Page 1

Pt 100 Temperature Input Module Type AJ65BT64RD3/AJ65BT-64RD4 User's Manual

Page 2

Page 3

SAFETY PRECAUTIONS

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full

attention to safety to handle the product correctly.

These precautions apply only to Mitsubishi equipment. Refer to the user's manual of the used CPU

module for a description of the programmable controller system safety precautions.

In this manual, the safety precautions are classified into two levels: "

WARNING" and " CAUTION".

WARNING

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

CAUTION

resulting in minor or moderate injury or property damage.

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

[Design Precautions]

WARNING

z In the case of a communication failure in the network, data in the master module are held.

Check the communication status information (SB, SW) and configure an interlock circuit in the sequence

program to ensure that the entire system will operate safely.

CAUTION

z Do not install the control lines or communication cables together with the main circuit lines or power cables.

Keep a distance of 100mm (3.94 inches) or more between them.

Failure to do so may result in malfunction due to noise.

Page 4

[Installation Precautions]

CAUTION

z Use the programmable controller in an environment that meets the general specifications in this manual.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the product.

z For protection of the switches, do not remove the cushioning material before installation.

z Securely fix the module with a DIN rail or mounting screws. Tighten the screws within the specified torque

range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

z Do not directly touch any conductive part of the module.

Doing so can cause malfunction or failure of the module.

[Wiring Precautions]

CAUTION

z Shut off the external power supply for the system in all phases before wiring.

Failure to do so may result in damage to the product.

z After installation or wiring, attach the included terminal cover to the module before turning it on for operation.

Undertightening can cause short circuit or malfunction.

z Ground the FG terminals to the protective ground conductor dedicated to the programmable controller.

Failure to do so may result in malfunction.

z Use applicable solderless terminals and tighten them within the specified torque range.

If any spade solderless terminal is used, it may be disconnected when the terminal screw comes loose,

resulting in failure.

z Check the rated voltage and terminal layout before wiring to the module, and connect the cables correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or failure.

z Tighten the terminal screw within the specified torque range.

Undertightening can cause short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

z Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

z Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or cables or

malfunction due to poor contact.

Page 5

[Wiring Precautions]

CAUTION

z Do not install the control lines or communication cables together with the main circuit lines or power cables.

Failure to do so may result in malfunction due to noise.

z When disconnecting the cable from the module, do not pull the cable by the cable part.

Loosen the screws of connector before disconnecting the cable.

Failure to do so may result in damage to the module or cable or malfunction due to poor contact.

[Startup and Maintenance Precautions]

CAUTION

z Do not touch any terminal while power is on.

Doing so may cause malfunction.

z Shut off the external power supply for the system in all phases before cleaning the module or retightening

the terminal screws.

Failure to do so may cause the module to fail or malfunction.

Undertightening the terminal screws can cause short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

z Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

z Do not drop or apply strong shock to the module.

Doing so may damage the module.

z After the first use of the product, do not mount/remove the terminal block to/from the module more than 50

times. (IEC 61131-2 compliant)

z Shut off the external power supply for the system in all phases before mounting or removing the module to

or from the panel.

Failure to do so may cause the module to fail or malfunction.

z Do not remove or change the platinum temperature-measuring resistor designation pin while energizing the

module.

If a platinum temperature-measuring resistor designation pin is removed or changed while energizing, it may

cause failure or malfunction.

z Before handling the module, touch a grounded metal object to discharge the static electricity from the

human body.

Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

z When disposing of this product, treat it as an industrial waste.

Page 6

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED

TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION

NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING

CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

y Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

y Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

y Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

Page 7

Revisions

* The manual number is noted at the lower left of the back cover.

Print Date *Manual Number Revision

May., 1998 SH(NA)-4001-A First printing

Oct., 2004 SH(NA)-4001-B Partial correction

SAFETY PRECAUTIONS,

Chapter 1, Section 2.1, 2.2, 3.1, 3.2, 3.2.2, 3.3.1, 3.3.4, 3.4.1, 3.4.2, 3.5.1,

Section 4.1, 4.2, 4.3, 4.5, 4.7.1, 4.7.2, Chapter 5, Section 5.1, 5.2, 6.1,

Addition

Conformation to the EMC Directive and Low Voltage Instruction, About

Manual, About the Generic Terms and Abbreviations, Product Structure,

Section 5.3, 5.4, 5.5, 5.6, WARRANTY

Deletion

Chapter 3, Section 5.2.1,

Jul., 2005 SH(NA)-4001-C Partial correction

SAFETY PRECAUTIONS

Dec., 2006 SH(NA)-4001-D Partial correction

SAFETY PRECAUTIONS, Section 2.1, 3.2, 3.6.1, 3.7.4, 4.1

Dec., 2010 SH(NA)-4001-E Partial correction

SAFETY PRECAUTIONS, Compliance with the EMC and Low Voltage

Directives, About Generic Terms and Abbreviations, Chapter 1, Section 2.1,

2.2, 3.1, 3.2, 3.2.2, 3.4.1, 4.2, 4.7.4, 5.2, 5.3, 5.6, 6.1, 6.4

Addition

CONDITIONS OF USE FOR THE PRODUCT

Deletion

Section 4.7.1

Renumbering

Section 4.7.2 to 4.7.5 → 4.7.1 to 4.7.4

Japanese Manual Version SH-3652-G

This manual does not imply guarantee or implementation right for industrial ownership or implementation

of other rights. Mitsubishi Electric Corporation is not responsible for industrial ownership problems caused

by use of the contents of this manual.

© 1998 Mitsubishi Electric Corporation

Page 8

Introduction

Thank you for purchasing the Mitsubishi Graphic Operation Terminal.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions and

performance of the graphic operation terminal you have purchased, so as to ensure correct use.

Please forward a copy of this manual to the end user.

Table of Contents

1. OVERVIEW 1-1 to 1-1

1.1 Features............................................................................................................................................................ 1- 1

2. SYSTEM CONFIGURATION 2-1 to 2-2

2.1 Overall Configuration ........................................................................................................................................ 2- 1

2.2 Applicable Systems........................................................................................................................................... 2- 2

3. SPECIFICATIONS 3-1 to 3-15

3.1 General Specification........................................................................................................................................ 3- 1

3.2 Performance Specification ................................................................................................................................ 3- 2

3.2.1 Specifications when connecting to a platinum temperature-measuring resistor.................................... 3- 3

3.2.2 Data link processing time....................................................................................................................... 3- 4

3.3 Function ............................................................................................................................................................ 3- 5

3.3.1 Function list............................................................................................................................................ 3- 5

3.3.2 Conversion enable/disable designation................................................................................................. 3- 6

3.3.3 Sampling processing/travel average processing designation................................................................ 3- 7

3.3.4 Wire breakage detection........................................................................................................................ 3- 9

3.3.5 Detected temperature ............................................................................................................................ 3-10

3.3.6 Designating the platinum temperature-measuring resistor type ............................................................ 3-10

3.4 I/O Signals in Respect to the Master Module.................................................................................................... 3-11

3.4.1 Remote I/O signal list............................................................................................................................. 3-11

3.4.2 I/O signal functions ................................................................................................................................ 3-12

3.5 Remote Register ............................................................................................................................................... 3-14

3.5.1 Remote register assignment.................................................................................................................. 3-14

3.5.2 Remote register for storing detected temperature (Address: RWrn to RWrn+11)................................. 3-15

4. SETTING AND PROCEDURE BEFORE OPERATION 4-1 to 4-12

4.1 Procedure before Operation .............................................................................................................................4- 1

4.2 Handling Precautions........................................................................................................................................ 4- 2

4.3 Part Identification and Setting ........................................................................................................................... 4- 3

4.4 Error Compensation by the Offset Value/Gain Value Setting ........................................................................... 4- 5

4.4.1 Initial settings for error compensation.................................................................................................... 4- 7

4.4.2 Error compensation procedure .............................................................................................................. 4- 8

4.5 Station Number Setting..................................................................................................................................... 4- 9

4.6 Orientation of Module Installation .....................................................................................................................4- 9

Page 9

4.7 Wiring................................................................................................................................................................ 4-10

4.7.1 Wiring example with CC-Link modules .................................................................................................. 4-10

4.7.2 Precautions when wiring to a platinum temperature-measuring resistor ............................................... 4-11

4.7.3 Connecting AJ65BT-64RD3 and platinum temperature-measuring resistor.......................................... 4-11

4.7.4 Connecting AJ65BT-64RD and platinum temperature-measuring resistor............................................ 4-12

5. PROGRAMMING 5-1 to 5-17

5.1 Programming Procedure................................................................................................................................... 5- 1

5.2 Program Example Conditions ........................................................................................................................... 5- 2

5.3 Program Examples when QCPU (Q Mode) Is Used ......................................................................................... 5- 5

5.4 Program Examples when QnACPU Is Used ..................................................................................................... 5-11

5.5 Program Example when ACPU/QCPU (A Mode) Is Used (Dedicated Instructions).......................................... 5-13

5.6 Program Example when ACPU/QCPU (A Mode) Is Used (FROM/TO Instructions).......................................... 5-16

6. TROUBLESHOOTING 6-1 to 6-5

6.1 Cause of Errors and Corrective Actions by LED Indication...............................................................................6- 1

6.2 When Wire Breakage Detection Flag is On ...................................................................................................... 6- 3

6.3 When E2PROM Error Flag is On....................................................................................................................... 6- 3

6.4 When Detected Temperature Value cannot be Read ....................................................................................... 6- 3

6.5 When Detected Temperature Value is Abnormal .............................................................................................6- 3

6.6 When There is a Communication Error between Master Station and AJ65BT-64RD....................................... 6- 4

APPENDIX A-1 to A-2

Appendix 1 Standard Thermal Electromotive Force of Platinum Temperature-Measuring Resistor .....................A- 1

Appendix 1.1 New JIS⋅IEC type (Pt100)....................................................................................................... A- 1

Appendix 1.2 Old JIS type (JPt100).............................................................................................................. A- 1

Appendix 2 External Dimensions Diagram ............................................................................................................A- 2

Page 10

About This Manual

The following are manuals related to this product.

Request for the manuals as needed according to the chart below.

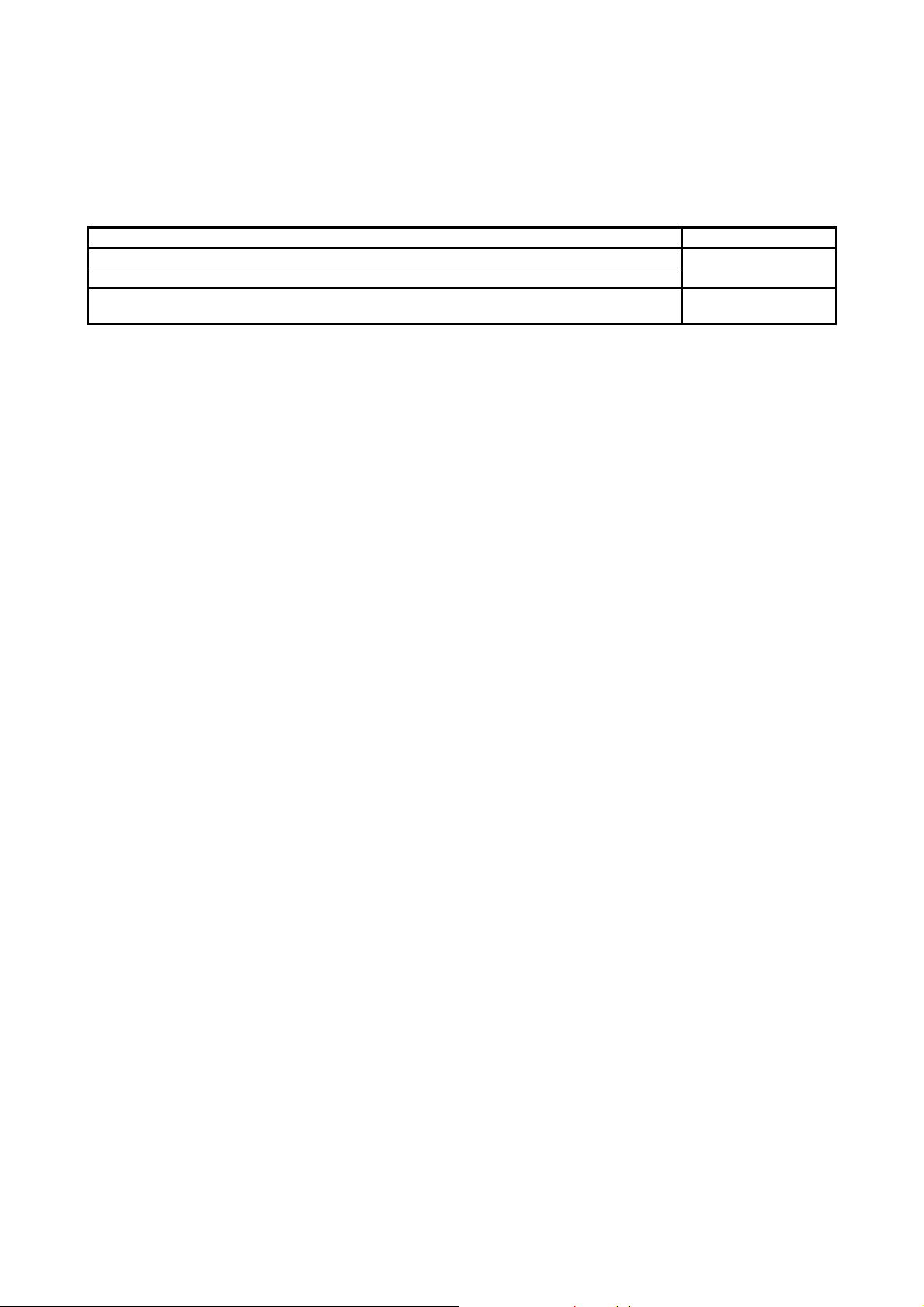

Related Manuals

Manual Name

CC-Link System Master/Local Module Type AJ61BT11/A1SJ61BT11 User's Manual

Describes the system configuration, performance specifications, functions, handling, wiring and

troubleshooting of the AJ61BT11 and A1SJ61BT11. (Sold separately)

CC-Link System Master/Local Module Type AJ61QBT11/A1SJ61QBT11 User's Manual

Describes the system configuration, performance specifications, functions, handling, wiring and

troubleshooting of the AJ61QBT11 and A1SJ61QBT11. (Sold separately)

CC-Link System Master/Local Module User's Manual

Describes the system configuration, performance specifications, functions, handling, wiring and

troubleshooting of the QJ61BT11N. (Sold separately)

Programming Manual type AnSHCPU/AnACPU/AnUCPU/QCPU-A (A Mode) (Dedicated

Instructions)

Explains the instructions extended for the AnSHCPU/AnACPU/AnUCPU/QCPU-A (A Mode).

(Sold separately)

MELSEC-L CC-Link System Master/Local Module User's Manual

Describes the system configuration, Performance specifications, functions, handling, wiring and

troubleshooting of the L26CPU-BT and LJ61BT11. (Sold separately)

Compliance with the EMC and Low Voltage Directives

Manual Number

(Model Code)

IB-66721

(13J872)

IB-66722

(13J873)

SH-080394E

(13JR64)

IB-66251

(13J742)

SH-080895ENG

(13JZ41)

(1) For programmable controller system

To configure a system meeting the requirements of the EMC and Low Voltage

Directives when incorporating the Mitsubishi programmable controller (EMC and

Low Voltage Directives compliant) into other machinery or equipment, refer to the

"EMC AND LOW VOLTAGE DIRECTIVES" chapter of the User's Manual for the

CPU module used.

The CE mark, indicating compliance with the EMC and Low Voltage Directives, is

printed on the rating plate of the programmable controller.

(2) For the product

For the compliance of this product with the EMC and Low Voltage Directives,

refer to the "CC-Link module" section in the "EMC AND LOW VOLTAGE

DIRECTIVES" chapter of the User's Manual for the CPU module used.

Page 11

About Generic Terms and Abbreviations

Unless otherwise specified, this manual uses the following generic terms and abbreviations to

explain the AJ65BT-64RD3/AJ65BT-64RD4 platinum temperature-measuring resistor Pt100

temperature input module.

Generic Term/

Abbreviation

GX Developer

GX Works2

ACPU Generic term for A0J2CPU, A0J2HCPU, A1CPU, A2CPU, A2CPU-S1, A3CPU, A1SCPU, A1SCPUC24-R2,

QnACPU Generic term for Q2ACPU, Q2ACPU-S1, Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU, Q2ASHCPU-S1, Q3ACPU,

QCPU (A mode) Generic term for Q02CPU-A, Q02HCPU-A and Q06HCPU-A.

QCPU (Q mode) Generic term for Q00JCPU, Q00CPU, Q01CPU, Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, Q25HCPU,

LCPU Generic term for L02CPU, L26CPU-BT.

Master station Station that controls a data link system.

Local station Station that has a programmable controller CPU and can communicate with the master station and other local

Remote I/O station Station that handles only bit unit information. (Input/output from/to external device)

Remote device station Station that handles bit unit information and word unit information. (Input/output from/to external device, analog

Remote station Generic term for remote I/O station and remote device station. Controlled by the master station.

Intelligent device station Station that can perform transient transmission, e.g. AJ65BT-R2. (Local station included)

Master module Generic term for modules that can be used as the master station.

SB Link special relay (for CC-Link)

SW Link special register (for CC-Link)

RX Remote input (for CC-Link)

RY Remote output (for CC-Link)

RWw Remote register (write area for CC-Link)

RWr Remote register (read area for CC-Link)

Product name of the software package for the MELSEC programmable controllers.

A1SHCPU, A1SJCPU, A1SJCPU-S3, A1SJHCPU, A1NCPU, A2NCPU, A2NCPU-S1, A3NCPU, A3MCPU,

A3HCPU, A2SCPU, A2SHCPU, A2ACPU, A2ACPU-S1, A3ACPU, A2UCPU, A2UCPU-S1, A2USCPU,

A2USCPU-S1, A2USHCPU-S1, A3UCPU and A4UCPU.

Q4APU and Q4ARCPU.

Q02PHCPU, Q06PHCPU, Q12PHCPU, Q25PHCPU, Q12PRHCPU, Q25PRHCPU,

Q00UJCPU,Q00UCPU,Q01UCPU,Q02UCPU, Q03UDCPU, Q04UDHCPU, Q06UDHCPU,

Q10UDHCPU,Q13UDHCPU, Q20UDHCPU,Q26UDHCPU, Q03UDECPU, Q04UDEHCPU, Q06UDEHCPU,

Q10UDEHCPU, Q13UDEHCPU, Q20UDEHCPU, Q26UDEHCPU,Q50UDEHCPU and Q100UDEHCPU.

One station is required for one system.

stations.

(AJ65BTB1-16D, AJ65SBTB1-16D, etc.)

data conversion)

Bit unit information that indicates the module operation status or data link status of the master station/local

station. Represented as SB for convenience.

16-bit unit information that indicates the module operation status or data link status of the master station/local

station. Represented as SW for convenience.

Information input from a remote station to the master station in bit unit. Represented as RX for convenience.

Information output from the master station to a remote station in bit unit. Represented as RY for convenience.

Information output from the master station to a remote device station in 16-bit unit. Represented as RWw for

convenience.

Information input from a remote device station to the master station in 16-bit unit. Represented as RWr for

convenience.

Description

Page 12

Packing List

This product consists of the following items.

Product name Quantity

AJ65BT-64RD3 platinum temperature-measuring resistor Pt100 temperature input module 1

AJ65BT-64RD4 platinum temperature-measuring resistor Pt100 temperature input module

AJ65BT-64RD3/AJ65BT-64RD4 platinum temperature-measuring resistor Pt100 temperature input module

user's manual (hardware)

1

Page 13

MEMO

Page 14

1. OVERVIEW MELSEC-A

1. OVERVIEW

This user's manual explains the specifications, part identification and wiring for the products listed

below, which are used as remote device stations for the CC-Link system:

The AJ65BT-64RD3 is a 3-wire system connecting module for the platinum temperature-measuring

resistor.

The AJ65BT-64RD4 is a 4-wire system connecting module for the platinum temperature-measuring

resistor.

(Hereinafter, the AJ65BT-64RD3 and AJ65BT-64RD4 will be collectively referred to as AJ65BT-64RD.)

The AJ65BT-64RD converts temperature data input from platinum temperature-measuring resistor Pt

100 (abbreviated as Pt 100 from here on) or platinum temperature-measuring resistor JPt 100

(abbreviated as JPt 100 from here on) to 16-bit signed BIN data (up to the first decimal place), or 32bit signed BIN data (up to the third decimal place).

1.1 Features

The following describes the features of AJ65BT-64RD.

(1) Stores temperature data

By directly connecting the old JIS or new JIS IEC type platinum temperature-measuring resistor

to AJ65BT-64RD, temperature data [°C] may be received as digital values.

For the detected temperature, values to the first place and third place below decimal point are

stored in the remote register.

(2) Conversion is possible at four channels per module.

Conversion of temperatures into digital values can be carried out at four channels in a single

AJ65BT-64RD module.

Also, the conversion enable/disable can be specified for individual channels.

(3) Designation of sampling processing and travel average processing

As a conversion method, either sampling processing or travel averaging processing can be

selected for each channel.

(4) Wire breakage detection is possible at individual channels.

The wire breakage of platinum temperature-measuring resistor or cable can be detected for each

channel.

(5) High overall accuracy

High-accuracy temperature detection is feasible with a tolerance of ±0.25 % of the full scale in

overall accuracy for normal temperature detection, and ±0.1 % of the full scale when the ambient

temperature is in the normal temperature range (25 °C ±5 °C).

1-1

Page 15

2. SYSTEM CONFIGURATION MELSEC-A

2. SYSTEM CONFIGURATION

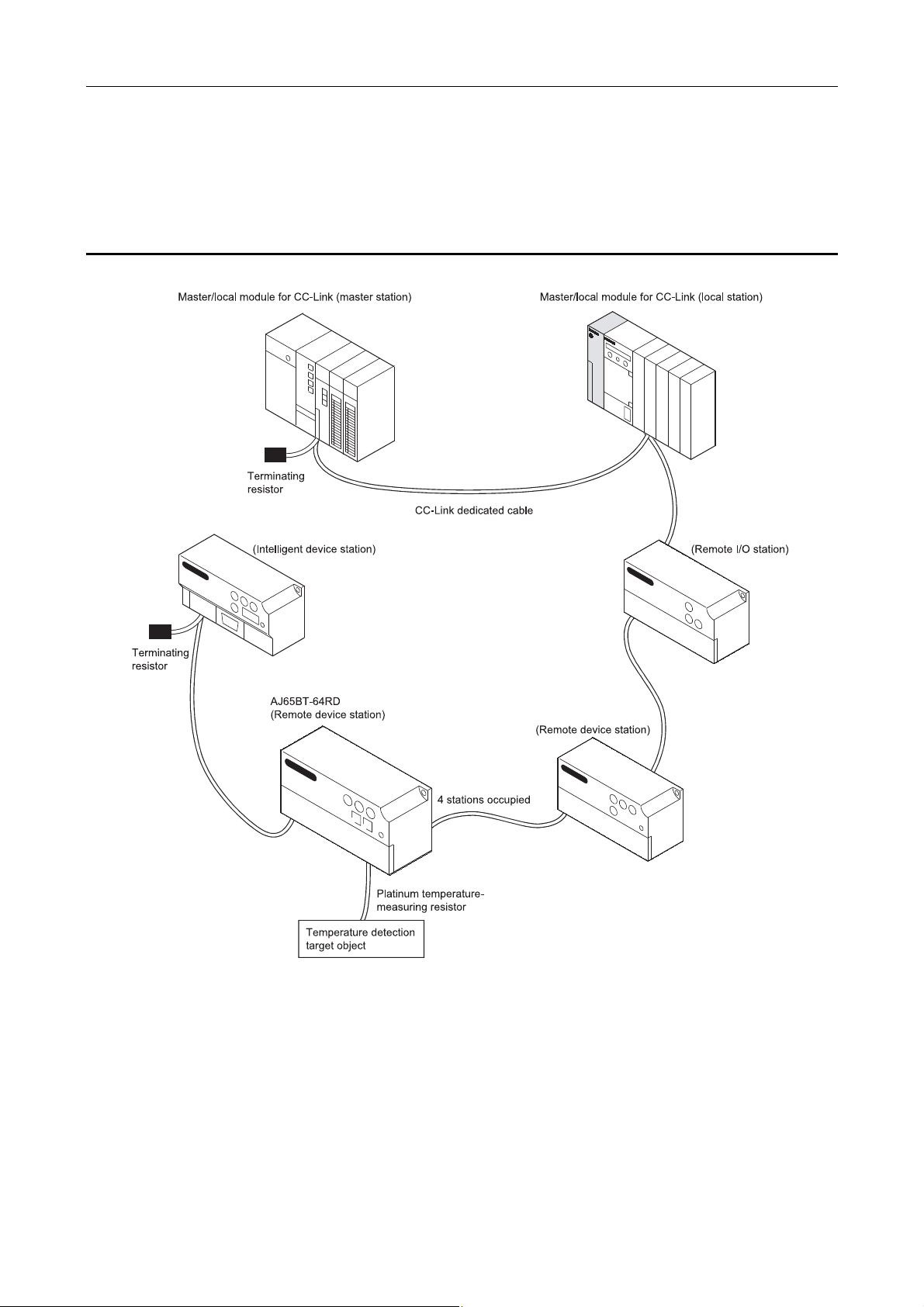

System configuration when using the AJ65BT-64RD is explained below.

2.1 Overall Configuration

The overall configuration when using the AJ65BT-64RD is shown below.

2-1

Page 16

2. SYSTEM CONFIGURATION MELSEC-A

2.2 Applicable Systems

This section explains applicable systems.

(1) Applicable master modules

For available master modules, visit the CC-Link Partner Association (CLPA) website at:

http://www.cc-link.org/

REMARK

Check the specifications of the master module before use.

POINT

When using the AJ61BT11, A1SJ61BT11, AJ61QBT11 or A1SJ61QBT11, use the one where the

following number (9707 B or later) is indicated in the DATE column of the rating plate.

The module where "9707 B" is not indicated in the DATE column cannot be used.

<Large type>

<Small type>

MITSUBISHI

PROGRAMMABLE CONTROLLER

DATE 9707 B

MITSUBISHI ELECTRIC CORP ORATION JAPAN

Date of

manufacture

Function

version

BD992D008H40

CPU UNIT

MODEL

DATE

9707 B

MITSUBISHI ELECTRIC BD992D008H40

Date of

manufacture

Function

version

(2) Restrictions on use of CC-Link dedicated instructions (RLPA, RRPA)

The CC-Link dedicated instructions (RLPA, RRPA) may be inapplicable depending on the used

programmable controller CPU and master module.

For details of the restrictions, refer to the A series master module user's manual (details) or

AnSHCPU/AnACPU/AnUCPU/QCPU-A (A mode) programming manual (dedicated instructions).

The AJ65BT-64RD accepts only the dedicated instructions RLPA and RRPA.

Refer to Section 5.5 for a program example that uses the dedicated instructions (RLPA, RRPA).

2-2

Page 17

3. SPECIFICATIONS MELSEC-A

3. SPECIFICATIONS

This section explains the AJ65BT-64RD the general specifications, performance specifications, and

transmission specifications.

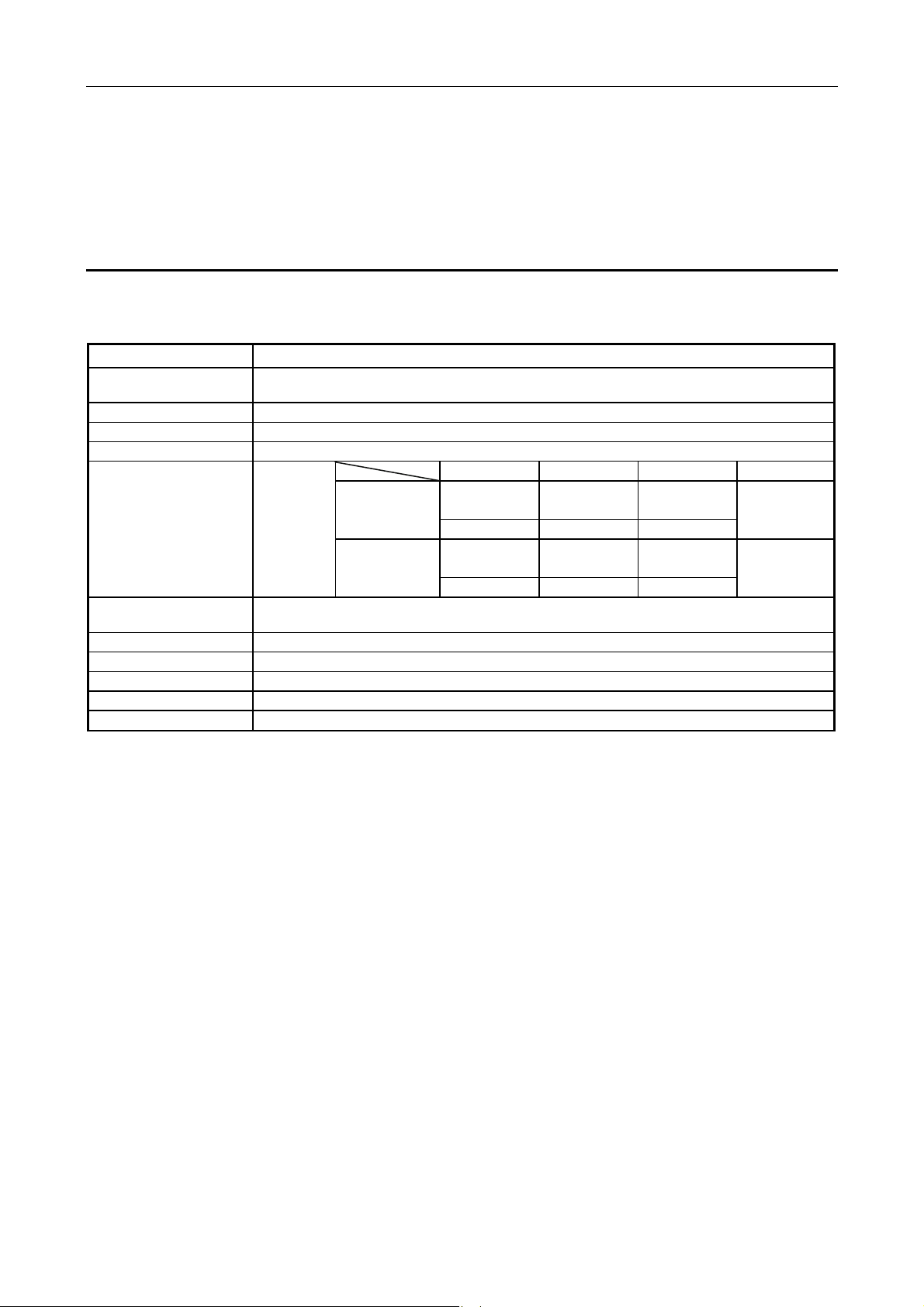

3.1 General Specification

This section explains the AJ65BT-64RD general specifications.

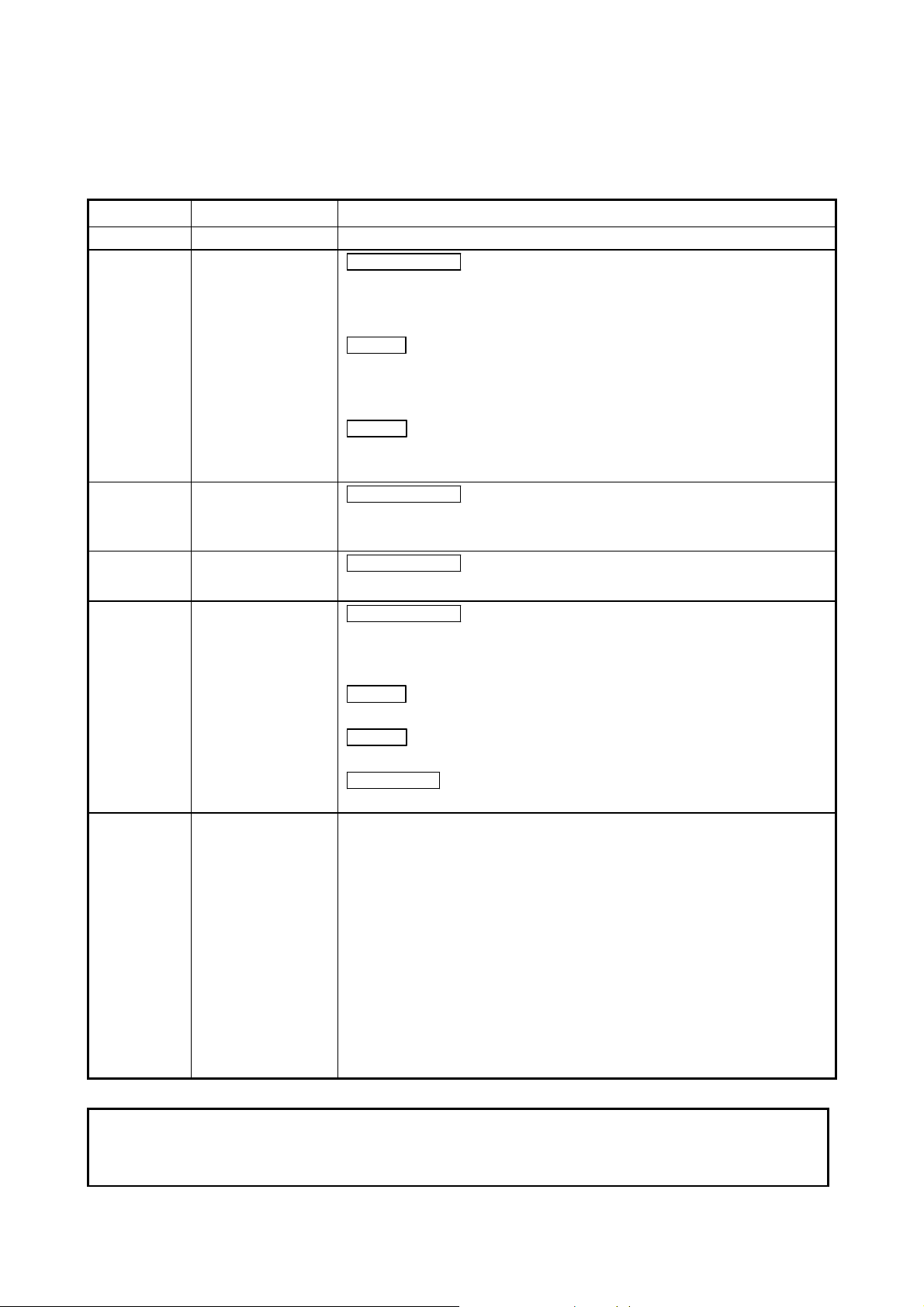

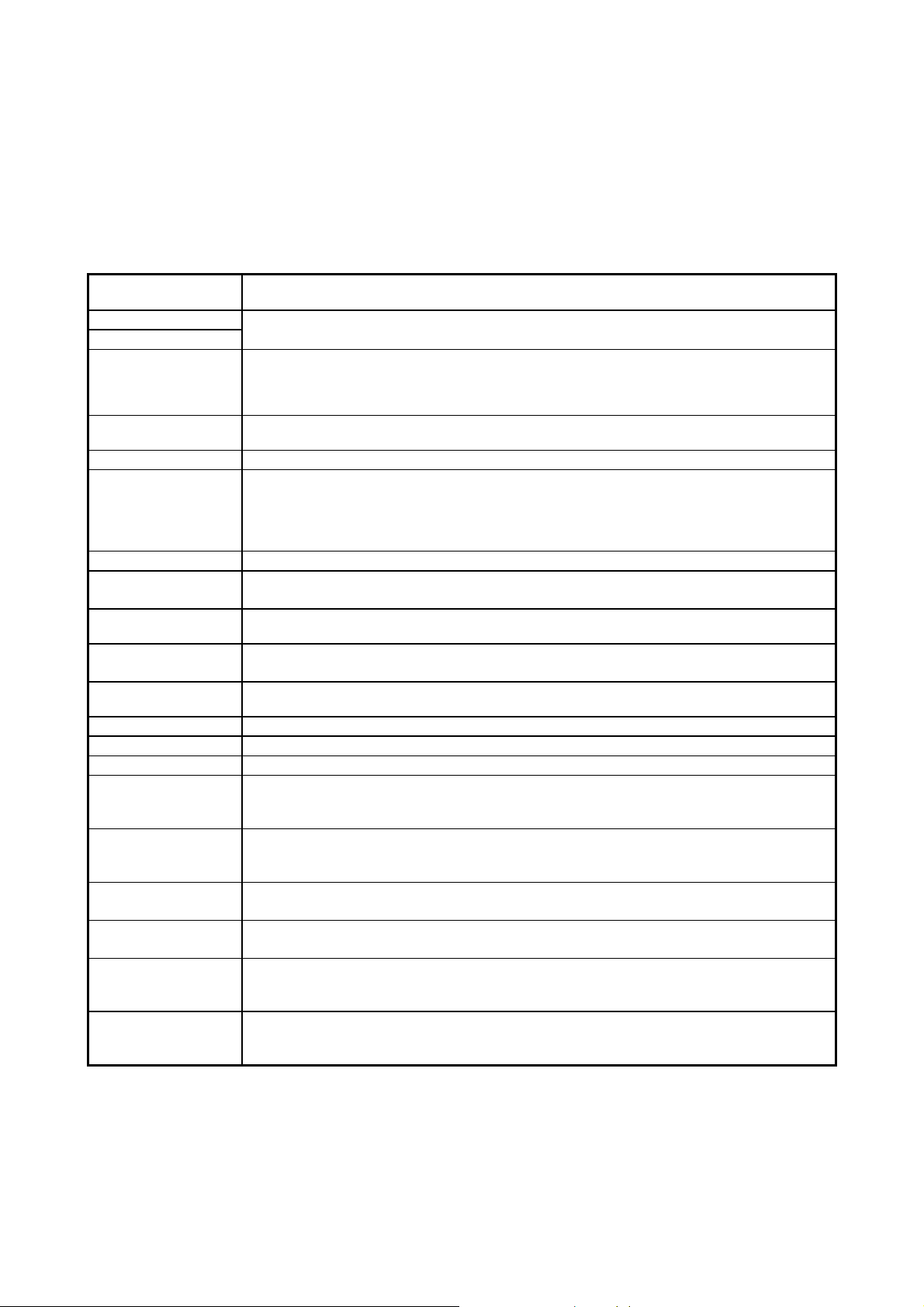

Table 3.1 General Specification

Item Specifications

Ambient operating

temperature

Ambient storage temperature -20 to 75 °C

Ambient operating humidity 10 to 90 %RH, Non-condensing

Ambient storage humidity 10 to 90 %RH, Non-condensing

Frequency Acceleration Amplitude No. of sweeps

Vibration resistance 9 to 150 Hz 9.8 m/s2 —

9 to 150 Hz 4.9 m/s2 —

Shock resistance Conforming to JIS B 3502, IEC 61131-2

Operating ambience No corrosive gases

Operating elevation *3 2000 m (6562 ft.) max.

Installation location Control panel

Over voltage category *1 II max.

Pollution level *2 2 max.

Conforming to

JIS B 3502,

IEC 61131-2

For intermittent

vibration

For continuous

vibration

(147 m/s

5 to 9 Hz

5 to 9 Hz

2

, 3 times in each of 3 directions X Y Z)

*1 : This indicates the section of the power supply to which the equipment is assumed to be

connected between the public electrical power distribution network and the machinery within the

premises. Category II applies to equipment for which electrical power is supplied from fixed

facilities. The surge voltage withstand level for up to the rated voltage of 300 V is 2500 V.

*2 : This index indicates the degree to which conductive material is generated in terms of the

environment in which the equipment is used. Pollution level 2 is when only non-conductive

pollution occurs. A temporary conductivity caused by condensation must be expected

occasionally.

*3 : Do not operate or store the programmable controller in the environment where the pressure

applied is equal to greater than the atmospheric pressure at the altitude of 0m. Doing so may

cause a malfunction. Please consult our branch office when the programmable controller is to be

operated under pressure.

0 to 55

°C

—

—

3.5mm

(0.14inches)

1.75mm

(0.069inches)

10 times in each

direction X, Y, Z

—

3-1

Page 18

3. SPECIFICATIONS MELSEC-A

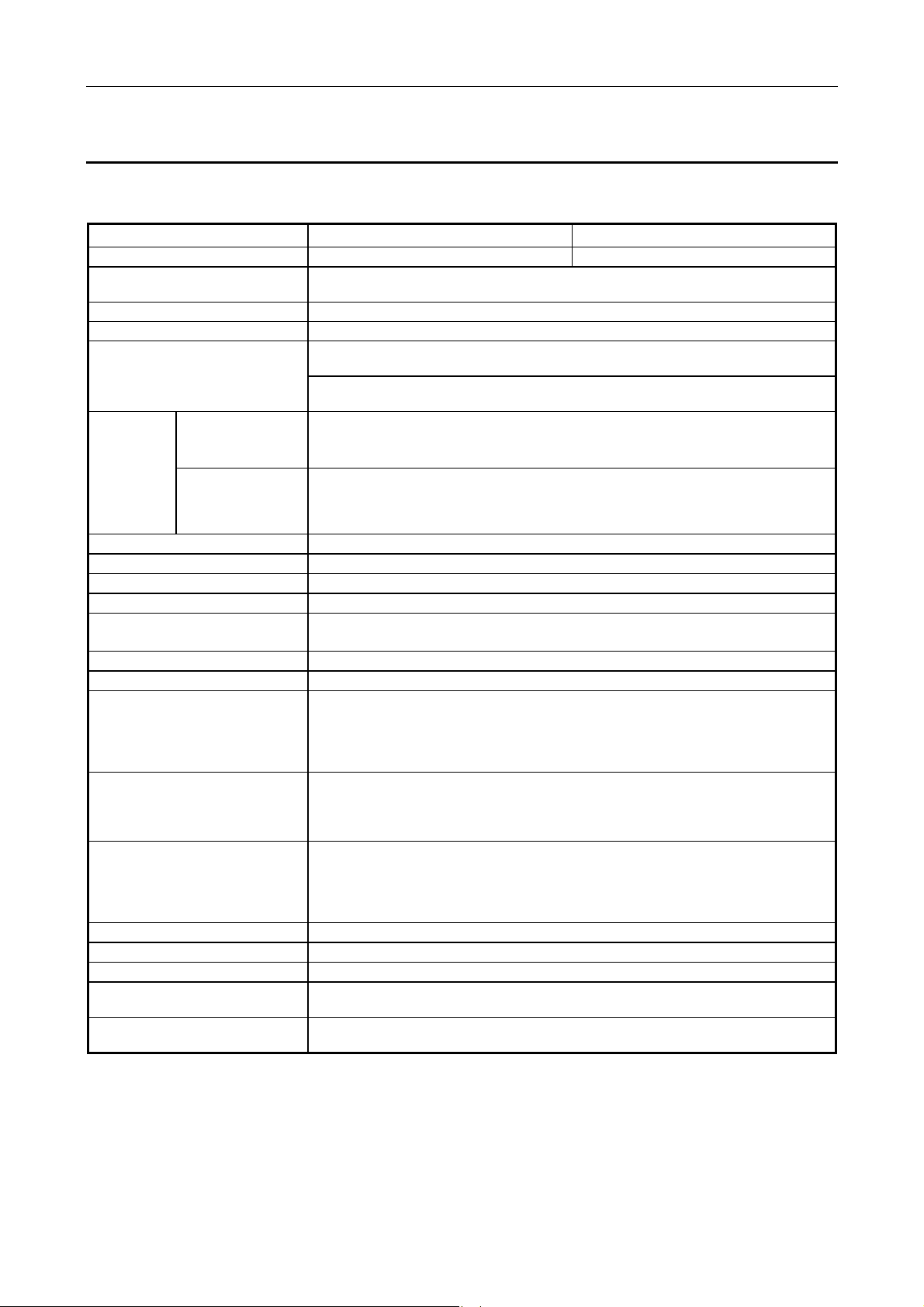

3.2 Performance Specification

The performance specification of the AJ65BT-64RD is explained below.

Item AJ65BT-64RD3 AJ65BT-64RD4

Measurement method 3-wire 4-wire

Connectable platinum temperaturemeasuring resistor

Output current for detecting temperature

Temperature input range –180 to 600 °C

Temperature detection

value

Overall

accuracy Operating ambient

Resolution 0.025 °C

Conversion speed (Sampling time) 40 ms/channel *1

Temperature input point 4-channel/module

CC-Link station type Remote device station

Occupied points

Connection cable

Noise durability Noise voltage 500 Vp-p, Noise width 1 μs by noise simulator of the noise frequency 25 to 60 Hz

Dielectric withstand voltage

Insulation method

Insulation resistor

Connection terminal block 27-point terminal block (M3.5 × 7 screws)

Supported cable size 0.75 to 2.00 mm2

Supported solderless terminal RAV 1.25-3.5, RAV 2-3.5 (Conform to JIS C 2805)

Module installation screw

Applicable DIN rail

Operating ambient

temperature

(25 ± 5 °C)

temperature (less than

20 °C, more than 30

°C)

Between batch of power supply system and ground

Between batch of power supply system and batch of communication system

Between batch of communication system and batch of temperature input

Between batch of temperature input and ground

500V AC 1 minute

Between the platinum temperature-measuring

resistor input and CC-Link transmission: Photocoupler insulation

Between the platinum temperature-measuring

resistor input and channel: no insulation

Between batch of power supply system and ground

Between batch of power supply system and batch of communication system

Between batch of communication system and batch of temperature input

Between batch of temperature input and ground

500 V DC, 10M

16-bit signed binary : –1800 to 6000

(value to one decimal place × 10)

32-bit signed binary : –180000 to 600000

(value to three decimal places × 1000)

± 0.1 % (accuracy for maximum value)

± 0.25 % (accuracy for maximum value)

4-station : RX/RY 128 points each

RWw/RWr 16 points each

Ω or more on the insulation resistance tester

M4 × 0.7 mm (0.03 in.) × 16 mm (0.63 in.) or more

Installation in the rail is possible, too.

TH 35-7.5 Fe, TH 35-7.5 Al, TH 35-15 Fe

Pt 100, JPt 100

1 mA

CC-Link dedicated cable

(conform to JIS C 2812)

3-2

Page 19

3. SPECIFICATIONS MELSEC-A

g

Performance specification (continued)

Item AJ65BT-64RD3 AJ65BT-64RD4

External power supply 24 V DC (18 to 30 V DC)

Internal consumed current 0.17 A (at 24VDC)

Allowable momentary power failure

period

Weight 0.38 (0.84) kg (lb.)

*1 : Conversion speed is the time until it is converted to the corresponding digital value after the

temperature has been input, and then stored in the remote register.

When the multiple channels are used, the conversion speed is “40 ms × number of the

conversion enable channels”

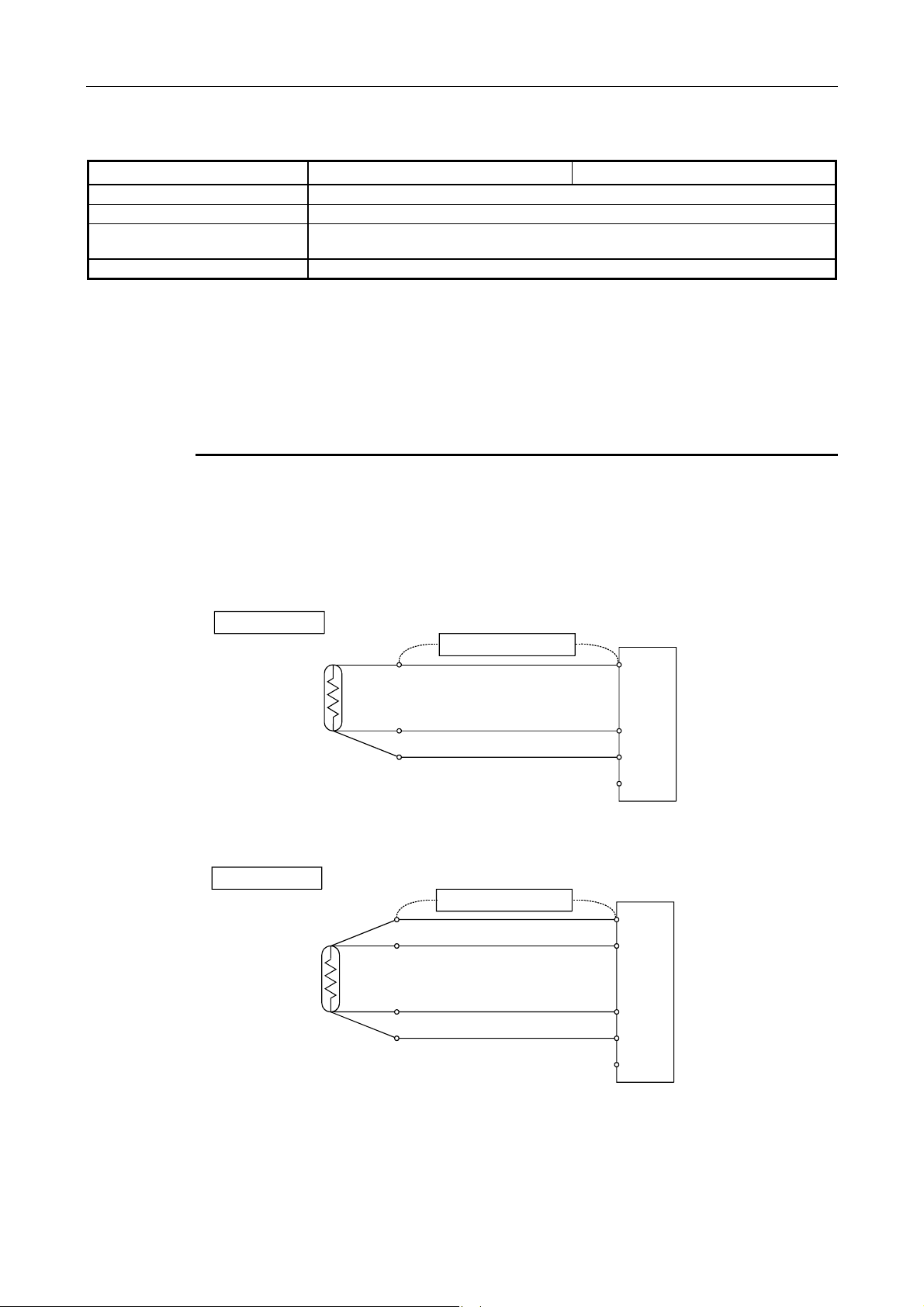

3.2.1 Specifications when connecting to a platinum temperature-measuring resistor

The following explains the specifications when connecting the AJ65BT-64RD and a platinum

temperature-measuring resistor.

(1) • The effect on the measured resistance by the discrepancy in the lead resistance value

connected to A, b is approximately

0.025 °C/10 m Ω.

• The lead resistance value between platinum temperature-measuring resistor and AJ65BT64RD3 should be 100 Ω or less per line.

1ms

AJ 65BT-64RD3

100 Ω or less per line

A

Plat in um t emperatu remeasurin

resistor

B

b

SLD

(2) The lead resistance value between between platinum temperature-measuring resistor and

AJ65BT-64RD4 should be 100 Ω or less per line.

AJ 65BT-64RD4

100 Ω or less per line

a

A

Platinum temp eratu remeasuring resistor

B

b

SLD

3-3

Page 20

3. SPECIFICATIONS MELSEC-A

3.2.2 Data link processing time

For the AJ65BT-64RD, the data link processing time shown below will be required in order to execute

each function.

For details of the link scan time, refer to the user's manual (details) of the used mater module.

Example) Data link processing time in asynchronous mode when the master module is the QJ61BT11

(normal value)

(1) Mater station (RY) → Remote device station (RY) processing time

[Expression]

SM + LS × 1 + Remote device station processing time [ms]

SM : Master station sequence program scan time

LS : Link scan time

Remote device station processing time: 1ms

(2) Master station (RX) ← Remote Device Station (RX) Processing Time

[Expression]

SM + LS × 1 + Remote device station processing time [ms]

SM : Master station sequence program scan time

LS : Link scan time

Remote device station processing time: (Number of used channels +1*) ×40ms

*: Internal processing time of AJ65BT-64RD

(3) Master station (RWr) ← Remote Device Station (RWr) Processing Time

[Expression]

SM + LS × 1 + Remote device station processing time [ms]

SM : Master station sequence program scan time

LS : Link scan time

Remote device station processing time: (Number of used channels +1*) ×40ms

*: Internal processing time of AJ65BT-64RD

POINT

The above are examples of processing time until the control of the output signal to the AJ65BT64RD from the programmable controller CPU or until input signals or remote registers are read.

The maximum time that takes for updating the detected temperature read by the programmable

controller CPU is “data link processing time + sampling time.”

3-4

Page 21

3. SPECIFICATIONS MELSEC-A

3.3 Function

The function of AJ65BT-64RD is explained below.

3.3.1 Function list

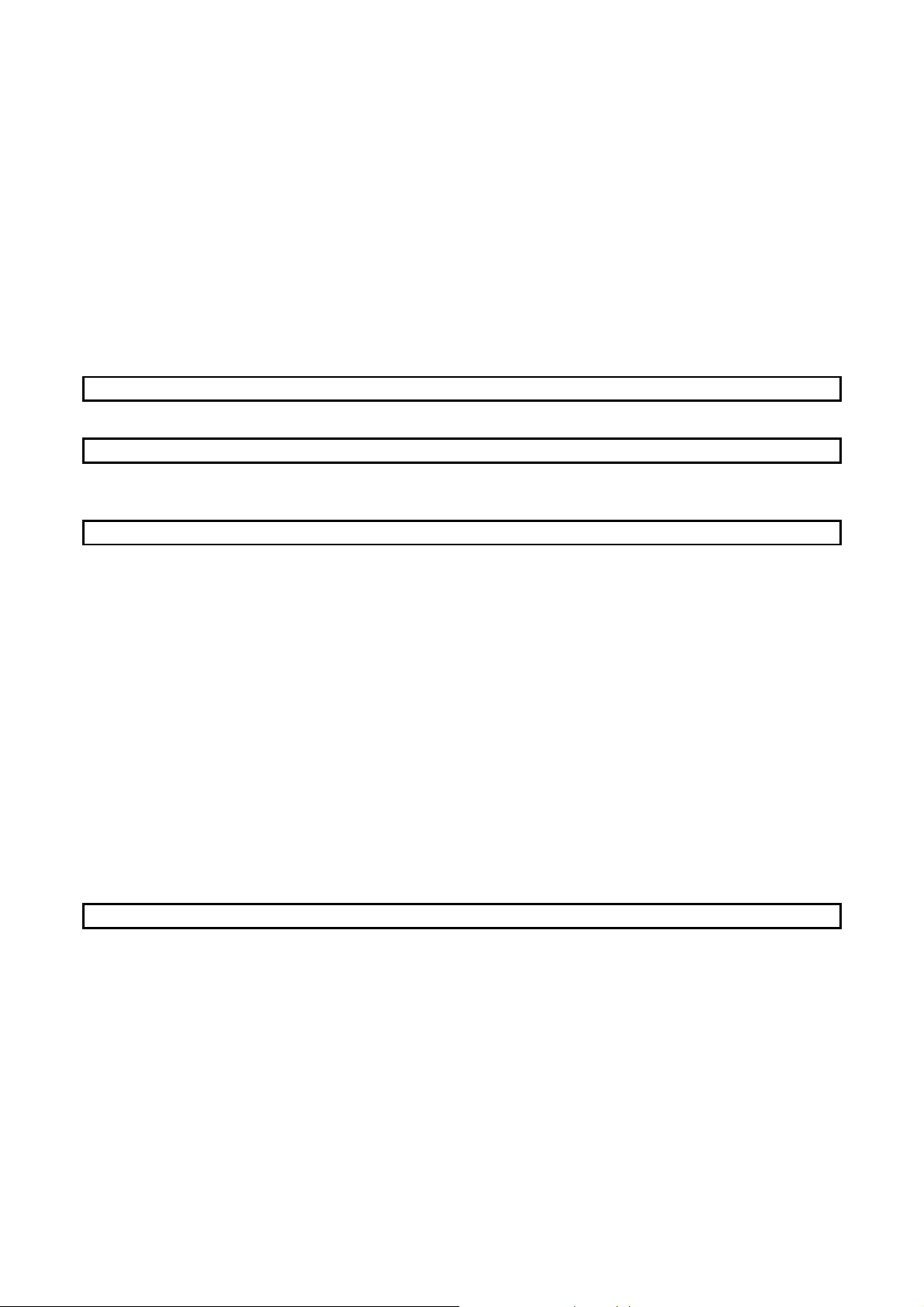

Below is a function list of the AJ65BT-64RD.

Item Description Reference section

Conversion enable/disable

designation

Sampling processing/travel

average processing designation

Wire breakage detection

Detected temperature storage

Designation of platinum

temperature-measuring resistor

type

• Performs conversion enable/disable settings by channel.

(Default ······ All channels disabled)

• Sampling time may be reduced by disabling the conversion

at channels not in use.

• Designates sampling processing or travel average

processing by channel.

(Default ······ All channels sampling processing)

• Detects wire breakage for the connected thermocouple by

channel.

• A value to one decimal place (16-bit signed binary) will be

stored in the remote register.

• Designates the type of platinum temperature-measuring

resistor to be used.

Usable platinum temperature-measuring resistors are the

following two types:

.....

• Pt100

(Conforms to JIS C 1604-1997, IEC 751-1983)

• JPt100

(Conforms to JIS C 1604-1981)

New JIS, IEC type

...

Old JIS type

Section 3.3.2

Section 3.3.3

Section 3.3.4

Section 3.3.5

Section 3.3.6

3-5

Page 22

3. SPECIFICATIONS MELSEC-A

3.3.2 Conversion enable/disable designation

Conversion may be enabled or disabled for each channel individually.

The setting of the conversion is made through the CH.

Setting Description

ON Wire breakage detection is conducted at the same time the temperature of the target object is taken.

OFF Neither temperature detection nor wire breakage detection is conducted.

AJ65BT-64RD

Remote I/O sig nal Remo te r egi st er

Enables conversion

ONRYn0

for CH. 1

RYn1

RYn2

RYn3

to

Enables conversion

ON

for CH. 2

Disable conversion

OFF

for CH. 3

Disable conversion

OFF

for CH. 4

conversion enable flags (RYn0 to RYn3).

CH. 1 detect ed temperat ure

265RWrn

value (16-bit)

RWrn +1

RWrn +2

RWrn +3

RWrn +4

RWrn +5

RWrn +6

RWrn +7

to

103275

CH. 2 detect ed temperat ure

1033

value (16-b it)

CH. 3 detect ed temperat ure

0

value (16-b it)

CH. 4 detect ed temperat ure

0

value (16-b it)

CH. 1 detec ted temp eratur e

26525

value (32-bit)

CH. 2 detec ted temp eratur e

value (32-bit)

(1) Relationship between conversion enable/disable designation and sampling time

By disabling conversion at the channels not in use, sampling time may be reduced.

<If all channels are conversion enabled>

40 ms × 4 channels = 160 ms

(= sampling time)

<If only one channel is conversion enabled>

40 ms × 1 channel = 40 ms (= sampling time)

(2) Changes caused by switching conversion enable/disable designation

<When changed from conversion disabled → enabled>

Sampling of the enabled channels will be commenced.

After the detected temperature values are stored in the remote register, the conversion

completion flag is turned on for the corresponding channel.

<When changed from conversion enabled → disabled>

Sampling of the disabled channels will be stopped.

The conversion completion flag is turned off for the corresponding channel.

For the detected temperature value stored in the remote register, the data immediately prior to

the disable setting will be retained.

3-6

Page 23

3. SPECIFICATIONS MELSEC-A

3.3.3 Sampling processing/travel average processing designation

The AJ65BT-64RD may designate sampling processing or travel average processing for each

individual channel.

The setting of sampling processing or travel average processing is made through the CH.

processing/travel average processing designation flags (RYn4 to RYn7).

Setting Description

ON Travel average processing

OFF Sampling processing

(1) Travel average processing

The average of the four detected temperature values that have been taken during each sampling

time (current value + three previous values) is calculated and stored in the remote register.

Also, since the average processing travels for each sampling, the most recent measured

temperature value may be obtained.

By using this, a scaling value can be obtained using the detected temperature value that has

undergone the average processing and stored in the remote register.

Sampling time

sampling

e

r

u

t

a

r

e

p

m

e

[°C]

T

Time [ms]

The data transition inside the remote register

1st storage 2nd storage 3rd storage

+++

4

+++

4

1st storage

2nd storage

3rd storage

+++

4

Remote register

Detected

temperature

value

3-7

Page 24

3. SPECIFICATIONS MELSEC-A

(2) Sampling processing

Stores the detected temperature value and scaling value are stored in the remote register by

each sampling time.

Sampling time

e

r

u

t

a

r

e

p

m

e

T

[°C]

1st storage

2nd storage

3rd storage

Time [ms]

The data transition inside the remote register

1st storage 2nd storage 3rd storage

Remote register

Detected

temperature

value

(3) Changes caused by altering sampling processing/travel average processing settings

<When changed from sampling processing → travel average processing>

The conversion completion flag is turned off for the corresponding channel.

After an average of four previously detected temperature values (three values from the present

and past value) is calculated and stored to the remote register, the conversion completion flag

for the corresponding channel is turned on.

<When changed from travel average processing → sampling processing>

The conversion completion flag is turned off for the corresponding channel.

After the most recent detected temperature value is stored in the remote register, the conversion

completion flag for the corresponding channel is turned on.

3-8

Page 25

3. SPECIFICATIONS MELSEC-A

3.3.4 Wire breakage detection

The AJ65BT-64RD detects wire breakage in the platinum temperature-measuring resistor or cable

used for each channel, and turns on the wire breakage detection flag (RXn4 to RXn7) for the

corresponding channel.

On the AJ65BT-64RD, the wire breakage detection are performed for channels that are enabled for

conversion.

The relationships between the wire breakage detection and conversion enable/disable are shown

below.

Connection status Conversion enabled/disabled setting Wire breakage detection flag

No b reak age

Breakage

No connection

POINT

• Be sure to set the channels having no platinum temperature-measuring resistor attached to

“conversion disabled.”

If a channel having no platinum temperature-measuring resistor attached is set to “conversion

enabled,” the wire breakage detection flag will turn on.

• The channels for which wire breakage detection turned on will retain the detected temperature

value immediately prior to the breakage detection, and the conversion completion flag for the

corresponding channel will turn off.

When the detected breakage is fixed, updating of detected temperature value after repair will

be resumed and the conversion completion flag will be turned on again.

• For platinum temperature-measuring resistor wiring details, refer to Section 4.7.

Conversion enabled

OFF

Conversion disabled

Conversion enabled ON

Conversion disabled OFF

Conversion enabled ON

Conversion disabled OFF

3-9

Page 26

3. SPECIFICATIONS MELSEC-A

3.3.5 Detected temperature

Temperatures in the range of -180 °C to +600 °C can be detected using the AJ65BT-64RD.

Of the temperature detected, the values to the first place and third place below decimal point are

stored in the remote register (Refer to Section 4.7).

(1) Value to the first place below decimal point

The value to the first place below the decimal point of the detected temperature is multiplied by

10, then stored as 16-bit signed binary data.

The data to be stored is in the range of – 1800 to + 6000.

Example: When the temperature detected at CH. 1 is 216.025 °C

216.0 25 °C 2160

To the 1st digit below Stored in the remote register, RWrn

decimal point (CH1 detected temperature (16-bit) storage area)

of AJ65BT-64RD.

(2) Value to the third place below decimal point

The value to the third place below decimal point of the detected temperature is multiplied by

1000, then stored as 32-bit signed binary data.

The data to be stored is in the range of -180000 to +600000.

Example: When the temperature detected at CH. is 216.025 °C

216.0 25 °C 216025

To the 3rd digit below Stored in the remote register, RWrn+4 and RWrn+5

decimal point (CH1 detected temperature (32-bit) storage area)

of AJ65BT-64RD.

10 times

1000 times

3.3.6 Designating the platinum temperature-measuring resistor type

The platinum temperature-measuring resistors listed below can be used for AJ65BT-64RD.

• Pt100

• JPt100

By setting the type of the platinum temperature-measuring resistor to be used using the platinum

temperature-measuring resistor designation pin, all channels are set to the designated type.

.............

...........

New JIS, IEC type (JIS C 1604-1997, IEC 751-1983)

Old JIS type (JIS C 1604-1981)

POINT

Two types of platinum temperature-measuring resistors cannot be used simultaneously.

When two types of platinum temperature-measuring resistors are used, the

channel which connects the resistor of a type different from designation cannot obtain a correct

detected temperature value.

3-10

Page 27

3. SPECIFICATIONS MELSEC-A

3.4 I/O Signals in Respect to the Master Module

The assignment of remote I/O signals and the functions is explained.

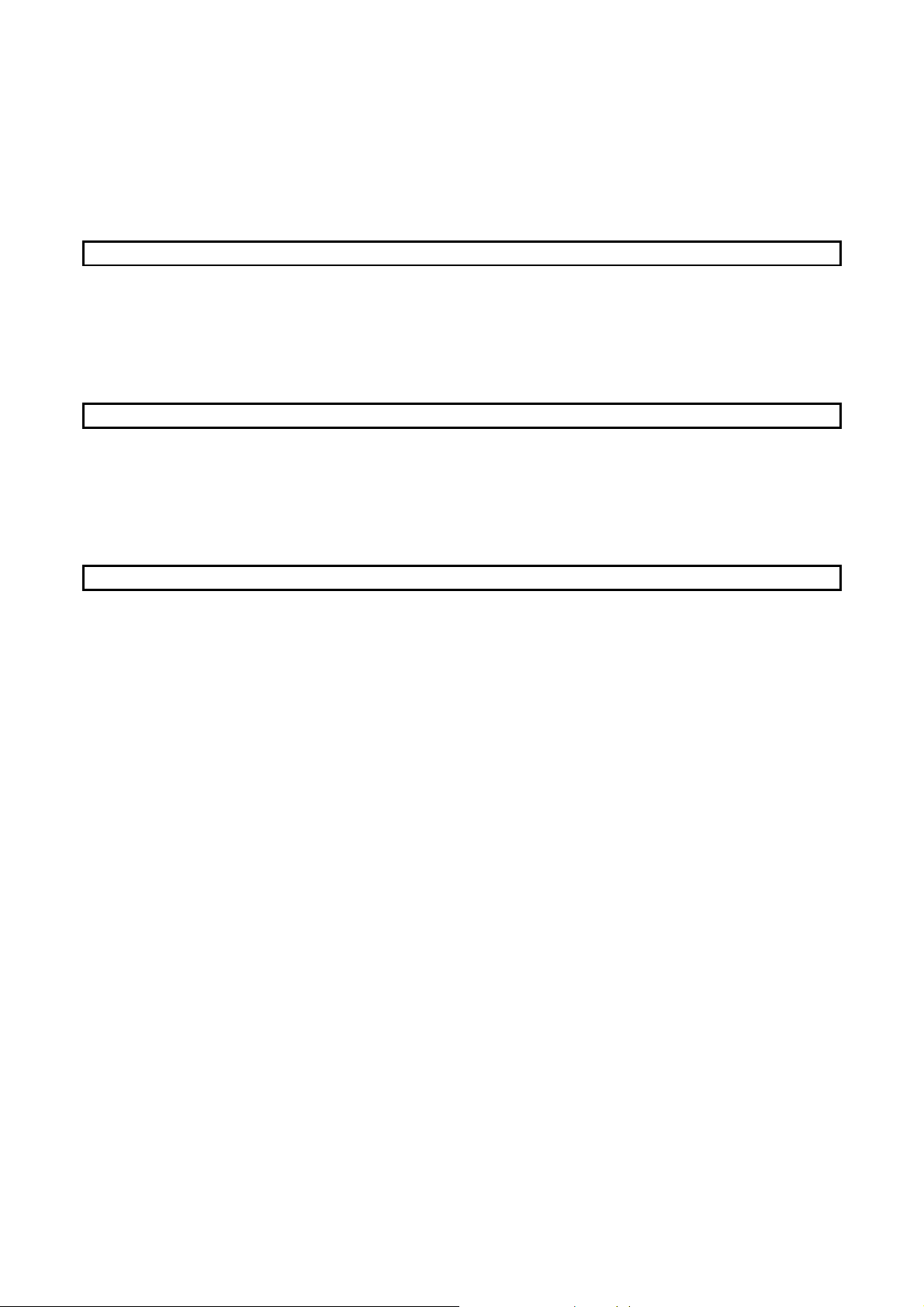

3.4.1 Remote I/O signal list

The AJ65BT-64RD uses 128 points for input and 128 points for output in respect to the data for the

master module.

The remote I/O signal assignment and the name of each signal are shown in the table below.

Device RX indicates an input signal to the master module from the AJ65BT-64RD, and device RY

indicates an output signal from the master module to the AJ65BT-64RD.

Signal direction : AJ65BT-64RD → Master module Signal direction : Master module → AJ65BT-64RD

Device No. Signal name Device No. Signal name

RXn0 CH.1 conversion completion flag RYn0 CH.1 conversion enable flag

RXn1 CH.2 conversion completion flag RYn1 CH.2 conversion enable flag

RXn2 CH.3 conversion completion flag RYn2 CH.3 conversion enable flag

RXn3 CH.4 conversion completion flag RYn3 CH.4 conversion enable flag

RXn4

RXn5

RXn6

RXn7

RXn8 E2PROM abnormal flag RYn8

RXn9 Test mode flag

RXnA to Use prohibited

to

RY (n+7) 6

RX (n+7) 7 RY (n+7) 7 Offset/gain value selection flag

RX (n+7) 8 Initial data processing request flag RY (n+7) 8 Initial data processing completion flag

RX (n+7) 9 Initial data setting completion flag RY (n+7) 9 Initial data setting request flag

RX (n+7) A Error status flag RY (n+7) A Error reset request flag

RX (n+7) B Remote READY RY (n+7) B

RX (n+7) C

to ——

RX (n+7) F RY (n+7) F

CH.1 wire breakage detection flag

CH.2 wire breakage detection flag

CH.3 wire breakage detection flag

CH.4 wire breakage detection flag

——

n : Addresses assigned to the master module by the station number setting.

POINT

Do not turn on the remote output signals that are prohibited in respect to the remote device from

the master module.

If the prohibited signals are output, the programmable controller system may malfunction.

RYn4 CH.1 sampling processing/travel average

RYn5 CH.2 sampling processing/travel average

RYn6 CH.3 sampling processing/travel average

RYn7 CH.4 sampling processing/travel average

to

processing designation flag

processing designation flag

processing designation flag

processing designation flag

Use prohibited

3-11

Page 28

3. SPECIFICATIONS MELSEC-A

3.4.2 I/O signal functions

The function of each remote I/O signal for the AJ65BT-64RD is explained below.

(1) Remote Input signal

Device No. Signal name Description

RXn0 to RXn3

RXn4 to RXn7

RXn8

RXn9 Test mode flag

RX (n+7) 8

RX (n+7) 9

RX (n+7) A

RX (n+7) B

CH.

conversion

completion flag

wire

CH.

breakage

detection flag

2

PROM

E

abnormal flag

Initial data

processing

request flag

Initial data

processing

request flag

Error status

flag

Remote

READY

The conversion completion flag turns on when the detected temperature value at all

conversion enabled channel is stored in the remote register after power on or a

hardware reset.

If the travel average processing is running, it will turn on when the detected

temperature value is converted and stored in the remote register after the travel

average processing has completed. The conversion completion flag changes

according to the conditions listed below.

• When conversion disabled is changed to enabled

The temperature detection of the enabled channels will be commenced.

After the detected temperature values are stored in the remote register, the

conversion completion flag is turned on for the corresponding channel.

• When conversion enabled is changed to disabled

The conversion completion flag is turned off for the corresponding channel.

For the values stored in the remote register, the data immediately prior to the

disable setting are retained.

For the platinum temperature-measuring resistor input circuit for all channels, when

only a single section of the I/O signal lines including the platinum temperaturemeasuring resistor is broken, the wire breakage detection flag is turned on for the

corresponding channel.

The detected temperature value when a wire breakage detection flag is turned on will

be maintained at the value immediately prior to the wire breakage, and then the

conversion completion flag will be turned off.

After the wire breakage has been removed, the wire breakage detection flag may be

turned off by turning on the error reset request flag.

Also, after the breakage has been fixed, the updating of detected temperatures value

will be resumed regardless of whether or not the wire breakage detection flag is reset,

and after the first update has been completed the conversion completion flag will turn

on once again.

After power on or a hardware reset, the internal memory (E

storage) is checked, and it turns on if there is an error.

At such times, the conversion function will stop.

When this flag turns on, the error reset request flag may not be used to reset (off)

because the module itself is malfunctioning (hardware error).

Turns on during test mode.

Turns off when reverted to normal mode.

After power on or a hardware reset, this is turned on because the AJ65BT-64RD

requests the initial data setting .

After the initial data processing is complete (initial data processing request flag

RY(n+7)8 is turned on), it turns off.

Turns on when initial data was required to change (initial data setting request flag

RY(n+7)9 is turned on).

After the initial data setting request flag is turned off when initial data setting is

complete, this also turns off.

Turns on when wire breakage detection flag or E

After the cause of the error has been removed, the flag may be reset (off) by turning

on the error reset request flag, but since the E

flag may also not be reset.

After power on or a hardware reset, this flag turns on when the initial data setting is

complete and the detected temperature value at all conversion-enabled channel has

been stored in the remote register.

Will not turn on when all channels are conversion disabled.

It will turn off for two seconds when the offset/gain switch is set to [OFFSET] during

test mode or when changed from [GAIN] to [SET].

Used as an interlock for read in respect to the master module.

2

PROM error flag turns on.

2

PROM error flag cannot be reset, this

2

PROM for offset/gain value

3-12

Page 29

3. SPECIFICATIONS MELSEC-A

(2) Remote output signal

Device No. Signal name Description

RYn0 to RYn3

RYn4 to RYn7

RY (n+7) 7

RY (n+7) 8

RY (n+7) 9

RY (n+7) A

CH.

conversion

enable flag

CH.

sampling

processing/

travel average

processing

specification

flag

Offset/gain

value selection

flag

Initial data

processing

completion flag

Initial data

setting request

flag

Error reset

request flag

It is possible to designate the conversion enabled or disabled for each channel.

By disabling the conversion at channels not in use, generation of unnecessary wire

breakage detection flags may be prevented and sampling time may be reduced.

ON : Conversion enabled

the temperature of the target object is taken.

OFF : Conversion disabled

is conducted.

By setting of conversion enable/disable, the following changes are made.

• When conversion is changed from disabled

Temperature detection of the enabled channel is commenced.

After the detected temperature value of the corresponding channel is stored in the

remote register, the conversion completion flag of the corresponding channel is

turned on.

• When the conversion is changed from enabled

The conversion completion flag is turned off for the corresponding channel.

For the detected temperature value stored in the remote register, the data

immediately prior to the disable setting will be retained.

It is possible to designate the sampling processing or travel average processing for

each independent channel.

ON : Travel average processing

OFF : Sampling processing

In travel average processing, an average value of four detected temperature value

samples that were taken during each sampling time is calculated and stored in the

remote register.

• When changed from sampling processing

The conversion completion flag for the corresponding channel is turned off.

An average value of four detected temperature value samples is calculated, and

after it has been stored to the remote register the conversion completion flag of the

corresponding channel is turned on.

• When changed from travel average processing

The conversion completion flag is turned off for the corresponding channel.

After the most recent detected temperature value is stored in the remote register,

the conversion completion flag for the corresponding channel is turned on.

Note : This flag is only valid when the initial data processing completion flag

(RY (n+7) 8) or initial data setting request flag (RY (n+7) 9) is on.

Select whether or not the offset/gain value will be set to “user setting” or “factory

setting.”

At the product shipment from factory, the same values for the factory settings are

stored in the E

ON : Factory setting (Offset-gain, 100.0

OFF : User setting

Note : This flag is only valid when the initial data processing compensation flag

After power on or hardware reset, the initial data are set in the module by turning this

flag on during the initial data processing request .

Used when designating sampling processing/travel average processing designation,

selecting offset/gain value.

Turned on when changing the initial values.

Used when designating sampling processing/travel average processing, selecting

offset/gain value.

When this flag is turned on, the wire breakage detection flag/write data error flag are

reset (turned off), and the error status flags are reset at the same time. However, the

2

PROM error flag may not be reset (turned off) and therefore the error status flag will

E

remain on.

2

PROM for storing the user setting offset/gain values.

(RY (n+7) 8) or initial data setting request flag (RY (n+7) 9) is on.

.....

wire breakage detection is conducted at the same time

....

neither temperature taking or wire breakage detection

→ enabled

→ disabled.

→ travel average processing

→ sampling processing

Ω (0 °C equivalent) -300 °C)

n : Address assigned to the master module by the station number setting.

3-13

Page 30

3. SPECIFICATIONS MELSEC-A

3.5 Remote Register

The AJ65BT-64RD is equipped with remote registers for data communication with the master module.

The assignment and data structure of the remote register are explained below.

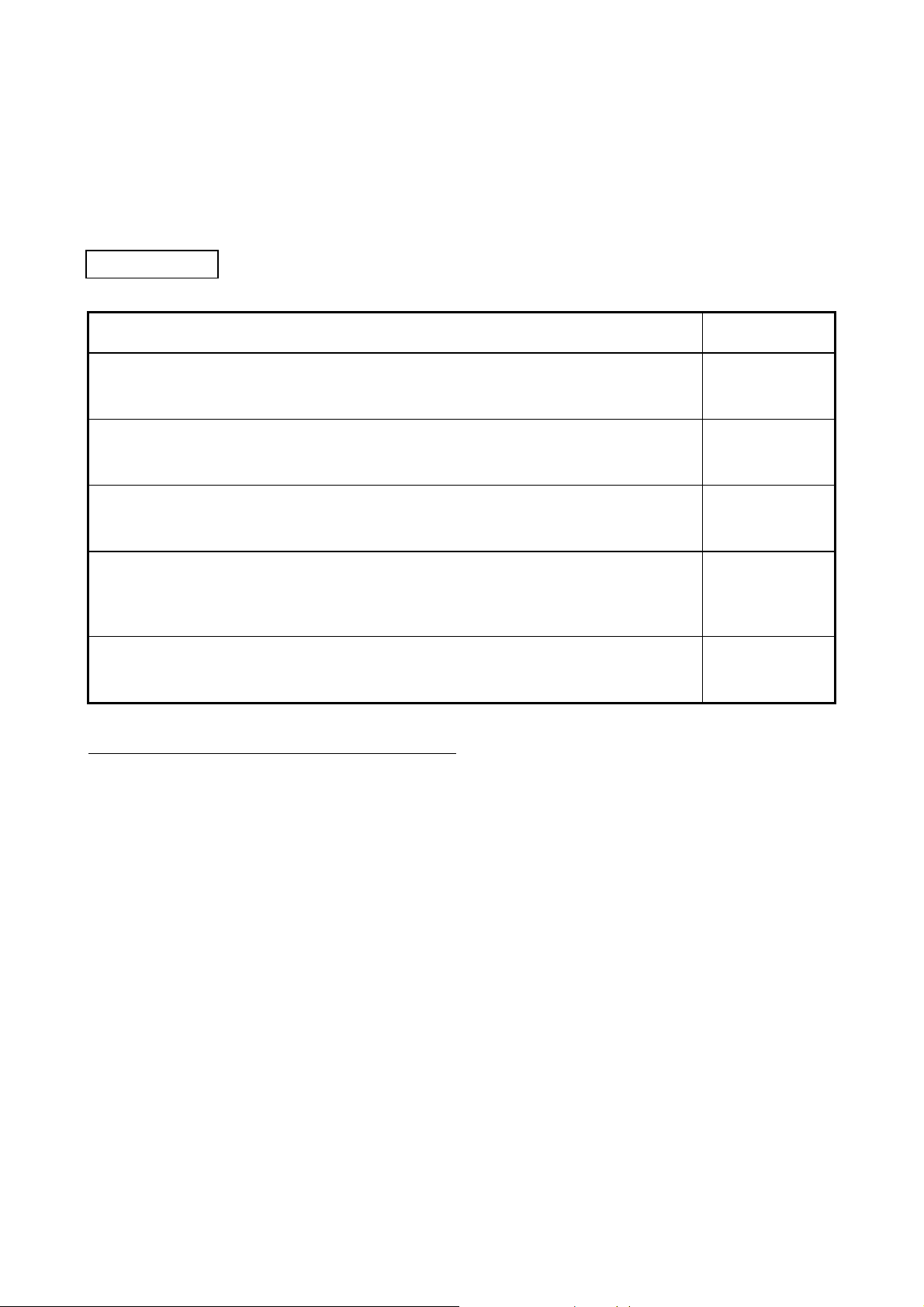

3.5.1 Remote register assignment

The remote register assignments are shown in the table below.

Communicati

on direction

Master

→

Remote

RWrn CH. 1 detected temperature value (16-bit)

RWrn +1 CH. 2 detected temperature value (16-bit)

RWrn +2 CH. 3 detected temperature value (16-bit)

RWrn +3 CH. 4 detected temperature value (16-bit)

RWrn +4

RWrn +5 Section

Remote RWrn +6 3.5.2

→ RWrn +7

Master RWrn +8

RWrn +9

RWrn +10

RWrn +11

RWrn +12

to Use prohibited — —

RWrn +15

Address Description Default value

RWwm

to

RWwm +15

Use prohibited

CH. 1 detected temperature value (32-bit)

CH. 2 detected temperature value (32-bit)

CH. 3 detected temperature value (32-bit)

CH. 4 detected temperature value (32-bit)

—

0

Reference

section

m,n : Address assigned to the master module by the station number setting

—

3-14

Page 31

3. SPECIFICATIONS MELSEC-A

3.5.2 Remote register for storing detected temperature (Address : RWrn to RWrn+11)

AJ65BT-64RD has two types of remote registers, for 16-bit data and 32-bit data, to store the detected

temperature values that are converted into digital values.

(1) 16-bit data storage (Address : RWrn to RWrn+3)

The value to the first place below decimal point of the detected temperature is multiplied by 10,

then stored as 16-bit signed binary data.

If the detected temperature value is negative, stores the compliment of 2.

0 is stored at power on.

Example 1 : When the detected temperature is 123.025 °C (Stores 1230)

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

0 0 0 0 0 1 0 0 1 1 0 0 1 1 1 0

Example 2 : When the detected temperature is –123.025 °C (Stores –1230)

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

1 1 1 1 1 0 1 1 0 0 1 1 0 0 1 0

(2) 32-bit data storage (Address : RWrn+4 to RWrn+11)

The value to the first place below decimal point of the detected temperature is multiplied by 1000,

then stored as 32-bit signed binary data.

If the detected temperature value is negative, stores the compliment of 2.

0 is stored at power on.

Example 1 : When the detected temperature is 123.025 °C (Stores 123025)

b31 b24 b23 b16b15 b8 b7 b0

0 0 00 0 0 0 0 0000000111100000 1 0 0 1 0 00 1

tototo

Example 2 : When the detected temperature is –123.025 °C (Stores –123025)

b31 b24 b23 b16 b15 b8 b7 b0

1 1 11 1 1 1 1 1111111000011111 0 1 1 0 1 11 1

to

to tototo

3-15

Page 32

4. SETTING AND PROCEDURE BEFORE OPERATION MELSEC-A

4. SETTING AND PROCEDURE BEFORE

OPERATION

The procedure before operation of AG65BT-64RD, part identification and setting, and the wiring

method are explained below.

4.1 Procedure before Operation

The procedure before operation of AJ65BT-64RD is explained below.

Start

Set the switches listed below on AJ65BT-64RD.

• Statio n number setting switch

• Transmission baud rate setting switch

Set the platinum temperature-measuring

resistor type designation pin.

Install the AJ65 BT-64RD.

Connect cables to the AJ65BT-64RD.

Programming

End

························· Refer to Section 4.3

························· Refer to Section 4.3

························· Refer to Section 4.2, 4.6

························· Refer to Section 4.7

························· Refer to Chapter 5

4-1

Page 33

4. SETTING AND PROCEDURE BEFORE OPERATION MELSEC-A

4.2 Handling Precautions

The handling precautions for AJ65BT-64RD is explained below.

CAUTION

(1) Tighten the module mounting screws and terminal block screws within the following ranges.

• Securely fix the module with a DIN rail or mounting screws. Tighten the screws

within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit,

or malfunction.

• For protection of the switches, do not remove the cushioning material before

installation.

• Do not directly touch any conductive part of the module.

Doing so can cause malfunction or failure of the module.

• Tighten the screw within the specified torque range.

Undertightening can cause short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit,

or malfunction.

• Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

• Do not touch any terminal while power is on.

Doing so may cause malfunction.

• Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

• Do not drop or apply strong shock to the module.

Doing so may damage the module.

• Shut off the external power supply for the system in all phases before mounting or

removing the module to or from the panel.

Failure to do so may cause the module to fail or malfunction.

• When disposing of this product, treat it as an industrial waste.

Screw area Tightening torque range

Module mounting screws (M4 screw) 0.78 to 1.18 N • m

Terminal block terminal screws (M3.5 screw) 0.59 to 0.88 N • m

Terminal block installation screws (M4 screw) 0.98 to 1.37 N • m

(2) W hen using a DIN rail adapter, install the DIN rail considering the precautions described below.

(a) Applicable DIN rail types (conform to JIS C 2812)

TH35-7.5Fe

TH35-7.5Al

TH35-15Fe

(b) Space between DIN rail installation screws

When installing a DIN rail, tighten the screws with a space of less than 200 mm (7.9 in.).

4-2

Page 34

4. SETTING AND PROCEDURE BEFORE OPERATION MELSEC-A

)3)7)8)

4.3 Part Identification and Setting

The part identification and setting method for AJ65BT-64RD is explained below.

2) 1)

9)

MITSUBISHI

MELSEC

AJ65BT-64RD

SW MODE

NORMAL

0

TEST CH.

1-4

TEST

9

RUN

L RUN

L ERR.

PW

SD

RD

STATION NO.B RATE

X10 X1

0

0

1

1

•

•

•

•

•

•

MODE OFFSET UP

0

9

•

•

2

•

3

•

4

1

2

3

4• •

GAIN DOWN

8

2

7

3

456

SET

0

1

9

2

3

456

RESET

4

No. Name Description

Station setting

switch

STATION NO.

1)

0

•

•

•

Transmission

baud rate

setting switch

2)

10 1

1

8

2

7

3

456

B RATE

0

•

•

•

Sets the station number of AJ65BT-64RD in the range of 1 to 61.

“ × 10” sets the ten’s place for a station number.

“ × 1” sets the one’s place for a station number.

0

1

9

2

3

456

Sets the transmission speed of AJ65BT-64RD (for data link).

Setting No. Transmission baud rate

0 156 kbps (factory setting)

1 625 kbps

1

2

3

4• •

2 2.5 Mbps

3 5 Mbps

4 10 Mbps

Other than 0 to 4

Unused (if a number other than 0 to 4 is used, the "L ERR. " LED is lit and

communication error occurs.)

6)

5)

(Factory setting : 00)

Mode switch

3)

Offset/gain

setting switch

4)

MODE

0

9

•

•

•

•

OFFSET

GAIN

1

4

SET

0 NORMAL

2

3

1 to 4 TEST CH. At a test mode, select a channel to perform error compensation.

9 TEST When executing error compensation, select TEST to enter the test mode after 2 seconds.

During a normal operation, select this to end the test mode.

(Factory setting)

OFFSET Compensation mode of offset value

GAIN Compensation mode of gain value

SET

Store the detected temperature value when the position is switched from

OFFSET/GAIN to SET as an offset value/gain value, in the internal memory of AJ65BT64RD.

4-3

Page 35

4. SETTING AND PROCEDURE BEFORE OPERATION MELSEC-A

No. Name Description

UP/DOWN

switch

5)

Reset switch

RESET

6)

LED for

operation

status display

7)

L RUN

L ERR.

Terminal block

8)

Platinum

temperaturemeasuring

9)

resistor type

designation pin

UP

DOWN

PW

RUN

SD

RD

Increase/decrease the offset value/gain value of the channel selected by the mode switch.

ON for less than 1.5 seconds : increase/decrease 0.025 °C at a time.

ON for more than 1.5 seconds : increase/decrease 0.1 °C per 0.04 second.

Hardware reset

Initialize the remote register of AJ65BT-64RD.

The initial data processing request flag turns on by turning the switch on.

PW

RUN

ON : Power is on

OFF : Power is off

Test mode

Normal

mode

ON : Normal operation

Flicker : Read data error occurred

OFF : 24 V DC power failure or WDT error

Flicker : Flickers when the offset/gain setting switch is set at OFFSET or GAIN

Flickers at 0.5-second intervals when the offset value or gain value being

used for compensation is within the setting range.

Flickers at 0.1-second intervals when the offset value or gain value being

used for compensation is out of the setting range (out of the temperature

input range or the gain value minus the offset value is smaller than +10°C).

In this case, the offset or gain value cannot be memorized.

OFF : Turns off when the offset/gain setting switch is positioned at SET

L RUN

ON : Normal communication

OFF : Communication disconnected (time over error)

SD The light comes on during data transmission

RD The light comes on during data receiving

ON : Communication data error (CRC error)

Station number, baud rate switch setting error

Flicker at regular intervals: Indicates that the station number or baud rate switch setting was

L ERR.

changed while power was on.

Flicker at irregular intervals: Indicates that the terminating resistor is not installed or the module or

CC-Link dedicated cable is affected by noise.

OFF: Normal communication

AJ65BT-64RD3

13579111315171921232527

DA D G

+24V 24G b4A4SLDb3A3b2A2SLDb1A1

2468101214161820222426

DB SLD (FG)

B4NCSLDB3NCB2NCSLDB1NC

AJ65BT-64RD4

13579111315171921232527

DA D G

+24V 24G b4A4SLDb3A3b2A2SLDb1A1

2468101214161820222426

DB SLD (FG)

B4a4SLDB3a3B2a2SLDB1a1

Designates the type of platinum temperature-measuring resistor to be connected to AJ65BT-64RD using a short pin as

either Pt100 (JIS, IEC type) or JPt100 (old JIS type).

(Factory setting is Pt100.)

When connecting Pt100

Circuit board

When connecting JPt100

Circuit board

4-4

Page 36

4. SETTING AND PROCEDURE BEFORE OPERATION MELSEC-A

4.4 Error Compensation by the Offset Value/Gain Value Setting

The AJ65BT-64RD error compensation is a function that compensates values at arbitrary 2 points

(offset value/gain value) within the usage temperature range at system startup or when a correct

temperature cannot be detected.

The error compensation is executed by reading the detected temperature value in the remote register

using a sequence program and monitoring the values using a peripheral device.

SW MODE

NORMAL

0

TEST CH.

1-4

TEST

9

RUN

L RUN

L ERR.

PW

SD

RD

STATION NO.B RATE

10 1

0

9

1

•01

•

•

•

MODE OFFSET UP

9

•

•

2

3

4••

0

1

2

3

4••

8

2

•

7

3

•

456

SET

GAIN DOWN

0

1

2

3

456

RESET

UP/DOWN adju stm ent of OFFSET/GAIN

OFFSET GAIN

Lower value of the two

points to be compensated

<

Higher value of the two

points to be compensated

(of fs et v alu e mo re than +10C°)

The following shows the characteristic of detected temperature value with respect to the input

temperature.

GAIN

80 [°C]0

Compensate the detected

temperature value to equal

the input temperature.

d

e

t

c

e

t

e

D

-50 [°C]

80 [°C]

79.7

e

u

l

a

v

e

r

u

t

a

r

e

p

m

e

t

Characteristics before

error compensation

Characteristics after

error compensation

Input temperature

Compensate the detected

temperature value to equal

the input temperature.

-49.7

-50 [°C]

OFFSET

• The error compensation can also be done by using a standard resistor instead of inputting

temperature directly to the platinum temperature-measuring resistor.

Standard resistive value of the platinum temperatureResistive value of standard resistor = measuring resistor against the input temperature to be the

offset value/gain value (Refer to Appendix 1).

4-5

Page 37

4. SETTING AND PROCEDURE BEFORE OPERATION MELSEC-A

POINT

• The offset value/gain value can be obtained with a high accuracy when error compensation is

carried out at the minimum and maximum temperatures in the range used.

• Set the offset value/gain value while monitoring the detected temperature value, using a

peripheral device.

• Always set the offset and gain values within the allowable temperature input range so that the

gain value minus offset value is greater than or equal to 10 °C.

If the offset value or gain value being used for compensation is out of the setting range, the

RUN LED fickers at a high speed (at 0.1 second intervals) and the offset or gain value will not

be stored even when the offset/gain setting switch is swiched to SET.

• The offset value and gain value are stored inside AJ65BT-64RD and are not erased even at

power off.

4-6

Page 38

4. SETTING AND PROCEDURE BEFORE OPERATION MELSEC-A

4.4.1 Initial settings for error compensation

The following shows the initial settings using a program designed for executing error compensation.

Star t

Create a prog ram th at designates a s amp li ng

processing and travel average processing *1

Create a prog ram th at reads the detec ted

temper atu re v alu es

End

*1 Only when executing error compensation with the value detected by travel average processing.

POINT

• Perform the initial settings for error compensation prior to entering the test mode (at normal

mode).

• During the test mode, disable the designation of the conversion enable/disable specification

flag, and enable conversion for the automatically selected channels and disable for the

unselected channels.

4-7

Page 39

4. SETTING AND PROCEDURE BEFORE OPERATION MELSEC-A

4.4.2 Error compensation procedure

The following shows the flow of error compensation.

Start

Set the mode switch to 9 for test mode.

Check that RUN LED is turned OFF.

RUN

Turns off

after 2

seconds

B

Select the channel to compensate using the mode

switch.

Input a value to be the offset value.

Set the offset/gain setting switch at OFFSET.

MODE

9

•

•

AJ65BT-64RD

0

1

2

3

4••

Pt100

RUN

Flickers at

0.5 second

intervals

MODE

9

•

•

Turn the knob

to the channel

to be set.

Or, input standard

resistive value

using a standard

resistor, etc.

-50 °C

OFFSET

GAIN

0

1

2

3

4••

SET

A

Input a value to be the gain value.

AJ65BT-64RD

Or, input standard

resistive value

80 °C

797

using a standard

resistor, etc.

OFFSET

SET

GAIN

800

UP

Pt100

Set the offset/gain setting switch at GAIN.

RUN

Flickers at

0.5 second

intervals

Adjust the detected temperature value to the gain

value using the UP/DOWN switch.

AJ65BT-64RD

DOWN

Set the offset/gain setting switch at SET to memorise

the gain value.

RUN

Off

OFFSET

SET

GAIN

Adjust the detected temperature value to the offset

value using the UP/DOWN switch.

AJ65BT-64RD

-497

500

UP

DOWN

Set the offset/gain setting switch at SET to memorise

the offset value.

RUN

Off

OFFSET

SET

GAIN

A

NO

B

Set the mode switch to 0 and return to the normal

mode.

Is compensation completed

for the channel used?

RUN

Turns on

after 2

seconds

End

YES

MODE

0

9

•

•

1

2

3

4••

POINT

Once an offset value or gain value is set in the test mode, the set value cannot be confirmed (the

set value is retained in the internal memory.)

4-8

Page 40

4. SETTING AND PROCEDURE BEFORE OPERATION MELSEC-A

4.5 Station Number Setting

The buffer memory addresses of the master module, where the remote I/O signals and read/write data