Page 1

PROGRAMMABLE

CONTROLLER

User

Positioning

'8

Manual

module

CATALOG

$

15.00

#

UMPM

type

MlTSUBlSHl

A

ELECTRIC

AD71

Page 2

REVISIONS

%The manual number

is

given on the bottom

left of

the back

cover.

Deletion

Section

“Instructions for Strategic Materials”

I

8.1.4

]

added

Page 3

INTRODUCTION

Thank you for choosing the Mitsubishi MELSEC-A Series of General Purpose Programmable

Controllers. Please read this manual carefully

A

copy of this manual should be forwarded to the end User.

so

that the equipment is used to its optimum.

Page 4

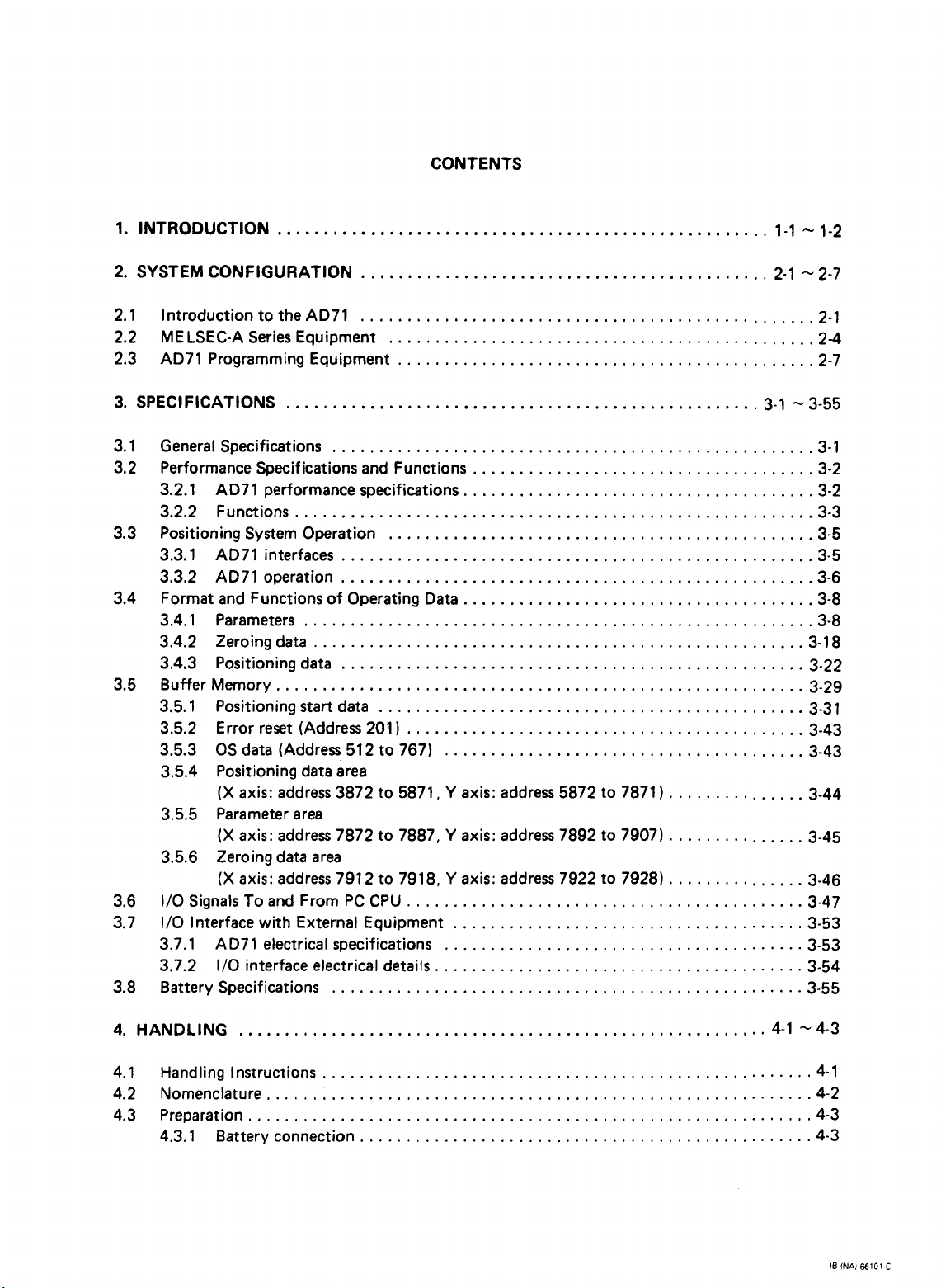

2 .

SYSTEM CONFIGURATION

CONTENTS

............................................

2-1 2-7

2.1 Introduction to

2.2 MELSEC-A Series Equipment

2.3 AD71 Programming Equipment

3.1

General Specifications

Performance Specifications and Functions

3.2

3.2.1 AD71 performance specifications.

3.2.2 Functions

3.3

Positioning System Operation

3.3.1 AD71 interfaces

3.3.2 AD71 operation

3.4

Format and Functions of Operating Data

3.4.1 Parameters

3.4.2 Zeroing data

3.4.3 Positioning data

BufferMemory

3.5

3.5.1 Positioning

3.5.2 Error reset (Address 201

3.5.3

3.5.4 Positioning data area

3.5.5 Parameter area

3.5.6 Zeroing data area

1/0 Signals

3.6

3.7

1/0

3.7.1 AD71 electrical specifications

3.7.2 1/0 interface electrical details

Battery Specifications

3.8

OS

(X

(X

(X

Interface with External Equipment

the

AD71

.................................................

....................................................

........................................................

...................................................

...................................................

.......................................................

.....................................................

..................................................

.........................................................

start

data

data (Address 512 to 767)

axis: address 3872 to 5871. Y axis: address 5872 to 7871

axis: address 7872 to 7887. Y axis: address 7892 to 7907)

axis: address 791 2 to 7918. Y axis: address 7922 to 7928)

To

and From

PC

...................................................

2.1

..............................................

.............................................

.....................................

.....................................

..............................................

......................................

..............................................

)

...........................................

.......................................

1

...............

...............

...............

CPU

...........................................

......................................

.......................................

........................................

24

2.7

3.1

3.2

3.2

3-3

3.5

3.5

3.6

3.8

3.8

3-18

3-22

3.29

3-31

3-43

3-43

3-44

3-45

3-46

3-47

3.53

3-53

3-54

3.55

4

.

HANDLING

4.1 Handling Instructions

4.2 Nomenclature

4.3 Preparation

4.3.1 Battery connection

.........................................................

...........................................................

............................................................

4-1 -4-3

.....................................................

.................................................

4-1

4-2

-4-3

4.3

I6

fNA1

56101

C

Page 5

5

.

LOADING AND INSTALLATION

........................................

5-1 %5-6

5.1 Installation Environments

5.2 System Design Precautions

5.3 Installation and Removal

5.4 Wiring

5.4.1 Wiring precautions

5.4.2 Drive unit connector

6

.

PROGRAMMING

6.1 Writing Programs

6.1.1 Program structure

6.1.2 Notes on programming

6.2 Notes on Use

6.3 ACPU Programming

6.3.1 Data

6.3.2 Data communication with

6.3.3

6.3.4

6.3.5 Inching

6.3.6 Position address teaching

6.3.7 Zeroing

6.3.8 Present value change

6.3.9 Positioning stop

6.4 ACPU Remote

6.4.1 Notes on programming

6.4.2 Reading and writing data

6.4.3 Program example

.................................................................

....................................................

........................................................

of

the A6GPP and AD71TU

......................................................

read

and write precautions

Start

positioning

Jog

operation program

.........................................................

.........................................................

1/0

Station Programming

.................................................

.................................................

..................................................

.................................................

...............................................

6-1 5 6-54

..................................................

..............................................

.....................................

.......................................

PC

program

..................................

..................................................

.............................................

............................................

...............................................

..................................................

.....................................

.............................................

...........................................

.................................................

5.1

5-2

5.3

5-5

5.5

5-6

6.1

6.1

6-3

6.5

6.6

6-6

6.7

6-15

6-23

6.25

6.29

6-37

6-39

6.41

6.46

6-46

6-48

6-51

7

.

CHECK

7.1

7.2 Tests and Adjustments

LISTS

General Check List

.......................................................

.......................................................

...................................................

7.2.1 Sequence check

7.2.2 Checking positioning operation

7-1

z7-3

7-1

-7-2

...................................................

.......................................

7.2

7-3

IB

INAI

ffi101.A

Page 6

8

.

TROUBLESHOOTING

................................................

8-1

'v

8-15

8.1 Error Detected by AD71

8.1.1 Data range errors

8.1.2 "HOLD" LED

8.1.3 Buffer memory write errors

8.1.4 AD71 BUSY (positioning) stop errors

8.2 Troubleshooting

8.2.1 General troubleshooting

8.2.2 Drive inoperative

8.2.3 Incorrect positioning.,

8.2.4 Speed wrong

8.2.5 Corrupted positioning data

8.2.6 Unrequested stop

8.2.7 Zeroing fault

9

.

MAINTENANCE

9.1 Unit Storage

9.2 Battery Change

9.2.1 Battery change frequency

9.2.2 Changing the battery

APPENDICES

....................................................

.........................................................

......................................................

............................................................

..........................................................

...................................................

...................................................

.....................................................

...................................................

.....................................................

.................................................

.....................................................

8.1

8.2

8.5

...........................................

...................................

.............................................

.............................................

..........................................

............................................

...............................................

.AP

P.l

8-5

8-6

8.7

8.7

8.8

8.10

8.11

8.12

8.13

8.14

91 9-4

9.1

9.2

9.2

9.4

APP-24

APPENDIX 1 Format Sheets

APPENDIX 2 AD71 Processing Times

APPENDIX 3 System Design Considerations

APPENDIX 4 Connection with Servo Motors

4.1 Connection with Mitsubishi MELSERVO-A

4.2 Connection with Oriental's Pulse Motor

4.3

Connection with Toei Electric's VELCONIC

4.4 Connection with Nikki Denso's DIGITAL S-PACK NDS-300

4.5

Connection with Yaskawa Electric's POSITION PACK-1OA and 10B.APP-15

APPENDIX 5 Dimensions

APPENDIX

INDEX

6

Positioning Data Number

...............................................

........................................

.................................................

and

...................................

...................................

Buffer

...................

......................

..................

Memory Address

......

Conversion Table . .AP P.17

.AP P.10

.AP

.AP P.13

.AP P.14

.AP P.16

.AP

P.1

.AP P.6

.AP

P.7

.AP P.9

P.l

1

IB

INAI

E6101C

Page 7

1.

INTRODUCTION

1.

INTRODUCTION

/MELSEC=A

The AD71

series of programmable controllers. The operation of the position

controller

system by using the extensive MELSEC-A series software features.

This manual covers both hardware and software and contains all the

information required to install and operate the unit to

The manual

Chapter 2 System Configuration

Chapter 3 Specifications

Chapter 4 Handling

is

a

position controller module for use with

may

be

adapted to suit the individual requirements of the

is

arranged

Explains the AD71 operating principles together with

glossary of terms and describes the MELSEC-A series

system configurations suitable for use with the AD71.

Gives the AD71 specifications, functions, a description of

the data required for operation,

external equipment, etc.

AD7 1 nomenclature,

as

follows:

1/0

etc.

the

MELSEC-A

its

optimum.

specifications with

a

Chapter 5 Loading and Installation

Gives AD71 installation and wiring instructions, etc.

Chapter 6 Programming

Explains the

AD71.

Chapter 7 Check Lists

Gives

pre-start-up

Chapter 8 Troubleshooting

Hardware and software fault finding

Chapter 9 Maintenance

Appendices

Gives AD71 dimensions, connection examples with

various servo motors, etc.

PC

programming required to control the

test

procedures.

1-1

IS

INA)

M101-A

Page 8

Refer also to the following manuals:

SWO-AD71P Operating Manual

AGGPP User's Manual

Al, A2, A3CPU

Relevant drive unit instruction manual

In

this

manual,

assume

Packing list:

that the

User's

AD71

AD71

Manual

I/O

numben

is

loaded

assigned

in

slot

0

from

of

the main

the PC CPU

base.

I

40-pin connector

Description

AD71

positioning unit

for

external wiring

I

Quantity

1

1

1

-3

Page 9

2.

SYSTEM

2.

SYSTEM

2.1

Introduction

CONFIGURATKlN

CONFIGURATION

to

the

PC

'C

ACPUl AI

thing unit

'1

AD71

~lse train,

/MELSEC--

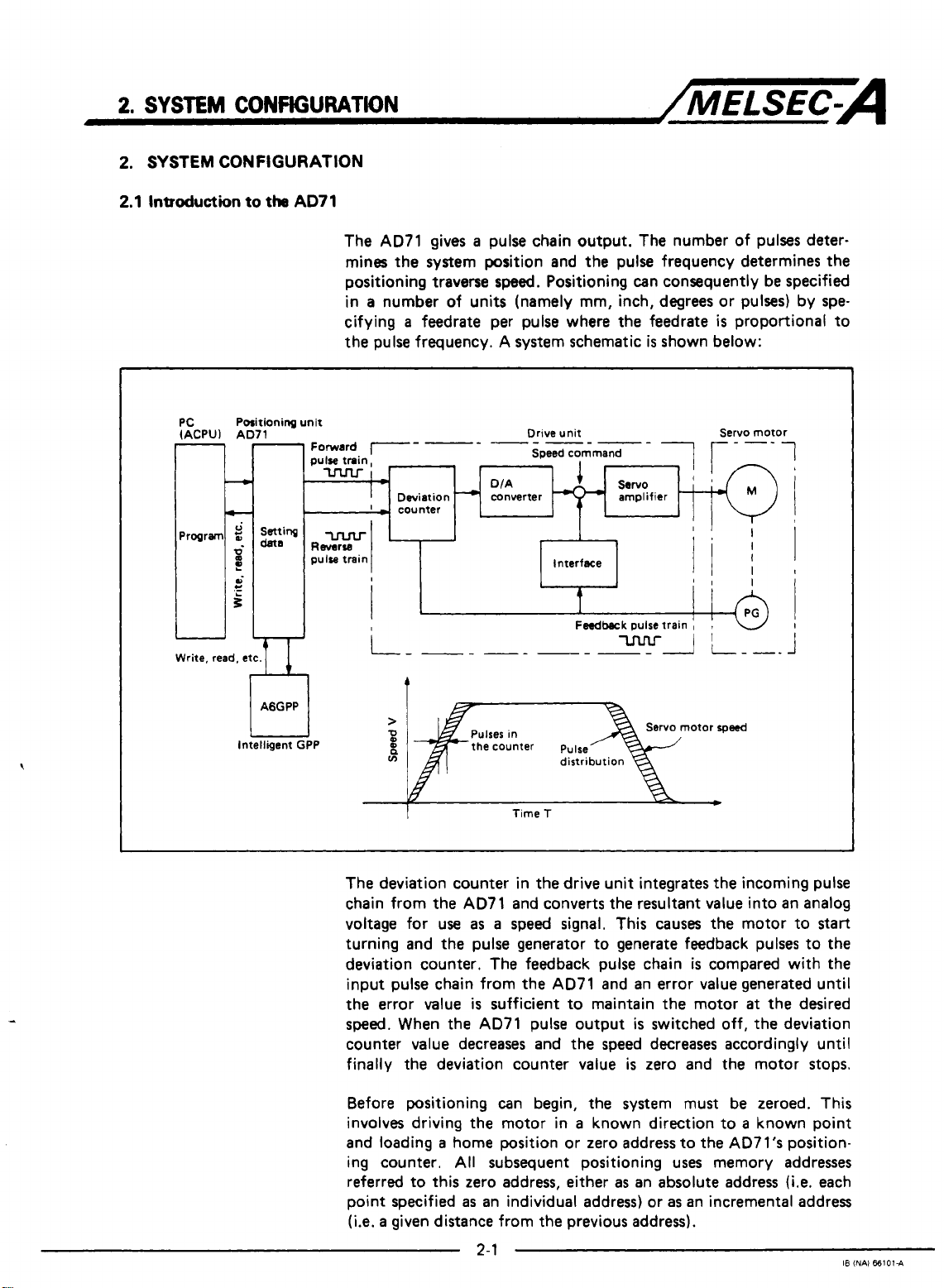

The AD71 gives a pulse chain output. The number of pulses deter-

mines the system position and the pulse frequency determines the

positioning traverse

in a number of units (namely mm, inch, degrees or pulses) by specifying a feedrate per pulse where the feedrate

the pulse frequency. A system schematic

Deviation

'

-

-1unter

r

-

speed.

DIA

converter

Positioning can consequently be specified

is

shown below:

Drive unit Servo motor

Speed command

is

proportional to

1

i

e

AGGPP

Intelligent GPP

i

'I

t

Feedback

>

2

n

ln

it

The deviation counter in the drive unit integrates the incoming pulse

chain from the AD71 and converts the resultant value into an analog

voltage for use

turning and the pulse generator to generate feedback pulses to the

deviation counter. The feedback pulse chain

input pulse chain from the AD71 and an error value generated until

the error value

sped.

counter value decreases and the speed decreases accordingly until

finally the deviation counter value

When the AD71 pulse output

the counter pulse

Time

T

as a speed signal. This causes the motor to

is

sufficient to maintain the motor

pulse train

otor

is

is

switched off, the deviation

is

zero and the motor stops.

I

!

I

I

rpwd

start

compared with the

at

the desired

Before positioning can begin, the system must be zeroed. This

involves driving the motor in a known direction to a known point

and loading a home position or zero address to the AD7l's position-

ing counter.

referred to this zero address, either

point specified

(i.e.

a

given distance from the previous address).

All

subsequent positioning uses memory addresses

as

an absolute address

as

an individual address) or

2-1

as

an incremental address

(Le.

each

I8

(NAI

661014

Page 10

2

SYSTEM

CONFIGURATION

/MELSEC-A

The system can be zeroed in one of three

dog." The "zeroing dog"

of

two

conditions which define the home position.

condition depends on the zeroing method used, this will be one of

the following:

0

A

zero phase signal from the rotary encoder.

0

A

mechanical stop followed by a timer timingout.

0

A

mechanical stop followed by a torque feedback signal from the

drive unit.

The operating data for the

consists

feedrates,

tioning data (containing the individual addresses,

start

Positioning data

defined by

There are

output, these are jog operation and inching. During jog operation,

the output pulse chain

the

output every time a manual pulse generator input signal

(The manual pulse generator

The inching function therefore requires the provision of an external

manual pulse generator hard wired to the

to operate effectively.

of

parameters (defining system constants such

etc.),

zeroing data (defining the zeroing process), posi-

data (defining which position to

is

referred to by a positioning data number, which

its

location in the buffer memory.

two

methods for manual control of the

PC

is

on however during inching a defined number of pulses

is

a

switch

AD71

is

is

maintained for

is

also referred to

stored in the buffer memory and

weys.

All

use a "zeroing

or

actuator which provides one

The

as

maximum

speeds,

start

at,

etc.).

AD71

pulse chain

as

long

as

the

jog signal from

as

"manual pulser").

AD71

connector in order

second

etc.) and

is

given.

is

is

Page 11

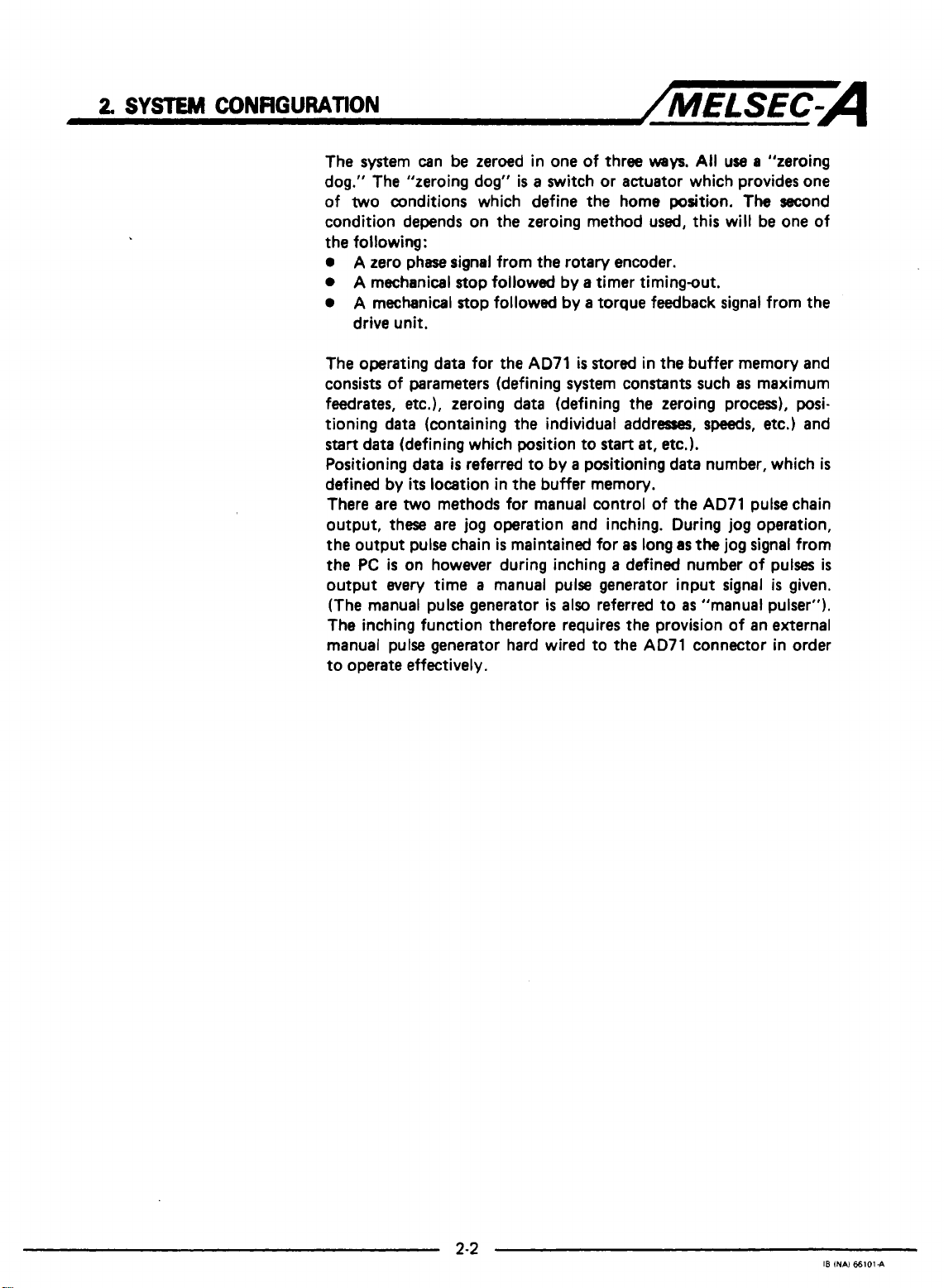

General design of positioning system

Pulse

generator

(PGI

Servo motor

A

:

Position detection increment (mm/p)

Vs : Command pulse frequency (p/s)

:

Number

n

L

:

Feed

R

:

Reduction ratio

V

:

Moving part speed (mm/s)

N

:

Motor speed (rpm)

K

:

Position

E

:

Deviation counter pulse value

PO

:

Zero point (pulse)

:

Address (pulse)

P

(1

)

Position detection increment

(2)

Command pulse frequency

of

pulse generator slits (slitshev)

screw lead (mm/rev)

loop

gain

(sec-'

W

1

P

(3)

Deviation counter pulse value

VS

E

=

-

(pulse)

K

Expression

output pulses

(1)

indicates the travel per pulse,

x

A.

Using expression

i.e.

(2).

calculate the command

the number of

pulse frequency from the work speed and position detection incre-

ment. Expression

(3)

indicates

the

relation between the command

pulse frequency and deviation counter pulse value.

Any of the four positioning units, (mm), (inch), (degree), and

(PULSE), may be selected individually for the X and

Y

axes.

Page 12

2,

SYSTEM

2.2

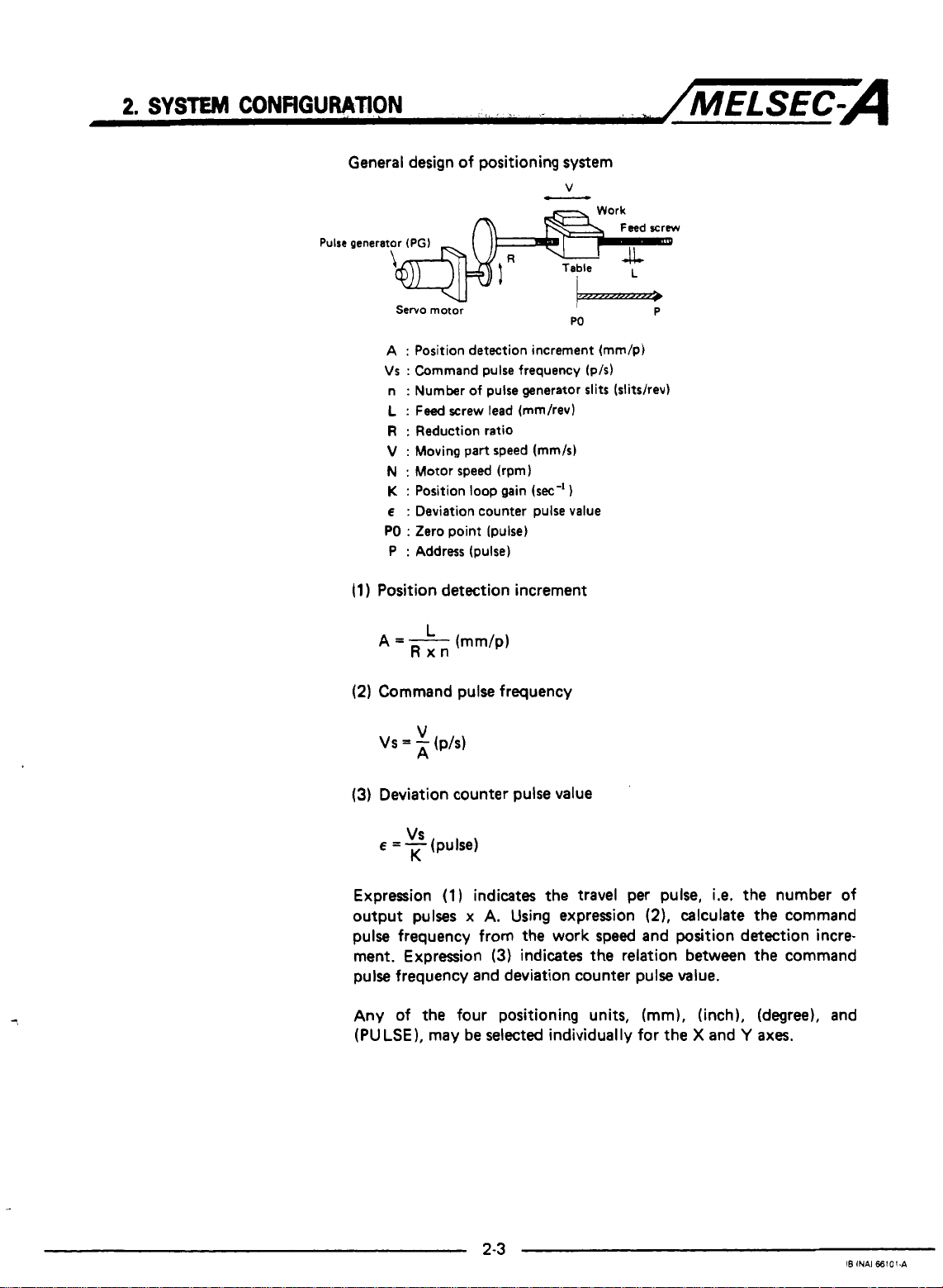

MELSEC-A Series Equipment

CONFIGURATION

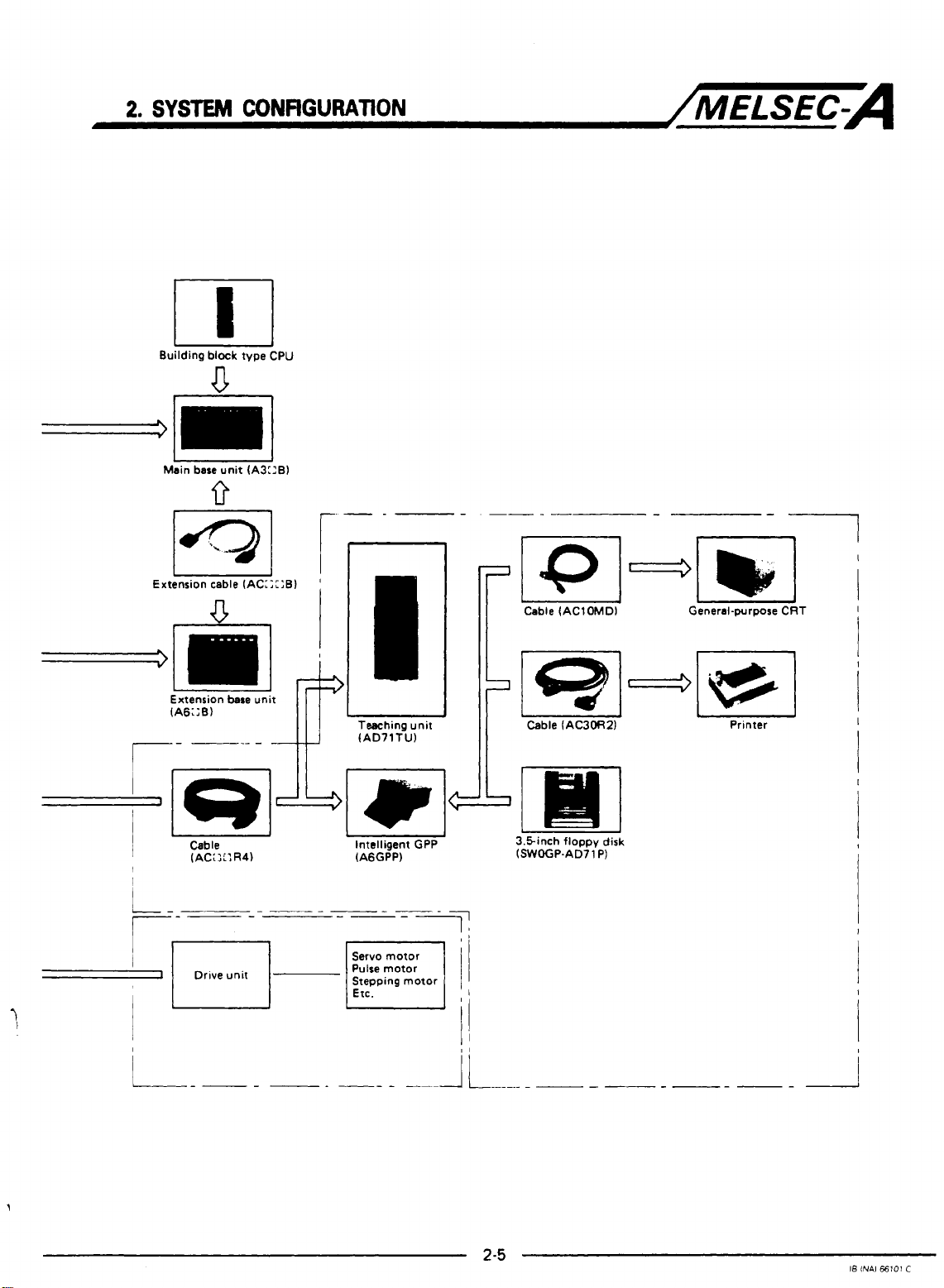

Fig.

ment

2.1

shows a schematic diagram

for

use

with the AD71.

/MELSEC-A

of

the MELSEC-A series equip-

I-

1

Battery

(AGBAT)

I

Positioning

(AD71)

J

module

I

iL

Note

I:

Fig.

For

2.2.

use

2.1

of the

positioning unit in

Overall

Configuration

2-4

the data

link

system,

refer

to

Section

18

INAI

66101C

Page 13

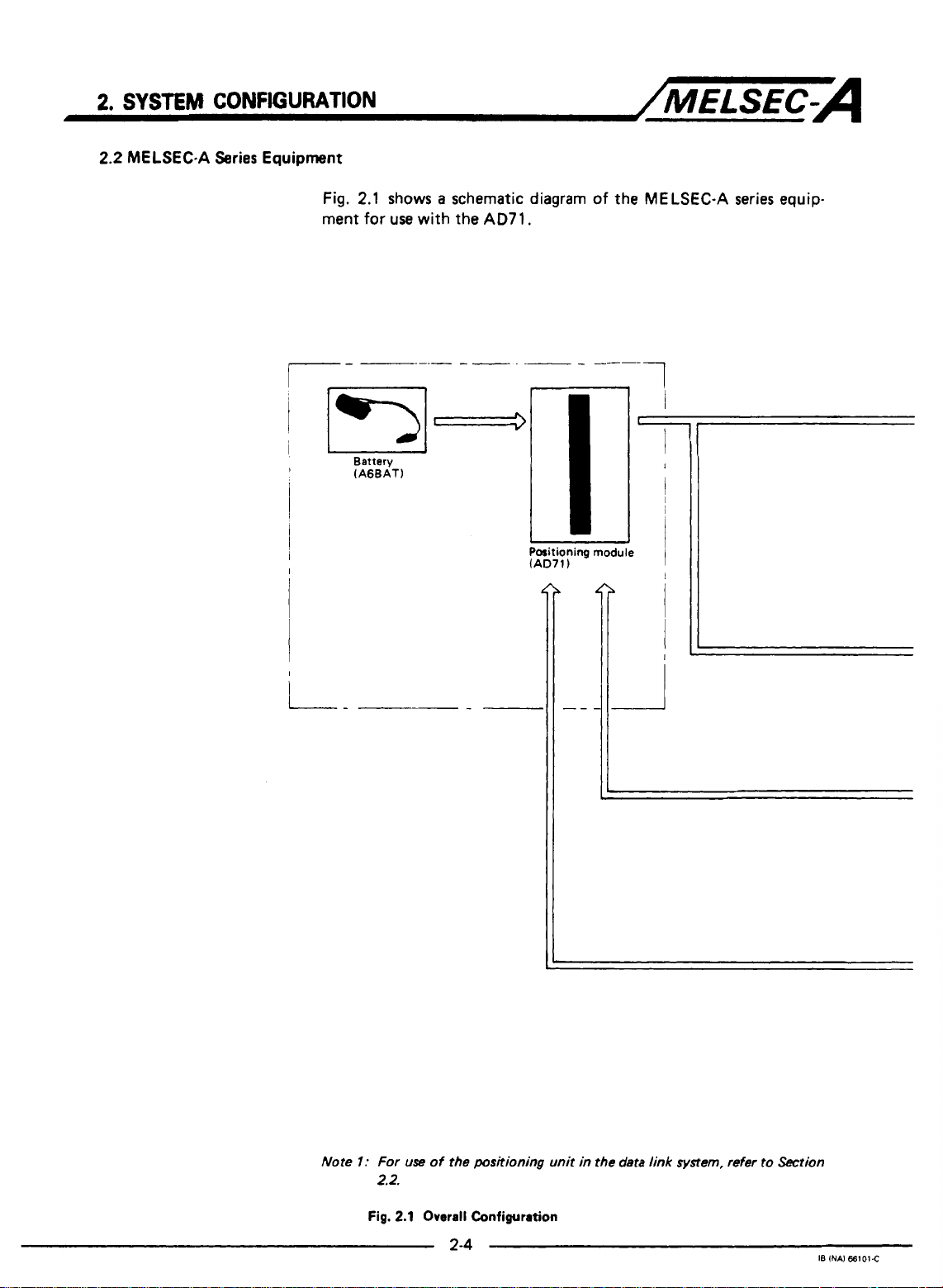

2.

SYSTEM

Building

CONFIGURATION

block

type CPU

U

/MELSEC-A

I

Main base unit (A3::B)

I

Extension cable (AC:;::B)

V

-lml&

Extension

(A6;:B)

--I

r-

r--=====-----

d

I

___---

I

Drive unit

n

I

I

'

I

I

I

I

bare

unit

L

Tesching unit

(AD71Tl.J)

1

1

L

I

Intelligent

4qArnI

(A6GPP) (SWOGP.AD71 P)

-

Servo motor

Pulse motor

Pulse motor

Stepping motor

Etc.

u

GPP 3.5inch floppy disk

-7

"

il

-

Printer

L"

I8

INAl

€6101

C

Page 14

.2

SYSTEM

CONFlGURATlON

The

AD71

can

/MELSEC-A

be

used with the following independent

CPUs:

Applicable model

Do

not use the

a

power supply (i.e.

The following

CPU

A1 (E)CPU P21/R21

A2(E)CPU P21/R21

A3(E)CPU P21/R21

A1 (EICPU

A2(E)CPU

A3(E)CPU

AD71

on any extension base which does not include

A5C:B).

types are required for a data link system.

c."

IB

INA)

66101.A

Page 15

2.

SYSTEM

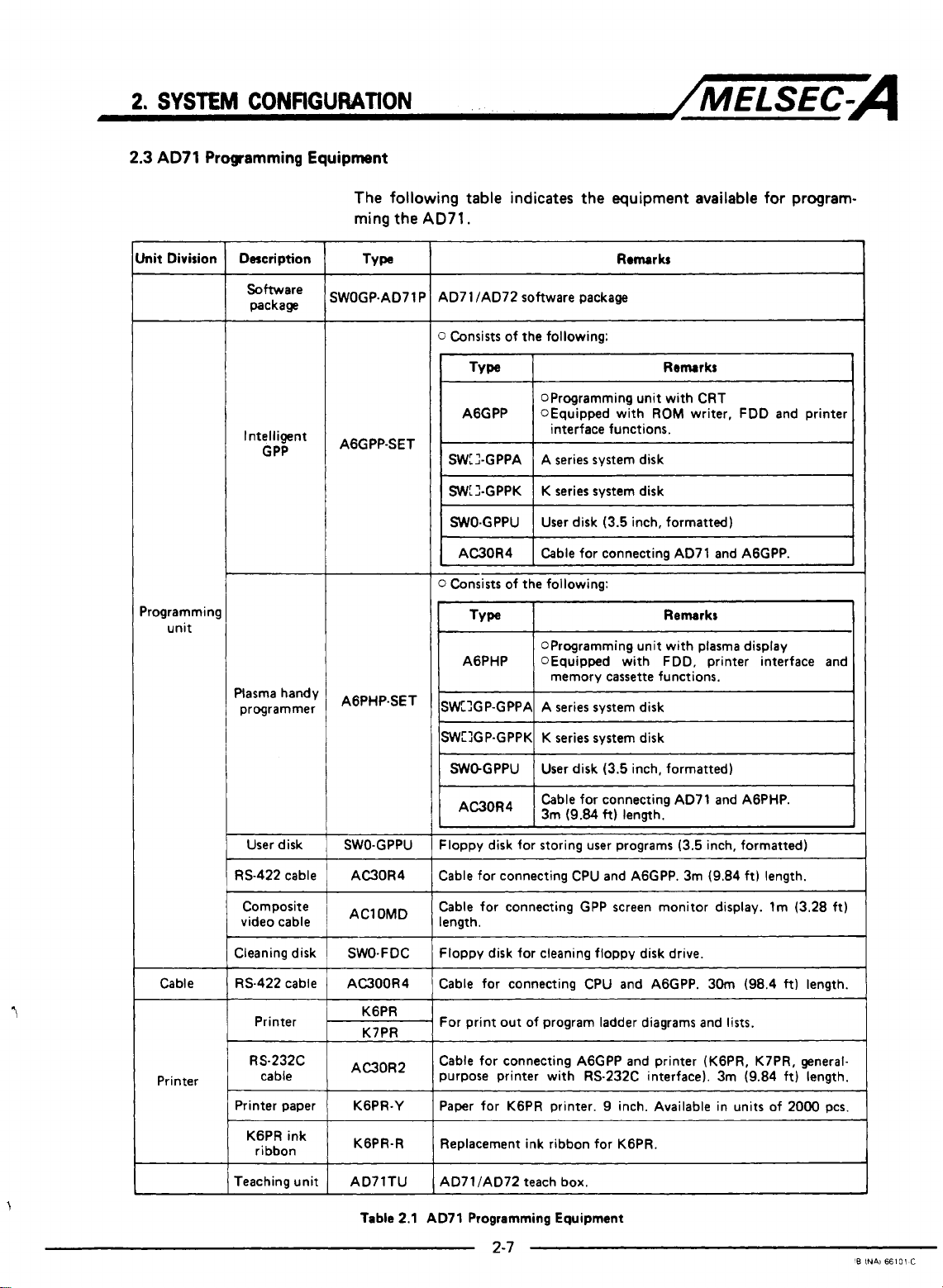

2.3

AD71

CONFIGURATION

Programming Equipment

..

hit

Division

'rogramming

unit

Description

Intelligent

GPP

Plasma handy

programmer

The following table indicates the equipment available

ming the

SWOGP-AD71

AGGPP-SET

AGPHP-SET

AD71.

Remarks

AD7 1 /AD72 software package

P

0

Consists of the following:

OProgramming unit with CRT

1

AGGPP

SWLI-GPPA

SWL2-GPPK

I

WO-GPPU I User disk (3.5 inch, formatted)

I

AC30R4 I Cable for connecting AD71 and AGGPP.

0

Consists of the following:

TYW

AGPHP OEquipped with FDD, printer interface and

SWXP-GPPA A series system disk

OEquipped with

1

interface functions.

A series system disk

K series system disk

OProgramming unit with plasma display

memory

ROM

cassette

writer, FDD and printer

Remarks

functions.

for

program-

I

User disk

RS-422 cable

Composite

video cable

Cleaning disk

Cable RS-422 cable

Printer

RS232C

Printer

cable

Printer paper

KGPR ink

ribbon

Teaching unit

SWO-GPPU

AC30R4

AClOMD

SWO-FDC

AC300R4

KGPR

K7PR

AC30R2

KGPR-Y

KGPR-R

ISW:lGP-GPPKI K series system disk

I

Sk-GPPU 1 User disk (3.5 inch, formatted)

1

AC30R4

1

Floppy disk for storing user programs (3.5 inch, formatted)

~~~~ ~~

Cable for connecting CPU and AGGPP. 3m (9.84 ft) length.

Cable for connecting GPP screen monitor display. lm (3.28 ft)

length.

Floppy disk for cleaning floppy disk drive.

Cable for connecting CPU and AGGPP. 30m (98.4

For print out of program ladder diagrams and lists.

Cable for connecting AGGPP and printer (KGPR, K7PR, generalpurpose printer with RS-232C interface). 3m (9.84 ft) length.

Paper for KGPR printer.

Replacement ink ribbon for KGPR.

AD7 1 /AD72 teach box.

~ ~~

Cable for connecting AD71 and AGPHP.

I

3m (9.84

I

~~~~~~~

ft)

length.

9

inch. Available in units of 2000 pcs.

ft)

length.

I

1

I

Table

2.1 AD71 Programming Equipment

L.

'B

INAi

66101

C

Page 16

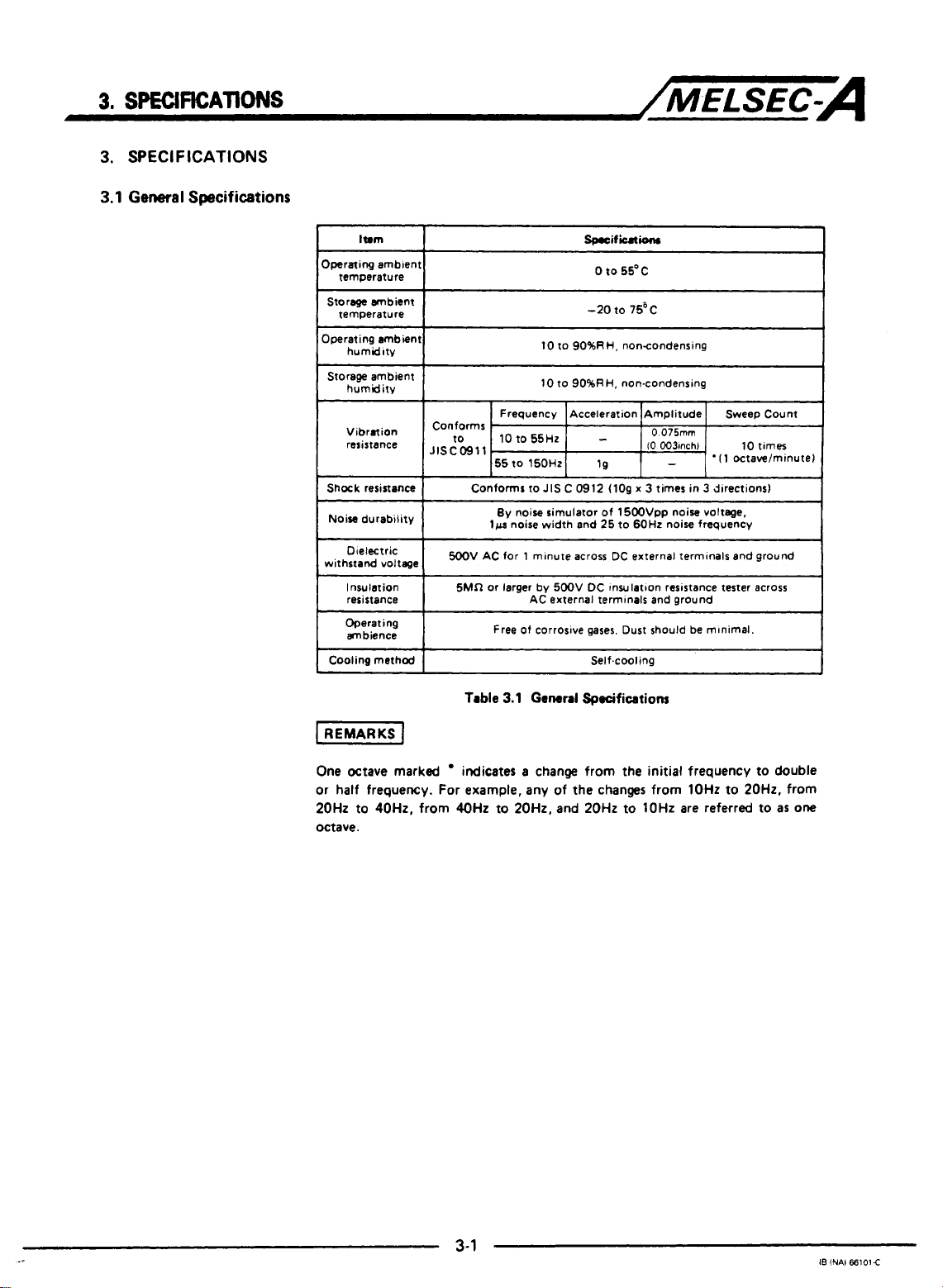

3.

SPECIFICATIONS

3.

SPECIFICATIONS

3.1

General

Specifications

/MELSEC-A

I

1-m

Operating amblent

I

temperature

Storage ambient

Operating ambient

hurnidlty

Storage ambient

humidity

resistance

Noise durability

I

wit~~~~~~tqeI

Insulation

resistance

Operating

ambience

Cooling method

I

I

Conforms

JIscosll

SOOV

Frequency

to

10

to 55Hz

55 to

Conforms to JIS C 0912 (109

By noise simulator

IN

noise width and 25 to

AC for 1 rnlnute across DC external terrnlnals and ground

5MR or larger by

Free of corrosive gases. Dust should be rnlnimal.

0

to

55O

c

-20

to 758c

90%RH,

10 to

90%RH,

10 to

Acceleration

150Hz

~ ~~~ ~ ~~~

500V

AC external terrnlnels and ground

noncondensing

non-condensing

~ ~~

Amplitude

0

-

lg

of 15OOVpp noise voltage,

DC lnsulatlon resostance tester across

Self-cooling

075mrn

10

0031nchl 10

-

x

3

times

in

MHz

noise frequency

3

-

Sweep Count

tarn&

'(1 octaveIminuteJ

directions) Shock resinance

I

I

I

Table

3.1

General

One Octave marked

or half frequency. For example, any

20Hz to 40Hz, from 40Hz to 20H2, and 20Hz to lOHz are referred to as

octave.

indicates a change from the initial frequency

Specifications

to

of

the changes from lOHz to 20H2, from

double

one

3-1

I8

iNAl

66101E

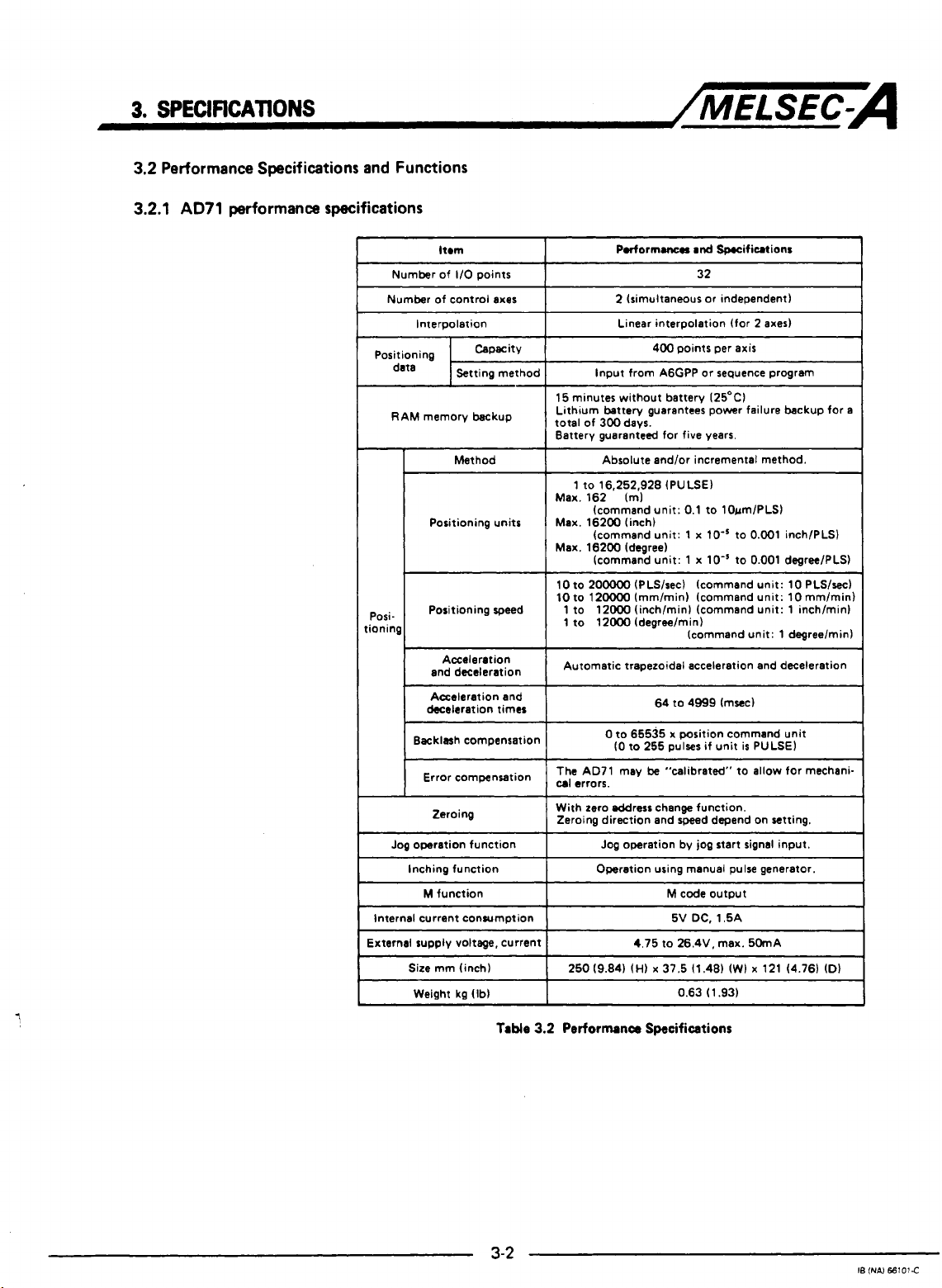

Page 17

3.

SfEClflCAllONS

3.2

Performance Specifications and Functions

3.2.1

AD71

performance specifications

/MELSEC-A

ltrm

1/0

Number of

Number of control axes

Interpolation

RAM memory backup

-

Posi-

,ionin

deceleration times

Backlash compensation

Error compensation

Jog

operation function

Inching function Operation using manual pulse generator.

M

Internal current consumption

External supply voltage, current

Size

Weight kg (Ib)

points

Method

Positioning units

Positioning speed

Acceleration

and deceleration

Acceleration and

Zeroing

function

mm (inch)

15 minutes without battery 125OC)

Lithum battew guarantees power failure backup for

total of 300 days.

Battery guaranteed for five years.

Max. 162 Im)

Max. 16200 (inch)

Max. 16200 (degree)

10

10 to 12oooO Immlmin) (command unit: 10mm/min)

1 to 12000 (inch/minl (command unit: 1 inch/minl

1 to 12000 (degree/min)

Automatic trapezoidal acceleration and deceleration

The AD71 may

cal

With zero eddrerc change function.

Zeroing direction and speed depand on setting.

Podormanerr

2 (simultaneous or independent)

Linear interpolation (for 2

Input from A6GPP or seguence program

Absolute and/or incremental method.

1 to 16,252,928 (PULSE)

(command unit: 0.1 to 10um/PLS)

(command unit:

(command unit: 1

to

200000

(PLS/sec) (command unit: 10 PLS/sec)

0

to 65535 x position command unit

(0

to

255

errors.

Jog operation by jog start signal input.

4.75 to 26.4V, max. 50mA

and

Specifications

32

~~ ~

400 points per

1

x

lo-'

x

lo-'

(command unit: 1 degreelmin)

64 to 4999 (msec)

pulses if unit

be

"calibrated" to allow for mechani-

M

code

output

DC,

1.5A

5V

0.63 (1.93)

axes)

axis

to 0.001 inch/PLS)

to 0.001 degreelPLS)

is

PULSE)

a

Table

3-2

3.2

Performance Specifications

IS

(NAI

66101C

Page 18

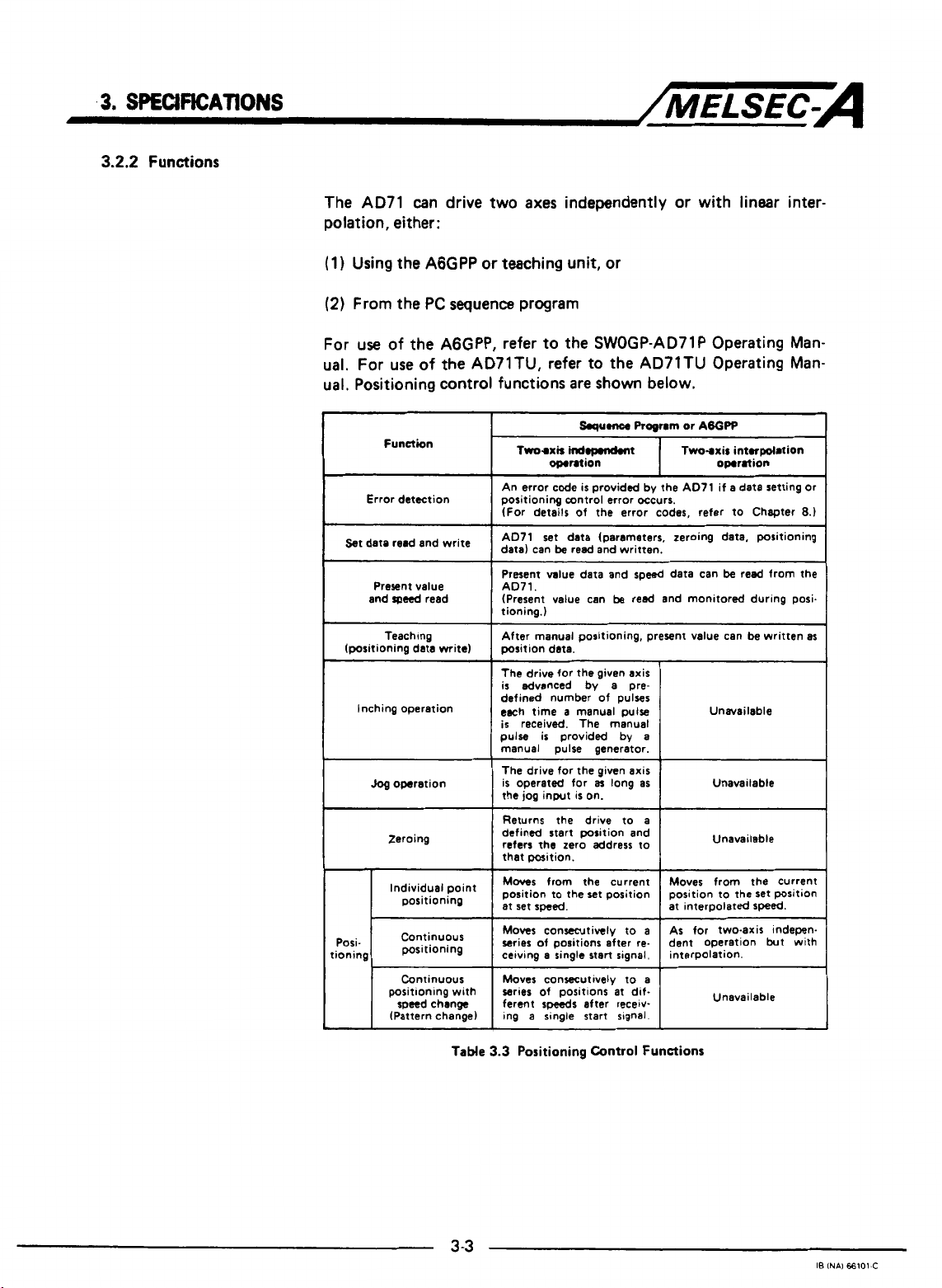

3.

SPECIFKAT1ONS

3.2.2

Functions

~/MELSEC-A

The AD71 can drive two axes independently or with linear interpolation, either:

(1)

Using the AGGPP

(2)

From the PC sequence program

For

use

of the AGGPP, refer to the SWOGP-AD71P Operating Manual. For use of

ual. Positioning control functions are

Function

Error detection

st

date

and

(positioning data mite)

Inching operation

and

Present value

speed

read

Teaching

Jog

operation

Zeroing

positioning

or

teaching unit, or

the

AD71TU, refer to the AD71TU Operating Man-

write

point

shown

~~

Squmce

Trm-axir

An error code

positioning control error occurs.

(For details of the error codes, refer to Chapter

I

AD71 set data (parameters, zeroing data, positioning

data) can

Present value data and

AD71.

(Present value can

tioning.)

After manual positioning, present value can be written as

position data.

The

is

defined number

each time a manual pulse

is

pulse

manual pulse generator.

The drive for the given axis

is

operated for

the

1

Returns the drive to a

defined start position and

refers the zero address to

I

that position.

Moves

position to the set position

set

at

indopmndmt

omntion

is

provided by the AD71 if a data setting or

be

read and written.

drive for the given axis

advanced by a pre-

received. The manual

is

provided by

from

is

on.

the

a~

jog

input

speed.

below.

Progrm

or

ABOPP

Two-axir intorpolation

omration

~~

~~~ ~~

speed

data can

be

reed and monitored during posi.

of

pulses

a

long

as

be

Unavailable

Unavailable

I

I

current

Unavailable

Moves from the current

position to the set position

at interDolated

read from

8.)

the

speed.

Posi-

tioning

Continuous

positioning

Continuous

positionlng with

speed change

(Pattern change)

TaMe

3

-3

series of positions

speeds

ferent

Ing

a single start slgnal.

3.3

Positioning

at

dif-

after recetv-

Control

Functions

Unavailable

I8

INAI

66101-C

Page 19

3.

SPECIFICATIONS

Note

I.

1:

Error compensation and backlash compenmtion functions are valid

for all the functions shown in Table

2:

An indexed code may

amciated processes during positioning. This

code.

3:

The

A071

present value can be rewritten before positioning

using the sequence program or AGGPP.

4:

Positioning

writing positioning start data to the buffer memory

39,

Y

axis:

may

300

to

be

used

be

executed continuously for up to

339).

/MELSEC-A

3.3.

as a digital signal for the control of

is

known as an

is

20

points by

(X

axis: 0 to

"M"

s?a,-ted

3-4

IB

INAJ

66101-A

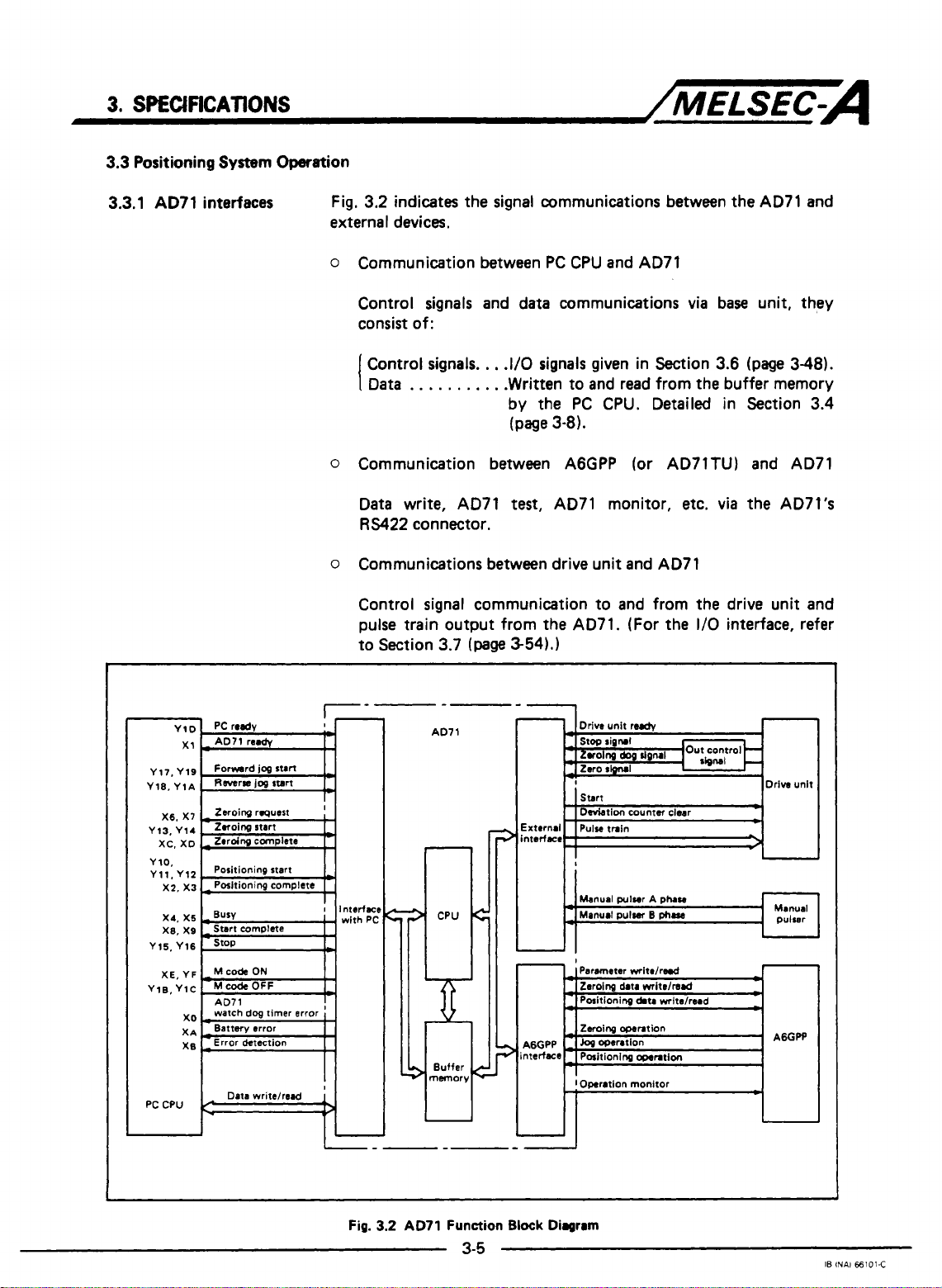

Page 20

3.

SPECWICATIONS

3.3

Positioning

3.3.1

AD71

System Operation

interfaces Fig, 3.2 indicates the signal communications between

external devices.

o

Communication between

PC

CPU and AD71

/MELSEC-A

the

AD71

and

Control signals and data communications

consist of:

Control signals.

Data

I

0

Communication between A6GPP (or AD71TU) and AD71

Data write, AD71

RS422

o

Communications between drive unit and AD71

Control signal communication to and from the drive unit and

pulse train output from the AD71. (For the

to Section 3.7

. . .

connector.

. . .

.

,

.I/O signals given in Section 3.6

.

.

. .

.Written to and read from the buffer memory

by the

(page

test,

(page

3-54).]

PC

CPU. Detailed in Section 3.4

3-81.

AD71 monitor,

via

base unit, they

(page

etc. via

the AD7l's

1/0

interface, refer

348).

PC

I

CPU

Data writelread

II-

Fig.

3.2

AD71

Function

3-5

-1

Block Diagram

IB

INAl

€6101-C

Page 21

3.

SPECIFICATIONS

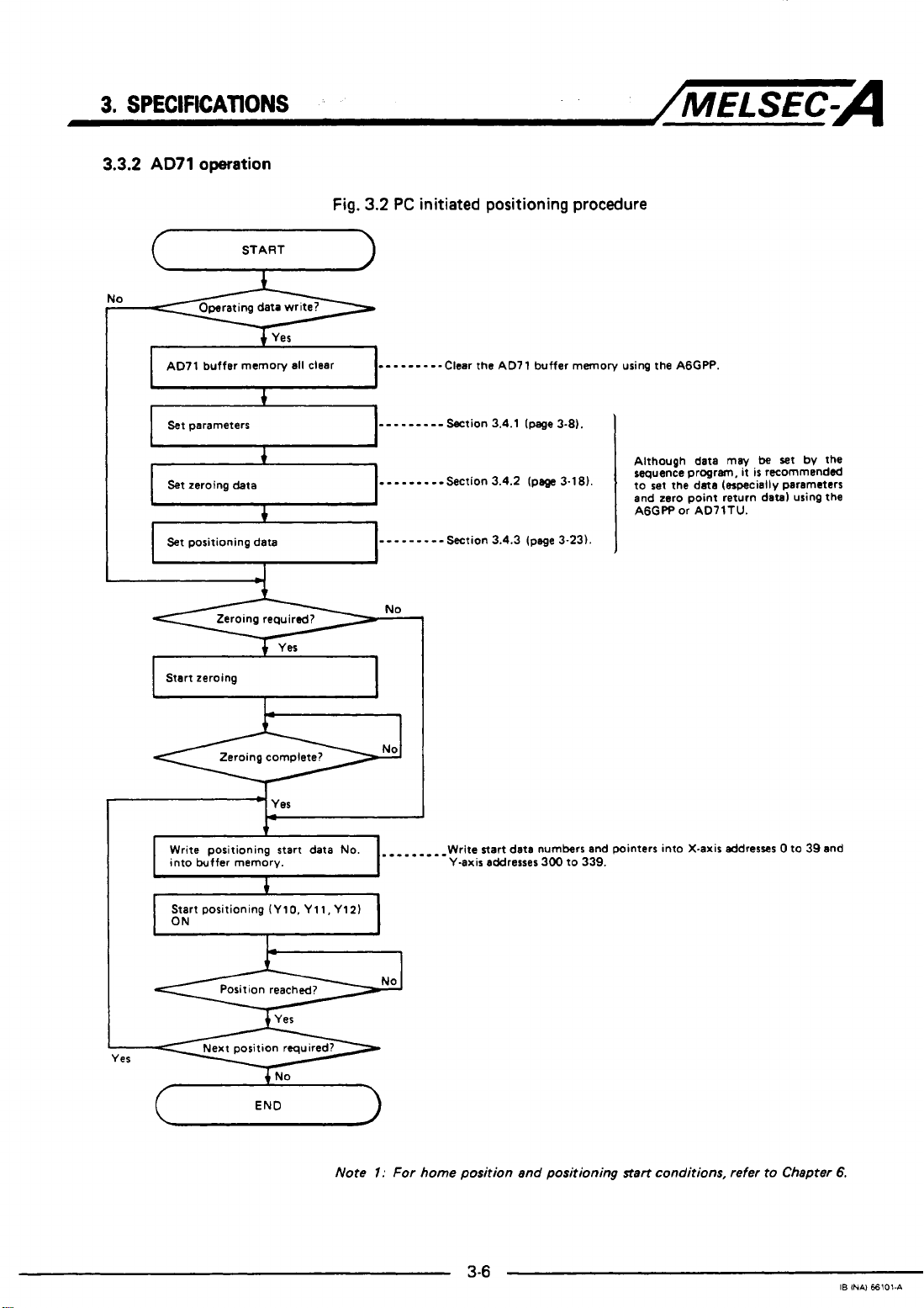

3.3.2

AD71

operation

START

u

AD71 buffer memory all clear

+

Yes

Fig.

3.2

-

PC

initiated positioning procedure

-

- - - - -

--Clear

the

AD7 1 buffer memory using the AGGW.

/MELSEC-A

Set

parameters

Set

zeroing data

Set

positioning data

I

Start zeroing

*

I

I

I

Write positioning start

into buffer memory.

Start positioning (Ylo, Yll,Y121

4

+

I

Zeroing required?

Zeroing complete?

L-

data

---------Section 3.4.1 (page3-8).

.

- -

-.

-

--Section 3.4.2

-

- -

-

-

- - -

-

Section 3.4.3 (page 3-231.

1

No.

Write start data numbers and pointers into X-axis addresses 0 to 39 and

Y-axis

addresses

I

(pe

3.1 81.

300 to 339.

Although data

sequence progrm,

to

set

the data (especially parameters

zero

and

AGGPP or AD71TU.

may

it

is

point return datal using the

be

set

bv

recommended

the

Note

I:

For home position and positioning

1-

start

conditions, refer to Chapter

6.

IB

INAI €6101-A

Page 22

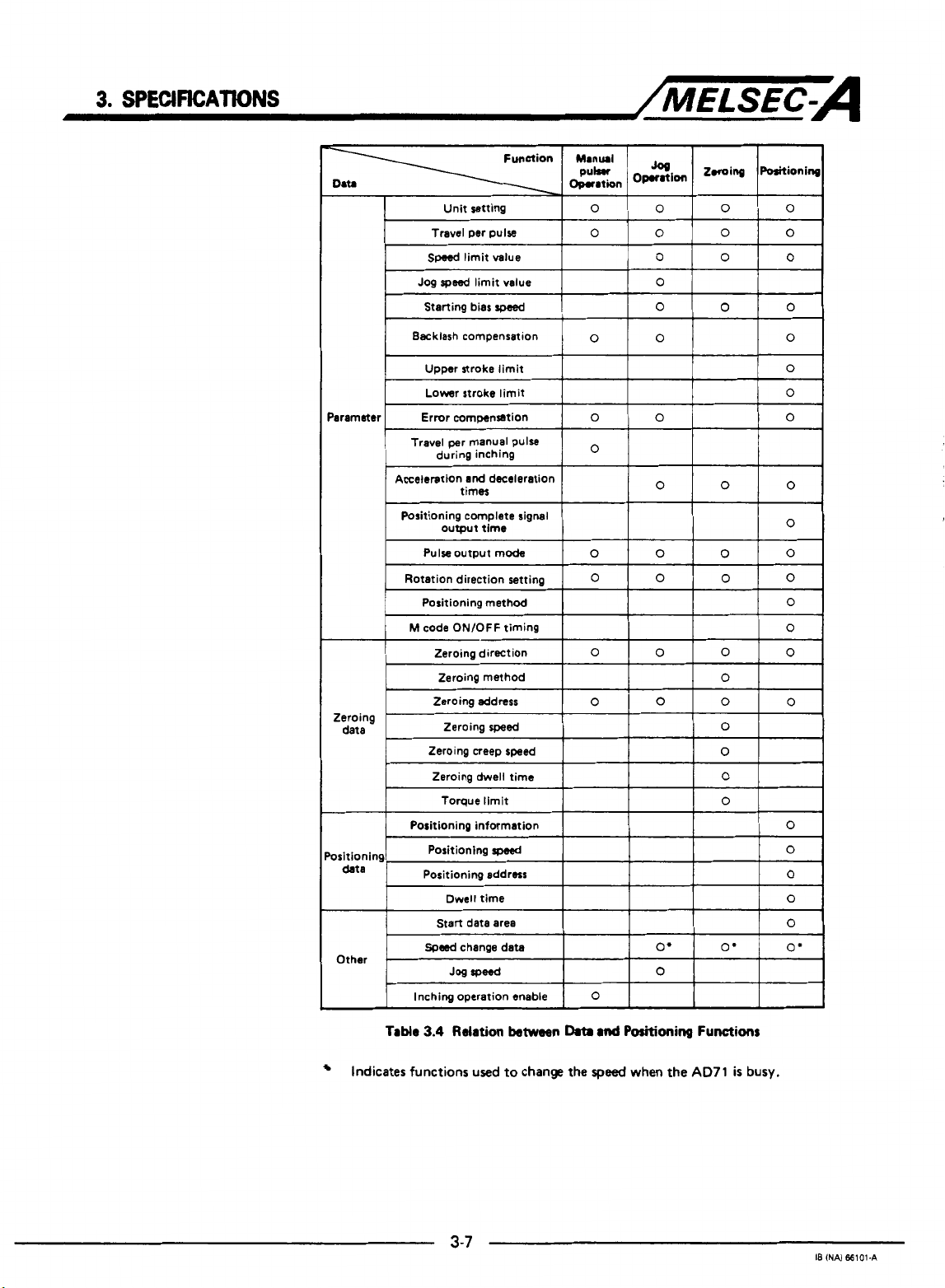

3.

SPECIFICATIONS

/MELSEC-A

Acceleration

and

deceleration

Table

3.4

Relation

Indicates functions used to change the

between

Data

3-7

md

Positioning

speed

when the

Functions

AD71

is

busy.

18

(NAI

66101-A

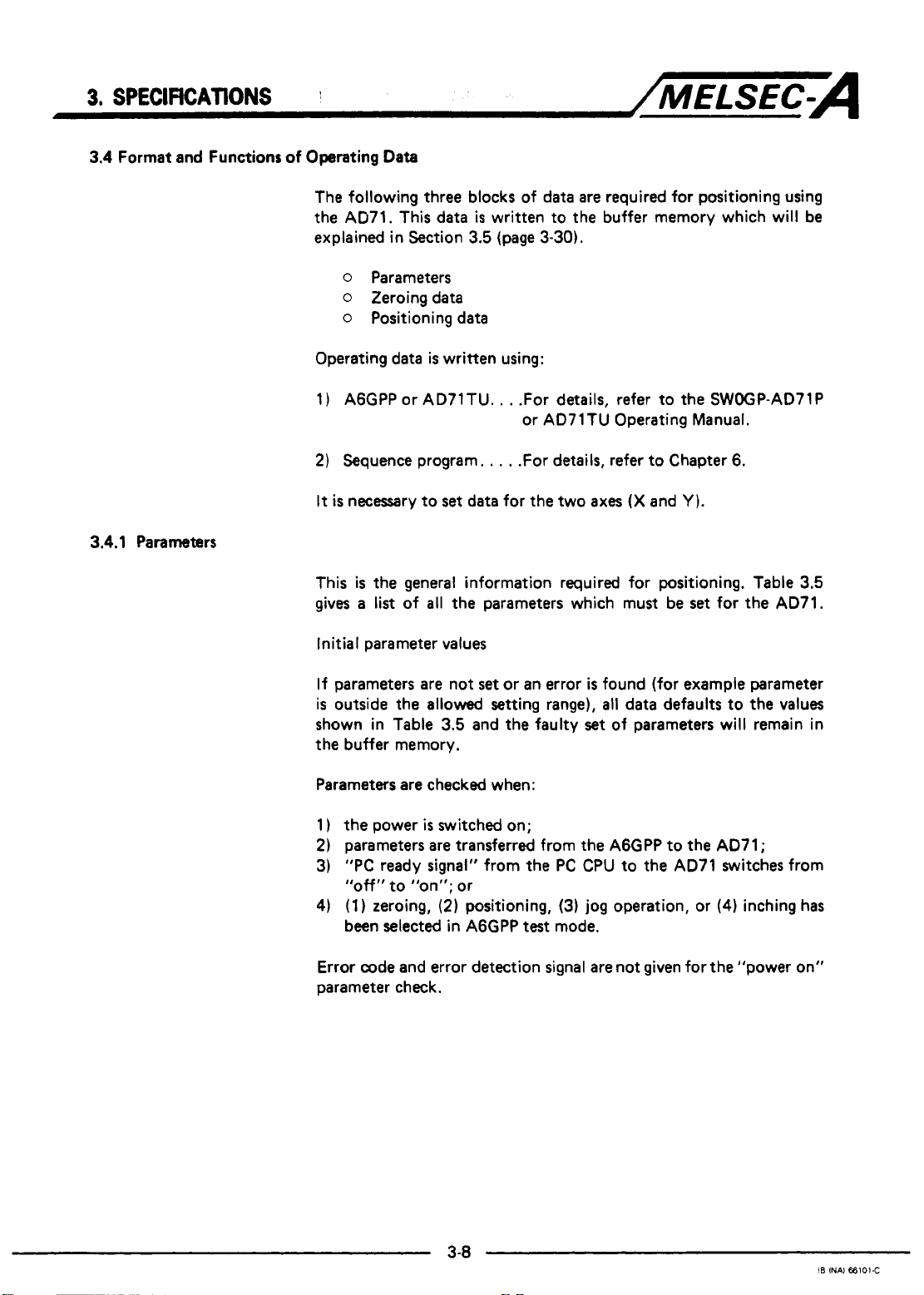

Page 23

3.

SPECIFICATIONS

3.4

Format and Functions

!

of

Operating Data

/MELSEC-A

3.4.1

Parameters

The following three blocks of data

the AD71. This data

explained in Section

o

Parameters

o

Zeroing data

o

Positioning data

Operating data

1)

AGGPP or AD71TU.

2)

Sequence program.

It

is

necessary to

This

is

the general information required for positioning. Table

gives

a

list

of all the parameters which must be

Initial parameter values

is

written to the buffer memory which will be

3.5

(page

is

written using:

. .

.

.

set

data for the two

3-30).

.For details, refer to the SWOGP-AD71P

or AD71TU Operating Manual.

.

.For details, refer to Chapter 6.

are

required for positioning using

axes

(X

and

Y

1.

set

for the AD71.

3.5

If parameters are not

is

outside the allowed

shown in Table

the buffer memory.

Parameters are checked when:

1)

the

power

is

2)

parameters are transferred from the A6GPP to the AD71;

3)

"PC

ready signal" from the

"off"

to

"on"; or

4)

(1) zeroing,

been selected in A6GPP

Error code and error detection signal are not given for the "power on"

parameter check.

set

or

setting

3.5

and the faulty

switched on;

(2)

positioning,

an error

range),

PC

(3)

test

mode.

is

found (for example parameter

all

data defaults to the values

set

of parameters will remain in

CPU to

jog operation, or

the

AD71 switches from

(4)

inching has

3-8

IB

INAl

66101-C

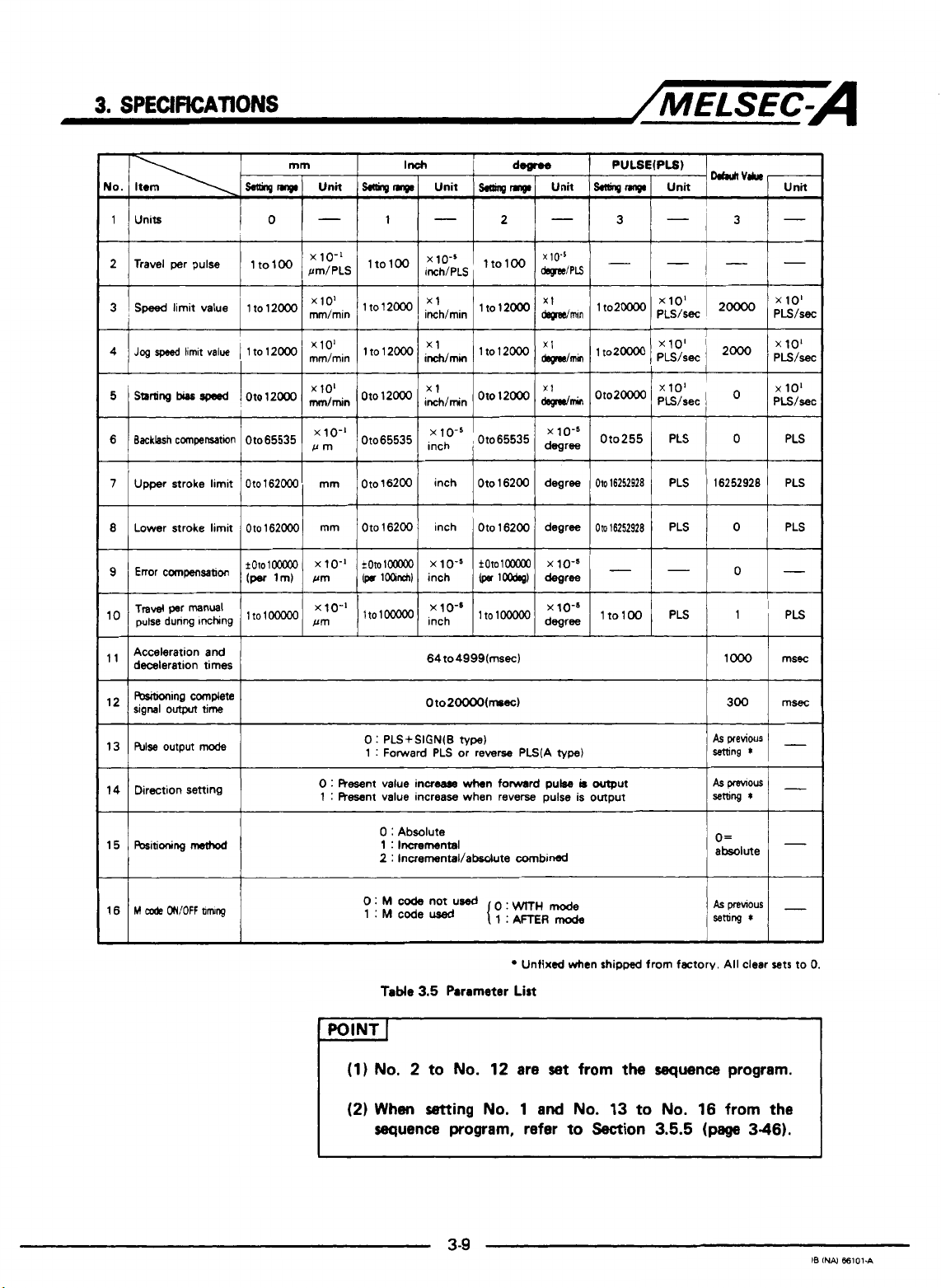

Page 24

3.

SPECIFICATIONS

2 Travel per pulse

x

/MELSEC-A

10-5

3

Speed

limit value 1 to 12OOO lt012000

~

I

'

5

starting

bias

rpesd I Oto 12000 oto12MX)

6 Backlashcompenration 01065535

7

Upper stroke limit Oto162000 mm Oto16200 inch Oto16200 degree

~~~ ~ ~ ~

8

Lower stroke limit

Acceleration and

deceleration times

I

R&itioning complete

signal

outpn

hlse

13

output

Oto

time

mode

xlol

mm,min

x 101 x1

,"Ao-'

Oto65535

162ooO mm Oto 16200 inch

0

1 : Forward PLS or rewrse PLS(A

zh,min

ih,min

i::{-5

Oto20000(mssc)

:

PLS+SIGN(B

lto12000

Oto

,

Oto65535

1

Oto

type)

12000

16200 degree

x1

wmin

xlo's

mree

type)

OtoZm

Or0255 PLS

Oto16252928

Om16252928

x 10'

PLS/sec

PLS 16252928

PLS

0

I

0

0

15

bitioning

method

0

:

Resent value increase

:

Resent value increaw when reverse pulse is output

1

0

:

Absolute

1

:

Incremental

2

:

Incrernental/absdute combined

0:

M

code

1:Mcoded

Table

not

3.5

wtmn

forward

used

o:

Parameter

pulse

WrrH

mode

Unfixed when

List

-

POINT

(1)

No,

(2)

When

sequence

I

2 to

No.

setting

program, refer

3-9

12 are

No.

1

set

and

No.

to

b

output

shipped

from

Section

from factory. All clear sets

the

sequence

13

to

No.

16 from

3.5.5

(page

absolute

O=

program.

3-46).

I-

to

0.

the

IB INN

ffi101.A

Page 25

3.

SPECIFICATIONS

/MELSEC-A

IMPORTANT

The AD71 automatically multiplies any numerical data

received from

For

example,

the

sequence

PLS/sec,

200

x

I

IMPORTANT

The

AD71 controls

pulses

For

this

actual

found

The AD71 can only deal with whole number multiples of 6.1,

so

the

second.

I

the

sequence program

if

the

AD71 receives the constant

program

the

sped

output

10'

PLS/wc.)

I

all

per

second.

rearon,

speed

as

follows

200

-

6.1

actual speed will

if

will

=

32.78688

a

speed

be

and

the

to

speeds

is

set

195.2

pulses

.....

be

by

the

relevant factor.

K

=

units have been defined

the drive

to a maximum accuracy of 6.1

to

32 x 6.1 = 195.2 pulses

is

2000 PLS/sec

200

pulses per second, the

per second. This may

200 from

as

(Le.

be

per

(1)

Unit

(2)

Travel per pulse

(3)

Speed limit value

Parameter data

Selects

Can be

=

0

0

0

0

0

the units (mm, inch, degree, or pulse) for positioning control.

set

degree).

Specifies the travel distance per pulse

mechanics of the system.

Controls the number of pulses contained in the pulse train from

the

AD71.

Specifies the maximum speed for positioning (or zeroing).

When the positioning speed called

the speed limit value, the speed

parameter.

When a new speed

program and this

is

limited to the value

is

explained

independently for X and

as

follows.

is

called during positioning by the sequence

is

greater than the speed limit value, the speed

set

by the parameter.

Y

axes

(e.9. X axis = mm,

as

determined

at

a

given time is greater than

is

limited to the value set by the

Y

by

axis

the

3-1

0

IS

INAI 66101-A

Page 26

(4)

Jog speed limit value

(5)

Starting

Starting

bias speed

Sptxifies

0

The

Table

0

When the jog

greater than

the

jog

sped

3.5

and must not

maximum

limit value must

speed

set

the

jog

speed

speed

for jog operation.

exceed

using

the

the

limit value,

be

within the range shown in

speed

limit value.

A6GPP or sequence program

the

jog

limit value.

*For

jog

operation, refer to Section

0

A minimum starting

speed

6.3.4

(page

is

required for the smooth operation

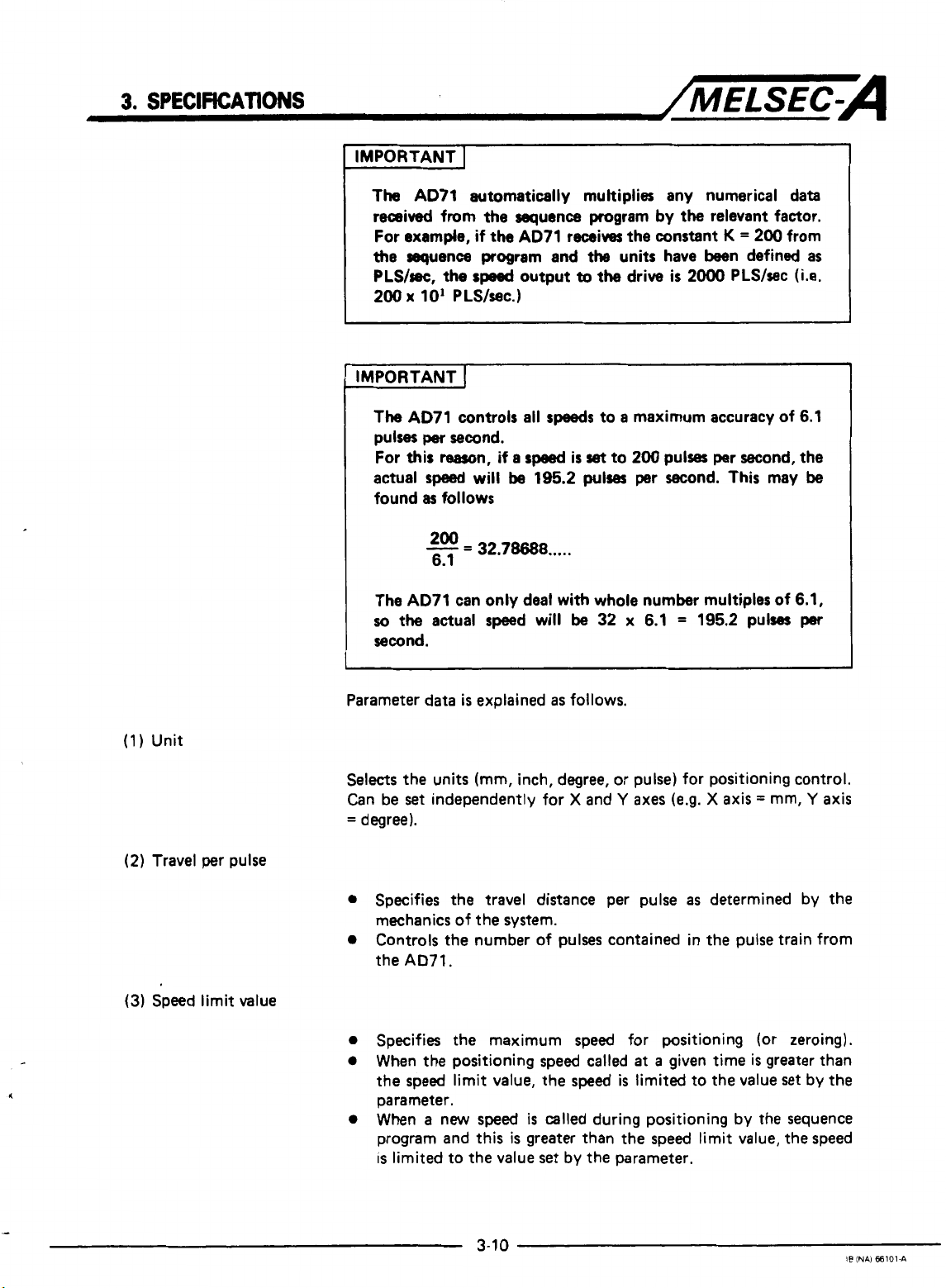

of some motors (e.g. stepping motors). This may be

starting bias speed.

0

The

starting bias speed

zeroing.

See

\

\

\

\

\

\

Fig.

3.3.

Positioning

Zeroing return speed

is

used for positioning,

speed

-.

- - -

t

.

has

been set

Aseleration and dcelrration

speeds

=o

speed

is

6-23).

jog

operation, and

if starting bias

if starting bias

kept to the

set

as

sped

spa&

is

a

I

(6) Backlash compensation

Fig.

3.3

spnd

Change

When

Starting

Bias

W

Is

For positioning with interpolation between axes,

speed

set

for the axis with

0

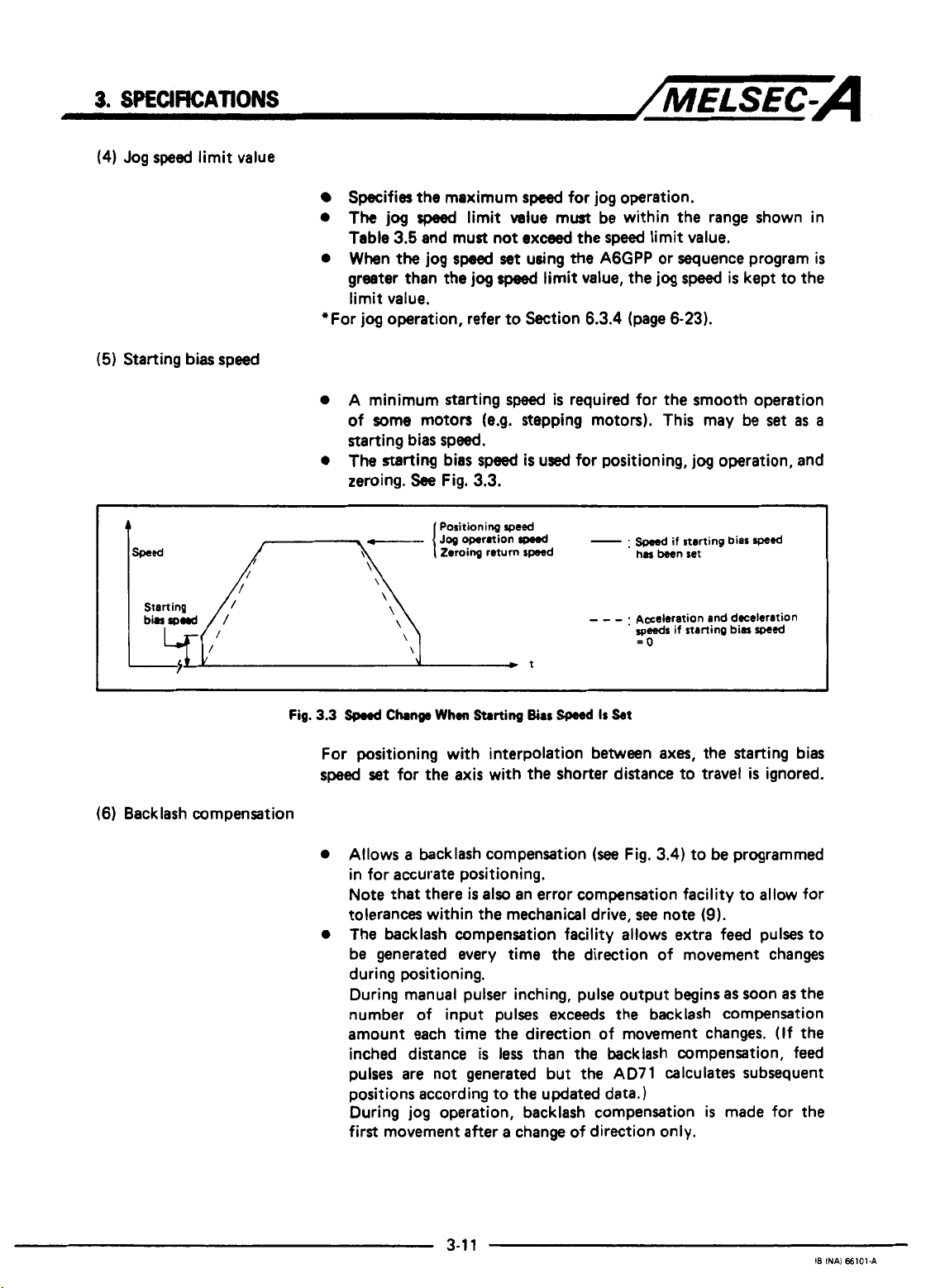

Allows a backlash compensation

the

shorter distance to travel

(see

in for accurate positioning.

Note that there

tolerances within

0

The backlash compensation facility allows extra feed pulses to

is

also

an error compensation facility to allow for

the

mechanical drive,

be generated every time the direction of movement changes

during positioning.

During manual pulser inching, pulse output begins

number of input pulses exceeds the backlash compensation

amount each time the direction of movement changes.

inched distance

pulses are not generated but

is

less

than the backlash compensation, feed

the

positions according to the updated data.)

During jog operation, backlash compensation

first movement after a change of direction only.

kt

the

starting bias

is

ignored.

Fig.

3.4)

to be programmed

see

note

(9).

as

soon

as

(If

AD71 calculates subsequent

is

made for the

the

the

Page 27

3.

SPECIFEATWNS

'-s,

/MELSEC=A

.

(7)

Upper stroke limit

(8)

Lower stroke limit

(9)

Error compensation

Backlash compensation

the backlash compensation, always zero the system.

I

Fig.

0

Defines

The stroke limit is checked before each positioning operation

and if outside the allowed range, positioning

During jog operation and manual pulser inching, the stroke limit

is

0

Defines the lower limit value of machine travel,

0

The stroke limit

and if outside the allowed range, positioning

During jog operation and manual pulser inching, the stroke limit

is

the

ignored.

ignored.

upper limit value of machine travel.

is

valid after zeroing. After redefining

f--

-+t-+--

3.4

is

checked before each positioning operation

backlash

Backlrsh

Zeroing

direction

Lead rrew

Work

Cornpansation

is

halted.

is

halted.

The AD71 may be calibrated to allow for mechanical errors in the

system. This

parameter and

1

)

Set

the

2)

Program the AD71 to provide lOOOmm travel.

3) Measure the actual distance travelled.

4)

Calculate the error,

E

5)

Set

E

6)

If using inches the calibration distance

degrees

The AD71 calculates the error compensation value Ec

Ec=

Where,

is

facilitated by providing an error compensation

is

found

as

follows (example for

error compensation to

E,

such that

=

lm - Measured value. (in

as

the error compensation parameter (in units of 10-lpm).

it

is

100 deg.

-x€

I:

S

=

Travel distance according to AD71

m = Measured distance for

E

=

Difference calculated in

n

=

lo4

=

10'

xn

I

when units are mm

when units are inch-' or degree-'

0.

mm)

S

(4)

above.

mm):

is

100 inch, and for

as

follows:

3-1

2

IB

INAI

66101-A

Page 28

3.

SPECWICATIONS

/MELSEC-A

Error compensation

positioning applications.

Backlash compensation, Bc, should

expression:

where,

(1

0)

Manual pulser inching travel increment

0

0

0

(1

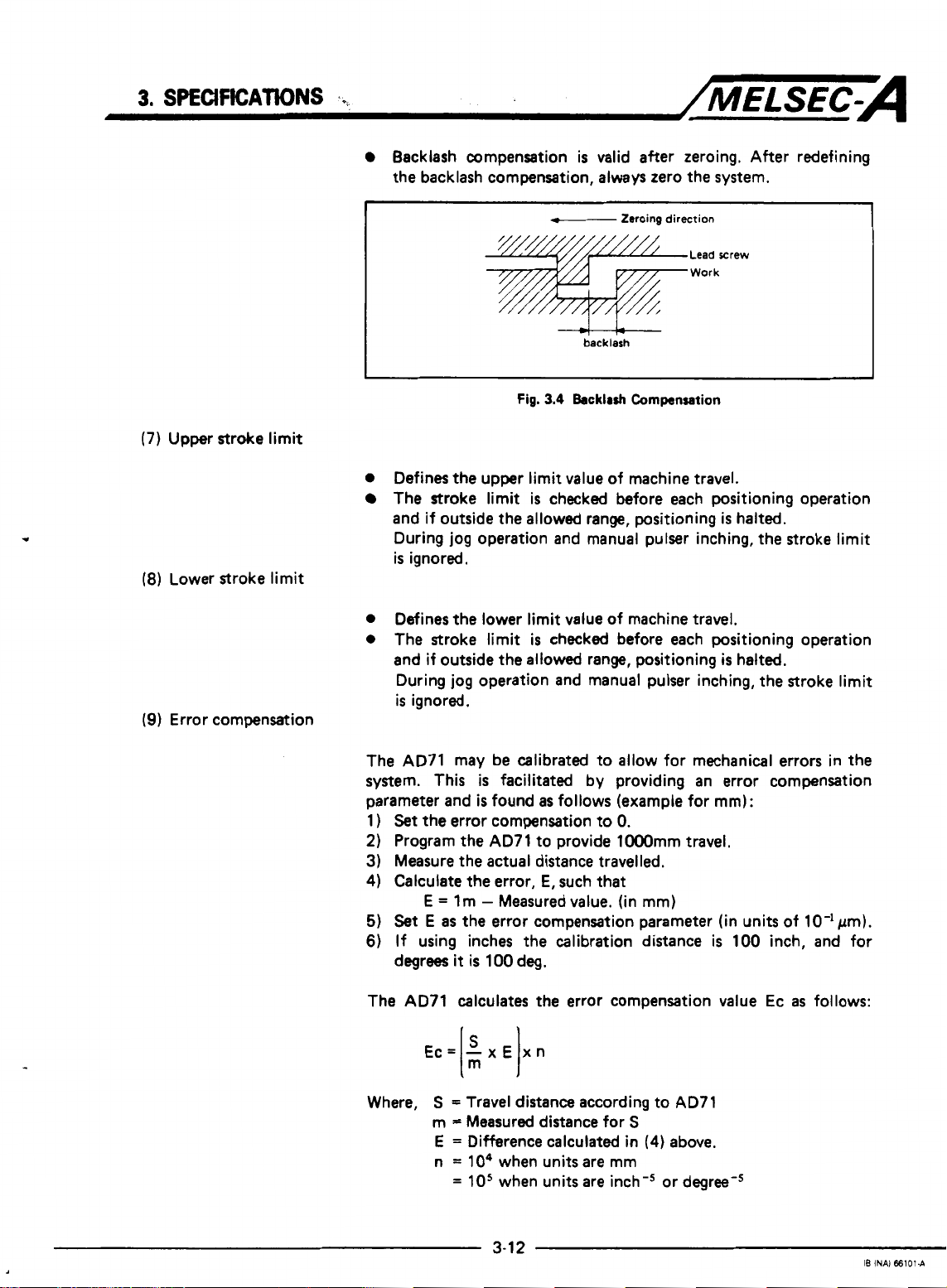

1 ) Acceleration and deceleration times

0

is

valid for: manual pulser inching, jogging and

be

set according to the following

Bc=BxE

B

=

Actual backlash

E

=

As above

Defines the distance travelled each time a manual pulser inching

command

is

given.

The AD71 counts the number of manual pulser inching commands input and transmits the appropriate number of output

pulses.

During manual pulser inching there

(The

speed

is

fixed

at

2oooO

PLS/sec.)

is

no automatic acceleration/

deceleration.

Defines the period of time from the start of positioning to

when

the speed limit value specified in the parameter

(Refer to

Fig.

3.5.)

is

reached.

Parameter

4

0,

8

v)

/*

Starting

bias speed Actual

*

Set acceleration time Set deceleration time

-acceleration

Fig.

speed

limit value

-

:

Swed

if starting bias speed

has been set

Acceleration

speeds

if starting bias

-0

time -deceleration time

3.5

Adoration

Positioning

md

Ikcrlaration

speed

-

Times

- -

The acceleration and deceleration times cannot be

dently.

Acceleration and deceleration are controlled

value.

When the positioning

meter

speed

limit, the

speed

is

very much lower than the para-

acceleration/deceleration

paratively short.

Acceleration/deceleration

time

is

valid for zeroing, positioning,

and jog operations.

For interpolation positioning, the

time for the axis with the longer travel

deceleration time for

the

other

axis

acceleration/deceleration

is

valid. (The acceleration/

is

ignored.)

and

deceleration

set

at

time

speed

indepen-

a

constant

is

com-

3-1

--

3

IB

INN

€6101-A

Page 29

3.

SPECIFICATIONS

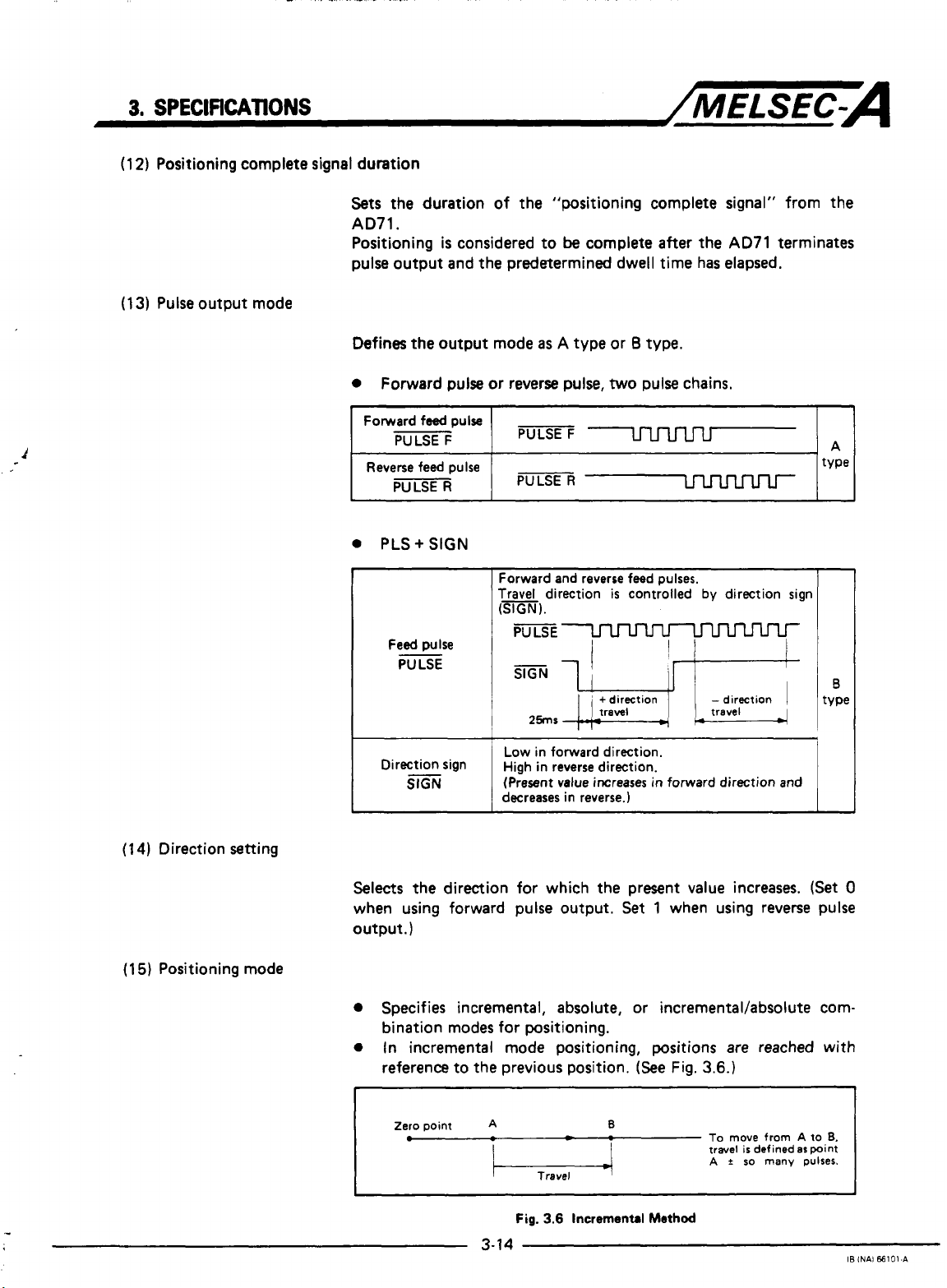

(1

2)

Positioning complete signal duration

(1

3)

Pulse output mode

/MELSEC-A

Sets the duration of the "positioning complete signal" from the

AD71.

Positioning

pulse output and the predetermined

is

considered to

be

complete after the

dwell

AD71

time has elapsed.

terminates

Defines the output mode

0

Forward pulse or reverse

0

PLS+

SIGN

Forward and reverse feed pulses.

Travel

(SIGN).

I

Direction Sign

slGN

I I

Low

High

(Present

decreases in reverse.)

as A type or 8 type.

pulse,

two

pulse chains.

direction

in forward direction.

in

reverse direction.

value increases

is

controlled

in

forward direction and

by

direction sign

I

(1

4)

Direction setting

(15)

Positioning mode

Selects

when using forward pulse output.

output.

the direction for which the present value increases.

Set

1

when using reverse pulse

)

(Set

0

Specifies incremental, absolute, or incrementaVabsolute combination modes for positioning.

0

In incremental mode positioning, positions

reference to the previous position.

Zero

point

.-

A

3-14

Fig.

-

3.6

Incremental

B

(See

Method

Fig.

are

3.6.)

To

move

travel

A t so

reached with

from

defined

many

A to

as

point

pulses.

is

6.

IB

INAl

66101-A

Page 30

3.

SPECIFKATIOMS

/MELSEC=A

0

In absolute mode positioning, positions are reached with refe

rence to a zero point address.

(See

Fig.

3.7.)

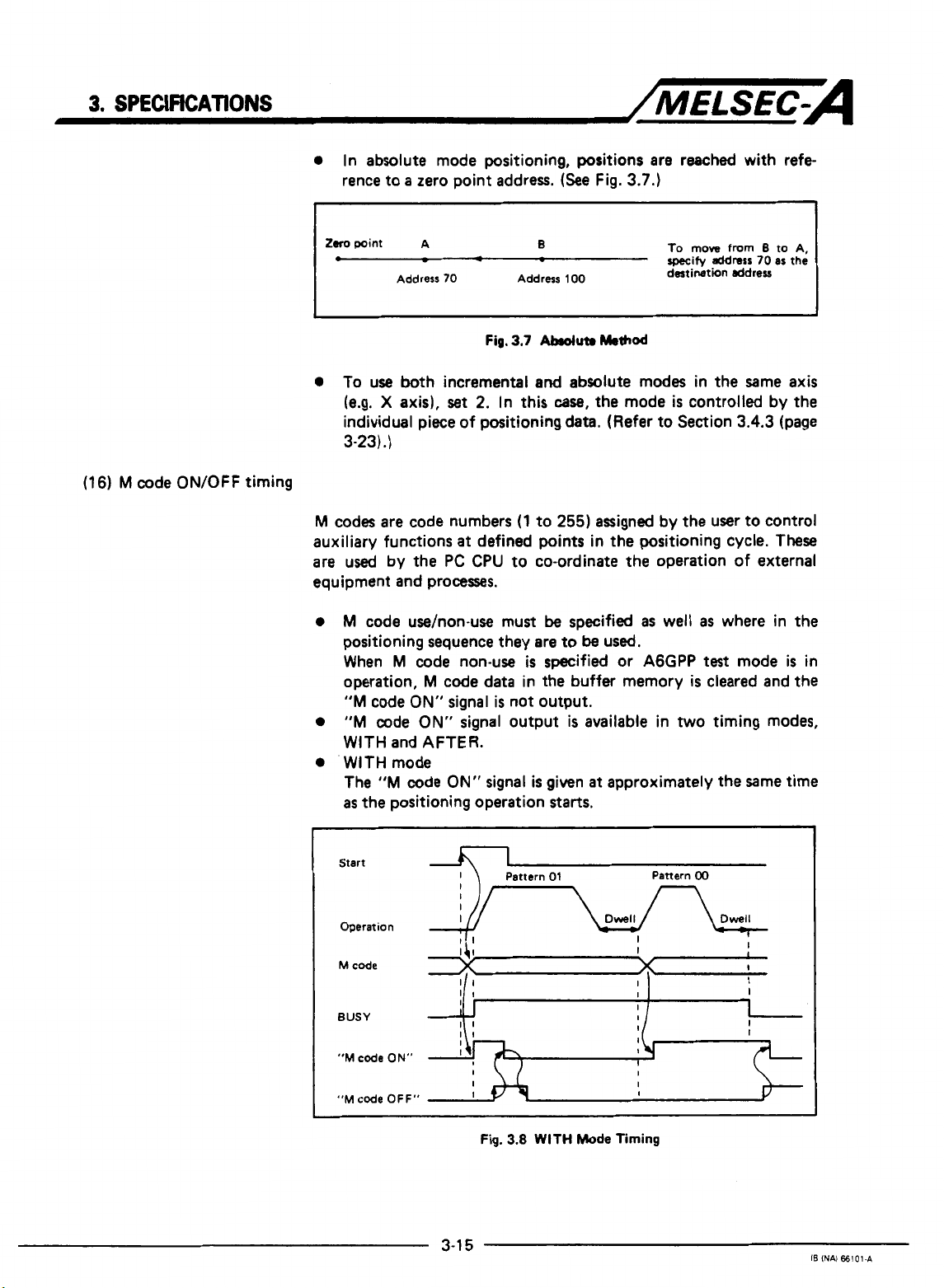

(16) M code ON/OFF timing

1

tom

point A

0

0

To use

(e.g. X axis),

Address

both

-

70

Fig.

incremental

set

2.

individual piece of positioning data. (Refer to Section

3-23)

.)

M

codes are code numbers

auxiliary functions

are used by the

at

defined

PC CPU

equipment and processes.

0

M

code

use/non-use must

positioning sequence they are to

When M code non-use

operation, M code

"M

code

ON"

0

"M

code

ON"

data in the buffer memory

signal is not output.

signal output

WITH and AFTER.

0

WITH mode

The

"M

code

ON"

signal

as

the positioning operation

B

Address

100

3.7

Abduta

and

absolute modes in the Same axis

In

this

case,

(1

to

255)

points

to co-ordinate

be

specified

be

is

specified or

is

is

given

starts.

Method

the mode

assigned by the user to control

in the positioning cycle.

the

operation of external

as

used,

A6GPP

available in

at

approximately the Same time

To

move

specify

destination ddreu

is

from

address

70

controlled by the

3.4.3

well

as

where in the

test

mode

is

cleared and the

two

timing modes,

B

to A,

as

(page

These

the

is

I

in

I

Start

Operation

"M

code

"M

code OFF"

ON"

3-1

I

I

I

I

I

I

5

Fig.

3.8

WITH

Mode

Timing

Pattern

00

IB

INAI

66101.A

Page 31

3.

SPECIFICATIONS

0

AFTER

The

has finished. In this mode, if the operation

complete the

I

Start

"M

mode

code

ON"

"M

signal

code

is

ON"

given

signal

/MELSEC-A

after

the positioning operation

is

is

not given.

stopped before

it

is

Operation

M

code

BUSY

"M

code

ON"

"M

code

OFF"

POINT

I

0

The

"M

in

the

0

The

M

and the

the

positioning pattern, refer to Section

3-23)

.)

The next positioning operation

code ON" signal

An error condition arises if the

at

the rise of the

started. The

I,

II

I

I1

11

Fig.

code

ON"

positioning data

code

is

ignored if the positioning pattern

"M

code

is

"M

01

Pattern

3.9

AFTER

signal

is

is

set

ON" signal

switched

start

code

ON"

Pattern

00

I]

I

x

x

if

I

I

Mode

Timing

not

given

if the

M

code

at

0.

is

not given, (For details of

3.4.3

is

not started until

off.

"M

code

ON" signal

signal and positioning

signal

is

turned

off

I

is

"11"

(page

the

is

is

when:

data

"M

on

not

_.

1.

"M

code

2.

PC

ready signal

3.

Zeroing, positioning,

is

selected

3-1

6

OFF" signal changes from

(Y

1D)

is

off;

or

jog

operation, or inching mode

in

the AGGPP

test

mode.

OFF

to ON;

I6

INAl

€6101-A

Page 32

3.

SPEClFKATlONS

/MELSEC-A

M

code

BUSY

"M

code

(WITH

mode)

"M

code

(AFTER

ON"

ON"

mode)

For a sequence of positions, the first of which are defined

pattern

"00" or

itself

I

I

I

is

"1 1

"01"

given

",

the

pattern data

at

"M

code

ON"

signal is not given until the first

is

reached. In this

case

the M code

the first position. This is illustrated below.

Pattern

00

Dwell

-

I'

1

I]

I

I

\,

I

as

"M

code

OFF"

Fig.

3.10

"M

code

ON"

Simrl

Timing

for

Positioning

haern

"1

1"

Page 33

3.

SPECIFICATIONS

3.4.2

Zeroing

data

/MELSEC=A

1

Zeroing direction

2

Zeroing method

4

I

Zeroing speed

~

1

to 12000

This defines a home position or zero point for

Table

3.6.

Zeroing data

1)

parameters or zeroing data

AD71;

2)

"PC

from

3)

zeroing, positioning, jog operation, or manual pulser inching

selected in

I

x101

I

mm/min

is

checked when:

ready

signal"

OFF

to

AGGPP

0

:

1

:

0

:

1

:

2

:

to

is

transferred from the

output from the

ON;

or

test

mode.

Forward direction(address increases)

Reverse direction(address decreases)

Pulse generator(PG1zero-point signal

Stop and dwell timer time-out

Stop and signal from drive unit

l2Oo0

1

inch/rnin

x1

I

lo

PC

l2OO0

~

deg/min

x1

CPU

the

to the

I

to2m

AD71.

A6GPP

AD71

Refer to

to the

changes

I

PLS/sec

xlol

is

to

2000

inch/rnin

~

x1

Zeroing Data

to

No.

Oto499(

1

7

No.

time

7

Torque limit

TsMe

3.6

I

POINT

J

(1)

NO.

3

(2)

When setting

gram, refer to Section

0

to

can

1

to

l2OoO deg/min

i

x

10'msec)

2

50(%)

be

set

and

No.

3.5.6

(WW

'

I

x1

by

the sequence program.

2

from

to20000

I

the

sequence Pro-

3-47).

PLS/sec

I

xlol

1

3-18

IB

lNAl 66101.A

Page 34

3.

SPECJFtCATlONS

/MELSEC-A

(1

Zeroing direction

(2)

Zeroing methods

Zeroing data

is

explained below:

Specifies the direction for zeroing.

IMPORTANT

Zetoing

speed.

Always

1

is

controlled according

Deceleration

ensure

that

is

the

to

the zeroing direction and

started when an actuator

zeroing

direction

is

correct for

is

drive system used.

Zero the system using one of the following methods,

require a "zeroing dog" or actuator to reduce the

speed

speed.

a)

Zero-phase signal from pulse generator

b)

Stop and dwell timer time-out

c)

Stop and signal from drive unit

(a)

Zero-phase signal from

PG

(PG)

operated.

the

all

methods

to the creep

The sequence of events

0

Zeroing signal received - move in appropriate direction,

0

"Zeroing dog" on

0

"Zeroing dog"

0

Zero phase signal

I

Fig.

3.11

J

I I I\

"Zeroing dog"

Zeroing Using a Zero-Phase Encoder

is

as

follows

-

start

decceleration to creep

off

-

continue

-

stop drive, zeroing complete.

Actuator signal starts deceleration.

Creep

(See

at

creep speed.

apead

Drift (axording to drive unit)

I

u

U

U

'//////////////

Adjust tha actuator

position

zerophme

and

Fig.

3.1

1):

speed.

Zero-phase signal

is

signal.

Torque limit valid range

an

Actuator

near

so

the

(method

that its

center

of

OFF

the

a1

Page 35

3.

SPECIFICATIONS

1

turn

of

~

-

PG

(b) Stop and dwell timer time-out

/MELSEC-A

+

The sequence of events

0

Zeroing signal received - move in appropriate direction.

0

”Zeroing dog“ on

start

dwell timer.

0

Work

is

stopped by mechanical stopper.

0

Dwell timer times out - zeroing complete.

(c)

Stop and signal from drive unit

The sequence

0

Zeroing signal received- move in appropriate direction.

0

“Zeroing dog“ on

0

Work

0

Feedback signal from drive unit (e.g. torque limit exceeded),

of

events

is

stopped by mechanical stopper.

zeroing complete. (The feedback signal

phase signal input).

Zeroing

speed

Actuator signal

is

as

follows (See Fig. 3.13-1

-

start

decceleration to creep speed and

is

as

-

start

follows

decceleration to creep speed.

starts

(See

deceleration.

Creep speed

Mechanical stop

Fig. 3.13-2):

is

fed into the zero-

1:

(3)

Zeroing address

(4) Zeroing speed

1

Fig.

3.13

Home

0

This address

upon completion of zeroing.

0

Set

the zeroing address to either the upper or lower stroke

limit

set

0

Sets the zeroing

is

set

in the parameters.

speed.

3-20

Positioning Using

as

the present value of the home position

Stop

Signal

(Refer to Fig. 3.14.)

IB

INAI

66101-C

Page 36

3.

SPECJRCATlONS

(5)

Creep

speed

0

This

is

the low

Fig.

3.14.)

0

This speed should be

as

well

as

Zeroing

speed

I

speed

used

to approach the home position.

set

with consideration for errors in zeroing

the impact with the end stop.

starts

deceleration.

Drift [according to drive unit)

Zero-phase signal

Adjust the actuator

position is near

zero-phase signal.

P//I////I////R

Torque

/MELSEC-A

(See

1

so

that it5

the

center

limit valid range

of

OFF

the

(6)

Zeroing dwell time

(7)

Torque limit

1

Fig.

3.14

Zeroing and

0

This

is

the period

turned on to when home positioning

0

Set

the

time interval to allow the creep

drive to hit the mechanical stopper.

0

When

the

dwell timer home positioning method

used,

this may

0

Sets

a

limit for the

is reached.

I

POINT

I

I

0

A D/A converter module

0

Any

value

torque limit zeroing method

Torque limit value

I

1-1

Read

of

time starting from when the actuator

be

set to any value within the setting range.

servo

within

the

setting range

PC

71

Creep

Speeds

is

complete.

speed

to stabilize and the

is

not being

motor torque after the creep speed

is

necessary

is

not

I

r:i::

for

torque limiting.

may

be

specified

being used.

Drive unit

if

the

J

is

I

I

Operation

I

by

program

Fig.

3-21

converter unit

3.15

Torque

(Analog amount)

I

Limit

Block

Diagram

IB

INAi

66101-C

Page 37

3.

SPEClFlCATlONS

3.4.3

Positioning data

:

/MELSEC-A

Positioning data

(i.e.

control other than home positioning, inching and jog operation).

Refer to Table

Table

3.7

for the X and Y axes,

The block of data used

in the positioning

Positioning data

b15

F

Positioning

information

I

b8

3.7.

shows

b7

VY

1

is

used in the

one block

respectively.

for

start

area

is

checked when positioning is started.

Setting

bO

?*

L

Positioning pattern

-

Positioning method

Valid only when incrementallabsolute combination

specified in parameter.

Positioning direction (valid in incremental mode only)

Unused (may be

AD71

to execute positioning control

of

positioning data.

positioning

of

the buffer memory.

Data

00

:

Positioning terminated

01

:

Positioning continued

:

Speed cham

11

I

0

:

Absolute

{

1

:

Incremental

0

:

Forward direction (address increase)

{

1

:

Reverse direction (address decrease)

is

dictated by the number

and

positioning then continued

0

or 1)

400

blocks can be

is

set

set

~~

c

Positioning speed

t

Positioning

address

Dwell time

1

rnm

I

'

1

to

12000

!

0

to

,162x107

I

x

10'

mm/min

x'o-'pm

Table

POINT

No.

l2O0O

0

to

162x107

3.7

Positioning Data List

I

2

to

No.

4

-

M

code

(0

M

to 255)

code

'

0

1 62 x 107

=

0

to

O'rnsec)

Sn

inch/min

x

Ot0499( x 1

can be set from

when

M

code

is

dearee

x1 x1

deg/min

x

O-sdeg

the

sequence program.

not mecified

'

to20000

0

to

16252928

PULS inch

x

10'

PLS/sec

PLS

1

I

Page 38

3.

SPECIFICATIONS

/MELSEC-A

(1)

Positioning information

Positioning data

is

explained below.

Separate the information for the X and

Positioning information consists of

following.

hl5

(a)

Positioning pattern

b8

b7

This specifies whether the operation

next

position, or if operation

position has been reached.

Continued operation

is

further divided

Y

axes.

16

bits and includes the

bO

Positioning method

Positioning direction

UnUred

--

is

to be halted after the current

M

code

is

to be continued to

as

follows:

the

1)

Consecutive positions are reached using

2)

The

speed

is

changed

at

the specified address and positioning

then proceeds in the same direction.

This pattern data

is

specified

tioning information.

Bit

1

Bit

0

Positioning pattarn

00

:

Positioning and

01

;

Positioning continued (in any direction)

11

:

Spaed

(in the same direction)

10

:

No

setting

Fig.

3.16

Positioning

the

same speed.

by

the first two bits of the posi-

chanped end positioning then continued

Pattern

*

3-23

IB

INN

66101-A

Page 39

3.

SPECIFICATIONS

0

Positioning end

/MELSEC=A

Drives to the specified address, positioning

is

complete after

the dwell time has elapsed.

Start

(Y

10)

..

Positioning commenced

0

Positioning continued

nmL

(X81

Fig.

3.17

Pattern

0

The positions are reached consecutively in the order specified

by

their data numbers

by

a

single

start

signal. (The

remains on during positioning.)

BUSY

signal

positioning commenced

BUSY

(X41

Positioning complete

P = address Dwell

V=ppeed

t = dwell time

I

Pattern

00

(X8)

should

Fig.

3.18

be

set for the

t,

Pattern

Pattern

,

V,

Dwell

ta

I

01

01

last

--

1

position in a series of

Pattern

continuous operations.

Pattern

caw,

01

may

the

patterns

be

set

for interpolation positioning.

for

the X and Y axes should

be

the same.

The X and Y axis patterns are checked before operation and

any error will stop positioning.

00

In

??

Dwell

tt

+

this

I

3-24

IB

INAI

€6101-A

Page 40

3.

SPECIFICATIONS

/MELSEC-A

0

Positioning continues with

The positions are reached consecutively in the order specified

by

their data numbers by a single

the speed may be changed but the direction remains

(Refer to

Start lYlOl

:ommenced

BUSY

(X14)

M

M

(X

code

code

18)

ON

Fig.

3.19.)

P

V

t

I

speed

=

address

=

speed

-

dwell

change

start

signal. During positioning,

(pulse)

(PIS)

(in

0.01 second increments)

1

the

same.

I

7

I

Fig.

3.19

Pattern

11

Table

3.8

shows

the positioning data for

Fig.

3.19.

conditions apply:

M

code ON/OFF timing

:

AFTER mode

Incremental/absolute method: Incremental and absolute

combined

In

the method column, Ab. indicates absolute

method and Inc. incremental method.

TaMo

3.8

Positioning Data

The following

i

I

1

3-25

I6

INN

€61014

Page 41

3.

SPECIFICATIONS

/MELSEC-A

POINT

I

For continuous positioning, pattern

more than nine times consecutively.

consecutive

down by placing

pattern

timer, pattern

Always set pattern

While pattern

and

the

after pattern

changed after deceleration has started, the new

ignored and,

"M

code

During positioning using pattern

code will

Interpolation positioning cannot

11

is

being used.

11

patterns

01

11

=

9

times, pattern

00

=

11

positioning method should remain unchanged, only

01

or

if

the

ON"

signal

be

ignored.

are

being

pattern data every nine

1

time).

00

in the final data block.

is

continuing,

00

may these

M

code

has

is

not

given.

11

Where

used, they must

01

=

1

the

direction of movement

be

changed. If the

been

set in WITH mode, the

11,

dwell time data and

be

specified when pattern

should not

a

large number of

be

11

patterns.

time, pattern

be

used

broken

(e.g.

11

=

speed

speed

M

9

is

is

(b) Positioning method

Incremental or absolute positioning must be specified assuming

that

it

has not been

Parameter data takes precedence over this data.

POINT

(c)

I

The positioning method cannot

been

specified.

The positioning

01

have been executed.

Positioning direction

For incremental mode positioning, the direction of travel relative

to the previous address must be specified.

increasing address numbers and

address numbers.)

In absolute mode, the positioning direction

set

method

in the parameters (item

be

can

chand

be

changed after patterns

if

(0

1

specifies reverse, decreasing

is

ignored.

15,

pattern

specifies forward,

page

11

00

3-9).

has

or

3-26

IB

1NA)

€61014

Page 42

3.

SPECIFKATIONS

/MELSEC-A

(d) M code

(2)

Positioning speed

Specifies

to 255)

The code should

During interpolation positioning, M codes

for the X and Y axes. (X-axis M code, buffer address

M

code, buffer address

Specifies

POINT

bfore operation, the

the

parameter

Positioning speed for linear interpolation

During linear interpolation positioning, the

with the furthest to travel takes precedence and

other

axis

an

"M"

the

speed

I

positioning

speed

is

derived

code relevant to that position address. (range:

be

set to 0 if

=

at

which the next position

parameter

rpeed

limit value

as

follows.

it

is

not required.

346.)

zpeed

exds

is

the

used.

limit

speed

speed

are

given individually

=

46.

is

to be approached.

is

checked

limit value, the

the

and if

set

for the axis

speed of the

0

Y-axis

(Short travel

-

-

(long

An example of this

data:

Parameter set value

Positioning data set value

To

move from point A (address

X-axis

travel

X-axis positioning

(This speed exceeds

axis

speed)

axis

is

given in

is

less than Y-axis travel

speed

the

speed limit value which

'peed)

:

speed

limit value

:

positioning

=

50 x

(short travel distance)

x

Fig.

0,

(long

travel

distance)

3.20

which

speed

0)

to point B (lwkp, 200kp),

so

Vy

-

=

loo

25KPLS/sec

200

uses

the following

X

Axis

POKPLS/sec

20KPLS/sec

=

50kp/s has precedence.

is

ignored in thiscase.)

50KPLS/sec

50KPLS/sec

Y

4

Axis

Page 43

3.

SPECIFKAlWNS

/MELSEC-A

Fig.

3.20

Linur

Interpolation

Note: For interpolation positioning, the actual positioning speed is

approximately

is extremely

1

WPB.

I

5%

lowr than the

low,

the error will

set

speed.

be

larger, e.g. about

(If

the set speed

10%

at

(3)

Positioning address

(4)

Dwell

time

POINT

The positioning address

incremental value.

The dwell time is the period of time indicated

1

During linear interpolation positioning

speed

of a given axis to

limit value

greatly.

For linear interpolation,

speeds

same value.

Positioning commenced

and

if

the

speed

(X81

exceed

travel

it

limits for

is

set

the set

distance for

is

suggested that

the

X

either

it

is

speed

the

and Y axes are

as

an absolute value or an

possible for

and

the

two

axes varies

the

positioning

set

in

Fig.

3.21 below.

the

speed

to

the

I

For

Speed

graph

Fig.

3.21

Pattern

During interpolation positioning, the longer dwell time value

valid irrespective of the distance travelled

axis

=

1.5

sec,

1.5

sec

is

valid.)

3-28

I

-

Dwell

00

(e.g.

if X axis = 1

pattern

sec

and

00

is

Y

IS