Page 1

High-Speed

Counter Module

User's Manual

(Hardware)

AJ65BT-D62

AJ65BT-D62D

AJ65BT-D62D-S1

Thank you for purchasing the Mitsubishi programmable controller

MELSEC-A series.

Prior to use, please read this and relevant manuals thoroughly to

fully understand the product.

MODEL AJ65BT-D62-U-H-E

MODEL

CODE

IB(NA)-66822-G(1806)MEE

© 1997 MITSUBISHI ELECTRIC CORPORATION

13JL44

Page 2

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause

hazardous conditions, resulting in death or severe

injury.

Indicates that incorrect handling may cause

hazardous conditions, resulting in minor or moderate

injury or property damage.

CAUTION

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals

carefully and pay full attention to safety to handle the product correctly.

In this manual, the safety precautions are classified into two levels:

" WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under

" CAUTION" may lead to serious consequences.

Observe the precautions of both levels because they are important for personal

and system safety.

Make sure that the end users read this manual and then keep the manual in a safe

place for future reference.

[Design Precautions]

WARNING

● If data link becomes faulty, the status of the faulty station changes as follows.

Using the communication status information, construct an interlock circuit in

the sequence program so that the system operates safety.

There is a risk of an accident due to output error or malfunction.

(1) All general-use inputs from this module turn off.

(2) All general-use outputs from this module turn off.

● The inputs and outputs may be turned on or off when a failure occurs within

the module. Provide a circuit that externally monitors the input and output

signals that might lead to a serious accident.

A-1

Page 3

[Design Precautions]

CAUTION

● Do not have control cables and communication cables bundled with or placed

near by the main circuit and/or power cables.

Wire those cables at least 100mm (3.94 inch) away from the main circuit

and/or power cables.

Not doing so could result in noise that would cause erroneous operation.

[Installation Precautions]

CAUTION

● Use each module in an environment as specified in the "general specification"

in the detailed manual.

Usage of the module outside the general specification range may cause

electric shock, fire, malfunction, product damage or deterioration.

● Tighten the module securely using DIN rail or installation screws within the

specified torque range of the installation screws. Loose screws may cause

falling or malfunction. Also, if the screws are too tight, it may cause falling or

malfunction due to damage of the screws or module.

● Do not touch the conductive area of the module.

Doing so may cause module malfunction or breakdowns.

[Wiring Precautions]

WARNING

● Perform installation and wiring after disconnecting the power supply at all

phases externally.

If the power is not disconnected at all phases an electric shock, product

damage or malfunction may result.

● When powering up or operating the module after performing installation or

wiring work, always attach the terminal cover that came with the product.

It may cause an electric shock if the terminal cover is not attached.

A-2

Page 4

[Wiring Precautions]

CAUTION

● Be sure to ground the FG terminal to the class-3 or higher grounding.

Otherwise there will be a danger of malfunctions.

● Use applicable solderless terminals and tighten them with the specified

torque. If any solderless spade terminal is used, it may be disconnected when

the terminal screw comes loose, resulting in failure.

● Perform correct wiring for the module according to the product's rated voltage

and terminal arrangement. Connecting to a power supply different from rating

or mis-wiring may cause fire and/or product failure.

● Fix terminal screws securely within the specified torque range. Loose terminal

screws may cause short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short

circuit, or malfunction.

● Make sure foreign objects do not get inside the module, such as dirt and wire

chips. It may cause fire, product failure or malfunction.

● Be sure to fix the wires or cables that are connected to the module in place,

either by running them through a duct or by using clamps.

If the cables are not fixed in one of these ways, dispersion, movement, or

careless pulling of the cables may cause damage to the module or

malfunction due to cable contact faults.

● Do not install the control lines together with the communication cables, or

bring them close to each other. Failure to do so may cause malfunctions due

to noise.

● When disconnecting a communication or power supply cable from the

module, do not pull on the cable itself.

Disconnect cables fitted with connectors by holding and pulling the cable

connector. Disconnect cables not fitted with a connector by removing the

screws from the part connected to the module.

Pulling on a cable that is connected to the module can cause damage to the

module or cable, or malfunction due to cable connection faults.

[Starting and Maintenance Precautions]

WARNING

● Do not touch the terminals when the power is on. It may cause an electric

shock or malfunction.

● Perform cleaning the module after turning off the all external power supply for

sure. If you do not switch off the external power supply, it will cause electric

shock.

A-3

Page 5

[Starting and Maintenance Precautions]

CAUTION

● Never try to disassemble or modify module. It may cause product failure,

malfunction, fire or cause injury.

● Do not drop or apply strong shock to the module case. Failure to do so may

damage the module.

● Make sure to switch all phases of the external power supply off before

installing or removing the module to/from the panel.

If you do not switch off the external power supply, it will cause failure or

malfunction of the module.

● Always set the setting pins for pulse and external input voltage after externally

shutting down all phases of the power supply.

Failure to shut down all phases of the power supply may cause a failure or

malfunction of the module.

● Do not install/remove the terminal block more than 50 times after the first use

of the product. (IEC 61131-2 compliant)

[Disposal Precautions]

CAUTION

● When disposing of the product, treat it as industrial waste.

A-4

Page 6

A-5

Page 7

A-6

Page 8

A-7

Page 9

A-8

Page 10

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in

conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any,

shall not lead to any major or serious accident; and

ii) where the backup and fail-safe function are systematically or

automatically provided outside of the PRODUCT for the case of any

problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of

being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY

(INCLUDING, BUT NOT LIMITED TO ANY AND ALL RESPONSIBILITY

OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT

LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR

DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR

EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING

CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the

PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT

in;

• Nuclear Power Plants and any other power plants operated by Power

companies, and/or any other cases in which the public could be

affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases

in which establishment of a special quality assurance system is

required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport

equipment such as Elevator and Escalator, Incineration and Fuel

devices, Vehicles, Manned transportation, Equipment for Recreation

and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or

property.

A-9

Page 11

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion,

authorize use of the PRODUCT in one or more of the Prohibited

Applications, provided that the usage of the PRODUCT is limited only for

the specific applications agreed to by Mitsubishi and provided further that

no special quality assurance or fail-safe, redundant or other safety features

which exceed the general specifications of the PRODUCTs are required.

For details, please contact the Mitsubishi representative in your region.

A-10

Page 12

REVISIONS

*The manual number is given on the bottom right of the cover.

Print date *Manual number Revision

October 1997 IB(NA)-66822-A First edition

November 1998 IB(NA)-66822-B Full revision

July 2005 IB(NA)-66822-C

September 2006 IB(NA)-66822-D

December 2011 IB(NA)-66822-E

April 2015 IB(NA)-66822-F

June 2018 IB(NA)-66822-G The standard name (standard number) for the

Partial correction

SAFETY PRECAUTIONS

Partial correction

SAFETY PRECAUTIONS

Partial correction

SAFETY PRECAUTIONS, MANUALS, Chapter 1,

2, Section 2.1, 2.2, 2.3, 2.4, Chapter 3, Section

4.1, 4.2, Chapter 5, Section 5.3, 5.4, 5.5

Addition

SAFETY PRECAUTIONS (Chinese),

CONDITIONS OF USE FOR THE PRODUCT

Partial correction

Section 2.1, 2.2, 2.3, 2.4, Chapter 3,

Section 4.1, 5.3

Chinese standardized law is added.

Japanese Manual Version IB-68910-G

This manual confers no industrial property rights or any rights of any other kind,

nor does it confer any patent licenses. Mitsubishi Electric Corporation cannot be

held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

© 1997 MITSUBISHI ELECTRIC CORPORATION

A-11

Page 13

CONTENTS

1. OVERVIEW .................................................................................................... 1

2. SPECIFICATION............................................................................................ 2

2.1 Performance Specifications for AJ65BT-D62........................................ 2

2.2 Performance Specifications for AJ65BT-D62D ..................................... 4

2.3 Performance Specifications for AJ65BT-D62D-S1 ............................... 6

2.4 Interface Specifications for External Device Connections..................... 8

3. PART IDENTIFICATION NOMENCLATURE AND SETTINGS.................... 12

4. LOADING AND INSTALLATION .................................................................. 17

4.1 Handling Precautions.......................................................................... 17

4.2 Installation Environment...................................................................... 18

5. WIRING ........................................................................................................ 19

5.1 Wiring Method to Each Module ........................................................... 19

5.2 Precautions When Wiring to the Pulse Generator .............................. 20

5.3 Example of Wiring for the Pulse Generator ......................................... 22

5.4 Example of Wiring Between a Control Device and External Input

Terminals (PRESET, F.START).......................................................... 25

5.5 Example of Wiring to the External Output Terminals (EQU1 to EQU2)

............................................................................................................ 26

6. EXTERNAL DIMENSIONS ........................................................................... 27

7. Information for the Chinese Standardized Low ............................................ 27

A-12

Page 14

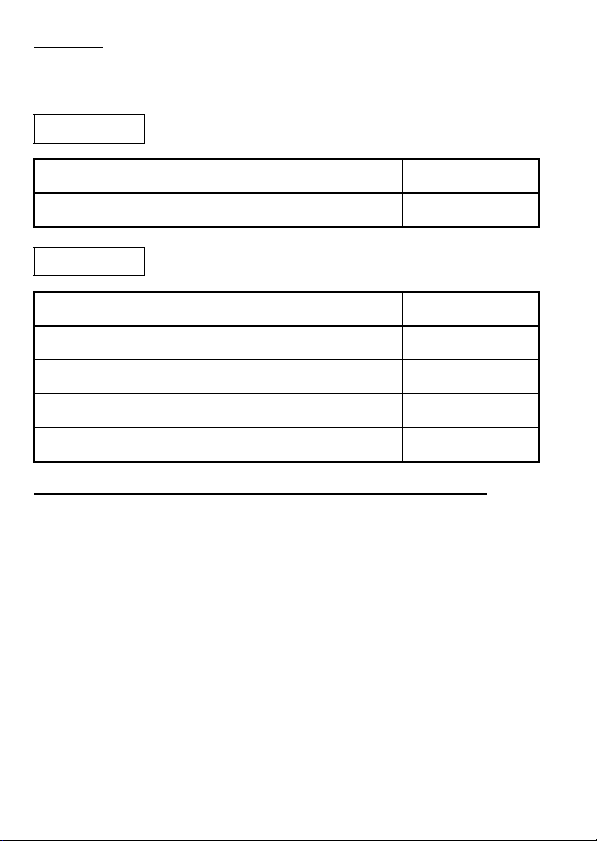

MANUAL

User's Manual

The manuals related to this product are listed below.

Please place an order as needed.

Manual name

High-Speed Counter Module type

AJ65BT-D62/AJ65BT-D62D/AJ65BT-D62D-S1 User's Manual

Related Manuals

Manual name

CC-Link System Master/Local Module Type AJ61BT11/A1SJ61BT11

User's Manual

CC-Link System Master/Local Module Type

AJ61QBT11/A1SJ61QBT11 User's Manual

CC-Link System Master/Local Module User's Manual

MELSEC-L CC-Link System Master/Local Module Use's Manual

Manual number

(Model code)

IB-66823

(13JL45)

Manual number

(Model code)

IB-66721

(13J872)

IB-66722

(13J873)

SH-080394E

(13JR64)

SH-080895ENG

(13JZ41)

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC

and Low Voltage Directives when incorporated into other

machinery or equipment, certain measures may be necessary.

Please refer to one of the following manuals.

• User's manual for the CPU module or head module used

• Safety Guidelines (this manual is included with the CPU module,

base unit, or head module)

The CE mark on the side of the programmable controller indicates

compliance with EMC and Low Voltage Directives.

(2) Additional measures

To ensure that this product maintains EMC and Low Voltage

Directives, please refer to one of the manuals listed under (1).

A-13

Page 15

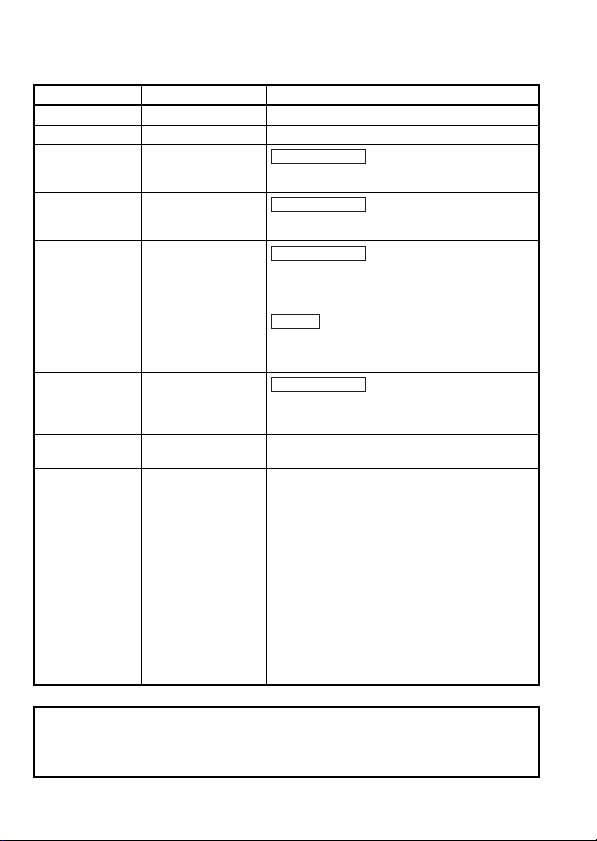

1. OVERVIEW

This manual describes specifications, handling, and wiring of the

AJ65BT-D62/AJ65BT-D62D/AJ65BT-D62D-S1 high-speed counter

modules (hereafter abbreviated as high-speed counter module) to be

used in a CC-Link system.

After unpacking the product you purchased, check to see that the

following equipment is included.

Product name Quantity

High-speed counter module 1

There are three types of high-speed counter module, as indicated

below:

Item AJ65BT-D62 AJ65BT-D62D AJ65BT-D62D-S1

Type

External input

Maximum counting speed

CC-Link station type Remote device station

Signal level 24-bit binary (0 to 16777215)

Counting switching 200k/10k

Preset

Function start

DC input sink

output type

5/12/24VDC, 2 to 5mA

Maximum

200kPPS

Differential input sink

Maximum 400kPPS

Phase 1: 400k

Phase 2: 300k

output type

Differential input

/10k

5/12/24VDC

2 to 5mA

1

Page 16

2. SPECIFICATION

Specifications for the high-speed counter module are given below.

For general specifications, refer to the user's manual.

2.1 Performance Specifications for AJ65BT-D62

Item Specification

Setting switch for counting speed switching HIGH side LOW side

Number of channels 2 channels

Count input

signal

Counter

Coincidence

output

External

input

External

output

CC-Link station type Remote device station

Number of occupied stations 4 stations

Connection cable CC-Link dedicated cable

Dielectric withstand voltage

Phase 1 phase input, 2 phase input

Signal level

(A, B)

Counting

speed

(maximum)

1 phase input 200kPPS 10kPPS

*1

2 phase input 200kPPS 7kPPS

5VDC

12VDC

24VDC

2 to 5mA

Signal level 24-bit binary 0 to 16777215

Model

Smallest count pulse width

Adjust rise/fall

time of input

to 2μs or less.

Duty ratio:

50%

UP/DOWN preset counter and ring counter

2.5 s

(1, 2 phase input)

5 s

2.5 s

functions

100 s

50

50

s

s

(1 phase

input)

Comparison range 24-bit binary

Comparison result

Set value < Count value

Set value = Count value

Set value > Count value

Preset 5/12/24VDC, 2 to 5mA

Function start

Response time

OFF ON: 0.5ms or less

ON OFF: 3ms or less

Coincidence output 2A/common

Response time 0.1ms or less

1 minute at 500V AC between batch of DC

external terminals and ground

142 s

(2 phase

71

input)

s71 s

2

Page 17

Item Specification

Insulation resistance

Noise durability

Connected terminal block 27 terminal blocks (seven M3.5 screws)

Applicable wire size 0.75 to 2.00mm

Applicable crimp contact RAV1.25-3, RAV2-3.5 (JIS C 2805 compliant)

Module installation screws

Applicable DIN rail

External power supply

Allowable momentary power failure period 1ms

Weight 0.41kg

*1 Counting speed is affected by the duration of rise and fall periods. The speeds that can be

counted are indicated in the table below.

Take note that the count may become incorrect when a pulse with a large rise or fall period

is counted.

Counting speed

setting switch

Rise/fall period

t = 2µs or less 200kPPS 200kPPS 10kPPS 7kPPS

t = 25µs or less 10kPPS 10kPPS 1kPPS 700PPS

t = 500µs - - 500PPS 250PPS

HIGH LOW

1 phase

input

2 phase

10M or more on an insulation resistance tester

at 500V DC between batch of DC external

terminals and ground

Based on a noise simulator with 500Vp-p noise

voltage, 1µs noise width and 25-60Hz noise

frequency

M4×0.7mm(0.03in.)×16mm(0.63in.) or larger

screws (tightening torque range 0.78 to 1.18N•m)

Can also be mounted using a DIN rail

TH35-7.5Fe, TH35-7.5Al, TH35-15Fe

(JIS C 2812 compliant)

18 to 28.8VDC

Current consumption: 70mA (for 24VDC)

input

1 phase

input

2 phase

input

2

tt

3

Page 18

2.2 Performance Specifications for AJ65BT-D62D

(2 phase

input)

(1 phase

input)

s

71

142 s

100 s

s

71

s50 s

50

Item Specification

Setting switch for counting speed switching HIGH side LOW side

Number of channels 2 channels

Phase 1 phase input, 2 phase input

Count input

signal

Signal level

(A, B)

Counting

speed

(maximum)

1 phase input 400kPPS 10kPPS

*1

2 phase input 300kPPS 7kPPS

Signal level 24-bit binary 0 to 16777215

Model

Counter

Smallest count pulse width

Adjust rise/fall

time of input

to 2μs or less.

Duty ratio:

50%

Comparison range 24-bit binary

Coincidence

output

Comparison result

Preset 5/12/24VDC, 2 to 5mA

External input

Function start

Response time

External

output

Coincidence output 2A/common

Response time 0.1ms or less

CC-Link station type Remote device station

Number of occupied stations 4 stations

Connection cable CC-Link dedicated cable

Dielectric withstand voltage

Insulation resistance

EIA Standard RS-422-A

Differential line driver level

(AM26LS31 (manufactured by Texas Instrument

Japan) or equivalent)

UP/DOWN preset counter and ring counter

2.5 s

1.25

1.25

s

(1 phase

input)

1 minute at 500V AC between batch of DC

external terminals and ground

10M or more across all DC external terminals

and grounding terminal using a 500VDC

insulation resistance tester

functions

3.3 s

1.65

1.65

s s

s

(2 phase

input)

Set value < Count value

Set value = Count value

Set value > Count value

OFF ON: 0.5ms or less

ON OFF: 3ms or less

4

Page 19

Item Specification

Noise durability

Connected terminal block 27 terminal blocks (seven M3.5 screws)

Applicable wire size 0.75 to 2.00mm

Applicable crimp contact RAV1.25-3, RAV2-3.5 (JIS C 2805 compliant)

Module installation screws

Applicable DIN rail

External power supply

Allowable momentary power failure period 1ms

Weight 0.42kg

*1 Counting speed is affected by the duration of rise and fall periods. The speeds that can be

counted are indicated in the table below.

Take note that the count may become incorrect when a pulse with a large rise or fall period

is counted.

Counting speed

setting switch

Rise/fall period

t = 0.1µs or less 400kPPS 300kPPS - -

t = 1.25µs or less 200kPPS 200kPPS 10kPPS 7kPPS

t = 12.5µs or less 20kPPS 20kPPS 1kPPS 700PPS

t = 250µs or less - - 500PPS 250PPS

HIGH LOW

1 phase

input

2 phase

Based on a noise simulator with 500Vp-p noise

voltage, 1µs noise width and 25-60Hz noise

frequency

M4×0.7mm(0.03in.)×16mm(0.63in.) or larger

screws (tightening torque range 0.78 to

1.18N•m)

Can also be mounted using a DIN rail

TH35-7.5Fe, TH35-7.5Al, TH35-15Fe

(JIS C 2812 compliant)

18 to 28.8VDC

2 phase

input

input

Current consumption: 100mA (for 24VDC)

1 phase

input

2

tt

5

Page 20

2.3 Performance Specifications for AJ65BT-D62D-S1

(2 phase

input)

(1 phase

input)

142 s

7171

100 s

5050

s s s s

Item Specification

Setting switch for counting speed switching HIGH side LOW side

Number of channels 2 channels

Phase 1 phase input, 2 phase input

Count input

signal

Signal level

(A, B)

Counting

speed

(maximum)

1 phase input 400kPPS 10kPPS

*1

2 phase input 300kPPS 7kPPS

Signal level 24-bit binary 0 to 16777215

Model

Counter

Smallest count pulse width

Adjust rise/fall

time of input

to 2μs or less.

Duty ratio:

50%

Comparison range 24-bit binary

Coincidence

output

Comparison result

Preset

External input

Function start 5/12/24VDC, 2 to 5mA

Response time

External

output

Coincidence output 2A/common

Response time 0.1ms or less

CC-Link station type Remote device station

Number of occupied stations 4 stations

Connection cable CC-Link dedicated cable

Dielectric withstand voltage

EIA Standard RS-422-A

Differential line driver level

(AM26LS31 (manufactured by Texas Instrument

Japan) or equivalent)

UP/DOWN preset counter and ring counter

2.5 s

1.25

1.25

s

s

(1 phase

input)

EIA Standard RS-422-A differential type line

{equivalent to AM26LS31 (Japan Texas

1 minute at 500V AC between batch of DC

external terminals and ground

functions

3.3 s

1.65

1.65

s

s

(2 phase

input)

Set value < Count value

Set value = Count value

Set value > Count value

driver level

Instruments make)}

OFF ON: 0.5ms or less

ON OFF: 3ms or less

6

Page 21

Item Specification

tt

Insulation resistance

Noise durability

Connected terminal block 27 terminal blocks (seven M3.5 screws)

Applicable wire size 0.75 to 2.00mm

Applicable crimp contact RAV1.25-3, RAV2-3.5 (JIS C 2805 compliant)

Module installation screws

Applicable DIN rail

External power supply

Allowable momentary power failure period 1ms

Weight 0.42kg

*1 Counting speed is affected by the duration of rise and fall periods. The speeds that can be

counted are indicated in the table below.

Take note that the count may become incorrect when a pulse with a large rise or fall period

is counted.

Counting speed

setting switch

Rise/fall period

t = 0.1µs or less 400kPPS 300kPPS - -

t = 1.25µs or less 200kPPS 200kPPS 10kPPS 7kPPS

t = 12.5µs or less 20kPPS 20kPPS 1kPPS 700PPS

t = 250µs or less - - 500PPS 250PPS

HIGH LOW

1 phase

input

2 phase

10M or more across all DC external terminals

and grounding terminal using a 500VDC

insulation resistance tester

Based on a noise simulator with 500Vp-p noise

voltage, 1µs noise width and 25-60Hz noise

frequency

M4×0.7mm(0.03in.)×16mm(0.63in.) or larger

screws (tightening torque range 0.78 to

1.18N•m)

Can also be mounted using a DIN rail

TH35-7.5Fe, TH35-7.5Al, TH35-15Fe

(JIS C 2812 compliant)

18 to 28.8VDC

2 phase

input

input

Current consumption: 120mA (for 24 VDC)

1 phase

input

2

7

Page 22

2.4 Interface Specifications for External Device

1/3W

1/3W

1/3W

Pulse input

voltage setting pin

For 5V

For 12V

For 24V

510

4.7k

4.7k

1/3W

1/3W

1/3W

Pulse input

voltage setting pin

For 5V

For 12V

For 24V

510

4.7k

4.7k

Connections

The table below indicates the external device interfaces for the AJ65BTD62, AJ65BT-D62D and AJ65BT-D62D-S1 high-speed counter

modules.

(1) External device interfaces for AJ65BT-D62

I/O

classify

-cation

Input

4.7k

4.7k

4.7k

4.7k

Internal Circuit

510

510

1/3W

1/3W

1/3W

External input

voltage setting pin

1/3W

1/3W

1/3W

External

input

voltage

setting pin

Terminal

number*1Signal Name Operation

Phase A pulse

input 24V

Phase A pulse

8

input 12V

(15)

Phase A pulse

9

Phase A pulse

(16)

input COM

Phase B pulse

input 24V

Phase B pulse

10

input 12V

(17)

Phase B pulse

11

Phase B pulse

(18)

input COM

Preset input

Preset input

12

For 5V

(19)

For 12V

For 24V

For 5V

For 12V

For 24V

Preset input

13

(20)

Function start

input 24V

Function start

14

input 12V

(21)

Function start

--

input 5V

input 5V

24V

12V

5V

COM

input 5V

8

Operating

Input

(guaranteed

value)

When ON 21.6 to 26.4V 2 to 5mA

When OFF 5V or less 0.1mA or less

When ON 10.8 to 13.2V 2 to 5mA

When OFF 4V or less 0.1mA or less

When ON 4.5 to 5.5V 2 to 5mA

When OFF 2V or less 0.1mA or less

When ON 21.6 to 26.4V 2 to 5mA

When OFF 5V or less 0.1mA or less

When ON 10.8 to 13.2V 2 to 5mA

When OFF 4V or less 0.1mA or less

When ON 4.5 to 5.5V 2 to 5mA

When OFF 2V or less 0.1mA or less

When ON 21.6 to 26.4V 2 to 5mA

When OFF 5V or less 0.1mA or less

When ON 10.8 to 13.2V 2 to 5mA

When OFF 4V or less 0.1mA or less

When ON 4.5 to 5.5V 2 to 5mA

When OFF 2V or less 0.1mA or less

Response

When ON 21.6 to 26.4V 2 to 5mA

When OFF 5V or less 0.1mA or less

When ON 10.8 to 13.2V 2 to 5mA

When OFF 4V or less 0.1mA or less

When ON 4.5 to 5.5V 2 to 5mA

When OFF 2V or less 0.1mA or less

Response

time

time

OFFON

0.5ms or less

OFFON

0.5ms or less

-

-

current

(guaranteed

value)

ONOFF

3ms or less

ONOFF

3m

s or less

Page 23

I/O

classify

-cation

Output

Internal Circuit

Terminal

number*1Signal Name Operation

22

(24)

23

(25)

26 12/24V

27 0V

Operating voltage :10.2 to 30V

EQU1

Rated current :0.5 A/point

Maximum inrush current: 4A 10 ms

Maximum voltage drop at ON: 1.5V

EQU2

Response time: OFFON 0.1 ms o r less

ONOFF 0.1 ms or less

Input voltage: 10.2 to 30V

Current consumption: 8mA (TYP 24VDC)

*1 Figure inside ( ) indicates the terminal number of channel 2.

Input

(guaranteed

value)

Operating

current

(guaranteed

value)

9

Page 24

(2) External device interfaces for AJ65BT-D62D

I/O

classify

-cation

Input

Output

Internal Circuit

5V

5V

510

4.7k

4.7k

510

4.7k

4.7k

1/3W

1/3W

1/3W

External input

voltage setting pin

1/3W

1/3W

1/3W

External

input

voltage

setting pin

For 5V

For 12V

For 24V

For 5V

For 12V

For 24V

Terminal

number*1Signal Name Operation

8

Phase A

(15)

pulse input

9

(16)

pulse input

10

(17)

pulse input

11

(18)

pulse input

Preset input

Preset input

12

(19)

Preset input

13

(20)

14

(21)

start input 5V

--

22

(24)

23

(25)

26 12/24V

27 0V

EIA Standard RS-422-A line receiver

(AM26C32 (manufactured by Texas

Instruments Japan Limited.) or equivalent)

Phase A

The specifications of line receiver are as

follows:

• VIT+ differential input ON voltage (H level

threshold voltage): 0.1V

• VIT- differential input OF F voltage (L level

Phase B

Phase B

Function

start input

Function

start input

Function

threshold voltage): -0.1V

• Vhys hysteresis voltage (VIT+ - VIT-):

60mV (A current type line driver cannot be

used.)

When ON 21.6 to 26.4V 2 to 5mA

24V

When OFF 5V or less 0.1m A or less

When ON 10.8 to 13.2V 2 to 5mA

12V

When OFF 4V or less 0.1m A or less

When ON 4.5 to 5.5V 2 to 5mA

5V

When OFF 2V or less 0.1m A or less

Response

COM

When ON 21.6 to 26.4V 2 to 5mA

When OFF 5V or less 0.1m A or less

24V

When ON 10.8 to 13.2V 2 to 5mA

When OFF 4V or less 0.1m A or less

12V

When ON 4.5 to 5.5V 2 to 5mA

When OFF 2V or less 0.1m A or less

Response

Operating voltage: 10.2 to 30V

EQU1

Rated current: 0.5A/point

Max. inrush current: 4A 10ms

Max. voltage drop at ON: 1.5V

EQU2

Response time: OFFON 0.1ms or less

ONOFF 0.1ms or less

Input voltage: 10.2 to 30V

Current consumption: 8mA (TYP 24VDC)

*1 Figure inside ( ) indicates the terminal number of channel 2.

time

time

Input

(guaranteed

value)

OFFON

0.5ms or less

OFFON

0.5ms or less

Operating

current

(guaranteed

value)

ONOFF

3ms or less

ONOFF

3ms or less

10

Page 25

(3) External device interfaces for AJ65BT-D62D-S1

I/O

classify

-cation

Internal Circuit

5V

5V

Input

Output

510Ω

4.7kΩ

4.7kΩ

5V

1/3W

1/3W

1/3W

External input

voltage setting pin

*1 Figure inside ( ) indicates the terminal number of channel 2.

For 5V

For 12V

For 24V

Terminal

number

*1

8

(16)

9

(17)

10

(18)

11

(19)

12

(20)

13

(21)

14

(22)

15

(23)

24

(25)

26 12/24V

27 0V

Signal

Operation

Name

Phase A

pulse input

Phase A

pulse input

EIA Standard RS-422-A line receiver

(AM26C32 (manufactured by Texas

Instruments Japan Limited.) or equivalent)

The specifications of line receiver are as

Phase B

follows:

pulse input

• VIT+ differential input ON voltage (H level

threshold voltage): 0.1V

• VIT- differential input O FF voltage (L level

Phase B

pulse input

Function

start input

Function

start input

Function

start input

threshold voltage): -0.1V

• Vhys hysteresis voltage (VIT+ - VIT-):

60mV (A current type line driver cannot be

used.)

Preset

input

Preset

input

When ON 21.6 to 26.4V 2 to 5mA

When OFF 5V or less 0.1mA or less

24V

When ON 10.8 to 13.2V 2 to 5mA

When OFF 4V or less 0.1mA or less

12V

When ON 4.5 to 5.5V 2 to 5mA

When OFF 2V or less 0.1mA or less

5V

Response

COM

time

Operating voltage: 10.2 to 30V

Rated current: 0.5 A/point

Maximum inrush current: 4A 10 ms

EQU1

Maximum voltage drop at ON: 1.5V

Response time: OFFON 0.1 ms or less

ONOFF 0.1 ms or less

Input voltage: 10.2 to 30V

Current consumption: 8mA (TYP 24VDC)

Input

(guaranteed

value)

OFFON

0.5ms or less

Operating

current

(guaranteed

value)

ONOFF

3ms or less

11

Page 26

3. PART IDENTIFICATION NOMENCLATURE AND

10

1

SETTINGS

This section shows the name of each part within the high-speed counter

module and explains how to set each switch. (The illustration below

indicates the AJ65BT-D62).

7) 6) 2) 1)

8) 3)4)

No. Name Description

Station number setting

1)

switch

Transmission baud

2)

rate setting switch

Used to set the transmission speed of the high-speed counter

module. (For data link)

Used to set the station number of the high-speed

counter module between 1 and 61.

(When shipped from the factory: 00)

Setting number Transmission baud rate

0 156kbps (factory set value)

1 625kbps

2 2.5Mbps

3 5Mbps

4 10Mbps

Other than 0 to 4

Not used

(When a number other than 0 to 4 is

used, the L ERR. LED lights up and

a communication error is

generated.)

9)

5)

12

Page 27

No. Name Description

Counting speed setting

3)

switch

Ring counter setting

4)

switch

5) Reset switch

6) LED display

LOW side: With Phase 1 input, up to 10kPPS and with Phase

HIGH side: With Phase 1 input, up to 400(200)kPPS and with

Set whether the ring counter function can be used.

• When ring counter used: ON side

• When ring counter not used: OFF side

Hardware reset

Initializes the remote register for the high-speed counter

module.

By turning the switch on, the initial data processing request flag

turns on.

Lit: power is on

PW

Unlit: power is off

Lit: operating normally

RUN

Unlit: 24V DC power supply is disconnected or WDT error

Lit: communication is normal

L RUN

Unlit: communication is disconnected (time over error)

SD SD: lit when data is being transmitted

RD RD: lit when data is being transmitted

On: Communication data error (CRC error)

Flashing at constant interval: Station number settings and

L ERR.

Flashing at non-constant

interval:

Off: Normal communication

2, up to 7kPPS can be counted.

Phase 2, up to 300(200)kPPS can be counted.

The figures in ( ) are for the AJ65BT-D62.

(When shipped from the factory: set at HIGH side)

(When shipped from the factory: set at OFF side)

baud rate settings are changed

during power supply.

Termination resistor is not

provided or the unit or the

dedicated cable for CC-Link is

subject to noise.

13

Page 28

No. Name Description

Lights up when voltage is being applied to the Phase A pulse

A

input terminal.

Lights up when voltage is being applied to the Phase B pulse

B

input terminal.

DEC Lights up during subtraction.

Lights up stays lit when voltage is being applied to the PRESET

terminal.

7) LED display

8) Terminal block

PRE

Turns off when the external preset detection reset command

rises.

Lights up when voltage is being applied to the F.START

F ST.

terminal.

Lights up when coincidence output set value No.1 = counter

EQU1

value.

Lights up when coincidence output set value No.2 = counter

EQU2

value. (This does not exist in the AJ65BT-D62D-S1 model.)

• For AJ65BT-D62

Pin

Number

Signal name

1DA15

2DB16

3SG17

4 SLD 18

5 24V 19 PRESET

6F.G.20 COM

7 24G 21 F.START

8

923EQU2

10

11 25 EQU2

CH1

12 PRESET 26 12/24V

13 COM 27 COM

14 F.START

Number

A

B

Pin

Signal name

A

B

CH2

22

24

CH1

CH2

EQU1

EQU1

14

Page 29

No. Name Description

• For AJ65BT-D62D

8) Terminal bl ock

Pin

Number

• For AJ65BT-D62D-S1

Pin

Number

Signal name

1DA15

2DB16 A

3SG17BB

4SLD18 B

5 24V 19 PRESET

6F.G.20 COM

7 24G 21 F.START

8

9A

10

11 B

12 PRESET 26 12/24V

13 COM 27 COM

14 F.START

1DA16

2DB17 A

3SG18BB

4SLD19 B

5 24V 20 PRESET

6 F.G. 21 PRESET

7 24G 22

8

9A

10

11 B

12 PRESET 27 COM

13 PRESET

14

15

CH1

Signal name

CH1

A

B

A

B

F.START

Number

A22

B24

Number

A23

B 25 CH2 EQU1

Pin

Pin

Signal name

A

CH2

EQU1

CH1

23 EQU2

25 EQU2

24 CH1 EQU1

26 12/24V

CH2

Signal name

CH2

EQU1

A

F.START

A

A

15

Page 30

No. Name Description

(When a jumper is connected to 24V)

(When a jumper is connected to 12V)

(When a jumper is connected to 5V)

Circuit board

Jumper

AJ65BT-D62

AJ65BT-D62D

AJ65BT-D62D-S1

This is the same for CH2.

Pulse/external input

9)

voltage setting pin

16

Page 31

4. LOADING AND INSTALLATION

4.1 Handling Precautions

(1) Do not drop or apply strong shock to the module case.

(2) Do not remove the module printed circuit board from the case.

This will cause a breakdown.

(3) Be careful not to let foreign matters such as fillings or wire chips

get inside the module. If these do get inside, remove them.

(4) Tighten the module installation screws within the following

tightening torque range.

Screw Tightening Torque Range

Module installation screws

(M4 screw)

Terminal block terminal screws

(M3.5 screw)

Module installation screws

(M4 screw)

(5) When using a DIN rail adapter, take note of the following points

when mounting the DIN rail.

(a) Applicable DIN rail type (JIS C 2812 compliant)

TH-35-7.5Fe

TH-35-7.5Al

TH-35-15Fe

(b) Screw spacing when mounting the DIN rail

When mounting the DIN rail, tighten the screws at a pitch of

200mm (7.84in.) or less.

0.78 to 1.18N•m

0.59 to 0.88N•m

0.78 to 1.18N•m

17

Page 32

4.2 Installation Environment

Do not install the A series programmable controller in the following

environment.

(1) Where the ambient temperature exceeds the 0 to 55°C range.

(2) Where the ambient humidity exceeds the 10 to 90% RH range.

(3) Where condensation is produced by sudden temperature changes.

(4) Where corrosive or combustible gas is present.

(5) Where dust, iron powder and other conductive powder, oil mist,

salt, or organic solvents are prevalent.

(6) In direct sunlight.

(7) Where a strong electric or magnetic field is generated.

(8) Where vibration and shock may be transmitted directly to the

module.

18

Page 33

5. WIRING

DA

DB

DG

SLD

FG

DA

DB

DG

SLD

FG

DA

DB

DG

SLD

FG

Master module

Terminal

resistor

Terminal

resistor

Remote moduleHigh-speed counter module

(Blue) (Blue) (Blue) (Blue)

CC-Link

dedicated cable

CC-Link

dedicated cable

(Yellow)

(White)

(Yellow)

(White)

(Yellow)

(White)

(Yellow)

(White)

This section explains the wiring for the high-speed counter module.

5.1 Wiring Method to Each Module

The following diagram shows the wiring of the master module, remote

module and high-speed counter module with dedicated cable for CCLink.

Point

Always connect the "terminal resistors" provided with the master module

to the modules at both ends of data link.

(Connect between DA and DB)

19

Page 34

5.2 Precautions When Wiring to the Pulse Generator

(1) Implement the following types of noise measures for high-speed

pulse input.

(a) Always use a twisted shielded wire and perform class 3

grounding.

(b) Do not run the twisted wire parallel to the power cord or I/O line

with a lot of noise. Secure a distance of 150mm (5.91in.) or

more and run the cable for the shortest distance possible.

(2) In the case of Phase 1 input, always wire to the Phase A side.

(3) The high-speed counter module counts up when a pulse-state

noise is input, resulting in a count error.

(4) Wiring for noise measure is indicated below.

Highspeed

counter

module

Inverter

Terminal

block

Terminal

block

*1

For a strong power device

such as an inverter, leave a

distance of 150mm (5.91in.)

or more from the I/O line

(Also be careful of the

wiring inside the panel.)

EWV

Joint box

*2

AC motor

Carrier

Encoder

*1 When using metal piping, avoid intermingling solenoid valves and inductive loads in the

same piping. Also, if an isolation distance from a strong power line such as duct wiring

cannot be secured, use a CVVS or other shielded cable for the strong power line.

20

Page 35

*2 Make the distance from the encoder to the joint box short. When there is long distance from

the high-speed counter module to the encoder, voltage drops will occur. Therefore, use a

measuring device such as a tester on the joint box terminal block to check whether the

voltage while the encoder is operating and at a standstill is within the rated voltage for the

encoder. If the drop in voltage is large, make the cable size thicker or use a 24V DC type

encoder with small current consumption.

• Grounding for the twisted, shielded cable is done on the encoder side (in the joint

box). (The following is an example of a connection for a 24V sink load.)

+24V

Current for the encoder

To A

To B

To the high-speed

counter module

The shielded cable for the encoder and that for the twisted cable

are connected inside the joint box. If the shielded cable for the

encoder is not grounded inside the encoder, then perform

grounding inside the joint box as shown by the dotted line.

0V

24V

E

A

B

To the encoder

E

21

Page 36

5.3 Example of Wiring for the Pulse Generator

(1) Example of wiring to an open collector output type pulse generator

(24V DC)

AJ65BT-D62

510

4.7k

4.7k

510

4.7k

4.7k

*Set the pulse input voltage setting pin to the side.

Pulse input

1/3W

voltage setting pin*

1/3W

1/3W

A

Shielded twisted

pair cable

A

Pulse input

1/3W

voltage setting pin*

1/3W

1/3W

24VDC

External

power supply

0V

B

B

Shielded twisted

pair cable

Point

The wiring between the AJ65BT-D62 and the encoder should be separate

from the power supply line and signal line.

• An example is shown below.

AJ65BT-D62

A

A

External

+

power

-

supply

• An example of wiring to be avoided.

AJ65BT-D62

A

A

External

+

power

-

supply

Shield

Shield

Pulse generator

OUT

24V

E

OUT

24V

E

24V

0V

OUT

24V

Encoder

0V

E

OUT

24V

Encoder

0V

E

22

Page 37

(2) Example of wiring to a voltage output type pulse generator (5V DC)

AJ65BT-D62

510

4.7k

4.7k

510

4.7k

4.7k

*Set the pulse input voltage setting pin to the side.

1/3W

1/3W

1/3W

1/3W

1/3W

1/3W

External

power

supply

Pulse input

voltage

setting pin*

Pulse input

voltage

setting pin*

5VDC

0V

A

A

B

B

Shielded twisted

Shielded twisted

(3) Example of wiring to the pulse generator for a line driver

(AM26LS31 or equivalent)

AJ65BT-D62D

Shielded twisted pair cable

A

A

Shielded twisted pair cable

B

B

pair cable

pair cable

Pulse generator

OUT

GND

E

OUT

GND

E

5VDC

0V

Pulse generator

A

A

E

B

B

E

External

VCC

power

GND GND

supply

23

VCC

Page 38

AJ65BT-D62D-S1

14050

14050

A

A

B

B

PRESET

PRESET

Shielded twisted

pair cable

Shielded twisted

pair cable

Shielded twisted

pair cable

Pulse generator

A

A

E

B

B

E

Z

Z

E

External

power

supply

VCC

GND

VCC

GND

24

Page 39

5.4 Example of Wiring Between a Control Device and External Input Terminals (PRESET, F.START)

(1) When the control device (sink load type) is 12V

AJ65BT-D62, AJ65BT-D62D, AJ65BT-D62D-S1

510

4.7k

4.7k

Internal circuit is set to PRESET.

AJ65BT-D62D-S1 has F.START only.

*Set the external input voltage setting pin to the side.

(2) When the control device (source load type) is 5V

AJ65BT-D62, AJ65BT-D62D, AJ65BT-D62D-S1

510Ω

4.7kΩ

4.7kΩ

• Internal circuit is set to PRESET.

• AJ65BT-D62D-S1 has F.START only.

* Set the external input voltage setting pin to the side.

CAUTION

External

input voltage

1/3W

setting pin*

1/3W

1/3W

PRESET or F.START

Shielded twisted

pair cable

COM

External

1/3W

1/3W

1/3W

input

voltage

setting pin*

PRESET or F.START

Shielded twisted

pair cable

Controller

COM

• Set the pulse/external input voltage setting pin correctly after confirming the

rated voltage for the external power supply.

If there is a fault in the wiring (setting mistake), fire or breakdown can be

caused.

• Always set the pulse/external input voltage setting pin after shutting down all

phases of the power supply externally.

If all phases are not shut down, this will cause a breakdown of the module or

an error in operation.

• Make sure the insertion direction of the jumper for the pulse/ external-input

voltage setting pin is correct.

Incorrect insertion direction may cause the module to breakdown.

Controller

12VDC

E

5VDC

E

Jumper

Jumper

<Incorrect><Correct>

25

Page 40

5.5 Example of Wiring to the External Output Terminals (EQU1 to EQU2)

When using an EQU terminal, an external power supply in the range of

10.2V DC to 30V DC is needed to operate the internal photocoupler.

Run the wires as shown below.

(1) AJ65BT-D62, AJ65BT-D62D

AJ65BT-D62, AJ65BT-D62D

EQU1

Load

(2) AJ65BT-D62D-S1

AJ65BT-D62D-S1

Point

Even when not using an EQU terminal, wire the 12/24V terminal (pin

number: 26) and the COM terminal (pin number: 27) to an external power

supply.

If they are not wired, SW0088 to SW008B (fuse blown status) of the

master module would be on.

EQU2

12/24V

COM

EQU1

12/24V

COM

26

Load

10.2V to 30V

Load

10.2V to 30V

Page 41

6. EXTERNAL DIMENSIONS

9.5

(0.37)

63 (2.48)

2- 4.5 mounting hole

56 (2.2)

65 (2.56)

142.9 (5.63)

151.9 (5.98)

(Unit: mm (in.))

7. Information for the Chinese Standardized Low

27

Page 42

Memo29Memo

28

Page 43

Page 44

WARRANTY

Mitsubishi will not be held liable for damage caused by factors found not to be the cause of

Mitsubishi; machine damage or lost profits caused by faults in the Mitsubishi products; damage,

secondary damage, accident compensation caused by special factors unpredictable by

Mitsubishi; damages to products other than Mitsubishi products; and to other duties.

Country/

Sales office/

Region

Tel

USA MITSUBISHI ELECTRIC AUTOMATION, INC.

500 Corporate Woods Parkway, Vernon Hills, IL

60061, U.S.A.

Tel : +1-847-478-2100

Mexico MITSUBISHI ELECTRIC AUTOMATION, INC.

Mexico Branch

Mariano Escobedo #69, Col. Zona Industrial,

Tlalnepantla Edo. Mexico, C.P.54030

Tel : +52-55-3067-7500

Brazil MITSUBISHI ELECTRIC DO BRASIL COMÉRCIO

E SERVIÇOS LTDA.

Avenida Adelino Cardana, 293, 21 andar,

Bethaville, Barueri SP, Brazil

Tel : +55-11-4689-3000

Germany MITSUBISHI ELECTRIC EUROPE B.V. German

Branch

Mitsubishi-Electric-Platz 1, 40882 Ratingen,

Germany

Tel : +49-2102-486-0

UK MITSUBISHI ELECTRIC EUROPE B.V. UK Branch

Travellers Lane, Hatfield, Hertfordshire, AL10 8XB,

U.K.

Tel : +44-1707-28-8780

Ireland MITSUBISHI ELECTRIC EUROPE B.V. Irish

Branch

Westgate Business Park, Ballymount, Dublin 24,

Ireland

Tel : +353-1-4198800

Italy MITSUBISHI ELECTRIC EUROPE B.V. Italian

Branch

Centro Direzionale Colleoni-Palazzo Sirio Viale

Colleoni 7, 20864 Agrate Brianza(Milano) Italy

Tel : +39-039-60531

Spain MITSUBISHI ELECTRIC EUROPE, B.V. Spanish

Branch

Carretera de Rubí, 76-80-Apdo. 420, 08190 Sant

Cugat del Vallés (Barcelona), Spain

Tel : +34-935-65-3131

France MITSUBISHI ELECTRIC EUROPE B.V. French

Branch

25, Boulevard des Bouvets, 92741 Nanterre Cedex,

France

Tel : +33-1-55-68-55-68

Czech

MITSUBISHI ELECTRIC EUROPE B.V. Czech

Republic

Branch

Avenir Business Park, Radlicka 751/113e, 158 00

Praha5, Czech Republic

Tel : +420-251-551-470

Poland MITSUBISHI ELECTRIC EUROPE B.V. Polish

Branch

ul. Krakowska 50, 32-083 Balice, Poland

Tel : +48-12-347-65-00

MITSUBISHI ELECTRIC EUROPE B.V.

Sweden

(Scandinavia)

Fjelievägen 8, SE-22736 Lund, Sweden

Tel : +46-8-625-10-00

Russia MITSUBISHI ELECTRIC (RUSSIA) LLC St.

Petersburg Branch

Piskarevsky pr. 2, bld 2, lit “Sch”, BC “Benua”, office

720; 195027 St. Petersburg, Russia

Tel : +7-812-633-3497

HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

NAGOYA WORKS : 1-14, YADA-MINAMI 5-CHOME, HIGASHI-KU, NAGOYA, JAPAN

When exported from Japan, this manual does not require application to the Ministry of Economy,

Trade and Industry for service transaction permission.

Sales office/

Country/

Tel

Region

MITSUBISHI ELECTRIC TURKEY A.Ş Ümraniye

Turkey

Branch

Serifali Mahallesi Nutuk Sokak No:5, TR-34775

Umraniye/Istanbul, Turkey

Tel : +90-216-526-3990

MITSUBISHI ELECTRIC EUROPE B.V. Dubai

UAE

Branch

Dubai Silicon Oasis, P.O.BOX 341241, Dubai,

U.A.E.

Tel : +971-4-3724716

ADROIT TECHNOLOGIES

South

20 Waterford Office Park, 189 Witkoppen Road,

Africa

Fourways, South Africa

Tel : +27-11-658-8100

MITSUBISHI ELECTRIC AUTOMATION (CHINA)

China

LTD.

No.1386 Hongqiao Road, Mitsubishi Electric

Automation Center, Shanghai, China

Tel : +86-21-2322-3030

SETSUYO ENTERPRISE CO., LTD.

Taiwan

6F, No.105, Wugong 3rd Road, Wugu District, New

Taipei City 24889, Taiwan

Tel : +886-2-2299-2499

MITSUBISHI ELECTRIC AUTOMATION KOREA

Korea

CO., LTD.

7F-9F, Gangseo Hangang Xi-tower A, 401,

Yangcheon-ro, Gangseo-Gu, Seoul 07528, Korea

Tel : +82-2-3660-9530

Singapore

MITSUBISHI ELECTRIC ASIA PTE. LTD.

307, Alexandra Road, Mitsubishi Electric Building,

Singapore 159943

Tel : +65-6473-2308

Thailand

MITSUBISHI ELECTRIC FACTORY AUTOMATION

(THAILAND) CO., LTD.

12th Floor, SV.City Building, Office Tower 1, No.

896/19 and 20 Rama 3 Road,

Kwaeng Bangpongpang, Khet Yannawa, Bangkok

10120, Thailand

Tel : +66-2682-6522

Vietnam

MITSUBISHI ELECTRIC VIETNAM COMPANY

LIMITED Hanoi Branch

6th Floor, Detech Tower, 8 Ton That Thuyet Street,

My Dinh 2 Ward, Nam Tu Liem District, Hanoi,

Vietnam

Tel : +84-4-3937-8075

Indonesia

PT. MITSUBISHI ELECTRIC INDONESIA

Gedung Jaya 11th Floor, JL. MH. Thamrin No.12,

Jakarta Pusat 10340, Indonesia

Tel : +62-21-3192-6461

India

MITSUBISHI ELECTRIC INDIA PVT. LTD. Pune

Branch

Emerald House, EL-3, J Block, M.I.D.C., Bhosari,

Pune-411026, Maharashtra, India

Tel : +91-20-2710-2000

Australia MITSUBISHI ELECTRIC AUSTRALIA PTY. LTD.

348 Victoria Road, P.O. Box 11, Rydalmere, N.S.W

2116, Australia

Tel : +61-2-9684-7777

Specifications subject to change without notice.

Loading...

Loading...