Minarik Drives XL Series Users Manual

Excel [XL] Series

USER’S MANUAL

MODELS

C4XL3025

C4XL3200A

Pulse-Width Modulated, Adjustable Speed,

Cased Drives for DC Brush Motors

Copyright © 2006 by

Minarik Drives

All rights reserved. No part of this manual may be reproduced or transmitted in any

form without written permission from Minarik Drives. The information and technical

data in this manual are subject to change without notice. Minarik Corporation and its

Divisions make no warranty of any kind with respect to this material, including, but

not limited to, the implied warranties of its merchantability and fitness for a given

purpose. Minarik Corporation and its Divisions assume no responsibility for any

errors that may appear in this manual and make no commitment to update or to keep

current the information in this manual.

Printed in the United States of America.

i

Safety Warnings

•

This symbol

Please read these sections carefully prior to performing any of

the instructions contained in that section.

denotes an important safety tip or warning.

SHOCK

HAZARD

AVOID

HEAT

KEEP

• Have a qualified electrical maintenance technician install, adjust

and service this equipment. Follow the National Electrical Code

and all other applicable electrical and safety codes, including the

provisions of the Occupational Safety and Health Act (OSHA),

when installing equipment.

• Reduce the chance of an electrical fire, shock, or explosion by

proper grounding, over-current protection, thermal protection,

and enclosure. Follow sound maintenance procedures.

It is possible for a drive to run at full speed as a result of

a component failure. Minarik strongly recommends the

installation of a master switch in the main power input to stop

the drive in an emergency.

Circuit potentials are at 115 VAC above earth ground.

Avoid direct contact with the printed circuit board or with circuit

elements to prevent the risk of serious injury or fatality. Use a

non-metallic screwdriver for adjusting the calibration trimpots.

Use approved personal protective equipment and insulated

tools if working on this drive with power applied.

DRY

AVOID

VIBRATION

ii

Contents

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Shielding guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Field Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Line Fusing for XL Series Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Voltage Follower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Before applying power: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Line starting and line stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Inhibit circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Decelerating to minimum speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Dynamic braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

MINIMUM SPEED (MIN SPD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

MAXIMUM SPEED (MAX SPD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

ACCELERATION (ACCEL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

DECELERATION (DECEL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

IR COMPENSATION (IR COMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

CURRENT LIMIT (CURR LIMIT) C4XL3025 or

TORQUE LIMIT (TORQ LIMIT) C4XL3200A . . . . . . . . . . . . . . . . . . . . . . . .30

Calibration with low voltage DC motors . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

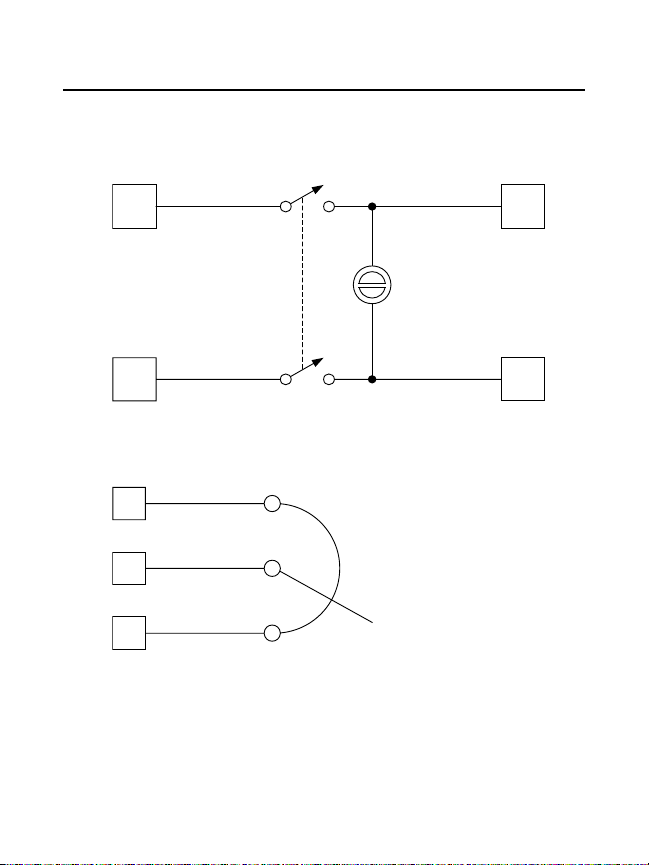

Leader-follower application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Single speed potentiometer control of multiple drives . . . . . . . . . . . . . . . . .35

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Before troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Certificate of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

AC Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Unconditional Warranty . . . . . . . . . . . . . . . . . . . . . .inside back cover

Tables

Table 1. Field Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Table 2. Fuse Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Table 3. Recommended Dynamic Brake Resistor Sizes . . . . . . . . . . . . . . . . . . .25

Table 4. AC Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

iii

iv

Illustrations

Figure 1. C4XL3025 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Figure 2. C4XL3200A Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

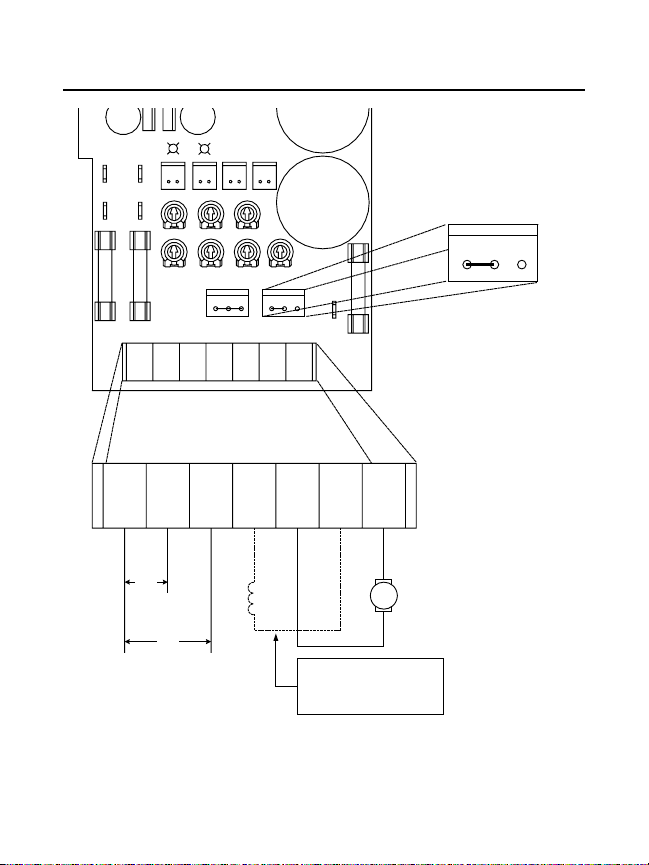

Figure 3. C4XL3025 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Figure 4. C4XL3200A Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Figure 5. Prewired Connections for Models C4XL3025 and C4XL3200A . . . . . .11

Figure 6. Voltage Follower Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 7. Cage-Clamp Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 8. Voltage Switch Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 9. Diagnostic LED Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 10. Inhibit Plug with Run/Coast to Zero Speed Switch . . . . . . . . . . . . . . .22

Figure 11. Run/Decelerate to Minimum Speed Switch . . . . . . . . . . . . . . . . . . . . .23

Figure 12. Dynamic Brake Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 13. C4XL3025 CURR LIMIT and IR COMP Settings . . . . . . . . . . . . . . . . .31

Figure 14. C4XL3200A TORQ. LIMIT and IR COMP Settings . . . . . . . . . . . . . . .31

Figure 15. C4XL3025 MAX SPEED Settings for

Low Voltage DC Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Figure 16. C4XL3200A MAX SPD Settings for

Low Voltage DC Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Figure 17. Leader-Follower Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Figure 18. Single Speed Potentiometer Control of Multiple Drives . . . . . . . . . . . .35

Figure 19. C4XL3025 Series Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 20. C4XL3200A Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Specifications

Model Number C4XL3025

Type: Cased

NEMA Rating NEMA 4X

AC Line Voltage 115 VAC/230 VAC, ±10%, 50/60 Hz, single phase

Line Fuse Rating 8 A

Horsepower Range @ 130 VDC Output 1/20–1/3 HP

Horsepower Range @ 240 VDC Output 1/8–1/2 HP

Maximum Armature Voltage Range @ 115 VAC Input 50–130 VDC

Maximum Armature Voltage Range @ 230 VAC Input 50–240 VDC

Minimum Speed Adjustment Range @ 115 VAC Input 0–65 VDC

Minimum Speed Adjustment Range @ 230 VAC Input 0–65 VDC

Maximum Armature Current 3 ADC

Field Voltage @ 115 VAC Input 50 VDC/100 VDC

Field Voltage @ 230 VAC Input 100 VDC/200 VDC

Maximum Field Current 1 ADC

Form Factor 1.05

Acceleration Time Range (no load)

for 0–130 VDC Armature Voltage Range 1–10 seconds

for 0–240 VDC Armature Voltage Range 1–19 seconds

Deceleration Time Range (no load)

for 0–130 VDC Armature Voltage Range 3–9 seconds

for 0–240 VDC Armature Voltage Range 4–19 seconds

Analog Input Voltage Range (signal must be isolated; S1 to S2)

for 0–130 VDC Armature Voltage 0–2.7 VDC

for 0–240 VDC Armature Voltage 0–5.0 VDC

1

2

Specifications

Speed Adjustment Potentiometer 10K ohms

Approximate Input Impedance (from S1 to S2) 100K ohms

Speed Regulation (at base speed) 1%

Weight 4.4 lb

Ambient Operating Temperature Range 10ºC–40ºC

Vibration 0.5g max (0 – 50 Hz)

0.1g max (above 50 Hz)

Specifications

Model Number C4XL3200A

Type Cased

NEMA Rating NEMA 4X

AC Line Voltage 115 VAC/230 VAC, ±10%, 50/60 Hz, single phase

Line Fuse Rating 15 A

Horsepower Range @ 130 VDC Output 1/4–1 HP

Horsepower Range @ 240 VDC Output 1/2–2 HP

Maximum Armature Voltage Range @ 115 VAC Input 50–130 VDC

Maximum Armature Voltage Range @ 230 VAC Input 50–240 VDC

Minimum Speed Adjustment Range @ 115 VAC Input 0–120 VDC

Minimum Speed Adjustment Range @ 230 VAC Input 0–120 VDC

Maximum Armature Current 10 ADC

Field Voltage @ 115 VAC Input 50 VDC/100 VDC

Field Voltage @ 230 VAC Input 100 VDC/200 VDC

Maximum Field Current 1 ADC

Form Factor 1.05

Acceleration Time Range (no load)

for 0–130 VDC Armature Voltage Range 1–10 seconds

for 0–240 VDC Armature Voltage Range 1–15 seconds

Deceleration Time Range (no load)

for 0–130 VDC Armature Voltage Range 1–10 seconds

for 0–240 VDC Armature Voltage Range 1–19 seconds

Analog Input Voltage Range (signal must be isolated; S1 to S2)

for 0–130 VDC Armature Voltage 0–2.7 VDC

for 0–240 VDC Armature Voltage 0–5.0 VDC

Speed Adjustment Potentiometer 10K ohms

3

4

Specifications

Approximate Input Impedance (from S1 to S2) 50K ohms

Speed Regulation (at base speed) 1%

Weight 7.4 lb

Ambient Operating Temperature Range 10ºC–40ºC

Vibration 0.5g max (0 – 50 Hz)

0.1g max (above 50 Hz)

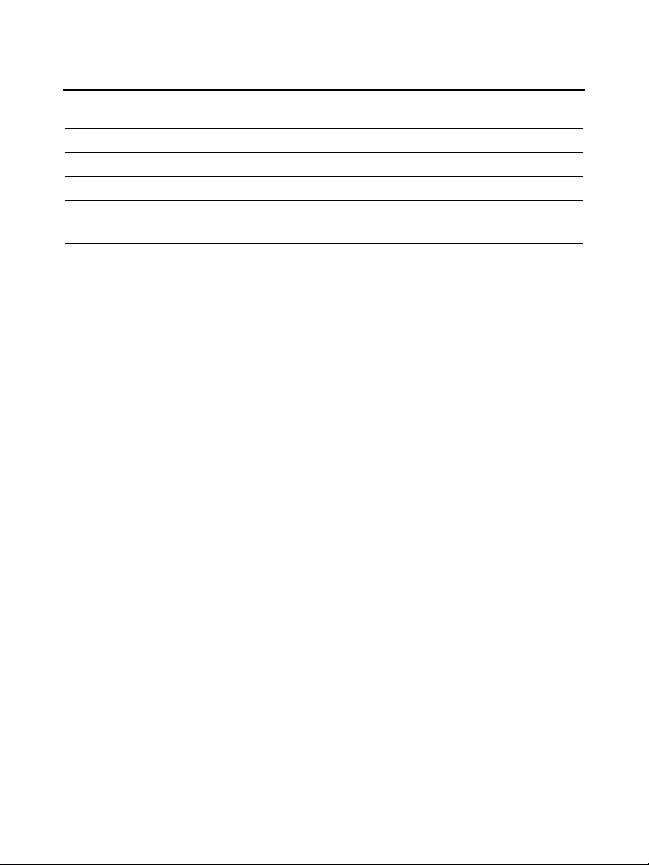

Dimensions

6.90 [175]

40

30 70

20 80

10 90

0 100

5

0.91 [23]

50

60

8.20 [207]

4.43 [112]

0.13 [3]

7.78 [197]

6.00 [152]

FOUR MOUNTING SLOTS 0.19 [5] WIDE

3.29 [83]

1.92 [49]

2.50 [63]

TWO 0.88 [22] KNOCKOUTS

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 1. C4XL3025 Dimensions

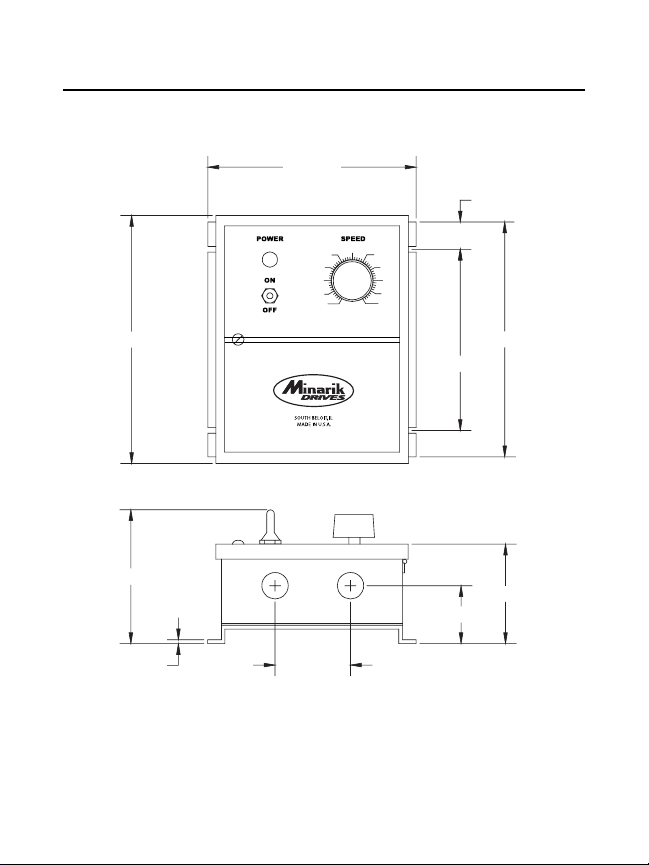

6 Dimensions

6.90 [175]

6.30 [159]

40 60

30 70

20 80

10 90

0 100

1.37 [35]

50

10.22 [259]

5.79 [146]

1.45 [37]

7.00 [177]

FOUR MOUNTING SLOTS 0.19 [5] WIDE

2.31 [58]

0.12 [3]

1.50 [38]

1.50 [38]

THREE 0.88 [22] KNOCKOUTS

ALL DIMENSIONS IN INCHES [ MILLIMETERS]

Figure 2. C4XL3200A Dimensions

9.75 [247]

4.69 [119]

Installation

Mounting

Nema 4X cased drives come with 0.88 inch (22 mm) conduit

knockout holes at the bottom of the case. The units may be

vertically wall mounted using the four 0.19 inch (5 mm) slotted

holes on the attached heat sink. For motor loads less than 5 ADC,

the drive may be bench mounted horizontally, or operated without

mounting.

1. Install the mounting screws through the drive’s four mounting

slots.

2. For access to the terminal strip, turn the slotted screw on the

front cover counterclockwise until it is free from the case. The

right side of the cover is hinged to the case. Pull the slotted

screw to open the case.

3. Carefully remove the 0.88 inch (22 mm) conduit knockouts by

tapping them into the case and twisting them off with pliers.

7

4. Install conduit hardware through the knockout holes. Connect

external wiring to the terminal block.

8 Installation

5. Grasp the slotted screw and tilt the front cover back into place.

Avoid pinching any wires between the front cover and the case.

6. Turn the slotted screw clockwise until tight to secure the front

cover.

7. Set the POWER switch to the OFF position before applying the

AC line voltage.

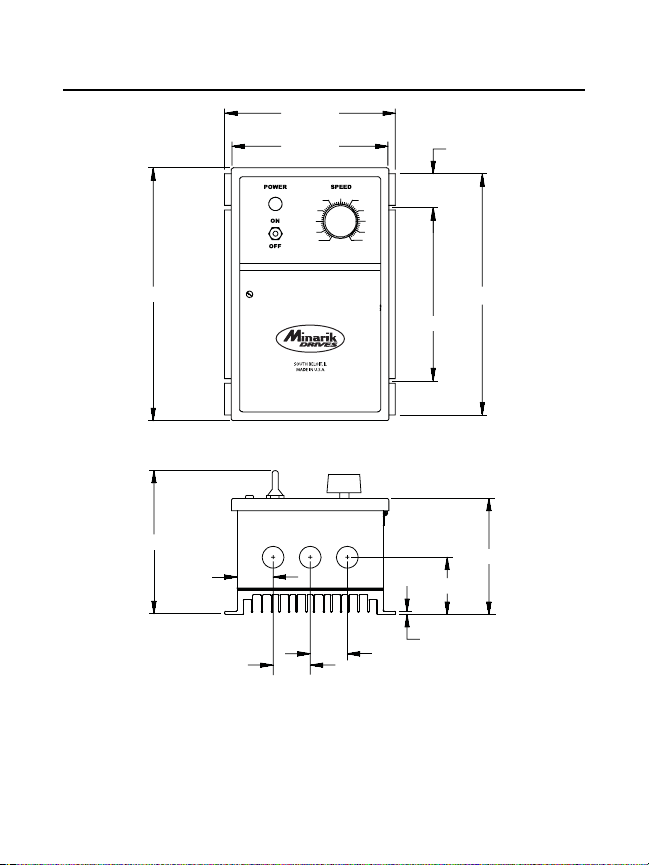

Connections

Minarik drives supply motor voltage to terminals A1 and A2 (A1 is

positive with respect to A2). It is assumed throughout this manual

that the driven motor will rotate clockwise (CW) while looking at the

output shaft protruding from the front of the motor. If the opposite is

desired, simply reverse the wiring of A1 and A2 with each other.

TB501

L1 115 230 F1 F2 A2 A1

9Installation

115

AC Line Voltage

115 or 230 VAC

230

Figure 3. C4XL3025 Connections

Motor

+

Field Output Shunt wound motors only.

See Field Output section for

connections.

Armature

Output

10 Installation

POWER ON

LIMIT

CURR

PS4

PS2

PS1

FAST-ACTING

IL501

IL502

SO501

115230L1

CURR

TORQ. LIMIT

S1

TB501

SO504S0503

+15

S2 S3

IR COMP

ACCELDECELMIN SPD

A1F+

INHIBIT

JOG

FUSE ONLY FU501

PS3

FAST-ACTING

FUSE ONLY FU502

SO502

POWER

MAX SPD

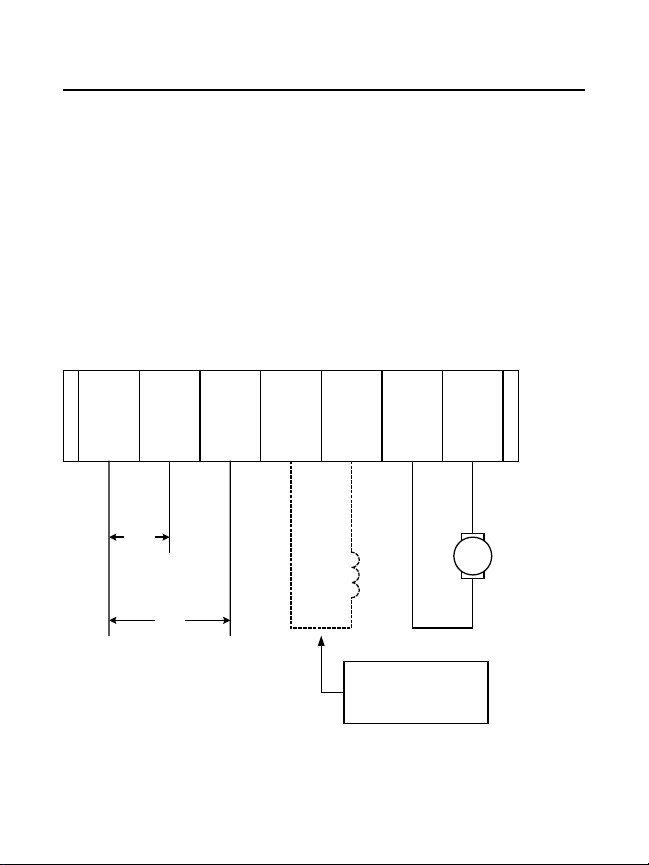

TB501

L1 230 115 F+ A1 F- A2

C505

FAST-ACTING

FUSE ONLY FU502

A2

JOGSPDSPD

IN

A2F-

SPD SPD JOG

IN

SPD and SPD IN are

prewired for speed adjust

poteniometer control.

To control speed with JOG

trimmer potentiometer,

connect SPD IN to JOG.

Motor will not turn if there is

no connection to SPD IN.

230

AC Line Voltage

115 or 230 VAC

115

Field Output Shunt wound motors only.

See Field Output section for

connections.

Figure 4. C4XL3200A Connections

Armature

Motor

Output

Power

Switch

11Installation

PS1

PS3

S1

S2

S3

black

white

violet

brown

grey

CW

black/white

Power

Light

white/black

10K ohm

Speed Adjust

Potentiometer

PS2

PS4

Figure 5. Prewired Connections for Models C4XL3025 and

C4XL3200A

Loading...

Loading...