Page 1

0

^^,

MITSUBISHI

MOIORS

Workshop

Mqnuql

chossis

SUPPTEMENT

3ClCloGiT'97

\/

v

v

:--E-_-------=--:

--

Pub. No.

PWUE9I

l9-F

:

:

Page 2

v

,r ,

\/

MITSUBISHI

3000GiT

WORKSHOP

SUPPLEMENT

FOREWORD

This Workshop Manual contains

removal,disassembly,

reassembly and installation, etc.

mechanics.

Use the

manual

TECHNICAL INFORMATION MANUAL

following manuals

required.

as

MANUAL

procedures

inspection,adjustment,

for

in

combination

PYUE92O1

for

service

with this

General

Fuel

Service Brakes

Supplemental

System

(SRS)

Restraint

E

IE

E

E

v

WORKSHOP

CHASSIS GROUP

ENGINE

ELECTRICAL

PARTS CATALOGUE

All information,

tions contained

time of

to

obligation.

publication.

make

MANUAL

GROUP

WIRING

illustrations

in this manual are current as at the

changes

at any

We,

PWUE9119

(Loose-leaf

PWUE9119-E

(Supplement)

PWEEN!trN

(Loose-leaf

PHUE92O1

(Loose-leaf

PHUE92O1-D

(Supplement)

PHUE92O1.E

(Supplement)

8608K4onAn

8608K454Atr

8608K406An

8608K407An

product

and

however, reserve the right

time without

edition)

edition)

edition)

prior

descrip-

notice

or

v

o Mitsubishi Motors Corporation

July 1996

Page 3

WARNINGS

(sRs)

WARNING!

(1)

(2)

(3)

(4)

EQUTPPED

lmproper

can lead

or

to the driver

lt it is

drying after

Service

only

MITSUBISHI

528

any component

possible

or

at an authorized

-

Supplemental Restraint

REGARDING

service

personal

to

(from

that

painting,

maintenance

dealer

of the

OF

VEHTCLES

or maintenance

iniury

rendering

the

remove

MITSUBISHI

personnel

or death_to_service

SRS components

oJ any

SRS or

oJ

the

the

SRS components

SRS component

dealer.

must

System

any SRS-related

SUPPLEMENTAL

any component

SRS inoperative).

are

subjected

thoroughly

(SRS),

before

component.

of the

personnel

to heat

(air

bag module,

or

SRS-related

review

this

beginning

SRS, or any

(from

manual,

RESTRAINT

SRS-related

inadvertent

over

93"C

SRS-ECU)

component

and

any service

firing

(200'F)

especially

SYSTEM

component,

of the

in

baking

beforehand.

must

be

or maintenance

iir Uagl

or in

performed

its

GROUp

of

u

lJ-

Page 4

v

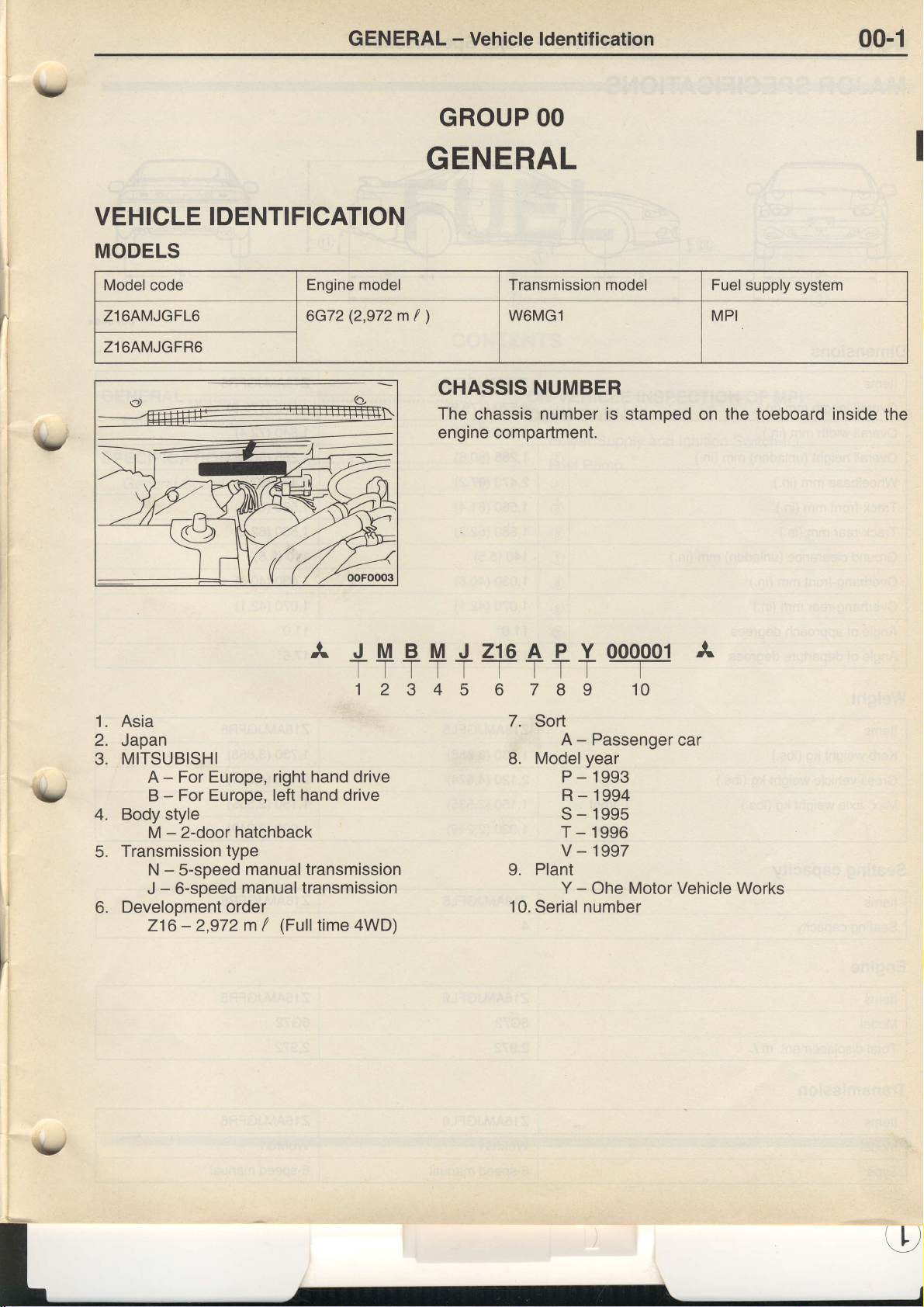

GENERAL

GROUP OO

GENERAL

-

Vehicle ldentification

00-1

i'

VEHICLE I DENTI

FICATION

MODELS

Model code

Zl6AMJGFL6 6G72(2,972m/)

Zl6AMJGFR6

Engine model Transmission model Fuel

A

JMBMJ216A PY

TTT-tTTTT_t

12

3 4 5

W6MG1 MPI

CHASSIS

The

chassis

engine

NUMBER

number is

compartment.

7I

6

supply system

stamped on the toeboard inside

000001

A

T

I

10

the

v

Asia

1.

2.

Japan

MITSUBISHI

3.

A - For Europe,

-

B

Body style

4.

M - 2-door

Transmission

5.

N - 5-speed

-

6-speed

J

Development

6.

216

right hand

For Europe, left hand drive

hatchback

type

manual transmission

manual transmission

order

-

2,972 m I

(Full

drive

time 4WD)

7.

8.

L

10.

Sort

A - Passenger

Model

Plant

Serial

year

P-1993

R-1994

s-1995

T - 1996

v-1997

-

Y

Ohe Motor Vehicle Works

number

car

Page 5

00-2

GENERAL

-

Major

Specifications

MAJOR

SPECIFICATIONS

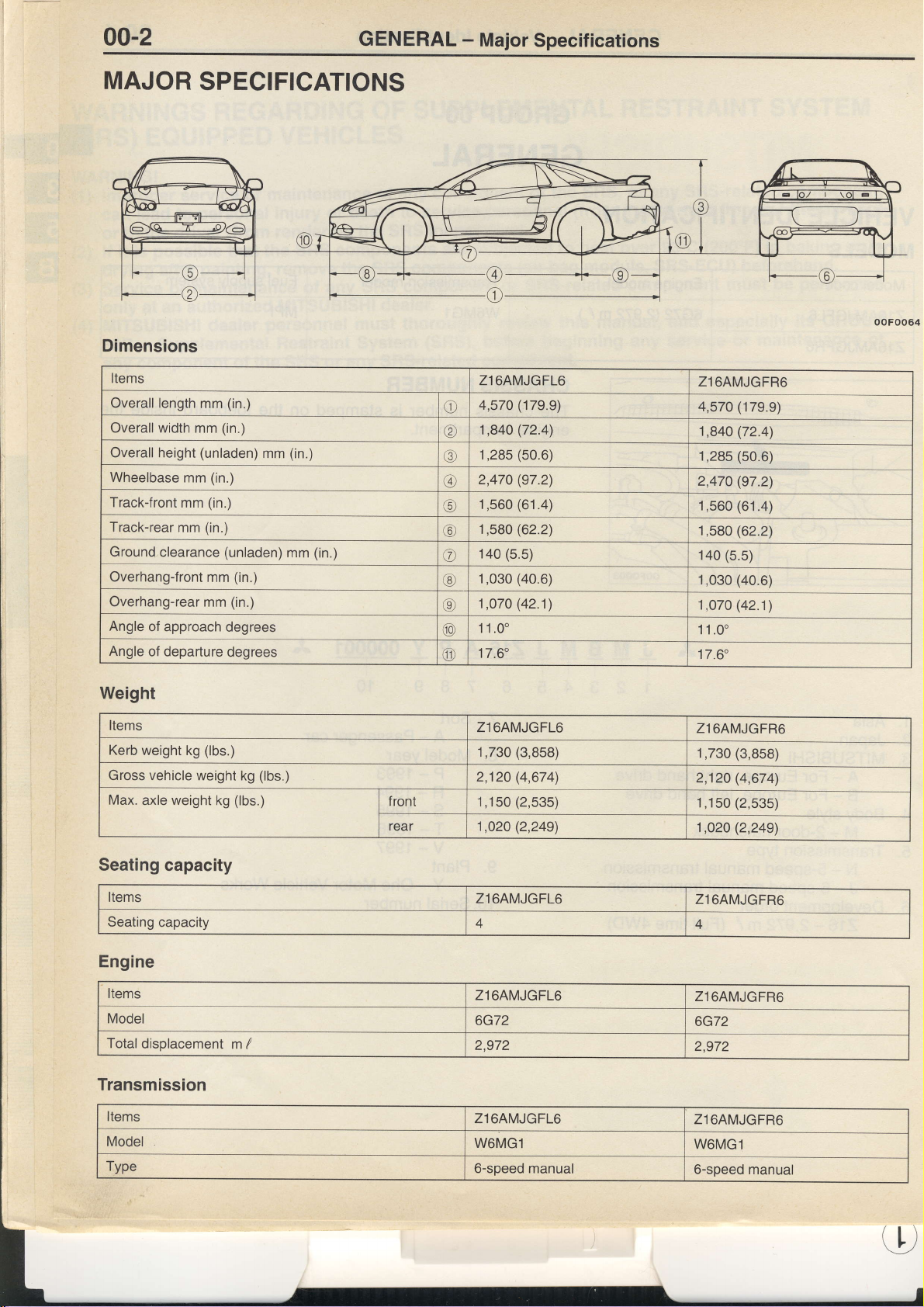

Dimensions

Items

Overall length

Overallwidth

Overall height

Wheelbase

Track-front

Track-rear

Ground

Overhang-front

Overhang-rear mm

Angle

of approach

Angle

of departure

mm

mm

(unladen)

mm

mm

(in.)

mm

clearance

(in.)

(in.)

(in.)

(in.)

(unladen)

(in.)

mm

(in.)

degrees

degrees

mm

(in.)

mm

(in.)

Zl6AMJGFL6

4,570

o

1,84O

@

1,285

@

2,470

@

1,560

!9

1,580

@

140

€)

1,030

@

1,070 (42.1)

o

11.0"

@

17.6'

o

(179.9)

(72.4\

(50.6)

(97.2)

(61.4)

(62.2)

(5.5)

(40.6)

Zl6AMJGFR6

(179.9)

4,570

1,84O (72.4)

(50.6)

1,285

(97.2)

2,470

1,560 (61.4)

1,580 (62.2)

(5.5)

140

(40.6)

1,030

(42.1)

1,070

11.0'

17.6'

ooFoo64

Weight

Items

Kerb

weight kg

Gross

Max.

axle weight

vehicle

(lbs.)

weight

kg

Seating capacity

Items

Seating

capacity

Engine

Items

Model

Total

displacement m

Transmission

Items

Model

Type

(lbs.)

kg

(lbs.)

I

f ront

rear

Zl64MJGFL6

(3,858)

1,730

(4,674)

2,120

(2,535)

1,150

(2,249)

1,O20

Zl64MJGFL6

4

Z1

6AMJGFL6

6G72

2,972

Z1

6AMJGFL6

W6MG1

6-soeed manual

Z.I64MJGFR6

(3,858)

1,730

2,120 (4,674)

(2,535)

1,150

(2,249)

1,02O

Z1

6AMJGFR6

4

Zl6AMJGFR6

6G72

2,972

Z1

6AMJGFR6

W6MG1

6-soeed manual

LL)

Page 6

Y

13-1

T

FUEL

CONTENTS

v

GENERAL

Outline

SPEC|F|CATTONS

General Specifications

of Change

................

......2

.............2

............2

.........2

ON.VEHICLE

coMPoNENTS

Power Supply and

Fuel Pump

INSPECTION OF

........

MPI

lgnition Switch-lG

...................... 3

......................... 5

.......3

v

Page 7

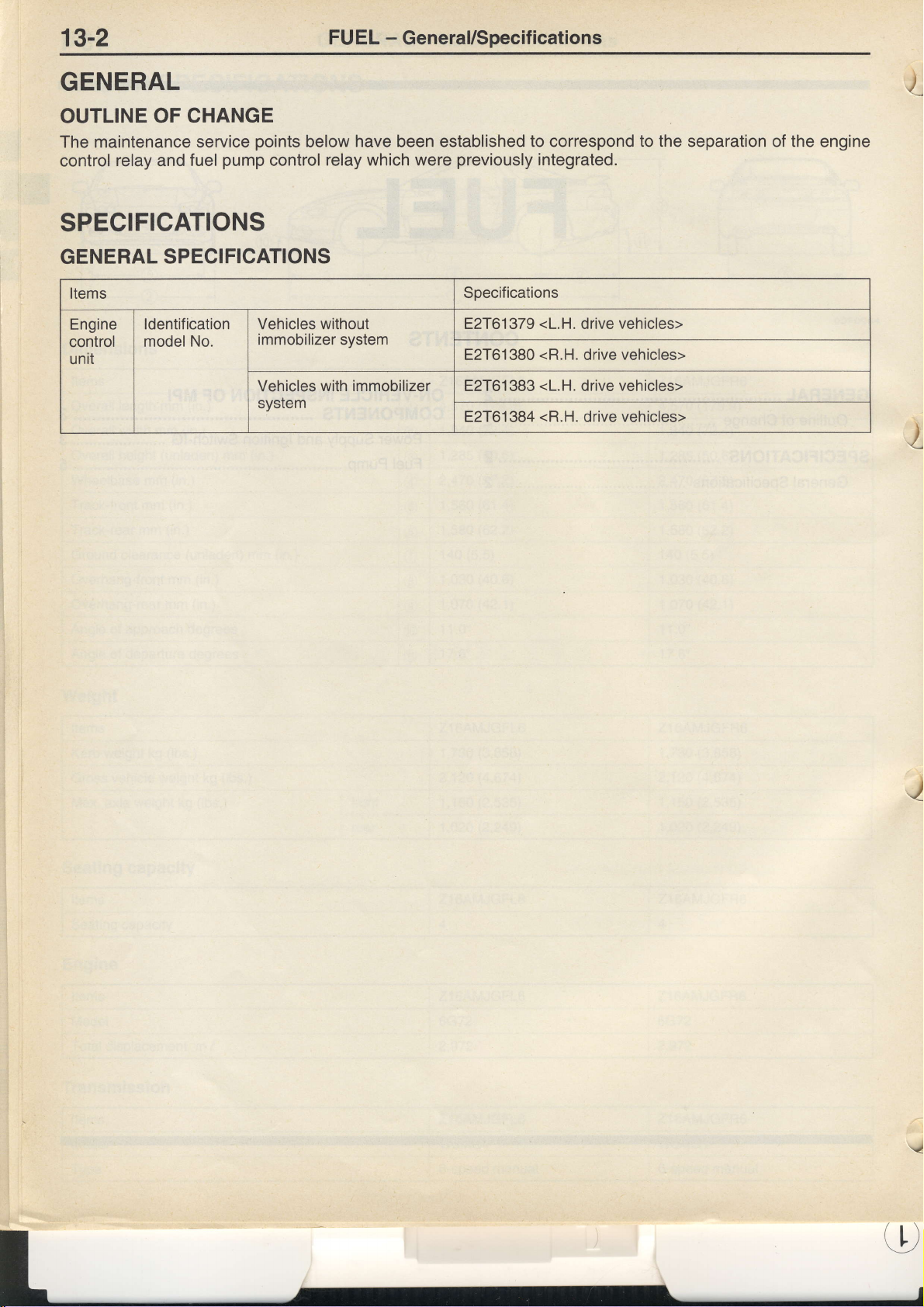

13-2

GENERAL

FU EL - General/Specif

ications

OUTLINE OF

The maintenance

control

relay

CHANGE

service

fuel

and

points

pump

control

SPECIFICATIONS

GENERAL

Items

Engine

control

unit

SPECIFICATIONS

ldentification

No.

model

Vehicles without

immobilizer system

Vehicles

system

below

have been established to correspond

relay which were

with immobilizer

previously

Specifications

E2T61379

E2T61380

E2T61383

E2T61384

integrated.

<L.H.

<R.H.

<L.H.

<R.H.

to the

vehicles>

drive

vehicles>

drive

drive vehicles>

vehicles>

drive

separation of the engine

L

J

v

o

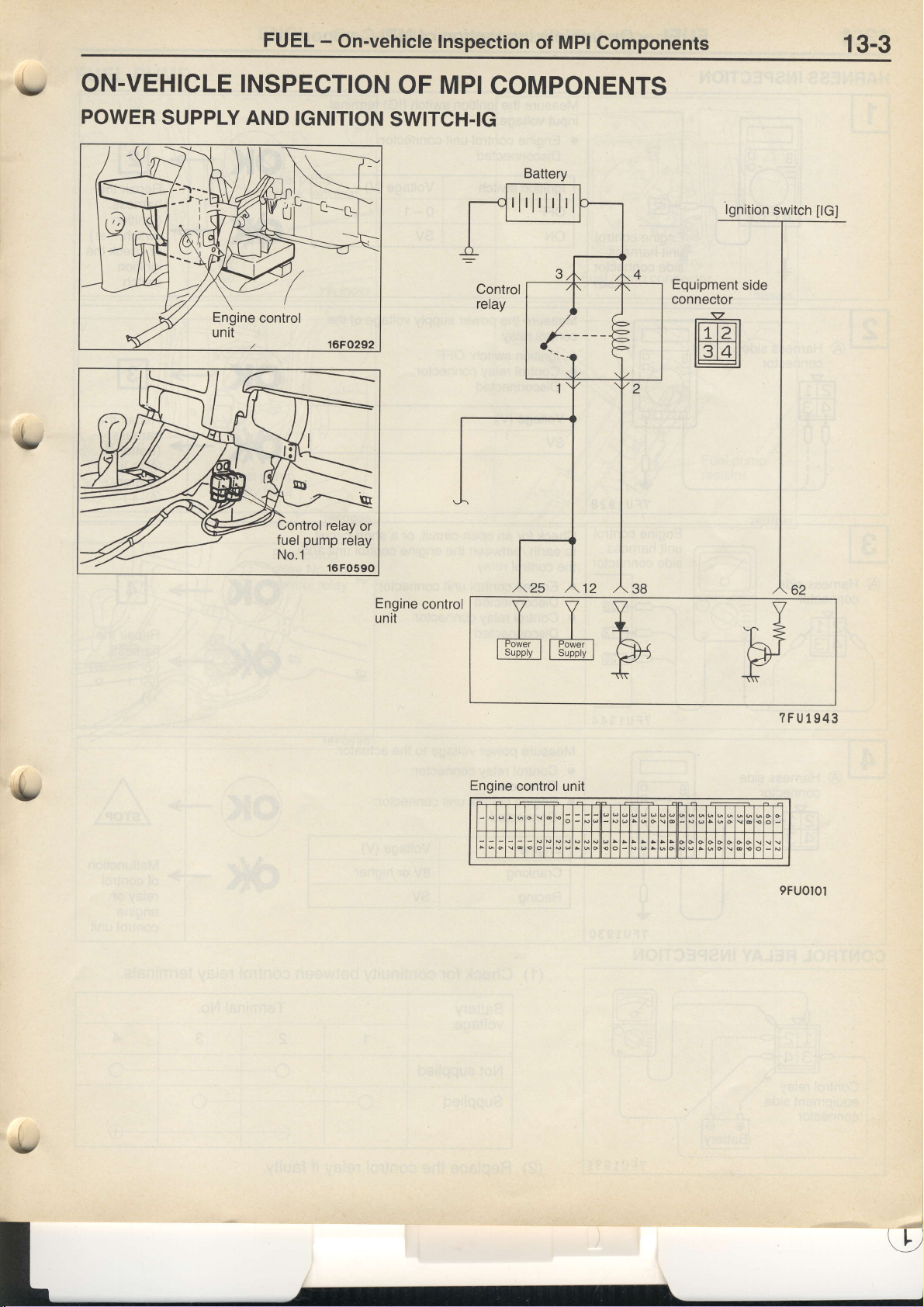

Page 8

FUEL

-

On-vehicle

Inspection

of MPI

Components

13-3

,ly

oN-vEHtcLE

POWER

SUPPLY

tNSpECTtON

AND

OF Mpt

IGNITION

SWITCH.IG

COMPONENTS

Battery

rlrlrlrlrl

lgnition

switch

[G]

Engine

unit

control

YVV

-j- -J-, L

l$il:;llG;;pi;l

Engine

control unit

pH

-\tr

V

I

A?

V

-ilri

?FU1943

9FU0l0l

Page 9

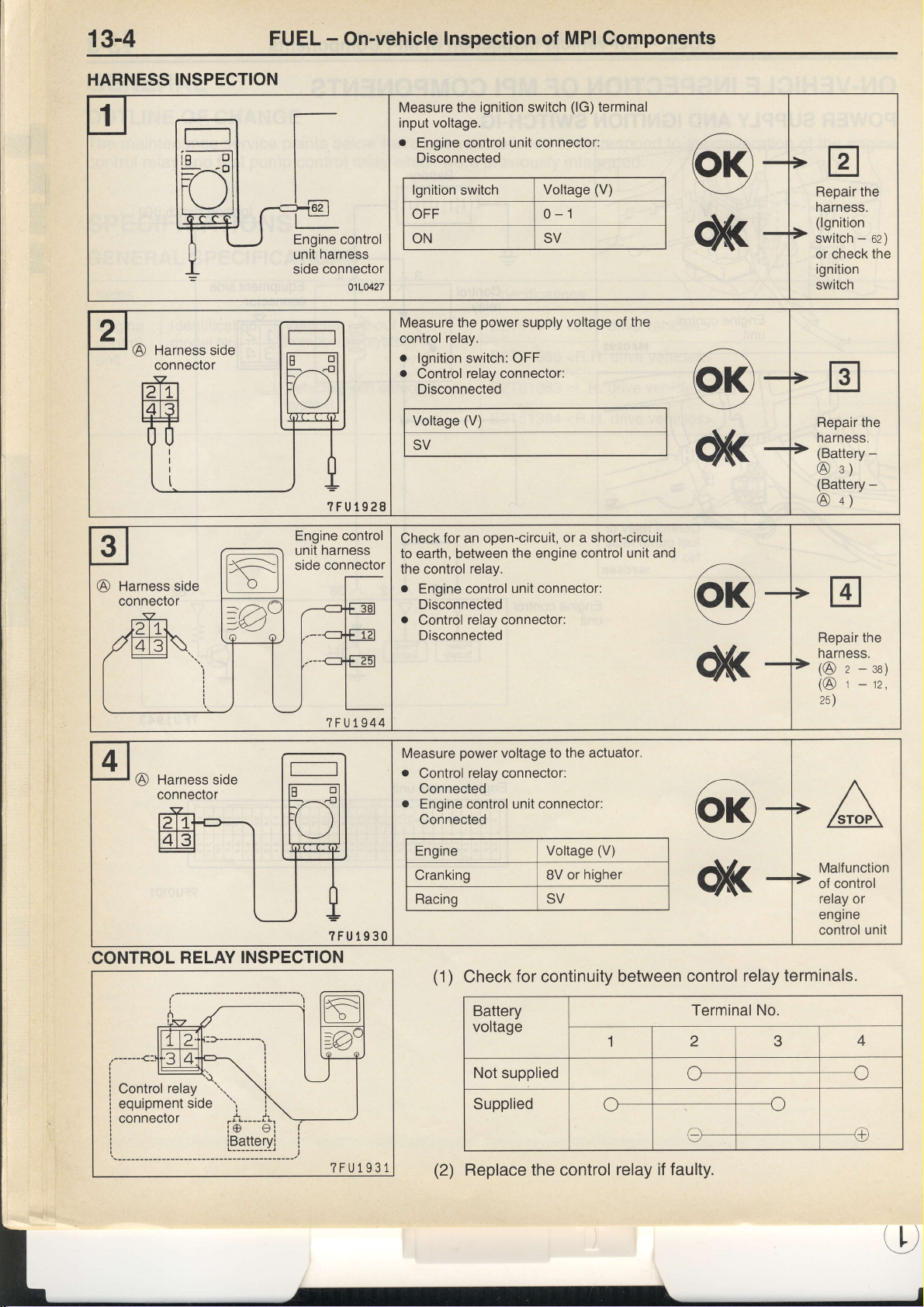

13-4

FUEL - On-vehicle

Inspection of

Measure

input voltage.

o

Engine control unit connector:

Disconnected

MPI Components

the ignition switch

(lG)

terminal

?FUt928

lgnition switch

OFF 0-1

ON SV

power

Measure the

relay.

control

o

lgnition

o

Control

Disconnected

Voltage

SV

Check

to

earth, between

the control relay.

o

Engine control unit

Disconnected

o

Control

Disconnected

switch:

relay

(V)

for an open-circuit,

relay

supply

OFF

connector:

the engine

connector:

Voltage

connector:

(V)

voltage

or a short-circuit

control unit and

of

the

Repair the

harness.

(lgnition

-

switch

or check

ignition

switch

oz

the

Repair the

harness.

(Battery

@

(Battery

@

Repair the

harness.

(@

(@

25)

s)

a)

z

r

-

-

-oa;

-rz,

)

CONTROL

RELAY

?FU1930

INSPECTION

?FU1931

Measure

o

.

power

voltage to

Control relay connector:

Connected

Engine

(1)

Check

control unit

for continuity

Connected

Engine

Cranking

Racing SV

Battery

voltage

Not

supplied

Supplied

(2)

Replace the control

the actuator.

connector:

Voltage

8V

(V)

or higher

between control

relay terminals.

Terminal No.

1 2 3

C

C-

--{

o-

relay if faulty.

Malfunction

of control

relay or

engine

control unit

4

---c

----@

Page 10

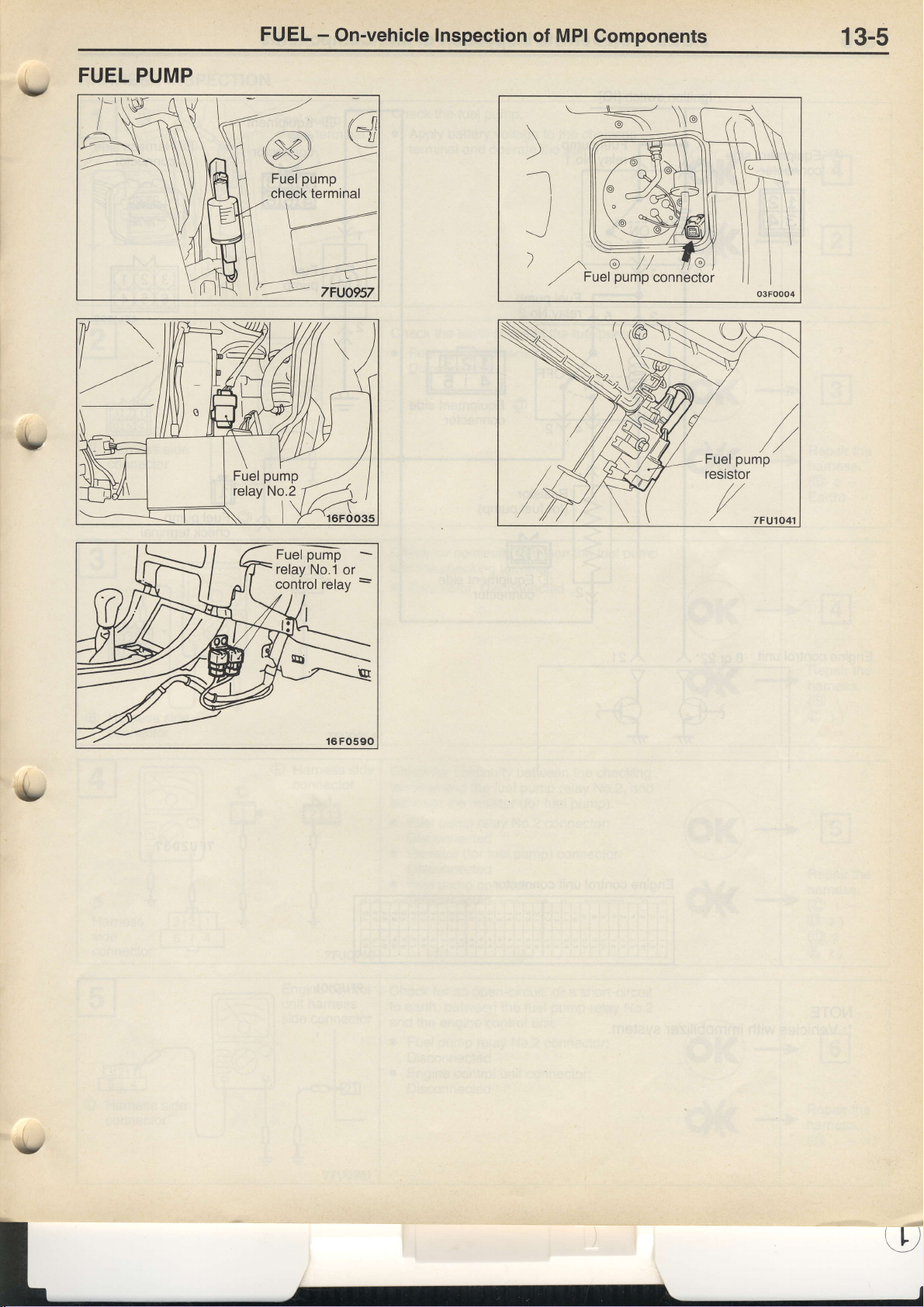

FUEL PUMP

FUEL

-

On-vehicle Inspection

of MPI

)

-t

Gomponents

13-5

r)

pump

Fuel

relay No.2

Fuel

relay

control relay

pump

No.1

or

\\

<t

11-!

:

*/

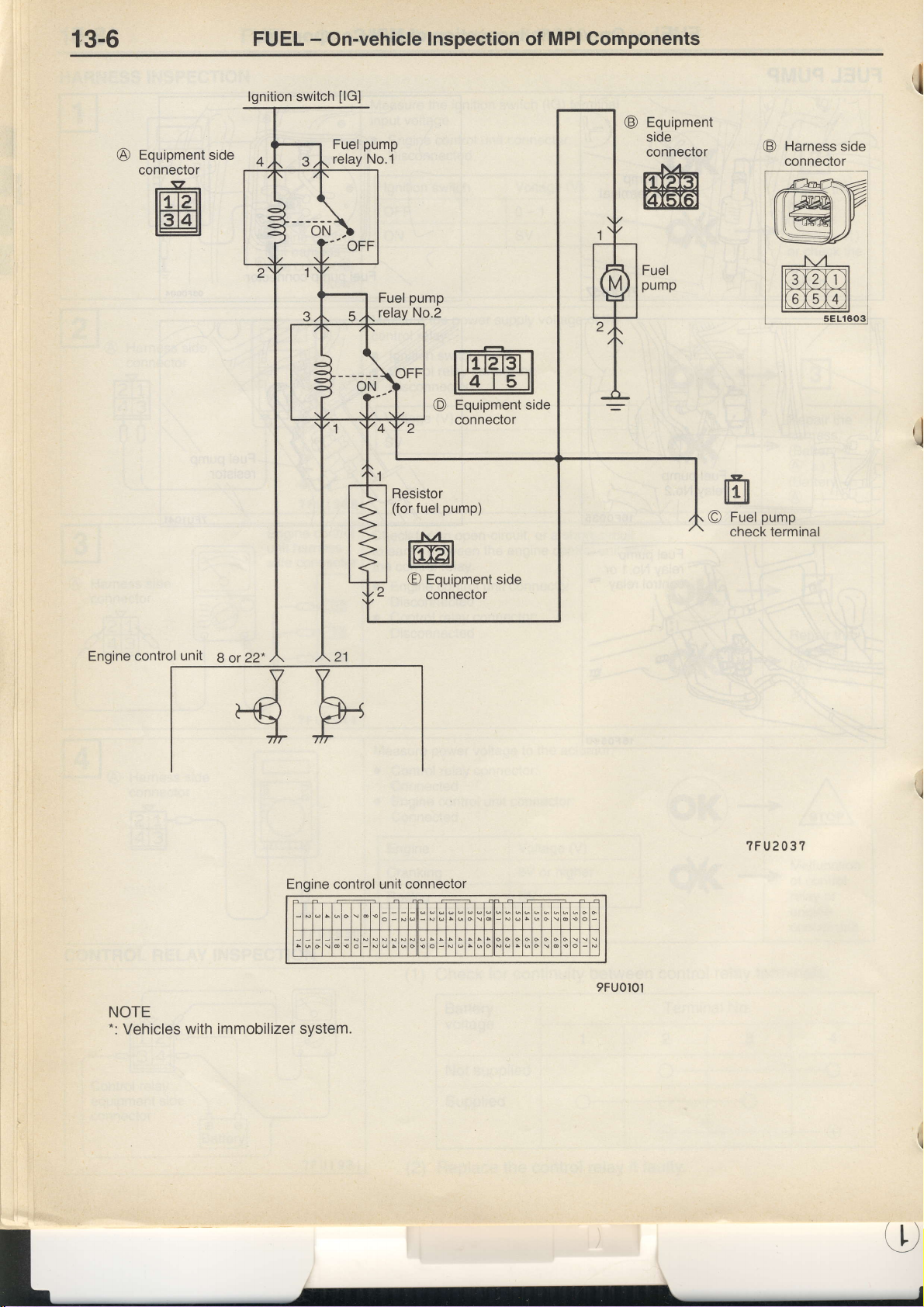

Page 11

1,3-6

FUEL - On-vehicle

lnspection of

MPI

Components

Equipment

connector

-g-

lml

il ltatl

lgnition switch

Fuel

relay No.1

|Gl

pump

Fuel

relay No.2

Resistor

(for

pump

Equipment

@

conneclor

pump)

fuel

-N/-

t@t

Equipment

O

connector

side

Equipment

@

side

connector

@

pump

Fuel

O

check terminal

Harness

connector

side

I

,l

Engine control

NOTE

-:

Vehicles

unit

with immobilizer

8 or

22*

Engine

system.

control

?FU203?

unit connector

9FU0l0l

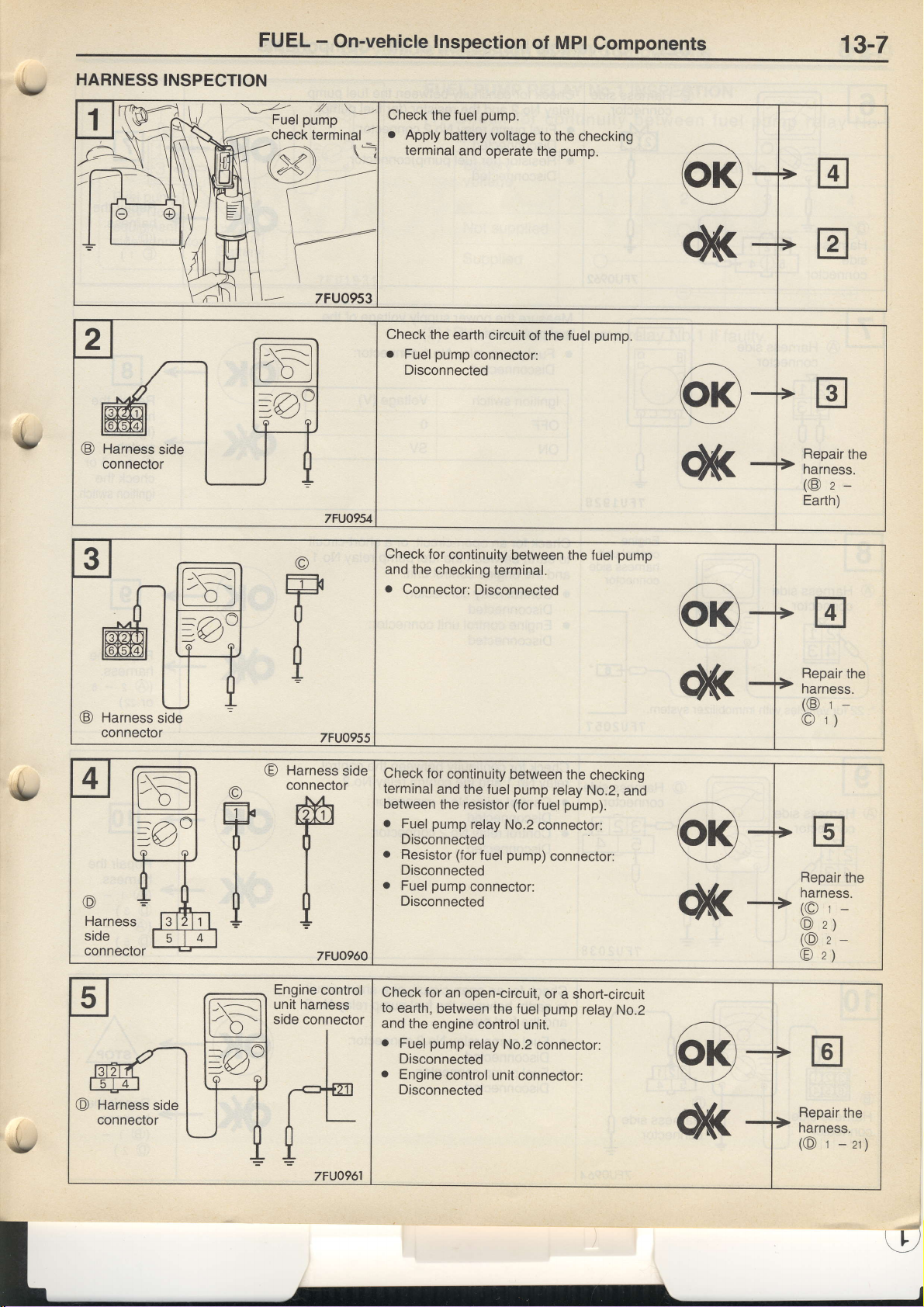

Page 12

FUEL

-

On-vehicle

Inspection

of MPI

Components

13-7

HARNESS

INSPECTION

l-Y-l

l-X-l

L____\z_J

Check the

o

Apply

battery

terminal

Check the

o

pump

Fuel

Disconnected

pump.

fuel

voltage

and

operate the

earth

circuit

connector:

to the

checking

pump.

of the fuel

pump.

Repair

the

narness.

(@zEarth)

v

Check

for

I-\-----l

l;\---=:l

tol

o

and the

o

checking

Connector:

continuity

terminal.

Disconnected

between

the fuel

pump

F

I

o

Check for

terminal

between

o

o

r

Disconnected

continuity

and the fuel

the resistor (for

pump

Fuel

Disconnected

Resistor (for

Disconnected

Fuel

pump

relay

fuel

connector:

between

pump

fuel

No.2

connector:

pump)

connector:

the

relay

pump).

checking

No.2,

and

T

Check

for

to

earth,

and

o

o

Disconnected

i

an open-circuit,

between

the

engine

control

pump

Fuel

Disconnected

Engine

relay

control

the fuel

unit connector:

unlt.

No.2

or

a short-circuit

pump

relay

connector:

No.2

Repair

the

narness.

(@t-

r)

O

Repair

the

harness.

(Ot-

z)

@

(Oz-

z)

O

Repair

the

harness.

-zr;

(@

r

Page 13

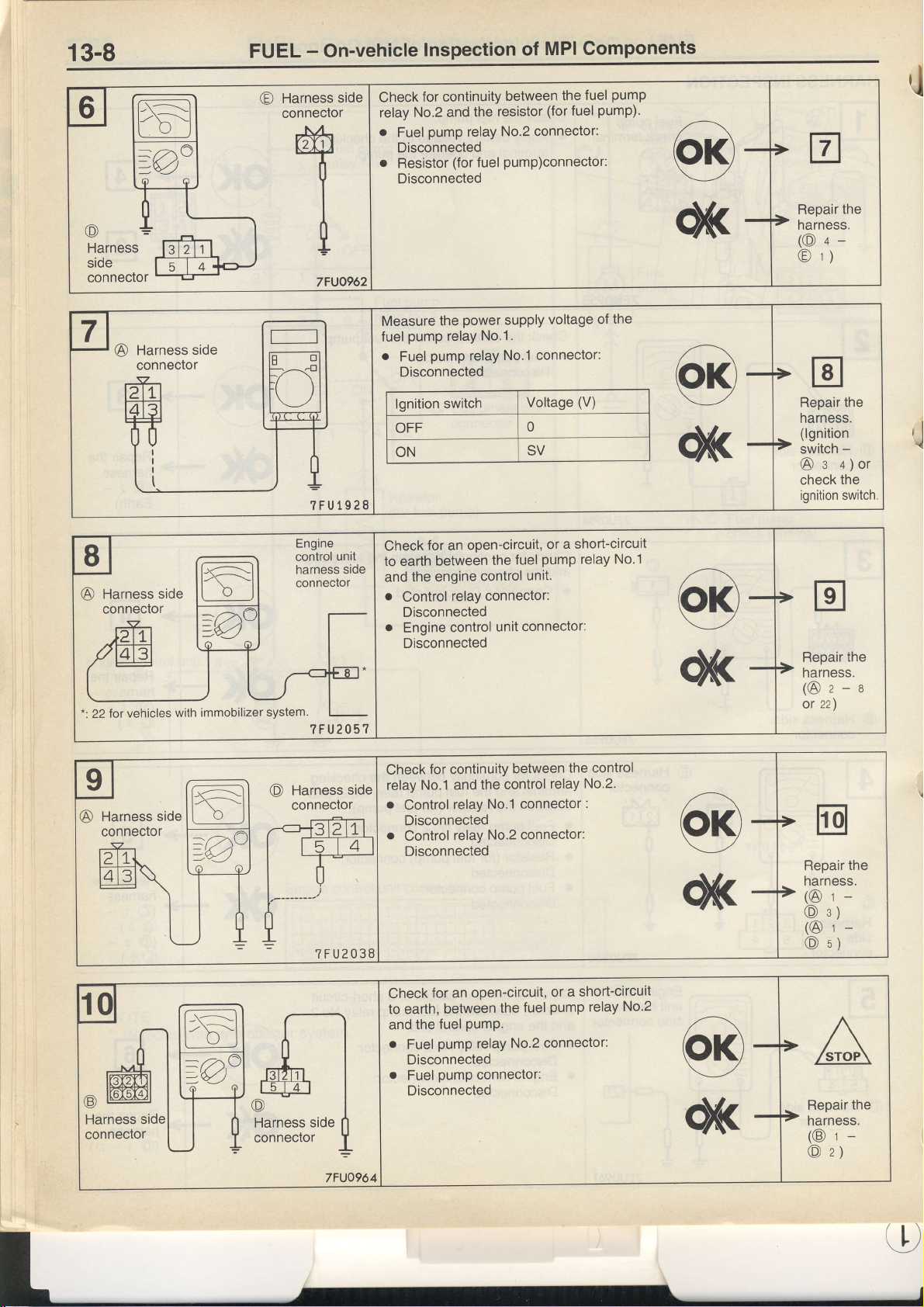

FUEL

-

On-vehicle

Inspection

MPI Components

of

?FU1928

for continuity

Check

No.2

relay

o

o

pump

Fuel

Disconnected

Resistor

Disconnected

Measure

fuel

o

the

pump

pump

Fuel

Disconnected

lgnition

OFF

ON

and the

relay

(for

fuel

power

No.1.

relay

relay

switch

between

resistor

No.2 connector:

pump)connector:

supply

No.1 connector:

the fuel

(for

fuel

voltage of

Voltage

0

SV

pump)'

(V)

pump

the

Repair the

narness.

(O+-

r)

@

Repair the

narness.

(lgnition

-

switch

+)or

e

@

the

check

switch.

ignition

rJ

,J

tFt

I-E-l

t ____v__J

?FU2038

Check

to earth

and

o

o

Check

relay No.1 and

.

o

Check

to earth,

between

engine

the

Control

Disconnected

Engine

Disconnected

Control

Disconnected

Control

Disconnected

and

r

o

relay

control

for continuity

relay

relay

for an

between

the fuel

pump relay No.2

Fuel

Disconnected

pump

Fuel

Disconnected

pumP.

open-circuit,

for an

or

pump

fuel

the

unit.

control

connector:

unit connector:

between

control

the

No.'l

No.2

open-circuit,

the

connector:

relay

connector:

connector:

or

pump

fuel

connector:

a short-circuil

a short-circuit

No.1

relay

the control

No.2.

No'2

relay

the

Repair

harness.

(@z-s

zz)

or

the

Repair

narness.

(@t-

s)

@

(@r-

s)

O

the

Repair

narness.

(@r-

z)

O

t,

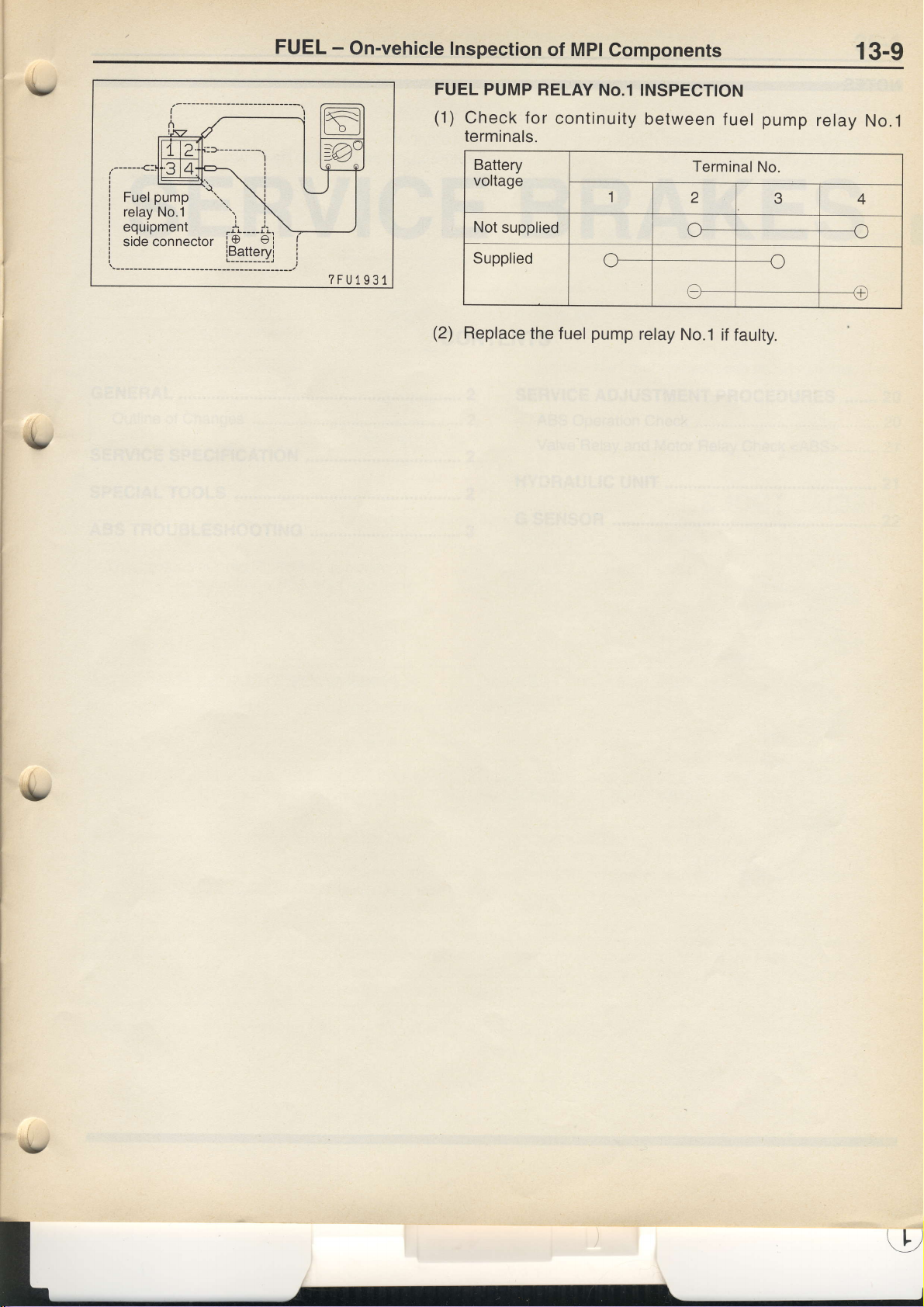

Page 14

FUEL

-

On-vehicle

Inspection

of MPI

Components

13-9

?FU1931

FUEL PUMP

(1)

Check for

terminals.

Battery

voltage

Not

supplied

Supplied

(2)

Replace

the fuel

RELAY

No.1 INSPECTTON

continuity

1

pump

between

Terminal

2

e--

relay

No.1 if

fuel

No.

fautty.

pump

3

1-)

relay

4

a)

@

No.1

rtz

Page 15

35-1

SERVICE

CONTENTS

{'

BRAKES

SERVICE ADJUSTMENT

ABS

Operation Check

Valve Relay

HYDRAULIC

G SENSOR

and Motor Relay

UNIT

PROCEDURES

Check

<ABS>

....................22

.....,.20

.....20

........21

..........21

(L,)

Page 16

35-2

SERVICE

BRAKES - General/Service

Specification/Special

Tools

GENERAL

OUTLINE

.

The hydraulic unit

.

The ABS

o

The

SERVICE

Items

Hydraulic unit

Resistance

G-sensor

SPECIAL

OF CHANGES

valve relay and

G-sensor

SPECIFICATION

solenoid

between

output

voltage

TOOLS

has been

and the

ABS-ECU have been

internal resistance

valve

speedsensor

V

made

the ABS

terminals

more lightweight and compact.

motor relay

have

been

separated

changed.

o OUT

IN

kO

installed

When

removed

When

mark facino down

from the

with

arrow

hydraulic unit.

-

4.54

-2.6

value

Standard

4.04

8.04 - 9.04

1.4 - 1.8

2.4

3.4 - 3.6

(

Tool

Number

MB991529

M8991638

M8991348

Name

ABS check

harness

ABS check

narness

Test harness set

Use

For checking

when

using

For checkino of

For checking

of ABS

the

of G-sensor

(Diagnosis

ABS warning lamp)

ABS

code display

(L

Page 17

SERVICE

BRAKES

-

ABS

Troubteshooting

35-3

i.

t

ABS

STANDARD

lnspection

(Refer

TROUBLESHOOTTNG

FLOW

No

diagnosis

or MUT-ll

communtcate

to P.35-14.)

code

can't

chart for

trouble

OF

symptoms

DIAGNOSTIC

Verify

TROUBLESHOOTING

complaint

Reoccurs

I

VY

I

oiaonosis

J

Read (and

diagnosis

(fault

memories

them.

codes

duration

(Refer

.----l-

Read

trouble

Inspection

(Refer

chart for

to P.35-6.)

cooe oisotaveol-

write

down)

and

tfre

and

are

how

erased).

to P.35-5.)

'

t

codes

Diagnosis

diaqnosis

all

displayed

service

manv

And

F""d,

l(Rerer

codes

c

oes not

I

"S""rb

to P.35-4.)

iagnosis

ciata

times

erase

No

Diagnosis

code displayed

reoccur

a"d"

code

displayed

I ntermittent

code

-t

o Diagnosis

N

I

malfunction

code

NOTES

The

Phenomenon

System

{t

ABS

ABS

braking

Diagnosis

WITH

phenomena

check

REGARD

listed

sound

operation sound

operation

(Long

distance)

detection

TO DIAGNOSIS

in

the following

Explanation

When

theengine

performed,

1.

sound

2.

sound

3. When

brake

(Thump:

For road

for vehicles

advise

being

too

condition

can

table

phenomenon

of

starting

the

tfr"

compartment,

and is

of the motor

generated

is

ABS

operates,.sound

application

suspension;

surfaces

with

ABS

customer

overconf

vary

depending

are not

"n

not

abnormal.

but

this is

an

abnormalitv.

inside

the

atong

with vibration

and release.

squeak;

rr"

can sometimes

to

drive

safely

ident.

on the

because

ABS hydraulic

of the

generated

is

from

tyres)

longer

be

on such

ioads

diagnosis

the

system

unit

brake

the vehicle

thanlhat

by lowering

code.

operation

check

operation (whine)

pedal. (scrapfng;

chassis

for

other

vehicles.

the

vehicle

is

deing

oib

to repeated

X.corJingty,

speed

"nJ"not

Page 18

35-4

SERVICE

BRAKES

-

ABS

Troubleshooting

W

4

NEE

diagnosis code

When

No.24

is output

DIAGNOSIS

DIAGNOSIS

With thE MUT.II

Connect

diagnosis

Caution

Turn the

necting the

Without

1. Use

2.

the MUT-II

the MUT-II

the special

No.1.

Turn the

the diagnosis

lamp.

FUNCTION

CODES CHECK

codes.

ignition switch

MUT-II.

ignition switch

to the diagnosis

off before connecting

tool to eadh diagnosis

to ON

codes

from the flashing of

connector, then check

and then take a

or discon-

connector

the ABS warning

terminal

reading

of

oN

OFF

secs.

r

Pause time Tens

3 secs. signal

no diagnosis

When

Place

division

2 secs.

is

code

Units

signal

14tO173

output

Page 19

SERVICE

BRAKES

-

ABS

Troubteshooting

35-5

ffiG:-=\\

U\\ED

ERASING

with

the

MUT-rr

1.

Connect

erase

the

NOTE

Commands

memory

stop the

used

again.

2.

Check the

has

been

Without

1.

the

Use the

No.1.

2. Turn

the--ignition

switch

below.

codes

will

DIAGNOSIS

the

diagnosis

cannot

has

been erased.

engine

CODES

MUT-II

codes.

be received

and

start it

diagnosis

erased.

MUT-II

special

tool

to

switch

off

and

on ten

Once this

has

be erased.

to

the

To

again.

codes

earth

diagnosis

to

ON and

times

been

diagnosis

from

the

check

to

the

The

MUT-II

confirm

connector

turn

as shown

done,

all

in

of the

connector,

MUT-II

diagnosis

after

codes,

can then

that

the

memory

terminal

the

stop

lamp

the

illustratioh

diagnosis

then

the

be

&

lgnition

ABS

warning

ABS-ECU

memory

switch

lamp

ON

OFF

ON

OFF

j

within

3sec.

i

#

within

i

i

1

sec.

First

within

i

i

1

sec.

Second

i

I

Third

i

within

;

t

sec.i,

T;rh*

i

i

Rtter

_i

erasing

14CO120

1

second,

is

complete.

Page 20

35-6

SERVICE

BRAKES

-

ABS

Troubleshooting

INSPECTION

Inspect according

Diagnosis

No.

code

11

12

13

14

15

16

21

22

23

24

26 G

CHART

to the inspection

Inspection

Front right

left wheel speed

Front

Rear right

Rear left

Wheelspeed

Power

right wheel speed

Front

left wheel speed sensor

Front

right wheel speed sensor

Rear

Rear left

sensor

FOR DIAGNOSIS

chart

item

wheel speed sensor

sensor

wheel speed sensor

wheel speed sensor

sensor

supply system

wheel

speed

sensor

CODES

that is appropriate

sensor

for the malfunction

Diagnosis

Open

content

circuit

Abnormal output

Short circuit

Ooen-crrcuit.

abnormal

short-circuit

signa.

output

signal

or

code.

Reference

35-7

35-8

35-8

35-9

35-9

page

38

41

42

43

44

45

46

47

48

51

53

63

switch system

lamp

Stop

Front right solenoid

left solenoid

Front

Rear right solenoid

Rear left solenoid

Front right solenoid

left solenoid

Front

right solenoid

Rear

Rear left solenoid

Valve relay

Motor relay,

valve

valve

valve lN

valve

valve OUT

valve OUT

motor

ABS-ECU

lN

valve

lN

lN

valve OUT

OUT

35-1 0

1

35-1

35-12

35-1 3

Reolace

ECU.

the

ABS-

Page 21

SERVICE

BRAKES

-

ABS

Troubteshooting

35-7

INSPECTION

9ode

The

speeo

Measure

E-10

.

.

{,

No.l1

ABS-ECU

sensors.

at the

Disconnect

sure from

Resistance

73,

OK: 1.4

the

69 and 70,71

-

PROCEDURE

,12,13,14

determines

ABS-ECU

the

connector

harness

values

1.8

kO

that

connector.

and mea-

side.

between

and 72,24

46

an open

Wheel

and

and

speed

circuit

FOR

sensor

occurs

in

Check

A-12,

Wheel

DIAGNOSIS

open

more

than one

the

followinq

A-33,

C-26,

speed

sensor inspection.

CODES

circuit

line

of wheel

conn'ectors.

E--i3

and

E-15

Probable

a

Malfunction

a

Malfunction

a

Malfunction

cause

of

wheel

of wirinq

of ABS-ECU

speed

harness

Check

wheel

and repair

Replace

sensor

or

the

harness

speed

sensor

if necessary.

the

wheel

connector

wire

between

and ABS-ECU.

speed

sensor.

each

v

Page 22

35-8

SERVICE

BRAKES

-

ABS

Troubleshooting

No.15

Code

speed

A wheel

circuit).

Wheel speed

soeclron.

speed sensor

Wheel

spectron.

Wheel

sensor

sensor

output

speed sensor

outputs an

installation

abnormal signal

in-

voltage in-

(Abnormal

(other

Wheel speed

Check the

wheel speed sensor

and

than an

repair

output

if necessary.

signal)

open or short-

inspection.

sensor

harness

wire between

ABS-ECU,

and

Probable

.

lmproper

o

Malfunction of

o

Malfunction

o

Malfunction

.

Malfunction

.

Malfunction of

each

cause

installation of

wheel

rotor

of

of wheel bearing

of wiring harness

ABS-ECU

wheel speed sensor

sensor

speed

Replace the wheel speed

Replace the rotor.

or connector

sensor.

Gode

The voltaqe

specified

output.

No.l6

value.

Caution

lf battery

returns

Before

Measure

E-10.

o

r

to standard

carrying

at

Disconnect

from the

sure

the engine.

Start

-

Body earth

83

System

OK:

Power supply

ABS-ECU

of the

lf the voltage

voltage

drops

out

the ABS-ECU

the connector

harness side.

Voltage

voltage

power

supply drops

relurns

or

value,

following

the

connector

mea-

and

between

system

to the specified

lower or

rises during

this code

is no

inspection,

rises higher

value, this code

inspection,

longer output.

check

following connectors.

the

Check

C-59, C-66

C-25,

trouble

Check

than the

no longer

is

this code

the

and C-78

symptoms.

Probable cause

.

Malfunction

.

Malfunction of ABS-ECU

will be output

battery

level,

of wiring harness

or connector.

as well.

refill it if necessary.

and

the harness

Check

ignition-switch and the

reparr rl necessary.

lf the

voltage

wire between

ABS-ECU,

the

and

tI)

Page 23

SERVICE BRAKES

-

ABS Troubteshooting

35-9

Code No.21

These

codes

o

When

does

.

Wnen

.

When the

due to

Measure

E-1 0.

.

Disconnect

sure

.

Resistance values

73,

OK: 1.4

are output

an open

not

output

a chrpped

sensor output

a defective

at the ABS-ECU

the connector

from

the harness

69 and 70,71

-

1.8 kf)

,22,23,24

at the followinq

circuit cannot

any signal

ptugged-up

or

sensor or a waroed

between

and 72,74

be fou'nd,

during

drops

connectors

and mea-

side.

46

Wheel

rotor

and anti-lock

and

and

speed

times:

but more

driving

tooth,

rotor.

at 8

sensor

than one wheel

km/h

or higher.

etc. is detected.

control is

continuouslv

Check

the following

A-12, A-33,

short

circuit Probable

speed

sensor

carried out

C-26, E-13

connectors.

and

E-15

.

Malfunction

o

Malfunction

o

Malfunction

o

Malfunction

.

Malfunction

cause

of wheel

of rotor

of wheel

of wiring

of ABS-ECU

speed

bearino

harnesi

Check the harness

wheel

speed sensor

and repair

Replace

Replace

the wheel

the rotor.

sensor

or

connector

wire

if necessary.

speed

between

and ABS-ECU,

each

sensor.

,s,

&

Code No.26

signal

Output is

.

.

Check

Measure

o

.

.

Check the

abnormal)

provided

G-sensor output

G-sensor

Disconnect

ments

lgnition

Voltage

OK: 2.3-2.7

system harness

G-sensor.

at ABS-ECU

connectors

on harness

switch:

between

following

G-sensor

in

the following

drops

below 0.5V or rises

is

(Refer

to P.35-22.)

connector E-1

and make

side.

ON

No.62

and 45

V

connector.

0.

measure.

(open-,

above 4.5V

system

cases.

broken or shorted

E-10

short-circuited

Replace

Check the following

Check trouble

Check harness

ECU,

Replace

or

G-sensor

and repair

ABS-ECU.

Probable

o

.

o

connector.

symptoms.

between

if necessary.

cause

G-sensor

Harness

ABS-ECU

defective

and

connector defective

defective

D-27

G-sensor and ABS-

;

Page 24

35-10

SERVICE

BRAKES

-

ABS

Troubleshooting

corle No-38 Stoo lamp

following

at the

output

are

codes

These

a"

WH;ih;

for

on

.

wd;

lamp

stop

the

Does

oft

switch

Measure

.

Disconnect

measure

.

Stop

o

Voliage

OK:

iiop

minLtes

15

Aa6-ECU

inl

switch

lamP

stoP

normallY?

ABS-ECU

at

the

at

switch

lamp

6etween

System

ramp

dr

system.

the connector

harness

ON.

36

voltage

is

swiicrr

although

more

Oetermines

illuminate

connector

side.

-

bodY

switch

not b5

inat

ancl

E-1 0.

and

earth

times:

turned

ABS

the

there

system

(when the

off

not operating)

is

opeh

is an

stop

circuil'in

lamp

Stop

inspection.

lamp

Stop

the

Check

No.17

fuse

if necessary.

repair

the

Check

C-65

C-50,

switch

lamp

harness

switch

inspection

switch

harness

and

following

C-79

and

stavs

the

of

between

ABS-ECU'

the

connectors.

Probable

a

Malfunction

o

Malfunction

a

Malfunction

installation

dedicated

and

cause

of stop

harness

of

ABS-ECU

of

Replace

lamp

or

switch

connector

stop

the

lamp

switch

Check

following

the

connector.

the

Check

and

switch

necessary.

harness

ABS-ECU'

the

between

and

stop

reparr

lamp

ll

Page 25

SERVICE

BRAKES

-

ABS

Troubteshooting

35-11

Code No.41,

The ABS-ECU

there

is

flows in

Solenoid

(Refer

to P.35-21.)

Measure

78

and ABS-ECU

r

Disconnect

measure

.

Continuity

terminals

OK:

HU

side

ABS-ECU

side

HU

side

ABS-ECU

side

always monitors

an open or

the solenoid

valve insDection

at hydraulic

at the harness

between

Conlinuitv

1234

tttl

30 31 78

5678

lttl

58

42,

43, 44,

short-circuit

even

though the ABS-ECU

unil

connector A-

connectors

the

connector

side.

the following

59 50

45, 46,

the solenoid

in the

E-10.

and

79

51

47,48

valve

solenoid

Solenoid valve

drive circuit. lt

coil or in a harness:

turns on it,

Check the

A-78.

Check the

draulic

rs necessary.

determines

and vice

following

C-25.

C-59 and E-10

harness

unit and ABS-ECU,

when

versa.

that

no

currenl

connectors.

between

and repdir

Probable

a

Malfunction

a

Malfunction

a

Malfunction

the hv-

cause

of harness

of hvdraulic

of Ai3S-ECU

or

connector

unit

Replace

the ABS-ECU.

Page 26

35-12

SERVICE

BRAKES

-

ABS

Troubleshooting

Code

i:[1!_ AgS-ECU

Measure

94.

.

.

Measure

o

.

No.51

lCommentl

,eO to i iolenoid

sropf

cohiinues

valve

relay.

Solenoid

(Refer

to be

is off,

relay

Thi6 diagnosis

at

Disconnect

the

sure at

between

Voltage

System

OK:

at

Disconnect

measure

Resistance

OK:60-120O

valve

P.35-21.)

to

valve

ABS-ECU

at

Valve

continually

supplied

the

the connector

harness

voltage

the connector

the

between

insPection

relaY

monitors

even

coil

to five

ABS-ECU

is then

code

relay connector

side.

-

bodY

5

connector

side.

harness

82-47

though

or more

judges

and

earth

E-10.

the

output.

A-

mea-

and

solenoid

solenoid

the

solenoid

thal there

circuit.

drive

valve

coils even

problem

is a

Replace

Check

link No.7

necessary.

Check

A-94 and

no currenl

lf

relay

thougn

wltn

the

the

and

the

or if.current

is.on.

_tne

tne Ats5

valve

harness

valve

tollowing

or C-96

C-94

is being

solenolo

valve

relaY.

between

relay,

connectors.

and

fusible

repair

Probable

o

Malfunction

.

Malfunciion

o

Malfunction

o

Malfunction

if

cause

of valve

of

of

of hydraulic

relaY

harness

wiring

ABS-ECU

Check

relay

necessary.

unit

harness

the

ABS-ECU,

and

or connector

between

and

valve

rePair

if

Measure

78 and

.

.

HU SidE

ABS.ECU

side

HU

ABS-ECU

side

Measure

77 and

.

.

HU side

at

ABS-ECU

Disconnect

measure

Continuity

terminals

OK:

side

valve

Disconnect

sure at

Continuity

terminals

OK:

hydraulic

connectors

the connector

harness side.

the

at

between

Continuity

1234

3|o

5678

5|u

hydraulic

at

ielay

the connector

harness

the

between

Continuity

connector

unit

the

t|u ?1,

311

5|o

51,

connector

unit

connector

side.

the

11

A-

E-10.

and

following

J,

A-

A-94.

mea-

and

following

Check

A-78,C-25

Check

draulic

It necessary.

Check

A-77 and

the

unit

the

A-94

and

following

the

E-10

harness

ABS-ECU,

and

following

connectors.

between

connectors'

the

and

hY-

repair

the

Check

unit and

draulic

if necessary.

harness

valve

between

relay, and

the

repair

hY-

Reolace

ABS-ECU.

the

Page 27

SERVICE

BRAKES

-

ABS

Troubleshooting

35-13

Code No.53

These

codes

when

not

operating,

When

s.etonds

When the

are output

the motor

the

motor relay

or more

motor relav

Caution

Because

should

MUT-II

ls

the sound

head?

A?:-ffi"t

Measure

77.

.

Disconnect

sure

.

Voltage

OK:

force'driving

be started

actuator

of the motor

relav

at motor

the

at the harness

between

System voltage

Motor

at the followinq

rela!

is on

etc.)

is off

(motor

continues

does not ooerite

test

insnection

relav

connector

connector

side.

5 - body

relay,

bul no

but

a signal is input

of

and

left to run

operating

(Rerer

and mea-

earth

motor

times:

sign-al is input

operating,

etc.)

the motor

for

Yes

to

A-

to the molor

to the motor

monitor

monitor

by means

a while

Check the

draulic

rr necessary.

Check the harness

link

necessarv.

after

unrt

No.7

and motor relay,

(motor

line

line for

5

of the

actuator

testing

harnesses

and ABS-ECU,

between

between fusible

Probable

o

.

is

.

.

is

completed.

the hv-

and repdir

repair

and

Malfunction

Malfunction

Malfunction

Malfunction

test

will

if

cause

of motor relav

of wiring harness

of hvdraulic

of ABS-ECU

drain

unit

the

or connector

battery,

the

engine

Measure

.

.

Measure

.

.

y.Blo_rrii"r",'"n

at ABS-ECU

Disconnect

sure

Resistance

OK:

Disconnect

sure at the harness

Resistance

earth

OK: 0. 1-0.3O

the

at the harness

78-88O

at ABS-ECU

connector

belween

the

connector

between

inspection (Refer

connector

and mea-

side

77-82

connector

and mea-

side.

65 - bodv

E-10.

E-10.

ro

Check the

draulic

unit and ABS-ECU,

if

necessary.

necessary.

Replace

Repair

Replace the

the

harness

hvdraulic

ABS-ECU.

between

Motor

the hv-

and reodir

earth. repair

unit.

Repair

Check

the harness

relay

and ABS-ECU,

essary.

if

between motor

and repair if

nec-

Page 28

35-14

INSPECTION

an understanding

Get

CHART

SERVICE

TROUBLE SYMPTOMS

FOR

the trouble symptoms

of

BRAKES

-

ABS Troubleshooting

check according

and

to the

inspection

procedure

chart.

Trouble symptom

Communication

possible.

is not

the ignition

When

not illuminate.

After the engine starts,

ABS operation

Faulty

with MUT-II

key is turned to

lamp remains

the

Caution

1. lf

steering

with low

sudden

customer,

movements are

frictional

braking

check

resistance, or

is not being applied.

if the

problem

2. During ABS operation,

phenomenaare

prevent

the wheels

to intermittent

due

from locking and

Communication

Communication

"ON"

(engine

illuminated.

Unequal

Insufficient braking

ABS operates

ABS operates

ing

Large brake

braking

conditions

made

with

with ABS only

stopped),

power

under

before

pedalvibration

when driving at

when

occurred

the brake

pedal

changes

is

possible.

systems

all

the

on both sides

power

normal braking conditions

vehicle stops under

is not

possible.

is not

ABS warning

(Caution

2.)

high speed,

passing

Because

while driving

vibrate or

may

over

of this,

bumps,

under such

may not be able

in hydraulic

not

an abnormality.

lamp

does

normal brak-

or when driving

the ABS

when

may operate even

getting

conditions

pressure

inside the brake

on

road

Reference

page

5

JC- tO

35-17

35-1 8

surfaces

Inspection

proceoure

No.

1 35-1

2

3

4 35-17

5

though

information

from the

as these.

to be depressed.

Such

line

to

Page 29

SERVICE

BRAKES

-

ABS Troubleshooting

35-15

,(,

rNspEcnoN

Inspection

Communication

(Communication

The cause

diagnosis

Measure at the diagnostic connector

.

Voltage between 16 and earth

OK: System

Measure

.

Continuity between 4 and

o

Continuitv between 5 and

OK:

Reolace the MUT-ll

is

line.

the diagnostic connector

at

Cohtinuitv

pRocEDURE

Procedure 1

MUT-II is not

with

with all systems

probably

a

voltage

defect in the

earth

earth

power

supply system

FoR TRoUBLE syMproMs

possible.

is not

possible.)

(including

Check the

A-11x. C-65. C-67 and

following connectors.

earth)

for the

C-79

Probable cause

o

Malfunction of the connector

.

Maliunction of the harness wire

Check the harness wire between the

power

repair if necessary.

and

Check the harness wire between the

diagnosis connector and earth, and

parr

rr necessary.

supply

and

diagnosis

connector

re-

ry

Page 30

35-16

SERVICE

BRAKES

-

ABS Troubleshooting

Inspection

procedure

Communication

(Communication

When communication

in the ABS-ECU

circuit

Measure at diagnosis

ABS-ECU connector

and

.

Disconnect the connector

the harness side.

sure at

.

Continuity

terminals

OK: Continuity

ABS-ECU

side

Diagnosis connector

stoe

Measure at

.

Disconnect the

sure at the harness side.

o

lgnition switch

.

Voltage between

OK: System

ABS-ECU connector

with the MUT-ll

connector C-70

between

connector and

ON

83 body earth

voltage

2

MUT-II is not

with

with ABS only

power

E-10.

and mea-

following

the

38

7

is not

circuit or an open circuit

68

1

E-1 0.

mea-

possible.

is not

possible,

Check

C-27,C-70

Gheck the

C-25, C-66

possible.)

probably

the cause

in the diagnosis

is

following connectors.

the

E-10

and

following connectors.

and C-78

an open

output circuit.

Probable cause

.

Blown fuse

o

Malfunction of wiring harness or connector

o

Malfunction

of ABS-ECU

the harness between the ABS-

Check

ECU and diagnosis connector, and

pair

if necessary.

Check the

inside the

ECU, and repair

harness

junction

if necessary.

between

block

fuse No.3

ABS-

and

re-

Measure

o

Disconnect

sure at the

.

Continuity

earth

OK: Continuity

ABS-ECU connector

at

the connector and

harness side.

between

55, 56 - body

E-10.

mea-

Page 31

SERVICE

BRAKES

-

ABS Troubleshooting

35-17

Inspection

When ignition

ABS warning

lf the lamp

supply circuit,

and the ABS-ECU.

Fuse inspection,

Measure

.

Disconnect

sure at the male

o

lgnition

o

Does

illuminate

earthed?

OK: llluminates

Check the harnesses

ABS-ECU

Repair,

Procedure

key

lamp

does not illuminate,

a_blown lamp

Multi-purpose

at connector

switch:

the ABS

and

if necessary.

D-16

the

ionnector and mea-

oin.

ON

warning lamp

when

connector D-16.

3

is turned

o'ON"

to

does not illuminate.

the

bulb, an open

terminal

between the

cause may

fuse

7 is

be: an open

cirbuit between

(engine

Refer

a Blown Fuse.

Check whether

bulb is burnt

Check the followinq

C-68.

stopped),

circuit in the lamp

the ABS warning

to Inspection

the

ABS warning

out.

D-04

C-78.

ana D-45

power

la'mp

Service Points

lamp

connectors.

Probable

o

Blown

.

o

for

fuse

Burnt out

Malfunction

ABS warning

cause

Replace

lamp

the ABS

of wiring hirness

bulb

or connector

warning

lamp

bulb

Inspection

Even

remains

The cause is

Procedure

after the

illuminated.

probably

NOTE

This trouble

normal)

Disconnect

o

Does the ABS warning

.

Disconnect

.

lgnition

o

Does the ABS

Check the harnesses

ABS-ECU.

symptom is limited

and the

switch:

diagnosis

connector D-16

ABS-ECU

ON

warning

Repair. if

necessarv.

4

engine is

a short-crrcuit in

code is a normal

and turn

lamp remain

connector

lamp

switch off?

belween

the combination

started,

the ABS warning

the ABS

to cases

the ignition

illuminated?

E-10.

switch

warning

lamp illumination

where

communication

diagnosis

to ON.

meter

and the

code.

lamp

circuit.

with

Probable

a

a

a

the MUT-II

Replace

the

cause

Malfunction

Malfunction

Malfunction

combination meter.

of combination

of ABS-ECU

of wiring

possible

is

meter

harness

(ABS-ECU

power

supply is

Page 32

35-18

SERVICE

BRAKES

-

ABS

Troubleshooting

Inspection

Brake

This varies

pioOfem

out the

Wheel speed

speclron

operation

depending

Ciagnbsis

following

Procedure

5

is abnormal.

driving

on the

isAifficutt.

inspection

sensor

Howeier,

installalion

conditions

if a normal

in-

the

and

diagnosis

Rotor

surface

road

code

inspection.

conditions,

is displayed,

so

carry

Probable

a

lmproper

a

lncorrect sensor

a

Foreign

a

Malfuhction

a

Malfunction

a

Malfunction

o

Malfunction

a

Malfunction

installation

material adhering

cause

harness

of wheel

rotor

of

wheel bearing

of

hydraulic

of

ABS-ECU

of

Replace

of wheel

contact

to

sensor

speed

unit

wheel

the

sensor

speed

wheel speed

speed

sensor

sensor.

the

Check

A-33, C-26,

A-12,

Measure

.

Disconnect

sure at

.

Resistance

nals

OK:

(The

ihould

spections

the

Check

E-10

following

ABS-ECU

at

the

46-73,

-

1.4

sensor

be

are carried

following

harness side

the connector

69-70,71-72

moved

connectors.

E-15

and

E-13

connector

and

value between

1.8 kC)

harness

and

connector

and

these

while

out.)

connector.

C-29.

mea-

terml74'75

in-

Page 33

SERVICE

BRAKES

-

ABS

Troubteshooting

35-19

SERVICE

The

following

1.

When

Item

No.

11

DATA

the

12

13

14

16

ABS-ECU

age

17

3B

G-sensor

Stop lamp

REFERENCE

items

can

system

Check

Front-right

sensor

Front-left

Rear-right

sensor

Rear-left

is

ltem

wheel

wheel

wheel

wheel

power

output

switch

be read

normal

speed

speed

speed

speed

supply

voltage

TABLE

by the

sensor

sensor

vott-

MUT-II

from

Checking

Do

a

lgnition

monitor

Vehicle

Perform

Depress

the

ABS-Ecu

Requirements

test run

switch

power

voltage

is

stationary.

actual running.

the

brake

supply

pedal.

input

voltage

data.

and valve

NormalValue

Vehicle

displayed

speedometer

and

identical.

System

2.4

Displayed

rises

drops

ON

speeds

MUT-II

voltage

-

2.6V

value

above

below

on the

are

or

2.5

V.

2.

When

When

ACTUATOR

The

MUT-II

the

the

diagnosis

activates

ABS-ECU

TEST

NOTE

1.

lf

the ABS-ECU

2'

Actuator

testing

Activation pattern

Hydraulic

pressure

increases

Hydraulic

Sote-

pressure

noid

vatve

l19r9s ,. i

Hydraulac

pressure

decreases

40-45

ON

Pump

motor

OFF

testing

exceeds

-l

I

i

i

i

!

i

tr

i

msi

shut

off ABS

system

stops

REFERENCE

the

following

runs

down,

is

only

10

km/h,

Start

of forced

actuation

actuator

possible

forced

Release

operation.

the ABS-ECU,

the

TABLE

actuators

when

actuation

for

testing.

testing

cannot

the vehicle

willcancels.

ACTUATOR

No.

01

02

03

the

MUT-II

pedal.

brake

display

be

carried

is

stationary.

TEST

Item

Solenoid

wheeland

Solenoid

and motor

Solenoid

wheeland

valve

valve

valve

data

will

be unreliable.

out.

lf

the vehicle

SPECIFICATIONS

for front-right

motor

for front-left

for

rear-right

motor

wheel

OFF

speed

Solenoid

pump

hydraulic

inspection

during

valves

motors

unit

actuator

in

the

(simple

mode)

and

o4

Solenoid

and motor

valve

for rear-left

wheel

Page 34

35-20

SERVICE

BRAKES

-

Service

Adiustment

Procedures

Main

wiring

harness

M8991638

i4co13o

SERVICE

ABS

WHEEL

2. Disconnect

3.

OPERATION

SPEED

Lift up

1.

specialtool

iotate

rotation

circuit

Wheel

speed

sensor

Terminal

No.

Output

When

ADJUSTMENT

SENSOR

vehicle

the

the ECU

to measure

wheel

the

per

second,

tester

or an

Front

19

20

voltage

measuring

70 mV or

When

lf the output

4.

reason

o

Faulty

replace

So

measuring

mV

100

could

wheel

the

CHECK

OUTPUT

release

and

harness

from

to be

P-P

voltage

be as

speed

wheel sPeed

measured

check

and

oscilloscope.

left

Front

right

14

15

with a

more

with an

more

or

is lower

follow:

sensor.

PROCEDURES

VOLTAGE

parking

the

connector

harness

the

at

the output

Rear

16

17

circuit

tester:

oscilloscope:

the

than

sensor.

CHECK

brake.

and

connector'

side

approximately

voltage using

left

above

Rear

18

46

values,

use

112-1

right

the

a

the

Inspecting

the

Use

from each

form

o

Start

1st

Wave

following

the engine,

gear

(vehicles

wheels

manually

NOTE

1.

Check

connector

wave

The

2.

vehicle

the

The output

3.

low, and

high.

Forms

method

wheel sensor

With An Oscilloscope

to observe

with an

and

rotate

the

(vehicles with manual

with automatic

that they

so

the connection

before

form

using

measurements

is

actually

voltage will be

similarly

it will be

transmission).

rotate

the

of

oscilloscope.

the

moving.

small

large

the output

voltage

wave

oscilloscope .

wheels by

front

transmission)

constant

at a

sensor

also

can

when the

when the

engaging

range

D

or

Turn the

speed.

harness

be taken

wheel

wheel

speed

speed

rear

and

while

is

is

Page 35

sERVlcE

BRAKES

-

service

Adjustment

procedure/Hydrautic

Unir

3S-21

$)iu""JrJy

VALVE

<ABS>

Remove

Battery

Continuity

Continuity

voltage

RELAY

the

splash

no voltage

with

voltage

AND

shield

Terminal

MOTOR

(FR)

and remove

No.

1

G-

0-

--{

--€

RELAY

the relavs.

3

CHECK

4

c-

--{

5

/lrel

,EL- I

€jFJ-Fffir

lf.X.Xetl

HYDRAULIC

UNIT

INSPECTION

SOLENOID

Measure

Standard

Solenoid

Front

Front

Rear

lN

Rear

lN

Front

OUT

Front

OUT

Rear

OUT

Rear

OUT

MOTOR

connect

the

hydraulic

VALVE

the

resistance

value:

valve

(right

lN

lN

(left

side)

(right

(left

side)

(right

(left

(right

(left

side)

side)

side)

side)

side)

side)

OPERATION

the

battery

unit

motor

CHECK

and

Caution

The

battery

power

should

second.

between

Measurement

terminals

-

1

11

11 11

-- | |

3-11

2-11

5-11

8-11

7-11

6-11

CHECK

check

to

operating

not

be applied

terminals.

Resistance

terminals.

8.04

4.O4

be

sure

can

be heard.

-

9.04

-

4.54

that

for

between

O

A

the

sound

more

than

of

1

Page 36

35-22

SERVICE

BRAKES

-

Hydraulic

UniUG-Sensor

INSTALLATION

BRAKE

1.

Connect

illustration.

(1)

From

(2)

From

(3)

From

(4)

From

(5)

From

and

(6)

From

and

SERVICE

PIPE

the

hydraulic

hydraulic

hydraulic

hydraulic

master

rear

master

rear

POINT

INSTALLATION

tube

R.H.

L.H.

to the

unit

unit

unit

unit

cylinder

line)

cylinder

line)

hydraulic

front brake

to

rear brake

to

rear brake

to

front brake

to

to hydraulic

to

unit as

(L.H.)

(R.H.)

(L.H.)

(R.H.)

hydraulic

unit

shown

(front L.H.

unit

(front

in the

R.H.

line

line

MB991

348

G-SENSOR

INSPECTION

1. Disconnect

special

connector.

Turn the

2.

following

Between

Standard

With the

that

so

take a

Between

Standard

voltage

lf the

4.

sure

to be

earth

and

the G-sensor

tool between

ignition

outPut

terminals

value:

special

label

the

reading

of

terminals

value: 3.4

is outside

that

wires,

switch

voltage.

No.2 and

-

2.4

tool still

surface

following

the

No.2 and

-

is

there

replace

connector

terminals

the

take

to ON

2.6

connected,

is facing

3.6

the standard

no abnormality

the G-sensor.

and

No.3.

V

straight

output

No.3.

V

connect

and

the disconnected

of

reading

a

secure

voltage'

value, after

the G-sensor

down,

power

in the

of

and

checking

supply

the

the

then

Page 37

528-1

SUPPLEMENTAL

RESTRAINT

0

SYSTEM

CONTENTS

TROUBLESHOOTING

AIR

(SRS)

Standard

Inspection

Inspection

Diagnosis

lnspection

lnspection

MODULE

BAG

Diagnostic

of

Flow

for

Chart

procedure

.........

Code

for

Chart

Procedure

AND

Troubleshooting

Diagnostic

Classified

Trouble Symptoms

for Trouble

Codes

CLOCK

.......".......'..'

by

.".-...'.'.'."

Symptoms'."'.'.

SPRING

.."...4

4

'.......

....'... 5

12

12

14

......

5

o

Page 38

52B'-2

SRS

-

SRS

Service

Precautions

SRS

SERVICE

1. In order

accidental

from

servicing,

precautions

manual.

not use

2.

during

the

this

Do

near SRS

P.52B-4.

on

3.

Never

Attempt

Components:

.

SRS

o

Clock

.

Air

Bag

(Driver's

SRS-ECU

PRECAUTIONS

to avoid

any electrical

components,

air bag

Spring

Module

injury

deployment

read and

procedures

and

Repair

to

control

front

or

side

connector

yourself

to

of the

carefully

described

equipment

test

except

unit

those

Following

the

(SRS-ECU)

passenger's

others

or

air bag

follow

all

in

or

on

specified

side)

Do not attempt

4.

the SRS.

replace

faulty,

the

lf

any

wiring

the

replace

following

table.

repair

to

the connectors

of

repair the

or

the wiring

harness.

harness

are diagnosed

wires are

lf the

wiring

harness

connectors

faulty,

as

diagnosed

according

as

of

to

Page 39

SRS

-

SRS

Service

precautions

528-3

16

to

19

21

pins,

yellow

Body

wiring

module

Body

passenger's

Body

Body

Body

Body

Body

(Drive/s

wiring

wiring

wiring

wiring

harness

wiring

wiring

harness---

harness

harness

harness

harness

harness

side)

-

side)

-

--.+

---r

-

.-+

Clock

spring

Air

bag

Diagnosis

Junction

Junction

SRS

Earth

block

block

warning

-

module

(Front

connector

(fuse

(fuse

lamp

Air

bag

No.1

No.1g)

1

)

Correct

wiring

Corrective

Correct

wiring

clock

Correct

wrnng

Correct

wiring

Correct

wiring

or

harness.

spring.

or

narness.

or replace

harness.

or replace

harness.

or

harness.

action

replace

Replace

replace

replace

each

each

each

each

body

Insulating

6.

SRS

and

7.

whenever

functions

8.

Make

you

9.

lf

NOTE

SERIOUS

THE

tape

components

clock

sprino

you

should

b*1"

-finish

servicirig

properly.

certain

have

PROCEDURES

that

the

questions

any

INJURY

CAN

ignition

AND

Battery

not

be

subjected

gryjp

about

RESULT

oa!1s

ql

tne

snb,

switch

the

is

SRS,

FROM

EQUIPMENT

5.

After

seconds

fottowing

enough

even

serious

deptoyment

immediatery

nected.

to

hear

over

the

vehicre

check

oFF

pr""r"

warning

when

the

.oitaciyour

UNINTENDED

SPECIFIED

disconnecting

or

m_ore^before

work.

vottage

after

injury_may

93.C,

The.sRS

to

the

battery

if

work

after

so

deptoy

result

the

remove

aflei[aintins

iamp

operation

MUT-II

IN

is

AIR

THIS

connected

tocal

distributor.

BAG

MANUAL.

the

battery

cable,

proc;eding

systdm

ihe

has

is

done

battery

the

to

or

DEPLOYMENT,

is

oeiiln-eo

air

bag

foi

been

from

aisconneci"-ol'"o

unintended

on

the

SRC

cabres

SRS-ECU,

make

sure

air

that

disconnected.

SO

wait

-tne

*ltn

io'i"t"in

JJrrortiirn"

"ii'O"g

"V"i",

oi""on-

"r"

bag

module

the

system

USE

ONLY

60

Page 40

52B'-4

SRS

-

Special

Tool/Test

EquipmenUTroubleshooting

SPECIAL

Tool

TEST

Tool

TOOL

Number

M8991613

EQUIPMENT

TROUBLESHOOTING

Name

check

SRS

harness

Name

Digital

multi-meter

Use

Checking

Use

Checking

a

Use

maximum

minimum

the

measurement

SRS

test

range

electrical

electrical

current

the SRS

the

multi-meter

circuitry

circuitry

which

for

is

resistance

of

the

2 mA

or

less at

STANDARD

Gathering

information

FLOW

Check

OF

from customer

diagnosis

co

i'*qrr**,'.*.il-

trouble

Inspection

syniptoms

(Refer

chart

for

P.52B-12.)

to

Verify

I

t

I

J

TROUBLESHOOTING

complaint

*"o".r,..

Diagnosis

displayed

diagnosis

trouble

P.528-5.)

to

P.528-5.)

to

DIAGNOSTIC

- I

d"

--T-

Recheck

1n

-=t-

Check

(Refer

irn"-@'l

(nefer

|

codes

code

code(s)

{

Diagnosis

displayed

then

erase

code

res

nol

agnosis

Diagnosis

No

cooe

|

reoccur

code

lntermittent

osrs

mallunction

Page 41

SRS

-

Troubleshooting

528-5

INSPECTION

Inspect

21,22,61,62

24,25,64,

according

65

CHART

to

Analog

Safing

Driver's

Front

SRS-ECU

Connector

SRS-ECU

lG,

lG,

SRS

sysrem

SRS

FOR

the inspection

G-sensor

G-sensor

side

passenger's

(A) power

(B) power

warning

warning

DIAGNOSIS

chart

system

system

air

bag

side

capacitor

lock

system

(deployed

circuit

circuit

lamp

lamp

drive

modute

air bag

svsrem

air bag)

system

system

drive

circuit

circuit

that

is

appropriate

in

the

SRS-ECU

in

the

SRS-ECU

(squib)

module (squib)

system

system

CODES

system

Lamp

Lamp

for

the

system

does

does

malfunction

not

illuminate.

not

switch

off.

code.

sRS-ECu

Driver's

Front

NOTE

,t,.'lff;J;,1ffii:t;:?n

(2)

ff

the

vehicle

displayed,

INSPECTION

Gode

It outputs

r

.

.

Replace

Ine

sH5-EL;U

When

When

When

No.14

this

the

analog

the

characteristics

the

output

the

SRS-ECU.

has,

check

the

PROCEDURE

Analog

monitors

code when

the

any

G-sens6r

from

the

non-volatite

side

passenger's

returns

a

discharged

batterv.

G-sensor

output

of

the

of the followinq

is not

operatiio

of

the

analog

analog

G-s6nsor

memory

air

bag

modure (squib

side

air

bag

to

normal,

battery

the

it

will

CLASSIFIED

system

analog

ari

G_sensor

is

in

G-sensor

Celecteo.

are abnormal

abnormal

the

inside

(EEpRoM)

ignition

modure

diasnosis

store

(squib

code

the

fault

BY

DIAGNOSIS

SRS-EC-

the

sRS-Ecu.

and

drive

ignition

wifl

codes

A/D

converter

circuit)

system

drive

circuit)

be

automaricaly

41

or 42.

CODE

Probable

.

Malfunction

svstem

svstem

erased,

when

cause

of

SRS-ECU

these

and

the

sRS

diagnosis

warning

cooes

are

Page 42

528-6

SRS

-

Troubleshooting

cocle No-l5 Safino G-sensor

open

This code

safinq

in" tiornte

Code

is output

G-sensor

ciuses

No.

inside

15

16

SRS-ECU.

Replace

lhe

CoO"

No.21

{errrrih\ svstem

diaqnosis

These

terminals

irJrorc

in"

Code

5f the

No.

drivefs

iiuses

21

22

61

62

is a short

if there

SRS-ECU.

the

for each

,22,61

are

codes

side

tor each

or

diagnosis

Trouble

Short

Driver's

or 62

if there

output

module

bag

air

diagnosis

Trouble

o

short

r

Short

a

Ooen

a

Open

a

Malfunction

o

Short

o

Short

code

circuit

code

svstem

circuit

No are

in

between

as

symPtom

in the

side

is abnormal

(squlb)'

are as

No

symPtom

driver's

in

sPring

clock

in

in driver's

crrcurt

in clock

circuit

of connector

in driver's

in driver's

the SRS'ECU

terminals

the

follows'

G-sensor

safing

module

bag

air

resistance

follows'

side

side

side

between

bag

air

side