Page 1

SERVICE MANUAL

Models

7145/7222/7228/7235

APRIL 2004

CSM-7145/7222/7228/7235

KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC.

Page 2

Page 3

7145/7222/7228/7235

SERVICE MANUAL

APRIL 2004

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Minolta Business

Solutions U.S.A., Inc. strongly recommends that all

servicing be performed by Konica Minolta-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Minolta Business Solutions

U.S.A., Inc., makes no representations or warranties,

either expressed or implied, that the information contained in this service manual is complete or accurate. It

is understood that the user of this manual must assume

all risks or personal injury and/or damage to the equipment while servicing the equipment for which this service manual is intended.

Corporate Publications Department

© 2004, KONICA MINOLTA BUSINESS SOLUTIONS U.S.A. , INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

IMPORTANT NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

DESCRIPTION ITEMS FOR DANGER, WARNING AND CAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

SAFETY WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-2

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-10

IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-10

SAFETY CIRCUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-11

INDICATION OF WARNING ON THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-13

List of major differences between the 7145, 7235, 7228 and 7222 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

List of options corresponding to the 7145/7235/7228/7222 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

I OUTLINE

1. OUTLINE OF SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

A. Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

B. Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

C. Copy paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

D. Machine data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

E. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

F. Consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

G. Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3. CENTER CROSS SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4. DRIVE SYSTEM DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4.1 Drum drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4.2 Cleaning/Developer agitation drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4.3 Fixing/Paper exit section/IT-101/RU-101 drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4.4 Developing drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4.5 Paper feed drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4.5.1 Drive from paper feed motor to loop clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4.5.2 Tray 1 drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

4.5.3 Tray 2 drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

4.5.4 Bypass feed drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

4.5.5 Registration clutch drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

4.6 ADU drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

4.7 Scanner drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

4.8 Toner supply drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

I OUTLINEII UNIT EXPLANATIONIII DIS./ASSEMBLY

i

2

Page 6

CONTENTS

I OUTLINEII UNIT EXPLANATIONIII DIS./ASSEMBLY

II UNIT EXPLANATION

1. SCANNER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

1.2.1 Initial operation when power is turned on and shading correction reading. . . . . . . . . . . . . . 2-2

1.2.2 Original reading mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

1.2.3 Original read control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

1.2.4 APS control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

1.2.5 AE control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

1.2.6 Image processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2. WRITE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.2.1 Image writing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.2.2 Write control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3. DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

3.2.1 Image formation timing (when copying two sheets) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

4. DEVELOPING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

4.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

4.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

4.2.1 Developing control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

4.2.2 Control of toner density in the developing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

5. TONER SUPPLY/CLEANING/RECYCLE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

5.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

5.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

5.2.1 Toner supply control when the toner level in the toner supply section gets reduced . . . . . 2-18

5.2.2 Toner supply control when toner density in the developing unit gets reduced . . . . . . . . . . 2-19

6. PAPER FEED UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

6.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

6.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

6.2.1 Tray up drive control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

6.2.2 Paper feed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

6.2.3 Remaining paper detection control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

6.2.4 Paper size detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

7. FIXING UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

7.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

7.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

7.2.1 Fixing temperature control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

7.2.2 Cleaning web control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

8. ADU/PAPER EXIT SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

8.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

8.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

8.2.1 Switching control of the paper exit/ADU conveyance path . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

8.2.2 ADU conveyance control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

8.2.3 Paper reverse control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2

ii

Page 7

CONTENTS

9. INTERFACE SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

9.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

10.NETWORK SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

10.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

11.OTHER CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

11.1 Parts energized when the main power switch is off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

11.2 Components operated when the power switch is on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

11.2.1 Components operated when the SW1 (Main power switch) is on . . . . . . . . . . . . . . . . . . . 2-38

11.2.2 Components operated when the SW2 (Sub power switch) is on . . . . . . . . . . . . . . . . . . . . 2-39

11.3 Fan control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

11.3.1 Composition of the cooling fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

11.3.2 Fan operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

11.4 Operation unit control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

11.4.1 Composition of operation unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

11.5 Counter control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

11.5.1 Counter composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

11.5.2 Counter operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

III DISASSEMBLY/ASSEMBLY

I OUTLINEII UNIT EXPLANATIONIII DIS./ASSEMBLY

1. EXTERNAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 Replacing the ozone filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 Replacing the filter cover assembly and suction filter/A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

2. DRIVE SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

2.1 Removing and reinstalling the motor units (main, fixing, feed, developing) . . . . . . . . . . . . . . . . . 3-3

2.2 Replacing the registration clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

2.3 Replacing the loop clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

2.4 Removing the ribbon cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

2.5 Reinstalling the ribbon cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3. SCANNER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.1 Screws that must not be removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.2 Adjusting the angle of the operation unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.3 Removing the operating unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.4 Removing the platen glass/slit glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.5 Removing and reinstalling the CCD unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.6 Replacing the exposure lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.7 Removing and reinstalling the exposure unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.8 Removing the optics wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.9 Installing the optics wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

4. WRITE UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

4.1 Removing and reinstalling the write unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

5. DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

5.1 Removing and reinstalling the drum unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

5.2 Removing and reinstalling the charging corona unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

5.3 Removing and reinstalling the charge control plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

5.4 Replacing the charging wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

5.5 Removing and reinstalling the drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

5.6 Removing and reinstalling the separation claw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

iii

2

Page 8

CONTENTS

I OUTLINEII UNIT EXPLANATIONIII DIS./ASSEMBLY

5.7 Removing and reinstalling the transfer and separation corona unit. . . . . . . . . . . . . . . . . . . . . . . 3-34

5.8 Replacing the transfer and separation wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

6. DEVELOPING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

6.1 Screws that must not be removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

6.2 Removing and reinstalling the developing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

6.3 Replacing the developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

7. TONER SUPPLY/CLEANING/RECYCLE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

7.1 Removing and reinstalling the toner bottle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

7.2 Removing and reinstalling the toner supply unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

7.3 Removing and reinstalling the cleaning blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

8. PAPER FEED UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

8.1 Replacing the paper feed roller and the feed roller (by-pass) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

8.2 Replacing the double feed prevention roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

8.3 Replacing the paper feed rubber and the feed rubber (tray 1). . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

8.4 Replacing the double feed prevention rubber (tray 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

8.5 Replacing the paper feed rubber and the feed rubber (tray 2). . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

8.6 Replacing the double feed prevention rubber (tray 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

8.7 Cleaning the paper dust removing brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

9. FIXING UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

9.1 Removing and reinstalling the fixing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

9.2 Replacing the fixing heater lamps/1, /2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

9.3 Removing and reinstalling the fixing claw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

9.4 Replacing the fixing web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

9.5 Removing and reinstalling the fixing heat roller, fixing pressure roller,

heat insulating sleeve/A, /B, fixing idling gear/B, fixing bearing/U, /L,

fixing heater lamp/1, /2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

9.6 Removing and reinstalling the fixing temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64

9.7 Removing and reinstalling the Fuse mounting plate assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

2

iv

Page 9

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the Safety and Important Warning Items described below to understand them before doing ser-

vice work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this copier as well as the risk of damage to

the copier, Konica Minolta Business Technologies, INC. (hereafter called the KMBT) strongly recommends that

all servicing be performed only by KMBT-trained service technicians.

Changes may have been made to this copier to improve its performance after this Service Manual was printed.

Accordingly, KMBT does not warrant, either explicitly or implicitly, that the information contained in this Service

Manual is complete and accurate.

The user of this Service Manual must assume all risks of personal injury and/or damage to the copier while ser-

vicing the copier for which this Service Manual is intended.

Therefore, this Service Manual must be carefully read before doing service work both in the course of technical

training and even after that, for performing maintenance and control of the copier properly.

Keep this Service Manual also for future service.

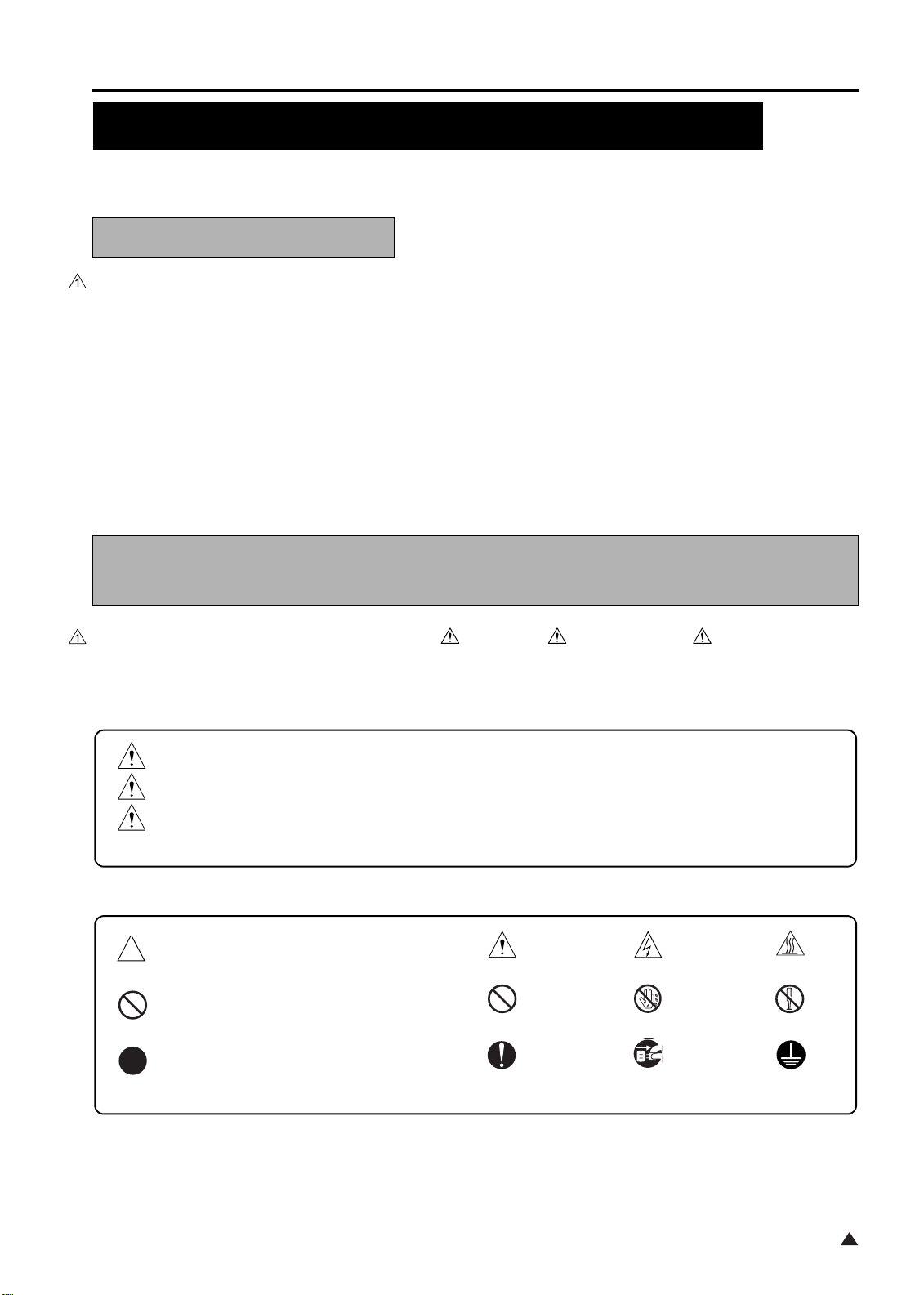

DESCRIPTION ITEMS FOR DANGER, WARNING AND CAUTION

In this Service Manual, each of three expressions “ DANGER”, “ WARNING”, and “ CAUTION” is defined

as follows together with a symbol mark to be used in a limited meaning.

When servicing the copier, the relevant works (disassembling, reassembling, adjustment, repair, maintenance,

etc.) need to be conducted with utmost care.

DANGER

WARNING

CAUTION

Symbols used for safety and important warning items are defined as follows:

:Precaution when using the copier.

:Prohibition when using the copier.

:Action having a high possibility of suffering death or serious injury

:Action having a possibility of suffering death or serious injury

:Action having a possibility of suffering a slight wound, medium trouble, and

property damage

General precaution Electric hazard High temperature

General prohibition Do not touch with wet hand Do not disassemble

:Direction when using the copier.

General instruction

S-1

Unplug

Ground/Earth

1

Page 10

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY WARNINGS

[1] MODIFICATIONS NOT AUTHORIZED BY

KONICA MINOLTA BUSINESS TECHNOLOGIES, INC.

Konica Minolta brand copiers are renowned for their high reliability. This reliability is achieved through high-qual-

ity design and a solid service network.

Copier design is a highly complicated and delicate process where numerous mechanical, physical, and electrical

aspects have to be taken into consideration, with the aim of arriving at proper tolerances and safety factors. For

this reason, unauthorized modifications involve a high risk of degradation in performance and safety. Such mod-

ifications are therefore strictly prohibited. the points listed below are not exhaustive, but they illustrate the rea-

soning behind this policy.

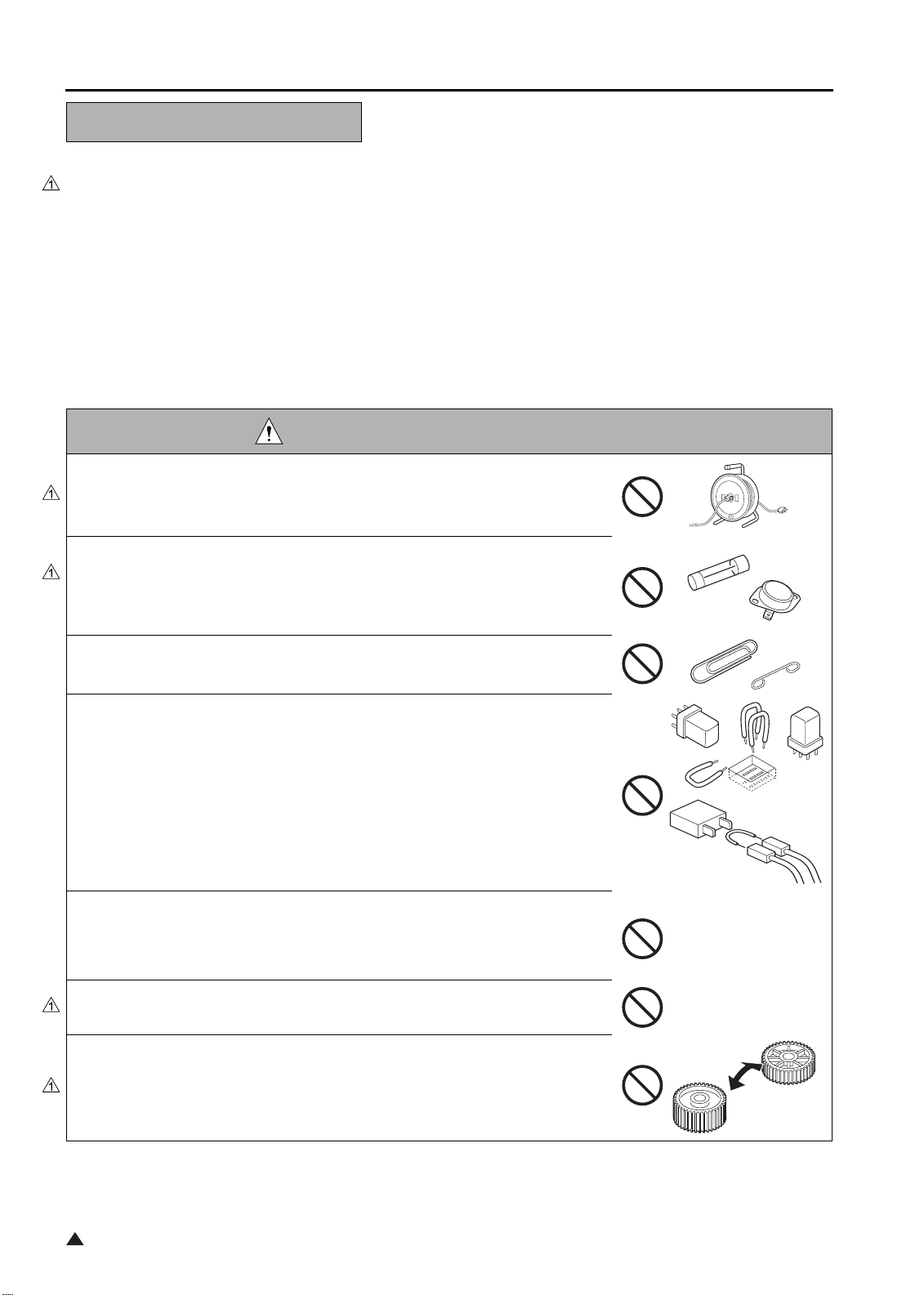

DANGER : PROHIBITED ACTIONS

• Using any cables or power cord not specified by KMBT.

• Using any fuse or thermostat not specified by KMBT. Safety will not be

assured, leading to a risk of fire and injury.

• Disabling fuse functions or bridging fuse terminals with wire, metal clips, sol-

der or similar object.

• Disabling relay functions (such as wedging paper between relay contacts)

• Disabling safety functions (interlocks, safety circuits, etc.) Safety will not be

assured, leading to a risk of fire and injury.

• Making any modification to the copier unless instructed by KMBT

• Using parts not specified by KMBT

1

S-2

Page 11

SAFETY AND IMPORTANT WARNING ITEMS

[2] CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE

Konica Minolta brand copiers are extensively tested before shipping, to ensure that all applicable safety stan-

dards are met, in order to protect the customer and customer engineer (hereafter called the CE) from the risk of

injury. However, in daily use, any electrical equipment may be subject to parts wear and eventual failure. In order

to maintain safety and reliability, the CE must perform regular safety checks.

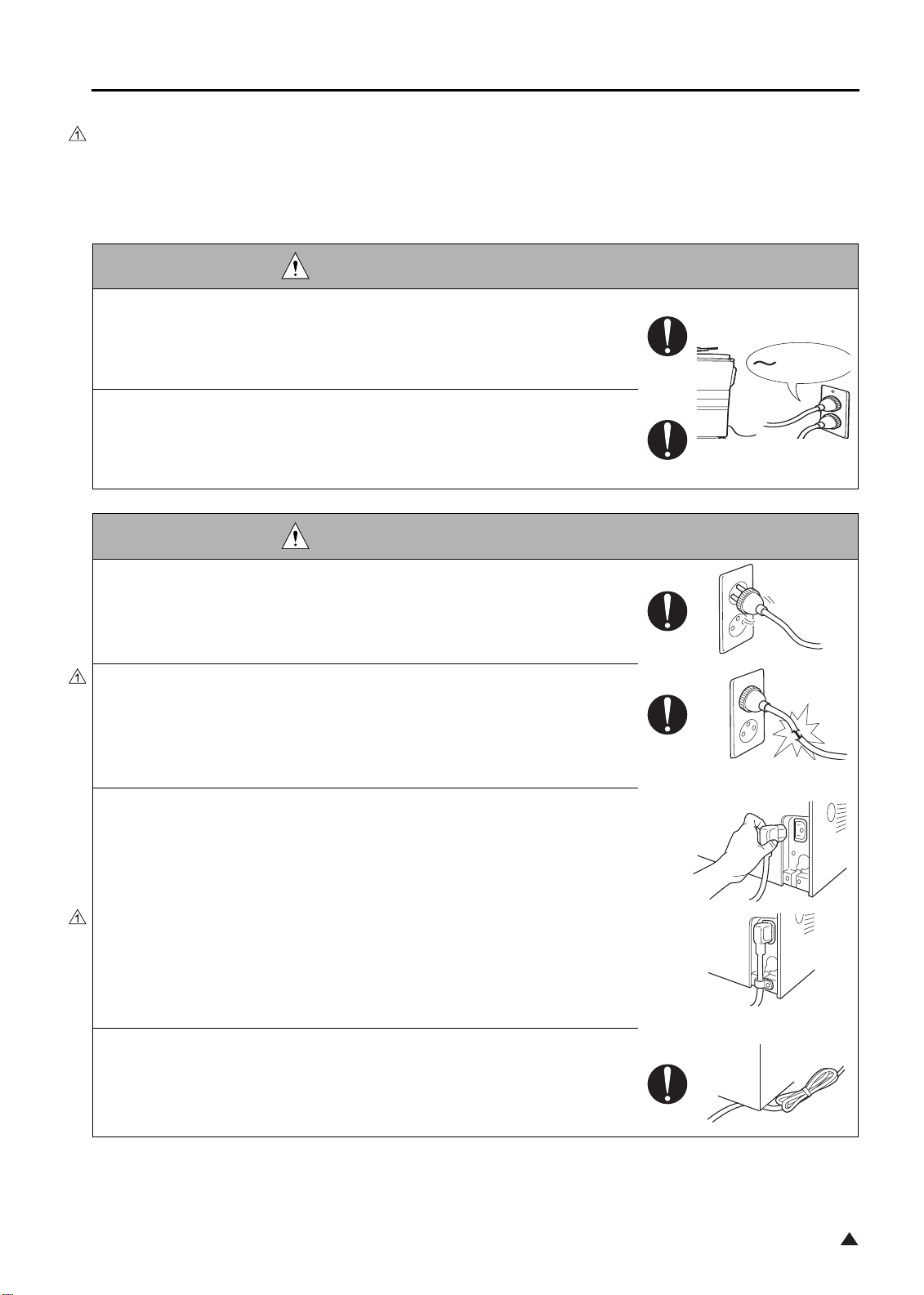

1.Power Supply

WARNING: Wall Outlet

• Check that mains voltage is as specified. Plug the power cord into the dedi-

cated wall outlet with a capacity greater than the maximum power consump-

tion.

If excessive current flows in the wall outlet, fire may result.

• If two or more power cords can be plugged into the wall outlet, the total load

must not exceed the rating of the wall outlet.

If excessive current flows in the wall outlet, fire may result.

kw

WARNING: Power Plug and Cord

• Make sure the power cord is plugged in the wall outlet securely.

Contact problems may lead to increased resistance, overheating, and the

risk of fire.

• Check whether the power cord is damaged. Check whether the sheath is

damaged.

If the power plug, cord, or sheath is damaged, replace with a new power

cord (with plugs on both ends) specified by KMBT. Using the damaged

power cord may result in fire or electric shock.

• When using the power cord (inlet type) that came with this copier, be sure to

observe the following precautions:

a. Make sure the copier-side power plug is securely inserted in the socket

on the rear panel of the copier.

Secure the cord with a fixture properly.

b. If the power cord or sheath is damaged, replace with a new power cord

(with plugs on both ends) specified by KMBT.

If the power cord (inlet type) is not connected to the copier securely, a

contact problem may lead to increased resistance, overheating, and risk

of fire.

• Check whether the power cord is not stepped on or pinched by a table and

so on.

Overheating may occur there, leading to a risk of fire.

S-3

1

Page 12

SAFETY AND IMPORTANT WARNING ITEMS

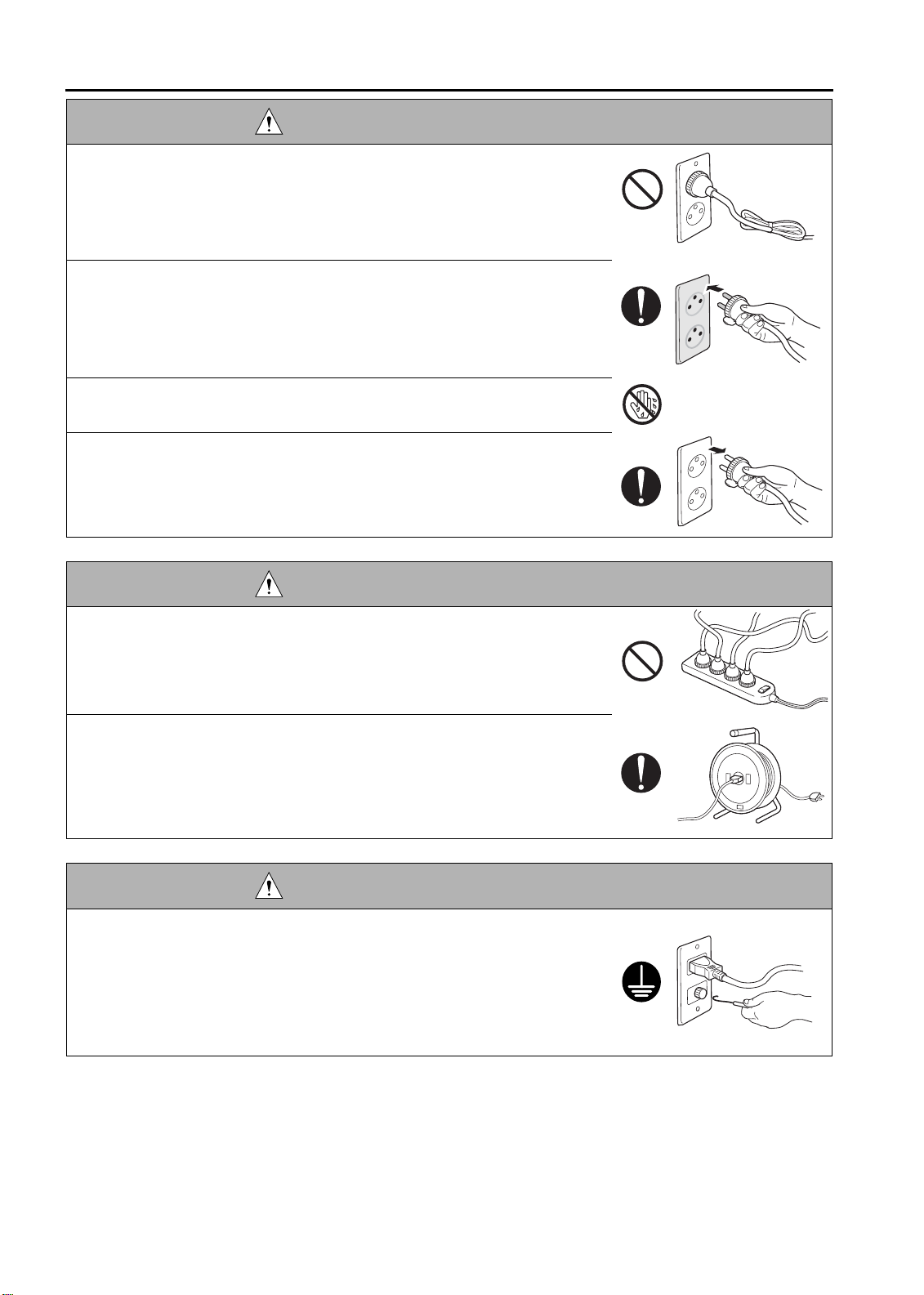

WARNING: Power Plug and Cord

• Do not bundle or tie the power cord.

Overheating may occur there, leading to a risk of fire.

• Check whether dust is collected around the power plug and wall outlet.

Using the power plug and wall outlet without removing dust may result in

fire.

• Do not insert the power plug into the wall outlet with a wet hand.

The risk of electric shock exists.

• When unplugging the power cord, grasp the plug, not the cable.

The cable may be broken, leading to a risk of fire and electric shock.

WARNING: Wiring

• Never use multi-plug adapters to plug multiple power cords in the same out-

let.

If used, the risk of fire exists.

• When an extension cord is required, use a specified one.

Current that can flow in the extension cord is limited, so using a too long

extension cord may result in fire.

Do not use an extension cable reel with the cable taken up. Fire may

result.

WARNING: Ground Lead

• Check whether the copier is grounded properly.

If current leakage occurs in an ungrounded copier, you may suffer electric

shock while operating the copier. Connect the ground lead to one of the

following points:

a. Ground terminal of wall outlet

b. Ground terminal for which Class D work has been done

S-4

Page 13

SAFETY AND IMPORTANT WARNING ITEMS

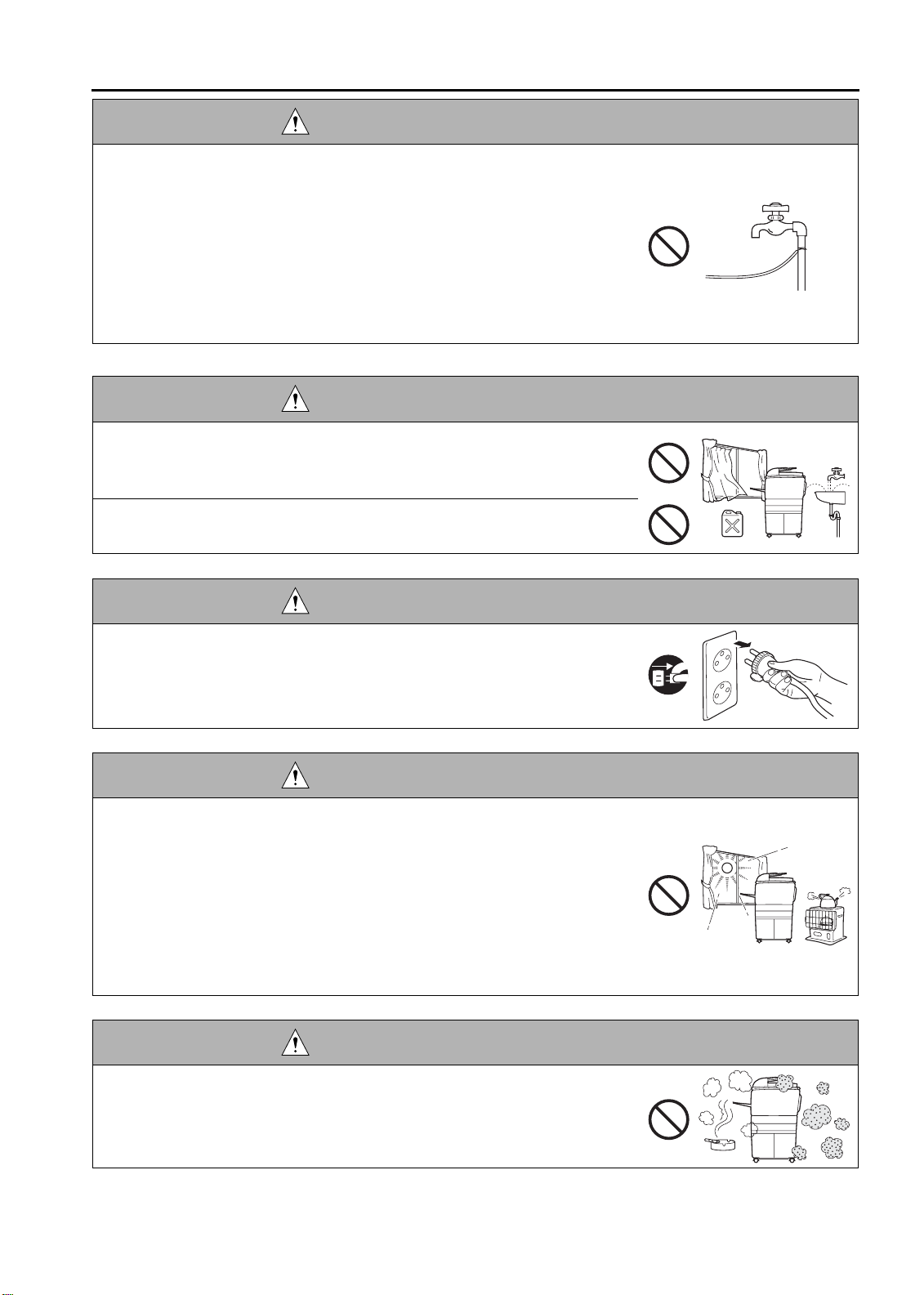

WARNING: Ground Lead

• Pay attention to the point to which the ground lead is connected.

Connecting the ground lead to an improper point such as the points listed

below results in a risk of explosion and electric shock:

a. Gas pipe (A risk of explosion or fire exists.)

b. Lightning rod (A risk of electric shock or fire exists.)

c. Telephone line ground (A risk of electric shock or fire exists in the case

of lightning.)

d. Water pipe or faucet (It may include a plastic portion.)

2.Installation Requirements

WARNING: Prohibited Installation Place

• Do not place the copier near flammable materials such as curtains or volatile

materials that may catch fire.

A risk of fire exists.

• Do not place the copier in a place exposed to water such as rain water.

A risk of fire and electric shock exists.

WARNING: Nonoperational Handling

• When the copier is not used over an extended period of time (holidays, etc.),

switch it off and unplug the power cord.

Dust collected around the power plug and outlet may cause fire.

CAUTION: Temperature and Humidity

• Do not place the copier in a place exposed to direct sunlight or near a heat

source such as a heater.

A risk of degradation in copier performance or deformation exists.

Do not place the copier in a place exposed to cool wind.

Recommended temperature and humidity are as follows:

Temperature: 10

Humidity: 10% to 80% (no dew condensation)

Avoid other environments as much as possible.

°

C

to 30

C

°

CAUTION: Ventilation

• Do not place the copier in a place where there is much dust, cigarette

smoke, or ammonia gas.

Place the copier in a well ventilated place to prevent machine problems

and image faults.

S-5

Page 14

SAFETY AND IMPORTANT WARNING ITEMS

CAUTION: Ventilation

• The copier generates ozone gas during operation, but it is not sufficient to be

harmful to the human body.

If a bad smell of ozone is present in the following cases, ventilate the

room.

a. When the copier is used in a poorly ventilated room

b. When taking a lot of copies

c. When using multiple copiers at the same time

CAUTION: Vibration

• When installing the copier, read the Installation Guide thoroughly. Be sure to

install the copier in a level and sturdy place.

Constant vibration will cause problems.

• Be sure to lock the caster stoppers.

In the case of an earthquake and so on, the copier may slide, leading to a

injury.

CAUTION: Inspection before Servicing

• Before conducting an inspection, read all relevant documentation (service

manual, technical notices, etc.) and proceed with the inspection following the

prescribed procedure in safety clothes, using only the prescribed tools. Do

not make any adjustment not described in the documentation.

If the prescribed procedure or tool is not used, the copier may break and a

risk of injury or fire exists.

• Before conducting an inspection, be sure to disconnect the power plugs from

the copier and options.

When the power plug is inserted in the wall outlet, some units are still pow-

ered even if the POWER switch is turned OFF. A risk of electric shock

exists.

• The area around the fixing unit is hot.

You may get burnt.

DANGER: Work Performed with the Copier Powered

• Take every care when making adjustments or performing an operation check

with the copier powered.

If you make adjustments or perform an operation check with the external

cover detached, you may touch live or high-voltage parts or you may be

caught in moving gears or the timing belt, leading to a risk of injury.

2

S-6

Page 15

SAFETY AND IMPORTANT WARNING ITEMS

DANGER: Work Performed with the Copier Powered

• Take every care when servicing with the external cover detached.

High-voltage exists around the drum unit. A risk of electric shock exists.

WARNING: Safety Checkpoints

• Check the exterior and frame for edges, burrs, and other damages.

The user or CE may be injured.

• Do not allow any metal parts such as clips, staples, and screws to fall into the

copier.

They can short internal circuits and cause electric shock or fire.

• Check wiring for squeezing and any other damage.

Current can leak, leading to a risk of electric shock or fire.

• When disconnecting connectors, grasp the connector, not the cable.

(Specifically, connectors of the AC line and high-voltage parts)

Current can leak, leading to a risk of electric shock or fire.

• Carefully remove all toner remnants and dust from electrical parts and elec-

trode units such as a charging corona unit.

Current can leak, leading to a risk of copier trouble or fire.

• Check high-voltage cables and sheaths for any damage.

Current can leak, leading to a risk of electric shock or fire.

• Check electrode units such as a charging corona unit for deterioration and

sign of leakage.

Current can leak, leading to a risk of trouble or fire.

• Before disassembling or adjusting the write unit incorporating a laser, make

sure that the power cord has been disconnected.

The laser light can enter your eye, leading to a risk of loss of eyesight.

• Do not remove the cover of the write unit. Do not supply power with the write

unit shifted from the specified mounting position.

The laser light can enter your eye, leading to a risk of loss of eyesight.

• When replacing a lithium battery, replace it with a new lithium battery speci-

fied in the Parts Guide Manual. Dispose of the used lithium battery using the

method specified by local authority.

Improper replacement can cause explosion.

S-7

Page 16

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Safety Checkpoints

• After replacing a part to which AC voltage is applied (e.g., optical lamp and

fixing lamp), be sure to check the installation state.

A risk of fire exists.

• Check the interlock switch and actuator for loosening and check whether the

interlock functions properly.

If the interlock does not function, you may receive an electric shock or be

injured when you insert your hand in the copier (e.g., for clearing paper

jam).

• Make sure the wiring cannot come into contact with sharp edges, burrs, or

other pointed parts.

Current can leak, leading to a risk of electric shock or fire.

• Make sure that all screws, components, wiring, connectors, etc. that were

removed for safety check and maintenance have been reinstalled in the orig-

inal location. (Pay special attention to forgotten connectors, pinched cables,

forgotten screws, etc.)

A risk of copier trouble, electric shock, and fire exists.

DANGER: HANDLING OF SERVICE MATERIALS

• Toner and developer are not harmful substances, but care must be taken not

to breathe excessive amounts or let the substances come into contact with

eyes, etc. It may be stimulative.

If the substances get in the eye, rinse with plenty of water immediately.

When symptoms are noticeable, consult a physician.

• Never throw the used cartridge and toner into fire.

You may be burned due to dust explosion.

S-8

Page 17

SAFETY AND IMPORTANT WARNING ITEMS

DANGER : HANDLING OF SERVICE MATERIALS

• Unplug the power cord from the wall outlet.

Drum cleaner (isopropyl alcohol) and roller cleaner (acetone-based) are

highly flammable and must be handled with care. A risk of fire exists.

• Do not replace the cover or turn the copier ON before any solvent remnants

on the cleaned parts have fully evaporated.

A risk of fire exists.

• Use only a small amount of cleaner at a time and take care not to spill any

liquid. If this happens, immediately wipe it off.

A risk of fire exists.

• When using any solvent, ventilate the room well.

Breathing large quantities of organic solvents can lead to discomfort.

[3] MEASURES TO TAKE IN CASE OF AN ACCIDENT

1. If an accident has occurred, the distributor who has been notified first must immediately take emergency

measures to provide relief to affected persons and to prevent further damage.

2. If a report of a serious accident has been received from a customer, an on-site evaluation must be carried

out quickly and KMBT must be notified.

3. To determine the cause of the accident, conditions and materials must be recorded through direct on-site

checks, in accordance with instructions issued by KMBT.

4. For reports and measures concerning serious accidents, follow the regulations given in “Serious Accident

Report/Follow-up Procedures”.

[4] CONCLUSION

1. Safety of users and customer engineers depends highly on accurate maintenance and administration.

Therefore, safety can be maintained by the appropriate daily service work conducted by the customer

engineer.

2. When performing service, each copier on the site must be tested for safety. The customer engineer must

verify the safety of parts and ensure appropriate management of the equipment.

S-9

1

Page 18

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY INFORMATION

IMPORTANT INFORMATION

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration implemented

regulations for laser products manufactured since August 1, 1976. Compliance is mandatory for products mar-

keted in the United States.

This copier is certified as a “Class 1” laser product under the U.S.

Department of Health and Human Services (DHHS) Radiation Performance Standard according to the Radiation

Control for Health and Safety Act of 1968. Since radiation emitted inside this copier is completely confined within

protective housings and external covers, the laser beam cannot escape during any phase of normal user opera-

tion.

S-10

Page 19

SAFETY CIRCUITS

SAFETY AND IMPORTANT WARNING ITEMS

This machine is provided with the following safety circuits

to prevent machine faults from resulting in serious acci-

dents.

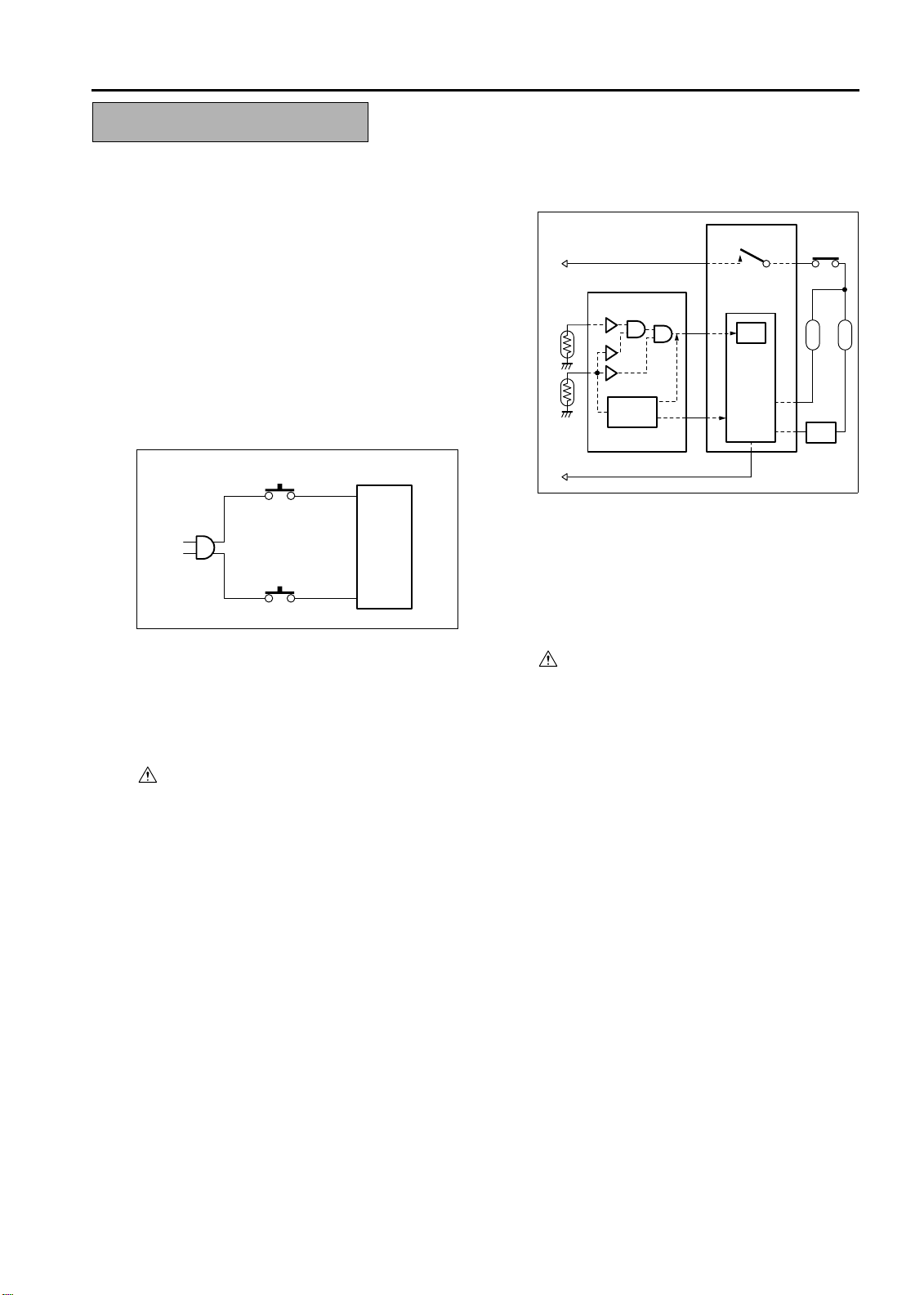

[1] Overall protection circuit

[2] L2 and L3 (fixing heater lamp/1, /2) overheat-

ing prevention circuit

These safety circuits are described below to provide

the service engineer with a renewed awareness of

them in order to prevent servicing errors that may

impair their functions.

[1] Overall protection circuit

CBR1

DCPS

CBR2

1. Protection by CBR1 and CBR2 (circuit

breaker/1, /2)

CBR1 and CBR2 interrupt the AC line instanta-

neously when an excessive current flows due

to a short in the AC line.

CAUTION:

The CBR1 and CBR2 functions must not

be deactivated under any circumstances.

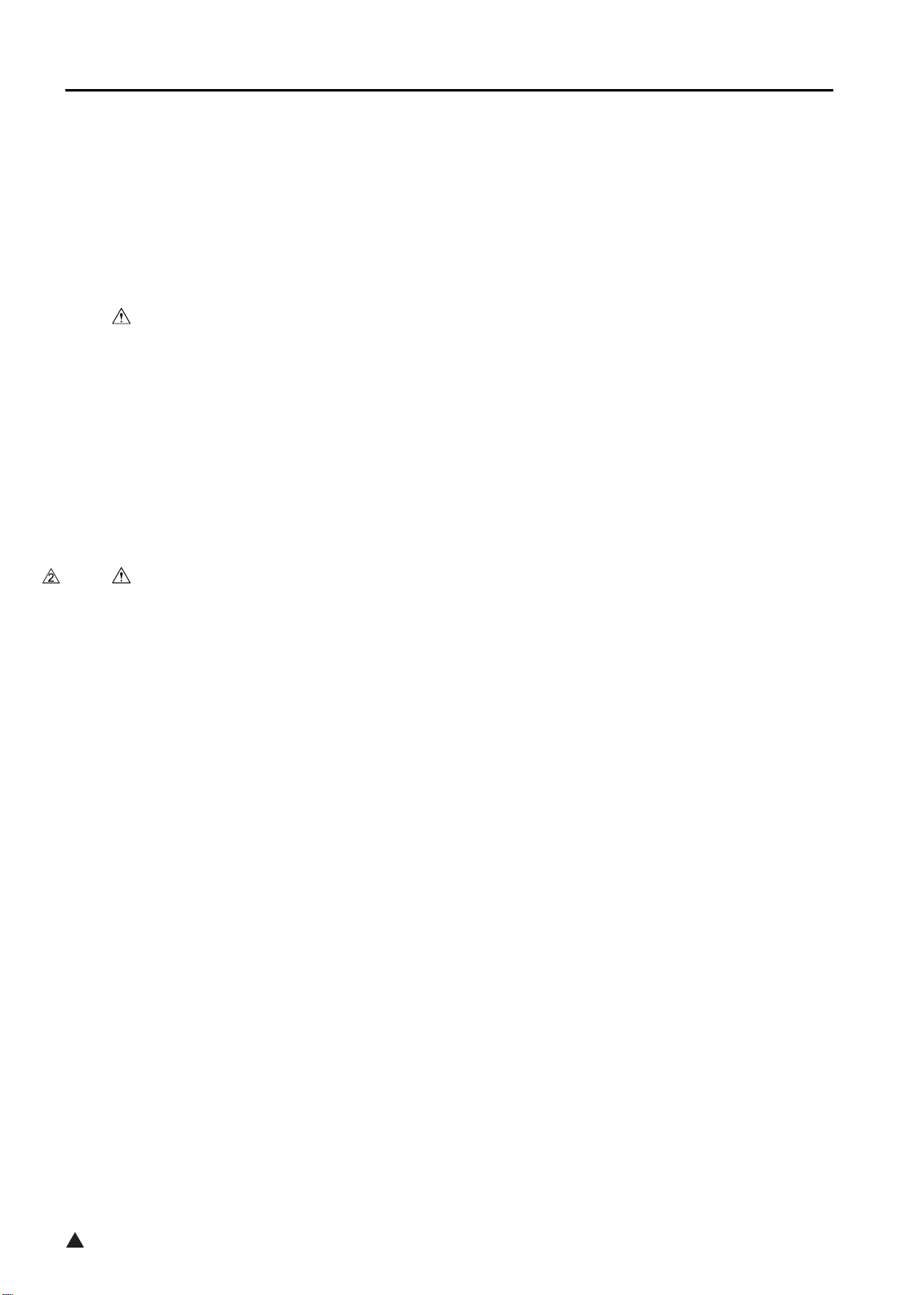

[2] L2 and L3 (fixing heater lamp/1, /2)

overheating prevention circuit

DCPS

RL1

CB

RL1

TH1 TH2

Control

section

AC driver

section

1. Protection by software

The output voltage from TH1, TH2 (fixing tem-

perature sensor/1, /2) is read by the CPU. If

this voltage is abnormal, L2 (fixing heater

lamp/1), L3 (fixing heater lamp/2) and RL1

(main relay) are turned OFF.

CAUTION:

The RL1 function must not be deactivated

under any circumstances.

TS

L2

FCB

L3

S-11

Page 20

SAFETY AND IMPORTANT WARNING ITEMS

2. Protection by the hardware circuit

The output voltages from TH1, TH2 (fixing tem-

perature sensor/1, /2) are compared with the

abnormality judgment reference value in the

comparator circuit. If the output voltage from

TH1 or TH2 exceeds the reference value, L2

(fixing heater lamp/1), L3 (fixing heater lamp/2)

and RL1 (main relay) are turned OFF in hard-

ware means.

CAUTION:

Periodically check the TH1, TH2 face

contacting the roller, and replace TH2 if

any abnormality is detected.

The RL1 function must not be deactivated

under any circumstances.

3. Protection by TS (thermostat)

When the fixing heat roller exceeds the speci-

fied value, TSs (thermostats) are turned OFF,

thus interrupting the power to L2 (fixing heater

lamp/1), and L3 (fixing heater lamp/2) directly.

CAUTION:

Do not use any other electrical conductor

in place of TS1 and TS2.

2

S-12

Page 21

SAFETY AND IMPORTANT WARNING ITEMS

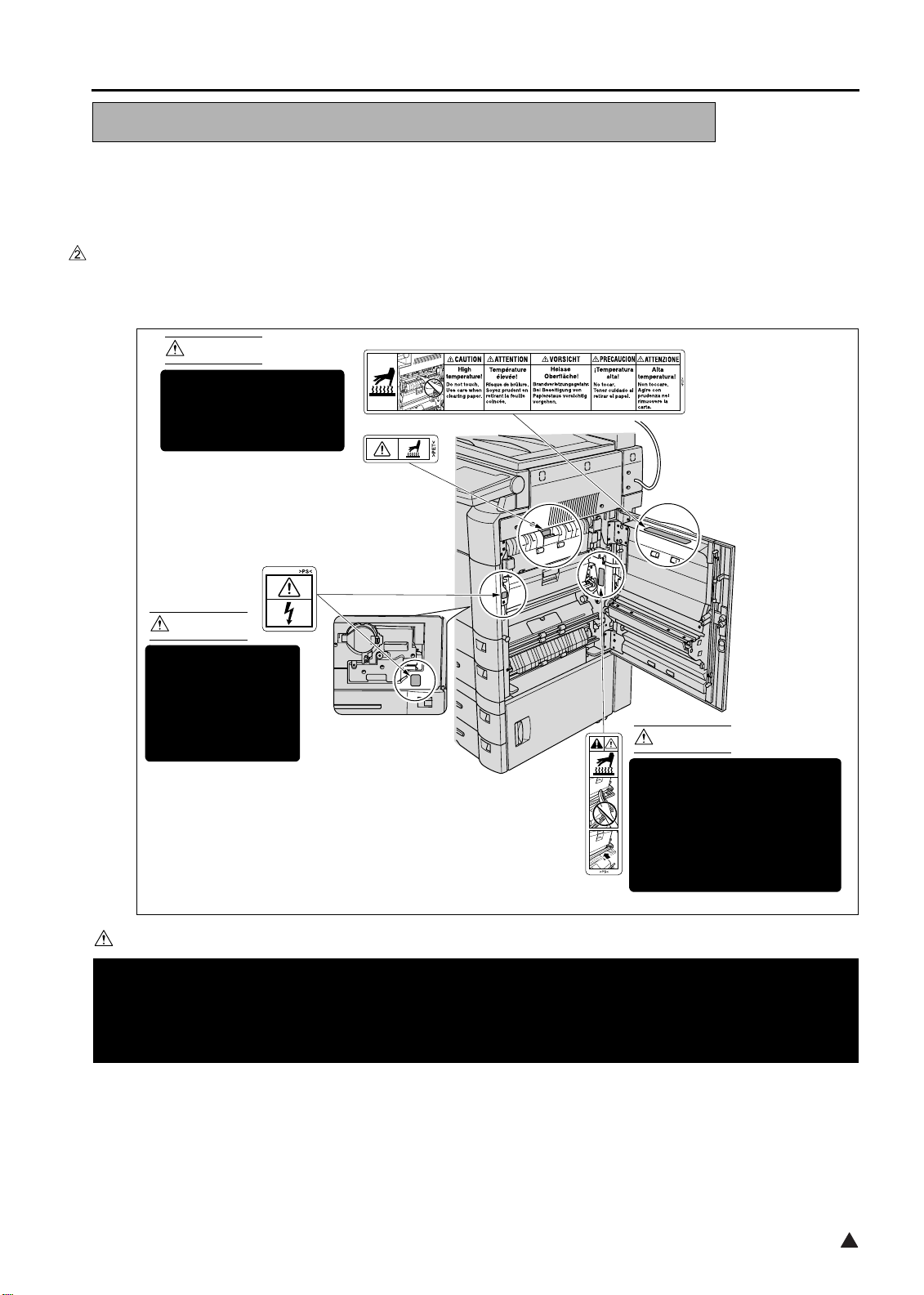

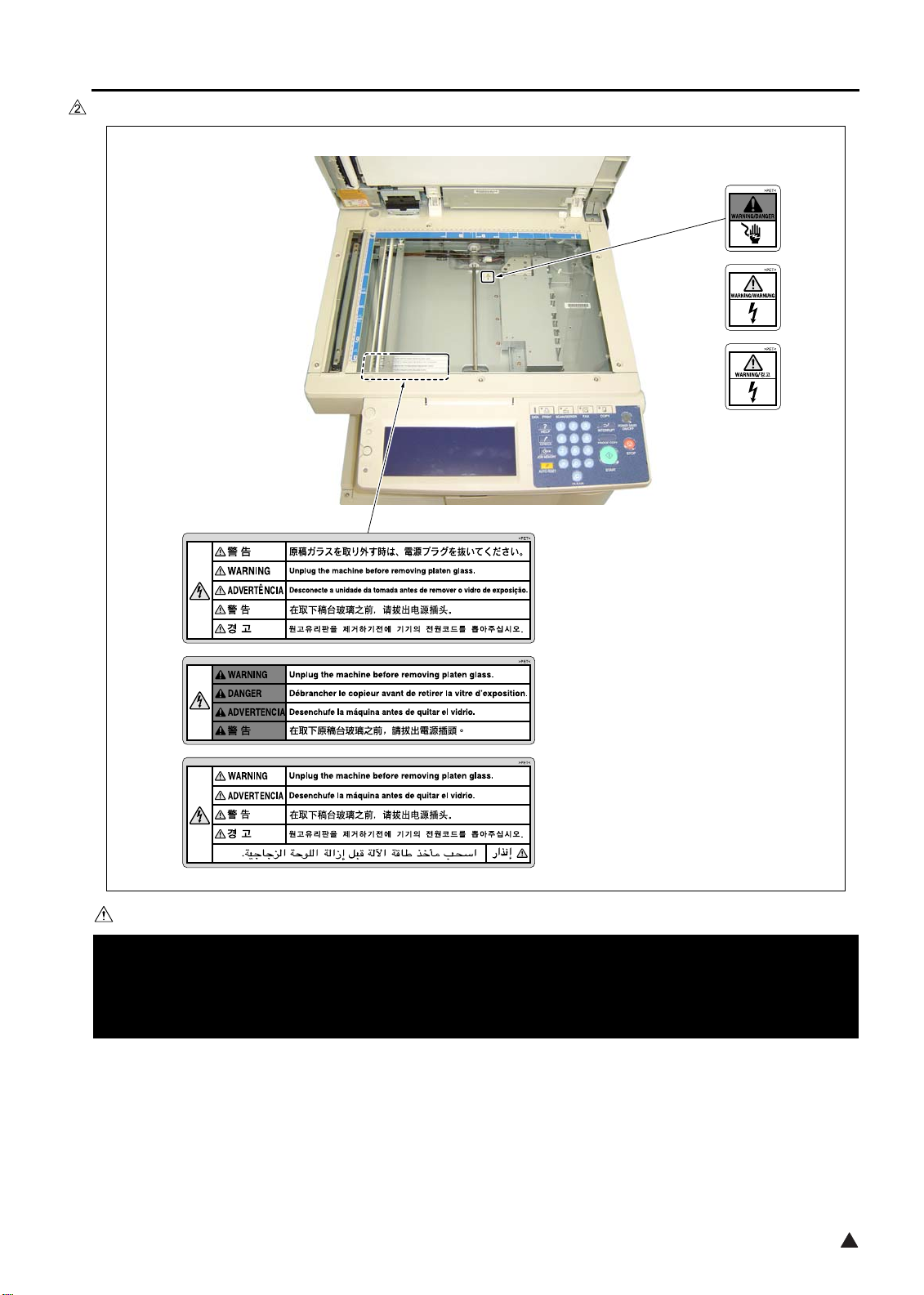

INDICATION OF WARNING ON THE MACHINE

Caution labels shown below are attached in some areas on/in the machine.

When accessing these areas for maintenance, repair, or adjustment, special care should be taken to avoid burns

and electric shock.

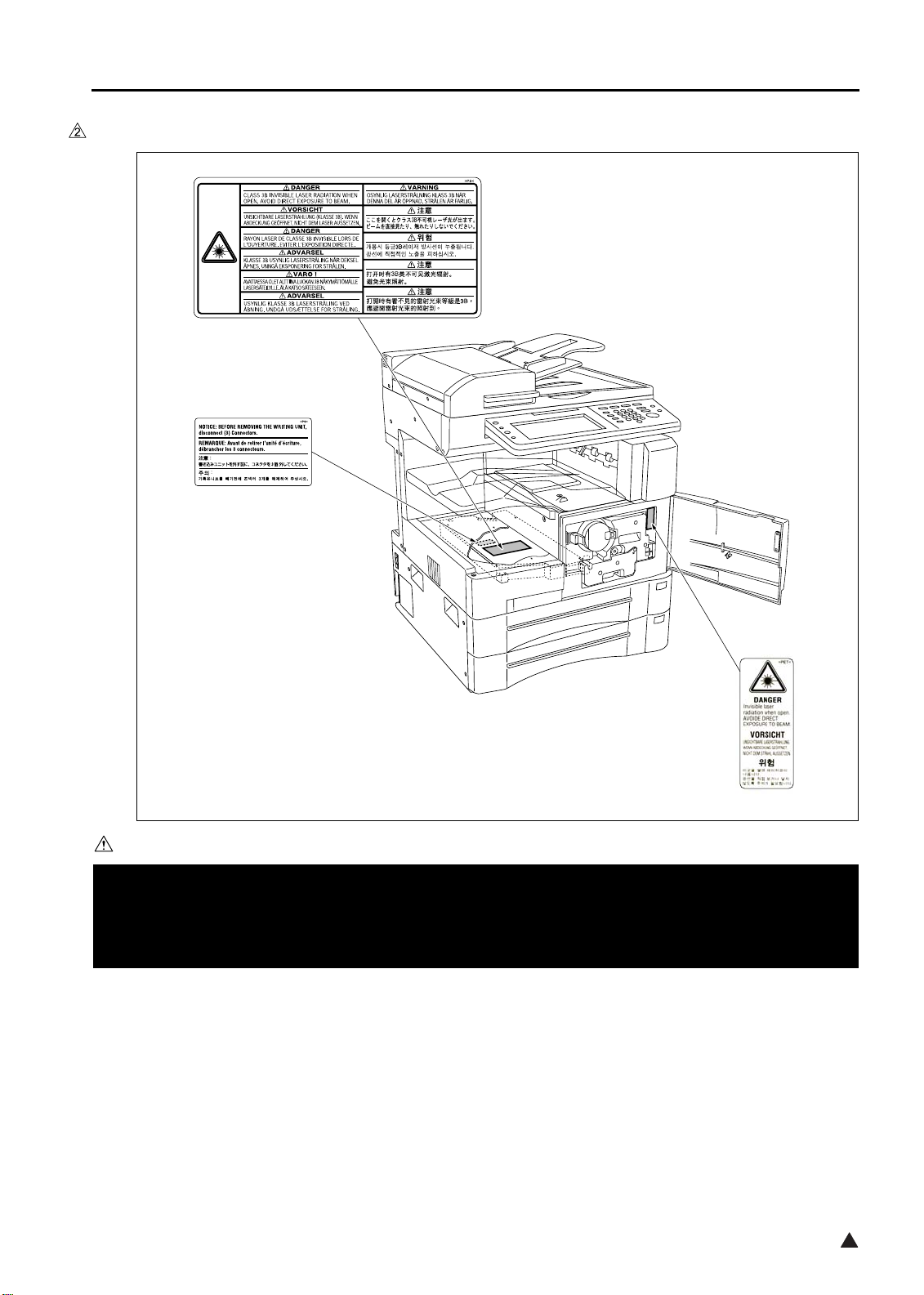

[1] Main body

1. Right side

<7145>

CAUTION

The fixing unit is very hot.

To avoid getting burned

DO NOT TOUCH.

CAUTION

This area generates

high voltage.

If touched, electrical

shock may occur.

DO NOT TOUCH!

(Inside of the main

body front door)

CAUTION

The roller shaft on the inside

(Inside of the main

body right side door)

of the cover is very hot.

To avoid getting burned DO

NOT TOUCH.

If the cover comes off, return

it to its original position.

7322sf001e

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-13

2

Page 22

SAFETY AND IMPORTANT WARNING ITEMS

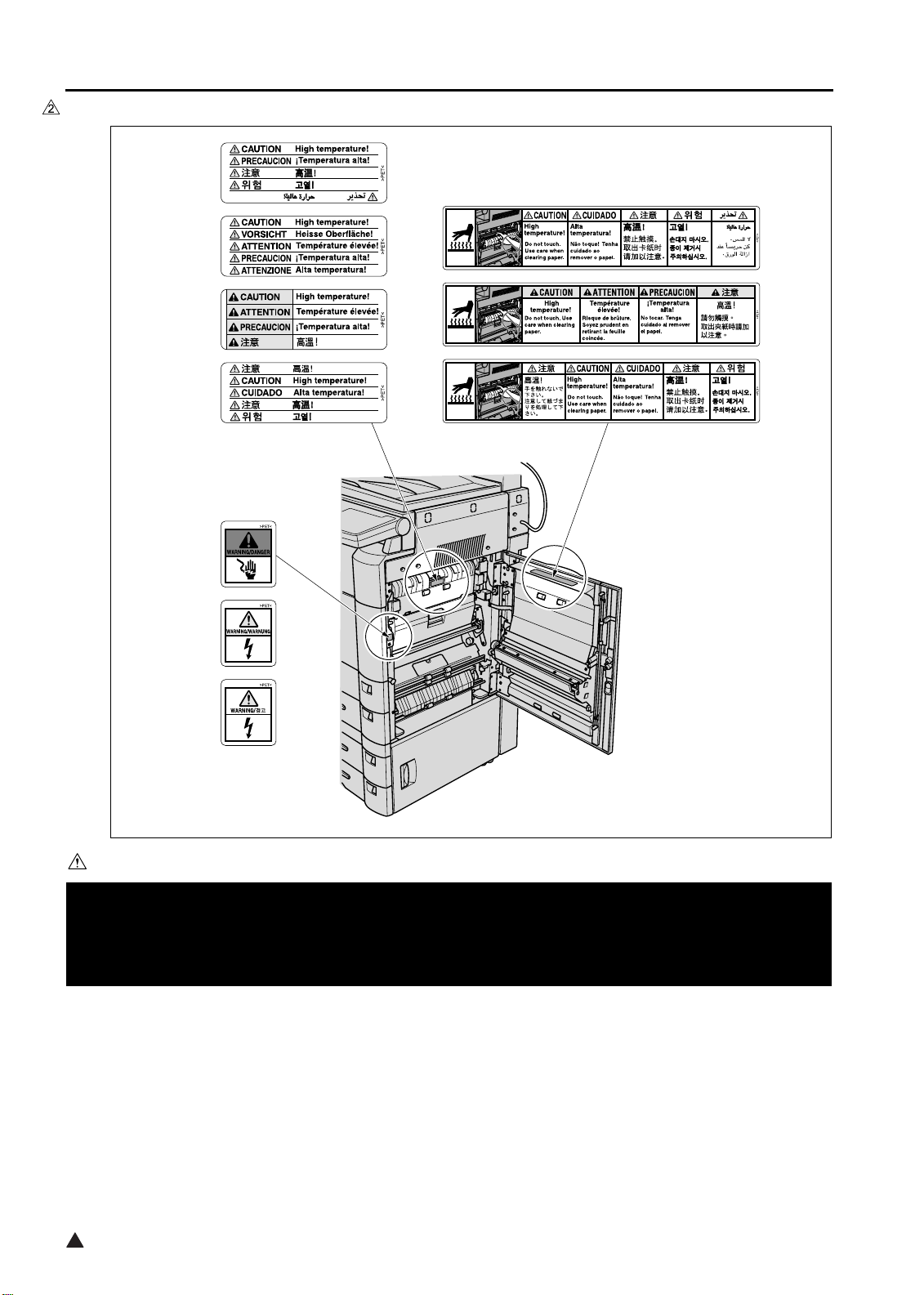

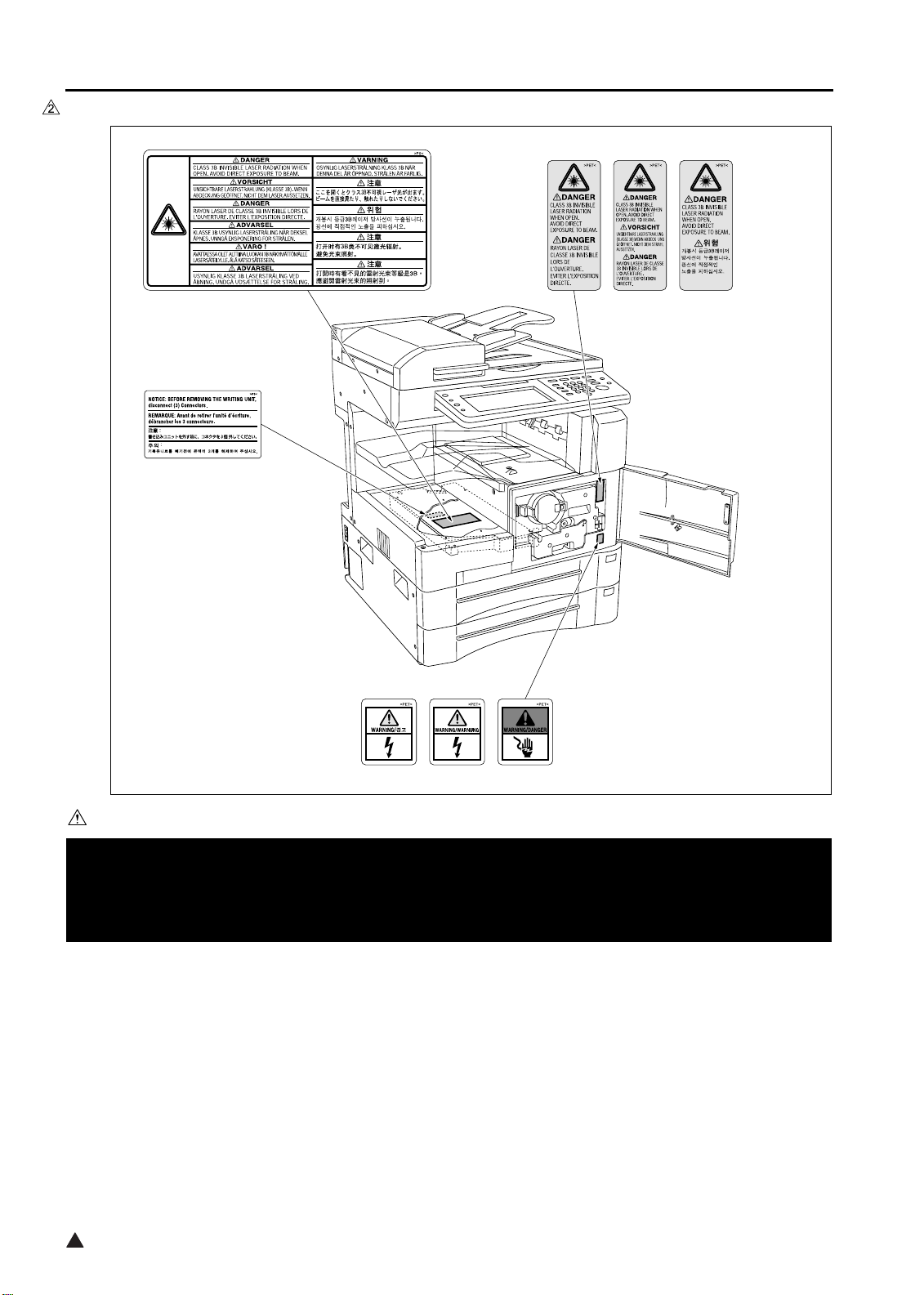

<7235/7228/7222>

7322sf002e

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

2

S-14

Page 23

2. Front side

<7145>

SAFETY AND IMPORTANT WARNING ITEMS

7322sf003e

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-15

2

Page 24

SAFETY AND IMPORTANT WARNING ITEMS

<7235/7228/7222>

7322sf004e

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

2

S-16

Page 25

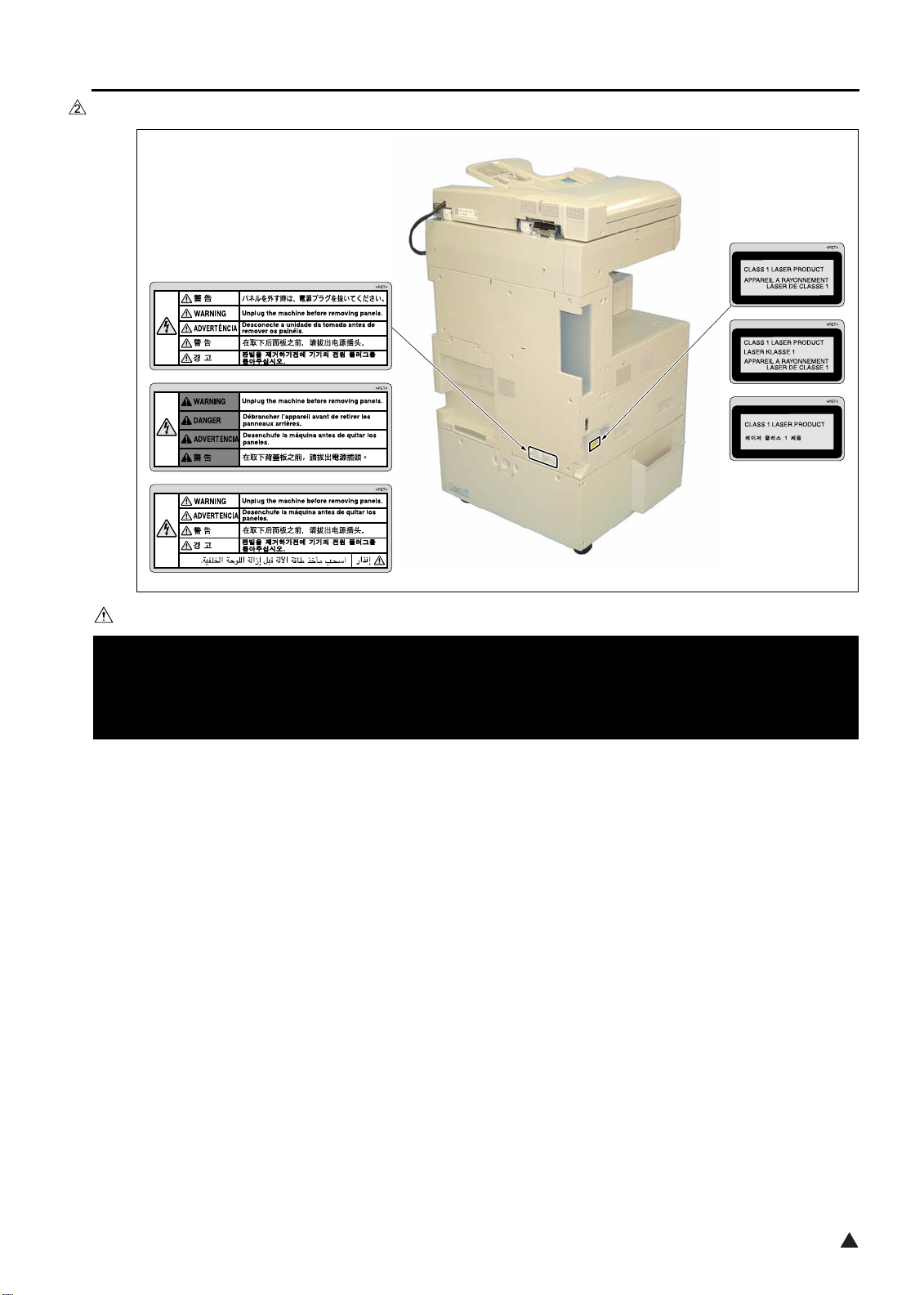

3. Rear/Left side (7235/7228/7222 only)

SAFETY AND IMPORTANT WARNING ITEMS

7322sf005e

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-17

2

Page 26

SAFETY AND IMPORTANT WARNING ITEMS

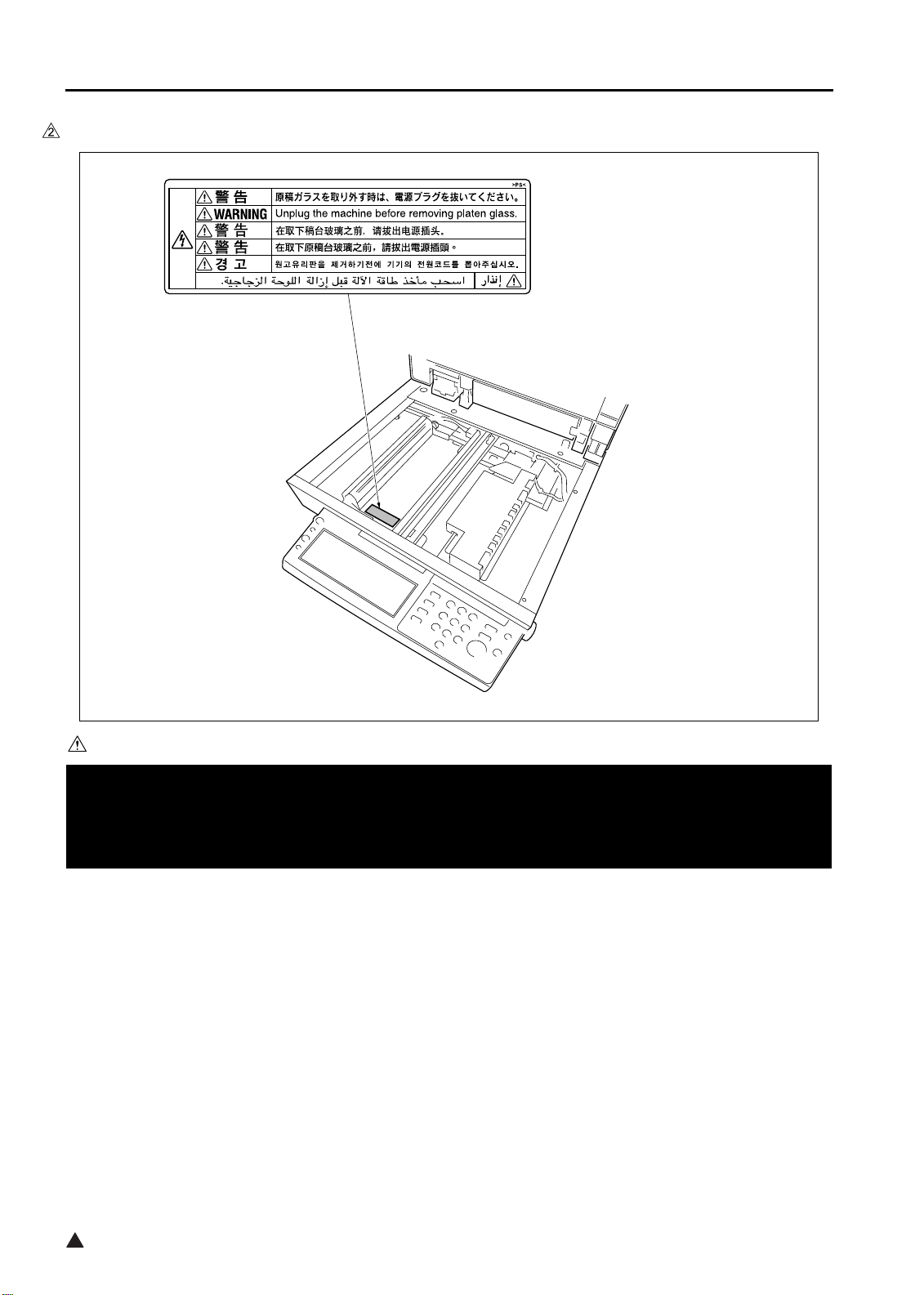

4. Scanner section

<7145>

7322sf006

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

2

S-18

Page 27

<7235/7228/7222>

SAFETY AND IMPORTANT WARNING ITEMS

7322sf007e

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-19

2

Page 28

SAFETY AND IMPORTANT WARNING ITEMS

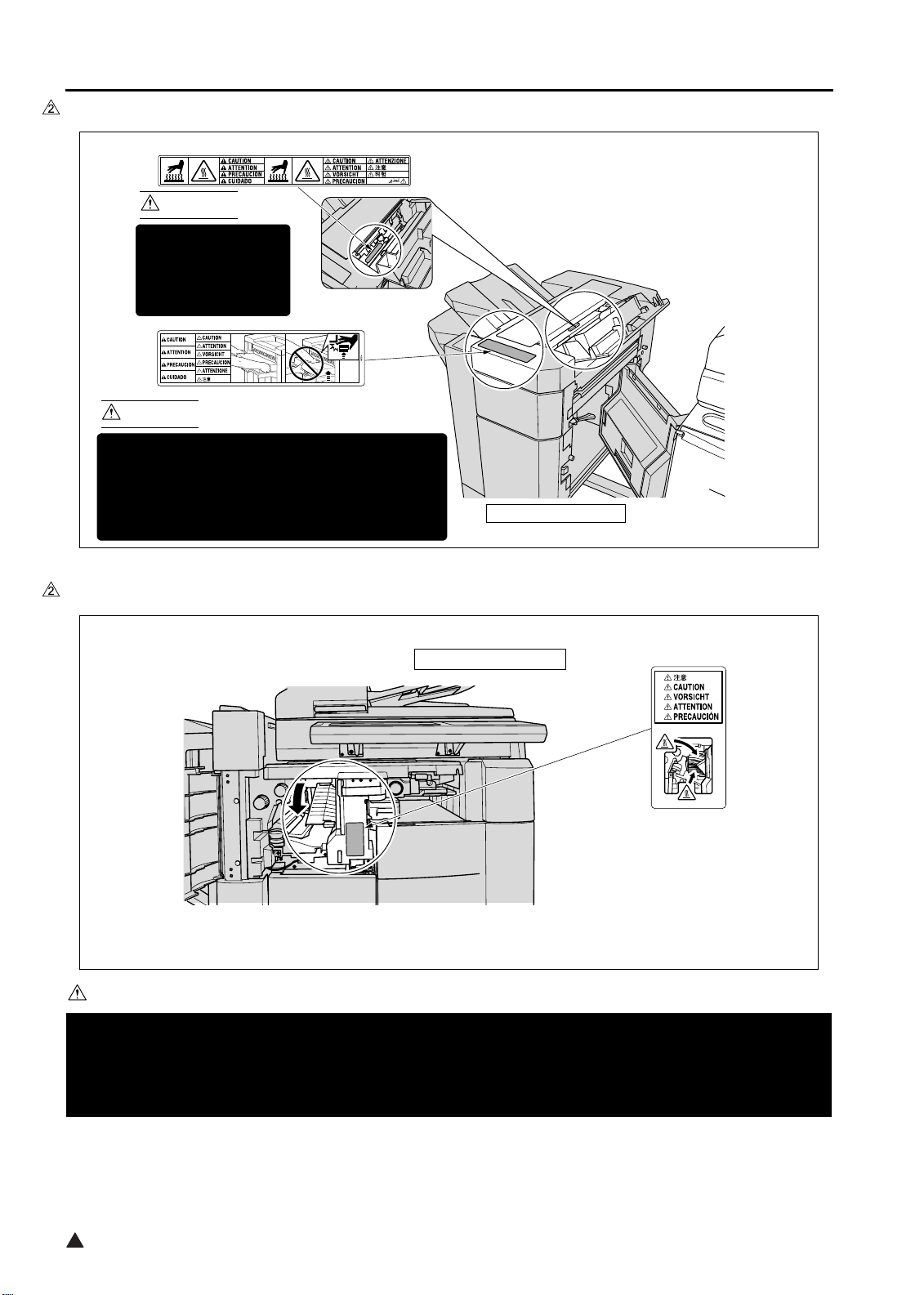

[2] FS-113

CAUTION

This area is very hot.

To avoid getting

burned DO NOT

TOUCH.

CAUTION

To avoid injury, DO NOT put your hand on the top

of the printed sheets. Be sure to hold both sides

of the printed sheets when removing them, and

DO NOT leave your hand on the printed sheets

while the primary (main) tray goes up.

(Inside of the Finisher)

FS-113 Finisher

7322sf009

[3] FS-114

FS-114 Finisher

7322sf010

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

2

S-20

Page 29

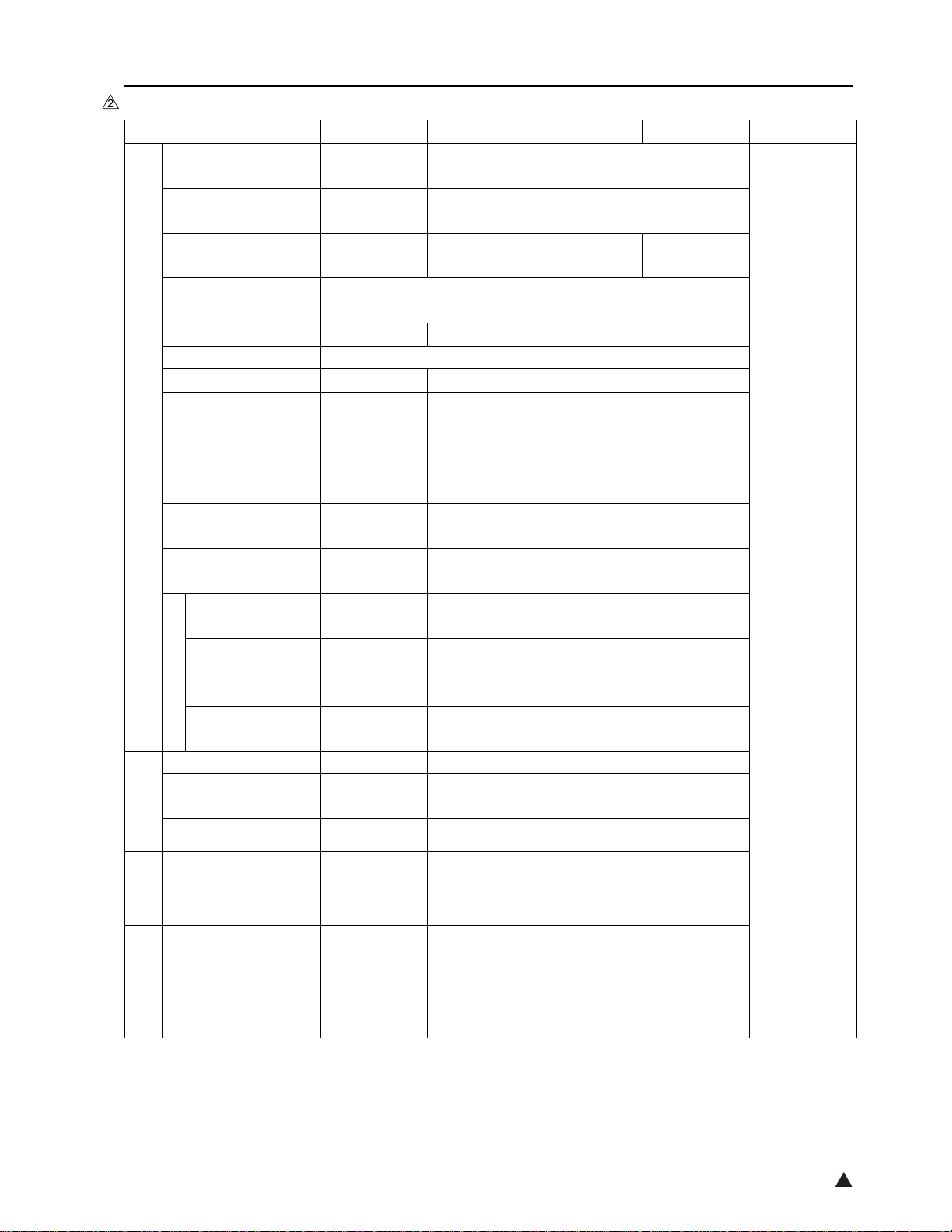

List of major differences between the 7145, 7235, 7228 and 7222

List of major differences between the 7145, 7235, 7228 and 7222

Classification 7145 7235 7228 7222 Reason

Warmup time

First copy out time

(8.5x11)

Continuous copy

speed (8.5x11)

Maximum E-RDH

memory

Less than

30 sec.

Less than

3.8 sec.

Less than

4.3 sec.

Less than 19 sec.

45 sheets/min. 35 sheets/min. 28 sheets/min.

320MB

DF Standard Optional

ADU Standard

Paper exit tray

Optional

Standard

23.2in (W)

Machine dimensions

(with DF and DB)

Specifications

Maintenance

Developer

Toner

Materials

Drum

x

23.4in (D)

x

42.6in (H)

Once every

120,000 copies

Exclusively

for 7145

Exclusively

for 7145

Exclusively

for 7145

23.4in (W) x 25.8in (D) x 44.6in (H)

Once every 100,000 copies

Exclusively for 7235/7228/7222

Exclusively for

7235 (Common

to 7135)

Exclusively for 7228/7222

(Common to 7022/7120/7135)

Exclusively for 7235/7228/7222

Flywheel f 103mm f 132mm

Developing sleeve

drive

Developing

motor

Main motor

Less than 4.9 sec.

22 sheets/min.

Change of

specifications

Vibration insulator Not provided Provided Not provided

Drive section

Scanner drive board Provided Not provided

section

Scanner

Laser 2 beams 1 beam

Number of rotations

of polygon motor

Polygon cooling Not provided Provided Not provided

Write section

27,165rpm 38,976rpm 33,070rpm

1

Change of

CPM

Change of

specifications

2

Page 30

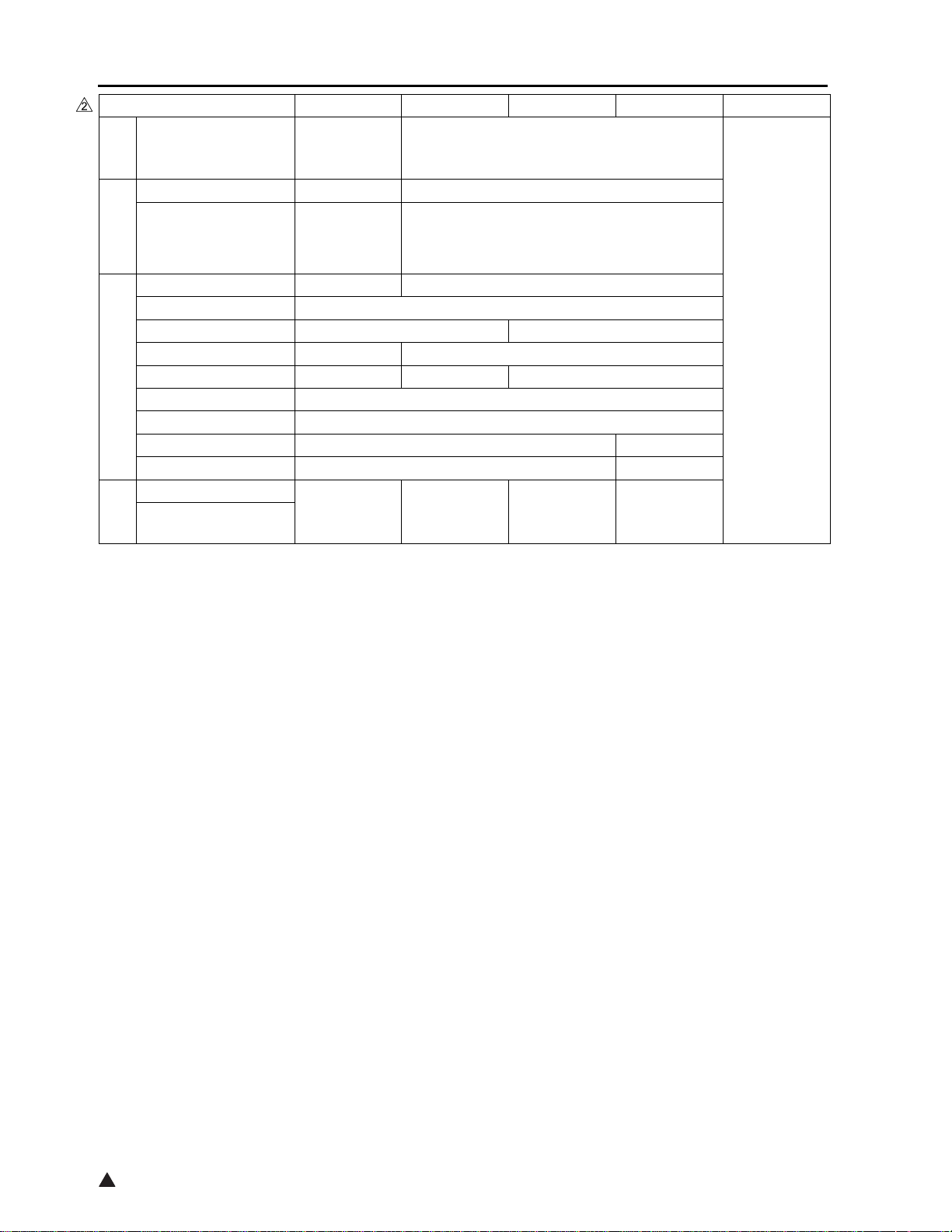

List of major differences between the 7145, 7235, 7228 and 7222

Classification 7145 7235 7228 7222 Reason

Exclusively

for 7145

Exclusively for 7235/7228/7222

Fixing

section

Fixing unit

Decurler roller Provided Not provided

ADU drive board Not provided Provided

ADU/Paper

exit section

Developing motor Provided Not provided

ADU motor Provided

Fixing cooling fan Provided Not provided

Internal cooling fan/2 Provided Not provided

Polygon cooling fan Not provided Provided Not provided

ADU gate solenoid Provided

Electrical parts

ADU sensor Provided

Timing sensor/U Provided Not provided

Timing sensor/L Provided Not provided

Overall control

Image control

Control

Exclusively

for 7145

Exclusively

for 7235

Exclusively

for 7228

Exclusively

Change of

specifications

for 7222

2

2

Page 31

List of options corresponding to the 7145/7235/7228/7222

List of options corresponding to the 7145/7235/7228/7222

Optional 7145 7235 7228 7222

RADF DF-318 Standard Not corresponding

DF-320

Finisher FS-112

FT-107

Not corresponding

Corresponding

Corresponding Not corresponding

FS-113

RU-101

FS-114

BK-114

Corresponding

PK-114

SK-114

Paper exit tray ET-101 Corresponding Corresponding*1

Inner tray IT-101 Corresponding

Desk DK-110

Not corresponding

Corresponding

DB DB-211

CorrespondingDB-411

LCT LT-203

ADU AD-307 Standard

Post script PS-344 Corresponding Not corresponding

PS-346

Printer

controller

FAX controll

board

2 lines

expansion kit

IP-432 Corresponding Not corresponding

IP-424

FK-102 Type-A

FK-103

FL-102 Corresponding Not corresponding

FL-103

Hard disk HD-103 Type-A

Not corresponding

Not corresponding

Corresponding

Corresponding

Corresponding Not corresponding

Not corresponding

Not corresponding

Corresponding

Corresponding

Corresponding

Total counter Standard Corresponding

Key counter Corresponding

*1 A paper exit tray is provided as standard equipment that is different from ET-101. When ET-101 is pro-

vided, it is integrated into the main body as seen from the point of design.

3

2

Page 32

List of options corresponding to the 7145/7235/7228/7222

Blank Page

4

Page 33

IOUTLINE

1. OUTLINE OF SYSTEM

[16]

OUTLINE OF SYSTEM

I OUTLINE

[14] [19][15]

[10]

[13]

[8]

[6]

[12]

[11]

[9]

[7]

[5]

[3]

[4]

[17]

[18][1]

[2]

1-1

7322ma1001

2

Page 34

OUTLINE OF SYSTEM

I OUTLINE

*1 As a standard equipment, the 7235/7228/7222 are provided with a paper exit tray that is different from

[1] Main body [10]

RADF (DF-318: 7145 provided as a standard equipment)

(DF-320: 7235/7228/7222)[2] LCT (LT-203)

[3] LCT DB (DB-411) [11] Paper exit tray (ET-101)*1

[4] 2-Tray DB (DB-211) [12] Finisher (FS-114)

[5] Conveyance unit (RU-101) [13] Additional tray (BK-114)

[6] Finisher (FS-113) [14] Punch kit (PK-114)

[7] Inner tray (IT-101) [15] Crease unit (included in SK-114)

[8] Finisher tray (FT-107: FS-112) [16] Saddle unit (SK-114)

[9] Finisher (FS-112: 7145 only) [17] Desk (DK-110: 7235/7228/7222 only)

[18] ADU (provided as a standard equipment)

[19] Platen cover (CV-109: 7235/7228/7222 only)

the one with which the ET-101 is equipped.

[7]

[5][6]

[1]

[8]

[1] Postscript (PS-344: 7145)

(PS-346: 7235/7228/7222)

Printer controller (IP-432: 7145)

[2]

(IP-424: 7235/7228/7222)

[3]

2 line expansion kit (shipments only to the

United States and

Oceania)

(FL-102:FK-102 Type-A)

(FL-103:FK-103)

[4] Fax control board(FK-102 Type-A: 7145)

(FK-103: 7235/7228/7222)

E-RDH expansion memory (MU-404: 64MB/MU-405: 128MB)

[5]

[2]

[4]

[3]

[6]

Hard disk (HD-103 Type-A)

[7]

Total counter

(7145 provided as standard equipment)

(In the case of the 7235/7228/7222, ship-

ments only to the United States are pro-

vided with the total counter.)

Key counter

[8]

Expansion memory for the printer controller

[9]

(Not displayed here. For details, see the

Service Manual of the controller.)

7145ma1020

2

1-2

Page 35

2. PRODUCT SPECIFICATIONS

A. Type

Type: Semi-console type (7145)

Desk-top type (7235/7228/7222)

Copying method: Indirect electrostatic method

Original table: Fixed

Original alignment: Left rear standard

Photosensitive material: OPC

Sensitizing method: Laser writing

Paper feed trays: Two trays (500 sheets x 2, 80g/m

Multisheet bypass tray (50 sheets, 80g/m

DB-211 (500 sheets x 2, 80g/m2 or 20lbs) *1

DB-411 (1500 sheets, 80g/m

LT-203 (2000 sheets, 80g/m

*1 Optional

B. Functions

2

or 20lbs)

2

or 20lbs) *1

2

or 20lbs) *1

PRODUCT SPECIFICATIONS

2

)

I OUTLINE

Original: Sheet, book, solid object (Thickness: up to 1.2in. Weight: up to 15lbs)

Maximum original size: A3, or 11 x 17

Copy size (for metric area):

Tray 1: B4, A4, A4R, B5, B5R, A5R, 8.5 x 14, 8.5 x 11, 8.5 x 11R, 5.5 x 8.5R, F4

Tray 2: A3, B4, A4, A4R, B5, B5R, A5R, 11 x 17, 8.5 x 11, 8.5 x 11R, F4

Bypass tray: A3, B4, A4, A4R, B5, B5R, A5R, B6R, 8.5 x 11R (7145 only),

8.5 x 11 (except the 7145), F4 (except the 7145)

ADU: A3, B4, A4, A4R, B5, B5R, A5R, 11 x 17, 8.5 x 11, 8.5 x 11R, 8.5 x 14, 5.5

x 8.5R, F4

Copy size (for inch area):

Tray 1: 8.5 x 14, 8.5 x 11, 8.5 x 11R, 5.5 x 8.5R, F4, B4R (7145 only), A4, A4R,

B5, A5R

Tray 2: 11 x 17, 8.5 x 14, 8.5 x 11, 8.5 x 11R, 5.5 x 8.5R, F4, A3, A4, A4R, A5R

Bypass tray: 11 x 17, 8.5 x 14, 8.5 x 11, 8.5 x 11R, 5.5 x 8.5R, A4

ADU: 11 x 17, 8.5 x 14, 8.5 x 11, 8.5 x 11R, 5.5 x 8.5R, A3, B4 (7145 only), A4,

A4R, B5, A5R, F4

Magnification:

Fixed magnification (for metric area):

x 1.00, x 1.41, x 1.22, x 1.15, x 0.86, x 0.82, x 0.71

Fixed magnification (for inch area):

x 1.00, x 2.00, x 1.55, x 1.29, x 0.77, x 0.65, x 0.50

Special ratio: Three kinds

Zoom magnification: x 0.25 to x 4.00 (at 1% step)

Vertical magnification: x 0.25 to x 4.00 (at 1% step)

Horizontal magnification: x 0.25 to x 4.00 (at 1% step)

1-3

2

Page 36

PRODUCT SPECIFICATIONS

Warm-up time: Less than 30 sec. (7145)

(at temperature of 68°F, Less than 19 sec. (7235/7228/7222)

at rated voltage)

First copy out time: Less than 3.8 sec. (7145)

I OUTLINE

Continuous copy speed: 45 copies/min. (7145)

(A4 or 8.5 x 11, 35 copies/min. (7235)

in memory copy) 28 copies/min. (7228)

Continuous copy count: Up to 999

No. of sheets loadable

on the paper exit tray: Up to 100 (8.5x11)

Copy density selection: AE, manual (9 steps), arbitrary density (2 modes)

Resolution:

Scan: 600 dpi x 600 dpi

Write: 600 dpi x 600 dpi

ERDH memory *1: Standard 64MB, Maximum 320MB

Interface section: Serial port (USB TypeB), Serial port (RS-232C), RJ45 Ethernet connector,

Network section: Ethernet frame type: IEEE 802.3/802.3/Ethernet II/

*1 Since the standard 64MB memory is packaged on the board, it is not possible to replace it with a new

one.

Only one slot is provided for expansion. It can be installed with MU-404 (64MB), MU-405 (128MB), or

256MB (commercially available).

For 256MB (commercially available), be sure to use those of make and model No. specified separately.

Less than 4.3 sec. (7235)

Less than 4.9 sec. (7228/7222)

* platen mode, manual density, life size, tray 1, paper exit with face down,

A4 or 8.5 x 11

22 copies/min. (7222)

Parallel port (IEEE1284 (Compatible, Nible, ECP))

IEEE 802.3 SNAP

Connecting type: 10 Base-T/100 Base-TX

Corresponding protocol: TCP/IP (BOOTP, ARP, ICMP, DHCP,

SNMP, HTTP, SMTP, POP3, FTP, IPP),

IPX/SPX, AppleTalk (EtherTalk),

Corresponding OS: Novell NetWare (3.x, 4.x, 5.x), Microsoft

Windows 95/98/Me, Microsoft Windows

NT4.0/2000/XP, Mac OS8.x and later,

Mac OS10.2.5

Multi-protocol: Automatic discrimination

Corresponding printing method: Peer-to-Peer (TCP/IP), LPD/LPR (TCP/

IP), PServer (IPX/SPX), RPrinter (IPX,

SPX), AppleTalk (EtherTalk)

General purpose utility: Web browser (Internet Explorer,

Netscape Navigator)

Status indicator LED: Green LED and orange LED, one for

each

2

1-4

Page 37

PRODUCT SPECIFICATIONS

Number of originals to be stored:More than 140 sheets under the following conditions:

Original: Konica standard chart

Density: Manual 5

Mode: Character/photograph

Memory capacity: 64MB (provided only as standard)

Job: Job in mode with page memory not used

C. Copy Paper

Plain paper: 60g/m2 or 17lbs to 105g/m2 or 28lbs, high-quality paper

Special paper *1 Label paper, OHP film, blueprint-master paper, 50g/m

or 16lbs high-quality paper (thin), 106g/m2 or 28lbs to 130g/m2 or 35lbs

high-quality paper (thick1), 131g/m

quality paper (thick2 *2)

*1 With bypass feed method, paper should be fed one sheet at a time. Double sided copy not allowed.

*2 Only bypass feed.

2

or 35lbs to 160g/m2 or 43lbs high-

2

or 13lbs to 59g/m

D. Machine Data

I OUTLINE

2

Power source: 230VAC –14% to 10.6% 50Hz/60Hz

120VAC –14% to 6% 60Hz

Power consumption: Maximum 1500W or less (fully optional)

Weight: Approximately 183lbs (with DF provided)

Dimensions: 7145: 23.2in (W) x 23.4in (D) x 42.6in (H) (with DF + DB)

7235/7228/7222: 23.4in (W) x 25.8in (D) x 44.6in (H) (with DF + DB)

E. Maintenance

Maintenance: Once every 120,000 copies (7145)

Once every 100,000 copies (7235/7228/7222)

F. Consumables

Developer: Exclusively for 7145

Exclusively for 7235/7228/7222

Toner: Exclusively for 7145

Exclusively for 7235 (Common to 7135)

Exclusively for 7228/7222 (Common to 7022/7120/7130)

Drum: Exclusively for 7145 (φ 60)

Exclusively for 7235/7228/7222 (φ 60)

1-5

2

Page 38

PRODUCT SPECIFICATIONS

G. Operating Environment

Temperature: 10°C to 30°C (50°F to 86°F)

Humidity: 10% RH to 80% RH

I OUTLINE

Note:

• The information herein may be subject to change for improvement without notice.

1-6

Page 39

3. CENTER CROSS SECTION

[18] [19] [20]

CENTER CROSS SECTION

[17]

[16]

[15]

[14]

[13]

[12]

I OUTLINE

[1]

[2]

[3]

[4]

[5]

[6]

[11]

[10]

[1] Fixing unit [10] DB

[2] Drum unit [11] Developing unit

[3] Separation corona unit [12] Tray 2

[4] Transfer corona unit [13] Tray 1

[5] ADU unit [14] Charging corona unit

[6] Bypass tray [15] Cleaning/toner recycling unit

[7] Paper feed path for making a double-sided

copy (DB unprovided)

[8] Paper feed path for making a double-sided

copy (DB provided)

[9] DB paper feed path [20] CCD unit

[16]

[17]

[18]

[19]

Toner bottle

Scanner unit

V-mirror unit

Exposure unit

[7]

[8]

[9]

7322ma1002

1-7

2

Page 40

DRIVE SYSTEM DIAGRAM

4. DRIVE SYSTEM DIAGRAM

4.1 Drum Drive

I OUTLINE

4.2 Cleaning/Developer Agitation Drive

[1]

[2]

[1] M1 (Main motor) [2] Drum drive shaft

[1]

[2]

[3]

[1] M1 (Main motor) [3] Developer agitation drive

[2] Cleaning/toner recycling unit drive

1-8

Page 41

4.3 Fixing/Paper Exit Section/IT-101/RU-101 Drive

DRIVE SYSTEM DIAGRAM

[4]

[3]

[1] IT-101 [4] Paper exit drive

[2] M11 (Fixing motor) [5] Drive coupling for IT-101 and RU-101

[3] Fixing unit drive

[5]

[1]

[2]

I OUTLINE

4.4 Developing Drive

In the case of the 7145

[4]

[1] Developing sleeve [3] M3 (Developing motor)

[2] Developing unit [4] Drum drive shaft

[1]

[2]

[3]

1-9

2

Page 42

DRIVE SYSTEM DIAGRAM

In the case of the 7235/7228/7222

I OUTLINE

[1]

[2]

[3]

[4]

7322ma1003

[1] M1 (Main motor) [3] Developing unit

[2] Developing sleeve [4] Drum drive shaft

4.5 Paper Feed Drive

4.5.1 Drive from paper feed motor to loop clutch

[2]

[1]

[1] MC2 (Loop clutch) [2] M9 (Paper feed motor)

2

1-10

Page 43

4.5.2 Tray 1 drive

DRIVE SYSTEM DIAGRAM

[5][4]

[1]

SD1 (1st paper feed solenoid/U)

[1]

Conveyance roller

[2]

[3] MC2 (Loop clutch) [5] Feed roller

[4] Driven when SD1

(1st paper feed solenoid/U) is on.

I OUTLINE

[2]

[3]

4.5.3 Tray 2 drive

[2]

[5]

[4]

MC2 (Loop clutch)

[1]

Feed roller

[2]

[3] SD2 (1st paper feed solenoid/L) [5] Conveyance roller

[4] Driven when SD2

(1st paper feed solenoid/L) is on.

[1]

[3]

1-11

Page 44

DRIVE SYSTEM DIAGRAM

4.5.4 Bypass feed drive

I OUTLINE

[1] MC2 (Loop clutch) [3] SD3 (Bypass solenoid)

[2] Conveyance roller [4] Driven when SD3 (Bypass solenoid) is on.

[4] [5]

[1]

[3]

[2]

[5] Paper feed roller

4.5.5 Registration clutch drive

[2]

[1]

[1] M9 (Paper feed motor) [2] MC1 (Registration clutch)

1-12

Page 45

4.6 ADU Drive

DRIVE SYSTEM DIAGRAM

[9]

I OUTLINE

[8]

[1]

[7]

[6]

[2]

[5]

[3]

[4]

[1] M1 (Main motor) [5] ADU roller

[2] Timing belt [6] ADU conveyance roller/2

[3] M9 (Paper feed motor) [7] Decurler roller

[4] M6 (ADU motor) [8] ADU conveyance roller/1

[9] M11 (Fixing motor)

1-13

Page 46

DRIVE SYSTEM DIAGRAM

4.7 Scanner Drive

I OUTLINE

[3]

[2]

[1] Optical wire/R [4] Exposure unit

[2] Optical wire/F [5] M2 (Scanner motor)

[3] V-mirror unit

[4]

[5]

[1]

1-14

Page 47

4.8 Toner Supply Drive

[5]

[4]

DRIVE SYSTEM DIAGRAM

I OUTLINE

[2]

[3]

[1] Toner agitation plate [4] M4 (Toner supply motor 1)

[2] Toner conveyance screw [5] M10 (Toner supply motor 2)

[3] SD9 (Toner solenoid)

[1]

1-15

Page 48

DRIVE SYSTEM DIAGRAM

I OUTLINE

Blank page

1-16

Page 49

II UNIT EXPLANATION

1. SCANNER SECTION

1.1 Composition

SCANNER SECTION

7235/7228/7222

[12][11][10][9][8][7]

CB

7145

SCDB

II UNIT EXPLANATION

CB

SCB

[2][3][4][5][6] [1]

Symbol Name Function or method

[1] INV1 (Exposure lamp inverter) L1 (Exposure lamp) turn on

[2] PS17 (APS sensor) Detection of original size in the direction of sub-scanning

[3] ADB (A/D converter board) Digital conversion of analog signal

[4] CCD unit Photoelectric conversion of read image (600dpi)

[5] Exposure unit Image reading

Light source slit exposure

Scan speed

• Forward: 230mm/sec. (in 1:1 magnification)

• Backward: 383mm/sec.

[6] Optical wire Transmission of driving force from M2 to the exposure unit and

the V-mirror unit (front and rear)

[7] V-mirror unit Reflection of reading light (2nd and 3rd mirrors)

[8] PS14 (Scanner HP sensor) Exposure unit HP detection

[9] L1 (Exposure lamp) Light source for reading image,

Xenon lamp

[10] L1INVB (Power supply board

for exposure lamp)

[11] M2 (Scanner motor) Driving of the optical wire used to move the exposure unit and

[12] PS15 (APS timing sensor) RADF open/close detection

Relay board for INV1 (Exposure lamp inverter) and L1 (Expo-

sure lamp)

the V-mirror unit

Three-phase step motor

7322ma2001e

2-1

2

Page 50

SCANNER SECTION

1.2 Operation

1.2.1 Initial operation when power is turned on and shading correction reading

When the SW2 (Sub power switch) comes on, the exposure unit starts a home position search. At this

time, the exposure unit uses the white reference plate attached on the back side of the original pressing

board for shading correction. However, two places on the white reference plate are read for correction.

The search procedure differs depending on whether the PS14 (Scanner HP sensor) is on or off while the

SW2 is on.

A. Home position search when the PS14 is turned on

II UNIT EXPLANATION

[1] Exposure unit standby position [3] Shading correction position 1

[2] PS14 [4] Shading correction position 2

[1][2][3][4]

7322ma2015

B. Home position search when PS14 is turned off

[1][2][3][4]

7322ma2016

[1] Exposure unit standby position [3] Shading correction position 1

[2] PS14 [4] Shading correction position 2

1.2.2 Original reading mode

The following two modes are available for original reading; platen mode and DF mode. In platen mode, the

exposure unit moves as necessary to scan the original for reading. In DF mode, the RADF side moves the

original while the exposure unit stays fixed in a specified position (DF reading position).

2

2-2

Page 51

SCANNER SECTION

A. Exposure unit movement in platen mode

In platen mode, the scan sequence depends on the copy density selection (either AE or manual).

(1) In manual density copy:

[1][6][2][3][4][5]

7322ma2017

Exposure unit standby position

[1]

PS14

[2]

Shading correction position 1

[3]

Shading correction position 2

[4]

[5] Position at which the approach run of the

exposure unit is started

[6] Position at which the reading of an image

is started

Note:

• When the tray 1 is selected manually, but not in APS, the shading operation is not executed.

(2) In AE copy:

[3][4][5][6]

[1][7]

[2]

Exposure unit standby position

[1]

AE scanning range

[2]

PS14

[3]

Shading correction position 1

[4]

[5] Shading correction position 2

[6] Position at which the approach run of the

exposure unit is started

[7] Position at which the reading of an image

is started

II UNIT EXPLANATION

7322ma2018

B. Exposure unit movement in DF mode

[1][2][3][4][5]

[1] Exposure unit standby position [4] Shading correction position 2

[2] PS14 [5] DF reading position

[3] Shading correction position 1

2-3

7322ma2019

2

Page 52

SCANNER SECTION

1.2.3 Original read control

The light from the exposure lamp reflects back from the original, passes through a lens, and hits the CCD

sensor. The CCD sensor generates an electric signal (analog signal) corresponding to the light intensity.

Then, according to the instruction from the SCB (System control board), the ADB (A/D conversion board)

converts this signal into a digital signal.

A. Original read timing

(1) Platen mode, when the manual density is being set

[2] [5]

II UNIT EXPLANATION

M2 (Scanner motor)

PS14 (Scanner HP sensor)

F

R

[1] [3] [4]

[1] START button (ON) [4]

[2] Exposure lamp (forward) [5] Exposure scanning (backward)

[3] Position to which the exposure unit starts

(2) Platen mode, when the AE density is being set

Position at which reading of the original starts

[6] [8][2] [5]

M2 (Scanner motor)

PS14 (Scanner HP sensor)

F

R

[4] [7][1]

[3][3]

START button (ON)

[1]

AE scanning (forward)

[2]

Position to which the exposure unit starts

[3]

Position at which reading of the AE density

[4]

started

2-4

AE scanning (backward)

[5]

Exposure lamp (forward)

[6]

Position at which reading of the original

[7]

starts

Exposure scanning (backward)

[8]

Page 53

B. Original read timing (DF mode) *1

SCANNER SECTION

[4][2]

M2 (Scanner motor)

F

R

PS14 (Scanner HP sensor)

M301

(Original feed motor)

R

250mm/s

230mm/s

F

460mm/s

M302

(Original conveyance motor)

F

230mm/s

460mm/s

[3]

PS308 (Original registration sensor)

[1]

[5] [6]

[1] START button (ON) [4] Exposure conveyance

[2] DF reading position [5]

[3] Position to which the original has been

conveyed in the specified distance.

Position at which reading of the original starts.

[6] Starting point from the DF reading position

to the home position (exposure unit).

*1 In the DF mode, the operation when the manual density setting and the AE density setting is the same.

II UNIT EXPLANATION

1.2.4 APS control

The APS control is carried out at close detection of the RADF, and controlled by the CB (Main body control

board), based on signals from the PS17 (APS sensor) and the CCD sensor. (For APS control by the

RADF, see DF service manual.)

A. APS operation

The PS17 (APS sensor) detects the original size in the sub scanning direction, while the CCD sensor

detects the original size in the main scanning direction.

B. Relationship between each of the sensors and the original size

Original size CCD sensor

(Length of detection: mm)

PS17

(ON/OFF)

A3 297 ON

11 x 17 279.4 ON

B4 257 ON

2-5

2

Page 54

SCANNER SECTION

II UNIT EXPLANATION

Original size CCD sensor

(Length of detection: mm)

8.5 x 14 *1 215.9 ON

8.5 x 11R 215.9 Metric system: ON Inch system: OFF

A4R 210 Metric system: ON Inch system: OFF

A4 297 OFF

8.5 x 11 279.4 OFF

B5R 257 OFF

A5R 210 OFF

B5 182 OFF

A5 148 OFF

5.5 x 8.5 139.7 OFF

B6 128 OFF

Postcard 102 OFF

*1 8.5 x 14 cannot be distinguished from 8.5 x 11R, and is detected as 8.5 x 11R.

(ON/OFF)

PS17

C. APS detection timing

(1) Platen mode (when the RADF is closed)

[1] [2]

PS17 (APS sensor)

PS15 (APS timing sensor)

PS303 (DF open/close sensor)

[1] 1st original size detection [2] 2nd original size detection

(2) Platen mode (when the RADF is open)

[1]

PS17 (APS sensor)

PS15 (APS timing sensor)

PS303 (DF open/close sensor)

[2]

[1] Original size detection [2] START button (ON)

2-6

Page 55

SCANNER SECTION

1.2.5 AE control

During AE scan, the CCD sensor provided on the ADB (A/D conversion board) reads the density level of

the original. The CPU on the SCB (System control board) process the data and, based on the results,

selects the γ correction curve that will best reproduce the original.

A. AE sampling range

(1) While in platen copying

Main scanning direction

• Based on the original size recognized in the APS or out-of-original erasure mode, the range excepting

10mm in front and in rear.

Sub-scanning direction

• The range of 30mm from the leading edge of the original. However, the range excepting L/100mm in

left and right when the length of the original is L mm.

[3]

10 mm

[1]

[2]

10 mm

L

100

30 mm

mm

L

100

L mm

mm

[1] Original [3] AE sampling range

[2] Leading edge of original

II UNIT EXPLANATION

2-7

Page 56

SCANNER SECTION

(2) While in DF copying

Main scanning direction

• Based on the original size recognized in the APS, the range excepting 20mm in front and in rear.

Sub-scanning direction

• The range between 1.5mm and 2.9mm from the leading edge of the original.

[3]

20 mm

[1]

[2]

20 mm

1.5 mm

1.4 mm

II UNIT EXPLANATION

2.9 mm

[1] Original [3] AE sampling range

[2] Leading edge of original

1.2.6 Image processing

A. AOC (Automatic offset control)

The analog offset voltage for the CCD sensor output is automatically adjusted by IC on the ADB (A/D

conversion board) so that this level becomes the lower limit for the A/D converter.

B. AGC (Automatic gain control)

The analog amplification for the CCD sensor output is automatically adjusted so that the CCD sensor

output level in the shading white correction becomes the upper limit for the A/D converter.

C. Shading correction

(1) Types of the shading correction

• White correction

• Black correction

(2) Execution timing

• At SW2 (Sub power switch) ON

• At the start of scan job

D. Other image processing

(1) Brightness/density conversion

(2) Text/dot pattern judgement

(3) Filtering

(4) Magnification change processing

(5) Error diffusion processing

(6) Data compression/elongation processing

2-8

Page 57

2. WRITE UNIT

2.1 Composition

WRITE UNIT

[11][10][9][8][7][6][5]

SCB

CB

7235 only

FM7

[3][4]

Symbol Name Function or method

[1] Index lens Converging of laser beams reflected from the index mirror

[2] INDEX (Index sensor board)

[3] Polygon mirror Laser beam scanning

[4] M5 (Polygon motor) Polygon mirror drive

[5] LDB (LD drive board) Laser emission drive

[6] Collimator lens Making diffused laser beam parallel

[7] Cylindrical lens 1

[8] Index mirror Reflection of laser beam upon the INDEX (Index senror board)

[9] fθ lens

[10] Cylindrical lens 2

[11] Dust-proof glass

FM7*1 Polygon cooling fan

Control of the laser write position in the main scanning direction

Hexahedron, 27,165rpm (7145) /38,976rpm (7235) /

33,071rpm (7228/7222)

DC brushless motor, PLL control

1-chip/2-beam system, 15mW 780mm (7145)

1-chip/1-beam system, 5mW 780mm (Except the 7145)

Correction of the laser path against error in the angle of the polygon mirror

Unified laser scanning speed against the laser irradiation surface on the drum

Correction of the laser path against error in the angle of the polygon mirror

Preventive measure for keeping the interior of the write unit clean

Cooling of the M5 (

Polygon motor

)

[1]

[2]

7322ma2002

II UNIT EXPLANATION

*1 7235 only

2-9

2

Page 58

WRITE UNIT

2.2 Operation