Page 1

Page 2

Page 3

• SAFETY PRECAUTIONS •

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full

attention to safety to handle the product correctly.

These precautions apply only to this product.

Refer to the user’s manual of the CPU module to use for a description of the programmable controller

system safety precautions.

In this manual, the safety precautions are classified into two levels: "

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

[DESIGN PRECAUTIONS]

WARNING" and " CAUTION".

WARNING

• For the operating status of each station after a data link failure, refer to Chapter 5 in this manual.

• The master station or local station cannot detect errors when a station specified as an error-

invalidated station becomes communication error.

CAUTION

• Do not install the control lines or communication cables together with main circuit lines or power

cables. Keep distance of 100mm (3.9 inch) or more between them. Failure to do so may result in

malfunction due to noise.

[INSTALLATION PRECAUTIONS]

CAUTION

• Use the programmable controller in an environment that meets the specifications in the user’s

manual of the CPU module used. Failure to do so may result in electric shock, fire, malfunction,

or damage to or deterioration of the product.

A - 1

Page 4

[INSTALLATION PRECAUTIONS]

CAUTION

• Insert the tabs at the bottom of the module into the holes in the base unit before mounting the

module. (For the Q2AS series modules, tighten the screws to the base unit with the specified

torque.)

Incorrect mounting may cause malfunction, failure, or drop of the module.

• Shut off the external power supply for the system in all phases before mounting or removing the

module.

Failure to do so may result in damage to the product.

• Do not directly touch any conductive part of the module.

Doing so can cause malfunction or failure of the module.

[WIRING PRECAUTIONS]

WARNING

• Shut off the external power supply for the system in all phases before wiring. Failure to do so

may result in electric shock or damage to the product.

• After wiring, attach the included terminal cover to the module before turning it on for operation.

Failure to do so may result in malfunction.

CAUTION

• Tighten the terminal screws within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

• Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

• Do not install the control lines or communication cables together with the main circuit lines or

power cables.

Doing so may cause malfunctions due to noise.

• Place the cables in a duct or clamp them.

If not, dangling cables may swing or inadvertently be pulled, resulting in damage to the module

or cables or malfunction due to poor contact.

• When disconnecting the cable from the module, do not pull the cable by the cable part. When

removing the cable with a connector, hold the connector on the side that is connected to the

module.

When removing the cable without a connector, loose the screws on the side that is connected to

the module.

Pulling the cable that is still connected to the module may result in damage to the module or

cable, or malfunction due to poor contact.

A - 2

Page 5

[WIRING PRECAUTIONS]

CAUTION

• Use applicable solderless terminals and tighten them within the specified torque range.

If any spade solderless terminal is used, it may be disconnected when the terminal screw comes

loose, resulting in failure.

[STARTUP AND MAINTENANCE PRECAUTIONS]

WARNING

• Do not touch any terminal while power is on.

Doing so can cause electric shock.

• Shut off the external power supply for the system in all phases before cleaning the module or

retightening the terminal screws or module fixing screws.

Failure to do so may result in electric shock.

Undertightening can cause drop of screw, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

CAUTION

• Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

• Shut off the external power supply for the system in all phases before mounting or removing the

module.

Failure to do so may cause the module to fail or malfunction.

• After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module more than 50 times (IEC61131-2 compliant) respectively.

Exceeding the limit of 50 times may cause malfunction.

• Before handling the module, touch a grounded metal object to discharge the static electricity

from the human body.

Failure to do so may cause the module to fail or malfunction.

[DISPOSAL PRECAUTIONS]

CAUTION

• When disposing of this product, treat it as industrial waste.

A - 3

Page 6

• CONDITIONS OF USE FOR THE PRODUCT •

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED

TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION NOT

INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING CONTAINED IN

MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL BULLETINS AND

GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

y Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

y Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

y Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 4

Page 7

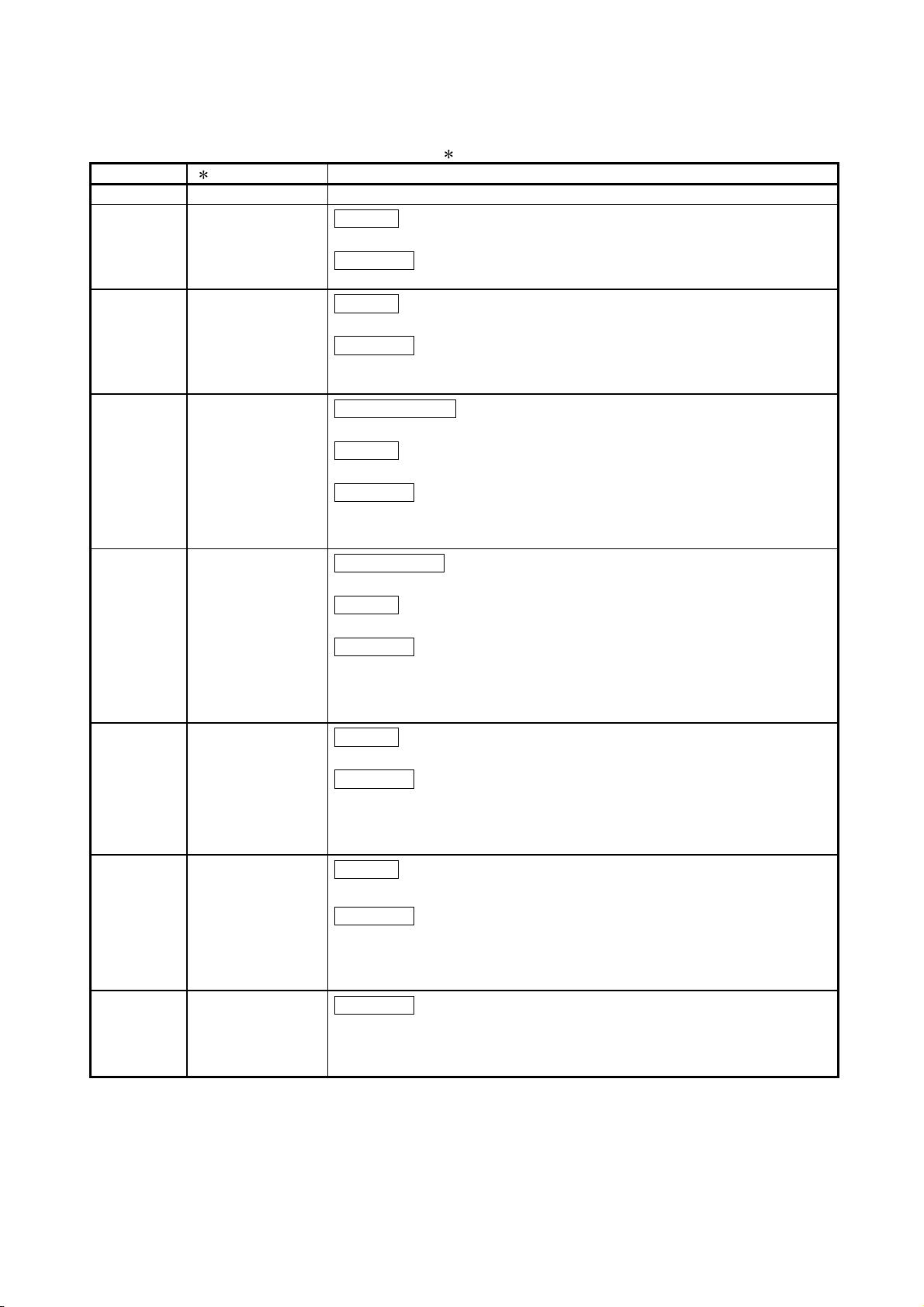

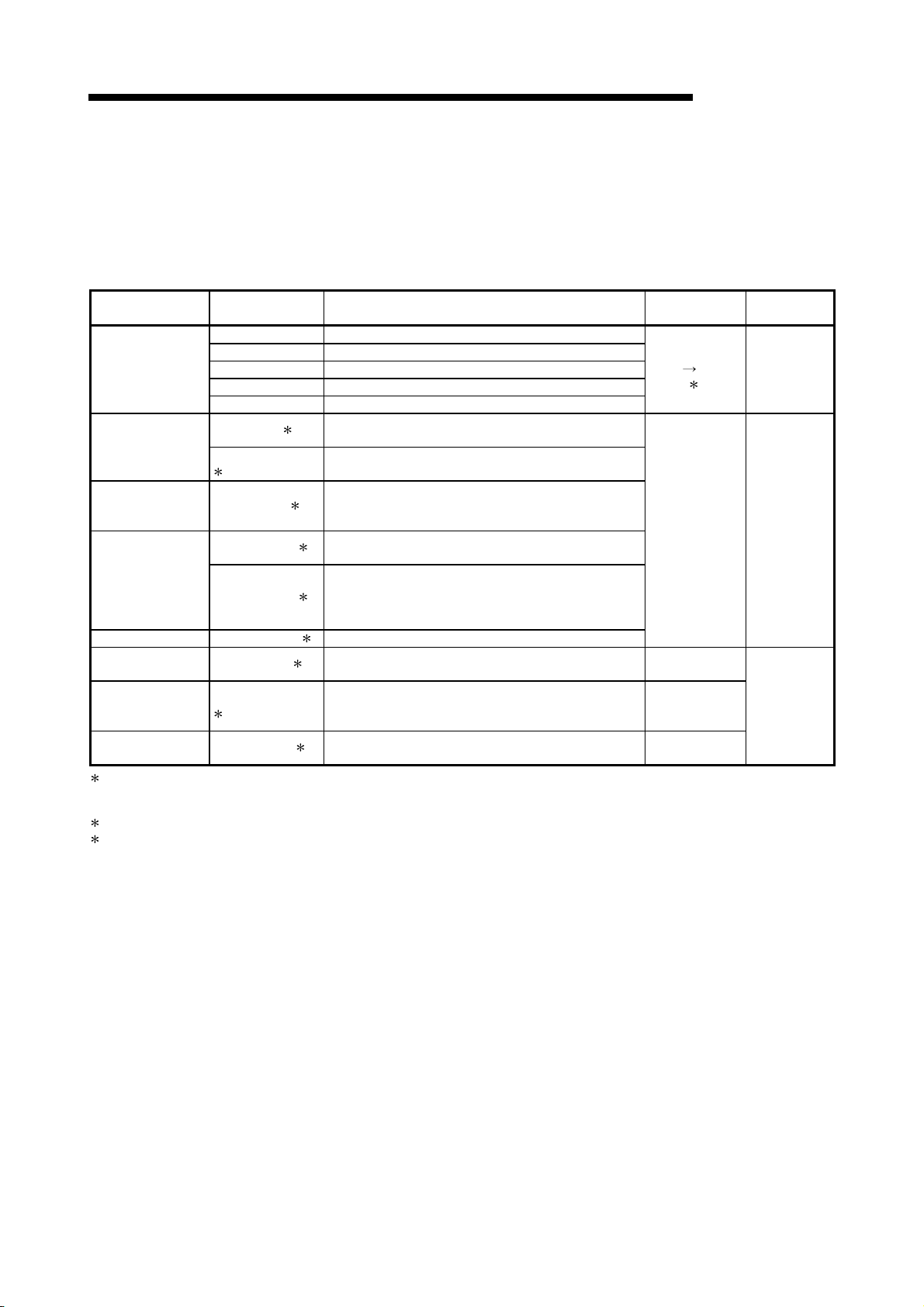

REVISIONS

The manual number is noted at the lower left of the back cover.

Print Date Manual Number Revision

Nov. 1996 IB (NA)-66722-A First printing

Feb. 1997 IB (NA)-66722-B

Addition

Section 3.2.1, 4.12.3, 13.2

Correction

Chapter 1, Section 1.1, 3.2, 3.4, 8.3.2, 13.1, 13.5

Aug. 1997 IB (NA)-66722-C

Addition

Section 1.1, 5.3.4, 5.4, Chapter 14, 15, 16

Correction

Chapter 1, Section 1.4, 1.5, 2.1, 2.2, 2.2.3, 3.2, 3.2.1, 3.3, 4.1, 5.1, 7.1,

7.2.1, 7.3, 7.5, 7.6.1, 7.6.3, 7.6.4, 7.7.1, 7.7.2, 7.8

Jan. 1998 IB (NA)-66722-D

Additional model

Section 1.4, 2.2.3

Addition

Section 15.7

Correction

Section 1.1, 3.3, 3.4.1, 3.5.1, 3.5.2, 4.3, 4.4, 4.5, 5.2, 8.3.1, 13.3,

Chapter 14, 15.1, 15.2.1, 15.6, 15.6.4, 15.6.5, 16.2.3, App1.1, App1.2

Mar. 2000 IB (NA)-66722-E

Jul. 2000 IB (NA)-66722-F

Jul. 2001 IB (NA)-66722-G

Jul. 2003 IB (NA)-66722-H

Addition model

Section 2.2.3

Addition

Section 7.6, 7.6.1, 7.6.2, 15.8

Correction

SAFETY PRECAUTIONS, Section 1.1, 1.5, 3.3, 3.5.1, 5.1, 5.2, 5.4.3,

7.3, 7.5, 8.3.2, 10.2.2, 12.2.2, 13.1, 13.3, 13.4.4, Chapter 14,

Section 15.1, 15.2.1, 15.5.2, 15.5.4, 15.5.5, 15.6, 15.7, Chapter 16

Addition

Section 2.2.4, 3.2.2

Correction

Section 1.4, 2.2.1, 2.2.3, 3.2, 3.2.1, 3.4.2, 3.5.1, 7.3, 7.6.2, 7.7.3, 7.7.4,

8.3.1, 9.1.1, 10.1.1, 10.2.2, 11.1.1, 11.1.2, 12.1.1, 12.1.4, 15.2.1,

App1.1, App1.2

Addition

Section 8.2

Correction

Section 2.2.3, 3.4.1, 3.4.2, 4.12.1, 5.4, 5.4.1, 5.4.2, 5.4.3, 7.2.1, 7.3, 7.5,

8.4.2, 9.2.1, 10.2.1, 11.2.1, 12.2.1, 13.1, 13.3, 13.4.2, 13.4.3, Chapter 14,

Section 15.1, 15.2.1, 15.6, 15.8.1

Correction

SAFETY PRECAUTIONS, About This manual, Section 2.2.3, 3.1, 3.3,

3.4.2, 3.5.1, 7.9, 10.2.1, 13.3, 15.2, 15.3, 15.10.1 to 15.10.3, 15.11.1 to

15.11.3

A - 5

Page 8

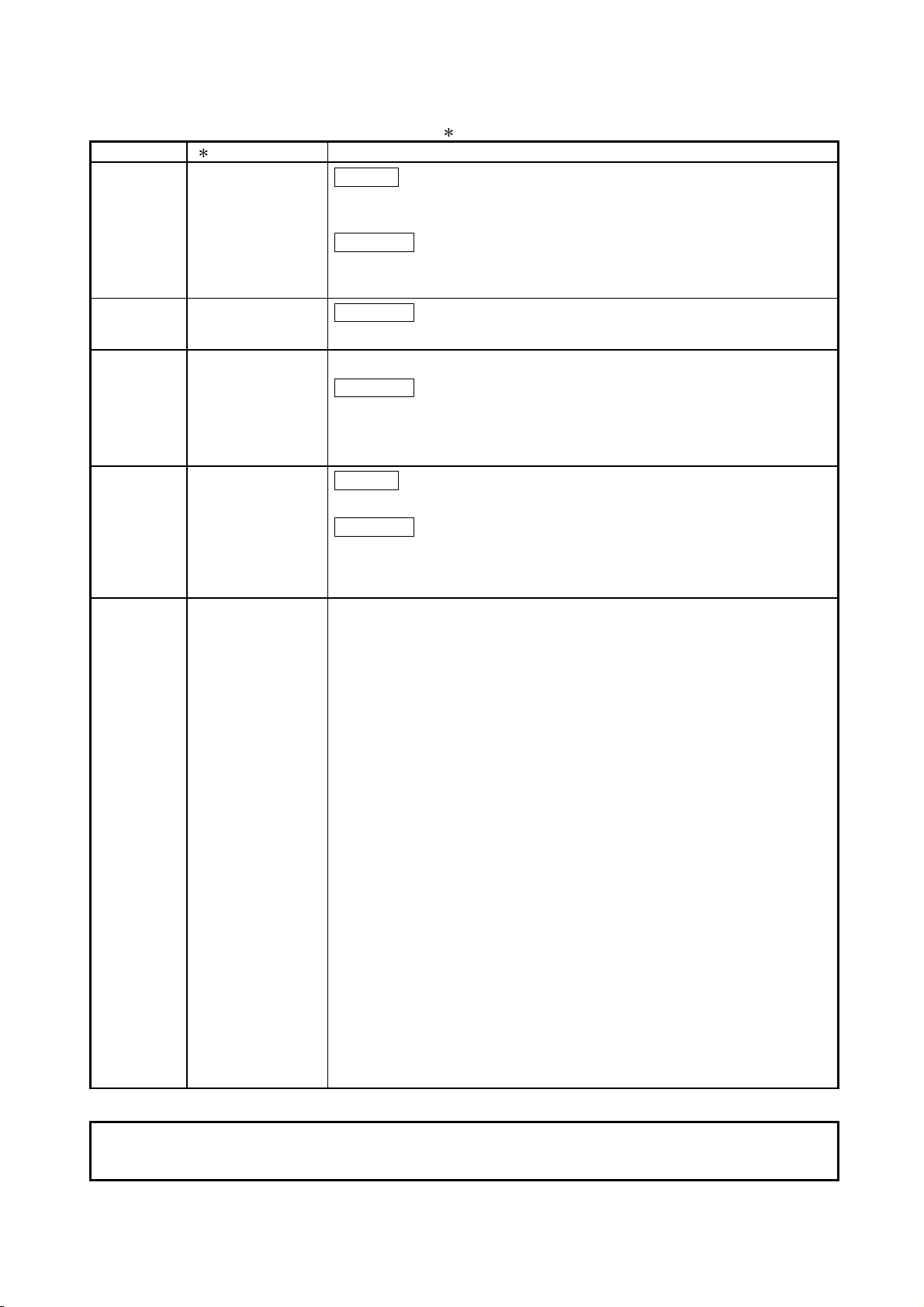

The manual number is noted at the lower left of the back cover.

Print Date Manual Number Revision

Apr. 2006 IB (NA)-66722-I

Addition

Conformation to the EMC Directive and Low Voltage Instruction,

Section 11.1

Correction

SAFETY PRECAUTIONS, Chapter 1, Section 2.2.2, 2.2.4, 3.2, 4.1, 4.8,

6.3, 7.5, 8.4.2, 11.3.2, 13.3

Sep. 2007 IB (NA)-66722-J

Correction

Section 1.4, 1.5, 2.1, 2.2.3, 3.5.2, 7.3, 8.4.1, 15.2.2, 15.7, App 1.2

Sep. 2009 IB (NA)-66722-K

"PLC" and "PC" were changed to "programmable controller".

Correction

SAFETY PRECAUTIONS, Compliance with the EMC and Low Voltage

Directives, Chapter 1, Section 1.5, 2.2.4, 3.1, 3.3, 3.4.2, 7.2.1, 7.3, 7.5,

7.6.2, 13.3, 15.2.1, App 2

Nov. 2012 IB (NA)-66722-L

Addition

CONDITIONS OF USE FOR THE PRODUCT

Correction

SAFETY PRECAUTIONS, Relevant Manuals, COMPLIANCE WITH EMC

AND LOW VOLTAGE DIRECTIVES, Chapter 1, Section 3.1, 3.5.1, 6.2,

7.3, 7.5, 7.7.3, 8.4.1, 8.4.2, 11.3.2, 13.3, 15.7

This manual does not imply guarantee or implementation right for industrial ownership or implementation of other rights.

Mitsubishi Electric Corporation is not responsible for industrial ownership problems caused by use of the contents of this

manual.

© 1996 Mitsubishi Electric Corporation

Japanese Manual Version SH-3604-M

A - 6

Page 9

INTRODUCTION

Thank you for purchasing the MELSEC-QnA Series programmable controller.

Before using the product, please read this manual thoroughly to gain an understanding of its functions so you

can use it properly.

Please forward a copy of this manual to the end user.

CONTENTS

SAFETY PRECAUTIONS..............................................................................................................................A- 1

CONDITIONS OF USE FOR THE PRODUCT .............................................................................................A- 4

REVISIONS ....................................................................................................................................................A- 4

INTRODUCTION ...........................................................................................................................................A- 6

MANUAL.........................................................................................................................................................A-12

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES ...............................................................A-12

1. OVERVIEW .....................................................................................................................................1- 1 to 1-15

1.1 How to Use This Manual......................................................................................................................... 1- 3

1.2 Characteristics......................................................................................................................................... 1- 4

1.3 Communication Overview....................................................................................................................... 1- 9

1.3.1 Communication between the master station and remote I/O station ............................................. 1- 9

1.3.2 Communication between the master station and remote device station ....................................... 1-10

1.3.3 Communication between the master station and local station .......................................................1-11

1.3.4 Compound system communication .................................................................................................1-12

1.4 Number of Occupied Stations and Station Number, Number of Modules and Number of Stations ....1-13

1.5 Generic Terms and Abbreviations.......................................................................................................... 1-14

2. SYSTEM CONFIGURATION..........................................................................................................2- 1 to 2- 8

2.1 Total Configuration .................................................................................................................................. 2- 1

2.2 Applicable System................................................................................................................................... 2- 2

2.2.1 Applicable CPU and number of modules that can be installed ...................................................... 2- 2

2.2.2 Precautions when configuring a system .......................................................................................... 2- 3

2.2.3 List of system equipment restricted by master/local module versions ........................................... 2- 6

2.2.4 About Ver. 1.10 ................................................................................................................................ 2- 7

3. SPECIFICATION.............................................................................................................................3- 1 to 3-37

3.1 General Specification .............................................................................................................................. 3- 1

3.2 Performance Specifications .................................................................................................................... 3- 2

3.2.1 Maximum overall cable distance (for Ver. 1.00).............................................................................. 3- 3

3.2.2 Maximum overall cable distance (for Ver. 1.10).............................................................................. 3- 5

3.3 CC-Link Dedicated Cable ....................................................................................................................... 3- 6

3.4 I/O Signals to the Programmable Controller CPU ................................................................................. 3- 7

3.4.1 I/O signal list ..................................................................................................................................... 3- 7

3.4.2 I/O signal details ............................................................................................................................... 3- 9

A - 7

Page 10

3.5 Buffer Memory......................................................................................................................................... 3-19

3.5.1 Buffer memory list ............................................................................................................................ 3-19

3.5.2 Buffer memory details ...................................................................................................................... 3-21

4. FUNCTIONS....................................................................................................................................4- 1 to 4-30

4.1 Function List ............................................................................................................................................ 4- 1

4.2 Communication Between the Master Station and Remote I/O Station ................................................. 4- 3

4.3 Communication Between the Master Station and Remote Device Station........................................... 4- 5

4.4 Communication Between the Master Station and Local Station ........................................................... 4-10

4.5 Communication in Compound Systems ................................................................................................. 4-16

4.6 Reserved Station Function ..................................................................................................................... 4-22

4.7 Error Invalid Station Function ................................................................................................................. 4-23

4.8 Data Link Status Setting When the Master Station Programmable Controller CPU Has an Error ......4-24

4.9 Setting the Status of Input Data from a Data Link Faulty Station.......................................................... 4-25

4.10 Module Reset Function from a Sequence Program ............................................................................ 4-26

4.11 Data Link Stop/Restart .......................................................................................................................... 4-27

4.12 RAS Function ........................................................................................................................................ 4-28

4.12.1 Automatic return function ............................................................................................................... 4-28

4.12.2 Slave station cut-off function.......................................................................................................... 4-29

4.12.3 Station number overlap checking function .................................................................................... 4-30

5. DATA LINK PROCESSING TIME ..................................................................................................5- 1 to 5-24

5.1 Status of Each Station When an Error Has Occurred ...........................................................................5- 1

5.2 Link Scan Time ....................................................................................................................................... 5- 4

5.3 Transmission Delay Time ....................................................................................................................... 5- 5

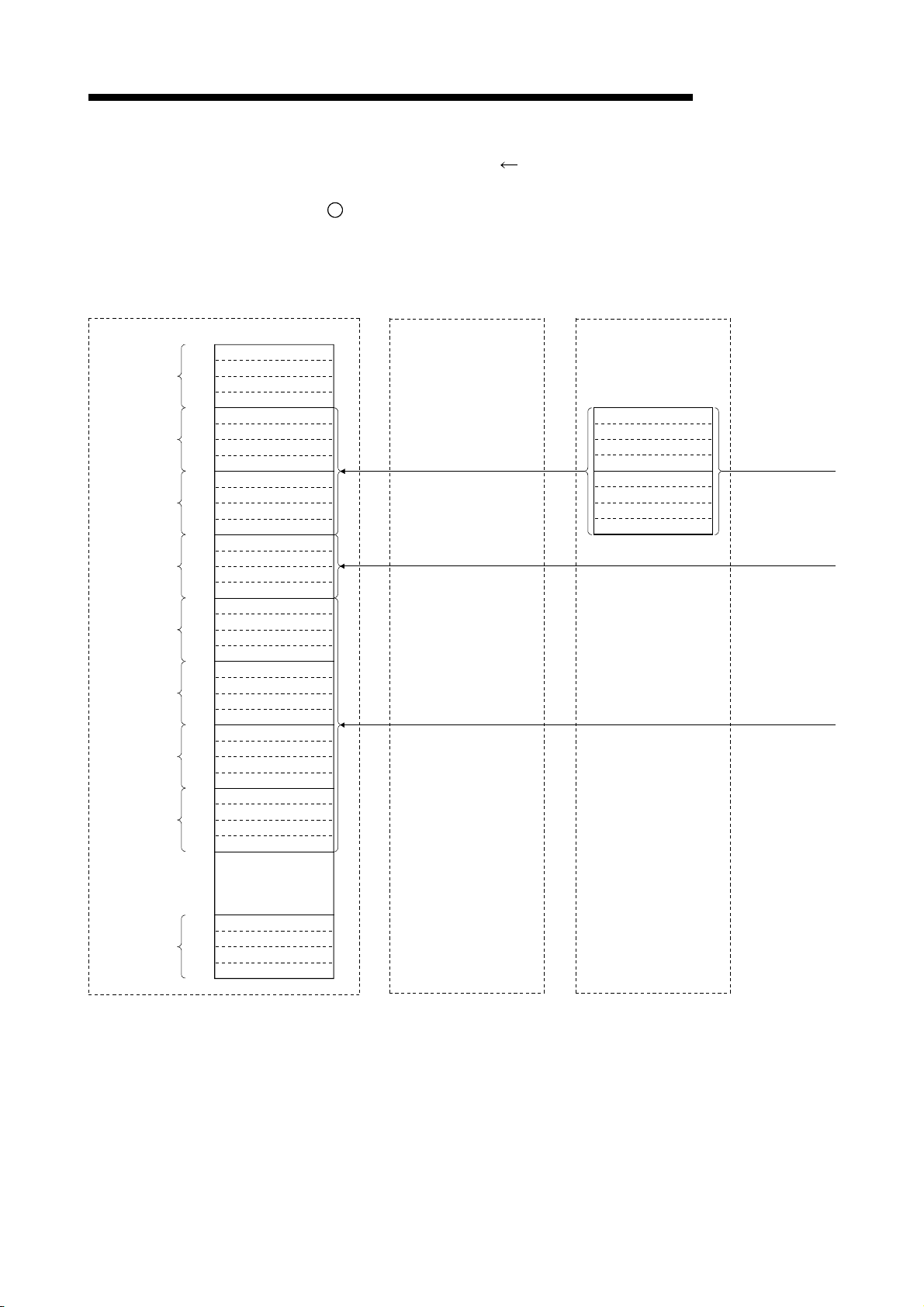

5.3.1 Master station

5.3.2 Master station

5.3.3 Master station

5.3.4 Master station

remote I/O station................................................................................................ 5- 5

remote device station ..........................................................................................5- 7

local station.......................................................................................................... 5-11

intelligent device station ...................................................................................... 5-15

5.4 Dedicated Instruction Processing Time.................................................................................................. 5-16

5.4.1 Master station

5.4.2 Local station

5.4.3 Master station

local station ......................................................................................................... 5-16

local station............................................................................................................ 5-20

intelligent device station ..................................................................................... 5-22

6. PARAMETER SETTING.................................................................................................................6- 1 to 6-10

6.1 Procedure from Parameter Setting to Data Link Startup....................................................................... 6- 1

2

6.1.1 Relationship between buffer memory, E

PROM and internal memory.......................................... 6- 1

6.1.2 Procedure from parameter setting to data link start........................................................................ 6- 3

6.2 Parameter Settings ................................................................................................................................. 6- 4

6.3 Setting from a Sequence Program ......................................................................................................... 6- 5

7. DATA LINK PROCEDURE .............................................................................................................7- 1 to 7-24

7.1 Data Link Procedure ............................................................................................................................... 7- 1

7.2 Installation and Setting............................................................................................................................ 7- 2

7.2.1 Precautions when handling the module .......................................................................................... 7- 2

7.2.2 Setting environment ......................................................................................................................... 7- 3

A - 8

Page 11

7.3 Name of Each Part and Settings ............................................................................................................ 7- 4

7.4 Checking Module Condition (Hardware Test) ........................................................................................ 7- 8

7.5 Module Wiring with CC-Link Dedicated Cable....................................................................................... 7-10

7.6 T-Branch Connection with the CC-Link Dedicated Cable ..................................................................... 7-11

7.6.1 T-Branch system configuration ........................................................................................................ 7-11

7.6.2 T-Branch communication specifications list .................................................................................... 7-12

7.7 Switch Settings ........................................................................................................................................ 7-14

7.7.1 Station number setting

(master station, local station, standby master station, and remote station) ................................... 7-14

7.7.2 Mode setting ..................................................................................................................................... 7-16

7.7.3 Transmission speed setting ............................................................................................................. 7-16

7.7.4 Condition setting............................................................................................................................... 7-17

7.8 Checking the Connection Condition (Line Test) ....................................................................................7-18

7.8.1 Checking connection and communication status with remote station/local station/standby master

station (line test 1) ............................................................................................................................ 7-18

7.8.2 Checking communication status with specific remote station/local station/standby master station

(line test 2) ........................................................................................................................................ 7-20

7.9 Checking Parameters (Parameter Confirmation Test) ..........................................................................7-22

8. PROGRAMMING ............................................................................................................................8- 1 to 8-22

8.1 Precautions When Programming ........................................................................................................... 8- 1

8.2 Precautions for Registering Parameters to E

2

PROM ........................................................................... 8- 3

8.2.1 Target module and versions ............................................................................................................8- 3

8.2.2 Precautions....................................................................................................................................... 8- 3

2

8.2.3 Program for registering parameters to E

PROM ............................................................................ 8- 4

8.3 Programming Procedure......................................................................................................................... 8- 6

8.3.1 Communication between the master station and remote I/O station ............................................. 8- 6

8.3.2 Communication between the master station and remote device station ....................................... 8- 7

8.3.3 Communication between the master station and local station ....................................................... 8- 8

8.3.4 Communication in a compound system ..........................................................................................8-10

8.4 Link Special Relay/Register (SB/SW) .................................................................................................... 8-12

8.4.1 Link special relay (SB) ..................................................................................................................... 8-12

8.4.2 Link special register (SW) ................................................................................................................ 8-16

9. COMMUNICATION BETWEEN THE MASTER STATION AND THE REMOTE

I/O STATION ...................................................................................................................................9- 1 to 9-12

9.1 System Configuration.............................................................................................................................. 9- 1

9.1.1 Setting of the master station ............................................................................................................ 9- 2

9.1.2 Setting of the remote I/O station ...................................................................................................... 9- 3

9.2 Creating a Program................................................................................................................................. 9- 4

9.2.1 Program for parameters................................................................................................................... 9- 4

9.2.2 Communication program.................................................................................................................. 9- 7

9.3 Performing the Data Link ........................................................................................................................ 9-10

9.3.1 Confirming the operation by LED display ........................................................................................ 9-10

9.3.2 Confirming the operation by the program ........................................................................................ 9-11

A - 9

Page 12

10. COMMUNICATION BETWEEN THE MASTER STATION AND THE REMOTE

DEVICE STATION................................................................................................................... 10- 1 to 10-14

10.1 System Configuration.......................................................................................................................... 10- 1

10.1.1 Setting of the master station ........................................................................................................10- 2

10.1.2 Setting of the remote device station ............................................................................................10- 3

10.2 Creating a Program............................................................................................................................. 10- 4

10.2.1 Program for parameters............................................................................................................... 10- 4

10.2.2 Communication program ............................................................................................................. 10- 7

10.3 Performing the Data Link .................................................................................................................... 10-12

10.3.1 Confirming the operation by LED display.................................................................................... 10-12

10.3.2 Confirming the operation by the program.................................................................................... 10-13

11. COMMUNICATION BETWEEN THE MASTER STATION AND THE LOCAL STATION .... 11- 1 to 11-16

11.1 Secured 32-bit Data ............................................................................................................................ 11- 1

11.2 System Configuration.......................................................................................................................... 11- 2

11.2.1 Setting of the master station ........................................................................................................11- 3

11.2.2 Setting of the local station ............................................................................................................ 11- 4

11.3 Creating a Program............................................................................................................................. 11- 5

11.3.1 Program for the mater station ...................................................................................................... 11- 5

11.3.2 Local station program .................................................................................................................. 11-11

11.4 Performing the Data Link .................................................................................................................... 11-14

11.4.1 Confirming the operation by LED display.................................................................................... 11-14

11.4.2 Confirming the operation by the program.................................................................................... 11-15

12. COMMUNICATION IN THE COMPOUND SYSTEM ............................................................. 12- 1 to 12-16

12.1 System Configuration.......................................................................................................................... 12- 1

12.1.1 Setting of the master station ........................................................................................................12- 2

12.1.2 Setting of the remote I/O station .................................................................................................. 12- 3

12.1.3 Setting of the remote device station ............................................................................................12- 3

12.1.4 Setting of the local station ............................................................................................................ 12- 4

12.2 Creating a Program............................................................................................................................. 12- 5

12.2.1 Program for the master station ....................................................................................................12- 5

12.2.2 Local station program .................................................................................................................. 12-13

12.3 Performing the Data Link .................................................................................................................... 12-14

12.3.1 Confirming the operation by LED display.................................................................................... 12-14

12.3.2 Confirming the operation by the program.................................................................................... 12-16

A - 10

Page 13

13. TROUBLESHOOTING............................................................................................................. 13- 1 to 13-18

13.1 Verification When a Trouble Occurs .................................................................................................. 13- 1

13.2 Troubleshooting When the "ERR" LED on the Master Station Is Flashing....................................... 13- 4

13.3 Error Codes ......................................................................................................................................... 13- 6

13.4 LED Display Status ............................................................................................................................. 13-12

13.4.1 When data link is normal.............................................................................................................. 13-12

13.4.2 When a cable is disconnected ..................................................................................................... 13-12

13.4.3 When a cable is shorted .............................................................................................................. 13-13

13.4.4 When the link is stopped at the master station ........................................................................... 13-13

13.4.5 When power supply to a remote I/O station is turned off............................................................ 13-14

13.4.6 When the power supply to a remote device station is turned off................................................ 13-14

13.4.7 When the power supply to the local station (programmable controller CPU) is turned off........ 13-15

13.4.8 When the station numbers are duplicate..................................................................................... 13-15

13.4.9 When the transmission speed is set incorrectly.......................................................................... 13-16

13.4.10 When the switch setting is changed during data link ................................................................ 13-16

13.4.11 When data link is started with the switch set outside the range ............................................... 13-17

13.4.12 When the remote I/O station is not set by the parameter (i.e., is set as reserved) ................. 13-17

13.4.13 When the remote device station is not set by the parameter (i.e., is set as reserved) ............ 13-18

13.4.14 When the local station is not set by the parameter (i.e., is set as reserved) ........................... 13-18

14. OVERVIEW (FUNCTION VERSION B OR LATER) .............................................................. 14- 1 to 14- 2

15. FUNCTIONS (FUNCTION VERSION B OR LATER) ............................................................. 15- 1 to 15-20

15.1 List of Functions .................................................................................................................................. 15- 1

15.2 Parameter Registration Function........................................................................................................ 15- 1

15.2.1 Network parameters..................................................................................................................... 15- 2

15.2.2 Automatic refresh parameters .....................................................................................................15- 3

15.3 Automatic Refresh Function ...............................................................................................................15- 3

15.4 Scan Synchronous Function............................................................................................................... 15- 4

15.4.1 Synchronous mode ......................................................................................................................15- 4

15.4.2 Asynchronous mode .................................................................................................................... 15- 5

15.5 Standby Master Function.................................................................................................................... 15- 6

15.5.1 Operation overview ......................................................................................................................15- 6

15.5.2 Settings on using the standby master function ...........................................................................15- 7

15.5.3 Link special relays/registers (SB, SW) relating to the standby master function ........................ 15- 8

15.5.4 Notes on using the standby master function ............................................................................... 15- 9

15.5.5 Program example on using the standby master function ...........................................................15-10

15.6 Dedicated Instructions ........................................................................................................................ 15-11

15.7 Communication Instructions (Software Version J and Later) ............................................................ 15-12

15.8 Remote I/O Net Mode ......................................................................................................................... 15-13

15.8.1 Features ....................................................................................................................................... 15-13

15.8.2 Software version corresponding to master module and its CPU................................................ 15-13

15.8.3 Set item......................................................................................................................................... 15-13

15.8.4 Link scan time .............................................................................................................................. 15-14

15.8.5 Precautions................................................................................................................................... 15-14

A - 11

Page 14

15.9 Temporary Error Invalid Station Specification Function ....................................................................15-15

15.9.1 I/O status of the temporary error invalid station specification..................................................... 15-15

15.9.2 Link special relays/registers (SB, SW) relating to the temporary error invalid station

specification function .................................................................................................................... 15-15

15.9.3 Execution procedure for the temporary error invalid station specification function ................... 15-17

15.10 Online Test Function ......................................................................................................................... 15-18

15.10.1 Parameter test............................................................................................................................ 15-18

15.10.2 Line test ...................................................................................................................................... 15-18

15.10.3 Network test ............................................................................................................................... 15-18

15.11 Monitor/Diagnosis Functions ............................................................................................................ 15-19

15.11.1 Line monitor (host station) .........................................................................................................15-19

15.11.2 Line monitor (other stations) ...................................................................................................... 15-19

15.11.3 Device monitor ........................................................................................................................... 15-20

16. COMMUNICATION WITH INTELLIGENT DEVICES

(FUNCTION VERSION B OR LATER) ................................................................................... 16- 1 to 16- 2

APPENDICES ...........................................................................................................................APP- 1 to APP- 5

Appendix 1 External Dimensions.............................................................................................................APP- 1

Appendix 1.1 AJ61QBT11 ...................................................................................................................APP- 1

Appendix 1.2 A1SJ61QBT11 ...............................................................................................................APP- 2

Appendix 2 Parameter Setting Sheet ......................................................................................................APP- 3

A - 12

Page 15

MANUAL

Relevant Manuals

The following manuals are to this product.

Order as needed, referring to the table below.

Manual Name

SW2IVD/NX-GPPQ GPP Function Software Package Operating Manual (Offline Version)

Describes the offline function of program creation method, print out method and file

maintenance, etc. on the SW2NX-GPPQ/SW2IVD-GPPQ.

(Same package)

SW2IVD/NX-GPPQ GPP Function Software Package Operating Manual (Online Version)

Describes the online function of monitor method and debugging method, etc. on the

SW2IVD-GPPQ/SW2NX-GPPQ.

(Same package)

GX Developer Version 8 Operating Manual

Explains the functions of GX Developer, such as the programming, printout, monitoring and

debugging methods.

(Sold separately)

QnACPU Programming Manual (Common Instructions)

Describes how to use sequence instructions, basic instructions and application instructions.

(Sold separately)

QnACPU PROGRAMMING MANUAL (Special Functions)

Describes dedicated instructions used in the Q2ACPU(S1), Q3ACPU, and Q4ACPU specialfunction modules.

(Sold separately)

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

Manual No.

(Model code)

IB-66775

(13J922)

IB-66774

(13J921)

SH-080373E

(13JU41)

SH-080810ENG

(13JW11)

IB-66616

(13JF48)

(1) For programmable controller system

To ensure that Mitsubishi programmable controllers maintain EMC and Low

Voltage Directives when incorporated into other machinery or equipment, certain

measures may be necessary. Please refer to one of the following manuals.

• User's manual for the CPU module used

• User's manual (hardware) for the CPU module or base unit used

(2) For the product

To ensure that this product maintains EMC and Low Voltage Directives, please

refer to one of the manuals listed under (1).

A - 13

Page 16

MEMO

A - 14

Page 17

1 OVERVIEW

1. OVERVIEW

MELSEC-QnA

The CC-Link system is a system that connects distributed modules such as I/O

1

modules, intelligent function modules, and special function modules using dedicated

cables so that these modules can be controlled by a programmable controller CPU.

This chapter describes outline of the CC-Link.

1

By distributing each module to the equipment device such as the conveyor line and

machine devices, the wiring conservation of the entire system can be accomplished.

2

Simple, high-speed communication can be accomplished with modules that handle

on/off data such as I/O or numeric data.

3

By connecting multiple programmable controller CPUs, a simple distributed system

can be configured.

4

Connections can be made to different types of devices made by partner

manufacturers, giving flexibility to the system.

Master station

Programmable

controller CPU

Remote I/O station

Partner manufacturer's

product

Remote device station

CC - Link system

Remote I/O station

Programmable

controller CPU

Local station

Master station................... Station which controls the remote I/O station, remote device

station, and local stations

Remote I/O station ...........Remote station which handles only on/off data

Remote device station .....Remote station which handles both on/off data and numeric

data

Local station .....................Station which has a CPU and can communicate with the

master station and other local stations

1 - 1

Page 18

1 OVERVIEW

AJ61QBT11 CC-Link System Master/Local

Module

(discontinued on September 2008)

A1SJ61QBT11 CC-Link system

Master/Local Module

MELSEC-QnA

When applying any of the program examples to the actual system, examine the

applicability and confirm that it will not cause system control problems.

After unpacking, please check that the following components are included.

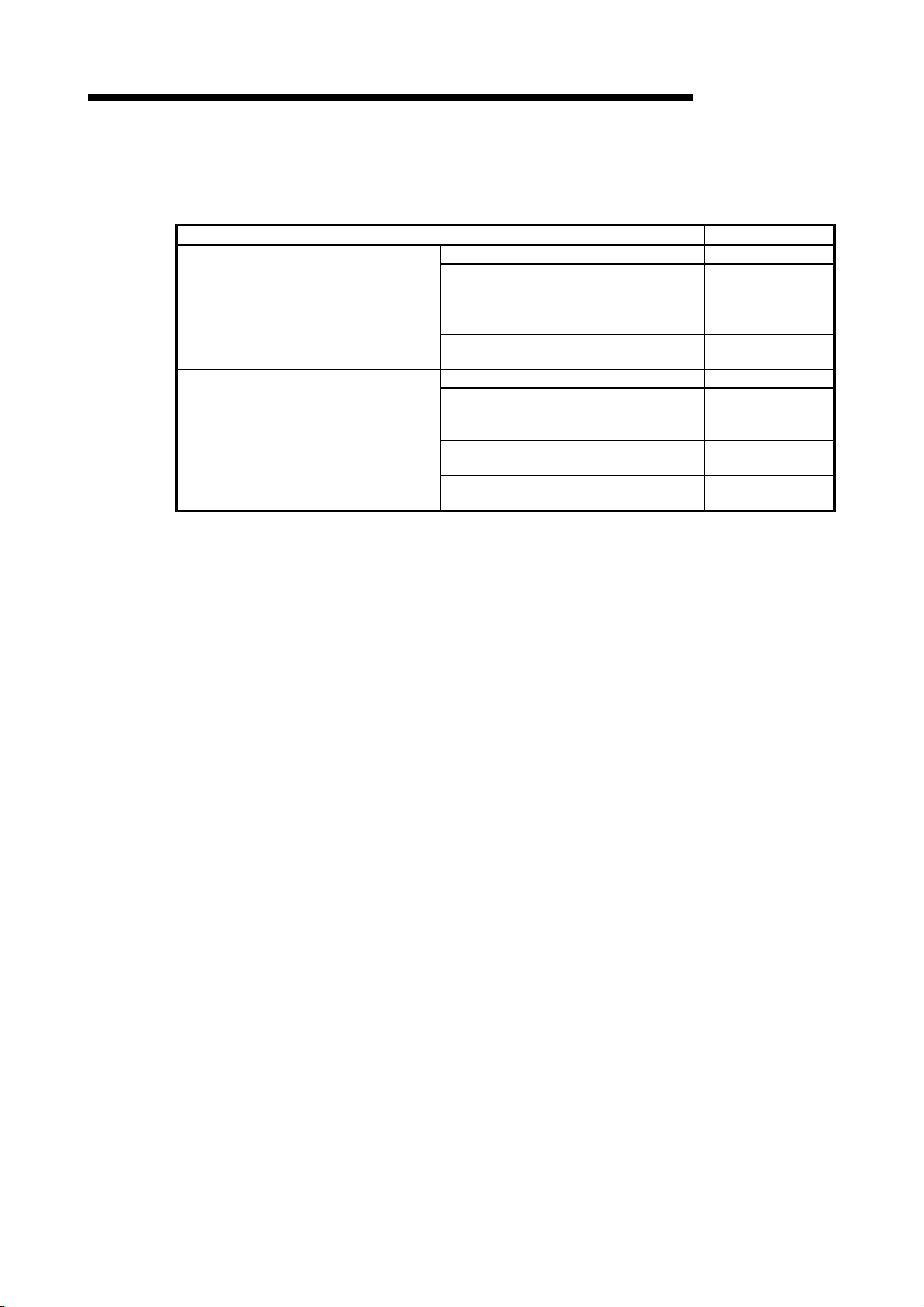

Product name Quantity

AJ61QBT11 1

AJ61QBT11 CC-Link System Master/Local

Module User's Manual (Hardware)

Terminating resistor (110 Ω, 1/2 W)

(All brown)

Terminating resistor (130 Ω, 1/2 W)

(brown, orange, brown)

A1SJ61QBT11 1

A1SJ61QBT11 CC-Link System

Master/Local Module User's Manual

(Hardware)

Terminating resistor (110 Ω, 1/2 W)

(All brown)

Terminating resistor (130 Ω, 1/2 W)

(brown, orange, brown)

1

2

2

1

2

2

1 - 2

Page 19

1 OVERVIEW

1.1 How to Use This Manual

The master/local module has the following functions added from the function version B

or later. The detailed descriptions of the additional functions are provided in Chapter 14

or later.

(1) Scan synchronous function

Link scan can be executed synchronized with the sequence scan.

(2) Standby master function

With this function, the data link can be continuously executed even if an error

occurs in the master station, by automatically switching to the standby master

station.

(3) Dedicated instructions

Transient transmission with the intelligent device and local station is possible.

In addition, read/write of data with handshake to/from the remote device is

feasible.

(4) Temporary error invalid station specification function

By specifying the corresponding remote station as a temporary error invalid

station, an error is not detected even if the module is replaced while in

communication.

(5) Parameter registration function

Parameters such as total number of connected stations and station information

can be set using dedicated instructions.

(6) Automatic refresh function

Data transferred by cyclic transmissions, such as RX and RY, can be refreshed

by the END processing to a desired device, when set up with the dedicated

instruction.

(7) Monitor/diagnosis function

Monitoring and diagnosing can be performed from a peripheral device.

(8) Online test function

Line testing and control of link such as starting up and stopping can be

performed from a peripheral device.

(9) Communication instruction (software version J manufactured in

Jan., 1998 or later)

Data communication with other stations is possible. Data read/write with other

stations is also possible.

(10) Dedicated instruction (software version J manufactured in Jan.,

1998 or later)

Device read/write with respect to the CPU of the specified station are possible.

(11) Remote I/O net mode (software version P manufactured in Sep.,

1998 or later)

When the system is configured only with the master station and the remote I/O

stations, the setting of the network parameters is eliminated and the link

scanning time is shortened by the use of the remote I/O net mode.

1 - 3

MELSEC-QnA

Page 20

1 OVERVIEW

1.2 Characteristics

MELSEC-QnA

The characteristics of the CC-Link are described below:

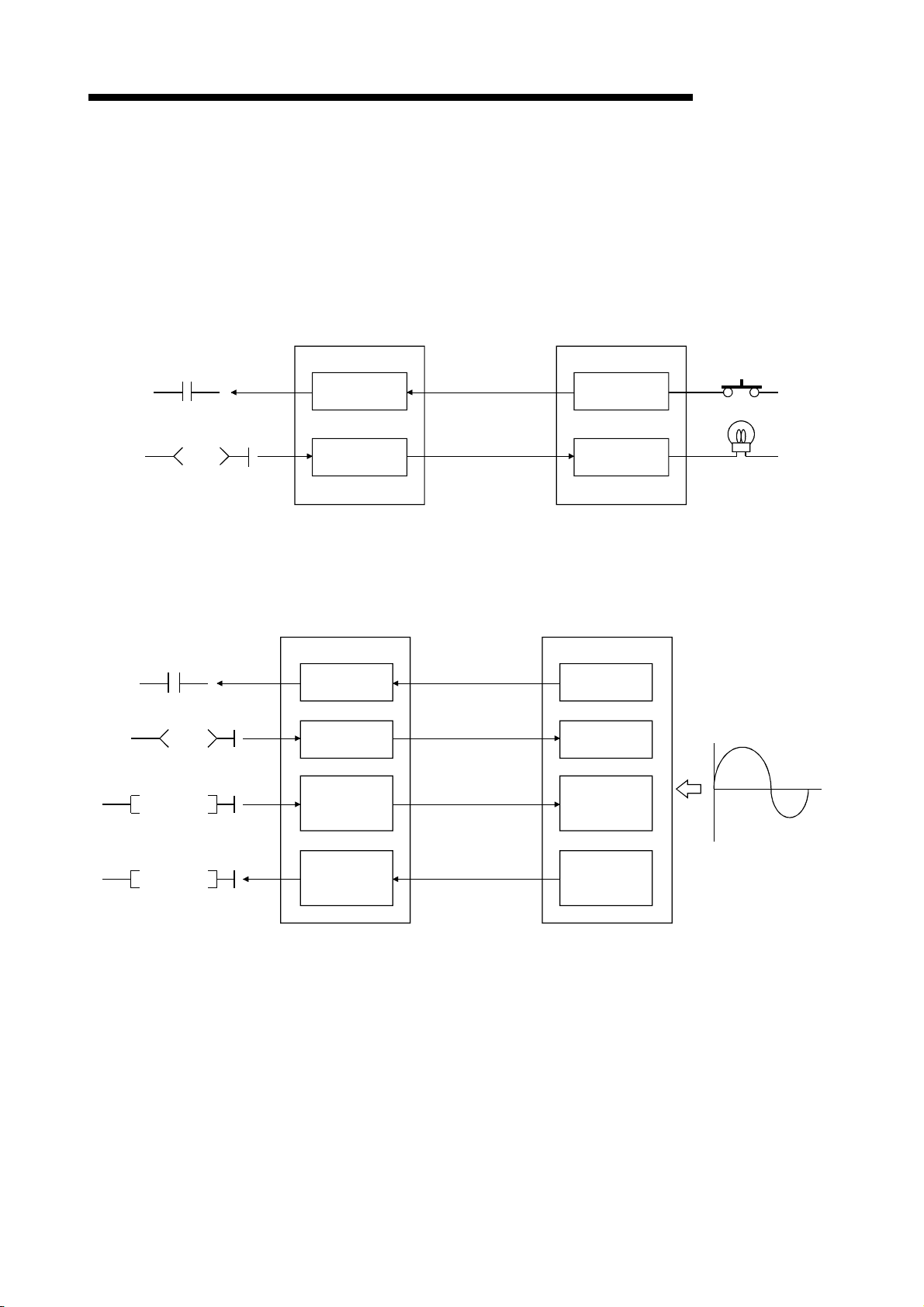

(1) Remote I/O station communication

The communication is performed with only on/off data (remote input RX and

remote output RY).

Master station

Remote I/O station

A/D conversion

completion flag

Offset·gain selection

A/D conversion

enable/disable specification

TO

Remote input

(RX)

Remote output

(RY)

Link scan

Link scan

Input

Output

(2) Remote device station communication

The communication is performed with on/off data (remote input RX and remote

output RY) and numeric data (remote register).

Master station

Remote input

(RX)

Remote output

(RY)

Remote register

(RWw)

Link scan

Link scan

Link scan

Remote device station

Remote input

(RX)

Remote output

(RY)

Remote register

(RWw)

Analog voltage

Digital output value

FROM

Remote register

(RWr)

Link scan

1 - 4

Remote register

(RWr)

Page 21

1 OVERVIEW

Master station

MELSEC-QnA

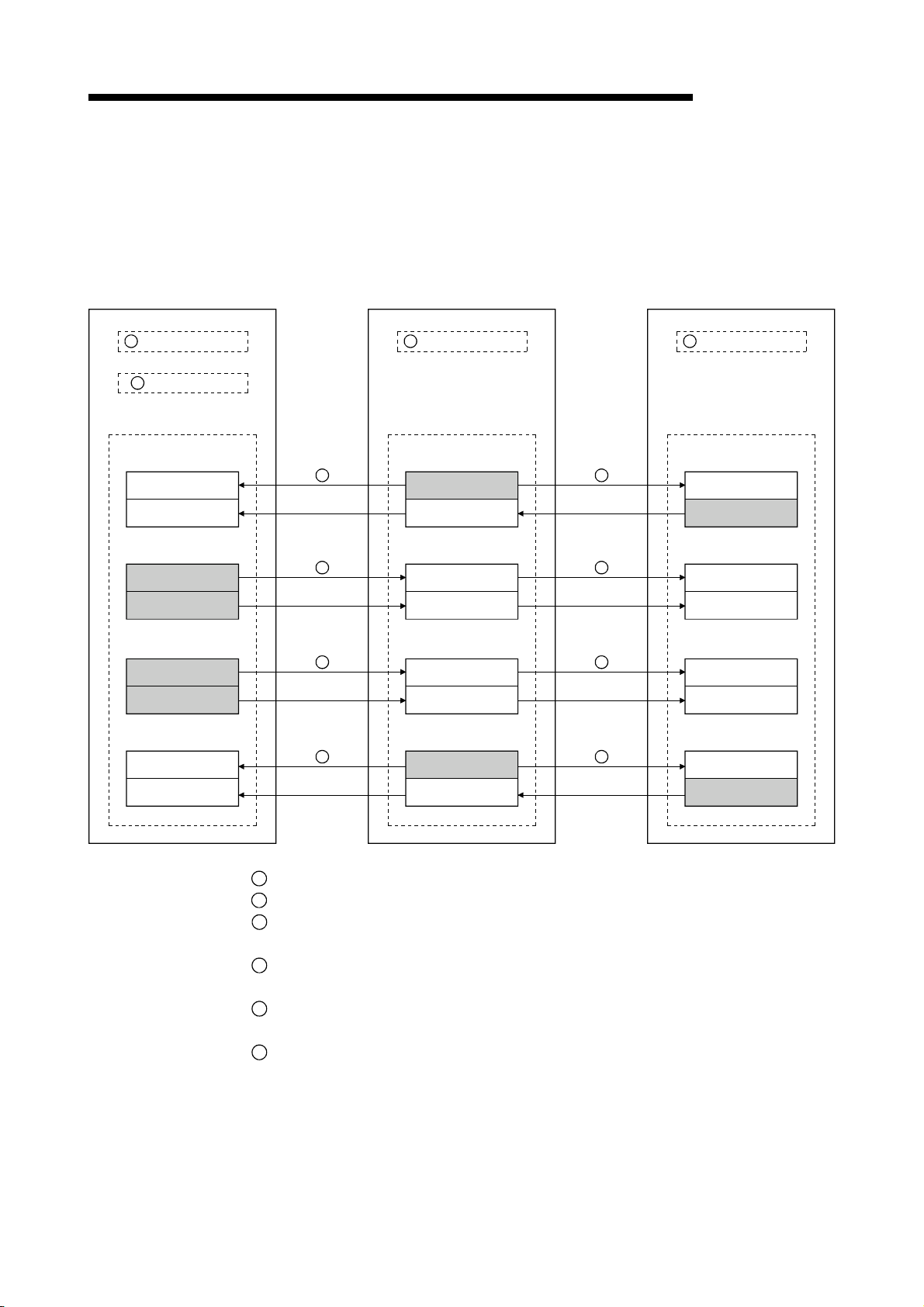

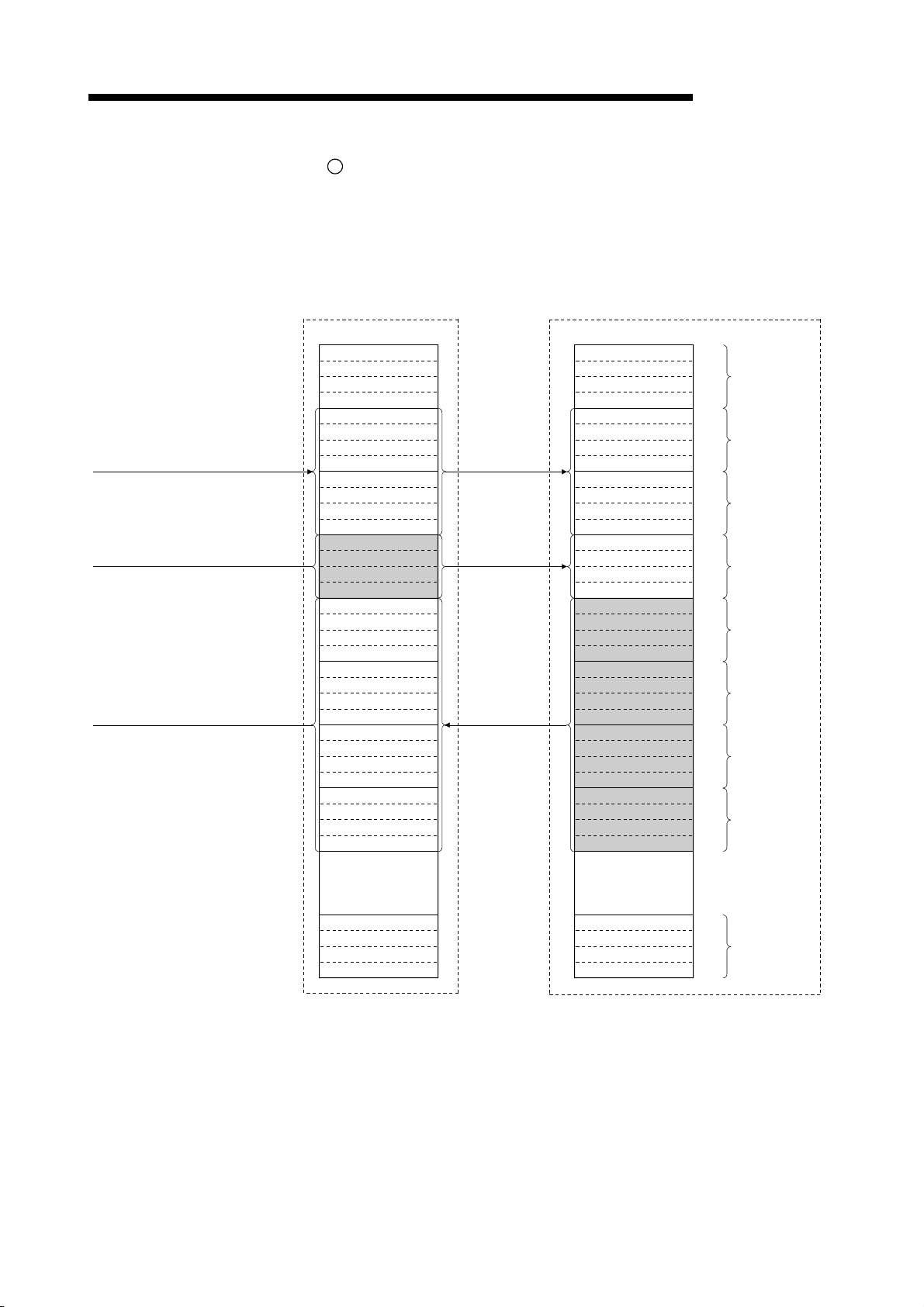

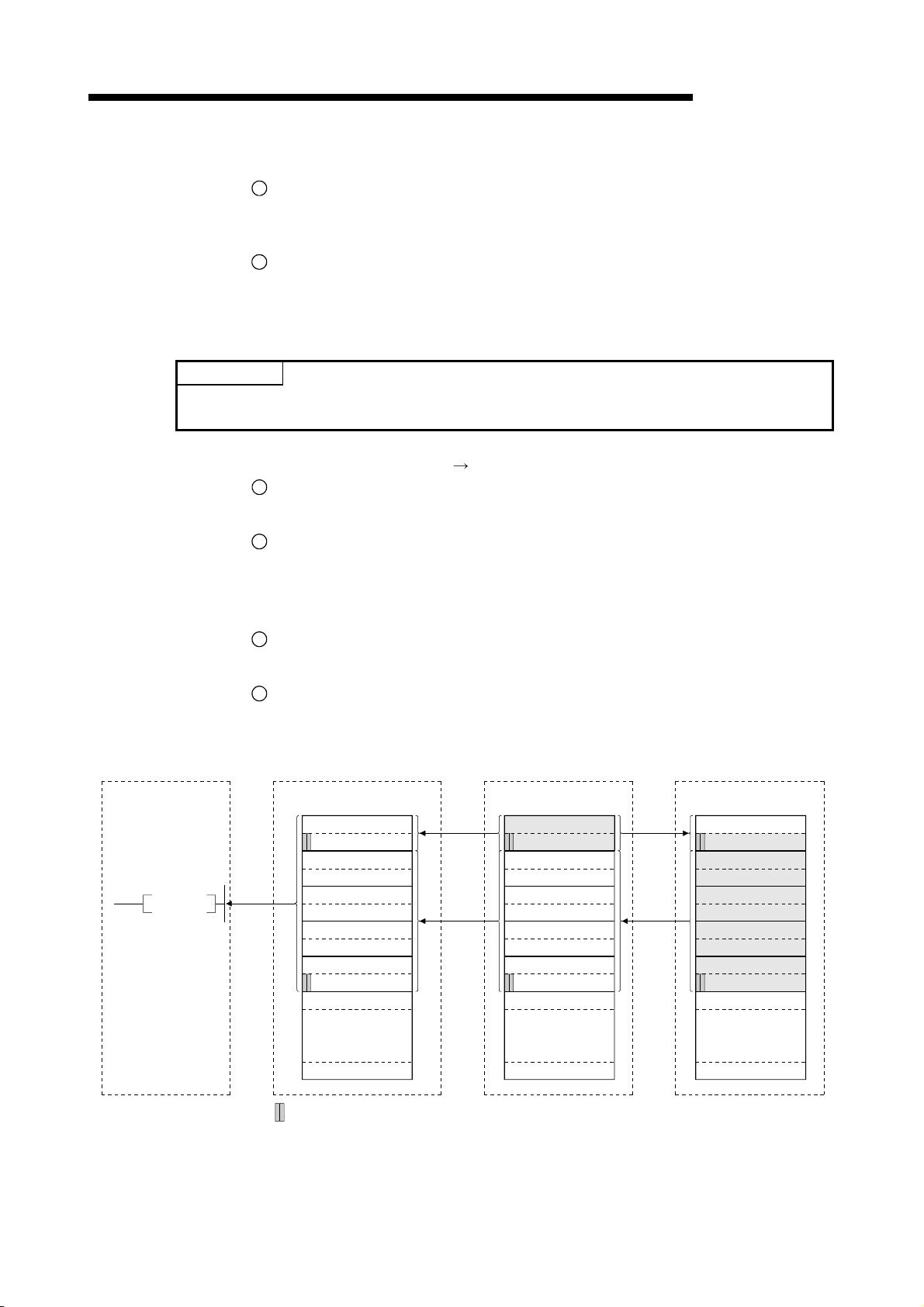

(3) Local station communication

The data communication between programmable controller CPUs can be

performed in N:N relationship with bit data (remote input RX and remote output

RY) and word data (remote register)

Local station

Local station

Remote input (RX)

Remote output (RY)

Remote register (RWw)

Remote register (RWr)

Link scan

Link scan

Link scan

Link scan

Remote output (RY)

Link scan

Remote input (RX)

Link scan

Remote register (RWr)

Link scan

Remote register (RWw)

Link scan

Remote output (RY)

Remote input (RX)

Remote register (RWr)

Remote register (RWw)

(4) Establishing high-speed transmission

When the transmission speed of 10Mbps is set, the link scan time

(communication time with the master station and remote station/local station) is

still at high speed, even when the maximum 64 stations are connected.

• Remote I/O (RX, RY) 2048 points ..................................................... 4 ms

• Remote I/O (RX, RY) 2048 points

+ remote register (RWw, RWr) 512 points ................ 7 ms

(5) System configurations are possible, according to requirements.

(a) Transmission distance

The total extended distance depends on the transmission speed, but

connections can be made between 100 m (at 10 Mbps) and 1.2 km (at 156

kbps).

(b) Number of connected stations

A maximum of 64 stations, including remote I/O stations, remote device

stations, and local stations can be connected to one master station.

Up to 64 remote I/O stations, 42 remote device stations, and 26 local

stations can be connected. (Refer to Section 2.1.)

1 - 5

Page 22

1 OVERVIEW

MELSEC-QnA

(6) Link points

2048 points of remote input (RX), 2048 points of remote output (RY), and 512

points of remote register (RW) can be used for communication in one system.

For one remote station or local station, 32 points of remote input (RX), 32 points

of remote output (RY), and 8 points of remote register (RW) (RWw: 4 points,

RWr: 4 points) can be handled.

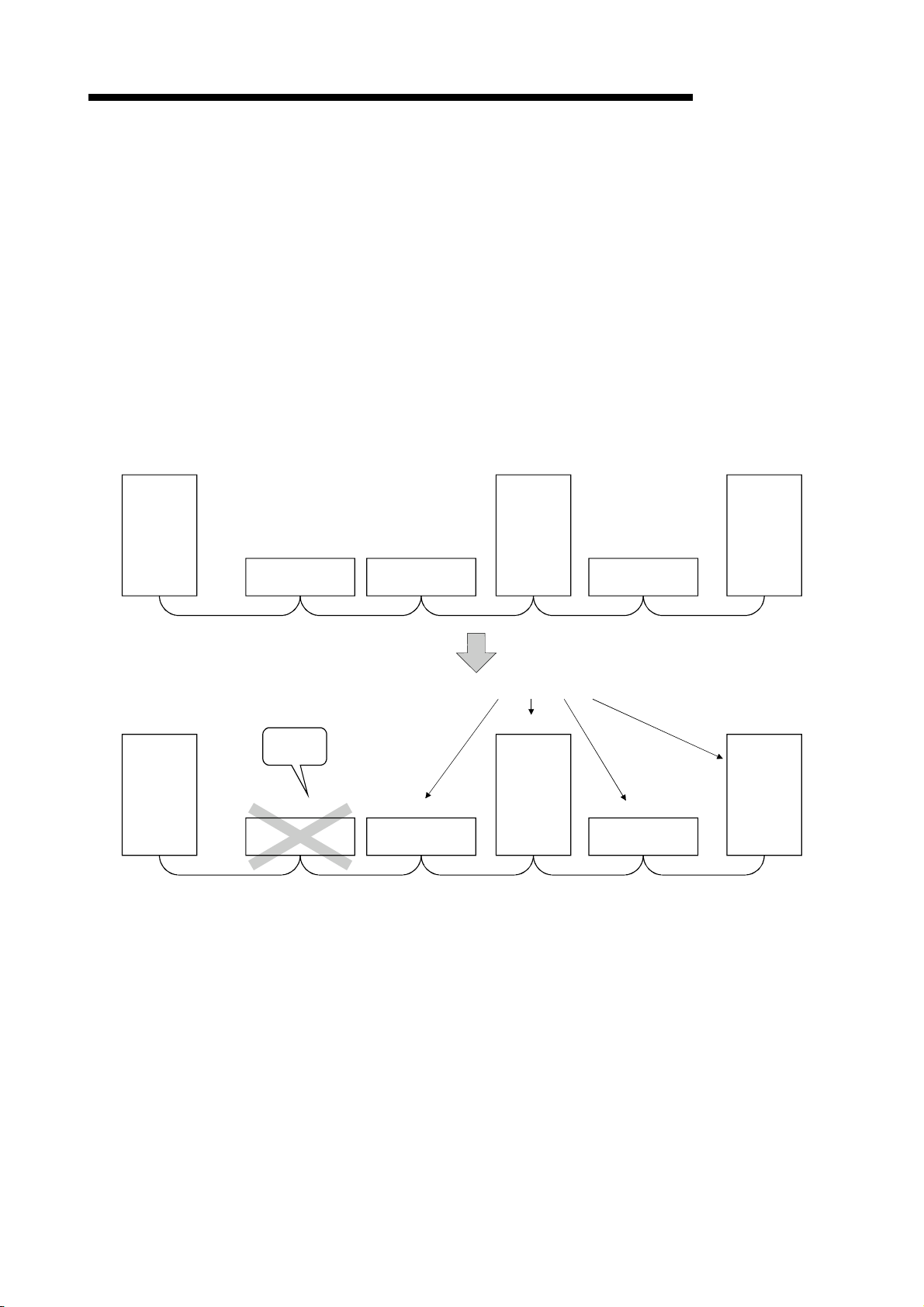

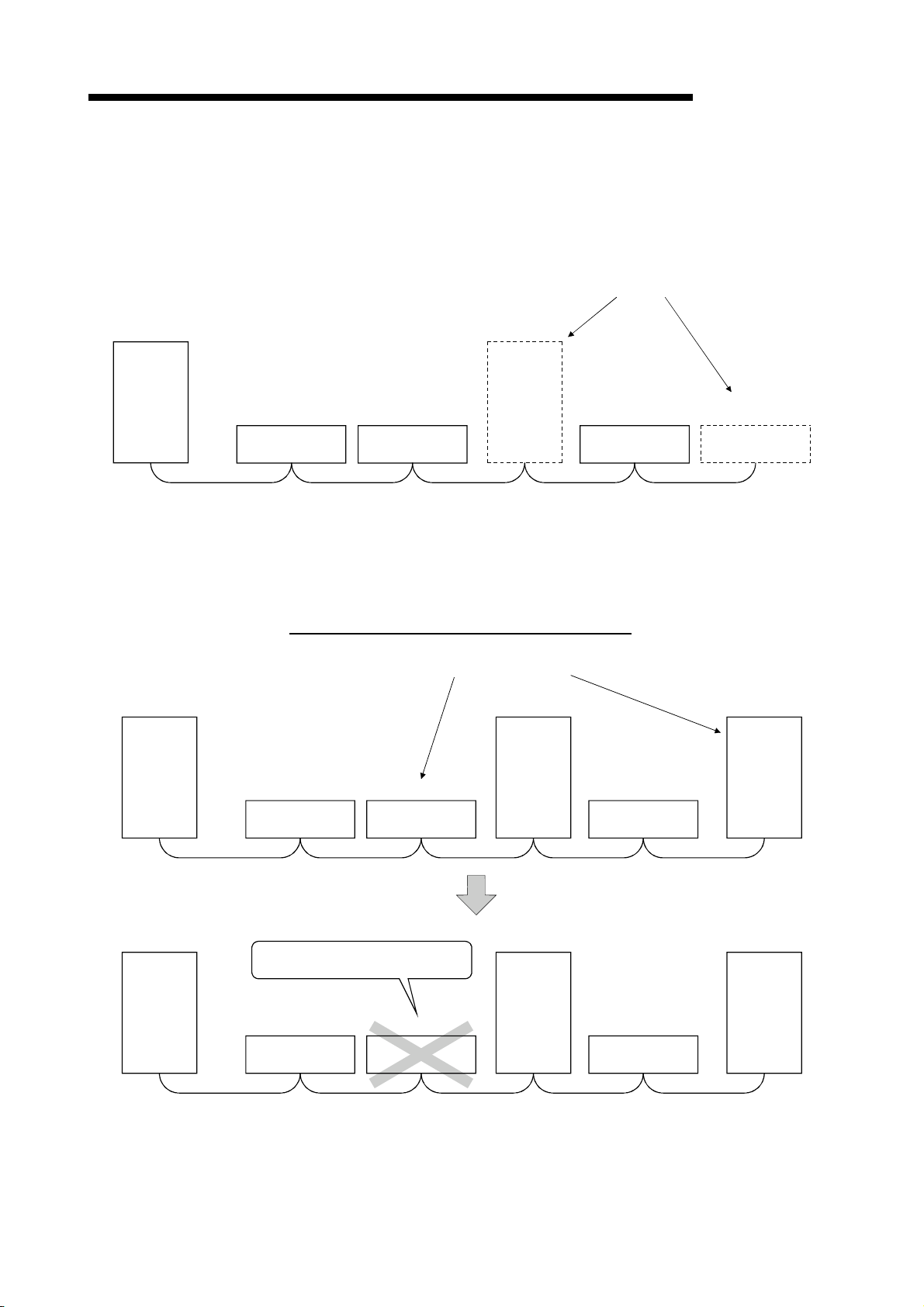

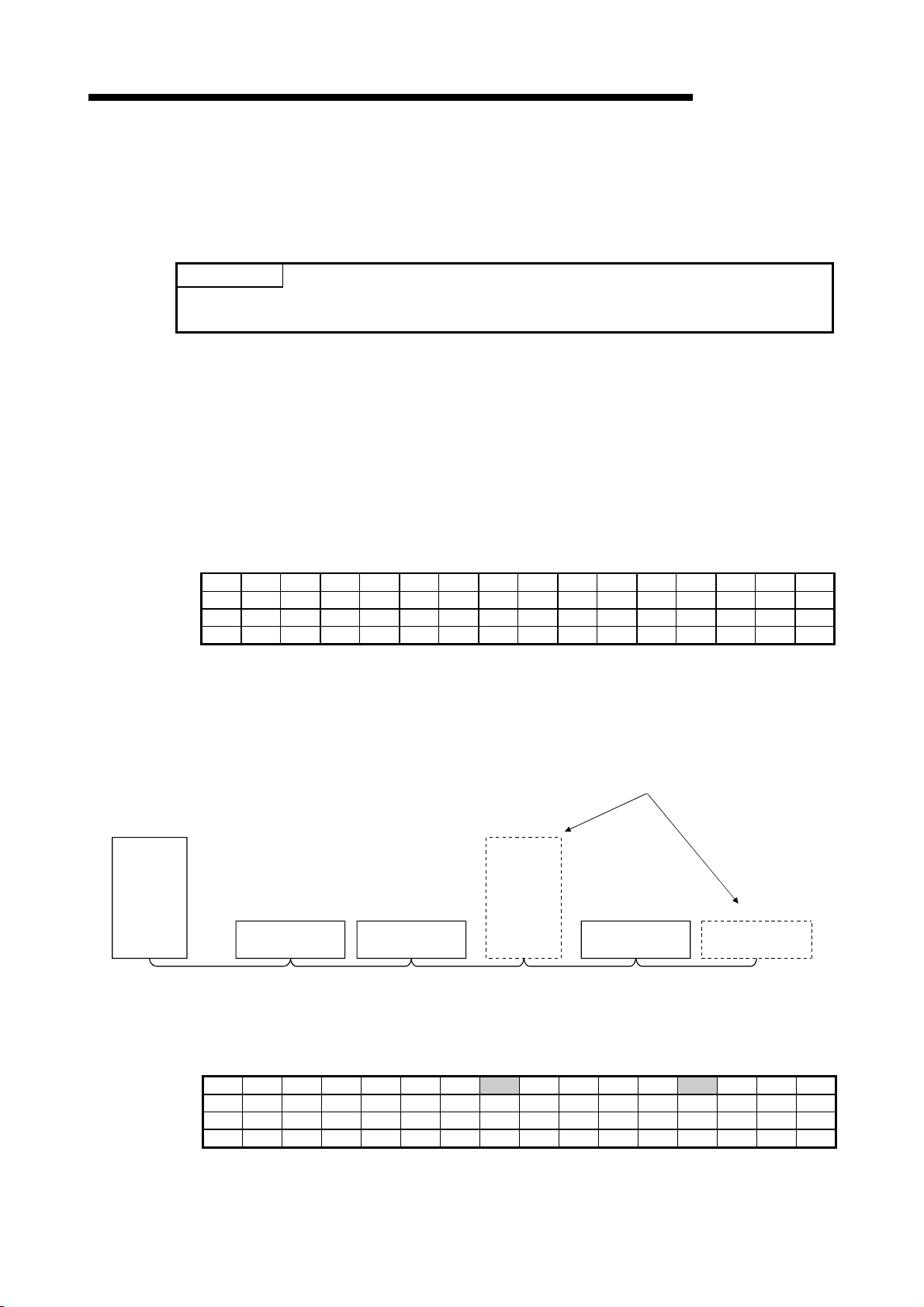

(7) System down prevention (Station cutoff function)

Because the system employs the bus method, even if there is a remote station or

local station which goes down due to power off, etc., it won't affect the

communication with other functioning remote/local stations.

Also, for the module using with the 2-piece terminal block, the module can be

replaced during data link.

Station No.4

Station No.7

Master

station

Master

station

Station No.1

Remote station

(occupies 2 stations)

Faulty

station

Station No.1

Remote station

(occupies 2 stations)

Station No.3

Remote station

(occupies 1 station)

Station No.3

Remote station

(occupies 1 station)

Local station

(occupies 1

station)

Data link continues

Station No.4

Local station

(occupies 1

station)

Station No.5

Remote station

(occupies 2 stations)

Station No.5

Remote station

(occupies 2 stations)

Local station

(occupies 4

stations)

Station No.7

Local station

(occupies 4

stations)

1 - 6

Page 23

1 OVERVIEW

MELSEC-QnA

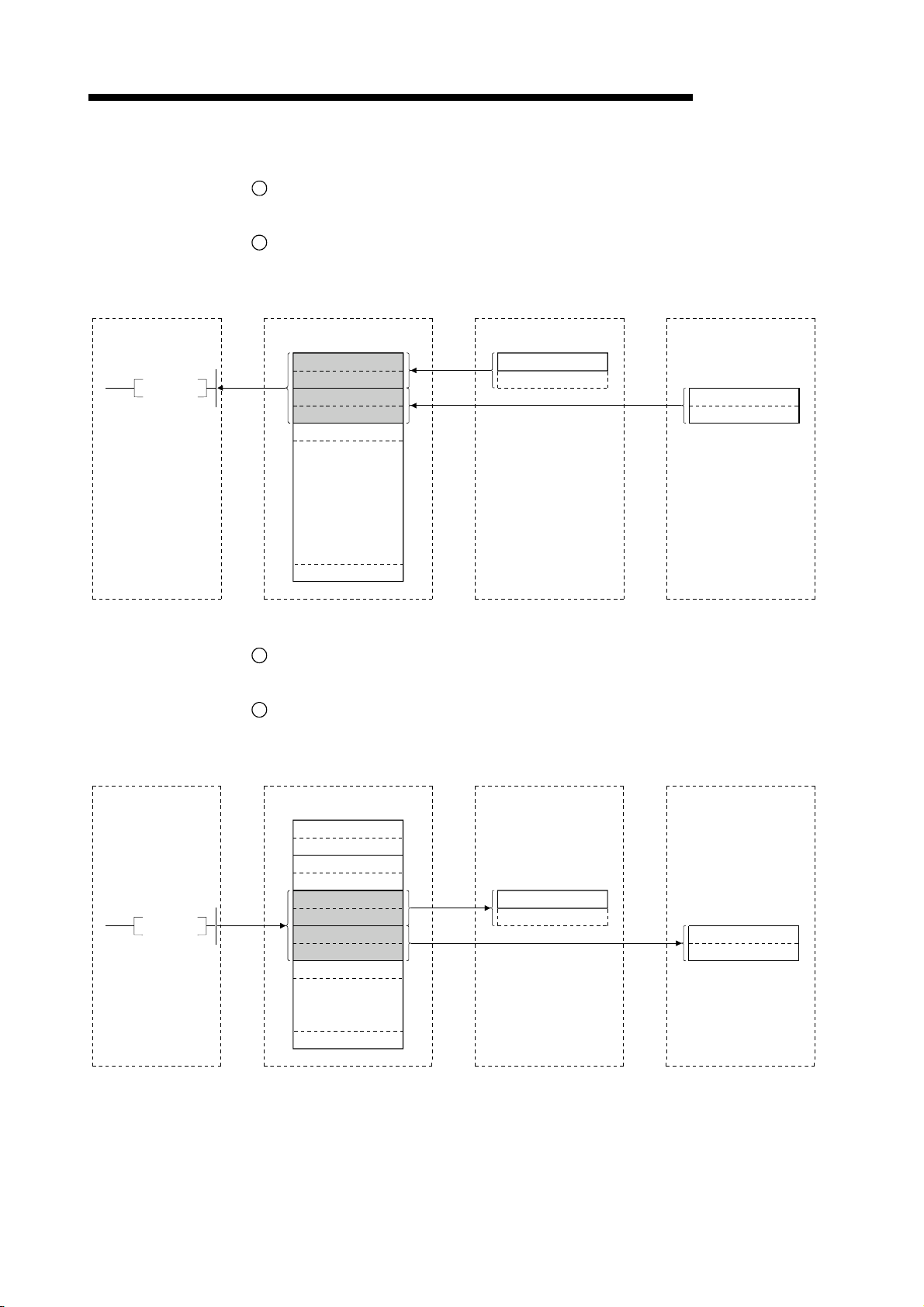

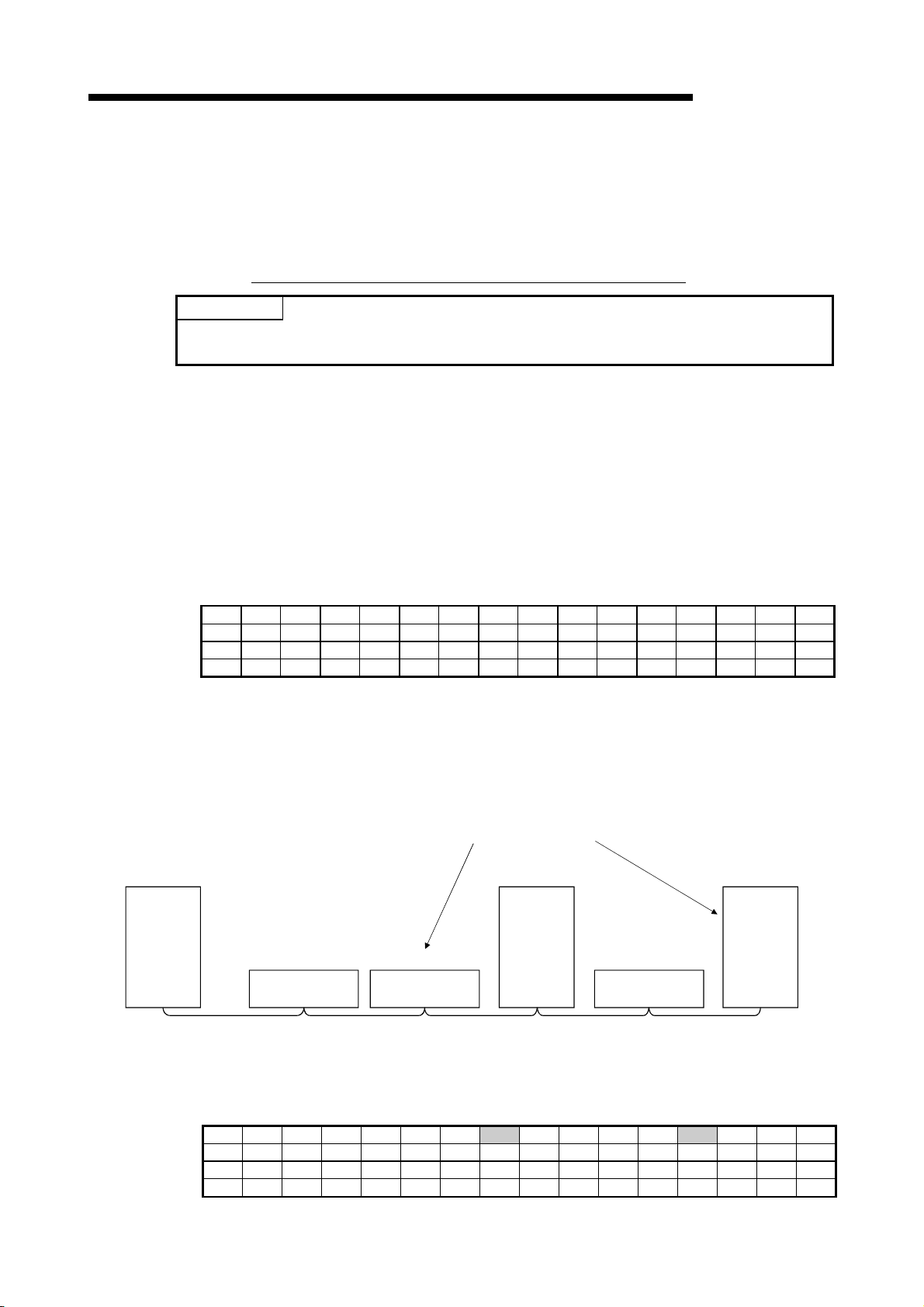

(8) Reserved station function

By setting the station which is not actually connected (station planned for

connection in the future) as a reserved station, the station will not be handled as

a faulty station.

Station planned for

connection in the future

(Reserved station)

Station No.4

Master

station

Station No.1

Remote station

(occupies 2 stations)

Station No.3

Remote station

(occupies 1 station)

Local station

(occupies 4

stations)

Station No.8

Remote station

(occupies 1 station)

(Reserved station)

Station No.9

Remote station

(occupies 1 station)

(9) Error invalid station function

A station that cannot perform data links because the power is turned off, etc., can

be handled as other than a "data-link faulty station" on the master station and the

local station.

Be careful, however, for errors will not be detected.

Stations to be set as error invalid stations

Station No.4

Master

station

Station No.1

Remote station

(occupies 2 stations)

Station No.3

Remote station

(occupies 1 station)

Local station

(occupies 1

station)

Station No.5

Remote station

(occupies 2 stations)

Station No.7

Local station

(occupies 4

stations)

Master

station

Does not result as a data-link faulty

station.

Station No.1

Remote station

(occupies 2 stations)

Station No.3

Remote station

(occupies 1 station)

1 - 7

Station No.4

Local station

(occupies 1

station)

Station No.5

Remote station

(occupies 2 stations)

Station No.7

Local station

(occupies 4

stations)

Page 24

1 OVERVIEW

Programmable controller CPU Master station

MELSEC-QnA

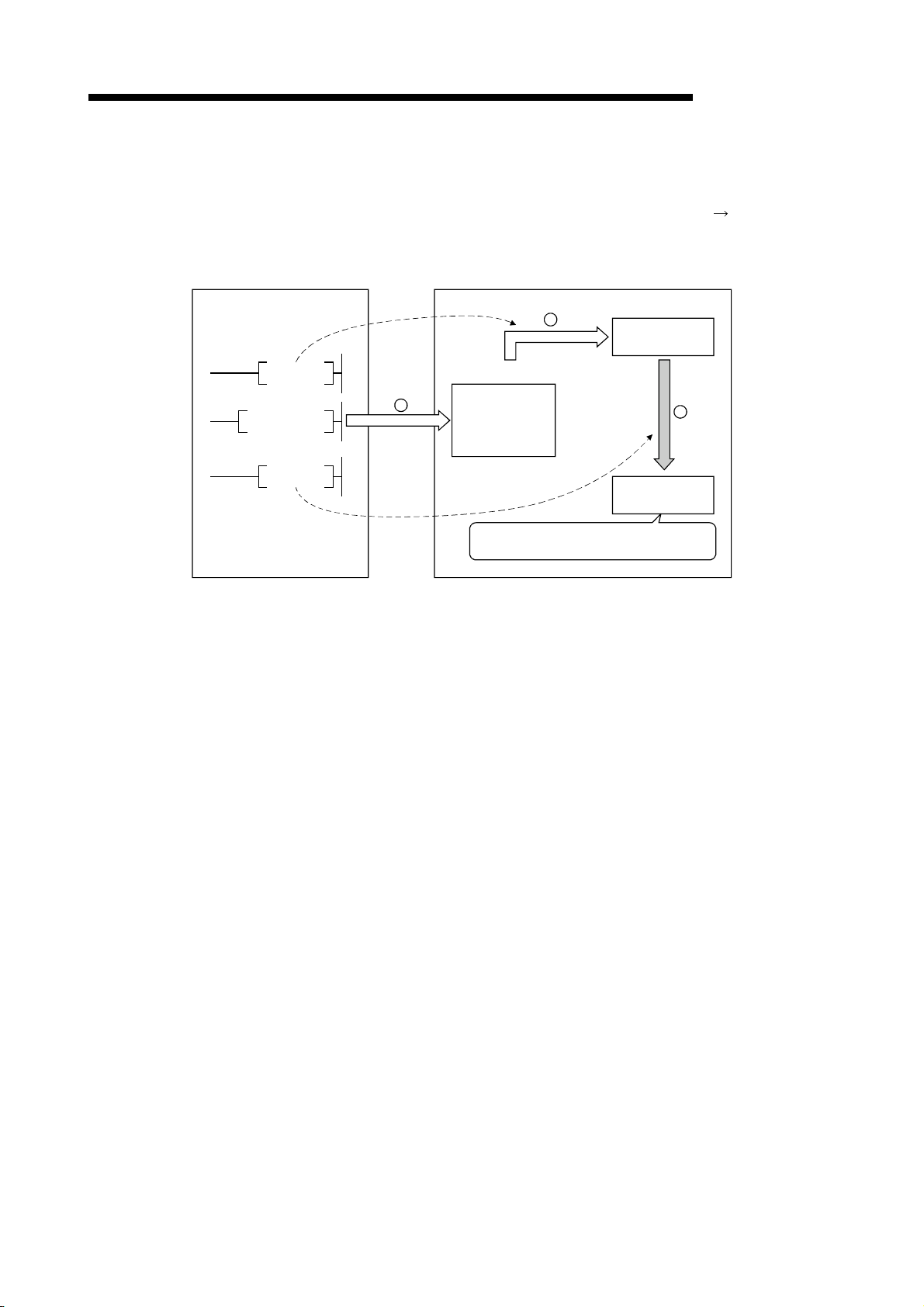

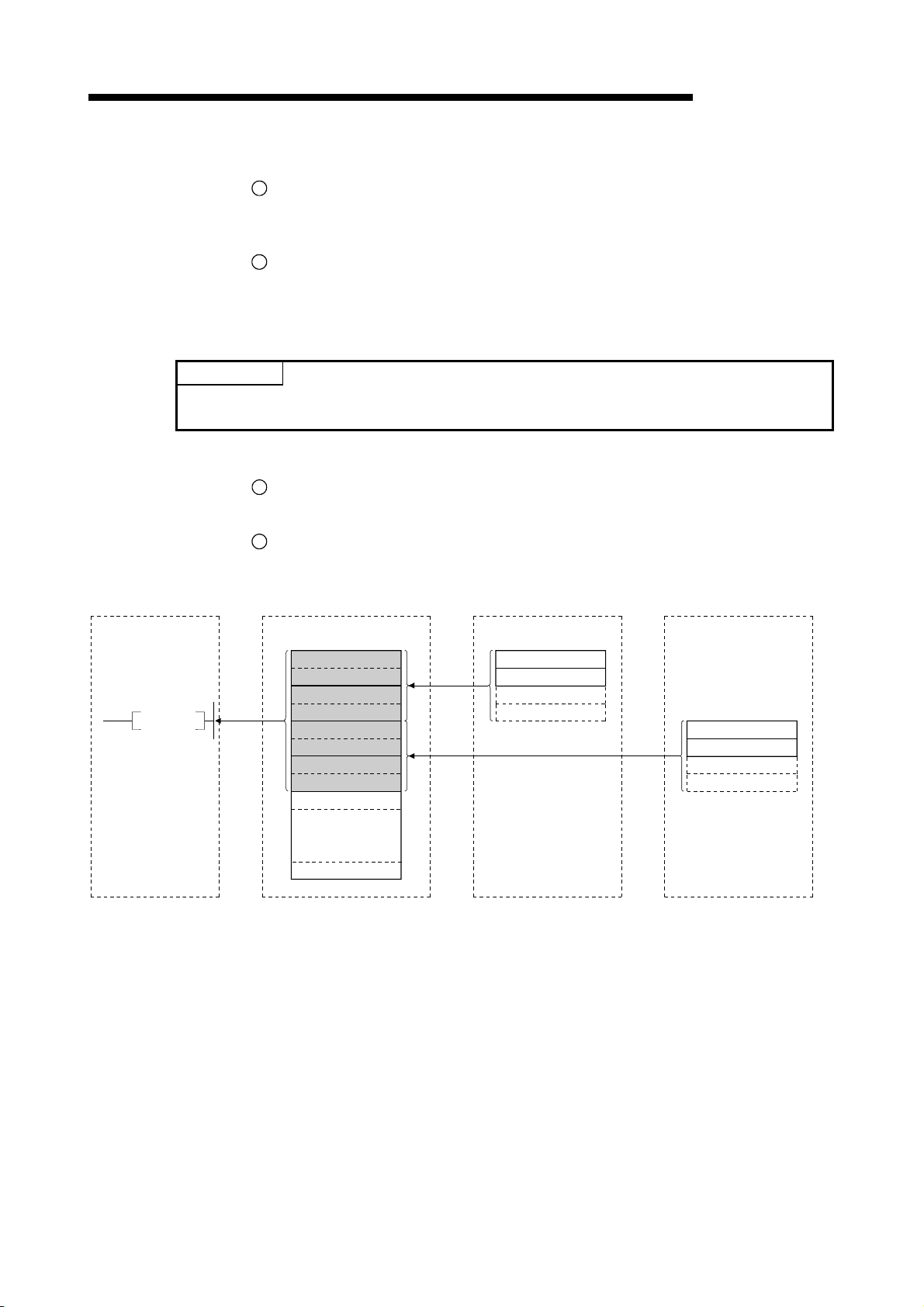

(10) Parameter registration to the E2PROM

By registering the parameters to the E2PROM, the parameter settings do not

have to be performed at each master station startup (power off

Because this is the E

is turned off.

2

PROM, parameters are stored even if the module's power

on).

2

SET YnA

1

TO

SET Yn8

Buffer memory

Parameter

information area

The data link is executed using the parameters

registered in the internal memory.

2

EPROM

3

Internal memory

(11) Data-link status setting for when a master station programmable

controller CPU error occurs

The data-link status can be set (stop/continue) to either stop or continue for when

a "operation stop error" occurs at the master station's programmable controller

CPU, such as SP. UNIT ERROR.

The data link between local stations can be continued.

"Operation continue errors" such as a BATTERY ERROR continue the data link

regardless of the setting.

(12) Input data from data-link faulty station status setting

The data input (received) from the data-link faulty station can be cleared or kept

(status right before an error is caused).

(13) Module reset function from the sequence program

When the switch setting is changed or an error occurs in the module, the module

can be reset from the sequence program without resetting the programmable

controller CPU.

(This excludes when the module has a module faulty (Xn0 is on).)

(14) RAS function

(a) Automatic return function

When a station is disconnected from the link due to power off, etc., and

returns to the normal status, the station can join the data link again

automatically.

(b) Link status check

Using the link special relay (SB) and link special register (SW) in the buffer

memory, the current data-link status can be checked.

(c) Diagnosis function

Using the switch setting, the hardware and cable conditions can be

checked.

1 - 8

Page 25

1 OVERVIEW

1.3 Communication Overview

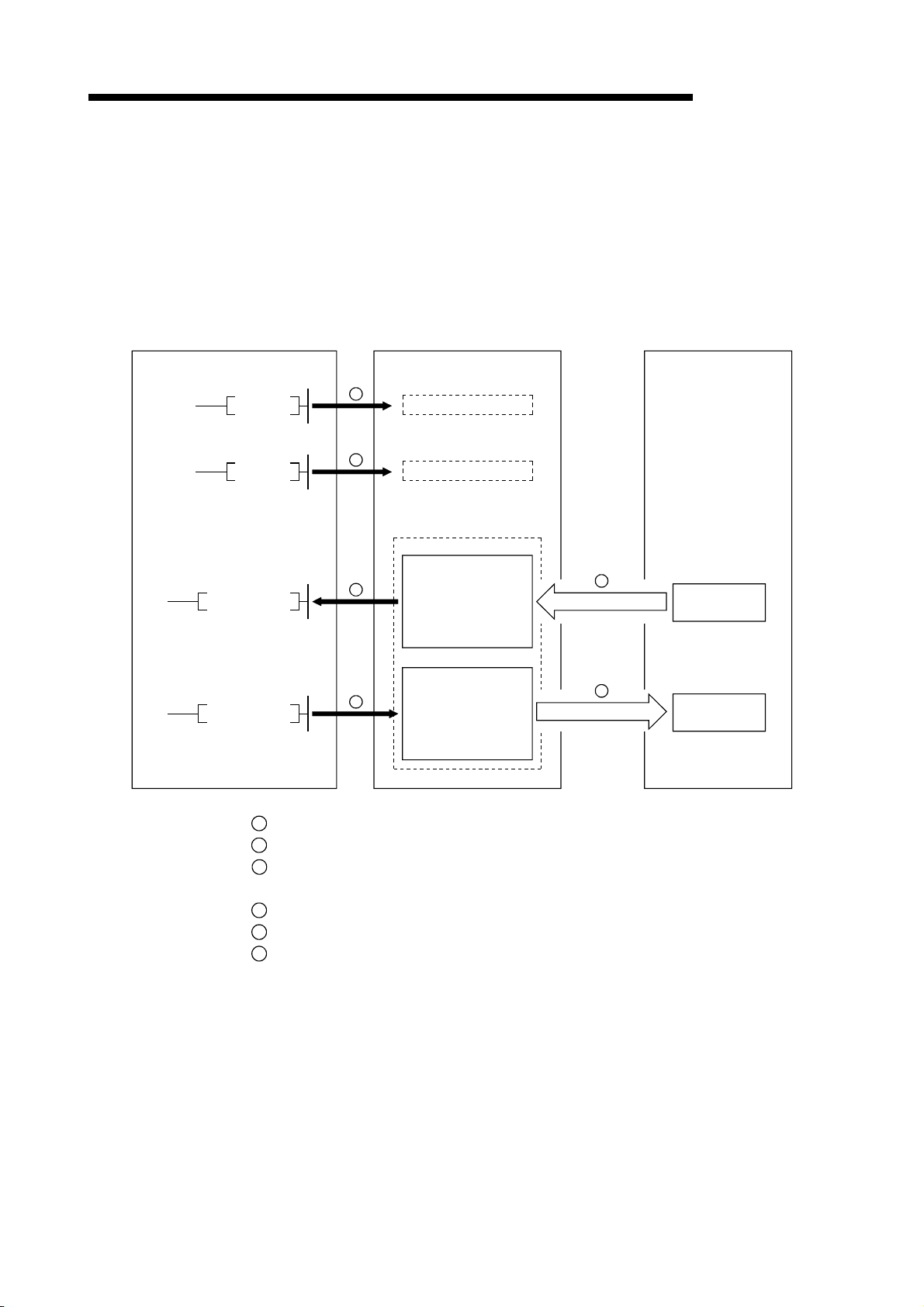

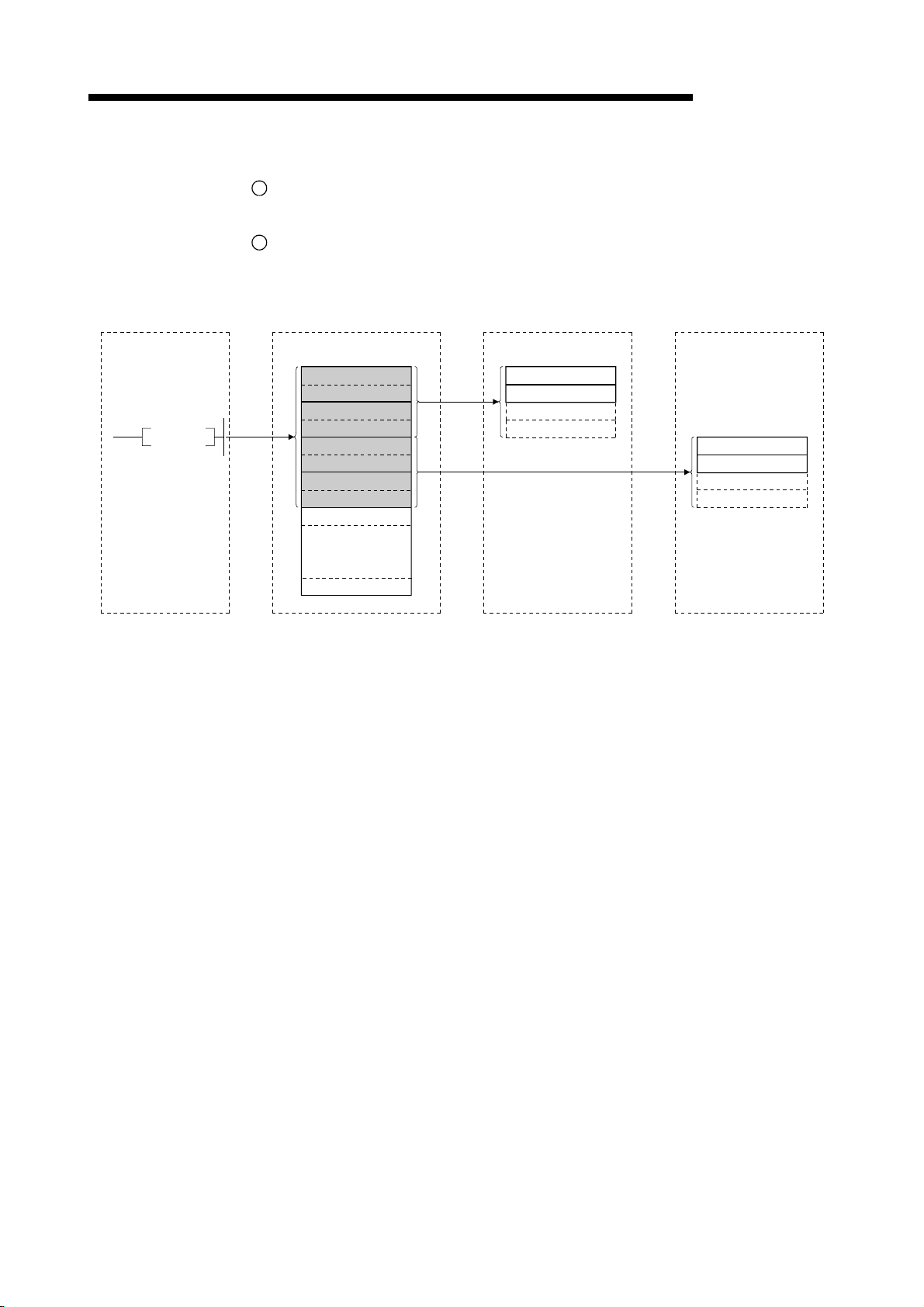

1.3.1 Communication between the master station and remote I/O station

The overview of the communication between the master station and remote I/O station

is described below.

Refer to Section 4.2 for details.

Programmable controller CPU

Master station

MELSEC-QnA

Remote I/O station

FROM

TO

SET Yn0

SET Yn6

1

2

4

5

Refresh instruction

Data link startup

Buffer memory

Remote input

(RX)

Remote output

(RY)

3

Link scan

6

Link scan

Input

Output

1

Turn on the refresh instruction.

2

Startup the data link.

3

By the link scan, the remote I/O station's input information is stored in the master

station's remote input (RX).

4

By the FROM instruction, read from the remote input (RX).

5

By the TO instruction, write the on/off data to the remote output (RY).

6

By the link scan, the remote I/O station's output is turned on/off.

1 - 9

Page 26

1 OVERVIEW

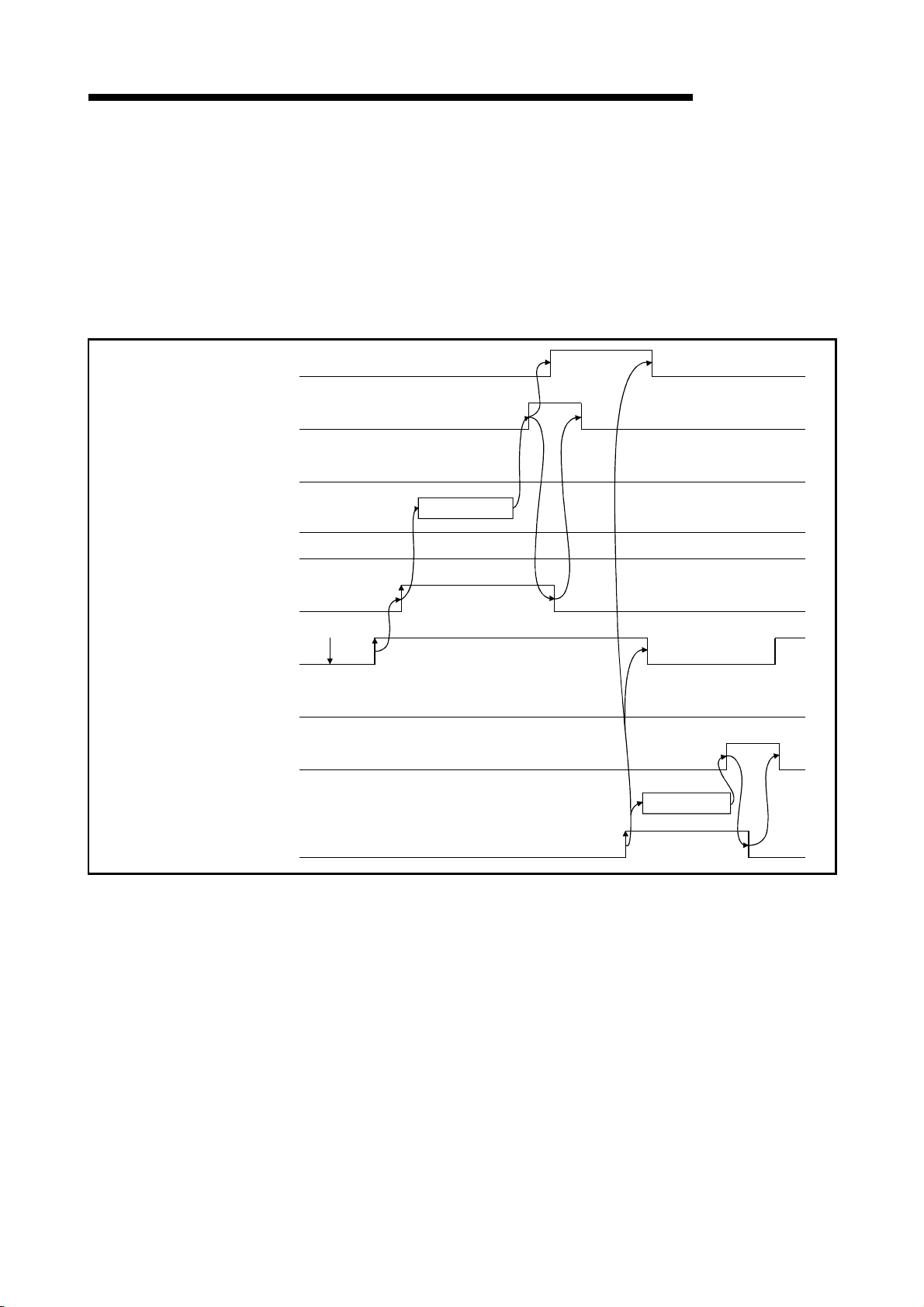

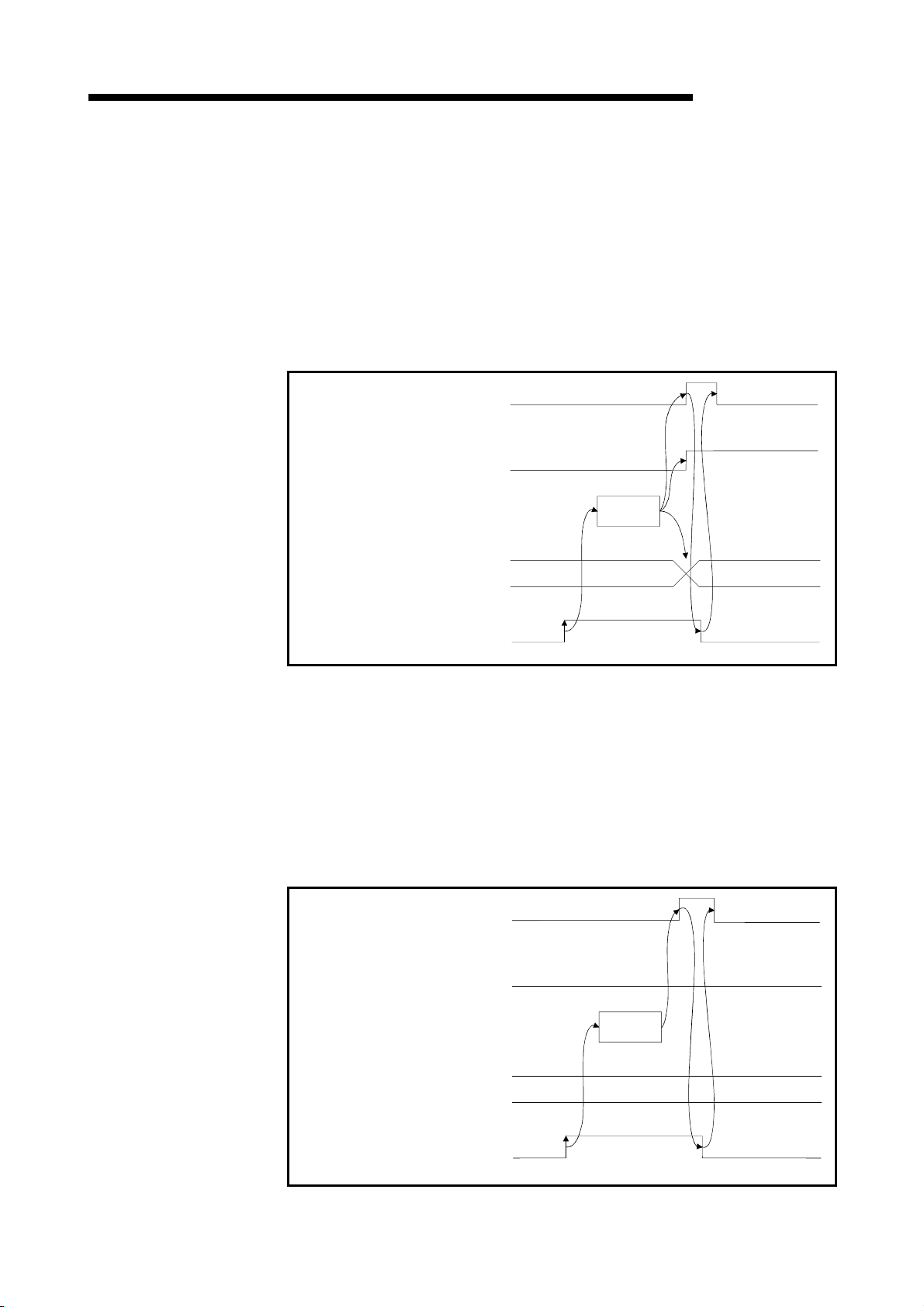

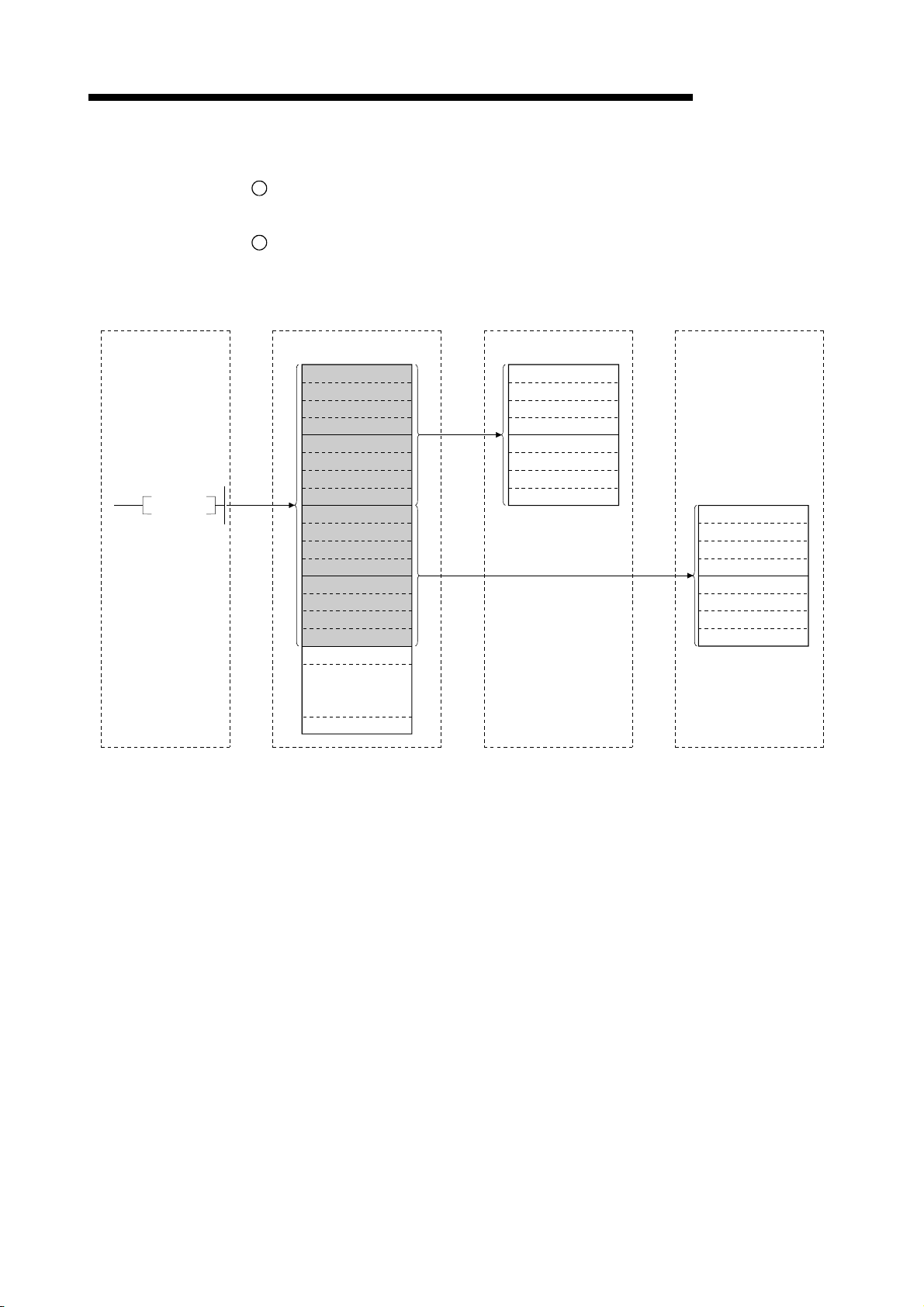

1.3.2 Communication between the master station and remote device station

The overview of the communication between the master station and remote device

station is described below.

Refer to Section 4.3 for details.

Programmable controller CPU

Master station

Remote device station

MELSEC-QnA

FROM

TO

TO

SET Yn0

SET Yn6

1

2

4

5

7

Refresh instruction

Data-link startup

Buffer memory

Remote input

(RX)

Remote output

(RY)

Remote register

(RWw)

3

Link scan

6

Link scan

8

Link scan

Remote input

(RX)

Remote output

(RY)

Remote register

(RWw)

9

Link scan

Remote register

(RWr)

FROM

10

Remote register

(RWr)

1

Turn on the refresh instruction.

2

Startup the data link.

3

By the link scan, the remote device station's remote input (RX) is stored in the

master station's remote input (RX).

4

By the FROM instruction, read data from the remote input (RX).

5

By the TO instruction, write data to the remote output (RY).

6

By the link scan, the remote device station's remote output (RY) is turned on/off.

7

By the TO instruction, write data to the remote register (RWw).

8

By the link scan, the data is sent to the remote device station's remote register

(RWw).

9

By the link scan, the remote device station's remote register (RWr) is sent to the

master station's remote register (RWr).

10

By the TO instruction, read data from the remote register (RWr).

1 - 10

Page 27

1 OVERVIEW

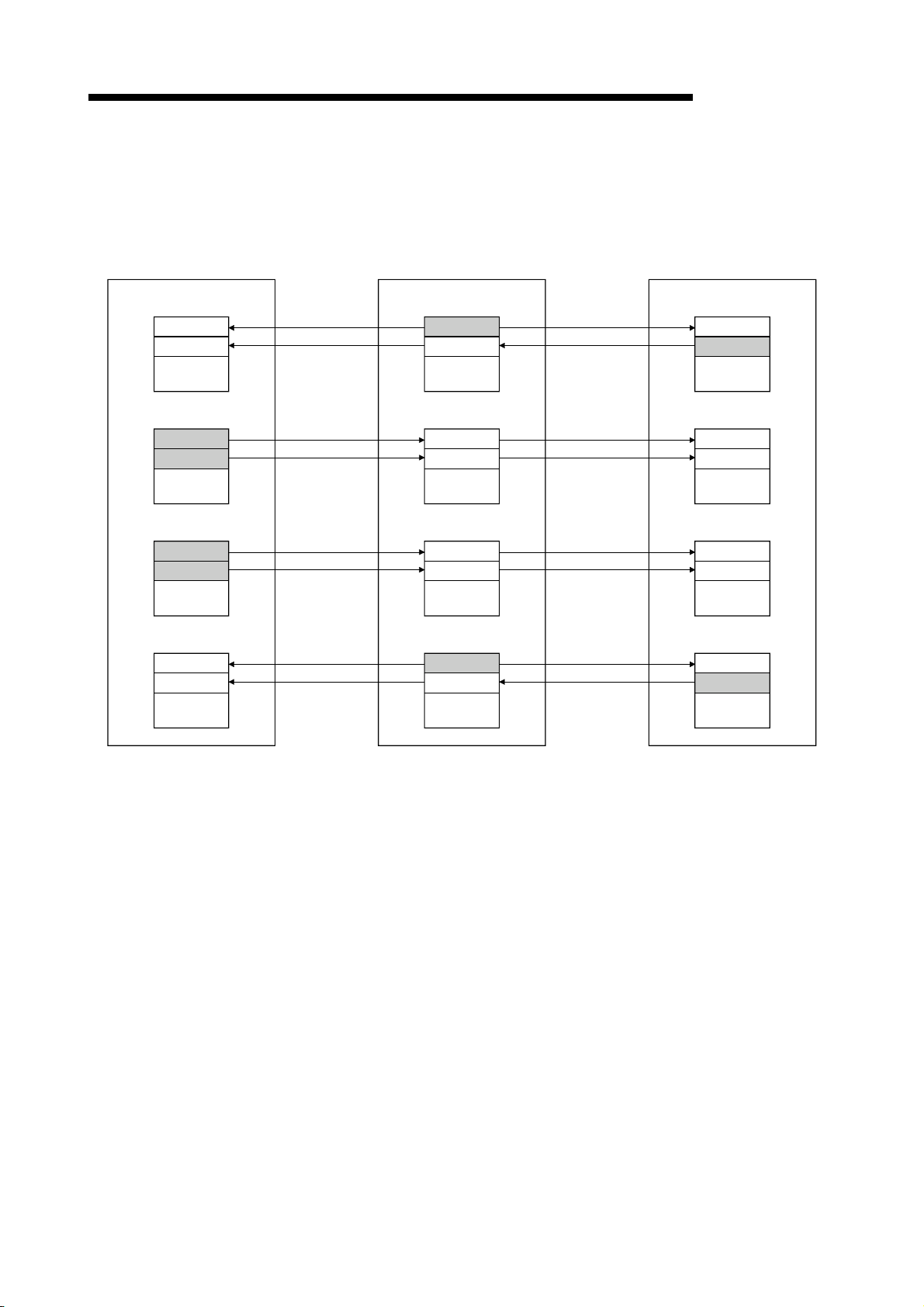

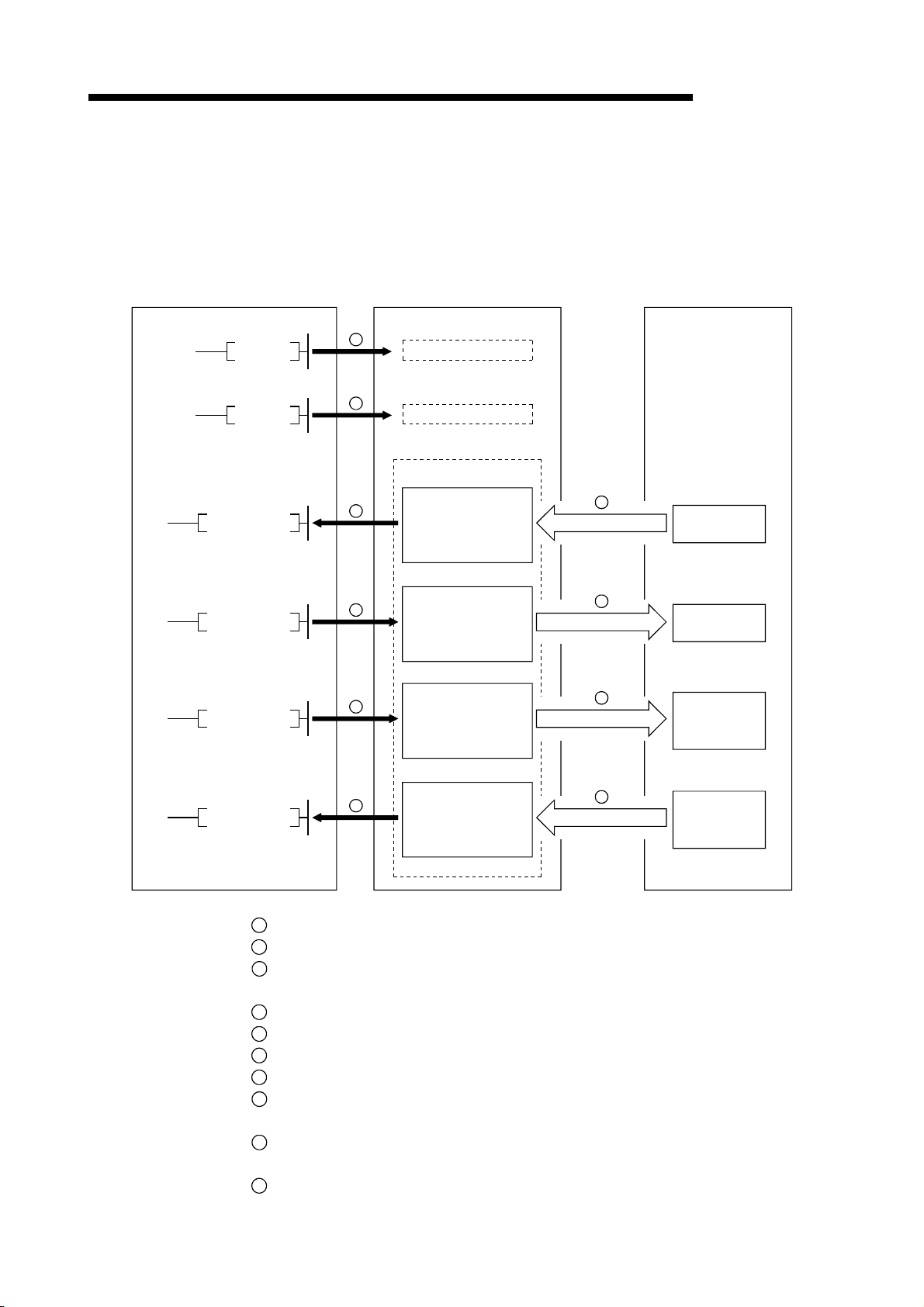

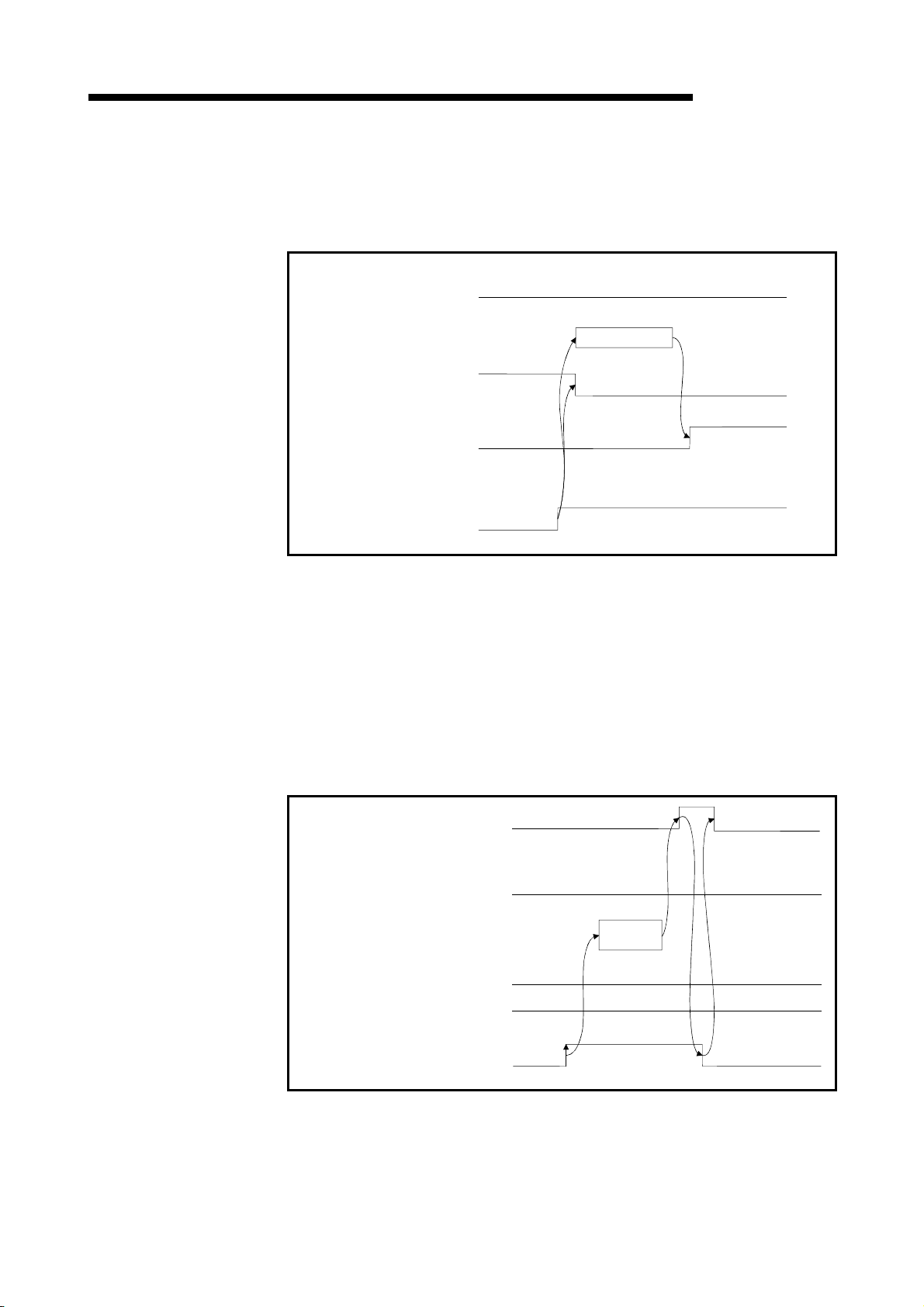

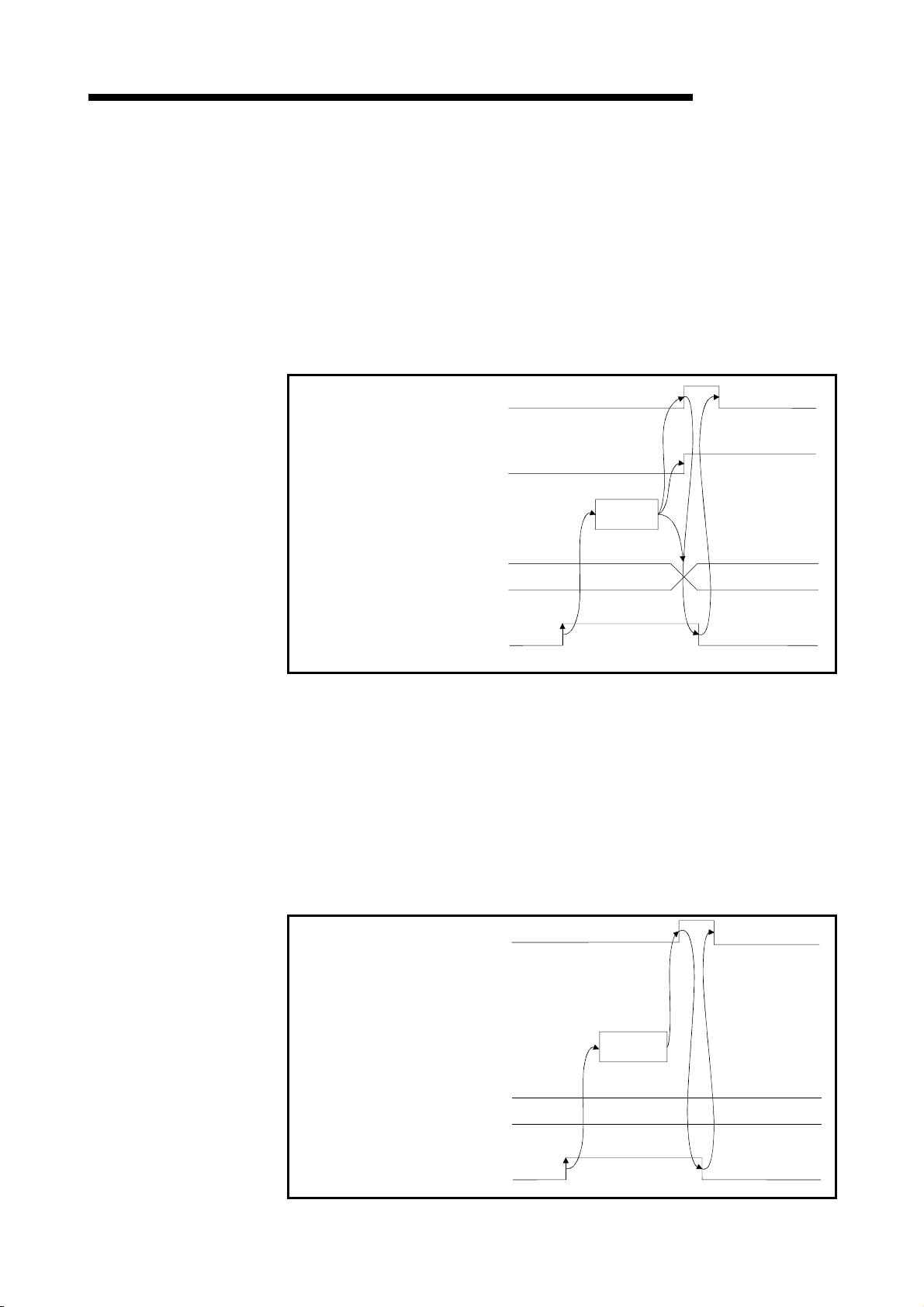

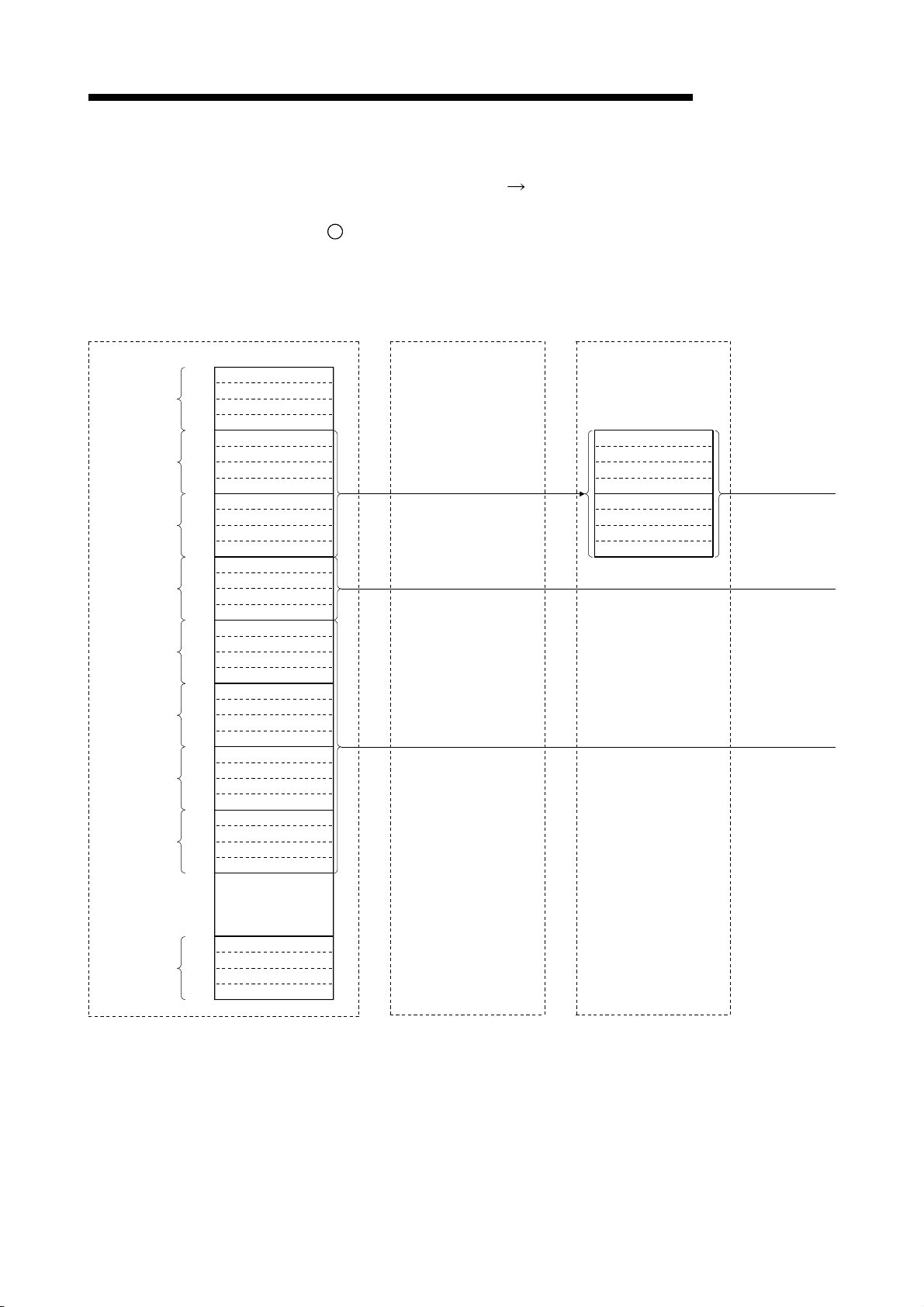

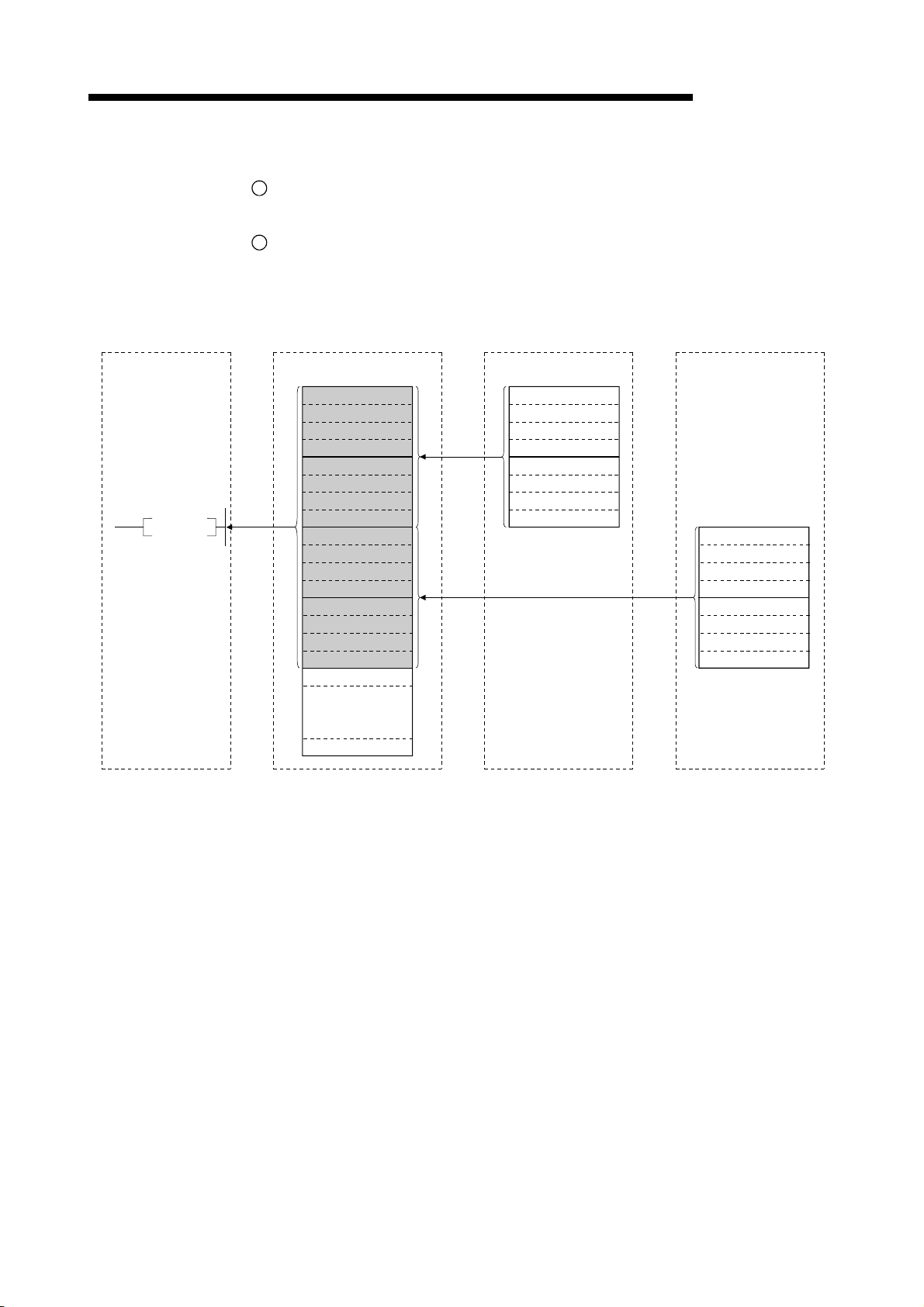

1.3.3 Communication between the master station and local station

The overview of the communication between the master station and local station is

described below.

Refer to Section 4.4 for details.

Master station

Local station

MELSEC-QnA

Local station

1

Refresh instruction

2

Data link startup

Buffer memory

Remote input (RX)

Remote output (RY)

Remote register (RWw)

Remote register (RWr)

3

Link scan

4

Link scan

5

Link scan

6

Link scan

1

Refresh instruction

Buffer memory

Remote output (RY)

Remote input (RX)

Remote register (RWr)

Remote register (RWw)

3

Link scan

4

Link scan

5

Link scan

6

Link scan

1

Refresh instruction

Buffer memory

Remote output (RY)

Remote input (RX)

Remote register (RWr)

Remote register (RWw)

1

Turn on the refresh instruction.

2

Startup the data link.

3

By the link scan, the data in the local station's remote output (RY) is sent to the

master station's remote input (RX) and other local stations' remote output (RY).

4

By the link scan, the data in the master station's remote output (RY) is sent to all

local station's remote input (RY).

5

By the link scan, the data in the master station's remote register (RWw) is sent to all

local stations' remote register (RWr).

6

By the link scan, the data in the local station's remote register (RWw) is sent to the

master station's remote register (RWr) and other local stations' remote register

(RWw).

1 - 11

Page 28

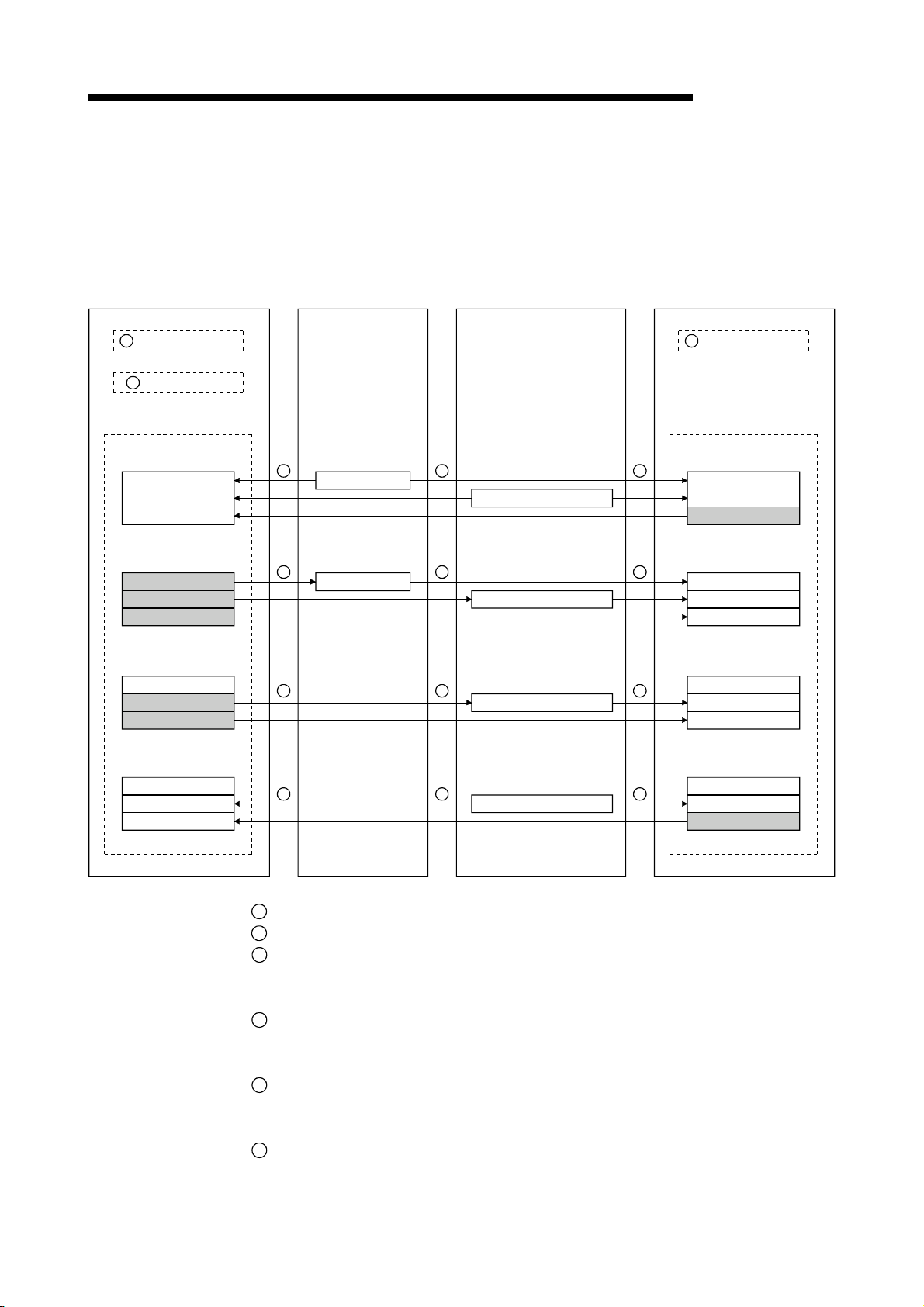

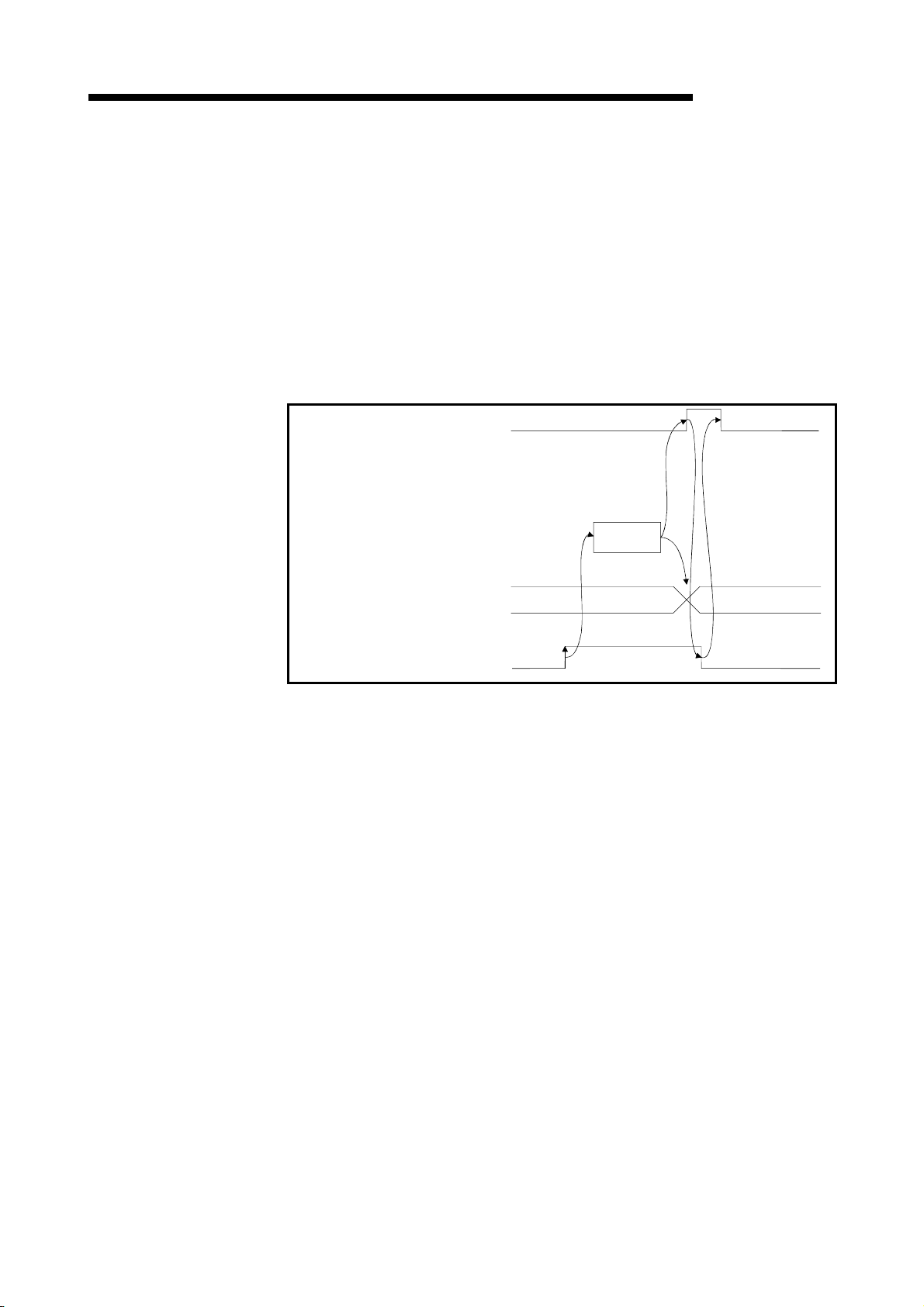

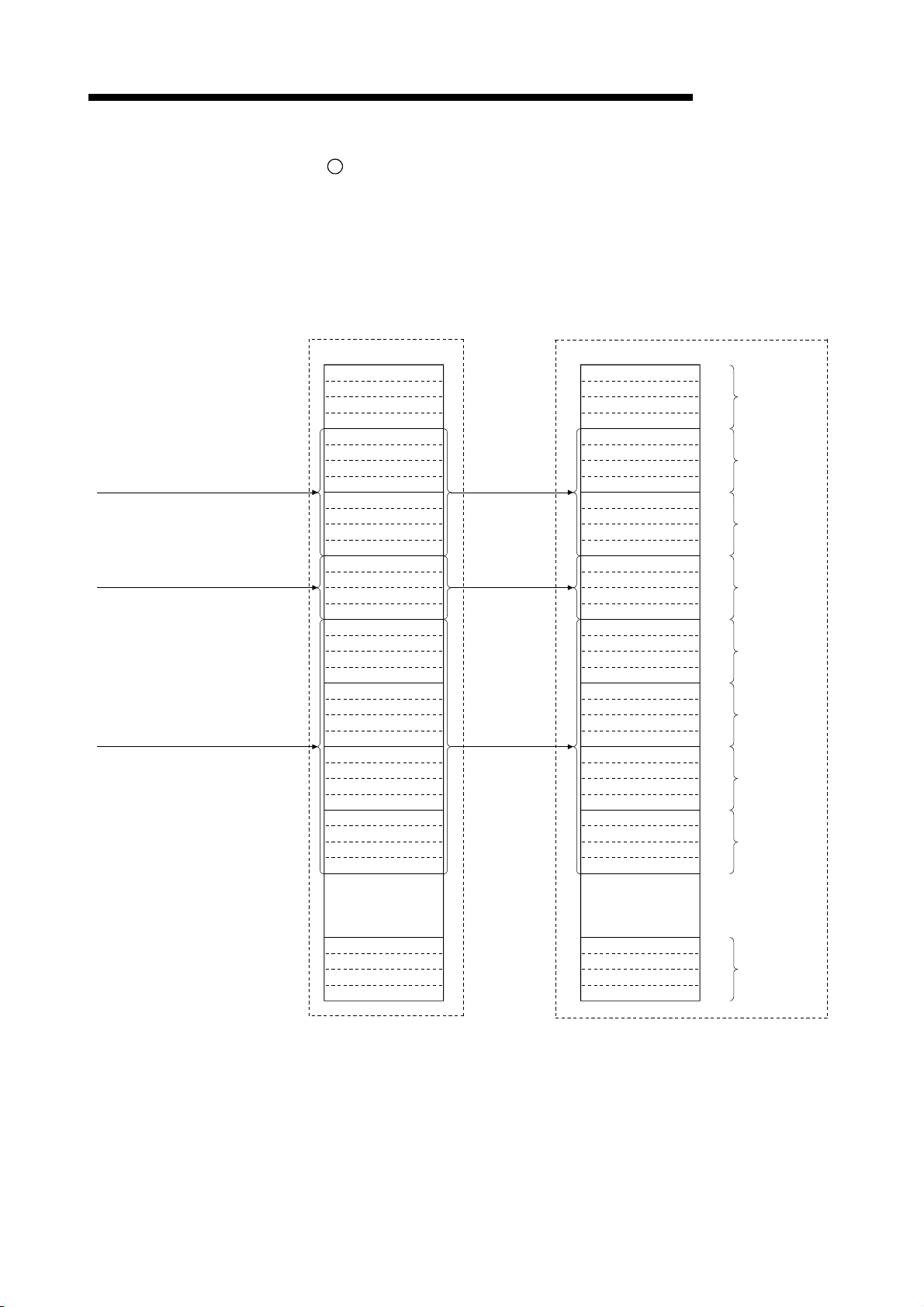

1 OVERVIEW

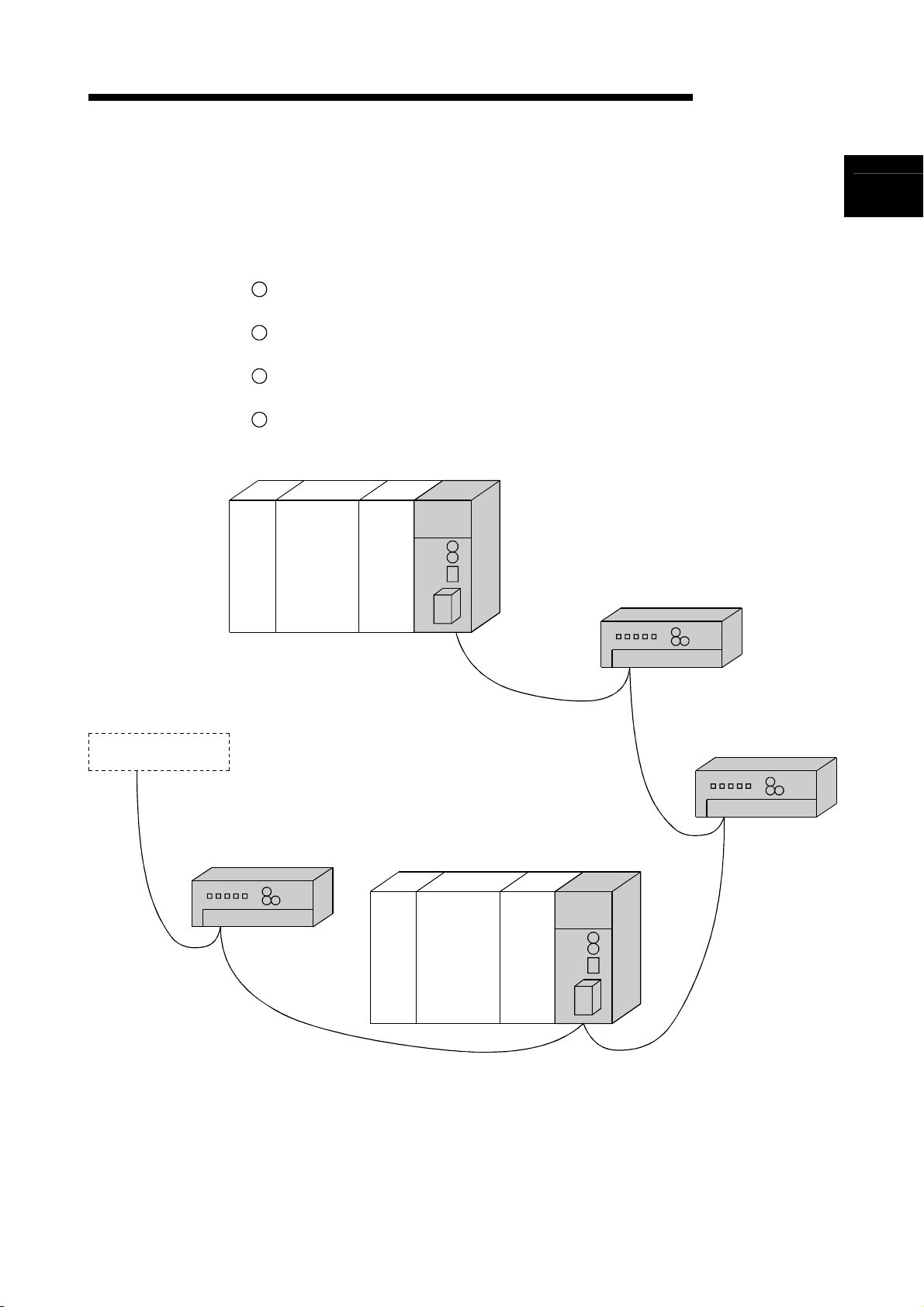

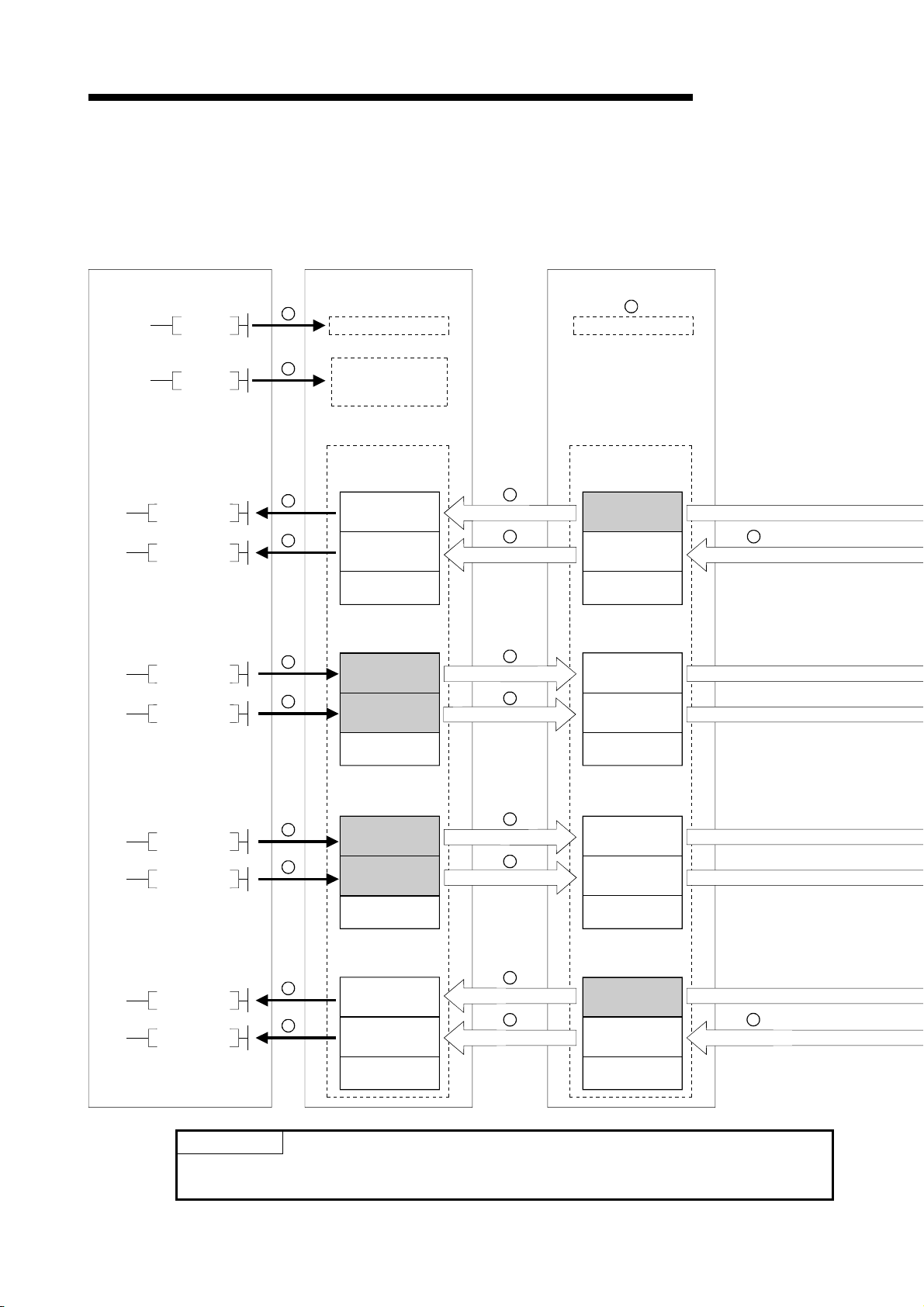

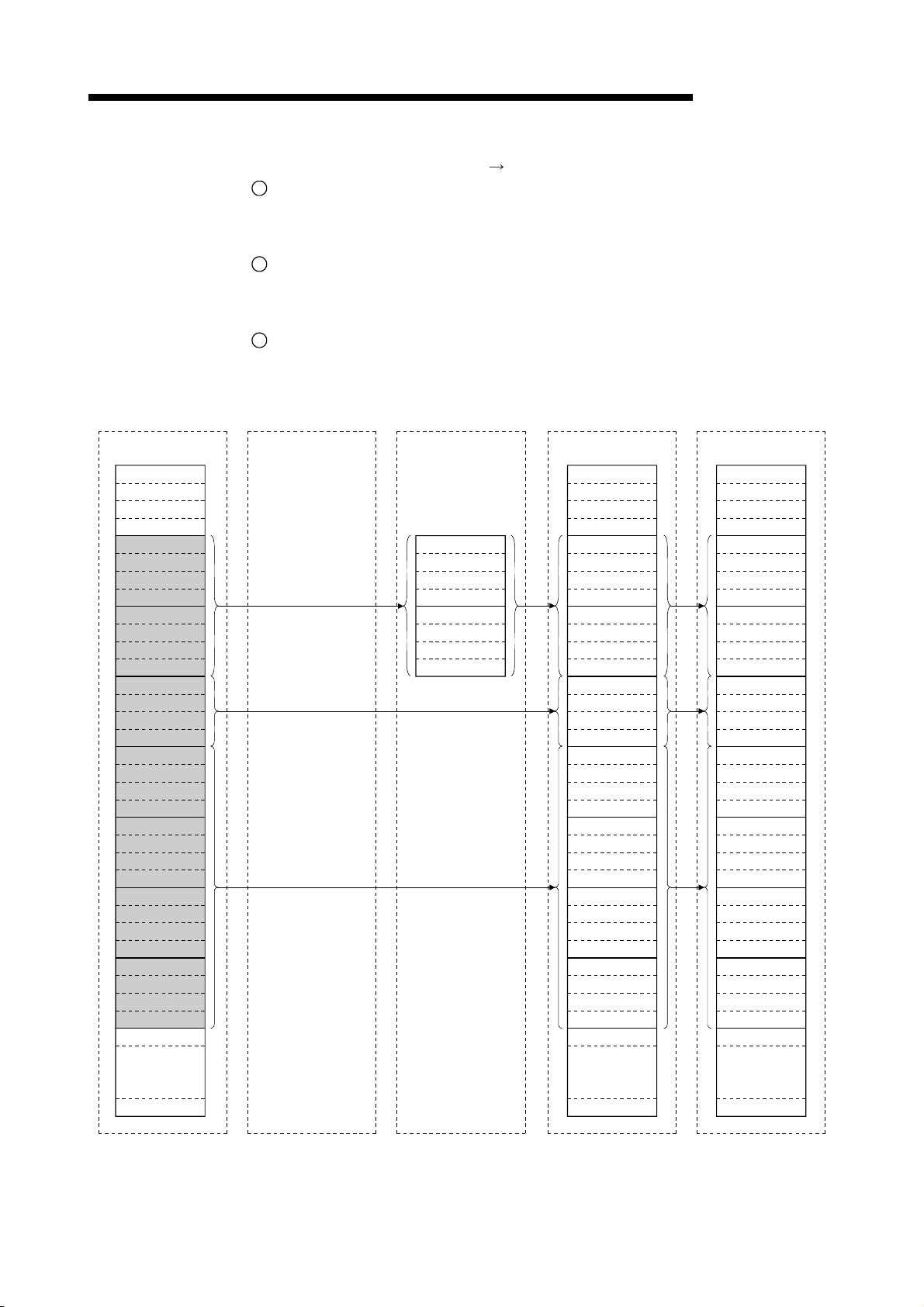

1.3.4 Compound system communication

The overview of compound system communication with remote I/O stations, remote

device stations, and local stations is described below.

Refer to Section 4.5 for details.

Master station

Remote I/O station

Remote device station

MELSEC-QnA

Local station

1

Refresh instruction

2

Data link startup

Buffer memory

Remote input (RX)

Remote output (RY)

Remote register (RWw)

Remote register (RWr)

3 3 3

4 4 4

5 5 5

6 6 6

Input

Remote input (RX)

Output

Remote output (RY)

Remote register (RWw)

Remote register (RWr)

1

Refresh instruction

Buffer memory

Remote output (RY)

Remote input (RX)

Remote register (RWr)

Remote register (RWw)

1

Turn on the refresh instruction.

2

Startup the data link.

3

By the link scan, data in the remote I/O station's and remote device station's remote

input (RX) and local station's remote output (RY) is sent to the master station's

remote input (RX) and local station's remote output (RY).

4

By the link scan, data in the master station's remote output (RY) is sent to the

remote I/O station's and remote device station's remote output (RY) and local

station's remote input (RX).

5

By the link scan, data in the master station's remote register (RWw) is sent to the

remote device station's remote register (RWw) and local station's remote register

(RWr).

6

By the link scan, data in the remote device station's remote register (RWr) and local

station's remote register (RWw) is sent to the master station's remote register (RWr)

and local station's remote register (RWw).

1 - 12

Page 29

1 OVERVIEW

MELSEC-QnA

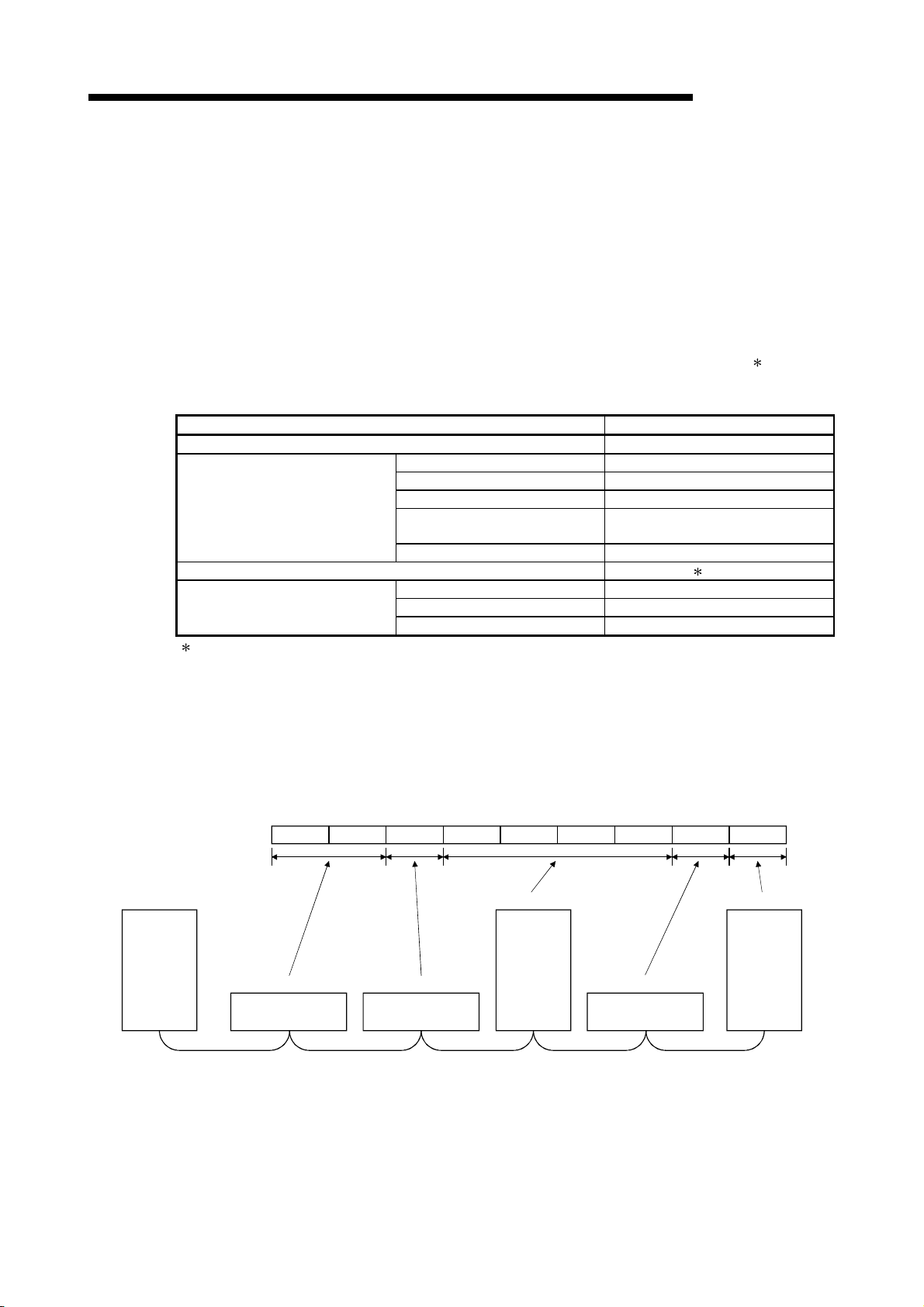

1.4 Number of Occupied Stations and Station Number, Number of Modules and Number of Stations

The relationship between number of occupied station and station number, and

between number of modules and number of stations is described below.

(1) Number of occupied stations

The number of occupied stations is fixed for each module (remote I/O station,

remote device station, and local station).

However, the number of occupied stations can be set (1 to 4 stations

) for local

stations.

Module Number of occupied stations

Remote I/O station (16 points and 32 points module) 1 station

AJ65BT-64AD 2 stations

AJ65BT-64DAV 2 stations

Remote device station

Local station 1 to 4 stations (changed by switch)

Intelligent device station

The AJ61QBT11 of hardware version F or later and the A1SJ61QBT11 of hardware version G or later are

compatible with this setting. For other than the above, the setting is 1 or 4 stations only.

AJ65BT-64DAI 2 stations

AJ65BT-D62

AJ65BT-D62D (S1)

A852GOT 2 or 4 stations

AJ65BT-R2(N) 1 station

AJ65BT-G4 1 station

AJ65BT-D75P2-S3 4 stations

4 stations

(2) Station number

When the number of occupied station for all connected stations is set to "1

station," the station number is set continuously from 1 (e.g. 1, 2, 3,... ).

However, when a station which occupies more than 2 stations is connected, the

setting must be performed considering the number of occupied stations.

Station No.5 Station No.6Station No.7 Station No.8 Station No.9Station No.4Station No.3Station No.2Station No.1

Master

station

Station No.1

Remote station

(occupies 2 stations)

Station No.3

Remote station

(occupies 1 station)

Station No.4

Local station

(occupies 4

stations)

Station No.8

Remote station

(occupies 1 station)

Station No.9

Local station

(occupies 1

station)

(3) Number of modules and number of stations

Number of modules is a physical module count.

Number of stations is a number of occupied stations for each module as stated in

(1).

In the system configuration example in (2), the number of modules is 5 and

number of stations is 9.

1 - 13

Page 30

1 OVERVIEW

MELSEC-QnA

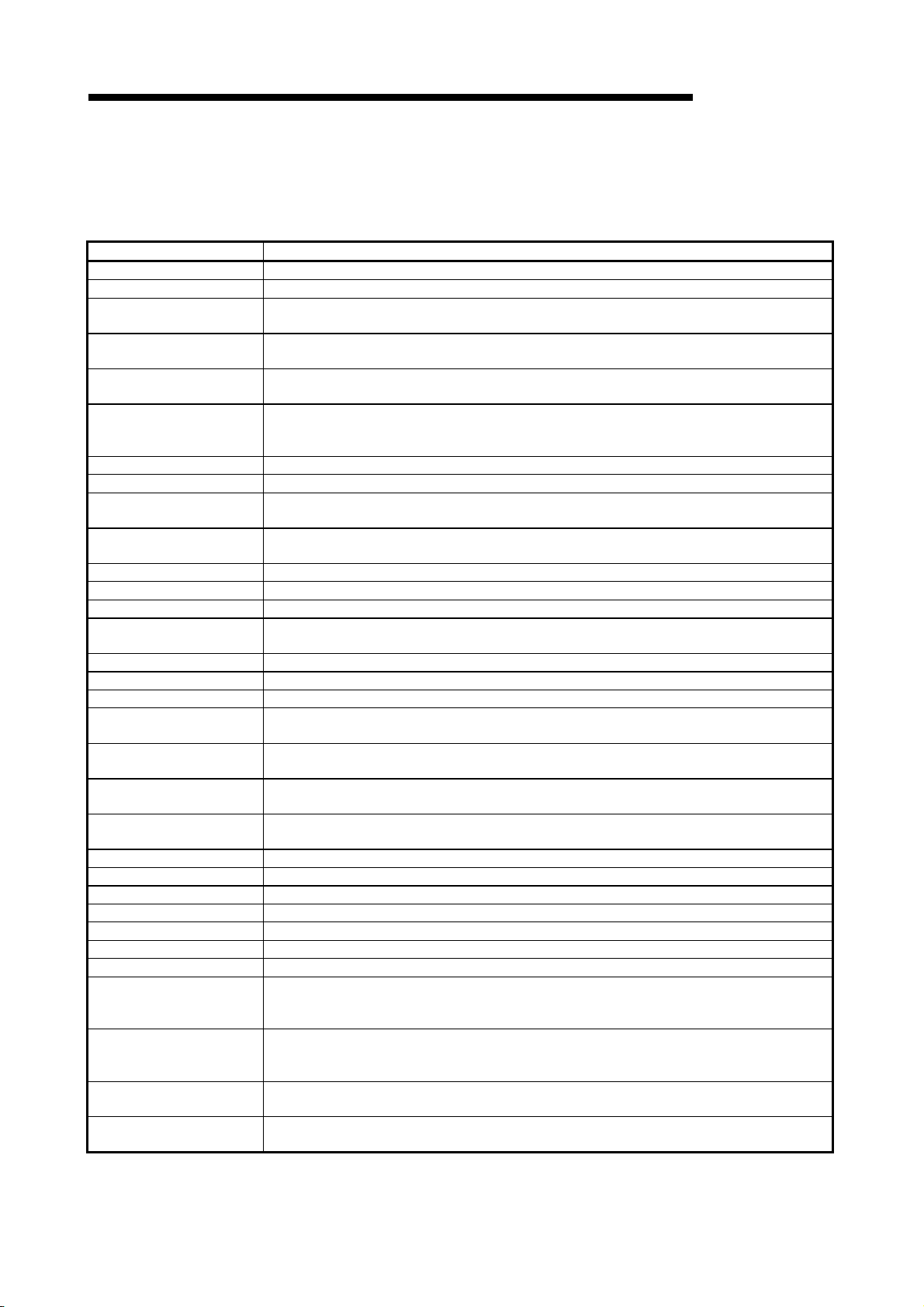

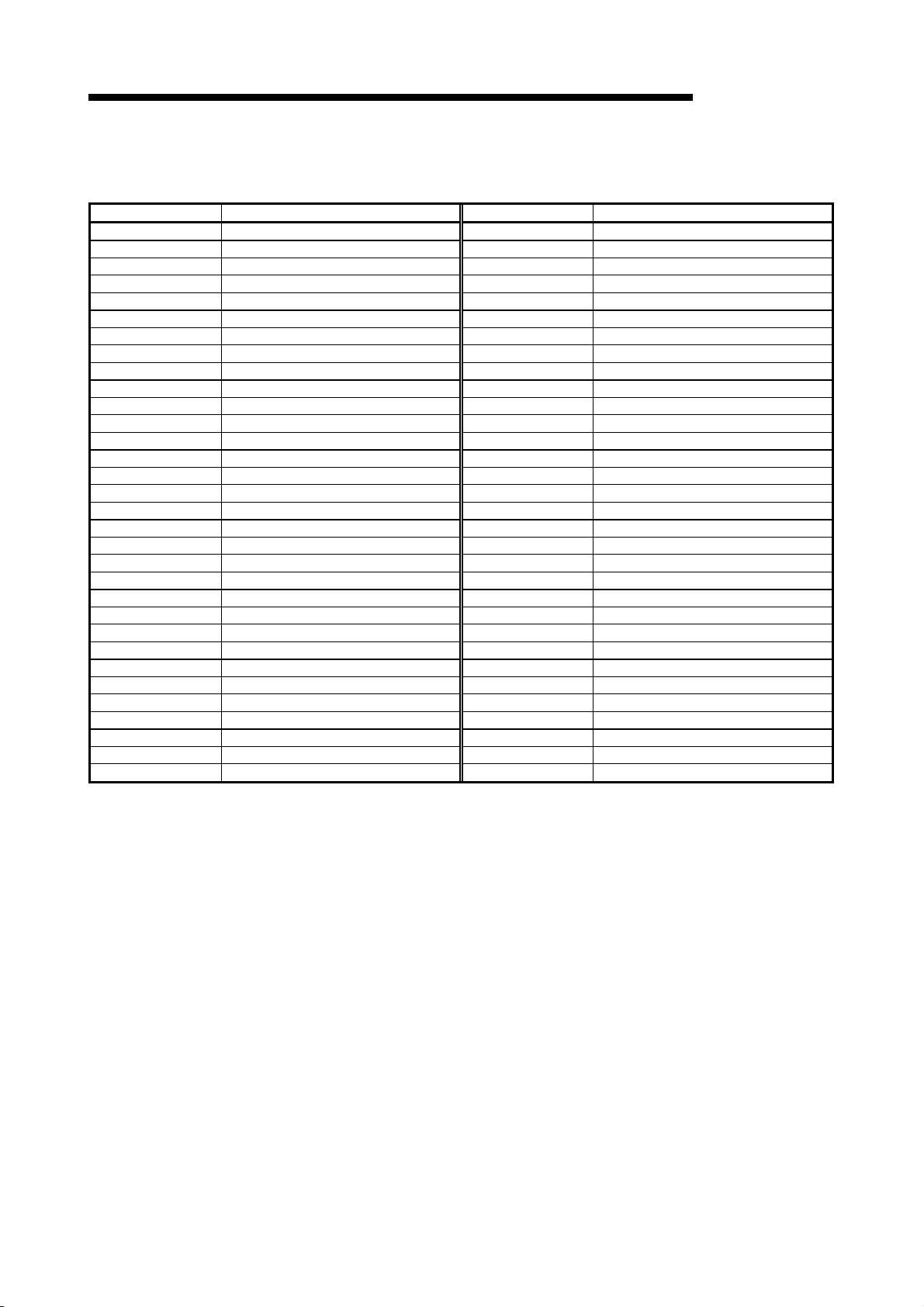

1.5 Generic Terms and Abbreviations

Generic terms and abbreviations used in this manual are shown below.

Generic Term/Abbreviation

AJ61QBT11 Abbreviation for the AJ61QBT11 CC-Link System Master/Local Module.

A1SJ61QBT11 Abbreviation for the A1SJ61QBT11 CC-Link System Master/Local Module.

Master station

Local station

Remote I/O station

Remote device station

Remote station Generic term for remote I/O station and remote device station. (Controlled by a master station)

Intelligent device station Station that can perform transient transmission, such as the AJ65BT-R2(N) (Including local station).

Standby master station

Slave station

Master/local module Generic term for the AJ61QBT11, and A1SJ61QBT11.

Master module Generic term for the AJ61QBT11, and A1SJ61QBT11 when they are used as master station.

Local module Generic term for the AJ61QBT11, and A1SJ61QBT11 when they are used as local station.

Remote module

AJ65BT-R2(N) Generic term for AJ65BT-R2 and AJ65BT-R2N.

Intelligent device module Module that can perform transient transmission, such as AJ65BT-R2(N) (including local module).

Remote I/O net mode Dedicated mode for sending and receiving data to and from the remote I/O station at high speed.

Remote net mode

Cycric transmission

Transient transmission

AnSCPU

AnCPU Generic term for the A1CPU, A2CPU, A2CPUS1, and A3CPU.

AnNCPU Generic term for the A1NCPU, A2NCPU, A2NCPUS1, and A3NCPU.

AnACPU Generic term for the A2ACPU, A2ACPUS1, and A3ACPU.

A2USCPU Generic term for the A2USCPU and A2USCPUS1.

AnUCPU Generic term for the A2UCPU, A2UCPUS1, A3UPU, and A4UCPU.

Q2ASCPU Generic term for the Q2ASCPU, Q2ASCPUS1, Q2ASHCPU, and Q2ASHCPUS1.

QnACPU Generic term for the Q2ACPU, Q2ACPUS1, Q3ACPU, and Q4ACPU.

SB

SW

RX

RY

Station that controls the data link system.

One master station is required for each system.

Station having a programmable controller CPU and the ability to communicate with the master and other

local stations.

Remote station that handles bit unit data only. (Performs input and output with external devices.)

(AJ65BTB1-16D, AJ65SBTB1-16D)

Remote station that handles bit unit and word unit data only. (Performs input and output with external

devices, and analog data conversion.)

(AJ65BT-64AD, AJ65BT-64DAV, AJ65BT-64DAI)

Backup station for data link control when the link to the master station is disconnected due to a

programmable controller CPU or power supply problem.

Generic term for the remote I/O station, remote device station, local station, intelligent device station and

standby master station.

Generic term for the AJ65BTB1-16D, AJ65SBTB1-16D, AJ65BT-64AD, AJ65BT-64DAV, AJ65BT-64DAI,

and A852GOT.

Mode that can communicate with all stations used for CC-Link (remote I/O station, remote device station,

local station, intelligent device station, and standby master station)

Transmission method by which to periodically communicate the contents of remote I/O, and remote

registers.

Transmission method with which the counterpart is specified and 1:1 communication is used at an

arbitrary timing.

Generic term for the A1SCPU, A1SCPU-S1, A1SJCPU, A1SJCPU-S3, A2SCPU, A2SCPU-S1, and

A1SCPUC24-R2.

Link special relay (for CC-Link)

Bit unit information that indicates the module operating status and data link status of the master

station/local station.

Link special register (for CC-Link)

16-bit unit information that indicates the module operating status and data link status of the master

station/local station.

Remote input (for CC-Link)

Information entered in bit units from the slave stations to the master station.

Remote output (for CC-Link)

Information output in bit units from the master station to the slave station

Description

1 - 14

Page 31

1 OVERVIEW

Generic Term/Abbreviation

RWw

RWr

Description

Remote register (Write area for CC-Link)

Information output in 16-bit units from the master station to the slave station.

Remote register (Read area for CC-Link)

Information entered in 16-bit units from the slave station to the master station.

MELSEC-QnA

1 - 15

Page 32

2 SYSTEM CONFIGURATION

2. SYSTEM CONFIGURATION

MELSEC-QnA

2.1 Total Configuration

2

Master station

The system configuration for the CC-Link is described in this chapter.

A total of 64 remote I/O stations, remote device stations, or local stations can be

connected for one master station.

However, the following conditions must be satisfied:

(1) {(1×a)+(2×b)+(3×c)+(4×d)} 64

a : Number of modules occupying 1 station c : Number of modules occupying 3 stations

b : Number of modules occupying 2 stations d : Number of modules occupying 4 stations

(2) {(16×A)+(54×B)+(88×C)} 2304

A : Number of remote I/O stations 64

B : Number of remote device stations 42

C : Number of local stations, standby master stations, intelligent device stations 26

Maximum 26

Local station Local station

A1SJ61QBT11

AJ61QBT11

A1SJ61BT11

AJ61BT11

A1SJ61QBT11

AJ61QBT11

Terminating resistor

(mandatory)

Maximum 42Maximum 26

CC-Link dedicated cable

Maximum 64

Remote I/O stationRemote device stationIntelligent device station

RS-232C

Interface module

AJ65BT-R2N

Analog-digital

conversion module

AJ65BT-64AD

Remote I/O module

AJ65BTB -

AJ65BTC -

Terminating resistor

(mandatory)

CC-Link dedicated cable

Total 64

2 - 1

Page 33

2 SYSTEM CONFIGURATION

2.2 Applicable System

The applicable CPU modules and the precautions for system configuration are

described below.

2.2.1 Applicable CPU and number of modules that can be installed

The applicable programmable controller CPU, data link system/network system, and

the number of modules that can be installed are shown in Table 2.1.

However, intelligent mode cannot be used for future plan.

Programmable

controller CPU

Data link and

network

Table 2.1 Number of modules that can be installed

Installation area A1SJ61QBT11 AJ61QBT11

A0J2CPU

A0J2HCPU

A1SCPU (S1)

A1SHCPU

A1SJCPU (S3)

A1SJHCPU (S8)

A1SCPUC24-R2

A2SCPU (S1)

A2SHCPU (S1)

A2ASCPU (S1/S30)

A2USHCPU-S1

Q2ASCPU (S1)

Q2ASHCPU (S1)

A1CPU

A2CPU (S1)

A3CPU

A1NCPU

A2NCPU (S1)

A3NCPU

A3MCPU

A3HCPU

A2ACPU (S1)

A3ACPU

A2UCPU (S1)

A3UCPU

A4UCPU

Q2ACPU (S1)

Q3ACPU

Q4ACPU

Q4ARCPU

MELSECNET remote I/O station Unusable Unusable

MELSECNET/B remote I/O station Unusable Unusable

AJ72LP25

AJ72LP15

MELSECNET/10

remote I/O station

AJ72QLP25

AJ72QBR15

A1SJ72QLP25

A1SJ72QBR15

Unusable Unusable

No restrictions No restrictions

Unusable

Unusable Unusable

Unusable No restrictions

No restrictions No restrictions

MELSEC-QnA

Unusable

No restrictions

2 - 2

Page 34

2 SYSTEM CONFIGURATION

2.2.2 Precautions when configuring a system

Design the system with the following considerations to prevent mis-input from the

remote I/O module:

(1) During power on and power off

Start the data link after turning on the power for the remote I/O module.

Turn off power for the remote I/O module after stopping the data link.

During

Master module

(Data-link status)

Remote I/O module

(Power supply status)

operation

During stop

(2) During momentary power failure of the remote I/O module

When momentary power failure occurs with the power (24VDC) supplied to the

remote I/O module, mis-input may occur.

(a) Cause for mis-input due to a momentary power failure

The remote I/O module hardware uses the power after internally converting

the module power (24VDC) in to 5VDC.

When momentary power failure occurs with the remote I/O module, the

following condition occurs:

(Time for the 5VDC in the internal remote I/O module to turn off) > (input

module on

Therefore, mis-input is caused when a refresh is performed within the time

indicated by

Remote I/O module

(Module power supply

and input external-power

supply)

off response time)

1

) in the diagram below.

ON

OFF

MELSEC-QnA

Data link start Data link stop

1

Remote I/O module

(Internal 5VDC)

Input (Xn)

Because the input external-power supply is turned off,

the input (Xn) turns off after the response time of input

module is turned off.

2 - 3

Page 35

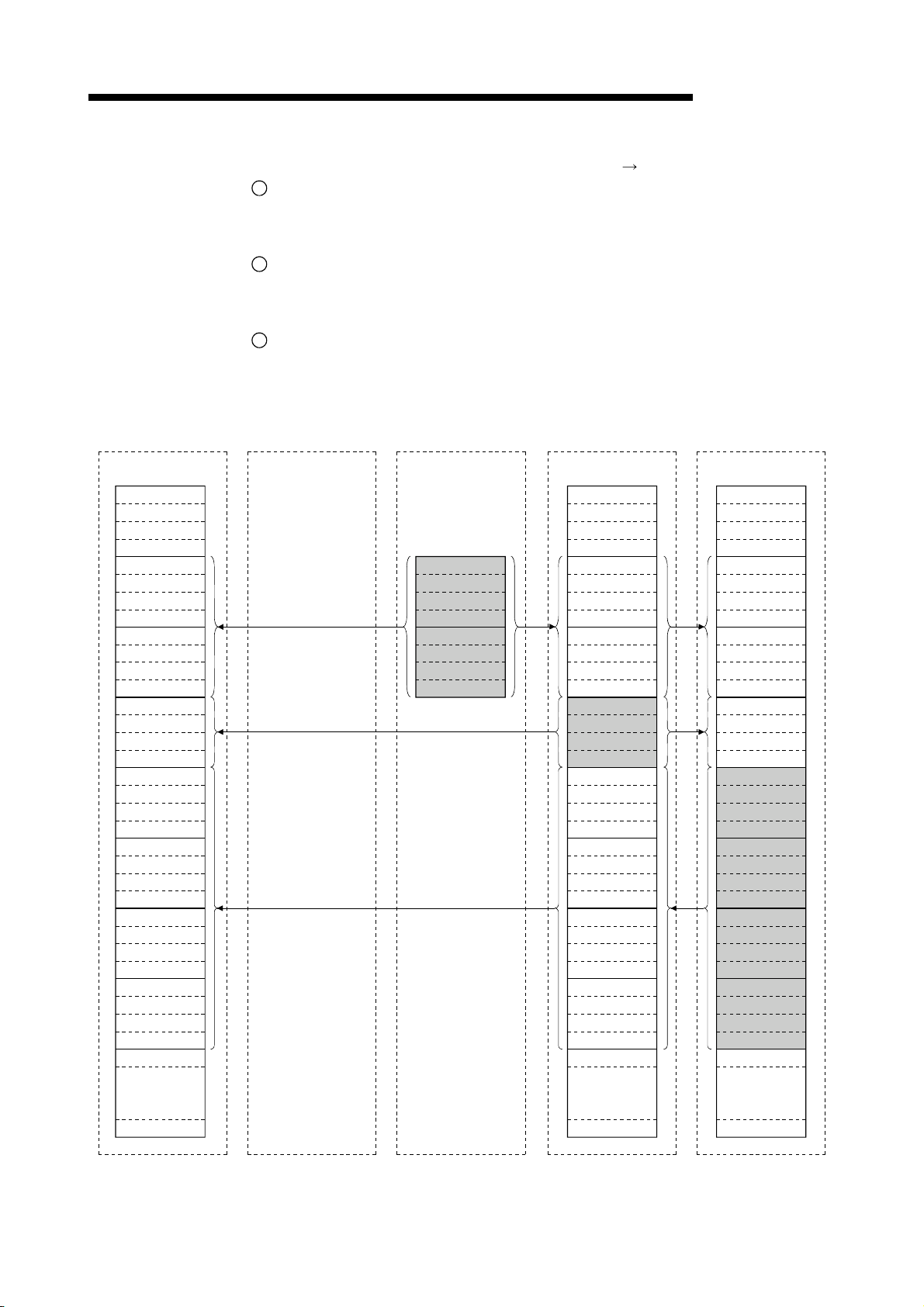

2 SYSTEM CONFIGURATION

(b) Countermeasure for mis-input

Wire the power supply cable for the power supply module, stabilized power,

and input/external-supply power of the AC input from the same power

source.

Programmable

controller CPU

MELSEC-QnA

For DC input

For AC input

Power supply module

Stabilized

power supply

Programmable

controller CPU

Power supply module

Stabilized

power supply

24VDC

24VDC

Master module

Module power supply

Master module

Module power supply

Remote I/O module

Input

external-supply

power

Remote I/O module

Input

external-supply

power

REMARK

When supplying power from one power source to multiple remote I/O modules, select the cable

and perform the wiring with considerations to the voltage decline from the cables.