Page 1

il

v

0

n

MtTSUBrSfril

MOTORS

Worlrshop

Mqnuql

chossis

SUPPLEMENT

,,v

L

SOOOGiT'gg

ffi

-:

---

:----:E--+=::-

###

Page 2

IvIITSUBISHI

General

Fuel

.

@

Iil

'!,

3Ct00GT

WORKSHOP

SUPPLEMENT

FOREWORD

Workshop

This

moval, disassembly,

sembly

Use the

combination

All information,

tions

time

to

obligation.

and

manuals

conlained

publication.

of

make changes

Manual

installation,

with this

illustrations

in

contains

inspection,

indicated

manual

manual

this

We,

at any

MANUAL

procedures

adjustment,

service

for

etc.

on the

however,

time

following

required.

as

product

and

are current

reserve

without

prior

mechanics.

page

descrip-

as at

the

notice or

for

reas-

the

right

re-

in

Engine

Heater,

Ventilation

and

Electrical

Air conditioner

IT

E

@

Mitsubishi

J.

t t lroroRs

Motors corporation

MITSUBISHI

coRFoRATrol{

(.,

Page 3

RELATED

PUBLICATIONS

TECHNICAL

WORKSHOP

Chassis

Engine

ELECTRICAL

PARTS

INFORMATION

<Europe>

<General

Australia>

<Europe>

<General

Australia>

<Europe>

<General

<Australia>

MANUAL

Group

Export,

Group

WIRING

Export,

CATALOGUE

Export,

MANUAL

GCC and

GCC

and

GCC>

PYUE92O1

PWUE9119

PWUE9119-E

PWUE9119-F

PWUE9119

PWUE92O3

PWUE9203-1

PWUE92O3-2

PWUE92O3.3

PWUE92O3-4

PWEEIf,

PHUE9201

PHU

E920

PHUE9201

PHUE9201

PHUE9406

PHUE9406-1

PH

UE9406-2 (Supplement)

8608K4O8Atr

8808K408An

BFASK4OSAN

(Loose-leaf

Supplement)

Supplement)

Loose-leaf

Basic)

Supplement)

Supplement)

Supplement)

Supplement)

nn (Loose-leaf

(Loose-leaf

-D

(Supplement)

1

-E

(Supplement)

-F

(Supplement)

(Basic)

(Supplement)

edition)

edition)

edition)

edition)

WARNINGS

(sRS)

WARNING!

(1)

lmproper

can.lead

bag)

(2)

at it

.-. 9r

(3)

Service

only

(4)

MITSUBISHI

5?B

of any

EQUTPPED

or to

possible

is

in.drying

or

at an

-

Supplemental

component

REGARDING

service

personal

to

the driver (from

after

maintenance_of

authorized

dealer

VEHTCLES

or maintenance

iniury

that

the SRS

painting,_remove

MITSUBISHI

personnel

Restraint

of

the SRS

or death

rendering

components

SRs

-qny

must

System

or

OF

SUPPLEMENTAL

of any

the

component

to se_rvice

the

SRS inoperative).-

are

SRS compon6nts

componeni

dealer.

thoroughly

(SRS),

any SRS-related

personnel

subjected

or SRS-relateJ

review

before

of the

(air

this manual,

beginning

component.-

RESTRAINT

SRS,

or any

(from

to heat

bag

module,

component

SRS-related

inidvertent

over

93"C

SRS-LCU)

and

especially

any

service

SYSTEM

component,

firing

(200.F)

must

be

or maintenance

'the

of

in

beforehandl

performed

its

GROUP

air

baking

Page 4

v

GENERAL

GENERAL OO

-

Vehicle ldentification

00-1

GENERAL

I

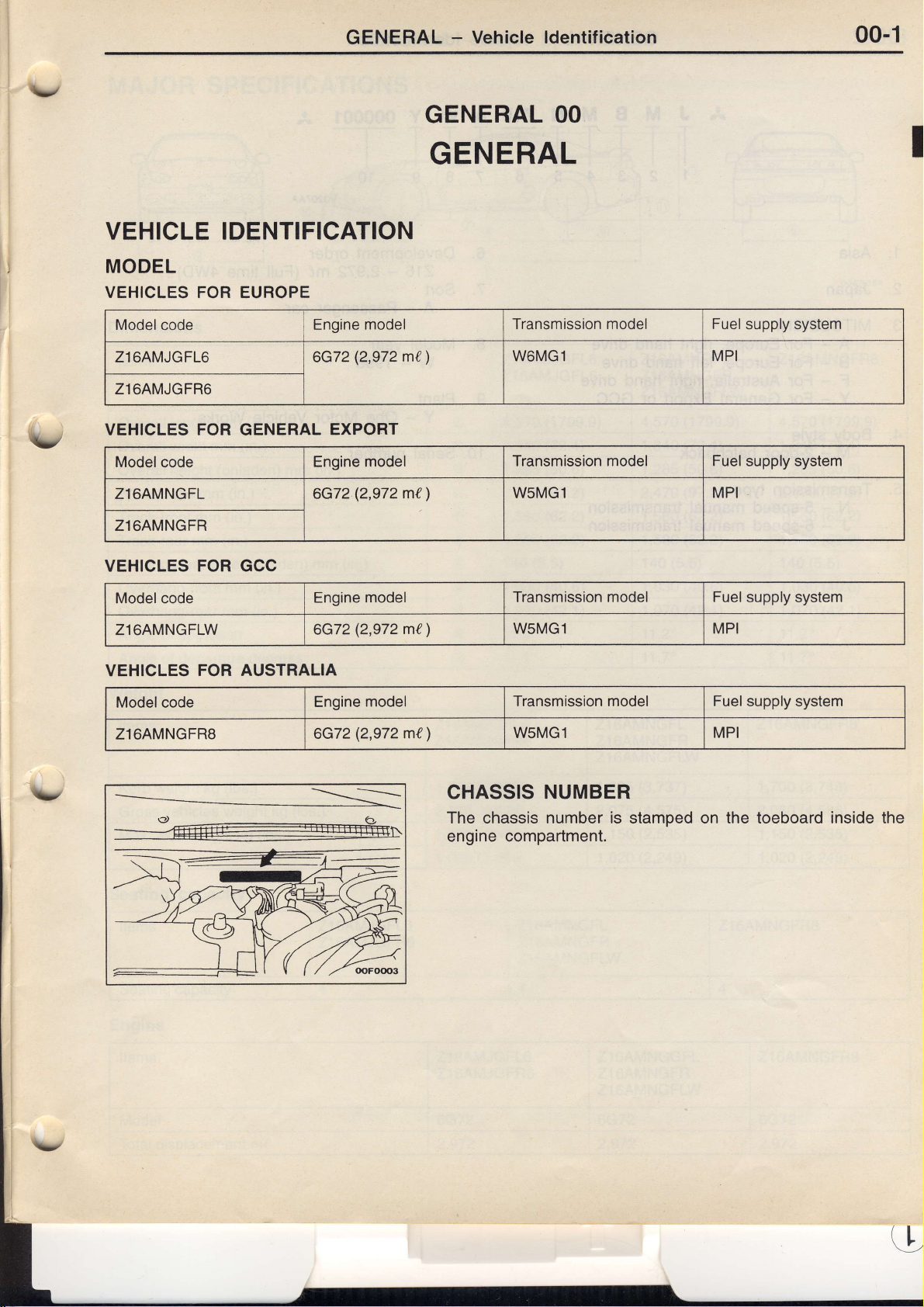

VEHICLE IDENTIFICATION

J

MODEL

VEHICLES FOR EUROPE

Model code Engine

Zl6AMJGFL6 6G72

Zl6AMJGFR6

VEHICLES FOR GENERAL

EXPORT

model

(2,972

m(

Transmission

)

W6MG1

model Fuel

MPI

supply system

v

Model code Engine

Zl6AMNGFL

Zl6AMNGFR

VEHICLES FOR GCC

Model code

6G72

Engine model

model

(2,972

m(

)

Transmission model Fuel supply system

WsMG1

Transmission model Fuel

MPI

supply system

Zl6AMNGFLW

VEHICLES

Modelcode

Zl6AMNGFRs

6G72

FOR AUSTRALIA

Engine

6G72

(2,972

model

(2,972

m(

)

m(

)

CHASSIS

The chassis number is stamped on the toeboard inside the

engine compartment.

WsMG1 MPI

Transmission model Fuel supply system

WsMG1 MPI

NUMBER

Page 5

00-2

GENERAL

-

Vehicle ldentification

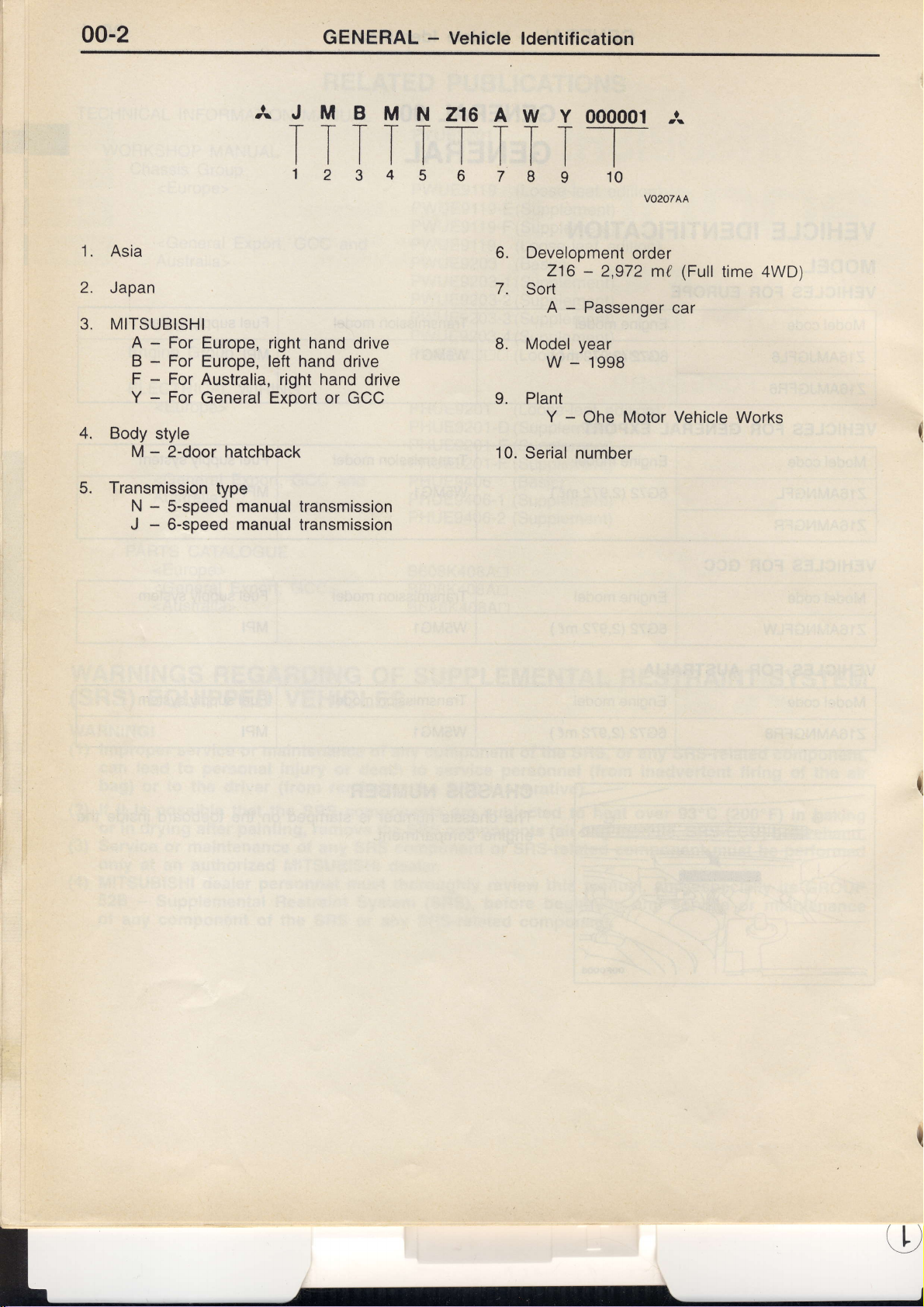

1. Asia

2.

Japan

MITSUBISHI

3.

4.

5.

-

A

-

B

F - For

Y - For

Body style

M - 2-door

Transmission

-

N

-

J

AJMBMN216AWY

TTTTT_I-TTT

ttttttltl

123456789

For Europe, right hand

For

Europe, left hand drive

Australia, right hand

General Export

hatchback

type

S-speed manual

6-speed manual

or GCC

transmission

transmission

drive

drive

000001

--r-

I

10

6. Development

216 - 2,972

7.

Sort

-

A

Passenger

Model

L

9. Plant

10.

Serial number

year

w - 1998

-

Y

Ohe Motor Vehicle

order

A

VO2OTAA

(Full

md

car

time 4WD)

Works

Page 6

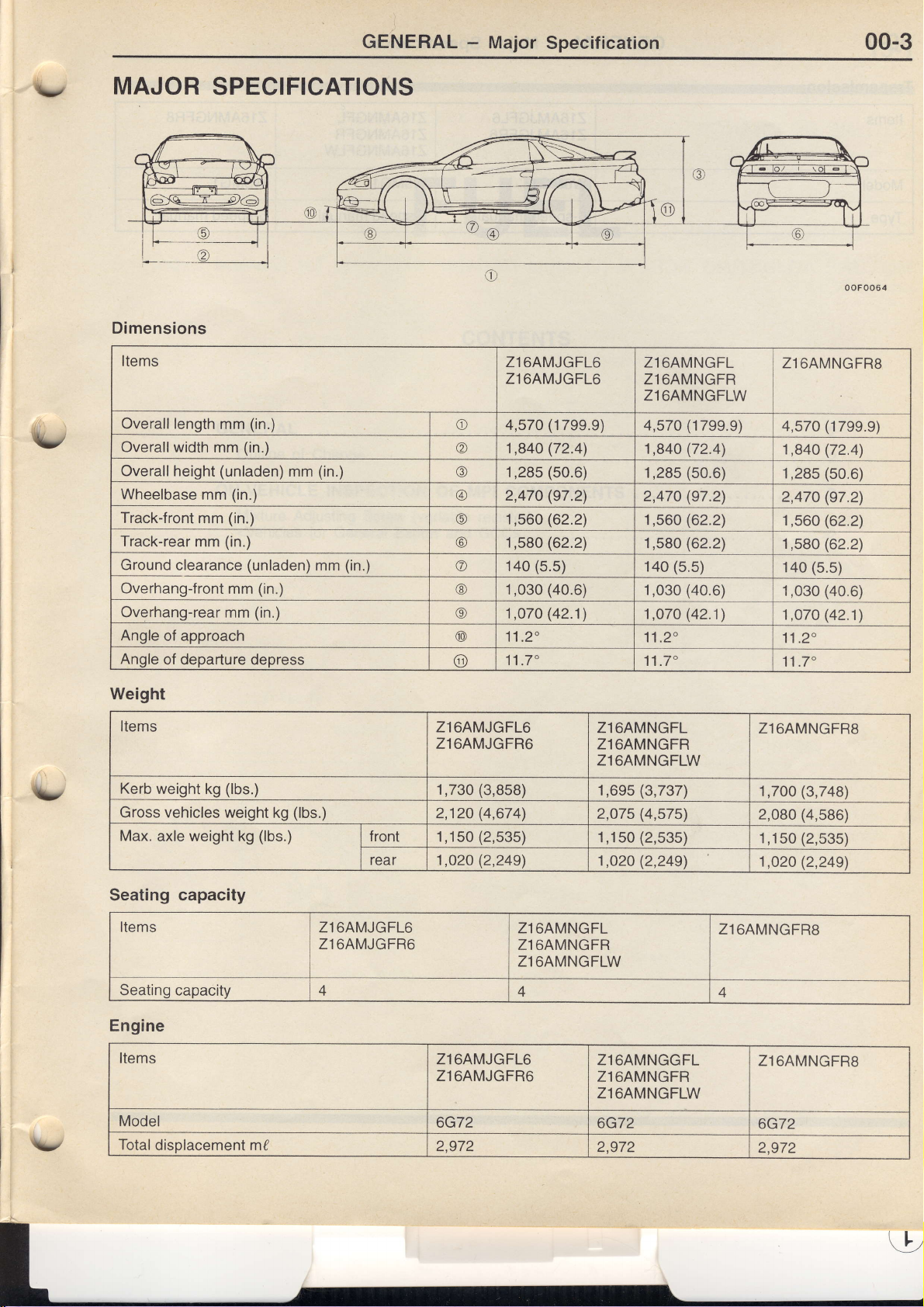

GENERAL - Major

Specification

00-3

ty

v

MAJOR

SPECIFICATIONS

Dimensions

Items

Overalllength

Overallwidth

Overallheight

Wheelbase

Track-front

Track-rear

Ground

Overhang-front

Overhang-rear

Angle

of approach

Angle

of

mm

mm

mm

mm

clearance

departure depress (,

(in.)

mm

(in.)

(unladen)

(in.)

(in.)

(in.)

mm

mm

mm

(unladen)

(in.)

(in.)

(in.)

mm

(in.)

Zl6AMJGFL6

Zl6AMJGFL6

o 4,570

@ 1,84O

@ 1,285

@ 2,470

@ 1,560

@ 1,580

O 140

@ 1,030

o 1,O7O

@ 11 .2"

(1799.9)

(72.4)

(50.6)

(97.2)

(62.2)

(62.2)

(5.s)

(40.6)

(42.1)

1'1 .7'

Zl6AMNGFL

Zl6AMNGFR

Zl64MNGFLW

(',t799.9)

4,570

(72.41

1,84O

(50.6)

1,28s

(97.21

2,470

(62.2)

1,560

(62.2)

1,580

(5.5)

140

(40.6)

1,030

(42.1)

1,070

'l.1

.2"

11 .7"

oo

Foo64

Z1

6AMNGFRs

(17e9.9)

4,570

(72.4)

1,840

(50.6)

1,285

(97.2)

2,470

(62.2)

1,560

(62.2)

1,580

(5.s)

140

(40.6)

1,030

(42.1)

1,07O

11 .2"

11 .7"

\/

v

Weight

Items

Kerb

weight kg

Gross vehicles weight

Max.

axle weight kg

(lbs.)

Seating capacaty

Items

Seating

Engine

Items

Model

Total

capacity 4

disolacement mf

kg

(lbs.)

(lbs.)

Zl6AMJGFL6

Zl6AMJGFR6

Zl6AMJGFL6

Zl6AMJGFR6

't,730

2,120

front

rear 1,O20

1,150

Zl6AMJGFL6

Zl6AMJGFR6

6G72

2,972

(3,858)

(4,674',)

(2,53s)

(2,249)

Zl6AMNGFL

Zl64MNGFR

Zl64MNGFLW

A

Zl6AMNGFL

Zl6AMNGFR

Zl6AMNGFLW

(3,737)

1,6e5

(4,s751

2,075

(2,535)

1,150

(2,249)

1,020

Zl6AMNGGFL

Zl6AMNGFR

Zl6AMNGFLW

6G72

2,972

Zl6AMNGFRs

(3,748)

1,700

(4,s86)

2,080

(2,535)

r

,150

(2,249)

1,020

Zl6AMNGFRs

4

Zl6AMNGFRS

6G72

2,972

Page 7

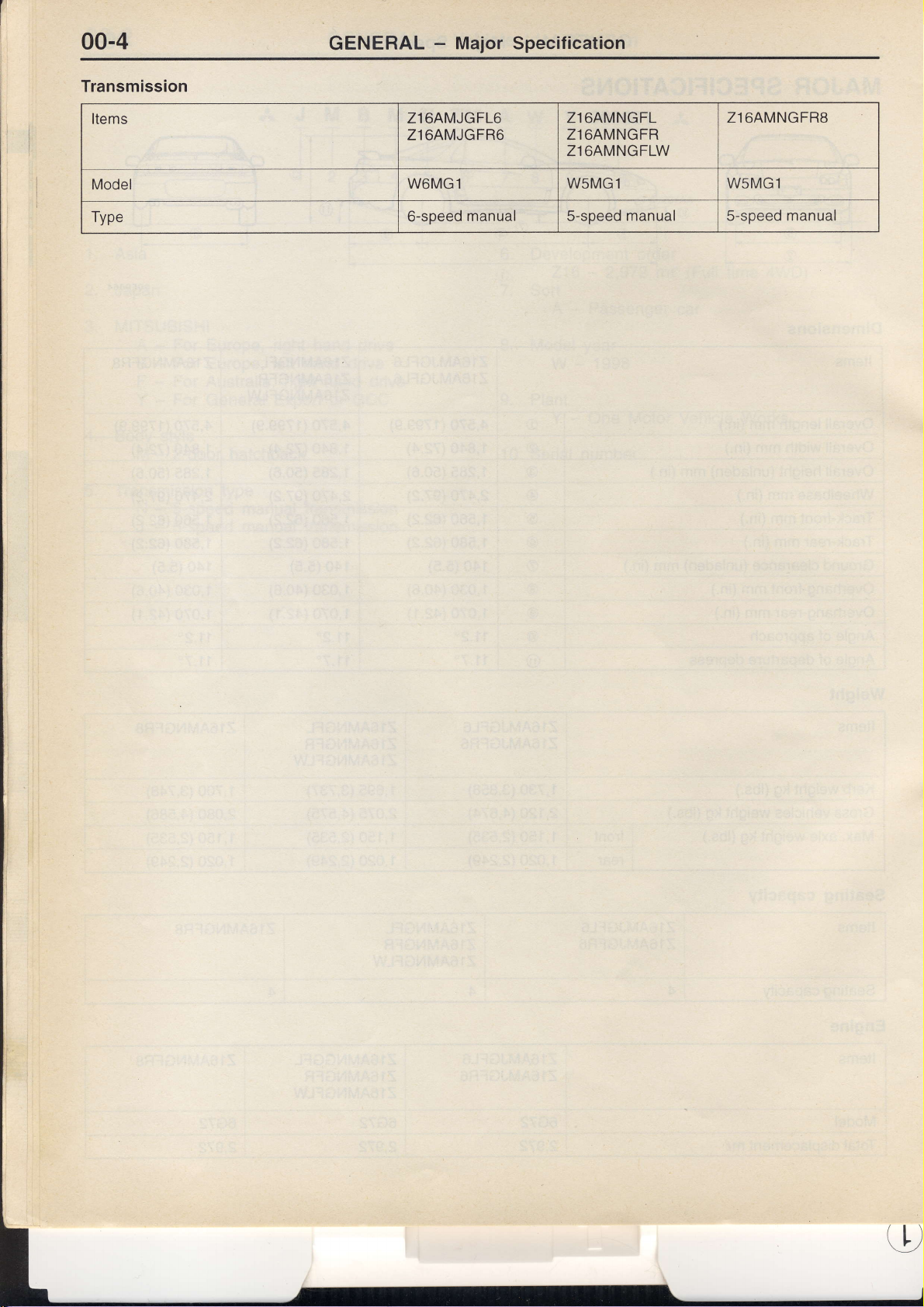

00-4

Transmission

GENERAL

-

Major

Specification

Items

Model

Type

Zl6AMJGFL6

Zl6AMJGFR6

W6MGl WsMG1

6-speed

manual 5-soeed manual 5-speed

Zl6AMNGFL

Zl6AMNGFR

Zl6AMNGFLW

Zl64MNGFRs

W5MG1

manual

[,

Page 8

v

13-1

FUEL

CONTENTS

GENERAL

Outline

ON.VEHICLE INSPECTION

Mixture

<Vehicles

of Change

Adjusting

for

Screw

General Export

OF MPI

(variable

COMPONENTS

resistor)

and GCC> .

.......

..

2

.. 2

2

Page 9

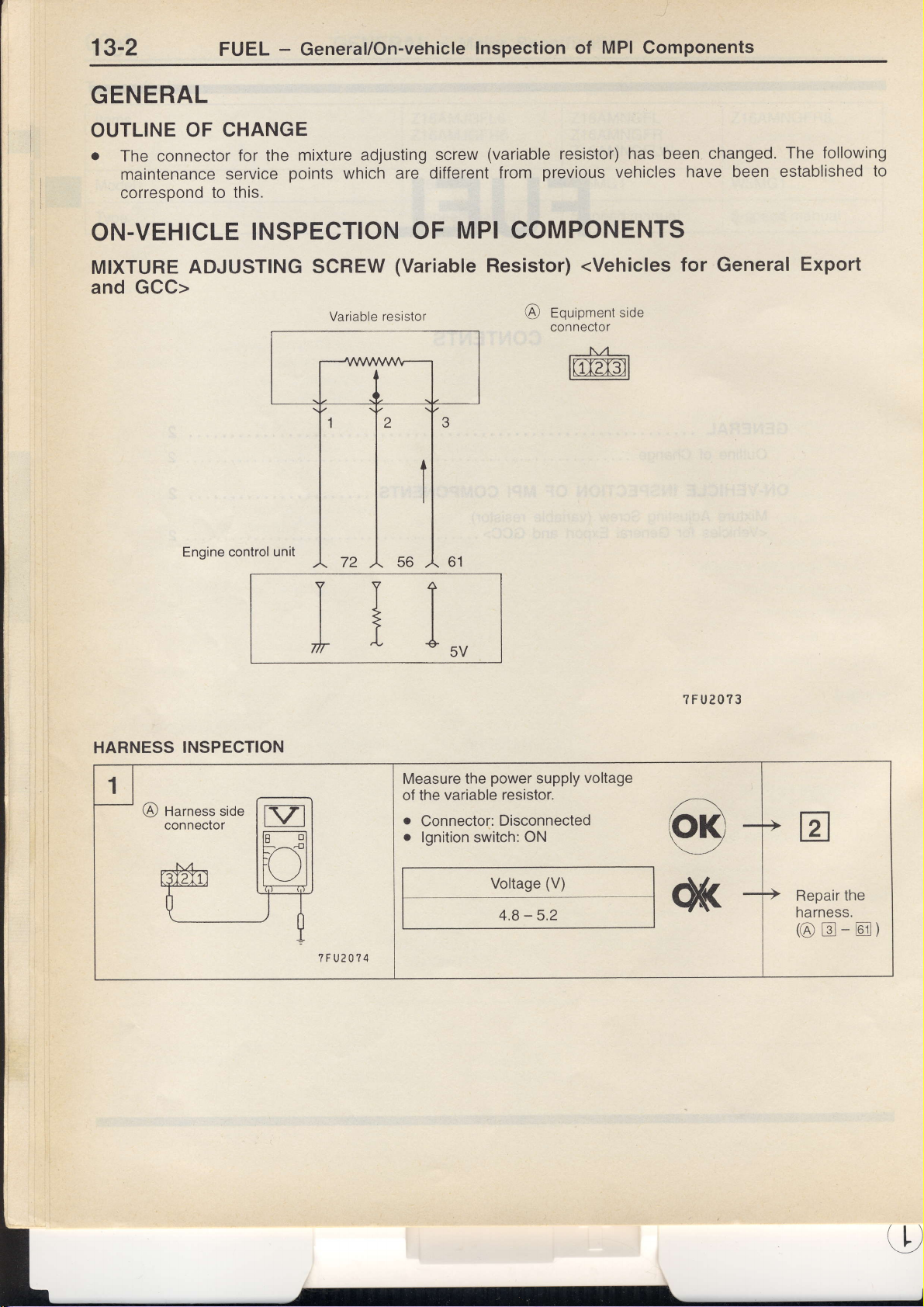

13-2 FUEL

GENERAL

CHANGE

OUTLINE

.

The connector

maintenance

correspond

ON-VEHICLE

OF

for the

service

to this.

INSPECTION

-

General/On-vehicle

mixture

points

adjusting screw

which are different

OF

MPI

Inspection

(variable resistor) has been

from

of

prevtous

Components

vehicles

have been

MPI COMPONENTS

changed.

established

The

following

to

MIXTURE

and Gcc>

ADJUSTING

Engine control

SCREW

Variable

resrstor

TTI

t*l

+

L

(Variable

Resistor)

tuu

<Vehicles

Equipment side

@

connector

ltir2ml

for

General

?FU2O?3

Export

HARNESS

INSPECTION

Measure the

of the variable

o

Connector:

o

lgnition switch:

power

Disconnected

Voltage

4.8 - 5.2

supply

resistor.

ON

(V)

voltage

@

OK

Repair

harness.

the

@tr-m)

o

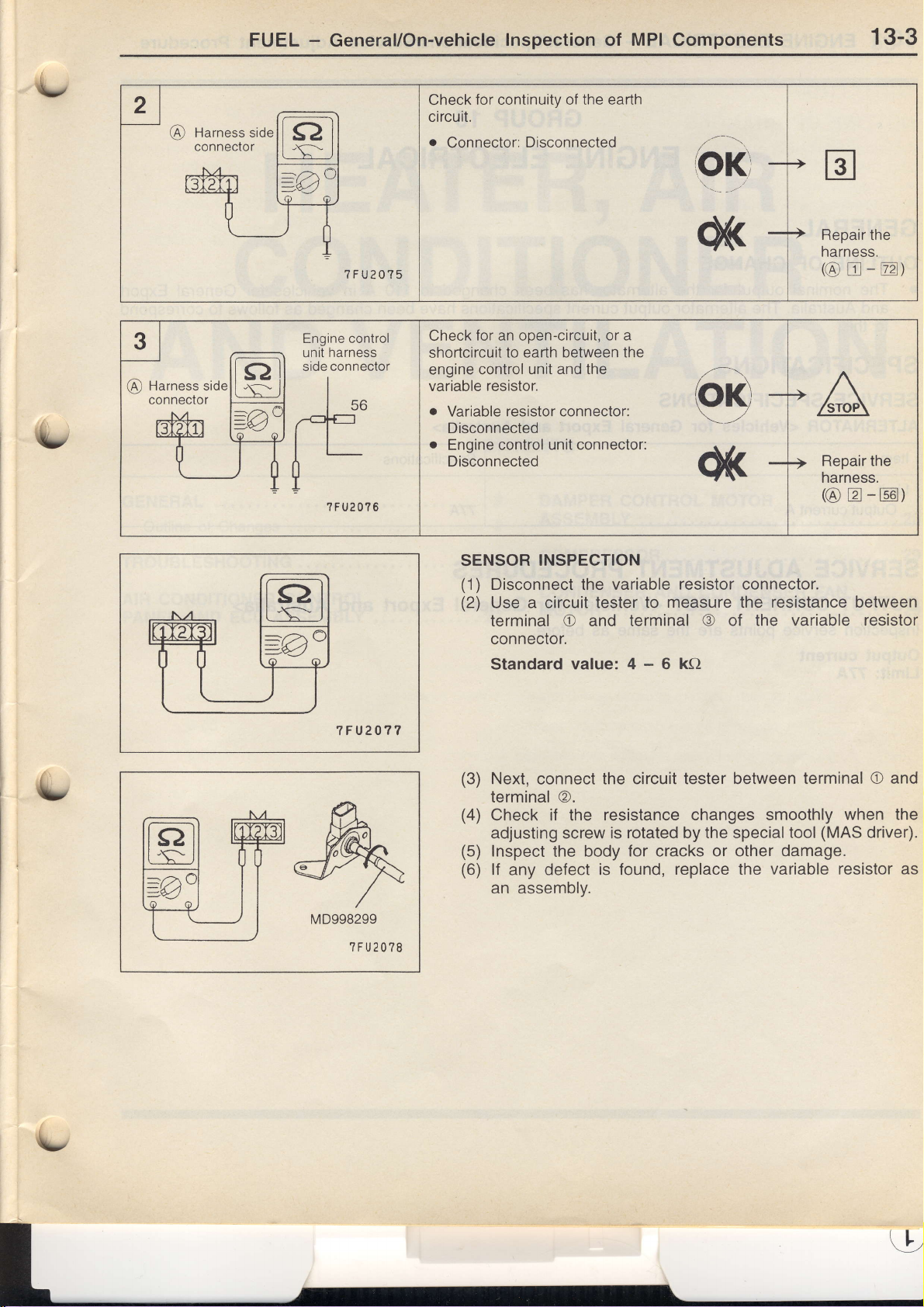

Page 10

FUEL

-

General/On-vehicle

Inspection

of

MPI

Components

13-3

[sz-l

L-f-_J

t-o]

I

t"\-

?FU2O?5

Engine control

harness

unrt

side connector

?FU2O?6

Check

circuit.

o

Check for an open-circuit,

shortcircuit

engine control unit

variable resistor.

for continuity of the earth

Connector:

o

Variable resistor connector:

Disconnected

o

Engine control

Disconnected

Disconnected

to earth between the

and

the

unit connector:

or a

Repair

narness.

the

@tr-E)

Repair the

harness.

-@)

(@

tr

t-CI-t

LJRJ

7 F U2077

fr

|vl

p.b.

W@L

@--f ,/

-:Jr

MD998299

r'a\

,/ \r

?FU2O?8

SENSOR

(1)

Disconnect

(2)

Use

terminal O and terminal

connector.

Standardvalue:4-6kO

(3)

Next, connect the circuit tester between

terminal @.

(4)

Check if the

adjusting screw

(5)

lnspect

(6)

lf

an

INSPECTION

variable

the

a circuit tester to

resistance changes smoothly

is rotated by the special tool

the body

defect

any

assembly.

is

resistor

measure the resistance between

@ of the

for cracks or other damage.

found,

replace the

connector.

variable resistor

terminal O and

when the

(MAS

variable resistor as

driveQ.

Page 11

16-1

ENGINE

ELECTRICAL

-

General/Specifications/Service

Adiustment

Procedure

GENERAL

CHANGE

OUTLINE

o

The

and

to this.

OF

nominal output

Australia.

The alternator

for the

SPECIFICATIONS

SERVICE

ALTERNATOR

Item

Limit

Output

SPECIFICATIONS

<Vehicles

current

A

for General

GROUP

ENGINE

allernator

output

current

Export and

ELECTRICAL

has been

specifications

16

changed

have been changed

Australia>

Specifications

774

110 A in

to

vehicles

follows to correspond

as

for General

Export

SERVICE

OUTPUT

Inspection

Output

Limit: 77A

current

ADJUSTMENT

CURRENT

service

points

TEST

the same

are

PROCEDURES

<Vehicles

for General

as before'

Export

Australia>

and

(L)

Page 12

55-1

\/

HEATER,

CONDITIONER

AND

GENERAL

Outline of Changes

TROUBLESHOOTING

AIR

CONDITIONER

PANEL AND ECU ASSEMBLY

CONTROL

VENTILATION

CONTENTS

.........2

. . .. . . .. 2

.....

.......27

DAMPER CONTROL

ASSEMBLY

COMPRESSOR

2

CONDENSER

MOTOR

AIR

MOTOR

.

AND CONDENSER

.......28

...29

FAN

..... 29

\,

Page 13

55-2 HEATER.

AIR CONDITTONER

GENERAL

CHANGES

OUTLINE

An air conditioning

the ECU

and

o

Troubleshooting

o

Removal

o

Removal

o

Inspection

o

Inspection

o

Inspection

OF

control

hal been

installation

and

installation

and

service

service

service

panel

adopted.

service

service

points

points

points

for operation

for

for

and

The

the

the condenser

TROUBLESHOOTING

AND

VENTILATION

ECU assembly

following

points

points

revolution

items

the air

for

for the

of

damper

the thermostat

pickup

fan motor

which

integrates the

been

have

conditioning

control

and

sensor

-

General/Troubleshooting

air conditioning

changed

control

to correspond

panel

motor assembly

compressor's

the

ECU

and

magnetic

control

to this.

assembly

clutch

panel

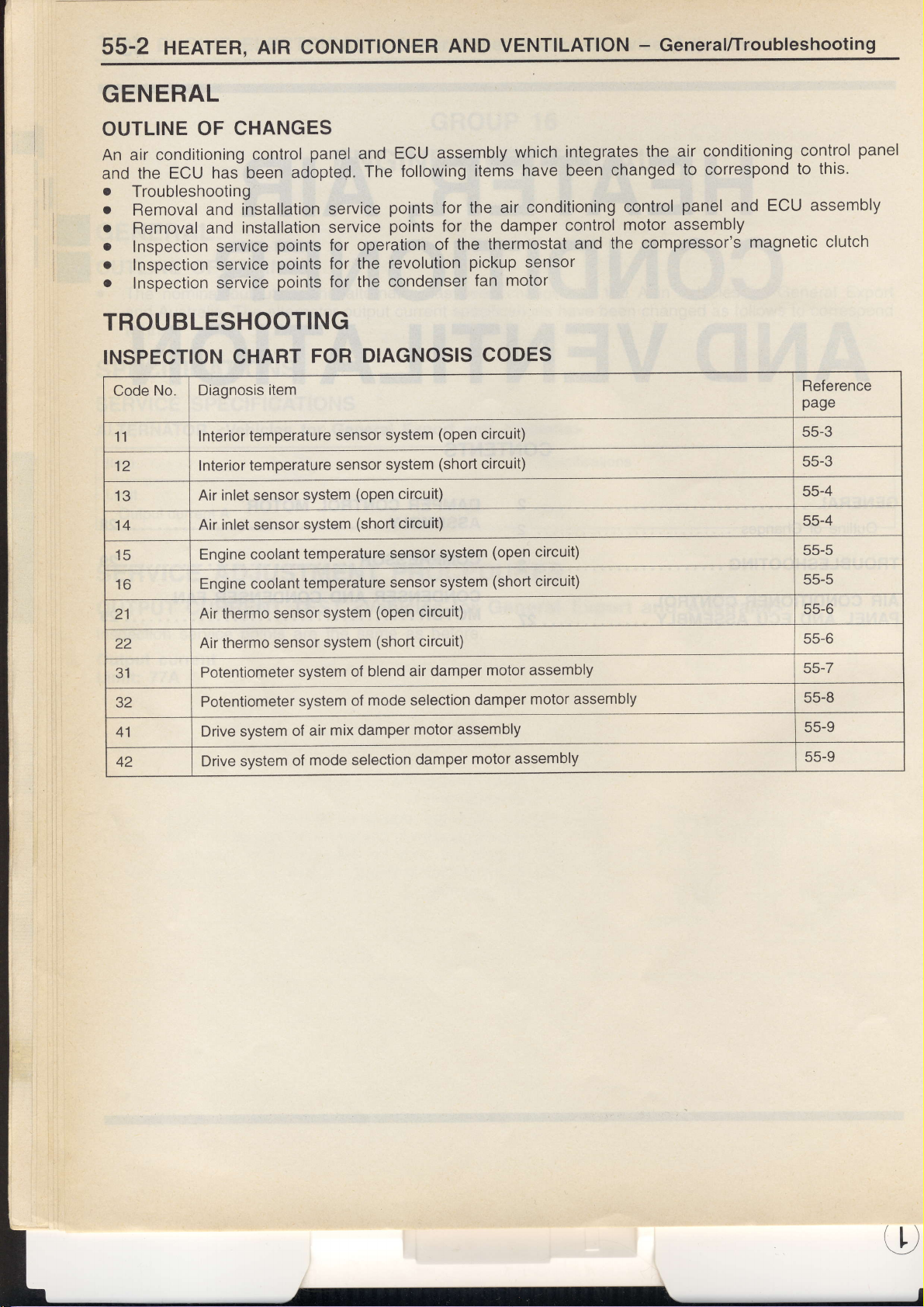

INSPECTION

No. Diagnosis

Code

11

12

13

14

15

16

21

22

31

32

41

42

CHART

lnterior temperature

Interior temperature

inlet sensor

Air

inlet sensor

Air

Engine coolant

Engine

Air thermo

Air thermo

Potentiometer

Potentiometer

Drive system

Drive system

item

coolant

sensor

sensor

system

system

of air

of

FOR

system

system

temperature

temperature

mode selection

DIAGNOSIS

sensor

sensor

system

system

mix damper

system

system

(open

(short

(open

(shott

blend air

ol

mode

of

circuit)

circuit)

sensor

sensor

CODES

(open

circuit)

(short circuit)

system

system

circuit)

circuit)

damper

selection

motor assembly

damper

(open

(short

motor

damper

motor

circuit)

circuit)

assembly

motor assembly

assembly

Reference

page

55-3

55-3

55-4

55-4

55-5

55-5

55-6

55-6

55-7

55-8

55-9

55-9

U

Page 14

HEATER,

INSPECTION PROCEDURES

AIR

CONDITIONER

FOR

AND

VENTILATION - Troubleshooting

DIAGNOSIS CODES

55-3

Code

ff ir

Measure at

o

.

Measure at the A/C-ECU connector

o

.

No.11

Oirg

Disconnect the connecl

harness

Voltage between terminal

OK: 5V

Connect the connector.

Voltage between

OK:

lhe

side connector

2.3 - 2.9V

12 lnterior temperature

or

lor<

V rrn

interior lemperature

the connector, and

(2)

terminal

(15)

and body earth

and

sensor connector

measure at the

C-97

body earth

sensor

F-01

system

Probable cause

i

.

Malfunction of

r

Malfunction ol harness

r

Malfunction of interior lemperalure sensor

.

Malfunction of the

Replace

the harness between the

Check

A/C-ECU.

the

Check the

F-01 , F-32

F-01 , F-32,

following connectors:

C-62

<L.H.

drive

<R.H.

drive vehicles>

connector

A/C-ECU

OK

V

iNG

V

interior

lo^

I

vehicles>

Repair

temperalure

Renair

iNo

I

sensor and

l*o

t-

Check the

the A/C-ECU, and if necessary.

Replace the

I

harness between

A/C-ECU.

the

interior temperature sensor and

I

i

Page 15

55-4 HEATER.

AtR

CONDTTTONER

AND

VENTILATION

-

Troubleshooting

No.13

Code

This diagnosis

is an oDen

there

Measure

.

.

Measure

.

.

at the

Disconnect

side conneclor.

between

Voltage

OK:5V

at the

Connect

Voltage

OK:

the connector.

between

-

2.3

inlet sensor

Air

is output

code

circuit

air lemperature

outside

connector,

the

terminal

A,/C-ECU

terminal

2.9 V

system

is a defective

if

there

harness.

in the

OK

V rrn

sensor

measure at

and

(2)

body

and

(7)

C-97.

and

body earth

connector

(open circuit)

connector

harness

the

earth

connector

C-19.

connection,

++

if

or

Replace

Check the

Check

Check

Probable

.

Malfunction

.

Malfunction

.

Malfunction

o

Malfunction

harness

following connectors:

the

the trouble

cause

of

oI harness

of the air

of the

between

symptom.

connector

inlet sensor

A/C-ECU

OK

l

V

inlet sensor

the air

C-05

and the

A/C-ECU

No.l4

Code

This diagnosis

input circuit.

Measure at

.

Connect

.

Voltage between

OK: 2.3

Reolace the

the

the

-

A/C-ECU

inlet

Air

is

code

A/C-ECU

connector.

terminal

V

2.9

sensor

if there

output

connector

(7)

and

system

is a short

C-97.

body

earth

(short

circuit

circuit)

in the air

inlet sensor

Check the

and

Reolace the

harness

repair

Probable

r

.

.

.

the

Check

repair

and

between

i{ necessary.

A,rC-ECU.

cause

Malfunction

Malfunction

Mal{unction

Malfunction

between the

harness

necessary.

if

the air inlet

harness

of

of connector

of the

of the

inlet sensor

air

A'IC-ECU

air inlet sensor and

sensor

and the

the

A/C-ECU'

A/C-ECU'

('

Page 16

HEATER,

AIR CONDITIONER

AND

VENTILATION

-

Troubleshooting

55-5

Gode

(open

This diagnosis

there

Engine

M""*,*"rrh"";gin".ootffiillG-

.

.

t

Measure at the

o

.

No.15

circuit)

is an open

coolant temperature

Disconnecl

connector

side

Voltage between

5V

OK:

Connect

Voltage

2.3

OK:

Engine

code

circuil

the connector.

terminal

fuC-ECU connector

connector.

the

-

terminal

2.9 V

between

coolant

is output

in the

sensor

(1)

(14)

if there

harness.

check

measure at

and

and body

T;,-

and

temperature

is a defective

the

eanh

-*

C-97.

earth

body

connector

harness

sensor

connection,

]

| -r

system

or il

-[cr*"r,t"

-

Check the trouble

Check

Probable

.

Malfunction

.

Malfunction of

o

Malfunction of

sensor

.

Malfunction

t"lr"*lgl""":1?r'

following connector:

the

cause

of connector

of the

-- -Ioi---

-

symptom.

harness

the engine

A/C-ECU

"-tt

;

C-35

coolant

-----

temperature

-

I

Repair

---

i

r

the following

Check

Code

(short

This diagnosis

lemperature sensor

Reolace the

No.l6

circuit)

code is output

tuC-ECU.

connector:

C-97

Engine coolant

is a short

input circuit.

if there

toK

I

temperature

in the engine

circuit

Reolace the

sensor system

coolant

Check

and the

A/C-ECU.

Probable

.

Malfunction

.

Malfunction

.

Malfunction

sensor

.

Malfunction

the harness

A/C-ECU,

cause

harness

of

connector

of

of the engine

of the

between

and repair

the

coolant

A/C-ECU

water temperature

heater

if necessary.

temperature

sensor

Page 17

5s-6

HEATER,

AIR

CONDITIONER

AND

VENTILATION

-

Troubleshooting

Code

This diagnosis

there

Air thermo

Measure

.

.

Measure

.

.

No.21

-un

is

sensor

at the

Disconnect

side connector.

Voltage

OK:5V

at the

Connecl

Voltage

2.3

OK:

belween

Air thermo

is

code

circuit

op"n

check

air thermo

conneclor,

the

terminal

fuC-ECU

conneclor.

the

between

-

terminal

2.9 V

output

in

the

t

sensor

and

(2)

connector

(8)

sensor

is a defective

if there

harness.

lox

connector

measure

and body

C-97.

and body

system

C-34.

harness

at the

earth

earth

(open circuit)

connector

connection,

'NG

-f+

or if

| : Y"llr"9li9l

I

Replace

Check

Replace

Check

Probable

.

Malfunction

o

Malfunction

r

Malfunction

the following

A/C-ECU.

the

following

the

cause

of connector

harness,

ol

air thermo

of the

A/C-ECU

of the

connector:

V

connector:

14

sensor

C-97

t{

C-34

the following

Check

Code

This diagnosis

Air thermo

No.22

inout circuit.

sensor

connector:

Air thermo

is output

code

check

C-97

sensor

if

there

system

short circuit

is a

(short circuit)

in the air

lhermo sensor

Probable

o

o

.

.

Checkthe

repair

and

cause

Malfunction

Malfunction

Malfunction

Malfunction

harness between

necessary.

i{

of harness

connector

of

of the

of the

the

air thermo

fuC-ECU

airthermo

sensorand

sensor

A/C-ECU,

the

Page 18

HEATER, AIR CONDITIONER

AND VENTILATION

-

Troubleshooting

55'7

Code

No.31 Potentiometer

motor assembly

This diagnosis code is output

potentiometer

earth circuit.

input circuit, or

if

there

if

there

is

tr,"19-1g;mft6;ad

lor

I rrn

Measure at the blend air damper

.

Disconnecl the connector. and measure at the

sroe conneclor.

.

Voltage belween terminal

OK:5V

Measure

.

Connect the conneclor.

o

Blend air damper

.

Voltage

OK: 4.7 - 5.0 V

A/C-ECU connector C-97.

at the

between terminal

position:

potentiometer

(4)

body earth

and

MAX.HOT

(5)

and body earlh

system of blend air

is an open or short

an open

circuit in the

connector C-14.

harness

circuit in the

power

damper

circuit or

Probable cause

r

Malfunction of the blend air damper motor

assembly

o

Malfunction of conneclor

o

Malfunction of harness

o

Malfunction

of the

Reprace

Check the following connector: C-97

.ry!!'.

t th"9!lh"

Check the

and the

t'"fqE

harness between the blend air damper

A/C-ECU.

A/C-ECU

OK

I

Y

NG

Repair

polentiometer

NG

Page 19

55-8

HEATER,

AIR

coNDlTloNER

AND

VENTILATION

-

Troubteshooting

Code

No.32 Potentiometer

damper

This

diagnosis

potentiometer

earth circuit.

1.. ,

Mode

selection

I

.

Voltage

OK:5V

Measure

.

r

.

at the A/C-ECU

Connect

Mode selection

Voltage

OK: 4.8 - 5.2 V

motor assembly

code is

input

circuit, or

damper

if

outpul

if

potentiometer

v ^,^

between

the connector.

between

terminal

damper

terminal

(4)

connector C-97.

position:

(6)

system of

there is an

there is

OK

and body earth

and

an open circuit in

check

DEF

body earth

open or short

mode

circuit in the

the

selection

power

,NG

--+

l

Probable

.

circuit or

.

.

.

Replace

Check the following

Check the following

cause

Malfunction

assembly

Malfunction

Malfunction

Malfunction

of the mode

of connector

of the A/C-ECU

of

connector:

connector:

harness

selection damper

C-97

C-15

motor

-l*

Checkthe harness

ler and

the A/C-ECU,

nepair

belweenthe

and

repair

mode

selection damDerpolentiome-

if necessary.

I

Page 20

HEATER,

AIR

CONDITIONER

AND VENTILATION

-

Troubleshooting

55-9

Code No.41

assembly

This diagnosis code

.

'

j

the lollowing

Check

C-14, C-98

the trouble symptom

Check

Code No.42

assembly

This diaonosis code

Drive system

is output

connectors:

i{

the

10K

v ^,^

Drive system

is output if the

of blend

motor drive circuit

of mode

motor drive

selection

circuit

air damper

is defective.

damper motor

is

defective.

motor

Probable cause

o

Malfunction of the blend air damper

assembly

o

Malfunction of connector

.

Malfunction

r

Malfunction of the

harness

oJ

A/C-ECU

Probable cause

o

Malfunction of the

assembly

o

Malfunction of connector

o

Malfunction of

r

Malfunction of the

mode

harness

A/C-ECU

selection

motor

damDer

motor

Check the following

c-t5, c-98

lox

V n,^

connectors:

Reptace

the harness belween the

Check

motor and the

F"pl"*

rh" A/C+CU

A/C-ECU.

mode selection damper

$t

Page 21

55.10

HEATER, AIR

CONDITIONER AND VENTILATION

-

Troubleshooting

INSPECTION

Trouble

Communication

Air conditioner

A/C

Temoerature

A/C

A/C

Blower

Blower

Air

Inside/outside

Defroster function

Radiator

symptom

graphic

outlet air temoerature

outlet

air temperature does not decrease. o

does not ooerale.

air amount cannot be chanqed.

port

outlet

fan

CHART

with the MUT-ll is not

does not

display on control

cannot be set. +

cannot be changed.

air selection

does not

does not operate. 12

FOR

operate.

does

is

not oossible. 10

operate. 11

TROUBLE

oossible.

panel

is blank. J

not increase

SYMPTOMS

Inspection

dure No.

I

I

z

5

8

proce-

Reference

55-1 1

55-1 2

55-13

55-13

55-1 3

55-1 3

55-1 4

55-1 5

55-1 5

55-1 6

55-17

55-1 8

page

Condenser

A/C-ECU

A/C

compressor control

fan does not operate. 13

power

supply

circuit

circuit

check

check 15

14

55-20

55-22

55-23

Page 22

HEATER,

AIR

CONDITIONER

AND VENTILATION

-

Troubteshooting

55-11

,lt

INSPECTION

Inspection

PROCEDURE

procedure

Communication

lf communication

that there

is not

A,/C

A/c-Ecu

of the

ls

communication

other system

@

c-70.

.

Voltage between terminal

and body earth

OK: lndication

-lNG

Measure at the

c-97.

.

.

tween 0 V and

Connect the

Voltage between

and body earth

Indication fluctuates be-

OK:

tween 0

with all other systems

is a malfunction

possible,

the

power

between

possible?

is

YES

I

I

fluctuates be-

A,/C-ECU connector

connector.

terminal

V and 12 V.

OK

with the

of the diagnosis

cause is

supply

MUT-ll and

12 V.

MUT-ll is not

probably

system

(11)

(17)

1

(eadh).

OK

NG

FOR

TROUBLE SYMPTOMS

possible

possible,

is not

lf

line.

communication

malfunction of the diagnosis

a

Measure at the

c-97.

,

.

.

Check

is a high

there

MUT-Il diagnosis line, and

the

if necessary.

Disconnect the

measure at the harness side

conneclor.

Voltage between

and body earth

OK: Battery

the trouble symptom.

Probable cause

possibilitr

with

only the

line

A/C-ECU connector

connector, and

terminal

voltage - 2

NG

o

r

or

(18)

V

Malfunction of connector or

Malfunction of

A/C-ECU

Cfre"f. tfre

tof lo;i''tg

c-70

OK

E!""!q!.gqg

Check the

sis connector and the

repair if

harness between the diagno-

necessary.

harness

Repair

sylqqt

ING

Y

"o"*"1..

]NG

V

A/C-ECU, and

i

Checkthe

sis connector

Check

c-70, c-97

Check the trouble symptom

Measure at the

c-98.

.

.

Measure at the

c-98.

r

o

harness between

and the

the following connectors:

Disconnect

measure

conneclor.

Voltage between

and body earth

OK:

Disconnect

measure at the

conneclor.

Continuity

(27), (35)

OK: Continuity

at the

Battery

and body

A/C-ECU.

NG

OK

NG

A/C-ECU connector

the connector,

harness side

terminal

voltage

A/C-ECU

the connector,

harness side

between

terminales

earth

the diagno-

and

(28)

connector

and

NG

NG

NG

the trouble

Check

Check the

symptom.

trouble symptom

Checkthe

block

necessary.

Check the

A,/C-ECU

if necessary.

harness

and the

and

between the

A/C-ECU,

harness

the

body earth, and

junction

and repair

between the

repair

if

Page 23

55-12

HEATER, AIR

CONDITIONER

AND VENTILATION - TTOUbICShOOtiNg

Inspection

Air

conditioner

lf

tf*

setting

ol the

procedure

2

does not operate.

is at 17'C, the cause is

blower or of the magnet clutch

probably

insufficient re{rigerant, or a

power

supply.

lo^

Is

any of the

I

o

Magnetic

.

Magnetic clutch relay check

o

Dual

Measure at the magnetic clutch relay connector A-46X.

.

Disconnect the conneclor, and measure at the

side conneclor.

(1)

Continuity between terminal

OK: Continuity

(2)

Voltage between terminal

OK: Battery voltage

r

A-46X, A-50. B-18

codes'11,21

clutch check

pressure

switch check

22 output?

and

(5)

and body earth

(4)

and body earth

t'tc

{ttl

harness

".,

I

|

Probable cause

r

Mallunction of blower

Replace

nepair

o

Insufficient

.

Mallunction of magnetic

o

Malfunction

o

Malfunction

o

Malfunction

.

Malfunction

o

Malfunction

.

Malfunction

r

Malfunction

refrigerant

of air

magnetic

of

refrigerant

of

of dual oressure switch

of connector or harness

of engine-ECU

of A/C-ECU

clutch

thermo sensor

clutch relay

temperature

switch

NG

malfunction

[lsercrror.rcHARTFoRD|AGNoS|ScoDES(RefertoP.55.2.)l

Check the

relay,

clutch

harness

belween the

and repair if

ttc

I

V

maonetic clutch

necessiry.

and the

maonetic

Check the harness

relay,

repair if necessary.

and

between the

ING

V

fusible link

and the magnetic clutch

Page 24

HEATER,

AIR

CONDITIONER

AND VENTILATION

-

Troubleshooting

55-13

Inspection

graphic

A/C

The cause

(earth).

Does

the A/C operate?

Inspection

procedure

probably

is

procedure

Temperature

The

cause is

system

Inspection

Inspection

A/C

lf the

increased,

operation

diagnosis

sysrem.

probably

or output

procedure

procedure

outlet air

outlet air temperature

the

cause is

of the

codes in order

3

display

cannot

system.

temperature

blend air damper. The

on

a malfunction

4

be set.

malfunction

a

'14

(Refer

to

5

does not

probably

to check the

control

of the A/C-ECU

of lhe temperature setting

P.55-22.)

does not increase.

a sensor malfunction

panel

increase when

MUT-ll

cause of the

can be used to check

is

blank.

power

supply

signal input

the temperature

problem

or a

problem

for each

system

setting is

with

the

separate

Probable

a

a

lnspection

Probable

.

.

Probable

.

.

.

o

.

.

cause

Malfunction

Malfunction

procedure

14

cause

Malfunction

Malfunction

cause

Malfunction

Malfunction

Malfunction

Malfunction

Malfunction

Malfunction

of connector

of A/C-ECU

(Refer

lo P.55-22.1

of connector

A/C-ECU

of

of

blend air damper

of

blend air damper

of blend

of

connector

interior

of

of A/C-ECU

or harness

air damper

or

temperature sensor

or harness

potentiometer

motor

harness

MUT.II

DIAGNOSIS

ls

any of

the codes 11, 12,

Inspection

A/C

outlet

lf

the

outlet air temperature

decreased,

sensor error, or

can be used

problem

MUT-II DIAGNOSIS

ls

any ol the

Replace

procedure

aar temperature

the

cause is

a

to check

for

each separate

codes 11, 12,13,

A/C-ECU.

the

CODE

probably

problem

the diagnosis

CODE

31 and 41

6

does not

a

with

operation

svstem.

14,21,22,31

output?

does

not decrease.

decrease when

problem

codes in

in A,/C system

of the blend

order to check

and 41

the temperature

operation

air damper. The

the cause

output?

INSPECTIONCHART

Probable

setting is

due to a

MUT-ll

of the

.

o

o

.

.

o

INSPECTION

P.55-2.)

FOR

cause

Malfunction

Malfunction

Malfunction

Malfunction

Malfunction

Malfunction

CHART FOR

DIAGNOSIS

of blend

of blend

of air

of connector

oI blend

of A/C-ECU

air damper

air damDer motor

thermo sensor

air damper

DIAGNOSIS

CODES

potentiometer

or harness

CODES

(Referto

(Refer

P.55-2.)

ro

Page 25

55.14

HEATER, AIR

CONDITIONER

AND VENTILATION - Troubleshooting

lnspection

Blower

lf no air comes out of the blower even though

cause is

a

Blower

a

Blower

Measure

.

Disconnect

side connector.

(1)

Continuity

OK: Continuity

(2)

Voltage

swilch: ON)

OK: Battery voltage

(3)

Voltage

OK: Battery voltage

Measure

.

Disconnect

side connector.

.

Voltage

switch: ON)

OK: Battery voltage

procedure

7

does not operate.

probably

motor

motor check

at the blower

at the blower

a malfunction of the blower motor relay circuit.

YES

V

relay

check

OK

I

the connector, and measure at

between terminal

between terminal

between terminal

the connector,

between lerminal

molor relay

(2)

(4)

(1)

motor

connector C-31.

and measure

(1)

and body earth

connector C-71.

and body earth

and body earth

and body earth

at the harness

the blower switch

harness

the

(lgnition

(lgnition

is

on, the

Probable

I

r

Malfunction of blower motor relay

I

o

Malfunction

]

I .

Malfunction

I

.

Malfunction

Inspection

*

Replace

Check the

earth, and

Check the

switch, and repair if necessary.

Check the harness between the blower motor relay

link No.6,

procedure

harness

repair

harness

and

cause

of blower motor

of connector or harness

A/C-ECtJ

oi

(Refer

14

between

if necessary.

between the blower motor relay and the ignition

repair if necessary.

P.55-22.)

to

blower motor relay and the

the

and the

body

fusible

Check the harness between

repair if necessary.

and

the blower

molor and

A/C-ECU.

the

t'

Page 26

HEATER,

AIR CONDITIONER

AND

VENTILATION

-

Troubleshooting

55-15

Inspection

procedure

Blower air amount

lf

blower does

the

probably

Measure at the

.

r

(1)

(2)

(3)

Measure at the

o

.

(1)

(2)

a

Blower switch

Connect

Continuity

Continuity

OK:

Voltage between terminal

ON)

switch:

Baltery

OK:

Voltage between

ON)

switch:

Approx.

OK:

switch

Blower

Connect

Voltage between

ON)

switch:

Approx.

OK:

Voltage belween

ON)

switch:

Approx. 1.3 V

OK:

not operate

malfunction of

power

transistor

posttion:

the conneclor.

between terminal

voltage - 2

terminal

1.3 V

A/C-ECU connector

position:

connector.

the

terminal

7 V

terminal

I

cannot

in any

power

the

connector C-18.

LO

(1)

and

(2)

and body

V

(4)

and body

(3)

LO

(1)

and body

(2)

and body

lo*

changed.

be

mode other than

transistor

NG

C-97.

system.

body earth

eanh

earth

earth

earth

(lgnition

(lgnition

(lgnition

(lgnition

Hl setting,

(2)

the cause

is

c-18

I

lch-""kthe trouble

n"pr"il in"

I

Check the

earth, and

NG

Check

motor, and

Check the

Replar

[-n"pU""

I

RePair

symptom

p"*"r

tri"iitt".

I"C+CU

cause

power

of

A/C-ECU

necessary.

Probable

.

Malfunction

o

Malfunction of connector

o

Malfunction of

harness between

repair if necessary.

the harness between

repair if

trouble svmptom.

tf,r"

the

the

ING

lNG

Y

transistor

or

oK

power

transistor and

power

transislor

harness

ilo

I

Repair

-

the body

and the blower

NG

I

lnspection

Air outlet

The cause

input system

codes

MUT-II DIAGNOSIS

ls either

Reolace the

procedure

port

probably

is

or output system.

in order to

code 32 or

A/C-ECU.

9

cannot

malfunclion

a

check the

CODE

code 42 output?

cause of

l*o

V

be changed.

of the air outlet

the

can

problem

The MUT-ll

OK

be

for

port

used to

each

changeover

check the diagnosis

separale

signal

system.

ra-===*

Probable

o

Malfunction

ootentiometer

.

Malfunction

.

Malfunction

o

Malfunction of connector

.

Malfunction of

INSPECTION CHART

n"P'i'

cause

mode selection damper

of

harness

or

damper

damper

ol mode selection

of mode selection

A/C-ECU

FOR DIAGNOSIS CODES

motor

(Referto

P.55-2.)

Page 27

55.16

HEATER,

AIR

coNDITIoNER

AND

VENTILATIoN

-

Troubleshooting

Inspection

procedure

lnside/outside

lf

inside/outside

changeover

'

Air

selection

o

Disconnecl

srde

o

Outside

.

.

Inside

.

switch is

damper

at the

connector.

air

YgLtage

OK:

10 V

air

select

YgLtage

OK: 10

air

the

select

between

between

V

air

selection

air

seleclion

on, lhe

motor

selection

connector,

button:

terminat

button:

terminal (2)

10

is

not

cause

V

check

lox

V

damper

and

ON

(1)

ON

is not

possible

probabry

is

motor

measure

and

body

and

body

possible.

even

when

a marfunction

.

connector

at the

harness

earth

earth

the

C-20

inside/outside

of the

NIN

NG

tl:_

air

serection

air

I

Replace

Check

Check

the A/C-ECU,

a

Malfunction

a

Malfunction

a

Malfunction

a

Malfunction

lnspection procedure

Check

the

foltowing

the

trouble

symptom.

the harness

between

and repair

of air

selection

of

air selection

of

connector

of A/C-ECU

14 (Refer

connector:

the air

if

necessarv.

damper

motor

damoer

or narness

p.5S-22.)

to

_____t

lruc

I

Repair

selection

damper

motor

I

and

Check

.v^r^

selection

lAir

Replace

I

the

trouble

damoer

the A/C-ECU.

symptom.

check

lrue

Y

_|.I>

Replace

the A/C-ECU

Repair

I

['

Page 28

HEATER, AIR

CONDTTIONER

AND VENTILATION - Troubleshooting

55'17

Inspection

procedure

Defroster function does

lf the defroster function does

the cause

changeover circuit.

lc1ni"

uoes tne

Can the air outlet

@

probably

is

op"*ting sound be

A'ru

o'eralet

malfunction of the A/C

a

port

be changed

heard when

11

not

operate

{ves

ir=,

loo

not

operate.

the

over?

when

the defroster switch

oi the air outlet

or

defroster switch is

--

t--

*o

No

li--]

is

turned on,

port

-l

Probable cause

I

e

I

o

I

i

o

o

Inspecrion

Inspection

Inspection

nep"it

Malfunction

Malfunction

system

Maliunction

Malfunction

procedure

procedure

procedure

14

2

9

of air conditioner drive svstem

of mode selection damper

of conneclor or harness

A/C-ECL

of

(Refer

lo P.55-22.)

(Reter

(Refer

P.55-12.)

to

P55-15.)

to

drive

I

iO/

Page 29

55.18

HEATER,

AIR

CONDITIONER AND

VENTILATION

-

Troubleshooting

Inspection

Radiator

lf the radiator

the cause is

such a case,

r^.

Radiator

i

Radiator

Measure

.

Disconnect

connector.

(1)

Continuity

(40)

OK: Continuity

(2)

Voltage

OK: Battery

(3)

Continuity

OK: Continuity

fan motor

fan motor

fan motor

at the

between terminal

between

procedure

12

does not

fan

does not

probably

the cooling

check

relay

radjator

lhe connector, and measure

terminal

voltage

between

operate even though

malfunction

a

performance

(LO.

fan motor relay

terminal

of

the

will

OK

t

Hl) check

lox

t ,., ^,^

(3)

and C-44 conneclor

(1)

and body

(5)

and 4-66

operate.

the air conditioner is

radiator

drop when the vehicle

(LO)

at the harness

earth

fan motor

A-04X

terminal

side

terminal

(4)

operating circuit.

F-+

operating,

is not moving

NG

Ntn

Replace

Replace

Check the

A-04X,

A-04X, A-80,

Check

Check the harness

conlrol

Check

A-04X.

Probable

o

Malfunction

o

In

Malfunction

o

Malfunction

following

C-24, C-21 . C-44

C-44

the trouble symptom,

unit, and repair if

the following

C-66. C-78

cause

of radiator fan

radiator

of

of connector or harness

connectors:

<L.H.

<R.H.

drive vehicles>

between

necessary.

connectors:

fan motor

drive vehicles>

the radiator fan

molor

relay

motor

(LO,

Hl)

and enoine

Check the harness

ignition

switch,

and if necessary.

Check the harness

fusible

link

5. and repair if

Check the harness

radiator fan

motor,

between

between

belween the radiator fan

and repair if necessary.

radiator

the

V

the radiator fan

necessary.

I

fan motor

ttc

relay

motor relav

motor relay

(LO)

(LO)

(LO)

and

and

and

t'

Page 30

Measure

.

Disconnect

connector.

(1)

Continuity

(3e)

OK:

(2)

Voltage

OK:

(3)

Continuity

HEATER,

radiator

at the

Continuity

Battery

connector,

the

belween

between

voltage

between

terminal

AtR CONDTTTONER

(Hl) A-O7X

relay

motor

fan

and

terminal

(.1

terminal

measure

(3)

and

and

)

(5)

and

C-44

body

4-66 terminal

harness

the

at

connector

earth

side

termlnal

(4)

AND

VENTILATION

trorot"

t*

[Cn""t<

'-

unit, and

control

I

I

-

,ym[tot*

repair

Troubleshooting

55-19

I

--]

V

if necessary.

Measure

o

Disconnect

Voltage

at the

the

between

radiator

connector,

terminal

fan

(2)

motor

and

and

Repair

4-66

measure

earth

body

at the

harness

side'

@

n-ozx, c-66,

I

L__--

harness

the

Check

switch,

ignition

Check the

fusible

Check

Check

radiator

harness

link 5, and

the

harness

the

fan motor,

-

c-78

between

repair

and

between

repair

following

between

and

radiator

the

if necessary.

radiator

the

if necessary.

connector:

radiator

the

if necessary.

repair

fan

A-07X

motor

{an molor

fan motor

relay

relay

relay

I

(Hl)

(Hl)

(Hl)

I

and

and

and

(.'

Page 31

55-20

HEATER,

AtR

coNDtnoNER

AND vENTtLATtoN

-

Troubleshooting

Inspection

Condenser

lf

the condenser

operating,

operating

vehicle

Condenser

I

Condenser

I

Measure

.

(1)

(2)

(3)

the cause is

circuit. In

is nol

fan

fan motor

al the condenser

Disconnect

connector

Continuity

(34)

OK:

Continuity

Voltage

between

OK: Battery

Continuily

OK: Continuitv

procedure

fan

motor

fan

does not

probably

such

moving.

motor

the conneclor,

between

voltage

between

a case, the

check

relay-(LO,

terminal

terminal

terminal

13

does not

operate

a malfunction

(Refer

to P.55-29)

loK

v

Hl) check

loK

v ,., .,^

fan

motor relay

and measure

(3)

and C-98

(5)

and

(4)

and A-59

operate

even

though the

cooling

(LO)

at the harness

conneclor

body earth

terminal

of the condenser fan

performance

air conditioner is

will

]-+

A-47X

sroe

terminal

(2)

motor

drop when

f-::+

n.tc

Probable

.

.

the

Reptace

Check

and A/C-ECU,

Check

A-47X, A-50

.

.

Replace

the harness

the following

cause

Maliunction

Malfunction

Dedicated

Malfunction

and repair

of

of condenser

fuse

of connector

between

connectors:

condenser

No.

the

if necessarv.

fan motor

fan

5

blown

or harness

condenser

molor

relay

fan motor

(LO,

relay

Hl)

(LO)

Measure

.

Voltage

OK: Battery voltage

Continued on

at

Disconnect

the condenser

between

next

the

connector,

lerminal

page

Check the following

A-47X, A-59

fan motor

(2)

A-59

and measure

and body

iox

V

earth

at the

connectors:

harness

side

Check

the harness

and fusible

Check

the harness

condenser

Check the

Check

the harness

wtre.

between

link

5, and repair

between

fan motor,

following

between

the

if

the

and

repair if

connector:

Y

the

condenser fan

condenser

necessary.

condenser

necessary.

A-59

NG

fan motor

fan

motor

motor

(LO)

relay

(LO)

and

and. earth

('

Page 32

HEATER,

AIR

CONDITIONER

AND

VENTILATION - Troubleshooting 55-21

Measure

r

(1)

(2)

(3)

at the condenser fan motor relay

Disconnect

connector.

Continuity between terminal

(3e)

OK: Continuity

Voltage

OK:

Voltage

lhe connector,

between

Battery voltage

between terminal

ery

OK

terminal

voltage

measure

and

(3)

and C-44 connector terminal

(1)

and body earth

(5)

and body

Check the following

A-44X, A-50

(Hl)

at the

earth

NG

A-44X

harness

connectors:

side

[bh""k

I

tt* f"il.*i"g

A-44X, A-50,

LA:11I, Luq.4-rg.g1tl

Check

the trouble symptom

Check the harness

and Engine control

Check the following connectors:

A-44X. A-50.

Check

Check

and ignition switch,

Check

Check the harness

fusible link

and

C-66. C-78

the trouble symptom.

harness

the

trouble

the

*"*"t.rt

C-24,

C-21 , C-44

"

between the condenser fan motor

unit, and

between the condenser fan motor relay

and

symptom.

between the condenser fan motor relay

5, and repair if necessary.

repair

repair if necessary.

<L.H.

drive

y9!fLe_s'

tryn

oK

if necessary.

vehictes>

Repair

lxc

I

relav

NG

l

(Hl)

(Hl)

(Hl)

Measure at the condenser fan motor A-59

ture above 105'C)

.

Disconnect

Voltage

OK: Battery voltage

the connector,

between

terminal

measure

and

(1)

and body earth

(engine

at the

coolant tempera-

harness

side.

the

Check

Check the harness

wire.

lollowing

connector:

between the condenser fan motor

A-59

and. earth

Page 33

55.22

HEATER"

AIR

coNDITIoNER

AND VENTILATION

-

Troubleshooting

Inspection

A/C-ECU

Measure

.

Disconnect

side

.

Vollage

OK: Battery voltage

Measure

o

Disconnecl

side

.

Voltage

switch: ON)

OK: Battery

procedure

power

at the A/C-ECU

the

connector.

between

at the fuC-ECU

the

connector.

between terminal

supply

connector,

terminal

connector,

voltage

14

circuit check

connector

and measure

(3)

and

connector

and measure

(28)

and

C-97.

al the harness

body earth

C-98.

at the harness

body earth

(lgnition

Check the trouble

Check the following

c-79, C-78

symptom

foK

connectors:

l*o

Repair

(

Measure

.

.

.

at

Disconnect

side

connector.

Continuity

OK:

Continuity

Continuity

OK: Continuity

A"/C-ECU

the

the connector,

between

between

terminal

terminal

conneclor C-98.

and measure

and body

127)

(35)

and body

al

the harness

earth

earth

Check

repair

and

the harness

if necessary.

between

the A/C-ECU

and the bodv

earth.

|lxl

(I,

'd

Page 34

HEATER,

AIR CONDITIONER

AND

VENTILATION

-

Troubleshooting

55-23

Inspection

compressor

A/C

Measure at the

.

Blower switch

o

Setting

.

Connecl the

.

Voltage between

switch: ON)

OK:

Measure at the magnetic

.

Blower switch and

r

Disconnect the

side connector.

.

Voltage between

OK:

Measure at the

.

Disconnect the

side

<Vehicles with immobilizer system>

.

Voltage between

<Vehicles without immobilizer

.

Voltage between terminal

OK:

procedure

A/C-ECU connector

and

temperature:

conneclor.

terminal

voltage

Battery

connector, and

lerminal

voltage

Battery

engine-ECU

connector.

Battery voltage

connector,

terminal

A,/C switch:

A/C switch:

15

control

17'C

(34)

clutch

(3)

connector

and

(22)

system>

(8)

'f

circuit

C-98.

ON

and

relay connector

ON

measure

and

measure at the

and body

and body eanh

check

body earth

at the

body earth

C-43

earth

o^

(lgnilion

A-46X.

harness

harness

the following

Check

c-98

E:e".

Check the

A-50. C-O'l . C-98

Check

A-80.

Check

engine-EOU,

following connectors:

the lollowing

A-50. A-46X

the harness

and

connector:

connectors:

between

if necessary.

repair

Repair

the magnetic clutch

lruc

V

relay and

the

Page 35

55.24

HEATER,

AIR

coNDITIoNER

AND

VENTILATIoN

-

Troubleshooting

DATA

Item

No.

11

15

21

25

31

32

LIST

Check

Interior

IUTE

Engine

temperature

sensor

Air

Photo

Blend

motor

ter

Mode

damper

eter

REFERENCE

item

tempera-

SENSOT

coolant

thermo

sensor

sensor

air damper

potentiome-

selection

potentiom-

TABLE

lgnition

lgnition

lgnition

lgnition

lgnition

Check

lgnition

condition

switch:

switch:

switch:

switch:

switch:

switch:

ON

ON

ON

ON

ON Damper

MAX.

HOT

MAX.

COOL

ON

Damper

FACE

position

position

Normalcondition

Inside

air

perature

are identical.

Heater

and

the

Evaporator

and

the

Amount

proportional

on the

Opening

Approx.100

Approx.

Opening

Approx.

temperature

displayed

core

surface

temperature

MUT-ll

MUT-ll

are

identical.

surface

temperature

are identical.

of

incident

voltage

to

MUT-Il.

degree

0

degree

0

(%)

and

on

the MUT-ll

temperature

displayed

temperature

displayed

light

displayed

(%)

tem-

on

on

is

CHECK

Terminal

No.

1

2

AT

THE

Check item

Air

conditioner

collector

Air

conditioning

A/C-ECU

power

transistor

power

transistor

TERMINALS

20POO31

Check

When

When

When

base

When

FOOT

FOOT/DEF.

DEF.

condition

blower

blower

blower

blower

switch

switch

switch is

switch is

is

at OFF

is

at LO

at Hl

at

Approx.

Approx.

Approx.

20POO30

00006895

OFF

50

75

100

Normalcondition

System

Approx.

Almost

OV

voltage

9 V

no voltage

(0

V)

When

blower

When

blower

3

A/C-ECU

backup

power

supply

At

alltimes

switch is

switch is

at LO

at Hl

Approx.

Approx.

System

2.5 V

voltage

1.3 V

Page 36

HEATER, AIR

CONDITIONER AND VENTILATION

-

Troubleshooting 55-25

Terminal

No.

4 Engine

o

a

8 Air thermo sensor inout

I Photo

10

15 Interior

17

Check

inout

Blend

rnpur

Mode selection damper

inout

Air inlet

Sensor

Diagnosis date output When

item

coolant temperature sensor

air damper motor

sensor

sensor

power

temperature sensor When

inout

(-)

supply At

potentiometer

potentiometer

Check condition

When

sensor section temoerature

(4

25'C

When

oosition

When damper is moved

position

When

25'C

When

25'C

At luminous

more

At luminous

25'C

kQ)

damoer is moved

sensor section temoerature is

(4

kf2)

sensor section temoerature is

(4

kO)

intensity of 100,000 lux

intensity of 0 lux

alltimes

sensor section temperature is

(4

kfi)

ignition switch is ON

MAX.

to

is

HOT

to DEF.

or

Normalcondition

2.3 - 2.9 V

-

4.7

4.8

2.3 - 2.9 V

2.3

-0.1 -

OV

4.8 - 5.2V

2.3 - 2.9 V

V <->

0

V

5.0

-

5.2 V

-

2.9 V

0.2 v

System voltage

18

19 Photo

20 Blend air damper motor and mode

21 Mode selection damper motor

22 Blend air damper motor

23 Air selection damper motor

z4

Diagnosis control input When ionition

sensor

selection damper

Mode

selection damper

(+)

potentiometers

(-)

motor

(+)

(-)

(-)

switch is ON

At

alltimes

At

alltimes

Set to FACE

seconds of

Set to DEF.

seconds

Set the

and set to MAX.

after 40 seconds of output)

Set the setting temperature to 32"C

and set to MAX. HOT

after 40 seconds of output)

Set

inside

to

seconds of output)

Set to outside

40 seconds of

Set to FACE

seconds of output)

position

output)

position (OFF

output)

of

setting

temperature

position (OFF

air

air

output)

position

(OFF

COOL

position

(OFF

atter 4O

after 40

17'C

to

position

position (OFF

after

(OFF

after 40

(OFF

40

after

Batteryvoltage-2V

OV

OV

10v

0.5 v

10v

0.5 v

0.5 v

10v

0.5 v

Set to DEF.

seconds of output)

position

(OFF

after 40

10v

Page 37

55.26

HEATER,

AIR

CONDITIONER

AND VENTILATION

-

TTOUbICShOOtiNg

Terminal

No.

ZJ

26

27

28

29

30 ILL

33 Engine-ECU

Check item

Blend air

Air

Earth

A/C-ECU

ILL

damper motor

selection damper

power

(rheostat)

earth

power

supply

output

motor

supply

(+)

(+)

Check condition

Set the setting temperature

and set to MAX.

40

after

Set the setting

and

after 40

Set to

seconds

Set to outside air

40 seconds

At alltimes

When ignition

At

When lighting

When

COOL

seconds

set to MAX. HOT

seconds

inside

of output)

alltimes

air mix

position

COOL

temperature

position

air

of output)

switch is

switch

damper is

position

of output)

position (OFF

of output)

(OFF

position

ON

is at ON

(OFF

at

17'C

to

(OFF

to 32'C

after 40

after

MAX.

Normalcondition

0.5 v

10v

10v

0.5 v

Continuity

System voltage

Continuity

System

OV

voltage

t4

@

34 A/C

35 Earth

output

When

air mix damper is

position

When

A/C is

When

A/C is

At alltimes

OFF

ON

at MAX. HOT

System voltage

OV

System

Continuity

voltage

@

u

Page 38

HEATER,

AND

VENTILATION

AIR

CONDITIONER

Air

Conditioner

ECU

Assembly

Control

Panel

and

55-27

AIR

CONDITIONER

REMOVAL

Pre-removal

o

Floor

Console Removal

af<

CONTROL

AND INSTALLATION

and Post-installation

and Installation

Operation

PANEL

AND

CAUTION:

When

don't

SRS-ECU.

SRS

installing

allow

any impact

ECU

or removing

ASSEMBLY

the ftoor

or

shock to the

console,

<A>

Removal

1.

Center

2.

Air

conditioning

NOTE

For

service

steps

air outlet

point,

refer

assembly

to

panel

Basic

control

and ECU

Manual.

420FO185

assembly

Page 39

55-28

HEATER.

AND VENTILATION

AIR CONDITIONER

-

Damper Control Motor

Assembly

DAMPER

REMOVAL

CAUTION:

When installing

don'l

SRS-ECU.

\

CONTROL MOTOR ASSEMBLY

AND INSTALLATION

SBS

allow any impact

removing

or

m-

\./

the floor console,

or shock to

the

11

10

"w

\\

:N>tr

Air

selection damper motor

assembly

1. Stopper

2. Glove

Air

3.

selection damper motor

blv

Blend air

removal steps

4. Floor

NOTE

For

seruice

Manual.

removal

box outer case

damper motor assembly

console

point,

steps

assem-

refer to Basic

7

1

,.t1

I

6

tr=-

<A>

5. Center outlet assembly

6. Air

7. Blend

Mode selection

assembly

8. Knee

9.

10.

11. Mode selection damper motor

conditioning

ECU assembly

air damper motor

removal steps

protector

Side console cover

Shower

sembly

duct and

control

damper motor

A 20 FOl

panel

lap

cooler duct

A4

and

assembly

as-

INSPECTION

Refer to Basic

Manual.

Page 40

HEATER,

AND

VENTILATION

AIR

CONDITIONER

Compressor

Condenser Fan

/ Condenser

Motor 55-29

COMPRESSOR

and

zt6Yil90

000071 34

ffir

ILiJI

220H0033

vo2oeAA

INSPECTION

THERMOSTAT

MAGNETIC

(1)

Dip

the

(2)

Check for

body

earth when

Standard

Continuity

No

(3)

While

compressor

and

earth

compressor.

The

condition

be considered

sound)

check is

REVOLUTION

Measure

connector.

Normal

lf

the measurement

resistance,

the resistance

resistance:

405

t 35 O when

CHECK

CLUTCH

thermostat in

continuity

value:

continuity

the

thermostat is

side

the

of the magnetic

made.

PICK

replace

AND

COMPRESSOR'S

OPERATION

engine

across

the

at approx.

at approx.

to the

negative (-)

of the

satisfactory if

UP

between

ambient

deviates

the revolution

terminals

engine oil is

on,

positive

terminal

compressor's

clutch

SENSOR

CHECK

oil.

(3)

heated:

110'C

connect

the

terminals

temperature

or

155'C

greatly

pick

or more

terminal

(+)

terminal

of

magnetic

operation

can

be heard

CHECK

up sensor

less

the battery

(1)

from

and compressor

point

at A

point

at B

(1)

at the

of

the battery

to the

clutch

sound

when

and

is

20.C

the

assembly.

(a

(2)

can

"click"

this

of the

above

RJST706022-040

A 20FO187

CONDENSER

AND

MOTOR

INSPECTION

CONDENSER

(1)

Apply

terminal

motor

(2)

Apply

terminal

motor

FAN MOTOR

battery voltage (+)

(3);

at this time,

turns.

battery voltage

(3);

at this

turns.

CONDENSER

CHECK

to

terminat

check

(+)

to terminal

time, check

that

that

(1)

and

the

condenser

(2)

and

the

condenser

FAN

ground

ground

(-)

fan

(-)

fan

Page 41

Pub. No.

ENGLISH

EUROPE AND

PWUE9I l9-G

Pub. No.

PWUEg203-5

EXPORT

{

A

mnsuBrsHr

MoroRS

coRpoRATroN

Jun. 1997

Printed

in Japan

(

{

L

Loading...

Loading...