Mitsubishi Electric Air-Conditioners For Building Application, CITY MULTI PMFY-P-NBMU-E Installation Manual

Page 1

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

Air-Conditioners For Building Application

INDOOR UNIT

PMFY-P·NBMU-E

Page 2

2

Contents

1. Safety precautions ................................................................................... 2

2. Installing the indoor unit ........................................................................... 3

3. Installing the refrigerant piping ................................................................. 5

4. Drainage piping work ............................................................................... 6

5. Electrical work .......................................................................................... 7

6. Test run .................................................................................................... 9

7. Installing the grille .................................................................................... 9

1.2. Before installation or relocation

Caution:

• Be extremely careful when transporting the units. Two or more persons are

needed to handle the unit, as it weighs 44 lbs. (20 kg) or more. Do not grasp

the packaging bands. Wear protective gloves as you can injure your hands

on the fins or other parts.

• Be sure to safely dispose of the packaging materials. Packaging materials,

such as nails and other metal or wooden parts may cause stabs or other

injuries.

Warning:

• Ask a dealer or an authorized technician to install the unit.

• For installation work, follow the instructions in the Installation Manual and use

tools and pipe components specifically made for use with refrigerant specified in the outdoor unit installation manual.

• The unit must be installed according to the instructions in order to minimize

the risk of damage from earthquakes, typhoons, or strong winds. An incorrectly installed unit may fall down and cause damage or injuries.

• The unit must be securely installed on a structure that can sustain its weight.

• If the air conditioner is installed in a small room, measures must be taken to

prevent the refrigerant concentration in the room from exceeding the safety

limit in the event of refrigerant leakage. Should the refrigerant leak and cause

the concentration limit to be exceeded, hazards due to lack of oxygen in the

room may result.

• Ventilate the room if refrigerant leaks during operation. If refrigerant comes

into contact with a flame, poisonous gases will be released.

• All electric work must be performed by a qualified technician according to

local regulations and the instructions given in this manual.

• Use only specified cables for wiring.

• The terminal block cover panel of the unit must be firmly attached.

• Use only accessories authorized by Mitsubishi Electric and ask a dealer or

an authorized technician to install them.

• The user should never attempt to repair the unit or transfer it to another location.

• After installation has been completed, check for refrigerant leaks. If refrigerant leaks into the room and comes into contact with the flame of a heater or

portable cooking range, poisonous gases will be released.

1.1. Before installation (Euvironment)

Caution:

• Do not use the unit in an unusual environment. If the air conditioner is installed in areas exposed to steam, volatile oil (including machine oil), or

sulfuric gas, areas exposed to high salt content such as the seaside, the

performance can be significantly reduced and the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced, flow,

or accumulate. If combustible gas accumulates around the unit, fire or explosion may result.

• Do not keep food, plants, caged pets, artwork, or precision instruments in

the direct airflow of the indoor unit or too close to the unit, as these items can

be damaged by temperature changes or dripping water.

• When the room humidity exceeds 80% or when the drainpipe is clogged, water may drip from the indoor unit. Do not install the indoor unit where such

dripping can cause damage.

• When installing the unit in a hospital or communications office, be prepared

for noise and electronic interference. Inverters, home appliances, high-frequency medical equipment, and radio communications equipment can cause

the air conditioner to malfunction or breakdown. The air conditioner may

also affect medical equipment, disturbing medical care, and communications

equipment, harming the screen display quality.

• Thermal insulation of the refrigerant pipe is necessary to prevent condensation. If the refrigerant pipe is not properly insulated, condensation will be formed.

• Place thermal insulation on the pipes to prevent condensation. If the drainpipe is installed incorrectly, water leakage and damage to the ceiling, floor,

furniture, or other possessions may result.

• Do not clean the air conditioner unit with water. Electric shock may result.

• Tighten all flare nuts to specification using a torque wrench. If tightened too

much, the flare nut can break after an extended period.

1.3. Before electric work

Caution:

• Be sure to install circuit breakers. If not installed, electric shock may result.

• For the power lines, use standard cables of sufficient capacity. Otherwise, a

short circuit, overheating, or fire may result.

• When installing the power lines, do not apply tension to the cables.

• Be sure to ground the unit. If the unit is not properly grounded, electric shock

may result.

• Use circuit breakers (ground fault interrupter, isolating switch (+B fuse), and

molded case circuit breaker) with the specified capacity. If the circuit breaker

capacity is larger than the specified capacity, breakdown or fire may result.

1. Safety precautions

1.4. Before starting the test run

Caution:

• Turn on the main power switch more than 12 hours before starting operation.

Starting operation just after turning on the power switch can severely damage the internal parts.

• Before starting operation, check that all panels, guards and other protective

parts are correctly installed. Rotating, hot, or high voltage parts can cause

injuries.

• Do not operate the air conditioner without the air filter set in place. If the air

filter is not installed, dust may accumulate and breakdown may result.

• Do not touch any switch with wet hands. Electric shock may result.

• Do not touch the refrigerant pipes with bare hands during operation.

• After stopping operation, be sure to wait at least five minutes before turning

off the main power switch. Otherwise, water leakage or breakdown may result.

s Before installing the unit, make sure you read all the “Safety precau-

tions”.

s Please report to your supply authority or obtain their consent before

connecting this equipment to the power supply system.

Warning:

Describes precautions that must be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that must be observed to prevent damage to the unit.

After installation work has been completed, explain the “Safety Precautions,” use,

and maintenance of the unit to the customer according to the information in the Operation Manual and perform the test run to ensure normal operation. Both the Installation Manual and Operation Manual must be given to the user for keeping. These

manuals must be passed on to subsequent users.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels affixed to the main unit.

Page 3

3

A

9-3/8 (247)

2-1/16(53)

11/16

(17.5)

11/16

(17.5)

13/16 (20)13/16 (20)

1-1/8

(28)

1-1/8 (28)

1-25/32 (45)

13/16 (20)

1-3/4 (45)

3/4 (20)

13-1/2 (340)

3

17 (430)

2

18-1/2 (470)

1

1-1/32 (26)

2-15/18 (74.5)

13/16 (20)

1-1/32 (26)

2-15/18 (74.5)

13/16 (20)

29-7/8 (759)

31-15/18 (811)

3

37-13/16 (960)

2

39-3/8 (1000)

1

4

2-11/16

(69)

2. Installing the indoor unit

1

2

3

4

6

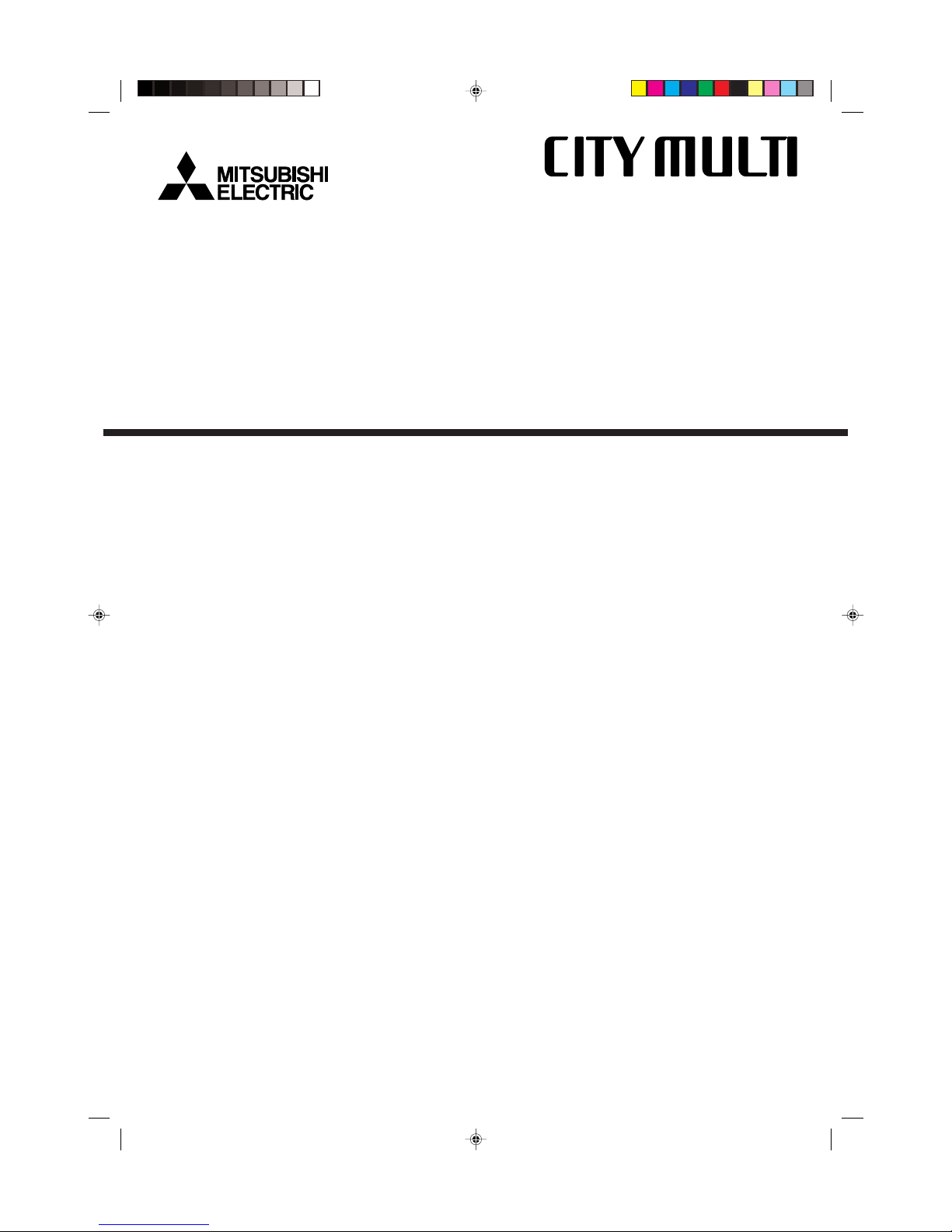

2.1. Check the indoor unit accessories (Fig. 2-1)

The indoor unit should be supplied with the following spare parts and accessories

(contained in the inside of the intake grille).

Accessory name Q’ty

1 Washer 4 pcs

2 Washer (with insulation) 4 pcs

3 Pipe cover 2 pcs

4 Band 4 pcs (Long) 2 pc (Short)

5 Screw 4 pcs M5 × 0.8 × 30 2 pcs M4 × 12

6 Glass tube 1pc

7 Plate for conduit 1pc

Fig. 2-1

5

7

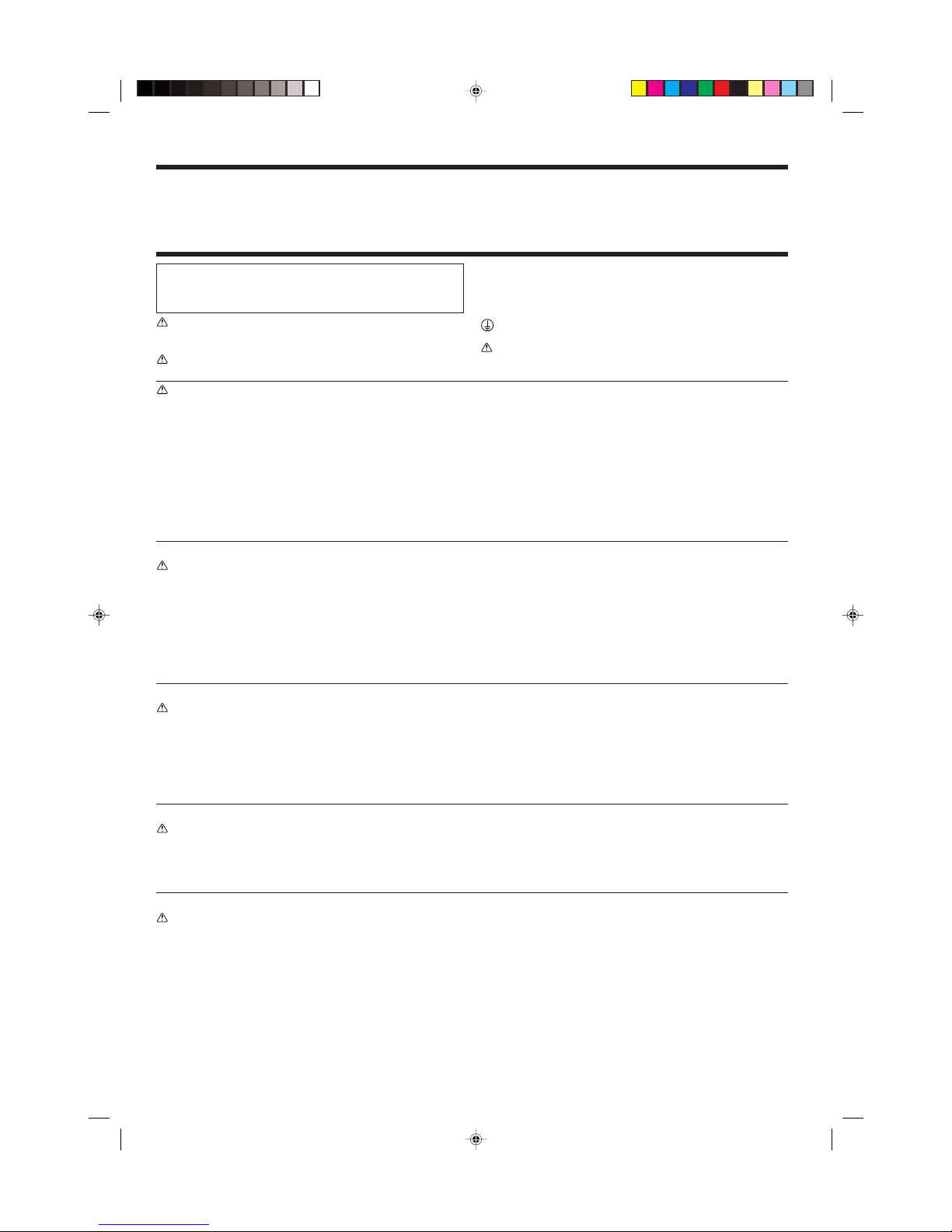

2.2. Service space (Fig. 2-2)

• The dimensions of ceiling opening can be regulated within the range shown in

following diagram; so center the main unit against the opening of ceiling, ensuring

that the respective opposite sides on all sides of the clearance between them becomes identical.

A Air intake

B Air outlet

C Ceiling panel

D Min. 7-7/8 in. (200 mm)

E Suspension bolts W3/8 or M10

F Grille

2.3. Ceiling openings and suspension bolt installation

locations (Fig. 2-3)

• Make an opening in the ceiling 17 in × 37-7/8 in (430 mm × 960 mm) in size. This

functions as a check window and will be needed later during servicing.

• If the dimensions are not accurate, when the grille is installed there may be gaps

between it and the indoor unit. This may result in dripping water or other problems.

• When deciding on placement, consider carefully the space around the ceiling and

make your measurements generous.

• Ceiling types and building construction differ. Therefore you should consult with the

builder and decorator.

A The centers of the ceiling opening and the indoor unit should be aligned.

1 Outer side of grille

2 Ceiling opening

3 Bolt pitch

4 Electric box

• Using the installation template (top of the package) and the gauge (supplied as an

accessory with the grille), make an opening in the ceiling so that the main unit can

be installed as shown in the diagram. (The method for using the template and the

gauge are shown.)

• Use M10 (3/8") suspension bolts.

* Suspension bolts are to be procured at the field.

• After suspending the indoor unit, you will have to connect the pipes and wiring

above the ceiling. Once the location has been fixed and the direction of the pipes

has been determined, place the refrigerant and drainage pipes, the wiring for the

remote controller, and the wiring that connects the indoor and outdoor units in their

desired locations before suspending the indoor unit. This is especially important in

cases where the ceiling is already in existence.

C

A

D

AB

4-5/16

(110)

9-1/16(230)

E

F

9-1/16(230)

Fig. 2-2

Fig. 2-3

in (mm)

in (mm)

Page 4

4

D

E

F

G

13-1/2

(340)

31-7/8 (811)

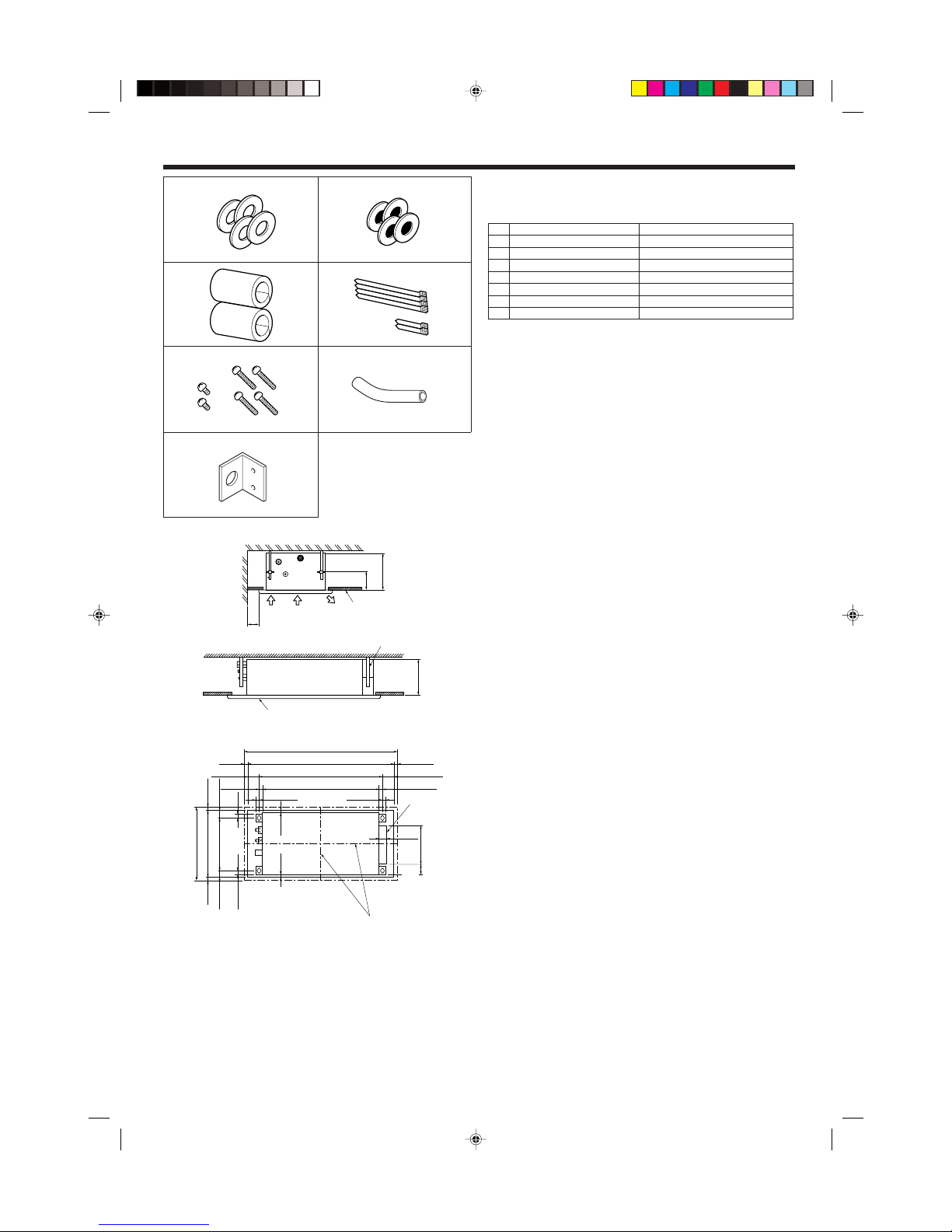

Check the pitch of the suspension bolt. (13-1/2 in. × 32 in. (340 mm × 811 mm)) (Fig.

2-6)

1. Thread washers 1 2 (supplied) and their nuts (procured locally) onto the sus-

pension bolt in advance.

* Do this in the following order (from the top): nut, insulated washer 2, washer

without insulation 1, two nuts.

* Position insulated washer 2 with the insulated surface pointing down, as in the

figure.

2. Lift the unit into place, aligned properly with the suspension bolt. Pass the bracket

between washers 1 and 2, which are already in place, and secure it. Do the

same in all four places.

* Make sure the suspension bolt extends 3/4 in. (20 mm) or more from the surface

of the ceiling. Otherwise you will not be able to install the cover panel (sold separately).

3. If the long opening in the bracket and opening in the ceiling do not align, adjust

them until they do.

4. Check that the four corners are all level, using a spirit level or clear plastic tubing

with water in it.

* Make sure that any slant in the unit after installation is less than 0.5 degrees

(approx. 1/4 in. (6 mm) on the long dimension of the unit).

5. Tighten all the nuts. (Fig. 2-7)

B

in. (mm)

in. (mm)

Fig. 2-6

A Suspension bolt (3/8" or M10)

B Ceiling surface

C Nut (3/8" or M10)

D Washer 2 (with insulation)

E Washer 1

F (Install with insulation facing down)

G Measurement to upper face of bracket

A Suspension bolt (3/8" or M10)

B Clear plastic tubing

C Underside of bracket

D Secure front panel here

E Make these surfaces are flush with each other (0 - 1/8 in. (0 - 3 mm))

Fig. 2-7

K

L

M

J

H

I

in. (mm)

in. (mm)

Fig. 2-4

Fig. 2-5

D Ceiling panel

E Rafter

F Beam

G Roof beam

H Use inserts rated at 250-350 lbs (100-150 kg) each (procure locally)

I Suspension bolts 3/8" (M10) (procure locally)

J Steel reinforcing rod

K C channel

L Channel suspension bracket

M M10 suspension bolt

2.4. Unit suspension procedures (Fig. 2-5)

Procure 3/8" bolts or M10 bolts locally.

• Adjust the length of the bolt’s protrusion from the ceiling surface beforehand.

*1. When using an extra upper nut in suspending the unit, in some cases you may

have to add it later.

A Suspension bolt

B Ceiling panel

C Nut

D Washer (with insulation) 2

E Washer (without insulation) 1

2. Installing the indoor unit

1 Wooden structures (Fig. 2-4)

• Use tie beams (single storied houses) or second floor beams (two story houses) as

reinforcing members.

• Wooden beams for suspending air conditioners must be sturdy and their sides

must be at least 2-3/8 in. (6 cm) long if the beams are separated by not more than

35-7/16 in. (90 cm) and their sides must be at least 3-9/16 in. (9 cm) long if the

beams are separated by as much as 70-7/8 in. (180 cm). The size of the suspension bolts should be 3/8" (ø10). (The bolts do not come with the unit.)

• Use channel, duct and other parts procured locally to suspend the indoor unit.

2 Ferro-concrete structures

Secure the suspension bolts using the method shown, or use steel or wooden hangers, etc. to install the suspension bolts.

A

C

D

E

C *1

B

Min. 51/64(20) Min. 1-3/16(30)

F

G

B

B

C

*

E

*

D

C

A

4-13/32(112)

Min. 51/64(20)

4-21/64

(110)

A

C

D

E

4-21/64

(110)

Page 5

5

A

9-13/16 (250) 11-3/8 (288.5)

4-4/16

(108)

2. Installing the indoor unit

2.5. Fresh air intake hole (Fig. 2-8)

At the time of installation, use the hole (knock out) located at the positions shown in

following diagram, as and when required.

Note:

Make sure that the fresh air intake is no more than 20% of the entire air intake

(when the air flow speed is set to its highest setting).

Caution:

Linkage of duct fan and air conditioner.

If a duct fan is used, be sure to link it with the air conditioner when outside air

is taken in.

Do not run just the duct fan. Otherwise, condensation may form.

A Fresh air intake hole (Knock out)

B 4-1/8 in. (ø2.8) burring hole

Fig. 2-8

in. (mm)

ø3-15/16

(ø100)

ø4-13/16

(ø122)

90°

B

A

3. Installing the refrigerant piping

A Flare cutting dimensions

Copper pipe O.D.

Flare dimensions

øA dimensions

1/4" (ø6.35) 11/32-23/64 (8.7 - 9.1)

3/8" (ø9.52) 1/2-33/64 (12.8 - 13.2)

1/2" (ø12.7) 41/64-21/32 (16.2 - 16.6)

5/8" (ø15.88) 49/64-25/32 (19.3 - 19.7)

3/4" (ø19.05) 15/16-61/64 (23.6 - 24.0)

B

C

D

Fig. 3-1

A Die

B Copper pipe

A

A

B

in. (mm)

in. (mm)

in. (mm)

3.1. Precautions

3.1.1. For devices that use R22 refrigerant

• Use the refrigeration oil applied to the flared sections.

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. Use refrigerant pipes with the thicknesses

specified in the table to the below. Make sure the insides of the pipes are

clean and do not contain any harmful contaminants such as sulfuric compounds, oxidants, debris, or dust.

90° ±0.5°

øA

R1/64 to R1/32

A

45°±2°

3.1.2. For devices that use R410A refrigerant

• Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration

oil applied to the flared sections.

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. Use refrigerant pipes with the thicknesses

specified in the table to the below. Make sure the insides of the pipes are

clean and do not contain any harmful contaminants such as sulfuric compounds, oxidants, debris, or dust.

Warning:

When installing or moving the air conditioner, use only the specified refrigerant (R410A) to charge the refrigerant lines. Do not mix it with any other refrigerant and do not allow air to remain in the lines. Air enclosed in the lines can

cause pressure peaks resulting in a rupture and other hazards.

P06, P08, P12, P15

Liquid pipe

1/4" (ø6.35) thickness 1/32" (0.8)

Gas pipe

1/2" (ø12.7) thickness 1/32" (0.8)

• Do not use pipes thinner than those specified above.

3.2. Connecting pipes (Fig. 3-1)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 212 °F (100 °C)

or more, thickness of 1/2 in. (12 mm) or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam insu-

lation materials (specific gravity of 0.03, thickness of 23/64 in. (9 mm) or more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening

flare nut.

• Use two wrenches to tighten piping connections.

• Use refrigerant piping insulation provided to insulate indoor unit connections. Insu-

late carefully.

B Flare nut tightening torque

Copper pipe O.D. Flare nut O.D. Tightening torque

in. (mm) in. (mm) ft·lbs. (N·m)

1/4" (ø6.35) 43/64 (17) 10-13 (14 - 18)

1/4" (ø6.35) 7/8 (22) 25-30 (34 - 42)

3/8" (ø9.52) 7/8 (22) 25-30 (34 - 42)

1/2" (ø12.7) 1-3/64 (26) 35-44 (49 - 61)

1/2" (ø12.7) 1-9/64 (29) 49-59 (68 - 82)

5/8" (ø15.88) 1-9/64 (29) 49-59 (68 - 82)

5/8" (ø15.88) 1-27/64 (36) 72-87 (100 - 120)

3/4" (ø19.05) 1-27/64 (36) 72-87 (100 - 120)

C Apply refrigerating machine oil over the entire flare seat surface.

D Use correct flare nuts meeting the pipe size of the outdoor unit.

Available pipe size

P06, P08, P12, P15

Liquid side

1/4" (ø6.35)

–

1/2" (ø12.7)

Gas side –

–

: Factory flare nut attachment to the heat-exchanger.

Fig. 3-2

A

Copper pipe O.D. Flare tool for R22 Flare tool for R410A

Clutch type

1/4" (ø6.35) 0-1/64 (0 - 0.5) 3/64-1/16 (1.0 - 1.5)

3/8" (ø9.52) 0-1/64 (0 - 0.5) 3/64-1/16 (1.0 - 1.5)

1/2" (ø12.7) 0-1/64 (0 - 0.5) 3/64-1/16 (1.0 - 1.5)

5/8" (ø15.88) 0-1/64 (0 - 0.5) 3/64-1/16 (1.0 - 1.5)

3/4" (ø19.05) 0-1/64 (0 - 0.5) 3/64-1/16 (1.0 - 1.5)

in. (mm)

Page 6

6

4. Drainage piping work

B

M

L

K

D

E

D

H

I

G

D

F

F

F

1

2

H

A

C

D

G

F

E

B

I

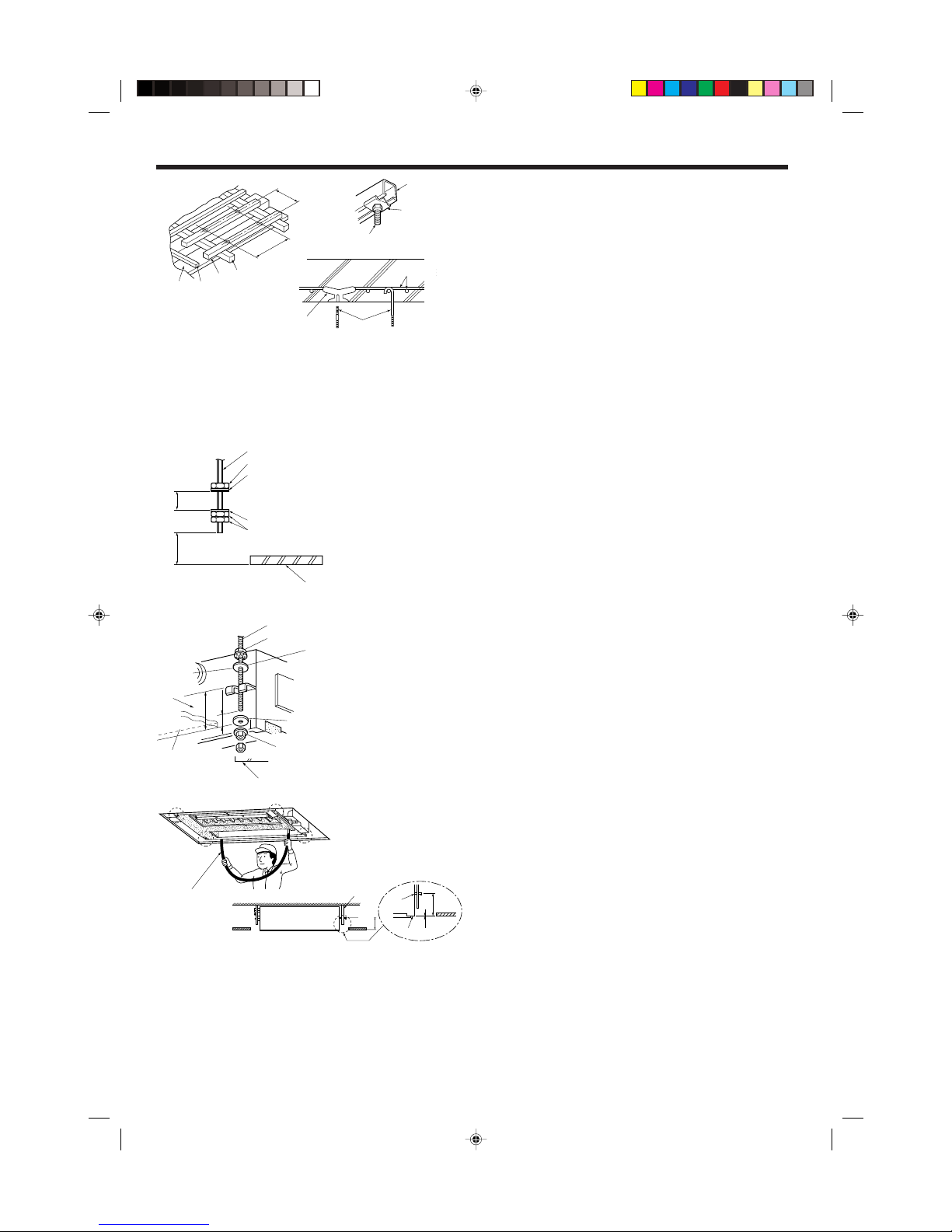

4.1. Drainage piping work

• Use O.D. ø26 PVC TUBE for drain piping and provide 1/100 or more downward

slope.

• Be sure to connect the piping joints using adhesive of polyvinyl chloride family.

• Observe the figure for piping work.

• Use attached drain hose to change the pipe extraction direction. (Fig. 4-1)

1 Correct piping

2 Wrong piping

A Insulation (3/8 in. (9 mm) or more)

B Downward slope (1/100 or more)

C Support metal

K Air bleeder

L Raised

M Odor trap

N Make as little as possible

O Make as great as possible (approx. 4 in. (10 cm))

Grouped piping (Fig. 4-2)

D VP20 (O.D. ø1" (ø26) PVC TUBE)

E Make it as large as possible

F Indoor unit

G Make the piping size large for grouped piping.

H Downward slope (1/100 or more)

I O.D. ø1-1/2" (ø38) PVC TUBE for grouped piping.

(3/8 in. (9 mm) or more insulation)

J Up to 19-11/16 in. (50 cm)

In cases of upward drainage

• The largest dimension possible for the vertical section at B is 60 cm from the lower

surface of the ceiling. Make this vertical section as short as possible.

Water drainage check

1. Fill the drainage pan with about 0.5 liters of water. (Don’t pour water directly into

the drain pump.)

2. Make a test run of the unit (in Cooling mode).

3. Check for water drainage at the transparent check window and the outlet of the

drainage pipe.

4. Stop the test run. (Don’t forget to turn off the power.) (Fig. 4-3)

Fig. 4-1

Fig. 4-2

A Ceiling panel

B Max. 23-5/8 in. (60 cm)

C Position of drain outlet

D Make as short as possible (Max. 6 in. (15 cm))

E Make as small as possible

F Downward slope (1/100 or more)

G Make as great as possible (Min. 4 in. (10 cm))

H Drainage pipe vertical section

I Water bottle (procure locally)

Fig. 4-3

FE

D

C

I

C

H

A·B

G

D

3.3. Refrigerant piping

1) Indoor unit

Installing procedures (Fig. 3-2)

1. Remove the flare nuts and caps from the indoor unit.

2. Flare-cut the liquid and gas pipes then apply refrigerating machine oil (to be lo-

cally procured) over the flare-cut seat surface.

3. Quickly connect the refrigerant piping.

∗ Remember to tighten the flare nuts with a double spanner.

4. Slide the supplied pipe cover 3 over the gas piping until it is pressed against the

sheet metal inside the unit.

5. Slide the provided pipe cover 3 over the liquid piping until it is pressed against

the sheet metal inside the unit.

6. Tighten the pipe cover 3 at the both ends 5/8 - 13/16 in. (15 - 20 mm) with the

supplied bands 4.

A Gas piping

B Liquid piping

C Band 4

D Pipe cover 3

E Turn the seam upward.

F Press the pipe cover against the

sheet metal.

G Refrigerant piping heat insulating ma-

terial

H Wrap tightly

I Cut off excess length of band.

Fig. 3-2

3. Installing the refrigerant piping

Max. 65ft.(20m)

2.5 to 5ft.(0.75–1.5m)

N

O

A

B

C

Max. 6in.(15cm)

J

F

Page 7

7

5. Electrical work

Fig. 5-1

5.1. Electric wiring (Fig. 5-1)

* Make sure all electrical wiring is complete before installing the cover panel.

1. Secure the provided sheet metal for conduit with provided screws to the side of

the unit (two screws).

2. Remove the cover from the address board (two screws).

3. Remove the cover from the electrical box (one screw).

4. Remove the screws securing the electrical box and lower the box (two screws).

5. Insert the wires into the electrical box.

6. Connect the wires securely to the terminal block.

* Be sure to make the various wires long enough so the box may be lowered from

the unit during servicing.

7. Secure the wires with the wiring clamp on the side of the electrical box.

8. Replace the parts you have removed to their original locations.

A means for the disconnection of the supply with an isolation switch, or similar de-

vice, in all active conductors shall be incorporated in the fixed wiring.

Power supply wiring

Power cable size (diameter) : more than 1.6 mm (AWG14)

Ground cable size (diameter) : 1.6 mm (AWG14)

* Use copper supply wires.

* Use the electric wires over the rating voltage 300 V.

* Instalation must be in accordance with the Natronal Electrical code (NEC) and all

appliciable codes. Field wiring material used must have a VW1 flame rating.

5.2. Connecting remote controller, indoor and outdoor

transmission cables (Fig. 5-2)

Pass the transmission cable and remote controller cable through the provided glass

tube and then secure both ends of the tube with the provided bands.

• Connect indoor unit TB5 and outdoor unit TB3. (Non-polarized 2-wire)

The “S” on indoor unit TB5 is a shielding wire connection. For specifications about

the connecting cables, refer to the outdoor unit installation manual.

• Install a remote controller following the manual supplied with the remote controller.

• Connect the remote controller’s transmission cable within 33 ft (10 m) using a

0.75 mm

2

core cable. If the distance is more than 33 ft (10 m), use a 1.25 mm

2

junction cable.

1 MA Remote controller

• Connect the “1” and “2” on indoor unit TB15 to a MA remote controller. (Non-polar-

ized 2-wire)

• DC 9 to 13 V between 1 and 2 (MA remote controller)

2 M-NET Remote controller

• Connect the “M1” and “M2” on indoor unit TB5 to a M-NET remote controller. (Non-

polarized 2-wire)

• DC 24 to 30 V between M1 and M2 (M-NET remote controller)

A Terminal block for indoor transmission cable

B Terminal block for outdoor transmission cable

C Remote controller

Constraints on transmission cable (Fig. 5-3)

Longest wiring length (L1+L2+L4 or L1+L3 or L2+L3+L4): less than 656 ft (200 m)

Length between indoor unit and remote controller (R): within 33 ft (10 m)

G Outdoor unit

H Earth

I BC controller

J Indoor unit

K M-NET Remote controller

L Non-polarized 2-wire

Note:

*1 Put the transmission cable earth via the outdoor unit’s earth terminal

to

the ground.

*2 If the remote controller cable exceeds 33 ft (10 m), use a 1.25 mm

2

(AWG16)

diameter cable over the exceeded portion, and add that exceeded portion

to within 656ft (200 m).

*3 The BC controller is required only for simultaneous cooling and heating

series R2.

5.3. Setting addresses (Fig. 5-4)

(Be sure to operate with the main power turned OFF.)

• There are two types of rotary switch setting available: setting addresses 1 to 9 and

over 10, and setting branch numbers.

1 How to set addresses

Example: If Address is “3”, remain SW12 (for over 10) at “0”, and match SW11(for

1 to 9) with “3”.

2 How to set branch numbers (Series R2 only)

Match the indoor unit’s refrigerant pipe with the BC controller’s end connection

number. Remain SW14 other than R2 at “0”.

• The rotary switches are all set to “0” when shipped from the factory. These switches

can be used to set unit addresses and branch numbers at will.

• The determination of indoor unit addresses varies with the system at site. Set them

referring to technical data.

Note:

Please set the switch SW5 according to the power supply voltage.

• Set SW5 to 230 V side when the power supply is 230 volts.

• When the power supply is 208 volts, set SW5 to 208 V side.

Fig. 5-2

1

2

AA

C

TB5 TB15 TB5 TB15

SM1M2 SM1M2

B

TB3

M1M2 21

C

21

AA

C

TB5 TB5

SM1M2 SM1 M2

C

B

TB3

M1M2

A Cover

B Electrical box

C Terminal block for power supply

D Terminal block for transmission cable

E Control board

F Address board

G Secure with the wiring clamp

H Terminal block for MA Remote controller

I Plate for conduit

J Screw (M4×12)

K Glass tube

L Band

A

F

B

I

J

C

E

F

H

L

K

D

G

Fig. 5-3

A

Fig. 5-4

G

I

JJJ

KK

KK

JJ

L

K

H

*1

*3

L1

L2

L4

r

L3

*2

SW14

0

SW11

0

SW12

0

12345678910

ON

OFF

SW1

SW5

220V

(208V)

240V

(230V)

SWC

CN82

CN43

Page 8

8

5. Electrical work

5.4. Sensing room temperature with the built-in sensor

in a remote controller

If you want to sense room temperature with the built-in sensor in a remote controller,

set SW1-1 on the control board to “ON”. The setting of SW1-7 and SW1-8 as necessary also makes it possible to adjust the air flow at a time when the heating thermometer is OFF.

5.5. Types of control cables

1. Wiring transmission cables: Shielding wire CVVS or CPEVS

• Cable diameter: More than 1.25 mm

2

(AWG16)

2. M-NET Remote control cables

Kind of remote control cable Shielding wire MVVS

Cable diameter More than 0.5 (AWG22) to 1.25 mm

2

(AWG16)

When 33 ft (10 m) is exceeded, use cable with

the same specifications as transmission line

wiring (HV)

3. MA Remote control cables

Kind of remote control cable 2-core cable (unshielded)

Cable diameter 0.3 mm

2

(AWG22) to 1.25 mm2 (AWG16)

Remarks

(mm)

F

A

H

C

D

E

G

I

I

I

H

B

J

H

(2)

(3)

B-1. B-2.

Fig. 5-5

Fig. 5-6

A Remote controller profile

B Required clearances surrounding

the remote controller

C Installation pitch

5.6. Remote controller

For wired remote controller

1) Installing procedures (Fig. 5-5)

(1) Select an installing position for the remote controller.

The temperature sensors are located on both remote controller and indoor unit.

s Procure the following parts locally:

Two piece switch box

Thin copper conduit tube

Lock nuts and bushings

(2) Seal the service entrance for the remote controller cord with putty to prevent pos-

sible invasion of dew drops, water, cockroaches or worms.

A For installation in the switch box:

B For direct installation on the wall select one of the following:

• Prepare a hole through the wall to pass the remote controller cord (in order to run

the remote controller cord from the back), then seal the hole with putty.

• Run the remote controller cord through the cut-out upper case, then seal the cut-

out notch with putty similarly as above.

B-1. To lead the remote controller cord from the back of the controller:

B-2. To run the remote controller cord through the upper portion:

(3) For direct installation on the wall

C Wall G Switch box

D Conduit H Remote controller cord

E Lock nut I Seal with putty

F Bushing J Wood screw

1-3/16

(30)

1-3/16

(30)

1-37/64 (46)

1-3/16

(30)

4-23/32 (120)

3-9/32 (83.5)

A

B

C

Page 9

9

5. Electrical work

1

A

Fig. 5-7

AB TB6

B

2) Connecting procedures (Fig. 5-7)

1 Connect the remote controller cord to the terminal block.

A To TB5 on the indoor unit

B TB6 (No polarity)

3) Temperature display setting

The initial temperature display setting is °C. Please change the setting to °F. Refer to

“Function selection of remote controller (Section 8)” in the operation manual for the

indoor unit.

4) Two remote controller setting

If two remote controllers are connected, set one to “Main” and the other to “Sub”. For

setting procedures, refer to “Function selection of remote controller” in the operation

manual for the indoor unit.

A ON/OFF button

B Test run display

C Indoor temperature liquid

line temperature display

D ON/OFF lamp

E Power display

F Error code display

Test run remaining time

display

G Set temperature button

H Mode selection button

I Fan speed button

M TEST button

Fig. 6-1

6. Test run

6.1. Before test run

s After completing installation and the wiring and piping of the indoor and

outdoor units, check for refrigerant leakage, looseness in the power supply

or control wiring, wrong polarity, and no disconnection of one phase in the

supply.

s Use a 500-volt megohmmeter to check that the resistance between the power

supply terminals and ground is at least 1.0 M

ΩΩ

ΩΩ

Ω.

s Do not carry out this test on the control wiring (low voltage circuit) termi-

nals.

Warning:

Do not use the air conditioner if the insulation resistance is less than 1.0 M

ΩΩ

ΩΩ

Ω.

Insulation resistance

6.2. Test run

The following 2 methods are available.

6.2.1. Using wired remote controller (Fig. 6-1)

1 Turn on the power at least 12 hours before the test run.

2 Press the [TEST] button twice. ➡ “TEST RUN” liquid crystal display

3 Press the [Mode selection] button. ➡ Make sure that wind is blown out.

4 Press the [Mode selection] button and switch to the cooling (or heating) mode.

➡ Make sure that cold (or warm) wind is blown out.

5 Press the [Fan speed] button. ➡ Make sure that the wind speed is switched.

6 Check operation of the outdoor unit fan.

7 Release test run by pressing the [ON/OFF] button. ➡ Stop

8 Register a telephone number.

The telephone number of the repair shop, sales office, etc., to contact if an error

occurs can be registered in the remote controller. The telephone number will be

displayed when an error occurs. For registration procedures, refer to the operation manual for the indoor unit.

Note:

• If an error code is displayed on the remote controller or if the air conditioner

does not operate properly, refer to the outdoor unit installation manual or

other technical materials.

• The OFF timer is set for the test run to automatically stop after 2 hours.

• During the test run, the time remaining is shown in the time display.

• During the test run, the temperature of the indoor unit refrigerant pipes is

shown in the room temperature display of the remote controller.

• When the VANE or LOUVER button is pressed, the message “NOT AVAILABLE” may appear on the remote controller display depending on the indoor

unit model, but this is not a malfunction.

˚F

˚F

SIMPLE

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

TEST RUN

COOL, HEAT

A

FCEDB

M

IH G

7. Installing the grille

7.1. Checking the contents

• This kit contains the following parts.

Accessory name Q’ty Remark

1 Grille 1

2 Screw 6 M5 × 0.8 × 16

3 Screw 1 4 × 16

7.2. Checks before setting in place

• Before installing the front panel, make sure the indoor unit is square with the ceiling

opening (or parallel to the angle between the wall and the ceiling).

• Check that the four points where the front panel will be secured are in contact with

the ceiling surface (see Fig. 7-1).

• Check that the insulation for the refrigerant pipes, drainage pipes, etc. is in place

and that wiring connections and arrangements are complete.

123

A Points for securing the grille

B Points for securing the grille

C Indoor unit

D Ceiling surface

E Drainage pan

F Places for securing front grille

G Make sure these surfaces are

flush with each other 0 - 1/8 in.

(0 - 3 mm).

Fig. 7-1

A

B

C

F

G

E

D

Page 10

10

• Adjust the front panel so that it fits properly in the angle between the ceiling and the

wall, and install the securing bolts 2 (supplied with this grille) in their four places at

left and right, leaving them slightly loose.

• Next tighten the securing bolts 2 and securing screws 3 in the center three places.

• Finally tighten the securing bolts 2 in the four places at left and right.

• At this point, make sure there are no gaps between the indoor unit and the front

panel, and between the front panel and the ceiling surface. If there are gaps, the

wind may come in and it may cause water to drip (see Fig. 7-3).

* Tighten the securing bolts 2 and securing screws 3 completely.

• Replace the air filter and screw cover, and press the intake grille on the place

marked Push until you hear it snap into place.

7.4. Checks after installing

• Check that there are no gaps between the indoor unit and the front panel, and

between the front panel and the ceiling surface. If there are gaps, the wind may

come in and condensation may result.

• Check that the air filter is in place.

7.3. Installing the grille

• Open the intake grille by pressing on the place marked Push, and remove the air

filter.

• Remove the screw cover in the middle of the blower.

• Open the upper and lower flaps on the indoor unit completely.

• Hook the temporary holding tabs on the front panel to the hooks on the indoor unit

(see Fig. 7-2).

A Hooks

B Open the upper and lower flaps completely

C Temporary holding tab

D Temporary holding tab

E Screw cover

A Ceiling surface

B Indoor unit

C Grille

D No gaps here

Fig. 7-2

Fig. 7-3

A

B

C

D

E

2

2

322

2

2

A

D

B

AD

C

7. Installing the grille

Page 11

Page 12

Please be sure to put the contact address/telephone number on

this manual before handing it to the customer.

This product is designed and intended for use in the residential,

commercial and light-industrial environment.

HEAD OFFICE: MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Printed in Japan

BG79U635H01

Loading...

Loading...