RG60U Series

RG60U RG60U-PCM

RG61U RG61U-PCM

User’s Manual

Dual Voltage, Adjustable Speed,

SCR Regenerative Drive for

Permanent Magnet DC Brush Motors

Copyright © 2009 by

Minarik Drives

All rights reserved. No part of this manual may be reproduced or transmitted in any

form without written permission from Minarik Drives. The information and technical

data in this manual are subject to change without notice. Minarik Drives makes no

warranty of any kind with respect to this material, including, but not limited to, the

implied warranties of its merchantability and fitness for a given purpose. Minarik

Drives assumes no responsibility for any errors that may appear in this manual and

makes no commitment to update or to keep current the information in this manual.

Printed in the United States of America.

SHOCKAVOID

OID

ON

i

Safety Warnings

• This symbol denotes an important safety tip or warning.

Please read these instructions carefully before performing

any of the procedures contained in this manual.

• DO NOT INSTALL, REMOVE, OR REWIRE THIS EQUIPMENT

WITH POWER APPLIED. Have a qualified electrical technician

install, adjust and service this equipment. Follow the National

Electrical Code and all other applicable electrical and safety

codes, including the provisions of the Occupational Safety and

Health Act (OSHA), when installing equipment.

•

Reduce the chance of an electrical fire, shock, or explosion by

proper grounding, over-current protection, thermal protection,

and enclosure. Follow sound maintenance procedures.

It is possible for a drive to run at full speed as a result

of a component failure. Minarik strongly recommends the

installation of a master switch in the main power input to

stop the drive in an emergency.

Circuit potentials are at 115 VAC or 230 VAC above earth

ground. Avoid direct contact with the printed circuit board or

with circuit elements to prevent the risk of serious injury or

fatality. Use a non-metallic screwdriver for adjusting the

calibration trimpots. Use approved personal protective

equipment and insulated tools if working on this drive with

power applied.

TI

ii

Contents

Regenerative Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Shielding guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Heat sinking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Line fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Speed adjust potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Power, fuse and motor connections . . . . . . . . . . . . . . . . . . . . . . .11

Voltage follower (isolated signal) . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Line voltage switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Armature voltage switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Feedback selector switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Voltage or Current Follower (non-isolated signal, -PCM models) . .19

Polarity reversal switch (-PCM models) . . . . . . . . . . . . . . . . . . . . . .19

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Before applying power: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Startup and shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

To start the drive: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Starting and Stopping Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Automatic restart upon power restoration . . . . . . . . . . . . . . . . . .23

Decelerate to a stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Coast to a stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Regenerative brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Invert Inhibit and Invert Enable . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

MINIMUM SPEED (MIN SPD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

MAXIMUM SPEED (MAX SPD) . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

FORWARD TORQUE (FWD TQ) . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

REVERSE TORQUE (REV TQ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

IR COMPENSATION (IR COMP) . . . . . . . . . . . . . . . . . . . . . . . . . . .35

FORWARD ACCELERATION (FWD ACC) . . . . . . . . . . . . . . . . . . . .36

REVERSE ACCELERATION (REV ACC) . . . . . . . . . . . . . . . . . . . . .36

DEADBAND (DB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

TACH GENERATOR (TACH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

MAX (RG60U-PCM isolation card) . . . . . . . . . . . . . . . . . . . . . . . . . .40

OFFSET (RG60U-PCM isolation card) . . . . . . . . . . . . . . . . . . . . . . .41

Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Connections to Minarik DLC600 . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

FWD-REV switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

FWD-STOP-REV switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Independent Adjustable Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Independent forward and reverse speeds . . . . . . . . . . . . . . . . . . . .46

Independent forward and reverse speeds with FWD-STOP-REV

switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Before applying power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Unconditional Warranty . . . . . . . . . . . . . . . . . . . . . .inside back cover

iii

Tables

Table 1. Recommended Line Fuse Sizes . . . . . . . . . . . . . . . . . . . . . . .8

Table 2. Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

iv

Illustrations

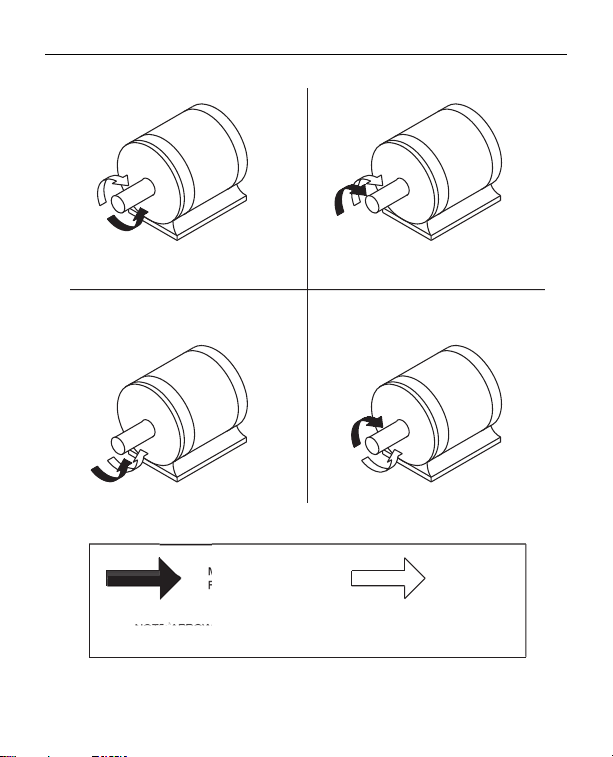

Figure 1. Four Quadrant Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

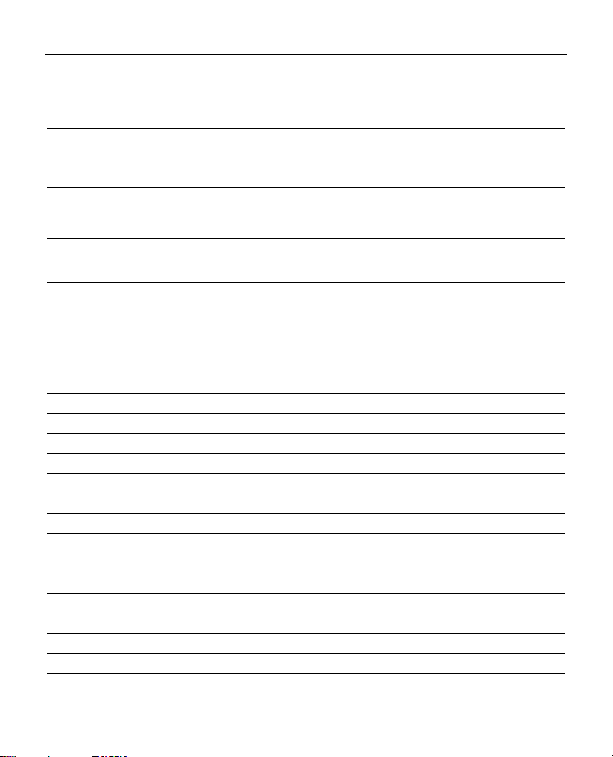

Figure 2. RG60U/RG61U Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . .2

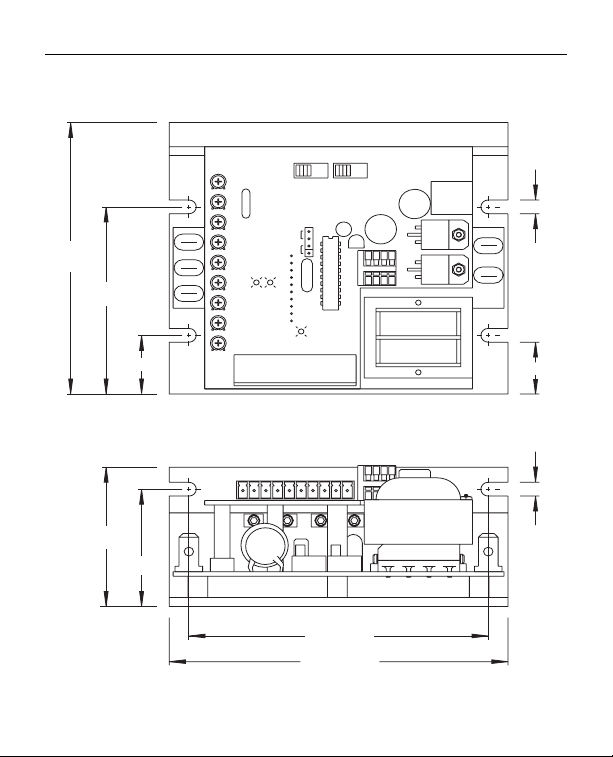

Figure 3. RG60U-PCM/RG61U-PCM Dimensions . . . . . . . . . . . . . . . . .3

Figure 4. Speed Adjust Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . .9

Figure 5. Screw Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Figure 6. Cage-Clamp Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . .10

Figure 7. Power and Motor Connections (Bottom Board) . . . . . . . . . .13

Figure 8. Speed Adjust Potentiometer Connections . . . . . . . . . . . . . .15

Figure 9. Voltage Follower Connection . . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 10. Line Voltage Switches (bottom board) . . . . . . . . . . . . . . . .17

Figure 11. Armature Voltage and Feedback

Selector Switch Locations (top board) . . . . . . . . . . . . . . . . .18

Figure 12. RG-60U-PCM connections and jumper settings . . . . . . . . .20

Figure 13. RUN/STOP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 14. INHIBIT / ENABLE Terminal TB503

and JP502 Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Figure 15. INHIBIT Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 16. ENABLE Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 17. RG60U Calibration Trimpot Locations . . . . . . . . . . . . . . . . .31

Figure 18. Deadband Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Figure 19. Typical FWD TQ, REV TQ, and

IR COMP Trimpot Settings . . . . . . . . . . . . . . . . . . . . . . . . .39

Figure 20. PCM Calibration Trimpot Locations . . . . . . . . . . . . . . . . . . .40

Figure 21. RG60U Connections to DLC600 . . . . . . . . . . . . . . . . . . . . .42

Figure 22. Forward-Reverse Switch . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Figure 23. Forward-Stop-Reverse Switch . . . . . . . . . . . . . . . . . . . . . . .44

Figure 24. Independent Adjustable Speeds (Forward Direction) . . . . .45

Figure 25. Independent Forward and Reverse Speeds . . . . . . . . . . .46

Figure 26. Independent Forward and Reverse Speeds with

a Forward-Stop-Reverse Switch . . . . . . . . . . . . . . . . . . . . .47

Regenerative Drives

Most non-regenerative, variable speed, DC drives control current

flow to a motor in one direction. The direction of current flow is the

same direction as the motor rotation. Non-regenerative drives

operate in Quadrant 1, and also in Quadrant 3 if the drive is

reversible (see Figure 1, page VI). Motors must stop before

reversing direction. Unless dynamic braking is used, non-

regenerative drives cannot decelerate a load faster than coasting to

a lower speed.

Regenerative drives operate in two additional quadrants: Quadrant

2 and Quadrant 4. In these quadrants, motor torque is in the

opposite direction of motor rotation.

This allows regenerative drives to reverse a motor without

contactors or switches, to control an overhauling load, and to

decelerate a load faster than it would take to coast to a lower

speed.

v

vi

ON

OR

E

ON

OR

I

I

V

I

Regenerative Drives

uadrant I

uadrant II

T

TATI

ARROWS IN OPPOSITE DIRECTION = REGENERATIVE ACTI

uadrant

uadrant I

MOT

TORQU

Figure 1. Four Quadrant Operation

Specifications

1

Model Current Range Horsepower Range

RG60U, RG60U-PCM 5.0* 1/4 - 1/2* 0 - 90

RG61U, RG61U-PCM 1.5 1/20 - 1/8 0 - 90

* Max. Armature Current = 10 ADC and

Max. Horsepower = 1 hp when mounted to heat sink kit part number 223-0159.

** Max. Armature Current = 10 ADC and

Max. Horsepower = 2 hp when mounted to heat sink kit part number 223-0159.

AC Line Voltage 115 VAC / 230 VAC, ±10%, 50/60 Hz, single phase

Form Factor 1.37 at base speed

Acceleration Time Range 0.5 – 6 seconds

Deceleration Time Range 0.5 – 6 seconds

Analog Input Voltage Range

(without -PCM option, signal must be isolated; S0 to S2) 0 to +/- 10 VDC

Input Impedance (S0 to S2) 30 kohms

Load Regulation

with Armature Feedback 1% base speed

with Tachogenerator Feedback 0.1% base speed

Vibration 0.5G max. (20–50 Hz)

Ambient Temperature Range 10°C – 55°C

Weight 1.1 lb

Armature Armature Voltage

(ADC) (VDC)

5.0** 1/4 – 1** 0 – 180

1.5 1/10 - 1/4 0 - 180

0.1G max. (> 50 Hz)

2

Dimensions

L2

3.70 [94]

2.55 [65]

0.80 [20]

L1

GND

FEEDBACKARMATURE

90-180 ARM-TACH

FWD

ACC

REV

ACC

MAX

SPD

IR

COMP

REV

TQ

FWD

TQ

DB

MIN

SPD

TACH

SW504

C504

JP502

C503

Y501

6.9

+15VS0S1S2S3

POWER

IC504

IC501

TB503

ENABLE

x

4.4

x

1.0

INVERT

INHIBIT

INVERT

ENABLE

LIMIT

FWD

REV

IL502IL501

TB502

IL503

RB1

-15V

RB2

T1

T2

TB501

HEATSINK DIMENSIONS (optional)

SW503

C502

C501

IC502

IC503

INHIBIT

T501

A1

A2

0.19 [5]

0.71 [18]

1.96 [50]

0.19 [5]

1.66 [42]

3.80 [97]

4.30 [109]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 2. RG60U/RG61U Dimensions

3.70 [94]

3.03 [77]

2.55 [65]

1.96 [50]

0.80 [20]

1.66 [42]

TB502

L2

L1

GND

INHENDIR

IC504

IC503

IC502

+5V

COMS3S2S1+IN

IC505

HEATSINK DIMENSIONS (optional)

6.9

MAX OFFSET

J502

C504

-IN

TB501

x 4.4 x 1.0

3Dimensions

A1

0.19 [5]

A2

C503

T503

J501

C502

C501

IC501

IC506

0.71 [18]

0.19 [5]

3.80 [97]

4.30 [109]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 3. RG60U-PCM/RG61U-PCM Dimensions

4

Installation

Mounting

Warning

Do not install, rewire, or remove this control with input power

applied. Doing so may cause fire or serious injury. Make sure

you have read and understood the Safety Warnings on page i

before attempting installation.

• Drive components are sensitive to electrostatic fields. Avoid

direct contact with the circuit board. Hold drive by the chassis

only.

• Protect the drive from dirt, moisture, and accidental contact.

• Provide sufficient room for access to the terminal block and

calibration trimpots.

• Mount the drive away from heat sources. Operate the drive

within the specified ambient operating temperature range.

• Prevent loose connections by avoiding excessive vibration of the

drive.

• Mount drive with its board in either a horizontal or vertical plane.

Six 0.19 in. (5 mm) wide slots in the chassis accept #8 pan head

screws. Fasten either the large base or the narrow flange of the

chassis to the subplate.

• The chassis should be earth grounded. Use a star washer

beneath the head of at least one of the mounting screws to

penetrate the anodized chassis surface and to reach bare metal.

Wiring

Warning

Do not install, rewire, or remove this control with input

power applied. Failure to heed this warning may result in fire,

explosion, or serious injury.

Circuit potentials are at 115 or 230 VAC above ground. To

prevent the risk of injury or fatality, avoid direct contact with the

printed circuit board or with circuit elements.

Do not disconnect any of the motor leads from the drive unless

power is removed or the drive is disabled. Opening any one

motor lead while the drive is running may destroy the drive.

• Use 18 AWG wire for speed adjust potentiometer wiring. Use 14

AWG wire for AC line (L1, L2) and motor (A1, A2) wiring.

5Installation

6

Installation

Shielding guidelines

Warning

Under no circumstances should power and logic leads be

bundled together. Induced voltage can cause unpredictable

behavior in any electronic device, including motor controls.

As a general rule, Minarik recommends shielding of all conductors.

If it is not practical to shield power conductors, Minarik

recommends shielding all logic-level leads. If shielding of all logic-

level leads is not practical, the user should twist all logic leads with

themselves to minimize induced noise.

It may be necessary to earth ground the shielded cable. If noise is

produced by devices other than the drive, ground the shield at the

drive end. If noise is generated by a device on the drive, ground

the shield at the end away from the drive. Do not ground both ends

of the shield.

If the drive continues to pick up noise after grounding the shield, it

may be necessary to add AC line filtering devices, or to mount the

drive in a less noisy environment.

Logic wires from other input devices, such as motion controllers

and PLL velocity controllers, must be separated from power lines in

the same manner as the logic I/O on this drive.

Heat sinking

The RG60U drive requires an additional heat sink when the

continuous armature current is above 5 ADC. Use Minarik heat sink

kit part number 223-0159. Use a thermally conductive heat sink

compound (such as Dow Corning®340 Heat Sink compound)

between the drive chassis and the heat sink surface for optimum

heat transfer.

Line fusing

Minarik drives should be used with fuses for protection. Use fast

acting fuses rated for 250 VAC or higher. Fuse L1 only when the

line voltage is 115 VAC. Fuse both L1 and L2 when the line voltage

is 230 VAC.

Table 1 on page 8 lists the recommended line fuse sizes.

7Installation

8

Installation

Table 1. Recommended Line Fuse Sizes

90 VDC Motor 180 VDC Motor Max. DC Armature AC Line Fuse

Horsepower Horsepower Current (amps) Size (amps)

1/20 1/10 0.5 3

1/15 1/8 0.8 3

1/8 1/4 1.5 5

1/6 1/3 1.75 5

1/4 1/2 2.5 8

1/3 3/4 3.5 8

1/2 1 5.0 10

3/4 1 1/2 7.5 15

1 2 10 20

Minarik Corporation offers two fuse kits: part number 050–0069

(3–8A Fuse Kit) and 050–0073 (5–20A Fuse Kit).

S

JUST

R

SK

STAR

R

UT

E

Installation

Speed adjust potentiometer

Warning

Be sure that the potentiometer tabs do not make contact with

the potentiometer enclosure. Grounding the input will cause

damage to the drive.

Mount the speed adjust potentiometer through a 0.38 in. (10 mm)

hole with the hardware provided (Figure 4). Install the circular

insulating disk between the panel and the 10K ohm speed adjust

potentiometer.

Twist the speed adjust potentiometer wire to avoid picking up

unwanted electrical noise. If speed adjust potentiometer wires are

longer than 18 in. (46 cm), use shielded cable. Keep speed adjust

potentiometer wires separate from power leads (L1, L2, A1, A2).

UNT THROUGH A 0.38 IN. (10 MM) HOL

W

9

N

WASHE

INSULATING DI

PEED AD

POTENTIOMETE

Figure 4. Speed Adjust Potentiometer

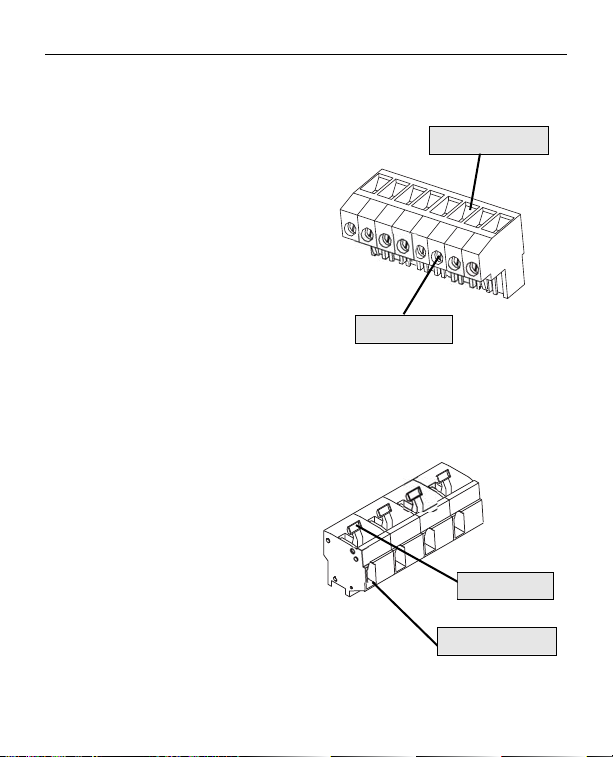

10 Installation

Connections

Screw terminal block

Most connections to the

RG60U drive are made to a

screw terminal block (part

number 160-0171). Using a

screwdriver, turn the terminal

block screw counterclockwise

to open the wire clamp.

Insert 18 AWG stripped wire

into the wire clamp. Turn the

terminal block screw

clockwise to clamp the wire.

Cage-clamp terminal block

Inhibit and enable

connections are made to a

cage-clamp terminal block. To

insert a wire into the terminal

block, press down on the

lever arm using a small

screwdriver. Insert 20 AWG

stripped wire into the wire

clamp in front of the terminal

block. Release the lever arm

to clamp the wire.

Wire Clamp

Screw

Figure 5. Screw Terminal Block

Lever Arm

Wire Clamp

Figure 6. Cage-Clamp

Terminal Block

Installation

Warning

Do not connect this equipment with power applied. Failure

to heed this directive may result in fire or serious injury.

Minarik strongly recommends the installation of a master

power switch in the voltage input line, as shown in Figure

7, page 13. The switch contacts should be rated at a minimum

of 200% of motor nameplate current and 250 volts.

Power, fuse and motor connections

Connect the power input leads, an external line fuse and a DC

motor to the drive’s printed circuit board (PCB) as shown in Figure

7, page 13.

Motor

Minarik drives supply motor voltage from A1 and A2 terminals. It is

assumed throughout this manual that, when A1 is positive with

respect to A2 , the motor will rotate clockwise (CW) while looking at

the output shaft protruding from the front of the motor. If this is

opposite of the desired rotation, simply reverse the wiring of A1 and

A2 with each other (A1 - and A2 +).

11

Connect a DC motor to PCB terminals A1 and A2 as shown in

Figure 7, page 13. Ensure that the motor voltage rating is

consistent with the drive’s output voltage.

12

Installation

Power input

Connect the AC line power leads to terminals L1 and L2, or to a

double-throw, single-pole master power switch (recommended).

Line fuse

Wire an external line fuse between the stop switch (if installed) and

the terminal board (Figure 7, page 13). An additional line fuse

should be installed on L2 if the input voltage is 230 VAC. Refer to

the line fuse table (Table 1 on page 8) for fuse ratings.

1

A2

D

30

5

5

30

O

501

TB50

R18

501

505

504

502

503

503

501

507

502

504

506

508

505

C510

C509

502

OU

D

USE

US

*

C

E

UT

5

o

30

C

O

E

US

O

2

30

C

U

O

Y

O

OR

R

R

R

R

R

R

RG60U BOTTOM BOARD

R

R

L

T

E T

* N

ADD F

VA

NL

T

INP

WITH 2

VA

r 2

11

13

Installation

T

M

A

T

T

T

1

T

N

T

-11

W

2

-2

11

V

M

LIN

A

INP

N

R

Figure 7. Power and Motor Connections (Bottom Board)

F

E

F

14

Installation

Speed adjust potentiometer connections

The motor can operate in one direction (unidirectional) or two

directions (bidirectional) depending on how the speed adjust

potentiometer is connected to the drive.

Connect the speed adjust potentiometer as shown in Figure 8(a),

page 15 for bidirectional operation. The motor does not operate

when the wiper is in the center position. Turning the wiper

clockwise (CW) from the center position causes the motor to rotate

in one direction, while turning the wiper counterclockwise (CCW)

causes rotation in the opposite direction.

Connect the speed adjust potentiometer as shown in Figure 8(b),

page 15 for unidirectional operation in the forward direction.

Connect the speed adjust potentiometer as shown in Figure 8(c),

page 15 for unidirectional operation in the reverse direction.

Refer to the Application Notes section for additional speed adjust

potentiometer connections.

M

OT

501

5V

5V

OT

501

5V

5V

M

OT

501

5V

5V

Installation

15

10K OH

PEED P

(b) Unidirectional Operation,

Forward Direction

Figure 8. Speed Adjust Potentiometer Connections

10K OH

PEED P

TB

(a) Bidirectional Operation

10K OHM

-1

+1

TB

PEED P

(c) Unidirectional Operation,

Reverse Direction

-1

+1

-1

+1

TB

16

501

5V

5V

Installation

Voltage follower (isolated signal)

The drive may be wired to follow a floating (isolated)

0 to ±10VDC signal that is isolated from earth ground instead

of using a speed adjust potentiometer. Connect the signal input

to S2, and the signal common to S0 (see Figure 9).

-1

1

±10 VDC SIGNAL

SIGNAL COMMON

TB

Figure 9. Voltage Follower Connection

NOTE: For configuration of a non-isolated voltage or current

signal, please refer to the -PCM option (page 19).

C507

SCR502

SCR501

SCR505

SCR506

SCR507

SCR508

SCR504

501

8

505

504

502

503

C506

0

SW502

SW501

C502

C501

501

SCR503

5

D

Installation

Line voltage switches

SW501 and SW502 on the bottom board are the line voltage

switches (see Figure 10). Set the switches to 115 VAC if the line

voltage is 115 VAC, or to 230 VAC if the line voltage is

230 VAC.

1

1

T

N

MOV

T

T

T

17

115-230230-11

Line Voltage Switches

SW501 & SW502

(115 VAC or 230 VAC)

T

Figure 10. Line Voltage Switches (bottom board)

18

Installation

Armature voltage switch

SW504 on the top board is the armature voltage selector switch.

Set SW504 to 90 if using a 90 VDC motor, or to 180 if using a 180

VDC motor. See Figure 11 for SW504 location.

Feedback selector switch

SW503 on the top board is the feedback selector switch. Set

SW503 to TACH if using a tachogenerator; otherwise, set it to ARM

for armature feedback. See Figure 11 for SW503 location.

Armature

Voltage Switch

(90 VDC or 180 VDC)

FWD

ACC

REV

ACC

C504

MAX

SPD

90 - 180 ARM - TACH

SW504

JP502

C503

FEEDBACKARMATURE

Selector Switch

SW503

IC504

Feedback

(ARM or TACH)

C502

Figure 11. Armature Voltage and Feedback

Selector Switch Locations (top board)

Voltage or Current Follower (non-isolated

signal, -PCM models)

PCM series drives can be configured to follow a grounded (non-

isolated) voltage or current signal. To configure the drive to follow

a voltage or current signal, connect the signal leads to the +IN and

-IN terminals on TB501, observing proper polarity. Ensure that the

following jumper terminals are properly set:

J501 Settings

Open pins 1 & 2 for -10 to +10 VDC signal or pot input.

Jumper pins 1 & 2 for 4 to 20 mA signal input.

J502 Settings

Jumper pins 2 & 3 for -10 to +10 VDC signal or pot input.

Jumper pins 1 & 2 for 4 to 20 mA signal input.

See Figure 12, page 20 for jumper and terminal locations.

Polarity reversal switch (-PCM models)

To reverse the output voltage polarity without changing the input

polarity, connect the DIR terminal to the +5V terminal on TB501 of

the PCM board. A single-pole, single-throw switch can be used as

a polarity reversal switch. Close the switch to reverse the output

voltage polarity. Open the switch to return the output voltage back

to its original polarity. See Figure 12, page 20 for polarity reversal

switch connections.

19Installation

20 Installation

S1S2S3

OPERATION

BI-DIRECTIONAL

CONNECTIONS

TB501

SPEED POTENTIOMETER

J502

JUMPER

SETTINGS

• Jumper pins 2 & 3

for -10 to +10 VDC

signal or pot input

• Jumper pins 1 & 2

OFFSETMAX

J502

TB502

cw

J501

for 4 to 20 mA

signal input

C503

1

IC505

IC504

FWD

10K OHM

SPEED ADJUST

POTENTIOMETER

REV

• Jumper pins 1 & 2

for 4 to 20 mA

signal input

• Open pins 1 & 2

T503

C504

IC503

- INS2S1

OPERATION

UNI-DIRECTIONAL

for -10 to +10 VDC

signal or pot input

C502

IC506

C501

IC501

J501

-IN

+IN

S1

S2

S3

COM

+5V

IC502

DIR

EN

INH

TB501

cw

TB501

10K OHM

4 to 20 mA

SIGNAL INPUT

SPEED ADJUST

-10 to +10 VDC or

DIRECTION

ENABLE

INHIBIT

SPEED ADJUST

POTENTIOMETER

SWITCH SETTINGS

Close the inhibit to brake the motor to a stop.

Close the enable to coast the motor to a stop.

Close direction switch to change directions.

Note: Invert inhibit terminals must not be shorted on middle board when using RG60U-PCM

Figure 12. RG-60U-PCM connections and jumper settings

Operation

Warning

Dangerous voltages exist on the drive when it is powered. BE

ALERT. High voltages can cause serious or fatal injury. For

your safety, use personal protective equipment (PPE) when

operating this drive.

Before applying power:

1. Verify that no conductive material is present on the printed

circuit board.

2. Ensure that all switches and jumpers are properly set.

21

22

Operation

Startup and shutdown

To start the drive:

1. Set the speed adjust potentiometer or reference voltage to zero

speed.

2. Apply AC line voltage.

3. Slowly turn the speed adjust potentiometer clockwise or

counterclockwise to rotate the motor in the forward or reverse

direction. If in a voltage follower mode, slowly increase the

voltage in either the positive or negative direction to rotate the

motor in the forward or reverse direction. Continue until the

desired speed is reached.

4. To decelerate the motor from set speed to a stop, reset the

speed adjust potentiometer to zero speed, or reference voltage

to zero. To coast the motor from set speed to a stop, remove

AC line voltage from the drive .

If the motor or drive does not perform as described, disconnect the

AC line voltage immediately. Refer to the Troubleshooting section

for further assistance.

Starting and Stopping Methods

Warning

Decelerating to minimum speed, regenerative braking, or

coasting to a stop is recommended for frequent starts and

stops. Do not use any of these methods for emergency

stopping. They may not stop a drive that is malfunctioning.

Removing AC line power (both L1 and L2) is the only

acceptable method for emergency stopping.

For this reason, Minarik strongly recommends installing an

emergency stop switch on both the L1 and L2 inputs (see

Figure 7, page 13).

Frequent decelerating to minimum speed or regenerative

braking produces high torque. This may cause damage to

motors, especially gearmotors that are not properly sized for

the application

Automatic restart upon power restoration

All drives automatically run to set speed when power is applied and

enabled.

23

24

Operation

Decelerate to a stop

The RUN/STOP switch in Figure 13 may be used to decelerate a

motor to a stop. Closing the switch between RB1 and RB2

decelerates the motor from set speed to a stop. The FWD ACC and

REV ACC trimpot settings determine the rate at which the will drive

decelerate to a stop and accelerate back to set speed. Set the switch

to the RUN position to accelerate the motor to set speed.

STOP

RUN

TB501

L1 A2L2

GND

T2

T1

RB1

RB2

-15V

+15V

S3

S2

S1

S0

TB501

T501

TACH

SPD

T2

T1

RB1

RB2

-15V

+15V

POWER

S3

S2

S1

S0

TQ

MIN

IL503

REVTQFWD

DB

FWD

LIMIT

IL502IL501

REV

TB502

Y501

TB503

ENABLE

INHIBIT

IC503

Figure 13. RUN/STOP Switch

ENABLE

INVERT

C501

IC502

COMP

IR

INHIBIT

A1

ACC

FWD

ACC

REV

SPD

MAX

C504

INVERT

SW504

JP502

IC501

C503

IC504

90-180 ARM-TACH

FEEDBACKARMATURE

SW503

C502

Operation

Regenerative brake

To regeneratively brake the motor, short the INHIBIT terminals on

TB503. Reopening the INHIBIT terminals causes the motor to

accelerate to set speed (see Figure 14, page 27 for INHIBIT

terminal locations and Figure 15, page 28 for INHIBIT settings).

Twist inhibit wires and separate them from other power-carrying

wires or sources of electrical noise. Use shielded cable if the inhibit

wires are longer than 18 in. (46 cm). If shielded cable is used,

ground only one end of the shield to earth ground. Do not ground

both ends of the shield.

Coast to a stop

To coast the motor to a stop without removing power to the drive,

short the ENABLE terminals on TB503 (see Figure 14, page 27 for

ENABLE terminal locations and Figure 16, page 29 for ENABLE

settings).

Momentarily shorting the ENABLE terminals will coast the motor to

zero speed, then accelerate back to set speed.

25

Completely shorting the ENABLE terminals will coast the motor to a

complete stop. Reopening the ENABLE terminals causes the

motor to accelerate to set speed.

26

Operation

Invert Inhibit and Invert Enable

INVERT modes reverse the function of the INHIBIT and ENABLE

terminals. Each drive is assembled with the INVERT INHIBIT and

INVERT ENABLE jumper settings open (jumpers on location 1 and

4 of JP502). See Figure 14, page 27 for JP502 location.

To activate the INVERT INHIBIT mode, jumper locations 1 and 2 of

JP502 (see Figure 15, page 28). In INVERT INHIBIT mode, the

motor will regeneratively brake when inhibit terminals are open. To

accelerate the motor to set speed, close the inhibit terminals.

To activate the INVERT ENABLE mode, jumper locations 3 and 4,

(see Figure 16, page 29). In INVERT ENABLE mode, the motor

will coast to a stop when the enable terminals are open. To

accelerate the motor to set speed, close the enable terminals.

INVERT INHIBIT & INVERT ENABLE

Jumper Settings (JP502)

FWD

ACC

REV

ACC

MAX

SPD

L2

IR

COMP

L1

REV

TQ

FWD

GND

TQ

DB

MIN

SPD

TACH

TB501

SW504

C504

INVERT

INHIBIT

INVERT

ENABLE

LIMIT

FWD

REV

IL502IL501

TB502

IL503

RB1

-15V

RB2

T1

T2

FEEDBACKARMATURE

90-180 ARM-TACH

JP502

C503

IC501

Y501

POWER

+15VS0S1S2S3

Operation

SW503

C502

IC504

C501

IC502

IC503

TB503

ENABLE

INHIBIT

T501

INHIBIT TERMINALS

ENABLE TERMINALS

27

A1

A2

Figure 14. INHIBIT / ENABLE Terminal TB503 and JP502 Locations

28

Operation

WHEN INHIBIT

INHIBIT MODE

TERMINALS ARE CLOSED

MOTOR REGENERATIVELY BRAKES

INHIBIT

CLOSED

TB503

TB503

ARE OPENED

INVERT INHIBIT MODE

WHEN INHIBIT TERMINALS

MOTOR REGENERATIVELY BRAKES

INHIBIT

OPEN

INHIBIT SETTINGS

OPEN

CONFIGURATION DRIVE RESPONSE

JP502

INHIBIT

INVERT

JP502

CLOSED

INHIBIT

INVERT

Figure 15. INHIBIT Settings

NOTE: The RG60U will operate in normal running mode when all jumpers on JP502 and all terminals on TB503

are simultaneously opened. Likewise, it will operate in normal running mode when all jumpers and terminals are

simultaneously closed.

TTES

EL

B

A

N

E SGNI

29Operation

e

30

ra

s

5B

l

a

T

n

im

no sla

ESN

O

PSER

EVI

R

D

N

O

I

T

A

R

UGI

FN

OC

DE

SLANIM

SO

DE

S

ED

N

T

EHW

SA

LC

N

O

M E

LBAN

E

3

0

5B

T

2

0

5P

J

IATN

DENIATNIAM

D

E

O

R

SOLC

C R

ET

P

I

O

AM

TS

EL

O

TOM

ER

BANE

OT

A

D

E

S

O

L

C

ENABLE

NEPO

TR

E

L

B

E

A

V

N

N

I

E

EDO

M

E

LBAN

E

TREVNI

3

0

5B

T

20

5P

J

STS

A

OPEN

OC

DENIATNIAM

R

OTOM

NE

H

W PO

TS

OT

D

E

S

O

L

C

TR

E

V

N

I

SLANIMRET ELBAN

D

E

NIA

TN

I

AM

ER

A

E

N

E

PO

ENABLE

E

L

B

A

N

E

N

E

PO

re

t d

ni

n

a

mret

s

r

epm

lla d

uj lla n

n

a

20

5

e

hw

PJ

n

o

s

re

pm

u

j

lla n

e

h

w e

d

om

g

ni

nn

ur l

amr

o

n

ni

e

t

ar

e

po lliw U0

6

GR

ehT

:

ET

ON

sgnitt

ed

om

g

n

e

in

S E

n

u

r

l

L

amr

B

o

A

n

N

ni

E

e

t

ar

.

6

e

po lliw

1

e

r

u

ti

,

g

iF

e

siw

eki

L

.

de

n

.d

ep

e

o

ylsu

s

o

l

c

yls

o

en

u

a

o

t

l

e

u

natl

mi

s e

umis

ra

30

Calibration

Warning

Dangerous voltages exist on the drive when it is powered.

When possible, disconnect the voltage input from the drive

before adjusting the trimpots. If the trimpots must be adjusted

with power applied, use insulated tools and the appropriate

personal protection equipment. BE ALERT. High voltages can

cause serious or fatal injury.

The RG60U has nine user adjustable trimpots: FWD ACC, REV

ACC, MAX SPD, IR COMP, REV TQ, FWD TQ, DB, MIN SPD, and

TACH. Each drive is factory calibrated to its maximum current

rating. Readjust the calibration trimpot settings to accommodate

lower current rated motors.

All adjustments increase with clockwise rotation, (CW) and

decrease with counterclockwise (CCW) rotation. Use a non-metallic

screwdriver for calibration. Each trimpot is identified on the printed

circuit board. See Figure 17, page 31 for RG60U calibration

trimpot locations.

1

5

FWD ACC

REV ACC

MAX SPD

IR COMP

REV TQ

FWD TQ

DB

MIN SPD

TACH

L2

L1

GND

FWD

ACC

REV

ACC

MAX

SPD

IR

COMP

REV

TQ

FWD

TQ

DB

MIN

SPD

TAC H

TB501

31Calibration

FEEDBACKARMATURE

90-180 ARM-TACH

SW504

C504

JP502

Y501

TB502

IL503

+15VS0S1

-15V

IC501

POWER

S3

C503

S2

INVERT

INHIBIT

INVERT

ENABLE

LIMIT

FWD

REV

IL502IL501

RB1

RB2

T1

T2

SW503

IC504

C

TB503

ENABLE

T50

Figure 17. RG60U Calibration Trimpot Locations

32

Calibration

MINIMUM SPEED (MIN SPD)

The MIN SPD trimpot setting determines the minimum speed when

the speed adjust potentiometer is turned full CCW. It is factory set

to zero speed. The minimum speed feature applies only when the

drive is operating in unidirectional mode.

To calibrate MIN SPD:

1. Set the speed adjust potentiometer to full CCW.

2. Adjust the MIN SPD trimpot until the desired minimum motor

speed is reached.

MAXIMUM SPEED (MAX SPD)

The MAX SPD trimpot setting determines the maximum

forward and reverse speed. It is factory set for maximum rated

motor speed.

To calibrate MAX SPD:

1. Set the MAX SPD trimpot full CCW.

2. Turn the speed adjust potentiometer CW so that the motor is

running at full speed.

3. Adjust the MAX SPD trimpot until the desired maximum motor

speed is reached.

Caution! Do not attempt to run motor above 90 VDC on 115 VAC

or above 180 VDC on 230 VAC.

Calibration

FORWARD TORQUE (FWD TQ)

Warning

Although FWD TQ can be set to 120% of motor nameplate

current rating, continuous operation beyond this rating may

damage the motor. If you intend to operate beyond this rating,

contact your Minarik representative for assistance.

The FWD TQ setting determines the maximum current limit for

accelerating and driving the motor in the forward direction. It is

factory set at 120% of maximum rated drive current.

See Figure 19 (page 39) for typical FWD TQ calibration settings or

use the following procedure to recalibrate FWD TQ:

1. With the power disconnected from the drive, connect a DC

ammeter in series with the armature.

2. Set the FWD TQ trimpot to minimum (full CCW).

3. Set the speed adjust potentiometer to maximum (full CW).

4. Carefully lock the motor armature. Be sure that the motor is

firmly mounted.

5. Apply line power. The motor should be stopped.

6. Slowly adjust the FWD TQ trimpot CW slowly until the armature

current is 120% of motor rated armature current.

7. Set the speed adjust potentiometer to minimum.

8. Remove the power from the drive.

9. Unlock the motor shaft.

10. Remove the ammeter in series with the motor armature if it is

no longer needed and re-apply power to the drive.

33

34

Calibration

REVERSE TORQUE (REV TQ)

Warning

Although REV TQ can be set to 120% of motor nameplate

curren rating, continuous operation beyond this rating may

damage the motor. If you intend to operate beyond this rating,

contact your Minarik representative for assistance.

The REV TQ setting determines the maximum current limit for

accelerating and driving the motor in the reverse direction. It is

factory set at 120% of maximum rated drive current.

See Figure 19 (page 39) for typical REV TQ calibration settings or

use the following procedure to recalibrate REV TQ:

1. With the power disconnected from the drive, connect a DC

ammeter in series with the armature.

2. Set the REV TQ trimpot to minimum (full CCW).

3. Set the speed adjust potentiometer to maximum (full CW).

4. Carefully lock the motor armature. Be sure that the motor is

firmly mounted.

5. Apply line power. The motor should be stopped.

6. Slowly adjust the REV TQ trimpot CW slowly until the armature

current is 120% of motor rated armature current.

7. Set the speed adjust potentiometer to minimum.

8. Remove the power from the drive.

9. Unlock the motor shaft.

10. Remove the ammeter in series with the motor armature if it is

no longer needed and re-apply power to the drive.

Calibration

IR COMPENSATION (IR COMP)

The IR COMP trimpot setting determines the degree to which

motor speed is held constant as the motor load changes. It is

factory set for optimum motor regulation.

See Figure 19 (page 39) for typical IR COMP calibration settings or

use the following procedure to recalibrate the IR COMP setting:

1. Set the IR COMP trimpot to minimum (full CCW).

2. Rotate the speed adjust potentiometer until the motor runs at

mid-speed without load (for example, 900 RPM for an 1800

RPM motor). A hand held tachometer may be used to measure

motor speed.

3. Load the motor armature to its full load armature current rating.

The motor should slow down.

4. While keeping the load on the motor, rotate the IR COMP

trimpot until the motor runs at the speed measured in step 2. If

the motor oscillates (overcompensation), the IR COMP trimpot

may be set too high (CW). Turn the IR COMP trimpot CCW to

stabilize the motor.

5. Unload the motor.

35

36

Calibration

FORWARD ACCELERATION (FWD ACC)

The FWD ACC setting determines the time the motor takes to ramp

to either a higher speed in the forward direction or a lower speed in

the reverse direction, within the limits of available torque. The

FWD ACC setting is factory set for its fastest forward acceleration

time.

Turn the FWD ACC trimpot CW to increase the forward

acceleration time, and CCW to decrease the forward acceleration

time.

REVERSE ACCELERATION (REV ACC)

The REV ACC setting determines the time the motor takes to ramp

to either a higher speed in the reverse direction or a lower speed in

the forward direction, within the limits of available torque. The REV

ACC setting is factory set for its fastest reverse acceleration time.

Turn the REV ACC trimpot CW to increase the reverse acceleration

time, and CCW to decrease the reverse acceleration time.

App

z

s

Calibration

DEADBAND (DB)

The deadband trimmer potentiometer determines the time that will

elapse between the application of current in one direction before

current is applied in the opposite direction.

The deadband trimmer potentiometer affects the resistance that a

motor has to changes in shaft position at zero speed. It does this

by applying AC voltage to the motor armature.

Deadband is factory calibrated with the notch at approximately the

3 o’clock position for 60 Hz AC line operation. Recalibrate the

deadband with the notch at the 9 o’clock position for 50 Hz AC line

operation. If you hear motor noise (humming), the deadband might

be set too high. Turn the deadband trimpot CCW until the motor

noise ceases.

37

Hz

lications

H

Application

Notch

Figure 18. Deadband Settings

38

Calibration

TACH GENERATOR (TACH)

Calibrate the TACH setting only when a tachogenerator is used.

The TACH setting, like the IR COMP setting, determines the

degree to which motor speed is held constant as the motor load

changes.

To calibrate the TACH trimpot:

1. Connect the tachogenerator to T1 and T2. The polarity is

positive (+) for T1 and negative (-) for T2 with the motor running

in forward direction.

2. Set SW503 to ARM for armature feedback.

3. Set the speed adjust potentiometer full CW. Measure the

armature voltage across A1 and A2 using a voltmeter.

4. Set the speed adjust potentiometer to 0 (zero speed).

5. Set SW503 to TACH for tachogenerator feedback.

6. Set the IR COMP trimpot to full CCW.

7. Set the TACH trimpot to full CW.

8. Apply line power.

9. Set the speed adjust potentiometer to full CW.

10. Adjust the TACH trimpot until the armature voltage is the same

value as the voltage measured in step 3.

Check that the tachogenerator is properly calibrated. The motor

should run at the same speed when SW503 is set to either

armature or tachogenerator feedback.

39Calibration

FWD TQ REV TQ IR COMP

FWD TQ REV TQ IR COMP

FWD TQ REV TQ IR COMP

FWD TQ REV TQ IR COMP

1 HP

90 VDC

10 ADC

3/4 HP

90 VDC

7.6 ADC

1/2 HP

90 VDC

5 ADC

1/4 HP

90 VDC

2.7 ADC

FWD TQ REV TQ IR COMP

FWD TQ REV TQ IR COMP

FWD TQ REV TQ IR COMP

FWD TQ REV TQ IR COMP

2 HP

180 VDC

9.2 ADC

1 HP

180 VDC

5 ADC

3/4 HP

180 VDC

3.8 ADC

1/2 HP

180 VDC

2.5 ADC

Figure 19. Typical FWD TQ, REV TQ, and IR COMP Trimpot Settings

40

Calibration

MAX (-PCM isolation card)

Determines the motor speed when the speed adjust potentiometer

is turned to full CW, or voltage signal is set to maximum. It is

factory set for maximum rated speed.

To calibrate, set the MAX trimpot to full CCW, or voltage signal to

maximum. Turn the main speed adjust potentiometer to full CW.

Adjust the MAX trimpot until the desired maximum motor speed is

reached. See Figure 20 for MAX trimpot location.

MAX & OFFSET

TRIMPOTS ON

PCM BOARD

OFFSETMAX

TB502

J502

IC504

IC503

1

IC505

C503

C504

T503

INHENDIR

IC502

+5V

COMS3S2S1+IN

J501

C502

C501

-IN

IC501

IC506

TB501

Figure 20. PCM Calibration Trimpot Locations

Calibration

OFFSET (-PCM isolation card)

Warning

This trimpot is set at the factory and should not need

adjustment. Do not adjust this trimpot unless you are

experiencing drift problems. Contact your Minarik

representative before attempting adjustment.

The RG60U-PCM has a factory-set offset to guarantee stability in a

stopped motor. To calibrate the OFFSET trimpot:

1. Ensure that the input power is turned OFF.

2. Set the input signal to zero.

3. Set the OFFSET trimpot to the approximate midrange or 50%.

Note: This is a 25-turn potentiometer. After setting the trimpot

to zero full CCW, make 5 full rotations to reach midrange, or 50%.

4. Apply power and observe the motor.

5. If the motor shaft drifts, or slowly rotates with no signal applied,

adjust the OFFSET trimpot until the motor shaft stops. The

direction and amount of trimpot adjustment depends on the

direction of the shaft rotation and connection of the motor leads.

See Figure 20 on page 40 for OFFSET trimpot location.

41

42

Application Notes

Connections to Minarik DLC600

MODEL DLC600

INPUT 115/230 VAC, 50/60 HZ, 50 mA

EARTH

GROUND

MINARIK CORPORATION - GLENDALE, CA 91201

G

www.minarikcorp.com

L1 L2 S1 S2 FIN + IN C

115 VA C

or

230 VAC

AC VOLTAGE

SIGNAL

INH

COMMON

INHIBIT SWITCH

OPEN to RUN

CLOSE to INHIBIT

MAGNETIC PICKUP

(NON-POLARIZED)

TB501 ON RG60U

RB1

+5 VDC OR +12 VDC

+15V S0S1S2S3-15VRB2T1T2

NOTE: ONLY ONE FEEDBACK DEVICE

(MAGNETIC PICKUP OR OPTICAL ENCODER)

MAY BE USED AT A TIME.

Figure 21. RG60U Connections to DLC600

OPTICAL

ENCODER

FWD-REV switch

1

G

D

501

503

501

C

502

501

503

501

LIMIT

FWD

REV

O

R

502

5V

5V

CH

Q

REV

Q

S

D

MIN

DB

M

JUST

R

Use a single-pole, two-position switch with a single speed adjust

potentiometer to plug reverse the motor (Figure 22).

43Application Notes

L

N

10K OH

PEED AD

POTENTIOMETE

TB

TA

P

-1

IL

1

P

WE

T

Figure 22. Forward-Reverse Switch

T

T

IL

IL

TB

Y

TB

I

5

44

L1

G

D

501

503

501

IC5

502

501

5

501

LIMIT

FWD

REV

O

R

502

5V

5V

CH

Q

REV

Q

S

D

MIN

DB

M

JUST

R

OP

Application Notes

FWD-STOP-REV switch

Use a single-pole, three-position switch with a single speed adjust

potentiometer to stop a motor between reversal (Figure 23). Set the

switch to the center position to decelerate the motor to a stop.

N

10K OH

PEED AD

POTENTIOMETE

TB

T

TA

P

-1

IL

1

P

WE

T

Figure 23. Forward-Stop-Reverse Switch

T

T

IL

IL

TB

Y

TB

0

03

501

O

R

5V

5V

CH

S

D

MIN

DB

M

M

2

1

Application Notes

Independent Adjustable Speeds

Connect two speed adjust potentiometers with a single-pole, two

position switch to select between two independent speeds shown

in the forward direction (Figure 24). The speed adjust

potentiometers can be mounted at two separate operating stations.

Total parallel resistance must equal 10 kohms.

45

TB

W

PEED

PEED

20K OH

20K OH

T5

Figure 24. Independent Adjustable Speeds (Forward Direction)

TA

P

-1

IL5

+1

P

WE

46

0

03

501

O

R

5V

5V

CH

S

D

MIN

DB

M

M

Application Notes

Independent forward and reverse speeds

Connect two speed adjust potentiometers as shown in Figure 25 to

select between independent forward and reverse speeds.

TA

P

-1

IL5

+1

P

WE

10K OH

10K OH

TB

T5

Figure 25. Independent Forward and Reverse Speeds

01

03

501

O

R

5V

5V

CH

S

D

MIN

M

M

OP

Application Notes

Independent forward and reverse speeds

with FWD-STOP-REV switch

Use a single-pole, three-position switch to stop the motor when the

switch is in the center position (Figure 26).

47

T

10K OH

10K OH

Figure 26. Independent Forward and Reverse Speeds with a

Forward-Stop-Reverse Switch

T5

TB

TA

P

-1

IL5

+1

P

WE

48

Troubleshooting

Warning

Dangerous voltages exist on the drive when it is powered.

When possible, disconnect the drive while troubleshooting.

High voltages can cause serious or fatal injury.

Before applying power

Check the following steps before proceeding:

1. The AC line voltage must be connected to the proper terminals.

2. Check that the voltage switches and jumpers are set correctly.

3. The motor must be rated for the drive’s rated armature voltage

and current.

4. Check that all terminal block connections are correct.

For additional assistance, contact your local Minarik distributor, or

the factory direct:

1-800-MINARIK (646-2745) or Fax: 1-800-394-6334

49Troubleshooting

Problem Possible

Causes

Line fuse blows. 1. Line fuse is the

wrong size.

2. Motor cable or

armature is shorted

to ground.

3. Nuisance tripping

caused by a

combination of

ambient conditions

and high-current

spikes (i.e.

reversing).

Suggested

Solutions

1. Check that the line

fuse is correct for the

motor size.

2. Check motor cable

and armature for

shorts.

3. Add a blower to cool

the drive

components;

decrease FWD TQ

and REV TQ

settings, or resize

motor and drive for

actual load demand,

or check for

incorrectly aligned

mechanical

components or

“jams”.

50

Troubleshooting

Problem Possible

Causes

Line fuse does not blow,

but the motor does not

run.

1. Speed adjust

potentiometer or

speed reference

voltage is set to zero

speed.

2. Speed adjust

potentiometer or

speed reference

voltage is not

connected to drive

input properly;

connections are

open.

3. INHIBIT terminals are

shorted.

4. S2 is shorted to S0.

5. Drive is in current

limit.

6. Drive is not receiving

AC line voltage.

7. Motor is not

connected.

Suggested

Solutions

1. Increase the speed

adjust potentiometer

setting or speed

reference voltage.

2. Check connections to

input. Verify that

connections are not

open.

3. Remove the short

from the INHIBIT

terminals.

4. Remove short.

5. Verify that motor is

not jammed.

Increase FWD TQ or

REV TQ setting if

they are set too low.

6. Apply AC line voltage

to L1 and L2.

7. Connect motor to A1

and A2.

Troubleshooting

51

Problem Possible

Causes

Motor runs too fast.

Motor will not reach the

desired speed.

Motor pulsates or

surges under load.

MAX SPD not

calibrated.

1. MAX SPD setting is

too low.

2. IR COMP setting is

too low.

3. Motor is overloaded.

4. Drive is in current

limit.

1. IR COMP is set too

high.

2. Motor bouncing in

and out of current

limit.

Suggested

Solutions

Calibrate MAX SPD.

1. Increase MAX SPD

setting.

2. Increase IR COMP

setting.

3. Check motor load.

Resize the motor if

necessary.

4. Verify torque

settings.

1. Adjust the IR COMP

setting slightly CCW

until the motor speed

stabilizes.

2. Make sure motor is

not undersized for

load; adjust FWD TQ

and REV TQ trimpot

CW.

52

Troubleshooting

Replacement Parts

Replacement parts are available form Minarik Corporation and

its distributors for this drive series.

Table 2. Replacement Parts

Model No. Symbol Description Minarik P/N

RG60U, RG61U SCR501–508 800 V, 25 A SCR 072–0067

Fuse Kits 3–8A Fuse Kit 050–0069

T501 DST-336 Transformer 230-0104

10K Ohm Potentiometer Kit 202–0104

2-Pin Jumper 164-0292

5–20A Fuse Kit 050–0073

NOTES

53

54

NOTES

Unconditional Warranty

A. Warranty - Mi nari k Drive s wa rran ts that its pro ducts w ill be f ree fro m de fect s in

workmanship and material for twelve (12) months or 3,000 hours, whichever comes first,

from date of manufacture thereof. Within this warranty period, Minarik Drives will repair

or replace, at its sole discretion, such products that are returned to Minarik Drives, 14300

De La Tour Drive, South Beloit, IL 61080-3006 USA.

warranty applies only to standard catalog products, and does not apply to specials. Any

This

returns for special controls will be evaluated on a case-by-case basis. Minarik Drives is

not

responsible for removal, installation, or any other incidental expenses incurred in

the product to and from the repair point.

shipping

B.

Disclaimer - The provisions of Para graph A are Mina rik Drives sole obligation and

exclude all other warranties of merchantability for use, express or implied. Minarik Drives

disclaims any responsibility whatsoever to the customer or to any other person for

further

to the person or damage or loss of property of value caused by any product that has

injury

been

subject to misuse, negligence, or accident, or misapplied or modified by unauthorized

persons or improperly installed.

Limitations of Liability - In the event of any cl aim for breech of any of Minarik Drives

C.

obligations,

warranty

of li ability that might, de spite Paragraph B, be decided against Minari k Drives by lawful

auth ority, Minar ik Dri ves sh all un der no circu mstanc es be liable for a ny consequential

damages, losses, or expen se arising in co nnect ion with th e use of, or inabilit y to use,

Minarik Drives

An

extension

on

warranty

If for any reason any of the foregoing provisions shall be ineffective, Minarik Drives liability

for

such

shall

Any action against Minarik Drives based upon any liability or obligation arising hereunder

or

within

whether express or implied, and particularly of any other claim or breech of

contained in Paragraph A, or of any other warranties, express or implied, or claim

product for any purpose whatsoever.

adjustment made under warranty does not void the warranty, nor does it imply an

of the original 12-month warranty period. Products serviced and/or parts replaced

a no-charge basis during the warranty period carry the unexpired portion of the original

only.

damages arising out of its manufacture or sale of equipment, or use thereof, whether

liability is based on warranty, contract, negligence, strict liability in tort, or otherwise,

not in any event exceed the full purchase price of such equipment.

under any law applicable to the sale of equipment or the use thereof, must be commenced

one year after the cause of such action arises.

14300 De La Tour Drive, South Beloit, IL 61080

Phone: 1-800-MINARIK (646-2745)

Fax: (815) 624-6960

www.minarikdrives.com

Document Number 250-0324, Rev. 6

Printed in the U.S.A – 11/09

Loading...

Loading...