Page 1

Brake Upgrade Options for the AWD 3000GT/Stealth

or "If it won't brake, fix it"

by Jeff Lucius

Topics

Introduction

Stock Brakes

Braking Torque

Brake Fluid

Brake Lines

Brake Pads

Brake Bedding

Rotors and Calipers

Synopsis

Acknowledgments

Introduction

Before you go out and spend possibly $2000 to $3000 or more for the "ultimate" stopping power for our

cars, consider first that the stock brakes on all years of Mitsubishi 3000GT VR4 and Dodge Stealth R/T

Twin Turbo are some of the best on production cars for the time period (1991-1999). The stock brakes

are entirely adequate for street use but can benefit from better fluid, stainless-steel braid-protected brake

lines, and Metal-Matrix or carbon-blend brake pads. For track or other performance use, an investment

in a rotor and caliper upgrade should be seriously considered.

In the table below are some performance results for stock brakes on new production 3000GT/Stealth (3S)

cars from popular car magazines. Braking distances from 60 to 0 mph approaching 110 feet are

considered outstanding for street cars. For comparison, Road & Track presents these selected 60-0 mph

stopping distances in their Dec 2000 and Dec 2004 issues (with 10' significant distances): Porsche 911

GT1, 98'; Lotus Elise, 105'; Mitsubishi Lancer Evolution, 108'; Ferrari Enzo, 109'; Ferrari 360 Modena,

110'; Mazda RX-8, 110'; Volvo S40 T5, 110'; Subaru Impreza WRX STi, 111'; Lexus IS 300, 113';

Mercedes-Bens SL500, 113'; Dodge Viper SRT-10, 114'; Audi TT Coupe, 116'; Chevrolet Corvette,

116'; Acura NSX, 117'; Ford GT, 117'; Volkswagon Toureg V8, 117'; Porsche 911 Turbo, 119'; Nissan

Skyline GTR, 120'; BMW M Roadster, 121'; Panoz Esperante, 122'; Saleen S7, 125'; Lamborghini

Diablo VT, 126'; Ameritech McLaren F1, 127'; Chevrolet Camaro SS, 129'.

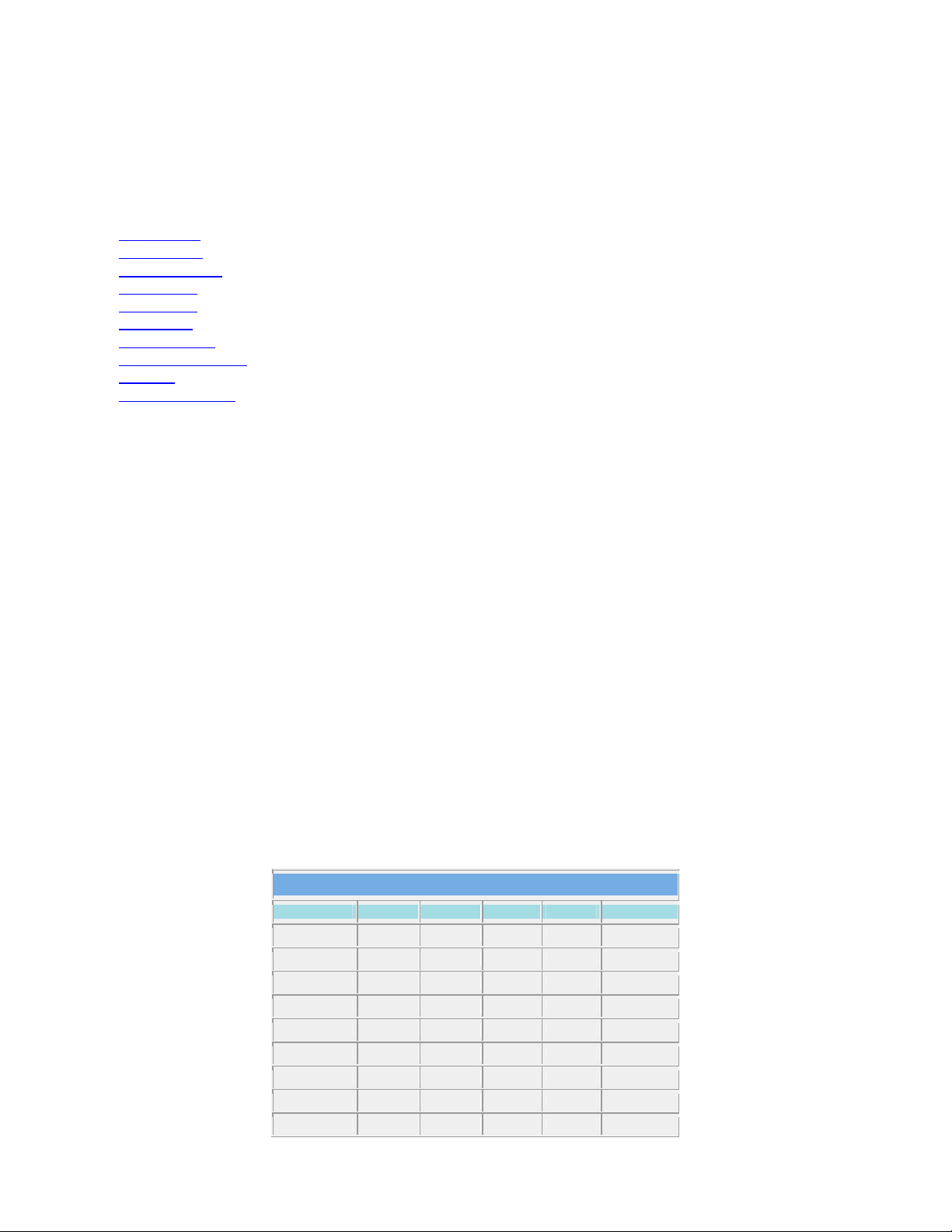

3S Stock Braking Performance

Magazine Issue Car 60-0 mph 80-0 mph 100-0 mph

Sports Car Int'l 9/90 '91 TT 120 ft 214 ft

Road & Track 9/90 '91 VR4 135 ft 237 ft

Motor Trend 3/91 '91 VR4 117 ft

Sports Car Int'l 12/93 '94 VR4 123 ft 223 ft

Sports Car Int'l 8/95 '95 VR4 123 ft

Road & Track 8/96 '97 VR4 347 ft in 4.5 s

Sports Car Int'l 10/96 '95 Spyder 134 ft

Motor Trend 5/97 '97 VR4 116 ft

Road & Track 1999 spec. '99 VR4 122 ft 218 ft

Page 2

The Road & Track 9/90 issue also tested for brake fade on their '91 VR4. Cool brakes required 15 lb of

pedal effort to execute a 0.5 g stop. After six of these 0.5 g stops in a row, pedal effort remained at 15 lb;

that is pretty good for street brakes.

The Road & Track 8/96 issue published the results of their 0-100-0 mph competition. The stock '97 VR4

did not do so well overall except that it had the best 100-0 mph stopping time of 4.5 seconds (347 ft). No

car in the competition decelerated faster. The four-wheel ABS system contributes to this success. Other

cars did stop in a shorter distance in this competition: HKS-modified Supra in 326 ft (5.1 s), BMW M3

in 334 ft (4.5 s), and Mercedes-Benz C36 in 340 ft (4.9 s). The Porsche 911 Turbo stopped in 363 ft (4.6

s). Interesting that the Supra had to be modified to be in this competition. I wonder ho w well a modified

VR4 would have done?

The objectives of braking system improvements are to reduce stopping distances (especially from high

speeds), tune the feel of the brakes (subject to the driver's preferences), and improve thermal control

(heat dissipation and temperature sensitivity). Though the tire-to-road interface always limits rapid

deceleration, I don't discuss tires here. Quite often a switch to stickier tires may be the easiest way to

improve your stopping distances. However, if repeated application of the brakes causes fade in the

application that you are using your car, whether it is the street or the track, then thermal control must be

a priority. Some of the information presented here is applicable to any automobile. However, I have

concentrated on improvements for the AWD 3000GT/Stealth braking systems.

The following steps (in order) should be considered when improving your braking system.

1. Improved brake cooling.

2. High-performance brake fluid.

3. Steel braided brake lines.

4. High-performance brake pads.

5. Larger rotors and calipers.

6. Master cylinders.

There are no commercial brake-cooling kits for our cars that I know about. Improved brake cooling for

3S cars generally takes the form of homemade combinations of venting, heating, and roof-drain parts

that direct cool air from the front of the car onto the rotors and calipers. Also, I am not aware of any

aftermarket master cylinders that are available. The master cylinder converts the force generated by the

brake pedal assembly into hydraulic fluid pressure. The stock master cylinder seems to provide a good

balance between fluid capacity (sufficient for our ABS system) and hydraulic pressure (1.133 times

pedal force). So I will concentrate on items 2 through 5 above. But first, I'll summarize the stock setup

and present the concept of braking torque.

Stock Brakes

The front brakes for all years of the AWD models use ventilated, iron-disc rotors with 4-piston, rigid,

iron calipers. The outside dimensions of the calipers changed in 1994 because of the larger rotors but the

internal parts (such as the pistons) and the brake pads did not change. The rear brakes for AWD models

up to 1993 use ventilated, iron-disc rotors with single-piston, floating, iron calipers. Starting with the

1994 model year, the AWD cars have rear brakes with twin-piston, rigid calipers. The drum-type

parking/emergency brakes are incorporated into the hat of the rear rotors. The master cylinder is the

2

Page 3

same for all model years, with a 26.9 mm (1.06") inside diameter, as is the vacuum-type brake booster,

with an approximate 7:1 boosting ratio of the brake pedal force. Mitsubishi recommends DOT3 or

DOT4 brake fluid for all years. Though not directly related to the brakes, the following wheel

information may be relevant when upgrading. All wheels (all sizes, all years) on all models (FWD or

AWD) have a 46 mm (1.81") offset with 5 lugs in a 114.3 mm (4.5") pitch circle diameter. The relevant

"performance" dimensions of the stock brake systems are summarized in the table below. Note that rotor

sizes are the actual outside diameters. The service manual specifications are "effective diameters", which

is likely near the middle of the brake pad.

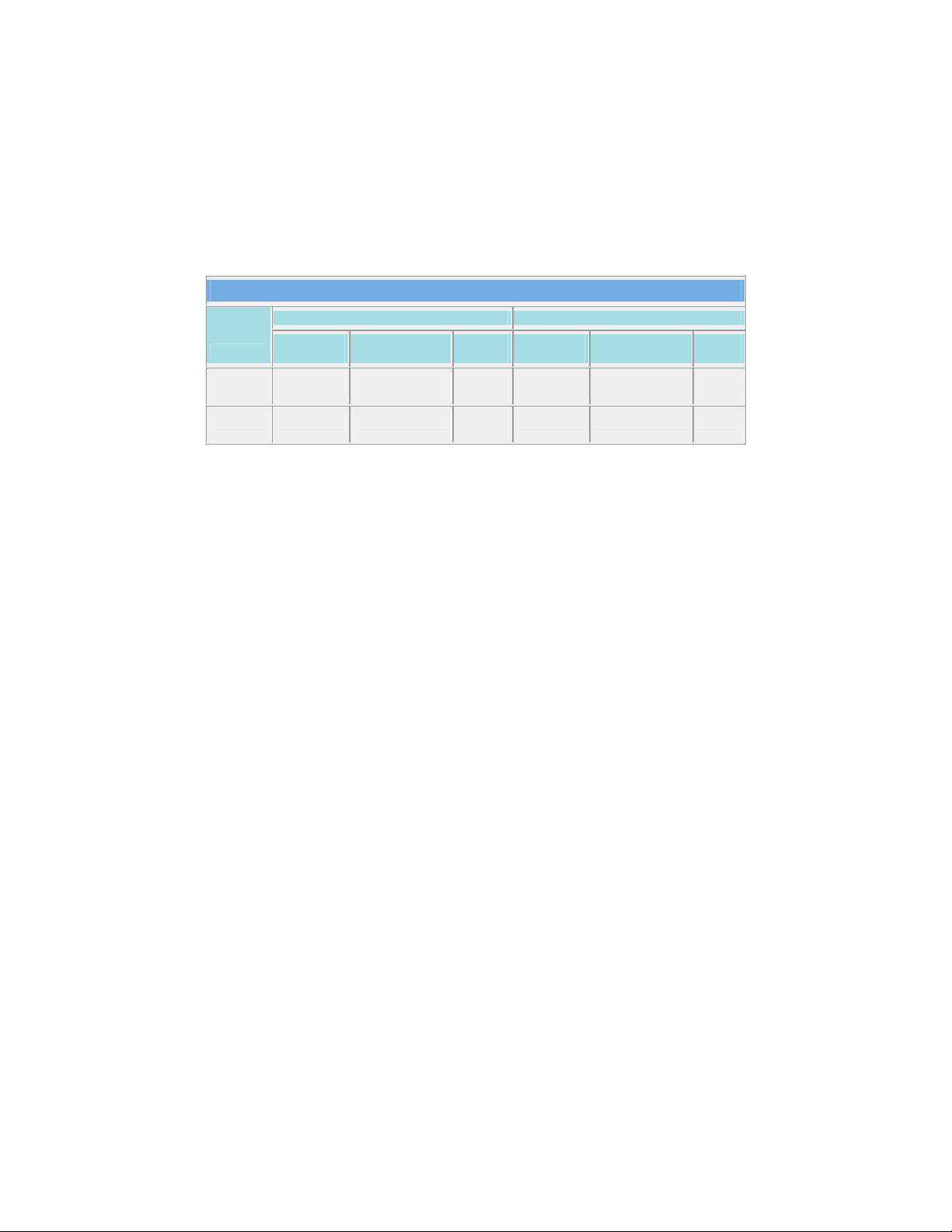

Stock Dimensions

Front Rear

AWD year

1991-1993

1994+

Rotor

O.D. mm (in)

295 (11.62) 30 (1.18)

314 (12.36) 30 (1.18)

Rotor

Thickness mm (in)

Cylinder

ID mm

40.4 x 2

+ 42.8 x 2

40.4 x 2

+ 42.8 x 2

Rotor

O.D. mm (in)

284 (11.19) 20 (0.79) 38.1 x 1

295 (11.62) 20 (0.79) 38.1 x 2

Rotor

Thickness mm (in)

Cylinder

ID mm

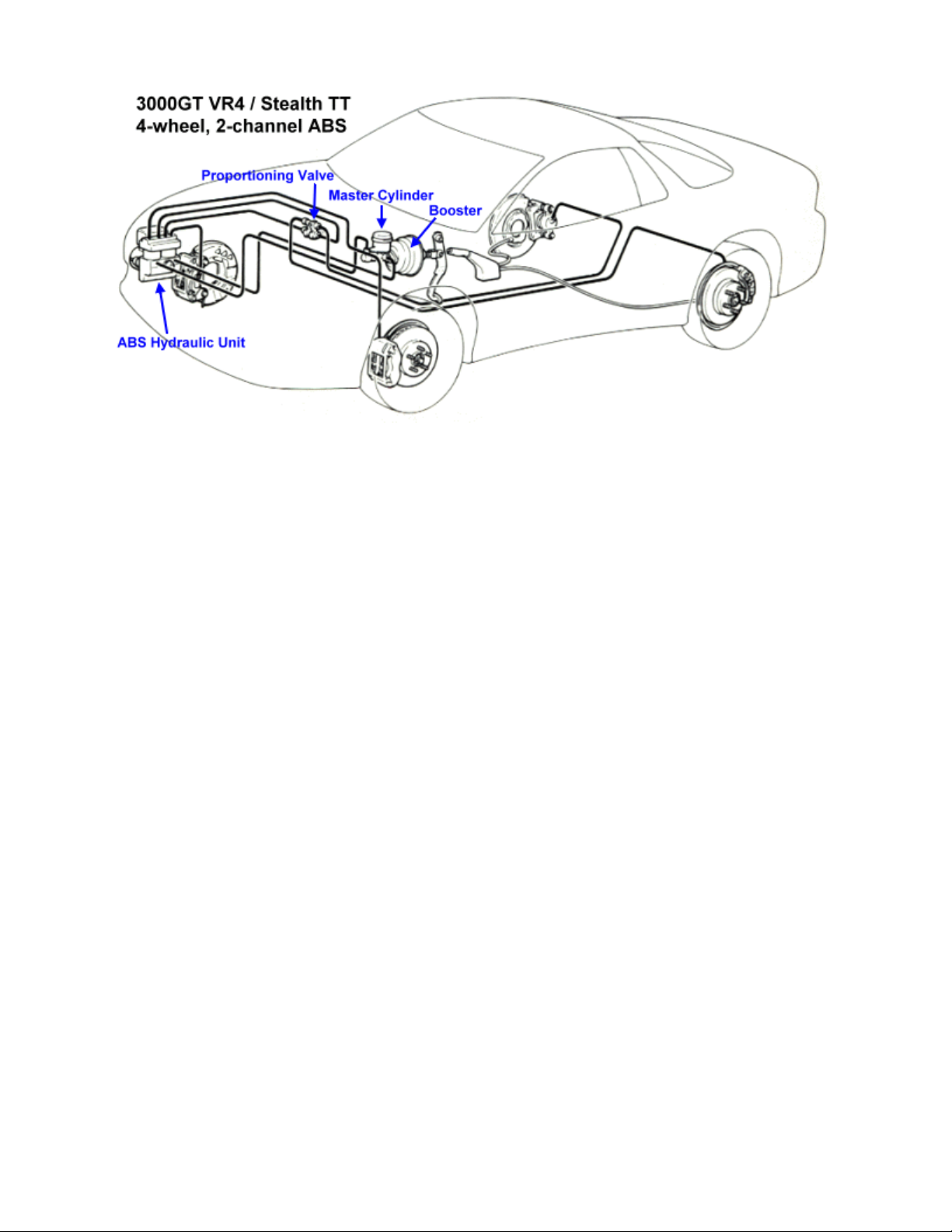

The 3000GT VR4 and Stealth TT utilize a 4-wheel, 2-channel ABS braking system, as shown in the

illustration below. The master cylinder contains two pistons which effectively divide the brake lines into

two separate hydraulic systems. One system is the left-front and right-rear brakes, and the other is the

right-front, left-rear brakes. This is done for safety in case a leak develops in one of these systems.

These two hydraulic lines go from the master cylinder to the ABS hydraulic unit (HU). The HU controls

the four output brake lines as two channels. One channel for each side of the car. However, because of

the use of select-low valves between the two rear wheels and between two wheels on one channel (same

side of car), a total of 3 wheels are controlled hydraulically at the same time. In order to prevent lock-up

of the rear brakes during heavy braking, a proportioning valve is used on the two brake lines going from

the HU to the rear brakes. For the hatchback AWD models, the output pressure will be the same as the

input pressure until there is 533 to 604 psi pressure in the rear brake lines (called the split point). At

pressures greater than this, the output pressure to the rear brakes will drop 34 to 42 percent. For the

convertible AWD models, the split point is higher at 704 to 775 psi and the pressure drop is lower, 25 to

34 percent. The preceding is for North American and European models. The proportioning valve for

vehicles bound for Australia was yet a third model. It had a split point in the range of 391 to 462 psi and

a pressure drop of about 25 percent.

3

Page 4

Braking Torque

Torque is a force acting to rotate a body about an axis. Torque can be directed to increase or decrease

rotation. Torque is the magnitude of the force times the perpendicular distance between the line of action

of the force and the axis. Braking torque (TB) then is the force applied by the caliper to the rotor (FB

)

C

times the effective radial distance the brake pads are from the center of the wheel (RE). The force

applied by the caliper is determined from the pressure in the hydraulic lines (PH) times the total piston

area in one half of the caliper (AP) times the brake pad coefficient of friction against the rotor (µ) times 2

(there are pads on both sides of the rotors). The complete expression is below.

TB = FB

x RE = [PH x AP x µ x 2] x RE

C

The pressure in the hydraulic lines (PH) is determined from the pressure exerted by the driver on the

brake pedal, the length of the brake pedal "arm", the brake booster, the size of the brake master cylinder,

and the condition of the brake fluid.

Please note that ultimately it is the friction of the tire acting against the road surface tha t actually stops

the car. If there is little friction, such as "balled" tires on ice, the car will not stop well regardless of

brake torque. On the other hand, if tire-road friction is good a car can come to a stop (eventually) with

no application of the brakes (let's imagine the drivetrain and its "drag" have been removed, as well as

aerodynamic drag).

The upgrades and maintenance discussed here are designed to optimize braking torque. Keeping the

brake fluid free of water and from excessive heating maximizes transfer of pressure from the master

cylinder to the calipers. Stainless-steel braid-protected brake lines reduce pressure transfer time from the

hard lines through the soft lines to the calipers. Good brake pads provide the optimum friction

coefficient, which is heat dependent, as well as assist in heat dissipation/absorption management. Rotors

can increase brake torque if they have a larger effective diameter, and can assist in heat dissipation.

Finally, better calipers provide optimal management of heat transfer to the brake fluid, and of force

multiplication using piston area, reduced pad vibration, reduced mounting flex, and optimized offset

loads.

4

Page 5

Before proceeding, let's look at how the braking torque is biased in the factory system. For all AWD

models, both front brakes have a total of 5441 mm2 of piston area and both rear brakes have a total of

2280 mm2 of piston area. When pressure is the same in all hydraulic lines, that is, when the ABS is not

activated and pressures are below the split point in the proportioning valve, there is a front bias of

5441/2280 or 2.38:1, or equivalently, the rear brakes pads get about 42% less pressure than the front

pads. The difference in effective diameter of the rotors further increases the front bias to an overall bias

F/R of 2.5:1 for 1991-1993 AWD models and 2.58:1 for 1994 and later AWD models. When braking

hard enough to exceed the split point pressure in the proportioning valve, overall front bias will increase

to about 3.85:1 for hatchback models and to about 3.38:1 for convertible models. For track use, there

may be some advantage in swicthing to the convertible's proportioning valve (higher split point), or if a

person could find one, the proportioning valve used in vehicles exported to Australia (lower split point).

For example, if the front brake bias has been increased through the use of larger rotors and same-asstock or greater piston area, then an increase of rear bias (about 12% or so) to balance this could be

achieved under hard braking by using the convertible's or Australian proportioning valve on the

hatchback.

Brake Fluid

The Haynes Automotive Reference Manual defines brake fluid as "A compounded liquid for use in

hydraulic brake systems, which must meet exacting conditions (impervious to heat, freezing, thickening,

bubbling, etc.)." Well, being impervious to heat is certainly the goal! The car's brakes convert the kinetic

energy of the car into thermal energy, or more simply, they heat up as they slow the car down. The heat

(energy) generated by the brake pads and rotors heats up the brake fluid in the calipers. If the fluid heats

up enough, it will boil creating vapor in the system. Vapor in the hydraulic system (whether it is from

brake fluid, water dissolved in the fluid, or air) is bad because it is compressible, reducing braking

efficiency, possibly to the point of loosing the brakes entirely. This is called brake fluid fade.

WARNING. Brake fluid is poison. Keep it away from skin and eyes. Do not

allow brake fluid to contact painted surfaces.

The DOT brake fluid classifications (

guidelines for manufacturers as to how impervious their fluid is to heat. The dry boiling point (when the

fluid is fresh and contains no water) is the temperature at which the fluid turns to vapor. The wet boiling

point (measured when the brake fluid contains 3.7% water) is related to how easily the brake fluid will

absorb water (or how hydroscopic the fluid is). The lower the wet boiling point, the more water the fluid

will absorb. Absorbing water is bad, so a higher wet boiling temperature means better brake fluid. And,

of course, a higher dry boiling point is good too.

The table below summarizes the DOT guidelines plus the relative advantages and disadvantages of each

fluid type. The actual performance may exceed the DOT guidelines and should be printed on the

container. For example, Pyroil Premium DOT 3 Brake Fluid states a minimum wet boiling point of

291ºF. DOT 3 and DOT 4 are polyglycol-based fluids and can be mixed with each other. DOT 5.1 can

also be mixed with DOT 3 and DOT 4, even though it is based on a different chemical and has about

half the viscosity. If DOT 5.1 is specified for an ABS system, do not add or use any other fluid type.

DOT 5 is silicone-based (not less than 70% by weight of a diorgano polysiloxane) and must not be

mixed with or contaminated by DOT 3, DOT 4, or DOT5.1.

49CFR571.116) include a set of minimum specifications that are

5

Page 6

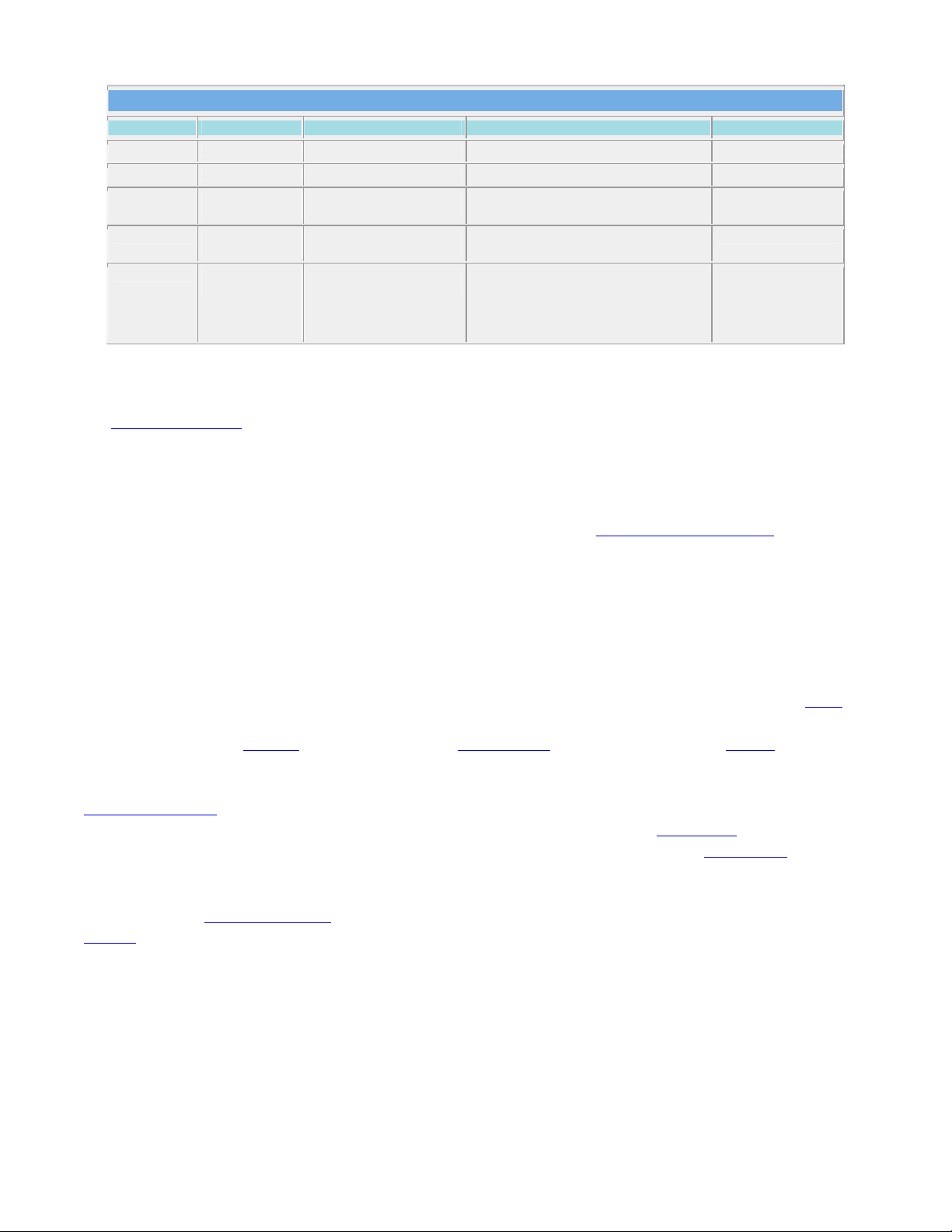

Standard Brake Fluids

DOT 3 DOT 4 DOT 5 DOT 5.1

Dry BP ºF (ºC)

Wet BP ºF (ºC)

Kin. Viscosity

mm2/second

Advantages

Disadvantages

401 (205) 446 (230) 500 (260) 500 (260)

284 (140) 311 (155) 356 (180) 356 (180)

1500 max @ -40ºF

1.5 min @ 212ºF

- Inexpensive

- Readily available

- Attacks paint!

- Most hydroscopic

1800 max @ -40ºF

1.5 min @ 212ºF

- Available at auto parts stores

- Less hydroscopic than DOT3

- Attacks paint!

- More expensive than DOT3

900 max @ -40ºF

1.5 min @ 212ºF

- Does not attack paint

- Does not absorb water

- DOES NOT mix with DOT3, DOT4, DOT5.1

- Water may "puddle" in the system

- Careful bleeding required

- Slightly compressible near its boiling pt.

- Very expensive, hard to find

900 max @ -40ºF

1.5 min @ 212ºF

- Superior performance

- Attacks paint!

- Expensive, hard to find

Probably the best thing you can do to maximize the performance of your brake fluid (any type) is to

change it regularly (at least once a year) to minimize the amount of water in the system. According to

the Car Care Council and SAE field tests, brake fluid can become contaminated by water (2% on

average) within 1 to 2 years, and in substantially less time in humid climates. Brake fluid (other than

DOT 5) readily absorbs water from the air in the master cylinder. This cannot be prevented and

changing (flushing) the brake fluid is the only solution. Alternating the use of different-colored fluids

can aid in knowing when the flushing process is complete. The dry boiling point of DOT 4 is higher than

the wet boiling point of the best brake fluid (Castrol SRF excepted). Speed Bleeder Products makes a

replacement bleeder screw for the brake calipers that allows one-person bleeding. Speed Bleeders cost

$7.00 each; you'll need 4 plus one for the clutch release cylinder if desired. For the Stealth and 3000GT

turbo models, use Speed Bleeder model SB1010 for front calipers and rear calipers, except use SB7100

for rear calipers on cars with 3/92-5/93 production dates. SB1010 also works for the clutch release

cylinder.

While our brake system will perform as designed using standard DOT 4, you may want to consider one

of the popular high-performance brake fluids, especially for racing situations. Some of these are Ate's

(Alfred Teves Engineering's) Super Blue Racing and "Super Gold" (same fluid but different color; also

called Ate Typ 200), Motul's 5.1 and Racing 600, AP Racing's 550 and Ultra 5.1, and NEO's "Super

DOT".

Raceshopper.com sells Ate Typ 200 (or Super Blue Racing) for $9.95/liter, and other brake fluids at

some of the best prices you will find. Motul Racing 600 can be purchased at

Other retailers sell AP Ultra 5.1 for about $20/liter and AP 550 for about $28/liter.

Porterfield for $18/liter.

Brake Man sells their

racing brake fluid for about $25/liter. NEO "Super DOT" 610 sells for about $12 per 12-oz can ($34/liter)

and has the highest wet and dry boiling points. Castrol SRF has very high boiling points as well, but at

about $65/liter (raceshopper.com) seems to me to be a bit expensive; but not nearly as expensive as

GS610 which sells for ~$84/liter! Ford Heavy Duty brake fluid is cheap ($6/liter) and has a very-high

dry boiling point, making it a favorite for the weekend racer that changes brake fluid frequently.

However, the DOT 3-rated wet boiling point makes Ford Heavy Duty less than desirable for street usage.

Do not mix any of these fluids, some of which are DOT 4 and others are DOT 5.1, with DOT 5 siliconebased systems.

6

Page 7

Dry BP ºF

(ºC)

Wet BP ºF

(ºC)

Price

per liter

Motul

Ultra

5.1

509

(265)

365

(185)

$12-14

High-Performance Brake Fluids

AP

Ate

Ford

AP

Ultra

(270)

(191)

~$14-

Typ

200

536

392

HD

550

(288)

290

(143)

5.1

518

(280)

375

(200)

$10-15 ~$6 ~$28 $25 ~$30 $34 ~$18-21 ~$36-40 $65-75 ~$30 ~$34 ~84

20

550

563

(295)

293

(145)

Brake

Man

577

(303)

300

(149)

Earl's

Hypertemp

421

585

(307)

421

(216)

NEO

585

(307)

421

(216)

Motul

Racing

600

585

(307)

421

(216)

AP

Super

600

590

(310)

410

(210)

Castrol

SRF

590

(310)

518

(270)

Motul

RBF

600

593

(311)

420

(216)

Ate Super Blue or Typ 200

Store Price/liter

raceshopper.com

Strictly German

DaliRacing

SP Motorsports

Spec Miata Superstore

Cobalt Friction Technologies

Mach V Motorsports

$9.95

$9.95

$10.00

$10.85

$10.95

$11.99

$14.00

NEO

Super

DOT 610

610

(321)

421

(216)

GS610

610

(321)

421

(216)

Ate Super Blue and Type 200 - the best deal in

performance brake fluid for the street at $9.95/liter.

Brake Lines

The brake fluid is contained in rigid steel tubing from the master cylinder to about 1 foot from the

calipers. To allow for movement in the suspension, a flexible rubber-coated nylon hose connects the

steel tubing to the calipers. These eight short hoses (two per wheel for the 3000GT/Stealth) can expand a

small amount as pressure increases in the system. The expansion of these hoses increases the hydraulic

volume of the brake system and causes a small delay in actuating the calipers. As the hoses age, their

expandability can increase. To reduce this delay and improve "pedal feel" (increased firmness and

reduced pressure), the rubber hoses can be replaced with nylon hoses covered by stainless steel braiding.

SMC (using lines and fittings from Goodridge) supplies a steel braided brake line kit (part number

46200-M3000) for our cars ('90-'95). The SMC kit costs from $200 to $250.

MVP Motorsports has

advertised this kit for as low as $188. Pictures of the SMC lines mounted on my car can be seen at 2-

brakelines.htm. New stainless-steel braid-protected brake lines are supplied with many of the

combination rotor and caliper upgrade kits mentioned later in the web page.

Brake Pads

As mentioned above, the brakes convert the cars kinetic energy (its forward or reverse movement) into

thermal energy (heat) in order to assist in stopping the car. Notice I said assist; this is because it is the

friction of the tire acting against the road surface that actually stops the car! The brake pads are pressed

against the rotor by the pistons in the calipers. The amount of force actually exerted on the rotor is

7

Page 8

determined by the force exerted on the pads by the caliper pistons multiplied by the brake pad

coefficient of friction against the rotor. Typical coefficients of friction are in the range of 0.25 to 0.50

when the rotors and pads are at their working temperatures. The exact value is not that important as the

driver can simply press harder on the brake pedal or use larger pistons in the caliper or larger rotors to

compensate for pads with a lower-than-average coefficient of friction. What is very important, though, is

how the coefficient of friction changes as the pads and rotors heat up. With hot rotors and pads the

coefficient of friction can drop dramatically (even below 0.10) depending on pad composition. This

condition is known as brake fade, which should not to be confused with "brake fluid fade" from vapor

in the brake lines or "green fade" from improperly bedded pads.

There are two solutions for brake fade: thermal management (such as cool air ducts or better rotor and

caliper design) or improved brake pad material. Performance brake pads maintain an acceptable and

relatively stable coefficient of friction under a variety of driving conditions and temperature ranges.

However, some pads designed for racing may require higher temps than are achieved on casual street

driving for optimal friction. For example, according to Rennsport the Ferodo DS11 racing pad doesn't

develop much friction until it is near 450ºF. Be sure to look at the manufacturer's working temperature

range for their product to be sure it is suitable for your intended use.

Green fade is caused by the rapid boiling out of the resins and glues used in pad construction to form a

liquid layer between rotor and pad, reducing the coefficient of friction to near zero. Green fade occurs

when brake pads are overheated before the material has had a chance to "cure" on the car. "Bedding in"

the brakes (see next section) causes this boiling out to occur in the first few heating cycles and so

"cures" the pad.

Based on composition, there are basically four types of brake pads. Organic pads are made of cellulose

bound with a phenolic resin, with less than 20% metal content. They have a good coefficient of friction

at low temperatures and are very quiet, but are not suitable for high performance applications. Semi-

metallic pads are similar to organic pads with some powdered metal added (typically 40% to 60% by

weight), usually brass, iron, or bronze, to stabilize the coefficient of friction at higher temperatures,

making them excellent for all-around use and quite common as OEM pads. Ceramic pads are similar to

semi-metallic pads except that metal content is reduced to about 15% and ceramic materials are added.

This can result in a pad that produces less visible dust (it's lighter color), is less noisy (vibration

frequency is above human hearing), and can handle higher brake temperatures with less fade than semimetallic pads. Bosch recommends against using ceramic pads for towing applications. Metallic pads

consist of at least 60% by weight powdered metal that is pressed into a mold at high temperature with a

some organic binder to form a somewhat homogeneous block (called sintered metal). Most metallic pads

have excellent grip at high temperatures but are not suitable for street use because they often are noisy,

grip poorly when cold, chew up rotors, and make black dust that gets deposited on the wheels. The

exceptions are Axxis/Repco/PBR/Autospeciality/Stillen Metal Matrix/Master/Lux pads that are made of

brass and bronze powder with a resin binder. Metal Matrix pads are excellent for street and mild track

use but are not ideal for heavy-duty track use. Metal Matrix pads generate minimal dust build up, wear

well, and work great with drilled rotors. Carbon blend pads are probably the ultimate pad for street and

track use. Carbon is added to a metallic or Kevlar matrix to improve heat absorption (cooler running

rotors) and durability (long-life yet low rotor wear) while providing excellent friction properties over a

wide range of temperatures (from cool street to hot track use). Carbon carbon pads must be used with

carbon rotors and are reserved for high-energy races like the Indianapolis 500.

There are several aftermarket brake pads available for stock VR4/TT calipers. The most popular are the

metal matrix brands by Axxis (

Autospecialty) and Stillen that cost from $45 to $60 for a front or rear set.

8

Page 9

These are available at many stores. Brembo makes OEM replacement pads for about $75 each set

(available at MVP Motorsports).

The Brake Man sells performance brake pads for our cars. They do not state pad composition. Contact

them for more information. Carbotech Engineering is a relatively new source for performance pads for

our cars. They offer several different pad compounds for both street and track use. Contact them for

more information.

KVR carbon fiber pads for the front calipers only can be found for about $60 at

Performance Friction makes carbon metallic pads for our cars; I am not sure where they can be

purchased. Nippon Power sells Hawk Ferro-Carbon pads for the Stealth and VR4 for about $65 a set.

They claim "Ferro-Carbon is a unique, high-tech friction material developed and manufactured by Hawk

Brake for the racing community. All Ferro-Carbon materials exhibit non-fade performance and have

been evaluated up to and beyond 1,800 degrees F. Each material offers lower wear rates and higher

torque values than all other competition materials available on the market today."

AP Racing makes carbon metallic front brake pads for 1991 to 1994 models (part no. CPFC460). AP

Racing also supplies paint kits, pyrometers, and temperature strips to directly check the temperature of

your pads and calipers (http://www.apracing.com/car/brakepad/temperature.htm)

Many people claim Pagid makes the best pads money can buy. Almost every Formula 1 and many

World Rally teams use them. Their brake pads resist fade up to 900 degrees Celsius, especially the

carbon RS4-2 model. Pagid closely guards the exact compounds used in their pad. They make a wide

variety of pads for both street and racing and the compound characteristics are described at

http://www.pagidusa.com/characteri.html. Some Pagid pads are reported to produce a lot of dust.

EBC Brakes sells carbon Kevlar blend brake pads for the stock Stealth and 3000GT calipers in their

"Greenstuff" line. They advertize a friction coefficient of 0.46 and heat fade resistance to 550 degree

Celcius. EBC claims there is no carbon content in these pads so that very little dust is produced. The

high level of Kevlar content also leads to very low rotor abrasion. No warm-up is needed with these

pads.

Porterfield offers carbon Kevlar pads (R4 and R4S models) for both front and rear stock calipers ($89-

$149 front, $69-$149 rear, depending on year). These pads also can produce a lot of dust. From

Porterfield's web site: "Carbon Kevlar pads are different because they are rotor friendly, work well hot

or cold, have very high friction level and exhibit no fade, and on some compounds offer little to no dust

or squeal. The difference between the R-4 and R-4S pad is the R-4 has a higher friction level and will

withstand higher temperatures than the R-4S. Also the R-4 was designed for racing use, if driven on the

street you may experience some dust and or squeal. The R-4S is designed for street and limited track use.

It is a serious high performance highway pad with high friction levels and is designed for driver's school,

and light track events. R-4S was designed to produce no squeal and less dust than OE pad."

Supercar Engineering sells Axxis, Carbotech, and Porterfield brake pads for stock front and rear calipers.

Accelerated Accessories.

9

Page 10

Porterfield Brake Products

To order contact: orders@speedtoys.com

Product Part number Price ($US)

Mitsubishi 3000GT SL (all years)

Front Rotors JBR 583 $79.95

Rear Rotors JBR 584 $80.00

Front Pads R4S AP 530 $83.00

Rear Pads R4S AP 383 $63.00

1st Gen Mitsubishi 3000GT VR4 (4/90 to 5/93 production)

Front Rotors JBR 582 $82.00

Rear Rotors JBR 585 $90.00

Front Pads R4S AP 531 $69.00

Rear Pads R4S AP 532 $56.00

2nd Gen Mitsubishi 3000GT VR4 (6/93+ production)

Front Rotors JBR 785 $104.50

Rear Rotors JBR 786 $99.00

Front Pads R4S AP 531 $69.00

Front Pads R4 AP 531 or R4E AP 531 $116.00

Rear Pads R4S AP 631 $76.00

Rear Pads R4 AP 631 or R4E AP 631 $95.00

Porsche Big Red Calipers

Front Pads R4S AP 594 $128.00

Front Pads R4 AP 594 or R4E AP 594 $137.00

Rotor prices are for each rotor. Check for current prices.

Rotors are made by Brembo, Bradi, ATE, or American made.

Add $45 per rotor for each of these processes: slotting, drilling, cryo-treatment

Pad prices are for both left and right wheels. Check for current prices.

All pads are a Carbon Kevlar blend made by AP Racing.

R-4: Race

Versatile and a superior performer.

R-4 S: Street High-performance & Limited Competition

The high performance street pad of choice. No dust or squeal.

Very high friction level even at cold temperatures.

R-4 E: Endurance Racing Pads with Longer Life

This is an endurance pad, especially formulated for long races.

It runs cool and wears longer than the R-4. Great for extended time events.

Clinton Battersby (of MMCd datalogging fame) recommends the following when replacing brake pads

to prevent caliper piston corrosion. To avoid sticky caliper pistons, remove the piston boot and apply a

little silicone grease to the end of the piston and boot.

Brake Bedding

New brake pads require a smooth rotor surface. If you have not replaced the rotors then have the surface

10

Page 11

turned (milled) so that no ridges or grooves can be felt with your fingernail. Be sure the rotor thickness

exceeds factory limits.

The manufacturer should supply brake bedding instructions specific for the pads you are using.

Sometimes the manufacturer cures the pads before shipping and so bedding is not required. If bedding is

required, the general procedure (from Rennsport) is to warm new brake pads with 25 to 30 stops,

gradually increasing pressure but not letting the pads get hot. After that a safely executed "panic" stop is

made from high speed (like from 100 mph at a drag strip) down to about 30 mph. The car is then parked

soon after without any pressure on the brake pedal until the brakes and rotors are cool to the touch. Tom

Wilson had the following to say about brake bedding for street-driven vehicles in his Technical

Correspondence column in the August 2004 issue of Road & Track magazine.

" Brake bedding provides several benefits to both brake pads and rotors. For starters, it thermally

relaxes a new rotor. It wipes off any minor machining nicks or light oils that may be present on the rotor.

It thermally adjusts the brake pads so the binding material in the pads does not "boil off" excessively,

and most famously, it applies a layer of brake pad material on the rotor to allow the most tenacious grip

possible.

Brake-bedding procedures vary, but all involve slowly bringing the brakes to operating temprature

and letting that temperature stabilize through the pads and rotors to thermally set the pads and rotors,

followed by minor cooling, then hard brake applications to transfer some pad material to the rotors,

then controlled cooling.

Frankly, the public isn't ready for such involved procedures. Enthusiasts may revel in the prospect of

making four stops from 80 mph at near lock-up; others would simply say it's illegal or akin to bungee

jumping.

By advising easy braking for a couple of hundred miles, the manufacturers achieve most of the goals

of proper bedding without bothering the owner. With a new car, such easy driving promotes good

engine break-in as well. The downside is a small amount of brake life or performance is not realized.

For the rare panic stop, this typically won't matter as other factors make a larger difference in stopping

distance, and as for wear, no one knows what they're missing and it typically takes years to realize any

benefits -- too long for the average consumer's attention span.

Racers and enthusiasts want every last erg of braking performance, so they'll go to the trouble to

educate themselves about brake bedding. But for general use it's not worth the trouble."

Rotors and Calipers

The stock rotors and calipers are adequate for any sane and legal street driving activity. However, if you

use your car on the track or just want improved braking to match improved engine power output, then

you want to consider upgrading the rotors and/or the calipers along with the other upgrades discussed

above. Any performance upgrade rotor for our cars will have a vented design (like the stock rotors) with

or without the addition of holes (cross drilling) or slots. Larger diameter rotors will improve both the

effective swept area as well as heat dissipation (more surface area). An upgrade caliper should have a

similar amount of total piston area as the stock calipers, or perhaps a little less. If going with a larger

rotor and caliper you want to be sure that they will fit in the wheels you are using. I leave it to the reader

to determine the merits (or lack thereof) of cross-drilled and/or slotted rotor designs over smooth-faced

rotors. However, I will provide the quote below from Tom Wilson's Technical Correspondence column

in the March 2003 issue of Road & Track magazine.

" Assuming minimal attention to where the holes are drilled, there is no meaningful difference between

cast-in and drilled-in holes in rotors. ... The real difference is between drilled and non-drilled rotors. All

11

Page 12

those holes detract from a rotor's mass, and high mass content is a main ingredient in avoiding warping.

As for cracking, all rotors will crack if overheated, and there is little difference between drilled and nondrilled rotors in that regard.

Cosmetics is why most rotors are drilled nowadays -- the old gassing problem that holes are supposed

to address is negligible with good pads and all but absurdly flamboyant street driving -- so, many

aftermarket brake tuners offer rotors with or without drilling to suit demand."

For the normally-aspirated, FWD cars, the front brake setup is the same as the 1993 to 1999 DSM turbo

cars (Eclipse and Talon); please check out Tom Stangl's web page for advice

http://www.vfaq.com/mods/BigBrakesInfo.html.

There are several stock-size rotor replacements for the AWD 3000GT/Stealth cars that may be better

than the factory rotors. The stock front rotors (1994+) are 314 mm x 30 mm and weigh about 17.2 lbs

(7.8 kg).

well on the street but may not be appropriate for race track use.

orders@speedtoys.com) are made by Brembo, Bradi, ATE, or un-named American company. Porterfield

offers cryogenic treatment for about $45-50 extra for each rotor. Stillen also offers OEM replacement

rotors (made by Brembo I think) that are either cross-drilled or slotted for $115 to $150 each (depending

on model). Brembo makes cross-drilled or slotted rotors for all 3000GTs/Stealths (both front and rear

axles, and FWD or AWD). MVP Motorsports sells the Brembo rotors for $121 to $190 each, depending

on model and axle. Supercar Engineering sells stock replacement front and rear rotors made by

Carbotech Engineering for all models and years of 3000GT/Stealth. Slotting and cryogenic treatment are

available.

For those of you with 1991 to 1993 AWD models, it is a relatively easy upgrade to switch to the 2piston rear calipers and larger rear rotors used on 1994+ AWD 3S cars (cars produced from 6/93).

PowerSlot and PowerStop rotors, with prices ranging from $100 to $140 for each rotor, work

Porterfield rotors ($80 to $105 from

12

Page 13

Caliper upgrade choices include StopTech 4-piston (with various combinations of 34, 36, 38, 40, 42,

and 44-mm pistons), Brembo 4-piston (2x40/44 mm), Porsche 4-piston (manufactured by Brembo;

2x38/44 mm, and 2x36/44 mm), Alcon 4-piston (2x38.1/44.5 mm), AP Racing 6-piston calipers

(2x27/32/38 mm), and MOV'IT 4-piston (2x36/44 mm). Trailing piston pairs are larger to compensate

for mechanical end load, which maximizes friction, and to reduce tapered wear. The caliper piston area

is calculated by finding the total piston area from one side of the caliper, regardless of the number of

pistons (that is, 1 piston is used for single-piston or 2-piston calipers, 2 pistons are used for 4-piston

calipers, and 3 pistons are used for 6-piston calipers). The stock VR4 front 4-piston calipers have

approximately 4.2 sq in of piston area each. Except for the largest calipers by Brembo and StopTech,

aftermarket calipers have less piston area per caliper (see the table below). Given the same pedal effort

by the driver, this means that the hydraulic pressure transferred to the pads by some of these calipers is

somewhat less than by the stock calipers. This can be advantageous when using larger rotors to optimize

front-rear brake torque balance.

Front Caliper Information

Caliper

Brembo F50 40.0 44.0 -- 2777 4.30 2.06% 9.6 7.01

StopTech ST40 "F50" 40.0 44.0 -- 2777 4.30 2.06% 9.6 7.01

Stock VR4/TT 40.4 42.8 -- 2721 4.22 0% 8.0 8.0

Alcon 38.1 44.5 -- 2695 4.18 -0.96% ? ?

StopTech ST40 "F40" 38.0 44.0 -- 2655 4.11 -2.43% 9.6 7.01

Brembo F40 38.0 44.0 -- 2655 4.11 -2.43% 9.6 7.01

Porsche Big Black 38.0 44.0 -- 2655 4.11 -2.43% 9.6 ?

Porsche Big Red 36.0 44.0 -- 2538 3.93 -6.73% 9.6 8.1

MOV'IT 36.0 44.0 -- 2538 3.93 -6.73% ?? ??

StopTech ST40 (332mm rotor) 38.0 42.0 -- 2520 3.91 -7.39% 9.6 7.01

AP Racing 27.0 32.0 38.0 2511 3.89 -7.72% 11.8 6.6

StopTech ST40 (355mm rotor) 36.0 40.0 -- 2274 3.53 -16.43% 9.6 7.01

StopTech ST40 (380mm rotor) 34.0 40.0 -- 2165 3.36 -20.43% 9.6 7.01

Piston 1

(mm)

Piston 2

(mm)

Piston 3

(mm)

Total Piston

Area (mm2)

Total Piston

Area (in2)

Difference

from stock

Brake Pad

Area (in2)

Weight

(lb)

So why upgrade the calipers? Six reasons:

• better heat absorption and dissipation from using larger brake rotors,

• lighter weight for reduced unsprung mass,

• larger brake pads for better heat capacity and wear rate,

• improved design for better strength and better force transfer to the pads,

• improved design for better heat transfer and reduced brake fluid heating, and

• for management of the force multiplication by the piston area when using larger rotors.

The stock 3000GT/Stealth Sumitomo calipers weigh about 8 lbs (3.6 kg) each. Brembo and StopTech

calipers weigh about 7 lbs (3.2 kg) each. The AP calipers weigh about 6.6 lbs (3 kg) each. I measured

the stock front pads to have about 8 sq in of surface area. The Brembo, Porsche, and StopTech pad area

is about 9.6 sq in, and the AP Racing pad area is about 11.8 sq in.

Please note that larger pads do not stop the car faster than smaller pads of the same compound at the

13

Page 14

same location on the rotor. Stopping force is determined by the applied pressure, the pad coefficient of

friction, and the distance the pad is from the center of the rotor (basically rotor diameter). Larger pads of

the same compound as smaller pads have a longer life and absorb more initial heat (better heat capacity).

When looking for a brake upgrade for better stopping distances and reduced brake fade, generally look

for larger diameter and thicker rotors, and calipers with slightly less piston area than stock. Larger rotors

provide better heat dissipation because of directional cooling vanes and more mass (thicker and larger

diameter). Calipers with less piston area will decrease the force transferred to the rotors in order to

balance the larger rotor diameter, and slightly decrease pedal travel. For example, the AP Racing 6-pot

calipers have about 7.7% less piston area, which should result in perhaps 7.7% less applied force but

also perhaps as much as 0.4 to 0.5 inch less pedal travel; they would be a good match with 355-mm

rotors for 1994+ 3S cars or 332-mm rotors for 1991-1993 models (assuming the factory rear brakes are

retained).

Upgrade rotors are available from the same manufacturers that provide

upgrade calipers, usually as part of big brake kits. Wheels with a

diameter of 17" or 18", or possibly larger, are required for these larger

rotors and calipers. Be sure to check with your vendors to be sure your

wheel and selected brake kit will work together.

AP Racing and Alcon Components make some of the best rotors in the

world according to Rennsport Systems, which says AP and Alcon rotors

are superior to Brembo rotors in terms of wear and crack resistance. For

what it's worth, Automotive Products Group Ltd. sold its subsidiary AP

Racing to Brembo in July 2000.

Alcon offers custom-made high-performance rotors (332 mm) and 4-

piston calipers but these have not been extensively tested on 3S cars.

Bozz Performance should be able to get the custom Alcon kit for about

$4300 (includes SS lines and pads, but at that price it should include

Front Rotor Information

Rotor

1991-1993 VR4/TT

1994 - end VR4/TT

StopTech 380 (14.96)

AP Racing 362 (14.25)

Brembo 355 (13.98)

Alcon 332 (13.07) ? (?)

Porsche GT2

max w/ "Big Red"

max w/ "Big Black"

MOV'IT 322 (12.68) 32 (1.26)

Diameter

mm (in)

295 (11.62)

314 (12.36)

355 (13.98)

332 (13.07)

355 (13.98)

343 (13.50)

343 (13.50)

322 (12.68)

332 (13.07)

322 (12.68)

Thickness

mm (in)

30 (1.18)

30 (1.18)

32 (1.26)

32 (1.26)

32 (1.26)

36 (1.42)

35.5 (1.40)

35.5 (1.40)

32 (1.26)

32 (1.26)

32 (1.26)

32 (1.26)

32 (1.26)

installation also!).

AP Racing brake kit, with 6-piston calipers and either 355-mm x 35.5-mm or 343-mm x 35.5-mm

The

rotors, is available from

Stillen, KVR Performance, and HP Racing for about $3000-3400. The AP

Racing kits include their larger-diameter vented discs, aluminum hats, 6-piston calipers, aluminum

mounting brackets, high-performance brake pads, and anti-rattle springs and inner wipers and dust seals

in the calipers.

Supercar Engineering offers 343 mm (13.5") by 35.6 mm AP rotors and calipers for

about $2700, and 362 mm (14.25") by 36 mm (1.42") AP rotors and calipers for about $3000.

StopTech claims their floating, two-piece, directional-vaned AeroRotors® flow more air than any rotor

available for superior cooling (see Rotor Airflow Chart). These rotors are available in 380-mm (14.96"),

355-mm (13.98"), 332-mm (13.07"), and 322-mm (12.68") diameters with a 32-mm (1.26") thickness

standard. However, these rotors can also be requested with 28-mm (1.1") or 35-mm (1.38") thickness.

StopTech says the rotor's special iron formulation reduces cracking under severe driving conditions.

AeroRotors are available in standard (smooth surface), slotted, or drilled. The 7075-T6 billet aluminum

hats are also directionally veined.

StopTech developes brake upgrade systems specifically to optimize brake balance and ABS

performance for the shortest stopping distances. They are available exclusively from Supercar

14

Page 15

Engineering for all models of the Stealth and 3000GT. The StopTech aluminum ST40 4-piston caliper is

a available with a choice of piston sizes. With 38-mm and 44-mm pistons the ST40 is a direct bolt-on

replacement for Brembo F40 calipers; with 40-mm and 44-mm pistons it is a replacement for the

Brembo F50. The StopTech ST40 uses Porsche-style brake pads, so a large variety of brake pads are

available. StopTech front brake kits are available for all models and years of 3000GT and Stealth in a

variety of rotor sizes and piston sizes for $1800 to $2900 from

Supercar Engineering. Included in the

kits are Inconel® anti-rattle spring washers that allow for rotor expansion, stainless-steel braid-protected

brake lines, rubber dust boots to keep dirt

and water away from pistons and piston

seals, and brake pads.

For balanced front-rear braking bias and

shortest stopping distances,

Supercar

Engineering and StopTech recommend the

piston and rotor combinations shown in the

StopTech and Supercar Engineering Recommendations

Rotor Diam.

mm (in)

380 (14.96) 28.81% 21.02% 2x34/40mm 2165 -20.43%

355 (13.98) 20.34% 13.06% 2x36/40mm 2274 -16.43%

332 (13.07) 12.54% 5.73% 2x38/42mm 2520 -7.39%

Diff. from

stock 295mm

Diff. from

stock 314mm

ST40 Pistons

Piston

area mm

Diff. from

stock

table to the right. As discussed in the

Braking Torque section above, torque applied by the calipers is directly proportional to the pad-to-axle

distance, or basically, rotor diameter. Hydraulic fluid force multiplication by the caliper is directly

proportional to the piston area size. Therefore, to maintain proper braking balance, as rotor diameter

increases the piston area should decrease approximately the same amount percentage-wise. Less piston

area than stock also decreases the pedal travel as there is less swept volume behind the pistons to fill

with fluid. These combinations of rotor diameter and pistons sizes should work well for 1991-1993

models (295-mm front rotors) and slightly increase front braking torque. However, the suggested

combinations will slightly decrease front braking torque for 1994+ models (314-mm front rotors).

Owners may want to discuss other piston size combinations (available at no additional charge) with

Supercar Engineering.

Supercar Engineering also offers a rear brake upgrade kit using the new StopTech ST22 2-piston

calipers (2x36-mm pistons, other sizes are available) and 328x28mm rotors. The calipers are made of

billet aluminum, weigh 4.4 lbs (2 kg) unloaded, use FMSI 961 brake pads, and include dust boots. This

kit will be available standalone (they retain the standard drum parking brake) or as part of a 4-wheel

upgrade kit.

Additional information concerning brake systems is available from StopTech at the links below.

Technical Articles

Stoppping Distance Vs. Brake Bias Chart

FAQ Index

15

Page 16

The Brembo Gran Tourismo Brake System ("F50") is available from some of the vendors listed above

from and MVP Motorsports at similar prices ($3000 range). The Brembo big brake kit includes 355-mm

x 32-mm, cross-drilled rotors with directional cooling vanes, two-piece, 4-piston (2x40/44 mm)

aluminum calipers with dust seals, anti-rattle clips, and mounting brackets, Goodridge stainless steel

brake lines, and high-performance street brake pads.

16

Page 17

Porsche is widely regarded to have some of the best brakes for street cars. Porsche calipers and rotors

are made by Brembo to Porsche's race-quality specifications. Porsche's "Big Red" brakes (named after

the caliper color and installed on the 993) have been modified by several companies to fit on our car's

front hubs. Currently, Supercar Engineering offers Porsche "Big Red" brake upgrade kits with 332x32mm rotors.

Darren Schilberg and Steve Lasher have some instructions for installing the Big Red calipers at their

web page http://www.team3s.com/~dschilberg/cars/brakes/BigReds_install.htm.

For some comments regarding the Big Red and some other big brake kits for our cars, please read the

information below that Ken Middaugh posted to the Team3S email list. I have added some emphasis and

performed minor editing, but the message content has not been changed. Prices are in $US. Please note

this post is over 4 years old. Recently, Philip Glazatov (Supercar Engineering) told me actual maximum

rotor size for "Big Red" and "Big Black" calipers is the opposite from that mentioned in the email below.

The correct information is in my Front Rotor Information table above.

Update: January 25, 2003

Gary Skanes, Sales Manager at

and "Big Black" kits are no longer available from KVR. KVR now exclusively uses the AP calipers in

their big brake kits for the 3S cars. These kits cost $2950 and include front calipers, front rotors and hats

(check with KVR for sizes), front brackets, braided lines for both front and rear calipers, performance

brake fluid, and street performance pads (front). KVR, a Canadian company in Ontario, can be contacted

at 800-636-0854 for more information.

Update: November 29, 2004

Brad Bedell's link is no longer active and presumably his Big Red kit is no longer available. It appears

from visiting Stillen's web site that they no longer sell big brake kits for 3S cars. MOV'IT still sells front

(322x32 rotor; monoblock caliper with 2x36/44-mm pistons) and rear brake (299x24 rotor; monoblock

caliper with ??? pistons) upgrade kits for the Stealth and 3000GT.

---------- Original Message ---------From: "Ken Middaugh"

To: [edited]

Cc: stealth_d@starnet.net; Team3S@stealth-3000gt.st

KVR Performance, notified a member of 3si.org that Porsche "Big Red"

17

Page 18

Sent: Thursday, October 12, 2000 12:40 PM

Subject: Team3S: Brake summary (long), was: Brake Kit Discount Available

As you may recall, some of us track and "deceleration" enthusiasts banded together in search of better,

reasonably priced brakes for our cars. There are already lots of kits available for our cars, but most are

expensive. We wanted something that was economical, yet was a big improvement over stock brakes.

Our original goal was to fund research and development of a 2 piece rotor for Brad Bedell's Porsche

"Big Red" upgrade kit. With a 2-piece rotor, Brad's kit would be very similar to Mov'it's $2800 kit but

we were hoping that Brad's kit with a 2-piece rotor would be about $2100. A lot of investigation was

done and here is a summary.

We ended up not spending any money on R&D since our investigation uncovered existing economical

solutions. It turns out that there would be little if any cost savings if Brad were to fabricate his own hats

for 2 piece rotors versus just buying them from a reputable and experienced manufacturer.

Front Kits

$1450

Brad's Big Red kit, http://home.austin.rr.com/overboost/. It currently sells without rotors but includes

Porsche 993 calipers, caliper mounting brackets, Goodridge stainless steel brake lines for 4 wheels, a set

of pads, and fluid. This is the entry point to serious brake upgrades and folks have reported dramatic

results. With a set of $250 Porterfield rotors you can seriously upgrade stock performance for about

$1700.

~$1900

KVR "Lobster" kit (his name for the Big Reds) with 2 piece Porsche rotors. Terry Gosse of KVR,

http://www.kvrperformance.com, has been doing custom brake kits for many years and has a lot of

knowledge and experience. Basically, he can do anything for any budget. This price was approximate,

and includes Porsche 993 calipers, mounting brackets, 2 piece rotors using Porsche GT2 322x32mm

disks and custom 6061 T6 aluminum hats, stainless steel lines for the front, AP racing fluid. I don't

know if this price would include SS lines for the rear, or include pads. However, this is basically the

same thing as the Mov'it kit for a lot less money. Porsche makes awesome disks. They are directionally

veined, the holes are cast and then drilled to final diameter. If desired, he could substitute other, larger

disks for about the same price. KVR also has directionally veined disks that you can get solid, cross

drilled, or slotted. The Porsche and KVR disks have "reasonable" replacement costs, less than $200 each.

The hats should last 5 racing seasons or a lifetime on the street.

~$2100

KVR "Big Black" kit with Porsche 928 S4 calipers with 2 piece rotors. This kit is the same as the above

Lobster kit except for the calipers. Terry Gosse of KVR says these calipers will be a better match for our

car since the 928 is a similar heavy weight, front engine car like ours (VR4). The Big Red calipers are

for lighter, rear engine cars. The Big Black calipers have 2x38x44mm pistons while the Big Red has

2x36x44mm pistons. This extra 2mm makes a big difference over 4 total pistons. Also the Big Black

calipers are bolted together more near the centerline and will deflect less than the Big Reds. The Big

Blacks use shorter 50mm pads, which deflect less than the Big Reds 60mm pads. The Big Blacks can

accommodate 332mm rotors while the Big Reds max size is 322mm. Finally, there are more pad choices

for the Big Blacks versus the Big Reds. This is IMHO the best deal of the survey.

~$2200

Stillen Brembo kit,

http://www.stillen.com/brakes/systems/systems.html. This was the price a few years

18

Page 19

ago. Some folks have this and are very happy, but others have reported that their cross drilled disks

crack and warp. The replacement disks are also costly. Supposedly, the Porsche treatment of Brembo

calipers in the above kits is better than the stock Brembo caliper in this kit. The calipers do compare to

the 928 though since the pistons are also 2x38x44mm.

~$2100 - $2800

Mov'it Big Red kit, http://www.ultimategarage.com. The Ultimate Garage's web site say they utilize the

Porsche 996 monobloc calipers (instead of the 993) and the GT2 2 piece rotors. These 996 calipers

would make it better than the above Lobster kit. Supposedly, our European friends can get these directly

from Mov'it for about $2100 although Ultimate Garage's price is $2800. I think Roger Gerl was

investigating becoming a Swiss distributor.

$2500 - $3000

AP Racing 6 piston caliper and 2 piece rotors. Terry said he could sell this kit for $2500 for a

KVR

group purchase of 5 or more. $3000 is the normal price. I'm not sure if this is the identical kit to the one

on Stillens web page. This is the entry to the "very serious" upgrades and is really a step above the

previous kits. It can accommodate 355x35.5mm rotors!

$3000+

There are other kits available but not investigated because of their prices. Mov'it's Terminator kits (14.9"

disks!!), Baer, and Wilwood, come to mind. Probably the awesome looking NewTech fits this category

too.

Rear Kits

~$1800 - $2600

Mov'it has a kit for the rear brakes too. It uses Boxter S components including a 299x24mm rotor. It

should cost about $1800 in Europe but $2600 in the states.

Summary

All of these kits including the Mov'it kits should fit '91+ 3000GTs and Stealths, as long as you have the

wheel clearance. To improve clearance and increase front track width (reduces under steer), you could

utilize a thicker facing on the hat with longer wheel studs. Since Mov'it is now using 996 calipers, it

would be worthwhile to compare them with the 928 S4 caliper. Regardless, Terry Gosse of KVR should

be able to build custom front kits with any caliper and any disk and still have unbeatable prices.

Happy braking,

Ken

---------- End Original Message ----------

19

Page 20

Synopsis

Improved braking usually means one or both of the following: (1) shorter and/or faster stops, (2)

reduced or eliminated brake fade. If you are already engaging the ABS then the braking system is

adequate for your needs or you need "stickier" tires or you need a better road surface. However, not all

uses of the brakes require that braking be taken to the point of exceeding the available tire-road friction

force (that is locking the brakes or excessively sliding the tire). These uses are encountered on the street

(for example, extended downhill grades, enthusiastic driving of the twisties, towing) and on the race

track. For this type of use brake fade is often a greater concern than faster stops.

When we need to stop more than once and may be using the brakes in a manner that does not come close

to engaging the ABS, we need to improve braking availability. This means not necessarily stopping

faster or shorter, but reducing or eliminating brake fade and brake fluid fade.

Brake fluid fade is reduced by:

• Regularly changing the brake fluid.

• Preventing or minimizing the amount of heat that gets to the fluid in the calipers.

• Using a brake fluid with high boiling points.

We can reduce brake fade by improving heat management to maintain the optimal temperature at the

rotor-pad interface to maximize brake pad coefficient of friction. This can be accomplished by:

• Using air or water to cool the brake area.

20

Page 21

• Using pads, calipers, and rotors that dissipate heat better.

• Switching to an entirely different rotor and pad setup, such as the carbon-ceramic brakes on the

new Ferrari 360 Challenge Stradale and the Ferrari Enzo (for those that have a spare $20,000

lying around) or the Porsche GT3 (at the bargain basement price of a little over $8000).

For shorter and faster stops you must have a road surface favorable for braking, meaning the road is not

excessively wet or oily or icy or covered with debris, sand, or gravel. You also need the stickiest tires

available. As usual, life involves compromises. Sometimes there are economic reasons or race "rules" or

strategy factors that prevent us from using the stickiest tires. Sometimes we need a certain flexibility or

stiffness or longevity or water-handling ability that may compromise the "stickiness" concerns.

When shorter stops means exerting more force on the wheels/tires, this can be accomplished by:

• Better driver management of the brake pedal.

• Using SS braid-protected brake lines (reduces pressure losses or delays).

• Using different pads (with materials and a coefficient of friction optimal for the use of the pads).

• Using a caliper with a total piston area appropriate to achieve balanced brake bias with the rear

brakes.

• Using a larger diameter rotor to increase the torque applied by the caliper to the wheel.

• Improving the front-rear braking distribution (could involve upgrading the rear rotors and

calipers, especially for 1991-1993 models).

The main advantage of the larger-rotor, different-caliper braking kits is improved heat management, that

is, reduced or eliminated brake fade. It would be interesting to see how much faster and shorter our cars

stop with the big brakes, but that does not seem to be the main reason for installing them.

Available Front Big Brake Kits

Manufacturer Rotor sizes (mm) Caliper pistons (mm)

Alcon 332x?? 2x38.1/44.5

AP Racing 343x35.5, 355x35.5, 362x36 2x27/32/38

Brembo 343x32, 355x32 2x38/44, 2x40/44

MOV'IT 322x32 2x36/44

Porsche 322x32, 332x32 2x36/44, 2x38/44

StopTech 332x32, 355x32, 380x32 (28 or 35 widths avail.) combinations of 34, 36, 38, 40, 42, 44

Available Rear Big Brake Kits

Manufacturer Rotor sizes (mm) Caliper pistons (mm)

MOV'IT 299x24 2x??

StopTech 328x28 2x36 (other sizes available)

21

Page 22

Acknowledgments

Some of the information presented here was gathered from various books, email lists, message boards,

and vendor web sites. I would like to acknowledge and thank the following for their contributions (in no

particular order).

• Stoptech High Performance Brake Systems (http://www.stoptech.com/)

• Avalon Ent Racing (http://www.avalonracing.net/)

• AP Racing (http://www.apracingusa.com/)

• James Walker, Jr. (http://www.teamscr.com/grmbrakes.htm)

• Ken Middaugh, Rich Merritt, and Jim Berry (with Team3S)

• Terry Saltzman (Grd4Spd Racing)

• Geoff Mohler (with Team3S and http://www.speedtoys.com/)

• Darren Schilberg (aka Flash) http://www.team3s.com/~dschilberg/)

• Philip V. Glazatov (http://supercar-engineering.com/)

• Jim Matthews (http://www.team3s.com/~matthews/brake_upgrade_considerations.html)

• Kenneth Streeter (http://www.vtr.org/maintain/brake-fluids.html)

• Mike Kojima (http://www.se-r.net/car_info/brake_performance.html)

• James Walker, Jr. (http://www.scirocco.org/faq/brakes/pulpfriction/pfpage1.html)

• Rennsport Systems (http://www.rennsportsystems.com/~porsche/2c.html)

• RPM.net (http://www.rpmnet.com/techart/fluid.shtml)

• US and Canadian Standard 116 (http://www.tc.gc.ca/actsregs/mvsa/jan98/english/mvsr116.html)

• MOV'IT (http://www.movit.de/)

Except for the small gif and jpg images, the content, images, photographs, text, and multimedia displayed are Copyright ©2000-2005 by Jeff Lucius and K2

Software. All rights reserved. No part, section, image, photo, article, or whole of this site may be reposted or redisplayed without permission of the author.

Page last updated January 17, 2005.

22

Loading...

Loading...