MM-PCM Series

USER MANUAL

MM03-115AC-PCM

MM03-230AC-PCM

MM10-115AC-PCM

MM10-230AC-PCM

www.minarikdrives.com

Dear Valued Consumer:

Congratulaons on your purchase of the MM-PCM Series

drive. This User Manual was created for you to get the most out

of your new device and assist with the inial setup. Please visit

www.minarikdrives.com to learn more about our other drives.

Thank you for choosing Minarik Drives!

© 2014 Minarik Drives. All rights reserved.

No part of this document may be reproduced or transmied in any form without wrien permission

from Minarik Drives. The informaon and technical data in this document are subject to change

without noce. Minarik Drives makes no warranty of any kind with respect to this material,

including, but not limited to, the implied warranes of its merchantability and tness for a given

purpose. Minarik Drives assumes no responsibility for any errors that may appear in this document

and makes no commitment to update or to keep current the informaon in this document.

MM-PCM Series

Safety First!

SAFETY WARNINGS

Text in gray boxes denote important safety ps or warnings.

Please read these instrucons carefully before performing any of

!

• DO NOT INSTALL, REMOVE, OR REWIRE THIS EQUIPMENT WITH

• Reduce the chance of an electrical fire, shock, or explosion by using

the procedures contained in this manual.

WARNING!

POWER APPLIED. Have a qualified electrical technician install, adjust

and service this equipment. Follow the National Electrical Code

and all other applicable electrical and safety codes, including the

provisions of the Occupational Safety and Health Act (OSHA), when

installing equipment.

proper grounding techniques, over-current protection, thermal

protection, and enclosure. Follow sound maintenance procedures.

It is possible for a drive to run at full speed as a result of a

component failure. Minarik Drives strongly recommends the

!

installaon of a master switch in the main power input to stop

WARNING!

the drive in an emergency.

Circuit potenals are at 115 VAC or 230 VAC above earth ground.

Avoid direct contact with the printed circuit board or with circuit

elements to prevent the risk of serious injury or fatality. Use a

non-metallic screwdriver for adjusng the calibraon trim pots.

Use approved personal protecve equipment and insulated tools

if working on this drive with power applied.

i

MM-PCM Series

Table of Contents

Section 1. Specifications ..................................................... 1

Section 2. Dimensions ......................................................... 2

Section 3. Installation ......................................................... 4

Heat Sinking ................................................................................. 4

Mounting ..................................................................................... 5

Speed Adjust Potentiometer .................................................. 6

Wiring .......................................................................................... 7

Shielding Guidelines.............................................................. 8

Line Fusing ........................................................................... 9

Connections.................................................................................11

Quick Disconnect Terminal Block ..........................................11

Power Inputs .......................................................................13

Motor ..................................................................................13

Field Output Connections .....................................................14

Run/Stop Switch ..................................................................15

Inhibit Switch ......................................................................15

Speed Adjust Potentiometer .................................................15

Analog Input Signal ..............................................................15

Section 4. Operation ......................................................... 17

Before Applying Power .................................................................17

Select Switches ............................................................................18

Signal Select Switch (SW501) ................................................18

Startup ........................................................................................19

Starting and Stopping Methods ....................................................20

Line Starting and Stopping ...................................................20

Dynamic Braking ..................................................................21

Inhibit Switch ......................................................................23

Run/Stop Switch ..................................................................24

Section 5. Calibration ....................................................... 25

Minimum Speed (MIN OUT) ..........................................................25

ii

Maximum Speed (MAX SPD) .........................................................26

Torque (TORQUE LIMIT) ................................................................27

IR Compensation (IR COMP) .........................................................28

Acceleration (ACCEL) ....................................................................30

Deceleration (DECEL) ...................................................................30

MM-PCM Series

Section 6.Application Notes ............................................... 31

Multiple Fixed Speeds .................................................................. 31

Adjustable Speeds Using Potentiometers In Series .........................32

Independent Adjustable Speeds .................................................... 33

RUN/JOG Switch - Inhibit Connection ............................................34

RUN/JOG Switch - Potentiometer Connection ................................35

Leader-Follower Application .........................................................36

Single Speed Potentiometer Control Of Multiple Drives .................37

Reversing .....................................................................................38

Section 7. Diagnostic LEDs ................................................. 39

Section 8. Troubleshooting ................................................ 40

Before Troubleshooting ................................................................40

Section 9. Accessories & Replacement Parts ....................... 43

Unconditional Warranty ..................................................... 44

iii

MM-PCM Series

List of Tables

Table 1 Recommended Line Fuse Sizes ........................................... 9

Table 2 Short Circuit Current Ratings ............................................10

Table 3 Minimum Recommended Dynamic Brake Resistor Values ...14

iv

MM-PCM Series

List of Figures

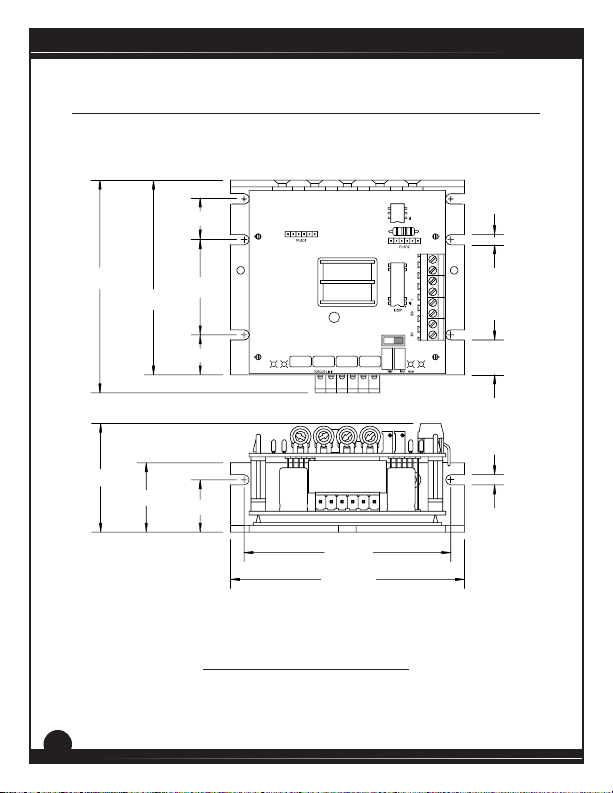

Figure 1 MM-PCM Dimensions ........................................................ 2

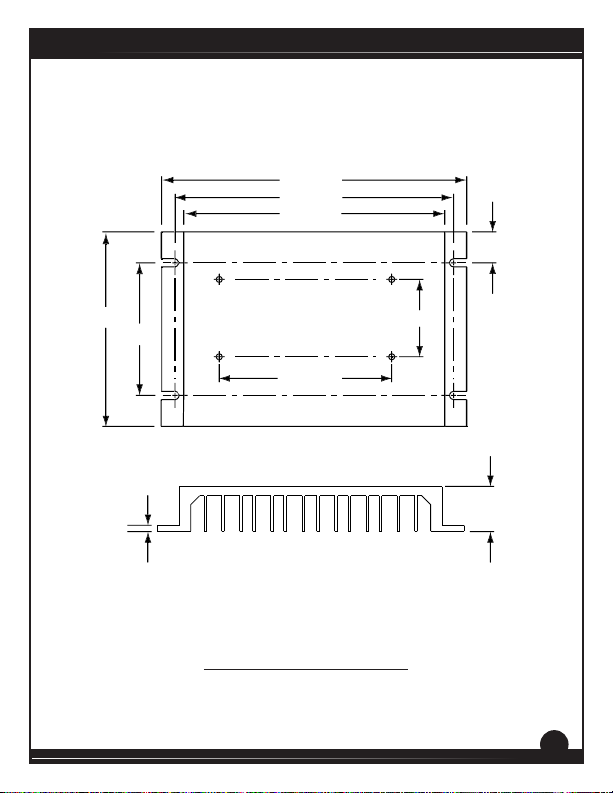

Figure 2 223-0159 Dimensions ........................................................ 3

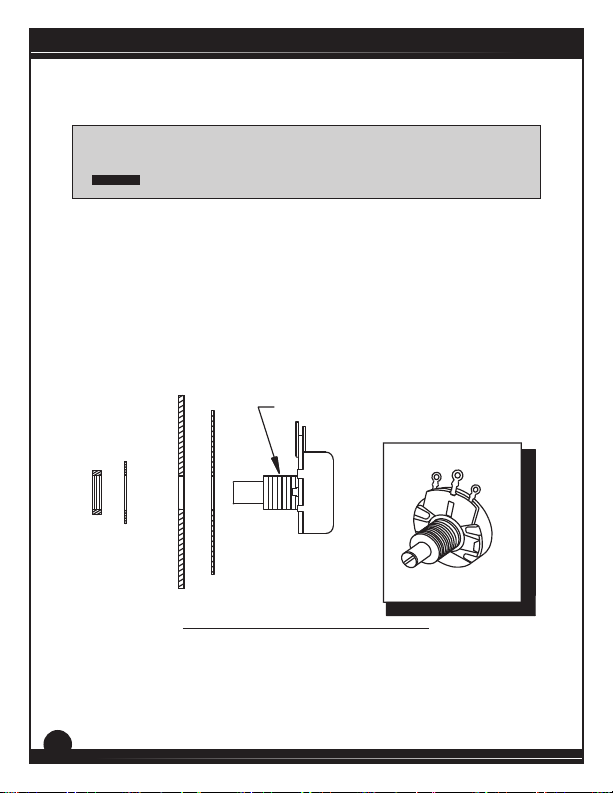

Figure 3 Speed Adjust Potentiometer .............................................. 6

Figure 4 Quick-Disconnect Terminal Block ......................................12

Figure 5 MM-PCM Connections ......................................................16

Figure 6 Signal Select Switch ..........................................................18

Figure 7 Dynamic Brake Wiring ......................................................22

Figure 8A Inhibit Terminals (Normally Closed) ..................................23

Figure 8B Inhibit Terminals (Normally Open) ....................................23

Figure 9 Recommended TORQUE LIMIT and IR COMP Settings .........29

Figure 10 Multiple Fixed Speeds ......................................................31

Figure 11 Adjustable Speeds Using Potentiometers in Series .............32

Figure 12 Independent Adjustable Speeds ........................................33

Figure 13 RUN/JOG Switch - Connection to Inhibit ............................34

Figure 14 RUN/JOG Switch - Connection to Speed Adjust

Potentiometer .................................................................35

Figure 15 Leader-Follower Application .............................................36

Figure 16 Single Speed Potentiometer Control of Multiple Drives ......37

Figure 17 Reversing Circuit Wiring ...................................................38

Figure 18 Diagnostic LED Locations ..................................................39

v

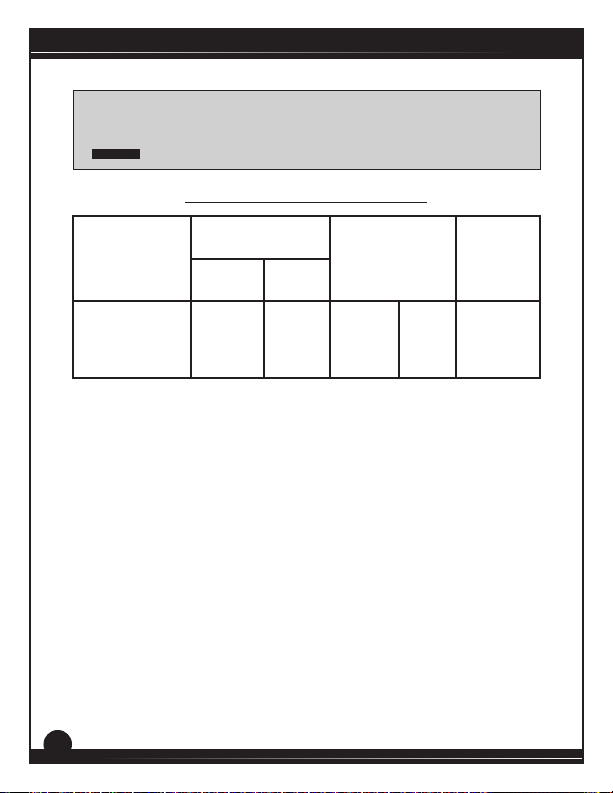

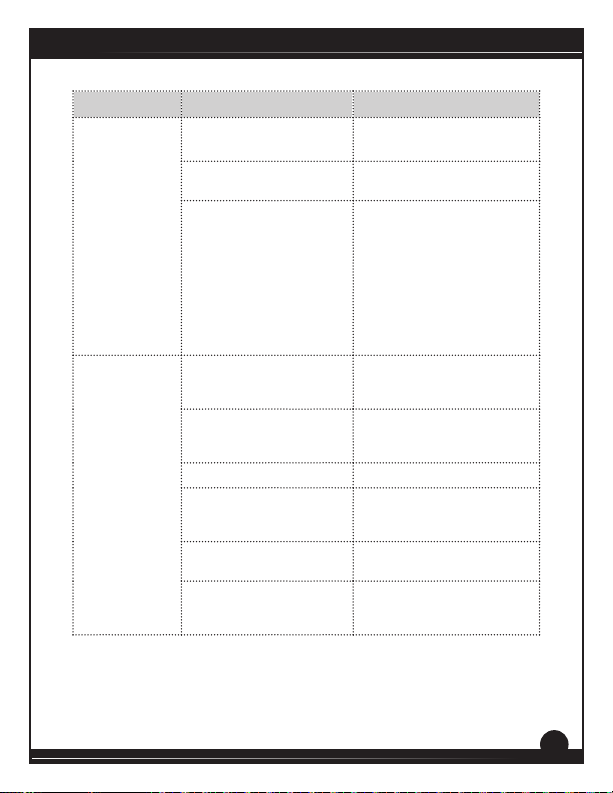

Section 1. Specifications

MM-PCM Series

Model

MM03-115AC-PCM

MM03-230AC-PCM

MM10-115AC-PCM*

MM10-230AC-PCM*

AC Line

Voltage

(VAC)

115

230

115

230

Armature

Voltage Range

(VDC)

0 - 90

0 - 180

0 - 90

0 - 180

Maximum

Armature

Current (ADC) HP Range

3.0 1/50 -1/4

10.0 1/8 - 1

1/25 - 1/2

1/4 - 2

* Heat sink kit part number 223-0159 must be used when the connuous

current output is over 5 amps.

AC Line Voltage 115 or 230 VAC ± 10%, 50/60 Hz, single phase

Field Voltage

with 115 VAC Line Voltage

with 230 VAC Line Voltage

Maximum Field Current 1 ADC

Acceleraon Time 0.1 - 10 sec

Deceleraon Time coast to a stop - 10 sec

Analog Input Range (S1 to S2)

Voltage Signal Range

Current Signal Range

Input Impedance (S1 to S2) >100K ohms

Form Factor 1.37 at base speed

Load Regulaon 2% base speed or beer

Speed Range 60:1

Vibraon 0.5G maximum (0 - 50 Hz)

Safety Cercaons UL/cUL Listed Equipment, File # E132235

Ambient Temperature Range 10° - 40° C

50 VDC (F1 to L1); 100 VDC (F1 to F2)

100 VDC (F1 to L1); 200 VDC (F1 to F2)

0 - 10 VDC

4 - 20 mA

0.1G maximum (> 50 Hz)

1

MM-PCM Series

Section 2. Dimensions

57.0 [19]

3 1 9 . [ 9 9 ]

6 1 .

2 [ 5 5 ]

3 8 5 . [ 1 9 ]

8 2 . 1 [ 3 3 ]

5 7 . 1 [ 4 4 ]

4 7 . 0 [ 9 1 ]

7 9 . 0 [ 5 2 ]

O

1 0 5 C

1

R 1 0 5

B T 1 0 5

3 2 5 4

+

1 0 5 C

P 4 0 5 P 3 0 5

P 6 0 5 P 5 0

5

L

0 5

I 3

I L 4 0

5

R W P

I O

R

C / M P

/ C I L M

DE C A L E

2 S

SW 1 0 5

V O L T

C R R

U

2 0

P

5

5

P 1 0

W C

W C

X A M

N I M

O T

S P

U

D

L I 1 0 5

L I 2 0 5

I

C C E L

H N

9 1 . 0 [ 5 ]

5 6 . 0 [ 6 1 ]

9 1 . 0 [5 ]

3 0 8 . [ 7 9 ]

0 3 . 4 [ 9 0 1 ]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 1. MM-PCM Dimensions

2

]

]

]

6.90 [ 17 5

6.30 [ 16 0

5.90 [ 150

MM-PCM Series

0.7 [18]

4.40 [112]

3.00 [76]

0.125 [3]

1.75 [44]

3.90 [100]

1.00 [26]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 2. 223-0159 Dimensions

3

MM-PCM Series

Section 3. Installation

Do not install, rewire, or remove this control with input power

applied. Failure to heed this warning may result in re, explosion,

!

Heat Sinking

Models MM10-115AC-PCM and MM10-230AC-PCM require an

addional heat sink when the connuous armature current is above 5

amps. Use Minarik Drives heat sink kit part number 223-0159. All other

chassis drives have sucient heat sinking in their basic conguraon.

Use a thermally conducve heat sink compound (such as Dow Corning®

340 Heat Sink Compound) between the chassis and the heat sink surface

for opmum heat transfer.

or serious injury. Make sure you read and understand the Safety

WARNING!

Precauons on page i before aempng to install this product.

4

MM-PCM Series

Mounng

• Drive components are sensitive to electrostatic discharge. Avoid

direct contact with the circuit board. Hold the drive by the chassis

or heat sink only.

• Protect the drive from dirt, moisture, and accidental contact.

• Provide sufficient room for access to the terminals and calibration

trim pots.

• Mount the drive away from heat sources. Operate the drive within

the specified ambient operating temperature range.

• Prevent loose connections by avoiding excessive vibration of the

drive.

• Mount the drive with its board in either a horizontal or vertical

plane. Eight 0.19” (5 mm) wide slots in the chassis accept #8 pan

head screws. Fasten either the large base or the narrow flange of

the chassis to the subplate.

• The chassis should be earth grounded. Use a star washer beneath

the head of at least one of the mounting screws to penetrate the

anodized surface and to reach bare metal.

5

MM-PCM Series

Speed Adjust Potenometer

Be sure that the potenometer tabs do not make contact with the

!

If using a remote potenometer with a chassis drive, mount the speed

adjust potenometer through a 0.38 in. (10 mm) hole with the hardware

provided (Figure 3). Install the circular insulang disk between the panel

and the 10K ohm speed adjust potenometer.

Twist the speed adjust potenometer wire to avoid picking up unwanted

electrical noise. If the speed adjust potenometer wires are longer than

18 in. (46 cm), use shielded cable. Keep the speed adjust potenometer

wires separate from power leads (L1, L2, A1, A2, F1, F2).

NUT

potenometer’s body. Grounding the input will cause damage to

WARNING!

the drive.

MOUNT THROUGH A 0.38 IN. (10 MM) HOLE

STAR

WASHER

INSULATING DISK

PANEL

SPEED ADJUST

POTENTIOMETER

CW

POT TAB ASSIGNMENTS

WIPER

CCW

Figure 3. Speed Adjust Potenometer

6

MM-PCM Series

Wiring

Do not install, rewire, or remove this control with input power

applied. Failure to heed this warning may result in re, explosion,

!

• Use 18 - 24 AWG wire for logic wiring. Use 14 - 16 AWG wire for

or serious injury.

WARNING!

Circuit potenals are at 115 or 230 VAC above ground. To prevent

the risk of injury or fatality, avoid direct contact with the printed

circuit board or with circuit elements.

Do not disconnect any of the motor leads from the drive unless

power is removed or the drive is disabled. Opening any one

motor lead while the drive is running may destroy the drive.

This product does not have internal solid state motor overload

protecon. It does not contain speed-sensive overload

protecon, thermal memory retenon or provisions to receive

and act upon signal from remote devices for over temperature

protecon. If motor over protecon is needed in the end-use

product, it needs to be provided by addional equipment in

accordance with NEC standards.

AC line and motor wiring.

7

MM-PCM Series

Shielding Guidelines

Under no circumstances should power and logic level leads be

!

As a general rule, Minarik Drives recommends shielding of all conductors.

If it is not praccal to shield power conductors, it is recommended

to shield all logic-level leads. If shielding of all logic-level leads is not

praccal, the user should twist all logic leads with themselves to

minimize induced noise.

It may be necessary to earth ground the shielded cable. If noise is

produced by devices other than the drive, ground the shield at the drive

end. If noise is generated by a device on the drive, ground the shield at

the end away from the drive. Do not ground both ends of the shield.

If the drive connues to pick up noise aer grounding the shield, it may

be necessary to add AC line ltering devices, or to mount the drive in a

less noisy environment.

Logic wires from other input devices, such as moon controllers and PLL

velocity controllers, must be separated from power lines in the same

manner as the logic I/O on this drive.

bundled together. Induced voltage can cause unpredictable

behavior in any electronic device, including motor controls.

WARNING!

8

MM-PCM Series

Line Fusing

Models MM03-115AC-PCM and MM10-115AC-PCM are preinstalled

with one line fuse in fuse holder FU501. Models MM03-230AC-PCM and

MM10-230AC-PCM are preinstalled with two line fuses in fuse holders

FU501 and FU502.

Models MM10-115AC-PCM and MM10-230AC-PCM are preinstalled

with 15 amp fuses. Models MM03-115AC-PCM and MM03-230AC-PCM

are preinstalled with a 5 amp fuse.

Preinstalled line fuses are rated for maximum horsepower. If the

horsepower rang of the motor being used is less than the maximum

horsepower rang of the drive, the line fuse may have to be replaced

with a lower rated one. Fuses should be rated for 250 VAC or higher and

approximately 150% of the maximum armature current. Refer to Table 1

to install a lower rated fuse.

Table 1. Recommended Line Fuse Sizes

90 VDC

Motor

Horsepower

1/20

1/15

1/8

1/6

1/4 1/2 2.5 5

1/3

1/2

3/4

1

180 VDC

Motor

Horsepower

1/10

1/8

1/4

1/3

3/4

1

2

Maximum DC

Armature Current

(amps)

0.5

0.8

1.5

1.7

3.5

5.0

7.5

10

Fuse Size

Minarik Drives oers fuse kits. See Secon 9: Accessories and

Replacement Parts for fuse kit part numbers.

AC Line

(amps)

1

1.5

3

3

8

10

15

15

9

MM-PCM Series

Short-circuit current rang (SCCR) is the maximum short-circuit

current that the speed control can safely withstand when

!

protected by a specic over-current protecve device(s).

WARNING!

Table 2. Short Circuit Current Rangs

Drive Model

MM10-230AC-PCM 5,000 250 V Non-time

Short Circuit

Current Rang Types of Branch

Maximum

Current, kA

Maximum

Voltage, V

Circuit Protection

Inverse

Delay

K5 Fuse

Time

Circuit

Breaker

Maximum

Rating of

Overcurrent

Protection

40 A

10

MM-PCM Series

Connecons

Do not connect this equipment with power applied. Failure to

heed this warning may result in re, explosion, or serious injury.

!

Quick-Disconnect Terminal Block

The quick-disconnect terminal block is composed of a 6-pin header

block and 6-screw terminal plug (Figure 4 on page 12). To use the quick-

disconnect terminal block:

Minarik Drives strongly recommends the installaon of a master

WARNING!

power switch in the voltage input line, as shown in Figure 5

(page 16). The switch contacts should be rated at a minimum of

200% of motor nameplate current and 250 volts.

1. Carefully pull terminal plug from header block.

2. With a small flat-head screwdriver, turn terminal plug screw

counterclockwise to open wire clamp.

3. Insert stripped wire into the large opening in front of the plug.

4. Turn the terminal plug screw clockwise to clamp the wire.

5. Repeat steps 2–4 for each terminal until all connections are

made. Make no connections to F1 and F2 if using a permanent

magnet motor.

6. Insert plug into header until securely fastened.

11

MM-PCM Series

Header Block

(mounted on the drive)

Terminal Plug

Figure 4. Quick-Disconnect Terminal Block

12

MM-PCM Series

Power Input

Connect the AC line power leads to terminals L1 and L2. Minarik Drives

recommends the use of a single-throw, double-pole master power

switch. The switch should be rated at a minimum of 250 volts and 200%

of motor current. Refer to Figure 5 on page 16.

Motor

Drives supply motor armature voltage from A1 and A2 terminals. It is

assumed throughout this manual that, when A1 is posive with respect

to A2, the motor will rotate clockwise (CW) while looking at the output

sha protruding from the front of the motor. If the motor does not

spin in the desired direcon, remove power and reverse the A1 and A2

connecons.

Connect a DC motor to terminals A1 and A2 as shown in Figure 5 on page

16. Ensure that the motor voltage rang is consistent with the drive’s

output voltage.

13

MM-PCM Series

Field Output Connecons

The eld output is for shunt wound motors only. Do not make

any connecons to F1 and F2 when using a permanent magnet

!

See Table 2 for eld output connecons. Use 14 - 16 AWG wire to

connect the eld output to a eld / shunt wound motor.

WARNING!

motor.

Table 2. Field Output Connecons

Line Voltage (VAC)

14

115

115

230

230

Approximate Field

Voltage (VDC)

50

100

100

200

Connect Motor

Field To

F1 and L1

F1 and F2

F1 and L1

F1 and F2

MM-PCM Series

Run/Stop Switch

See page 24 for a detailed explanaon of the Run/Stop switch. If no Run/

Stop switch is desired, a jumper must be placed between terminals 1 and

2 (factory preinstalled).

Inhibit Switch

See page 23 for a detailed explanaon of the Inhibit switch.

Speed Adjust Potenometer

Use a 10K ohm, 1/4 W potenometer for speed control. Connect the

counter-clockwise end of the potenometer to S1, the wiper to S2, and

the clockwise end to S3. If the potenometer works inversely of the

desired funconality (e.g. to increase motor speed you must turn the

potenometer counterclockwise), power o the drive and swap the S1

and S3 connecons. Refer to Figure 5 on page 16.

Analog Input Signal

Instead of using a speed adjust potenometer, the drive may be wired

to follow an analog input voltage or current signal that is either isolated

or non-isolated from earth ground. Connect the signal common (-) to S1.

Connect the signal reference (+) to S2.

Refer to Figure 6 on page 18 for switch SW501 sengs and locaon.

An analog input voltage range of 0–10 VDC or 4–20 mA is required to

produce an armature voltage range of 0–90 VDC with 115 VAC line

voltage, or 0-180 VDC with 230 VAC line voltage.

15

1 S

2 S

3 S 5 3

0 5

(

)

O

M

S

T S U J

O

O

R

U

S / T P O

S

H C

C

(

)

S

H C

(

g

)

0 5

O T R O

E

O

D

(

) y

p

:

C

0 5

d

C

0 0

d

p

:

C

0 0

d

C

0 0

d

C

r o

0 3 2

C

T U

O

O

O C

C

O N S O

O

U C

D

MM-PCM Series

M O T

1

B T

1 0 K

H

D A D E E P

P

I T N E T

W

N

R

E T E M

T I W

n u r o t e s o l c

SIGNAL CONNECTIONS ON TOP “LOGIC” BOARD

1

B T

M O T

M

1 1 5 A V

A V

P N I

POWER

SWITCH

P D N A R

T A M R A U R

R E W

E N N

B N O T T O P " M

I T

Figure 5. MM-PCM Connecons

D R A O B " C I G O L " P O T N O D E T A C O L

T I B I H N I

T I W

a p e e s

s n o i t p o r o f 32 e

NOTE: DO NOT make

any connections to

F1 and F2 if using a

permanent magnet motor.

L E I F R

l n o s r o t o m d n u o w t n u h s

R E W C R I

t u

n i C A V 5 1 1 r o F

l e i F t l o V -

r o f 1 L o t t c e n n o

1 r o f 2 F o t t c e n n o

l e i F t l o V -

t u

n i C A V 0 3 2 r o F

1 r o f 1 L o t t c e n n o

l e i F t l o V -

2 r o f 2 F o t t c e n n o

l e i F t l o V -

B " T I O R A

16

Section 4. Operation

Change voltage switch sengs only when the drive is

disconnected from AC line voltage. Make sure both switches are

!

Before Applying Power

set to their correct posion. If the switches are improperly set

to a lower voltage posion, the motor will not run at full voltage

WARNING!

and may cause damage to the transformer. If the switches are

improperly set to a higher voltage posion, the motor will

overspeed, which may cause motor damage, or result in bodily

injury or loss of life.

Dangerous voltages exist on the drive when it is powered. BE

ALERT. High voltages can cause serious or fatal injury. For your

safety, use personal protecve equipment (PPE) when operang

this drive.

If the motor or drive does not perform as described, disconnect

the AC line voltage immediately. Refer to the Troubleshoong

secon, page 40, for further assistance.

1. Verify that no foreign conductive material is present on the

printed circuit board.

2. Ensure that switch SW501 is properly set.

MM-PCM Series

17

5 4

MM-PCM Series

Select Switches

Signal Select Switch (SW501)

Set the signal select switch SW501 to either CURR to use a current input

signal or VOLT to use a voltage input signal or potenometer. See Figure

6.

+

P 4 0 5 P 3 0 5

E D C E L A C C E L

I 1 0 5 C

S W 1 0 5

U C R R

P 2 0 5

N I M

C W

T U O

V O L T

S3 2 1 3

S 2

S 1

Armature Voltage

P 1 0 5

X A M

C W

S P D

I L 2 0 5

Select (SW503)

L I 1 0 5

H N I R N U

Figure 6. Signal Select Switch

18

MM-PCM Series

Startup

1. Turn the speed adjust potentiometer full counterclockwise

(CCW) or set the input voltage or current signal to minimum.

2. Apply AC line voltage.

3. Slowly advance the speed adjust potentiometer clockwise

(CW) or increase the input voltage or current signal. The motor

slowly accelerates as the potentiometer is turned CW or as the

input voltage or current signal is increased. Continue until the

desired speed is reached.

4. Remove AC line voltage from the drive to coast the motor to a

stop.

19

MM-PCM Series

Starng and Stopping Methods

Dynamic braking, coasng to a stop, or decelerang to minimum

!

Automac Restart Upon Power Restoraon

All drives automacally run to set speed when power is applied, the

inhibit is not acve, and the Run/Stop switch is set to Run (closed).

Line Starng and Stopping

Line starng and stopping (applying and removing AC line voltage) is

recommended for infrequent starng and stopping of a drive only. When

AC line voltage is applied to the drive, the motor accelerates to the speed

set by the speed adjust potenometer or analog signal. When AC line

voltage is removed, the motor coasts to a stop.

speed is recommended for frequent starts and stops. Do not use

any of these methods for emergency stopping. They may not stop

WARNING!

a drive that is malfunconing. Removing AC line power (both

lines) is the only acceptable method for emergency stopping.

For this reason, Minarik Drives strongly recommends installing

an emergency stop switch on both AC line inputs (see Figure 5

on page 16).

Frequent starng and stopping can produce high torque. This

may cause damage to motors, especially gearmotors that are not

properly sized for the applicaon.

20

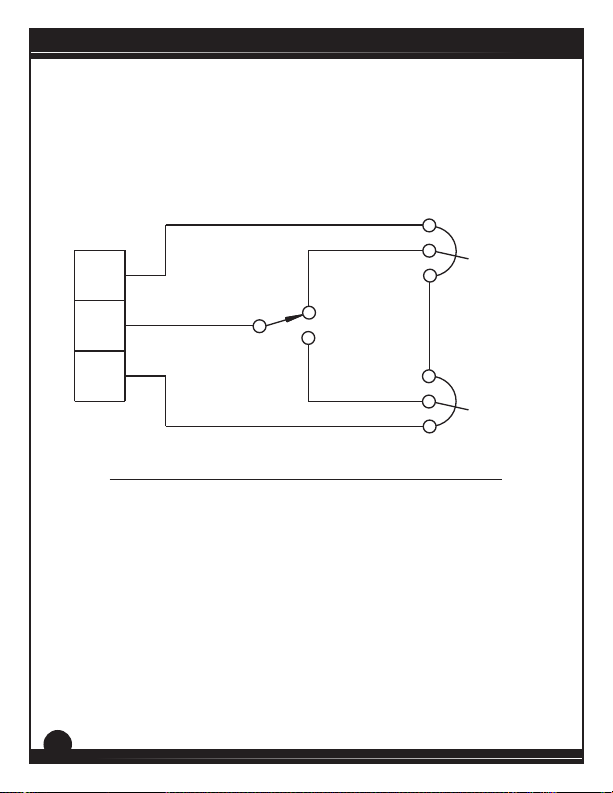

Dynamic Braking

Wait for the motor to completely stop before switching back to

RUN. This will prevent high armature currents from damaging

!

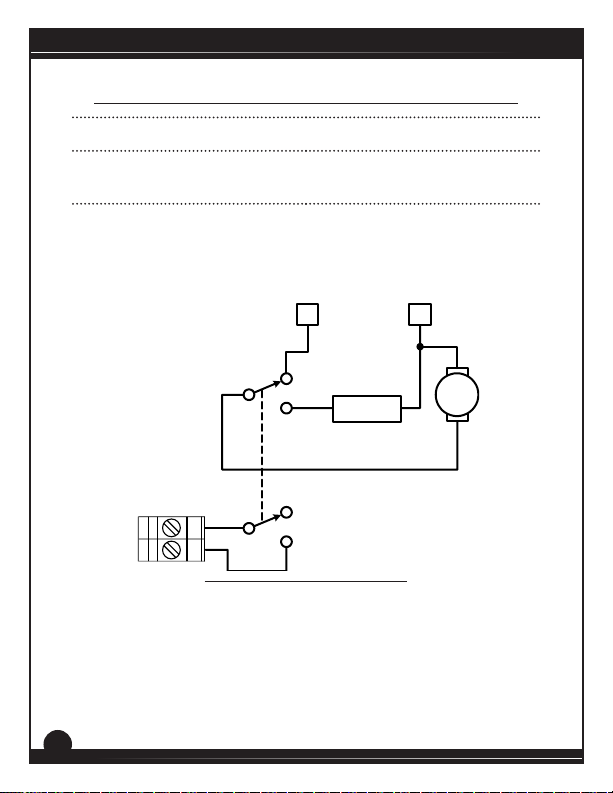

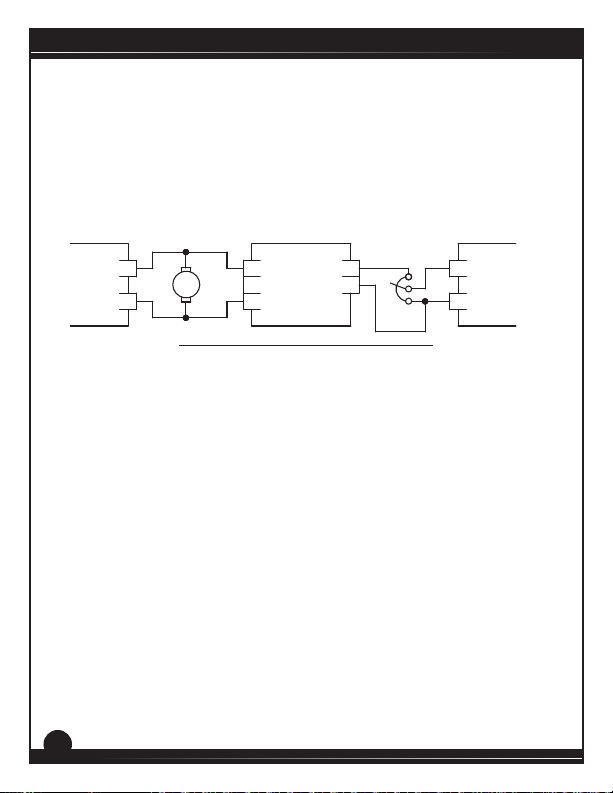

Dynamic braking may be used to rapidly stop a motor (Figure 7 on page

22). For the RUN/BRAKE switch, use a two pole, two posion switch

rated for at least the armature voltage rang and 150% of the armature

current rang. For the dynamic brake resistor, use a 40 wa minimum,

high power, wirewound resistor.

Sizing the dynamic brake resistor depends on load inera, motor voltage,

and braking me. Use a lower-value, higher-waage dynamic brake

resistor to stop a motor more rapidly. Refer to Table 3 on page 22 for

recommended dynamic brake resistor sizes.

WARNING!

the motor or drive.

MM-PCM Series

21

MM-PCM Series

Table 3. Minimum Recommended Dynamic Brake Resistor Values

Motor Armature Voltage Dynamic Brake Resistor Value

90 VDC

180 VDC

15 ohms

30 ohms

For motors rated 1/17 horsepower and lower, a brake resistor is not

necessary since the armature resistance is high enough to stop the

motor without demagnezaon. Replace the dynamic brake with

12-gauge wire.

A1

RU N

DYNAMIC BRAK E

BRAKE

4 3

RESIST OR

A2

MOTO R

Figure 7. Dynamic Brake Wiring

22

MM-PCM Series

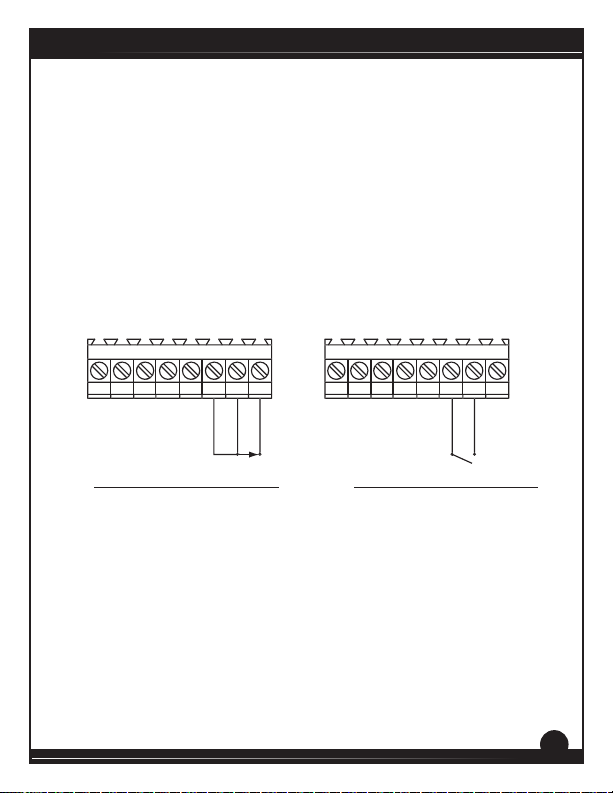

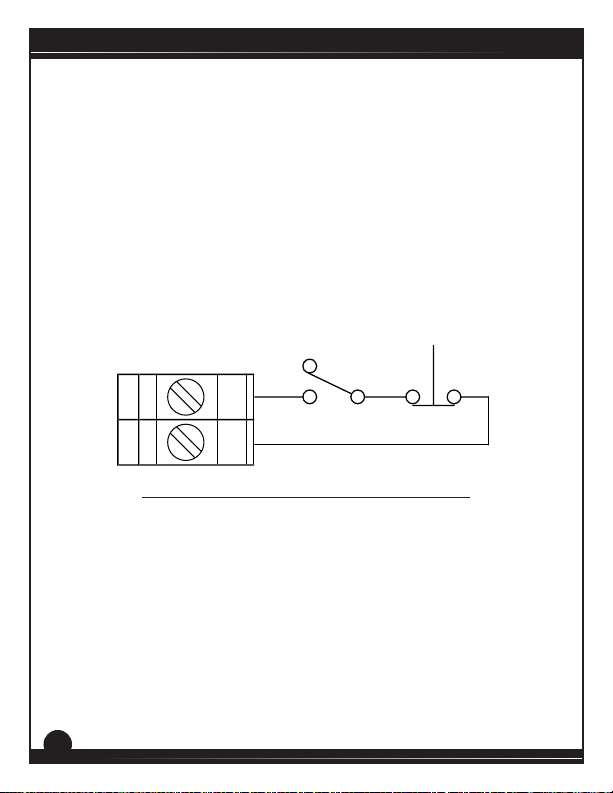

Inhibit Switch

Connect an inhibit switch as shown in Figure 8A or 8B. Acvang the

inhibit circuit causes the motor to coast to a stop. Deacvang the inhibit

circuit accelerates the motor to set speed at a rate controlled by the

ACCEL trim pot.

Twist inhibit wires and separate them from power-carrying wires or

sources of electrical noise. Use shielded cable if the inhibit wires are

longer than 18 inches (46 cm). If shielded cable is used, ground only one

end of the shield to earth ground. Do not ground both ends of the shield.

TB501 (LOCATED ON TOP “LOGIC” BOARD) TB501 (LOCATED ON TOP “LOGIC” BOARD)

2 S 1 S 3 S

2 1 3 5 4

O T N E P O

T I B I H N I

Figure 8A. Inhibit Terminals

(Normally Closed)

2 S 1 S 3 S

2 1 3 5 4

C L S O T E O

T I B I H N I

Figure 8B. Inhibit Terminals

(Normally Open)

23

MM-PCM Series

Run/Stop Switch

The Run/Stop switch may be used to decelerate a motor to a minimum

speed. Opening the Run/Stop switch decelerates the motor from set

speed to a minimum speed determined by the MIN OUT trim pot seng.

If the MIN OUT trim pot is set to zero speed, the motor decelerates to

zero speed when the Run/Stop switch is opened. The DECEL trim pot

seng determines the rate at which the drive decelerates. By closing the

Run/Stop switch, the motor accelerates to set speed at a rate determined

by the ACCEL trim pot seng. See Figure 5 on page 16 for switch locaon

and wiring.

NOTE: If no run/stop switch is used, a jumper must be placed between

terminals 1 and 2 (factory preinstalled).

24

MM-PCM Series

Section 5. Calibration

Dangerous voltages exist on the drive when it is powered. When

possible, disconnect the voltage input from the drive before

!

MM-PCM series drives have user-adjustable trim pots. Each drive is

factory calibrated to its maximum current rang. Readjust the calibraon

trim pot sengs to accommodate lower current rated motors.

All adjustments increase with CW rotaon, and decrease with CCW

rotaon. Use a non-metallic screwdriver for calibraon. Each trim pot is

idened on the printed circuit board.

adjusng the trim pots. If the trim pots must be adjusted with

WARNING!

power applied, use insulated tools and the appropriate personal

protecon equipment. BE ALERT. High voltages can cause serious

or fatal injury.

25

MM-PCM Series

Minimum Speed (MIN OUT)

The MIN OUT seng determines the minimum motor speed when the

speed adjust potenometer or input voltage or current signal is set for

minimum speed. It is factory set for zero speed.

To calibrate the MIN OUT:

1. Set the speed adjust potentiometer or input voltage or current

signal for minimum speed.

2. Adjust MIN OUT until the desired minimum speed is reached or

is just at the threshold of rotation.

Maximum Speed (MAX SPD)

The MAX SPD seng determines the maximum motor speed when the

speed adjust potenometer or input voltage or current signal is set for

maximum speed.

To calibrate MAX SPD:

1. Set the speed adjust potentiometer or input voltage or current

signal for maximum speed.

2 . Adjust MAX SPD until the desired maximum speed is reached.

Note: Check the MIN out and MAX SPD adjustments aer recalibrang

to verify that the motor runs at the desired minimum and maximum

speed.

26

MM-PCM Series

Torque (TORQUE LIMIT)

TORQUE LIMIT should be set to 150% of motor nameplate current

rang. Connuous operaon beyond this rang may damage the

!

The TORQUE LIMIT seng determines the maximum torque for

accelerang and driving the motor. To calibrate TORQUE LIMIT, refer to

the recommended TORQUE LIMIT sengs in Figure 9 on page 29 or use

the following procedure:

motor. If you intend to operate beyond the rang, contact your

WARNING!

Minarik Drives representave for assistance.

1. With the power disconnected from the drive, connect a DC

ammeter in series with the armature.

2. Set the TORQUE LIMIT trim pot to minimum (full CCW).

3. Set the speed adjust potentiometer full CW or input voltage

signal to maximum speed.

4. Carefully lock the motor armature. Be sure that the motor is

firmly mounted.

5. Apply line power. The motor should be stopped.

6. Slowly adjust the TORQUE LIMIT trim pot CW until the armature

current is 150% of motor rated armature current.

7. Turn the speed adjust potentiometer CCW or decrease the

input voltage signal.

8. Remove line power.

9. Remove the stall from the motor.

10. Remove the ammeter in series with the motor armature if it is

no longer needed.

27

MM-PCM Series

IR Compensaon (IR COMP)

The IR COMP seng determines the degree to which motor speed is held

constant as the motor load changes.

Use the following procedure to recalibrate the IR COMP seng:

1. Set the IR COMP trim pot to minimum (full CCW).

2. Increase the speed adjust potentiometer or input voltage signal

until the motor runs at midspeed without load (for example,

900 RPM for an 1800 RPM motor). A handheld tachometer may

be used to measure motor speed.

3. Load the motor armature to its full load armature current

rating.The motor should slow down.

4. While keeping the load on the motor, rotate the IR COMP trim

pot until the motor runs at the speed measured in step 2. If

the motor oscillates (overcompensation), the IR COMP trim pot

may be set too high (CW). Turn the IR COMP trim pot CCW to

stabilize the motor.

5. Unload the motor.

See Figure 9 on page 29 for recommended IR COMP sengs.

28

MM-PCM Series

MM03-115AC-PCM MM10-115AC-PCM

P M O C R I

HP:

VOLTS:

AMPS:

HP:

VOLTS:

AMPS:

HP:

VOLTS:

AMPS:

R O T O M

1/4

90 VDC

2.50 ADC

1/10

90 VDC

1.00 ADC

1/50

90 VDC

0.20 ADC

E U Q R O T

T I M I L

HP:

VOLTS:

AMPS:

HP:

VOLTS:

AMPS:

HP:

VOLTS:

AMPS:

1

90 VDC

10.0 ADC

1/2

90 VDC

5.00 ADC

1/8

90 VDC

1.25 ADC

E U Q R O T R O T O M P M O C R I

T I M I L

MM03-230AC-PCM MM10-230AC-PCM

HP:

VOLTS:

AMPS:

HP:

VOLTS:

AMPS:

HP:

VOLTS:

AMPS:

R O T O M

1/2

180 VDC

2.50 ADC

1/3

180 VDC

1.67 ADC

1/25

180 VDC

0.20 ADC

E U Q R O T

T I M I L

HP:

VOLTS:

AMPS:

HP:

VOLTS:

AMPS:

HP:

VOLTS:

AMPS:

2

180 VDC

10.0 ADC

1

180 VDC

5.00 ADC

1/4

180 VDC

1.25 ADC

E U Q R O T R O T O M P M O C R I

T I M I L

P M O C R I

Figure 9. Recommended TORQUE LIMIT and IR COMP Sengs

(actual sengs may vary with each applicaon)

29

MM-PCM Series

Acceleraon (ACCEL)

The ACCEL seng determines the me the motor takes to ramp to a

higher speed. See Specicaons on page 1 for approximate acceleraon

mes. ACCEL is factory set for the shortest acceleraon me (full CCW).

To set the acceleraon me:

1. Set the speed adjust potentiometer or input voltage signal for

minimum speed. The motor should run at minimum speed.

2. Set the speed adjust potentiometer or input voltage signal for

maximum speed. Measure the time it takes the motor to go

from minimum to maximum speed.

3. If the time measured in step 2 is not the desired acceleration

time, turn the ACCEL trim pot CW for a longer acceleration time

or CCW for a shorter acceleration time. Repeat steps 1 through

2 until the acceleration time is correct.

Deceleraon (DECEL)

The DECEL seng determines the me the motor takes to ramp to a

lower speed. See Specicaons on page 1 for approximate deceleraon

mes. DECEL is factory set for the shortest deceleraon me (full CCW).

To set the deceleraon me:

1. Set the speed adjust potentiometer or input voltage signal for

maximum speed. The motor should run at maximum speed.

2. Set the speed adjust potentiometer or input voltage signal for

minimum speed. Measure the time it takes the motor to go

from maximum to minimum speed.

3. If the time measured in step 2 is not the desired deceleration

time, turn the DECEL trim pot CW for a longer deceleration time

or CCW for a shorter deceleration time. Repeat steps 1 through

2 until the deceleration time is correct.

30

MM-PCM Series

Section 6.Application Notes

Mulple Fixed Speeds

Replace the speed adjust potenometer with a series of resistors with a

total series resistance of 10K ohms (Figure 10). Add a single pole, mulposion switch with the correct number of posions for the desired

number of xed speeds.

R1

S3

S2

S1

Figure 10. Mulple Fixed Speeds

R4

R2

TOTAL SERIES

RESISTANCE

R3

10K OHMS

31

MM-PCM Series

Adjustable Speeds Using Potenometers In Series

Replace the speed adjust potenometer with a series of resistors with a

total series resistance of 10K ohms (Figure 11). Add a single pole, mulposion switch with the correct number of posions for the desired

number of xed speeds.

CW

S3

S2

S1

HIGH

SPEED

LOW

SPEED

Figure 11. Adjustable Speeds Using Potenometers In Series

32

5K

OHM

CW

5K

OHM

MM-PCM Series

Independent Adjustable Speeds

Replace the speed adjust potenometer with a single pole, mulposion switch, and two or more potenometers in parallel, with a total

parallel resistance of 10K ohms. Figure 12 shows the connecon of two

independent speed adjust potenometers that can be mounted at two

separate operang staons.

S3

S2

SPEED 2

SPEED 1

S1

Figure 12. Independent Adjustable Speeds

CW CW

20K

OHM

20K

OHM

33

MM-PCM Series

RUN/JOG Switch - Inhibit Connecon

Using a RUN/JOG switch is recommended in applicaons where quick

stopping is not needed and frequent jogging is required. Use a single pole,

two posion switch for the RUN/JOG switch, and a single pole, normally

closed, momentary operated pushbuon for the JOG pushbuon.

Connect the RUN/JOG switch and JOG pushbuon to the inhibit plug

as shown in Figure 13. The motor coasts to a stop when the RUN/JOG

switch is set to JOG. Press the JOG pushbuon to jog the motor. Return

the RUN/JOG switch to RUN for normal operaon.

JOG

PUSHBUTTO N

RUN

4 3

JOG

Figure 13. RUN/JOG Switch - Connecon to Inhibit

34

MM-PCM Series

RUN/JOG Switch - Potenometer Connecon

Connect the RUN/JOG switch and the JOG pushbuon as shown in Figure

14. When the RUN/JOG switch is set to JOG, the motor decelerates to

minimum speed (minimum speed is determined by the MIN OUT trim

pot seng). Press the JOG pushbuon to jog the motor. Return the RUN/

JOG switch to RUN for normal operaon.

S3

S2

S1

JOGRUN

JOG

PUSHBUTTON

CW

10K OHM

SPEED ADJUST

POTENTIOMETER

Figure 14. RUN/JOG Switch - Connecon to Speed Adjust Potenometer

35

MM-PCM Series

Leader-Follower Applicaon

In this applicaon, use a PCM4 to monitor the speed of the leader motor

(Figure 15). The PCM4 isolates the leader motor from the follower

drive, and outputs a voltage proporonal to the leader motor armature

voltage. The follower drive uses this voltage reference to set the speed of

the follower motor. An oponal rao potenometer may be used to scale

the PCM4 output voltage.

(+)

Leader

Drive

9

A1

MOTOR

A2

8

7

(+)

PCM4

(-)

TB501

Figure 15. Leader-Follower Applicaon

TB502

2

1 (-)

10K Ohm

(optional)

S2

Follower

Drive

S1

36

MM-PCM Series

Single Speed Potenometer Control Of Mulple Drives

Mulple drives can be controlled with a single speed adjust potenometer

using a USIM-8 at the input of each drive to provide isolaon (Figure 16).

Oponal rao potenometers can be used to scale the USIM-8 output

voltage, allowing independent control of each drive.

ratio pot A

(optional )

10K Ohms

ratio pot B

(optional)

10K Ohms

ratio pot H

(optional)

10K Ohms

A1

Drive

S2

A

Drive

Drive

A2

A1

B

A2

A1

H

A2

S1

S2

S1

S2

S1

10K Ohms

S3

S2

S1

+

1

-

+

2

-

USIM-8

+

8

-

Figure 16. Single Speed Potenometer Control of Mulple Drives

Mot o

Mot o

Mot o

r

A

r

B

r

H

37

MM-PCM Series

Reversing

A dynamic brake may be used when reversing the motor direcon

(Figure 17). Use a three pole, three posion switch rated for at least the

maximum DC armature voltage and maximum braking current. Wait for

the motor to stop completely before switching it to either the forward

or reverse direcon. See the Dynamic braking secon on page 22 for

recommended dynamic brake resistor sizes.

A1 A2

DYNAMIC

BRAK E

RESIST OR

MOT OR

4 3

FWD

BRAK E

RE V

Figure 17. Reversing Circuit Wiring

38

MM-PCM Series

Section 7. Diagnostic LEDs

MM-PCM series drives are equipped with four diagnosc LEDs:

• Current Limit (C/LIM): Red LED lights whenever the drive reaches

current limit.

• Inhibit (INH): Red LED lights whenever the inhibit circuit is active.

• Power (PWR): Green LED lights whenever AC line voltage is applied

to the drive.

• Run (RUN): Green LED lights whenever the drive is applying a signal

to the motor.

Current Limit

LED

+

1 0 5 C

U C R R

P 2 0 5

N

I M

0 5

E U T D E C E L

R O T Q I M I L

P 4 0 5 P 3 0 5

5 P 5

P 6 0

L I 3 0 5

L I 4

0 5

R W P

R

I O C / M P

/ C I L M

T U O

C E

A C

L

Power LED

Figure 18. Diagnosc LED Locaons

I 1 0 5 C

S3 2 1

S 2

S W 1 0 5

S 1

P 1 0 5

X A M

C W

C W

S P D

L I 1 0 5

I 2 0 5

L

H N

I R N U

Inhibit LEDRun LED

39

MM-PCM Series

Section 8. Troubleshooting

Dangerous voltages exist on the drive when it is powered. When

possible, disconnect the drive while troubleshoong. High

!

Before Troubleshoong

Perform the following steps before starng any procedure in this

section:

For addional assistance, contact your local Minarik Drives distributor

or the factory direct:

voltages can cause seroius or fatal injury.

WARNING!

1. Disconnect AC line voltage from the drive.

2. Check the drive closely for damaged components.

3. Check that no conductive or other foreign material has become

lodged on the printed circuit board.

4. Verify that every connection is correct and in good condition.

5. Verify that there are no short circuits or grounded

connections.

6. Check that the selection switch settings are correctly set.

7. Check that the drive’s rated armature is consistent with the

motor ratings.

(800) MINARIK or FAX: (800) 394-6334

40

MM-PCM Series

PROBLEM POSSIBLE CAUSE SUGGESTED SOLUTIONS

Line fuse

blows.

Line fuse does

not blow, but

the motor does

not run.

1. Line fuse is the wrong size. 1. Check that the line fuse is

2. Motor cable or armature is

shorted to ground.

3. Nuisance tripping caused by

a combination of ambient

conditions and high-current

spikes (i.e. reversing).

1. Speed adjust potentiometer

or input voltage signal is set

to zero speed.

2. INHIBIT mode is active. 2. Add a short between terminals

3. S2 is shorted to S1. 3. Remove the short.

4. Drive is in current limit. 4. Verify that the motor is not

5. Drive is not receiving AC line

voltage.

6. Motor is not connected. 6. Remove power. Connect the

correct for the motor size.

2. Check motor cable and

armature for shorts.

3. Add a blower to cool the

drive components, decrease

TORQUE LIMIT settings, resize

motor and drive for actual

load demand, or check for

incorrectly aligned mechanical

components or “jams”. See

page 27 for information on

adjusting the TORQUE LIMIT

trim pot.

1. Increase the speed adjust

potentiometer setting or input

voltage or current signal.

3 and 4 and remove any short

between terminals 4 and 5.

jammed. Increase TORQUE

LIMIT setting if set too low.

5. Apply AC line voltage.

motor to A1 and A2. Reapply

power.

41

MM-PCM Series

PROBLEM POSSIBLE CAUSE SUGGESTED SOLUTIONS

Motor does not

stop when the

speed adjust

potenometer

is full CCW.

Motor runs in

the opposite

direcon

Motor runs too

fast.

Motor will

not reach the

desired speed.

Motor pulsates

or surges under

load.

1. MIN OUT is set too high. 1. Calibrate MIN OUT.

1. Motor connections to A1

and A2 are reversed.

1. MAX SPD is set too high. 1. Calibrate MAX SPD.

1. MAX SPD setting is too low. 1. Increase MAX SPD setting.

2. IR COMP setting is too low. 2. Increase IR COMP setting.

3. TORQUE LIMIT setting is too

lo w.

4. Motor is overloaded. 4. Check motor load. Resize the

1. IR COMP is set too high. 1. Adjust the IR COMP setting

2. Motor bouncing in and out

of current limit.

1. Remove power. Reverse

connections to A1 and A2.

Reapply power.

3. Increase TORQUE LIMIT setting.

motor and drive if necessary.

slightly CCW until the motor

speed stabilizes.

2. Make sure motor is not

undersized for load; adjust

TORQUE LIMIT trim pot CW.

42

MM-PCM Series

Section 9. Accessories & Replacement Parts

Displays

Closed Loop ................................................................................ DLC600

Open Loop....................................................................................... VT-8

Heat Sinks

Chassis .................................................................................... 223-0159

Kits

Potenometer & Connector

Pot Kit ................................................................................. 202-0079

Fuse

1.5 - 5 Amp Fuse Kit ............................................................ 050-0066

1 - 8 Amp Fuse Kit with Pico Fuse ....................................... 050-0068

3 - 8 Amp Fuse Kit with Pico Fuse ....................................... 050-0069

5 - 15 Amp Fuse Kit ............................................................. 050-0071

Logic Cards

Current Sensing

5 Amps .................................................................................... CSC1-5

20 amps ................................................................................ CSC1-20

43

MM-PCM Series

Unconditional Warranty

A. Warranty

Minarik Drives warrants that its products will be free from defects in workmanship and material

for twelve (12) months or 3000 hours, whichever comes rst, from date of manufacture thereof.

Within this warranty period, Minarik Drives will repair or replace, at its sole discreon, such

products that are returned to Minarik Drives, 14300 De La Tour Drive, South Beloit, Illinois 61080

USA.

This warranty applies only to standard catalog products, and does not apply to specials. Any

returns of special controls will be evaluated on a case-by-case basis. Minarik Drives is not

responsible for removal, installaon, or any other incidental expenses incurred in shipping the

product to and from the repair point.

B. Disclaimer

The provisions of Paragraph A are Minarik Drives’s sole obligaon and exclude all other

warranes of merchantability for use, expressed or implied. Minarik Drives further disclaims

any responsibility whatsoever to the customer or to any other person for injury to the person

or damage or loss of property of value caused by any product that has been subject to misuse,

negligence, or accident, or misapplied or modied by unauthorized persons or improperly

installed.

C. Limitaons of Liability

In the event of any claim for breach of any of Minarik Drives’s obligaons, whether expressed

or implied, and parcularly of any other claim or breach of warranty contained in Paragraph

A, or of any other warranes, expressed or implied, or claim of liability that might, despite

Paragraph B, be decided against Minarik Drives by lawful authority, Minarik Drives shall under no

circumstances be liable for any consequenal damages, losses, or expenses arising in connecon

with the use of, or inability to use, Minarik Drives’s product for any purpose whatsoever.

An adjustment made under warranty does not void the warranty, nor does it imply an extension

of the original 12-month warranty period. Products serviced and/or parts replaced on a

no-charge basis during the warranty period carry the unexpired poron of the original warranty

only.

If for any reason any of the foregoing provisions shall be ineecve, Minarik Drives’s liability

for damages arising out of its manufacture or sale of equipment, or use thereof, whether such

liability is based on warranty, contract, negligence, strict liability in tort, or otherwise, shall not in

any event exceed the full purchase price of such equipment.

Any acon against Minarik Drives based upon any liability or obligaon arising hereunder or

under any law applicable to the sale of equipment or the use thereof, must be commenced within

one year aer the cause of such acon arises.

44

www.minarikdrives.com

14300 DE LA TOUR DRIVE

SOUTH BELOIT, IL 61080

(800) MINARIK

250-0248 Rev 2

Loading...

Loading...