Minarik Drives NRG-4Q Series Users Manual

NRG-4Q Series

USER MANUAL

Four Quadrant, Regenerative PWM Drives

For DC Brush Motors

MODELS

NRG02-D240AC-4Q

NRG02-D240AC-4Q-PCM

NRG05-D240AC-4Q

NRG05-D240AC-4Q-PCM

NRG10-115AC-4Q

NRG10-115AC-4Q-PCM

Copyright © 2005 by

Minarik Corporation

All rights reserved. No part of this manual may be reproduced or transmitted in any

form without written permission from Minarik Corporation. The information and

technical data in this manual are subject to change without notice. Minarik

Corporation and its Divisions make no warranty of any kind with respect to this

material, including, but not limited to, the implied warranties of its merchantability

and fitness for a given purpose. Minarik Corporation and its Divisions assume no

responsibility for any errors that may appear in this manual and make no

commitment to update or to keep current the information in this manual.

Printed in the United States of America.

i

Safety Warnings

• This symbol l denotes an important safety message. Please read these

sections very carefully before performing any calibration, repair, or other

procedure contained in this manual.

• Have a qualified electrical maintenance technician install, adjust, and service

this equipment. Follow the National Electrical Code and all other applicable

electrical and safety codes, including the provisions of the Occupational Safety

and Health Act (OSHA), when installing equipment.

• Reduce the chance of an electrical fire, shock, or explosion by proper grounding,

over current protection, thermal protection, and enclosure. Follow sound

maintenance procedures.

It is possible for a drive to run at full speed as a result of a

component failure. Minarik strongly recommends the installation

of a master switch in the main power input to stop the drive in an

emergency.

Circuit potentials are at 120 VAC or 240 VAC above earth ground.

Avoid direct contact with the printed circuit board or with circuit

elements to prevent the risk of serious injury or fatality. Use a

non-metallic screwdriver for adjusting the calibration trimpots.

Use insulated tools if working on this drive with power applied.

L

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Shielding guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Speed adjust potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Heat sinking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Line fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cage-clamp terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Power input connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Motor connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Regenerative dump resistor connections . . . . . . . . . . . . . . . . . . .12

Top board terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Signal and optional switch connections . . . . . . . . . . . . . . . . . . . . . . . .16

Speed adjust potentiometer connections . . . . . . . . . . . . . . . . . . . . . . .18

Voltage follower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Slide switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

ARMATURE VOLTAGE OUT (SW501) . . . . . . . . . . . . . . . . . . . . .20

FEEDBACK SELECT (SW502) . . . . . . . . . . . . . . . . . . . . . . . . . .20

Headers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

INHIBIT PERSONALITY (JMP501) . . . . . . . . . . . . . . . . . . . . . . .20

CONTROL MODE (JMP502) . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

INHIBIT MODE (JMP503) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

CURRENT LIMIT OUT (J502) . . . . . . . . . . . . . . . . . . . . . . . . . . .21

OUTPUT HEADER (J504) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Before applying power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Startup and shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

ii

Contents

Reversing the drive: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Starting and stopping methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Line starting and line stopping . . . . . . . . . . . . . . . . . . . . . . . . . .26

Automatic restart upon power restoration . . . . . . . . . . . . . . . . . .26

Decelerating to minimum speed . . . . . . . . . . . . . . . . . . . . . . . . .26

Inhibit terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Regenerative dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Torque (Current) Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

NRG-4Q-PCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

MINIMUM SPEED (MIN SPD) . . . . . . . . . . . . . . . . . . . . . . . . . . .35

INHIBIT OFFSET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

INPUT OFFSET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

FORWARD MAXIMUM SPEED (FWD MAX) . . . . . . . . . . . . . . . . .38

REVERSE MAXIMUM SPEED (REV MAX) . . . . . . . . . . . . . . . . .38

REGULATION (IR COMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

MOTOR TORQUE LIMIT and REGEN TORQUE LIMIT . . . . . . . . .40

FORWARD ACCELERATION (FWD ACCEL) . . . . . . . . . . . . . . . .42

REVERSE ACCELERATION (REV ACCEL) . . . . . . . . . . . . . . . . .43

TACHOMETER (TACH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Connection to other Minarik devices . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Optional speed adjust potentiometer connections . . . . . . . . . . . . . . . . .49

FWD-MIN SPD-REV Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Independent Adjustable Speeds . . . . . . . . . . . . . . . . . . . . . . . . .50

Independent forward and reverse speeds . . . . . . . . . . . . . . . . . .51

Independent forward and reverse speeds using a

FWD-MIN SPD-REV switch . . . . . . . . . . . . . . . . . . . . . . . . .52

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Before applying power: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

iiiContents

Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

CURRENT LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

REGEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

OVER VOLTAGE COAST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

CE Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Certificate of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Compliance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

OEM Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

AC Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Unconditional Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

iv Contents

v

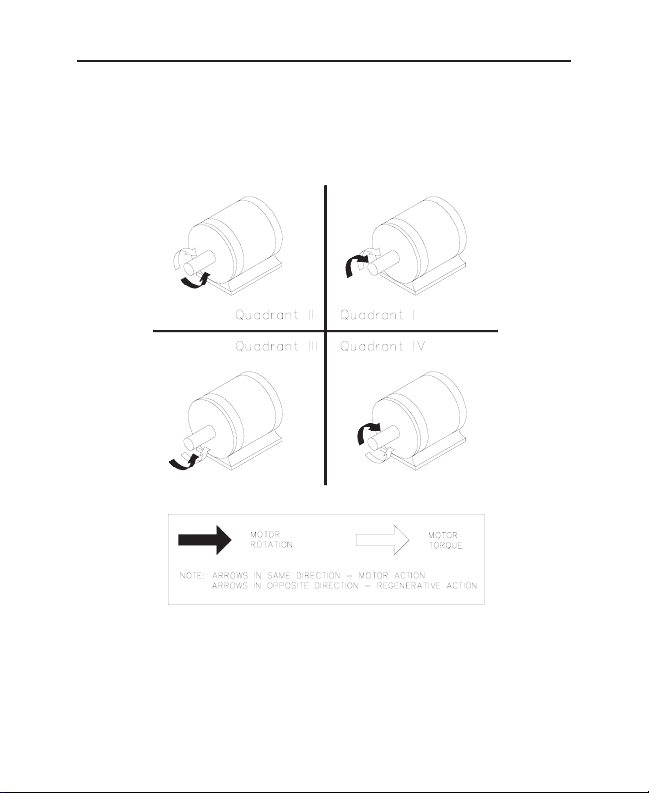

Figure 1. Four Quadrant Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

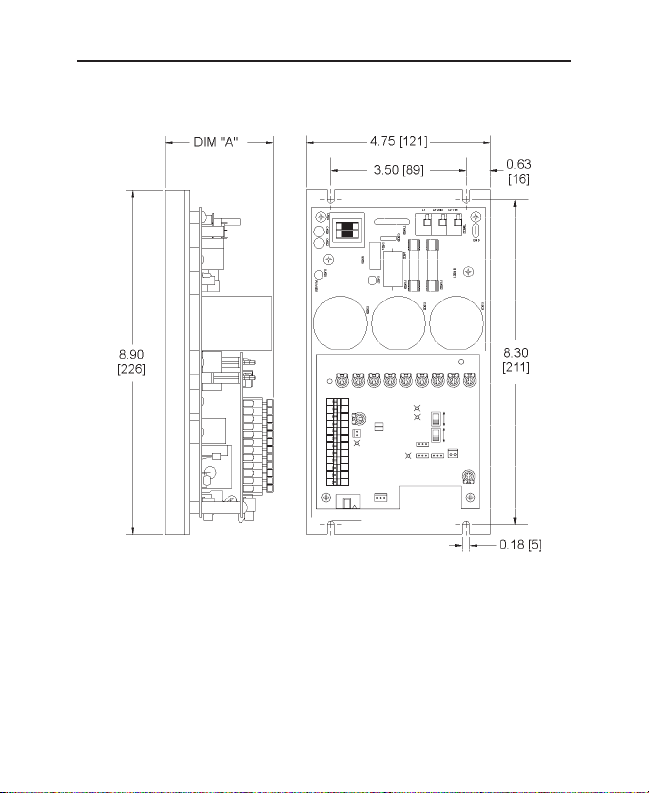

Figure 2. NRG–4Q Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

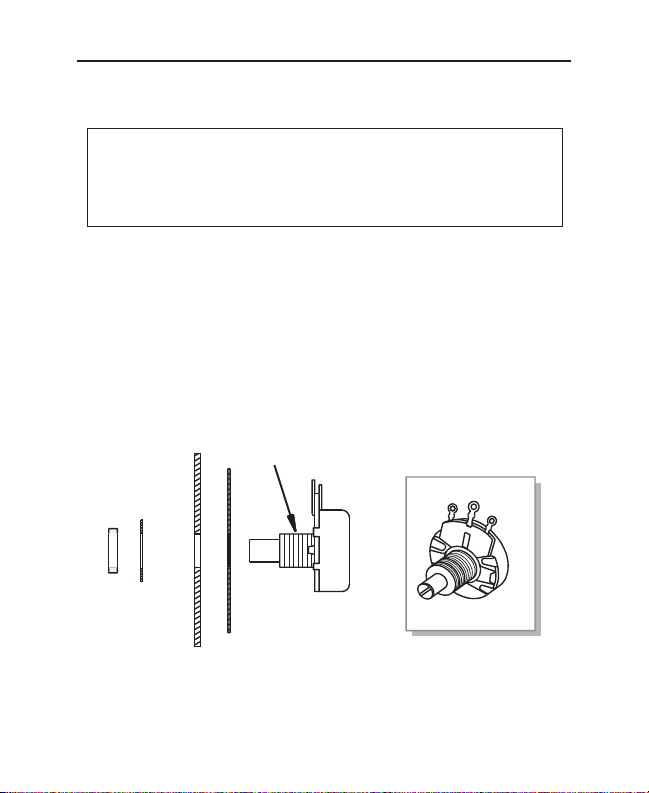

Figure 3. Speed Adjust Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 4. Cage-Clamp Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Figure 5. Bottom Board Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 6. Top Board Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 7. Speed Adjust Potentiometer Connections . . . . . . . . . . . . . . . . . .18

Figure 8. Voltage Follower Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 9. Slide Switches, Headers and Terminals . . . . . . . . . . . . . . . . . . . .22

Figure 10. Regenerative Dump Circuit Connection . . . . . . . . . . . . . . . . . . . .30

Figure 11. Calibration Trimpot Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Figure 12. Typical Motor Torque, Regen Torque and IR Comp Settings

for NRG02/05-4Q Series Drives . . . . . . . . . . . . . . . . . . . . . . . . .45

Figure 13. Typical Motor Torque, Regen Torque and IR Comp Settings

for NRG10-4Q Series Drives . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Figure 14. NRG–4Q Connection to DIGI-LOK Controls . . . . . . . . . . . . . . . . .47

Figure 15. NRG Connection to 200–0386A Limit Switch Logic Board . . . . . . .48

Figure 16. FWD / MIN SPD / REV Switch . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Figure 17. Independent Adjustable Speeds (Forward Direction) . . . . . . . . . . .50

Figure 18. Independent Forward and Reverse Speeds . . . . . . . . . . . . . . . . .51

Figure 19. Independent Forward and Reverse Speeds Using a

FWD / MIN SPD / REV Switch . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Figure 20. Diagnostic LED Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Figure 21. CE Shielding, Ground and Filtering Connections . . . . . . . . . . . . .64

Illustrations

vi

Table 1. Recommended Line Fuse Sizes . . . . . . . . . . . . . . . . . . . . . . . . . .9

Table 2. Inhibit Plug Harness Assembly . . . . . . . . . . . . . . . . . . . . . . . . . .27

Table 3. Regenerative Dump Resistor Values . . . . . . . . . . . . . . . . . . . . . .28

Table 4. AC Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Tables

vii

Minarik’s NRG–4Q Series drives are four-quadrant, regenerative PWM

drives. These open chassis drives come with the following features:

Pulse width modulation. Lower form factor than SCR drives (1.03 versus

1.37) throughout the motor speed range. Motor runs with greater efficiency

and less maintenance.

Four quadrant regenerative operation. see Regenerative drives section on

page ix.

Inhibit personality. Set the inhibit for your application needs: regenerative

brake for fast stopping, or coast for slower stopping. Normally open or

normally closed.

On board fusing. Protects the drive from high line current.

Cage-clamp terminals. Quicker and easier wiring than screw terminals.

Regenerative braking. No contactors required. No electromechanical

components to overheat or wear out.

Reverse on the fly. Switch from forward to reverse instantaneously.

Dual voltage input. Power the drive with either 120 VAC or 240 VAC.

Autoranging power supply.

Tachogenerator feedback option. Improve the speed regulation from

approximately 1% (armature feedback) to 0.1% with tachogenerator

feedback.

NRG–4Q Drives

viii NRG-4Q Drives

Diagnostic LEDs. Allows easy visual inspection of the drive status. Motor,

regen, current limit, and over voltage.

+15 and –15 VDC supply (50 mA maximum capacity each). Power external

devices with the drive’s power supply.

User adjustable trimpots. Calibrate the drive precisely to your application

needs.

ix

Most non-regenerative variable-speed DC drives control current flow to a

motor in one direction. The direction of current flow is the same direction as

the motor rotation. Non-regenerative drives operate in Quadrant 1, and also

in Quadrant 3 if the drive is reversible (see Figure 1 on page x).

Motors must stop before reversing direction. Unless dynamic braking is used,

non-regenerative drives cannot decelerate a load faster than coasting to a

lower speed.

Regenerative drives operate in two additional quadrants: Quadrant 2 and

Quadrant 4. In these quadrants, motor torque is in the opposite direction of

motor rotation. This allows regenerative drives to reverse a motor without

contactors or switches, to control an overhauling load, and to decelerate a

load faster than it would take to coast to a lower speed.

Regenerative Drives

x Regenerative Drives

Figure 1. Four Quadrant Operation

1

Model Number NRG02–D240AC–4Q (-PCM)

Type Open Chassis

AC Line Voltage 120 VAC or 240 VAC, ±10%, 50Hz or 60 Hz, single phase

Maximum Continuous Armature Current 2 ADC

Horsepower Range @ 130 VDC Output 1/20 – 1/4

Horsepower Range @ 240 VDC Output 1/10 – 1/2

Maximum Armature Voltage Range @ 120 VAC Input 0–130 VDC

Maximum Armature Voltage Range @ 240 VAC Input 0–240 VDC

Minimum Speed Adjustment Range @ 120 VAC Input 0–60 VDC

Minimum Speed Adjustment Range @ 240 VAC Input 0–120 VDC

Form Factor 1.05

Acceleration Time Range 0.1–20 seconds

Deceleration Time Range 0.1–20 seconds

Input Signal Range (signal must be isolated)** – 10 to +10 VDC

Input Impedance 47k Ohm

Speed Regulation (% of base speed) 1% open loop; 0.1% tach feedback

Tachogenerator Voltage Output Range 7 V/1000 RPM to 50V/1000 RPM

Vibration 0.5G max. (0–50 Hz); 0.1G max. (>50 Hz)

Weight 1.9 lb

Ambient Operating Temperature Range* 10°C–40°C

*External air flow is required to ensure temperature limits are not exceeded.

** (-PCM) drives do not require an isolated signal.

Specifications

2 Specifications

Model Number NRG05–D240AC–4Q (-PCM)

Type Open Chassis

AC Line Voltage 120 VAC or 240 VAC, ±10%, 50Hz or 60 Hz, single phase

Maximum Armature Current 5 ADC

Horsepower Range @ 130 VDC Output 1/8 – 3/4

Horsepower Range @ 240 VDC Output 1/4 – 1.5

Maximum Armature Voltage Range @ 120 VAC Input 0–130 VDC

Maximum Armature Voltage Range @ 240 VAC Input 0–240 VDC

Minimum Speed Adjustment Range @ 120 VAC Input 0–60 VDC

Minimum Speed Adjustment Range @ 240 VAC Input 0–120 VDC

Form Factor 1.05

Acceleration Time Range 0.1–20 seconds

Deceleration Time Range 0.1–20 seconds

Input Signal Range (signal must be isolated)** – 10 to +10 VDC

Input Impedance 47k Ohm

Speed Regulation (% of base speed) 1% open loop; 0.1% tach feedback

Tachogenerator Voltage Output Range 7V/1000 RPM to 50V/1000 RPM

Vibration 0.5G max. (0–50 Hz); 0.1G max. (>50 Hz)

Weight 1.9 lb

Ambient Operating Temperature Range* 10°C–40°C

*External air flow is required to ensure temperature limits are not exceeded.

** (-PCM) drives do not require an isolated signal.

Model Number NRG10–115AC–4Q (-PCM)

Type Open Chassis

AC Line Voltage 120 VAC, ±10%, 50Hz or 60 Hz, single phase

Maximum Armature Current 10 ADC

Horsepower Range @ 130 VDC Output 1/4 – 1.5

Maximum Armature Voltage Range @ 120 VAC Input 0–130 VDC

Minimum Speed Adjustment Range @ 120 VAC Input 0–60 VDC

Form Factor 1.05

Acceleration Time Range 0.1–20 seconds

Deceleration Time Range 0.1–20 seconds

Input Signal Range (signal must be isolated)** – 10 to +10 VDC

Input Impedance 47k Ohm

Speed Regulation (% of base speed) 1% open loop; 0.1% tach feedback

Tachogenerator Voltage Output Range 7V/1000 RPM to 50V/1000 RPM

Vibration 0.5G max. (0–50 Hz); 0.1G max. (>50 Hz)

Weight 1.9 lb

Ambient Operating Temperature Range* 10°C–40°C

*External air flow is required to ensure temperature limits are not exceeded.

** (-PCM) drives do not require an isolated signal.

3Specifications

4

Figure 2. NRG–4Q Dimensions

All dimensions in inches [millimeters]

NRG02–D240AC–4Q (-PCM) 2.79 [71]

NRG05–D240AC–4Q (-PCM) 3.13 [80]

NRG10–115AC–4Q (-PCM) 3.62 [92]

Dimensions

Model Height (Dim. “A”)

REGEN

MOTOR

FWD

REV

IR COMP

TACH

TORQUE

TORQUE

ACCEL

ACCEL

P509 P505 P503 P504 P507 P501 P506 P502 P510

1

+15 -15 S0 S3 S1 S2 RB2 RB1 COM DIR T1 T2

INHIBIT

OFFSET

IL504

CURRENT

LIMIT

12

+

- CURRENT

LIMIT

OUT

IL502

MOTOR

IL501

REGEN

JMP502

JMP501

C503

CONTROL MODE

INHIBIT

C502

1&2=VEL MODE

J502

PERSONALITY

2&3=CUR MODE

1&2=COAST

2&3=BRAKE

1 2 3

JMP503

INHIBIT MODE

JMP502

1&2=NO

2&3=NC

1 2 3

JMP501

IL503

OVER

VOLTAGE

COAST

J504

OUTPUTS

1=Iout

2=COM

3=Yout

1 2 3

J504J501

MIN

REV

FWD

SPD

MAX

MAX

SW501

130 VDC

ARMATURE

VOLTAGE OUT

240 VDC

ARMATURE

FEEDBACK

TACH/CUR MODE

SW502

1 2 3

JMP503

INHIBIT

P511

INPUT

OFFSET

5

Warning

Do not install, rewire, or remove this control with input power

applied. Doing so may cause fire or serious injury. Make sure you

have read and understood the Safety Warnings on page i before

attempting installation.

The chassis must be earth grounded. Use a star washer beneath the

head of at least one of the mounting screws to penetrate the

anodized chassis surface and to reach bare metal.

L

• Drive components are sensitive to electrostatic fields. Avoid direct contact

with the circuit board. Hold drive by the chassis only.

• Protect the drive from dirt, moisture, and accidental contact.

• Provide sufficient room for access to the terminal block and calibration

trimpots.

• Mount the drive away from heat sources. Operate the drive within the

specified ambient operating temperature range.

• Prevent loose connections by avoiding excessive vibration of the drive.

Installation

Mounting

6 Installation

• Mount the drive with its board in either a horizontal or vertical plane.

Preffered mounting is with fins vertical. Four 0.19 in. (5 mm) wide slots in

the chassis accept #8 pan head screws.

Wiring

• Use 18-24 AWG wire for speed adjust potentiometer wiring. Use 14–16

AWG wire for AC line (L1, L2) and motor (A1 and A2) wiring.

Warning

Do not install, remove, or rewire this equipment with power applied.

Doing so may cause fire or serious injury.

Circuit potentials are at 120 or 240 VAC above ground. To prevent

the risk of injury or fatality, avoid direct contact with the printed

circuit board or with circuit elements.

Do not disconnect any of the motor leads from the drive unless

power is removed or the drive is disabled. Opening any one motor

lead may destroy the drive. Do not fuse the motor line.

L

V

7Installation

As a general rule, Minarik recommends shielding of all conductors.

If it is not practical to shield power conductors, Minarik recommends

shielding all logic-level leads. If shielding logic leads is not practical, the

user should twist all logic leads with themselves to minimize induced noise.

It may be necessary to earth ground the shielded cable. If noise is produced

by devices other than the drive, ground the shield at the drive end. If noise is

generated by a device on the drive, ground the shield at the end away from

the drive. Do not ground both ends of the shield.

If the drive continues to pick up noise after grounding the shield, it may be

necessary to add AC line filtering devices, or to mount the drive in a less

noisy environment.

Logic wires from other input devices, such as motion controllers and PLL

velocity controllers, must be separated from power lines in the same manner

as the logic I/O on this drive.

Warning

Under no circumstances should power and logic leads be bundled

together. Induced voltage can cause unpredictable behavior in any

electronic device, including motor controls.

L

Shielding guidelines

8 Installation

Install the circular insulating disk between the mounting panel and the 10K

ohm speed adjust potentiometer (see Figure 3). Mount the speed adjust

potentiometer through a 0.38 inch (10 mm) hole with the hardware provided.

Twist the speed adjust potentiometer wire to avoid picking up unwanted

electrical noise. If potentiometer leads are longer than 18 inches (46 cm),

use shielded cable.

Figure 3. Speed Adjust Potentiometer

Warning

Be sure that the potentiometer tabs do not make contact with the

potentiometer enclosure. Grounding the input will cause damage

to the drive.

L

Speed adjust potentiometer

MOUNT THROUGH A 0.38 IN. (10 MM) HOLE

WIPER

CW

NUT

STAR

WASHER

INSULATING DISK

PAN EL

SPEED ADJUST

POTENTIOMETER

POT TAB ASSIGNMENTS

CCW

9Installation

Heat sinking

All NRG-4Q Series drives have sufficient heat sinking in their basic

configurations. No additional heat sinking is required.

Line fusing

NRG Series drives have preinstalled line fuses. When replacing the line

fuses, use fast acting fuses rated for 250 VAC or higher, and at least 200%

of the armature current. See Table 1 for recommended line fuse sizes.

Table 1. Recommended Line Fuse Sizes

90 VDC Motor 180 VDC Motor Max. DC Armature AC Line Fuse

Horsepower Horsepower Current (amps) Size (amps)

1/20 1/10 0.5 3

1/15 1/8 0.8 3

1/8 1/4 1.5 5

1/6 1/3 1.7 5

1/4 1/2 2.6 8

1/3 3/4 3.5 8

1/2 1 5.0 10

3/4 - 7.6 15

1 - 10 20

10 Installation

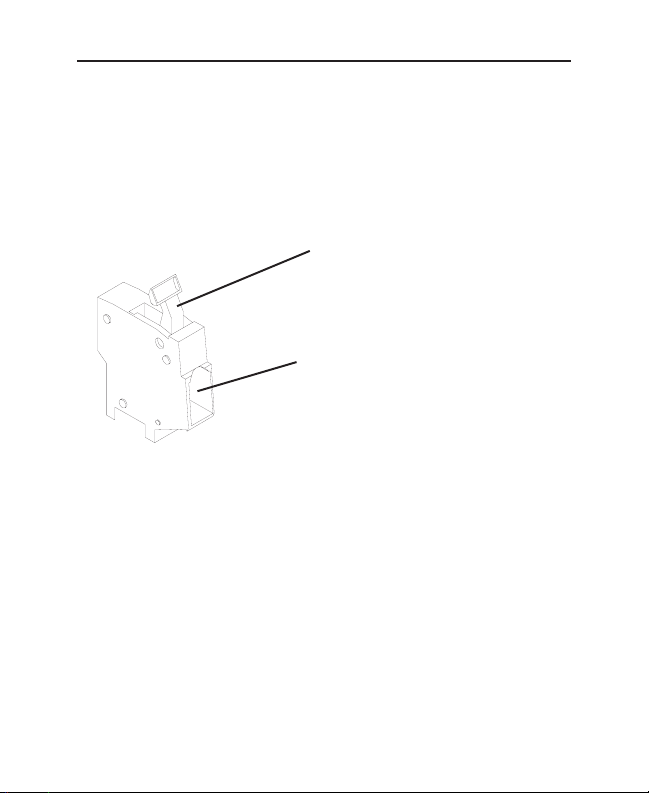

Cage-clamp terminals

All connections are made to cage-clamp terminals. To insert a wire into the

cage-clamp terminal:

1. Press down on the lever arm using a

small screwdriver. Unnecessary force

may cause damage.

2. Insert wire into the wire clamp.

3. Release the lever arm to clamp wire.

Figure 4. Cage-Clamp Terminal

11Installation

Connect the power input leads and a DC motor to TB501 and TB502 on the

drive’s printed circuit board (PCB) as shown in Figure 5 on page 13.

Power input connections

Connect the AC line voltage leads to terminals L1 and L2 on terminal board

TB502, or to a double-throw, single-pole master power switch

(recommended). If the line voltage is 120 VAC, connect the AC line voltage

leads to terminals L1 and

L2 (115). If the line voltage is 240 VAC, connect the AC line voltage leads to

terminals L1 and L2 (230).

Warning

Do not connect this equipment with power applied. Doing so may

cause fire or serious injury.

Minarik strongly recommends the installation of a master power

switch in the voltage input line, as shown in Figure 5 (page 13).

The switch contacts should be rated at a minimum of 200% of

motor nameplate current and 250 volts.

Do not connect 240 VAC line voltage to terminal L2 (115).

Fire or serious damage to the drive may result.

L

Connections

12 Installation

Motor connections

Minarik drives supply motor voltage from A1 and A2 terminals. It is assumed

throughout this manual that, when A1 is positive with respect to A2 , the

motor will rotate clockwise (CW) while looking at the output shaft protruding

from the front of the motor. If this is opposite of the desired rotation, simply

reverse the wiring of A1 and A2 with each other.

Connect a DC motor to TB501 terminals A1 and A2 as shown in Figure 5

(page 13). Ensure that the motor voltage rating is consistent with the drive’s

output voltage.

Regenerative dump resistor connections

If you plan to use braking to stop the motor or if reversing on the fly is

required, you must connect a regenerative dump resistor to TB501 terminals

DB+ and DB- as shown in Figure 5 (page 13).

The regenerative dump resistor reduces the voltage across the bus

capacitors (C503 and C504) when they reach their maximum voltage rating.

This occurs when the motor regenerates voltage back to the drive. Bus

capacitor maximum voltage ratings are 400 VDC for 240 VAC drives, and 200

VDC for 120 VAC drives. For more information on regenerative braking,

refer to the Regenerative braking section on page 28.

13Installation

Figure 5. Bottom Board Connections

Power and Ground Connections

Motor and Regenerative Dump Resistor Connections

Regenerative

Dump

Resistor

Loading...

Loading...