Page 1

WORK STAND W-300 INSTRUCTION MANUAL

Please read this instructions carefully before use.

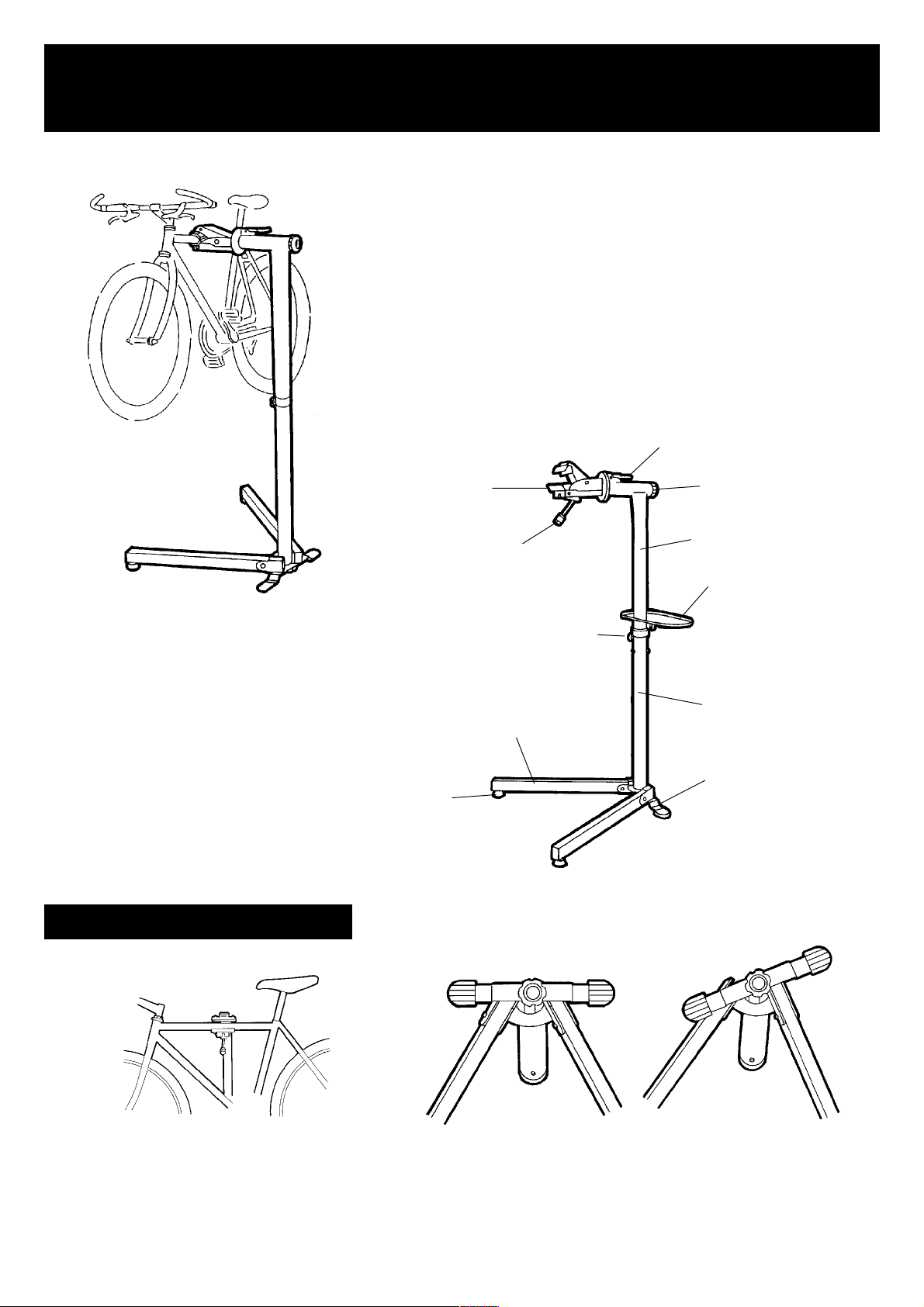

Thank you for purchasing Minoura “

W-300 has foldable leg mechanism so you can save the storage

space when you don’t use this stand.

Also the clamp jaws can rotate fully 360 degrees and fix at any

angle, so you can keep your standing position during your work

even for maintenance on lower part of your bike such as the bottom

bracket or the derailleur.

In addition, this stand can be used as a bike display stand.

Clamp Jaws

Clamp Lever

W-300W-300

W-300” bike repair stand.

W-300W-300

Gear Lever

Clamp Knob

Upper Frame

Tool Tray

(option)

IMPORTANT NOTE

Foot Adjuster

Frame Knob Bolt

Leg

O

Lower Frame

Plate Leg

X

Do NOT use W-300 without

clmaping the frame, otherwise the

bike may fall off.

Set the Plate Leg on proper position otherwise the

stability will be compromised and cause the W-300

to tip during use.

- 1 -

Page 2

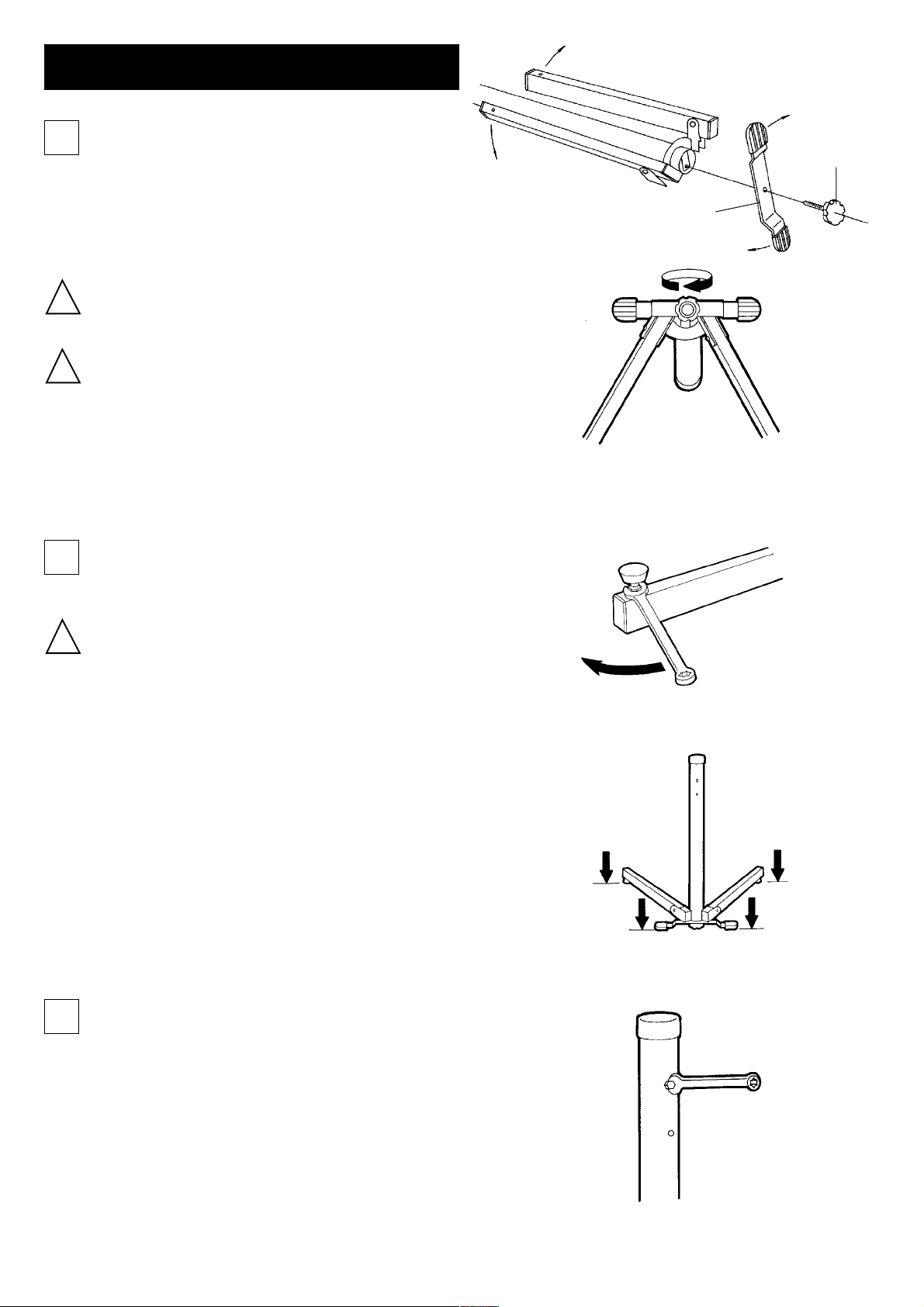

HOW TO SET-UP YOUR W-300

Place the Lower Frame on the level floor and

1

fully open the Leg. Attach the Plate Leg onto

the bottom of the Lower Frame and secure it

with supplied Knob Bolt. (see Fig. A & B)

Be careful not to pinch your finger when you open the leg.

!

Be sure the Plate Leg is installed properly so the Plate Leg

!

doesn’t come over any guide projections. These are

Knob Bolt

Plate Leg

(Fig. A)

located on the bottom of the Lower Frame.

Install the Foot Adjuster on both legs. (see Fig. C)

2

This adjuster is very important for keeping the stand

!

stable for your own safety.

Once you place the completed Lower Frame on the floor,

you should check if ALL edges are touching the floor at

same time (see Fig. D) and adjust the length of each Foot

Adjuster if nessessary. Then fix the position by tightening

the lock nut with a 10mm open wrench.

(Fig. B)

(Fig. C)

Fix the Height Adjusting Screw at your prefered position.

3

There are two holes on the Lower Frame. If you choose the

upper hole, the total stand height will be around 1.3 meter. If

you choose the lower hole, the total height will become 10 cm

lower. (see Fig. E)

- 2 -

(Fig. D)

(Fig. E)

Page 3

Insert the Upper Frame into the Lower Frame (see Fig. F) then

4

fix the position by tightening the supplied small knob bolt and

the spring. (see Fig. G)

Make sure if the direction of the Upper Frame is correct

!

that the “V” shaped cut-off on the bottom of the Upper

Frame must be on the Height Adjusting Screw.

The wrong direction will not align the frame rotation and

will cause stability issues when you clamp your bike on the

W-300.

If you purchased the optional “Tool Tray”, insert it to the Upper

5

Frame before inserting the Upper Frame into the Lower Frame,

and tighten the knob bolt to fix the position and angle. (see Fig.

H)

The Tool Tray is made of steel plate, so you may be in-

!

jured if you scratch the edge of the plate with your finger.

Be careful. (see Fig. I)

If the pedal or something hits the tray during crank rota-

!

tion, move the tray to be behind so its behind the stand

(Fig. F)

(Fig. G)

(Fig. H)

frame.

Insert the Clamp Jaws to the upper horizontal tube of the

6

Upper Frame, insert the washer from the backside then

tighten the knob nut. (see Fig. J)

If you tighten the knob nut so tight, the clamp jaws may

!

not rotate easily. The proper amount of tightening should

be so the clamp jaws can rotate smoothly but without any

!

(Fig. I)

(Fig. J)

looseness.

- 3 -

Page 4

HOW TO USE THE CLAMP

W-300 has unique one lever operation system for both opening/shutting and adjusting the jaws.

Please read the following operation manual carefully and use it effectively and safely.

TO ADJUST THE JAWS

When the clearance between the clamp jaws and the bike is too small,

turn the adjuster knob on the lever anti-clockwise.

When the clearance between the clamp jaws and the bike is too great,

turn the adjuster knob on the lever clockwise. (see Fig. K)

TO OPEN/SHUT THE JAWS

Simply pull down the Clamp Lever, the jaws will open.

Pull up the lever, the jaws will shut. (See Fig. L)

Do NOT adjust the knob AFTER shutting the jaws be-

!

cause this operation will NOT securely hold your bike!

Adjust first, then shut the jaws.

When the turning the adjuster knob anti-clockwise with

!

the lever in the open position, do NOT over-tighten or

force the knob as this will damage the threads on the

lever.

When turning the adjuster knob clockwise with the

lever in the open position, do NOT loosen the knob too

much as this will unthread the lever and could damage

the mechanism.

(Fig. K)

(Fig. L)

TO ROTATE THE JAWS

Push down the Gear Lever to unlock the clamp jaws, then grab and rotate the jaws.

HOW TO REPLACE THE CLAMP RUBBER

1

Remove both E-rings which hold the clamp rubber with a

plier. (see Fig. M)

- 4 -

(Fig. M)

Page 5

2

3

Remove and replace the clamp rubber. (see Fig. N)

(Fig. N)

Push the E-rings onto the rubber projections and finish the

installing new clmap rubber. (see. Fig. O)

(Fig. O)

IF THE CLAMP LEVER HAS COMPLETELY FALLEN OFF...

1

2

3

Once you had removed the thread of the roll nut in the clamp

jaws compeletely by your improper adjustment (Fig. P), you

cannot use it any more.

To fix the problem, remove the clamp bolt completely from

the roll nut (see Fig. Q), then tighten the clamp bolt again and

stop when the first a few threads are seen from the roll nut.

(see Fig. R)

Be sure NOT to over-tighten the bolt until NO threads remain

from the roll nut, otherwise the later steps for adjustment may

be difficult.

Insert the tip of the bolt to the rear roll nut (may be hidden in

the square tubing) and keep this position.

This bolt has a special thread that is opposite to the one on

farthest part. This system makes both roll nuts come together

(Fig. P)

(Fig. Q)

4

when you tighten the bolt.

Stop tightening when the clearance between the roll nuts is

apporoximately one inch (see Fig. S), and check if it becomes

possible to set the bolt down completely in the horrow of the

frame.

- 5 -

(Fig. R)

1 inch

(Fig. S)

Page 6

CONTACT:CONTACT:

CONTACT:

CONTACT:CONTACT:

FOR MORE INFORMATION

MINOURA JAPAN HEAD OFFICEMINOURA JAPAN HEAD OFFICE

MINOURA JAPAN HEAD OFFICE

MINOURA JAPAN HEAD OFFICEMINOURA JAPAN HEAD OFFICE

1197-1 Godo, Anpachi, Gifu 503-2305 JAPAN

Phone (+81) 584-27-3131 / Fax (+81) 584-27-4258

Email : minoura@minoura.jp

http://www.minoura.jp

MINOURA NORTH AMERICAMINOURA NORTH AMERICA

MINOURA NORTH AMERICA

MINOURA NORTH AMERICAMINOURA NORTH AMERICA

(for U.S. and Canada resident only)(for U.S. and Canada resident only)

(for U.S. and Canada resident only)

(for U.S. and Canada resident only)(for U.S. and Canada resident only)

1996 East Avenue, Hayward, CA94541-5454 U.S.A.

Phone 1-510-538-8599 / Fax 1-510-538-5899

Email : MinouraUSA@ATTglobal.net

MADE IN JAPAN

Copyright ©2001 MINOURA CO.,LTD.

- 6 -

Loading...

Loading...