................................................................................................... 12- 2

12.2 Auxiliary functions specifically for machine zero point returns ......................................................... 12- 4

12.2.1 Zero point return retry function ................................................................................................... 12- 4

12.2.2 Zero point shift function ............................................................................................................. 12- 8

12.3 Functions for compensating the control ............................................................................................. 12- 11

12.3.1 Backlash compensation function ................................................................................................. 12- 11

12.3.2 Electronic gear function ............................................................................................................... 12- 13

A - 12

Page 15

12.3.3 Near pass mode function ............................................................................................................. 12- 18

12.4 Functions to limit the control ............................................................................................................... 12- 22

12.4.1 Speed limit function ...................................................................................................................... 12- 22

12.4.2 Torque limit function ..................................................................................................................... 12- 24

12.4.3 Software stroke limit function ....................................................................................................... 12- 27

12.4.4 Hardware stroke limit function ..................................................................................................... 12- 33

12.5 Functions to change the control details .............................................................................................. 12- 35

12.5.1 Speed change function ................................................................................................................ 12- 35

12.5.2 Override function .......................................................................................................................... 12- 40

12.5.3 Acceleration/deceleration time change function ......................................................................... 12- 42

12.5.4 Torque change function ............................................................................................................... 12- 45

12.6 Absolute position restoration function ................................................................................................ 12- 47

12.7 Other functions .................................................................................................................................... 12- 53

12.7.1 Step function................................................................................................................................. 12- 53

12.7.2 Skip functi on ................................................................................................................................. 12- 58

12.7.3 M code output function ................................................................................................................. 12- 60

12.7.4 Teaching function ......................................................................................................................... 12- 64

12.7.5 Command in-position function ..................................................................................................... 12- 69

12.7.6 Stepping motor mode function ..................................................................................................... 12- 72

12.7.7 Acceleration/deceleration processing function ............................................................................ 12- 75

12.7.8 Indirectly specification func tion .................................................................................................... 12- 78

13. COMMON FUNCTIONS 13- 1 to 13- 10

13.1 Outline of common functions ............................................................................................................. 13- 2

13.2 Parameter initialization function ......................................................................................................... 13- 3

13.3 Execution data backup function ........................................................................................................ 13- 5

13.4 LED display function .......................................................................................................................... 13- 7

13.5 Clock data function.............................................................................................................................. 13- 10

14. TROUBLESHOOTING 14- 1 to 14- 40

14.1 Troubleshooting when the "ERR" LED on the Master Module is Flashing ...................................... 14- 2

14.2 Error and warning details ................................................................................................................... 14- 4

14.3 List of errors ....................................................................................................................................... 14- 8

14.4 List of warnings ................................................................................................................................... 14- 34

14.5 Start during error history ..................................................................................................................... 14- 40

APPENDICES Appendix- 1 to Appendix- 62

Appendix 1 Change with Upgrade .................................................................................................. Appendix- 2

Appendix 2 External dimension drawing ........................................................................................ Appendix- 3

Appendix 3 Format sheets ............................................................................................................ Appendix- 4

Appendix 3.1 Positioning module operation chart .................................................................... Appendix- 4

Appendix 3.2 Parameter setting value entry table ..................................................................... Appendix- 6

Appendix 3.3 Positioning data setting value entry table ............................................................ Appendix- 12

Appendix 4 Positioning data (No. 1 to 100), List of buffer memory addresses ............................ Appendix- 13

A - 13

Page 16

Appendix 5 Connection examples with servo amplifiers manufactured

by MITSUBISHI Electric Coporation ............................................................................ Appendix- 16

Appendix 5.1 Connection example of D75P2 and MR-H

(Differential driver (Open collector)) ...................................................................... Appendix- 16

Appendix 5.2 Connection example of D75P2 and MR-J2/J2S-

(Differential driver (Open collector)) ...................................................................... Appendix- 18

Appendix 5.3 Connection example of D75P2 and MR-C

(Differential driver (Open collector)) .................................................................... Appendix- 20

Appendix 6 Connection examples with stepping motors manufactured

by ORIENTALMOTOR Co., Ltd. .................................................................................. Appendix- 21

Appendix 6.1 Connection example of D75P2 and VEXTA UPD (Open collector) ..................... Appendix- 21

Appendix 7 Connection examples with servo amplifiers manufactured

by Panasonic Co., Ltd. ................................................................................................. Appendix- 22

Appendix 7.1 Connection example of D75P2 and MINAS-A series (Differential driver) ........... Appendix- 22

Appendix 8 Connection examples with servo amplifiers manufactured

by SANYO DENKI Co., Ltd. ......................................................................................... Appendix- 23

Appendix 8.1 Connection example of D75P2 and PYO series (Differential driver) ................... Appendix- 23

Appendix 9 Connection examples with servo amplifiers manufactured

by YASKAWA Electric Corporation .............................................................................. Appendix- 24

Appendix 9.1 Connection example of D75P2 and -

Appendix 10 Comparisons with A1SD75P

Appendix 11 MELSEC Explanation of positioning terms ................................................................ Appendix- 27

Appendix 12 Positioning control troubleshooting ............................................................................ Appendix- 49

Appendix 13 List of buffer memory addresses ................................................................................ Appendix- 55

-S3 and AD75P -S3 modules ................................ Appendix- 25

A

A

A

series (Differential driver) .................... Appendix- 24

INDEX Index- 1 to Index- 10

A - 14

Page 17

ABOUT MANUALS

The following manuals are also related to this product.

In necessary, order them by quoting the details in the tables below.

Related Manuals

Manual Name

AJ65BT-D75P2-S3 Positioning Module User's Manual (Hardware)

This manual describes performance specifications, input/output interface, names of each part and

startup procedures of the AJ65BT-D75P2-S3 positioning module. (enclosed with module)

Manual Number

(Model Code)

IB-66829

(13JL48)

CC-Link System Master/Local Module Type AJ61BT11/A1SJ61BT11 User's Manual

This manual describes the system configuration, performance specifications, functions, handling, wiring

and troubleshooting of the AJ61BT11 and A1SJ61BT11 (sold separately).

CC-Link System Master/Local Module Type AJ61QBT11/A1SJ61QBT11 User's Manual

This manual describes the system configuration, performance specifications, functions, handling, wiring

and troubleshooting of the AJ61QBT11 and A1SJ61QBT11 (sold separately).

MELSEC-Q CC-Link System Master/Local Module User's Manual

This manual describes the system configuration, performance specifications, functions, handling, wiring

and troubleshooting of the QJ61BT11N (sold separately).

MELSEC-L CC-Link System Master/Local Module User's Manual

This manual describes system configuration, performance specifications, functions, handling, wiring, and

troubleshooting of the LCPU with built-in CC-Link (sold separately).

MELSEC iQ-R CC-Link System Master/Local Module User's Manual (Application)

This manual describes functions, parameter settings, programming, troubleshooting, I/O signals, and

buffer memory of the CC-Link system master/local module (sold separately).

Type AnSHCPU/AnACPU/AnUCPU/QCPU-A (A Mode) Programming Manual (Dedicated

Instructions)

This manual describes the instructions extended for the AnSHCPU/AnACPU/AnUCPU/QCPU-A (A

Mode) (sold separately).

IB-66721

(13J872)

IB-66722

(13J873)

SH-080394E

(13JR64)

SH-080895ENG

(13JZ41)

SH-081270ENG

(13JX19)

IB-66251

(13J742)

QnACPU Programming Manual (Special Function Module)

This manual describes dedicated instructions for the special function modules (sold separately).

SH-4013

(13JF56)

MELSEC iQ-R Programming Manual (Instructions, Standard Functions/Function Blocks)

This manual describes instructions for the CPU module, dedicated instructions for the intelligent function

modules, and standard functions/function blocks (sold separately).

SH-081266ENG

---

Positioning module software package type SW1IVD-AD75P Operating Manual

This manual describes the methods of creating data (such as parameters and positioning data.),

transmitting the data to the module, monitoring the positioning and testing, using the above software

package (enclosed with each software package product).

IB-66714

(13J915)

GX Configurator-AP Version 1 Operating Manual

This manual describes the methods of creating data (such as parameters and positioning data),

transmitting the data to the module, monitoring the positioning and testing, using the above software

package (sold separately)

*1

.

IB-66900

(13J948)

*1 This manual is stored in the CD-ROM of the software package as PDF file.

For those who would like to order the manual separately, the printed version is optionally available and so

please ask it with the manual number (model code) in the table above.

A - 15

Page 18

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low

Voltage Directives when incorporated into other machinery or equipment, certain

measures may be necessary. Please refer to one of the following manuals.

User's manual for the CPU module or head module used

Safety Guidelines

(This manual is included with the CPU module, base unit, or head module.)

The CE mark on the side of the programmable controller indicates compliance

with EMC and Low Voltage Directives.

(2) Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please

refer to one of the manuals listed under (1).

A - 16

Page 19

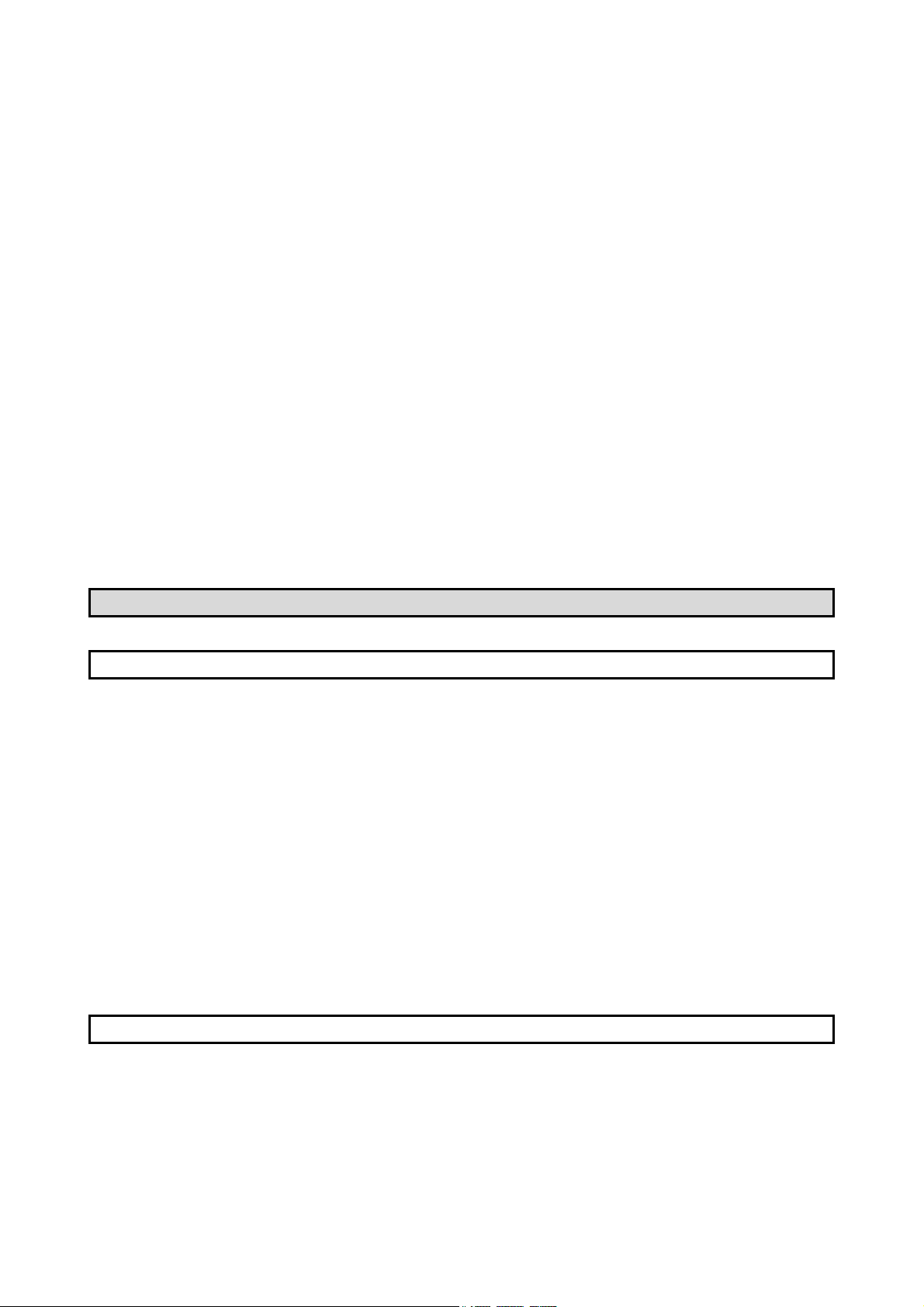

USING THIS MANUAL (1)

10 Decimal

10

The symbols used in this manual are shown below.

Unless otherwise specified, the "buffer memory" indicates the buffer memory of

the D75P2.

M

....... Symbol indicating master module buffer memory address.

Pr.*

....... Symbol indicating positioning parameter and zero point return

parameter item.

Da.*

....... Symbol indicating positioning data, start block data and condition

data item.

Md.*

....... Symbol indicating monitor data item.

Cd.*

....... Symbol indicating control data item.

(A serial No. is inserted in the * mark.)

Indication of values in this manual

The buffer memory address, error code and warning code are indicated in a

decimal value.

The X/Y device is indicated in a hexadecimal value.

The setting data and monitor data is indicated in a decimal or hexadecimal value.

An “H” attached at the end of the value indicates a hexadecimal value.

(Examples)

Hexadecimal

H

A - 17

Page 20

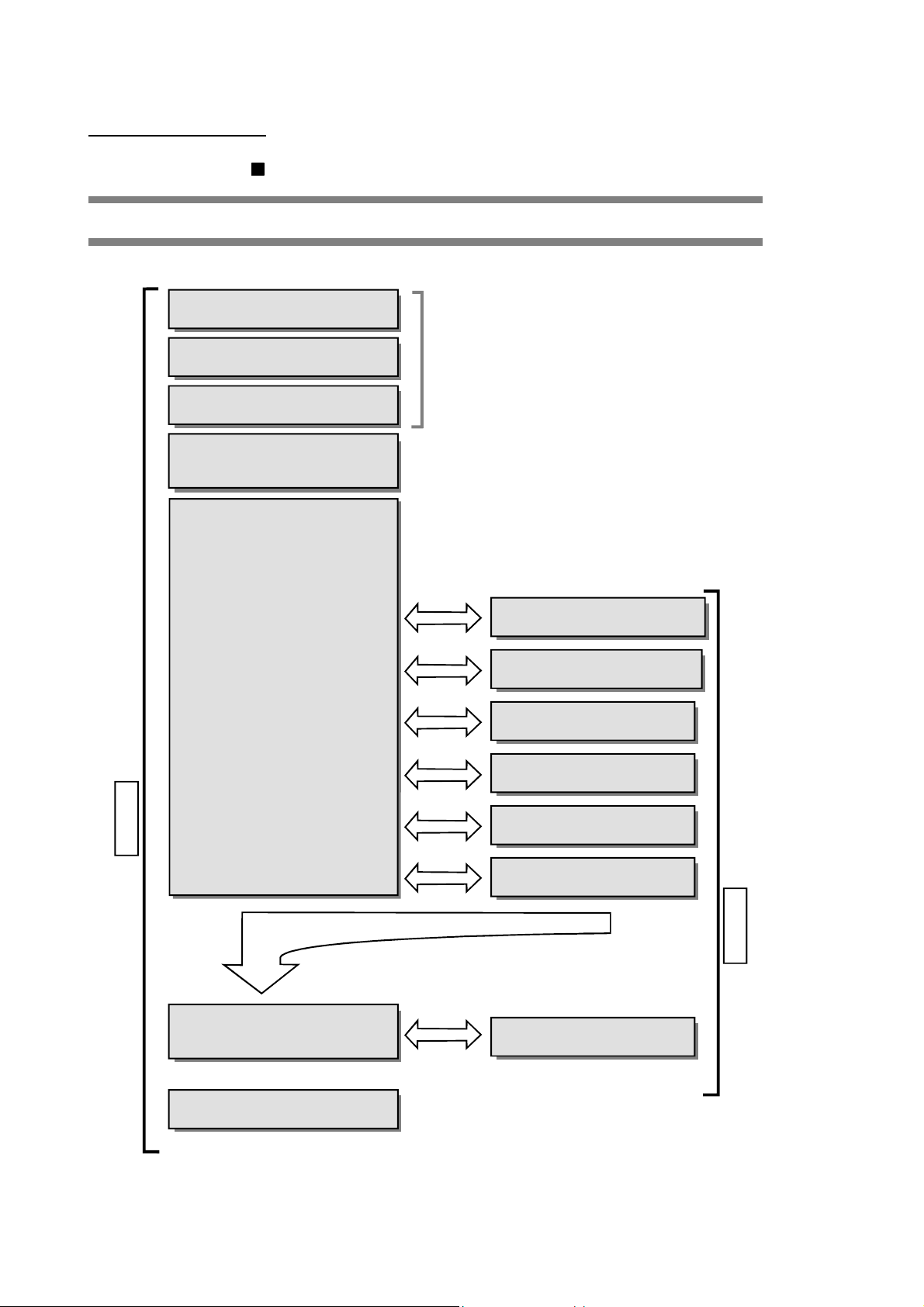

USING THIS MANUAL (2)

1) 2) 3) 4) 5) Test operation 6) Actual operation

The methods for reading this manual are shown below.

Chapter 1 PRODUCT OUTLINE

Chapter 2 SYSTEM CONFIGURATION

Chapter 3 SPECIFICATIONS AND

FUNCTIONS

Chapter 4 INSTALLATION, WIRING

AND MAINTENANCE OF

THE PRODUCT

Chapter 5 DATA USED FOR

POSITIONING CONTROL

5.1 Types of data

5.2 List of parameters

5.3 List of positioning data

5.4 List of start block data

5.5 List of condition data

5.6 List of monitor data

5.7 List of control data

1) Understand the product functions and specifications,

and design the system.

2) Install and wire the product

3) Set the parameters

4) While referring to lists in "SECTION 2" and "Chapter 5",

set the data required for each control

Chapter 8 ZERO POINT RETURN

CONTROL

Chapter 9 MAIN POSITIONING

CONTROL

Chapter 10

POSITIONING CONTROL

Chapter 11 MANUAL CONTROL

ADVANCED

SECTION 1 PRODUCT SPECIFICATIONS AND HANDLING

Chapter 6

FOR POSITIONING CONTROL

Chapter 7

AND DATA PROCESS

*Understand the data process in the D75P2 as necessary.

SEQUENCE PROGRAM USED

MEMORY CONFIGURATION

Chapter 12 CONTROL AUXILIARY

FUNCTIONS

Chapter 13

5) Create a sequence program for control

Chapter 14 TROUBLESHOOTING

6) Remedies for "Errors" and "Warnings"

COMMON FUNCTIONS

A - 18

SECTION 2 CONTROL DETAILS AND SETTING

Page 21

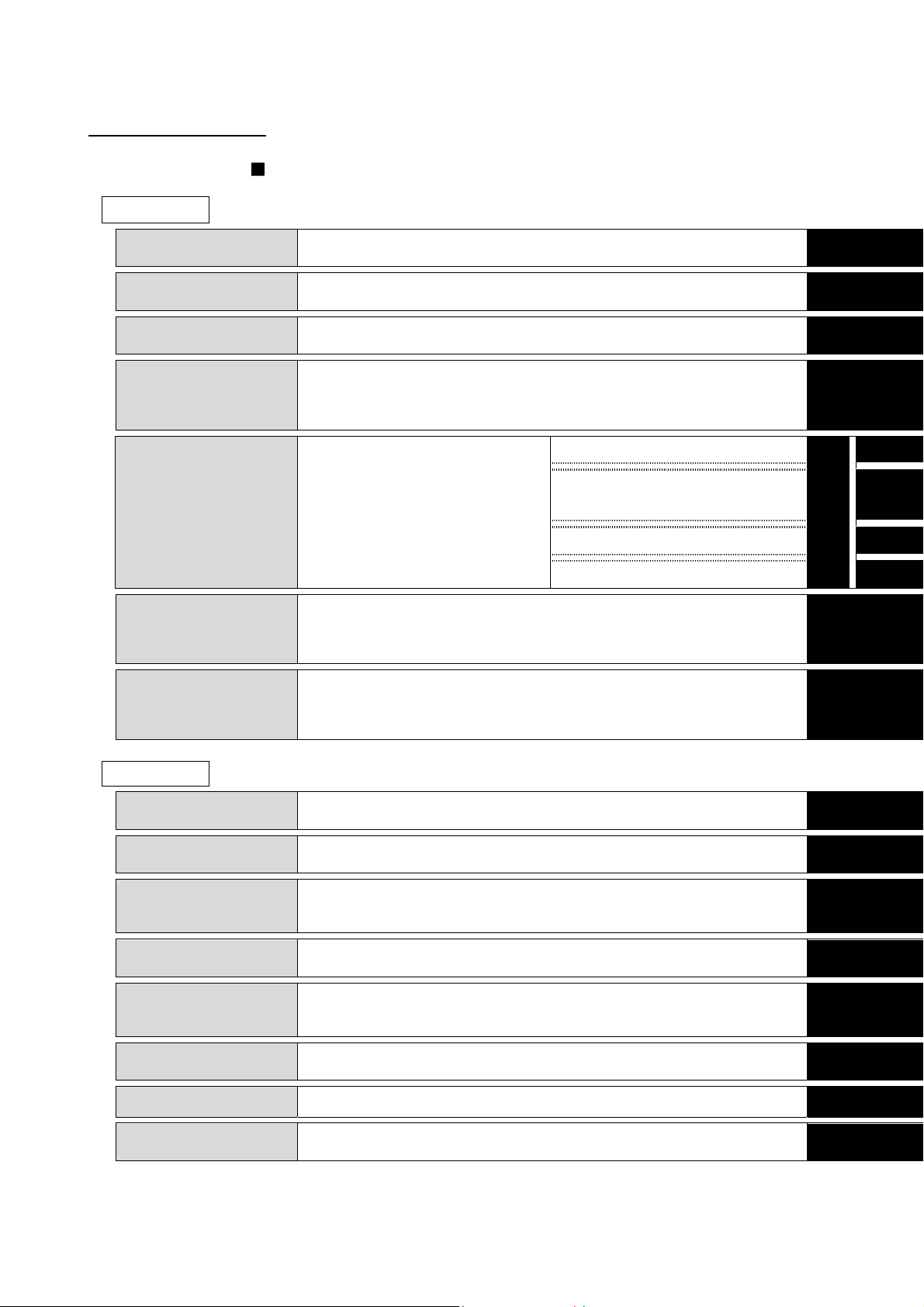

USING THIS MANUAL (3)

The contents of each chapter are shown below.

SECTION 1 PRODUCT SPECIFICATIONS AND HANDLING

1 PRODUCT OUTLINE

2 SYSTEM

CONFIGURATION

3 SPECIFICATIONS

AND FUNCTIONS

4 INSTALLATION,

WIRING AND

MAINTENANCE OF

THE PRODUCT

The basic contents for understanding positioning control using D75P2 are

described.

The devices required for positioning control using D75P2 are described.

The D75P2 functions and performance specifications, etc., are described.

The procedures for installing and wiring the D75P2, the precautions and

maintenance are described.

List of parameters

1

2

3

4

Pr.

List of positioning data

List of start block data

List of condition data

List of monitor data

List of control data

5 DATA USED FOR

POSITIONING

CONTROL

The setting items, setting details and

range, default values, and setting

destination buffer memory address for

the parameters and data required for

positioning control are described.

6 SEQUENCE

PROGRAM USED

FOR POSITIONING

CONTROL

7 MEMORY

CONFIGURATION

AND DATA

PROCESS

SECTION 2 CONTROL DETAILS AND SETTING

8 ZERO POINT

RETURN CONTROL

9 MAIN POSITIONING

CONTROL

10 ADVANCED

POSITIONING

CONTROL

11 MANUAL CONTROL

12 CONTROL

AUXILIARY

FUNCTIONS

13 COMMON

FUNCTIONS

14 TROUBLESHOOTING The errors and warnings detected by the D75P2 are described.

The sequence program required for positioning control is described.

(Create an actual program using this program as a reference.)

The D75P2 memory configuration and data process are described.

(Read this as required.)

The details and settings for zero point return control are described.

The details and examples of settings for "Main positioning control" using the

"Positioning data" are described.

The details and examples of settings for "Advanced positioning control" using

the "Positioning data" are described.

The settings and sequence programs required for JOG operation or manual

pulse generator operation are described.

The settings and sequence programs required for using the auxiliary functions

are described.

The settings and sequence programs required for using the common functions

are described.

APPENDICES

Examples of wiring, a glossary and list of buffer memory addresses are

described. (Read this as required.)

Da.

5

Md.

Cd.

6

7

8

9

10

11

12

13

14

APPENDICES

A - 19

Page 22

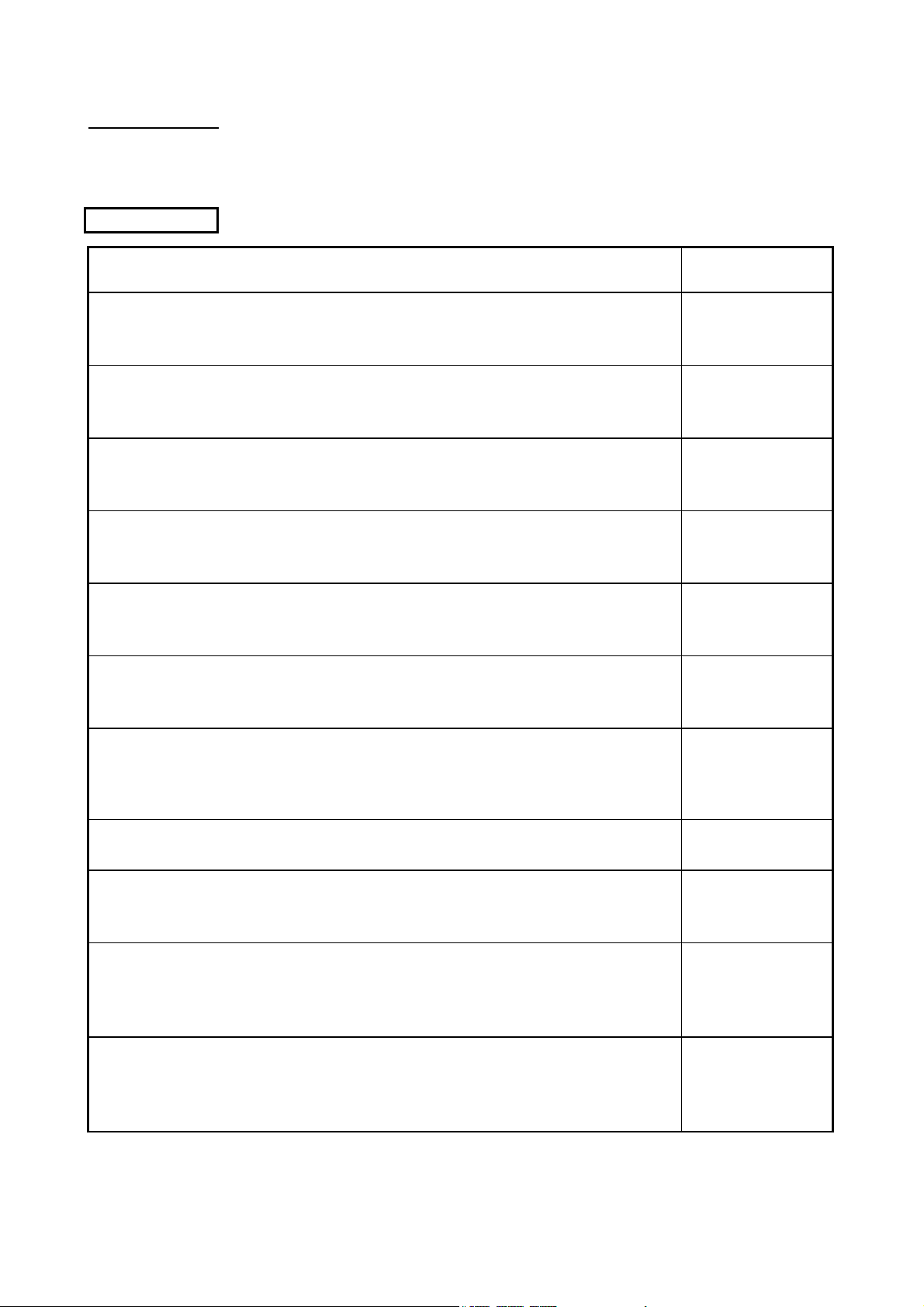

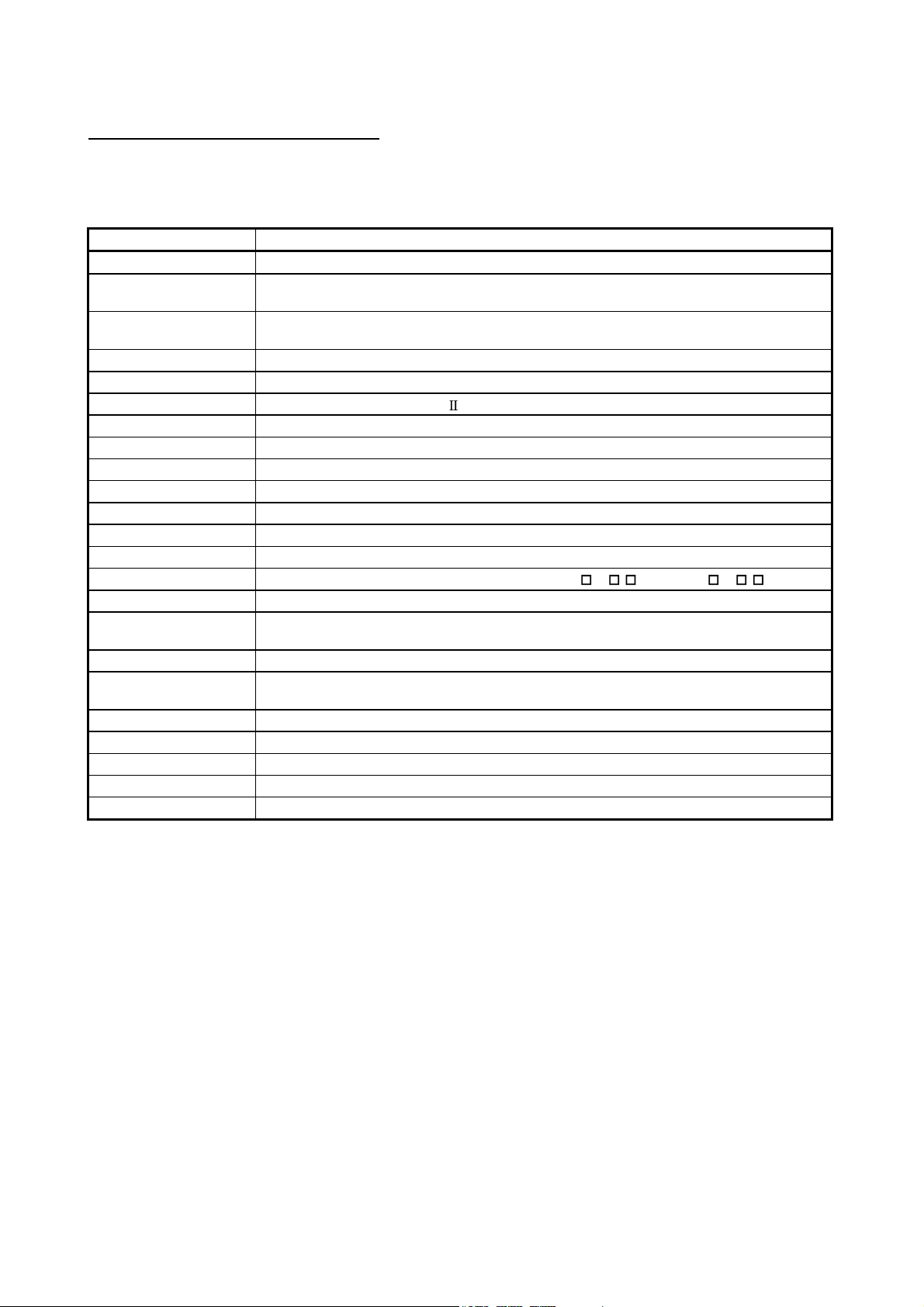

GENERIC TERMS AND ABBREVIATIONS

Unless specially noted, the following generic terms and abbreviations are used in this

manual.

Generic term/abbreviation Details of generic term/abbreviation

D75P2 Generic term for positioning module AJ65BT-D75P2-S3 type.

Peripheral device

AD75 software package

Drive unit Abbreviation for pulse input compatible drive unit (servo amplifier, stepping motor).

Manual pulse generator Abbreviation for manual pulse generator (prepared by user).

Data link system Abbreviation for MELSECNET ( ) and MELSECNET/B data link system.

Network system Abbreviation for MELSECNET/10 network system.

I/F Abbreviation for interface.

DOS/V personal computer IBM PC/AT® and compatible DOS/V compliant personal computer.

Personal computer Generic term for DOS/V personal computer.

Workpiece Generic term for moving body such as workpiece and tool, and for various control targets.

CC-Link Abbreviation for Control & Communication Link.

Master station Station that controls remote, local and intelligent device stations in a CC-Link system.

Remote I/O station Remote station that handles only bit data. (AJ65BTB - , AJ65BTC - )

Local station Station that has a CPU and can communicate with the master station and other local stations.

Intelligent device station

Master module Generic term for modules that can be used as the master station.

Cyclic transmission

Transient transmission Function that updates data for specified station at access request of PLC CPU.

RX Remote input.

RY Remote output.

RWw Remote register. (Write area)

RWr Remote register. (Read area)

Generic term for DOS/V personal computer that can run the following "AD75 Software

Package".

Generic term for "SW1IVD-AD75P type positioning module software package" and "GX

Configurator-AP Version 1 (SW0D5C-AD75P-E)."

Slave station in a CC-Link system that can make transient transmission, such as D75P2 or

AJ65BT-R2.

Transmission method that updates contents of remote input/output and remote registers

periodically.

A - 20

Page 23

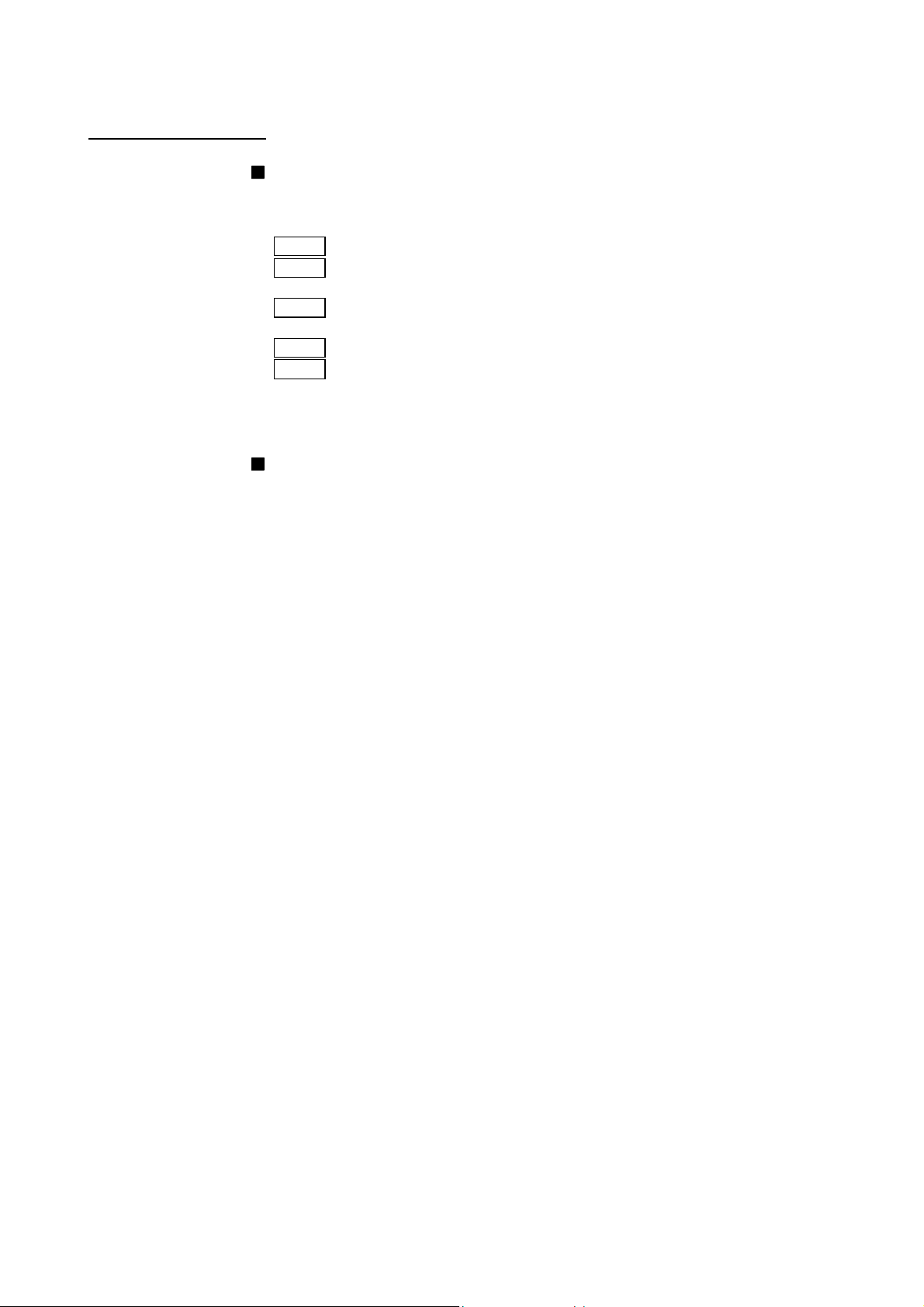

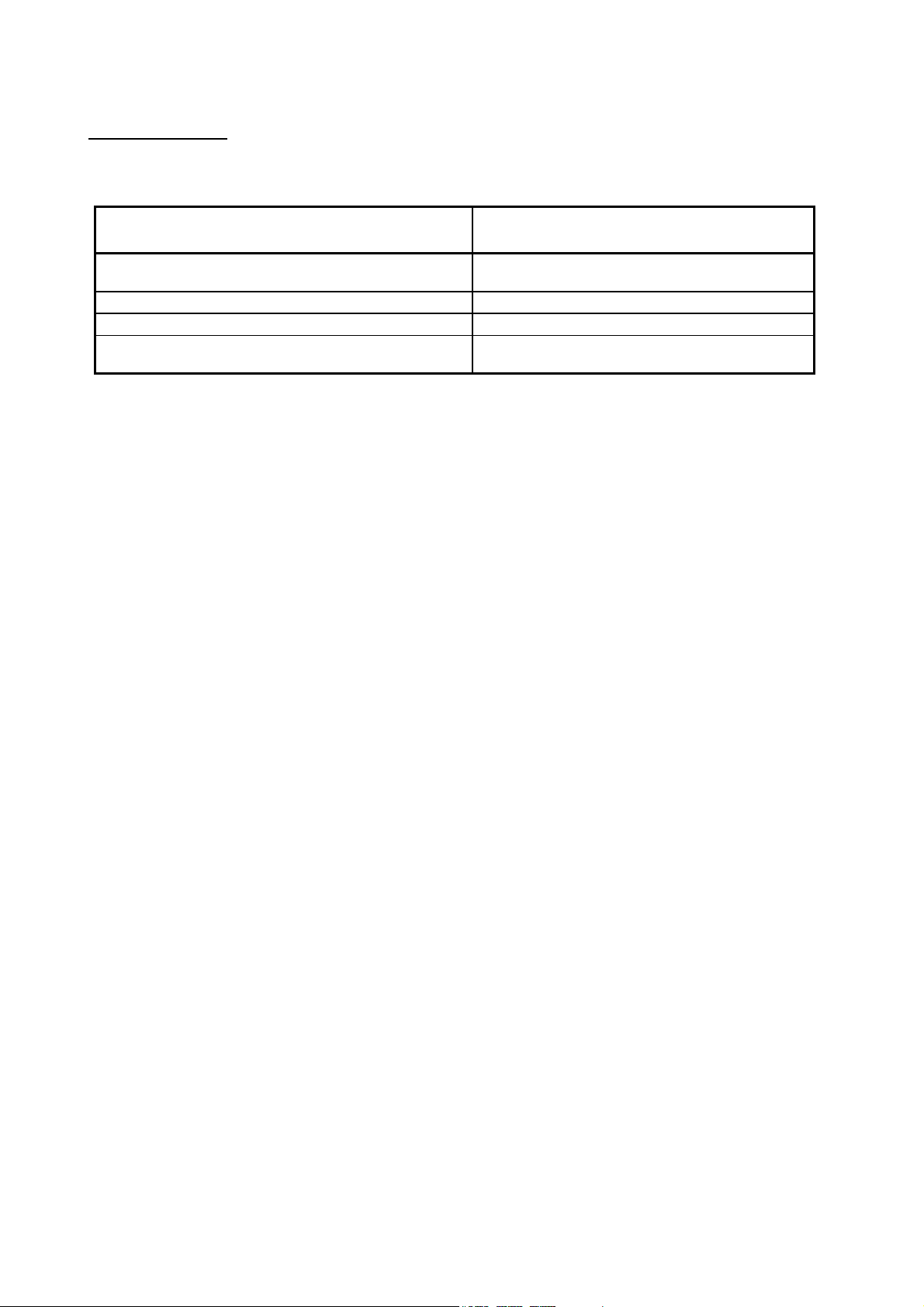

ENCLOSED PARTS

The D75P2 product configuration is shown below.

Part name Quantity

External device connection connector

(10136-3000VE, Sumitomo 3M)

Connector cover (10336-56 F0-008, Sumitomo 3M) 2

Module (AJ65BT-D75P2-S3) 1

AJ65BT-D75P2-S3 Positioning Module User's Manual

(Hardware)

2

1

A - 21

Page 24

MEMO

A - 22

Page 25

SECTION 1

PRODUCT SPECIFICATIONS AND HANDLING

SECTION 1

SECTION 1 is configured for the following purposes (1) to (5).

(1) To understand the outline of positioning control, and the D75P2 specifications

and functions

(2) To carry out actual work such as installation and wiring

(3) To set parameters and data required for positioning control

(4) To create a sequence program required for positioning control

(5) To understand the memory configuration and data transmission process

Read "SECTION 2" for details on each control.

Chapter 1 PRODUCT OUTLINE ................................................................................... 1- 1 to 1- 20

Chapter 2 SYSTEM CONFIGURATION ....................................................................... 2- 1 to 2- 12

Chapter 3 SPECIFICATIONS AND FUNCTIONS ........................................................ 3- 1 to 3- 43

Chapter 4 INSTALLATION, WIRING AND MAINTENANCE OF THE PRODUCT ..... 4- 1 to 4- 30

Chapter 5 DATA USED FOR POSITIONING CONTROL ............................................ 5- 1 to 5-112

Chapter 6 SEQUENCE PROGRAM USED FOR POSITIONING CONTROL ............. 6- 1 to 6- 66

Chapter 7 MEMORY CONFIGURATION AND DATA PROCESS ............................... 7- 1 to 7- 16

APPENDICES

Page 26

MEMO

Page 27

Chapter 1

2

1

3

4

PRODUCT OUTLINE

The purpose and outline of positioning control using D75P2 are explained in this chapter.

By understanding "What can be done", and "Which procedures to use" beforehand, the

positioning system can be structured smoothly.

5

6

7

1.1 Positioning control ........................................................................................................ 1- 2

1.1.1 Features of D75P2 .......................................................................................... 1- 2

1.1.2 Purpose and applications of positioning control ............................................ 1- 4

1.1.3 Mechanism of positioning control ................................................................... 1- 6

1.1.4 Outline design of positioning system.............................................................. 1- 8

1.1.5 Communicating signals between D75P2 and each module ........................ 1- 10

1.2 Flow of system operation ............................................................................................ 1- 12

1.2.1 Flow of all processes ..................................................................................... 1- 12

1.2.2 Outline of starting ........................................................................................... 1- 14

1.2.3 Outline of stopping ......................................................................................... 1- 16

1.2.4 Outline for restarting ...................................................................................... 1- 17

1.3 Outline of communication ............................................................................................ 1- 1 8

1.3.1 Cyclic transmission ........................................................................................ 1- 19

1.3.2 Transient transmission................................................................................... 1- 20

8

9

10

11

12

13

14

APPENDICES

1 - 1

Page 28

A

1 PRODUCT OUTLINE

1.1 Positioning control

1.1.1 Features of D75P2

MELSEC-

The features of the D75P2 are shown below.

(1) Compatibility with distributed system

The D75P2 can be installed near distributed servo amplifiers and stepping

motors.

(2) Ease of compatibility with absolute position detection system

(a) Connection of an absolute position-compatible servo system provides

compatibility with an absolute position detection system.

(b) Once the zero point position has been established, the axis can return to

the address prior to power-on by absolute position restoration.

(c) In the absolute position detection system, the zero point position can be

established by data setting method zero point return.

This makes the wiring of near-point dogs, etc. unnecessary.

(3) Control by mechanical inputs

External inputs, such as external start, stop, and speed/position changeover,

allow positioning control to be performed without use of sequence programs.

(4) Ample positioning control functions

(a) Various functions required for the positioning system, such as positioning

control to random position, fixed-dimension feed control and uniform speed

control are provided.

1) Up to 600 positioning data items containing the positioning address,

control method and operation pattern, etc., can be set for each axis.

Positioning for each axis is carried out using this positioning data. (2axis interpolation control, and multiple axes using simultaneous start is

possible.)

2) Linear control (2-axis simultaneous execution possible) is possible with

positioning for each axis. This control can carry out independent

positioning with one positioning data item, or can carry out continuous

positioning with continuous execution of multiple positioning data items.

3) With multiple axes positioning, linear interpolation control or circular

interpolation control using two axes is possible. This control can carry

out independent positioning with one positioning data item, or can carry

out positioning with continuous execution of multiple positioning data

items.

(b) The control method designated with each positioning data includes position

control, speed control and speed/position changeover control.

(c) Continuous positioning with multiple positioning data items is possible with

the operation pattern set by the user using positioning data.

With the above multiple positioning data as one block, continuous

positioning of multiple blocks is possible.

1 - 2

Page 29

A

1 PRODUCT OUTLINE

(5) High-speed pulse output and long distance with drive unit

(6) Easy maintenance

MELSEC-

(d) The zero point return control has been strengthened.

1) The near-point dog method (one method), stopper stop method (three

types), and count method (two types) zero point return methods have

been prepared as the "machine zero point return" zero point return

method.

2) To realize zero point return control to the machine zero point from a

random position, the zero point return retry function has been prepared.

(The machine zero point is the position used as the start point for

control such as positioning control. The machine zero point is

established with the machine zero point return in item 1) above.)

(e) Automatic trapezoidal acceleration/deceleration and S-curve

acceleration/deceleration have been prepared as the

acceleration/deceleration methods. The user can select from automatic

trapezoidal acceleration/deceleration or S-curve acceleration/deceleration.

(a) The D75P2 has a differential driver and open collector pulse output

interface.

Connect to either according to the type of drive unit.

(b) When connected to the differential driver, the speed and distance have

been increased.

When connected to differential driver : 400kpps, max. 10m,

When connected to open collector : 200kpps, max. 2m

The maintenance of the D75P2 has been improved with the following matters.

(a) The various data, such as the positioning data and parameters, are stored

on a flash ROM in the D75P2.

This allows the data to be held without a battery.

(b) The error display, machine system input and zero point input state can be

confirmed with the 17-segment display.

(c) The primary diagnosis has been improved by detailing the error details.

(d) Up to 16 history items each for the error and warning information can be

held, so the details of the errors and warnings that have occurred can be

confirmed easily.

1 - 3

Page 30

A

a

1 PRODUCT OUTLINE

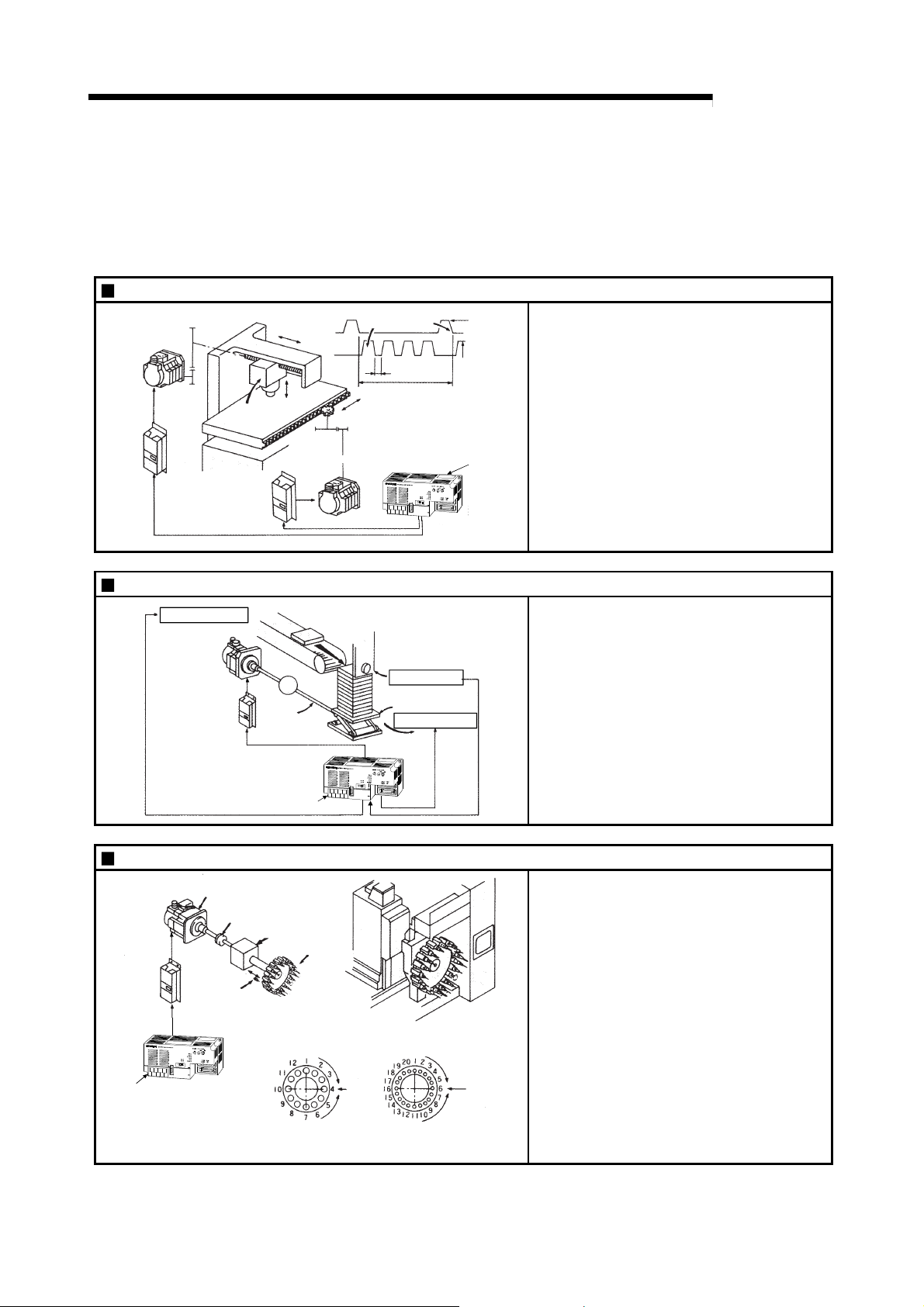

1.1.2 Purpose and applications of positioning control

"Positioning" refers to moving a moving body, such as a workpiece or tool (hereinafter,

generically called "workpiece") at a designated speed, and accurately stopping it at the

target position. The main application examples are shown below.

Punch press (X, Y feed positioning)

Servo

mplifier

Palletizer

Y axis

servomotor

Conveyor control

Servomotor

(with brakes)

Servo amplifier

Gear and ball screw

Press head

Servo

amplifier

Y axis

X axis

servomotor

G

Reduction

gears

Ball screw

(From D75P2)

X axis

Conveyor

320mm

Y axis

X axis

Gear and rack & pinion

160mm

Press

punching

12 s

X axis

Y axis

Position detector

Palletizer

Unloader control

15m/min

(2000r/min)

15m/min

(1875r/min)

D75P2

MELSEC-

To punch insulation material or leather, etc.,

as the same shape at a high yield, positioning

is carried out with the X axis and Y axis

servos.

After positioning the table with the X axis

servo, the press head is positioned with the Y

axis servo, and is then punched with the

press.

When the material type or shape changes, the

press head die is changed, and the positioning

pattern is changed.

Using the servo for one axis, the palletizer is

positioned at a high accuracy.

The amount to lower the palletizer according to

the material thickness is saved.

D75P2

Compact machining center (ATC magazine positioning)

Servomotor

Servo

amplifier

D75P2

Coupling

Positioning

pin

Reduction

gears

ATC tool

magazine

Tool

(12 pcs., 20 pcs.)

Rotation direction

for call ing

11, 12, 1, 2 or 3

Current

value

retrieval

position

Rotation direction

for calling 5, 6, 7, 8, 9 or 10

<No. of tools: 12> <No. of tools: 20>

Rotation direction

for calling

17 to 20, 1 to 5

Current

value

retrieval

position

Rotation direction

for calling 7 to 16

1 - 4

The ATC tool magazine for a compact

machining center is positioned.

The relation of the magazine's current value

and target value is calculated, and positioning

is carried out with forward run or reverse run to

achieve the shortest access time.

Page 31

A

1 PRODUCT OUTLINE

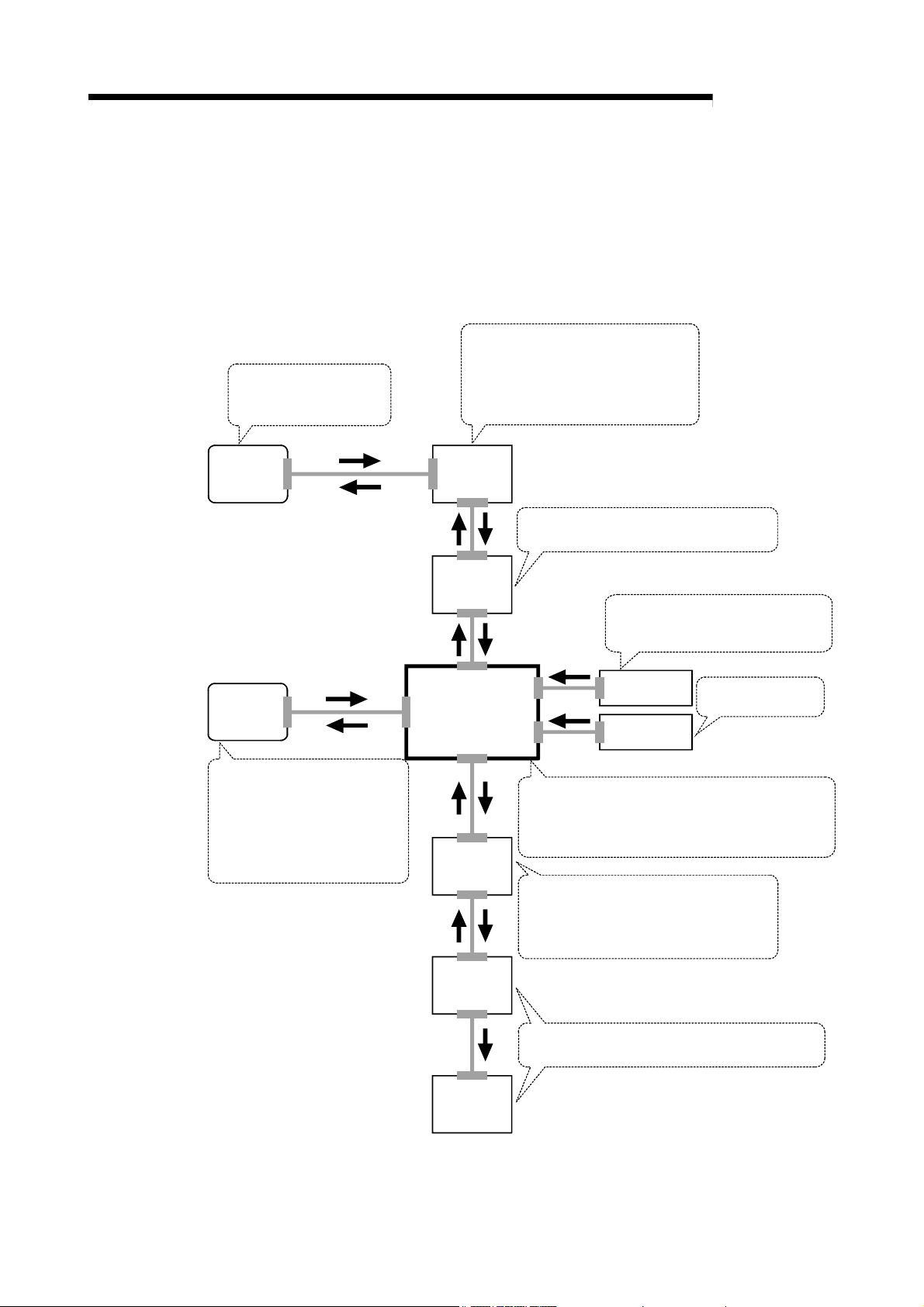

Lifter (Storage of Braun tubes onto aging rack)

B conveyor

Lifter C

Counterweight

Reduction

gears

G1

Servomotor

(with brakes)

conveyor

A conveyor Servo amplifier

Loader

Servomotor

Servo amplifier

Aging rack

G2

Positioning module

D75P2-S3

Index table (High-accuracy indexing of angle)

D75P2

Unloader

Loader/unloader

MELSEC-

During the aging process of braun tubes,

storage onto the rack is carried out by

positioning with the servo.

The up/down positioning of the lifter is carried

out with the 1-axis servo, and the horizontal

position of the aging rack is positioned with the

2-axis servo.

The index table is positioned at a high accuracy

using the 1-axis servo.

Digital switch

Index table

Worm gears

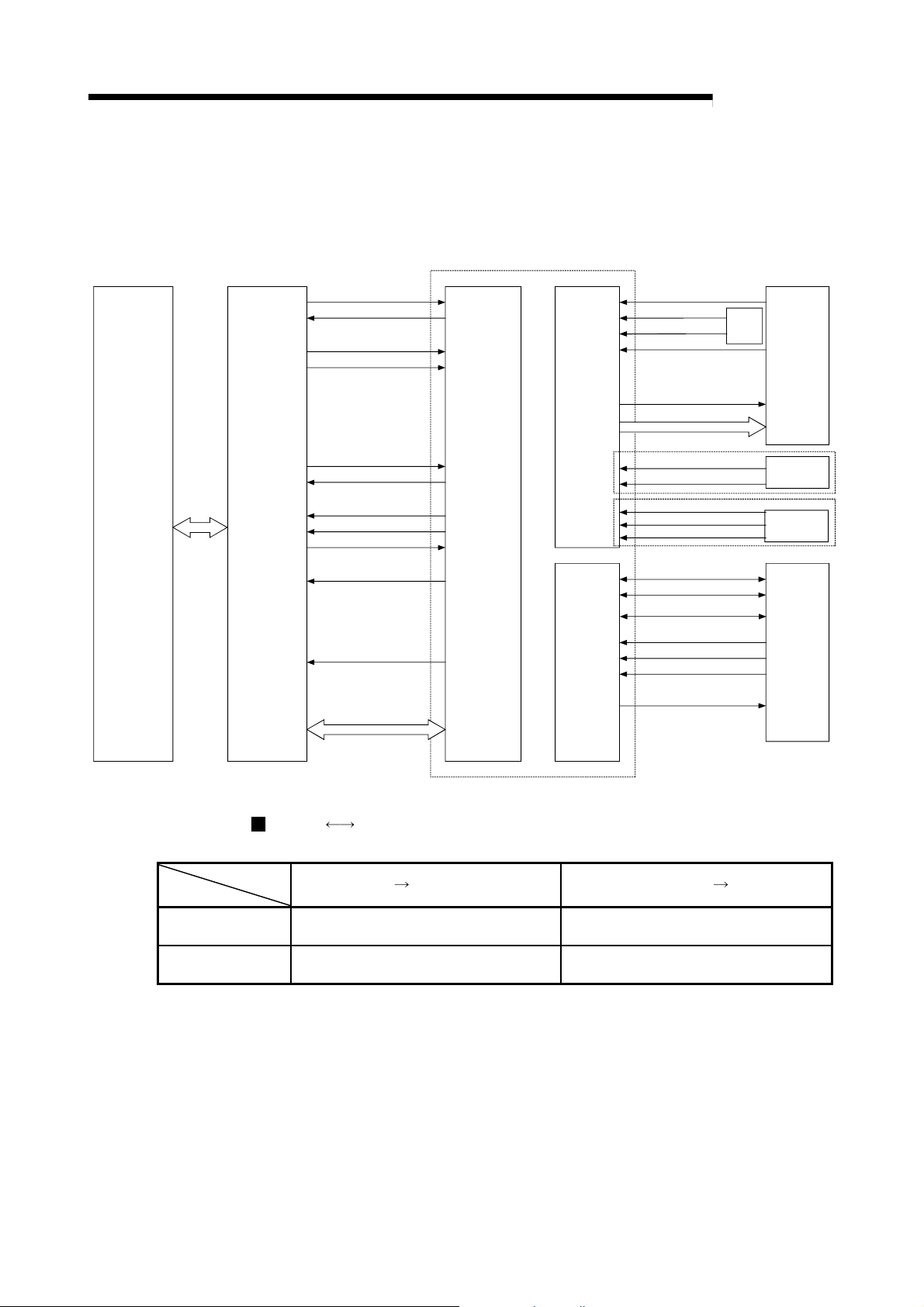

Inner surface grinder

Servomotor

Inverter

AC220V

60Hz

D75P2

Servo

amplifier

Motor

1M

G

Fix the grinding

stone, feed the

workpiece, and grind.

Operation panel

a

b

c

Workpiece

Grinding stone

a. Total feed

d

amount (mm)

b. Finishing

e

feed amount (mm)

c. Compensation

amount (mm)

Detector

Servomotor

Motor

G

1M

Inverter

Servo

amplifier

d. Rough grind ing speed (mm/s)

e. Fine grindi ng

speed ( mm/s)

The grinding of the workpiece's inner surface

is controlled with the servo and inverter.

The rotation of the workpiece is controlled with

the 1-axis inverter, and the rotation of the

grinding stone is controlled with the 2-axis

inverter. The workpiece is fed and ground with

the 3-axis servo.

1 - 5

Page 32

A

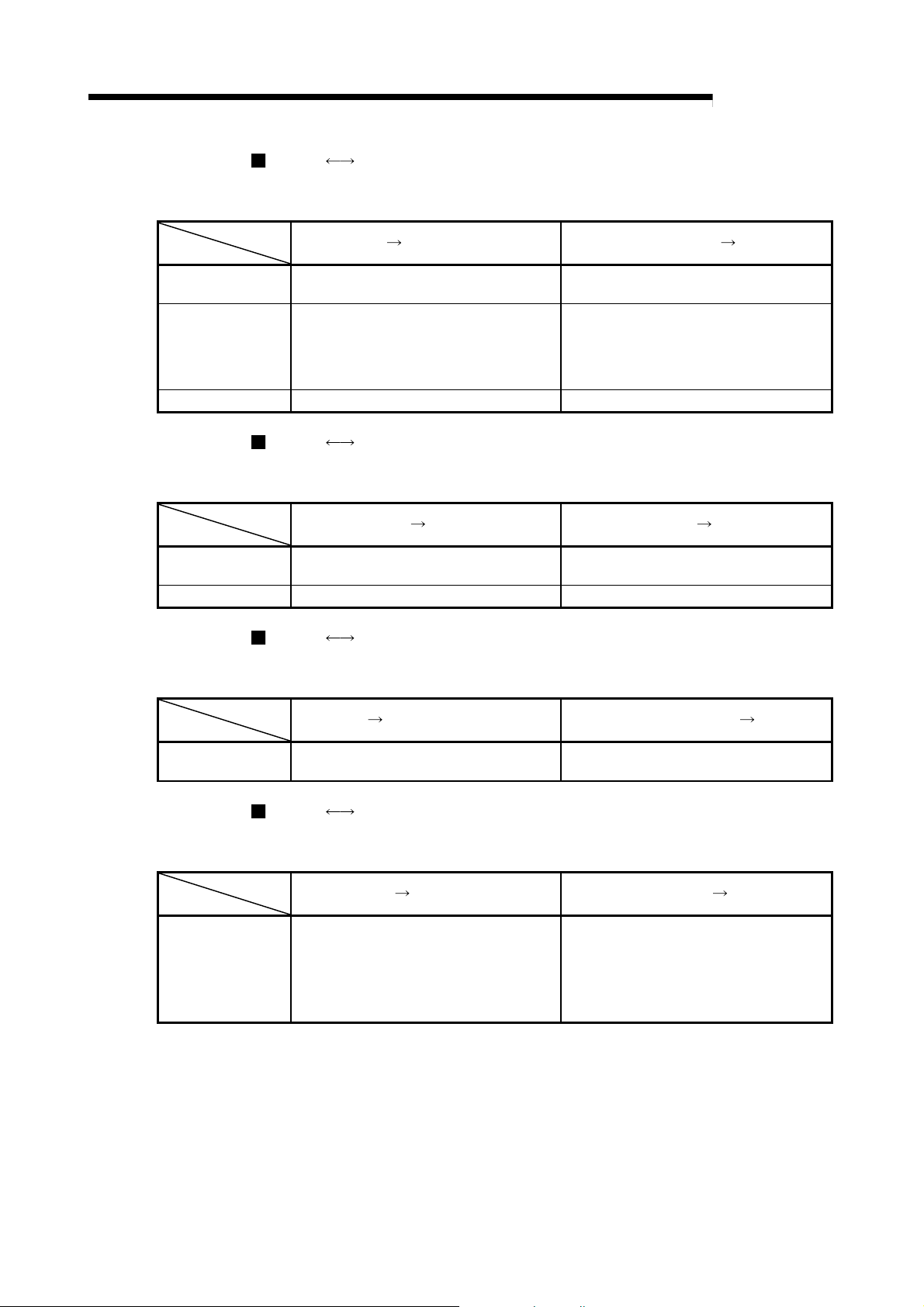

1 PRODUCT OUTLINE

1.1.3 Mechanism of positioning control

Positioning control using the D75P2 is carried out with "pulse signals". (The D75P2 is a

module that generates pulses). In the positioning system using the D75P2, various

software and devices are used for the following roles. The D75P2 realizes complicated

positioning control when it reads in various signals, parameters and data and is

controlled with the PLC CPU.

Creates control order and

conditions as a sequence

program.

GPP function

software

package

Stores the created program.

The D75P2 outputs the start signal and

stop signal following the stored program.

D75P2 errors, etc., are detected.

PLC CPU

MELSEC-

AD75

software

package

Sets the parameters and

positioning data for control.

Outputs the start command for

JOG operation, etc., during test

operation with the test mode.

Monitors the positioning operation.

CC-Link

master/local

module

D75P2 positioning

module

Servo

amplifier

Communicates with the D75P2, using RX as

input and RY as output.

Outputs signals such as the start

signal, stop signal, limit signal and

control changeover signal to the D75P2.

External signal

Manual pulse

generator

Stores the parameter and data.