Page 1

INNOVATIONS

IN BINOCULAR ENGINEERING (II)

W

HAT’S THE BENEFIT OF ED-GLASS IN A TELESCOPE

?

MINOX GmbH •Walter-Zapp-Str. 4 •D-35578 Wetzlar •Tel.: +49 (0) 6441 / 917-0 •Fax: +49 (0) 6441 / 917-612 •www.minox.com

Minox information order number: 99 199

The experience gathered over decades in the

production of top quality optical systems has

brought forth MINOX products with a performance reaching the limits of technical feasibility.The profound knowledge in the production

of top-class lenses led to stringent quality

standards which apply to MINOX binoculars

and telescopes as well. Continuous innovation

at MINOX means a clear advantage for the observer in image sharpness and brightness.With

ED glass (also called FL for fluoride glass and

APO for apochromatically corrected) MINOX is

setting new standards in nature observation.

What are the advantages

of ED glass in telescopes?

White light is split into its component colors

when it passes through a prism or a lens. The

reason for this, as with other transparent materials, is the change in the refractive index for

the different colors, known as the dispersion of

the glass in question.The amount of dispersion

in the different types of optical glass depends

on the glass composition, i.e. dispersion is a

material constant of the glass used.

This color dispersion of incident light means

that the image of an object imaged by a simple lens is split into many colored partial images which are not only positioned at different

locations behind the lens, but also differ in

size. If you pick up such an image on a screen

or look at it with a magnifying glass, which is

what the eyepiece represents, instead of sharp

details and contours you will see, depending

on the focusing, a more or less sharp core in

one color, e.g. blue-green,which is surrounded

by a more or less blurred corona in a different

color, e.g. red.Altogether the image is unsharp

due to this chromatic aberration which, in principle, cannot be eliminated by a single lens.

As the specific dispersion of the various types

of optical glass materials are – fortunately –

different, by combining at least 2 lenses of different glass types it is possible to correct their

chromatic aberration. Every optical system of

any real use, whether a photo lens or binocu-

lars, therefore features at least 2 lenses of different glass types.

By designing the correct radius of the lens elements and selecting the right types of glass

materials, the optics engineer can position at

least two of the colored partial images at the

same place and match their size. The remaining residual aberration for the other colors is

usually so slight that the image already appears free from chromatic error. This is then referred to as a chromatically corrected or achromatic system.

The remaining residual aberration of an achromatic lens, however small, will show up if the

intermediate image is subsequently magnified

or looked at through a strong magnifying

glass, i.e. eyepiece. Particular attention must be

paid in photo lenses with long focal lengths or

binoculars with high magnification > 10x and

spotting scopes to ensure that the residual

aberration is reduced as much as possible.

Fortunately, chemists and glass manufacturers

have been able to melt special glass types

containing fluoride which either feature particularly low dispersion, known as Extra-Low

Dispersion glass types, or glass where the refractive index changes in a different way to the

majority of "normal" optical glass, these being

referred to as glass types with anomalous partial dispersion. For the sake of simplicity, these

two types are usually referred to in combined

form as ED glass. This glass type was first used

in the photographic sector for telephoto lenses

with long focal lengths and high speeds, for a

particularly extensive color correction.

By using this type of glass it is possible to position the color partial images at the same place for the entire visible light (across the visible

spectrum) and perfectly match their size. Unwanted color contours are thus effectively eliminated. This is then referred to as apochromatic color correction.

The use of special glass containing fluoride in

the new MINOX binoculars with high magnification and MINOX spotting scopes, has successfully passed on this proven technology

from extreme photo lenses to binoculars. In

spite of the high magnification and light gathering power of the lenses, the residual chromatic aberrations have been significantly reduced by these means.The image provided by

the new MINOX binoculars and MINOX spotting scopes with ED glass is free from any disturbing color fringes or glare, i.e. it is rich in

contrast with pin-sharp definition.

There are, however, some negative aspects

with ED glass types, which should not remain

unmentioned: They are considerably more expensive than normal glass types, the processing method is more difficult and is therefore

more costly, the specific gravity and consequently the weight of the lenses is frequently

higher. Nevertheless, this excess in expenditure does pay off.With ED glass the optical performance of the MINOX binoculars and MINOX

spotting scopes with high magnification is improved significantly. This glass provides a plastic image exceptionally rich in detail and with

high color rendition throughout the visual

field. The observer is able to see a true-to-life

image, even under critical light conditions.

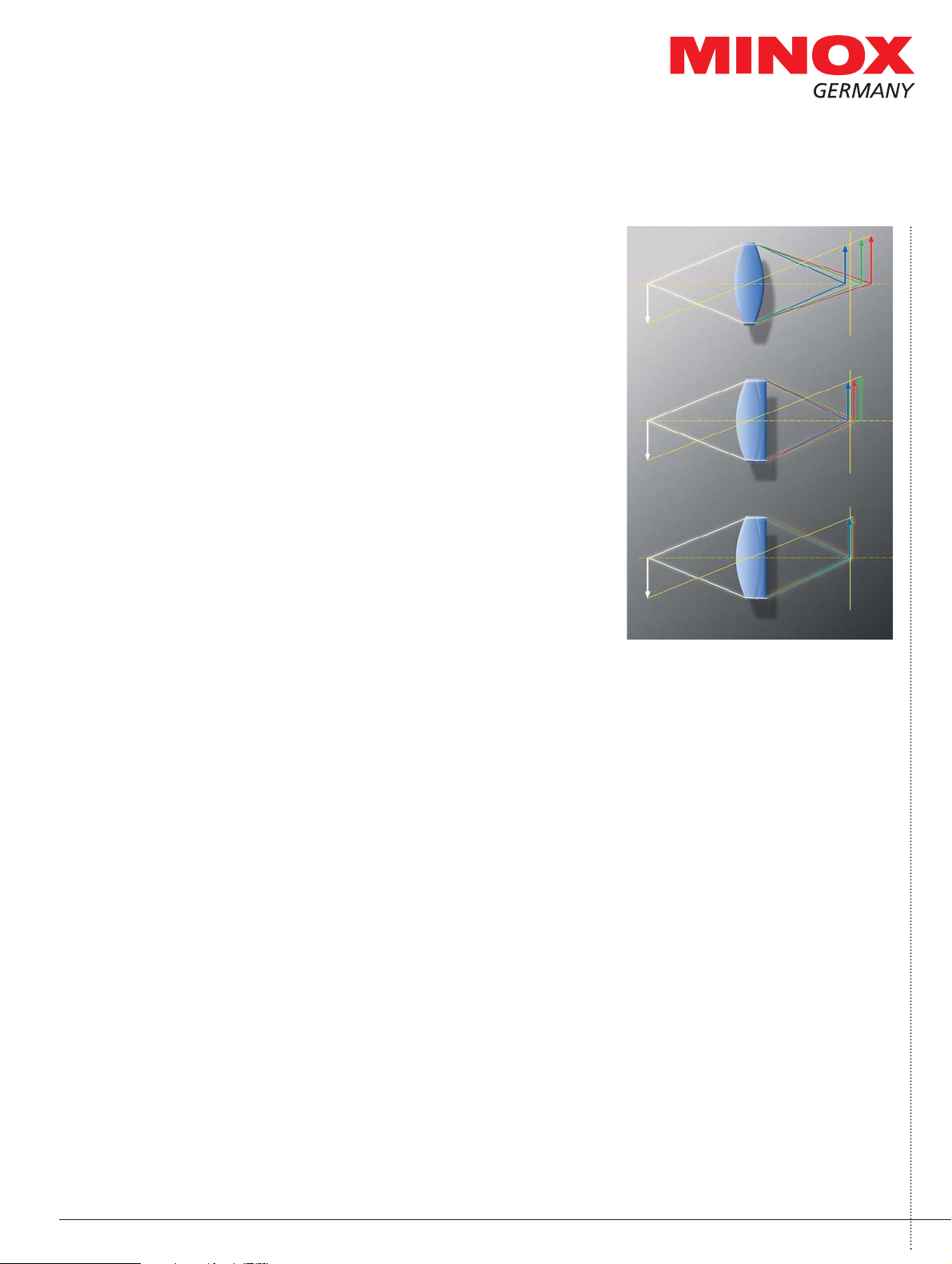

Simple lens element, not color corrected.

Two lens element with achromatic color correction.

Two lens element using ED/ fluorid glass with

apochromatic color correction.

Heussinger Grafik Design, Solms

Loading...

Loading...